Preparation method and application of a kind of hydroxy iron sulfate sludge-based biochar

A technology of ferric hydroxy sulfate and biochar, which is applied in water pollutants, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as inability to arsenic, adsorption, etc. Realize the effect of reducing and harmless

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

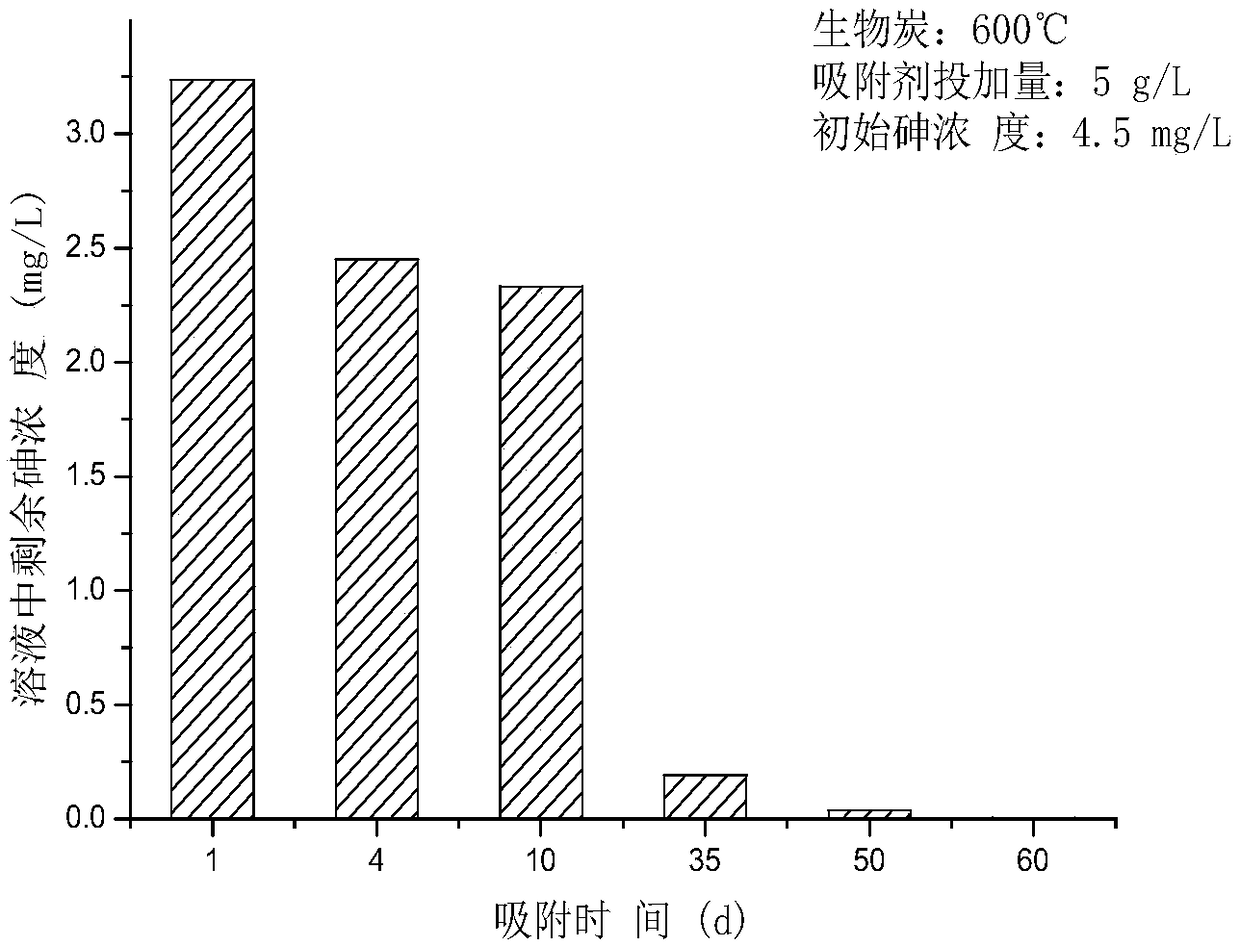

Image

Examples

Embodiment 1

[0023] A preparation method for ferric hydroxysulfate sludge-based biochar, comprising the following steps:

[0024] 1. Add sulfuric acid with a concentration of 9.2mol / L to adjust the pH to 4 in the municipal sludge with a moisture content of 2wt% in the aerated air-lifting plug-flow reactor, and react for 24 hours to make the sludge The endogenous iron is precipitated and the precipitation rate is 50%;

[0025] 2. Insert acidophilic Thiobacillus ferrooxidans into the above sludge, the inoculation amount is 10wt%, the sludge after inoculation is continuously aerated, stays in the reactor for 48h, and reacts to the Fe in the sludge solution 2+ The oxidation rate is greater than 95%, and iron hydroxysulfate sludge is obtained;

[0026] 3. Dewater the above iron hydroxysulfate sludge by pressure filtration, the moisture content of the dehydrated sludge is 55-65%, and the dehydrated sludge is dried at 105°C for 8 hours;

[0027] 4. Grind the above-mentioned dried sludge through...

Embodiment 2

[0033] A preparation method for ferric hydroxysulfate sludge-based biochar, comprising the following steps:

[0034] 1. Add sulfuric acid with a concentration of 9.2mol / L to adjust the pH to 4 in the municipal sludge with a moisture content of 3wt% in the aerated air-lifting plug-flow reactor in an independent grid, and react for 48 hours to make the sludge in the sludge The endogenous iron is precipitated and the precipitation rate is 80%;

[0035] 2. Insert acidophilic Thiobacillus ferrooxidans into the above sludge, the inoculation amount is 10wt%, the sludge after inoculation is continuously aerated, stays in the reactor for 48h, and reacts to the Fe in the sludge solution 2+ The oxidation rate is greater than 95%, and iron hydroxysulfate sludge is obtained;

[0036] 3. Dewater the above iron hydroxysulfate sludge by pressure filtration, the moisture content of the dehydrated sludge is 65%, and the dehydrated sludge is dried at 105°C for 8 hours;

[0037] 4. Grind the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com