Aluminum dihydrogen phosphate-silica powder composite high-temperature binder and preparation method thereof

A technology of aluminum dihydrogen phosphate and high-temperature binders, which is applied in the field of inorganic high-temperature binders, can solve problems such as high curing temperature and low bonding strength, and achieve good high-temperature stability, good thermal shock resistance, and short production cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

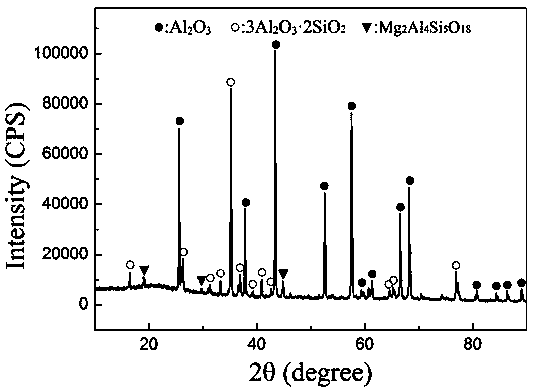

[0025] A preparation method of aluminum dihydrogen phosphate-silicon micropowder composite high-temperature binder, the steps are as follows:

[0026] 25-28 parts by weight of ρ-Al 2 o 3 powder, 12-15 parts by weight of 0.2-0.6 mm tabular alumina, 12-15 parts by weight of 0.5-1.0 mm tabular alumina, 22-25 parts by weight of silicon micropowder, 8-11 parts by weight of aluminum dihydrogen phosphate, 8 ~11 parts by weight of magnesium oxide and 15~20 parts by weight of water are mixed in a mixer for 15~20 minutes to obtain aluminum dihydrogen phosphate-silicon micropowder composite high-temperature binder.

[0027] After the aluminum dihydrogen phosphate-silicon micropowder composite high-temperature binder prepared in this example was fired at 1300 °C to 1600 °C, the Young's modulus, flexural strength, compressive strength and shear strength of the binder were tested. As shown in the table below:

[0028] .

Embodiment 2

[0030] A preparation method of aluminum dihydrogen phosphate-silicon micropowder composite high-temperature binder, the steps are as follows:

[0031] 26-29 parts by weight of ρ-Al 2 o 3 powder, 10-13 parts by weight of 0.2-0.6 mm tabular alumina, 10-13 parts by weight of 0.5-1.0 mm tabular alumina, 21-24 parts by weight of silicon micropowder, 10-13 parts by weight of aluminum dihydrogen phosphate, 10 -13 parts by weight of magnesium oxide and 15-20 parts by weight of water are mixed in a mixer for 15-20 minutes to obtain aluminum dihydrogen phosphate-silicon micropowder composite high-temperature binder.

Embodiment 3

[0033] A preparation method of aluminum dihydrogen phosphate-silicon micropowder composite high-temperature binder, the steps are as follows:

[0034] 27-30 parts by weight of ρ-Al 2 o 3 powder, 11-14 parts by weight of 0.2-0.6 mm tabular alumina, 11-14 parts by weight of 0.5-1.0 mm tabular alumina, 20-23 parts by weight of silicon micropowder, 9-12 parts by weight of aluminum dihydrogen phosphate, 9 12 parts by weight of magnesium oxide and 15-20 parts by weight of water are mixed in a mixer for 15-20 minutes to obtain a composite high-temperature binder of aluminum dihydrogen phosphate-silicon micropowder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com