Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8523 results about "New materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

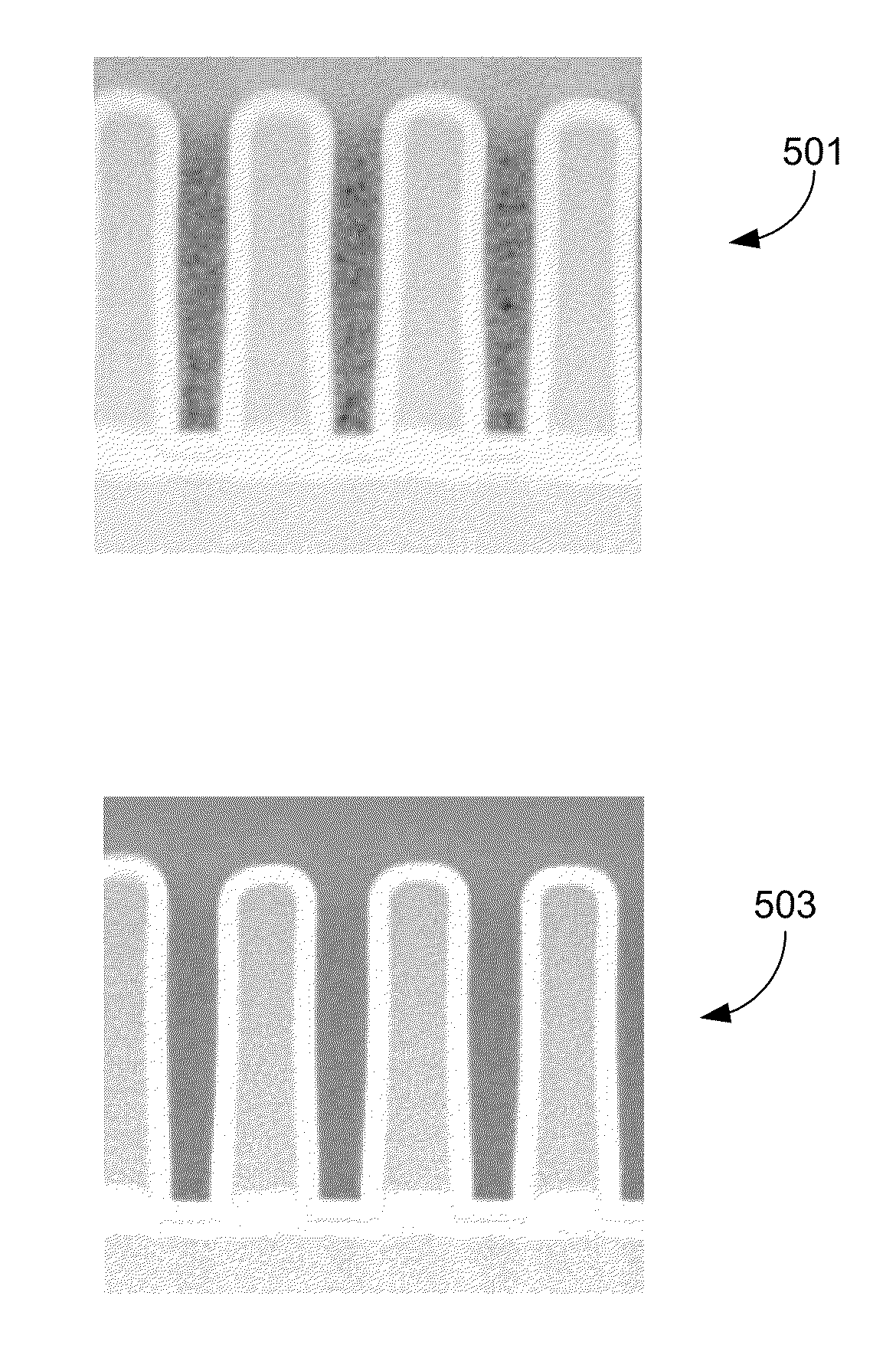

Methods and apparatus for forming flowable dielectric films having low porosity

InactiveUS20150118863A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingPorosityNew materials

Provided herein are methods and apparatus for forming flowable dielectric films having low porosity. In some embodiments, the methods involve plasma post-treatments of flowable dielectric films. The treatments can involve exposing a flowable film to a plasma while the film is still in a flowable, reactive state but after deposition of new material has ceased.

Owner:LAM RES CORP

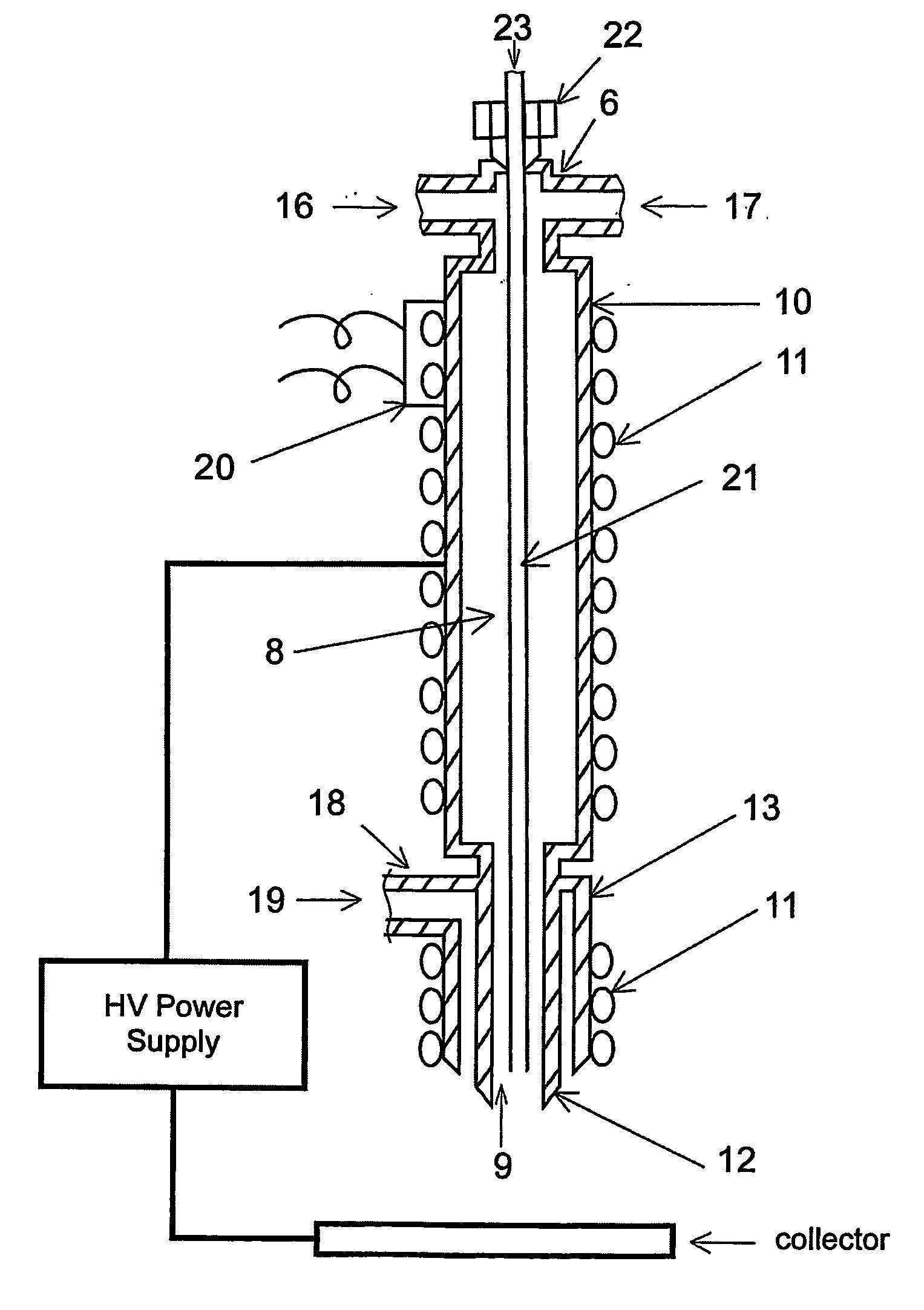

Nanofibers, and apparatus and methods for fabricating nanofibers by reactive electrospinning

ActiveUS20070018361A1Broaden applicationEasy to controlElectric discharge heatingInorganic material artificial filamentsFiberElectrospinning

Apparatus and methods for fabricating nanofibers by reactive electrospinning are described. An electrospinning process is coupled with an in-line reactor where chemical or photochemical reactions take place. This invention expands the application of the electrospinning and allows the production of nanofibers of crosslinked polymers and other new materials, such as gel nanofibers of ceramic precursors.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

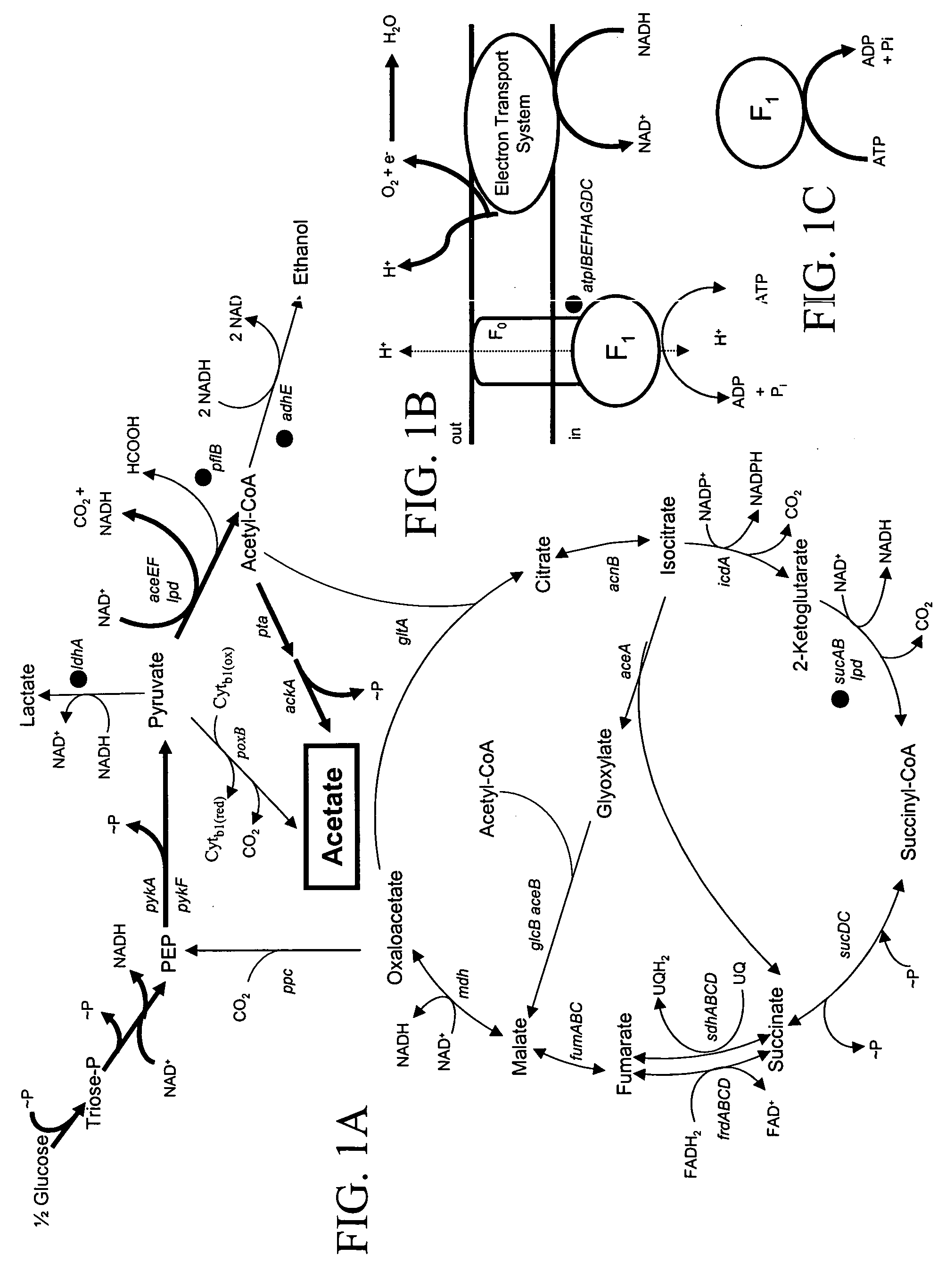

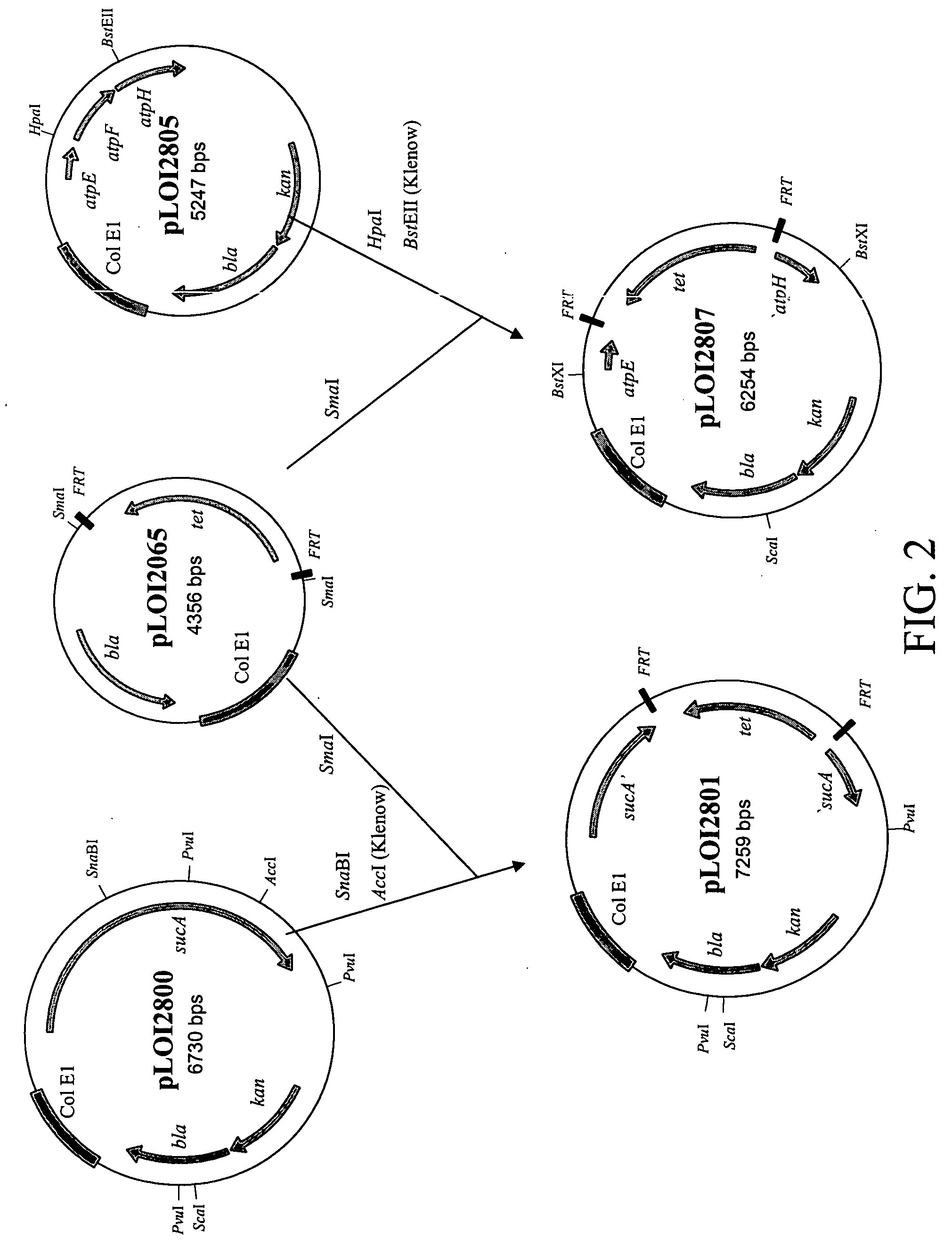

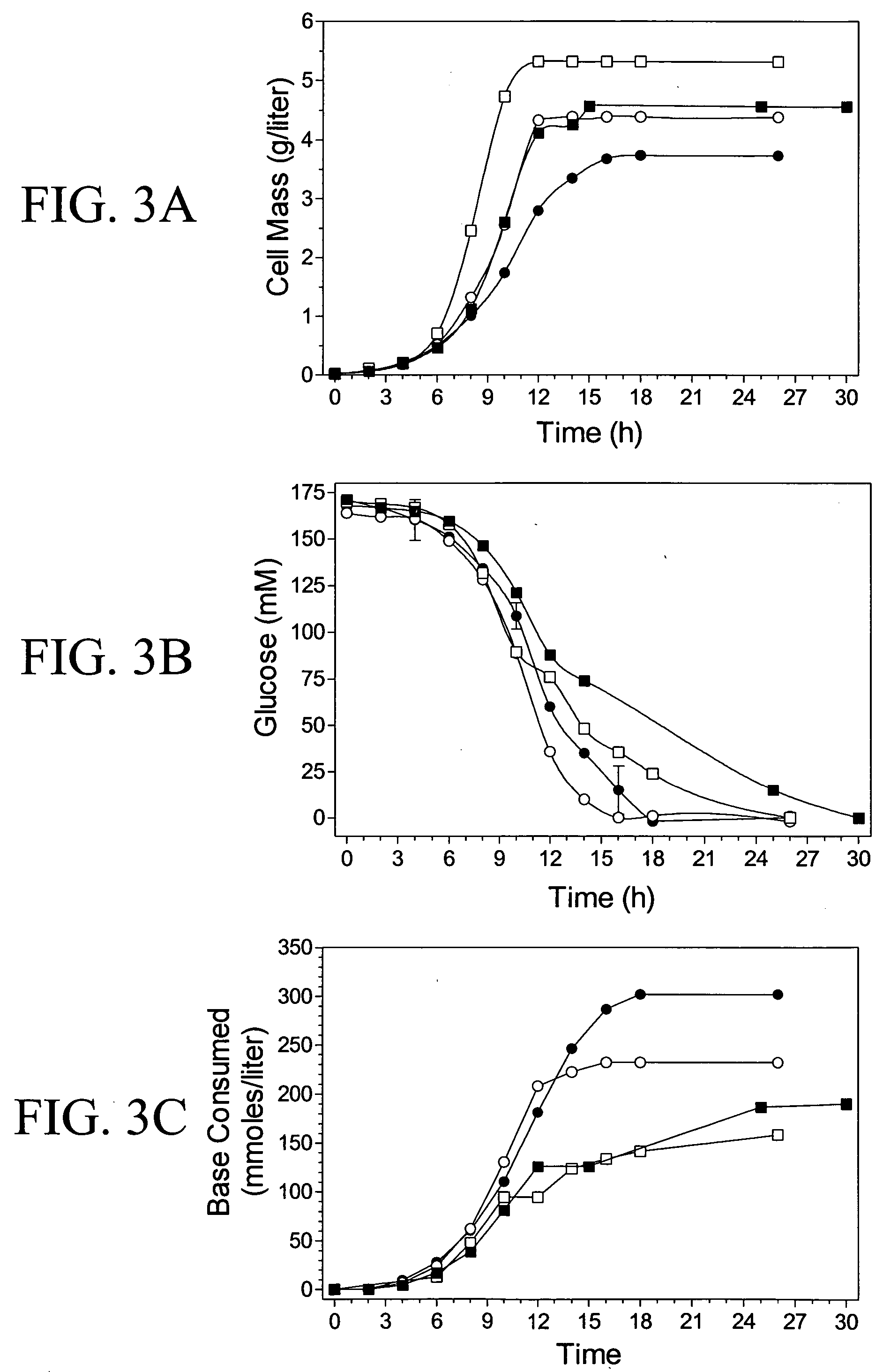

Materials and methods for the efficient production of acetate and other products

InactiveUS20040152159A1Increase productionIncrease acetate productionBacteriaHydrolasesGenes mutationAcetic acid

The subject invention provides materials and methods wherein unique and advantageous combinations of gene mutations are used to direct carbon flow from sugars to a single product. The techniques of the subject invention can be used to obtain products from native pathways as well as from recombinant pathways. In preferred embodiments, the subject invention provides new materials and methods for the efficient production of acetate and pyruvic acid.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

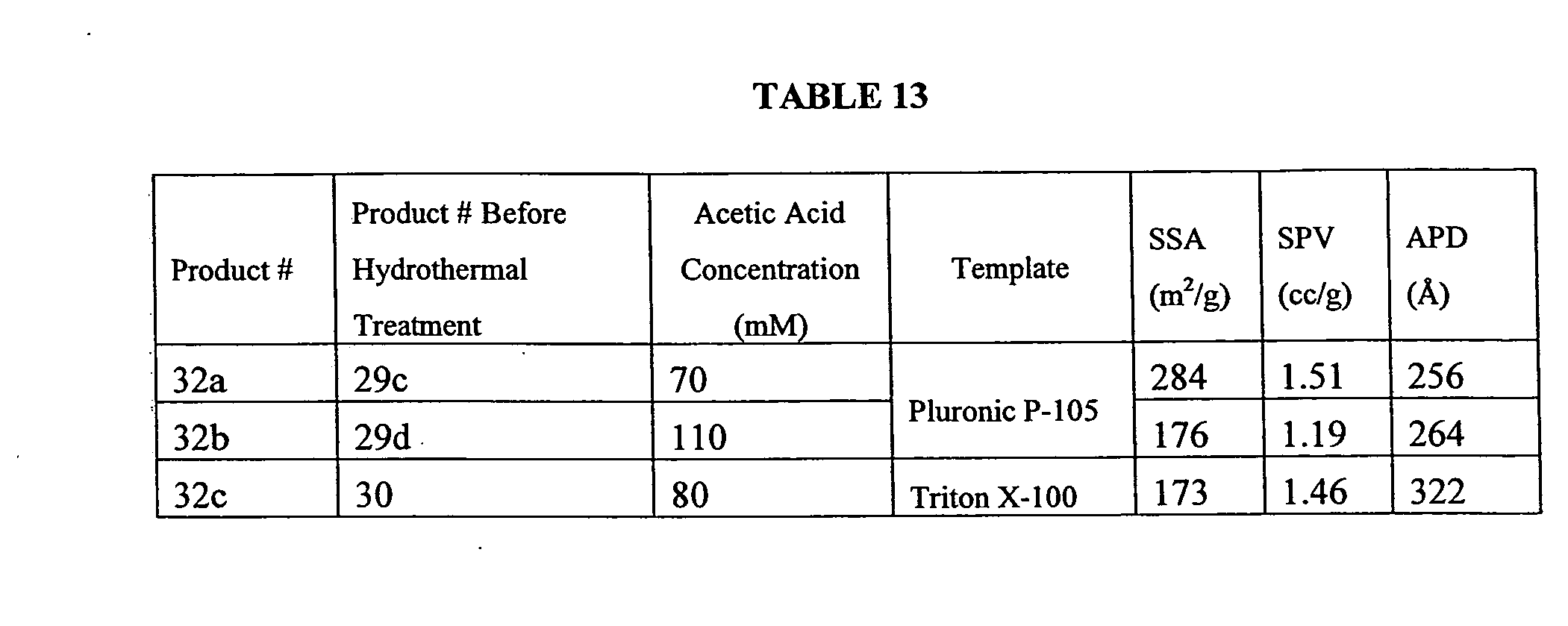

Preparation method of mesonic pore molecular sieve carrier material

The present invention belongs to the field of inorganic nanometer material technology, in particular, it relates to a method for preparing mesoporous molecular sieve carrier material by using diblockmacromolecular polymer. It is characterized by that under the acid condition it uses polyoxyethylene-polyoxybutylene diblock macromolecular surfactant as template agent and makes hydrothermal synthesis at 100 deg.C to prepare mesoporous silicon oxide material with two-dimensional hexagonal structure with high degree of order and large specific surface area and laminate silicon oxide material withhigh degree of order. These new material can be used as catalyst, catalyst carrier, adsorption film, organic-inorganic composite material, sensor and chromatographic packing, etc.

Owner:FUDAN UNIV

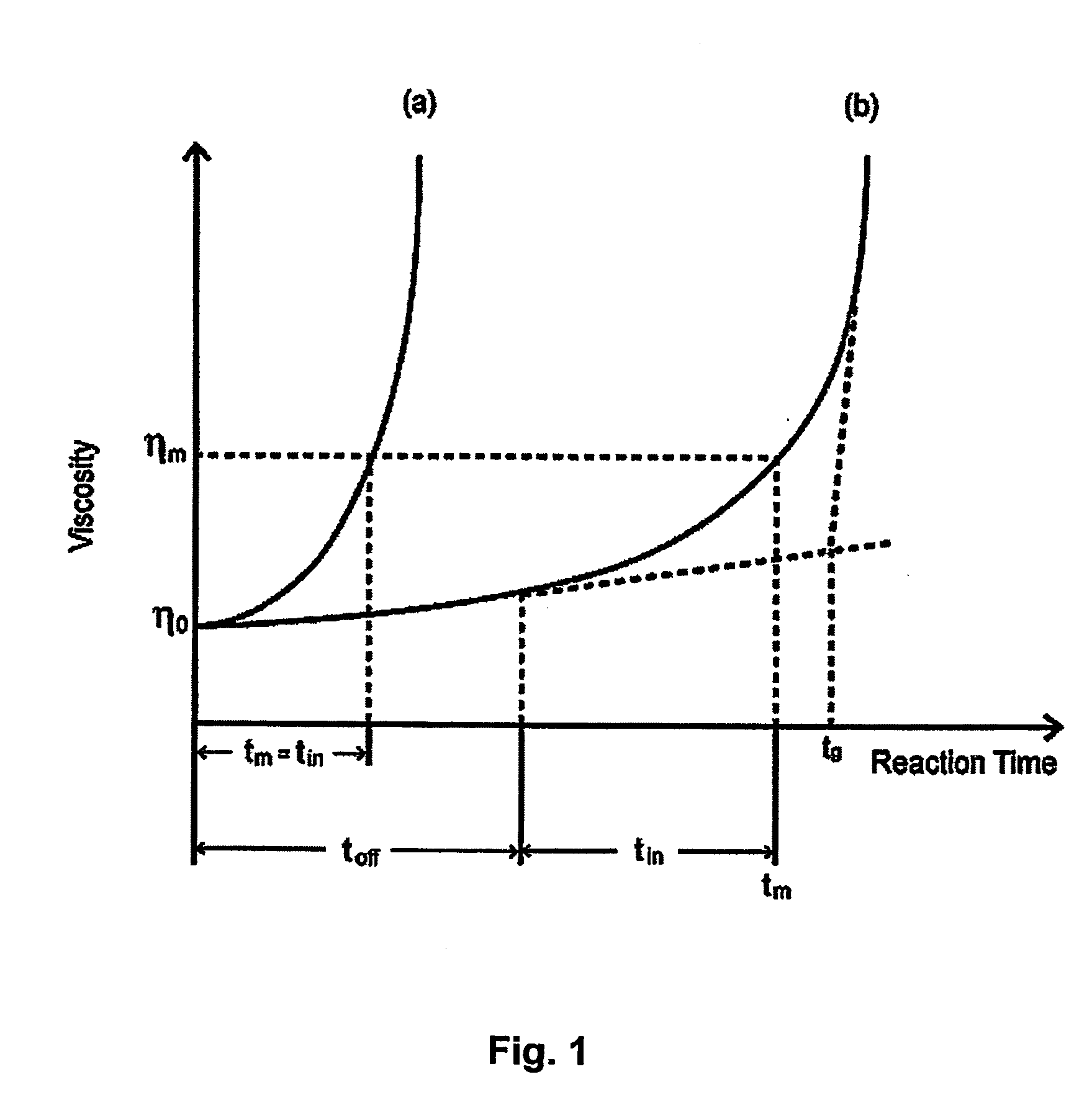

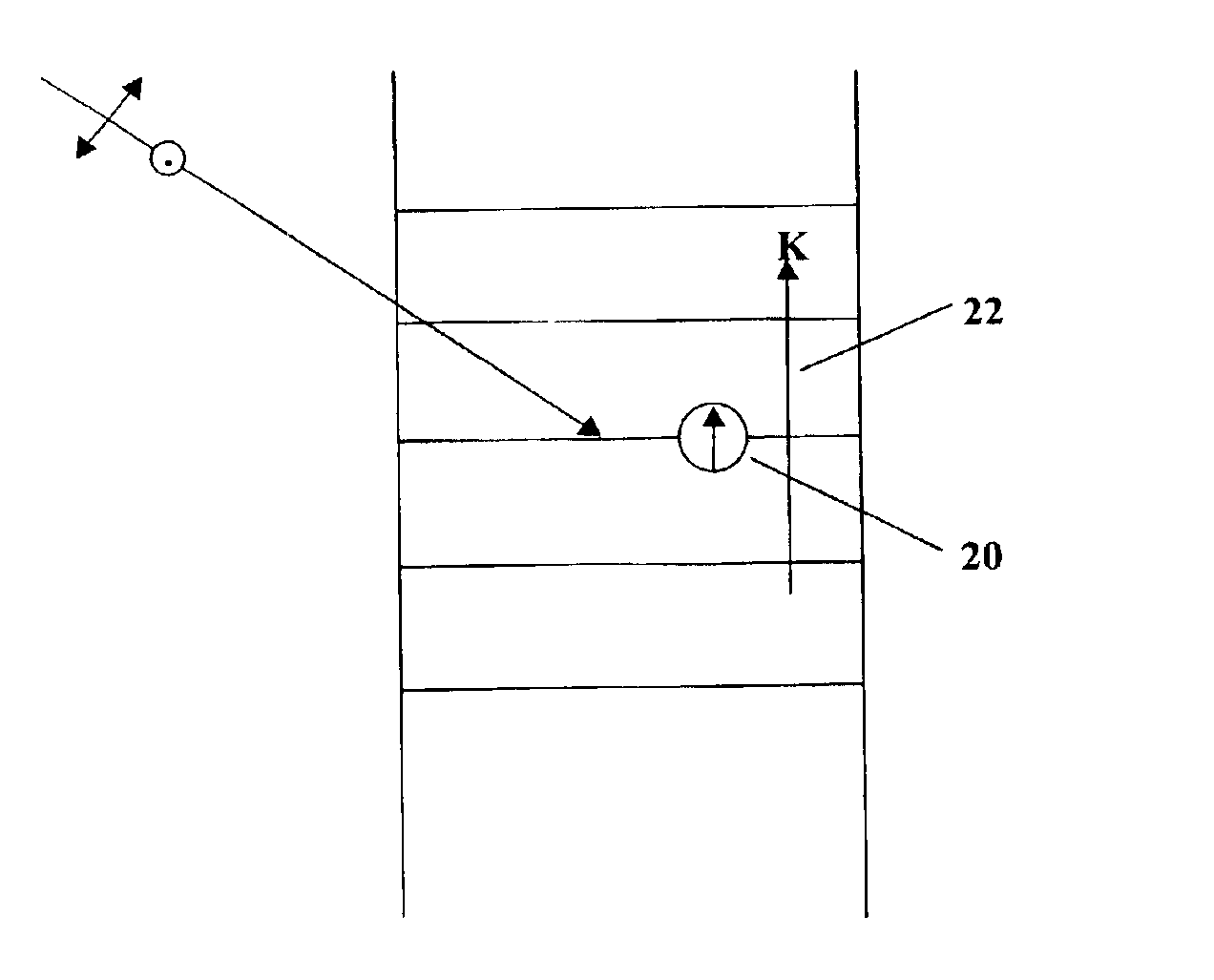

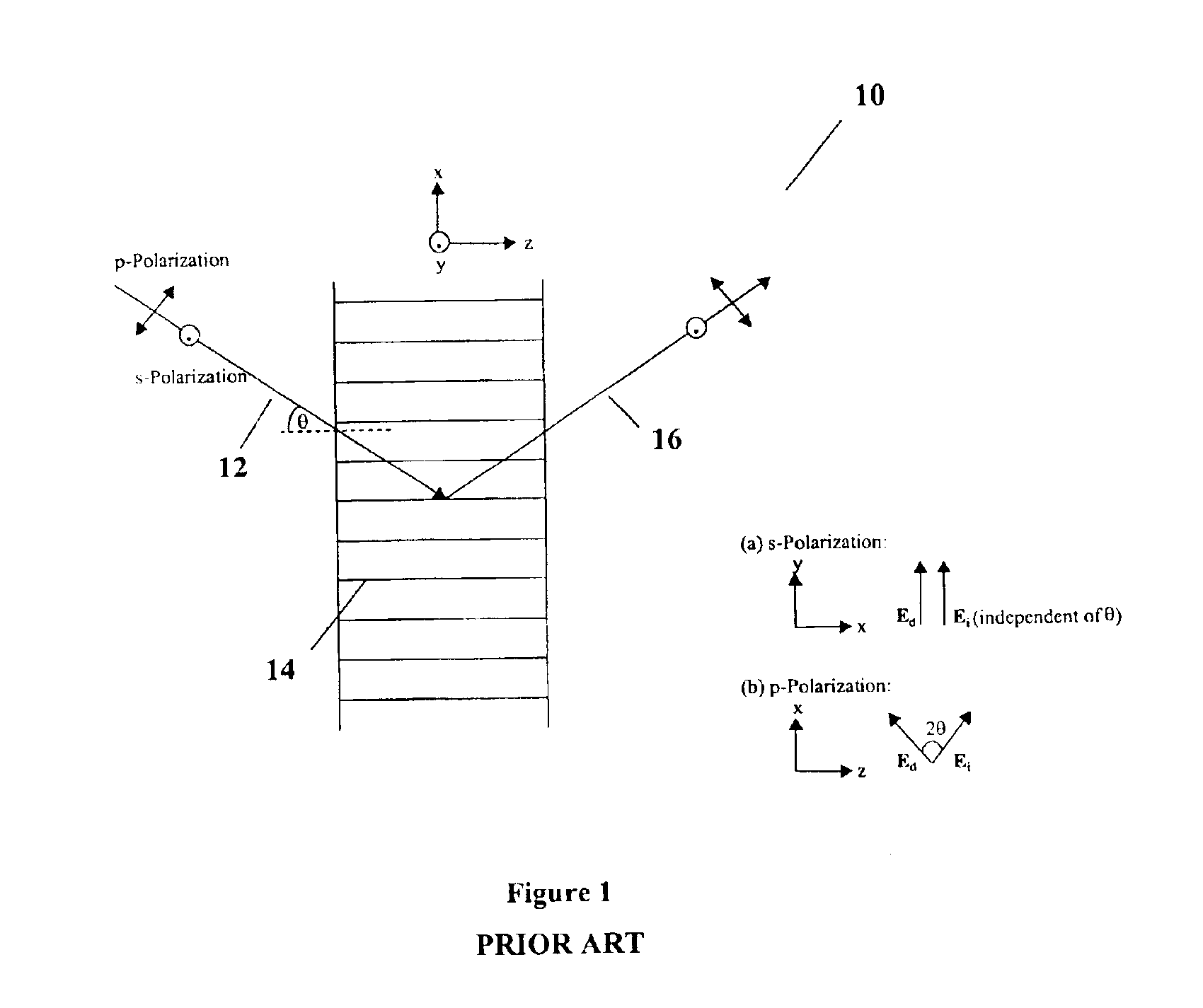

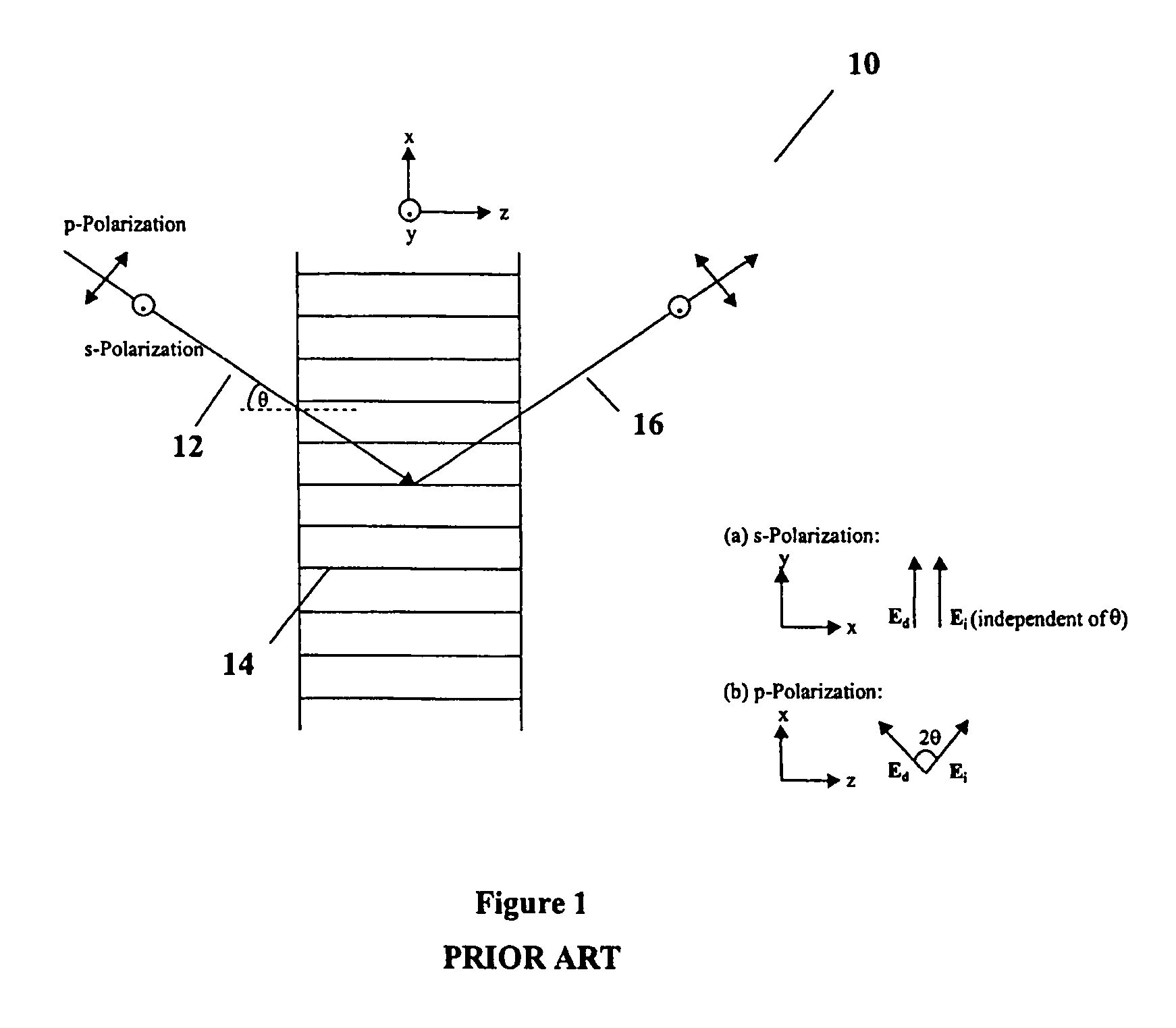

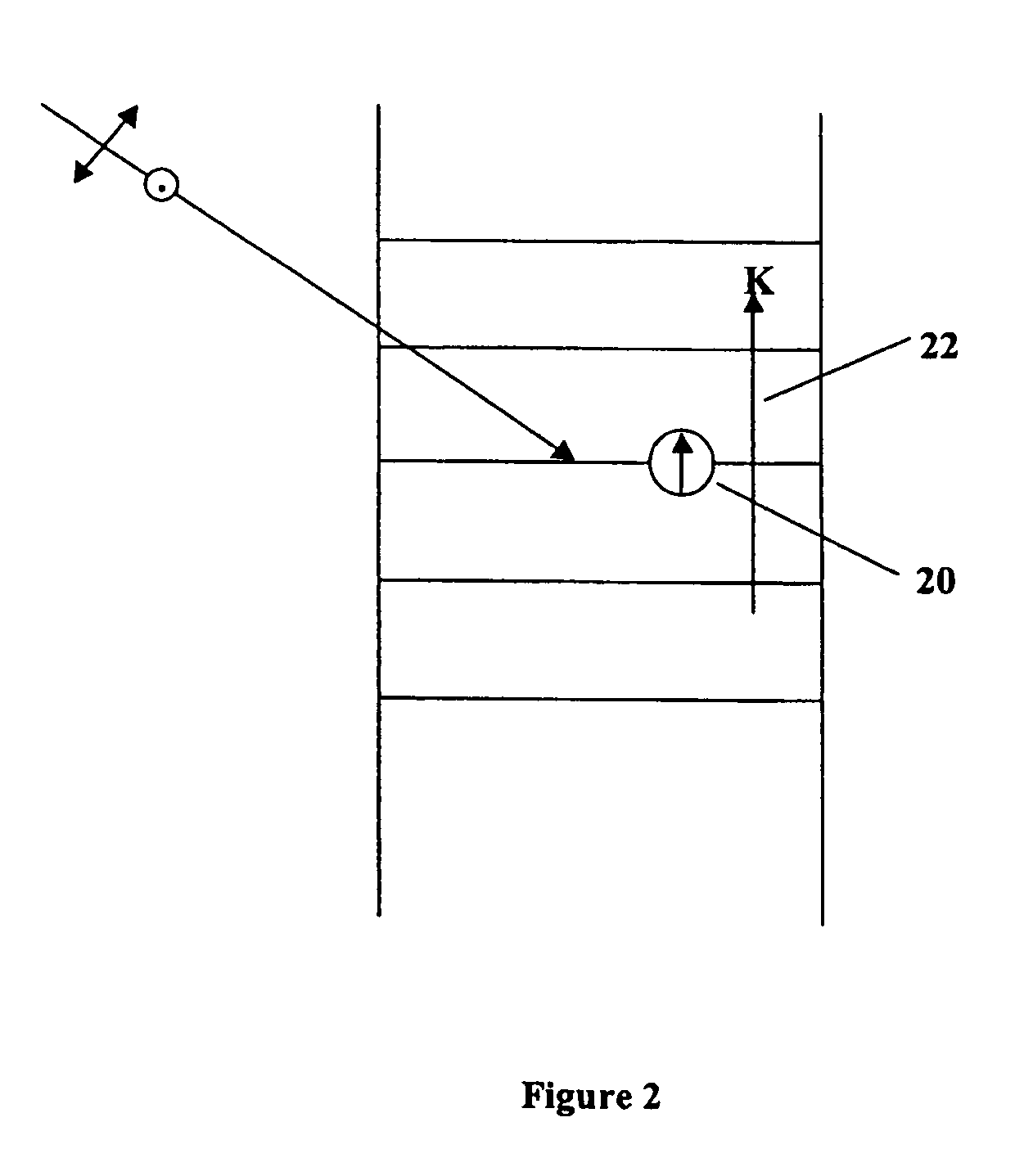

Optimizing performance parameters for switchable polymer dispersed liquid crystal optical elements

InactiveUS6950173B1Reduce smogLimiting operation temperatureNon-linear opticsOptical elementsDisplay deviceEngineering

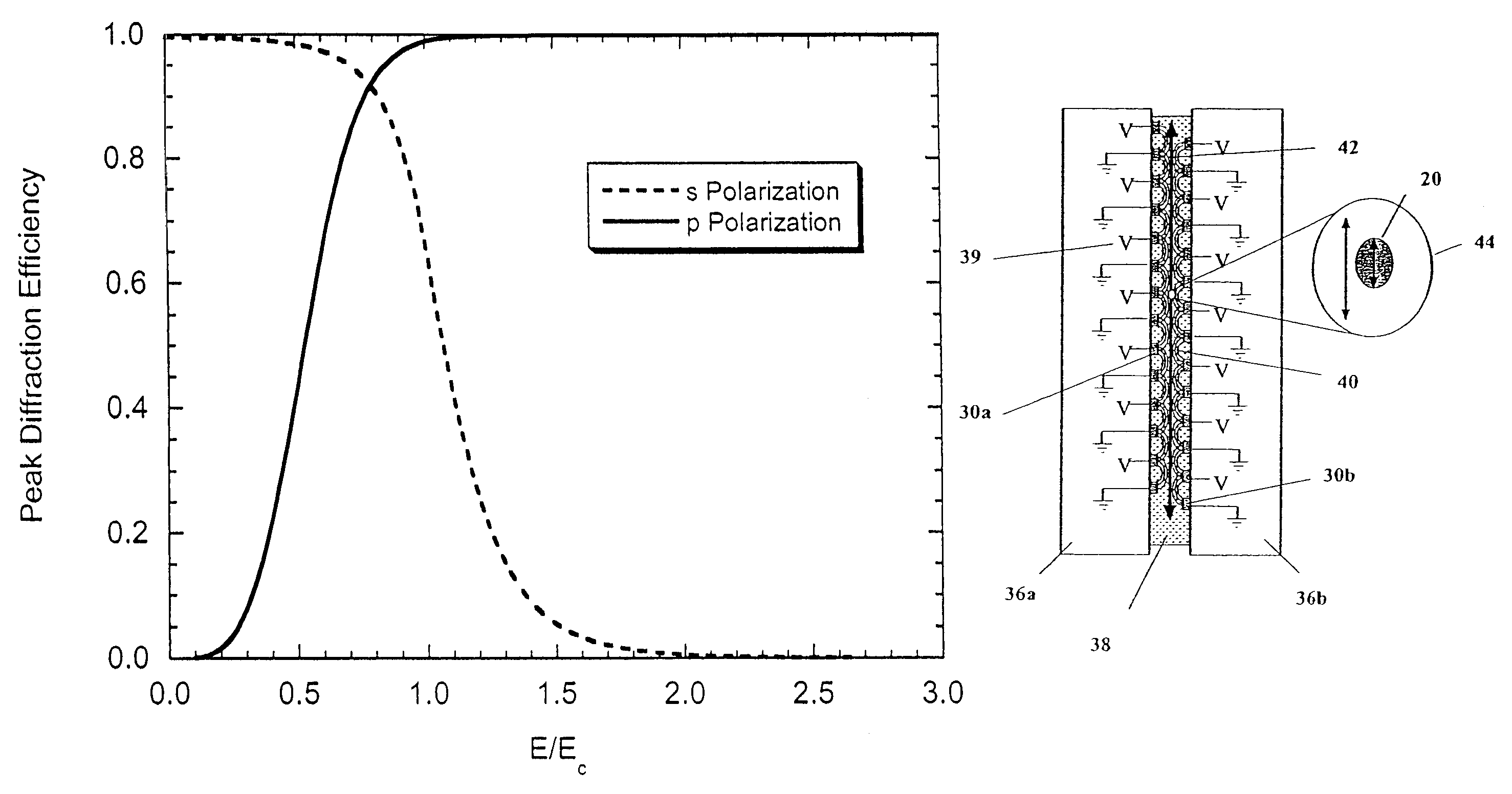

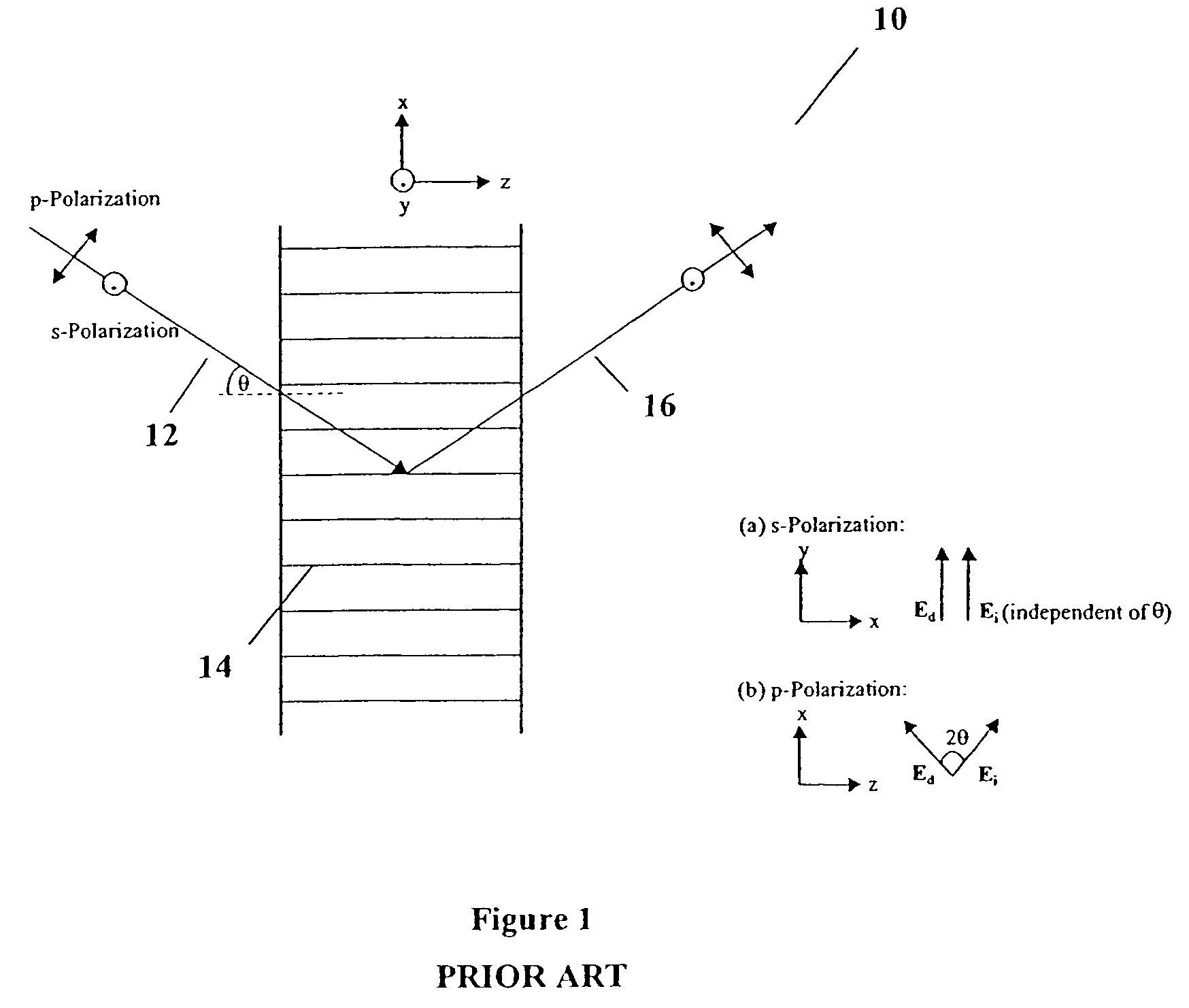

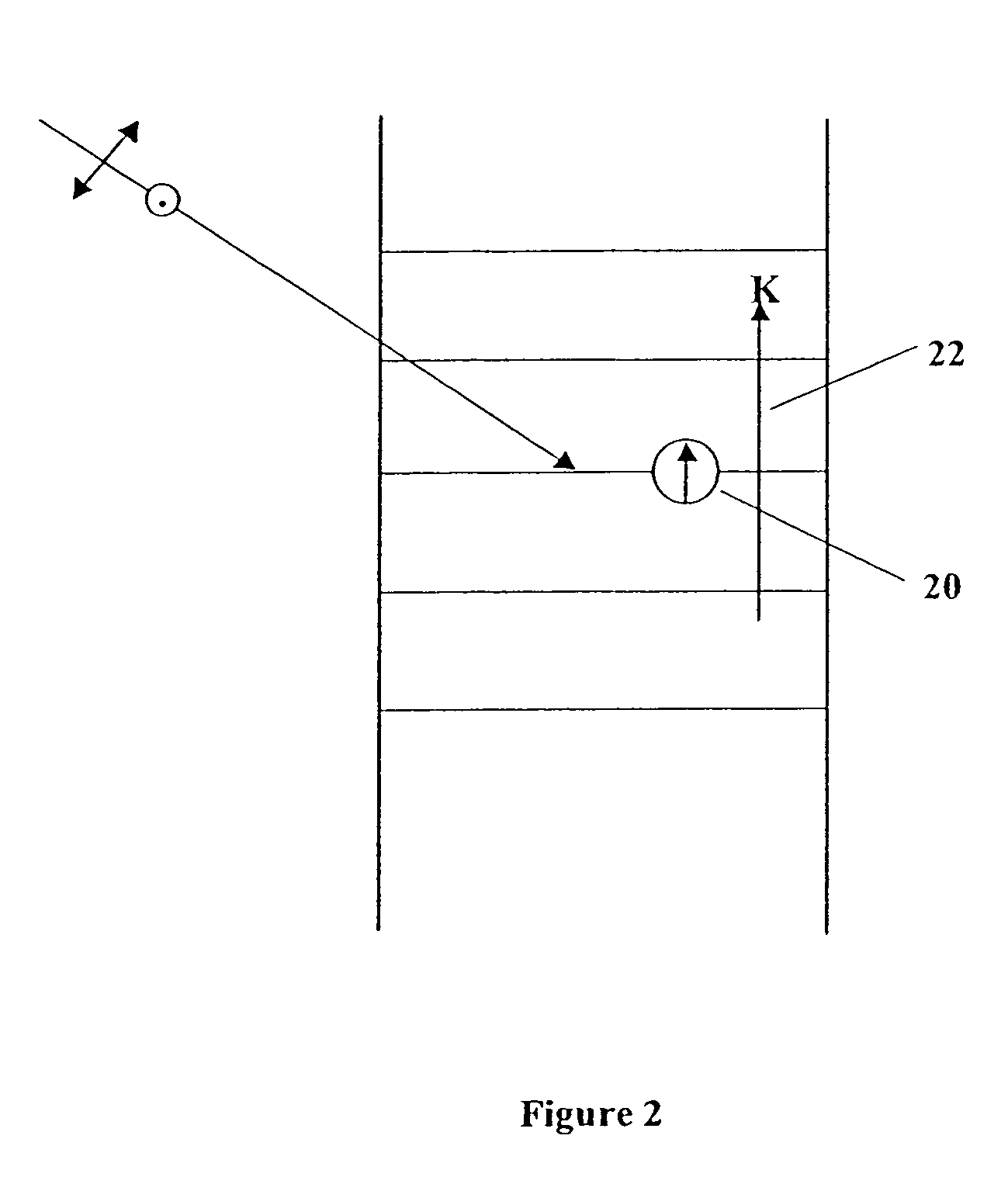

Described herein are the materials, mechanisms and procedures for optimizing various performance parameters of HPDLC optical devices in order to meet differing performance requirements. These optimization tailoring techniques include control and independent optimization of switchable HPDLC optical devices to meet the demanding requirements of anticipated applications for, inter alia, the telecommunications and display industries. These techniques include optimization of diffraction efficiency, i.e., index modulation, polarization dependence control, haze, cosmetic quality, control of response and relaxation time, voltage driving for on and off switching, and material uniformity. This control and independent optimization tailors properties of switchable HPDLC optical devices according to the specific requirements of the application of the switchable HPDLC optical device. The invention disclosed herein retains the desirable attributes of the multi-functional acrylate system for forming HPDLC optical devices, but adds new materials to the acrylate system and / or new process control to the recording to optimize performance parameters as may be needed for specific applications. This results in high optical quality switchable holograms with good diffraction efficiency and low, stable switching voltage.

Owner:LEIDOS

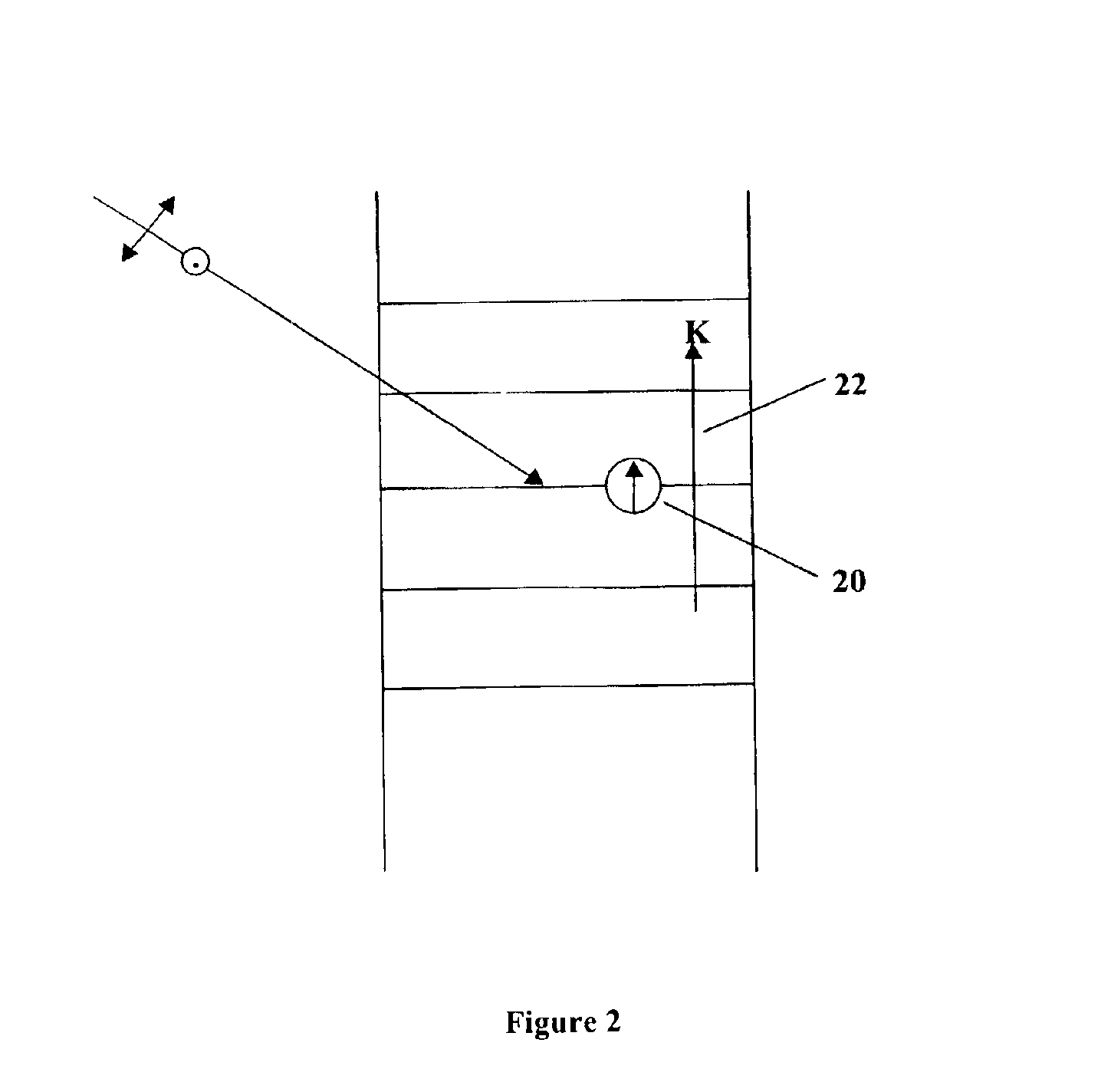

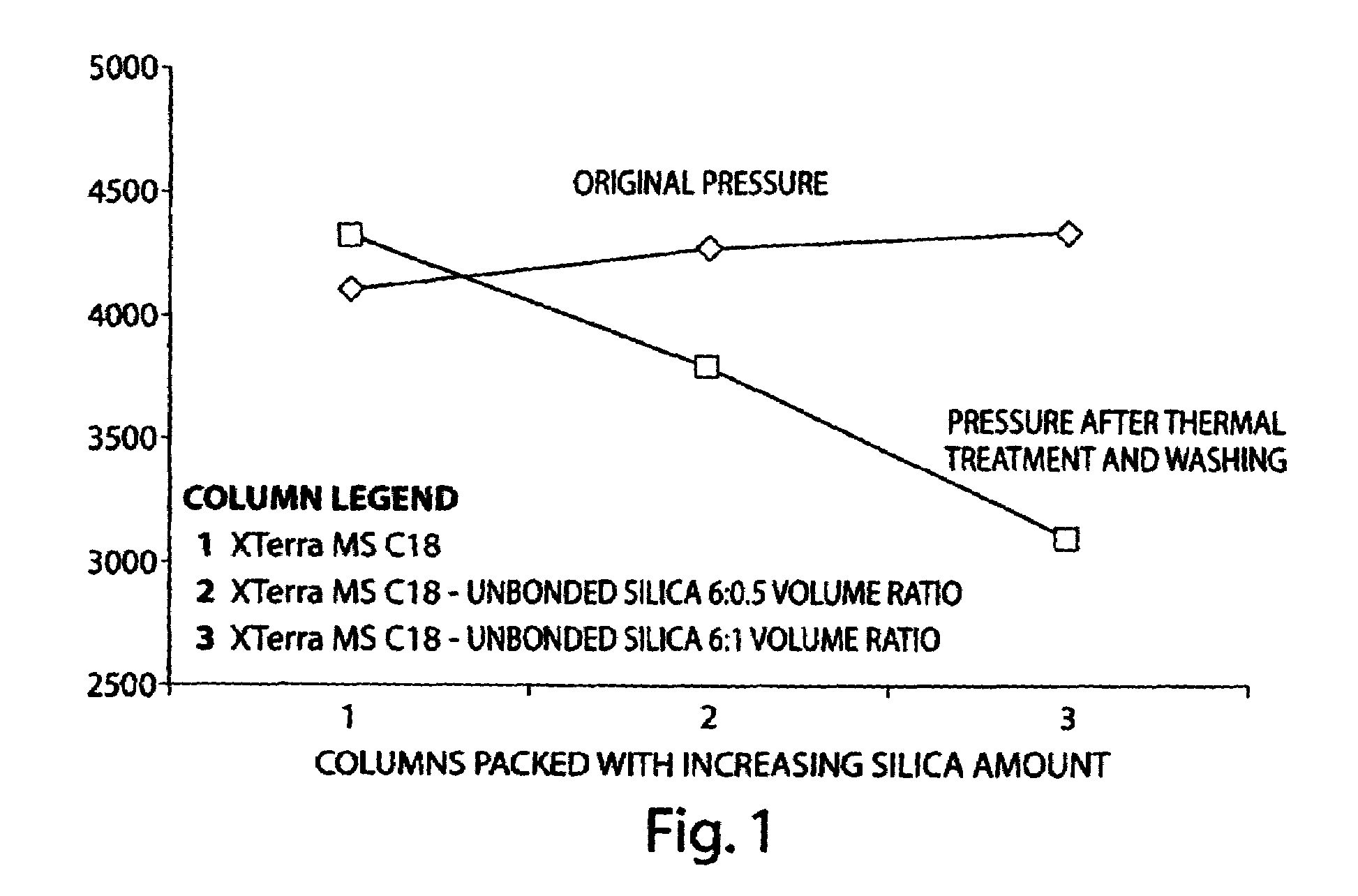

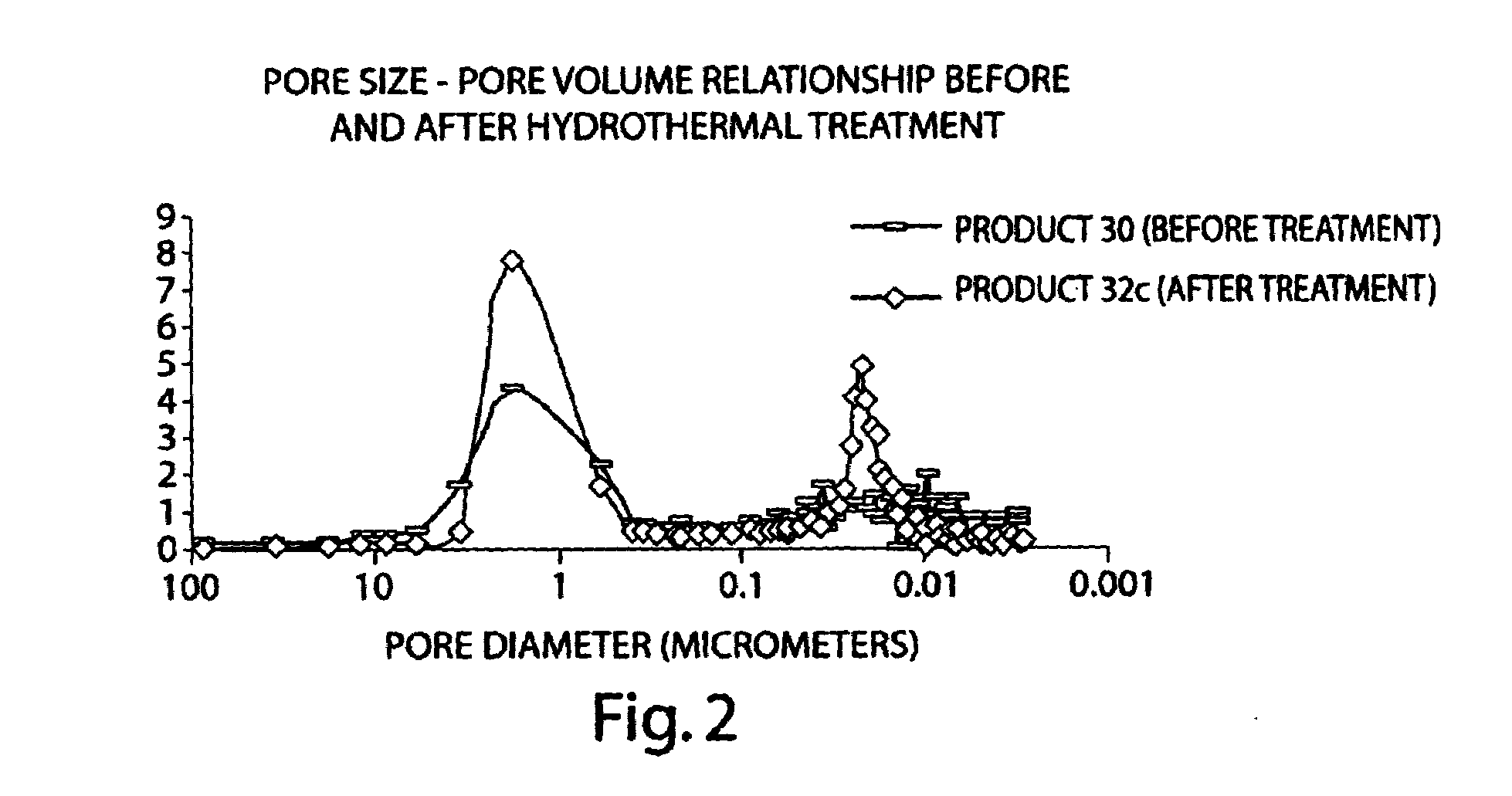

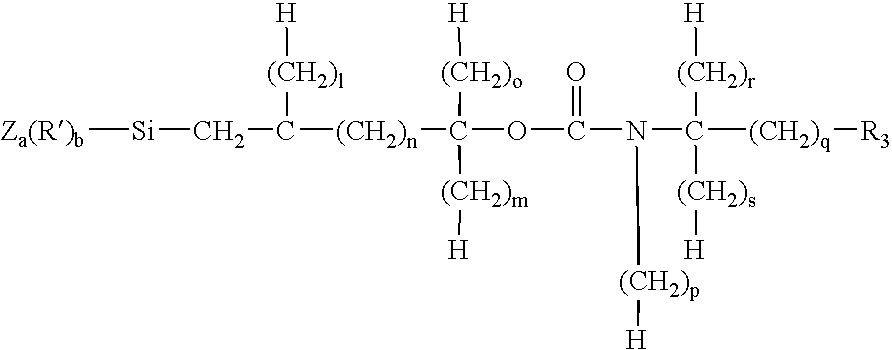

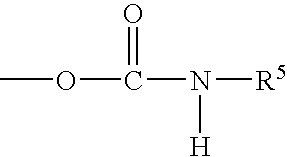

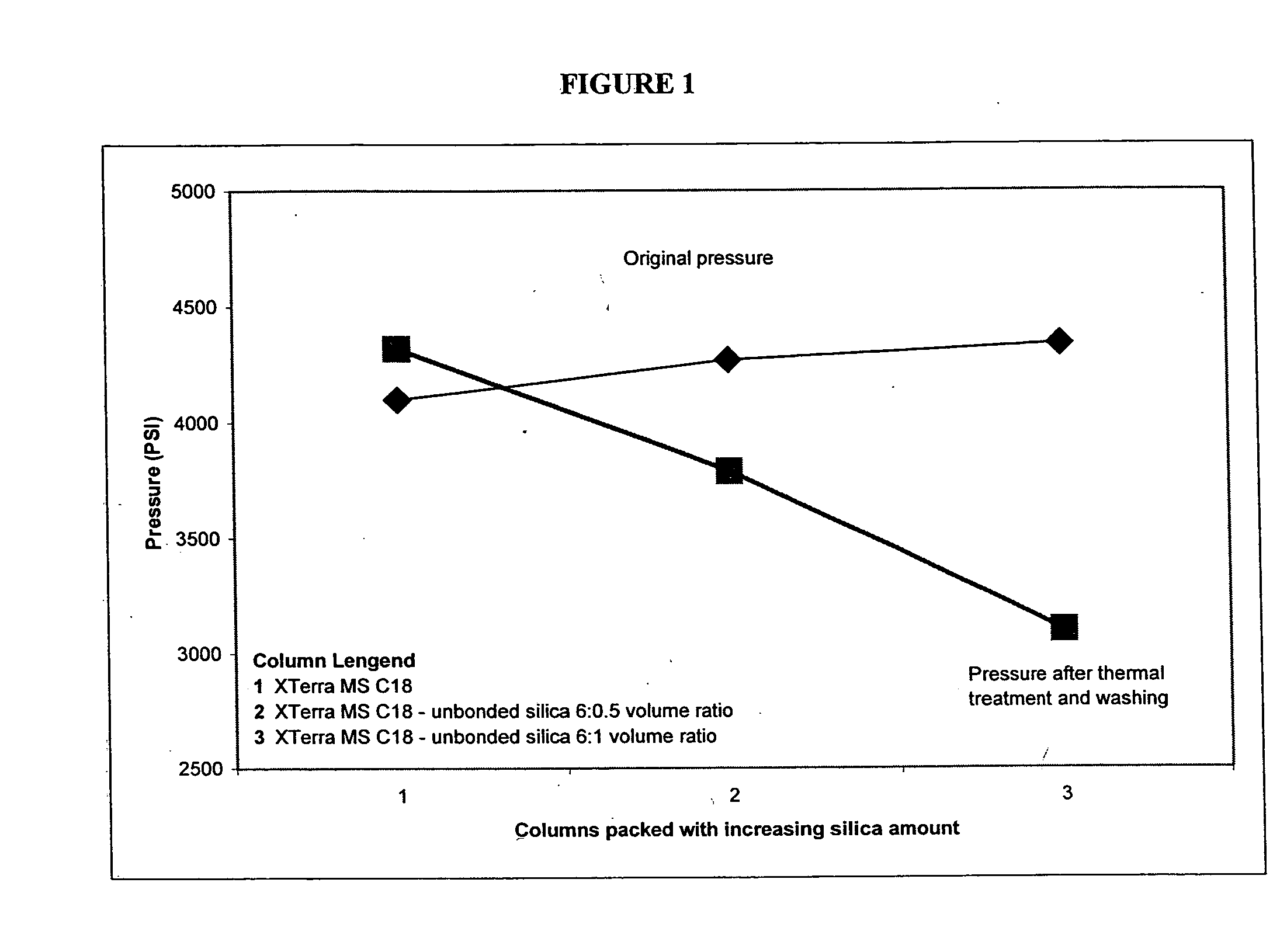

Porous inorganic/organic hybrid monolith materials for chromatographic separations and process for their preparation

InactiveUS7250214B2Extended service lifeReduce back pressureComponent separationIon-exchanger regenerationChromatographic separationNew materials

Novel materials for chromatographic separations, processes for their preparation, and separation devices containing the chromatographic materials. In particular, the novel materials are porous inorganic / organic hybrid monolith materials, which desirably may be surface modified, and which offer more efficient chromatographic separations than that known in the art.

Owner:WATERS TECH CORP

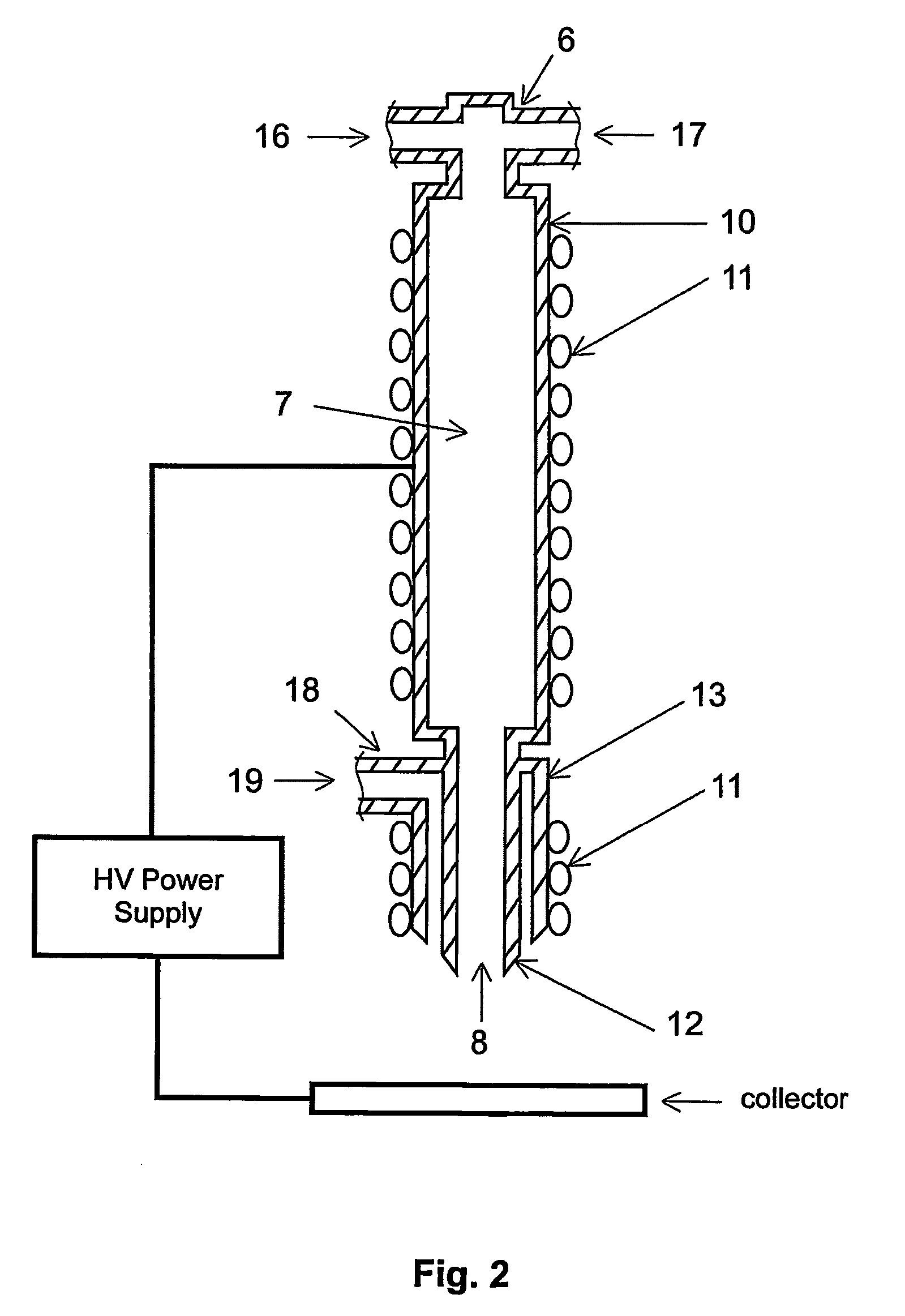

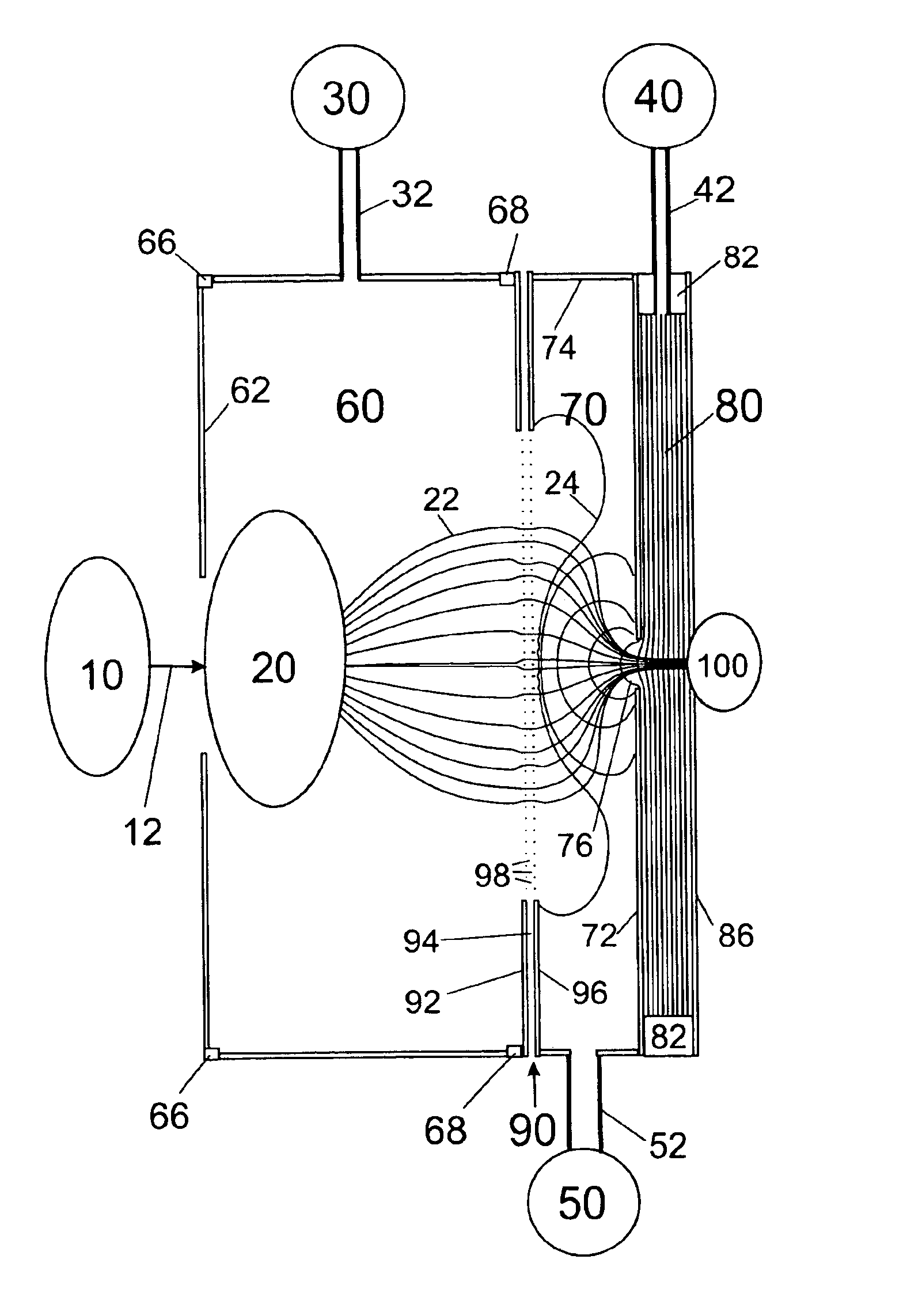

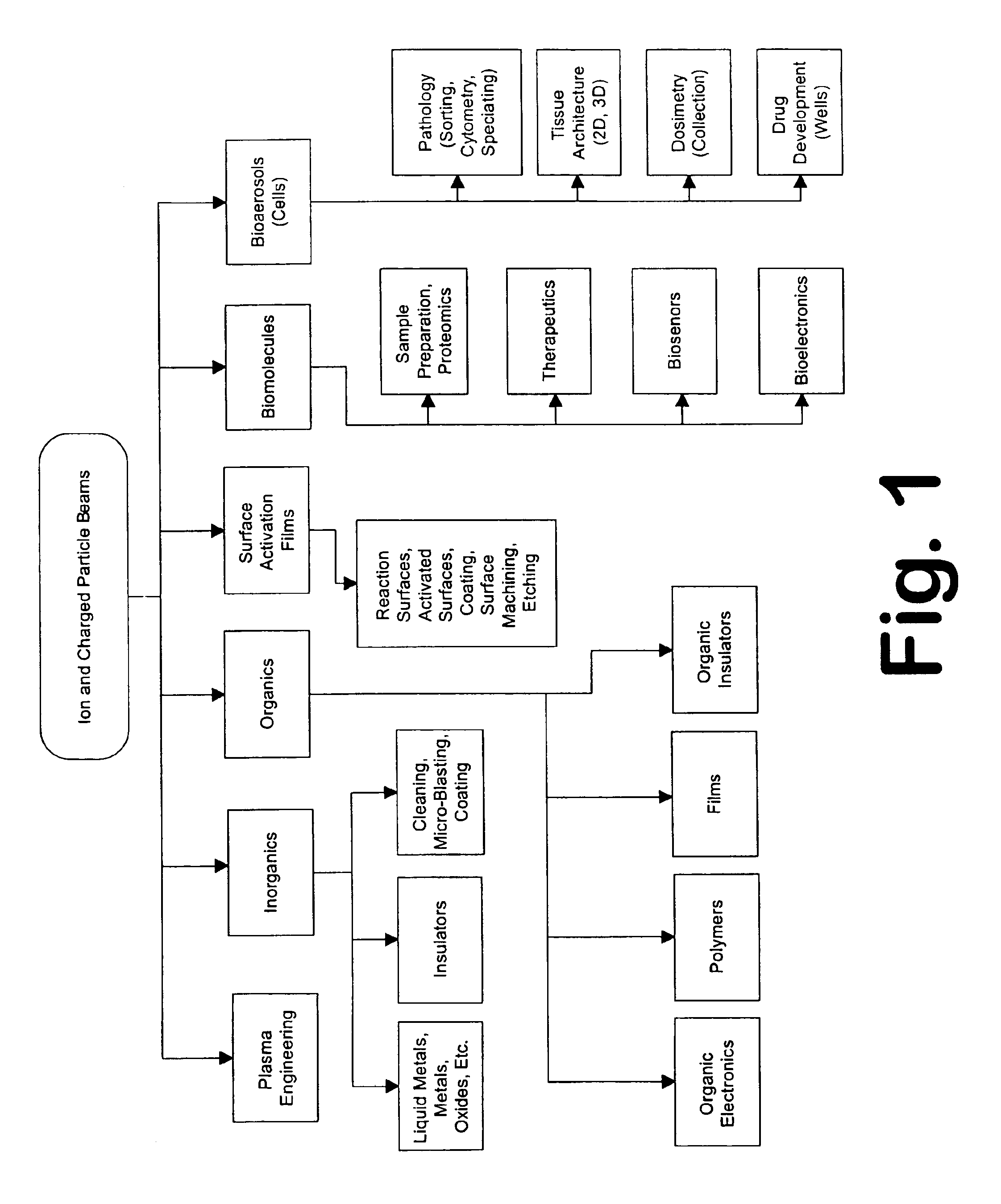

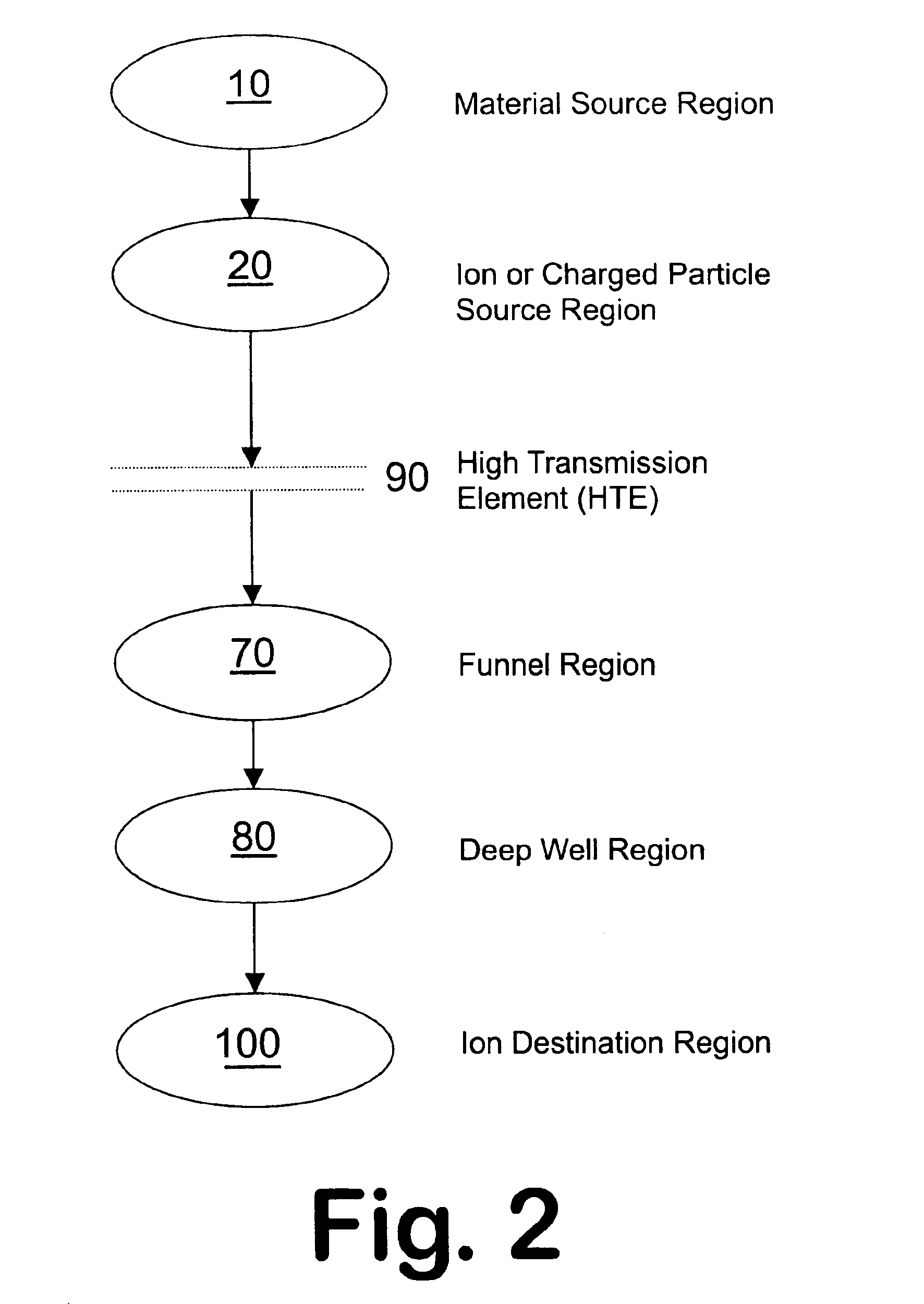

Ion and charged particle source for production of thin films

InactiveUS6878930B1Efficiency problemStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsIon clustersImage resolution

The present invention includes a delivery means of material to be deposited onto thin film surfaces with precise spatial, temporal, compositional, and energy resolution for controlled reactions, patterning (2-dimensional and 3-dimensional), and removal of materials or reaction products of materials from thin film surfaces. The device includes a near atmospheric pressure means of generating ions, ion clusters, or charged particles as a material form to deliver said materials onto substrate surfaces. The device relies on shaped, patterned, conformal ion lenses, and individually addressable lens elements of a lens arrays to create an integrated deposition system for printed patterns of thin films. The devices and methods provide a novel approach to delivering materials to a surface, removing materials from a surface, or creating new materials at or on the surface. These methods and devices may be used in applications of thin film deposition, micro-electronics and semi-conductor manufacturing, printing, surface interfacial layers, coating, painting, sample and reagent treatment, preparation for sensors, chemical analysis, and fabricating 2- and 3-dimensional structures and devices.

Owner:WILLOUGHBY ROSS CLARK +2

Porous inorganic/organic hybrid particles for chromatographic separations and process for their preparation

InactiveUS7223473B2Chromatographic cation exchangersComponent separationChromatographic separationNew materials

Novel material for chromatographic separations, processes for its preparation, and separations devices containing the chromatographic material. In particular, the disclosure describes porous inorganic / organic hybrid particles having a chromatographically-enhancing pore geometry, which desirably may be surface modified, and that offer more efficient chromatographic separations than that known in the art.

Owner:WATERS TECH CORP

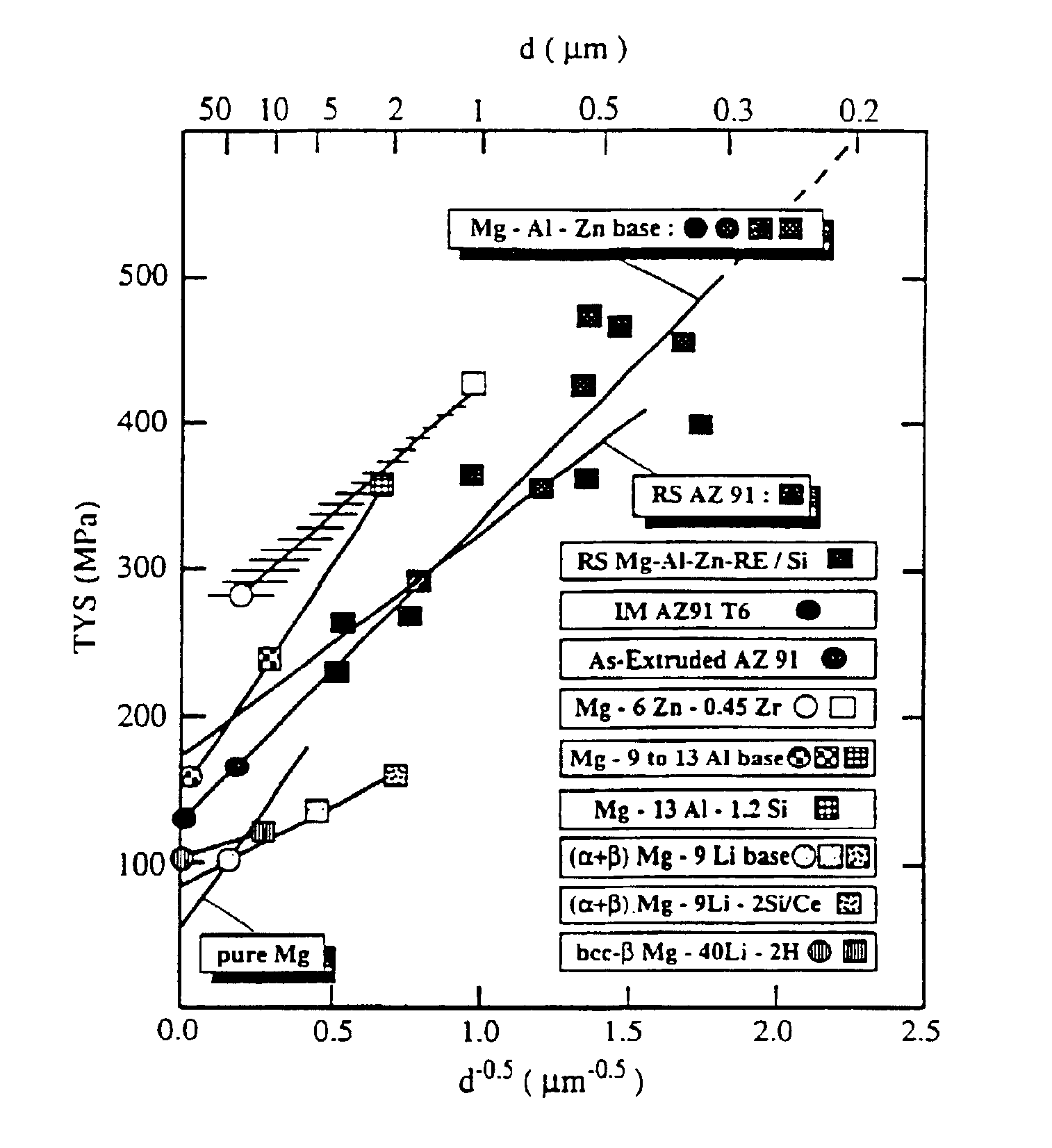

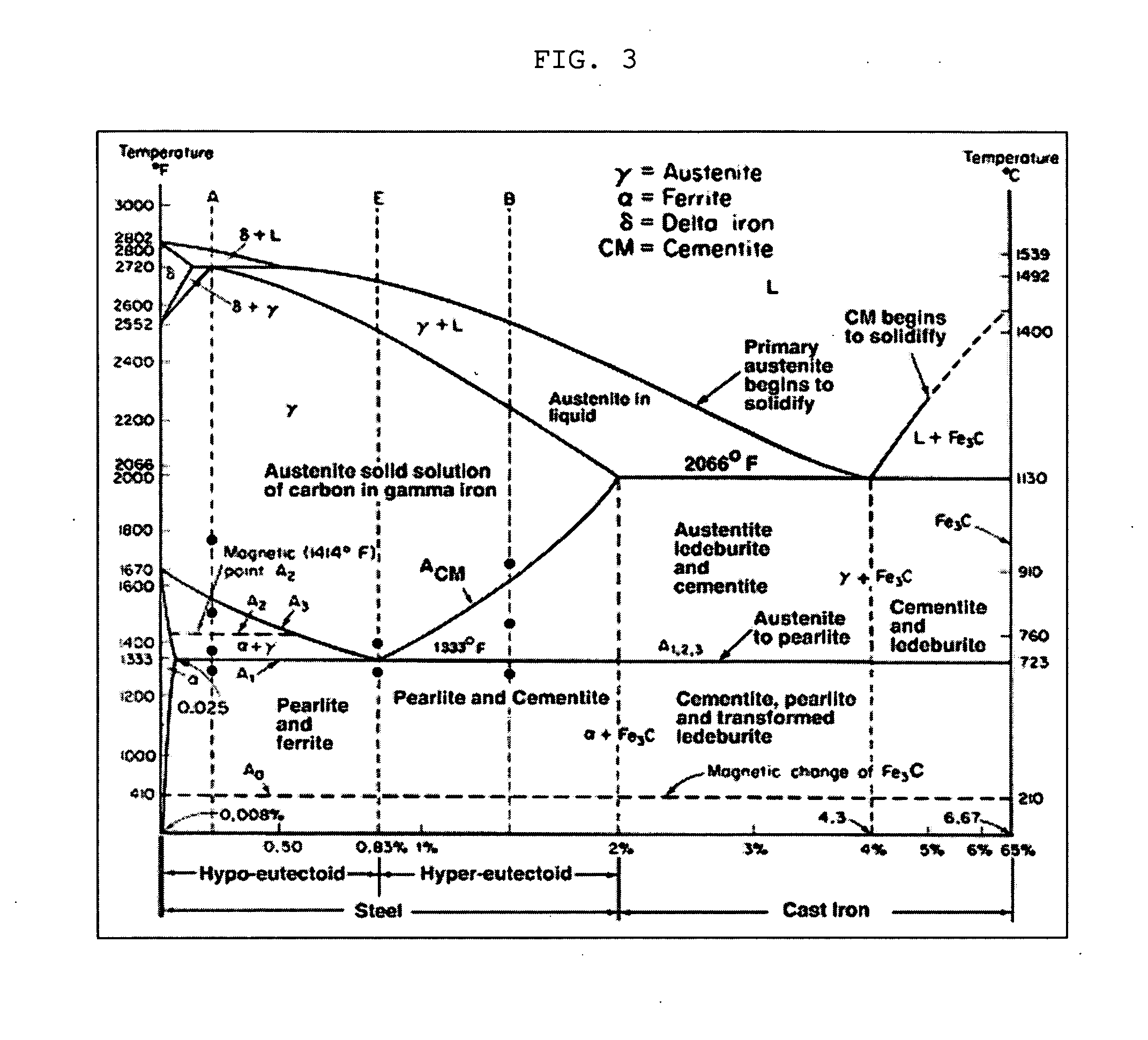

Selected processing for non-equilibrium light alloys and products

InactiveUS6908516B2Reduce resistanceMultiplies numberVacuum evaporation coatingSputtering coatingGas phaseMaterials science

A new class of light or reactive elements and monophase α′-matrix magnesium- and aluminum-based alloys with superior engineering properties, for the latter being based on a homogeneous solute distribution or a corrosion-resistant and metallic shiny surface withstanding aqueous and saline environments and resulting from the control during synthesis of atomic structure over microstructure to net shape of the final product, said α′-matrix being retained upon conversion into a cast or wrought form. The manufacture of the materials relies on the control of deposition temperature and in-vacuum consolidation during vapor deposition, on maximized heat transfer or casting pressure during all-liquid processing and on controlled friction and shock power during solid state alloying using a mechanical milling technique. The alloy synthesis is followed by extrusion, rolling, forging, drawing and superplastic forming for which the conditions of mechanical working, thermal exposure and time to transfer corresponding metastable α′-matrix phases and microstructure into product form depend on thermal stability and transformation behavior at higher temperatures of said light alloy as well as on the defects inherent to a specific alloy synthesis employed. Alloying additions to the resulting α′-monophase matrix include 0.1 to 40 wt. % metalloids or light rare earth or early transition or simple or heavy rare earth metals or a combination thereof. The eventually more complex light alloys are designed to retain the low density and to improve damage tolerance of corresponding base metals and may include an artificial aging upon thermomechanical processing with or without solid solution heat and quench and annealing treatment for a controlled volume fraction and size of solid state precipitates to reinforce alloy film, layer or bulk and resulting surface qualities. Novel processes are employed to spur production and productivity for the new materials.

Owner:HEHMANN FRANZ

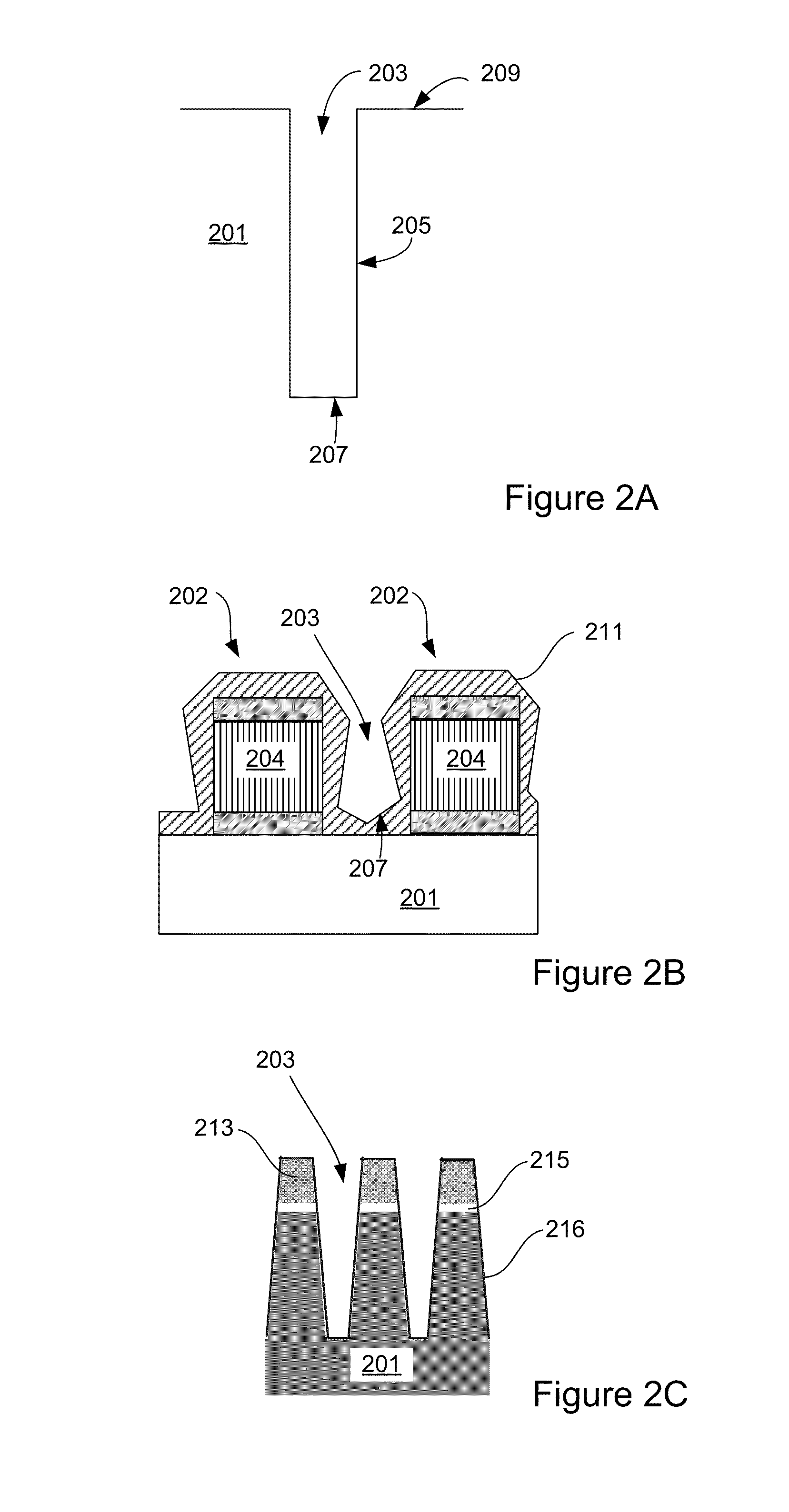

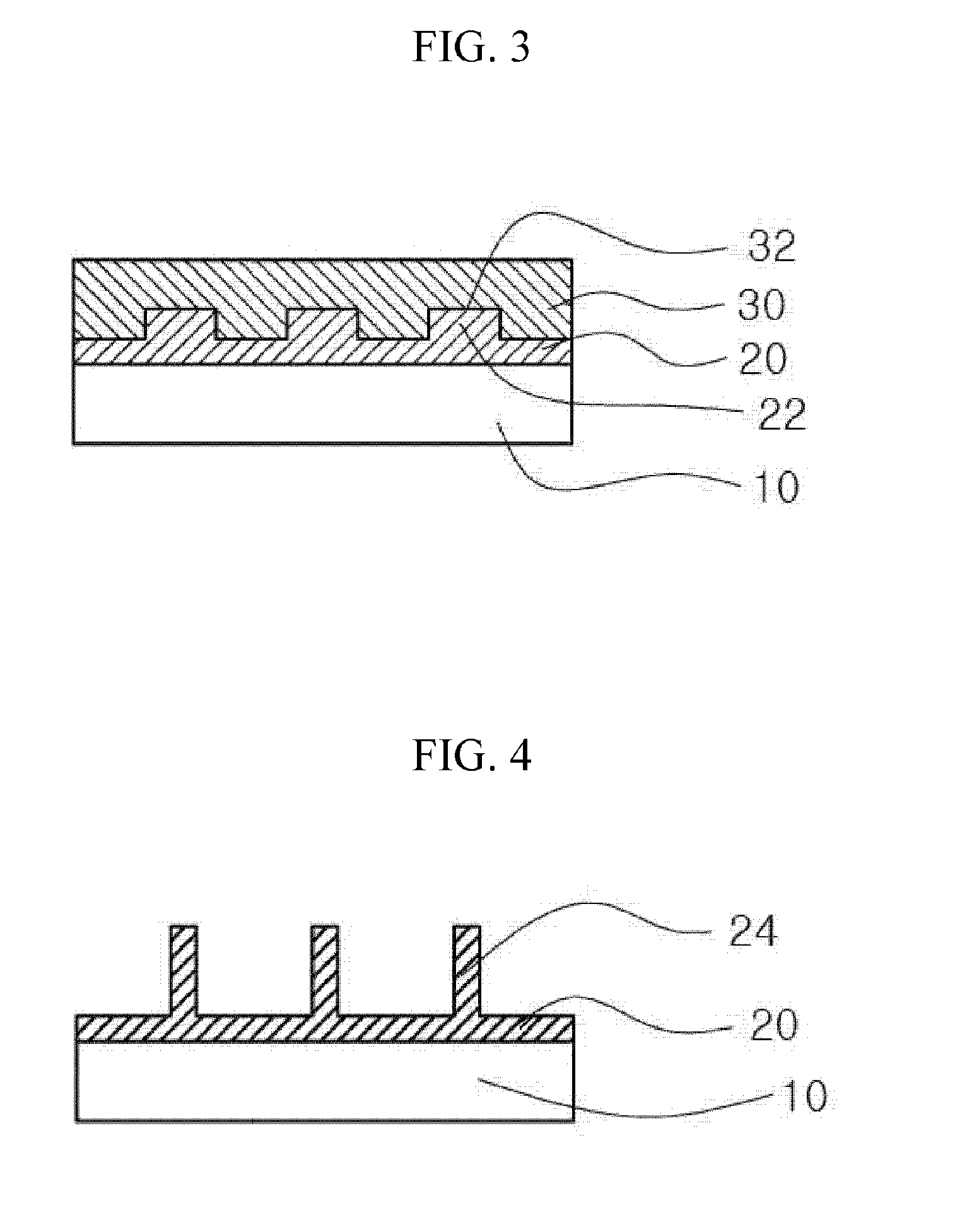

Method for forming nanostructure having high aspect ratio and method for forming nanopattern using the same

InactiveUS20080000871A1Simple and economical processHigh aspect ratioDecorative surface effectsIndividual molecule manipulationPolymer scienceCarbon nanotube

Provided is a method of forming a nanostructure having a nano-sized diameter and a high aspect ratio through a simple and economical process. To form the nanostructure, a polymer thin film is formed on a substrate and a mold is brought to contact the polymer thin film. Then, a polymer patterning is formed to contact the background surface of an engraved part of the mold, and then the polymer pattern is extended out by removing the mold out of the polymer thin film. The nanostructure forming method of the present research can reproduce diverse cilia optimized in the natural world. Also, it can be used to develop new materials with an ultra-hydrophobic property or a high adhesiveness. Further, it can be applied to a nanopattern forming process for miniaturizing electronic devices and to various ultra-precise industrial technologies together with carbon nanotube, which stands in the highlight recently.

Owner:SEOUL NAT UNIV R&DB FOUND

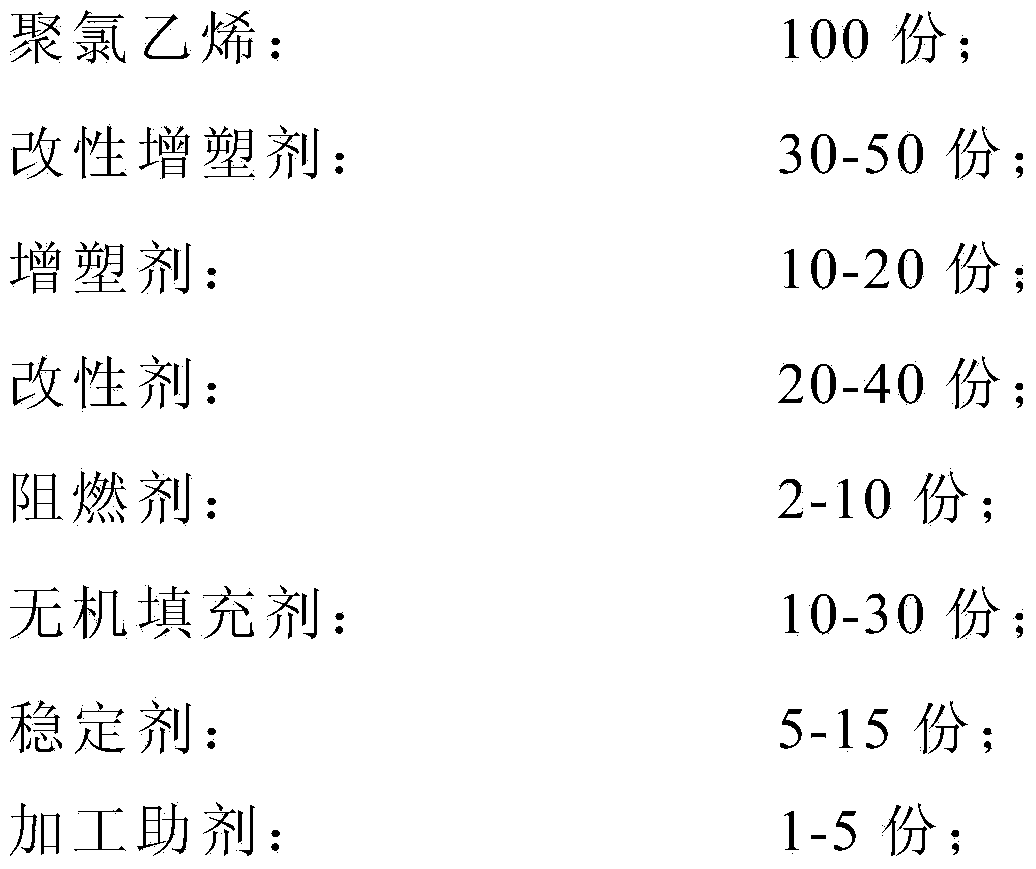

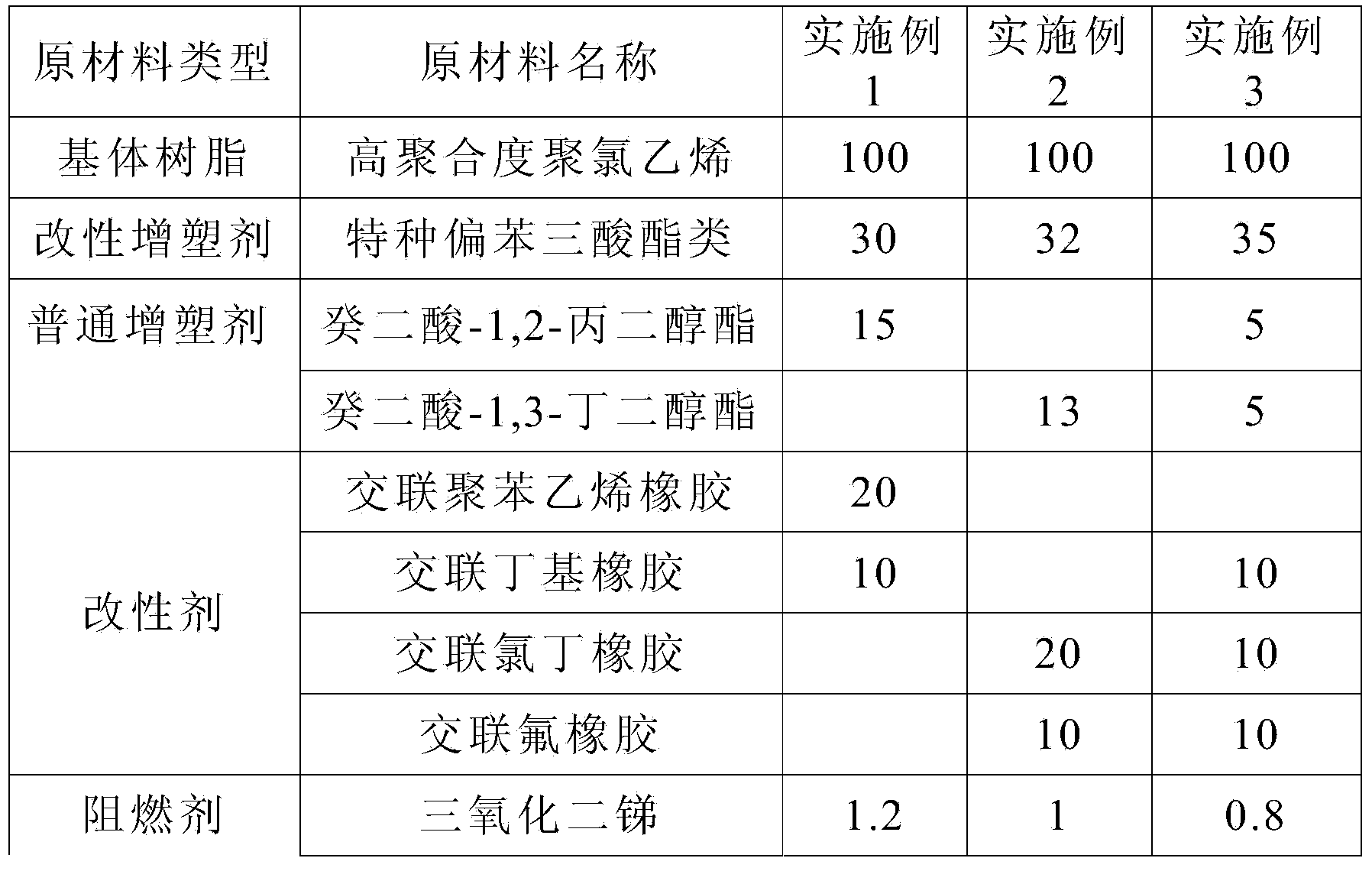

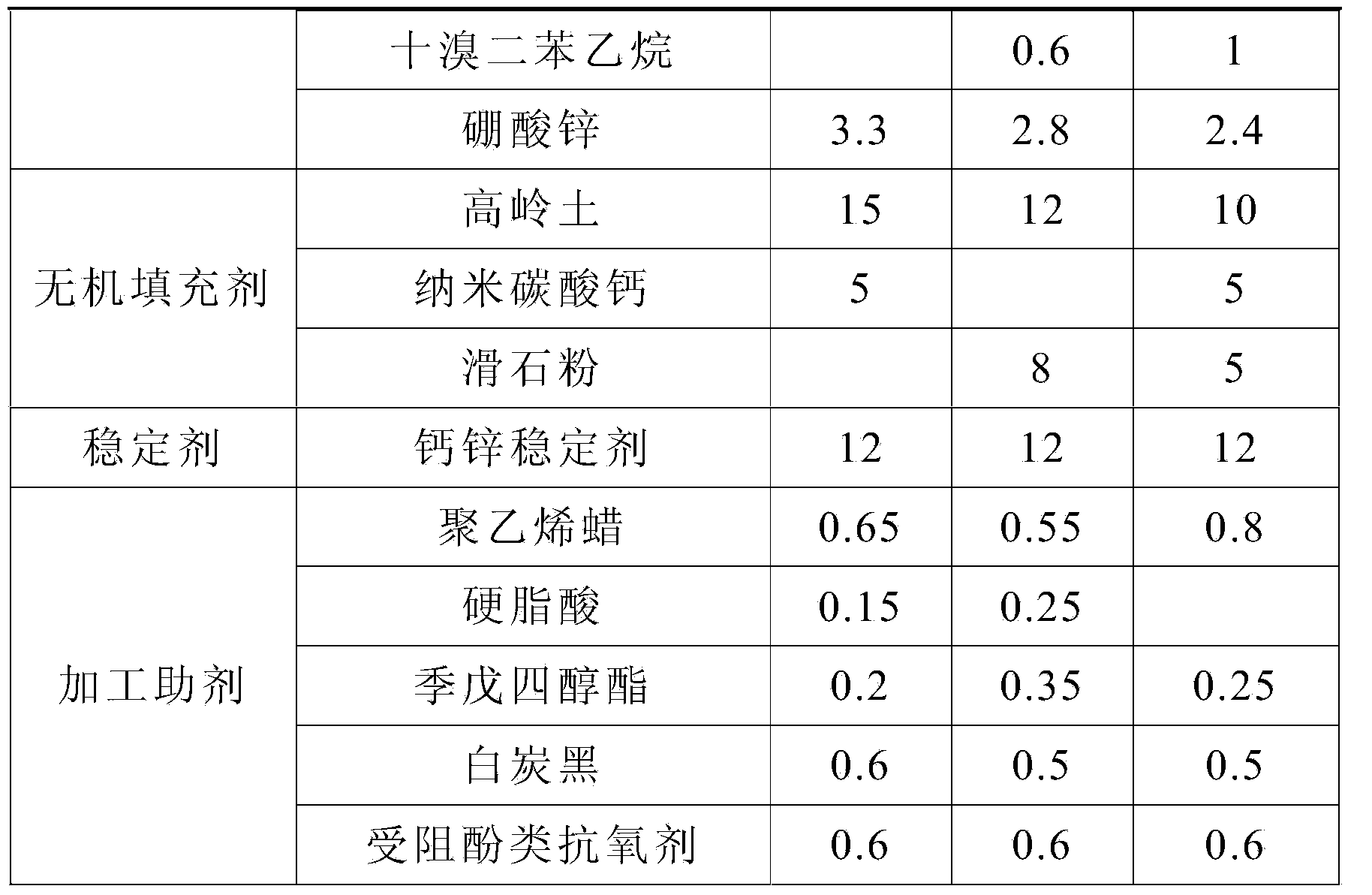

High-temperature resistant thermoplastic polyvinyl chloride cable material and preparation method thereof

ActiveCN103524946AGood physical propertiesHigh strengthInsulated cablesInsulated conductorsProcedure AgentsPolyvinyl chloride

The invention relates to a high-temperature resistant thermoplastic polyvinyl chloride cable material, belonging to the technical field of new materials. The cable material consists of the following components in parts by weight: 100 parts of polyvinyl chloride, 30-50 parts of modified plasticizer, 10-20 parts of plasticizer, 20-40 parts of modifier, 2-10 parts of flame retardant, 10-30 parts of inorganic filler, 5-15 parts of stabilizer and 1-5 parts of processing aid. A preparation method of the cable material comprises the following steps: weighing the raw materials according to the components and weight parts of the cable material; uniformly mixing the polyvinyl chloride and adding the modified plasticizer and the common plasticizer; heating and stirring and adding other raw materials; discharging from a high mixing machine and feeding into a twin-screw extruder for extrusion and granulation; and performing air cooling to obtain the final product. The cable material has the advantages that the physical property is good, the applicable temperature range is wide, little pollution is caused, the flame retardance is good, the smoke output in combustion is low, the preparation method is simple, and the cost is low.

Owner:江西一舟数据技术有限公司

Composite type high-conductivity polymer material and preparation method thereof

ActiveCN101891914AImprove conductivityAvoid damageNon-conductive material with dispersed conductive materialPolymer scienceConductive polymer

The invention discloses a composite type high-conductivity polymer material and a preparation method thereof, which belongs to the technical field of new materials. The composite type high-conductivity polymer material is characterized by comprising the following raw materials in percentage by weight: 40-62 wt% of base resin compositions, 18-25 wt% of super conductive carbon black, 10-30 wt% of rubber filling oil, 1-3 wt% of low molecular wax, 0.2-0.8 wt% of fluoroelastomer processing aid (PPA), 0.5-2 wt% of lubricant, 1.5-3 wt% of inorganic filler and 0.5-2.5 wt% of other aids. The compositetype high-conductivity polymer material has the advantages of excellent high conductivity, environmental stress cracking resistance, weatherability, ozone resistance, ultraviolet resistance, favorable high temperature resistance, high impact resistance, oil resistance, solvent resistance and mechanical property, and can be used as an environment-friendly conductive polymer sheath material of an combined through earth line, a metal anticorrosive material of other ground cable, a conductive plastic cladding material of a conductive plastic cable positive wire, an optical cable flexible sheath material, and the like.

Owner:SHANDONG KEHONG WIRE & CABLE TECH CO LTD

Optimizing performance parameters for switchable polymer dispersed liquid crystal optical elements

InactiveUS7570405B1Limiting operation temperatureDelay transitionNon-linear opticsOptical elementsDisplay deviceEngineering

Described herein are the materials, mechanisms and procedures for optimizing various performance parameters of HPDLC optical devices in order to meet differing performance requirements. These optimization tailoring techniques include control and independent optimization of switchable HPDLC optical devices to meet the demanding requirements of anticipated applications for, inter alia, the telecommunications and display industries. These techniques include optimization of diffraction efficiency, i.e., index modulation, polarization dependence control, haze, cosmetic quality, control of response and relaxation time, voltage driving for on and off switching, and material uniformity. This control and independent optimization tailors properties of switchable HPDLC optical devices according to the specific requirements of the application of the switchable HPDLC optical device. The invention disclosed herein retains the desirable attributes of the multi-functional acrylate system for forming HPDLC optical devices, but adds new materials to the acrylate system and / or new process control to the recording to optimize performance parameters as may be needed for specific applications. This results in high optical quality switchable holograms with good diffraction efficiency and low, stable switching voltage.

Owner:LEIDOS INC

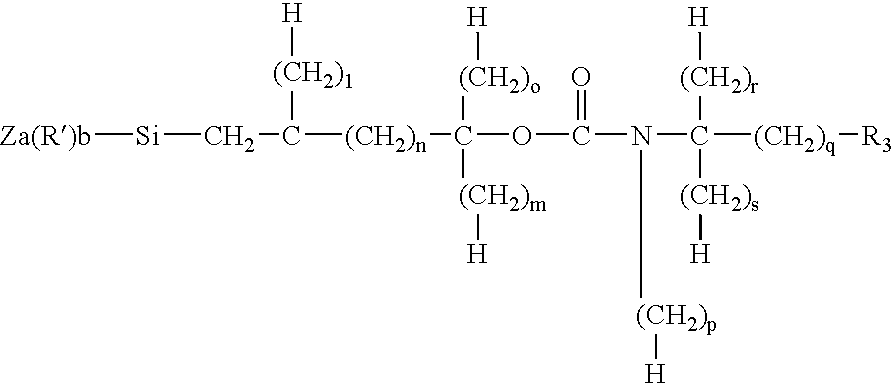

Method of producing an interpenetrating polymer network (ipn), the ipn and use thereof

ActiveUS20060148985A1Prevent steppingEasy to useBulk chemical productionPlasma techniquePolymer networkSolvent

The invention comprises a method of producing an interpenetrating polymer network (IPN) comprising the steps of I) providing a silicone polymer composition; (ii) providing one or more monomers for a polymer; (iii) providing a solvent for the one or more monomers; iv) exposing said silicone polymer composition to said one or more monomers and said solvent to precipitate monomer within said silicone polymer composition and v) polymerizing said monomer to form an IPN, wherein said solvent has a surface tension at the exposing step of about 15 mNZm or less. It is preferred that the solvent, which is preferably CO2, in the exposing step is in or near its supercritical state. The method is fast and simple, and the dispersion of the monomers may be controled to thereby controle the amount and distribution of the interpenetrating network in the silicone material. Further more the method results in new materials, where silicone polymers are used as the basic materials.

Owner:PTT HLDG APS

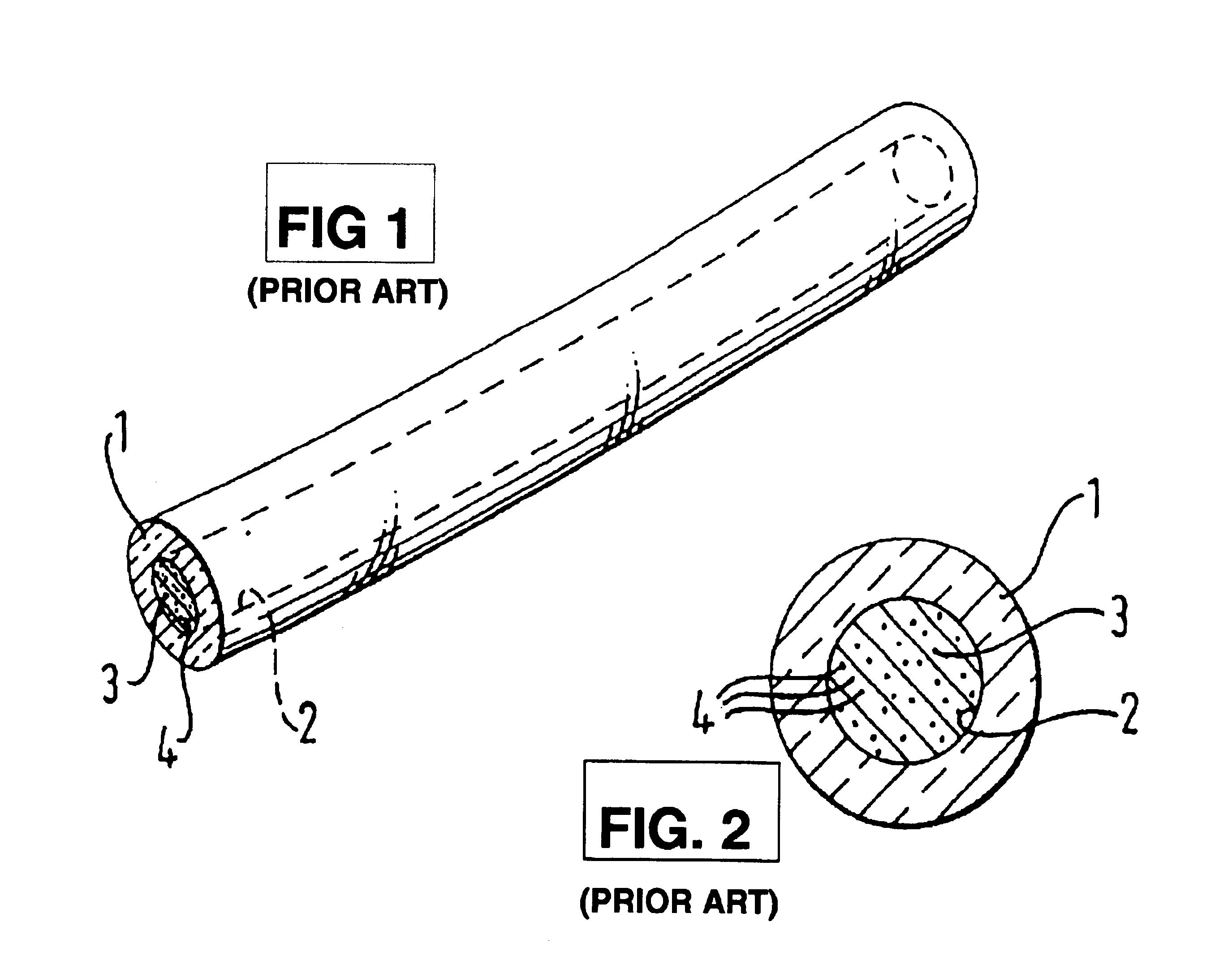

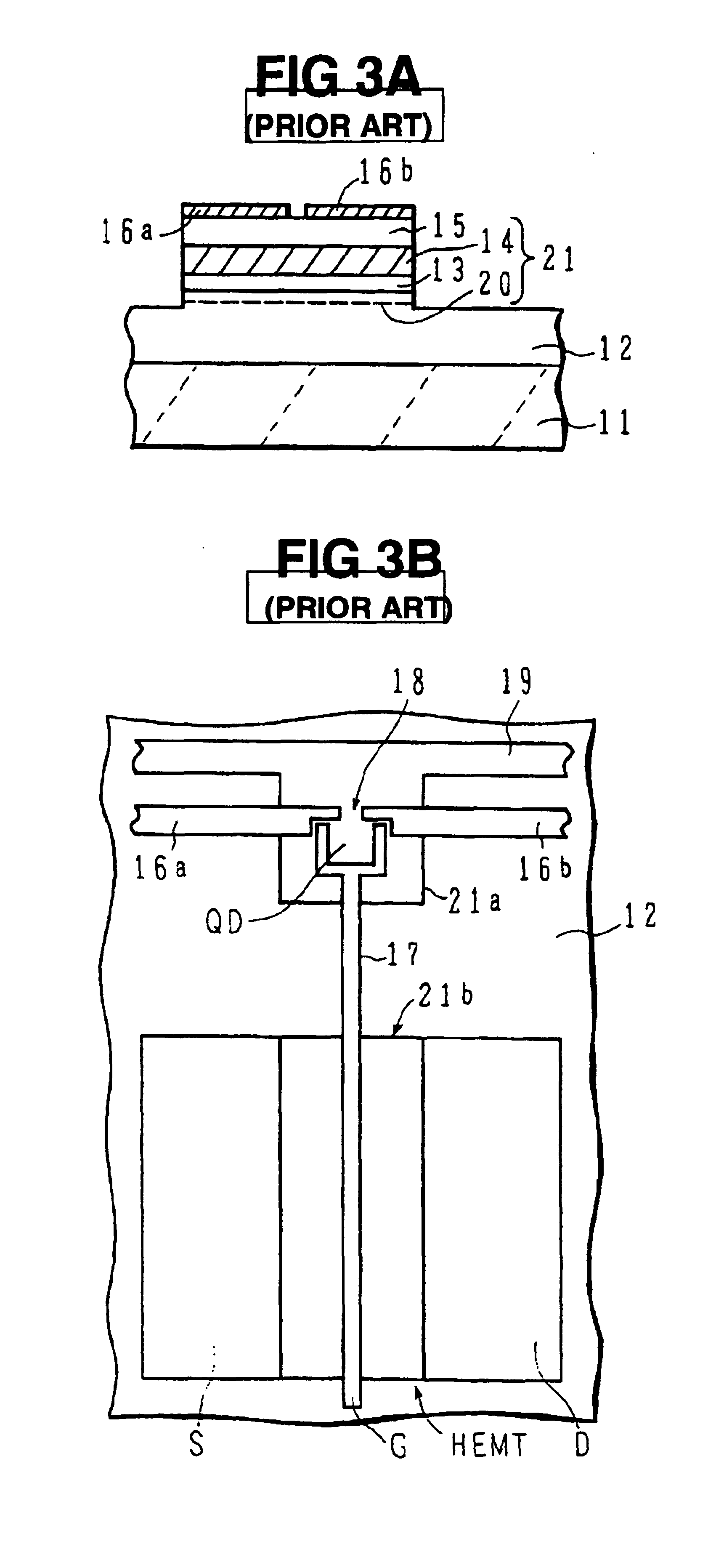

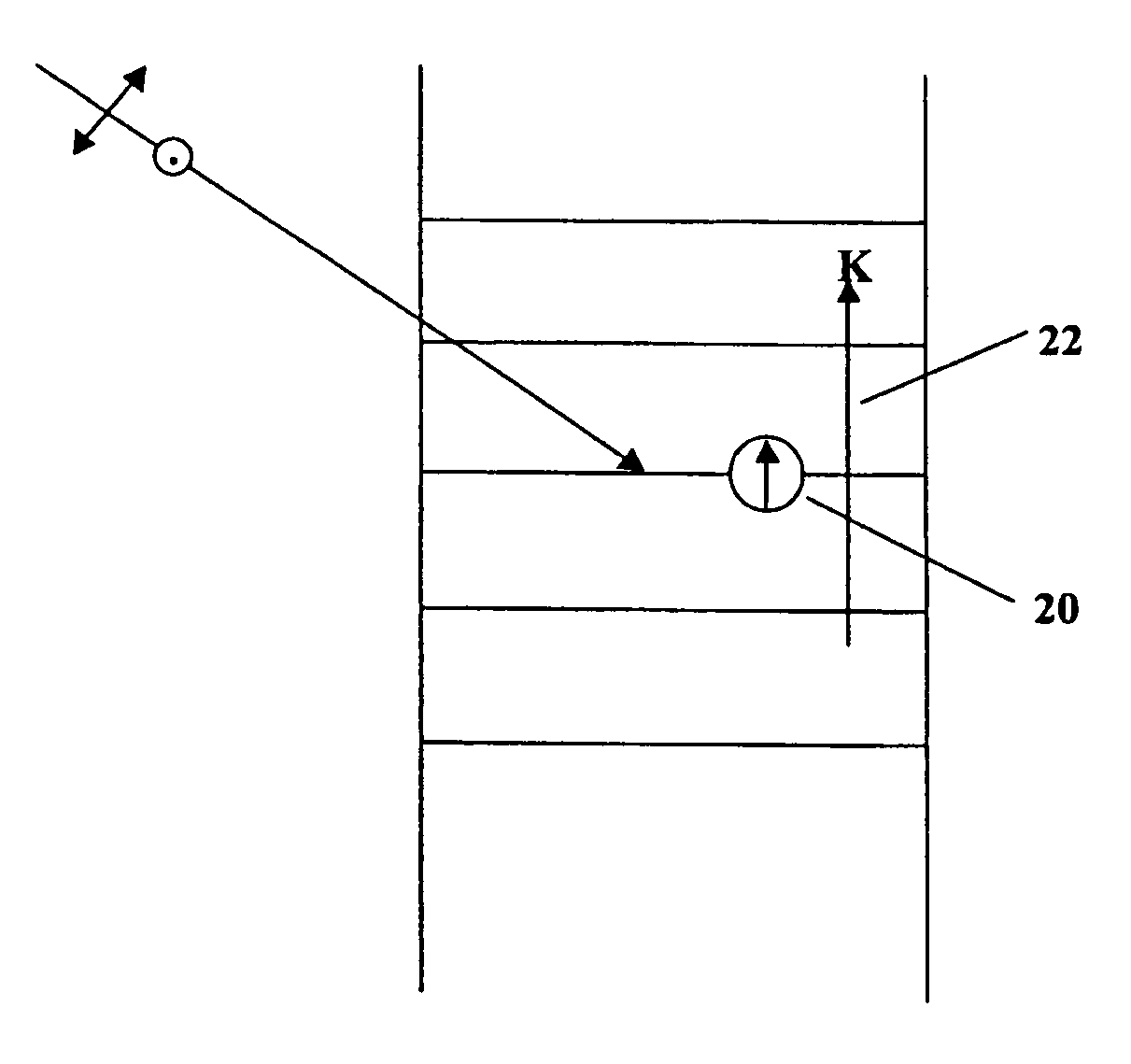

Fiber incorporating quantum dots as programmable dopants

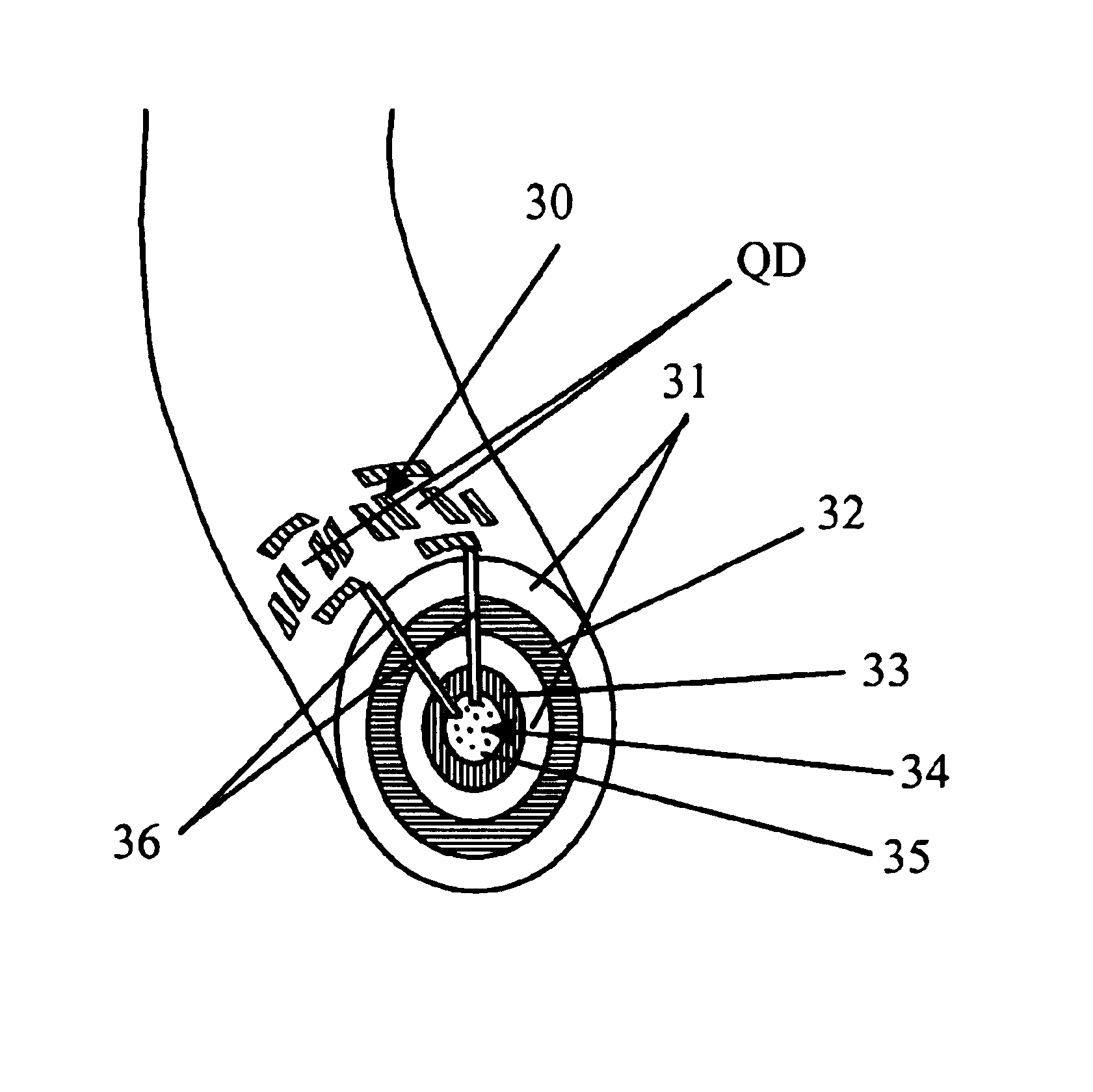

InactiveUS6978070B1Control distortionAltering their doping characteristicsMaterial nanotechnologyCladded optical fibreFiberArtificial atom

A programmable dopant fiber includes a plurality of quantum structures formed on a fiber-shaped substrate, wherein the substrate includes one or more energy-carrying control paths (34), possibly surrounded by an insulator (35), which pass energy to quantum structures. Quantum structures may include quantum dot particles (37) on the surface of the fiber or electrodes (30) on top of barrier layers (31) and transport layer (32) which form quantum dot devices (QD). The energy passing through the control paths (34) drives charge carriers into the quantum dots (QD), leading to the formation of “artificial atoms” with real-time tunable properties. These artificial atoms then serve as programmable dopants, which alter the behavior of surrounding materials. The fiber can be used as a programmable dopant inside bulk materials, as a building block for new materials with unique properties, or as a substitute for quantum dots or quantum wires in certain applications.

Owner:RAVENBRICK

Controlling haze in holographically polymerized polymer dispersed liquid crystal optical elements

InactiveUS7072020B1Limiting operation temperatureDelay transitionNon-linear opticsOptical elementsDisplay deviceEngineering

Described herein are the materials, mechanisms and procedures for optimizing various performance parameters of HPDLC optical devices in order to meet differing performance requirements. These optimization tailoring techniques include control and independent optimization of switchable HPDLC optical devices to meet the demanding requirements of anticipated applications for, inter alia, the telecommunications and display industries. These techniques include optimization of diffraction efficiency, i.e., index modulation, polarization dependence control, haze, cosmetic quality, control of response and relaxation time, voltage driving for on and off switching, and material uniformity. This control and independent optimization tailors properties of switchable HPDLC optical devices according to the specific requirements of the application of the switchable HPDLC optical device. The invention disclosed herein retains the desirable attributes of the multi-functional acrylate system for forming HPDLC optical devices, but adds new materials to the acrylate system and / or new process control to the recording to optimize performance parameters as may be needed for specific applications. This results in high optical quality switchable holograms with good diffraction efficiency and low, stable switching voltage.

Owner:LEIDOS

Photocatalytic type self-repairing super-hydrophobic coating and preparation method thereof

ActiveCN103409028ASimple preparation processWith super weather resistancePolyurea/polyurethane coatingsPolyester coatingsSuperhydrophobeOrganic solvent

The invention belongs to the technical field of new chemical materials and relates to a photocatalytic type self-repairing super-hydrophobic coating and a preparation method thereof. The coating comprises the following materials: 10-50 percent of thermoplastic film-forming resin, 5-20 percent of low-surface energy material, 1-10 percent of photocatalytic active nano particles, 5-40 percent of hydrophobicity nano particles and 20-60 percent of organic solvent. The preparation method comprises the following steps: firstly, allowing nano particles to be subjected to fluorosilane modification to obtain the hydrophobicity nano particles; then, weighing all components of the coating for mixing, and performing high-speed shearing dispersing to obtain the coating provided by the invention. The coating can be applied to the surfaces of base materials such as steel material, aluminium alloy, plastic and composite in the way of brushing, spraying and the like, and a lotus leaf type super-hydrophobic coating can be obtained through drying. The coating can realize super-hydrophobic self-repairing through UV irradiation after being polluted by organic pollutant or subjected to mechanical wear by external forces, so that the coating has extremely good super-hydrophobic performance and perdurability, and the long-term using performance under the outdoor environments is also ensured.

Owner:FUDAN UNIV

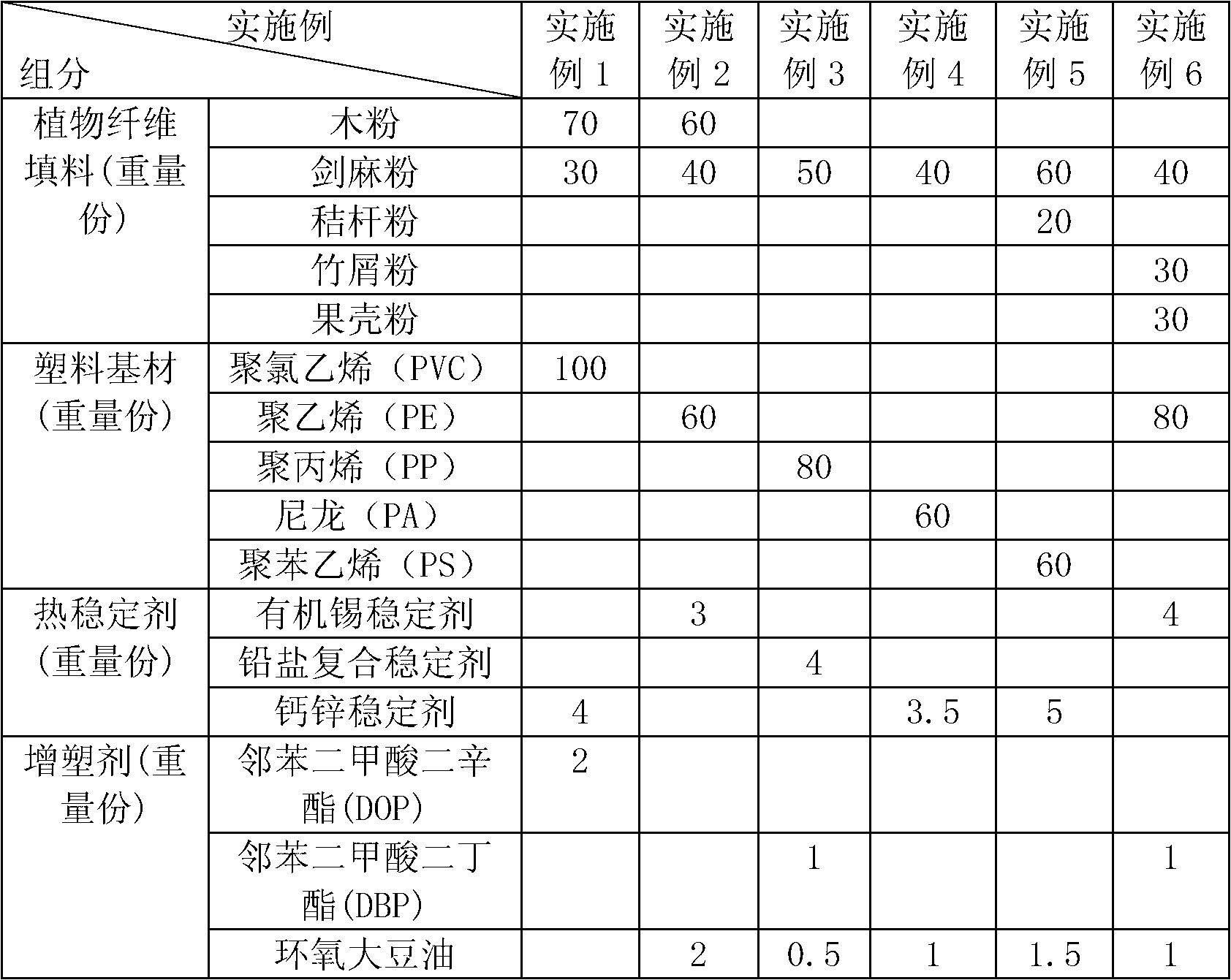

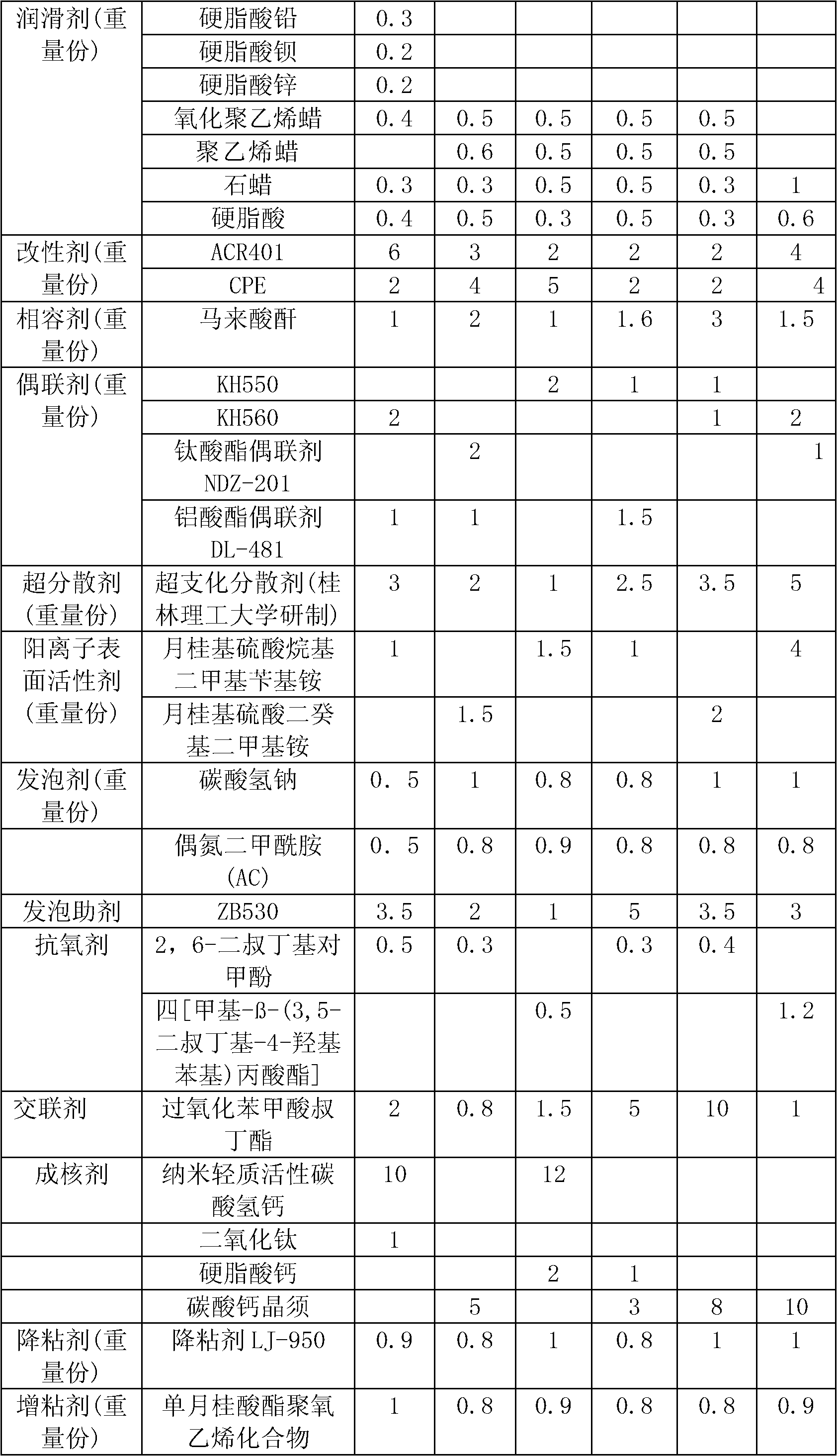

New macromolecule fiber composite material

The invention discloses a new macromolecule fiber composite material which is prepared by the following components in parts by weight, 40-100 parts of plant fiberfill, 60-100 parts of plastic base material, 3.5-5 parts of heat stabilizer, 1-2 parts of plasticizer, 1.6-2 parts of lubricating agent, 4-8 parts of modifying agent, 1-3 parts of compatilizer, 2-3 parts of coupling reagent, 1-5 parts of super dispersing agent, 1-4 parts of positive ion surface active agent, 1-1.8 parts of foaming agent, 1-5 parts of blowing promoter, 0.3-1.2 parts of antioxygen, 1-10 parts of cross-linking agent, 1-20 parts of nucleating agent, 0.8-1 part of viscosity reducer, 0.8-1 part of tackifier and 3.2-13.4 parts of other auxiliaries. The new composite material can not easily cause wet swelling and air shrinkage, and is low in expansibility and water absorbability, so that the prepared product has good stability.

Owner:GUILIN SHUKANG BUILDING MATERIAL

Nanostructured composite reinforced material

ActiveUS20120177905A1Maximum performanceImprove material performanceMaterial nanotechnologyAnimal housingDecrease weightAlloy

A family of materials wherein nanostructures and / or nanotubes are incorporated into a multi-component material arrangement, such as a metallic or ceramic alloy or composite / aggregate, producing a new material or metallic / ceramic alloy. The new material has significantly increased strength, up to several thousands of times normal and perhaps substantially more, as well as significantly decreased weight. The new materials may be manufactured into a component where the nanostructure or nanostructure reinforcement is incorporated into the bulk and / or matrix material, or as a coating where the nanostructure or nanostructure reinforcement is incorporated into the coating or surface of a “normal” substrate material. The nanostructures are incorporated into the material structure either randomly or aligned, within grains, or along or across grain boundaries.

Owner:UT BATTELLE LLC +1

Method for preparing hydrophobic SiO2 aerogel

The invention relates to a method for preparing lyophobic SiO2 aerogel, belonging to the technical field of new material preparation. The method comprises the steps: tetraethyl orthosilicate, absolute ethyl alcohol and oxalic acid solution are firstly mixed in a container for sealing, and then the mixed solution is put into water bath, hydrolyzed under agitation and added with ammonia dropwise; when gel is formed, the absolute ethyl alcohol is added into the gel for exchanging the water in the gel; n-hexane is used for exchanging ethanol in the gel; wet gel which is processed by solvent exchange and aging is dipped into the mixed solution of modifying agent and n-hexane for surface modification, then the n-hexane is added for exchanging the unreacted modifying agent; finally, a test tube is sealed by a aluminum foil provided with a needle hole and is placed into an oven for classified drying under normal pressure, so that the modified SiO2 aerogel is obtained. The SiO2 aerogel prepared by the method has the advantages of high porosity, large specific surface area, good hydrophobic property, etc. The method has the advantages of mild reaction condition, easy control of the reaction as well as simple and convenient process flow.

Owner:YANGZHOU TIANCHEN FINE CHEM +1

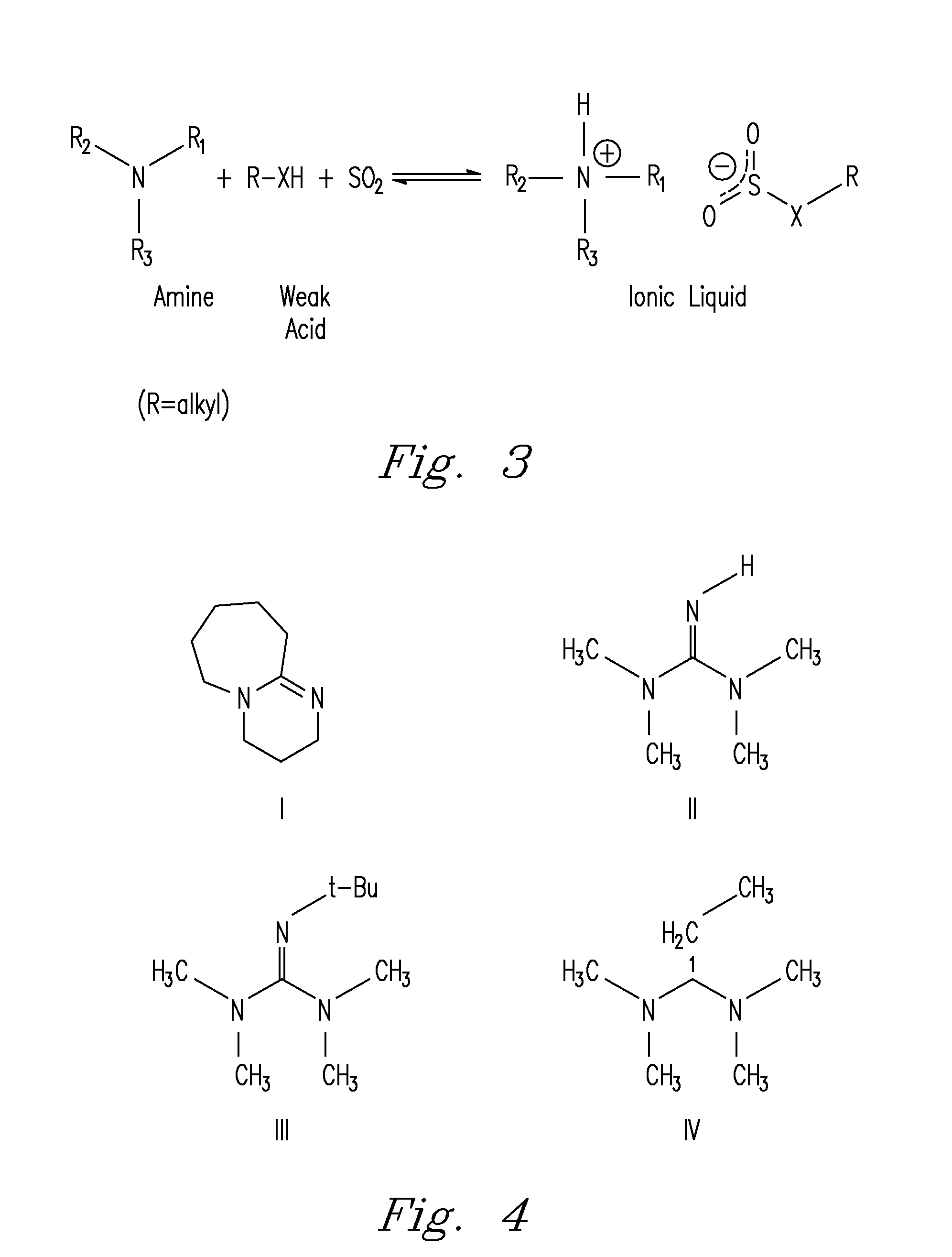

Capture and Release of Mixed Acid Gasses With Binding Organic Liquids

ActiveUS20090136402A1Reduced thermodynamic stabilityLess energy inputCombination devicesGas treatmentChemical reactionIonic liquid

Reversible acid-gas binding organic liquid systems that permit separation and capture of one or more of several acid gases from a mixed gas stream, transport of the liquid, release of the acid gases from the ionic liquid and reuse of the liquid to bind more acid gas with significant energy savings compared to current aqueous systems. These systems utilize acid gas capture compounds made up of strong bases and weak acids that form salts when reacted with a selected acid gas, and which release these gases when a preselected triggering event occurs. The various new materials that make up this system can also be included in various other applications such as chemical sensors, chemical reactants, scrubbers, and separators that allow for the specific and separate removal of desired materials from a gas stream such as flue gas.

Owner:BATTELLE MEMORIAL INST

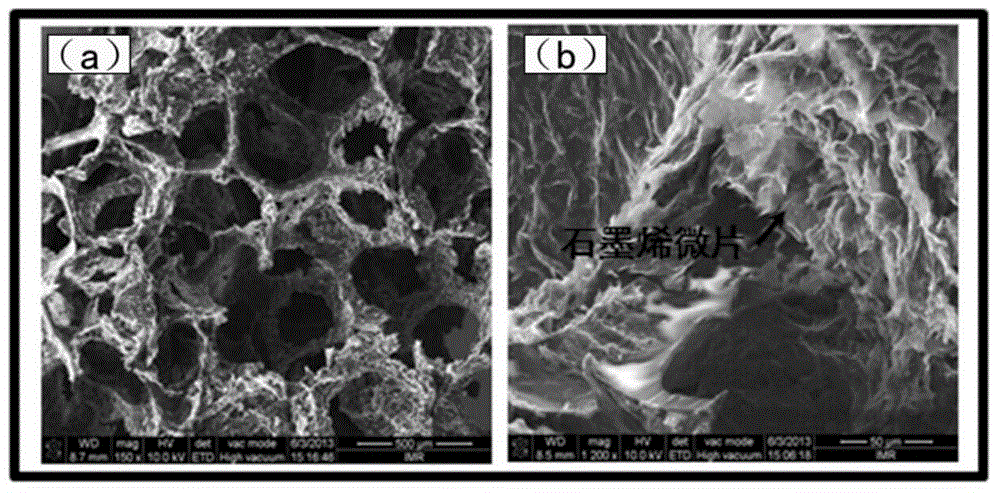

Application of graphene composite material electromagnetic shielding material

ActiveCN105694427AGood electromagnetic shieldingImprove flexibilityElectromagnetic shieldingElectromagnetic radiation

The invention discloses an application of a graphene composite material as an electromagnetic shielding material, and belongs to the technical field of new materials and applications thereof. The graphene composite material with isotropic and three dimensional connected conductive network skeleton is prepared through uniformly coating the surface of a foam sponge skeleton with a graphene material by compounding graphene and foam sponge. The electromagnetic shielding performance of the material is excellent, and the electromagnetic shielding effectiveness of the material with the thickness of 1.5mm can reach 40dB. The material can bear 80% compression deformation, has good flexibility and elasticity, and has a density of about 0.05g / cm<3>, and the unit density electromagnetic shielding effectiveness can reach 800dB.cm<3> / g. The material can effectively shield electromagnetic radiation interference, improve the reliability of electronic products and prolong the service life of the electronic products as an electromagnetic shielding material. The graphene composite material has characteristics of massive preparation by adopting an industrial method, low cost, light weight and high efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Heteratom doped carbon nano-tube-graphene complex and preparation method thereof

ActiveCN103407985AHigh reactivityImprove conductivityMaterial nanotechnologyGrapheneCarbon nanotubeElectrochemistry

The present invention discloses a heteratom doped carbon nano-tube-graphene complex and a preparation method thereof, and belongs to the technical field of new material preparation. The complex comprises carbon nano-tubes and graphene, wherein heteroatoms are introduced into the complex. The preparation method comprises: adopting catalyst active component loading layered material as a catalyst, adopting chemical vapor deposition, and growing the heteratom doped carbon nano-tube and graphene complex in the presence of a heteratom source. The heteratom doped carbon nano-tube-graphene complex has excellent characteristics of more active sites, good conductivity, easy chemical modification and the like based on maintaining of intrinsic e excellent performances of carbon nano-tubes and graphene, and provides good application prospects in the fields of catalysis, electrochemistry, energy storage and conversion, electronic devices, and the like. The preparation method has characteristics of simpleness, easy engineering magnification, and macroscopic quantity preparation achievement so as to promote carbon nano-tube-graphene complex industrial application.

Owner:TSINGHUA UNIV

Method for preparing metallic organic frame films

InactiveCN101890305AEasy to separatePromote nucleationSemi-permeable membranesMetal frameworkReaction temperature

The invention belongs to the technical field of novel materials, and relates to a method for preparing metallic organic frame films(MOFs). The method is characterized in that: after a pretreated carrier is modified or not modified and coated or not coated with a crystal seed layer, the low-high temperature crystallization is performed by changing a reaction temperature; by controlling a relative speed between nucleation and crystal growth, a great deal of nuclei are formed on the surface of the carrier at the low-temperature stage, and the nuclei formed at the high-temperature stage are quickly grown; and thus, the metallic organic frame separation film which is dense, continuous, firm, free of cracks and defects and possesses higher separation performance on a micromolecular system is prepared on the carrier. The invention solves the problem that the bonding force between the metallic frame organic matters and the carrier is weak, the problem that the nucleus forming density on the carrier is so low that the continuous dense MOFs film is difficultly formed on the carrier, and provides a method for preparing the metallic organic frame films(MOFs) which are easily operated and controlled, in particular, the metallic organic frame films(MOFs) with the high separation performance prepared on the tube-shaped carrier.

Owner:DALIAN UNIV OF TECH

Porous inorganic/organic hybrid monolith materials for chromatographic separations and process for their preparation

InactiveUS20070135304A1Reduce back pressureComponent separationIon-exchanger regenerationChromatographic separationNew materials

Novel materials for chromatographic separations, processes for their preparation, and separation devices containing the chromatographic materials. In particular, the novel materials are porous inorganic / organic hybrid monolith materials, which desirably may be surface modified, and which offer more efficient chromatographic separations than that known in the art.

Owner:WATERS TECH CORP

Lead-free alloy solder containing rare-earth and more alloy components

InactiveCN1346728ALower melting temperatureAdjust mechanical propertiesWelding/cutting media/materialsSoldering mediaRare-earth elementChemical composition

A lead-free alloy solder containing rare-earth elements and multiple other elements for electronic package contains Ag (0.1-5 wt.%), Cu (0.1-1 wt.%), Bi (0.1-8 wt.%), In (0.1-7.5 wt.%), Sb (0-8 wt.%), the mixture of La and Ce or the mixture of La, Ce and one or both of Pr and Nd (0.01-2 wt.%) and Sn (the balance). It has liquidus temp less than 210 deg.c (even 190 deg.C or lower), less than 15 deg.c for liquidus and solidus temp difference, at least 60 MPa of yield strength, at least 18% of elongation percentage, excellent wetting ability, and high soldering quality.

Owner:DALIAN UNIV OF TECH

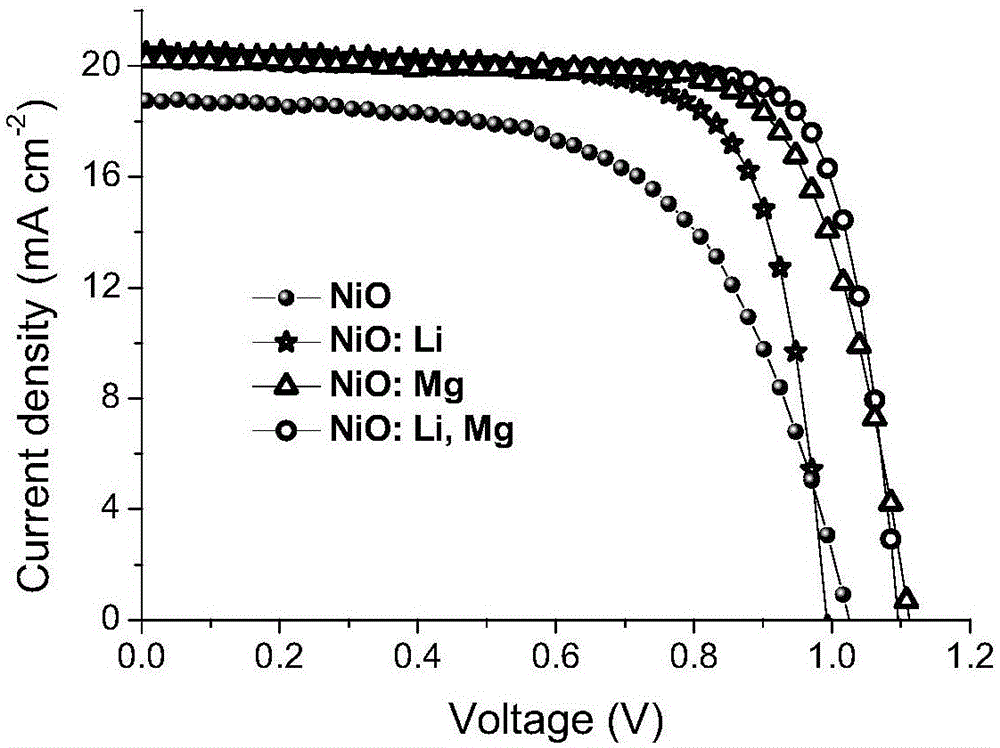

Perovskite solar cell based on doped NiO hole transport layer and preparation method thereof

ActiveCN105070834AImprove conductivityImprove transmittanceFinal product manufactureSolid-state devicesHysteresisPerovskite solar cell

The invention discloses a trans-planar perovskite solar structure based on a doped NiO hole transport layer and a preparation method thereof, and belongs to the field of new material solar cells. The perovskite solar cell in the prior art has problems such as poor stability and poor photoelectric conversion performance. The invention provides a trans-planar perovskite solar cell based on a doped NiO hole transport layer. The preparation method of the solar cell comprises the following steps: depositing a NiO dense layer doped with Mg, Li and other hetero atoms of certain concentration on a conductive substrate as a hole transport layer; preparing a perovskite film, wherein the perovskite film is made of APbX3, A=CH3NH3+ or CH(NH2)2+ or the mixture of the two, and X=Cl-, Br- and I- or the mixture thereof; depositing an electron transport layer PCBM; depositing an interface modification layer (including one of LiF, BCP and TiOX); and finally, depositing a layer of metal electrode (Ag or Al). By using the doped NiO dense film as a hole transport layer, the cell has stable and efficient performance, and the hysteresis is small. Industrialization of the perovskite solar cell is easy to realize.

Owner:HUAZHONG UNIV OF SCI & TECH

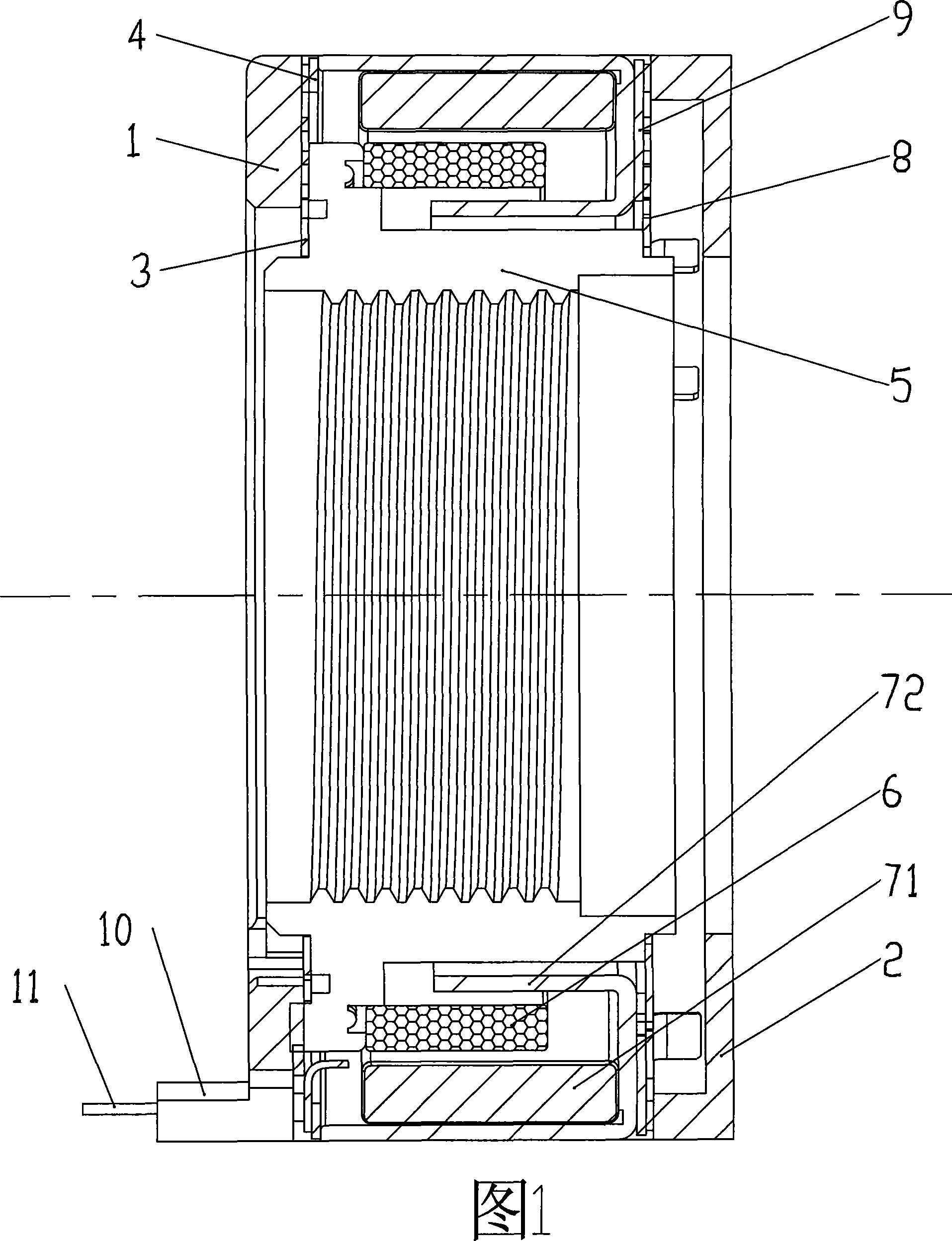

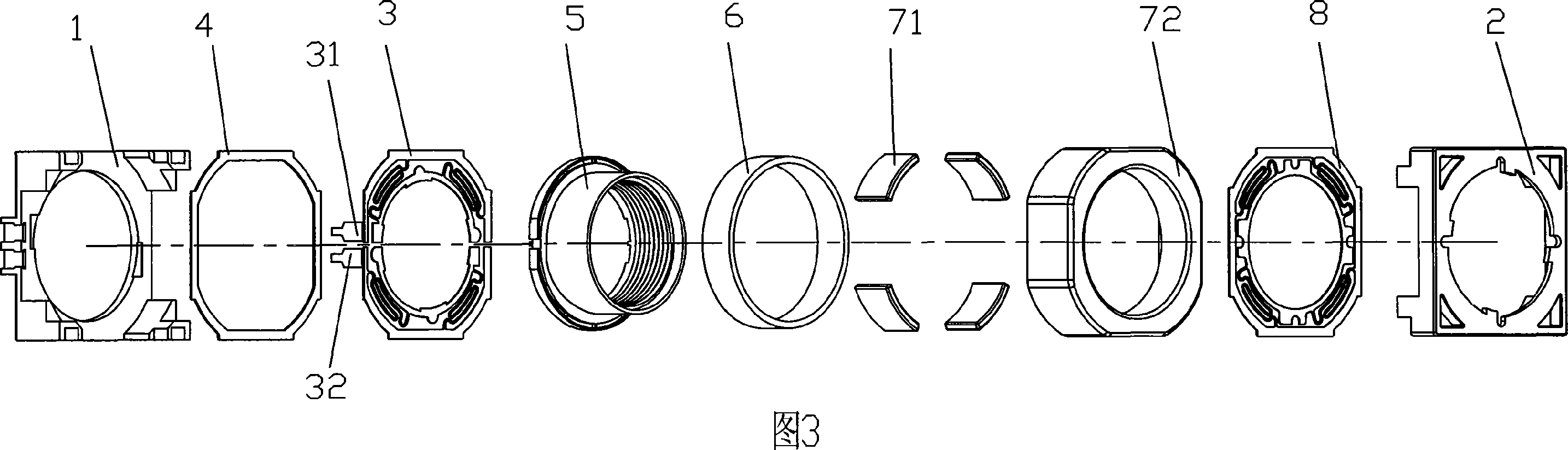

Ultrasmall type voice coil motor

A voice coil motor of miniaturized type is featured as applying simple design on radial size of motion-carry base and new material for front and rear spring plates, using separation design on left and right branch plates of said rear spring plate and optimum design on shape as well as distribution of permanent magnetic unit, applying convex-concave fastening design on front-back cover of shell and between front covers for realizing miniatured- size of voice coil motor.

Owner:YIXING GUIXIN MAGNETOELECTRIC HI TECH

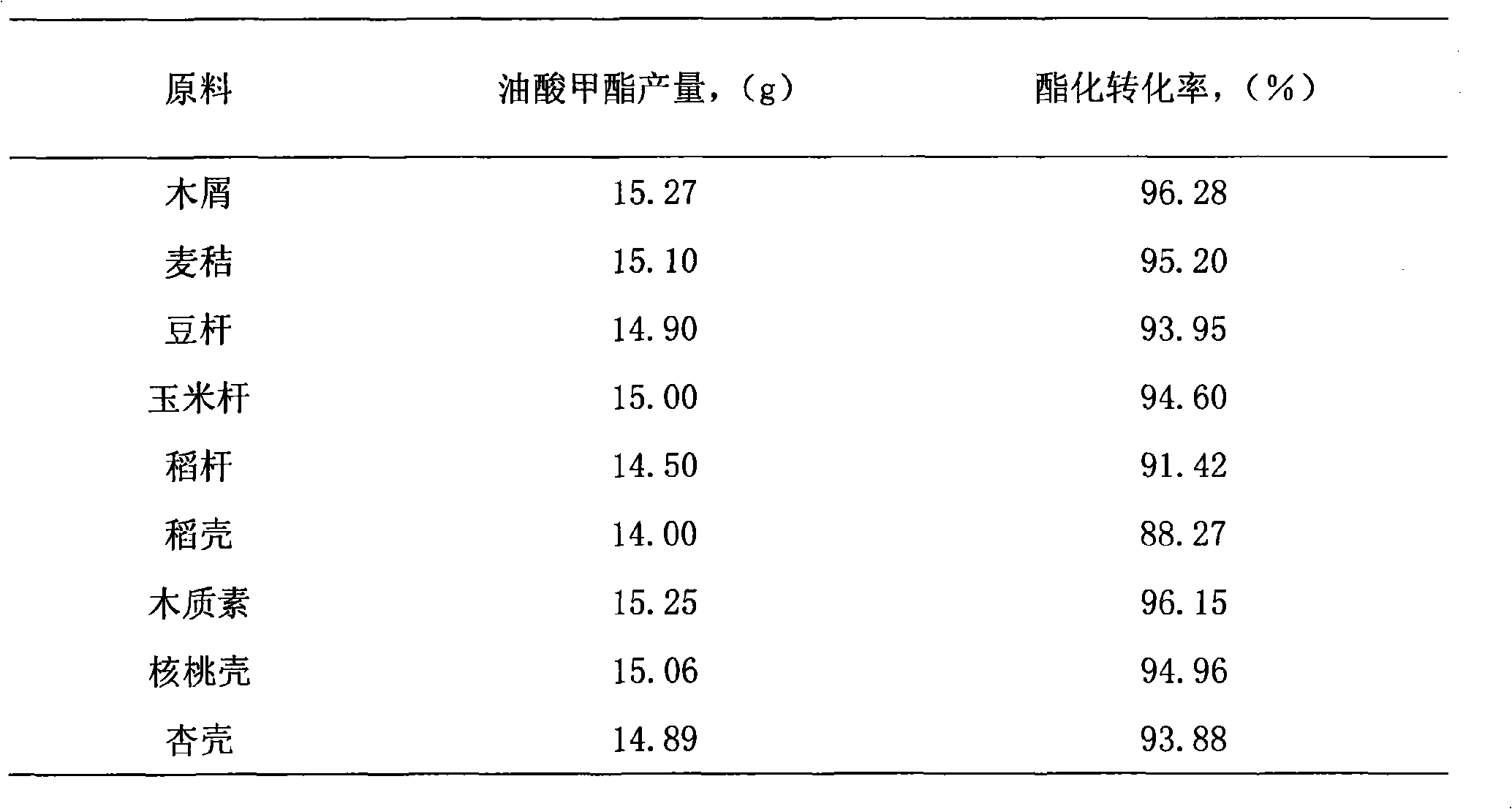

Method for preparing biocarbon solid acid catalyst and biodiesel

InactiveCN101298566AReduce manufacturing costAbundant and renewable resourcesPhysical/chemical process catalystsPreparation by ester-hydroxy reactionBiodieselSolid acid

The invention pertains to the new material technical field, and relates to a method for preparing a carbonaceous solid acid catalyst and biodiesel by taking pure natural biological substances as raw materials. The method is characterized by: taking the pure natural and renewable biological substances as the raw materials; adopting the technical route and method of low-temperature carbonization firstly, oxidation secondly and sulfonation then according to the constituent and structural characteristics to prepare the bio-carbonaceous solid acid catalyst; and adopting a continuous rectification-water separating esterification reaction technology to produce the biodiesel by carrying out the catalytic esterification reaction of a free fatty acid or waste oil and short chain alcohol. The raw materials adopted by the invention are rich in resources, low in price, pure natural and renewable, which pertains to waste utilization; the preparation technology is simple with moderate and controllable reaction conditions; the catalyst has the advantages of high activity, good stability, easy recycling and no corrosion to equipment, which is an really environment-friendly catalyst, thus being applicable to the large scale industrial production of the biodiesel. The method can also be applied to a plurality of organic reactions such as alkylation, hydrolysis and hydration, etc.

Owner:DALIAN UNIV OF TECH

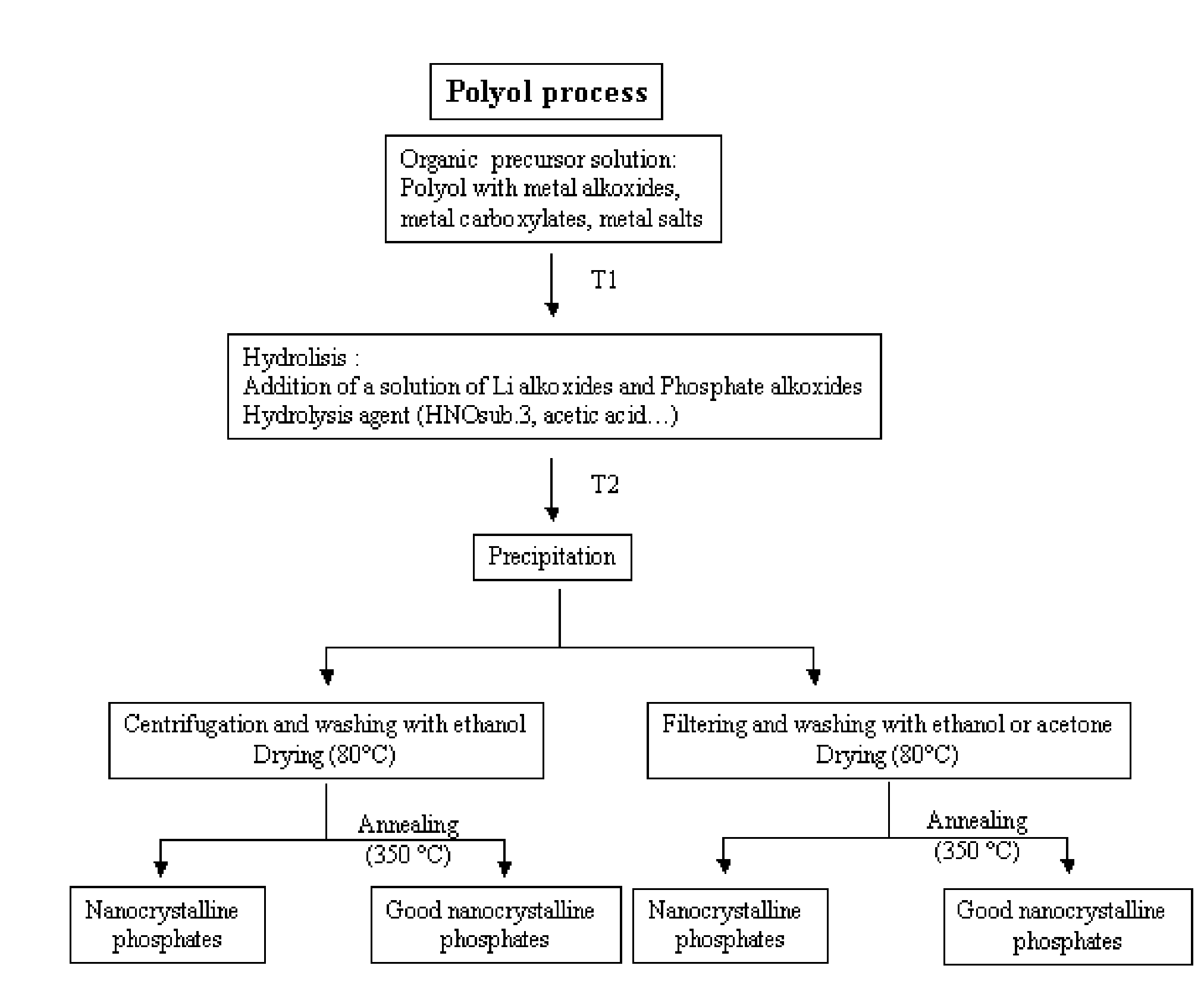

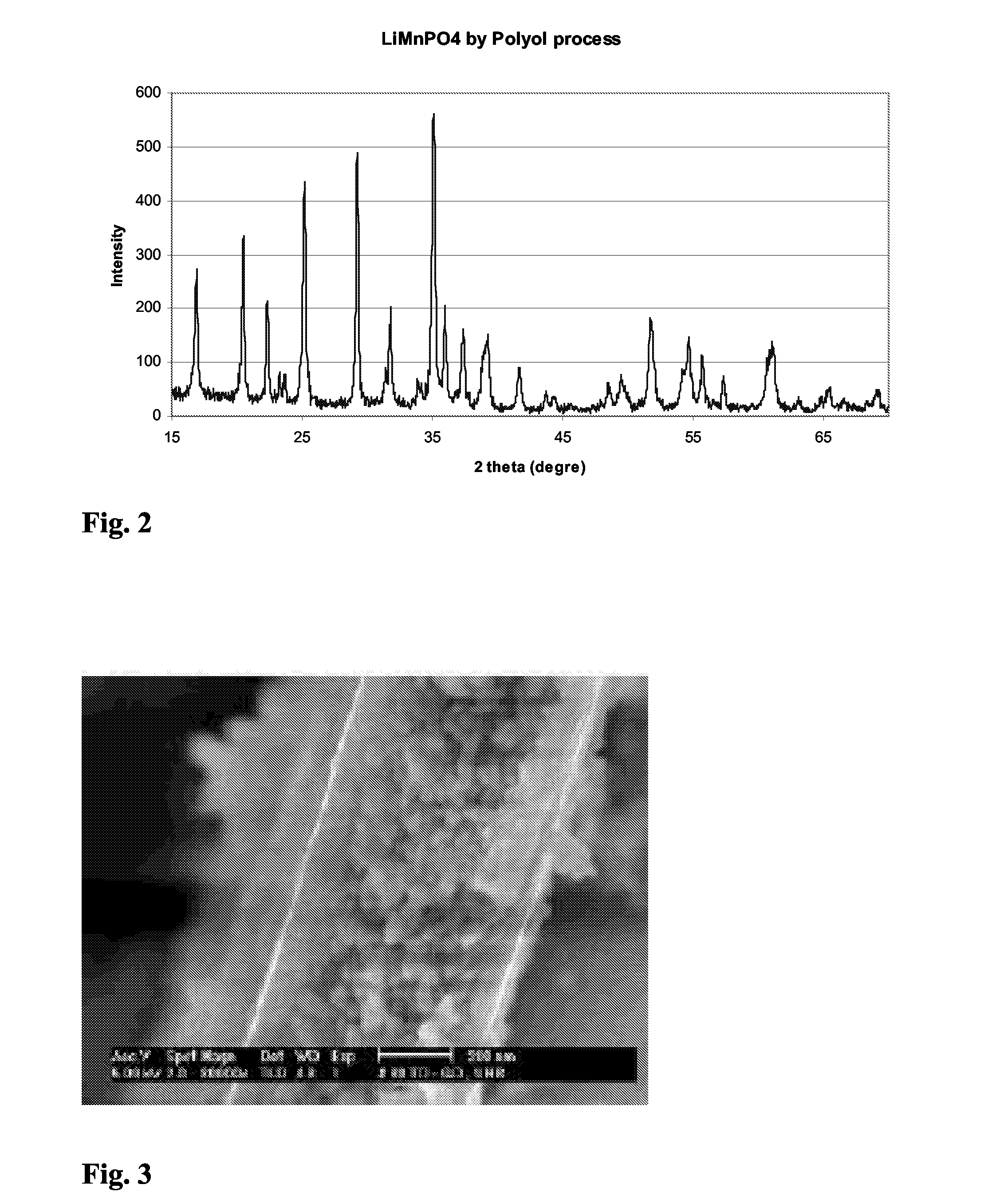

Synthesis of nanoparticles of lithium metal phosphate positive material for lithium secondary battery

InactiveUS20090186275A1Improve material performanceImprove electrochemical performanceNon-metal conductorsPhosphatesPhosphateLithium metal

Novel process for the preparation of finely divided, nano-structured, olivine lithium metal phosphates (LiMPO.sub.4) (where metal M is iron, cobalt, manganese, nickel, vanadium, copper, titanium and mix of them) materials have been developed. This so called Polyol” method consists of heating of suited precursor materials in a multivalent, high-boiling point multivalent alcohol like glycols with the general formula HO—(—C2H4O—).sub.n-H where n=1-10 or HO—(—C3H6O—).sub.n.-H where n=1-10, or other polyols with the general formula HOCH2—(—C3H5OH—).sub.n-H where n=1-10, like for example the tridecane-1,4,7,10,13-pentaol. A novel method for implementing the resulting materials as cathode materials for Li.-ion batteries is also developed.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com