Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

612 results about "Ceramic insulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

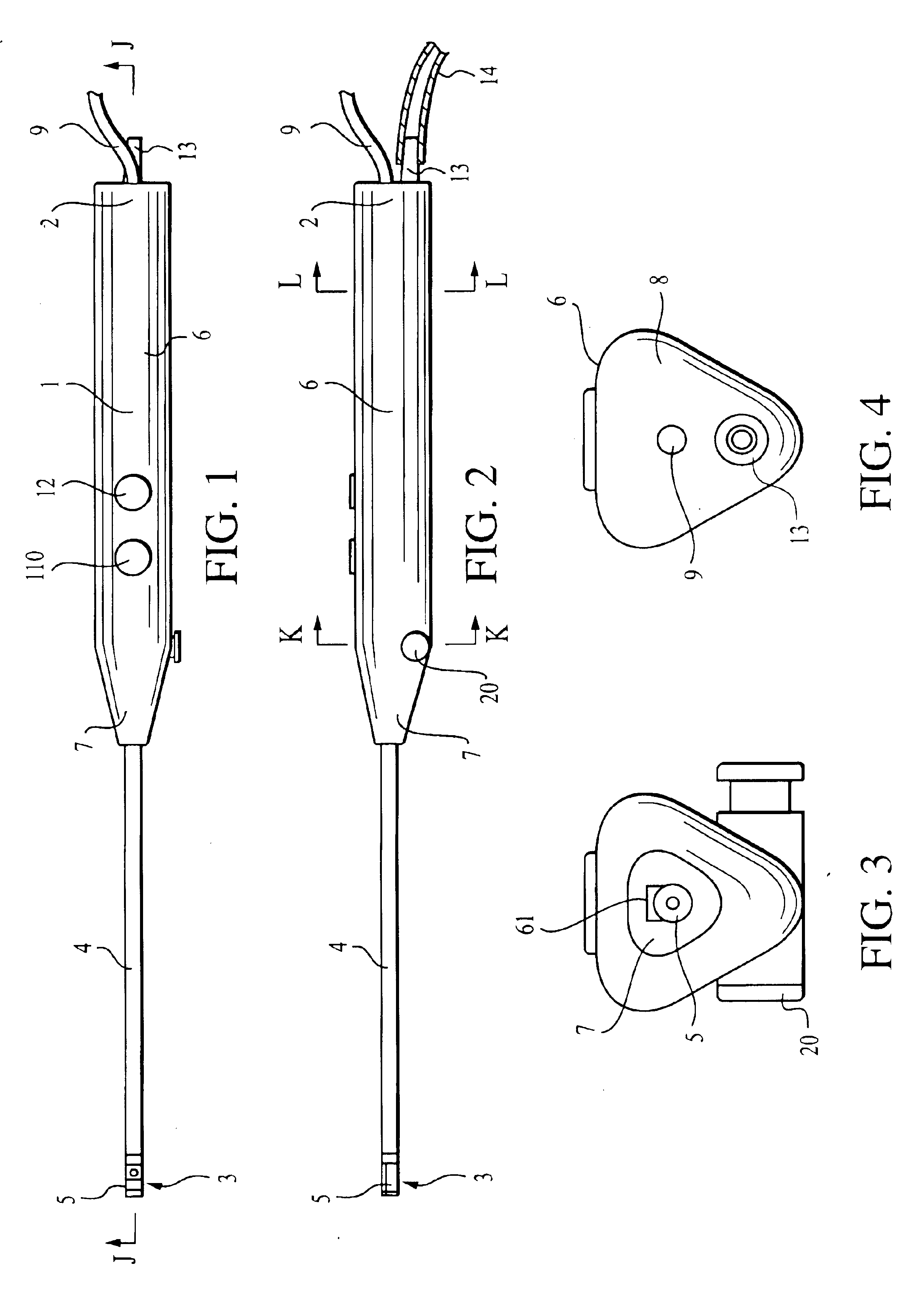

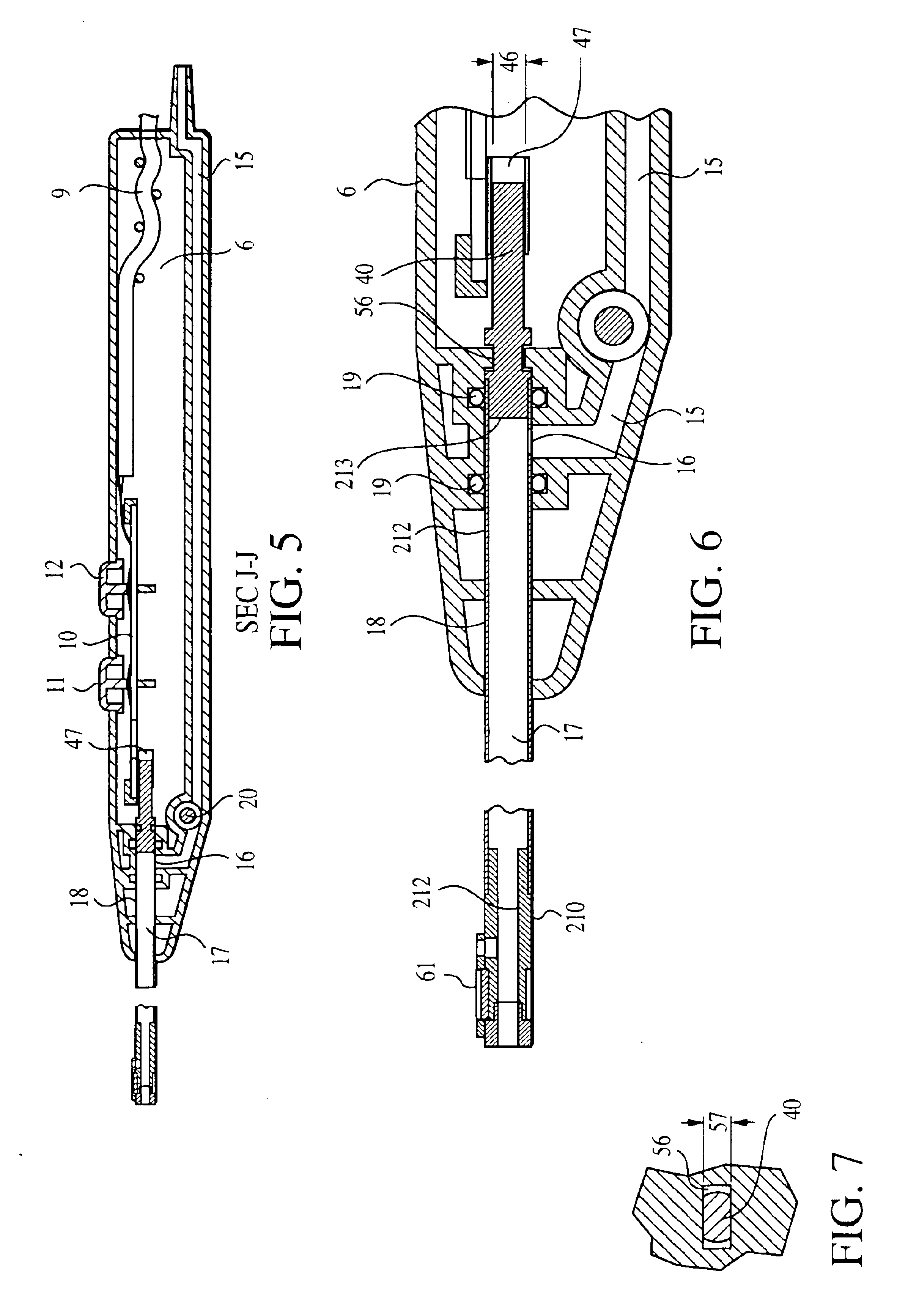

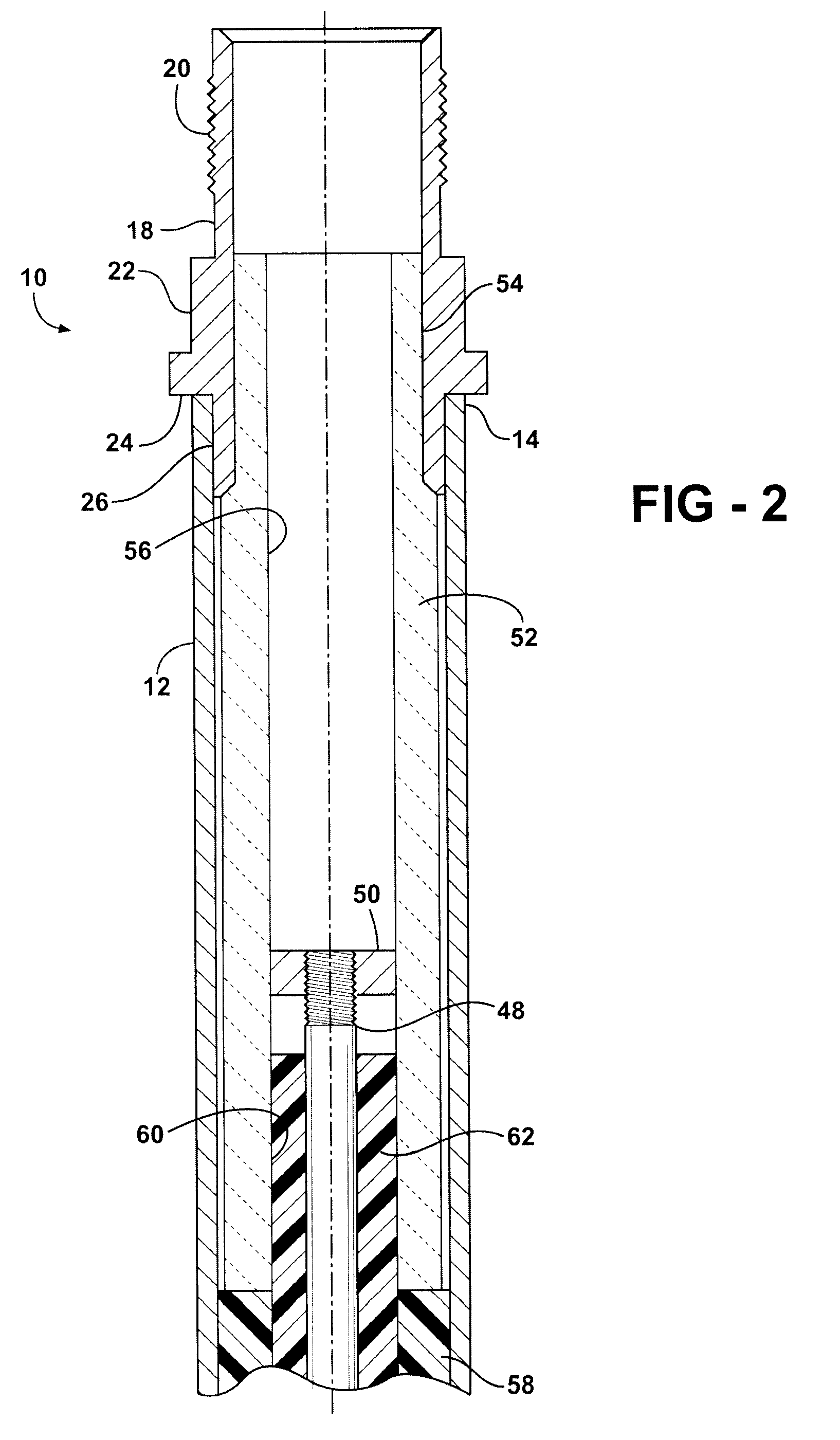

Electrosurgical ablator with aspiration

InactiveUS6840937B2Produce precise and complexPrecise and complex and shapeSurgical instruments for heatingSurgical instruments for aspiration of substancesMechanical engineeringCorneal ablation

An aspirating ablator of simple construction and low cost is disclosed. The aspirating ablator is provided with a mandrel connected to a tubular member which houses a suction assembly. An electrode having a rectangular ablation surface formed of multiple parallel ribs or protuberances is assembled onto the mandrel so that the ablation surface is parallel with the longitudinal axis of the mandrel. A ceramic insulator provided with an opening of rectangular shape is assembled to the electrode-mandrel assembly. The insulator is further provided with a cylindrical passage in communication and aligned with a radial passage of the mandrel.

Owner:ELECTROSURGERY ASSOCS

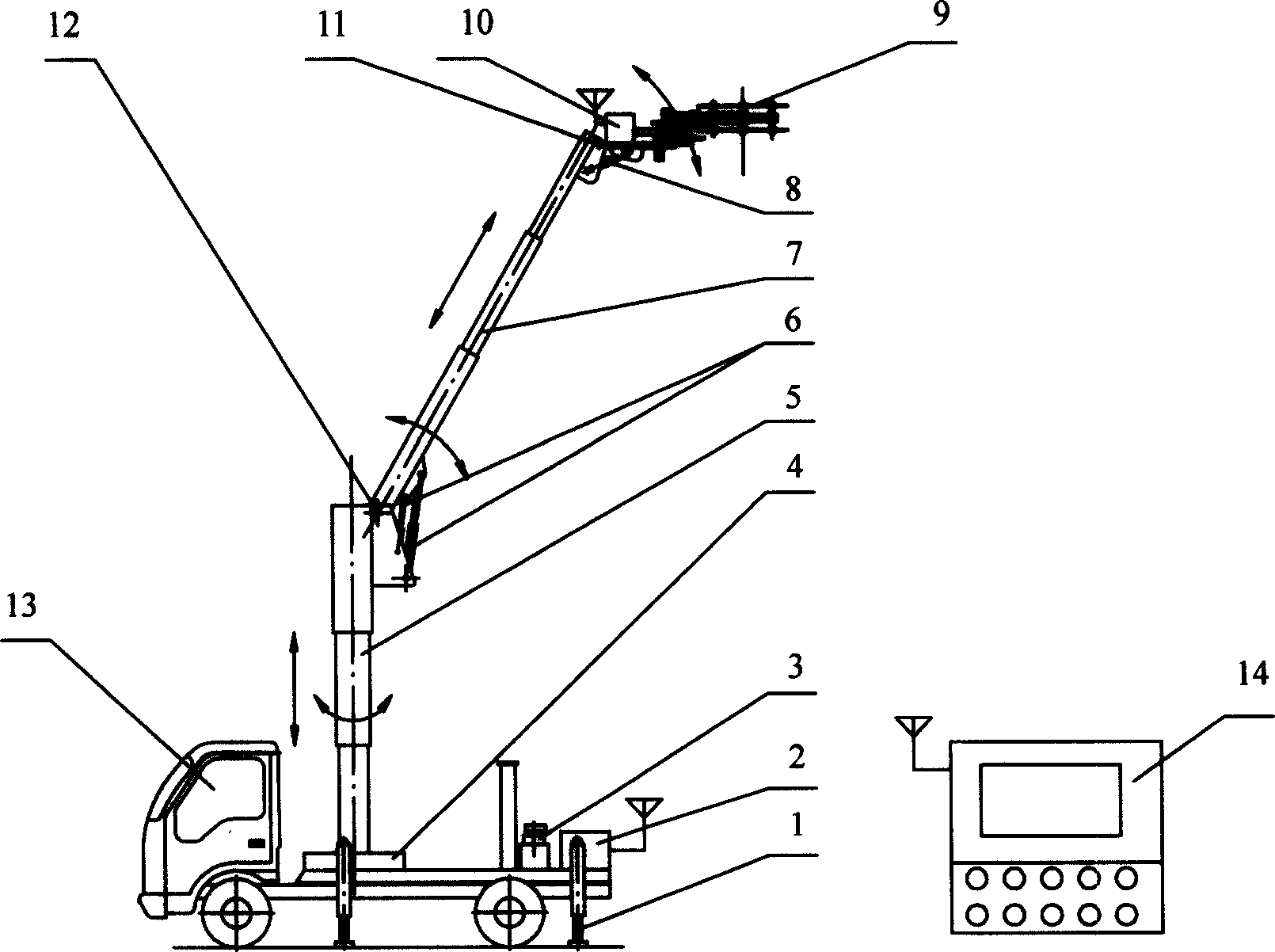

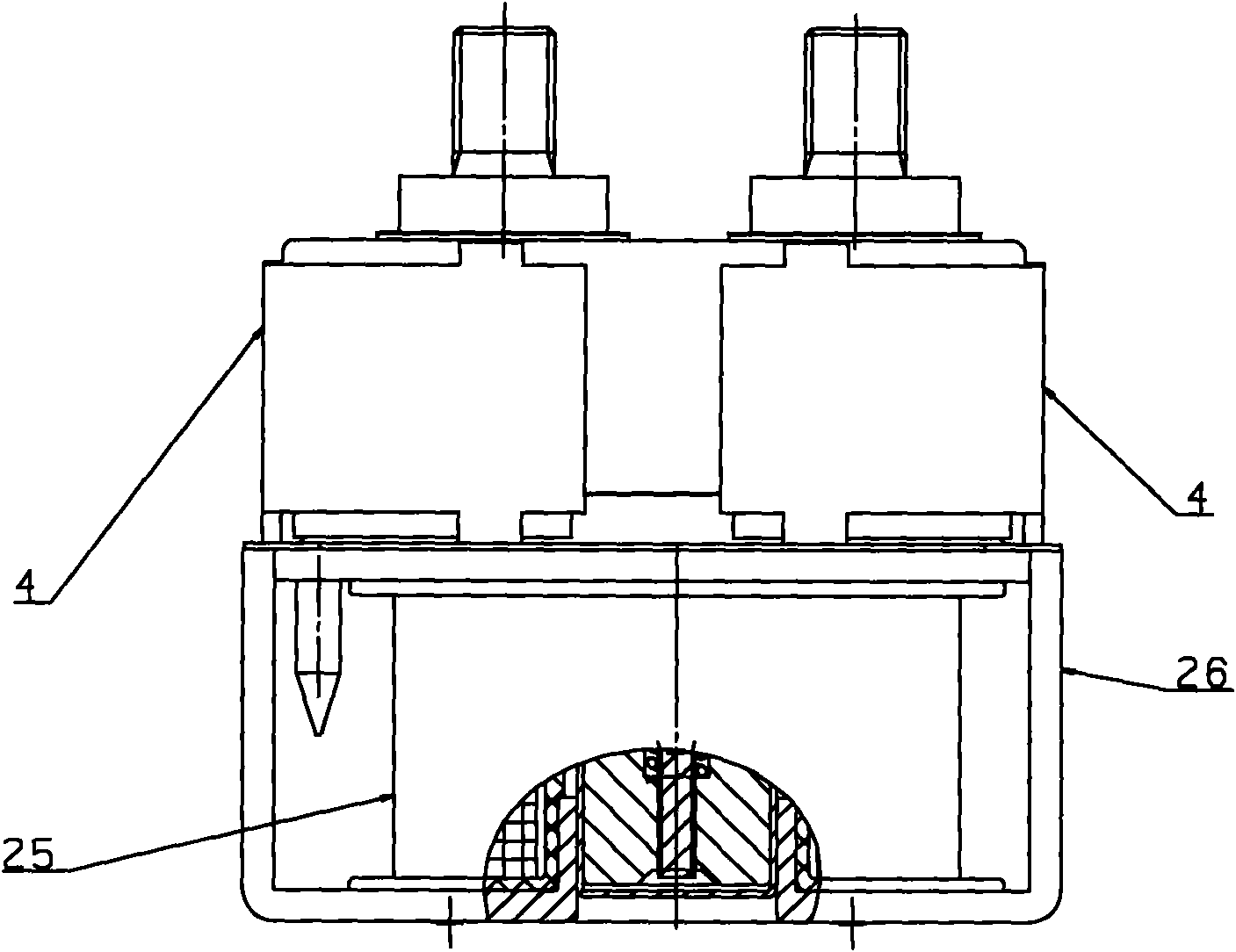

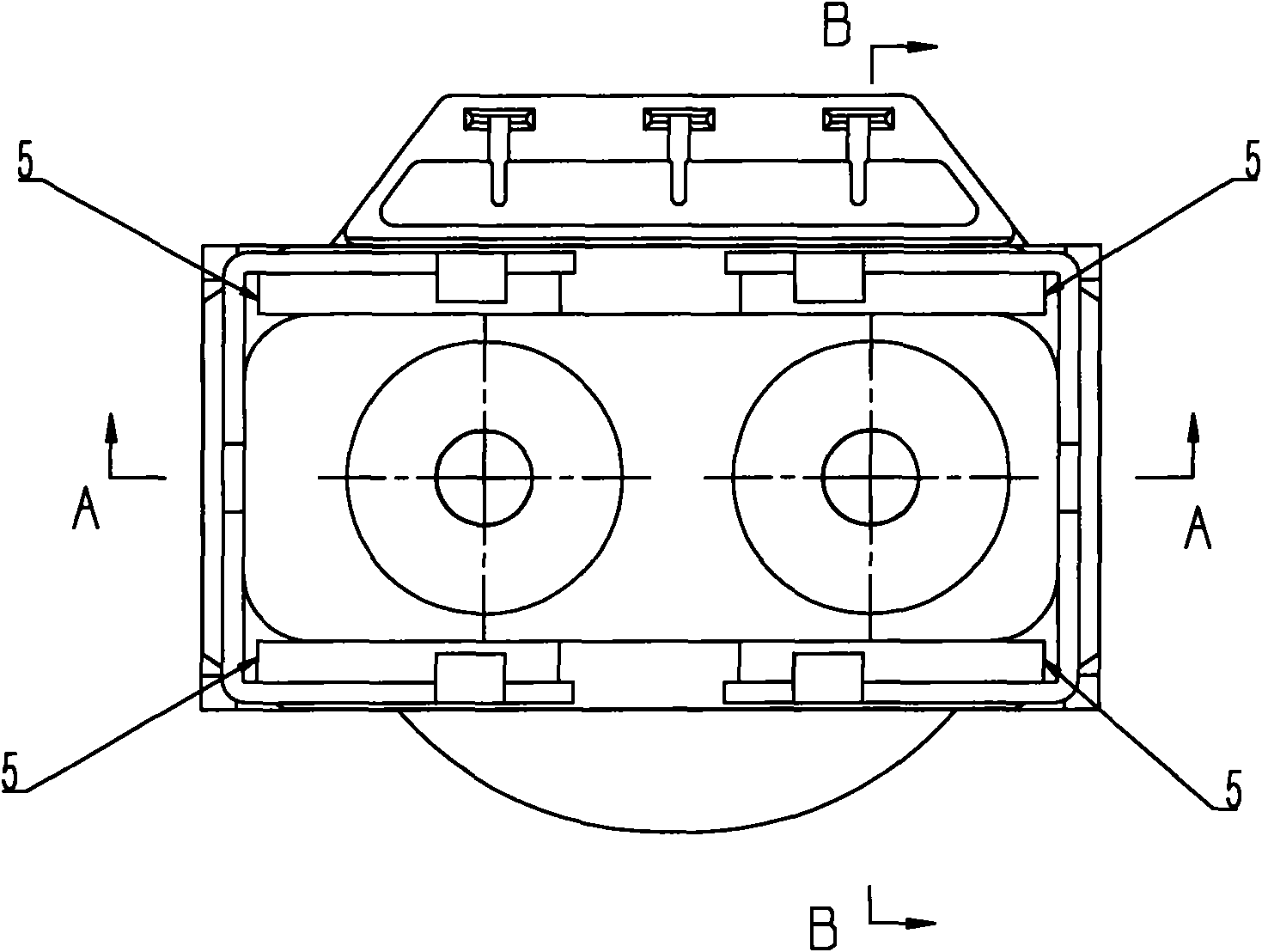

Joint-telescopic type super high voltage live cleaning robot

InactiveCN1586827AAvoid accidental touchGuarantee the safety of lifeJointsCleaning using toolsControl systemJoints types

The telescopic joint type robot for superhigh voltage live cleaning is used in cleaning. The robot has hand claw connected to small arm via the first joint, hand claw rotating oil cylinder with piston rod hinged to hand claw and cylinder hinged to small arm, small arm connected to the large arm via the second joint, small arm rotating oil cylinder with piston rod hinged to small arm and cylinder hinged to large arm, large arm fixed onto the rotary platform, rotary platform fixed onto movable carrier, automatic hydraulic leveling system and cradle head on the movable carrier and remotely controlled operating terminal for data exchange with central control system via radio communication. The present invention has less joints, simple structure, light weight and easy working and assembling, and may position ceramic insulator accurately.

Owner:SHANGHAI JIAO TONG UNIV

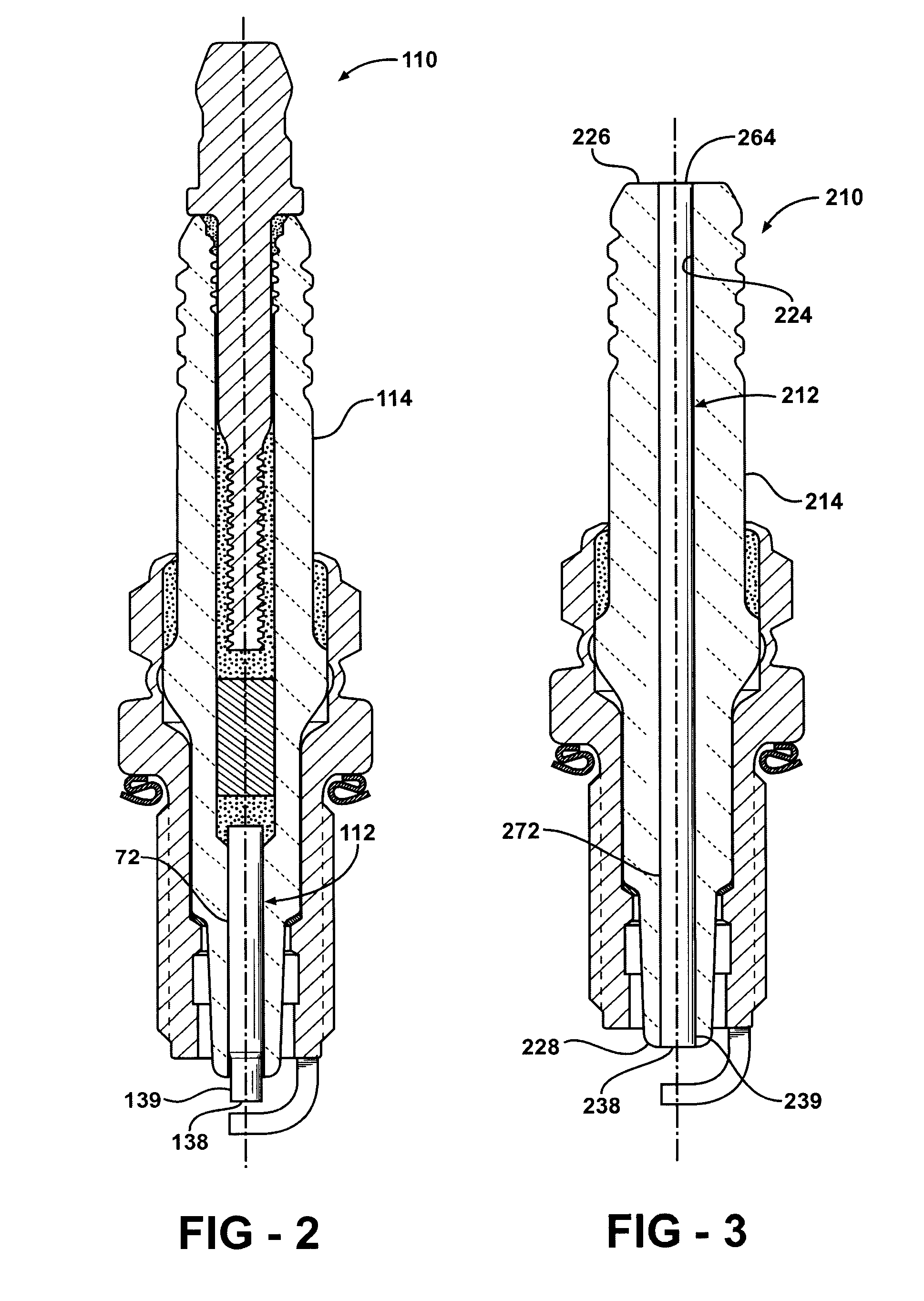

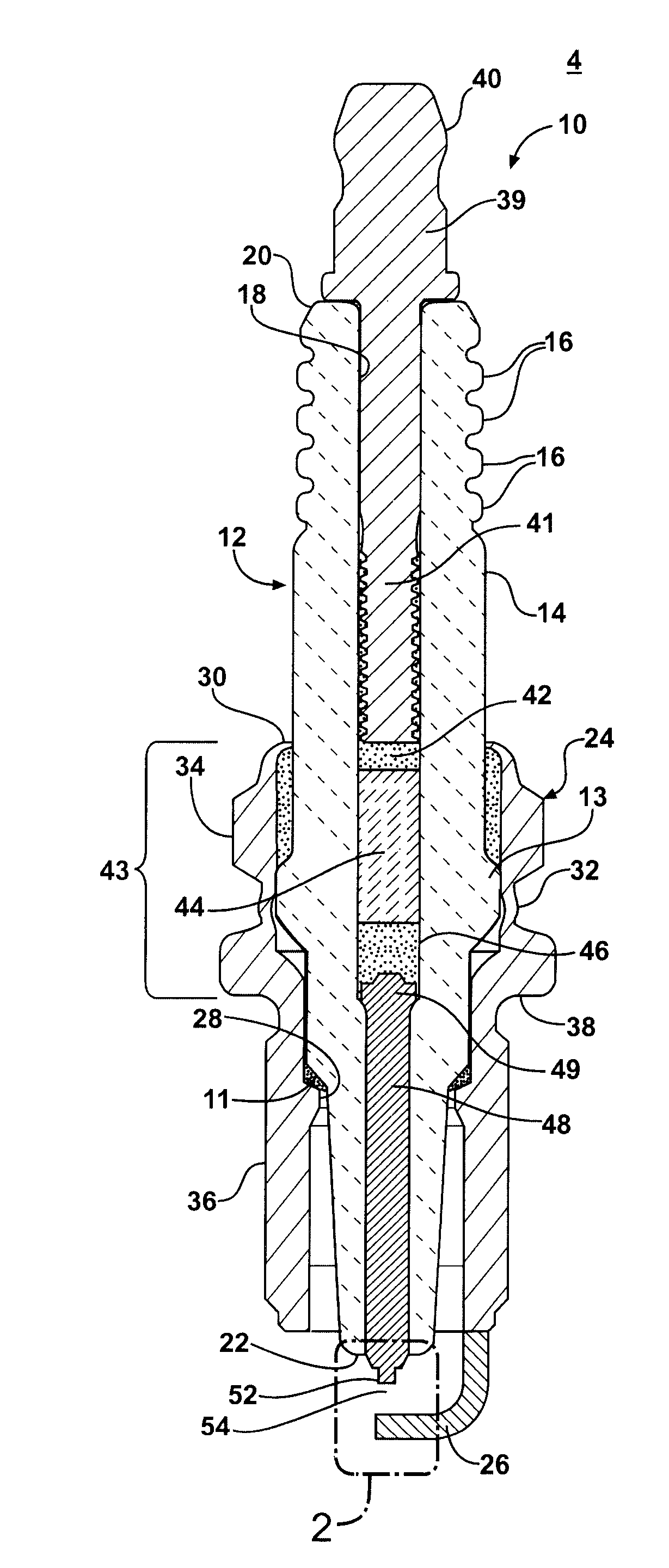

Electrode for an Ignition Device

An electrode for an ignition device is made from a Ni-based nickel-chromium-iron alloy which has improved resistance to high temperature oxidation, sulfidation, corrosive wear, deformation and fracture includes, by weight of the alloy: 14.5-25% chromium; 7-22% iron; 0.2-0.5% manganese; 0.2-0.5% silicon; 0.1-2.5% aluminum; 0.05-0.15% titanium; 0.01-0.1% total of calcium and magnesium; 0.005-0.5% zirconium; 0.001-0.01% boron, and the balance substantially Ni. It may also include at least one rare earth element selected from the group consisting of: yttrium, hafnium, lanthanum, cerium and neodymium in amounts ranging from 0.01-0.15% by weight, and incidental impurities, including cobalt, niobium, molybdenum, copper, carbon, lead, phosphorus or sulfur. These total of these impurities will typically be controlled to limits of 0.1% cobalt, 0.05% niobium, 0.05% molybdenum, 0.01% copper, 0.01% carbon, 0.005% lead, 0.005% phosphorus and 0.005% sulfur. The ignition device may be a spark plug which includes a ceramic insulator, a conductive shell, a center electrode disposed in the ceramic insulator having a terminal end and a sparking end with a center electrode sparking surface, and a ground electrode operatively attached to said shell having a ground electrode sparking surface, the center electrode sparking surface and the ground electrode sparking surface defining a spark gap therebetween. At least one of the center electrode or the ground electrode includes the solution-strengthened Ni-based nickel-chromium-iron alloy. The Ni-based nickel-chromium-iron alloy electrodes of the invention may also include a core with thermal conductivity greater than that of the Ni-based nickel-chromium-iron alloy, such as copper or silver or their alloys.

Owner:FEDERAL MOGUL WORLD WIDE LLC

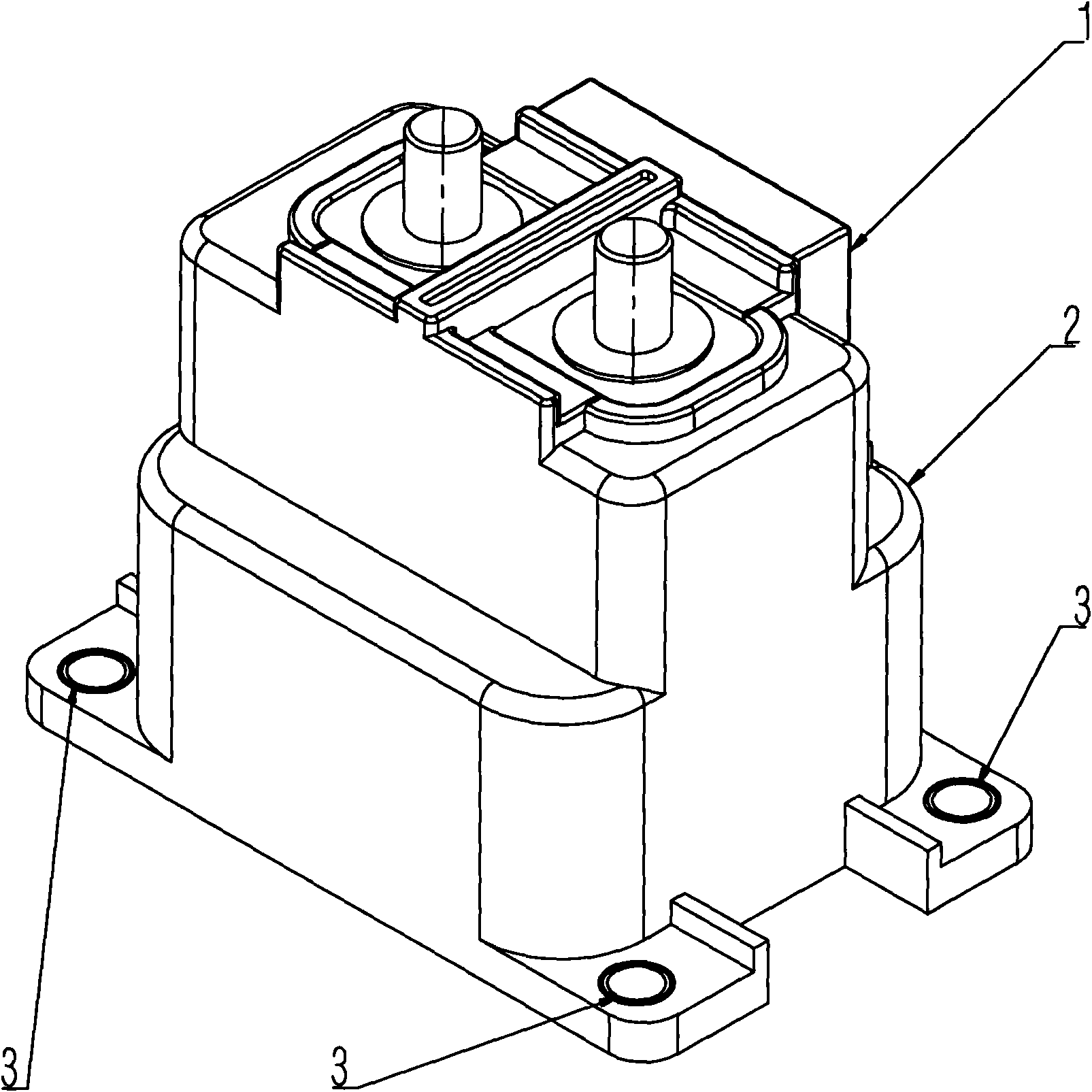

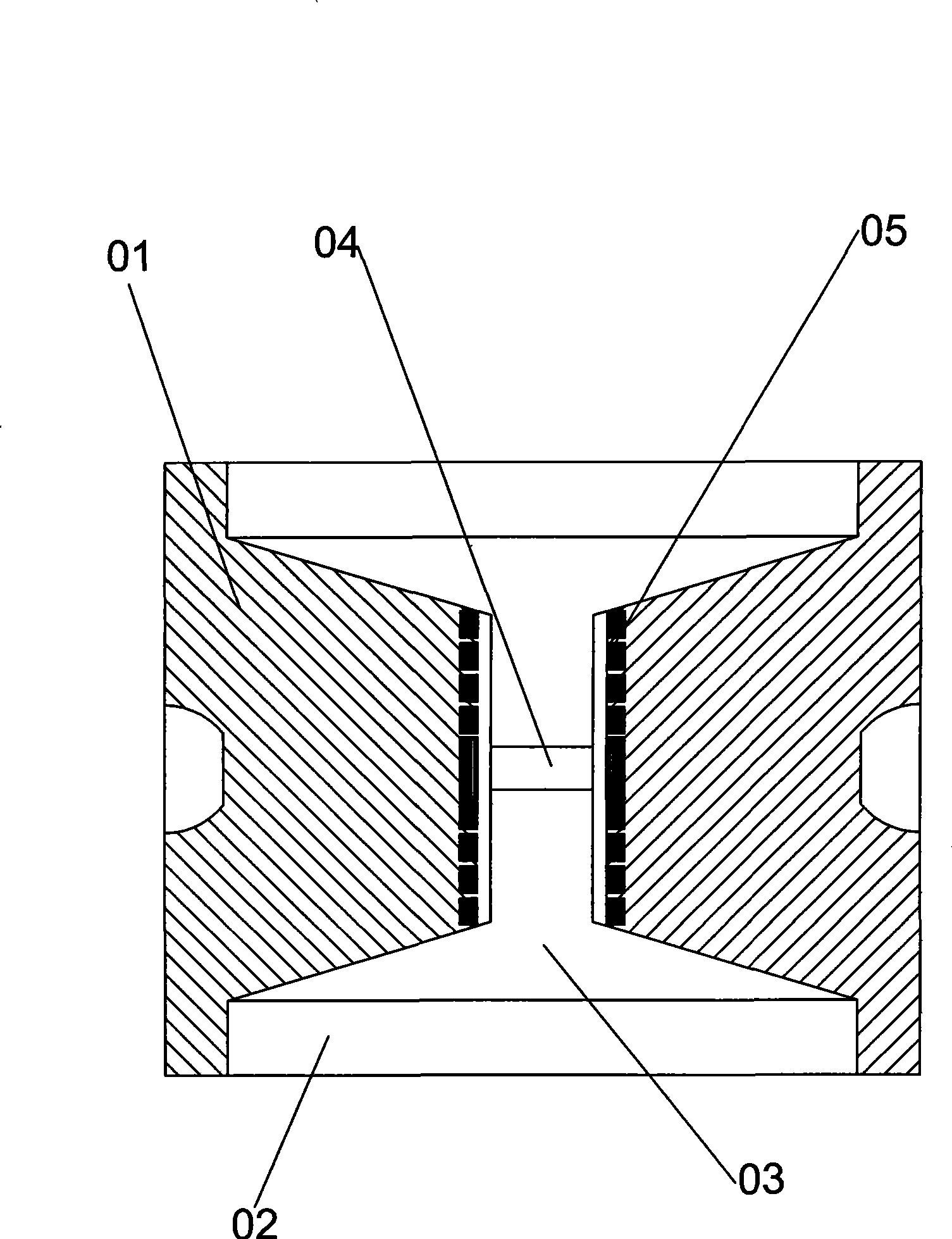

High voltage DC vacuum relay with high reliability and long service life

ActiveCN101677044AGuaranteed arc breaking capabilityImprove insulation performanceElectromagnetic relay detailsNon-polarised relaysShock resistanceHigh pressure

The invention discloses a high voltage DC vacuum relay with high reliability and long service life, which is arranged inside a vacuum cavity body that is sealed and connected by meal and ceramic; a ceramic insulator is connected between a movable contact component and a push rod in a sliding way; the good vacuum performance and electric insulation performance of the ceramic insulator can be utilized to lead the movable contact and a fixed contact to main good electric insulation together with a magnetic circuit system formed by a magnetic guide yoke iron plate of the relay, an iron core and the like no matter in a state of connection or disconnection, so that current interruption capability of the relay can be guaranteed when DC high-voltage load is switched; a vacuum chamber body and allparts in side the vacuum chamber body formed by the high voltage DC vacuum relay have low enough saturated vapor pressure and are treated by high temperature baking exhaust, so that the vacuum degreein the vacuum chamber body can ensure the work demand of the relay on switching heavy current and the DC high-voltage load for a long time; furthermore, the relay also has the advantages of simple andcompact structure, small volume, light weight, strong shock resistance and impact resistance, simple technique process, low production cost and large batch production.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

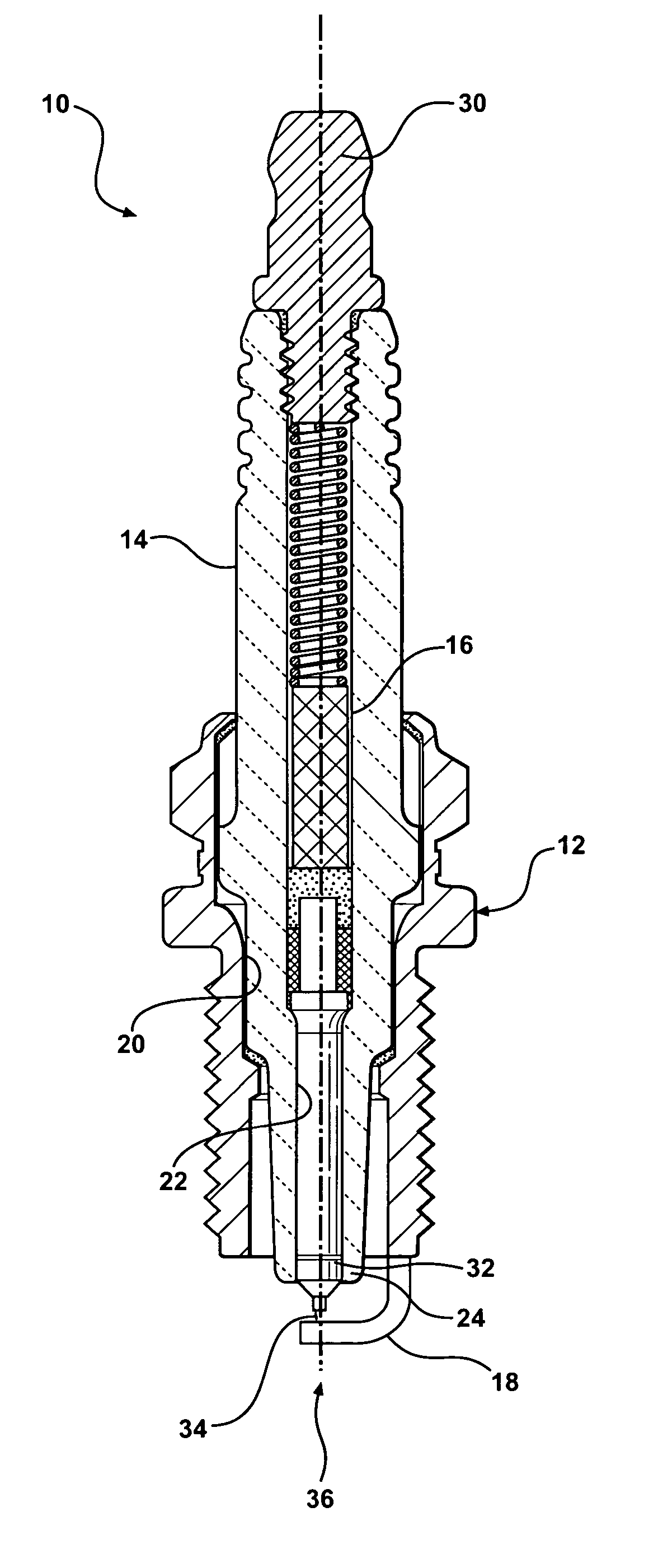

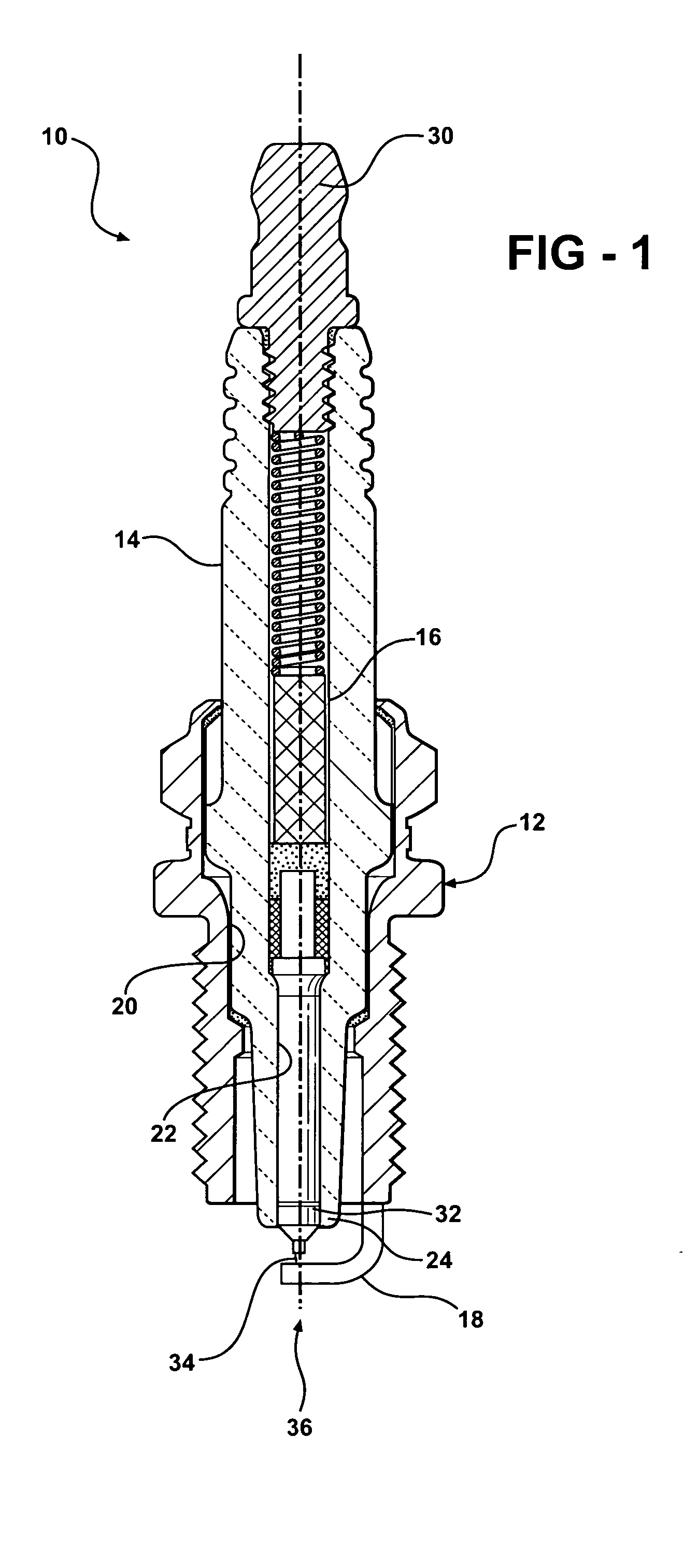

Ceramic electrode, ignition device therewith and methods of construction thereof

A spark plug, a center electrode therefore and method of construction is provided. The spark plug has a generally annular ceramic insulator extending between a terminal end and a nose end. A conductive shell surrounds at least a portion of the ceramic insulator and a ground electrode having a ground electrode sparking surface is operatively attached to the shell. An elongate center electrode has a body extending between opposite ends, wherein the body is compacted and sintered of a conductive or semi-conductive ceramic material. One of the electrode ends provides a center electrode sparking surface to provide a spark gap between the center electrode sparking surface and the ground electrode sparking surface.

Owner:FEDERAL MOGUL IGNITION

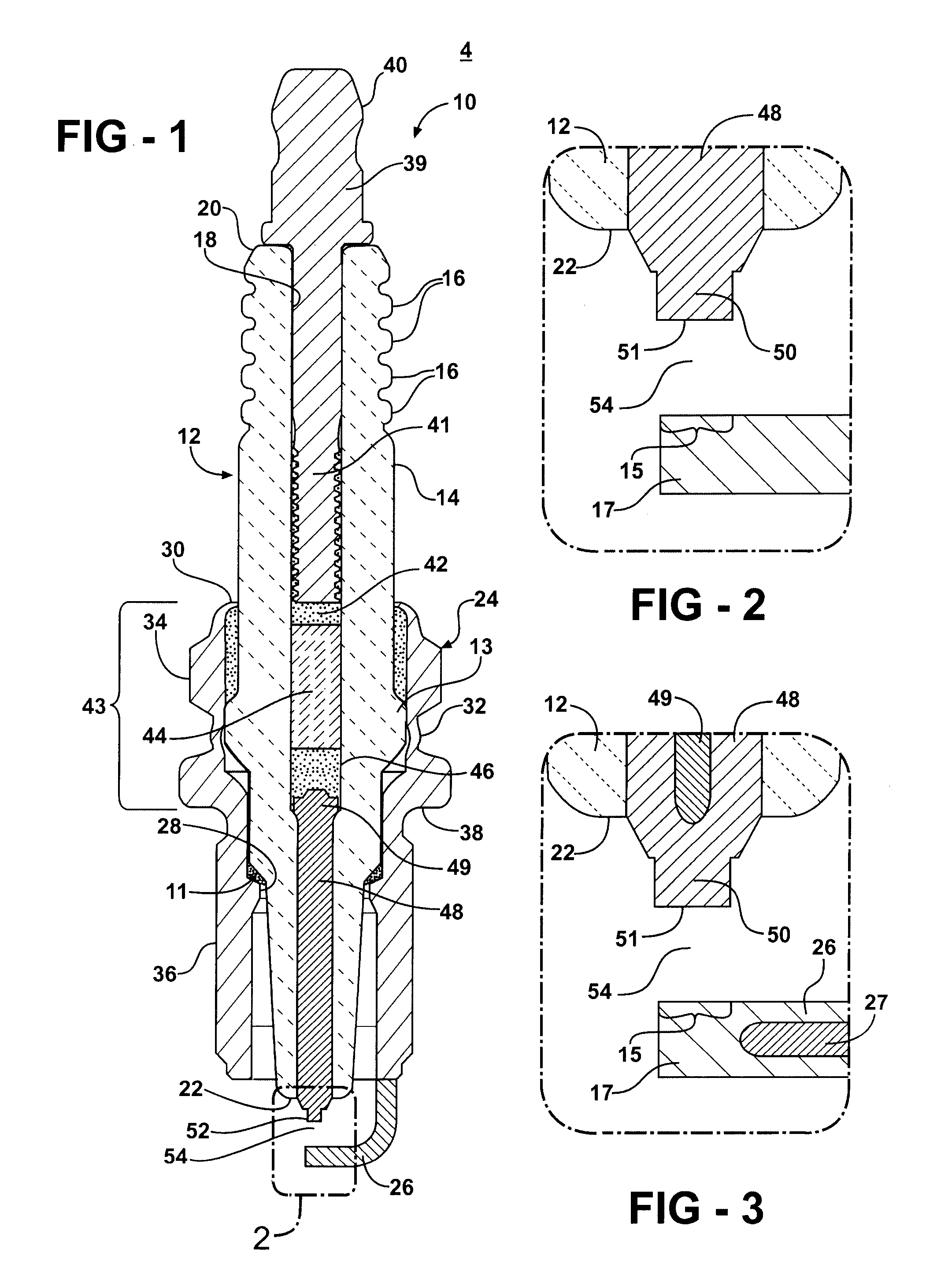

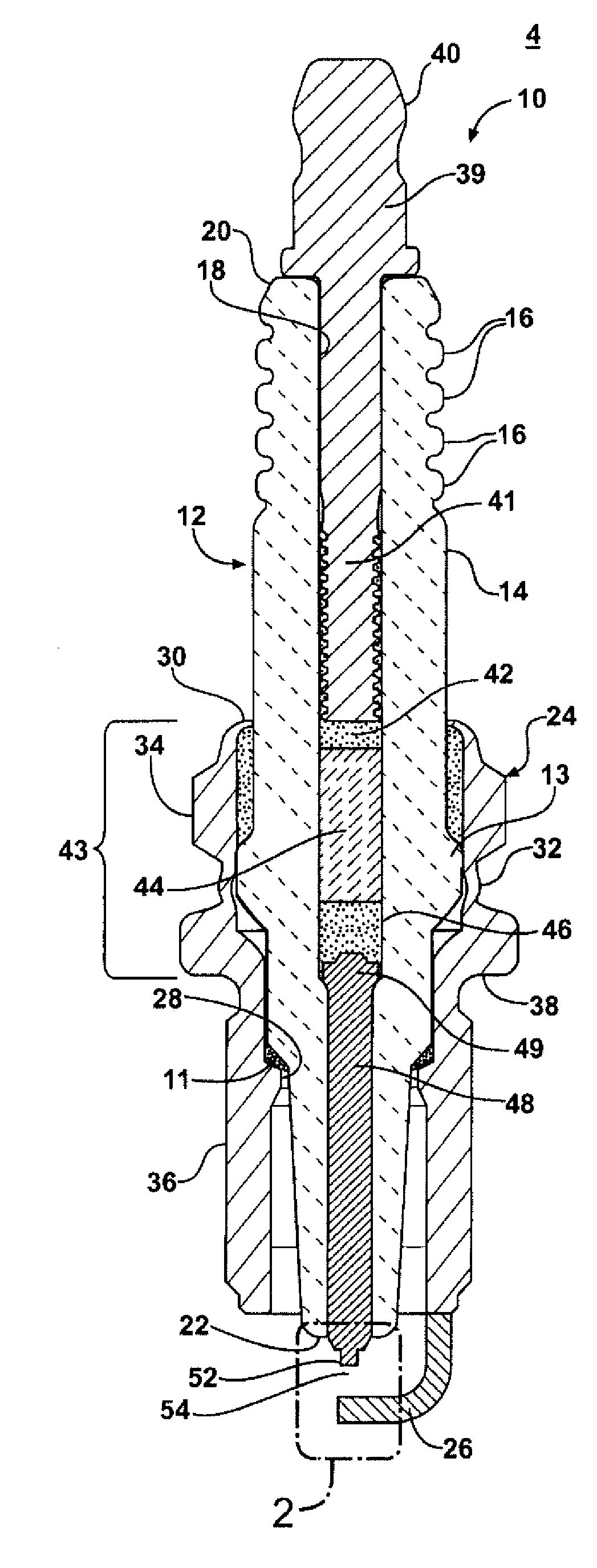

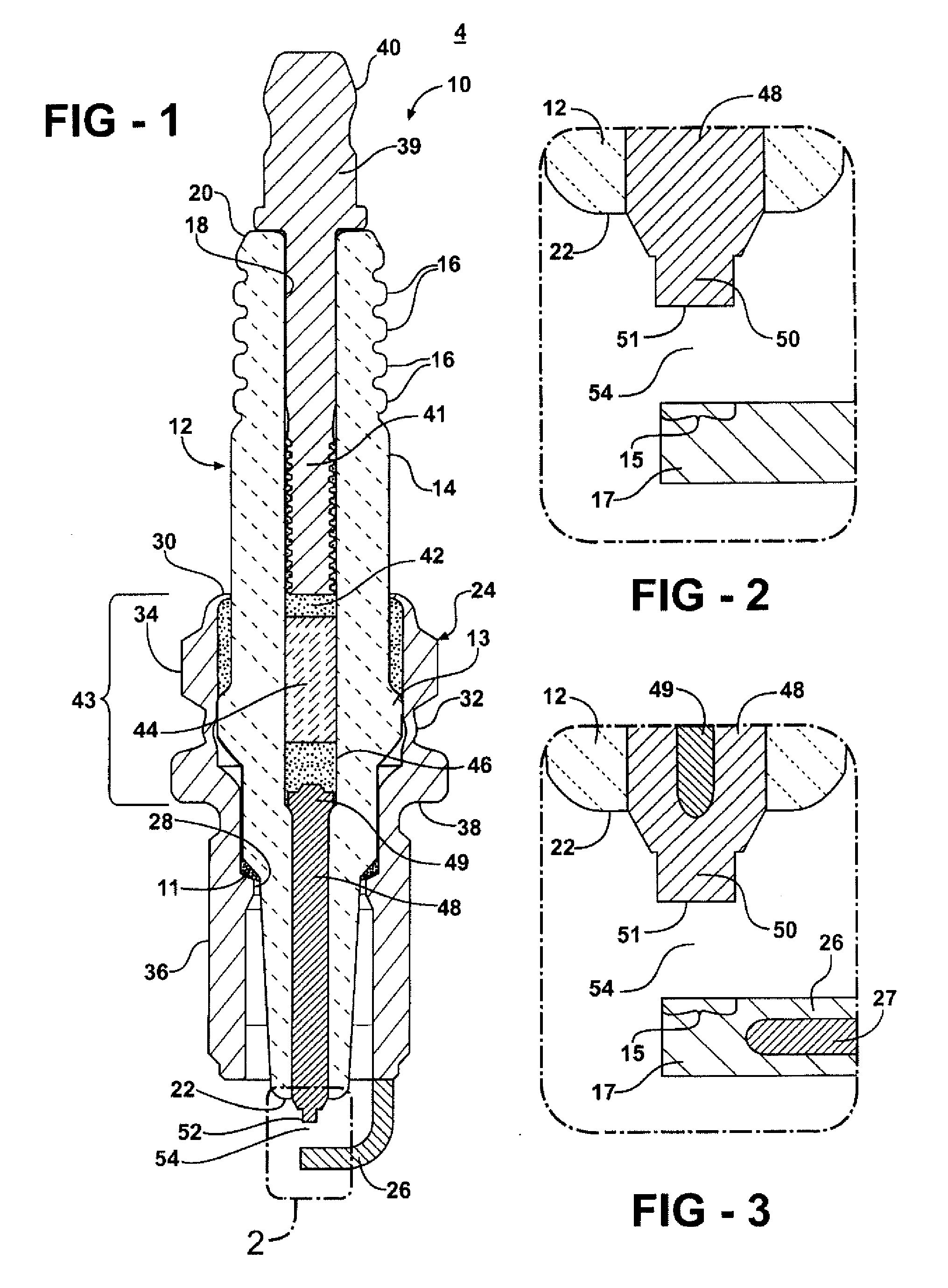

Spark Plug With Fine Wire Ground Electrode

InactiveUS20070290593A1Strong and more secure jointFacilitates various attachment mechanismSparking plugsEngineeringInternal combustion engine

A spark plug for a spark-ignited internal combustion engine includes a generally tubular ceramic insulator. A conductive shell surrounds at least a portion of the ceramic insulator and includes at least one ground electrode. A center electrode is disposed in the ceramic insulator. The center electrode has an upper terminal end and a lower sparking end in opposing relation to the ground electrode, with a spark gap defining the space therebetween. The ground electrode extends from an anchored end adjacent the shell to a distal end adjacent the spark gap. The ground electrode includes a ledge formed on its distal end having at least one inset planar surface and an inset back wall. A high-performance metallic sparking tip is attached to the distal end of the ground electrode. The sparking tip has a base end disposed in surface-to-surface contact with the inset planar surface of the ledge. A particular advantage of the invention is achieved by the inset planar surface completely covering the base end of the sparking tip and extending outwardly therefrom to provide an exposed peripheral interface whereby optional attachment methods, such as welds may be applied, if desired, about at least a portion of the exposed periphery of the base end. In addition, portions of the sparking tip may abut the inset back wall, upper surface of center electrode or both enabling attachment of the sparking tip to the points where it abuts these surfaces.

Owner:FEDERAL MOGUL WORLD WIDE LLC

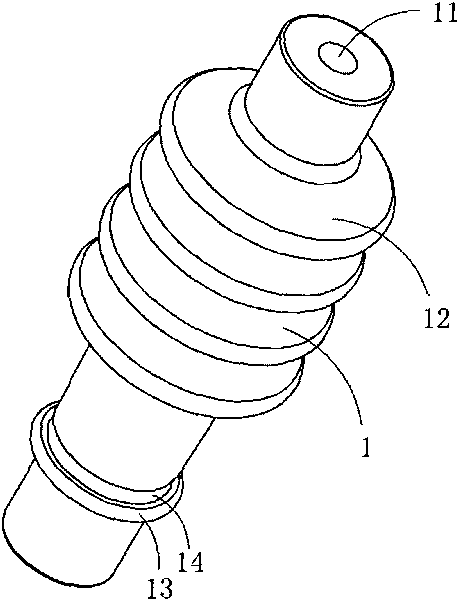

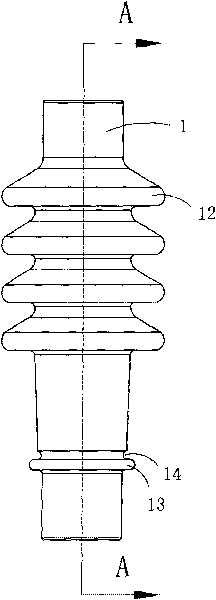

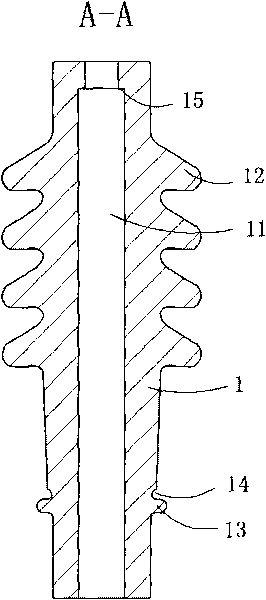

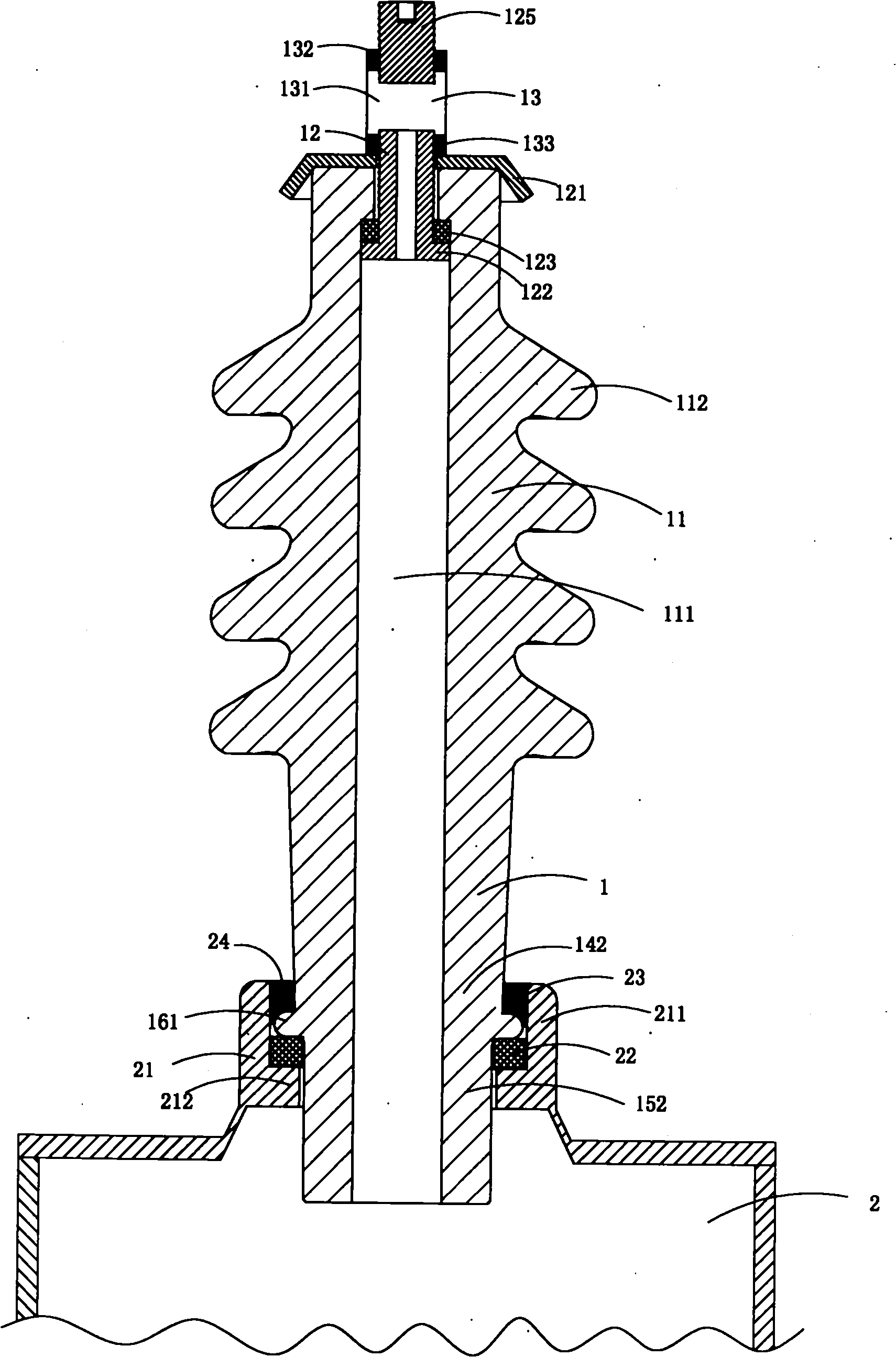

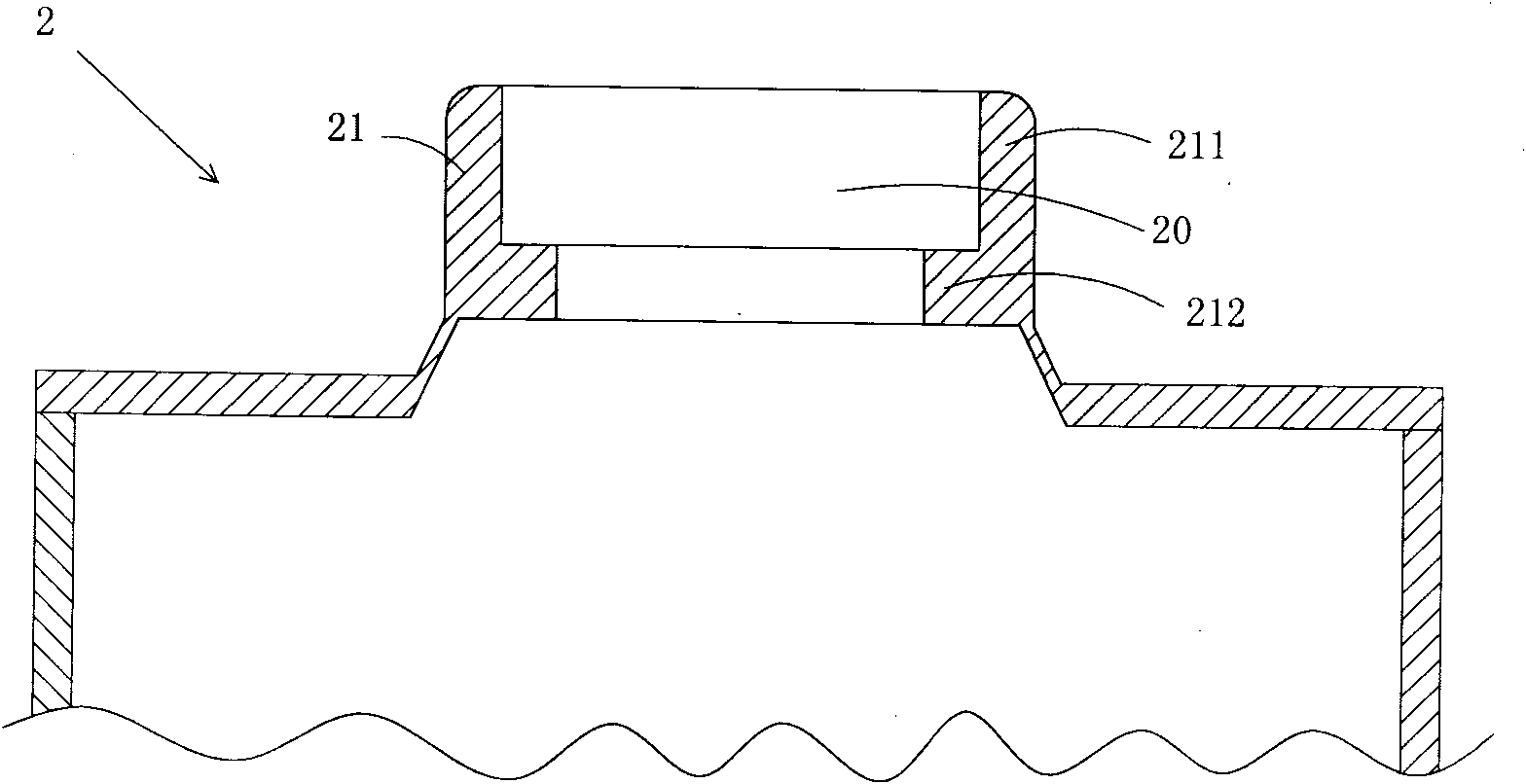

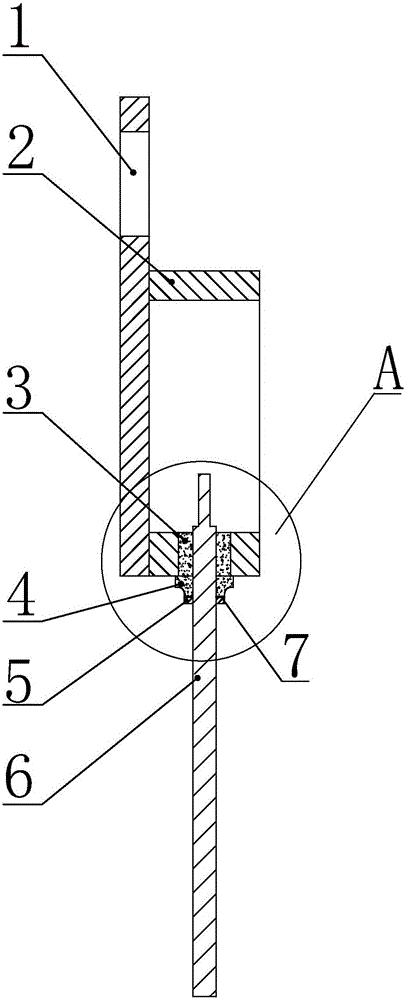

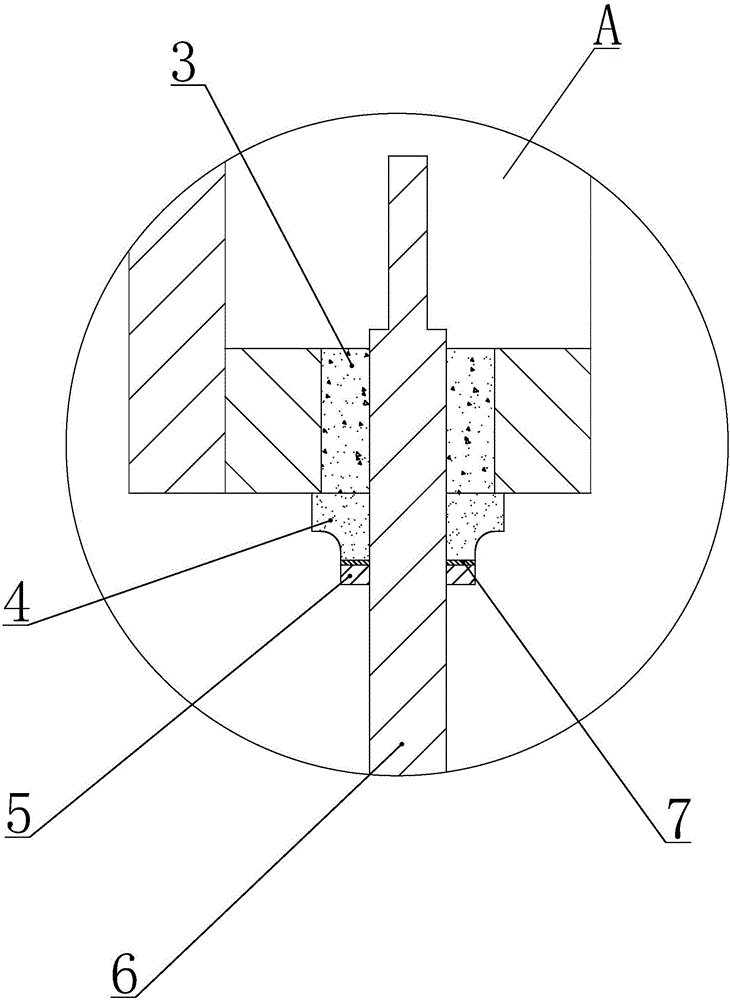

Ceramic insulator and high voltage power capacitor insulator device

ActiveCN101719402AImprove convenienceSolder undercutCapacitorsLead-in/lead-through insulatorsMetallurgyCapacitor

The invention discloses a ceramic insulator and a high voltage power capacitor insulator device. The ceramic insulator comprises a ceramic insulator body, wherein the middle outer wall is provided with a plurality of umbrella skirts, and the lower wall is provided with an annular locating lug boss; and an annular groove is arranged between the annular locating lug boss and the umbrella skirts. The insulator device comprises the ceramic insulator body, a wiring assembly and a mounting assembly; the mounting assembly comprises a metal mounting seat and a seal ring; the metal mounting seat is tubular, the upper end of the metal mounting seat is provided with a welding part, the lower end is provided with a blocking part, and the blocking part is positioned below the annular locating lug boss; the seal ring is positioned between the lower surface of the annular locating lug boss and the blocking part; the welding part is higher than the annular groove of the insulator body; and the inner wall of the welding part of the metal mounting seat, the outer wall of the insulator body and the annular locating lug boss enclose a welding space, and welding flux is arranged in the welding space. The invention is convenient to mount and operate and effectively enhances the production efficiency.

Owner:STATE GRID CORP OF CHINA +3

Electrode for an Ignition Device

InactiveUS20080308057A1Improve the immunityGood synergySparking plugsElectric spark ignitersNiobiumManganese

An electrode for an ignition device is made from a dilute nickel alloy which has improved resistance to high temperature oxidation, sulfidation, corrosive wear, deformation and fracture and includes at least 90% by weight of nickel; zirconium; boron and at least one element from the group consisting of aluminum, magnesium, silicon, chromium, titanium and manganese. The weight ratio of Zr / B may range from about 0.5 to 150, and may include amounts of, by weight of the alloy, 0.05-0.5% zirconium and 0.001-0.01% boron. The oxidation resistance of the alloy may also be improved by the addition of hafnium to the alloy in an amount that is comparable to the amount of zirconium, which may include an amount of, by weight of the alloy, 0.005-0.2% hafnium. Electrodes of dilute nickel alloys which include aluminum and silicon, as well as those which include chromium, silicon, manganese and titanium, are particularly useful as spark plug electrodes. These electrode alloys of the may also include at least one of cobalt, niobium, vanadium, molybdenum, tungsten, copper, iron, carbon, calcium, phosphorus or sulfur as trace elements, generally with specified maximum amounts. The ignition device may be a spark plug which includes a ceramic insulator, a conductive shell, center electrode and ground electrode. The center electrode, ground electrode, or both, may be made from the dilute nickel alloy of the invention. These electrodes may also include a core with thermal conductivity greater than that of the dilute nickel alloy, such as copper or silver or their alloys.

Owner:FEDERAL MOGUL WORLD WIDE

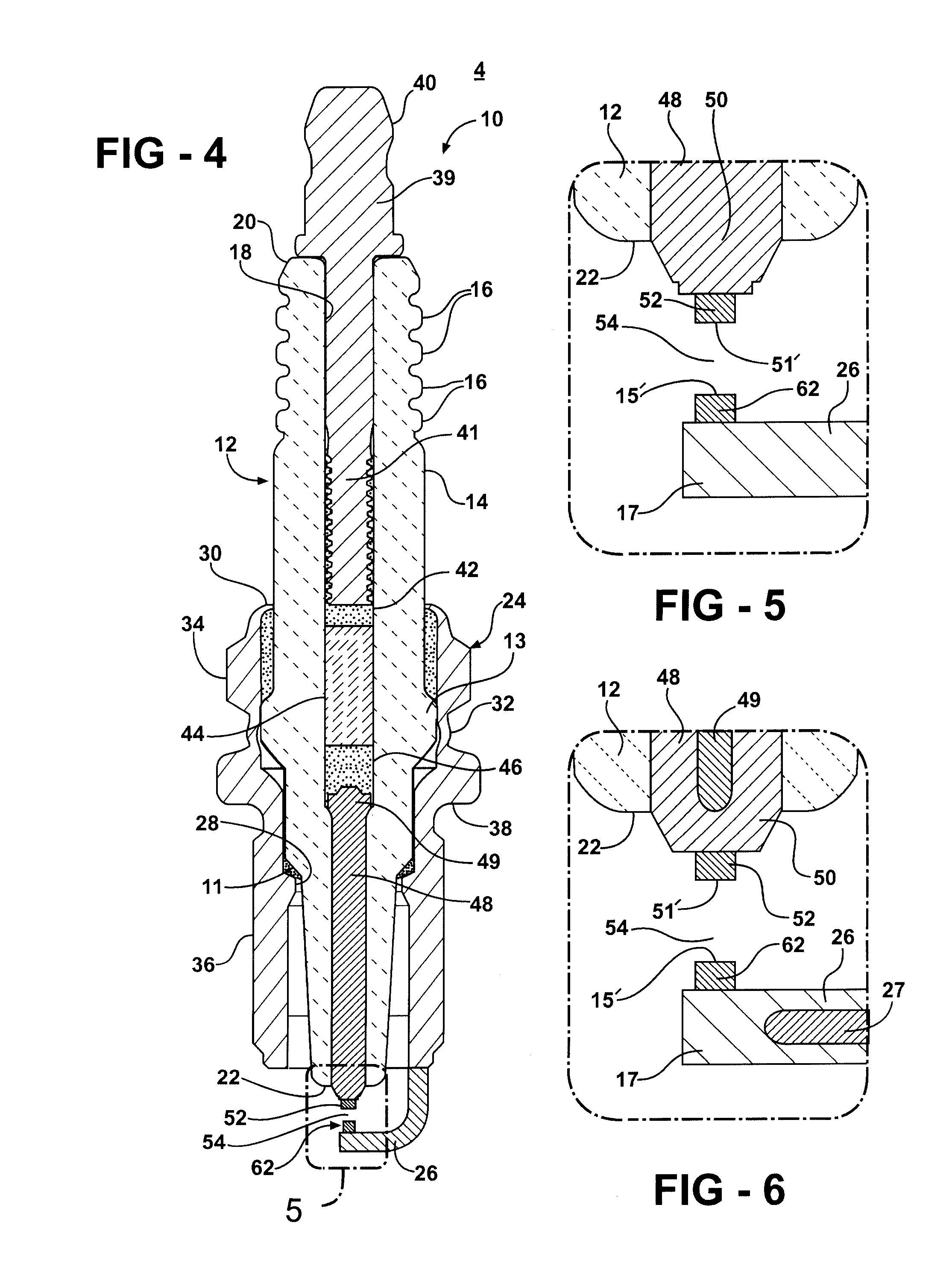

Glass sintered high temperature and high pressure sealing electric connector

ActiveCN103474831AHigh temperature resistanceProne to compressive stressSecuring/insulating coupling contact membersCoupling contact membersElectrical conductorUltra high pressure

A glass sintered high temperature and high pressure sealing electric connector comprises conductor pins (11) used for transmitting currents, wherein a glass insulator (12) and a ceramic insulator (13) wrap each conductor pin (11), a metal outer shell (14) is arranged on the peripheries of the glass insulators (12) and on the peripheries of the ceramic insulators (13), the conductor pins (11), the glass insulators (12), the ceramic insulators (13) and the metal outer shell (14) are combined into a whole through the glass sintering process. The conductor pins (11) are made of expansion alloy, the glass insulators (12) are made of electronic seal glass, and the metal outer shell (14) is made of nickel-based superalloy. According to the electric sealing connector, pressure can be more easily produced between glass and a substrate, the micro combination degree of sealing between glass and metal is improved, and accordingly the probability that air leakage occurs in the sintering process or in the use process is greatly lowered.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

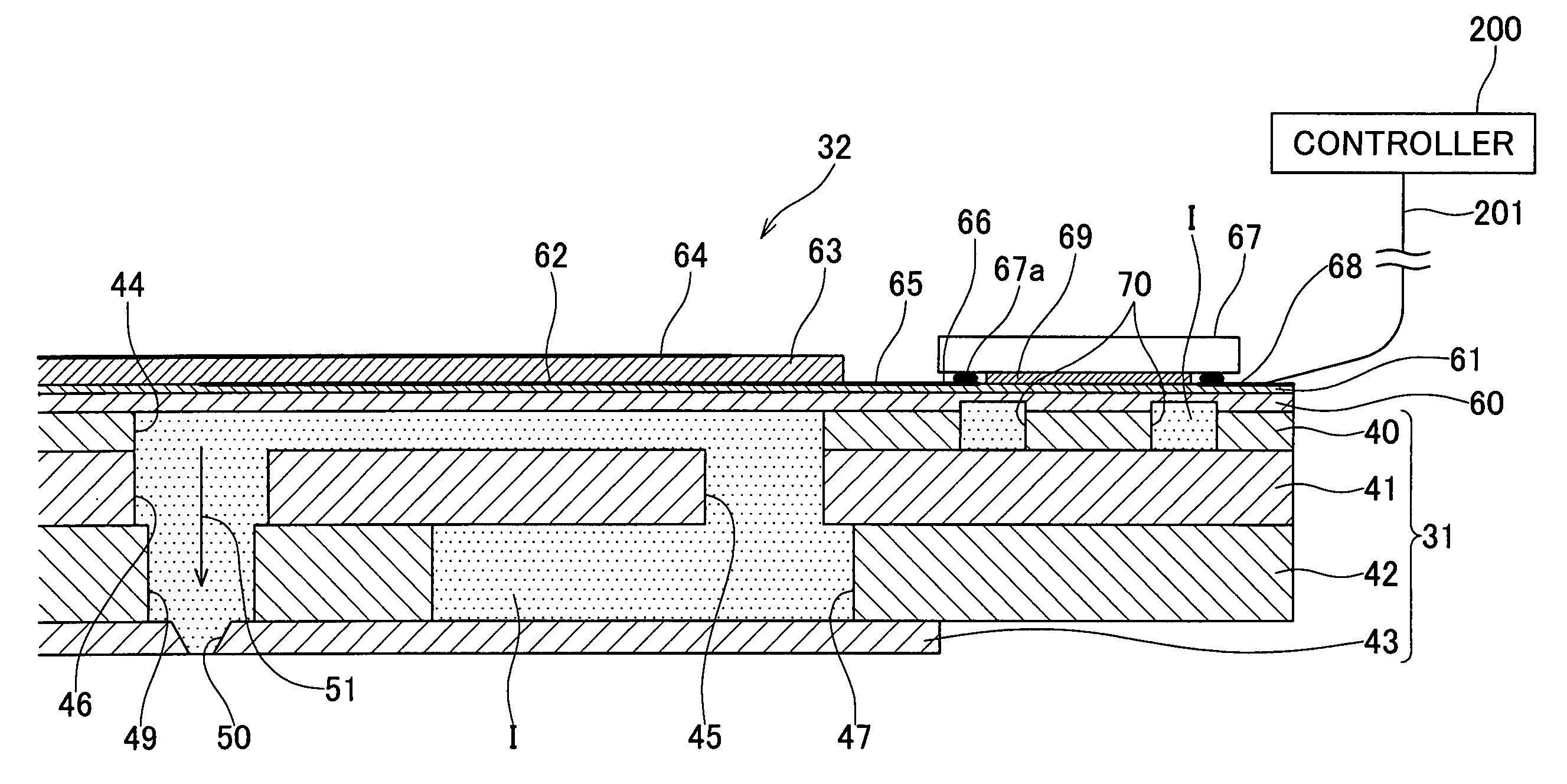

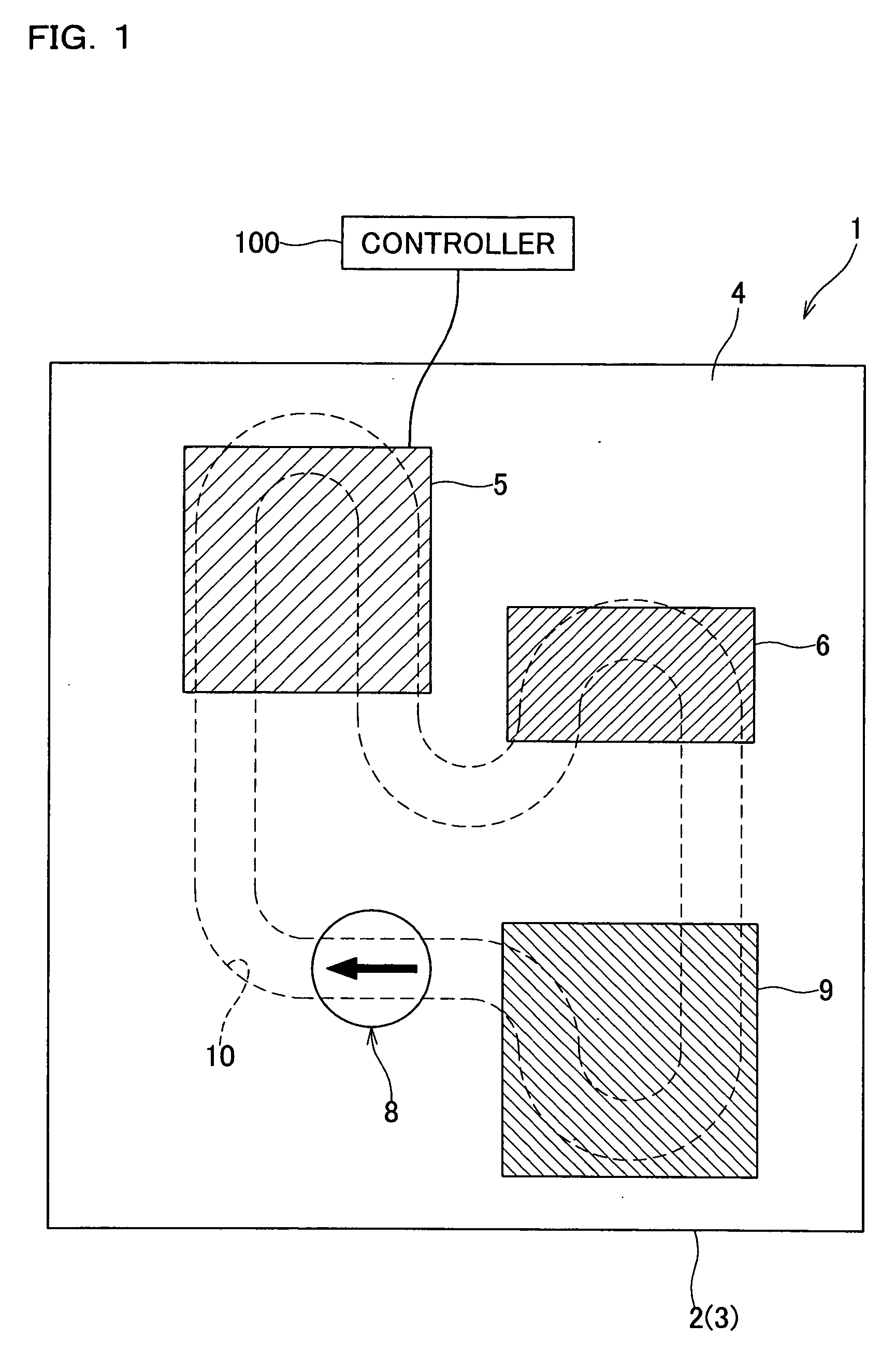

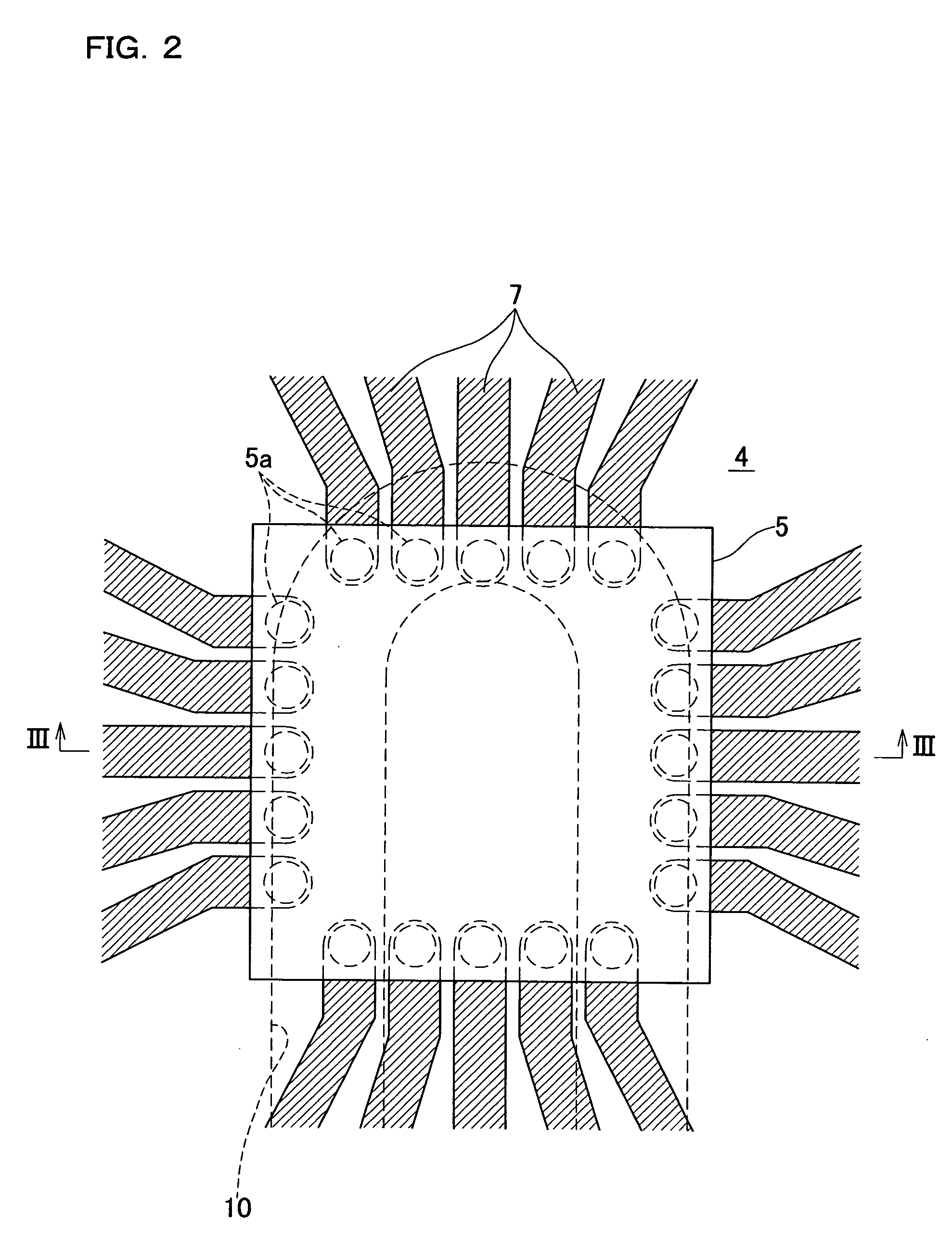

Substrate mounted with electronic element thereon and liquid ejection head including the substrate

InactiveUS7352591B2Effective radiationImprove thermal conductivityInking apparatusSemiconductor/solid-state device detailsEngineeringElectronic component

A substrate mounted with an electronic element thereon comprises a metal base, a ceramic insulator, and a radiator. The insulator is provided on a first side of the base. The insulator has a heat-generating electronic element mounted on a side thereof opposite to a side thereof facing the first side of the base. The radiator has a radiation capability higher than both of a radiation capability of the insulator and a radiation capability of the base, and radiates heat transmitted from the electronic element via the insulator to the base.

Owner:BROTHER KOGYO KK

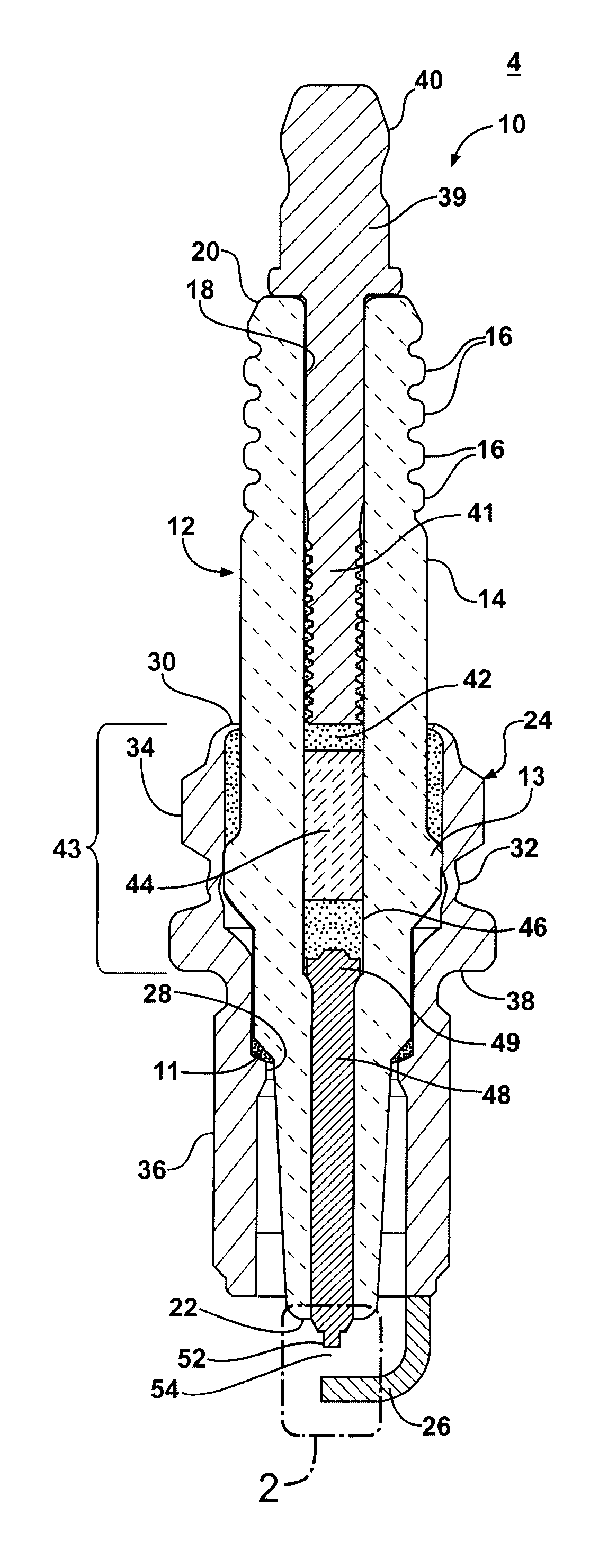

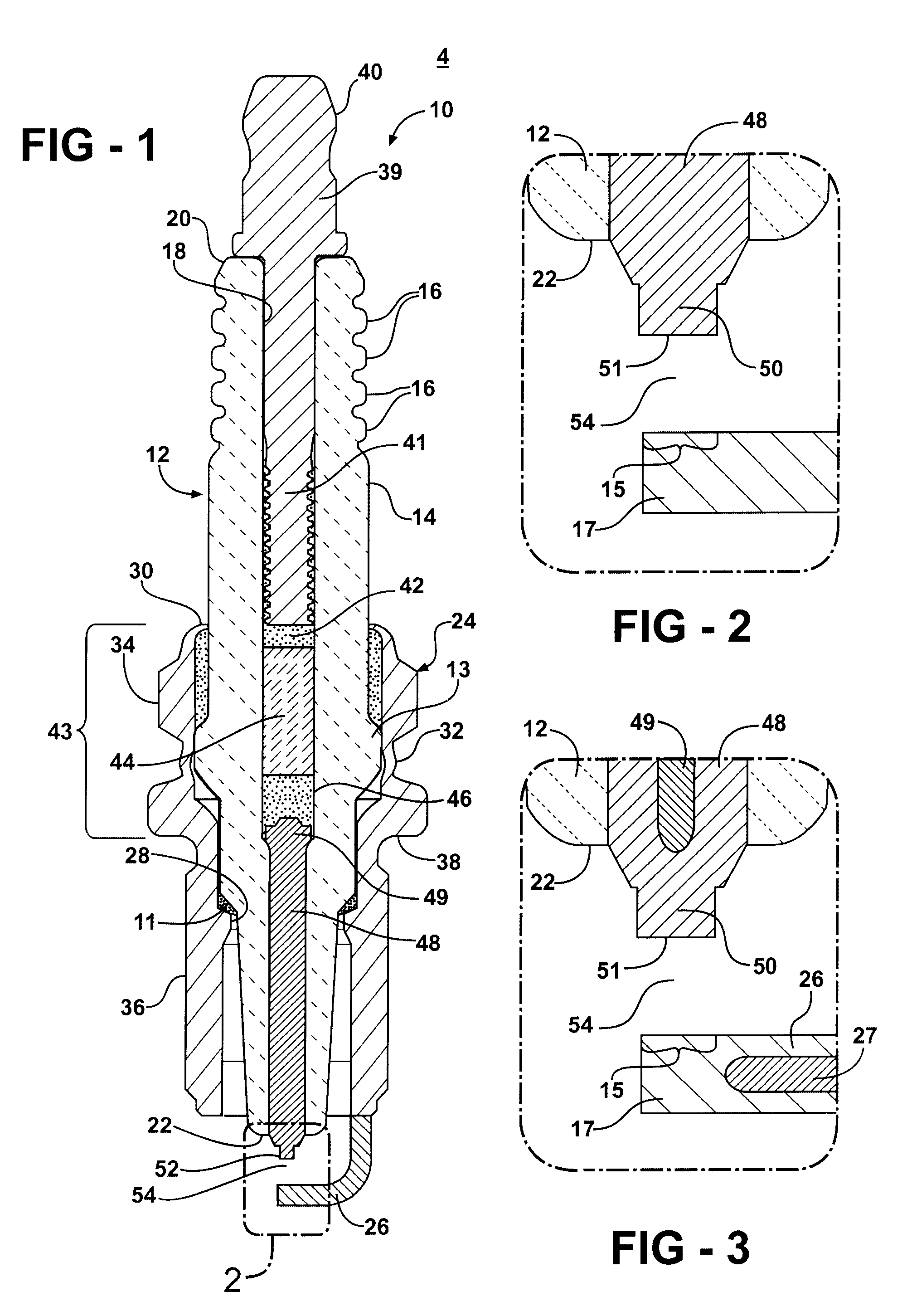

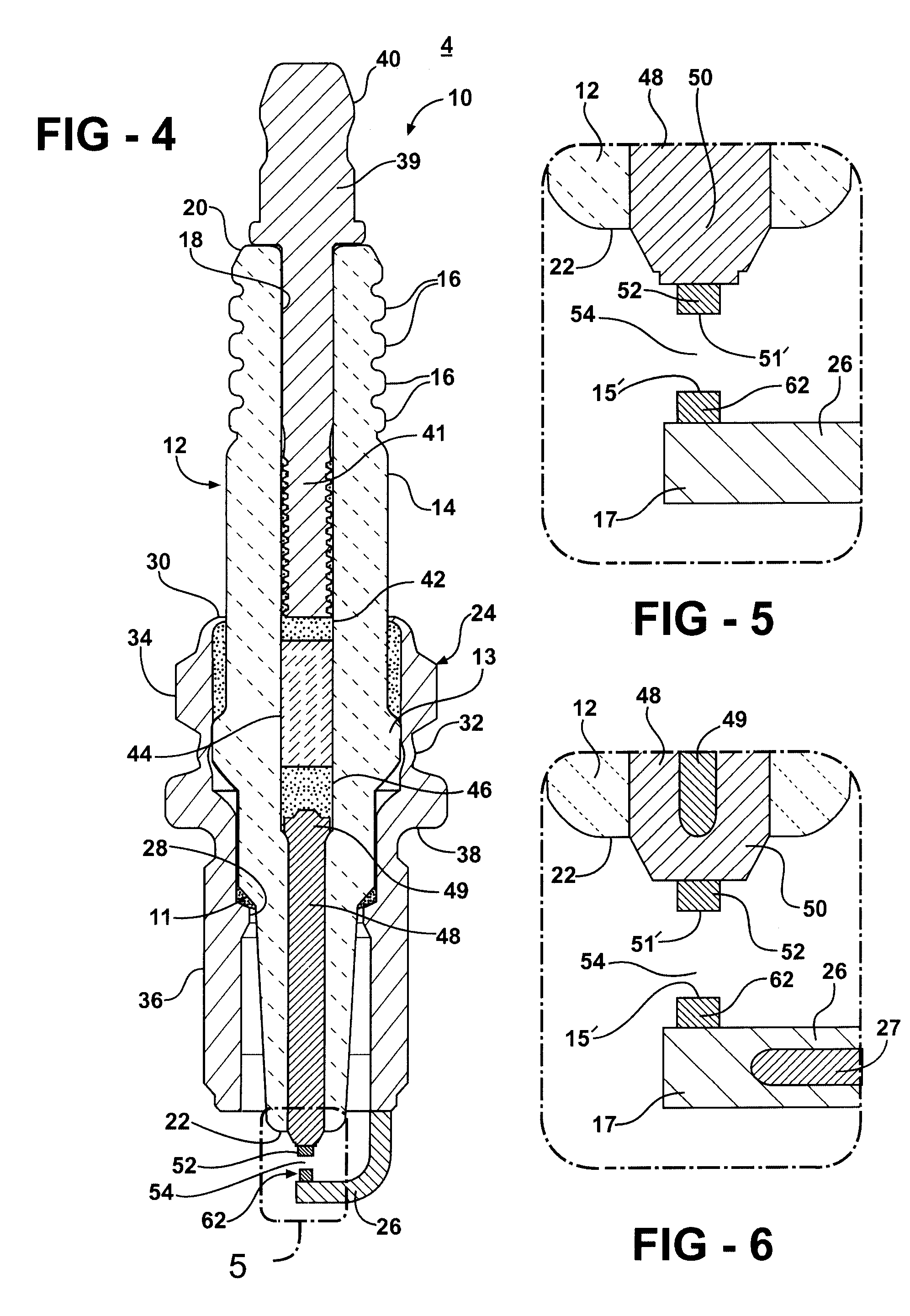

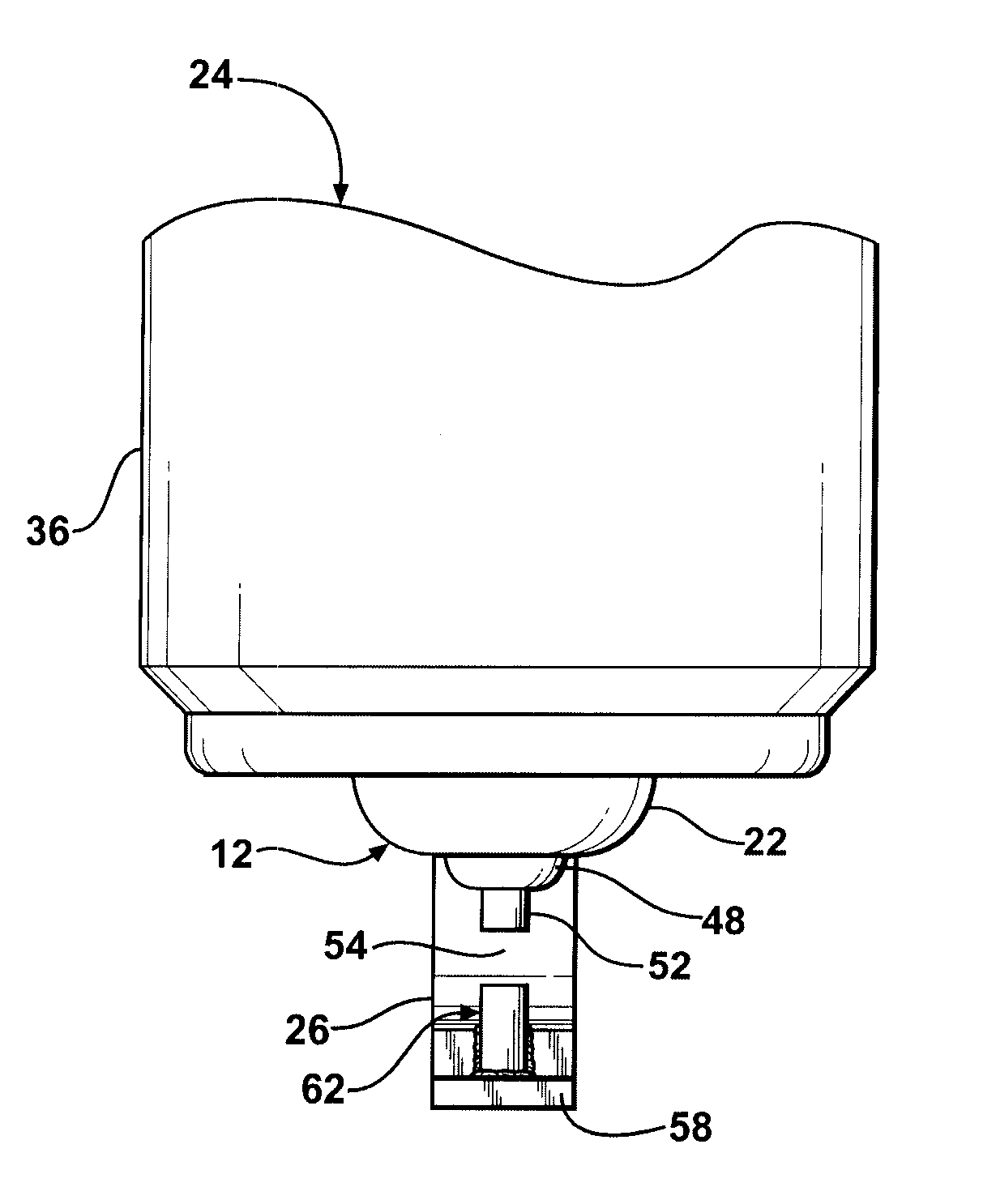

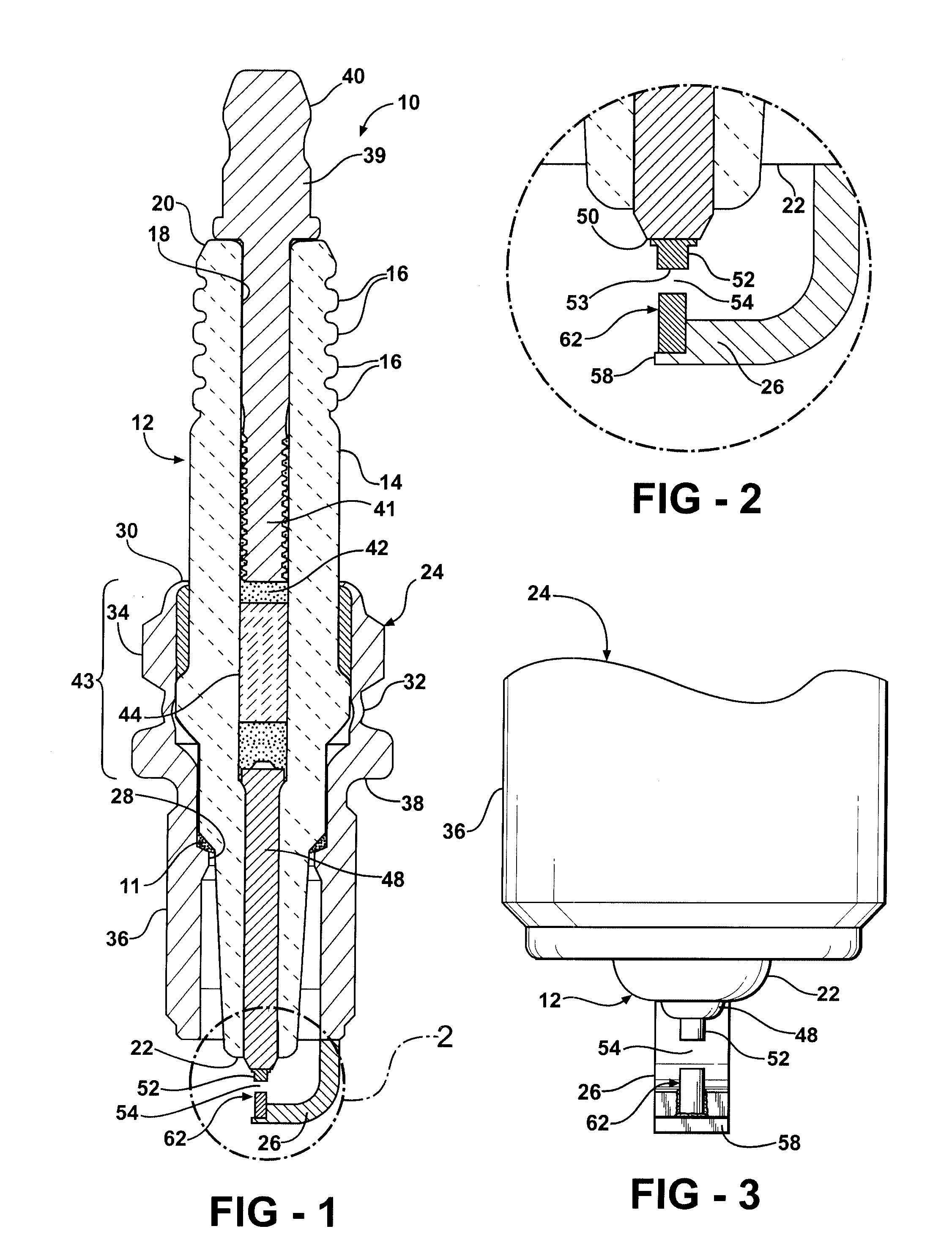

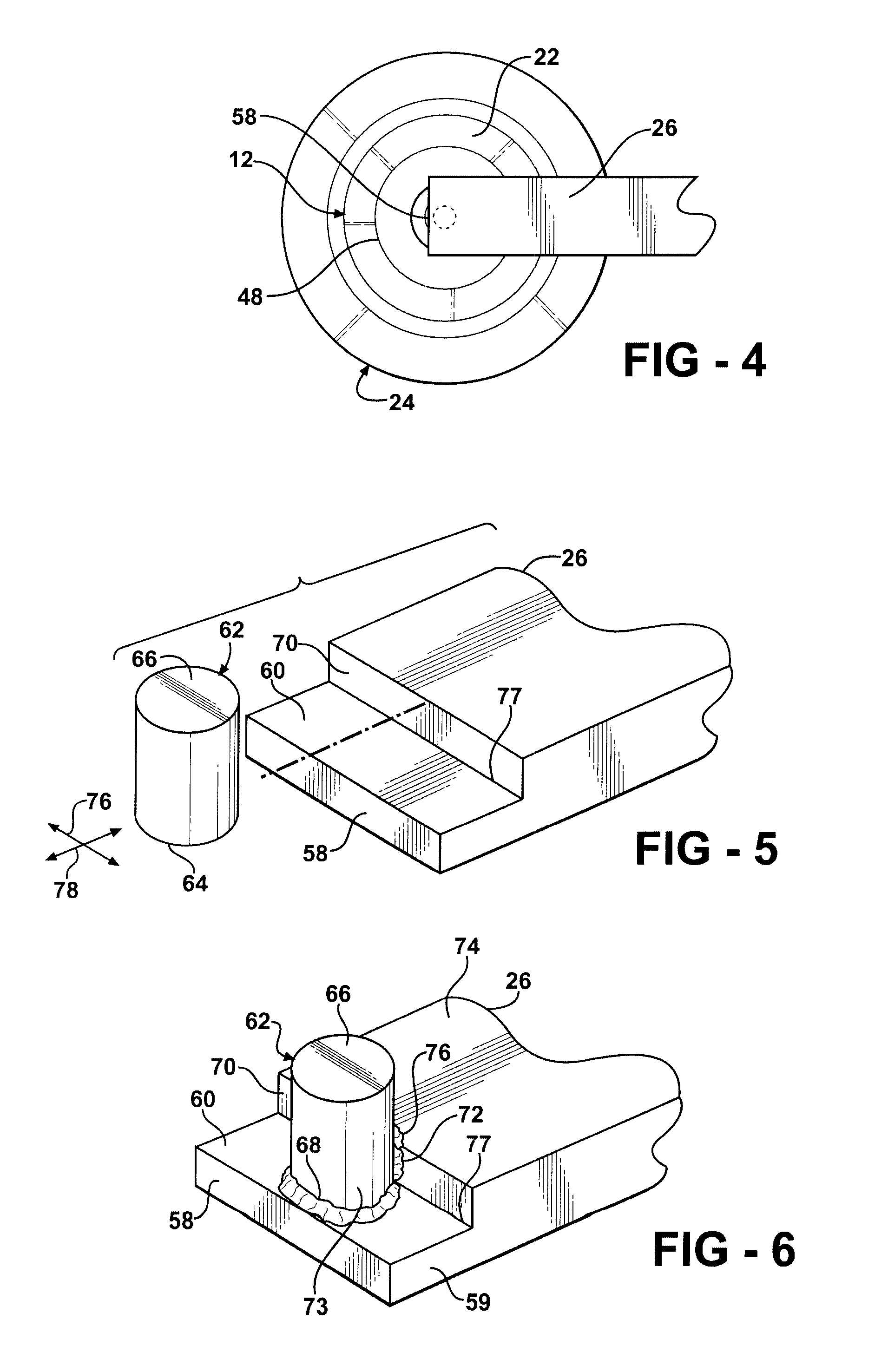

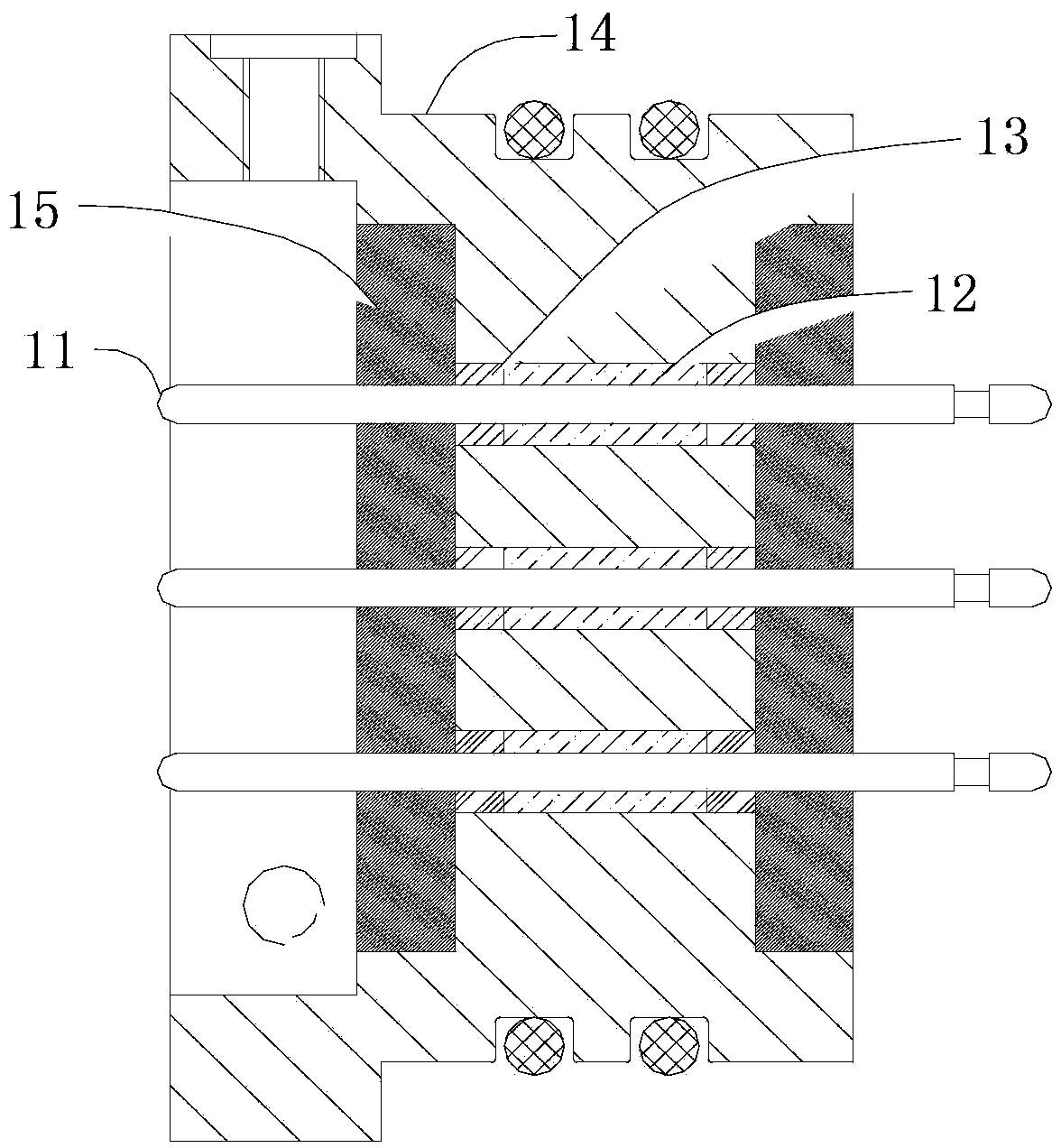

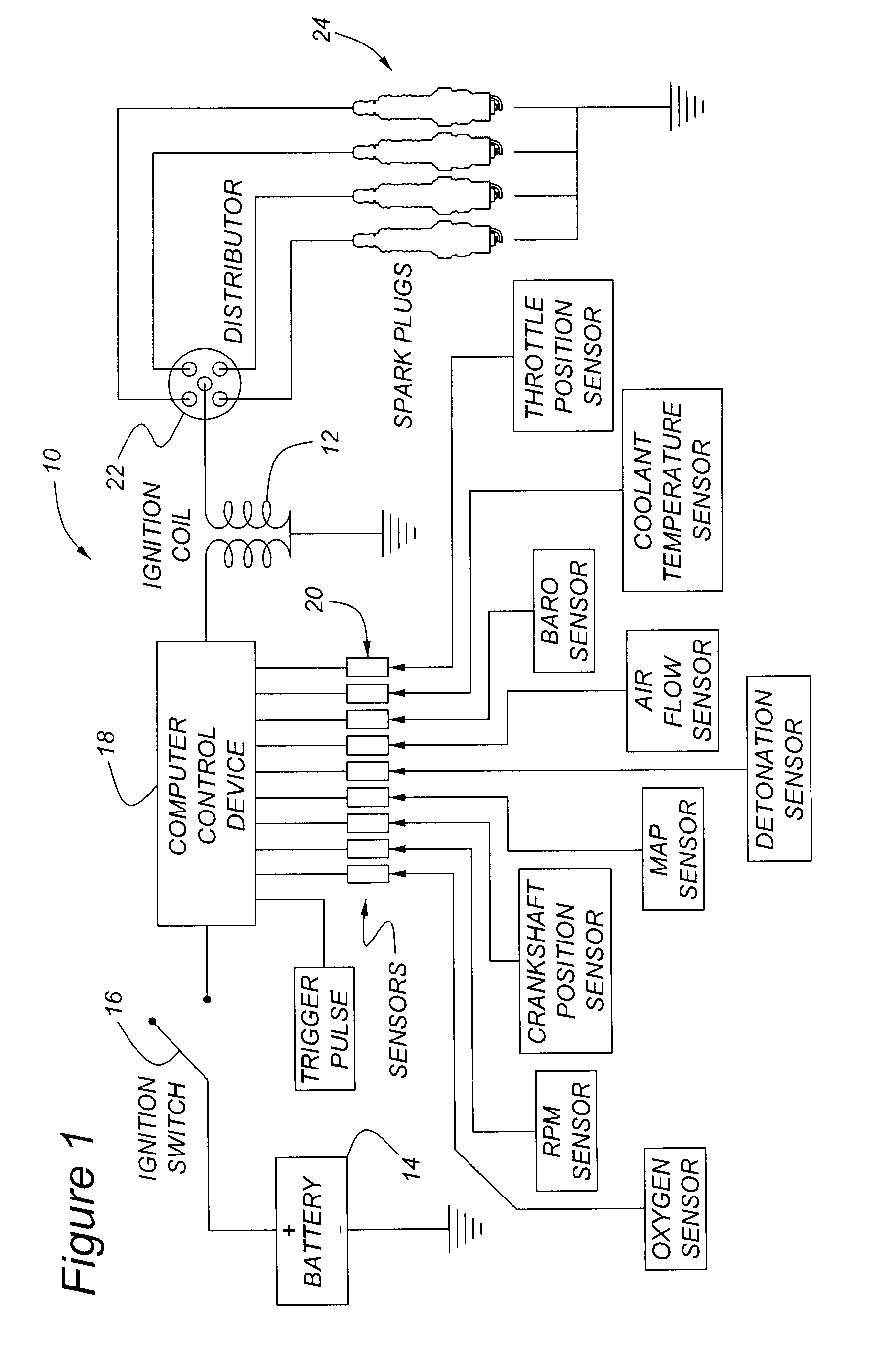

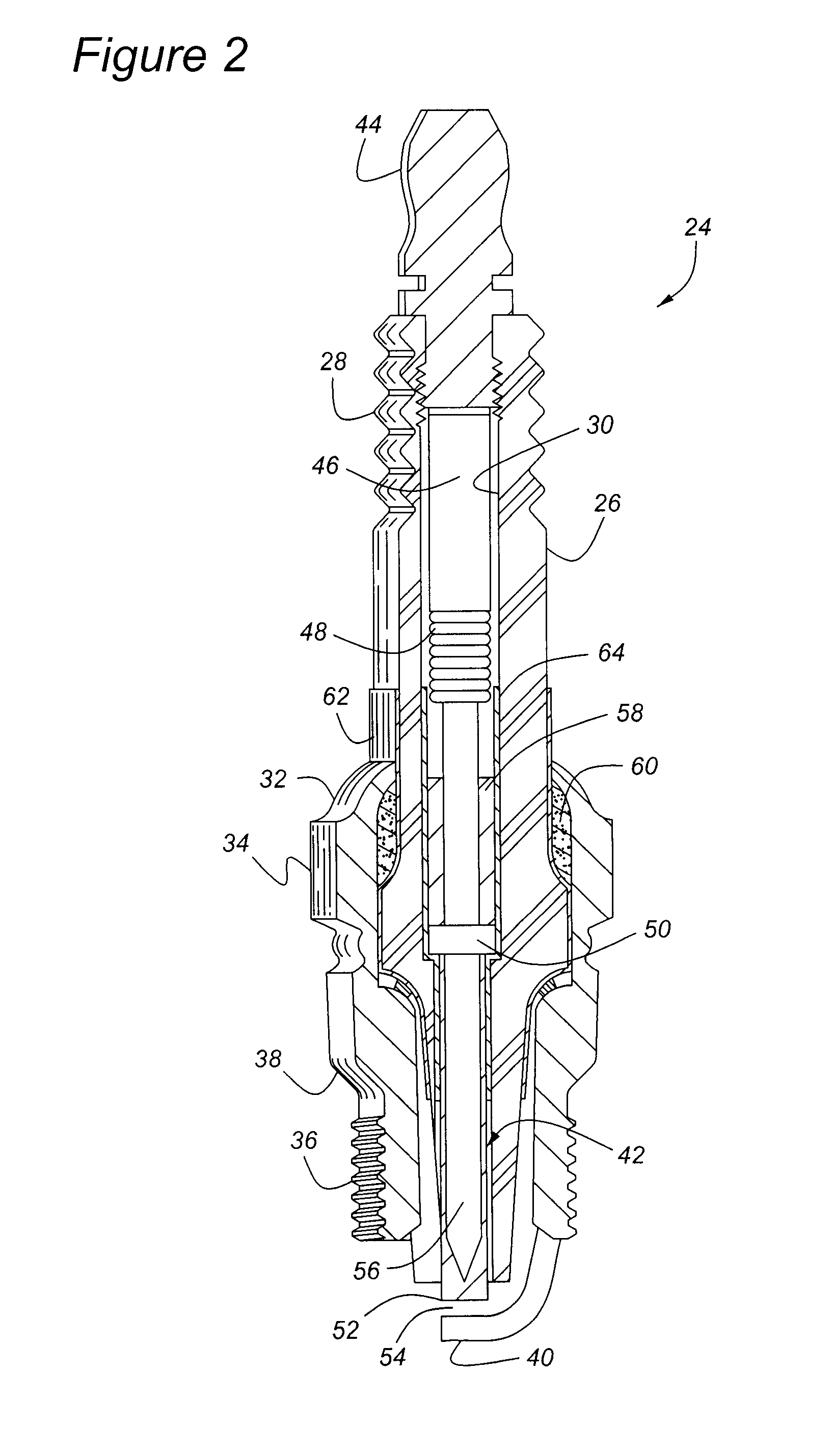

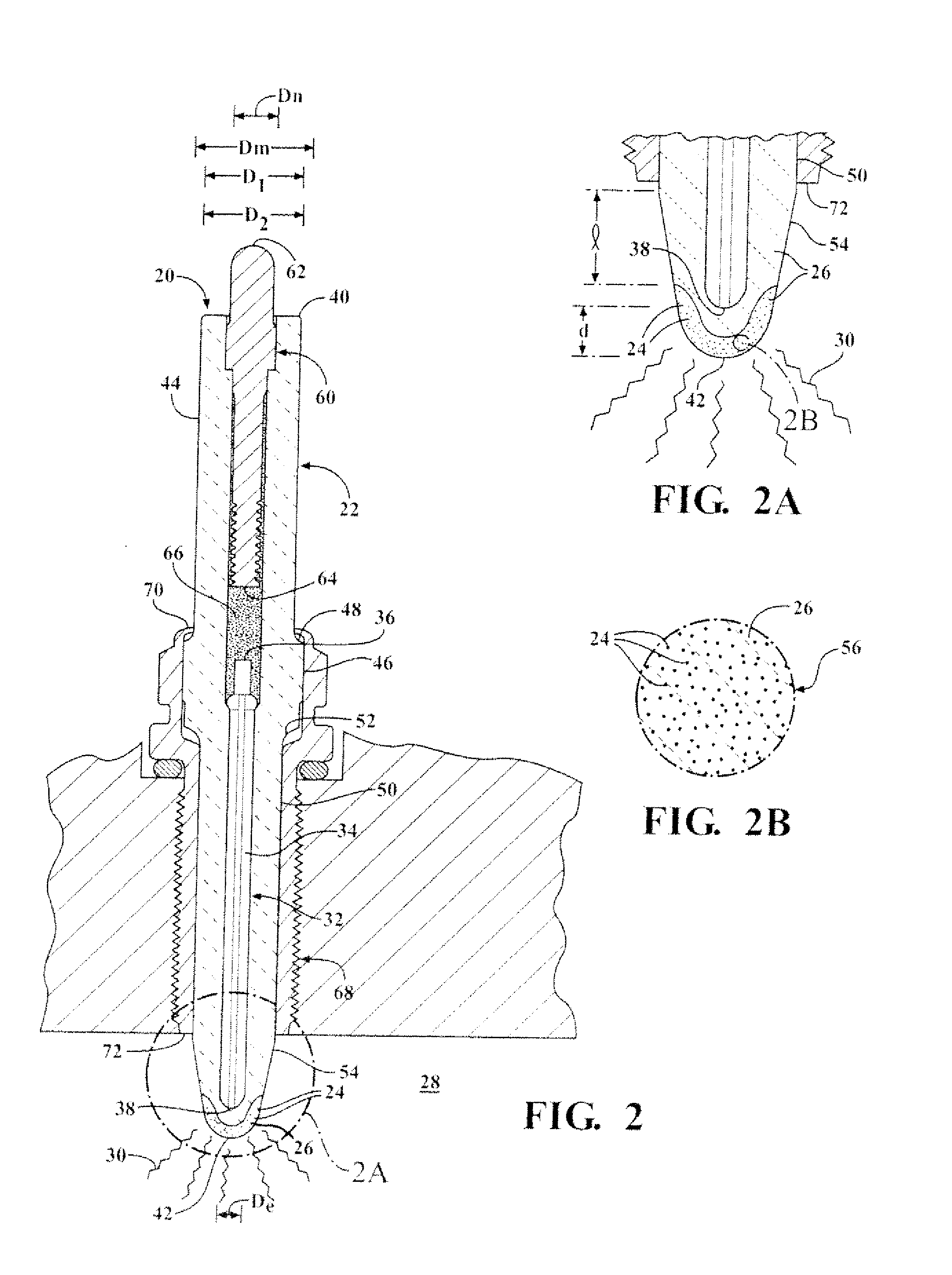

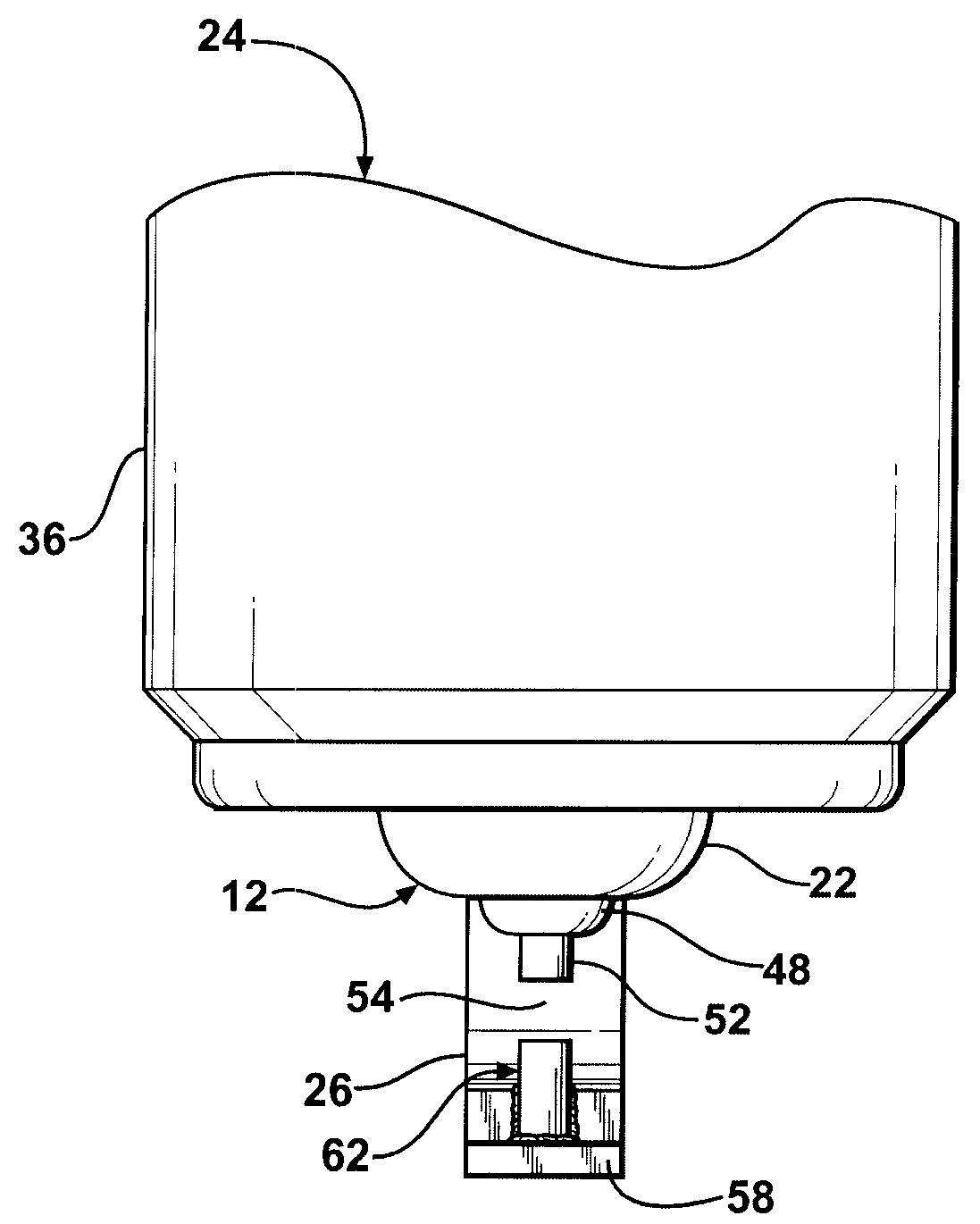

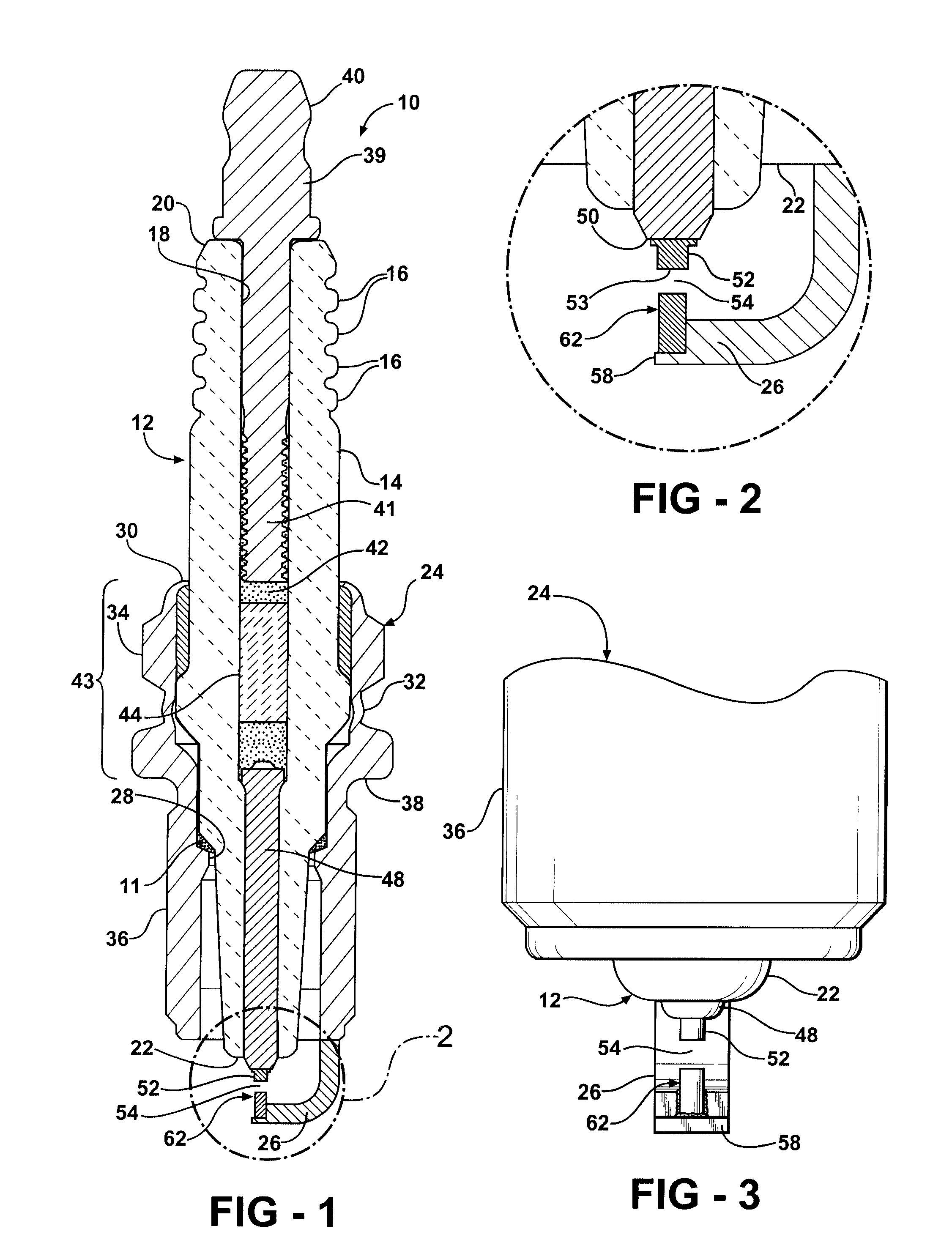

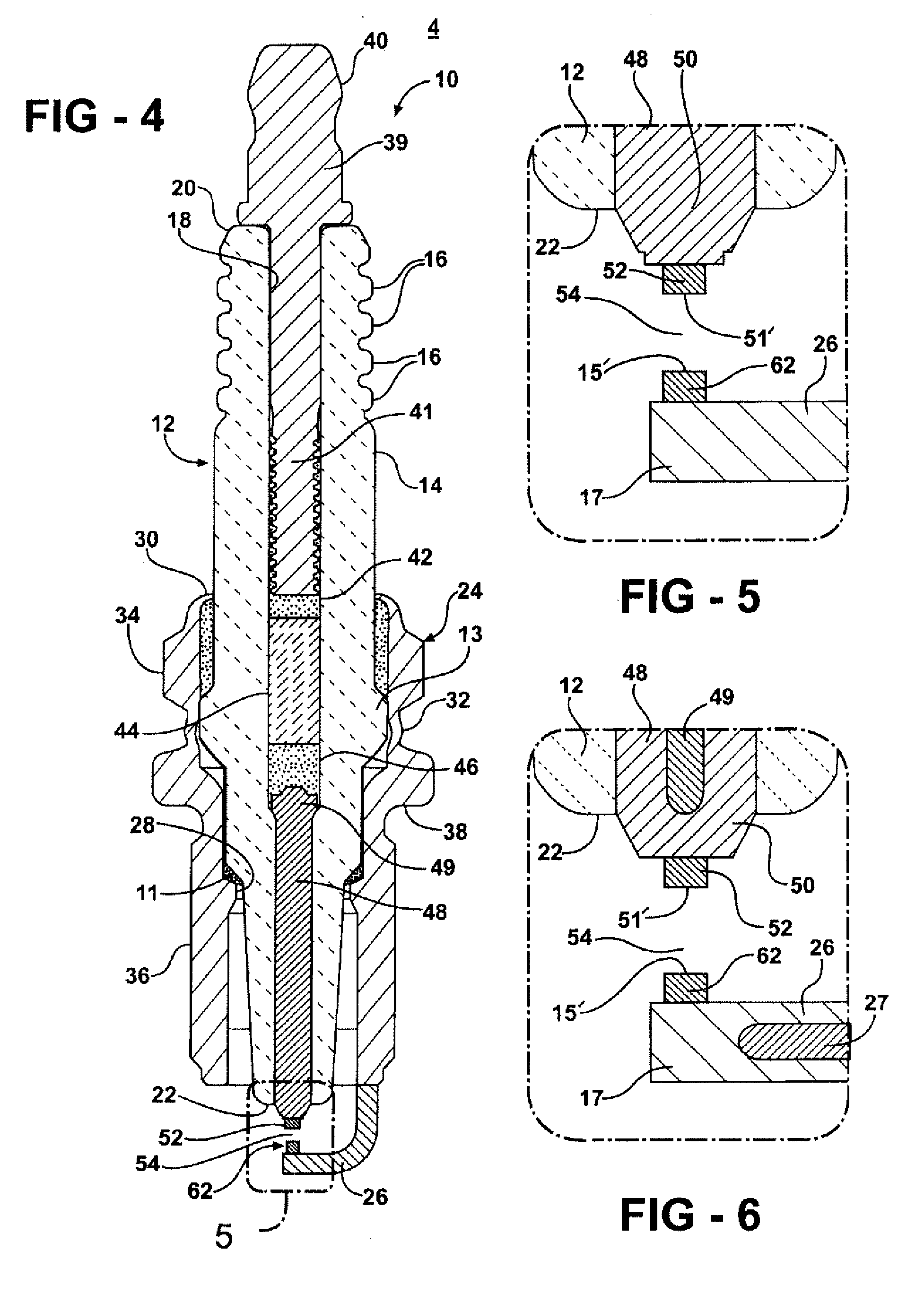

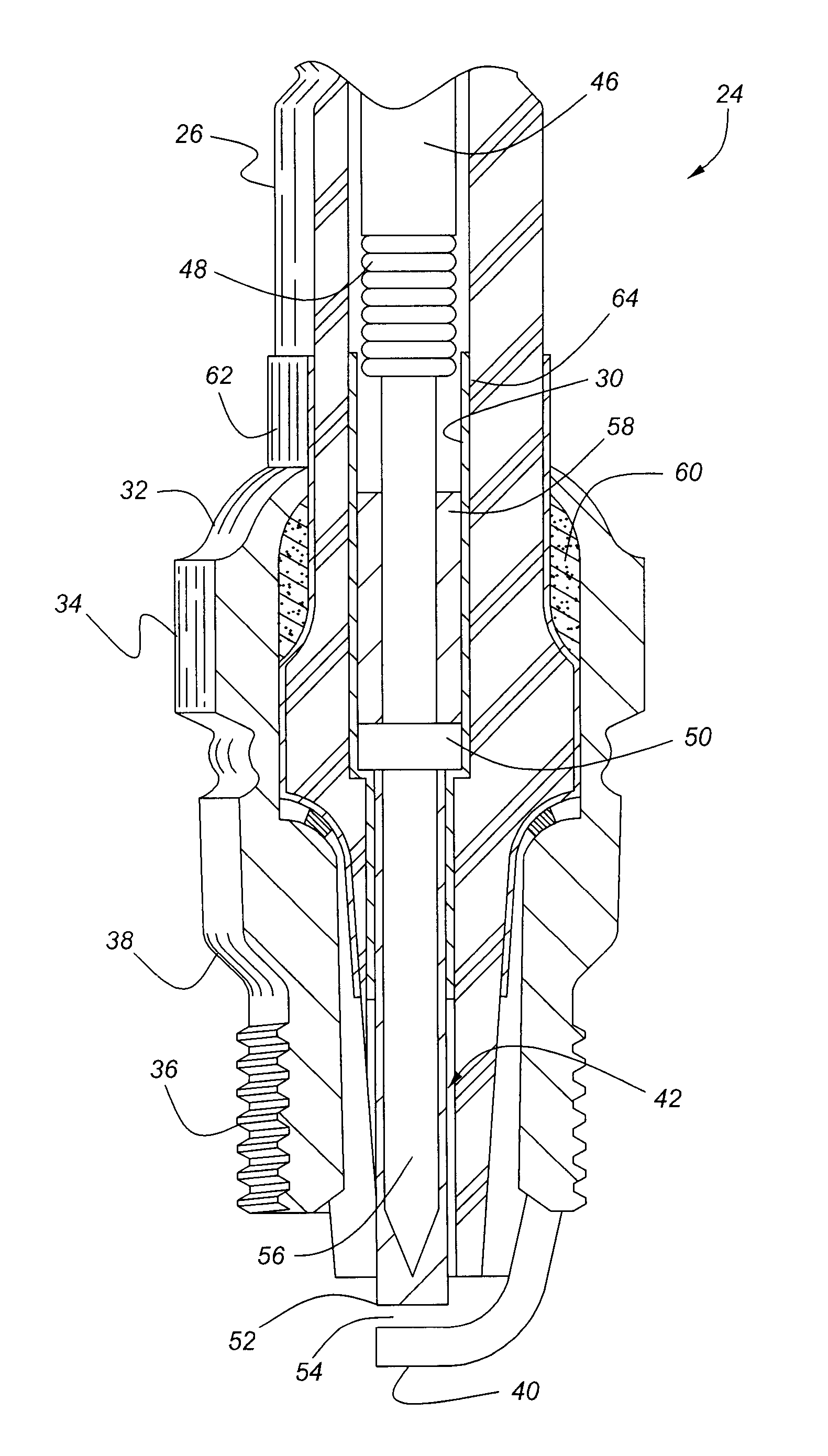

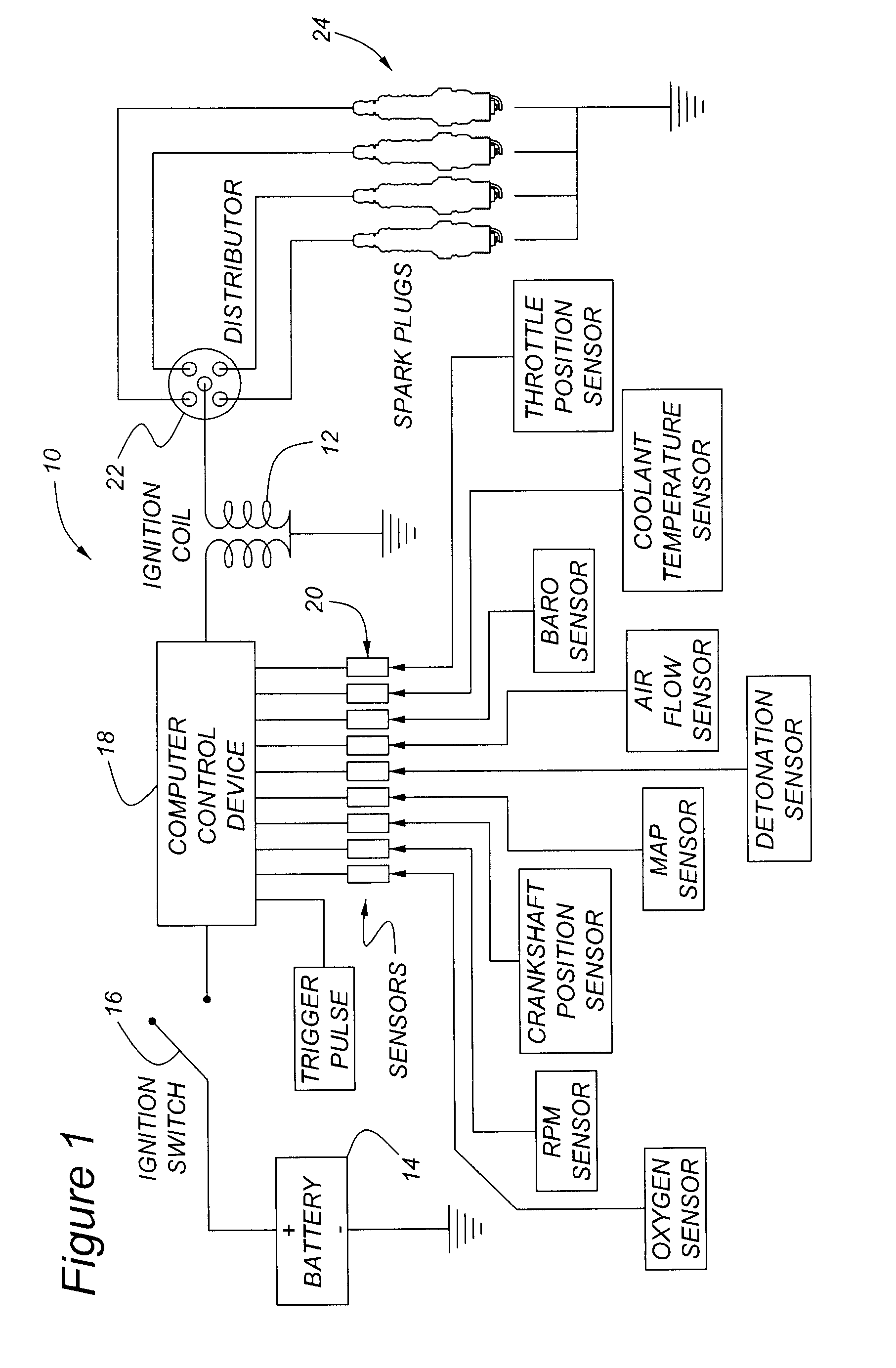

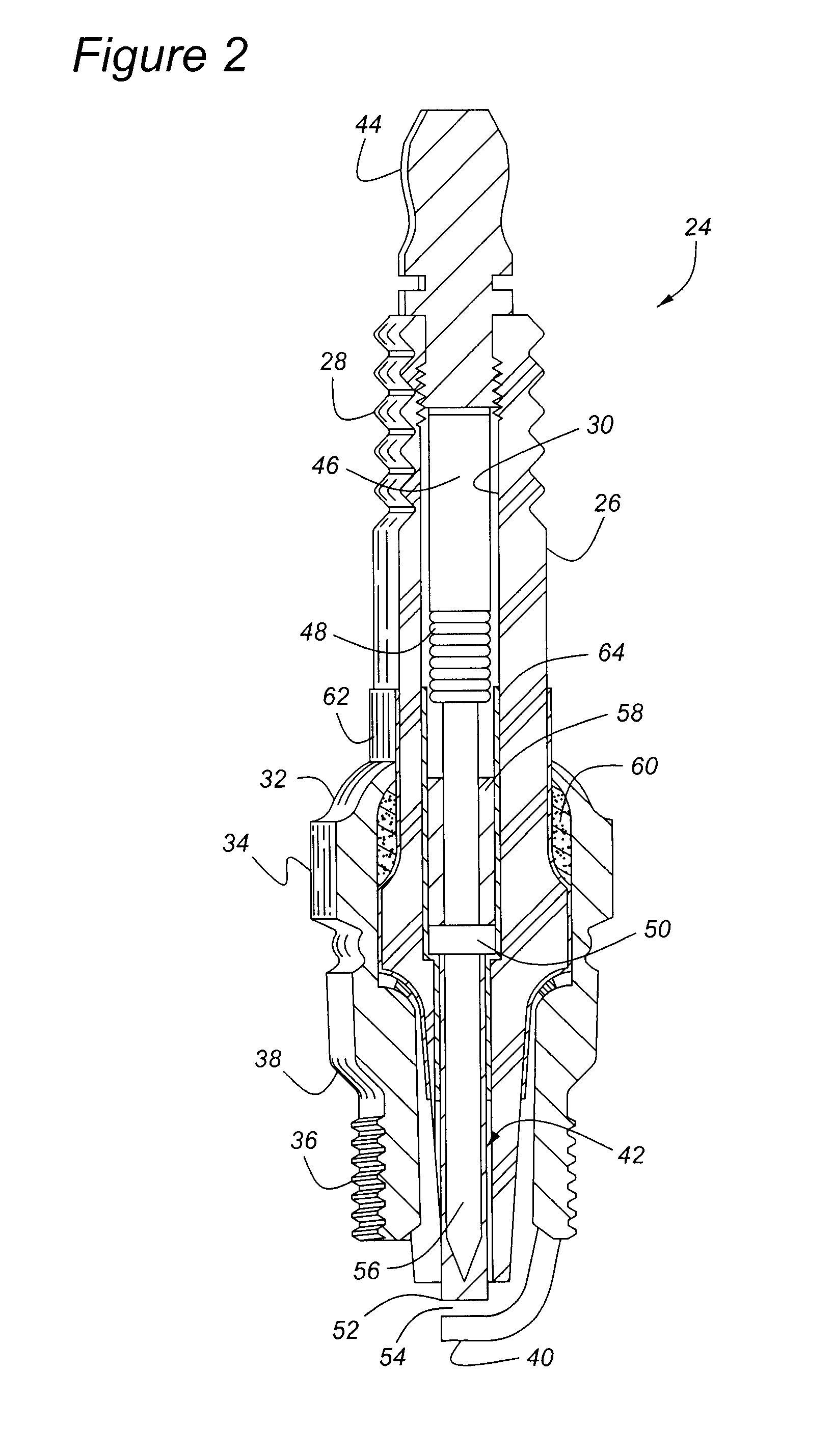

Metallic insulator coating for high capacity spark plug

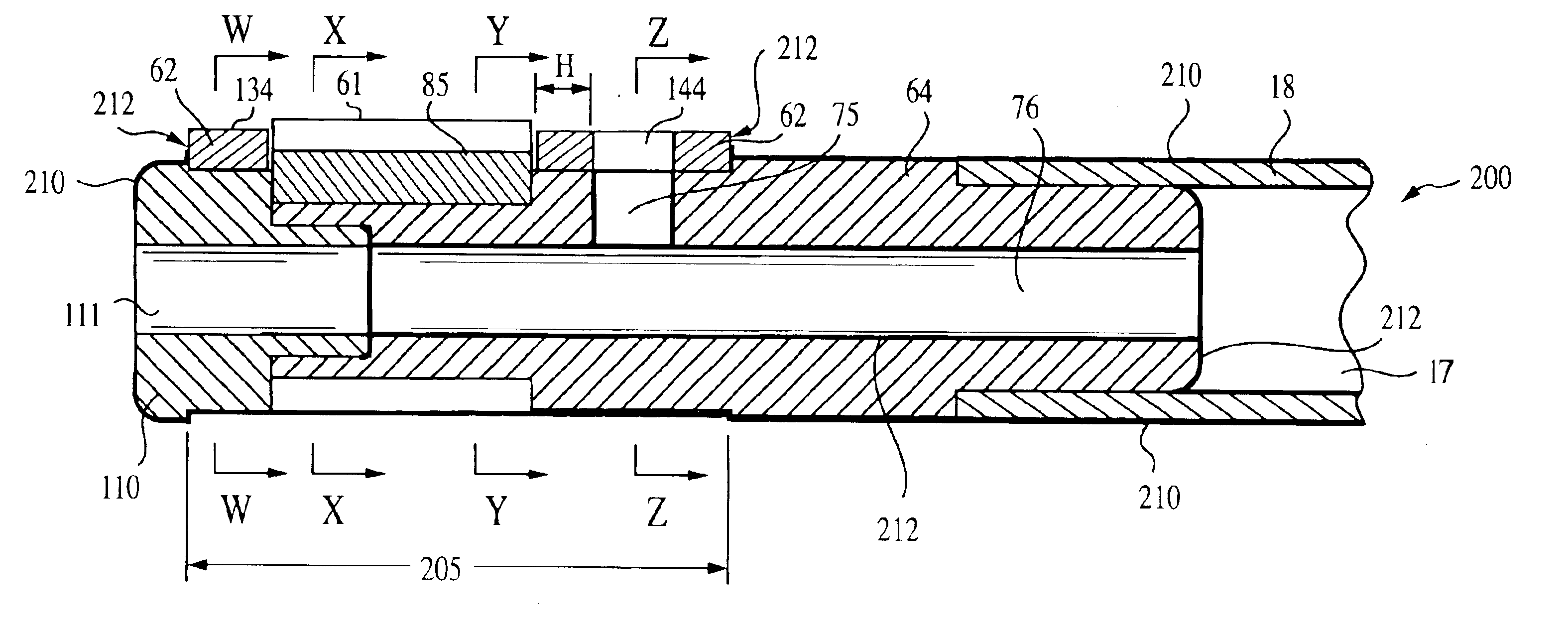

A spark plug (24) is used in an ignition system (10) of the type for creating a precisely timed spark to ignite an air / fuel mixture in an internal combustion engine. The spark plug (24) is provided with an integrated capacitor feature to increase the intensity of its spark. The capacitor feature is formed by applying metallic film (62, 64) to the inner (30) and outer surfaces of a tubular insulator (26). The insulator (26), made from an alumina ceramic material, forms a dielectric and sustains an electrical charge when an electrical differential is established between the inner (64) and outer (62) metallic films. The stored electrical charge is discharged with the firing of a spark in the spark gap (54). The inner (64) and outer (62) metallic films can be applied as a paint or ink directly to the surfaces of the insulator (26), or can be mixed with a glazing compound to form conductive coatings simultaneous with the glazing operation. Ganged (62′) or serpentine (62″) micro-plates can be formed within either or both of the inner and outer metallic films to increase the charge-carrying surface area. The metallic film (62, 64) is specially selected from materials that will not migrate into the porous matrix of the ceramic insulator (26). The metallic film (62, 64) is preferably gold, platinum, copper, or a platinum group metal.

Owner:PASSAIC RIVER CO INC

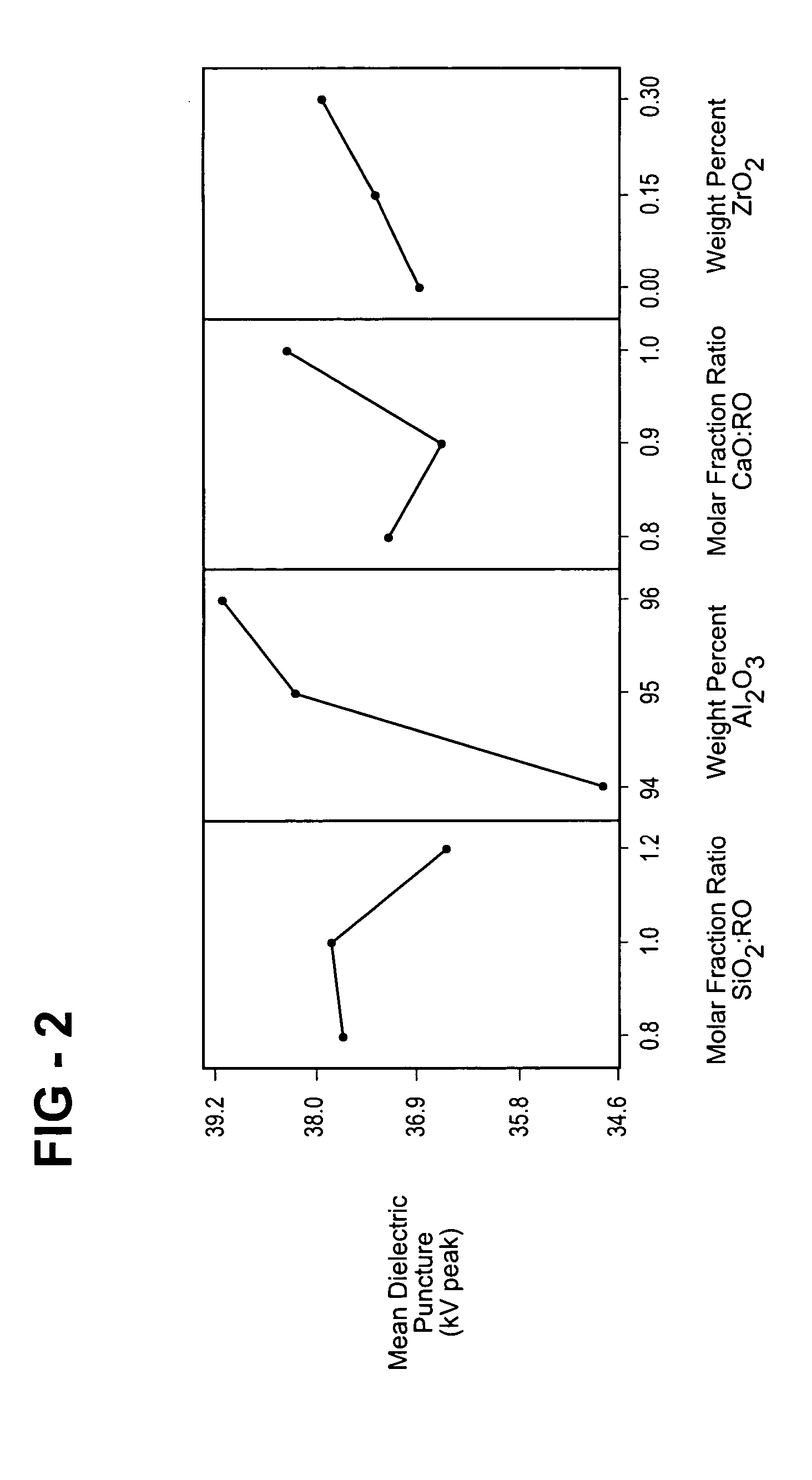

Ceramic with improved high temperature electrical properties for use as a spark plug insulator

ActiveUS20050110382A1Improved dielectric breakdown propertyImproved shunt resistanceSparking plugsElectrical resistance and conductanceElectricity

A ceramic includes alumina in an amount between about 90 and about 99% by weight, a zirconium containing compound in an amount between about 0 and about 1% by weight, and an oxide mixture in an amount between about 1 and about 10% by weight. The oxide mixture includes a glass former and a network modifier, wherein the molar ratio of the glass former to the network modifier ranges between about 0.8:1 and 1.2:1. The ceramic insulator is particularly adapted for use as an insulator in a spark plug to provide improved dielectric strength and shunt resistance of greater than one 1000 megaohms at 1000 degrees Fahrenheit, so as to reduce the shunting of the spark plug and thereby improve the quality of the spark generated by the spark plug.

Owner:FEDERAL MOGUL WORLD WIDE LLC

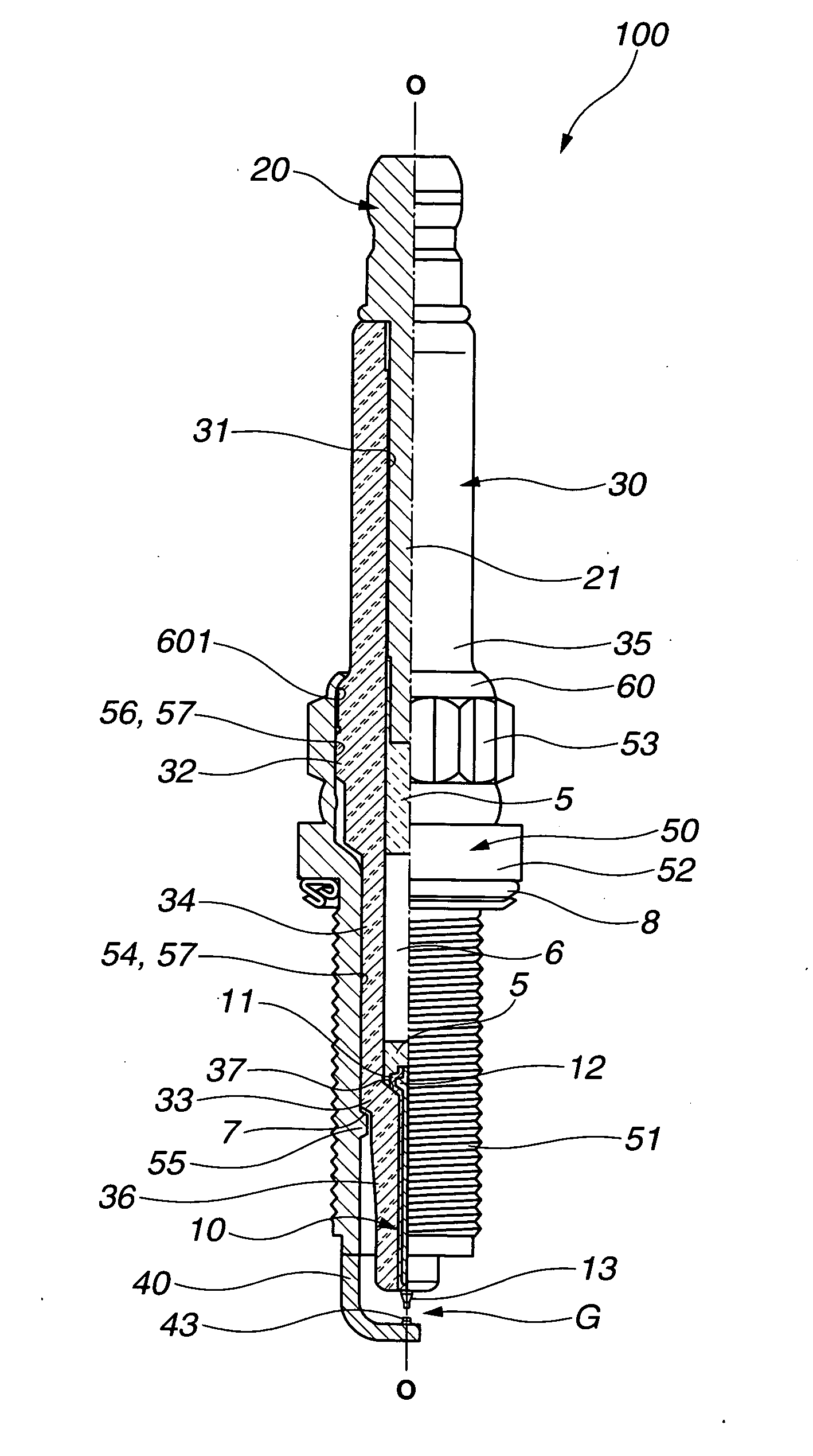

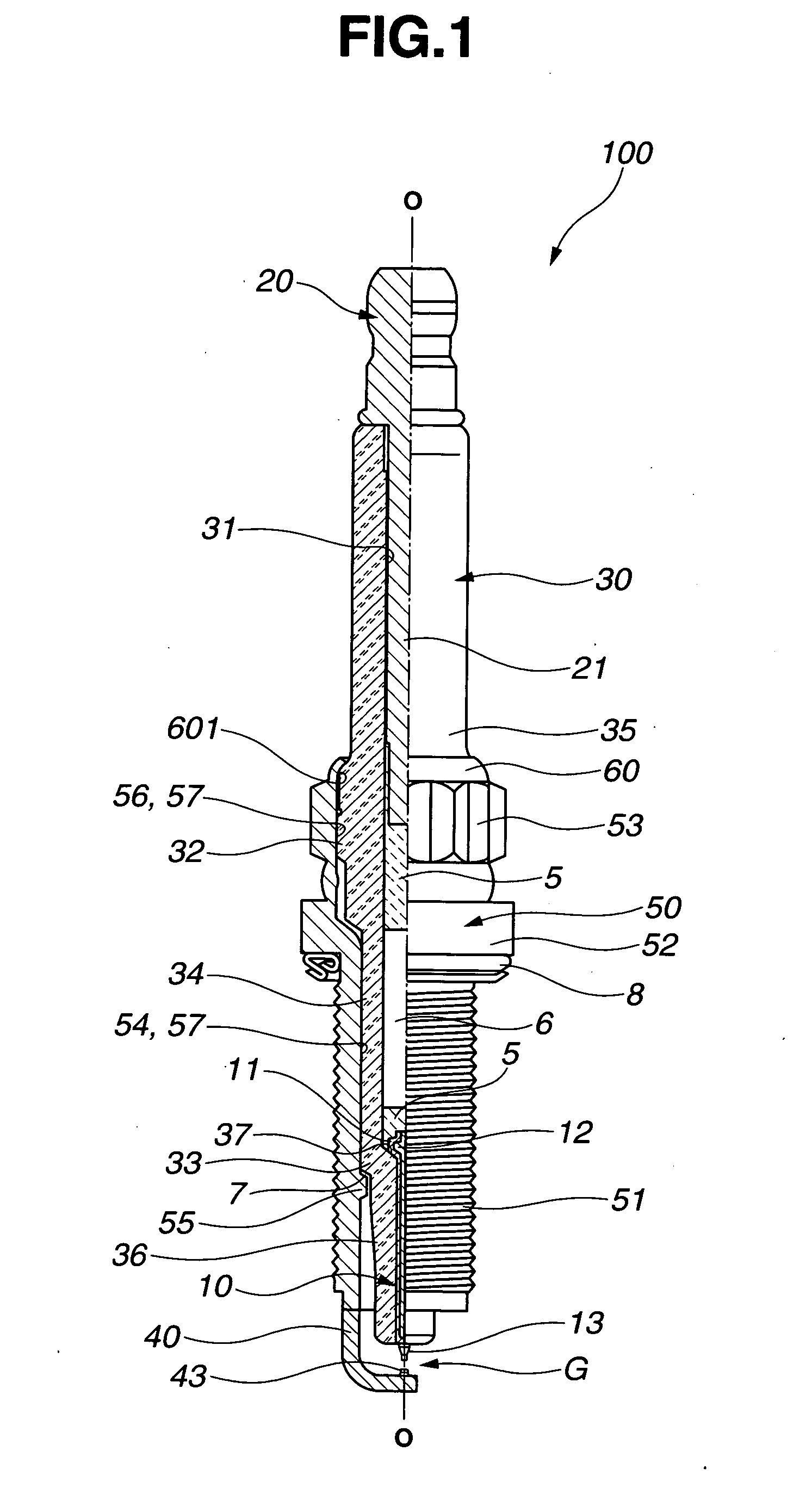

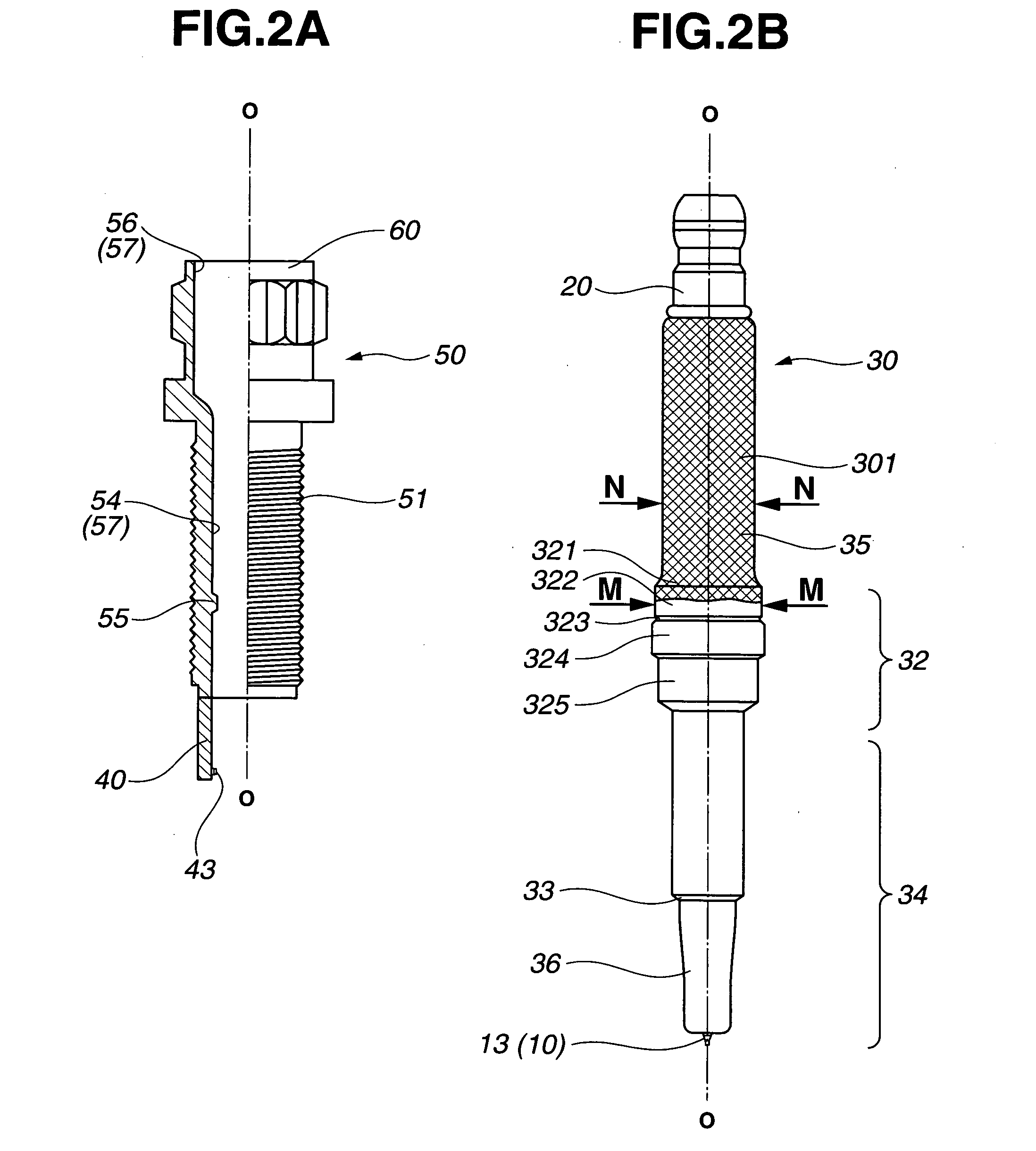

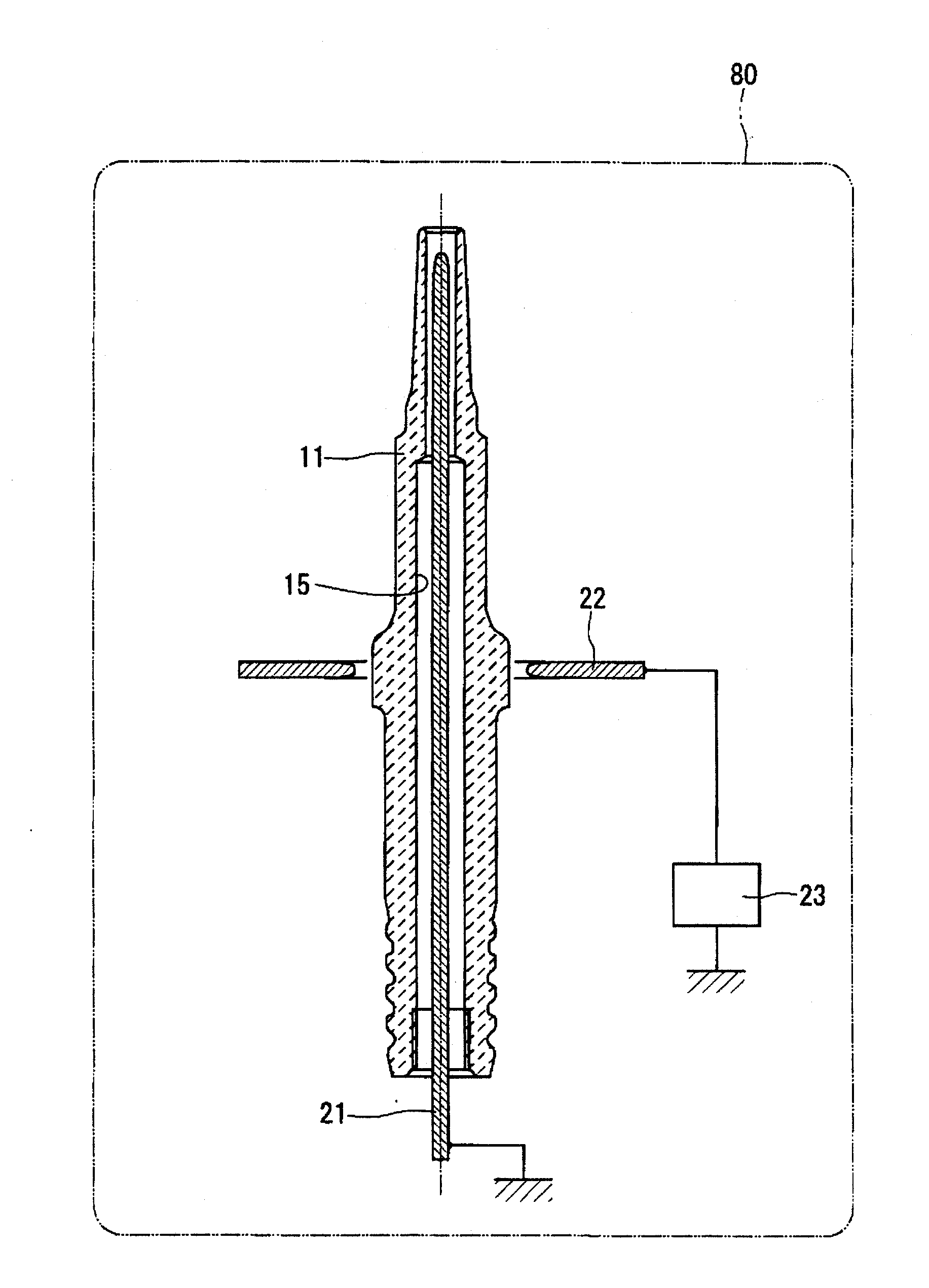

Spark plug

A spark plug is provided with a metal shell and a ceramic insulator to support therein a center electrode. The ceramic insulator includes a front portion with a stepped outer surface, a middle portion, a rear portion and a shoulder portion defined between the middle and rear portions. A difference between the outer diameters of the middle and rear portions of the ceramic insulator is 1.8 mm or smaller. The metal shell includes a radially inward protrusion to retain thereon the stepped outer surface of the ceramic insulator and a rear end portion crimped onto the shoulder portion of the ceramic insulator. An inner circumferential surface of the crimped shell portion has a region held in contact with the insulator shoulder portion with a radially innermost point of the crimped shell portion being spaced radially apart from the ceramic insulator and axially apart from the insulator shoulder portion.

Owner:NGK SPARK PLUG CO LTD

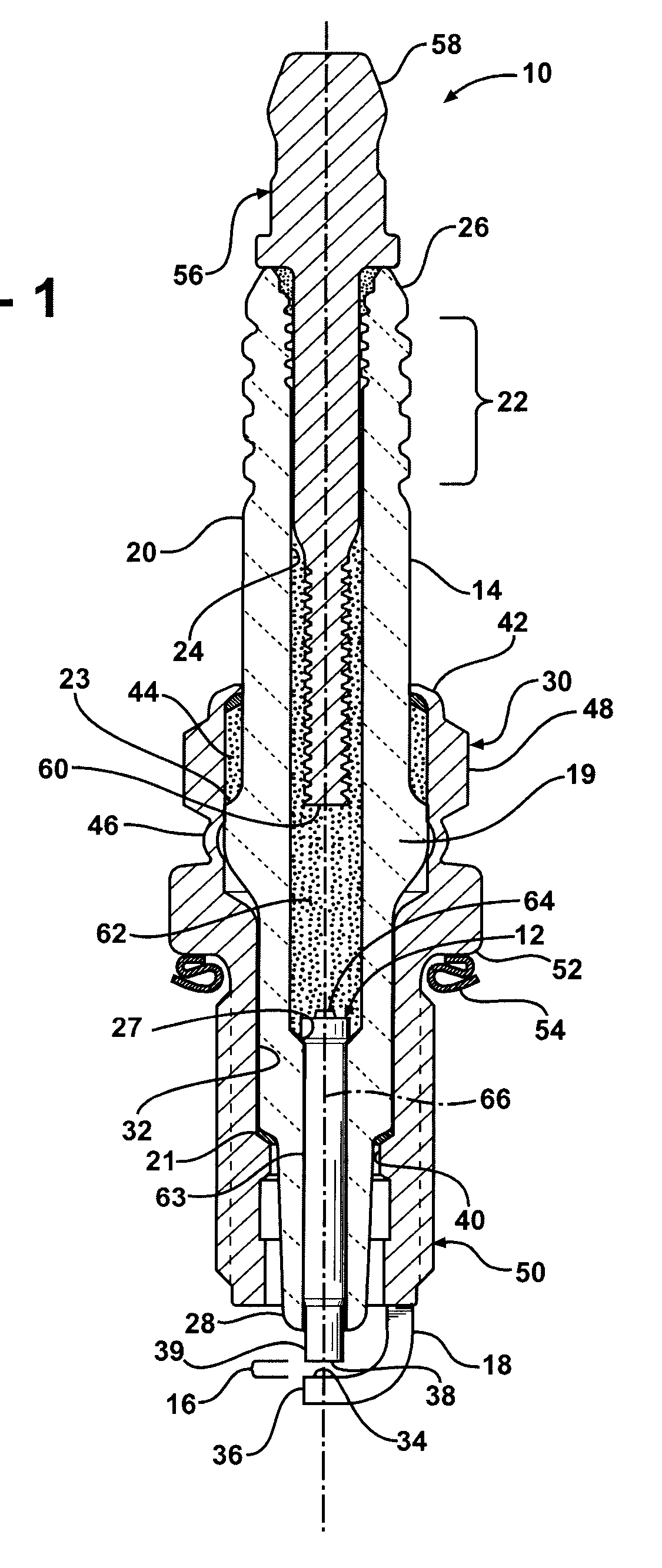

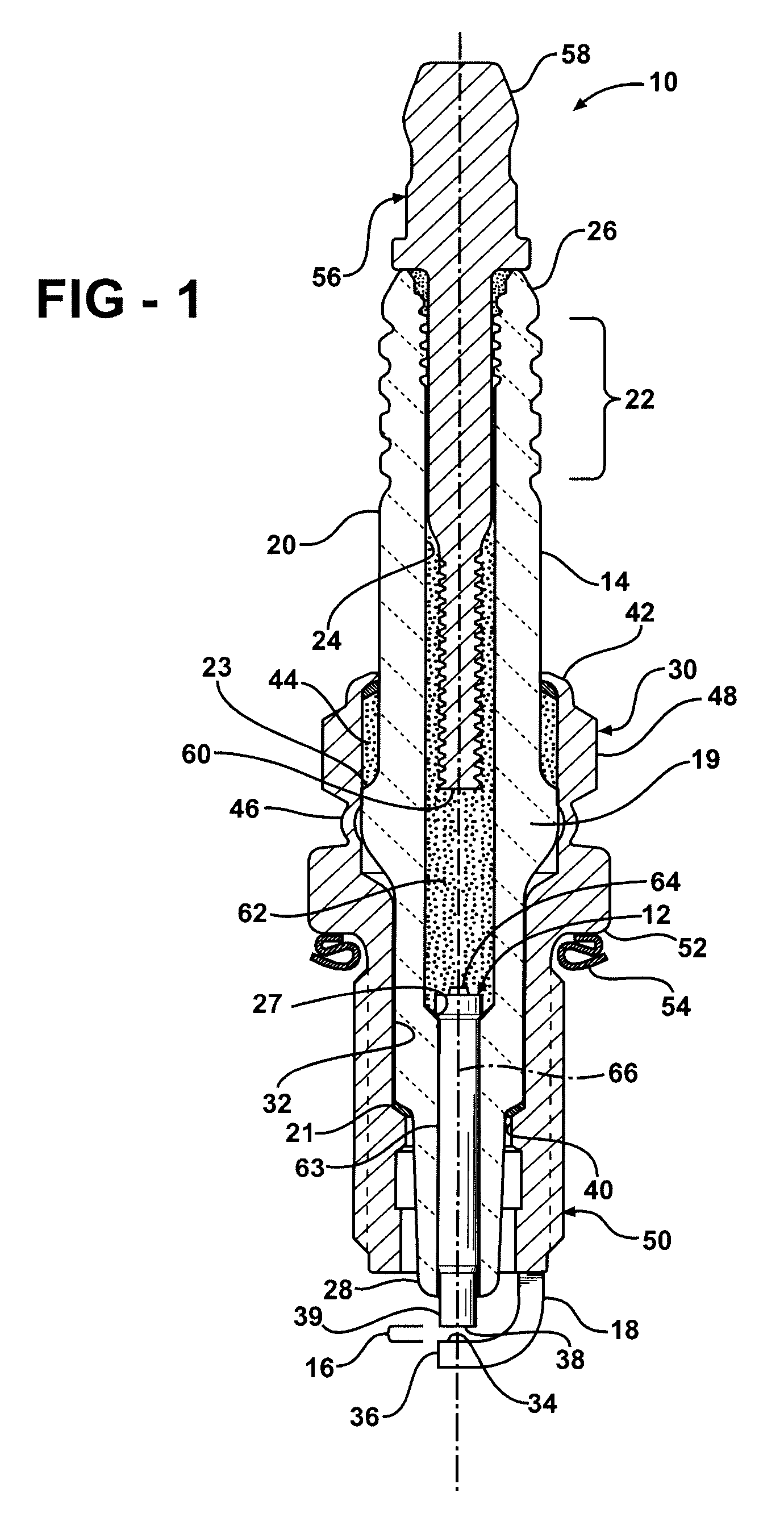

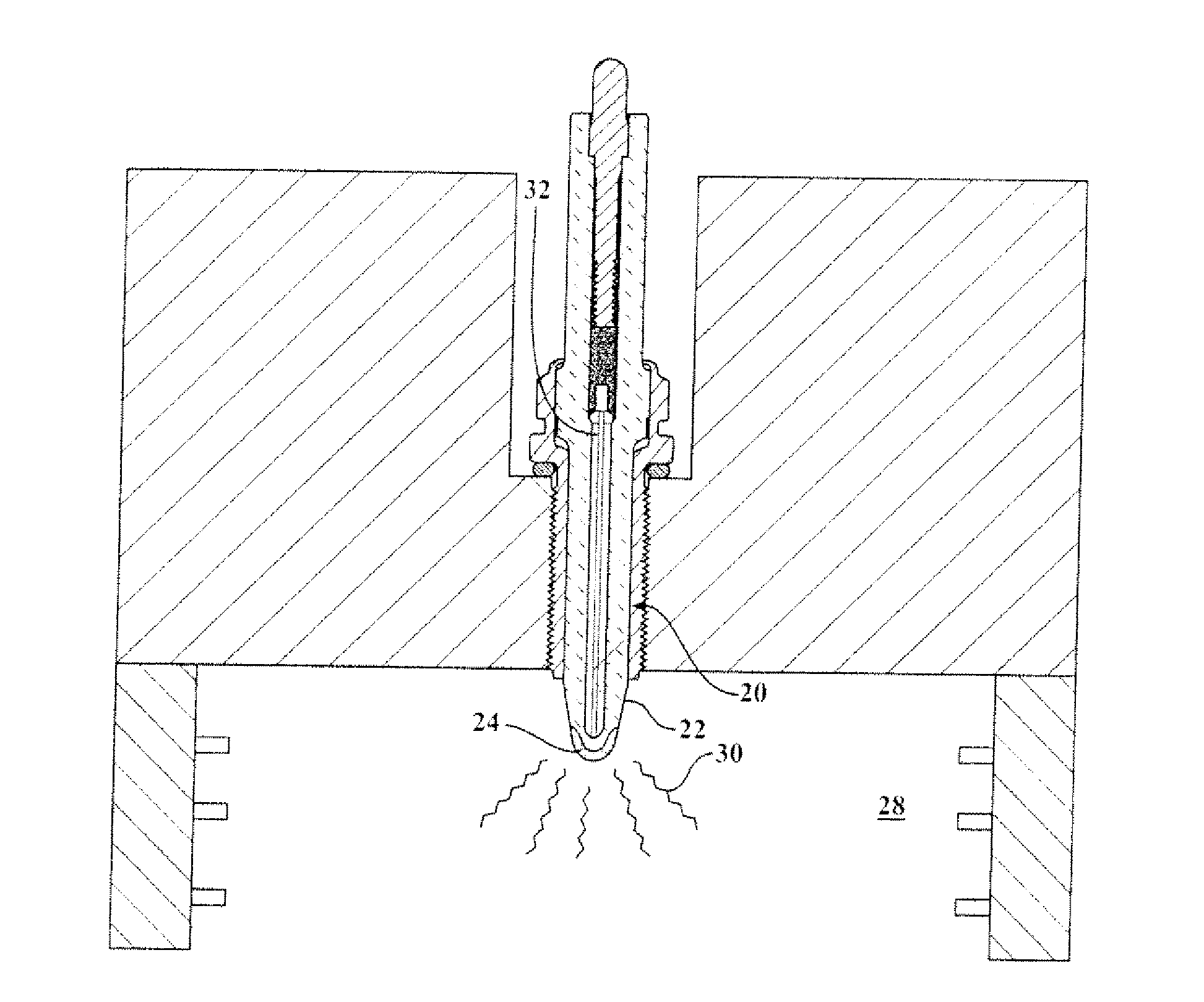

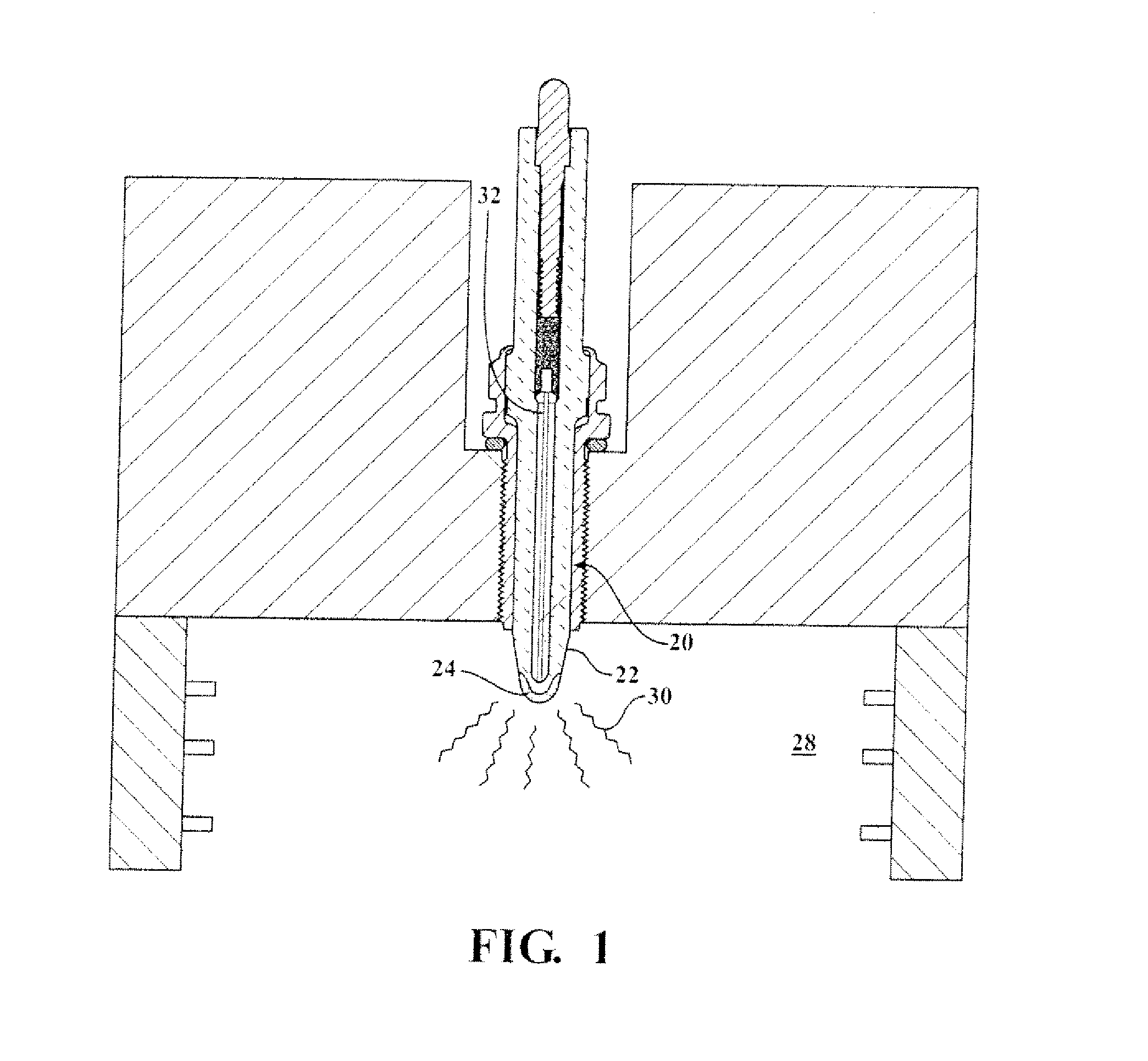

Non-thermal plasma ignition arc suppression

ActiveUS20120112620A1Eliminates arcingReduces arcingSpark gapsEngine ignitionCombustion chamberEngineering

An igniter (20) of a corona ignition system emits a non-thermal plasma in the form of a corona (30) to ionize and ignite a fuel mixture. The igniter (20) includes an electrode (32) and a ceramic insulator (22) surrounding the electrode (32). The insulator (22) surrounds a firing end (38) of the electrode (32) and blocks the electrode (32) from exposure to the combustion chamber (28). The insulator (22) presents a firing surface (56) exposed to the combustion chamber (28) and emitting the non-thermal plasma. A plurality of electrically conducting elements (24) are disposed in a matrix (26) of the ceramic material and along the firing surface (56) of the insulator (22), such as metal particles embedded in the ceramic material or holes in the ceramic material. The electrically conducting elements (24) reduce arc discharge during operation of the igniter (20) and thus improve the quality of ignition.

Owner:FEDERAL MOGUL IGNITION

Power capacitor

InactiveCN101916656AOmit the welding processSave processFixed capacitor housing/encapsulationFixed capacitor terminalsEngineeringElectric power

The invention discloses a power capacitor which comprises a capacitor shell and a wiring terminal fixed on the capacitor shell. The wiring terminal comprises a ceramic insulator main body and a wiring assembly arranged on the top end of the ceramic insulator main body. The ceramic insulator main body is provided with a through hole along the central axis per se, the external wall of the middle part of the insulator main body is provided with a plurality of umbrella skirts, and the lower part of the insulator main body is provided with a welding part. The capacitor shell is provided with a fixed installation seat for fixedly installing the ceramic insulator main body. The welding part of the insulator main body is fixed on the fixed installation seat through a welding mode. The invention has the advantages of fewer processing steps and lower manufacturing cost.

Owner:王海龙

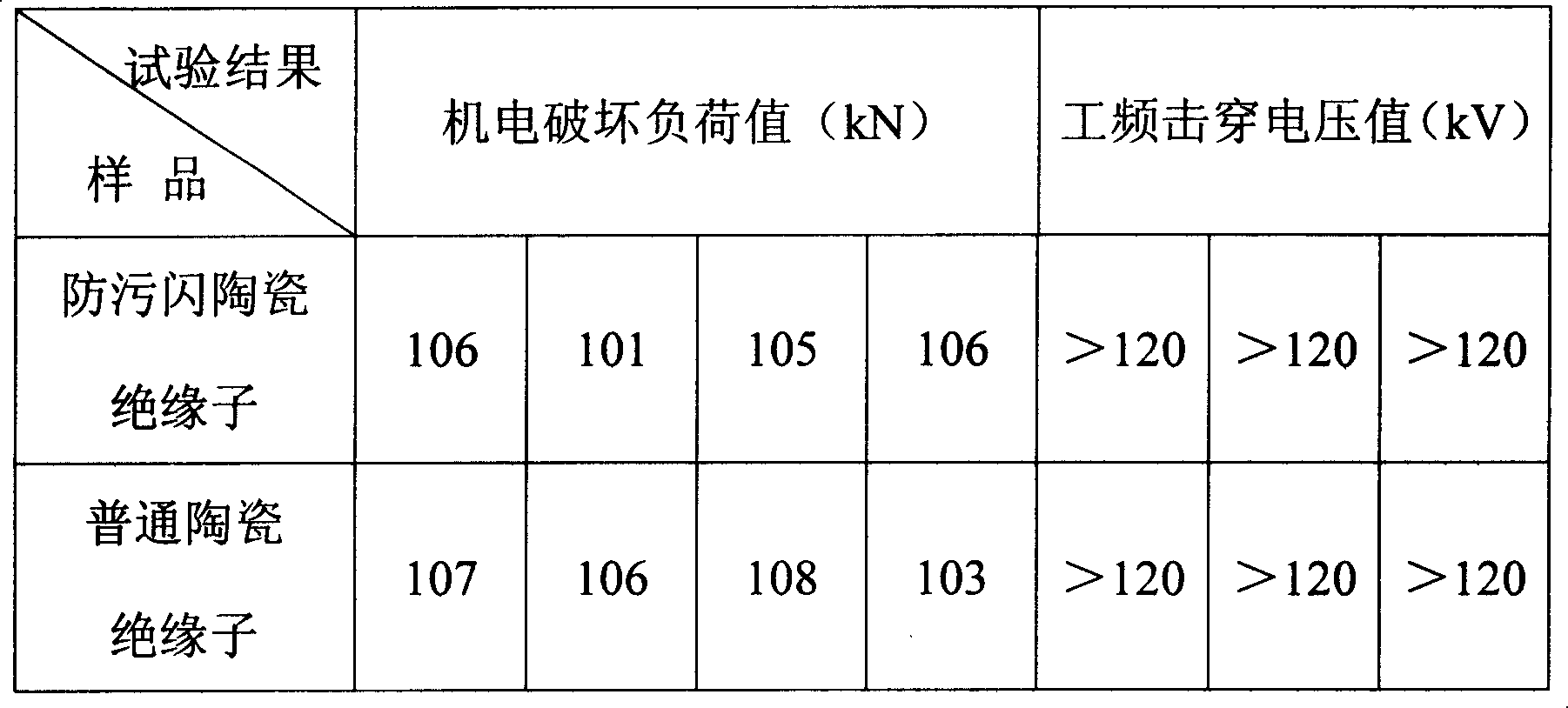

Aluminum oxide electric porcelain

InactiveCN1990420ALittle dispersion of strengthImprove reliabilityPlasticizerUltimate tensile strength

The invention relates to alumina oxide electric porcelain, belonging to transmission and distribution device, which in detail is an insulator for transmission line. The proportioning by weight comprises: industrial alumina oxide 20-40%, feldspar 12-28%, clay 45-55%, and alumina silicate-magnesium plasticizer 1-3%. The produced disc suspended ceramic insulator is characterized by strong strength, long durability and good pollution resistance and so on.

Owner:叶胜平

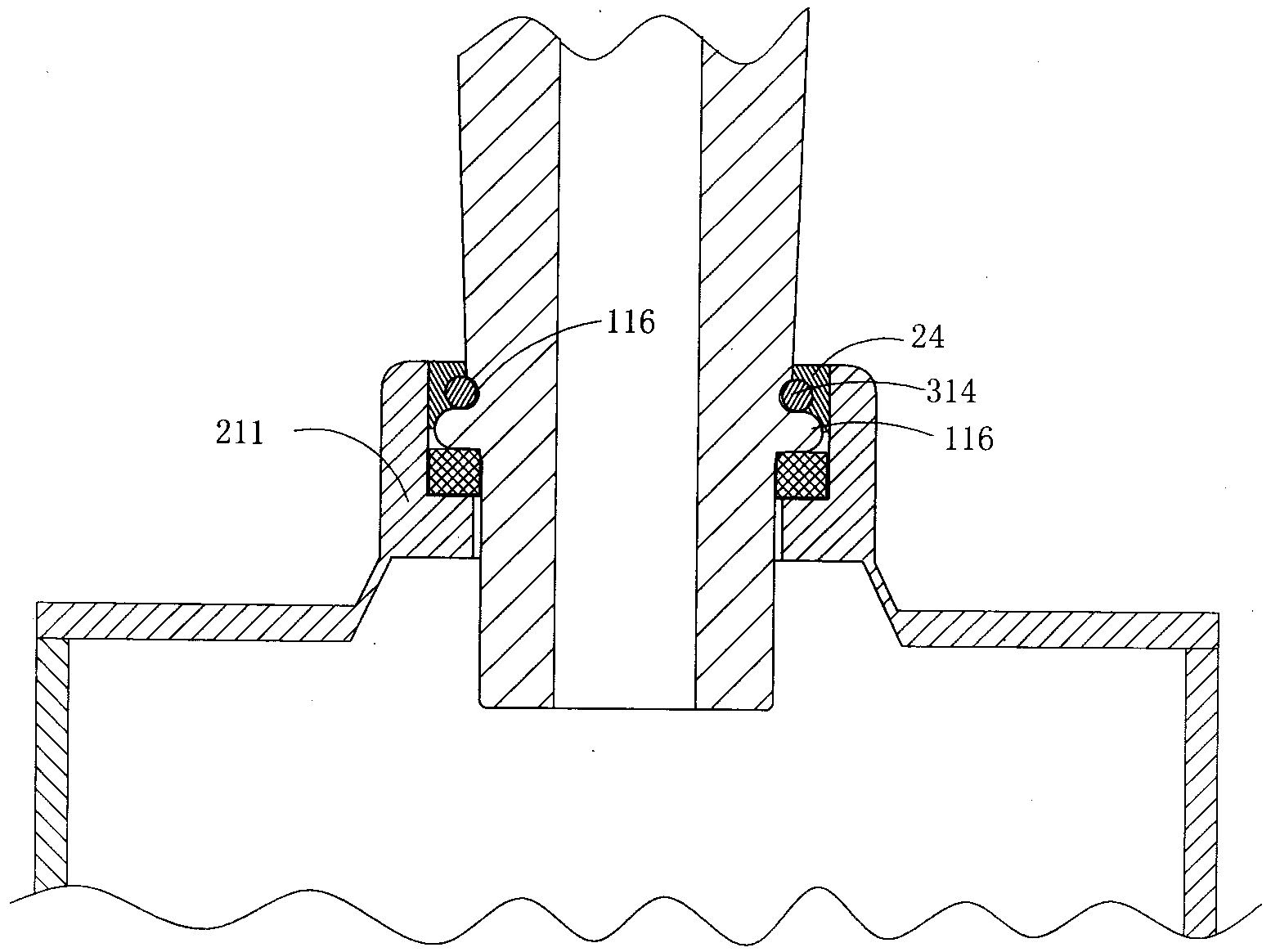

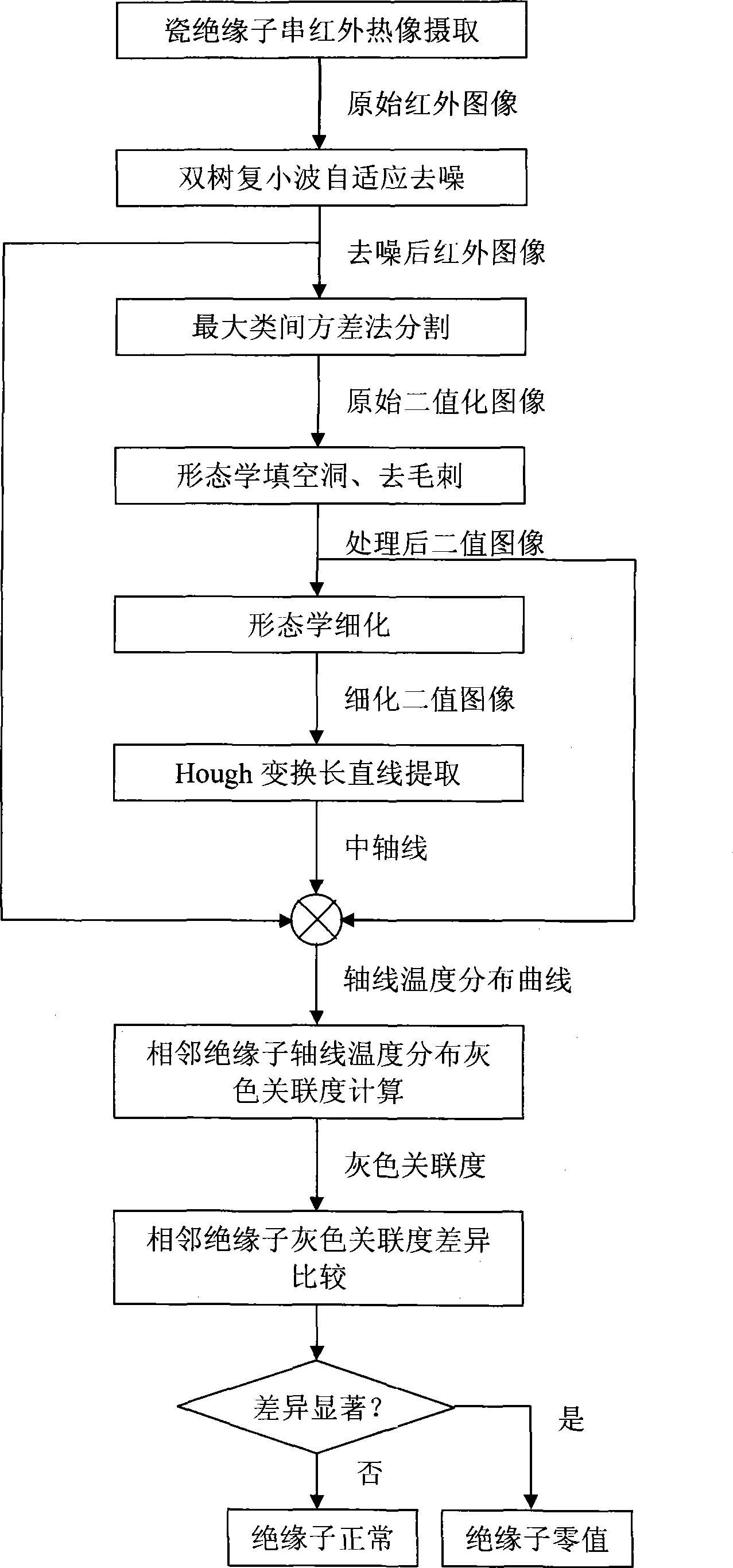

On-line detection method for AC power transmission line porcelain zero resistance insulator based on infrared thermal imaging

ActiveCN101487866AReduce workloadReduce pollution flashover accidentsImage analysisElectrical testingElectric power transmissionAlternating current

The invention relates to an on-line detection method for ceramic zero resistance insulators on an alternating current transmission line based on infrared thermal imaging, and belongs to the field of power transmission. The invention aims to provide an on-line detection method for ceramic zero resistance insulators with safety, economy, high efficiency and high accuracy. The invention adopts the technical proposal that when a ceramic insulator string has a zero resistance insulator, the spread voltage of other insulators is boosted, the reactance of the whole insulator string is reduced, the leakage current of the insulator string is increased, and the heating difference of the good insulators and the zero resistance insulators is increased. By shooting thermal field images of the insulator string through a high-precision infrared imaging instrument, adopting image processing technology to extract axial temperature distribution curves of the insulator string, and utilizing the difference of the axial temperature distribution curves of the adjacent insulators, the method achieves accurate judgment of the state of the insulators. The method can be used for zero resistance detection for the ceramic insulators on the alternating current transmission line in grade of 110KV and above voltage, and is applied to lightening workload of detection greatly and improving secure operation level of a power system.

Owner:湖南湖大华龙电气与信息技术有限公司

Ceramic with improved high temperature electrical properties for use as a spark plug insulator

ActiveUS7169723B2Reduce diversionQuality improvementSparking plugsElectricityUltimate tensile strength

A ceramic includes alumina in an amount between about 90 and about 99% by weight, a zirconium containing compound in an amount between about 0 and about 1% by weight, and an oxide mixture in an amount between about 1 and about 10% by weight. The oxide mixture includes a glass former and a network modifier, wherein the molar ratio of the glass former to the network modifier ranges between about 0.8:1 and 1.2:1. The ceramic insulator is particularly adapted for use as an insulator in a spark plug to provide improved dielectric strength and shunt resistance of greater than one 1000 megaohms at 1000 degrees Fahrenheit, so as to reduce the shunting of the spark plug and thereby improve the quality of the spark generated by the spark plug.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Spark plug with fine wire ground electrode

InactiveUS7808165B2Extended service lifeImproved performance characteristicsSparking plugsFine lineEngineering

Owner:FEDERAL MOGUL WORLD WIDE LLC

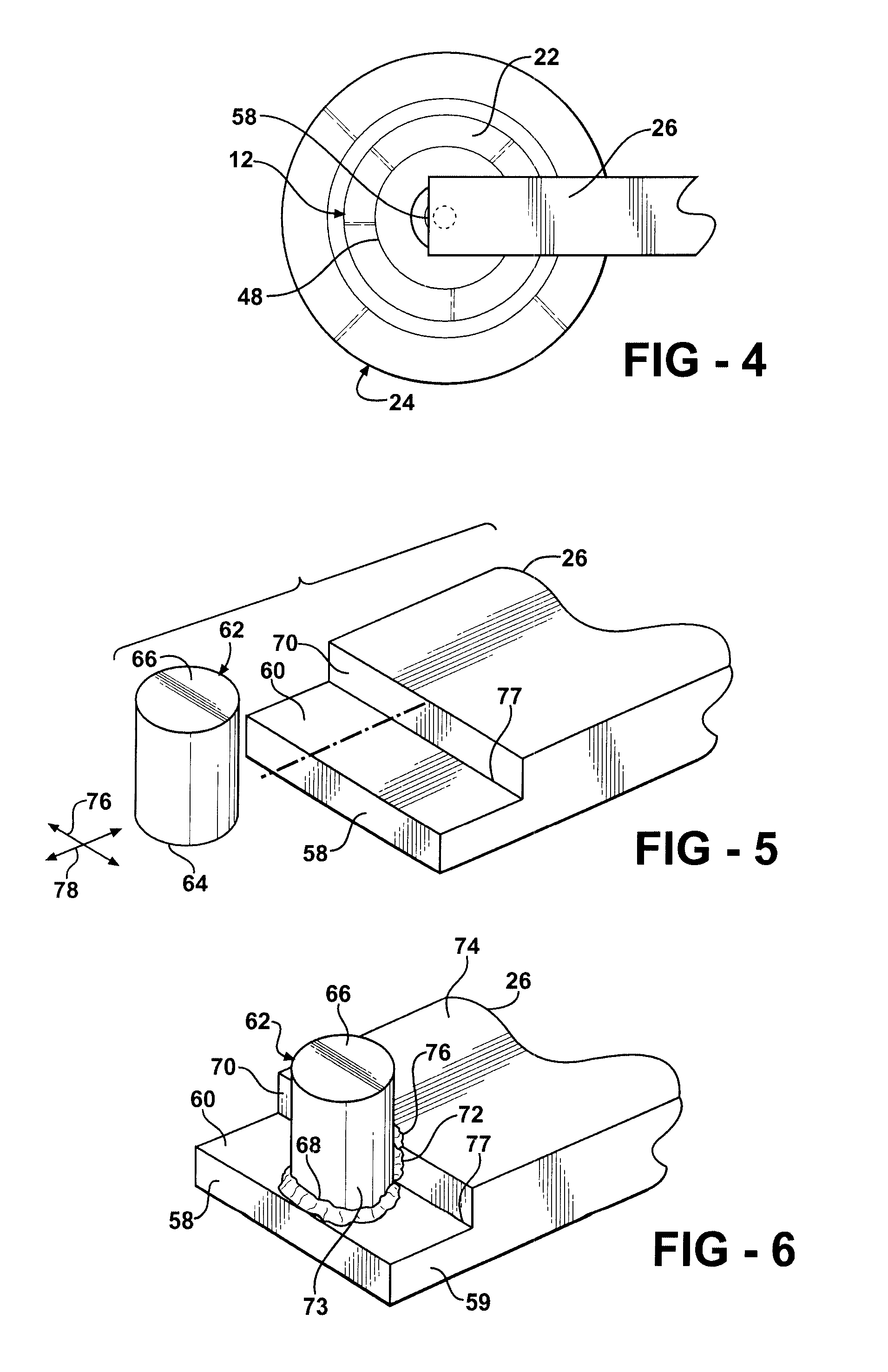

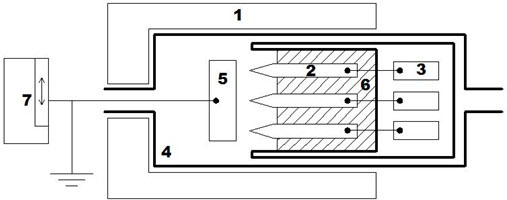

Test method and apparatus for spark plug ceramic insulator

A test method for a spark plug ceramic insulator includes placing a first electrode in an inner hole of the ceramic insulator and placing a second electrode on an outer peripheral side of the ceramic insulator, developing a defect in the ceramic insulator by the application of a first voltage onto the ceramic insulator between the first and second electrodes and detecting the defect in the ceramic insulator by the application of a second voltage, which is lower than a flashover voltage that causes a flashover of the ceramic insulator, onto the ceramic insulator between the first and second electrodes.

Owner:NGK SPARK PLUG CO LTD

Electrode For An Ignition Device

InactiveUS20090107440A1Improve the immunityRupture and fatigue and resistanceSparking plugsWelding/cutting media/materialsNiobiumManganese

An electrode for an ignition device is made from a dilute nickel alloy which has improved resistance to high temperature oxidation, sulfidation, corrosive wear, deformation and fracture and includes at least 90% by weight of nickel; zirconium; boron and at least one element from the group consisting of aluminum, magnesium, silicon, chromium, titanium and manganese. The weight ratio of Zr / B may range from about 0.5 to 150, and may include amounts of, by weight of the alloy, 0.05-0.5% zirconium and 0.001-0.01% boron. The oxidation resistance of the alloy may also be improved by the addition of hafnium to the alloy in an amount that is comparable to the amount of zirconium, which may include an amount of, by weight of the alloy, 0.005-0.2% hafnium. Electrodes of dilute nickel alloys which include aluminum and silicon, as well as those which include chromium, silicon, manganese and titanium, are particularly useful as spark plug electrodes. These electrode alloys of the may also include at least one of cobalt, niobium, vanadium, molybdenum, tungsten, copper, iron, carbon, calcium, phosphorus or sulfur as trace elements, generally with specified maximum amounts. The ignition device may be a spark plug which includes a ceramic insulator, a conductive shell, center electrode and ground electrode. The center electrode, ground electrode, or both, may be made from the dilute nickel alloy of the invention. These electrodes may also include a core with thermal conductivity greater than that of the dilute nickel alloy, such as copper or silver or their alloys.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Method for manufacturing high-voltage electro-ceramic insulator

InactiveCN102815924AHigh mechanical strengthImprove electrical performanceClaywaresIron removalMixed materials

The invention discloses a method for manufacturing high-voltage electro-ceramic insulator, which comprising the following steps: (1) selecting high-voltage electro-ceramic material components according to weight proportion; (2) mixing materials; (3) grinding mixed materials in a ball milling method; (4) sieving the grinded materials; (5) removing iron; (6) pressing soil; (7) staling the materials; (8) pugging the soil at vacuum; (9) molding the materials; (10) drying the material; (11) washing billets; (12) glazing the billets; (13) overlying sand on the billets; (14) baking the billets; (15) inspecting porcelain; (16) cutting the porcelain; (17) grinding the porcelain; (18) cementing the porcelain; (19) detecting problems; and (20) packaging a product and putting the product in storage. According to advantages of the method, the product is characterized by excellent electric performance, good insulation performance, high mechanical strength, small figure, beautiful appearance, convenient mounting and has good mechanical performance and good insulation puncture strength and can satisfy the current high-voltage transport demand preferably.

Owner:大悟县博源电瓷厂

Method for manufacturing anti pollution flashover high tension ceramic and glass insulators

ActiveCN1686951AAnti-agingBest integrated anti-fouling flash functionQuartz/glass/vitreous enamelsHigh pressureSurfactant free

The present invention discloses a high voltage ceramic and glass insulator with the function of resisting pollution flashover and its preparation method. Said method includes the following processes: firstly, preparing titanium dioxide base sol, adding surfactant into the sol, then applying the titanium dioxide sol containing the above-mentioned surfactant or containing no surfactant on the surface of high-voltage ceramic and glass insulator, low-temperature heat treatment to make the titanium dioxide sol be solidified on the insulator surface so as to form a layer of nano inorganic film capable of raising pollution flashover resisting function of genral ceramic insulator.

Owner:FUZHOU UNIV +2

Metallic insulator coating for high capacity spark plug

A spark plug (24) is used in an ignition system (10) of the type for creating a precisely timed spark to ignite an air / fuel mixture in an internal combustion engine. The spark plug (24) is provided with an integrated capacitor feature to increase the intensity of its spark. The capacitor feature is formed by applying metallic film (62, 64) to the inner (30) and outer surfaces of a tubular insulator (26). The insulator (26), made from an alumina ceramic material, forms a dielectric and sustains an electrical charge when an electrical differential is established between the inner (64) and outer (62) metallic films. The stored electrical charge is discharged with the firing of a spark in the spark gap (54). The inner (64) and outer (62) metallic films can be applied as a paint or ink directly to the surfaces of the insulator (26), or can be mixed with a glazing compound to form conductive coatings simultaneous with the glazing operation. Ganged (62′) or serpentine (62″) micro-plates can be formed within either or both of the inner and outer metallic films to increase the charge-carrying surface area. The metallic film (62, 64) is specially selected from materials that will not migrate into the porous matrix of the ceramic insulator (26). The metallic film (62, 64) is preferably gold, platinum, copper, or a platinum group metal.

Owner:PASSAIC RIVER CO INC

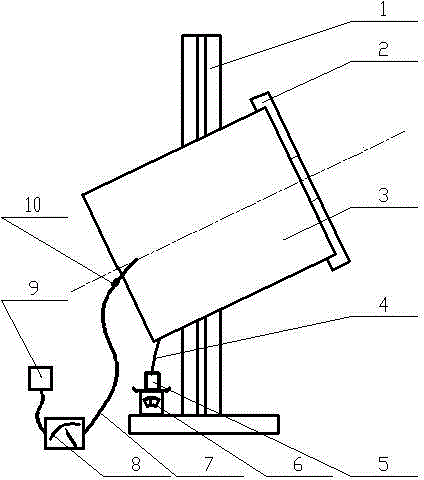

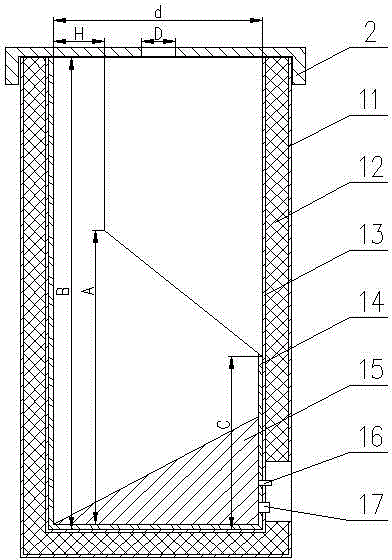

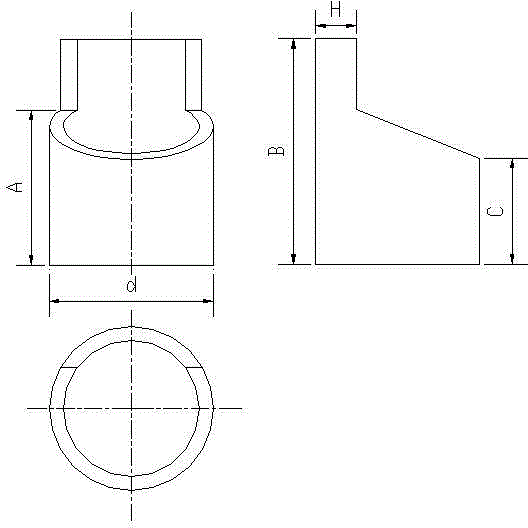

Static electricity atomizing charge-to-mass ratio measuring device

InactiveCN103149461AAccurate measurementReduce charge errorElectrical measurementsMeasurement deviceMass ratio

The invention discloses a static electricity atomizing charge-to-mass ratio measuring device which comprises a fogdrop collection device, a fogdrop weighing device, a fogdrop electric quantity measuring device and a data collection and processing system. The fogdrop collection device is a liquid collection cylinder (3) which comprises a liquid collection outer cylinder (11) and a liquid collection inner cylinder (13), and ceramic insulators (12) are arranged in the liquid collection outer cylinder (11) and the liquid collection inner cylinder (13). A graphite inner cylinder (14) is arranged in the liquid collection inner cylinder (13), slope graphite is adopted by the graphite inner cylinder (14), the diameter of the graphite inner cylinder (14) is d, a long bus of the graphite inner cylinder is B, a short bus of the graphite inner cylinder is C, the diameter of an opening of a cylinder cover is D, the distance between a intersecting line of the middle portion cross section and a cylinder bottom is A, the distance between the intersecting line of the middle portion cross section and the long bus is H, and the parameter of he graphite inner cylinder (14) is that A=(0.35-0.45) B; d: A: C =2: 2: 1, B= (13-15)H. A slope cylinder block (15) is arranged in the graphite inner cylinder (14).

Owner:JIANGSU UNIV

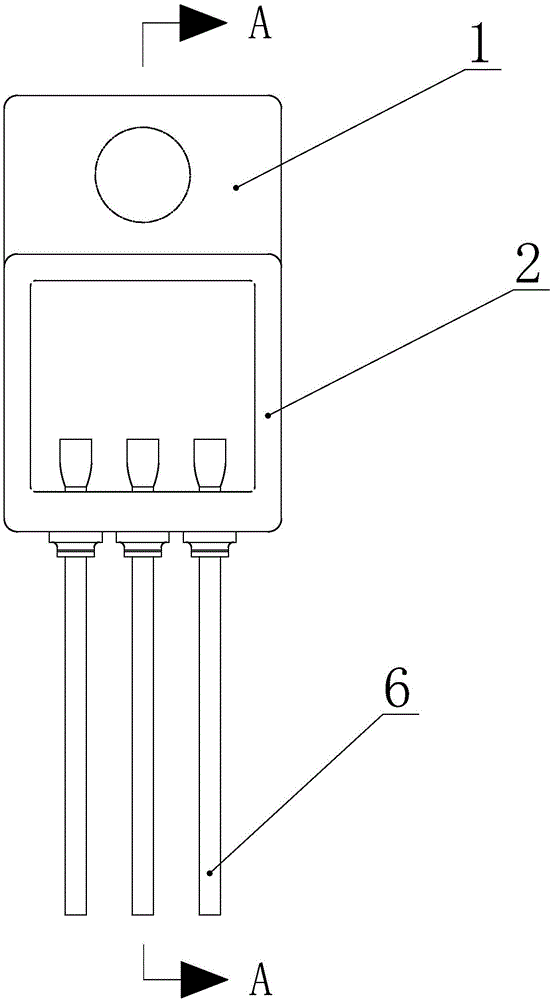

Glass ceramic composite insulator packaging shell and manufacturing method thereof

ActiveCN105788779AImprove impact resistanceOvercome fragileInsulatorsHigh resistanceComposite insulators

The invention discloses a glass ceramic composite insulator packaging shell. The shell comprises a metal baseplate, a metal wall, a glass ceramic composite insulator, a metal sealing ring, an extraction electrode and a welding portion metallization layer. The invention provides the glass ceramic composite insulator. Advantages of a glass insulator and a ceramic insulator are possessed. Through reasonably designing structures of the insulators, an installation position, a connection method and the like, disadvantages of the two insulators are overcome. An electrical requirement of a power device to a high resistance is satisfied, and the glass ceramic composite insulator has high intensity and a high impact resistance capability so that a high reliable requirement of the power device is satisfied. A thermal resistance is small, efficiency is high and reliability is high too so that the packaging shell of the power device which is installed with the glass ceramic composite insulator possesses good performance. A production technology is simple, production efficiency is increased and large batch production is convenient. The invention also discloses a manufacturing method of the glass ceramic composite insulator packaging shell.

Owner:济南市半导体元件实验所

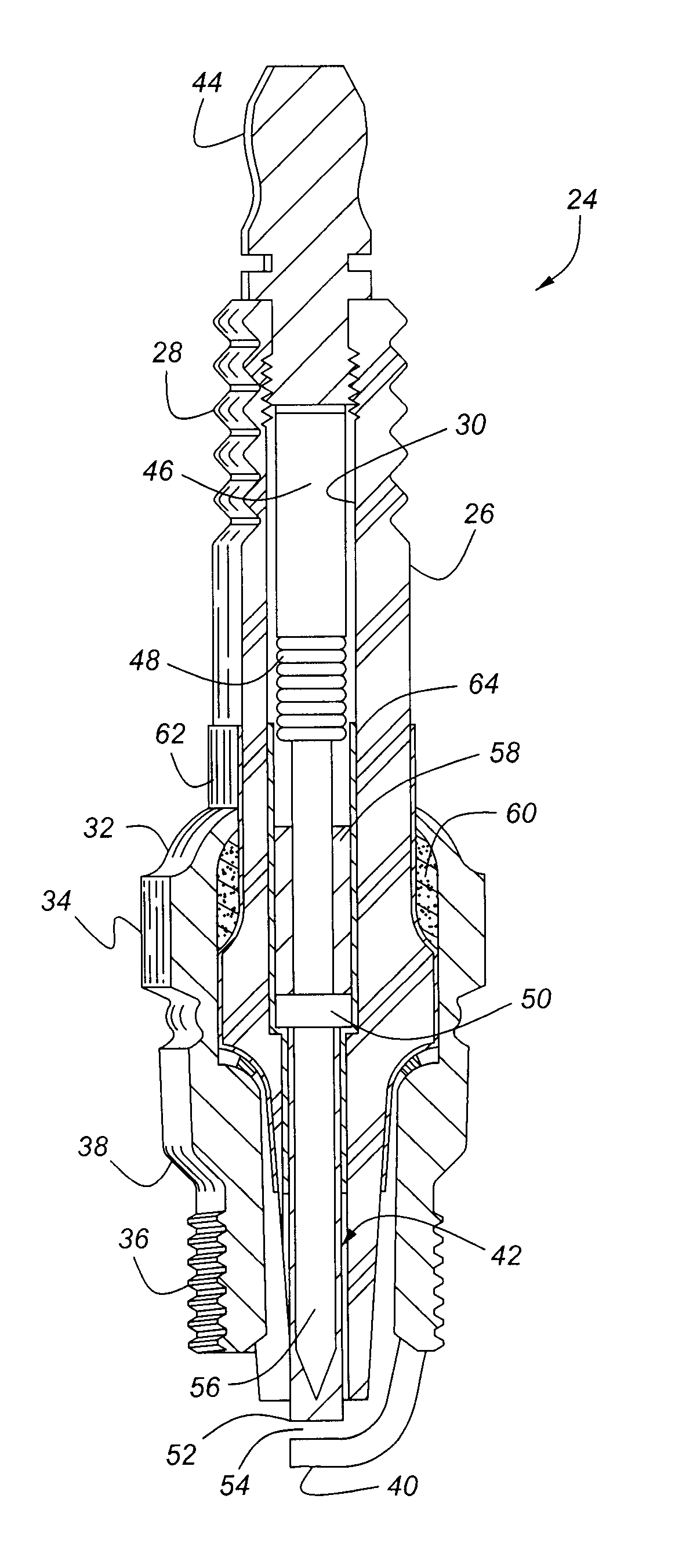

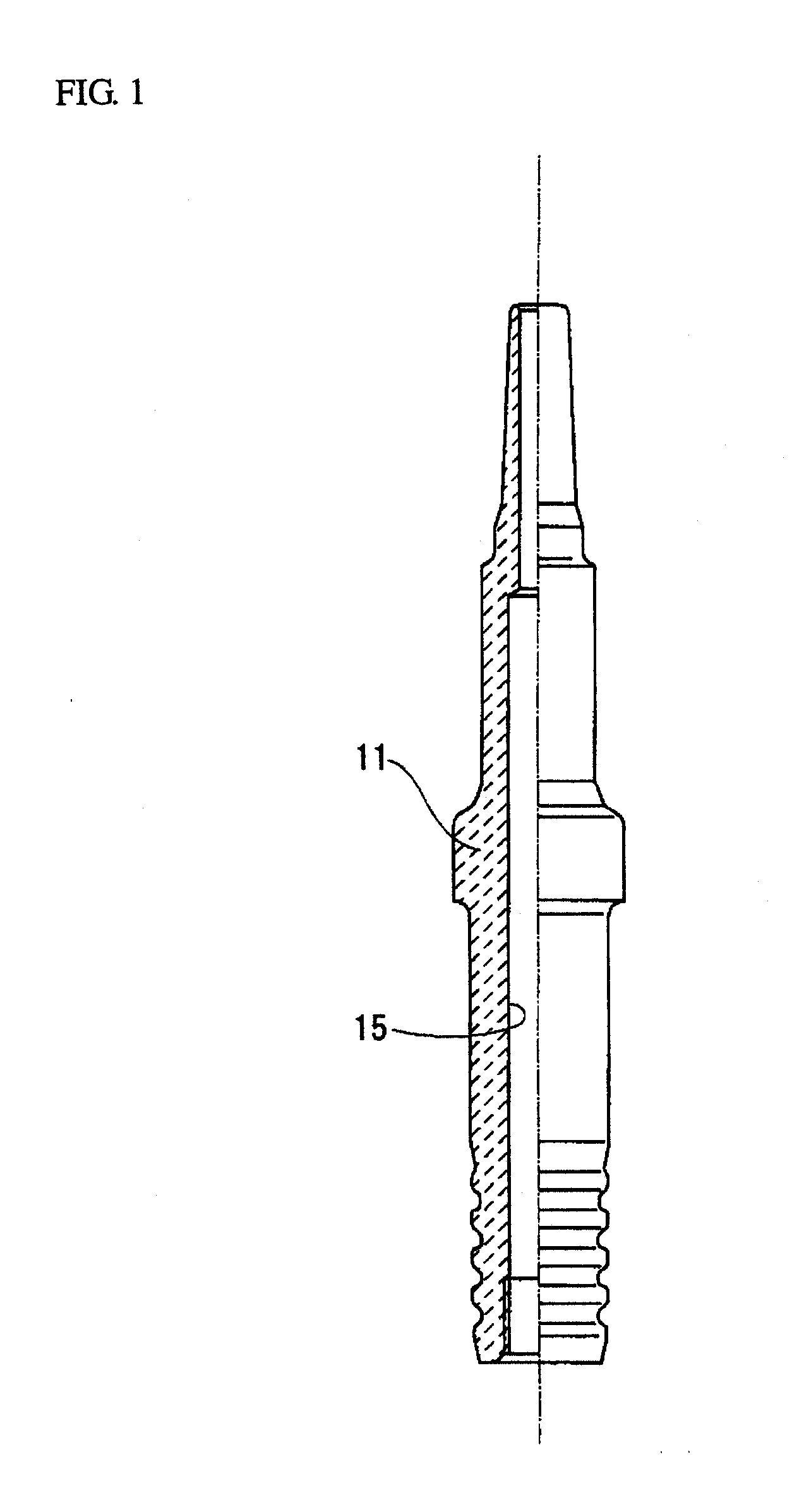

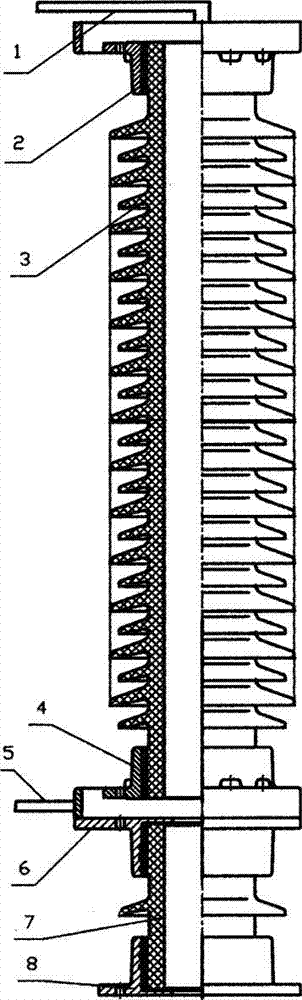

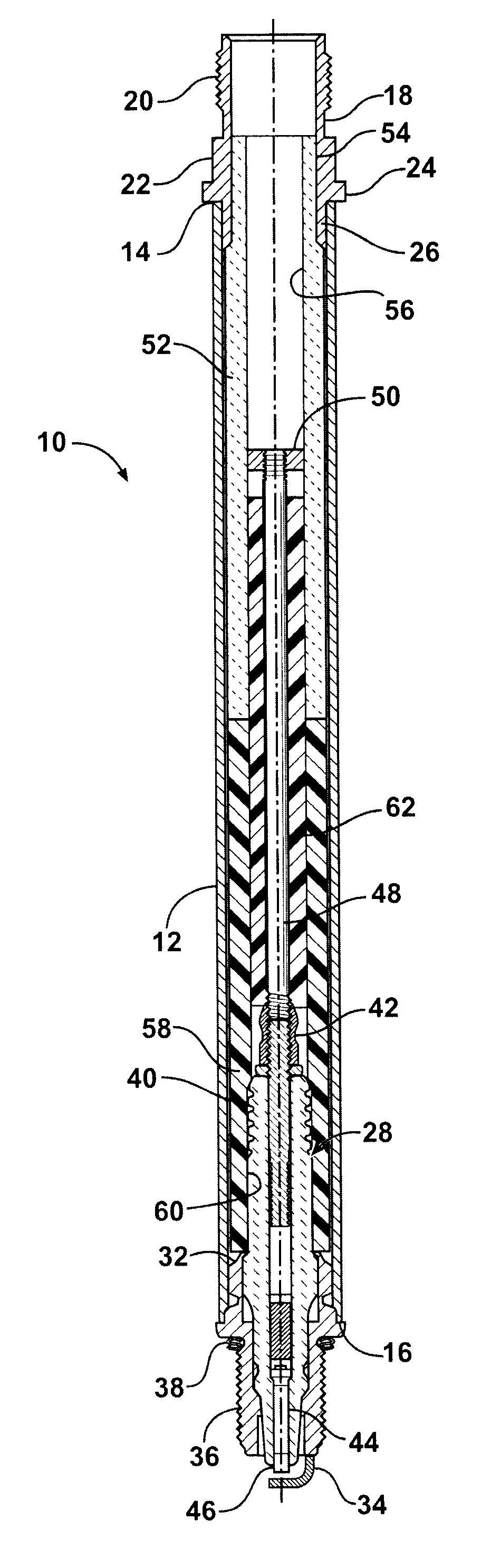

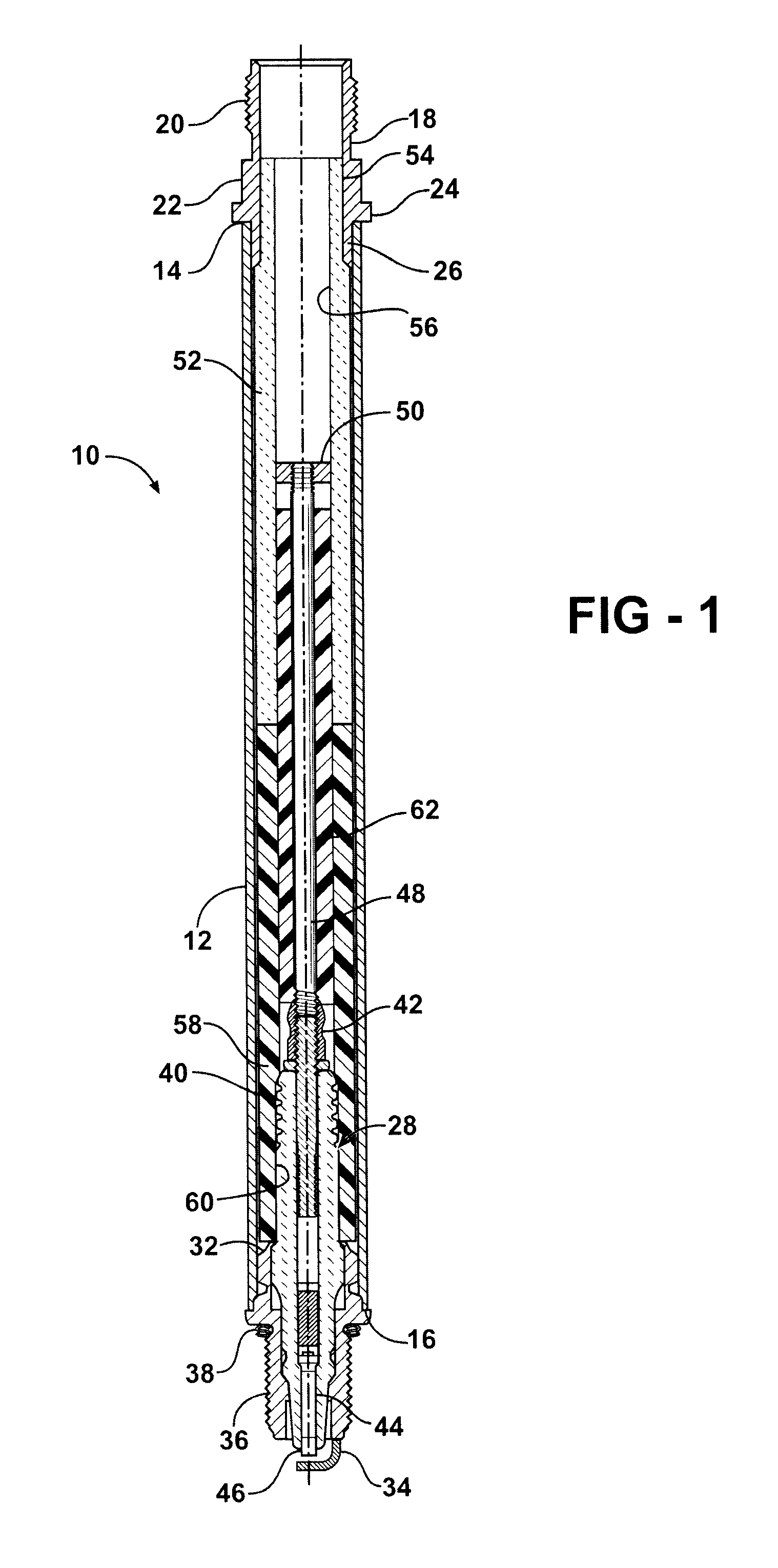

14 mm extension spark plug

A spark plug assembly (10) for engine applications where the combustion chamber is difficult to access when servicing or replacing a spark plug. The spark plug assembly (10) includes a fairly traditional spark plug component (28) to which an elongated tubular conduit (12) is attached, such as by welding, to a portion of the metallic shell (32). The conduit (12) contains an upper ceramic insulator (52) adjacent its top end (14) disposed in end-to-end abutting contact with an outer elastomeric insulator (58). The ceramic insulator of the spark plug component (28), herein referred to as a lower ceramic insulator (30), is surrounded by the outer elastomeric insulator (58) and held securely within the conduit (12) thereby. An inner elastomeric insulator (62) is disposed in a continuous passageway formed between aligned central bores formed in the respective upper ceramic (52) and outer elastomeric (58) insulators. The inner elastomeric insulator (62) supports and further electrically isolates an elongated electrically conductive center electrode extension (48) that is in direct electrical conductivity with the center electrode (44) of the spark plug component (28). An ignition lead wire makes electrical contact with the center electrode extension (48) and thereby delivers electrical energy at timed intervals to the spark gap.

Owner:FEDERAL MOGUL IGNITION

Substrate mounted with electronic element thereon and liquid ejection head including the substrate

InactiveUS20060023436A1Improve thermal conductivityEffective radiationInking apparatusSemiconductor/solid-state device detailsEngineeringHeat spreader

A substrate mounted with an electronic element thereon comprises a metal base, a ceramic insulator, and a radiator. The insulator is provided on a first side of the base. The insulator has a heat-generating electronic element mounted on a side thereof opposite to a side thereof facing the first side of the base. The radiator has a radiation capability higher than both of a radiation capability of the insulator and a radiation capability of the base, and radiates heat transmitted from the electronic element via the insulator to the base.

Owner:BROTHER KOGYO KK

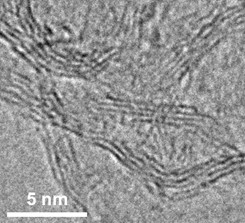

Device and method for fast preparing large-area vertically aligned graphene

ActiveCN102560437AAchieve vertical growthReduce dosageChemical vapor deposition coatingPtru catalystElectrical battery

Owner:ZHEJIANG UNIV

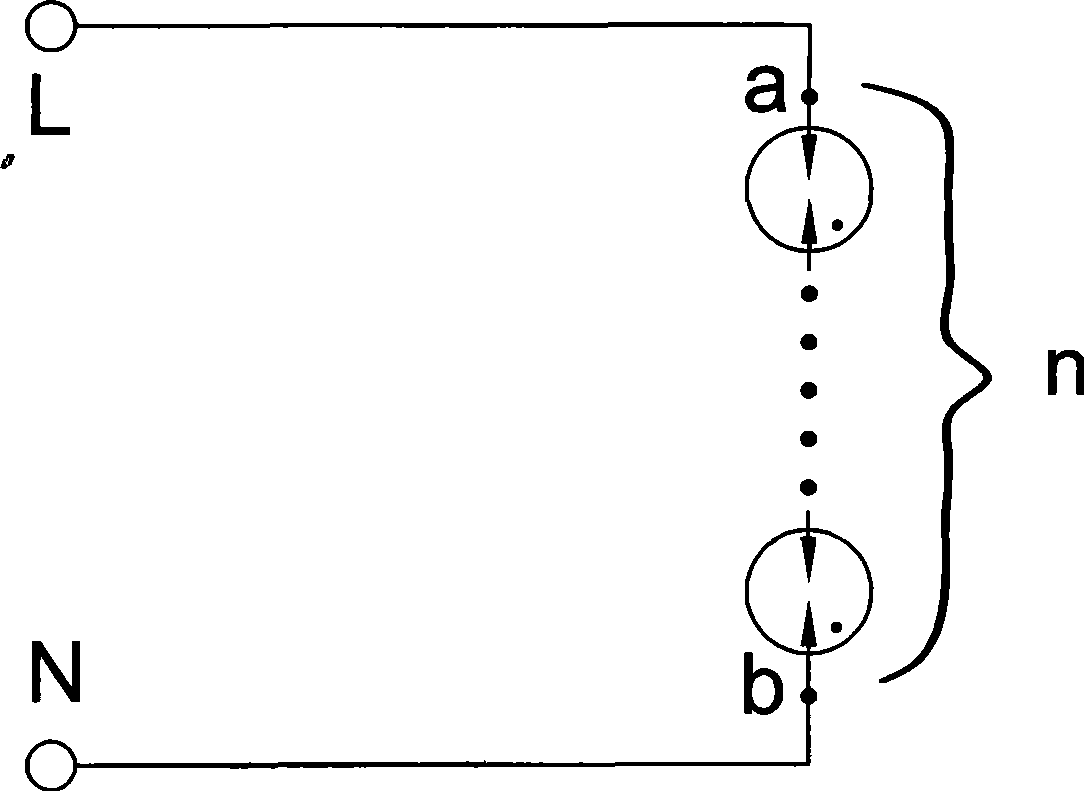

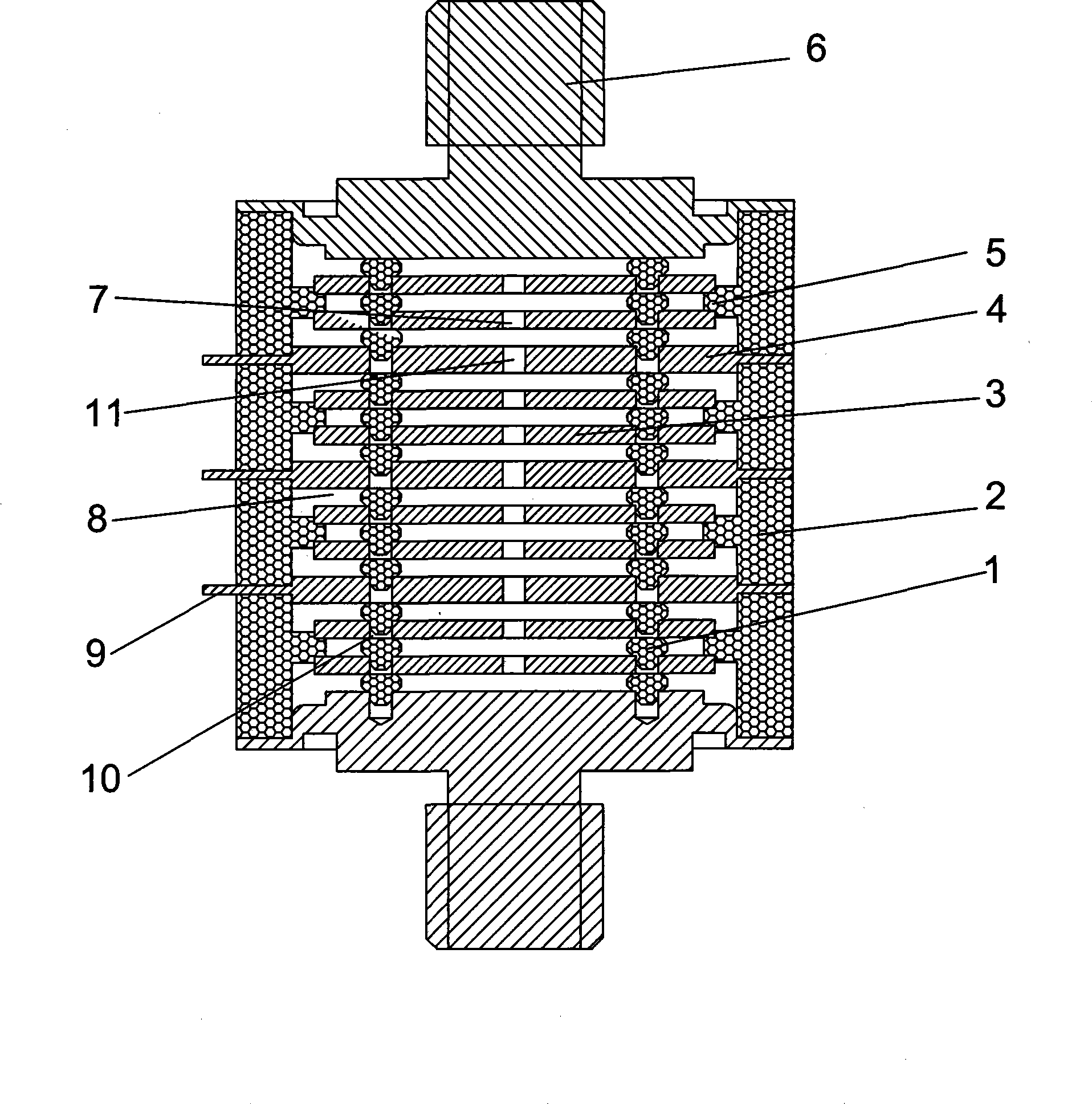

Multi-clearance ceramet gas discharge tube with circumscribing triggering terminal

InactiveCN101378178AAvoid potential hazardsMeet the requirements of the best solution for lightning protectionOvervoltage arrestors using spark gapsOvervoltageMetal

The invention relates to the technical field of discharge tubes, in particular to a multi-gap metal ceramic gas discharge tube with external contact terminals, which comprises a ceramic locating nail, a metalized ceramic insulator, a discharge gap electrode separator, a discharge gap transitional connection separator, a screw electrode and terminals; the two ends of at least two layers of ring metalized ceramic insulators are connected with the screw electrode so as to form multi-gap space sealed with inert gas; the ring metalized ceramic insulators are integrally formed with a ring flange; the upper end surface and the lower end surface of the ring flange support two electrode separators with the discharge gap; the electrode separators with the discharge gap are provided with ceramic locating nail holes and discharge extending holes; the discharge gap transitional connection separator is arranged between the two metalized ceramic insulators and opened with the discharge extending holes; and after terminal overvoltage is integrally formed on the discharge gap transitional connection separator, the discharge tube is extinguished automatically, thus achieving the result of no after-flow.

Owner:GUANGZHOU HOPEWELL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com