How Nichrome Wire Enhances Fire Safety Equipment?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Wire in Fire Safety: Background and Objectives

Nichrome wire has played a pivotal role in enhancing fire safety equipment over the past several decades. This alloy, composed primarily of nickel and chromium, has unique properties that make it particularly suitable for use in various fire detection and prevention systems. The evolution of nichrome wire in fire safety applications can be traced back to the mid-20th century when its high electrical resistance and heat-resistant qualities were first recognized as valuable in this context.

The primary objective of incorporating nichrome wire into fire safety equipment is to improve the reliability, efficiency, and responsiveness of these critical systems. By leveraging the wire's consistent electrical properties across a wide temperature range, manufacturers have been able to develop more accurate and durable fire detection devices. This has led to significant advancements in early warning systems, which are crucial for minimizing property damage and saving lives in the event of a fire.

One of the key areas where nichrome wire has made a substantial impact is in smoke detectors. The wire's ability to maintain a stable temperature when an electrical current passes through it allows for the creation of more sensitive and reliable ionization chambers within these devices. This has resulted in faster detection times and reduced false alarms, addressing two of the most pressing concerns in fire safety technology.

The development of nichrome wire applications in fire safety equipment has been driven by increasingly stringent building codes and safety regulations worldwide. As governments and safety organizations have recognized the importance of early fire detection and suppression, there has been a growing demand for more sophisticated and dependable fire safety systems. This has spurred ongoing research and development efforts to optimize the use of nichrome wire in various fire safety applications.

In recent years, the focus has shifted towards integrating nichrome wire-based components with smart building technologies and Internet of Things (IoT) systems. This trend aims to create more comprehensive and interconnected fire safety networks that can provide real-time data and automated responses to potential fire hazards. The goal is to not only detect fires more quickly but also to enable more efficient evacuation procedures and facilitate faster emergency response times.

As we look to the future, the continued evolution of nichrome wire in fire safety equipment is expected to address emerging challenges in urban development, such as the increasing prevalence of high-rise buildings and the need for more advanced fire protection in industrial settings. The ongoing refinement of nichrome wire properties and its integration with cutting-edge technologies promises to further enhance the effectiveness of fire safety systems, ultimately contributing to safer living and working environments for people around the world.

The primary objective of incorporating nichrome wire into fire safety equipment is to improve the reliability, efficiency, and responsiveness of these critical systems. By leveraging the wire's consistent electrical properties across a wide temperature range, manufacturers have been able to develop more accurate and durable fire detection devices. This has led to significant advancements in early warning systems, which are crucial for minimizing property damage and saving lives in the event of a fire.

One of the key areas where nichrome wire has made a substantial impact is in smoke detectors. The wire's ability to maintain a stable temperature when an electrical current passes through it allows for the creation of more sensitive and reliable ionization chambers within these devices. This has resulted in faster detection times and reduced false alarms, addressing two of the most pressing concerns in fire safety technology.

The development of nichrome wire applications in fire safety equipment has been driven by increasingly stringent building codes and safety regulations worldwide. As governments and safety organizations have recognized the importance of early fire detection and suppression, there has been a growing demand for more sophisticated and dependable fire safety systems. This has spurred ongoing research and development efforts to optimize the use of nichrome wire in various fire safety applications.

In recent years, the focus has shifted towards integrating nichrome wire-based components with smart building technologies and Internet of Things (IoT) systems. This trend aims to create more comprehensive and interconnected fire safety networks that can provide real-time data and automated responses to potential fire hazards. The goal is to not only detect fires more quickly but also to enable more efficient evacuation procedures and facilitate faster emergency response times.

As we look to the future, the continued evolution of nichrome wire in fire safety equipment is expected to address emerging challenges in urban development, such as the increasing prevalence of high-rise buildings and the need for more advanced fire protection in industrial settings. The ongoing refinement of nichrome wire properties and its integration with cutting-edge technologies promises to further enhance the effectiveness of fire safety systems, ultimately contributing to safer living and working environments for people around the world.

Market Analysis for Advanced Fire Safety Equipment

The market for advanced fire safety equipment has been experiencing significant growth in recent years, driven by increasing awareness of fire hazards, stringent safety regulations, and technological advancements. The global fire safety equipment market is projected to reach substantial value in the coming years, with a compound annual growth rate that outpaces many other industrial sectors.

Nichrome wire, a key component in many fire safety devices, plays a crucial role in enhancing the effectiveness and reliability of these systems. The demand for nichrome wire in fire safety applications is closely tied to the overall growth of the fire safety equipment market. This alloy's unique properties, including high resistance to heat and corrosion, make it an ideal material for use in smoke detectors, fire alarms, and other critical safety devices.

The residential sector represents a significant portion of the market for advanced fire safety equipment incorporating nichrome wire. With the increasing adoption of smart home technologies, there is a growing demand for interconnected fire safety systems that can provide early warning and automated responses to fire threats. Commercial and industrial sectors also contribute substantially to the market, driven by the need to comply with workplace safety regulations and protect valuable assets.

Geographically, North America and Europe lead the market for advanced fire safety equipment, owing to strict building codes and high levels of safety awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid urbanization, increasing construction activities, and growing investments in infrastructure development.

The market is characterized by the presence of both established players and innovative startups. Major companies are focusing on research and development to introduce more sophisticated and efficient fire safety solutions that leverage nichrome wire technology. These advancements include improved sensor sensitivity, longer battery life, and enhanced connectivity features.

Challenges in the market include price sensitivity, especially in emerging economies, and the need for regular maintenance and replacement of fire safety devices. However, these challenges are offset by the increasing emphasis on fire prevention and the potential cost savings associated with early fire detection and suppression.

Looking ahead, the market for advanced fire safety equipment is poised for continued growth. Factors such as the implementation of stricter fire safety codes, the rise of smart cities, and the integration of artificial intelligence and Internet of Things (IoT) technologies in fire safety systems are expected to drive innovation and market expansion. The role of nichrome wire in these advancements remains crucial, ensuring that fire safety equipment continues to evolve to meet the changing needs of consumers and businesses alike.

Nichrome wire, a key component in many fire safety devices, plays a crucial role in enhancing the effectiveness and reliability of these systems. The demand for nichrome wire in fire safety applications is closely tied to the overall growth of the fire safety equipment market. This alloy's unique properties, including high resistance to heat and corrosion, make it an ideal material for use in smoke detectors, fire alarms, and other critical safety devices.

The residential sector represents a significant portion of the market for advanced fire safety equipment incorporating nichrome wire. With the increasing adoption of smart home technologies, there is a growing demand for interconnected fire safety systems that can provide early warning and automated responses to fire threats. Commercial and industrial sectors also contribute substantially to the market, driven by the need to comply with workplace safety regulations and protect valuable assets.

Geographically, North America and Europe lead the market for advanced fire safety equipment, owing to strict building codes and high levels of safety awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid urbanization, increasing construction activities, and growing investments in infrastructure development.

The market is characterized by the presence of both established players and innovative startups. Major companies are focusing on research and development to introduce more sophisticated and efficient fire safety solutions that leverage nichrome wire technology. These advancements include improved sensor sensitivity, longer battery life, and enhanced connectivity features.

Challenges in the market include price sensitivity, especially in emerging economies, and the need for regular maintenance and replacement of fire safety devices. However, these challenges are offset by the increasing emphasis on fire prevention and the potential cost savings associated with early fire detection and suppression.

Looking ahead, the market for advanced fire safety equipment is poised for continued growth. Factors such as the implementation of stricter fire safety codes, the rise of smart cities, and the integration of artificial intelligence and Internet of Things (IoT) technologies in fire safety systems are expected to drive innovation and market expansion. The role of nichrome wire in these advancements remains crucial, ensuring that fire safety equipment continues to evolve to meet the changing needs of consumers and businesses alike.

Current Challenges in Fire Safety Technology

Fire safety technology has made significant strides in recent years, yet several challenges persist in ensuring optimal protection against fire hazards. One of the primary concerns is the reliability and effectiveness of fire detection systems. While smoke detectors have become ubiquitous, they often struggle with false alarms triggered by cooking fumes, steam, or dust particles. This undermines public trust in these systems and can lead to complacency when real emergencies occur.

Another critical challenge lies in the response time of fire suppression systems. Traditional sprinkler systems, while effective, may not activate quickly enough in rapidly spreading fires. This delay can result in significant property damage and potential loss of life. Additionally, water-based suppression systems pose risks in certain environments, such as data centers or electrical installations, where water damage can be as detrimental as fire damage.

The durability and performance of fire-resistant materials under extreme conditions remain areas of concern. Many fire-resistant coatings and materials degrade over time or lose their effectiveness when exposed to high temperatures for extended periods. This necessitates frequent inspections and replacements, increasing maintenance costs and potentially leaving gaps in fire protection.

In the realm of personal protective equipment (PPE) for firefighters, balancing heat resistance with mobility and comfort continues to be a significant challenge. Current firefighting suits, while providing crucial protection, can be cumbersome and limit the wearer's agility in dangerous situations. Moreover, the integration of advanced technologies, such as real-time health monitoring and environmental sensors, into PPE without compromising its primary protective function presents ongoing difficulties.

The increasing complexity of modern buildings and infrastructure also poses challenges for fire safety technology. High-rise structures, underground facilities, and large-scale industrial complexes require sophisticated fire safety systems that can operate effectively across diverse environments. Ensuring seamless integration and communication between various components of these systems, including detection, alarm, and suppression mechanisms, remains a persistent challenge.

Lastly, the advent of new materials and technologies in construction and manufacturing introduces unforeseen fire risks. For instance, the growing use of lithium-ion batteries in electric vehicles and energy storage systems presents unique fire hazards that traditional fire safety equipment may not be adequately prepared to handle. Developing specialized solutions for these emerging risks while maintaining broad applicability is a complex balancing act for fire safety technology developers.

Another critical challenge lies in the response time of fire suppression systems. Traditional sprinkler systems, while effective, may not activate quickly enough in rapidly spreading fires. This delay can result in significant property damage and potential loss of life. Additionally, water-based suppression systems pose risks in certain environments, such as data centers or electrical installations, where water damage can be as detrimental as fire damage.

The durability and performance of fire-resistant materials under extreme conditions remain areas of concern. Many fire-resistant coatings and materials degrade over time or lose their effectiveness when exposed to high temperatures for extended periods. This necessitates frequent inspections and replacements, increasing maintenance costs and potentially leaving gaps in fire protection.

In the realm of personal protective equipment (PPE) for firefighters, balancing heat resistance with mobility and comfort continues to be a significant challenge. Current firefighting suits, while providing crucial protection, can be cumbersome and limit the wearer's agility in dangerous situations. Moreover, the integration of advanced technologies, such as real-time health monitoring and environmental sensors, into PPE without compromising its primary protective function presents ongoing difficulties.

The increasing complexity of modern buildings and infrastructure also poses challenges for fire safety technology. High-rise structures, underground facilities, and large-scale industrial complexes require sophisticated fire safety systems that can operate effectively across diverse environments. Ensuring seamless integration and communication between various components of these systems, including detection, alarm, and suppression mechanisms, remains a persistent challenge.

Lastly, the advent of new materials and technologies in construction and manufacturing introduces unforeseen fire risks. For instance, the growing use of lithium-ion batteries in electric vehicles and energy storage systems presents unique fire hazards that traditional fire safety equipment may not be adequately prepared to handle. Developing specialized solutions for these emerging risks while maintaining broad applicability is a complex balancing act for fire safety technology developers.

Existing Nichrome Wire Solutions in Fire Safety

01 Composition and structure optimization

Enhancing nichrome wire properties through optimizing its composition and structure. This includes adjusting the ratio of nickel and chromium, adding other alloying elements, or modifying the wire's microstructure to improve its electrical and mechanical characteristics.- Composition and structure optimization: Enhancing nichrome wire properties through optimizing its composition and structure. This includes adjusting the ratio of nickel and chromium, adding other alloying elements, or modifying the wire's microstructure to improve its electrical and mechanical properties.

- Surface treatment and coating: Applying various surface treatments or coatings to nichrome wire to enhance its performance. This may involve techniques such as oxidation, nitriding, or applying protective layers to improve corrosion resistance, electrical conductivity, or thermal stability.

- Heat treatment and annealing processes: Implementing specific heat treatment and annealing processes to improve the properties of nichrome wire. These processes can help reduce internal stresses, enhance ductility, and optimize the wire's overall performance for various applications.

- Manufacturing and processing techniques: Developing advanced manufacturing and processing techniques for nichrome wire production. This includes innovative drawing methods, precision control of wire diameter, and specialized forming processes to achieve desired characteristics and improve overall quality.

- Application-specific enhancements: Tailoring nichrome wire properties for specific applications such as heating elements, sensors, or electronic components. This involves optimizing the wire's resistance, temperature coefficient, and other characteristics to meet the requirements of particular industries or products.

02 Surface treatment and coating

Applying various surface treatments or coatings to nichrome wire to enhance its performance. These treatments can improve corrosion resistance, oxidation resistance, or electrical properties of the wire, extending its lifespan and functionality in different applications.Expand Specific Solutions03 Heat treatment and annealing processes

Implementing specific heat treatment and annealing processes to enhance the properties of nichrome wire. These thermal processes can improve the wire's ductility, reduce internal stresses, and optimize its electrical resistance characteristics.Expand Specific Solutions04 Manufacturing and processing techniques

Developing advanced manufacturing and processing techniques for nichrome wire production. This includes improved drawing methods, precision control of wire diameter, and innovative winding techniques to enhance the wire's overall quality and performance in various applications.Expand Specific Solutions05 Application-specific enhancements

Tailoring nichrome wire properties for specific applications such as heating elements, sensors, or electronic components. This involves customizing the wire's characteristics to meet the unique requirements of different industries and use cases, improving its efficiency and reliability in targeted applications.Expand Specific Solutions

Key Players in Fire Safety and Nichrome Wire Industry

The market for nichrome wire in fire safety equipment is in a growth phase, driven by increasing safety regulations and demand for advanced fire protection systems. The global fire safety equipment market is projected to reach significant size, with nichrome wire playing a crucial role in various devices. Technologically, nichrome wire applications are mature but continue to evolve, with companies like Zhongtian Technology, Jiangsu Qidi Alloy, and BSH Hausgeräte leading innovations. These firms, along with others like Baker Hughes and Panasonic, are investing in R&D to enhance the wire's performance in fire detection and suppression systems, indicating a competitive and dynamic landscape.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has incorporated Nichrome wire technology into their fire safety product line, particularly in their advanced smoke detectors and fire alarm systems. The company utilizes Nichrome wire's stable electrical resistance properties to create highly sensitive heat detection elements. Bosch's innovative approach involves combining Nichrome wire sensors with their proprietary signal processing algorithms, resulting in faster and more accurate fire detection[5]. Their systems can differentiate between various types of fires based on the heat signature detected by the Nichrome wire elements, allowing for tailored response strategies. Additionally, Bosch has developed self-testing mechanisms using Nichrome wire to ensure continuous reliability of their fire safety equipment[6].

Strengths: High accuracy in fire detection, ability to differentiate fire types, and enhanced system reliability through self-testing. Weaknesses: Potentially higher product costs and the need for specialized technicians for installation and maintenance.

ALL CLEAR FIRE SYSTEMS LLC

Technical Solution: ALL CLEAR FIRE SYSTEMS LLC has developed advanced fire safety equipment utilizing Nichrome wire technology. Their systems incorporate Nichrome wire heating elements in smoke detectors and fire alarms, enhancing sensitivity and reducing false alarms. The company's innovative approach involves using Nichrome wire's precise temperature control capabilities to create a more responsive and accurate detection system[1]. By leveraging the wire's high resistance and stability at elevated temperatures, ALL CLEAR has designed fire suppression systems that can quickly activate in response to heat, providing faster and more effective fire control[3].

Strengths: Improved sensitivity and accuracy in fire detection, faster response times, and reduced false alarms. Weaknesses: Potentially higher initial costs and the need for specialized maintenance due to the advanced technology.

Innovative Nichrome Wire Technologies for Fire Protection

Infrared lamp, method of manufacturing the same, and heating apparatus using the infrared lamp

PatentInactiveUS20050136785A1

Innovation

- A carbon-based heating element with a specific resistance change rate between lit and unlit states is controlled within ±20%, using a sintered body formed by mixing carbon with metallic or semi-metallic compounds, and connecting multiple short heating elements via electrodes and terminals to form a long heating element, ensuring stability and efficient thermal distribution.

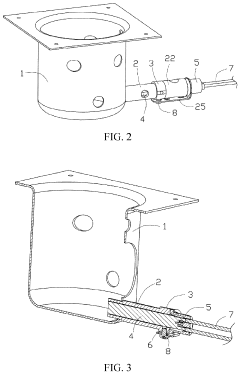

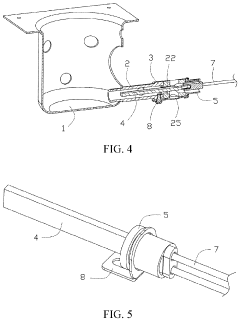

Silicon nitride ceramic heating and ignition device for granular fuel barbecue oven

PatentActiveUS20230165403A1

Innovation

- A silicon nitride ceramic heating and ignition device with a silicon nitride ignition rod made by sintering molybdenum wire and silicon nitride at 1780 degrees Celsius, providing excellent thermal conductivity, oxidation resistance, and corrosion resistance, combined with a heat dissipation flange ceramic sleeve assembly and stainless steel sheet bending support for improved sealing, insulation, and adjustable positioning to prevent shaking and facilitate replacement.

Regulatory Framework for Fire Safety Equipment

The regulatory framework for fire safety equipment plays a crucial role in ensuring the effectiveness and reliability of fire protection systems, including those incorporating nichrome wire technology. Governments and international organizations have established comprehensive standards and regulations to govern the design, manufacture, installation, and maintenance of fire safety equipment.

In the United States, the National Fire Protection Association (NFPA) sets forth numerous codes and standards that directly impact the use of nichrome wire in fire safety equipment. NFPA 72, the National Fire Alarm and Signaling Code, provides guidelines for the application of heat detectors and other sensing devices that may utilize nichrome wire. Additionally, NFPA 70, also known as the National Electrical Code, outlines requirements for electrical wiring and equipment, which is relevant to the integration of nichrome wire in fire safety systems.

The Occupational Safety and Health Administration (OSHA) also enforces regulations pertaining to fire safety in workplaces. These regulations often reference NFPA standards and mandate the use of approved fire detection and suppression equipment, which may incorporate nichrome wire technology.

On an international level, the International Organization for Standardization (ISO) has developed several standards related to fire safety equipment. ISO 7240, for instance, provides specifications for fire detection and alarm systems, which may include components utilizing nichrome wire. These standards are often adopted or adapted by national regulatory bodies worldwide.

In the European Union, the Construction Products Regulation (CPR) and the harmonized standard EN 54 series set requirements for fire detection and fire alarm systems. These regulations ensure that fire safety equipment, including those with nichrome wire components, meet stringent performance and reliability criteria.

Many countries have their own regulatory bodies and standards for fire safety equipment. For example, in the United Kingdom, the British Standards Institution (BSI) publishes standards such as BS 5839 for fire detection and alarm systems. Similarly, Australia and New Zealand follow the AS/NZS 1670 series of standards for fire detection, warning, control, and intercom systems.

Regulatory frameworks also address the testing and certification of fire safety equipment. Underwriters Laboratories (UL) in the United States and the Loss Prevention Certification Board (LPCB) in the UK are among the organizations that provide third-party testing and certification services to ensure compliance with relevant standards.

As technology evolves, regulatory frameworks are continuously updated to address new developments and improve safety measures. The integration of nichrome wire in fire safety equipment must adhere to these evolving regulations to ensure optimal performance and reliability in fire protection systems.

In the United States, the National Fire Protection Association (NFPA) sets forth numerous codes and standards that directly impact the use of nichrome wire in fire safety equipment. NFPA 72, the National Fire Alarm and Signaling Code, provides guidelines for the application of heat detectors and other sensing devices that may utilize nichrome wire. Additionally, NFPA 70, also known as the National Electrical Code, outlines requirements for electrical wiring and equipment, which is relevant to the integration of nichrome wire in fire safety systems.

The Occupational Safety and Health Administration (OSHA) also enforces regulations pertaining to fire safety in workplaces. These regulations often reference NFPA standards and mandate the use of approved fire detection and suppression equipment, which may incorporate nichrome wire technology.

On an international level, the International Organization for Standardization (ISO) has developed several standards related to fire safety equipment. ISO 7240, for instance, provides specifications for fire detection and alarm systems, which may include components utilizing nichrome wire. These standards are often adopted or adapted by national regulatory bodies worldwide.

In the European Union, the Construction Products Regulation (CPR) and the harmonized standard EN 54 series set requirements for fire detection and fire alarm systems. These regulations ensure that fire safety equipment, including those with nichrome wire components, meet stringent performance and reliability criteria.

Many countries have their own regulatory bodies and standards for fire safety equipment. For example, in the United Kingdom, the British Standards Institution (BSI) publishes standards such as BS 5839 for fire detection and alarm systems. Similarly, Australia and New Zealand follow the AS/NZS 1670 series of standards for fire detection, warning, control, and intercom systems.

Regulatory frameworks also address the testing and certification of fire safety equipment. Underwriters Laboratories (UL) in the United States and the Loss Prevention Certification Board (LPCB) in the UK are among the organizations that provide third-party testing and certification services to ensure compliance with relevant standards.

As technology evolves, regulatory frameworks are continuously updated to address new developments and improve safety measures. The integration of nichrome wire in fire safety equipment must adhere to these evolving regulations to ensure optimal performance and reliability in fire protection systems.

Environmental Impact of Nichrome Wire in Fire Safety

The environmental impact of nichrome wire in fire safety equipment is a crucial consideration in the development and deployment of these life-saving devices. Nichrome wire, an alloy primarily composed of nickel and chromium, plays a significant role in various fire safety applications, including smoke detectors, heat sensors, and fire suppression systems. However, its use also raises important environmental concerns that must be addressed.

One of the primary environmental considerations is the production process of nichrome wire. The mining and refining of nickel and chromium can have substantial ecological impacts, including habitat destruction, soil erosion, and water pollution. These processes often require significant energy inputs, contributing to greenhouse gas emissions and climate change. Additionally, the manufacturing of nichrome wire involves high-temperature processes that further increase its carbon footprint.

The durability and corrosion resistance of nichrome wire contribute to its longevity in fire safety equipment, which can be seen as an environmental advantage. Longer-lasting components reduce the frequency of replacements, thereby minimizing waste generation and the need for additional resource extraction. However, this durability also presents challenges at the end of the product's life cycle.

Disposal of fire safety equipment containing nichrome wire requires careful consideration. While the wire itself is recyclable, its integration into complex devices can make separation and recycling difficult. Improper disposal may lead to the release of heavy metals into the environment, potentially contaminating soil and water sources. This underscores the importance of developing effective recycling and disposal protocols for fire safety equipment.

The use of nichrome wire in fire safety applications also has indirect environmental benefits. By enhancing the effectiveness of fire detection and suppression systems, it helps prevent or mitigate fires, which can have devastating environmental consequences. Fires release large amounts of pollutants and greenhouse gases, destroy natural habitats, and can lead to the release of hazardous materials. Thus, the environmental impact of nichrome wire must be weighed against its role in preventing these larger-scale environmental disasters.

Efforts to mitigate the environmental impact of nichrome wire in fire safety equipment are ongoing. Research into more sustainable production methods, such as using renewable energy sources in manufacturing, is promising. Additionally, the development of alternative materials with similar properties but lower environmental footprints is an area of active investigation. These efforts aim to balance the critical need for effective fire safety measures with the imperative of environmental stewardship.

One of the primary environmental considerations is the production process of nichrome wire. The mining and refining of nickel and chromium can have substantial ecological impacts, including habitat destruction, soil erosion, and water pollution. These processes often require significant energy inputs, contributing to greenhouse gas emissions and climate change. Additionally, the manufacturing of nichrome wire involves high-temperature processes that further increase its carbon footprint.

The durability and corrosion resistance of nichrome wire contribute to its longevity in fire safety equipment, which can be seen as an environmental advantage. Longer-lasting components reduce the frequency of replacements, thereby minimizing waste generation and the need for additional resource extraction. However, this durability also presents challenges at the end of the product's life cycle.

Disposal of fire safety equipment containing nichrome wire requires careful consideration. While the wire itself is recyclable, its integration into complex devices can make separation and recycling difficult. Improper disposal may lead to the release of heavy metals into the environment, potentially contaminating soil and water sources. This underscores the importance of developing effective recycling and disposal protocols for fire safety equipment.

The use of nichrome wire in fire safety applications also has indirect environmental benefits. By enhancing the effectiveness of fire detection and suppression systems, it helps prevent or mitigate fires, which can have devastating environmental consequences. Fires release large amounts of pollutants and greenhouse gases, destroy natural habitats, and can lead to the release of hazardous materials. Thus, the environmental impact of nichrome wire must be weighed against its role in preventing these larger-scale environmental disasters.

Efforts to mitigate the environmental impact of nichrome wire in fire safety equipment are ongoing. Research into more sustainable production methods, such as using renewable energy sources in manufacturing, is promising. Additionally, the development of alternative materials with similar properties but lower environmental footprints is an area of active investigation. These efforts aim to balance the critical need for effective fire safety measures with the imperative of environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!