Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143 results about "Carbon dioxide absorbent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A carbon dioxide scrubber is a device which absorbs carbon dioxide (CO2). It is used to treat exhaust gases from industrial plants or from exhaled air in life support systems such as rebreathers or in spacecraft, submersible craft or airtight chambers.

Method and means for capture and long-term sequestration of carbon dioxide

InactiveUS20090081096A1High heat of reactionHigh regeneration energyCombination devicesGas treatmentSolubilityAmbient pressure

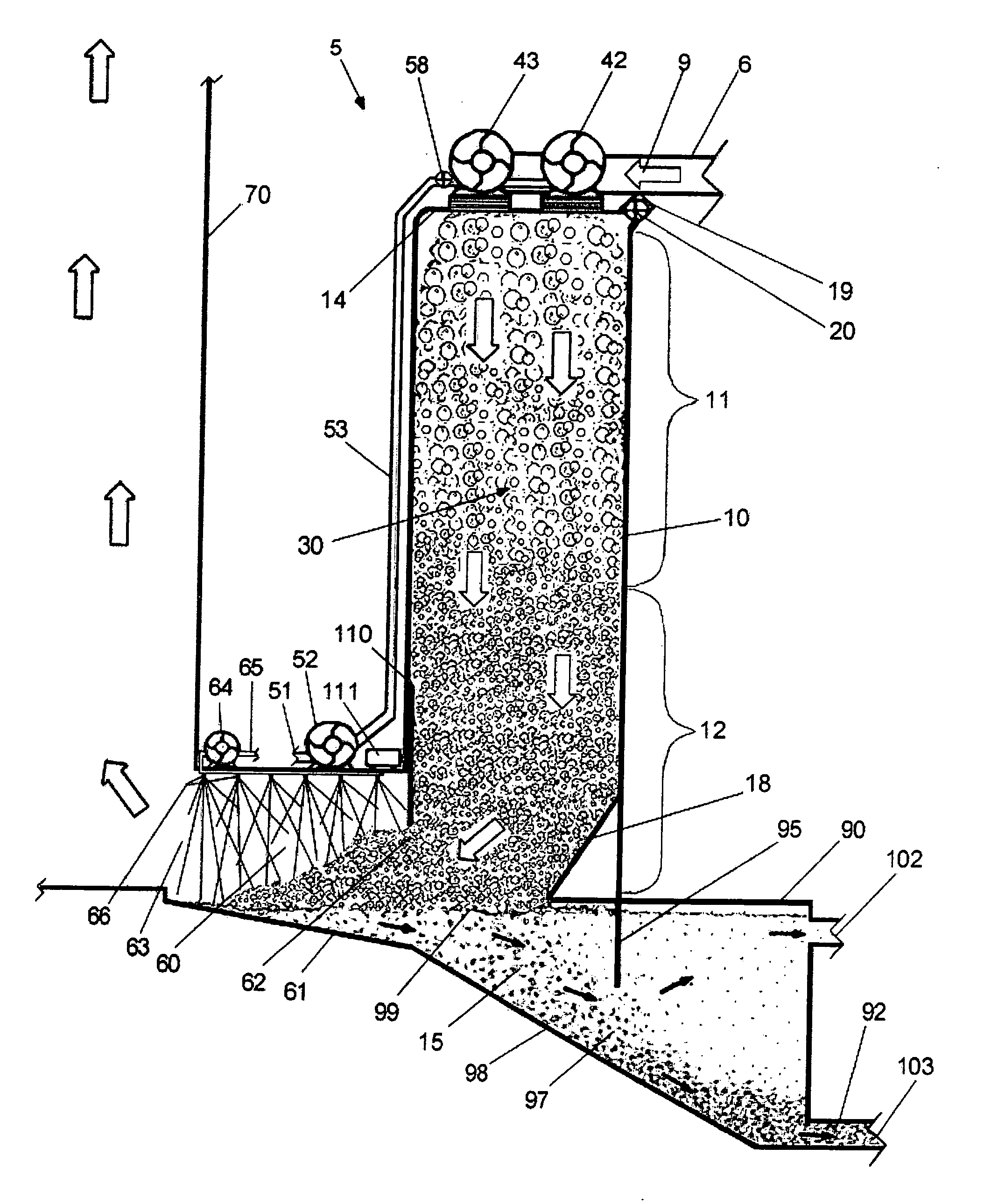

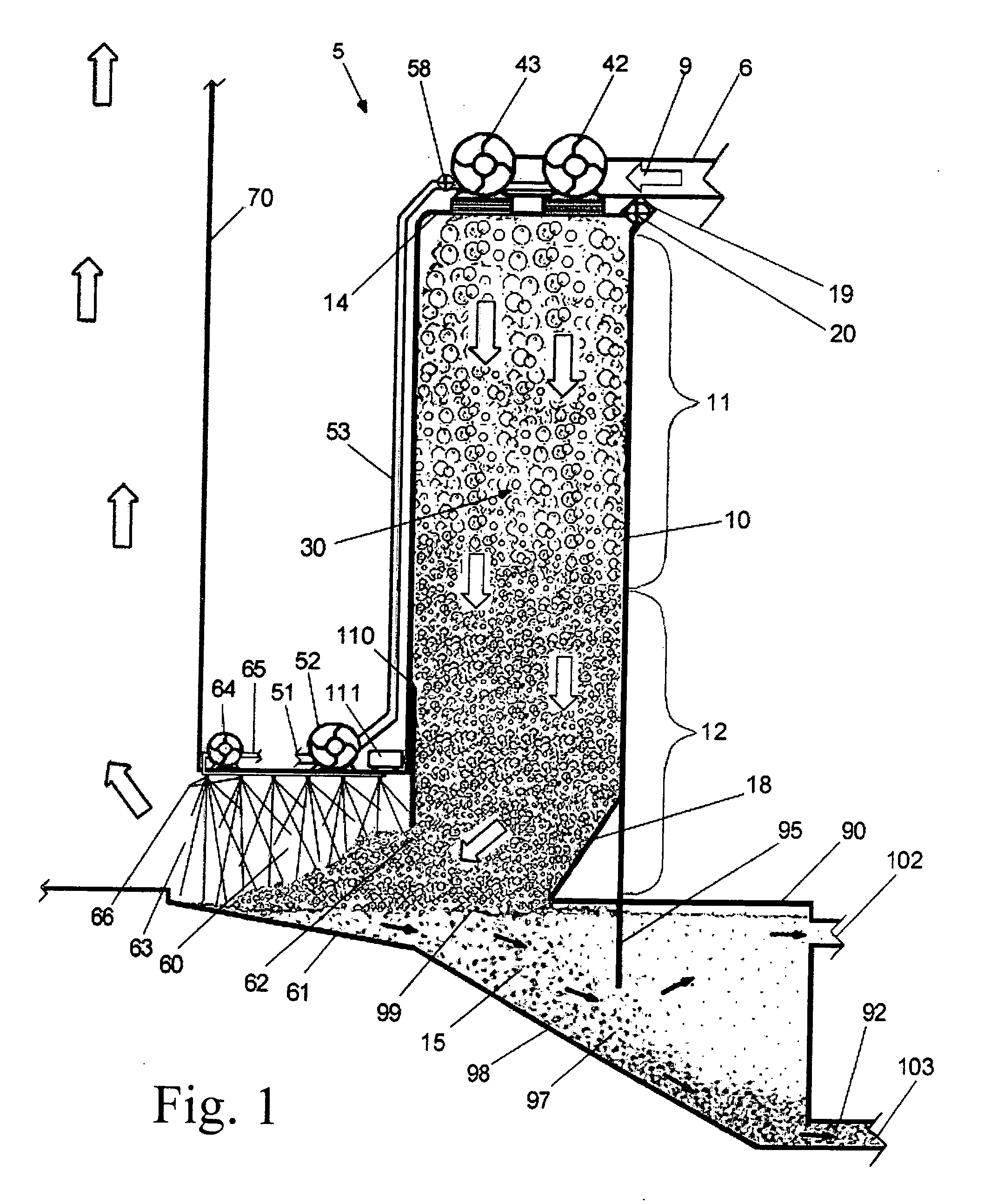

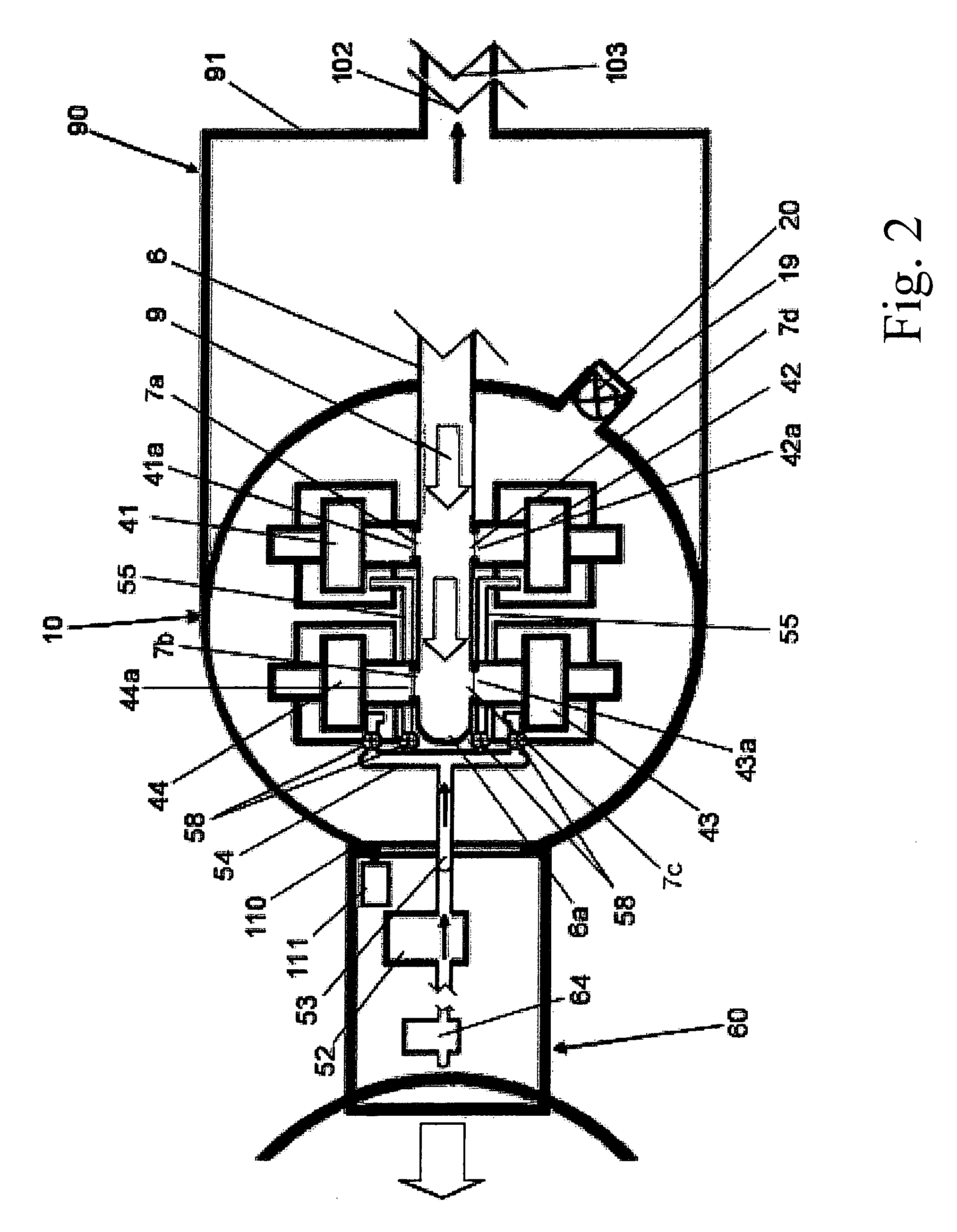

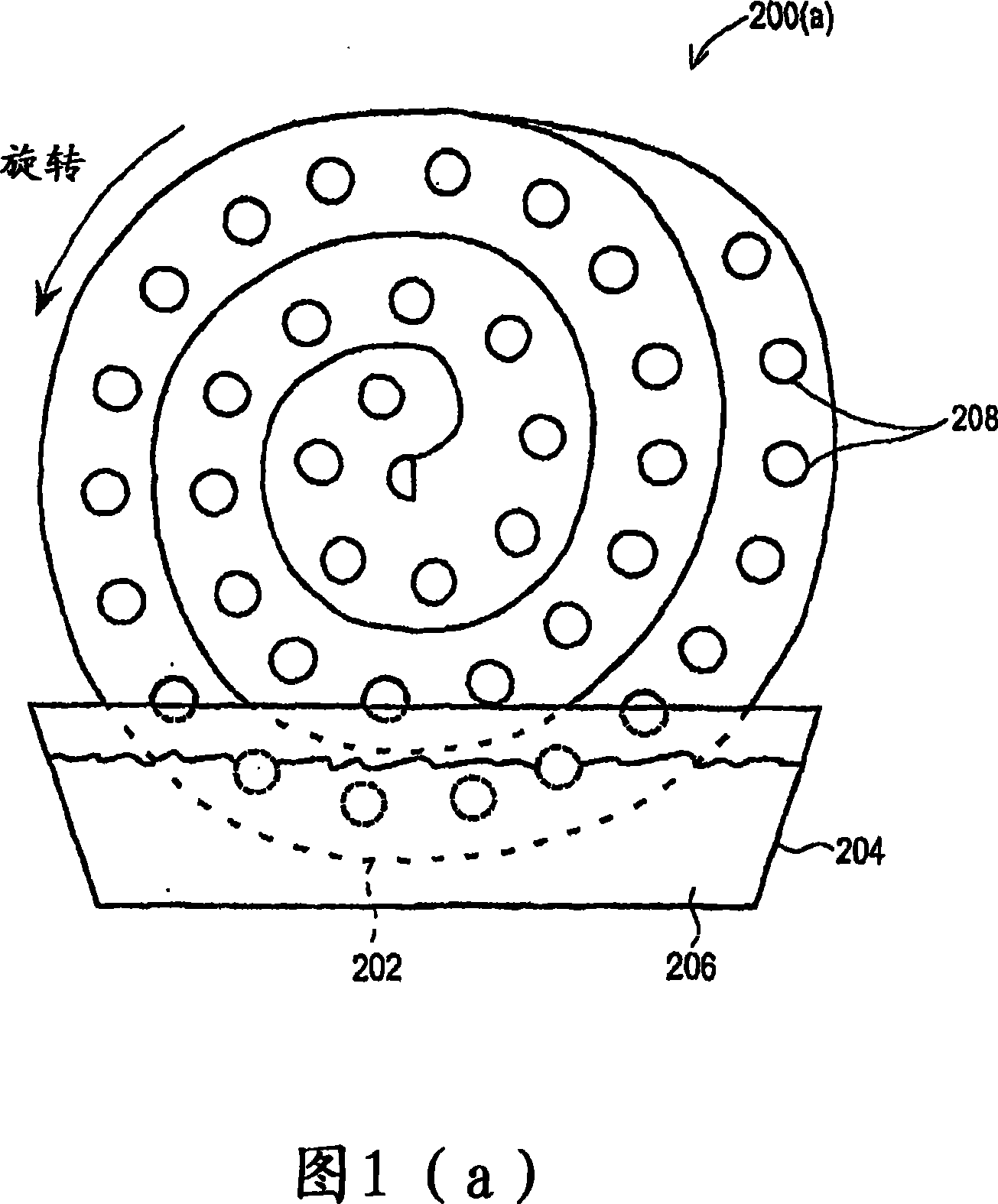

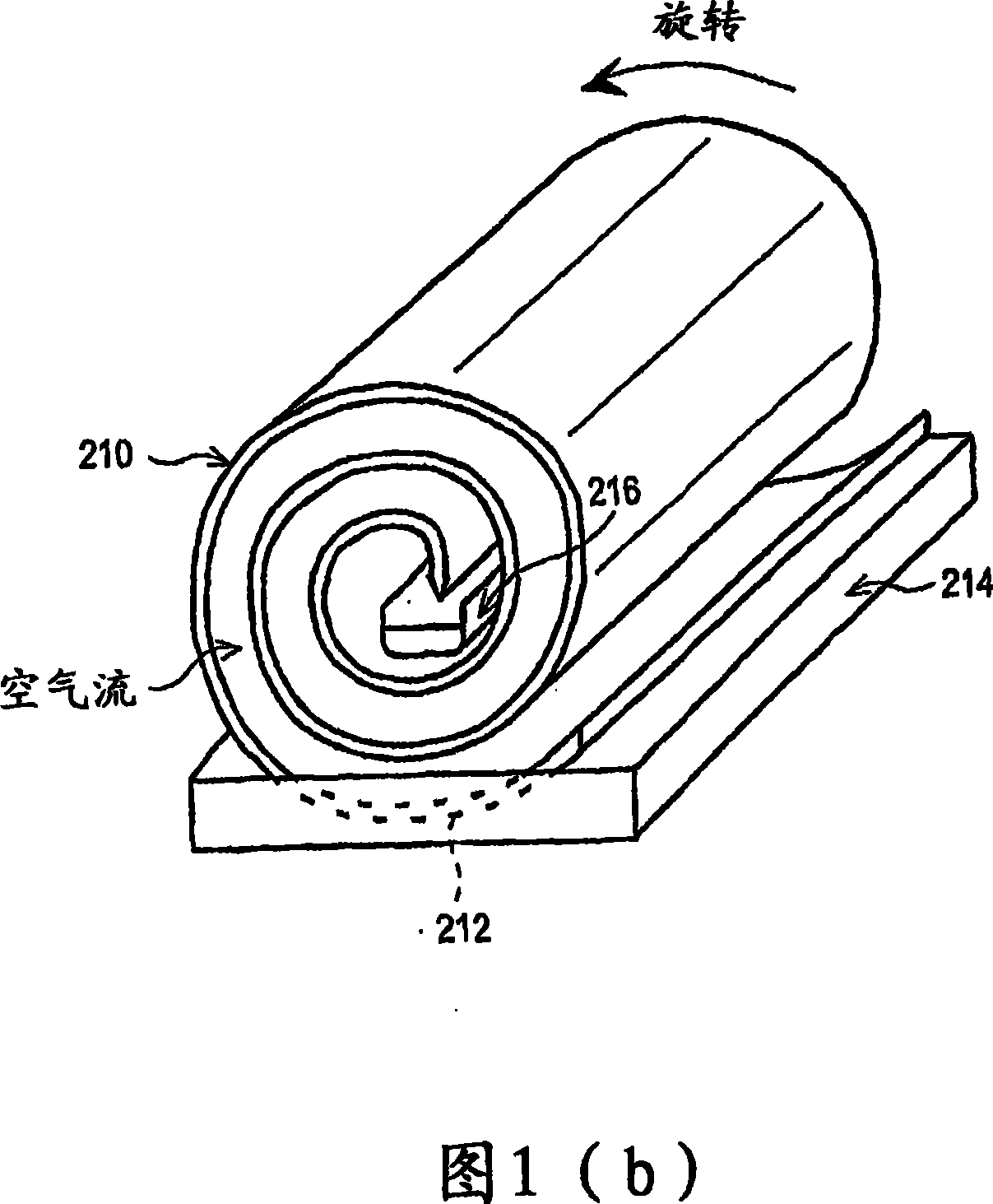

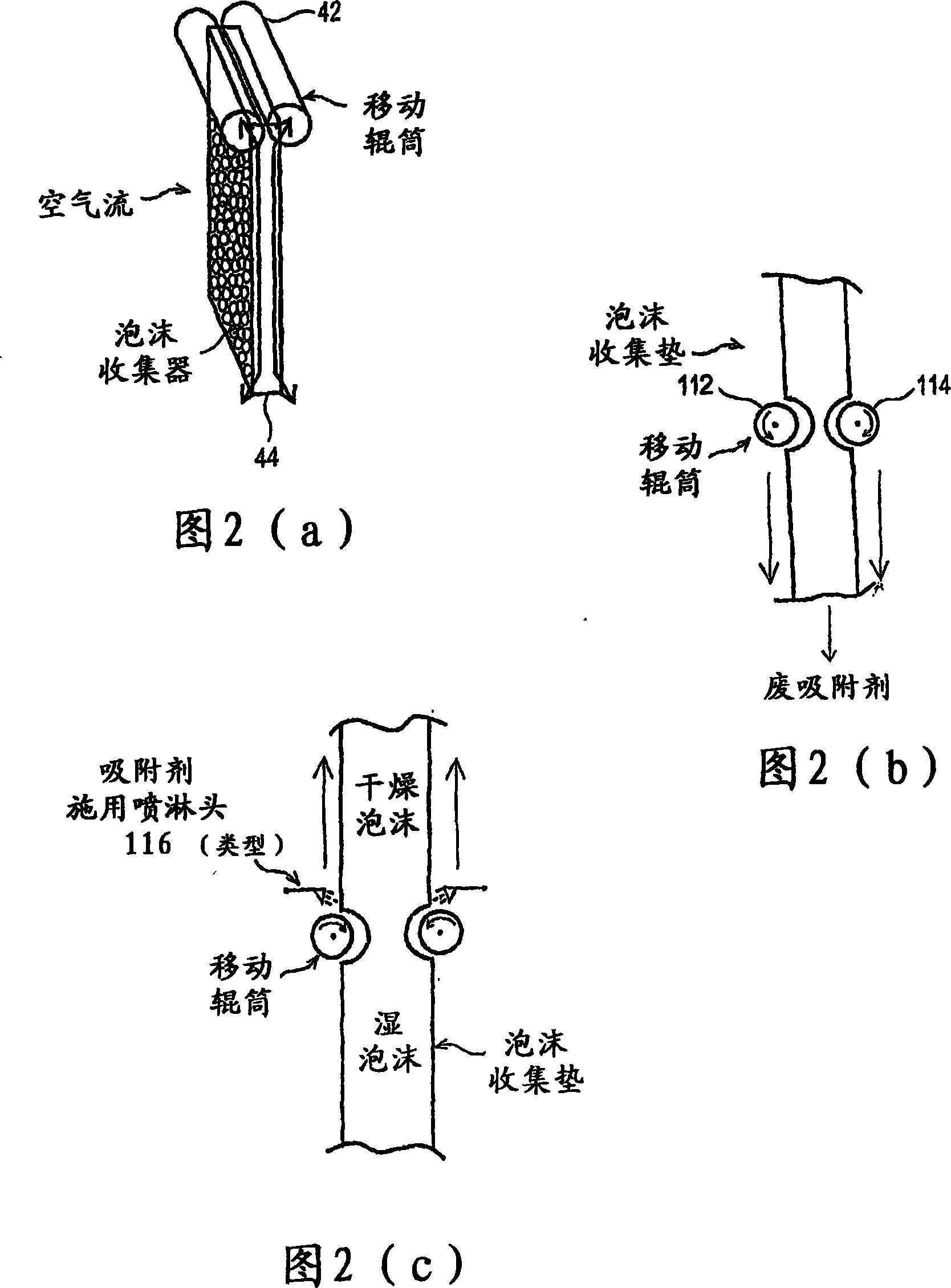

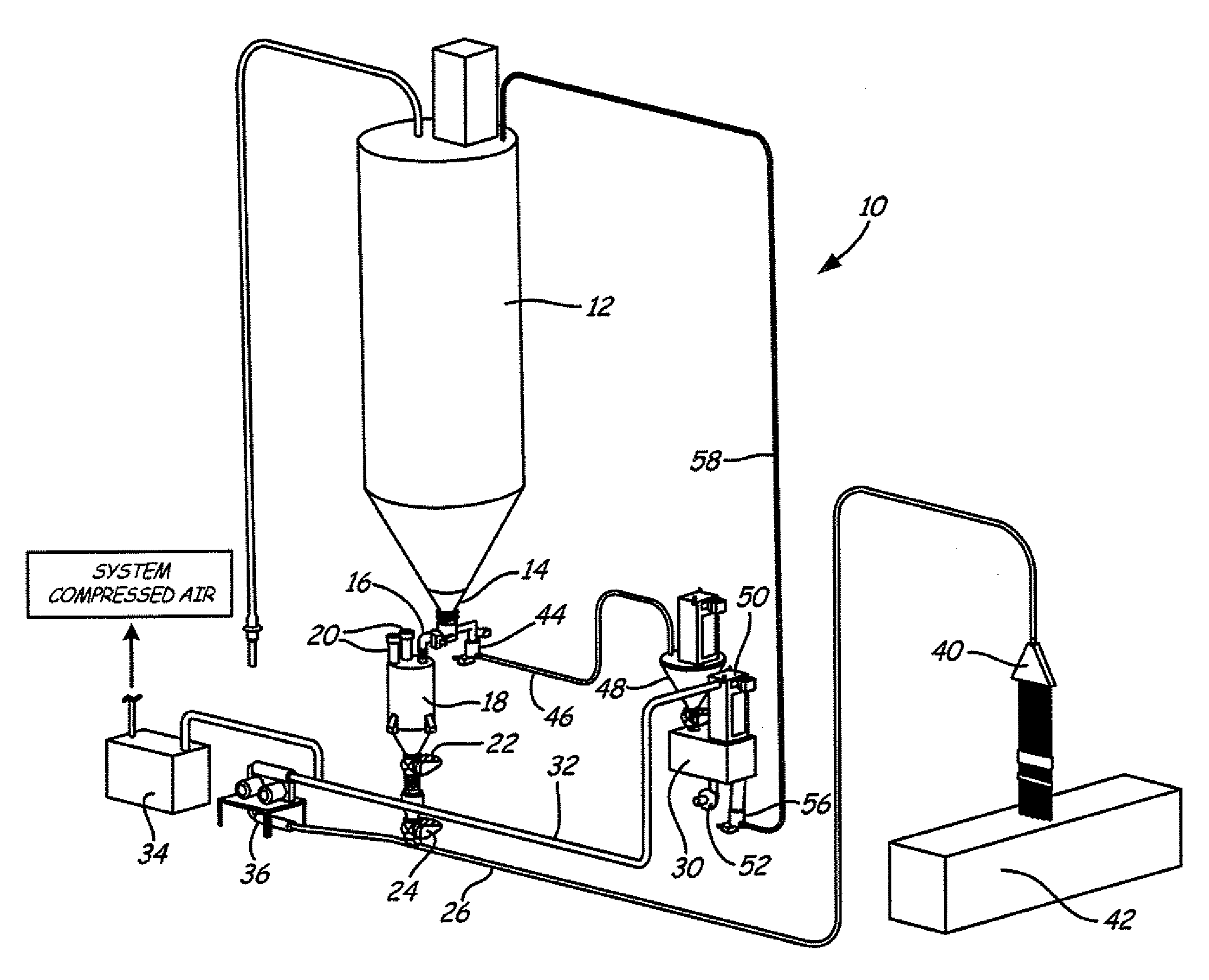

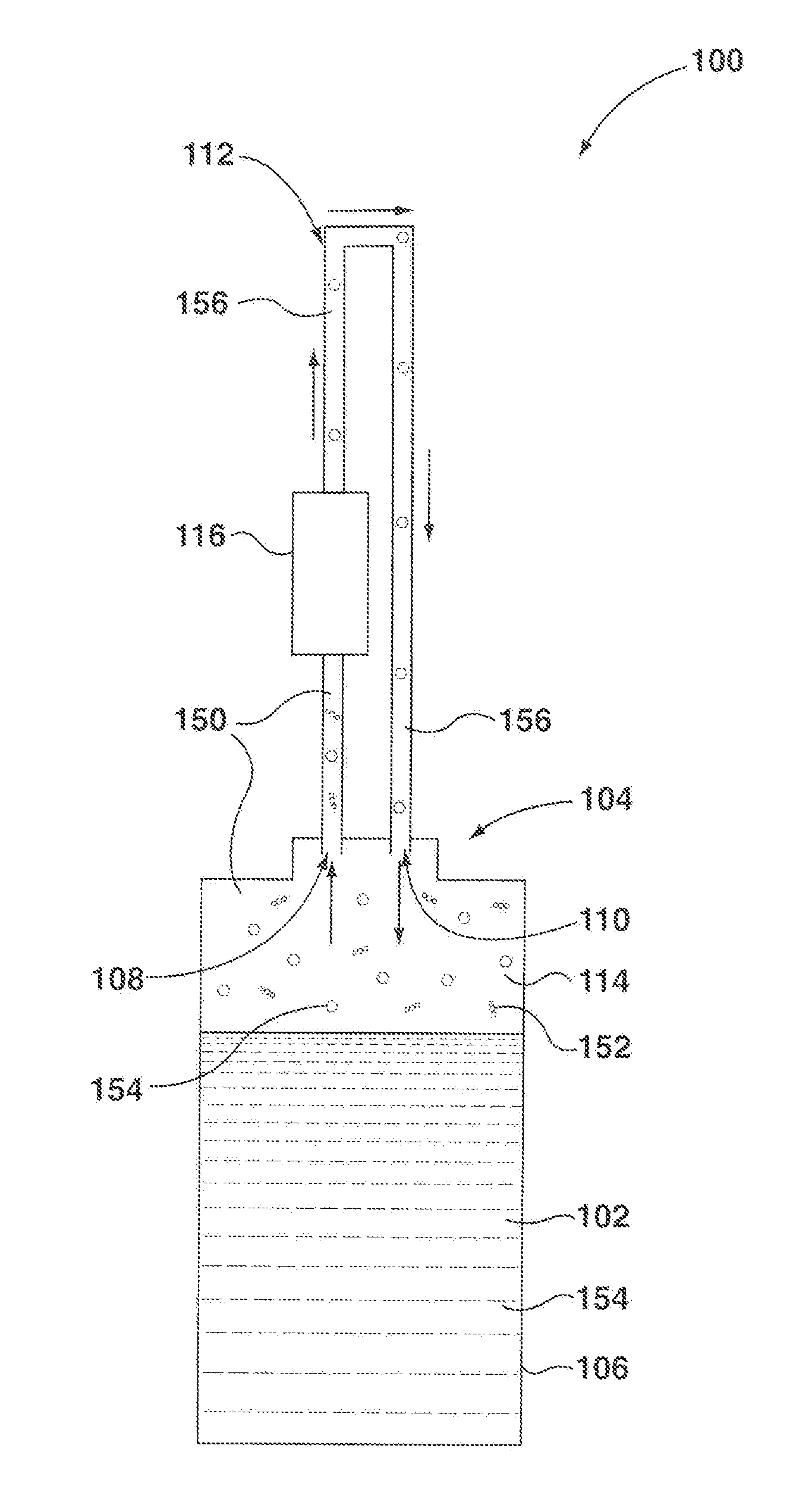

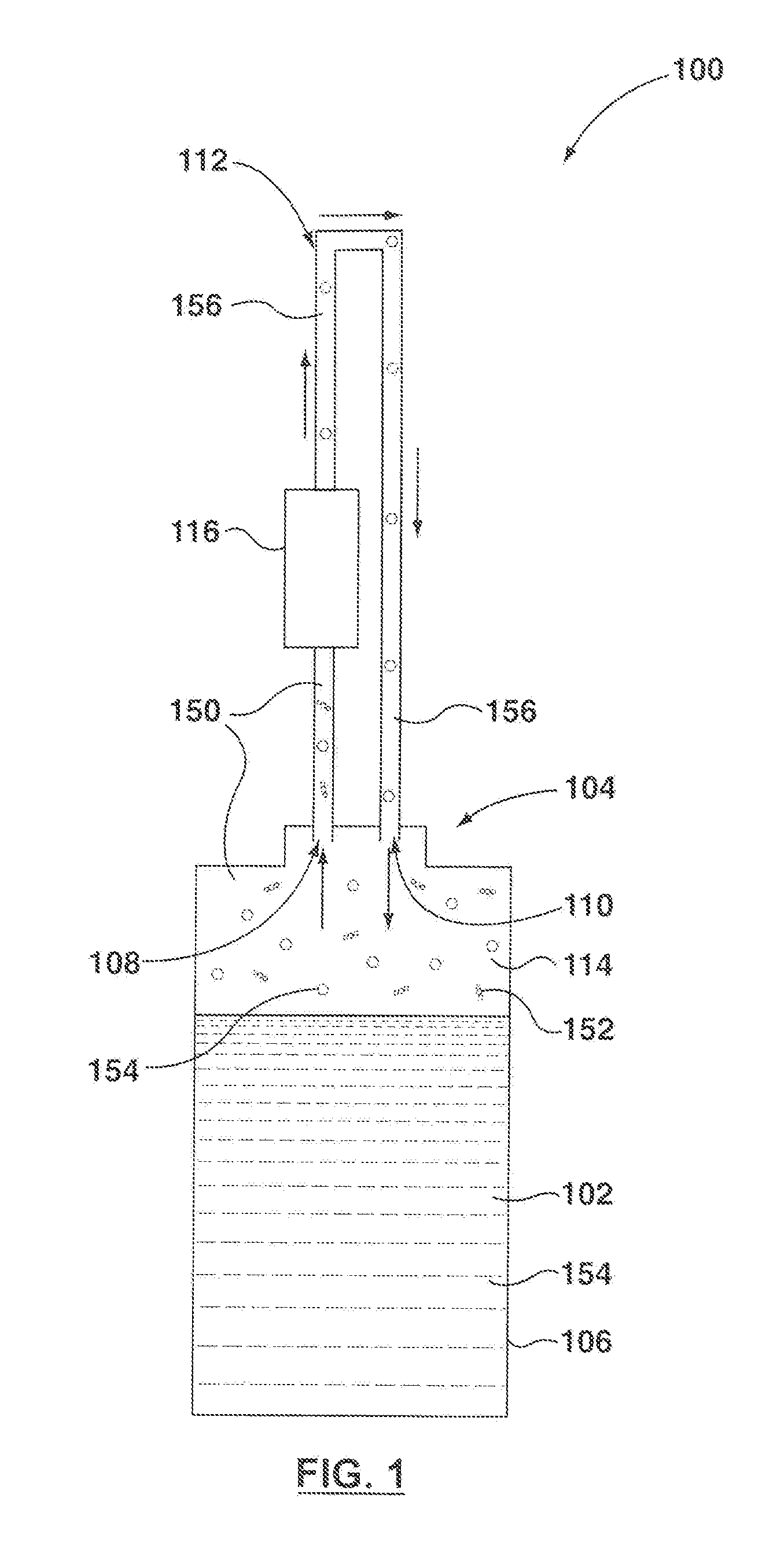

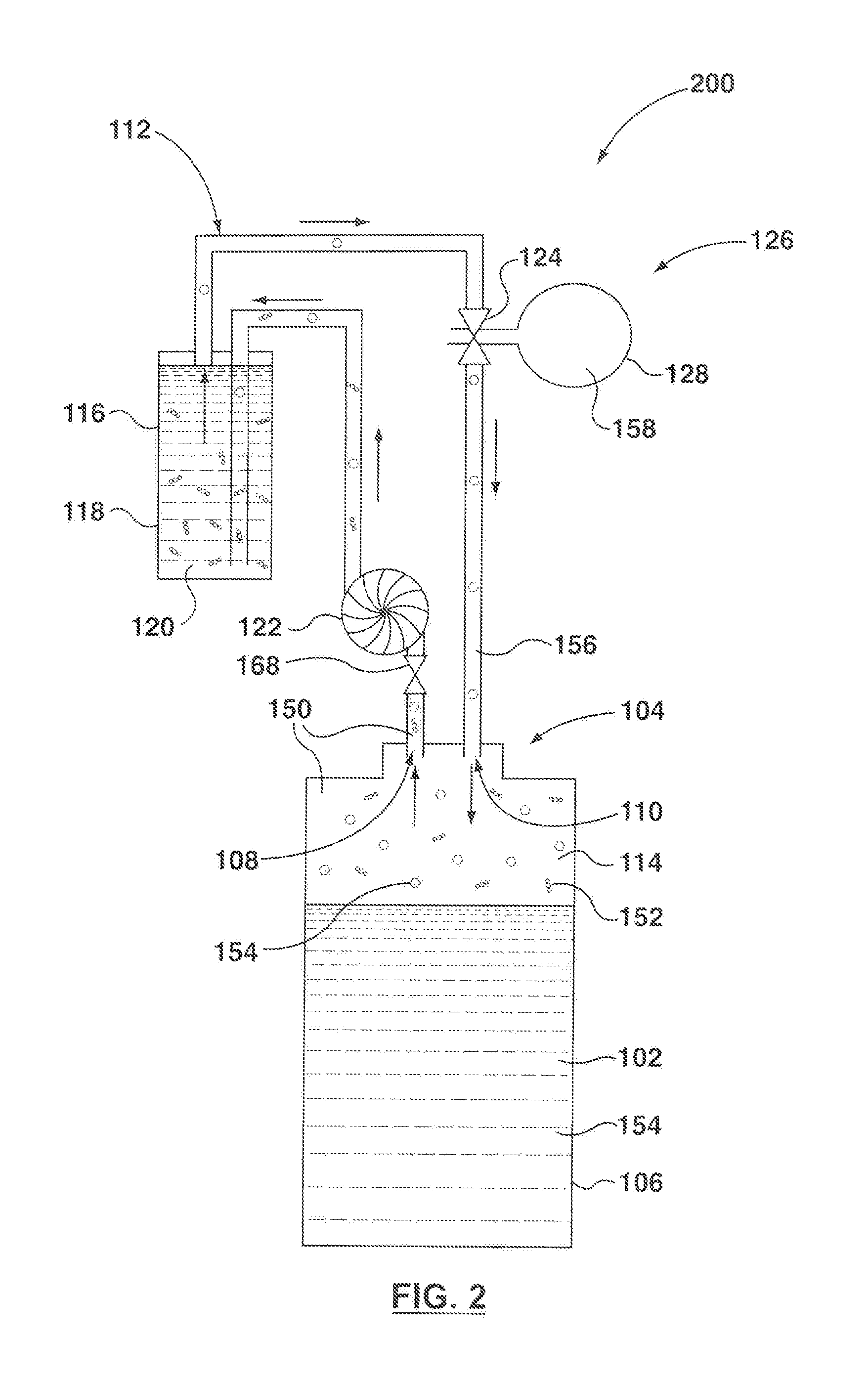

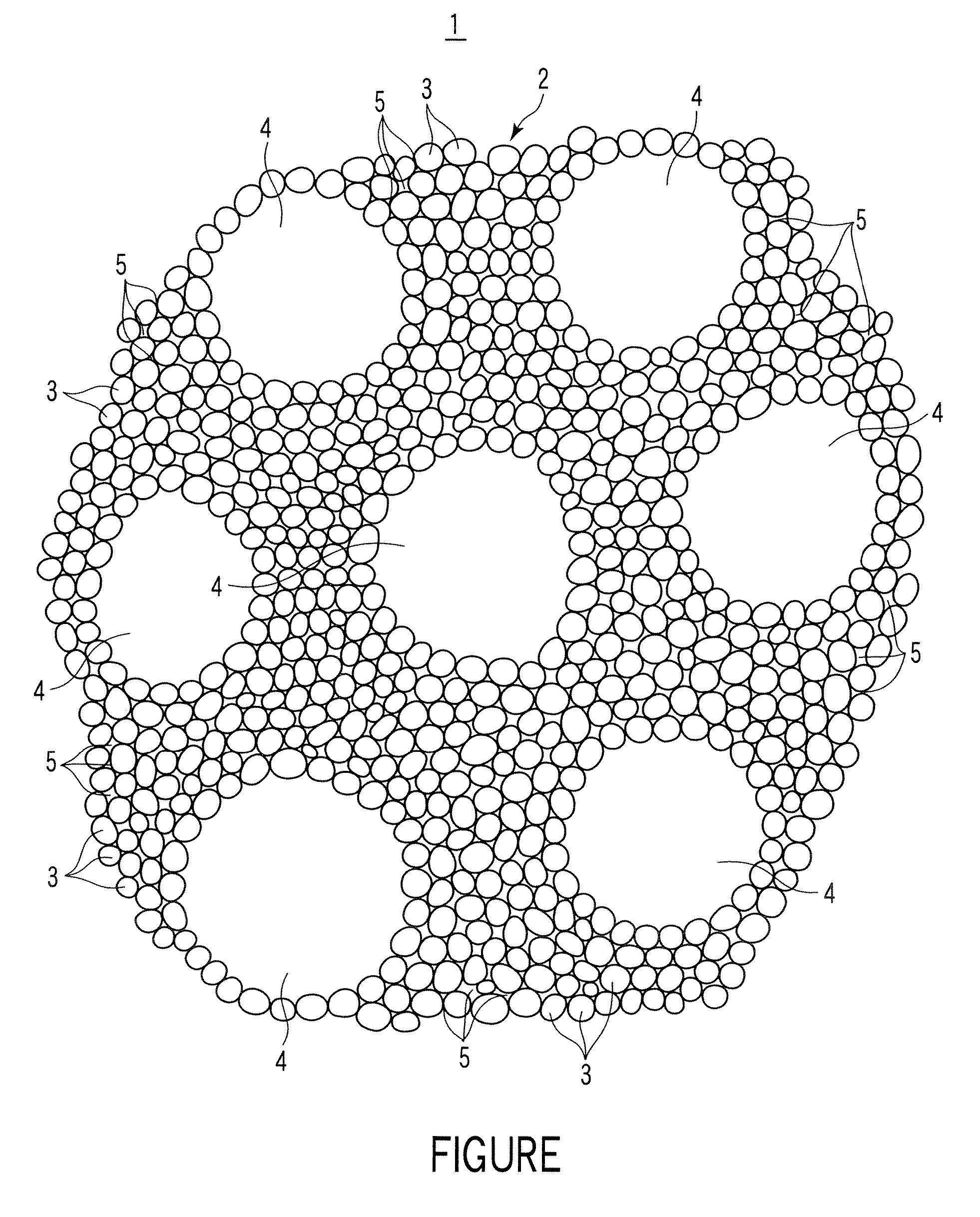

The invention teaches a practical method of recovering CO2 from a mixture of gases, and sequestering the captured CO2 from the atmosphere for geologic time as calcium carbonate and provides a CO2 scrubber for carbon capture and sequestration. CO2 from the production of calcium oxide is geologically sequestered. A calcium hydroxide solution is produced from the environmentally responsibly-produced calcium oxide. The CO2 scrubber incorporates an aqueous froth to maximize liquid-to-gas surface area and time-of-contact between gaseous CO2 and the calcium hydroxide solution. The CO2 scrubber decreases the temperature of the liquid and the mixed gases, increases ambient pressure on the bubbles and vapor pressure inside the bubbles, diffuses the gas through intercellular walls from relative smaller bubbles with relative high vapor pressure into relative larger bubbles with relative low vapor pressure, and decreases the mean-free-paths of the CO2 molecules inside the bubbles, in order to increase solubility of CO2 and the rate of dissolution of gaseous CO2 from a mixture of gases into the calcium hydroxide solution.The CO2 scrubber recovers gaseous CO2 directly from the atmosphere, from post-combustion flue gas, or from industrial processes that release CO2 as a result of process. CO2 reacts with calcium ions and hydroxide ions in solution forming insoluble calcium carbonate precipitates. The calcium carbonate precipitates are separated from solution, and sold to recover at least a portion of the cost of CCS.

Owner:WESTEC ENVIRONMENTAL SOLUTIONS

CO2 separator method and apparatus

InactiveUS6929680B2Operation efficiency can be improvedLess methane is lostCarbon compoundsLandfill technologiesProduct gasRefrigeration

Owner:CONSORTIUM SERVICES MANAGEMENT GROU

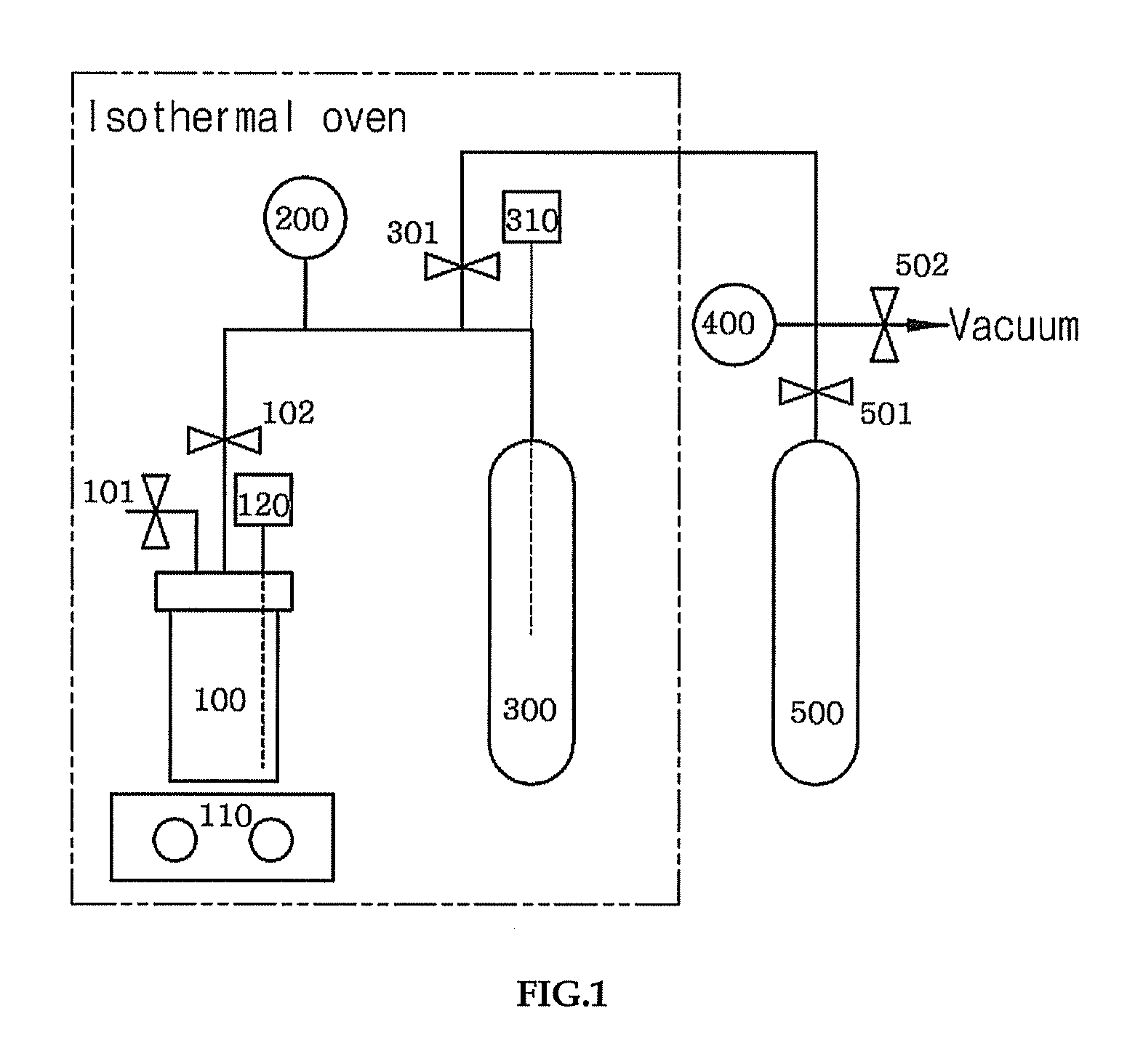

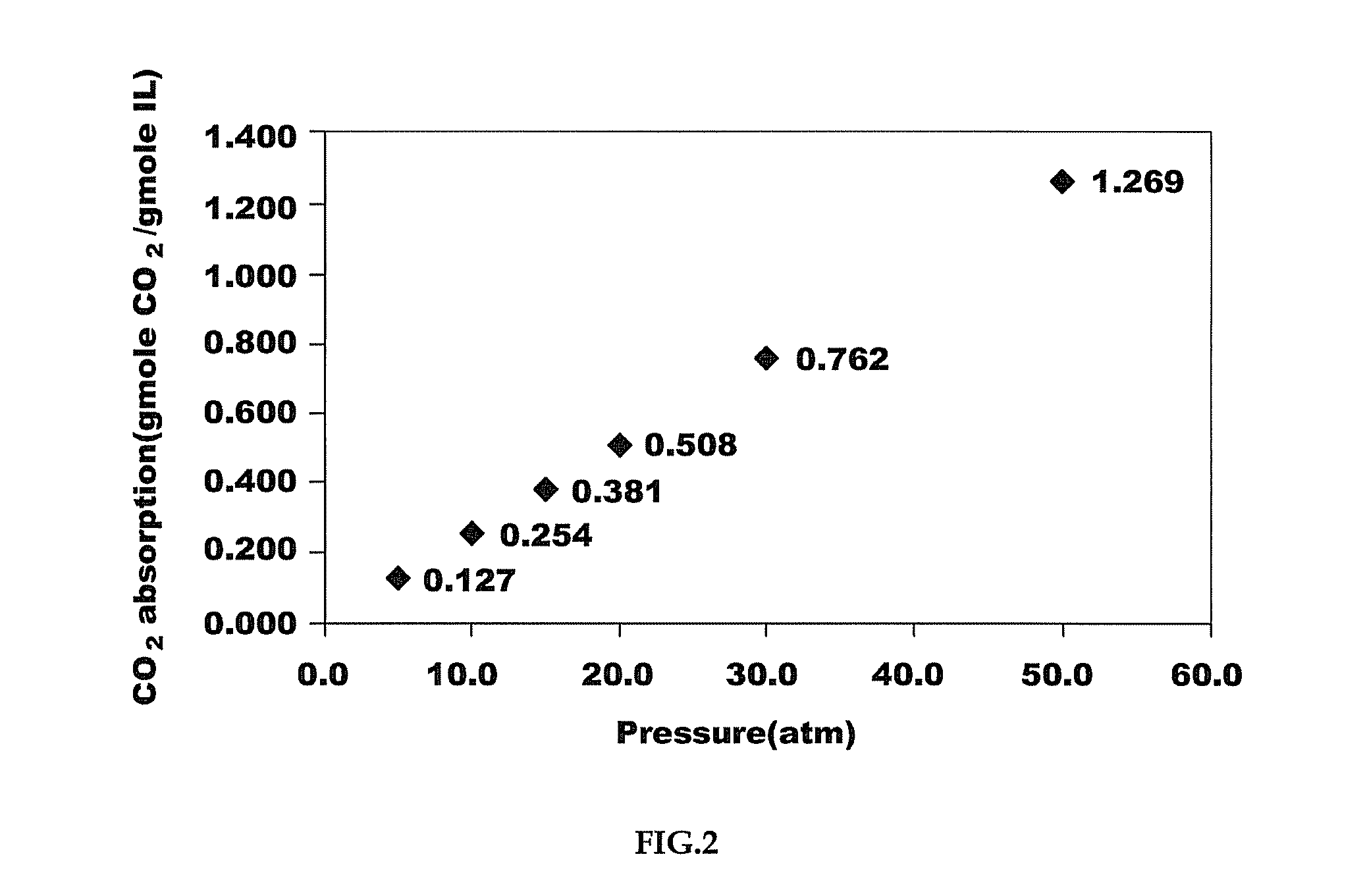

Green carbon dioxide absorbent

InactiveCN101700454APromote absorptionReduce energy consumptionProductsCarbon compoundsSolventAqueous solution

The invention relates to green carbon dioxide absorbent which is aqueous solution compounded from alkaline ionic liquid and organic amine, wherein the mass ratio of the alkaline ionic liquid to the organic amine is 0.2-1:1. The total mass concentration of the solute of the aqueous solution is 20-40 percent. The alkaline ionic liquid which is the functional ionic liquid is used as the additive and is compounded with the organic amine which is the traditional removing solvent to obtain the compound absorbent which can improve the acid gas absorption performance, reduce the process energy consumption and ensure the zero emission of the energy and has the characteristics of reutilization and economical efficiency.

Owner:NANJING UNIV

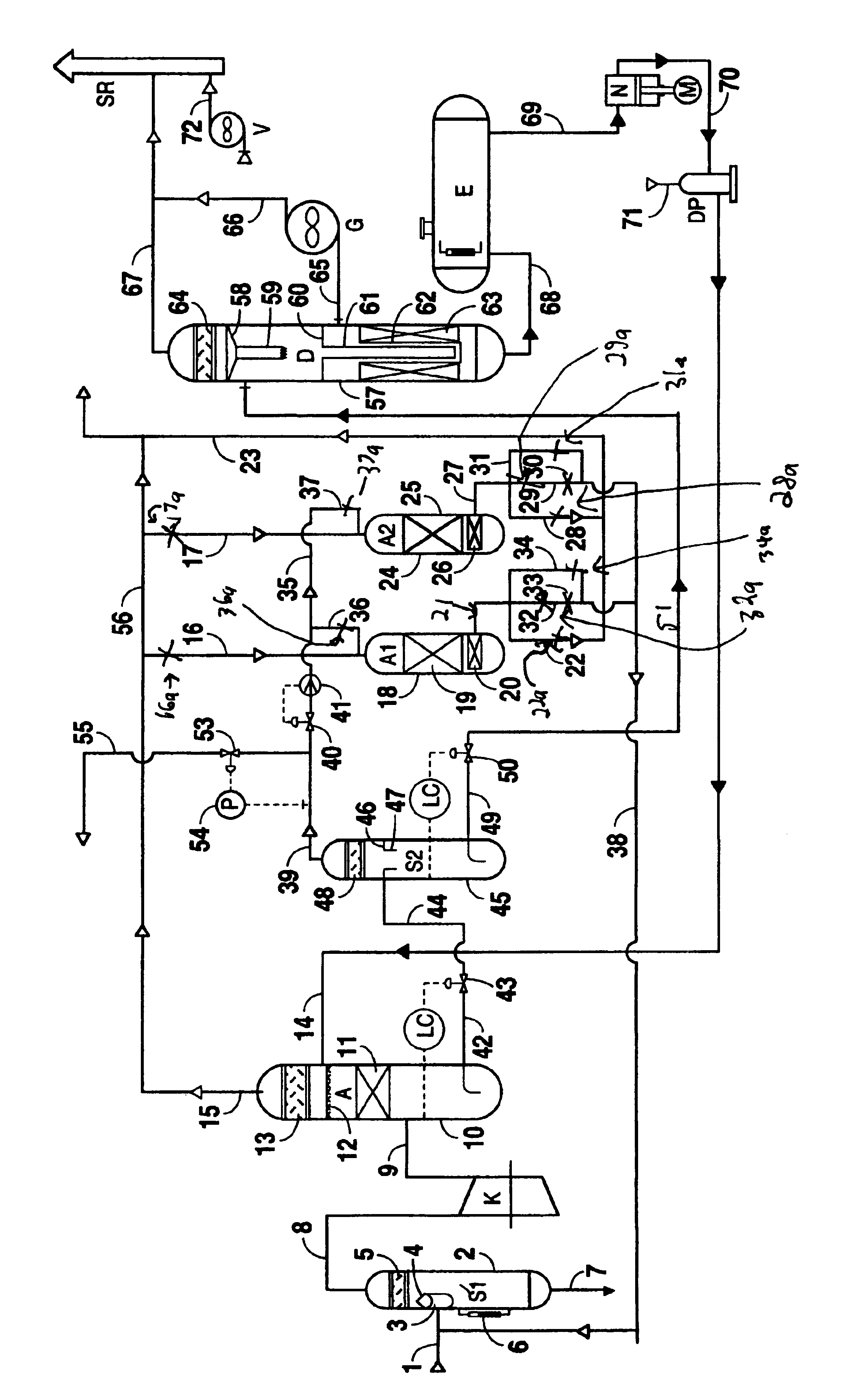

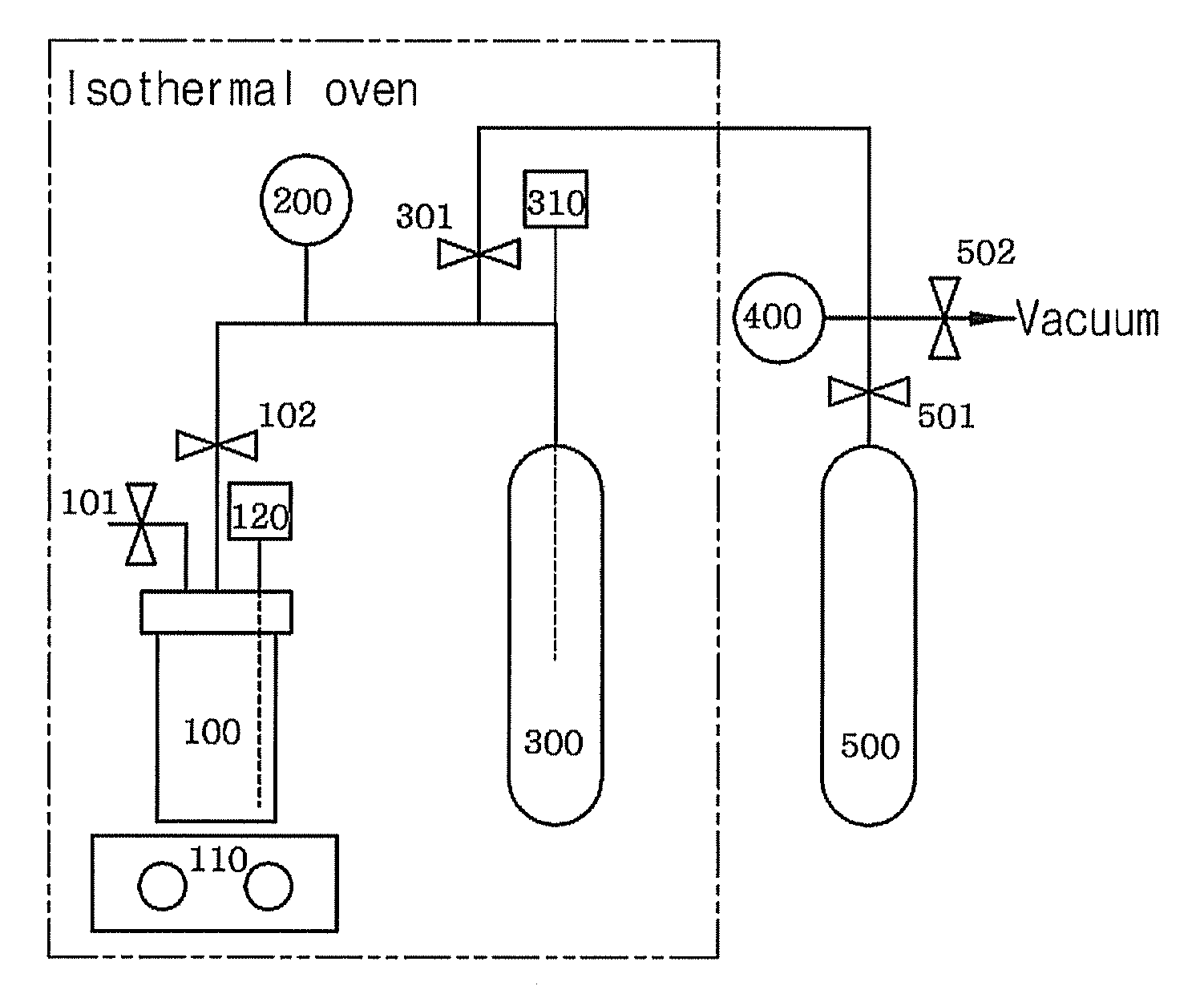

Chemical link coupling catalytic reforming hydrogen making method and device

InactiveCN101439844ARealize recyclingLow costHydrogen separationChemical recyclingCatalytic reformingDecomposition

The invention provides a low-cost, high-benefit and environment-friendly method for hydrogen production by coupling and catalytic reforming of chemical chains and a device thereof. The method couples the chemical circulation process that a carbon dioxide absorbent absorbs and releases carbon dioxide and the reaction process that a hydrogen-containing substance produces hydrogen by catalytic reforming to realize the regeneration and recovery of a catalyst and the carbon dioxide absorbent and realize the hydrogen production process with low cost, high benefit, and environmental protection through a catalyst regeneration device and an absorbent calcination decomposition device.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

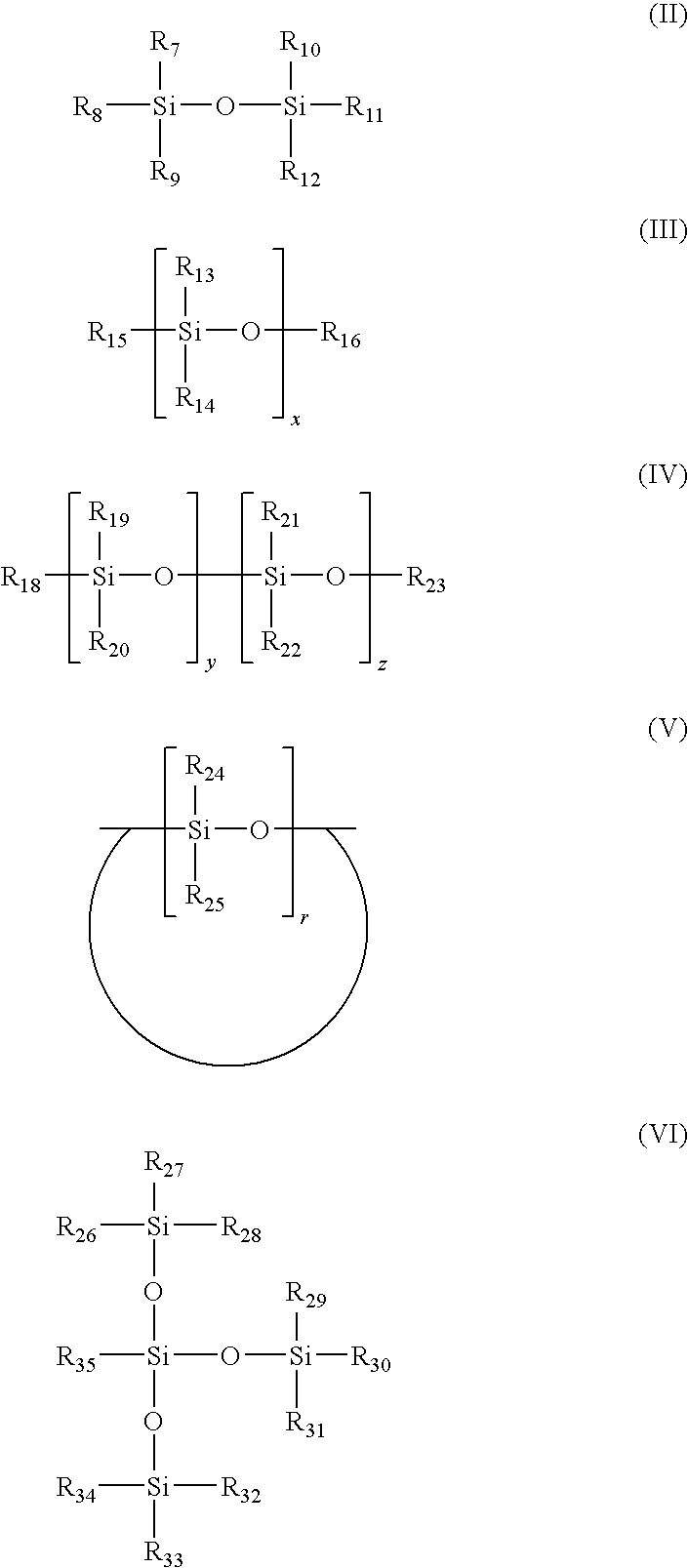

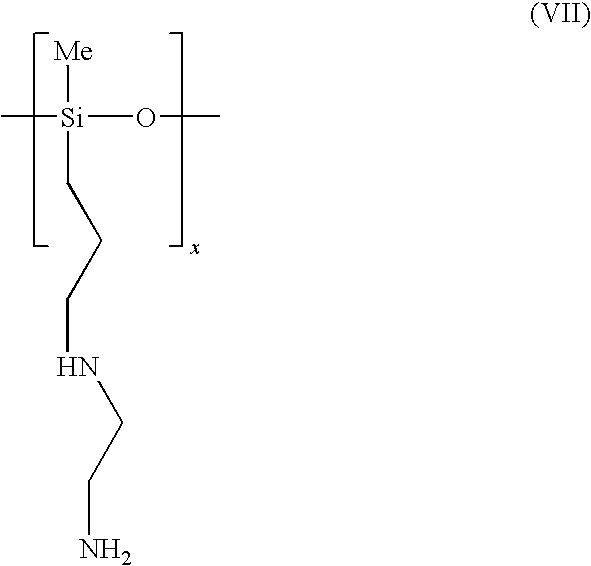

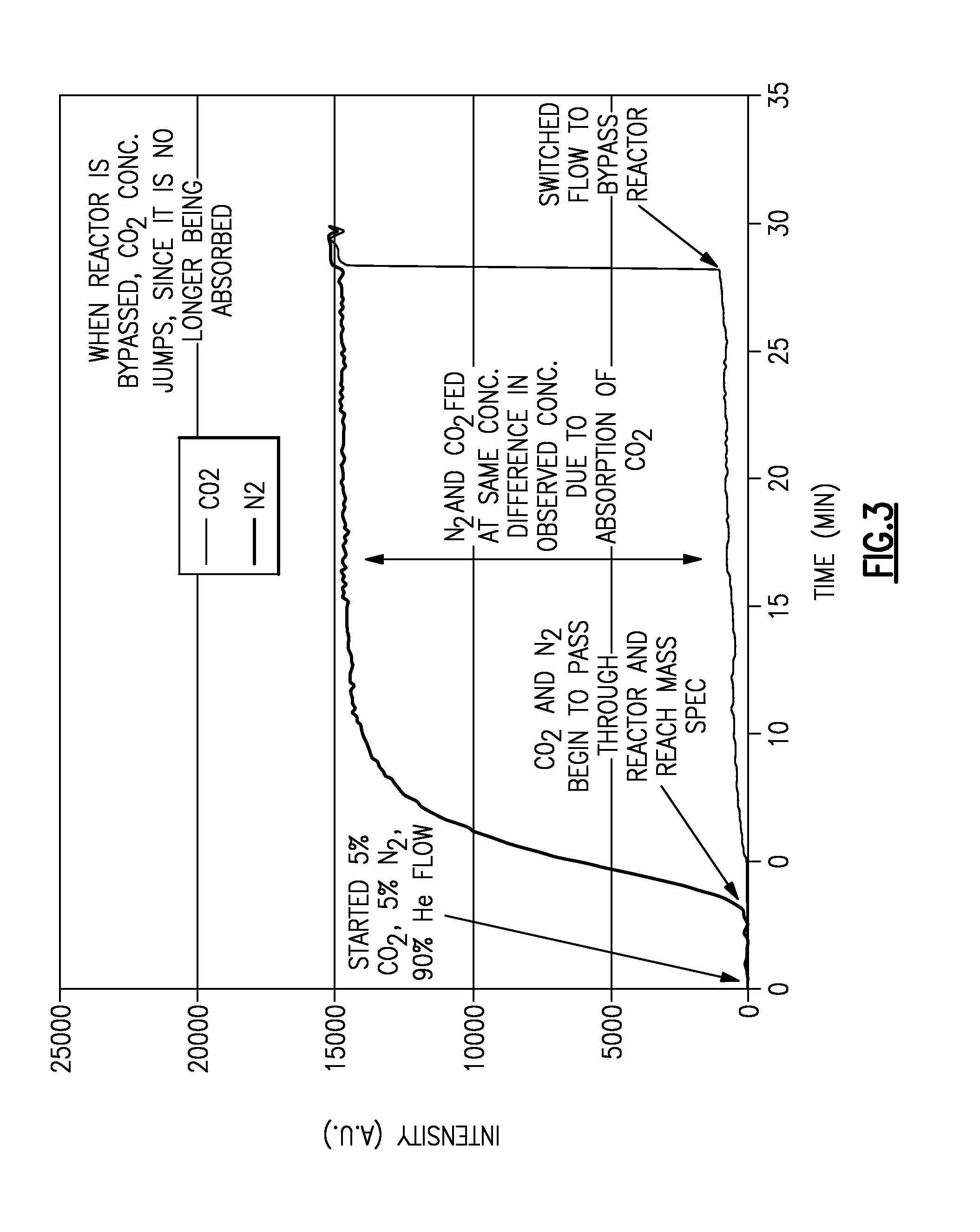

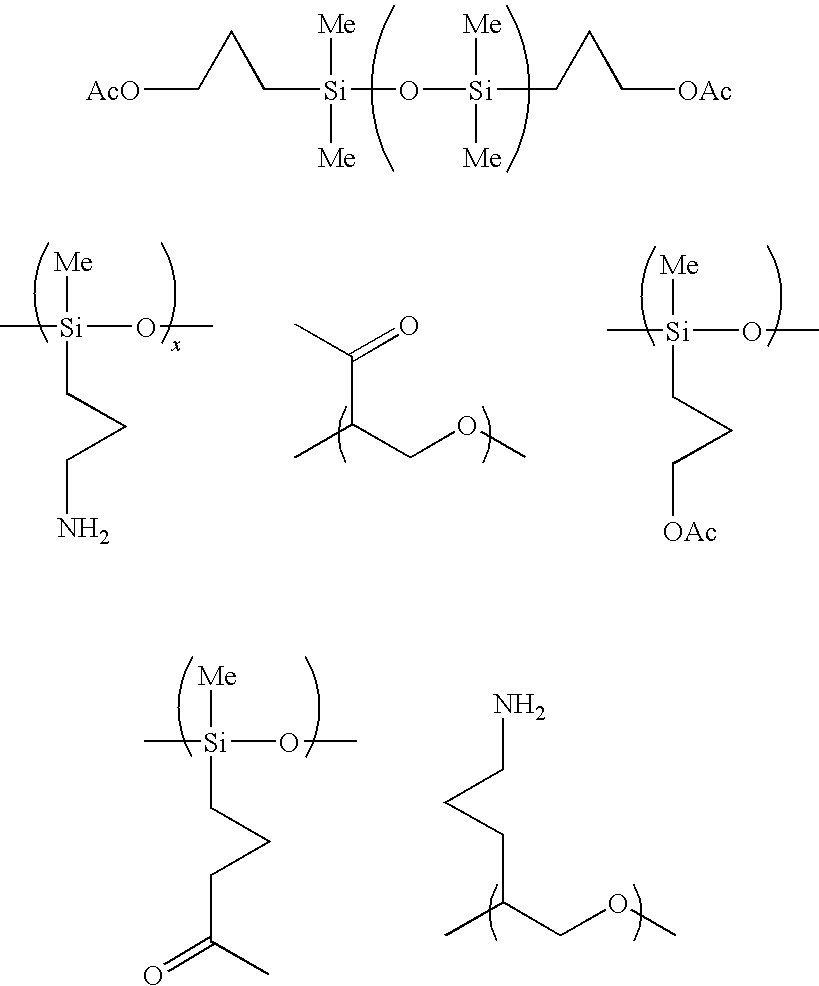

Liquid carbon dioxide absorbent and methods of using the same

InactiveUS20100154639A1Low costImprove thermal stabilityOther chemical processesUsing liquid separation agentPower stationLiquid carbon

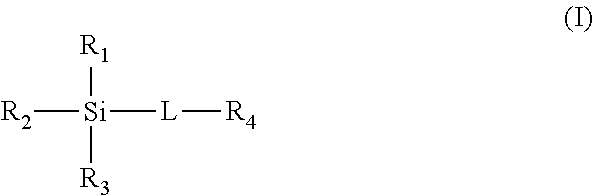

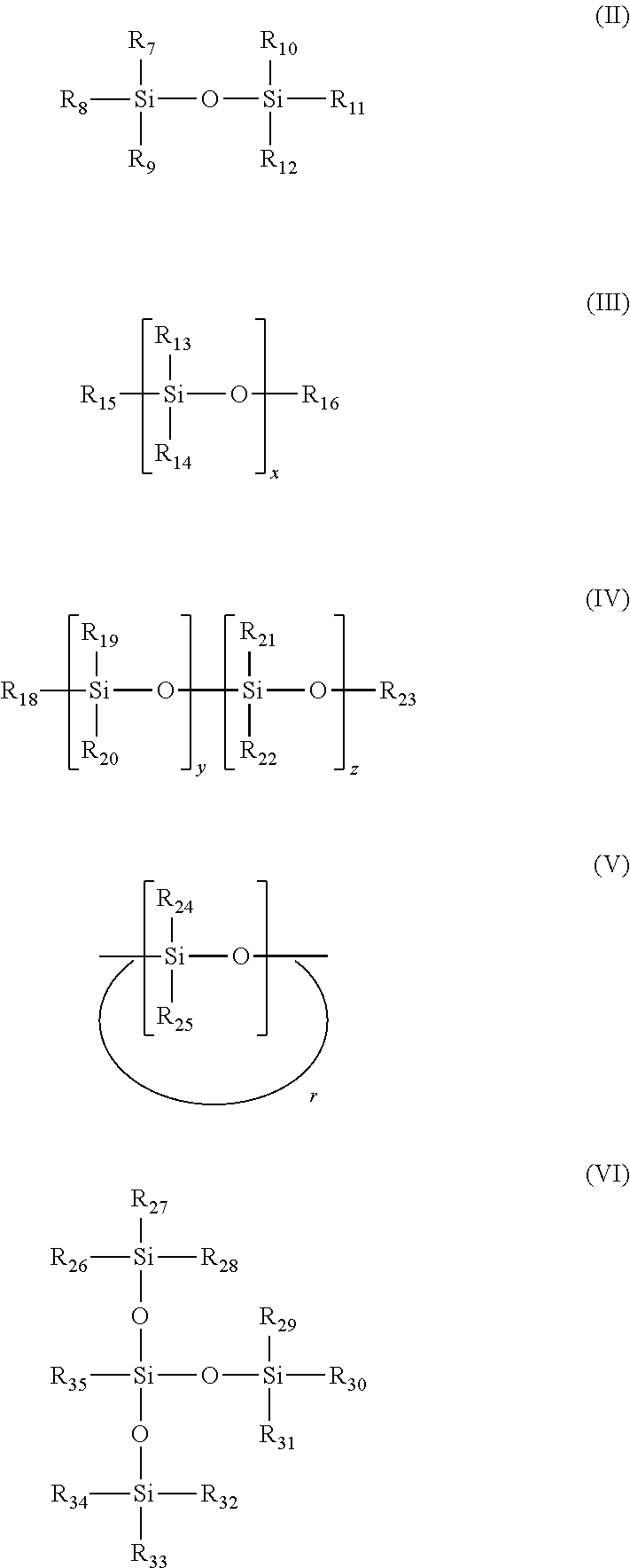

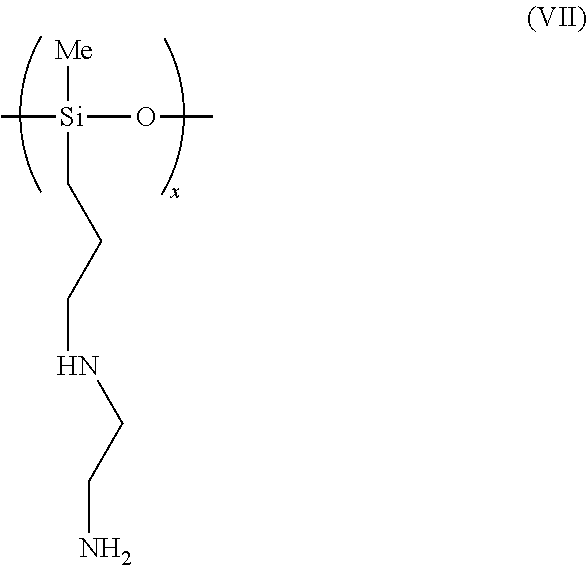

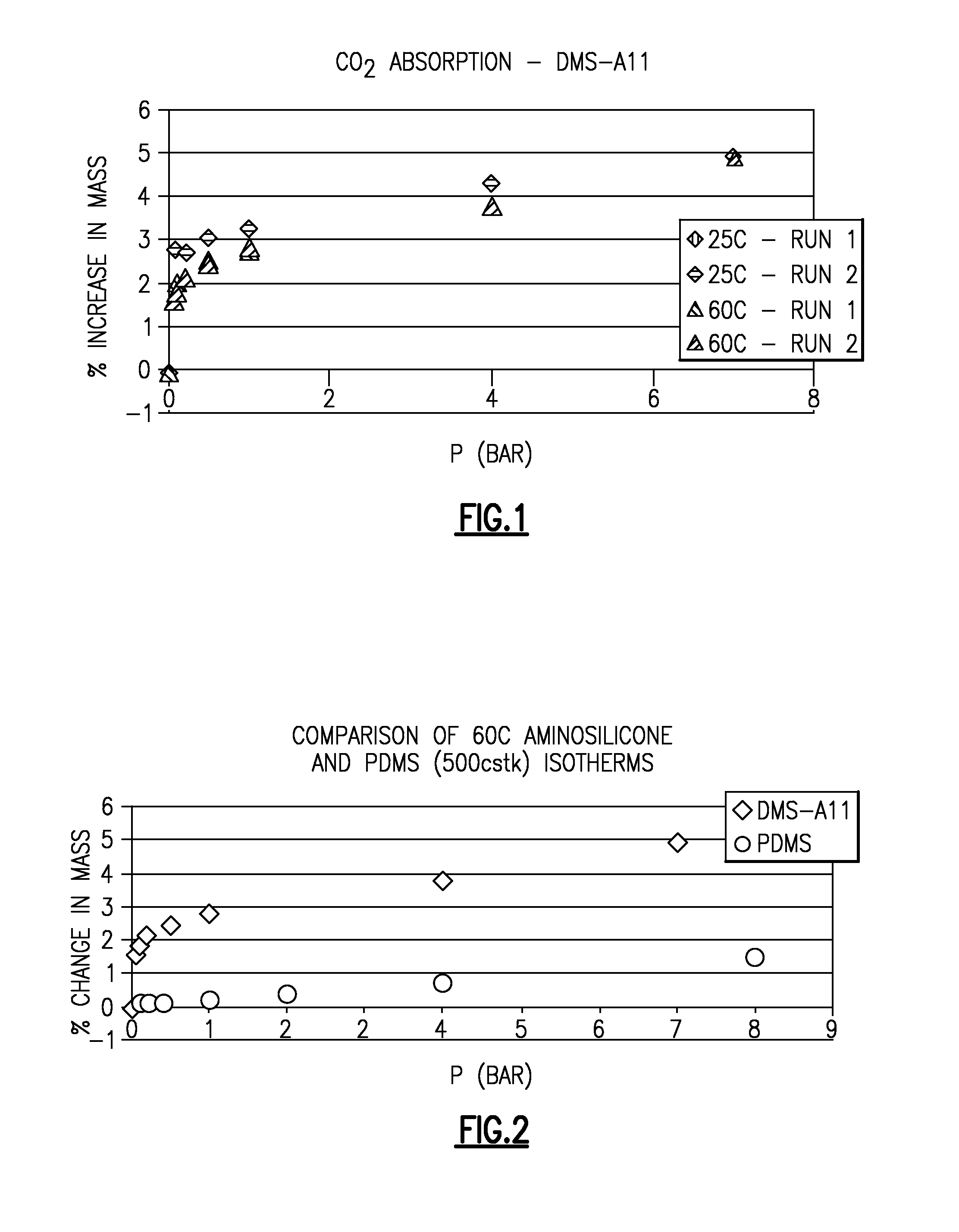

A carbon dioxide absorbent comprising (i) a liquid, nonaqueous silicon-based material, functionalized with one or more groups that either reversibly react with CO2 or have a high-affinity for CO2 is provided and (ii) a hydroxy-containing solvent. The absorbent may be utilized in methods to reduce carbon dioxide in an exhaust gas, and finds particular utility in power plants.

Owner:GENERAL ELECTRIC CO

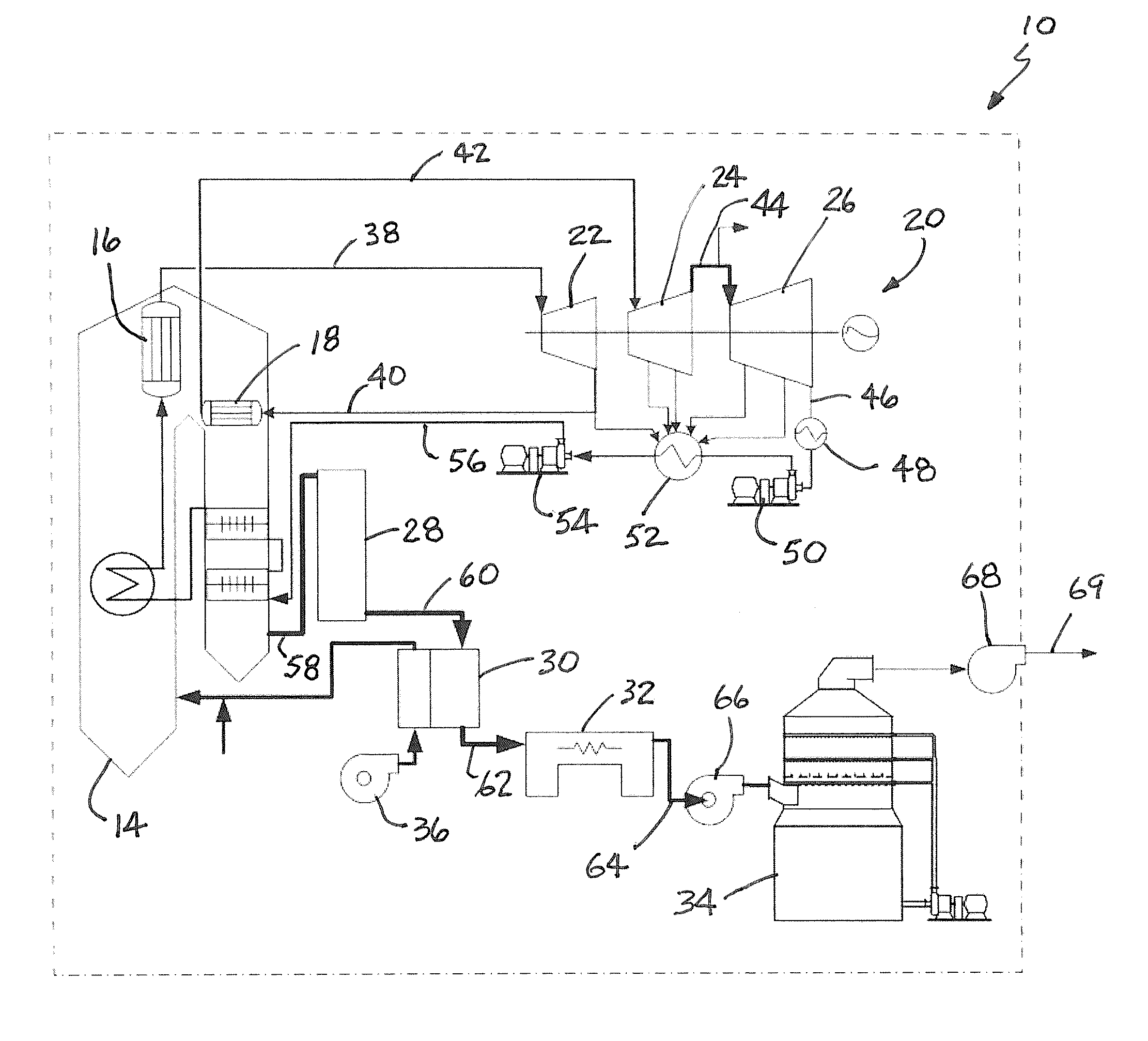

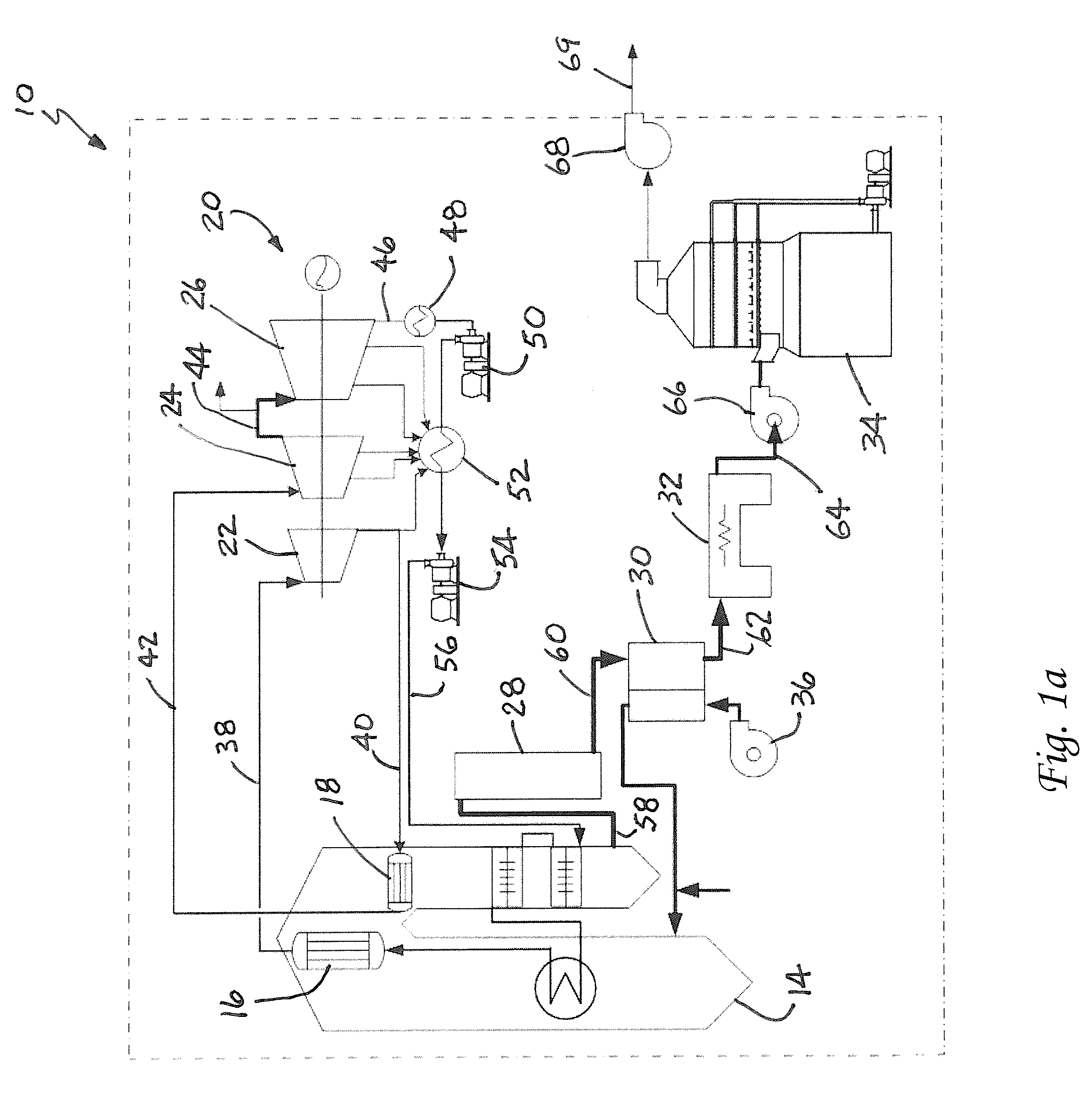

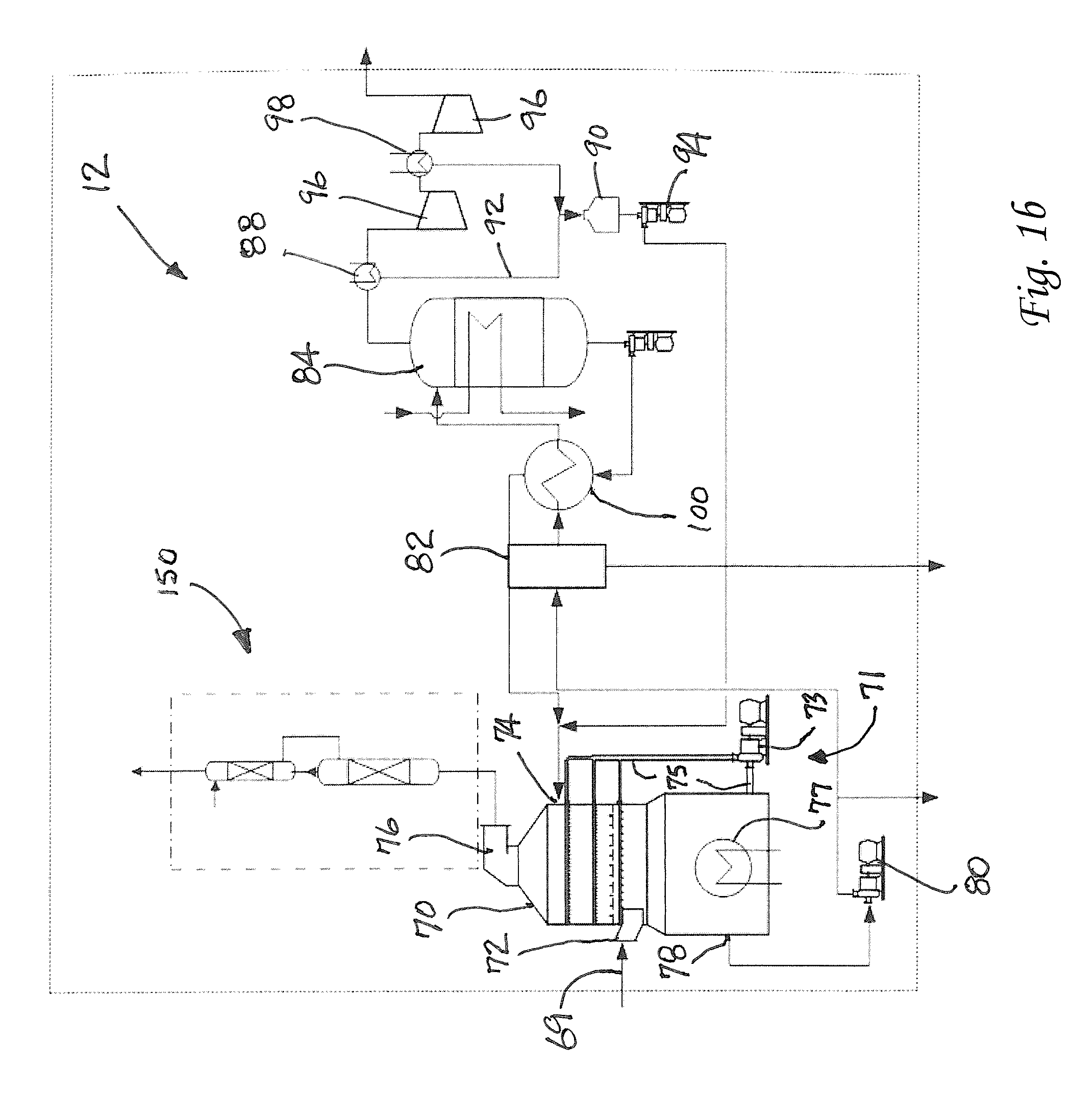

Method for Removing CO2 from Coal-Fired Power Plant Flue Gas Using Ammonia as the Scrubbing Solution, with a Chemical Additive for Reducing NH3 Losses, Coupled with a Membrane for Concentrating the CO2 Stream to the Gas Stripper

ActiveUS20110311429A1Improve concentrationCombination devicesMembranesAmmoniaCarbon dioxide scrubber

A method for removing and capturing carbon dioxide from a fluid stream includes the steps of exposing the fluid stream to an aqueous scrubbing solution that removes and holds carbon dioxide from the fluid stream, passing the aqueous scrubbing solution through a membrane in order to separate excess water from the scrubbing solution and increase the concentration of carbon dioxide in the scrubbing solution, heating the scrubbing solution having an increased concentration of carbon dioxide so as to release carbon dioxide gas and recycling the scrubbing solution. A carbon dioxide capture apparatus includes a carbon dioxide scrubber, a membrane downstream from the scrubber for separating water and concentrating carbon dioxide in a scrubbing solution and a stripper vessel.

Owner:UNIV OF KENTUCKY RES FOUND

Active air-regulating agent for air-regulating temperature-control device

InactiveCN103621618AInhibition of respirationInhibitory activityFruit and vegetables preservationContainers preventing decayCellular respirationEvaporation

The invention belongs to the field of active air-regulating agents used in storage and transportation, and particularly relates to an active air-regulating agent for an air-regulating temperature-control device. The active air-regulating agent for the air-regulating temperature-control device is characterized by comprising a carbon dioxide absorbent, a deoxidizing agent, an ethylene removal agent, a humidity control agent and a carbon dioxide releasing agent. By adopting the active air-regulating agent in the invention, influences from the proportion of nitrogen, oxygen, carbon dioxide, ethylene and the like in the gas on the storage of fruits and vegetables, and meat are reduced, and the active air-regulating agent has the effects of inhabiting the breath of cells, delaying the processes of after-ripening and aging, preventing water evaporation and restraining microbial activities; in addition, the oxide and carbon dioxide are controlled in an appropriate proportion, so that better fresh-keeping effect is achieved, and the storage and transportation of foods are facilitated.

Owner:SHANDONG INST OF COMMERCE & TECH

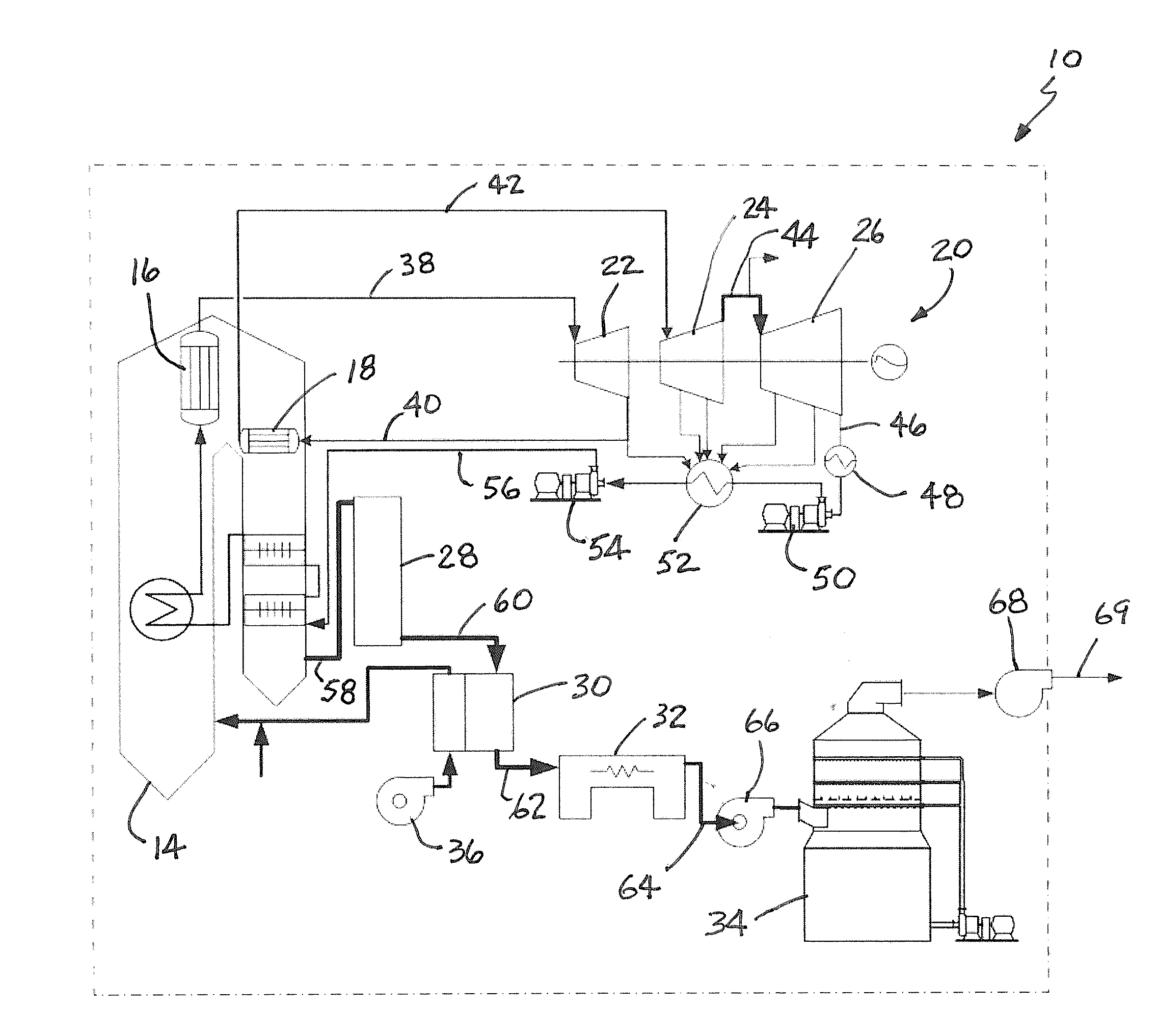

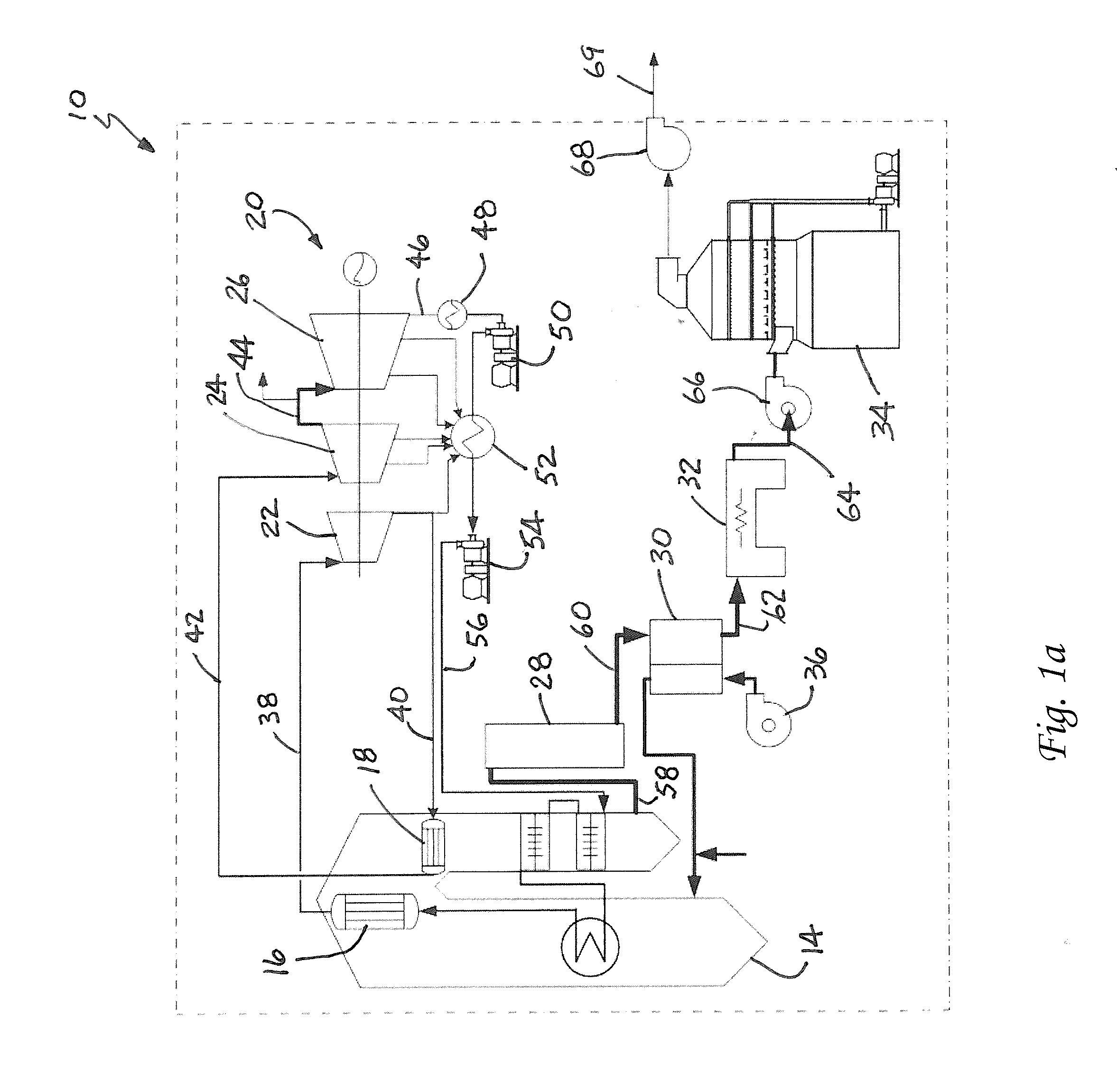

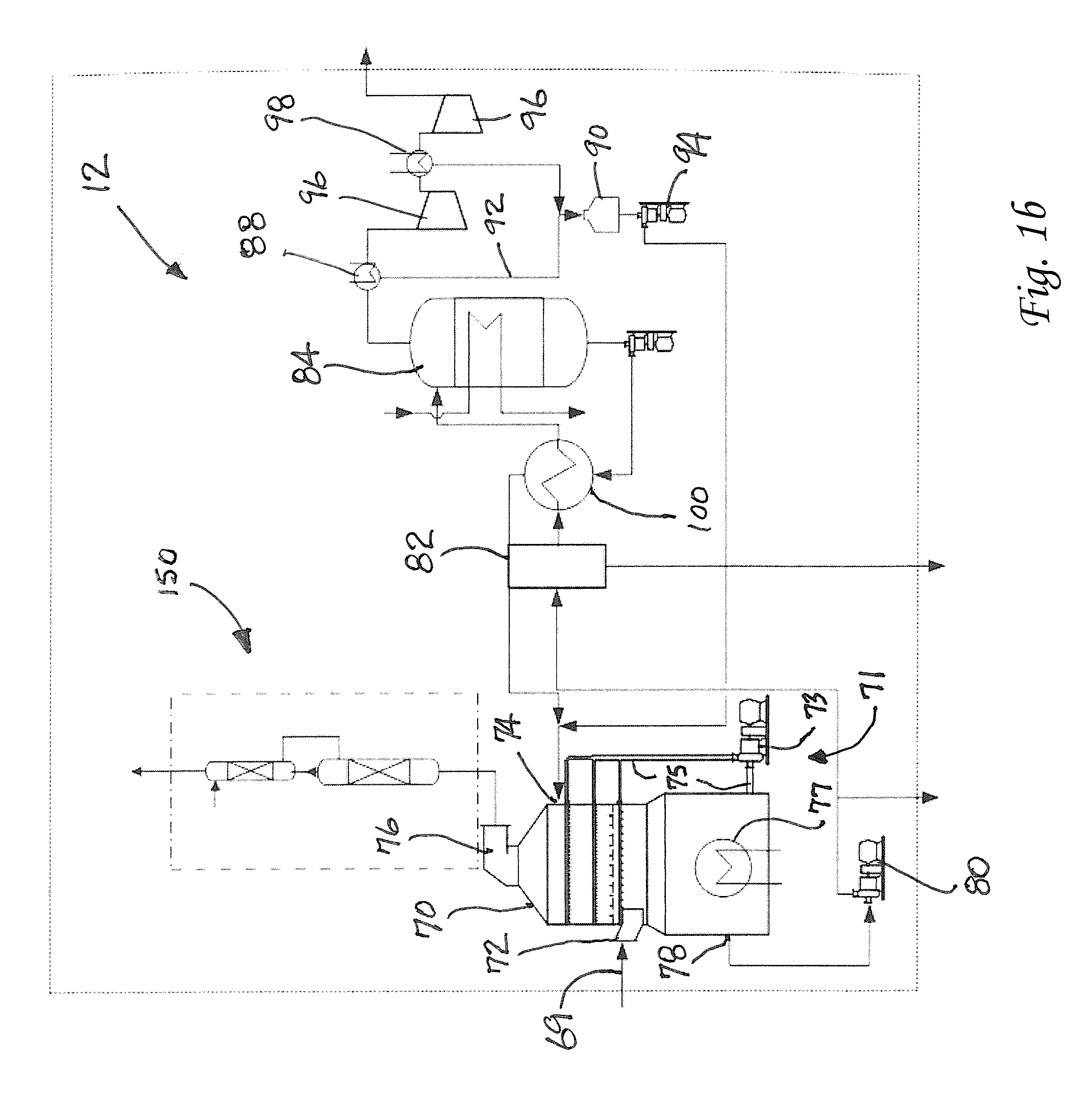

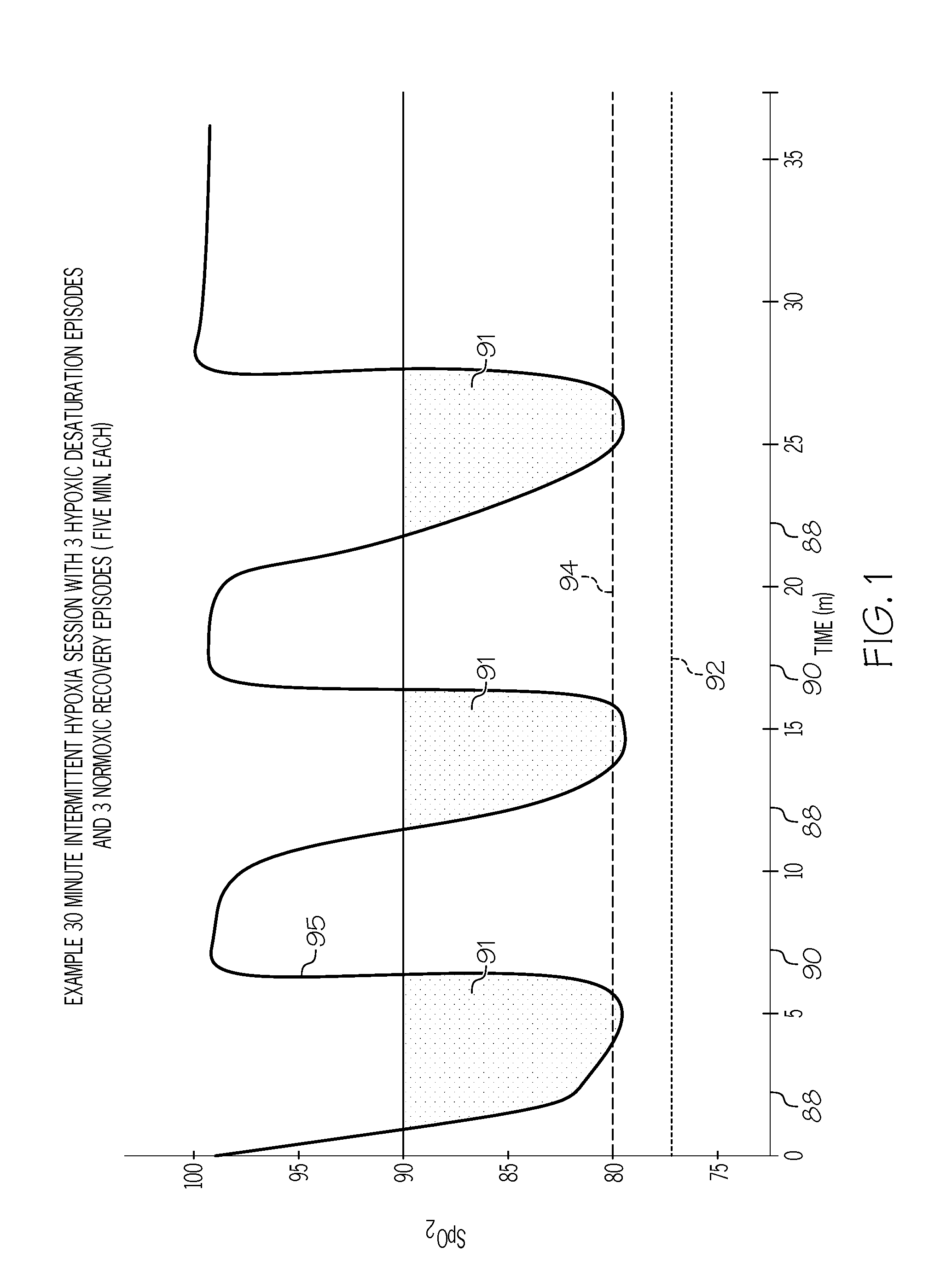

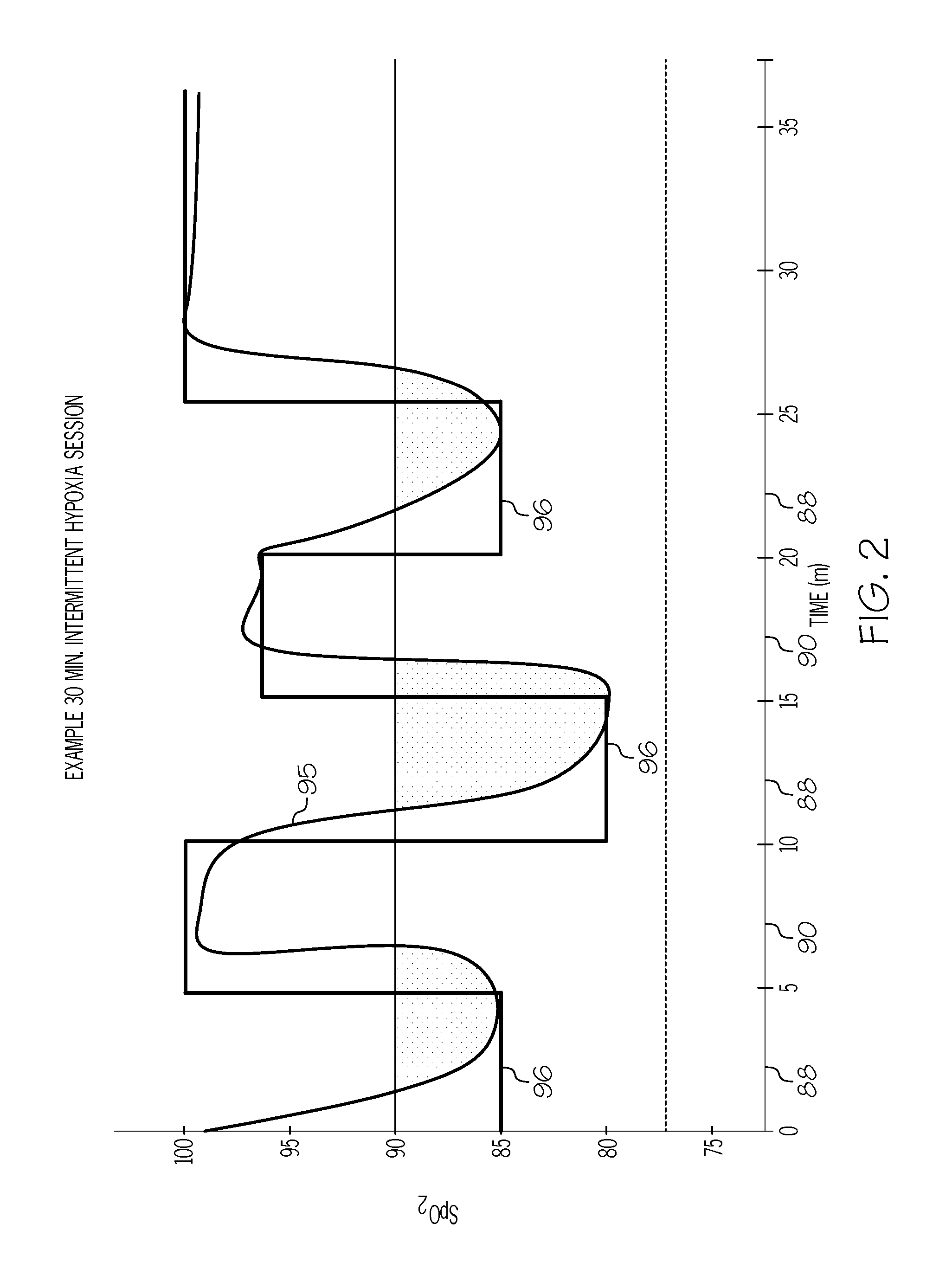

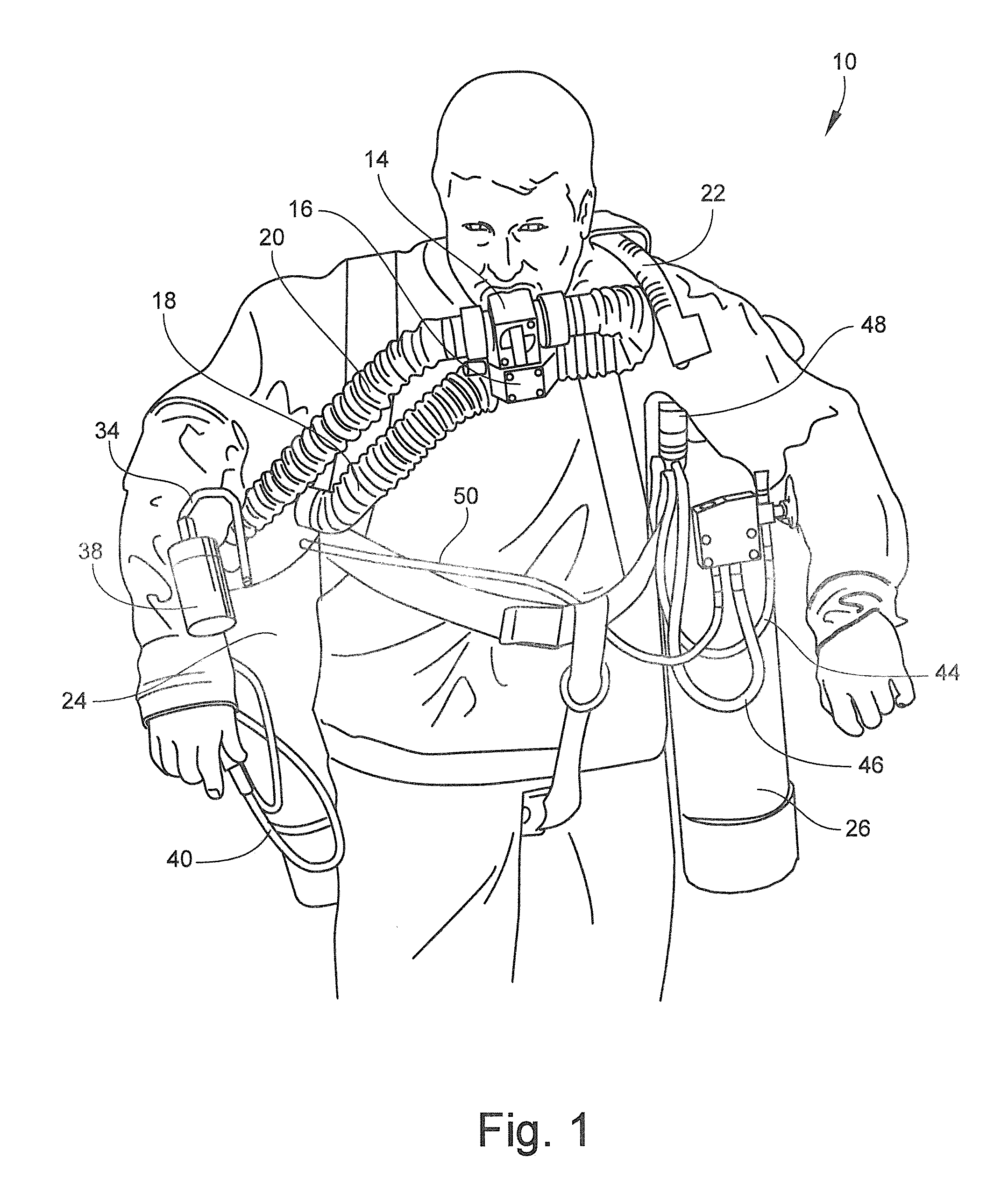

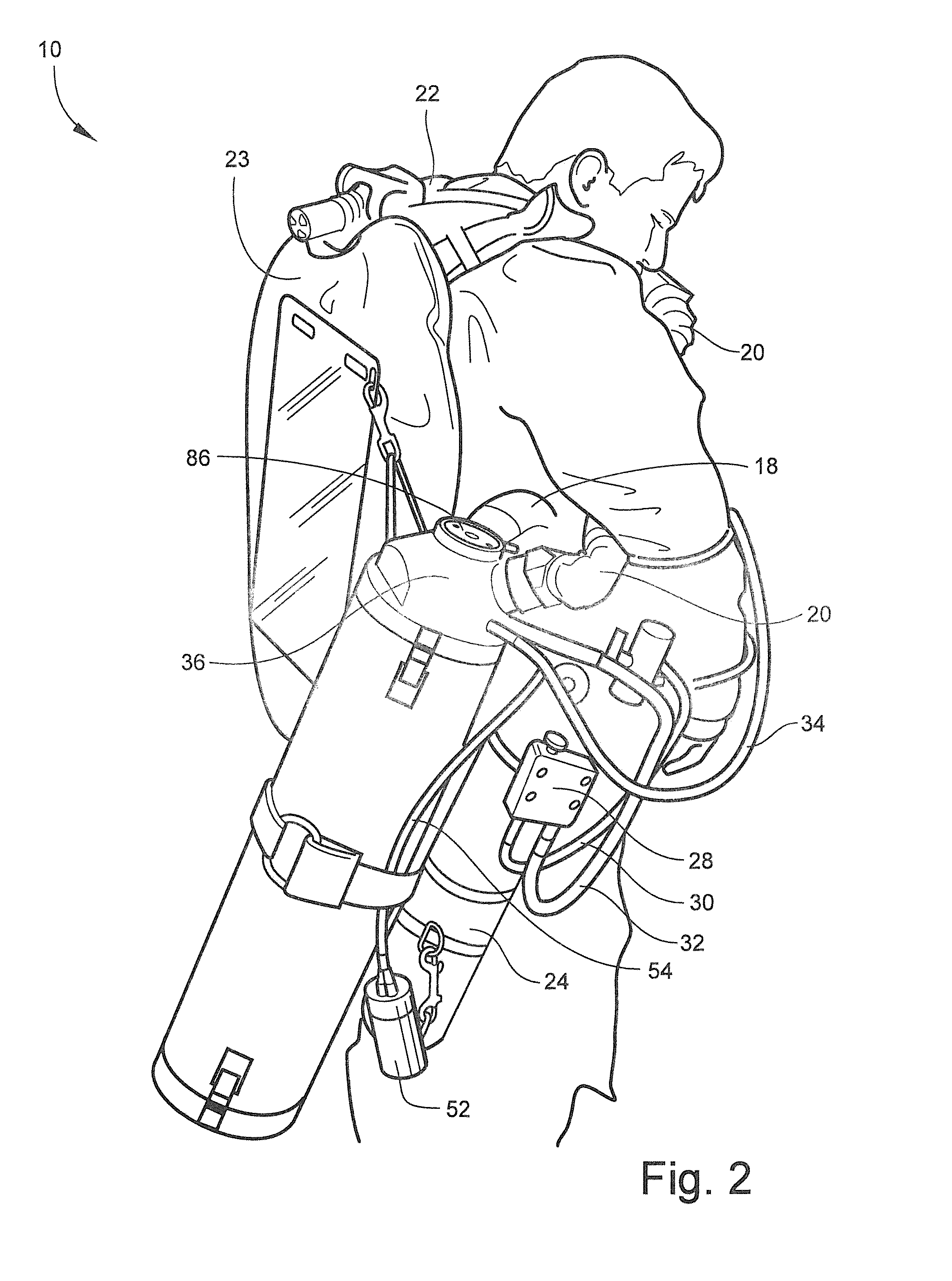

Hypoxic Breathing Apparatus and Method

InactiveUS20160095994A1Gas treatmentOperating means/releasing devices for valvesIntensive care medicineCarbon dioxide scrubber

A breathing apparatus includes a breathing mask, hose, and first housing in fluid communication with the hose and breathing mask. The first housing has first and second chambers which are separated by a barrier comprising a carbon dioxide scrubber. The breathing apparatus is configured to conduct hypoxic therapy and tailor the therapeutic session to the patient while collecting data about patient response.

Owner:THIRD WIND LLC

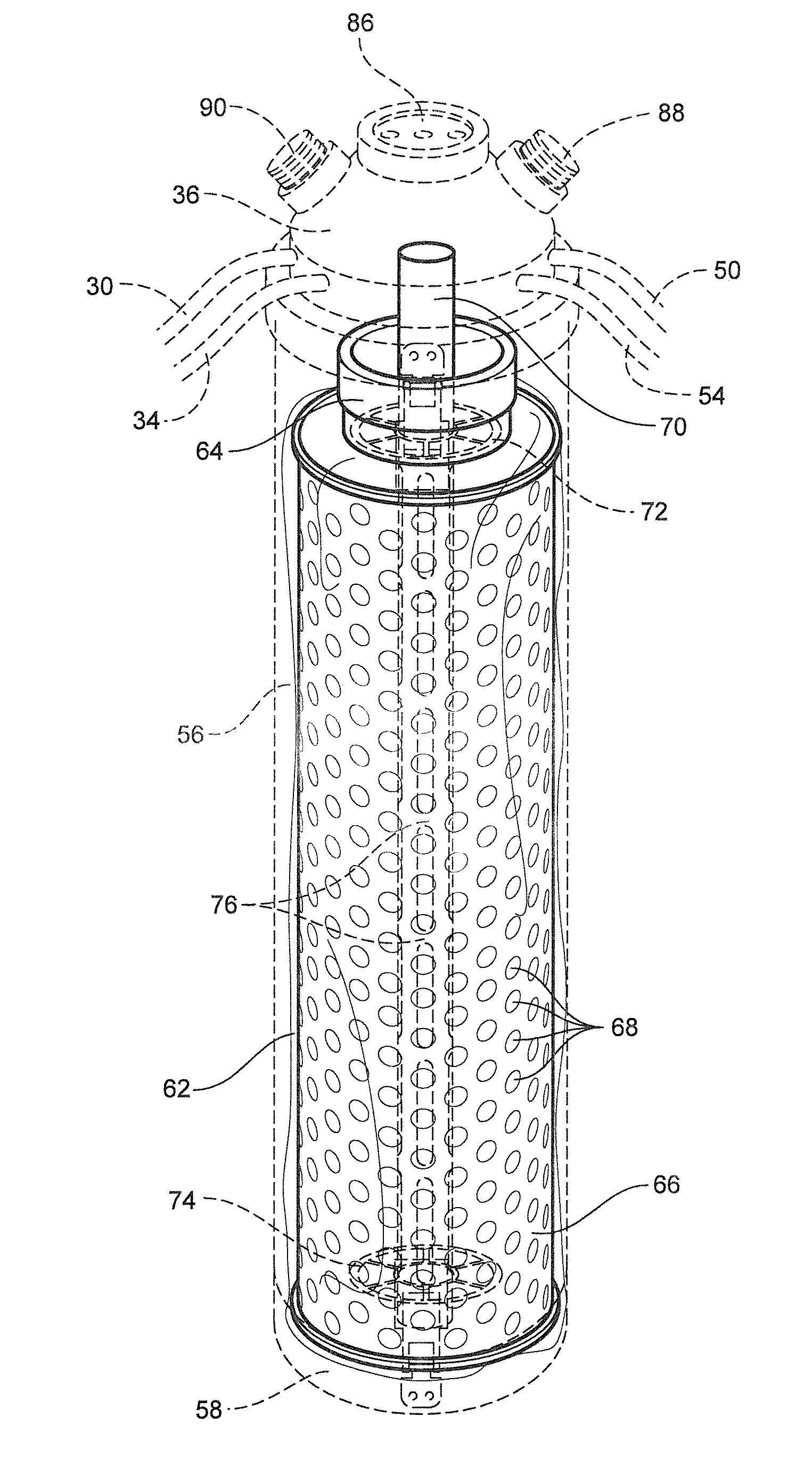

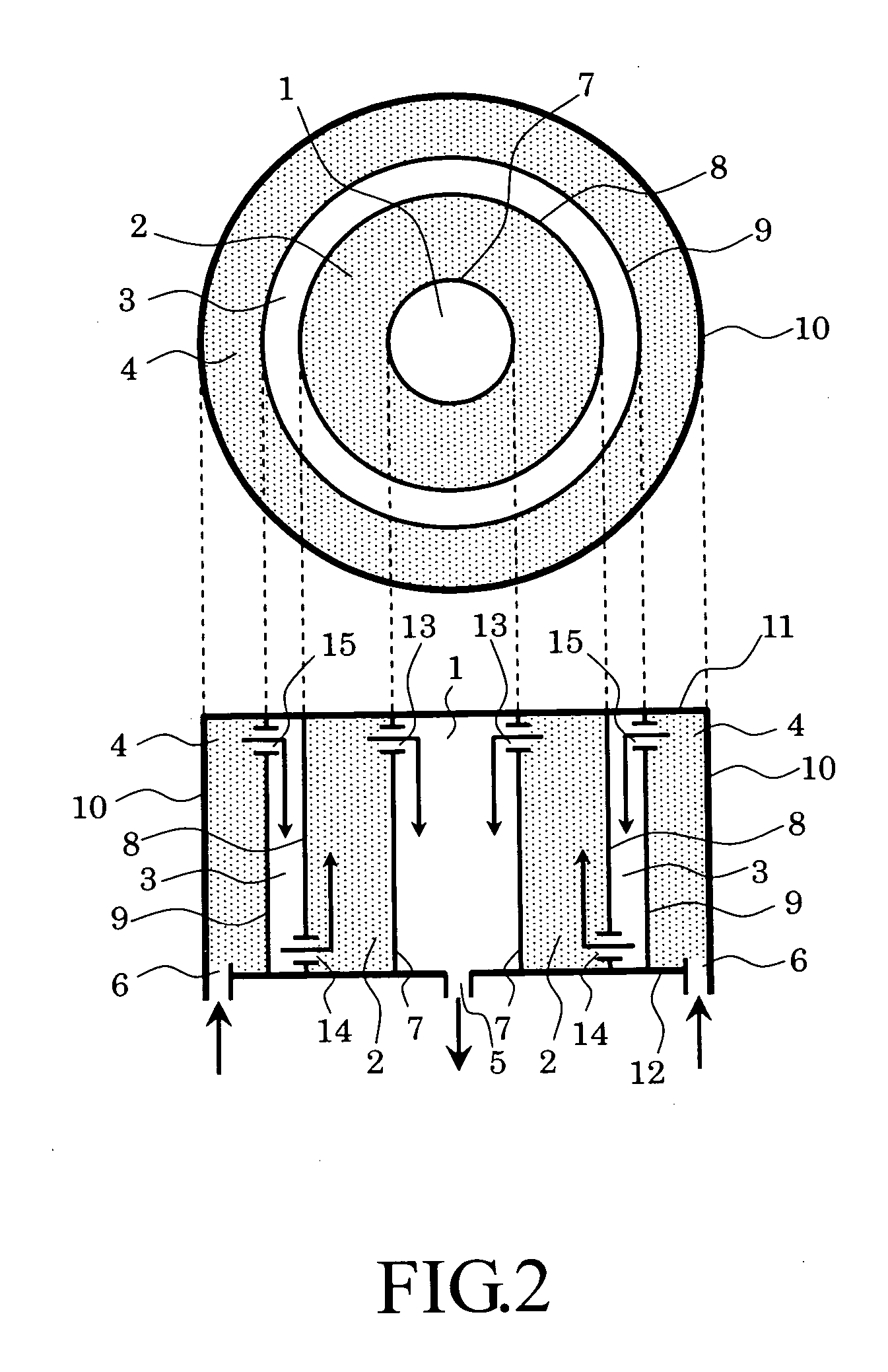

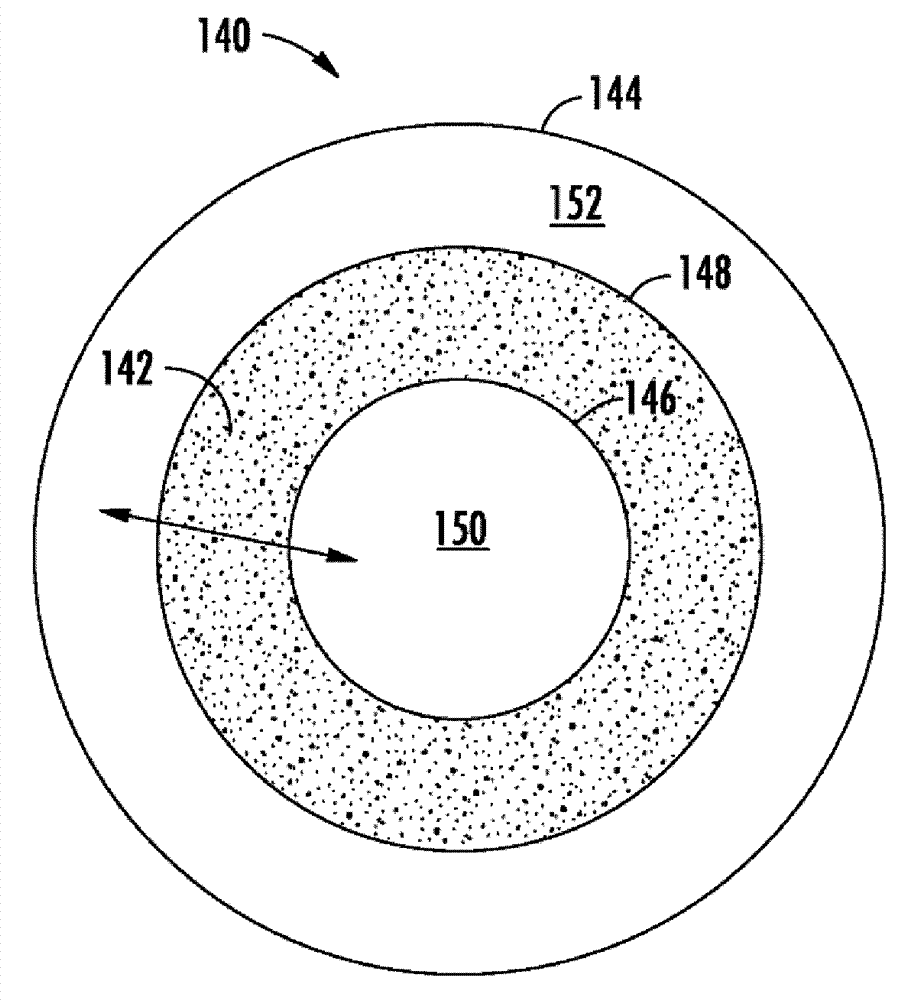

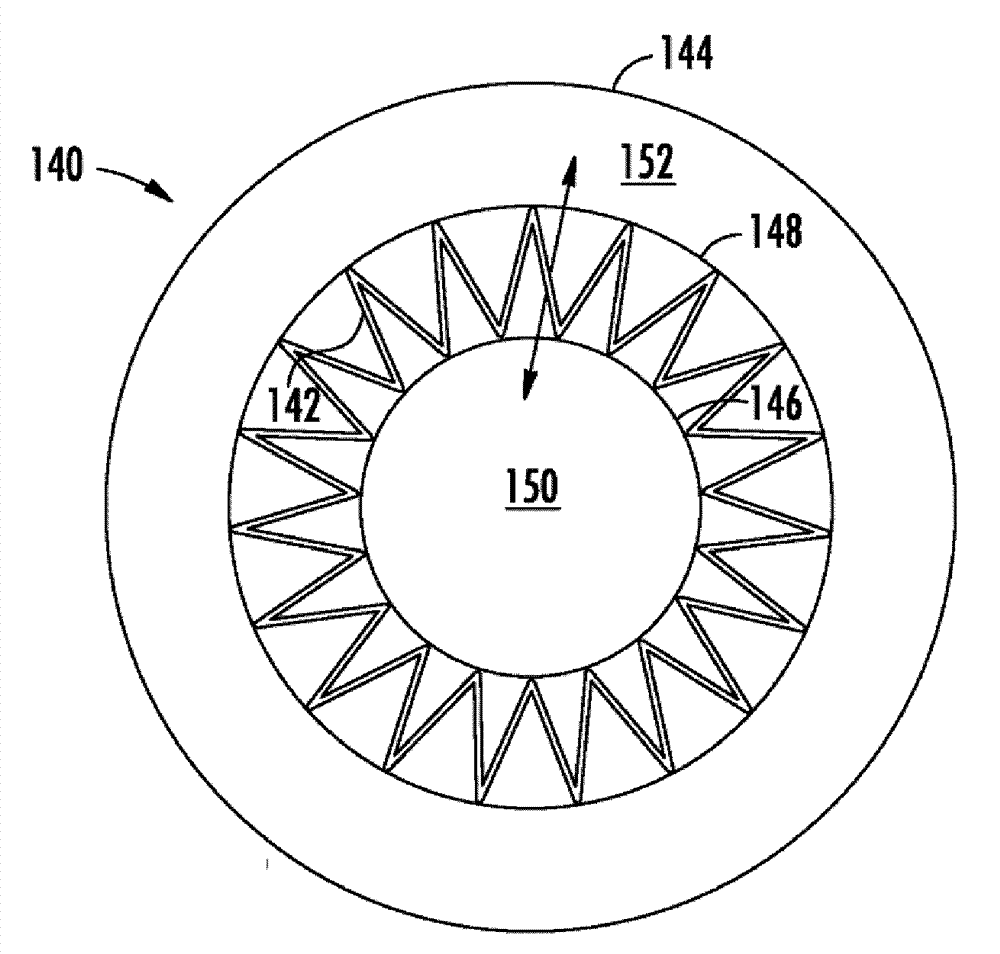

Closed circuit rebreather

InactiveUS20100242966A1RespiratorsOperating means/releasing devices for valvesCo2 absorptionEngineering

A closed circuit rebreather including a breathing hose assembly, head assembly and internal counterlung assembly having axial and radial gas flow passageways therethrough, wherein the assembly is housed within a tank and includes a scrubber substantially enclosed along its longitudinal length within a water impervious counterlung bladder, the scrubber including foraminous inner and outer tubes having a carbon dioxide absorbent material filling the space therebetween.

Owner:JOHNSON CHARLES L

Liquid carbon dioxide absorbents, methods of using the same, and related systems

A carbon dioxide absorbent composition is described, including (i) a liquid, nonaqueous silicon-based material, functionalized with one or more groups that either reversibly react with CO2 or have a high-affinity for CO2; and (ii) a hydroxy-containing solvent that is capable of dissolving both the silicon-based material and a reaction product of the silicon-based material and CO2. The absorbent may be utilized in methods to reduce carbon dioxide in an exhaust gas, and finds particular utility in power plants.

Owner:AIR PROD & CHEM INC

Liquid carbon dioxide absorbent and methods of using the same

A carbon dioxide absorbent comprising a liquid, nonaqueous oligomeric material, functionalized with one or more groups that either reversibly react with CO2 or have a high-affinity for CO2 is provided. The absorbent may be utilized in methods to reduce carbon dioxide in an exhaust gas, and finds particular utility in power plants.

Owner:GENERAL ELECTRIC CO

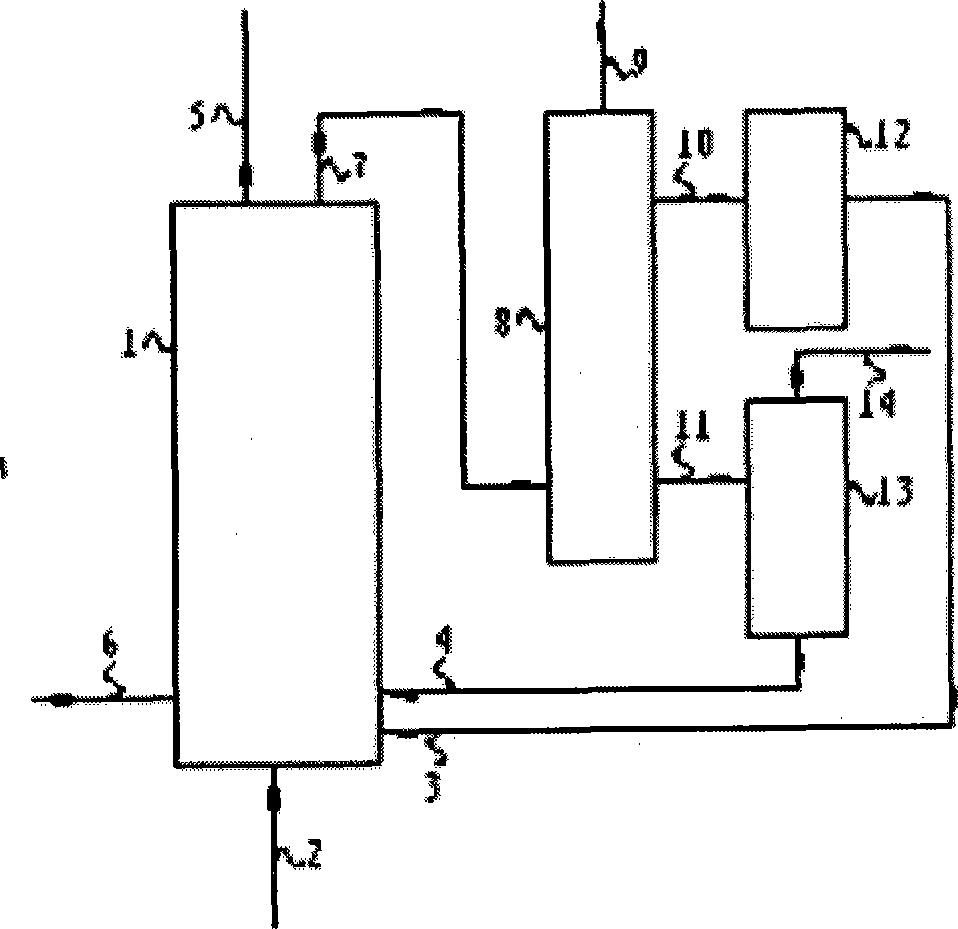

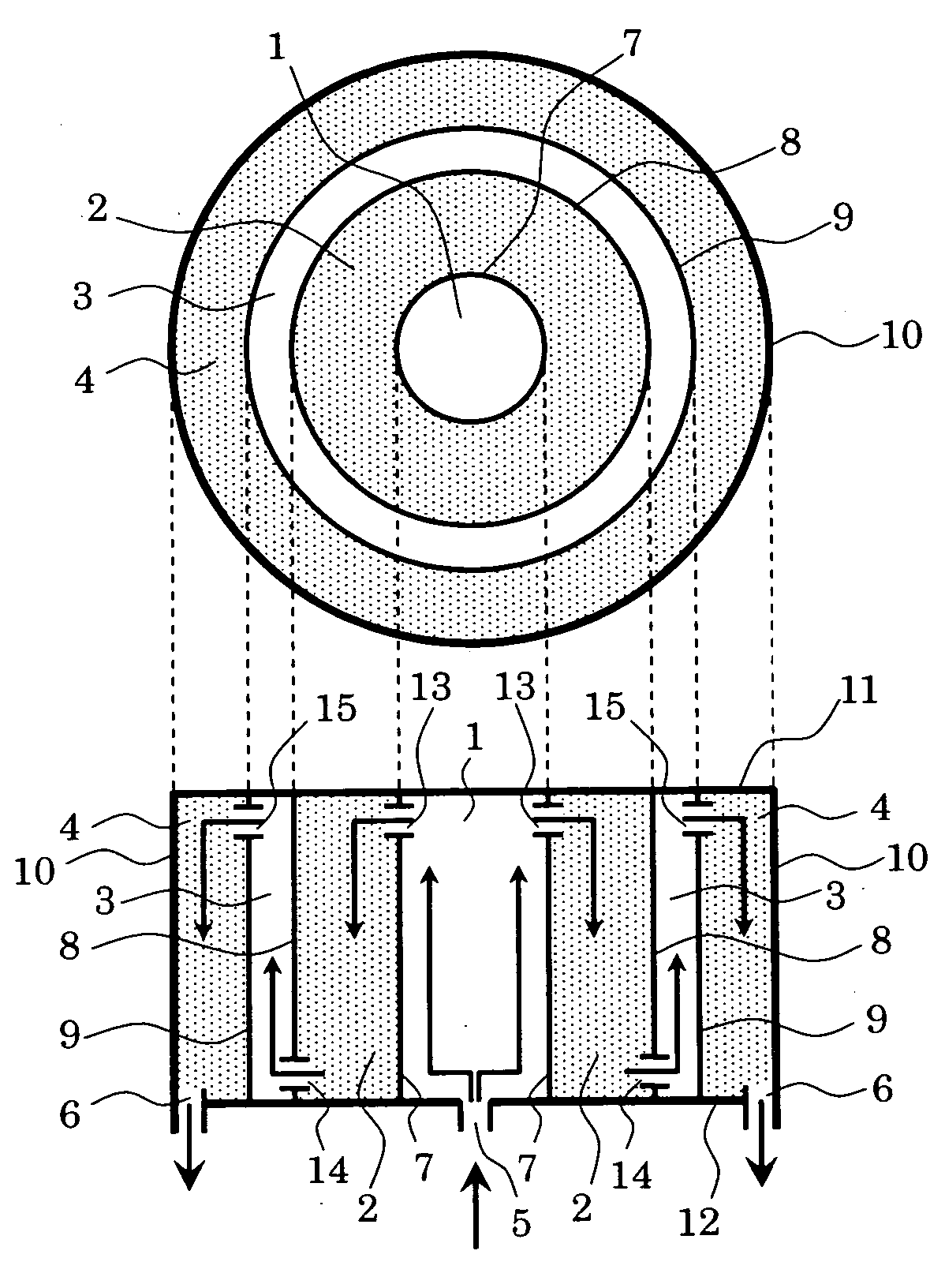

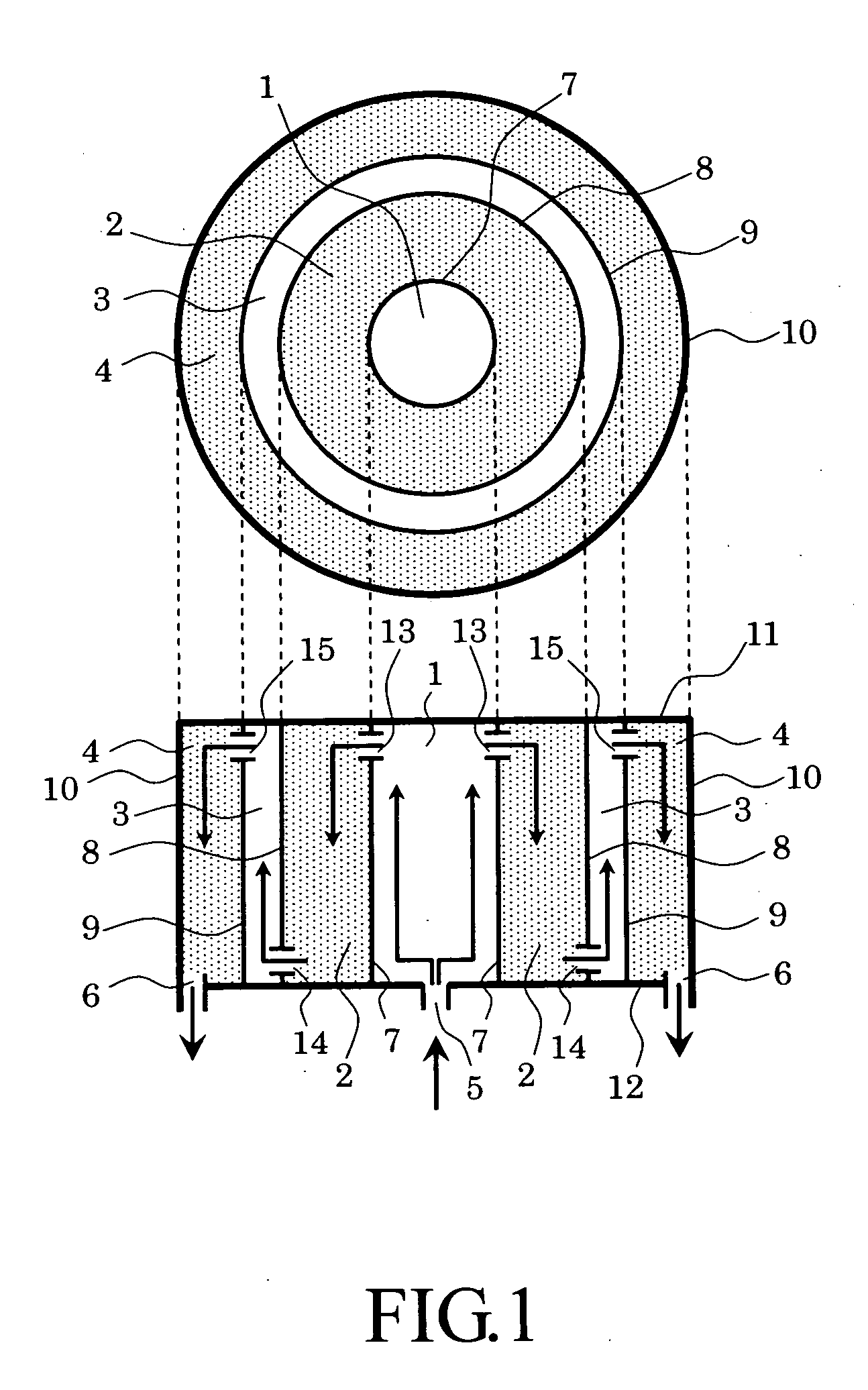

Chemical reaction apparatus

InactiveUS20050025682A1High hydrogen yieldIncreased hydrogen productionPhysical/chemical process catalystsHydrogen separation using solid contactHydrogenChemical reaction

A chemical reaction apparatus includes a reaction chamber and a carbon dioxide absorbent chamber disposed behind the reaction chamber in adjacent to it. The reaction chamber generates a gas containing hydrogen and carbon dioxide from the material gas, and the carbon dioxide absorbent chamber absorbs carbon dioxide from the gas generated from the reaction chamber.

Owner:KK TOSHIBA

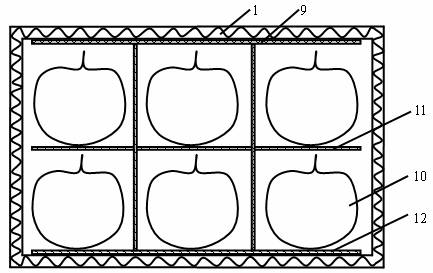

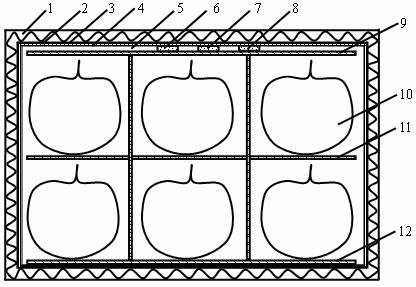

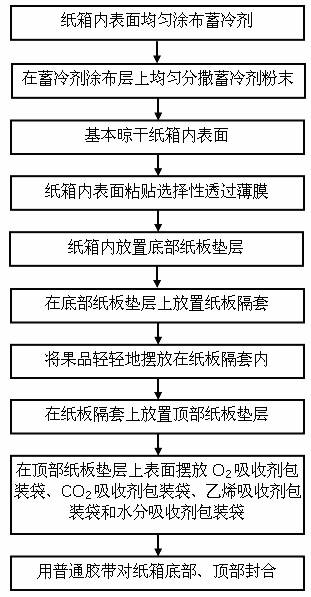

Fruit preserving carton and fruit preserving and storing method utilizing same

InactiveCN102009792AImprove preservation qualityExtended shelf lifeFruit and vegetables preservationPackaging under vacuum/special atmosphereCardboardCarton

The invention discloses a fruit preserving carton, wherein a coating layer is coated on the inner surface of the carton, a cold storing agent powder layer is uniformly scattered on the coating layer, then a selective permeable thin film is stuck on the inner surface of the cold storing agent powder layer, and an oxygen absorbent, a carbon dioxide absorbent, an ethylene absorbent and a water absorbent are respectively uniformly flatly laid and placed on the upper surface of a top paperboard cushion layer. The invention further discloses a carton preserving and storing method utilizing the fruit preserving carton, and the method comprises the following steps: placing fruits among partitions of the carton; then laying the top paperboard cushion layer on a paperboard spacing sleeve; uniformly flatly laying packaging bags filled with the oxygen absorbent, the carbon dioxide absorbent, the ethylene absorbent and the water absorbent respectively on the top paperboard cushion layer; and finally sealing the bottom and top of the carton in which fruits are well loaded. By utilizing the fruit preserving carton and the carton preserving and storing method, the preserving and storing quality of the fruits can be significantly improved, the preservation period is prolonged, requirements of food hygiene can be completely met, storage and transportation can be carried out conveniently, and the cost is low.

Owner:XIAN UNIV OF TECH

Removal of carbon dioxide from air

The present invention relates to a method for removing CO2 from air comprising exposing an absorbent-covered surface to air. The invention also provides means for exposing air to a CO2 absorbent. In another aspect, the present invention provides methods and apparatus for separating bound carbon dioxide (CO2) in absorbents.

Owner:GLOBAL RES TECH

Carbon dioxide absorbent and preparation method

ActiveCN101104128AHigh strengthReduce humidityDispersed particle separationAir quality improvementCalcium hydroxideLithium hydroxide

The invention discloses the carbon dioxide absorbent and the preparation method. The carbon dioxide absorbent includes the sodium hydroxide which is the added auxiliary absorbing agent of the lithium hydroxide, and the aluminium sesquioxide of the intensifier. The preparation method of the carbon dioxide absorbent is that the lithium hydroxide is crashed to the extent with the granularity larger than 80-screen mesh by a disintegrator, the sodium hydroxide and the aluminium sesquioxide are dried, and then are mixed evenly pro rata, the mixed materials are fed into a rotary tablet pressing machine for being pressed to tablet shapes, and then are put into the oven for drying. The carbon dioxide absorbent containing the lithium hydroxide is added with the sodium hydroxide and the aluminium sesquioxide, and the intensity is increased obviously. The percentage of the dust is less than or equal to zero point four percent, the phenomena of throat choking are obviously reduced, and the humidity of the exhaled gas is largely reduced, the gas is easy to be cooled after being inhaled, so people who wear the respirator containing the carbon dioxide absorbent will feel more comfortable. The preparation method is rather simple.

Owner:CCTEG SHENYANG RES INST

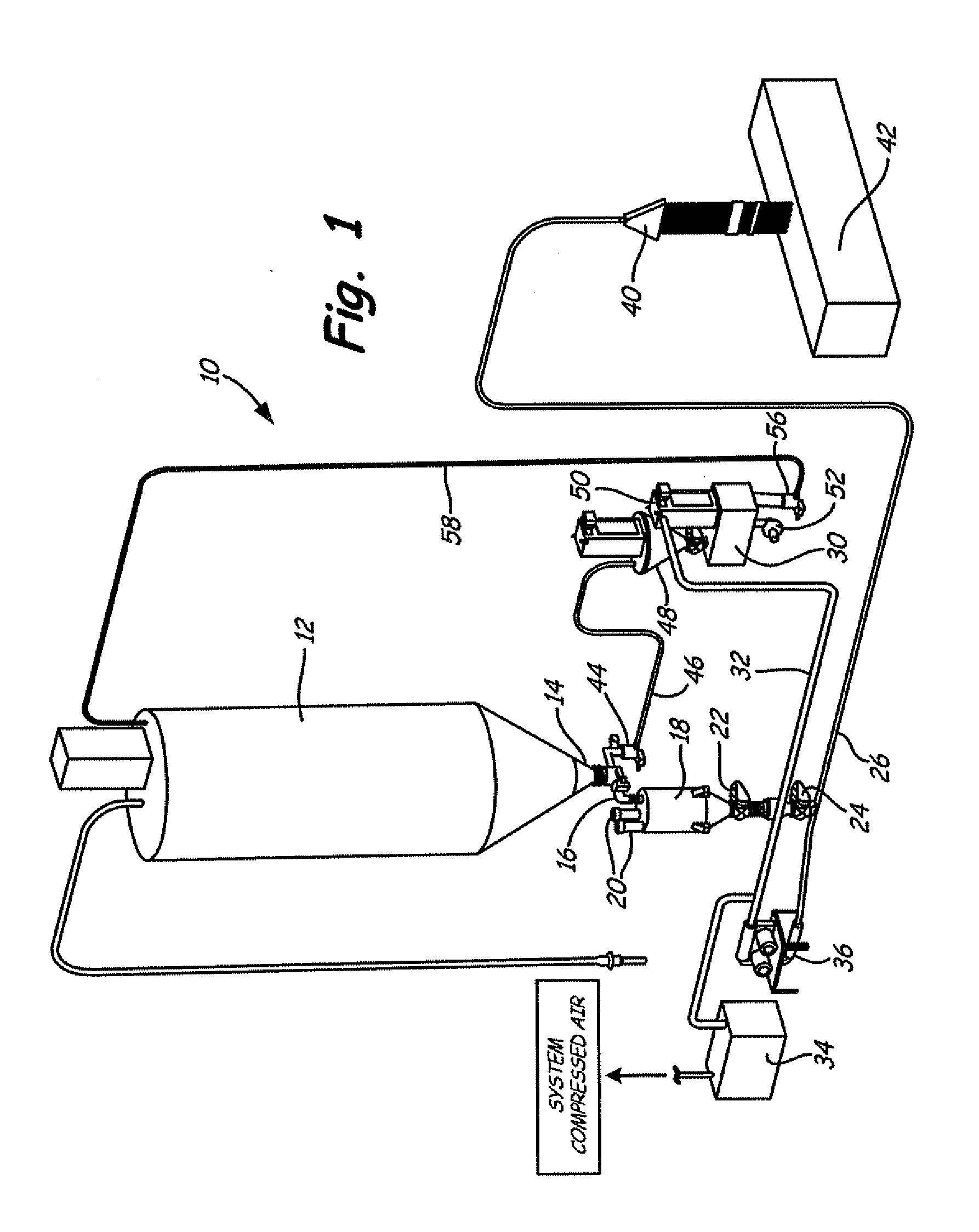

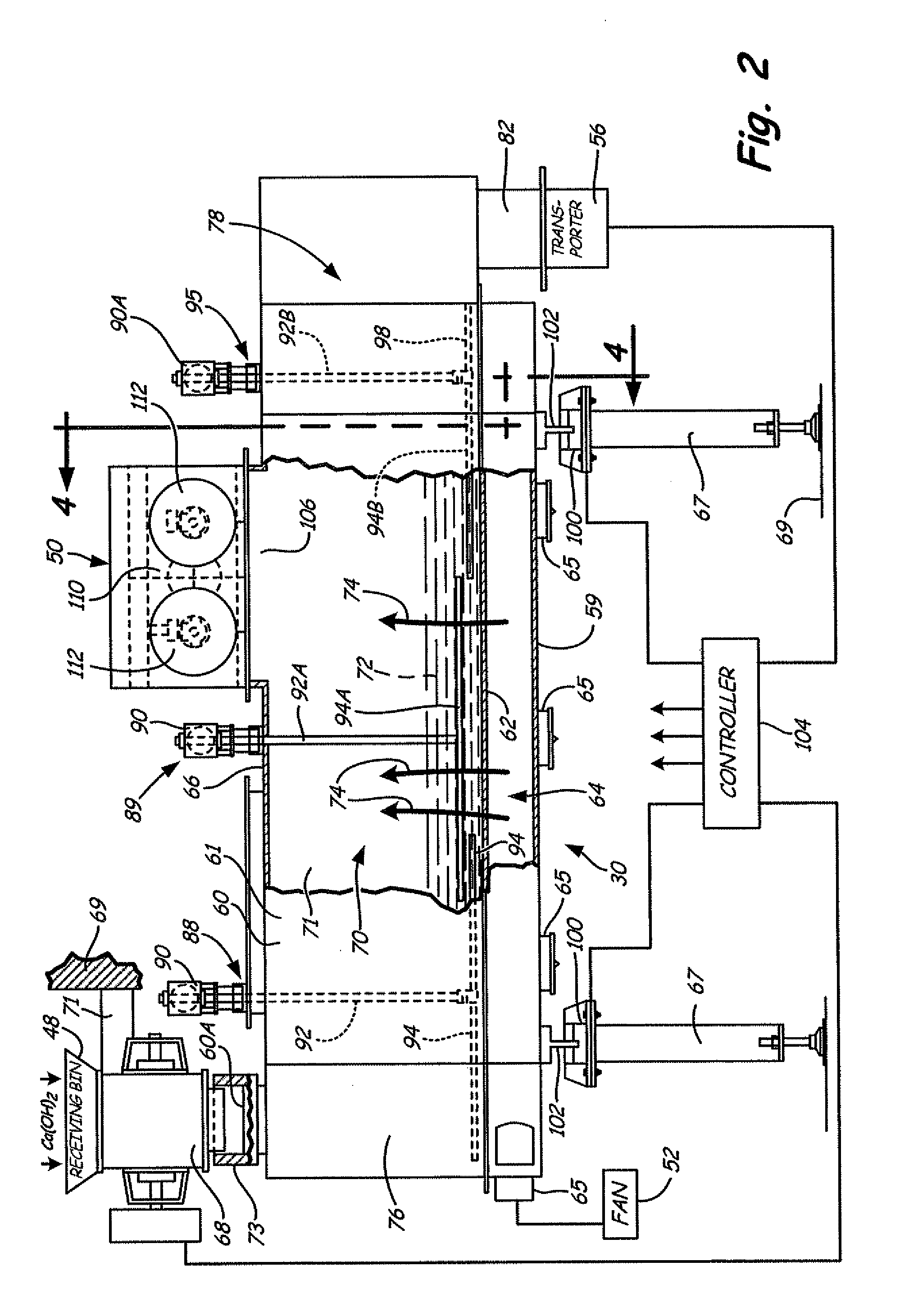

Fluidized Bed Carbon Dioxide Scrubber For Pneumatic Conveying System

InactiveUS20110206586A1Avoid problemsGas treatmentHydrogen sulfidesFluidized bedEnvironmental engineering

A pneumatic conveying system for conveying hydrated lime is provided with ambient air for the pneumatic conveying system from a scrubber that removes carbon dioxide from the ambient air used in the conveying system. The scrubber includes a bed of hydrated lime through which ambient air is passed, to react carbon dioxide in the air with the hydrated lime in a reaction that forms limestone and water. The air that has passed through the fluidized bed, which is essentially carbon dioxide free, is also passed through a filter to remove particles suspended in the carbon dioxide free air. The carbon dioxide free air from the filter is provided to the pneumatic conveying system. The use of carbon dioxide free air ensures that the hydrated lime being transported in the conveying system will not react in the various conduits and ducts of the pneumatic conveying system to cause problems.

Owner:NOL TEC SYST

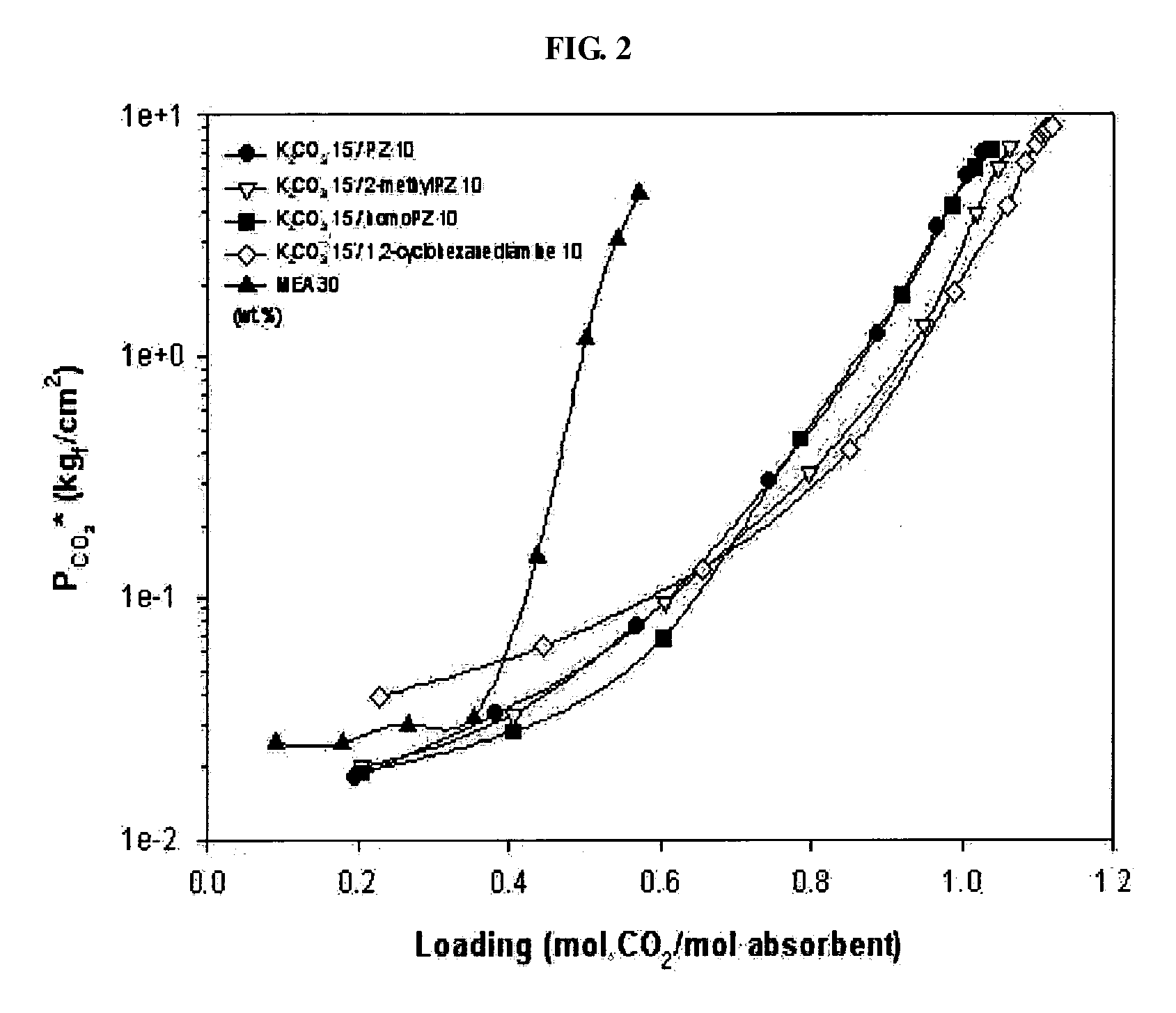

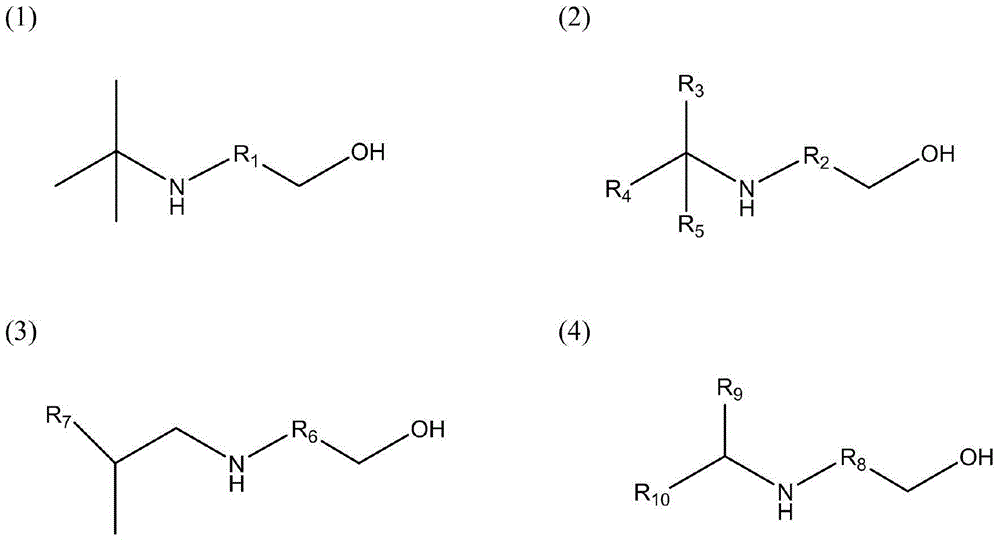

Alkali-Carbonate-Based Carbon Dioxide Absorbent Containing Added Sterically Hindered Cyclic Amines, and Method for Removing Carbon Dioxide Removing Using Same

ActiveUS20120308457A1Improve absorption rateReduce the amount requiredGas treatmentOther chemical processesCo2 absorptionAlkali carbonate

The present invention relates to a carbon dioxide absorbent, and more particularly, to an alkali carbonate-based carbon dioxide absorbent containing added sterically hindered cyclic amines, and to a method for removing carbon dioxide using same. By adding sterically hindered cyclic amines to an alkali carbonate material, the rate of carbon dioxide absorption is increased, renewable energy is reduced, and salt production and phase separation do not occur.

Owner:KOREA INST OF ENERGY RES

Mango dedicated fertilizer

The present invention discloses a mango dedicated fertilizer, including compost, green manure, ash fertilizer, humic acid fertilizer, a microbial fertilizer and a light carbon mixture, wherein the compost is piled up by straw and livestock manure, the green manure is a green plant nutrition fertilizer, the ash fertilizer is composited by plant ash, straw ash and bran ash, the humic acid fertilizer is cyclo-imino acid, the microbial fertilizer is 'three torches' bio-fertilizer, and the light carbon mixture is a carbon dioxide absorbent. The mango dedicated fertilizer is mixed by multiple compounds, and is low in cost and good in effect. Mango trees have fewer diseases after applying the fertilizer, and are high in nutrient absorption efficiency and high in fruit yield.

Owner:常熟市新靓文辅亚农艺发展有限公司

Non-aqueous chemical absorbent for separating and purifying carbon dioxide

InactiveCN107789951ASimple ingredientsFast absorption rateGas treatmentGaseous fuelsAbsorption capacityDesorption

The invention provides a non-aqueous chemical absorbent for treating carbon dioxide in gas mixtures, and belongs to the field of technologies for capturing carbon dioxide. The non-aqueous chemical absorbent comprises, by weight, 20%-50% of organic alcohol amine and 50-80% of alcohol ether solvents. The non-aqueous chemical absorbent has the advantages that the non-aqueous chemical absorbent whichis a carbon dioxide absorbent is high in absorption rate, absorption capacity and rate and low in desorption temperature, and the solvents are low in volatility, specific heat capacity and latent heatof vaporization; energy consumption and the cost of capturing procedures can be effectively reduced as compared with the traditional aqueous solution systems, the non-aqueous chemical absorbent can be applied to processes for capturing and separating carbon dioxide in the gas mixtures such as natural gas, synthesis gas and flue gas from power plants, and the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Apparatus and method for preserving the aroma of a fermentable beverage

ActiveUS20150322390A1Removal rateEasy accessBy-product recoveryLiquid degasification with auxillary substancesGas concentrationFermentation

A fermentation apparatus for preserving the aroma of a fermentable beverage is provided. The fermentation apparatus comprises a flow passage fluidly connectable to the headspace located above a fermentable beverage in a fermentation container. A carbon dioxide scrubber in the flow passage receives a headspace fluid mixture comprising at least carbon dioxide gas and an aromatic fluid originating from the fermenting beverage. When the headspace fluid mixture contacts the carbon dioxide scrubber, the carbon dioxide scrubber retains a modified fluid in the flow passage. The modified fluid has a lower carbon dioxide gas concentration and a higher aromatic fluid concentration than the headspace fluid mixture. The flow passage directs the modified fluid back to the headspace to at least partially retain the aromatic fluid in the fermentable beverage in the fermentation container. A method for preserving the aroma of a fermentable beverage is also provided.

Owner:AROMALOC INC

Carbon dioxide absorbent and method of manufacturing carbon dioxide absorbent

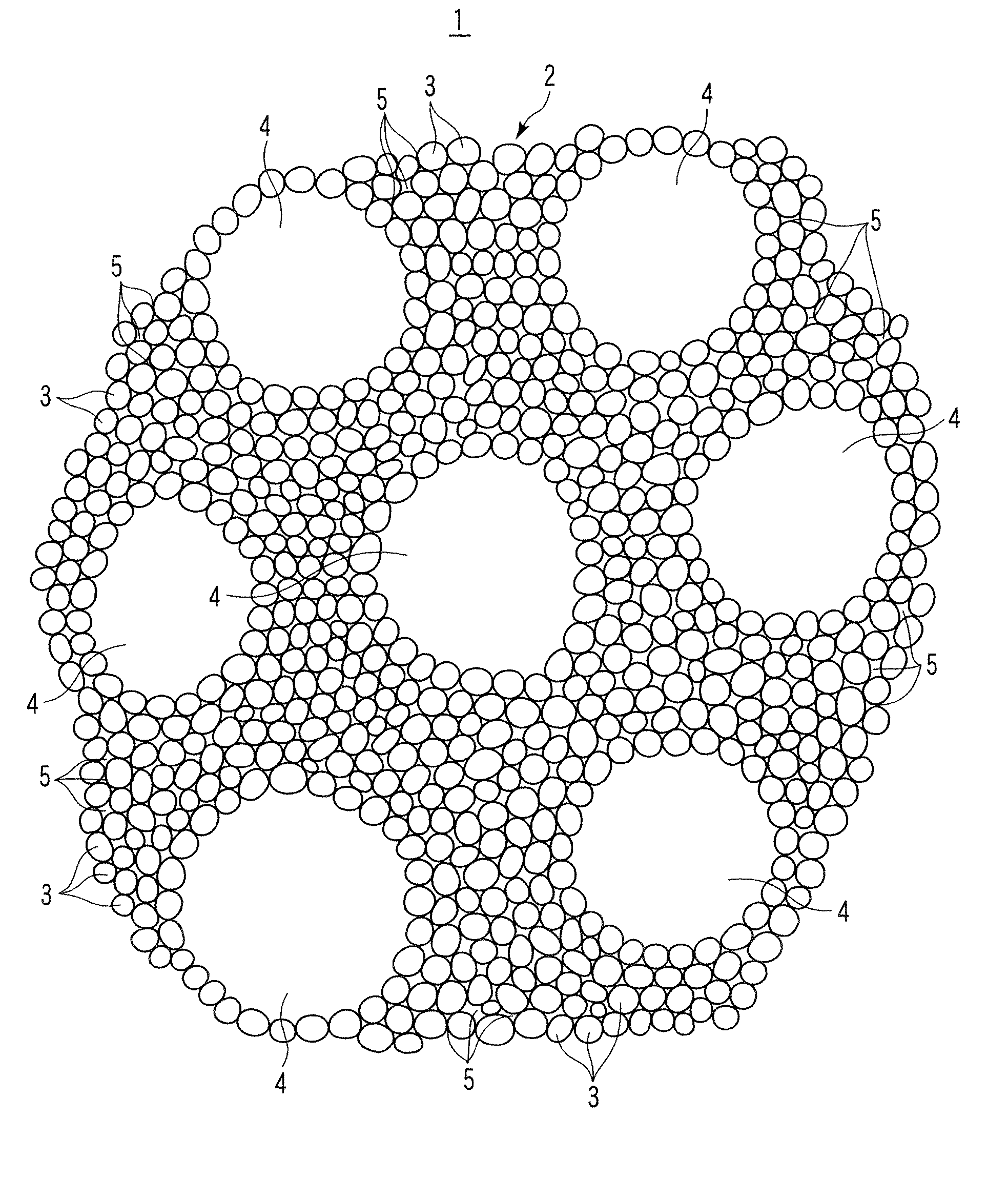

A carbon dioxide absorbent includes a porous body containing a large number of lithium composite oxide particles having an average particle diameter of 2 to 7 μm, the porous body having a porosity of 30 to 80% and also having pores with a diameter of 10 to 25 μm occupying at least 15% by volume of the entire pores.

Owner:KK TOSHIBA

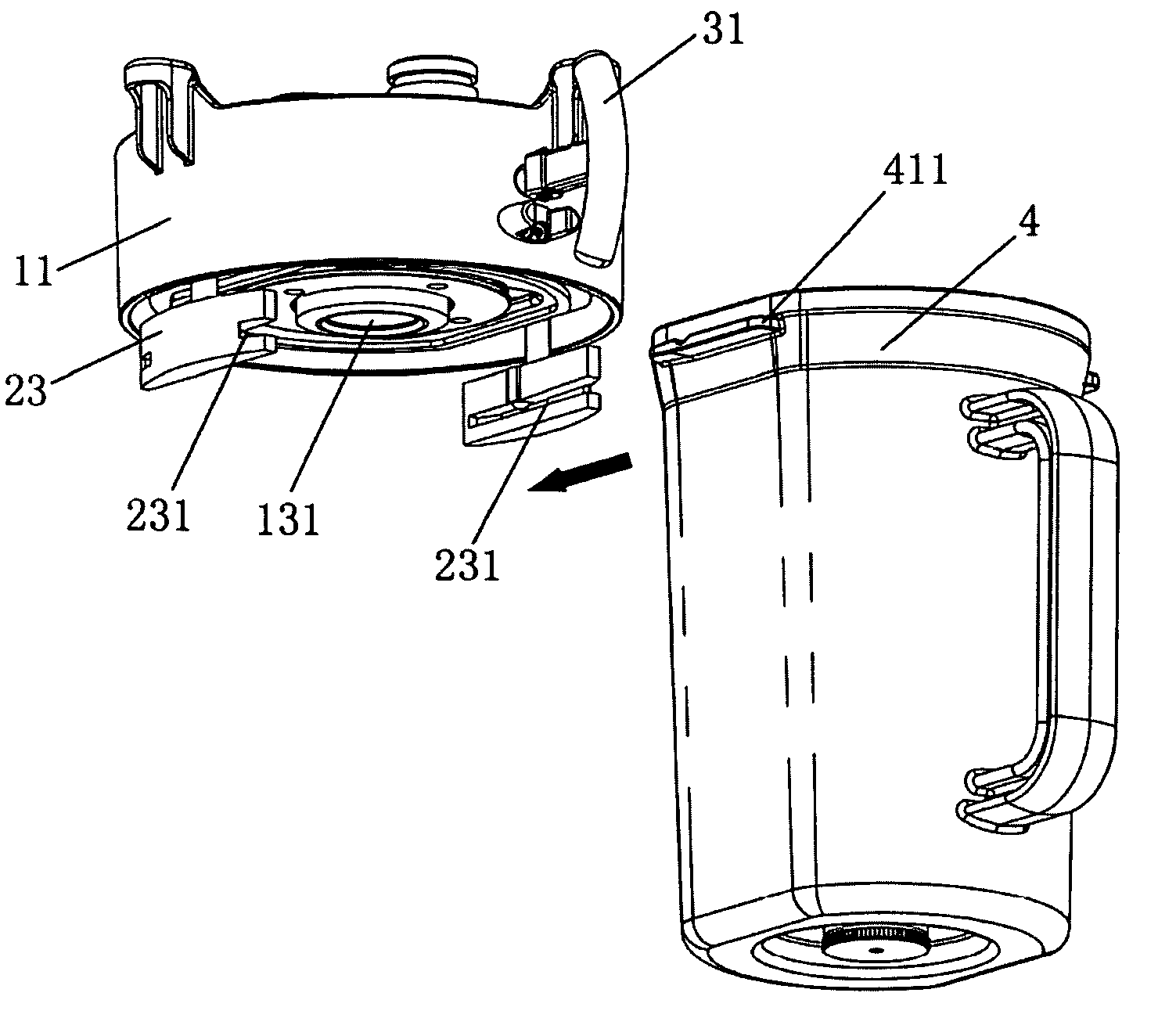

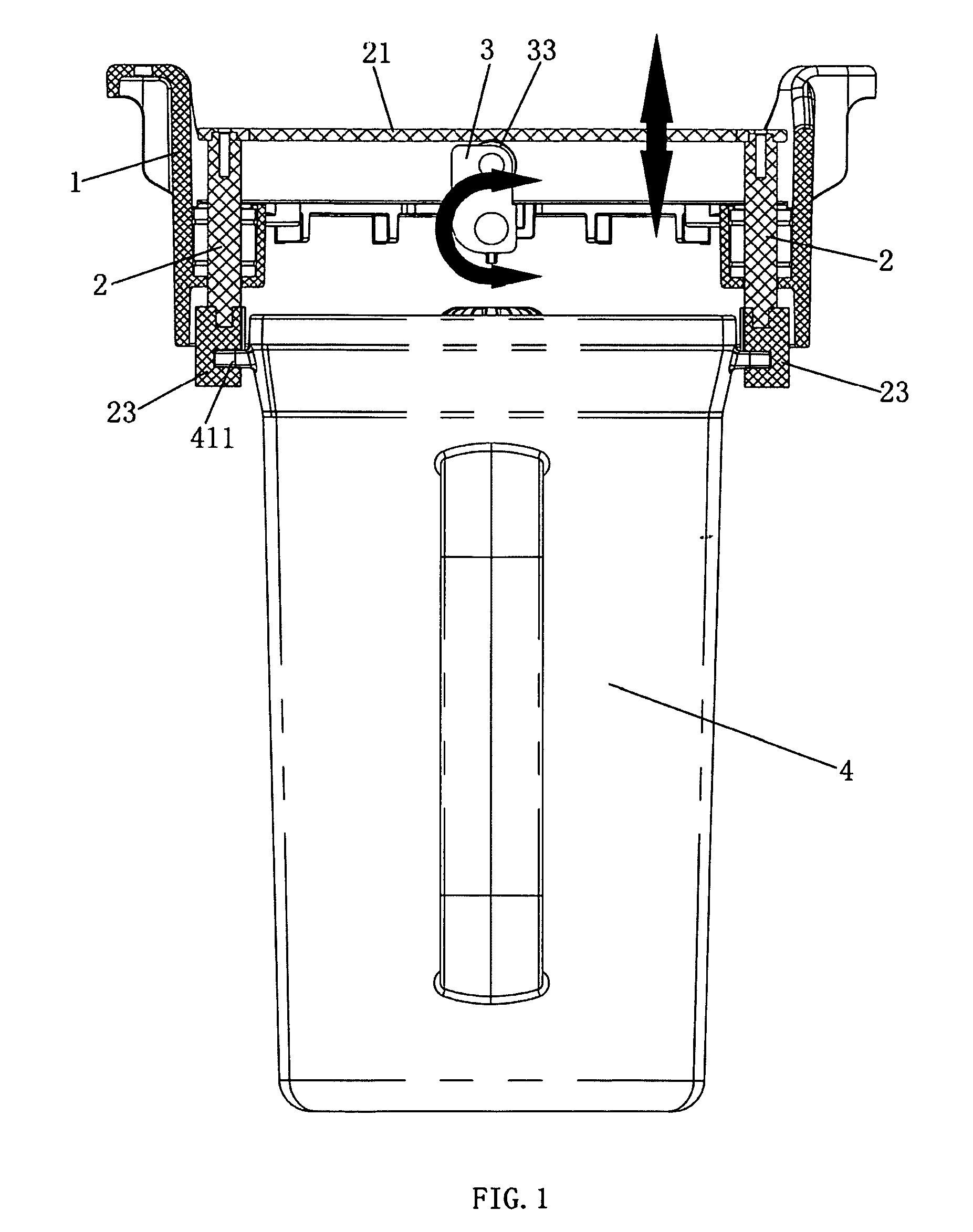

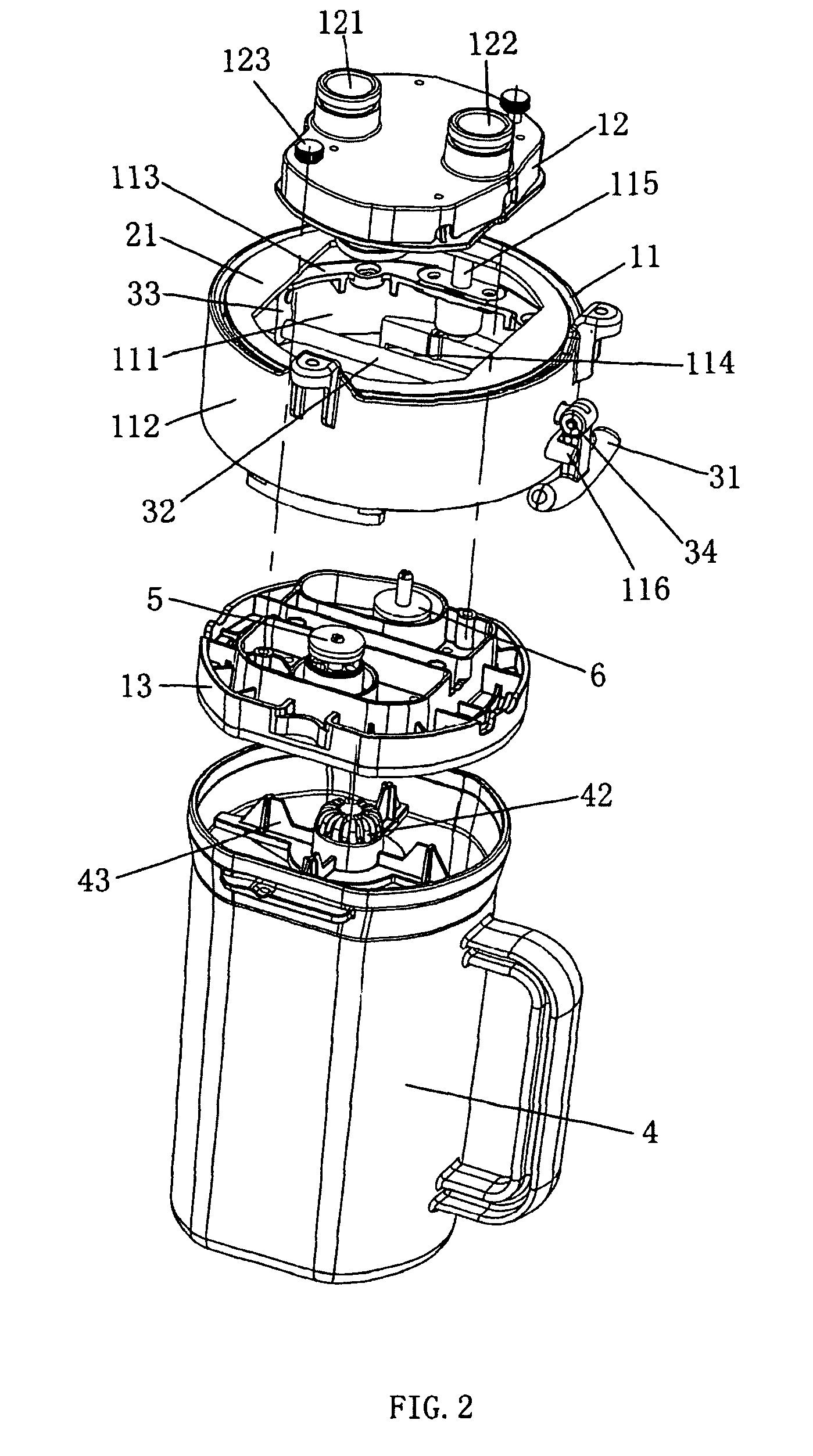

Apparatus for installing or uninstalling carbon dioxide absorbent canister

ActiveUS7964024B2Easy to operateCompact structureRespiratorsBreathing filtersCo2 absorptionMechanical engineering

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Middle-low temperature regenerated carbon dioxide capturing absorbent and application method thereof

ActiveCN105032123AReduce energy consumptionReduce corrosionDispersed particle separationAir quality improvementProduct gasTower

A middle-low temperature regenerated carbon dioxide capturing absorbent is composed of the following components in percentage by weight: 10 to 80% of low temperature regenerated amine, 5 to 25% of pH adjuster, 0 to 10% of auxiliary agent, and the balance being water. When the absorbent is used, low temperature regenerated carbon dioxide absorbent in an absorbing tower reacts with gas containing carbon dioxide to form a rich liquor, the absorbing temperature is 30 to 50 DEG C, and the absorbing tower pressure is 0.05 to 6 MPa. The rich liquor is preheated in a barren liquor / rich liquor heat exchanger to flash-evaporate part of carbon dioxide gas, after flash evaporation the rich liquor is transferred to a regeneration tower to carry out low temperature pyrolysis, the rich liquor is converted into barren liquor, at the same time carbon dioxide is generated; the temperature of the bottom of the regeneration tower is 70 to 100 DEG C, the generated hot barren liquor in the regeneration tower is conveyed to the absorbing tower for capturing carbon dioxide after going through the heat exchanger, and thus the whole absorption-regeneration-absorption circle is completed. The provided absorbent can be regenerated at a low temperature, and thus the capturing cost can be reduced in multiple aspects.

Owner:HUANENG CLEAN ENERGY RES INST

Method for removing CO2 from coal-fired power plant flue gas using ammonia as the scrubbing solution, with a chemical additive for reducing NH3 losses, coupled with a membrane for concentrating the CO2 stream to the gas stripper

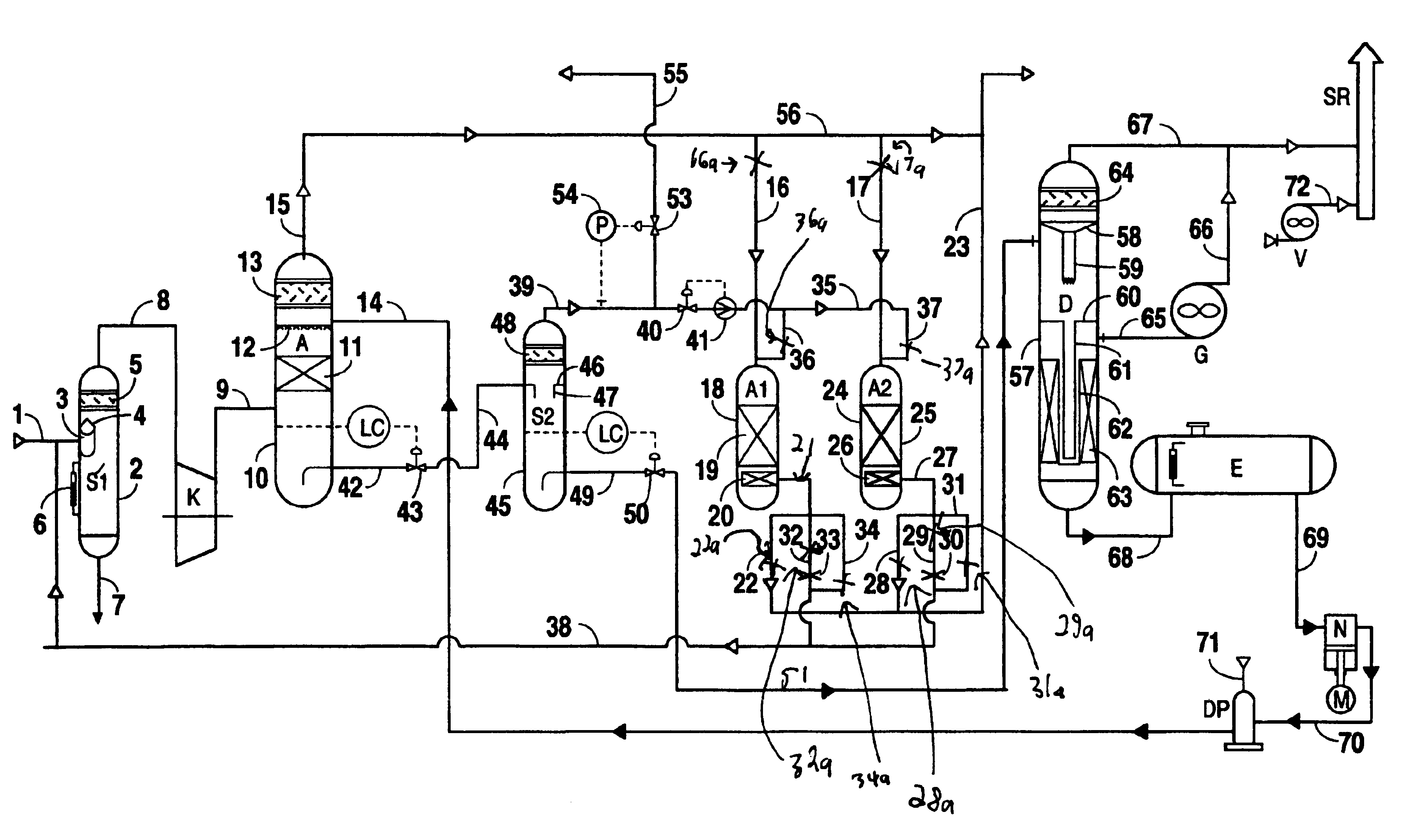

A method for removing and capturing carbon dioxide from a fluid stream includes the steps of exposing the fluid stream to an aqueous scrubbing solution that removes and holds carbon dioxide from the fluid stream, passing the aqueous scrubbing solution through a membrane in order to separate excess water from the scrubbing solution and increase the concentration of carbon dioxide in the scrubbing solution, heating the scrubbing solution having an increased concentration of carbon dioxide so as to release carbon dioxide gas and recycling the scrubbing solution. A carbon dioxide capture apparatus includes a carbon dioxide scrubber, a membrane downstream from the scrubber for separating water and concentrating carbon dioxide in a scrubbing solution and a stripper vessel.

Owner:UNIV OF KENTUCKY RES FOUND

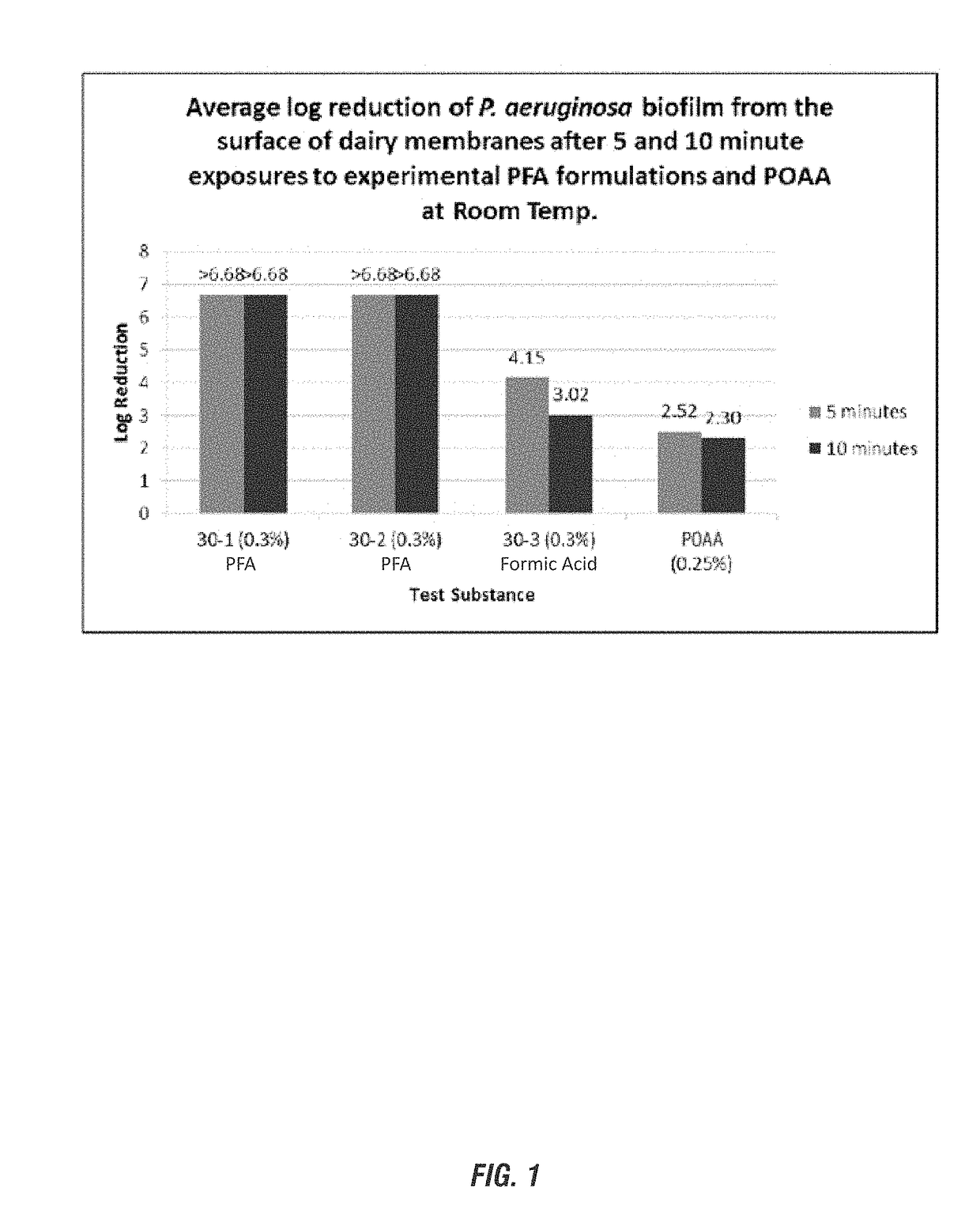

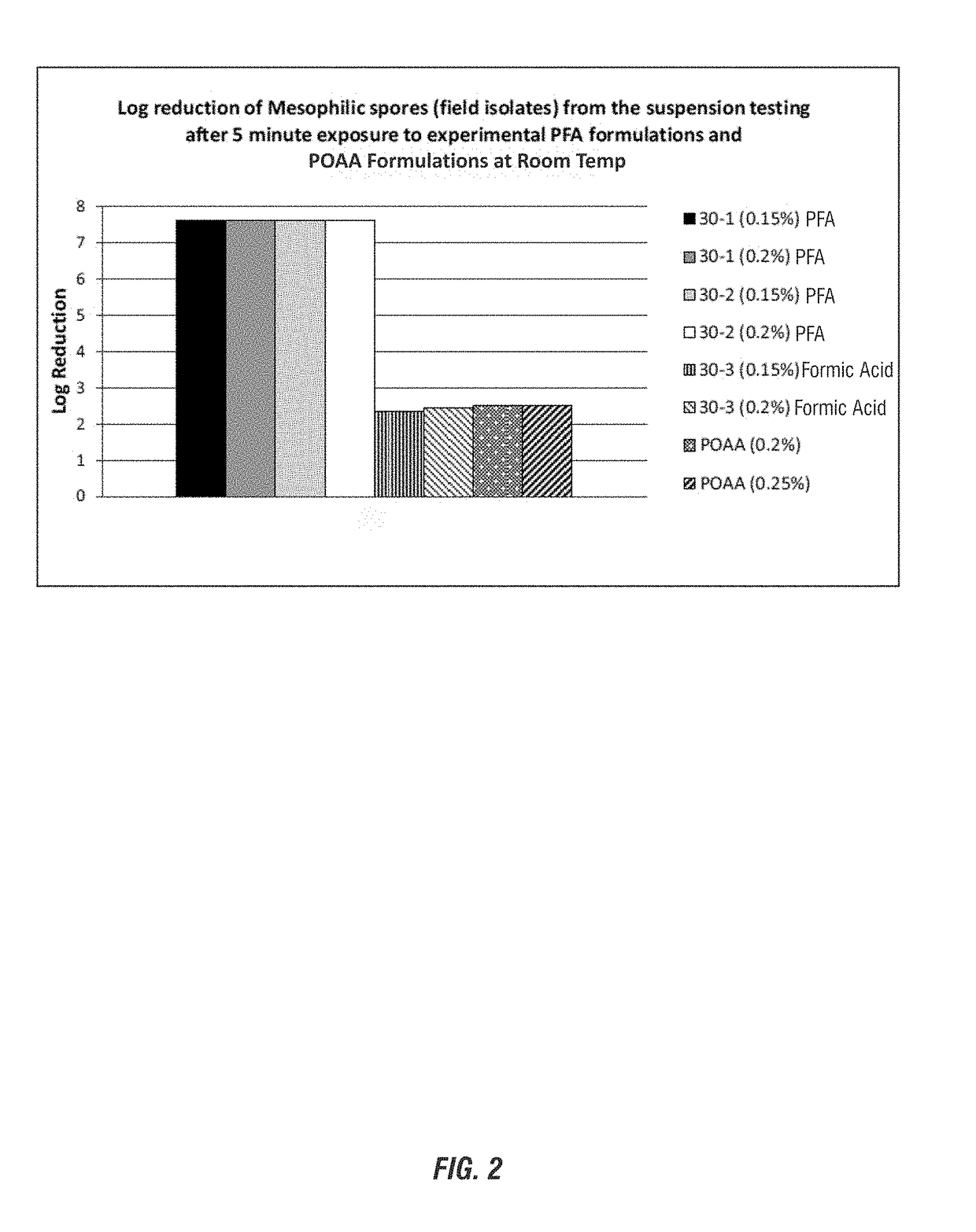

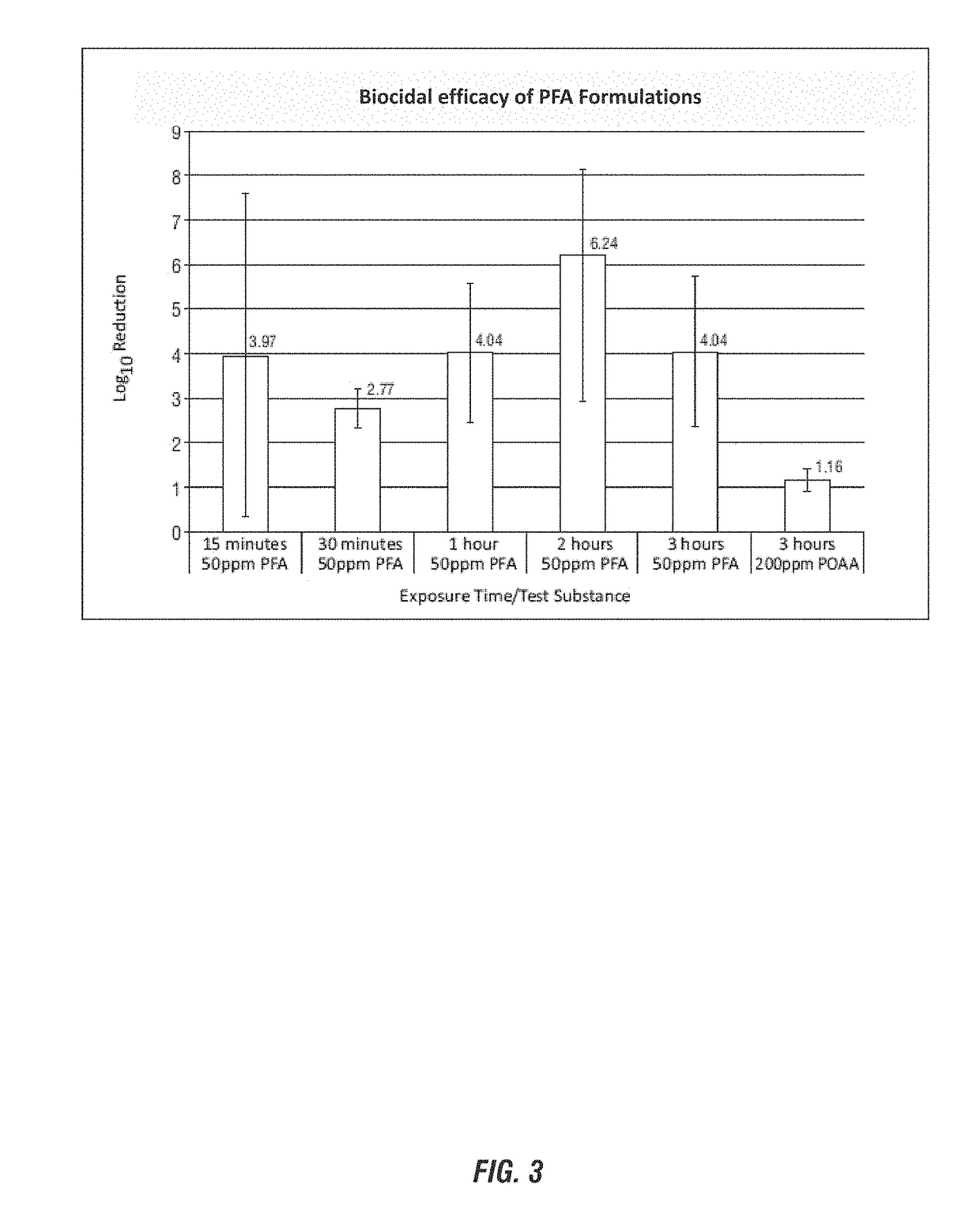

Performic acid biofilm prevention for industrial co2 scrubbers

ActiveUS20170295784A1Broaden applicationExtension of timeBiocideAnimal repellantsAlcoholBiofilm growth

Peroxyformic acid compositions for removal of biofilm growth and other contaminants and impurities from industrial processing hard surfaces are disclosed. In particular, peroxyformic acid compositions may be dosed on site and / or generated in situ for the reduction and prevention of biofilms on the hard surfaces. Methods of employing the peroxyformic acid compositions for removal of biofilm growth and other impurities such as aldehydes and alcohols from industrial CO2 effluent are also disclosed which beneficially provide ambient biofilm control and break down more rapidly than other peracids, allowing for extended runs between CIP cleaning, including a reduction and / or elimination of cleaning of the scrubbers and other industrial surfaces.

Owner:ECOLAB USA INC

Amidium-based ionic liquids for carbon dioxide absorption

The present invention relates to a carbon dioxide absorbent, an ionic liquid obtained by reacting amide and an organic acid and a method of using the same. The amidium-based ionic liquid of the present invention has excellent CO2 absorption capability, which is hardly reduced even with repeated use, is easy to synthesize and has low manufacturing cost thus being useful as a CO2 absorbent.

Owner:HYUNDAI MOTOR CO LTD +1

Control of atmosphere within a closed environment

ActiveCN103687494AFruit and vegetables preservationDispersed particle separationRipeningGaseous atmosphere

A method and apparatus are disclosed for controlling a concentration of carbon dioxide in a gaseous atmosphere within a closed environment of a refrigerated transport container to maintain the concentration of carbon dioxide therein at a desired level. A carbon dioxide scrubber apparatus operates alternately in an adsorption mode and a regeneration mode. When a perishable produce is stowed in the closed environment, for example in a cargo box of a refrigerated transport container, the concentration of carbon dioxide may be maintain at a desired level to retard ripening of the perishable produce.

Owner:CARRIER CORP

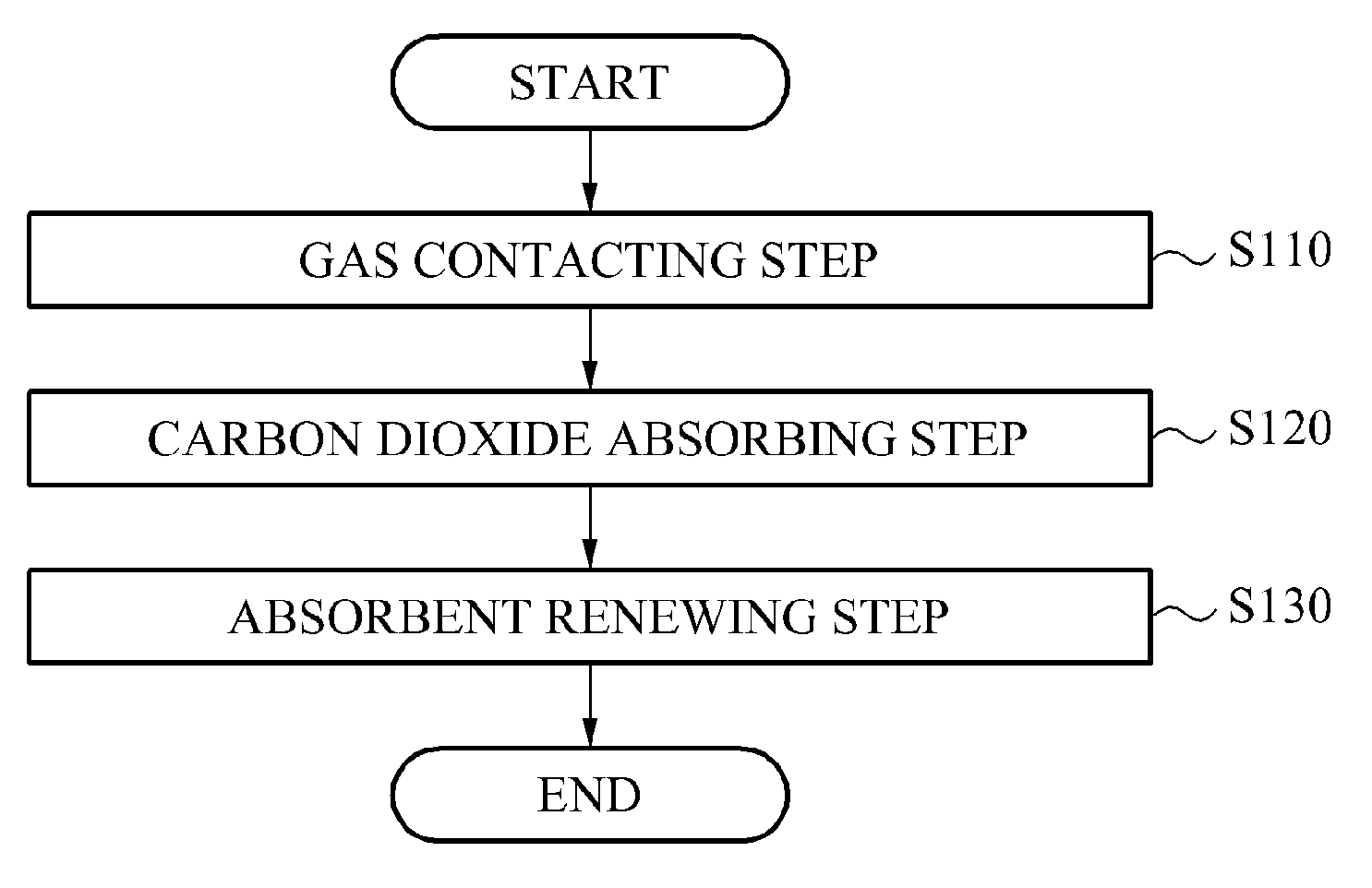

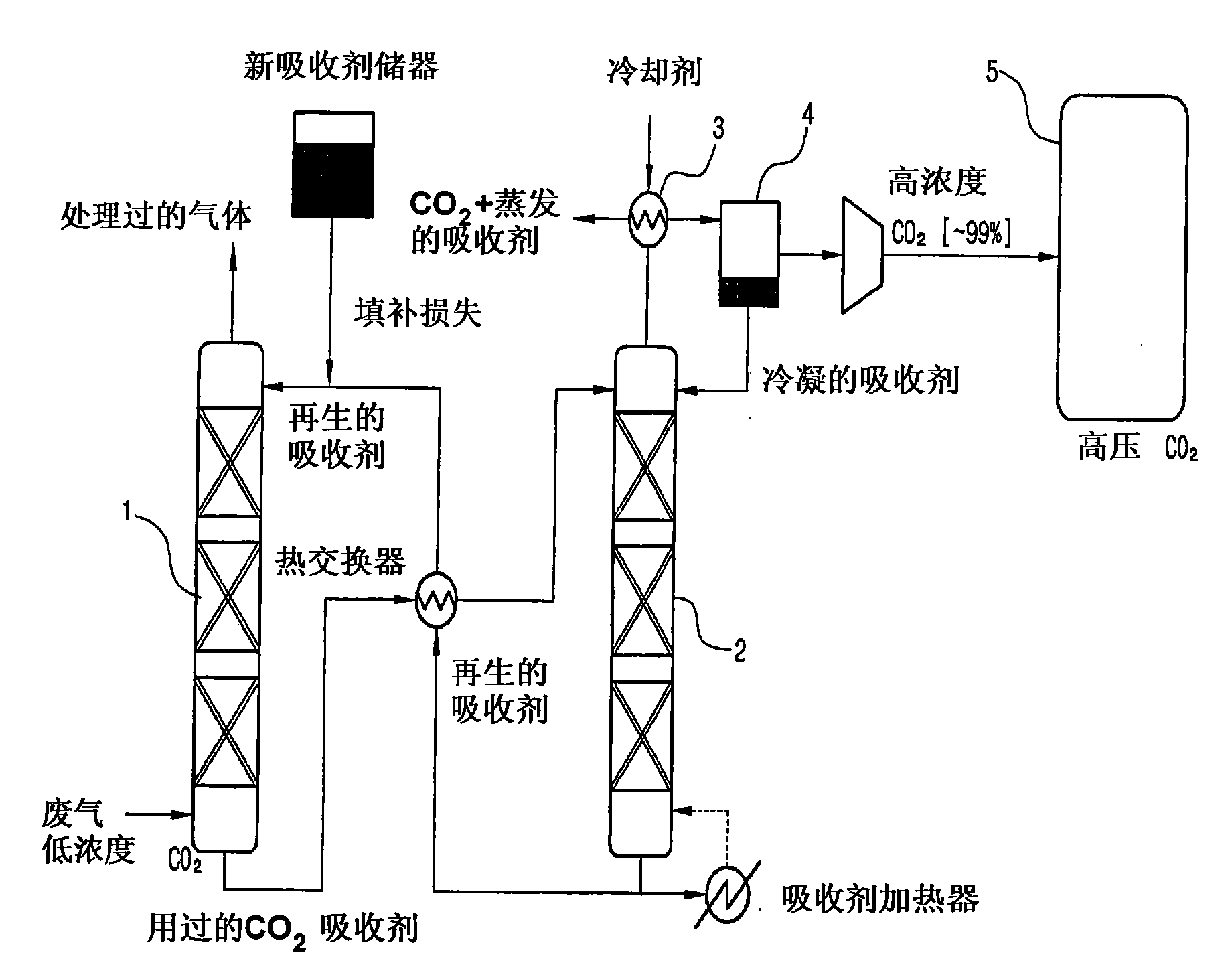

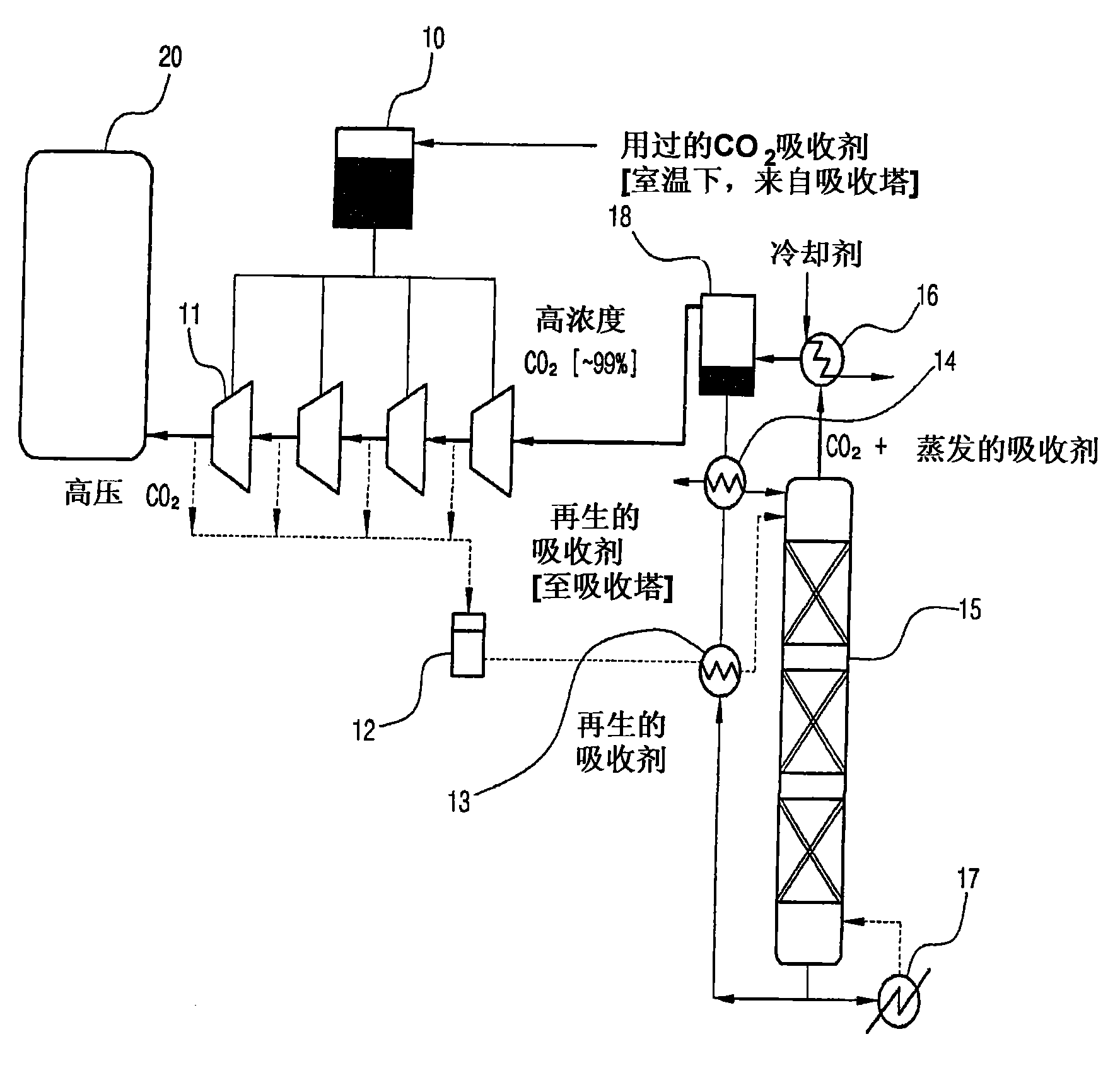

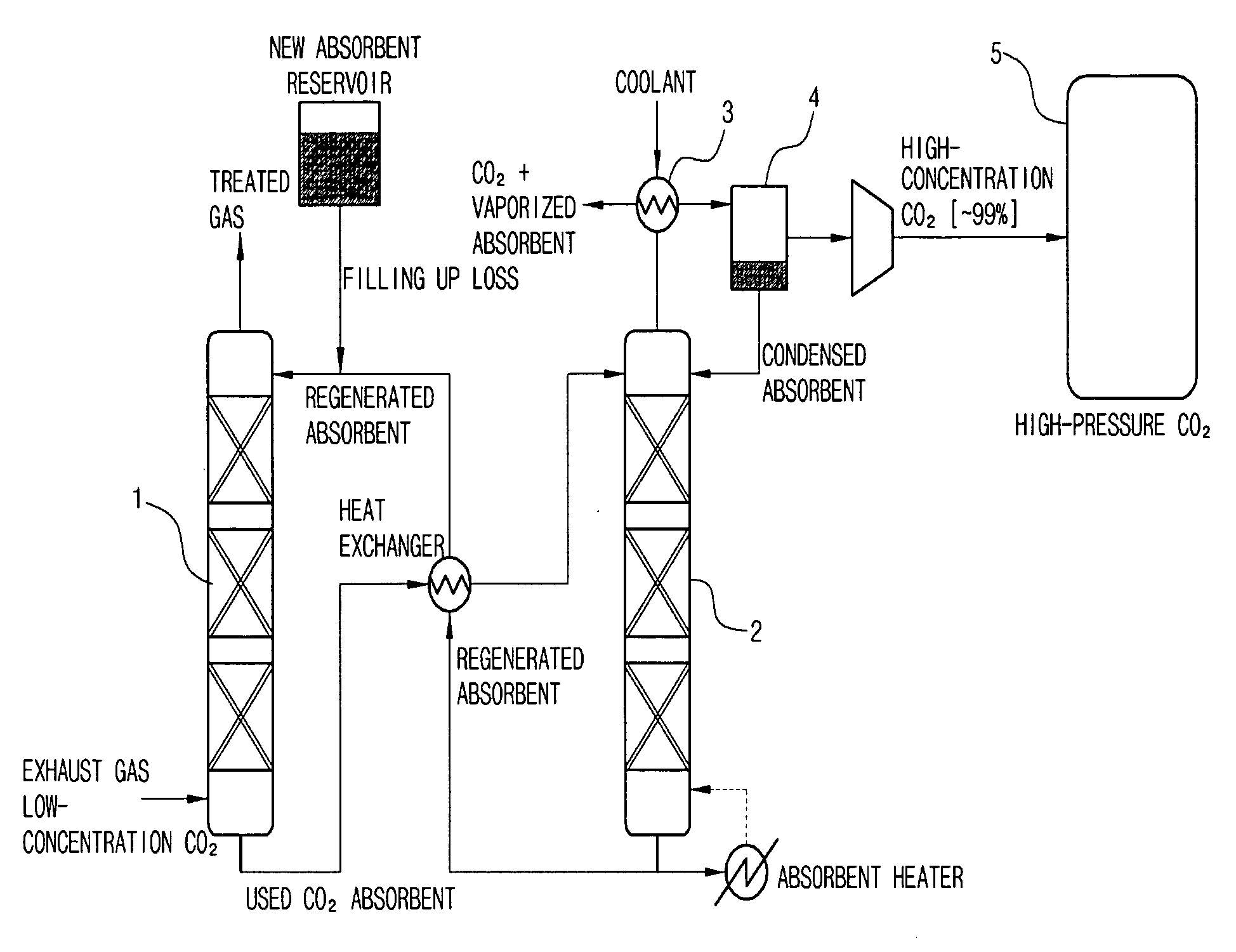

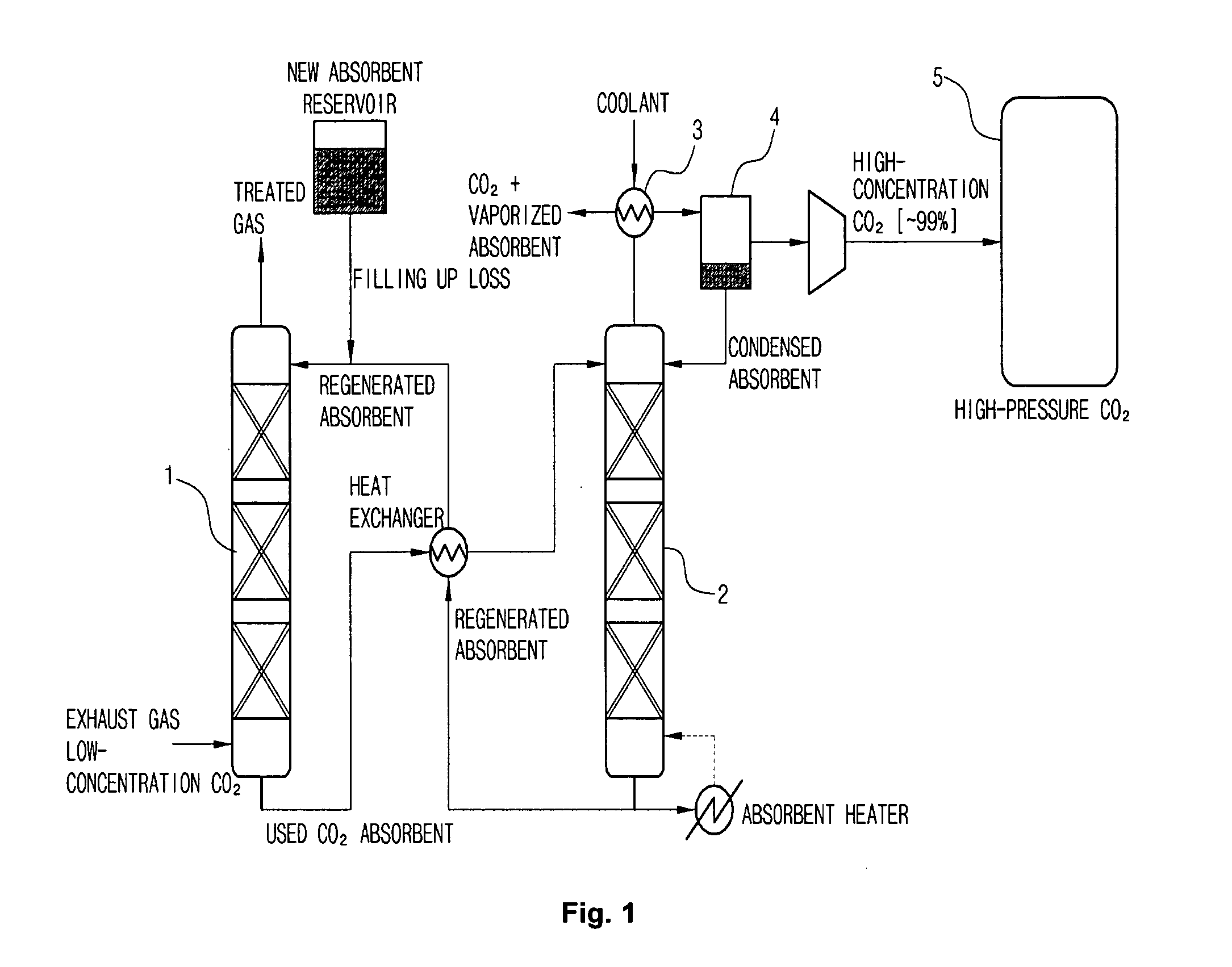

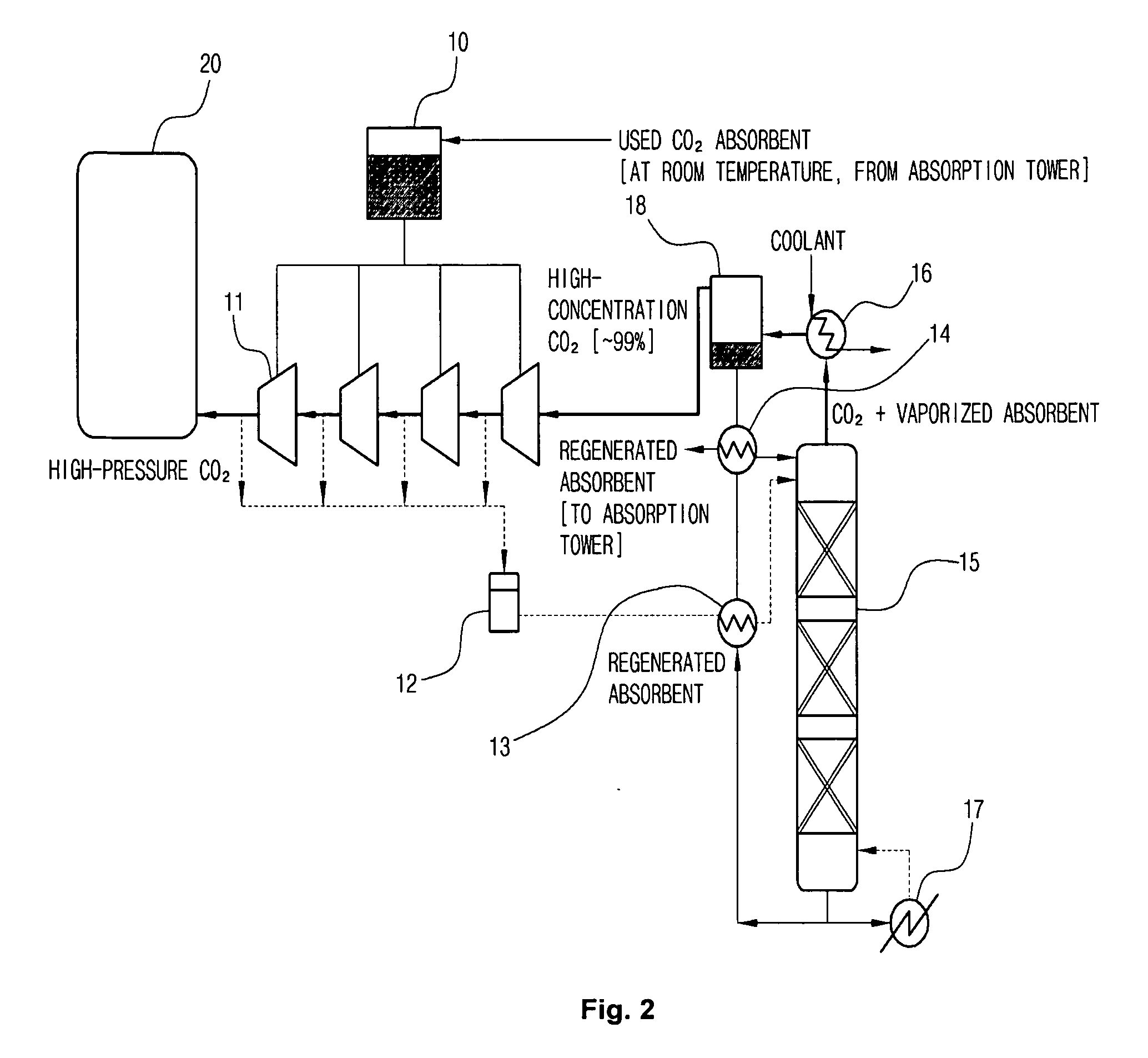

Method of regenerating carbon dioxide absorbent

The present invention provides a method of regenerating a carbon dioxide absorbent which absorbs carbon dioxide emitted from various anthropogenic sources including fossil fuel combustion processes, industrial production processes, and natural gas processing. In the method, the absorbent is preheated using heat generated in a process of compressing the separated carbon dioxide in a compressor and the preheated absorbent is delivered to an absorbent flow control tank, before the used absorbent is delivered to a regeneration tower, thereby improving energy efficiency.

Owner:HYUNDAI MOTOR CO LTD +1

Medical carbon dioxide absorbent soda lime and preparation method thereof

InactiveCN102258938AImprove brittlenessNot easy to dryDispersed particle separationAir quality improvementMedicineCo2 absorption

The invention discloses soda lime as a medical carbon dioxide absorbent and a preparation method thereof. The soda lime comprises the following components in percentage by weight: 75-85% of Ca(OH), 0.5-5% of NaOH, 0-3% of KOH, 0.1-1% of humectant, 0.5-5% of disintegrating agent, 0.005-1% of pH indication coloring agent and 10-20% of water. The soda lime prepared by the invention has better friability, is uneasy to generate fine power and dry, and the CO2 absorption rate meets the requirement of national drug standards.

Owner:SHANGHAI INST OF PHARMA IND CO LTD

Method of regenerating carbon dioxide absorbent

The present invention provides a method of regenerating a carbon dioxide absorbent which absorbs carbon dioxide emitted from various anthropogenic sources including fossil fuel combustion processes, industrial production processes, and natural gas processing. In the method, the absorbent is preheated using heat generated in a process of compressing the separated carbon dioxide in a compressor and the preheated absorbent is delivered to an absorbent flow control tank, before the used absorbent is delivered to a regeneration tower, thereby improving energy efficiency.

Owner:HYUNDAI MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com