Advances in Isocyanate-Free Alternatives for Industry Use

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate-Free Tech Evolution and Objectives

Isocyanate-based polyurethanes have been a cornerstone in various industries for decades, prized for their versatility and performance. However, growing concerns over health and environmental impacts have driven a significant shift towards isocyanate-free alternatives. This technological evolution aims to maintain or enhance the desirable properties of polyurethanes while eliminating the risks associated with isocyanates.

The development of isocyanate-free technologies has been propelled by stringent regulations and increasing consumer awareness. The European Union's REACH regulation and similar global initiatives have set the stage for this transition, pushing manufacturers to innovate and adapt. The primary objective is to create safer, sustainable alternatives that can match or surpass the performance of traditional polyurethanes across various applications.

Key milestones in this technological journey include the introduction of non-isocyanate polyurethanes (NIPUs) in the early 2000s, which opened new avenues for research and development. These early NIPUs, while promising, often fell short in terms of performance or cost-effectiveness, setting the stage for further innovation.

The evolution of isocyanate-free technologies has seen a multi-pronged approach. One significant direction has been the development of bio-based alternatives, leveraging renewable resources to create environmentally friendly solutions. Another focus has been on improving the reaction kinetics and crosslinking mechanisms of NIPUs to enhance their mechanical properties and processing characteristics.

Recent advancements have targeted specific industry needs. For instance, in the coatings sector, water-based polyurethane dispersions free from isocyanates have gained traction. In the adhesives industry, efforts have been made to develop isocyanate-free formulations that maintain high bond strength and durability.

The overarching goal of this technological evolution is to achieve a balance between performance, safety, and sustainability. This involves not only replacing isocyanates but also optimizing the entire production process to reduce energy consumption and minimize waste. As the technology progresses, there is an increasing focus on scalability and cost-effectiveness to ensure widespread adoption across industries.

Looking ahead, the objectives for isocyanate-free technologies include expanding their application range, further improving their performance metrics, and reducing production costs. There is also a growing emphasis on developing 'smart' materials that can adapt to environmental conditions or offer additional functionalities beyond those of traditional polyurethanes.

The development of isocyanate-free technologies has been propelled by stringent regulations and increasing consumer awareness. The European Union's REACH regulation and similar global initiatives have set the stage for this transition, pushing manufacturers to innovate and adapt. The primary objective is to create safer, sustainable alternatives that can match or surpass the performance of traditional polyurethanes across various applications.

Key milestones in this technological journey include the introduction of non-isocyanate polyurethanes (NIPUs) in the early 2000s, which opened new avenues for research and development. These early NIPUs, while promising, often fell short in terms of performance or cost-effectiveness, setting the stage for further innovation.

The evolution of isocyanate-free technologies has seen a multi-pronged approach. One significant direction has been the development of bio-based alternatives, leveraging renewable resources to create environmentally friendly solutions. Another focus has been on improving the reaction kinetics and crosslinking mechanisms of NIPUs to enhance their mechanical properties and processing characteristics.

Recent advancements have targeted specific industry needs. For instance, in the coatings sector, water-based polyurethane dispersions free from isocyanates have gained traction. In the adhesives industry, efforts have been made to develop isocyanate-free formulations that maintain high bond strength and durability.

The overarching goal of this technological evolution is to achieve a balance between performance, safety, and sustainability. This involves not only replacing isocyanates but also optimizing the entire production process to reduce energy consumption and minimize waste. As the technology progresses, there is an increasing focus on scalability and cost-effectiveness to ensure widespread adoption across industries.

Looking ahead, the objectives for isocyanate-free technologies include expanding their application range, further improving their performance metrics, and reducing production costs. There is also a growing emphasis on developing 'smart' materials that can adapt to environmental conditions or offer additional functionalities beyond those of traditional polyurethanes.

Market Demand Analysis for Safer Alternatives

The market demand for safer alternatives to isocyanates in industrial applications has been steadily increasing due to growing awareness of health and environmental concerns associated with traditional isocyanate-based products. Isocyanates, widely used in polyurethane production, adhesives, coatings, and sealants, have been linked to respiratory issues, skin irritation, and potential carcinogenic effects. This has led to stricter regulations and a shift in consumer preferences towards safer, more sustainable options.

The global market for isocyanate-free alternatives is experiencing significant growth, driven by several factors. Environmental regulations, such as REACH in Europe and similar initiatives worldwide, are pushing industries to adopt safer chemicals. Occupational health and safety concerns have also prompted many companies to seek alternatives that reduce worker exposure risks. Additionally, consumer demand for eco-friendly products has created new opportunities for isocyanate-free solutions in various sectors, including construction, automotive, and furniture manufacturing.

Key market segments showing strong demand for isocyanate-free alternatives include construction adhesives, automotive coatings, and flexible foams. The construction industry, in particular, has been quick to adopt safer alternatives due to increased focus on indoor air quality and sustainable building practices. The automotive sector is exploring isocyanate-free coatings to meet stringent VOC regulations and improve worker safety in manufacturing processes.

Market research indicates that the Asia-Pacific region is expected to witness the highest growth rate in the adoption of isocyanate-free alternatives. This is attributed to rapid industrialization, increasing environmental awareness, and stringent regulations in countries like China and India. North America and Europe continue to be significant markets, driven by established regulatory frameworks and consumer preferences for sustainable products.

Despite the growing demand, challenges remain in the widespread adoption of isocyanate-free alternatives. These include performance limitations compared to traditional isocyanate-based products, higher costs associated with research and development of new formulations, and the need for retooling existing manufacturing processes. However, ongoing technological advancements and increasing scale of production are gradually addressing these barriers, making isocyanate-free alternatives more competitive and accessible.

The market for safer alternatives is also benefiting from collaborations between chemical companies, research institutions, and end-users. These partnerships are accelerating the development of innovative solutions that meet or exceed the performance of isocyanate-based products while offering improved safety profiles. As a result, the market is witnessing the introduction of novel bio-based alternatives and hybrid systems that combine the benefits of different chemistries to achieve desired properties without relying on isocyanates.

The global market for isocyanate-free alternatives is experiencing significant growth, driven by several factors. Environmental regulations, such as REACH in Europe and similar initiatives worldwide, are pushing industries to adopt safer chemicals. Occupational health and safety concerns have also prompted many companies to seek alternatives that reduce worker exposure risks. Additionally, consumer demand for eco-friendly products has created new opportunities for isocyanate-free solutions in various sectors, including construction, automotive, and furniture manufacturing.

Key market segments showing strong demand for isocyanate-free alternatives include construction adhesives, automotive coatings, and flexible foams. The construction industry, in particular, has been quick to adopt safer alternatives due to increased focus on indoor air quality and sustainable building practices. The automotive sector is exploring isocyanate-free coatings to meet stringent VOC regulations and improve worker safety in manufacturing processes.

Market research indicates that the Asia-Pacific region is expected to witness the highest growth rate in the adoption of isocyanate-free alternatives. This is attributed to rapid industrialization, increasing environmental awareness, and stringent regulations in countries like China and India. North America and Europe continue to be significant markets, driven by established regulatory frameworks and consumer preferences for sustainable products.

Despite the growing demand, challenges remain in the widespread adoption of isocyanate-free alternatives. These include performance limitations compared to traditional isocyanate-based products, higher costs associated with research and development of new formulations, and the need for retooling existing manufacturing processes. However, ongoing technological advancements and increasing scale of production are gradually addressing these barriers, making isocyanate-free alternatives more competitive and accessible.

The market for safer alternatives is also benefiting from collaborations between chemical companies, research institutions, and end-users. These partnerships are accelerating the development of innovative solutions that meet or exceed the performance of isocyanate-based products while offering improved safety profiles. As a result, the market is witnessing the introduction of novel bio-based alternatives and hybrid systems that combine the benefits of different chemistries to achieve desired properties without relying on isocyanates.

Current State and Challenges in Isocyanate-Free Solutions

The current state of isocyanate-free alternatives in industrial applications is characterized by significant progress, yet substantial challenges remain. Recent advancements have led to the development of various isocyanate-free solutions, primarily driven by health and environmental concerns associated with traditional isocyanate-based products. These alternatives include polyurethane dispersions (PUDs), silane-terminated polymers (STPs), and bio-based polyols.

Polyurethane dispersions have gained traction due to their low volatile organic compound (VOC) content and improved safety profile. They offer excellent adhesion properties and chemical resistance, making them suitable for coatings and adhesives. However, challenges persist in achieving the same level of performance as isocyanate-based counterparts, particularly in terms of durability and heat resistance.

Silane-terminated polymers have emerged as promising alternatives, especially in sealants and adhesives. These moisture-curing systems provide good adhesion to various substrates and offer improved UV stability. Nevertheless, their slower curing rates and higher costs compared to traditional isocyanate-based systems remain significant hurdles for widespread adoption.

Bio-based polyols derived from renewable resources such as vegetable oils and lignin have shown potential in reducing the environmental impact of polyurethane production. While these alternatives offer sustainability benefits, challenges persist in achieving consistent quality and performance across different batches of bio-based raw materials.

One of the primary technical obstacles facing isocyanate-free solutions is the difficulty in replicating the reactivity and cross-linking efficiency of isocyanates. This limitation often results in slower curing times and reduced mechanical properties, particularly in high-performance applications such as automotive coatings and industrial adhesives.

Another significant challenge is the higher production costs associated with many isocyanate-free alternatives. The specialized raw materials and processing techniques required for these solutions often lead to increased manufacturing expenses, making it difficult for them to compete with established isocyanate-based products on a cost basis.

Regulatory pressures and evolving environmental standards continue to drive research and development in this field. However, the lack of standardized testing methods and performance criteria for isocyanate-free alternatives poses challenges for industry-wide adoption and comparison of different solutions.

Polyurethane dispersions have gained traction due to their low volatile organic compound (VOC) content and improved safety profile. They offer excellent adhesion properties and chemical resistance, making them suitable for coatings and adhesives. However, challenges persist in achieving the same level of performance as isocyanate-based counterparts, particularly in terms of durability and heat resistance.

Silane-terminated polymers have emerged as promising alternatives, especially in sealants and adhesives. These moisture-curing systems provide good adhesion to various substrates and offer improved UV stability. Nevertheless, their slower curing rates and higher costs compared to traditional isocyanate-based systems remain significant hurdles for widespread adoption.

Bio-based polyols derived from renewable resources such as vegetable oils and lignin have shown potential in reducing the environmental impact of polyurethane production. While these alternatives offer sustainability benefits, challenges persist in achieving consistent quality and performance across different batches of bio-based raw materials.

One of the primary technical obstacles facing isocyanate-free solutions is the difficulty in replicating the reactivity and cross-linking efficiency of isocyanates. This limitation often results in slower curing times and reduced mechanical properties, particularly in high-performance applications such as automotive coatings and industrial adhesives.

Another significant challenge is the higher production costs associated with many isocyanate-free alternatives. The specialized raw materials and processing techniques required for these solutions often lead to increased manufacturing expenses, making it difficult for them to compete with established isocyanate-based products on a cost basis.

Regulatory pressures and evolving environmental standards continue to drive research and development in this field. However, the lack of standardized testing methods and performance criteria for isocyanate-free alternatives poses challenges for industry-wide adoption and comparison of different solutions.

Existing Isocyanate-Free Technical Solutions

01 Polyurethane alternatives

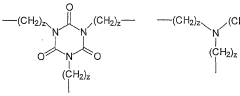

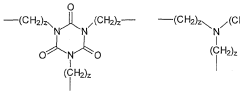

Development of isocyanate-free polyurethane alternatives using non-isocyanate chemistry. These alternatives often involve the reaction of cyclic carbonates with amines to form urethane linkages without the use of isocyanates. This approach offers improved safety and environmental benefits while maintaining desirable polyurethane properties.- Non-isocyanate polyurethane alternatives: Development of non-isocyanate polyurethane (NIPU) systems as alternatives to traditional isocyanate-based polyurethanes. These systems often involve the reaction of cyclic carbonates with amines to form urethane linkages without the use of isocyanates. NIPUs offer improved safety and environmental benefits while maintaining desirable polyurethane properties.

- Epoxy-based alternatives: Utilization of epoxy-based systems as isocyanate-free alternatives in various applications. These systems often involve the reaction of epoxy resins with hardeners or curing agents to form crosslinked networks. Epoxy-based alternatives can provide excellent adhesion, chemical resistance, and mechanical properties comparable to isocyanate-based systems.

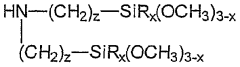

- Silane-terminated polymers: Development of silane-terminated polymers as isocyanate-free alternatives for adhesives, sealants, and coatings. These systems typically involve the use of moisture-curable silane-terminated polyethers or polyurethanes. They offer good adhesion, flexibility, and weatherability without the use of isocyanates.

- Bio-based and renewable alternatives: Exploration of bio-based and renewable materials as isocyanate-free alternatives. These include the use of plant-based oils, sugars, and other natural resources to create polymers with similar properties to traditional polyurethanes. Bio-based alternatives offer improved sustainability and reduced environmental impact.

- Acrylic-based systems: Development of acrylic-based systems as isocyanate-free alternatives for various applications. These systems often involve the use of acrylic monomers or oligomers that can be cured through various mechanisms, such as UV radiation or thermal processes. Acrylic-based alternatives can offer good weatherability, chemical resistance, and optical properties.

02 Bio-based and renewable raw materials

Utilization of bio-based and renewable raw materials to create isocyanate-free polymers and coatings. This includes the use of plant-based oils, sugars, and other natural resources to develop sustainable alternatives to traditional isocyanate-based products. These materials often offer improved biodegradability and reduced environmental impact.Expand Specific Solutions03 Silane-terminated polymers

Development of silane-terminated polymers as isocyanate-free alternatives for adhesives, sealants, and coatings. These polymers cure through moisture-induced crosslinking, offering good adhesion properties and flexibility without the use of isocyanates. They are particularly useful in construction and automotive applications.Expand Specific Solutions04 Epoxy-based systems

Formulation of epoxy-based systems as alternatives to isocyanate-containing products. These systems often involve the reaction of epoxy resins with various hardeners or curing agents to create high-performance coatings, adhesives, and composites. Epoxy-based alternatives can offer excellent chemical resistance and durability.Expand Specific Solutions05 Acrylic and methacrylic polymers

Development of acrylic and methacrylic polymer systems as isocyanate-free alternatives for various applications. These polymers can be formulated to provide similar properties to polyurethanes, such as flexibility, durability, and weather resistance. They are often used in coatings, adhesives, and sealants where isocyanate-free options are desired.Expand Specific Solutions

Key Players in Isocyanate-Free Industry

The market for isocyanate-free alternatives in industrial applications is in a growth phase, driven by increasing environmental and health concerns. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like BASF, Wanhua Chemical, and Mitsui Chemicals leading innovation. These firms are developing novel chemistries and processes to create high-performance, sustainable alternatives to traditional isocyanates. While some solutions have reached commercial viability, ongoing research and development efforts by key players suggest that the technology is still evolving, with potential for further improvements in performance and cost-effectiveness.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed STABiO™, an innovative isocyanate-free polyurethane technology. This system utilizes bio-based raw materials and a unique curing mechanism that does not require isocyanates[4]. The STABiO™ technology involves the reaction of polyfunctional carbonate compounds with amino-terminated polyethers or polyesters, resulting in urethane-like structures without the use of isocyanates[5]. This process allows for the production of materials with properties similar to conventional polyurethanes, including high durability and chemical resistance. Mitsui Chemicals has successfully applied this technology in various applications, such as coatings, adhesives, and sealants, demonstrating its versatility and potential for wide-scale industrial adoption[6].

Strengths: Bio-based raw materials, reduced environmental impact, versatile applications. Weaknesses: May require specialized equipment for processing, potential limitations in achieving certain material properties.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed a series of non-isocyanate polyurethane (NIPU) technologies, focusing on sustainable and environmentally friendly alternatives. Their approach involves the use of cyclic carbonates and polyamines to create urethane-like linkages without the need for isocyanates[7]. This technology, known as NHPU (Non-isocyanate Hybrid Polyurethane), combines the benefits of traditional polyurethanes with improved environmental and health profiles. Wanhua has successfully applied this technology in various sectors, including coatings, adhesives, and elastomers. Their NIPU products have shown excellent chemical resistance, weatherability, and mechanical properties comparable to conventional polyurethanes[8]. Additionally, Wanhua has invested in scaling up production capabilities for these isocyanate-free alternatives, demonstrating their commitment to sustainable chemistry[9].

Strengths: Improved safety profile, environmentally friendly, wide range of applications. Weaknesses: Potentially higher production costs, may require modifications to existing manufacturing processes.

Core Innovations in Non-Isocyanate Technologies

Isocyanate free foamable mixtures

PatentInactiveEP1368398A1

Innovation

- Development of isocyanate-free foamable mixtures comprising C1-C8 alkoxysilane-terminated organic prepolymers, a low-viscosity reactive diluent, a blowing agent, and a curing catalyst, which form a three-dimensional network during curing, reducing viscosity and enabling easy handling while maintaining mechanical properties.

Isocyanate free foamable mixtures

PatentWO2002068491A1

Innovation

- Development of isocyanate-free foamable mixtures comprising C1-6 alkoxysilane-terminated organic prepolymers, a low-viscosity reactive diluent, a blowing agent, and a curing catalyst, where the reactive diluent is incorporated into the network during curing to reduce viscosity and ensure safe handling and rapid curing.

Environmental Impact Assessment

The environmental impact assessment of isocyanate-free alternatives for industry use reveals significant potential benefits compared to traditional isocyanate-based products. These alternatives, primarily developed to address health and safety concerns, also offer substantial environmental advantages.

One of the key environmental benefits is the reduction of volatile organic compound (VOC) emissions. Many isocyanate-free alternatives, such as water-based polyurethane dispersions and UV-curable systems, have lower VOC content than their isocyanate counterparts. This reduction in VOCs contributes to improved air quality and helps mitigate the formation of ground-level ozone, a major component of smog.

Furthermore, isocyanate-free alternatives often have a lower carbon footprint. The production processes for these alternatives typically require less energy and generate fewer greenhouse gas emissions compared to the manufacture of isocyanate-based products. This aligns with global efforts to combat climate change and reduce industrial carbon emissions.

Water-based isocyanate-free systems also present advantages in terms of water pollution prevention. Unlike solvent-based isocyanate products, which can contaminate water sources if not properly handled, water-based alternatives pose a lower risk of water pollution. This is particularly important for industries operating near sensitive aquatic ecosystems.

In terms of waste management, many isocyanate-free alternatives offer improved end-of-life options. Some bio-based alternatives are biodegradable, reducing the environmental impact of disposal. Additionally, certain isocyanate-free products can be more easily recycled or repurposed, contributing to circular economy principles and reducing the overall waste generated by industrial processes.

The use of renewable raw materials in some isocyanate-free alternatives further enhances their environmental profile. Bio-based polyols derived from vegetable oils or other renewable sources reduce dependence on fossil fuels and promote sustainable resource management. This shift towards renewable inputs aligns with broader sustainability goals and helps conserve non-renewable resources.

However, it's important to note that the environmental impact of isocyanate-free alternatives can vary depending on the specific formulation and application. Some alternatives may require more complex production processes or additional additives, potentially offsetting some environmental gains. Comprehensive life cycle assessments are necessary to fully understand the environmental implications of these alternatives across their entire lifecycle.

Despite these considerations, the overall trend suggests that isocyanate-free alternatives offer significant potential for reducing the environmental footprint of various industrial processes. As research and development in this field continue, it is likely that the environmental benefits of these alternatives will further increase, supporting the transition towards more sustainable industrial practices.

One of the key environmental benefits is the reduction of volatile organic compound (VOC) emissions. Many isocyanate-free alternatives, such as water-based polyurethane dispersions and UV-curable systems, have lower VOC content than their isocyanate counterparts. This reduction in VOCs contributes to improved air quality and helps mitigate the formation of ground-level ozone, a major component of smog.

Furthermore, isocyanate-free alternatives often have a lower carbon footprint. The production processes for these alternatives typically require less energy and generate fewer greenhouse gas emissions compared to the manufacture of isocyanate-based products. This aligns with global efforts to combat climate change and reduce industrial carbon emissions.

Water-based isocyanate-free systems also present advantages in terms of water pollution prevention. Unlike solvent-based isocyanate products, which can contaminate water sources if not properly handled, water-based alternatives pose a lower risk of water pollution. This is particularly important for industries operating near sensitive aquatic ecosystems.

In terms of waste management, many isocyanate-free alternatives offer improved end-of-life options. Some bio-based alternatives are biodegradable, reducing the environmental impact of disposal. Additionally, certain isocyanate-free products can be more easily recycled or repurposed, contributing to circular economy principles and reducing the overall waste generated by industrial processes.

The use of renewable raw materials in some isocyanate-free alternatives further enhances their environmental profile. Bio-based polyols derived from vegetable oils or other renewable sources reduce dependence on fossil fuels and promote sustainable resource management. This shift towards renewable inputs aligns with broader sustainability goals and helps conserve non-renewable resources.

However, it's important to note that the environmental impact of isocyanate-free alternatives can vary depending on the specific formulation and application. Some alternatives may require more complex production processes or additional additives, potentially offsetting some environmental gains. Comprehensive life cycle assessments are necessary to fully understand the environmental implications of these alternatives across their entire lifecycle.

Despite these considerations, the overall trend suggests that isocyanate-free alternatives offer significant potential for reducing the environmental footprint of various industrial processes. As research and development in this field continue, it is likely that the environmental benefits of these alternatives will further increase, supporting the transition towards more sustainable industrial practices.

Regulatory Framework for Isocyanate-Free Products

The regulatory framework for isocyanate-free products has been evolving rapidly in response to growing concerns about the health and environmental impacts of traditional isocyanate-based materials. Governments and regulatory bodies worldwide have been implementing stricter guidelines and standards to promote the development and adoption of safer alternatives.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has played a crucial role in driving the shift towards isocyanate-free products. REACH has imposed stringent requirements on the use of isocyanates, particularly in consumer products, leading manufacturers to seek alternative solutions. The EU has also introduced specific regulations targeting isocyanates in various industries, such as the construction sector, where limitations on the use of diisocyanates have been implemented.

The United States Environmental Protection Agency (EPA) has been actively involved in regulating isocyanates under the Toxic Substances Control Act (TSCA). The EPA has conducted risk assessments on several isocyanates and has proposed restrictions on their use in certain applications. Additionally, the Occupational Safety and Health Administration (OSHA) has established exposure limits and safety protocols for workers handling isocyanates, further incentivizing the development of safer alternatives.

In Asia, countries like Japan and South Korea have also introduced regulations to limit the use of isocyanates in various industries. Japan's Chemical Substances Control Law (CSCL) and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) have both implemented measures to control the use of hazardous substances, including isocyanates.

The regulatory landscape has also seen the emergence of voluntary certification programs and eco-labels that promote isocyanate-free products. These initiatives, such as the GreenGuard Certification and the Blue Angel eco-label, have gained traction in the market, providing consumers with assurance about the safety and environmental performance of products.

Industry-specific regulations have been particularly impactful in driving the adoption of isocyanate-free alternatives. For instance, in the automotive sector, regulations aimed at reducing volatile organic compound (VOC) emissions have led to increased interest in water-based and other isocyanate-free coatings. Similarly, in the furniture and bedding industry, flammability standards have been updated to accommodate newer, safer materials that do not rely on isocyanates.

As the regulatory framework continues to evolve, it is expected that more comprehensive and stringent regulations will be implemented globally. This ongoing regulatory pressure is likely to accelerate research and development efforts in isocyanate-free technologies, fostering innovation and driving market adoption of safer alternatives across various industries.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has played a crucial role in driving the shift towards isocyanate-free products. REACH has imposed stringent requirements on the use of isocyanates, particularly in consumer products, leading manufacturers to seek alternative solutions. The EU has also introduced specific regulations targeting isocyanates in various industries, such as the construction sector, where limitations on the use of diisocyanates have been implemented.

The United States Environmental Protection Agency (EPA) has been actively involved in regulating isocyanates under the Toxic Substances Control Act (TSCA). The EPA has conducted risk assessments on several isocyanates and has proposed restrictions on their use in certain applications. Additionally, the Occupational Safety and Health Administration (OSHA) has established exposure limits and safety protocols for workers handling isocyanates, further incentivizing the development of safer alternatives.

In Asia, countries like Japan and South Korea have also introduced regulations to limit the use of isocyanates in various industries. Japan's Chemical Substances Control Law (CSCL) and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) have both implemented measures to control the use of hazardous substances, including isocyanates.

The regulatory landscape has also seen the emergence of voluntary certification programs and eco-labels that promote isocyanate-free products. These initiatives, such as the GreenGuard Certification and the Blue Angel eco-label, have gained traction in the market, providing consumers with assurance about the safety and environmental performance of products.

Industry-specific regulations have been particularly impactful in driving the adoption of isocyanate-free alternatives. For instance, in the automotive sector, regulations aimed at reducing volatile organic compound (VOC) emissions have led to increased interest in water-based and other isocyanate-free coatings. Similarly, in the furniture and bedding industry, flammability standards have been updated to accommodate newer, safer materials that do not rely on isocyanates.

As the regulatory framework continues to evolve, it is expected that more comprehensive and stringent regulations will be implemented globally. This ongoing regulatory pressure is likely to accelerate research and development efforts in isocyanate-free technologies, fostering innovation and driving market adoption of safer alternatives across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!