Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77 results about "Deterministic analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

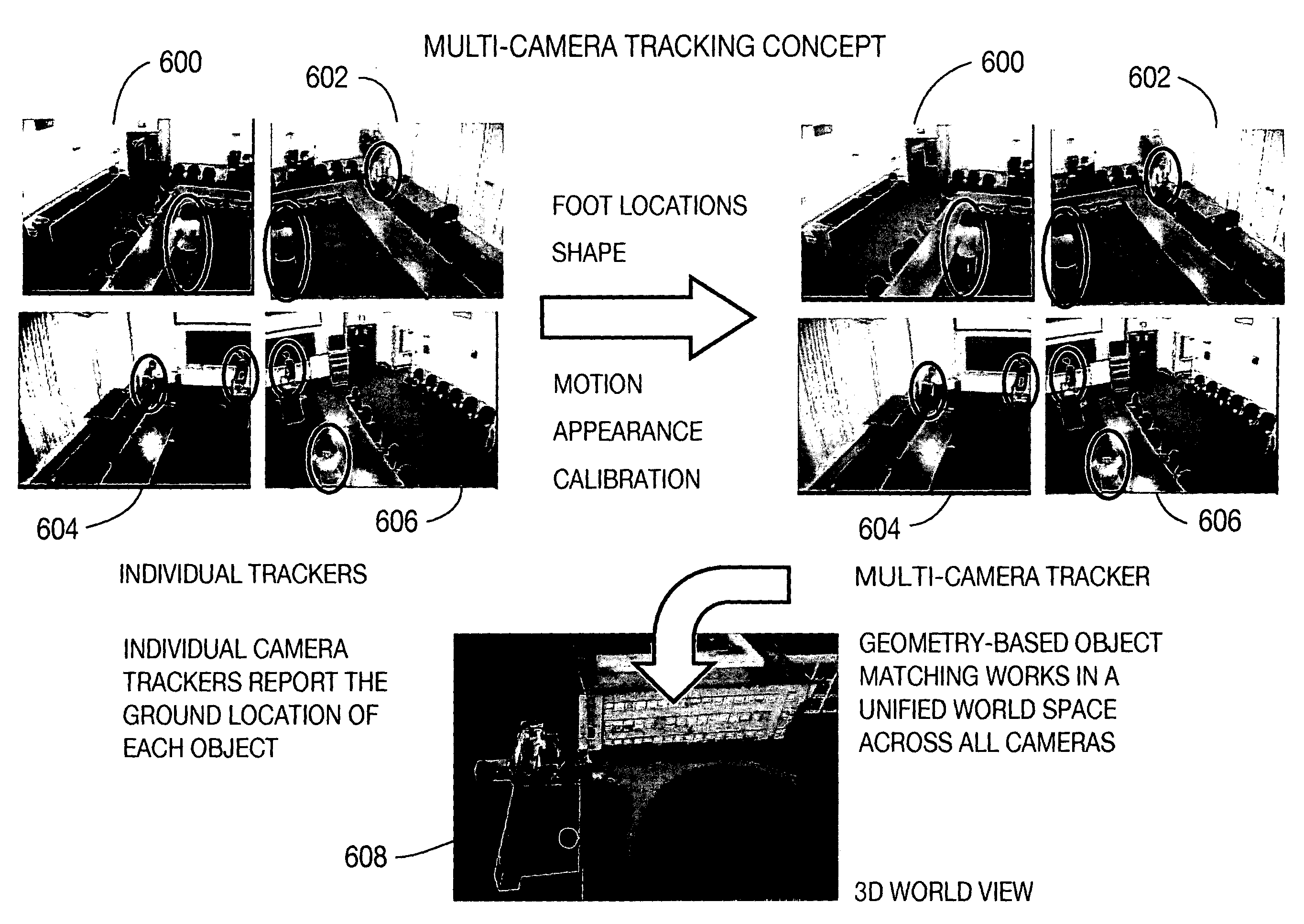

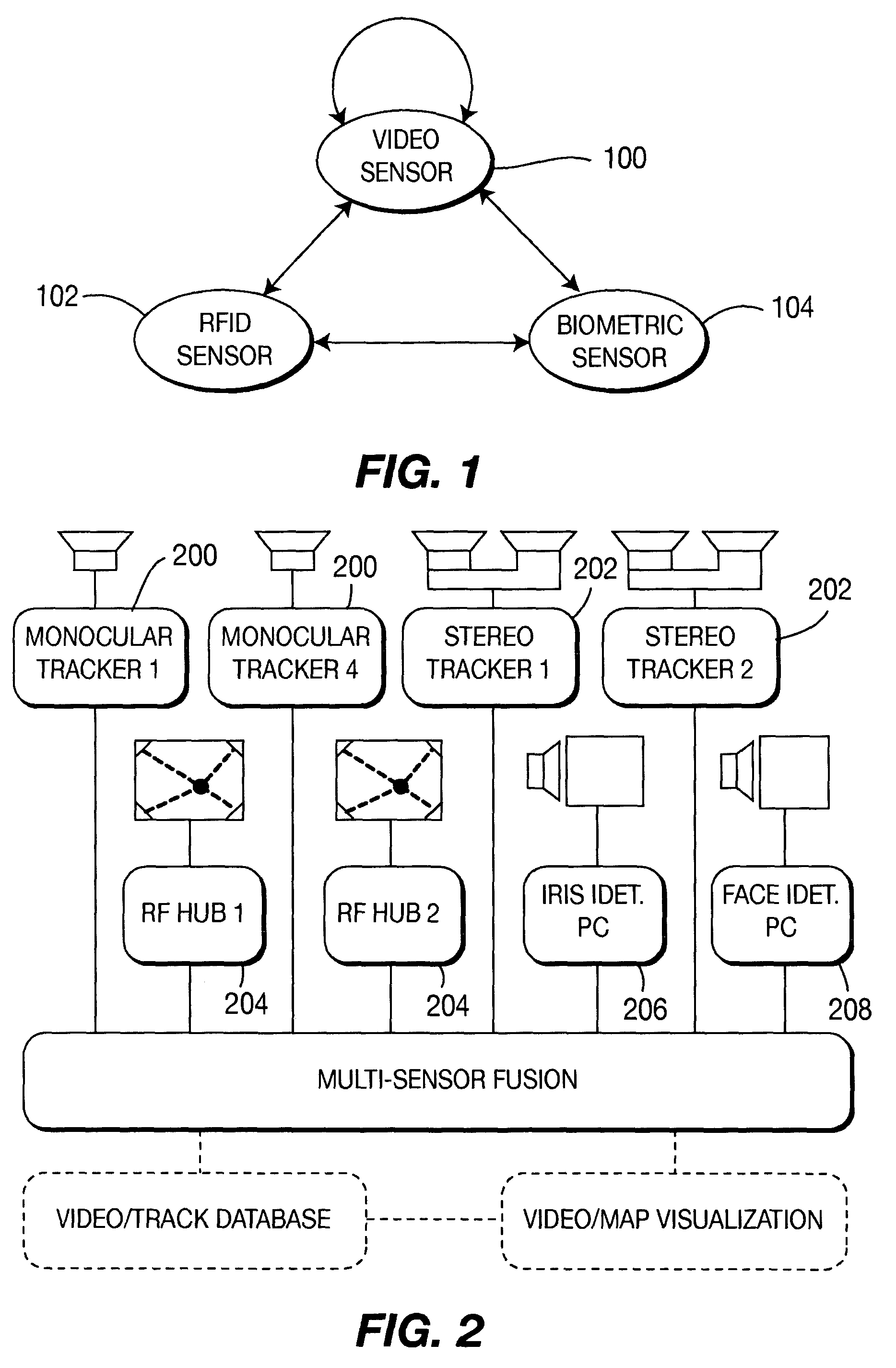

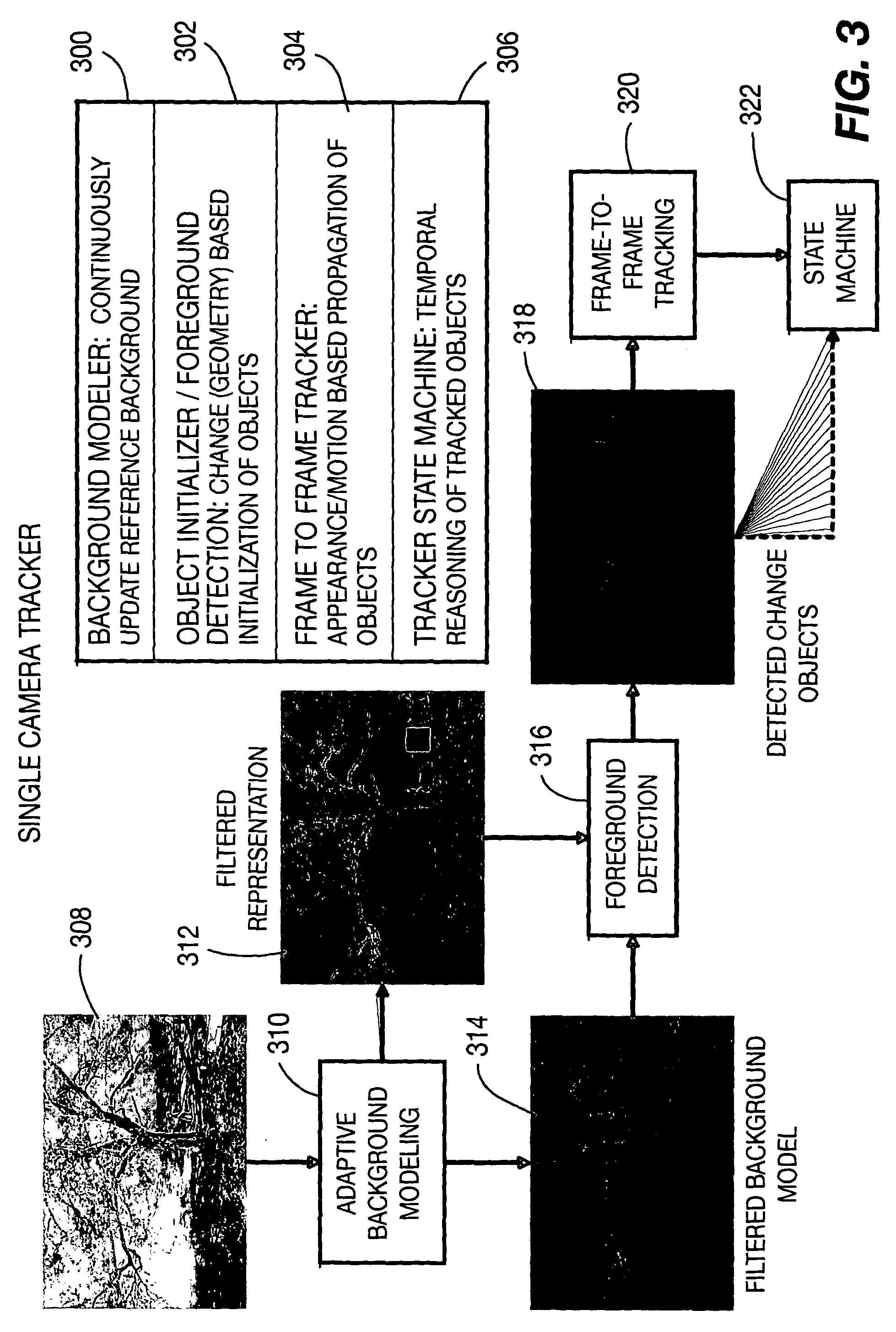

Method and apparatus for stereo, multi-camera tracking and RF and video track fusion

Owner:SRI INTERNATIONAL

Method and system for integrated uncertainty analysis

InactiveUS20050004833A1Efficient analysisSimulator controlComputation using non-denominational number representationNormal densityComputer architecture

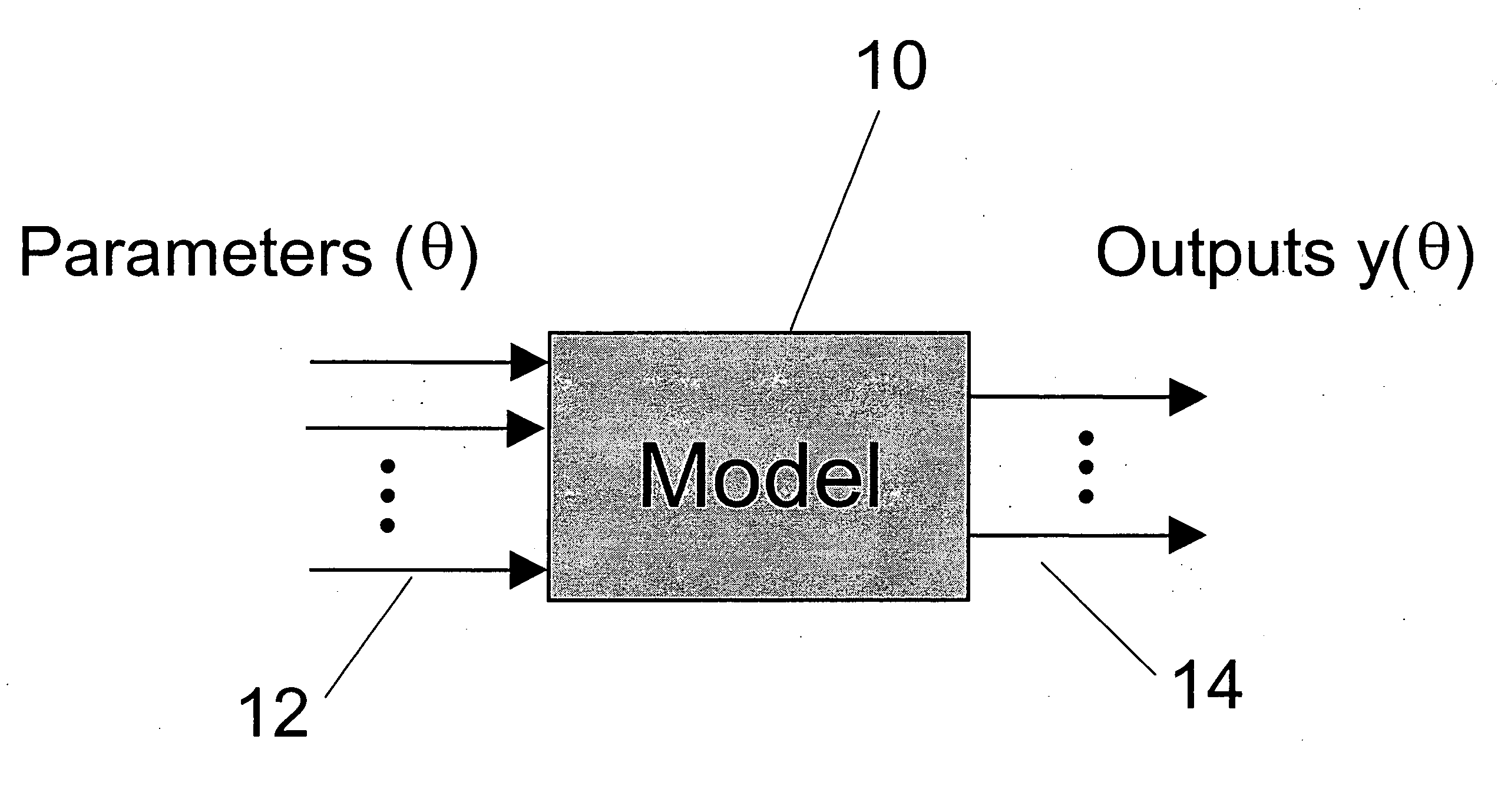

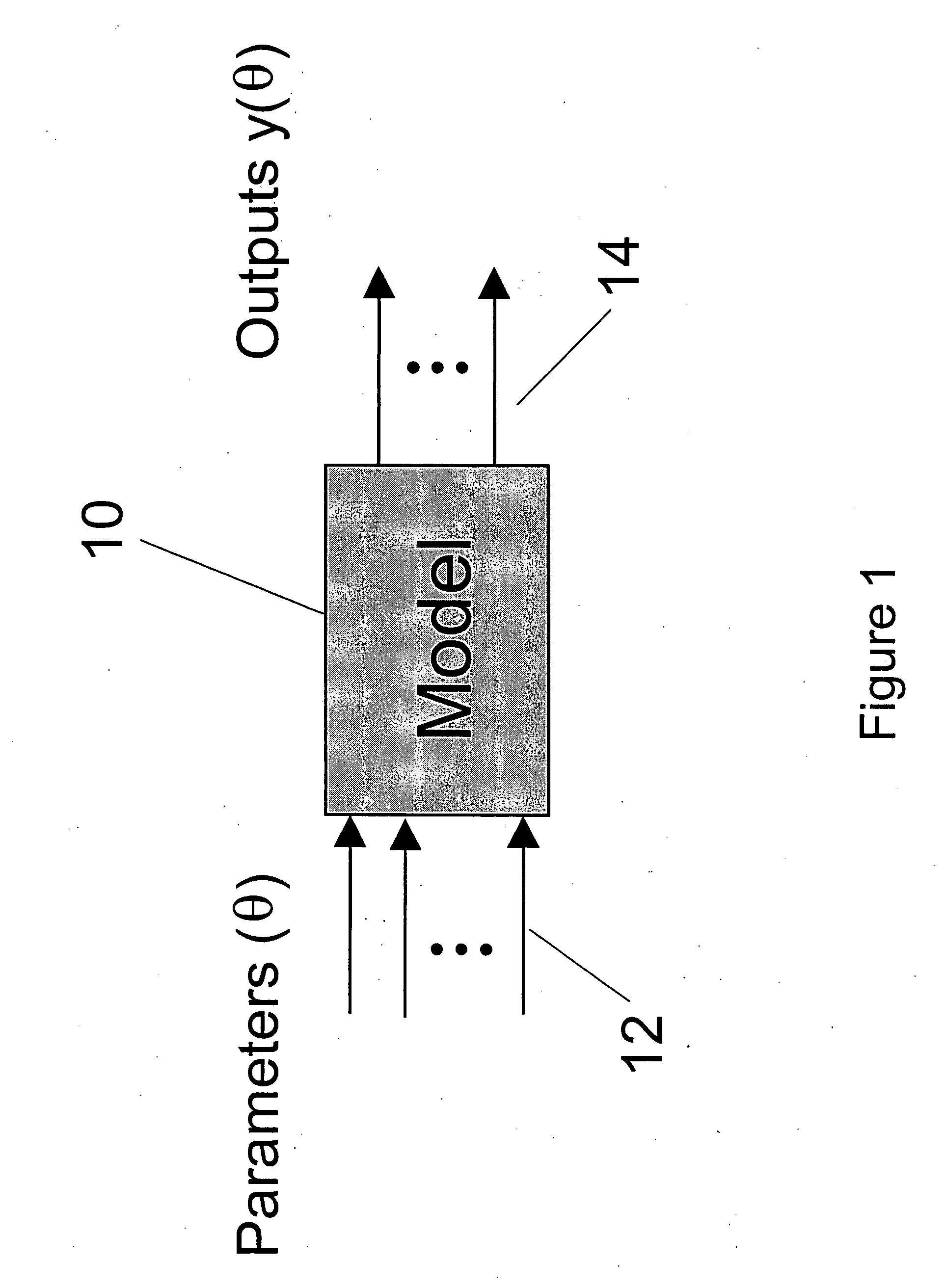

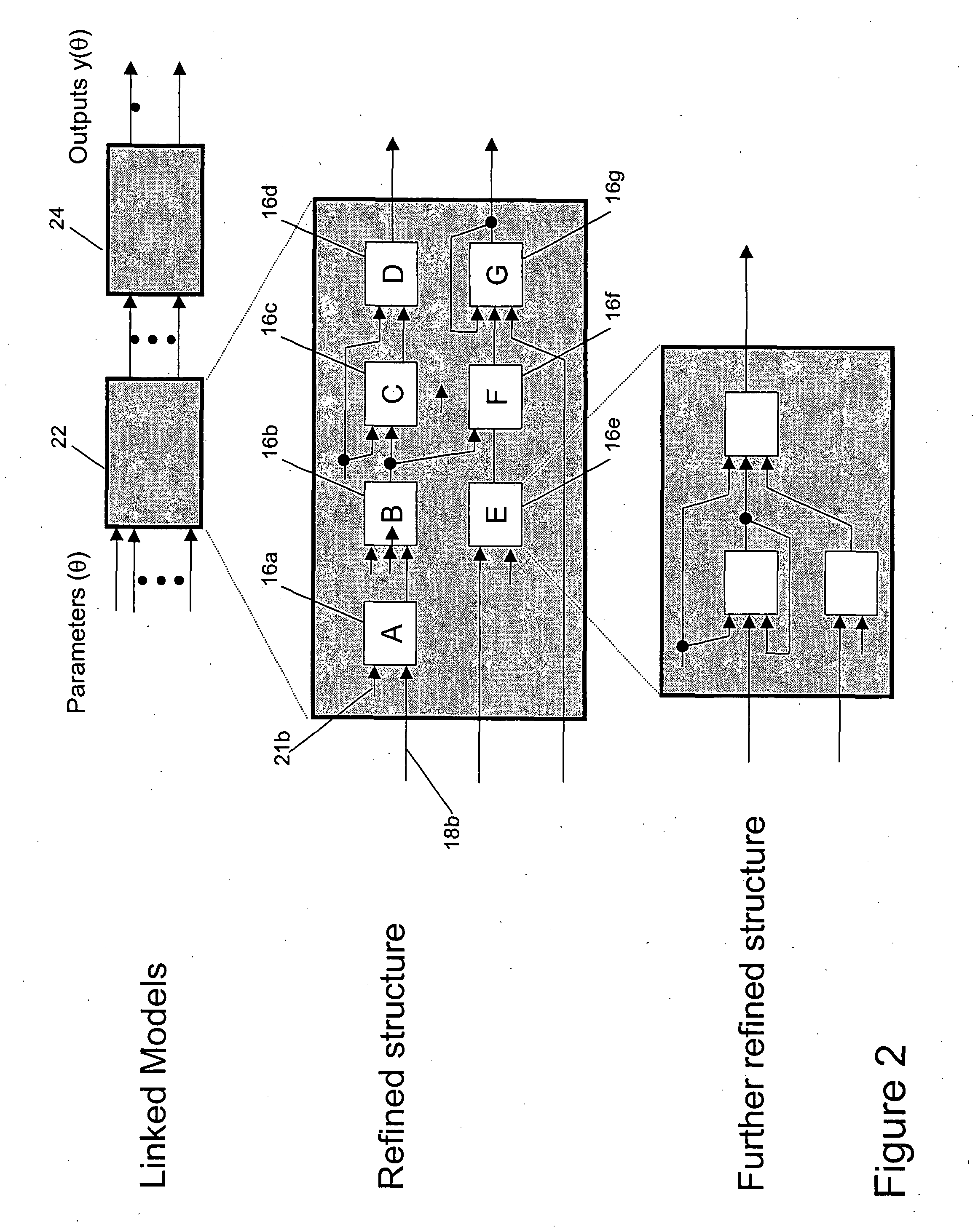

A system and a method are provided for performing an integrated uncertainty analysis on a system having interacting modules. The interaction of the modules includes data transfer between the modules with the output of one module being indicative of the input of another module. An uncertainty analysis is performed on each module based on given probability density functions of each input to the module. The uncertainty analysis may include developing a deterministically equivalent model for one or more modules. Data may be provided from one module to another in a uniform format. Thus, two or more modules may be integrated with uncertainties in the inputs of one module being effectively propagated to the inputs of another module. A plurality of modules may thus be modeled as a single integrated system. The integrated system may be replaced with a deterministically equivalent model, preferably of a further reduced order. In this manner, key uncertainties in particular inputs may be isolated. Once these inputs are identified, resources may be effectively allocated to minimize the impact of those inputs on the variability of the results.

Owner:REACTION DESIGN

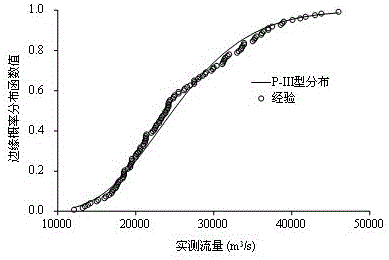

Hydrological model comprehensive uncertainty analysis method based on Copula function

ActiveCN105808868AGet the combined uncertaintyAccurate captureSpecial data processing applicationsHydrometryDeterministic analysis

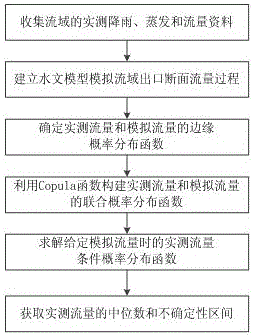

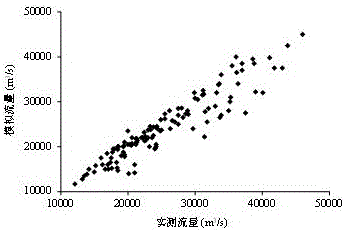

The invention discloses a hydrological model comprehensive uncertainty analysis method based on a Copula function. The method comprises the following steps: (1) collecting data information of a water basin; (2) establishing a hydrological model to simulate a water basin outlet section flow process; (3) determining a marginal probability distribution function of actually measured flow and simulation flow; (4) using the Copula function to construct an united probability distribution function of the actually measured flow and the simulation flow; (5) solving a condition probability distribution function of the actually measured flow while the simulation flow is given; (6) acquiring median of the actually measured flow and an uncertainty interval. Through the adoption of the method disclosed by the invention, the uncertainties of the model parameter and the model structure can be more comprehensively considered at the same time so as to obtain the comprehensive uncertainty of the hydrological model. The method disclosed by the invention is independent from a certainty hydrological model, and can be synergistically integrated with the certainty hydrological model with any complexity without adding any assumption on the model, and a universal theoretical frame is provided for the analysis of the comprehensive uncertainty of the hydrological model.

Owner:WUHAN UNIV

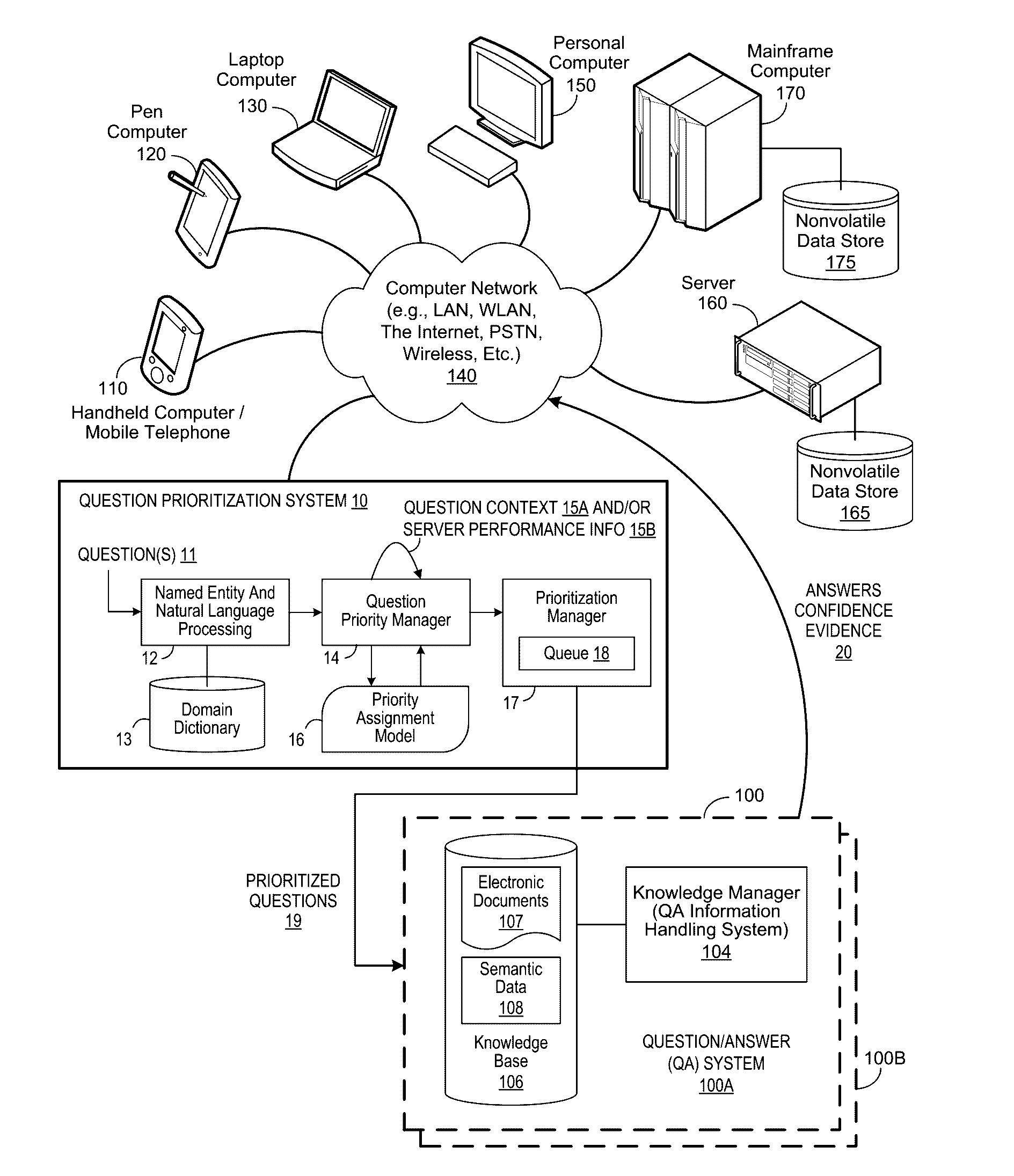

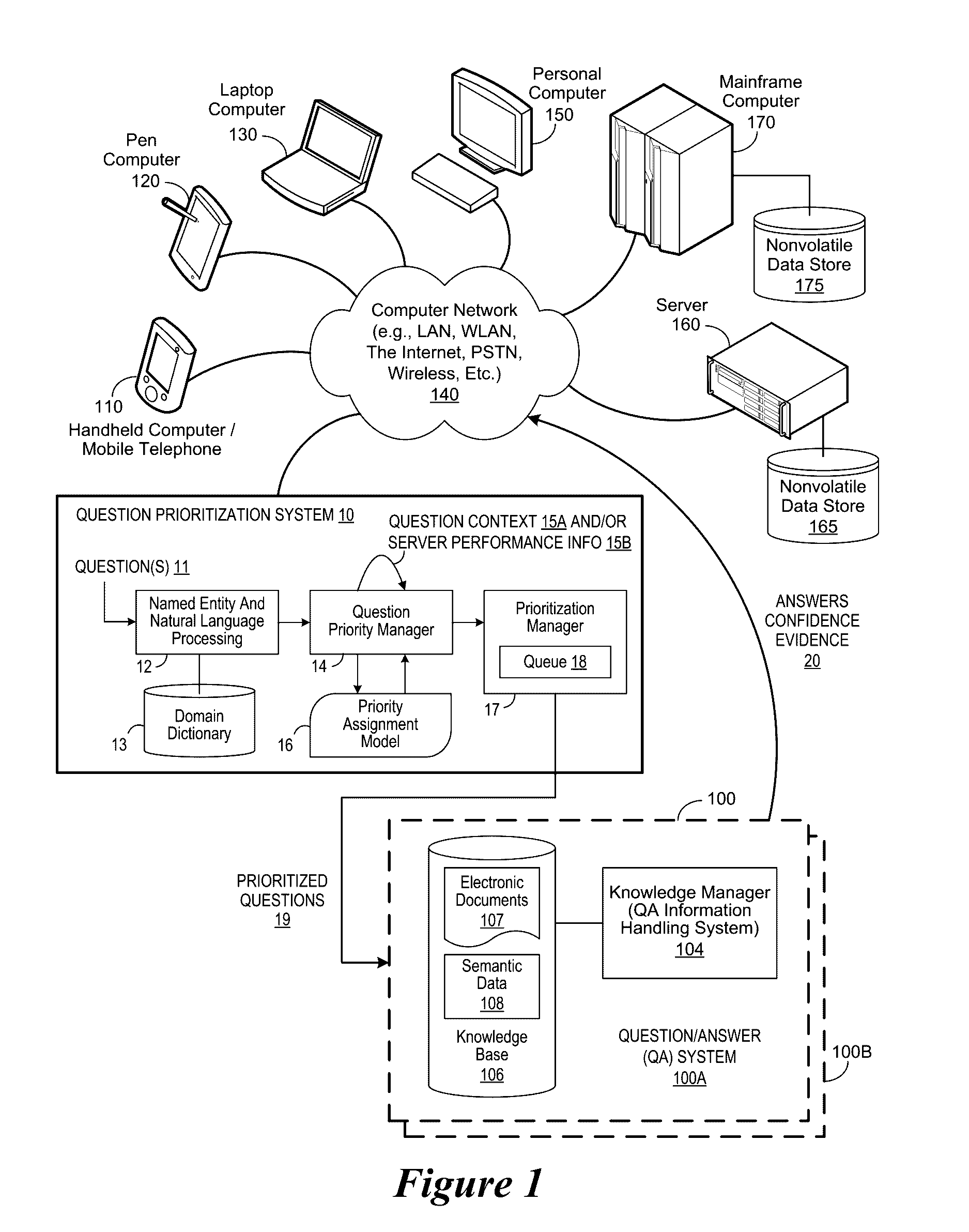

Crowd Sourcing of Device Sensor Data for Real Time Response

InactiveUS20170004213A1Relational databasesGeographical information databasesTime responseCrowd sourcing

A system, method, and computer-readable medium for performing a crowdsourcing data analysis operation. More specifically, the crowdsourcing data analysis operation receives data from a plurality of crowd sourced devices, aggregates the data received from the plurality of crowd sourced devices and maps the data received from the plurality of crowd sourced devices to a cohort (i.e., a group of individuals used in a study who have something in common). In certain embodiments, the crowdsourcing data analysis operation analyzes the data received from the plurality of crowd sourced devices to provide a deterministic analysis to infer a likelihood of potential incidents related to a group of individuals at any given time. Additionally in certain embodiments, the mapping of the data received from the plurality of crowd sourced devices includes binding the data to a physical or logical location.

Owner:IBM CORP

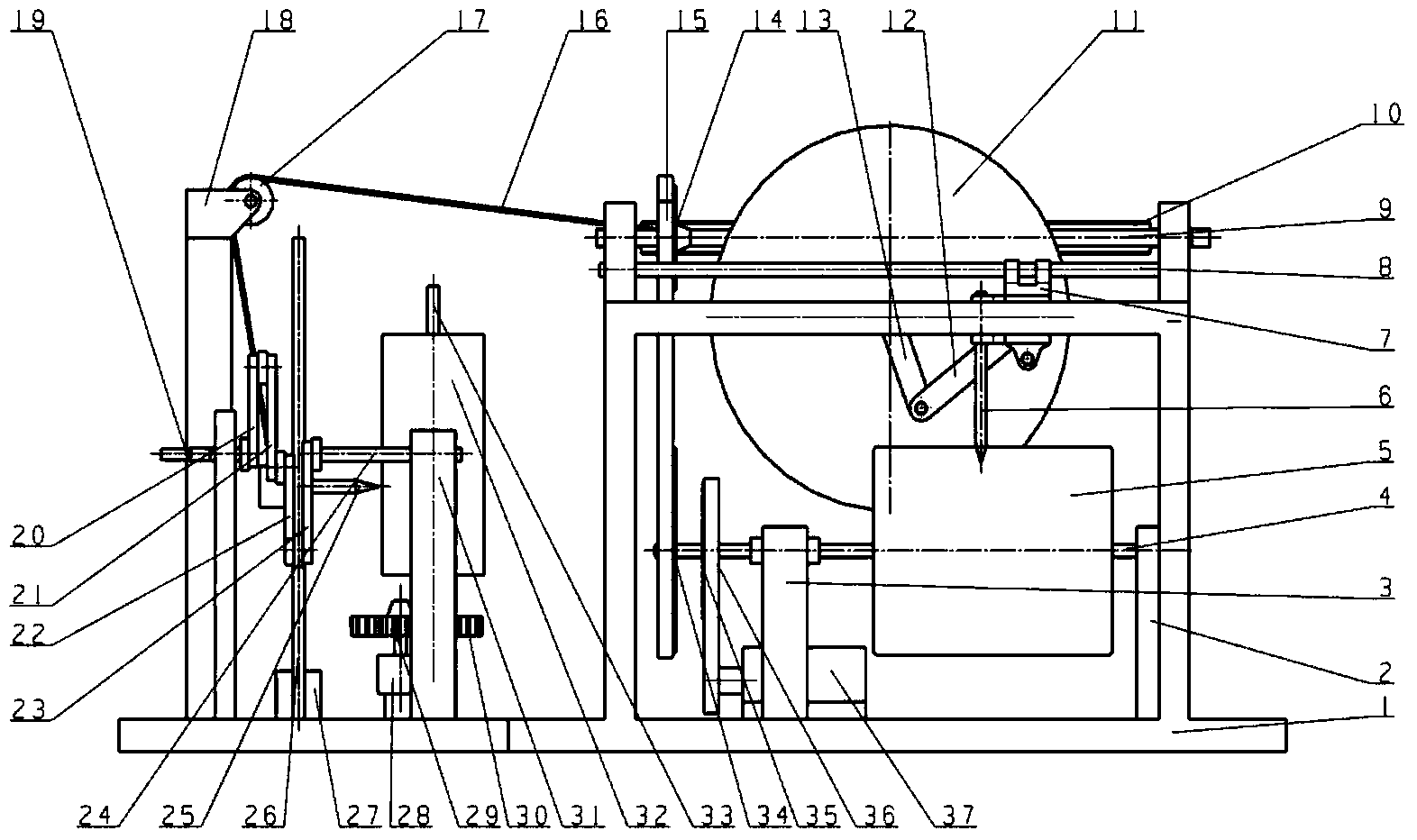

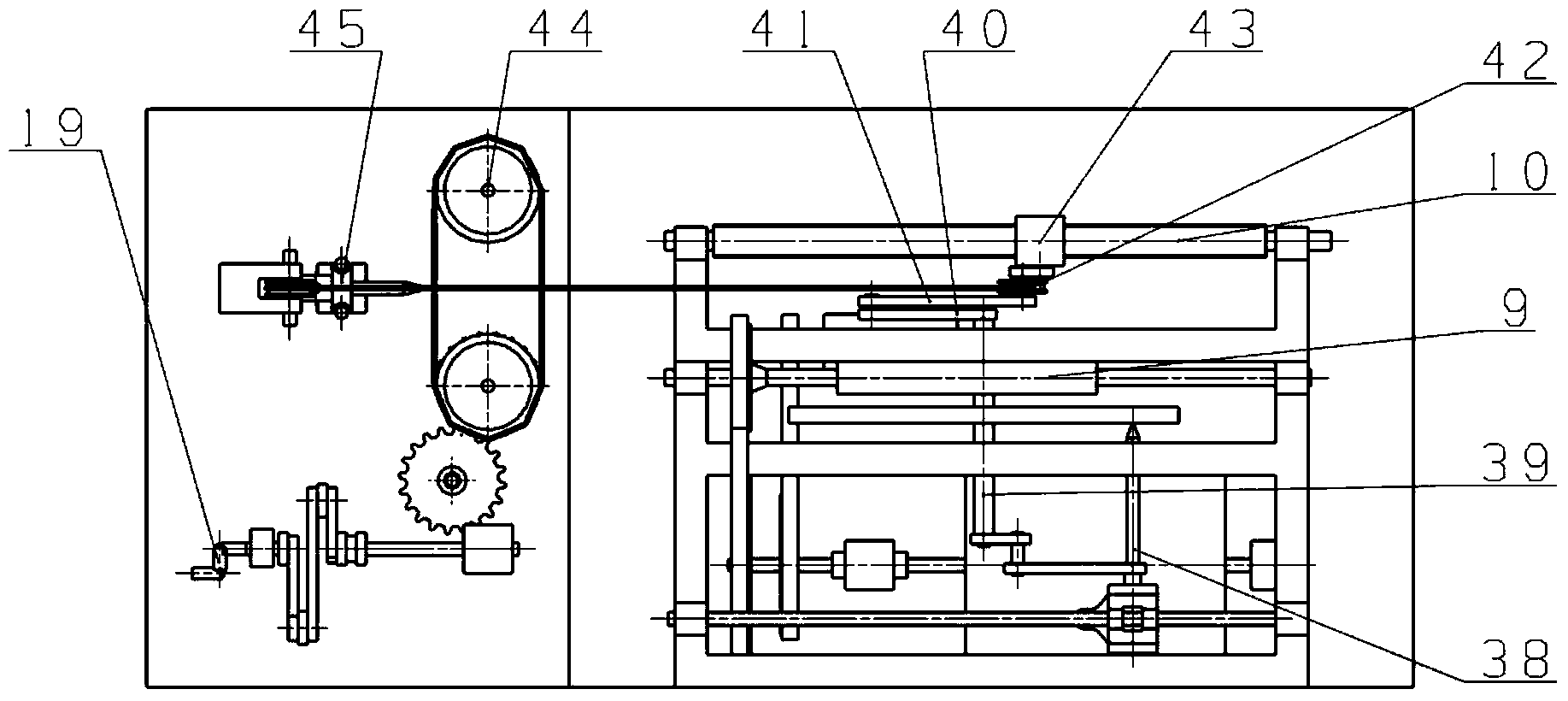

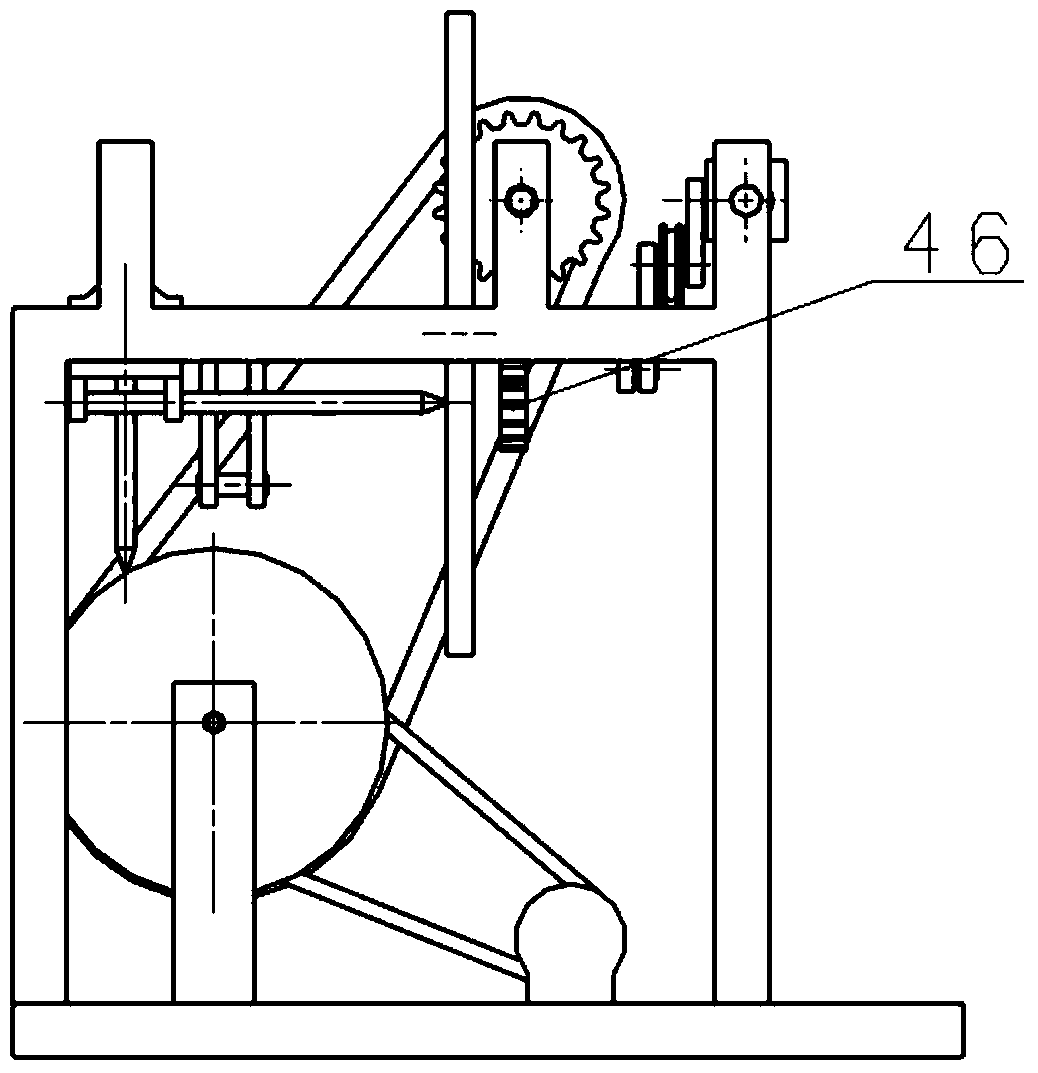

Link mechanism based multifunctional teaching aid

The invention discloses a link mechanism based multifunctional teaching aid which comprises a main teaching aid driving mechanism, a slider speed describing mechanism, a cam curve describing mechanism, a link speed describing mechanism and a motion certainty analysis mechanism, the main teaching aid driving mechanism, the slider speed describing mechanism and the cam curve describing mechanism are arranged on a main teaching aid support, and the main teaching aid support comprises a horizontal base plate and a rectangular frame fixed on one side of the horizontal base plate. Knowledge points of various mechanical principles are represented through a plurality of link mechanisms arranged on the main teaching support, teaching effect can be improved, and classroom teaching is enabled to be more targeted and applicable.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

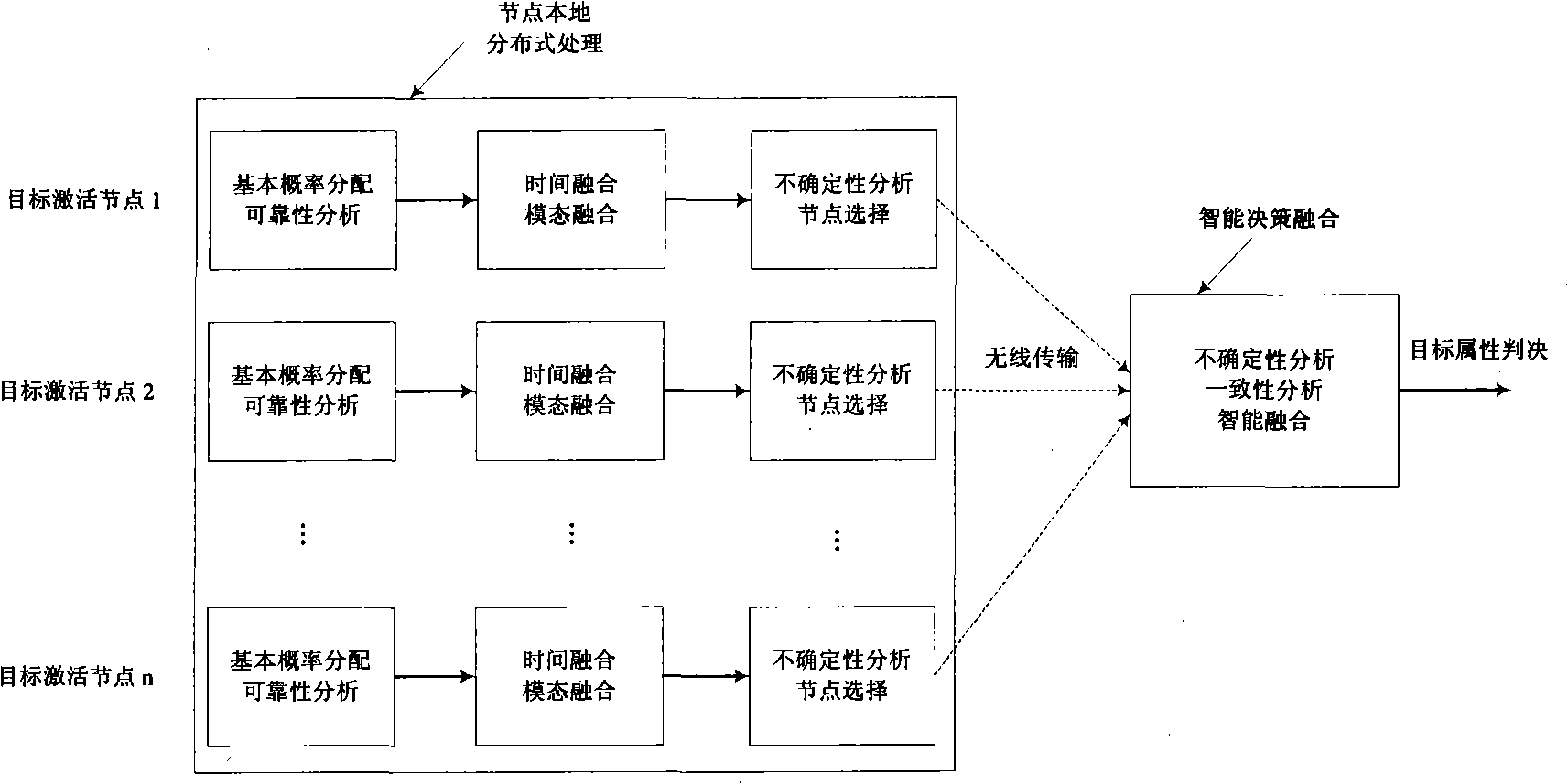

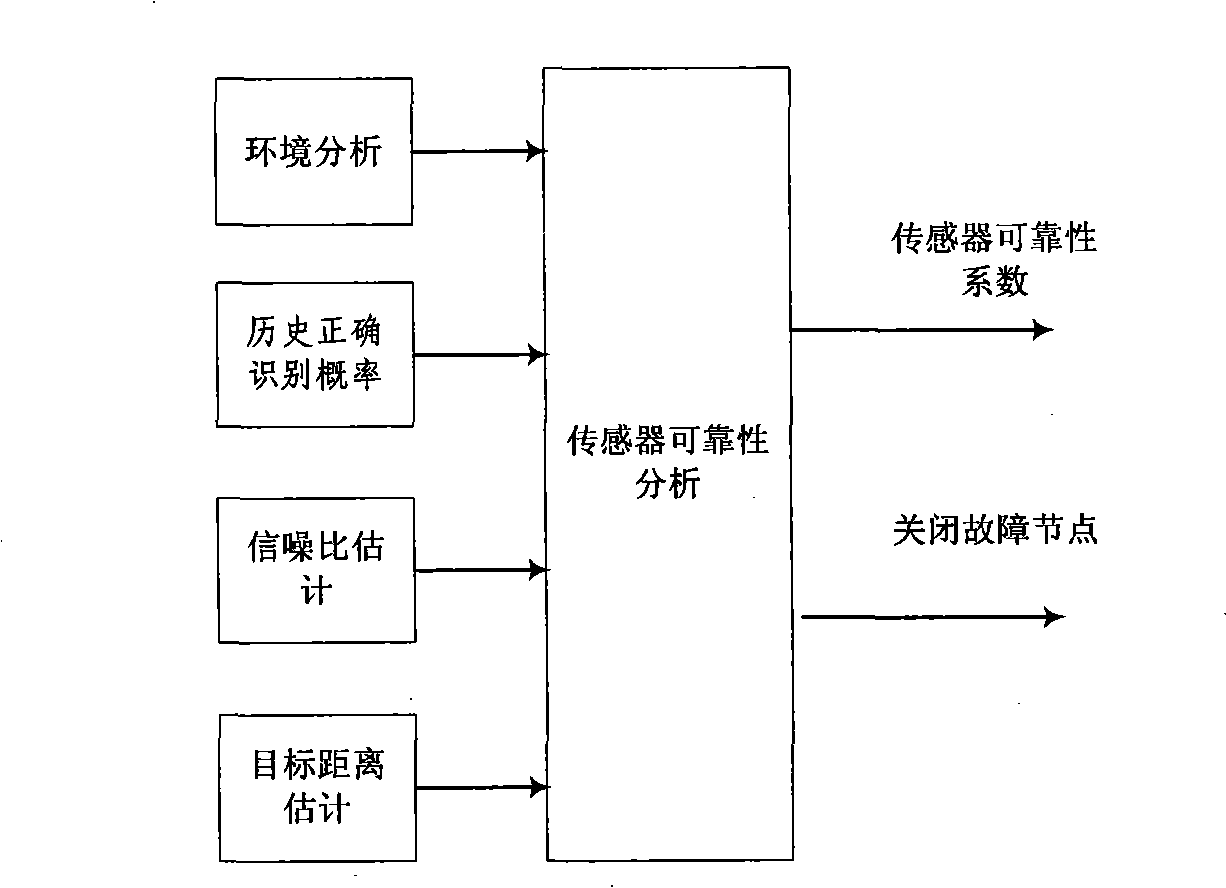

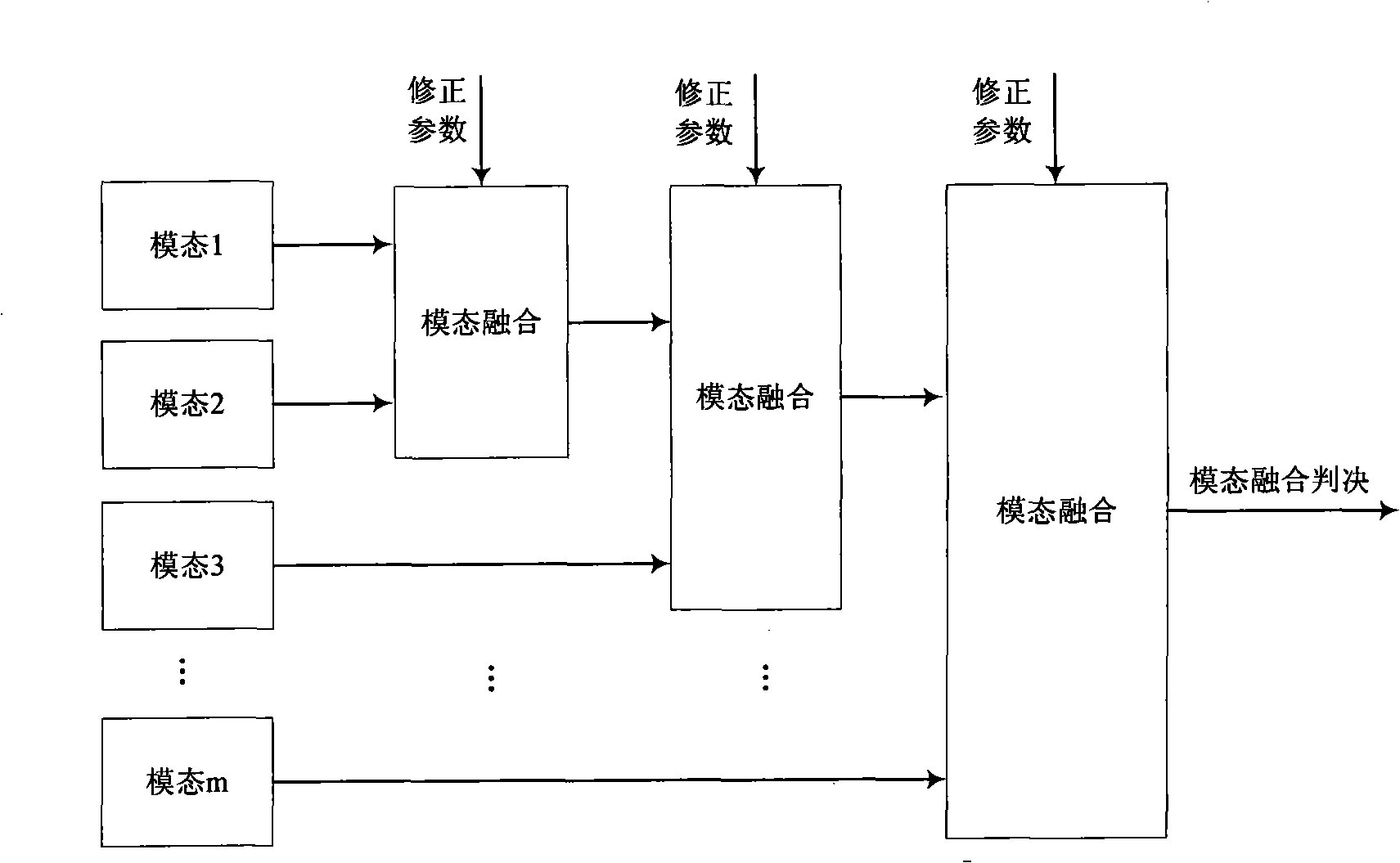

Method for recognizing distributed amalgamation of wireless sensor network

InactiveCN101282243AReduce consumptionScalableData switching by path configurationTransmission monitoringDeterministic analysisInformation integration

The present invention provides a distributed fusion recognizing method of wireless sensor network. Firstly each node of the wireless sensor network is established with a respective elementary probability distribution model, a sensor reliability analysis model, an uncertainty analysis model and a consistency analysis model. Then these node enabled by the target is executed with estimation to the elementary probability distribution function and sensor reliability analysis. Each node is executed with a time fusion in order to realize result synchronization. A modality fusion should be executed to the node which is equipped with a plurality of types of sensors. Then through analyzing the uncertainty to the recognizing result, the on-line self-adopting selection is executed. When the fusion center receives the element probability distribution and sensor reliability parameter transmitted by the selected node, the consistency analysis is executed. The information fusion is executed combining the reliability of sensor, and the uncertainty and consistency of result, and in this way the distributed fusion recognizing is realized.

Owner:JIAXING WIRELESS SENSOR NETWORKS CENT CAS

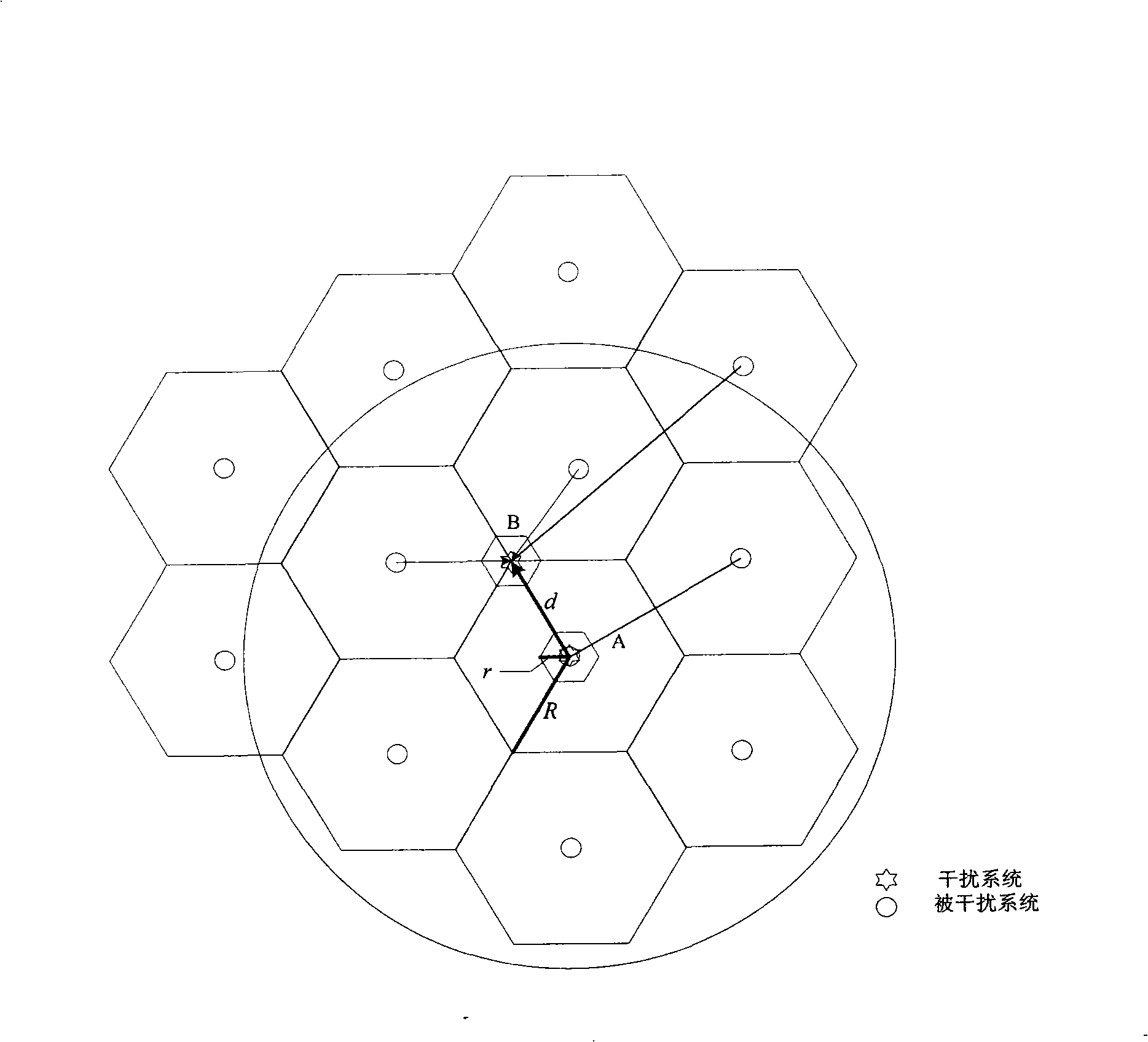

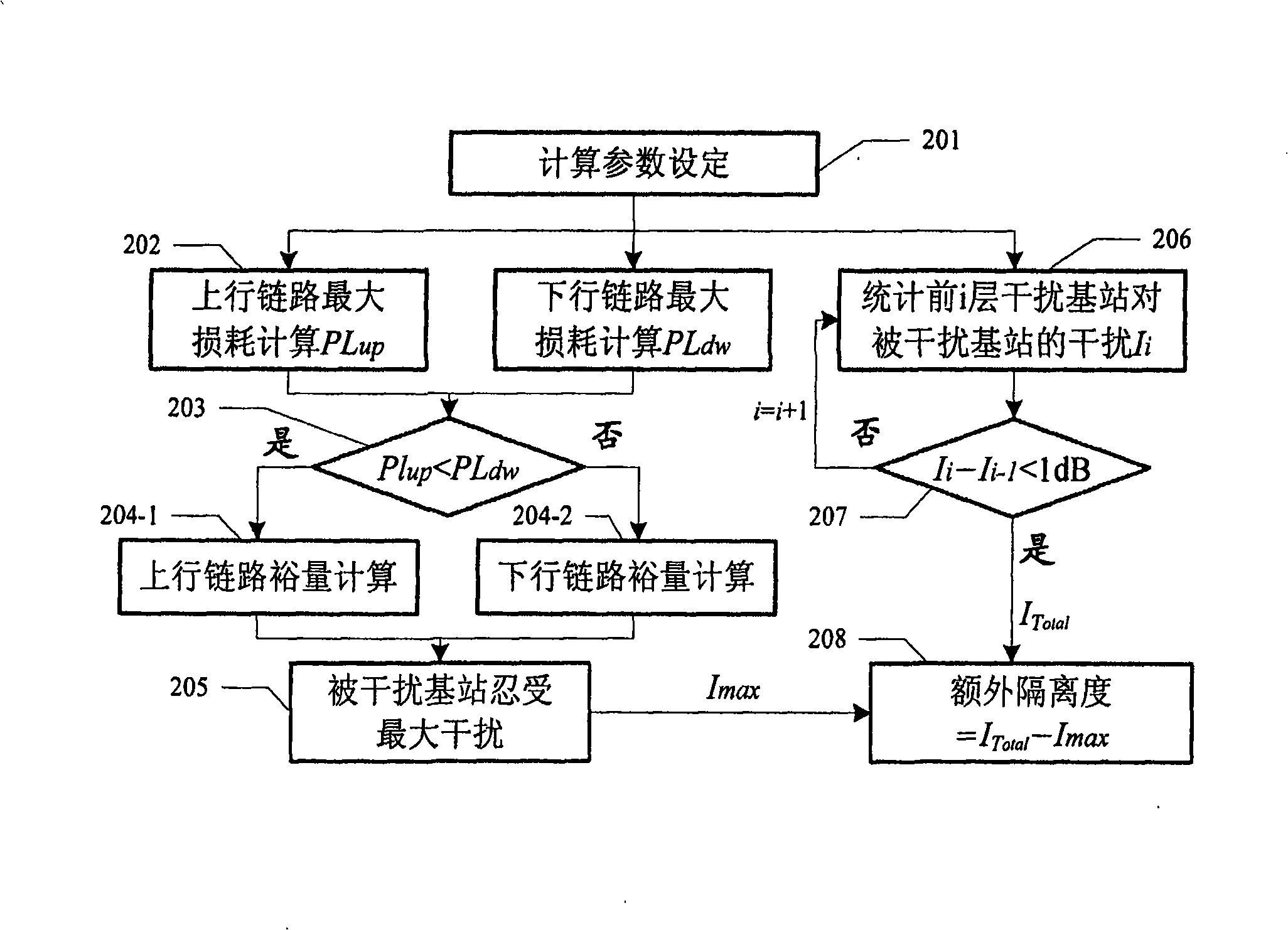

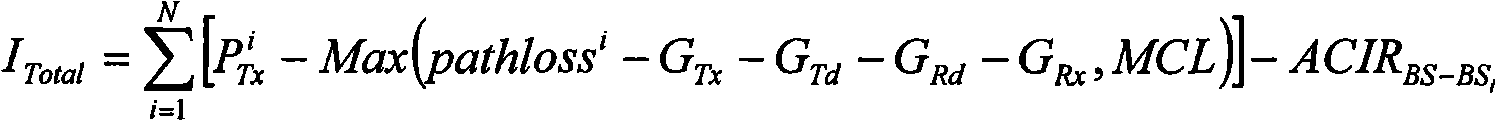

Method and system for confirming interference between base stations of mobile communication system

ActiveCN101345546AAccurately get the maximum external disturbanceImprove accuracyDiversity/multi-antenna systemsRadio/inductive link selection arrangementsCommunications systemDeterministic analysis

The invention provides a method for promoting computation accuracy for interference between cellular mobile communication system base station, computation device for accomplishing the method, base station including the computation device and radio communication system. In the invention, analyzing a good many of shortcomings combining practical network topology structure according to existing definability , calculating accumulating interference of multiple interference base station to present interference base station, simultaneously considering transmission model between interfered system base station and terminal, determining the maximum interference the interference base station can bear from coverage confined angle, further evaluating the method for interference avoidance minimum separation. Definability computation accuracy is dramastically promoted in the inventive interference definability analysis method compared to traditional MCL analysis method, which provides assurance for quickly and accurately evaluating interference between different mobile communication system base stations.

Owner:CHINA TELECOM CORP LTD

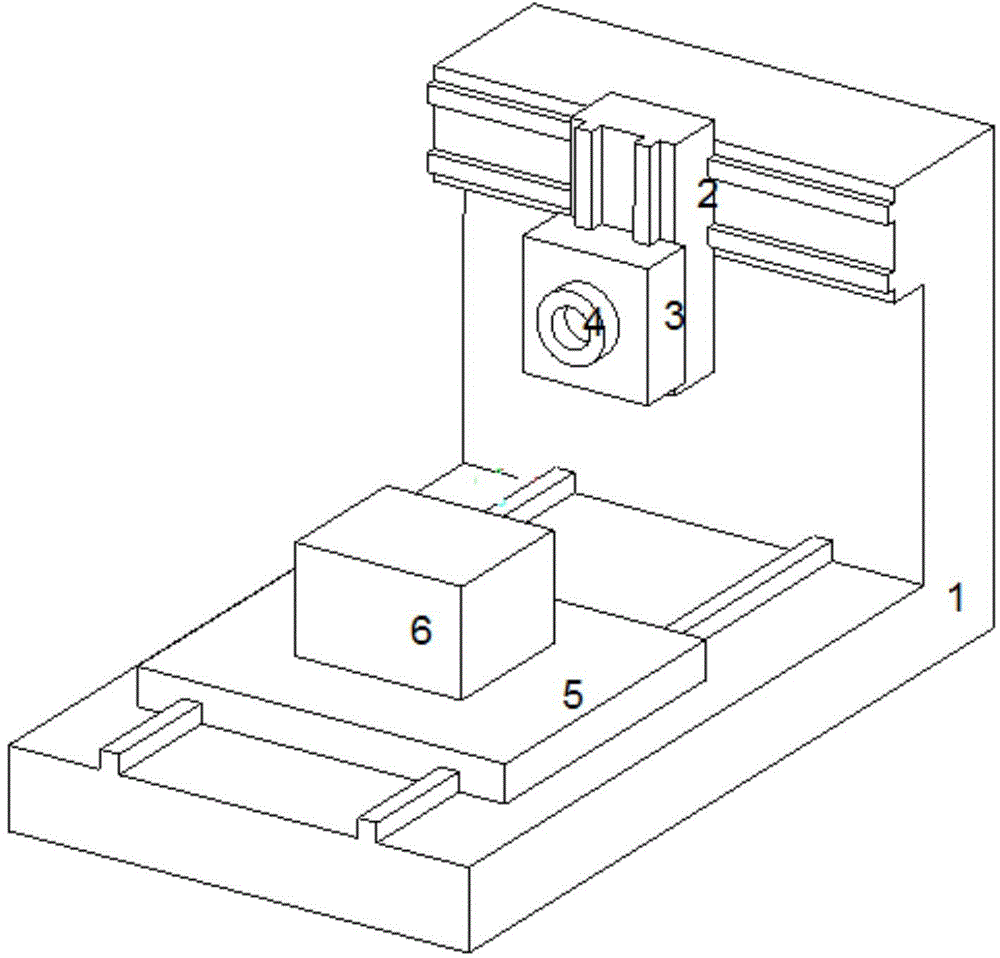

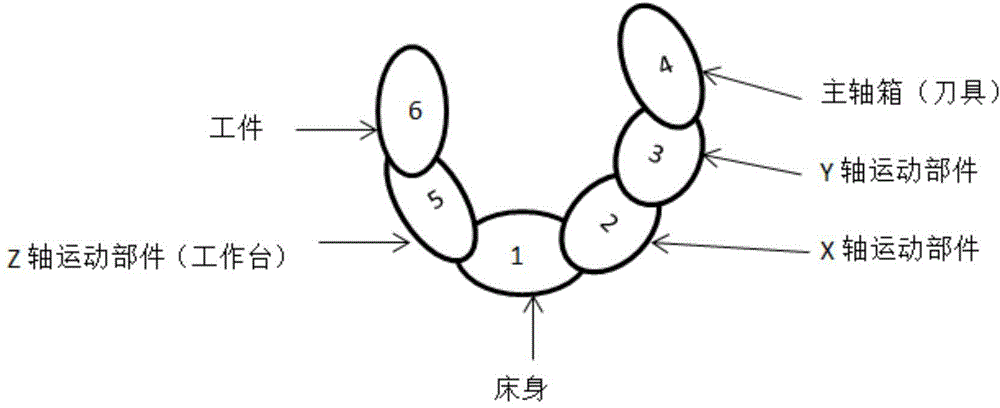

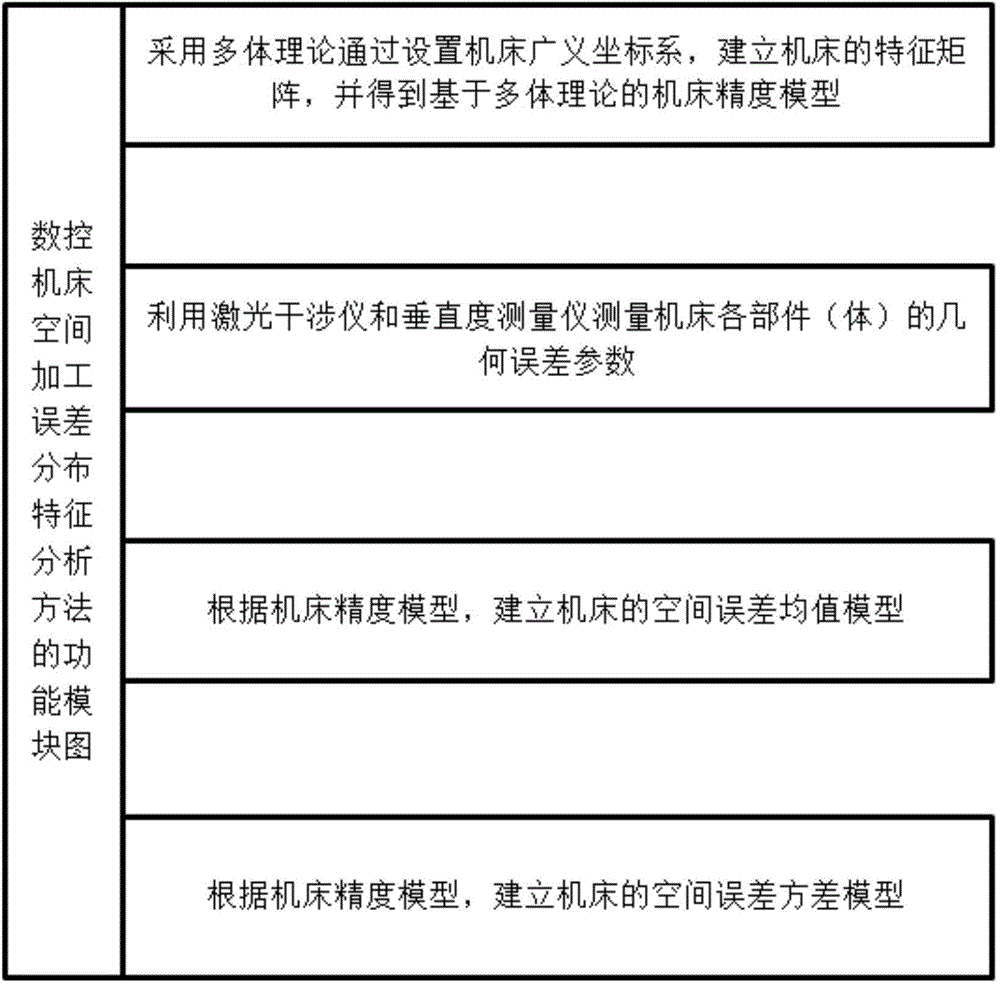

Analysis method on basis of distribution characteristics of space machining error of numerical control machine tool

ActiveCN104050316AReduce uncertaintySpecial data processing applicationsGeometric errorNumerical control

The invention discloses an analysis method on the basis of distribution characteristics of a space machining error of a numerical control machine tool, belongs to the field of accuracy design of a machine tool and particularly relates to an analysis method on the basis of the distribution characteristics of the space error. On the basis of space geometric error deterministic modeling and geometric error measurement which are established by a multibody system and the matrix total differential and random process principle, a space error deterministic analysis model of a precision horizontal machining center is established and the distribution characteristics of a geometric error and the space machining error of the machine tool are analyzed. The invention discloses a novel machine tool design concept and fundamentally solves the problem of accuracy of the machine tool. Guiding suggestions also can be given to actual assembling and machining, so that output of the error is reduced, machining accuracy of the numerical control machine tool is improved and the problem of accuracy of the machine tool is fundamentally solved.

Owner:BEIJING UNIV OF TECH +1

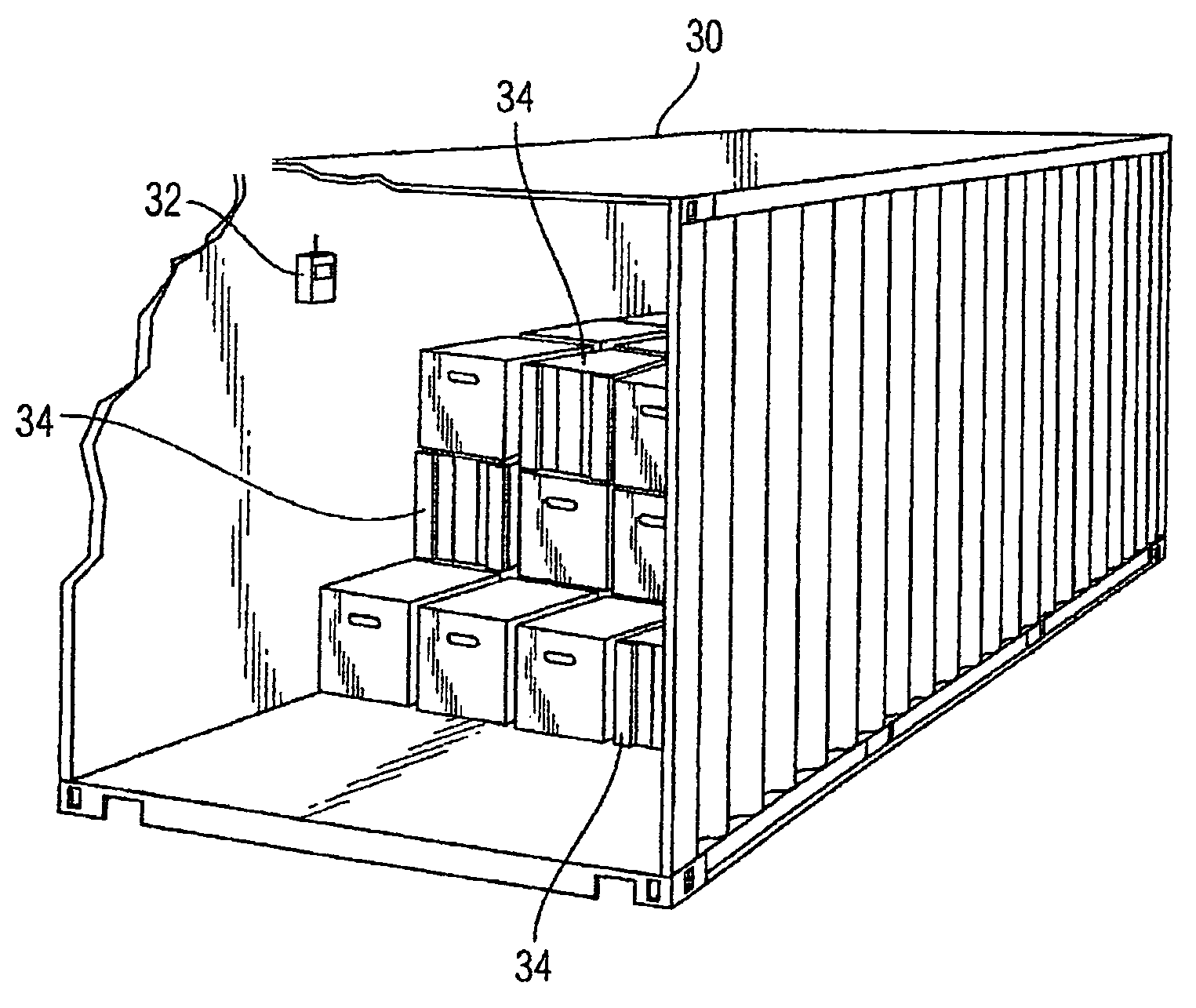

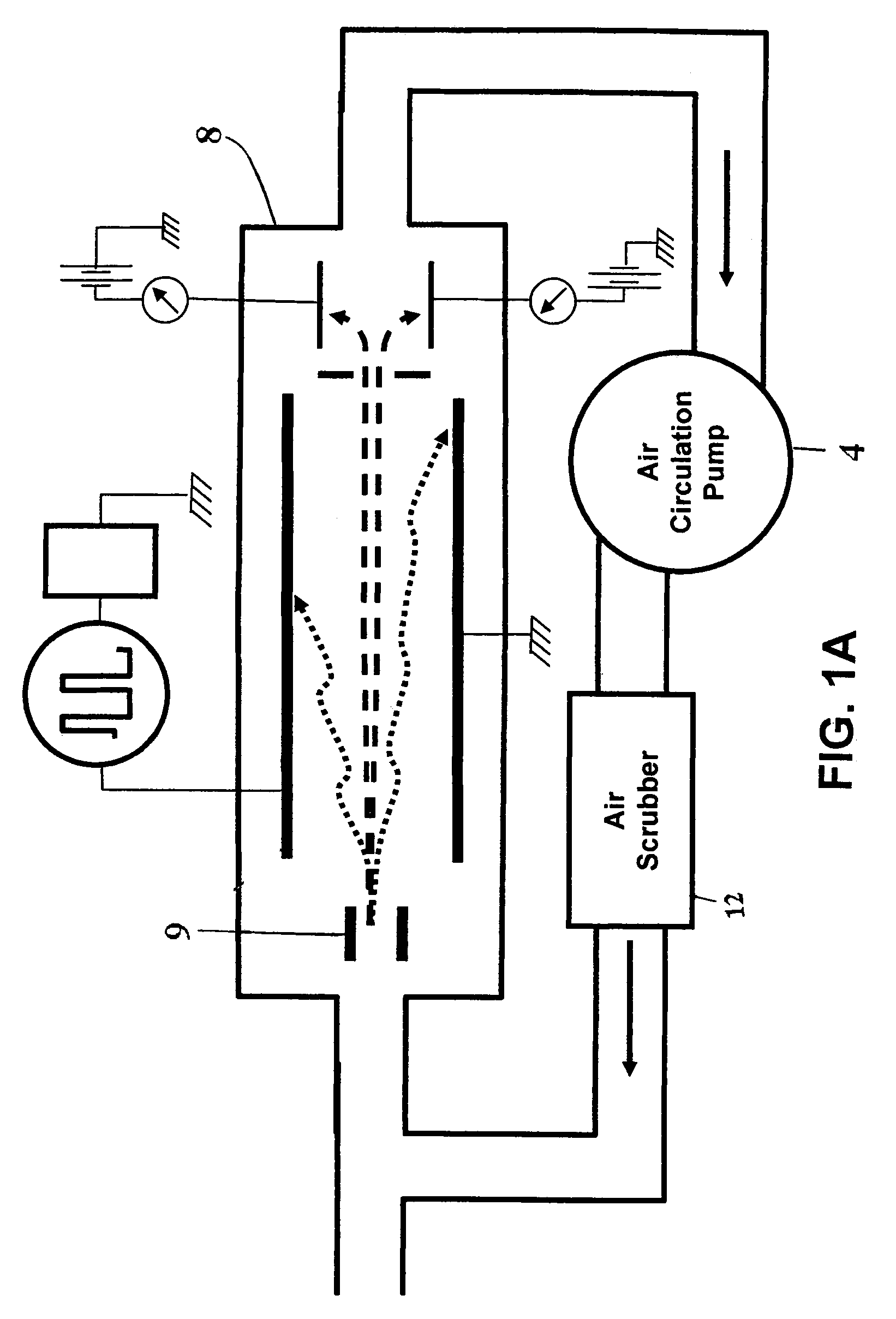

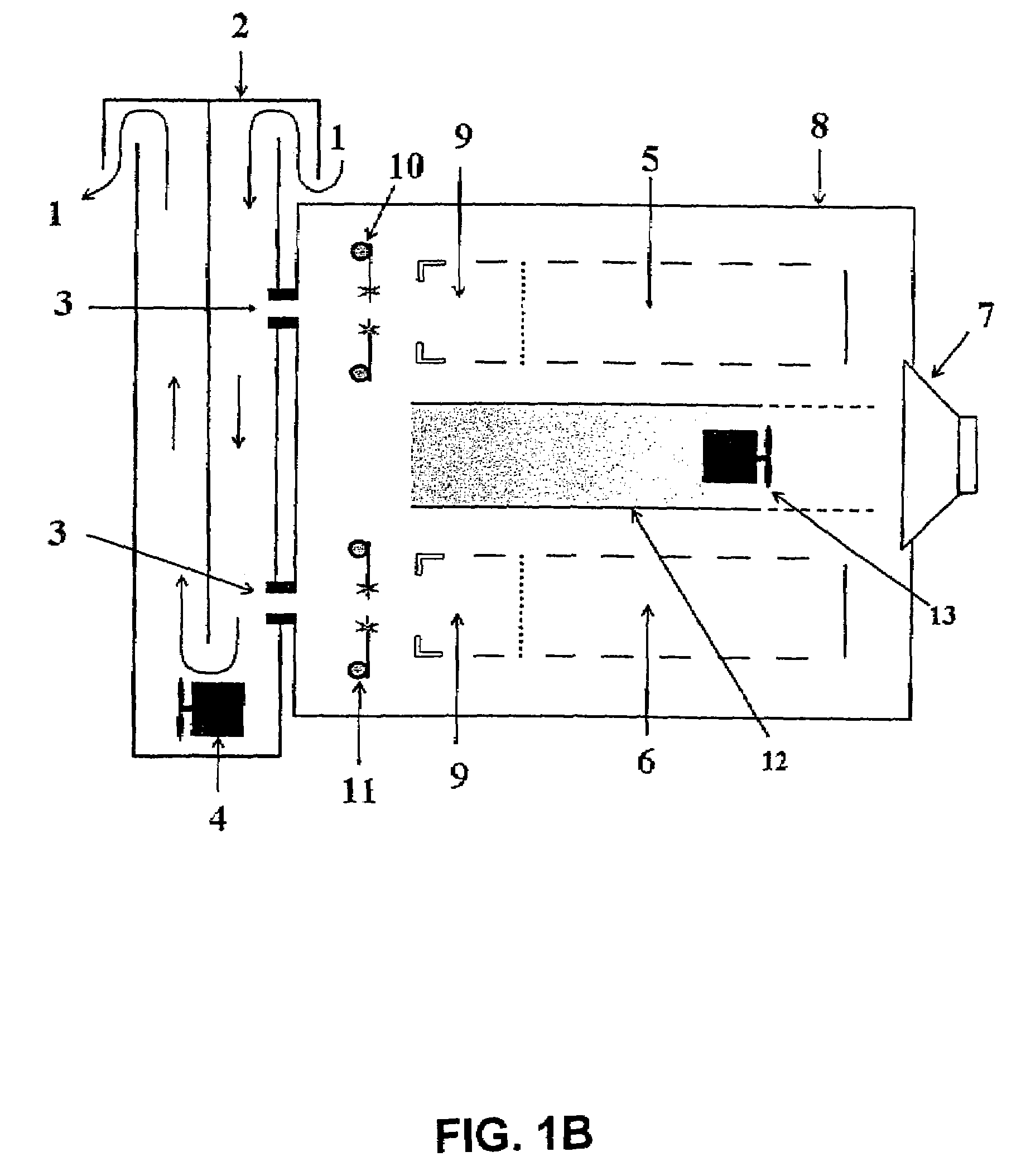

Detection and identification method for in-transit determination of chemical contraband, decaying animal and vegetable matter, and concealed humans in cargo shipping containers and other secure spaces

InactiveUS20070277589A1High sensitivityStrong specificityMaterial analysis by electric/magnetic meansUsing mechanical meansDeterministic analysisIllicit drug

A chemical analysis method for detecting, identifying and reporting contraband, illegal drugs, explosives, toxic chemicals, decaying animal and vegetable matter, and concealed human beings located in secure spaces such as cargo shipping containers. Chemical analysis results are accumulated and added to effect definitive analyses over extended periods of time while the containers are in transit. Individual containers are equipped with a device employing the method. The analysis method consists of accumulation and addition of analytical chemical instrumentation, measurements of trace quantities of target chemical vapors inside of shipping containers while the containers are in transit. Cumulative and additive spectrometric analyses coupled with increased target chemical concentrations, due to chemical vapor build up over the long periods of time that containers are in transit, result in significantly increased electronic signal-to-noise in spectrometric measurements and increased spectrometric signal strengths that are indicative of the presence of target chemicals.

Owner:HARDEN CHARLES S

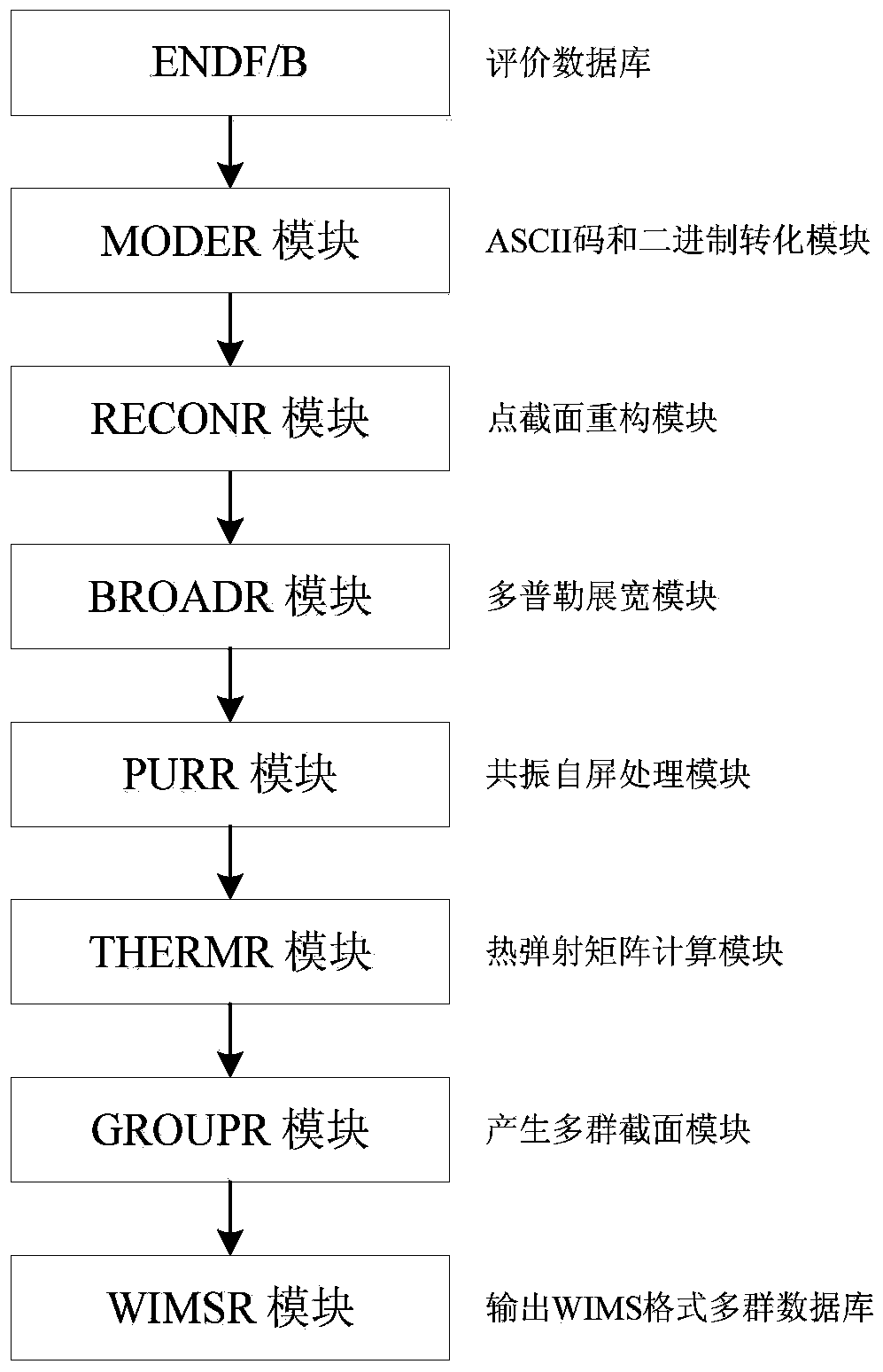

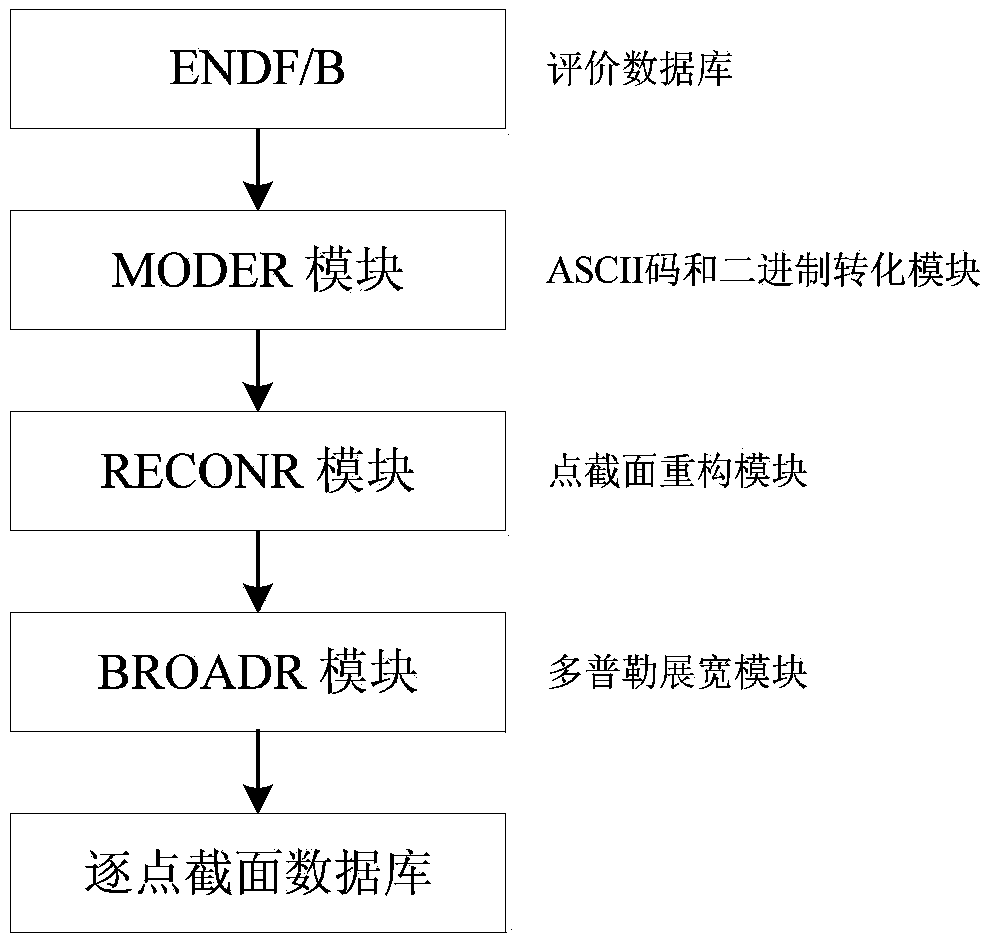

Multi-group section perturbation method for uncertainty analysis of reactor physics calculation

ActiveCN105373667AGuaranteed accuracyImprove computing efficiencySpecial data processing applicationsResonant energyDeterministic analysis

The invention relates to a multi-group section perturbation method for uncertainty analysis of reactor physics calculation. The multi-group section perturbation method comprises the following steps: (1), on the basis of ENDF / B, making a multi-group section database and a point-by-point section database at different temperatures by using a nuclear database section processing program NJOY, and making the point-by-point section database in a resonant reaction channel at a resonant energy section into an ultra-fine-group database according to the equal rib width; (2), perturbing the point-by-point section database in the energy section corresponding to a certain energy group in a certain reaction channel so as to obtain a perturbed point-by-point section database; (3), strictly transferring perturbation of the point-by-point section database into the multi-group section database by using a linear and nonlinear perturbation transferring method; and (4), reconstructing by adopting a reaction channel section self-consistency principle to obtain a perturbed multi-group section database. According to the invention, the section of a basic reaction channel can be finely sampled; approximate treatment in the multi-group section perturbation process can also be reduced; and thus, a precise multi-group section sample can be obtained.

Owner:XI AN JIAOTONG UNIV

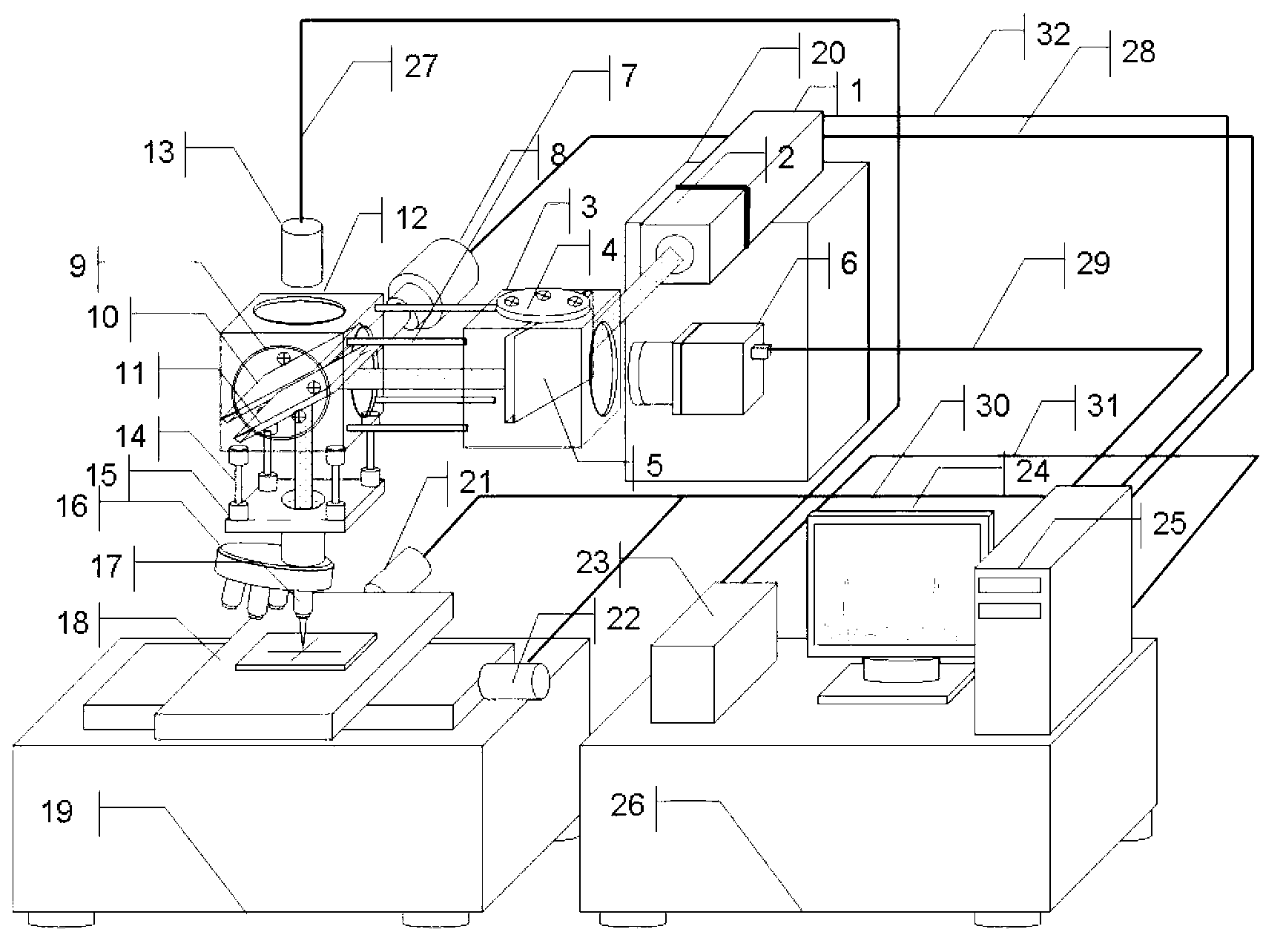

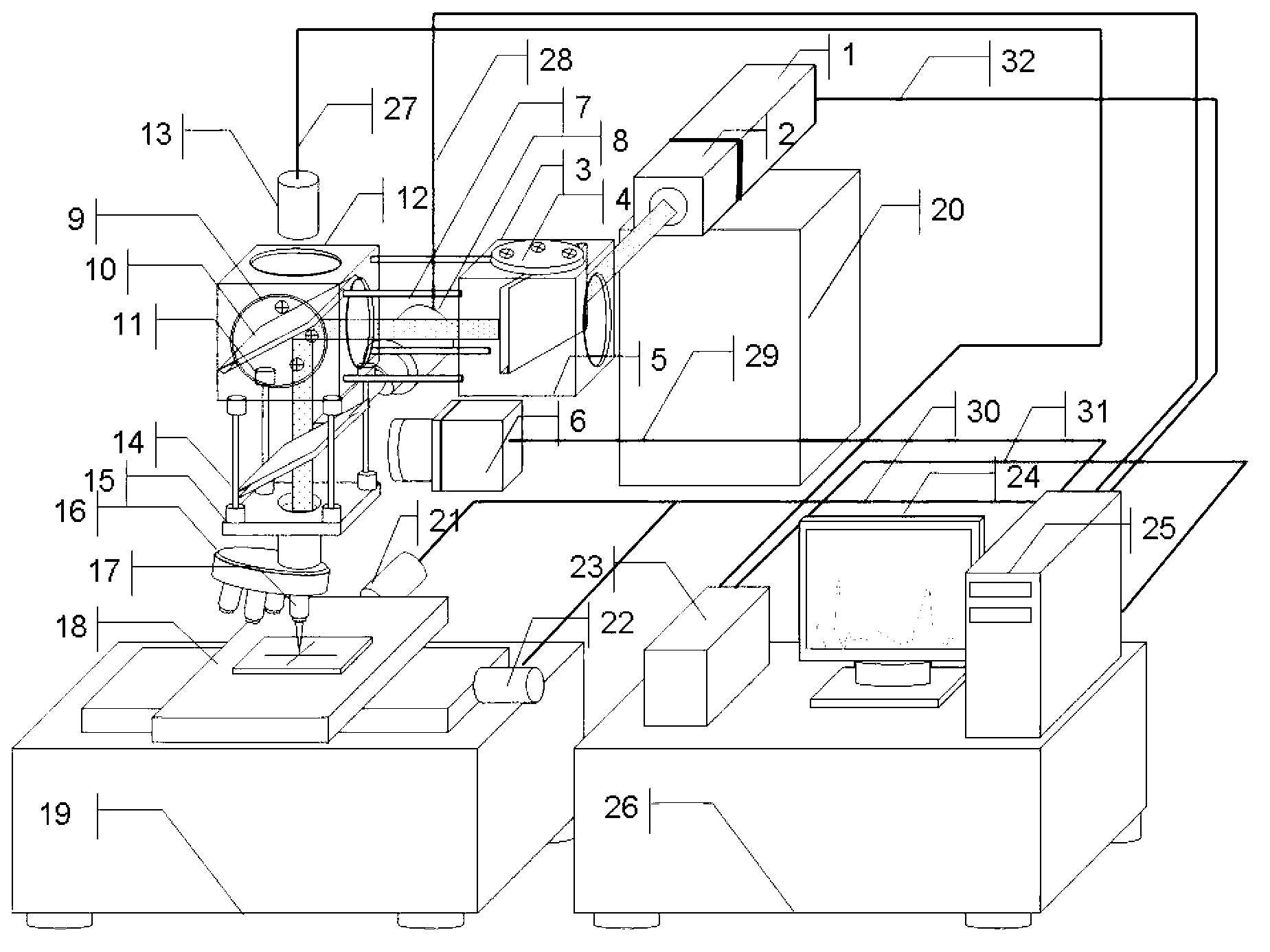

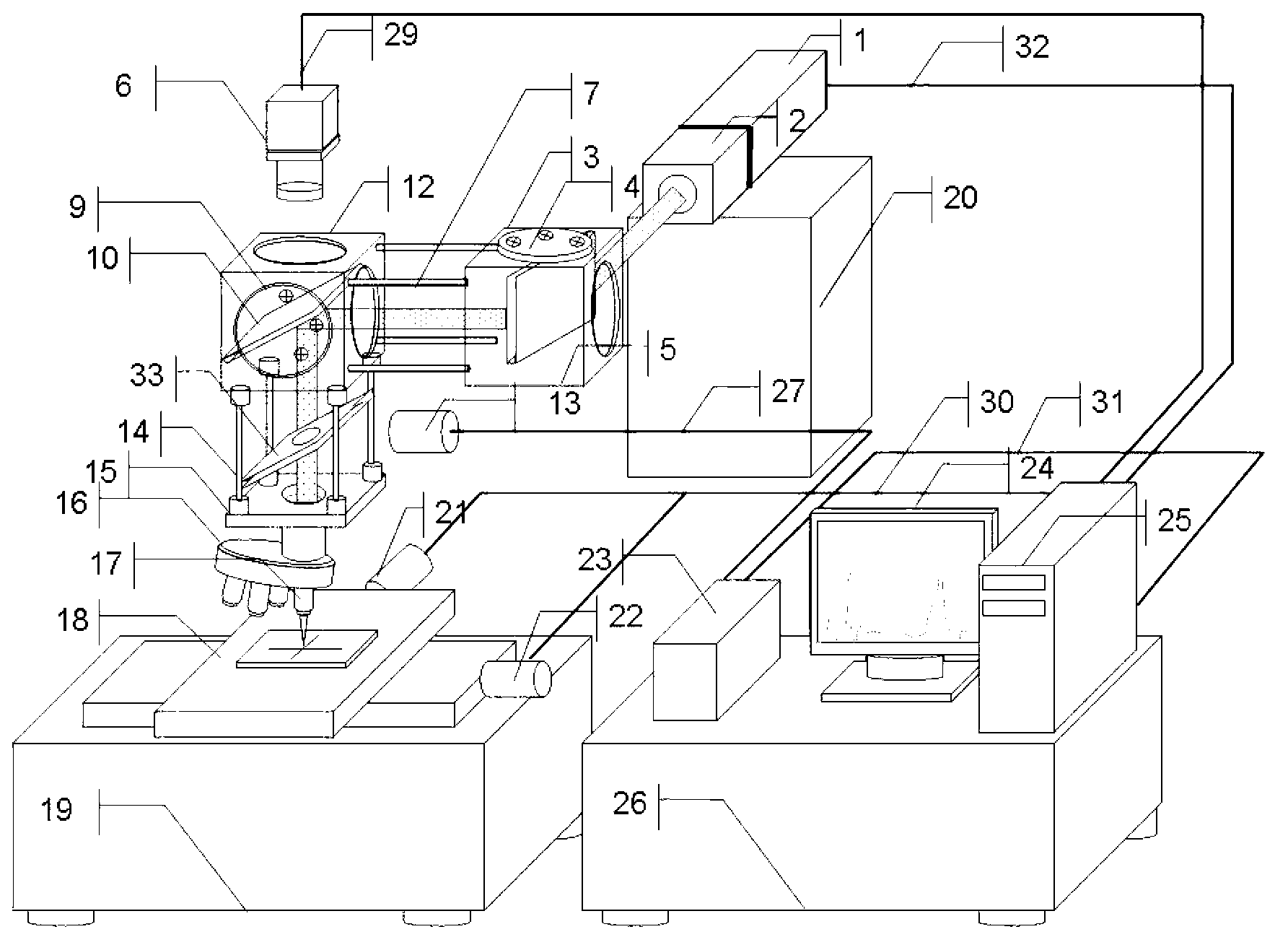

Integrated laser probe component analyzer for macroscopic and micro-area component analysis

ActiveCN103267746ARealize accurate qualitative analysisFast switching speedAnalysis by material excitationIndependent functionPrincipal component analysis

The invention belongs to the technical field of laser precision detection and discloses an integrated laser probe component analyzer for macroscopic and micro-area component analysis. The integrated laser probe component analyzer comprises a laser, a frequency multiplication module, two cage-type cubes, two laser wavelength reflectors, an industrial camera, a spectrum collector, an object lens converter, a focusing object lens, a spectrometer and a computer. A front end of a light outlet of the laser is provided with the frequency multiplication module. The laser is in an electric signal communication relationship with the computer. The integrated laser probe component analyzer can realize accurate qualitative analysis and high-precision quantitative analysis of macroscopic and micro-area components, can realize fast seamless switching of macroscopic and micro-area component analysis, has a modularization design and a compact structure, and improves an equipment integrated level. All the modules have independent functions and can be operated and maintained easily. Through the optical path modularization design, users can conveniently carry out optical path calibration before use so that operation time is saved and an analysis precision is improved.

Owner:WUHAN XINRUIDA LASER ENG +1

Detection and identification method for in-transit determination of chemical contraband, decaying animal and vegetable matter, and concealed humans in cargo shipping containers and other secure spaces

InactiveUS7468672B2High sensitivityStrong specificityMaterial analysis by electric/magnetic meansAlarmsDeterministic analysisIllicit drug

A chemical analysis method for detecting, identifying and reporting contraband, illegal drugs, explosives, toxic chemicals, decaying animal and vegetable matter, and concealed human beings located in secure spaces such as cargo shipping containers. Chemical analysis results are accumulated and added to effect definitive analyses over extended periods of time while the containers are in transit. Individual containers are equipped with a device employing the method. The analysis method consists of accumulation and addition of analytical chemical instrumentation, measurements of trace quantities of target chemical vapors inside of shipping containers while the containers are in transit. Cumulative and additive spectrometric analyses coupled with increased target chemical concentrations, due to chemical vapor build up over the long periods of time that containers are in transit, result in significantly increased electronic signal-to-noise in spectrometric measurements and increased spectrometric signal strengths that are indicative of the presence of target chemicals.

Owner:HARDEN CHARLES S

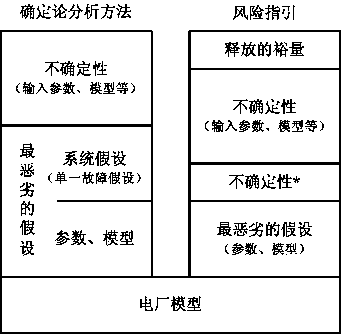

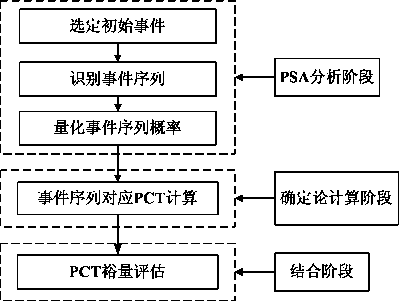

Risk-informed nuclear power plant LLOCA (large break loss of coolant accident) analysis method

The invention discloses a risk-informed nuclear power plant LBLOCA (large break loss-of-coolant accident) analysis method. The method mainly comprises the following steps: 1) selecting an initial event as a nuclear power plant LLOCA; 2) according to a risk system evaluation method, establishing an event tree under the initial event, and indentifying all possible response sequences of a safety system for mitigation measures of a nuclear power plant after occurrence of the LLOCA; 3) for the event tree analysis results, combining with fault tree analysis and taking various failure data into overall consideration, quantizing occurrence possibility of all event sequences; 4) calculating peak cladding temperature corresponding to each event sequence; and 5) estimating peak cladding temperature margin of the LLOCA. By introducing a probability risk evaluation technique to a conventional deterministic analysis method, a purpose of taking overall consideration of cognitive uncertainty and accidental uncertainty of the nuclear power plant is achieved, and analysis result is closer to actual situations of the nuclear power plant.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

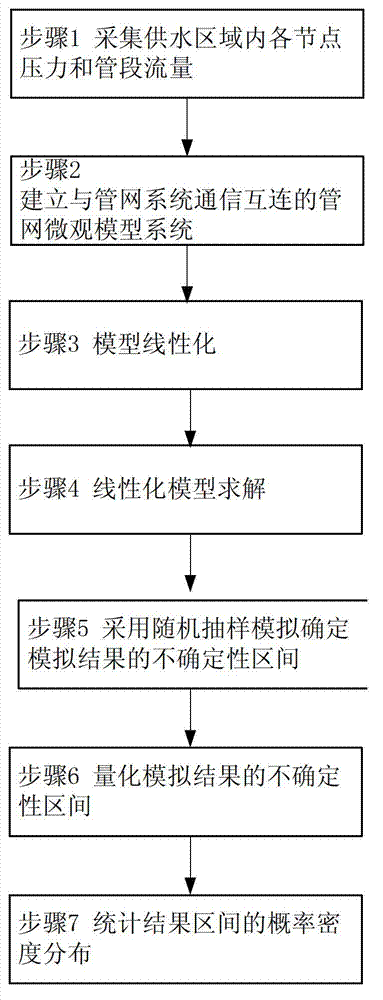

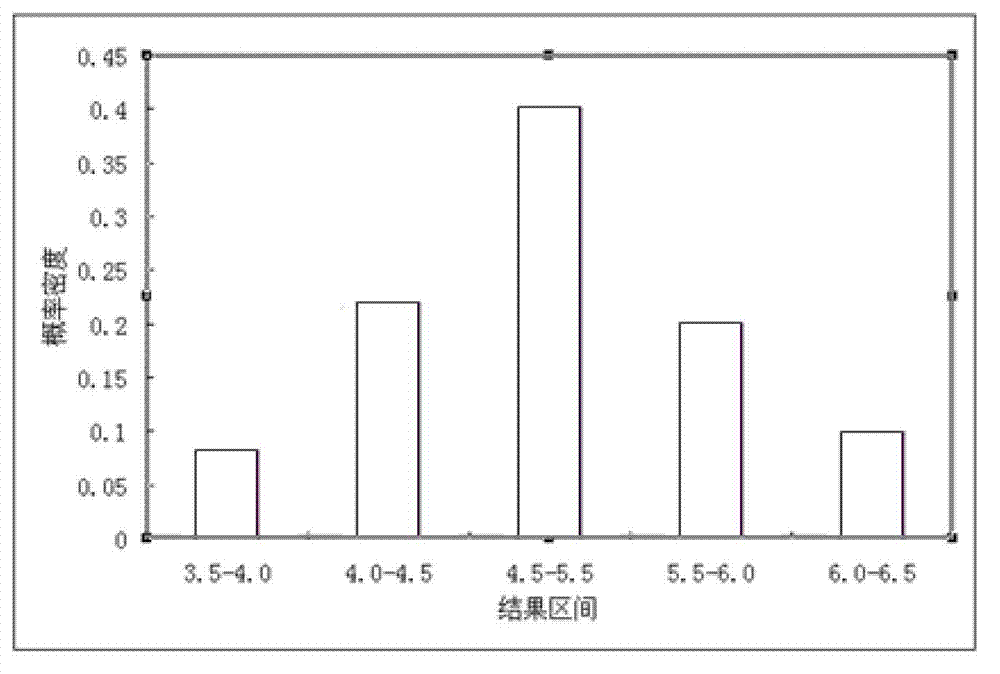

Method for quantifying computed result non-determinacy interval of water supply pipe network model

The invention relates to the field of non-determinacy analysis of a water supply pipe network model, in particular to a method for quantifying the computed result non-determinacy interval of a water supply pipe network model. The method comprises the following steps of: acquiring the pressure of each node and the pipe section flow in a water supply region; analyzing a potential data non-determinacy interval according to a system error and an accidental error; establishing a pipe network micro-model system communicated with a pipe network system; resolving a linear model; determining the non-determinacy interval of a simulated result by adopting random sampling simulation; quantifying the non-determinacy interval of the simulated result; and counting the probability density distribution of a result interval. The method has the beneficial effects that: resolving pipe network model linearization and linearized solution method for model by analyzing the non-determinacy intervals of measured data and model parameters, the non-determinacy interval of the simulated result is determined by adopting random sampling simulation, and a novel thought is provided for model accuracy estimation.

Owner:SHANGHAI MUNICIPAL WATER RESOURCES DEV & UTILIZATION NAT ENG CENT

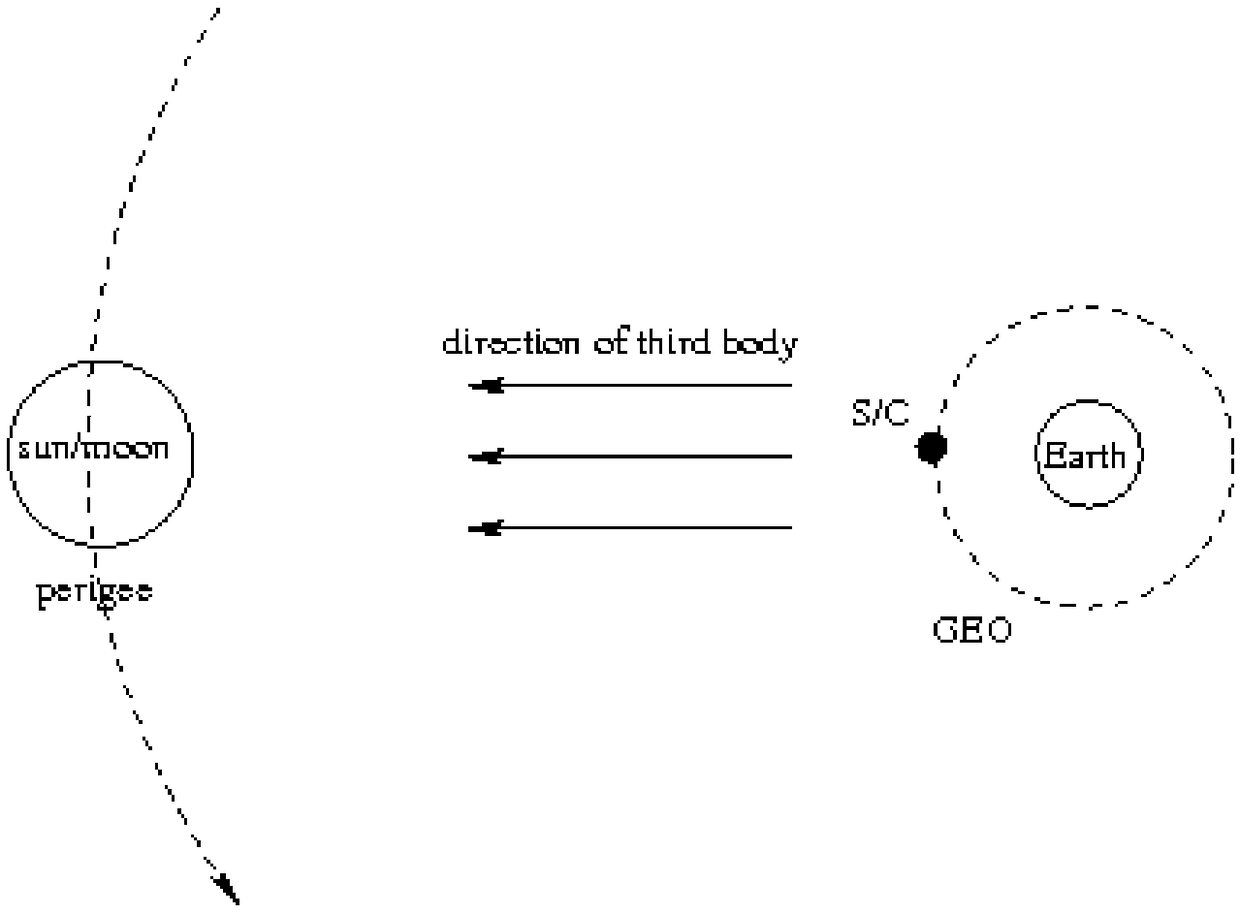

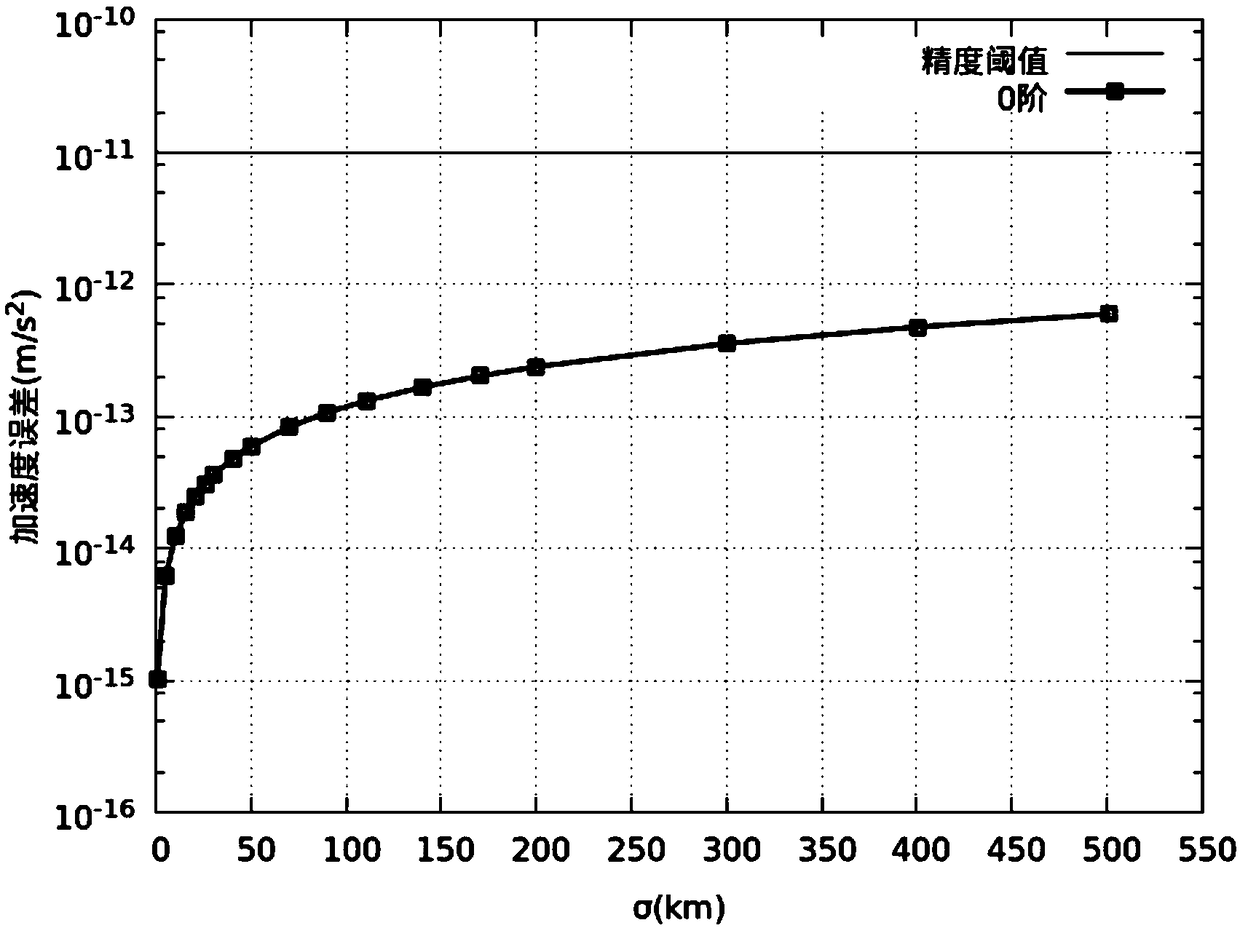

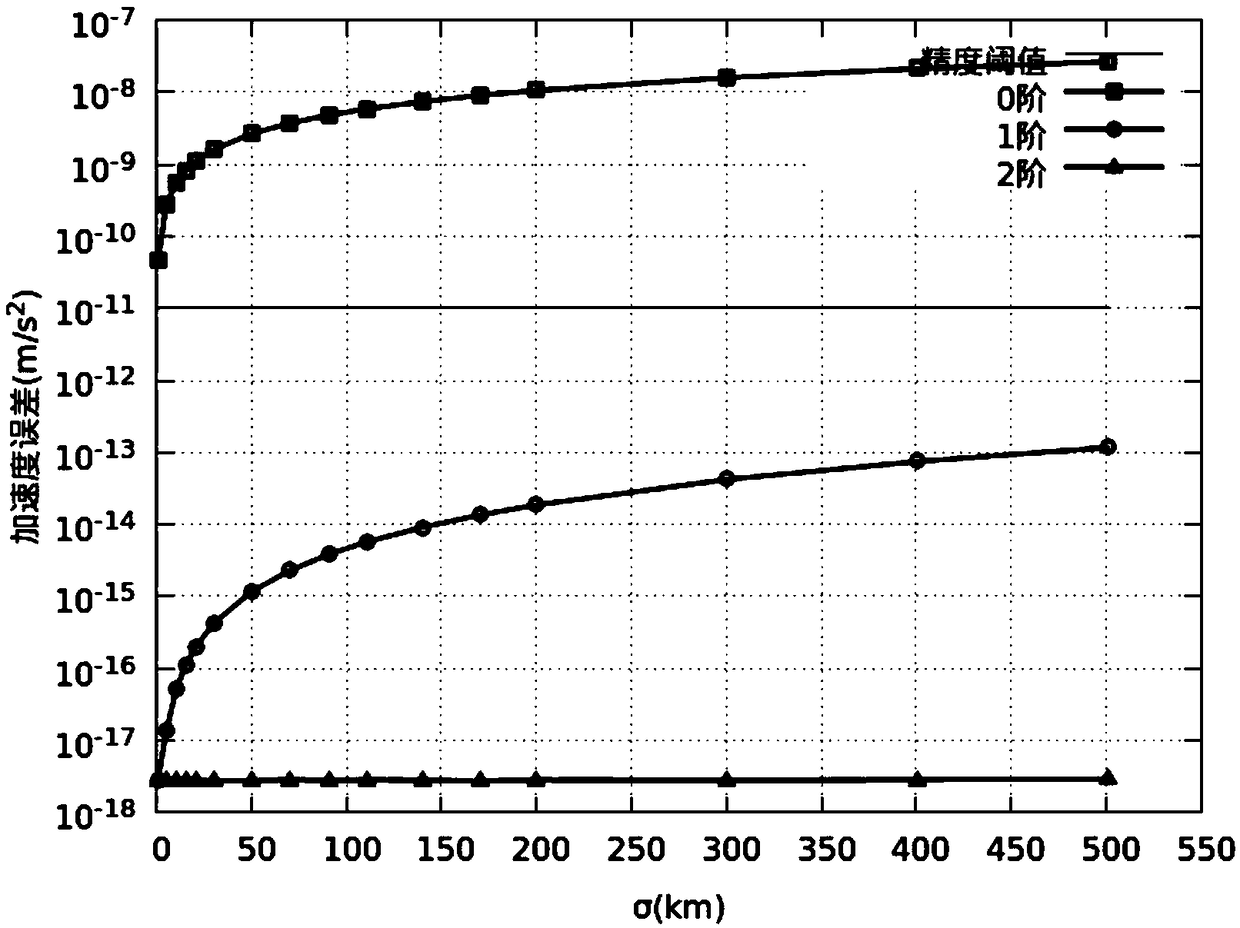

A method of geostationary satellite orbit uncertainty evolution based on differential algebra

ActiveCN109255096AReduce computing timeHigh precisionComplex mathematical operationsNatural satelliteDynamic models

The invention discloses an orbital uncertainty analysis method based on differential algebra technology. Based on Taylor expansion of multivariate functions and polynomial operation framework, and based on the dynamic model of geosynchronous satellite orbit element description, solar pressure to the kinetic model, the third gravitational perturbation and the three perturbation terms of the Earth'soblateness are added in the dynamic model , the right term of the dynamic model is expanded along the nominal orbit by Taylor expansion, the expansion polynomial with initial deviation as variable isobtained, Under the frame of differential algebra, the orbital state expressed by the polynomial with the initial deviation as variable at any time is obtained, and the concrete value of the initialdeviation is brought into the polynomial result to obtain the state of the final spacecraft. The invention analyzes the optimal expansion order, the balance calculation time and the calculation precision according to different perturbation forces. The method can be used to analyze the orbit evolution of geostationary satellites with initial state deviation and parameter uncertainty, and can also be used in other spacecraft orbit evolution and attitude evolution missions.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

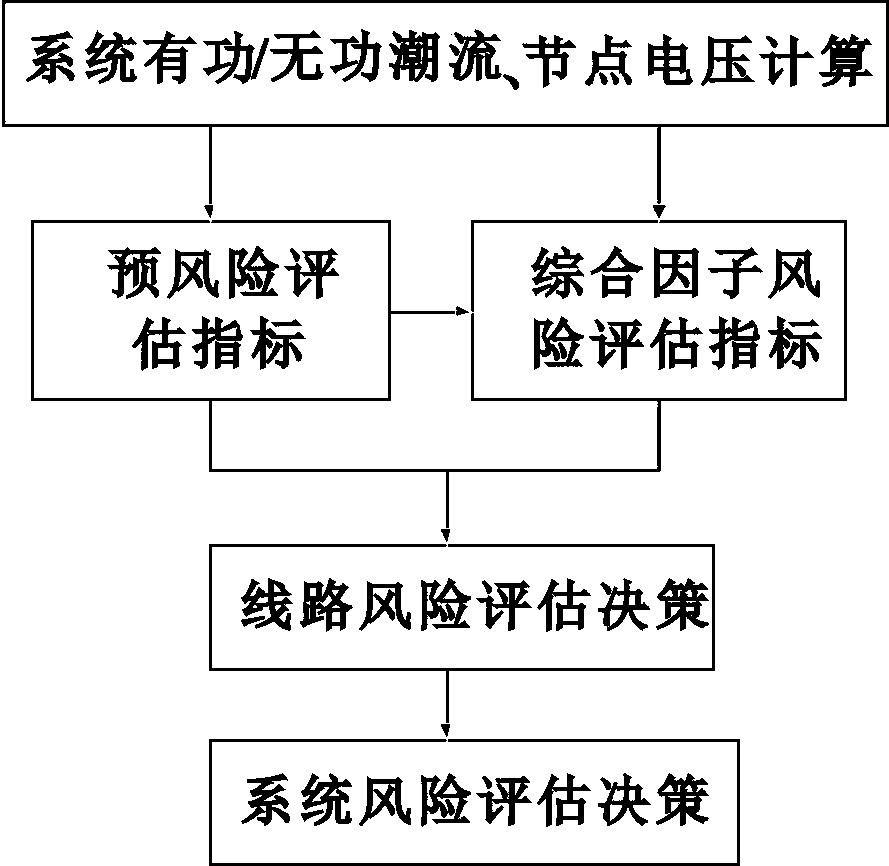

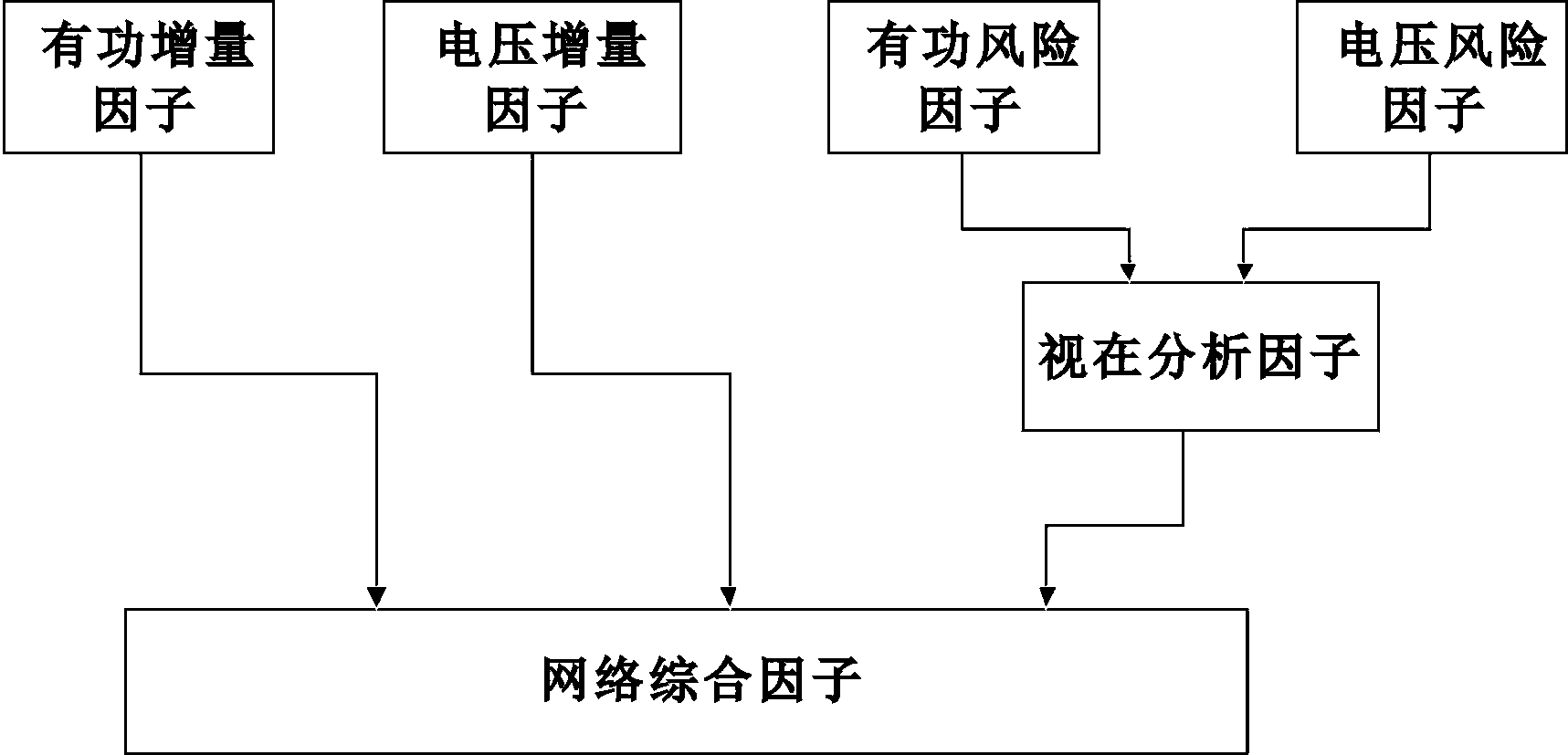

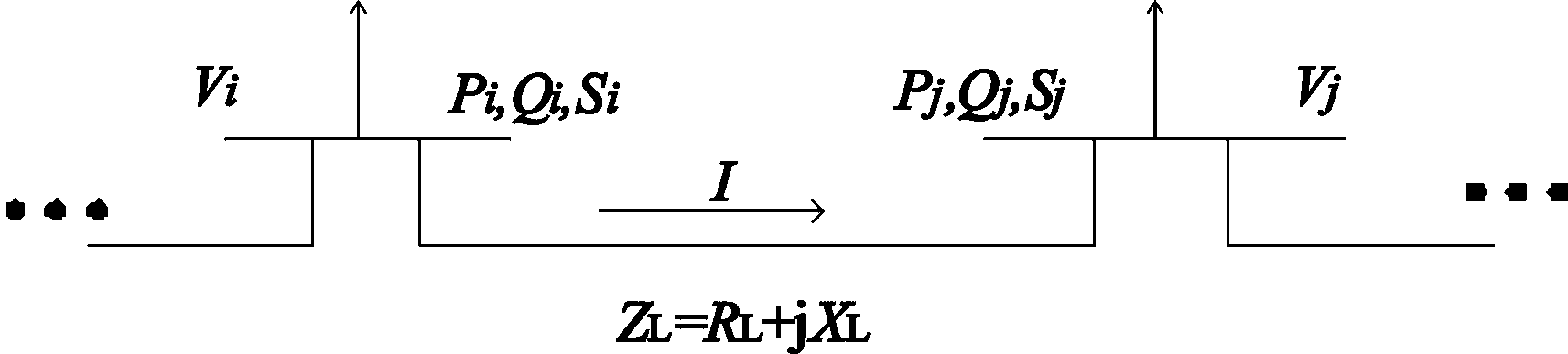

Electric power system risk assessment method based on deterministic analysis

ActiveCN104376506ASafe and stable operationData processing applicationsCascading failureDeterministic analysis

The invention discloses an electric power system risk assessment method based on the deterministic analysis. The tide current shifting and node voltage changing caused after a system is disturbed are comprehensively taken into consideration, and a more thorough power grid vulnerability comprehensive analysis index is put forward. The method comprises the following steps that firstly, a system topological structure is analyzed, the tide current distribution of the system after stable running and disturbing is calculated and comprises active tide current and reactive tide current of branch circuits, node voltages and a phase angle difference of the node voltages; secondly, assessment indexes in an assessment system are calculated and comprise a pre-risk assessment factor and a network comprehensive risk assessment factor; thirdly, risk assessment is carried out on an electric power system according to the set index levels. According to the electric power system risk assessment method, the system risk information is more comprehensively reflected, a unified index risk decision is made for tide current threshold-crossing, voltage instability and cascading failure possibly existing in the system, and operators can make rapid and accurate judgment and take measures to guarantee safe and stable running of the system in time.

Owner:通达电磁能股份有限公司

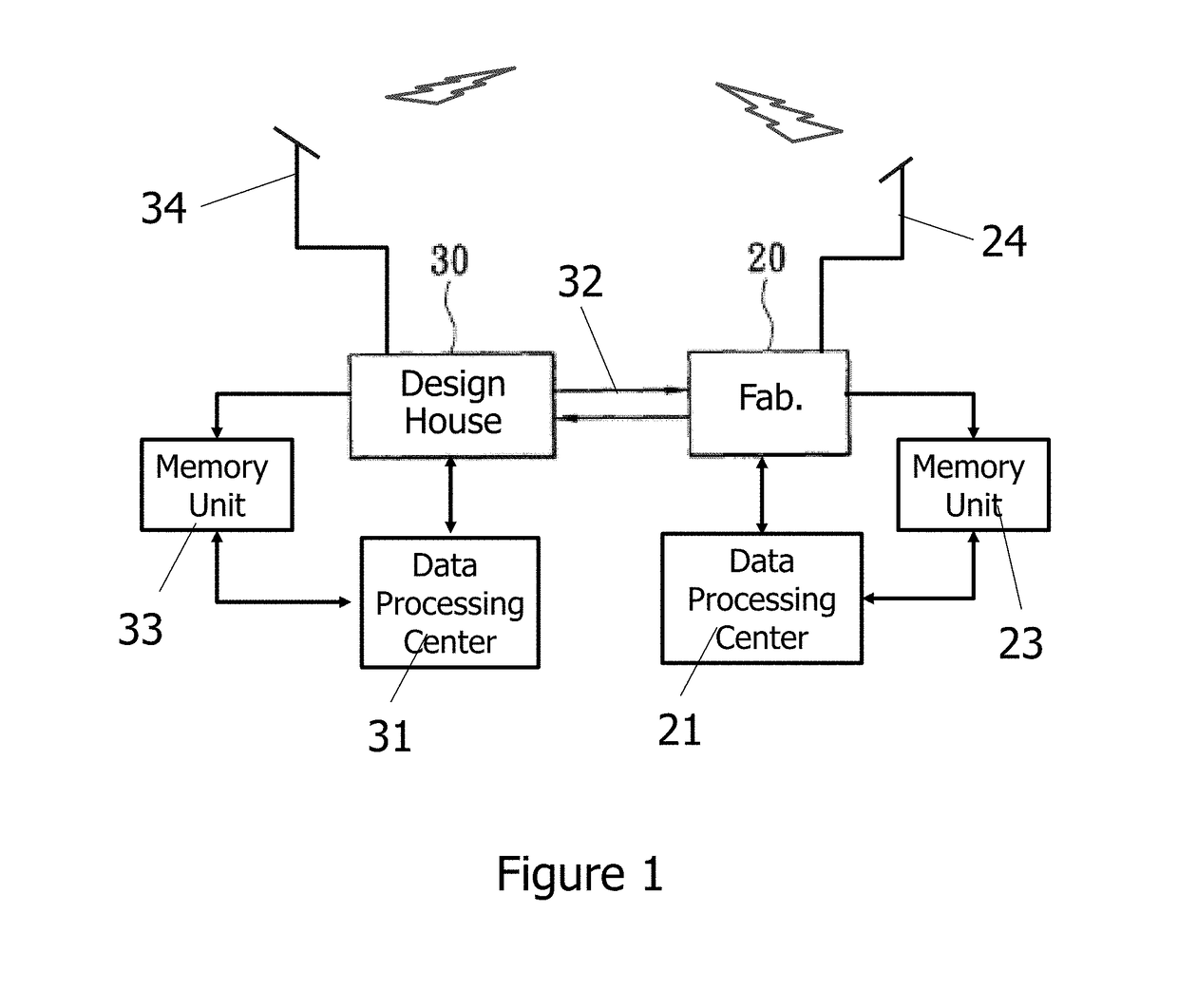

Smart defect calibration system and the method thereof

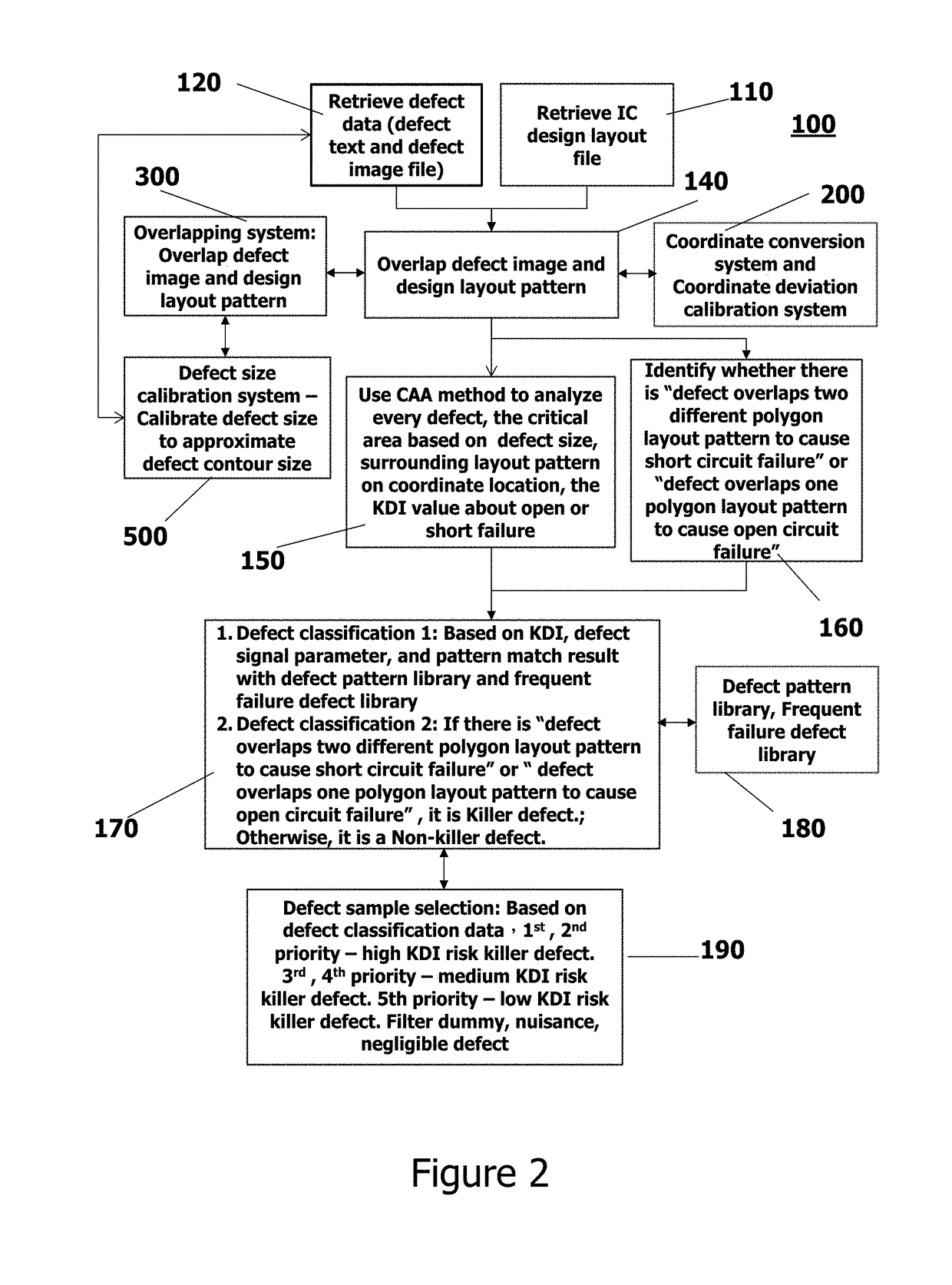

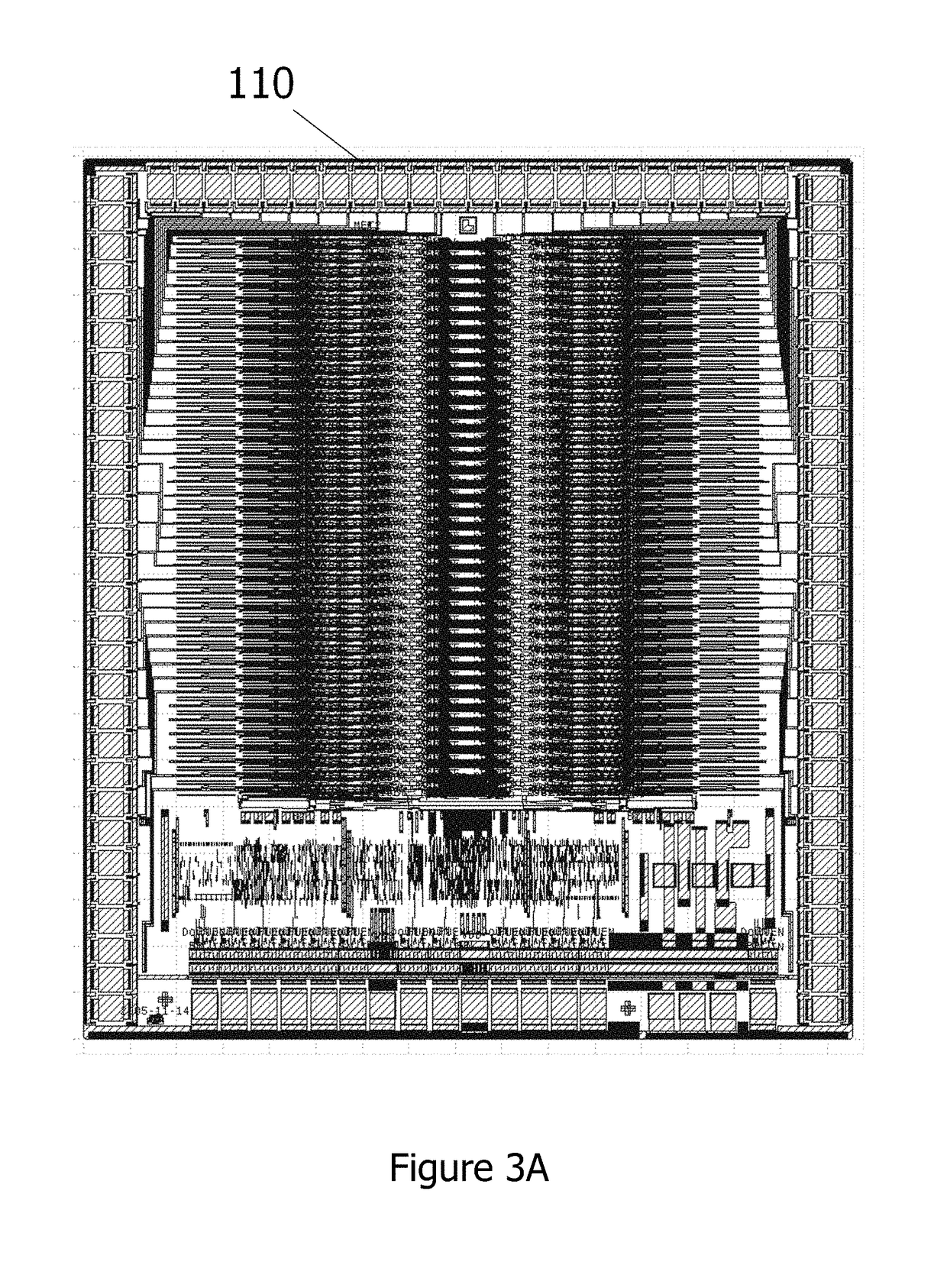

ActiveUS20190086340A1High accurate calibrated defect size valueLess-incorrect judgmentImage enhancementImage analysisDeterministic analysisPattern matching

The present invention relates to a Smart Defect Calibration, Diagnosis, Sampling System and The Method Thereof for manufacturing fab is provided. The intelligent defect diagnosis method comprises: receiving pluralities of defect data, design layout data, analyzing the defect data, design layouts, by a Critical Area Analysis (CAA) system, wherein the analyzing step further contains the sub-steps: superposing the defect contour pattern and the design layout, performing CAA to identify a killer or non-killer defect based on the open or short failure probability, defects are classified as high, medium, low, or negligible risk defect based on the Killer Defect Index, defect signal parameters, selecting defect samples based on the defect classification data, selecting alarm defect and filtering false defect with pattern match with defect pattern library and frequent failure defect library, performing coordinate conversion and pattern match between image contour and design layout for coordinate correction, creating a CAA accuracy correction system and defect size calibration system by analyzing original defect size data and defect contour size from image analysis, evaluating the defect size using measurement uncertainty analysis with statistical analysis methods to reach the purposes of increasing CAA accuracy and Killer Defect identification rate.

Owner:ELITETECH TECH

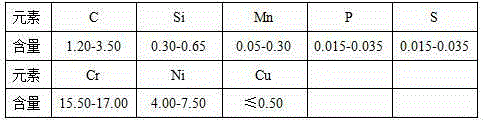

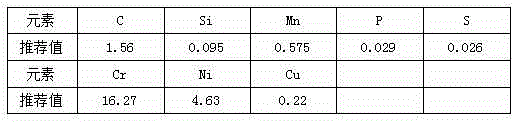

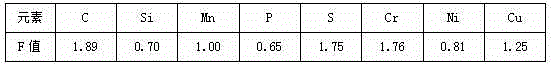

Preparation method of high-carbon stainless steel standard sample

ActiveCN104359735AHigh utility valueMeet the requirements of the standard samplePreparing sample for investigationChemical compositionHigh carbon

The invention discloses a preparation method of a high-carbon stainless steel standard sample, belonging to the field of detection of metallurgical samples. The preparation method disclosed by the invention comprises the steps of designing a casting mould, baking the casting mould and a steel ladle, selecting components, controlling the process of a casting process, demoulding, detecting physical performances, processing the sample, detecting the homogeneity of chemical components, carrying out deterministic analysis and determining effective height. The physical performances, the structural state, the component range and the homogeneity of the standard sample prepared by the invention can be satisfied; furthermore, the preparation cost is reduced; the sampling number is increased; at least 100 standard samples can be prepared every time; the number is above 20 times of that of die casting sampling; the preparation number can satisfy current production requirements; and thus, the standard sample preparation process has very high practical value and great popularization value in other matter test rooms.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

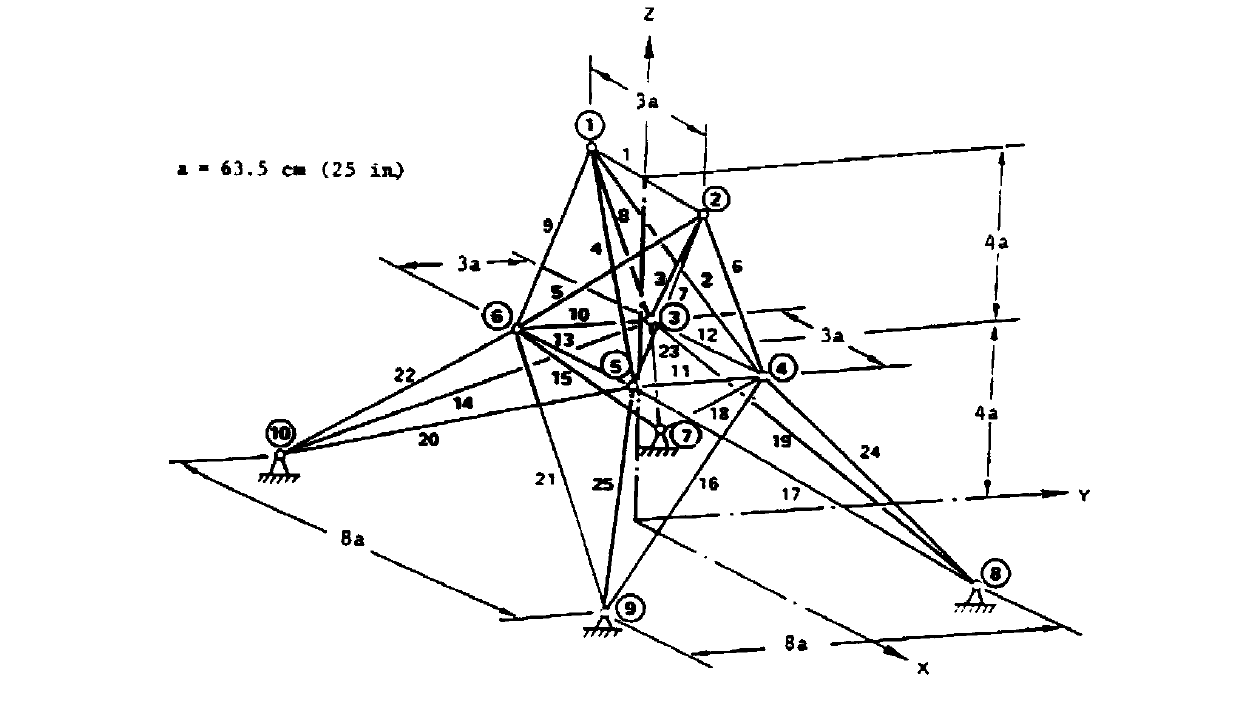

Finite element analysis method for spatial variability structure of geotechnical parameters in sequential Gaussian simulation

InactiveCN107862146AImprove assignment precisionLimit arbitrarinessDesign optimisation/simulationSpecial data processing applicationsConditional random fieldDeterministic analysis

The invention discloses a finite element analysis method for a spatial variability structure of geotechnical parameters in sequential Gaussian simulation. On the basis of the spatial variability structure of the parameters, a conditional random field is simulated, and the method has the obvious advantage of simulating the directional anisotropic parametric random field and is simple; according toan adopted parametric random field simulation method, with limited space observation data as known hard data, random field simulation is conducted according to second-order statistical characteristicsof the parameters under the condition, the assignment accuracy of the random field is improved, and the randomness of the random field is limited to a certain extent; the random field data generatedaccording to orthogonal grids is determined according to the shape contour of a specific calculation model, and unit data outside the contour is removed, so that the random field data of the calculation model is imported into finite element software for deterministic analysis and can be applied to repeated deterministic analysis of specific engineering landslide calculation examples, and characteristic parameters of sufficient calculation results are counted and used for evaluating the stability of a specific landslide instance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

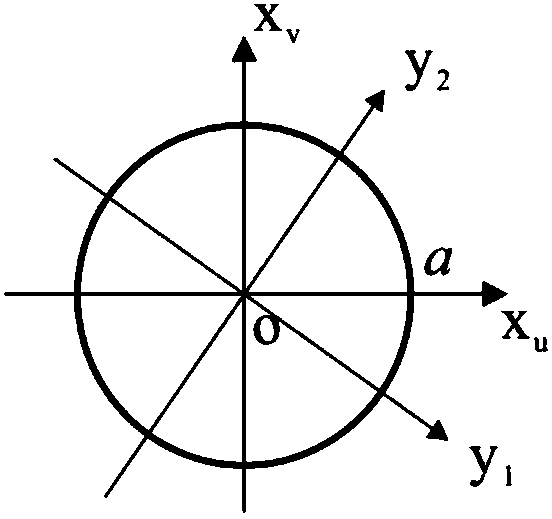

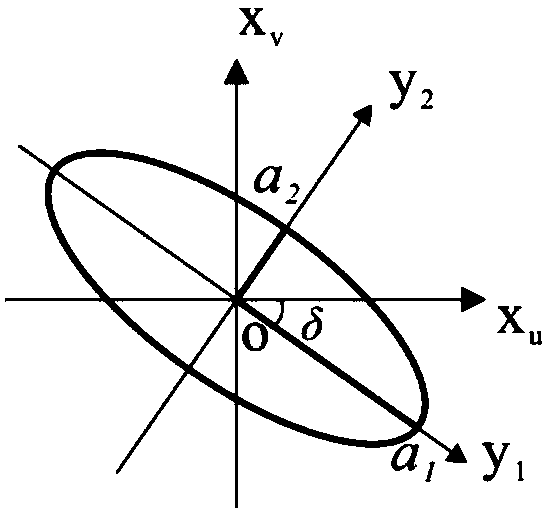

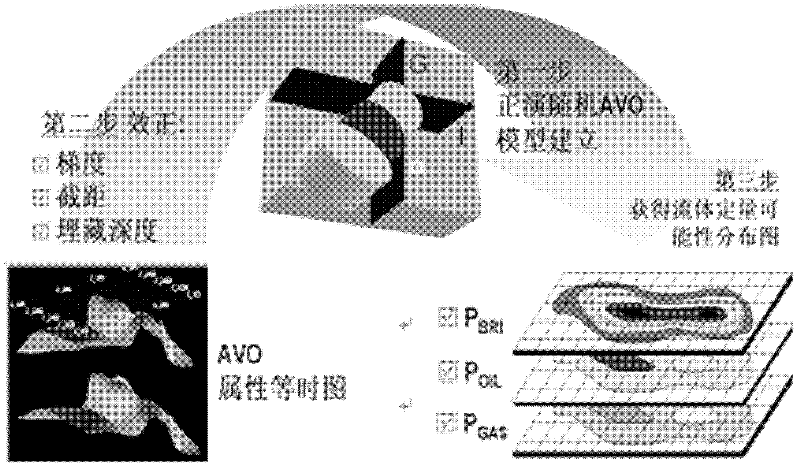

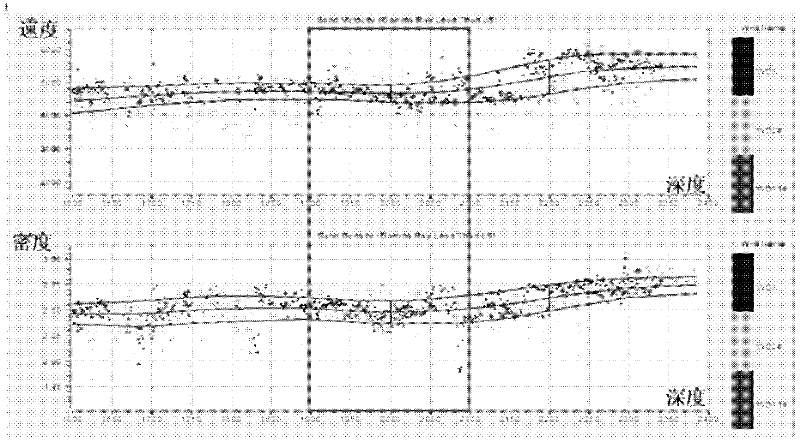

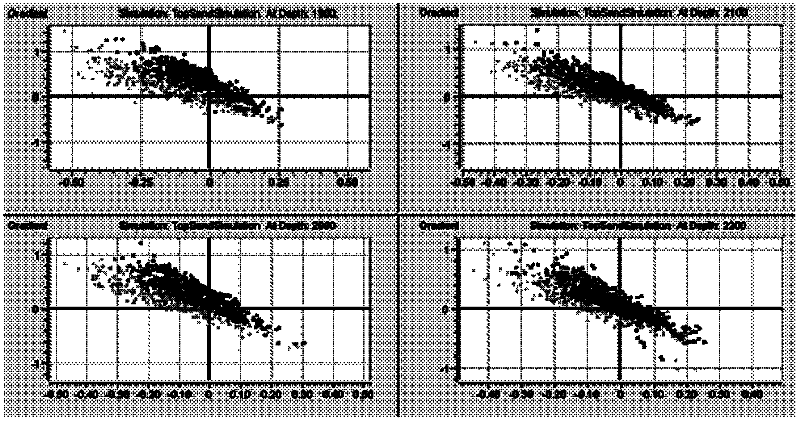

A method for quantitative prediction of gas-bearing probability by pre-stack afi inversion

ActiveCN102288996AAccurate extractionSeismic signal processingRandom combinationDeterministic analysis

The invention discloses a method for quantificationally predicting gas containing probability through prestack automatic fault indication (AFI) inversion, which comprises the following steps of: using log information for carrying out trend analysis, carrying out random simulation on the probability distribution condition of n depth layer characterization parameters of a target layer section, and obtaining the random geology model in different depth positions through the random combination of different parameters; carrying out fluid replacement on each random geology model, obtaining the corresponding response of sandstone models in various fluid states and forming three different depth template patterns; and correcting amplitude versus offset (AVO) attribute points of the actual chemical mechanical polishing (CMP) gather data body, projecting the corrected actual data point results to the corresponding depth template patterns and obtaining the quantificationally predicted probability distribution of the gas containing probability. The method of the invention solves the problem of uncertainty of the AVO existing in the oil gas detection and belongs to a method of converting the uncertainty in the AVO analysis into the certainty of the gas containing probability distribution, and the accurate gas containing probability distribution is obtained through the quantitative inversion of the gas containing probability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

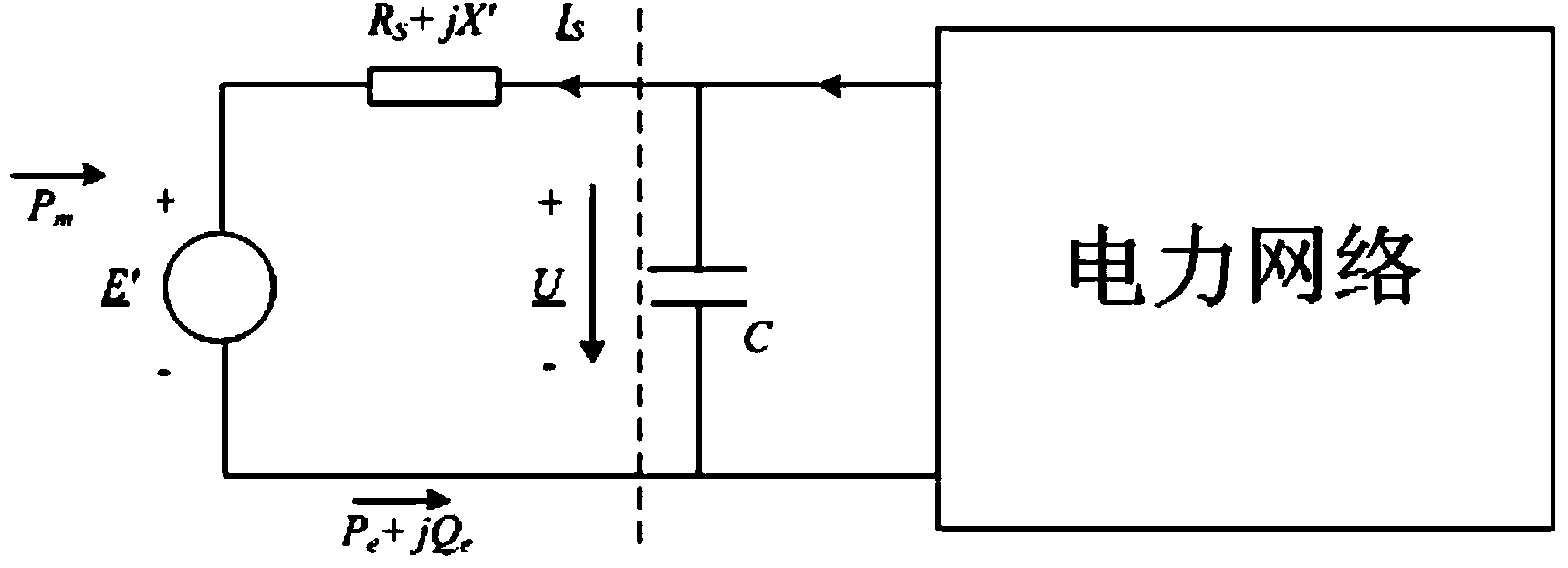

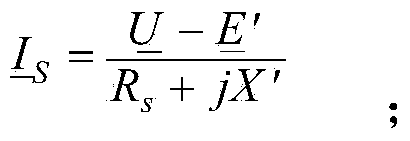

Method for analyzing stochastic stability of electric power system containing wind electricity

InactiveCN103915839AOvercoming the shortcomings of not being accurate enoughOvercome the shortcomings of insufficient accuracy of deterministic analysis methodsAc network circuit arrangementsElectricityElectric power system

The invention belongs to the field of power systems, and particularly relates to a method for analyzing the stochastic stability of an electric power system containing wind electricity. The method includes the steps that a stochastic differential equation is used for conducting modeling on stochastic disturbance existing in the system, an applicable stochastic stability definition is provided, the stochastic differential equation theory, an Ito formula and a stochastic Lyapunov energy function method are used for finding out a practical stochastic asymptotically mean square stability criterion, and a stochastic stability criterion of a system with uncertain state matrix parameters is derived. According to the method, the essence of the stochastic stability can be revealed more accurately, the defect that a deterministic analysis method is not accurate enough can be overcome, a model can be made to be more accurate, and a new theory and a new method can be provided for improving system control; the stochastic stability definition suitable for a electric power time-varying parameter system is provided from the point of a stochastic system is provided; a practical stability criterion of a stochastic time-varying parameter system of the electric power system is provided; compared with other methods, the method has conciseness and practicability.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

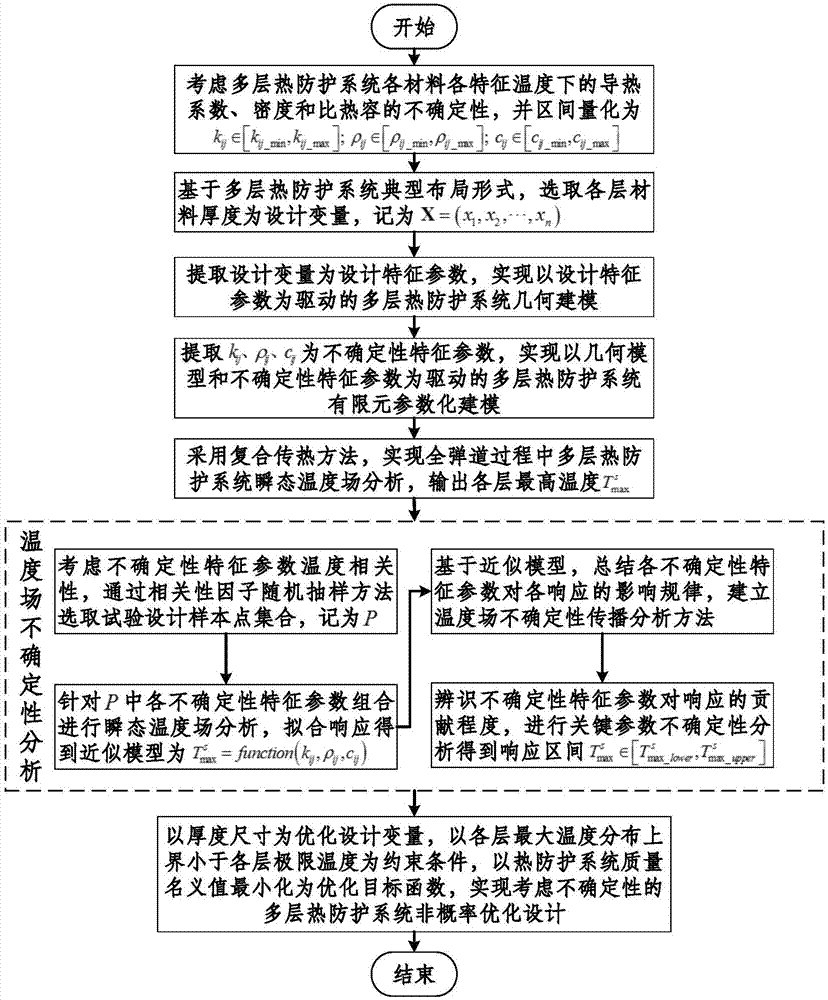

Non-probabilistic uncertainty analysis and optimization design method of multilayer thermal protection system based on experimental design

ActiveCN106874588AImprove safety and reliabilityLight in massGeometric CADDesign optimisation/simulationDeterministic analysisFeature parameter

The invention discloses a non-probabilistic uncertainty analysis and optimization design method of a multilayer thermal protection system based on experimental design. The method comprises the following steps that (1) a thermal conductivity coefficient, density and specific heat capacity are selected as uncertain parameters to achieve an interval expression of each uncertain parameter; (2) thickness of each layer and the uncertain parameters are extracted as characteristic parameters to achieve fully parametric modeling, analyzing and solving; (3) a correlation of the uncertain parameters is considered, a random sampling method of correlation factors is put forward, and test samples are selected; (4) an approximate model is constructed according to the samples, influence of uncertain parameters on response is analyzed, optimization selection is carried out, and an uncertainty analysis method of a multilayer structure temperature field is established; (5) the thickness of each layer is taken as a design variable, the constraint condition is that temperature of each layer is smaller than an allowable value, quality minimization is taken as a target function, an optimization model is constructed, and the optimization design of the multilayer thermal protection system is achieved. According to the non-probabilistic uncertainty analysis and optimization design method of the multilayer thermal protection system based on the experimental design, and through efficient uncertainty analysis and optimization, the efficiency of a thermal protection system structure is improved.

Owner:BEIHANG UNIV

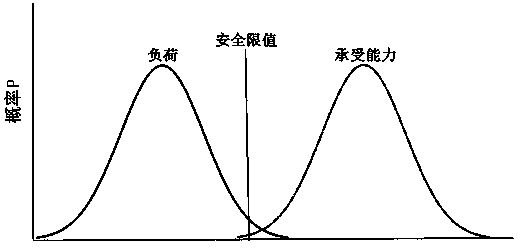

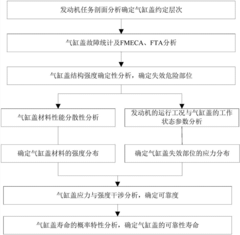

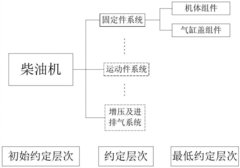

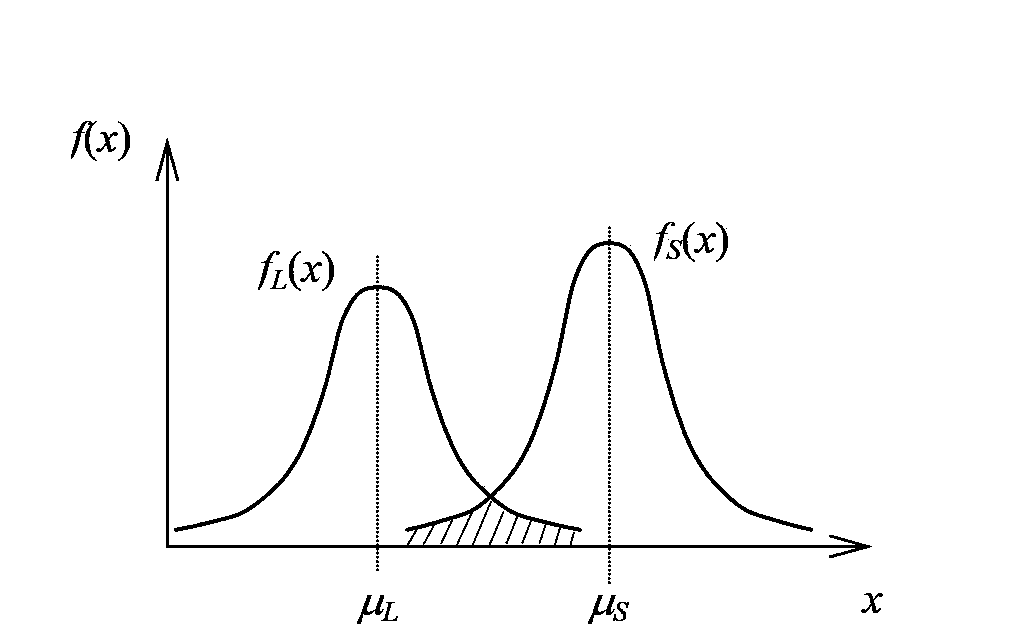

Method for evaluating reliability life of cylinder head

ActiveCN107992693AGuide structure designGeometric CADDesign optimisation/simulationDispersityStructural reliability

The invention provides a method for evaluating the reliability life of a cylinder head. The method includes: selecting the mission profile of an engine according to the purpose and service conditionsof the engine, and defining the operation time and working state parameters of the engine under different working conditions; in the indenture level of the engine and the cylinder head, determining the main failure mode of the cylinder head; performing deterministic analysis on the cylinder head to determine the weak part of the cylinder head structure; performing dispersity analysis on the material performance of the cylinder head to determine the ultimate strength distribution of the cylinder head; determining the loading condition and dispersity of the cylinder head under the selected working condition, and analyzing the stress distribution of the dangerous part of the cylinder head under the corresponding working condition; performing structural reliability analysis on the cylinder head; determining the probability distribution features of the fatigue life of the cylinder head and the reliability life, satisfying different reliability requirements, of the cylinder head. By the method, the reliability life of the cylinder head can be evaluated in the development stage of the engine, and the structural design and reasonable utilization of the cylinder head can be well guided.

Owner:CHINA NORTH ENGINE INST TIANJIN

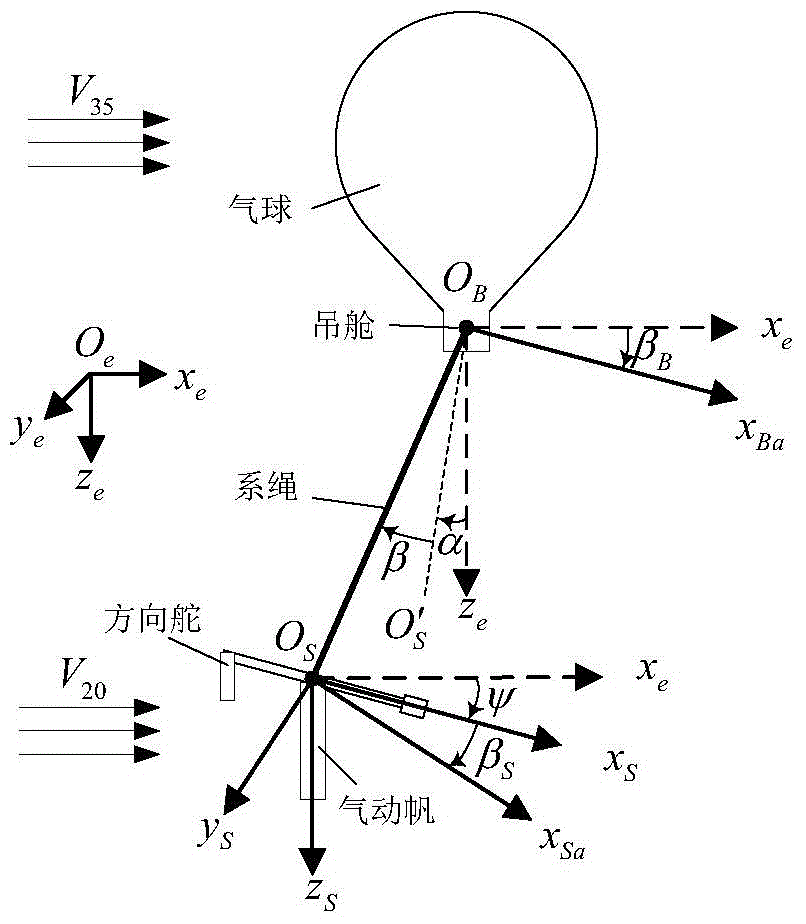

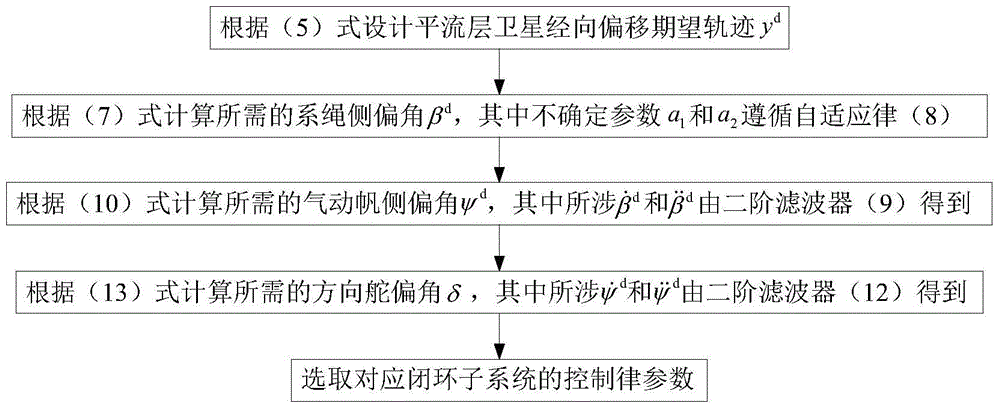

Hierarchical control method for warp offset of stratospheric satellite with model parameter uncertainty

InactiveCN104635495AEffective high precision controlAvoid difficultiesPosition/course control in three dimensionsAdaptive controlDeterministic analysisDesign control

The invention discloses a hierarchical control method for warp offset of a stratospheric satellite with model parameter uncertainty. The hierarchical control method comprises seven steps: firstly, performing parameter uncertainty analysis on a six-degree-of-freedom dynamical model, overcoming the difficult point that a warp offset control law of the stratospheric satellite cannot be directly designed by an integral feedback linearization method, extracting cascade subsystem models containing uncertain parameters in a ball-rope subsystem, a rope-sail subsystem and a sail-rudder subsystem from the six-degree-of-freedom dynamical model; decomposing the control problem into three sub problems, and respectively designing control laws of the three sub problems based on the subsystem models; respectively selecting parameters of three cascade subsystem controllers, enabling the response speed of the sail-rudder subsystem to be greater than that of the rope-sail subsystem, and enabling the response speed of the rope-sail subsystem to be greater than that of the ball-rope subsystem; finally, reliably realizing high-precision control over the warp offset of the stratospheric satellite under the condition that the model parameters are uncertain.

Owner:BEIHANG UNIV

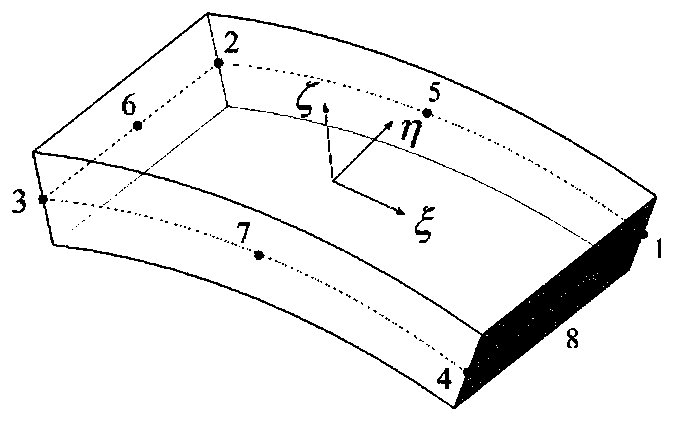

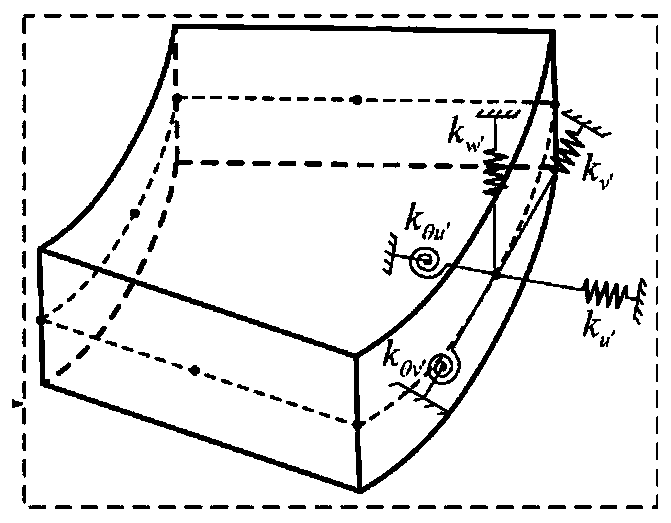

Bolt connection cylindrical shell structure frequency response function uncertainty analysis method with flange

ActiveCN110020460AHigh solution accuracyImprove computing efficiencyDesign optimisation/simulationSpecial data processing applicationsDeterministic analysisFinite element method

The invention belongs to the technical field of mechanical dynamics, and particularly relates to a bolt connection cylindrical shell structure frequency response function uncertainty analysis method with a flange. According to the method, eight-node degradation shell unit is adopted, and a kinetic model of bolt connection flange-cylindrical shell is established through a finite element method; bolt connection is simulated through discretizing modeling by using a spring unit, and the effectiveness of the built model is verified through a modal test; the uncertainty of the bolt connection stiffness is considered, the frequency response function interval range when the connection stiffness in five directions under a cylindrical coordinate system is an uncertainty parameter is solved based ona Chebyshev polynomial agent model and an interval analysis method, and under the deterministic inherent frequency, the Monte-Carlo sampling method is used for solving the frequency response functioninterval range, and the solving precision and efficiency of the two methods are compared; and finally, the multi-parameter uncertainty system frequency response function interval range is solved.

Owner:NORTHEASTERN UNIV

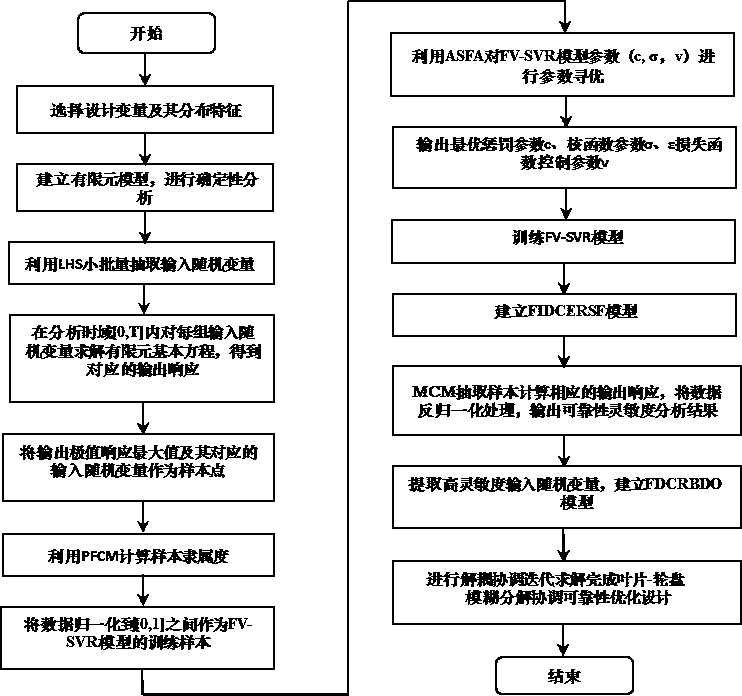

Fuzzy intelligent decomposition-coordination extreme response surface method of reliability optimization design

InactiveCN107729658AImprove reliabilityImprove calculation accuracyGeometric CADMulti-objective optimisationDeterministic analysisDecomposition

The invention discloses a fuzzy intelligent decomposition-coordination extreme response surface method of reliability-based optimal design. The method comprises the specific steps that the output response of a blade in the corresponding failure mode and the output response of a turbine disc in the corresponding failure mode are obtained respectively through heat-structure coupling certainty analysis; a fuzzy intelligent decomposition-coordination extreme response surface function (FIDCERSF) is constructed; dynamitic reliability sensitivity analysis is conducted by using an MCM; a fuzzy decomposition-coordination reliability-based optimal design model (FDCRBDO) is constructed. The method has strong advantages in the aspect of the overall reliability optimization design of a structure in a multi-component and multi-failure mode.

Owner:HARBIN UNIV OF SCI & TECH

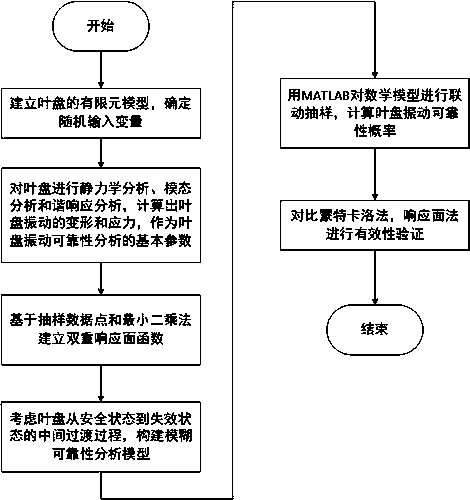

Fuzzy double response surface method for calculating vibration reliability of blade disk

PendingCN108710724AEasy to useImprove computing efficiencyDesign optimisation/simulationComplex mathematical operationsStatic timing analysisElement model

The invention discloses a fuzzy double response surface method for calculating the vibration reliability of a blade disk. The method comprises the following steps: building a finite element model of the blade disk; determining a basic parameter which affects the vibration reliability of the blade disk as a random input variable; acquiring the basic parameter for analyzing the vibration reliabilityof the blade disk through static analysis, modal analysis and harmonious response analysis of the model, thus completing the deterministic analysis of the blade disk; building a double response surface mathematical model; building a fuzzy reliability analysis mathematical model, and analyzing the vibration reliability of the blade disk; and verifying the effectiveness of the fuzzy double responsesurface method. The method disclosed by the invention is high in calculation speed and high in the precision, can directly show a varying relation of an output response, and provides a new way for the reliability engineering analysis.

Owner:HARBIN UNIV OF SCI & TECH

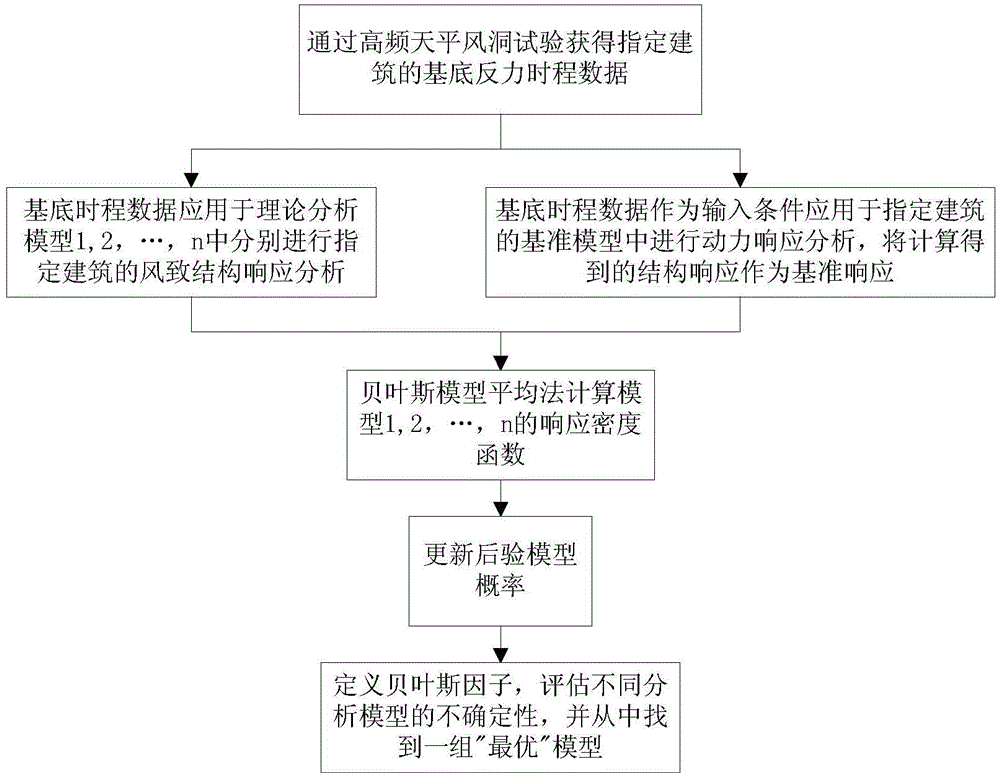

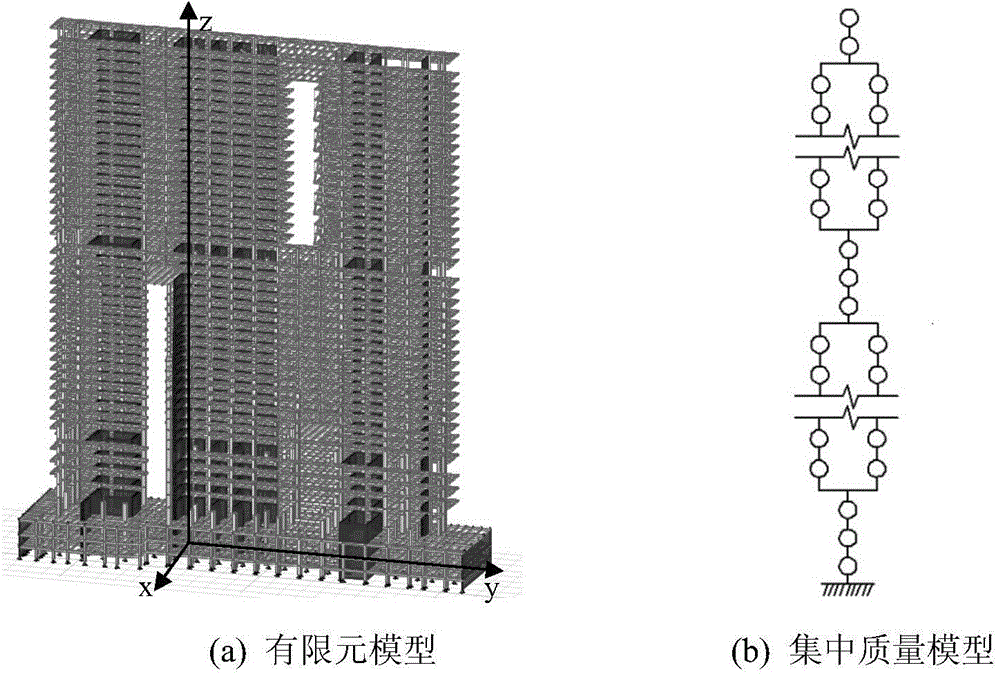

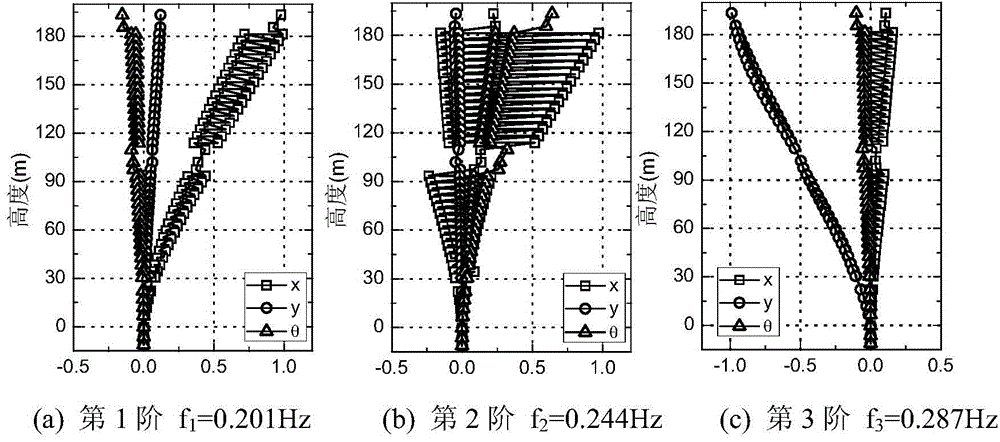

Uncertainty analysis method for high-rise building wind response analysis models

ActiveCN104794332AThe result is accurate and reliableImprove computing efficiencySpecial data processing applicationsScale modelDeterministic analysis

The invention discloses an uncertainty analysis method for high-rise building wind response analysis models. The uncertainty analysis method includes the steps that firstly, base reaction force time interval data of designated building scale models are obtained through a high-frequency balance wind tunnel test, and the base data are converted into a prototype; secondly, the batch of time interval data are applied to different theoretical analysis models to conduct wind response analysis of designated buildings respectively; meanwhile, the same batch of base time interval data serve as input conditions to be applied to reference models of the designated buildings to conduct dynamic response analysis, and calculated structure responses serve as the reference responses; finally, based on the principle of the Bayesian model average method, the probability expression of the structure responses is established and applied to different analysis models to conduct model selection and response prediction uncertainty analysis; Bayesian factors are defined, and uncertainty of different analysis models is evaluated, and the set of optima models are found from the analysis models.

Owner:ZHEJIANG UNIV

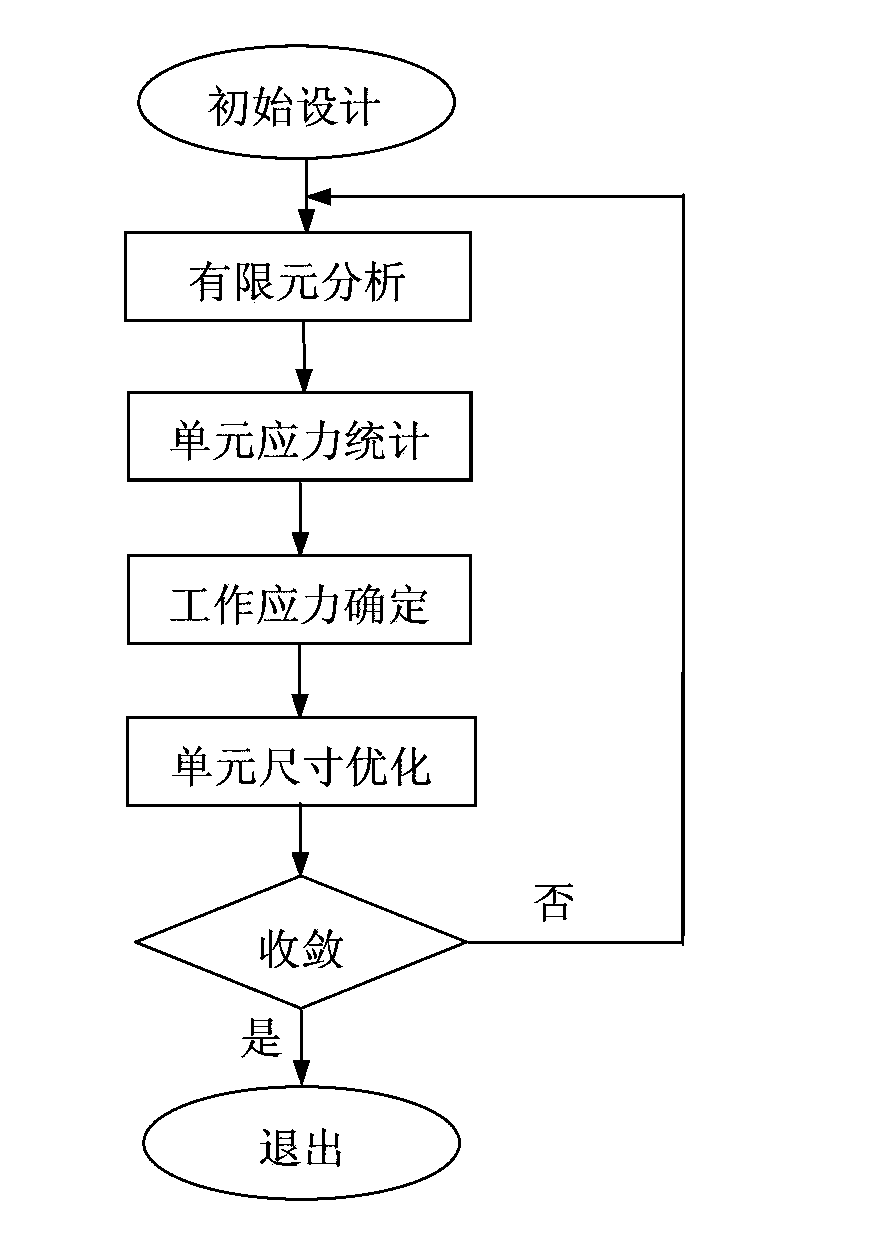

Structural probability optimized design method

ActiveCN103870614AImprove reliabilitySimple structural designSpecial data processing applicationsProbabilistic methodStructural reliability

The invention discloses a structural probability optimized design method and belongs to the aviation structure optimized design field. According to the structural probability optimized design method, probability characteristics of a mean value and a variance of stress / strain are obtained due to processing of a stress / strain calculation result through a mathematical statics method based on the structural finite element analysis, then the size of the stress is confirmed according to a structural design requirement for reliability, and finally the structural optimized design is performed through a fully stressed / full strain method. According to the above processing methods, the structural design is improved greatly, the structural weight is reduced and the structural reliability is improved compared with an initial design, on one hand, the stress obtained through calculation through a probability method can show structural reliability requirement and is greatly improved compared with the deterministic analysis, and on the other hand, the weight is reduced and structural reliability is guaranteed confirming to requirements due to the design through the fully stressed / fully strain method.

Owner:上海秦耀航空试验技术有限公司

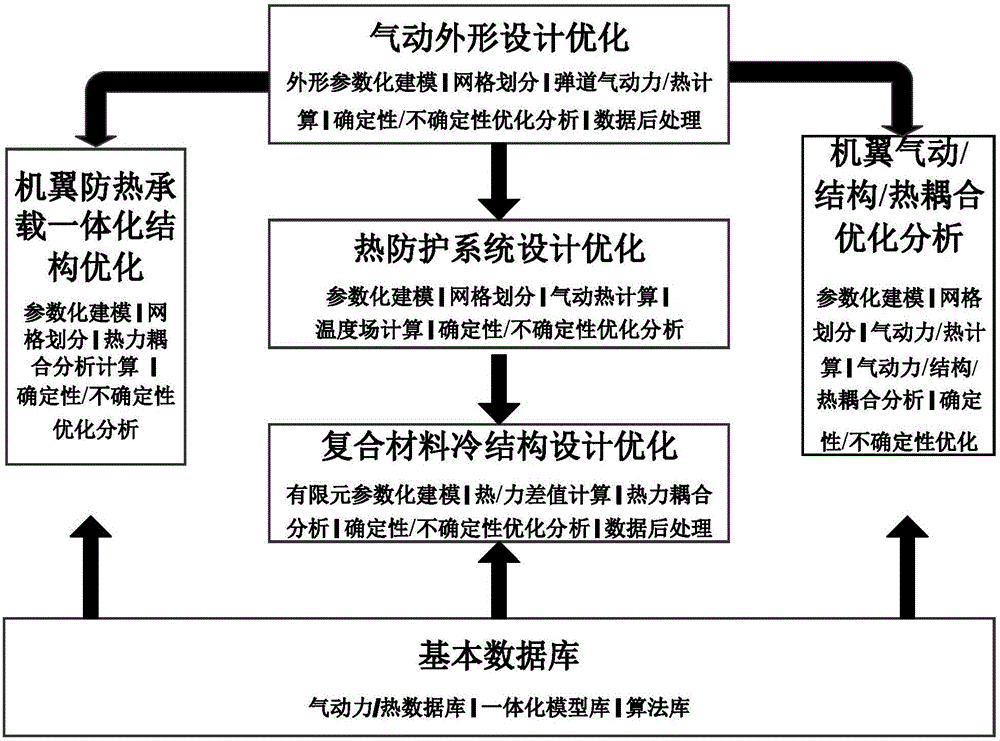

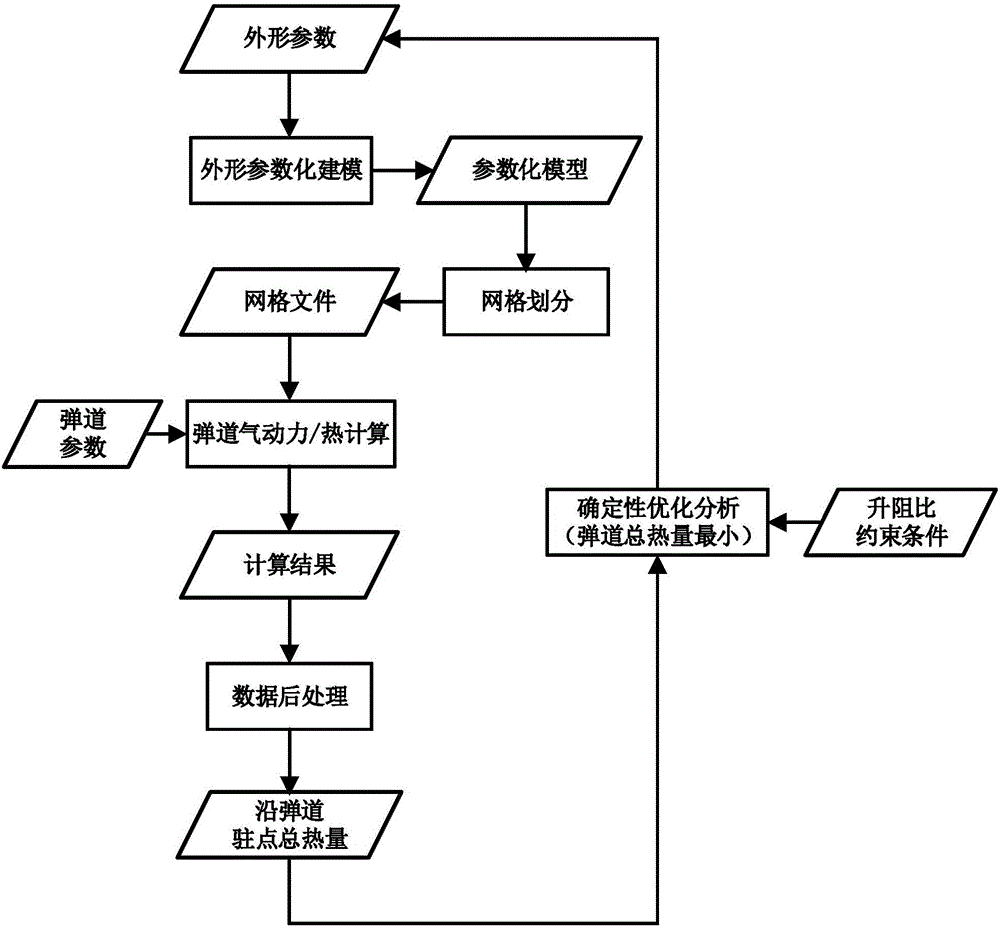

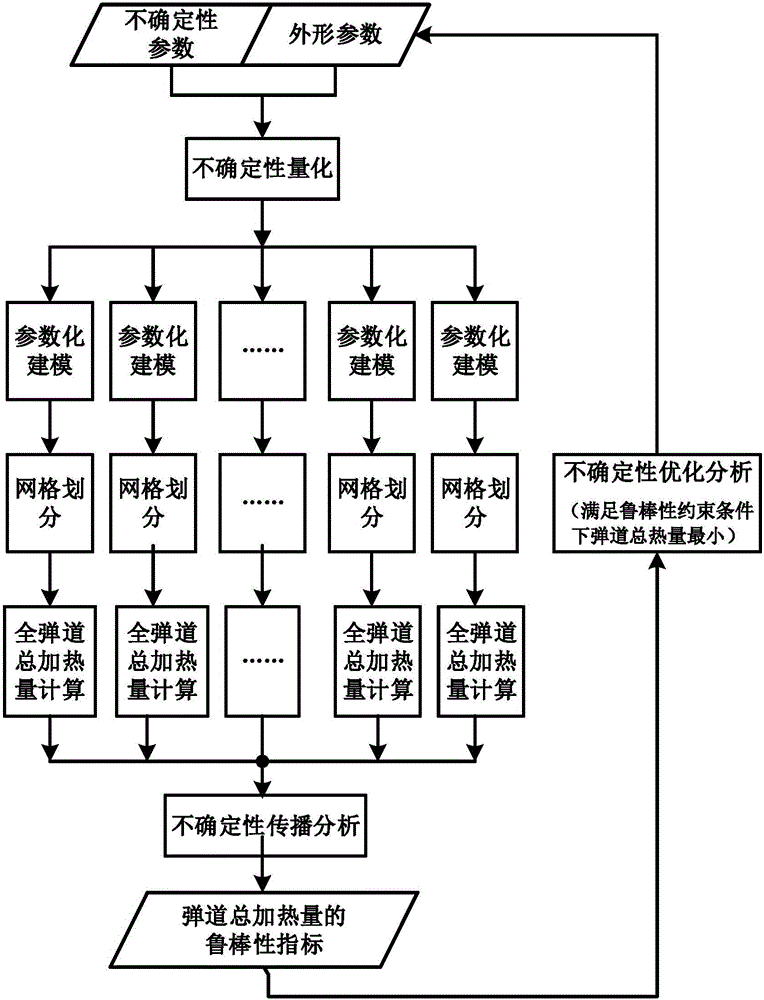

Aircraft structure function integrated design platform system based on uncertain optimization

ActiveCN106407586AEasy to modifyEasy maintenanceGeometric CADSustainable transportationSystems designUncertain optimization

Owner:宁波智正伟盈信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com