Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

175 results about "Fracture treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment of fractures involves the joining of the broken bones either by immobilizing the area and allowing the bone to heal on its own, or surgically aligning the broken bones and stabilizing it with metal pins, rods or plates. Sometimes, the broken bone fails to re-join and heal even after treatment.

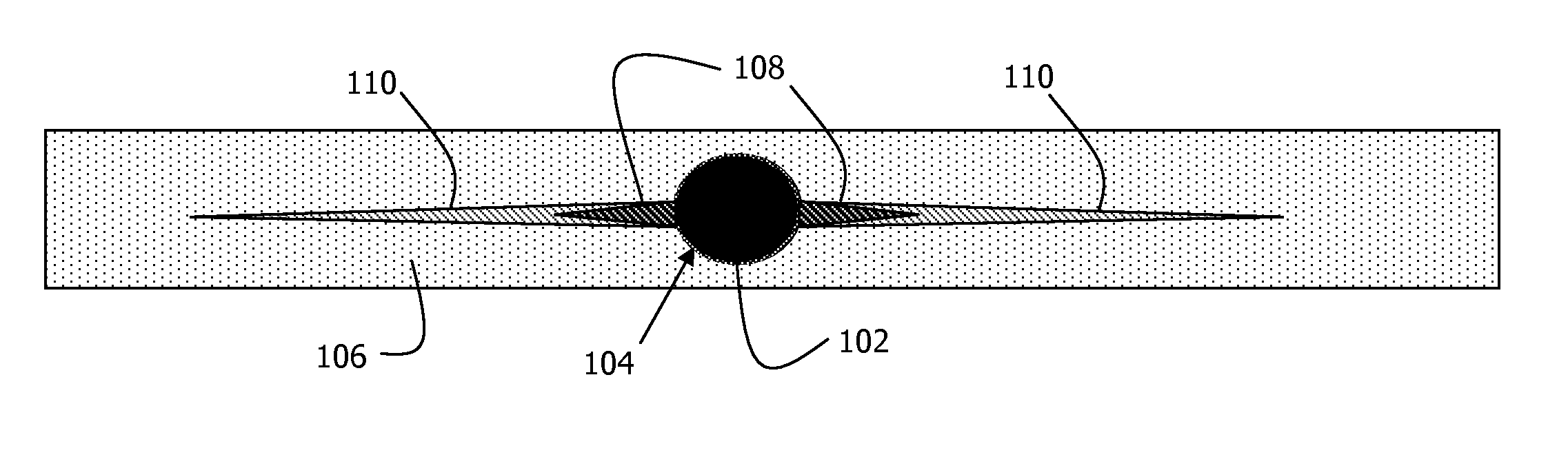

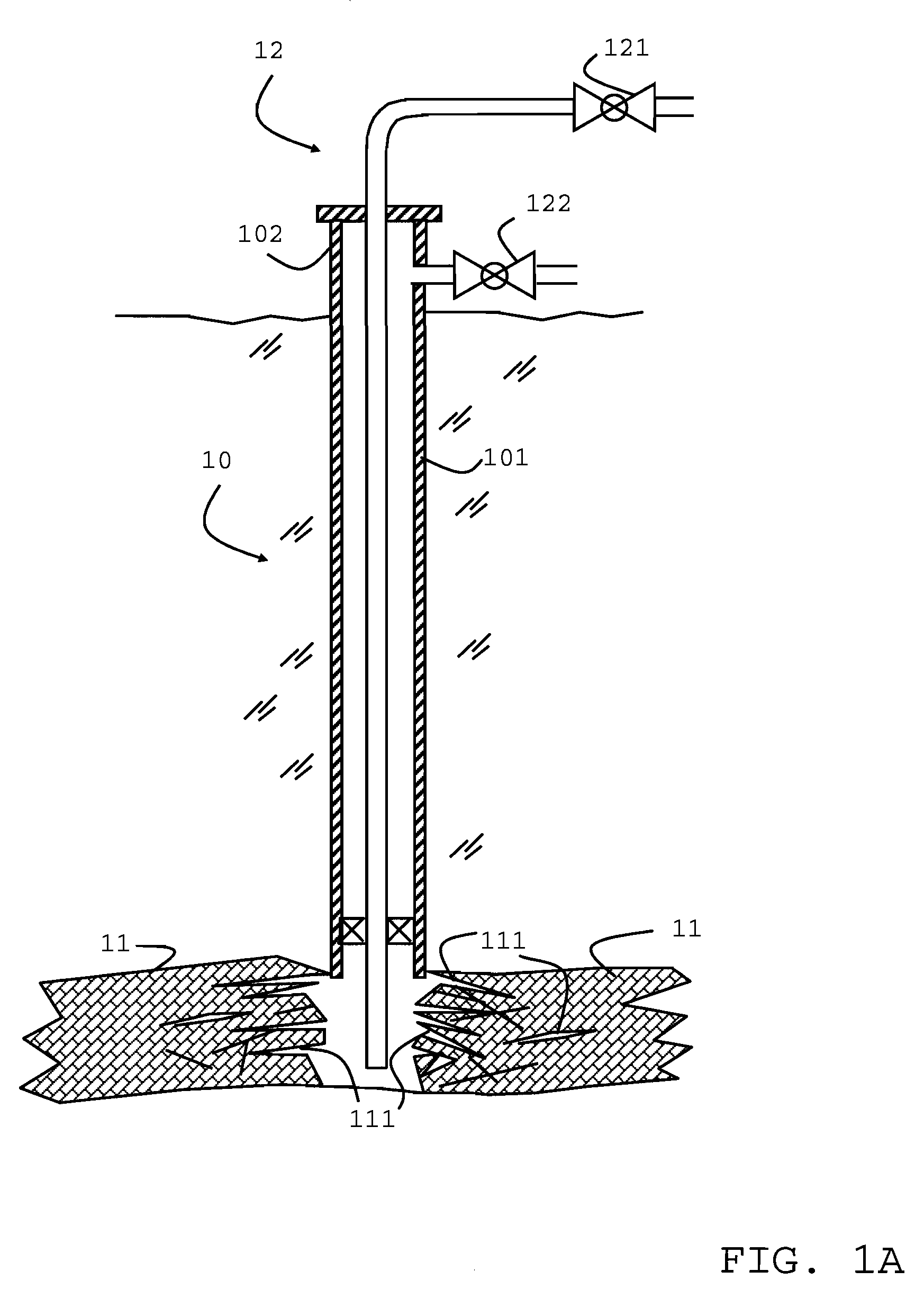

Means and method for assessing the geometry of a subterranean fracture during or after a hydraulic fracturing treatment

A method is given of fracturing a subterranean formation including the step of a) pumping at least one device actively transmitting data that provide information on the device position, and further comprising the step of assessing the fracture geometry based on the positions of said at least one device, or b) pumping metallic elements, preferably as proppant agents, and further locating the position of said metallic elements with a tool selected from the group consisting of magnetometers, resistivity tools, electromagnetic devices and ultra-long arrays of electrodes, and further comprising the step of assessing the fracture geometry based on the positions of said metallic elements. The method allows monitoring of the fracture geometry and proppant placement.

Owner:SCHLUMBERGER TECH CORP

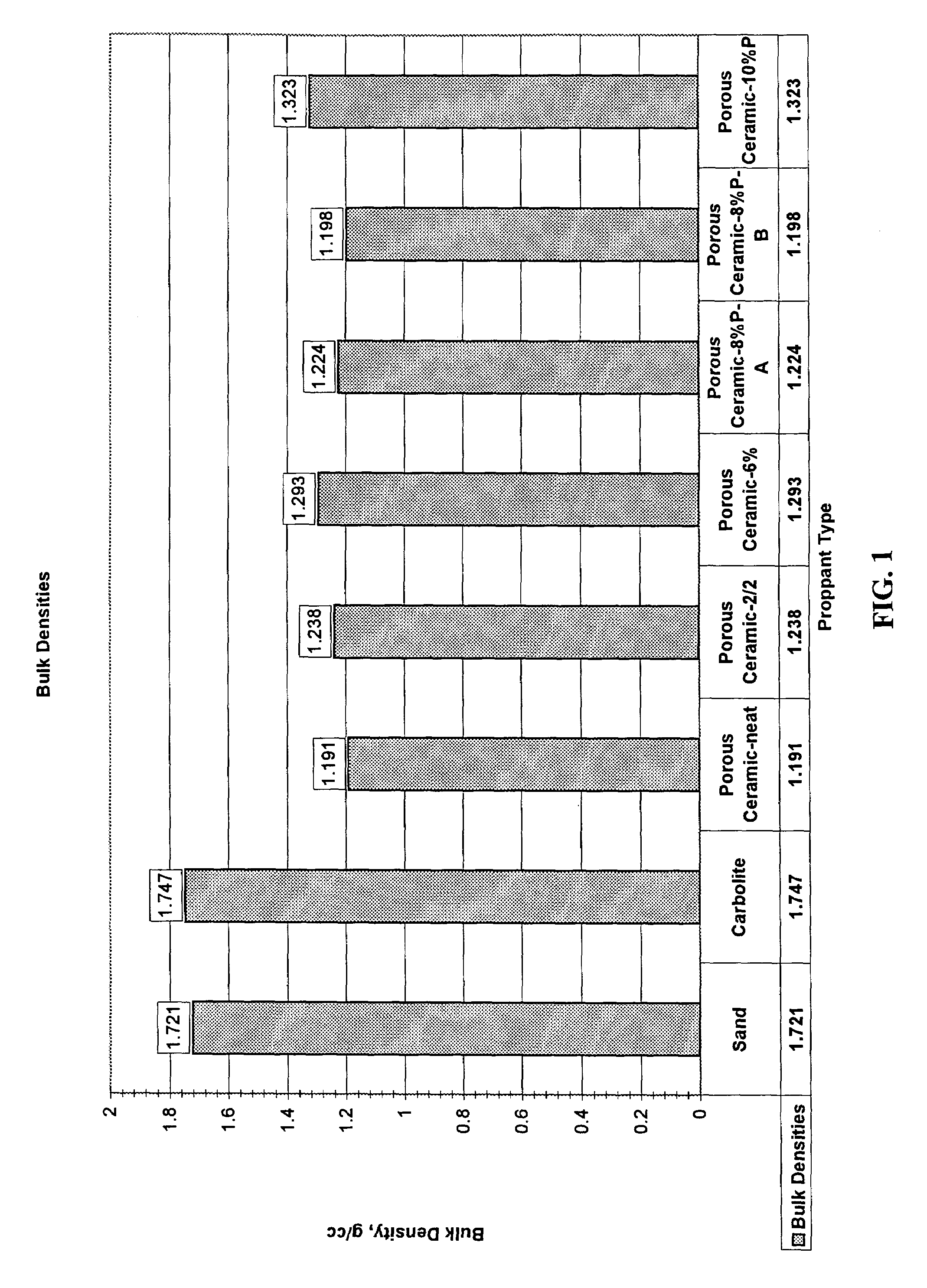

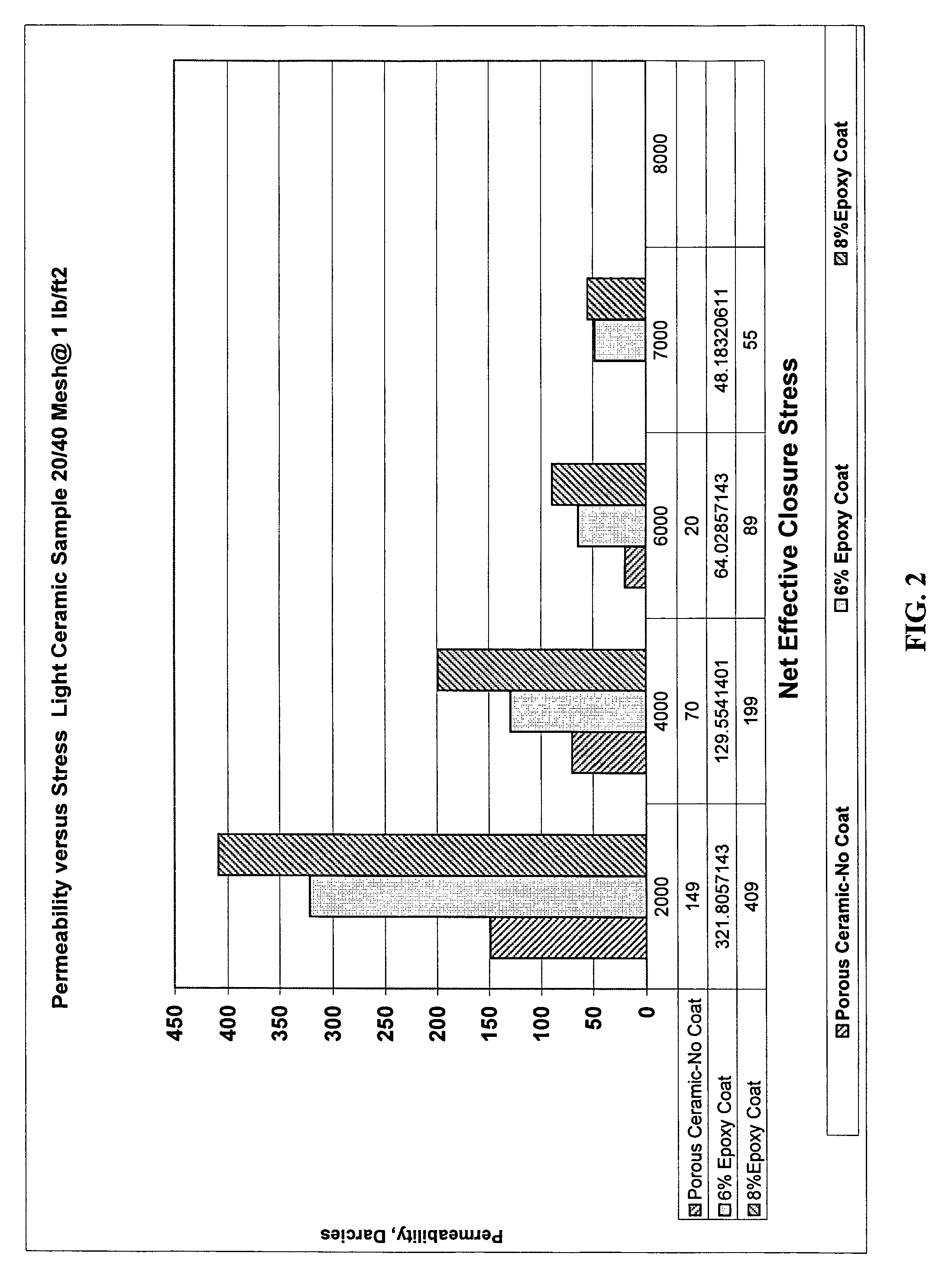

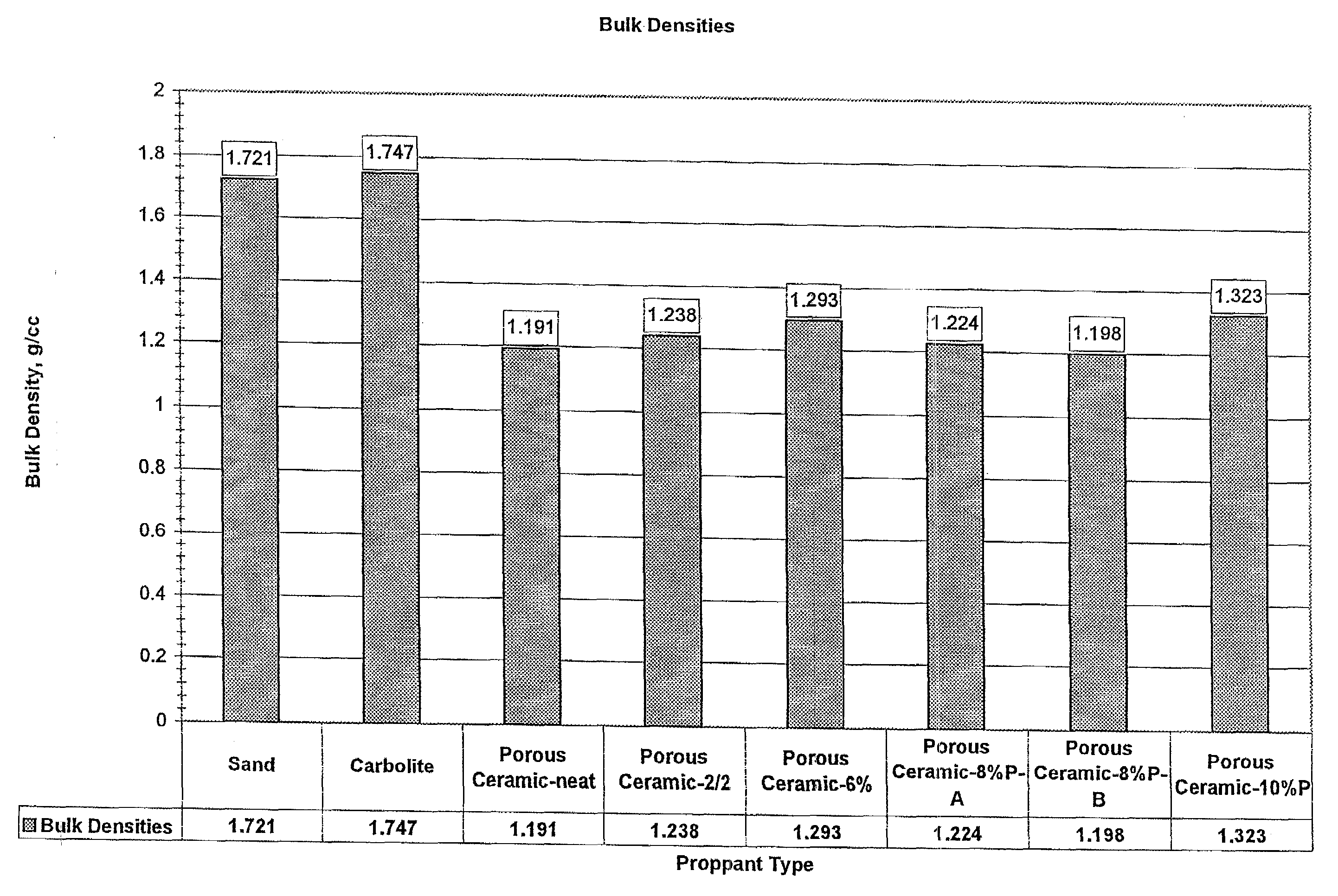

Method of treating subterranean formations with porous particulate materials

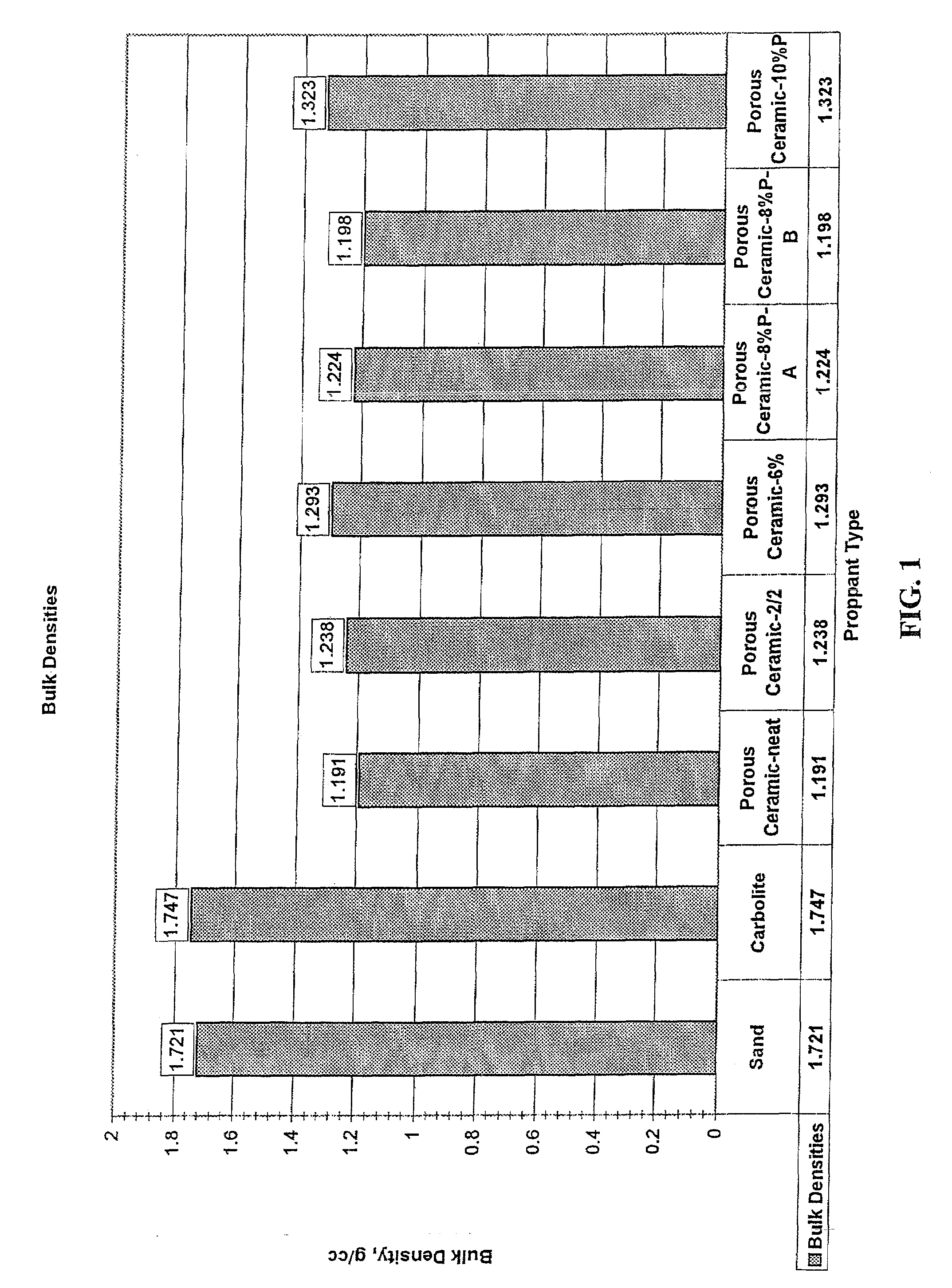

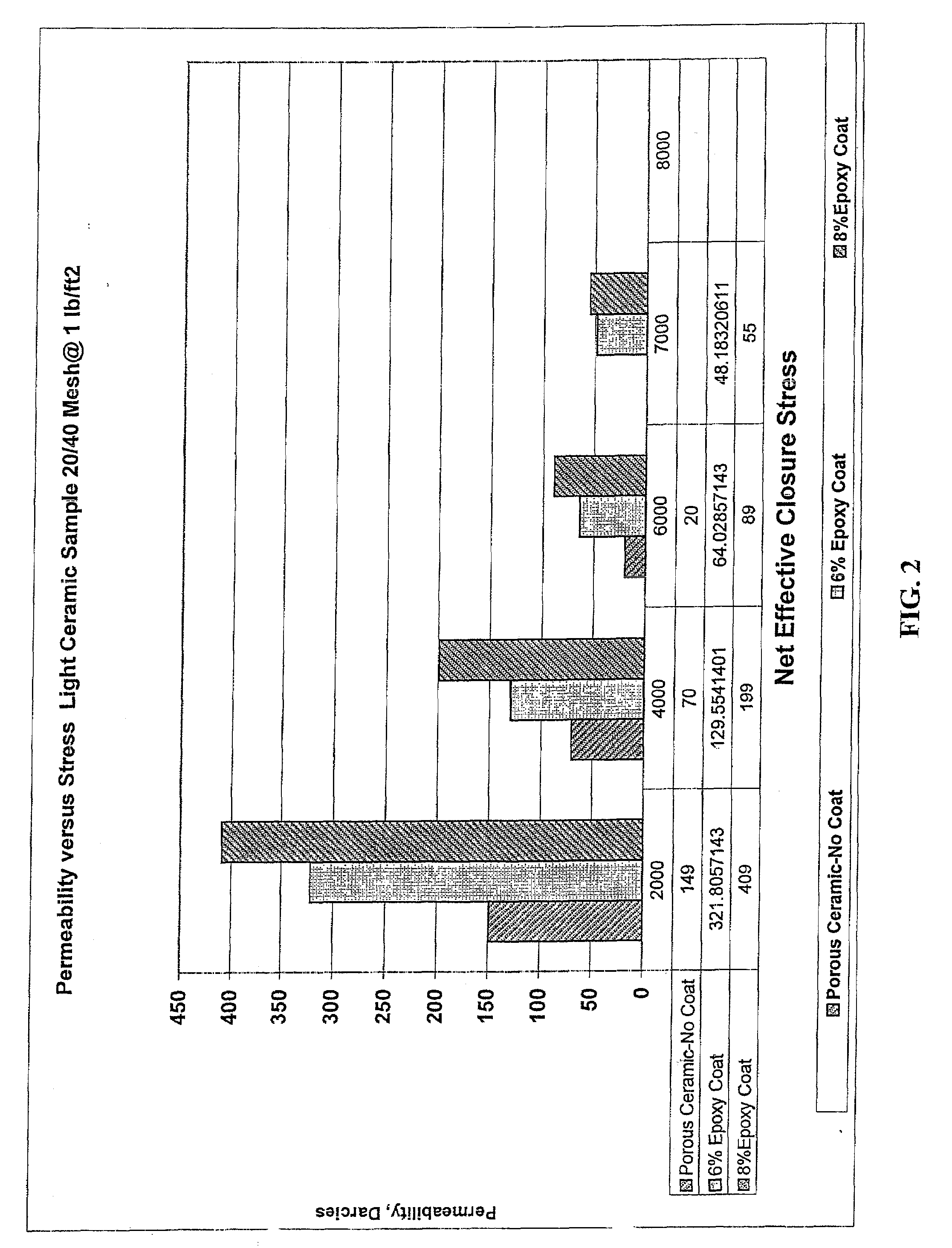

ActiveUS7426961B2Improve system performanceReduce and prevent productionFluid removalDrilling compositionApparent densityParticulates

Methods and compositions useful for subterranean formation treatments, such as hydraulic fracturing treatments and sand control that include porous materials. Such porous materials may be selectively configured porous material particles manufactured and / or treated with selected glazing materials, coating materials and / or penetrating materials to have desired strength and / or apparent density to fit particular downhole conditions for well treating such as hydraulic fracturing treatments and sand control treatments. Porous materials may also be employed in selected combinations to optimize fracture or sand control performance, and / or may be employed as relatively lightweight materials in liquid carbon dioxide-based well treatment systems.

Owner:BAKER HUGHES INC

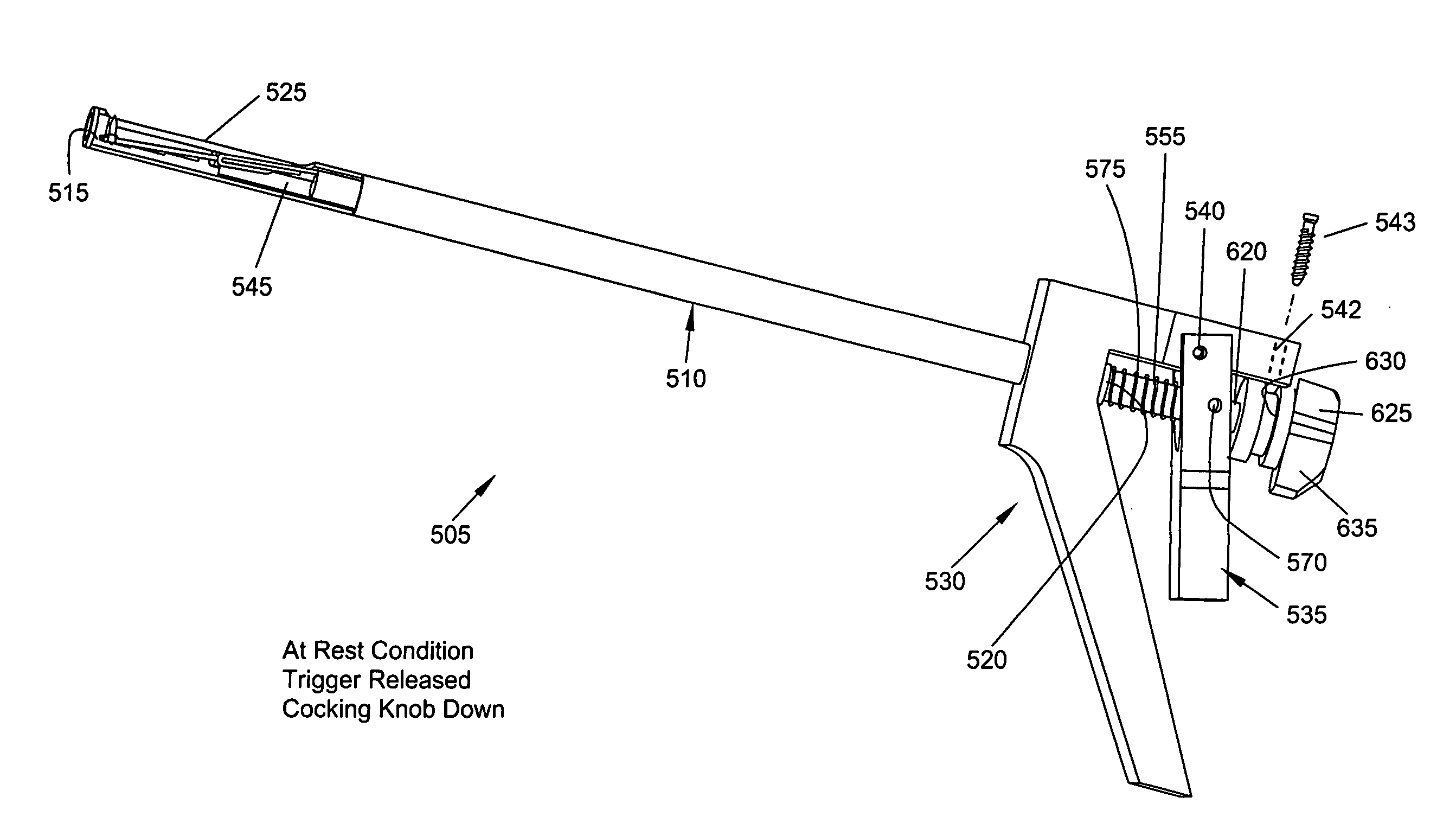

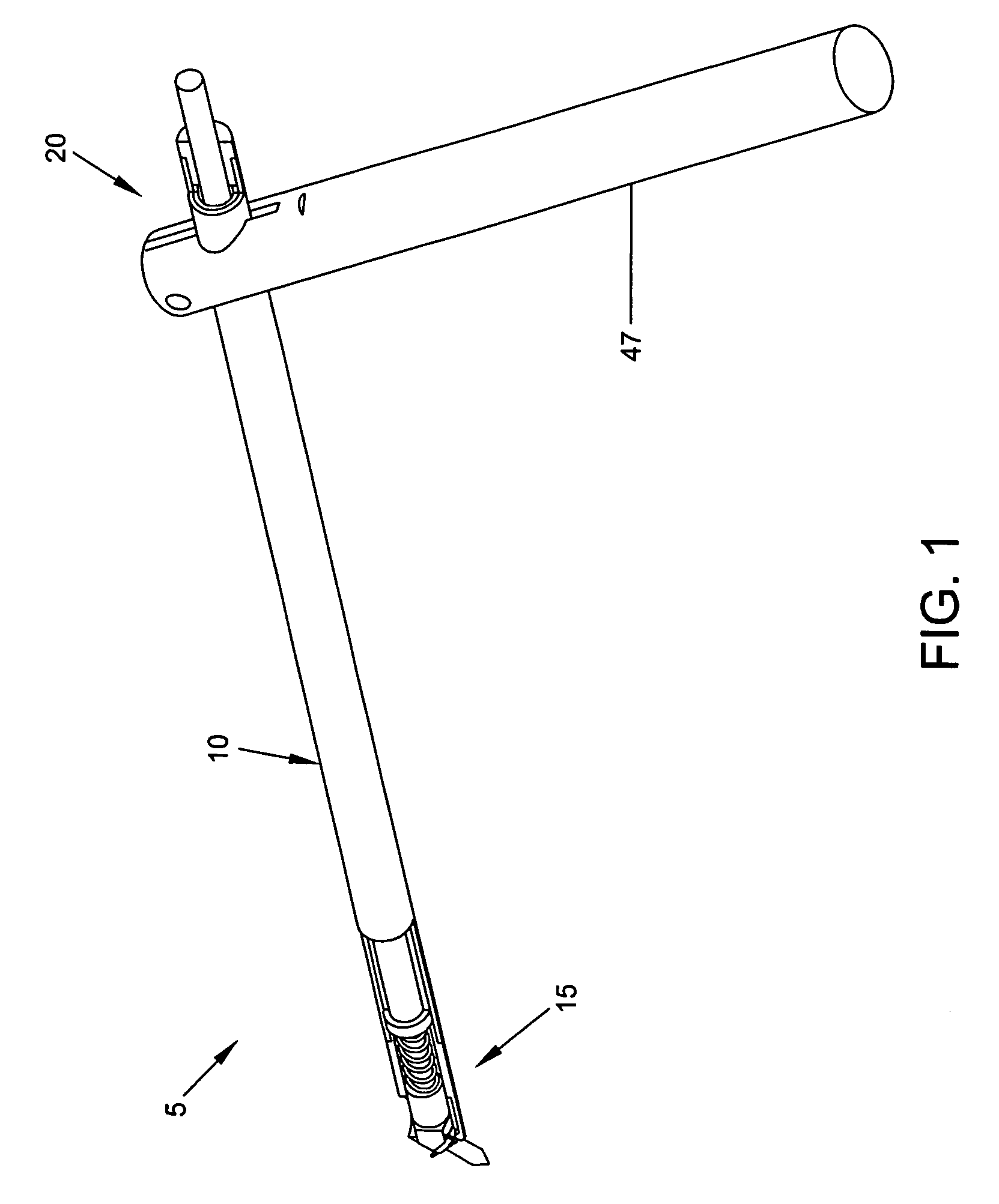

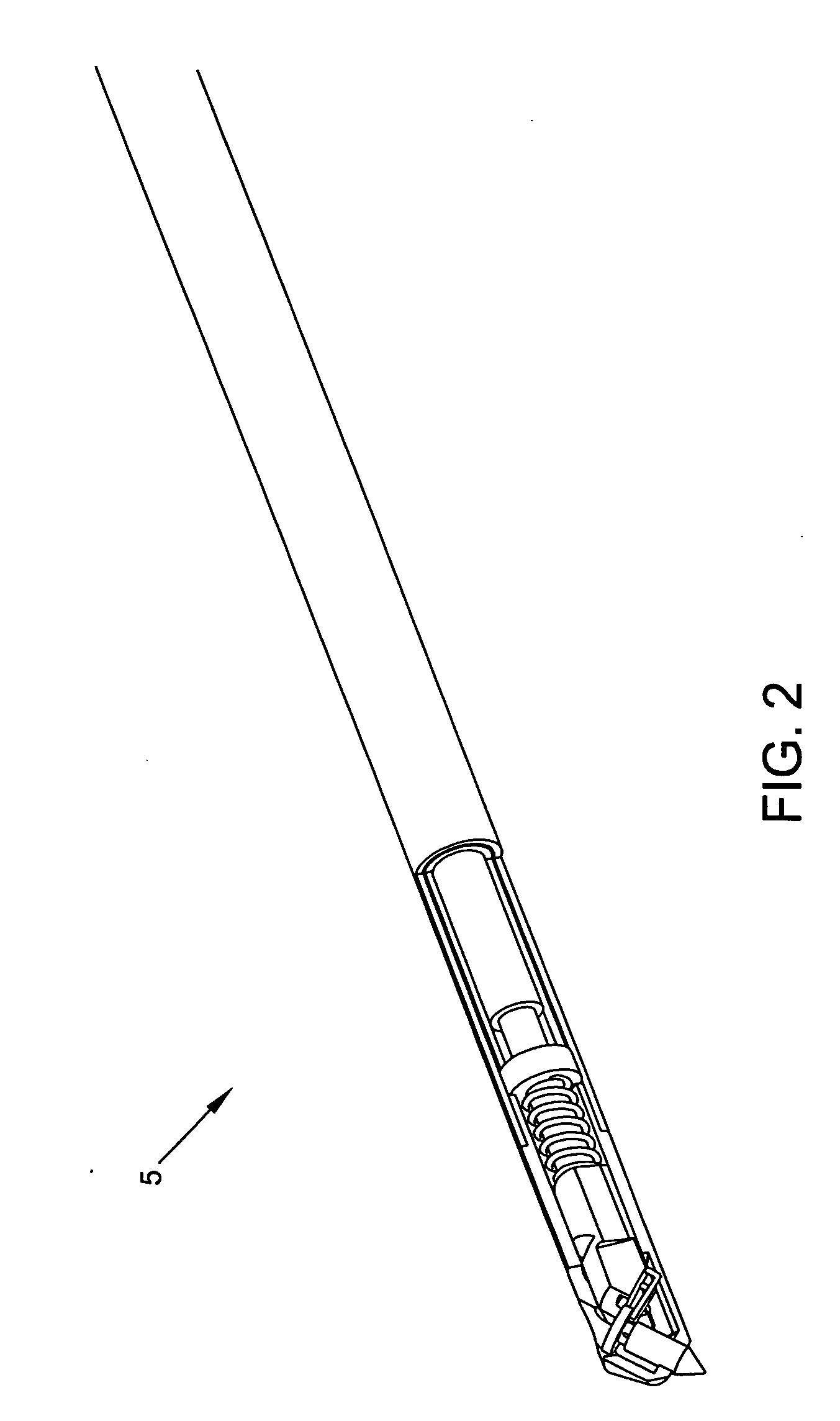

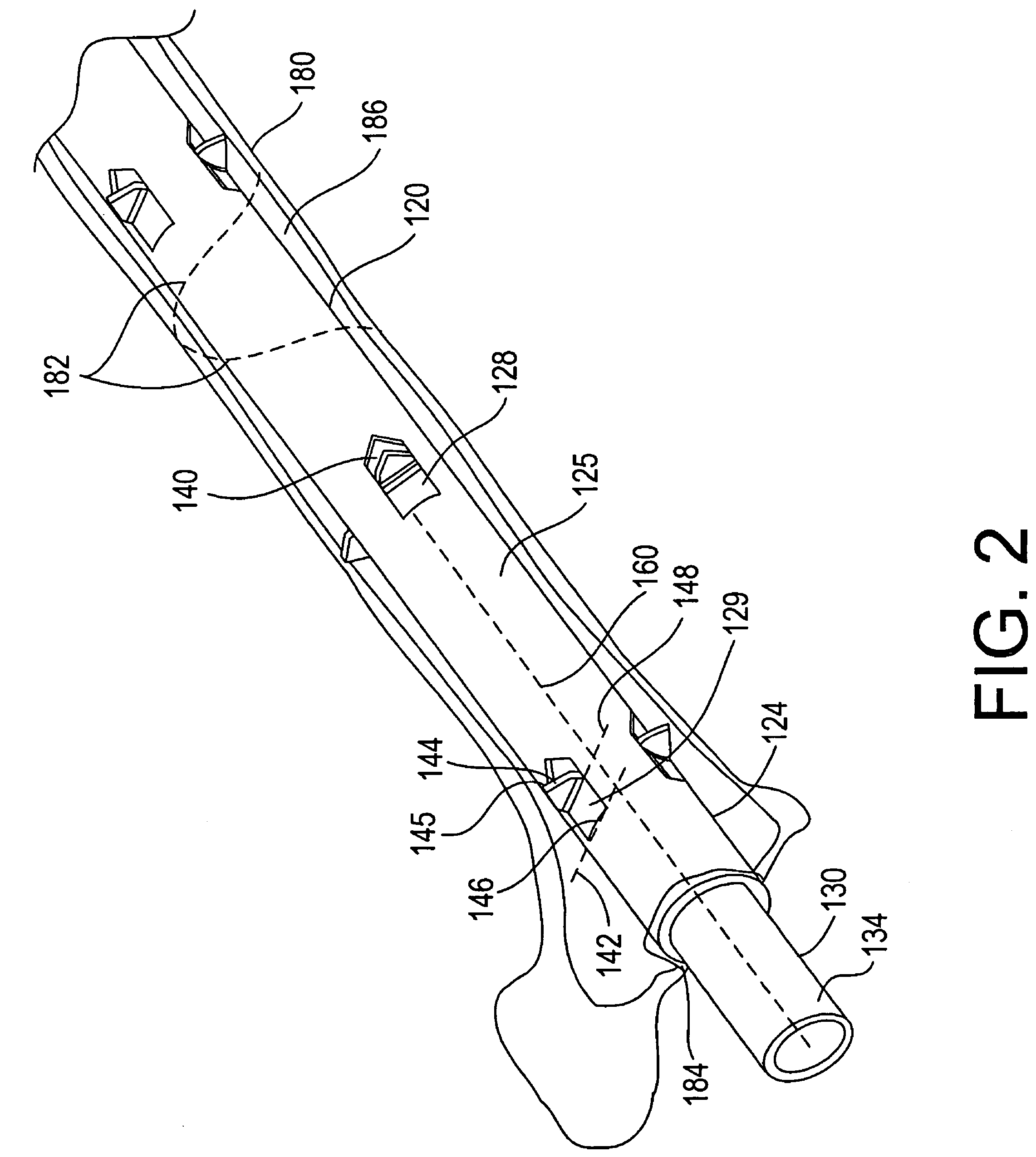

Method and apparatus for performing arthroscopic microfracture surgery

A microfracture instrument for applying microfracture therapy to a bone, the microfracture instrument comprising:an elongated shaft comprising a distal end and a proximal end;a needle comprising a body terminating in at least one sharp point, the needle being movably mounted to the distal end of the shaft for movement between an extended position for engaging the bone with the at least one sharp point of the needle and a retracted position for withdrawing the at least one sharp point of the needle from the bone; anda drive shaft movably mounted to the elongated shaft, the drive shaft being connected to the body of the needle so that movement of the drive shaft relative to the elongated shaft moves the needle between its extended position and its retracted position.

Owner:STRYKER CORP

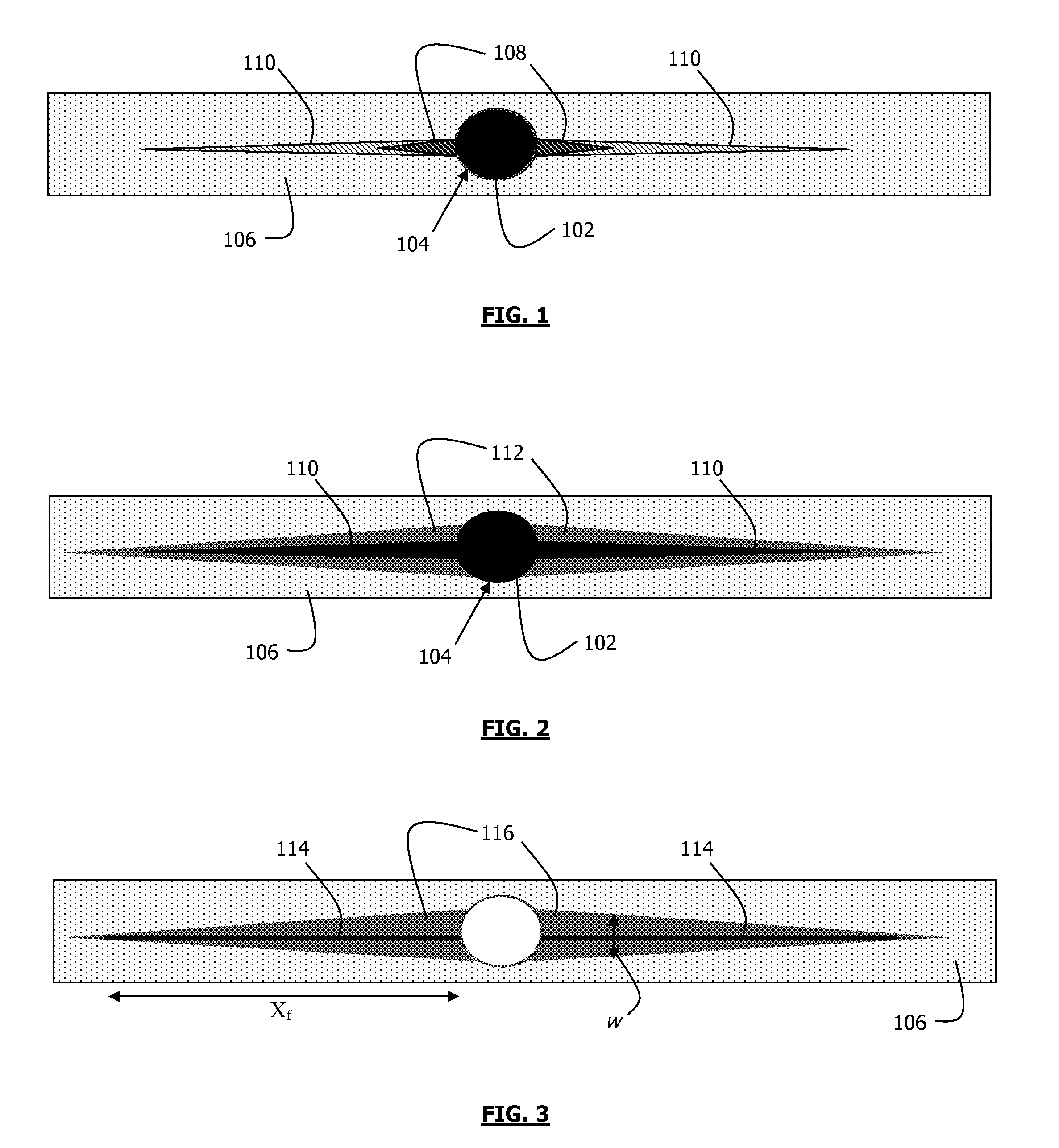

Method for Treating a Subterranean Formation

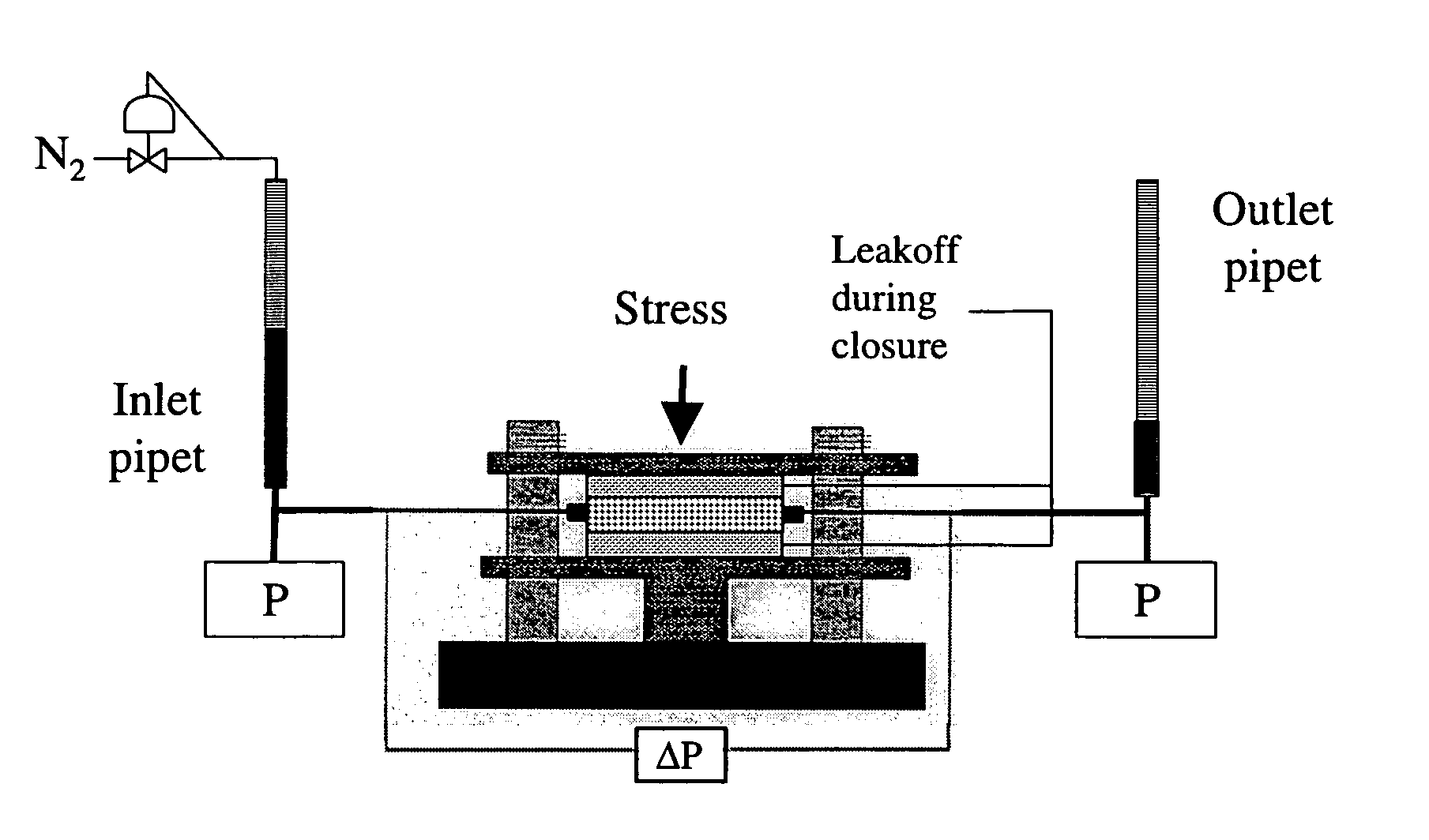

ActiveUS20070235189A1Improve permeabilityReduce penetrationFluid removalFlushingAcid fracturingHydraulic fracturing

Disclosed are acid fracturing methods for subterranean siliceous formations employing a viscous dissolving fluid to create a permeable conduit that bypasses the near wellbore damage. The viscous dissolving fluids used according to the invention are acid-fracturing treatment fluids containing a dissolving agent viscosified with a material such as a viscoelastic surfactant, and the fluid is injected into a sandstone formation at a pressure sufficient to create a hydraulic fracture. Also, the viscous dissolving fluid leaks off into the faces of the fracture thus “stimulating” the formation. Hence when the hydraulic fracture has closed there is a part of the formation that has been effectively stimulated, creating a pathway for fluids to preferentially flow to the wellbore. The formation may then be flowed back to produce a substantial volume of the treatment fluid.

Owner:SCHLUMBERGER TECH CORP

Method of fracturing a coalbed gas reservoir

InactiveUS20070227732A1Improve efficiencyAvoid damageFluid removalCarbon-dioxide storageCoal swellingCoal

Owner:SCHLUMBERGER TECH CORP

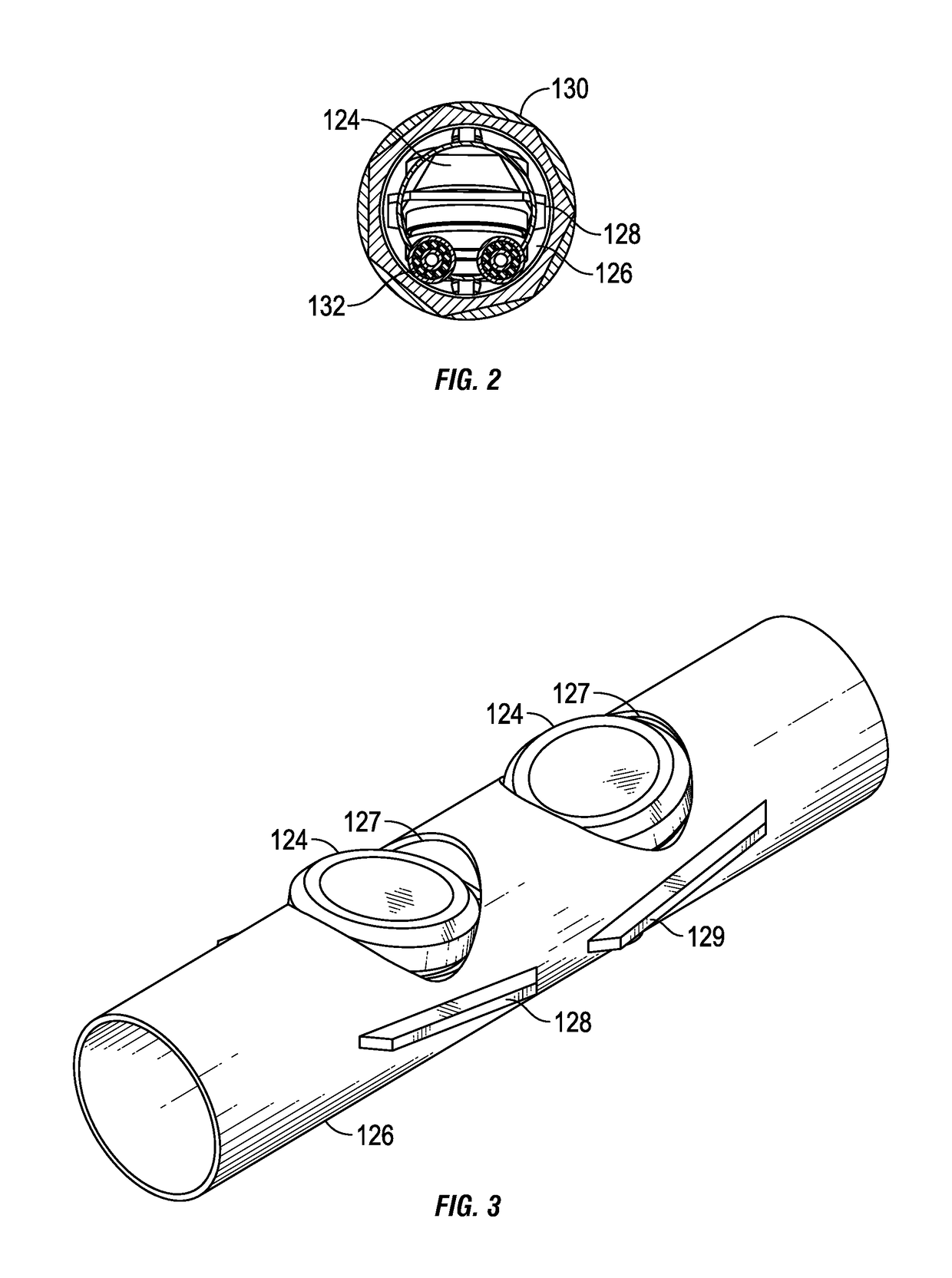

Bone fracture treatment devices and methods of their use

InactiveUS7828802B2Stabilize the fractured boneSuture equipmentsInternal osteosythesisActuatorBiomedical engineering

A bone treatment device comprises a shaft having a tubular wall, a lumen extending within the tubular wall, openings through the tubular wall, and anchoring elements adjacent the openings that can be deployed out of the openings in the presence of an actuating force within the shaft lumen. The bone treatment device may further comprise an actuator configured to be received within the shaft lumen to deploy the anchoring elements out of the openings.

Owner:EXPANDING ORTHOPEDICS

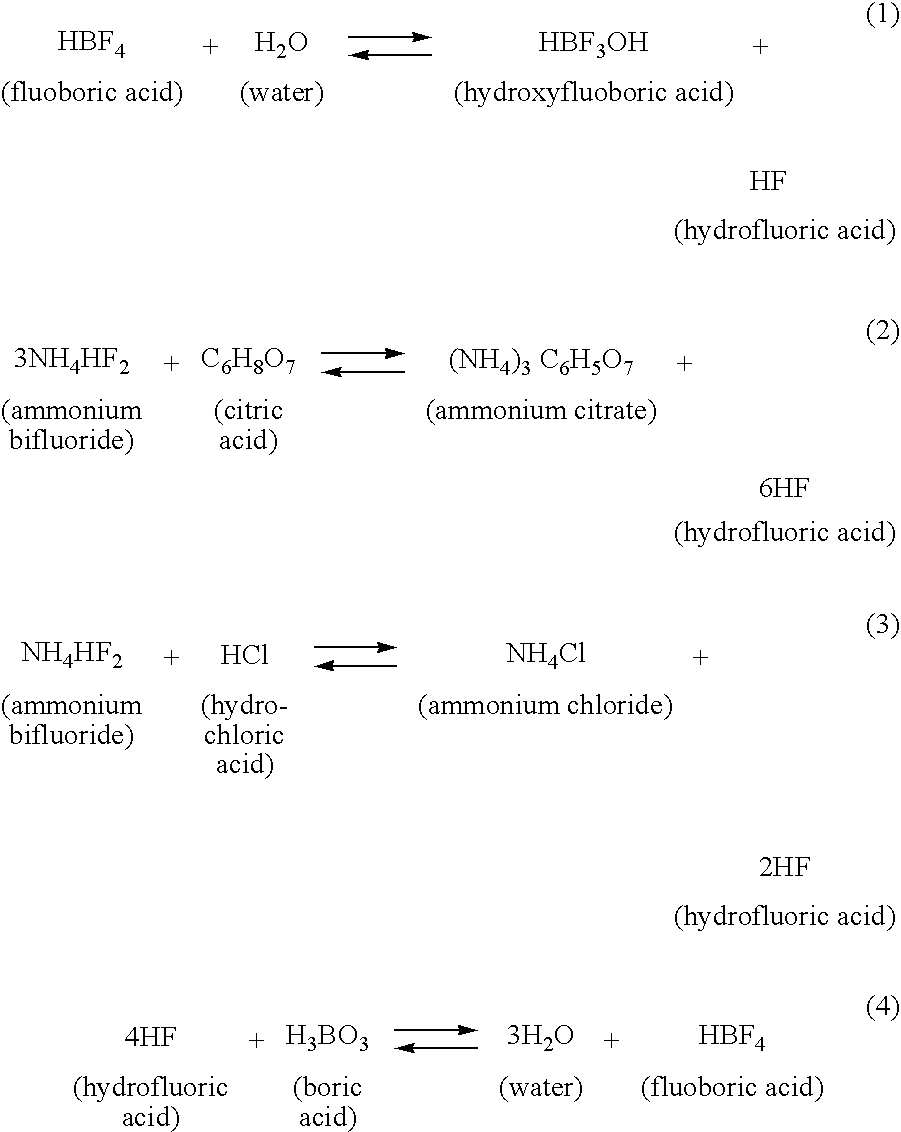

Simultaneous Method for Combined Acidizing and Proppant Fracturing

InactiveUS20140367100A1Improve CAPF technologyStimulated is largeFluid removalFlushingMedicineOil phase

A treatment fluid for use in a combined acidizing and proppant fracturing treatment, the treatment fluid comprising: (A) an emulsion comprising: (i) a continuous oil phase; (ii) an internal aqueous phase comprising: (a) water; and (b) a source of an acid; and (iii) an emulsifier; and (B) a proppant. A method of fracturing a treatment zone of a well, the method comprising the steps of: (I) forming a treatment fluid according to the invention; and (II) introducing the treatment fluid into the zone at a rate and pressure greater than the fracture gradient of the zone.

Owner:HALLIBURTON ENERGY SERVICES INC

Method for treating a subterranean formation

ActiveUS7306041B2Improve permeabilityHigher the percentage of acidFluid removalFlushingAcid fracturingHydraulic fracturing

Disclosed are acid fracturing methods for subterranean siliceous formations employing a viscous dissolving fluid to create a permeable conduit that bypasses the near wellbore damage. The viscous dissolving fluids used according to the invention are acid-fracturing treatment fluids containing a dissolving agent viscosified with a material such as a viscoelastic surfactant, and the fluid is injected into a sandstone formation at a pressure sufficient to create a hydraulic fracture. Also, the viscous dissolving fluid leaks off into the faces of the fracture thus “stimulating” the formation. Hence when the hydraulic fracture has closed there is a part of the formation that has been effectively stimulated, creating a pathway for fluids to preferentially flow to the wellbore. The formation may then be flowed back to produce a substantial volume of the treatment fluid.

Owner:SCHLUMBERGER TECH CORP

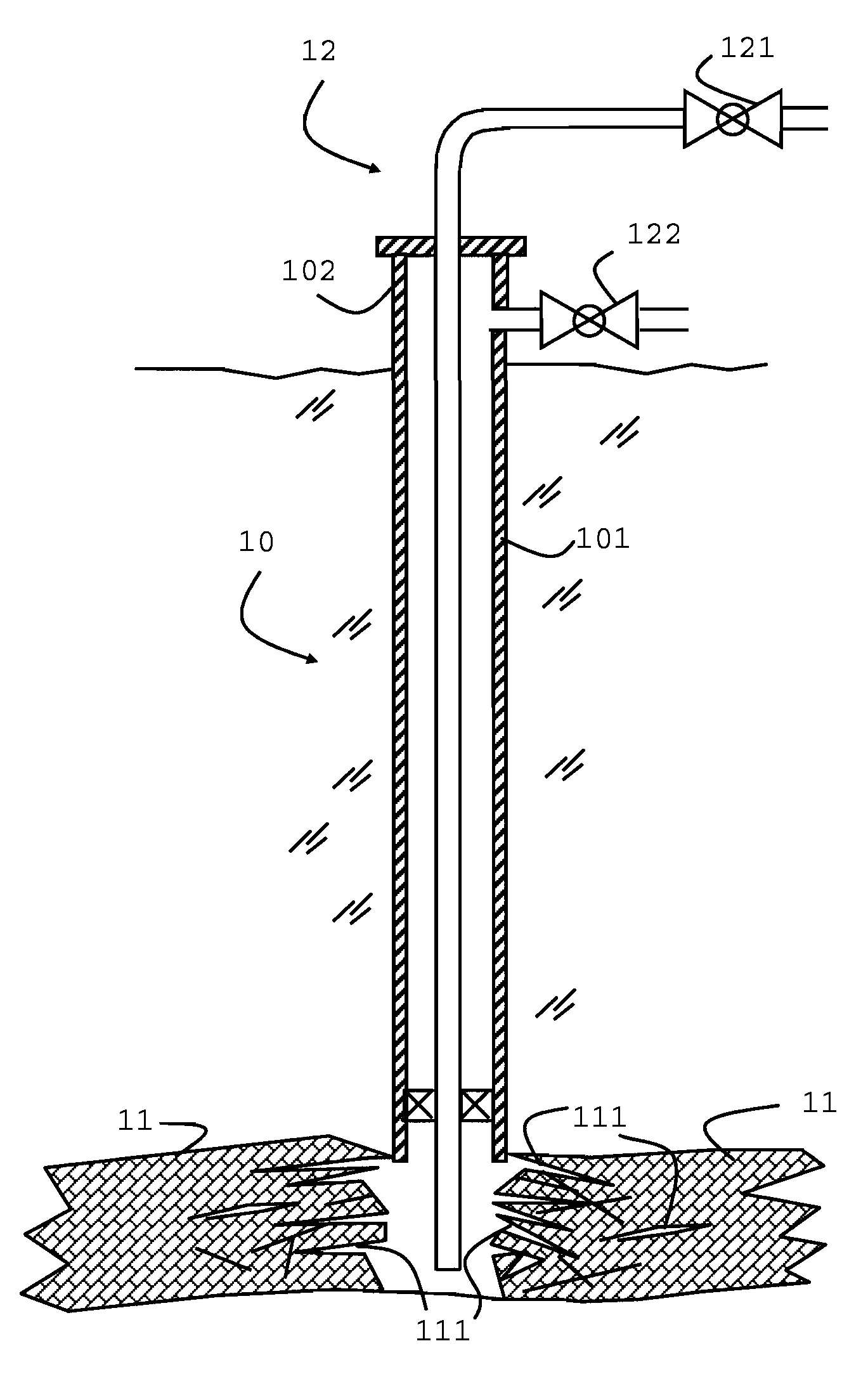

Hydraulic fracturing

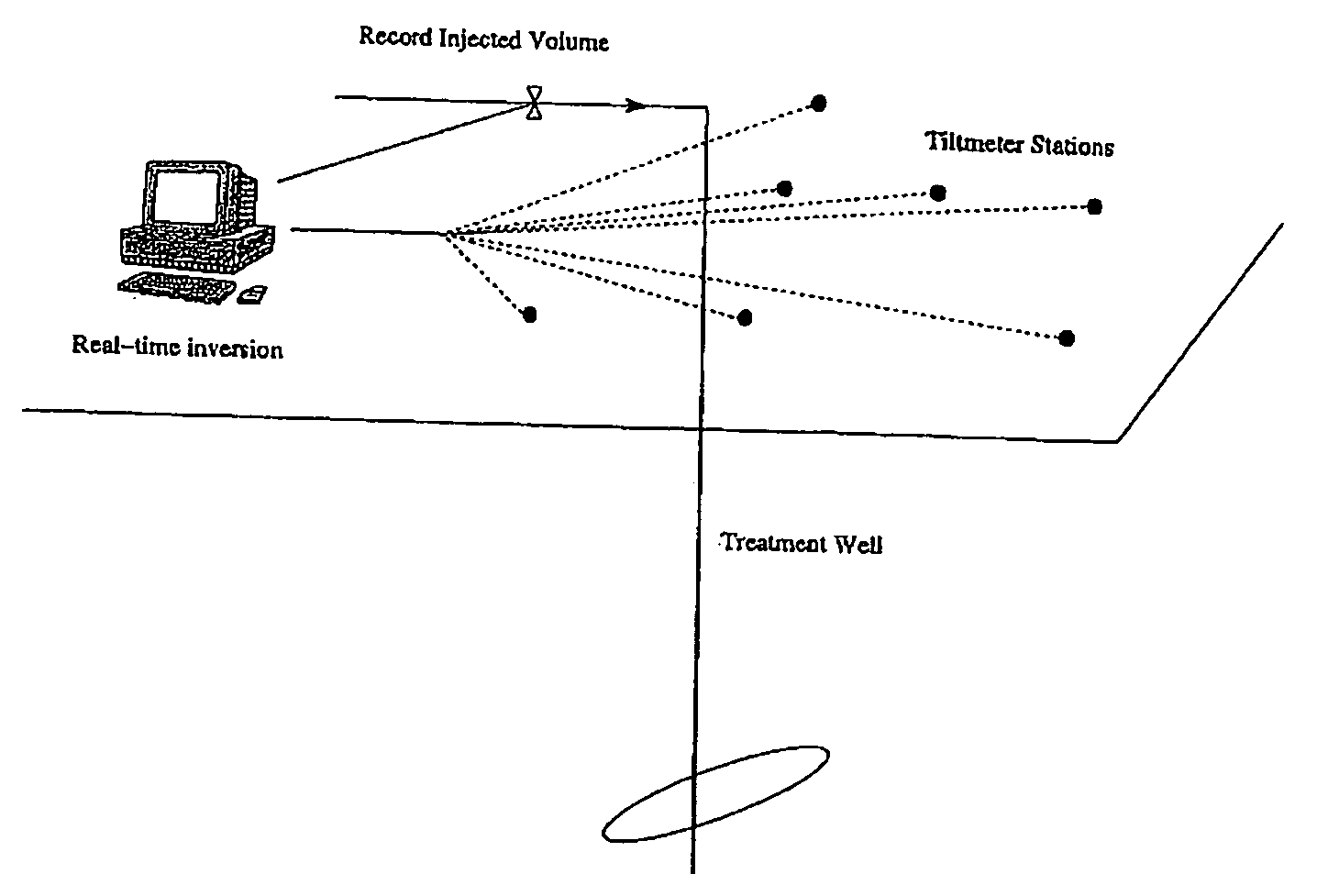

Method and apparatus for monitoring growth of fracture during hydraulic fracturing treatment of a ground formation. A series of tiltmeters are positioned at spaced apart tiltmeter stations at which tilt changes due to hydraulic fracturing treatment are measurable by those tiltmeters. Tilt measurements obtained from the tiltmeters at progressive times during the fracture treatment are compared with estimated tilt changes estimated from an assumed hydraulic fracturing propagation. Useful values for initially undetermined values of parameters of the model are derived using an inverse procedure. The data analysis may be performed in real time as the hydraulic treatment progresses using differing propagation models to determine a most probable model.

Owner:COMMONWEALTH SCI & IND RES ORG

Well treating materials and methods

ActiveUS20080011477A1Liquid surface applicatorsSynthetic resin layered productsParticulatesHydraulic fracturing

The present invention is directed to an improved thermoplastic material-coated particulate composition useful for hydraulic fracturing treatments, gravel packing for sand control or other well formation treatments and especially the related methods of its use and is particularly directed to using a thermoplastic material as part of a particulate composition in a method for enhancing the stabilization of and reducing particulate flowback and fines transport in a well formation.

Owner:GEORGIA PACIFIC CHEM LLC

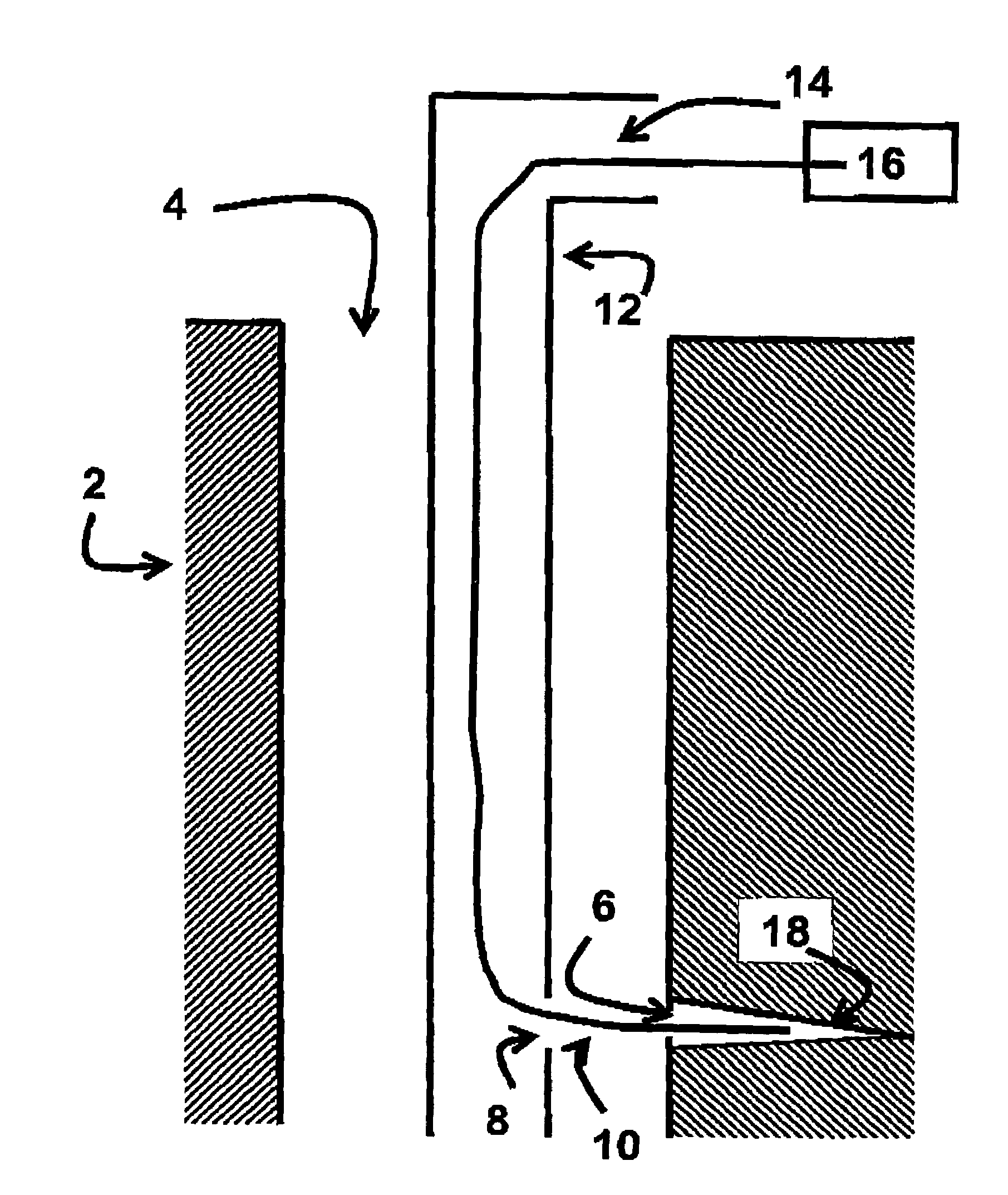

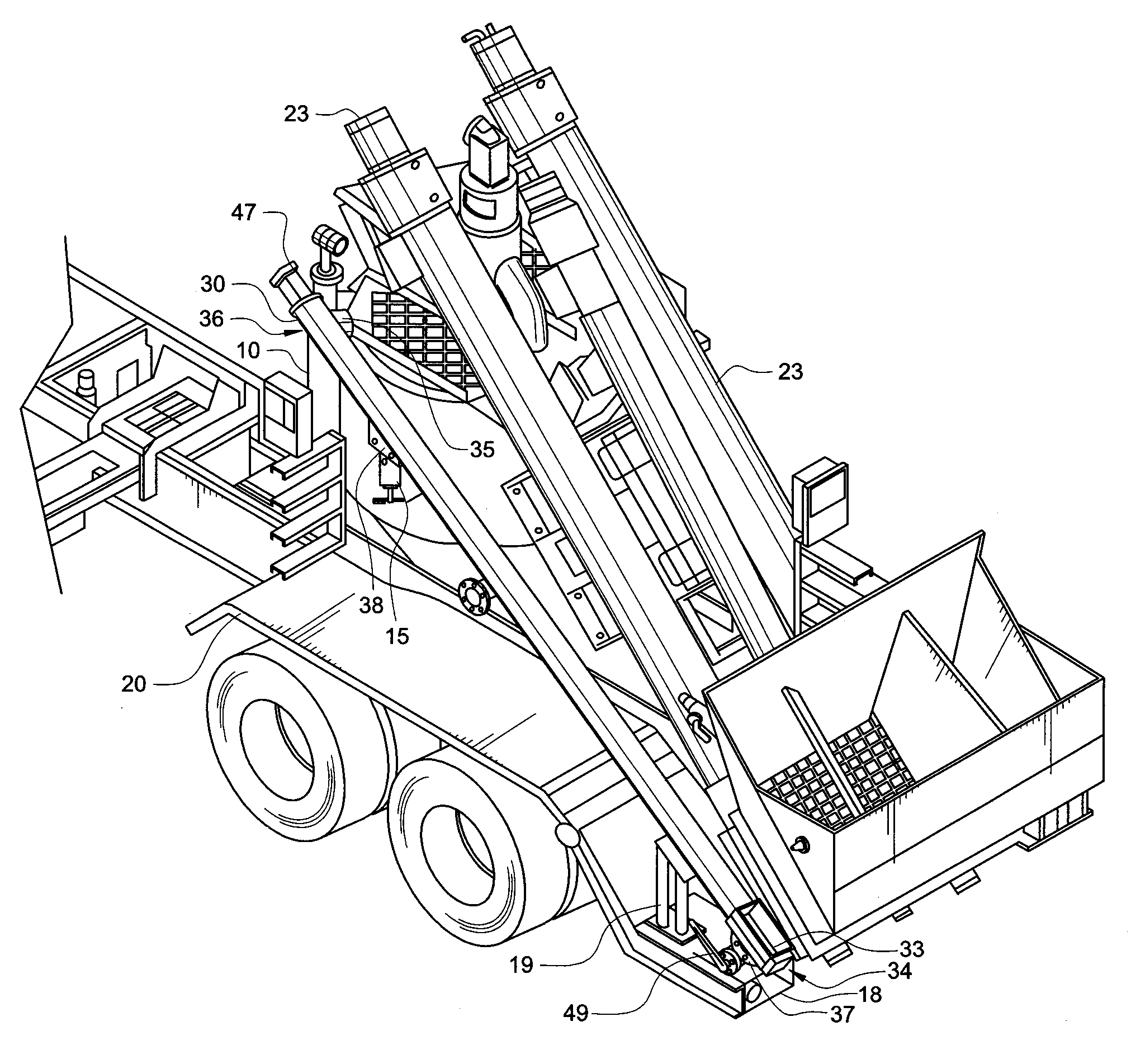

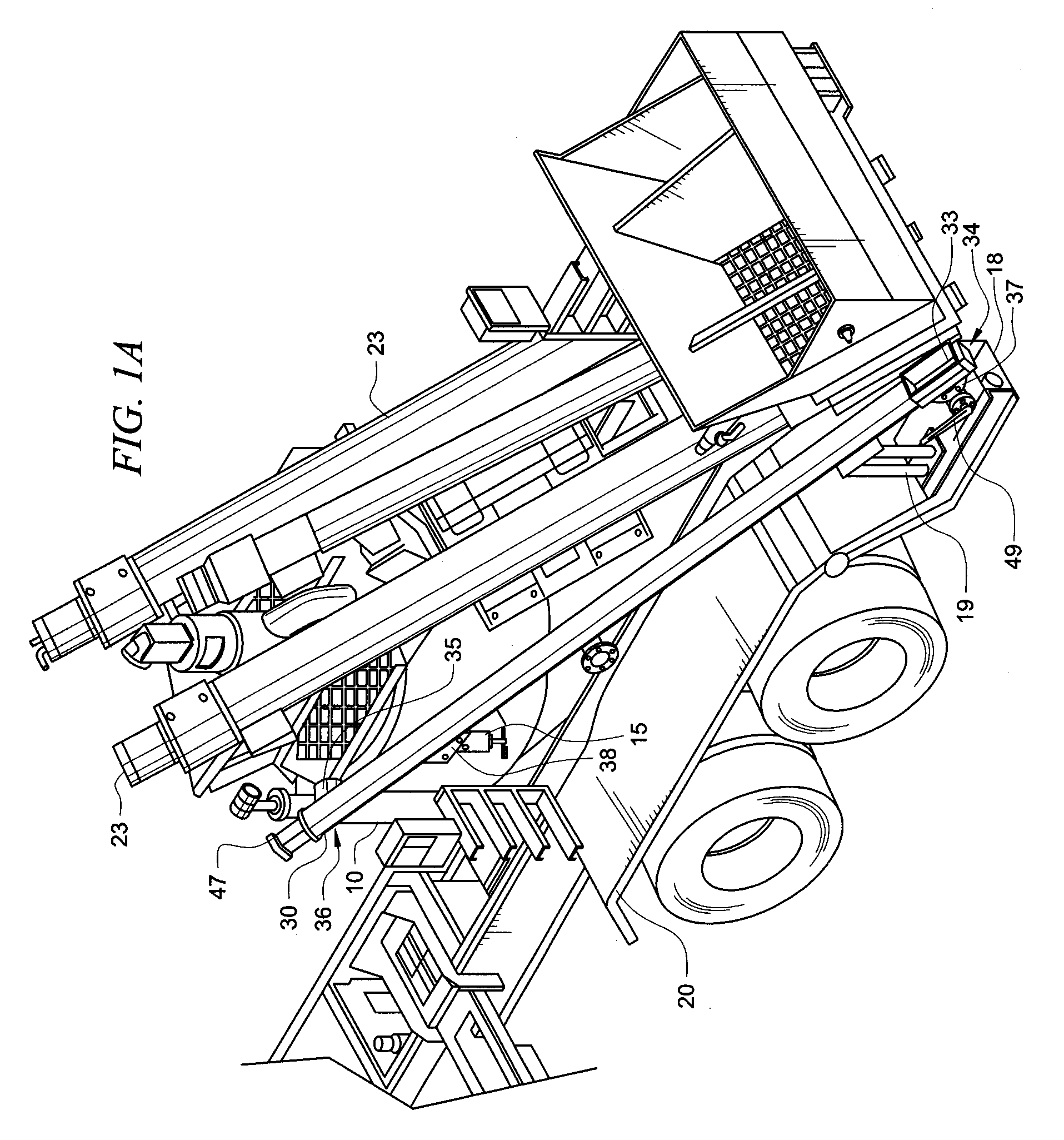

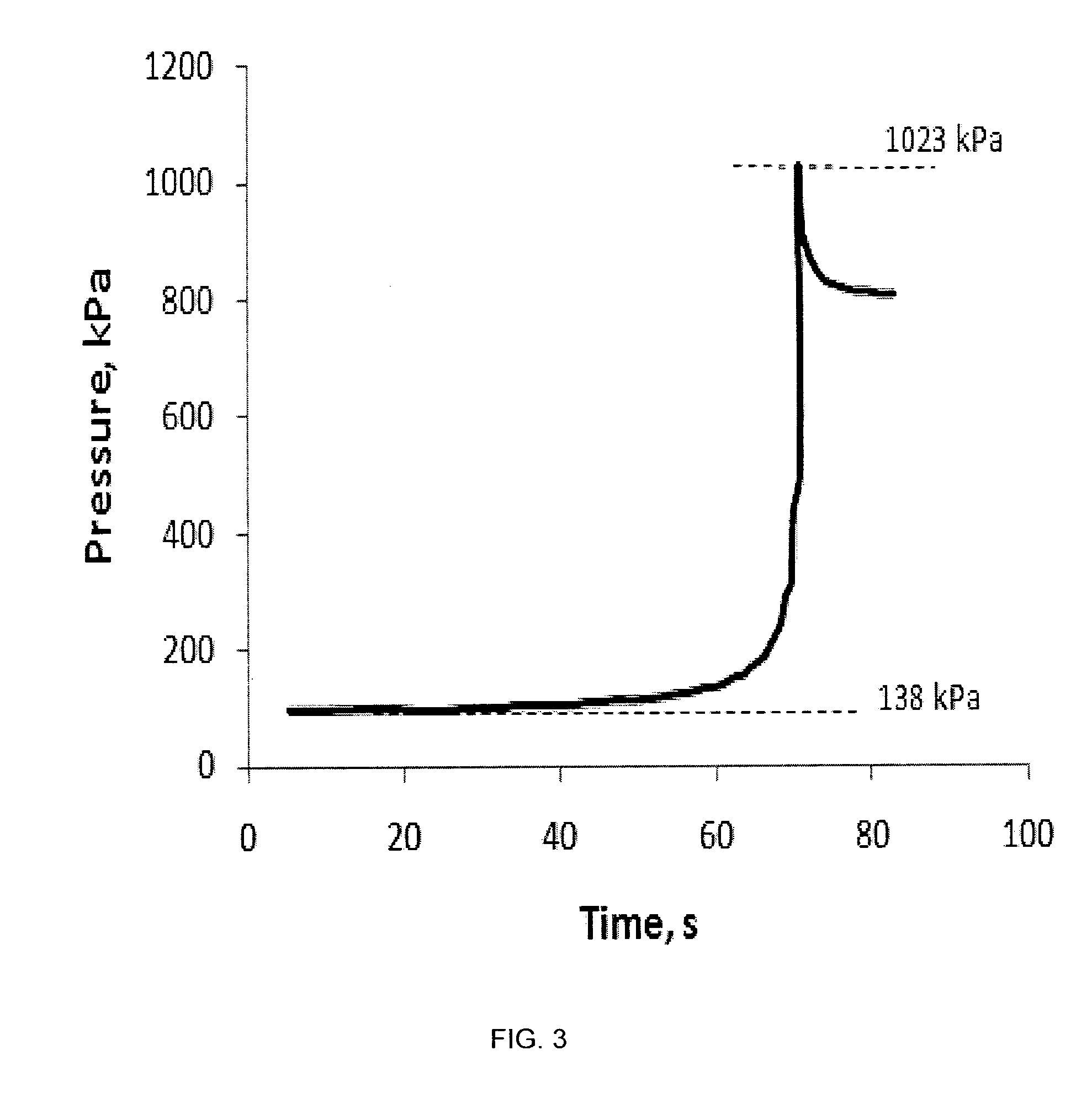

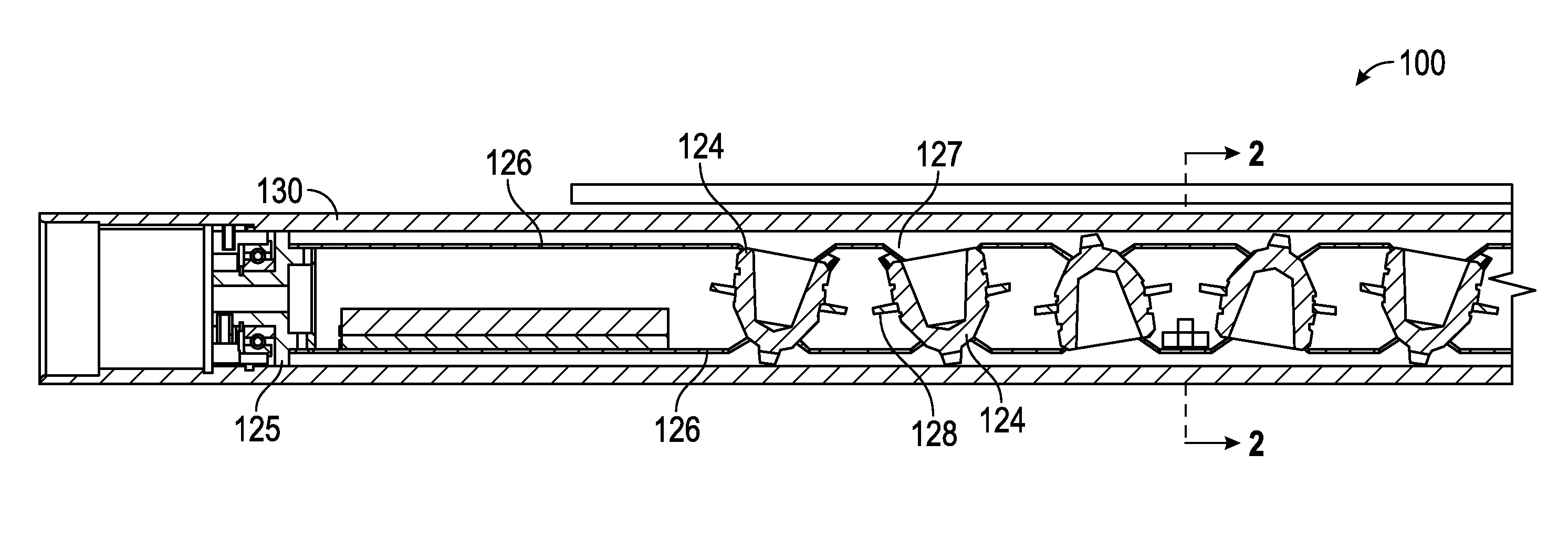

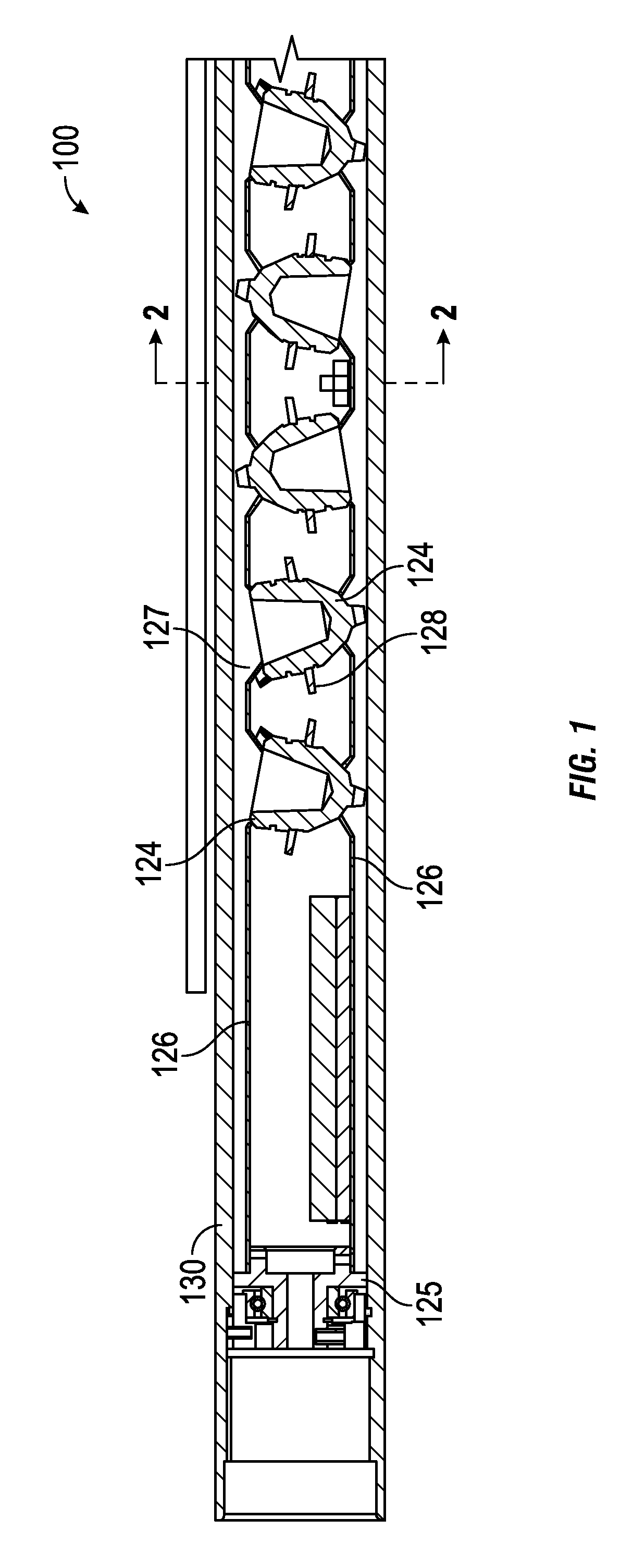

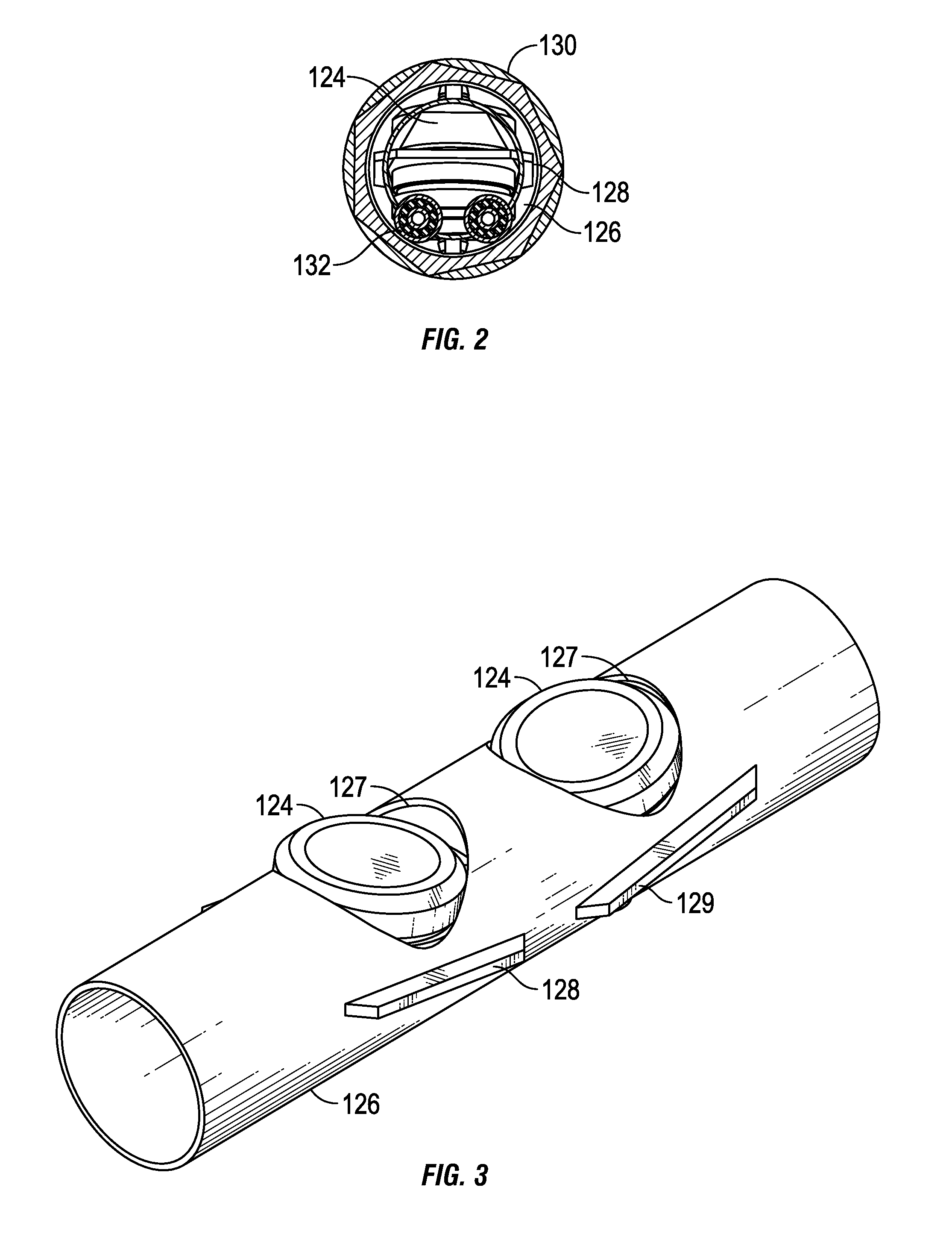

Dry additive metering into portable blender tub

Oil wells may be fracture treated on-site in order to stimulate production. Such fracture treatment may be performed using a portable blender tub to mix fracturing fluid, proppant, and dry chemical additive into an injection slurry. A mechanical conveyance device may be adjustably attached to the portable blender tub, so that in its first position it is stowed for transport, while in its second position it is deployed for operation. When deployed, the mechanical conveyance device may mechanically convey and meter dry chemical additive into the blender tub, allowing a handler to feed and meter dry chemical additive while standing on the ground. This allows for improved safety and efficiency in fracture treating a wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

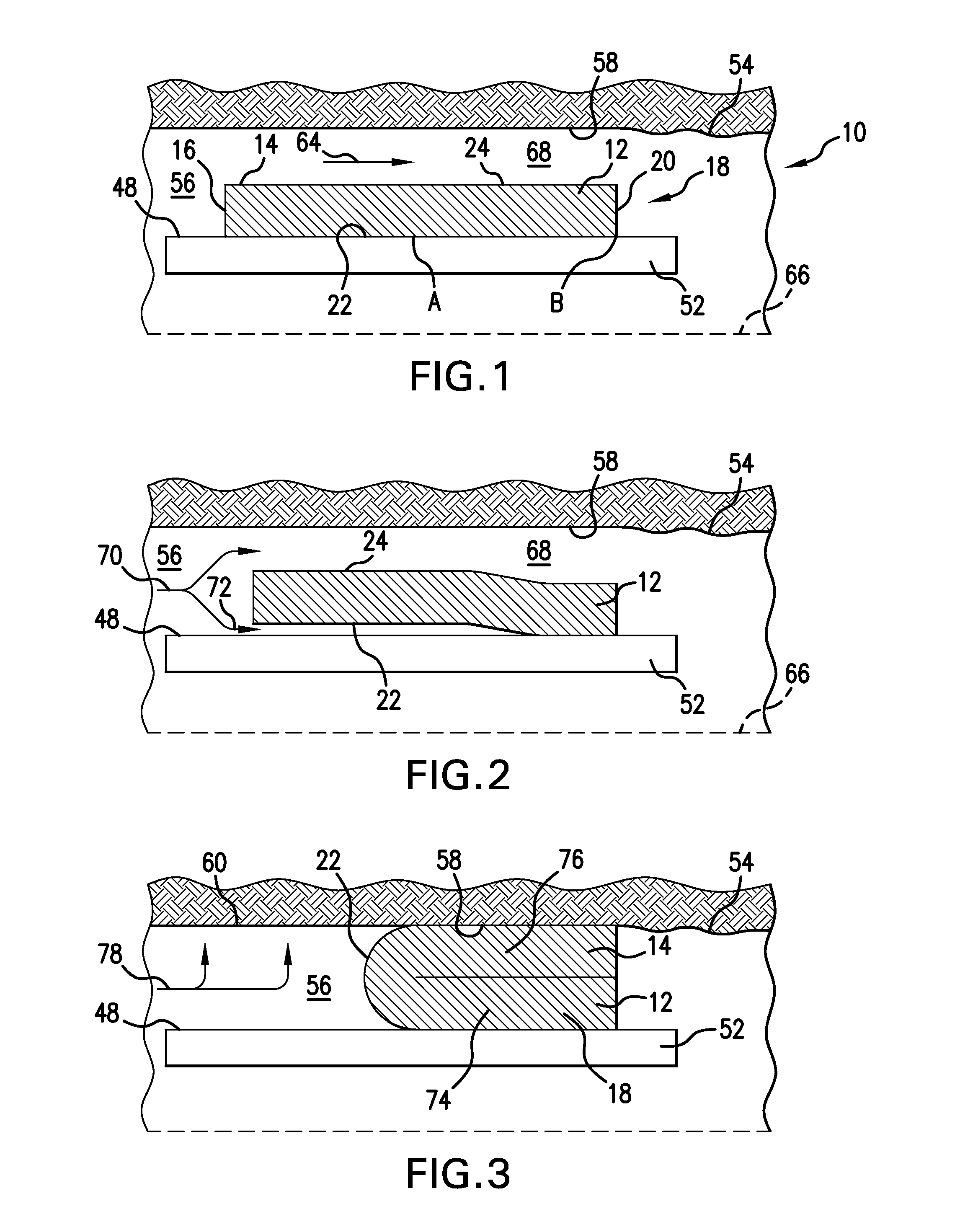

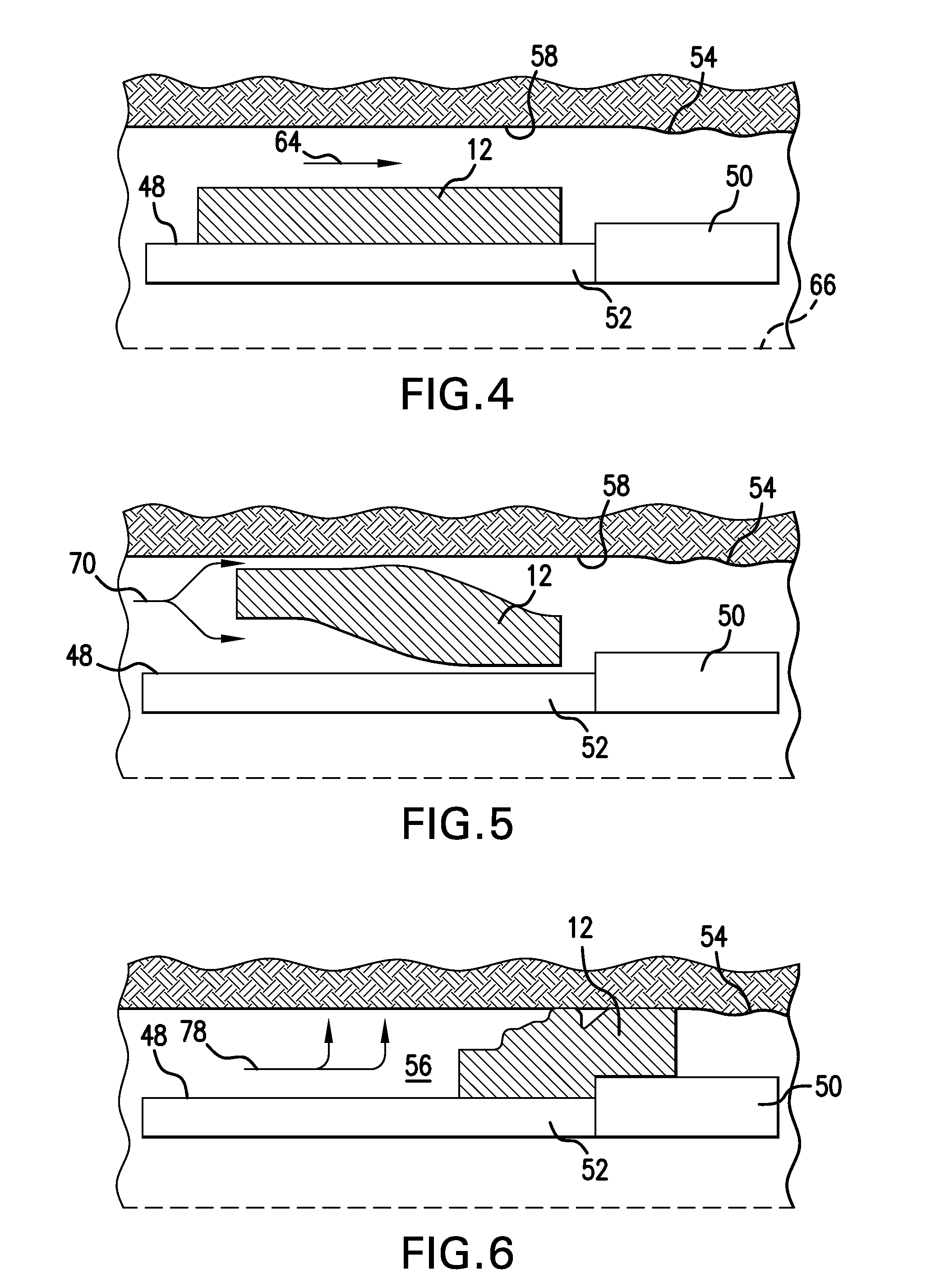

Hydraulic fracture diverter apparatus and method thereof

An apparatus positionable along a downhole string. The apparatus includes a flexible structure retained on a surface of the string in a first condition. The flexible structure movable by a flow to substantially fill an annular space between the string and a radially positioned structure in a second condition. A method of diverting fracturing treatments in a wellbore is also included.

Owner:BAKER HUGHES INC

Hydraulic Fracturing Method

A method is given for diverting injected slickwater in a hydraulic fracturing treatment. The diversion fluid is preferably a substantially proppant free viscous fluid that causes a net pressure increase and plugging of some of the microfractures in the initial fracture system created, which induces formation of supplementary microfractures connected to the initial fracture network and in-creases the contact area with the formation rock. The method generates a greater fracture network complexity and thus a higher contact area with the reservoir during a single treatment cycle.

Owner:SCHLUMBERGER TECH CORP

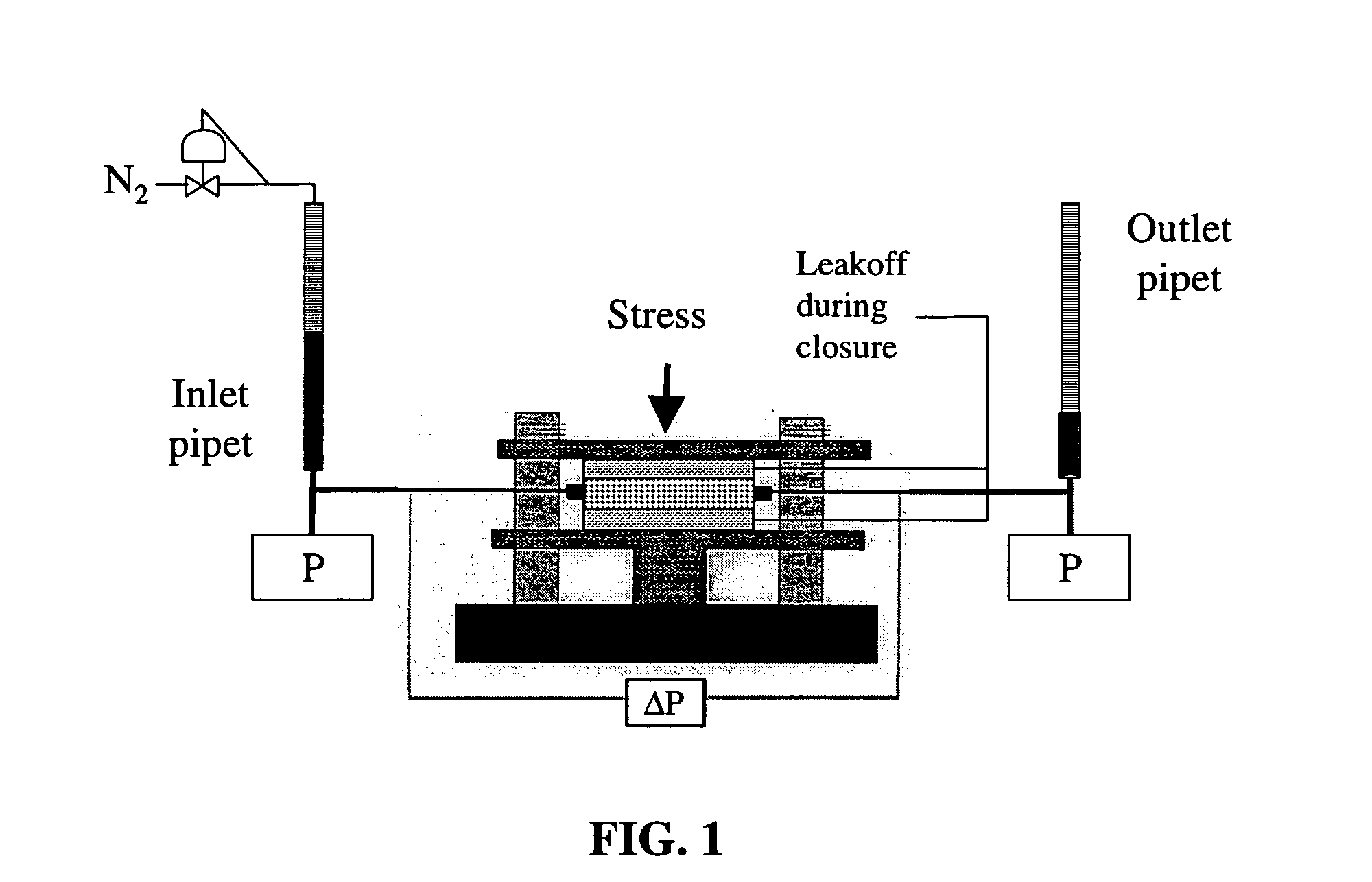

Fluid loss additive for enhanced fracture clean-up

InactiveUS20060278389A1Reduce molecular weightLow gradientSurveyFluid removalHydraulic fracturingPolymer

A hydraulic fracturing method is disclosed that includes designing a fracture treatment including a fluid pumping schedule to fracture a subterranean formation according to a design model that accounts for cumulative filter cake thickness, including polymer concentrated at the fracture surfaces, to provide a propped fracture width effectively greater than the cumulative filter cake thickness, and injecting fluids through a wellbore into the formation essentially according to the fluid pumping schedule of the fracture treatment design. A fracturing method is also disclosed that includes placing a high breaker loading in the filter cake. A composition is disclosed which comprises a fluid viscosified with a polymer and a fluid loss additive comprising a delayed breaker.

Owner:SCHLUMBERGER TECH CORP

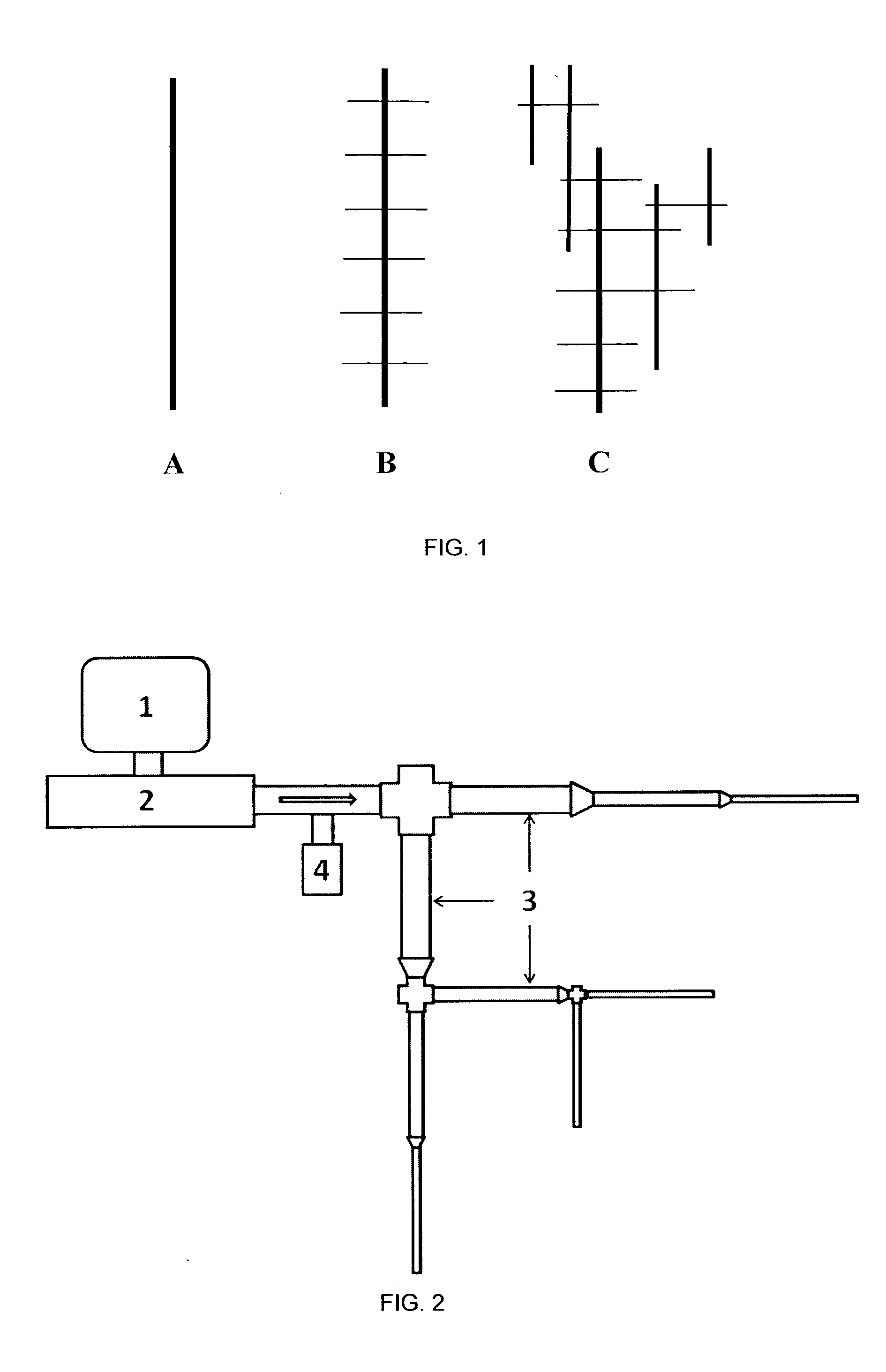

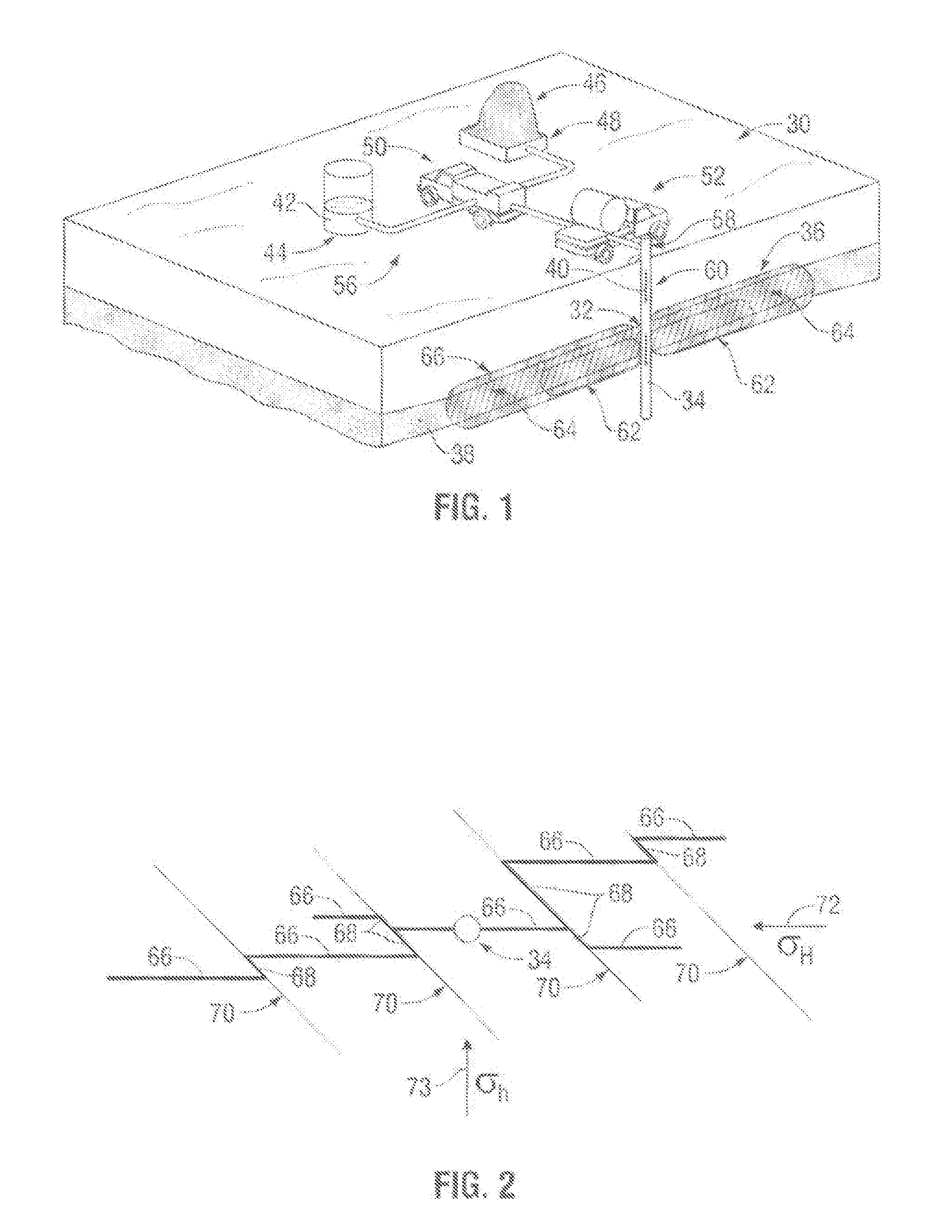

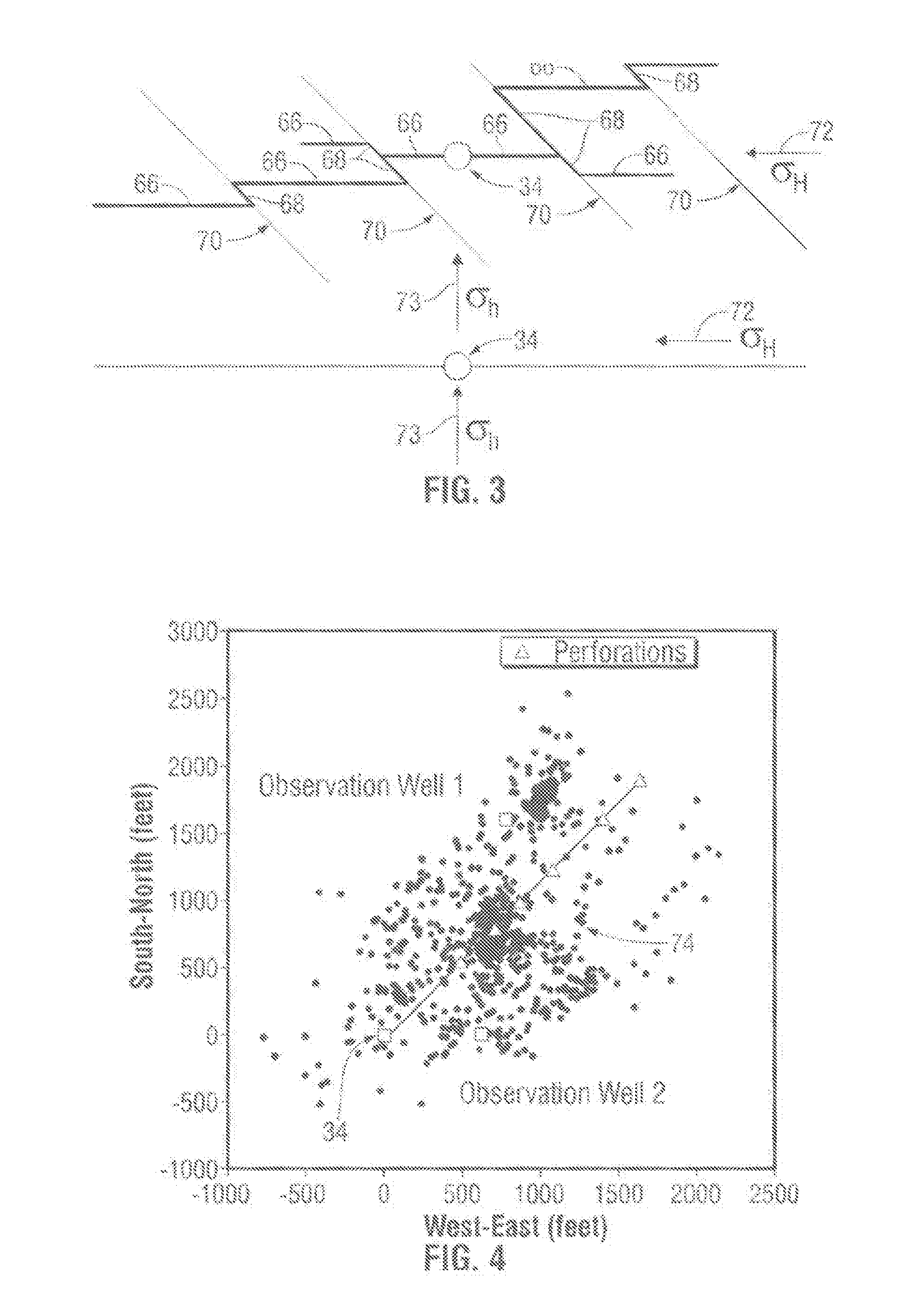

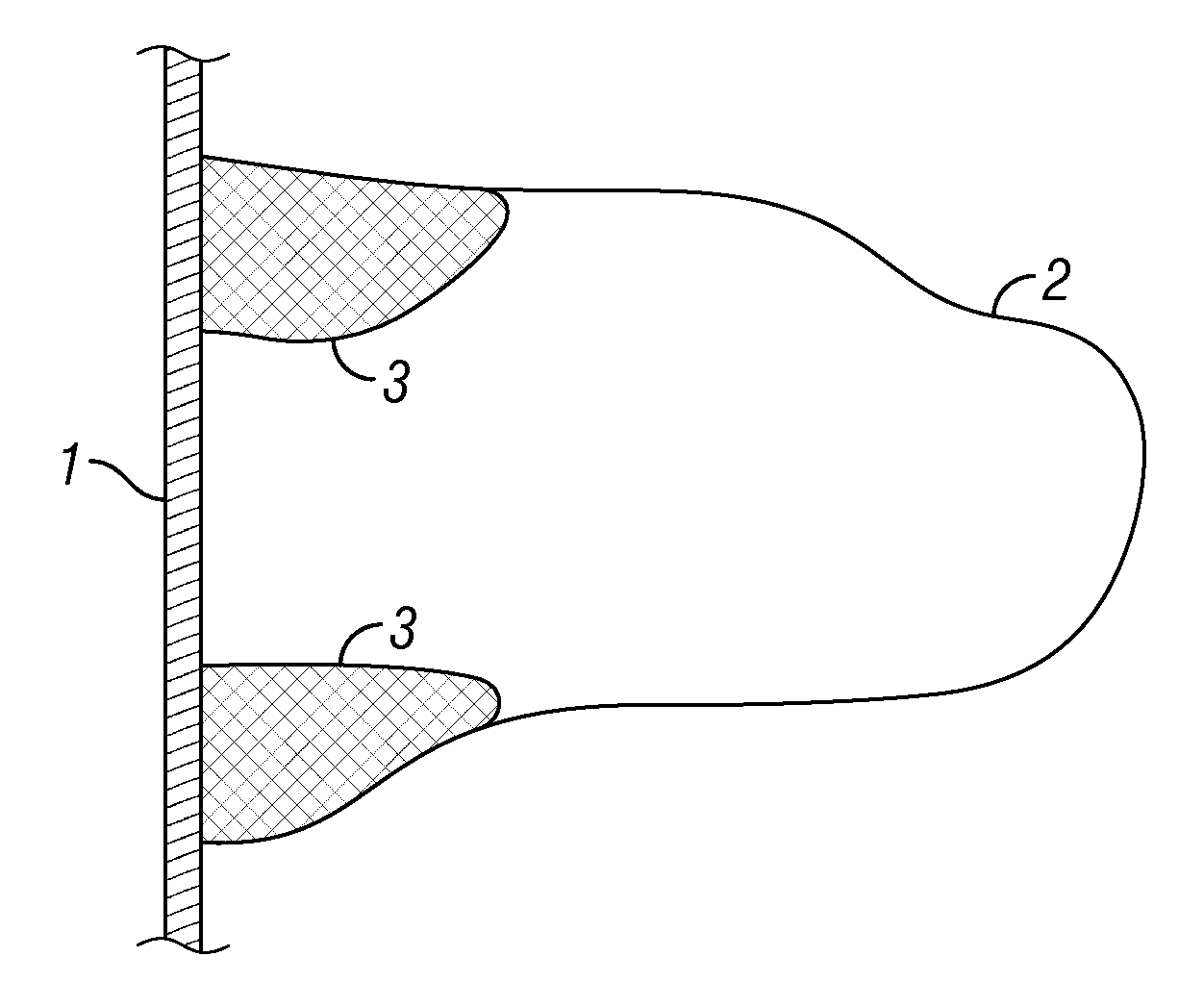

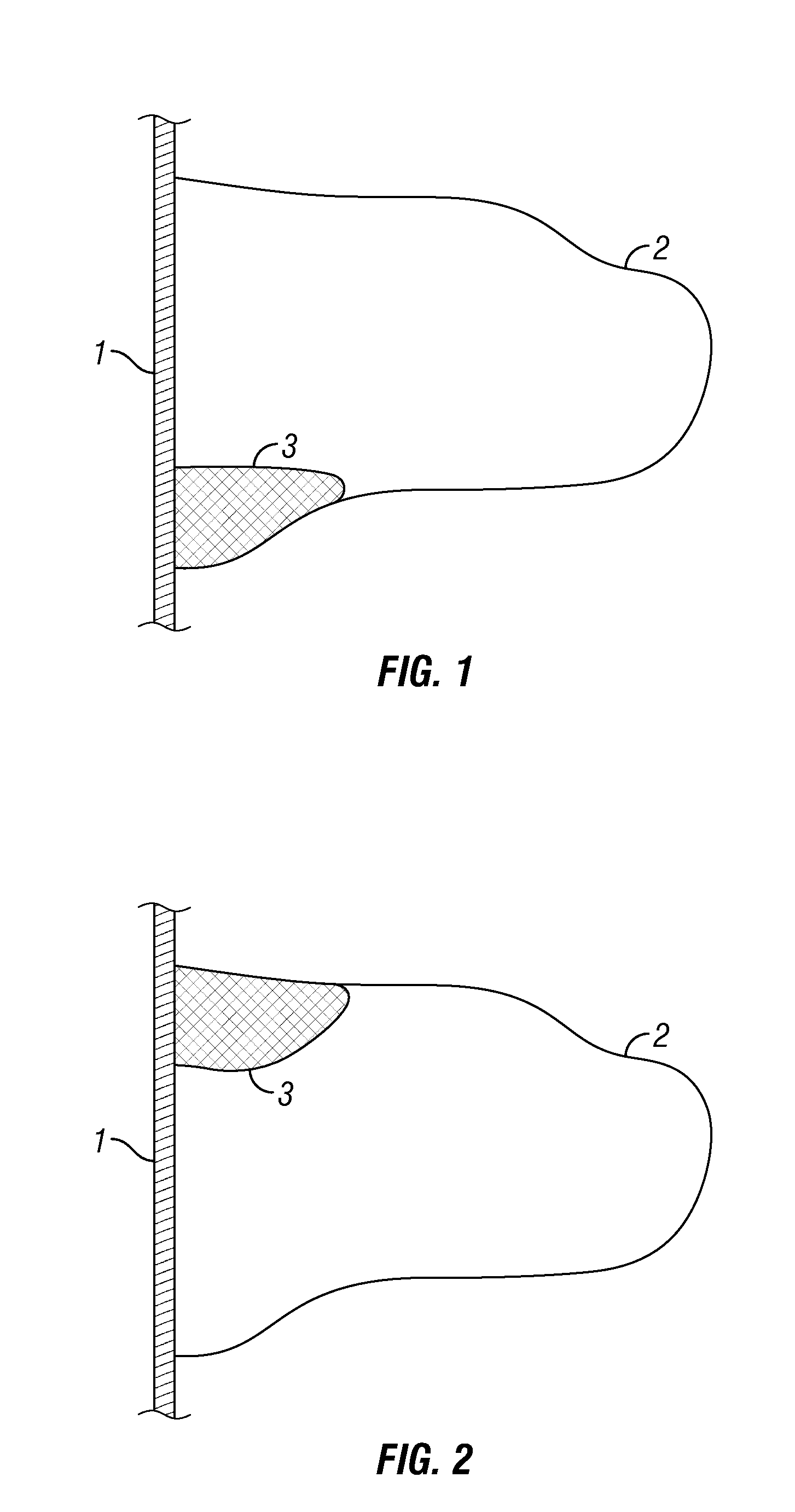

Method for increasing fracture area

ActiveUS20130140020A1Convenient treatmentIncrease the lengthSurveyFluid removalMining engineeringHydraulic fracturing

A technique enables improvements in hydraulic fracturing treatments on heterogeneous reservoirs. Based on data obtained for a given reservoir, a fracturing treatment material is used to create complex fractures, which, while interacting with the interfaces and planes of weakness in the reservoir, develop fracture connectors, e.g. step-overs, which often grow for short distances along these planes of weakness. The technique further comprises closing or sealing at least one of the fracture connectors to enable reinitiation of fracturing from the truncated branches, and to subsequently develop additional connectors. As a result, the overall fracturing becomes more complex (more branches and more surface area per unit reservoir volume is created), which leads to an increase in the effective fracture area and improved fluid flow through the reservoir.

Owner:SCHLUMBERGER TECH CORP

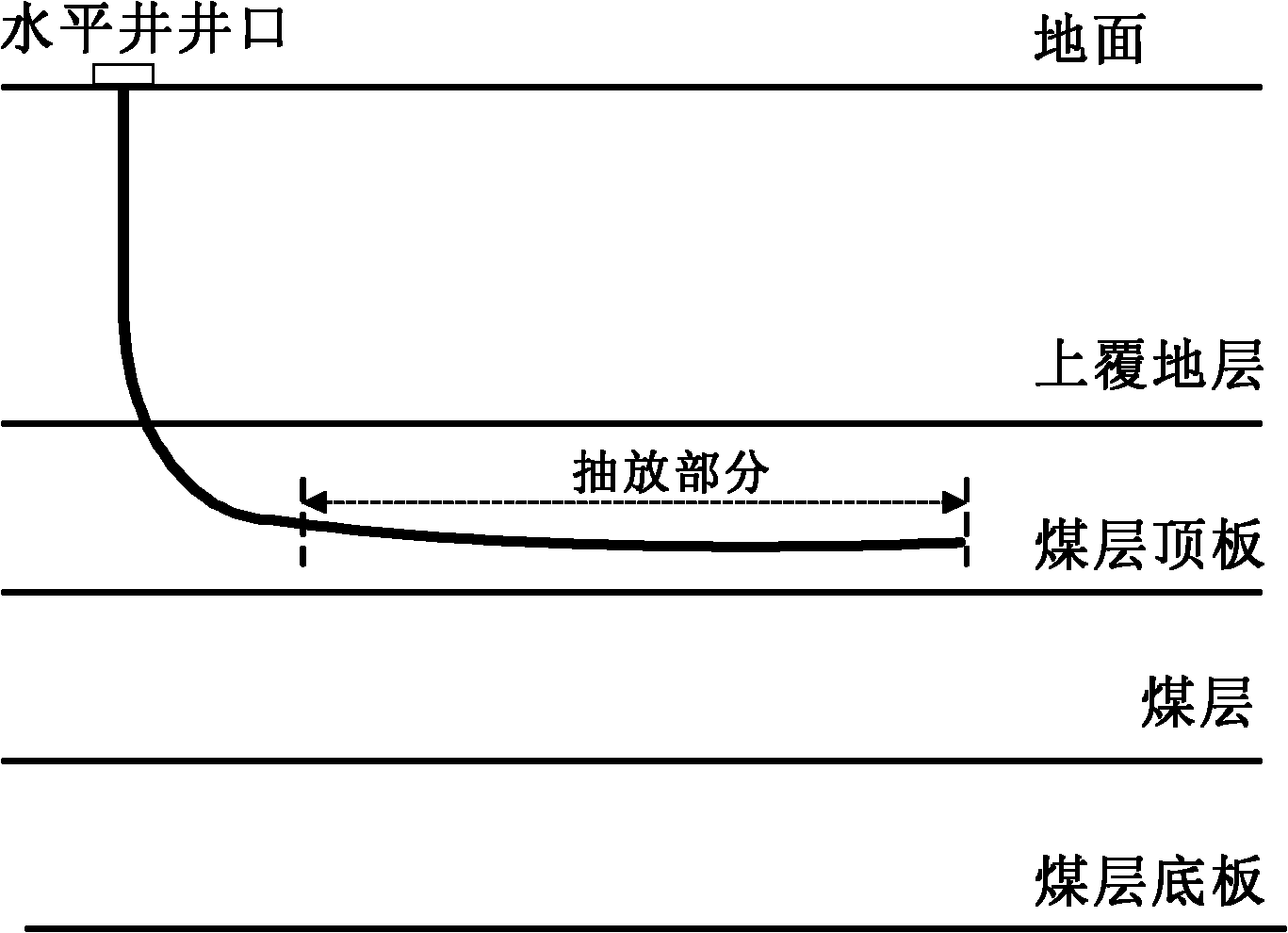

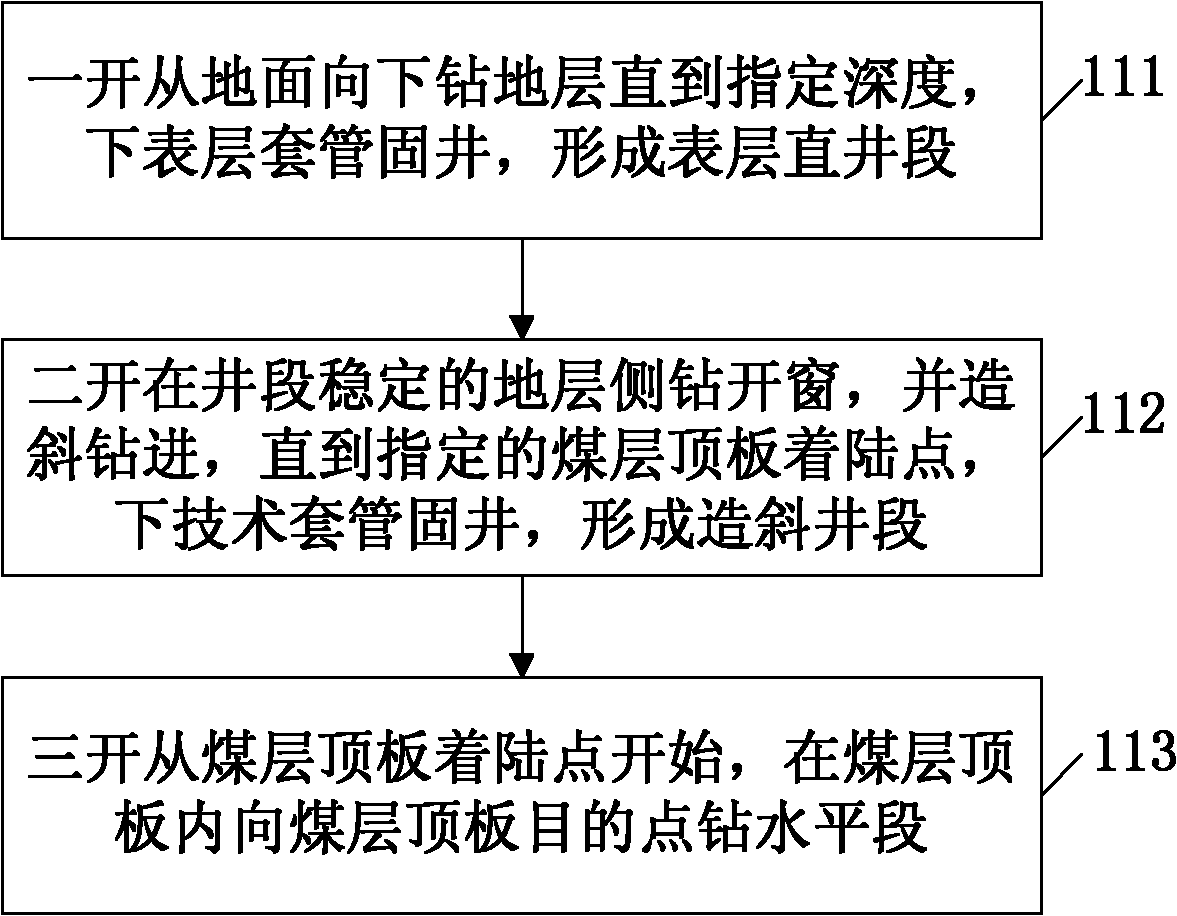

Drainage method of gas in coal bed

The invention discloses a drainage method of gas in a coal bed, and relates to the technical field of exploitation of coal mines and coal gas beds. By the drainage method, the gas can be rapidly and efficiently drained, the effect of coal-bed gas pressure can be lowered, and the safety of the coal mine operation is greatly improved. The technical scheme provided by the embodiment of the invention has lower cost, and manual work and energy consumption are saved. The drainage method provided by the invention comprises the following steps: drilling at least one horizontal well from the ground surface to the roof of the coal bed, wherein, each horizontal well has a drainage part positioned on the roof of the coal bed; carrying out fracture treatment on the drainage part of each horizontal well to form a crack which penetrates through the roof of the coal bed downwards and extends into the coal bed; and draining the gas in the coal bed by utilizing the crack.

Owner:CHINA UNITED COALBED METHANE NAT ENGRES CENT +1

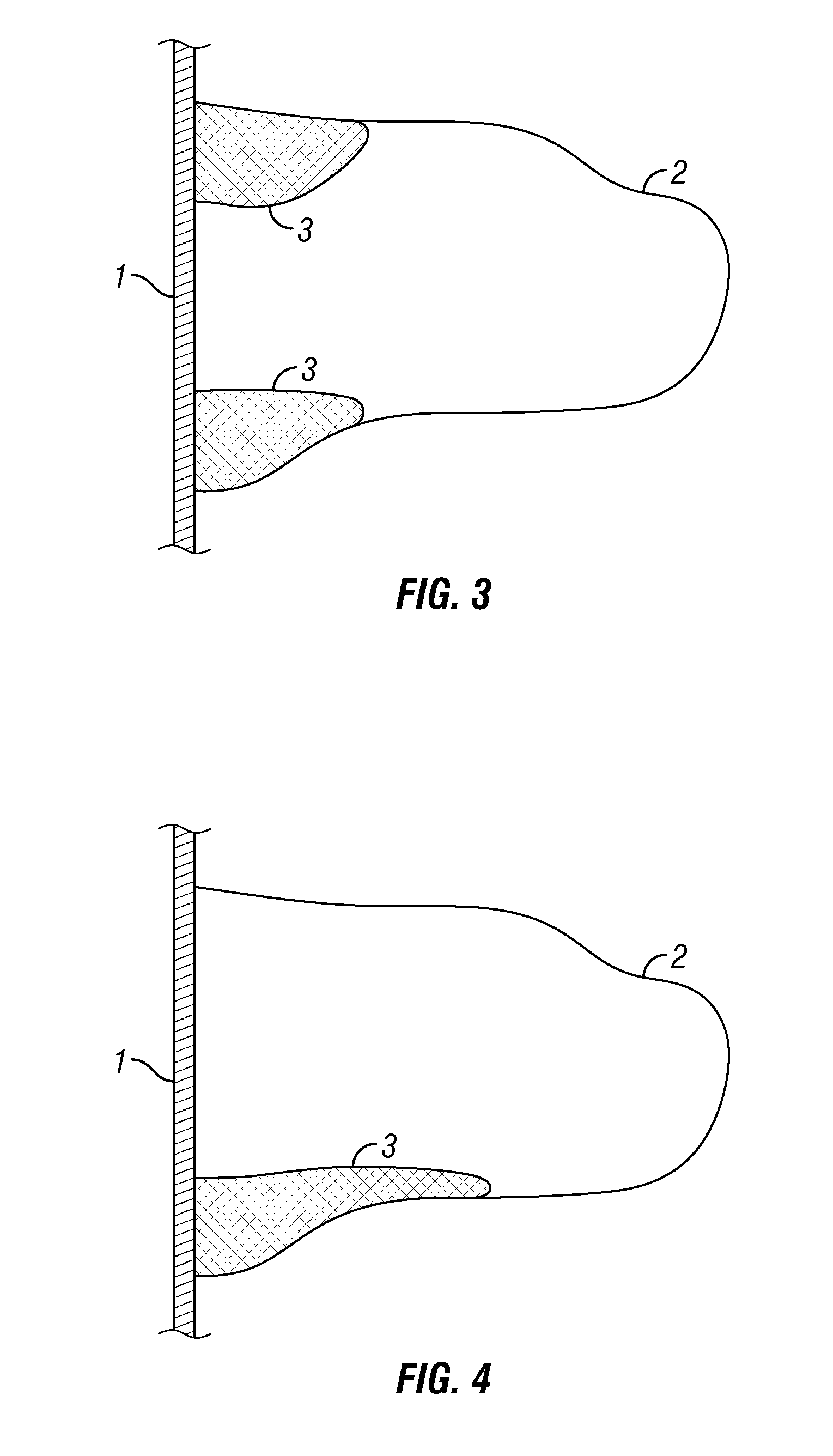

Hydraulic fracture height growth control

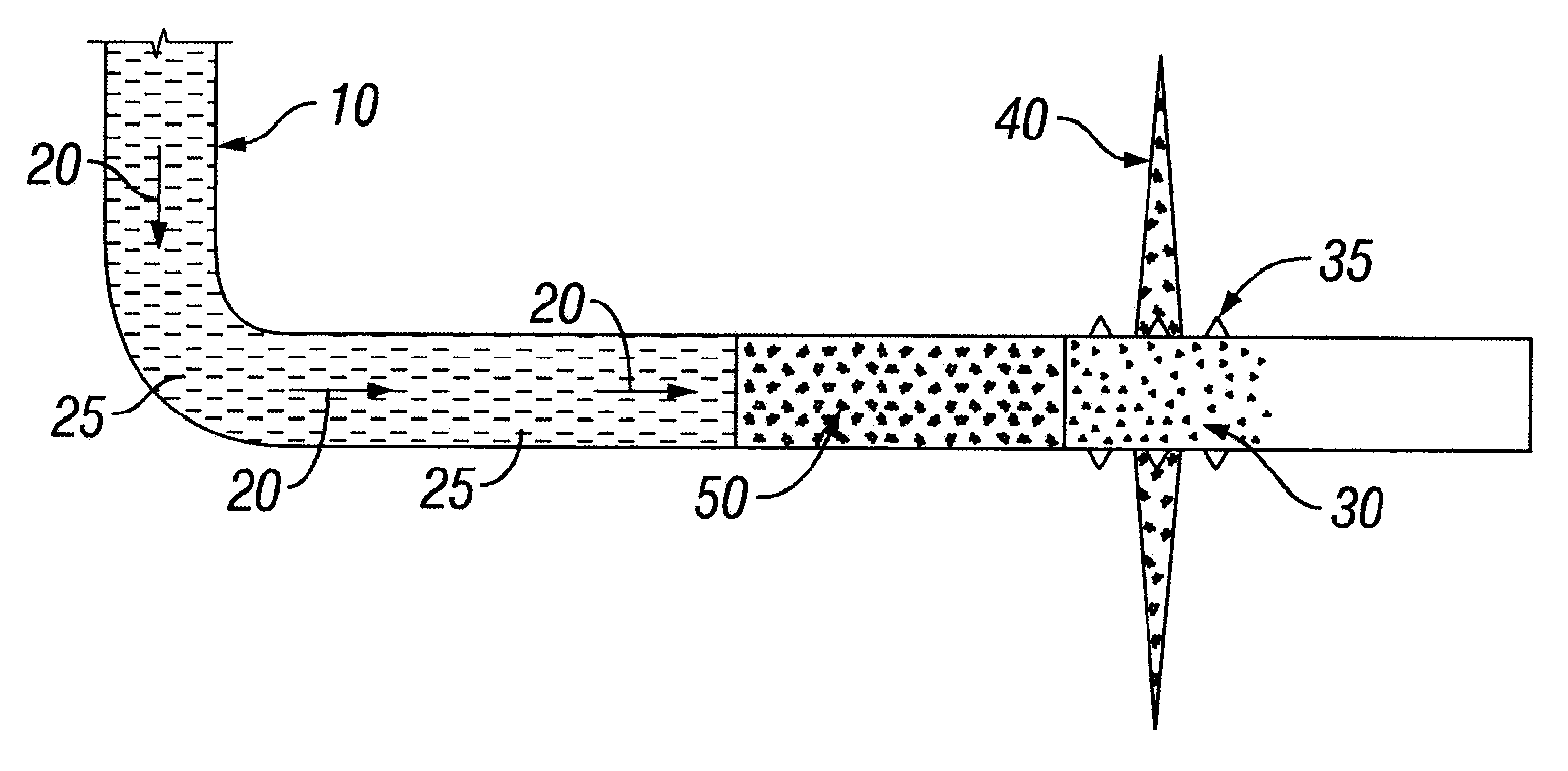

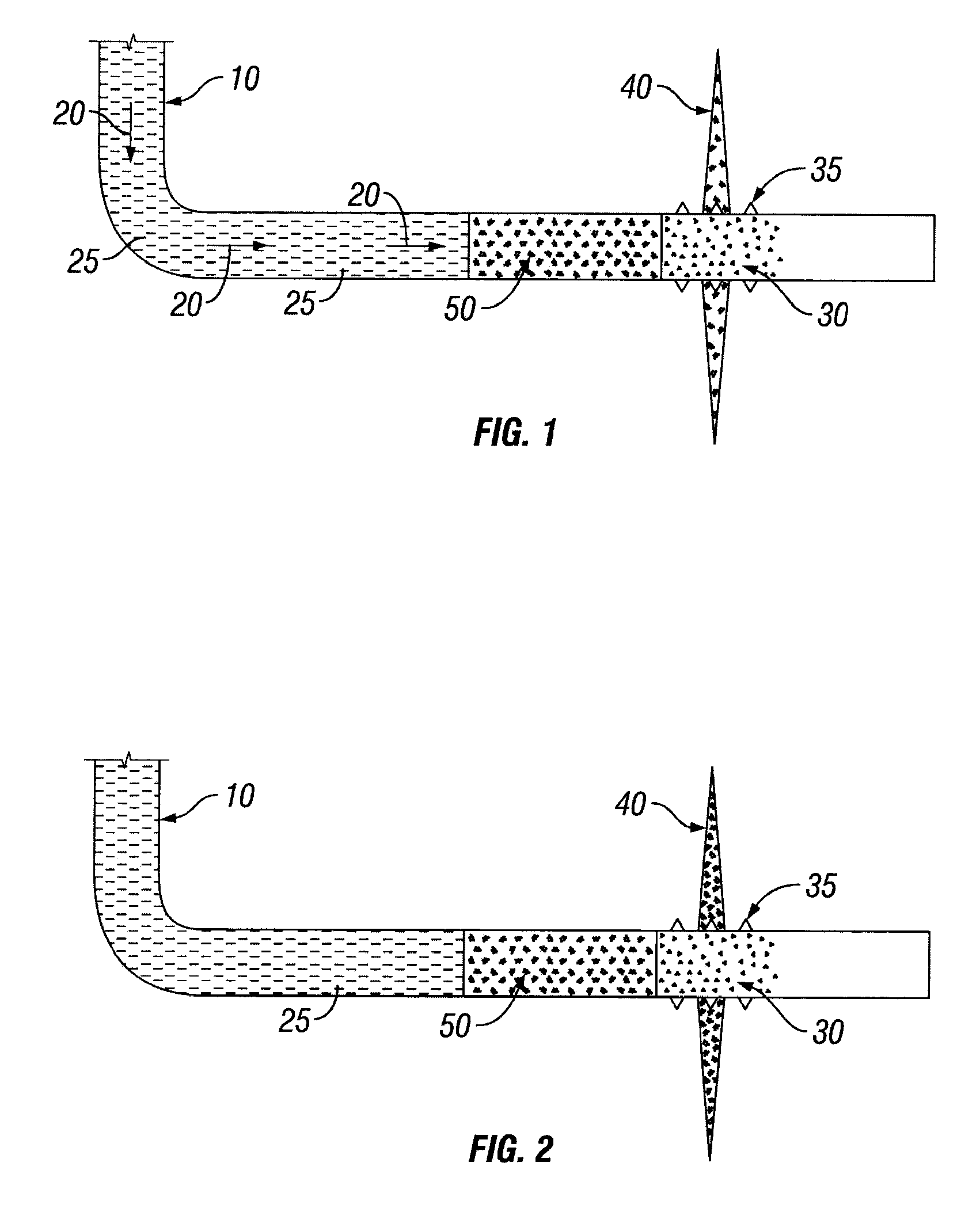

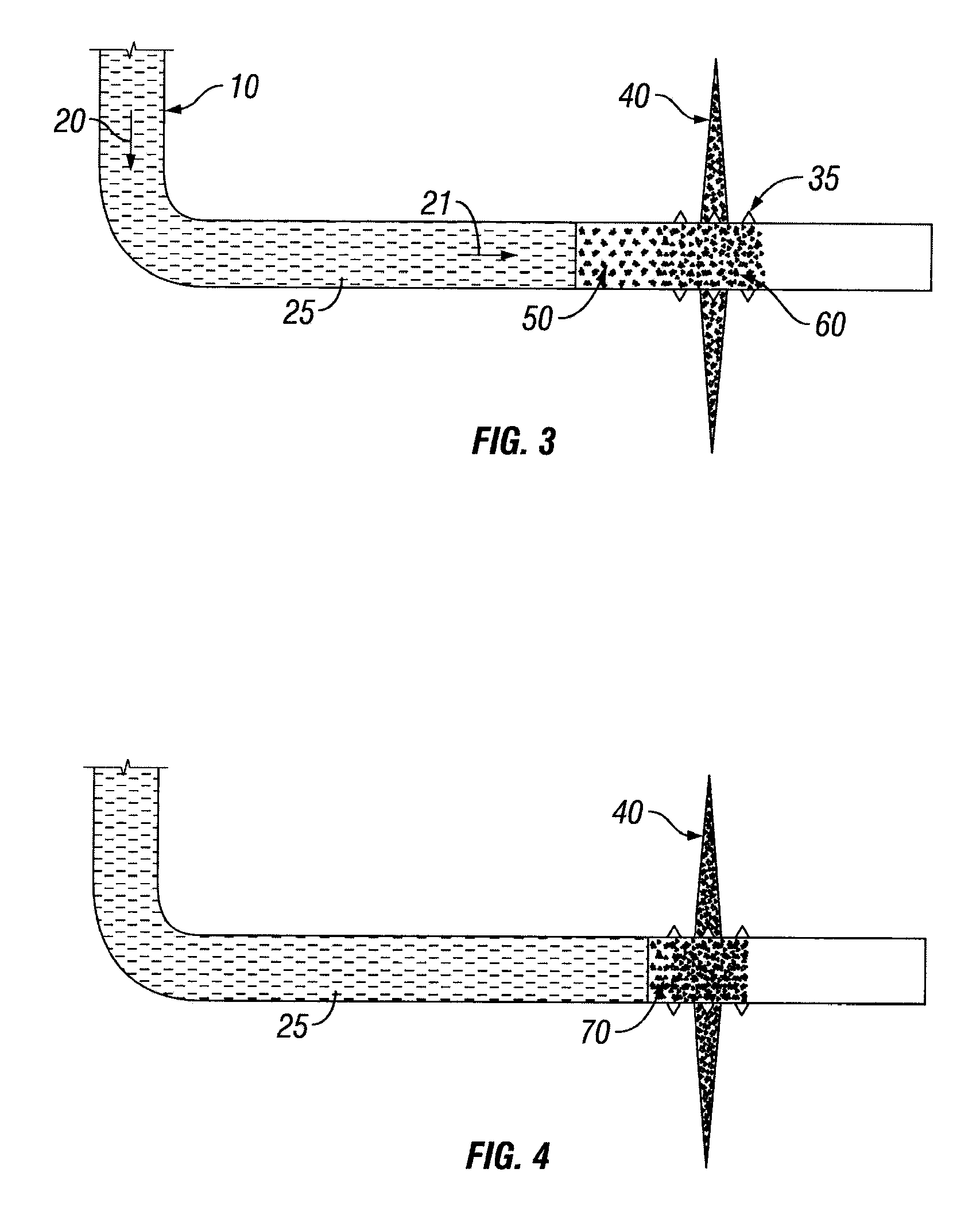

A method is given for creating a fracture, in a subterranean formation, that has a fluid flow barrier at the top, at the bottom, or at both the top and the bottom. The method is applied before or during a conventional hydraulic fracturing treatment and is used to limit undesired vertical growth of a fracture out of the productive zone. A lower-viscosity pad fluid is used to initiate the fracture; a higher-viscosity fluid containing barrier particles is then injected; a lower-viscosity particle-free fluid is then injected to promote settling (or rising) of the barrier particles and to finger through the slug of barrier particles and cut it into an upper and lower portion. If the barrier is to be at the bottom of the fracture, the barrier particles are denser than the fluids; if the barrier is to be at the top of the fracture, the barrier particles are less dense than the fluids. Optionally, between the barrier transport stage and the subsequent lower-viscosity stage, there may be a stage of a higher viscosity particle-free fluid that pushes the barrier particles farther into the fracture. To provide both upper and lower particles in one treatment, the pad stage may be of higher-viscosity, or the barrier particles may include particles less dense than, and more dense than, the fluid.

Owner:SCHLUMBERGER TECH CORP

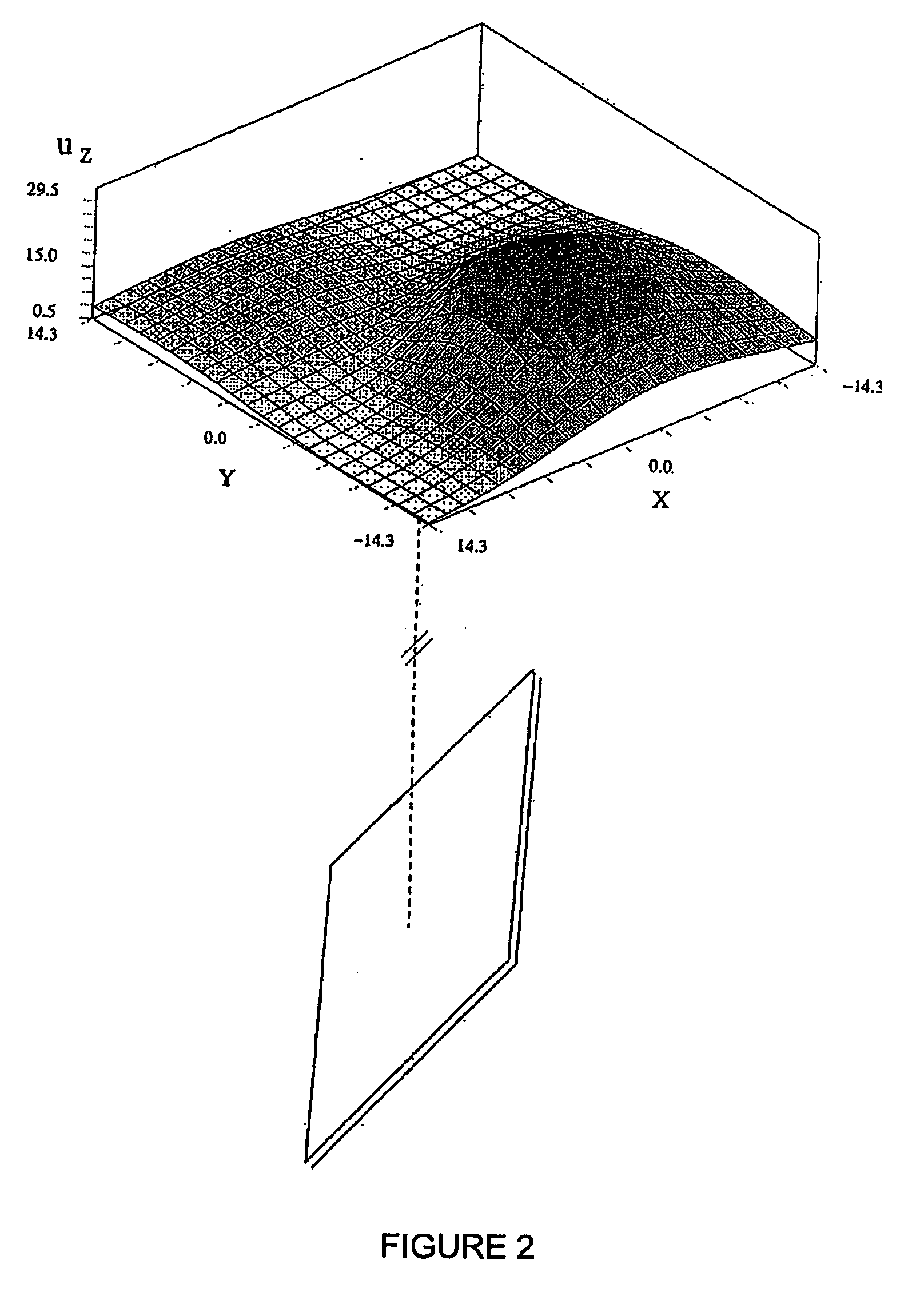

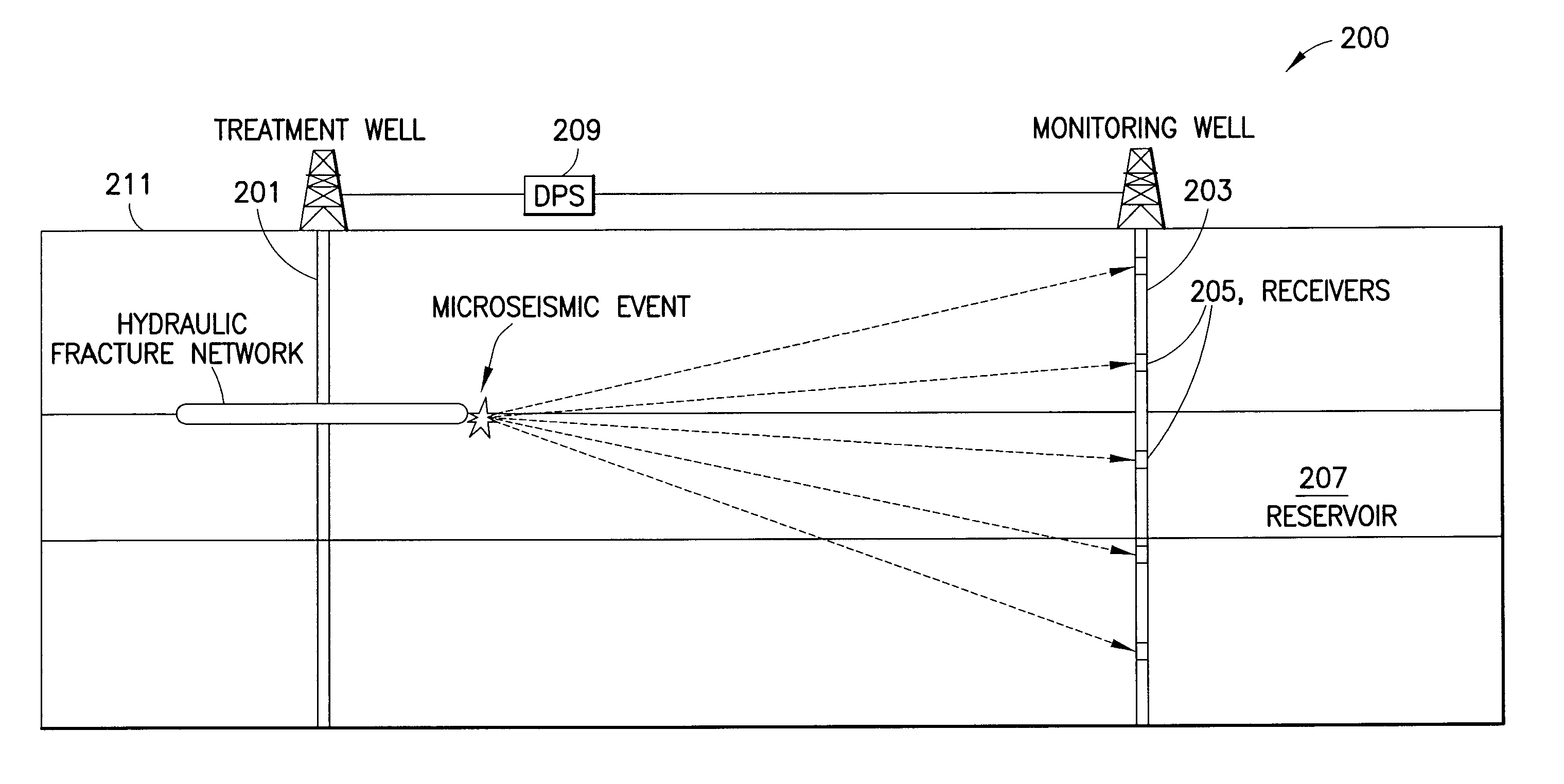

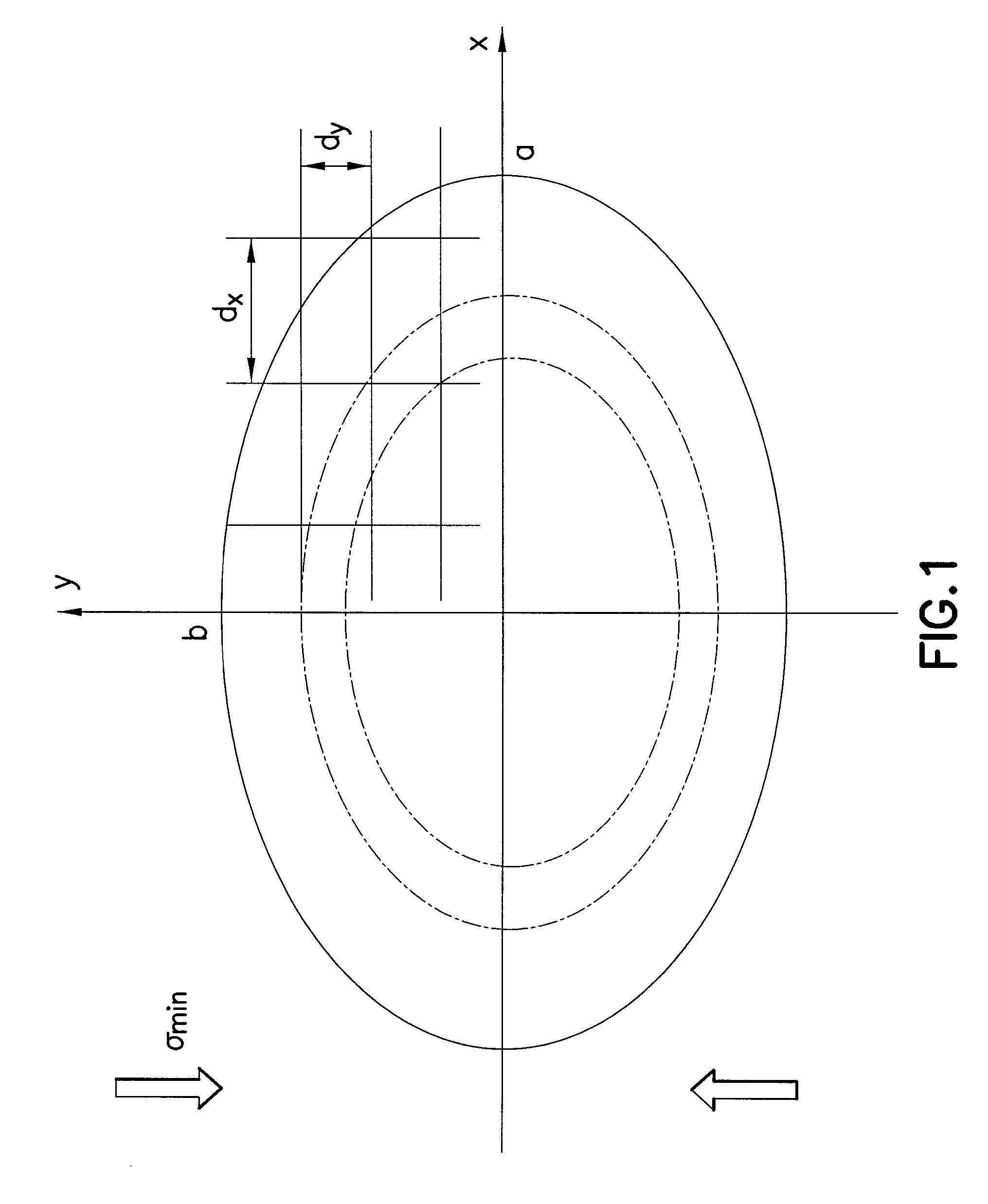

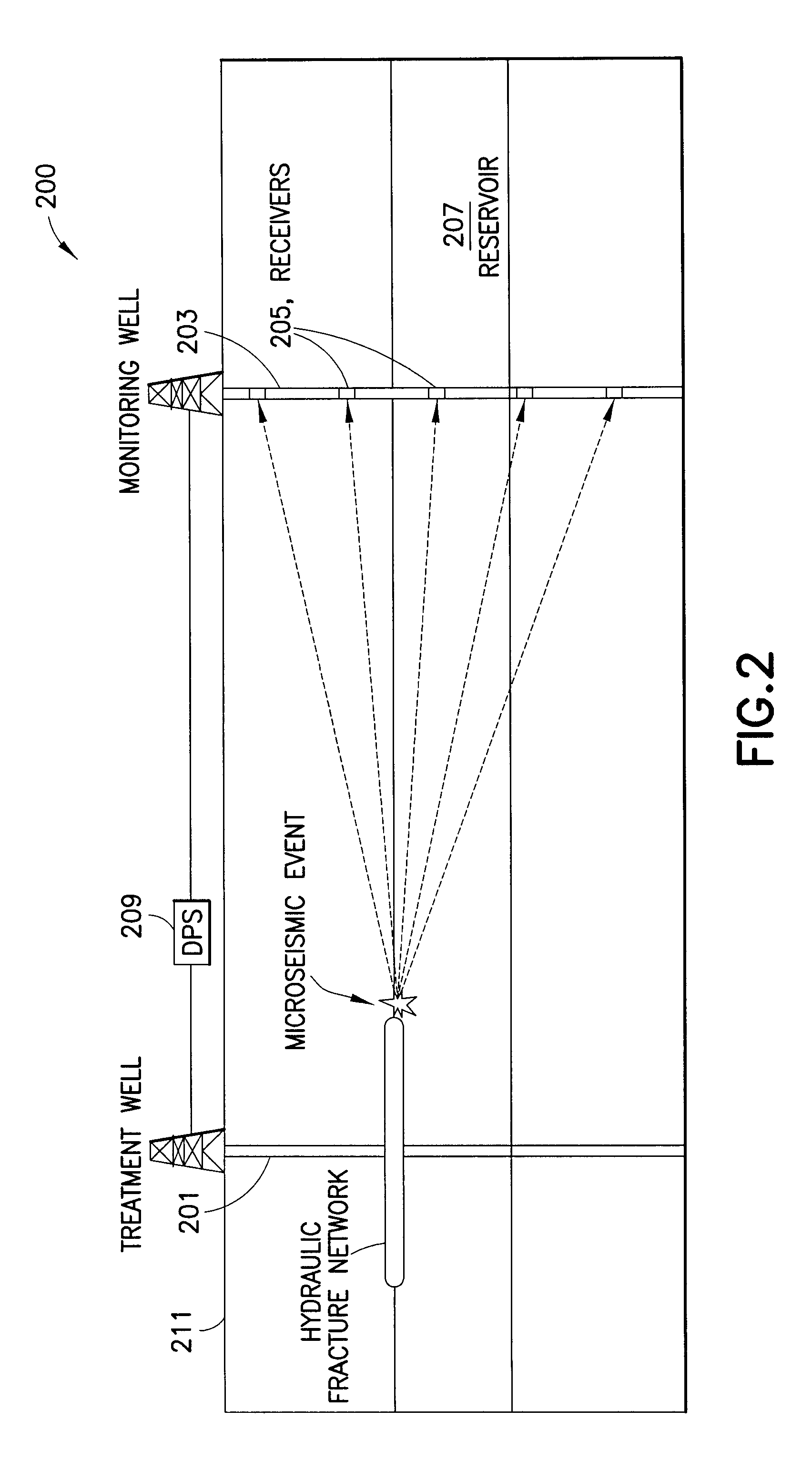

Method and apparatus for efficient real-time characterization of hydraulic fractures and fracturing optimization based thereon

ActiveUS8498852B2Reduce complexityReducing resourceFluid removalAnalogue processes for specific applicationsGeomorphologyField data

Methods and systems for characterizing hydraulic fracturing of a subterranean formation based upon inputs from sensors measuring field data in conjunction with a fracture model. Such characterization can be generated in real-time to automatically manipulate surface and / or down-hole physical components supplying hydraulic fluids to the subterranean formation to adjust the hydraulic fracturing process as desired. The hydraulic fracture model as described herein can also be used as part of forward calculations to help in the design and planning stage of a hydraulic fracturing treatment. In a preferred embodiment, the fracture model constrains geometric and geomechanical properties of the hydraulic fractures of the subterranean formation using the field data in a manner that significantly reduce the complexity of the fracture model and thus significantly reduces the processing resources and time required to provide accurate characterization of the hydraulic fractures of the subterranean formation.

Owner:SCHLUMBERGER TECH CORP

Fluid loss additive for enhanced fracture clean-up

A hydraulic fracturing method is disclosed that includes designing a fracture treatment including a fluid pumping schedule to fracture a subterranean formation according to a design model that accounts for cumulative filter cake thickness, including polymer concentrated at the fracture surfaces, to provide a propped fracture width effectively greater than the cumulative filter cake thickness, and injecting fluids through a wellbore into the formation essentially according to the fluid pumping schedule of the fracture treatment design. A fracturing method is also disclosed that includes placing a high breaker loading in the filter cake. A composition is disclosed which comprises a fluid viscosified with a polymer and a fluid loss additive comprising a delayed breaker.

Owner:SCHLUMBERGER TECH CORP

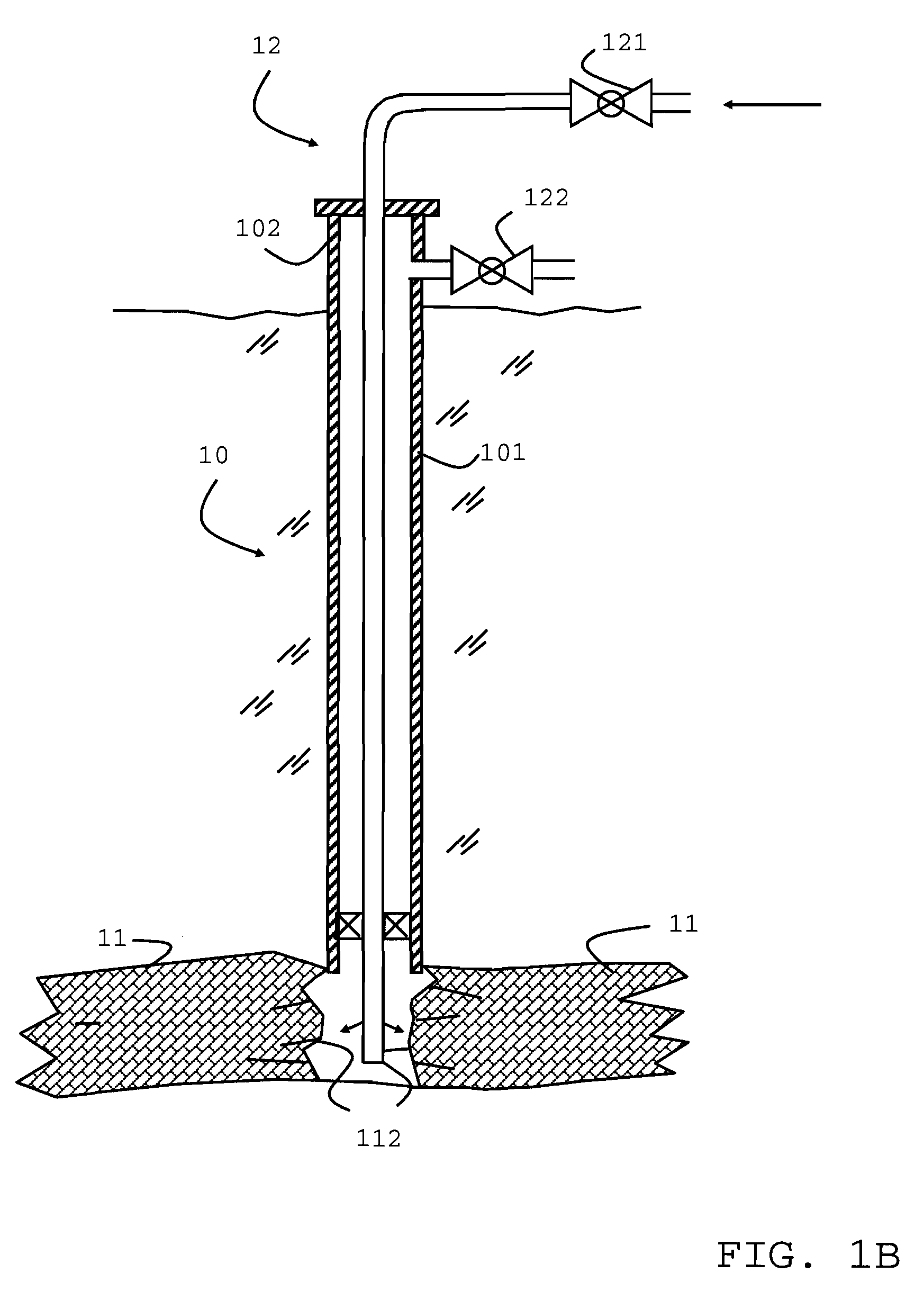

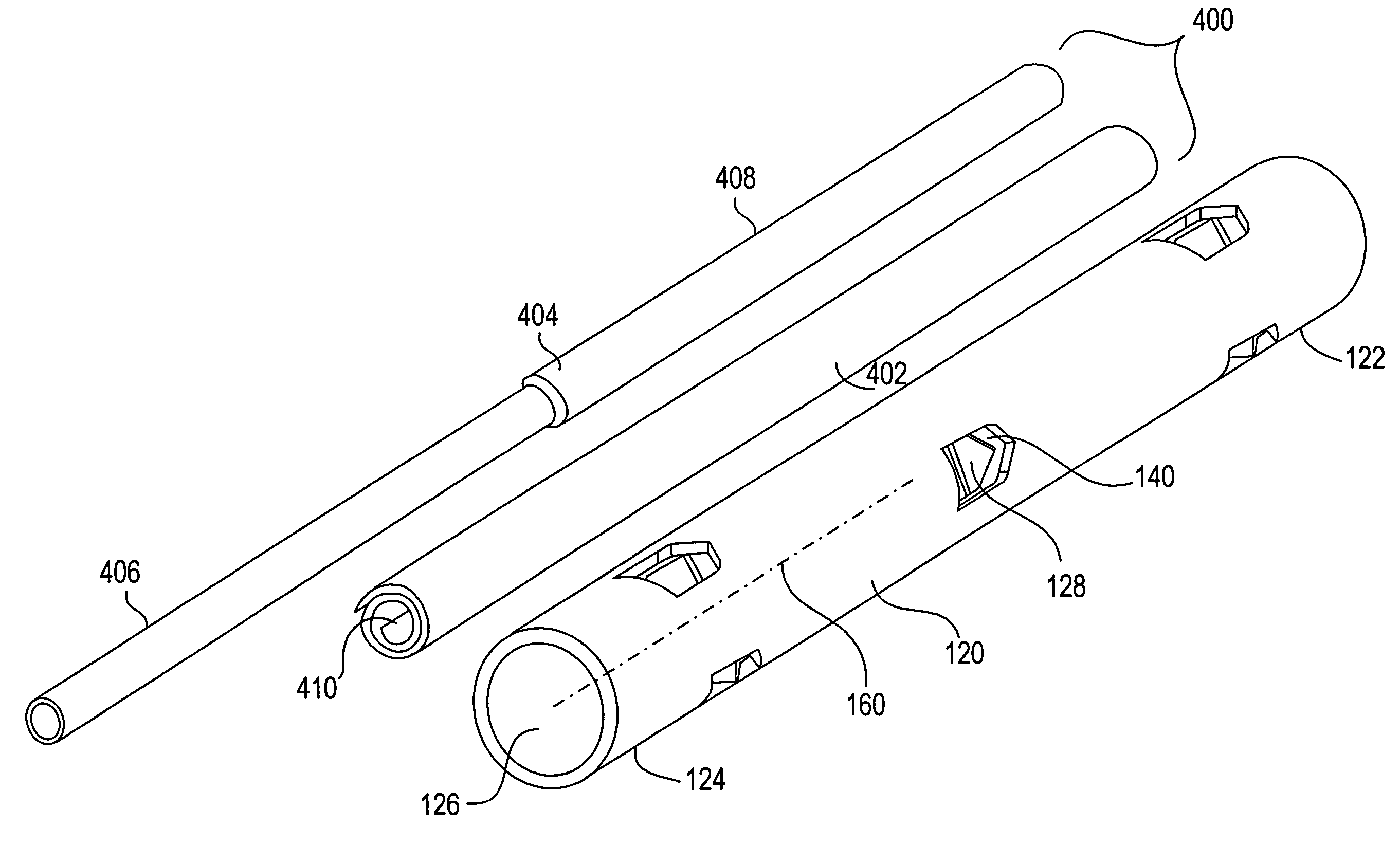

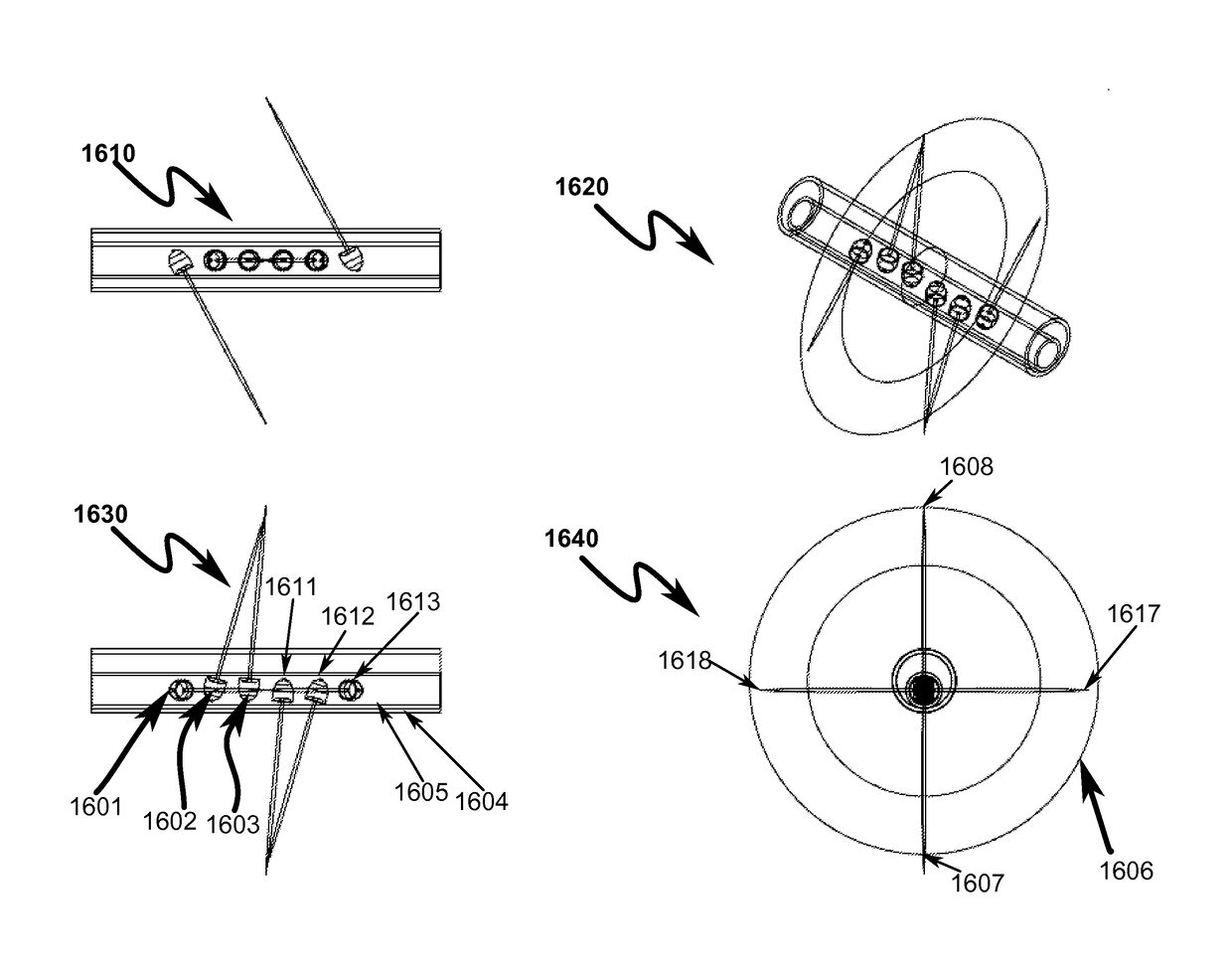

Limited entry phased perforating gun system and method

A limited entry perforating phased gun system and method for accurate perforation in a deviated / horizontal wellbore is disclosed. The system / method includes a gun string assembly (GSA) deployed in a wellbore with shaped charge clusters. The charges are spaced and angled such that, when perforated, they intersect at a preferred fracturing plane. Upon fracturing, the fractures initiate at least principal stress location in a preferred fracturing plane perpendicular to the wellbore from an upward and downward location of the wellbore. Thereafter, the fractures connect radially about the wellbore in the preferred fracturing plane. The fracture treatment in the preferred fracturing plane creates minimal tortuosity paths for longer extension of fractures that enables efficient oil and gas flow rates during production.

Owner:WELLS FARGO BANK NAT ASSOC +1

Method of isolating open perforations in horizontal wellbores using an ultra lightweight proppant

An improved method for building a plug in a horizontal wellbore using a fluid pill pumped into the wellbore at the end of a fracturing treatment. The fluid pill includes a high concentration of an ultra lightweight proppant, such as a neutrally buoyant proppant or an ultra lightweight proppant mixture. The fluid pill is pumped down the wellbore until it almost reaches fractures within a zone of interest. The pumping is then ceased or reduced, allowing the fractures to partially close. The ultra lightweight proppant remains suspended within the fluid pill while stationary. The pumping is then resumed at a very slow rate or as a short pump burst, thus causing the proppant in the fluid pill to bridge off until a bridge plug is formed.

Owner:BAKER HUGHES INC

Injectable compound bone cement and preparation method thereof

ActiveCN102526798AImprove collapse resistanceEasy injectionProsthesisCalcium biphosphateBiocompatibility Testing

The invention discloses injectable compound bone cement and a preparation method thereof. The invention further discloses a kit for preparing the injectable compound bone cement. The kit comprises solid powder and a curing liquid, wherein the solid powder comprises calcium phosphate bone cement powder and chitosan microspheres; and the curing liquid contains glycerophosphate. The injectable compound bone cement is prepared by uniformly mixing the solid power with the curing liquid, has superior scattering resistance, superior injection performance, rapid self-curing performance, high compressive strength and high biocompatibility, and can be used for preparing a biomedical material applied to bone defect reconstruction, bone fracture treatment and bone repair.

Owner:EAST CHINA UNIV OF SCI & TECH

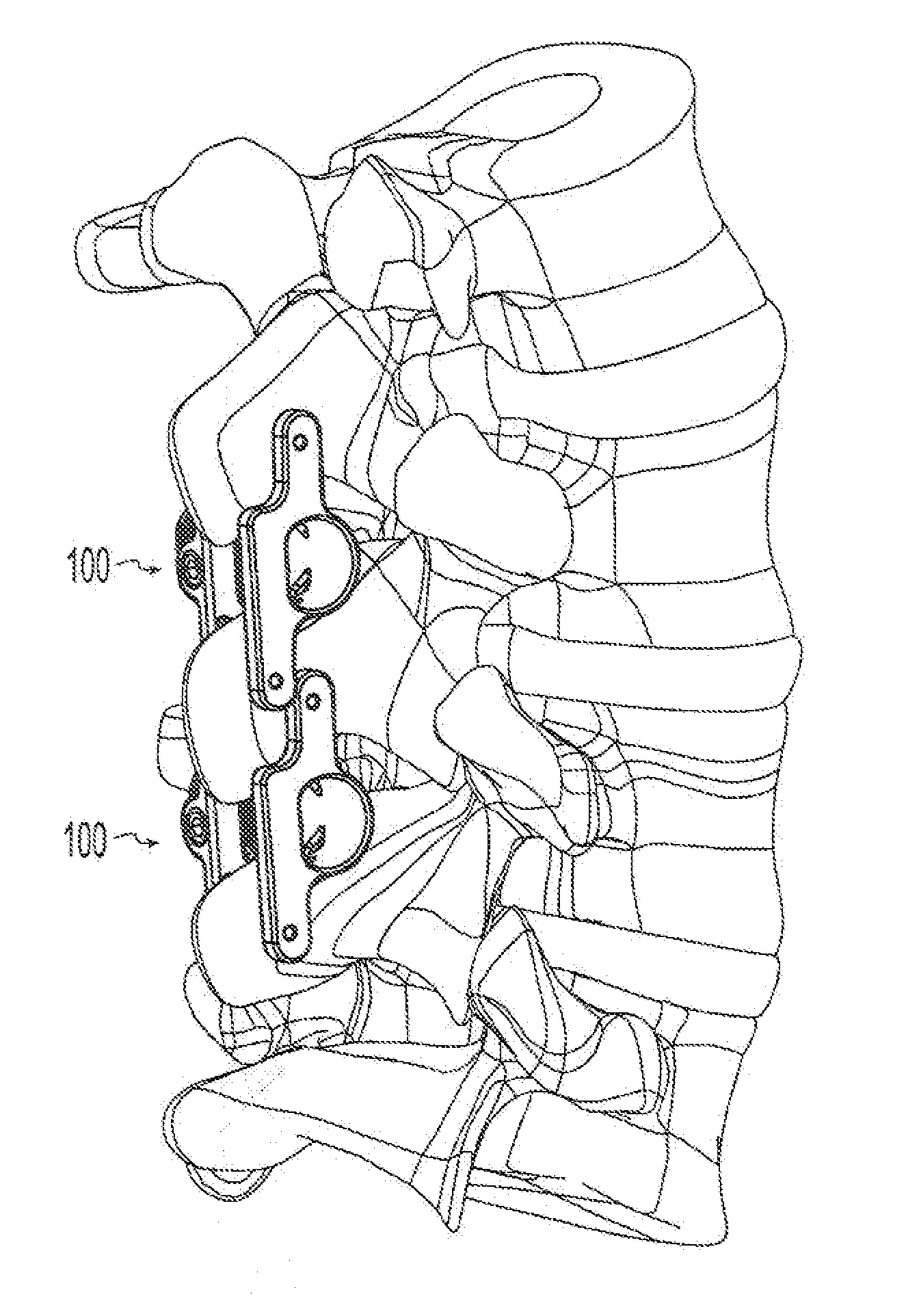

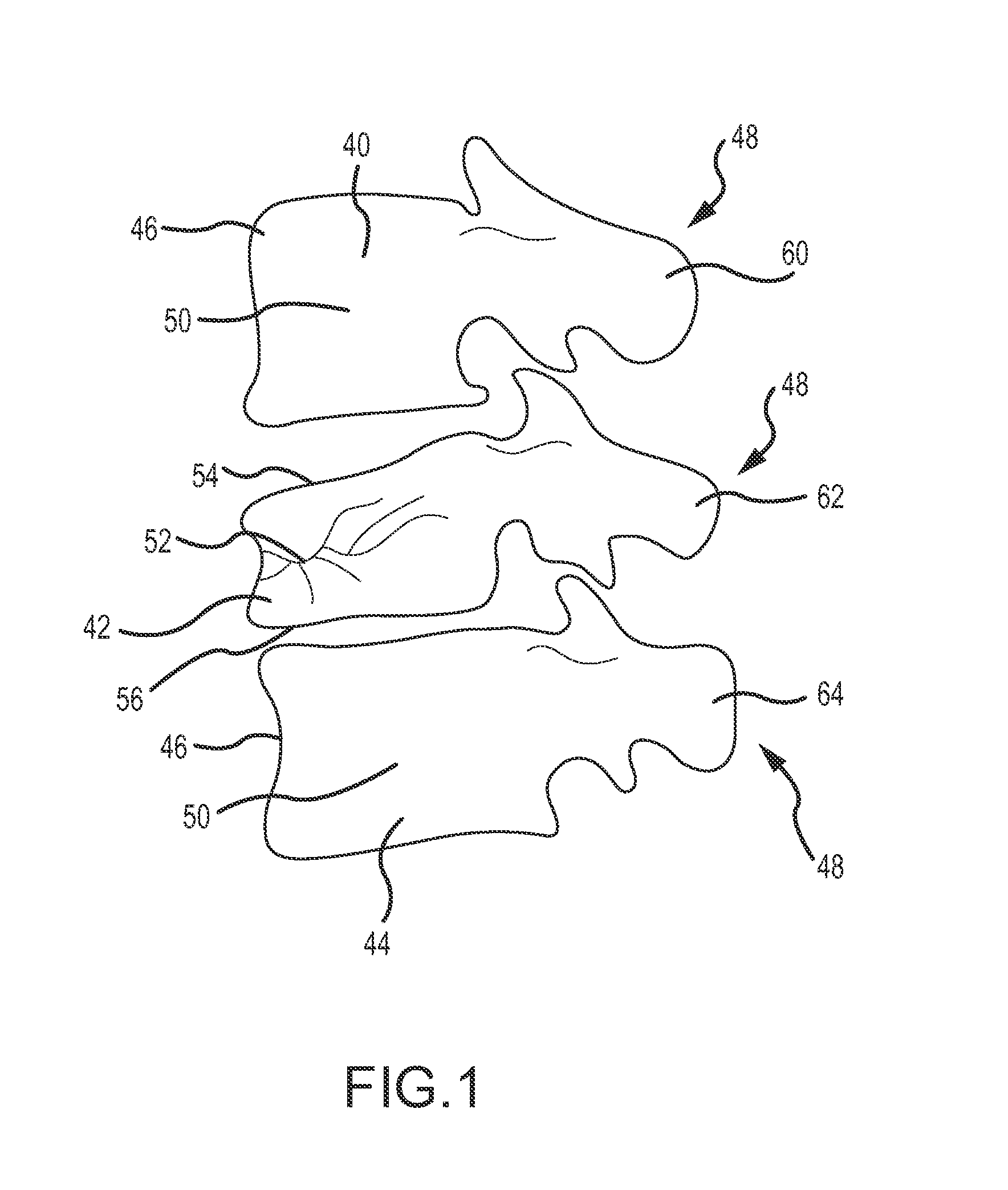

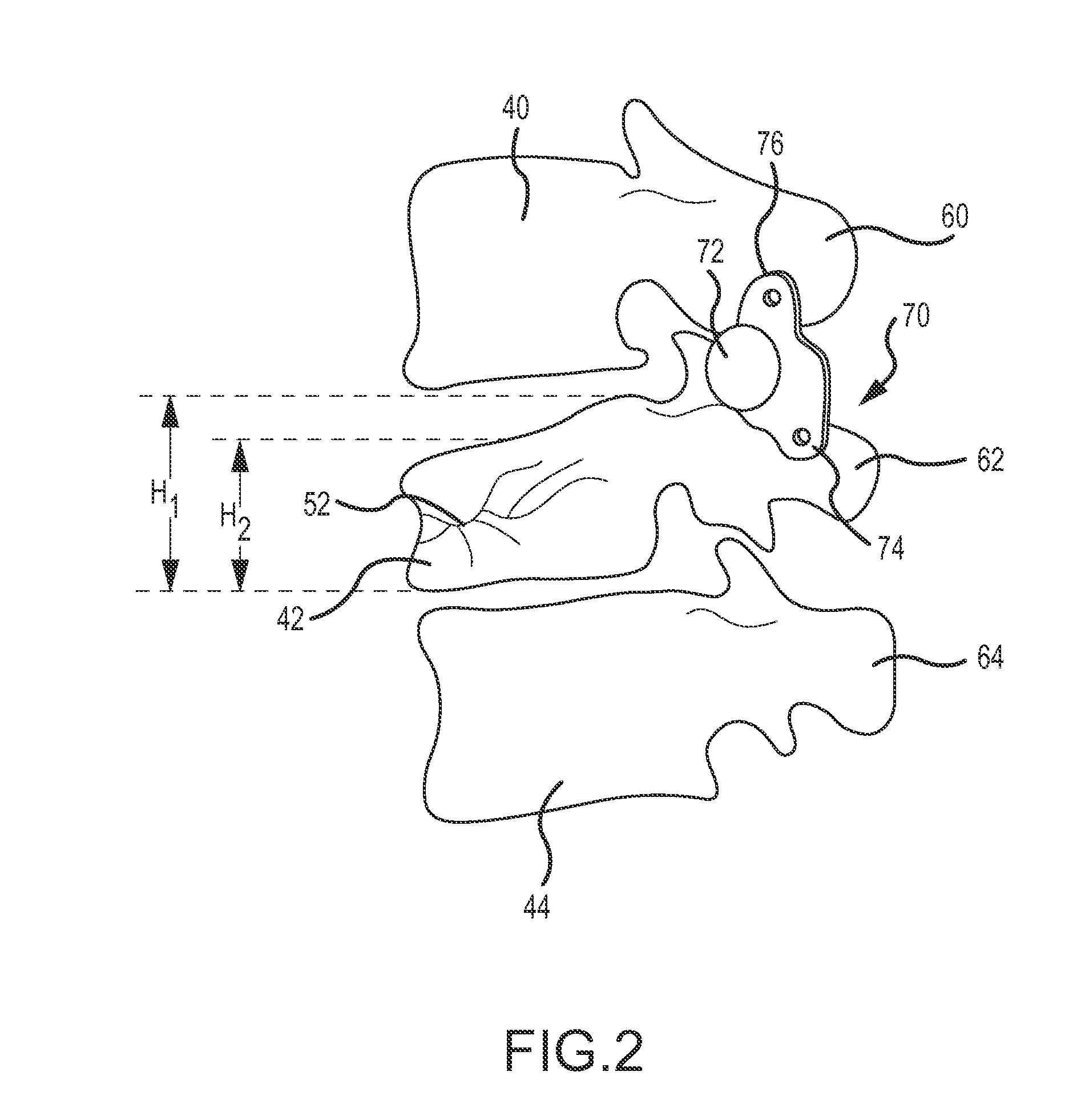

Methods for compression fracture treatment with spinous process fixation systems

Embodiments presently disclosed generally relate to the treatment of spinal fractures, such as spinal compression fractures. In one embodiment, a method of treating a spinal fracture includes identifying a vertebra having an untreated fracture, coupling a first device to the spinous processes of the vertebra with the fracture and a vertebra positioned directly superior to the fractured vertebra, and coupling a second device to the spinous processes of the vertebra with the fracture and the vertebra directly inferior to the fractured vertebra.

Owner:LANX INC

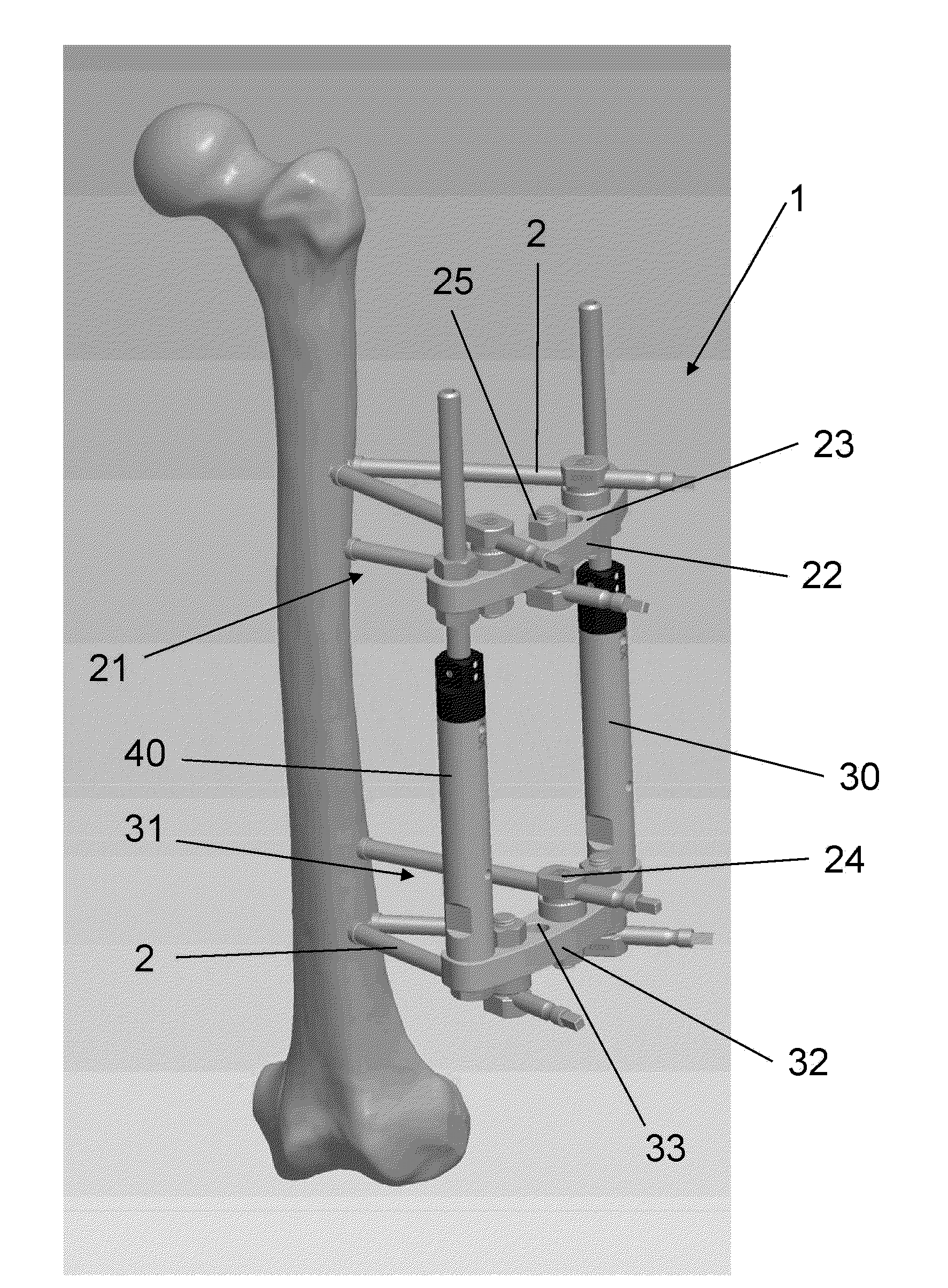

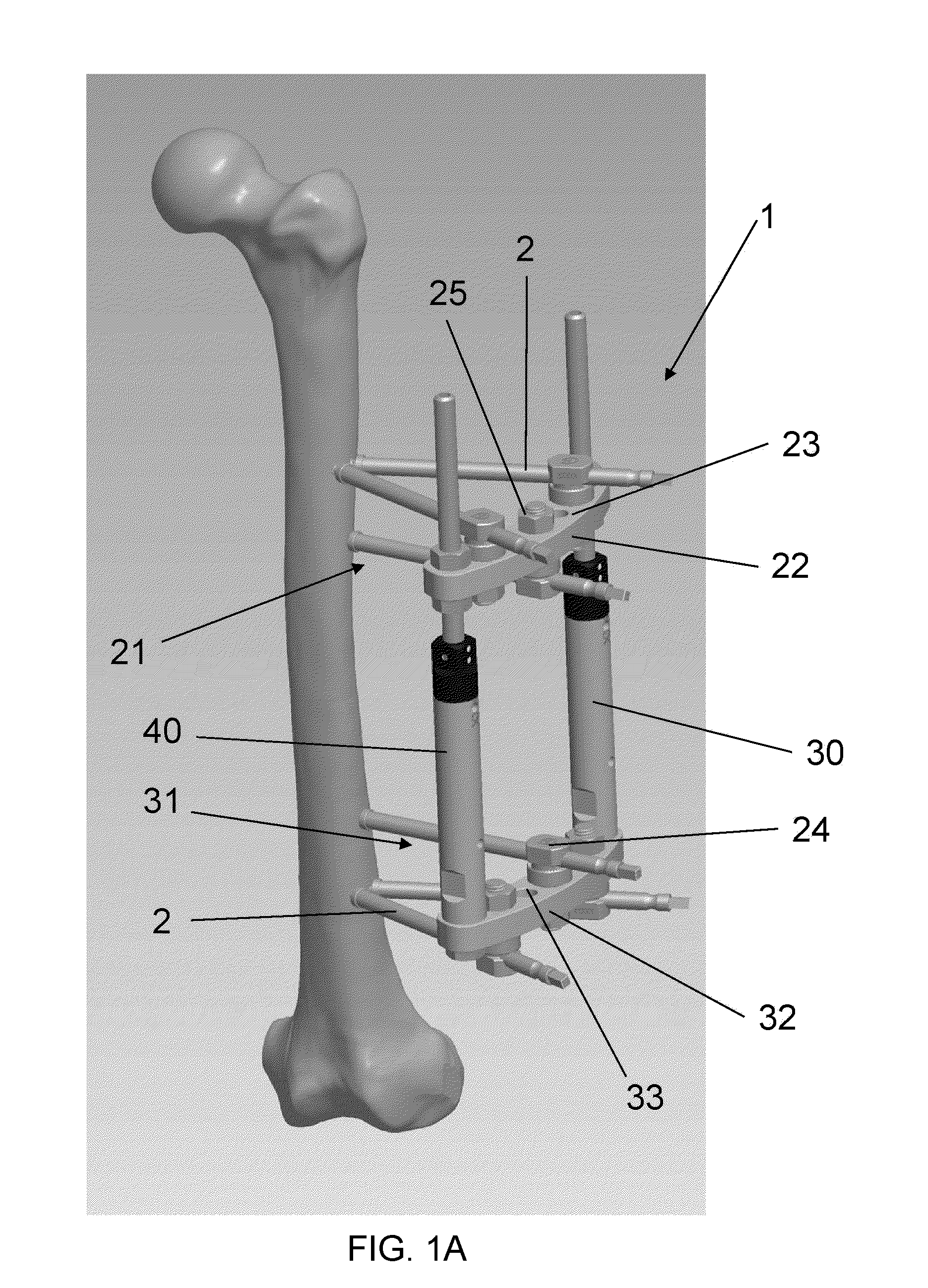

Method for Treating a Fracture of a Bone Having a Medullary Canal

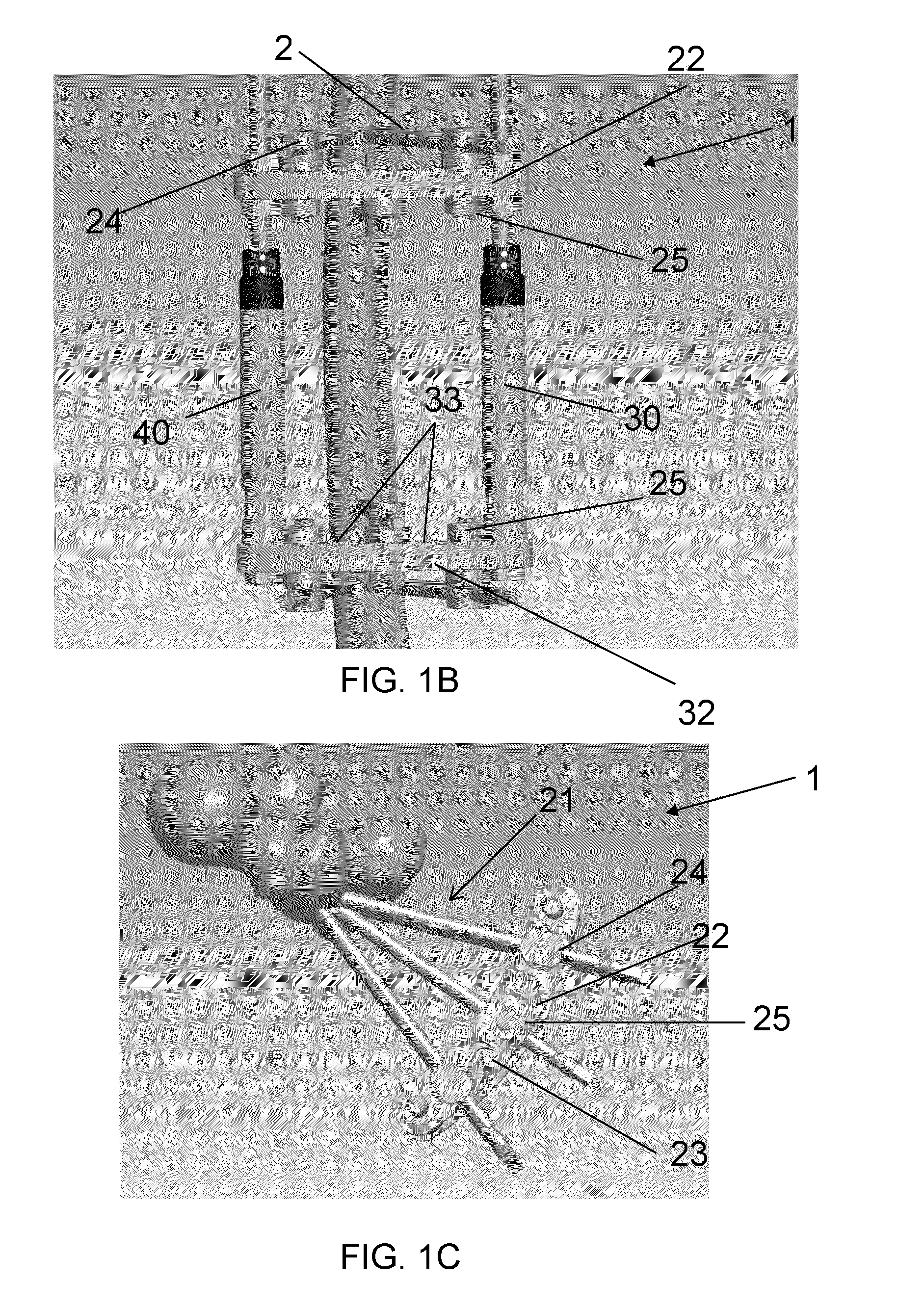

A method for treating a fracture of a bone with a medullary canal. A first and a second group of three elongated monocortical pins are provided. Each pin has a stem with a first end portion having a conical shape with an external thread for insertion into a cortical portion of a bone. Each pin of the first and second group of three monocortical pins is inserted a predetermined distance from the bone fracture, and penetrates only into the cortical portion of the bone without reaching the medullary cavity, the pins of the first and second group being inserted such that they are not coplanar to each other. The stems of the pins of the first and groups are blocked to a first and a second common clamp element respectively. The first and second clamp elements are joined to a common rod to form a rigid external fixation system.

Owner:ORTHOFIX SRL

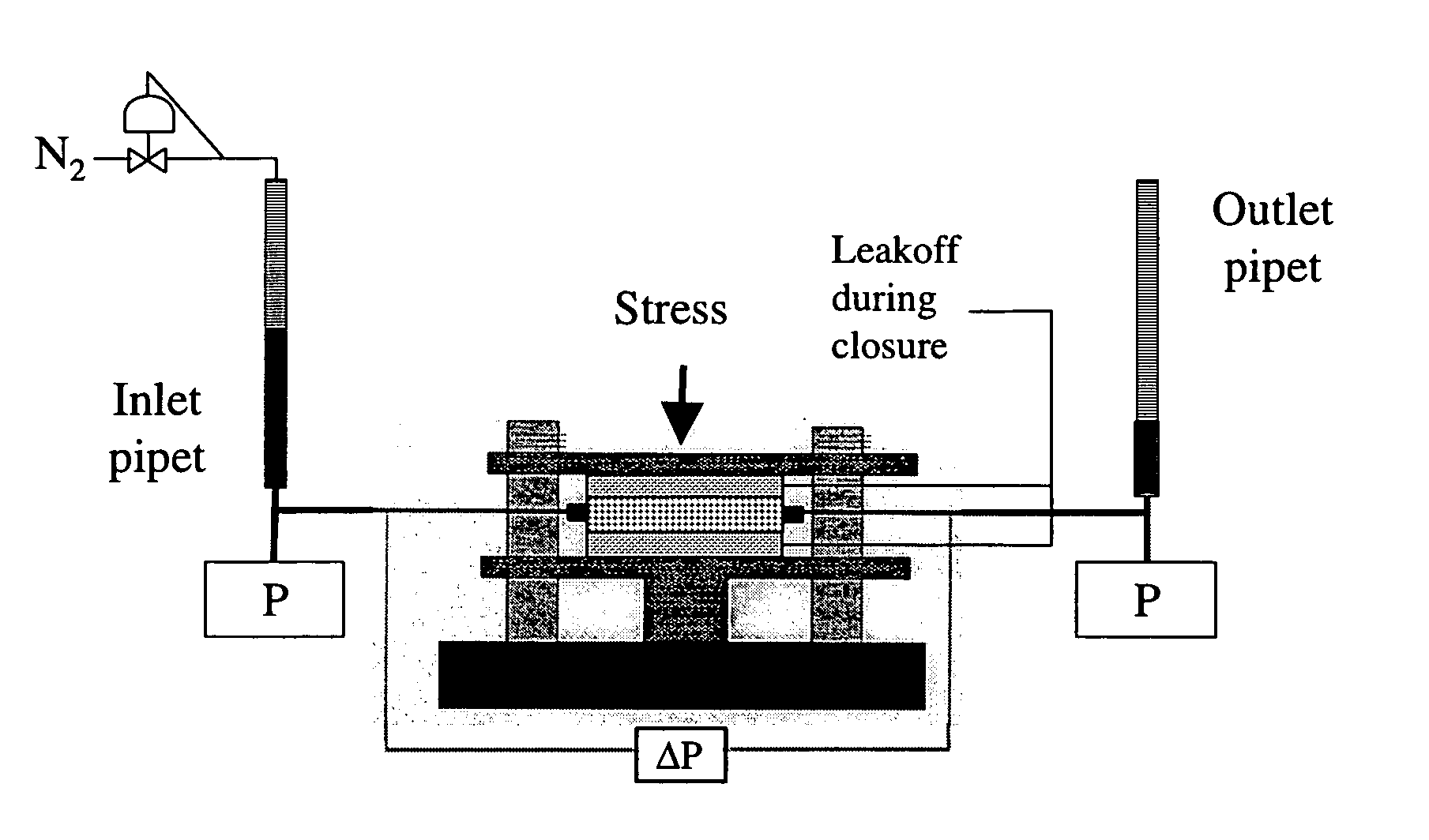

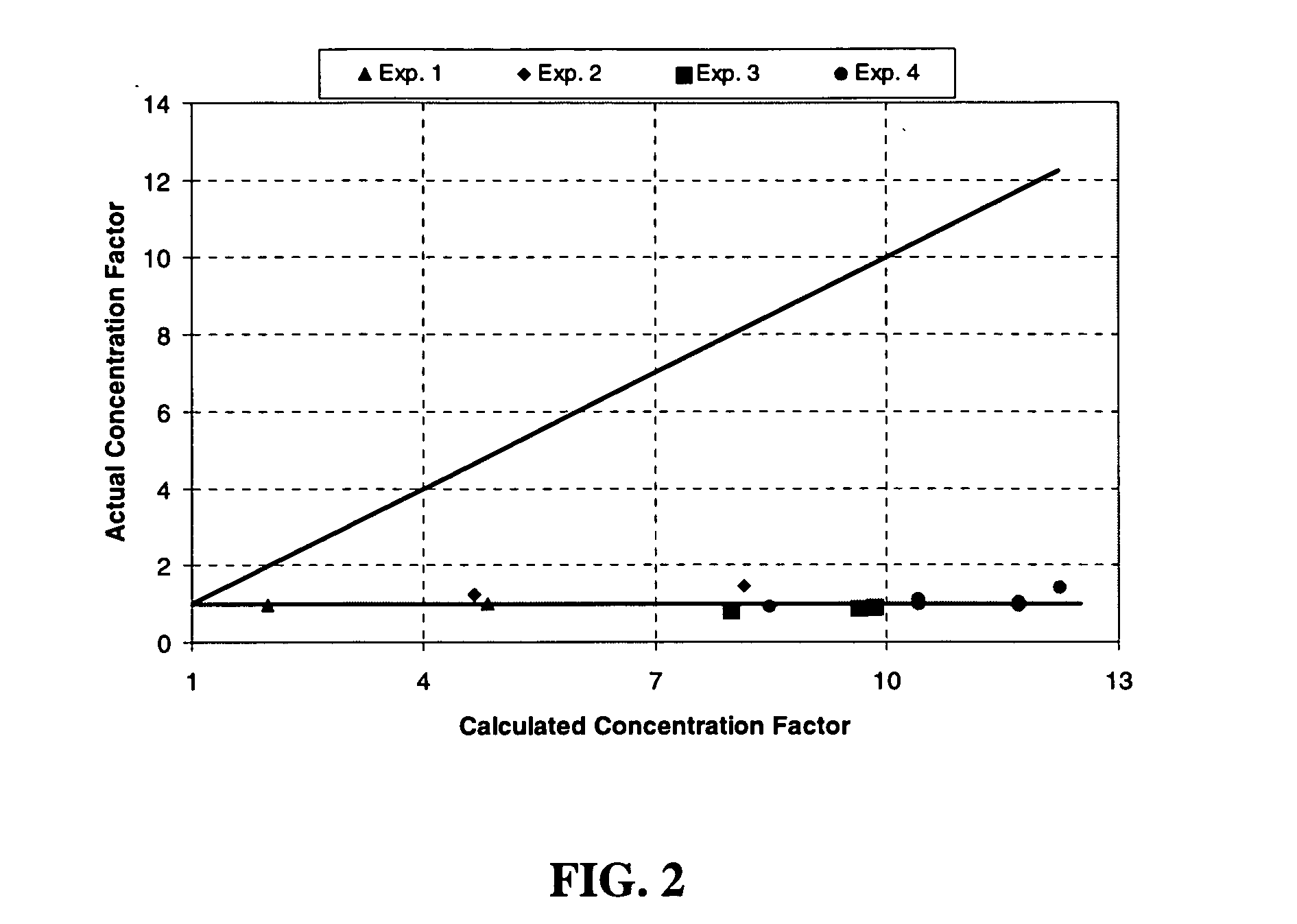

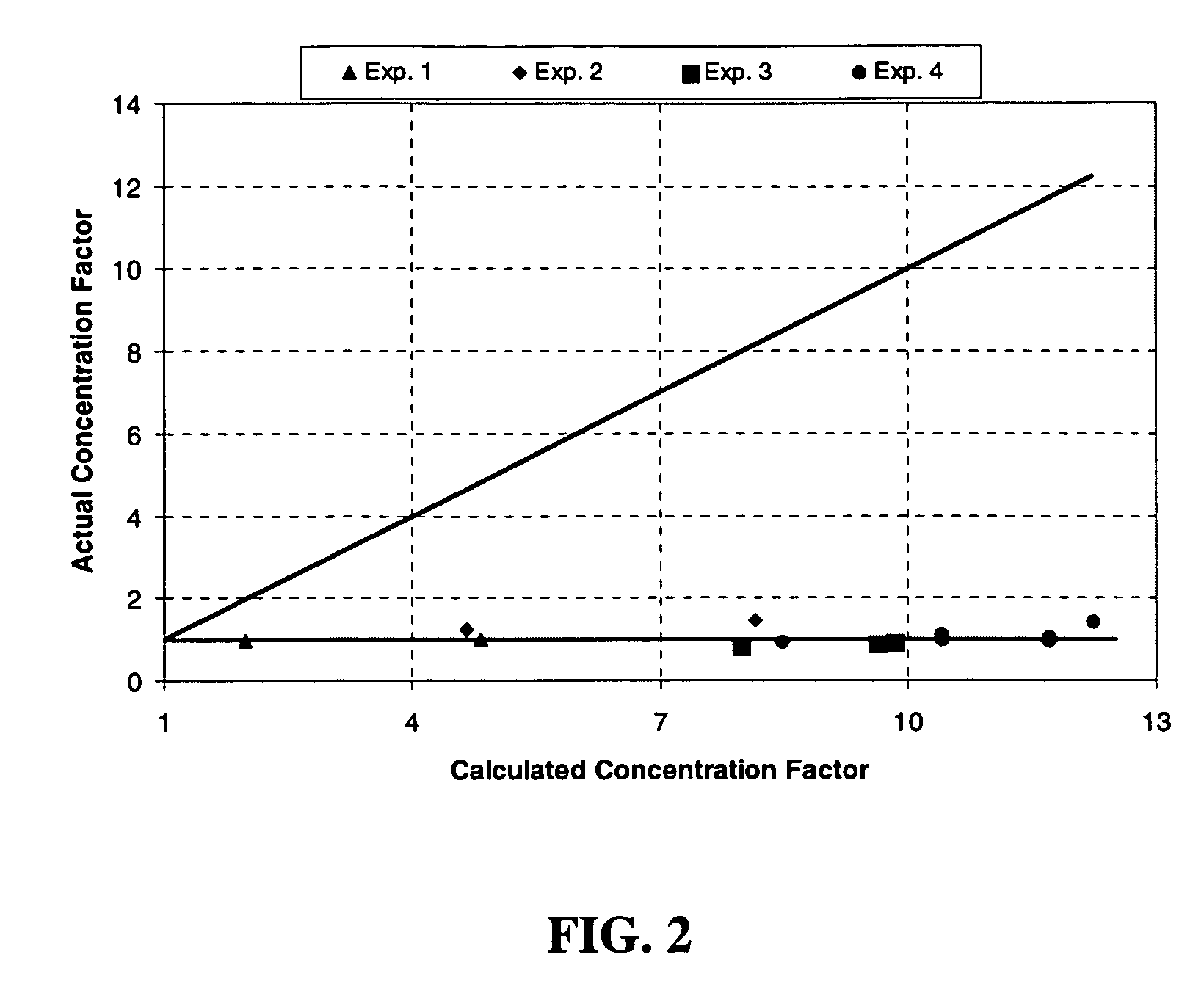

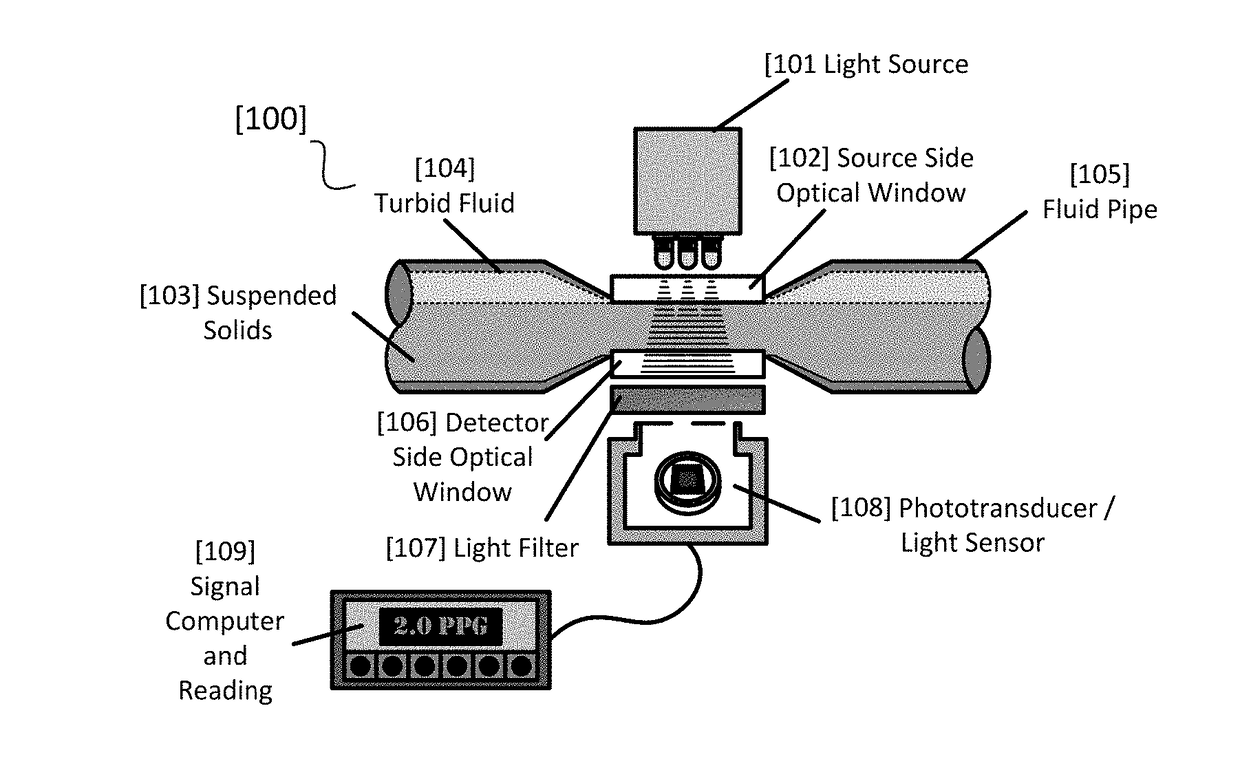

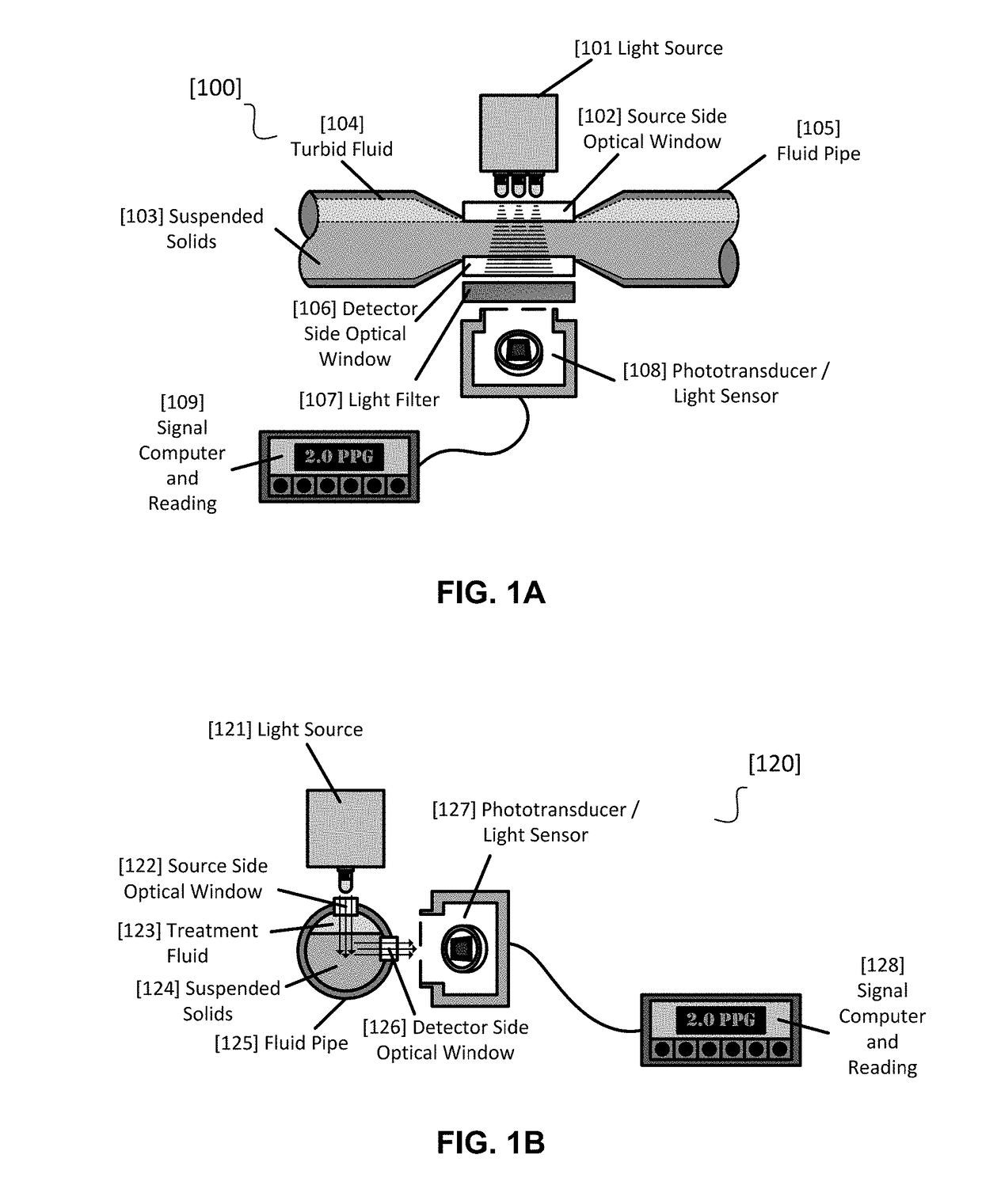

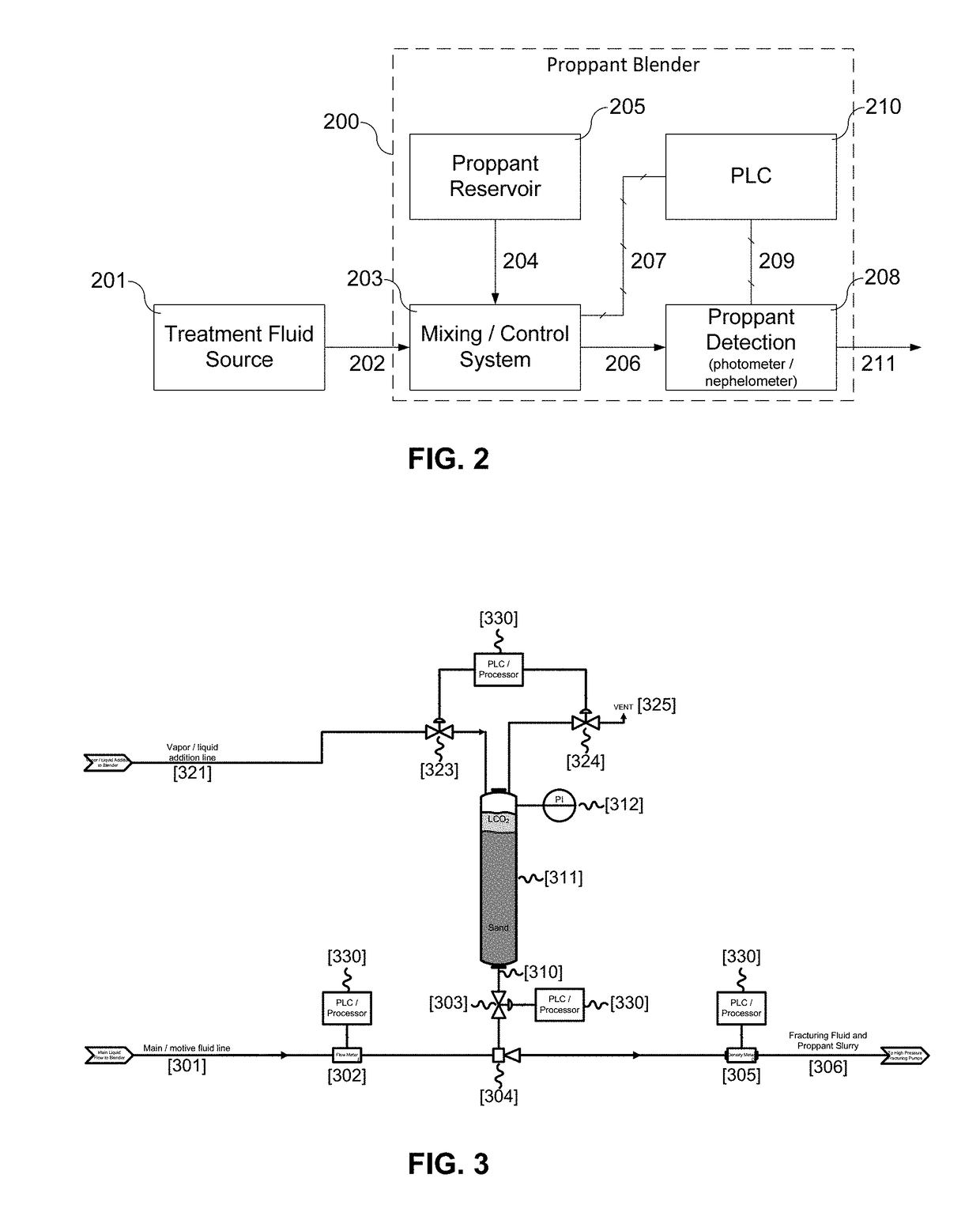

Photometer/nephelometer device and method of using to determine proppant concentration

InactiveUS20170212029A1Investigating moving fluids/granular solidsScattering properties measurementsHydrocotyle bowlesioidesPhysical chemistry

A system is described that provides for the measurement and control of proppant concentration in a liquefied gas fluid stream utilizing a non-nuclear optical detection device such as a near-infrared (NIR), visible (Vis), and ultraviolet (UV) photometer / nephelometer to be used in the fracture treatment of subterranean hydrocarbon formations.

Owner:PRAXAIR TECH INC

Method for enhancing methane production from coal seams

InactiveUS20050082058A1Reduce effective stressEnhancing fracture void volumeFluid removalCoal matrixMethane production

Discloses a three step process to stimulate well production of methane from coal seams, wherein step one provides for injection of a treating gas into a well bore intersecting a coal seam, step two includes a shut-in period and step three comprises the placement of a propped fracture treatment. In step one, the injection of the treating gas physically opens pre-existing paths of weakness in the coal. As the treating gas travels along these planes of weakness, it preferentially adsorbs onto the coal and displaces the methane. This displacement process induces shrinkage of the coal matrix, which further increases the size of the intervening existing fractures. The second step, or shut-in period, allows time for this gas exchange process to substantially complete, thereby maximizing the effect of matrix shrinkage and enhancement of the intervening fractures. The third step provides for placement of a propped fracture treatment into this enhanced fracture system. Propping of the enhanced fractures ensures that they remain open, even as removal of water and methane work to close the fractures by increasing effective stress within the coals. The result is a stimulated coal seam that maintains enhanced permeability during production operations.

Owner:BUSTIN ROBERT MARK +1

Limited Entry Phased Preforating Gun System and Method

A limited entry perforating phased gun system and method for accurate perforation in a deviated / horizontal wellbore is disclosed. The system / method includes a gun string assembly (GSA) deployed in a wellbore with shaped charge clusters. The charges are spaced and angled such that, when perforated, they intersect at a preferred fracturing plane. Upon fracturing, the fractures initiate at least principal stress location in a preferred fracturing plane perpendicular to the wellbore from an upward and downward location of the wellbore. Thereafter, the fractures connect radially about the wellbore in the preferred fracturing plane. The fracture treatment in the preferred fracturing plane creates minimal tortuosity paths for longer extension of fractures that enables efficient oil and gas flow rates during production.

Owner:WELLS FARGO BANK NAT ASSOC +1

Method of Fracturing Hydrocarbon-Bearing Formation With Coated Porous Polyolefin Particulate

InactiveUS20090095473A1Reduce and prevent productionImprove system performanceFluid removalDrilling compositionParticulatesApparent density

Methods and compositions useful for subterranean formation treatments, such as hydraulic fracturing treatments and sand control that include porous materials. Such porous materials may be selectively configured porous material particles manufactured and / or treated with selected glazing materials, coating materials and / or penetrating materials to have desired strength and / or apparent density to fit particular downhole conditions for well treating such as hydraulic fracturing treatments and sand control treatments. Porous materials may also be employed in selected combinations to optimize fracture or sand control performance, and / or may be employed as relatively lightweight materials in liquid carbon dioxide-based well treatment systems.

Owner:BAKER HUGHES HLDG LLC

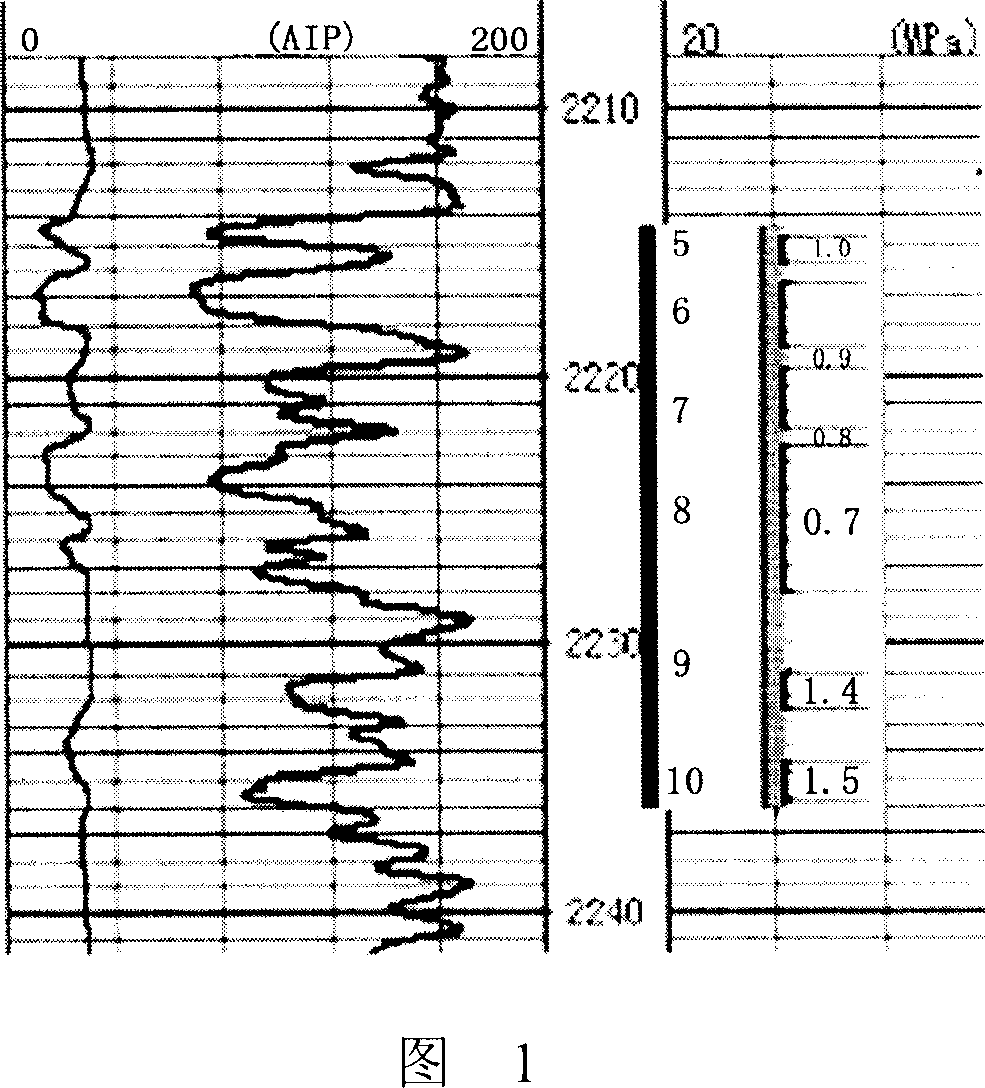

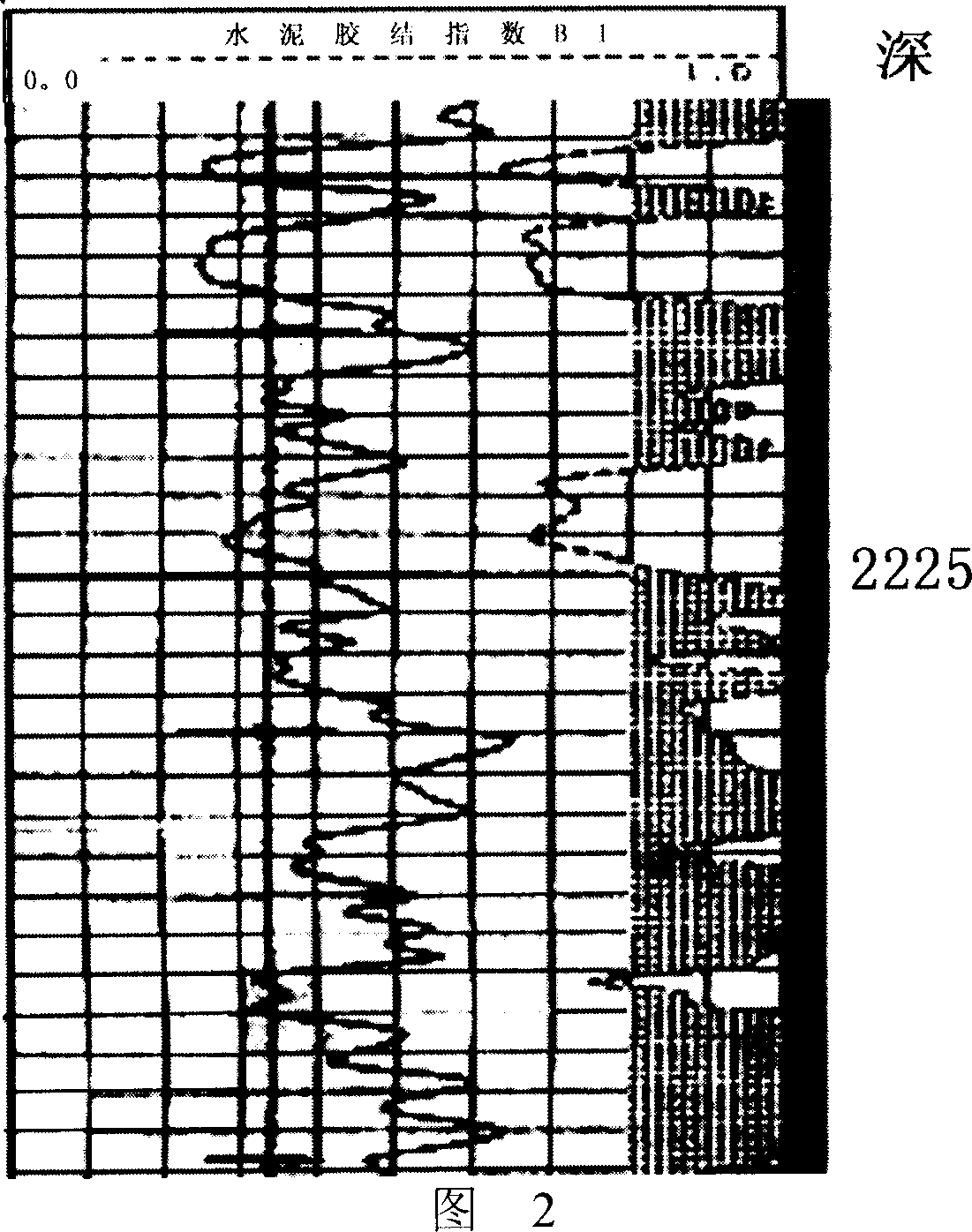

Zonation method of thin interbed in low infiltration of fracturing layer segment

InactiveCN1959062AImprove the degree of transformationImprove the blocking effectFluid removalComputer scienceLine segment

The present invention relates to a low permeable thin-interbedding fractured interval layering method. Said method includes the following steps: (1) defining effective barrier bed; (2) making restraining barrier protection, adopting low-displacement variable-displacement and low thickener concentration fracture treatment; and (3) making separate layer fracturing treatment. Said method can utilize interbed property, interbed thickness and core intersection to make division of fractured interval and can make the layer whose restraining barrier and oil layer earth stress difference value is greater than 4 MPa and restraining barrier thickness is greater than 2 m implement separate layer fracturing treatment.

Owner:DAQING OILFIELD CO LTD

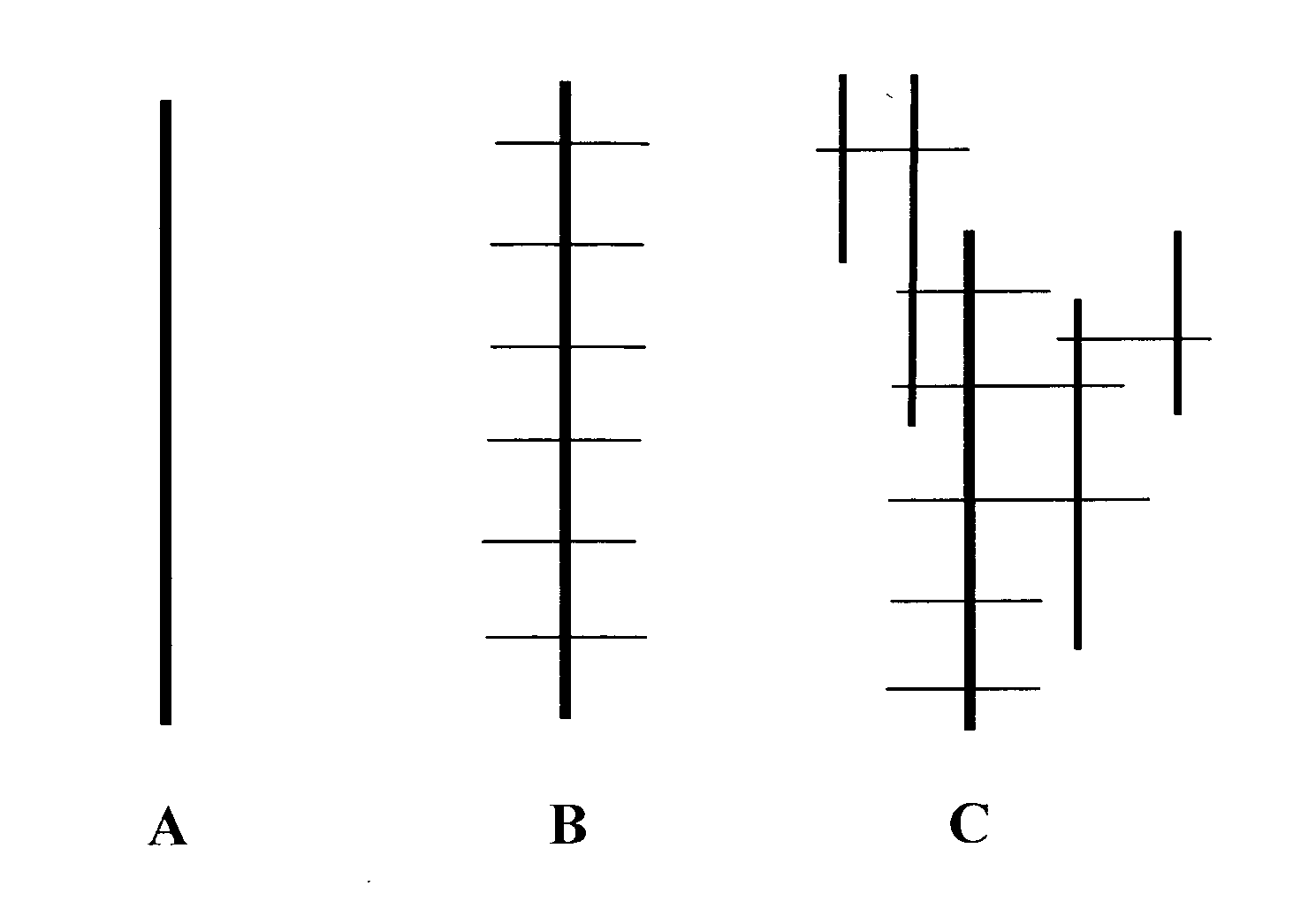

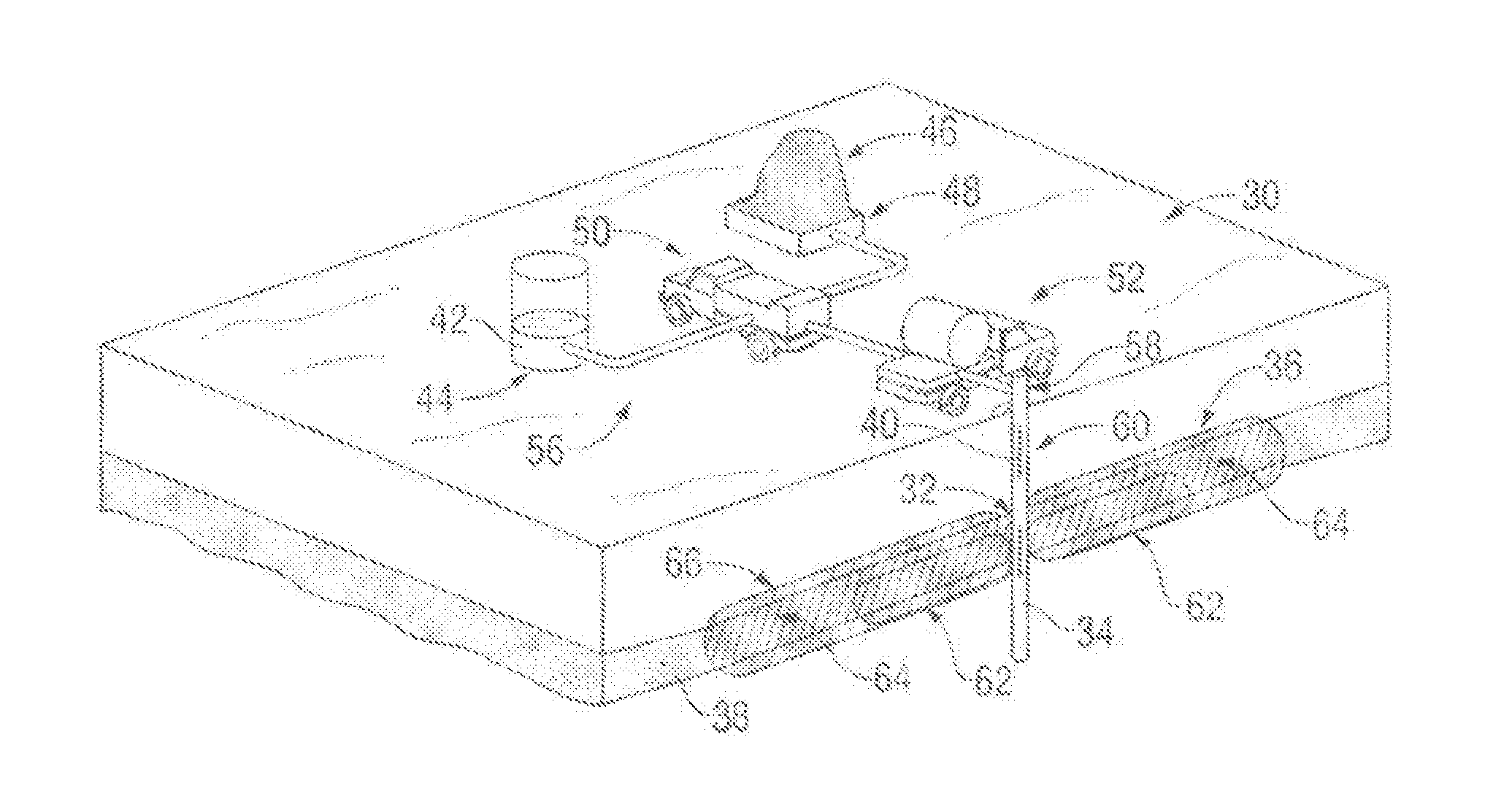

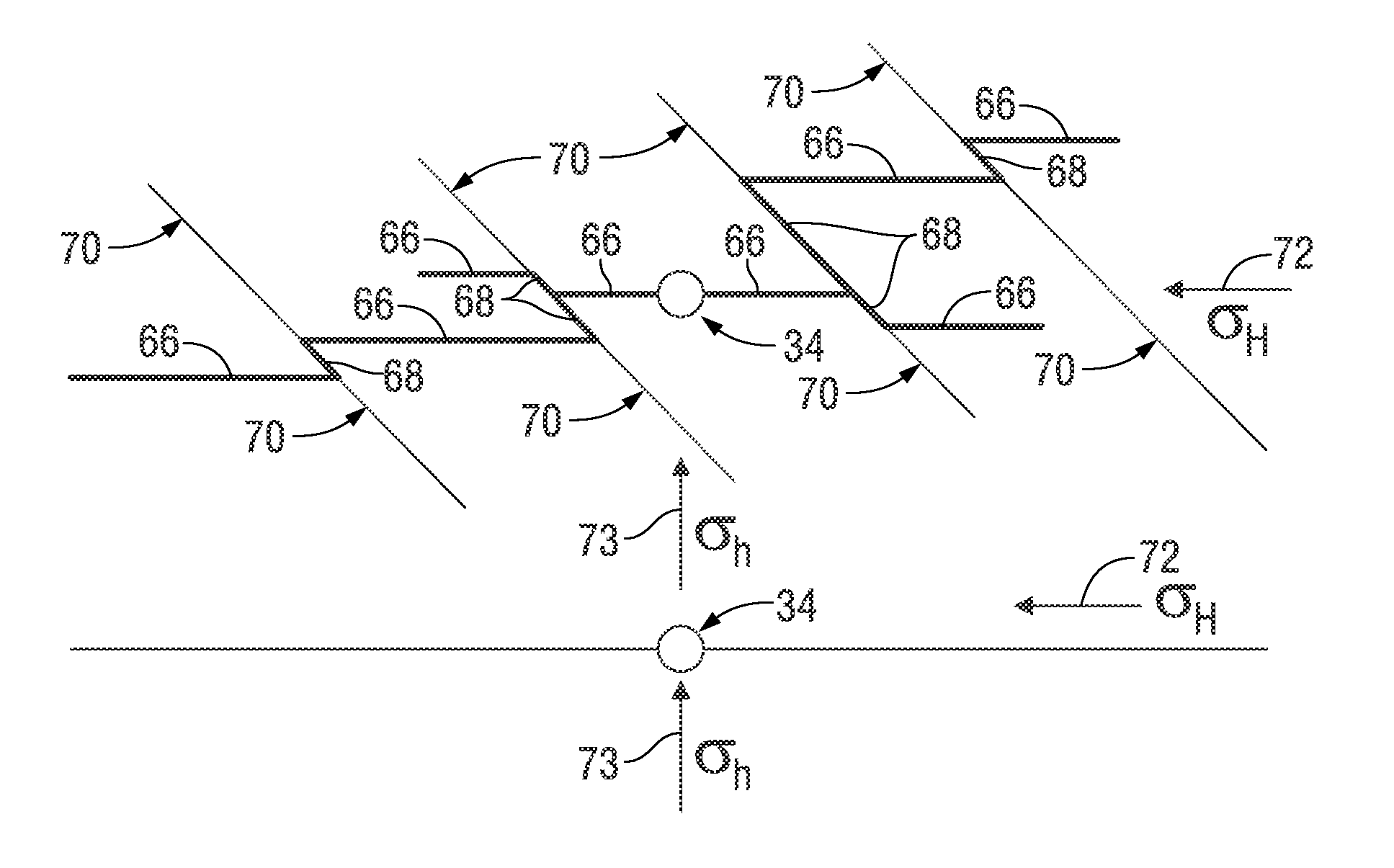

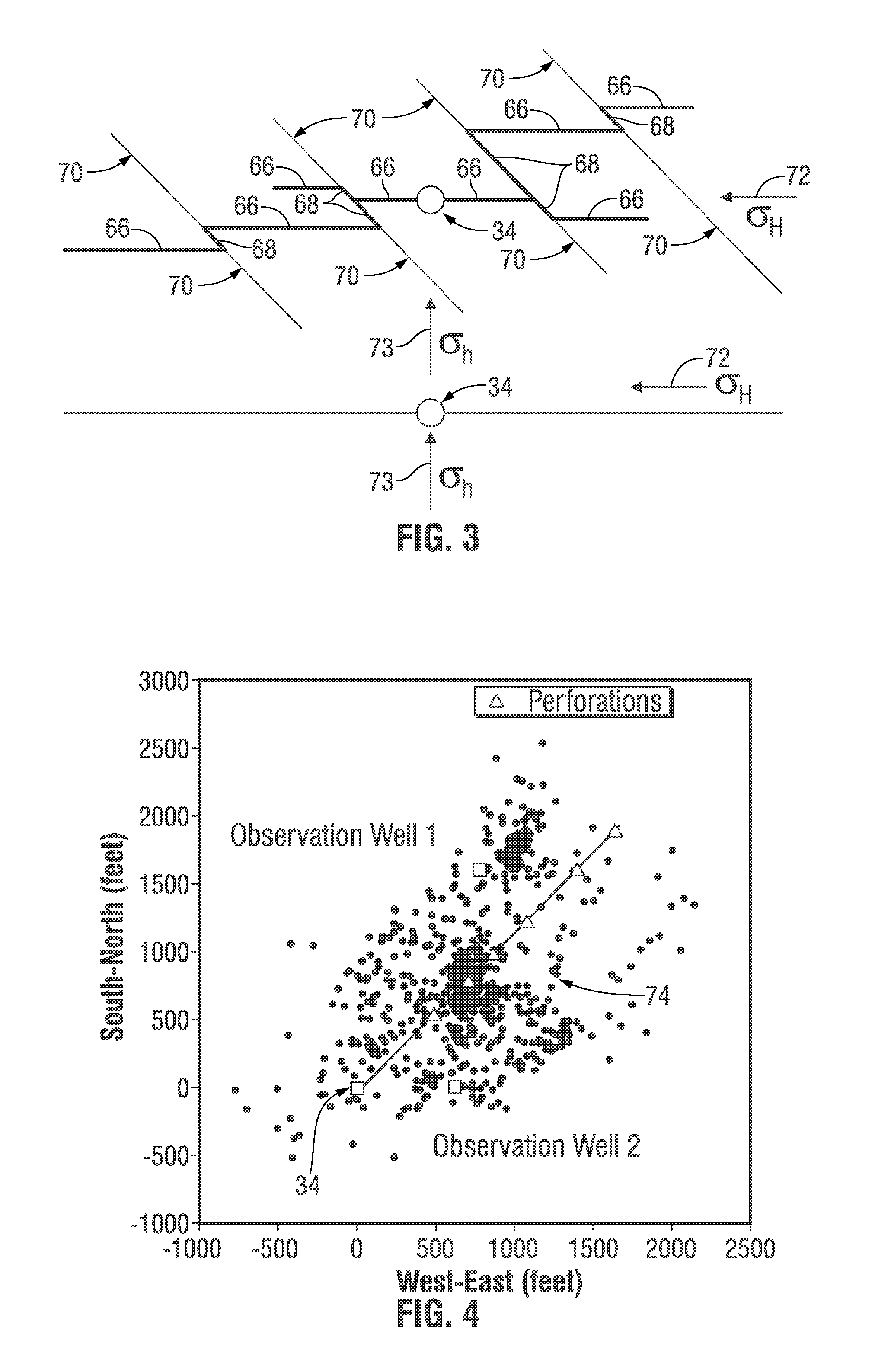

Method for increasing fracture area

ActiveUS9140109B2Convenient treatmentIncrease the lengthFluid removalShortest distanceReservoir volume

A technique enables improvements in hydraulic fracturing treatments on heterogeneous reservoirs. Based on data obtained for a given reservoir, a fracturing treatment material is used to create complex fractures, which, while interacting with the interfaces and planes of weakness in the reservoir, develop fracture connectors, e.g. step-overs, which often grow for short distances along these planes of weakness. The technique further comprises closing or sealing at least one of the fracture connectors to enable reinitiation of fracturing from the truncated branches, and to subsequently develop additional connectors. As a result, the overall fracturing becomes more complex (more branches and more surface area per unit reservoir volume is created), which leads to an increase in the effective fracture area and improved fluid flow through the reservoir.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com