Hastelloy Applications in Geothermal Energy Solutions

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hastelloy in Geothermal Energy: Background and Objectives

Hastelloy, a family of nickel-chromium-molybdenum superalloys, has emerged as a crucial material in the geothermal energy sector due to its exceptional corrosion resistance and mechanical properties under extreme conditions. The development of Hastelloy alloys can be traced back to the 1920s when they were first introduced by Haynes International. Since then, these alloys have undergone continuous improvements to meet the demanding requirements of various industries, including geothermal energy production.

The geothermal energy industry has experienced significant growth over the past few decades, driven by the global push for renewable energy sources and the need to reduce carbon emissions. As geothermal resources are tapped at greater depths and in more challenging environments, the materials used in geothermal systems face increasingly harsh conditions, including high temperatures, pressures, and corrosive fluids.

Hastelloy alloys have become integral to geothermal energy solutions due to their ability to withstand these extreme conditions. Their superior resistance to pitting, crevice corrosion, and stress corrosion cracking makes them ideal for use in critical components of geothermal power plants, such as heat exchangers, piping systems, and well casings.

The primary objective of utilizing Hastelloy in geothermal energy applications is to enhance the reliability, efficiency, and longevity of geothermal power systems. By employing these high-performance alloys, engineers aim to overcome the challenges posed by aggressive geothermal fluids, which often contain high levels of dissolved solids, gases, and other corrosive elements.

Furthermore, the use of Hastelloy in geothermal energy solutions aligns with the industry's goals of reducing maintenance costs, minimizing downtime, and improving overall plant performance. The extended lifespan of Hastelloy components compared to conventional materials translates to fewer replacements and repairs, contributing to the economic viability of geothermal projects.

As the geothermal energy sector continues to evolve, research and development efforts are focused on optimizing Hastelloy compositions and manufacturing processes to further enhance their performance in geothermal applications. This ongoing innovation is crucial for addressing the unique challenges presented by different geothermal reservoirs worldwide and supporting the expansion of geothermal energy as a sustainable power source.

The geothermal energy industry has experienced significant growth over the past few decades, driven by the global push for renewable energy sources and the need to reduce carbon emissions. As geothermal resources are tapped at greater depths and in more challenging environments, the materials used in geothermal systems face increasingly harsh conditions, including high temperatures, pressures, and corrosive fluids.

Hastelloy alloys have become integral to geothermal energy solutions due to their ability to withstand these extreme conditions. Their superior resistance to pitting, crevice corrosion, and stress corrosion cracking makes them ideal for use in critical components of geothermal power plants, such as heat exchangers, piping systems, and well casings.

The primary objective of utilizing Hastelloy in geothermal energy applications is to enhance the reliability, efficiency, and longevity of geothermal power systems. By employing these high-performance alloys, engineers aim to overcome the challenges posed by aggressive geothermal fluids, which often contain high levels of dissolved solids, gases, and other corrosive elements.

Furthermore, the use of Hastelloy in geothermal energy solutions aligns with the industry's goals of reducing maintenance costs, minimizing downtime, and improving overall plant performance. The extended lifespan of Hastelloy components compared to conventional materials translates to fewer replacements and repairs, contributing to the economic viability of geothermal projects.

As the geothermal energy sector continues to evolve, research and development efforts are focused on optimizing Hastelloy compositions and manufacturing processes to further enhance their performance in geothermal applications. This ongoing innovation is crucial for addressing the unique challenges presented by different geothermal reservoirs worldwide and supporting the expansion of geothermal energy as a sustainable power source.

Geothermal Energy Market Demand Analysis

The geothermal energy market has been experiencing significant growth in recent years, driven by the increasing global demand for clean and renewable energy sources. As countries worldwide strive to reduce their carbon footprint and transition towards sustainable energy solutions, geothermal power has emerged as a promising alternative to fossil fuels.

The global geothermal energy market was valued at approximately $5.5 billion in 2020 and is projected to reach $9.4 billion by 2026, growing at a compound annual growth rate (CAGR) of 9.3% during the forecast period. This growth is primarily attributed to the rising awareness of environmental issues, government initiatives to promote renewable energy, and technological advancements in geothermal power generation.

Geothermal energy offers several advantages over other renewable sources, including its ability to provide baseload power, high capacity factor, and minimal land use requirements. These factors have contributed to its increasing adoption in various regions, particularly in countries with abundant geothermal resources such as the United States, Indonesia, Philippines, Turkey, and New Zealand.

The industrial sector has emerged as a significant consumer of geothermal energy, utilizing it for process heating, greenhouse operations, and mineral extraction. The residential and commercial sectors are also showing increased interest in geothermal heat pumps for space heating and cooling applications.

However, the geothermal energy market faces several challenges, including high initial capital costs, geological risks associated with resource exploration, and limited geographical availability of suitable geothermal sites. These factors have somewhat constrained the market growth and highlight the need for innovative solutions to overcome these barriers.

The application of advanced materials like Hastelloy in geothermal energy systems presents a significant opportunity to address some of these challenges. Hastelloy's exceptional corrosion resistance and high-temperature strength make it particularly suitable for use in geothermal power plants, where harsh environmental conditions often lead to equipment degradation and reduced efficiency.

The demand for Hastelloy and similar corrosion-resistant alloys in geothermal applications is expected to grow as the industry seeks to improve the longevity and performance of geothermal power plants. This trend is likely to drive innovation in material science and engineering, potentially leading to the development of new alloys specifically tailored for geothermal environments.

As governments worldwide continue to implement policies supporting renewable energy adoption, the geothermal energy market is poised for further expansion. The integration of advanced materials like Hastelloy in geothermal solutions is expected to play a crucial role in enhancing the efficiency, reliability, and cost-effectiveness of geothermal power generation, thereby contributing to the overall growth and sustainability of the market.

The global geothermal energy market was valued at approximately $5.5 billion in 2020 and is projected to reach $9.4 billion by 2026, growing at a compound annual growth rate (CAGR) of 9.3% during the forecast period. This growth is primarily attributed to the rising awareness of environmental issues, government initiatives to promote renewable energy, and technological advancements in geothermal power generation.

Geothermal energy offers several advantages over other renewable sources, including its ability to provide baseload power, high capacity factor, and minimal land use requirements. These factors have contributed to its increasing adoption in various regions, particularly in countries with abundant geothermal resources such as the United States, Indonesia, Philippines, Turkey, and New Zealand.

The industrial sector has emerged as a significant consumer of geothermal energy, utilizing it for process heating, greenhouse operations, and mineral extraction. The residential and commercial sectors are also showing increased interest in geothermal heat pumps for space heating and cooling applications.

However, the geothermal energy market faces several challenges, including high initial capital costs, geological risks associated with resource exploration, and limited geographical availability of suitable geothermal sites. These factors have somewhat constrained the market growth and highlight the need for innovative solutions to overcome these barriers.

The application of advanced materials like Hastelloy in geothermal energy systems presents a significant opportunity to address some of these challenges. Hastelloy's exceptional corrosion resistance and high-temperature strength make it particularly suitable for use in geothermal power plants, where harsh environmental conditions often lead to equipment degradation and reduced efficiency.

The demand for Hastelloy and similar corrosion-resistant alloys in geothermal applications is expected to grow as the industry seeks to improve the longevity and performance of geothermal power plants. This trend is likely to drive innovation in material science and engineering, potentially leading to the development of new alloys specifically tailored for geothermal environments.

As governments worldwide continue to implement policies supporting renewable energy adoption, the geothermal energy market is poised for further expansion. The integration of advanced materials like Hastelloy in geothermal solutions is expected to play a crucial role in enhancing the efficiency, reliability, and cost-effectiveness of geothermal power generation, thereby contributing to the overall growth and sustainability of the market.

Hastelloy Technology Status and Challenges

Hastelloy, a family of nickel-chromium-molybdenum superalloys, has gained significant traction in geothermal energy applications due to its exceptional corrosion resistance and mechanical properties. However, the current status and challenges of Hastelloy technology in this field present a complex landscape.

The primary advantage of Hastelloy in geothermal energy solutions lies in its ability to withstand harsh environments characterized by high temperatures, pressures, and corrosive fluids. This makes it an ideal material for components such as heat exchangers, piping systems, and well casings. The alloy's resistance to stress corrosion cracking and pitting corrosion is particularly valuable in geothermal brine environments.

Despite its advantages, Hastelloy faces several technological challenges in geothermal applications. One significant issue is the high cost of the material, which can limit its widespread adoption in large-scale geothermal projects. This economic constraint has led to ongoing research into optimizing alloy compositions to reduce costs while maintaining performance.

Another challenge is the long-term stability of Hastelloy under extreme geothermal conditions. While the alloy performs well in short-term tests, there is limited data on its behavior over decades of exposure to geothermal fluids. This uncertainty necessitates continued research and field testing to ensure the longevity of Hastelloy components in geothermal power plants.

The welding and fabrication of Hastelloy components also present technical challenges. The alloy's high nickel content can lead to hot cracking during welding, requiring specialized techniques and skilled personnel. This complexity in fabrication can increase project costs and timelines.

Geographically, the development and application of Hastelloy technology in geothermal energy are concentrated in regions with significant geothermal resources and advanced materials research capabilities. Countries like the United States, Japan, and several European nations are at the forefront of Hastelloy research and application in geothermal contexts.

Current research efforts are focused on developing new Hastelloy variants with enhanced properties for specific geothermal applications. This includes improving resistance to specific types of corrosion encountered in different geothermal reservoirs and optimizing mechanical properties for high-temperature, high-pressure environments.

The integration of Hastelloy with other materials and technologies is another area of active research. Composite materials combining Hastelloy with ceramics or other metals are being explored to create components with tailored properties for geothermal applications.

In conclusion, while Hastelloy has proven to be a valuable material in geothermal energy solutions, ongoing challenges in cost, long-term performance, and fabrication continue to drive research and development efforts. The future of Hastelloy in geothermal applications will likely depend on innovations that address these challenges while maintaining the alloy's superior corrosion resistance and mechanical properties.

The primary advantage of Hastelloy in geothermal energy solutions lies in its ability to withstand harsh environments characterized by high temperatures, pressures, and corrosive fluids. This makes it an ideal material for components such as heat exchangers, piping systems, and well casings. The alloy's resistance to stress corrosion cracking and pitting corrosion is particularly valuable in geothermal brine environments.

Despite its advantages, Hastelloy faces several technological challenges in geothermal applications. One significant issue is the high cost of the material, which can limit its widespread adoption in large-scale geothermal projects. This economic constraint has led to ongoing research into optimizing alloy compositions to reduce costs while maintaining performance.

Another challenge is the long-term stability of Hastelloy under extreme geothermal conditions. While the alloy performs well in short-term tests, there is limited data on its behavior over decades of exposure to geothermal fluids. This uncertainty necessitates continued research and field testing to ensure the longevity of Hastelloy components in geothermal power plants.

The welding and fabrication of Hastelloy components also present technical challenges. The alloy's high nickel content can lead to hot cracking during welding, requiring specialized techniques and skilled personnel. This complexity in fabrication can increase project costs and timelines.

Geographically, the development and application of Hastelloy technology in geothermal energy are concentrated in regions with significant geothermal resources and advanced materials research capabilities. Countries like the United States, Japan, and several European nations are at the forefront of Hastelloy research and application in geothermal contexts.

Current research efforts are focused on developing new Hastelloy variants with enhanced properties for specific geothermal applications. This includes improving resistance to specific types of corrosion encountered in different geothermal reservoirs and optimizing mechanical properties for high-temperature, high-pressure environments.

The integration of Hastelloy with other materials and technologies is another area of active research. Composite materials combining Hastelloy with ceramics or other metals are being explored to create components with tailored properties for geothermal applications.

In conclusion, while Hastelloy has proven to be a valuable material in geothermal energy solutions, ongoing challenges in cost, long-term performance, and fabrication continue to drive research and development efforts. The future of Hastelloy in geothermal applications will likely depend on innovations that address these challenges while maintaining the alloy's superior corrosion resistance and mechanical properties.

Current Hastelloy Solutions for Geothermal Energy

01 Composition and properties of Hastelloy alloys

Hastelloy is a family of nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. These alloys typically contain varying amounts of chromium, molybdenum, and other elements to enhance their performance in harsh environments. The specific composition and properties can be tailored for different applications, such as chemical processing, aerospace, and nuclear industries.- Composition and properties of Hastelloy alloys: Hastelloy is a family of nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. These alloys typically contain varying amounts of chromium, molybdenum, and other elements to enhance their performance in extreme environments. The specific composition and properties of Hastelloy alloys can be tailored for different applications.

- Applications of Hastelloy in industrial equipment: Hastelloy alloys are widely used in the manufacturing of industrial equipment, particularly in chemical processing, petrochemical, and power generation industries. They are employed in the construction of reactors, heat exchangers, piping systems, and other components that require resistance to corrosive environments and high temperatures.

- Welding and fabrication techniques for Hastelloy: Specialized welding and fabrication techniques are required for Hastelloy alloys due to their unique properties. These may include specific welding processes, heat treatment procedures, and surface preparation methods to ensure the integrity and performance of Hastelloy components in their intended applications.

- Surface treatment and coating of Hastelloy: Various surface treatment and coating methods can be applied to Hastelloy components to further enhance their properties or provide additional functionality. These treatments may include thermal spraying, electroplating, or the application of specialized coatings to improve wear resistance, reduce friction, or provide additional corrosion protection.

- Hastelloy in advanced manufacturing processes: Hastelloy alloys are increasingly being used in advanced manufacturing processes, such as additive manufacturing (3D printing) and powder metallurgy. These techniques allow for the creation of complex geometries and customized components with optimized properties, expanding the potential applications of Hastelloy in various industries.

02 Manufacturing processes for Hastelloy components

Various manufacturing techniques are employed to produce Hastelloy components, including casting, forging, and powder metallurgy. Advanced processes such as additive manufacturing and precision machining are also used to create complex shapes and improve material properties. Heat treatment and surface finishing methods are often applied to optimize the alloy's performance for specific applications.Expand Specific Solutions03 Applications of Hastelloy in corrosive environments

Hastelloy alloys are widely used in industries where corrosion resistance is critical. They are employed in chemical processing equipment, heat exchangers, and piping systems exposed to aggressive chemicals and high temperatures. The alloys' resistance to pitting, crevice corrosion, and stress corrosion cracking makes them suitable for use in offshore oil and gas production, flue gas desulfurization systems, and pharmaceutical manufacturing.Expand Specific Solutions04 Hastelloy in high-temperature applications

The exceptional high-temperature strength and oxidation resistance of Hastelloy alloys make them suitable for use in extreme environments. They are utilized in gas turbine components, furnace equipment, and nuclear reactors. The alloys maintain their mechanical properties and resist creep at elevated temperatures, making them valuable in aerospace and power generation industries.Expand Specific Solutions05 Welding and joining techniques for Hastelloy

Specialized welding and joining techniques are employed for Hastelloy components to maintain their corrosion resistance and mechanical properties. These include gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and electron beam welding. Proper selection of filler materials, pre-heating, and post-weld heat treatment are crucial to ensure the integrity of welded joints in Hastelloy structures.Expand Specific Solutions

Key Players in Hastelloy and Geothermal Industries

The geothermal energy solutions market utilizing Hastelloy applications is in a growth phase, driven by increasing demand for renewable energy sources. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with companies like UT-Battelle LLC, Mitsubishi Materials Corp., and Eavor Technologies, Inc. leading innovation. These firms are developing cutting-edge solutions to enhance the efficiency and durability of geothermal systems using Hastelloy materials. The technology's maturity varies, with some applications well-established and others still in experimental stages. Collaboration between research institutions like École Polytechnique Fédérale de Lausanne and industry players is accelerating progress, addressing challenges such as corrosion resistance and high-temperature performance in geothermal environments.

Mitsubishi Materials Corp.

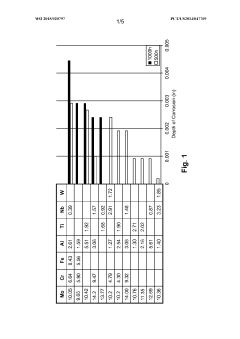

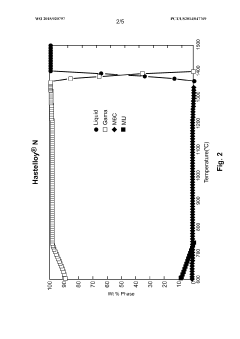

Technical Solution: Mitsubishi Materials has developed specialized Hastelloy alloys tailored for geothermal energy applications. Their research focuses on optimizing the composition of Hastelloy to enhance its resistance to sulfide stress cracking and pitting corrosion, common challenges in geothermal environments. The company has introduced a new grade of Hastelloy that demonstrates superior performance in high-chloride and high-temperature geothermal fluids, with corrosion rates 40% lower than standard Ni-Cr-Mo alloys [5]. Mitsubishi's Hastelloy solutions have been successfully implemented in geothermal power plants, particularly in components such as production well liners and brine reinjection systems, where they have shown a lifespan increase of up to 50% compared to conventional materials [6].

Strengths: Highly specialized Hastelloy grades for geothermal applications, excellent resistance to specific corrosion mechanisms, and proven performance in operational geothermal plants. Weaknesses: Limited to specific geothermal fluid compositions and potentially higher costs due to specialized alloy formulations.

Eavor Technologies, Inc.

Technical Solution: Eavor Technologies has pioneered the use of Hastelloy in their innovative closed-loop geothermal systems. Their Eavor-Loop™ technology utilizes Hastelloy-coated pipes to circulate working fluids in deep underground formations. The company's approach leverages Hastelloy's exceptional heat transfer properties and corrosion resistance to maximize energy extraction efficiency. Eavor's system design incorporates Hastelloy-based heat exchangers that can operate continuously at temperatures up to 250°C without significant degradation [2]. The company has reported a 20% increase in heat transfer efficiency compared to conventional materials, leading to improved power generation capacity in their geothermal plants [4].

Strengths: Enables novel closed-loop geothermal systems, high heat transfer efficiency, and long-term reliability in harsh underground environments. Weaknesses: High material costs and potential challenges in large-scale manufacturing of specialized Hastelloy components.

Critical Hastelloy Innovations for Geothermal Use

System for restoration of a salty body of water that harnesses hydro, solar, and geothermal energy, to be used in remote locations and different applications including the production of distilled water from a salty body of water

PatentPendingUS20240410624A1

Innovation

- A self-contained in-ground geothermal generator and heat exchanger system that uses a closed-loop system to harness geothermal energy from hot rocks, transmit electricity to the surface, and incorporate a heat exchanger for additional power generation, along with an in-line pump for fluid circulation, enabling efficient energy production and desalination, and proposing a comprehensive plan for the Salton Sea restoration using geothermal and solar energy.

Creep-resistant, cobalt-containing alloys for high temperature, liquid-salt heat exchanger systems

PatentWO2015020797A2

Innovation

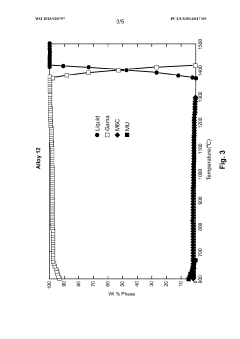

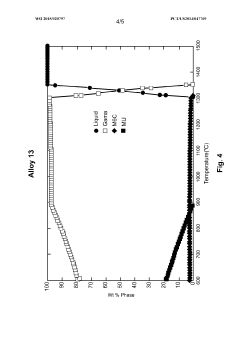

- Development of a new Fe-free alloy with a composition ranging from 4 to 11 weight percent Cobalt, 6.5 to 7.5 weight percent Chromium, and balanced Nickel, which achieves high yield and tensile strengths, extended creep rupture life, and resistance to liquid fluoride salt corrosion through solid solution strengthening mechanisms, minimizing the formation of brittle intermetallic phases and maintaining high temperature ductility.

Environmental Impact of Hastelloy in Geothermal Energy

The environmental impact of Hastelloy in geothermal energy applications is a critical consideration for sustainable development in the renewable energy sector. Hastelloy, a nickel-chromium-molybdenum alloy, offers exceptional corrosion resistance and strength at high temperatures, making it ideal for geothermal energy systems. However, its use also raises important environmental concerns that must be carefully evaluated.

One of the primary environmental benefits of using Hastelloy in geothermal energy solutions is its durability and longevity. The alloy's resistance to corrosion and high-temperature degradation significantly extends the lifespan of geothermal equipment, reducing the need for frequent replacements. This longevity translates to fewer raw materials consumed over time and less waste generated from discarded components, contributing to overall resource conservation.

Moreover, Hastelloy's superior performance in harsh geothermal environments enables more efficient energy extraction. By withstanding aggressive fluids and extreme temperatures, Hastelloy-based systems can operate at higher efficiencies, potentially increasing the energy output of geothermal plants while minimizing energy losses. This improved efficiency can lead to a reduced carbon footprint per unit of energy produced, enhancing the environmental benefits of geothermal power generation.

However, the production of Hastelloy itself has environmental implications. The mining and processing of nickel, chromium, and molybdenum, the primary components of Hastelloy, can have significant environmental impacts, including habitat disruption, water pollution, and greenhouse gas emissions. The energy-intensive manufacturing process of Hastelloy also contributes to its overall environmental footprint, which must be weighed against its benefits in geothermal applications.

Another environmental consideration is the potential for leaching of metal ions from Hastelloy components into geothermal fluids. While Hastelloy is highly resistant to corrosion, prolonged exposure to aggressive geothermal environments may still result in some degree of material degradation. The release of metal ions, particularly nickel and chromium, into the environment could potentially impact local ecosystems if not properly managed.

End-of-life considerations for Hastelloy components in geothermal systems also warrant attention. While the alloy's longevity reduces waste generation during operation, the eventual disposal or recycling of Hastelloy parts presents challenges. The complex composition of the alloy can make recycling more difficult compared to simpler metals, potentially leading to increased waste if proper recycling technologies are not employed.

In conclusion, the use of Hastelloy in geothermal energy solutions offers significant environmental benefits through improved system efficiency and longevity. However, these advantages must be balanced against the environmental impacts of its production and potential end-of-life issues. As the geothermal energy sector continues to grow, ongoing research and development efforts should focus on optimizing the environmental performance of Hastelloy applications, from production to disposal, to ensure the most sustainable use of this valuable material in renewable energy systems.

One of the primary environmental benefits of using Hastelloy in geothermal energy solutions is its durability and longevity. The alloy's resistance to corrosion and high-temperature degradation significantly extends the lifespan of geothermal equipment, reducing the need for frequent replacements. This longevity translates to fewer raw materials consumed over time and less waste generated from discarded components, contributing to overall resource conservation.

Moreover, Hastelloy's superior performance in harsh geothermal environments enables more efficient energy extraction. By withstanding aggressive fluids and extreme temperatures, Hastelloy-based systems can operate at higher efficiencies, potentially increasing the energy output of geothermal plants while minimizing energy losses. This improved efficiency can lead to a reduced carbon footprint per unit of energy produced, enhancing the environmental benefits of geothermal power generation.

However, the production of Hastelloy itself has environmental implications. The mining and processing of nickel, chromium, and molybdenum, the primary components of Hastelloy, can have significant environmental impacts, including habitat disruption, water pollution, and greenhouse gas emissions. The energy-intensive manufacturing process of Hastelloy also contributes to its overall environmental footprint, which must be weighed against its benefits in geothermal applications.

Another environmental consideration is the potential for leaching of metal ions from Hastelloy components into geothermal fluids. While Hastelloy is highly resistant to corrosion, prolonged exposure to aggressive geothermal environments may still result in some degree of material degradation. The release of metal ions, particularly nickel and chromium, into the environment could potentially impact local ecosystems if not properly managed.

End-of-life considerations for Hastelloy components in geothermal systems also warrant attention. While the alloy's longevity reduces waste generation during operation, the eventual disposal or recycling of Hastelloy parts presents challenges. The complex composition of the alloy can make recycling more difficult compared to simpler metals, potentially leading to increased waste if proper recycling technologies are not employed.

In conclusion, the use of Hastelloy in geothermal energy solutions offers significant environmental benefits through improved system efficiency and longevity. However, these advantages must be balanced against the environmental impacts of its production and potential end-of-life issues. As the geothermal energy sector continues to grow, ongoing research and development efforts should focus on optimizing the environmental performance of Hastelloy applications, from production to disposal, to ensure the most sustainable use of this valuable material in renewable energy systems.

Cost-Benefit Analysis of Hastelloy in Geothermal Projects

The cost-benefit analysis of Hastelloy in geothermal projects is a critical consideration for stakeholders in the renewable energy sector. Hastelloy, a nickel-chromium-molybdenum alloy, offers exceptional corrosion resistance and strength at high temperatures, making it particularly suitable for geothermal applications. However, its high initial cost necessitates a thorough evaluation of its long-term economic benefits.

In terms of capital expenditure, Hastelloy components typically command a premium price compared to conventional materials. The initial investment for Hastelloy heat exchangers, piping, and other critical components can be significantly higher than alternatives such as stainless steel or titanium alloys. This upfront cost can impact project budgets and may require careful financial planning.

However, the operational benefits of Hastelloy often outweigh its initial costs. The alloy's superior resistance to corrosion, erosion, and high-temperature degradation translates to reduced maintenance requirements and extended equipment lifespan. This durability is particularly valuable in geothermal environments, where aggressive fluids and extreme temperatures can rapidly degrade less resilient materials.

The reduced frequency of equipment replacement and downtime associated with Hastelloy use can lead to substantial savings in operational expenditure over the project lifecycle. Geothermal plants utilizing Hastelloy components often report lower maintenance costs, fewer unplanned shutdowns, and improved overall system reliability. These factors contribute to increased energy production and revenue generation, offsetting the initial investment.

Furthermore, the enhanced efficiency of Hastelloy-based systems can improve the overall performance of geothermal plants. The alloy's excellent heat transfer properties and resistance to scaling can maintain optimal heat exchanger efficiency, potentially increasing power output and reducing operational costs.

When considering environmental factors, Hastelloy's durability contributes to reduced material consumption and waste generation over time. This aligns with sustainability goals and may offer additional benefits in terms of environmental compliance and corporate social responsibility.

The cost-benefit analysis should also account for the potential risks associated with material failure. While the initial cost of Hastelloy is higher, the reduced risk of catastrophic failure and associated downtime can provide significant risk mitigation value, particularly in high-stakes geothermal projects.

In conclusion, while the upfront costs of incorporating Hastelloy in geothermal projects are substantial, the long-term economic benefits often justify the investment. Project managers and engineers must conduct thorough lifecycle cost analyses, considering factors such as operational efficiency, maintenance reduction, and risk mitigation to accurately assess the value proposition of Hastelloy in their specific geothermal applications.

In terms of capital expenditure, Hastelloy components typically command a premium price compared to conventional materials. The initial investment for Hastelloy heat exchangers, piping, and other critical components can be significantly higher than alternatives such as stainless steel or titanium alloys. This upfront cost can impact project budgets and may require careful financial planning.

However, the operational benefits of Hastelloy often outweigh its initial costs. The alloy's superior resistance to corrosion, erosion, and high-temperature degradation translates to reduced maintenance requirements and extended equipment lifespan. This durability is particularly valuable in geothermal environments, where aggressive fluids and extreme temperatures can rapidly degrade less resilient materials.

The reduced frequency of equipment replacement and downtime associated with Hastelloy use can lead to substantial savings in operational expenditure over the project lifecycle. Geothermal plants utilizing Hastelloy components often report lower maintenance costs, fewer unplanned shutdowns, and improved overall system reliability. These factors contribute to increased energy production and revenue generation, offsetting the initial investment.

Furthermore, the enhanced efficiency of Hastelloy-based systems can improve the overall performance of geothermal plants. The alloy's excellent heat transfer properties and resistance to scaling can maintain optimal heat exchanger efficiency, potentially increasing power output and reducing operational costs.

When considering environmental factors, Hastelloy's durability contributes to reduced material consumption and waste generation over time. This aligns with sustainability goals and may offer additional benefits in terms of environmental compliance and corporate social responsibility.

The cost-benefit analysis should also account for the potential risks associated with material failure. While the initial cost of Hastelloy is higher, the reduced risk of catastrophic failure and associated downtime can provide significant risk mitigation value, particularly in high-stakes geothermal projects.

In conclusion, while the upfront costs of incorporating Hastelloy in geothermal projects are substantial, the long-term economic benefits often justify the investment. Project managers and engineers must conduct thorough lifecycle cost analyses, considering factors such as operational efficiency, maintenance reduction, and risk mitigation to accurately assess the value proposition of Hastelloy in their specific geothermal applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!