The Role of Vacuum Pumps in Novel Biocompatible Material Production

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech Evolution in Biomaterials

The evolution of vacuum pump technology in biomaterials production has been marked by significant advancements over the past few decades. Initially, vacuum pumps were primarily used for basic deaeration processes in material synthesis. However, as the demand for more sophisticated biocompatible materials grew, so did the requirements for vacuum technology.

In the early stages, rotary vane pumps dominated the field, offering reliable performance for general vacuum applications. These pumps were sufficient for creating low-pressure environments necessary for basic material processing. As the complexity of biomaterials increased, the need for higher vacuum levels and cleaner processing environments became apparent.

The introduction of oil-free scroll pumps in the 1990s marked a significant milestone. These pumps eliminated the risk of oil contamination, a critical factor in biocompatible material production. This innovation allowed for the creation of purer materials with enhanced biocompatibility, opening new possibilities in medical implants and tissue engineering.

The early 2000s saw the rise of turbomolecular pumps in biomaterial research and production. These high-speed pumps could achieve ultra-high vacuum levels, enabling more precise control over material properties at the molecular level. This advancement was particularly crucial for developing nanostructured biomaterials with specific surface characteristics.

Concurrent with pump technology improvements, vacuum measurement and control systems also evolved. The integration of mass spectrometers and residual gas analyzers allowed for real-time monitoring of gas composition during material processing. This capability ensured the purity of the vacuum environment and the resulting biomaterials.

In recent years, the focus has shifted towards energy efficiency and sustainability. Modern vacuum pumps used in biomaterial production are designed to consume less power while maintaining high performance. Additionally, the development of smart pumping systems with predictive maintenance capabilities has improved the reliability and uptime of production processes.

The latest frontier in vacuum pump technology for biomaterials involves the integration of artificial intelligence and machine learning. These advanced systems can optimize vacuum conditions in real-time based on material properties and processing requirements, leading to more consistent and higher-quality biocompatible materials.

As we look to the future, emerging trends point towards the development of compact, modular vacuum systems tailored specifically for biomaterial production. These systems promise to offer greater flexibility and scalability, potentially revolutionizing the field of personalized medicine and on-demand biomaterial manufacturing.

In the early stages, rotary vane pumps dominated the field, offering reliable performance for general vacuum applications. These pumps were sufficient for creating low-pressure environments necessary for basic material processing. As the complexity of biomaterials increased, the need for higher vacuum levels and cleaner processing environments became apparent.

The introduction of oil-free scroll pumps in the 1990s marked a significant milestone. These pumps eliminated the risk of oil contamination, a critical factor in biocompatible material production. This innovation allowed for the creation of purer materials with enhanced biocompatibility, opening new possibilities in medical implants and tissue engineering.

The early 2000s saw the rise of turbomolecular pumps in biomaterial research and production. These high-speed pumps could achieve ultra-high vacuum levels, enabling more precise control over material properties at the molecular level. This advancement was particularly crucial for developing nanostructured biomaterials with specific surface characteristics.

Concurrent with pump technology improvements, vacuum measurement and control systems also evolved. The integration of mass spectrometers and residual gas analyzers allowed for real-time monitoring of gas composition during material processing. This capability ensured the purity of the vacuum environment and the resulting biomaterials.

In recent years, the focus has shifted towards energy efficiency and sustainability. Modern vacuum pumps used in biomaterial production are designed to consume less power while maintaining high performance. Additionally, the development of smart pumping systems with predictive maintenance capabilities has improved the reliability and uptime of production processes.

The latest frontier in vacuum pump technology for biomaterials involves the integration of artificial intelligence and machine learning. These advanced systems can optimize vacuum conditions in real-time based on material properties and processing requirements, leading to more consistent and higher-quality biocompatible materials.

As we look to the future, emerging trends point towards the development of compact, modular vacuum systems tailored specifically for biomaterial production. These systems promise to offer greater flexibility and scalability, potentially revolutionizing the field of personalized medicine and on-demand biomaterial manufacturing.

Biocompatible Material Market Trends

The biocompatible material market has been experiencing significant growth in recent years, driven by increasing demand in healthcare, pharmaceuticals, and medical devices. This trend is expected to continue as the global population ages and healthcare needs expand. The market for biocompatible materials is projected to reach substantial value in the coming years, with a compound annual growth rate outpacing many other sectors in the medical industry.

One of the key factors fueling this growth is the rising prevalence of chronic diseases and the subsequent need for advanced medical treatments and implants. Cardiovascular diseases, orthopedic conditions, and dental problems are among the primary areas driving the demand for biocompatible materials. Additionally, the increasing adoption of minimally invasive surgical procedures has created a surge in demand for specialized biocompatible materials that can be used in these advanced techniques.

The field of tissue engineering and regenerative medicine has also emerged as a significant contributor to the biocompatible materials market. As research in stem cell therapy and organ regeneration progresses, the need for sophisticated biocompatible scaffolds and matrices has grown substantially. This has led to the development of novel biomaterials that can support cell growth and tissue regeneration while maintaining biocompatibility.

In the pharmaceutical sector, the trend towards personalized medicine and targeted drug delivery systems has spurred innovation in biocompatible materials. Nanoparticles, hydrogels, and other advanced delivery systems require materials that can interact safely with biological systems while effectively carrying and releasing therapeutic agents. This has opened up new avenues for research and development in the biocompatible materials space.

The market is also seeing a shift towards more sustainable and eco-friendly biocompatible materials. With increasing environmental concerns, there is a growing demand for materials that are not only safe for human use but also have minimal ecological impact. This has led to research into biodegradable polymers and materials derived from renewable sources, aligning with broader sustainability goals in the healthcare industry.

Geographically, North America and Europe continue to dominate the biocompatible materials market, owing to their advanced healthcare infrastructure and significant investment in research and development. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by improving healthcare access, increasing medical tourism, and rising disposable incomes in countries like China and India.

As the market evolves, there is an increasing focus on developing multi-functional biocompatible materials that can serve multiple purposes within a single application. This trend is particularly evident in the field of smart implants and biosensors, where materials need to be not only biocompatible but also capable of interacting with biological systems in sophisticated ways.

One of the key factors fueling this growth is the rising prevalence of chronic diseases and the subsequent need for advanced medical treatments and implants. Cardiovascular diseases, orthopedic conditions, and dental problems are among the primary areas driving the demand for biocompatible materials. Additionally, the increasing adoption of minimally invasive surgical procedures has created a surge in demand for specialized biocompatible materials that can be used in these advanced techniques.

The field of tissue engineering and regenerative medicine has also emerged as a significant contributor to the biocompatible materials market. As research in stem cell therapy and organ regeneration progresses, the need for sophisticated biocompatible scaffolds and matrices has grown substantially. This has led to the development of novel biomaterials that can support cell growth and tissue regeneration while maintaining biocompatibility.

In the pharmaceutical sector, the trend towards personalized medicine and targeted drug delivery systems has spurred innovation in biocompatible materials. Nanoparticles, hydrogels, and other advanced delivery systems require materials that can interact safely with biological systems while effectively carrying and releasing therapeutic agents. This has opened up new avenues for research and development in the biocompatible materials space.

The market is also seeing a shift towards more sustainable and eco-friendly biocompatible materials. With increasing environmental concerns, there is a growing demand for materials that are not only safe for human use but also have minimal ecological impact. This has led to research into biodegradable polymers and materials derived from renewable sources, aligning with broader sustainability goals in the healthcare industry.

Geographically, North America and Europe continue to dominate the biocompatible materials market, owing to their advanced healthcare infrastructure and significant investment in research and development. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by improving healthcare access, increasing medical tourism, and rising disposable incomes in countries like China and India.

As the market evolves, there is an increasing focus on developing multi-functional biocompatible materials that can serve multiple purposes within a single application. This trend is particularly evident in the field of smart implants and biosensors, where materials need to be not only biocompatible but also capable of interacting with biological systems in sophisticated ways.

Vacuum Technology Challenges in Biomaterial Synthesis

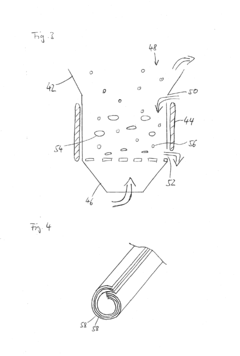

The synthesis of novel biocompatible materials presents unique challenges in vacuum technology, particularly in maintaining precise environmental conditions essential for material integrity and purity. Vacuum pumps play a crucial role in this process, serving as the cornerstone for creating and sustaining the controlled atmospheres required for biomaterial production.

One of the primary challenges lies in achieving and maintaining ultra-high vacuum levels necessary for certain biomaterial synthesis processes. These extreme vacuum conditions are critical for preventing contamination and ensuring the desired molecular structure and properties of the final product. However, reaching and sustaining such low pressures demands advanced pump technologies and meticulous system design.

Another significant hurdle is the management of outgassing during the synthesis process. As biomaterials often involve complex organic compounds, the potential for material degradation or unwanted chemical reactions due to residual gases is high. This necessitates the implementation of sophisticated pumping strategies and gas handling techniques to mitigate these risks effectively.

The need for cleanliness in biocompatible material production poses additional challenges for vacuum technology. Traditional pump oils and lubricants can introduce contaminants, compromising the biocompatibility of the synthesized materials. This has led to the development and adoption of oil-free and dry pumping technologies, which, while solving the contamination issue, often come with their own set of operational challenges and limitations.

Temperature control during vacuum processes is another critical aspect that demands innovative solutions. Many biomaterials are temperature-sensitive, requiring precise thermal management throughout the synthesis process. This necessitates the integration of advanced cooling systems with vacuum pumps, adding another layer of complexity to the overall system design.

The scalability of vacuum systems for industrial-scale biomaterial production presents yet another challenge. As processes move from laboratory to production scales, maintaining consistent vacuum quality and performance across larger volumes becomes increasingly difficult. This scaling issue often requires re-engineering of pump configurations and vacuum chamber designs to ensure uniform conditions throughout the production environment.

Lastly, the dynamic nature of biomaterial synthesis processes often requires vacuum systems capable of rapid pressure changes and precise control over gas composition. This demand for flexibility and responsiveness in vacuum technology pushes the boundaries of current pump designs and control systems, driving innovation in adaptive and intelligent vacuum solutions.

One of the primary challenges lies in achieving and maintaining ultra-high vacuum levels necessary for certain biomaterial synthesis processes. These extreme vacuum conditions are critical for preventing contamination and ensuring the desired molecular structure and properties of the final product. However, reaching and sustaining such low pressures demands advanced pump technologies and meticulous system design.

Another significant hurdle is the management of outgassing during the synthesis process. As biomaterials often involve complex organic compounds, the potential for material degradation or unwanted chemical reactions due to residual gases is high. This necessitates the implementation of sophisticated pumping strategies and gas handling techniques to mitigate these risks effectively.

The need for cleanliness in biocompatible material production poses additional challenges for vacuum technology. Traditional pump oils and lubricants can introduce contaminants, compromising the biocompatibility of the synthesized materials. This has led to the development and adoption of oil-free and dry pumping technologies, which, while solving the contamination issue, often come with their own set of operational challenges and limitations.

Temperature control during vacuum processes is another critical aspect that demands innovative solutions. Many biomaterials are temperature-sensitive, requiring precise thermal management throughout the synthesis process. This necessitates the integration of advanced cooling systems with vacuum pumps, adding another layer of complexity to the overall system design.

The scalability of vacuum systems for industrial-scale biomaterial production presents yet another challenge. As processes move from laboratory to production scales, maintaining consistent vacuum quality and performance across larger volumes becomes increasingly difficult. This scaling issue often requires re-engineering of pump configurations and vacuum chamber designs to ensure uniform conditions throughout the production environment.

Lastly, the dynamic nature of biomaterial synthesis processes often requires vacuum systems capable of rapid pressure changes and precise control over gas composition. This demand for flexibility and responsiveness in vacuum technology pushes the boundaries of current pump designs and control systems, driving innovation in adaptive and intelligent vacuum solutions.

Current Vacuum Solutions for Biomaterials

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed. These pumps are designed to handle specific gases and maintain ultra-high vacuum levels required in semiconductor fabrication. Features may include corrosion-resistant materials, contamination control mechanisms, and integration with process control systems.

- Energy-efficient vacuum pump systems: Innovations in vacuum pump technology have focused on improving energy efficiency. These developments include the use of variable speed drives, advanced motor designs, and intelligent control systems. Such improvements result in reduced power consumption, lower operating costs, and decreased environmental impact.

- Multi-stage vacuum pump configurations: Multi-stage vacuum pump designs have been created to achieve higher vacuum levels and improved pumping performance. These configurations typically combine different pump types or multiple pumping stages in series. This approach allows for efficient operation across a wide range of pressure conditions and applications.

- Vacuum pump noise reduction techniques: Various methods have been developed to reduce noise levels in vacuum pump operation. These techniques include acoustic enclosures, vibration isolation systems, and optimized pump designs that minimize noise generation. Such innovations contribute to improved working environments and compliance with noise regulations in industrial settings.

02 Application-specific vacuum pump configurations

Vacuum pumps have been developed for specific applications, such as semiconductor manufacturing, medical devices, and industrial processes. These specialized configurations may incorporate features like contamination control, precise pressure regulation, or compatibility with certain gases or materials to meet the unique requirements of different industries.Expand Specific Solutions03 Integration of vacuum pumps in larger systems

Vacuum pumps are often integrated into larger systems or equipment to provide necessary vacuum conditions. This integration may involve custom designs, control interfaces, or modular configurations to seamlessly incorporate the pump into the overall system architecture, enhancing functionality and efficiency.Expand Specific Solutions04 Energy-efficient vacuum pump technologies

Efforts have been made to develop energy-efficient vacuum pump technologies, focusing on reducing power consumption while maintaining performance. These advancements may include improved motor designs, intelligent control systems, or novel pumping mechanisms that optimize energy usage and minimize operational costs.Expand Specific Solutions05 Maintenance and reliability enhancements

Innovations in vacuum pump design have addressed maintenance and reliability concerns. These improvements may include self-diagnostic features, easy-to-service components, or materials that enhance durability and extend operational lifetimes. Such advancements aim to reduce downtime and maintenance costs associated with vacuum pump systems.Expand Specific Solutions

Key Vacuum Pump Manufacturers

The vacuum pump market for novel biocompatible material production is in a growth phase, driven by increasing demand in healthcare and biotechnology sectors. The global market size is estimated to be in the billions, with steady annual growth. Technologically, the field is moderately mature but continues to evolve, with companies like Pfeiffer Vacuum GmbH, Edwards Ltd., and Leybold AG leading innovation. These firms are developing more efficient, precise, and specialized vacuum pumps tailored for biocompatible material applications. Emerging players such as IDEX Health & Science LLC are also making significant contributions, particularly in integrating vacuum technology with microfluidics and optics for advanced biomedical research and production processes.

Pfeiffer Vacuum GmbH

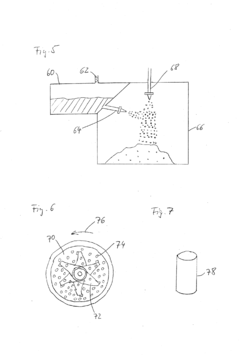

Technical Solution: Pfeiffer Vacuum GmbH has developed advanced vacuum pump technologies specifically tailored for biocompatible material production. Their HiPace turbomolecular pumps utilize a hybrid bearing system, combining ceramic ball bearings and permanent magnetic bearings, to achieve high pumping speeds and ultimate pressures[1]. This technology enables the creation of ultra-clean environments essential for producing novel biocompatible materials. The company has also introduced the HiScroll oil-free scroll pump series, which provides contamination-free vacuum conditions crucial for sensitive biomedical applications[2]. These pumps incorporate a hermetically sealed pumping chamber and tip seal technology, ensuring no oil or particle contamination in the process[3].

Strengths: High pumping efficiency, contamination-free operation, and adaptability to various biomedical applications. Weaknesses: Higher initial cost compared to traditional vacuum pumps and potential complexity in maintenance for advanced models.

Edwards Ltd.

Technical Solution: Edwards Ltd. has pioneered the development of dry pumping technology for biocompatible material production. Their nXDS scroll pump series utilizes an innovative tip-seal design that significantly extends the pump's operational life and maintains consistent performance over time[4]. This technology is particularly beneficial in continuous bioprocessing applications. Edwards has also introduced the iXM series of dry multi-stage roots pumps, which offer high pumping speeds and deep ultimate vacuum levels without the risk of oil contamination[5]. These pumps incorporate advanced rotor designs and intelligent control systems, allowing for precise vacuum control in critical biocompatible material synthesis processes[6].

Strengths: Long operational life, consistent performance, and suitability for continuous bioprocessing. Weaknesses: Higher power consumption in some models and potential limitations in handling certain corrosive gases used in biocompatible material production.

Innovative Vacuum Pump Designs

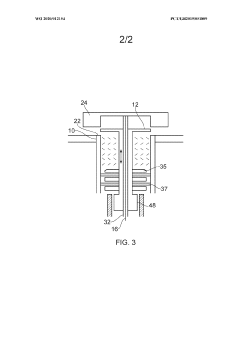

Vacuum pump with through channel and vacuum chamber

PatentWO2020012154A1

Innovation

- A vacuum pump design featuring a rotor, stator, and a controllable valve plate with an axial passage for central substrate mounting and power connections, allowing for uniform gas flow and fast pressure control, along with the option of magnetic levitation for rotor positioning and actuator-controlled axial movement of the valve plate to optimize inlet conductance.

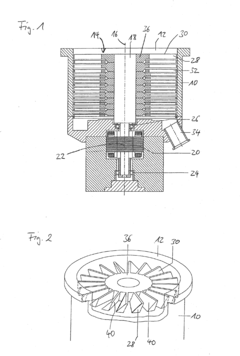

Vacuum pump

PatentActiveEP2740943A2

Innovation

- Incorporating nanoparticles into the material of pump components, such as rotor disks, to enhance mechanical and thermal resistance, using a metal matrix with nanoparticles like carbon nanotubes that improve strength and heat resistance while maintaining metallic properties, allowing for increased operational reliability and longevity.

Regulatory Framework for Medical Device Manufacturing

The regulatory framework for medical device manufacturing plays a crucial role in ensuring the safety and efficacy of novel biocompatible materials produced using vacuum pump technology. This framework encompasses a complex set of guidelines, standards, and regulations that manufacturers must adhere to throughout the production process.

In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing medical device manufacturing. The FDA classifies medical devices into three categories based on their risk level and intended use. Class I devices are considered low-risk and are subject to general controls, while Class II devices require special controls and premarket notification. Class III devices, which are often implantable or life-sustaining, undergo the most rigorous premarket approval process.

For manufacturers utilizing vacuum pumps in the production of biocompatible materials, compliance with Good Manufacturing Practices (GMP) is essential. GMP guidelines ensure that products are consistently produced and controlled according to quality standards. These practices cover various aspects of production, including facility design, equipment maintenance, personnel training, and documentation.

The International Organization for Standardization (ISO) provides several standards relevant to medical device manufacturing. ISO 13485, for instance, specifies requirements for a quality management system in the medical device industry. This standard is particularly important for manufacturers using vacuum pumps in biocompatible material production, as it addresses risk management and design control processes.

In the European Union, the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) govern the production and marketing of medical devices. These regulations emphasize post-market surveillance and require manufacturers to implement a quality management system. For vacuum pump-assisted biocompatible material production, compliance with these regulations is crucial for market access in the EU.

Manufacturers must also consider environmental regulations when using vacuum pumps in production processes. Many countries have specific guidelines for the handling and disposal of potentially hazardous materials used in medical device manufacturing. Additionally, energy efficiency standards may apply to the operation of vacuum pumps in production facilities.

As the field of biocompatible materials continues to evolve, regulatory frameworks are adapting to address new challenges. Emerging technologies, such as 3D printing and nanotechnology, are pushing regulators to develop new guidelines for novel manufacturing processes. Manufacturers using vacuum pumps in biocompatible material production must stay informed about these regulatory developments to ensure ongoing compliance and market access.

In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing medical device manufacturing. The FDA classifies medical devices into three categories based on their risk level and intended use. Class I devices are considered low-risk and are subject to general controls, while Class II devices require special controls and premarket notification. Class III devices, which are often implantable or life-sustaining, undergo the most rigorous premarket approval process.

For manufacturers utilizing vacuum pumps in the production of biocompatible materials, compliance with Good Manufacturing Practices (GMP) is essential. GMP guidelines ensure that products are consistently produced and controlled according to quality standards. These practices cover various aspects of production, including facility design, equipment maintenance, personnel training, and documentation.

The International Organization for Standardization (ISO) provides several standards relevant to medical device manufacturing. ISO 13485, for instance, specifies requirements for a quality management system in the medical device industry. This standard is particularly important for manufacturers using vacuum pumps in biocompatible material production, as it addresses risk management and design control processes.

In the European Union, the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) govern the production and marketing of medical devices. These regulations emphasize post-market surveillance and require manufacturers to implement a quality management system. For vacuum pump-assisted biocompatible material production, compliance with these regulations is crucial for market access in the EU.

Manufacturers must also consider environmental regulations when using vacuum pumps in production processes. Many countries have specific guidelines for the handling and disposal of potentially hazardous materials used in medical device manufacturing. Additionally, energy efficiency standards may apply to the operation of vacuum pumps in production facilities.

As the field of biocompatible materials continues to evolve, regulatory frameworks are adapting to address new challenges. Emerging technologies, such as 3D printing and nanotechnology, are pushing regulators to develop new guidelines for novel manufacturing processes. Manufacturers using vacuum pumps in biocompatible material production must stay informed about these regulatory developments to ensure ongoing compliance and market access.

Environmental Impact of Vacuum Processes

The environmental impact of vacuum processes in the production of novel biocompatible materials is a critical consideration for sustainable manufacturing practices. Vacuum pumps, while essential for creating controlled environments, can contribute significantly to energy consumption and waste generation. The primary environmental concerns associated with vacuum processes include high energy usage, potential emissions of harmful gases, and the disposal of pump oils and other consumables.

Energy consumption is a major factor in the environmental footprint of vacuum-based production methods. High-performance vacuum pumps often require substantial electrical power to operate, particularly when maintaining ultra-high vacuum conditions necessary for certain biocompatible material synthesis processes. This energy demand can lead to increased carbon emissions if the power source is not from renewable energy. Manufacturers are increasingly focusing on developing energy-efficient pump designs and implementing smart control systems to optimize power usage during production cycles.

Emissions from vacuum processes can also pose environmental risks. While vacuum systems are designed to contain and control gases, leaks or improper handling of process gases can result in the release of potentially harmful substances into the atmosphere. This is particularly concerning when working with reactive or toxic gases that may be used in the production of specialized biocompatible materials. Stringent containment protocols and advanced gas scrubbing systems are essential to mitigate these risks and ensure compliance with environmental regulations.

The use of pump oils and lubricants in vacuum systems presents another environmental challenge. These substances require periodic replacement and proper disposal to prevent contamination of soil and water resources. The shift towards dry pump technologies in recent years has helped reduce the reliance on oil-based systems, thereby minimizing this particular environmental concern. However, the production and disposal of dry pump components still require careful consideration from a lifecycle perspective.

Water consumption is an often-overlooked aspect of vacuum processes in biocompatible material production. Cooling systems for vacuum pumps can consume significant amounts of water, especially in large-scale industrial applications. Implementing closed-loop cooling systems and water recycling technologies can help reduce the overall water footprint of these processes.

As the demand for biocompatible materials grows, the industry is increasingly focusing on developing more environmentally friendly vacuum technologies. This includes the integration of renewable energy sources to power vacuum systems, the implementation of heat recovery systems to utilize waste heat, and the development of more efficient pump designs that require less maintenance and have longer operational lifespans. Additionally, the adoption of lifecycle assessment methodologies is helping manufacturers to identify and address the environmental impacts across the entire production chain, from raw material extraction to end-of-life disposal of equipment.

Energy consumption is a major factor in the environmental footprint of vacuum-based production methods. High-performance vacuum pumps often require substantial electrical power to operate, particularly when maintaining ultra-high vacuum conditions necessary for certain biocompatible material synthesis processes. This energy demand can lead to increased carbon emissions if the power source is not from renewable energy. Manufacturers are increasingly focusing on developing energy-efficient pump designs and implementing smart control systems to optimize power usage during production cycles.

Emissions from vacuum processes can also pose environmental risks. While vacuum systems are designed to contain and control gases, leaks or improper handling of process gases can result in the release of potentially harmful substances into the atmosphere. This is particularly concerning when working with reactive or toxic gases that may be used in the production of specialized biocompatible materials. Stringent containment protocols and advanced gas scrubbing systems are essential to mitigate these risks and ensure compliance with environmental regulations.

The use of pump oils and lubricants in vacuum systems presents another environmental challenge. These substances require periodic replacement and proper disposal to prevent contamination of soil and water resources. The shift towards dry pump technologies in recent years has helped reduce the reliance on oil-based systems, thereby minimizing this particular environmental concern. However, the production and disposal of dry pump components still require careful consideration from a lifecycle perspective.

Water consumption is an often-overlooked aspect of vacuum processes in biocompatible material production. Cooling systems for vacuum pumps can consume significant amounts of water, especially in large-scale industrial applications. Implementing closed-loop cooling systems and water recycling technologies can help reduce the overall water footprint of these processes.

As the demand for biocompatible materials grows, the industry is increasingly focusing on developing more environmentally friendly vacuum technologies. This includes the integration of renewable energy sources to power vacuum systems, the implementation of heat recovery systems to utilize waste heat, and the development of more efficient pump designs that require less maintenance and have longer operational lifespans. Additionally, the adoption of lifecycle assessment methodologies is helping manufacturers to identify and address the environmental impacts across the entire production chain, from raw material extraction to end-of-life disposal of equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!