Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117 results about "INDUCTION TREATMENT" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Induction heat treatment is frequently used to harden to the exterior of a material because the surface of the material is the first to become heated during the induction heat treatment process. This, and the fact that it is easily controlled, makes induction heat treatment an excellent process for surface hardening.

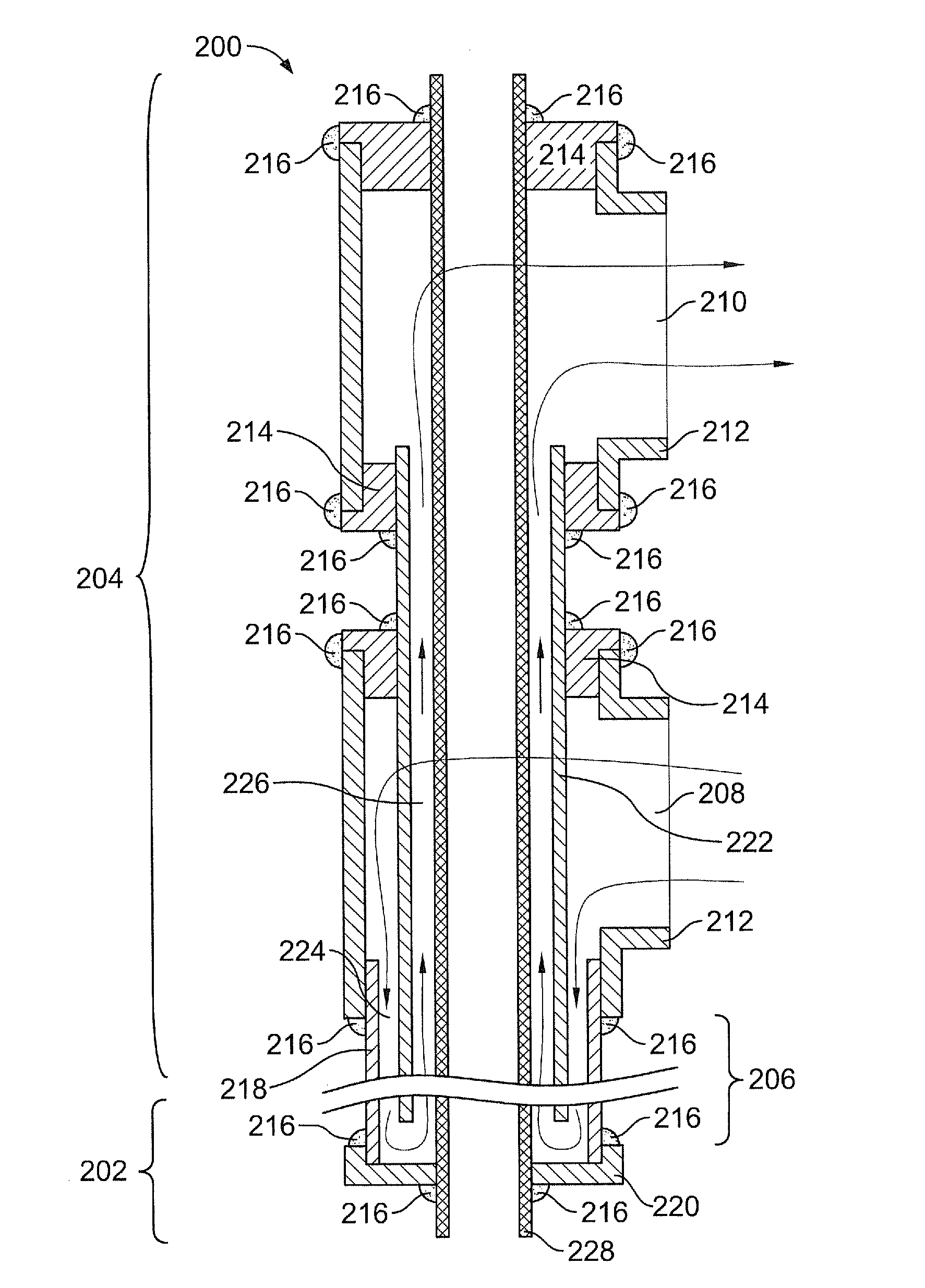

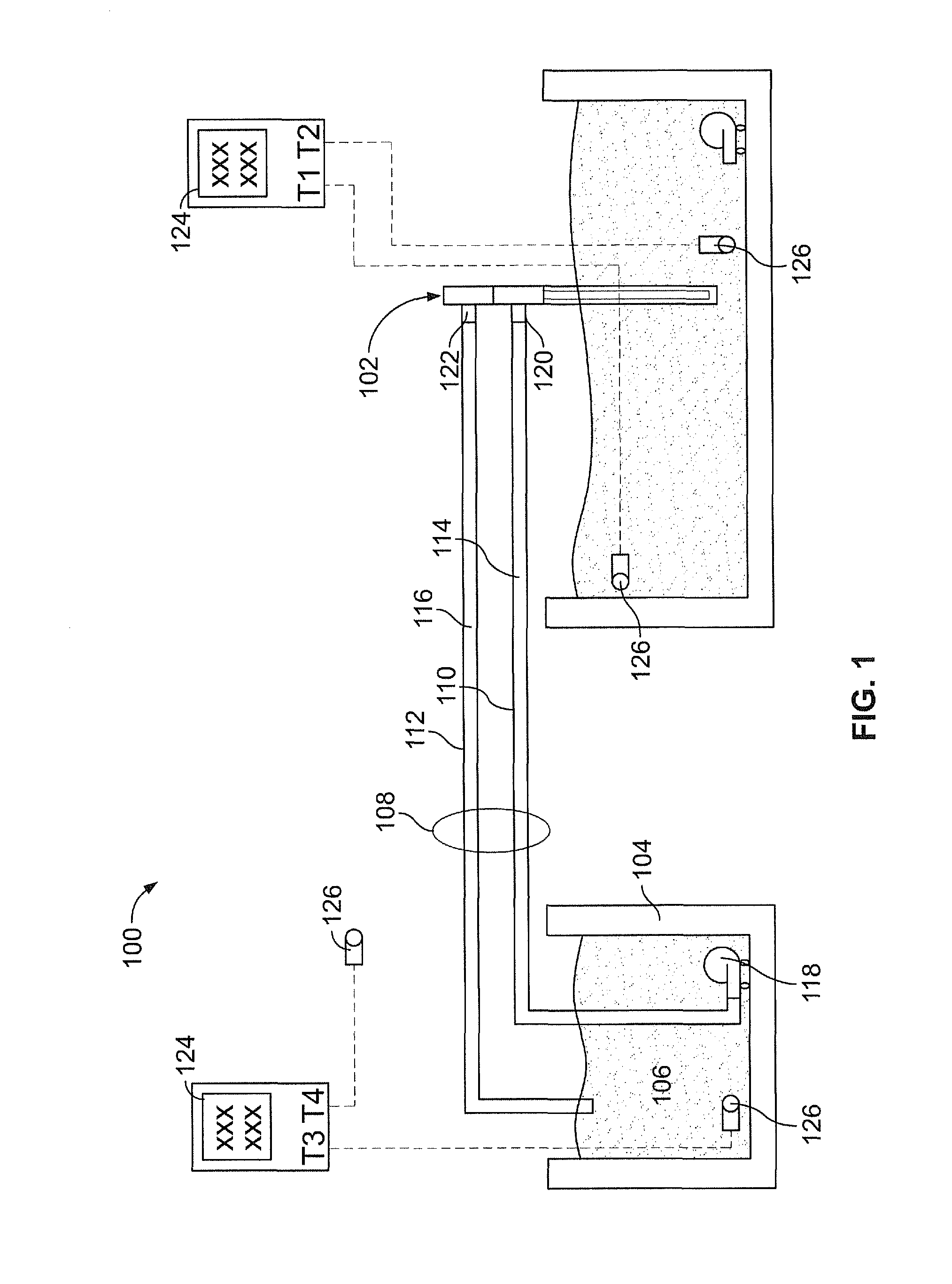

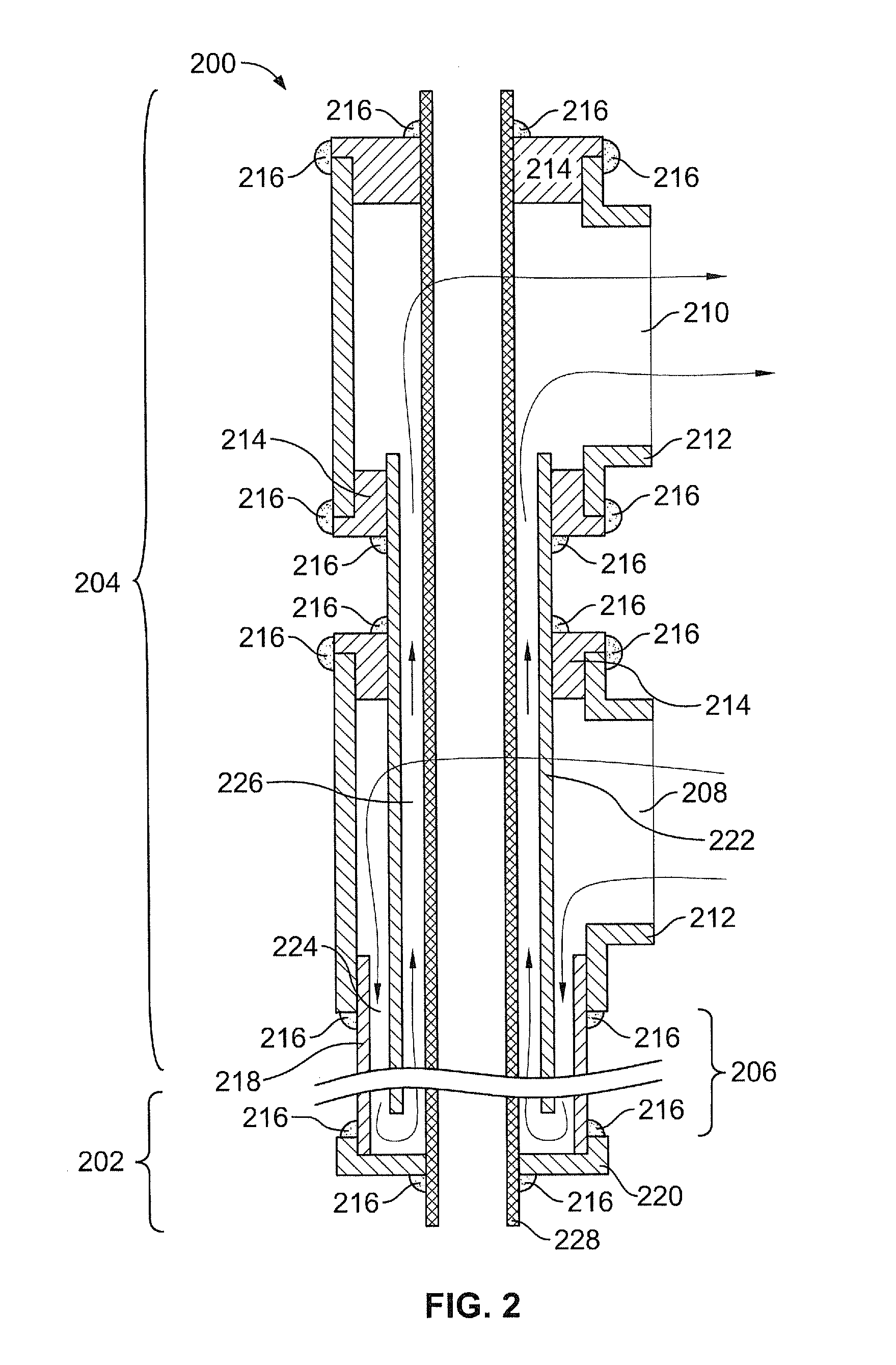

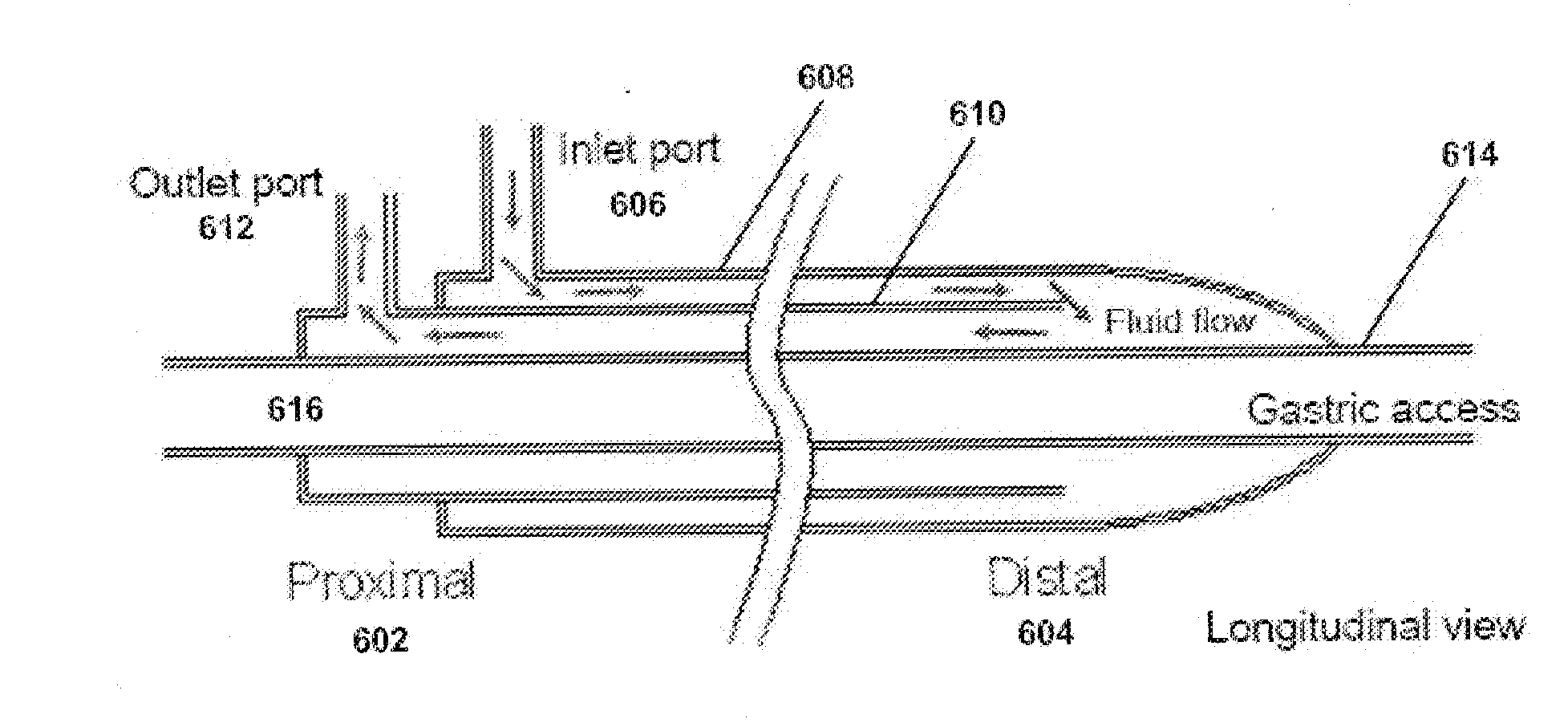

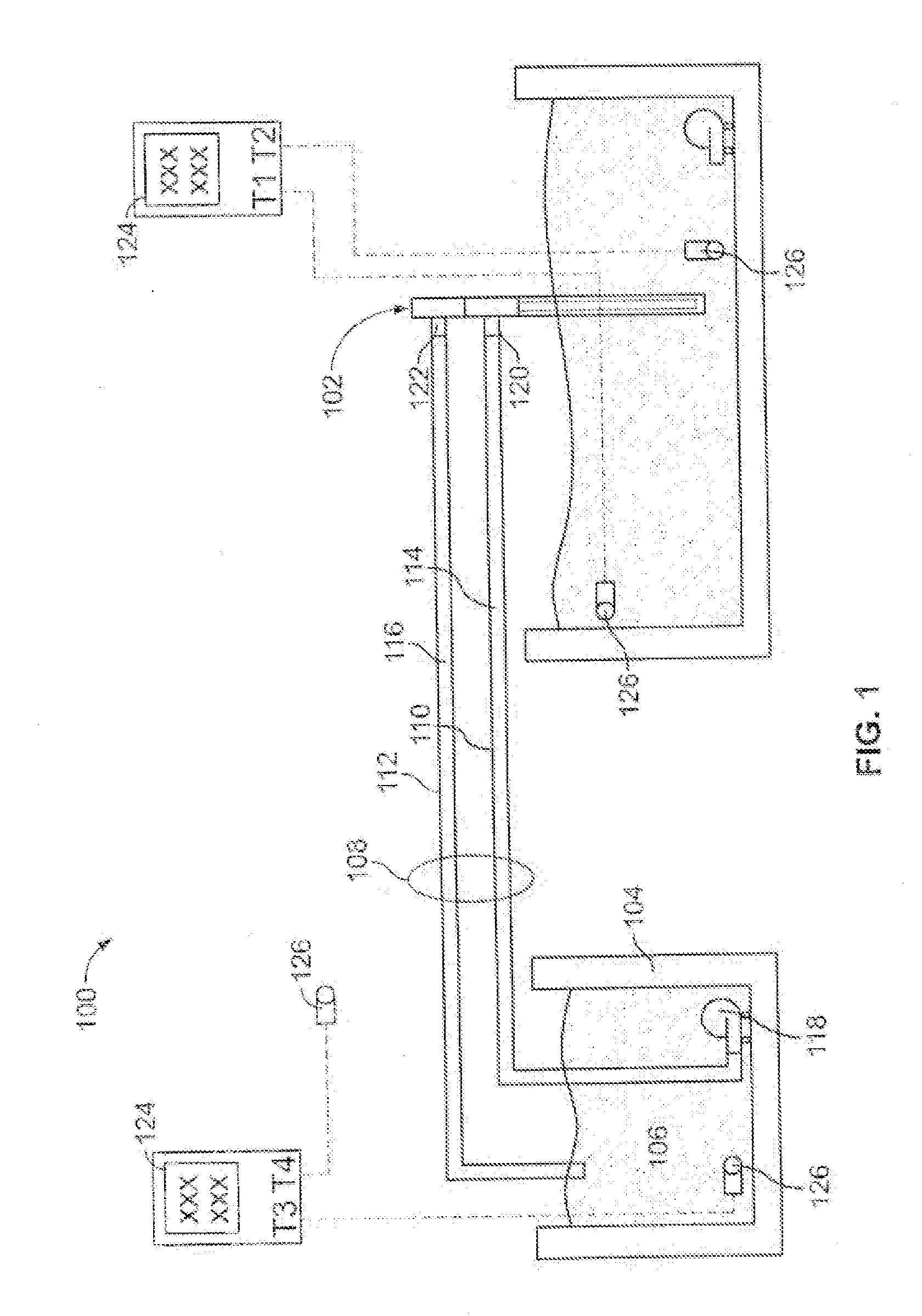

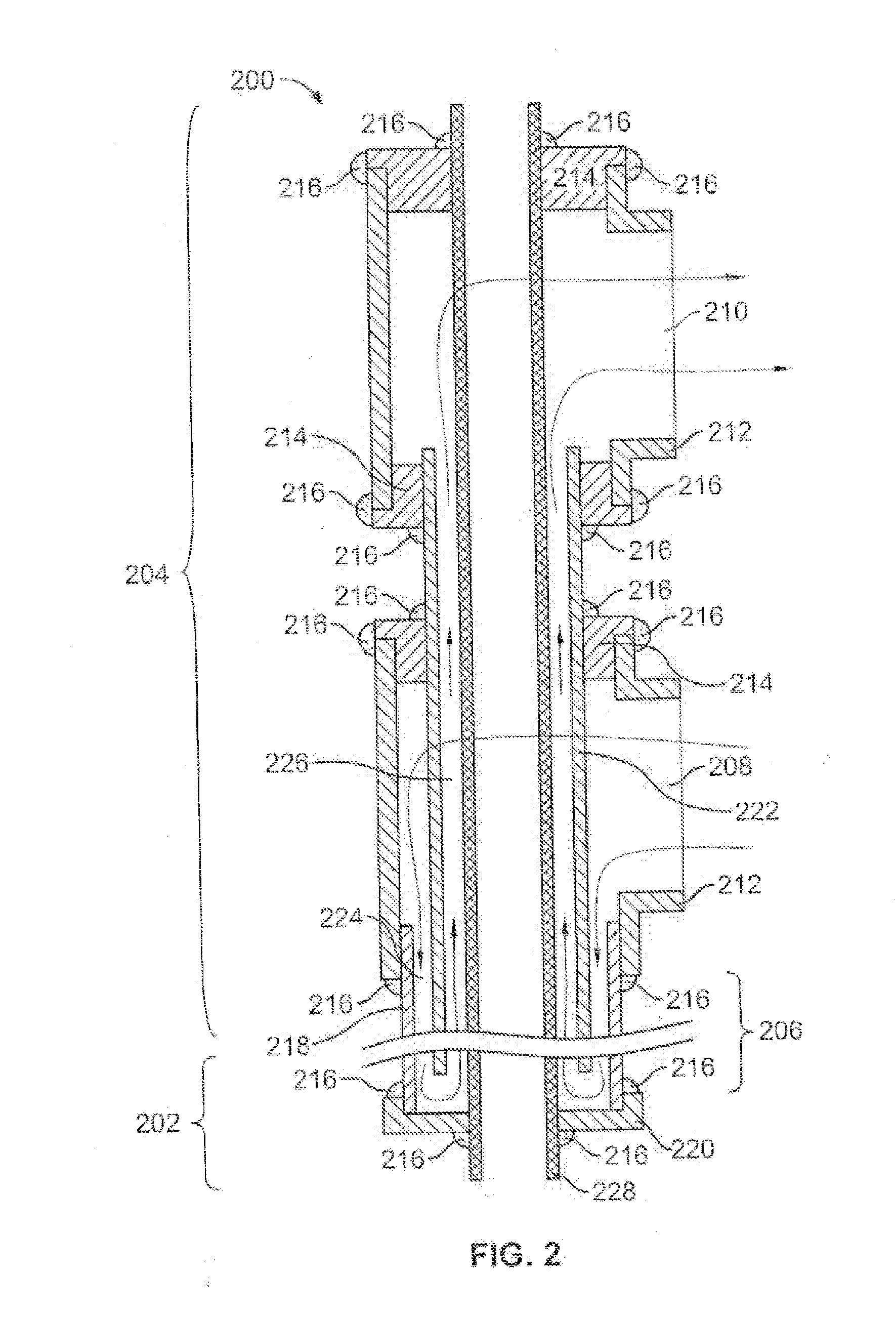

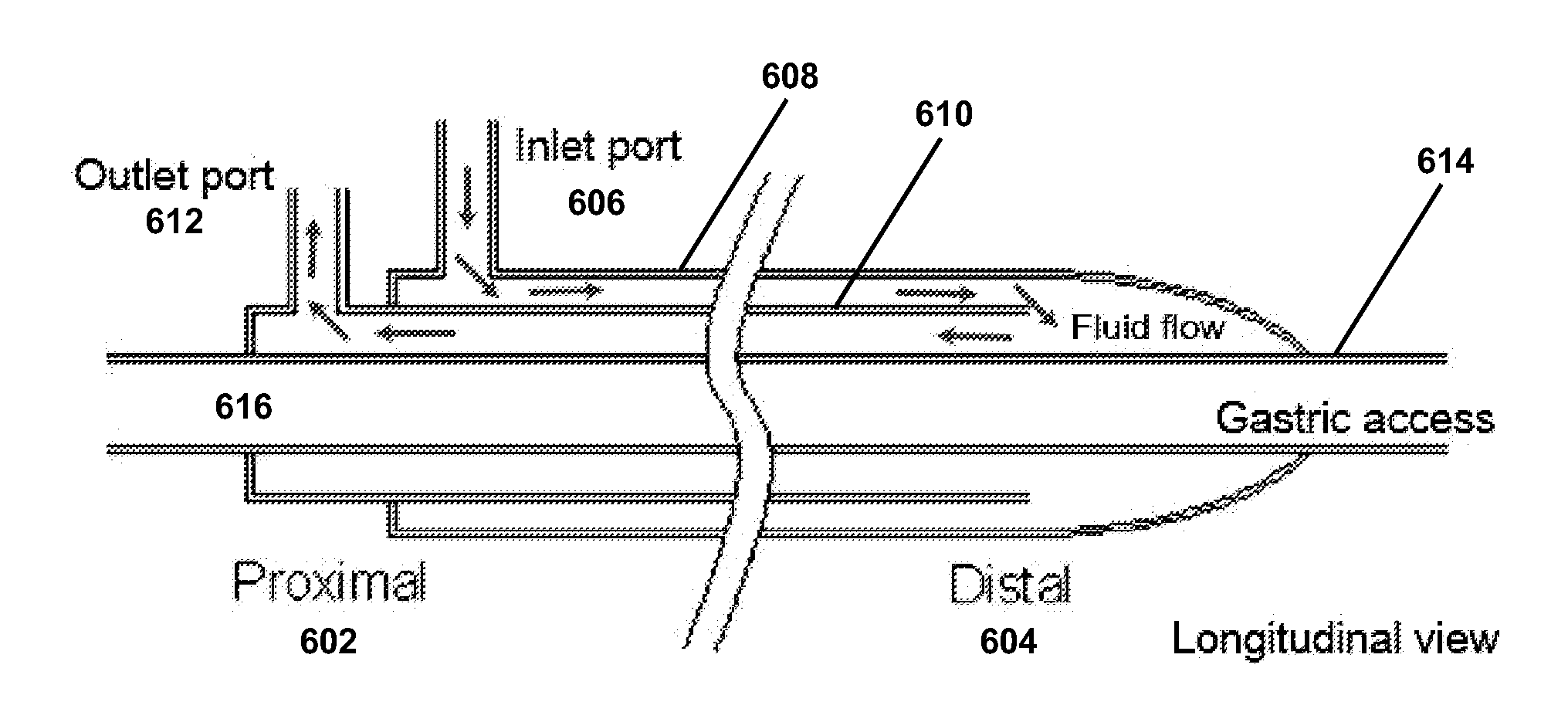

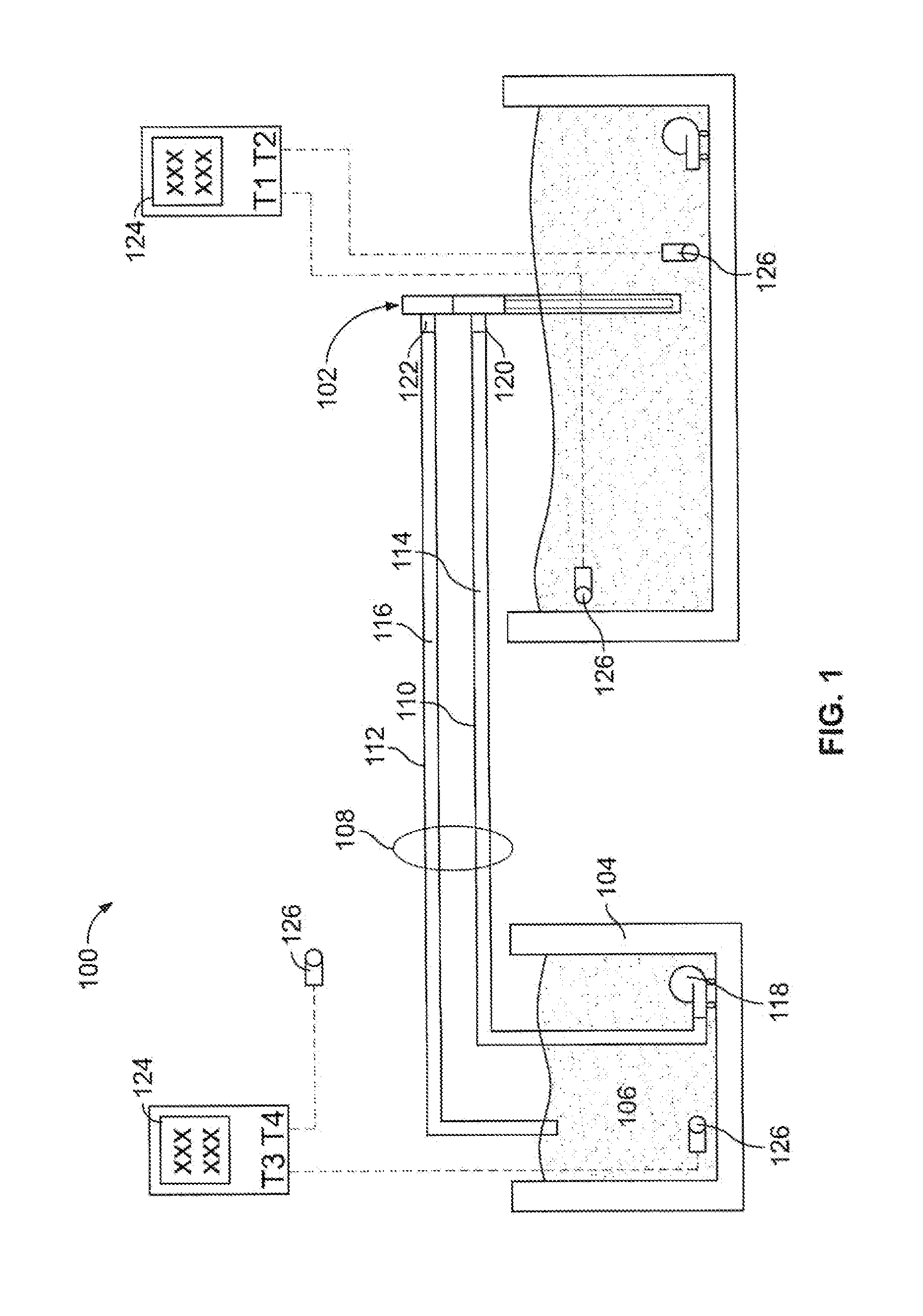

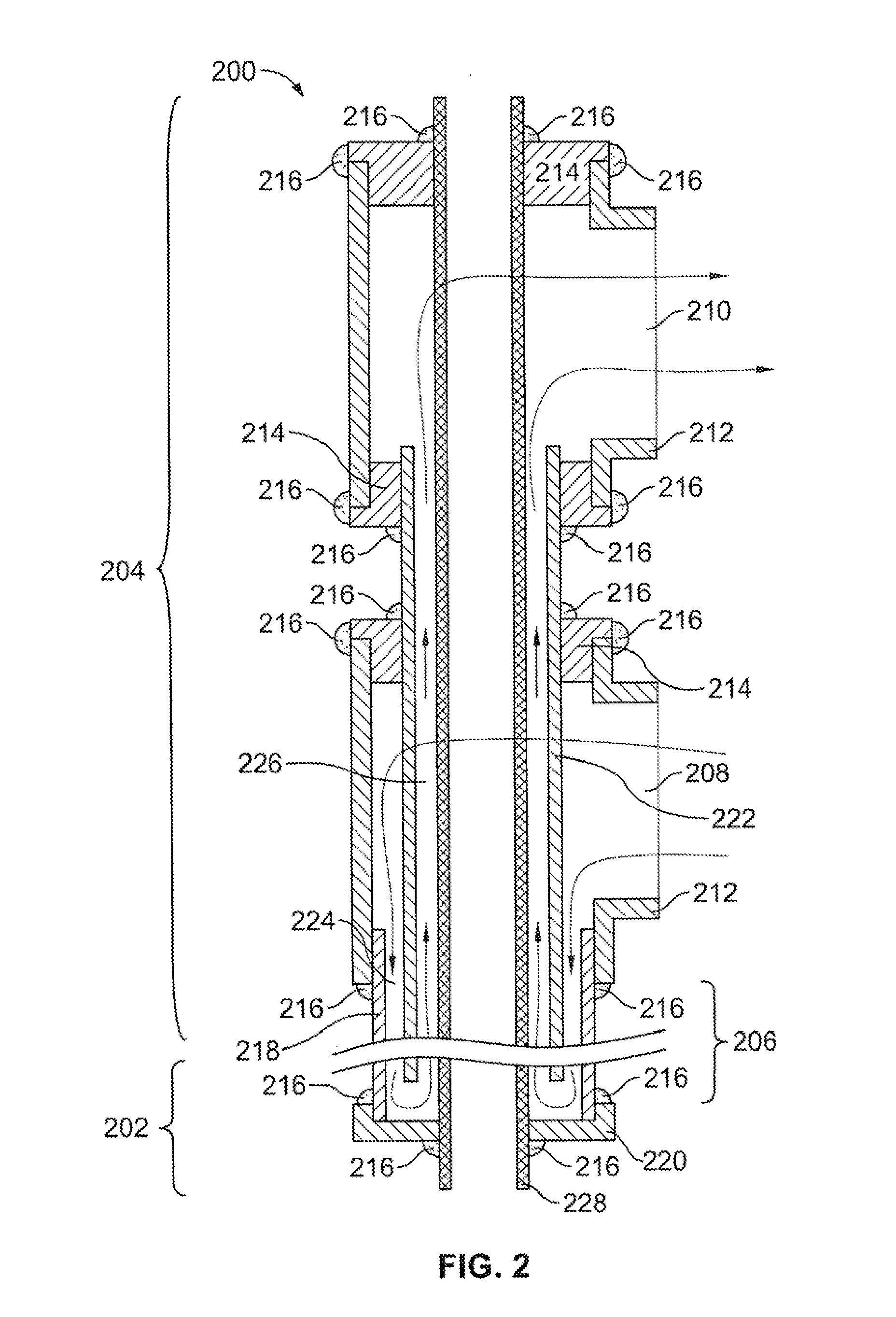

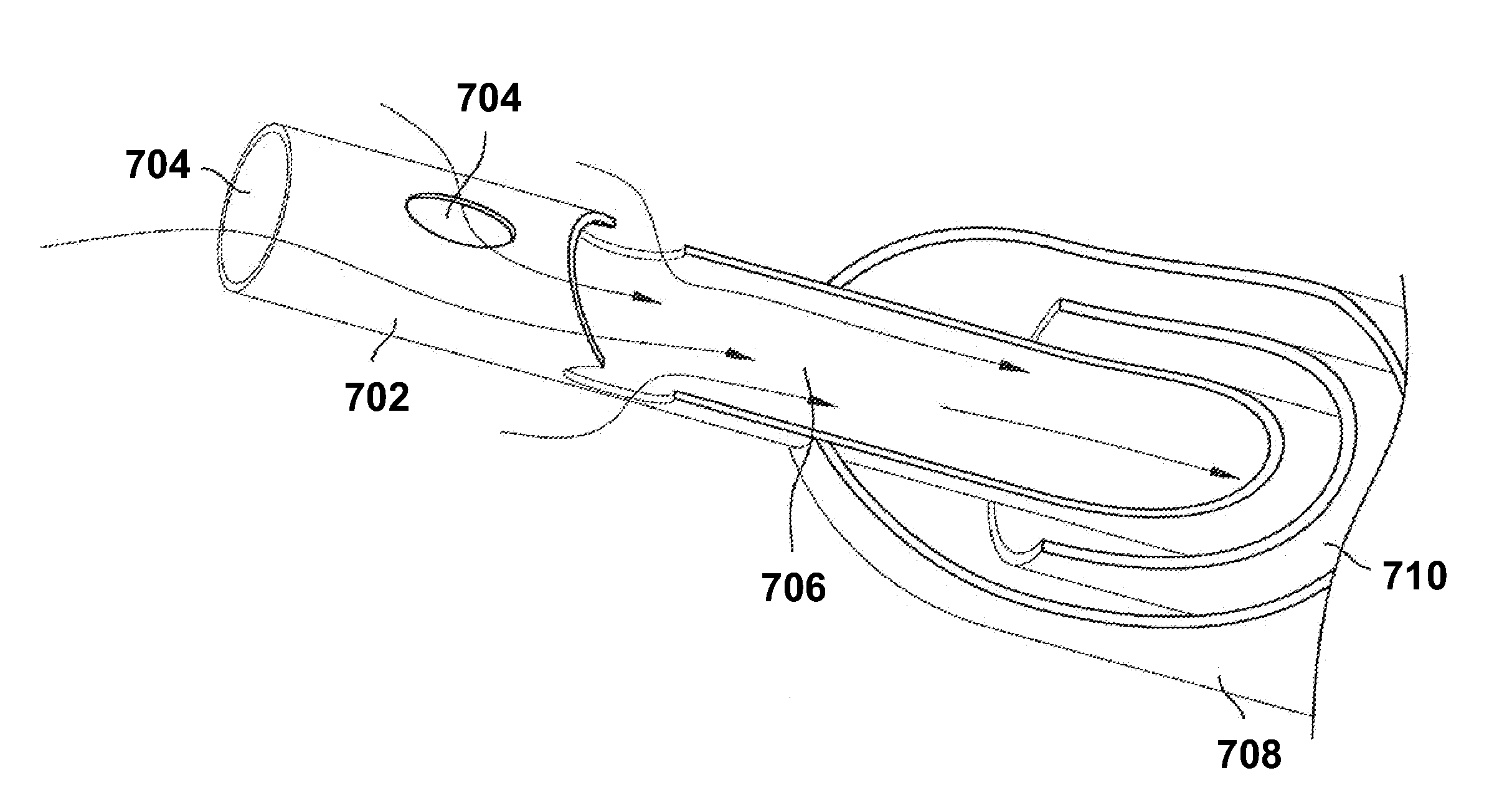

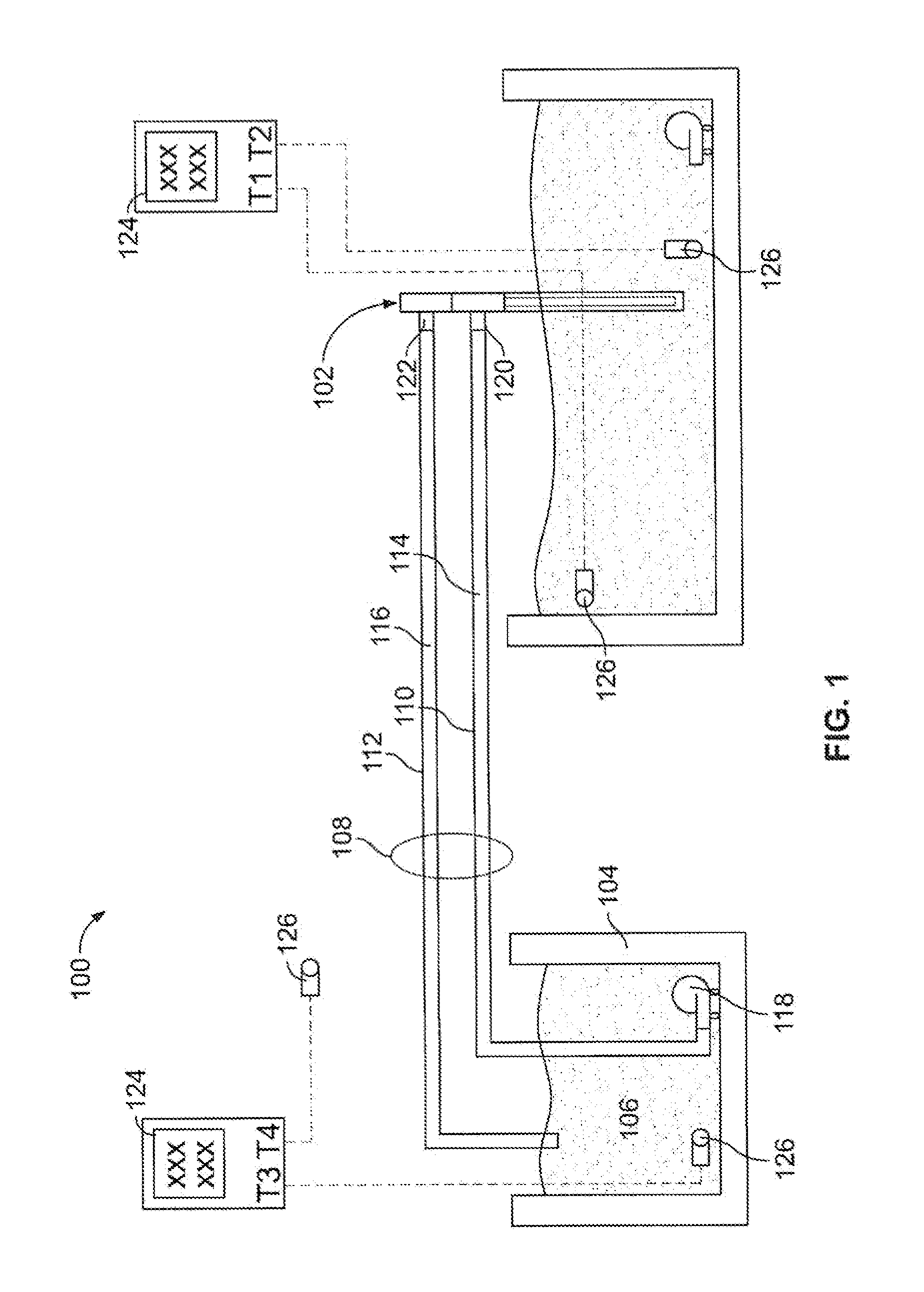

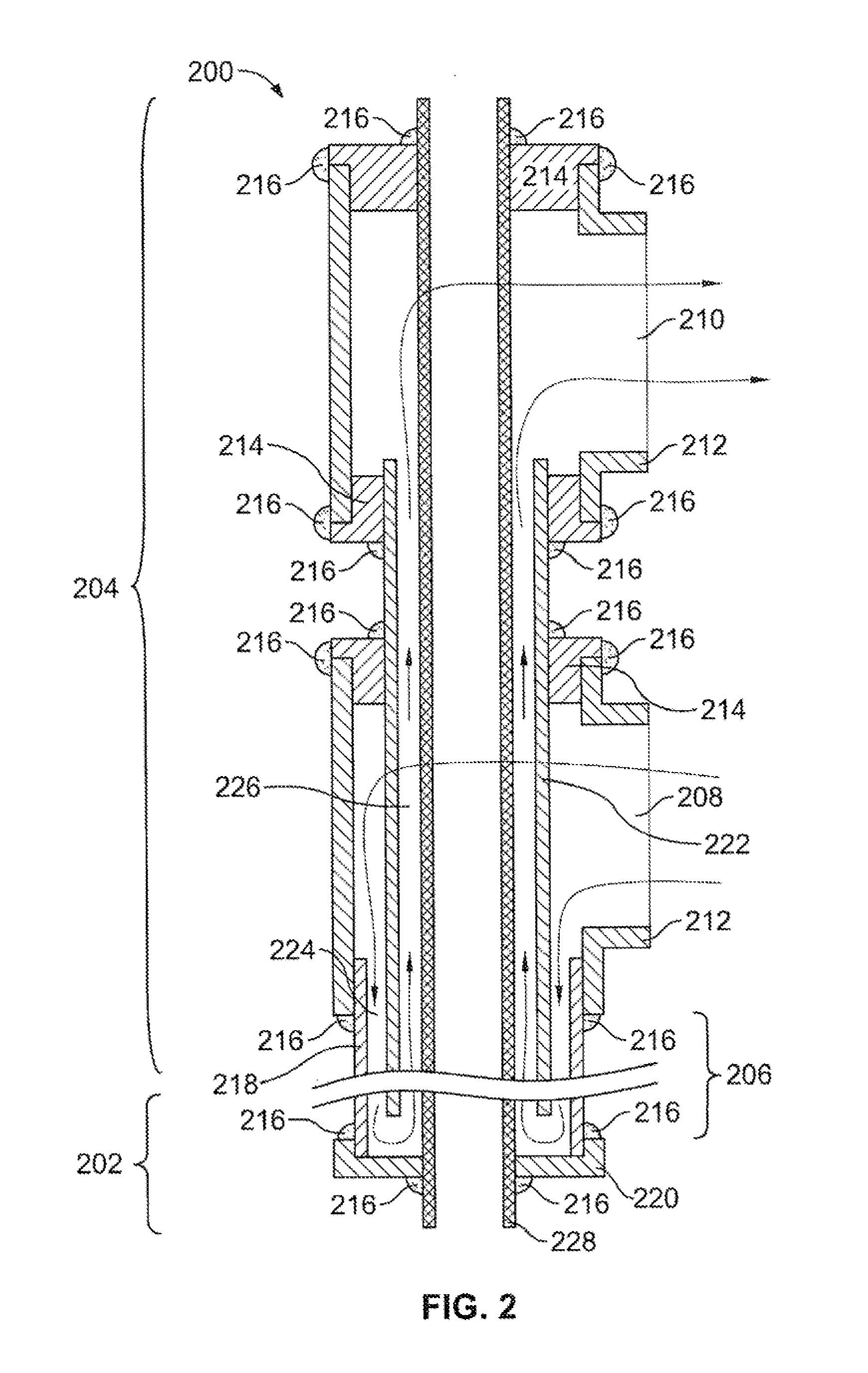

Devices and Methods For Controlling Patient Temperature

ActiveUS20100217361A1Full circulationAdditive manufacturing apparatusSurgeryOesophagramPhysical therapy

Relatively non-invasive devices and methods for heating or cooling a patient's body are disclosed. Devices and methods for treating ischemic conditions by inducing therapeutic hypothermia are disclosed. Devices and methods for inducing therapeutic hypothermia through esophageal cooling are disclosed. Devices and methods for operative temperature management are disclosed.

Owner:ADVANCED COOLING THERAPY INC

Devices and methods for controlling patient temperature

Relatively non-invasive devices and methods for heating or cooling a patient's body are disclosed. Devices and methods for treating ischemic conditions by inducing therapeutic hypothermia are disclosed. Devices and methods for inducing therapeutic hypothermia through esophageal cooling are disclosed. Devices and methods for operative temperature management are disclosed.

Owner:ADVANCED COOLING THERAPY INC

Nano-crystal large poresize mesopore oxide material and its preparation method

InactiveCN1948161AWell-ordered pore structureHighly ordered pore structureTantalum compoundsTitanium dioxideSpace groupOrganic solvent

Owner:FUDAN UNIV

Devices and Methods For Controlling Patient Temperature

Owner:ADVANCED COOLING THERAPY INC

Process for transformation of mature trees of Eucalyptus plants

InactiveUS6563024B1Efficient conversionImprove abilitiesHybrid cell preparationOther foreign material introduction processesShootINDUCTION TREATMENT

The present invention discloses a process for transforming mature trees of Eucalyptus plants comprising: induction adventitious shoots from segments of the explant obtained from an adult tree of a Eucalyptus plant, preculturing the adventitious shoots in infection induction medium, infecting the adventitious shoots subjected to infection induction treatment with infection medium containing Agrobacterium tumefaciens, and rotary-culturing the infected explant segments in sterilization medium containing antibiotic; whereby sterilizing and forming transgenic calli, which regenerate transgenic plants by way of formation of shoot primordia by rotary-culturing under illumination.

Owner:OJI PAPER CO LTD

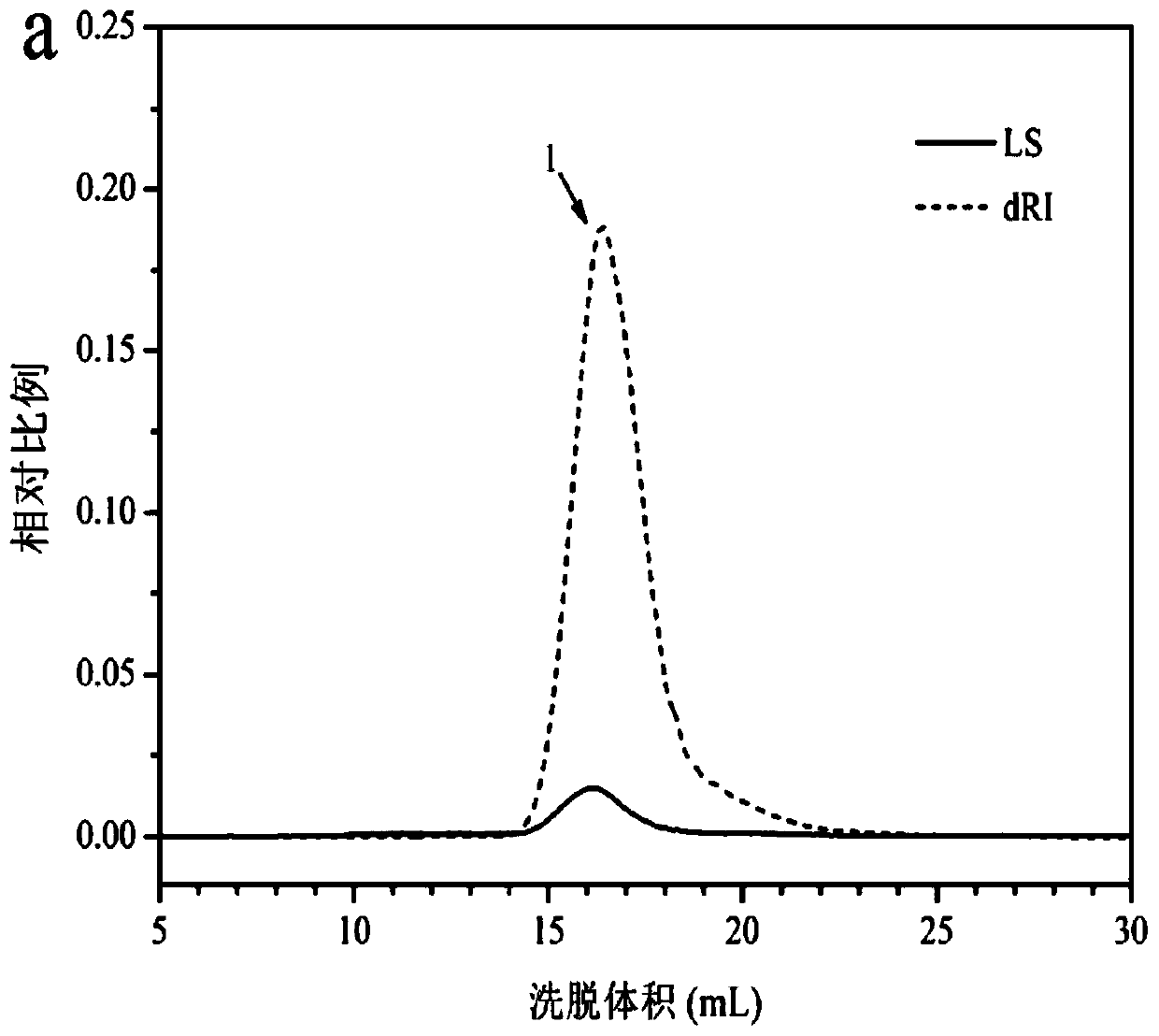

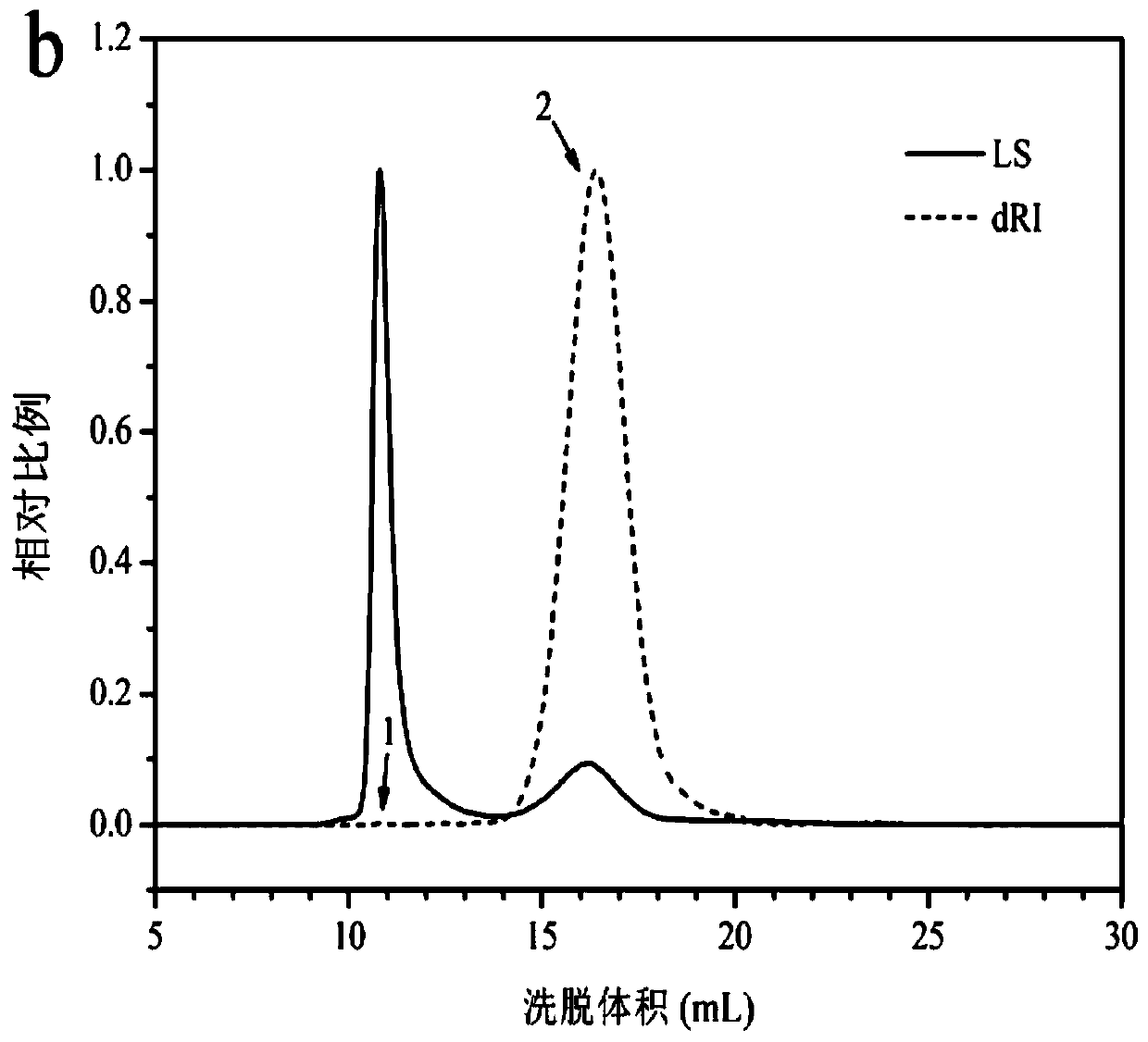

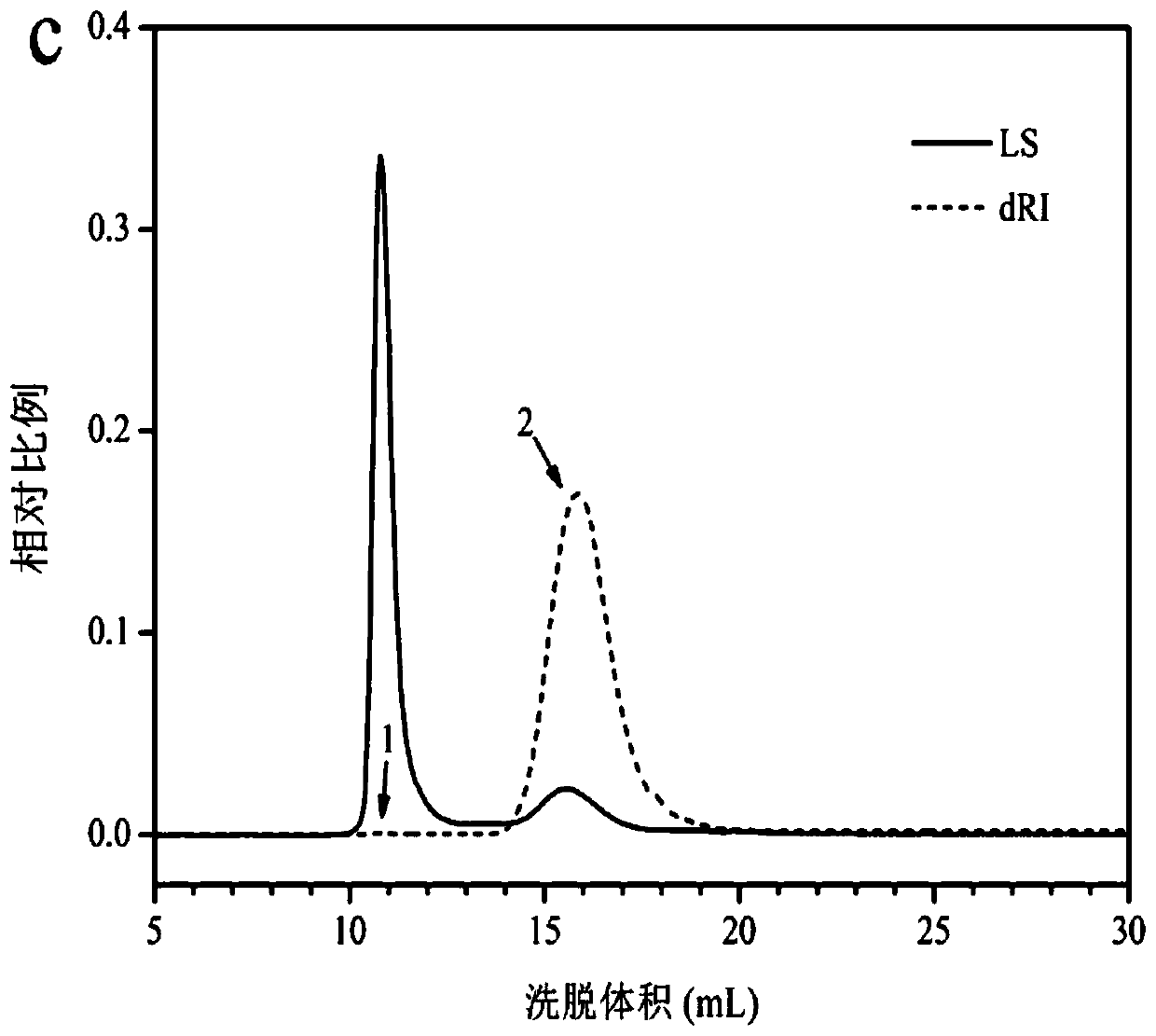

Bifunctional starch-based composite nanoparticle as well as preparation method and application thereof

ActiveCN110606995ARich academic contentUniform degree of polymerizationFermentationComposite nanoparticlesINDUCTION TREATMENT

The invention discloses a bifunctional starch-based composite nanoparticle as well as a preparation method and an application thereof. The preparation method comprises the following steps: hydrolyzingstarch to form linear dextrin, and grading the linear dextrin by adopting an alcohol-alcohol gradient precipitation method to obtain linear dextrin with uniform molecular weight distribution; carrying out oxidation treatment on the linear dextrin through an oxidation system to obtain oxidized dextrin; carrying out complexation reaction on the oxidized dextrin and curcumin to form an oxidized dextrin-curcumin complex, so that the oxidized dextrin-curcumin / chitosan hydrochloride composite nanoparticles and chitosan hydrochloride form the oxidized dextrin-curcumin / chitosan hydrochloride composite nanoparticles. According to the method, the aqueous phase solution of the bifunctional starch-based composite nanoparticles containing the gellan is uniformly mixed with the primary emulsion, the obtained double emulsion is subjected to calcium ion induction treatment to obtain the double emulsion gel, and the double emulsion gel has good oxidation resistance and long-term storage stability andcan be applied to the fields of protection of nutritional ingredients, drug delivery, preparation of cosmetics and the like.

Owner:HEFEI UNIV OF TECH

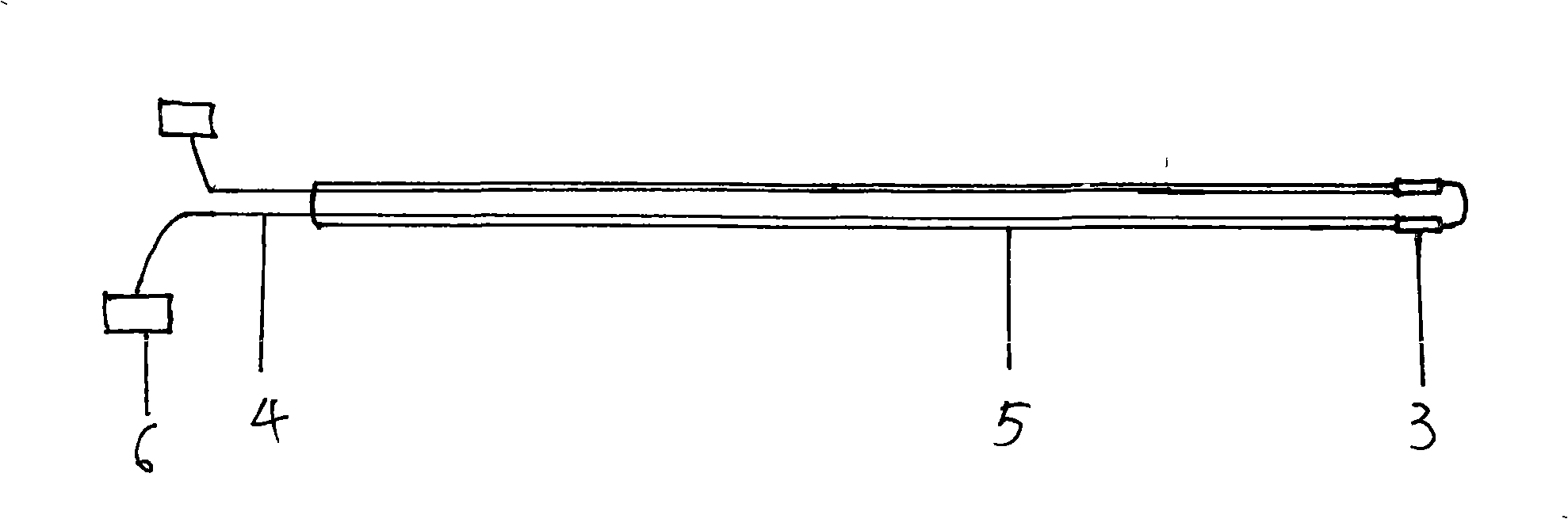

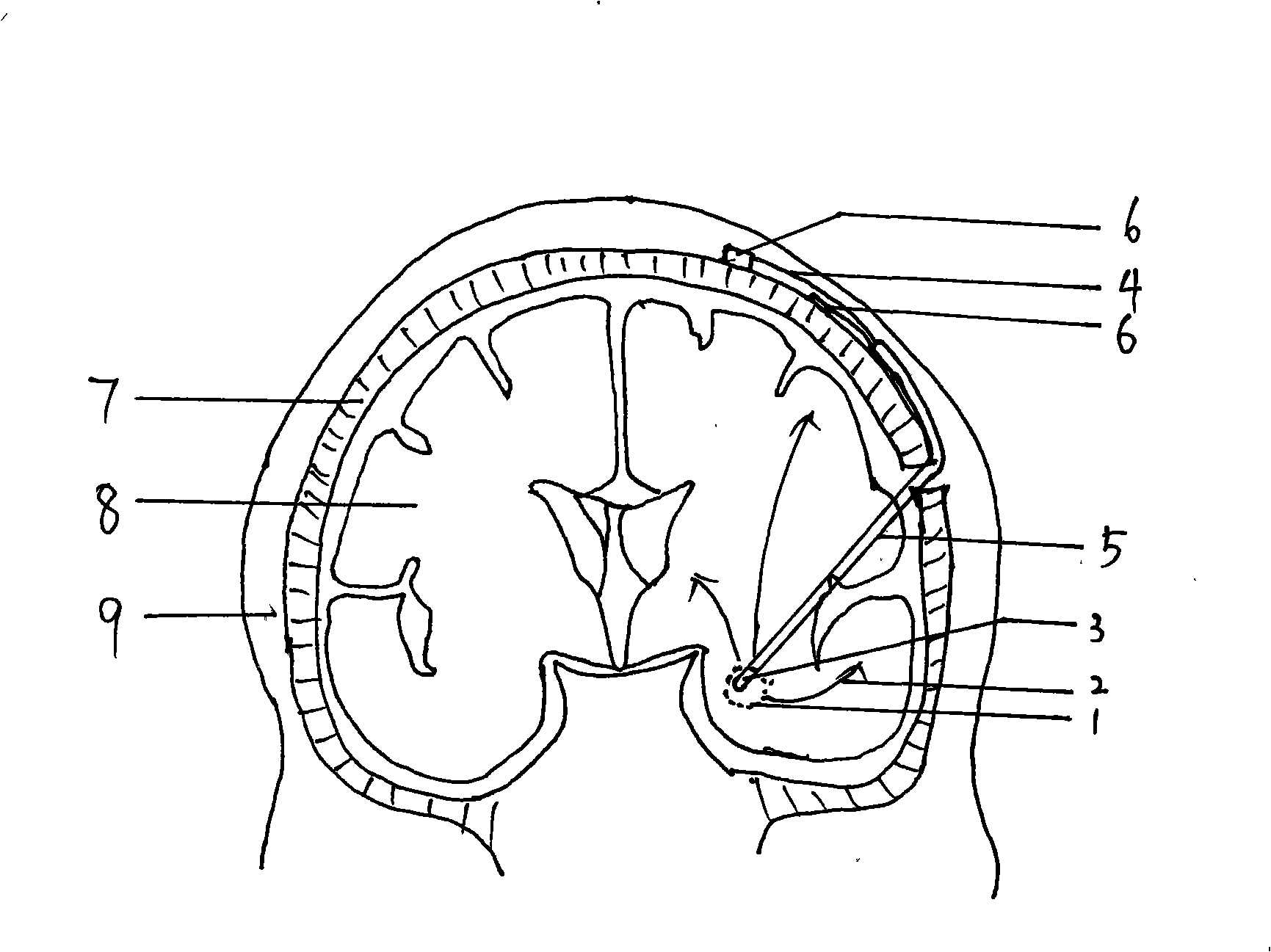

Deep brain epileptic discharge induction treatment method and equipment

InactiveCN101322866AGuaranteed electrophysiological activityConvenient for explosive high voltageInternal electrodesExternal electrodesLow voltageEpileptogenic focus

The invention discloses an induction therapy method for epileptic discharge in deep brain of an epileptic and a device thereof, which is of a new medical concept and a new medical device. The therapy method and the device of the invention are used for curing an epileptogenic focus in the deep brain area of the epileptic, particularly for the intractable epileptic by using medicines. The device of the invention comprises a needle-shaped electrode in the brain, a guide wire with an insulating layer, a protection sheath for silica gel guide wires and an electrode plate under the scalp. The method and the device of the invention are characterized in that the induction method is adopted to induce the hypersynchrony discharge of the epileptic under the skin outside the skull, an electrode made by the material with high electrical conductivity is embedded to epileptic discharge parts in the brain and connected to the electrode plate outside the skull by the guide wire that is made by the material with high electrical conductivity and is provided with the outer insulating layer, the electric potential difference between the high voltage in the explosive discharge of the epilepsy and the low voltage outside the skull is utilized to induce the explosive discharge current to the exterior of the brain, thereby avoiding the clinic epileptic seizure formed by the discharge induction of the epilepsy and realizing the aim of curing the epilepsy.

Owner:梁树立

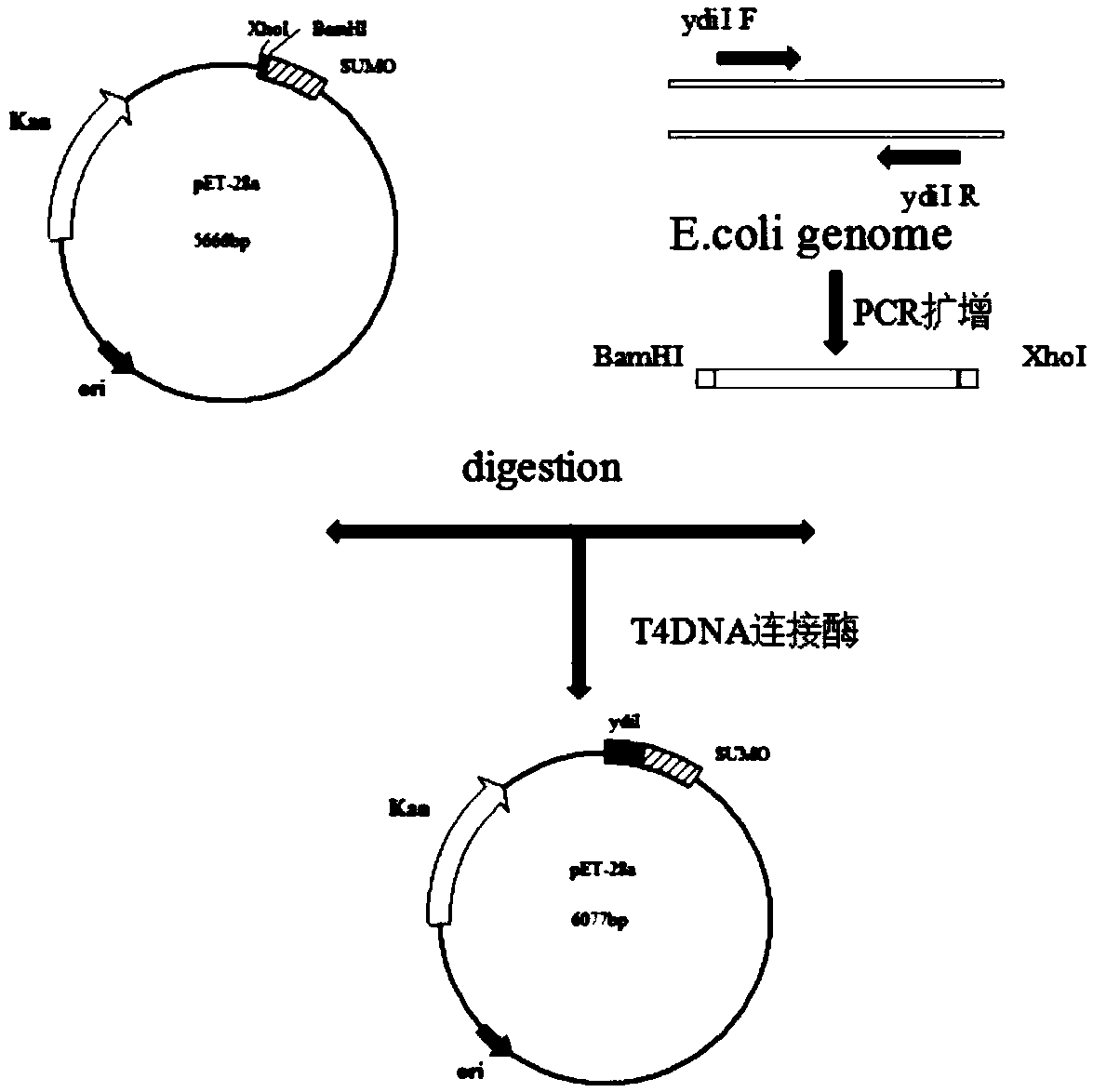

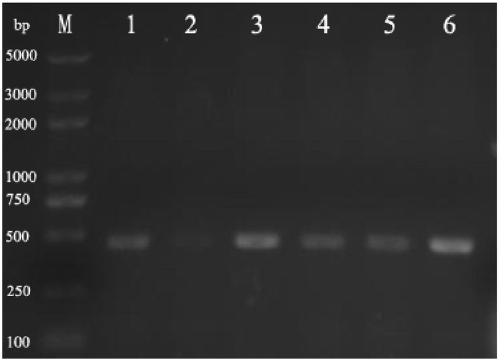

Method for preparing 10-hydroxy-2-caproleic acid through escherichia coli engineering bacteria resting cells

ActiveCN109402182AAchieve biosynthesisImprove conversion rateBacteriaHydrolasesEscherichia coliINDUCTION TREATMENT

The invention relates to a method for preparing 10-hydroxy-2-caproleic acid through escherichia coli engineering bacteria resting cells. The method includes the following steps that (1) escherichia coli engineering bacteria containing recombinant plasmids pET-28a-ydiI is constructed; (2) the escherichia coli engineering bacteria containing the recombinant plasmids pET-28a-ydiI is taken to prepareinduced cells; and (3) the induced cells are cultured in a transformed culture medium to obtain the resting cells, and 10-hydroxy capric acid is then added into the culture medium to prepare the 10-hydroxy-2-caproleic acid. According to the method for preparing the 10-hydroxy-2-caproleic acid through the escherichia coli engineering bacteria resting cells, positive recombinant escherichia coli, containing thioesterase, modified through genetic engineering is disclosed for the first time, after special induction treatment, the 10-hydroxy-2-caproleic acid can be produced by fermentation throughthe resting cells, and a large quantity of biosynthesis of the 10-hydroxy-2-caproleic acid is realized.

Owner:QILU UNIV OF TECH

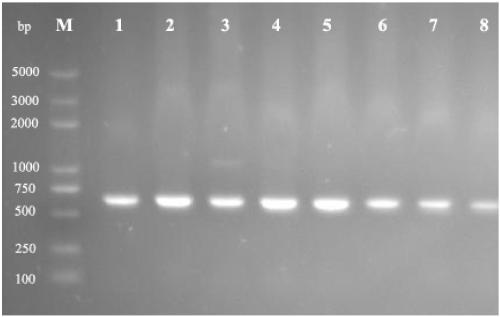

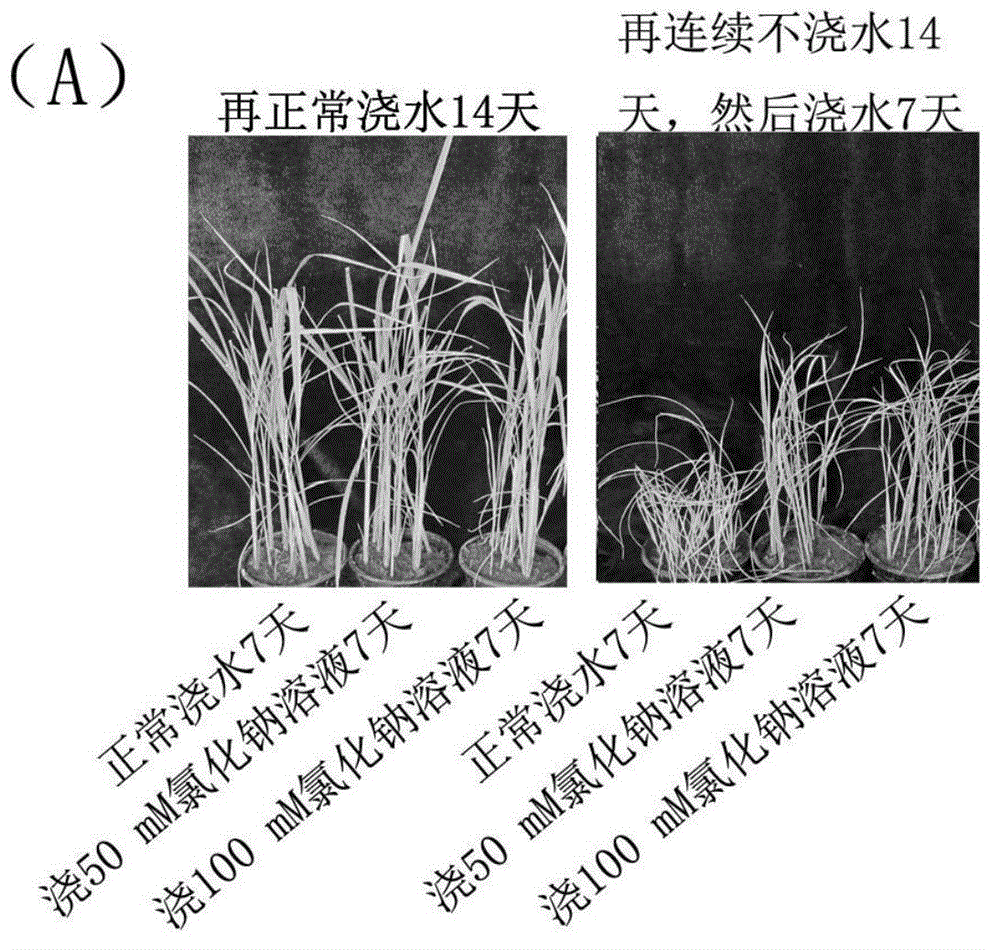

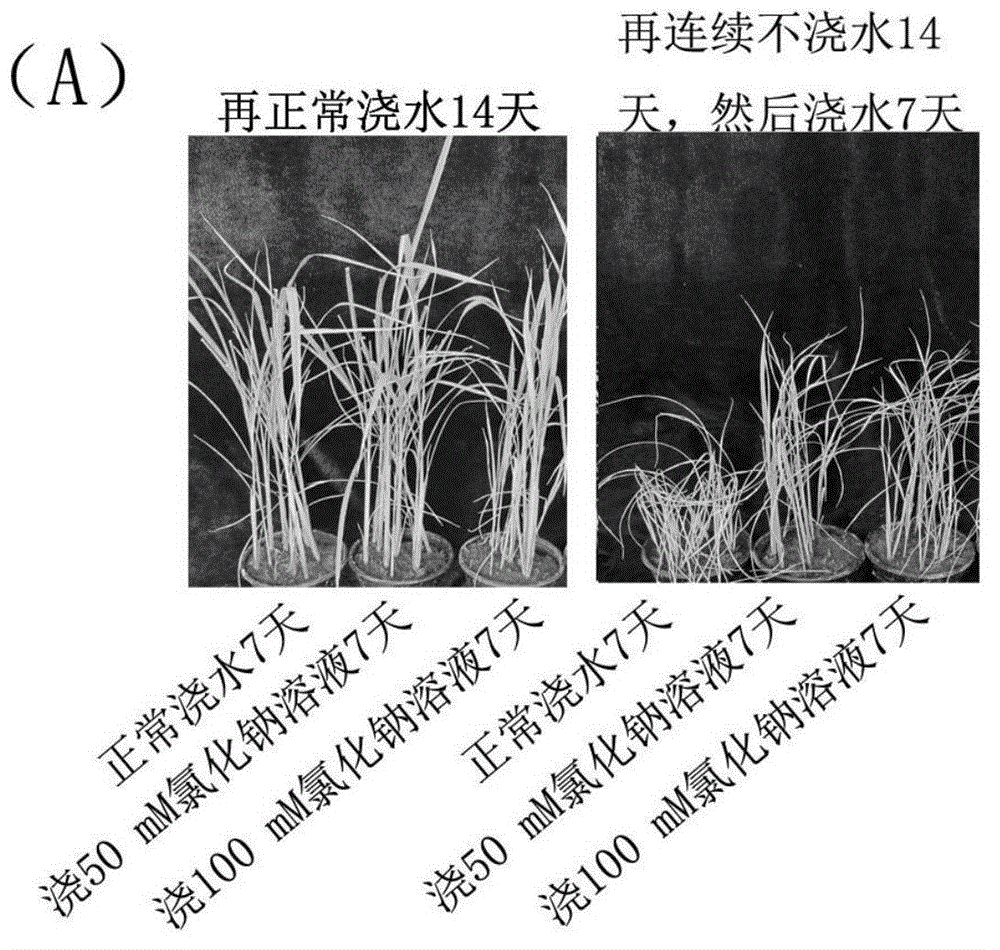

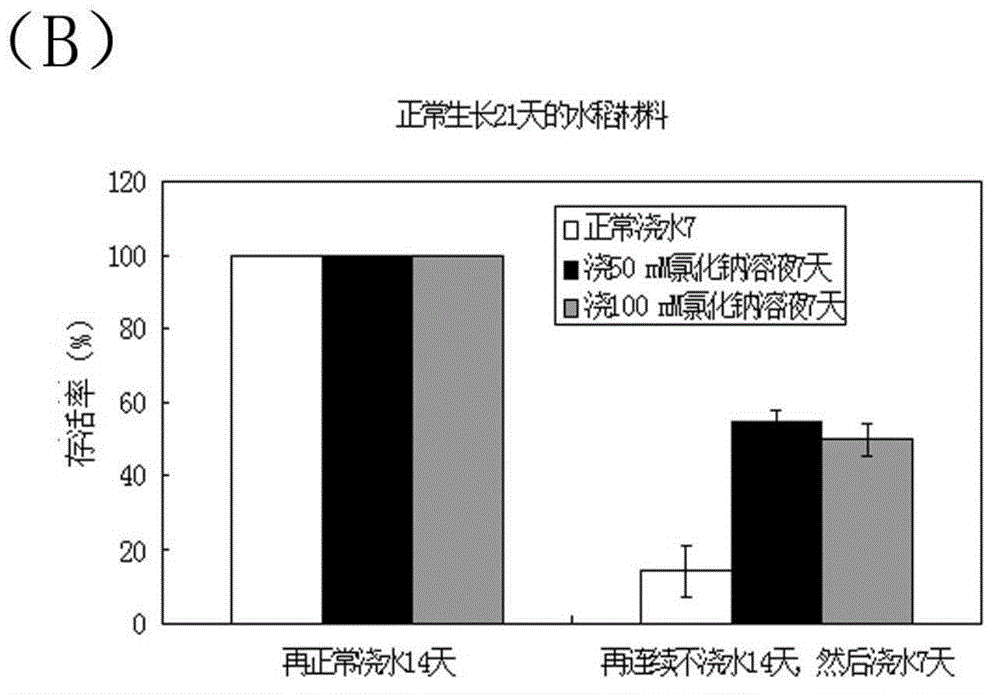

Method for improving drought resistance of paddy rice, alfalfa and Bermuda grass through drought induction treatment

InactiveCN103141277AImprove drought resistanceIncrease productionHorticulture methodsSeed coating/dressingINDUCTION TREATMENTRhizome

The invention discloses a method for improving drought resistance of paddy rice, alfalfa and Bermuda grass through drought induction treatment. The method comprises the following steps: A, planting: fertilizing, deeply ploughing and leveling a seedling land, fertilizing base fertilizers, preparing the land before sowing, sterilizing soil with ferrous sulfate, and leveling a bed surface; growing seedlings of paddy rice: firstly culturing seedlings in a certain farmland; cleaning alfalfa seeds, carrying out coating treatment on the seeds before sowing, ventilating, transmitting light and carrying out field management; carrying out lawn planting on Bermuda grass with two methods of seed sowing and rhizome propagation, and sowing seeds in late spring and early summer; B, seedling management: watering in seedling early period; and C, drought induction treatment: no watering paddy rice, alfalfa and Bermuda grass at any period of growth stage continuously so as to induce drought stress, and watering according to normal condition in other periods. The method is easy to implement, simple and convenient to operate and quick to take effect, and drought resistance of plants can be improved in short period of time, so that the crop yield and herbage yield during seasonal drought and at drought areas are increased.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

High-seedling-rate culture method for tissue culture of Polygala fallax stems

ActiveCN106577281AReduce browningAvoid vitrificationHorticulture methodsPlant tissue cultureINDUCTION TREATMENTTaproot

The invention relates to a high-seedling-rate culture method for tissue culture of Polygala fallax stems. The method comprises steps as follows: explants are collected and disinfected, axillary buds are obtained through induced culture, strong stems are obtained through strong seedling culture, tissue culture stems are obtained through subculture proliferation, induced root treated stems are obtained through root induction treatment and rooting is performed outside test tubes. Semi-lignified branches with axillary buds not germinated yet are adopted, leaves are removed, and branches at least comprising one internode stem are cut to serve as the explants. With the adoption of the steps, formation of taproots of Polygala fallax seedlings is facilitated, the seedling quality is improved, the yield of the Polygala fallax medicinal material is increased, descendant seedlings cannot vary easily, and the method has very great significance in culture and medicinal material production of the Polygala fallax seedlings.

Owner:福建省农业科学院农业生物资源研究所

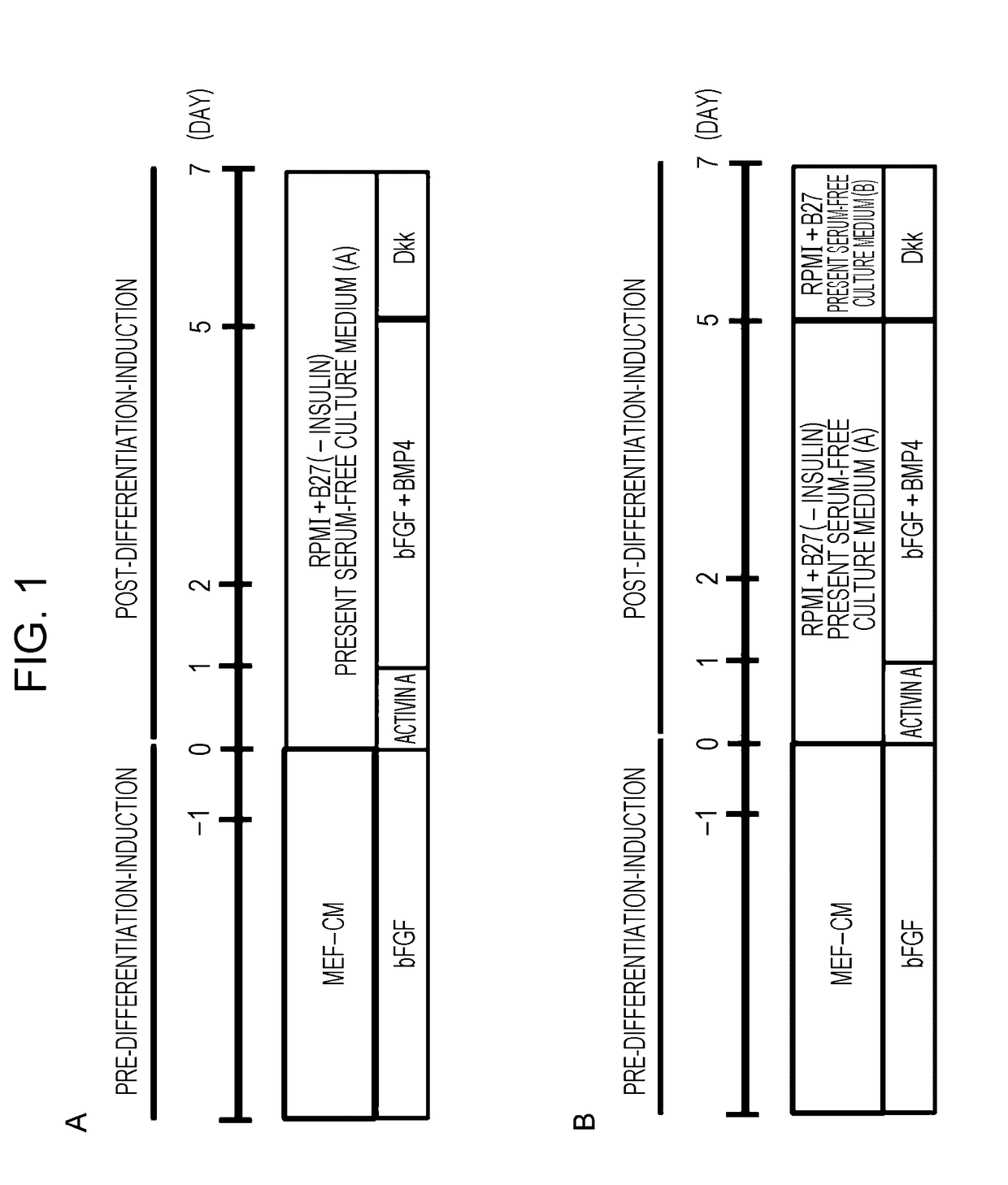

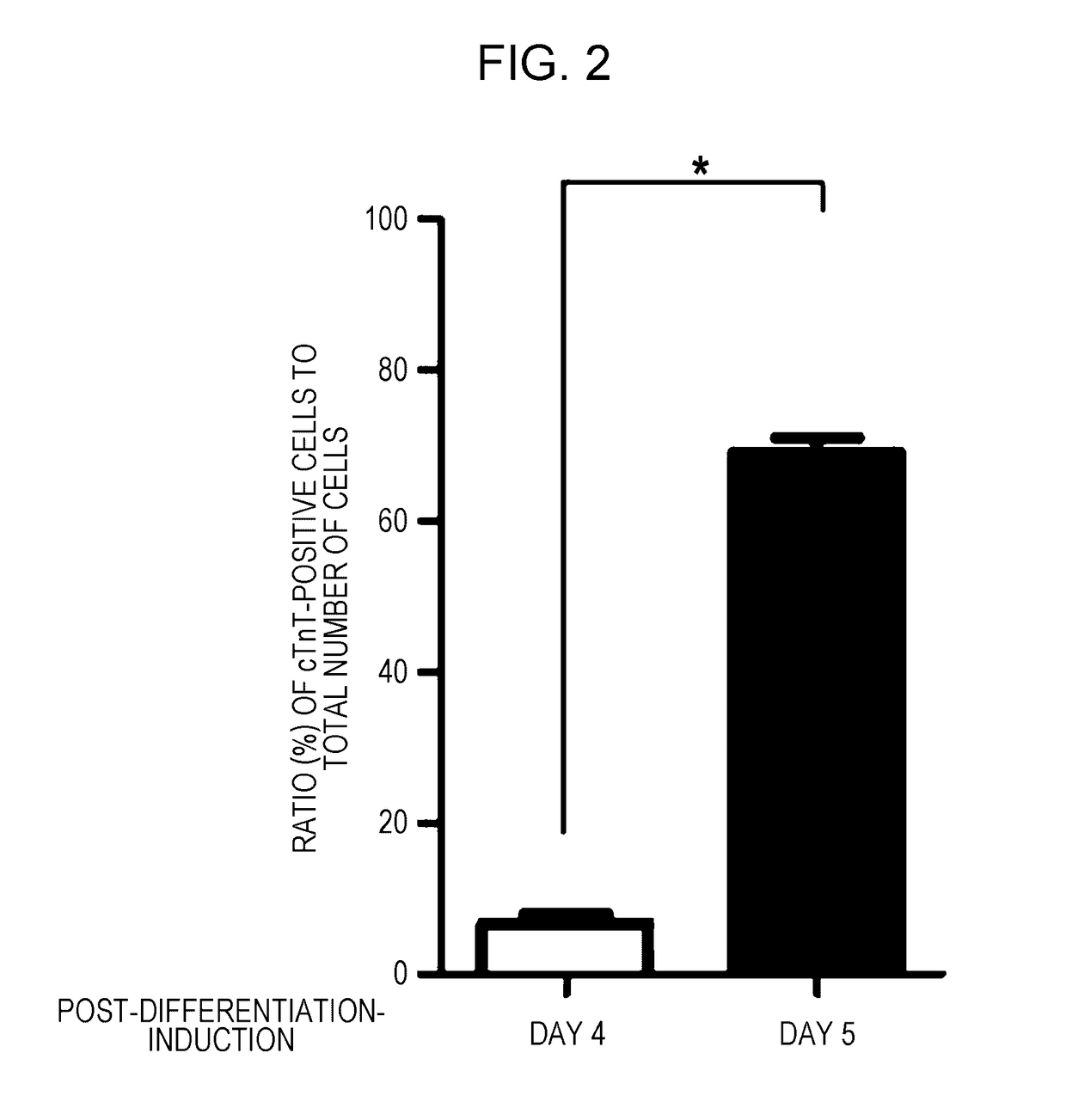

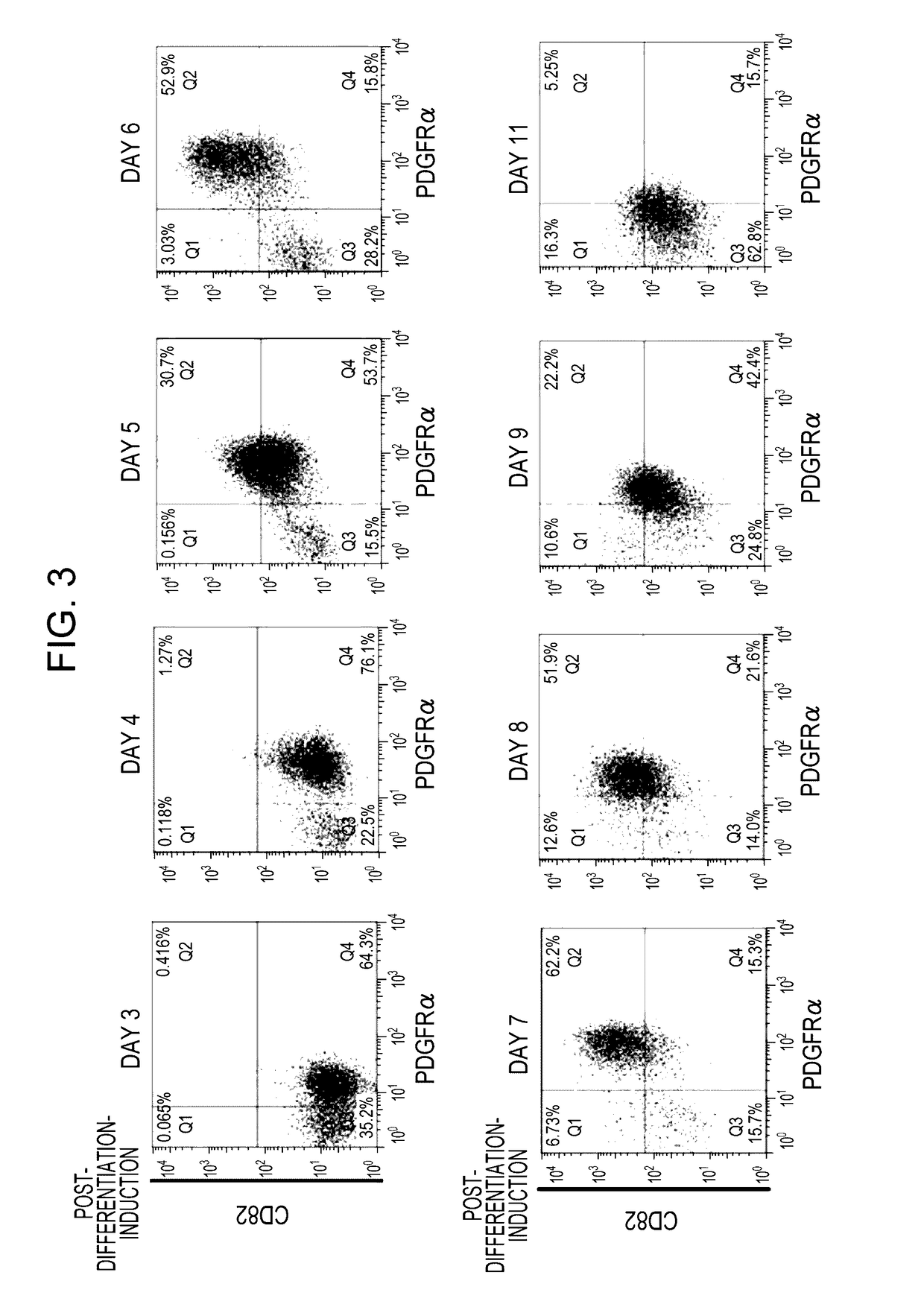

Cd82-positive cardiac progenitor cells

ActiveUS20170067023A1Low rateIncrease ratingsMammal material medical ingredientsSkeletal/connective tissue cellsINDUCTION TREATMENTCardiac muscle cell

An object of the present invention is to provide a myocardial progenitor cell that is specifically induced to differentiate into a cardiomyocyte, and a method for preparing the myocardial progenitor cell. A method for preparing a CD82-positive cell includes, in sequence, a step (a) of obtaining stem cells, a step (b) of subjecting the stem cells to induction treatment of differentiation into cardiovascular cells, and a step (c) of separating, from the stem cells having been subjected to the induction treatment of differentiation in the step (b), a CD82-positive cell being negative for at least one cell surface marker selected from CD73, CD44, CD105, CD121a, CD18, and CD120a. This method enables preparation of a CD82-positive cell for use as a myocardial progenitor cell.

Owner:KYOTO UNIV MED PHARM COLLABORATION BUILDING

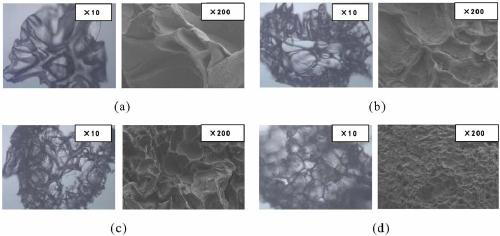

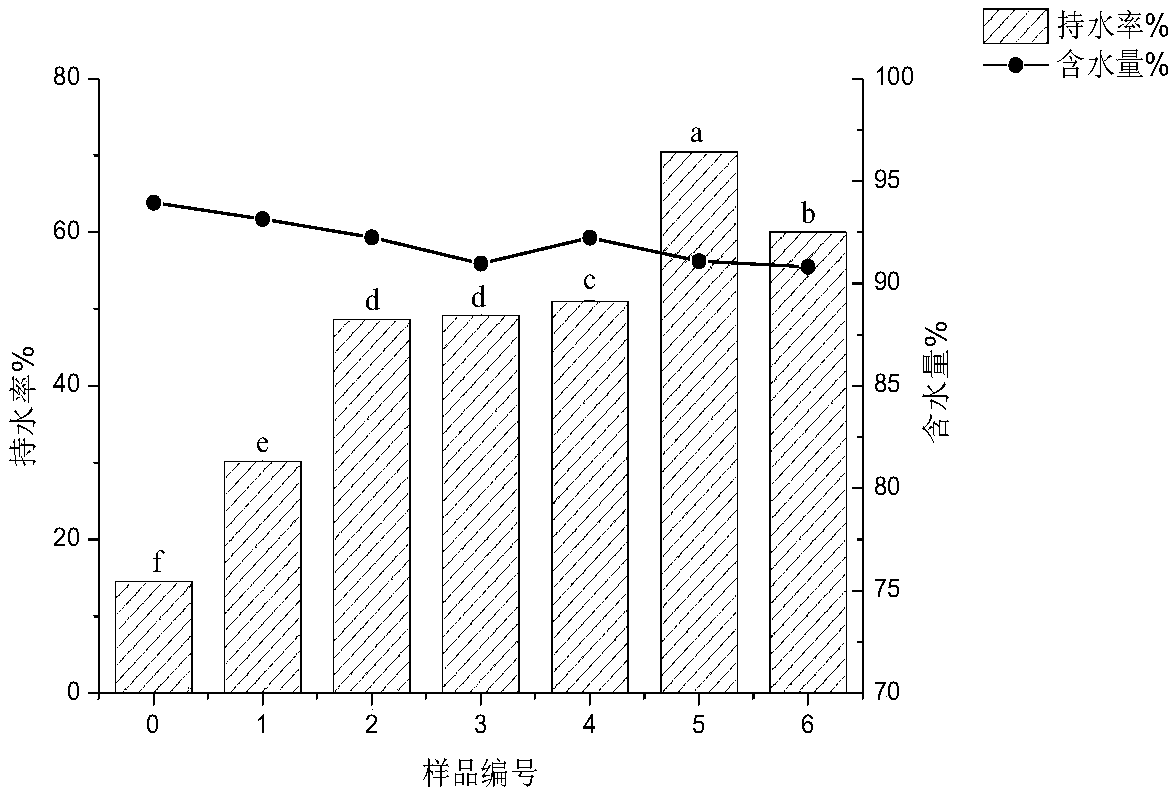

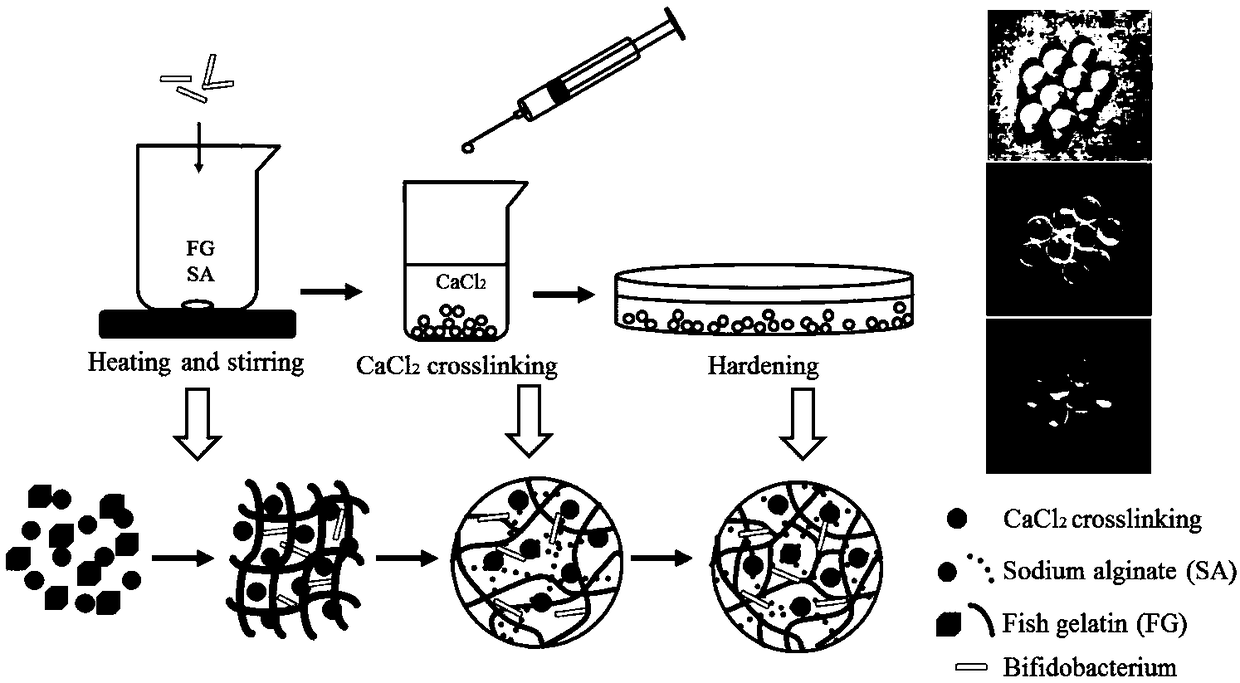

Fish gelatin/sodium alginate double-network complex hydrogel, preparation method thereof and obtained probiotic microcapsule

InactiveCN109232920AHigh gel strengthIncrease moisture contentOn/in organic carrierDouble networkAtherion elymus

The invention discloses fish gelatin / sodium alginate double-network complex hydrogel, a preparation method thereof and an obtained probiotic microcapsule, and belongs to the field of microcapsules. When the fish gelatin and sodium alginate gel as single network gel is used, the disadvantages of poor mechanical performance and stability are shown, and embedding of probiotics is not facilitated so as to cause the problems of low embedding ratio of the probiotics and small protection degree of the probiotics. According to the technical scheme, a sodium alginate solution is prepared and is fully hydrated; the fish gelatin is added into the hydrated sodium alginate solution to obtain a mixed solution; the mixed solution is heated, subjected to induction treatment, and is cooled to obtain a gelmixed solution; the gel mixed solution is added into a first calcium ion solution at constant speed and is molded, and then the molded gel is added into a second calcium ion solution and is hardened.The fish gelatin / sodium alginate double-network complex hydrogel disclosed by the invention can be applied to embedding of the probiotics and has the advantages of high embedding ratio and high survival rate of the probiotics.

Owner:SHANDONG UNIV

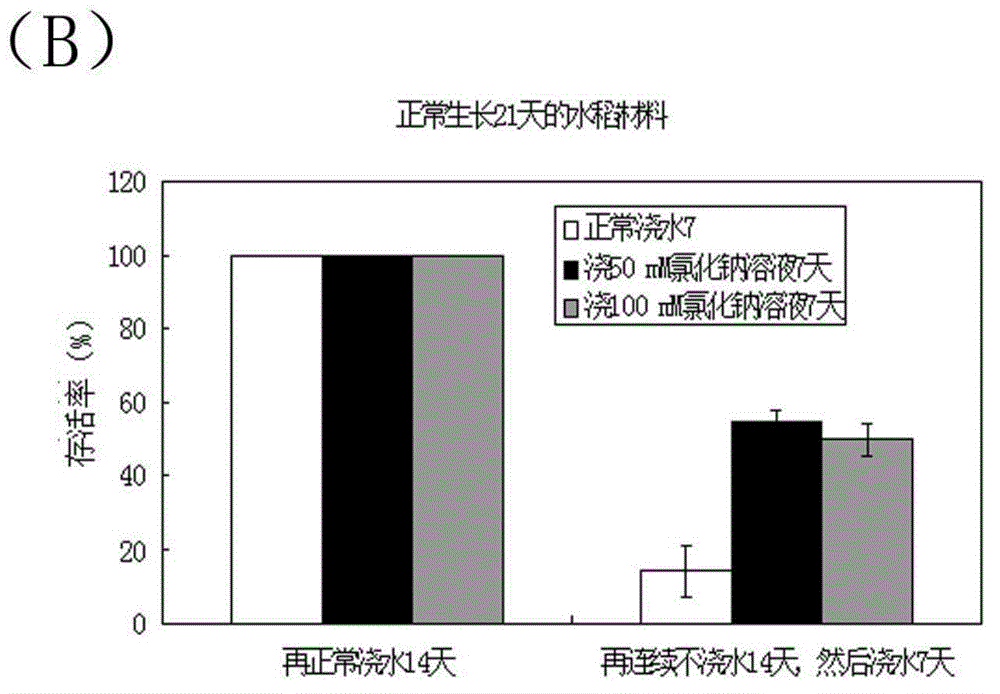

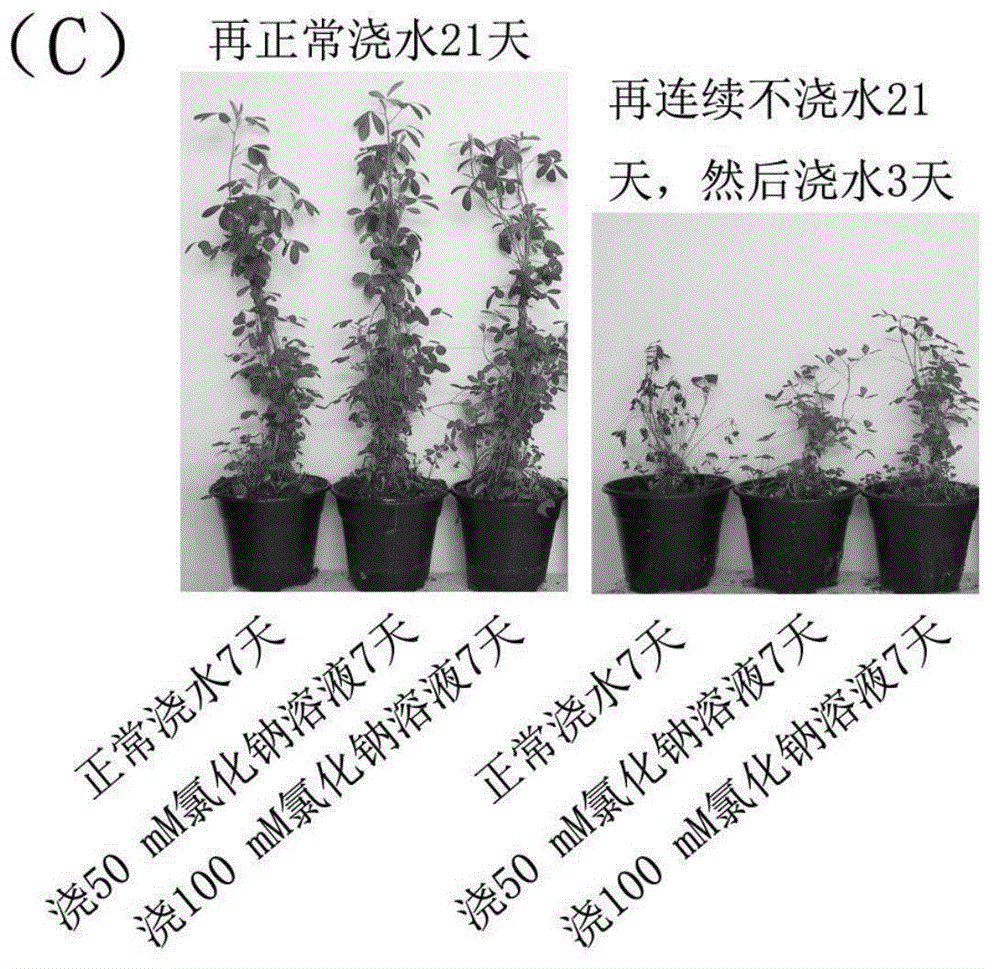

Method for improving drought resistance of paddy rice, alfalfa and Bermuda grass through low-salt induction treatment

InactiveCN103141279AImprove drought resistanceIncrease productionSeed coating/dressingHorticultureINDUCTION TREATMENTRhizome

The invention discloses a method for improving drought resistance of paddy rice, alfalfa and Bermuda grass through low-salt induction treatment. The method comprises the following steps: A, planting: fertilizing, deeply ploughing and leveling a seedling land, fertilizing base fertilizers, preparing the land before sowing, sterilizing soil with ferrous sulfate, and leveling a bed surface; growing seedlings of paddy rice: firstly culturing seedlings in a certain farmland; cleaning alfalfa seeds, carrying out coating treatment on the seeds before sowing, ventilating, transmitting light and carrying out field management; carrying out lawn planting on Bermuda grass with two methods of seed sowing and rhizome propagation, and sowing seeds in late spring and early summer; B, seedling management: watering in seedling early period; and C, low-salt induction treatment: continuously pouring sodium chloride solution with low concentration for a given period on paddy rice, alfalfa and Bermuda grass seedlings in growth stage. The method is easy to implement, simple and convenient to operate and quick to take effect, the drought resistance of plants is improved during a short period, the crop yield during seasonal drought or at arid areas is improved, and the ecological benefits and economic benefits of lawn vegetation conservation and water and soil conservation are achieved.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

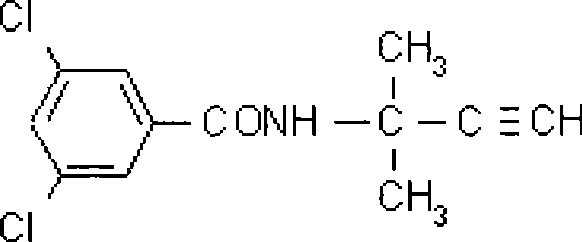

Breeding method for inducing parthenogenesis of corn by propyzamide

InactiveCN102960242ALow toxicityThere is no difficulty in identifyingPlant genotype modificationParthenogenesisPollination

The invention relates to a breeding method for inducing parthenogenesis of corn by propyzamide, belonging to the field of polyploid breeding of plants. The breeding method specifically comprises the following steps of: preparing an inducer with the content of 5 mu mol / L-200mu mol / L by the propyzamide and water; performing induction treatment on filaments, wherein the inducer is sprayed or smeared onto the filaments which grow to about 2.5cm long after emerging, and mature seeds are harvested to get genotype homozygous diploid seeds; and selecting and identifying the seeds according to a conventional method, and selecting a head progeny row which conforms to a breeding goal, thus finally getting a homozygous corn inbred line. The breeding method disclosed by the invention has the positive effects of omitting artificial pollination, being simple, being easy to implement, low in cost, high in efficiency and suitable for large-scale use.

Owner:SHENYANG JINSEGU SPECIAL CORN

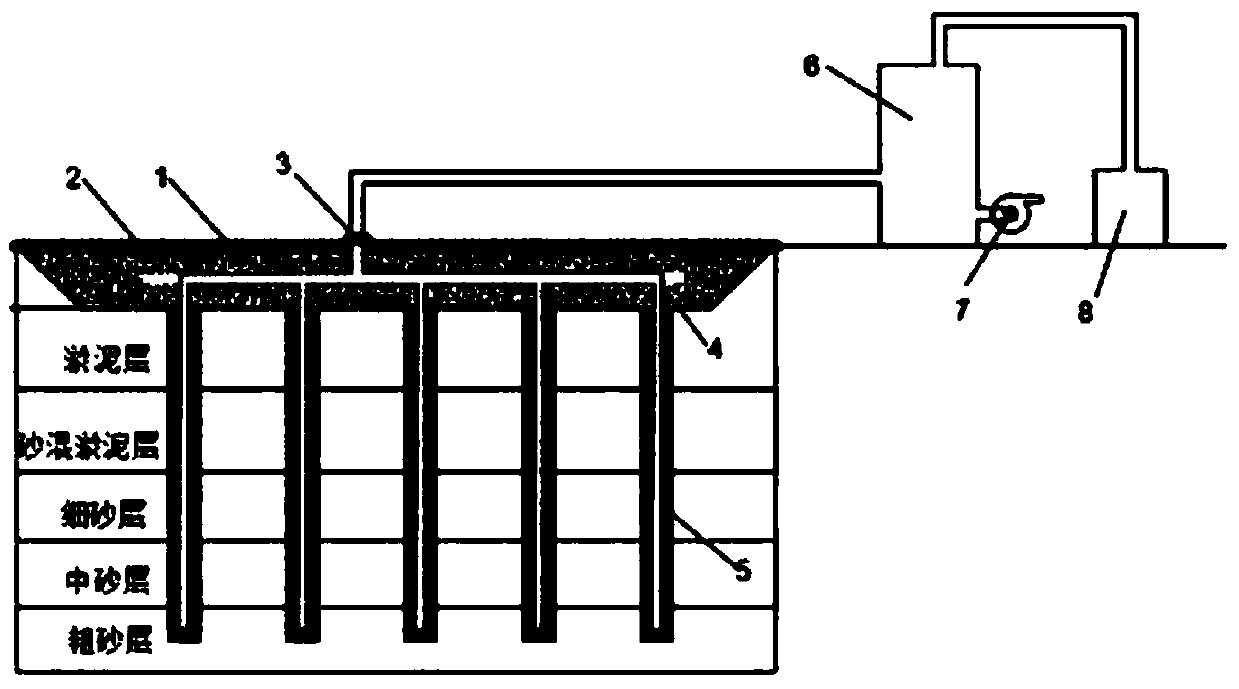

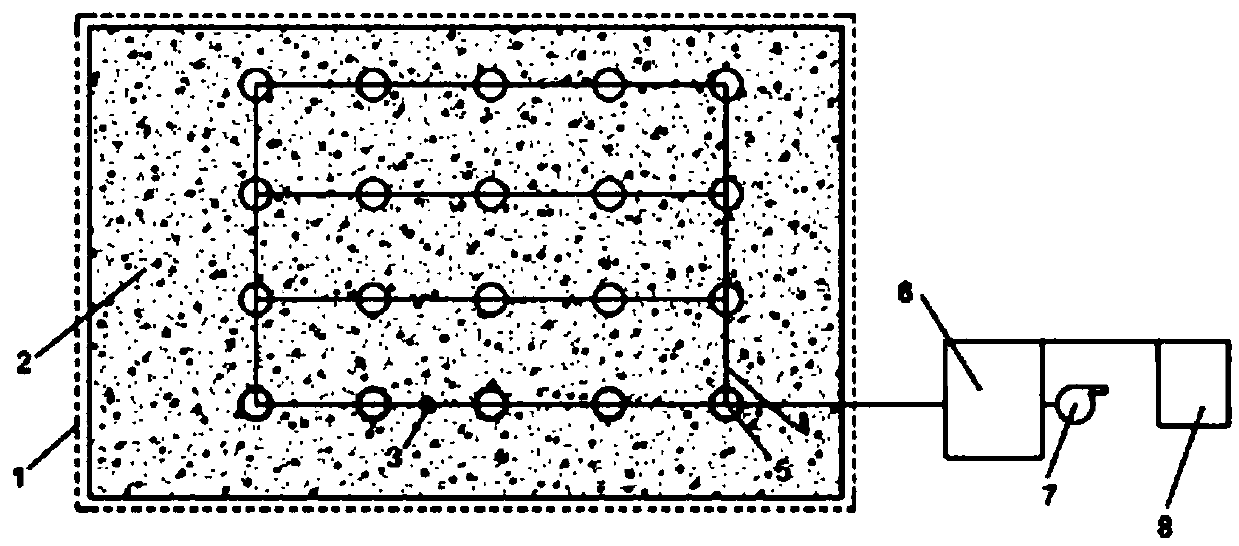

Method for reinforcement treatment of soft soil foundation by combining vacuum preloading and microorganism sand fixation technology

ActiveCN108999179AHigh strengthPrevent liquefactionSoil preservationEngineeringUltimate tensile strength

The invention discloses a method for reinforcement treatment of a soft soil foundation by combining vacuum preloading and microorganism sand fixation technology. The method comprises the following steps of (1) ground leveling, (2) drainage hole arrangement, (3) drainage strip and hose burying, (4) sand cushion layer laying, (5) plastic sealing film laying, (6) connection of a hose with a vacuum pump and a water pump, (7) negative pressure microorganism induction treatment and (8) drainage and vacuum preloading. Firstly, sandy soil is solidified by microorganism sand fixation, and then consolidation of soft soil in a silt layer is carried out by vacuum preloading. Compared with a traditional single vacuum preloading method, the method for reinforcement treatment of the soft soil foundationby combining vacuum preloading and the microorganism sand fixation technology can significantly improve the strength of the foundation, shortens the construction period and prevents liquidation of a sandy soil foundation.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

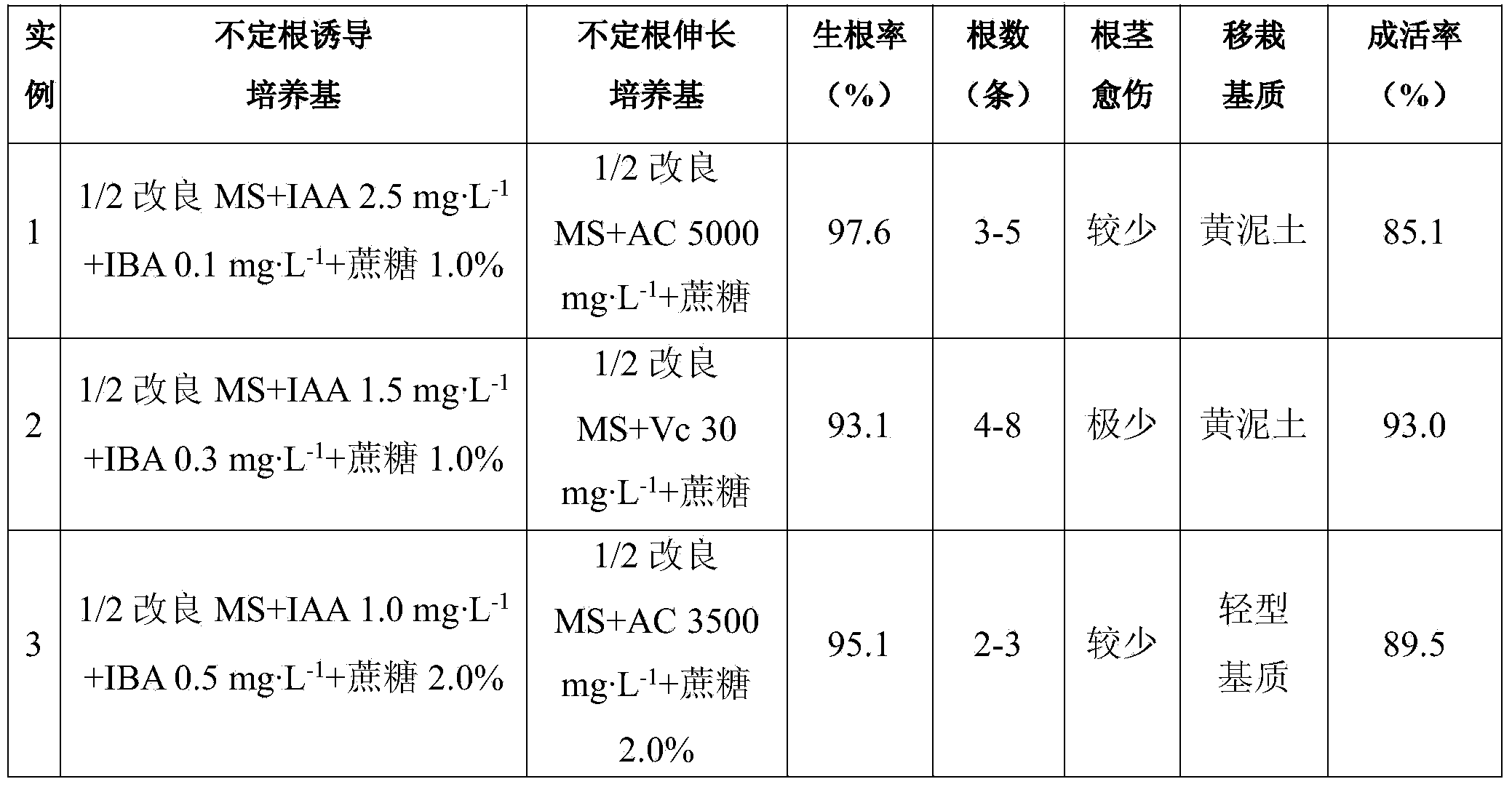

Method for promoting pinus massoniana tissue-cultured subcultured bud to root

ActiveCN103749310APromotes and improves rootingQuality improvementPlant tissue cultureHorticulture methodsSucrosePeat

The invention discloses a method for promoting a pinus massoniana tissue-cultured subcultured bud to root. The method comprises the following steps: selecting the robust and half lignified pinus massoniana tissue-cultured subcultured bud with a seedling height of 2-3 cm; by adopting different culture media in a two-step rooting method, inoculating the subcultured bud in a 1 / 2 modified MS culture medium IV that contains indoleacetic acids, indolebutyric acids and sucrose; conducting induction treatment on an adventitious root primordium 21-28 d; transplanting the subcultured bud to a 1 / 2 modified MS culture medium V that contains activated carbon or ascorbic acids, and sucrose, without auxins, in order to promote the adventitious root to express and extend; transplanting a rooted regeneration plant to a mixed matrix that contains yellow soil or peat soil, vermiculite and perlite for cultivating. According to the invention, the method can tremendously promote and improve the rooting condition of the subcultured bud, the rooting rate of the pinus massoniana subcultured bud is above 93.1%, and the highest rooting rate is as high as 97.6%; the root system quality is higher; the survival rate of transplanting is above 85.1%, and the highest survival rate of transplanting is as high as 93.0%; the method has good economic benefits and social benefits.

Owner:GUANGXI FORESTRY RES INST

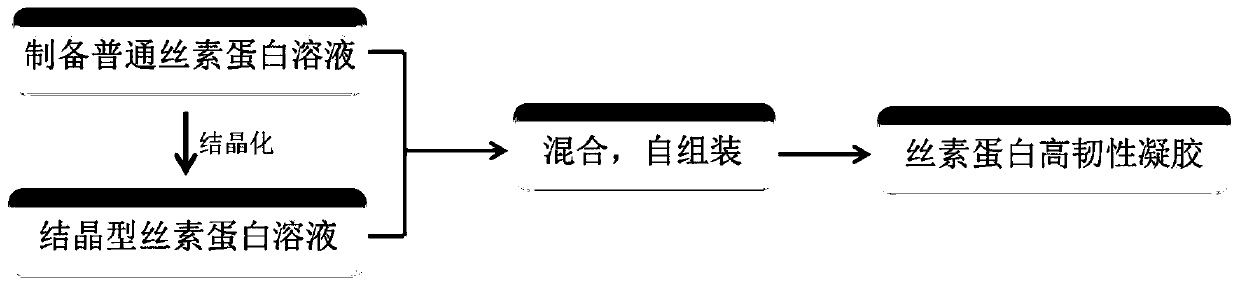

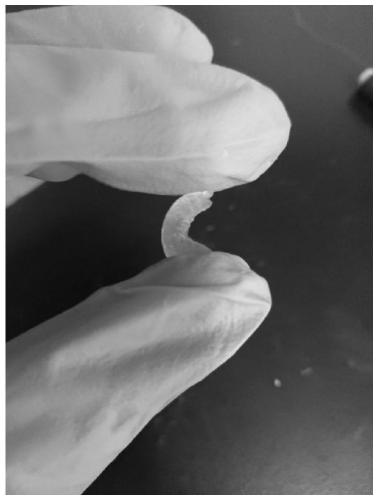

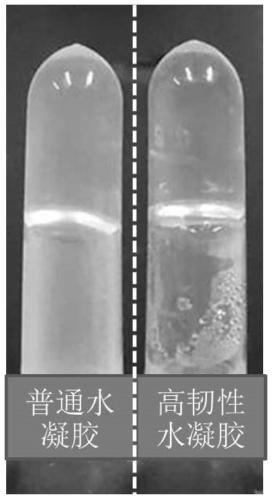

High-toughness silk fibroin gel preparation method

The invention discloses a high-toughness silk fibroin gel preparation method, which comprises: carrying out crystallization induction treatment on a common fibroin solution to obtain a crystallization type silk fibroin solution, mixing the crystallization type silk fibroin solution and a common fibroin solution, and obtaining the high-toughness silk fibroin gel under the action of self-assembly. According to the present invention, with the method, the gelation time, the toughness and other performances of the hydrogel can be controlled by changing the silk fibroin solution concentration, the crystallization type silk fibroin size, the crystallization type silk fibroin content, the self-assembly temperature and other parameters; and the method has characteristics of mild preparation process, no requirement of cross-linking agents and other toxic organic reagents, environmentally-friendly and controllable preparation conditions and no waste residue, provides the new method for the preparation of functional hydrogels, and can be used for biomedicine, tissue engineering and other fields.

Owner:HANGZHOU DIANZI UNIV

Combined mutation breeding method for rape

InactiveCN105900833AHigh mutation rateMutation methods are safeCultivating equipmentsPlant genotype modificationNutrient solutionINDUCTION TREATMENT

The invention discloses a combined mutation breeding method for rape. The method comprises the steps of: selecting rape seeds in season, conducting soaking with ethanol and hot water respectively, then performing soaking in an aqueous solution added with a-protease, carrying out germination accelerating, subjecting the obtained rape plumules to continuous illumination culture, then transferring the rape plumules into a medium to conduct magnetic induction treatment, taking the plant height and oil output as the indexes to perform preliminary screening to obtain dwarf and high-oil rape seedlings, transferring the screened oil rape seedlings into an SH solid medium, injecting a chemical inducer every 4h-6h to the seedling roots, spraying a nutrient solution to the seedlings every day, carrying out continuous mutagenesis, and transferring the obtained rape plants into nutrient soil, taking the plant height and oil output as the indexes, carrying out repeated orientation and subcultured breeding, and gradually increasing the breeding rate of dwarf and high-oil rape plants. The method provided by the invention employs physical mutagenesis and chemical mutagenesis for combined breeding, and is beneficial to expand the breeding method of rape and improve the breeding efficiency of rape breeding.

Owner:林淑录

Buckwheat cell culture method for improving buckwheat cell synchronization

The invention discloses a buckwheat cell culture method for improving buckwheat cell synchronization. The method comprises the following steps: preprocessing buckwheat callus cells, inoculating the preprocessed buckwheat callus cells into different culture mediums, and performing multi-link synchronization induction treatment under different culture conditions. Therefore, the cells in different division periods can be adjusted to be in specific cell division period, the use efficiency of an inductor can be effectively improved, and the synthesis of secondary metabolites in the cultured cells is facilitated.

Owner:CHENGDU UNIV

Method for rapidly breeding of tallow tree plants

InactiveCN107041309ASuitable for industrial seedling cultivationSave germplasm materialHorticulture methodsPlant tissue cultureDisinfectantGermplasm

The invention discloses a method for rapid breeding of Chinese tallow tree plants, which comprises the following steps: taking materials, pretreatment of explants, induction treatment of adventitious roots of the explants, colonization of the explants, and management of the seedling formation of the explants. The present invention has the advantages of: firstly, germplasm materials are saved, and reproductive efficiency is improved; secondly, materials are conveniently obtained, and materials are abundant, and the produced plants can maintain the original excellent traits of female plants; thirdly, the speed of obtaining seedlings is fast , rapid propagation speed; fourth, avoiding the influence and limitation of natural factors such as seasons and regions, and also avoiding the tediousness of the process of tissue culture and breeding of Chinese tallow tree and the defect of low survival rate of subsequent tissue culture regenerated seedlings domestication and transplanting; fifth, The cost of producing regenerated seedlings is low, and the operation method is simple, which is suitable for the industrialization of Chinese tallow tree seedlings; Sixth, strictly optimize and control the composition and concentration of the rooting promotion liquid; Seventh, the type and concentration selection of disinfectants, nutritional supplements, and nutritional substrates It also strictly cooperates with the growth process of Chinese tallow tree.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Treating method for chemically inducing parthenogenesis of corn

ActiveCN104604674AStrong moisturizing abilitySolve pollutionPlant genotype modificationComing outPollen

The invention provides a treating method for chemically inducing parthenogenesis of corn. The method is characterized by comprising the following steps: adding roll paper into an inductive agent and carrying out stirring so as to prepare paper paste; sleeving a female ear with a paper bag before filament emergence; picking off the paper bag when filaments come out and transversely cutting off a basal part at the top of the bud of the female ear with a blade so as to form a circular cross section which has filaments at the center and husk leaves at the periphery; picking up the paper paste with dressing pliers, placing the paper paste on the cross section and allowing the paper paste to closely contact with the cross section and fill in space formed after the cutting; restoring pulled-open husk leaves to original positions so as to allow the paper paste to be packed in the husk leaves; and finally, sleeving the treated ear with the paper bag again. The invention has the following beneficial effects: the problem of pollen pollution difficult to overcome in a conventional chemical-induction treatment method is thoroughly overcome; threat to human health is avoided; induction operation is carried out under completely open conditions; an induction rate is improved; loss of the liquid of the inductive agent is small; and compared with a conventional selfing line breeding method, the breeding period in the method provided by the invention is shortened by more than 5 generations.

Owner:SHENYANG TEYIJIA CORN TECH

High-hardness impact-resistant cold rolled steel working roll and processing technique thereof

ActiveCN103173688AImprove hardenabilityImprove stabilityFurnace typesRollsWork rollChemical composition

The invention discloses a high-hardness impact-resistant cold rolled steel working roll. The working roll adopts low-alloy high-strength steel, and the low-alloy high-strength steel comprises chemical components (C, Si, Mn, Cr, Mo, V, Ti, S and P) and the balance of Fe and inevitable impurities. The processing technique of the cold rolled steel working roll comprises the following steps of: teeming, forging forming, heat treatment after forging, machining for forming, ultrasonic flaw detection, modulating treatment, preheating, line-frequency induction treatment, tempering, finish machining, ultrasonic flaw detection, coarse grinding of grinding machine, finish machining for modifying R, ultrasonic surface flaw detection, hardness detection of finished product, and packaging and storing. In the chemical component proportion of the cold rolled steel working roll, Si and Mn with lower price are selected to improve the hardenability of the material and change the bainite in material tissues, the form distributed tissues has higher stability, tenacity, crack initiation resistance capability, as well as high crack propagation resistance capability.

Owner:JIANGYIN RUNYUAN MACHINERY

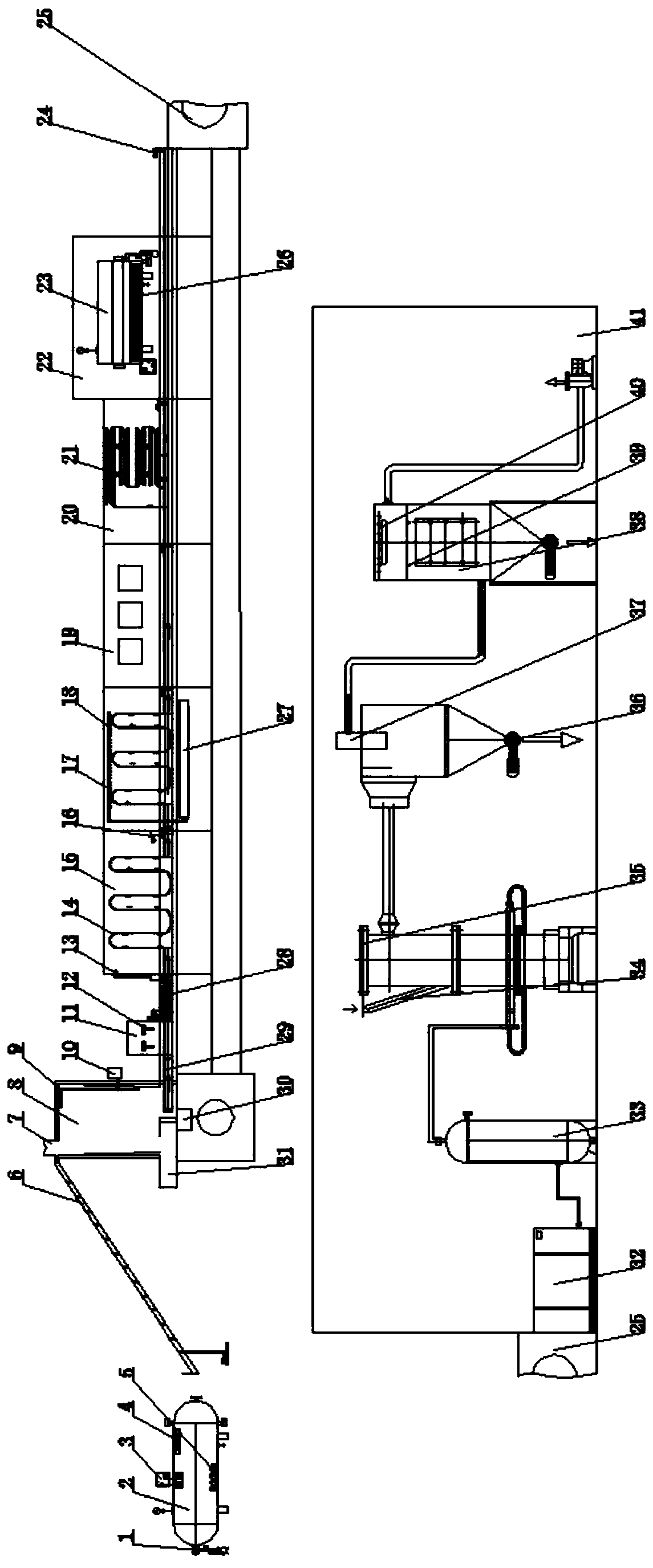

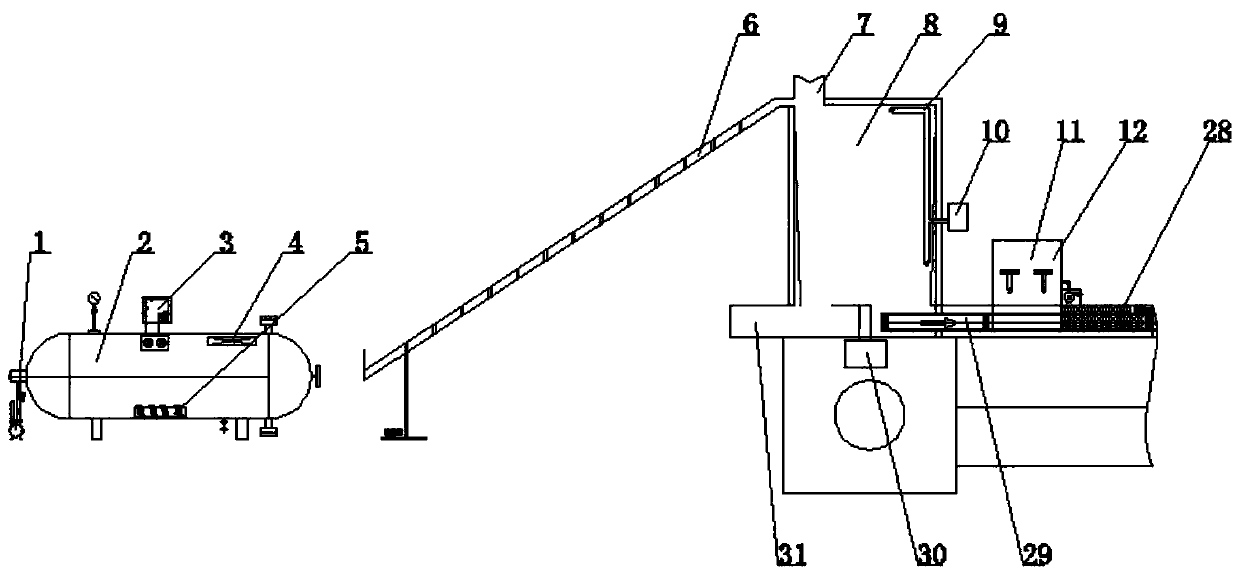

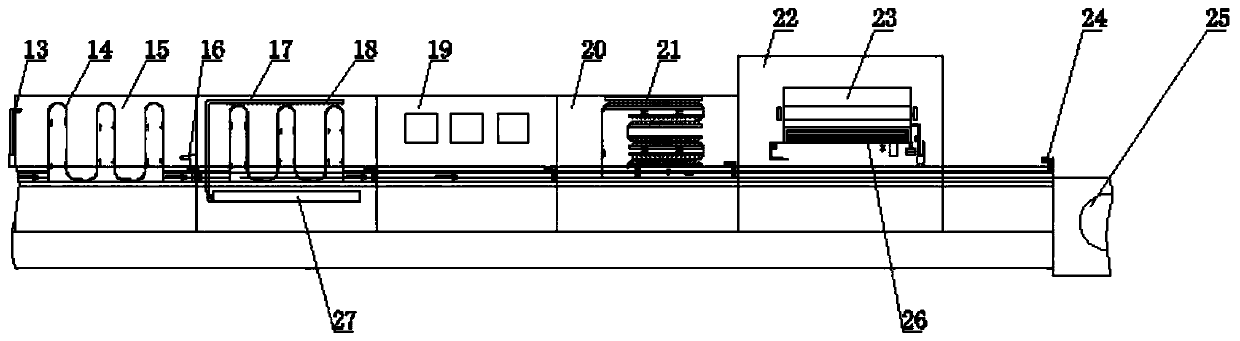

Yacon fruit flake and whole powder multielement joint processing production system

PendingCN109832585AWith cavitation effectWith mechanical shear effectFruits/vegetable preservation by irradiation/electric treatmentFood shapingFreeze-dryingCyclonic separation

The invention belongs to the technical field of agricultural product processing devices, relates to a pulverizing device, and in particular relates to a yacon fruit flake and whole powder multielementjoint processing production system. A pretreatment unit, a peeling and slicing unit, an anti-browning unit, an anti-caking treatment unit and a high-speed nitrogen flow pulverizing unit are mounted sequentially from the upstream side to the downstream side of the working procedure, wherein the pretreatment unit comprises an airtight decompression tank; an ultrasonic generation device and a magnetic field generation device are arranged in the airtight decompression tank; the peeling unit comprises a centrifugal peeling device and a slicing device; the centrifugal peeling device and the slicingdevice are sequentially mounted; the anti-browning unit comprises an anti-browning induction treatment device, an anti-metal ion induction treatment device and an anti-caramelization browning treatment device; the anti-caking treatment unit comprises a microwave drying device, an anti-caking polarity remover spray device and a freeze drying device; the high-speed nitrogen flow pulverizing unit comprises a nitrogen generating device, a nitrogen tank, a nitrogen pulverizer and a cyclone separator; and the cyclone separator is provided with a multi-stage discharge port.

Owner:SDIC ZHONGLU FRUIT JUICE

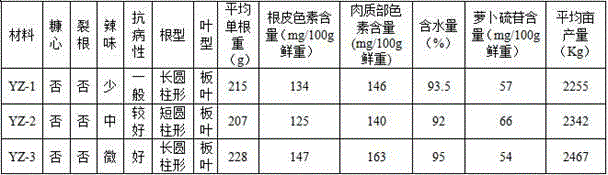

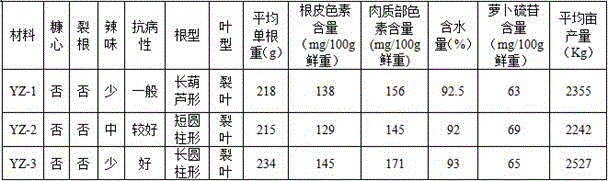

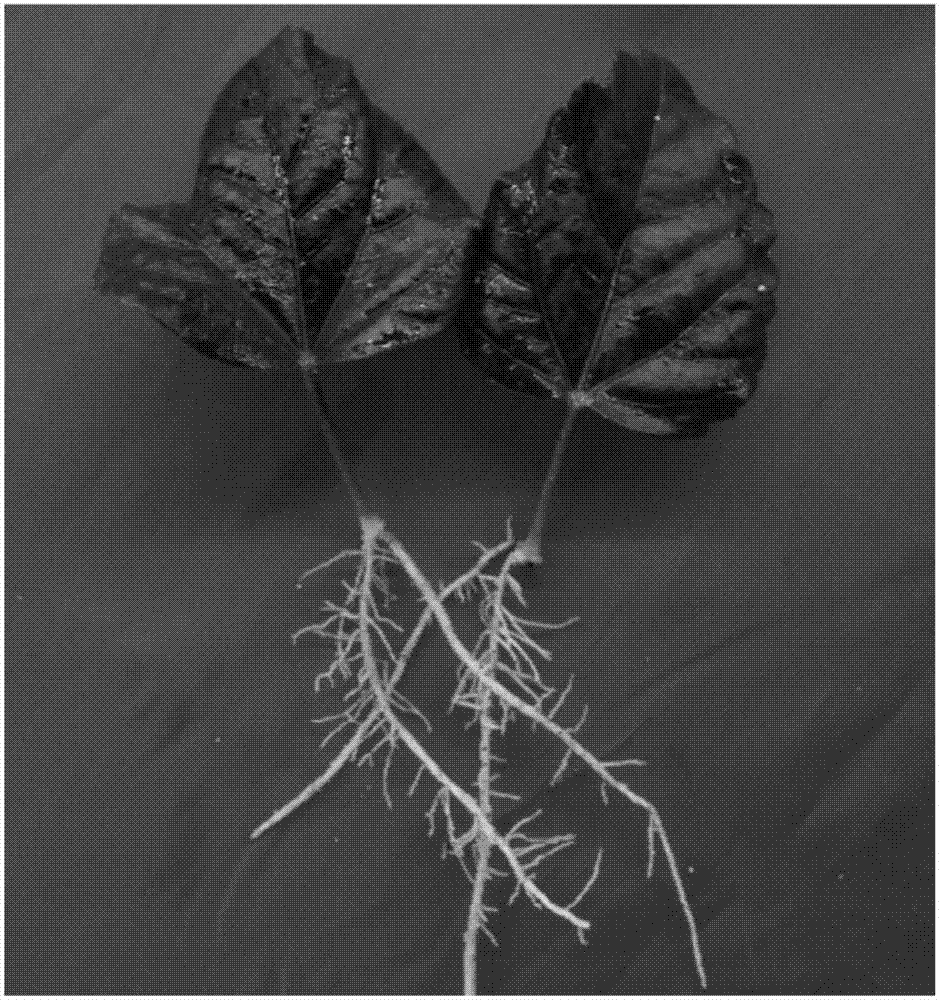

Breeding method of carmine radish

ActiveCN104303995AExtended functional periodStrong stress resistancePlant genotype modificationPloidySelfing

The invention discloses a breeding method of carmine radish. The breeding method comprises the following steps: selecting different types of carmine radishes, selectively choosing excellent strains according to the breeding target, carrying out selfing for 5 to 6 generations, carrying out breeding selection; after selfing for 5 to 6 generations, selecting different types of stable selfing lines, subjecting the selected selfing lines to a colchicine induction treatment in the seedling period, then carrying out ploidy identification; after the ploidy identification, selecting the excellent strains that do not generate variation, hybridizing the selected excellent strains; selecting the excellent strains after the hybridization, carrying out directive breeding through a pedigree breeding method, and obtaining the stable carmine radish selfing lines after 6 generations. The obtained carmine radish has the advantages of high pigment content, crispy taste, less spicy taste, hollow and cracked root resistance, large and straight shape, and suitability for direct eating.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

Efficient cultivation method for excellent strains of Danish hibiscus

ActiveCN107006326ASuitable for factory breedingAvoid introducingGrowth substratesFertilising methodsNatural factorHibiscus

The invention discloses an efficient cultivation method for excellent strains of Danish hibiscus. The method comprises the following steps of material collecting, explant pretreatment, explant adventitious root induction treatment, explant field planting and explant seedling establishment management. The method has the advantages that material collecting is convenient, the materials are rich, and regeneration plants can keep the original excellent character of a maternal plant; operation is easy, the reproduction speed is high, and meanwhile the type and concentration of a rooting promotion solution are strictly optimized and controlled; type and concentration selection of disinfectant, nutritious fluid, nutritious substrates and the like is strictly matched with essential elements needed in the Danish hibiscus plant growing process, and introduction of harmful elements is avoided; explants are placed in a mixed nutritious substrate to directly root in a greenhouse, seedling establishment is achieved through one step, and influences and limits of natural factors such as seasons and territories are avoided; the cost is low, operation is easy, mastering is easy, reproduction expanding can be achieved, and the method is suitable for factory cultivation of the Danish hibiscus.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

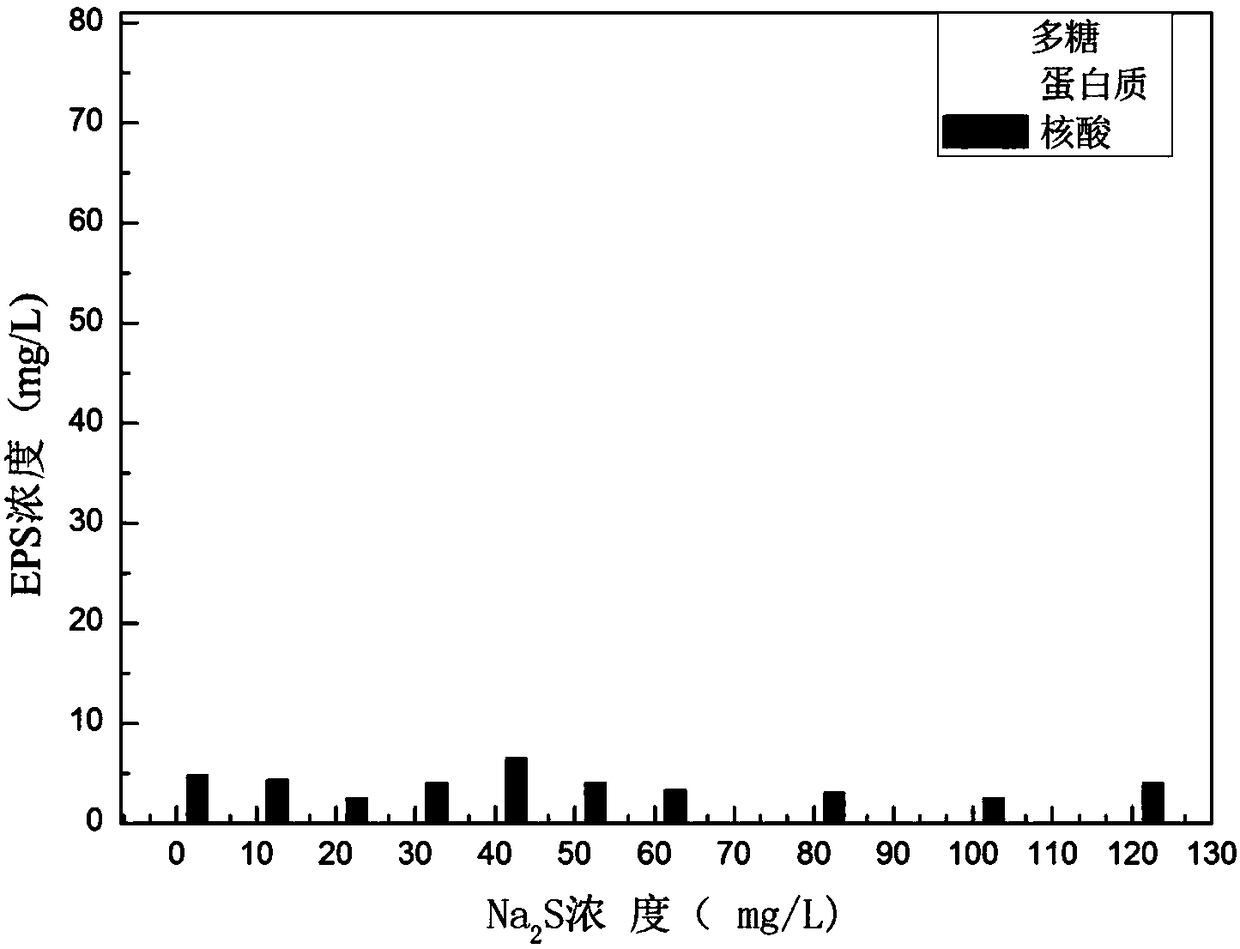

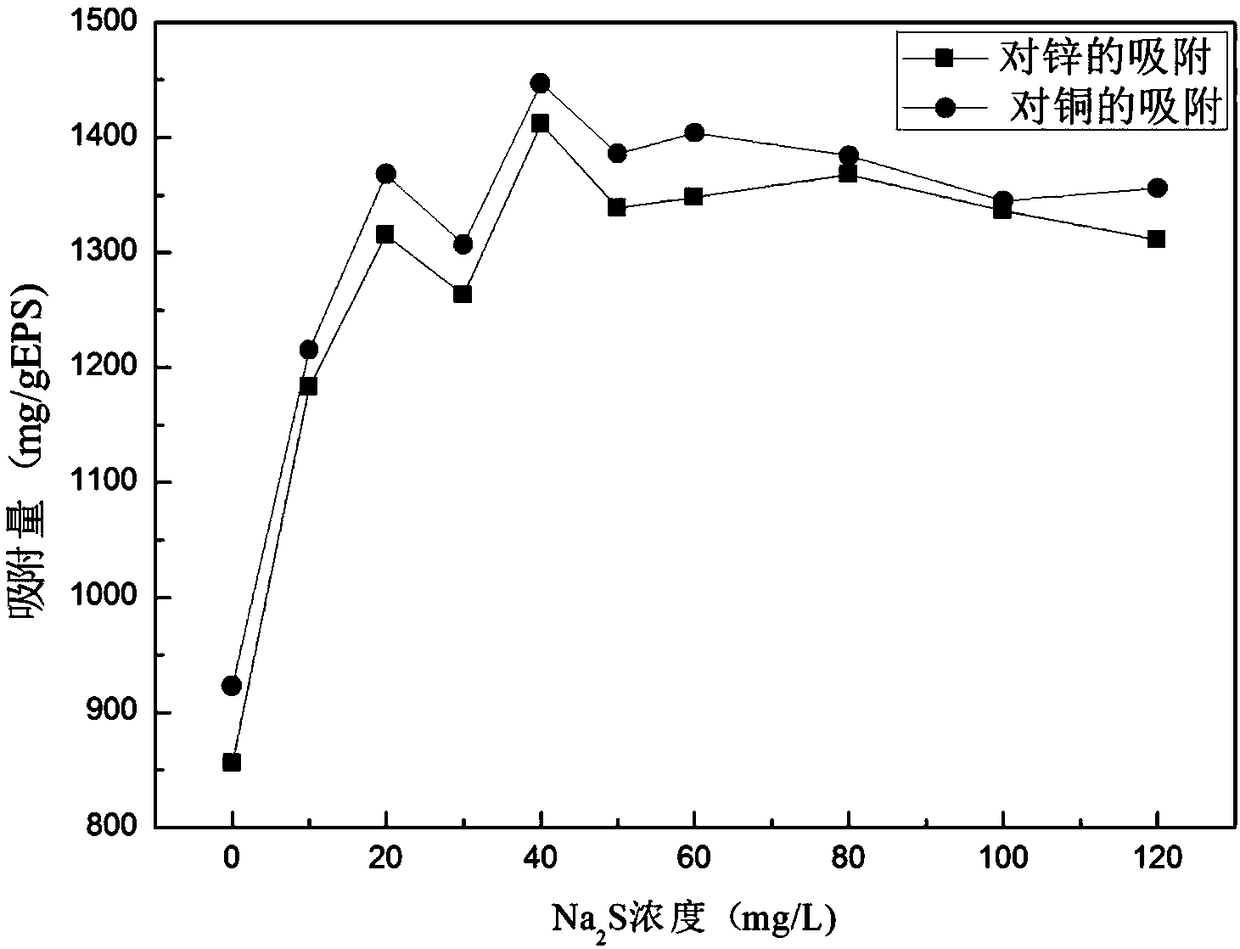

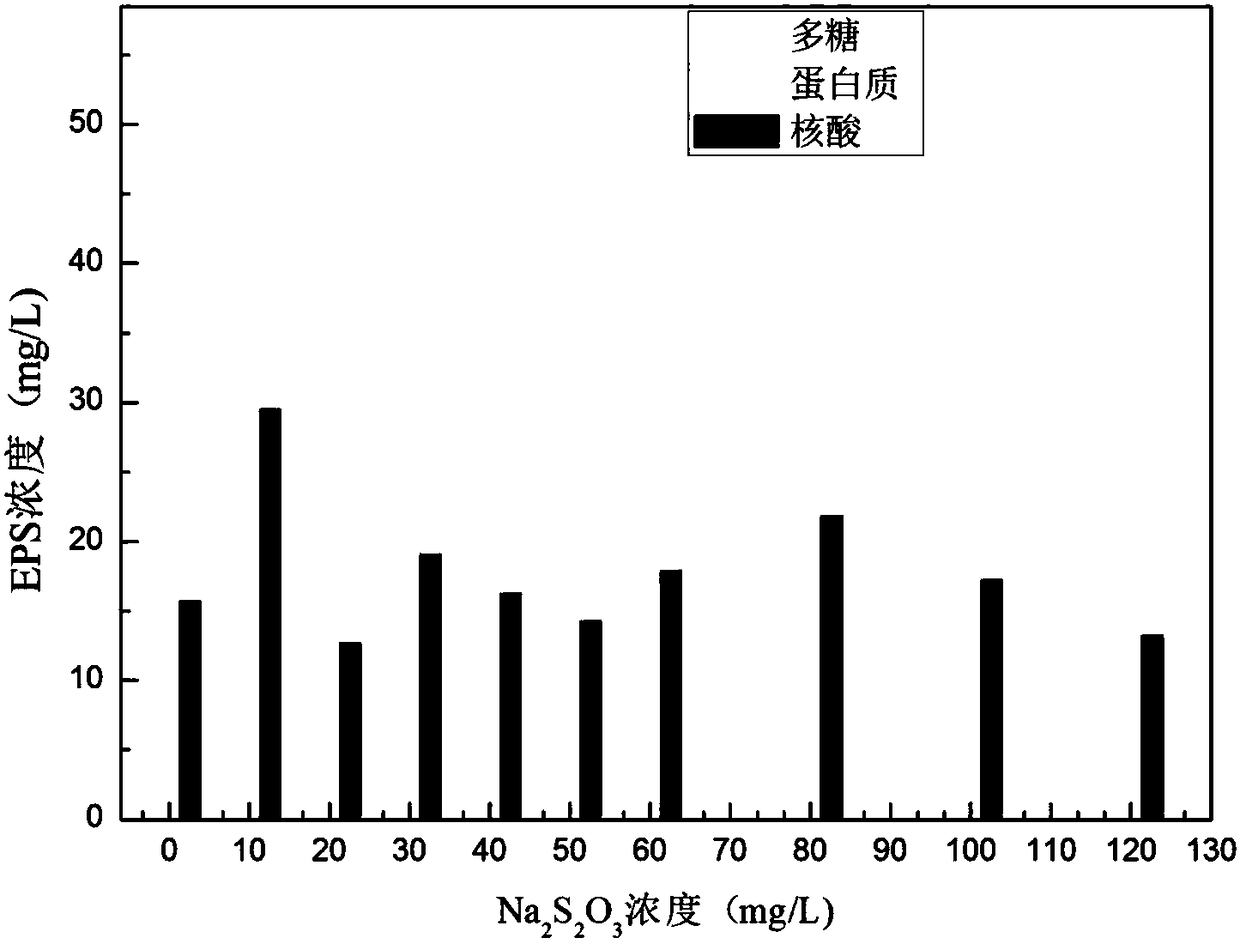

Extracellular polymeric substance and preparation method thereof, heavy metal treating agent and heavy metal waste water treating method

ActiveCN108504695AEasy to operateImprove adsorption capacityWater contaminantsFermentationSulfite saltINDUCTION TREATMENT

The invention relates to the technical field of environment microorganism and waste water treatment, in particular to an extracellular polymeric substance and a preparation method thereof, a heavy metal treating agent and a heavy metal waste water treating method. The preparation method for the extracellular polymeric substance comprises the following steps that exogenous sulfur induction treatment is carried out on an aerobic heterotrophic bacterium to obtain the extracellular polymeric substance; the exogenous sulfur is one or more of sodium sulfide, sodium sulfite, sodium thiosulfate and sodium hydrosulfite. The preparation method is operated simply, and environmentally-friendly, it can be known through the test data that after the exogenous sulfur induction is carried out, the composing proportion of the extracellular polymeric substance changes correspondingly, the adsorption quantity for cuprum<2+> and zinc<2+> of the extracellular polymeric substance nearly reaches 1 gram per gram or above, the excellent adsorption effect is shown, and the technical problem that the poor removal capacity of the microorganism extracellular polymeric substance for the heavy metal is solved.

Owner:GUANGDONG UNIV OF TECH

Devices and Methods For Controlling Patient Temperature

Owner:ADVANCED COOLING THERAPY INC

Novel method for detecting platelet aggregation ability

InactiveCN102564917AAvoid the centrifugation processHigh speedIndividual particle analysisInducerINDUCTION TREATMENT

The invention relates to a novel method for detecting platelet aggregation ability, belonging to the field of clinical laboratory medicine. The method uses an impedance technology detecting instrument which can simultaneously count platelets and measure the particle volume (size) of the platelets to directly detect the platelet aggregation ability of whole blood samples, and plasma is not separated. During detection, one blood sample is divided into two parts, one part of blood sample is directly detected without adding a platelet aggregation inducer, the other part of blood sample is detected after adding the platelet aggregation inducer to carry out induction treatment, and finally the two obtained detecting results as basic data are compared to calculate the platelet aggregation ability.

Owner:SINNOWA MEDICAL SCI & TECH

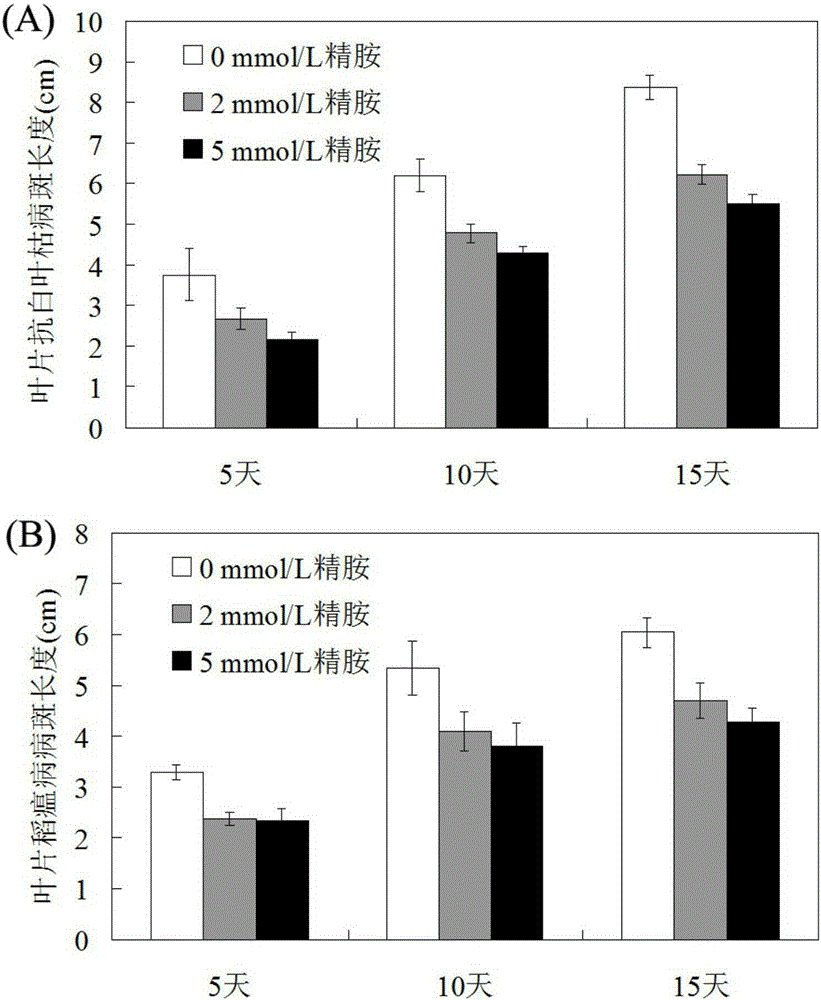

Method for improving rice resistance to bacterial leaf blight and rice blast through spermine induction treatment

The invention discloses a method for improving rice resistance to bacterial leaf blight and rice blast through spermine induction treatment. The method comprises the steps of preparation of planting land, seedling management and spermine induction treatment, wherein the step of spermine induction treatment comprises the sub-step of continuously irrigating a spermine solution with the concentration of 2 to 10 mmol / L (preferentially 2 to 5 mmol / L) to rice at an adult stage, wherein the daily irrigating amount of the amine solution per mu is 800 to1200 L, and the total irrigating time is 4 to 7 days. The method is easy to implement, simple and convenient to operate and quick in effect, the rice resistance to the bacterial leaf blight and the rice blast can be improved in the short time, loss caused when the bacterial leaf blight and the rice blast of rice outbreak can be effectively avoided, and economic benefits can be improved.

Owner:HAINAN UNIVERSITY

Preparation method of microarc oxidation film doped ceramic micropowder on aluminum drill pipe surface

ActiveCN104775144AExtended service lifeHigh hardnessAnodisationPlasma electrolytic oxidationBoron nitride

The invention discloses a preparation method of a microarc oxidation film doped ceramic micropowder on an aluminum drill pipe surface, which comprises the following steps: a common direct-current or alternating-current microarc oxidation power supply is adopted, a workpiece aluminum drill pipe is connected to the positive pole of the power supply, and the negative pole adopts a common lead plate or stainless steel plate; the workpiece and negative pole are completely put in a microarc oxidation solution together, wherein the temperature of the oxidation solution is controlled at 20-50 DEG C; one or more of titanium carbide, boron carbide, boron nitride and chromium nitride ceramic micropowders subjected to targeting induction treatment is / are added; and under the current density of 3-30 A / dm<2>, the ceramic powder in the solution reaches the aluminum drill pipe surface, thereby preparing the microarc oxidation ceramic film containing one or more of titanium carbide, boron carbide, boron nitride and chromium nitride ceramic micropowders on the drill pipe surface. The microarc oxidation ceramic film has higher density and higher hardness. The method is beneficial to enhancing the wear resistance of the microarc oxidation ceramic film on the aluminum drill pipe surface and prolonging the service life of the aluminum drill pipe.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com