Method for aluminizing and chromizing surface of nickel-based high-temperature alloy used on turbine blade or guider

A nickel-based high-temperature alloy and turbine blade technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of limited corrosion resistance of aluminized coating, unable to guarantee supply, etc., and achieve superior performance , good thermal corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

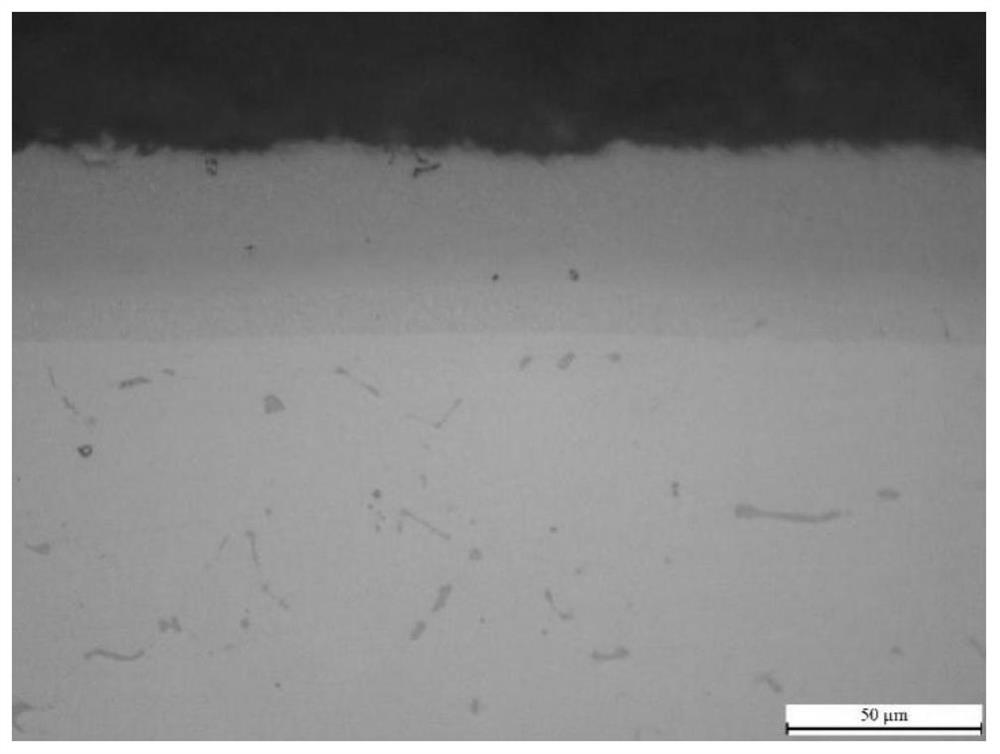

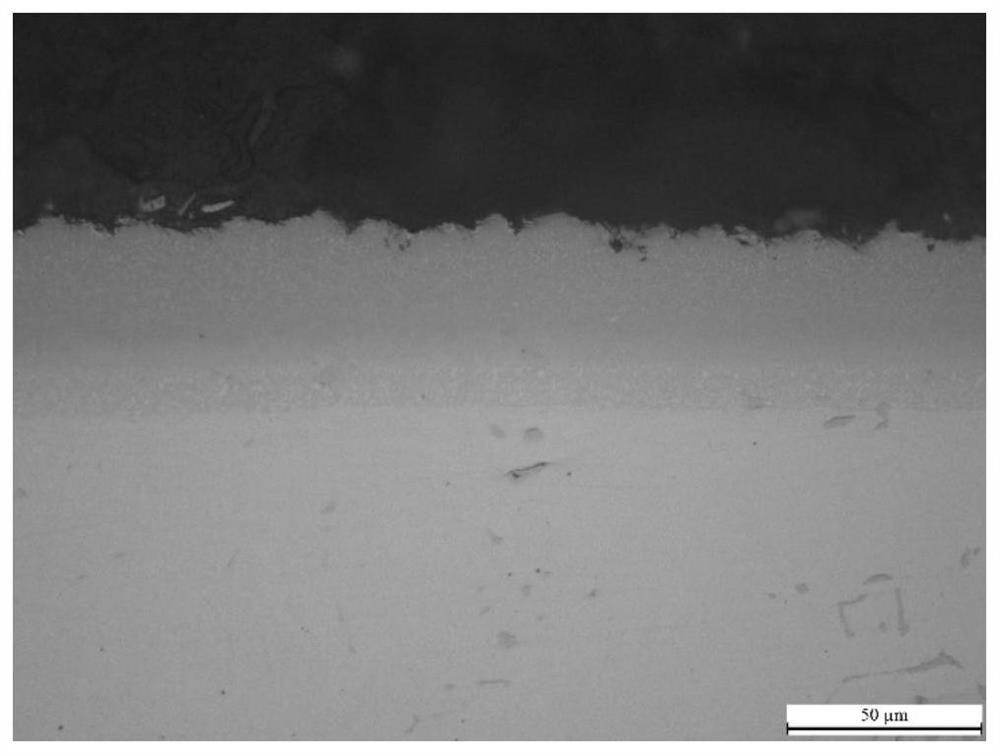

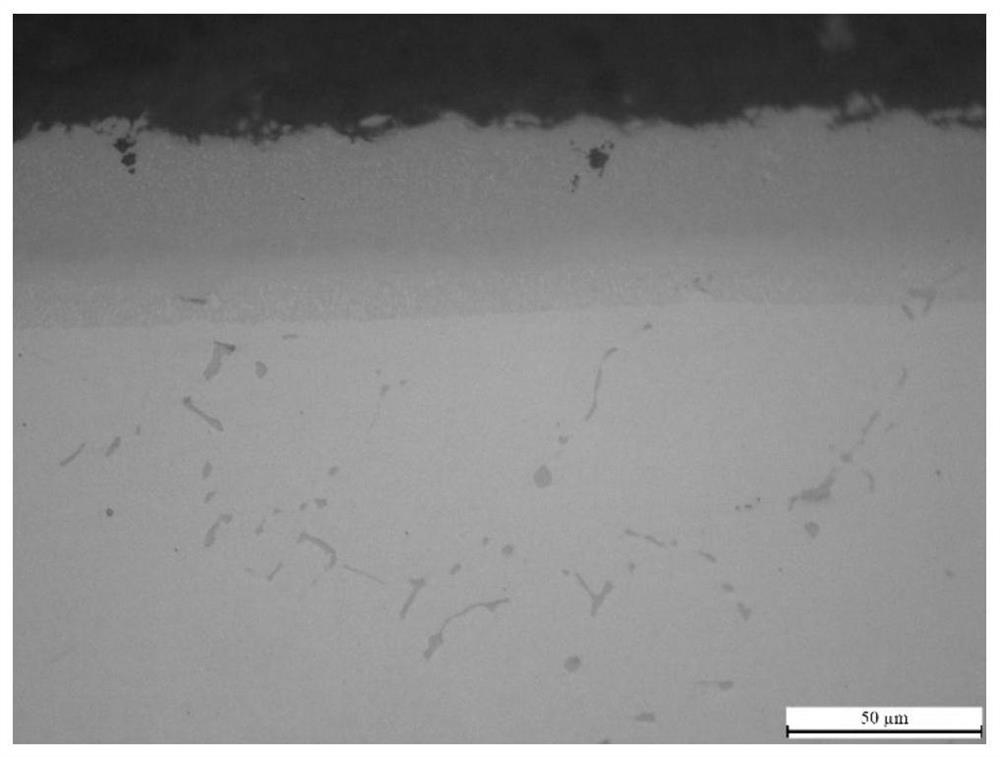

Image

Examples

Embodiment 1

[0022]The aluminum chrome method of this embodiment is carried out as follows:

[0023]1, the infiltration configuration, with a mass ratio, the raw material powder, the alumina powder content of 50%, the chrome powder content of 39%, the aluminum powder content of 10%, 1% ammonium chloride; and use a drum type The ball mill grinds the powder ball for 9.5 h to give a mixed bleeding.

[0024]2, pretreatment of bleging agent: calcine the ball after milling, the calcination temperature is controlled at 1100 ° C, and the holding time is controlled at 15.5 h, after the calcination is completed, the chamber is cooled. Then, in the baked bure agent, add a relative raw material total amount of aluminum powder, 1% chromium powder and 0.4% NH.4CL; then bleed at 1030 ° C for 11 h, after the air was burned, the furnace was cooled to give a sample.

[0025]3, parts pretreatment: Totally blow up the part with 200 目 砂, pressure 0.28MPa, after blowing, the blower cleans the surface residual sand, obtains th...

Embodiment 2

[0036]1, the infiltration configuration, with a mass ratio, the raw material powder, the alumina powder content of 50%, the chrome powder content of 44%, the aluminum powder content of 5%, 1% ammonium chloride content; and use roller type The ball mill grinds the powder ball for 9.5 h to give a mixed bleeding.

[0037]2, pretreatment of bleging agent: calcine the ball after milling, the calcination temperature is controlled at 1100 ° C, and the holding time is controlled at 15.5 h, after the calcination is completed, the chamber is cooled. Then, in the baked bure agent, add a relative raw material total amount of aluminum powder, 1% chromium powder and 0.4% NH.4CL; then bleed at 1030 ° C for 11 h, after the air was burned, the furnace was cooled to give a sample.

[0038]3, parts pretreatment: Totally blow up the part with 200 目 砂, pressure 0.28MPa, after blowing, the blower cleans the surface residual sand, obtains the pretreatment parts, the parts in this example are nickel groups. High...

experiment example 2

[0048]The results of the corrosion resistance test of the experimental example 2 and the contraction example 2 are shown in Table 2.

[0049]Table 2

[0050] Example 2 Contrast 2 Corrosion potential -1.32-1.89

[0051]From the experimental results, the corrosion resistance performance of Experimental Example 2 is superior to Comparative Example 2. Further, the diffusion of the permeability layer of the contraction is uneven, and some are crackled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com