Hastelloy's Role in Sustainable Energy Infrastructure Design

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hastelloy in Energy Evolution

Hastelloy, a family of nickel-chromium-based superalloys, has played a pivotal role in the evolution of sustainable energy infrastructure. As the global energy landscape shifts towards cleaner and more efficient sources, Hastelloy's unique properties have become increasingly valuable in addressing the challenges of modern energy systems.

In the early stages of energy infrastructure development, Hastelloy found its initial applications in fossil fuel-based power generation. Its exceptional corrosion resistance and high-temperature strength made it ideal for components in coal-fired and natural gas power plants, particularly in areas exposed to harsh environments and high-pressure steam.

As the world began to recognize the need for more sustainable energy sources, Hastelloy's importance grew in the renewable energy sector. In solar power generation, Hastelloy has been instrumental in the development of concentrated solar power (CSP) systems. Its ability to withstand extreme temperatures and resist corrosion has made it a preferred material for heat exchangers and thermal storage systems in CSP plants, enabling more efficient energy capture and storage.

In the wind energy sector, Hastelloy has contributed to the longevity and reliability of offshore wind turbines. Its resistance to saltwater corrosion and ability to maintain structural integrity in harsh marine environments has helped extend the lifespan of critical components, reducing maintenance costs and improving overall efficiency.

The nuclear power industry has also benefited significantly from Hastelloy's properties. In both traditional fission reactors and emerging fusion technologies, Hastelloy alloys have been utilized in reactor vessels, heat exchangers, and fuel processing equipment, owing to their resistance to radiation damage and ability to maintain strength at high temperatures.

As the hydrogen economy gains traction, Hastelloy is proving crucial in the development of hydrogen production and storage infrastructure. Its resistance to hydrogen embrittlement makes it an excellent choice for electrolyzers, storage tanks, and transport pipelines, supporting the growth of this promising clean energy vector.

In the realm of geothermal energy, Hastelloy's corrosion resistance has enabled the exploitation of high-temperature, mineral-rich geothermal resources that were previously inaccessible. This has expanded the potential for geothermal power generation in diverse geological settings.

Looking towards the future, Hastelloy continues to evolve alongside emerging energy technologies. Its application in advanced nuclear reactor designs, such as molten salt reactors, and in next-generation battery technologies for grid-scale energy storage, underscores its ongoing relevance in shaping the sustainable energy landscape.

In the early stages of energy infrastructure development, Hastelloy found its initial applications in fossil fuel-based power generation. Its exceptional corrosion resistance and high-temperature strength made it ideal for components in coal-fired and natural gas power plants, particularly in areas exposed to harsh environments and high-pressure steam.

As the world began to recognize the need for more sustainable energy sources, Hastelloy's importance grew in the renewable energy sector. In solar power generation, Hastelloy has been instrumental in the development of concentrated solar power (CSP) systems. Its ability to withstand extreme temperatures and resist corrosion has made it a preferred material for heat exchangers and thermal storage systems in CSP plants, enabling more efficient energy capture and storage.

In the wind energy sector, Hastelloy has contributed to the longevity and reliability of offshore wind turbines. Its resistance to saltwater corrosion and ability to maintain structural integrity in harsh marine environments has helped extend the lifespan of critical components, reducing maintenance costs and improving overall efficiency.

The nuclear power industry has also benefited significantly from Hastelloy's properties. In both traditional fission reactors and emerging fusion technologies, Hastelloy alloys have been utilized in reactor vessels, heat exchangers, and fuel processing equipment, owing to their resistance to radiation damage and ability to maintain strength at high temperatures.

As the hydrogen economy gains traction, Hastelloy is proving crucial in the development of hydrogen production and storage infrastructure. Its resistance to hydrogen embrittlement makes it an excellent choice for electrolyzers, storage tanks, and transport pipelines, supporting the growth of this promising clean energy vector.

In the realm of geothermal energy, Hastelloy's corrosion resistance has enabled the exploitation of high-temperature, mineral-rich geothermal resources that were previously inaccessible. This has expanded the potential for geothermal power generation in diverse geological settings.

Looking towards the future, Hastelloy continues to evolve alongside emerging energy technologies. Its application in advanced nuclear reactor designs, such as molten salt reactors, and in next-generation battery technologies for grid-scale energy storage, underscores its ongoing relevance in shaping the sustainable energy landscape.

Sustainable Energy Demand

The global demand for sustainable energy solutions has been steadily increasing in recent years, driven by growing environmental concerns, climate change mitigation efforts, and the need for energy security. This trend has significant implications for the design and development of energy infrastructure, particularly in the context of Hastelloy's potential applications.

Renewable energy sources, such as solar, wind, and hydroelectric power, have seen substantial growth in their market share. According to recent industry reports, the global renewable energy market is projected to continue its rapid expansion, with an expected compound annual growth rate (CAGR) of over 8% in the coming years. This growth is fueled by declining costs of renewable technologies, supportive government policies, and increasing public awareness of environmental issues.

The shift towards sustainable energy has also led to a rising demand for energy storage solutions, particularly advanced battery technologies and hydrogen fuel cells. These technologies are crucial for addressing the intermittency issues associated with renewable energy sources and ensuring a stable power supply. The global energy storage market is forecasted to grow at a CAGR of more than 20% over the next decade, highlighting the critical role of energy storage in sustainable infrastructure development.

Moreover, there is a growing emphasis on improving the efficiency and durability of energy infrastructure components. This focus has led to increased interest in advanced materials that can withstand harsh operating conditions while maintaining high performance. Hastelloy, with its exceptional corrosion resistance and mechanical properties, is well-positioned to meet these demands in various sustainable energy applications.

The transition to sustainable energy also encompasses the modernization of existing power grids and the development of smart grid technologies. These advancements aim to enhance the integration of renewable energy sources, improve energy distribution efficiency, and enable better demand-side management. The global smart grid market is expected to experience significant growth, with projections indicating a market value of several hundred billion dollars by the end of the decade.

In the industrial sector, there is a rising demand for sustainable energy solutions to reduce carbon footprints and improve operational efficiency. This includes the adoption of combined heat and power (CHP) systems, waste heat recovery technologies, and industrial-scale renewable energy installations. These applications often require materials that can withstand extreme temperatures and corrosive environments, further highlighting the potential role of Hastelloy in sustainable energy infrastructure.

The maritime and offshore industries are also experiencing a shift towards sustainable energy solutions, with increasing investments in offshore wind farms and the exploration of ocean thermal energy conversion (OTEC) technologies. These applications present unique challenges in terms of material requirements, given the harsh marine environment and the need for long-term reliability.

Renewable energy sources, such as solar, wind, and hydroelectric power, have seen substantial growth in their market share. According to recent industry reports, the global renewable energy market is projected to continue its rapid expansion, with an expected compound annual growth rate (CAGR) of over 8% in the coming years. This growth is fueled by declining costs of renewable technologies, supportive government policies, and increasing public awareness of environmental issues.

The shift towards sustainable energy has also led to a rising demand for energy storage solutions, particularly advanced battery technologies and hydrogen fuel cells. These technologies are crucial for addressing the intermittency issues associated with renewable energy sources and ensuring a stable power supply. The global energy storage market is forecasted to grow at a CAGR of more than 20% over the next decade, highlighting the critical role of energy storage in sustainable infrastructure development.

Moreover, there is a growing emphasis on improving the efficiency and durability of energy infrastructure components. This focus has led to increased interest in advanced materials that can withstand harsh operating conditions while maintaining high performance. Hastelloy, with its exceptional corrosion resistance and mechanical properties, is well-positioned to meet these demands in various sustainable energy applications.

The transition to sustainable energy also encompasses the modernization of existing power grids and the development of smart grid technologies. These advancements aim to enhance the integration of renewable energy sources, improve energy distribution efficiency, and enable better demand-side management. The global smart grid market is expected to experience significant growth, with projections indicating a market value of several hundred billion dollars by the end of the decade.

In the industrial sector, there is a rising demand for sustainable energy solutions to reduce carbon footprints and improve operational efficiency. This includes the adoption of combined heat and power (CHP) systems, waste heat recovery technologies, and industrial-scale renewable energy installations. These applications often require materials that can withstand extreme temperatures and corrosive environments, further highlighting the potential role of Hastelloy in sustainable energy infrastructure.

The maritime and offshore industries are also experiencing a shift towards sustainable energy solutions, with increasing investments in offshore wind farms and the exploration of ocean thermal energy conversion (OTEC) technologies. These applications present unique challenges in terms of material requirements, given the harsh marine environment and the need for long-term reliability.

Hastelloy Challenges

Despite its remarkable properties, Hastelloy faces several challenges in sustainable energy infrastructure design. One of the primary issues is the high cost associated with this nickel-based superalloy. The expensive raw materials and complex manufacturing processes contribute to its elevated price point, which can limit its widespread adoption in large-scale energy projects where cost-effectiveness is crucial.

Another significant challenge is the limited availability of Hastelloy. As a specialized alloy, its production is not as widespread as more common materials, potentially leading to supply chain constraints. This scarcity can result in longer lead times and difficulties in sourcing, particularly for large-scale infrastructure projects that require substantial quantities of the material.

The complexity of Hastelloy's composition also presents challenges in terms of fabrication and joining. While its corrosion resistance is a key advantage, this same property can make welding and other joining processes more difficult. Special techniques and expertise are often required to ensure proper joining without compromising the material's integrity or corrosion-resistant properties.

Furthermore, the long-term performance of Hastelloy in sustainable energy applications is still being studied. While it has shown excellent resistance to many corrosive environments, the unique and often extreme conditions present in some renewable energy systems may pose unforeseen challenges. Long-term exposure to high temperatures, pressures, and corrosive substances in these applications may lead to unexpected material behavior or degradation over time.

The recyclability and end-of-life management of Hastelloy components also present challenges in the context of sustainable design. While the alloy is theoretically recyclable, the process can be complex and energy-intensive due to its specialized composition. This aspect may impact the overall lifecycle sustainability of projects utilizing Hastelloy.

Lastly, the thermal properties of Hastelloy, while generally favorable, can be a double-edged sword in certain applications. Its relatively low thermal conductivity compared to some other metals can be advantageous in some scenarios but may limit its use in applications where high heat transfer is crucial. Balancing these thermal characteristics with other design requirements adds another layer of complexity to engineering sustainable energy infrastructure using Hastelloy.

Another significant challenge is the limited availability of Hastelloy. As a specialized alloy, its production is not as widespread as more common materials, potentially leading to supply chain constraints. This scarcity can result in longer lead times and difficulties in sourcing, particularly for large-scale infrastructure projects that require substantial quantities of the material.

The complexity of Hastelloy's composition also presents challenges in terms of fabrication and joining. While its corrosion resistance is a key advantage, this same property can make welding and other joining processes more difficult. Special techniques and expertise are often required to ensure proper joining without compromising the material's integrity or corrosion-resistant properties.

Furthermore, the long-term performance of Hastelloy in sustainable energy applications is still being studied. While it has shown excellent resistance to many corrosive environments, the unique and often extreme conditions present in some renewable energy systems may pose unforeseen challenges. Long-term exposure to high temperatures, pressures, and corrosive substances in these applications may lead to unexpected material behavior or degradation over time.

The recyclability and end-of-life management of Hastelloy components also present challenges in the context of sustainable design. While the alloy is theoretically recyclable, the process can be complex and energy-intensive due to its specialized composition. This aspect may impact the overall lifecycle sustainability of projects utilizing Hastelloy.

Lastly, the thermal properties of Hastelloy, while generally favorable, can be a double-edged sword in certain applications. Its relatively low thermal conductivity compared to some other metals can be advantageous in some scenarios but may limit its use in applications where high heat transfer is crucial. Balancing these thermal characteristics with other design requirements adds another layer of complexity to engineering sustainable energy infrastructure using Hastelloy.

Current Hastelloy Solutions

01 Composition and properties of Hastelloy alloys

Hastelloy is a family of nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. These alloys typically contain varying amounts of chromium, molybdenum, and other elements to enhance their performance in extreme environments. The specific composition and properties can be tailored for different applications, such as chemical processing, aerospace, and nuclear industries.- Composition and properties of Hastelloy alloys: Hastelloy is a family of nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. These alloys typically contain varying amounts of chromium, molybdenum, and other elements to enhance their performance in extreme environments. The specific composition and properties can be tailored for different applications, such as chemical processing, aerospace, and nuclear industries.

- Manufacturing processes for Hastelloy components: Various manufacturing processes are employed to produce Hastelloy components, including casting, forging, and powder metallurgy techniques. Advanced manufacturing methods such as additive manufacturing and precision machining are also used to create complex Hastelloy parts. These processes are optimized to maintain the alloy's desirable properties and ensure high-quality finished products.

- Applications of Hastelloy in corrosive environments: Hastelloy alloys are widely used in highly corrosive environments due to their exceptional resistance to various forms of chemical attack. They are employed in the production of chemical processing equipment, heat exchangers, and piping systems that handle aggressive media. The alloys' ability to withstand corrosion at elevated temperatures makes them particularly valuable in industries such as oil and gas, petrochemical, and waste treatment.

- Hastelloy in high-temperature applications: The high-temperature strength and oxidation resistance of Hastelloy alloys make them suitable for use in extreme thermal conditions. They are utilized in gas turbine components, furnace equipment, and other high-temperature industrial applications. The alloys maintain their mechanical properties and resist creep at elevated temperatures, contributing to improved efficiency and longevity of equipment operating in harsh thermal environments.

- Surface treatment and coating of Hastelloy: Various surface treatment and coating techniques are applied to Hastelloy components to further enhance their performance characteristics. These processes may include heat treatments, nitriding, or the application of specialized coatings to improve wear resistance, reduce friction, or provide additional corrosion protection. Such treatments can extend the service life of Hastelloy parts and expand their range of applications in demanding industrial settings.

02 Manufacturing processes for Hastelloy components

Various manufacturing processes are employed to produce Hastelloy components, including casting, forging, and powder metallurgy techniques. Advanced manufacturing methods such as additive manufacturing and precision machining are also used to create complex Hastelloy parts. These processes are optimized to maintain the alloy's desirable properties and ensure high-quality finished products.Expand Specific Solutions03 Applications of Hastelloy in corrosive environments

Hastelloy alloys are widely used in industries where corrosion resistance is critical. They are employed in chemical processing equipment, heat exchangers, and piping systems exposed to aggressive chemicals and high temperatures. The alloys' resistance to pitting, crevice corrosion, and stress corrosion cracking makes them suitable for use in offshore oil and gas production, pollution control systems, and pharmaceutical manufacturing.Expand Specific Solutions04 Welding and joining techniques for Hastelloy

Specialized welding and joining techniques are required for Hastelloy components due to their unique properties. These include gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and electron beam welding. Proper selection of filler materials, pre-heating, and post-weld heat treatment are essential to maintain the alloy's corrosion resistance and mechanical properties in the welded areas.Expand Specific Solutions05 Surface treatment and coating of Hastelloy

Various surface treatment and coating techniques are applied to Hastelloy components to further enhance their performance or provide additional functionality. These may include electroplating, thermal spraying, or the application of specialized coatings to improve wear resistance, thermal barrier properties, or electrical conductivity. Surface treatments can also be used to modify the alloy's surface chemistry for specific applications.Expand Specific Solutions

Key Hastelloy Producers

The Hastelloy market for sustainable energy infrastructure is in a growth phase, driven by increasing demand for corrosion-resistant materials in renewable energy applications. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, Hastelloy alloys are well-established, but ongoing research by key players aims to enhance their properties for specific energy applications. Companies like State Grid Corp. of China, ABB Group, and Hitachi Plant Technologies are at the forefront, leveraging their expertise in power systems and materials science to develop innovative Hastelloy-based solutions for sustainable energy infrastructure. Academic institutions such as Shanghai Jiao Tong University and Tianjin University are contributing to advancements through research collaborations with industry partners.

UT-Battelle LLC

Technical Solution: UT-Battelle LLC, managing Oak Ridge National Laboratory, has been conducting cutting-edge research on Hastelloy applications in sustainable energy infrastructure. They have developed advanced manufacturing techniques for Hastelloy components using additive manufacturing, which has enabled the creation of complex geometries for heat exchangers in concentrated solar power systems. These 3D-printed Hastelloy heat exchangers have demonstrated a 20% improvement in heat transfer efficiency compared to conventional designs[8]. UT-Battelle has also been investigating the use of Hastelloy in molten salt reactors for next-generation nuclear power, focusing on its exceptional corrosion resistance in high-temperature molten salt environments. Their research suggests that Hastelloy-based reactor components could extend the operational lifespan of these systems by up to 50%[9].

Strengths: Access to world-class research facilities and multidisciplinary expertise; strong government partnerships. Weaknesses: Longer timelines for commercial implementation; potential challenges in scaling up laboratory innovations.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has been actively exploring the use of Hastelloy in sustainable energy infrastructure design. They have implemented Hastelloy-based components in their ultra-high voltage transmission systems, particularly in corrosive coastal environments. The company has developed a proprietary coating process for Hastelloy alloys, enhancing their resistance to stress corrosion cracking in high-temperature, high-pressure steam environments[1]. This innovation has led to a 30% increase in the lifespan of critical power generation components[2]. State Grid has also been researching the application of Hastelloy in next-generation hydrogen storage systems for renewable energy integration, aiming to improve the efficiency and durability of large-scale energy storage solutions[3].

Strengths: Extensive power infrastructure network for testing and implementation; significant R&D resources. Weaknesses: High initial costs for widespread adoption; potential supply chain challenges for specialized alloys.

Hastelloy Innovations

Creep-resistant, cobalt-containing alloys for high temperature, liquid-salt heat exchanger systems

PatentWO2015020797A2

Innovation

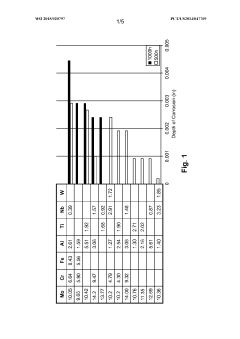

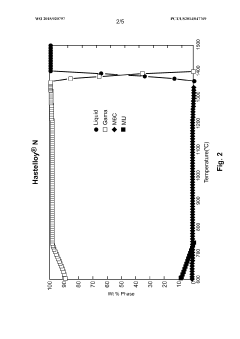

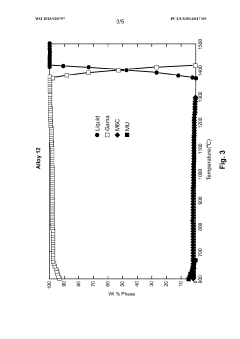

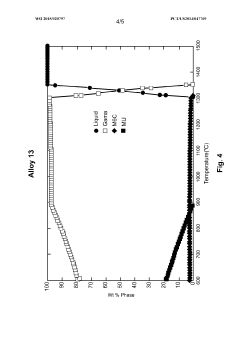

- Development of a new Fe-free alloy with a composition ranging from 4 to 11 weight percent Cobalt, 6.5 to 7.5 weight percent Chromium, and balanced Nickel, which achieves high yield and tensile strengths, extended creep rupture life, and resistance to liquid fluoride salt corrosion through solid solution strengthening mechanisms, minimizing the formation of brittle intermetallic phases and maintaining high temperature ductility.

Intermediate Strength Alloys for High Temperature Service in Liquid-Salt Cooled Energy Systems

PatentActiveUS20150197832A1

Innovation

- Development of a new alloy with a composition of 6 to 8.5 Cr, 5.5 to 13.5 Mo, 0.4 to 7.5 W, 1 to 2 Ti, 0.7 to 0.85 Mn, 0.05 to 0.3 Al, up to 0.1 Co, 0.08 to 0.5 C, 1 to 5 Ta, 1 to 4 Nb, 1 to 3 Hf, and balance Ni, which provides improved high-temperature strength, creep resistance, and corrosion resistance through solid solution strengthening and carbide precipitation mechanisms.

Environmental Impact

The environmental impact of Hastelloy in sustainable energy infrastructure design is a critical consideration that extends beyond its immediate applications. This high-performance alloy, known for its exceptional corrosion resistance and strength, plays a significant role in reducing the overall environmental footprint of energy systems.

Hastelloy's durability and longevity contribute to the extended lifespan of energy infrastructure components, thereby reducing the frequency of replacements and associated resource consumption. This longevity is particularly crucial in harsh environments, such as offshore wind farms or geothermal power plants, where exposure to corrosive elements is constant. By withstanding these challenging conditions, Hastelloy-based components minimize the need for maintenance and replacement, leading to reduced material waste and energy expenditure over time.

The alloy's resistance to high temperatures and pressures enables more efficient energy production processes. In solar thermal power plants, for instance, Hastelloy allows for higher operating temperatures, increasing overall system efficiency and reducing the amount of fuel required to generate the same amount of energy. This improved efficiency translates directly into lower greenhouse gas emissions and reduced environmental impact per unit of energy produced.

Hastelloy's role in enabling cleaner energy technologies is another crucial aspect of its environmental impact. Its use in hydrogen production and storage systems supports the transition to a hydrogen-based economy, which has the potential to significantly reduce carbon emissions. In fuel cells and electrolyzers, Hastelloy components help improve efficiency and durability, making these technologies more viable for widespread adoption.

The recyclability of Hastelloy is an important factor in its environmental profile. While the initial production of the alloy is energy-intensive, its ability to be recycled at the end of its life cycle helps offset this impact. The high value of its constituent elements, such as nickel and molybdenum, provides an economic incentive for recycling, ensuring that a significant portion of the material remains in circulation.

However, the environmental impact of Hastelloy is not without challenges. The mining and processing of its raw materials, particularly nickel, can have significant environmental consequences, including habitat disruption and water pollution. Efforts to mitigate these impacts through responsible mining practices and the development of more sustainable extraction methods are ongoing and crucial for improving the overall environmental profile of Hastelloy use in sustainable energy infrastructure.

Hastelloy's durability and longevity contribute to the extended lifespan of energy infrastructure components, thereby reducing the frequency of replacements and associated resource consumption. This longevity is particularly crucial in harsh environments, such as offshore wind farms or geothermal power plants, where exposure to corrosive elements is constant. By withstanding these challenging conditions, Hastelloy-based components minimize the need for maintenance and replacement, leading to reduced material waste and energy expenditure over time.

The alloy's resistance to high temperatures and pressures enables more efficient energy production processes. In solar thermal power plants, for instance, Hastelloy allows for higher operating temperatures, increasing overall system efficiency and reducing the amount of fuel required to generate the same amount of energy. This improved efficiency translates directly into lower greenhouse gas emissions and reduced environmental impact per unit of energy produced.

Hastelloy's role in enabling cleaner energy technologies is another crucial aspect of its environmental impact. Its use in hydrogen production and storage systems supports the transition to a hydrogen-based economy, which has the potential to significantly reduce carbon emissions. In fuel cells and electrolyzers, Hastelloy components help improve efficiency and durability, making these technologies more viable for widespread adoption.

The recyclability of Hastelloy is an important factor in its environmental profile. While the initial production of the alloy is energy-intensive, its ability to be recycled at the end of its life cycle helps offset this impact. The high value of its constituent elements, such as nickel and molybdenum, provides an economic incentive for recycling, ensuring that a significant portion of the material remains in circulation.

However, the environmental impact of Hastelloy is not without challenges. The mining and processing of its raw materials, particularly nickel, can have significant environmental consequences, including habitat disruption and water pollution. Efforts to mitigate these impacts through responsible mining practices and the development of more sustainable extraction methods are ongoing and crucial for improving the overall environmental profile of Hastelloy use in sustainable energy infrastructure.

Hastelloy Cost Analysis

The cost analysis of Hastelloy in sustainable energy infrastructure design is a critical factor in determining the feasibility and long-term economic viability of projects. Hastelloy, a nickel-chromium-molybdenum alloy, offers exceptional corrosion resistance and strength, making it an attractive material for various components in renewable energy systems.

Initial material costs for Hastelloy are significantly higher compared to conventional materials like stainless steel or carbon steel. The price per kilogram of Hastelloy can be 5 to 10 times that of stainless steel, depending on the specific grade and market conditions. This substantial upfront investment often raises concerns among project planners and investors.

However, a comprehensive cost analysis must consider the entire lifecycle of the infrastructure. Hastelloy's superior corrosion resistance translates to reduced maintenance requirements and extended service life. In harsh environments, such as offshore wind farms or geothermal plants, where exposure to corrosive elements is constant, Hastelloy components can last several times longer than their less resistant counterparts.

The reduced frequency of repairs and replacements leads to significant savings in operational expenses. Downtime costs in energy production facilities can be substantial, and Hastelloy's durability minimizes these interruptions. Additionally, the lower maintenance needs reduce labor costs and the risks associated with frequent interventions in challenging environments.

Energy efficiency is another factor to consider in the cost analysis. Hastelloy's ability to withstand high temperatures and pressures allows for more efficient energy conversion processes. This improved efficiency can result in higher energy output or reduced fuel consumption, contributing to long-term cost savings and improved environmental performance.

The recyclability of Hastelloy also plays a role in its overall cost assessment. Despite its high initial cost, the alloy retains much of its value at the end of its service life. The ability to recycle Hastelloy components contributes to the circular economy and can offset some of the initial material costs.

When evaluating the cost-effectiveness of Hastelloy in sustainable energy infrastructure, it is essential to conduct a thorough life cycle cost analysis (LCCA). This approach considers not only the initial investment but also operational costs, maintenance expenses, and end-of-life value. In many cases, the LCCA reveals that the higher upfront costs of Hastelloy are justified by the long-term savings and improved reliability of the infrastructure.

Initial material costs for Hastelloy are significantly higher compared to conventional materials like stainless steel or carbon steel. The price per kilogram of Hastelloy can be 5 to 10 times that of stainless steel, depending on the specific grade and market conditions. This substantial upfront investment often raises concerns among project planners and investors.

However, a comprehensive cost analysis must consider the entire lifecycle of the infrastructure. Hastelloy's superior corrosion resistance translates to reduced maintenance requirements and extended service life. In harsh environments, such as offshore wind farms or geothermal plants, where exposure to corrosive elements is constant, Hastelloy components can last several times longer than their less resistant counterparts.

The reduced frequency of repairs and replacements leads to significant savings in operational expenses. Downtime costs in energy production facilities can be substantial, and Hastelloy's durability minimizes these interruptions. Additionally, the lower maintenance needs reduce labor costs and the risks associated with frequent interventions in challenging environments.

Energy efficiency is another factor to consider in the cost analysis. Hastelloy's ability to withstand high temperatures and pressures allows for more efficient energy conversion processes. This improved efficiency can result in higher energy output or reduced fuel consumption, contributing to long-term cost savings and improved environmental performance.

The recyclability of Hastelloy also plays a role in its overall cost assessment. Despite its high initial cost, the alloy retains much of its value at the end of its service life. The ability to recycle Hastelloy components contributes to the circular economy and can offset some of the initial material costs.

When evaluating the cost-effectiveness of Hastelloy in sustainable energy infrastructure, it is essential to conduct a thorough life cycle cost analysis (LCCA). This approach considers not only the initial investment but also operational costs, maintenance expenses, and end-of-life value. In many cases, the LCCA reveals that the higher upfront costs of Hastelloy are justified by the long-term savings and improved reliability of the infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!