Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

468 results about "Copper hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper(I) hydroxide is the hydroxide of the metal copper with the chemical formula of CuOH. It is a mild, highly unstable alkali. The color of pure CuOH is yellow or orange-yellow, but it usually appears rather dark red because of impuries.

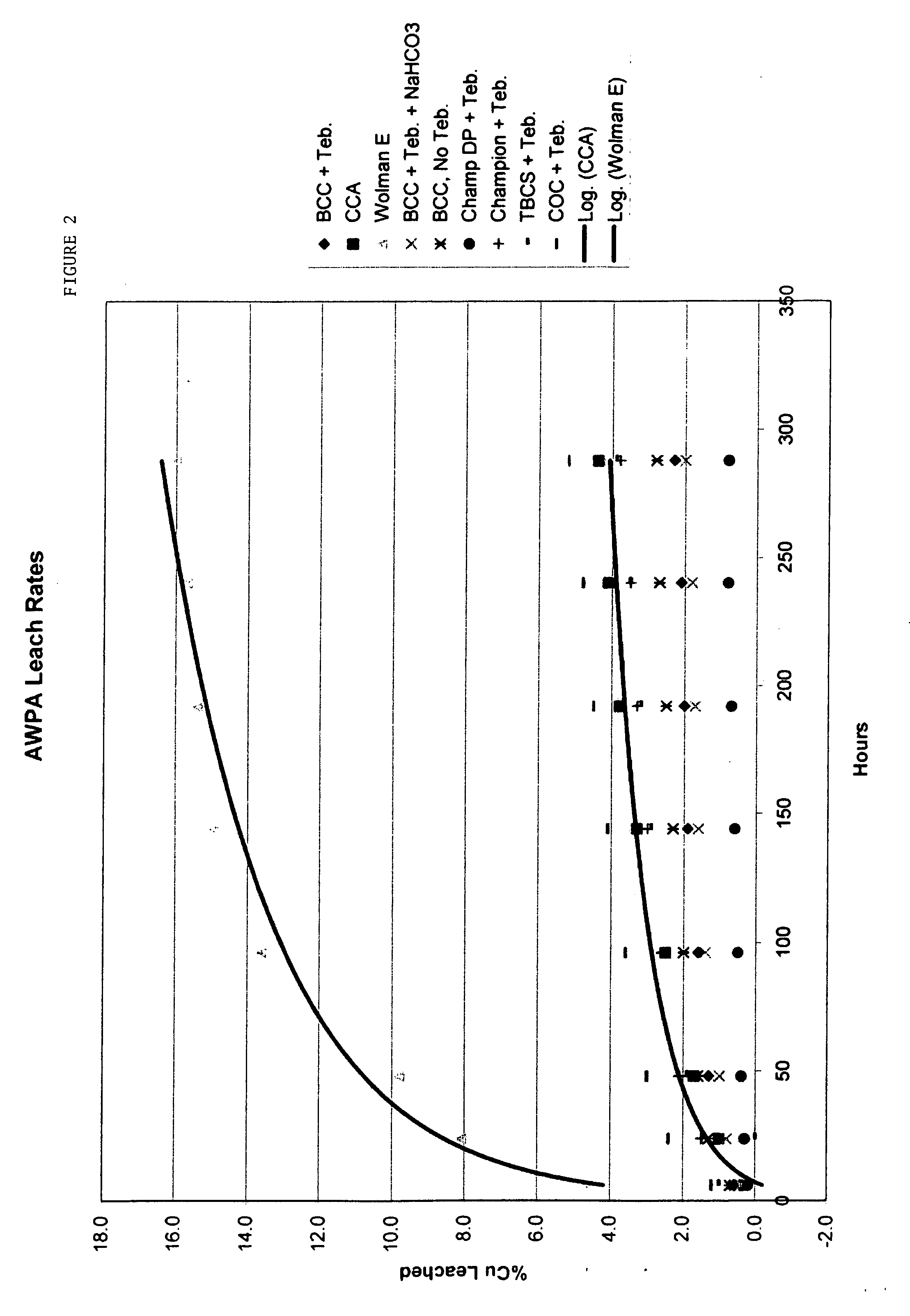

Composition, method of making, and treatment of wood with an injectable wood preservative slurry having biocidal particles

A method of preserving wood includes injecting into the wood an effective amount of a aqueous wood-injectable biocidal slurry, said a wood-injectable biocidal slurry containing dispersants and sub-micron biocidal particles selected from at least one of the following classes: 1) a plurality of particles containing at least 25% by weight of a solid phase of sparingly soluble salts selected from copper salts, nickel salts, tin salts, and / or zinc salts; 2) a plurality of particles containing at least 25% by weight of a solid phase of sparingly soluble metal hydroxides selected from copper hydroxide, nickel hydroxide, tin hydroxide, and / or zinc hydroxide; 3) a plurality of particles containing at least 25% by weight of a solid phase comprising a substantially-insoluble organic biocide selected from triazoles, chlorothalonil, iodo-propynyl butyl carbamate, copper-8-quinolate, fipronil, imidacloprid, bifenthrin, carbaryl, strobulurins, and indoxacarb; 4) a plurality of particles containing on the outer surface thereof a substantially-insoluble organic biocide; 5) a plurality of particles containing a solid phase of a biocidal, partially or fully glassified composition comprising at least one of Zn, B, Cu, and P. The particles may advantageously contain metallic copper, a leachability barrier, pigments, dyes, or other adjuvants disposed on the outer surface thereof.

Owner:OSMOSE

Use of sub-micron copper salt particles in wood preservation

InactiveUS20060062926A1Little dangerSmall particle sizeBiocideLiquid surface applicatorsPhosphateCopper nitrate

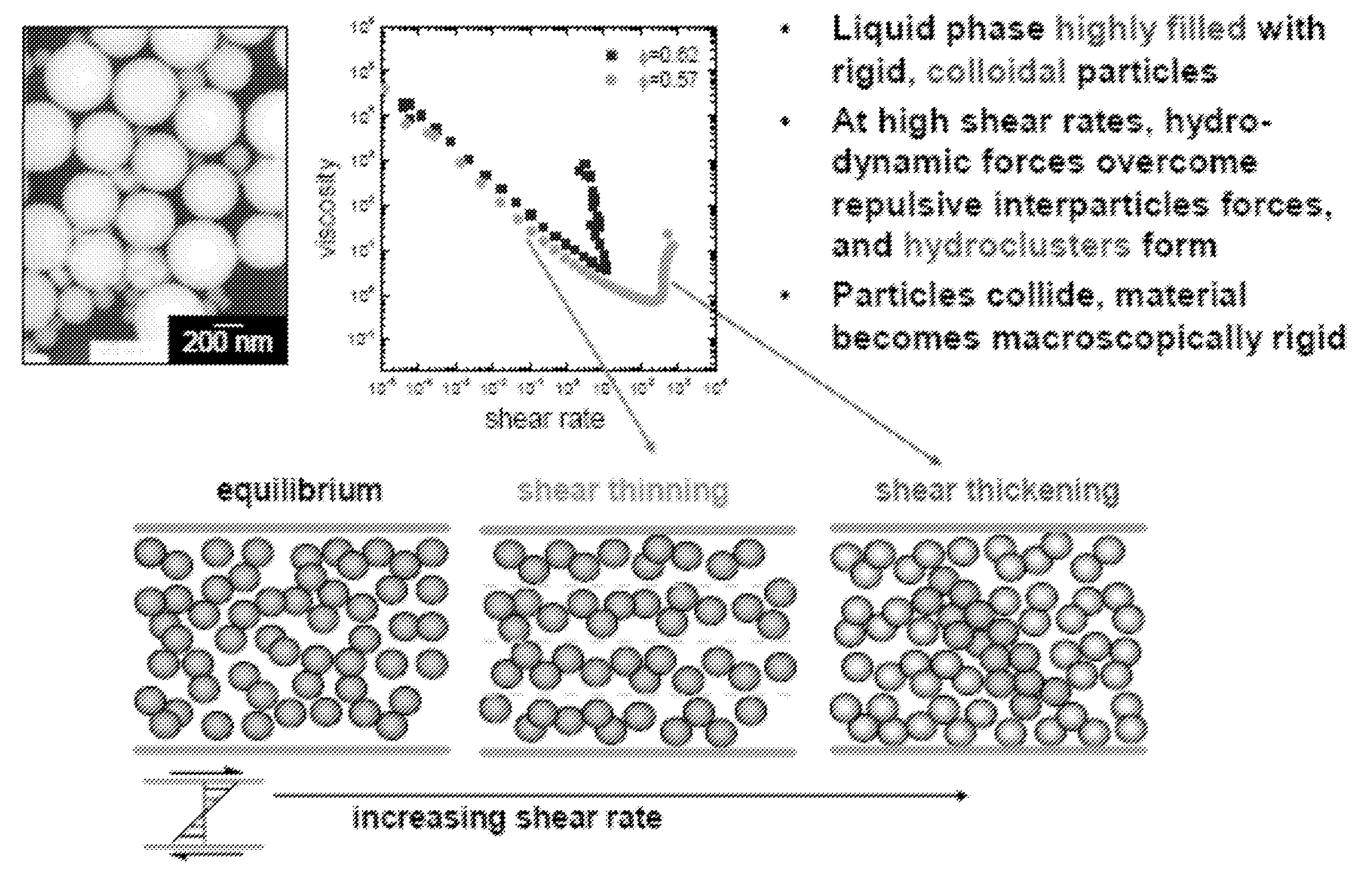

A method for preserving wood by injecting into the wood a slurry having: particles of a sparingly soluble copper salt, copper hydroxide, or both, wherein the weight average diameter d50 of the particles in the slurry is between 0.1 microns and 0.7 microns and the d98 of the particles in the slurry is less than about 1 micron; a dispersant; and water. The dispersant is anionic or a mix of anionic and non-ionic. Advantageously, less than 20% by weight of the particles have a diameter less than 20 nanometers. Useful copper salts include basic copper carbonate, tri-basic copper sulfate, copper oxychloride, basic copper nitrate, basic copper borate, copper borate, basic copper phosphate, or copper silicate. The slurry most preferably includes copper hydroxide particles. The slurry further advantageously includes at least one organic biocide, wherein at least a portion of the organic biocide is coated on the particles.

Owner:OSMOSE

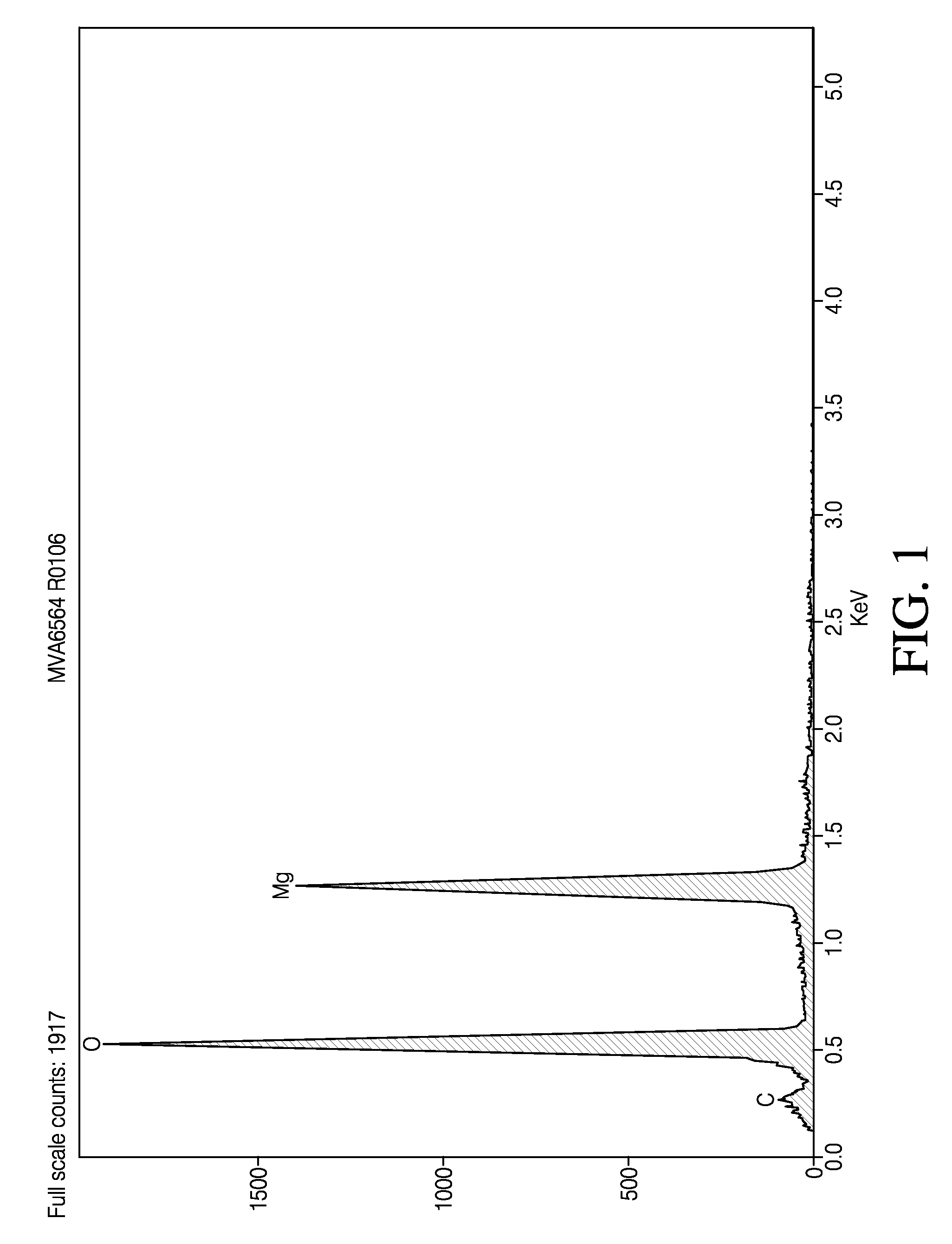

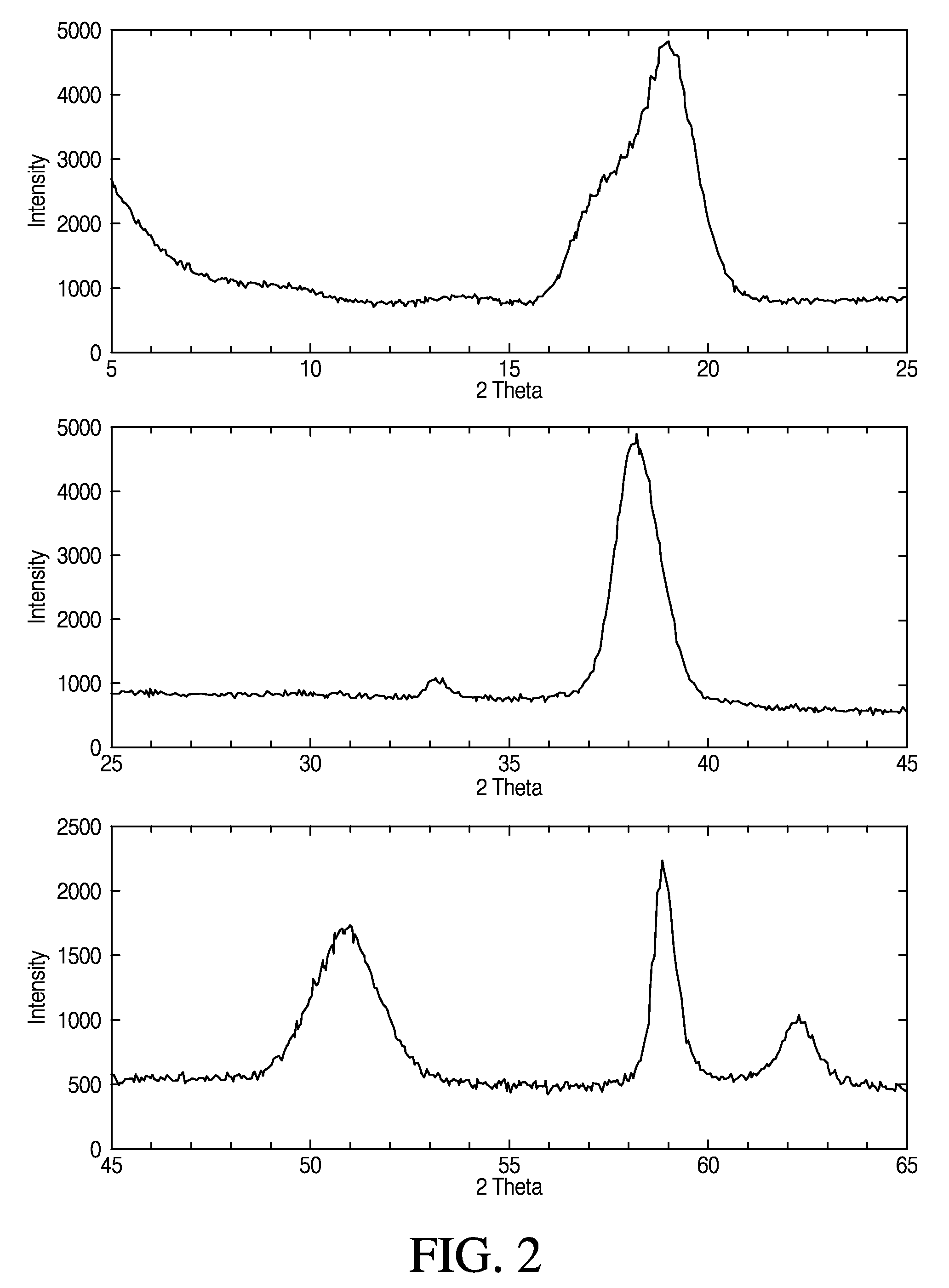

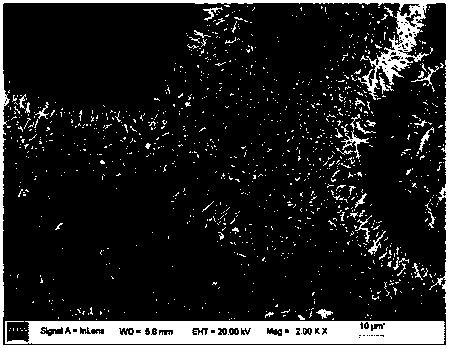

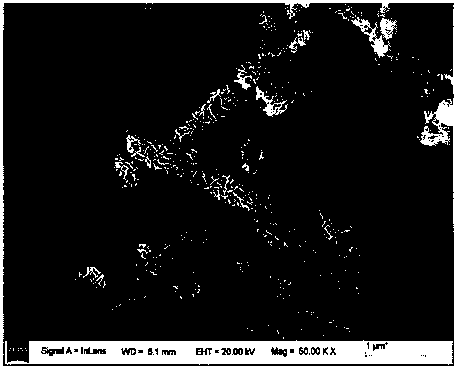

Nanoplatelet copper hydroxides and methods of preparing same

Nanoplatelet forms of metal hydroxide and metal oxide are provided, as well as methods for preparing same. The nanoplatelets are suitable for use as fire retardants and as agents for chemical or biological decontamination.

Owner:AQUA RESOURCES CORP

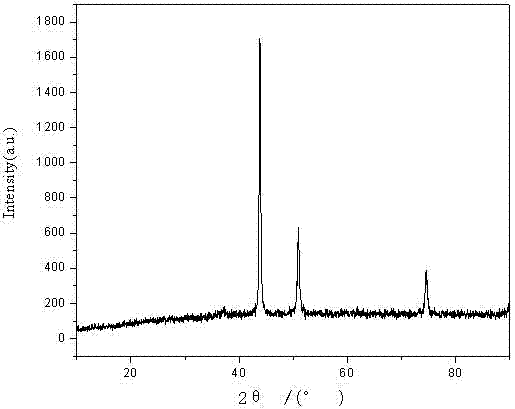

Electrode material in hollow tubular structure, and preparation method for electrode material

InactiveCN105513831AExcellent supercapacitor performanceIncrease loadHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceElectrochemical corrosion

The invention provides an electrode material in a hollow tubular structure, and the electrode material is in the hollow tubular structure which consists of a composite hydroxide / copper hydroxide / copper-contained metal substrate. The chemical formulation of the composite hydroxide is MxM'y(OH)2, wherein M is Ni2+ or Co2+, M' is Co2+, Al3+, or Fe3+. According to the invention, a method of solution dipping and constant potential deposition, and a copper hydroxide nanowire array grows on the copper-contained metal substrate in an in-situ manner. The composite hydroxide is deposited on a copper hydroxide nanorod in electrolyte containing mixed metal salt solution in a manner of electro-deposition through employing the method of constant potential deposition. Meanwhile, electrochemical corrosion enables the copper hydroxide nanorod to be dissolved in a process of electro-deposition, thereby obtaining the hollow tubular structure of the composite hydroxide / copper hydroxide / copper-contained metal substrate. The electrode material is good in super-capacitance performance, and can be used for a super-capacitor.

Owner:BEIJING UNIV OF CHEM TECH +1

Method for preparing copper hydroxide phosphate micro-crystals with different shapes

InactiveCN103101897AShape-controlled synthesis achievedSimple process routePhysical/chemical process catalystsPhosphorus compoundsPhosphatePhosphoric acid

The invention belongs to the field of preparation of inorganic nonmetallic materials and in particular relates to a method for preparing copper hydroxide phosphate micro-crystals with different shapes. The method comprises the following steps of: uniformly dissolving a soluble bivalent copper salt and soluble phosphate in an alcohol and water mixed solution in certain ratio; fully stirring to perform a reaction; performing a hydrothermal reaction on the alcohol and water mixed solution continuously; filtering; cleaning; and drying to obtain an objective product. According to the method for preparing the copper hydroxide phosphate micro-crystals with different shapes, the process is simple and easy to operate, the product purity is high, the preparation cost of the product is low, the obtained product comprises micron-sized micro-crystals with different shapes and can be used as a visible-light response photocatalyst. The prepared copper hydroxide phosphate micro-crystals with different shapes can be used as the visible-light response photocatalyst and has wide application prospect in the field of degradation of dye wastewater and indoor harmful gas, photo-catalytic disinfection and the like.

Owner:BOHAI UNIV

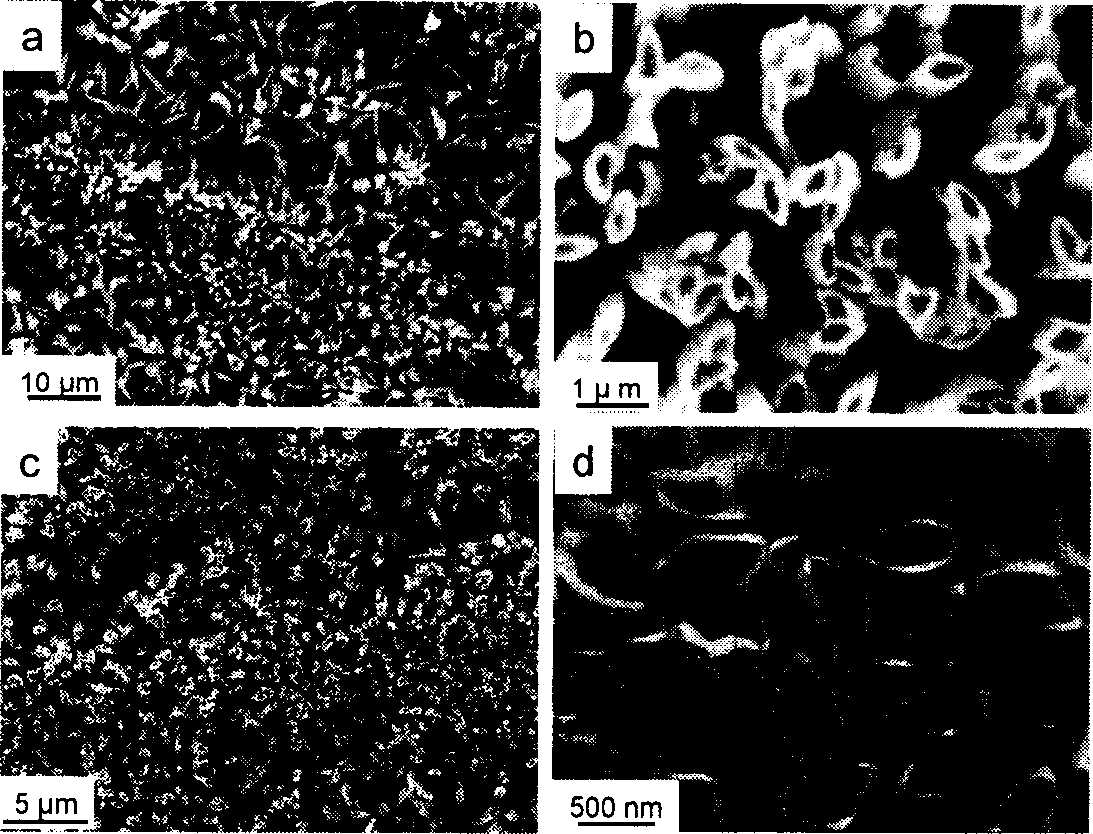

Production of oxide copper nanometer tube array

InactiveCN1817785ANeat and orderly arrayNeat and orderly growthNanostructure manufactureCopper oxides/halidesCopper oxideCopper foil

Owner:HEFEI UNIV OF TECH

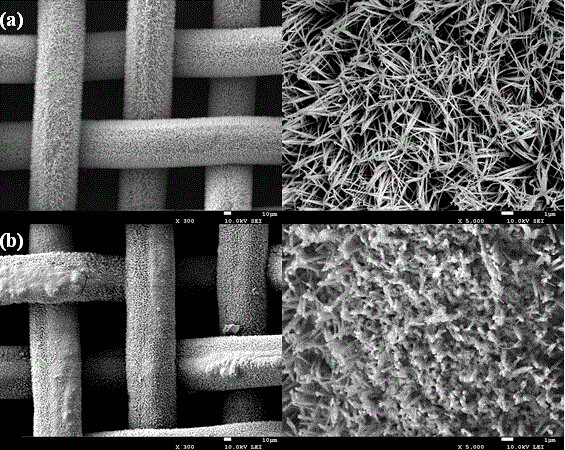

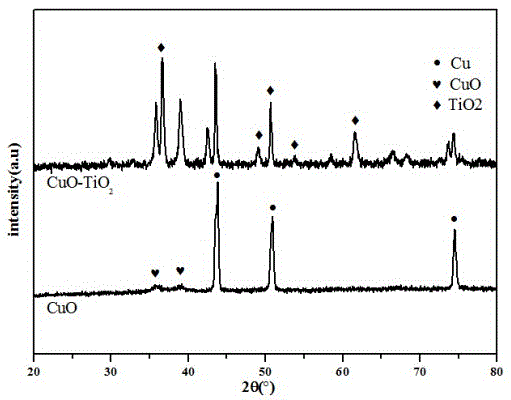

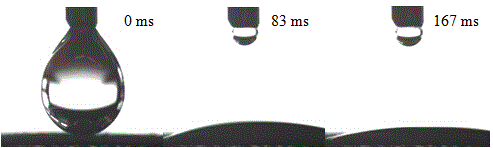

Preparation method of nano-structure oil-water separation net membrane with self-cleaning and underwater super-oleophobic characteristics

InactiveCN105641973AEasy to separateAvoid wastingNon-miscible liquid separationNano structuringCopper oxide

The invention discloses a preparation method of a metal net membrane with self-cleaning and underwater super-oleophobic characteristics. The metal net membrane can achieve efficient oil-water separation and self cleaning. A traditional oil-water separation membrane has the defects that a preparation technology is complex, regeneration is difficult, and repeated using can not be achieved. With a copper net being a substrate, an anodic oxidation method is adopted for generating a copper hydroxide nanowire array, multiple layers of titanium dioxide are deposited on the nanowire array through layer-by-layer self-assembly, and the copper net membrane covered by a copper oxide / titanium dioxide composite membrane layer is generated through roasting. The net membrane is high in mechanical performance and resistant to high heat, has the super-hydrophilic and underwater super-oleophobic characteristics, can efficiently separate an oil-water mixture and meanwhile can perform self cleaning under photocatalysis active illumination of the titanium dioxide layer to achieve regeneration and repeated using. Compared with the preparation technology of the existing oil-water separation membrane, the method facilitates scale expansion, preparation is easy, raw materials are environmentally friendly, the cost is low, cyclic reuse can be achieved, and the net membrane is a novel oil-water separation net membrane which is more environmentally friendly and affordable.

Owner:SICHUAN UNIV

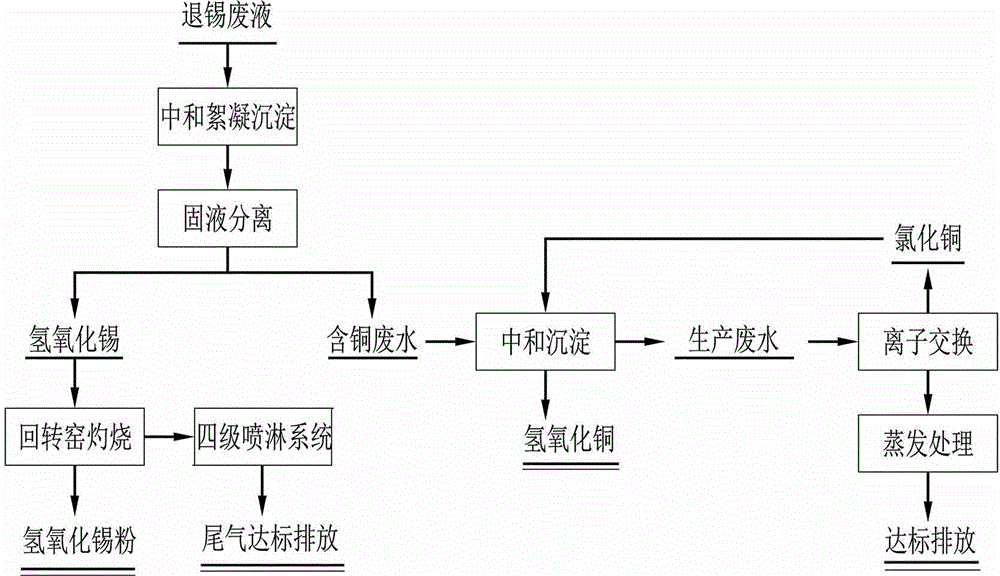

Tin stripping waste liquid treating method

InactiveCN104986892AMake full use of resourcesMaintain stabilityMultistage water/sewage treatmentProcess efficiency improvementLiquid wastePolyacrylamide

A tin stripping waste liquid treating method comprises the following steps: adding sulfate into a tin stripping waste liquid, adjusting the pH value to be 1.0-1.5, then adding a polyacrylamide flocculating agent to recycle tin, adding ammonia water with the concentration of 18-25% into copper-containing wastewater, conducting neutralization to recycle copper, and conducting further treatment on the wastewater. According to the method, sulfate is added into the tin stripping waste liquid, so that the effect of tin hydroxide colloid coagulation is achieved, and the usage amount is ammonia water can also be reduced; in the neutralization process, a certain amount of the PAM (polyacrylamide) flocculating agent is added, so that metallic tin is precipitated in the form of tin hydroxide; under the acidic condition, most metallic copper dissociates in a supernatant in the form of copper ions, the tin hydroxide is obtained through solid-liquid separation, and the filtrate is subjected to neutralization, so that copper in the filtrate is precipitated in the form of copper hydroxide, and the copper hydroxide is subjected to solid-liquid separation through a filter press, that is, in different acidity and alkalinity systems, the forms of metal ions are different, so that the metal ions are separated, tin and copper in the tin stripping waste liquid can be recycled in steps, and the resources in the tin stripping waste liquid can be fully utilized.

Owner:QINGYUAN XINLV ENVIRONMENTAL TECHNOLOGY CO LTD

Environmentally-friendly treatment method and device for organosilicon slurry

ActiveCN102390860AAvoid the disadvantages of escaping and polluting the environmentEasy to recycleMultistage water/sewage treatmentCopper oxides/halidesEnvironmental resistanceSlurry

The invention relates to an environmentally-friendly treatment method and an environmentally-friendly treatment device for slurry produced in an organosilicon monomer synthesis process. The method comprises the following steps of: cooling organosilicon slurry and then introducing into a closed hydrolysis tank filled with alkaline solution; reacting high boiling residue with alkaline water in the slurry through stirring to generate neutral or alkaline granular hydrolyzate; collecting to the bottom of the hydrolysis tank and recovering; and flowing copper hydroxide flocculent precipitate produced by the reaction from an upper overflow port of the closed hydrolysis tank along with aqueous solution. The invention also provides the closed hydrolysis tank. By adopting the environmentally-friendly treatment method for the organosilicon slurry, the defects of incomplete hydrolysis of organosilicon high boiling residue and high probability of forming acid mist in the prior art are overcome; and the hydrolyzate is recovered under the condition of guaranteeing full hydrolysis of the slurry. Copper in the slurry is converted into the copper hydroxide precipitate for recycling. The problems ofenvironmental friendliness and safety are solved; and the slurry treatment cost is saved.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

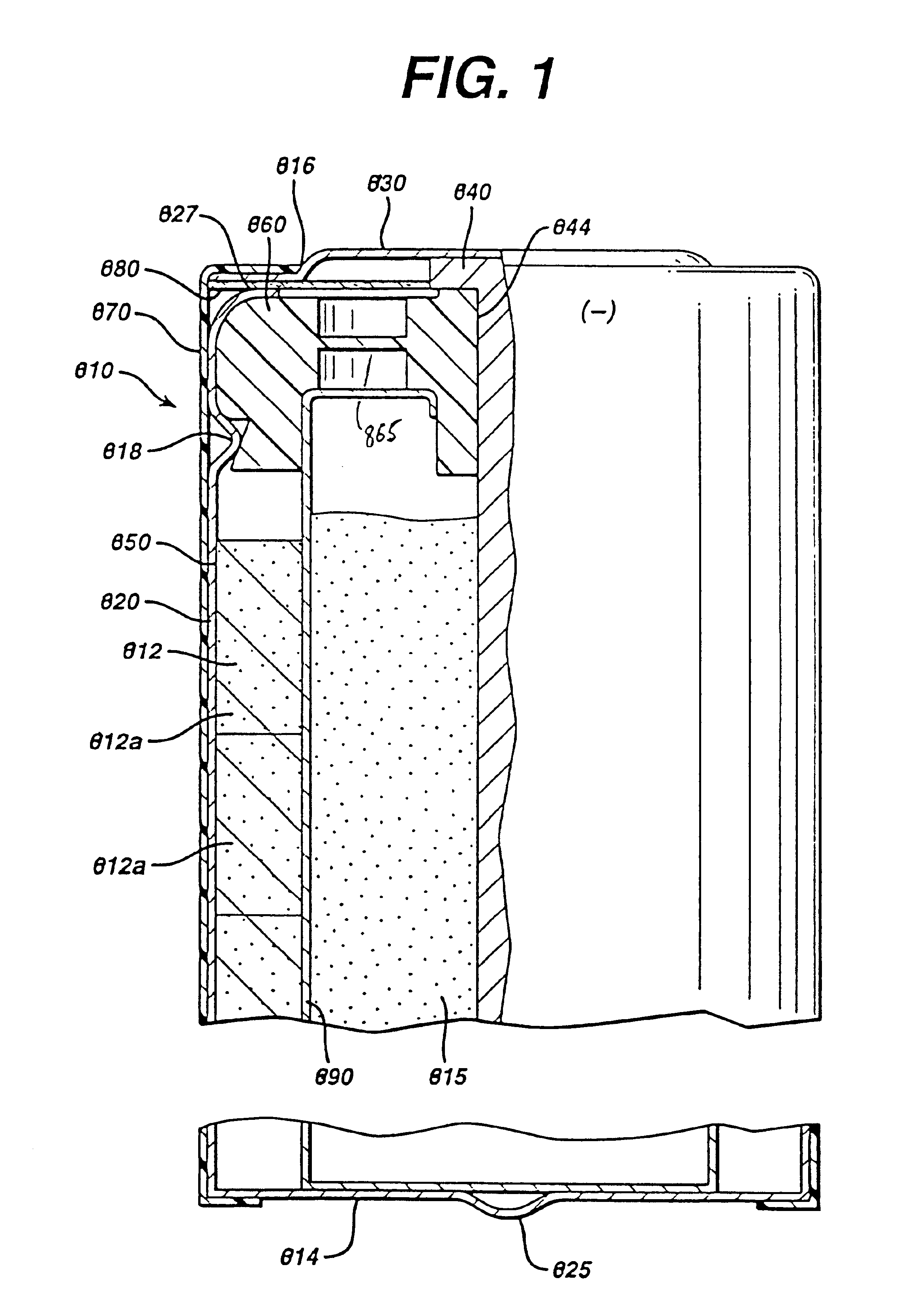

Alkaline cell with improved cathode

InactiveUS6841302B2Reduce cathode resistanceElevates cell 's running voltageAlkaline accumulatorsPositive electrodesFiberCarbon nanofiber

An alkaline cell having an anode comprising zinc, an aqueous alkaline electrolyte, a cathode mixture comprising cathode active material comprising copper oxide or copper hydroxide. Graphitic carbon, preferably expanded graphite or graphitic carbon nanofibers are added to the cathode mixture thereby resulting in a sharp drop in cathode resistivity. The cathode active material preferably comprises between about 80 and 92 percent by weight of the cathode. The sharp drop in cathode resistivity resulting from the addition of expanded graphite or graphitic carbon nanofibers makes the cell suitable for use as a primary alkaline cell having good capacity. The graphitic carbon, preferably graphitic nanofibers comprise preferably between about 4 and 10 percent by weight of the cathode. The carbon nanofibers have an average diameter desirably less than 500 nanometers, preferably between about 50 and 300 nanometers.

Owner:DURACELL U S OPERATIONS

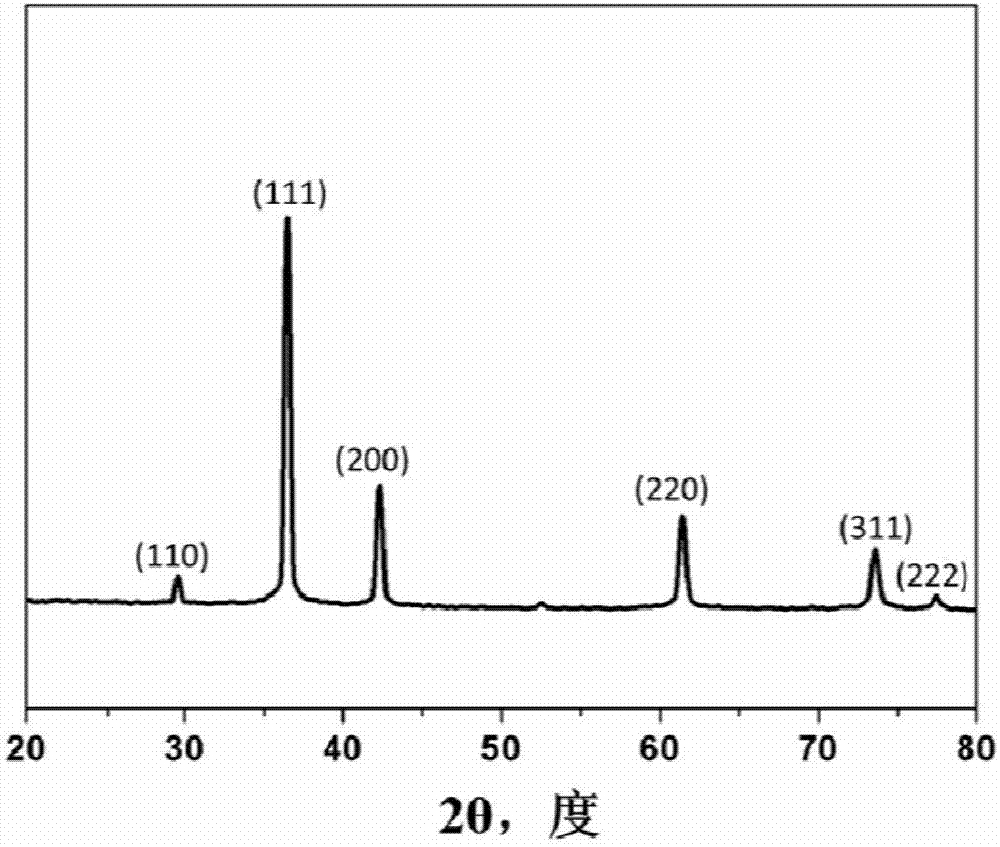

Cuprous oxide nanocrystalline with adjustable morphology and dimension as well as preparation method and application thereof

ActiveCN107473257AMorphology regulationParticle Size ControlNanotechnologyCopper oxides/halidesPhotocatalytic degradationReaction system

The invention discloses a cuprous oxide nanocrystalline with adjustable morphology and dimension as well as a preparation method and an application thereof. The preparation method comprises the following steps: copper hydroxide which is used as a precursor is synthesized; the pH value of the system is regulated; the system whose pH value is regulated is reduced in order to obtain cuprous oxide nanocrystalline. A surfactant is not needed to add, the cuprous oxide nanocrystalline with specific morphology and dimension can be obtained by adjusting the pH value of the reaction system, and the nanocrystalline can be used for photocatalytic degradation of organic pollutants, and the method is a rapid, simple and green preparation method of cuprous oxide nanocrystalline.

Owner:INST OF CHEM CHINESE ACAD OF SCI

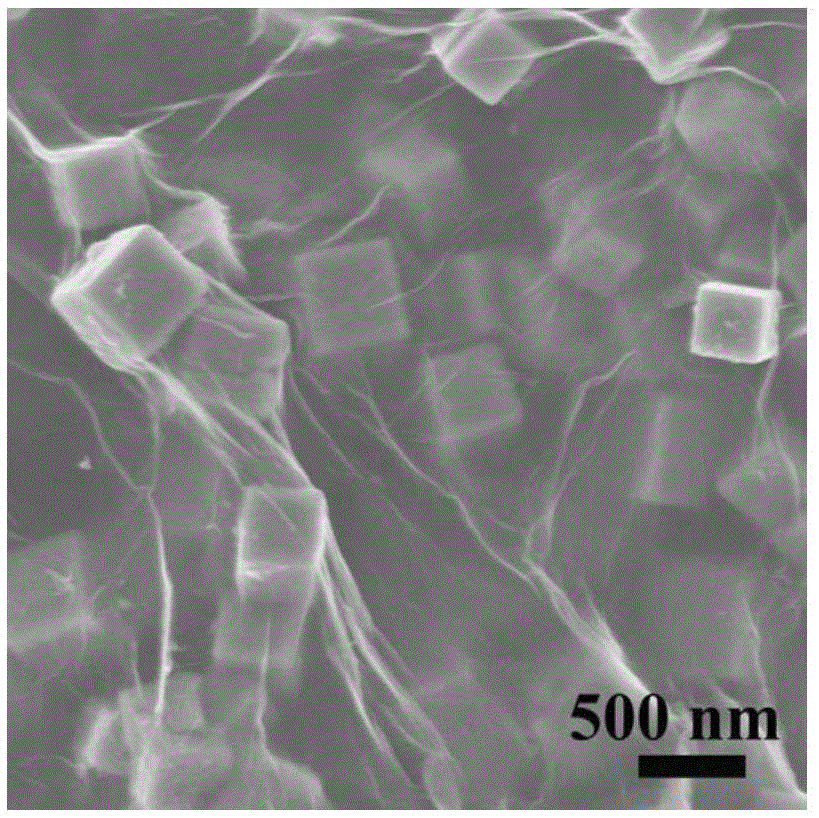

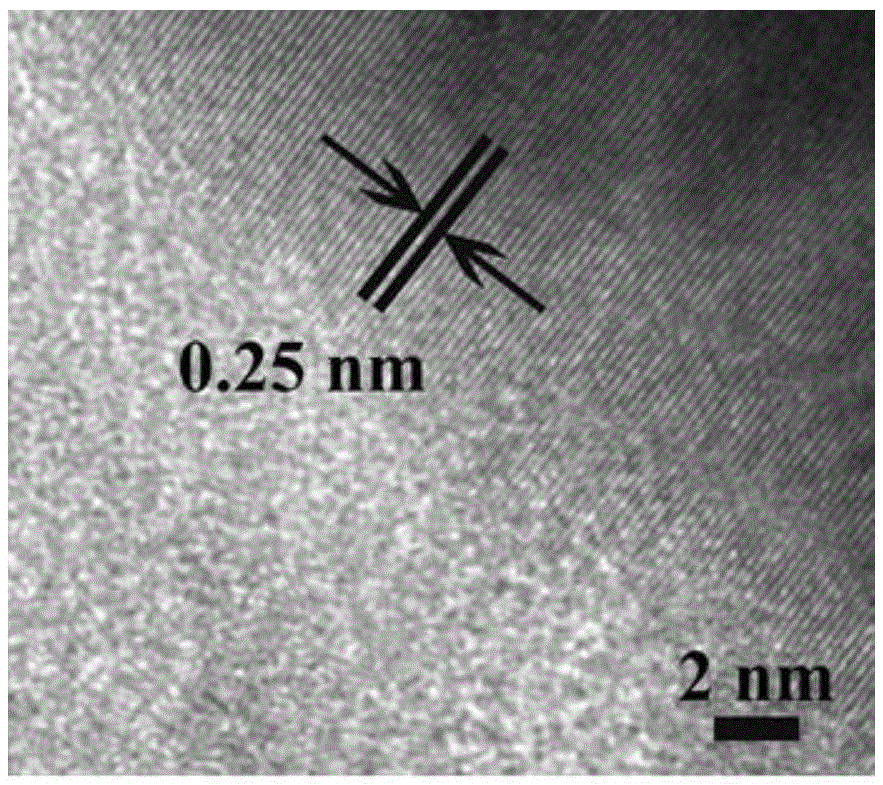

Preparation method of cubic cuprous oxide/graphene nanocomposite

InactiveCN105664943AGood lookingImprove photocatalytic efficiencyWater/sewage treatment by irradiationWater treatment compoundsWater bathsGraphene nanocomposites

The invention discloses a preparation method of a cubic cuprous oxide / graphene nanocomposite with efficient photocatalysis capability. According to the method, the composite can be prepared with a simple one-pot reduction method. Firstly, graphene oxide is prepared with an improved Hummers method, copper sulfate pentahydrate and graphene oxide are ultrasonically dispersed in water and mechanically stirred in a water bath at the temperature of 50-60 DEG C to be uniformly mixed, a sodium hydroxide solution is dropwise added to the mixture, copper hydroxide precipitates are formed, then, a glucose solution is added, the mixture reacts for 2-3 h, sufficient reduction is performed, centrifugation, washing and drying are performed, and a cubic cuprous oxide / graphene photocatalyst with the efficient photocatalysis capability is obtained. The process is simple, the cost is low, the product has uniform morphology, and the cubic cuprous oxide / graphene nanocomposite has excellent capability of photocatalytic degradation of organic dye under the visible light and has great application potential in environmental governance and solar energy utilization.

Owner:SHANGHAI JIAO TONG UNIV

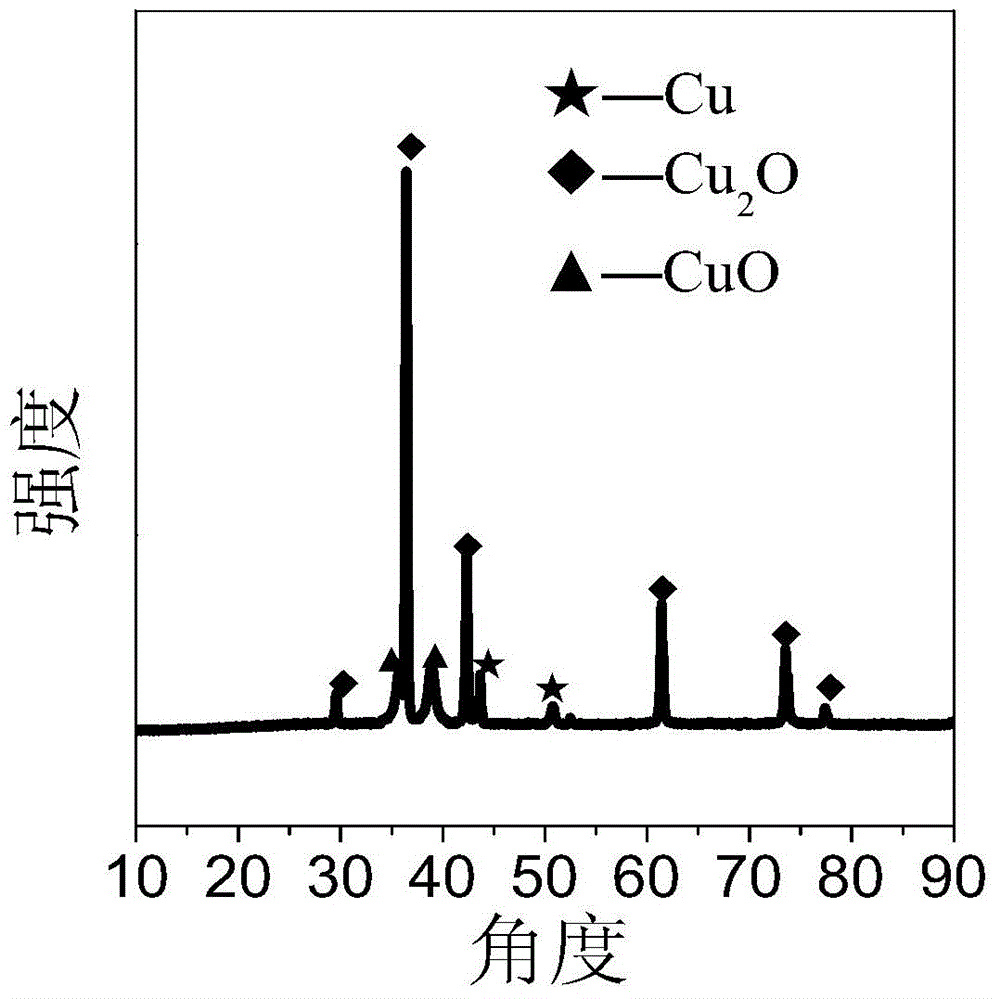

Copper-based Cu-Cu2O-CuO catalyst as well as preparation method and application thereof

ActiveCN104857958AControllable ratioEvenly distributedGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsCopper(II) oxideVacuum drying

The invention provides a copper-based Cu-Cu2O-CuO catalyst for an organic silicon monomer synthesis reaction as well as a preparation method and an application of the copper-based Cu-Cu2O-CuO catalyst. The catalyst comprises components in percentage by mass as follows: 0-40% of elementary Cu, 40%-90% of Cu2O and 0-40% of CuO, and the sum of mass percentages of all the components is 100%. The method comprises steps as follows: a copper salt is dissolved to form a copper salt solution; an alkaline solution is dropwise added to the copper salt solution, and copper hydroxide precipitate is obtained and then converted into CuO precipitate; then a certain quantity of reducing agent is dropwise added to a CuO suspension for a controllable reduction reaction; obtained reaction products are filtered, washed and subjected to vacuum drying, and then the multicomponent copper-based catalyst is obtained. The experimental process route is simple, the controllability is high, and the prepared multicomponent copper-based catalyst is smaller in particle size and evener in particle size distribution, contains controllable components and shows the higher M2 selectivity and the higher silicon powder raw material conversion ratio.

Owner:TAIXING SMELTING PLANT

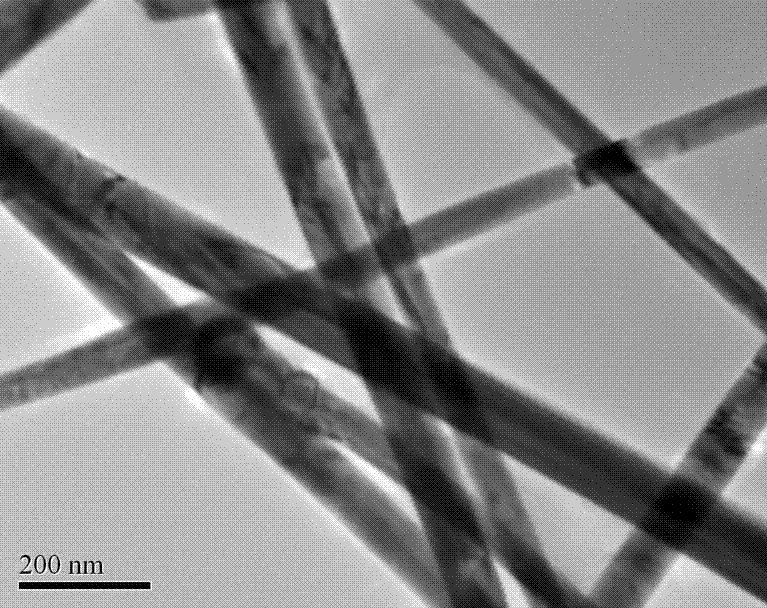

Preparation method for copper nanowire

ActiveCN103084581AEasy to removeVolatilePolycrystalline material growthFrom normal temperature solutionsHydroxylaminePotassium hydroxide

The invention belongs to the technical field of novel function nanometer material preparation, and discloses a preparation method for a copper nanowire. Reducing agent is added to copper source on the premise that morphology control agent and chemical potential control agent are exist in water solution, and the copper nanowire are obtained after separation and under the condition that reaction is carried out for at least one hour in temperature of 25 DEG C to 100 DEG C, wherein the copper source is one or combination of copper hydroxide and copper oxide, the morphology control agent is one kind or combination of more than two kinds of polyethylene polyamine, the chemical potential control agent is one or combination of sodium hydroxide and potassium hydroxide, and the reducing agent is one or combination of hydrazine hydrate and hydroxylamine. The preparation method for the copper nanowire has the advantages of being simple in technology and device, cheap and easy-getting in raw materials, low in cost, high in productivity, suitable for large-scale industrial production, and the like. Prepared copper nanometers are uniform in diameter, diameters and lengths of the copper nanometers can be controlled through changing concentration of the morphology control agent and concentration and reaction temperature of the copper resource.

Owner:HENAN UNIVERSITY

Reduction process of preparing nano cuprous oxide wire

Owner:NANJING UNIV

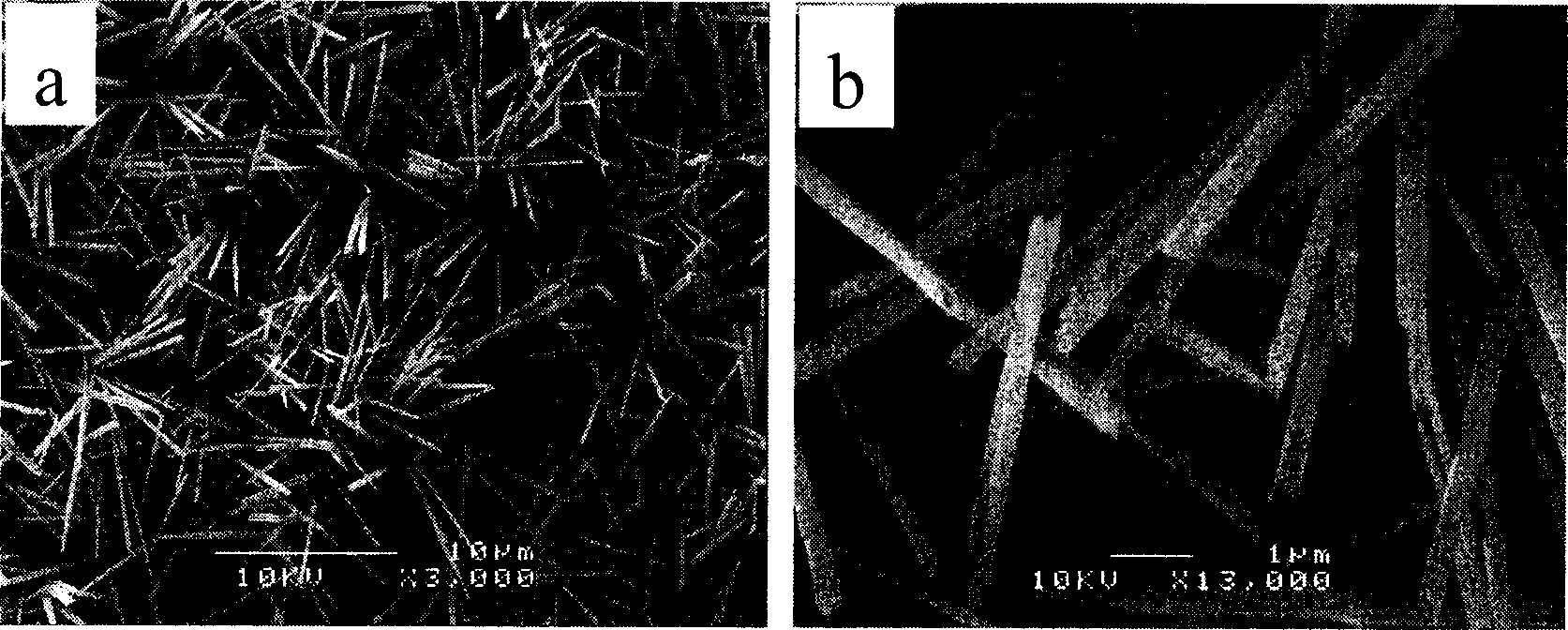

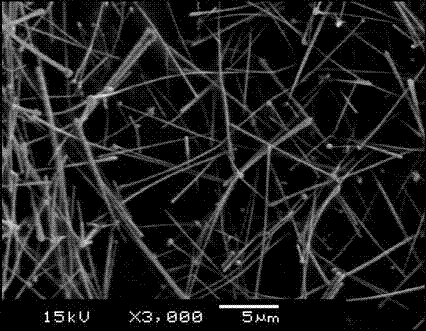

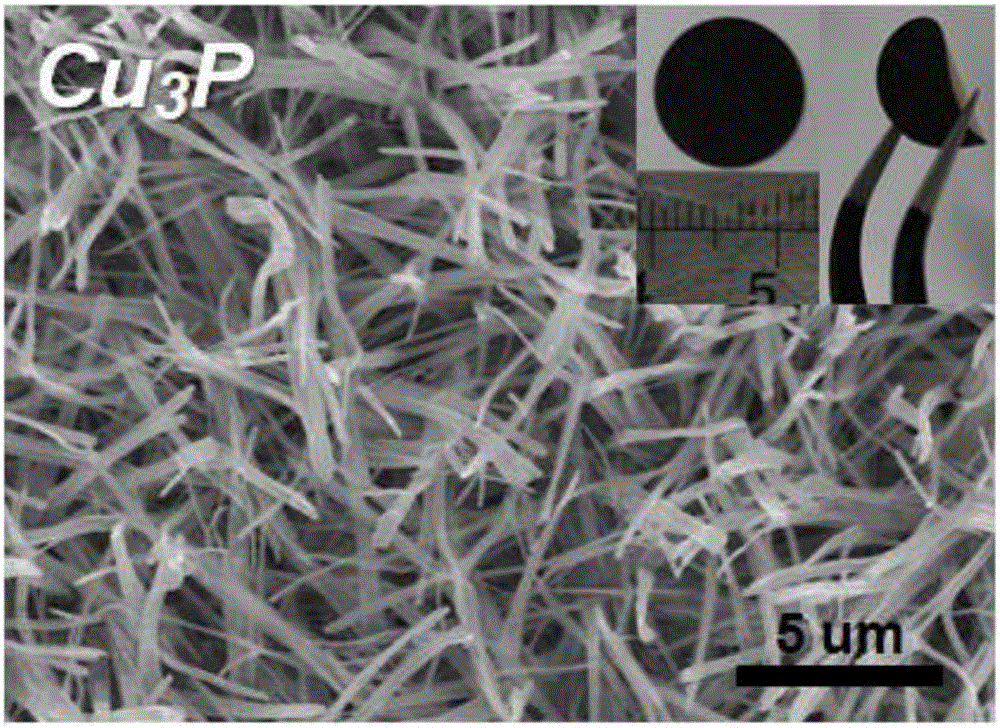

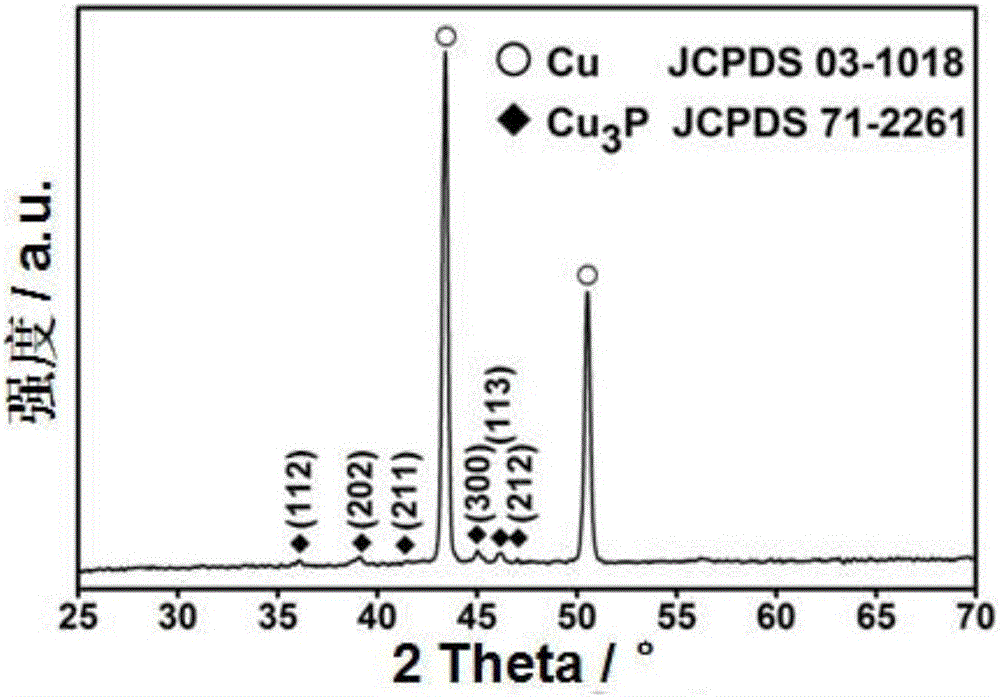

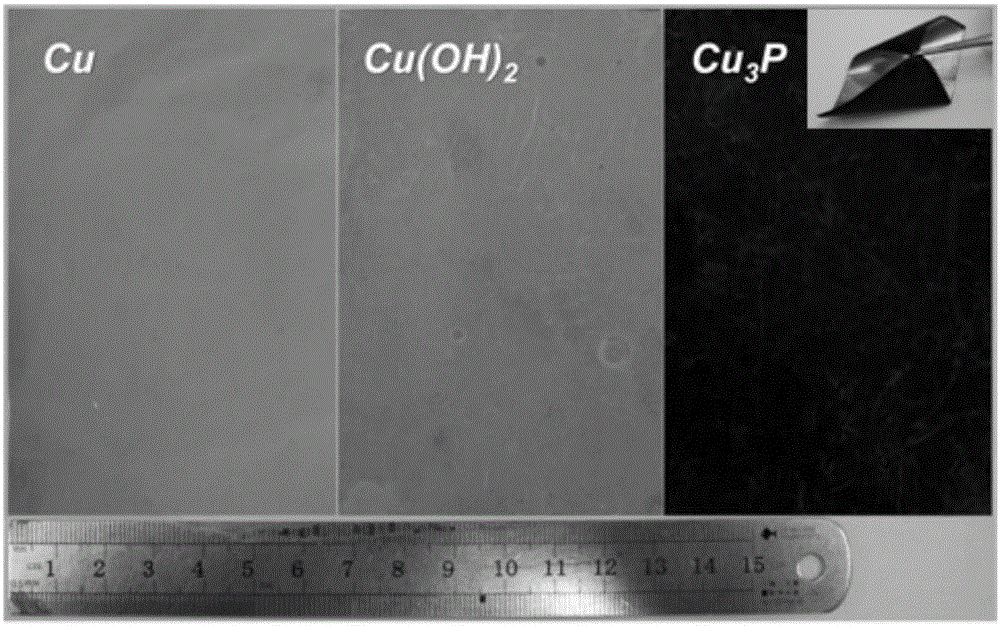

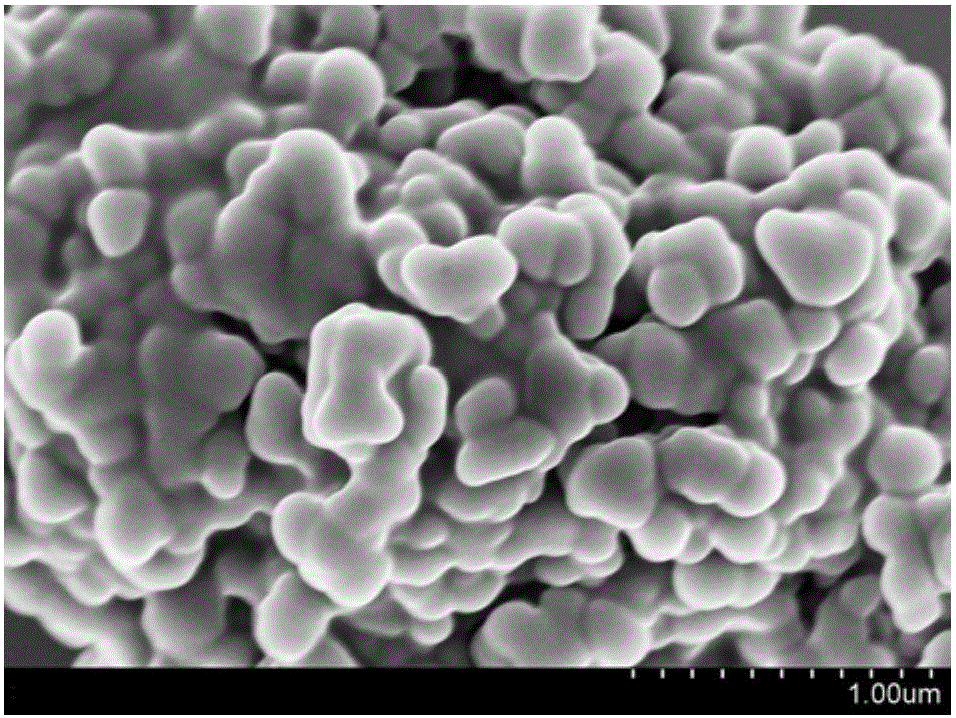

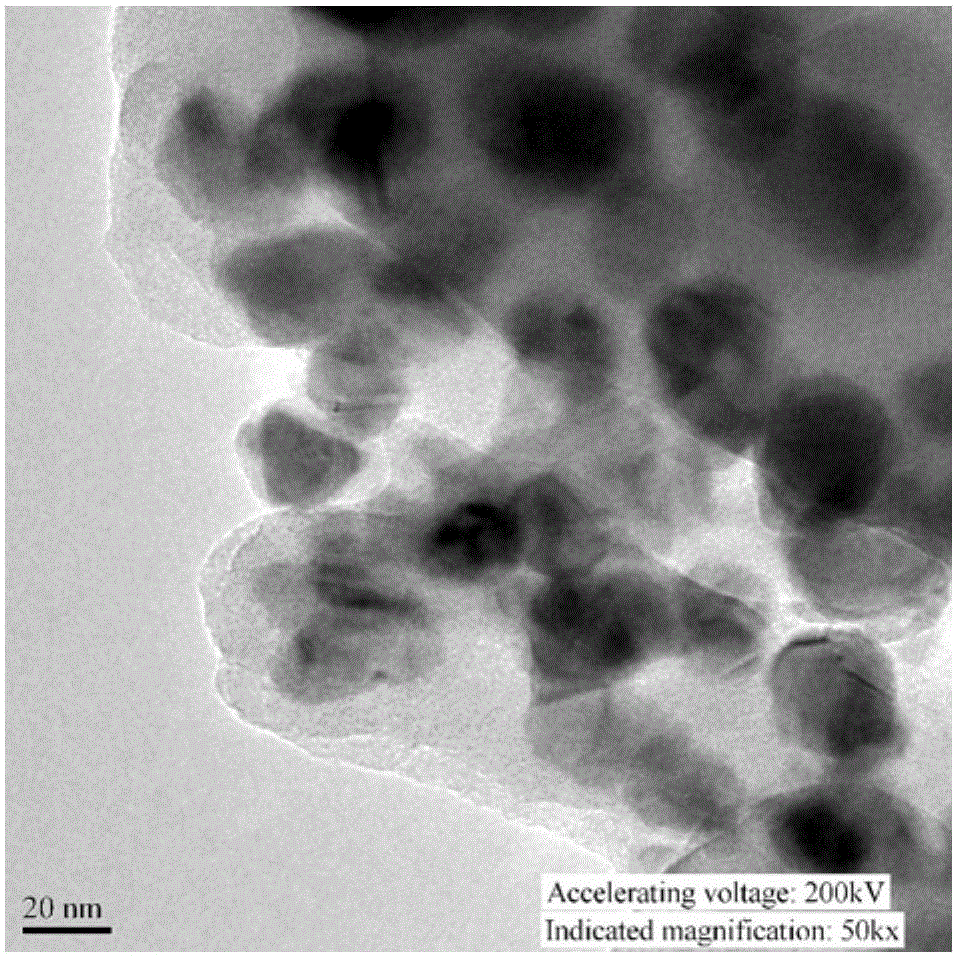

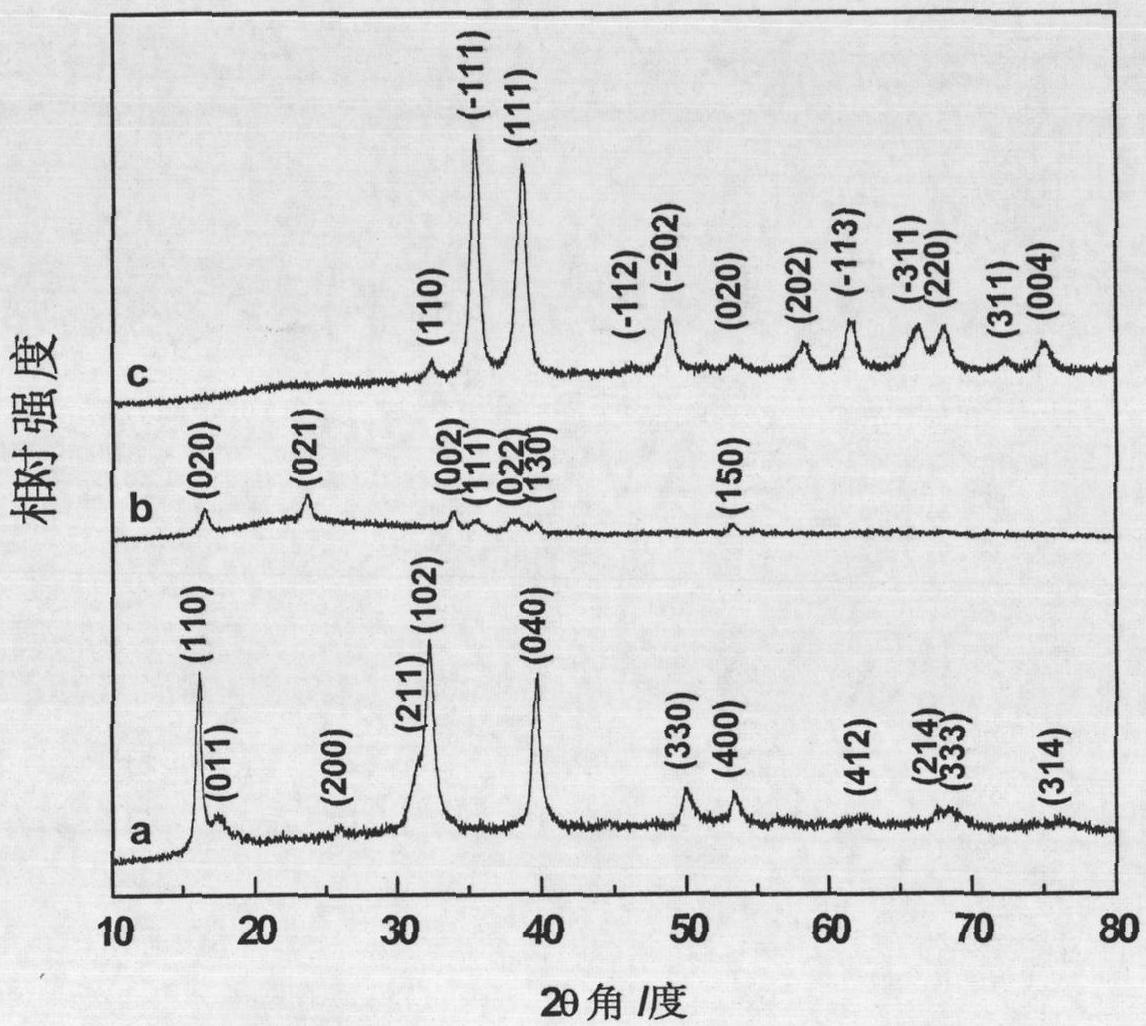

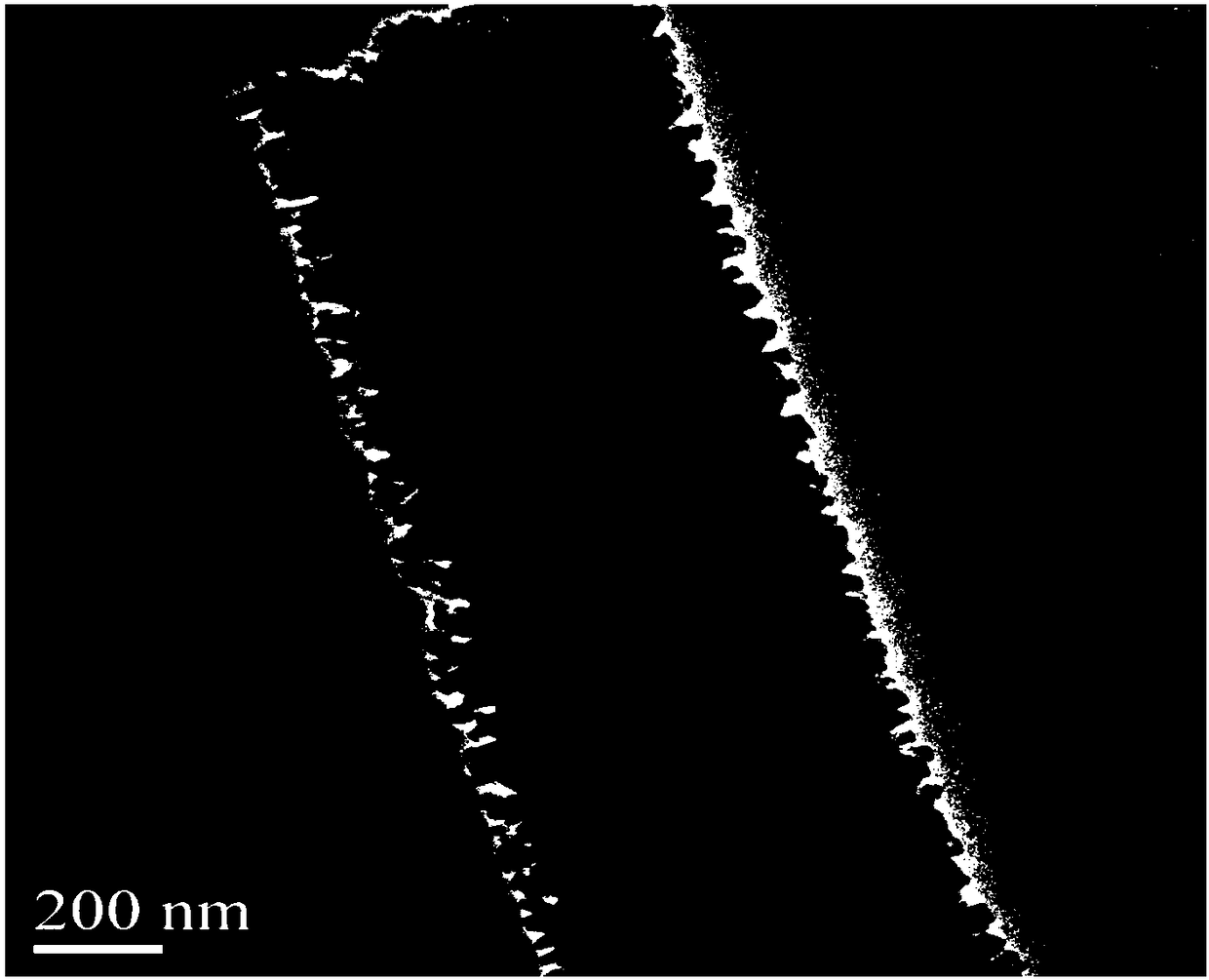

Preparation method of Cu3P nanowire negative electrode, Cu3P nanowire negative electrode prepared by method and application of Cu3P nanowire negative electrode

ActiveCN105845932ALow costThe process steps are simpleCell electrodesSecondary cellsNanowireElectrical battery

The invention relates to a preparation method of a Cu3P nanowire negative electrode, the Cu3P nanowire negative electrode prepared by the method and an application of the Cu3P nanowire negative electrode. The method comprises the following steps: (a) immersing one surface of a copper foil into a mixed water solution of persulfate and hydroxide for reaction, and forming a copper hydroxide nanowire in one side surface of the copper foil; and (b) putting excessive hypophosphite into the middle part of a tube furnace, putting the copper foil formed with the copper hydroxide nanowire in one side surface into the downstream part, discharging air in the tube furnace by an inert gas, then heating the air and reacting a generated hydrogen phosphide gas and the copper foil formed with the copper hydroxide nanowire in one side surface under a low-temperature condition to obtain a Cu3P nanowire negative electrode material in in-situ, unilateral and massive growth on the basis of a copper foil base. The material can be directly used as the negative electrode material for sodium-ion half-batteries and all-batteries. The processing steps are simple; the cost is relatively low; and enlarged production and large-scale promotion are facilitated.

Owner:SUZHOU UNIV

Preparation method for copper/cuprous oxide/cyclized polyacrylonitrile visible-light-driven photocatalyst

InactiveCN105126917ASmall particle sizeEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsDehydrogenationIon exchange

The invention discloses a preparation method for a copper / cuprous oxide / cyclized polyacrylonitrile visible-light-driven photocatalyst, and belongs to the technical field of environmental cleaning photocatalyst new materials. The preparation method includes the steps of firstly, preparing a nanometer copper hydroxide / photocatalyst compound by synchronously conducting solvent conversion and in-situ ion exchange reaction with photocatalyst, cupric nitrate and sodium hydroxide as raw materials; secondly, reducing copper hydroxide into cuprous oxide in situ through ascorbic acid; thirdly, conducting thermal treatment under the nitrogen atmosphere, reducing a small amount of cuprous oxide into elementary substance copper while cyclization and dehydrogenation are conducted on polyacrylonitrile to form a conjugated structure, and obtaining the copper / cuprous oxide / cyclized polyacrylonitrile visible-light-driven photocatalyst. The raw materials are wide in source, cost is low, the preparation method is simple and suitable for large-scale production, cyclized polyacrylonitrile can improve the separation efficiency of photoproduction electron holes and absorption of the visible light areas and can have a protection and optical corrosion reduction effect on copper / cuprous oxide, and the obtained catalyst is remarkable in adsorption and photocatalytic effect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for recycling copper, indium and gallium from waste copper-indium-gallium target

The invention relates to a method for recycling copper, indium and gallium from a waste copper-indium-gallium target. The method comprises the following steps that copper, indium and gallium are dissolved in acid to be in corresponding ionic states; then neutralization and sedimentation are performed to form corresponding hydroxides; then, a concentrated NaOH solution is used for separation to remove gallium, a simple substance of gallium is electrolyzed and recycled, and a water electrolyte containing NaOH generated in the electrolytic process is used for secondary gallium separation; the copper hydroxide and the indium hydroxide are dissolved in acid again, a kerosene solution of di(2-ethylhexyl phosphoric acid) is used for extracting In3+ into an organic phase, and Cu2+ is still in the water phase; iron power is used for replacing a simple substance of copper from the water phase containing Cu2+; and concentrated hydrochloric acid is used for reversely extracting In3+ into the water phase, and then aluminum powder is used for replacement to obtain a simple substance of indium. According to the method, the copper recycling rate is not smaller than 97.1%, the indium recycling rate is not smaller than 97.3%, and the gallium recycling rate is not smaller than 97.9%, so that operation is easy and convenient, and the cost is low.

Owner:北京大昱光伏科技有限公司

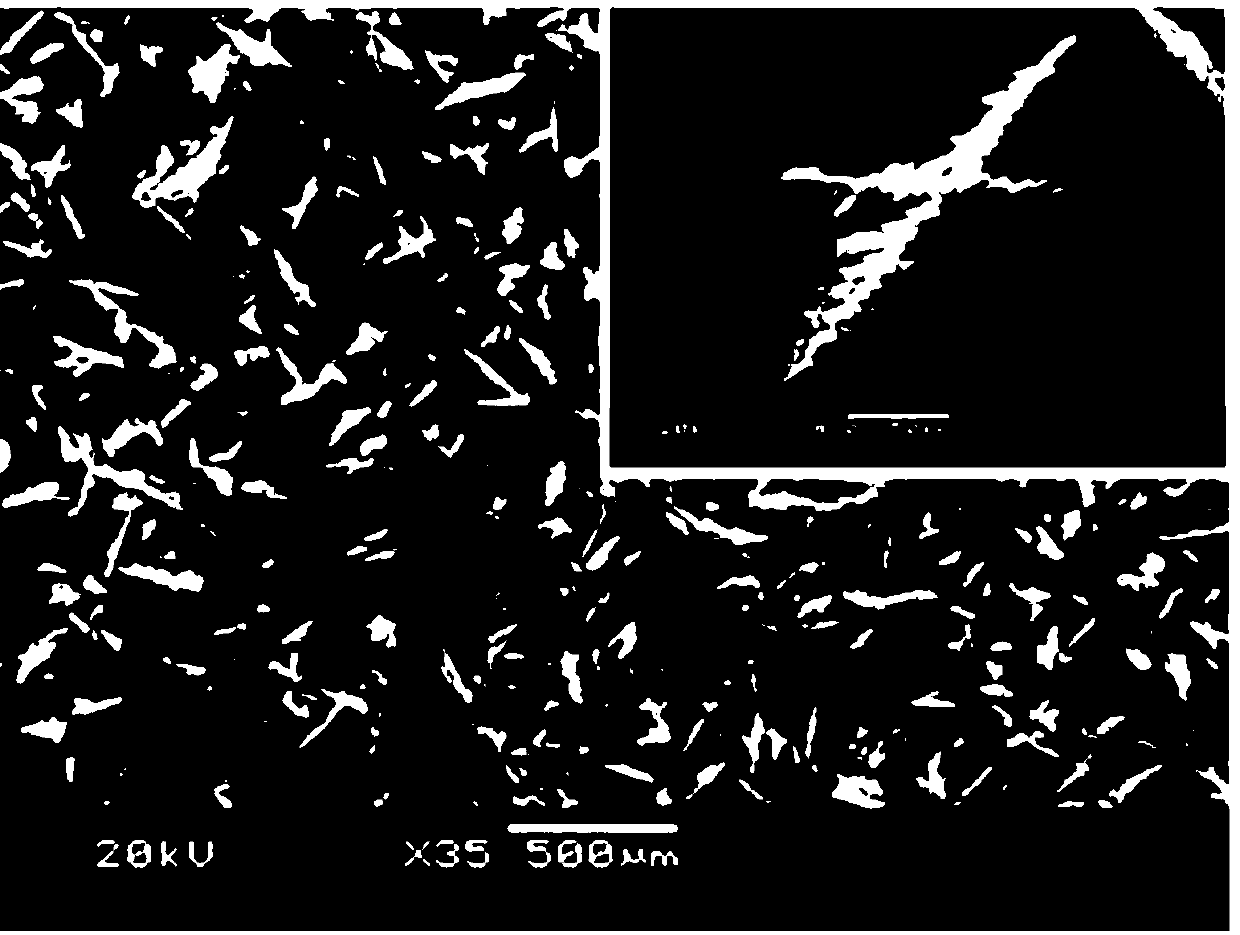

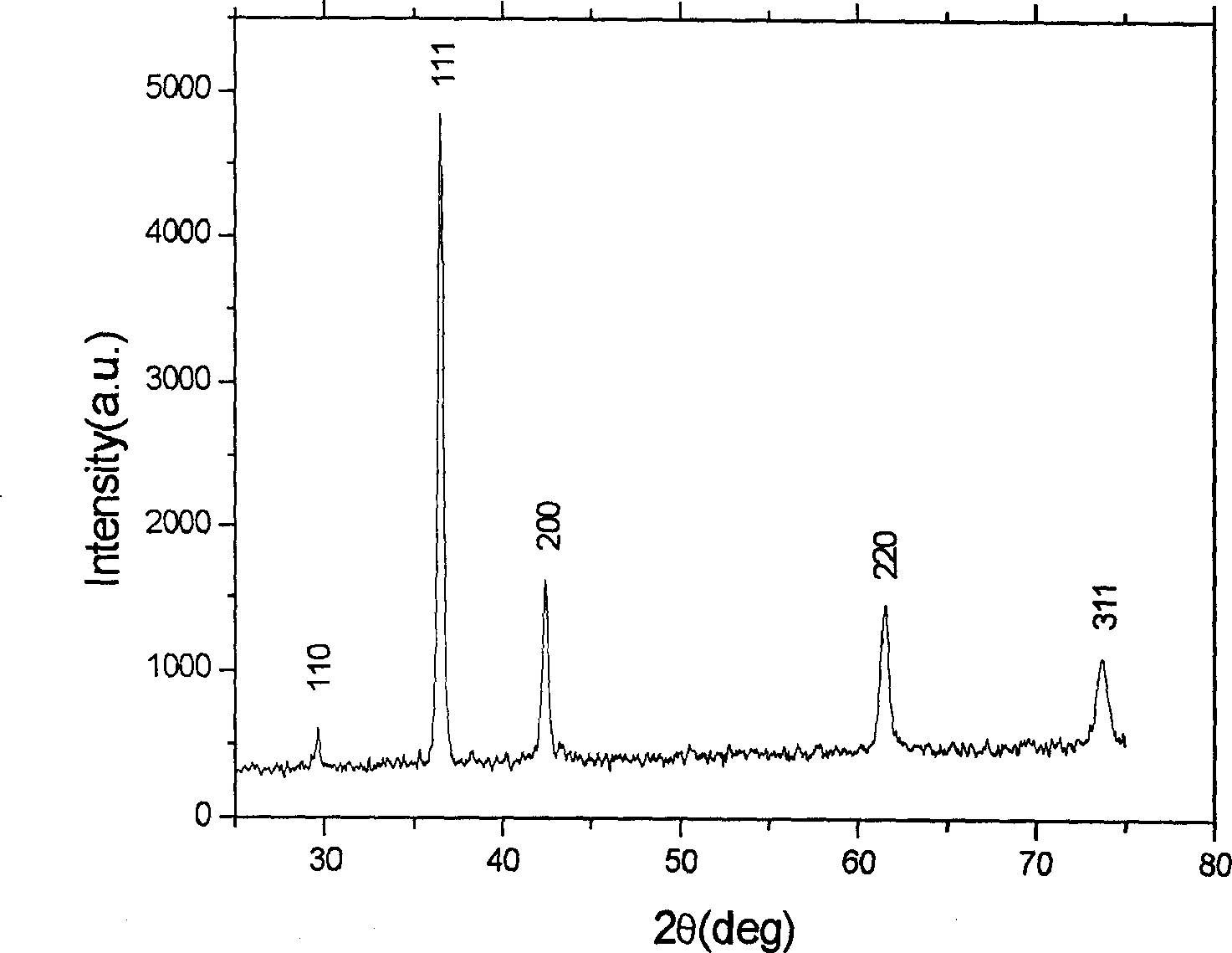

Preparation of highly pure copper oxide from waste etchant

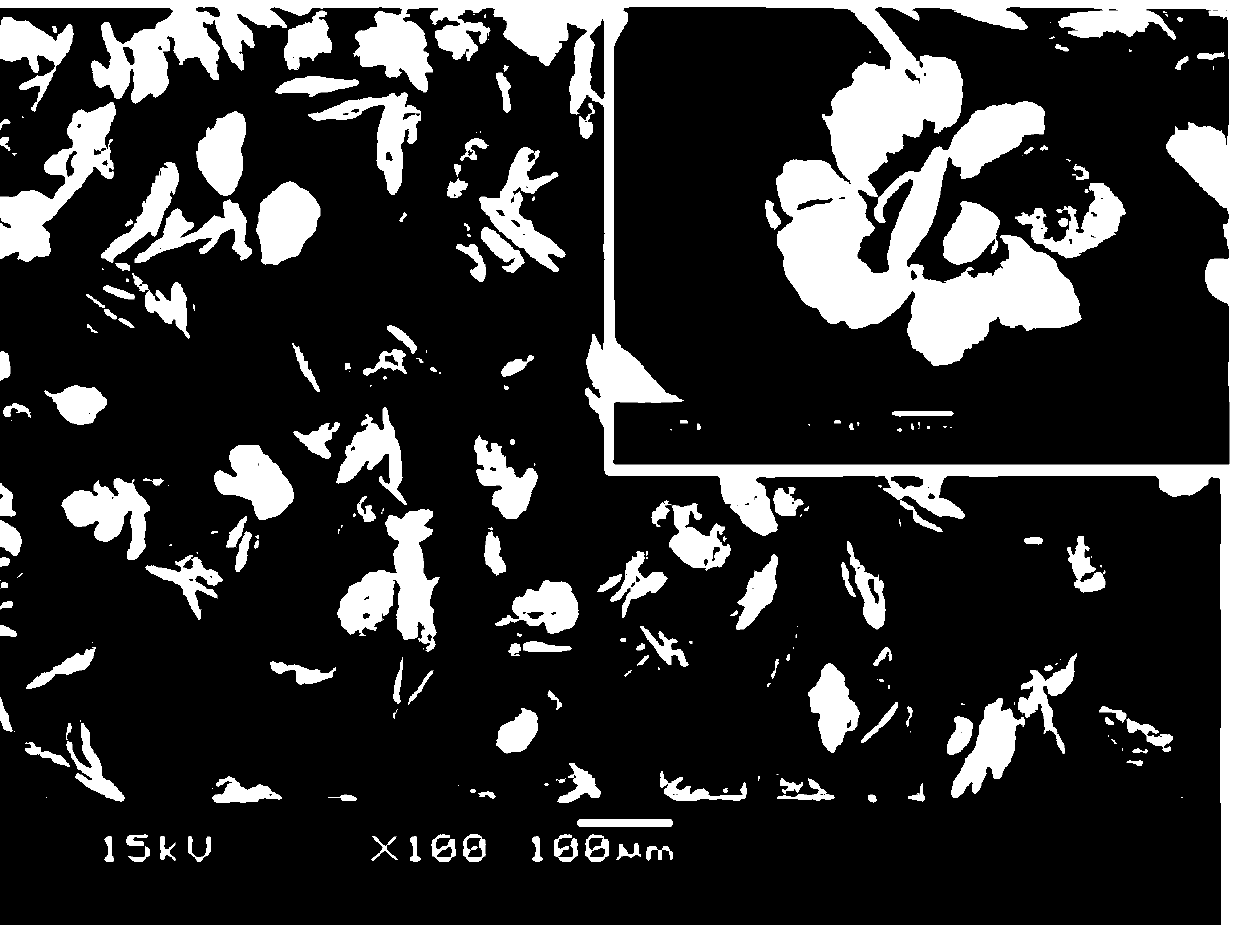

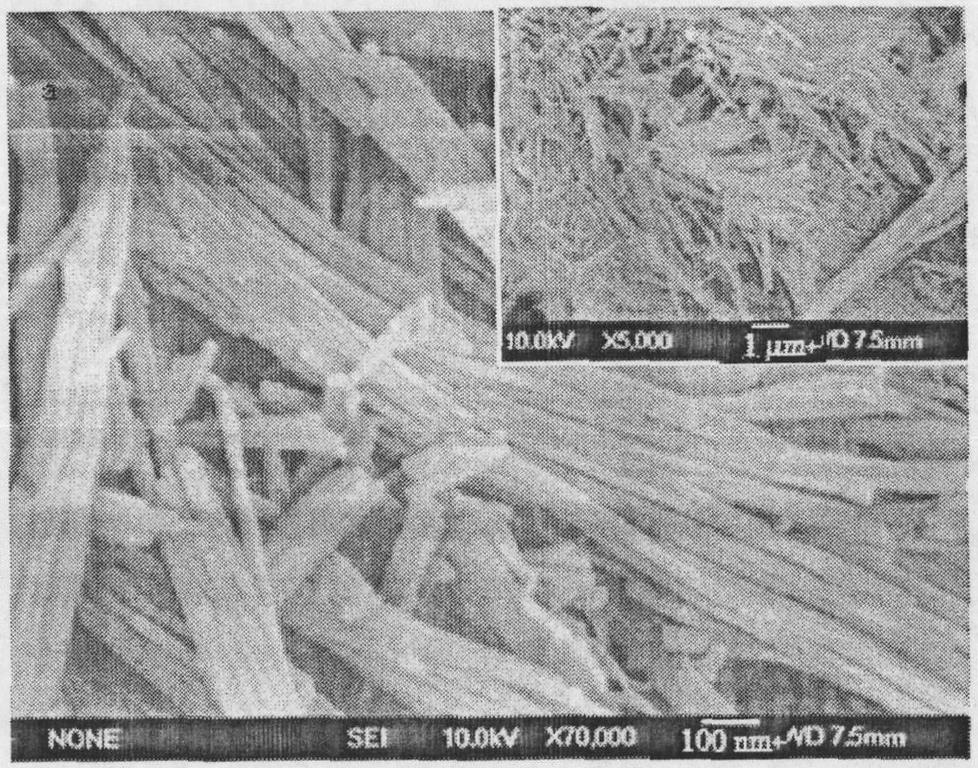

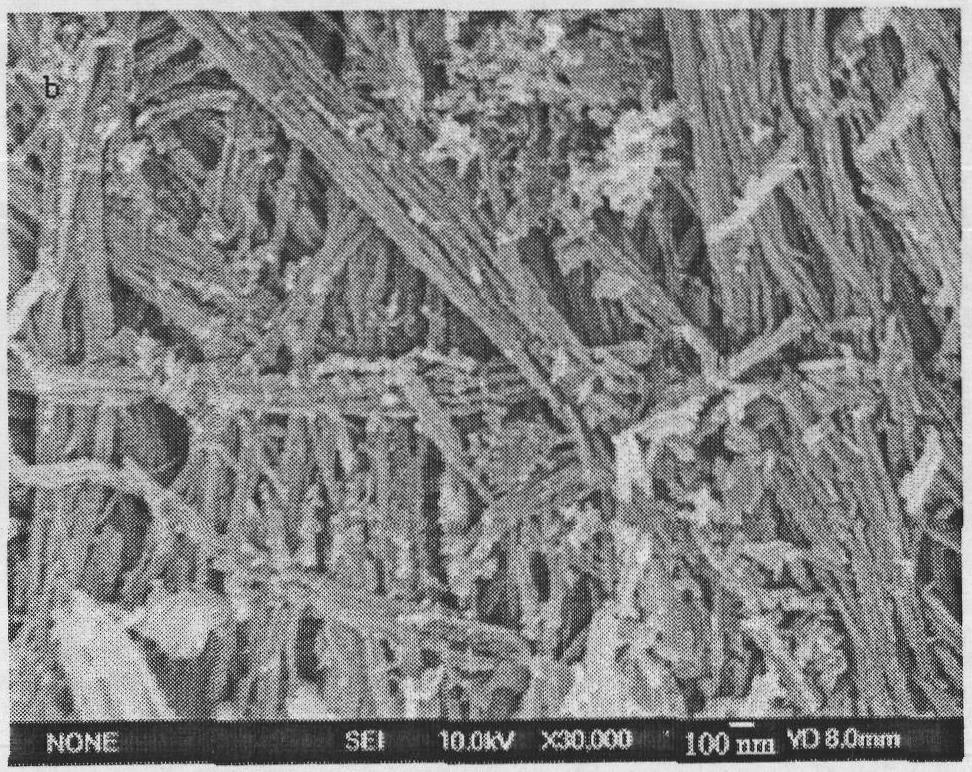

InactiveUS6649131B2Oxygen/ozone/oxide/hydroxideGold compoundsCrystal morphologyAqueous sodium hydroxide

A method for recycling copper oxide includes: a first step in which a sodium hydroxide aqueous solution is added to acidic copper chloride waste etchant produced in the PCB industry, to obtain copper hydroxide slurry; and a second step in which the slurry obtained in the first step is heated and sintered to thereby prepare a needle-form copper oxide. Since copper oxide has a purity of more than 99.0 wt % and the needle-form crystal morphology, so that it has an excellent filtering ability and homogeneous particle size distribution.

Owner:MYUNG JIN CHEM

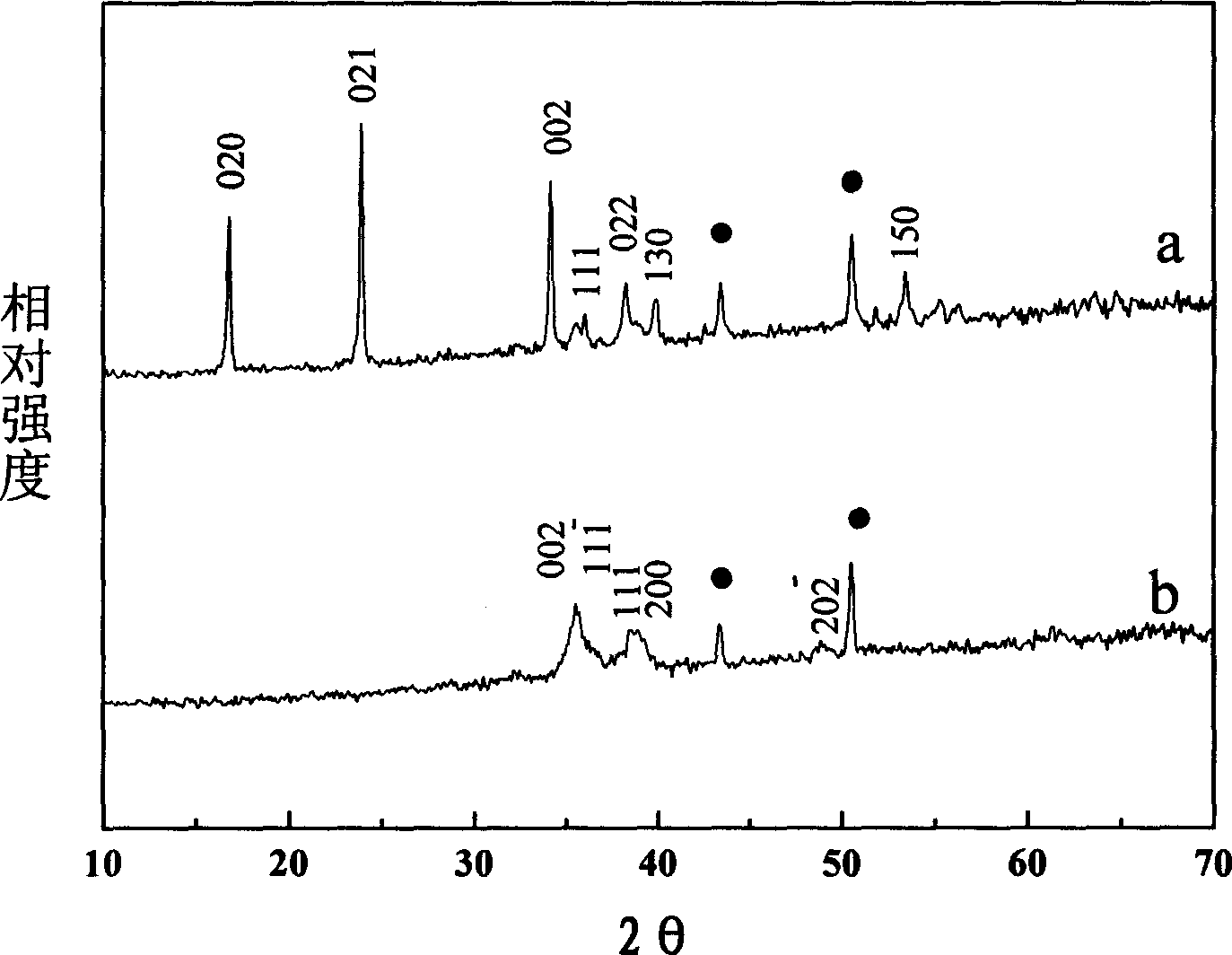

Method for preparing copper hydroxide and copper oxide nano material and application

InactiveCN101792172AQuick response conditionsMild reaction conditionsNanostructure manufactureCopper oxides/halidesDistilled waterCopper oxide

The invention discloses a method for preparing a copper hydroxide and copper oxide nano material, which comprises the following steps: dispersing atacamite serving as a precursor into distilled water to form suspension, then dripping NaOH solution into the suspension with stirring to make the molar ratio of the NaOH to the precursor be 6: 1-100: 1, continuously stirring the solution to fully react the precursor to generate Cu(OH)2 sediment and Cu(OH)4<2-> solution mixture after the dripping of the NaOH solution is finished, treating the mixture by ultrasound to generate Cu(OH)2 and / or CuO nano material, and performing thermal inversion reaction on the generated Cu(OH)2 nano material to form CuO nano material. The method realizes the control of product phase and appearance by effectively controlling the ultrasound time and / or the temperature rise of the thermal inversion reaction, and has the advantages of mild reaction condition, quickness, simple operation, low cost, strong controllability of product structure, good reproducibility and easy implementation of large-scale production.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

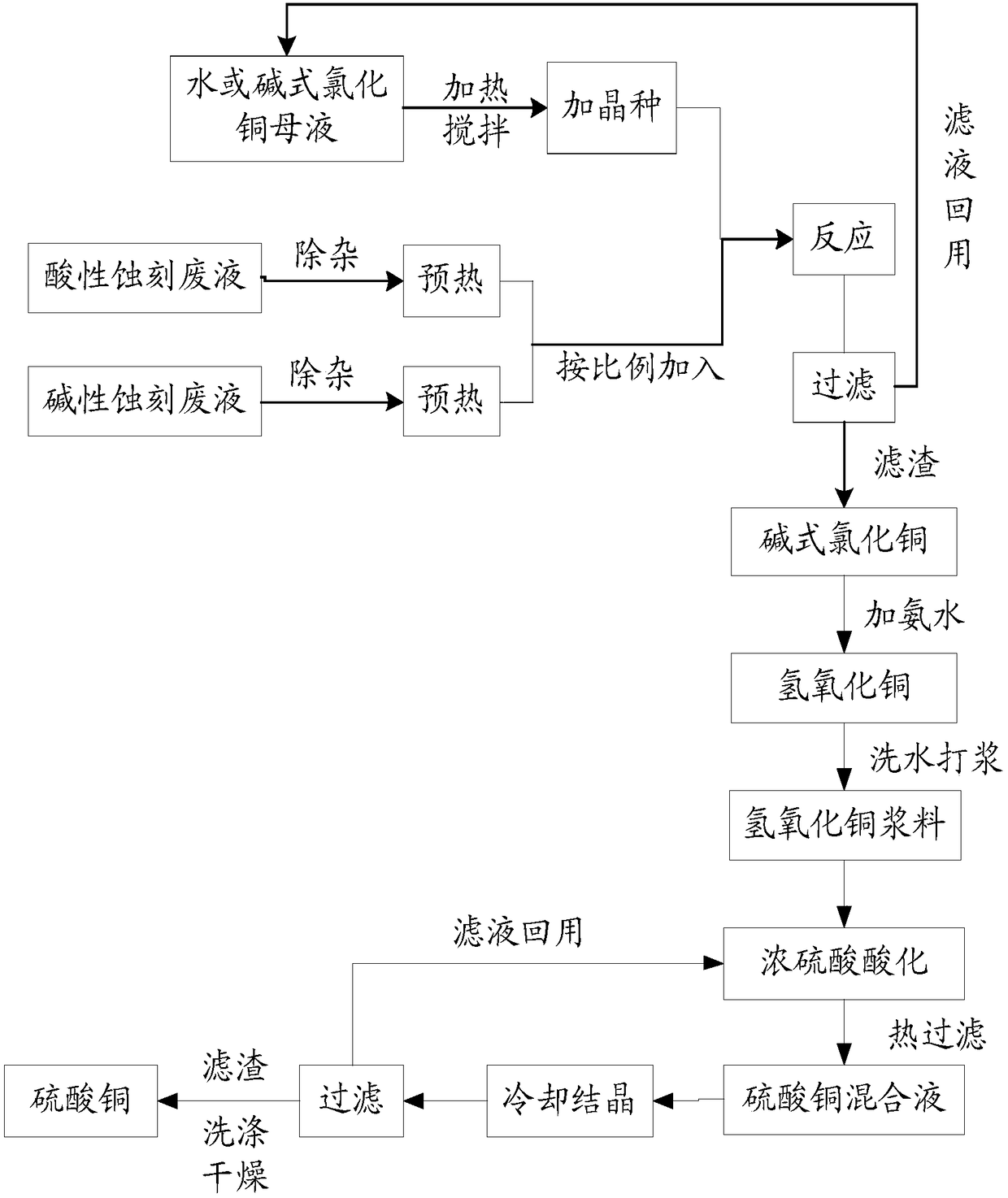

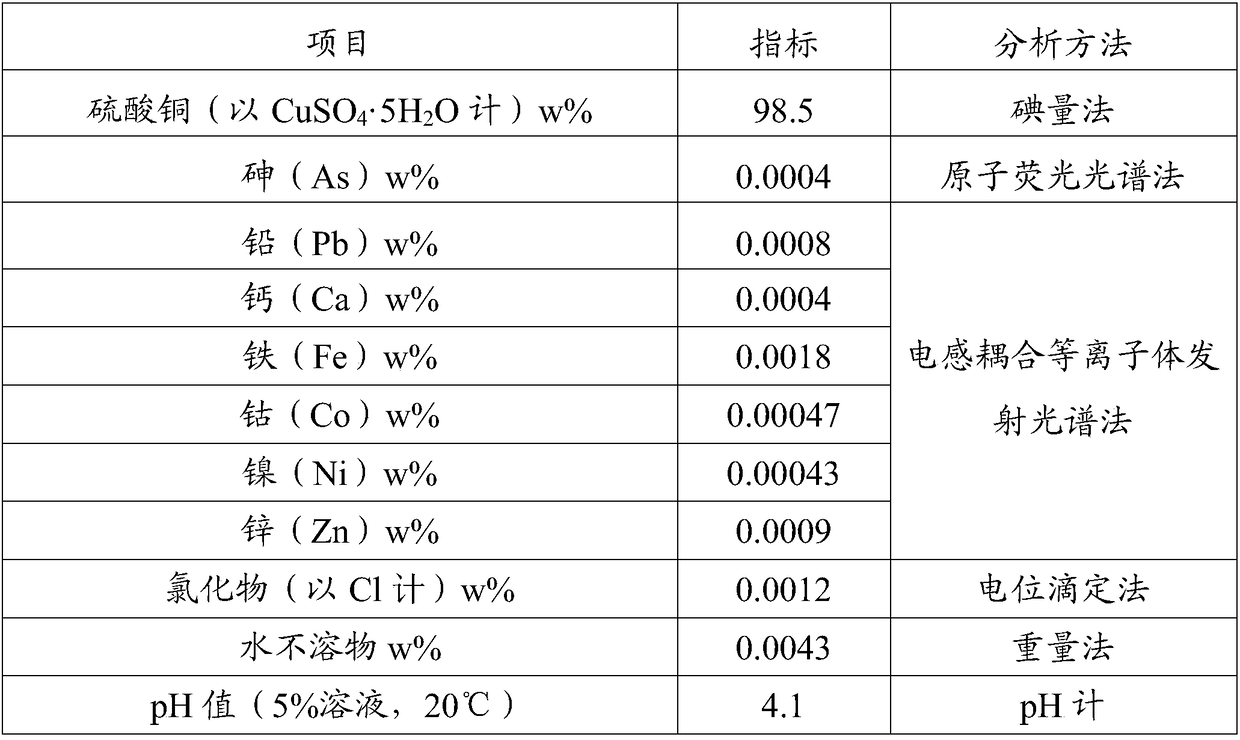

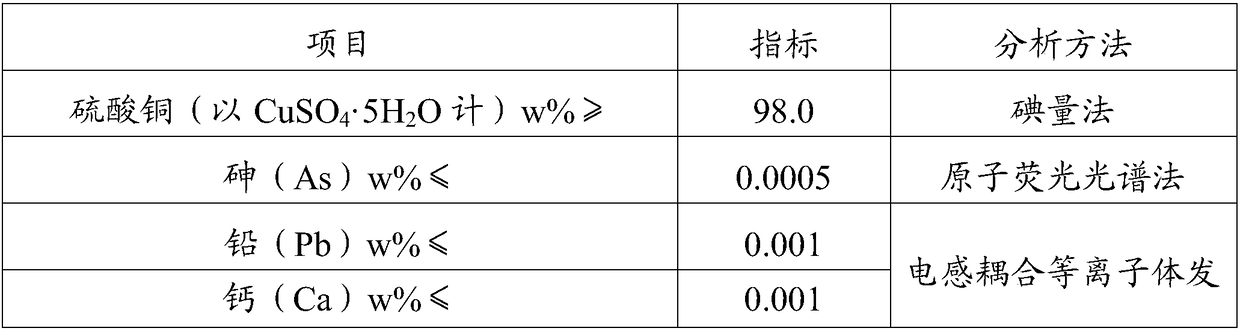

Production method of copper sulfate

ActiveCN108341424AReduce temperature gapResponse control is appropriateCopper sulfatesAcid etchingFiltration

The invention discloses a production method of copper sulfate. The production method comprises the following steps: adding an oxidizing agent into an acid etching waste solution to oxidize cuprous ions and ferrous ions in the acid etching waste solution; then regulating a pH value to reach 1.7 to 1.9 and carrying out stirring and reaction; then adding activated carbon again; performing settlementlayering and taking supernatant liquid to perform filtration to obtain an impurity-removed acid etching waste solution; adding soluble magnesium salt into an alkali etching waste solution and carryingout stirring and reaction; then performing settlement layering and taking supernatant liquid to obtain an impurity-removed alkali etching waste solution; performing mixed reaction on the impurity-removed acid etching waste solution and the impurity-removed alkali etching waste solution to obtain basic copper chloride; converting basic copper chloride ammonia into copper hydroxide; then performingfiltration on copper hydroxide, washing and purifying copper hydroxide and pulping copper hydroxide; then adding sulfuric acid to be acidified until pH is 0.5 to 1.0; then performing heat filtration,cooling crystallization, solid-liquid separation and drying treatment to obtain copper sulfate. Copper sulfate produced by the method can reach electroplating grade standard; moreover, a recovery ratio of copper in the etching waste solutions is high.

Owner:东莞市恒建环保科技有限公司

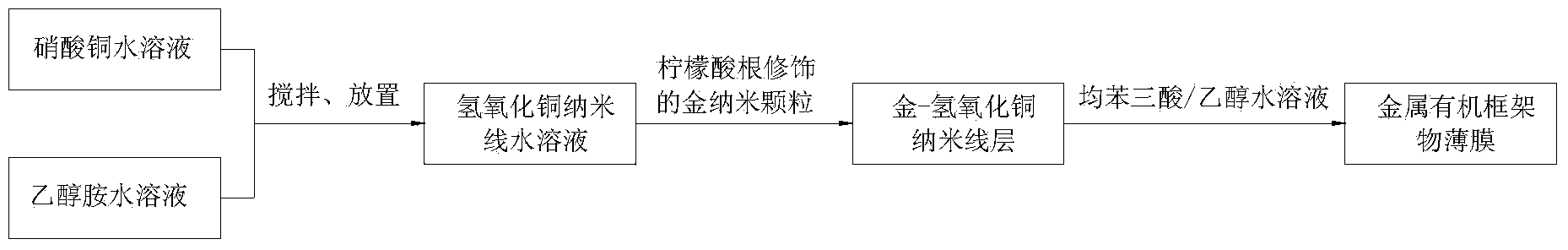

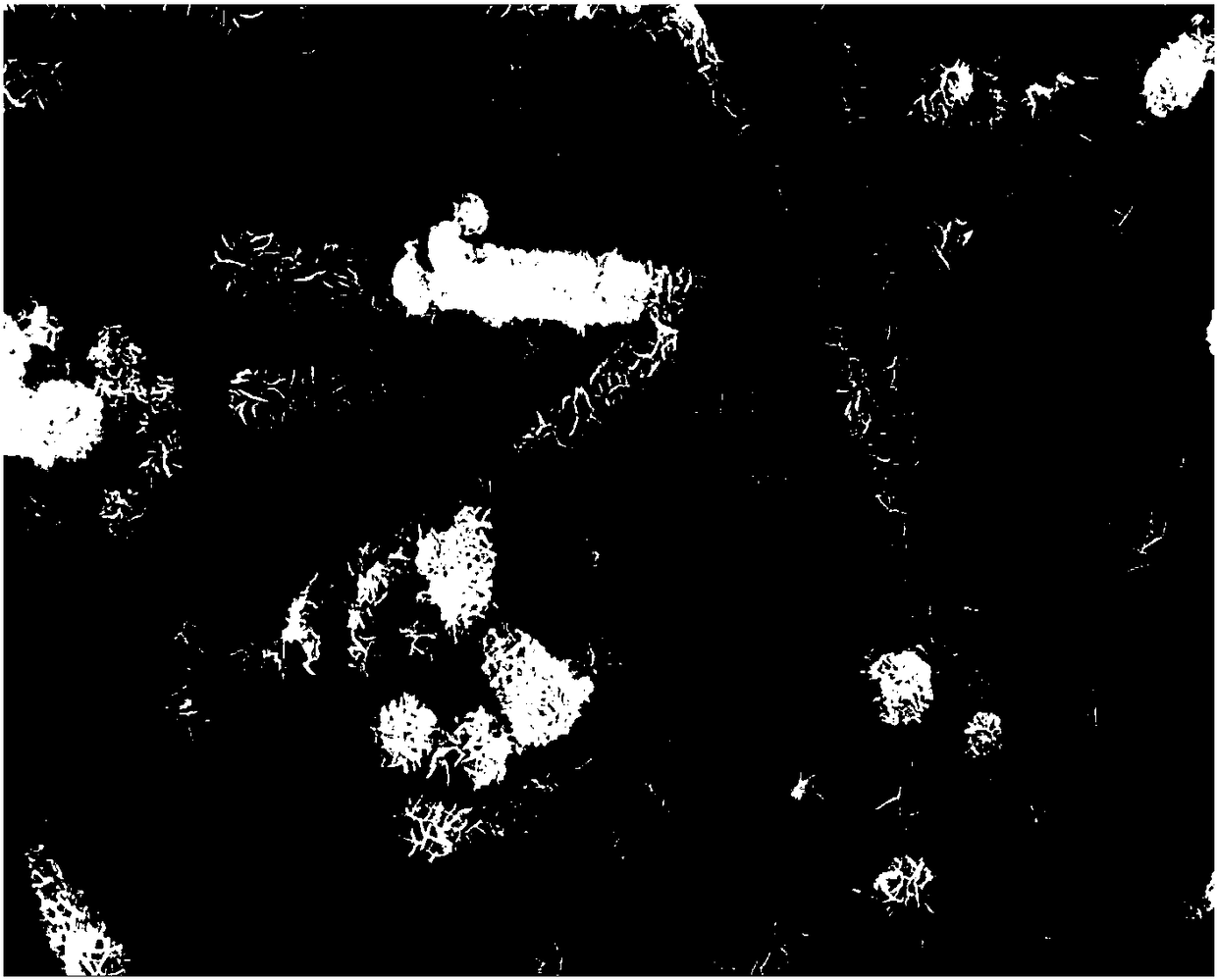

Preparation method of metal organic framework material film as well as product and application of metal organic framework material film

The invention discloses a preparation method of a metal organic framework material film, wherein the preparation method comprises the following steps: mixing 1-1.5mM ethanol amine aqueous solution with a same volume of 2-5mM copper nitrate aqueous solution by stirring magnetically, carrying out sealed reaction to obtain a copper hydroxide nanowire solution; then mixing 30-60ml of the copper hydroxide nanowire solution with 1-2ml of gold nanoparticle modified by citric acid root, filtering through a filtering film, and then depositing on the filtering film to obtain a gold-copper hydroxide nanowire layer; finally mixing the gold-copper hydroxide nanowire layer with 10-20ml of 4-10mM trimesic acid / ethanol aqueous solution to react for 1-5 hours, thus obtaining the metal organic framework material film. The invention also discloses application of the metal organic framework material film prepared by the preparation method and application of the metal organic framework material film in gas separation. The metal organic framework material film is formed by stacking cubic crystals; an exposed crystal plane is a {100} family of crystal plane.

Owner:ZHEJIANG UNIV

Catalyst for preparing multi-carbon product by electro-reduction of carbon dioxide and carbon monoxide and preparation method and application thereof

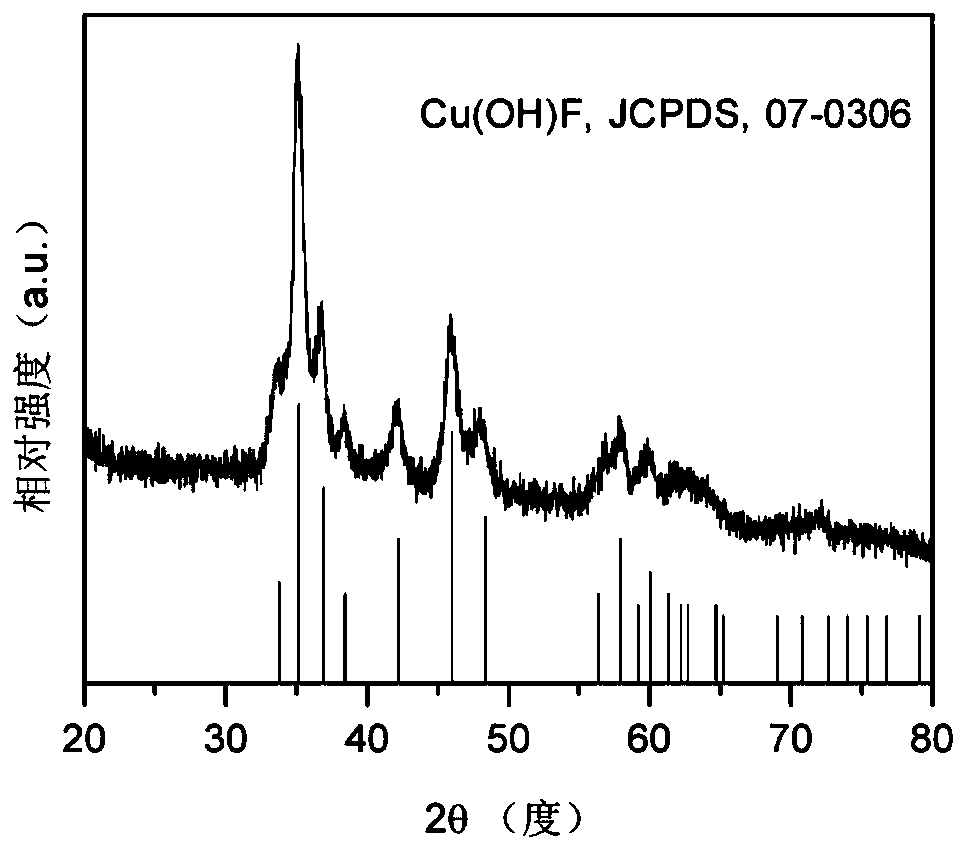

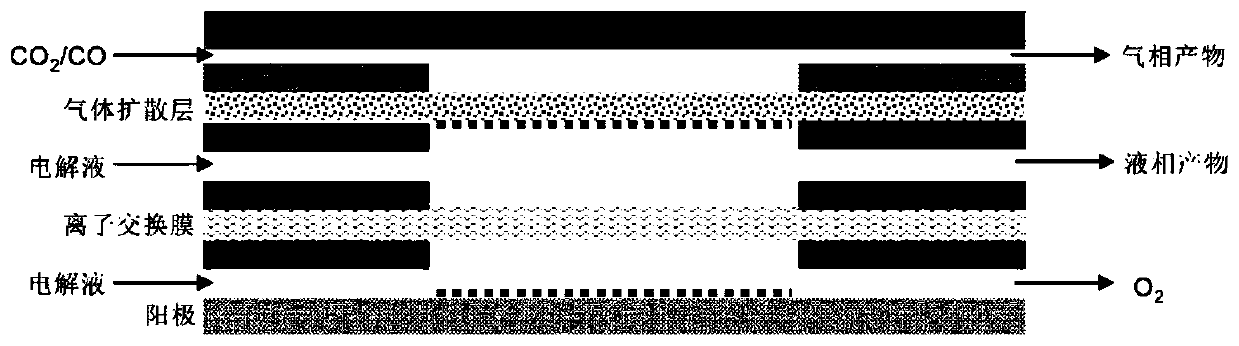

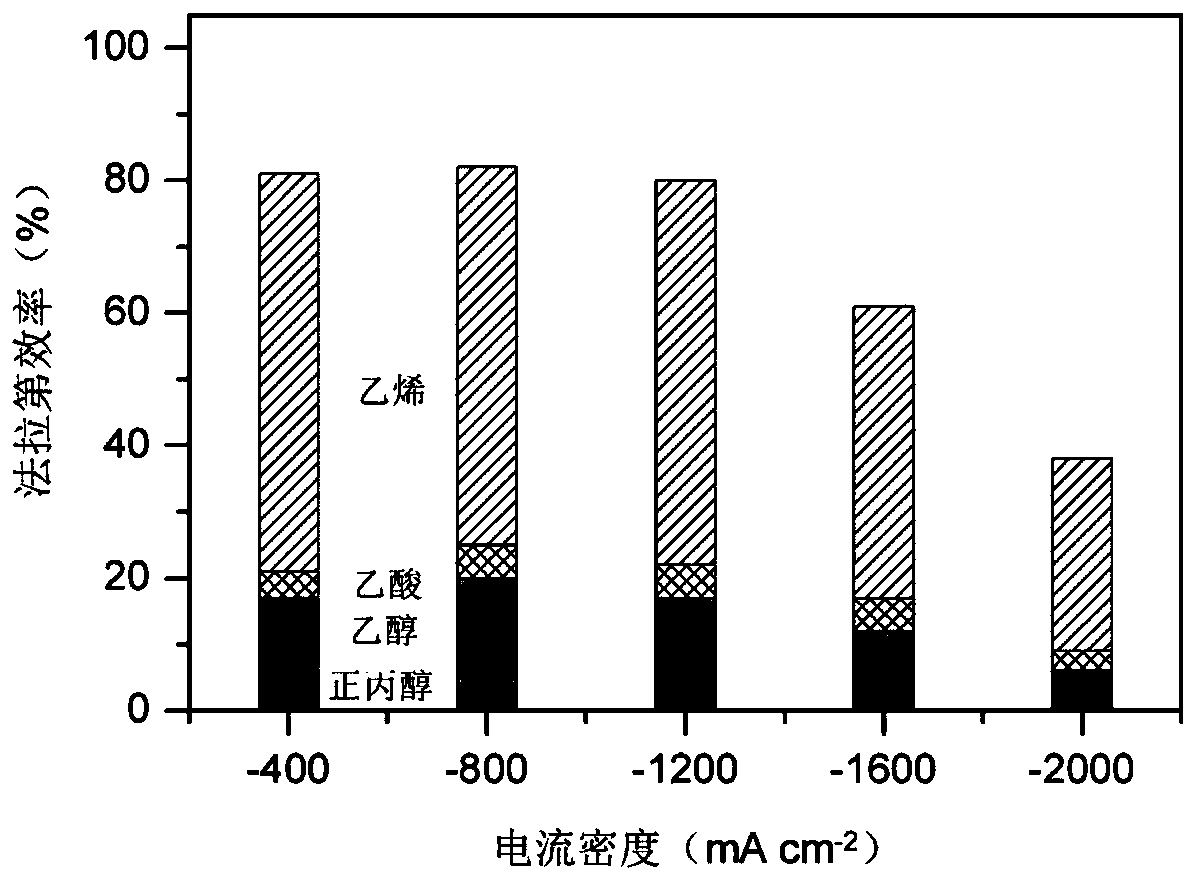

ActiveCN111229261ASimple manufacturing methodMild reaction conditionsElectrolytic organic productionMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHalogen

The invention discloses a catalyst for preparing a multi-carbon product by electro-reduction of carbon dioxide and carbon monoxide as well as a preparation method and application thereof, and belongsto the field of electro-catalysis. The catalyst is a halogen-modified copper electro-catalyst, and halogen comprises at least one of fluorine, chlorine, bromine and iodine. The preparation method of the catalyst comprises the following steps: loading a copper halide precursor on a gas diffusion layer, and carrying out electric reduction to obtain the halogen-modified copper electro-catalyst, wherein the copper halide precursor comprises at least one of a fluorine copper hydroxide precursor and other copper halide precursors except the fluorine copper hydroxide precursor. The catalyst is applied to a reaction for preparing a multi-carbon product by electrically reducing carbon dioxide and carbon monoxide, is high in reaction activity, high in selectivity and stable in catalytic performance,and maintains very high multi-carbon product selectivity in a very wide current range.

Owner:XIAMEN UNIV

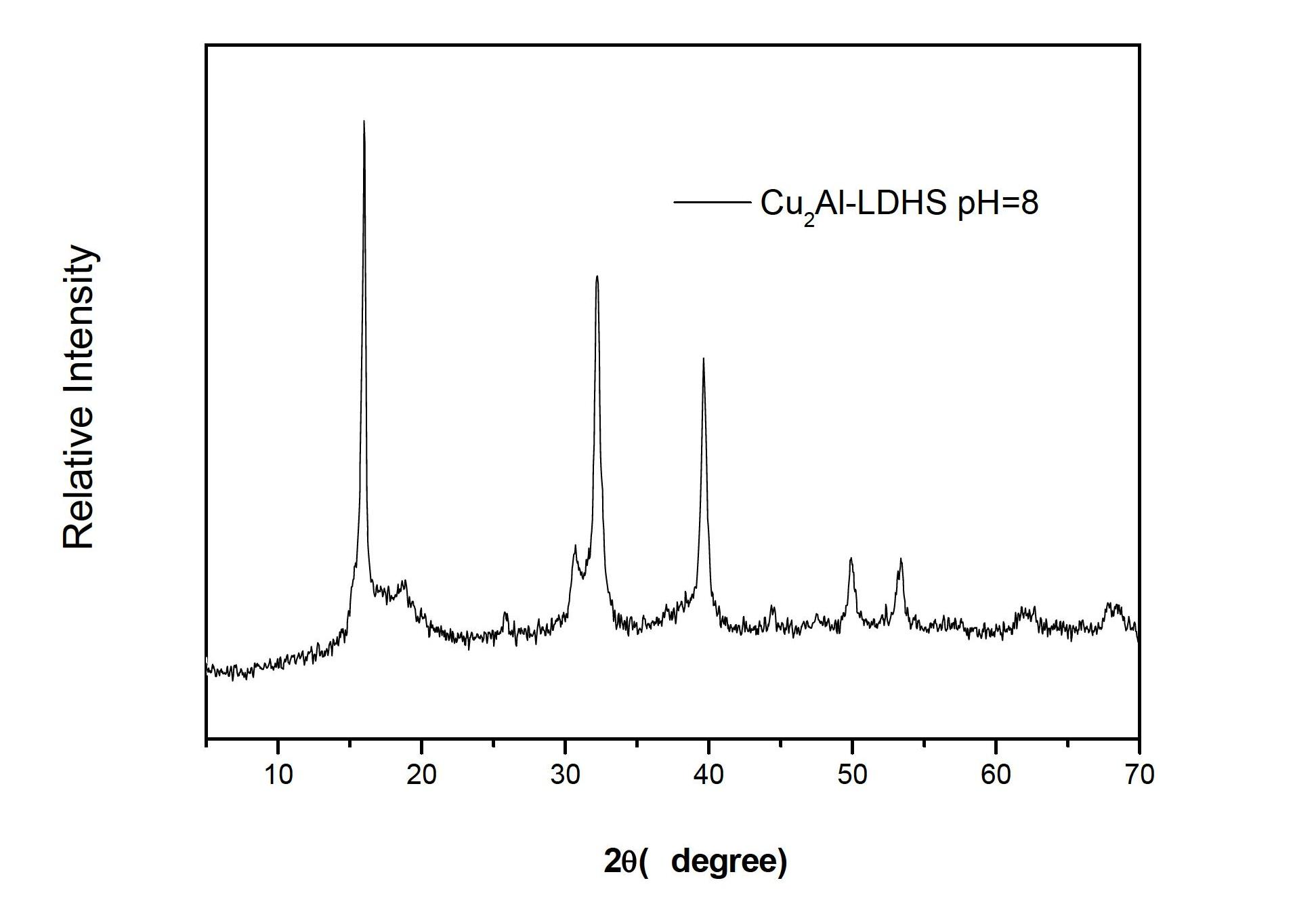

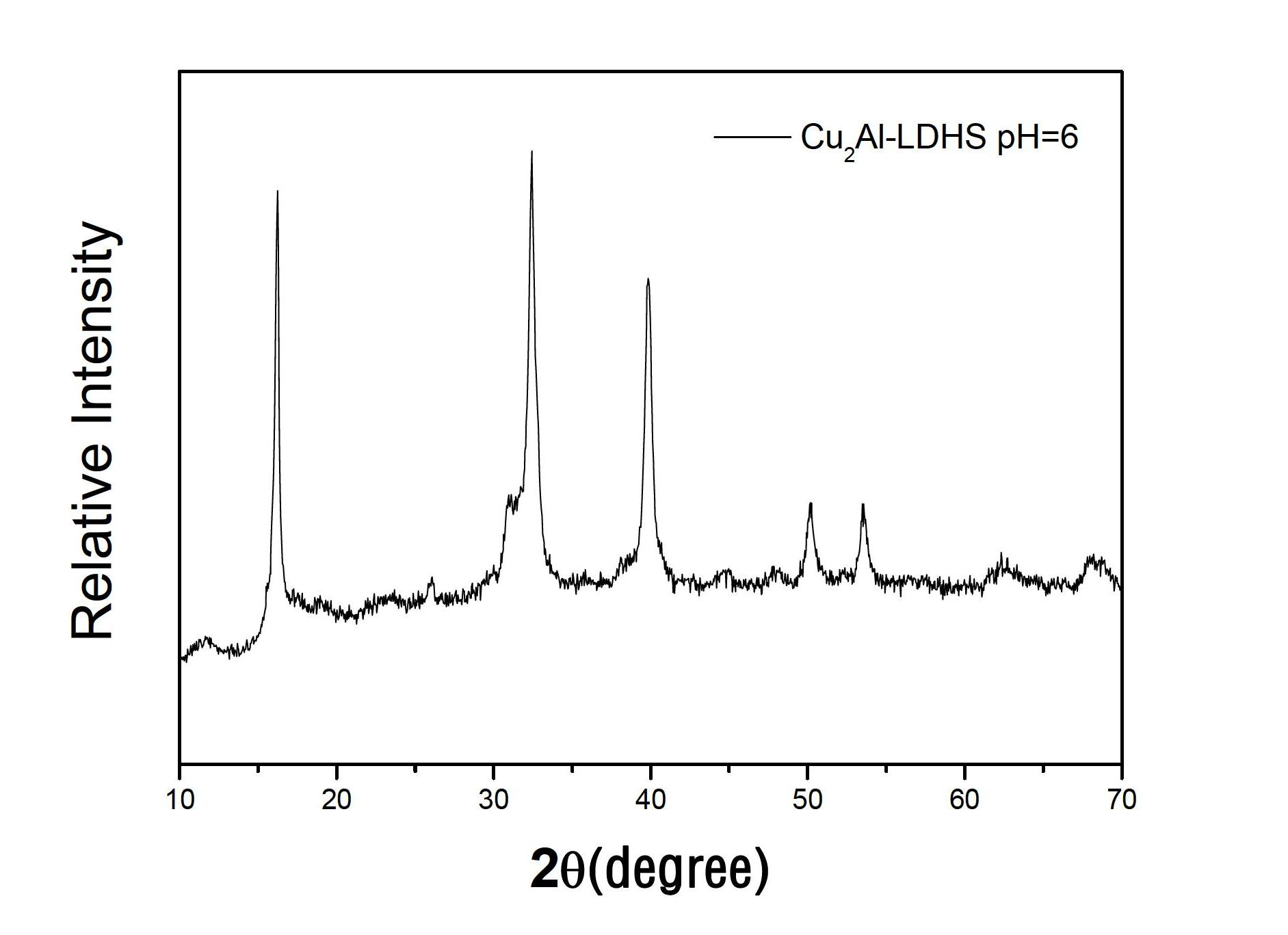

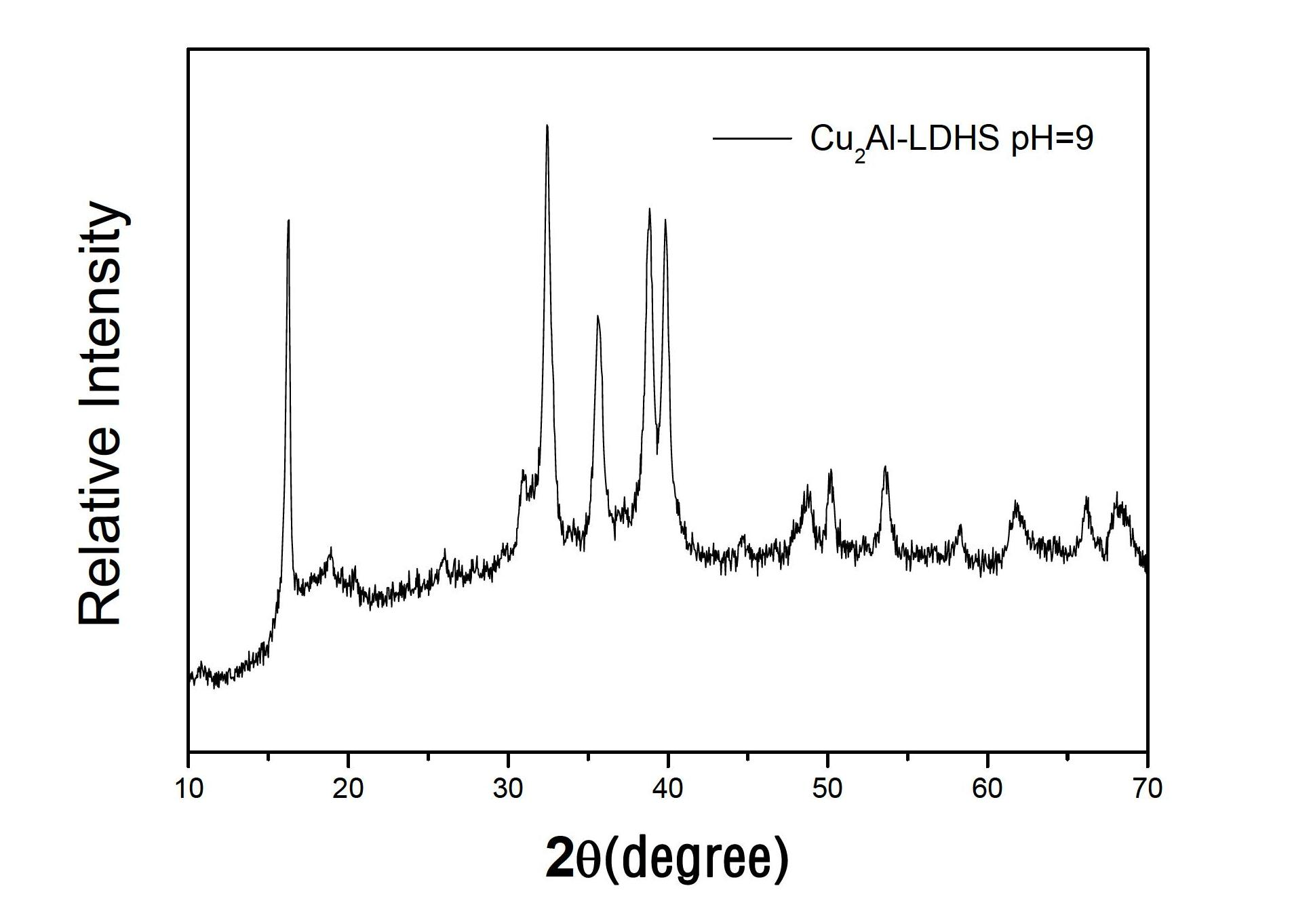

Preparation method for copper and aluminium hydrotalcite

ActiveCN102659164AAtom utilization is highLow cost of industrializationCopper compoundsAluminium chlorideHydrotalcite

The invention discloses a preparation method for copper and aluminium hydrotalcite. The preparation method comprises the following steps of: (1) weighing a copper source and aluminium chloride according to a 2:1 molar ratio of Cu:Al, wherein the copper source is copper oxide or copper hydroxide, dissolving the copper oxide or copper hydroxide and the aluminium chloride in deionized water to be prepared into a mixed liquor in a reaction vessel, heating and stirring the mixed liquor at the constant temperature of 30-40 DEG C till all the copper oxide or copper hydroxide is dissolved, i.e. the color of the solution becomes blue; (2) adjusting the pH value of the solution obtained in the step (1), leading the pH value of the solution not to be higher than 8, and continuously reacting for 2-4h at the temperature of 30-40 DEG C; (3) crystallizing the slurry reacted in the step (2) at the constant temperature of 30-40 DEG C; and (4) filtering, washing, drying and grinding reaction liquid crystallized in the step (3) to obtain the copper and aluminium hydrotalcite. The preparation method has the advantages that used raw materials are low in cost and easily obtained, the conversion rate of atoms is high, and the industrialization cost can be reduced.

Owner:徐州宏阳新材料科技股份有限公司

Iron-copper oxide/copper base electrode material and preparation method thereof

ActiveCN108538609AMake up for the mismatch of positive and negative specific capacitiesIncrease energy densityHybrid capacitor electrodesCell electrodesCapacitanceFerric hydroxide

The invention provides an iron-copper oxide / copper base electrode material and a preparation method thereof. The iron-copper oxide / copper base electrode material is expressed as Fe3O4 / CuO / copper base.A copper hydroxide nanowire array, i.e. Cu(OH)2 / copper base, is grown on the copper base in an in-situ way; then ferric hydroxide is electrodeposited on the Cu(OH)2 / copper base in the electrolyte solution containing iron ions by using the method of potentiostatic electro-deposition so as to form the hollow tubular structure Fe(OH)3 / Cu(OH)2 / copper base; and then the ferric hydroxide is transformedinto ferric oxide and the copper hydroxide is transformed into copper oxide through high temperature roasting, and the hollow tubular structure is maintained so that the hollow tubular structure Fe3O4 / CuO / copper base material is obtained. The material has great super capacitance performance and is suitable for being used as the supercapacitor electrode material.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method for durable antibacterial cellulose fibres

ActiveCN109440450AImprove antibacterial propertiesHigh whiteness valueBiochemical fibre treatmentVegetal fibresSodium bicarbonateZinc hydroxide

The invention provides a preparation method for durable antibacterial cellulose fibres. The preparation method comprises the following steps: S1, removing impurities from cellulose fibres in a physical mechanical mode to obtain impurity-removed fibres; S2, performing pre-treatment on the impurity-removed fibres, and dewatering to obtain dewatered fibres, wherein the pre-treatment comprises a cleaning process and / or a refining and bleaching process; S3, performing antibacterial finishing on the dewatered fibres with an antibacterial working liquid to obtain durable antibacterial cellulose fibres, wherein the antibacterial working liquid comprises an antibacterial agent, an alkaline auxiliary agent and a penetrating agent; the antibacterial agent is one or more of magnesium carbonate, coppernitrate, copper chloride, copper hydroxide, copper carbonate, basic cupric carbonate, zinc chloride, zinc sulphate, zinc hydroxide and zinc carbonate; and the alkaline auxiliary agent is one or moreof sodium hydroxide, potassium hydroxide, sodium bicarbonate, ammonium carbonate, ammonia water, sodium phosphate and sodium carbonate. The prepared cellulose fibres have a durable antibacterial effect; and the whiteness value of the fibres is high.

Owner:山东欣悦健康科技有限公司 +1

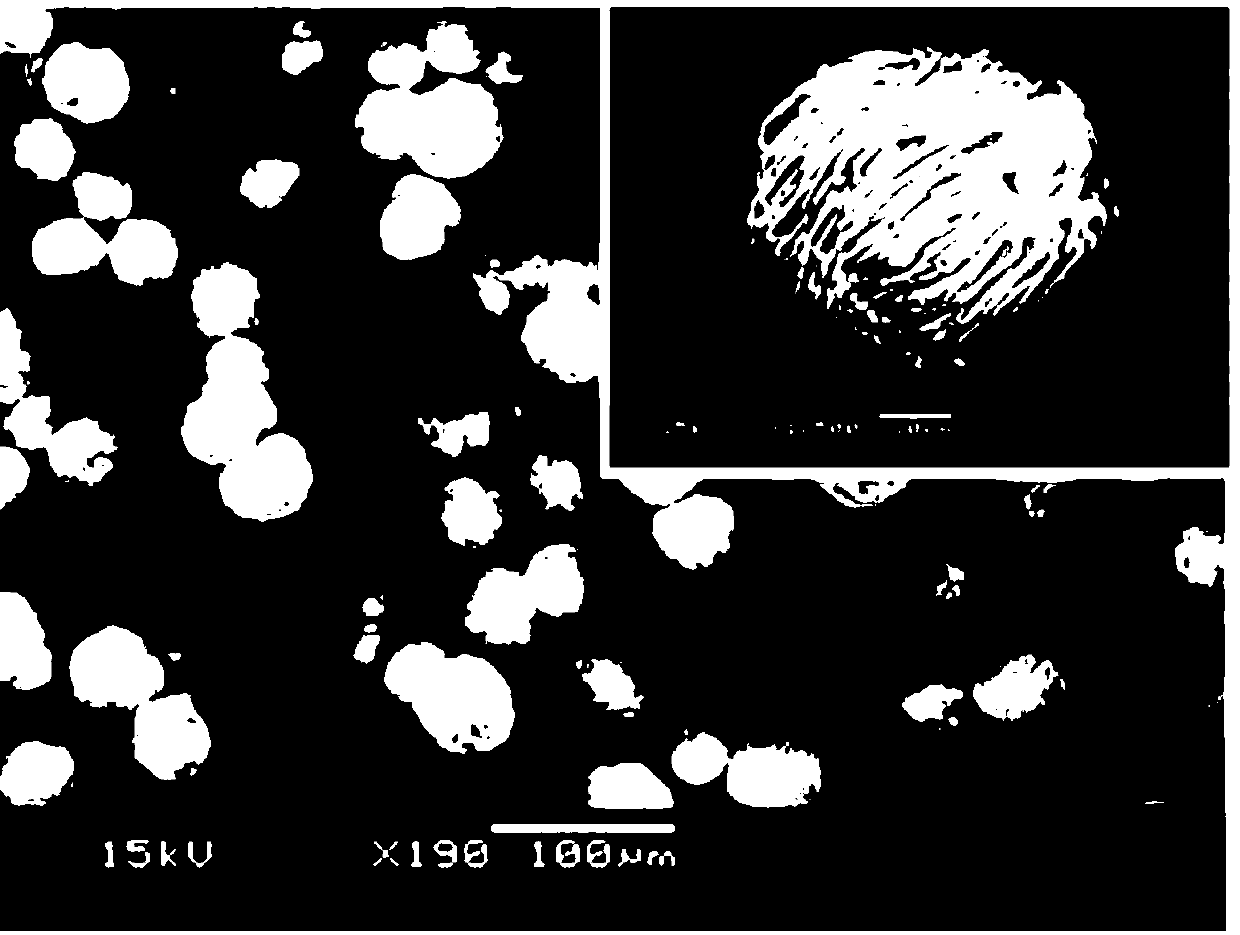

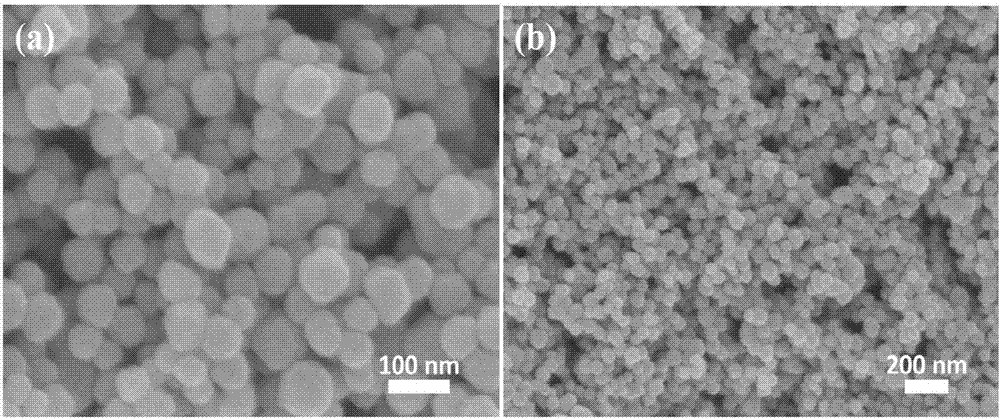

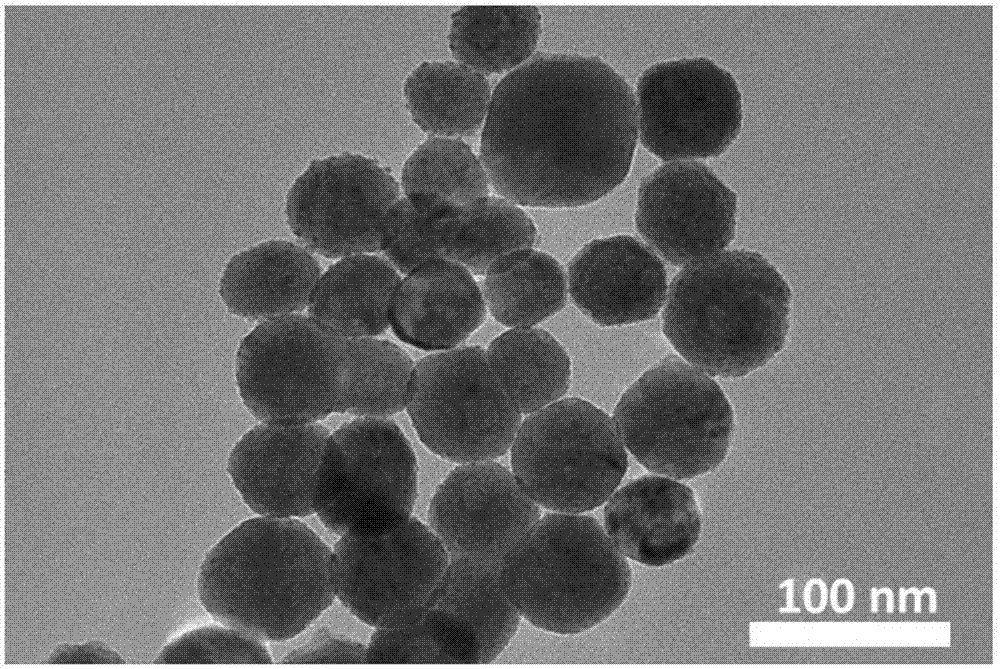

Cuprous oxide powder and method of producing same

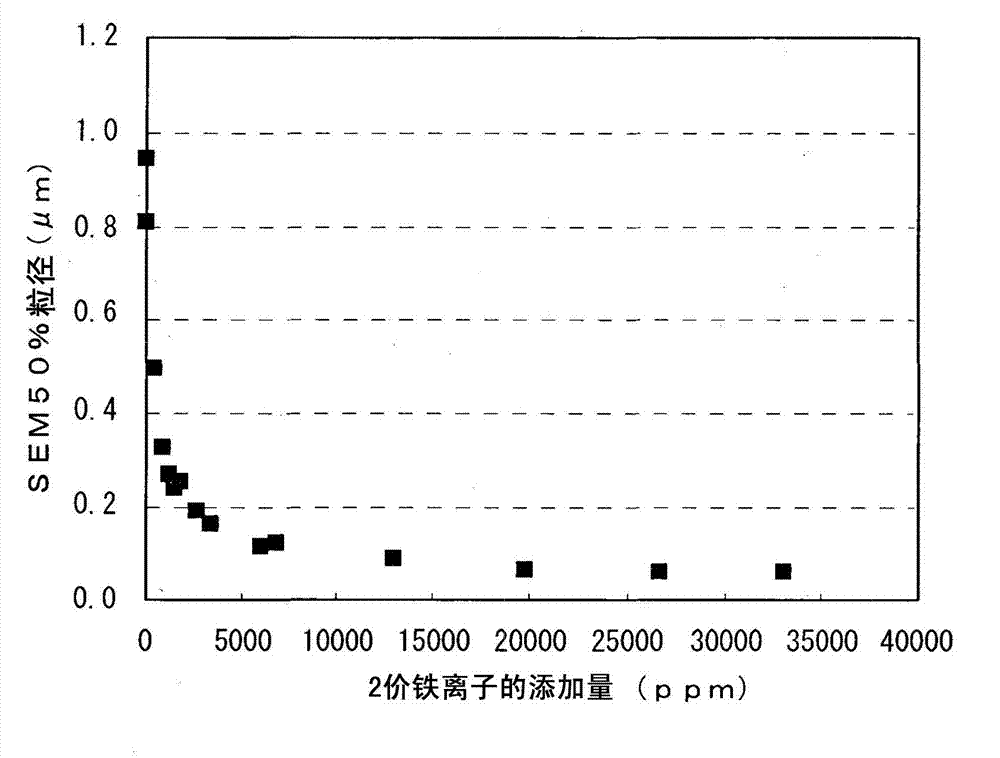

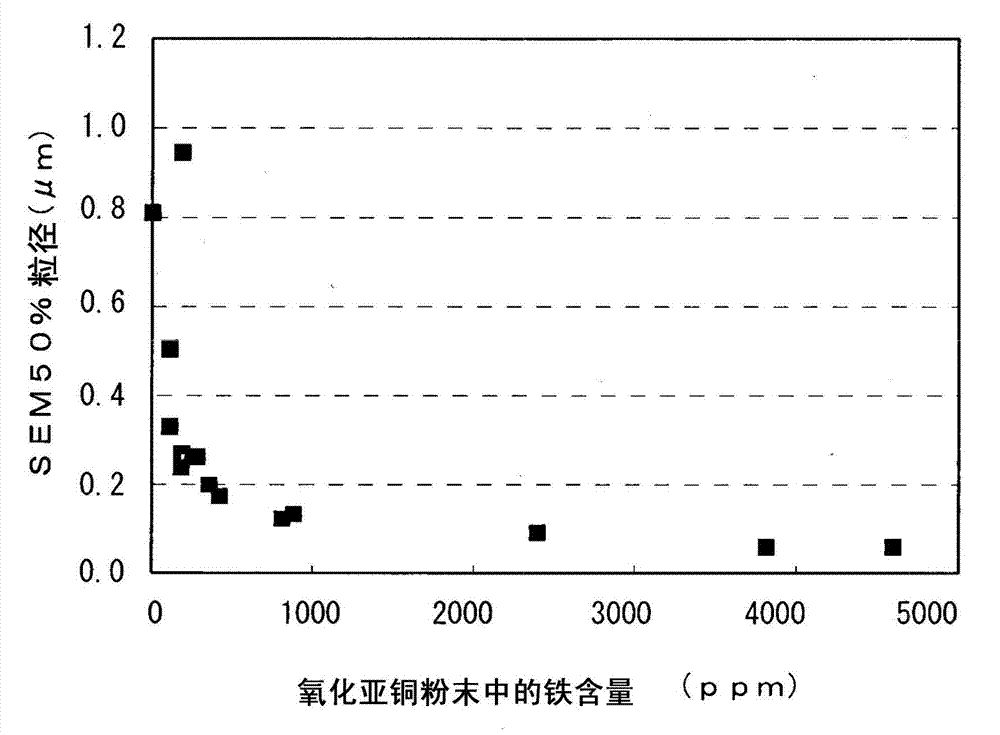

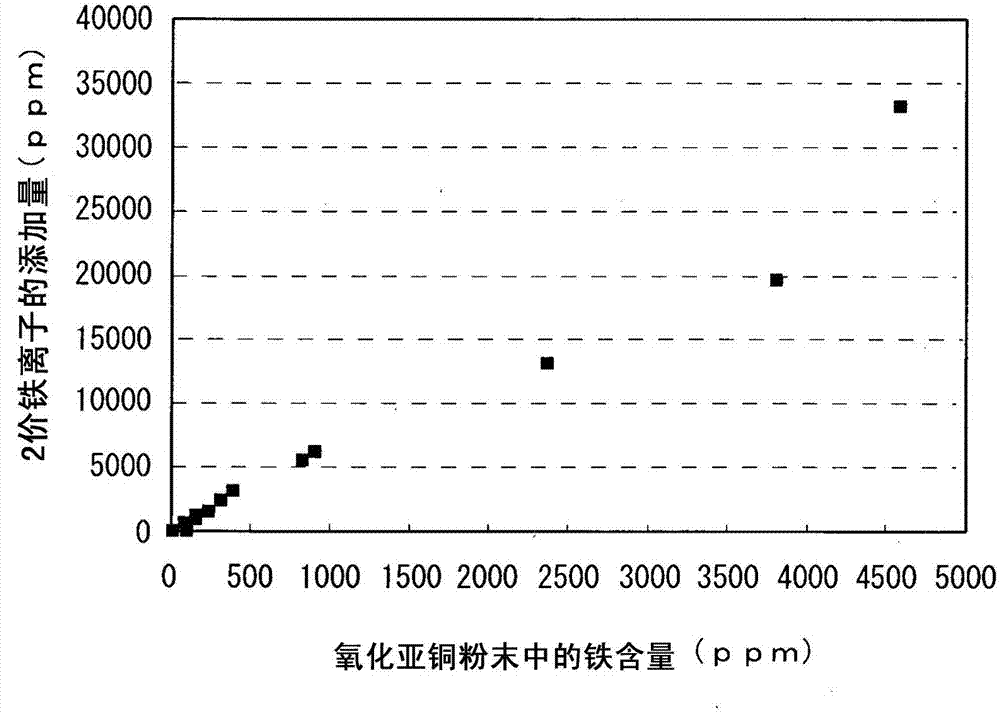

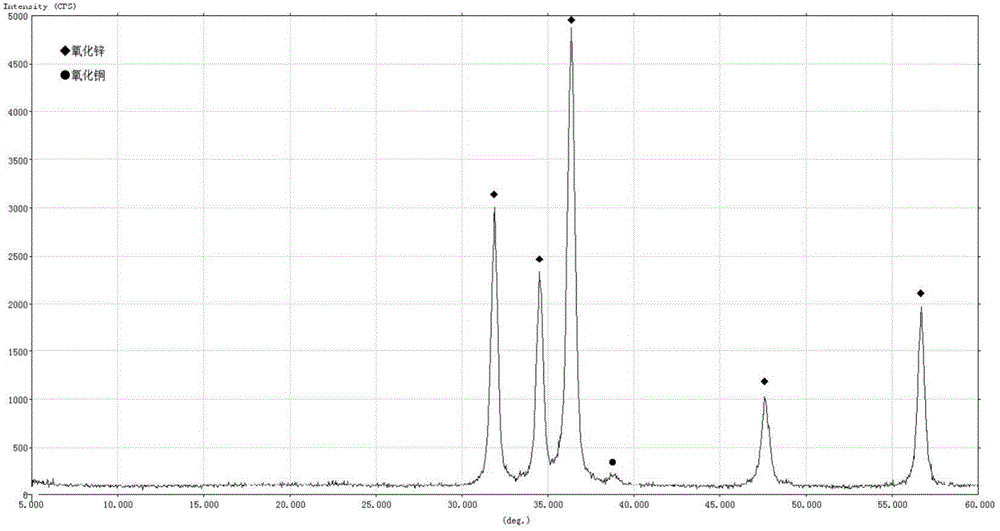

A cuprous oxide powder with a particle diameter smaller than those found in the prior art, and a method of producing the cuprous oxide powder by the chemical reduction method are provided. This method of producing cuprous oxide powder involves adding an alkaline solution to a copper ion-containing solution (or adding a copper ion-containing solution to an alkaline solution) to generate copper hydroxide, and thereafter adding a reducing agent such as a reducing sugar to reduce and precipitate the cuprous oxide particles, wherein, before generating the copper hydroxide, divalent iron ions are added to the copper ion-containing solution in the amount of 0.00001-0.04 mols (10-40000ppm) relative to the amount of copper ions in the copper ion-containing solution, and a cuprous oxide powder containing 30ppm or more iron is produced which has a 0.5mum or lower average primary particle diameter measured by a scanning electron microscope (SEM) and a 0.8mum or lower 50% particle diameter (D50 diameter) calculated by a laser diffraction-type particle size distribution measurement.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Preparation method of zinc oxide normal-temperature desulfurizing agent

The invention provides a preparation method of zinc oxide normal-temperature desulfurizing agent. The method comprises the following steps: firstly forming respective unstable precipitate of partial zinc salt and copper salt; and then completely translating residual zinc salt and copper salt not participating the precipitation in a bipyramid rotary vacuum reaction kettle and above unstable precipitates into stable zinc hydroxide and copper hydroxide, roasting to obtain compound powder of zinc oxide and copper oxide, and then preparing the zinc oxide normal temperature desulfurizing agent. The preparation method of the zinc oxide normal temperature desulfurizing agent provided by the invention has a simple process step, and less requirements on condition control and equipment operation, and the sulfur capacity of the prepared zinc oxide normal temperature desulfurizing agent at normal temperature reaches up to 20.3% and more; and therefore, the preparation method provided by the invention is suitable for large-scale production, and has high actual application value.

Owner:SHENYANG SANJUKAITE CATALYST +1

Algae killing and inhibiting method for water body

InactiveCN1432533AImprove protectionNo pollutionWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment apparatusElectrolysisCooling tower

The present invention discloses algae killing and inhibiting method for water body. Electrolysis equipment is set on vehicle, boat, floated apparatus, cooling tower system or other apparatus near thewater body, and the electrodes are contacted with water body. The anode is made of copper material, and the cathode material is copper, iron, aluminium, graphite or other conductive material. The copper density in the water body is 0.4-4 mg / L for inhibiting algae and 3-8 mg / L for killing algae. Produced copper hydroxide is exhausted to water body continuously or intermittently to kill or inhibit algae. The said method can be used for killing and inhibit algae and bacteria without producing environmental pollution.

Owner:陈丹 +1

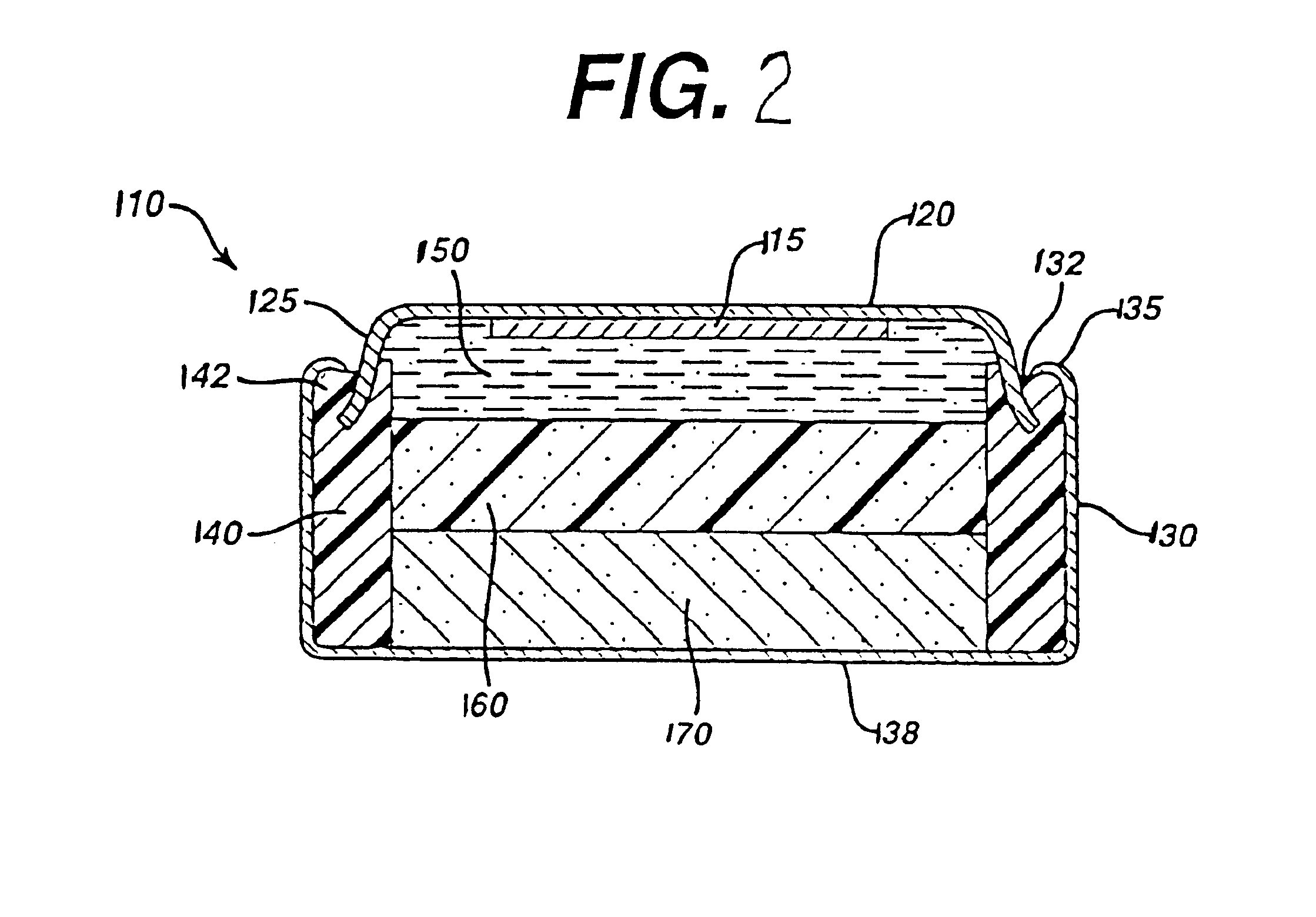

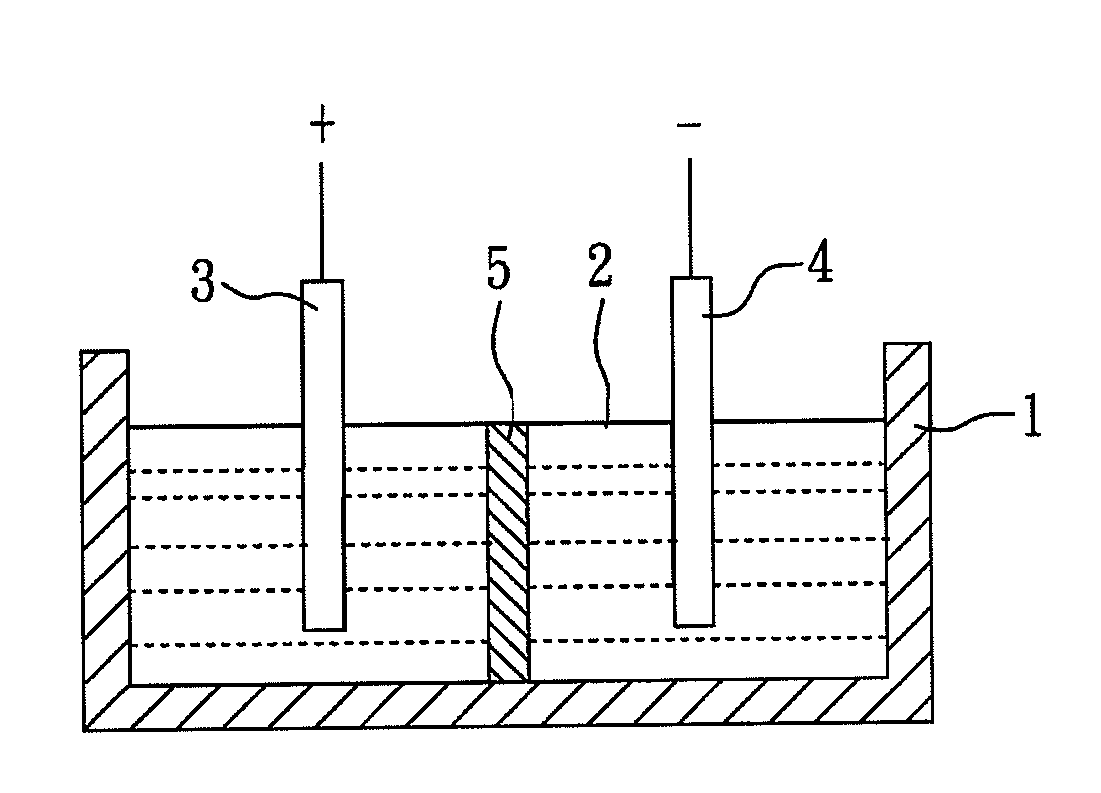

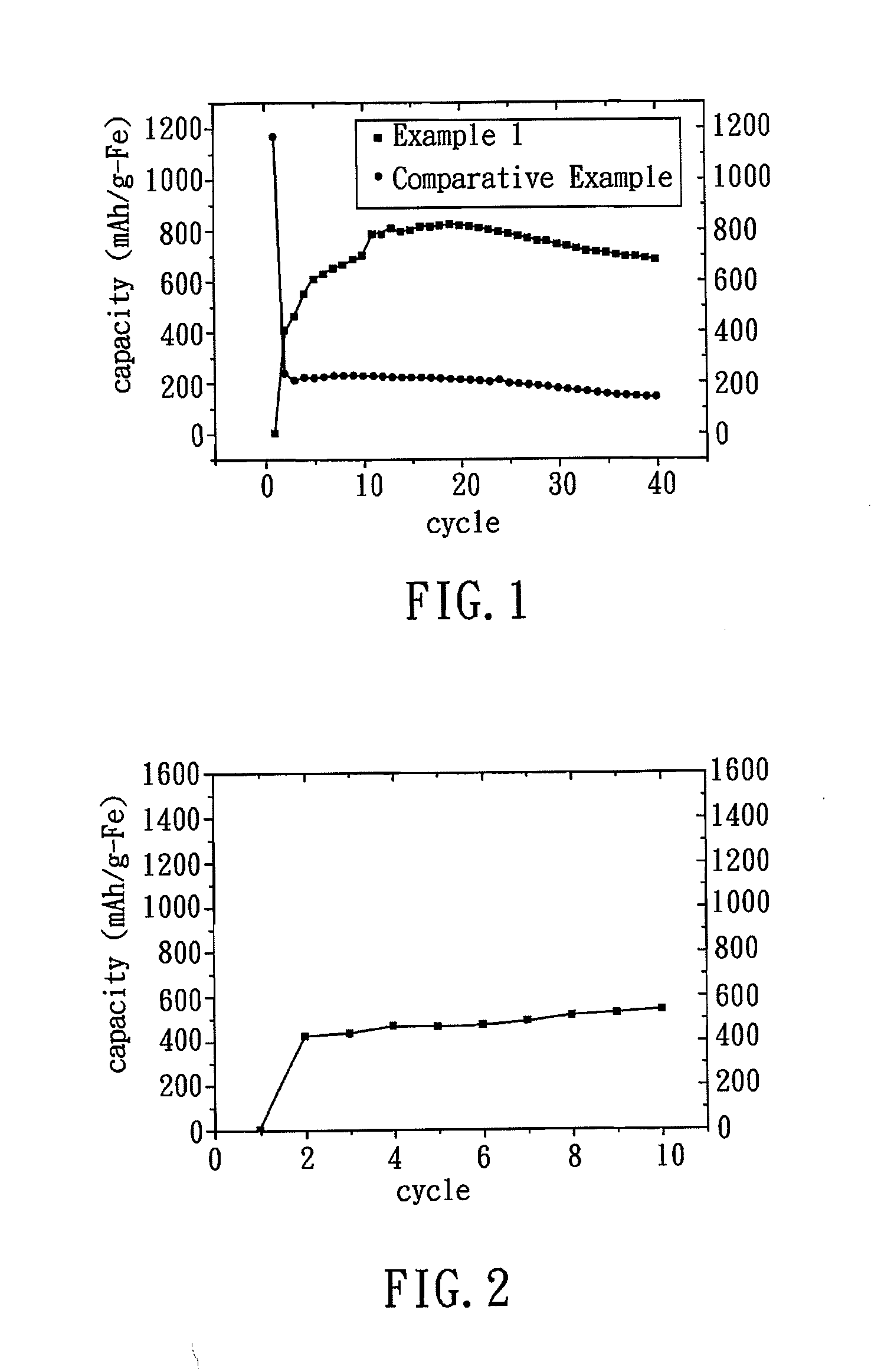

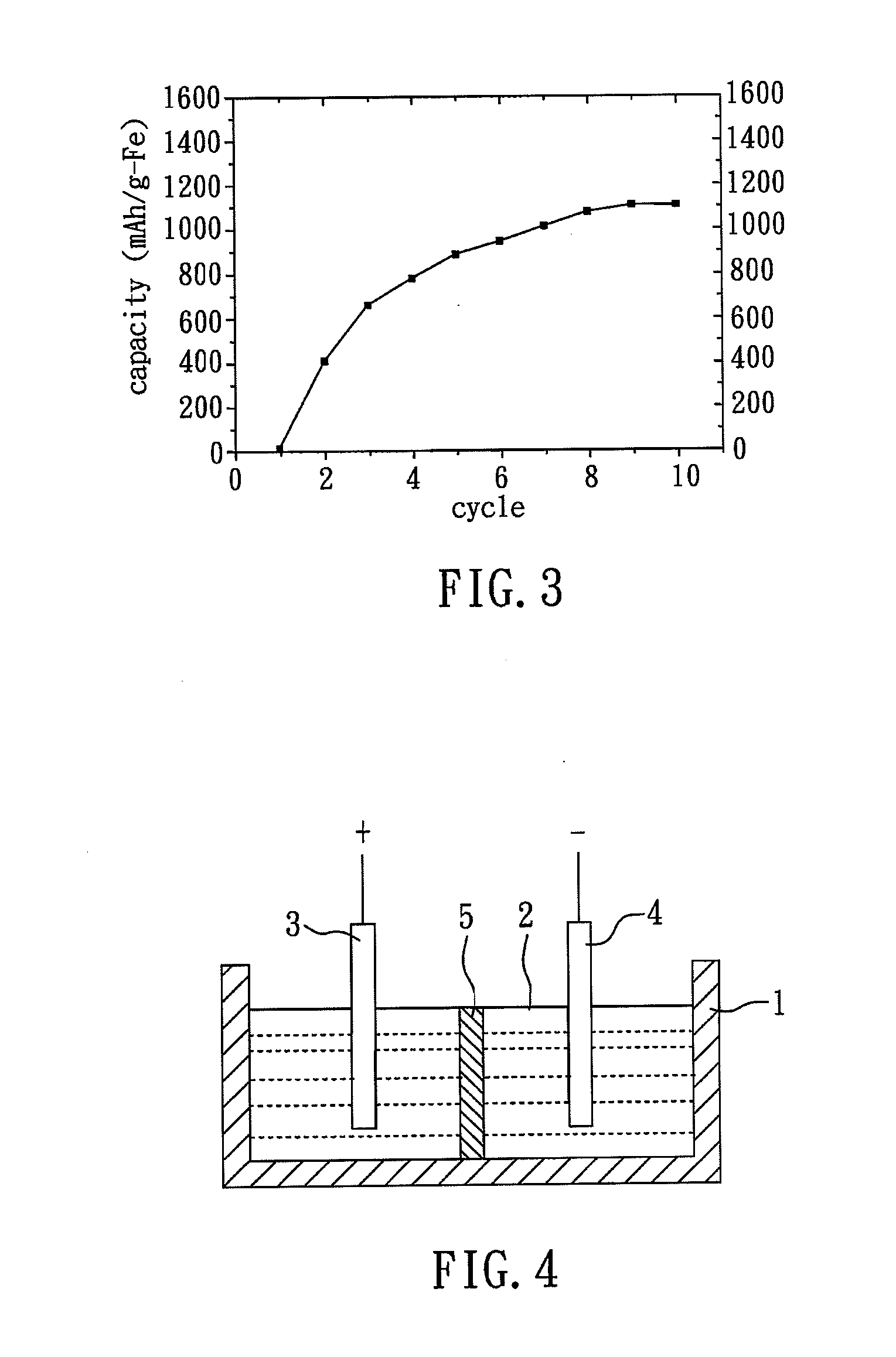

Composite material for negative electrode, method for fabricating the same and electrochemical device using the same

ActiveUS20110236747A1Large capacityLarge scaleSilver accumulatorsNon-metal conductorsIndiumNickel salt

The present invention relates to a composite material for a negative electrode, including: a plurality of iron oxide particles; and a conductivity improver, which is selected form the group consisting of copper, cobalt, nickel, tin, antimony, bismuth, indium, silver, gold, lead, cadmium, carbon black, graphite, copper salt, cobalt salt, nickel salt, tin salt, antimony salt, bismuth salt, indium salt, silver salt, gold salt, lead salt, cadmium salt, copper hydroxide, cobalt hydroxide, nickel hydroxide, stannic hydroxide, antimony hydroxide, bismuth hydroxide, indium hydroxide, silver hydroxide, gold hydroxide, lead hydroxide, cadmium hydroxide and the combination thereof. In the case of applying the composite material for a negative electrode according to the present invention in an electrochemical device, the improved charge / discharge characteristics and high capacity can be achieved. In addition, the present invention further provides a method for fabricating the above-mentioned composite material for a negative electrode and an electrochemical device using the same.

Owner:NATIONAL TSING HUA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com