Pressure steam sterilization five-class chemical indicator lumen verification device

A technology of pressure steam and chemical indication, applied in the medical field, can solve the problems of non-traceability of verification devices, being easily affected by steam, and poor adhesion of color-changing inks, so as to maintain production quality and purity, easy to attach and form, The effect of enhancing the steam resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

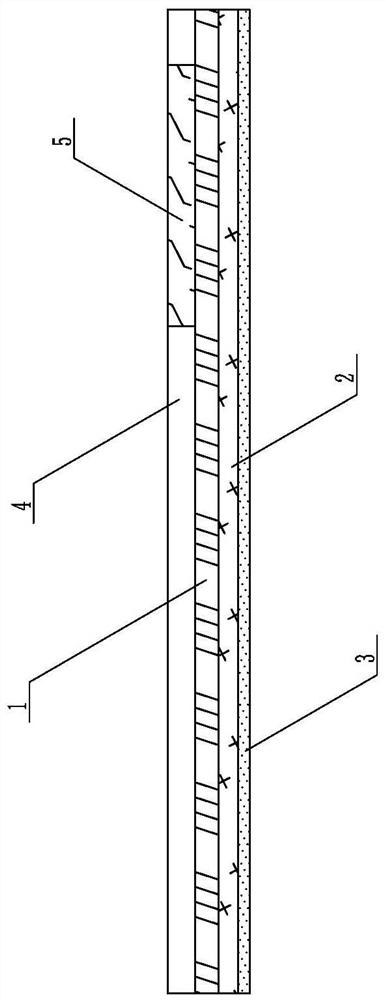

[0062] The indicator ink 2 is composed of the following components by mass percentage: 40% reactant; 5% developer; 20% adhesive; 5% antioxidant; 15% dilution solvent; 10% stabilizer; 5% glass fiber;

[0063] The indicator ink 2 is prepared by the following preparation process:

[0064] Step 1: Prepare materials, take the reactants, color developer, antioxidant, stabilizer, dilution solvent and adhesive according to the components and take them for later use;

[0065] Step 2: freezing at low temperature, respectively placing the release agent and the adhesive in a sealed container to freeze at low temperature to become solid;

[0066] Step 3: crushing and mixing, the solids obtained in step 2 are pulverized by a pulverizer in a low-temperature environment and then mixed, and fully mixed by a stirrer;

[0067] Step 4: heat up, step 3 continue to stir and mix and gradually increase the ambient temperature to room temperature, continue to stir for 40 minutes to obtain the base li...

specific Embodiment 2

[0072] The indicator ink 2 is composed of the following components by mass percentage: 50% reactant; 5% developer; 15% adhesive; 10% antioxidant; 10% dilution solvent; 5% stabilizer; 5% glass fiber;

[0073] The indicator ink 2 is prepared by the following preparation process:

[0074] Step 1: Prepare materials, take the reactants, color developer, antioxidant, stabilizer, dilution solvent and adhesive according to the components and take them for later use;

[0075] Step 2: freezing at low temperature, respectively placing the release agent and the adhesive in a sealed container to freeze at low temperature to become solid;

[0076] Step 3: crushing and mixing, the solids obtained in step 2 are pulverized by a pulverizer in a low-temperature environment and then mixed, and fully mixed by a stirrer;

[0077] Step 4: heat up, step 3 continue to stir and mix and gradually increase the ambient temperature to room temperature, continue to stir for 60 to obtain the base liquid, an...

specific Embodiment 3

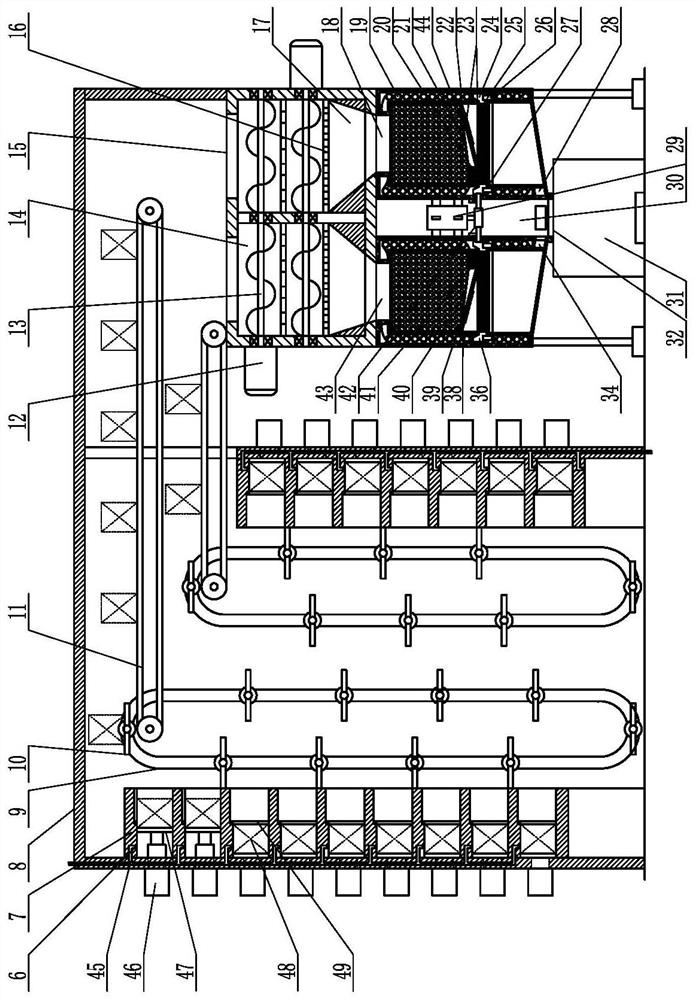

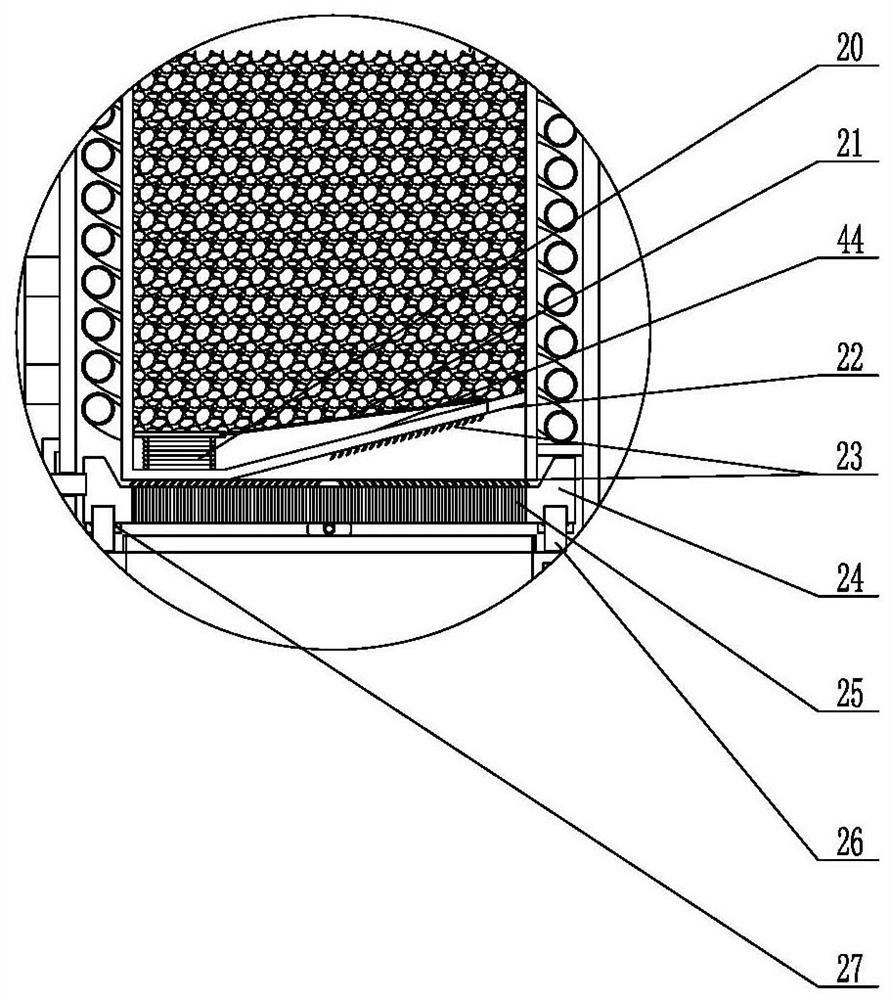

[0084] Such as figure 2 with 3 As shown, in this embodiment, step 2 and step 3 are carried out in the integrated freezer and pulverizer.

[0085] The integrated freezing and pulverizing machine includes a freezing chamber 8, in which a freezing functional area and a crushing functional area are set, and the freezing functional area and the crushing functional area are connected by a material transmission device. The freezer 8 has a refrigeration function for ordinary industrial refrigerators, and its temperature adjustment range is 0-minus 24 degrees Celsius.

[0086] On the side wall of the freezing functional area, several freezing boxes 7 with cube-shaped freezing spaces are vertically arranged. The freezing box 7 is provided with a discharge cylinder 46 towards the end of the outer wall of the freezing functional area, and the freezing box 7 faces the inside of the freezing functional area. One end of the electric trapdoor 49 is provided with an electric trapdoor 49, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com