High-efficiency copper-removal mixture and application thereof

A combination agent and copper removal agent technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of sewage COD increase, solid-liquid separation difficulty, sulfide, etc., to achieve the goal of reducing COD Increase, improve the treatment effect, and evenly spread the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Including the following weight percentages of A component and B component:

[0033] Among them, component A contains cross-linked starch: 20 parts;

[0034] Dicumyl hydroperoxide: 10 parts;

[0035] Carbon disulfide: 15 parts;

[0036] Sodium hydroxide: 25 parts;

[0037] Water: 80 parts;

[0038] Wherein, component B contains polyferric sulfate: 15 parts;

[0039] Polyaluminum ferric chloride: 15 parts;

[0040] Polyacrylamide: 12 parts;

[0041] Water: 60 parts;

[0042] Specifically, the cross-linked starch, carbon disulfide and sodium hydroxide are all in powder form, and the particle size is 0.2-0.8um.

[0043] Specifically, the cross-linked starch is epichlorohydrin cross-linked starch.

[0044] Instructions:

[0045] Specifically, the following steps are included:

[0046] a) Mix cross-linked starch and dicumyl hydroperoxide and place them in a kneader, kneading for 1 hour at a temperature below 40°C;

[0047] b) Mix the material obtained in step a wit...

Embodiment 2

[0056] Including the following weight percentages of A component and B component:

[0057] Among them, component A contains cross-linked starch: 20 parts;

[0058] Dicumyl hydroperoxide: 10 parts;

[0059] Carbon disulfide: 15 parts;

[0060] Sodium hydroxide: 25 parts;

[0061] Water: 80 parts;

[0062] Wherein, component B contains polyferric sulfate: 15 parts;

[0063] Polyaluminum ferric chloride: 15 parts;

[0064] Polyacrylamide: 12 parts;

[0065] Water: 60 parts;

[0066] Instructions:

[0067] a) Mix cross-linked starch and dicumyl hydroperoxide and place them in a kneader, kneading for 1 hour at a temperature below 40°C;

[0068] b) Mix the material obtained in step a with carbon disulfide, sodium hydroxide, and water and place it in a reactor, heat the reactor to 60-70°C and vacuumize and keep it warm for 2 hours, and adjust the pH to 7.0-8.0 to obtain Group A Minute;

[0069] c) Add component A to the circuit board waste water until the pH is 9.0-10.5, fu...

Embodiment 3

[0074] Including the following weight percentages of A component and B component:

[0075] Among them, component A contains cross-linked starch: 20 parts;

[0076] Dicumyl hydroperoxide: 10 parts;

[0077] Carbon disulfide: 15 parts;

[0078] Sodium hydroxide: 25 parts;

[0079] Water: 80 parts;

[0080] Wherein, component B contains polyferric sulfate: 15 parts;

[0081] Polyaluminum ferric chloride: 15 parts;

[0082] Polyacrylamide: 12 parts;

[0083] Water: 60 parts;

[0084] Using method is with embodiment 2,

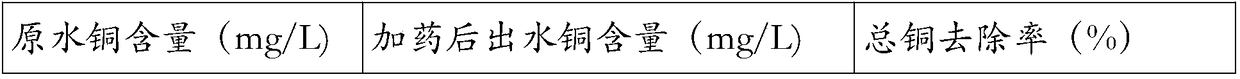

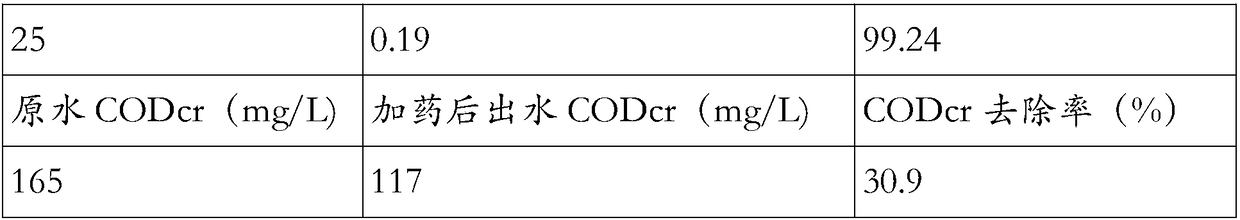

[0085] Table 3 is a comparison table of copper content and CODcr index when the final pH of the high-efficiency copper removal agent is 8 after being added to the wastewater.

[0086]

[0087]

[0088] Comparing with Example 2, it can be known that the total copper removal rate and CODcr removal rate change are small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com