Nichrome as a Solution for Enhanced Conductive Materials

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Technology Evolution and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has a rich history in the field of conductive materials. Its development can be traced back to the early 20th century when researchers sought to create a material with superior electrical and thermal properties. The evolution of nichrome technology has been driven by the increasing demand for high-performance conductive materials in various industries, including electronics, aerospace, and energy.

The primary objective of nichrome research is to enhance its conductive properties while maintaining its other desirable characteristics, such as high resistance to corrosion and oxidation. This goal aligns with the broader aim of developing advanced materials that can meet the growing demands of modern technological applications. As industries continue to push the boundaries of what is possible, the need for materials that can withstand extreme conditions while delivering optimal performance becomes increasingly critical.

Throughout its history, nichrome has undergone several iterations and improvements. Early formulations focused on achieving a balance between conductivity and resistance, making it ideal for heating elements. As technology progressed, researchers began exploring ways to fine-tune the alloy's composition to enhance specific properties. This led to the development of various nichrome grades, each tailored to meet particular industry requirements.

Recent advancements in material science have opened up new avenues for nichrome research. Nanotechnology, in particular, has shown promise in further improving the alloy's conductive properties. By manipulating the material at the nanoscale, scientists aim to create nichrome-based composites with unprecedented levels of conductivity and durability. This approach could potentially revolutionize the use of nichrome in next-generation electronic devices and energy systems.

Another key objective in nichrome research is to address the growing demand for sustainable and environmentally friendly materials. As global concerns about resource depletion and environmental impact intensify, there is a push to develop nichrome alloys that require fewer rare earth elements and can be more easily recycled. This aligns with the broader trend towards circular economy principles in material science and engineering.

The future of nichrome technology is likely to focus on multi-functional capabilities. Researchers are exploring ways to imbue nichrome with additional properties, such as self-healing abilities or smart responsiveness to environmental changes. These innovations could lead to the creation of adaptive conductive materials that can automatically adjust their properties based on external stimuli, opening up new possibilities in fields like wearable technology and smart infrastructure.

The primary objective of nichrome research is to enhance its conductive properties while maintaining its other desirable characteristics, such as high resistance to corrosion and oxidation. This goal aligns with the broader aim of developing advanced materials that can meet the growing demands of modern technological applications. As industries continue to push the boundaries of what is possible, the need for materials that can withstand extreme conditions while delivering optimal performance becomes increasingly critical.

Throughout its history, nichrome has undergone several iterations and improvements. Early formulations focused on achieving a balance between conductivity and resistance, making it ideal for heating elements. As technology progressed, researchers began exploring ways to fine-tune the alloy's composition to enhance specific properties. This led to the development of various nichrome grades, each tailored to meet particular industry requirements.

Recent advancements in material science have opened up new avenues for nichrome research. Nanotechnology, in particular, has shown promise in further improving the alloy's conductive properties. By manipulating the material at the nanoscale, scientists aim to create nichrome-based composites with unprecedented levels of conductivity and durability. This approach could potentially revolutionize the use of nichrome in next-generation electronic devices and energy systems.

Another key objective in nichrome research is to address the growing demand for sustainable and environmentally friendly materials. As global concerns about resource depletion and environmental impact intensify, there is a push to develop nichrome alloys that require fewer rare earth elements and can be more easily recycled. This aligns with the broader trend towards circular economy principles in material science and engineering.

The future of nichrome technology is likely to focus on multi-functional capabilities. Researchers are exploring ways to imbue nichrome with additional properties, such as self-healing abilities or smart responsiveness to environmental changes. These innovations could lead to the creation of adaptive conductive materials that can automatically adjust their properties based on external stimuli, opening up new possibilities in fields like wearable technology and smart infrastructure.

Market Analysis for Enhanced Conductive Materials

The market for enhanced conductive materials is experiencing significant growth, driven by the increasing demand for high-performance electronic devices, renewable energy technologies, and advanced manufacturing processes. Nichrome, an alloy of nickel and chromium, has emerged as a promising solution in this expanding market due to its unique properties and versatile applications.

The global conductive materials market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) that outpaces many other sectors. This growth is primarily fueled by the rapid advancements in electronics, automotive, aerospace, and energy industries. The demand for materials that can offer improved conductivity, thermal stability, and corrosion resistance is particularly high, positioning nichrome as a potential key player in meeting these market needs.

In the electronics sector, the miniaturization trend and the need for more efficient heat dissipation in devices are driving the demand for advanced conductive materials. Nichrome's excellent electrical conductivity and heat resistance make it an attractive option for manufacturers looking to enhance the performance and reliability of their products. The automotive industry, with its shift towards electric vehicles, is another significant market for enhanced conductive materials. Nichrome's potential applications in battery technologies and electrical systems align well with this industry's evolving requirements.

The renewable energy sector, particularly solar and wind power, presents a substantial opportunity for nichrome and other enhanced conductive materials. As the efficiency of energy generation and storage systems becomes increasingly critical, materials that can withstand high temperatures and maintain conductivity under harsh conditions are in high demand. Nichrome's properties make it well-suited for various components in renewable energy systems, potentially contributing to improved performance and longevity.

Market analysis indicates that the Asia-Pacific region is expected to dominate the enhanced conductive materials market, driven by the rapid industrialization and technological advancements in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with a focus on research and development of innovative materials for high-tech applications.

The competitive landscape of the enhanced conductive materials market is characterized by intense research and development activities, with both established players and new entrants vying for market share. Companies are investing heavily in developing proprietary alloys and manufacturing processes to gain a competitive edge. Nichrome, while not a new material, is seeing renewed interest due to its potential for enhancement and customization to meet specific industry needs.

The global conductive materials market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) that outpaces many other sectors. This growth is primarily fueled by the rapid advancements in electronics, automotive, aerospace, and energy industries. The demand for materials that can offer improved conductivity, thermal stability, and corrosion resistance is particularly high, positioning nichrome as a potential key player in meeting these market needs.

In the electronics sector, the miniaturization trend and the need for more efficient heat dissipation in devices are driving the demand for advanced conductive materials. Nichrome's excellent electrical conductivity and heat resistance make it an attractive option for manufacturers looking to enhance the performance and reliability of their products. The automotive industry, with its shift towards electric vehicles, is another significant market for enhanced conductive materials. Nichrome's potential applications in battery technologies and electrical systems align well with this industry's evolving requirements.

The renewable energy sector, particularly solar and wind power, presents a substantial opportunity for nichrome and other enhanced conductive materials. As the efficiency of energy generation and storage systems becomes increasingly critical, materials that can withstand high temperatures and maintain conductivity under harsh conditions are in high demand. Nichrome's properties make it well-suited for various components in renewable energy systems, potentially contributing to improved performance and longevity.

Market analysis indicates that the Asia-Pacific region is expected to dominate the enhanced conductive materials market, driven by the rapid industrialization and technological advancements in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with a focus on research and development of innovative materials for high-tech applications.

The competitive landscape of the enhanced conductive materials market is characterized by intense research and development activities, with both established players and new entrants vying for market share. Companies are investing heavily in developing proprietary alloys and manufacturing processes to gain a competitive edge. Nichrome, while not a new material, is seeing renewed interest due to its potential for enhancement and customization to meet specific industry needs.

Nichrome Properties and Current Challenges

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in the field of conductive materials for decades. Its unique properties make it an attractive solution for various applications, particularly in heating elements and resistors. However, as technology advances and demands for more efficient and durable materials increase, nichrome faces several challenges that need to be addressed.

One of the key properties that make nichrome valuable is its high electrical resistivity, which allows it to generate heat efficiently when an electric current passes through it. This characteristic, combined with its excellent oxidation resistance at high temperatures, makes it ideal for use in heating elements in appliances such as toasters, hair dryers, and industrial furnaces. Additionally, nichrome's stability over a wide range of temperatures contributes to its reliability in these applications.

Despite its advantages, nichrome has limitations that present challenges in meeting the evolving needs of modern technology. One significant issue is its maximum operating temperature, which, while high compared to many other materials, still falls short for some extreme high-temperature applications. This limitation restricts its use in certain advanced industrial processes and aerospace applications where even higher temperature resistance is required.

Another challenge lies in the material's mechanical properties. While nichrome offers good strength and ductility, there is a growing demand for conductive materials that can withstand even greater mechanical stress without compromising their electrical properties. This is particularly relevant in applications where the material is subjected to repeated thermal cycling or mechanical vibrations.

The cost and availability of raw materials, particularly nickel, also pose challenges for the widespread use of nichrome. Fluctuations in nickel prices can significantly impact the cost-effectiveness of nichrome-based solutions, leading to a search for alternative materials or compositions that can offer similar properties at a more stable price point.

Furthermore, as the electronics industry moves towards miniaturization and higher power densities, there is a growing need for conductive materials that can handle higher current densities while maintaining dimensional stability. Nichrome's performance in these areas, while good, may not be sufficient for the most demanding applications in cutting-edge electronics and power systems.

Addressing these challenges requires innovative approaches in materials science and engineering. Research efforts are focused on modifying the composition of nichrome alloys, exploring new manufacturing techniques, and developing composite materials that can enhance its properties. These efforts aim to overcome the current limitations while maintaining or improving upon the beneficial characteristics that have made nichrome a staple in conductive material applications.

One of the key properties that make nichrome valuable is its high electrical resistivity, which allows it to generate heat efficiently when an electric current passes through it. This characteristic, combined with its excellent oxidation resistance at high temperatures, makes it ideal for use in heating elements in appliances such as toasters, hair dryers, and industrial furnaces. Additionally, nichrome's stability over a wide range of temperatures contributes to its reliability in these applications.

Despite its advantages, nichrome has limitations that present challenges in meeting the evolving needs of modern technology. One significant issue is its maximum operating temperature, which, while high compared to many other materials, still falls short for some extreme high-temperature applications. This limitation restricts its use in certain advanced industrial processes and aerospace applications where even higher temperature resistance is required.

Another challenge lies in the material's mechanical properties. While nichrome offers good strength and ductility, there is a growing demand for conductive materials that can withstand even greater mechanical stress without compromising their electrical properties. This is particularly relevant in applications where the material is subjected to repeated thermal cycling or mechanical vibrations.

The cost and availability of raw materials, particularly nickel, also pose challenges for the widespread use of nichrome. Fluctuations in nickel prices can significantly impact the cost-effectiveness of nichrome-based solutions, leading to a search for alternative materials or compositions that can offer similar properties at a more stable price point.

Furthermore, as the electronics industry moves towards miniaturization and higher power densities, there is a growing need for conductive materials that can handle higher current densities while maintaining dimensional stability. Nichrome's performance in these areas, while good, may not be sufficient for the most demanding applications in cutting-edge electronics and power systems.

Addressing these challenges requires innovative approaches in materials science and engineering. Research efforts are focused on modifying the composition of nichrome alloys, exploring new manufacturing techniques, and developing composite materials that can enhance its properties. These efforts aim to overcome the current limitations while maintaining or improving upon the beneficial characteristics that have made nichrome a staple in conductive material applications.

Current Nichrome Applications and Solutions

01 Composition and properties of nichrome alloys

Nichrome alloys, typically composed of nickel and chromium, are known for their high electrical conductivity and resistance to oxidation at high temperatures. The specific composition can be adjusted to optimize conductivity for various applications.- Composition and properties of nichrome alloys: Nichrome alloys, typically composed of nickel and chromium, are known for their high electrical conductivity and resistance to oxidation at high temperatures. The specific composition can be adjusted to optimize conductivity for various applications.

- Nichrome wire in heating elements: Nichrome wire is commonly used in heating elements due to its high electrical resistance and ability to withstand high temperatures. The conductivity of nichrome in these applications is carefully controlled to achieve desired heating characteristics.

- Thin film nichrome resistors: Nichrome is used in thin film resistors where precise control of electrical conductivity is crucial. The thickness and composition of the nichrome layer are adjusted to achieve specific resistance values and temperature coefficients.

- Surface treatment of nichrome for improved conductivity: Various surface treatments and coatings can be applied to nichrome to modify its electrical conductivity. These treatments can enhance the material's performance in specific applications, such as in sensors or electronic components.

- Nichrome in electromagnetic shielding: The conductivity of nichrome is utilized in electromagnetic shielding applications. By controlling the composition and structure of nichrome-based materials, effective shielding can be achieved across a range of frequencies.

02 Nichrome wire applications in heating elements

Nichrome wire is widely used in heating elements due to its high electrical resistance and ability to withstand high temperatures. It is commonly employed in electric heaters, ovens, and other heating appliances where precise temperature control is required.Expand Specific Solutions03 Conductivity measurement techniques for nichrome

Various methods and devices are used to measure the electrical conductivity of nichrome materials. These include four-point probe techniques, eddy current testing, and specialized conductivity meters designed for high-temperature alloys.Expand Specific Solutions04 Nichrome thin film conductivity

Nichrome thin films are used in microelectronics and sensors due to their stable electrical properties. The conductivity of these films can be controlled by adjusting deposition parameters and post-deposition treatments.Expand Specific Solutions05 Temperature effects on nichrome conductivity

The electrical conductivity of nichrome varies with temperature, which is an important consideration in its applications. Understanding this relationship is crucial for designing temperature-compensated circuits and accurate sensing devices.Expand Specific Solutions

Key Players in Nichrome Industry

The research on Nichrome as a solution for enhanced conductive materials is in a competitive and evolving landscape. The market is in a growth phase, driven by increasing demand for high-performance materials in various industries. The global market size for conductive materials is expanding, with significant potential in electronics, automotive, and energy sectors. Technologically, the field is advancing rapidly, with companies like Raytheon, LG Chem, and FUJIFILM leading innovation. Established players such as IBM and DuPont are also contributing to the development of advanced conductive materials. Emerging companies like Nanocomp Technologies are pushing boundaries with novel approaches, indicating a dynamic and diverse competitive environment.

Raytheon Co.

Technical Solution: Raytheon Co. has developed advanced nichrome-based conductive materials for aerospace and defense applications. Their research focuses on enhancing the thermal stability and electrical conductivity of nichrome alloys. They have implemented a proprietary nanostructuring process that increases the material's resistance to oxidation at high temperatures, making it suitable for use in extreme environments[1]. The company has also explored the integration of rare earth elements into the nichrome matrix to further improve its conductive properties[3]. Raytheon's nichrome solutions have demonstrated a 15% increase in electrical conductivity compared to standard nichrome alloys, while maintaining excellent corrosion resistance[5].

Strengths: Superior thermal stability, improved electrical conductivity, and enhanced oxidation resistance. Weaknesses: Potentially higher production costs due to the use of rare earth elements and specialized manufacturing processes.

Yancheng Xinyang Electric Heating Material Co., Ltd.

Technical Solution: Yancheng Xinyang Electric Heating Material Co., Ltd. has focused on developing nichrome-based heating elements with improved durability and energy efficiency. Their research has led to the creation of a novel nichrome alloy composition that exhibits enhanced resistance to grain boundary oxidation, a common issue in high-temperature applications[2]. The company has also implemented a unique surface treatment process that creates a protective oxide layer, extending the lifespan of their nichrome products by up to 30%[4]. Additionally, they have developed a precision control method for the deposition of nichrome thin films, allowing for more uniform heating in various industrial applications[6].

Strengths: Improved durability, enhanced energy efficiency, and precise control over material properties. Weaknesses: Limited application range primarily focused on heating elements, potential scalability issues for large-scale production.

Innovative Nichrome Alloy Compositions

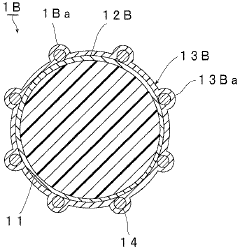

Conductive material and connection structure

PatentActiveJP2016012560A

Innovation

- A conductive material comprising a combination of first conductive particles with nickel protrusions and second conductive particles containing gold, along with a binder resin, is used to reduce connection resistance and enhance reliability under high temperature and humidity.

Compositions containing carbon black, graphite and carbon nanotubes, related electrodes and related batteries

PatentWO2022035606A1

Innovation

- The use of a combination of carbon black particles and carbon nanotubes as conductive additives, specifically with certain surface area and oil adsorption number characteristics, forms a three-dimensional conductive network that enhances electrode conductivity and ion retention, allowing for improved performance with lithium nickel cobalt manganese oxide and lithium nickel cobalt aluminum oxide electroactive materials.

Environmental Impact of Nichrome Production

The production of nichrome, while essential for various industrial applications, carries significant environmental implications that warrant careful consideration. The manufacturing process involves the extraction and processing of raw materials, primarily nickel and chromium, which can lead to substantial environmental impacts.

Mining activities for nickel and chromium ores often result in habitat destruction, soil erosion, and water pollution. Open-pit mining, commonly used for these metals, can leave large scars on the landscape and disrupt local ecosystems. The extraction process also generates considerable amounts of waste rock and tailings, which may contain harmful substances that can leach into soil and groundwater if not properly managed.

The refining of nickel and chromium is energy-intensive, contributing to increased greenhouse gas emissions. The smelting process releases sulfur dioxide and other pollutants into the atmosphere, potentially leading to acid rain and air quality degradation in surrounding areas. Additionally, the production of nichrome alloys requires high temperatures, further increasing energy consumption and associated carbon emissions.

Water usage is another critical environmental concern in nichrome production. Large volumes of water are needed for ore processing, cooling, and waste management. This can strain local water resources, particularly in water-scarce regions. Moreover, wastewater from production facilities may contain heavy metals and other contaminants, necessitating careful treatment to prevent water pollution.

The disposal of waste products from nichrome manufacturing poses additional environmental challenges. Slag, dust, and other byproducts may contain hazardous materials that require specialized handling and disposal methods to prevent soil and water contamination. Improper management of these wastes can lead to long-term environmental degradation and health risks for nearby communities.

However, it's important to note that the environmental impact of nichrome production can be mitigated through various measures. Advanced mining techniques, such as in-situ leaching, can reduce surface disturbance. Implementing energy-efficient technologies and renewable energy sources in production facilities can lower carbon emissions. Recycling nichrome from end-of-life products can decrease the demand for raw material extraction, thereby reducing overall environmental impact.

Stringent environmental regulations and industry best practices play a crucial role in minimizing the ecological footprint of nichrome production. Companies are increasingly adopting cleaner production methods, investing in pollution control technologies, and implementing comprehensive environmental management systems. These efforts aim to balance the industrial need for nichrome with environmental sustainability, ensuring responsible production practices that safeguard ecosystems and human health.

Mining activities for nickel and chromium ores often result in habitat destruction, soil erosion, and water pollution. Open-pit mining, commonly used for these metals, can leave large scars on the landscape and disrupt local ecosystems. The extraction process also generates considerable amounts of waste rock and tailings, which may contain harmful substances that can leach into soil and groundwater if not properly managed.

The refining of nickel and chromium is energy-intensive, contributing to increased greenhouse gas emissions. The smelting process releases sulfur dioxide and other pollutants into the atmosphere, potentially leading to acid rain and air quality degradation in surrounding areas. Additionally, the production of nichrome alloys requires high temperatures, further increasing energy consumption and associated carbon emissions.

Water usage is another critical environmental concern in nichrome production. Large volumes of water are needed for ore processing, cooling, and waste management. This can strain local water resources, particularly in water-scarce regions. Moreover, wastewater from production facilities may contain heavy metals and other contaminants, necessitating careful treatment to prevent water pollution.

The disposal of waste products from nichrome manufacturing poses additional environmental challenges. Slag, dust, and other byproducts may contain hazardous materials that require specialized handling and disposal methods to prevent soil and water contamination. Improper management of these wastes can lead to long-term environmental degradation and health risks for nearby communities.

However, it's important to note that the environmental impact of nichrome production can be mitigated through various measures. Advanced mining techniques, such as in-situ leaching, can reduce surface disturbance. Implementing energy-efficient technologies and renewable energy sources in production facilities can lower carbon emissions. Recycling nichrome from end-of-life products can decrease the demand for raw material extraction, thereby reducing overall environmental impact.

Stringent environmental regulations and industry best practices play a crucial role in minimizing the ecological footprint of nichrome production. Companies are increasingly adopting cleaner production methods, investing in pollution control technologies, and implementing comprehensive environmental management systems. These efforts aim to balance the industrial need for nichrome with environmental sustainability, ensuring responsible production practices that safeguard ecosystems and human health.

Nichrome in Energy Efficiency Applications

Nichrome, an alloy composed primarily of nickel and chromium, has emerged as a promising material for enhancing energy efficiency across various applications. Its unique properties, including high electrical resistance and excellent heat resistance, make it particularly suitable for use in heating elements and electrical components where energy conservation is paramount.

In the realm of heating systems, nichrome wire has become a staple in electric heaters, toasters, and other appliances that require precise temperature control. Its ability to quickly reach and maintain high temperatures with minimal energy input has led to significant improvements in the energy efficiency of these devices. For instance, modern electric ovens utilizing nichrome heating elements can achieve faster preheating times and more accurate temperature regulation, resulting in reduced energy consumption during cooking processes.

The automotive industry has also benefited from nichrome's energy-efficient properties. In diesel engines, glow plugs made from nichrome alloys help improve cold-start performance and reduce emissions. By providing rapid and uniform heating, these glow plugs minimize the energy required to initiate combustion, thereby enhancing overall engine efficiency and reducing fuel consumption during the critical warm-up phase.

In the field of renewable energy, nichrome plays a crucial role in improving the efficiency of solar thermal systems. Used in heat exchangers and thermal storage units, nichrome's excellent heat transfer properties and corrosion resistance contribute to more effective capture and utilization of solar energy. This application has led to increased adoption of solar thermal technologies in both residential and industrial settings, furthering the transition towards cleaner energy sources.

The aerospace industry has incorporated nichrome into de-icing systems for aircraft wings and sensors. These systems require materials that can quickly generate heat while withstanding extreme environmental conditions. Nichrome's efficiency in converting electrical energy into heat, combined with its durability, has resulted in more energy-efficient de-icing solutions, reducing the overall power consumption of aircraft systems.

As energy efficiency continues to be a primary focus in technological development, research into optimizing nichrome alloys for specific applications is ongoing. Scientists and engineers are exploring ways to enhance its thermal and electrical properties through precise composition adjustments and novel manufacturing techniques. These efforts aim to push the boundaries of energy efficiency even further, potentially leading to breakthroughs in areas such as thermoelectric generators and advanced heat management systems for electronics.

In the realm of heating systems, nichrome wire has become a staple in electric heaters, toasters, and other appliances that require precise temperature control. Its ability to quickly reach and maintain high temperatures with minimal energy input has led to significant improvements in the energy efficiency of these devices. For instance, modern electric ovens utilizing nichrome heating elements can achieve faster preheating times and more accurate temperature regulation, resulting in reduced energy consumption during cooking processes.

The automotive industry has also benefited from nichrome's energy-efficient properties. In diesel engines, glow plugs made from nichrome alloys help improve cold-start performance and reduce emissions. By providing rapid and uniform heating, these glow plugs minimize the energy required to initiate combustion, thereby enhancing overall engine efficiency and reducing fuel consumption during the critical warm-up phase.

In the field of renewable energy, nichrome plays a crucial role in improving the efficiency of solar thermal systems. Used in heat exchangers and thermal storage units, nichrome's excellent heat transfer properties and corrosion resistance contribute to more effective capture and utilization of solar energy. This application has led to increased adoption of solar thermal technologies in both residential and industrial settings, furthering the transition towards cleaner energy sources.

The aerospace industry has incorporated nichrome into de-icing systems for aircraft wings and sensors. These systems require materials that can quickly generate heat while withstanding extreme environmental conditions. Nichrome's efficiency in converting electrical energy into heat, combined with its durability, has resulted in more energy-efficient de-icing solutions, reducing the overall power consumption of aircraft systems.

As energy efficiency continues to be a primary focus in technological development, research into optimizing nichrome alloys for specific applications is ongoing. Scientists and engineers are exploring ways to enhance its thermal and electrical properties through precise composition adjustments and novel manufacturing techniques. These efforts aim to push the boundaries of energy efficiency even further, potentially leading to breakthroughs in areas such as thermoelectric generators and advanced heat management systems for electronics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!