Vacuum Pump Design for Enhanced Biosensor Technology

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution

Vacuum pump technology has undergone significant evolution since its inception, playing a crucial role in the development of biosensor technology. The journey began with simple mechanical pumps in the early 20th century, which provided basic vacuum capabilities but were limited in their ability to achieve high vacuum levels required for sensitive biosensor applications.

The 1950s saw the introduction of diffusion pumps, which marked a significant leap forward in vacuum technology. These pumps utilized heated oil vapor to create a high-speed jet that trapped gas molecules, allowing for much higher vacuum levels. This advancement enabled more precise biosensor measurements and expanded the range of detectable analytes.

The 1960s and 1970s brought about the development of turbomolecular pumps, which revolutionized vacuum technology. These pumps use high-speed rotors to impart momentum to gas molecules, effectively pumping them out of the system. Turbomolecular pumps offered cleaner, oil-free vacuums, which was particularly beneficial for biosensor applications requiring ultra-high purity environments.

In the 1980s and 1990s, cryogenic pumps emerged as a powerful tool for achieving ultra-high vacuums. By condensing gases onto extremely cold surfaces, these pumps could maintain exceptionally low pressures, further enhancing the sensitivity and reliability of biosensors.

The turn of the millennium saw the rise of dry pumps, which eliminated the need for oil or other lubricants. This development was particularly significant for biosensor technology, as it reduced the risk of sample contamination and improved overall system cleanliness.

Recent years have witnessed the integration of smart technologies into vacuum pump design. IoT-enabled pumps with real-time monitoring and predictive maintenance capabilities have enhanced the reliability and efficiency of biosensor systems. Additionally, the miniaturization of vacuum pumps has allowed for the development of portable and point-of-care biosensor devices, expanding their applications in field diagnostics and personalized medicine.

The latest frontier in vacuum pump evolution for biosensor technology involves the development of hybrid systems that combine multiple pumping technologies. These systems aim to optimize vacuum performance across different pressure ranges, providing tailored solutions for specific biosensor applications. Furthermore, ongoing research into novel materials and nanotechnology promises to yield even more compact, efficient, and precise vacuum pumps, potentially revolutionizing the field of biosensor technology in the coming years.

The 1950s saw the introduction of diffusion pumps, which marked a significant leap forward in vacuum technology. These pumps utilized heated oil vapor to create a high-speed jet that trapped gas molecules, allowing for much higher vacuum levels. This advancement enabled more precise biosensor measurements and expanded the range of detectable analytes.

The 1960s and 1970s brought about the development of turbomolecular pumps, which revolutionized vacuum technology. These pumps use high-speed rotors to impart momentum to gas molecules, effectively pumping them out of the system. Turbomolecular pumps offered cleaner, oil-free vacuums, which was particularly beneficial for biosensor applications requiring ultra-high purity environments.

In the 1980s and 1990s, cryogenic pumps emerged as a powerful tool for achieving ultra-high vacuums. By condensing gases onto extremely cold surfaces, these pumps could maintain exceptionally low pressures, further enhancing the sensitivity and reliability of biosensors.

The turn of the millennium saw the rise of dry pumps, which eliminated the need for oil or other lubricants. This development was particularly significant for biosensor technology, as it reduced the risk of sample contamination and improved overall system cleanliness.

Recent years have witnessed the integration of smart technologies into vacuum pump design. IoT-enabled pumps with real-time monitoring and predictive maintenance capabilities have enhanced the reliability and efficiency of biosensor systems. Additionally, the miniaturization of vacuum pumps has allowed for the development of portable and point-of-care biosensor devices, expanding their applications in field diagnostics and personalized medicine.

The latest frontier in vacuum pump evolution for biosensor technology involves the development of hybrid systems that combine multiple pumping technologies. These systems aim to optimize vacuum performance across different pressure ranges, providing tailored solutions for specific biosensor applications. Furthermore, ongoing research into novel materials and nanotechnology promises to yield even more compact, efficient, and precise vacuum pumps, potentially revolutionizing the field of biosensor technology in the coming years.

Biosensor Market Trends

The biosensor market has been experiencing significant growth and transformation in recent years, driven by advancements in technology, increasing healthcare needs, and a growing focus on personalized medicine. This market is characterized by a diverse range of applications, including medical diagnostics, environmental monitoring, food safety, and industrial process control.

In the healthcare sector, biosensors have gained substantial traction due to their ability to provide rapid, accurate, and cost-effective diagnostic solutions. The rising prevalence of chronic diseases, such as diabetes and cardiovascular disorders, has fueled the demand for point-of-care testing devices that utilize biosensor technology. This trend is expected to continue as healthcare systems worldwide seek to improve patient outcomes while reducing overall costs.

The environmental monitoring segment has also witnessed considerable growth, with biosensors being increasingly employed to detect pollutants, pathogens, and toxins in air, water, and soil. This expansion is driven by stricter environmental regulations and a growing public awareness of the importance of environmental protection.

In the food industry, biosensors are gaining prominence as tools for ensuring food safety and quality. The ability of these devices to rapidly detect contaminants, allergens, and pathogens has made them invaluable in maintaining food supply chain integrity and meeting regulatory requirements.

The industrial sector is another area where biosensors are finding increased applications, particularly in process monitoring and quality control. Industries such as pharmaceuticals, biotechnology, and chemical manufacturing are adopting biosensor technology to enhance production efficiency and ensure product quality.

A key trend shaping the biosensor market is the integration of advanced technologies such as nanotechnology, microfluidics, and artificial intelligence. These innovations are enabling the development of more sensitive, specific, and user-friendly biosensor devices. Additionally, the miniaturization of biosensors is opening up new possibilities for wearable and implantable devices, further expanding the market potential.

The global biosensor market is projected to maintain strong growth in the coming years. Factors contributing to this growth include technological advancements, increasing investment in research and development, and the expanding applications of biosensors across various industries. The market is also benefiting from the growing trend towards personalized medicine and the increasing adoption of point-of-care diagnostics.

However, challenges such as high development costs, regulatory hurdles, and the need for skilled personnel to operate complex biosensor systems may impact market growth. Despite these challenges, the overall outlook for the biosensor market remains positive, with opportunities for innovation and market expansion across multiple sectors.

In the healthcare sector, biosensors have gained substantial traction due to their ability to provide rapid, accurate, and cost-effective diagnostic solutions. The rising prevalence of chronic diseases, such as diabetes and cardiovascular disorders, has fueled the demand for point-of-care testing devices that utilize biosensor technology. This trend is expected to continue as healthcare systems worldwide seek to improve patient outcomes while reducing overall costs.

The environmental monitoring segment has also witnessed considerable growth, with biosensors being increasingly employed to detect pollutants, pathogens, and toxins in air, water, and soil. This expansion is driven by stricter environmental regulations and a growing public awareness of the importance of environmental protection.

In the food industry, biosensors are gaining prominence as tools for ensuring food safety and quality. The ability of these devices to rapidly detect contaminants, allergens, and pathogens has made them invaluable in maintaining food supply chain integrity and meeting regulatory requirements.

The industrial sector is another area where biosensors are finding increased applications, particularly in process monitoring and quality control. Industries such as pharmaceuticals, biotechnology, and chemical manufacturing are adopting biosensor technology to enhance production efficiency and ensure product quality.

A key trend shaping the biosensor market is the integration of advanced technologies such as nanotechnology, microfluidics, and artificial intelligence. These innovations are enabling the development of more sensitive, specific, and user-friendly biosensor devices. Additionally, the miniaturization of biosensors is opening up new possibilities for wearable and implantable devices, further expanding the market potential.

The global biosensor market is projected to maintain strong growth in the coming years. Factors contributing to this growth include technological advancements, increasing investment in research and development, and the expanding applications of biosensors across various industries. The market is also benefiting from the growing trend towards personalized medicine and the increasing adoption of point-of-care diagnostics.

However, challenges such as high development costs, regulatory hurdles, and the need for skilled personnel to operate complex biosensor systems may impact market growth. Despite these challenges, the overall outlook for the biosensor market remains positive, with opportunities for innovation and market expansion across multiple sectors.

Vacuum Tech Challenges

Vacuum pump technology plays a crucial role in the development and performance of advanced biosensor systems. However, several significant challenges persist in this field, hindering the full potential of biosensor applications. One of the primary obstacles is achieving and maintaining ultra-high vacuum levels required for sensitive biosensor operations. Current vacuum pump designs struggle to consistently reach and sustain pressures below 10^-9 Torr, which is essential for many cutting-edge biosensor applications.

Another major challenge lies in minimizing contamination within the vacuum system. Biosensors often deal with extremely small sample sizes and minute molecular interactions. Even trace amounts of contaminants introduced by the vacuum pump can significantly interfere with sensor readings and compromise the accuracy of results. Developing pump designs that reduce outgassing and particle generation while maintaining high pumping speeds remains a complex engineering problem.

Energy efficiency and heat management present additional hurdles in vacuum pump design for biosensor technology. Many high-performance vacuum pumps consume substantial amounts of power and generate considerable heat during operation. This not only increases operational costs but can also affect the thermal stability of sensitive biosensor components. Striking a balance between pumping efficiency and energy consumption while managing thermal output is a persistent challenge for engineers in this field.

Noise and vibration reduction is another critical area of concern. Biosensors often require extremely stable environments for accurate measurements. Vibrations produced by vacuum pumps can introduce noise into sensor readings and potentially damage delicate components. Developing pump designs that minimize mechanical vibrations without compromising pumping performance is an ongoing challenge in the industry.

Scalability and miniaturization of vacuum pump systems pose significant difficulties, particularly for portable or point-of-care biosensor applications. As biosensor technology trends towards more compact and mobile platforms, there is a growing demand for smaller, lighter vacuum pumps that can deliver high performance. However, reducing pump size while maintaining the required vacuum levels and pumping speeds presents considerable engineering challenges.

Lastly, the integration of smart features and real-time monitoring capabilities into vacuum pump systems for biosensors is an emerging challenge. As biosensor technology becomes more sophisticated, there is an increasing need for vacuum pumps that can provide real-time data on pressure levels, contamination, and system performance. Developing reliable sensors and control systems that can operate effectively in high-vacuum environments without introducing additional complications is a complex task that requires innovative solutions.

Another major challenge lies in minimizing contamination within the vacuum system. Biosensors often deal with extremely small sample sizes and minute molecular interactions. Even trace amounts of contaminants introduced by the vacuum pump can significantly interfere with sensor readings and compromise the accuracy of results. Developing pump designs that reduce outgassing and particle generation while maintaining high pumping speeds remains a complex engineering problem.

Energy efficiency and heat management present additional hurdles in vacuum pump design for biosensor technology. Many high-performance vacuum pumps consume substantial amounts of power and generate considerable heat during operation. This not only increases operational costs but can also affect the thermal stability of sensitive biosensor components. Striking a balance between pumping efficiency and energy consumption while managing thermal output is a persistent challenge for engineers in this field.

Noise and vibration reduction is another critical area of concern. Biosensors often require extremely stable environments for accurate measurements. Vibrations produced by vacuum pumps can introduce noise into sensor readings and potentially damage delicate components. Developing pump designs that minimize mechanical vibrations without compromising pumping performance is an ongoing challenge in the industry.

Scalability and miniaturization of vacuum pump systems pose significant difficulties, particularly for portable or point-of-care biosensor applications. As biosensor technology trends towards more compact and mobile platforms, there is a growing demand for smaller, lighter vacuum pumps that can deliver high performance. However, reducing pump size while maintaining the required vacuum levels and pumping speeds presents considerable engineering challenges.

Lastly, the integration of smart features and real-time monitoring capabilities into vacuum pump systems for biosensors is an emerging challenge. As biosensor technology becomes more sophisticated, there is an increasing need for vacuum pumps that can provide real-time data on pressure levels, contamination, and system performance. Developing reliable sensors and control systems that can operate effectively in high-vacuum environments without introducing additional complications is a complex task that requires innovative solutions.

Current Pump Solutions

01 Rotor and stator design optimization

Vacuum pump design focuses on optimizing the rotor and stator configuration to enhance efficiency and performance. This includes improving the shape, material, and arrangement of rotor blades and stator vanes to maximize pumping capacity and minimize energy consumption. Advanced manufacturing techniques and materials are employed to create precise geometries that reduce internal leakage and friction.- Rotor and stator design optimization: Vacuum pump designs focus on optimizing rotor and stator configurations to enhance efficiency and performance. This includes improvements in rotor blade geometry, stator vane arrangements, and the interaction between these components to maximize pumping capacity and minimize energy consumption.

- Sealing mechanisms for vacuum pumps: Advanced sealing technologies are crucial in vacuum pump design to maintain high vacuum levels and prevent leakage. This involves developing innovative sealing materials, optimizing seal geometries, and implementing dynamic sealing systems that adapt to varying operational conditions.

- Multi-stage vacuum pump configurations: Multi-stage vacuum pump designs are employed to achieve higher vacuum levels and improved pumping efficiency. These configurations involve a series of pumping stages, each optimized for specific pressure ranges, allowing for better overall performance across a wide range of operating conditions.

- Integration of smart technologies in vacuum pumps: Modern vacuum pump designs incorporate smart technologies such as sensors, IoT connectivity, and advanced control systems. These features enable real-time monitoring, predictive maintenance, and automated optimization of pump performance based on operational data and environmental conditions.

- Energy-efficient and environmentally friendly designs: Vacuum pump designs are increasingly focused on improving energy efficiency and reducing environmental impact. This includes the development of low-friction materials, optimized motor designs, and the integration of energy recovery systems to minimize power consumption and heat generation during operation.

02 Sealing and lubrication systems

Effective sealing and lubrication are crucial in vacuum pump design to maintain performance and longevity. Innovations include advanced sealing technologies to prevent air leakage, and sophisticated lubrication systems that ensure proper oil distribution while minimizing oil contamination in the vacuum chamber. These improvements contribute to higher vacuum levels and extended pump life.Expand Specific Solutions03 Cooling and temperature management

Thermal management is a key aspect of vacuum pump design, focusing on efficient heat dissipation to maintain optimal operating temperatures. This involves innovative cooling systems, strategic placement of cooling channels, and the use of heat-resistant materials. Effective cooling enhances pump efficiency, extends component lifespan, and ensures consistent performance under various operating conditions.Expand Specific Solutions04 Control systems and smart technologies

Modern vacuum pump designs incorporate advanced control systems and smart technologies to optimize performance and energy efficiency. This includes the integration of sensors, microprocessors, and software that enable real-time monitoring, automatic adjustment of operating parameters, and predictive maintenance capabilities. These features enhance pump reliability, reduce downtime, and improve overall system efficiency.Expand Specific Solutions05 Multi-stage and hybrid pump designs

Innovative vacuum pump designs often utilize multi-stage configurations or hybrid systems that combine different pumping mechanisms. These approaches allow for achieving higher vacuum levels, improved pumping speeds, and greater versatility across various applications. By integrating multiple pump types or stages, designers can optimize performance characteristics for specific operational requirements and enhance overall system efficiency.Expand Specific Solutions

Key Industry Players

The vacuum pump design for enhanced biosensor technology market is in a growth phase, driven by increasing demand for advanced diagnostic tools. The global biosensor market is projected to reach significant size, with vacuum pump technology playing a crucial role in improving sensitivity and accuracy. Companies like Edwards Ltd. and ANEST IWATA Corp. are at the forefront of vacuum pump technology, while major healthcare players such as F. Hoffmann-La Roche Ltd., Medtronic MiniMed, Inc., and Abbott Laboratories are integrating these advancements into their biosensor products. The technology is maturing rapidly, with research institutions like Arizona State University and ETH Zurich contributing to innovations, indicating a competitive landscape balanced between established manufacturers and emerging research-driven entities.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump designs specifically tailored for biosensor applications. Their latest innovation involves a compact, high-performance turbomolecular pump system that achieves ultra-high vacuum levels necessary for sensitive biosensor measurements. The pump incorporates a novel rotor design with optimized blade geometry, allowing for improved pumping speeds and higher compression ratios[1]. Additionally, Edwards has implemented advanced magnetic bearing technology, reducing friction and wear while enhancing pump reliability and longevity[3]. The pump system also features intelligent control algorithms that adapt to varying gas loads, ensuring stable vacuum conditions across different biosensor operational modes[5].

Strengths: High vacuum performance, reduced maintenance, and adaptive control for various biosensor applications. Weaknesses: Potentially higher initial cost and complexity compared to traditional pump designs.

F. Hoffmann-La Roche Ltd.

Technical Solution: F. Hoffmann-La Roche Ltd. has developed an innovative vacuum-assisted microfluidic platform for enhanced biosensor technology. Their system utilizes a miniaturized vacuum pump integrated directly into lab-on-a-chip devices, enabling precise control of fluid flow and sample handling. The pump design incorporates piezoelectric actuators for generating vacuum, allowing for rapid and accurate manipulation of microliter-scale samples[2]. Roche's technology also features a unique valve system that maintains stable vacuum levels while minimizing sample evaporation, crucial for long-term biosensor measurements[4]. Furthermore, the company has implemented advanced surface treatments within the pump components to reduce protein adsorption and enhance overall biosensor sensitivity[6].

Strengths: Highly integrated design, precise sample control, and improved biosensor sensitivity. Weaknesses: Limited to microfluidic applications and potentially higher manufacturing costs.

Core Vacuum Innovations

Vacuum pump

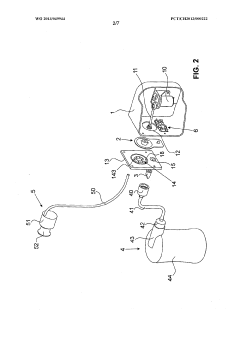

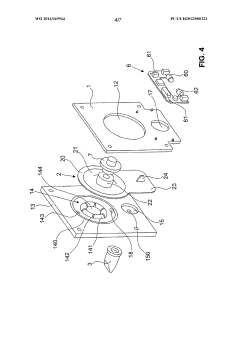

PatentWO2013049944A1

Innovation

- A compact vacuum pump design incorporating a pressure sensor within the pump chamber, utilizing a sensor diaphragm that deflects with pressure changes, allowing for accurate on-site measurement and control, eliminating the need for additional lines and reducing leakage losses.

Vacuum pump

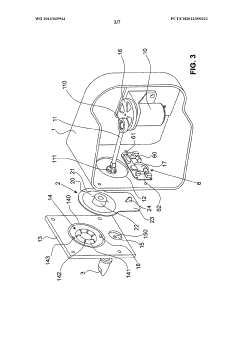

PatentActiveEP2747803A1

Innovation

- A compact vacuum pump design with a pressure sensor integrated within the pump chamber, utilizing a sensor diaphragm that deflects with pressure changes, allowing for accurate measurement and control without additional lines, using optical detection means to determine the sensor membrane's position and convert it into a measurable vacuum value.

Regulatory Compliance

Regulatory compliance is a critical aspect of vacuum pump design for enhanced biosensor technology. The development and implementation of these pumps must adhere to various national and international standards to ensure safety, reliability, and performance. In the context of biosensor applications, compliance with regulatory requirements is particularly crucial due to the sensitive nature of biological samples and the potential impact on human health.

One of the primary regulatory bodies overseeing vacuum pump design for biosensor technology is the Food and Drug Administration (FDA) in the United States. The FDA's Center for Devices and Radiological Health (CDRH) regulates medical devices, including biosensors and associated equipment. Manufacturers must comply with the FDA's Quality System Regulation (QSR) and Good Manufacturing Practices (GMP) to ensure the safety and efficacy of their products.

In Europe, the European Medicines Agency (EMA) and the European Commission play significant roles in regulating biosensor technology. The CE marking is mandatory for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards. Vacuum pump manufacturers must adhere to the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) when their products are intended for use in biosensor applications.

ISO standards are also crucial for vacuum pump design in biosensor technology. ISO 13485 specifies requirements for quality management systems in medical device manufacturing, while ISO 14971 addresses risk management for medical devices. These standards ensure that vacuum pumps meet the necessary quality and safety requirements for use in sensitive biosensor applications.

Environmental regulations, such as the Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, impact vacuum pump design by restricting the use of certain materials and chemicals. Manufacturers must consider these regulations when selecting components and materials for their pumps.

Compliance with electromagnetic compatibility (EMC) standards is essential to prevent interference with other electronic devices in laboratory settings. Standards such as IEC 61326-1 and FCC Part 15 ensure that vacuum pumps do not emit harmful electromagnetic radiation or interfere with sensitive biosensor measurements.

As biosensor technology continues to advance, regulatory requirements are likely to evolve. Manufacturers must stay informed about changes in regulations and standards to ensure ongoing compliance. This may involve regular audits, documentation updates, and product redesigns to meet new requirements. Additionally, as biosensors find applications in new fields, such as point-of-care diagnostics or environmental monitoring, vacuum pump designers may need to consider additional regulatory frameworks specific to these areas.

One of the primary regulatory bodies overseeing vacuum pump design for biosensor technology is the Food and Drug Administration (FDA) in the United States. The FDA's Center for Devices and Radiological Health (CDRH) regulates medical devices, including biosensors and associated equipment. Manufacturers must comply with the FDA's Quality System Regulation (QSR) and Good Manufacturing Practices (GMP) to ensure the safety and efficacy of their products.

In Europe, the European Medicines Agency (EMA) and the European Commission play significant roles in regulating biosensor technology. The CE marking is mandatory for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards. Vacuum pump manufacturers must adhere to the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) when their products are intended for use in biosensor applications.

ISO standards are also crucial for vacuum pump design in biosensor technology. ISO 13485 specifies requirements for quality management systems in medical device manufacturing, while ISO 14971 addresses risk management for medical devices. These standards ensure that vacuum pumps meet the necessary quality and safety requirements for use in sensitive biosensor applications.

Environmental regulations, such as the Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, impact vacuum pump design by restricting the use of certain materials and chemicals. Manufacturers must consider these regulations when selecting components and materials for their pumps.

Compliance with electromagnetic compatibility (EMC) standards is essential to prevent interference with other electronic devices in laboratory settings. Standards such as IEC 61326-1 and FCC Part 15 ensure that vacuum pumps do not emit harmful electromagnetic radiation or interfere with sensitive biosensor measurements.

As biosensor technology continues to advance, regulatory requirements are likely to evolve. Manufacturers must stay informed about changes in regulations and standards to ensure ongoing compliance. This may involve regular audits, documentation updates, and product redesigns to meet new requirements. Additionally, as biosensors find applications in new fields, such as point-of-care diagnostics or environmental monitoring, vacuum pump designers may need to consider additional regulatory frameworks specific to these areas.

Energy Efficiency

Energy efficiency is a critical aspect of vacuum pump design for enhanced biosensor technology. As biosensors become increasingly sophisticated and miniaturized, the demand for more efficient vacuum pumps grows. These pumps play a crucial role in maintaining the precise environmental conditions required for accurate biosensor readings.

In recent years, significant advancements have been made in improving the energy efficiency of vacuum pumps used in biosensor applications. One key approach has been the development of variable speed drives, which allow pumps to adjust their operation based on the specific requirements of the biosensor system. This dynamic adjustment capability reduces energy consumption during periods of lower demand, resulting in substantial energy savings over time.

Another important innovation in energy-efficient vacuum pump design is the implementation of advanced materials and coatings. These materials, such as low-friction ceramics and specialized polymers, reduce internal friction and heat generation within the pump, leading to improved overall efficiency. Additionally, the use of high-performance lubricants and optimized sealing systems further contributes to energy conservation by minimizing power losses due to friction and leakage.

The integration of smart control systems has also played a significant role in enhancing the energy efficiency of vacuum pumps for biosensor technology. These systems utilize sensors and algorithms to continuously monitor and optimize pump performance, ensuring that energy consumption is minimized without compromising the required vacuum levels. Some advanced systems even incorporate machine learning capabilities, allowing the pump to adapt its operation based on historical usage patterns and environmental factors.

Heat recovery systems have emerged as another innovative approach to improving energy efficiency in vacuum pump design. By capturing and repurposing the heat generated during pump operation, these systems can significantly reduce the overall energy footprint of biosensor setups. The recovered heat can be used for various purposes, such as maintaining optimal temperatures in other parts of the biosensor system or supporting auxiliary processes in the laboratory environment.

Furthermore, the development of hybrid vacuum systems, which combine different pumping technologies, has shown promise in achieving higher energy efficiency. These systems leverage the strengths of various pump types, such as rotary vane and turbomolecular pumps, to optimize performance across different pressure ranges and operating conditions. By seamlessly transitioning between pump types, hybrid systems can maintain the required vacuum levels while minimizing energy consumption throughout the entire operational cycle.

As the field of biosensor technology continues to evolve, the focus on energy-efficient vacuum pump design is expected to intensify. Future developments may include the integration of renewable energy sources, such as solar or wind power, to further reduce the environmental impact of biosensor systems. Additionally, ongoing research into novel pumping mechanisms and materials holds the potential for breakthrough innovations that could revolutionize the energy efficiency of vacuum pumps in biosensor applications.

In recent years, significant advancements have been made in improving the energy efficiency of vacuum pumps used in biosensor applications. One key approach has been the development of variable speed drives, which allow pumps to adjust their operation based on the specific requirements of the biosensor system. This dynamic adjustment capability reduces energy consumption during periods of lower demand, resulting in substantial energy savings over time.

Another important innovation in energy-efficient vacuum pump design is the implementation of advanced materials and coatings. These materials, such as low-friction ceramics and specialized polymers, reduce internal friction and heat generation within the pump, leading to improved overall efficiency. Additionally, the use of high-performance lubricants and optimized sealing systems further contributes to energy conservation by minimizing power losses due to friction and leakage.

The integration of smart control systems has also played a significant role in enhancing the energy efficiency of vacuum pumps for biosensor technology. These systems utilize sensors and algorithms to continuously monitor and optimize pump performance, ensuring that energy consumption is minimized without compromising the required vacuum levels. Some advanced systems even incorporate machine learning capabilities, allowing the pump to adapt its operation based on historical usage patterns and environmental factors.

Heat recovery systems have emerged as another innovative approach to improving energy efficiency in vacuum pump design. By capturing and repurposing the heat generated during pump operation, these systems can significantly reduce the overall energy footprint of biosensor setups. The recovered heat can be used for various purposes, such as maintaining optimal temperatures in other parts of the biosensor system or supporting auxiliary processes in the laboratory environment.

Furthermore, the development of hybrid vacuum systems, which combine different pumping technologies, has shown promise in achieving higher energy efficiency. These systems leverage the strengths of various pump types, such as rotary vane and turbomolecular pumps, to optimize performance across different pressure ranges and operating conditions. By seamlessly transitioning between pump types, hybrid systems can maintain the required vacuum levels while minimizing energy consumption throughout the entire operational cycle.

As the field of biosensor technology continues to evolve, the focus on energy-efficient vacuum pump design is expected to intensify. Future developments may include the integration of renewable energy sources, such as solar or wind power, to further reduce the environmental impact of biosensor systems. Additionally, ongoing research into novel pumping mechanisms and materials holds the potential for breakthrough innovations that could revolutionize the energy efficiency of vacuum pumps in biosensor applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!