Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

663 results about "Full band" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and method for communicating voice and data between a customer premises and a central office

InactiveUS6061392AEfficient implementationLow costFrequency-division multiplex detailsTelephonic communicationTelecommunications linkModem device

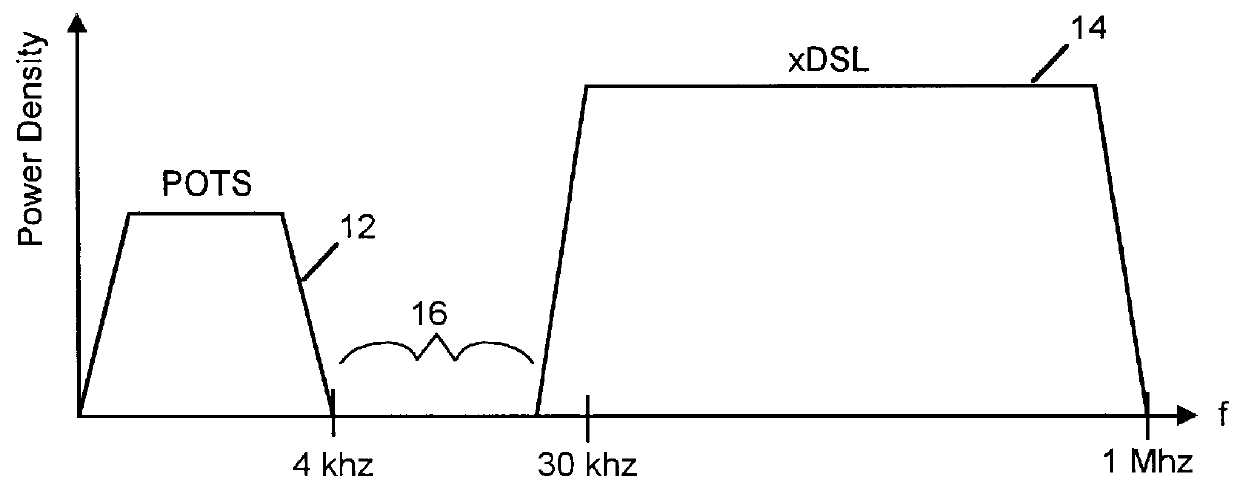

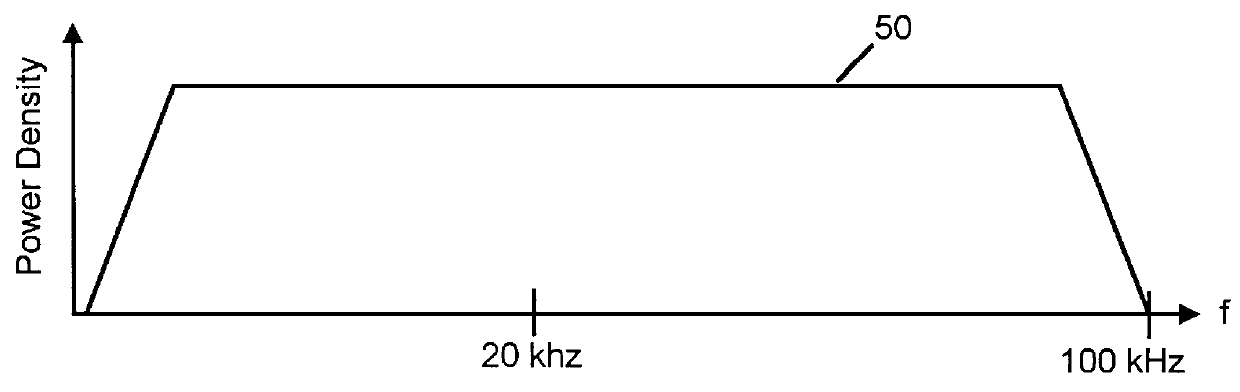

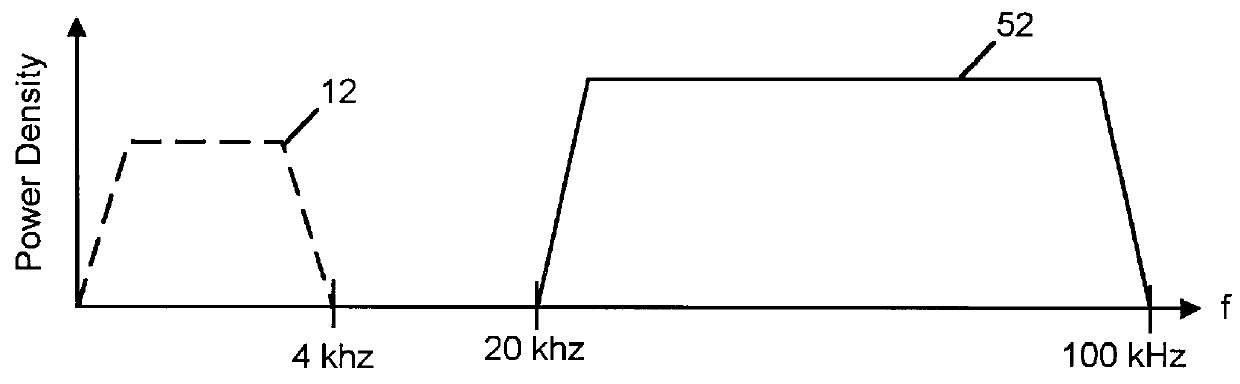

A method and apparatus are provided for communicating data across a communication link, in a manner that senses and dynamically adapts to the simultaneous transmission of voice information across the local loop. In accordance with one aspect of the invention, a method is provided for dynamically communicating data over a local loop using a modem comprising the steps of transmitting data in a full-band transmission state, sensing a band-limiting condition, and adjusting the transmission of data from the full-band transmission state to a bandlimited transmission state, in response to the sensing step. In accordance with the method, data may be transmitted by the modem across the local loop at the same time that voice information is communicated via telephone across the same local loop. A significant aspect of the present invention is the dynamic allocation of the data transmission bandwidth, whereby the invention senses a condition indicative of whether voice information is being communicated. If so, then the system shifts and / or narrows the data transmission bandwidth to allow for voice communications without interference from or with the data transmission. However, when no voice information is being communicated, the invention dynamically allocates the data transmission bandwidth to utilize at least a portion, if not all, of the frequency band otherwise used for communicating voice information.

Owner:PARADYNE CORP

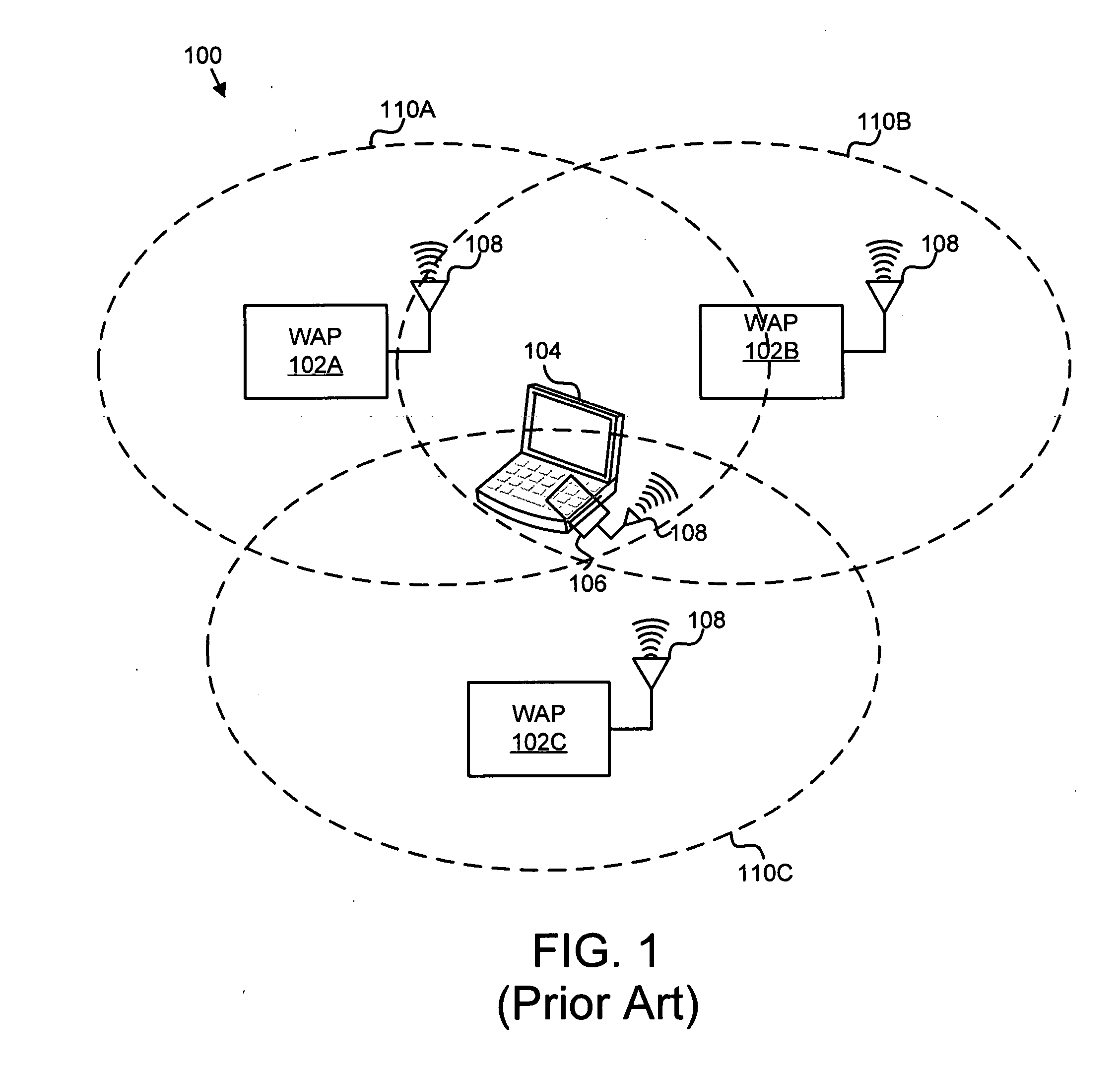

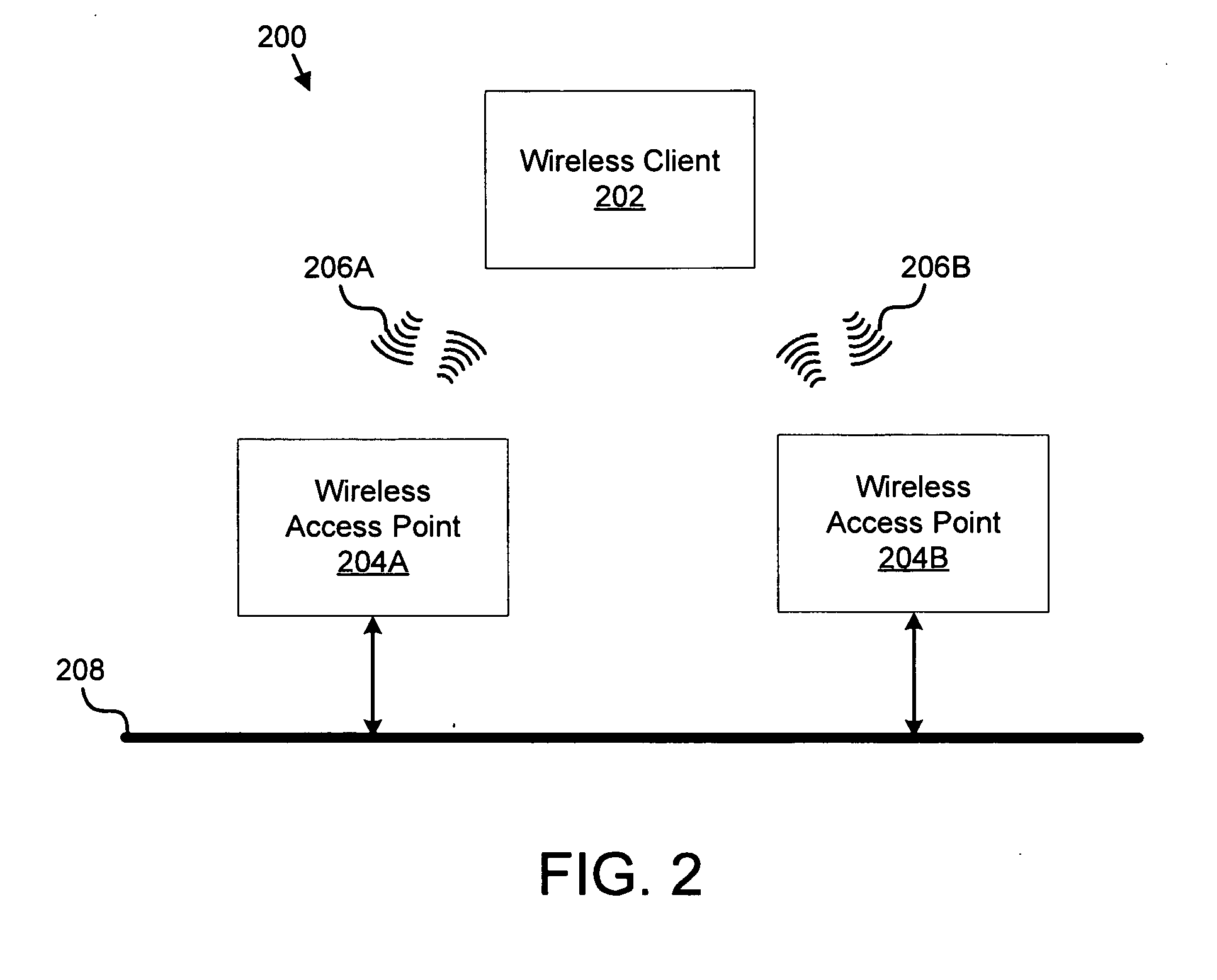

Apparatus, system, and method for rapid wireless network association

ActiveUS20060189311A1Fast internetAssess restrictionRadio/inductive link selection arrangementsTelecommunicationsFrequency spectrum

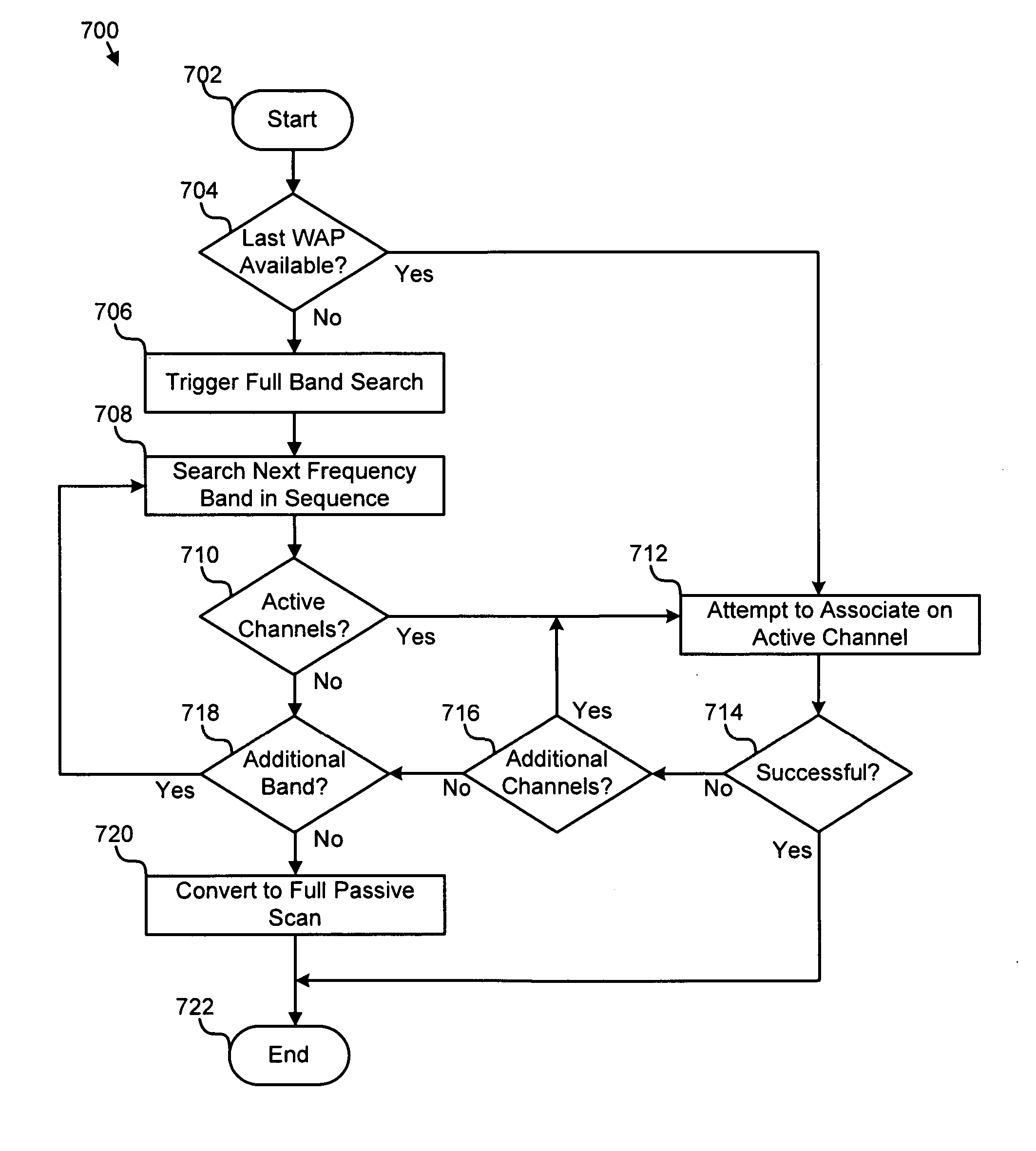

An apparatus, system, and method are disclosed for rapid wireless network association. The apparatus includes a logic unit containing a plurality of modules configured to functionally execute the necessary steps of conducting a preliminary full band search on a predefined frequency spectrum to identify the frequency of an active communication channel, investigate the availability of the active communication channels identified during the preliminary search, and associate with a wireless network device on the available active communication channel. These modules in the described embodiments include a search module, an investigation module, and an association module. Beneficially such an apparatus, system, and method provide for more efficient searching, scanning, and association than typically found in wireless networks.

Owner:LENOVO PC INT

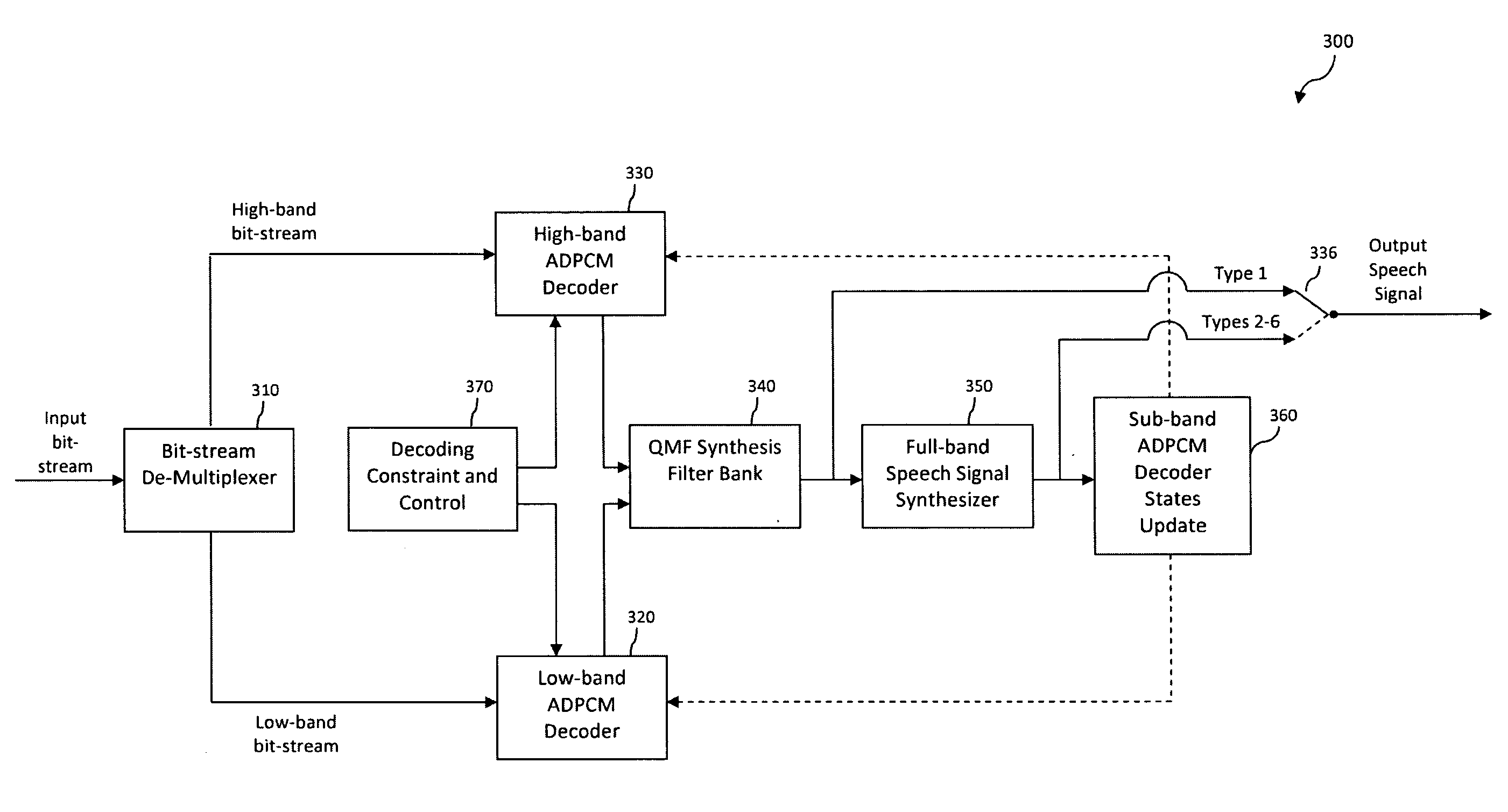

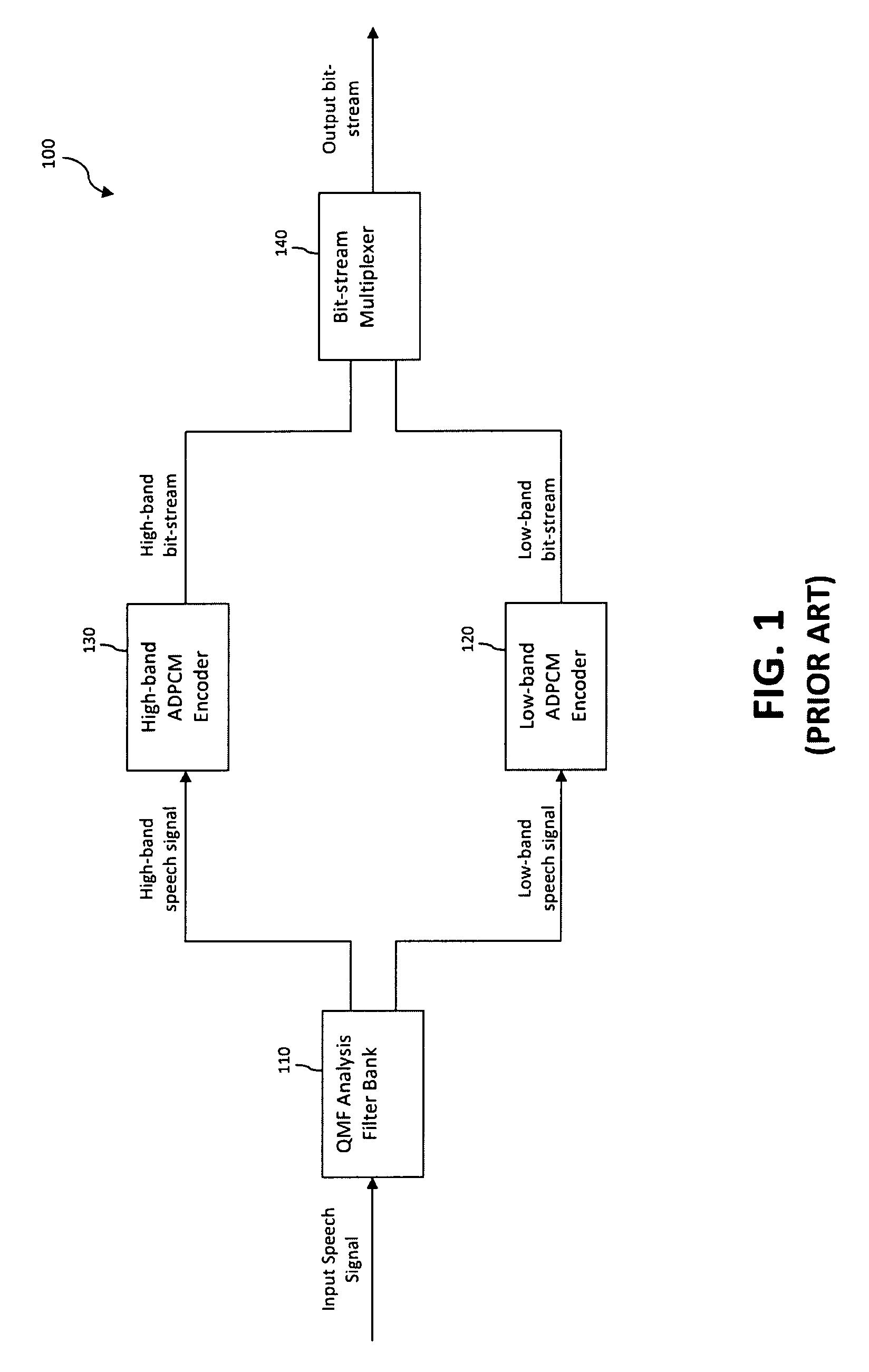

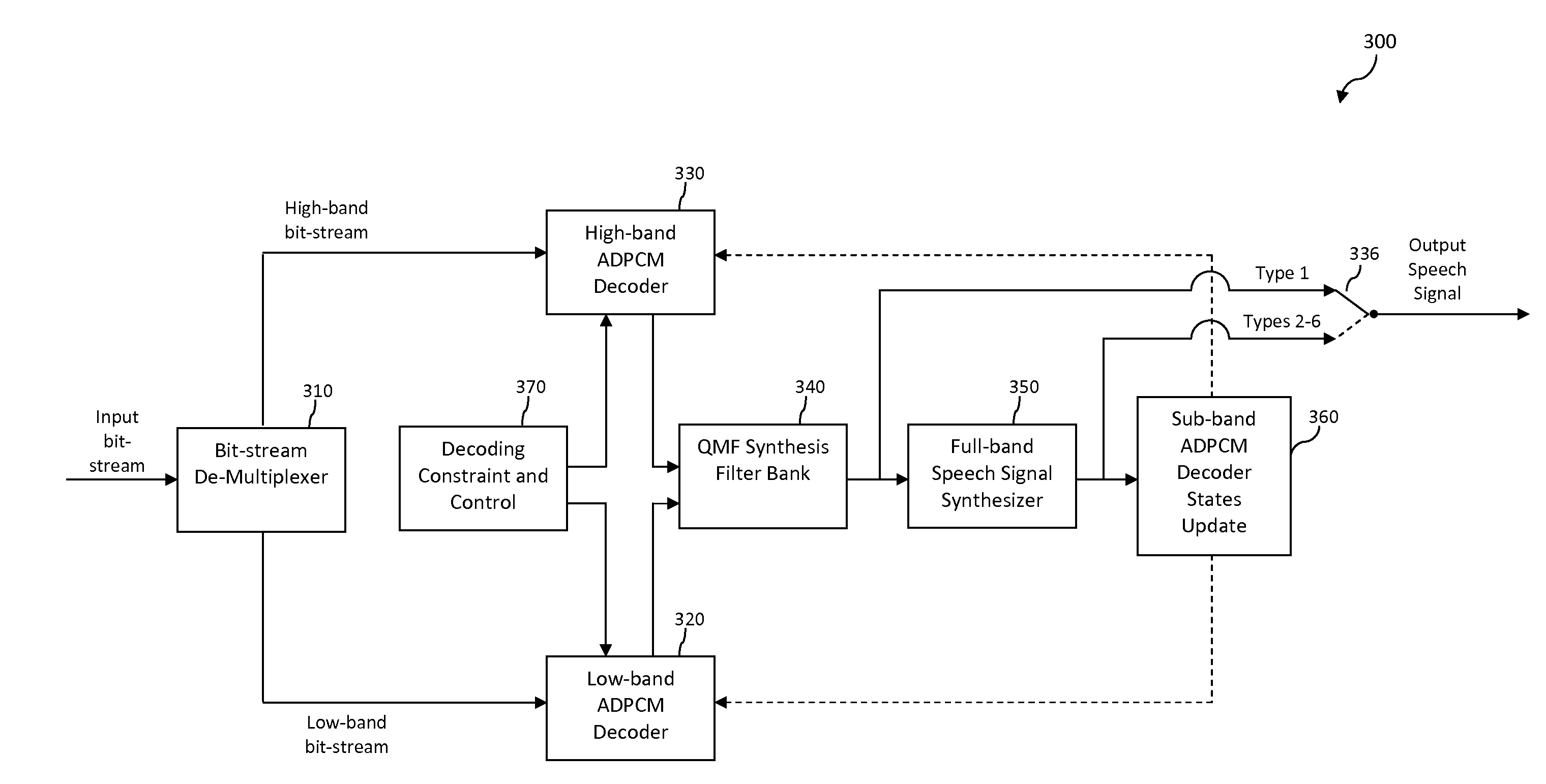

Packet Loss Concealment for Sub-band Predictive Coding Based on Extrapolation of Full-band Audio Waveform

A technique for concealing the effect of a lost frame in a series of frames representing an encoded audio signal in a sub-band predictive coding system is provided. In accordance with the technique, one or more received frames in the series of frames are decoded to generate a full-band output audio signal, wherein the full-band output audio signal comprises a combination of at least a first sub-band decoded audio signal and a second sub-band decoded audio signal. The full-band output audio signal corresponding to the one or more received frames is stored. Then, a full-band output audio signal corresponding to the lost frame is synthesized, wherein synthesizing the full-band output audio signal corresponding to the lost frame comprises performing waveform extrapolation based on the stored full-band output audio signal corresponding to the one or more received frames.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

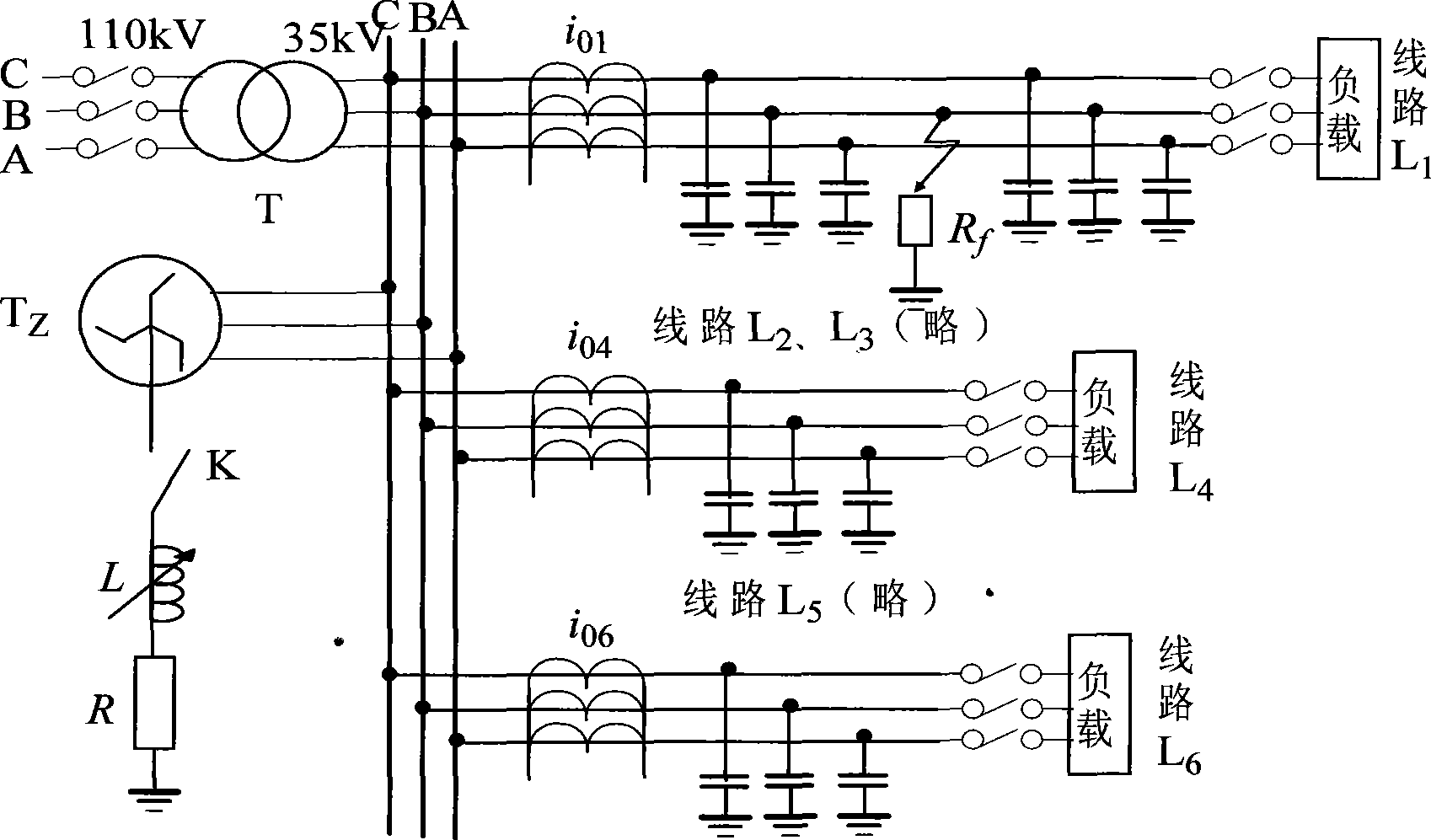

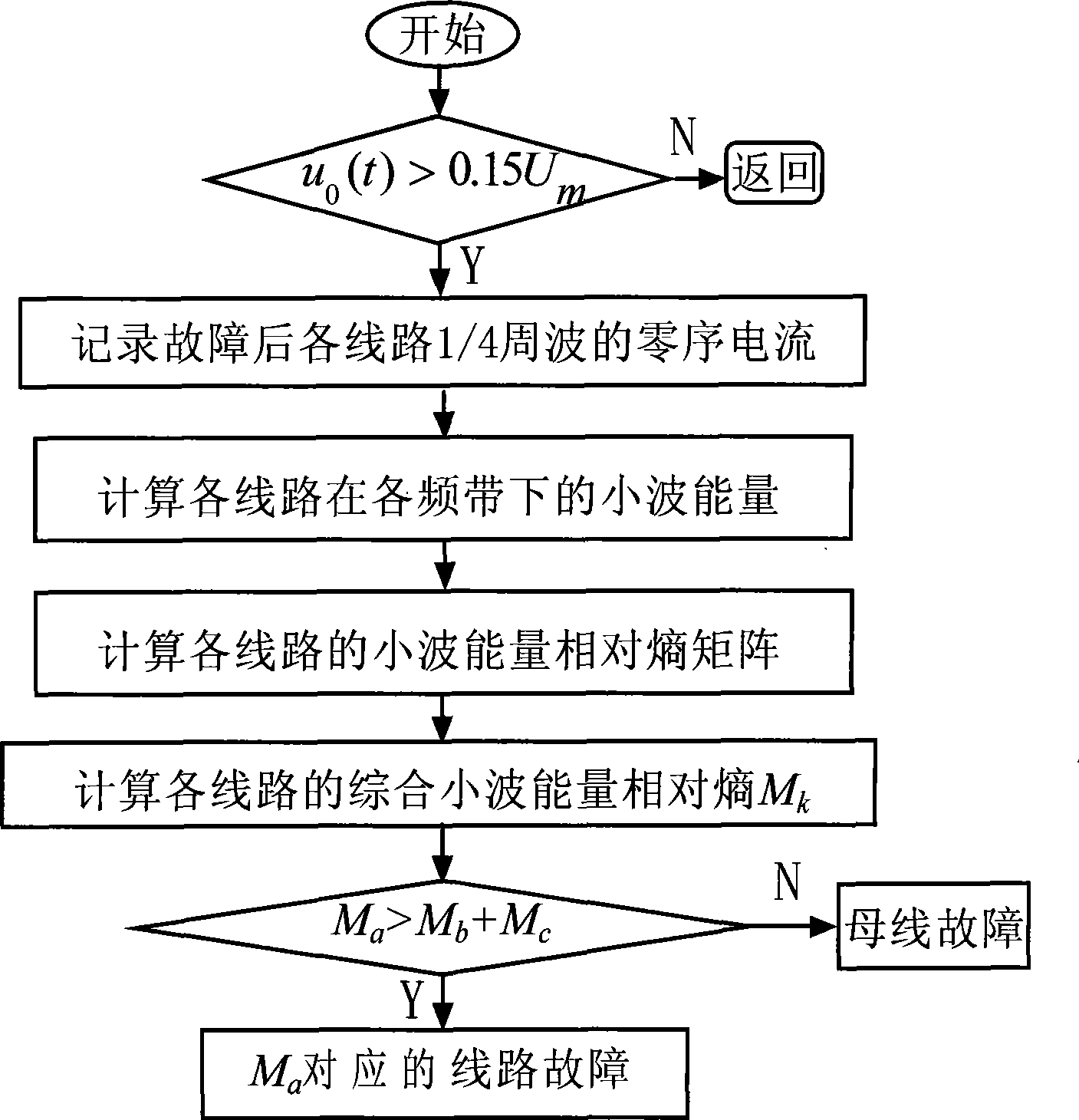

Method for fault line selection of cable-wire mixed line of electric distribution network by using wavelet energy relative entropy

The invention relates to a self-adaptive method for fault line selection of a cable-wire mixed line of an electric distribution network by using full-band wavelet energy relative entropy. The method comprises the following steps: when the zero-sequence voltage instantaneous value of a bus is out of limit, starting a fault line selection device immediately; performing wavelet decomposition on zero-sequence current in 1 / 4 cycle after the fault of each line, performing single reconstruction on wavelet decomposition coefficients under each scale, and calculating the wavelet energy under each band of the zero-sequence current of each line by using reconstruction coefficients; and calculating the wavelet energy relative entropy under each band of each line and solving the comprehensive wavelet energy relative entropy of each line by combining the super-strong recognition capability of the relative entropy to slight differences between signals, and self-adaptively selecting out the fault line by comparing the size of the full band comprehensive wavelet energy relative entropy of each line. Theoretical analyses and a large number of emulations show that the method effectively avoids the influence caused by a CT saturation discontinuous angle on the line selection, and is applicable to the cable-wire mixed lines, pure cable lines and pure aerial lines.

Owner:KUNMING UNIV OF SCI & TECH

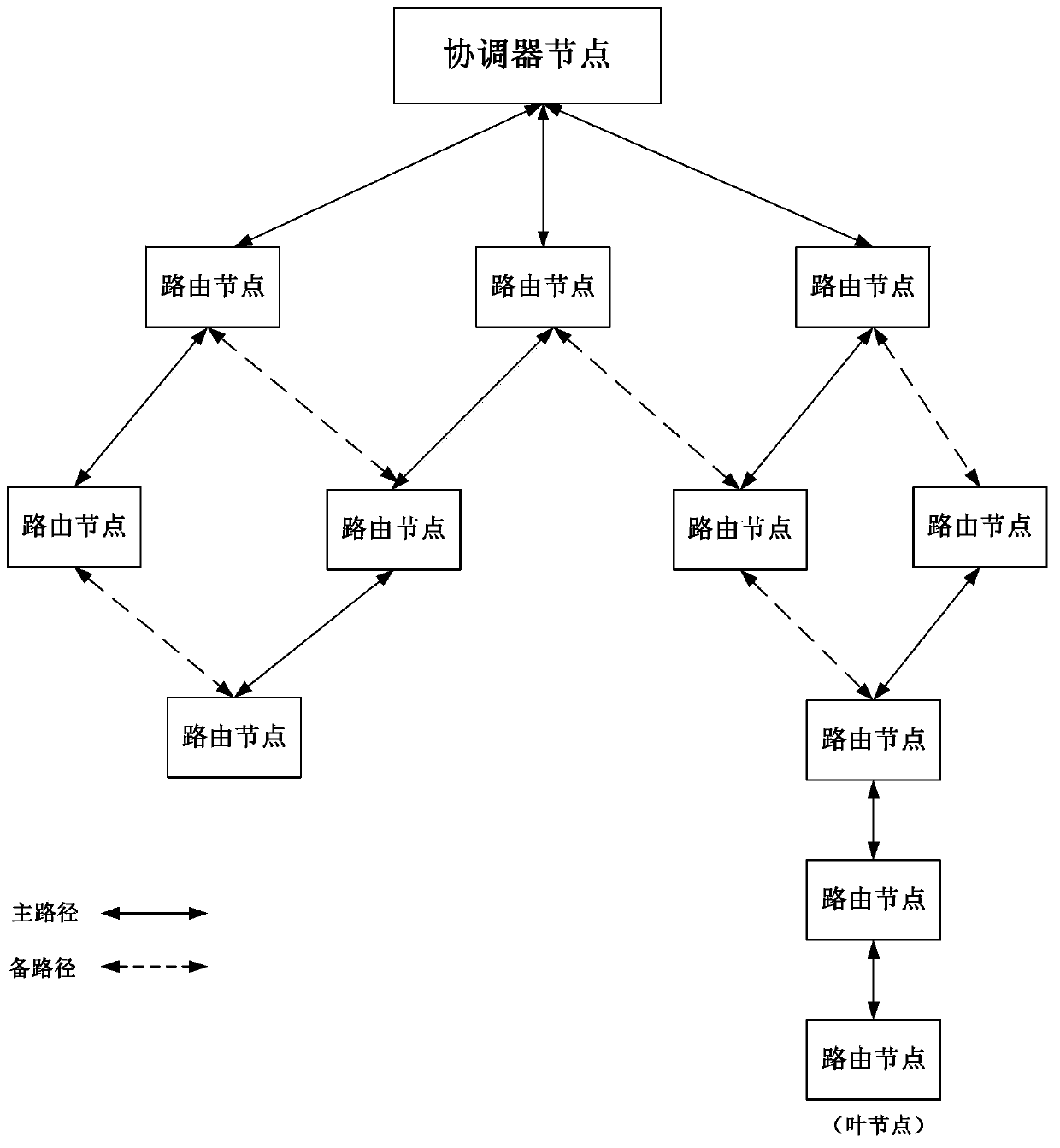

Micropower wireless network ad-hoc networking method based on multi-channel frequency hopping

ActiveCN103428899AFast networkingSimple networkingTransmission systemsNetwork topologiesFrequency spectrumTelecommunications link

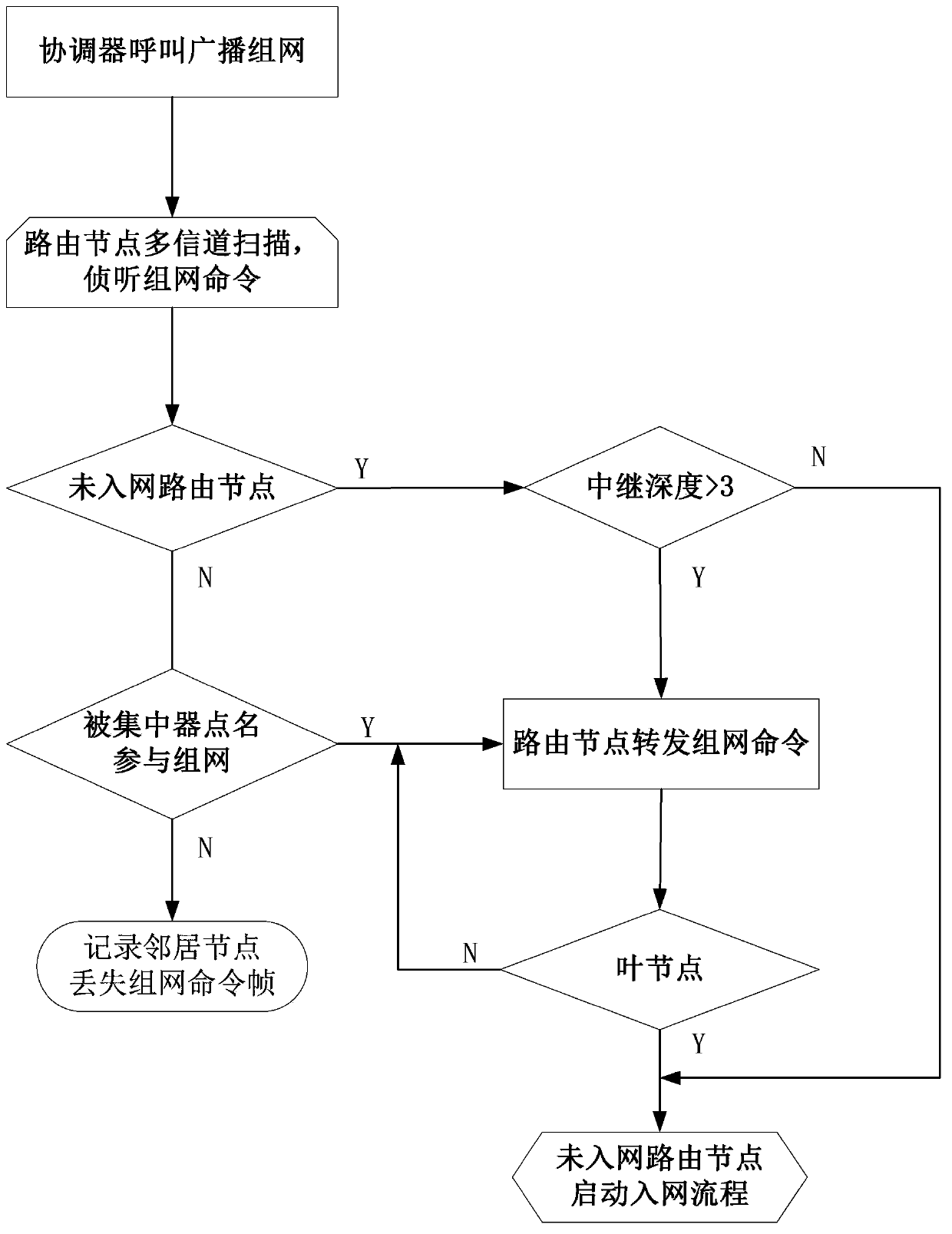

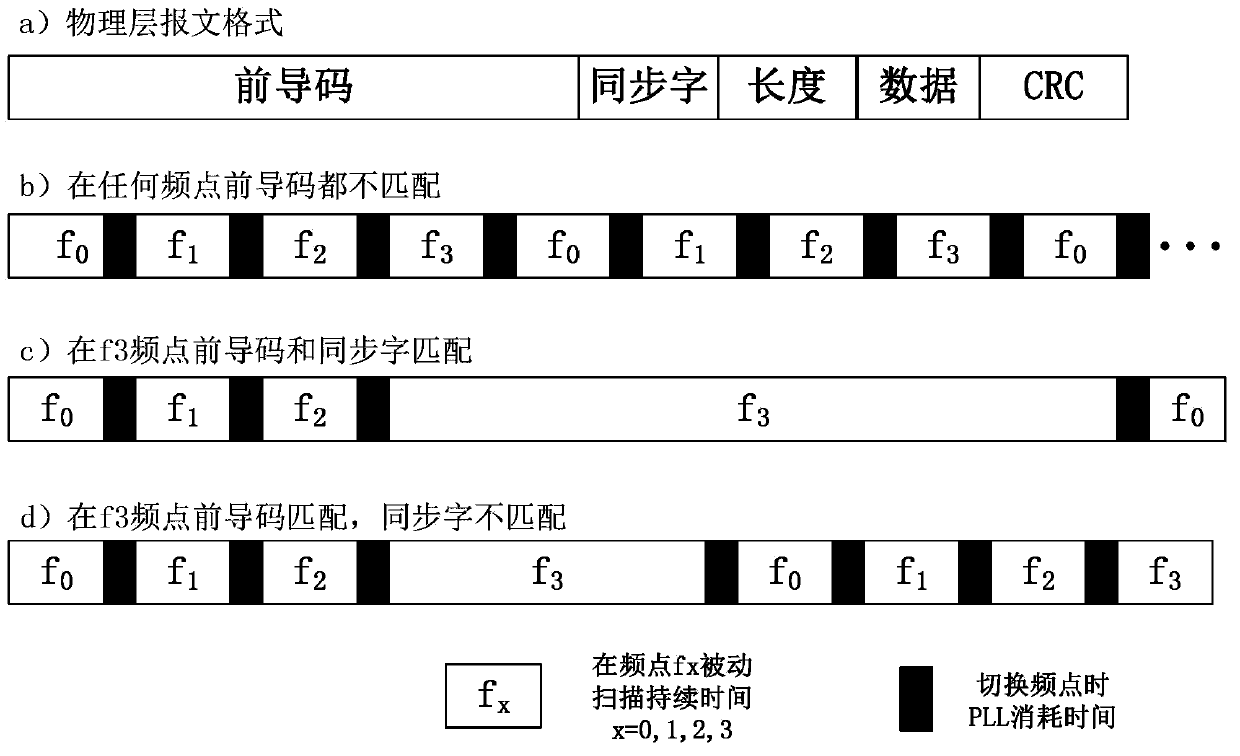

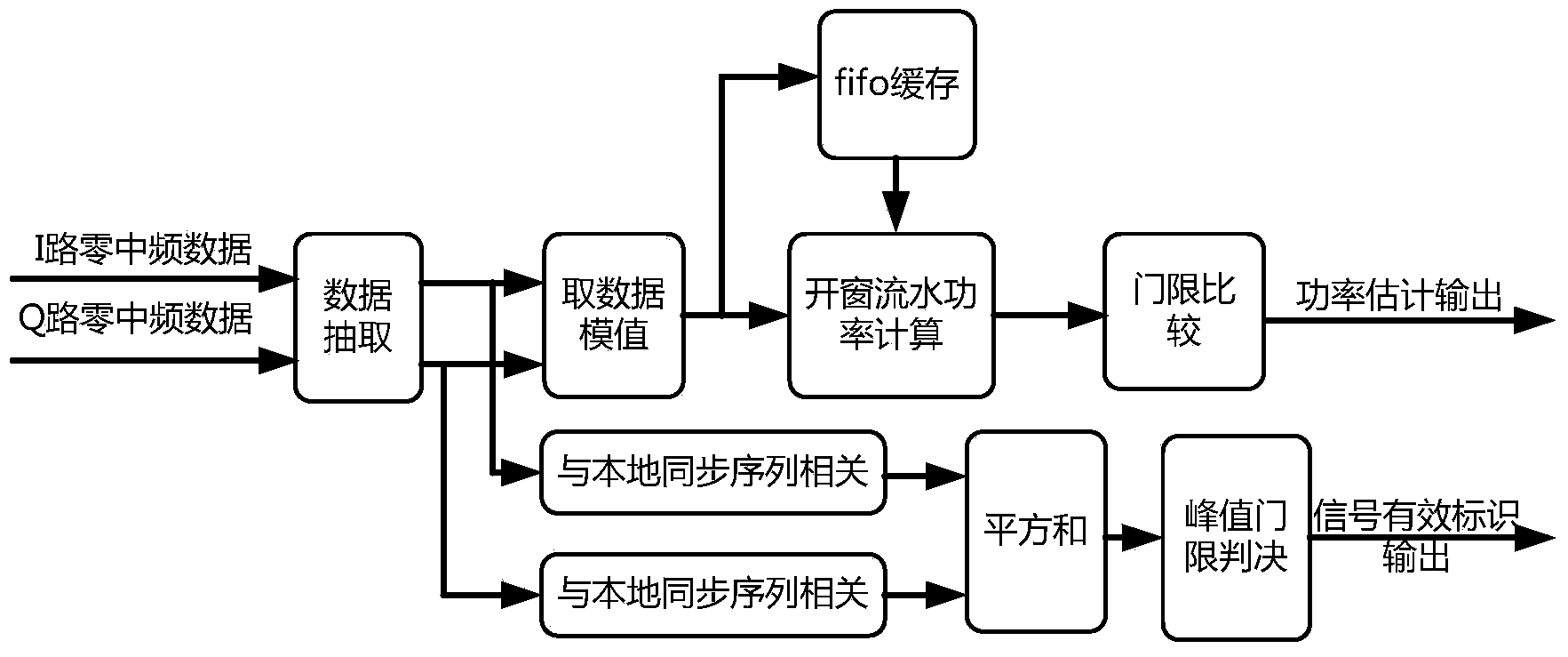

The invention discloses a micropower wireless network ad-hoc networking method based on multi-channel frequency hopping. A coordinator node is used for starting building of a whole sub network, an in-network routing node is controlled to conduct hop-by-hop grouping in a specified period to start broadcast networking of out-network routing nodes in the first hop range, manage complete routes from itself to the routing nodes in the region of the in-network routing node and conduct link maintenance and transparent transmission of application messages. The routing nodes are used for conducting multi-channel passive scanning receiving, automatically select an optimized route by capturing the whole route from a coordinator to the neighborhood nodes in the first hop range and actively report the whole captured route to the coordinator in a communication link active period. The whole networking process is quick, simple, free of manual participation and the like. Meanwhile, the coordinator controls the communication link active period, effectively prevents broadcast storm, prevents the out-network routing nodes from actively starting access applications periodically in full band and can share spectrum resources with other devices in a day parting mode. System expandability and scalability are good.

Owner:ZHUHAI ZHONGHUI MICROELECTRONICS

Multi-channel self-adaptation frequency-hopping processing method and system suitable for aeronautical ad-hoc network

ActiveCN104270169ADesign without explicit requirementsGuaranteed anti-interference abilityTransmissionFrequency spectrumHandling system

The invention discloses a multi-channel self-adaptation frequency-hopping processing method suitable for an aeronautical ad-hoc network. The method comprises the steps of (1) evaluating all frequency points; (2) dividing a frequency-hopping full band into m physical channels, and initially allocating n frequency points to each physical channel to form frequency sets; (3) selecting frequency points with the lowest power in other physical channels to replace interfered frequency points in the selected physical channel; (4) dynamically selecting the current idlest physical channel according to the idleness degree of the current physical channels when information to be sent of a node MAC layer is sent; (5) carrying out modulation and frequency-hopping transmission on framed data through the selected physical channels. The invention further discloses a multi-channel self-adaptation frequency-hopping processing system suitable for the aeronautical ad-hoc network. The system comprises a spectrum sensing module, a self-adaptation frequency point allocating module and channel idleness degree statistics module. According to the multi-channel self-adaptation frequency-hopping processing method and system suitable for the aeronautical ad-hoc network, the network reliability is improved through spectrum sensing processing and design of self-adaptation frequency point allocation protocols.

Owner:CHINESE AERONAUTICAL RADIO ELECTRONICS RES INST

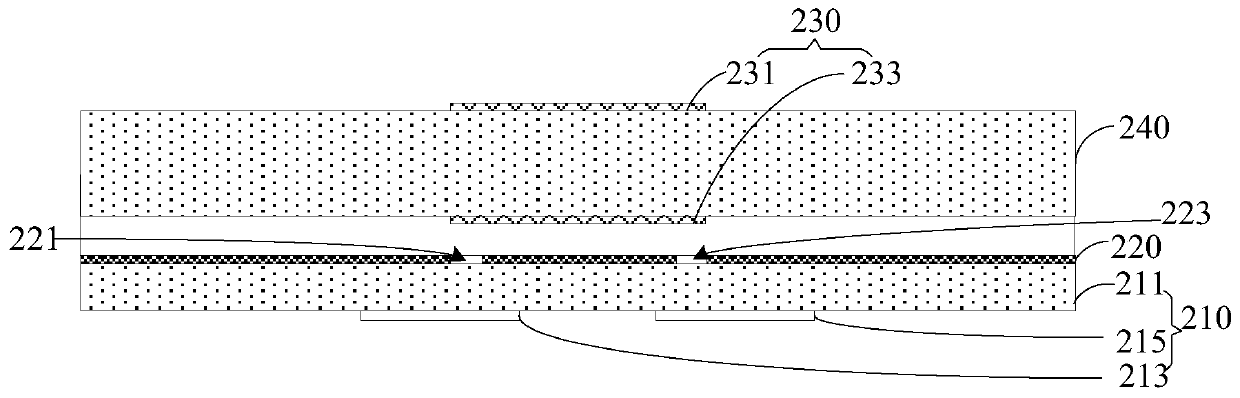

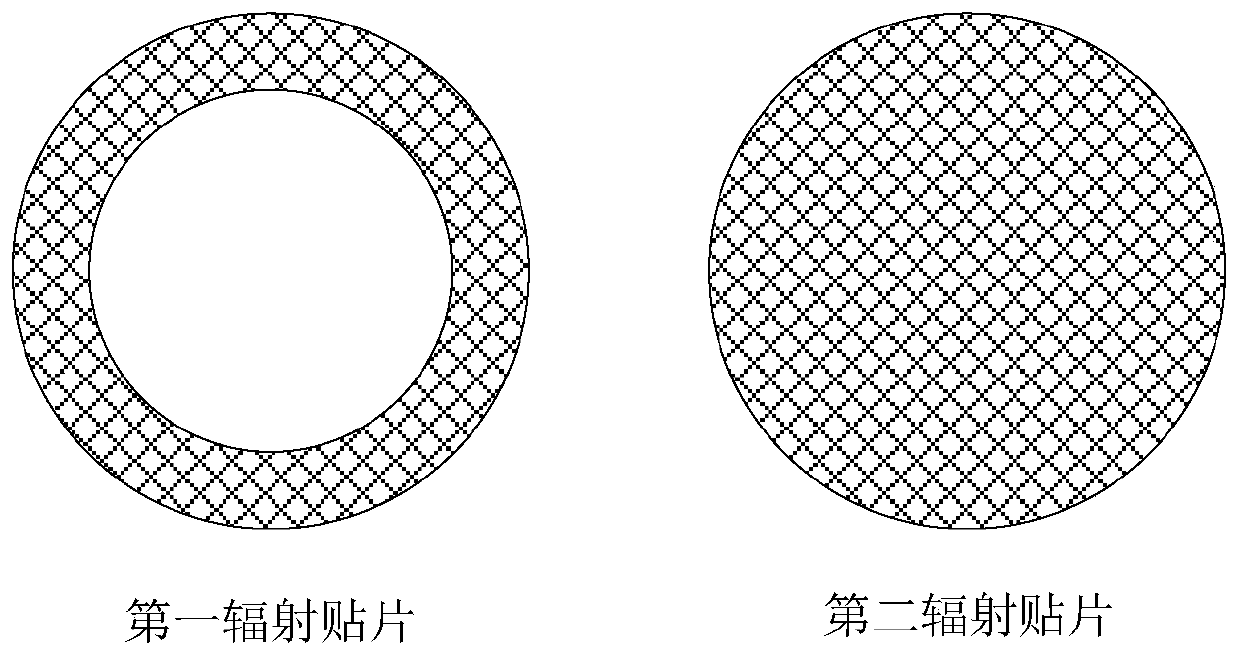

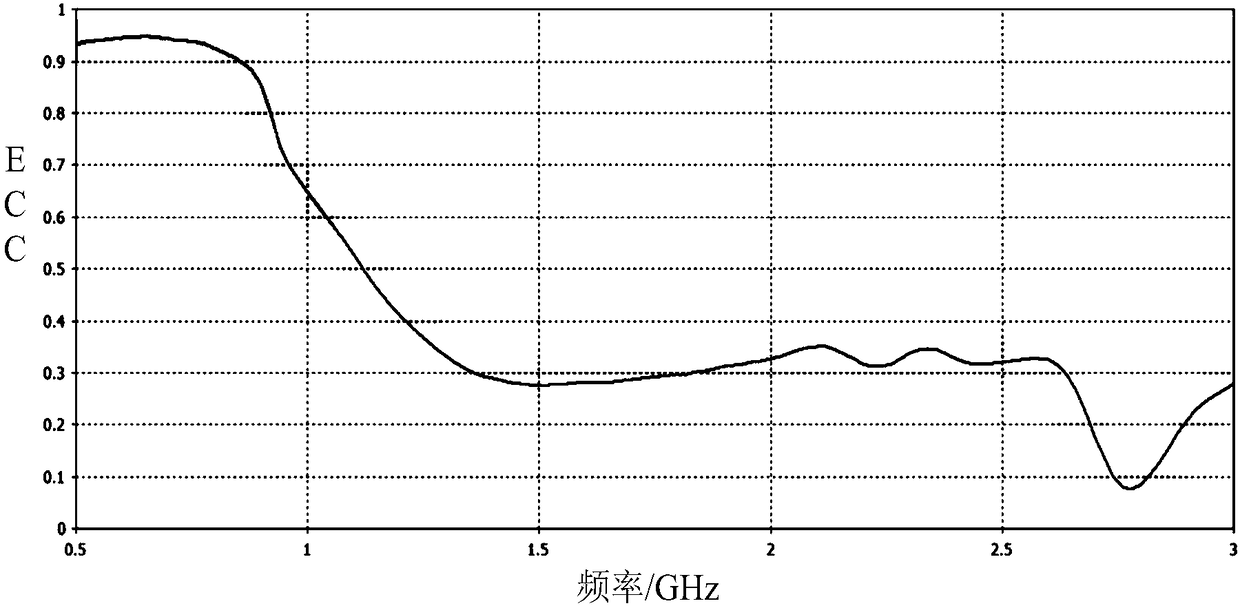

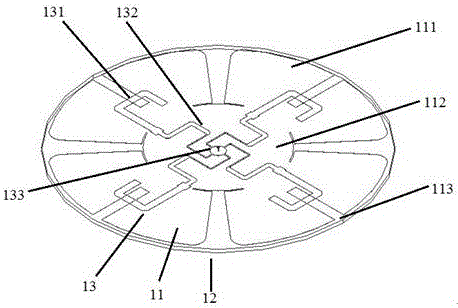

Antenna module and electronic equipment

ActiveCN110048224AHigh gainImprove efficiencySimultaneous aerial operationsRadiating elements structural formsResonanceDielectric substrate

The invention relates to an antenna module and electronic equipment. The antenna module comprises a feed layer, a grounding layer, a dielectric substrate and a laminated antenna, wherein the groundinglayer is positioned on the feed layer and is provided with a first gap and a second gap which are separated and orthogonally arranged in the polarization direction; the dielectric substrate is positioned on the grounding layer; the laminated antenna comprises a first radiation patch and a second radiation patch which are arranged corresponding to the first gap and the second gap, wherein the first radiation patch and the second radiation patch are located on the two sides of the back of the dielectric substrate respectively, and the orthographic projection of the first radiation patch is arranged on the second radiation patch, wherein the feed layer passes through the first gap and the second gap and is used for feeding the laminated antenna to enable the first radiation patch to generateresonance at the first frequency band and to enable the second radiation patch to generate resonance at the second frequency band, so that the impedance bandwidth of the antenna module can meet the millimeter wave full-band requirement of 3GPP specification, and the antenna radiation with the full frequency band, the dual polarization, the high efficiency and the high gain is realized.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

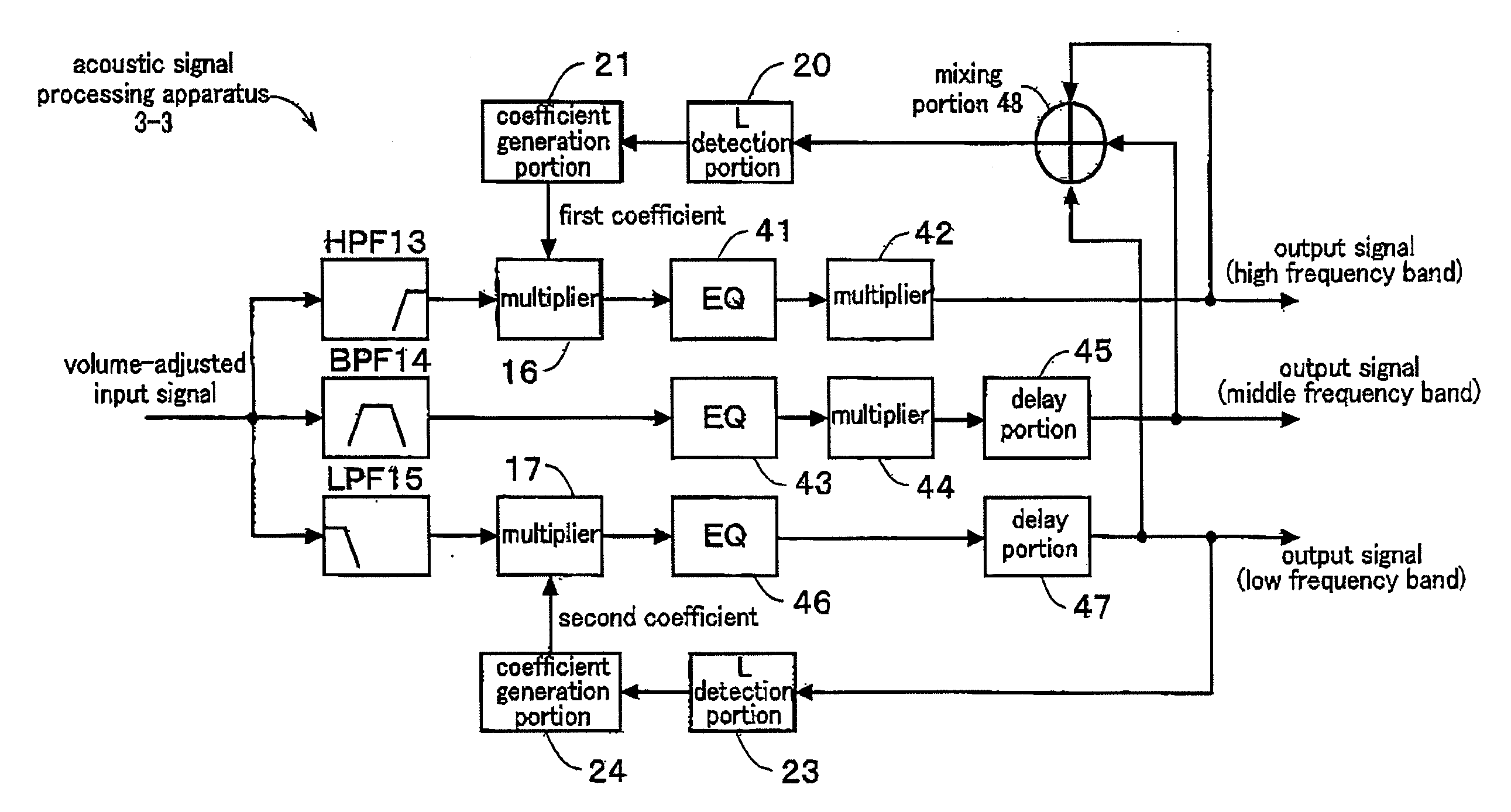

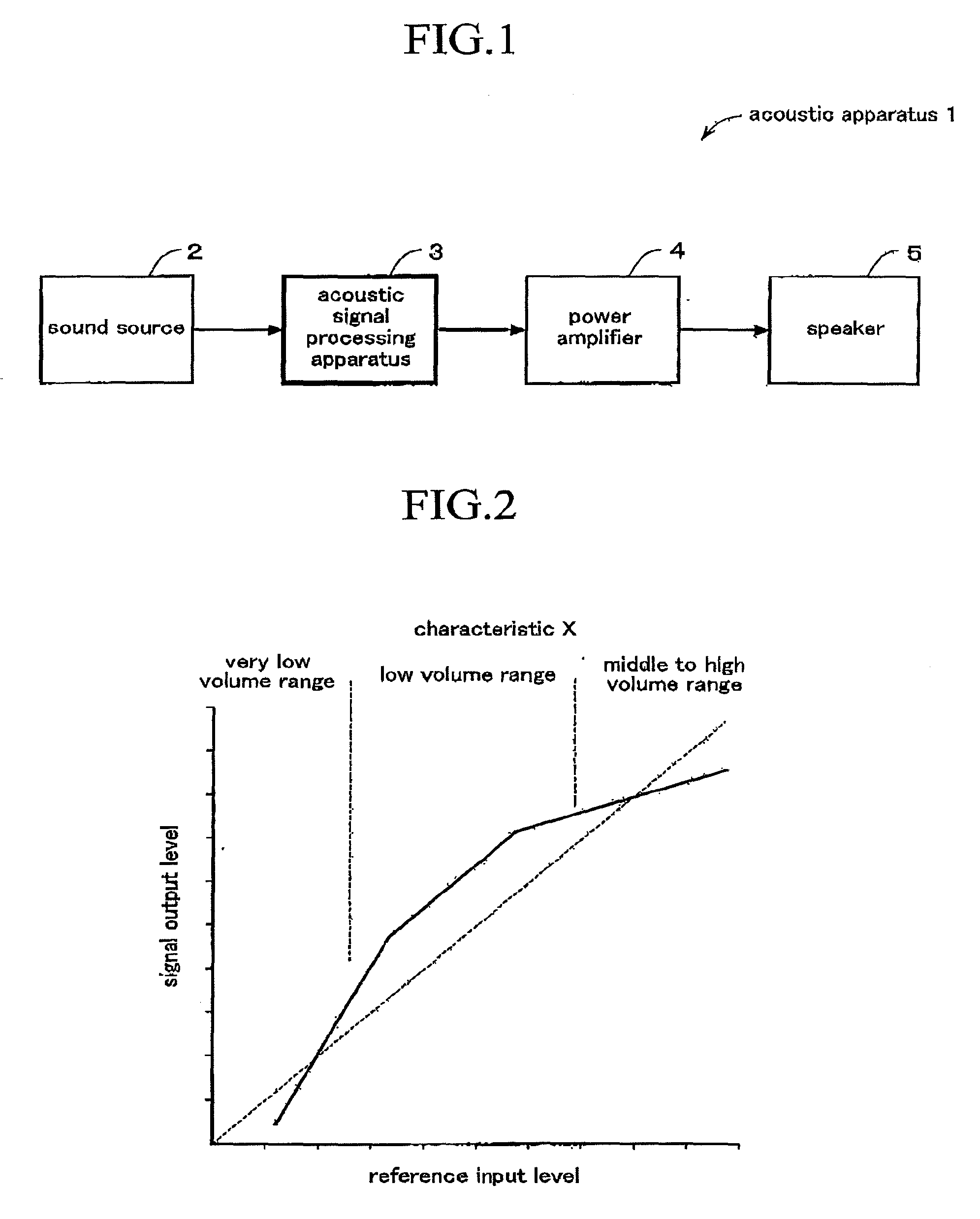

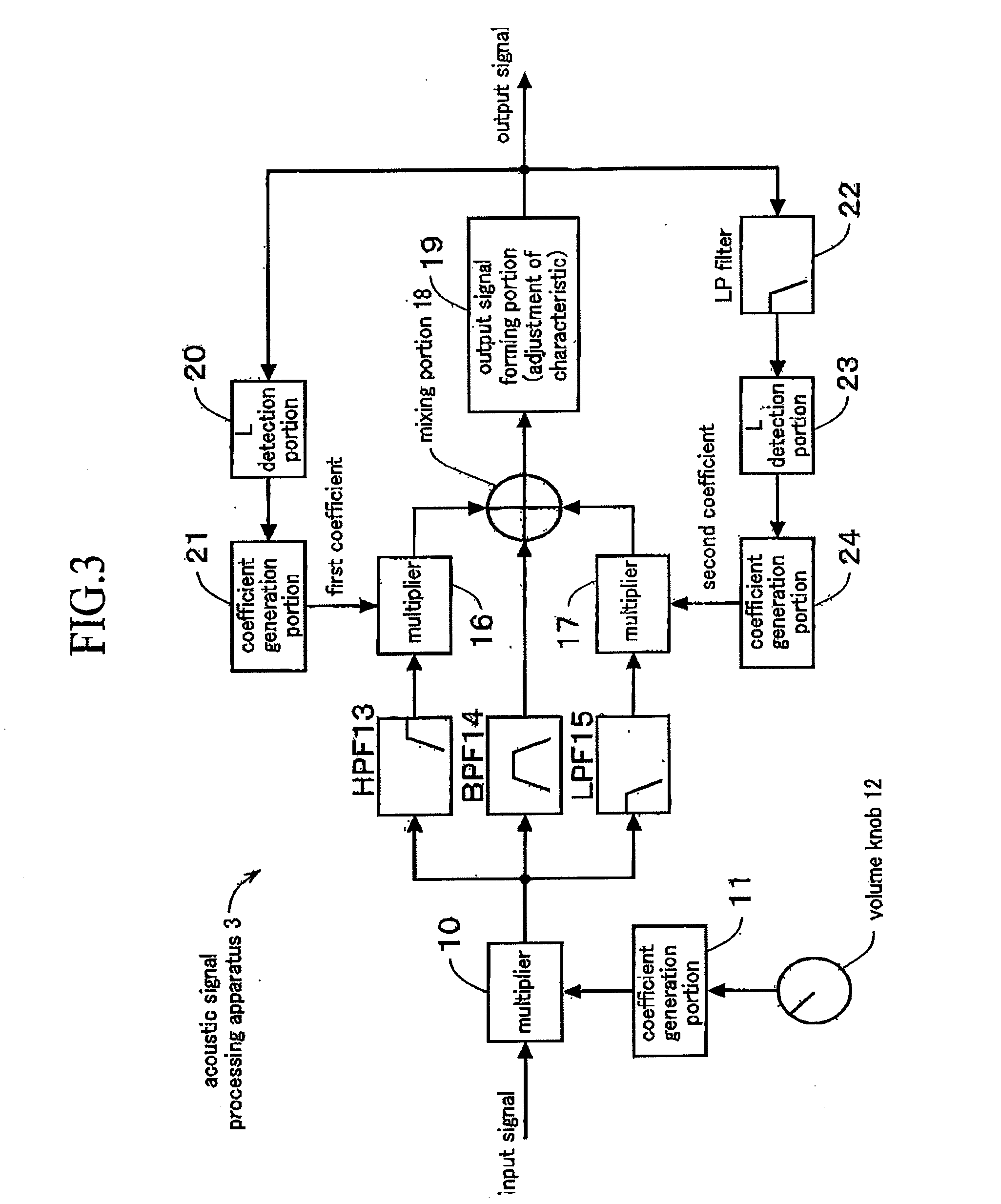

Acoustic signal processing apparatus

An acoustic signal's high frequency component extracted by an HPF 13 is multiplied in a multiplier 16 by the first coefficient to control the level of the high frequency component. The first coefficient is generated by a coefficient generation portion 21 in accordance with the full band level of an output signal. A low frequency component extracted by an LPF 15 is multiplied in a multiplier 17 by the second coefficient to control the level of the low frequency component. The second coefficient is generated by a coefficient generation portion 24 in accordance with the level of the output signal's low frequency component extracted by an LP filter 22. The level control of the low frequency component of the output signal and the level control of the high frequency component of the output signal are done separately, resulting in the loudness control which is suitable for the characteristic of the acoustic signal.

Owner:YAMAHA CORP

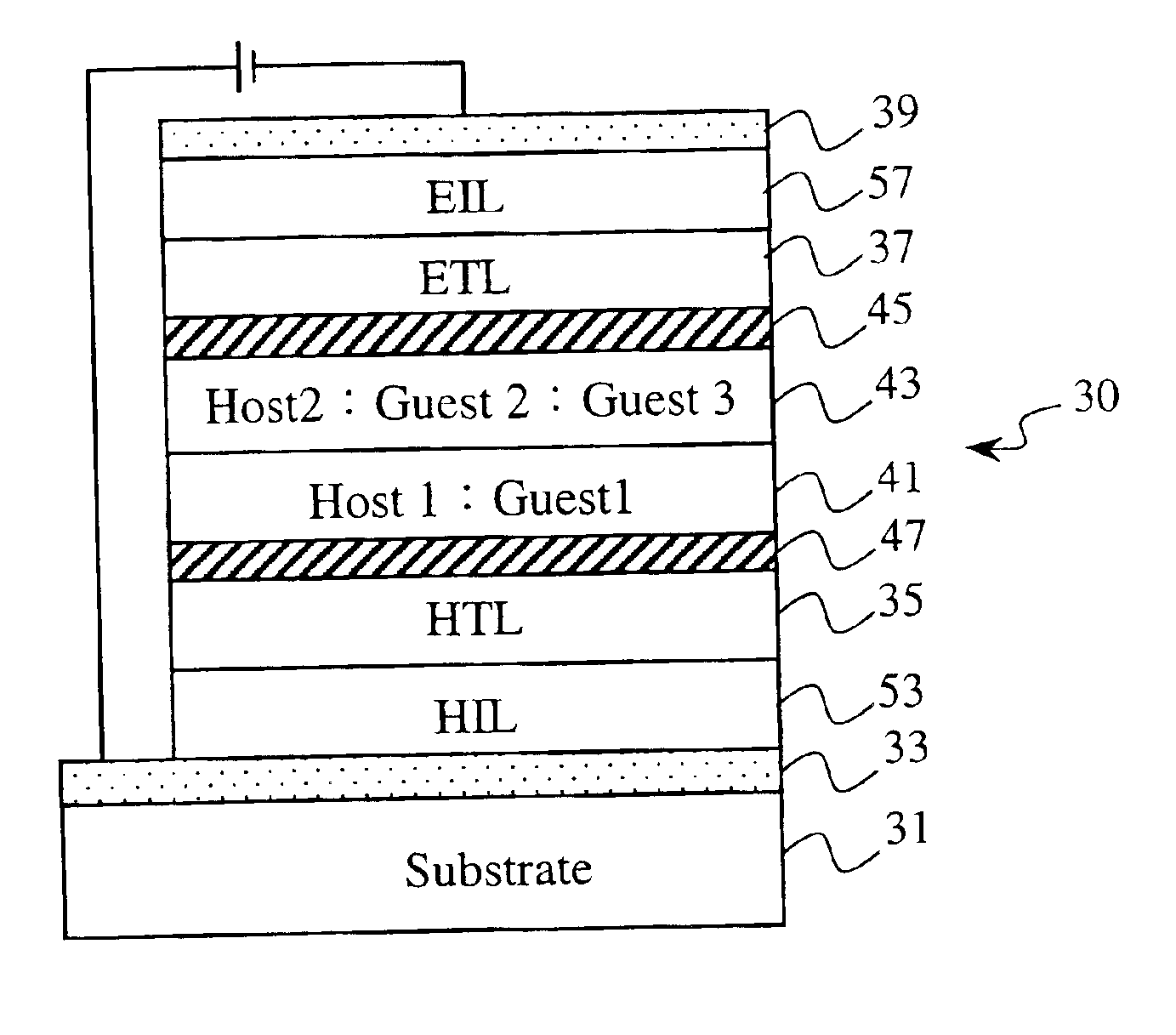

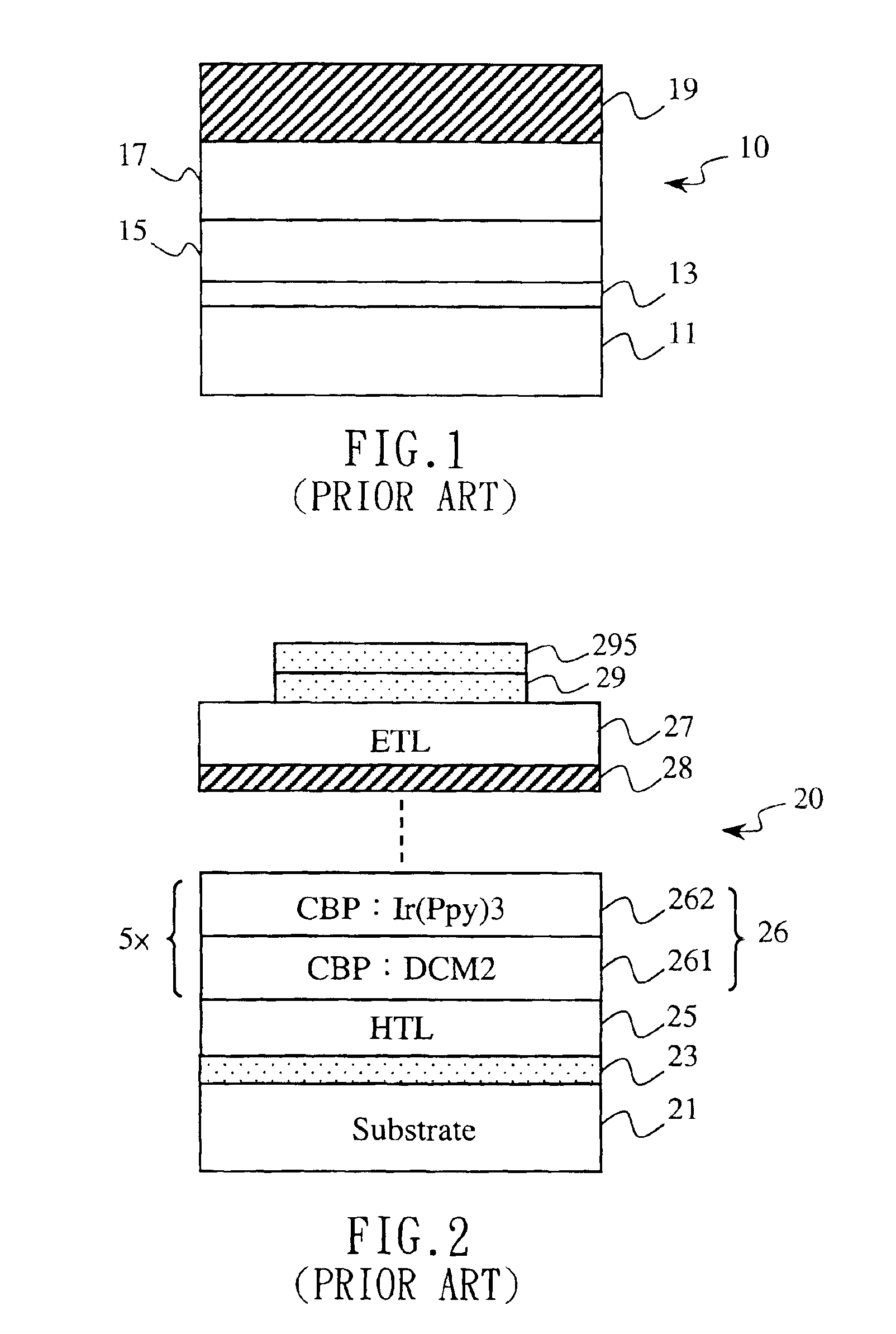

Organic electroluminescent device and method for producing the same

InactiveUS6933522B2Improve distributionThe implementation process is simpleDischarge tube luminescnet screensElectroluminescent light sourcesExternal biasHole transport layer

An organic electroluminescent device with the feature of three-wavelength luminescence is provided. The device includes a hole transporting layer, an electron blocking layer, a first host material layer, a second host material layer, a hole blocking layer, and an electron transporting layer placed between an anode and a cathode in turn. In which, the first host material layer has a first guest luminous substance mixed therein for projecting a first color light source (B), while the second host material layer correspondingly has a second guest luminous substance and a third guest luminous substance mixed therein for projecting a second color light source (G) and a third color light source (R), respectively, under the effect of an external bias voltage, wherein said second guest luminous substance or said third guest luminous substance may be a phosphorescence substance. Thus, not only a continuously full-band, full-colored light source featuring three-wavelength may be acquired directly by means of the combination of RGB colors, but also an effective utilization of phosphorescence substance and thus significantly raised luminescence efficiency may be obtained.

Owner:OPTO TECH

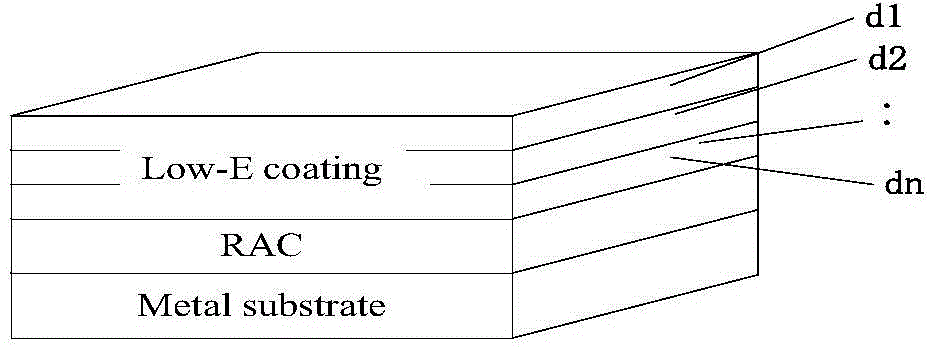

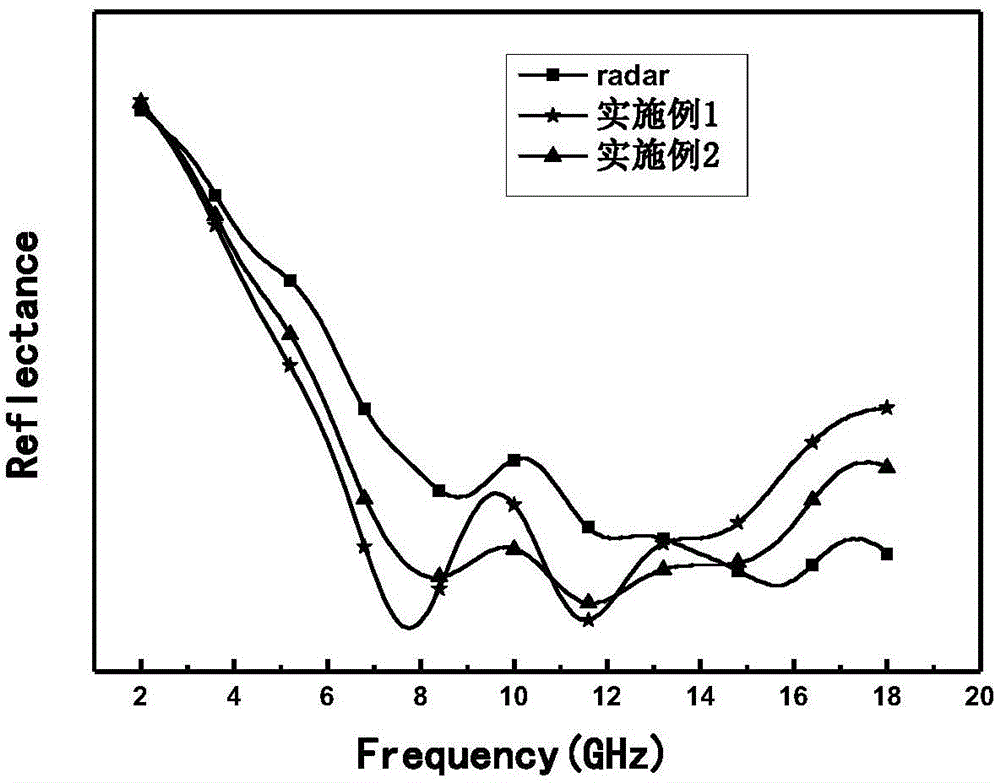

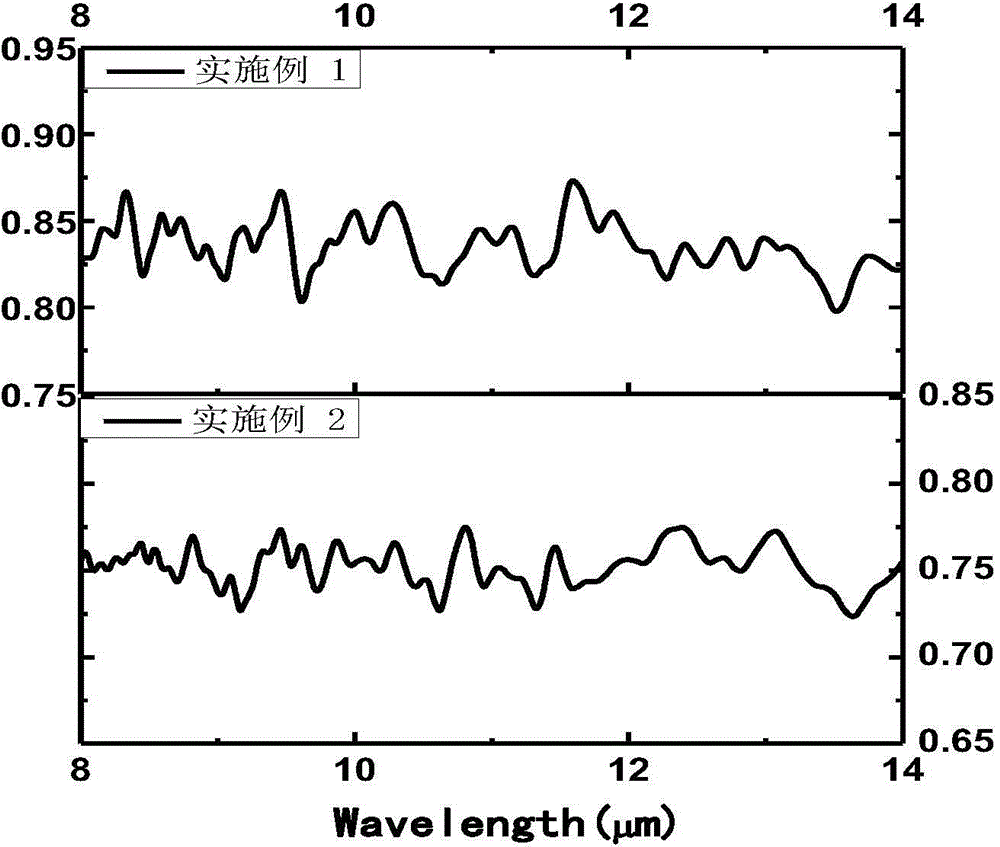

Method for coating infrared stealth coating on object surface coated with radar absorbing coating

ActiveCN103980806AImprove radar absorbing performanceReduce IR emissivityPolyurea/polyurethane coatingsPaints with free metalsRadarMetallurgy

The invention discloses a method for coating an infrared stealth coating on an object surface coated with a radar absorbing coating, and belongs to the technical field of a functional material. The method comprises the following concrete processes: 1, preparing each coating carrier of a corresponding infrared stealth coating, a component A of the infrared stealth coating and a component B of the infrared stealth coating; 2, cleaning the object surface coated with the radar absorbing coating; 3, mixing and evenly agitating a to-be-used inner coating carrier with the component A and the component B, and spraying on the surface of the radar absorbing coating by adopting a compressed gas manner, and drying; 4, sequentially taking the to-be-used coating carrier to mix and evenly agitate with the component A and the component B in a manner same as spraying of the inner layer, spraying and drying by adopting the compressed gas manner to the outermost layer. The method has the advantages that the infrared emitting ability can be reduced to below 0.25, meanwhile, the radar absorbing performance of the coating can be significantly improved within the full-band range of 1-18GHz, and excellent infrared / radar and stealth performances are achieved.

Owner:成都佳驰电子科技股份有限公司

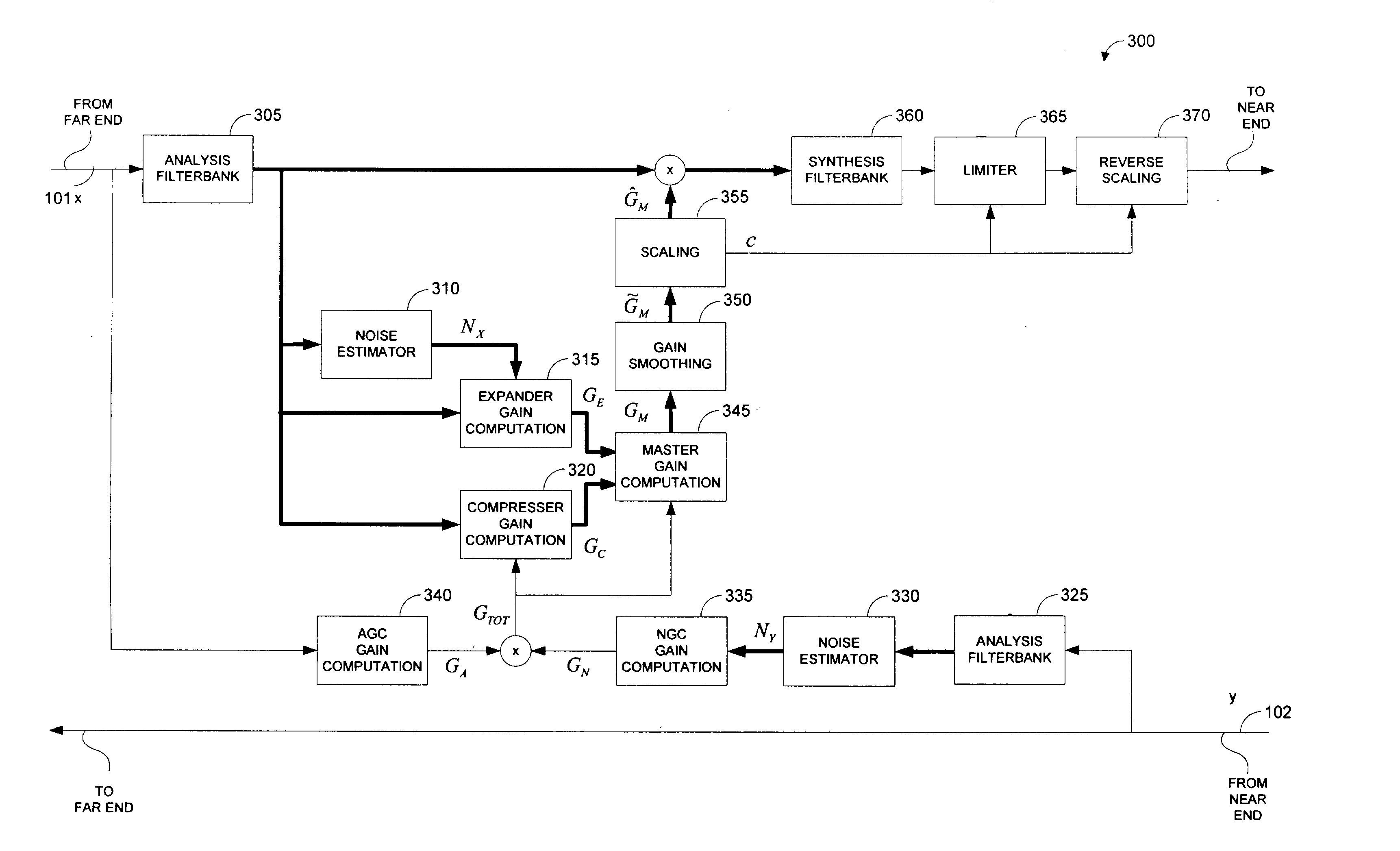

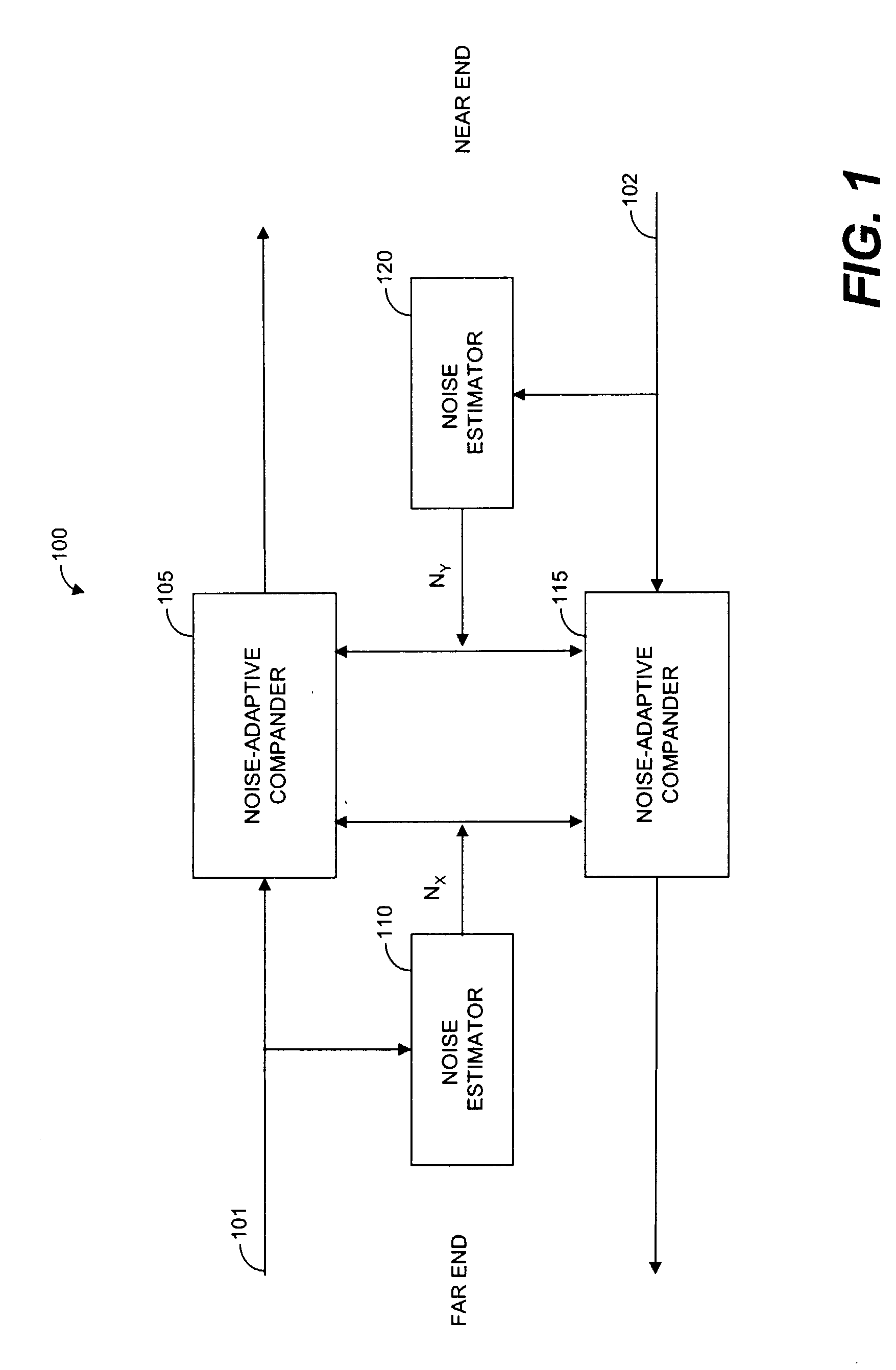

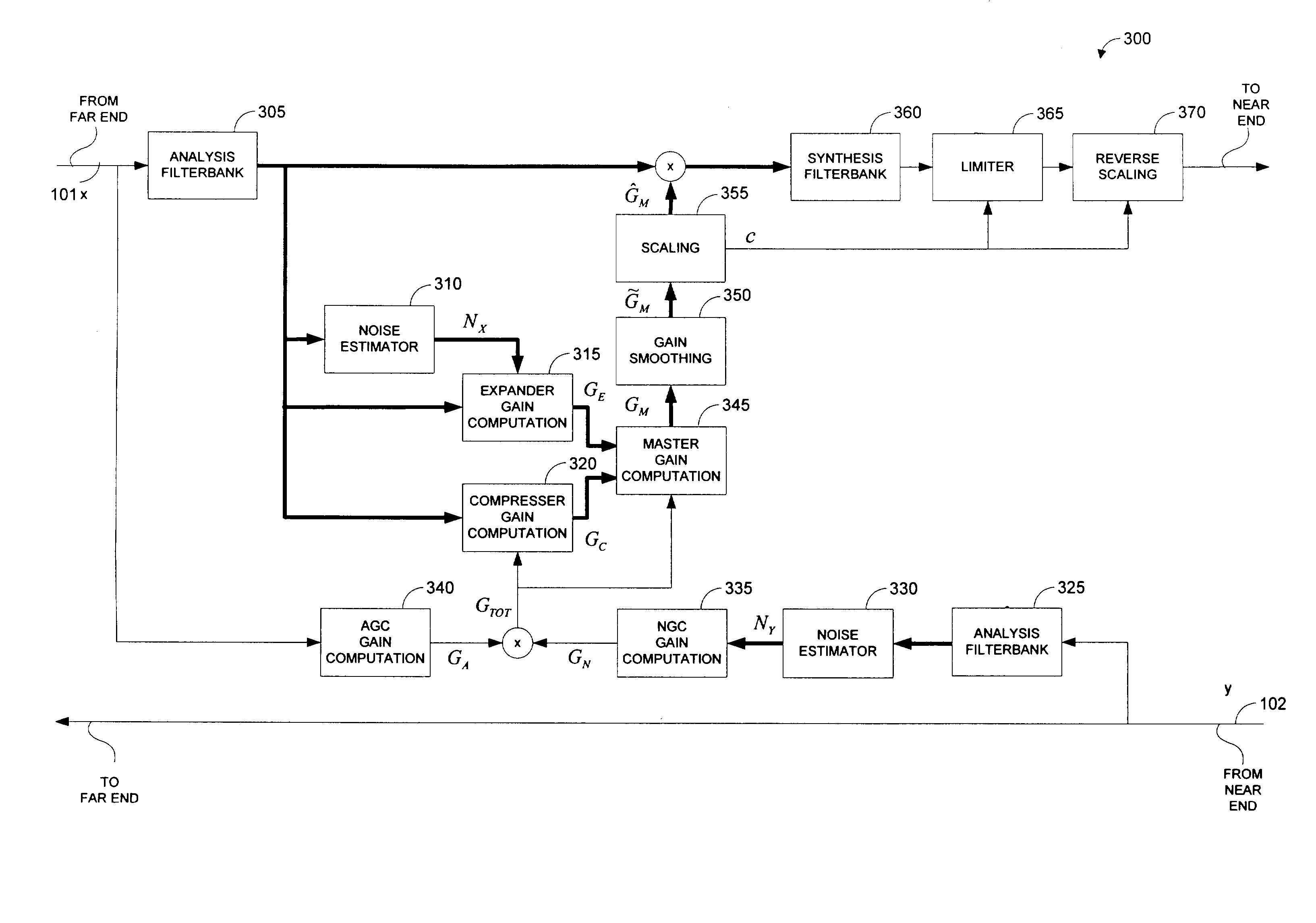

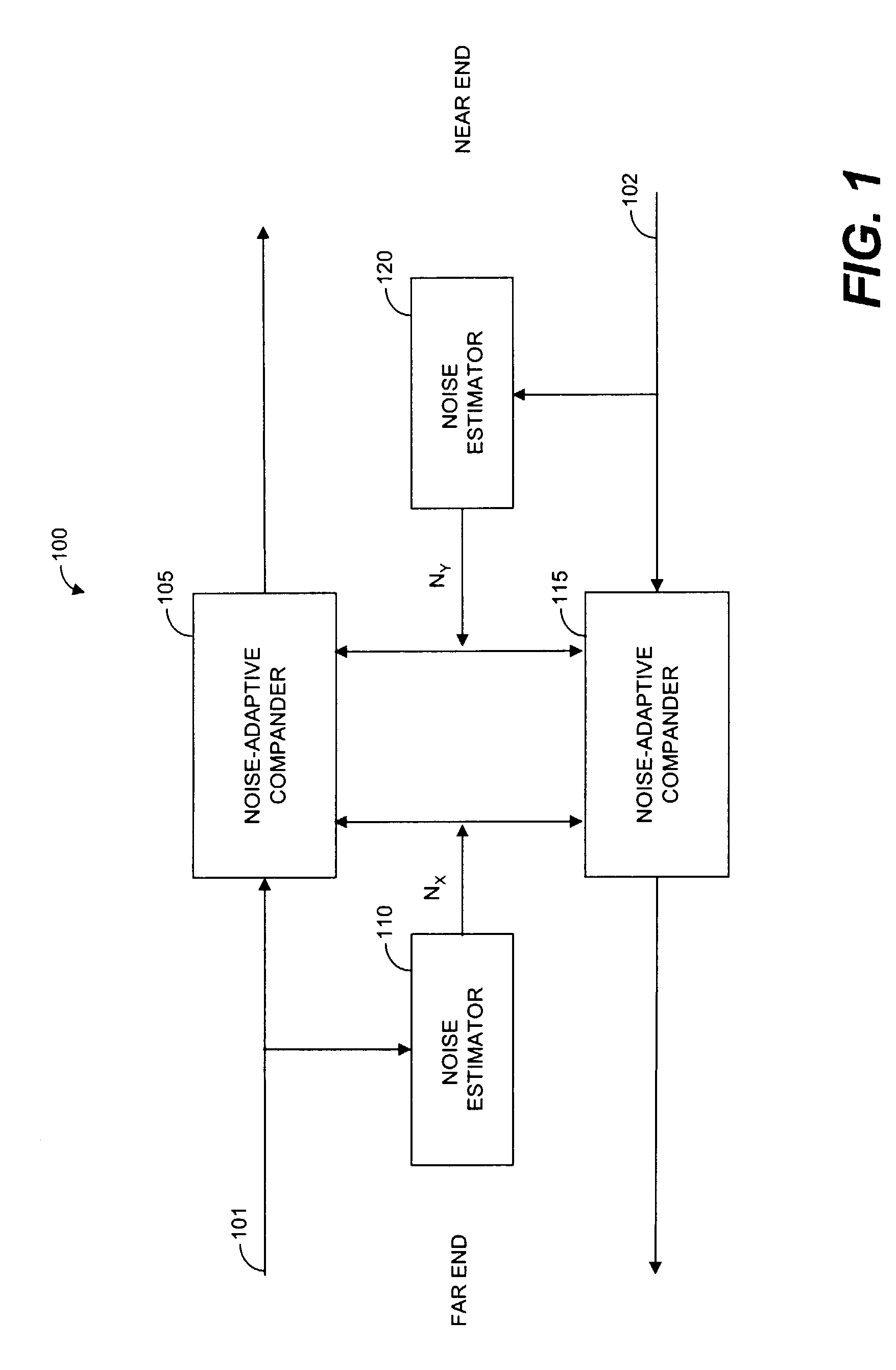

Systems and methods for far-end noise reduction and near-end noise compensation in a mixed time-frequency domain compander to improve signal quality in communications systems

InactiveUS20040101038A1Improve clarityReduce inconvenienceTwo-way loud-speaking telephone systemsFrequency-modulated carrier systemsTime domainCommunications system

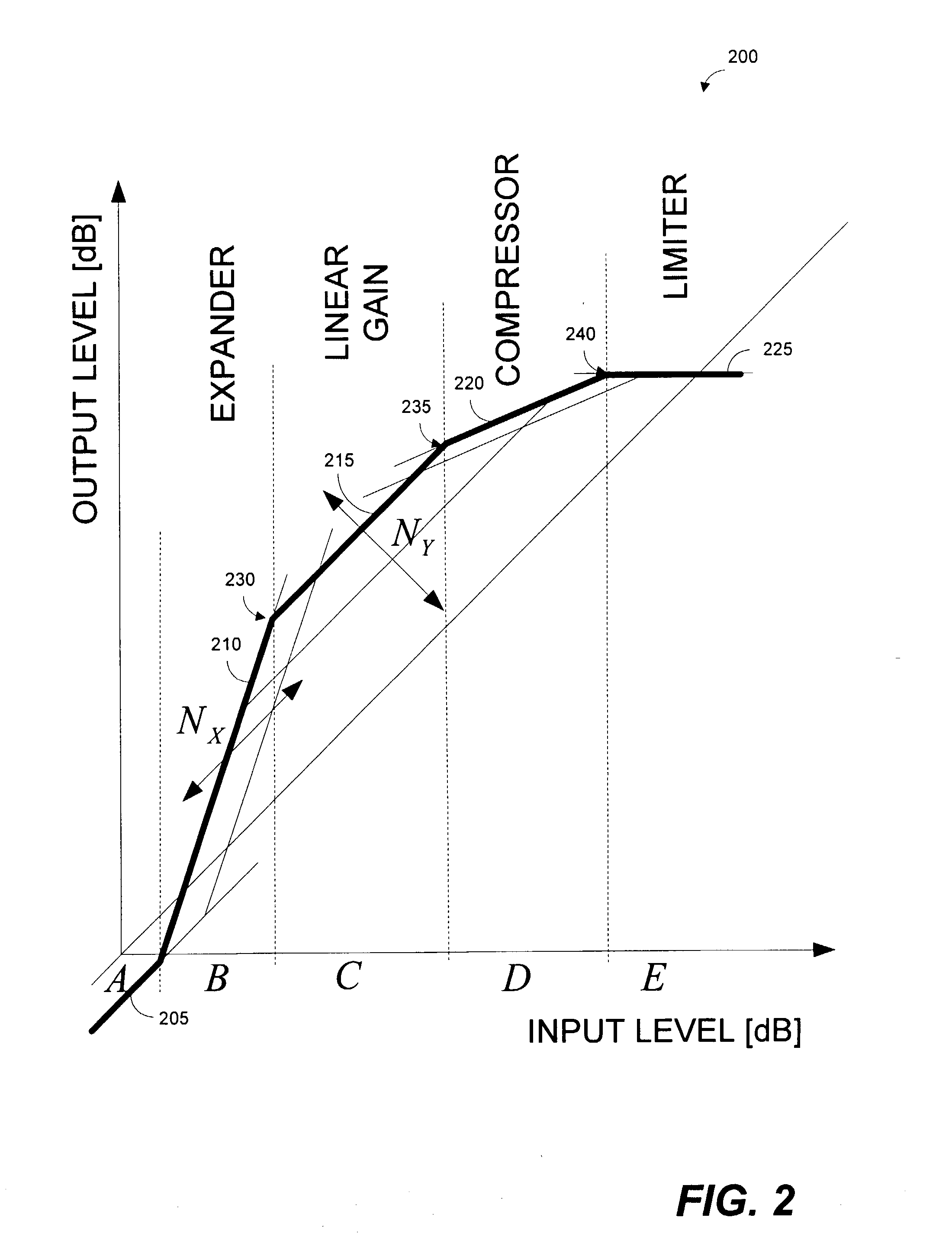

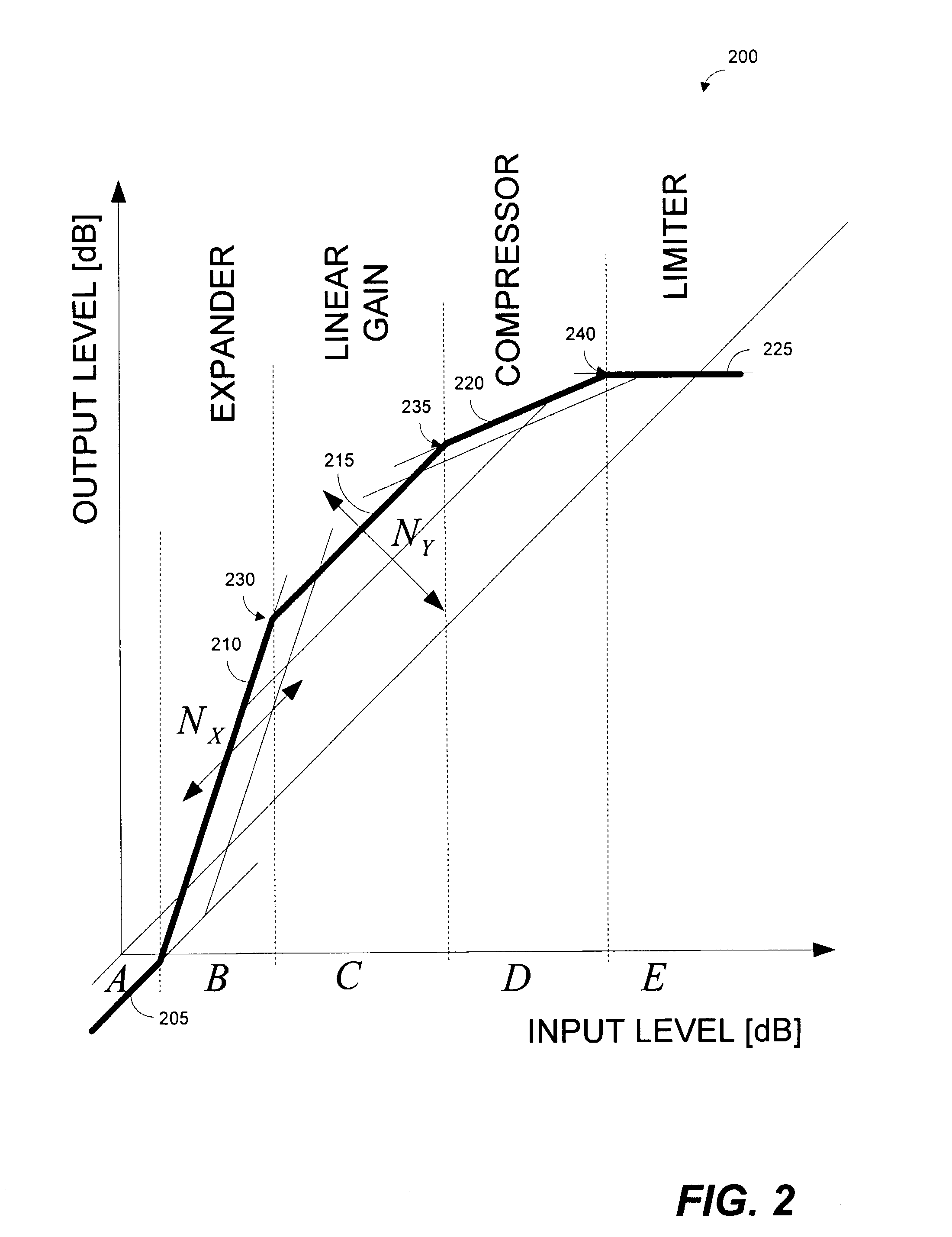

Methods and systems for a mixed time-frequency domain compander, where the expander and compressor are applied in the frequency domain (subbands), while the limiter and the linear gain are applied in the time-domain (full band). Far-end noise reduction is achieved by adapting the expander gain to the far-end noise, near-end noise compensation is achieved by adapting the linear gain and the compressor gain to the near-end noise. The range of the linear gain section is set individually for each subband, but the linear gain is essentially applied to the full band signal via a scaling procedure. The scaling procedure first reduces the compander gain in the frequency domain by a scaling factor and then performs the reciprocal reverse scaling in the time domain. Far-end noise reduction is coupled to near-end noise compensation in order to avoid cross-modulation of the far-end noise by the near-end noise.

Owner:LUCENT TECH INC

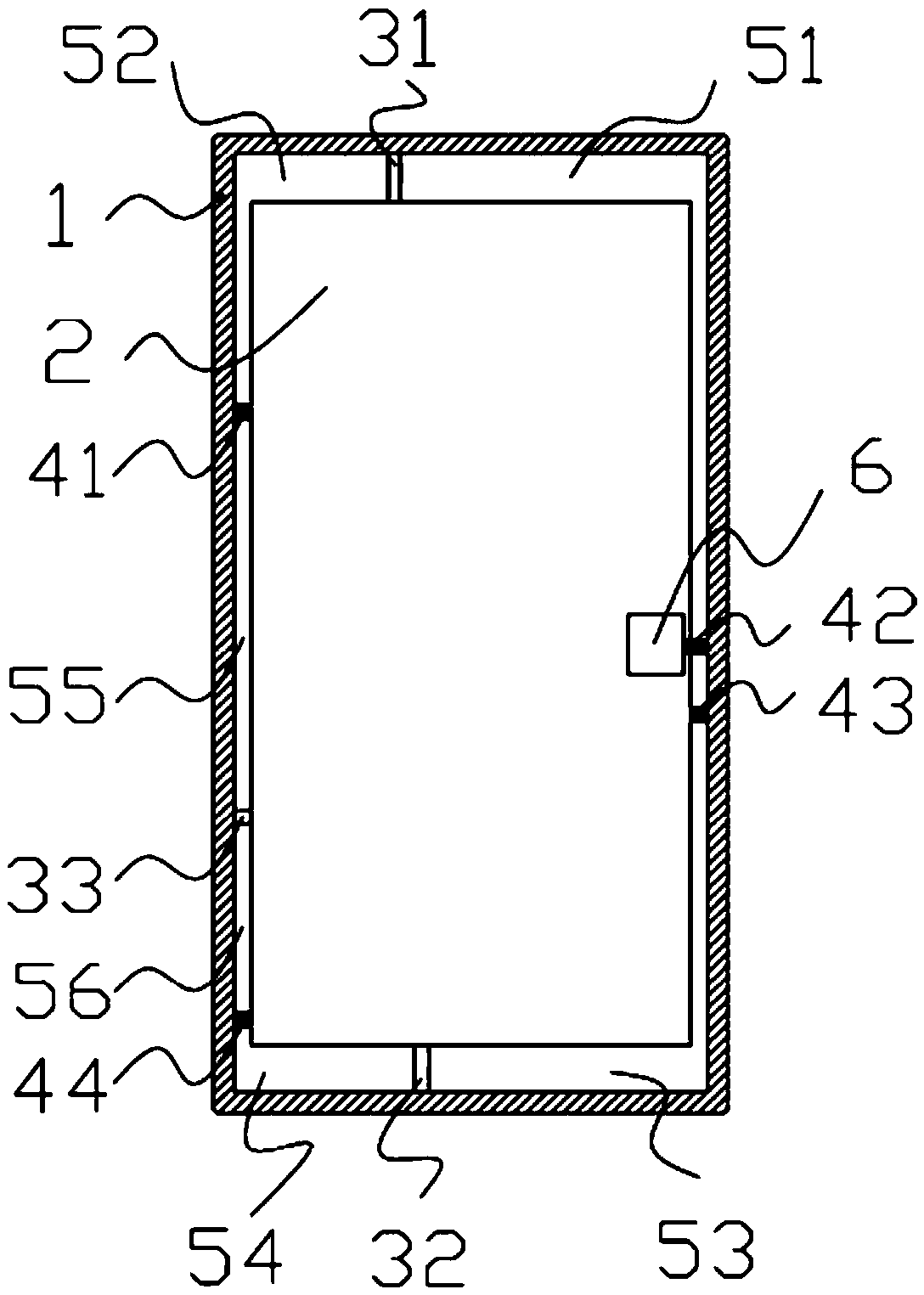

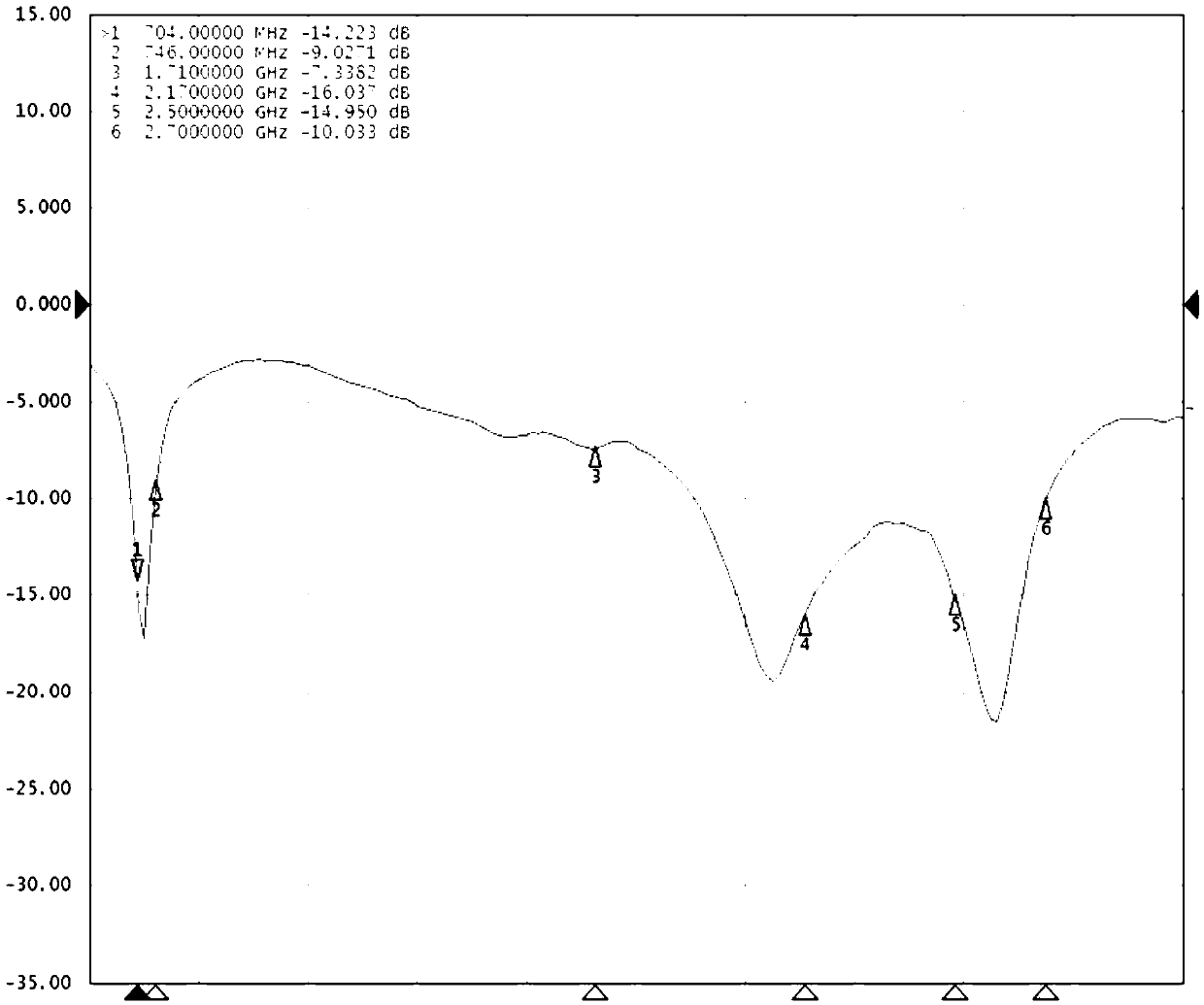

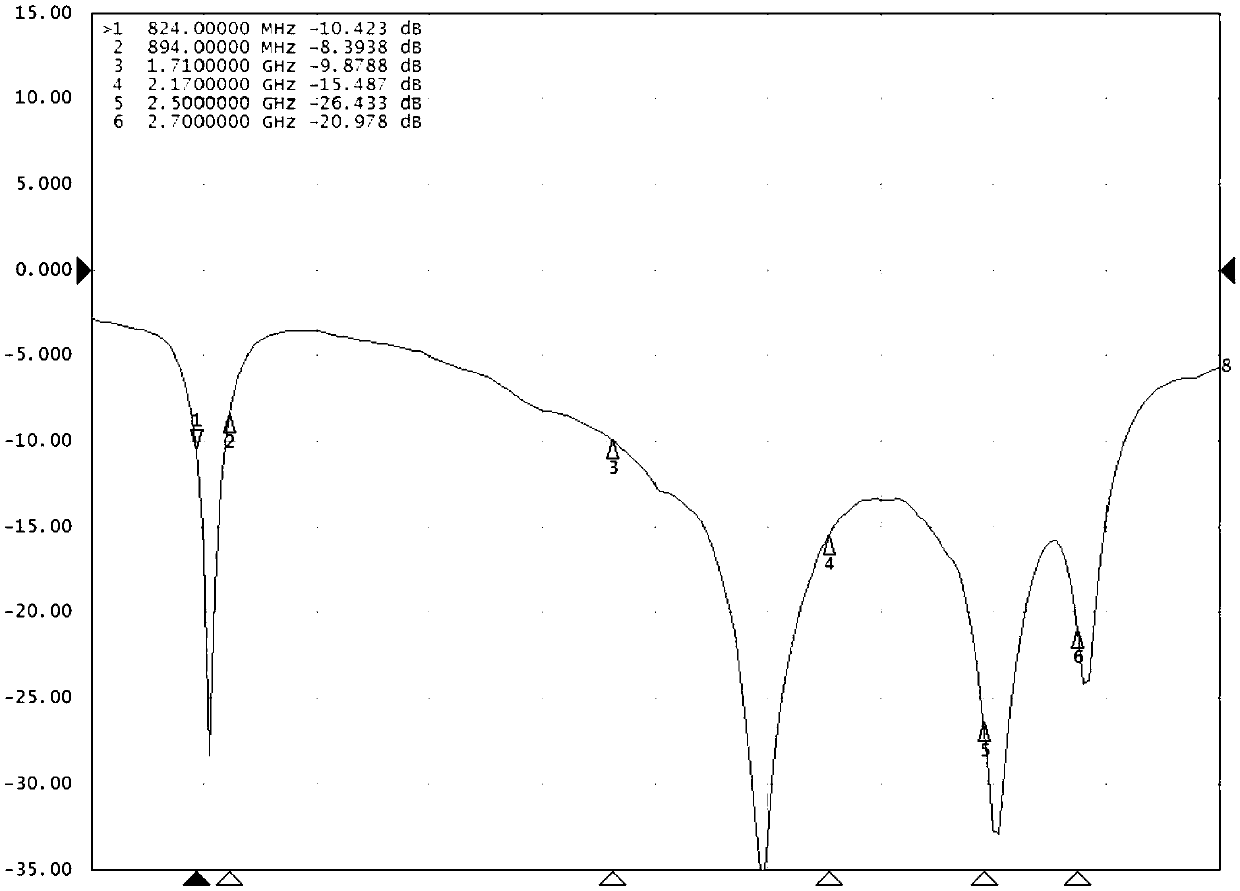

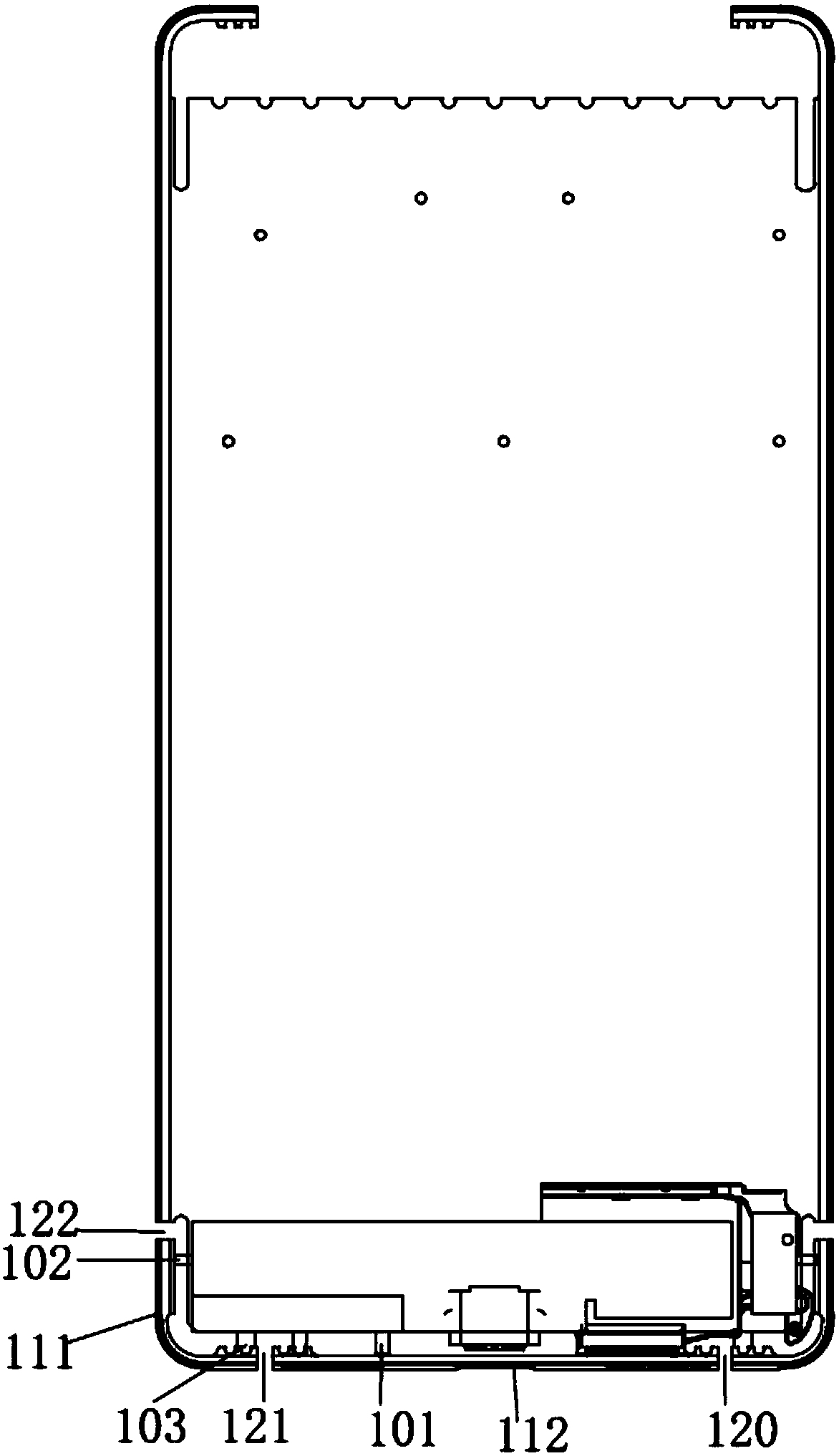

Antenna of mobile terminal and mobile terminal

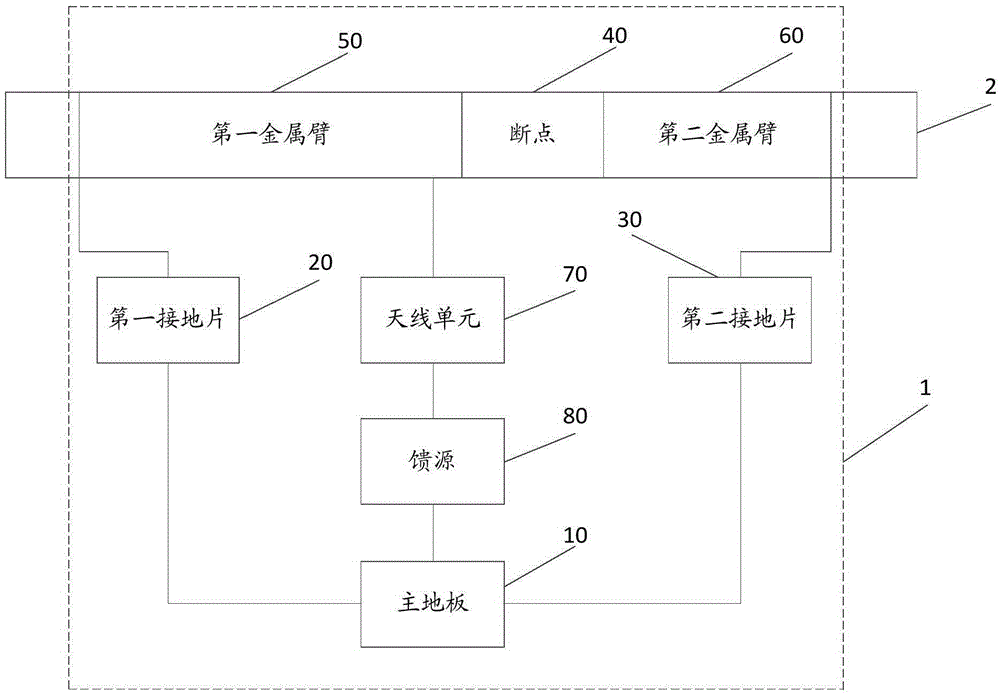

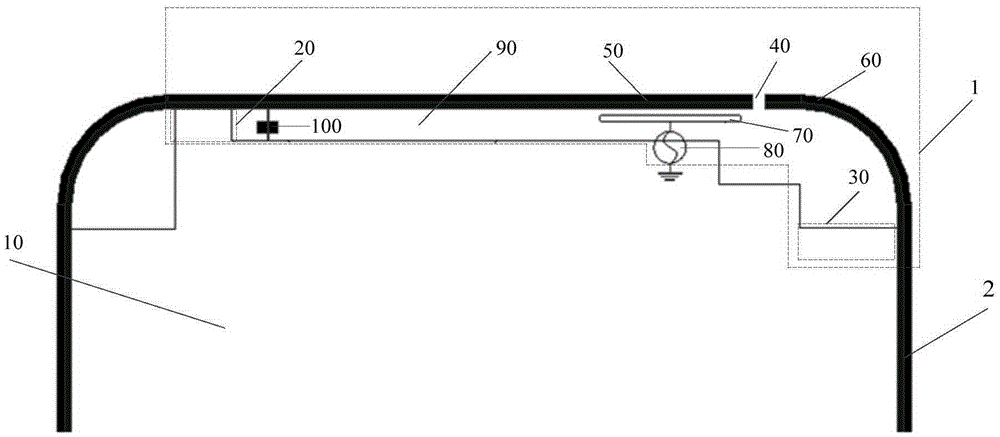

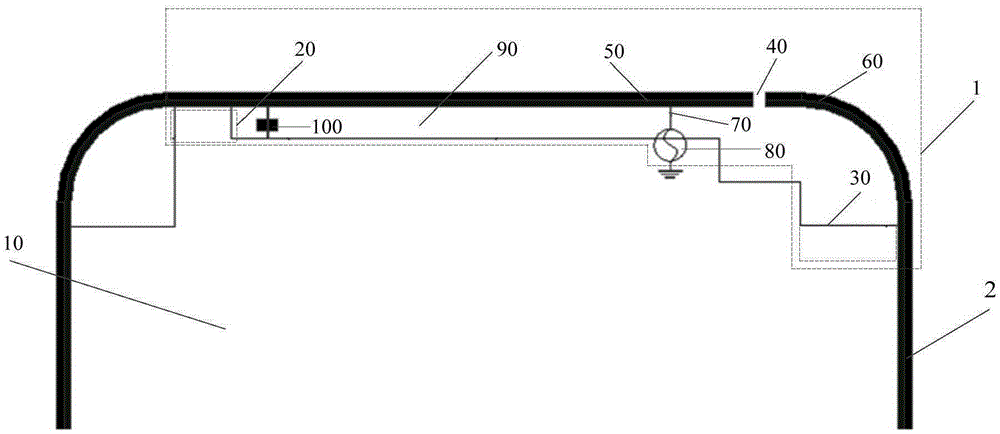

InactiveCN105244599ASave spaceAntenna supports/mountingsAntenna earthingsEngineeringComputer terminal

The invention provides an antenna of a mobile terminal and the mobile terminal. The antenna comprises a main floor, a first ground lug, a second ground lug, a breakpoint, a first metal arm, a second metal arm, an antenna unit and a feed source, wherein the first ground lug is respectively connected with a first position in a metal middle frame of the mobile terminal and the main floor; the second ground lug is respectively connected with a second position in the metal middle frame and the main floor; the breakpoint is arranged on the metal middle frame; the first metal arm is formed by the metal middle frame between the first position and the breakpoint; the second metal arm is formed by the metal middle frame between the second position and the breakpoint; the antenna unit is arranged between one end of the first metal arm close to the breakpoint and the main floor; and the feed source is connected with the antenna unit and the main floor respectively and arranged between the antenna unit and the main floor. A full-band main antenna can be arranged in a very small clearance at the upper part of the mobile terminal, so that the space is saved for overall layout; the antenna has good performance; and the overall antenna has only one breakpoint, so the antenna is more attractive.

Owner:VIVO MOBILE COMM CO LTD

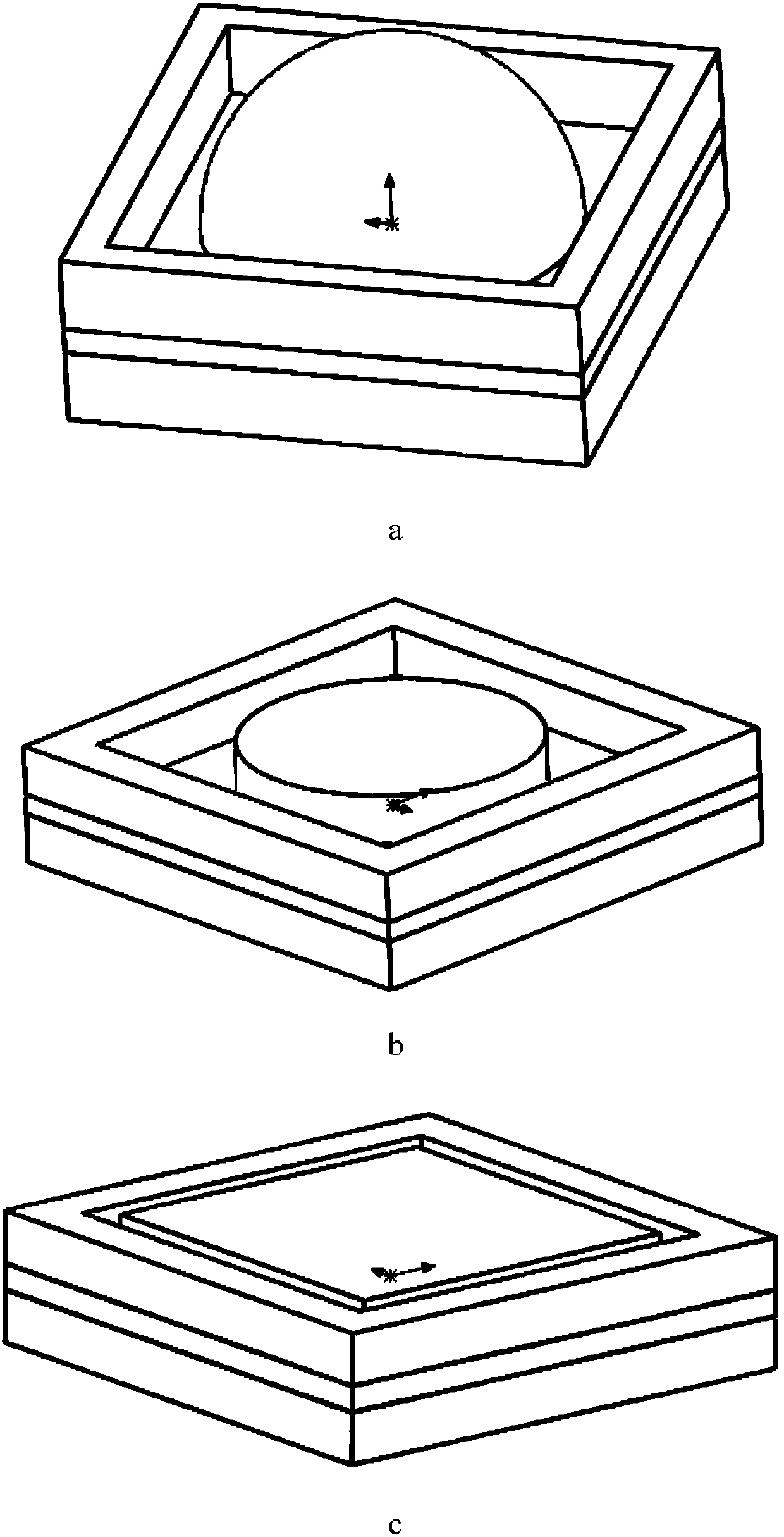

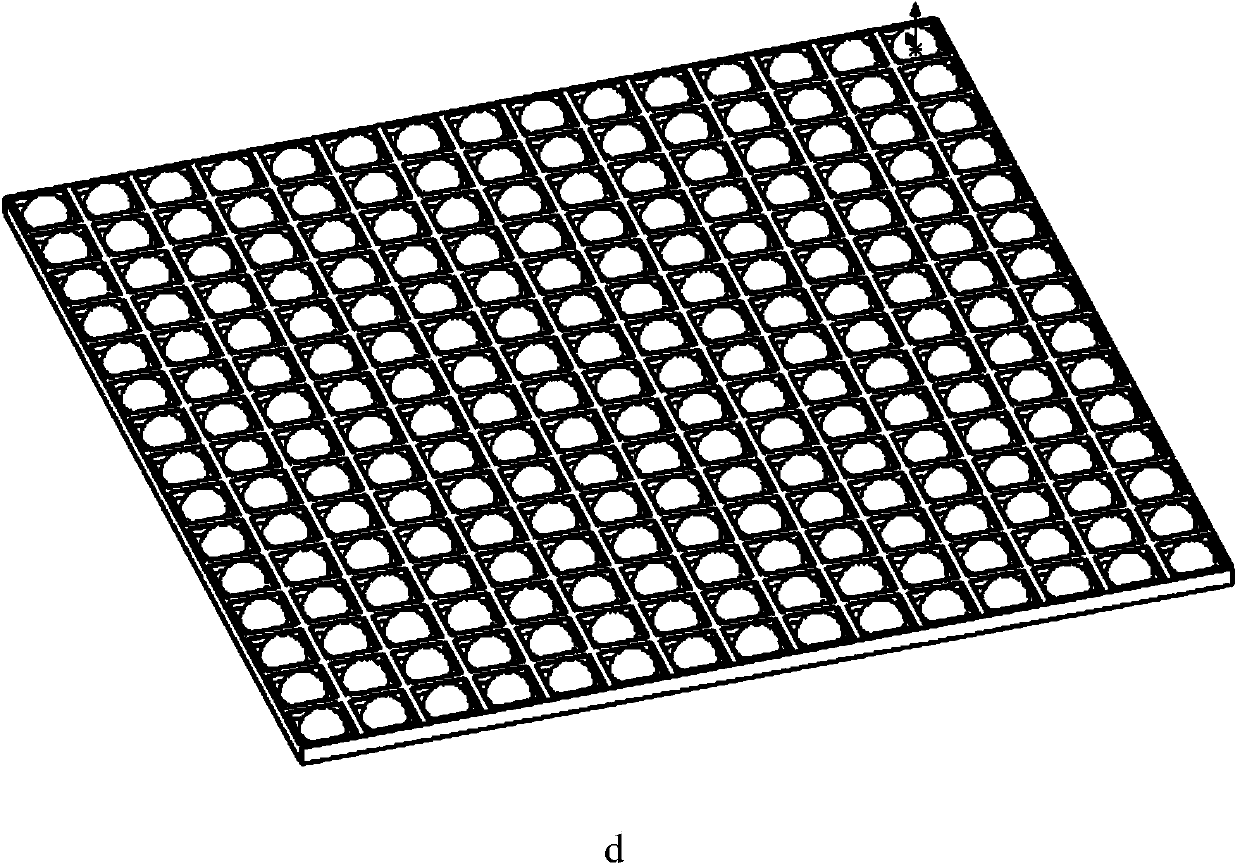

Light two-component soft thin layer local resonance acoustic material structure

InactiveCN103996396AMeet the requirements of low frequency sound insulationMeet lightweight requirementsSound producing devicesEffective solutionResonance

The invention discloses a light two-component soft thin layer local resonance acoustic material structure. The same kind of light flexible materials provide weight and elasticity, and another kind of light flexible materials provide a two-component soft thin type local resonance unit with local rigidness. The local resonance unit can control transmission of mechanical waves 2-3 magnitude orders larger than structure size, and a wide band gap is achieved. According to the structure, a full band gap can be opened under the low-frequency stage below 500 Hz, a vertical band gap can be formed at the super-low-frequency stage below 100 Hz, and the requirements for low-frequency damping and noise reducing of thin-wall pieces such as a carrying tool can be well met. The designed structure has the advantages of being low in thickness, light in weight, soft, wide in vertical band gap and convenient to machine, material cost is low, the structure can be directly arranged on carrying tools such as a bus and a train conveniently, and an effective solution is provided for low-frequency damping and noise reducing of a practical carrying tool.

Owner:XI AN JIAOTONG UNIV

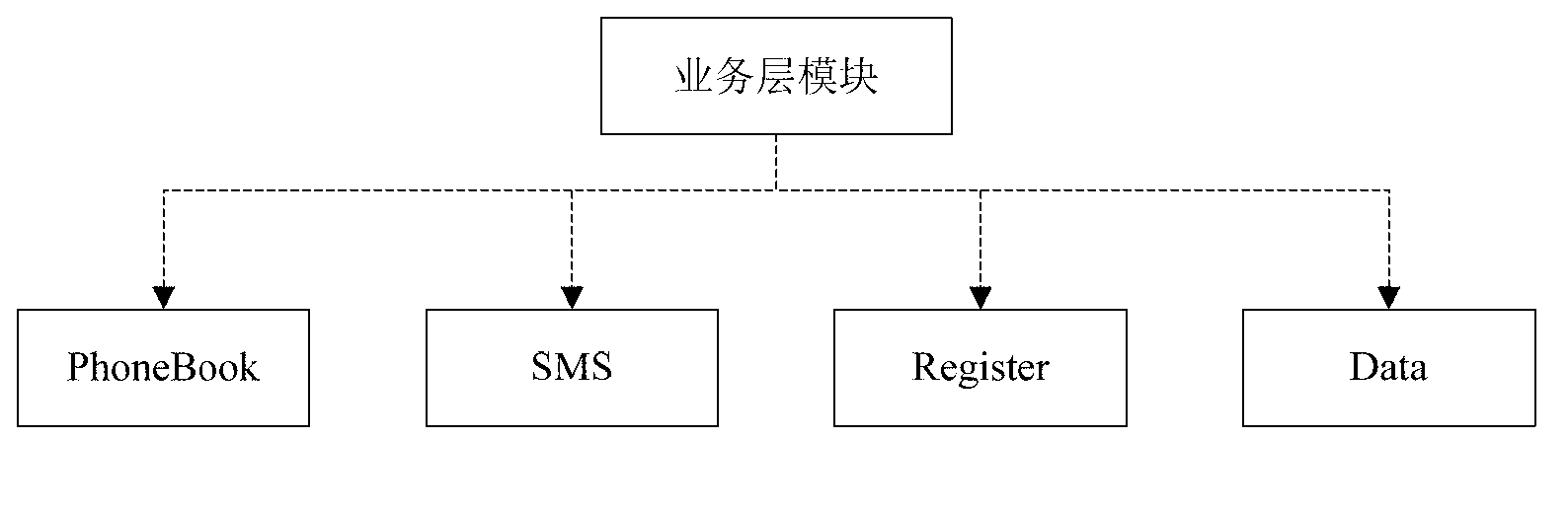

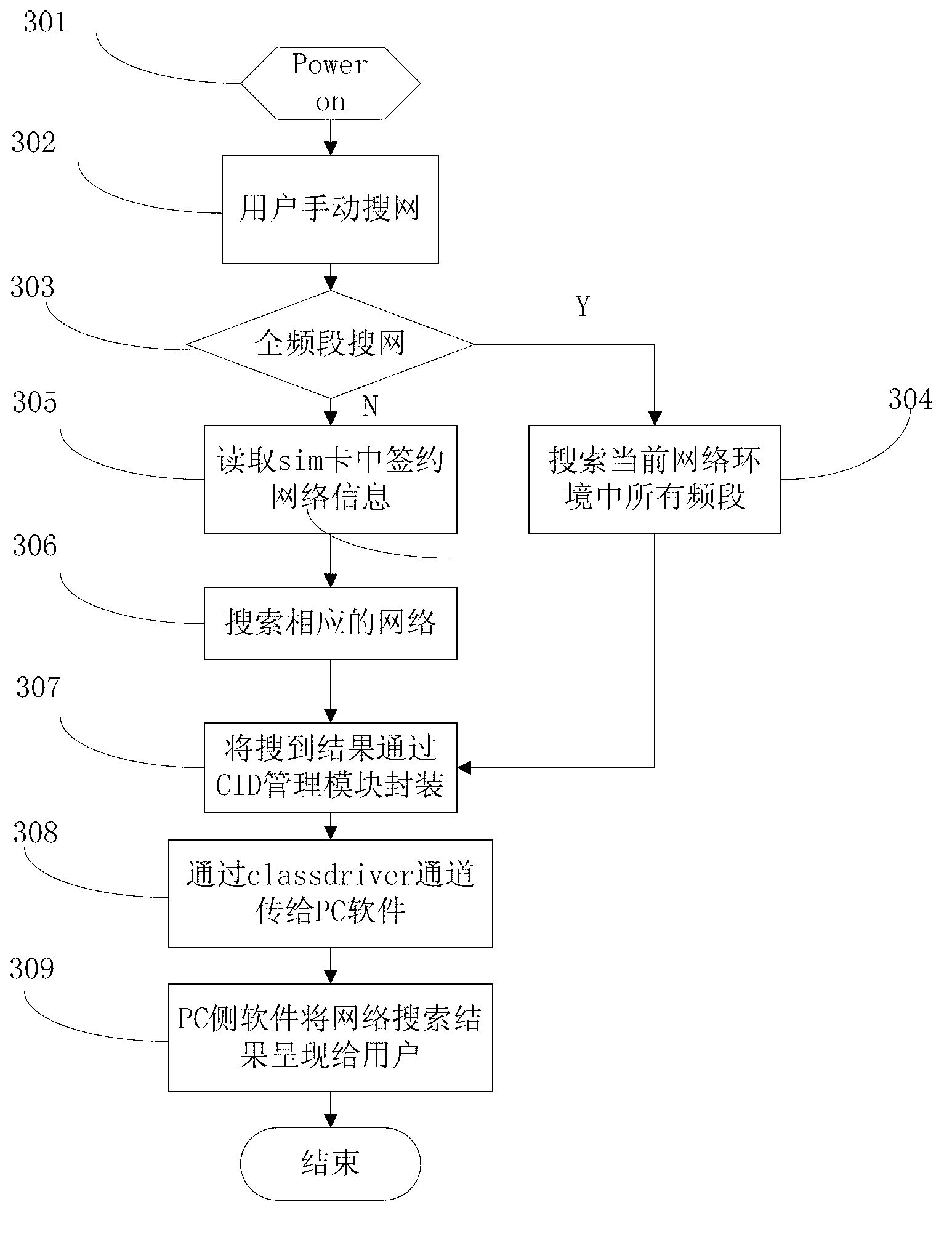

Quick network finding method, system and mobile terminal

ActiveCN103068009AImprove experienceSpeed up network searchAssess restrictionThe InternetComputer module

The invention discloses a quick network finding method, system and mobile terminal, relating to the field of mobile communication. The method comprises the following steps: a personal computer (PC) with a Windows 8 system generates a network searching instruction for searching for a network in full band or limited band according to a user request, and sending the network searching instruction to a mobile terminal for surfing the Internet; the mobile terminal performs network searching in full band or limited band according to the network searching instruction; in the case of full-band network searching, the mobile terminal performs network searching in all supported bands and sends the network searching results to the PC; and in the case of limited-band network searching, the mobile terminal reads the signed network information in an SIM (subscriber identity module) card and signed with an operator of the SIM card, searches for the corresponding network according to the signed network information and sends the network searching results to the PC. According to the invention, the mobile terminal can quickly find a network and has a strong real-time property.

Owner:ZTE CORP

Systems and methods for far-end noise reduction and near-end noise compensation in a mixed time-frequency domain compander to improve signal quality in communications systems

InactiveUS7242763B2Two-way loud-speaking telephone systemsSubstation equipmentTime domainCommunications system

Methods and systems for a mixed time-frequency domain compander, where the expander and compressor are applied in the frequency domain (subbands), while the limiter and the linear gain are applied in the time-domain (full band). Far-end noise reduction is achieved by adapting the expander gain to the far-end noise, near-end noise compensation is achieved by adapting the linear gain and the compressor gain to the near-end noise. The range of the linear gain section is set individually for each subband, but the linear gain is essentially applied to the full band signal via a scaling procedure. The scaling procedure first reduces the compander gain in the frequency domain by a scaling factor and then performs the reciprocal reverse scaling in the time domain. Far-end noise reduction is coupled to near-end noise compensation in order to avoid cross-modulation of the far-end noise by the near-end noise.

Owner:LUCENT TECH INC

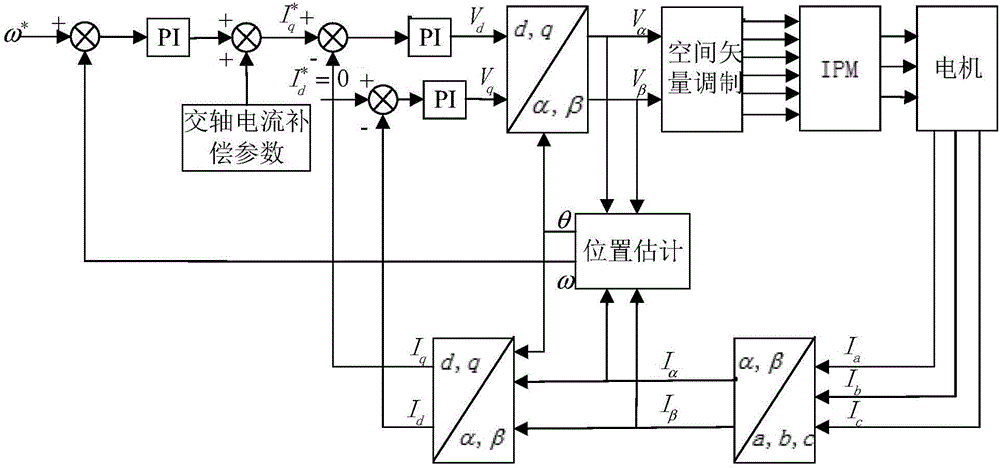

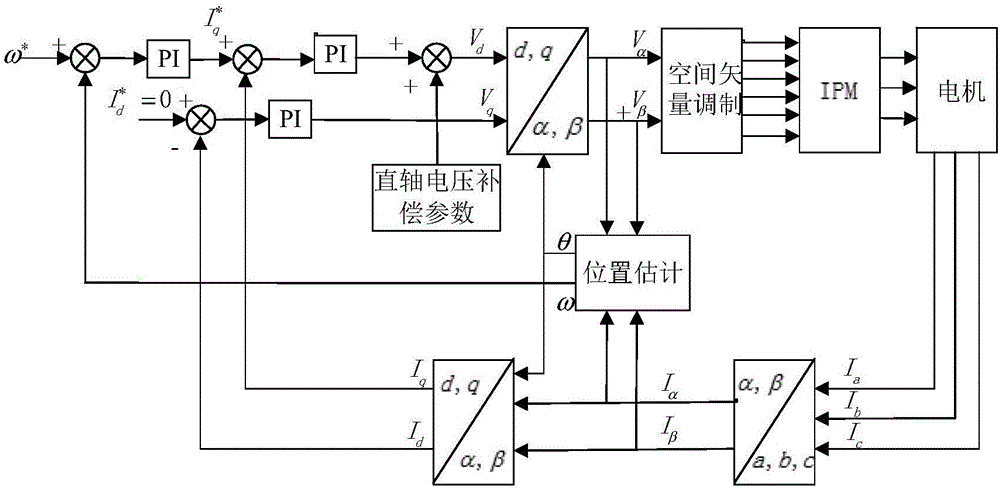

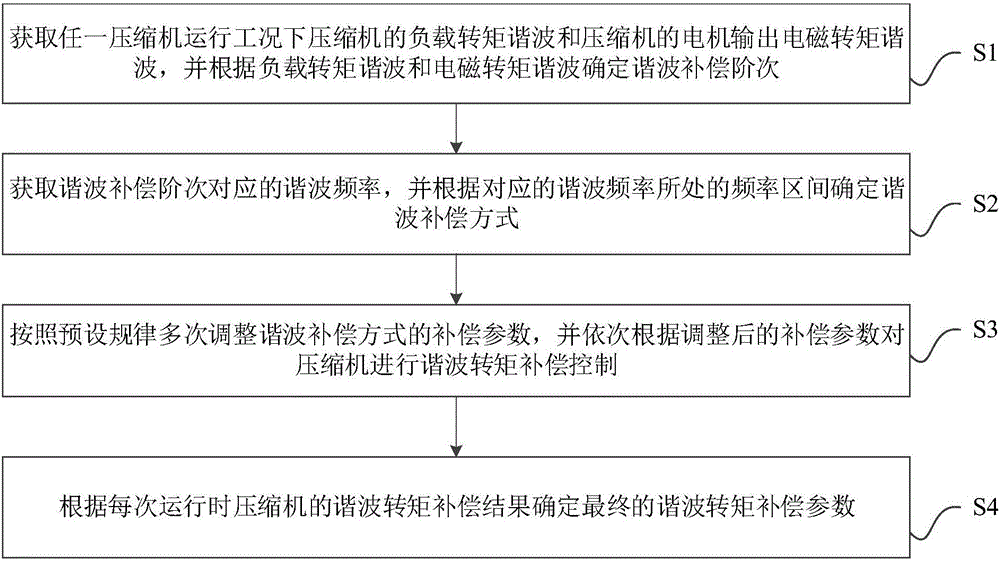

Air conditioner and harmonic torque compensation method and control method and device of compressor

ActiveCN106655940AReduce vibrationImprove stabilityElectronic commutation motor controlAC motor controlHarmonicLoad torque

The invention discloses an air conditioner and a harmonic torque compensation method and control method and device of a compressor. The harmonic torque compensation method comprises the following steps of obtaining a load torque harmonic of the compressor and a motor output electromagnetic torque harmonic of the compressor under any operating condition of the compressor, and determining a harmonic compensation order according to the load torque harmonic and the electromagnetic torque harmonic; obtaining a harmonic frequency corresponding to the harmonic compensation order and determining a harmonic compensation mode according to a frequency interval in which the corresponding harmonic frequency is located; adjusting compensation parameters of the harmonic compensation mode for multiple times according to a default rule and carrying out harmonic torque compensation control on the compressor according to the adjusted compensation parameters in sequence; and determining the final harmonic torque compensation parameters according to the harmonic torque compensation result of the compressor during each operation. Therefore, full-band harmonic torque control of low-order harmonics and high-order harmonics cannot be achieved, and the motor output torque of the compressor better tracks the load torque of the compressor.

Owner:GUANGDONG MEIZHI COMPRESSOR

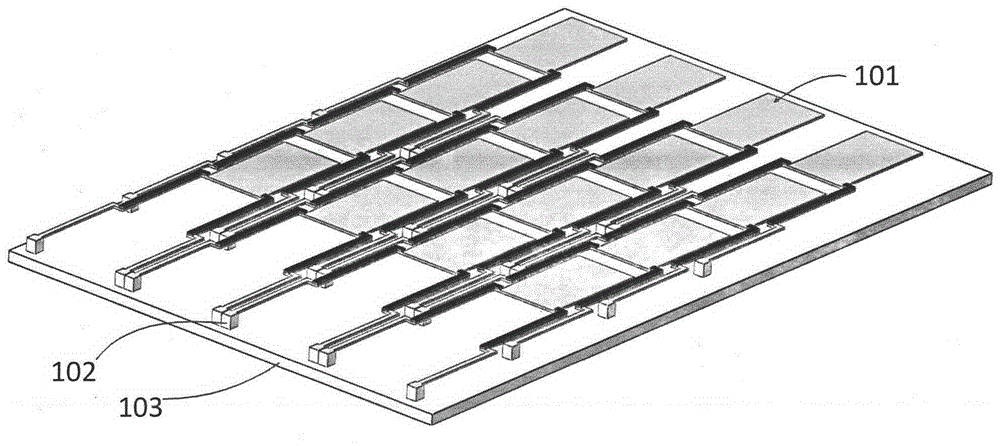

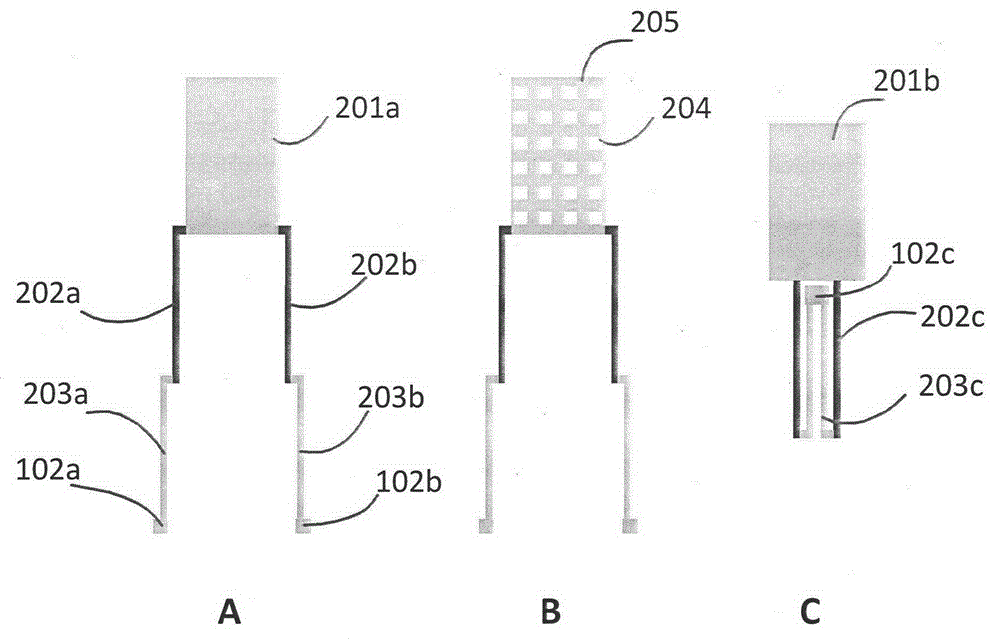

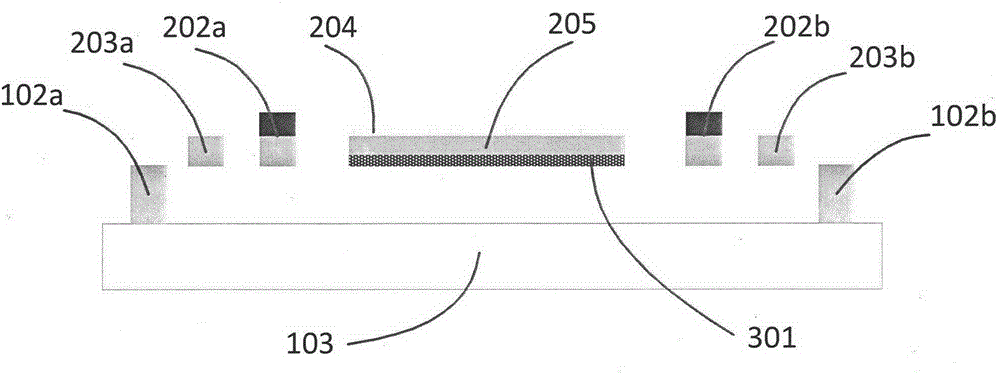

Optical readout focal plane array and preparation method thereof

InactiveCN104792420AHigh sensitivityImprove absorption efficiencyTelevision system detailsLayered productsThermal isolationEnergy absorption

An uncooled focal plane array (FPA) for imaging at full-band infrared and terahertz regime is provided. The FPA utilizes bimaterial cantilever array as the pixels (101) and are fabricated on a visible light transparent substrate (103). The bimaterail cantilever (101) comprises an absorber (102), two bimaterial legs (202), two thermal isolation legs (203), two anchors (102), and a mirror. The radiation to be detected casts on the front side of bimaterial cantilevers (101), while the transparent substrate (103) is illuminated by visible light to readout the deformation of the bimaterial cantilevers (101) caused by the energy absorption by the absorber (102). The FPA is fabricated by surface sacrificial layer processes, especially by using metamaterial to enhance the function of the absorber and polyimide as the sacrificial layer. The advantages of the uncooled focal plane array include multiband work,high sensitivity and resolution, good reliability and uniformity, low cost and easy fabrication.

Owner:PEKING UNIV

Packet Loss Concealment for Sub-band Predictive Coding Based on Extrapolation of Sub-band Audio Waveforms

A technique is described for concealing the effect of a lost frame in a series of frames representing an encoded audio signal in a sub-band predictive coding system. In accordance with the technique, a first synthesized sub-band audio signal is synthesized, wherein synthesizing the first synthesized sub-band audio signal comprises performing waveform extrapolation based on a stored first sub-band decoded audio signal. A second synthesized sub-band audio signal is also synthesized, wherein synthesizing the second synthesized sub-band audio signal comprises performing waveform extrapolation based on the stored second sub-band decoded audio signal. The first synthesized sub-band audio signal and the second synthesized sub-band audio signal are combined to generate a synthesized full-band output audio signal corresponding to a lost frame.

Owner:AVAGO TECH INT SALES PTE LTD

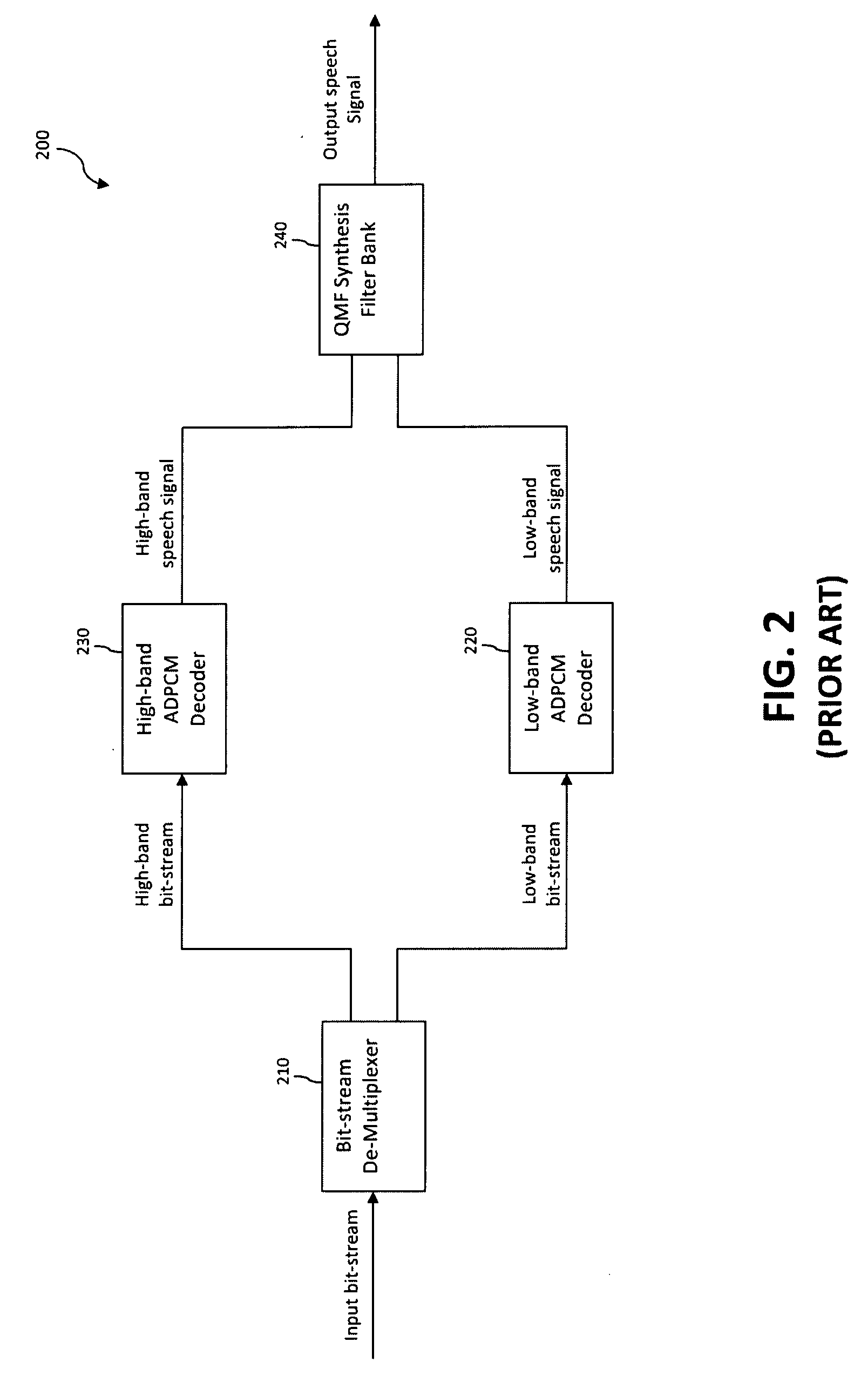

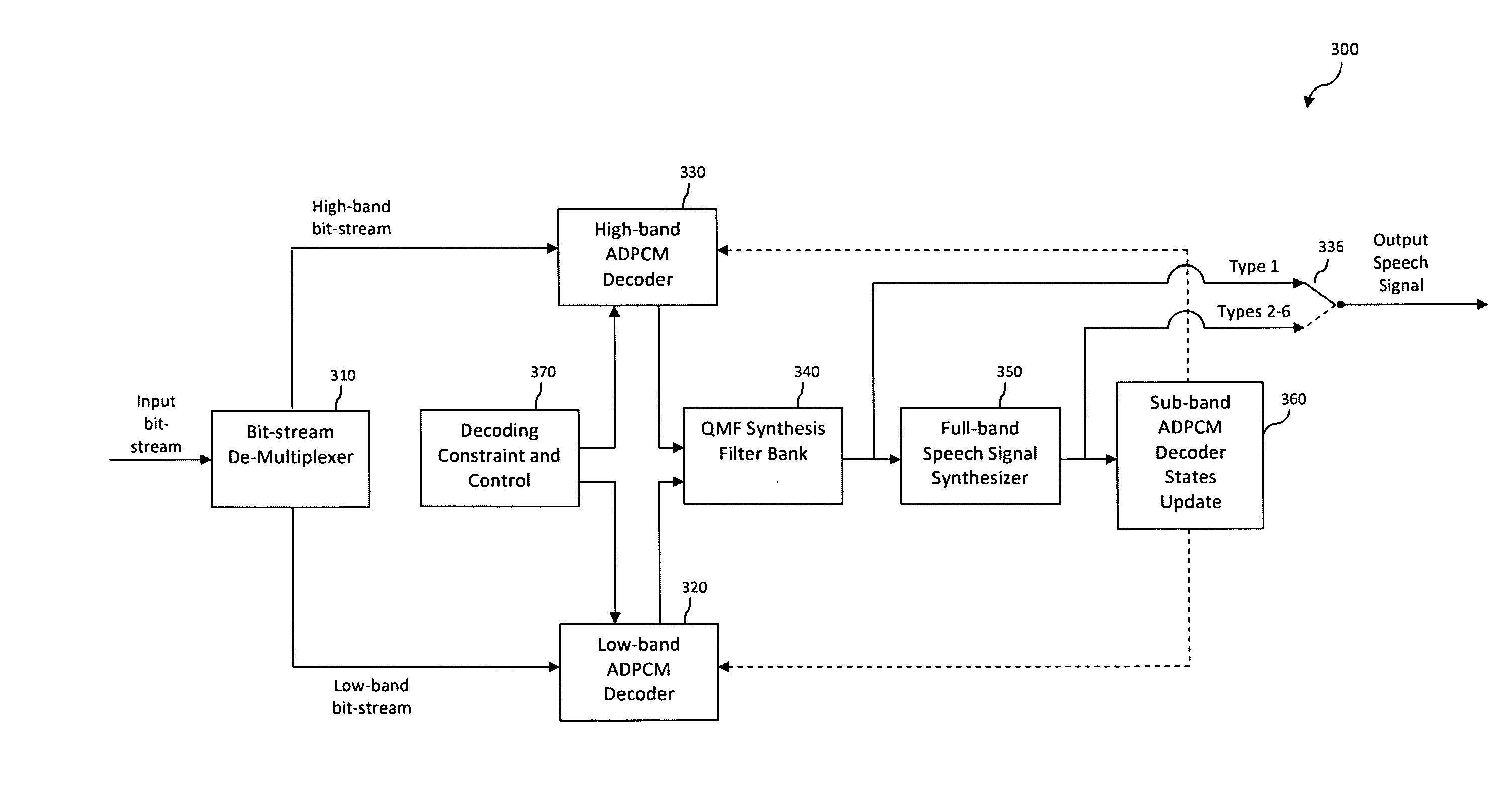

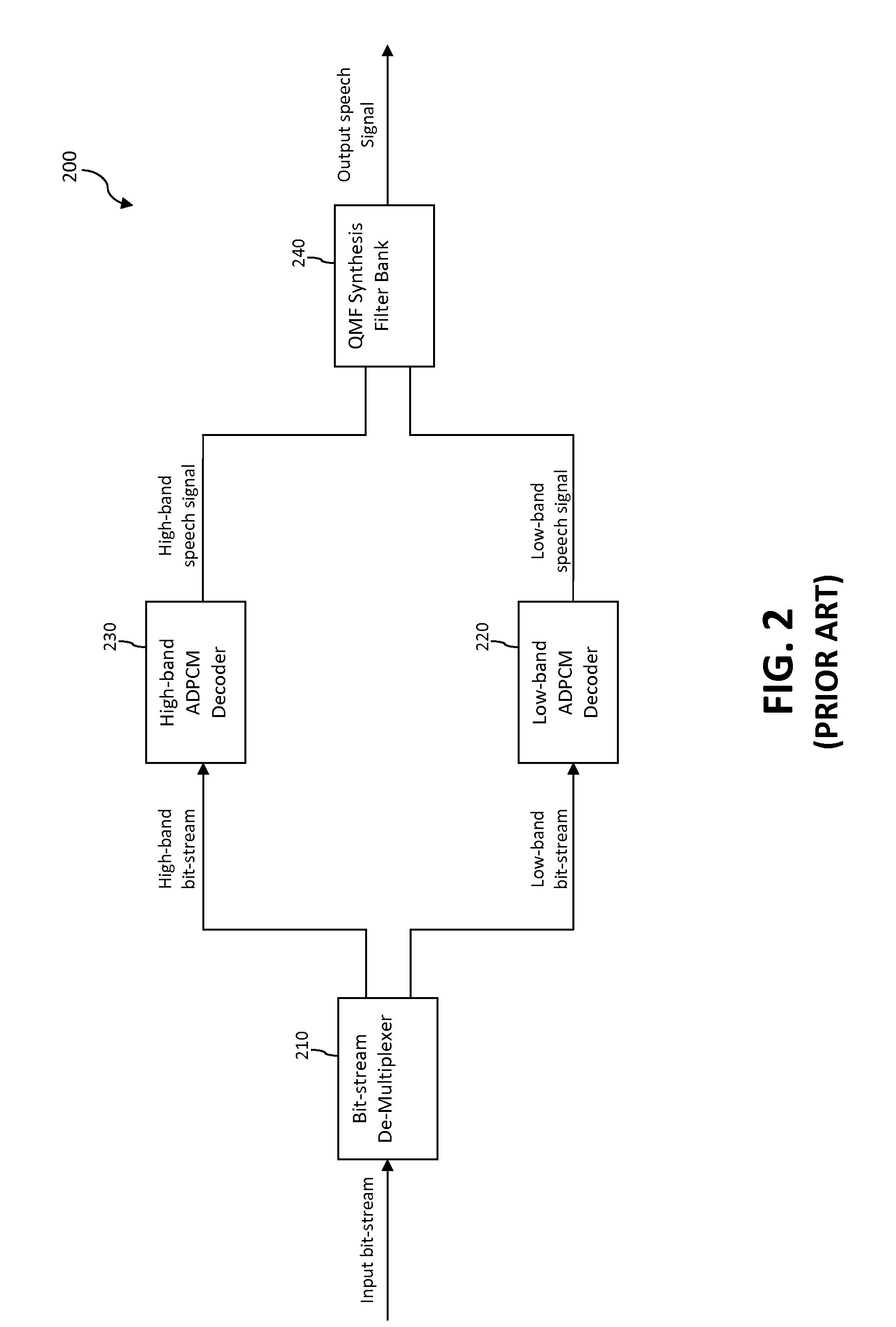

Packet loss concealment for sub-band predictive coding based on extrapolation of sub-band audio waveforms

ActiveUS20090240492A1Analogue conversionSpeech analysisPacket loss concealmentLinear predictive coding

A technique is described for concealing the effect of a lost frame in a series of frames representing an encoded audio signal in a sub-band predictive coding system. In accordance with the technique, a first synthesized sub-band audio signal is synthesized, wherein synthesizing the first synthesized sub-band audio signal comprises performing waveform extrapolation based on a stored first sub-band decoded audio signal. A second synthesized sub-band audio signal is also synthesized, wherein synthesizing the second synthesized sub-band audio signal comprises performing waveform extrapolation based on the stored second sub-band decoded audio signal. The first synthesized sub-band audio signal and the second synthesized sub-band audio signal are combined to generate a synthesized full-band output audio signal corresponding to a lost frame.

Owner:AVAGO TECH INT SALES PTE LTD

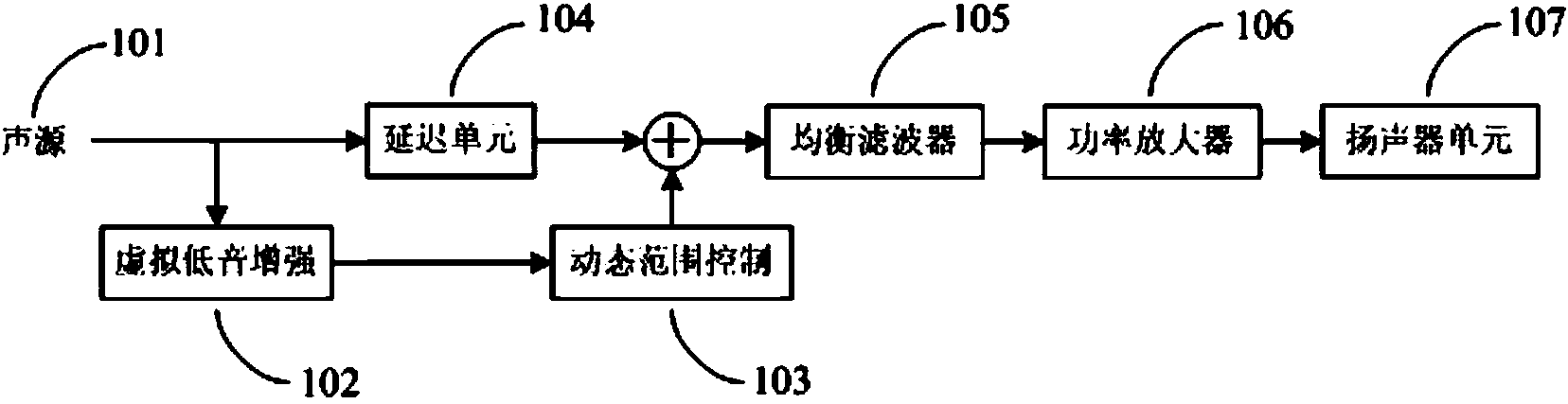

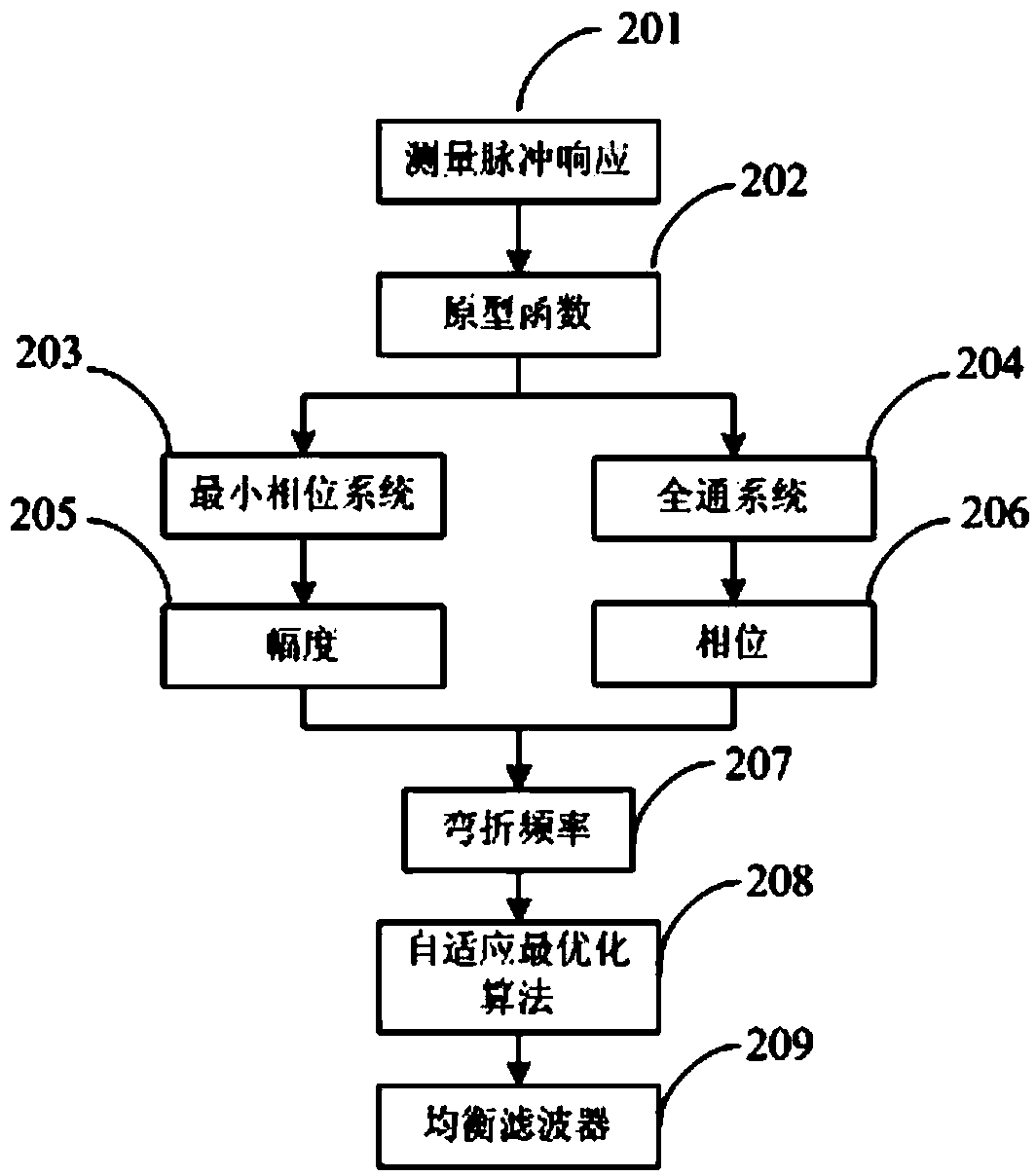

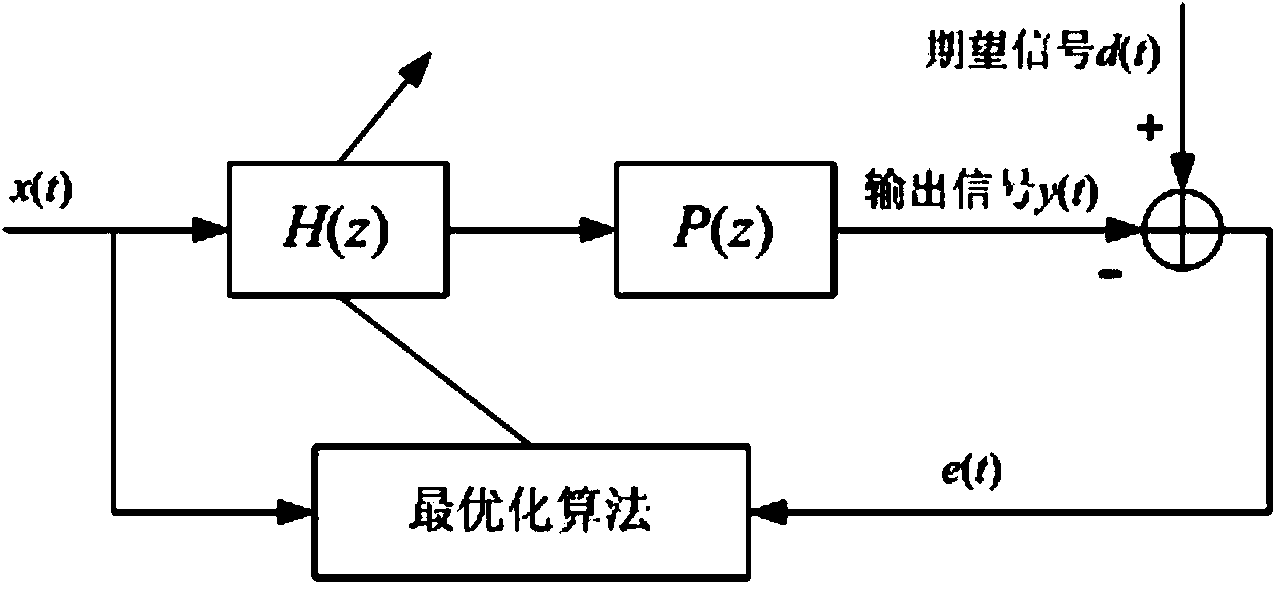

Automatic loudspeaker equalization method

ActiveCN103634726AImprove performanceImprove sound reproduction abilityStereophonic systemsTransducer circuitsHarmonicEqualization

The invention provides an automatic loudspeaker equalization system, particularly relates to an automatic loudspeaker equalization method, and aims to improve sound replaying performance of a loudspeaker system on full bands. The method includes measuring pulse responses at one or more position points in a room by a microphone to acquire a frequency response of each position point and low-frequency lower limit of the loudspeaker system, and acquiring an equilibrium filter by the adaptive optimization algorithm to compensate the loudspeaker system. For low-frequency signals with frequency lower than the lower-limit frequency of the loudspeaker system, ultraharmonics components of fundamental-frequency signals are generated according to the psychoacoustics based fundamental-frequency missing principle and are superposed with delayed original sound signals after being subjected to gain control, and accordingly, the sound replaying performance of the loudspeaker system on full bands is improved.

Owner:SUZHOU SONAVOX ELECTRONICS

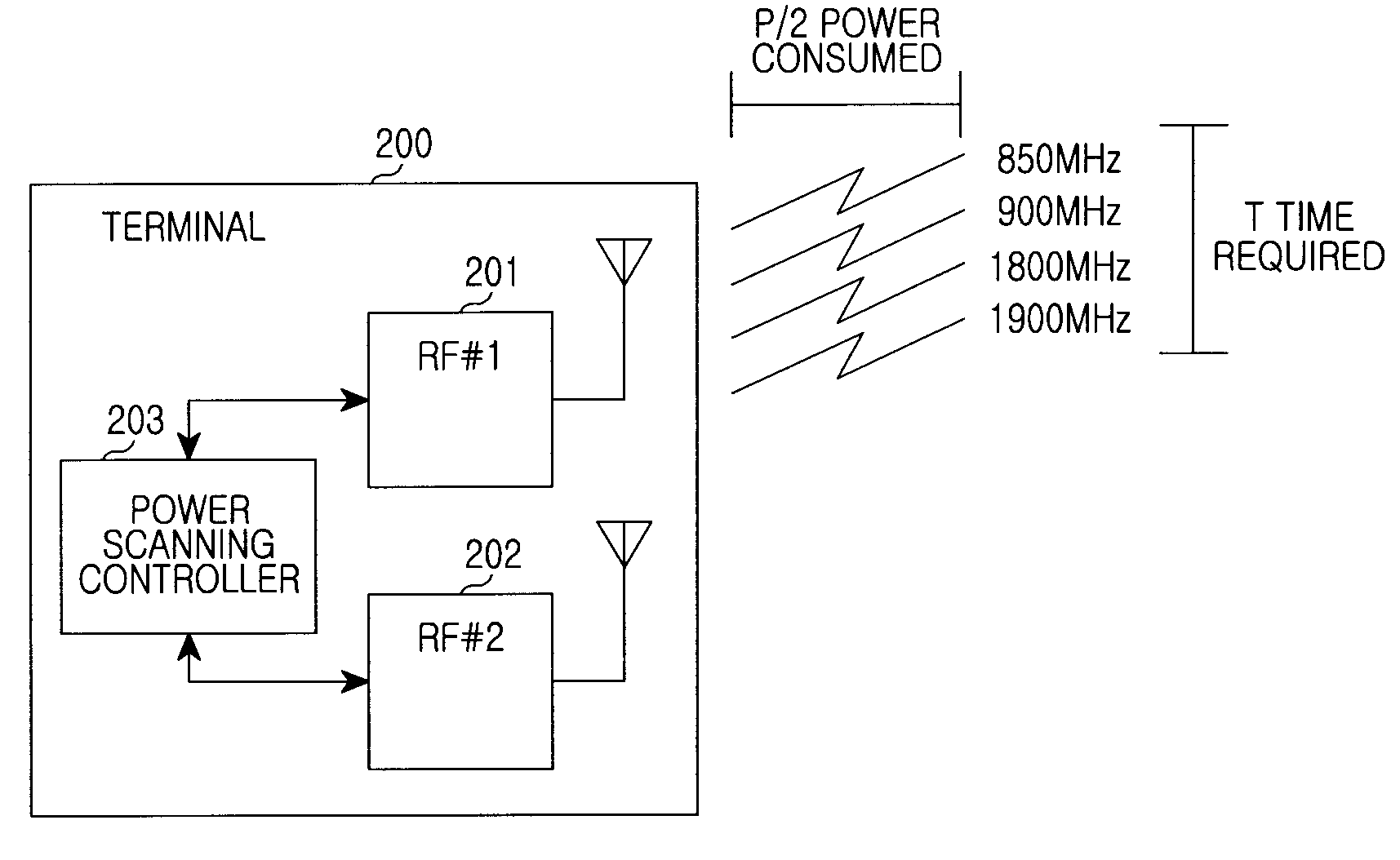

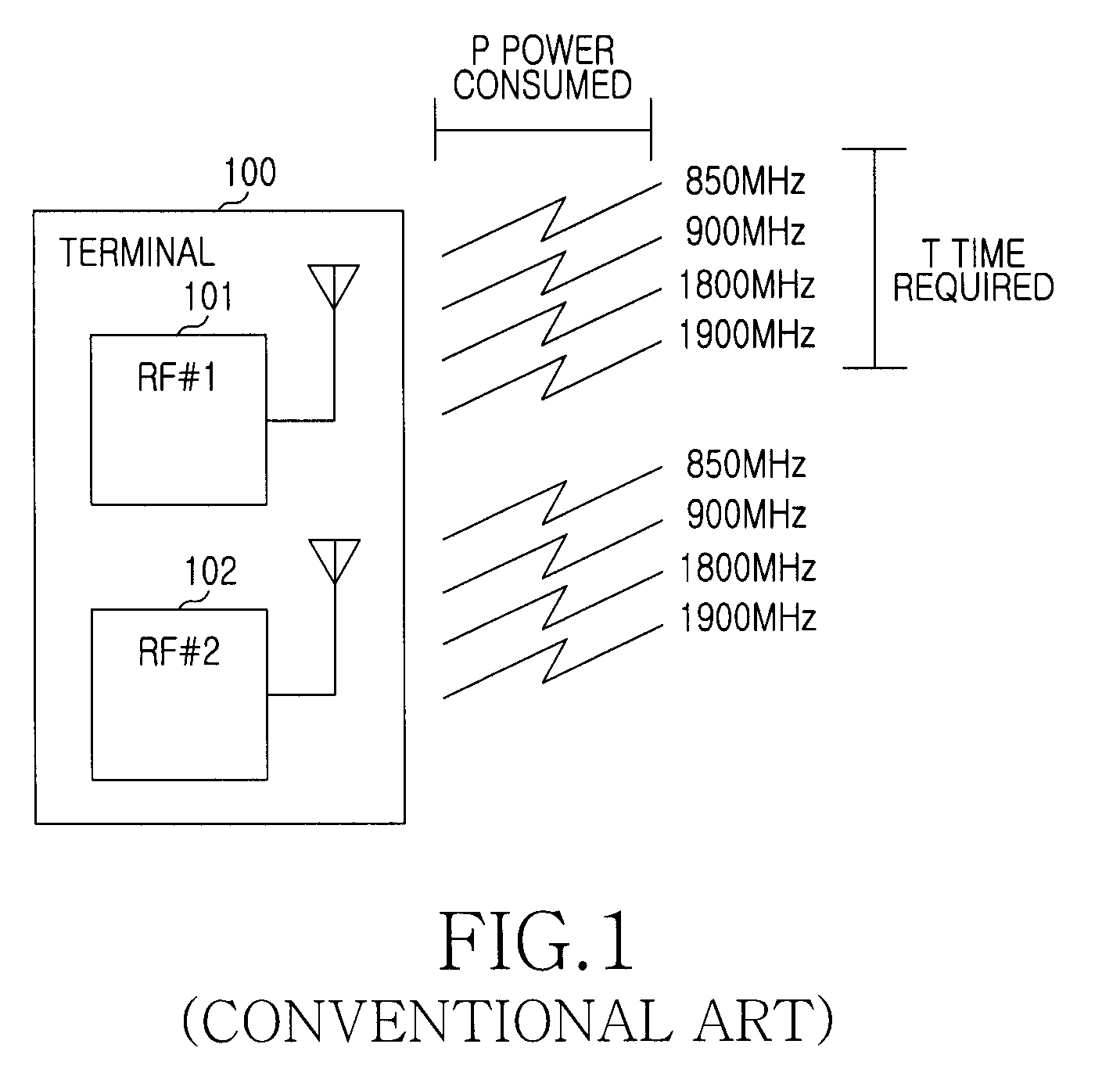

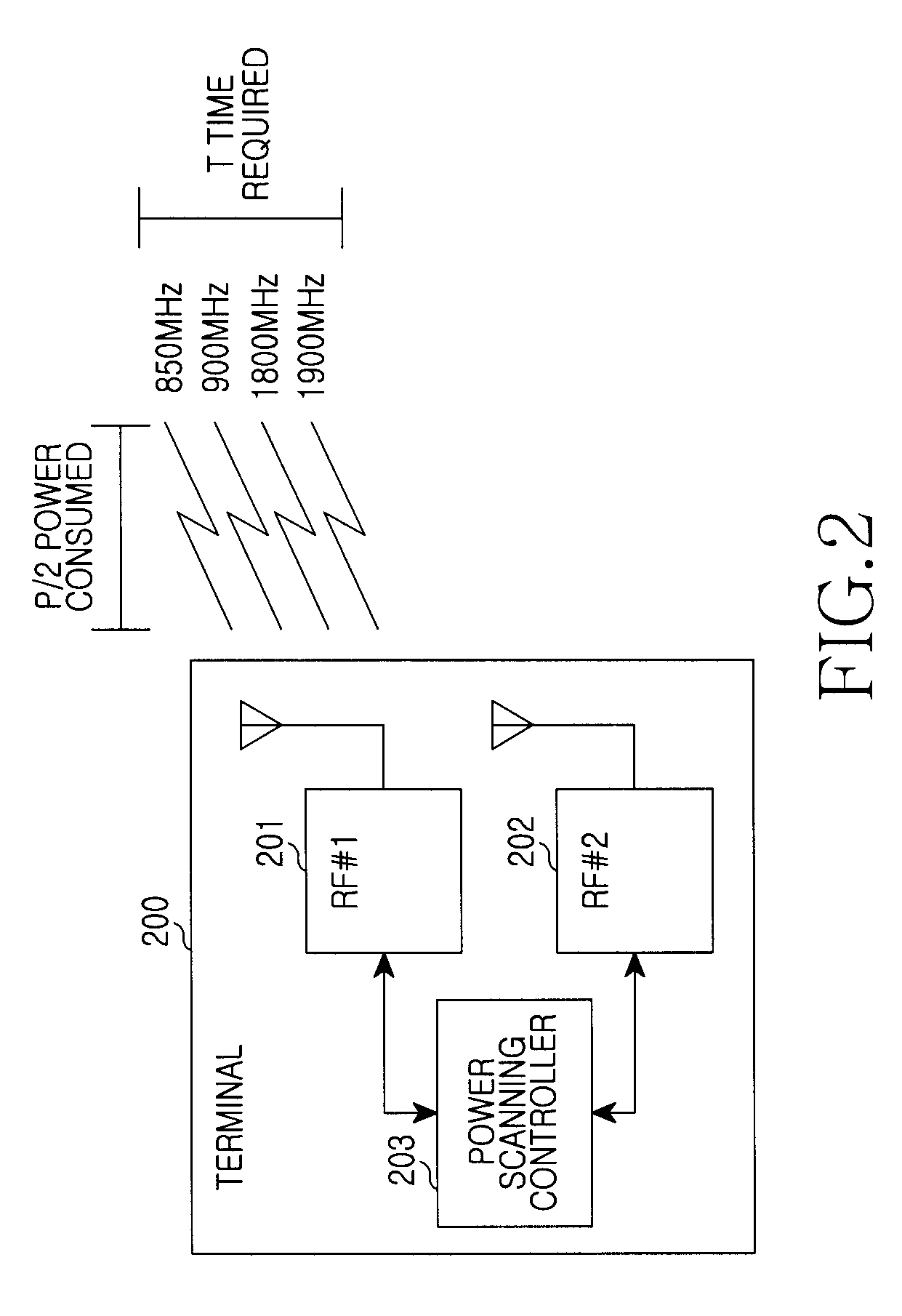

Apparatus and method for power scanning in mobile communication terminal with dual sim card

ActiveUS20100273524A1Improve power performanceImprove timing performanceAssess restrictionSubstation equipmentEngineeringRadio frequency

An apparatus and method for providing a power scanning in a terminal with two or more Radio Frequency (RF) chips are provided. The method includes selecting one RF chip from the two or more RF chips, performing the power scanning on a full band supported by the selected RF chip by using the selected RF chip, gathering a power scanning result obtained by performing the power scanning, and sharing the power scanning result gathered by using the selected RF chip with an unselected RF chip.

Owner:SAMSUNG ELECTRONICS CO LTD

Tunable antenna structure for completely closed metal-frame mobile phone

InactiveCN105375109AImprove quality requirementsSimple structureSimultaneous aerial operationsAntenna supports/mountingsResonanceClosed loop

The invention relates to a tunable antenna structure for a completely closed metal-frame mobile phone. An LTE main antenna feed point is arranged between a PCB and one side of a metal frame; an LTE diversity antenna feed point is arranged between the PCB and one side opposite to the LTE main antenna feed point; a GPS / WiFi feed point, a first frame ground point and a fourth frame ground point are arranged between the PCB and the other side; the first frame ground point and the fourth frame ground point are located at two sides of the GPS / WiFi feed point; a second frame ground point and a third frame ground point are arranged between the PCB and one side opposite to the GPS / WiFi feed point; a tunable device is arranged on the PCB and is connected with the second frame ground point; an LTE antenna is directly connected with a GPS / WiFi antenna through the feed point and the metal frame for feeding; and the metal frame is grounded through the ground points to form an antenna closed loop and to generate antenna resonance. The tunable device tunes low-frequency bandwidth and meets LTE full-band coverage.

Owner:SUZHOU NANOANT COMM TECH CO LTD

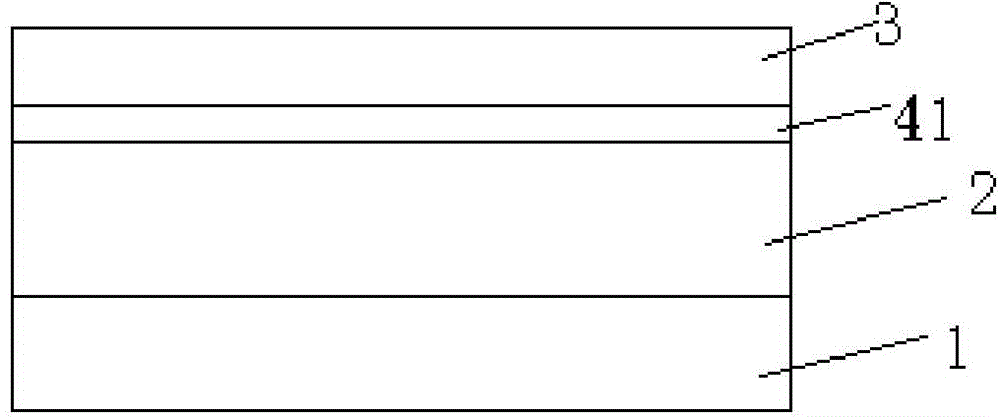

Planar optical waveguide and manufacturing method thereof

ActiveCN104635298AExcellent refractive index distributionAdvantages: The refractive index of the isolation layer is lower than that of the upper cladding or lower claddingOptical waveguide light guideIsolation layerFull band

The invention discloses a planar optical waveguide and a manufacturing method thereof. The planar optical waveguide comprises a lower cladding, a waveguide core layer, an isolation layer and an upper cladding; the refractive index of the upper cladding is equal to that of the lower cladding and is higher than that of the isolation layer; the isolation layer is formed on the lower cladding; the waveguide core layer is packaged completely in the isolation layer; the upper cladding is formed on the isolation layer. The refractive index distribution of the planar optical waveguide is optimized, the loss of a device is reduced, and the 1250-1650 full band width performance can be realized more easily.

Owner:广东瑞芯源技术有限公司

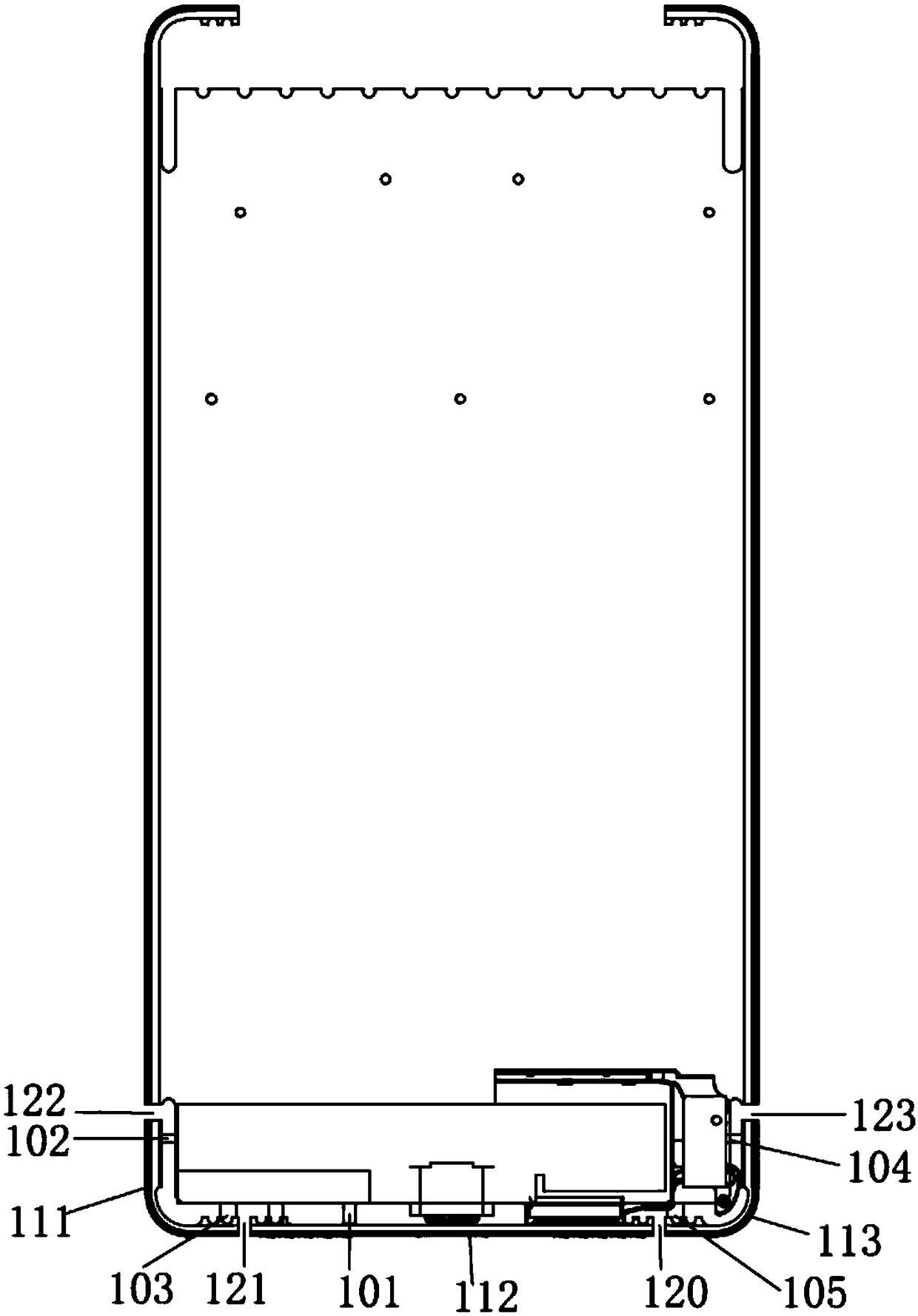

Antenna system and terminal

InactiveCN108199132AAffect the appearance sizeDoes not affect launchSimultaneous aerial operationsAntenna supports/mountingsCarrier signalFull band

The embodiment of the invention relates to the field of communication equipment and discloses an antenna system and a terminal. The antenna system comprises a first antenna, a second antenna, a firstfeeding point, a second feeding point and a first grounding point, wherein the first antenna and the second antenna are obtained through cutting a metal border of the terminal from a breaking joint, asecond breaking joint and a third breaking joint; the first antenna is located between the first breaking joint and the second breaking joint and connected with the first feeding point; the second antenna is located between the second breaking joint and the third breaking joint and connected with the second feeding point; the first grounding point is located at the edge position, close to the second breaking joint, of the first antenna; the first breaking joint and the second breaking joint are located on a short-edge side surface of the metal border of the terminal; the third breaking jointis located on a first long-edge side surface of the metal border of the terminal; and the first feeding point and the second feeding point are arranged on a printed circuit board. According to the antenna system, the terminal can work on a full band, the condition that a high frequency and a low frequency can simultaneously exist in different states is met and the requirements of carrier aggregation are met.

Owner:AAC PRECISE MFG TECH CHANGZHOU

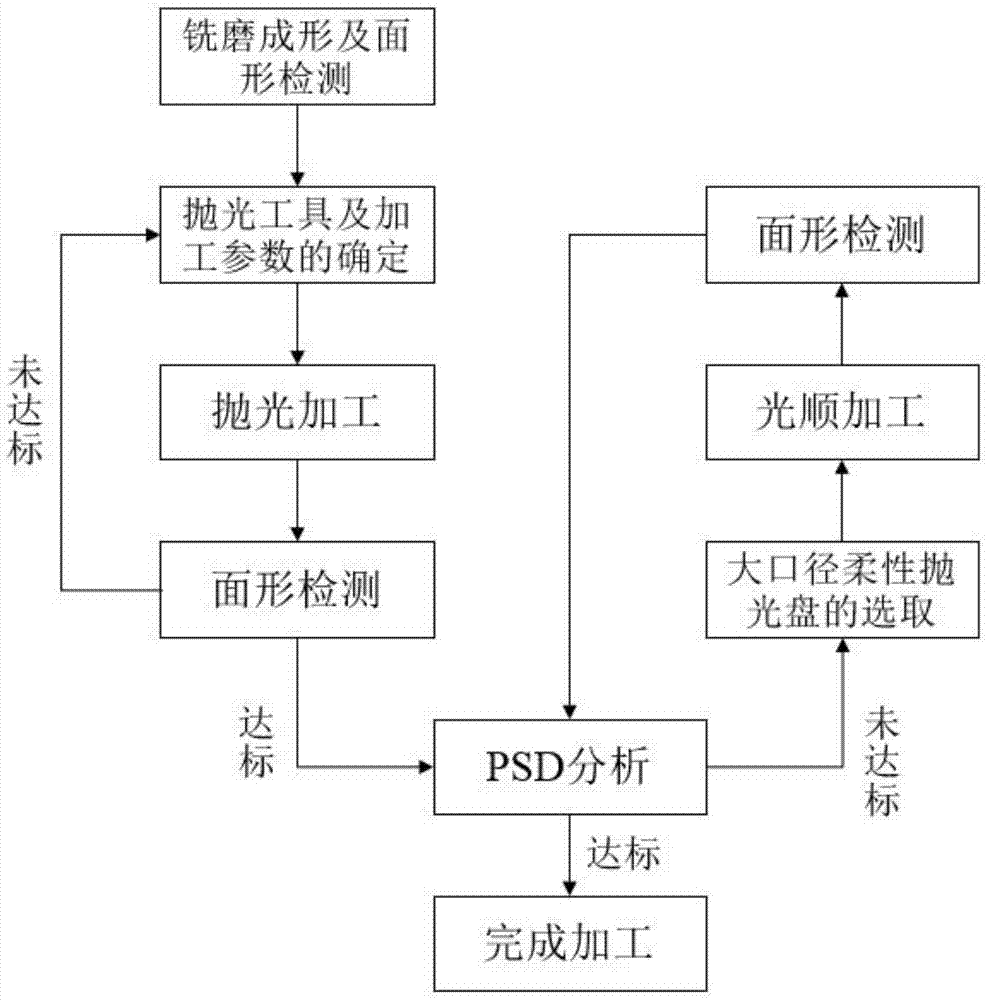

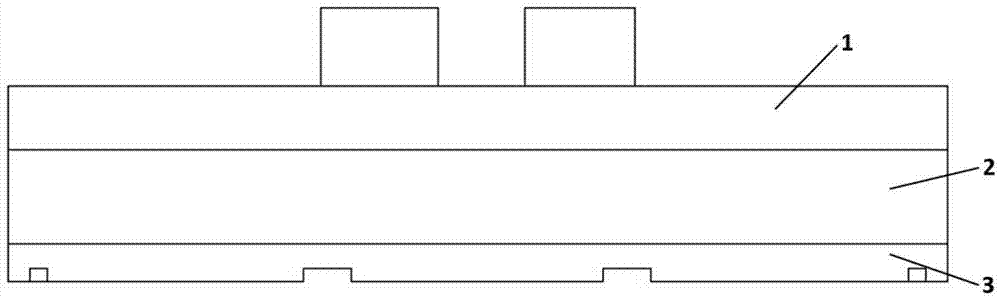

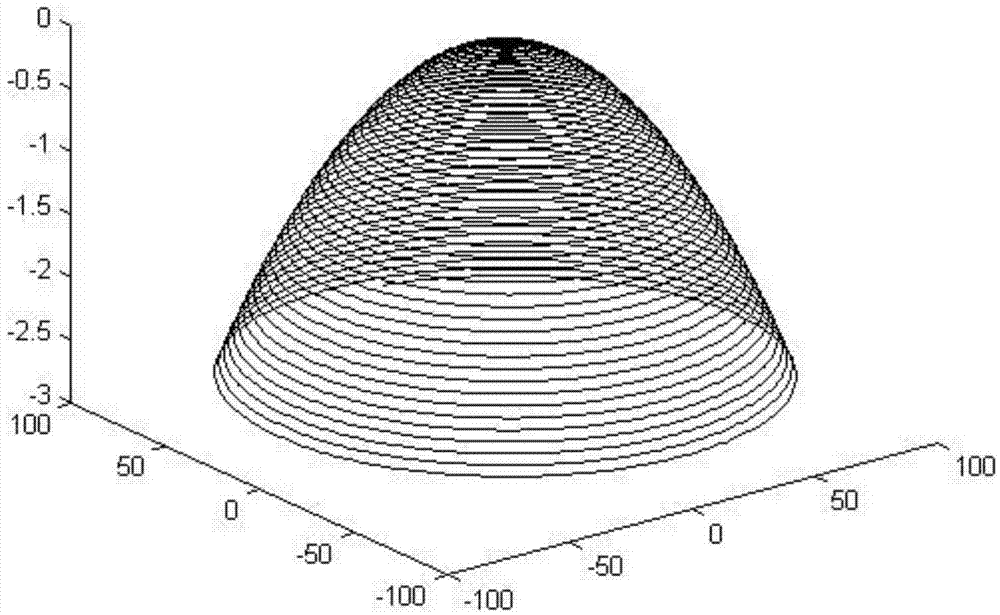

Full-band high-precise machining method for aspheric surface optical element

ActiveCN104772661ALow costSuppression of medium and high frequency errorsOptical surface grinding machinesGrinding feed controlNumerical controlEngineering

The invention discloses a full-band high-precise aspheric surface machining method. The method mainly comprises the following steps: 1) detecting the surface shape of a to-be-machined aspheric surface which is formed by milling and grinding by using an interferometer; 2) according to the error data of the surface shape to be machined, selecting a suitable flexible polishing small tool, and determining machining parameters of a numerical control machine tool by combining a removal function of the small tool; 3) placing an aspheric surface element to be machined on a machining platform of the machine tool, inputting machining parameters, and executing a polishing process by adopting a variable step pitch spiral machining path; 4) after one-period polishing is completed, detecting the surface shape of the aspheric surface element, and repeating the steps 2, 3 and 4 until the precision of the low-frequency surface shape of the aspheric surface reaches a standard according to the feedback situation of the error data of the surface shape; 5) performing PSD (Power Spectral Density) analysis on the surface shape data of the low-frequency surface shape which reaches the standard, selecting a flexible polishing small tool with a large diameter according to medium-high frequency error frequency distribution characteristics determined by a PSD curve, performing fairing process machining on the aspheric surface optical element, and repeating several times until the medium-high frequency error is controlled effectively. According to the full-band high-precise machining method for the aspheric surface optical element, the full-band high-precise machining of the aspheric surface optical element is completed by only using a CCOS (Computer Controlled Optical Surfacing) numerical control small grinding head machine tool.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

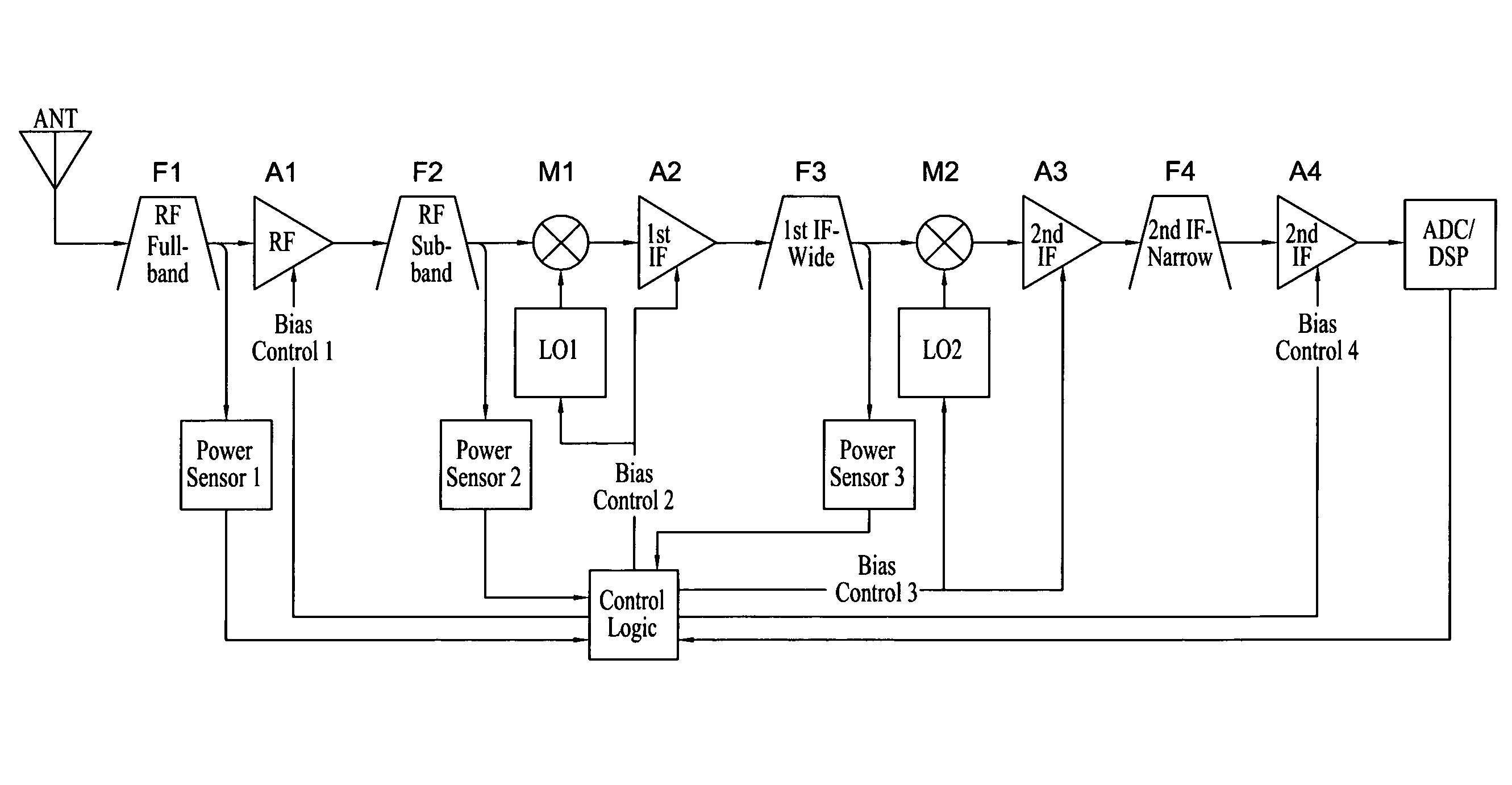

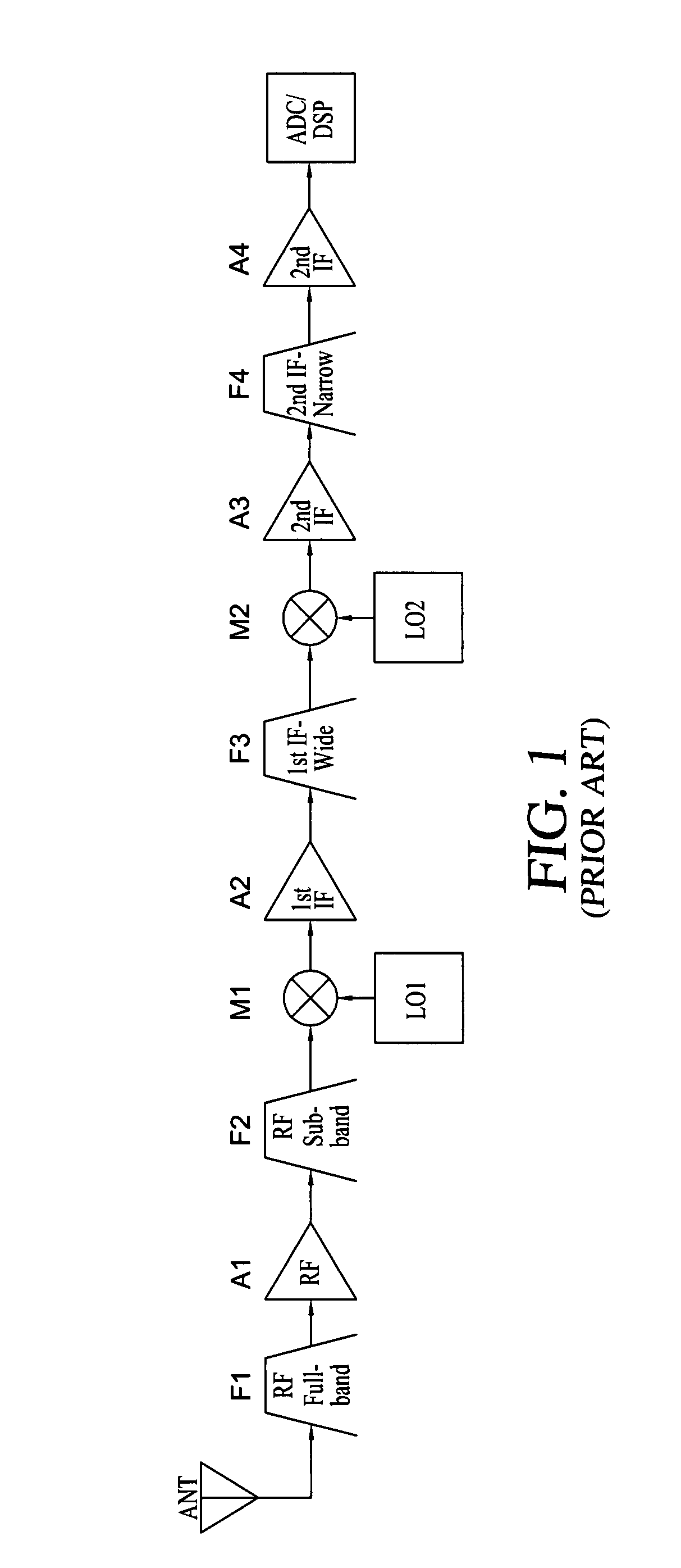

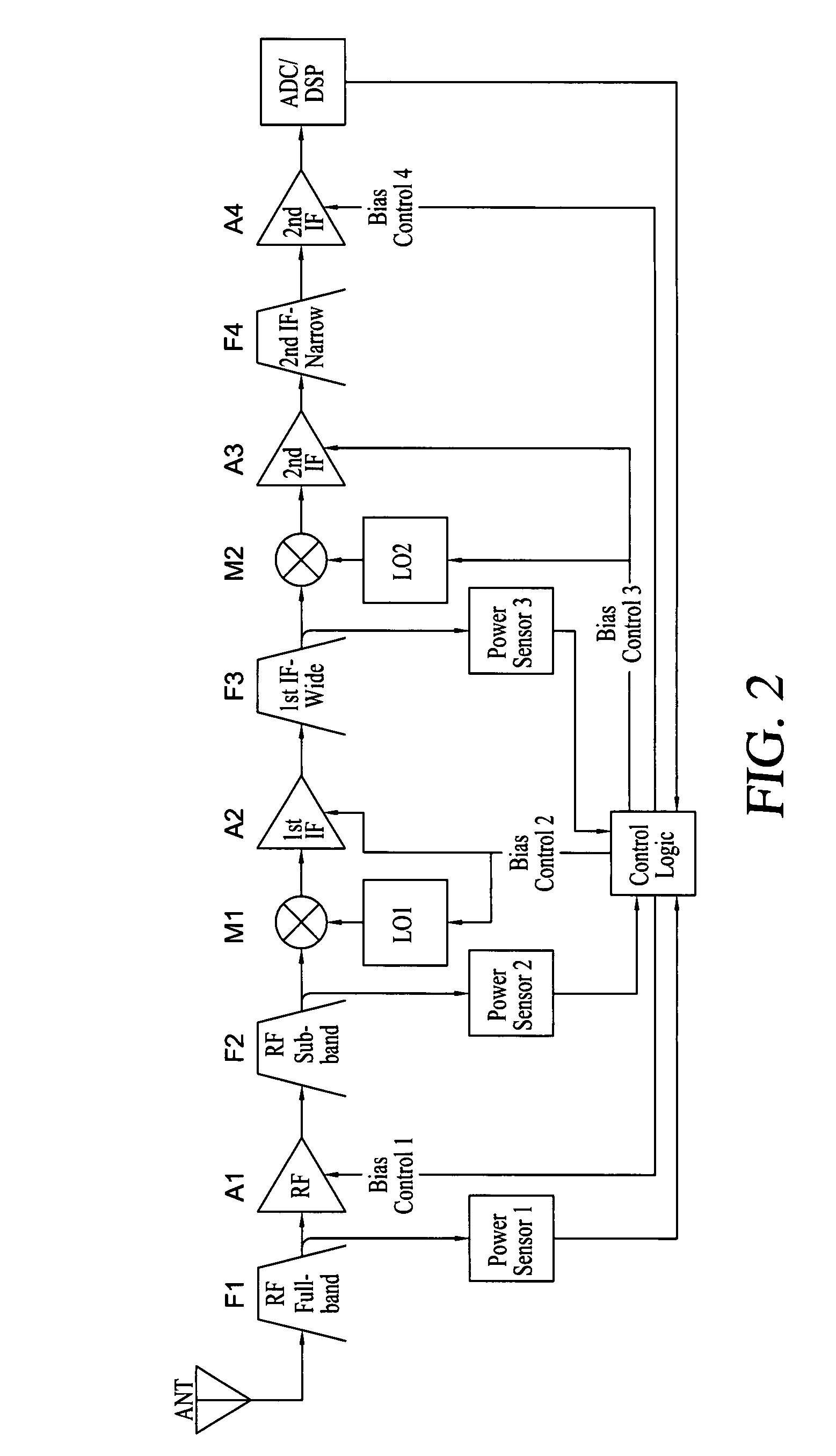

RF receiver utilizing dynamic power management

ActiveUS7639998B1Reduce power consumptionReduce thermal loadRadio transmissionAmplifier detailsPower sensorDigital signal processing

A radio frequency (RF) receiver utilizing dynamic power management for administration of power consumption. The RF receiver includes an RF antenna, an RF full band filter, an RF amplifier, an RF sub-band filter, a first local oscillator, an RF mixer, a first IF amplifier, an IF wide band filter, a second local oscillator, an IF mixer, two secondary IF amplifiers, an IF narrow band filter, a digital signal processing subsystem, three power sensors, and a control logic subsystem. Based on its location in the system, each power sensor has a unique threshold setting that is set just below a total RF power level where desired signal degradation might occur. The control logic subsystem utilizes outputs of the power sensors to detect a total RF power present due to interfering signals plus a desired signal within an entire bandwidth present at each stage and dynamically manages power by adjusting bias of each stage accordingly via its bias control outputs.

Owner:ROCKWELL COLLINS INC

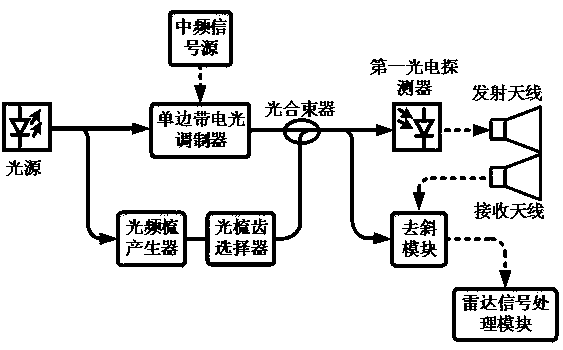

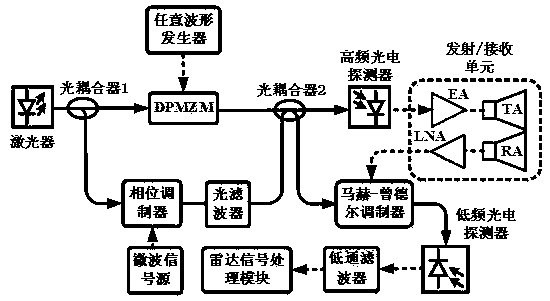

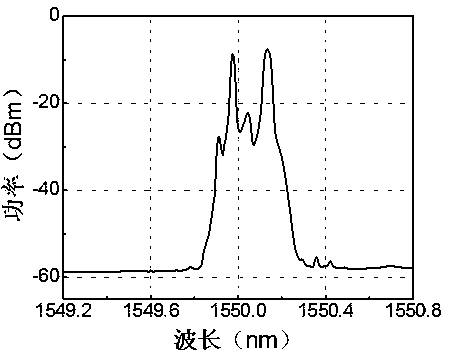

Microwave photon full-band radar detection method and microwave photon full-band radar

ActiveCN108919244AFlexible operationImprove work efficiencyRadio wave reradiation/reflectionIntermediate frequencyFull wave

The invention discloses a microwave photon full-band radar detection method. The microwave photon full-band radar detection method comprises the steps that suppression carrier single sideband modulation is carried out on an optical carrier with a frequency of fL by using an intermediate frequency chirp signal to obtain a linear frequency swept first-order sideband optical signal; a single comb signal is selected from optical frequency comb signals with frequency distribution fOC=fL+ / -Nfc to combine beams with the linear frequency swept first-order sideband optical signal, wherein N=0, 1, 2, 3... L, and L is a positive integer; the obtained combined beam optical signal is converted into an electrical signal, and the electrical signal is transmitted to a target as a radar detection signal; and the combined beam optical signal is taken as a reference optical signal, a target reflected electrical signal is subjected to optical domain frequency conversion and deskewing processing to obtainan intermediate frequency signal carrying target information, and the target information is extracted from the intermediate frequency signal. The invention further discloses a microwave photon full-band radar. The microwave photon full-band radar detection method and the microwave photon full-band radar can quickly and conveniently adjust the working wave band of the radar and the radar signal parameters in the full wave band range, the structure is simple, and the detection efficiency is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

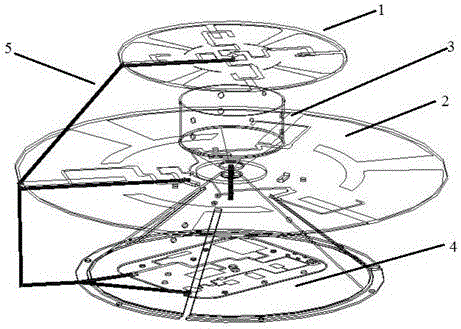

Multi-frequency dual-polarized omnidirectional antenna

ActiveCN106848530AImprove working bandwidthRealize slot coupling feedParticular array feeding systemsAntenna supports/mountingsOmnidirectional antennaWi-Fi

The invention discloses a multi-frequency dual-polarized omnidirectional antenna and relates to the technical field of dual-polarized omnidirectional antennas. The multi-frequency dual-polarized omnidirectional antenna comprises upper and lower two microstrip antenna arrays, an asymmetric bi-conical antenna, a multiplexer, a side feed structure and an antenna radome, wherein the upper and lower two microstrip antenna arrays are parallel to each other and are arranged at the top and the middle of the asymmetric bi-conical antenna separately; the multiplexer is arranged at inner side of the bottom of the asymmetric bi-conical antenna; and the side feed structure is arranged on the side of the whole antenna and connected with upper and lower two microstrip antenna array feed points and two output ports of the multiplexer separately. The multi-frequency dual-polarized omnidirectional antenna covers 2 / 3 / 4G and WLAN and Wi-Fi working bands, and has multi-frequency vertical and horizontal dual-polarized omnidirectional radiation functions. The upper microstrip antenna array is arranged at the top of the asymmetric bi-conical antenna to form orthogonal arrangement; the asymmetric bi-conical antenna is arranged at the center of the lower microstrip antenna array to form cored orthogonal arrangement. According to a structure combination method, the isolation degree between a vertically polarized port and a horizontally polarized port in a full band can be significantly improved and the operation bandwidth of the antenna is improved.

Owner:SOUTHEAST UNIV +1

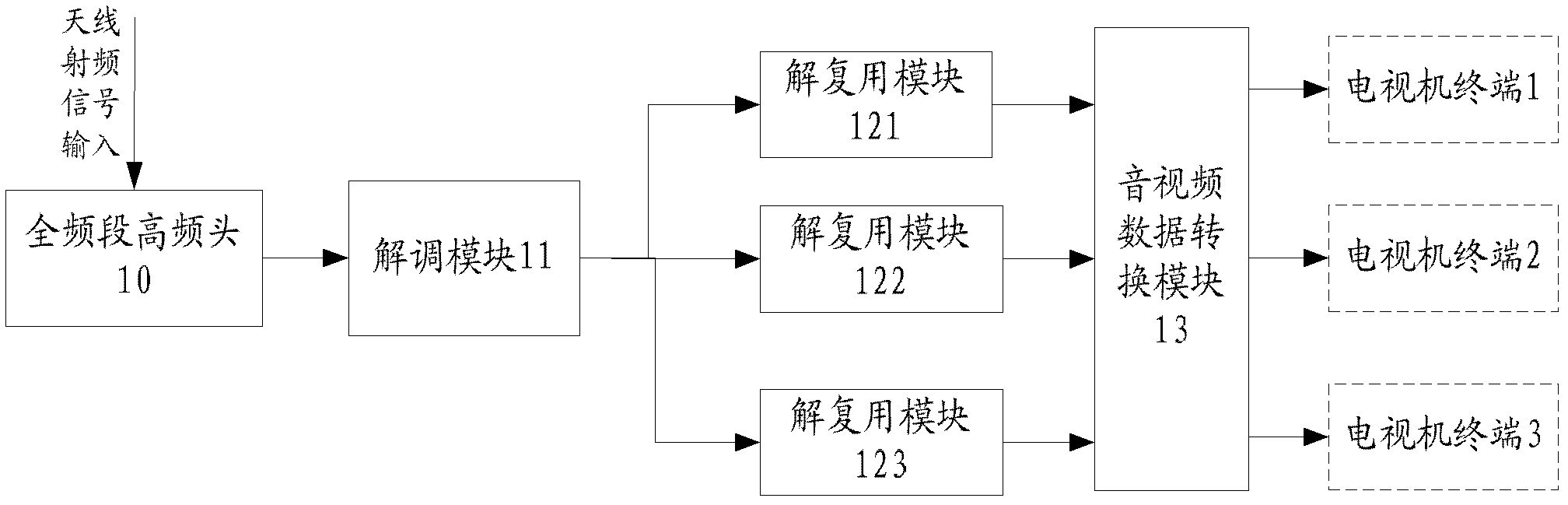

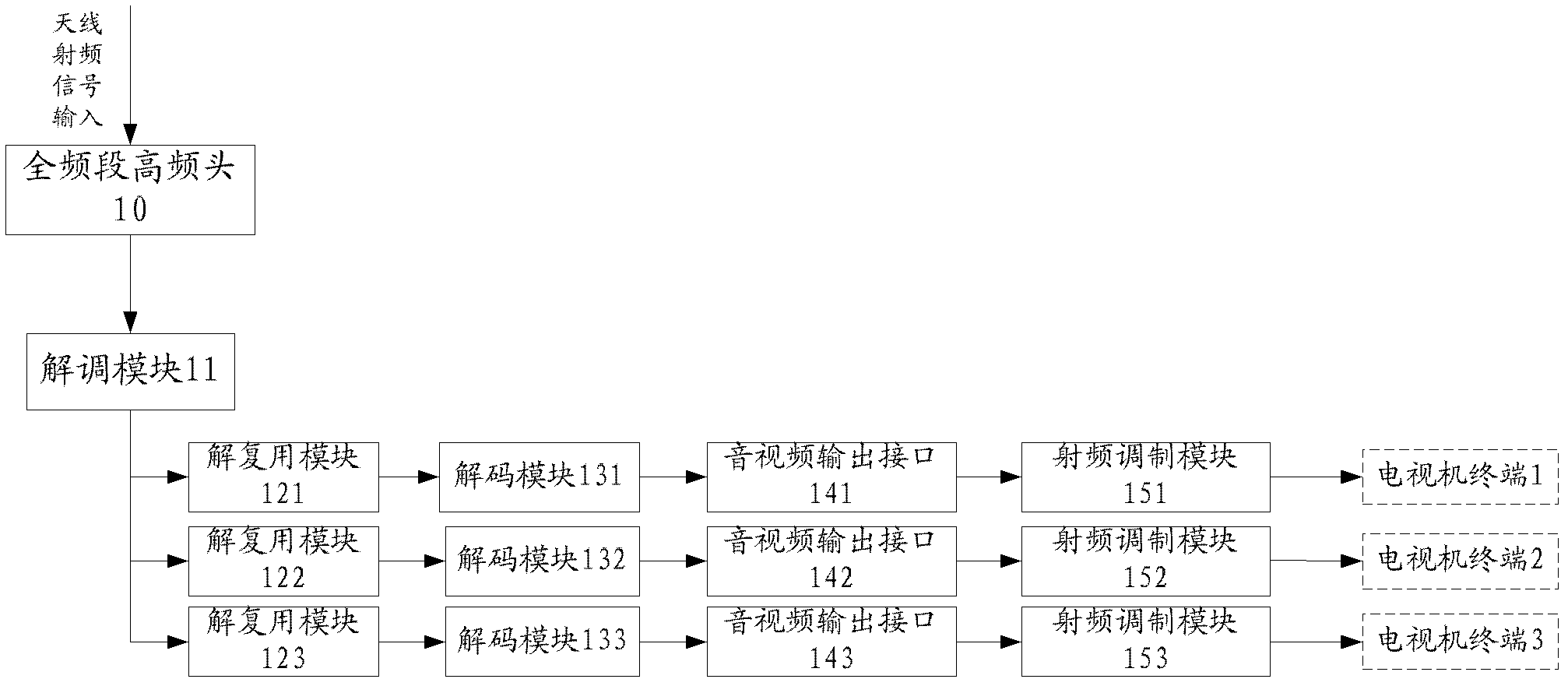

Set-top box for supporting multiple television terminals and method

ActiveCN102547431AImprove experienceSelective content distributionMultiplexingIntermediate frequency

The invention discloses a set-top box for supporting multiple television terminals, which comprises a full-band high-frequency head, a demodulator module, a plurality of demultiplexing / multiplexing modules and an audio / video data conversion module. The full-band high-frequency head is used for converting locked antenna radio-frequency signals in a plurality of frequency points into medium-frequency signals and transmitting the medium-frequency signals to the demodulator module, the demodulator module is used for demodulating program transmission streams of a plurality of channels from the medium-frequency signals and respectively transmitting the program transmission streams to the demultiplexing / multiplexing modules, and the demultiplexing / multiplexing modules are used for analyzing audio / video data in the programs of the channels from the program transmission streams according to the program demanded by a user; and the audio / video data conversion module is used for converting the audio / video data in the programs of the channels into signals capable of being identified by television terminals and outputting the signals to the television terminals. The invention also discloses a method for realizing support of a plurality of television terminals through the set-top box. The set-top box can support multiple television terminals so that users can simultaneously watch television programs, the optional programs of each television are not limited to one frequency point, the scope of selection of the television terminals can be broadened, and the user experience can be enhanced.

Owner:SHENZHEN SKYWORTH DIGITAL TECH CO LTD

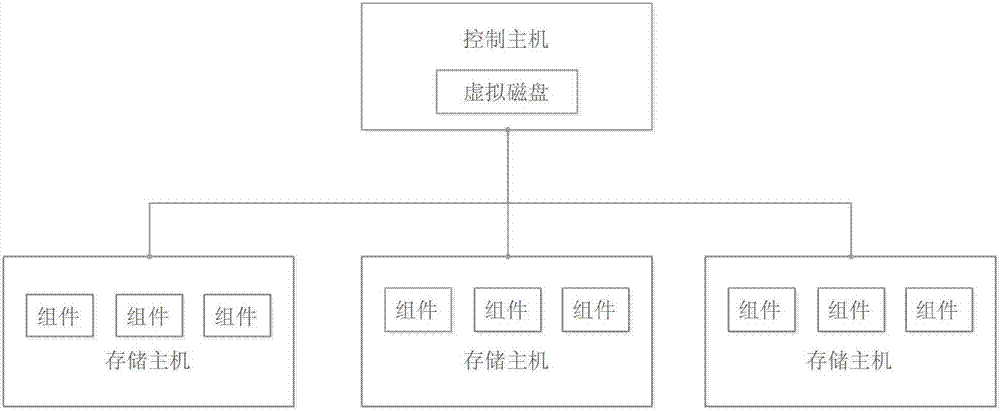

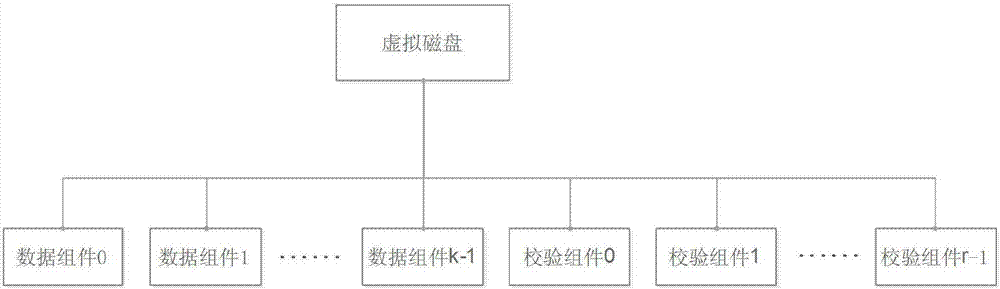

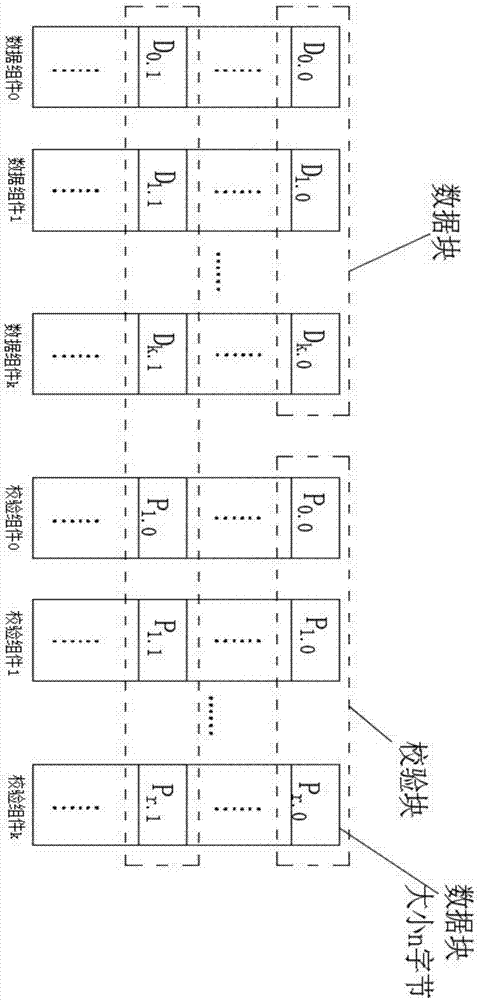

Erasure code optimization method for distributed storage system

InactiveCN107094186AReduce sizeImprove securityRedundant data error correctionTransmissionComplete dataComputer architecture

The invention provides an erasure code optimization method for a distributed storage system. The method utilizes the characteristics of an erasure code to reduce the size of a band of the erasure code. The small strip can meet full band writing and the read and completed data is minimized for an un-full band part. When the data is greater than large IO, the small band can split request data into a plurality of bands, a memory reference technology is utilized to carry out merging of the small bands at a logical layer, so that the large IO can be split and the performance cannot be affected. According to the erasure code optimization method, the band of the erasure code is minimized, so that the data volume for reading the completed data is reduced when the un-full band is written. A front segment can ensure higher read-write performance without setting a buffer pool, so that the data security is greatly increased and the memory consumption of the front segment is reduced.

Owner:深圳市联云港科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com