Method and device for continuously preparing glutaraldehyde

A technology for glutaraldehyde and dihydropyran, applied in the field of continuous production of glutaraldehyde, high-purity glutaraldehyde continuous production method and production equipment, can solve the problems of slow reaction speed, high impurity content, and many by-products , to achieve the effect of no stirring energy consumption, simple equipment structure and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

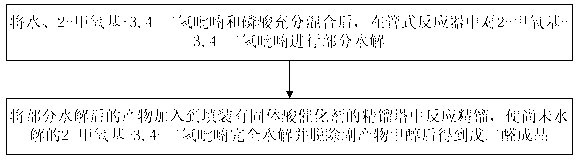

Method used

Image

Examples

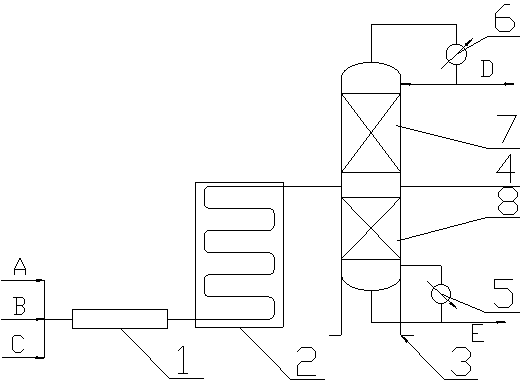

Embodiment 1

[0033] The static mixer that the embodiment of the present invention adopts is SV-3.5 / 32 type, and the tubular reactor volume is 0.2m 3 , the diameter of the rectification tower is Φ600, and the filling specification of the rectification tower is Dn25 SO 4 2- / TiO 2 -AL 2 o 3 -Al solid acid Raschig ring catalytic rectification filler 9m (this filler is equivalent to 2~2.5 theoretical plates per meter), of which, the rectification section is 5m, and the stripping section is 4m.

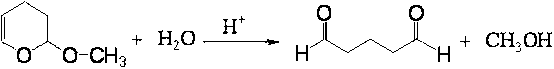

[0034] First, feed 2-methoxy-3,4-dihydropyran 800kg / h, water 960kg / h and phosphoric acid 0.5kg / h into the static mixer; In a tubular reactor, it is hydrolyzed at 95°C and 1.0Mpa (the residence time is about 6 minutes based on the feed volume and the volume of the tubular reactor). The hydrolysis conversion of 2-methoxy-3,4-dihydropyran after partial hydrolysis was 86%.

[0035] Secondly, the hydrolyzate after partial hydrolysis in the tubular reactor is passed into the rectification tower, and th...

Embodiment 2

[0039] First of all, this embodiment adopts the device in Embodiment 1 and the production process is the same, 600 kg / h of 2-methoxy-3,4-dihydropyran, 760 kg / h of water and 0.35 kg of phosphoric acid are introduced into the static mixer / h. In a tubular reactor, hydrolyze at 80°C and 0.3Mpa (the residence time is about 9 minutes according to the volume of the feed and the volume of the tubular reactor), after partial hydrolysis, 2-methoxy-3,4- The hydrolysis conversion rate of dihydropyran was 89%.

[0040] Secondly, in the reactive distillation process, the reactive distillation conditions are as follows: the pressure at the top of the tower is 46KPa, the temperature at the bottom of the tower is 86°C, and the reflux ratio is 0.7.

[0041] Finally, 349.9kg / h distillate was obtained from the top of the tower, among which, methanol 165.7kg / h, glutaraldehyde 6kg / h, 2-methoxy-3,4-dihydropyran 2.5kg / h and water 167.7 kg / h. Obtain glutaraldehyde finished product from the bottom ...

Embodiment 3

[0044] The static mixer that the embodiment of the present invention adopts is SV-2.3 / 20 type, and the tubular reactor volume is 0.15m 3 , the diameter of the rectification tower is Φ450, the packing is bagged β-zeolite 16m (each meter of this packing is equivalent to 1 theoretical plate), among them, the rectification section is 10m, and the stripping section is 6m.

[0045] First, feed 2-methoxy-3,4-dihydropyran 300kg / h, water 400kg / h and phosphoric acid 0.2kg / h into the static mixer; In a type reactor, it is hydrolyzed at 75°C and 0.2Mpa (the residence time is about 13 minutes based on the feed volume and the volume of the tubular reactor). The hydrolysis conversion rate of 2-methoxy-3,4-dihydropyran after partial hydrolysis was 90%.

[0046] Secondly, the hydrolyzate after partial hydrolysis in the tubular reactor is passed into the rectification tower, and the reaction rectification conditions are as follows: the pressure at the top of the tower is 33KPa, the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com