Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

323 results about "Impact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

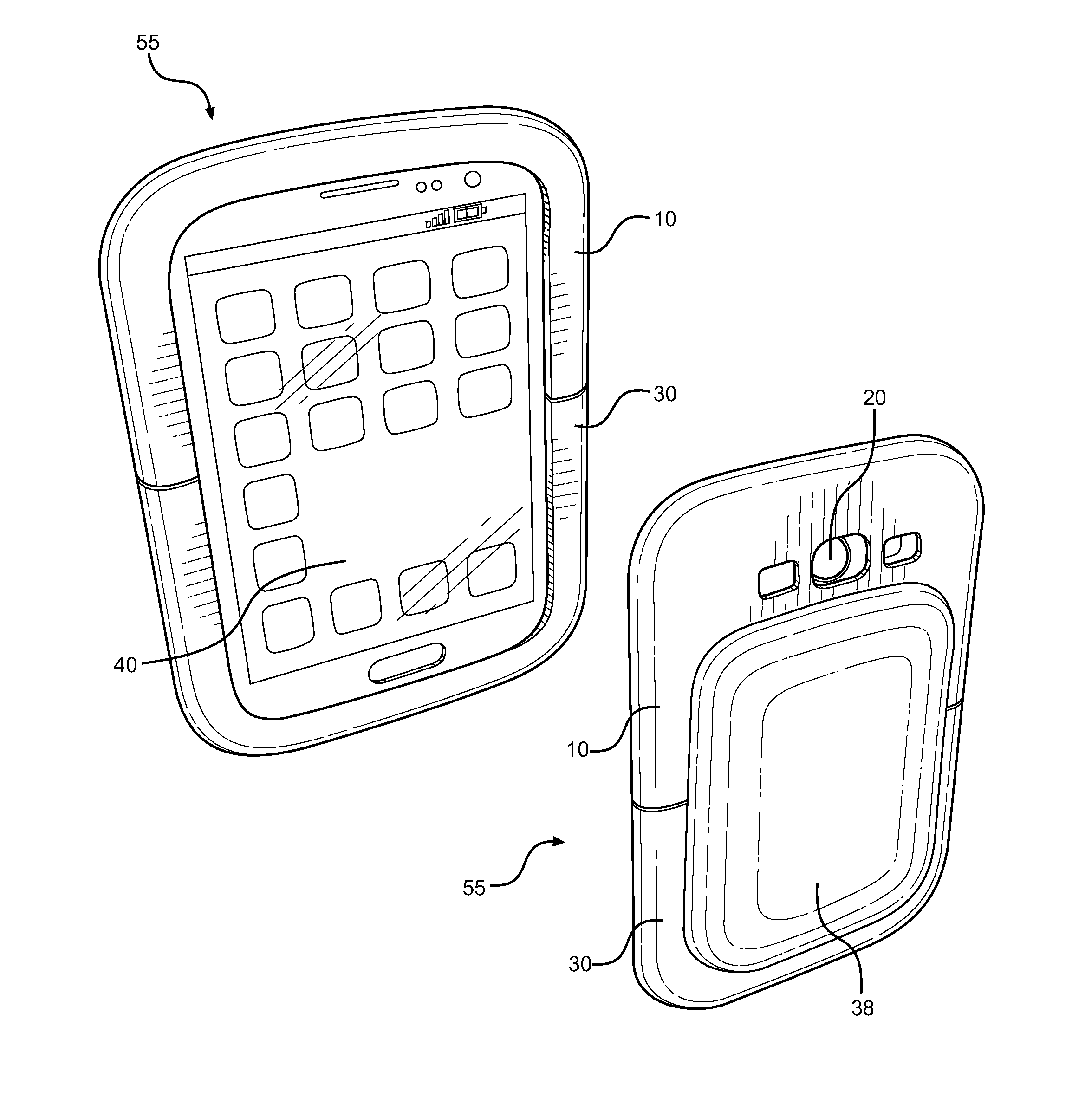

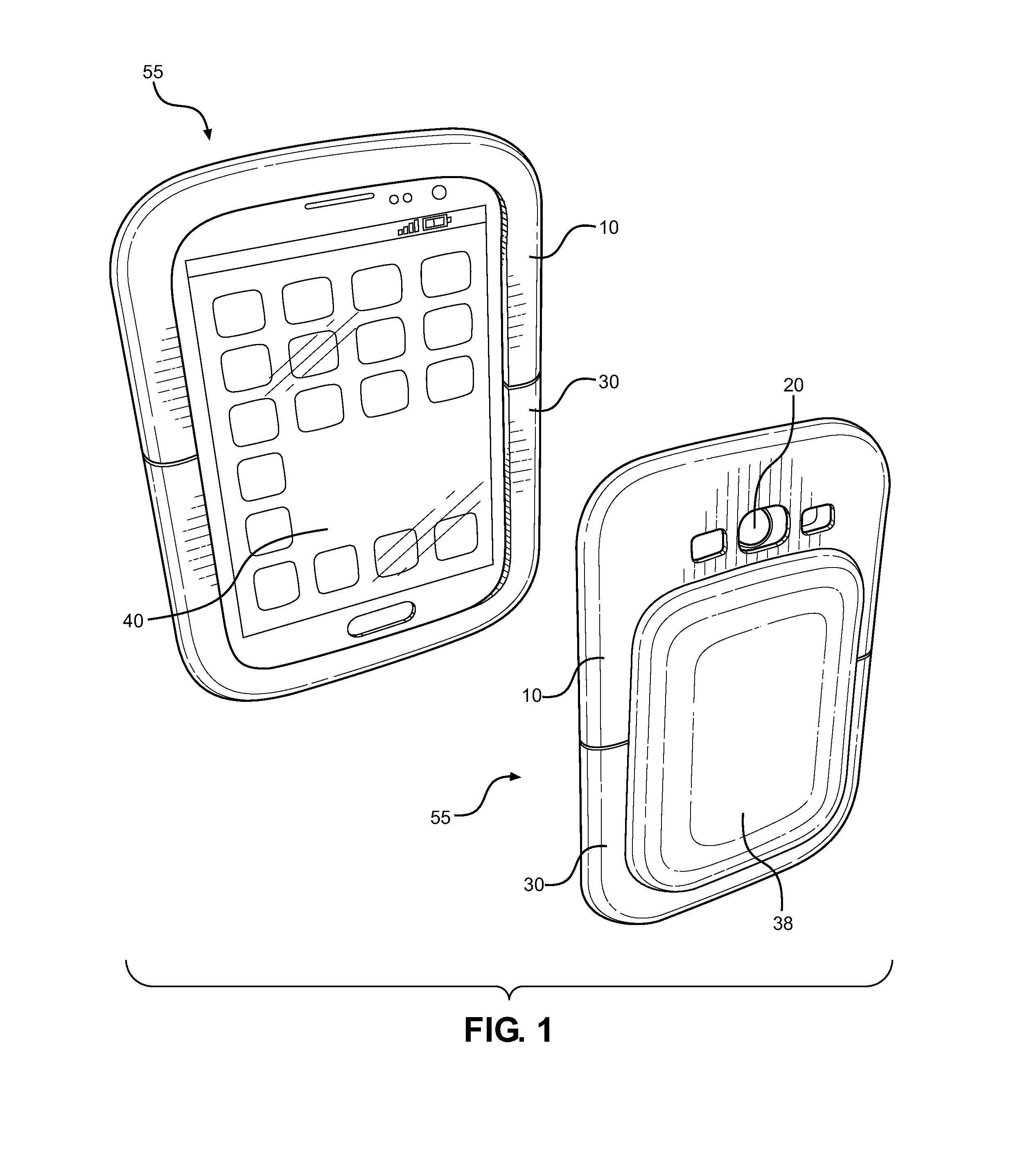

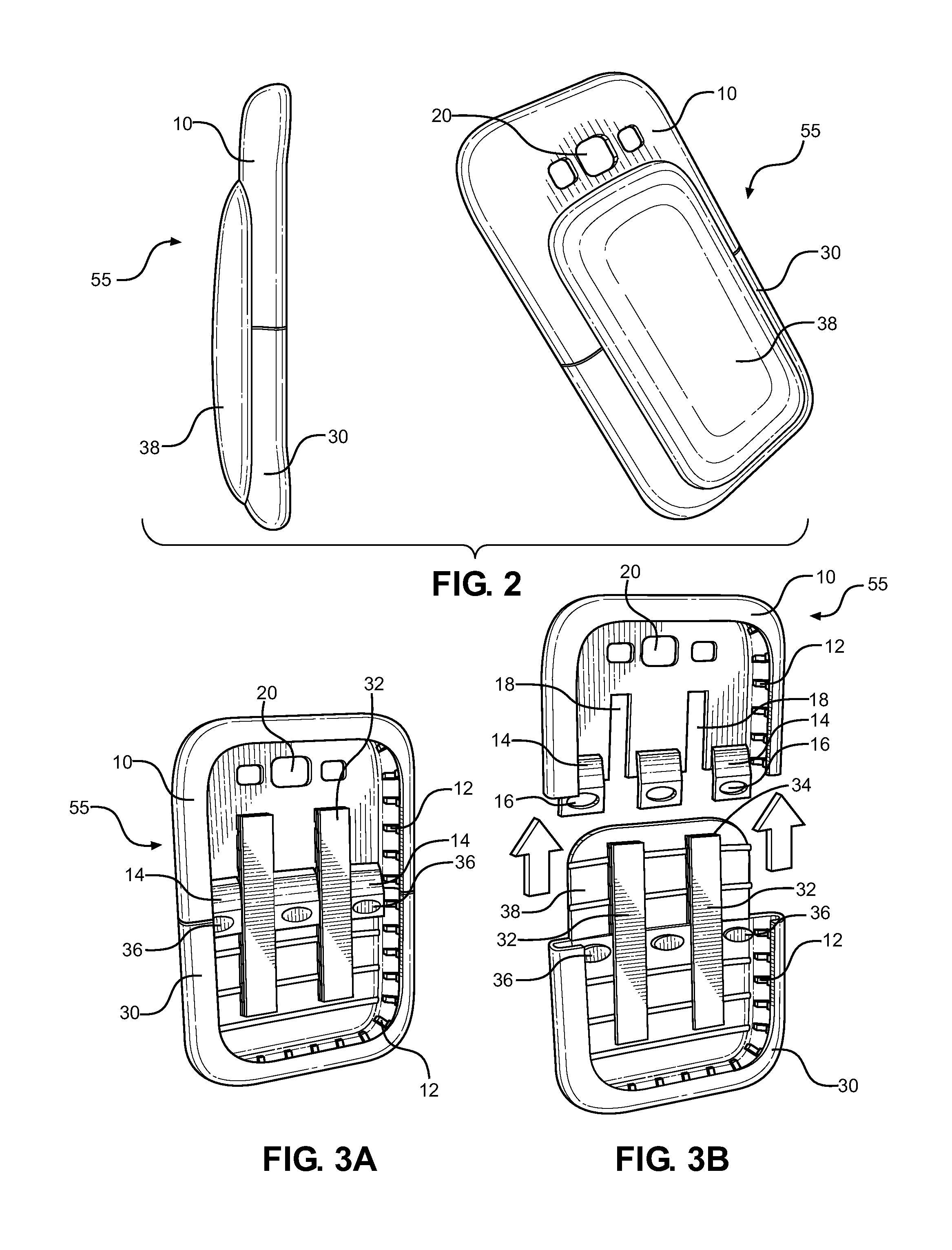

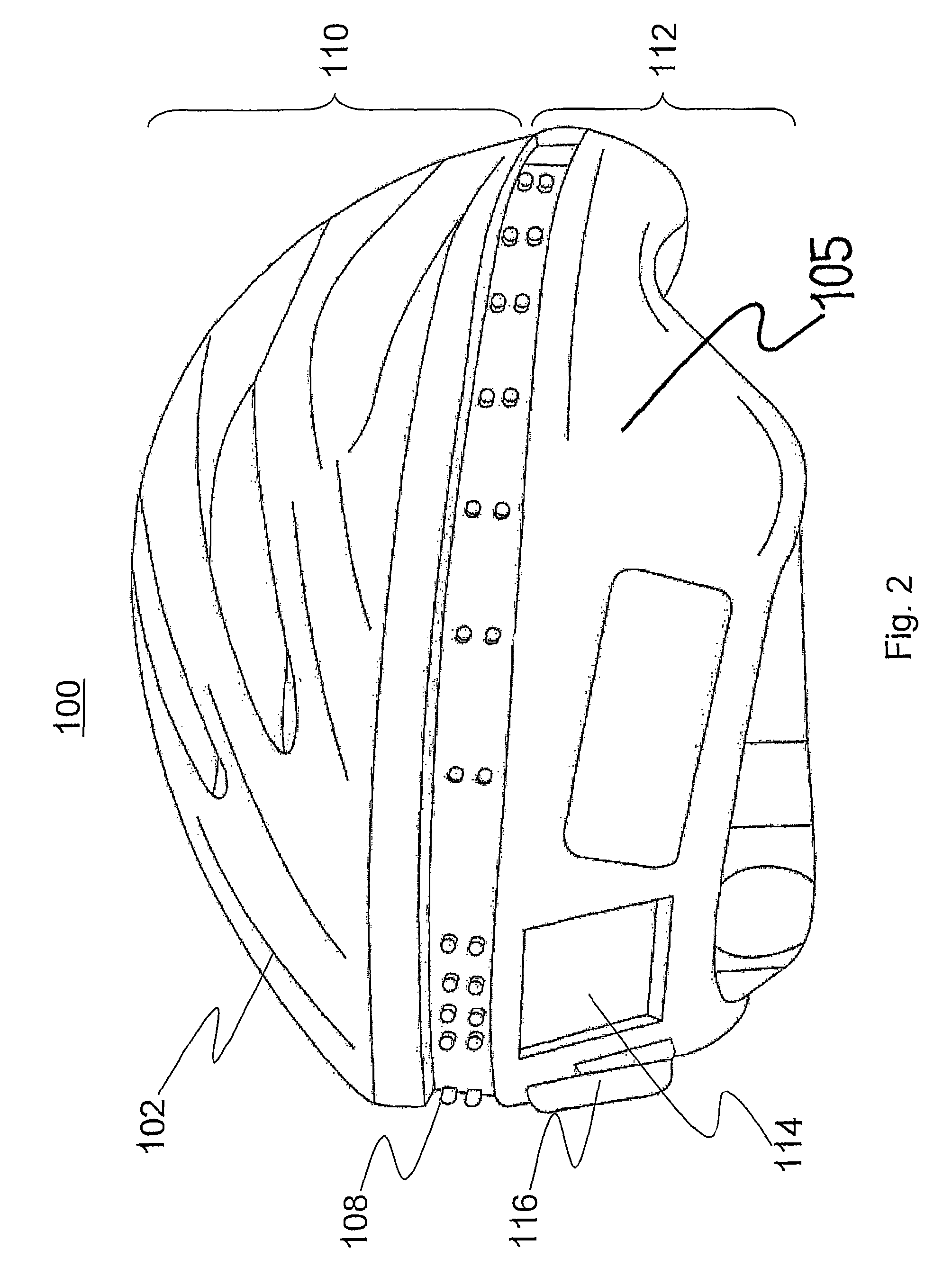

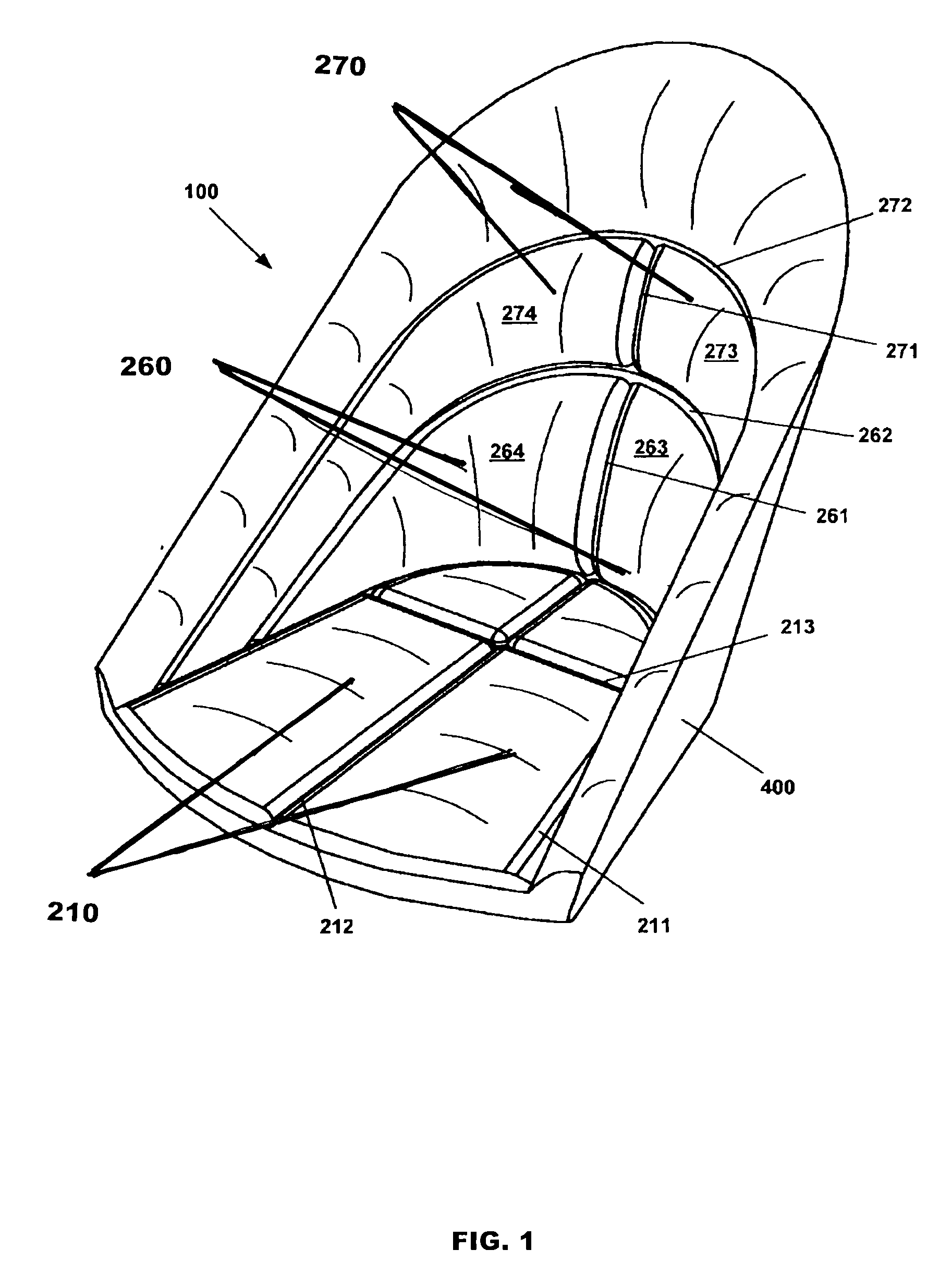

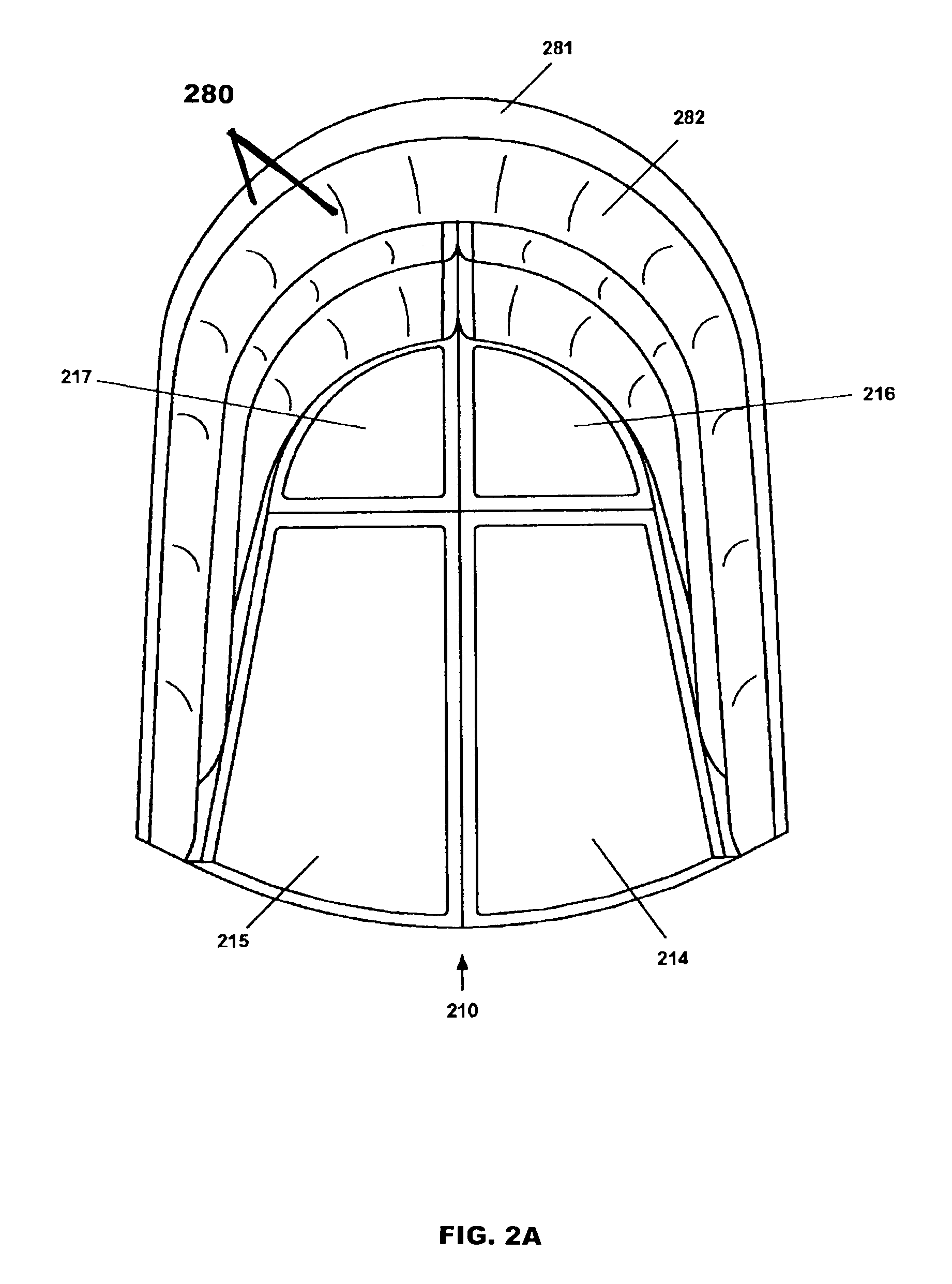

Shock-absorbent electronic device case

The present invention describes a multi-piece electronic device case comprising multiple shock absorbing features. The device includes an upper protective shell, a lower shell, and a rear-mounted shock panel which form the casing around an electronic device. The upper and lower shells are shaped to include a gap between the case and the electronic device. Within the gap are a plurality of curved, force attenuating panels therein that are configured to flex when impacted, thereby distributing the forces applied to the impacted area. Additionally, the backs of the shells include slots for receiving bumper inserts that further distribute impact forces that occur on the upper and lower sides of the electronic device.

Owner:TANG WAI

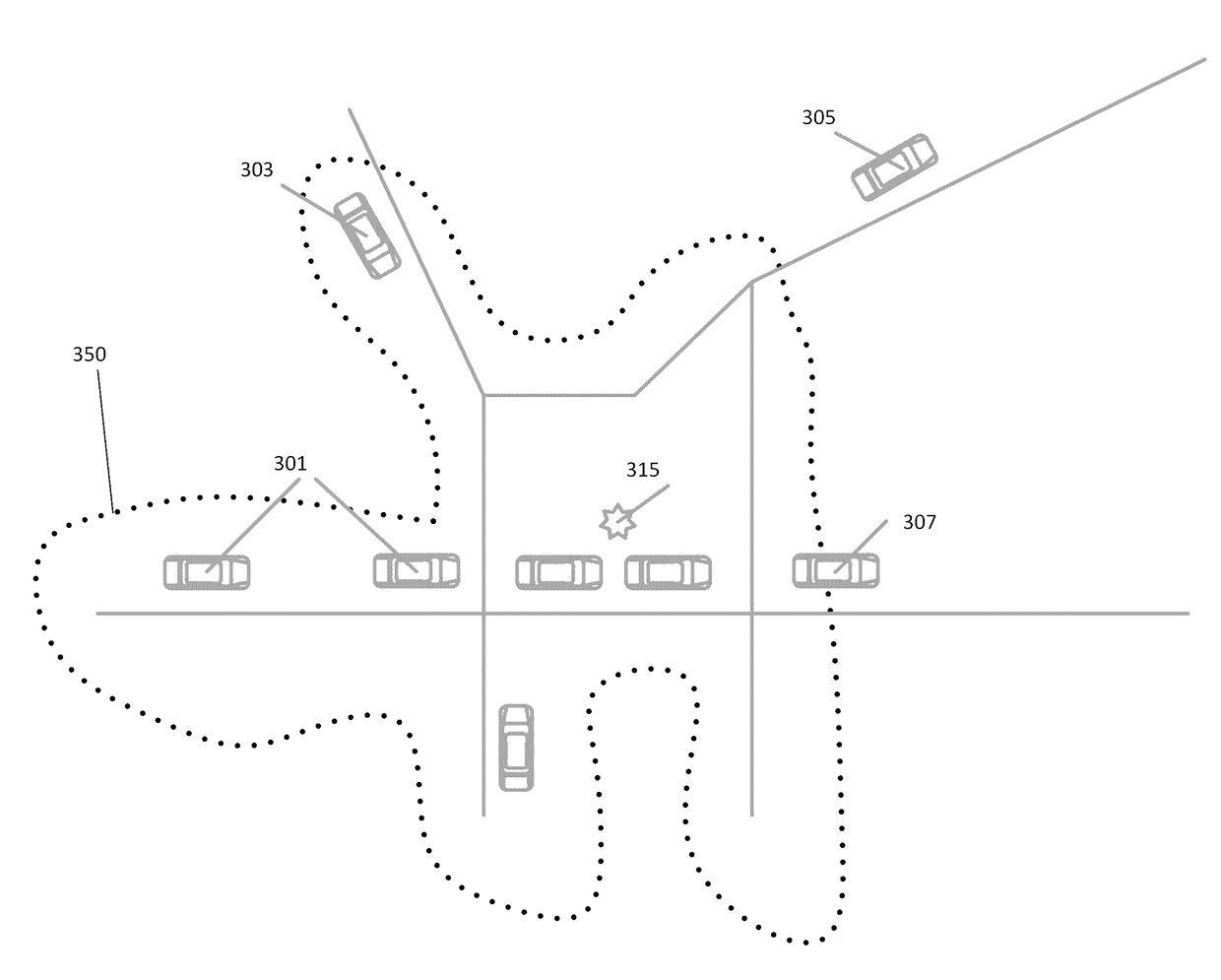

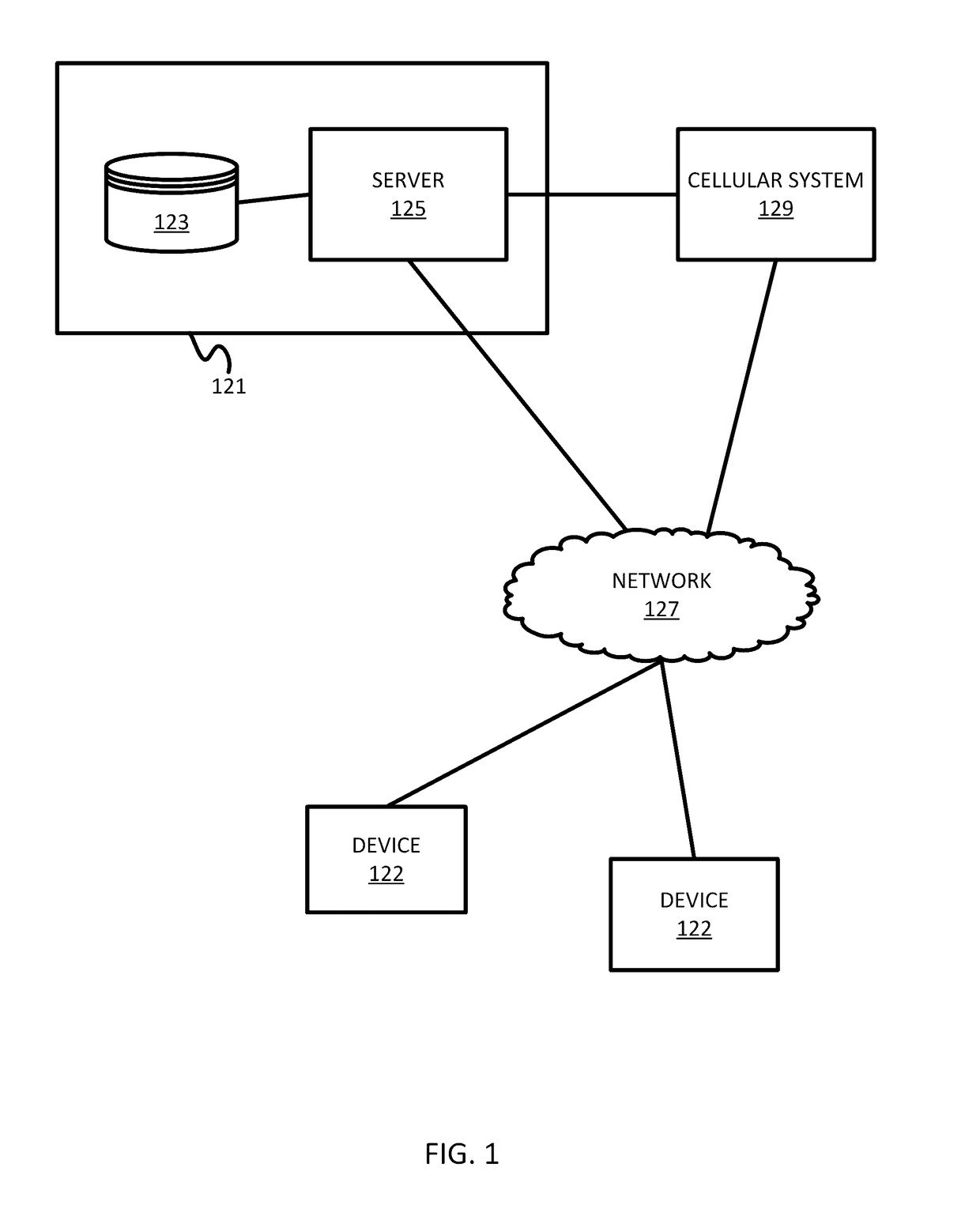

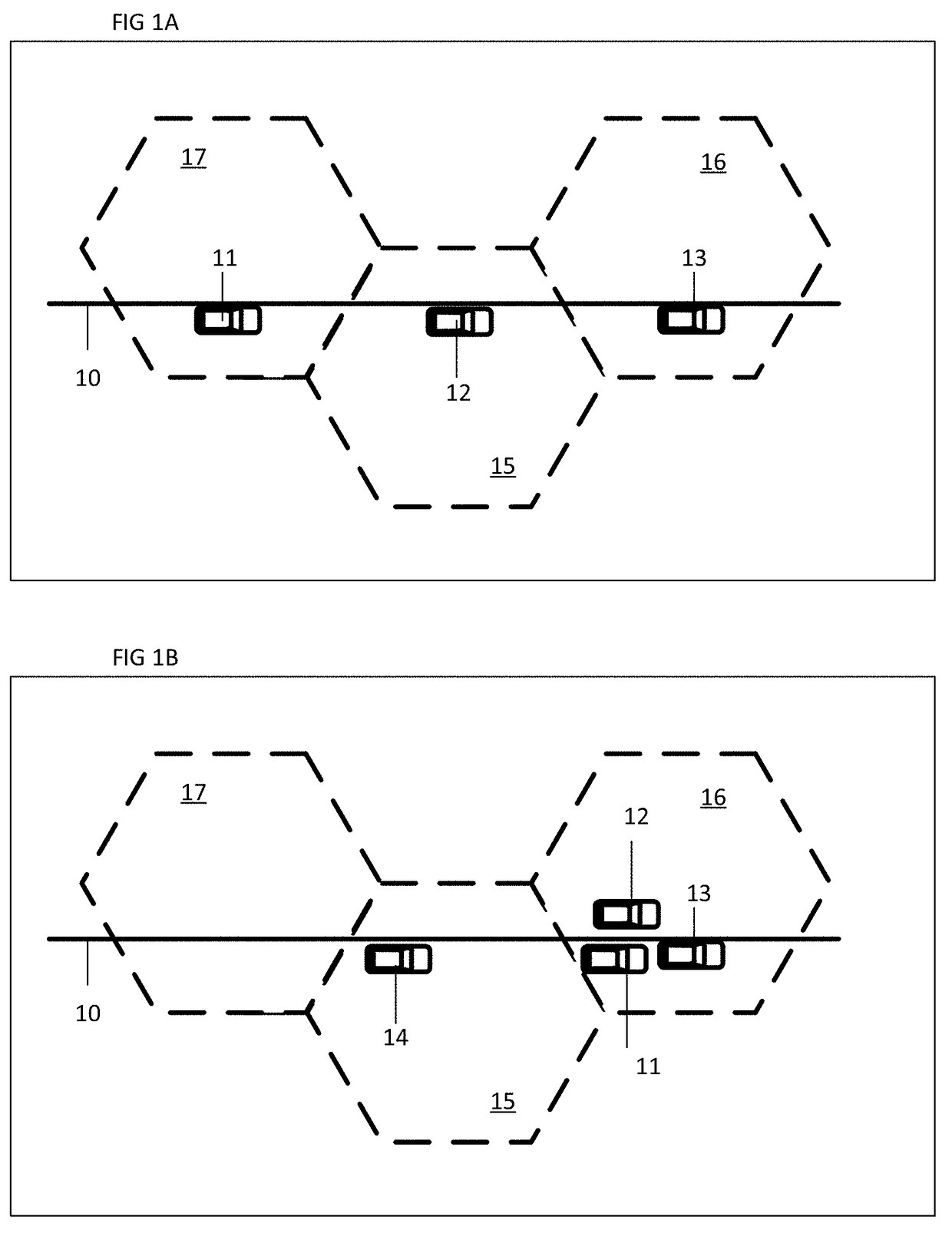

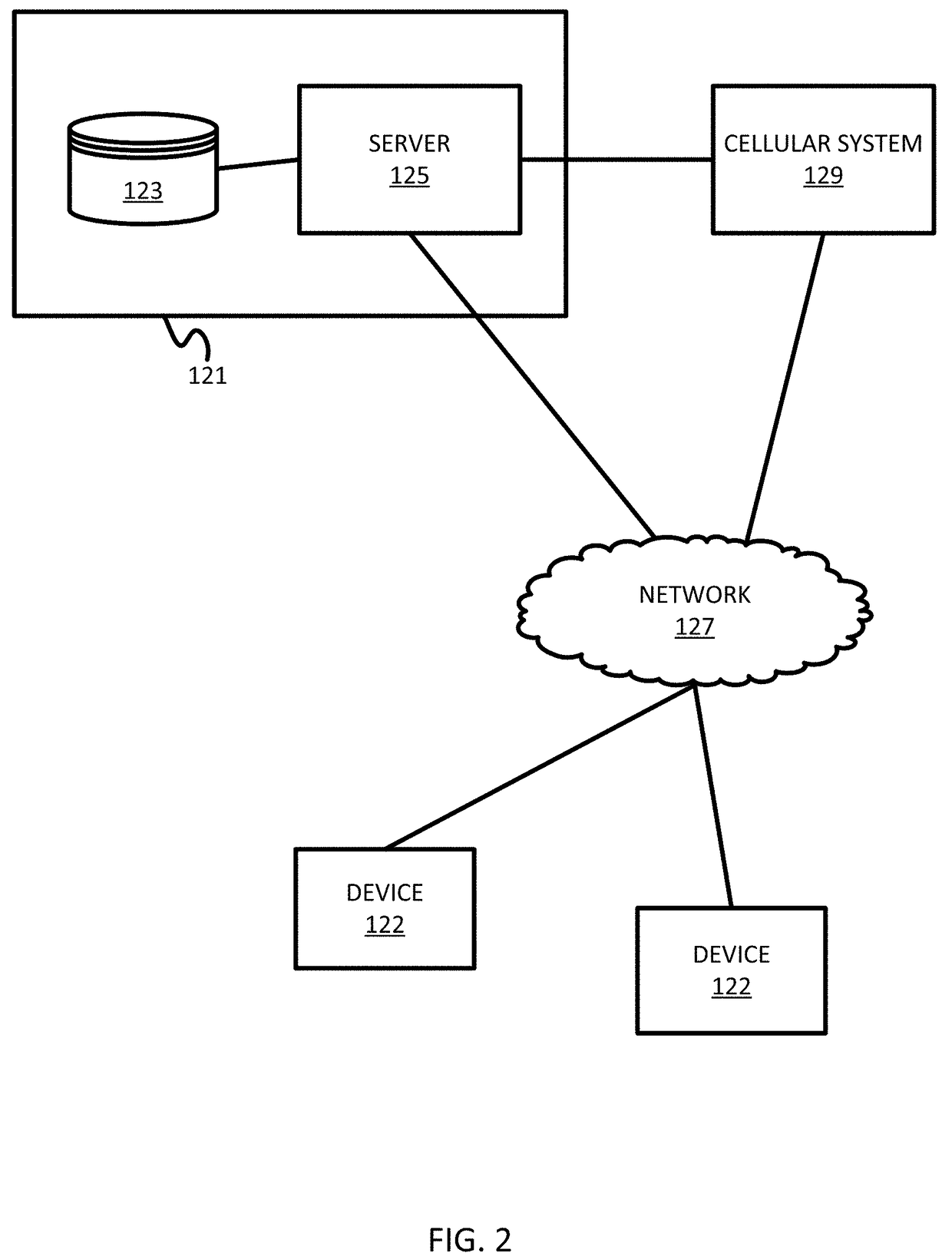

Transmission of Targeted Roadway Alerts

ActiveUS20170098373A1Emergency connection handlingDetection of traffic movementImpact areaComputer science

A method and apparatus for transmission of targeted roadway alerts. A server receives a first description of an incident. The server determines an impact area of the incident based on the description. The server generates a geographic polygon based on the impact are of the incident. The server overlays the geographic polygon on a first cellular map and transmits an alert message to one or more devices located within a cell of the first cellular map that contains at least a portion of the geographic polygon.

Owner:HERE GLOBAL BV

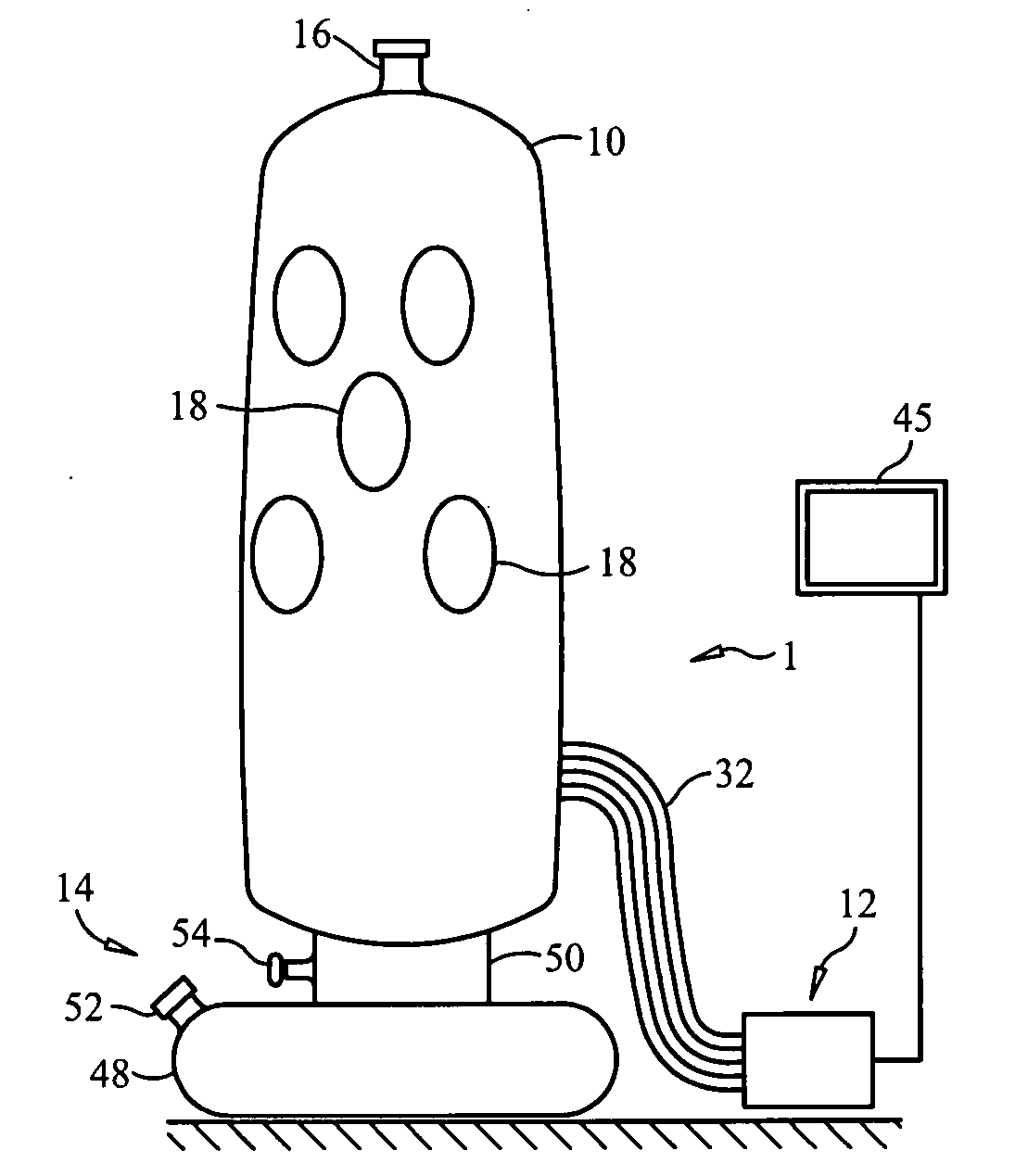

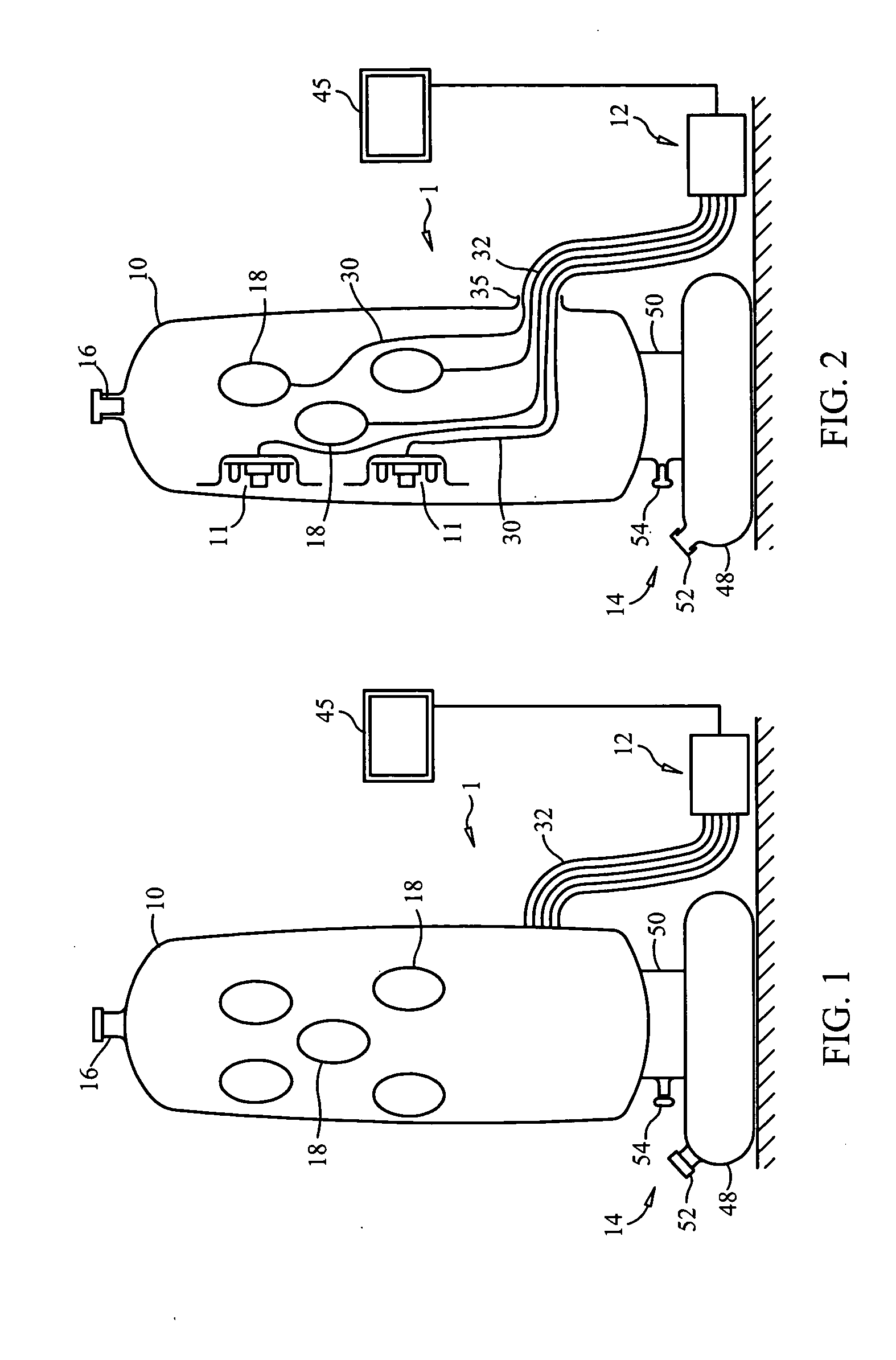

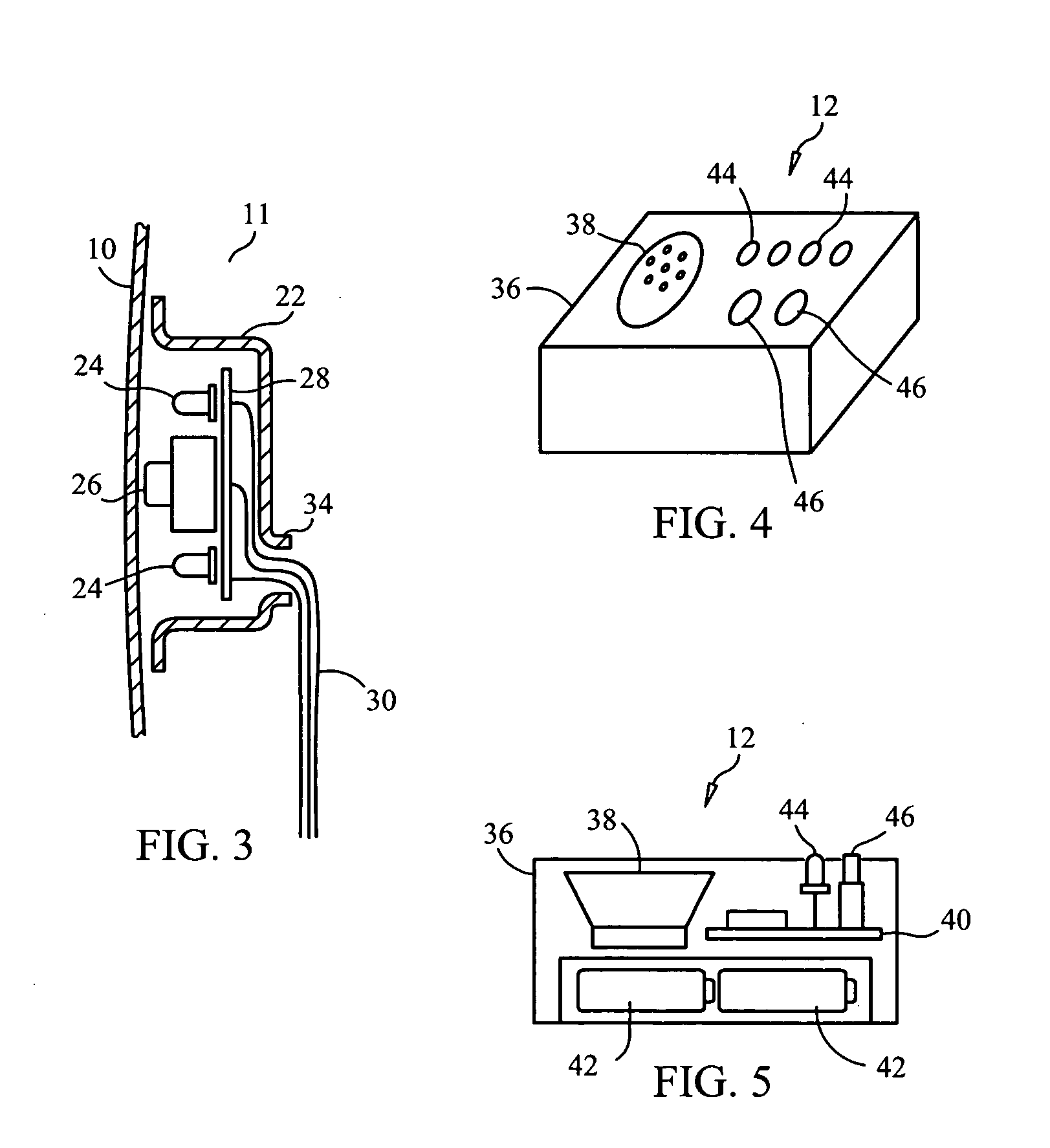

Inflatable punching bag

An inflatable punching bag includes an inflatable bag, at least one sensor device, a control box and a base. At least one impact area is formed on the inflatable bag. A single sensor device is attached behind each impact area. Each sensor device preferably includes a sensor case, at least one light source and an impact sensor. A control box preferably includes a power source, a sound transducer and an electrical circuit. The electrical circuit receives input from at least one impact sensor. The electrical circuit provides a light output through the at least one light source, an audible output through the sound transducer and a video output through a video display. The base preferably includes a weighted portion and intermediate portion. The weighted portion is filled with a dense solid or liquid to provide radial support for the inflatable punching bag. The intermediate portion is disposed between the base and the inflatable bag.

Owner:NG WAI JIM

Stabilization method for lead projectile impact area

Owner:FORRESTER KEITH E

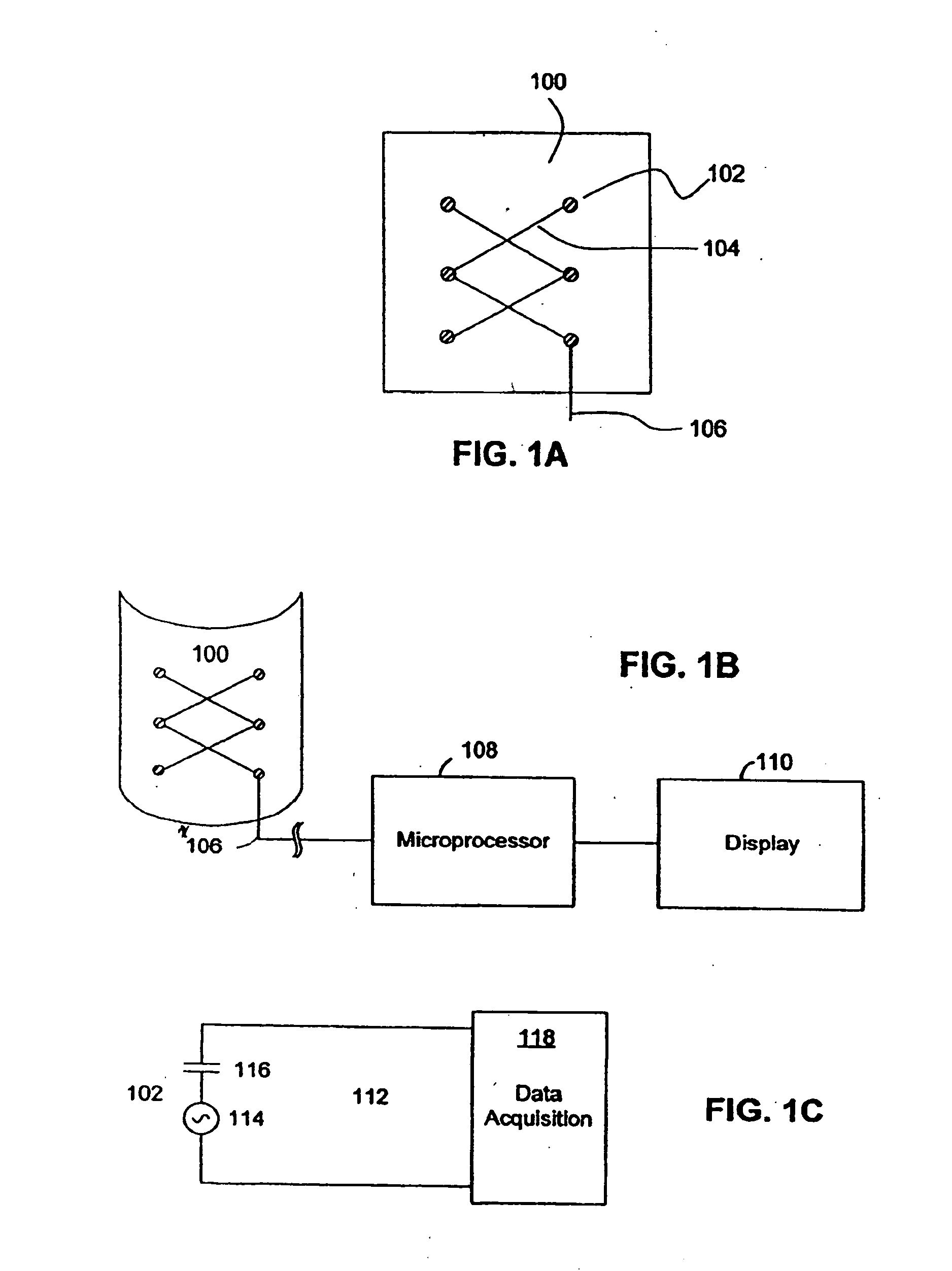

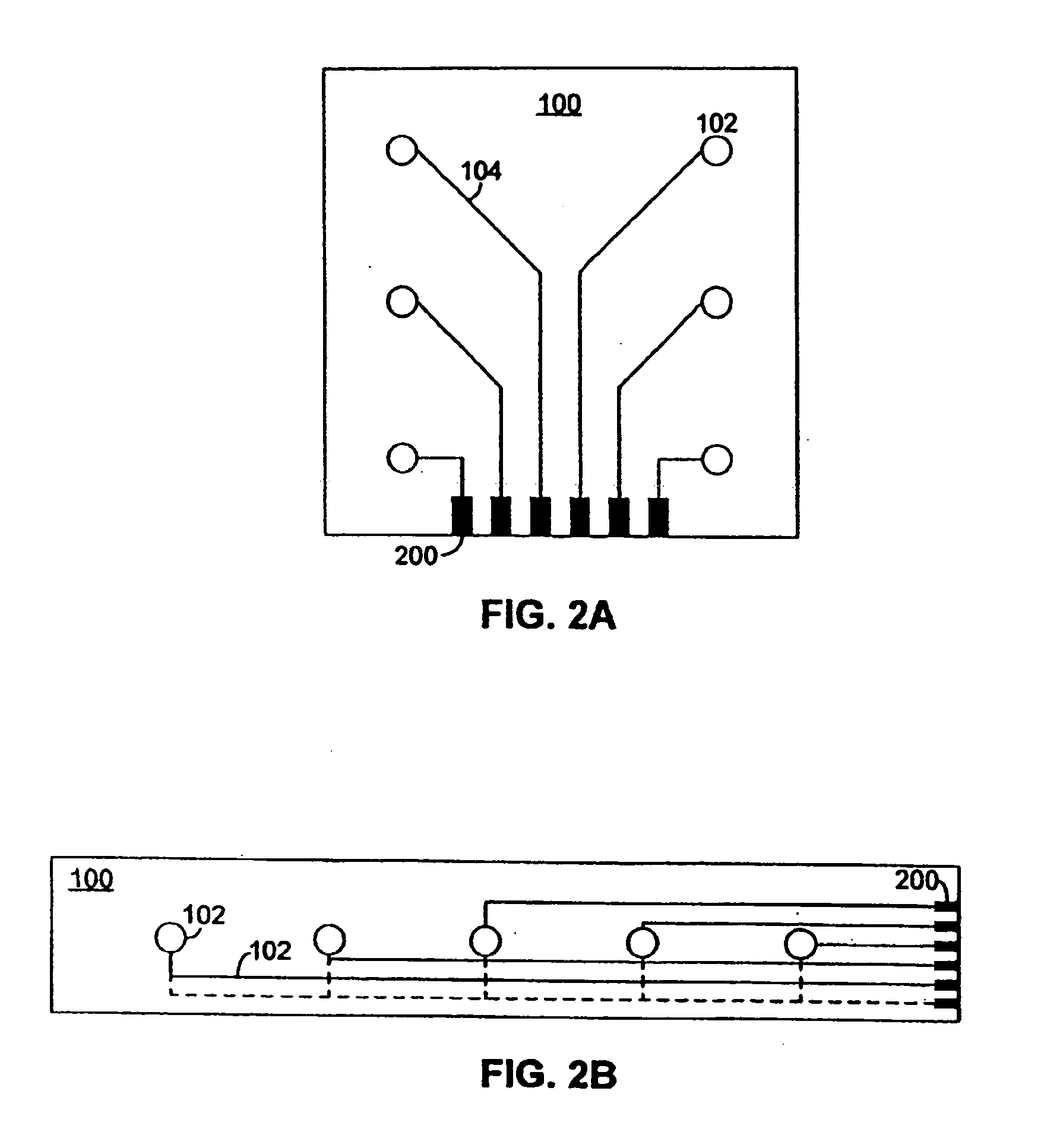

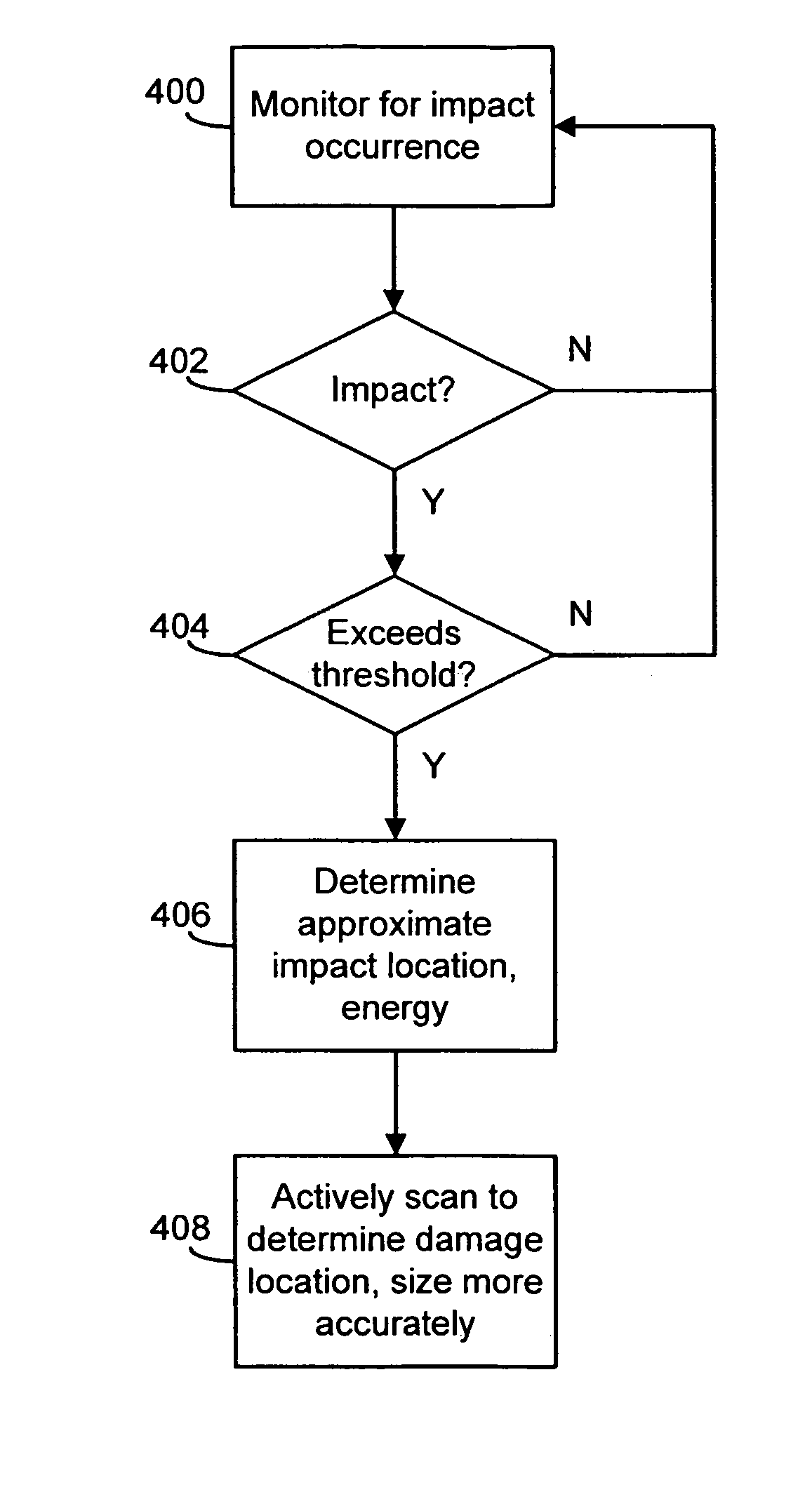

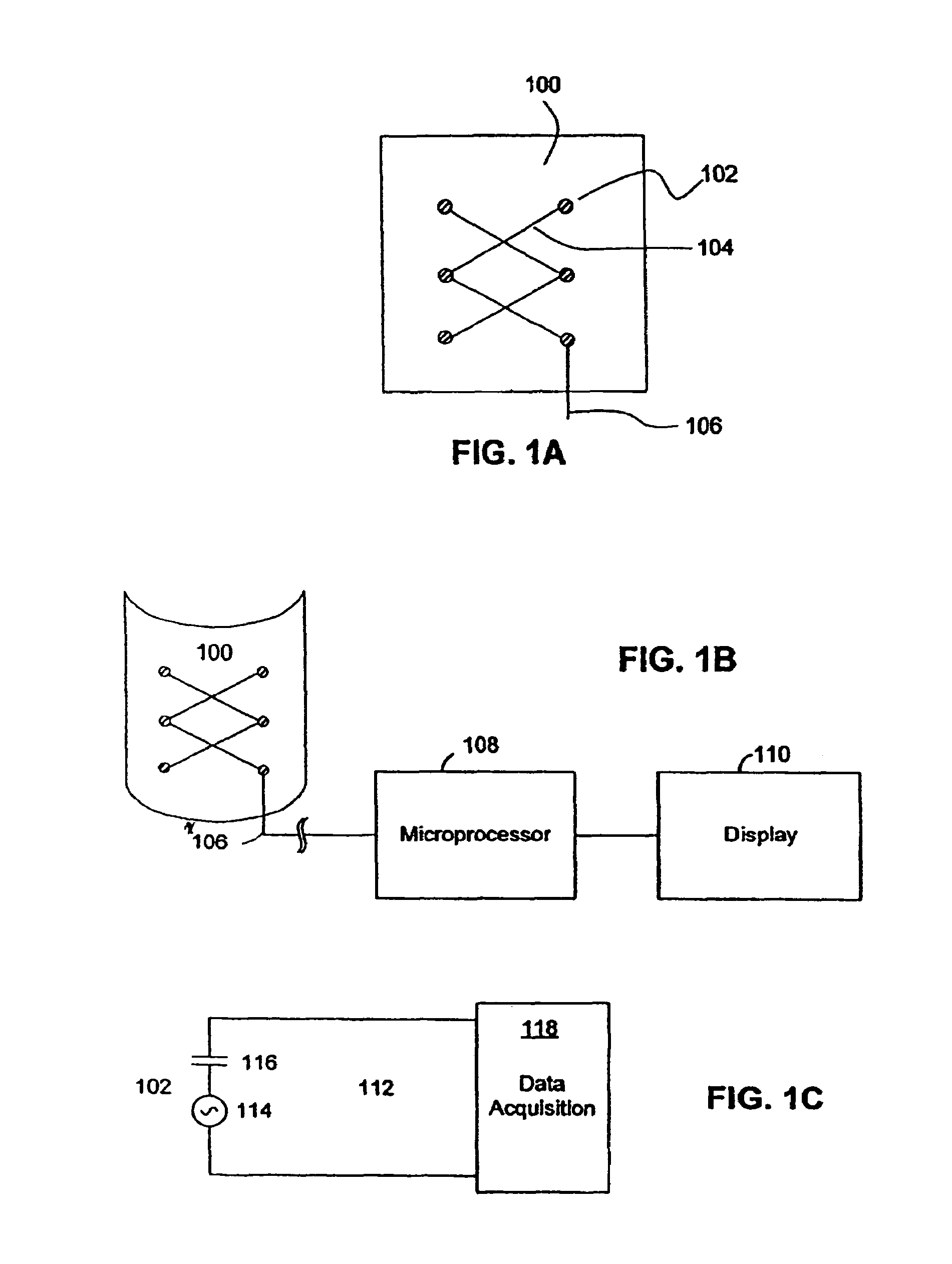

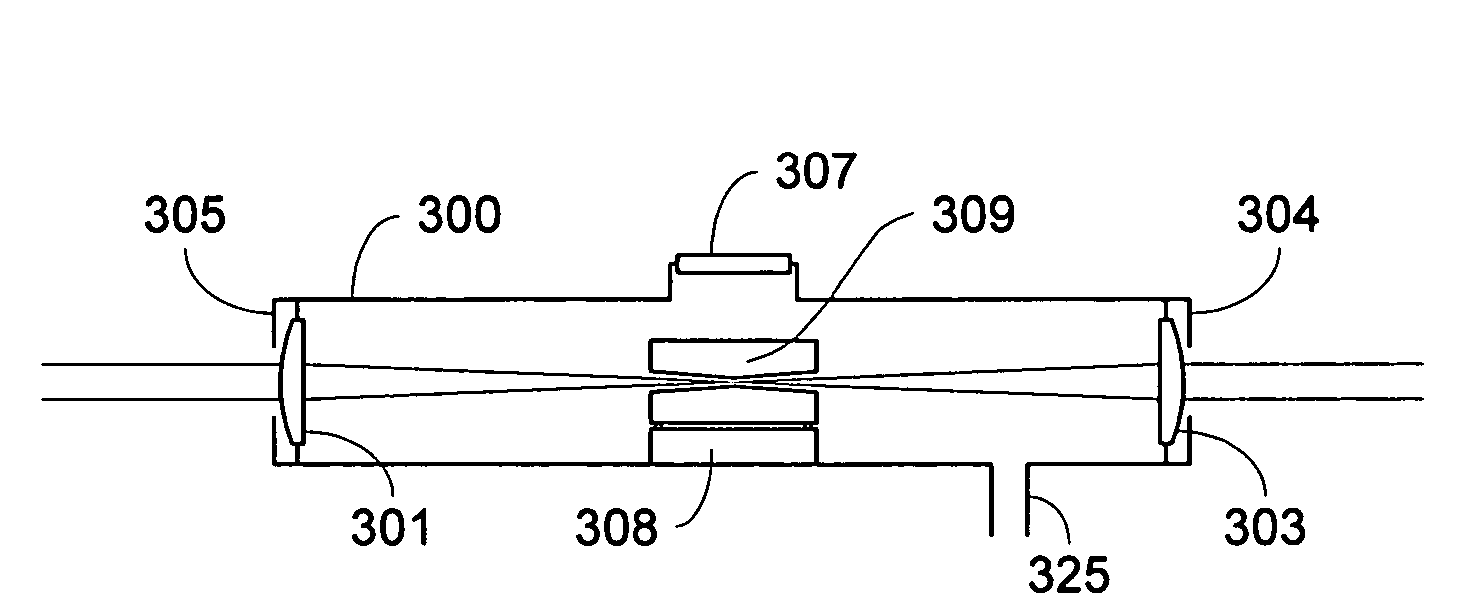

Method and apparatus for detecting a load change upon a structure and analyzing characteristics of resulting damage

ActiveUS20060079747A1Easy to determineVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerEngineering

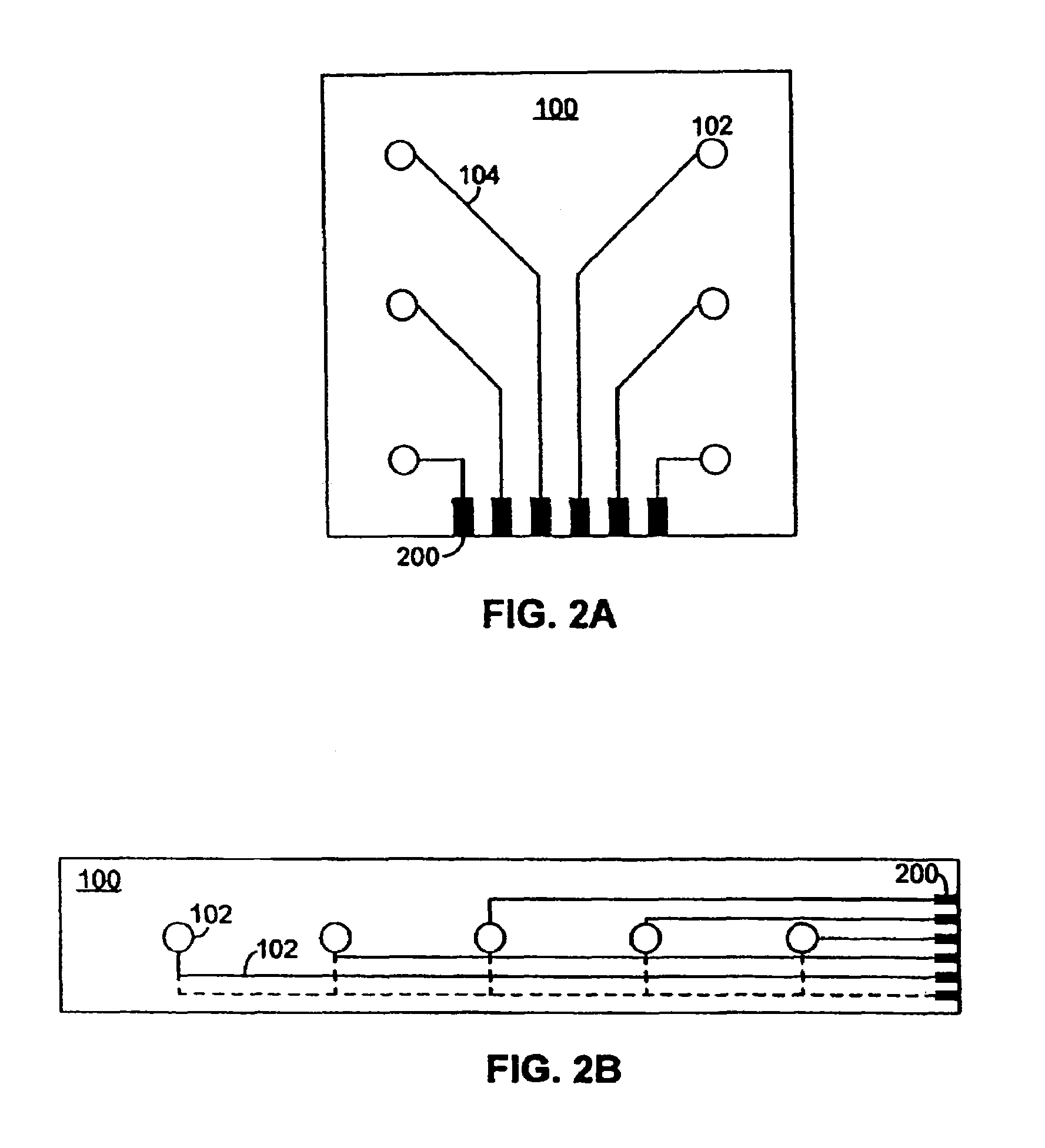

A sensor network is attached to a structure and employed to detect and analyze load changes. The sensor network has transducers, capable of acting as both passive sensors and active actuators, integrated within it. In a passive mode, the transducers detect load changes upon the structure, such as impacts. Upon detection of a load change, the transducers are engaged in an active mode to actively scan the impact area to determine the location and size of any resulting damage region. In this manner, passive and active systems are integrated within a single, convenient layer that possesses the best features of both active systems and passive systems.

Owner:ACELLENT TECH

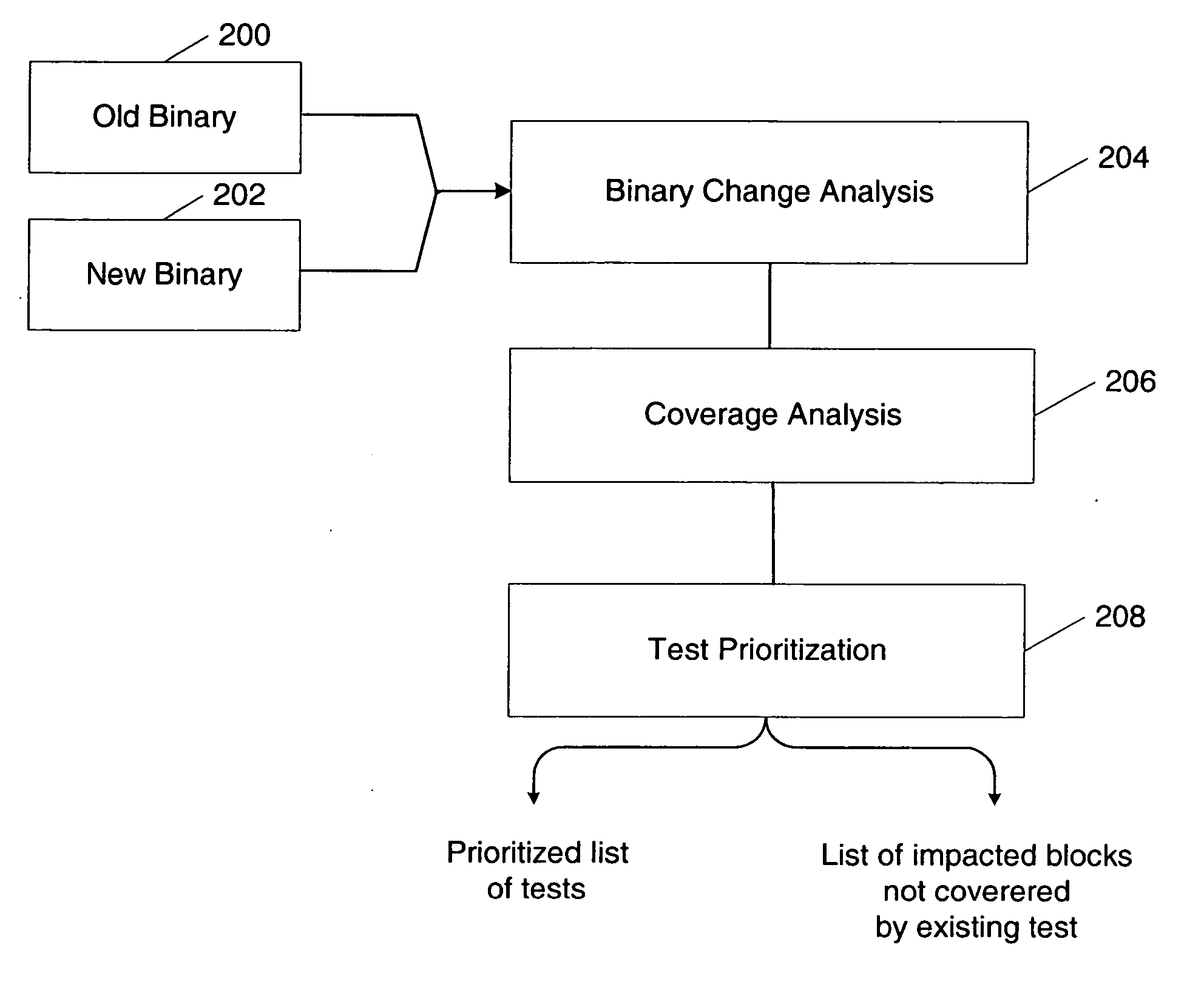

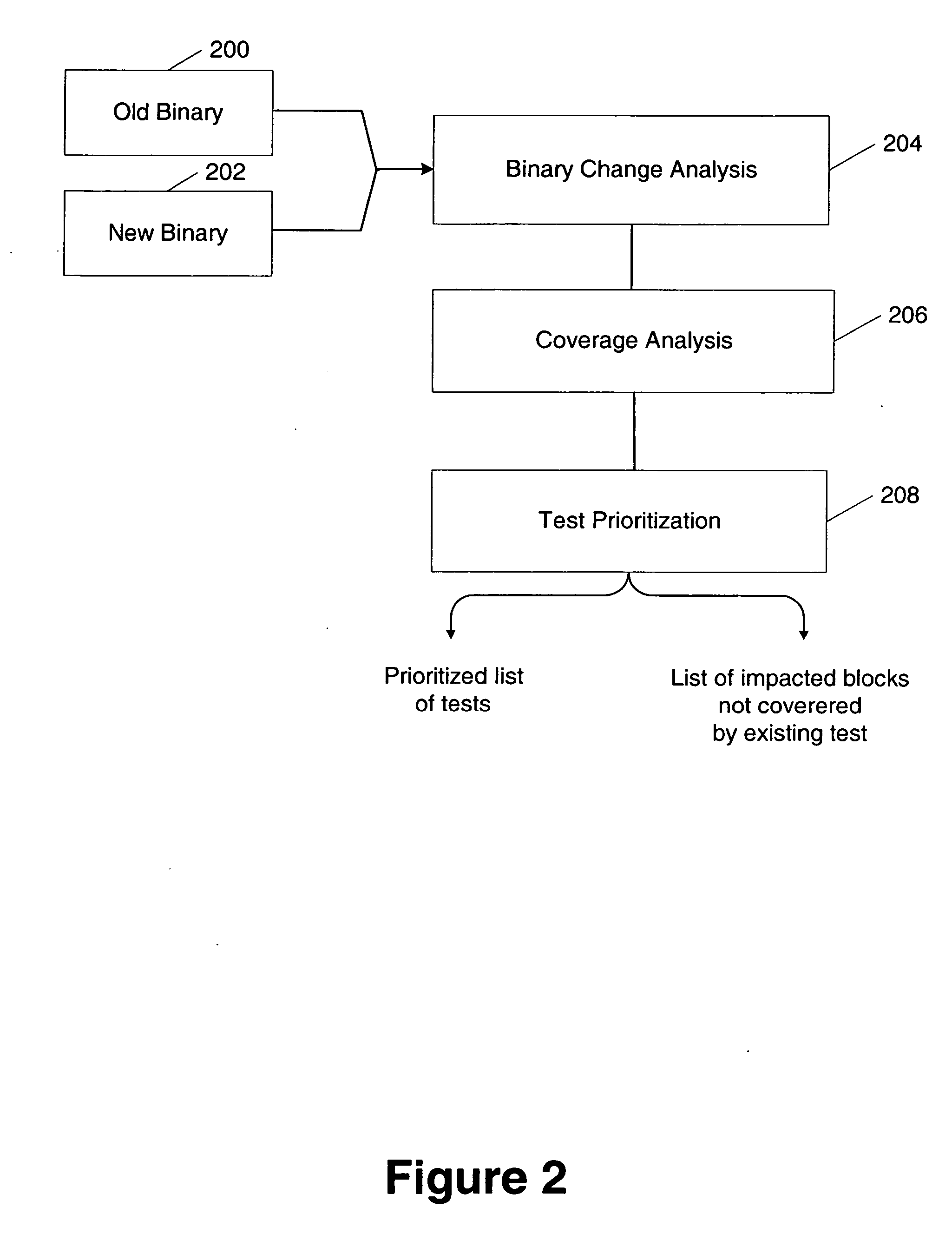

Method and apparatus for prioritizing software tests

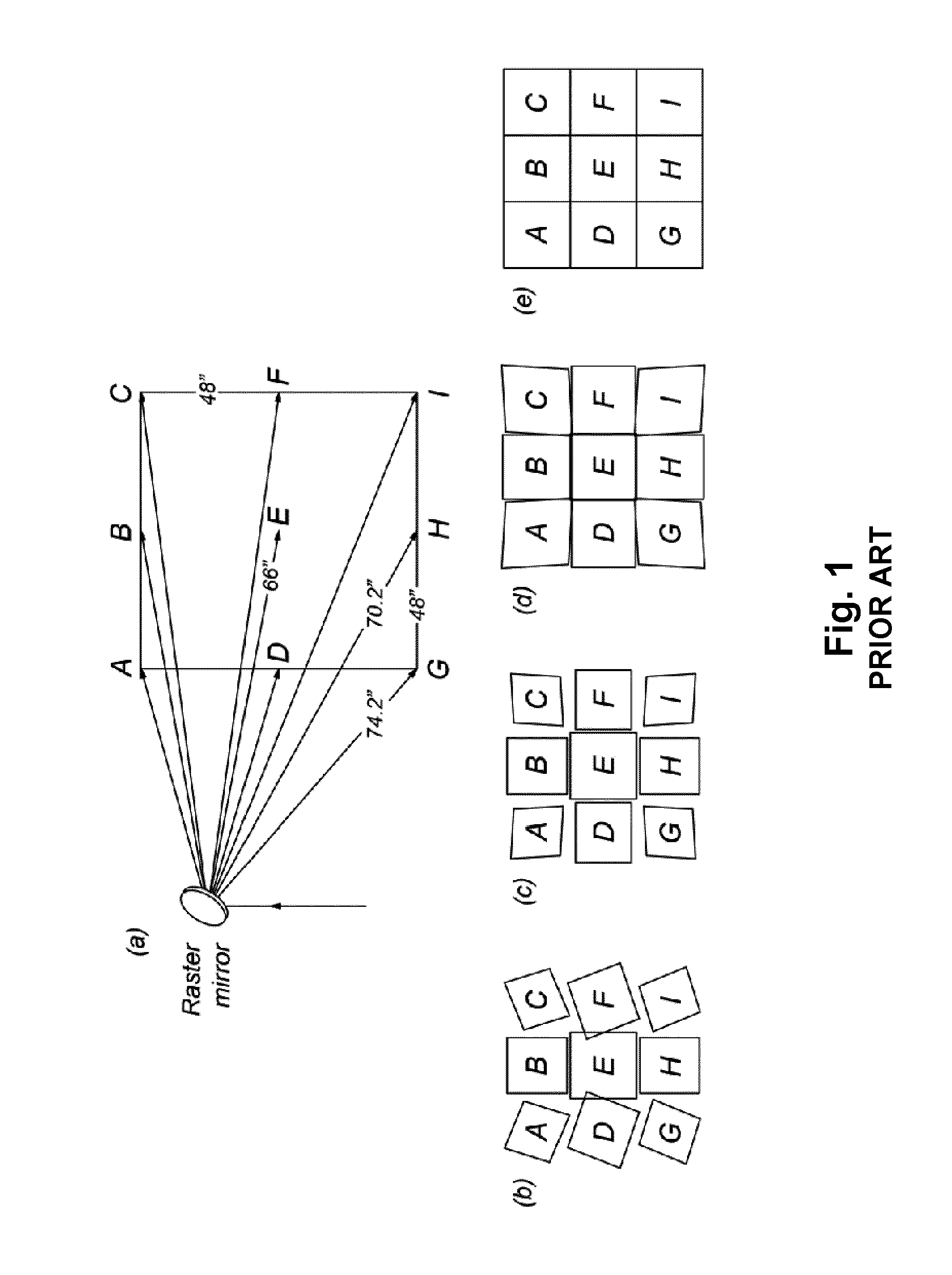

InactiveUS20060129994A1Raise priorityHighly prioritizedSoftware testing/debuggingSpecific program execution arrangementsComputerized systemRow-major order

A computer system and method is provided for prioritizing software tests. Software tests are prioritized based on coverage indicators for the software tests and an indication of impacted areas of the software. Each of the coverage indicators indicates which portions of the software are executed for a respective one of the software tests. The portions of the software include at least one of a plurality of blocks. The indication of impacted areas of the software indicates ones of the plurality of blocks that are modified or new with respect to a previous version of the software. A prioritized list of software tests is output. The prioritized list includes at least one test sequence.

Owner:MICROSOFT TECH LICENSING LLC

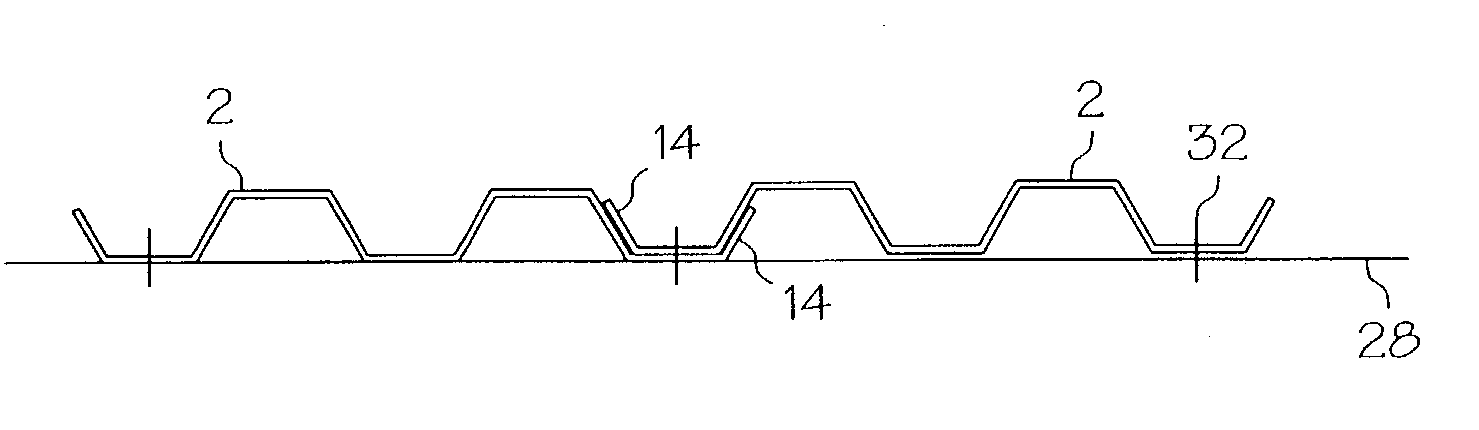

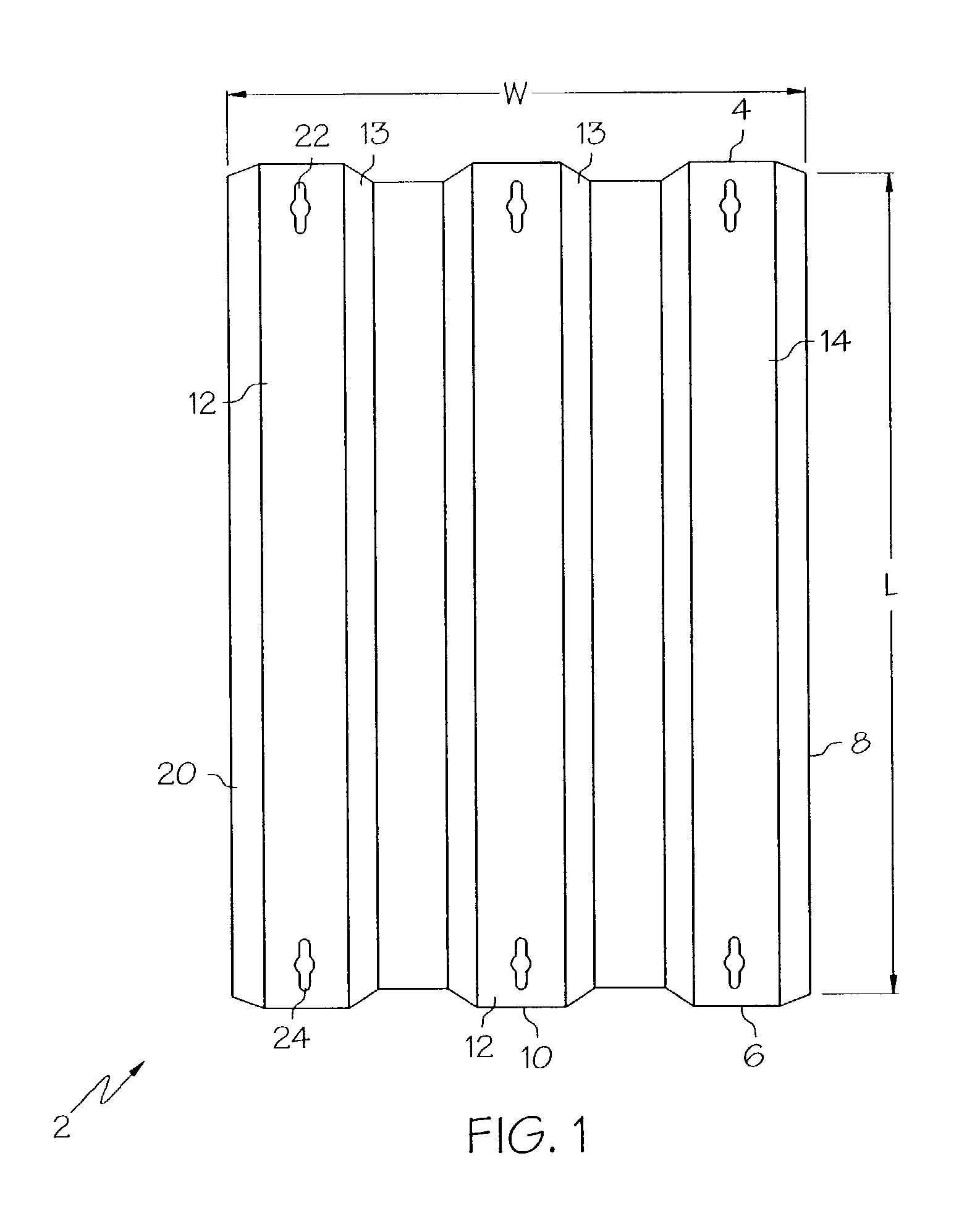

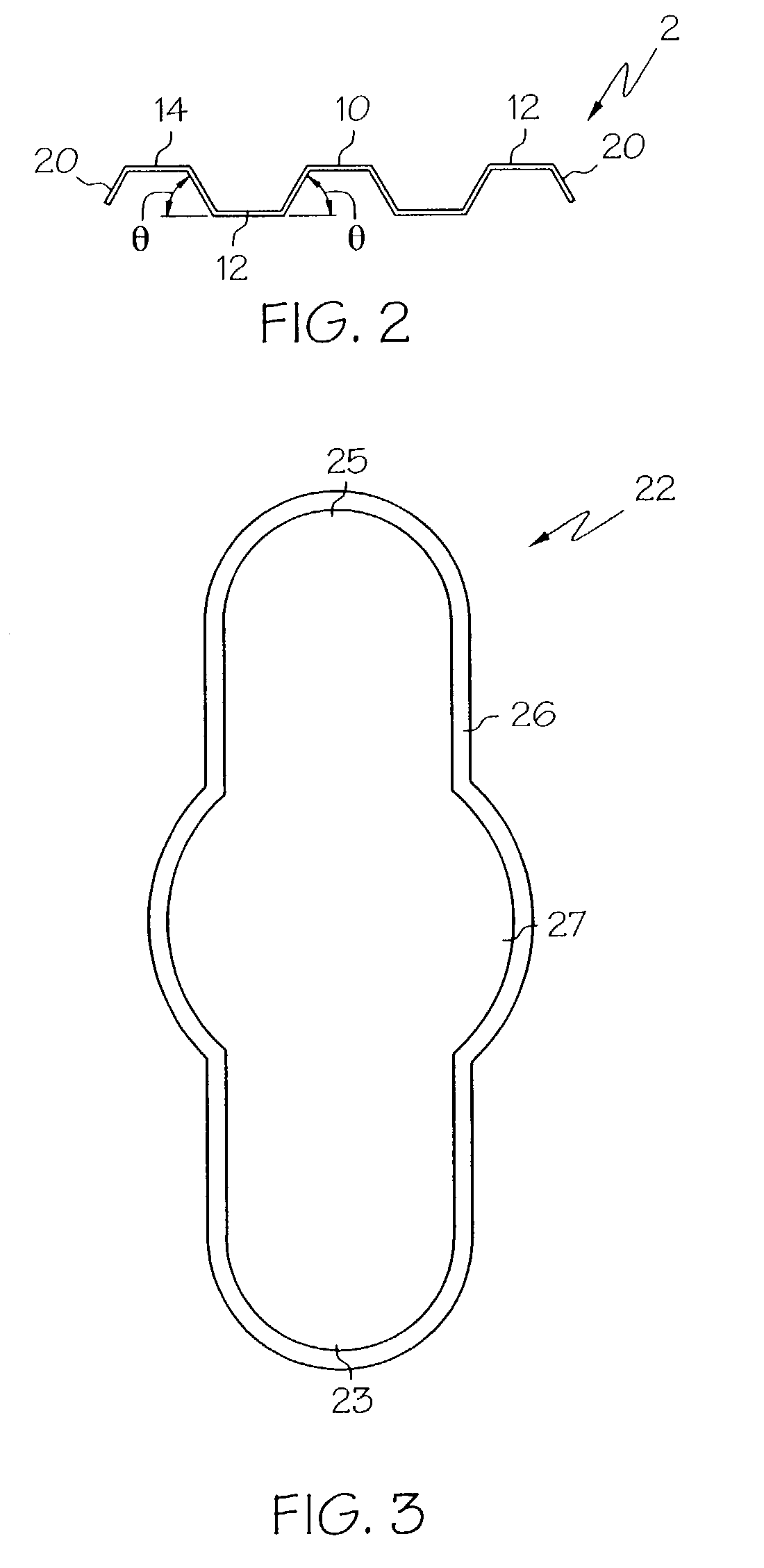

Plastic sheets for use in protecting openings in walled structures

Sheets and sheet kits for use in protecting openings in a walled structure are provided. The sheets are generally plastic sheets having at least one corrugated region and a pair of lateral corrugated regions. The corrugated region and the lateral corrugated regions are configured such that the sheet can resist a missile weighing about 9.4 lbs (4.3 kgs), having a cross-sectional impact area of about 5.25 in2 (34 cm2), and impacting the sheet at a velocity of about 50 ft / s (15.24 m / s). The sheet kits include mounting tracks. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that is will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:PARAGON PLASTIC SHEET

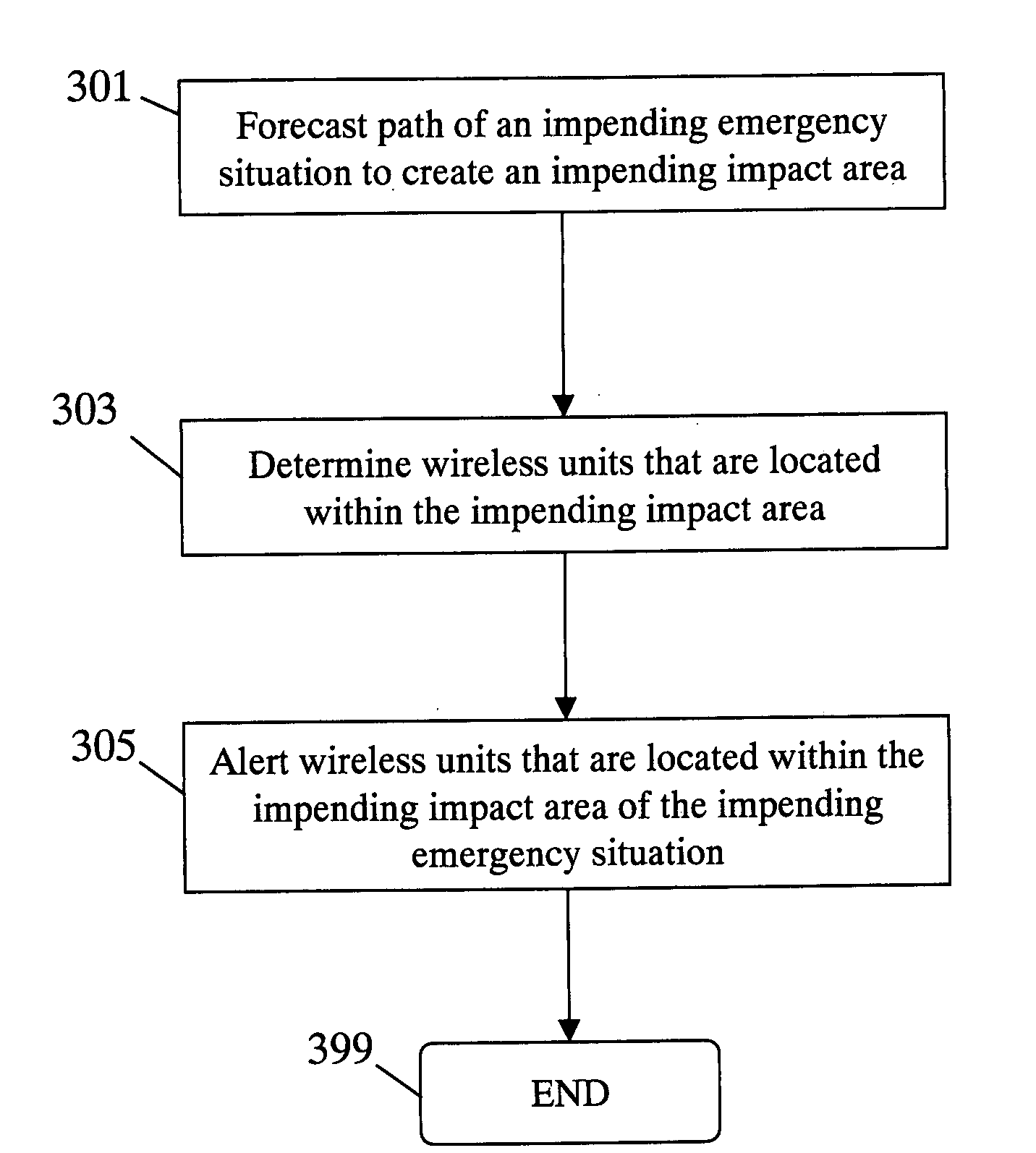

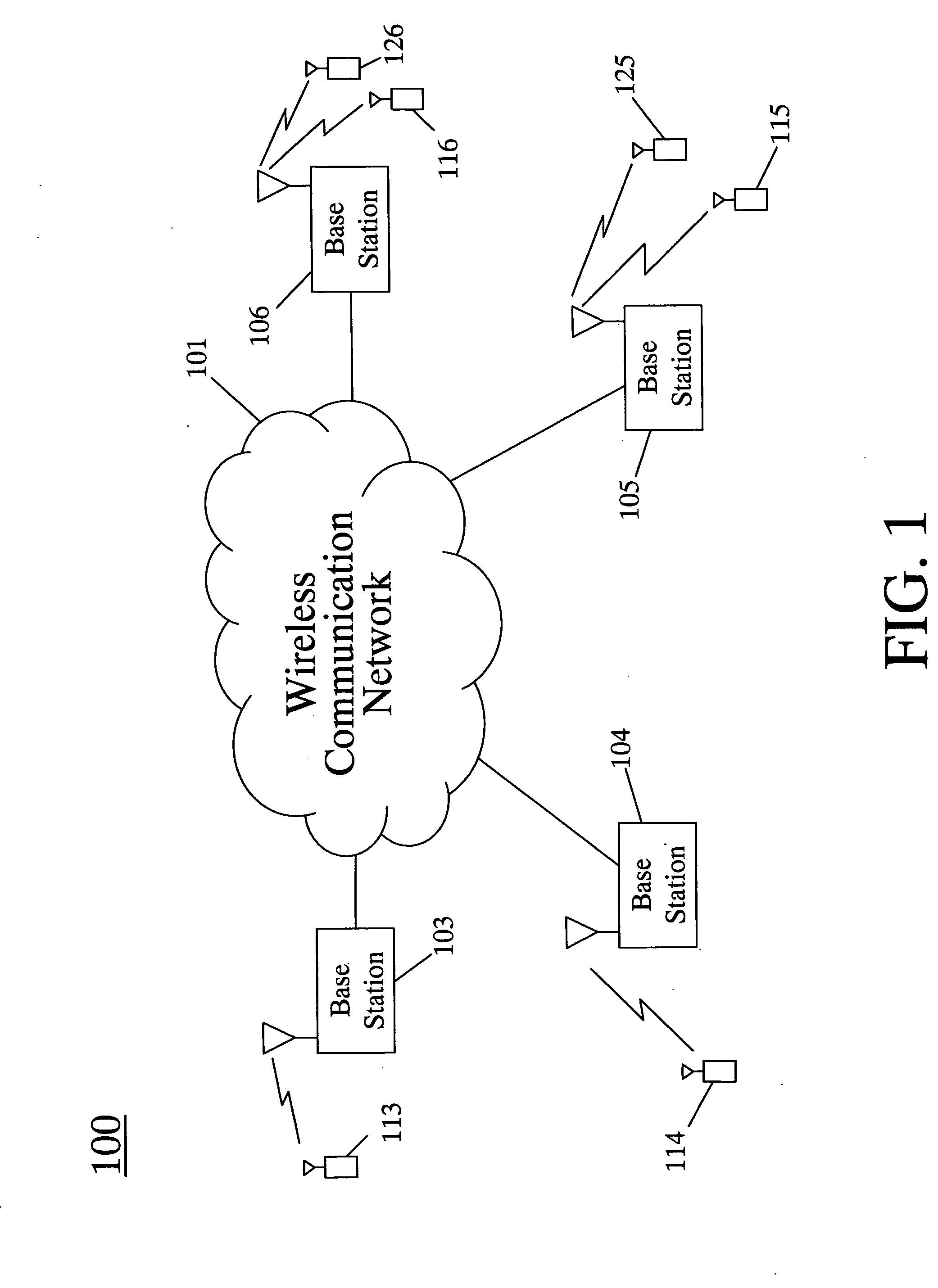

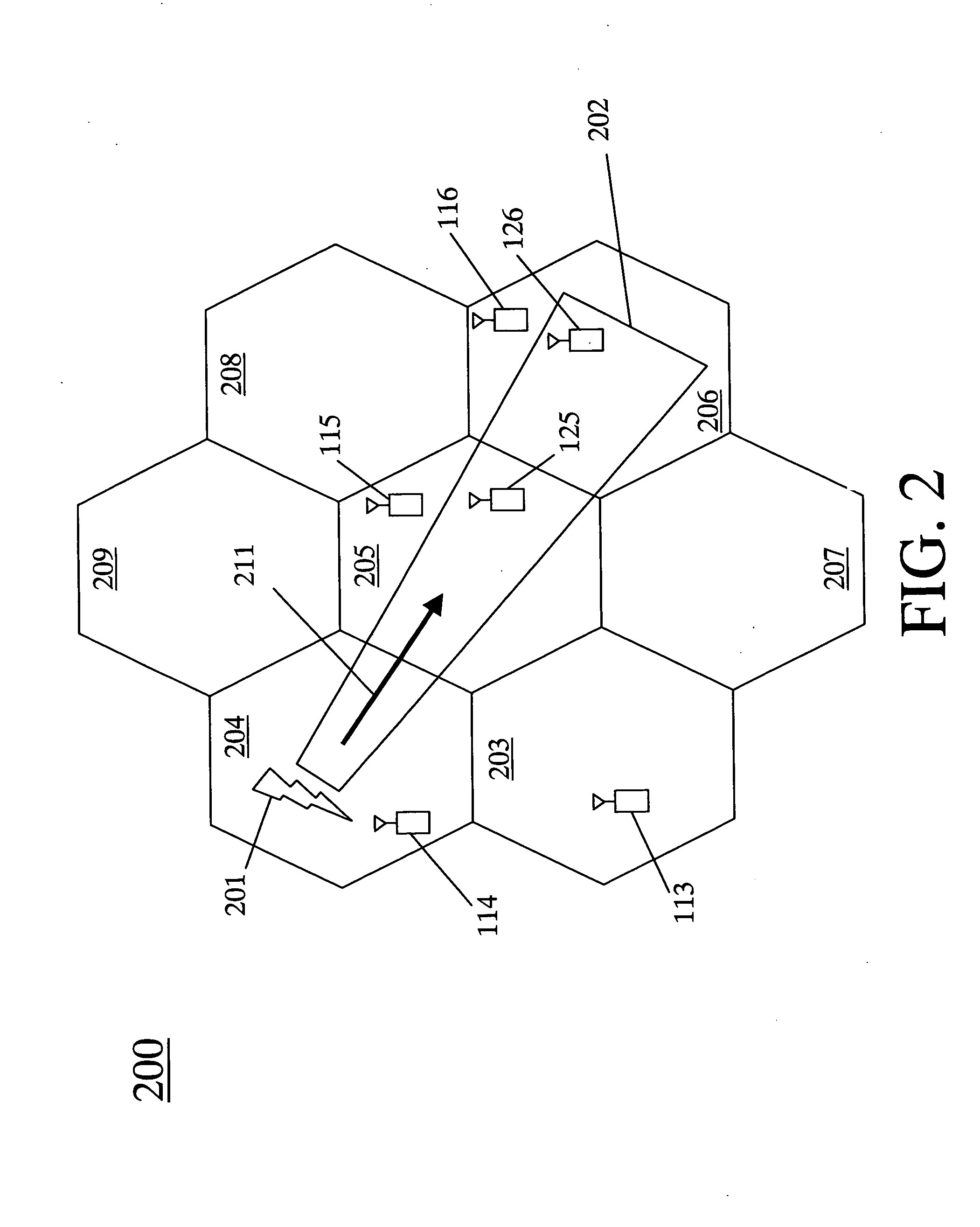

Method for alerting wireless units of an impending emergency situation

InactiveUS20060025106A1Faster and more accuratelyEmergency connection handlingTelephonic communicationEngineeringImpact area

The present invention provides a method for alerting wireless units of an impending emergency situation. A wireless communication network or government authority forecasts the path of an impending emergency situation to create an impending impact area. The wireless communication network determines the wireless units that are located within the impending impact area. The wireless communication network alerts the wireless units that are located within the impending impact area of the impending emergency situation, providing multi-media instructions to the users of the wireless units.

Owner:LUCENT TECH INC

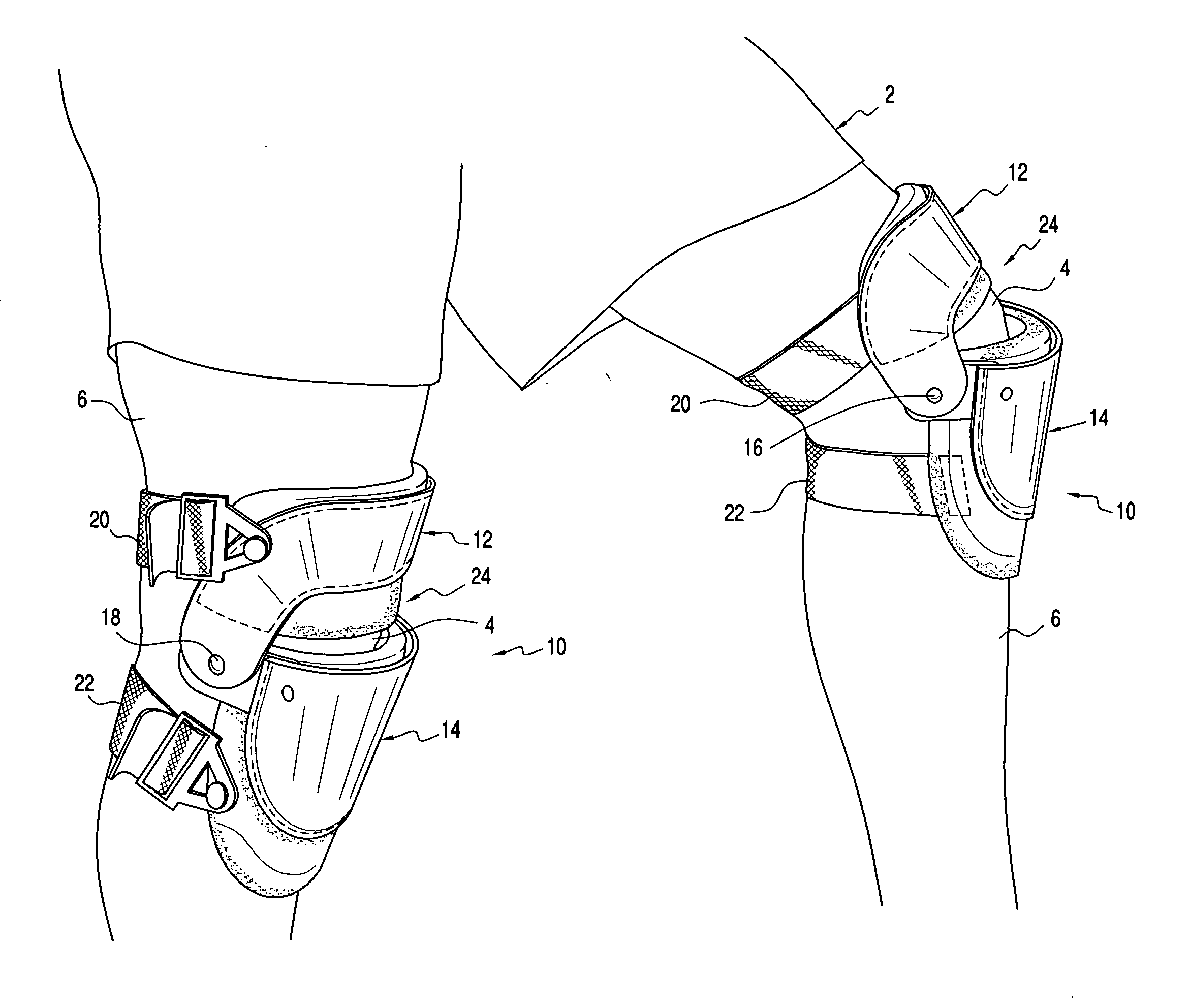

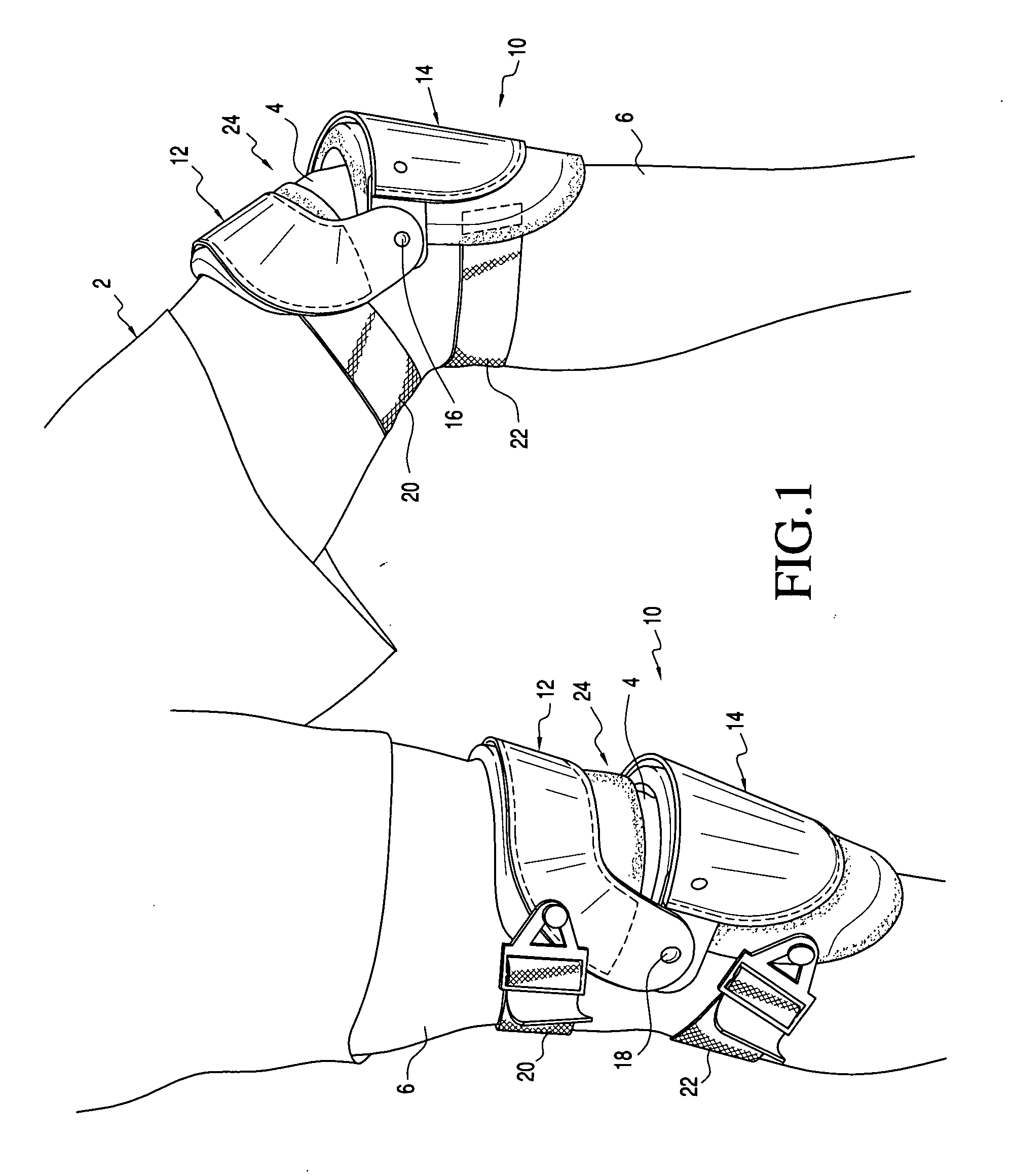

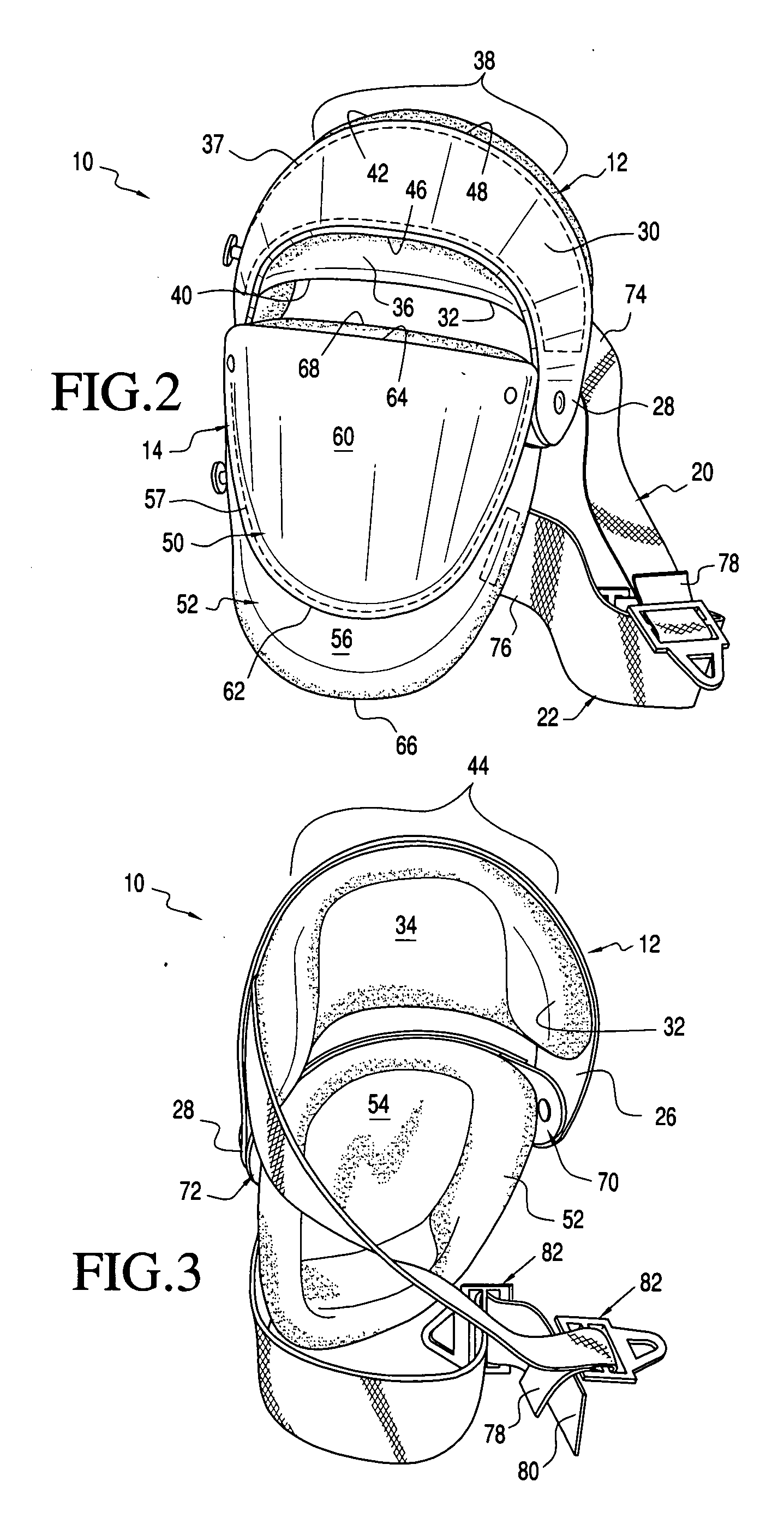

Joint protection device

InactiveUS20050277859A1Overcome drawbackOvercome shortcomingNon-surgical orthopedic devicesProtective garmentEngineeringImpact area

A device made in accordance with the present invention provides adequate joint protection for a user when the user is involved in activities wherein the joint is likely to have a limited impact area. This invention provides a joint protection device that is comfortable to wear because it is lightweight; well ventilated; designed to provide easily accommodate movement of the limbs without moving off the joint; and configured not to pinch or “bite” the user's skin. The present invention provides a joint protection device having a two-piece design, wherein an upper portion is pivotally connected to a lower portion with an opening between the portions. The device is removably attached to a user's joint with attachment members that are connected to the device and that wrap around the limb of the user. The device of the present invention does not substantially encompass the joint. Rather, the lower portion includes a substantially rigid portion that is operably configured to cover only a minimal area and preferably just the impact area of the joint, and the upper portion has a general u-shape that extends from opposing sides and above the joint.

Owner:CARLSMITH BRUCE S

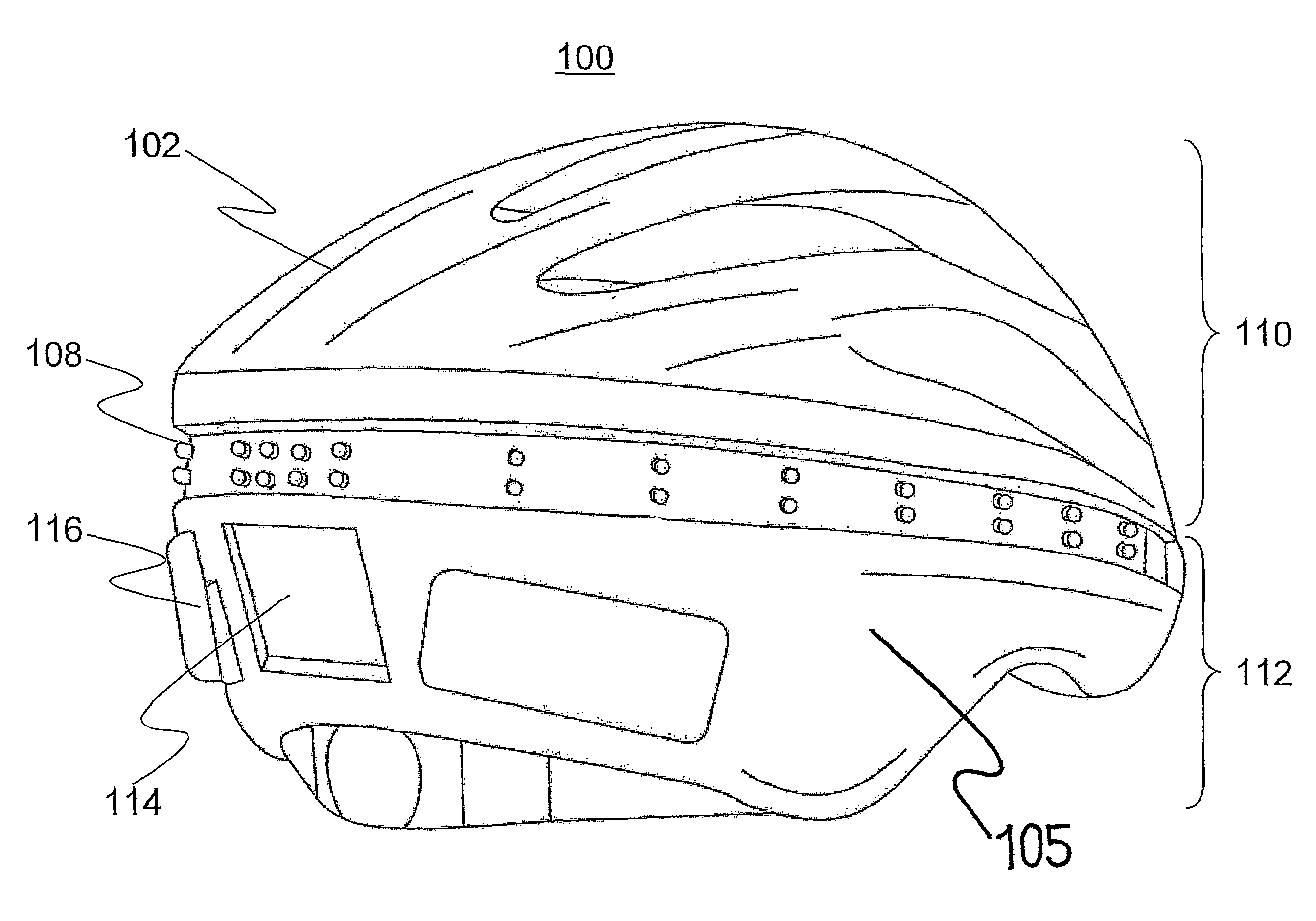

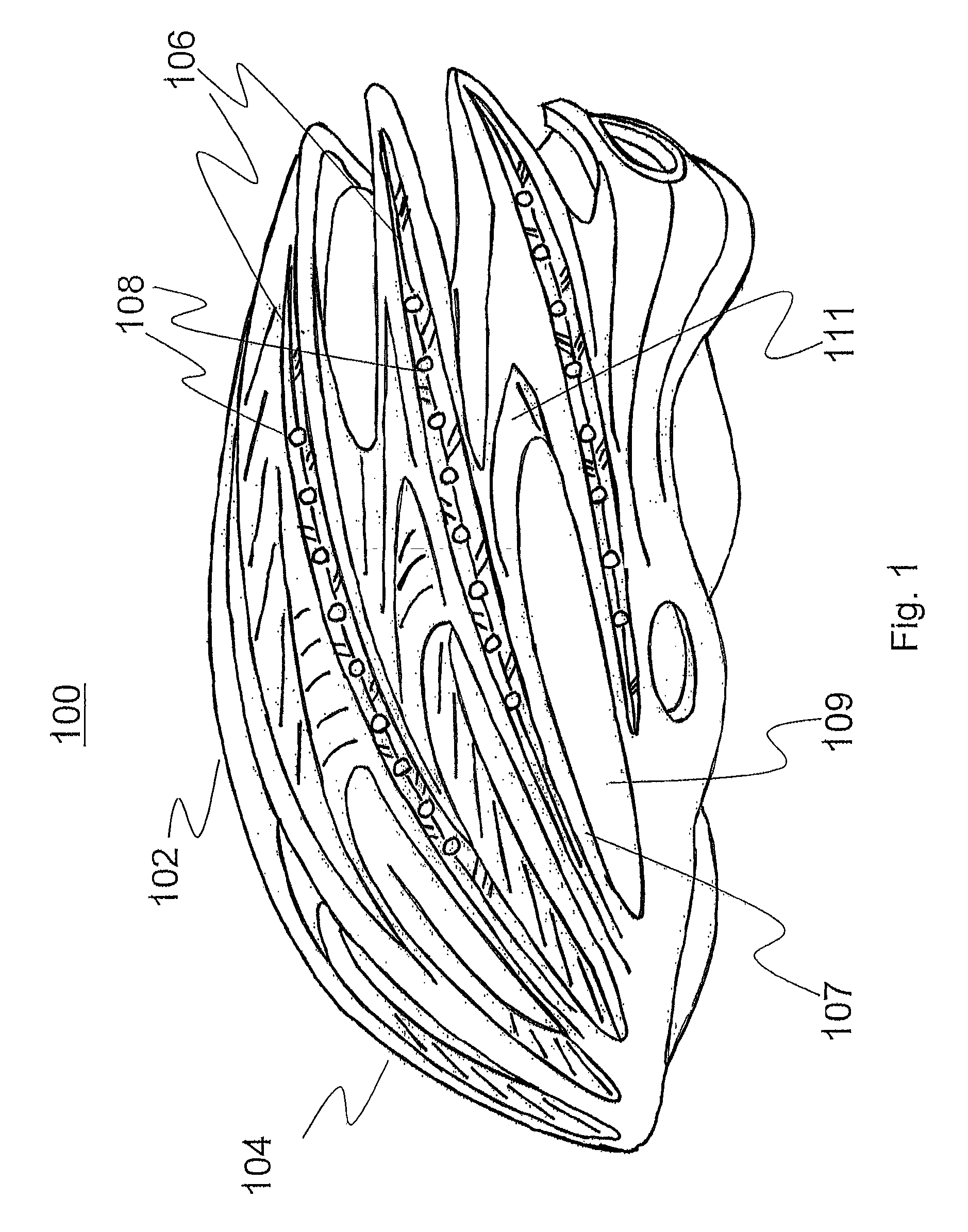

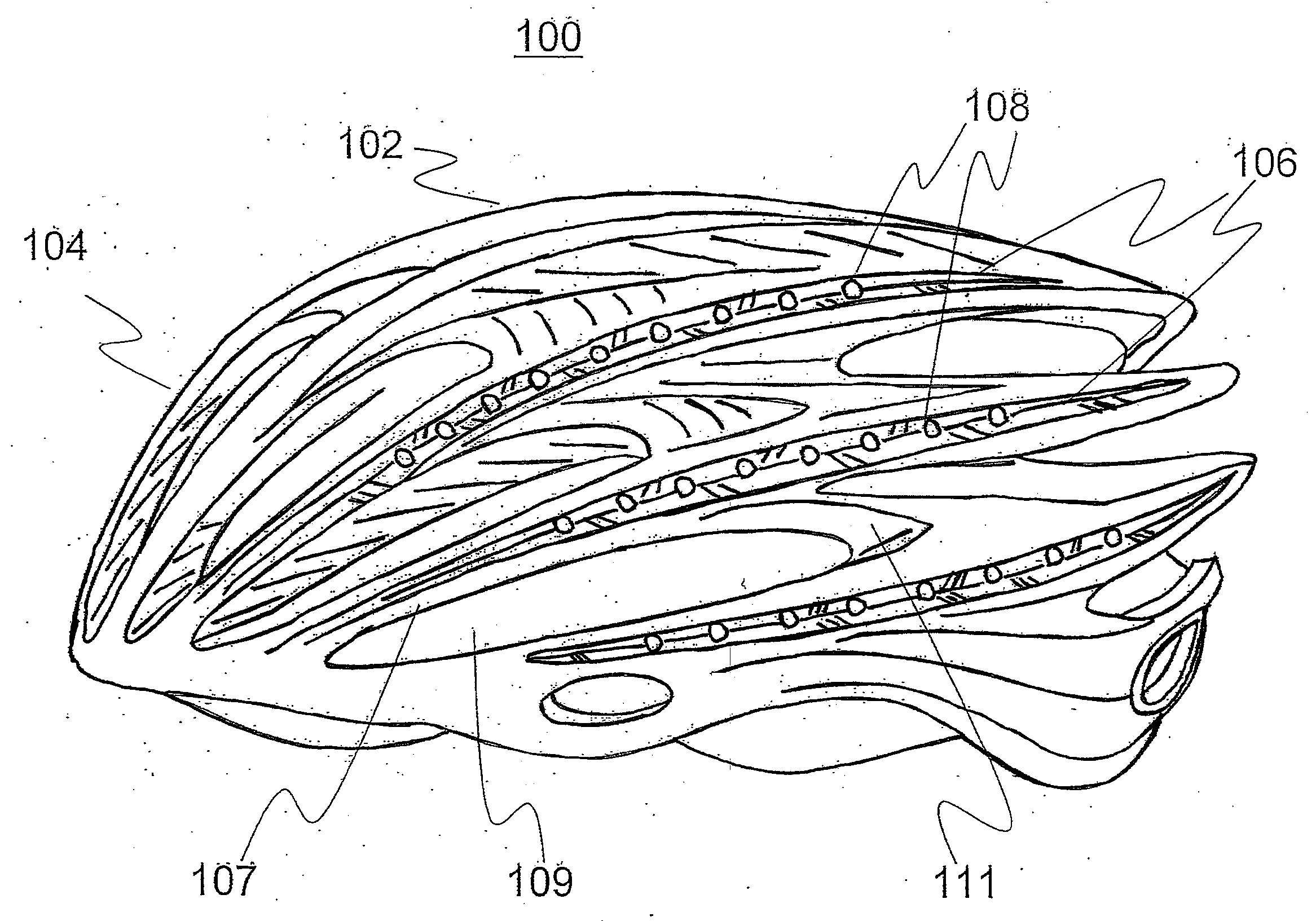

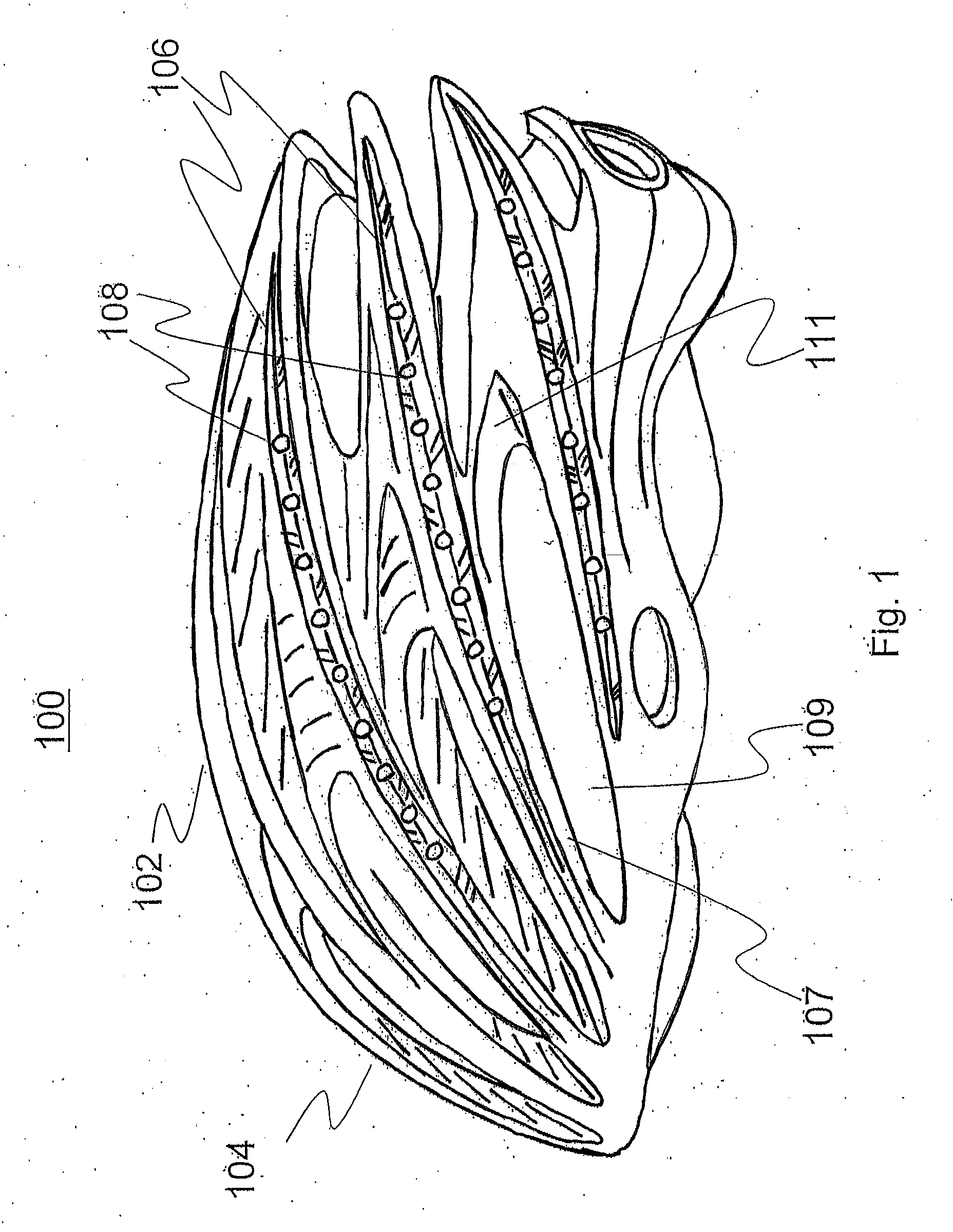

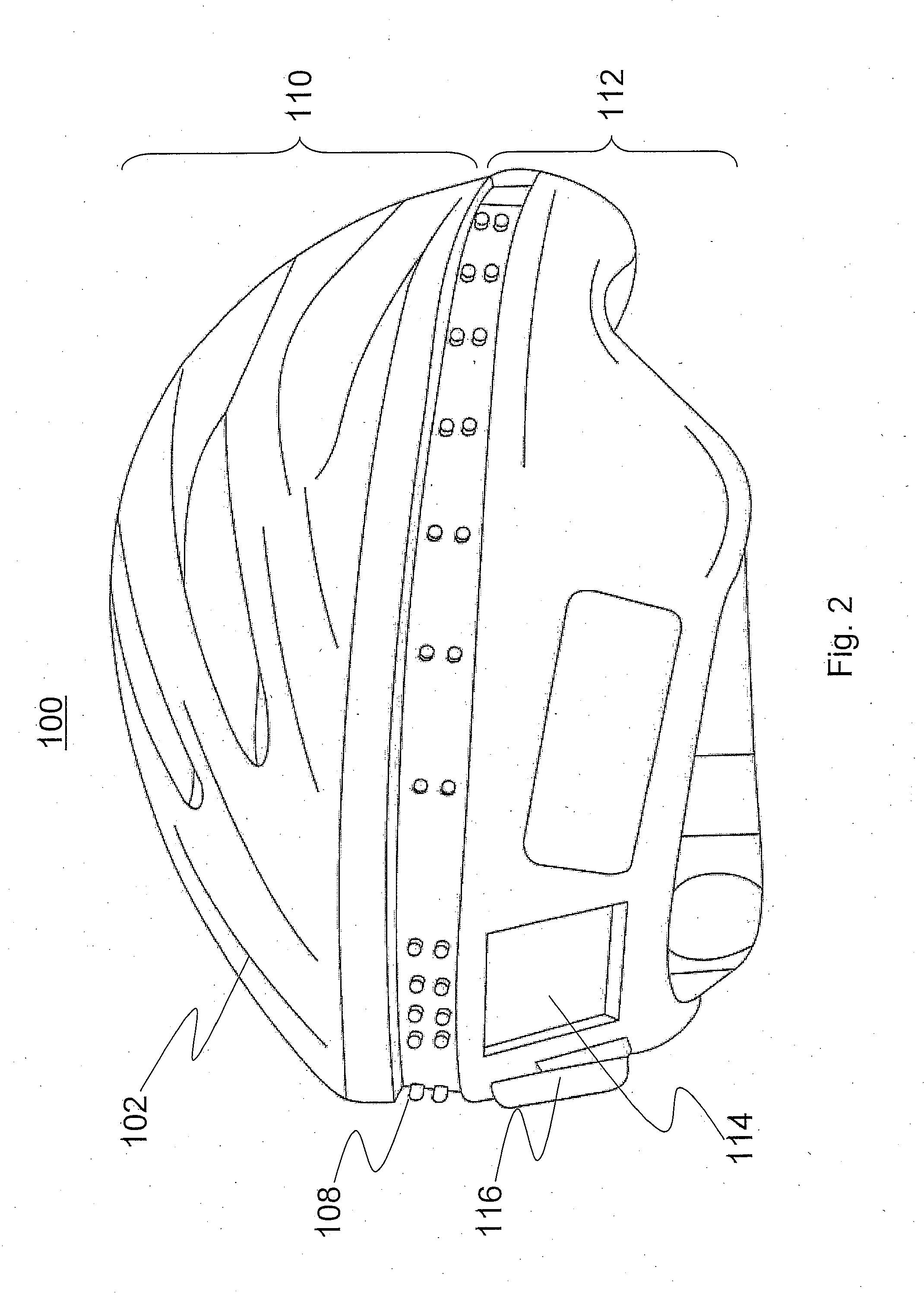

Illuminated helmet with programmable lamps and proximity sensor

InactiveUS8157402B2Reduce risk of damageReduce the risk of injuryLighting support devicesDisplay meansProximity sensorEngineering

An illuminated helmet with a plurality of lamps positioned in at least one recess, a controller to operate the lamps in a flashing pattern, and a proximity sensor to activate the controller and lamps upon detection of a user's head. The recesses for the lamps and other components are located in a non-impact area of the helmet. The lamps are arranged to be visible to a viewer from any angle, and the flashing patterns of the lamps are programmed to draw the attention of the human eye.

Owner:BARSEVENTY

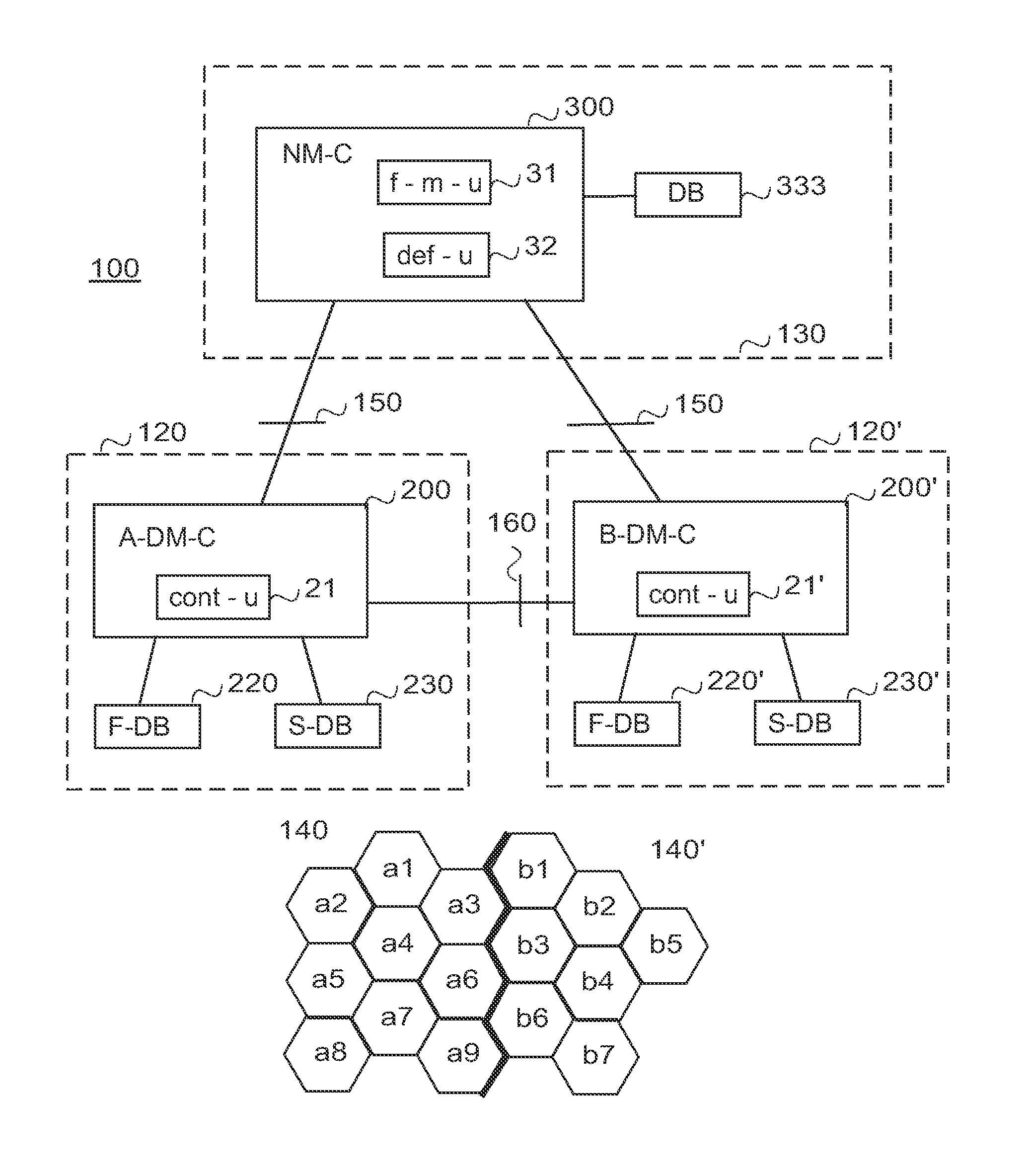

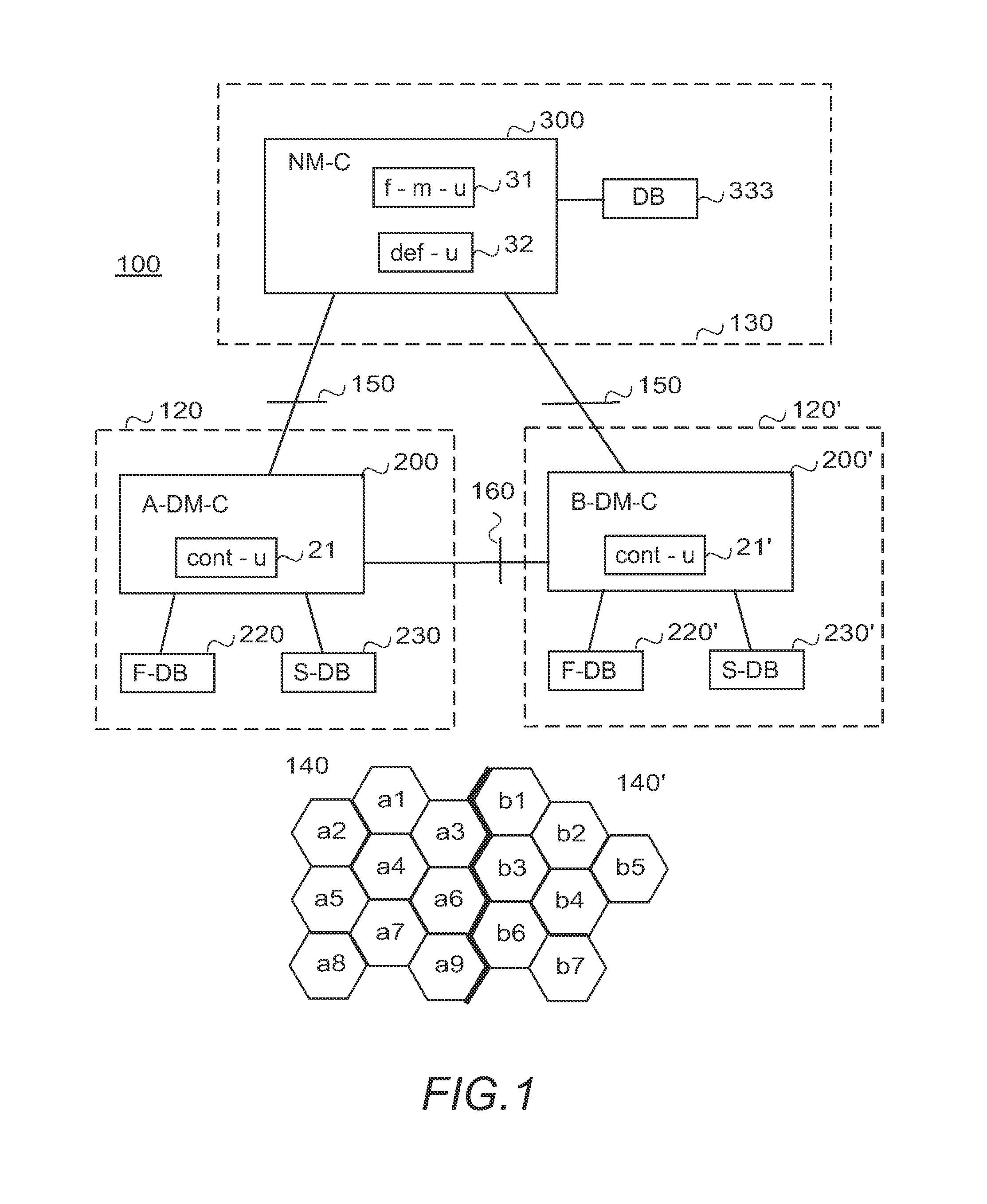

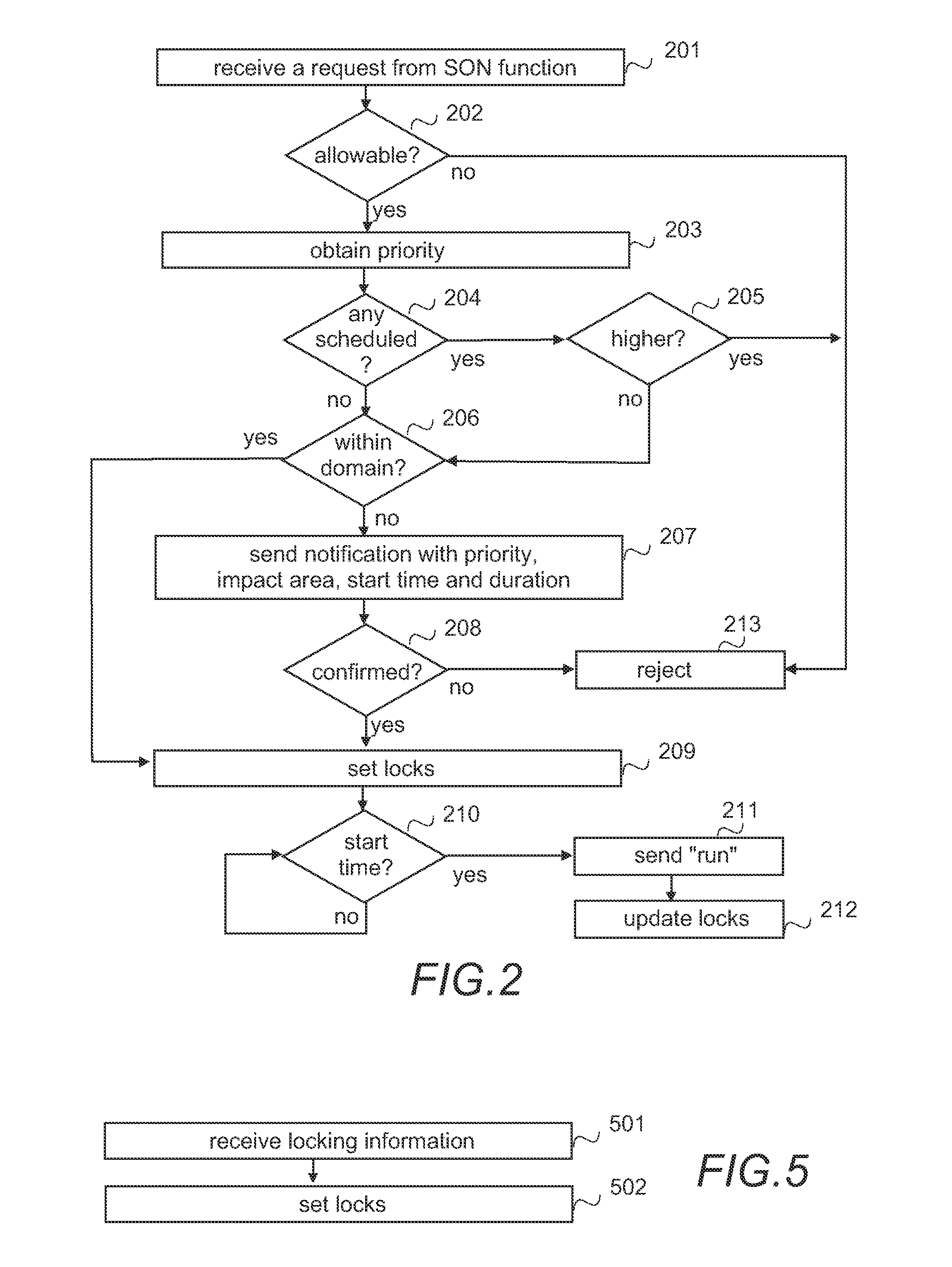

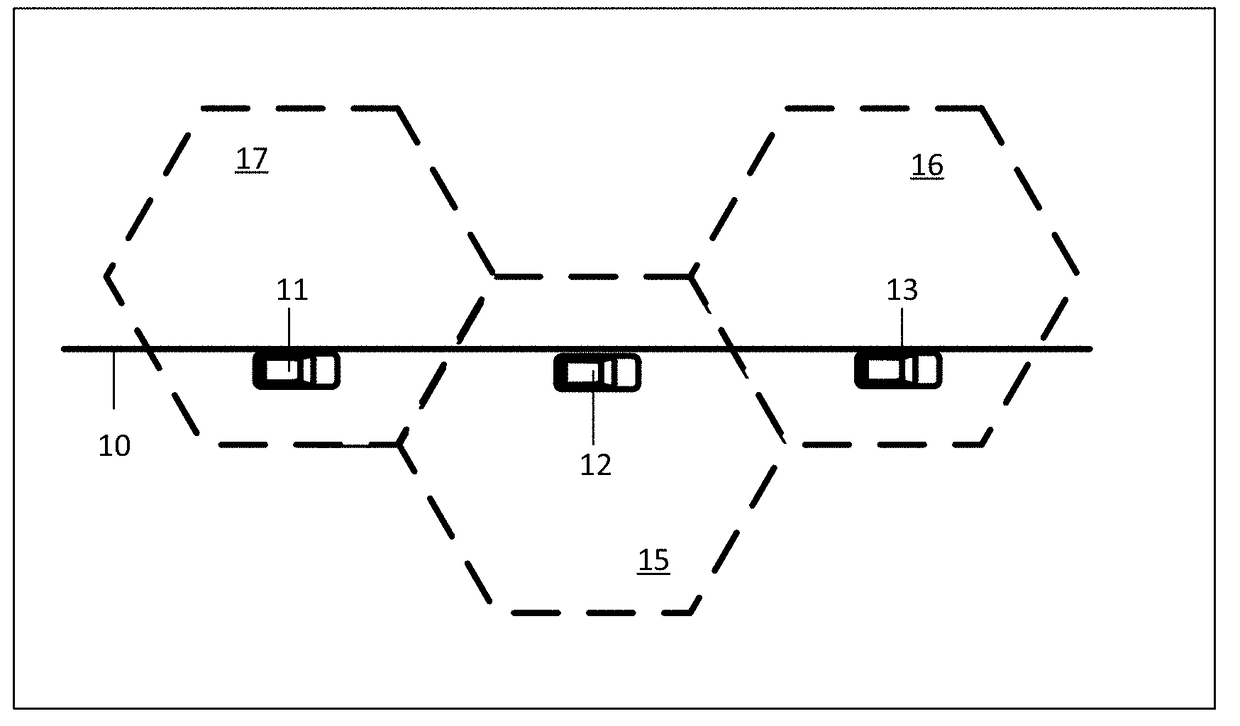

Coordination in self-organizing networks

ActiveUS20140040450A1Less processing capacityLess exchangingNetwork topologiesDigital computer detailsImpact areaSelf-organizing network

To decide, whether or not a SON function instance is allowed to execute, a priority, an impact time and an impact area for the SON function instance is determined, and priorities of other SON function instances scheduled to be run during the impact time of the requesting SON function instance and having an overlapping impact area are compared to the priority of the requesting SON function instance.

Owner:NOKIA SOLUTIONS & NETWORKS OY

Illuminated helmet

InactiveUS20090303698A1Reduce risk of damageThickness minimizationLighting support devicesDisplay meansProximity sensorEngineering

The present invention provides an illuminated helmet with a plurality of lamps positioned in at least one recess in the helmet to reduce the risk of damage to the lamps and prevent the lamps from injuring a user during an accident. The illuminated helmet also provides specific recesses for the lamps and other components located in a non-impact area of the helmet to further reduce the risk of injury from the components and lamps in an accident. Furthermore, the illuminated helmet provides a proximity sensor mounted within the helmet that lacks mechanical parts and automatically activates the lamps when the helmet is worn by a user, improving the safety and reliability of the proximity sensor and overall helmet. The lamps are arranged in such a manner as to be visible to a viewer from any angle, and the flashing patterns of the lamps are uniquely programmed to draw the attention of the human eye.

Owner:BARSEVENTY

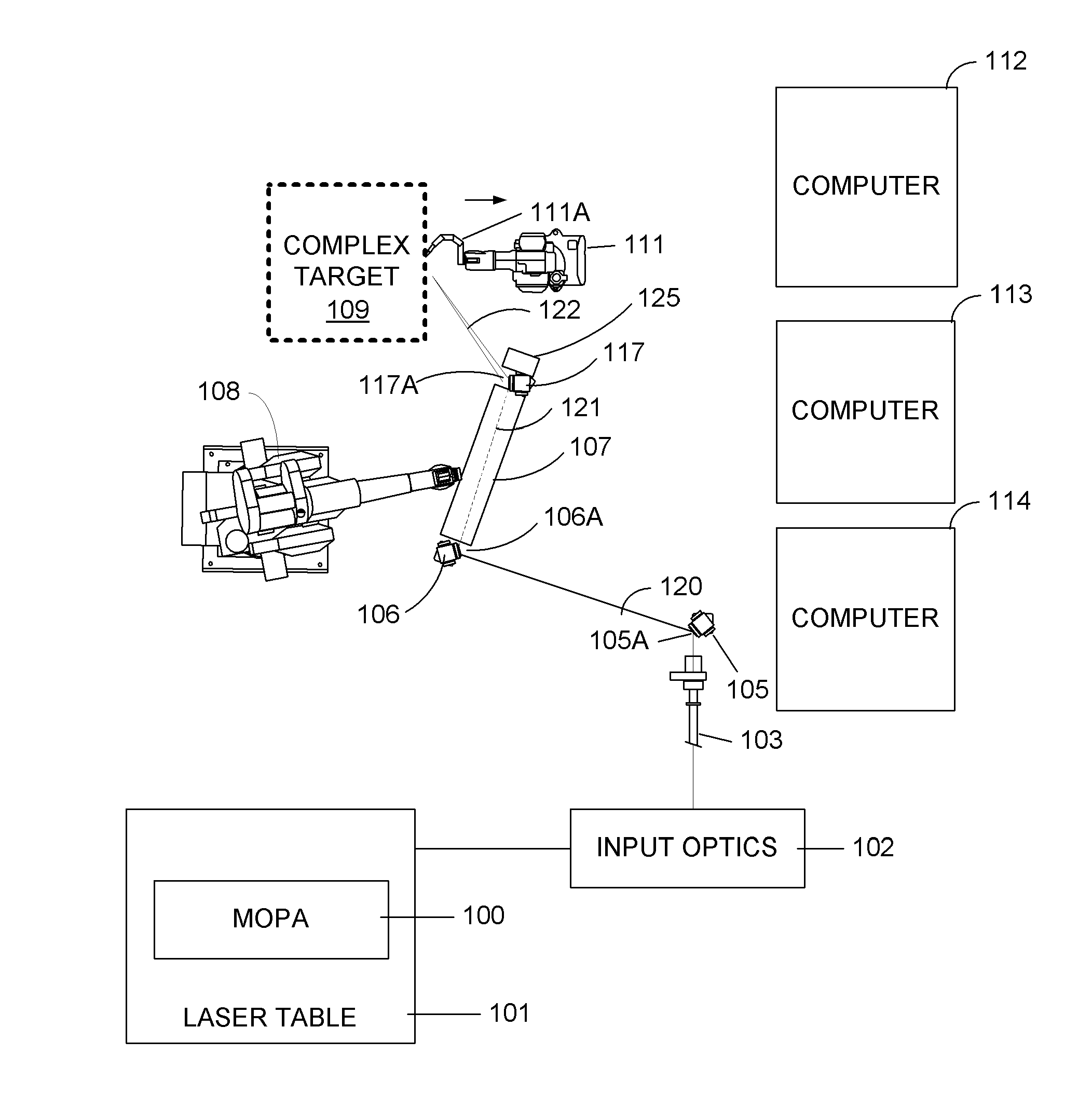

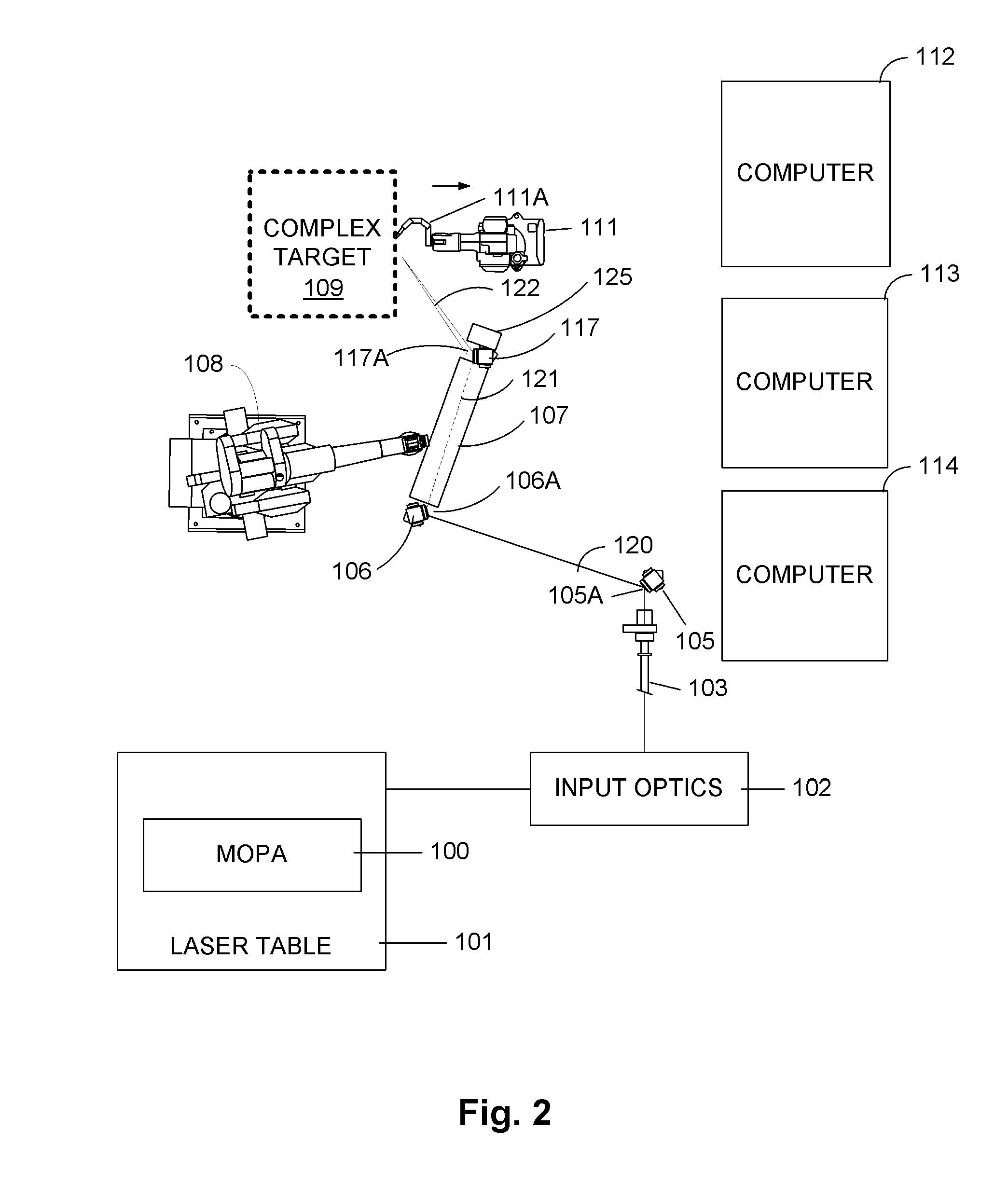

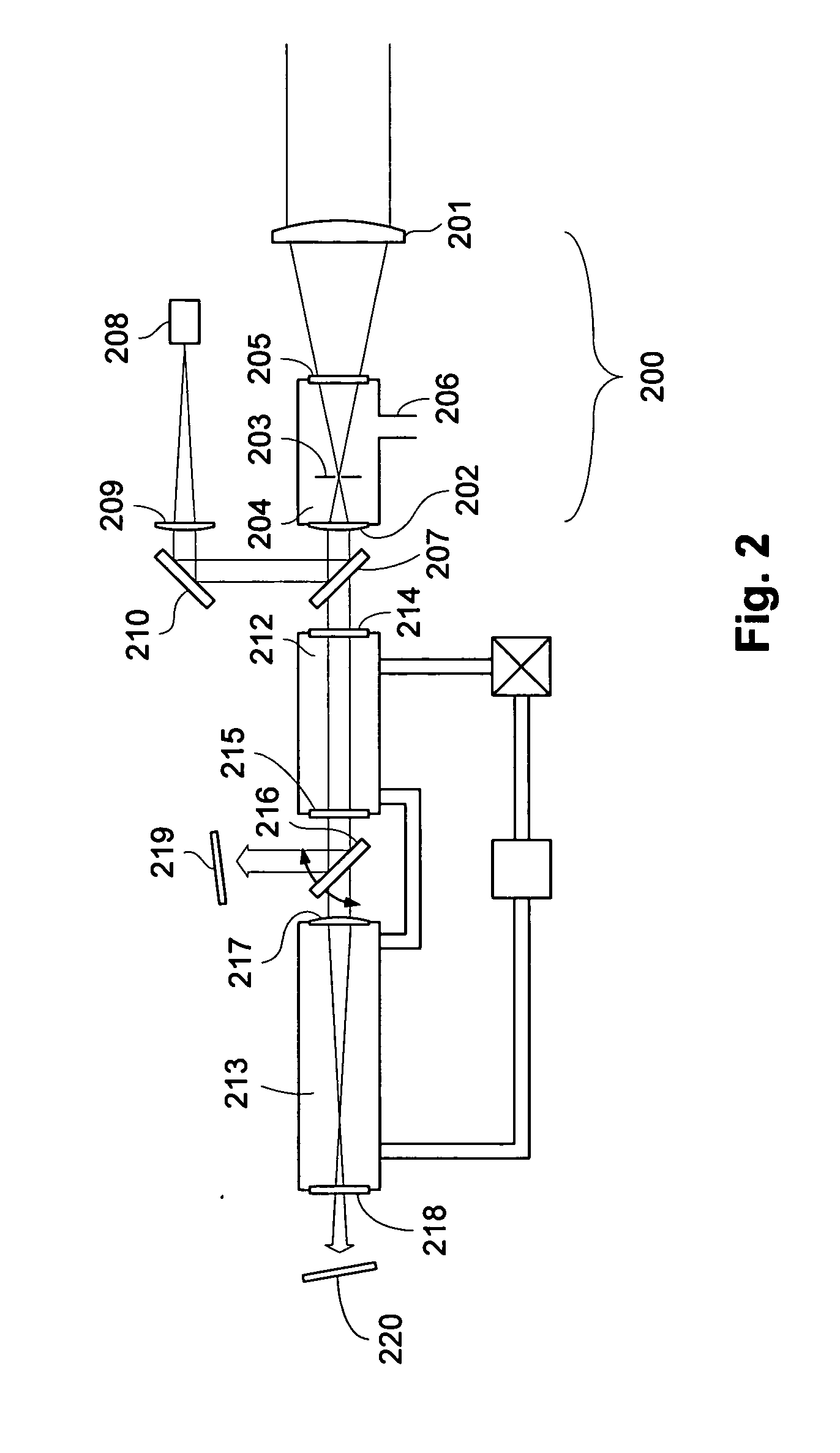

Flexible beam delivery system for high power laser systems

ActiveUS20110253690A1Photometry using reference valueLaser beam welding apparatusHigh power lasersLight beam

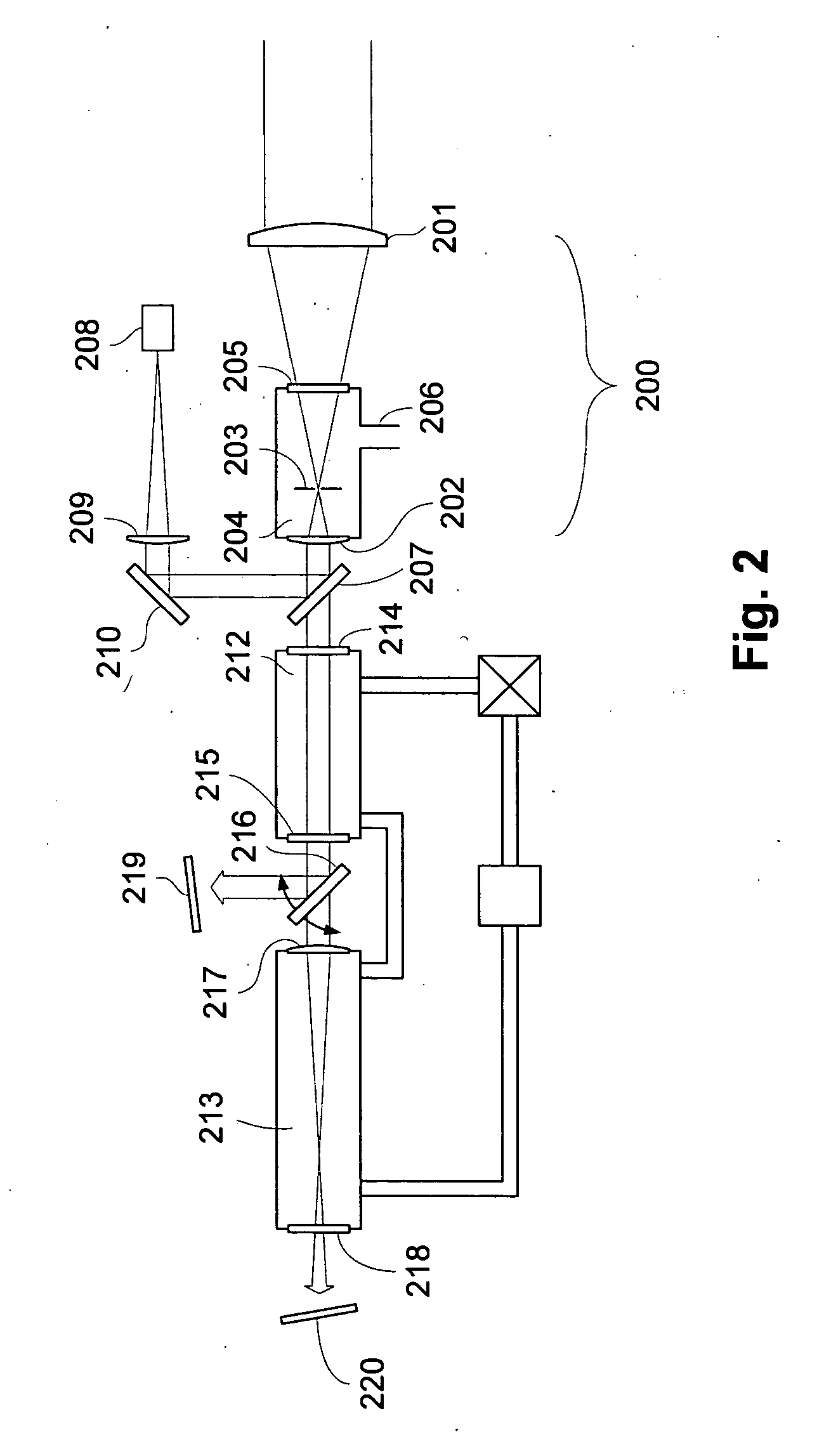

A beam delivery technology for high power laser systems, like laser peening systems, for work pieces which may have compound curvatures, includes placing an optical assembly having a receiving optic, beam formatting optics and a scanner mounted thereon, in a position to receive laser pulses from a laser source and within an operating range of the process area. Polarized laser pulses are delivered to the receiving optic while the position of the optical assembly remains unchanged. The pulses proceed through the beam formatting optics to the scanner, and are direct to respective impact areas having nominal shapes and locations on the work piece. The scanning process includes for each laser pulse, setting direction, divergence, polarization, rotation and aspect ratio of the laser pulses output from the scanner, to control the polarization, shape and location on respective impact areas.

Owner:METAL IMPROVEMENT

Method and apparatus for detecting a load change upon a structure and analyzing characteristics of resulting damage

ActiveUS7458266B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerEngineering

A sensor network is attached to a structure and employed to detect and analyze load changes. The sensor network has transducers, capable of acting as both passive sensors and active actuators, integrated within it. In a passive mode, the transducers detect load changes upon the structure, such as impacts. Upon detection of a load change, the transducers are engaged in an active mode to actively scan the impact area to determine the location and size of any resulting damage region. In this manner, passive and active systems are integrated within a single, convenient layer that possesses the best features of both active systems and passive systems.

Owner:ACELLENT TECH

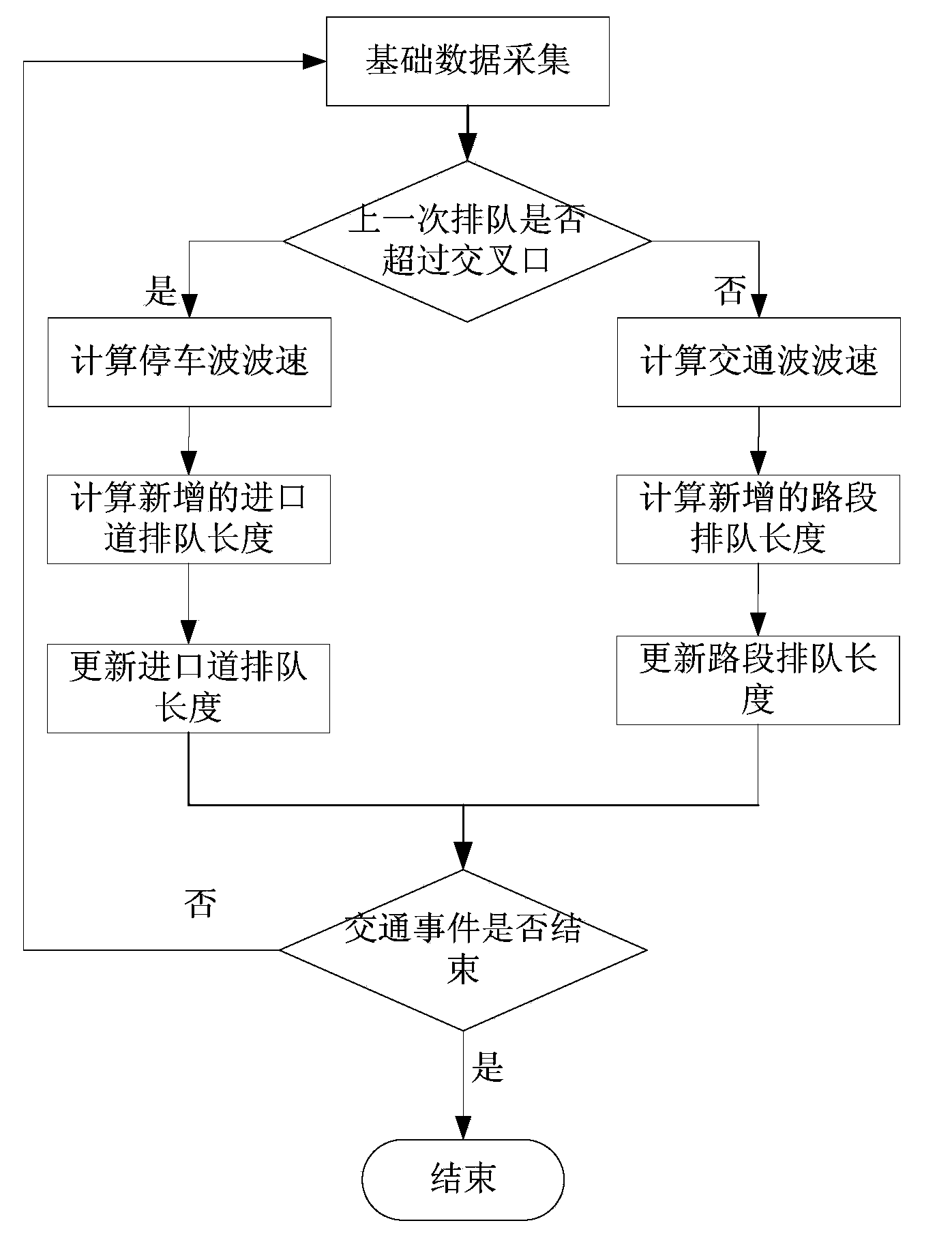

Method for determining traffic incident impact areas and durations on basis of coil detection

The invention relates to a method for determining traffic incident impact areas and durations on the basis of coil detection. The method includes enabling coils to acquire traffic flow and spot average speed data at preset intervals when traffic incidents occur, and updating queuing lengths of road sections; updating queuing lengths of various access roads when the queuing lengths of the road sections are larger than the distances from traffic incident occurrence spots to intersections; updating dissipation lengths of the road sections and the queuing lengths of the various access roads when the traffic incidents are completed; updating dissipation lengths and the queuing lengths of the various access roads when the dissipation lengths of the road sections are larger than the distances from the traffic incident occurrence spots to the intersections; determining that the traffic incidents are completely finished when the dissipation lengths of the various access roads are larger than the corresponding queuing lengths, and determining the incident impact areas and the durations. Compared with the prior art, the method has the advantages that development of the traffic incidents is observed in real time by the aid of the coils, accordingly, the traffic incident impact areas and the impact durations can be accurately estimated, and a decision basis can be provided for traffic control and management.

Owner:TONGJI UNIV

Diverter valve with multiple valve seat rings

InactiveUS20050263194A1Reduce impact stressExtended component lifeDirection controllersServomotor componentsEngineeringImpact area

A diverter valve includes a valve bore having a set of valve seats associated with each fluid outlet port. Each set of valve seats is at least partially separated from one another by a flow channel. The valve seat configuration increases the impact area for the valve element. As a result, the impact force upon seating against the valve seats is reduced. Moreover, by including flow channels between the sets of valve seats, the switching force and performance of the valve element is not adversely affected.

Owner:HONEYWELL INT INC

Wireless network optimization

ActiveUS20180063002A1Data processing applicationsDetection of traffic movementImpact areaWireless network

Methods and apparatuses are provided for optimizing a wireless network. A description of a traffic incident is received. An impact area is generated from the description. A geographic polygon is generated based on the impact area. The network usage of the geographic polygon is determined. A message including the network usage for the geographic polygon may be transmitted to a mobile network operator.

Owner:HERE GLOBAL BV

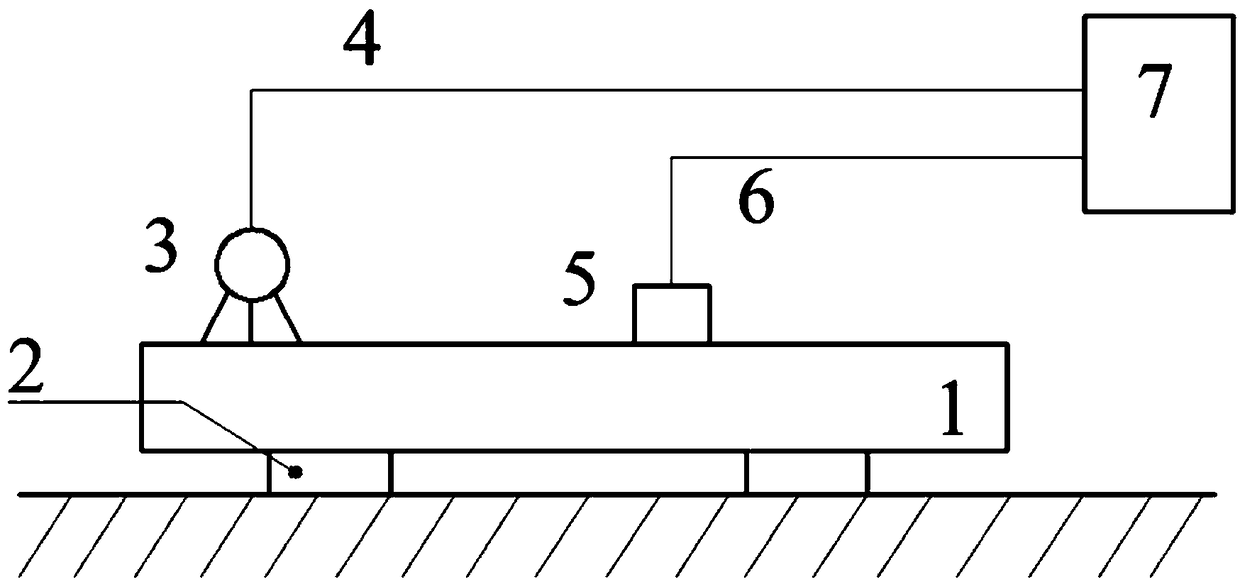

Surface strengthening method for metal component by vibration-assisted laser shock treatment

ActiveCN108660307AImprove mechanical propertiesImprove fatigue lifeVibration exciterMechanical property

The invention relates to the field of new techniques of laser processing and vibration aging, in particular to a surface strengthening method for a metal component by vibration-assisted laser shock treatment. According to the method, by combining laser shock strengthening technology with vibration aging treatment, a vibration exciter is used to excite vibration, a sensor picks up vibration, the vibration frequency is controlled to keep the amplitude value within a specified range, laser lap impact strengthening treatment is carried out with the aid of vibration aging treatment so that more serious plastic deformation can be generated on the surface of the metal component, and high-amplitude residual compressive stress is induced in an impact area; meanwhile under the condition that laser beam irradiates the metal surface, vibration further refines or even nanocrystallizes the surface grain, and under the action of the temperature field, vibration reduces the thermal stress field gradient, and thus the residual stress inside the material is uniformized; and the mechanical properties of the metal component are remarkably improved, and the metal surface is strengthened, so that the fatigue life of the metal component is prolonged effectively, and initiation and expansion of fatigue cracks are prevented.

Owner:JIANGSU UNIV

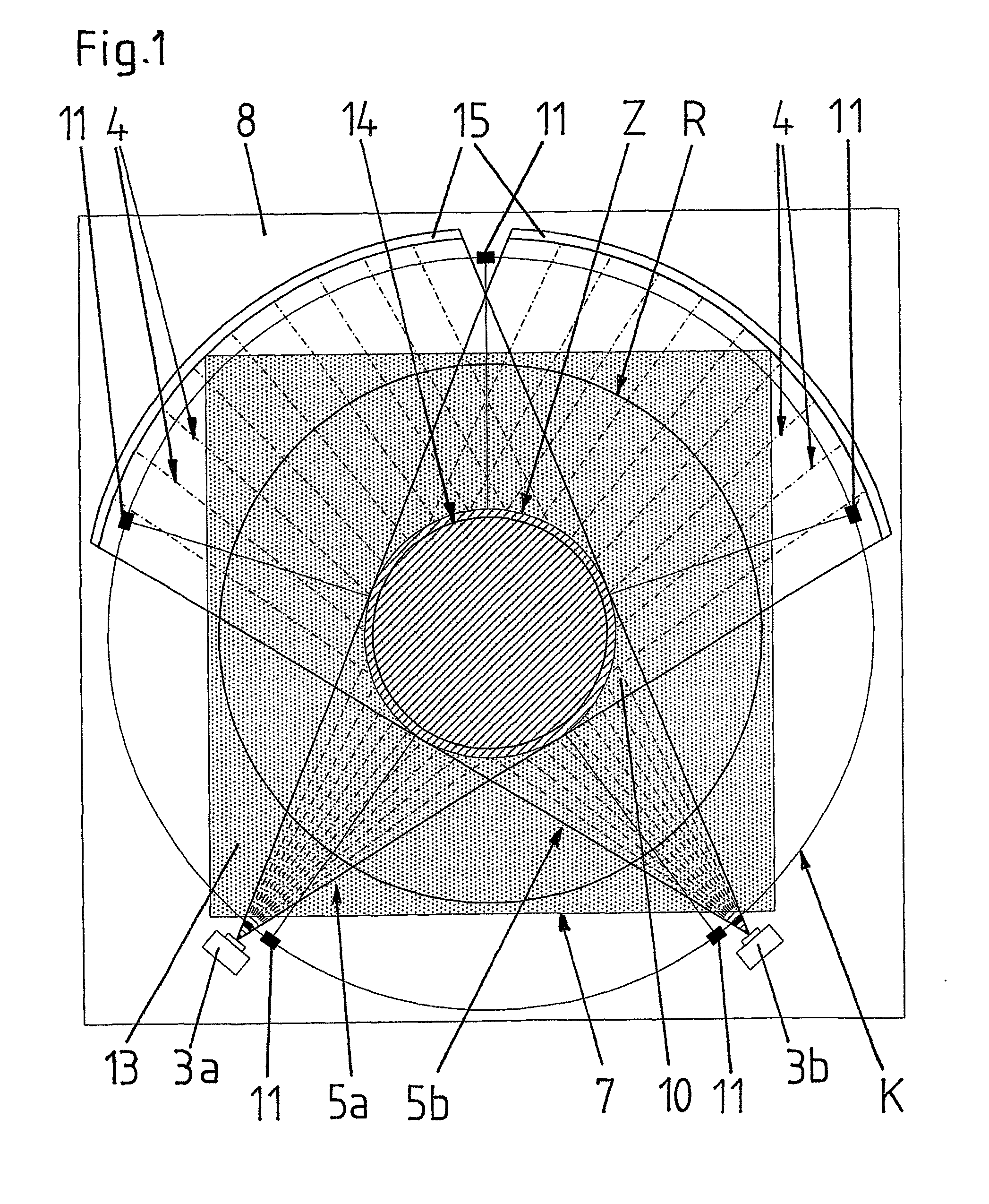

Method for electronically determining the shooting position on a shooting target

InactiveUS20120194802A1Simple processLow running costOptical detectionMaterial analysis by optical meansElectronic systemsOptical measurements

The invention relates to a method for electronically determining the shooting position on a shooting target. Said shooting position is determined in a first impact area (Z) on the shooting target exclusively in an opto-electronic manner and in a second impact area on the shooting target exclusively in an acousto-electronic manner.Said method enables the shooting position to be determined by means of relatively economical electronic systems and with only low running costs for user material, in which the shooting position is determined by means of an optical measurement system only in the relatively small central impact area (Z), which normally has a high impact frequency and which requires high precision for determining the shooting position, whereas the shooting position in the relatively large edge area surrounding said central area is determined by means of an economical acoustic system.

Owner:SIUS

Method for preventing electric precipitation explosion venting during blowing igniting of semi-steel steelmaking

ActiveCN103555880AAvoid explosive limitReduce missed gun accidentsManufacturing convertersSteelmakingEvaporative cooler

The invention provides a method for preventing electric precipitation explosion venting during blowing igniting of semi-steel steelmaking, and belongs to the technical field of converter steelmaking methods. According to the technical scheme, the mixed gas of oxygen and nitrogen is used for igniting and blowing in the blowing stage, instead of single oxygen; the total amount of the mixed gas is the amount of the oxygen supplied for normal blowing, wherein the flow rate of oxygen is 50 to 60% of the amount of oxygen supplied for normal blowing; the gas supply pressure required by normal blowing is provided to a smelting pool; the jet impact area and penetration depth are improved; the igniting time is reduced; if the raise of the temperature of an inlet of an evaporative cooler is beyond 4 DEG C, the flow rate of oxygen can be gradually raised, and simultaneously the flow rate of nitrogen can be reduced; the nitrogen is stopped after the flow rate of oxygen is raised to reach the normal oxygen supply; and the contents of CO and O2 in smoke are controlled to be beyond the explosion venting range. According to the method, the problem which enables the enterprise to be bothered for a long time that electric precipitation explosion venting occurs during blowing igniting of converter semi-steel steelmaking can be solved in a simple way; the potential risk is removed; the production can be carried out smoothly; a great contribution is brought for the safe and efficient production of semi-steel steelmaking.

Owner:HEBEI IRON AND STEEL

Vehicle door trim impacter and method for determining rigidity value of vehicle door trim

InactiveCN101718630AImprove protectionSave development timeVehicle testingMaterial strength using single impulsive forceLinear motionEngineering

The invention provides a vehicle door trim impacter and a method for determining a rigidity value of a vehicle door trim. The vehicle door trim impacter is based on the human body profile outline characteristic and comprises a chest area impacter, an abdomen area impacter, a huckle area impacter, a high-pressure air cylinder and a guide rod, wherein the chest area impacter comprises an impact contact surface with the geometrical characteristic of a human body chest profile; the abdomen area impacter comprises an impact contact surface with geometrical characteristic of the human body abdomen profile; the huckle area impacter comprises an impact contact surface with the geometrical characteristic of the human body huckle profile; the guide rod is set into a linear motion output piece of the high-pressure air cylinder; and the tail end of the guide rod is connected with the chest area impacter, the abdomen area impacter or the huckle area impacter. In the method, each impacted area of the trim is impacted by the impacter and kinetic parameters in the impact process can be measured, thereby obtaining the rigidity value of each area of the trim; and the method is used for optimizing the rigidity design of the trim.

Owner:SAIC MOTOR

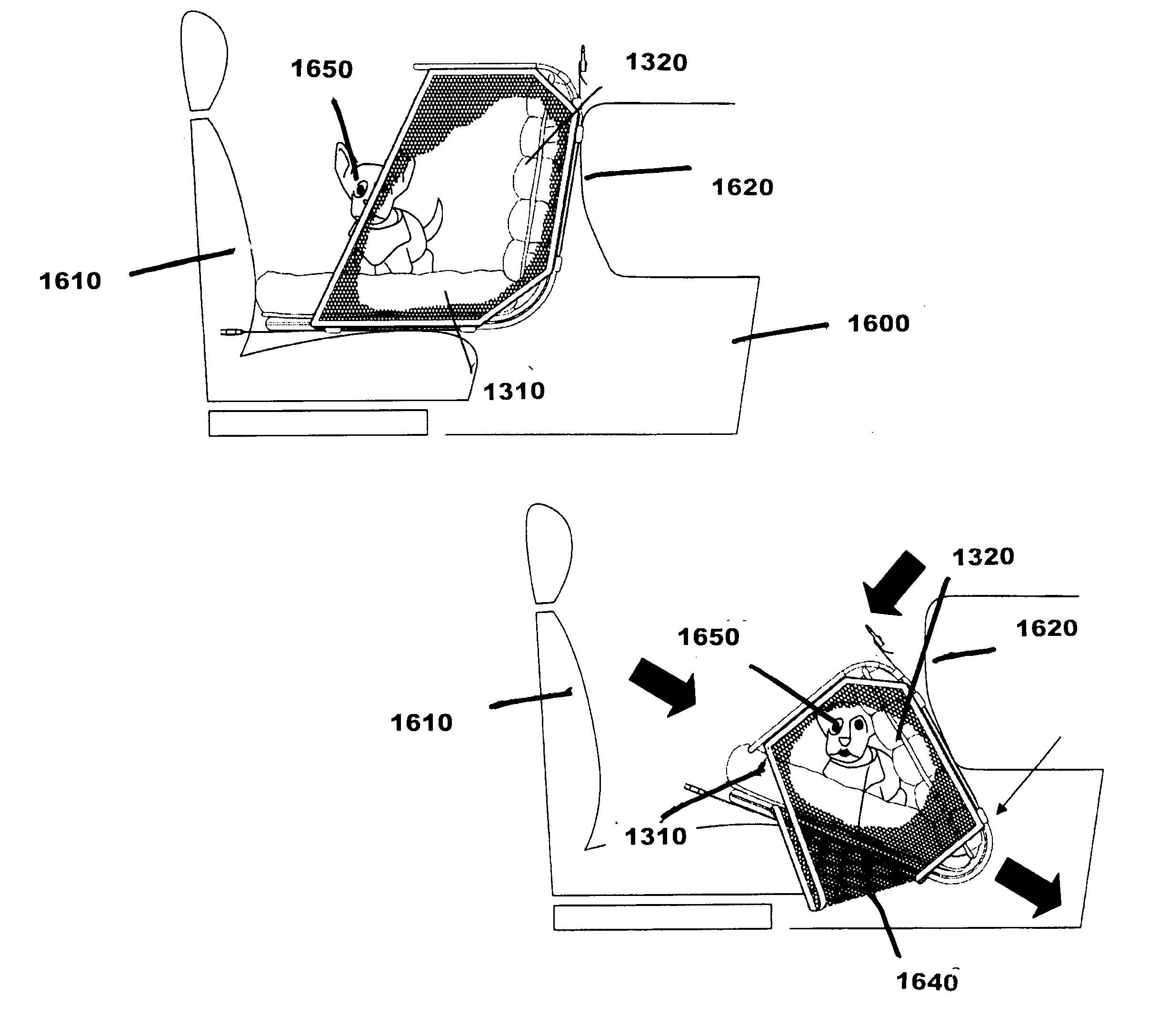

Pet Impact Protector

ActiveUS20090126638A1Easy to installEasy to removeVehicle seatsPedestrian/occupant safety arrangementCar seatImpact area

A pet impact protector is disclosed. This device is directed to a cleanable, removable device for a vehicle car seat comprising a contiguous pliable material having a pet seating area and a pet capture area. The pet impact protector is designed such that the force of the pet impact protector plus the pet, upon impact with the vehicle during a stop or slowing of the vehicle, causes the pet impact protector to partially collapse and form a protective impact area around the pet. This device is directed to the reduction of injury to a pet riding in a vehicle during an accident, stop or slowdown of the vehicle.

Owner:BENNETT GARY RAY

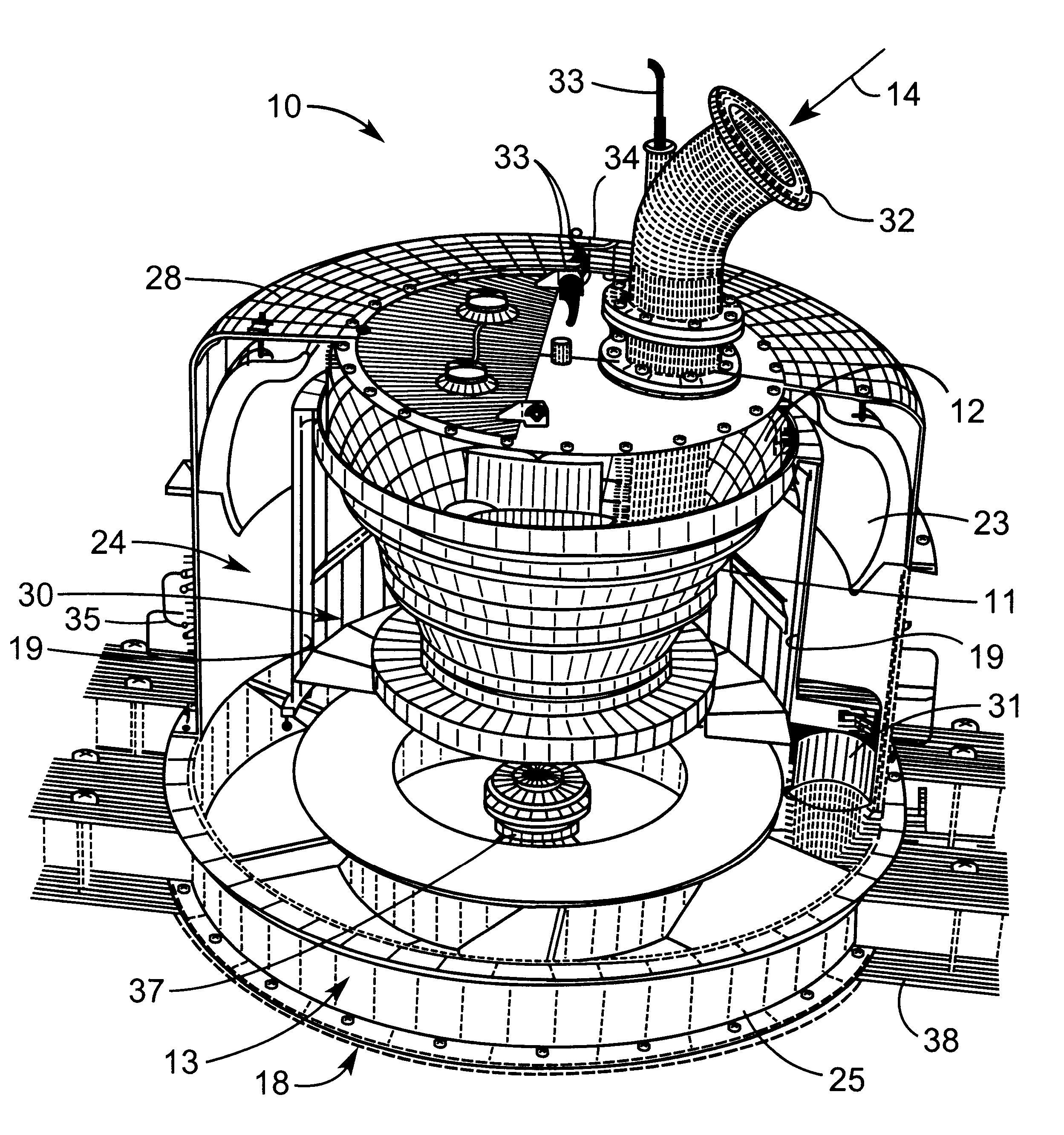

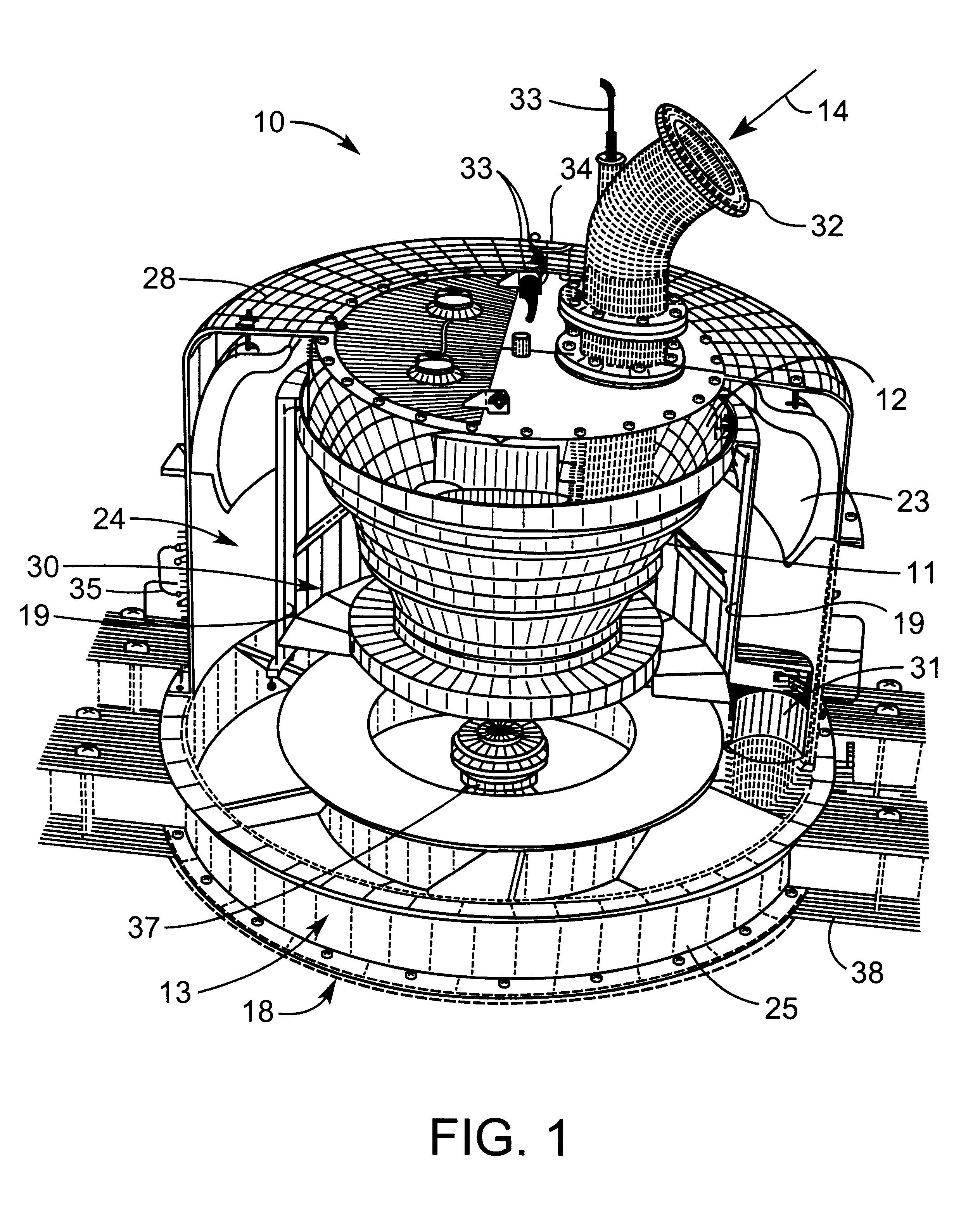

Centrifugal separation apparatus and method of using the same

InactiveUS6267899B1Water/sewage treatment by centrifugal separationSugar crystal separationCentrifugationEngineering

Centrifugation separations apparatus including centrifugation means having an inlet, a liquids discharge and a solids discharge, a deflector operatively associated with the solids discharge, wherein the solids discharge is adapted to operatively discharge solids being discharged from the centrifugation means at a trajectory and the deflector is adapted to interrupt the trajectory to decelerate and change the direction of travel of the solids, or wherein the deflector is operatively associated with the solids discharge and cooperable with solids being discharged from the solids discharge whereby buildup of solids on the deflector is substantially prevented, or wherein the solids discharge includes a lip configuration which causes the trajectories of the discharging crystals to be relatively independent of their size and / or their residual syrup / moisture content, or including support means, such as a spider like construction having one or more webs substantially parallel to the angular motion of the solids being discharged from the solids discharge, operatively supporting the centrifugation means whereby the impact area for solids discharged from the solids discharge may be minimized, or including blending means operatively associated with the solids discharge for blending solids discharged from the centrifugation separations apparatus.

Owner:STG FCB HLDG

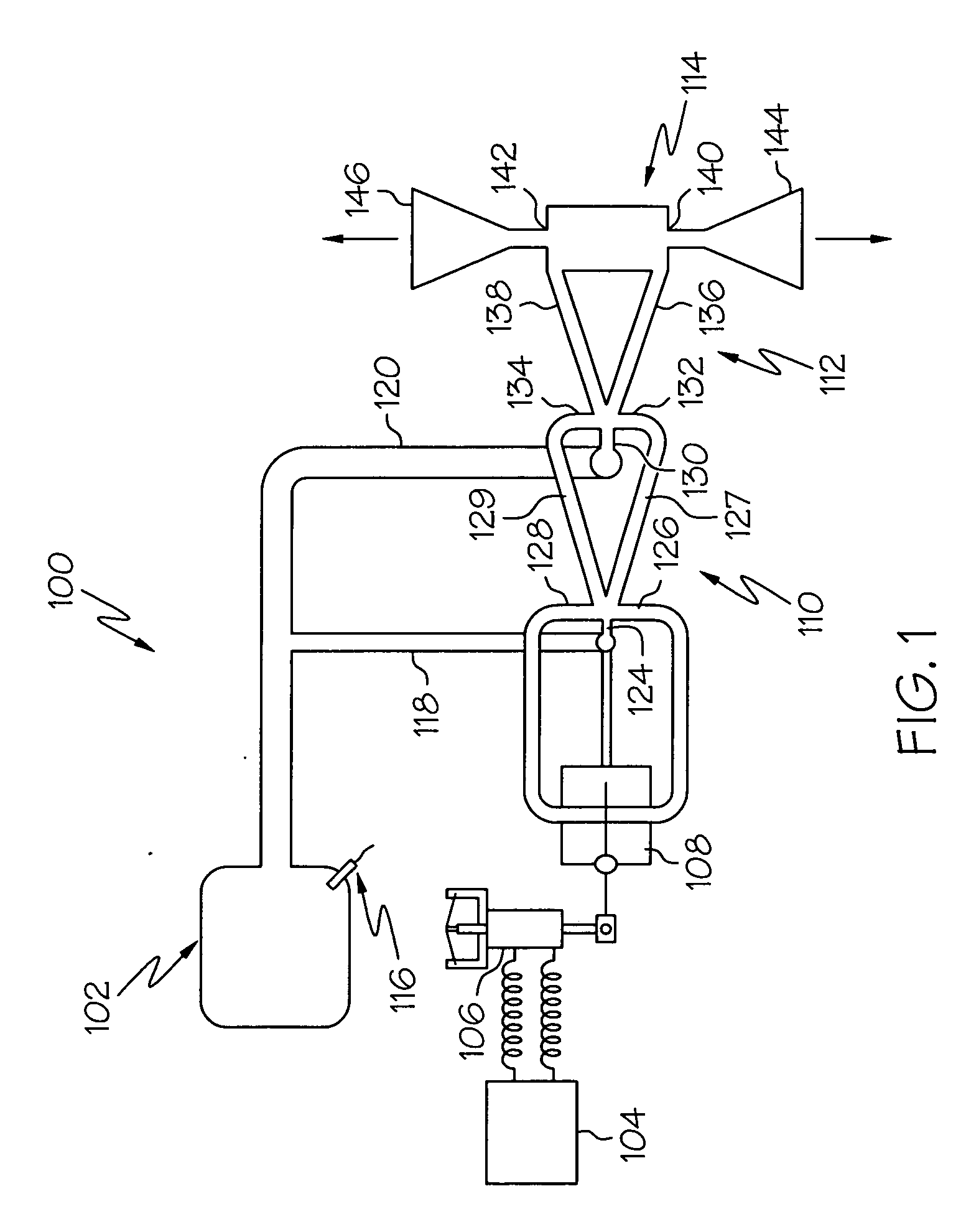

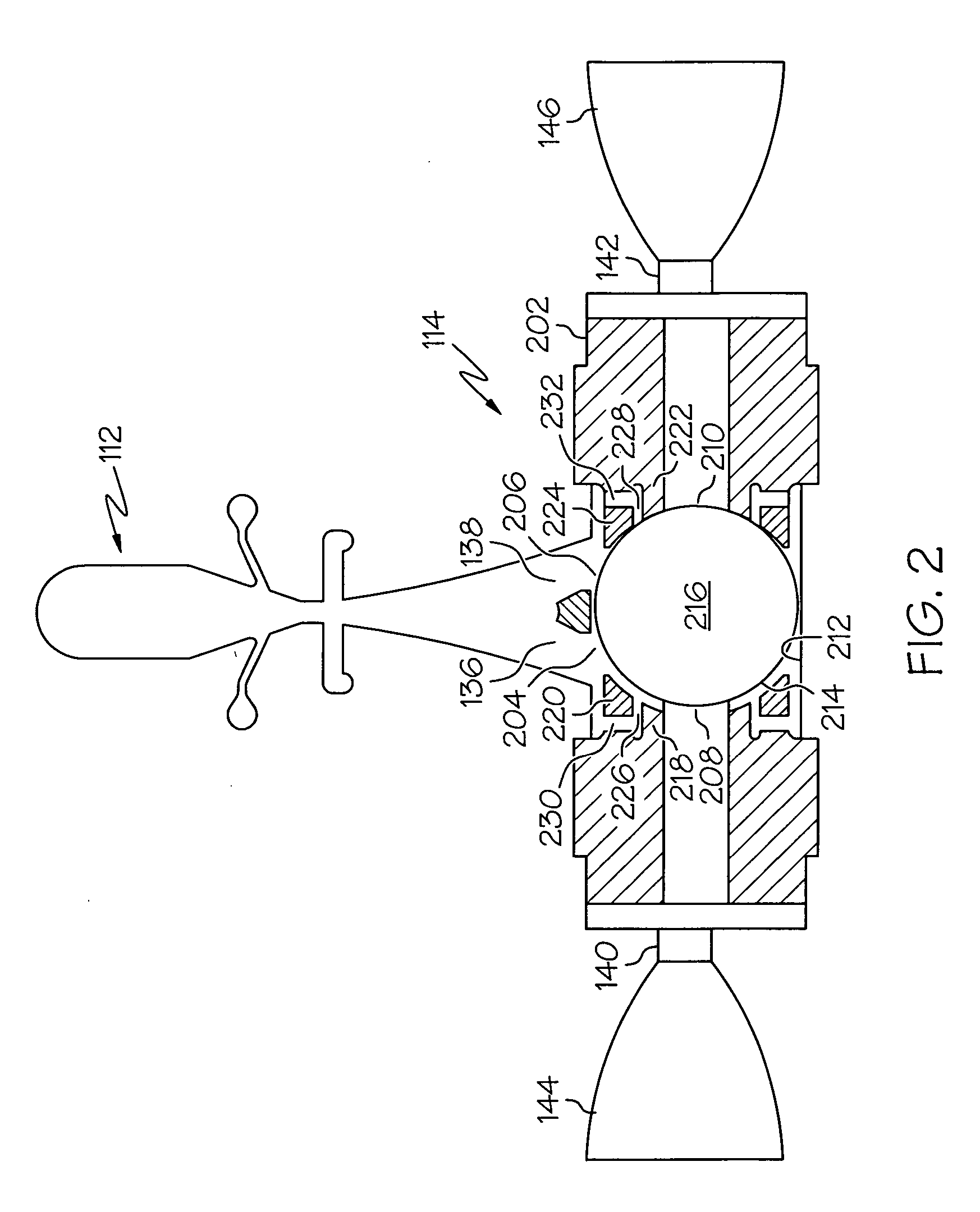

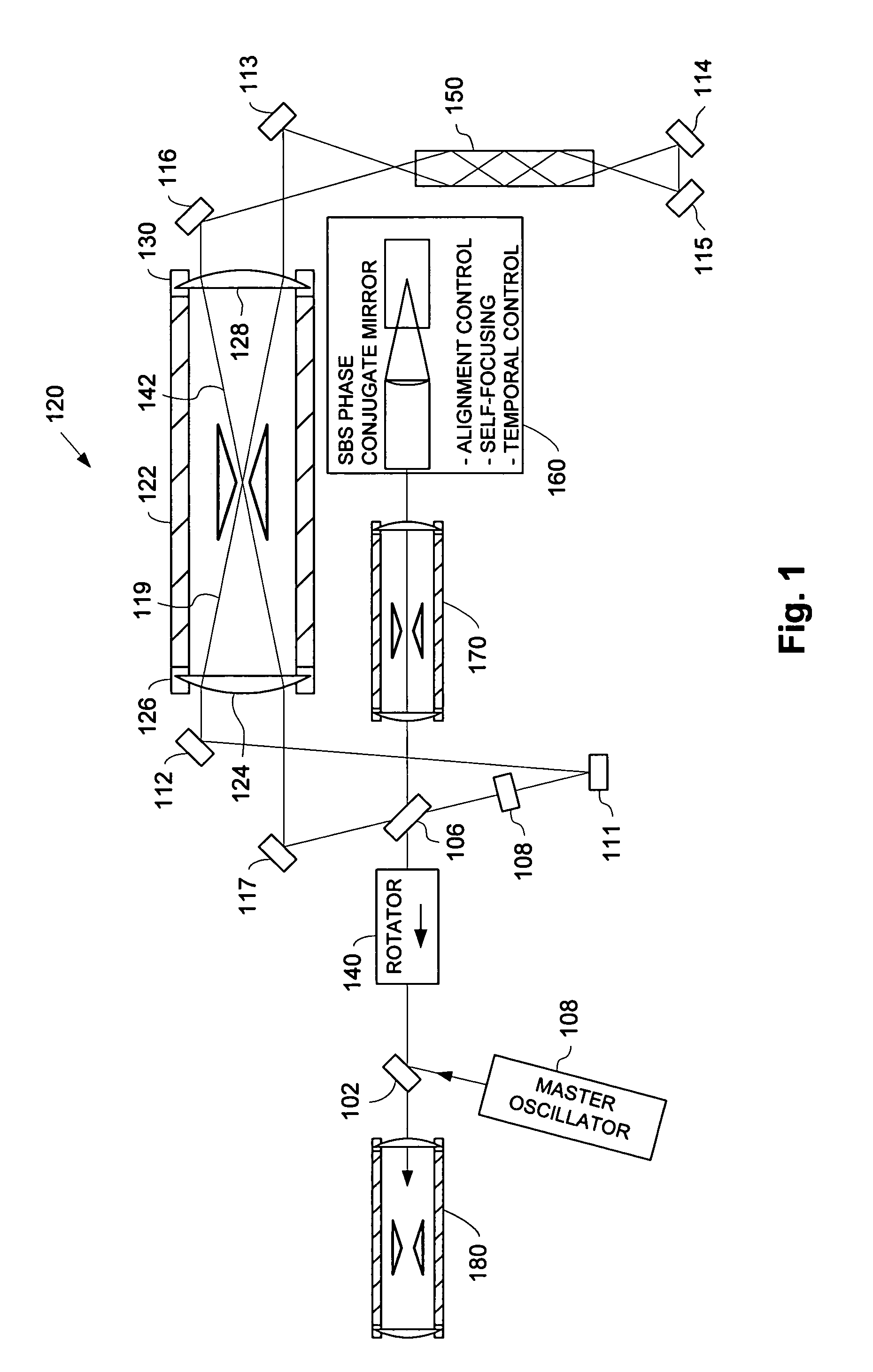

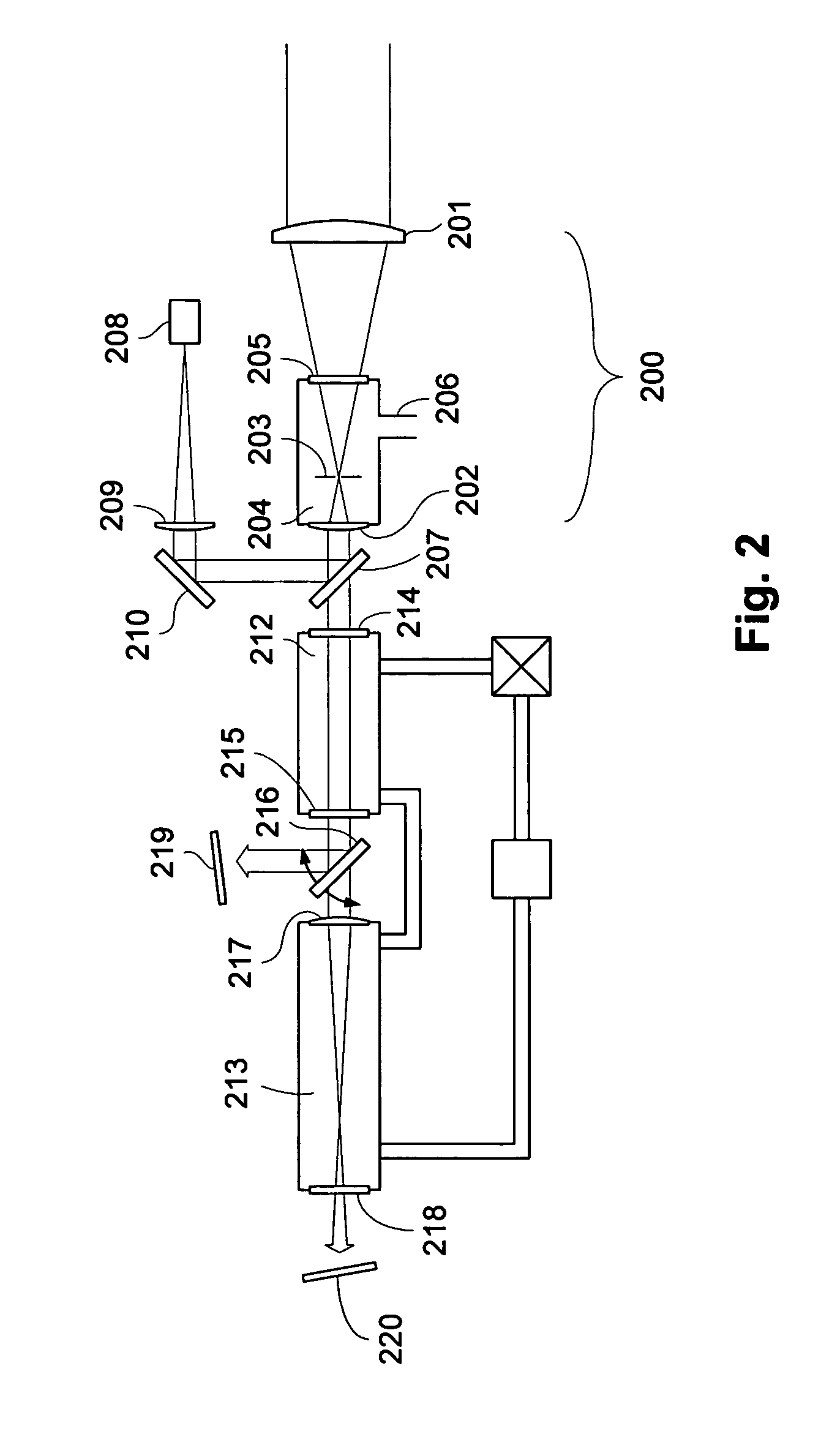

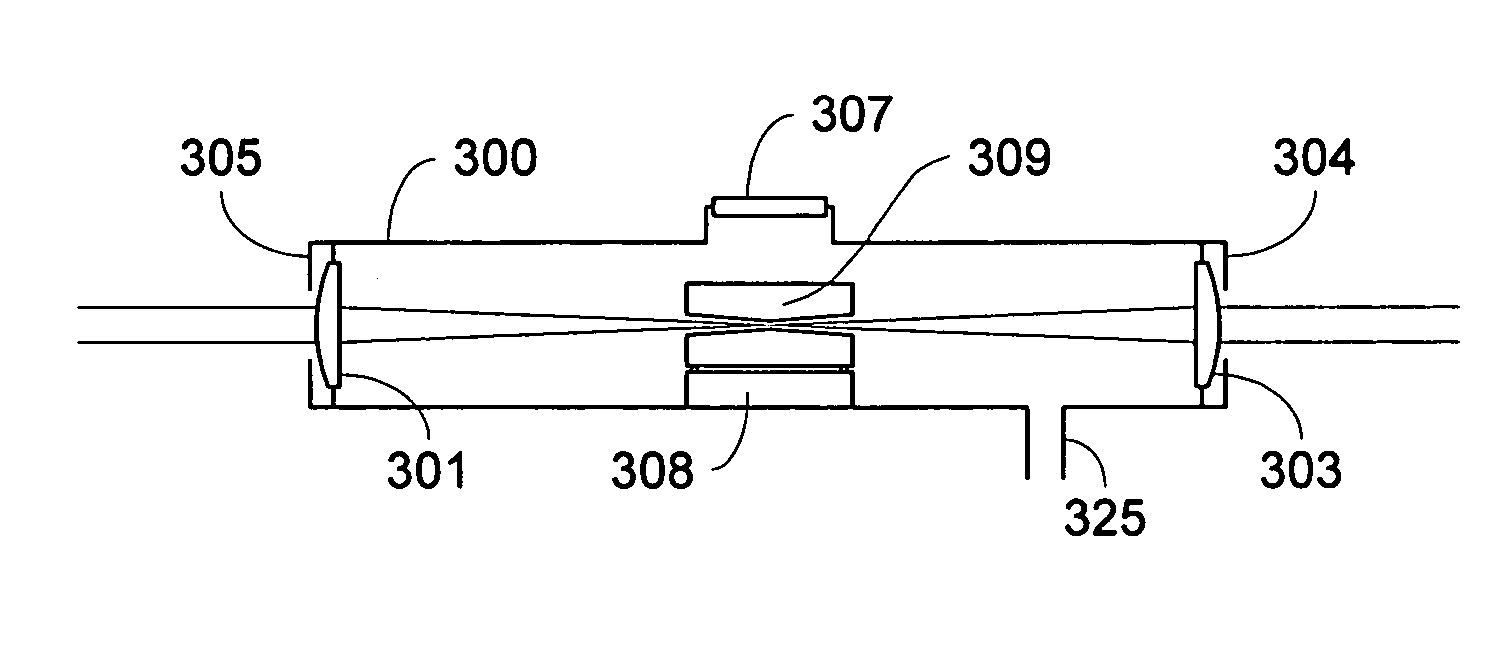

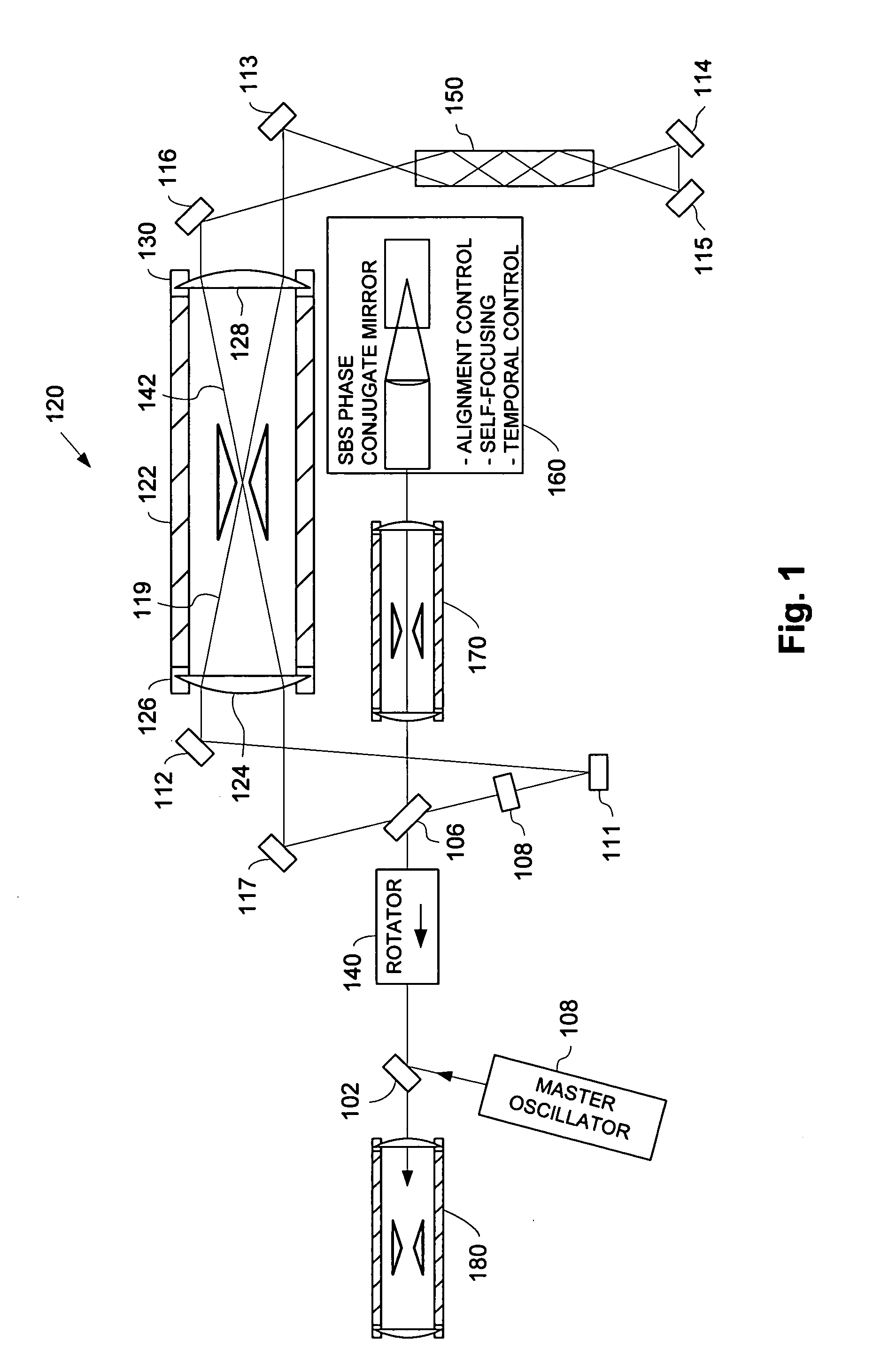

Relay telescope for high power laser alignment system

ActiveUS20060061854A1Avoid damageFluence levels at the impact areas of the blocked beams are reducedLaser using scattering effectsOptical resonator shape and constructionAngle of incidenceHigh power lasers

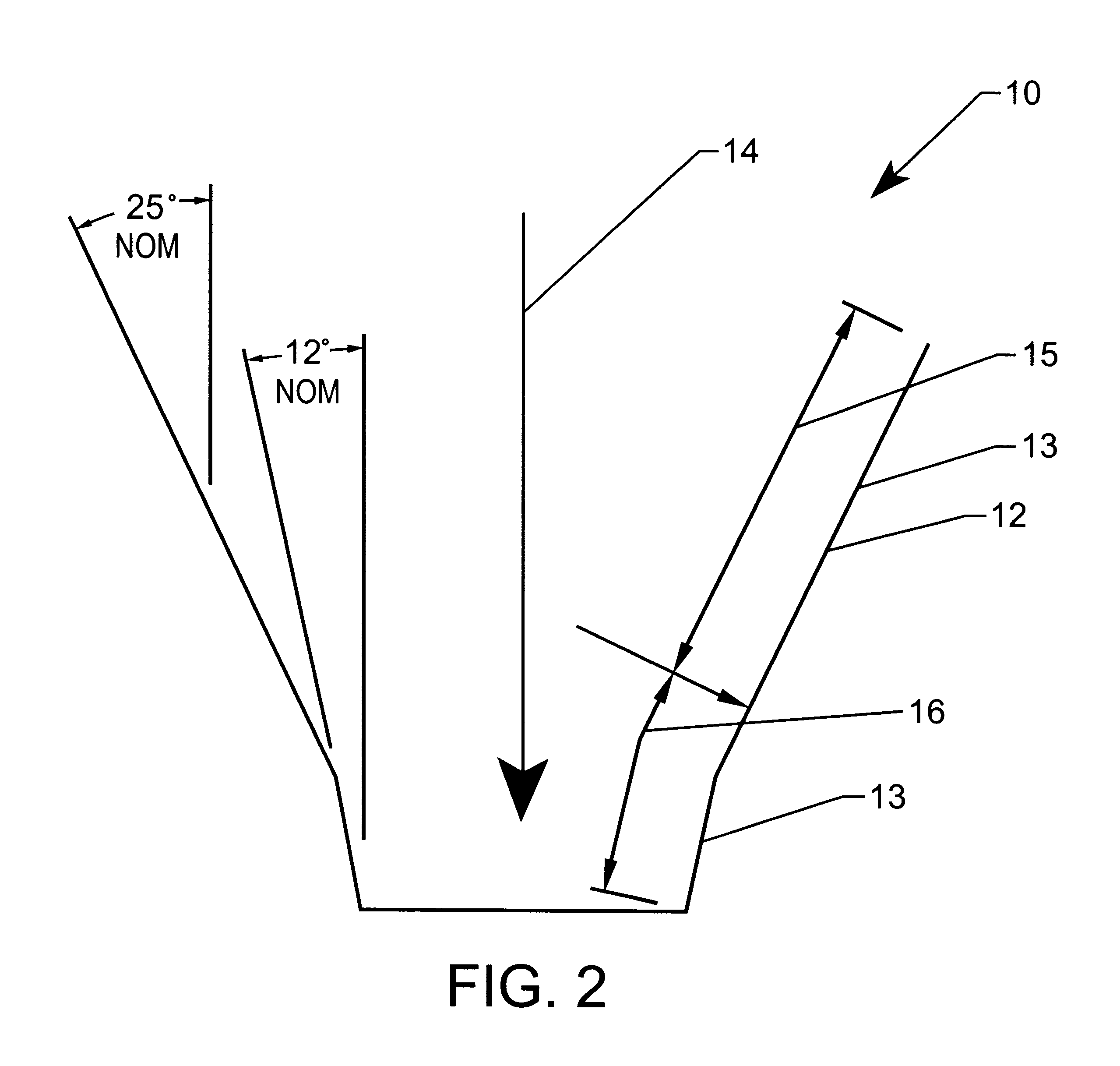

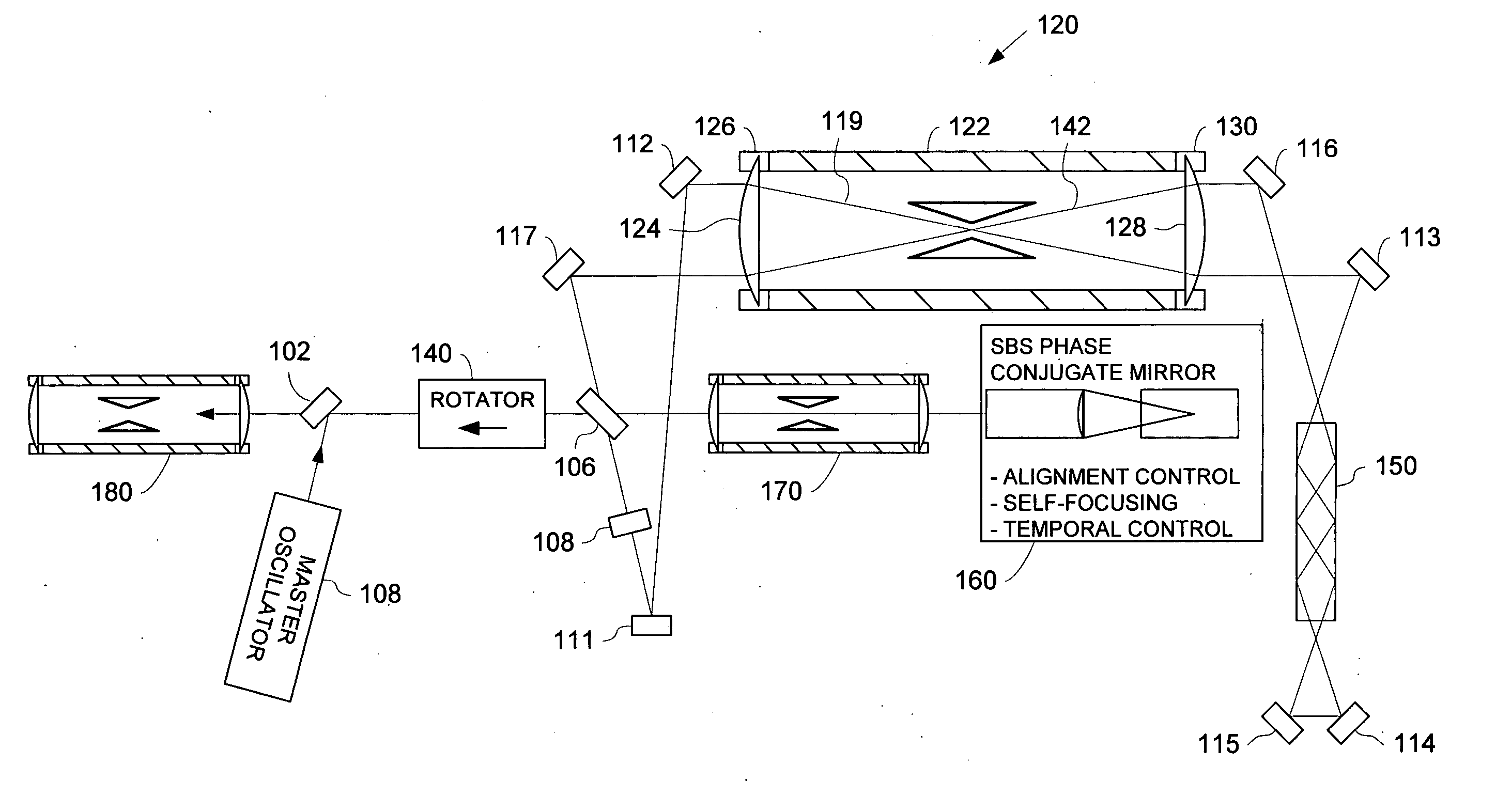

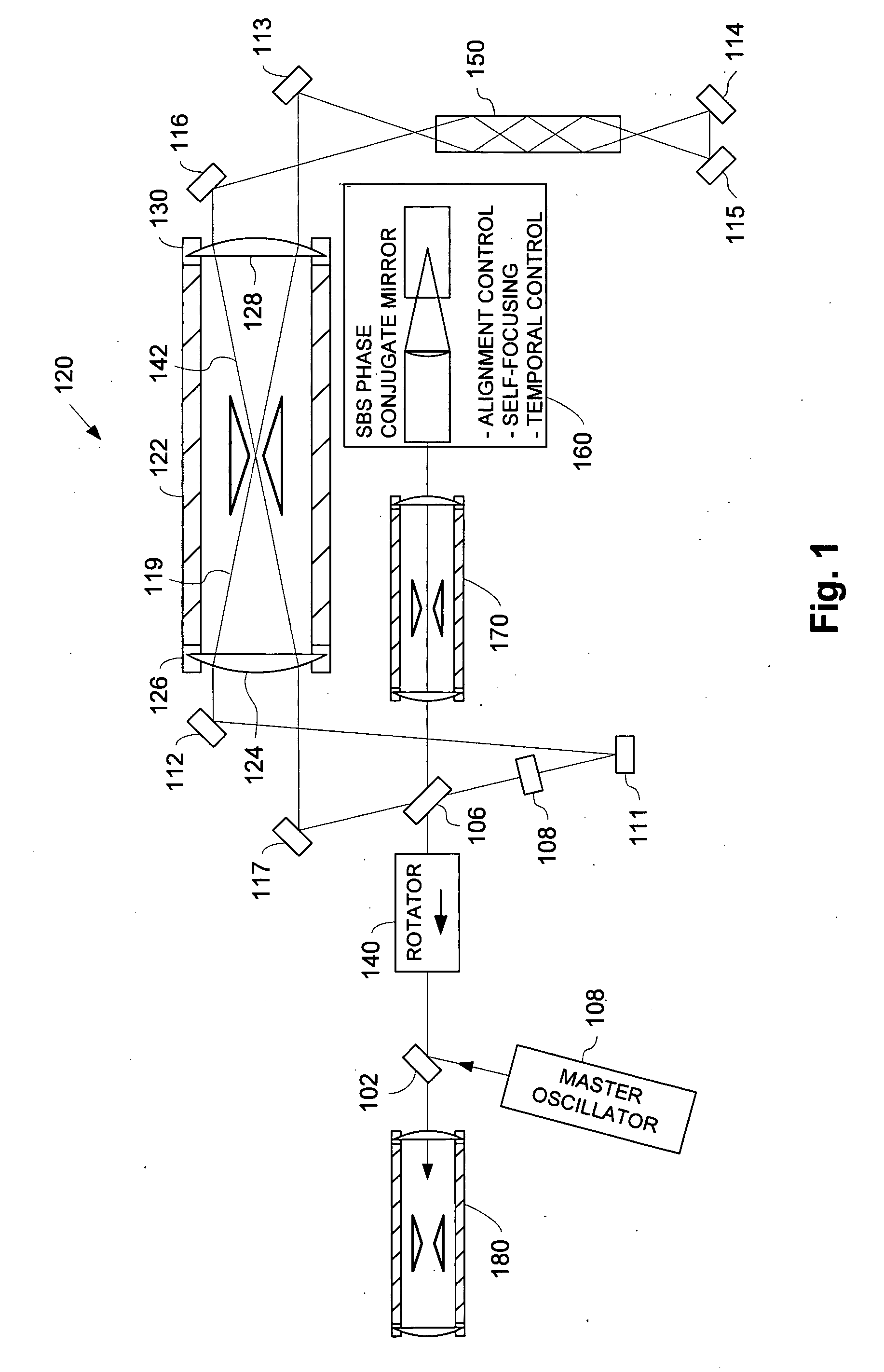

A laser system includes an optical path having an intracavity relay telescope with a telescope focal point for imaging an output of the gain medium between an image location at or near the gain medium and an image location at or near an output coupler for the laser system. A kinematic mount is provided within a vacuum chamber, and adapted to secure beam baffles near the telescope focal point. An access port on the vacuum chamber is adapted for allowing insertion and removal of the beam baffles. A first baffle formed using an alignment pinhole aperture is used during alignment of the laser system. A second tapered baffle replaces the alignment aperture during operation and acts as a far-field baffle in which off angle beams strike the baffle a grazing angle of incidence, reducing fluence levels at the impact areas.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

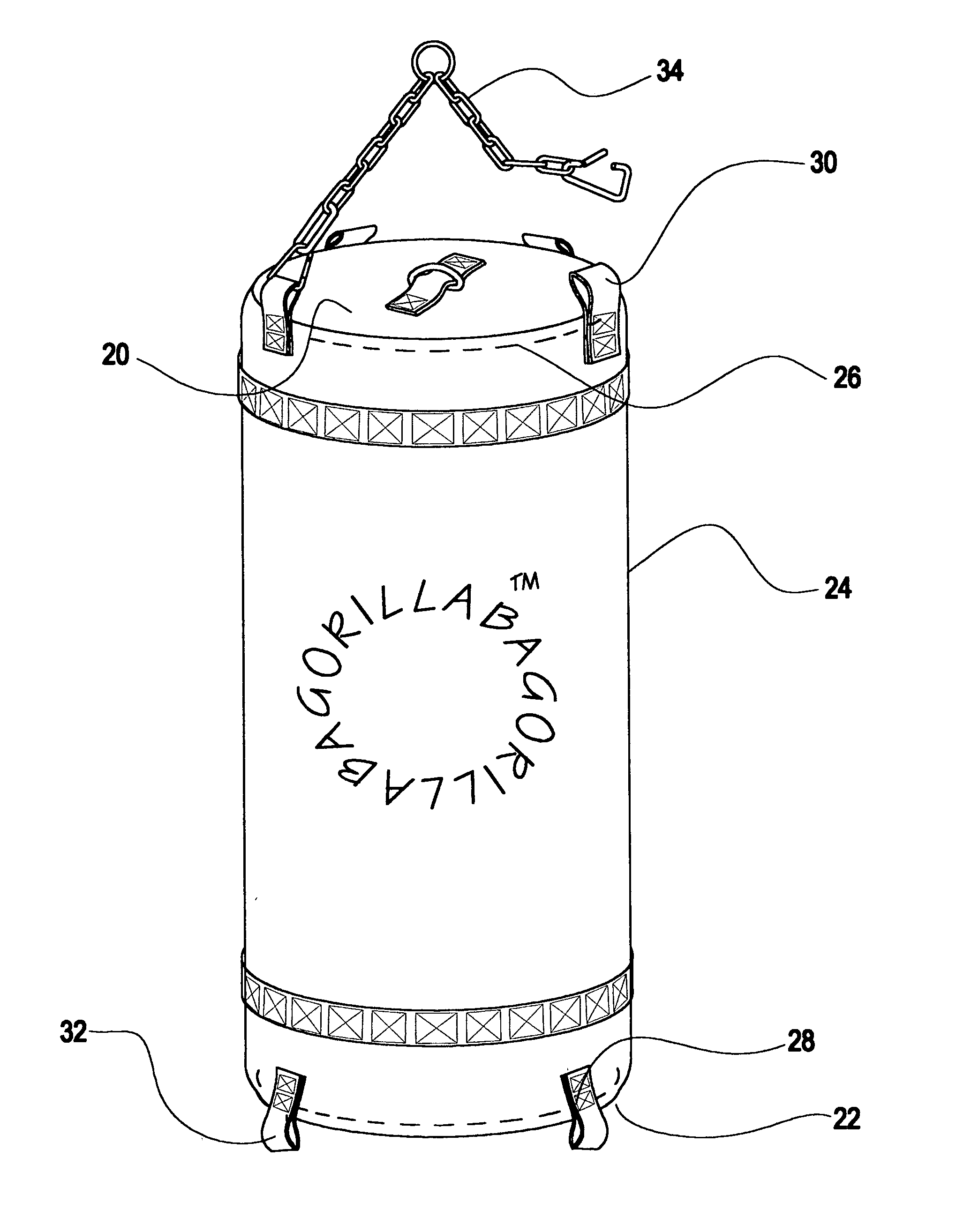

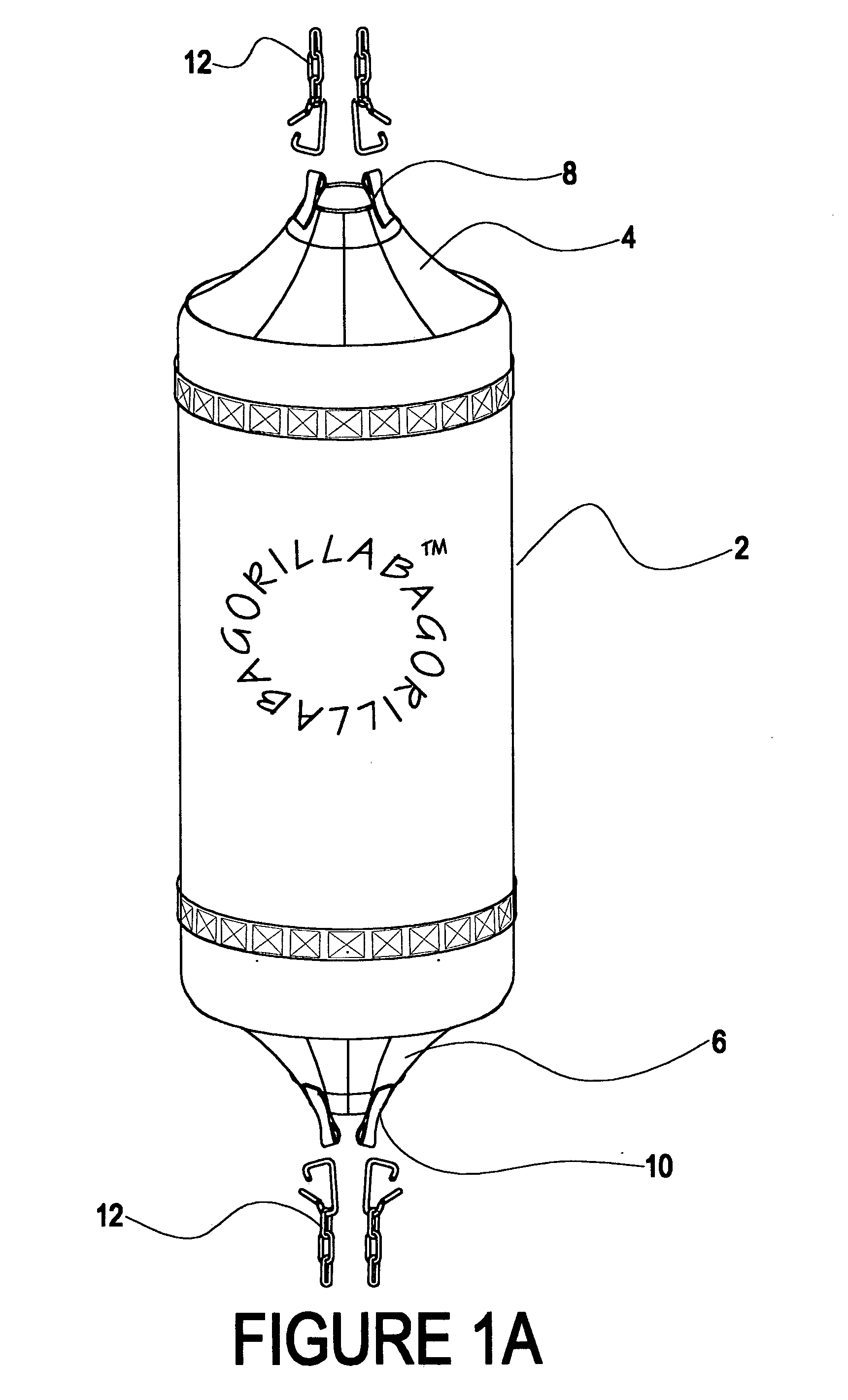

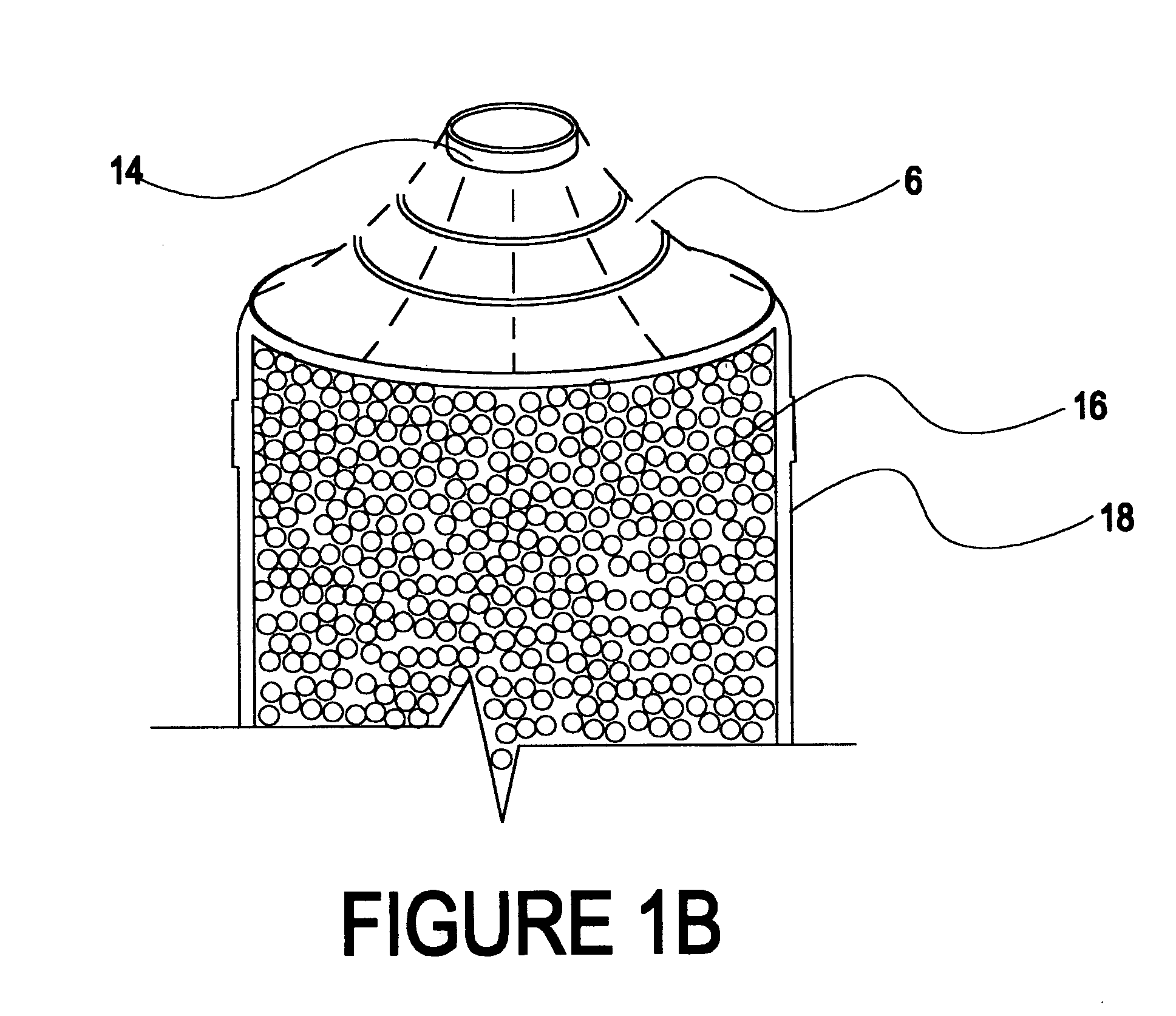

Training bag

InactiveUS20060100067A1Maintain consistency in bag resistanceEffective resistanceSport apparatusPunchingEngineering

Owner:WASHBURN MICHAEL +1

Relay telescope including baffle, and high power laser amplifier utilizing the same

ActiveUS7110171B2Fluence levels at the impact areas of the blocked beams are reducedAvoid damageLaser using scattering effectsOptical resonator shape and constructionHigh power lasersAngle of incidence

A laser system includes an optical path having an intracavity relay telescope with a telescope focal point for imaging an output of the gain medium between an image location at or near the gain medium and an image location at or near an output coupler for the laser system. A kinematic mount is provided within a vacuum chamber, and adapted to secure beam baffles near the telescope focal point. An access port on the vacuum chamber is adapted for allowing insertion and removal of the beam baffles. A first baffle formed using an alignment pinhole aperture is used during alignment of the laser system. A second tapered baffle replaces the alignment aperture during operation and acts as a far-field baffle in which off angle beams strike the baffle a grazing angle of incidence, reducing fluence levels at the impact areas.

Owner:METAL IMPROVEMENT CO INC +1

Stabilization method for lead projectile impact area

InactiveUS20030143031A1Increase surface areaLow water solubilityTin compoundsSolid waste disposalHealth riskEngineering

The invention pertains to a method for reducing the leaching of lead from lead projectile impact area acting to collect or stop such projectiles. The method includes contacting the lead projectile impact area with a seed of dry granular lead stabilizing agents. The seeding or coating of lead stabilizing agents provides a means to stabilize lead in the bullet / shot impact area while also allowing for future lead bullets, fragments, or lead shot fired into the soil to be stabilized upon contact with the lead stabilizing agent seeds or contact with rainwater leaching through the lead stabilizing agent seeds produced from the projectile coating, or excess seed from the lead shell projectiles. This method eliminates the need to remove or re-treat range soils and greatly reduces the environmental and health risks associated with the use of lead as projectiles in the open environment as well as at control trap ranges.

Owner:FORRESTER KEITH E

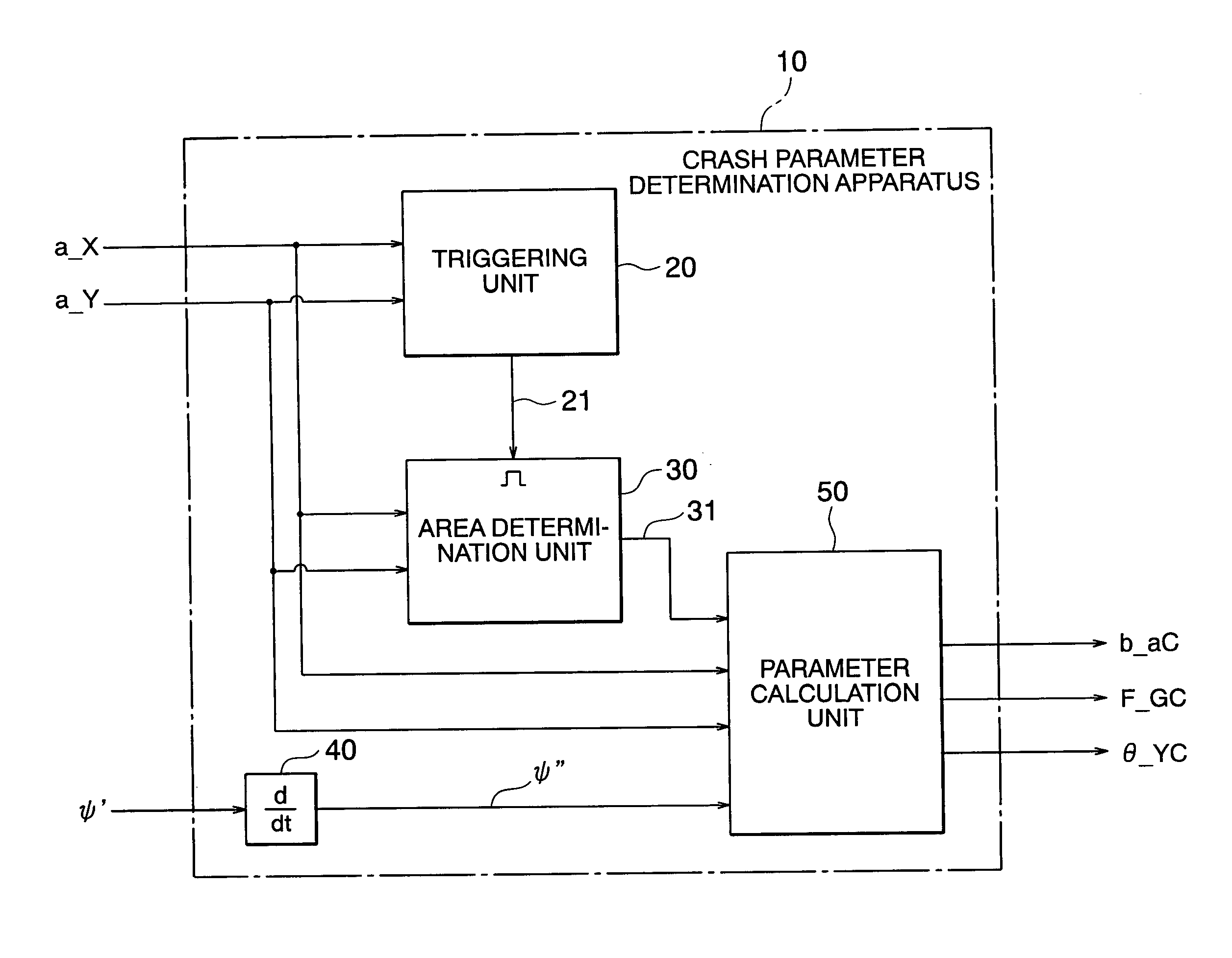

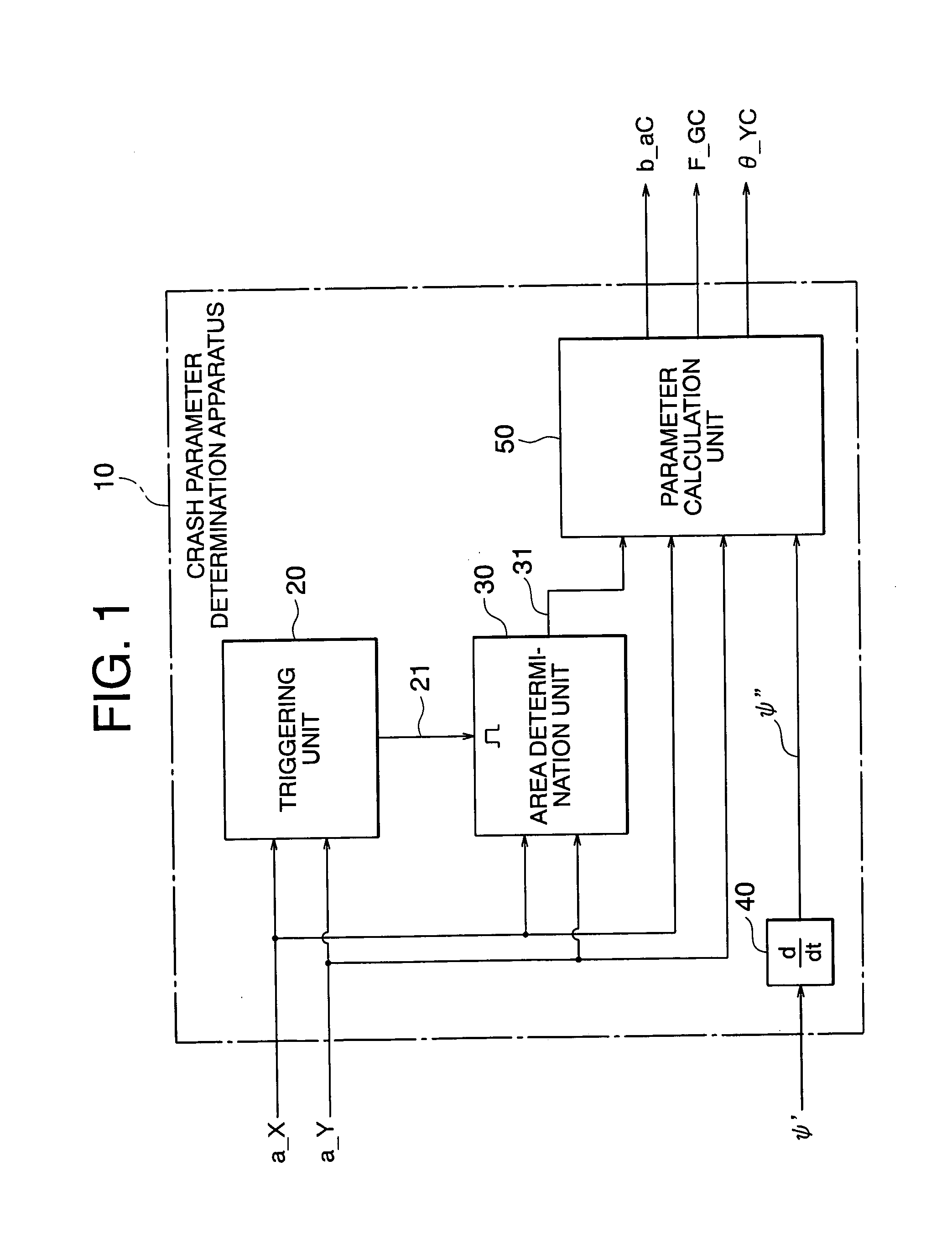

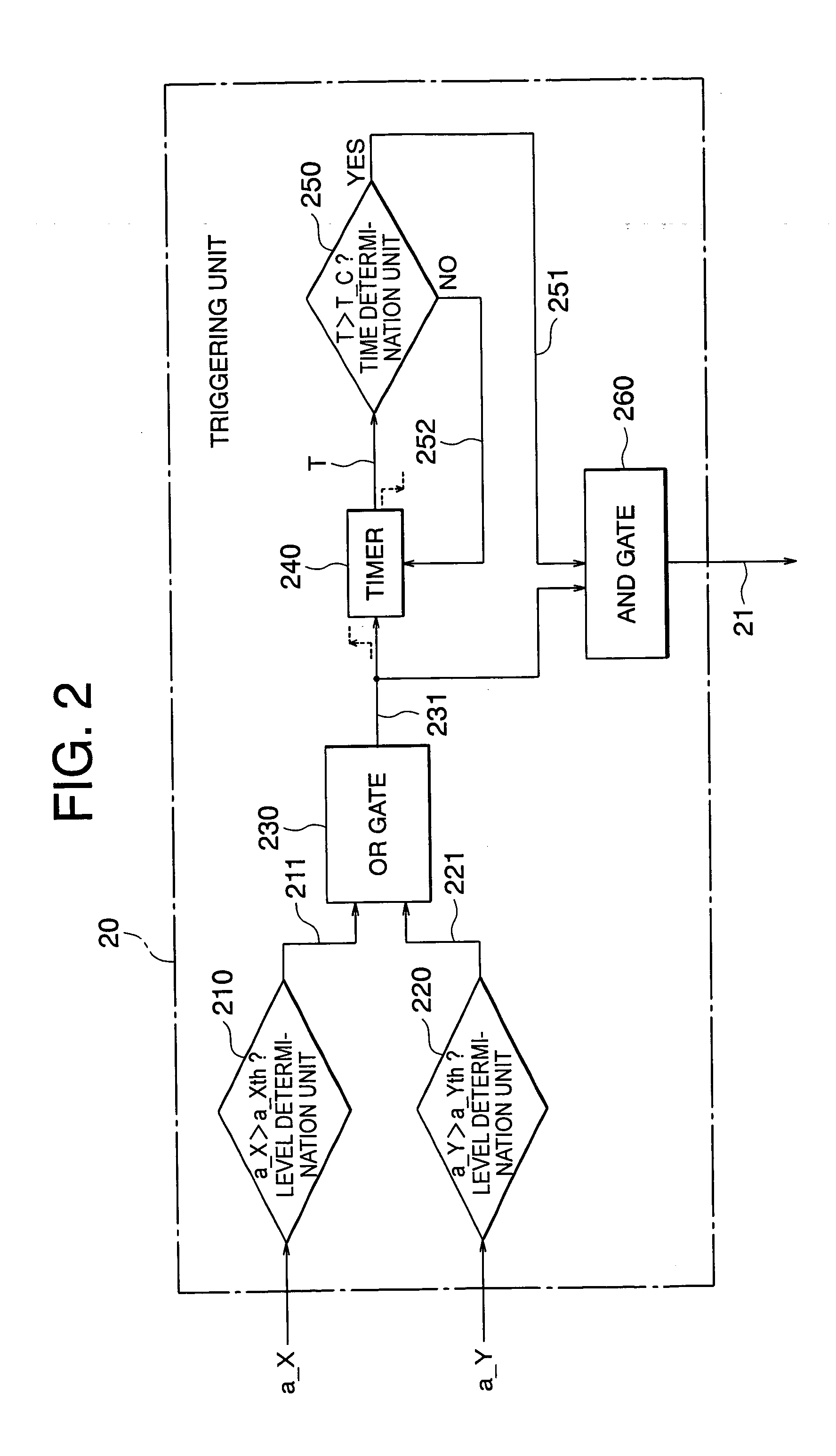

Vehicle accident analyzing apparatus

InactiveUS20060100762A1More informationAccurate reconstructionDigital data processing detailsPedestrian/occupant safety arrangementLow speedIn vehicle

To provide a vehicle accident analyzing apparatus in which reconstruction quality of low speed crashes is improved. An impact parameter determination apparatus 10 is provided with a triggering unit 20 which uses input signals from in-vehicle sensors, and an area determination unit 30, and a parameter calculation unit 50. The triggering unit 20 generates a trigger signal 21 based on the input signals for triggering the area determination unit 30 and the parameter calculation unit 50. The area determination unit 30 uses the input signals to calculate the most probable impact area 31. The parameter calculation unit 50 calculates the final desired crash parameters based on the input signals and the most probable impact area 31.

Owner:MITSUBISHI ELECTRIC CORP

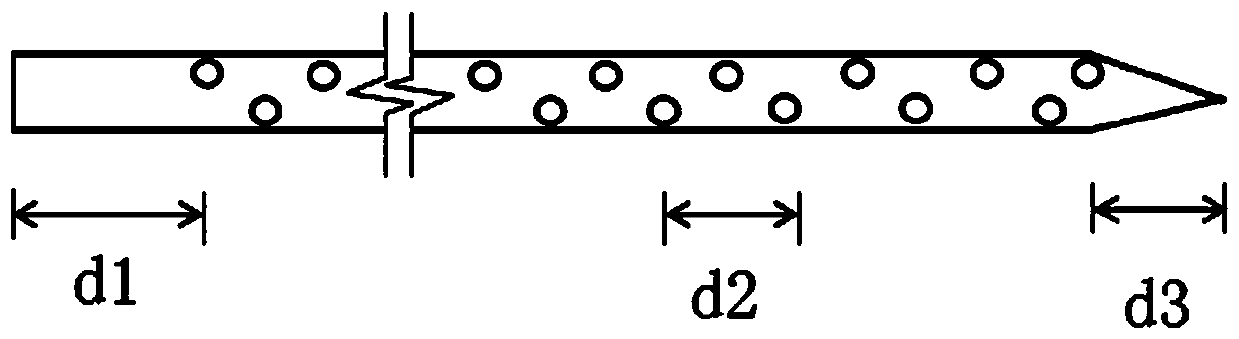

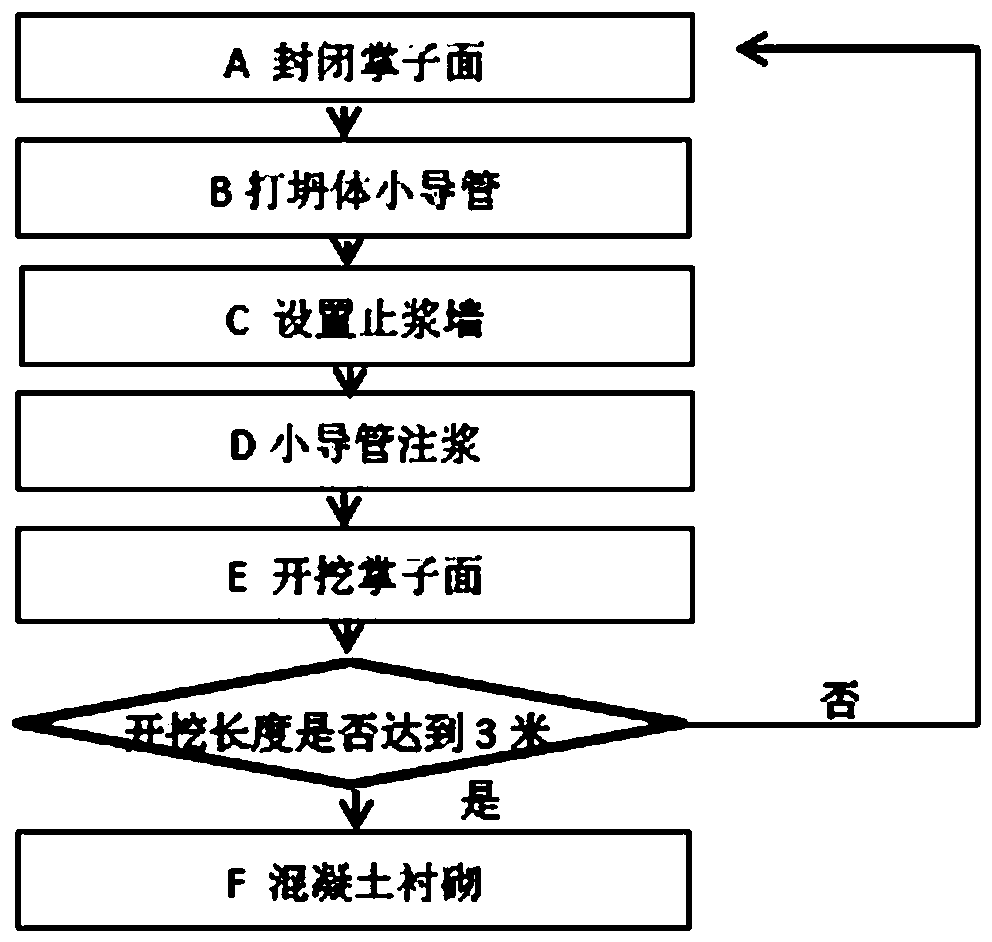

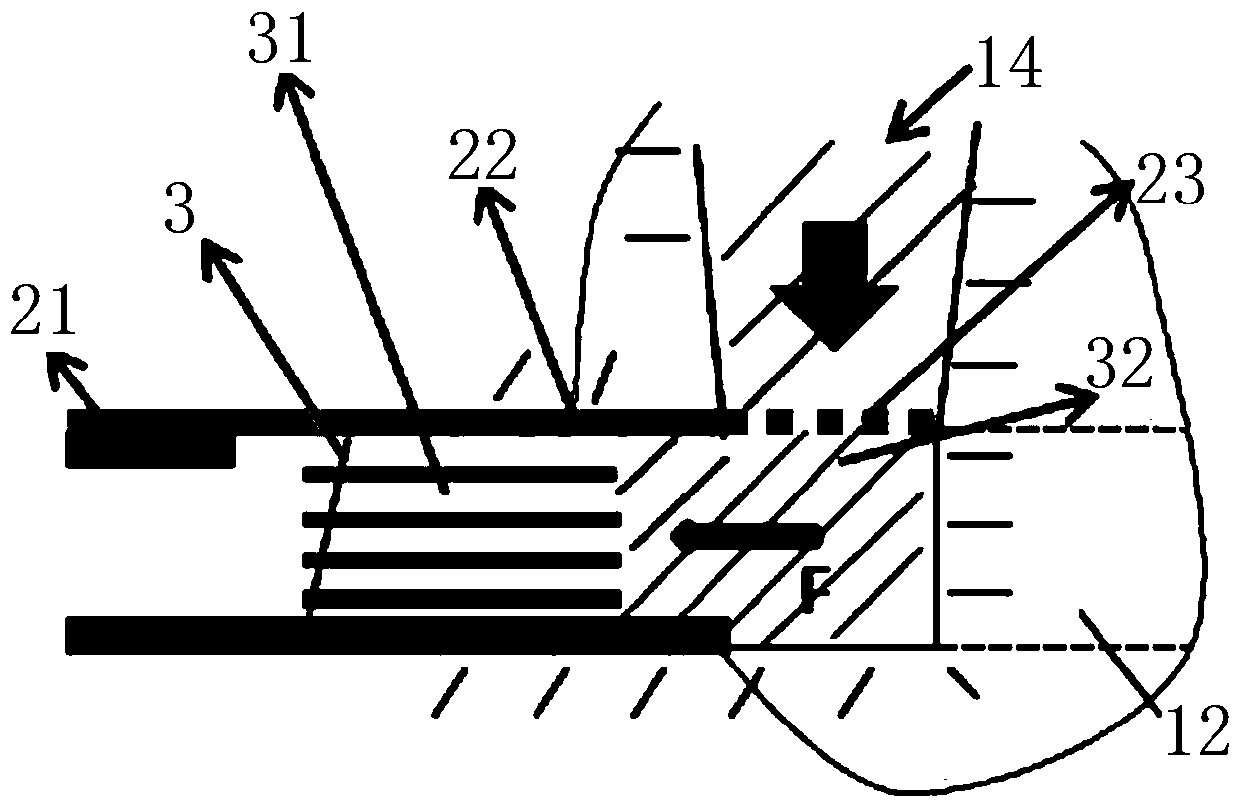

Construction method used after tunnel integral type collapse

ActiveCN107165652AStable supportAvoid the disadvantages of inoperabilityUnderground chambersTunnel liningStructural engineeringImpact area

Owner:DATANG LINZHOU THERMAL POWER CO LTD

Relay telescope, high power laser alignment system, and laser peening method and system using same

ActiveUS20050094250A1Avoid damageFluence levels at the impact areas of the blocked beams are reducedLaser using scattering effectsOptical resonator shape and constructionAngle of incidenceHigh power lasers

A laser system includes an optical path having an intracavity relay telescope with a telescope focal point for imaging an output of the gain medium between an image location at or near the gain medium and an image location at or near an output coupler for the laser system. A kinematic mount is provided within a vacuum chamber, and adapted to secure beam baffles near the telescope focal point. An access port on the vacuum chamber is adapted for allowing insertion and removal of the beam baffles. A first baffle formed using an alignment pinhole aperture is used during alignment of the laser system. A second tapered baffle replaces the alignment aperture during operation and acts as a far-field baffle in which off angle beams strike the baffle a grazing angle of incidence, reducing fluence levels at the impact areas.

Owner:METAL IMPROVEMENT CO INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com