Preparation method of HEPES (hydroxyethylpiperazine ethane sulfonic acid) molecule guided porous zinc oxide microspheres

A technology of porous zinc oxide and microspheres, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of increasing process complexity and environmental pollution, and achieve the effects of low price, good repeatability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 A preparation method for porous zinc oxide microspheres, comprising the steps of:

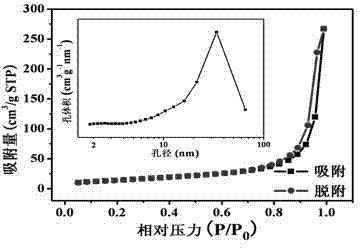

[0024] Dissolve 2 mmol of zinc acetate in 30 mL of triethylene glycol (TEG), sonicate for 10 min to completely disperse the zinc acetate, then add 5 mmol of hydroxyethylpiperazineethanesulfonic acid (HEPES) and place the reaction mixture in the liner 100 mL polytetrafluoroethylene stainless steel autoclave, at 150 o C under reaction for 6 hours; after centrifugal washing to remove residual solvent and HEPES, the product was placed at 60 o C and dried for 24 hours, after cooling, porous zinc oxide microspheres with high specific surface area can be obtained. The specific surface area of this sample is 51.9 m 2 / g, the average pore diameter is 30 nm.

[0025] figure 1 It is the diffraction pattern of the sample of Example 1 obtained by Bruker axs D8 type X-ray diffraction analyzer (XRD). It can be seen from the spectrum that the diffraction peaks of the spectrum corresp...

Embodiment 2

[0029] Example 2 A preparation method for porous zinc oxide microspheres, comprising the steps of:

[0030] Dissolve 4 mmol of zinc acetate in 50 mL of diethylene glycol (DEG), sonicate for 10 min to completely dissolve the zinc acetate, then add 8 mmol of hydroxyethylpiperazineethanesulfonic acid (HEPES) and place the reaction mixture in the liner 100 mL polytetrafluoroethylene stainless steel autoclave, at 150 o Reaction at C temperature for 15 hours; after centrifugal washing to remove residual solvent and HEPES, the product was placed at 60 o C and dried for 24 hours, after cooling, porous zinc oxide microspheres with high specific surface area can be obtained. The specific surface area of this sample is 63.1 m 2 / g, with an average pore size of 5 nm.

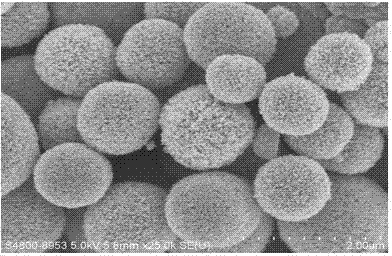

[0031] Figure 5 It is a topography diagram of the sample of Example 2 observed by a Hitachi S4800 scanning electron microscope (SEM). It can be seen from the figure that the synthesized zinc oxide is spherical wi...

Embodiment 3

[0032] Example 3 A preparation method for porous zinc oxide microspheres, comprising the steps of:

[0033] Dissolve 3 mmol of zinc acetate in 40 mL of dimethylformamide (DMF), sonicate for 10 min to completely dissolve the zinc acetate, then add 6 mmol of hydroxyethylpiperazineethanesulfonic acid (HEPES), and place the reaction mixture in In a stainless steel autoclave lined with 100 mL polytetrafluoroethylene, at 150 o Reaction at C temperature for 12 hours; after centrifugal washing to remove residual solvent and HEPES, the product was placed at 60 o C and dried for 24 hours, after cooling, porous zinc oxide microspheres with high specific surface area can be obtained. The specific surface area of this sample is 56.9 m 2 / g, the average pore diameter is 32 nm.

[0034] Image 6 It is a topography diagram of the sample of Example 3 observed by a Hitachi S4800 scanning electron microscope (SEM). It can be seen from the figure that the synthesized zinc oxide is spheri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com