Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104 results about "Factor level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Levels of a Factor. The number of levels of a factor or independent variable is equal to the number of variations of that factor that were used in the experiment. If an experiment compared the drug dosages 50 mg, 100 mg, and 150 mg, then the factor "drug dosage" would have three levels: 50 mg, 100 mg, and 150 mg.

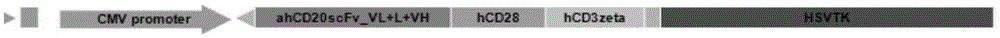

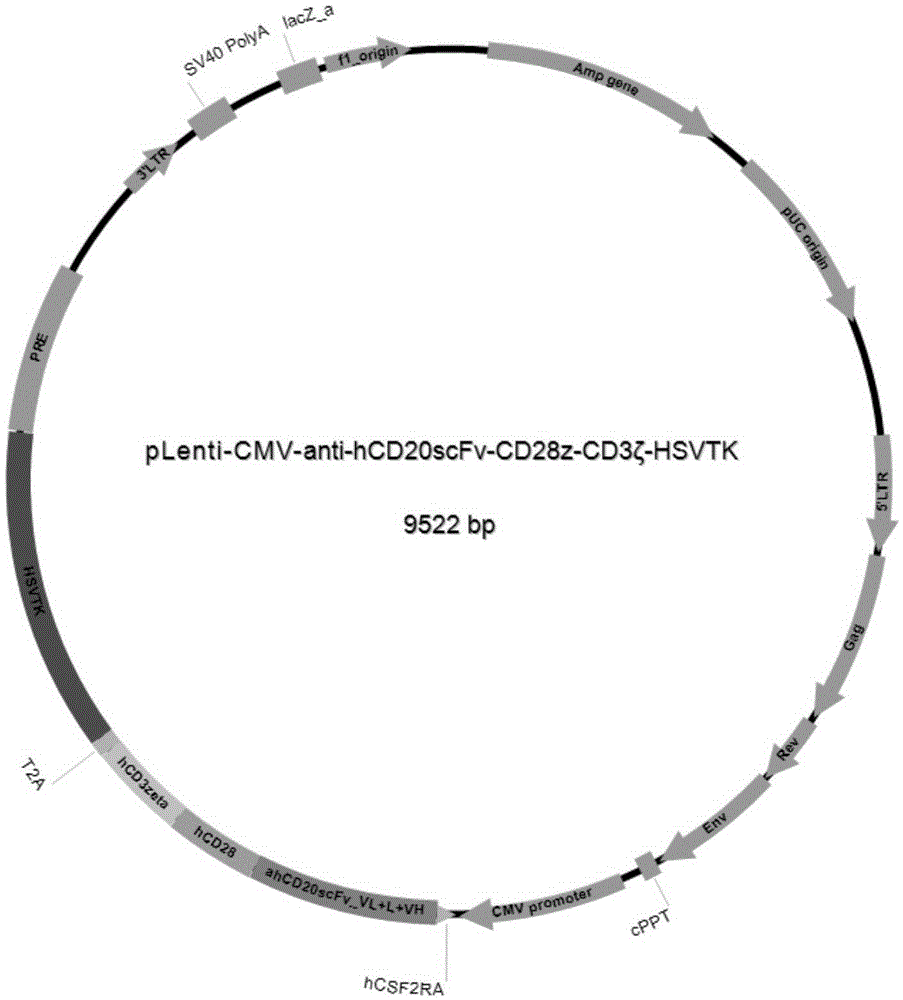

Chimeric antigen receptor immune cell provided with safety switch as well as preparation method and application of chimeric antigen receptor immune cell

InactiveCN106755023AImprove effectivenessImprove securityGenetic material ingredientsMammal material medical ingredientsAbnormal tissue growthAntigen receptors

The invention relates to a chimeric antigen receptor (CAR) immune cell provided with a safety switch as well as a preparation method and an application of the CAR immune cell. The CAR immune cell carrying the safety mechanism (the safety switch) comprises a CAR coding nucleotide sequence, wherein the structure of the nucleotide sequence comprises a receptor structural domain for recognizing tumor-specific antigen or tumor-associated antigen, a transmembrane-stimulation structural domain, a CD3[zeta] stimulating signal transduction region and a suicide gene region. The CAR immune cell can be obtained as different immunological effect cells are amplified and a CAR sequence carrying a suicide mechanism is transduced; corresponding antigens of tumor cells are recognized by virtue of CAR; and the CAR immune cell can generate a specific killing effect on the tumor cells. The CAR immune cell, when used, is infused in a gradient mode and dynamic change in related cell factor levels is monitored; in case of need, a suicide gene can be started by virtue of drugs to scavenge the immunological effect cells, so that optimal balance between safety and a curative effect is achieved; therefore, the safety of the technology applied to the treatment of tumors in the clinical field is guaranteed to the greatest extent.

Owner:AFFILIATED HOSPITAL CHINA ACADEMY OF MILITARY MEDICAL SCI +1

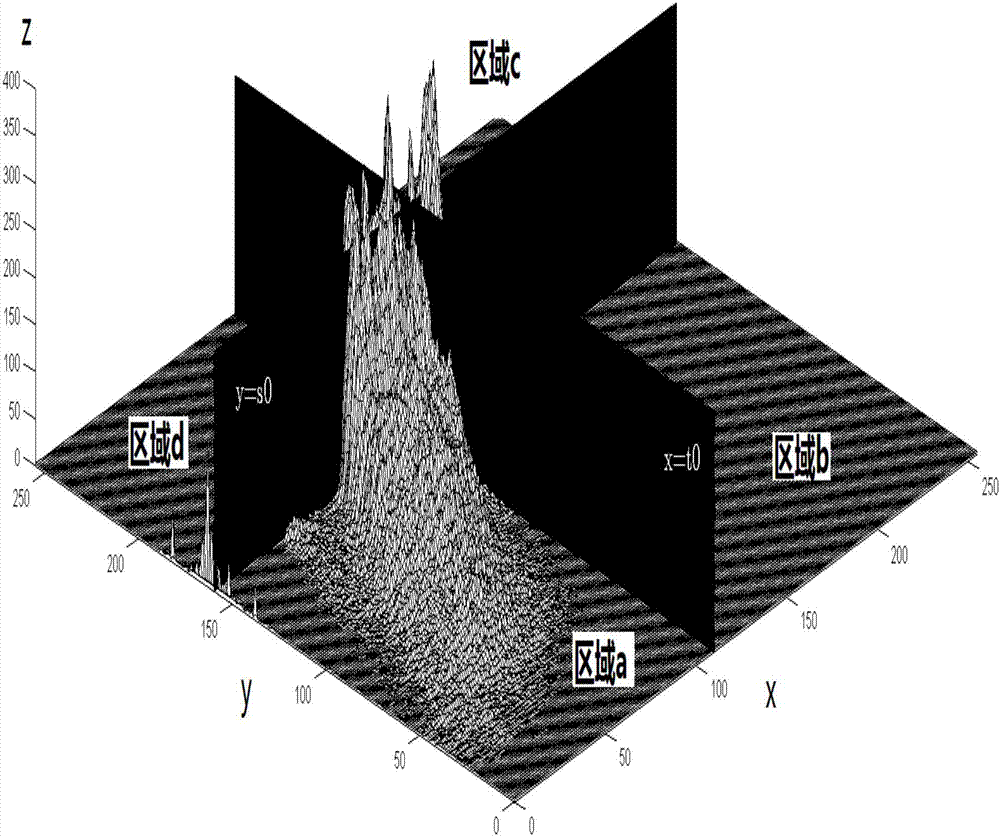

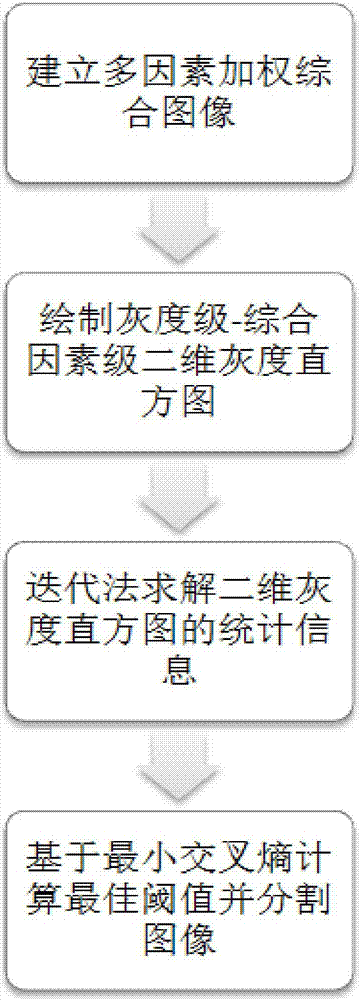

Multi-factor two-dimension grey level histogram based threshold segmentation method

InactiveCN107369159ASolve the problem of losing key information of imagesGuaranteed credibilityImage analysisOptical measurementsIterative method

The invention provides a multi-factor two-dimension grey level histogram based threshold segmentation method belonging to the technical field of computer optical measurement. According to the invention, a multi-factor weight integrating image is created, a two-dimension grey level histogram is drawn and cross entropy is used for calculating the threshold value for segmenting the image. First, the weight integrating image based on three factors including neighborhood average gray level, gradient strength and gradient direction level. Further, a gray level image is combined and a gray level-integrated factor level two-dimension gray level histogram is drawn. Then an iteration method is adopted for solving gray level average values of foreground and background pixels. Finally, based on the minimum cross entropy, the optimal threshold value is calculated and the optimal threshold value is used for segmenting the image. The method provided by the invention solves a problem of image key information loss of a prior two-dimension gray level histogram; data accuracy and method reliability are ensured. The credibility of the threshold value and the image segmenting effect are improved. The whole threshold value segmenting algorithm is good in adaptability and high in validity.

Owner:DALIAN UNIV OF TECH

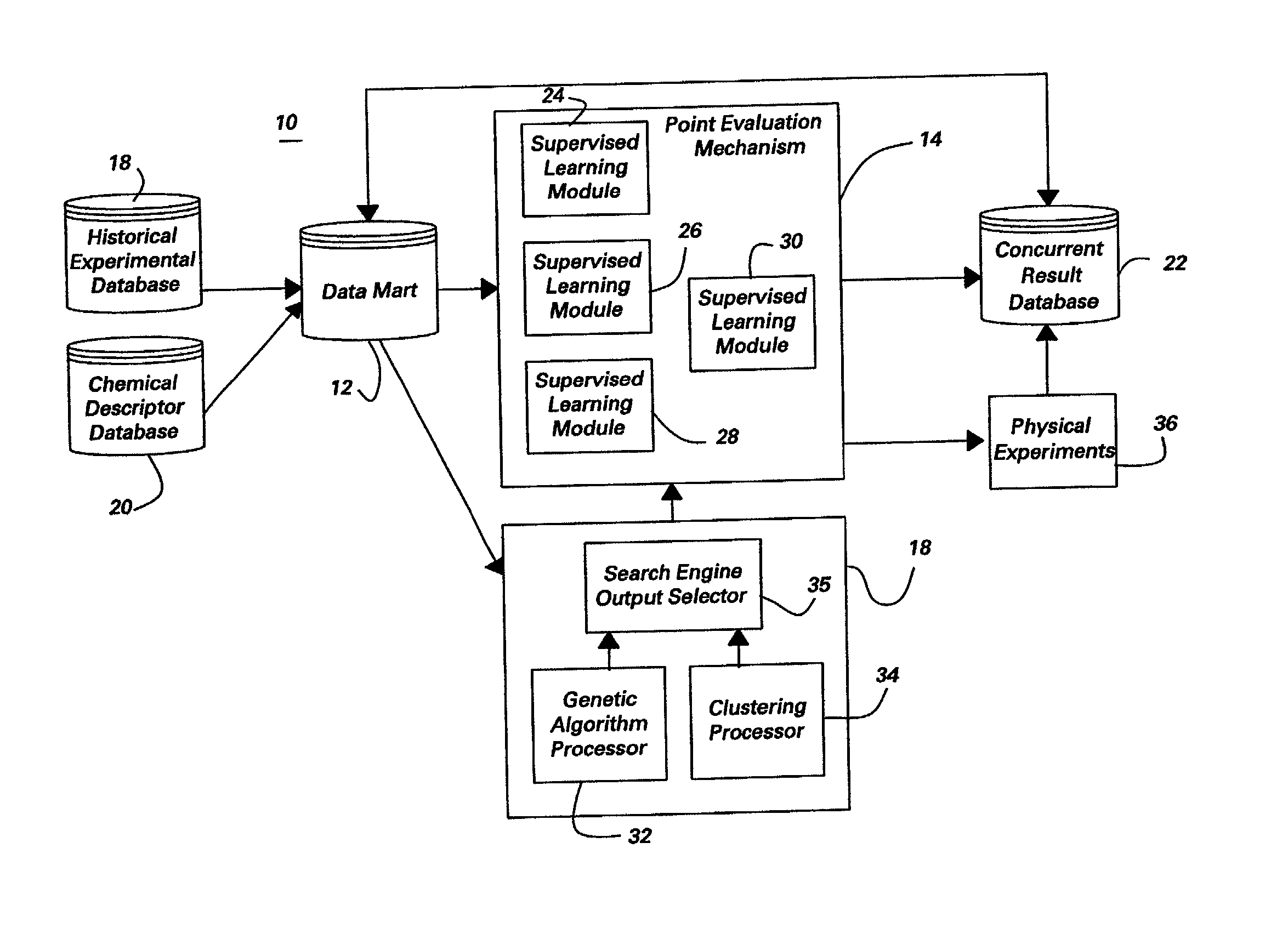

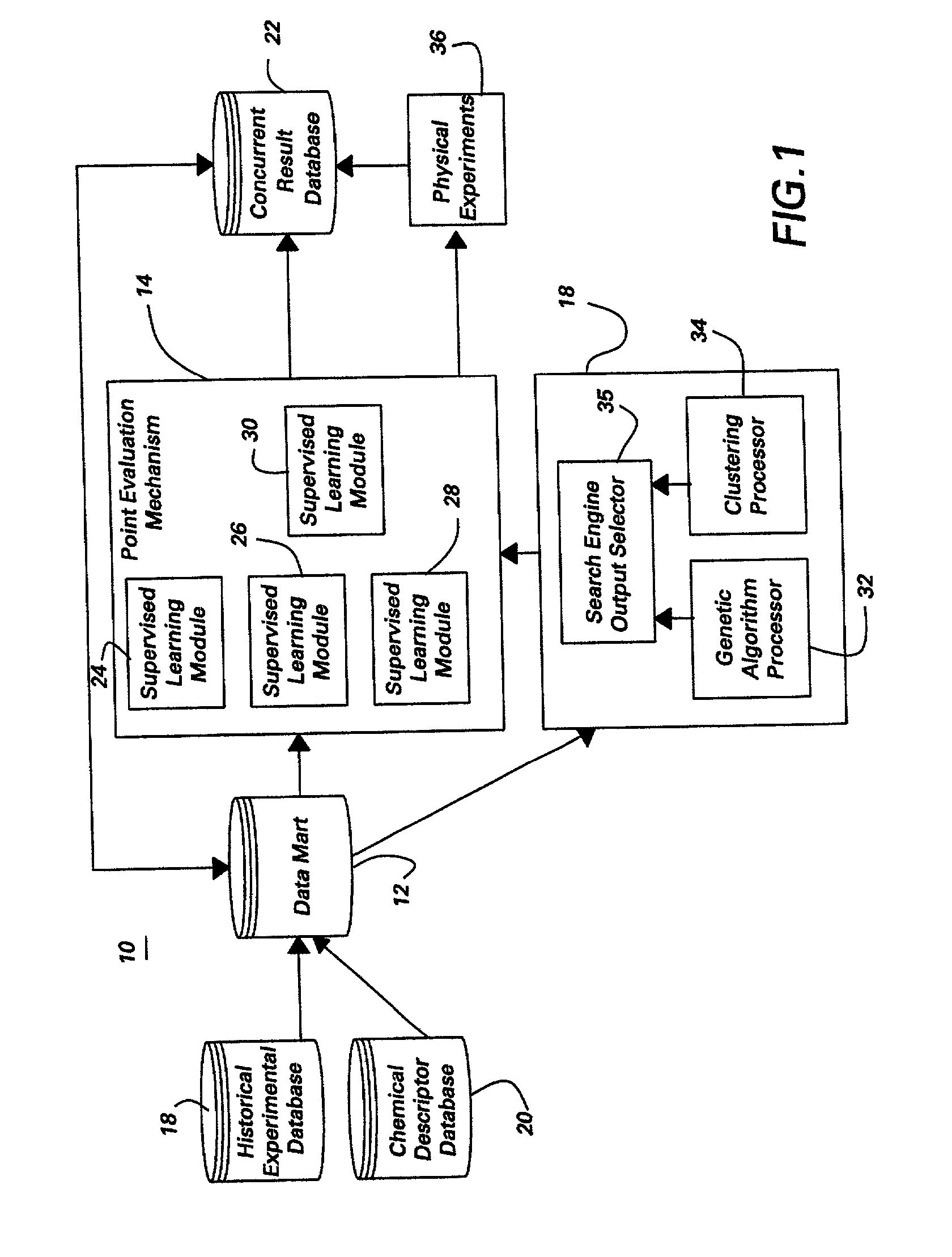

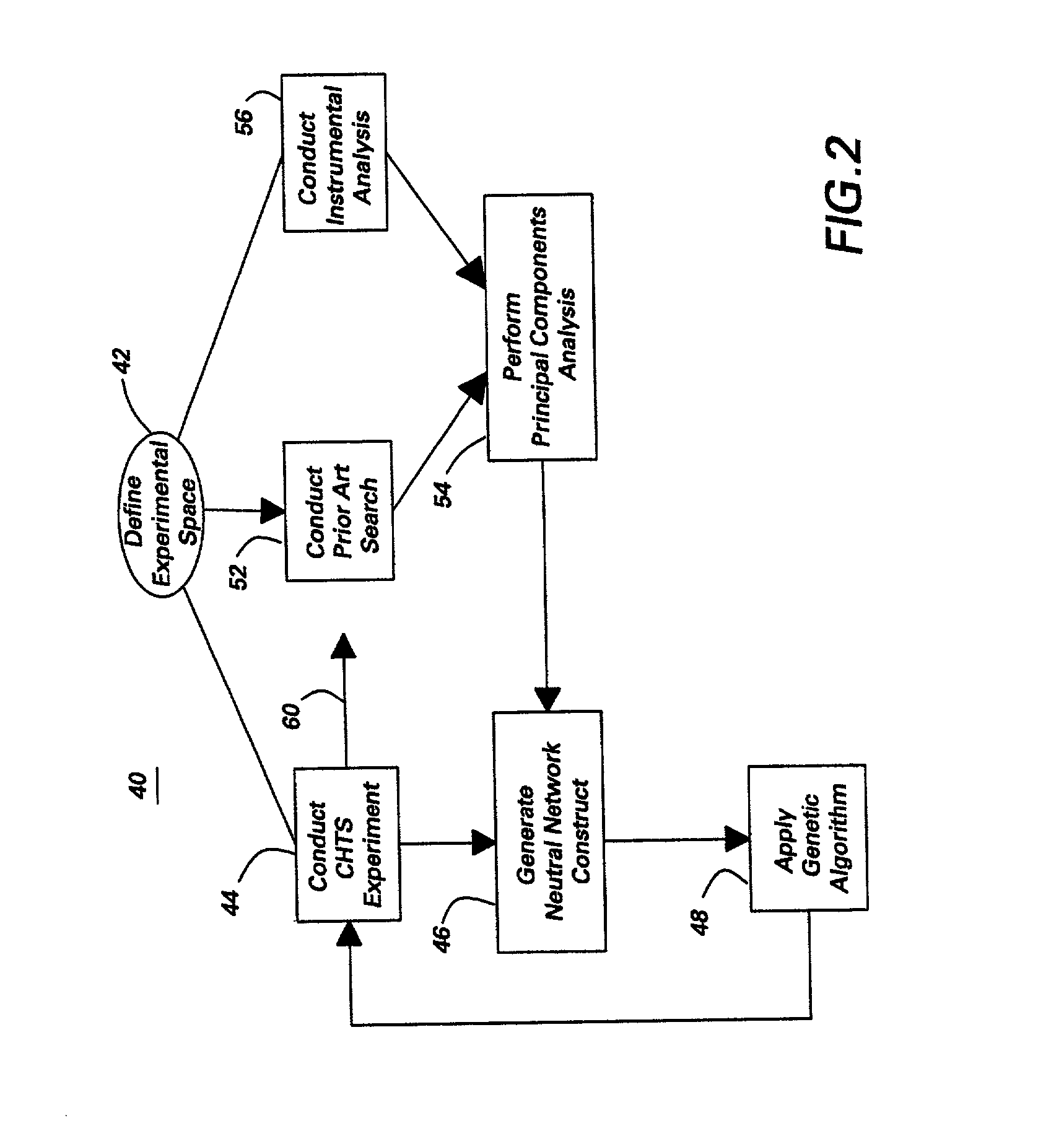

Neural network method and system

InactiveUS20030018598A1Reduce dimensionalityImprove generalization abilityGenetic modelsDigital computer detailsNerve networkGenetic algorithm

A neural network construct is trained according to sets of input signals (descriptors) generated by conducting a first experiment. A genetic algorithm is applied to the construct to provide an optimized construct and a CHTS experiment is conducted on sets of factor levels proscribed by the optimized construct.

Owner:GENERAL ELECTRIC CO

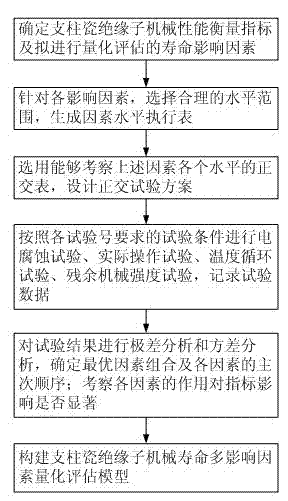

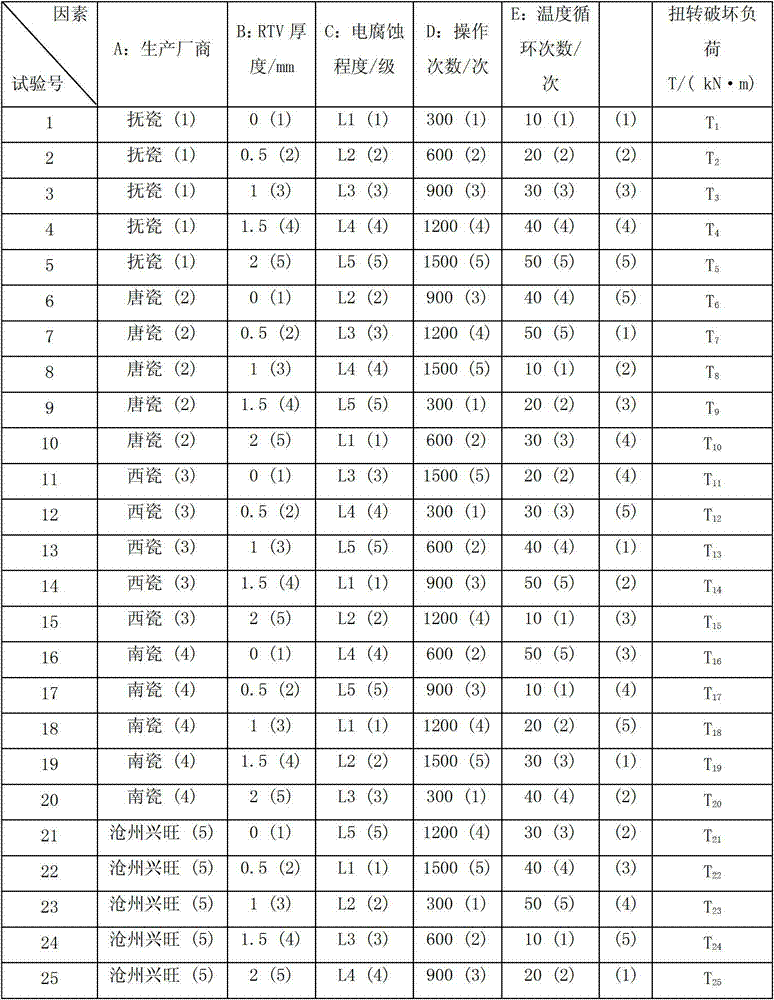

Method for detecting factors influencing mechanical life of support porcelain insulator

InactiveCN103093110AIncrease profitReduce test volumeSpecial data processing applicationsLife timeMeasurable Indicator

The invention relates to a method for detecting factors influencing a mechanical life of a support porcelain insulator. The method for detecting the factors influencing the mechanical life of the support porcelain insulator comprises the following steps: step 1, support porcelain insulator mechanical performance measurable indicators and life influencing factors which are planned to conduct quantitative evaluation are confirmed; step 2, a level range is chosen so as to generate a factor level execution table according to the influencing factors; step 3, orthogonal tables capable of inspecting each level of the factors are chosen, and orthogonal test steps are confirmed; step 4, relative tests according to required test conditions of each test number are carried out in sequence, and test data are recorded; step 5, the test data are analyzed, optimal factor combinations and a primary and secondary sequence of each influencing factor are confirmed, and whether influences of functions of each factor upon indicators are notable or not is judged; and step 6, a model for quantitative evaluation of the factors affecting the mechanical life of the support porcelain insulator is built according to test results. The method for detecting the factors influencing the mechanical life of the support porcelain insulator has the advantages of reducing test numbers, improving test subject utilization rate, and obtaining the rule of influence of each factor upon the indicators accurately.

Owner:WUHAN UNIV +1

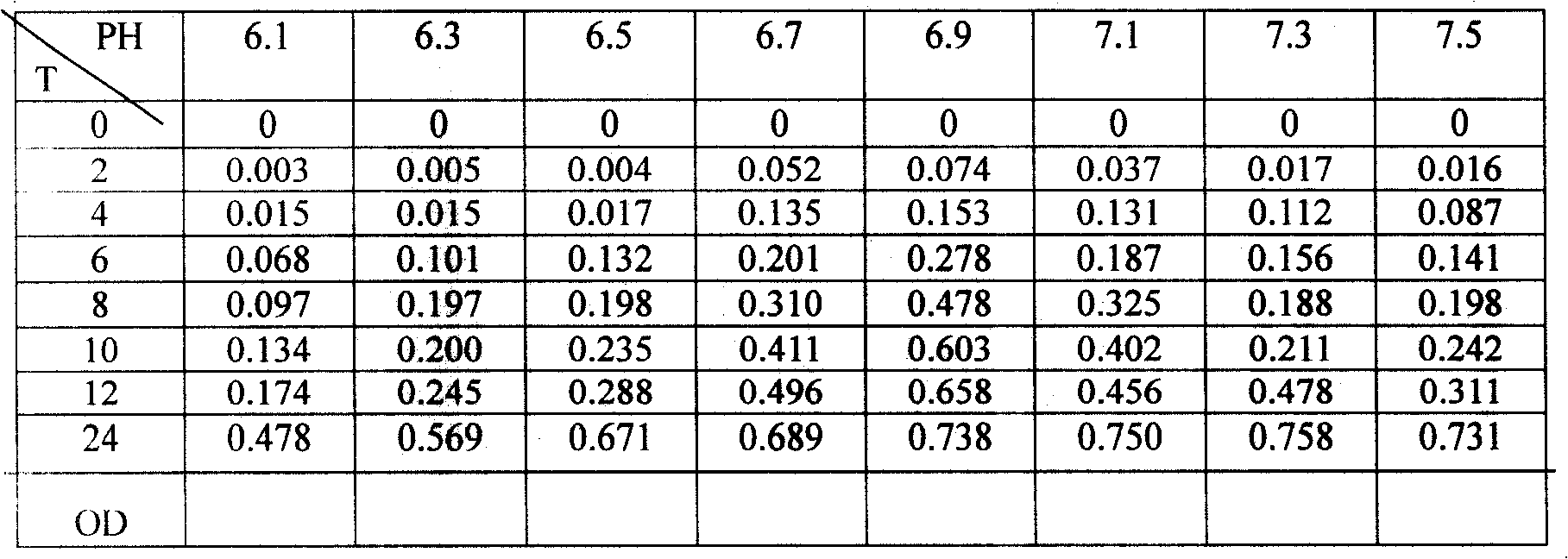

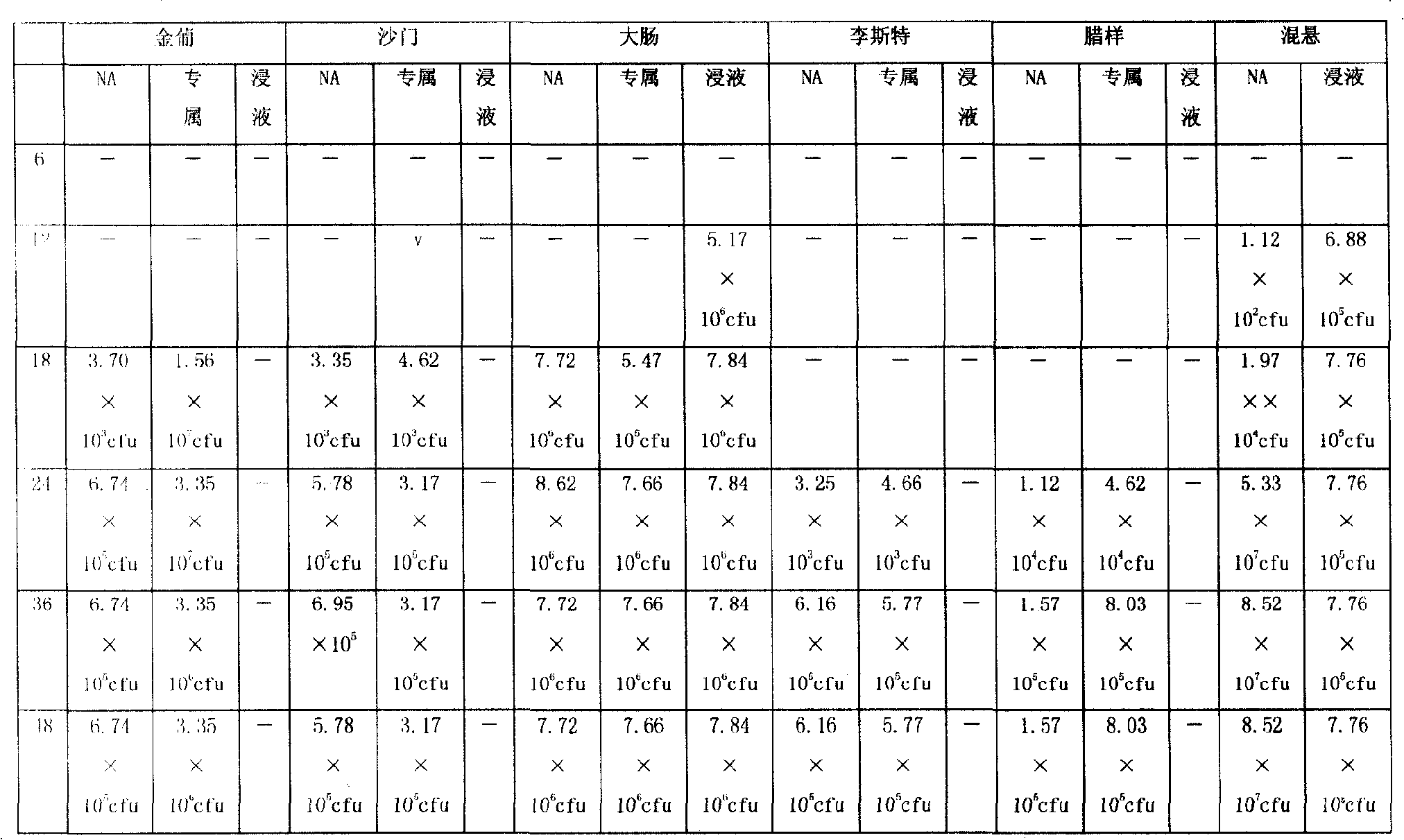

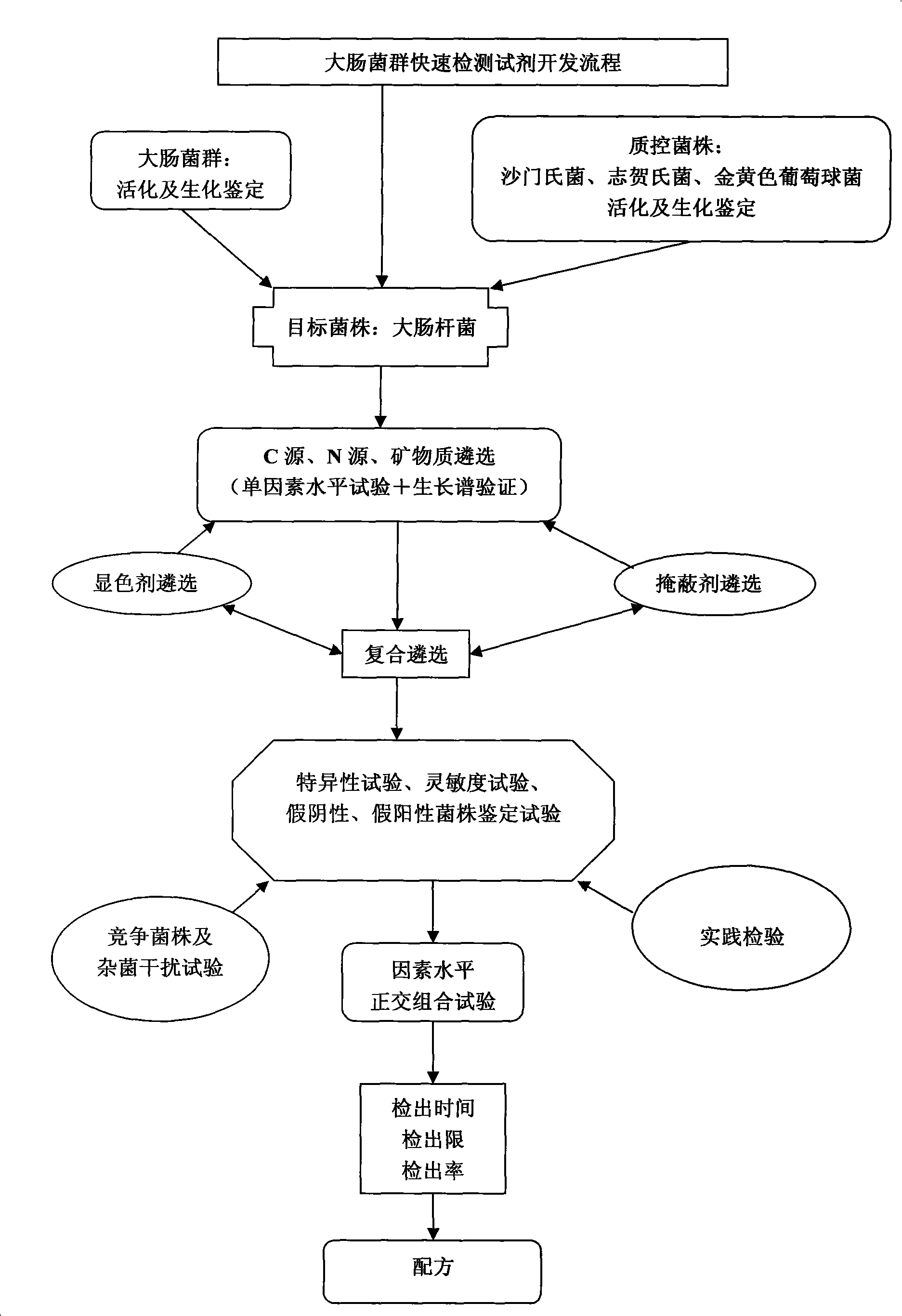

Composite quick colour-developing examination and check agent for coliform group bacteria, researching and developing flow scheme thereof

InactiveCN101294190AGrowth inhibitionMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementEscherichia coliNutrition

The invention relates to a process for the research and development of a colon-bacillus composite and speedy chromogenic identification reagent. The process is characterized in that: 1. First, the quality control method is determined through activation identification and biochemical identification of coliform groups, salmonella, shigella and staphylococcus aureus; 2. Basic nutrients are selected according to the needs of target strains; 3. It is verified by the auxanogram method that proper nutrition environments, carbon sources, nitrogen sources, minerals, microelements, nutrilits, etc. are all necessary for the growth and breeding of microbes; without any one thereof, the microbes can not grow, metabolize and breed normally; 4. A visualization reagent, a masking reagent and a synergistic agent are selected; 5. Composite selection is conducted; 6. The feasibility of the composite selection formula is verified through tests, verifications and examinations on the indexes of a speedy chromogenic substrate, including the specificity test, the sensitivity test, the real sample inspection, the false negative and false positive strain identification, the stability test, the repeatability test, the competing strain and mixed bacterium interference test, the detection time and detection rate tests. 7. The most suitable formula is selected through a factor level orthogonal combination test.

Owner:姚毓才

Lactobacillus fermentum strain suo for adjusting intestinal tract motion and preventing constipation and use thereof

ActiveCN104498383AStrong acid resistanceIncrease the push rateMilk preparationBacteriaAcid-fastFeces

The invention discloses Lactobacillus fermentum suo for adjusting intestinal tract motion and preventing constipation and a use thereof. The Lactobacillus fermentum suo has a preservation number of CCTCC NO: M2013511, has strong acid resistance, has a survival rate of 92.46+ / -4.06% after being arranged in an artificial gastric juice with a pH value of 3.0 for 3h, can slowly grow in cholate with a concentration of 1.0%, has a growth rate 17.36+ / -1.19% that of cholate-free culture, has cell hydrophobicity of 68.44+ / -2.48% and can normally grow in the human intestinal tract. Lactobacillus fermentum suo can relieve constipation-caused mouse weight reduction, reduce tarry stool excretion time, improve a small intestine propulsion rate, improve serum MTL, Gas, ET, AchE, SP and VIP factor levels to different degrees, reduce a SS factor, improve food intake and water intake, relieve reduction of a stool excretion mount, the number of stool particles and stool water content and can produce a certain constipation prevention effect similar to those of constipation treatment drugs.

Owner:江苏新申奥生物科技有限公司

Feed additive, preparation method and application of feed additive

InactiveCN103843972AIncrease profitHigh nutritional valueBacteriaFood processingFood additiveNutrition

The invention discloses a feed additive, a preparation method and application of the feed additive. The preparation method of the feed additive comprises the steps of transferring activated lactobacillus strains to a sterilized MRS culture medium from glycerinum for culture to obtain a seed solution; carrying out primary and secondary enlarged cultivation on the seed solution in the MRS culture medium, inoculating into the sterilized solid culture medium for solid feed fermentation through an intermittent oxygen-introduction facultative anaerobic fermentation mode, and drying to obtain the feed additive. According to the preparation method of the feed additive, lactobacillus fermented soybean meal, bran, rice bran, straw, cottonseed cake, corncob powder, bagasse and other agricultural wastes are utilized for effectively reducing the antinutritional factor level in the raw materials, and the nutrition utilization rate is increased; the prepared feed additive is rich in antimicrobial peptide and other prebiotic substances secreted by lactobacillus through fermentation and metabolic processes, thereby having a prebiotic function and being healthy. The feed additive can be applied to an animal feed.

Owner:GUANGZHOU YOURUI BIOSCI

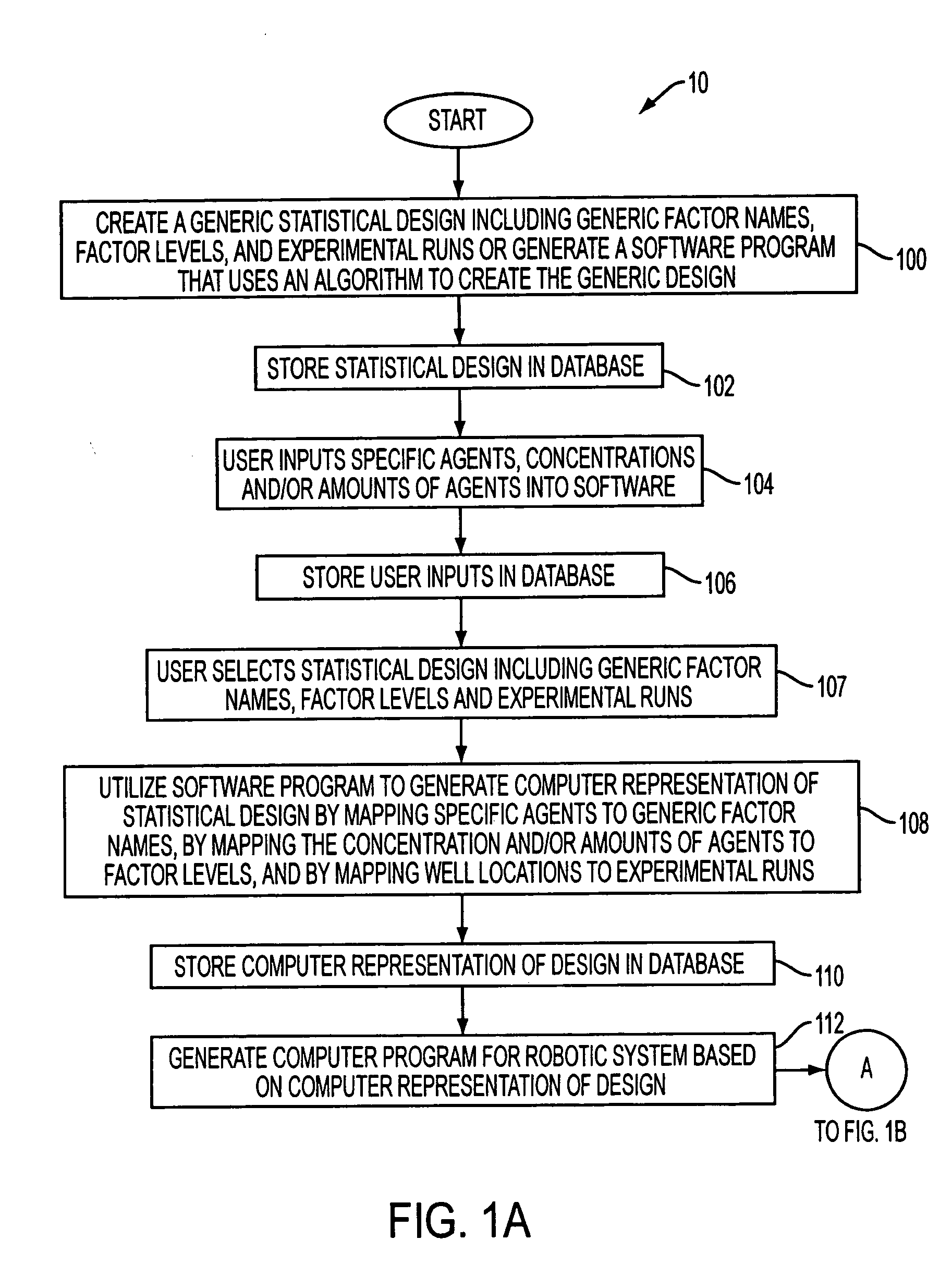

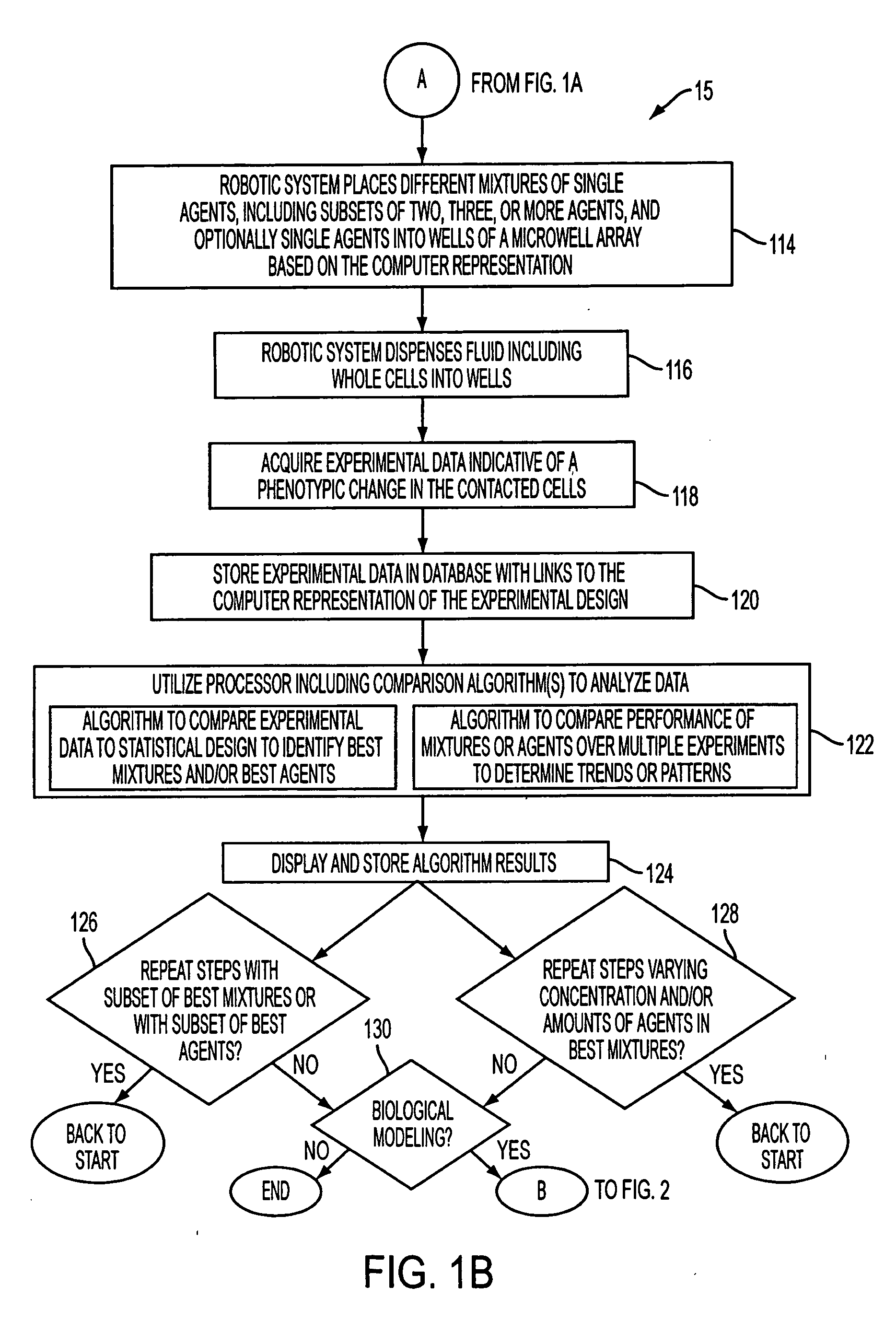

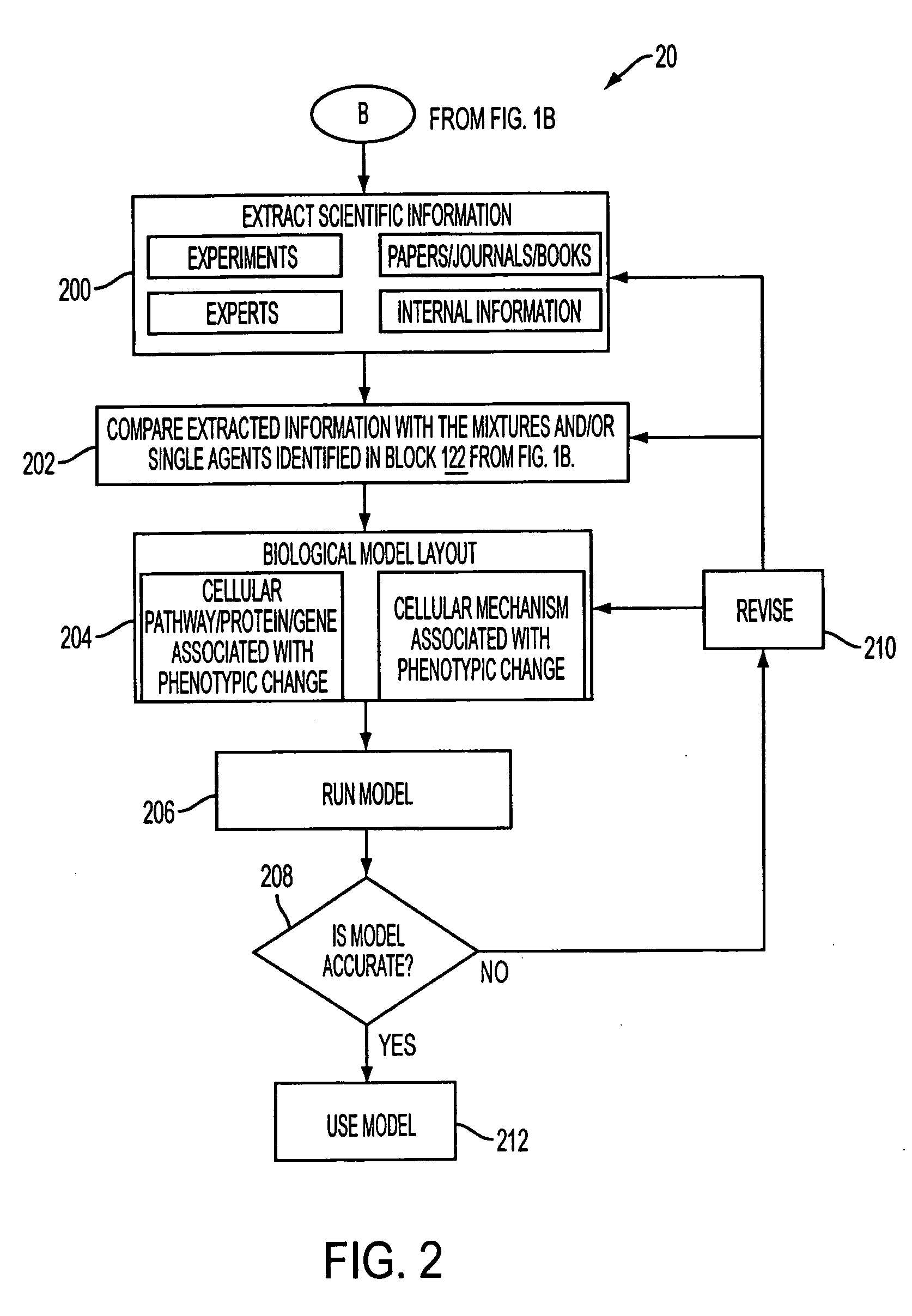

Automated media optimization technology

InactiveUS20050154534A1Efficient changePreparing sample for investigationVertebrate cellsCell typeComputer science

An automated system and method for identifying agents capable of eliciting a phenotypic change in a cell-type. The method includes the steps of providing a statistical design including generic factor names, factor levels and experimental runs, and utilizing a software program to generate a computer representation of the statistical design by automatically mapping the identities of the agents to the generic factor names, concentrations or amounts of the agents to the factor levels, and the locations of the receptacles to the experimental runs. The method also includes placing different mixtures of single agents, such as peptones, into receptacles in the array based on the computer representation of the statistical design, contacting the placed mixtures with cells, acquiring experimental data from the contacted cells, and utilizing a processor including an algorithm for comparing the acquired data with the statistical design to identify peptone combinations and concentrations that optimize cell culture conditions.

Owner:BECTON DICKINSON & CO

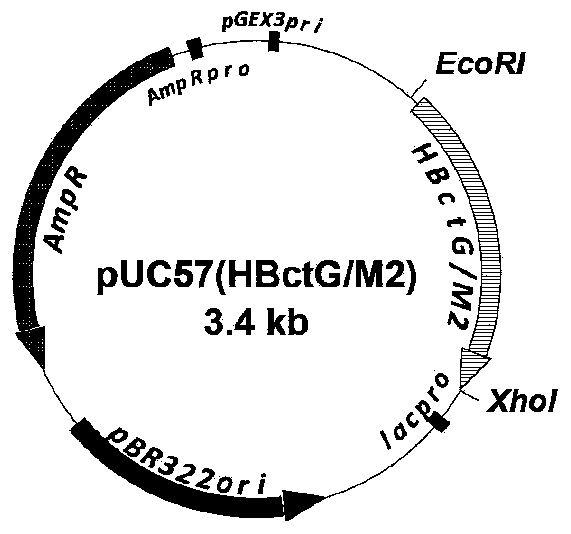

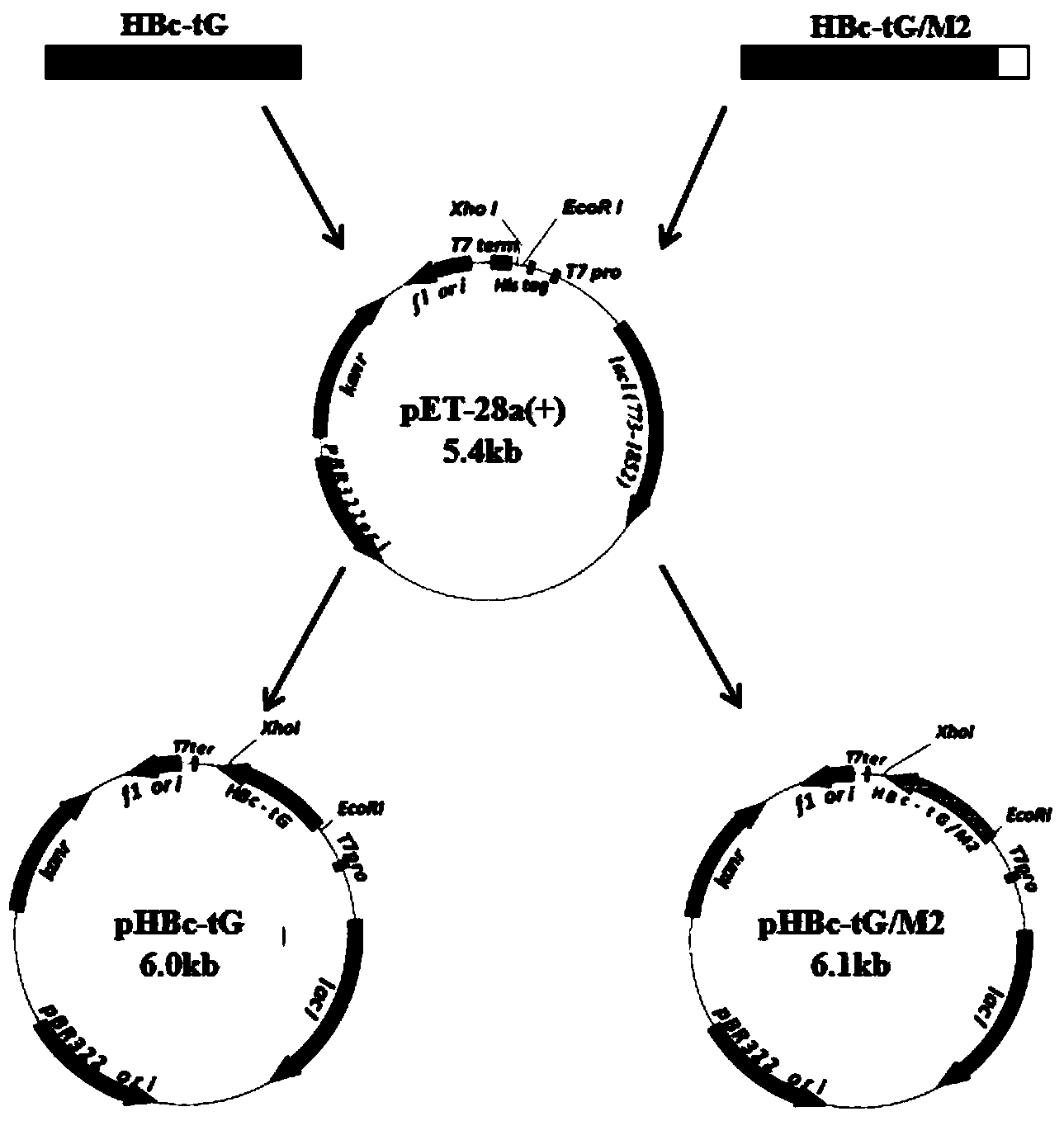

Respiratory syncytial virus virus-like particle vaccine as well as preparation method and application thereof

InactiveCN104293741AStrong immune memoryBacteriaInactivation/attenuationEscherichia coliRespiratory syncytial virus antibody

The invention belongs to the field of biotechnology, and particularly relates to a respiratory syncytial virus (RSV) virus-like particle (VLPs) subunit vaccine as well as a preparation method and application thereof. The component of the vaccine is chimeric antigen protein which is fusion-expressed together with neutral antigenic epitope of an RSVG protein or simultaneously with the antigenic epitope of T cells of an M2 protein by taking hepatitis B virus core protein as a carrier. The high-purity antigen component is prepared by efficiently expressing antigen protein in escherichia coli and then performing in-vitro purification, degeneration and renaturation and self assembling into virus-like particles (VLPs). The RSVG protein contained in the VLPs and the antigenic epitope of the T cells of the M2 protein are simultaneously expressed, so that the capability of the vaccine for introducing specific immunity response and anti-RSV infection immunity protection can be enhanced, the balanced Th1 / Th2 immunity response can be induced and the RSV vaccine is prevented from enhancing the incidence of diseases. Animals are immunized and inoculated with VLPs vaccines to induce organisms to generate high-level RSV neutral antigens, enhanced Th1 cell factor level and effective protection on RSV attack infection.

Owner:WUHAN UNIV

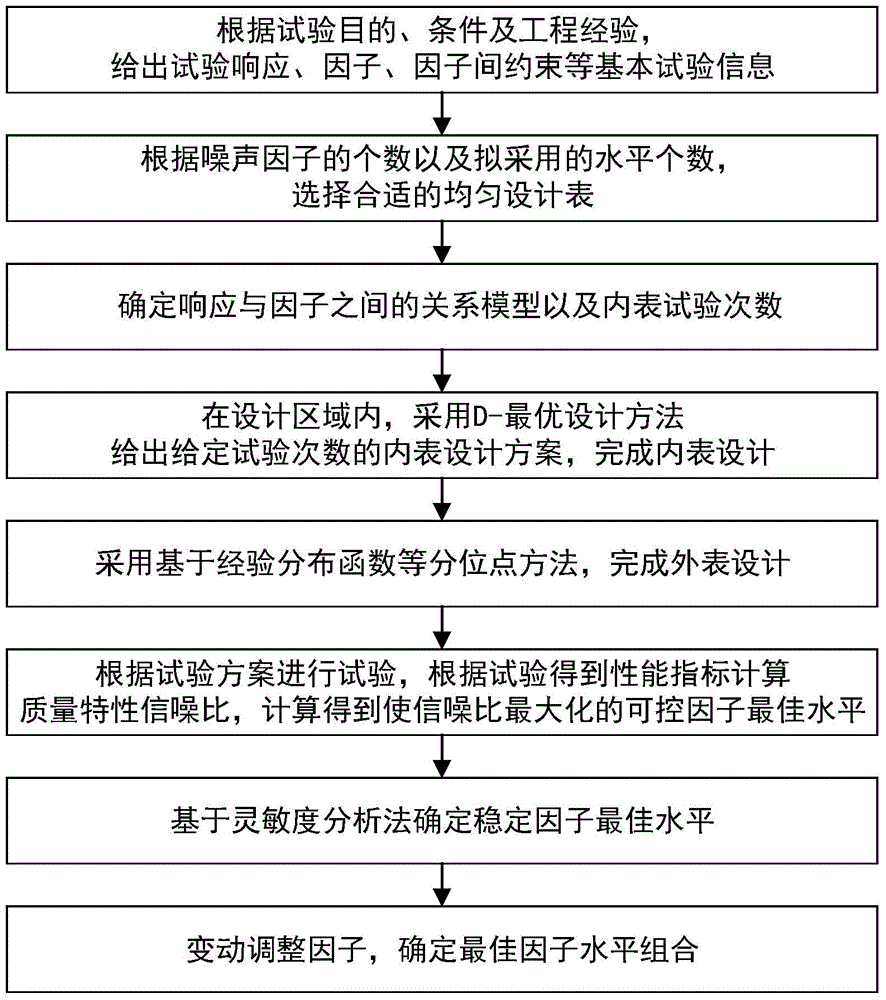

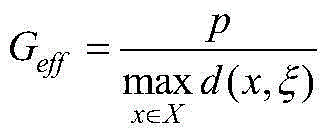

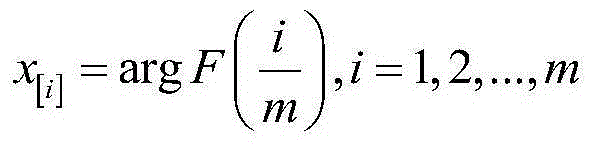

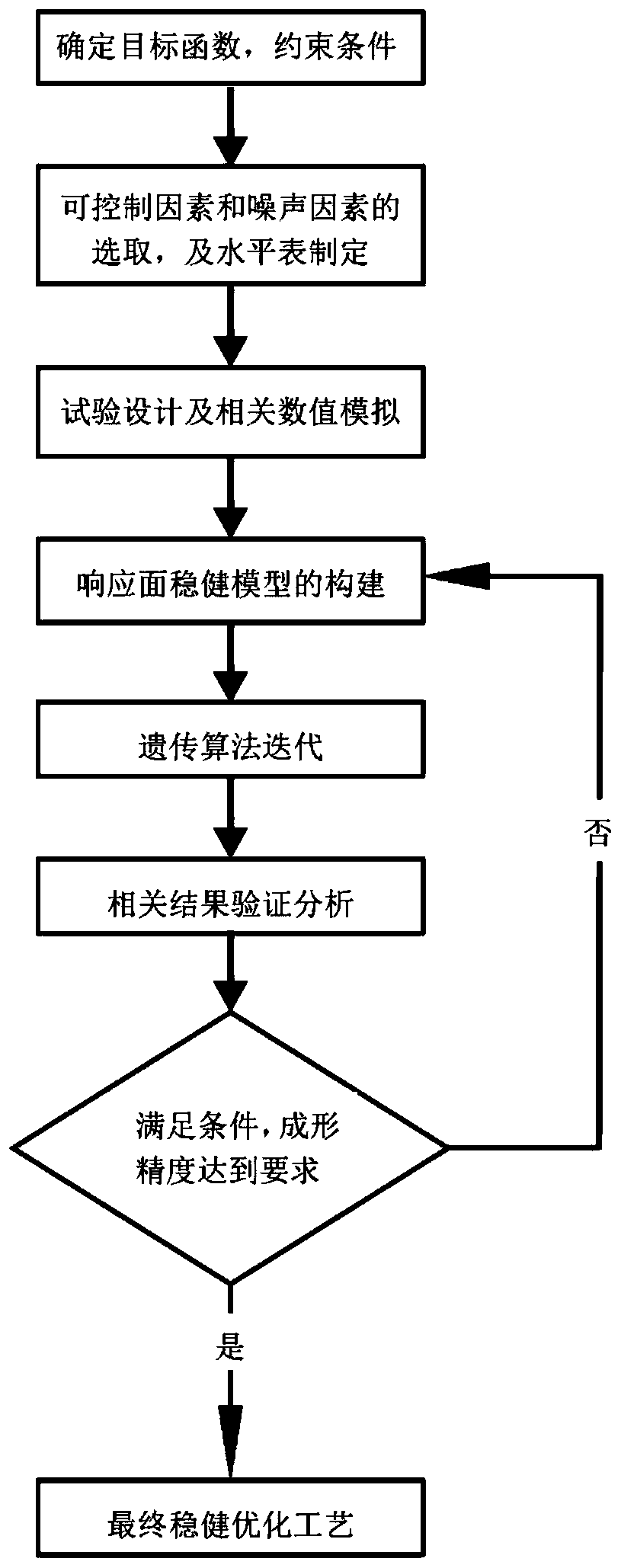

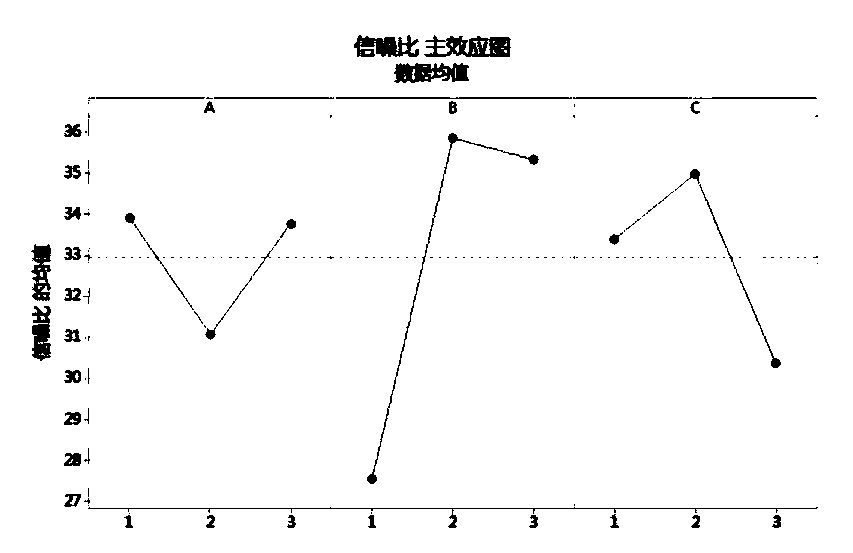

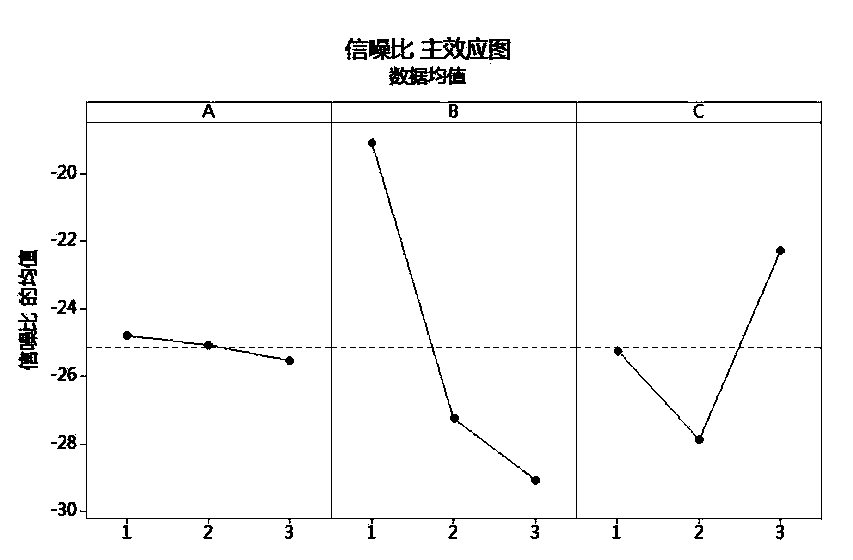

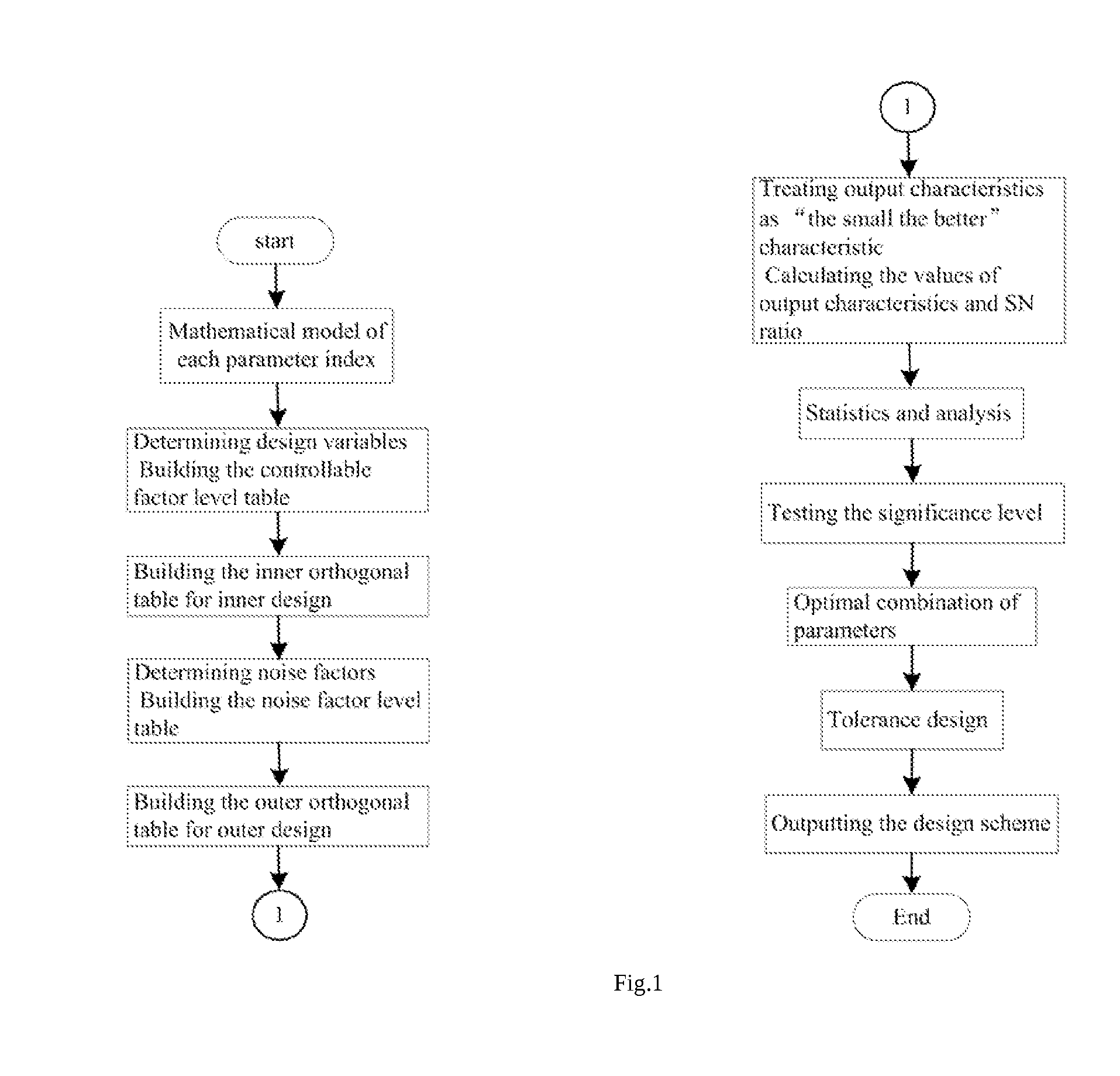

D-optimal inner table design based Taguchi experimental design method

InactiveCN105046079AFlexible Experimental DesignEfficient Design of ExperimentsSpecial data processing applicationsRelational modelSignal-to-noise ratio (imaging)

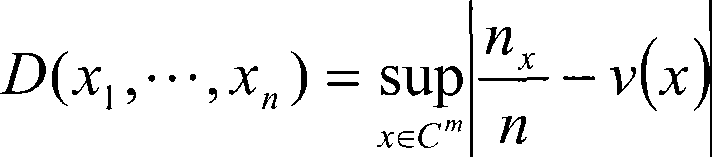

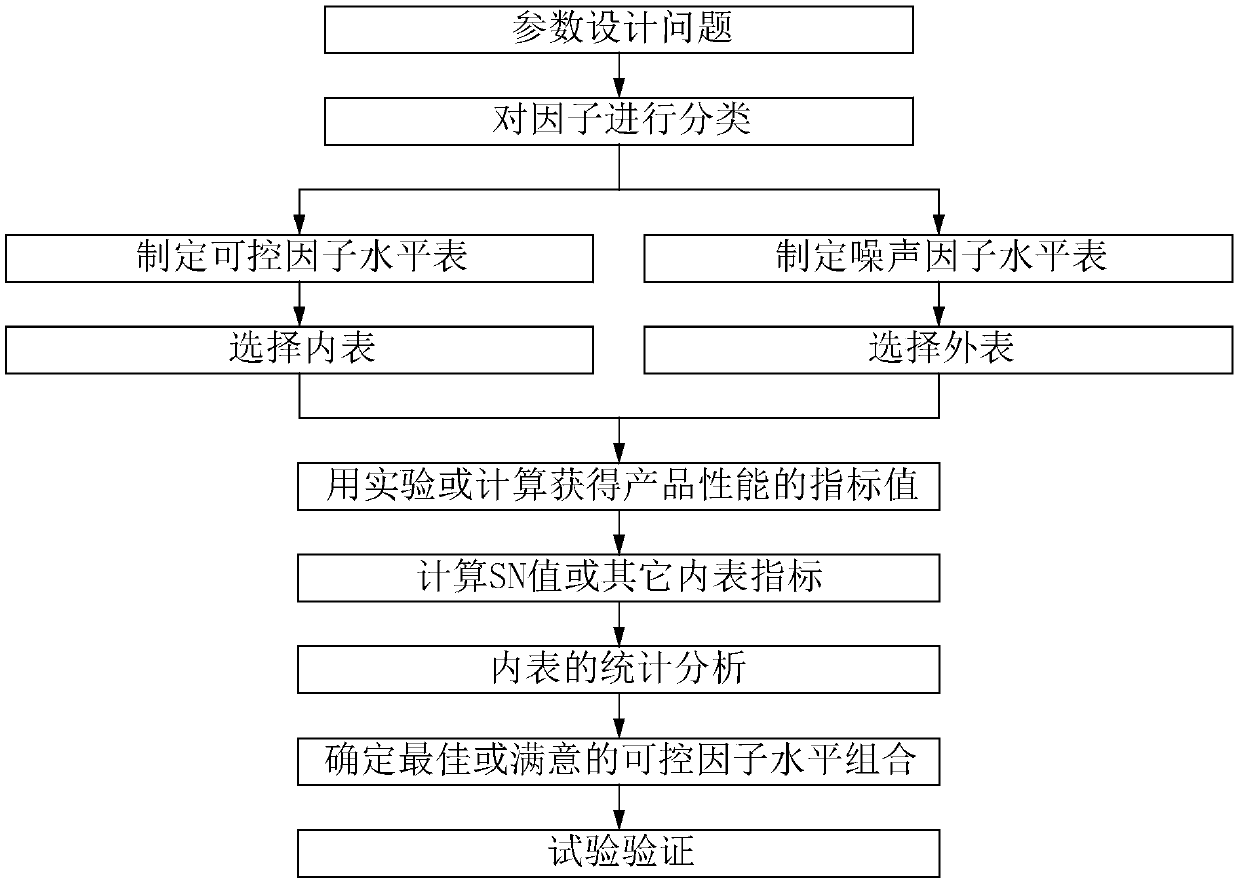

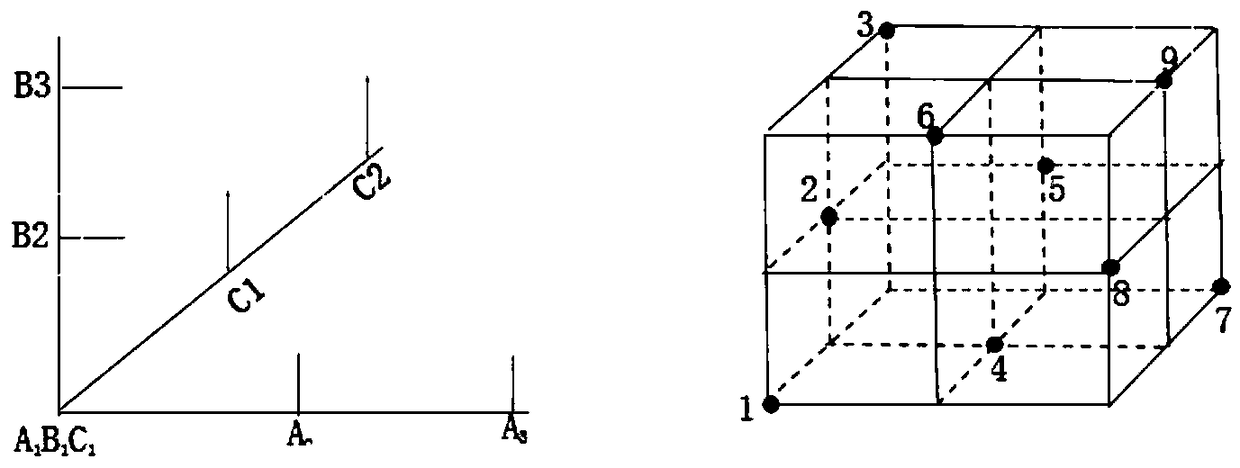

The present invention provides a D-optimal inner table design based Taguchi experimental design method. The method comprises specific steps of: 1. providing basic experimental information including experimental responses, factors, inter-factor restrictions and the like according to experimental objectives, conditions and engineering experience; 2. selecting a proper uniform design table according to the number of noise factors and the number of proposed levels; 3. determining a relationship model between the responses and the factors, and the number of times of inner table experiments; 4. in a design area, providing an inner table design scheme with given experimental times by using the D-optimal design method, and completing the inner table design; 5. completing external table design by using an empirical distribution function based point equal-division method; 6. performing an experiment according to an experimental scheme, calculating a signal-to-noise ratio of mass properties by using performance indexes obtained from the experiment, and calculating the optimal level of a controllable factor that enables the signal-to-noise ratio to be maximized; 7. determining the optimal level of a stable factor by a sensitivity analysis method; and 8. changing and adjusting the factors to determine an optimal factor level combination.

Owner:BEIHANG UNIV

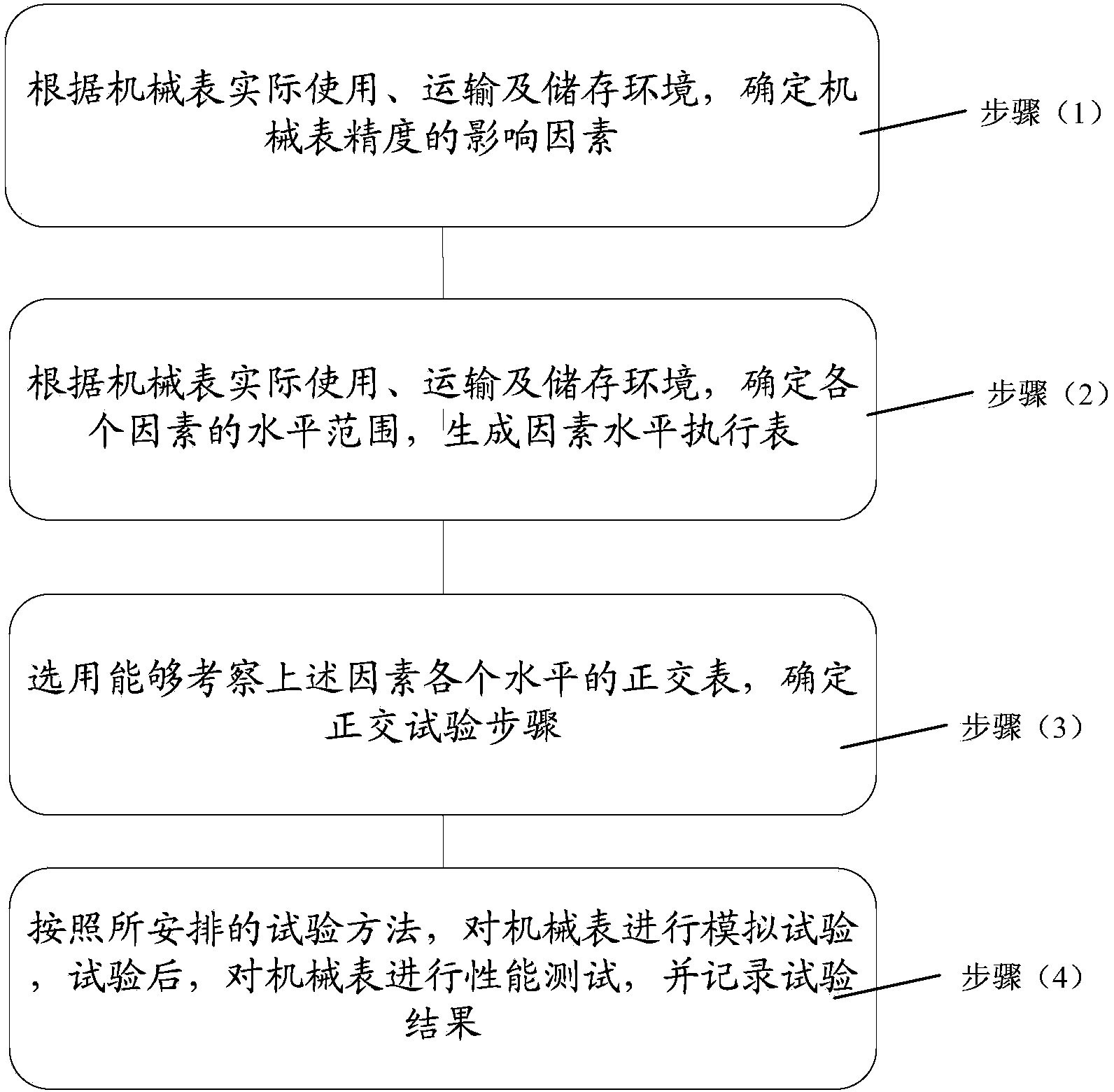

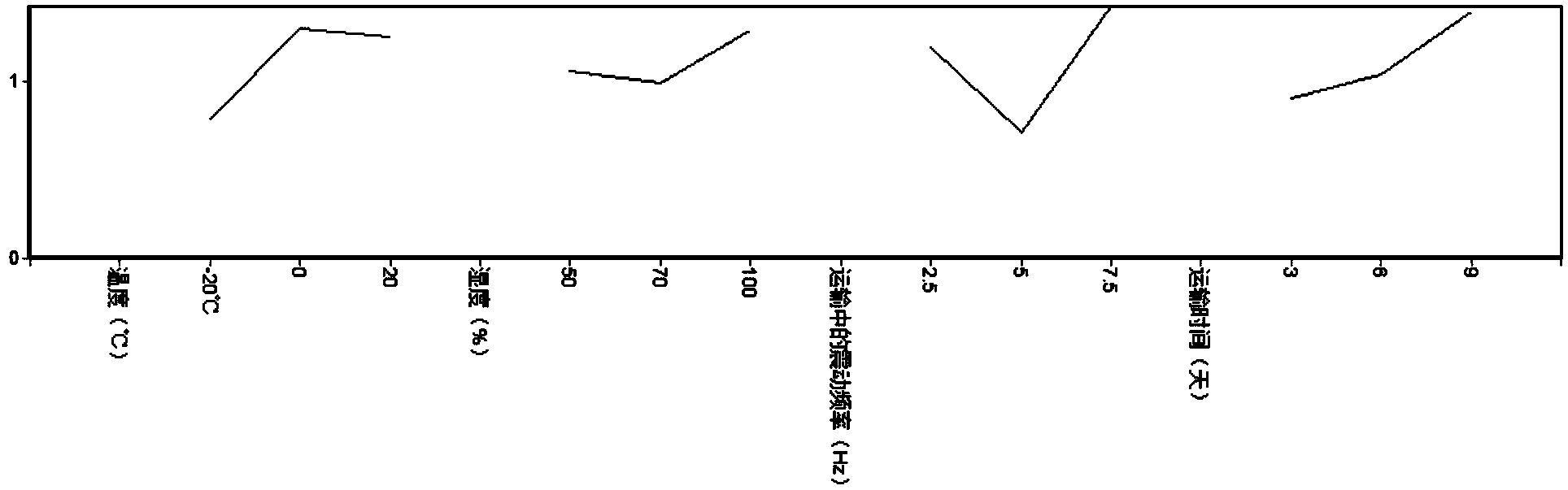

A method for detecting precision influence factors of a common mechanical watch

Provided is a method for detecting precision influence factors of a common mechanical watch. The common mechanical watch does not comprise a quakeproof mechanical watch and a mechanical watch, of which the antimagnetic performance is above 4800A / m<2>. The detection method comprises the followings steps: 1) determining influence factors of precision of the mechanical watch according to actual use, transportation and storage environment of the mechanical watch; 2) determining level range of each factor and generating a factor level execution table according to the actual use, transportation and storage environment of the mechanical watch; 3) selecting and using an orthogonal table capable of checking each level of the factors and determining orthogonal test steps; and 4) carrying out simulation test on the mechanical watch, and after test, carrying out performance test on the mechanical watch and recording test results. According to the method, not only various factors influencing the precision of the mechanical watch and the influence degree can be obtained in the trial production stage of the products, thereby providing basis for actual use, transportation and storage of the product; but also the quantitative evaluation can be carried out on the various factors influencing the precision of the mechanical watch.

Owner:ZHUHAI ROSSINI WATCH IND

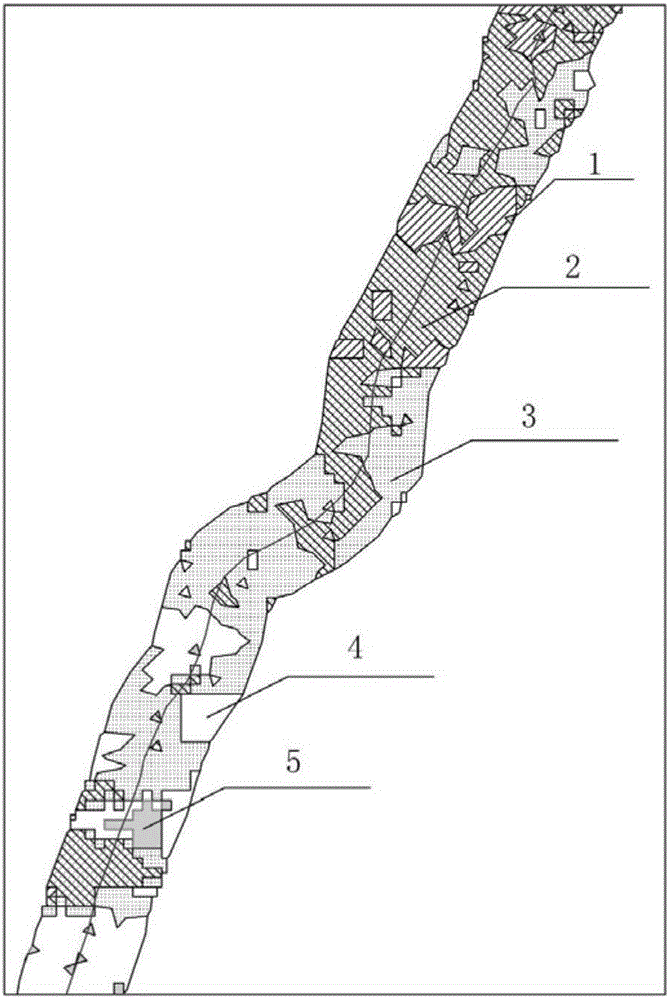

Vegetation restorability evaluation method based on investigation and factor correction

Provided is a vegetation restorability evaluation method based on investigation and factor correction. The method includes that according to the natural vegetation types and the main environmental factor spatial distribution, the regional vegetation factor level and the main environmental factor level are defined, the points selected from the mutual uncoordinated parts of the two levels are subjected to uncoordinated point screening, on-site reconnaissance and reexamination, the environmental factors are developed and are combined with the main environmental factor evaluation result to define the serial environmental factor levels, the consistency of the levels with the actual site is evaluated, the vegetation factors and the environmental factors finally for the vegetation restorability evaluation are determined, and the final vegetation restorability level is evaluated. The evaluation method is scientific, practical, and is suitable for application.

Owner:CHINA ACAD OF TRANSPORTATION SCI

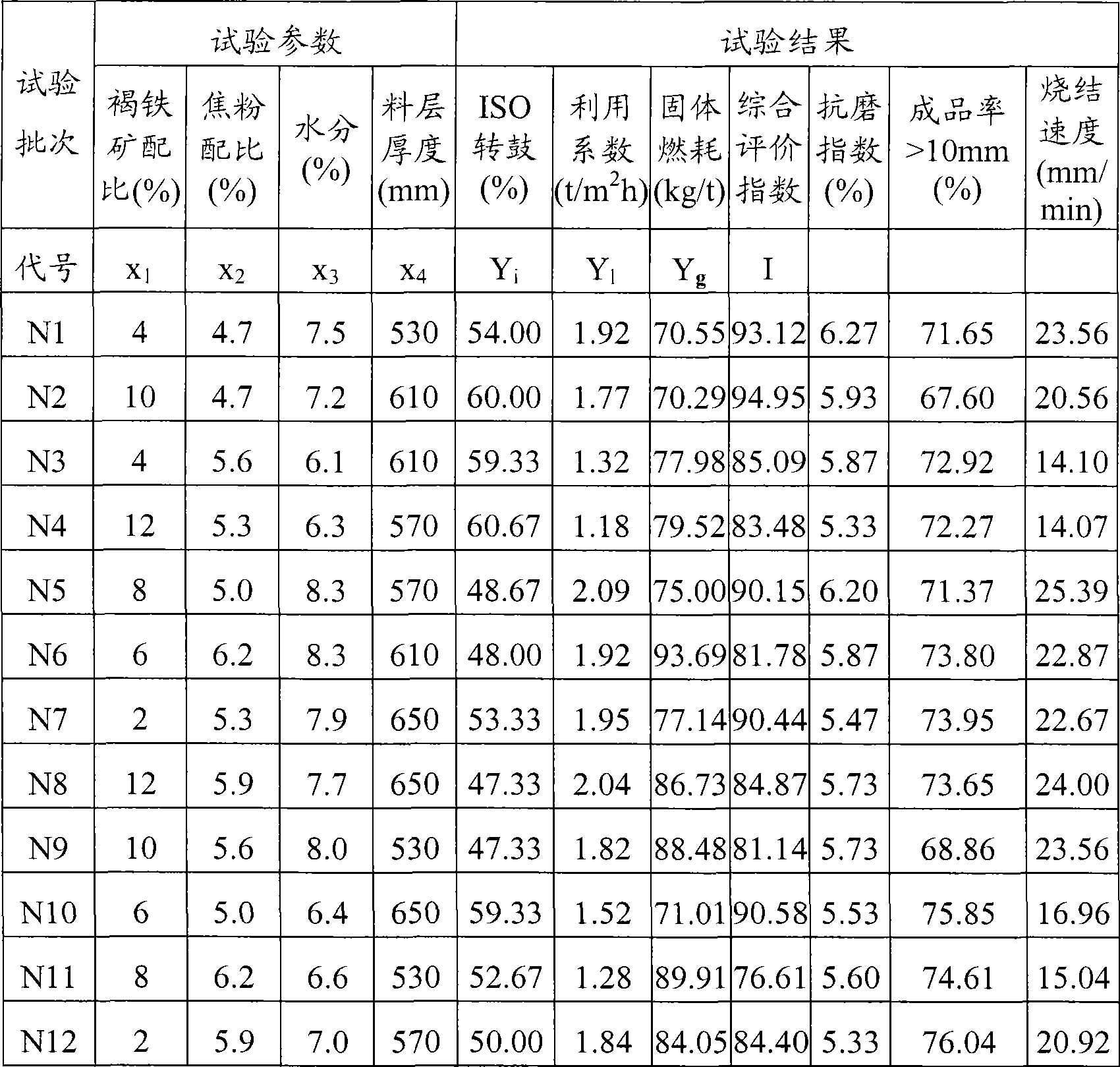

Iron ore sintering test method

The invention discloses an iron ore sintering test method which includes steps as follows: confirming object and influence factor of the iron ore sintering test method for processing multi-factor multi-level test; selecting suitable uniform design test method for confirming a used uniform design table; processing iron ore ingredient, mixing, igniting and air suction sintering test according with the confirmed uniform design table for obtaining a series test result; utilizing the test result corresponding to the factor level of the uniform design table for analyzing, using method of direct preferential and model optimum for confirming an optimum parameter combination of the iron ore sintering, and processing must validated test. The method can shorten test time, reduce energy consumption and obtain test result with high efficiency and high quality.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

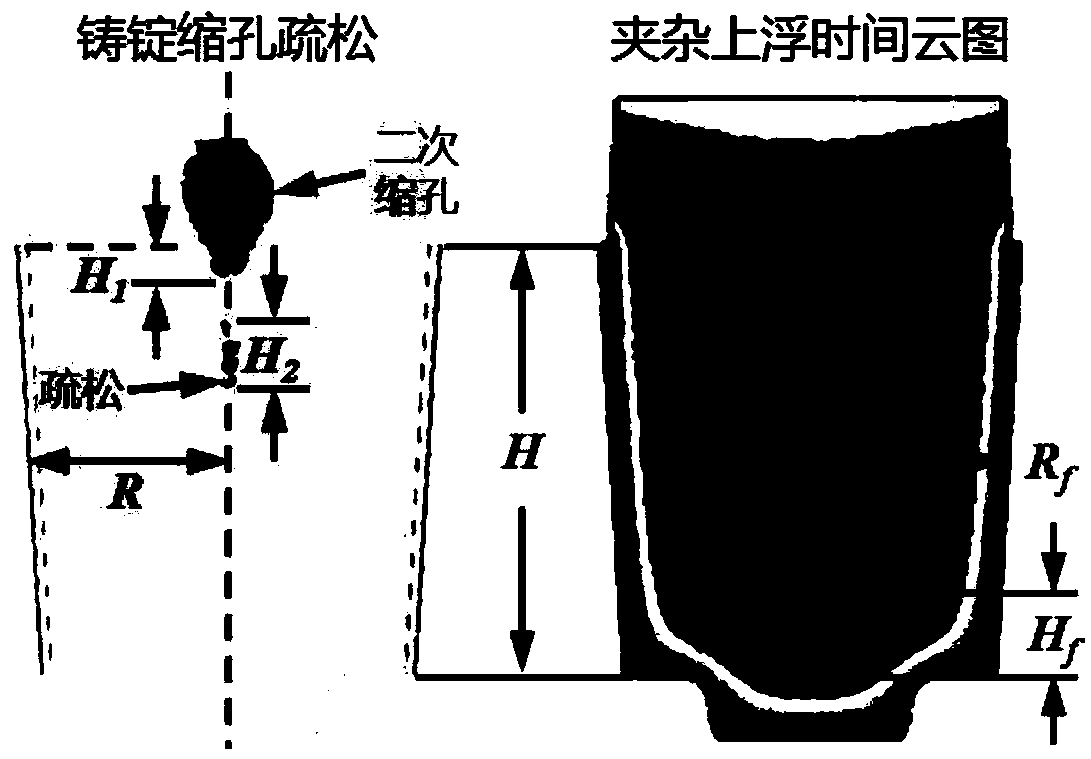

Ingot casting quality evaluation method based on numerical simulation

ActiveCN108733959AReduce R&D costsShorten development timeDesign optimisation/simulationSpecial data processing applicationsIngot castingCasting defect

The invention discloses an ingot casting quality evaluation method based on numerical simulation. A factor which affects the quality of an ingot casting is taken as an investigation factor, a multi-factor multi-level full factorial orthogonal test is designed, the solidification process of each experiment is simulated and calculated through numerical simulation software, a first quality evaluationstandard coefficient which contains an ingot casting defects is established, an investigation factor and an equation corresponding to the first value are obtained through linear fitting, and responseoptimization is adopted to find the corresponding factor level, i.e., a parameter with the optimal ingot casting performance when the first value is a minimum value. A probability that metallurgy defects are generated in an ingot casting solidification process is lowered so as to improve ingot casting quality.

Owner:KUNMING UNIV OF SCI & TECH

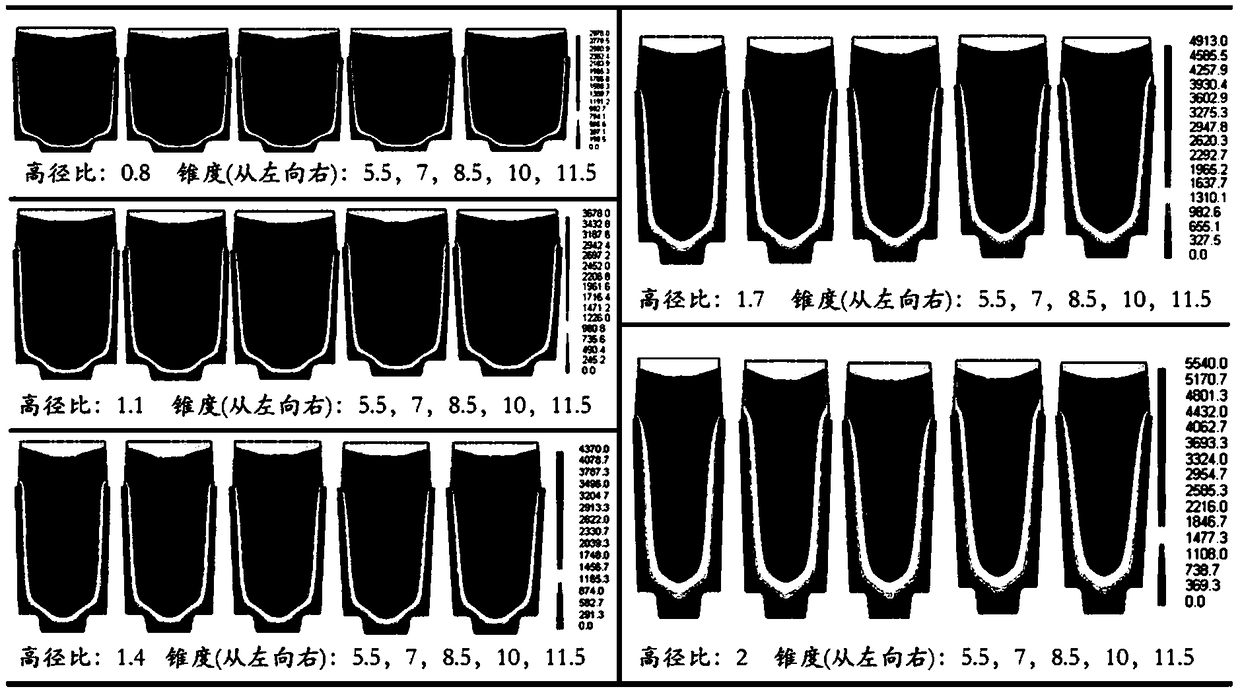

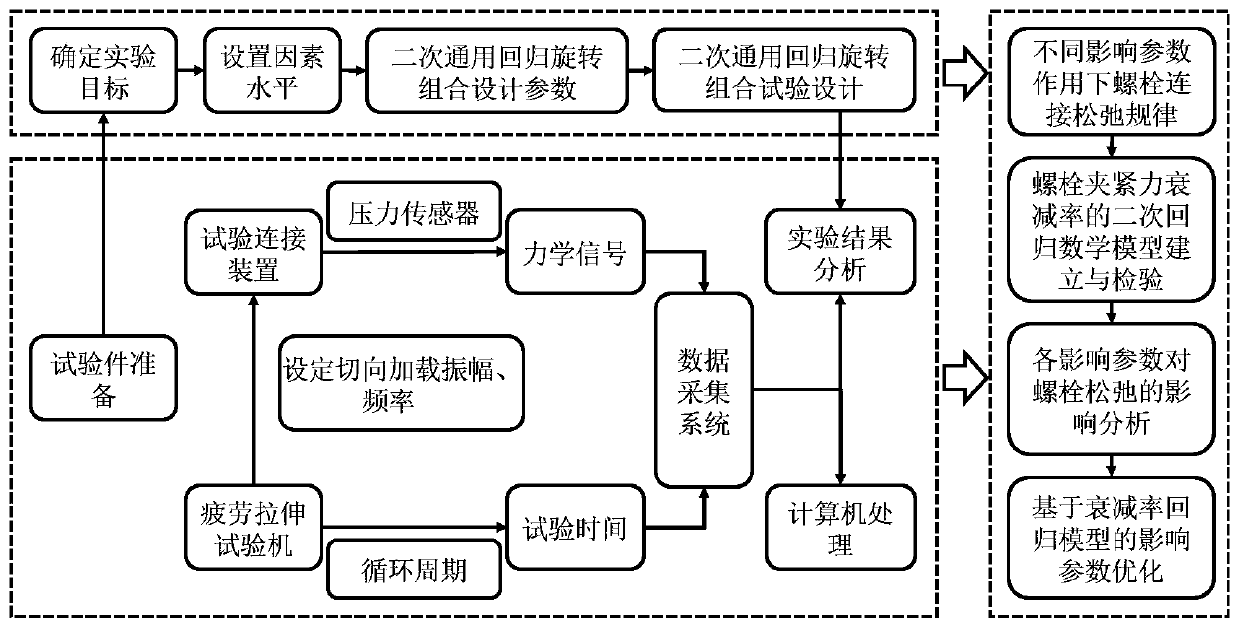

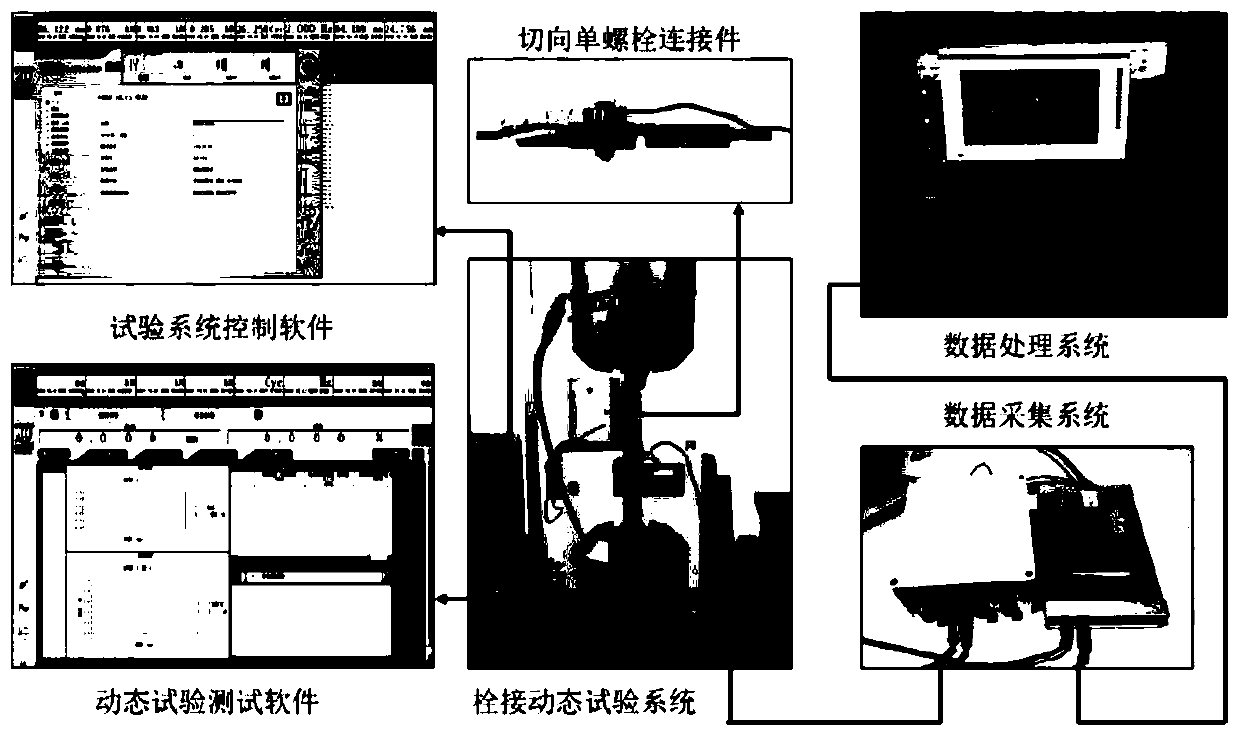

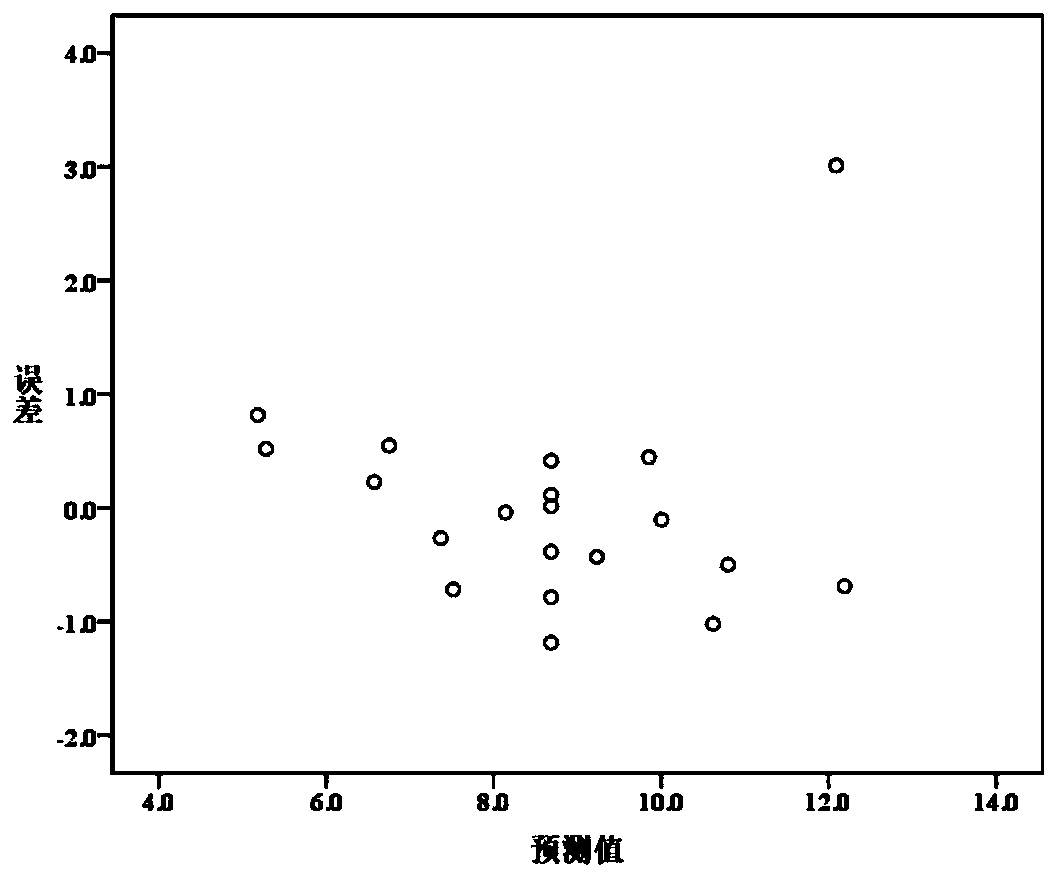

Bolt looseness main influence parameter evaluation and looseness relieving method under vibration working condition

ActiveCN110222311ABest combination of valuesSolve many trialsMachine part testingLoad modified fastenersUltrasound attenuationMathematical model

The invention discloses a method for evaluating main influence parameters of bolt looseness under a vibration working condition and relieving the looseness of the bolt, which comprises the following steps of: setting factor levels according to the influence parameters of bolt looseness under the vibration working condition and a range, and designing parameters and a test scheme by adopting a secondary universal rotation combination method. Test process, the change of the bolt clamping force is collected by a pressure sensor; obtaining the change rule of the clamping force of bolt connection along with time at a time node, and establishing a quadratic regression mathematical model of the attenuation rate of the bolt clamping force and the looseness influence parameters to obtain the most important influence parameters of bolt looseness under the vibration working condition and the influence proportion of each factor on the bolt looseness. The clamping force attenuation rate of the regression model is optimized through the lingo, optimized parameters for relieving bolt looseness are obtained, a large amount of time and repeated test times are saved, a theoretical basis is laid for abolt looseness solution, and the optimization design for relieving bolt looseness has scientificity.

Owner:BEIJING UNIV OF TECH

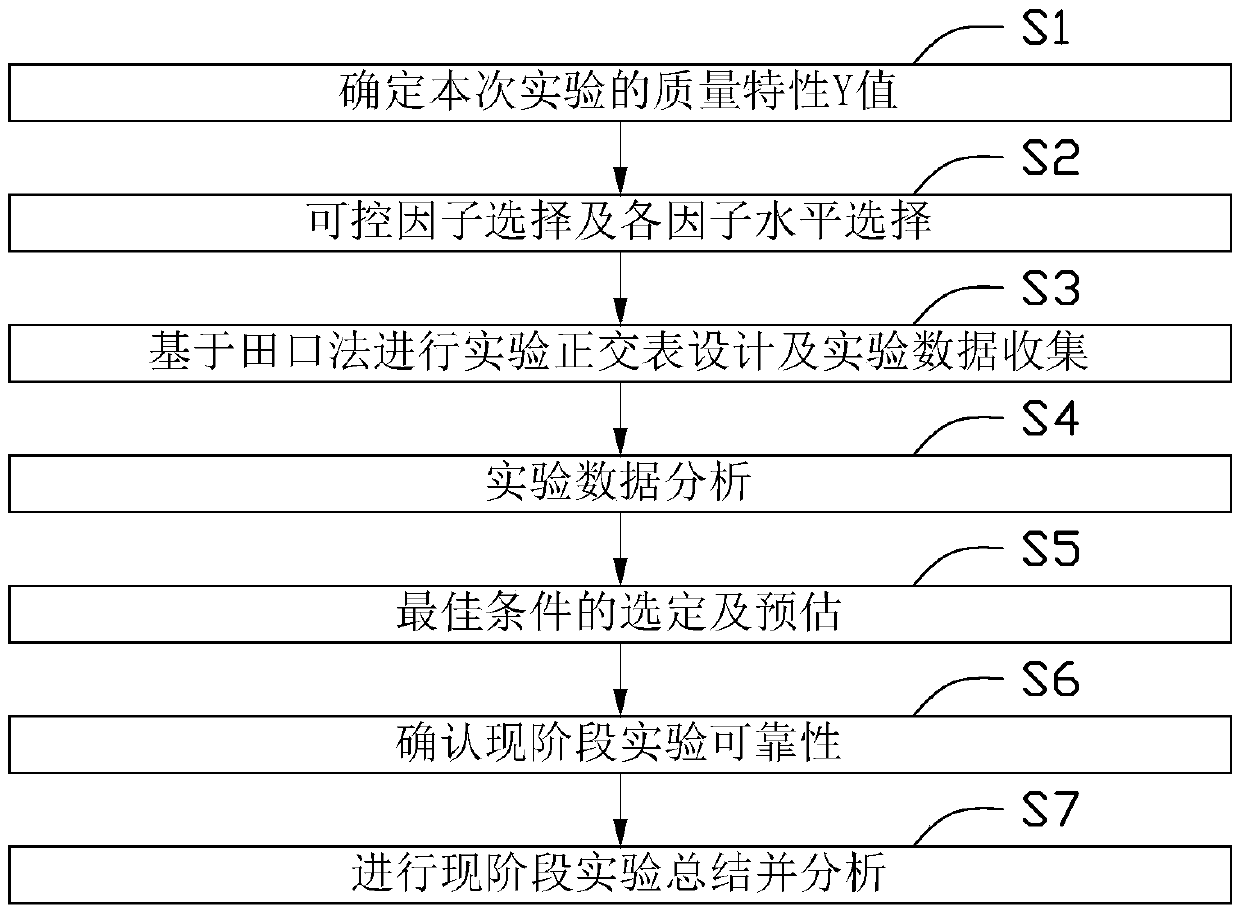

Optimization method for metal 3D printing technology parameters

InactiveCN110560685AReduce optimization costsReduce the number of experimentsAdditive manufacturing apparatusIncreasing energy efficiencyExperimental data analysisLayer thickness

The invention provides an optimization method for metal 3D printing technology parameters. The method comprises the steps of determining a quality characteristic Y value of this experiment; selectingcontrollable factors and all factor levels; designing an experiment orthogonal table and collecting experiment data based on a Taguchi method; analyzing the experiment data; selecting and estimating an optimal condition; determining the experiment reliability of the present stage; carrying out an experiment summary of the present stage and carrying out analysis. According to the optimization method for the metal 3D printing technology parameters, based on the Taguchi method, the experiment frequency is reduced, and the cost of optimizing the technology parameters is lowered. The rule of the influence of the controllable technology parameters such as powder spreading layer thickness, laser power, scanning speed and scanning line spacing distance on the specific density of a metal 3D printing part is disclosed.

Owner:FUSHIRUI PRECISION IND ZHENGZHOU CO LTD

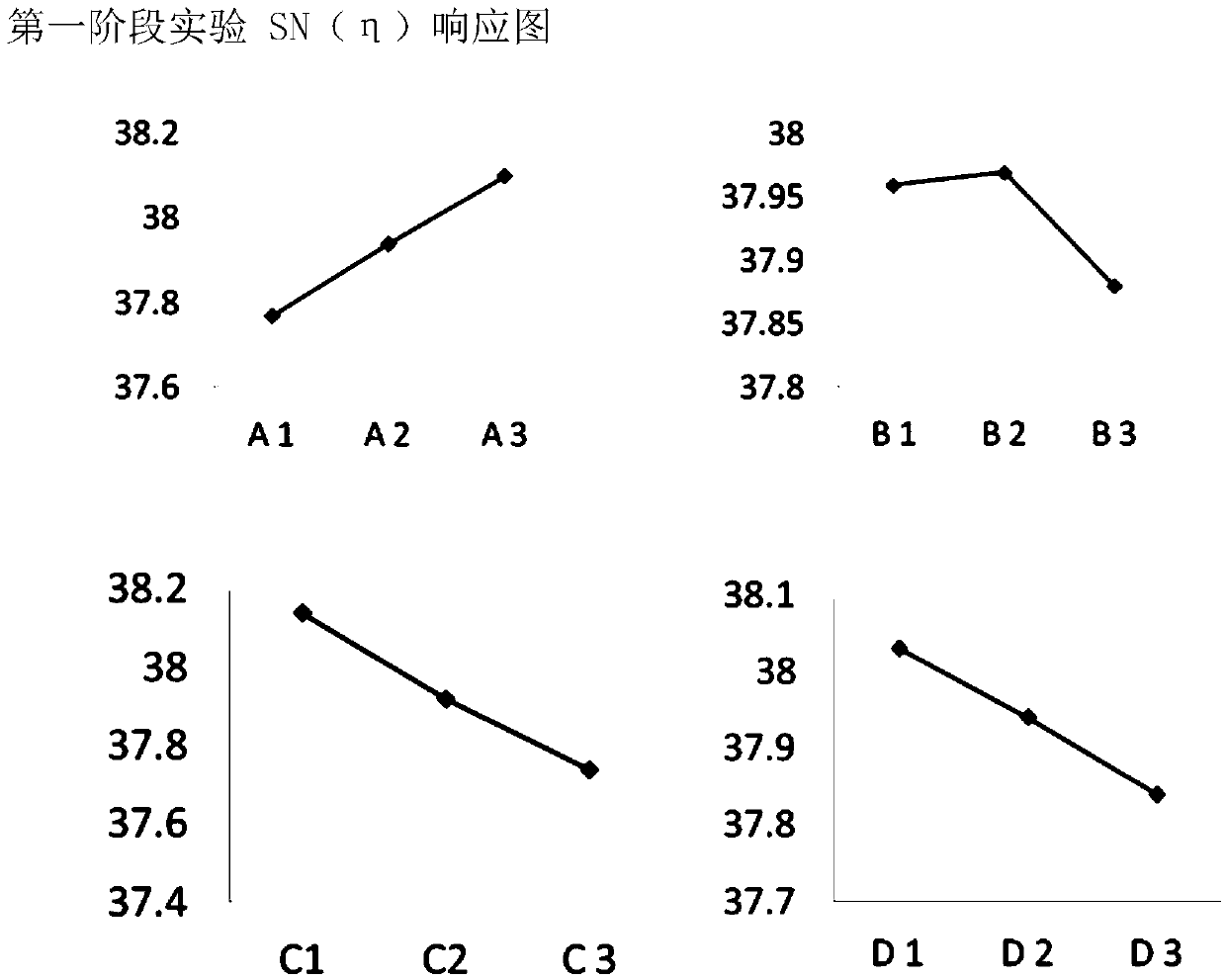

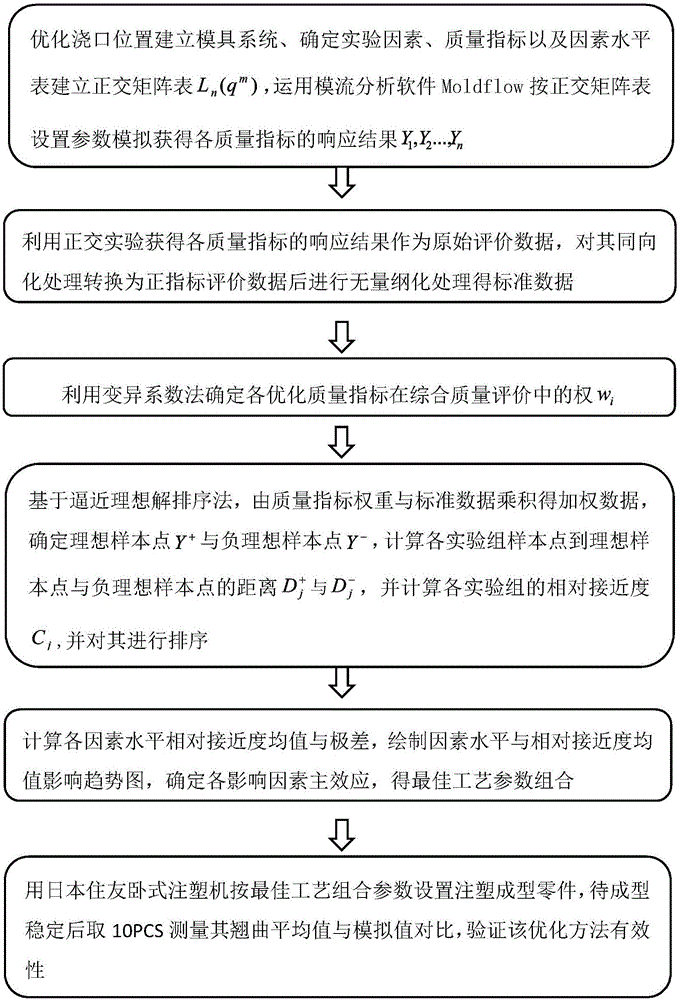

Method for multi-objective quality comprehensive evaluation optimization of injection molding technology

InactiveCN106682297ADesign optimisation/simulationSpecial data processing applicationsPattern recognitionObjective quality

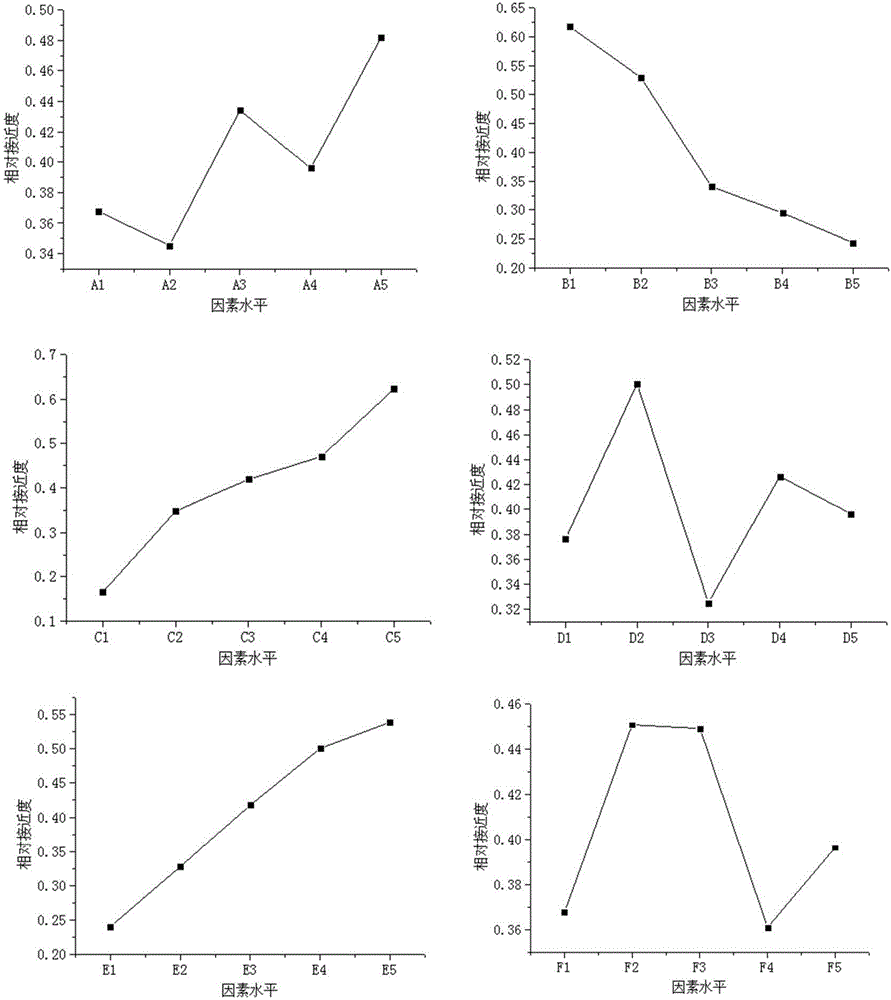

The invention relates to the technical field of injection molding and especially relates to a method for multi-objective quality comprehensive evaluation optimization of an injection molding technology. The method comprises the steps that response data of each quality index is obtained through combination of an orthogonal experiment method and mold flow analysis software Moldflow; then, by a variation coefficient method, the weight of each quality index in comprehensive evaluation quality is determined; secondly, a technique for order preference by similarity to an ideal solution is used to compute a relative similarity degree between each sample point and an ideal sample point; experimental sequence sequencing is conducted, wherein the priority is higher with the larger relative similarity degree; and then, a relative similarity mean and a range of each factor level are computed, and an influence tendency picture of the relative similarity means and factor levels is drawn, so factor main effects can be obtained. In this way, an optimal technological parameter combination with consideration of multi-objective quality can be obtained.

Owner:JIANGSU UNIV

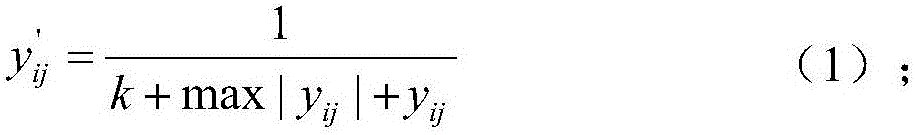

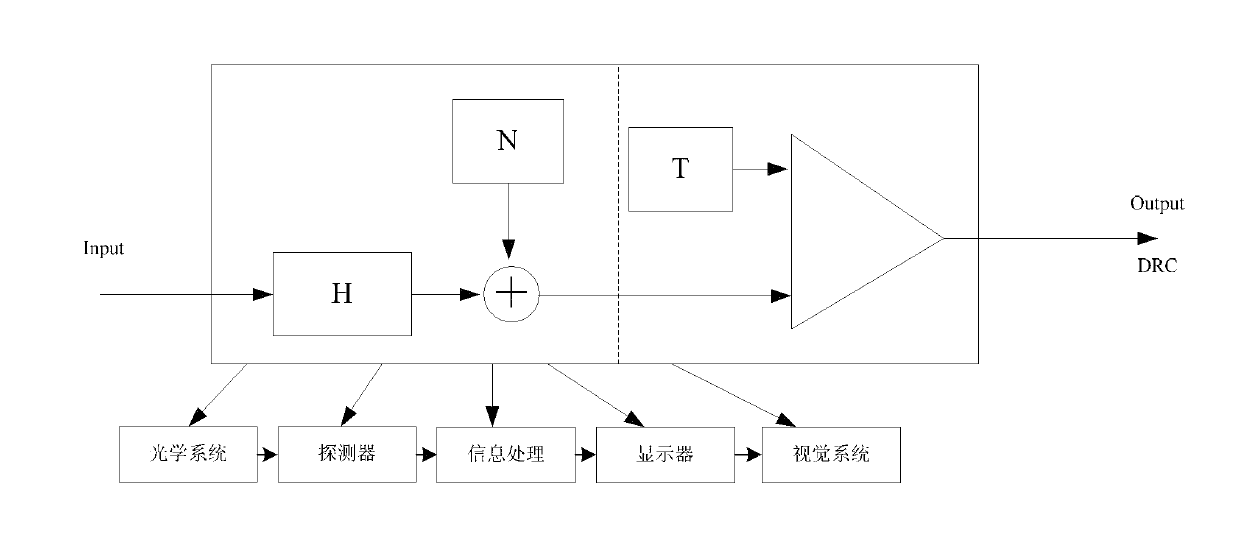

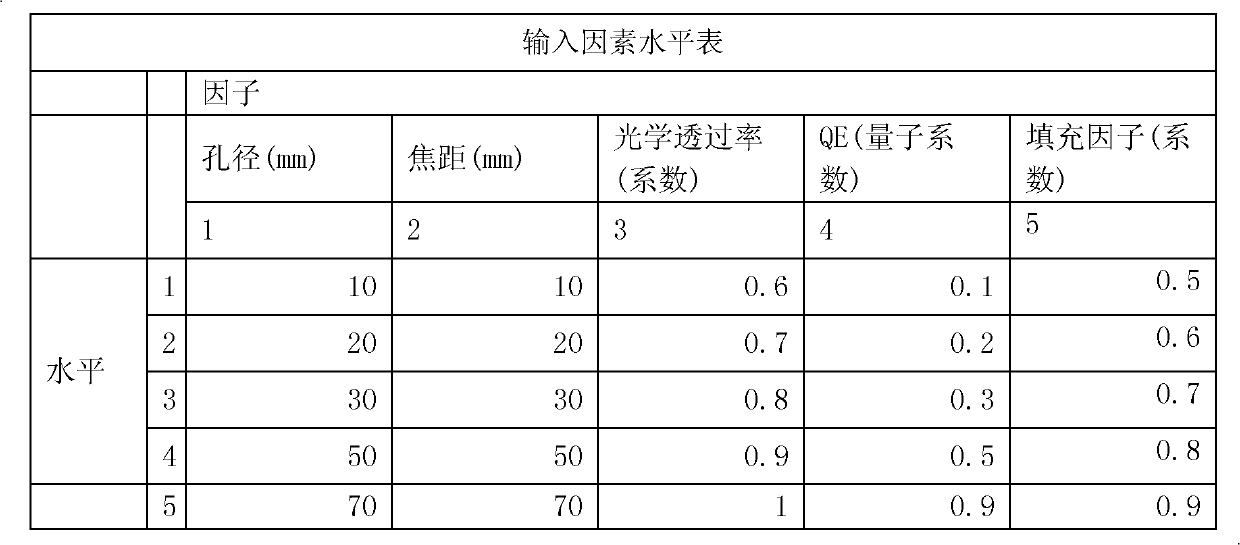

Performance evaluation experiment analysis method for photo-electric imaging system

ActiveCN102567608AFully reflectTypical reflectionSpecial data processing applicationsAnalysis methodSensitivity analyses

The invention relates to a performance evaluation experiment analysis method for a photo-electric imaging system, which includes the following steps: building a photo-electric imaging system performance prediction model; dividing input factor sets and output index sets in the photo-electric imaging system performance prediction model; conducting screening experiment on the input factor sets; dividing input factor levels of the model according to screening experiment results and building a model input factor level graph; selecting orthogonal graphs according to the model input factor level graph to form experiment schemes; invoking the performance prediction model to calculate the output index sets corresponding to each experiment scheme; and performing range analysis and sensitivity analysis by aid of the output index sets and finishing the experiment analysis process. The performance evaluation experiment analysis method for the photo-electric imaging system can compteltely, typically and equilibrium comparably reflect effects of all experiment input factors on experiment indexes with the fewest experiment times, analyzes and determines the optimum level of all the experiment input factors and primary and secondary relations of all the experiment input factors in effects on the output indexes through a range method, and simultaneously analyzes the sensitivity degree of the input factors on the output indexes through a sensitivity analysis method.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Compound traditional Chinese medicine for treating endometriosis and preparation method and application thereof

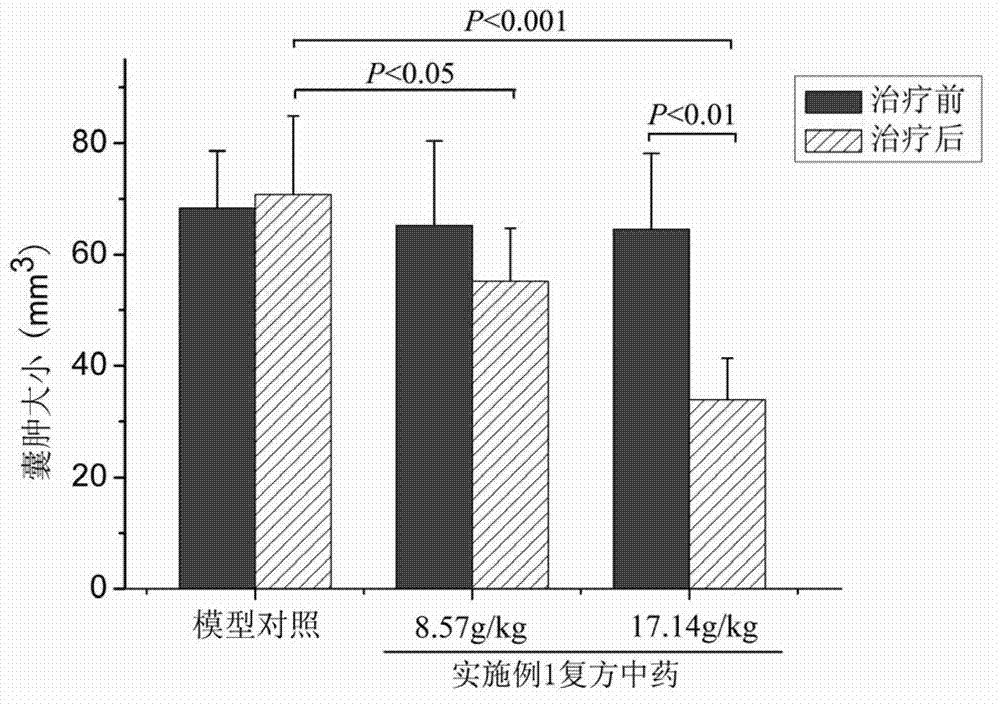

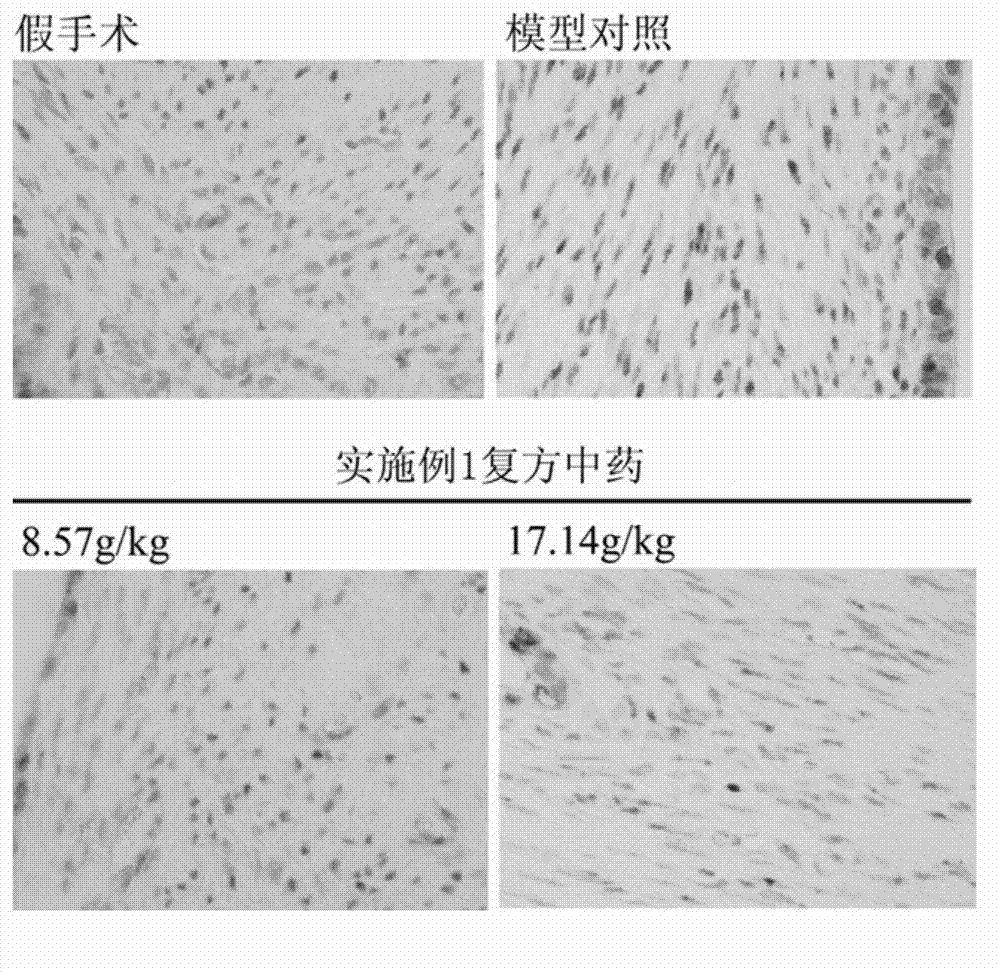

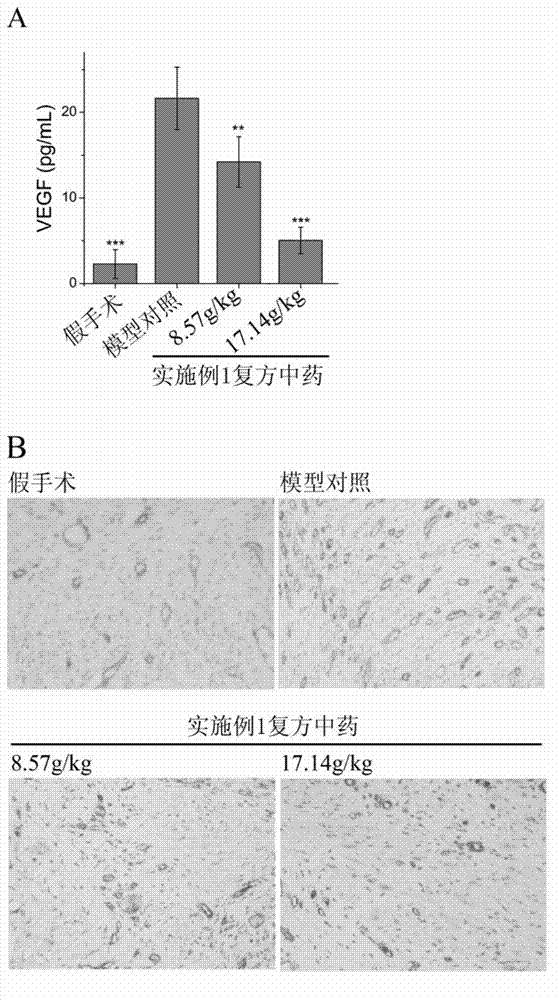

ActiveCN102813773APrevent proliferationSuppress generationSexual disorderPlant ingredientsMyrrhPeritoneal fluid

The invention discloses compound traditional Chinese medicine for treating endometriosis. The compound traditional Chinese medicine comprises, by weight, 8-12 parts of Pollen Typhae, 8-12 parts of trogopterus dung, 1-3 parts of dragon's blood, 12-20 parts of astragali radix, 8-12 parts of dipsacus root, 8-12 parts of roasted myrrh, 8-12 parts of corydalis yanhusuo, and 8-12 parts of szechwan chinaberry fruit. The invention further discloses a preparation method and application of the compound traditional Chinese medicine. The compound traditional Chinese medicine brings the advantages of multi-targeted treating of traditional Chinese medicine into full play. Lab observation of development of ectopic endometrium in a drug inhibited rat endometriosis model shows that the compound traditional Chinese medicine can inhibit development of endometriosis in terms of inhibiting cell proliferation, angiogenesis and invasion in ectopic endometrium tissues, lowering inflammatory cell factor level in peritoneal fluid and the like.

Owner:JIANGSU PROVINCE INST OF TRADITIONAL CHINESE MEDICINE

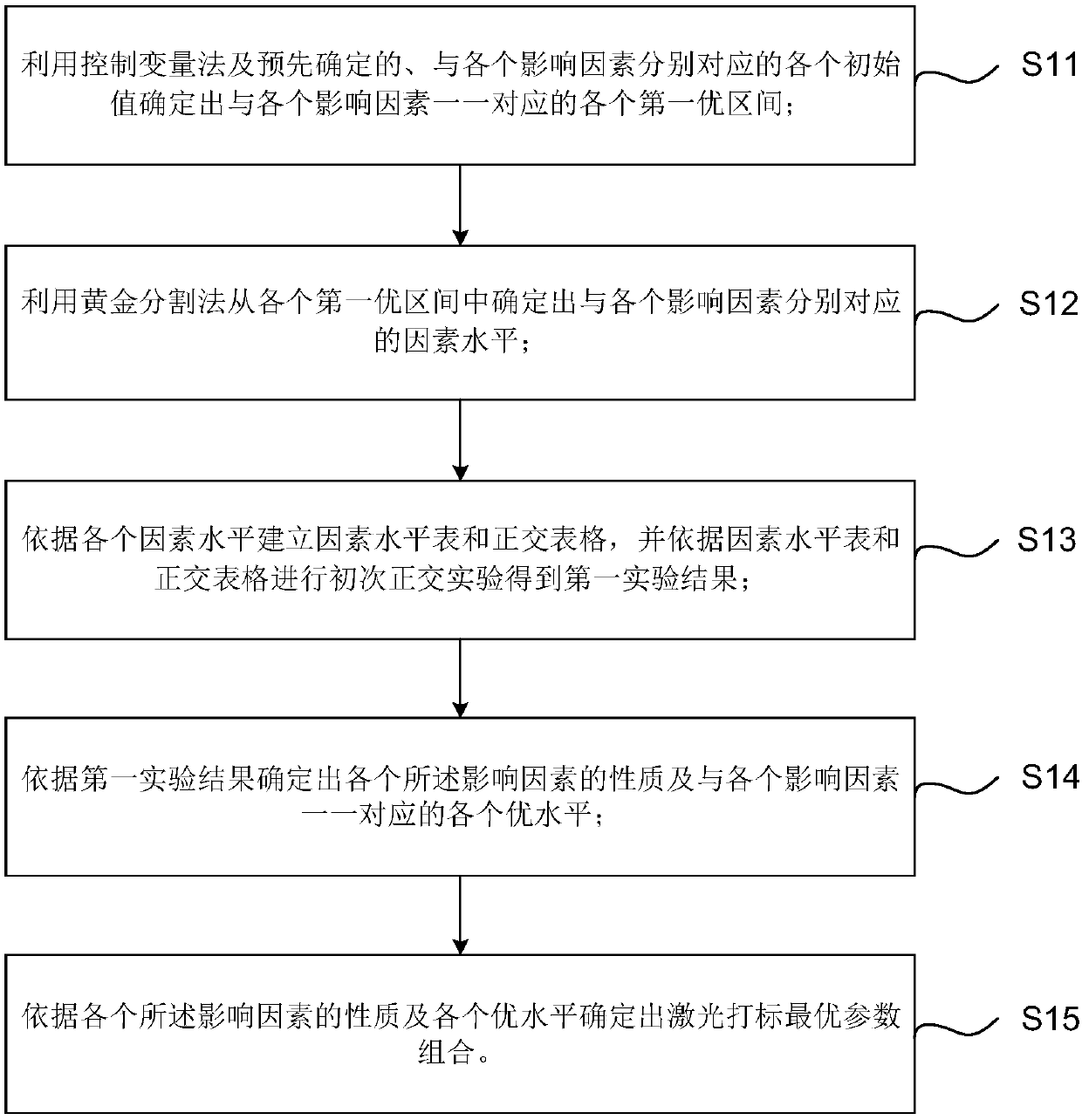

Method, device and system for calculating laser processing system technological parameters

ActiveCN108038297AHigh precisionImprove pattern qualityMulti-objective optimisationSpecial data processing applicationsLaser processingComputational physics

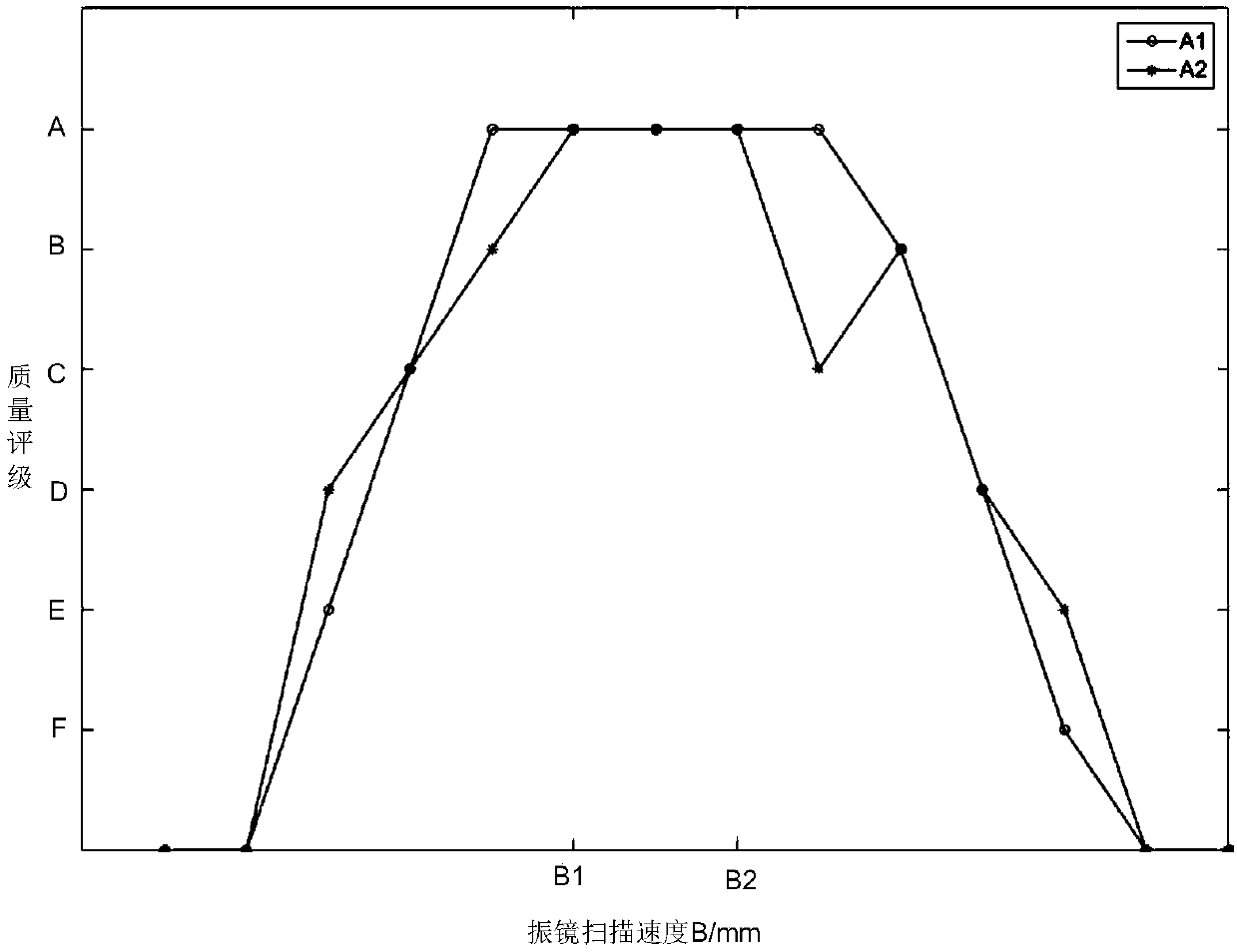

The embodiment of the invention discloses a method, device and system for calculating laser processing system technological parameters. The method for calculating the laser processing system technological parameters includes the steps of adopting a control variable method and various initial values to determine all first good intervals which are in one-to-to correspondence with all influence factors, wherein all the initial values correspond to all the influence factors; adopting a golden section method to determine factor levels which correspond to all the influence factors respectively fromall the first good intervals; according to all the factor levels, establishing a factor level list and a orthogonal form, and according to the factor level list and the orthogonal form, carrying out an orthogonal experiment for the first time to obtain first experiment results; according to the first experiment results, determining characteristics of all the influence factors and all good levels,wherein all the good levels are in one-to-one correspondence with all the influence factors; according to the characteristics of all the influence factors and all the good levels, determining an optimal technical parameter combination. By the adoption of the method, device and system for calculating the laser processing system technological parameters, the accuracy of the factor levels, the accuracy of the factor level list and the accuracy of the orthogonal form are improved, and therefore the accuracy of the optimal technical parameter combination is improved.

Owner:GUANGDONG ZHENGYE TECH

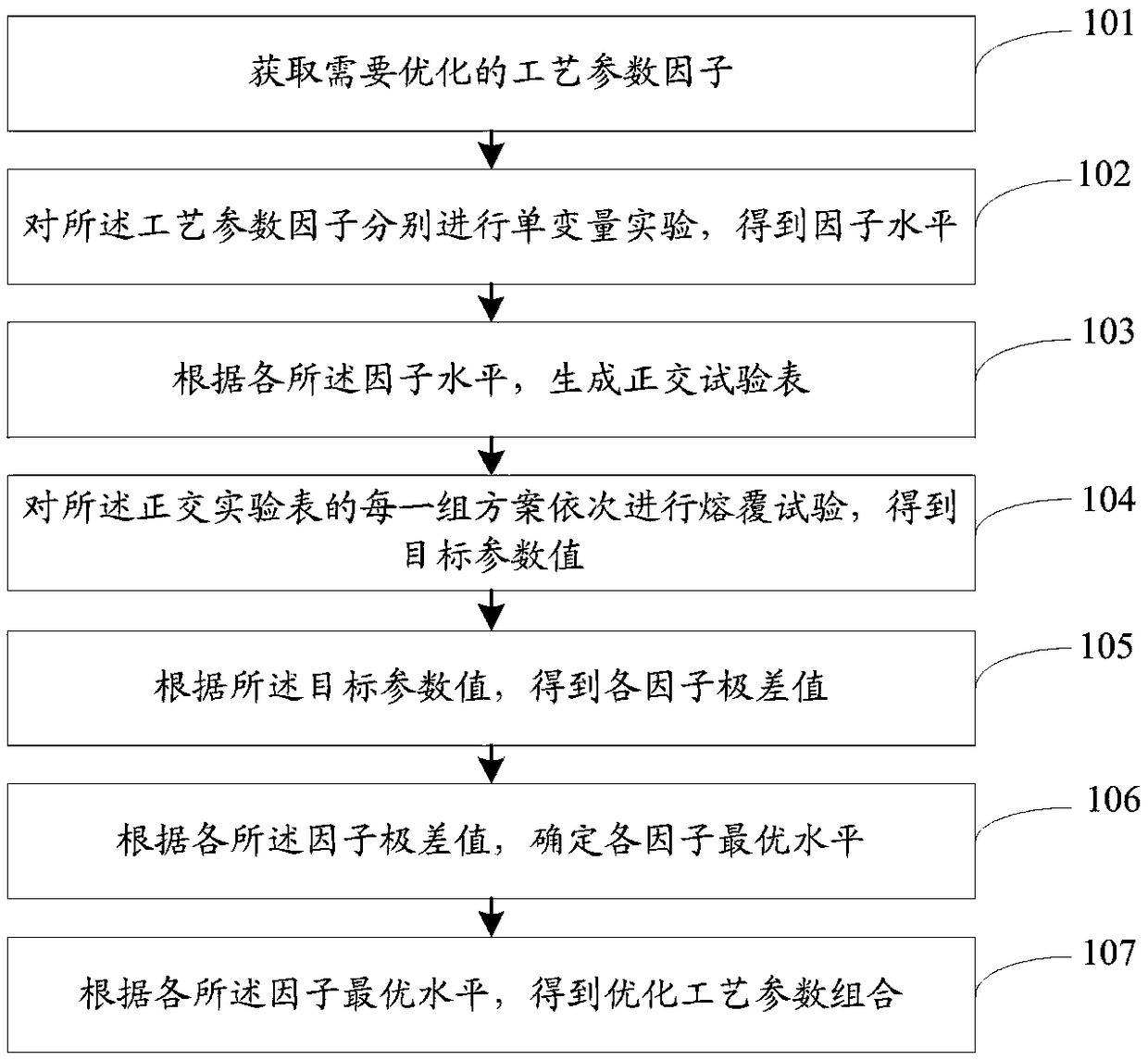

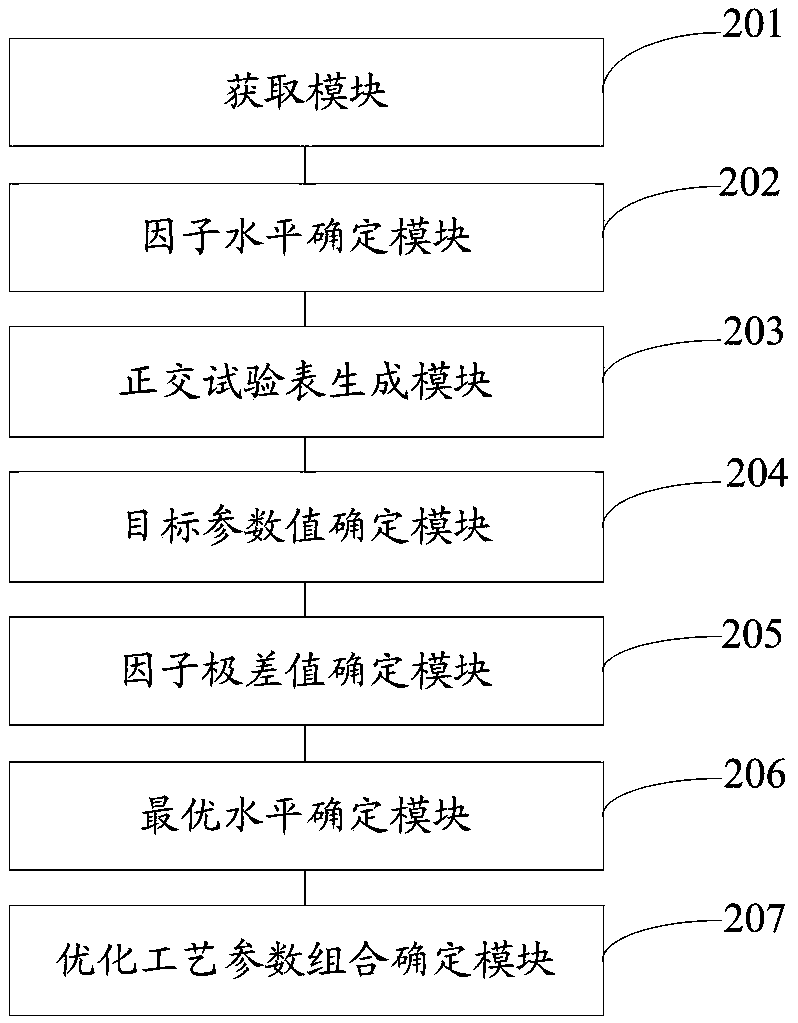

Electron beam cladding process parameter optimization method and system based on orthogonal method

InactiveCN109473145AAvoid cumbersome experiment cyclesReduce unnecessary data processingChemical processes analysis/designOrthogonal methodComputer science

The invention discloses an electron beam cladding process parameter optimization method based on an orthogonal method and an electron beam cladding process parameter optimization system based on the orthogonal method. The electron beam cladding process parameter optimization method comprises the following steps: acquiring process parameter factors required to be optimized; performing univariate experiments on the process parameter factors respectively to obtain factor levels; according to all the factor levels, generating an orthogonal experimental table; sequentially performing a cladding test on each set of scheme in the orthogonal experimental table to obtain target parameter values; according to the target parameter values, acquiring the extremely poor value of each factor; according to the extremely poor value of each factor, determining the optimal level of each factor; according to the optimal level of each factor, acquiring an optimized process parameter combination. Through adoption of the electron beam cladding process parameter optimization method or the electron beam cladding process parameter optimization system, a complicated experimental cycle can be effectively avoided and unnecessary data processing is reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

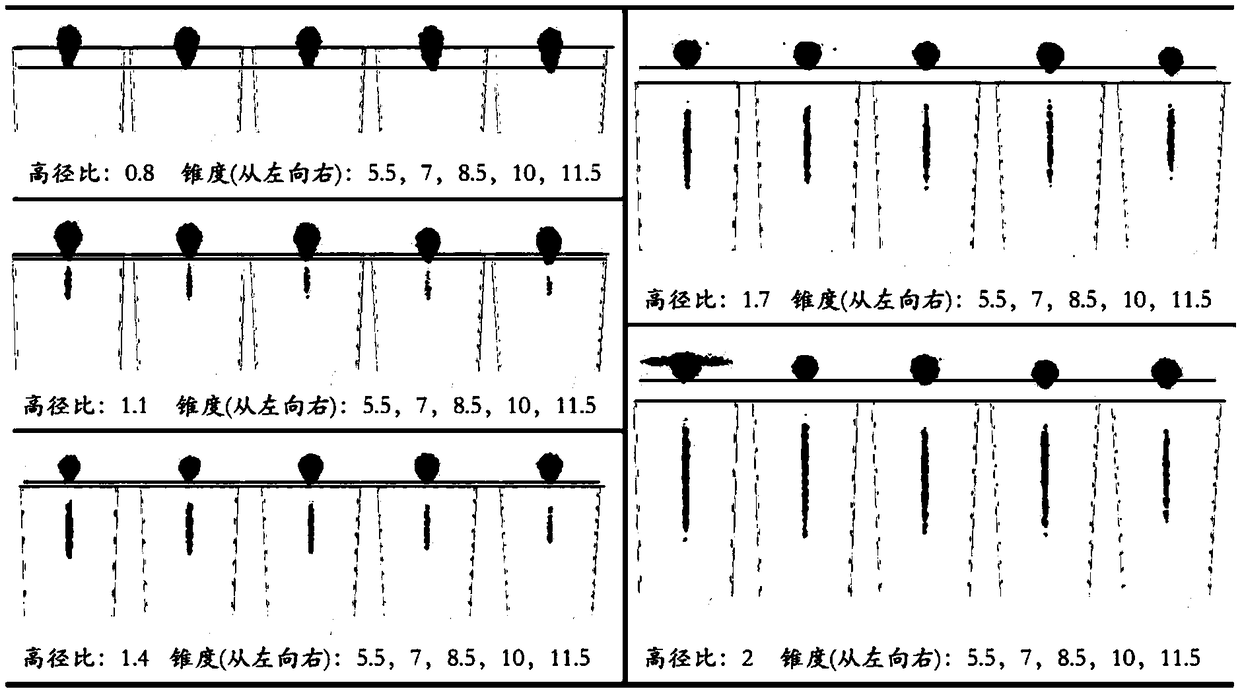

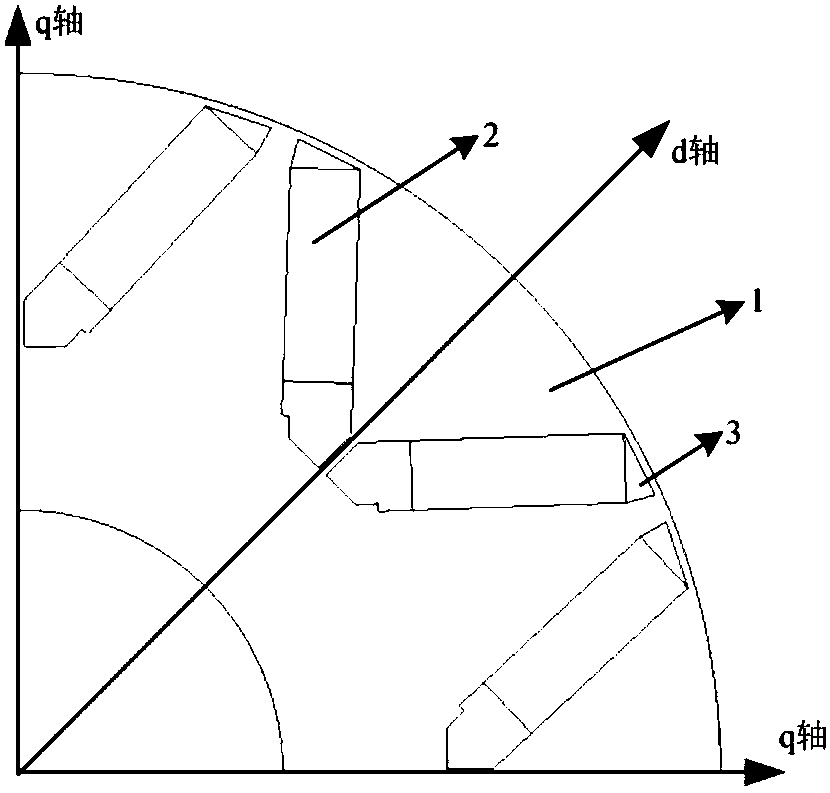

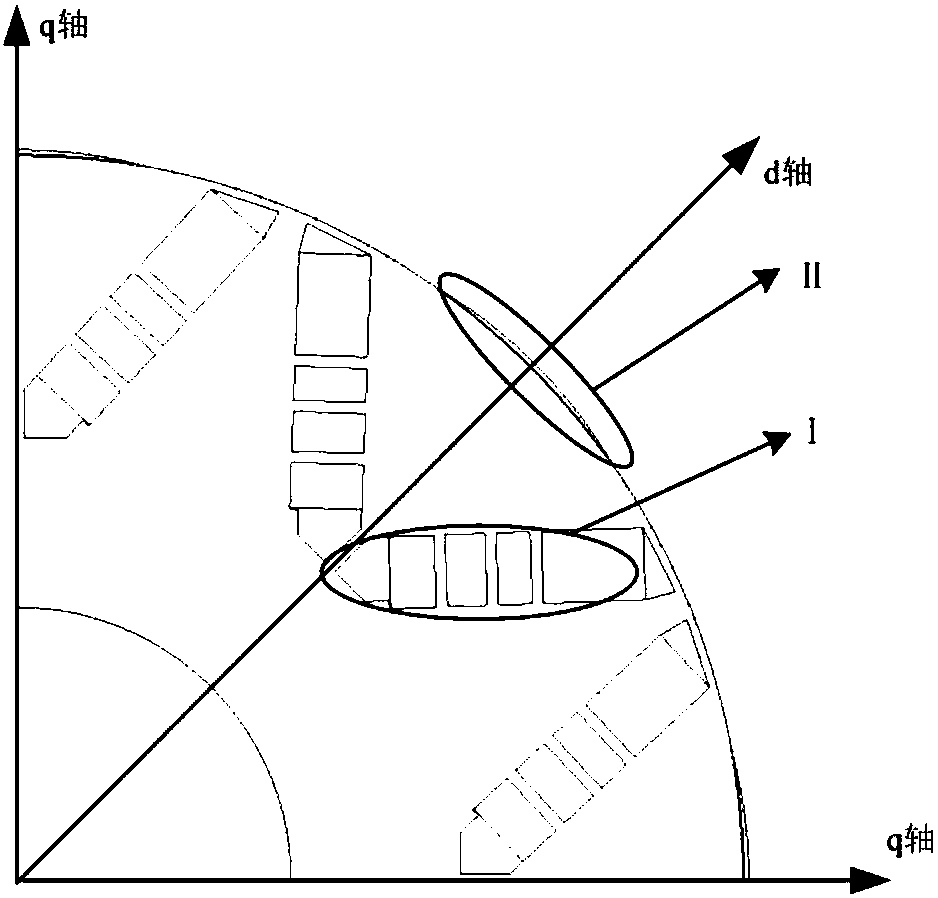

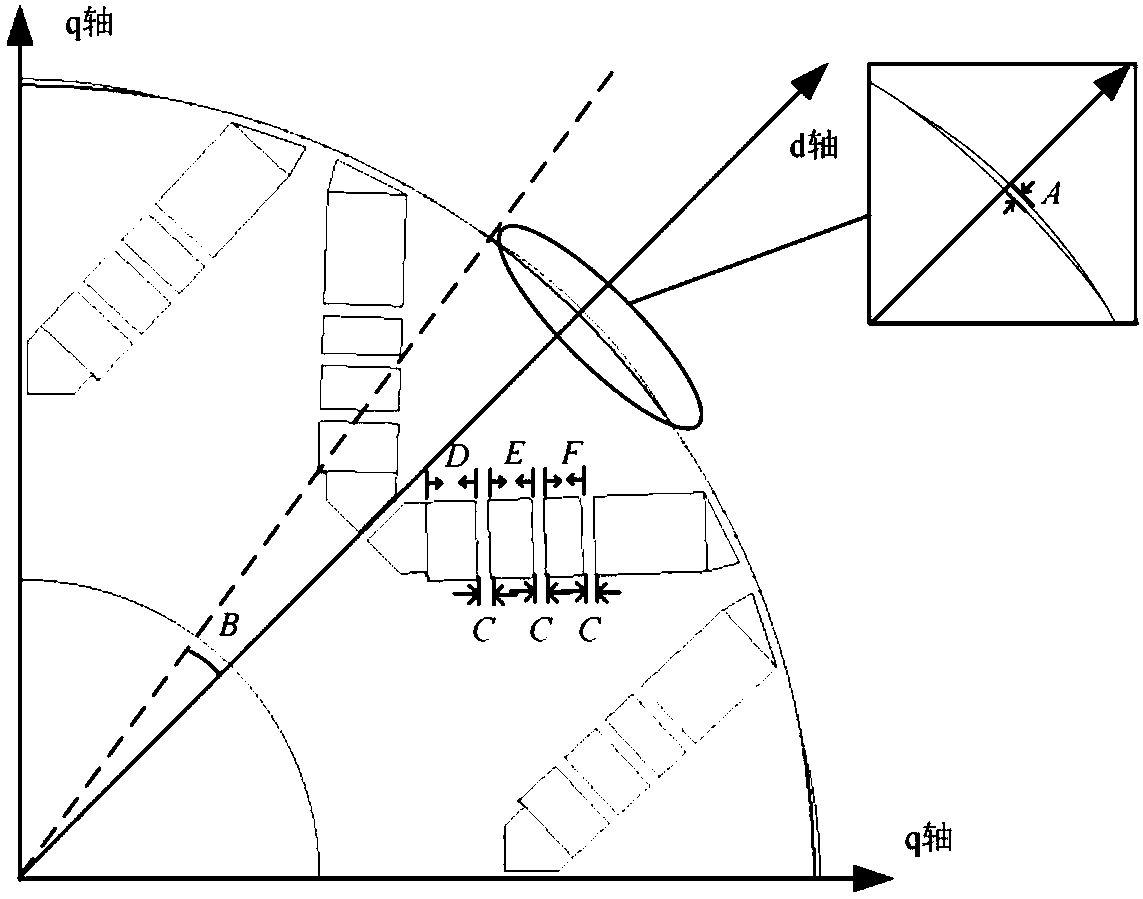

Rotor structural robustness design method for widening built-in permanent magnet synchronous motor speed range

ActiveCN108566004AExtended speed rangeImprove stabilityMagnetic circuit rotating partsPermanent magnet synchronous motorEngineering

The invention relates to a rotor structural robustness design method for widening a built-in permanent magnet synchronous motor speed range. The method comprises: determining the initial rotor structure of a motor and providing a permanent magnet with a single-layer V-shaped structure; improving the rotor structure of the motor; using a Taguchi method to optimize the above improved structural scheme, and determining an optimization variable, an optimization objective and a constraint condition; establishing a factor level table; performing finite element simulation on the motor under differentconditions, and obtaining the values of d-axis inductance, the q-axis inductance and the electromagnetic torque under different factor levels; performing average value analysis; performing variance analysis on a result based on the average analysis; and determining the optimal solution and improving a prototype.

Owner:TIANJIN UNIV

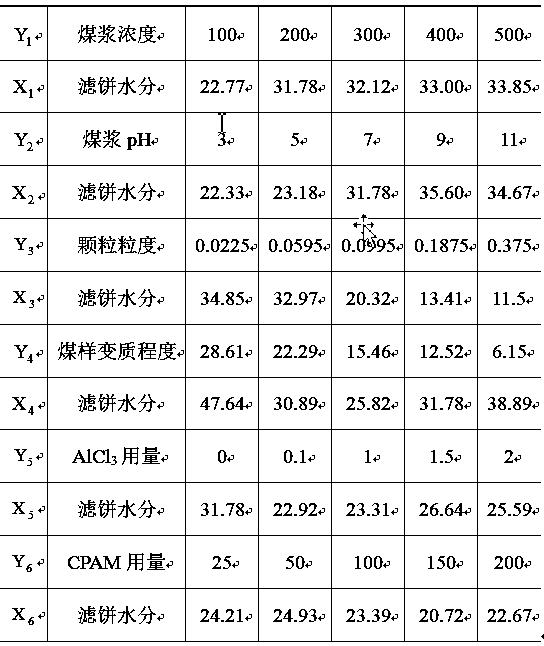

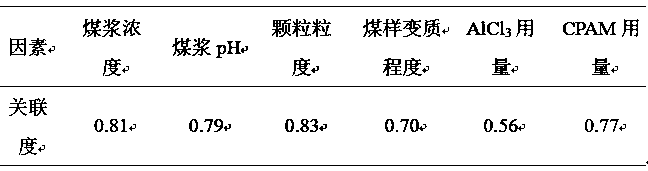

Slime filter cake moisture influence factor evaluation method based on grey correlation analysis

InactiveCN107392488AReduced Quantity RequirementsSmall amount of calculationResourcesGrey correlation analysisEngineering

The invention relates to a slime filter cake moisture influence factor evaluation method based on grey correlation analysis. The slime filter cake moisture influence factor evaluation method based on grey correlation analysis includes the steps: clearly knowing about the influence factor and the factor level of the slime filter cake moisture; measuring the test data of the filter cake moisture under each factor level; utilizing the grey correlation analysis method to solve the Deng'S correlation degree of each factor between the slime filter cake moisture; and through ordering of magnitude of the correlation degree, clearly knowing about the main influence factor of the slime filter cake moisture. The slime filter cake moisture influence factor evaluation method based on grey correlation analysis has the advantages of simplicity, practicality, low calculated amount, and accurate calculated result, and can effectively determine the significance of each factor on the slime filter cake moisture and provide theoretical basis for effectively reducing the filter cake moisture.

Owner:TAIYUAN UNIV OF TECH

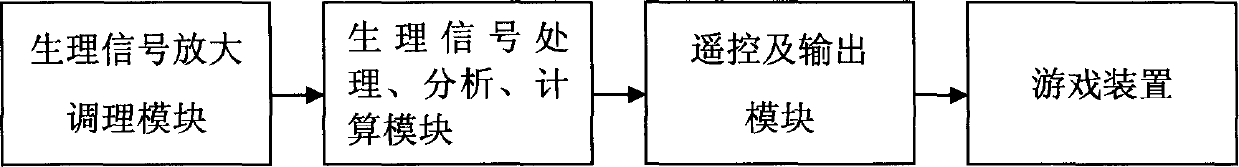

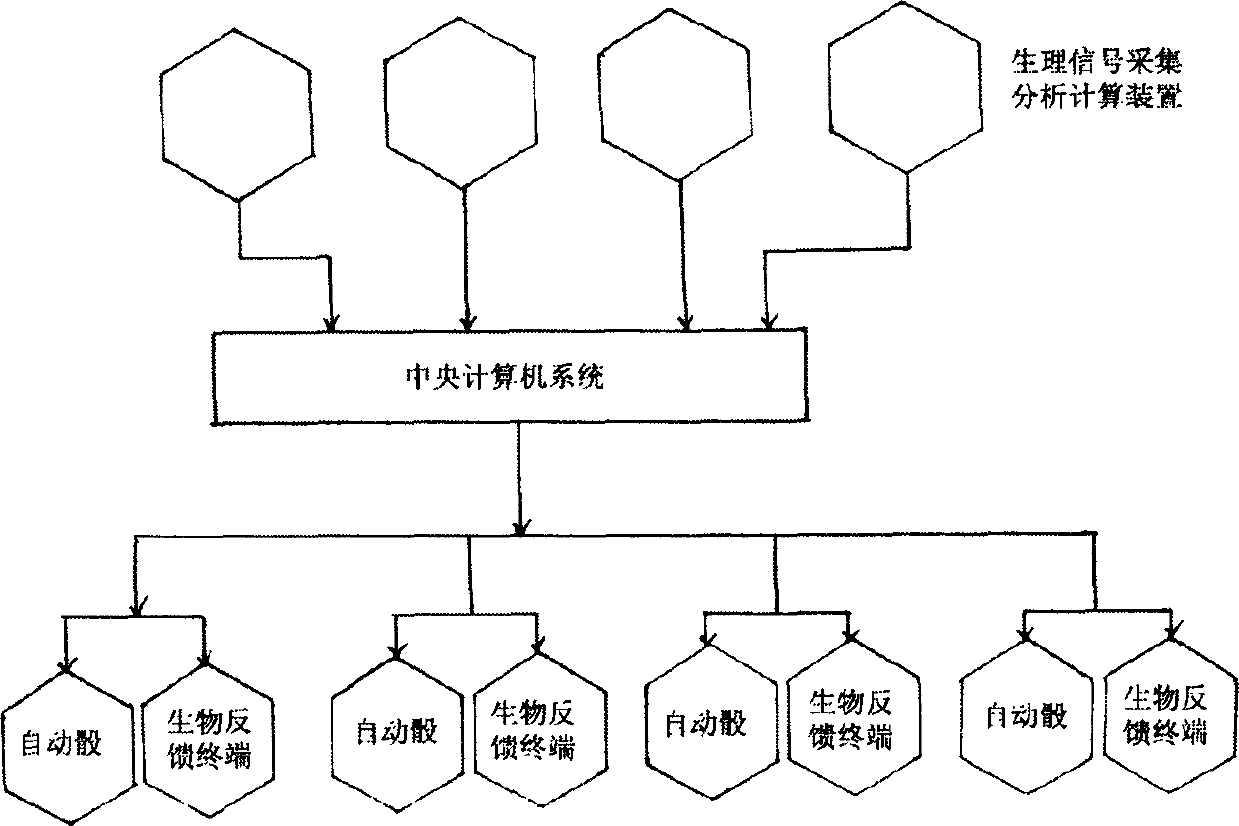

Automatic dice device controlled with physiological signal

InactiveCN1772324AAdd funIncrease entertainmentIndoor gamesDiagnostic recording/measuringBiological feedbackBiofeedback training

The present invention relates to automatic dice game device, and is especially one automatic dice game device controlled with the physiological signal of the player. The automatic dice game device consists of playerí»s physiological signal acquiring unit, signal processing and analyzing calculation unit, and automatic dice game unit. In game, the physiological signals of all the players are collected, regulated, processed and analyzed to calculate the multiplying factors representing the changes in the physiological states of the players, the game result is decided according to the multiplying factor levels of the players, and the game result is converted into command transmitted to the CPU of the computer in the automatic dice game device to control the dice to show corresponding points. The automatic dice game device makes dice game more interest and may be also used in biological feedback training and relaxing training.

Owner:高春平

Robust design method for metal corrugated pipe hydraulic bulging process

PendingCN110378011AForming Quality ControlGeometric CADDesign optimisation/simulationEngineeringRobust design

The invention discloses a robust design method for a metal corrugated pipe hydraulic bulging process. The method comprises the following steps: selecting a quality evaluation index for optimizing thecorrugated pipe hydraulic bulging process as an optimization target and an optimization constraint condition; enabling material parameters to serve as noise factors, process parameters to serve as controllable factors, and formulating a factor level table; performing a virtual test by adopting a Taguchi robust design method, and calculating each process condition combination in the test table to obtain a quality characteristic result; calculating the signal-to-noise ratio of the quality characteristic according to the obtained quality characteristic result, converting the signal-to-noise ratiointo standardized quality loss, and synthesizing comprehensive quality loss; selecting the comprehensive quality loss as an optimization target, and constructing a response surface robust model of the comprehensive quality loss and a design variable by adopting a regression method; and solving an optimal value of the constructed response surface robust model of the comprehensive quality loss andthe design variable by using a genetic algorithm. The method can solve the problems that in the traditional metal corrugated pipe hydraulic bulging process, quality control is inaccurate, the productpercent of pass is low, and consistency is poor.

Owner:XI'AN PETROLEUM UNIVERSITY

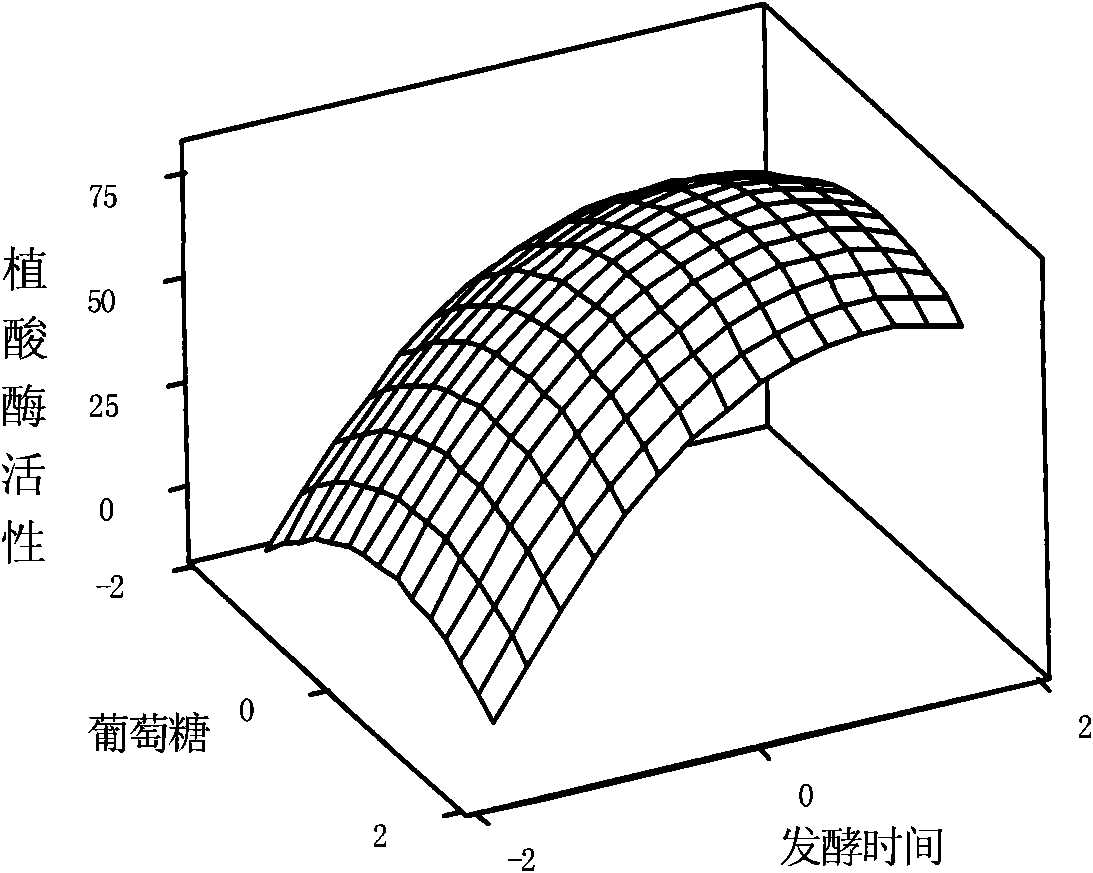

Culture medium and method for producing phytase by using vinegar residue as raw material through solid fermentation

The invention provides a culture medium and a method for producing phytase by using vinegar residues as raw materials through solid fermentation. The adopted culture medium of the method comprises vinegar residues, glucose and bean slag, wherein according to the total weight of a solid culture medium, the content of the glucose is 7.2 percent by weight, and the content of the bean slag is 5.1 percent by weight. By a PB test, three factors of the glucose, the bean slag and fermentation time which have obvious influence for a fermentation result are obtained and a method of steepest ascent is adopted to select factor levels of a maximum response value for the selected important factors, then, a central composite test is adopted to be combined with response surface analysis (RSM) to obtain arelational expression between the response value and the important factors, and the important factor level of the maximum response value is calculated, thereby an optimal fermentation condition for producing the phytase through the solid fermentation is ensured, namely, the content of the glucose is 7.2 percent by weight, the content of the bean slag is 5.1 percent by weight, and the fermentationtime is 271 hours. By a verifying test, the activity even value of the phytase is 98.37U / g DMR under the condition.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

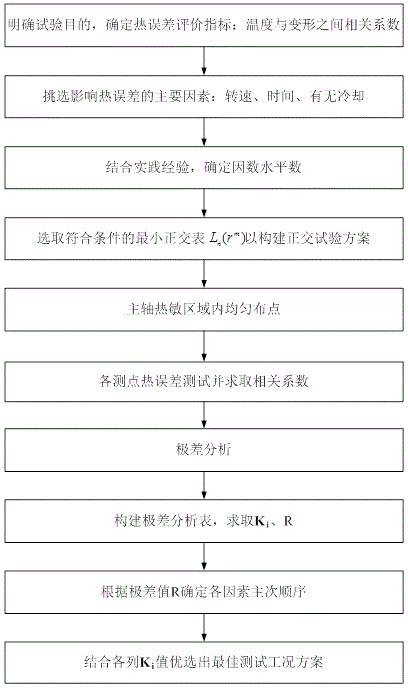

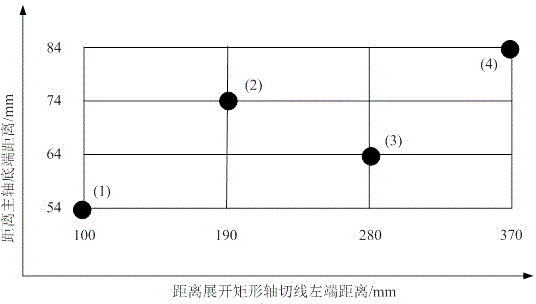

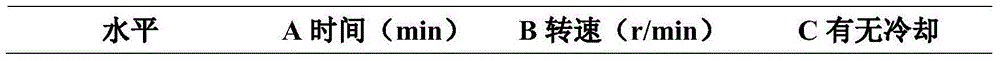

Machine tool spindle thermal error optimum working condition determination method based on orthogonal test analysis

InactiveCN104827339AReduce the number of trialsTypicalMeasurement/indication equipmentsMaintainance and safety accessoriesCorrelation coefficientTest design

The invention discloses a machine tool spindle thermal error optimum working condition determination method based on orthogonal test analysis. The method comprises the following steps: correlation coefficients between the temperature and the thermal deformation are determined to serve as thermal error evaluation indexes, the rotating speed, the time and the cooling or no cooling are selected as test design factors, and a level number of each factor is determined; an orthogonal table Ln(rm) according with fewer conditions is selected according to the level number of the factor, wherein L is a code name of the orthogonal table, n is a transverse row number of the orthogonal table, r is the factor level number, and m is a longitudinal line number of the orthogonal table; a spindle thermosensitive area is cut along a shaft tangent line to spread to form a rectangle, and measuring points are uniformly arranged in divided grids in the rectangular area; and each measuring point is tested in sequence to obtain correlation coefficients of the thermal errors of each measuring point according to the orthogonal arrangement of the measuring points, and the range analysis is performed to determine a thermal error test optimum working condition scheme. On the basis of reducing the test times, the method enables the tests to have the typicality and the tidiness comparability, and the working condition optimization and the arrangement point efficiency and reliability are realized.

Owner:NANTONG UNIVERSITY

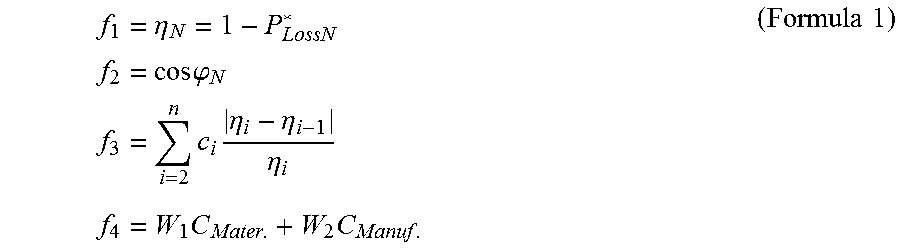

Robust design method for a textile-manufacturing-dedicated, high-efficient, energy-saving, multiphase asynchronous motor

ActiveUS20150127303A1Improve efficiencyIncrease powerAerodynamics improvementComputer aided designMathematical modelWire cutting

A robust design method for a textile-manufacturing-dedicated, high-efficient, energy-saving, multiphase asynchronous motor, includes the following steps: designating a motor; designating design method; designating design variables of the high-efficient, energy-saving, multiphase asynchronous motor; building mathematical models of each index respectively to constitute a robust design model with multiple indexes; building the controllable factor level table; selecting appropriate orthogonal table according to the number of the optimizing variables and the level number of each variable; building an inner orthogonal table for inner design; building an outer orthogonal table for outer design; computing the values of the output characteristics and signal to noise ratio of the experimental schemes determined by the inner and outer orthogonal tables; determining the optimal combination of parameters; going through tolerance design; drawing the parts of the textile-manufacturing-dedicated, high-efficient, energy-saving, multiphase asynchronous motor according to the optimal design scheme, wire-cutting the mold, dieing, laminating, coiling, inserting windings, dipping paint and assembling. Combining the actual operating characteristics of textile-manufacturing-dedicated motor, a high-efficient, energy-saving, multiphase asynchronous motor with stable performance, reliable operation and low cost is achieved. The motor achieves the optimal balance between the quality and cost, and enhances the market competitiveness.

Owner:TIANJIN POLYTECHNIC UNIV

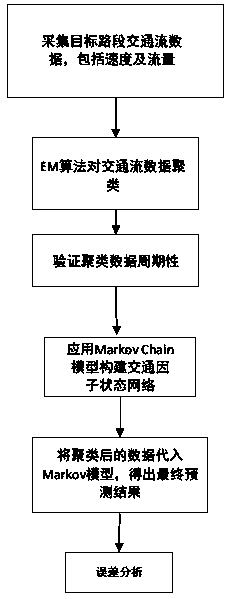

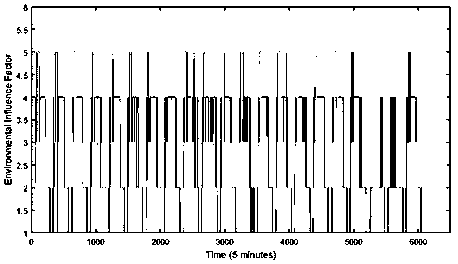

Markov chain model based traffic factor network construction method

InactiveCN109377761ADetection of traffic movementForecastingTraffic flowGaussian mixture distribution

The invention provides a Markov chain model based traffic factor network construction method. According to the method, captured speed and flow data serve as system factors, and a traffic factor network established via higher-order multi-component Markov chain simulates inherent complex space-time relation in the traffic network. Knowledge in the traffic field is applied to modeling, internal connection between traffic data is taken into consideration, and traffic factor values are clustered and analyzed. An EM algorithm based Gaussian mixture distribution model is used to learn historical datareversely, a lot of traffic flow parameter data is clustered and analyzed, and different traffic parameter clusters correspond to different traffic states in the practical traffic system, namely environment influential factor levels. The traffic factor state network is constructed by high order and multiple components on the basis, and thus, more accurate data prediction and correction can be realized.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of novel adjuvant for haemophilus parasuis disease inactivated vaccines

PendingCN105833267AImprove Hps antibody titerIncrease IL-2, IL-4 levelsAntibacterial agentsAntibody medical ingredientsPhagocyteAntigen

The invention relates to a preparation method for a novel adjuvant for haemophilus parasuis disease inactivated vaccines .The method comprises the following steps of 1, separating and extracting bacterial strains and preparing bacteria solution antigen; 2, preparing a vaccine stock solution; 3, preparing finished vaccines, wherein a ginkgo biloba extract is selected as an adjuvant, and ginkgo biloba polyvalent inactivity vaccines of different concentrations, components and contents are prepared and obtained .The effective components of polysaccharose substances of the adjuvant are prepared through separation and extraction of traditional Chinese herbal medicine ginkgo biloba plants and then combined with haemophilus parasuis polyvalent inactivity vaccines, and the haemophilus parasuis ginkgo biloba adjuvant inactivated vaccines are prepared .The inactivated vaccines have the good immune modulating function, can regulate lymphocyte and phagocyte activity, can regulate the cell factor level in body serum, and have the advantages of being natural, low in toxicity, free of drug residues and the like .

Owner:LONGYAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com