Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

557 results about "Passenger train" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

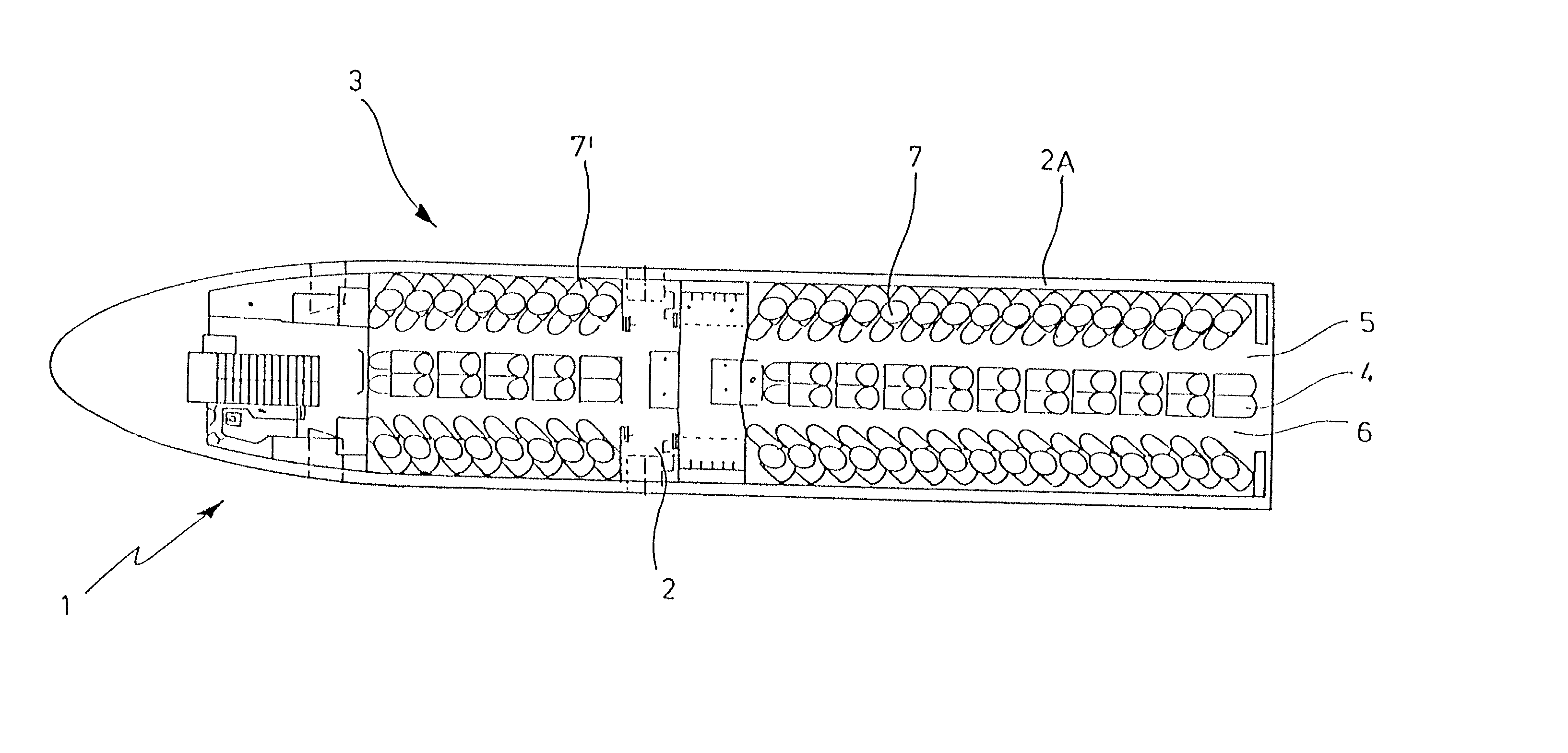

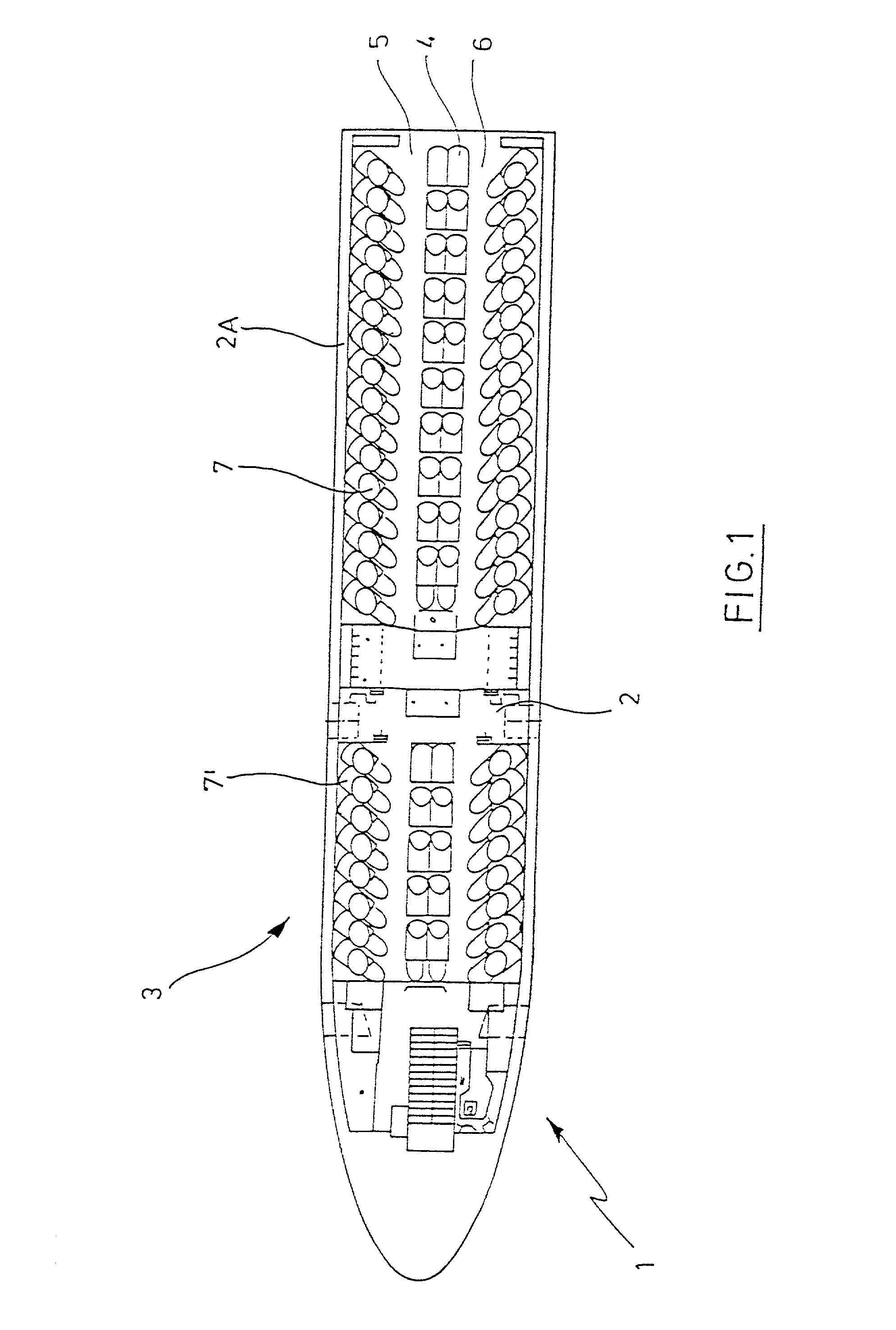

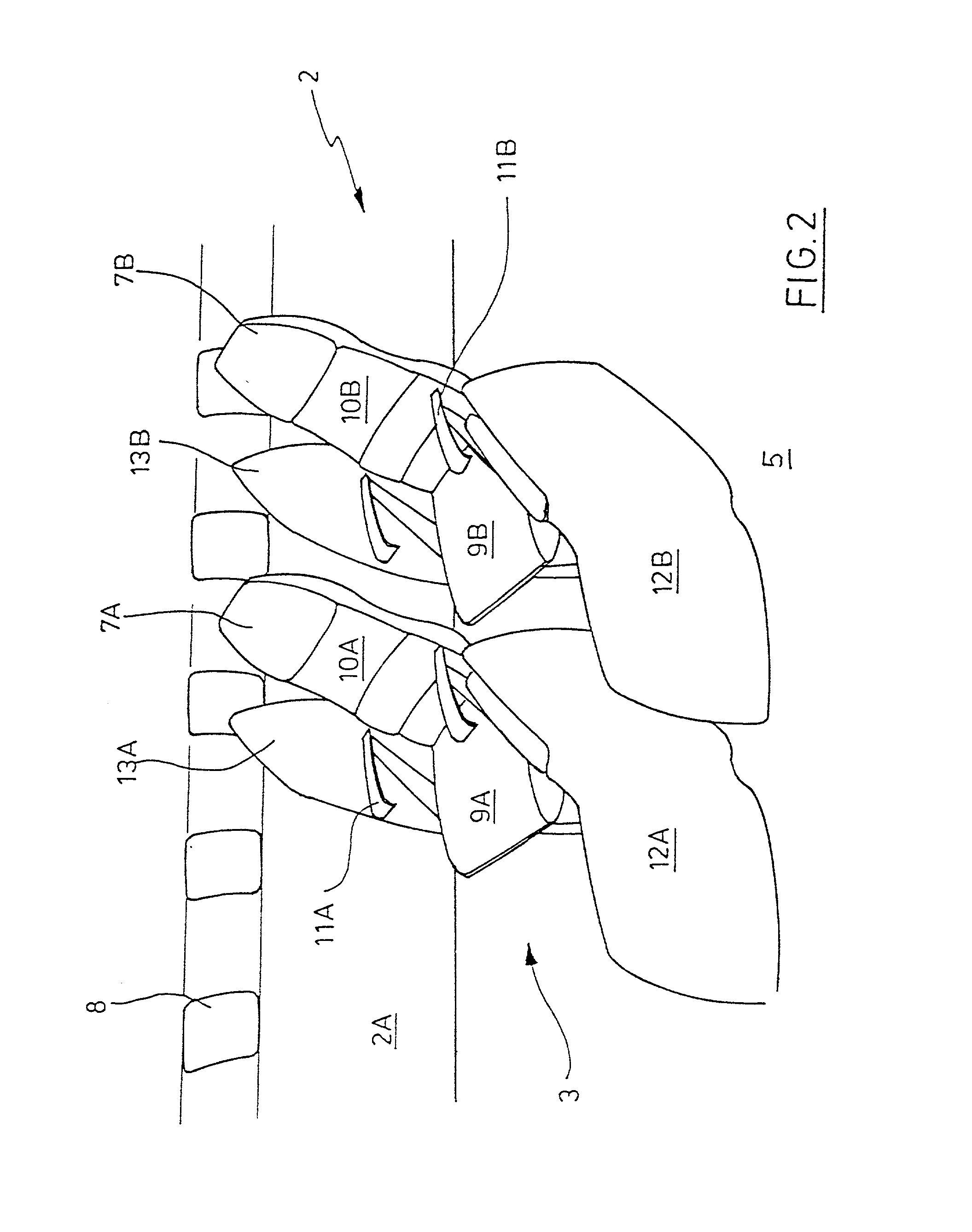

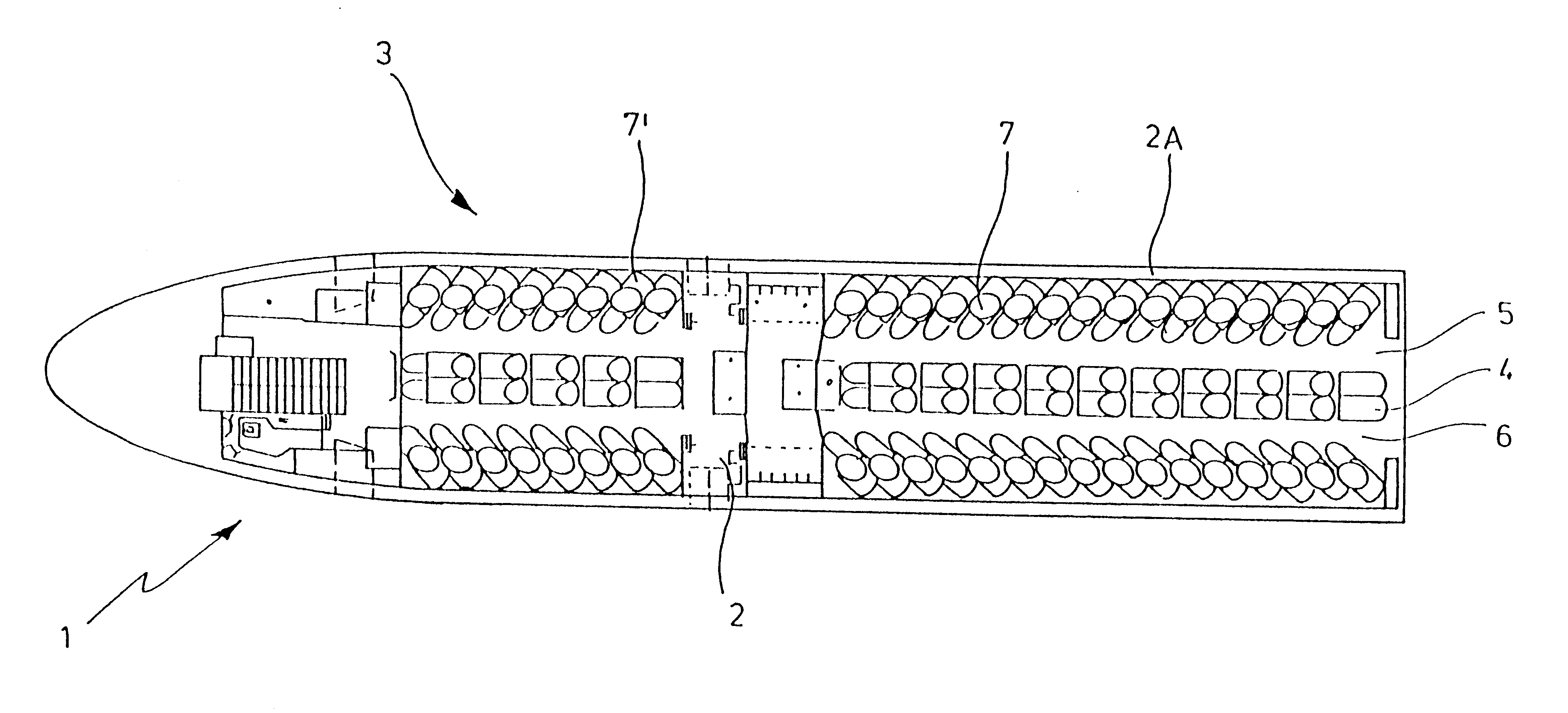

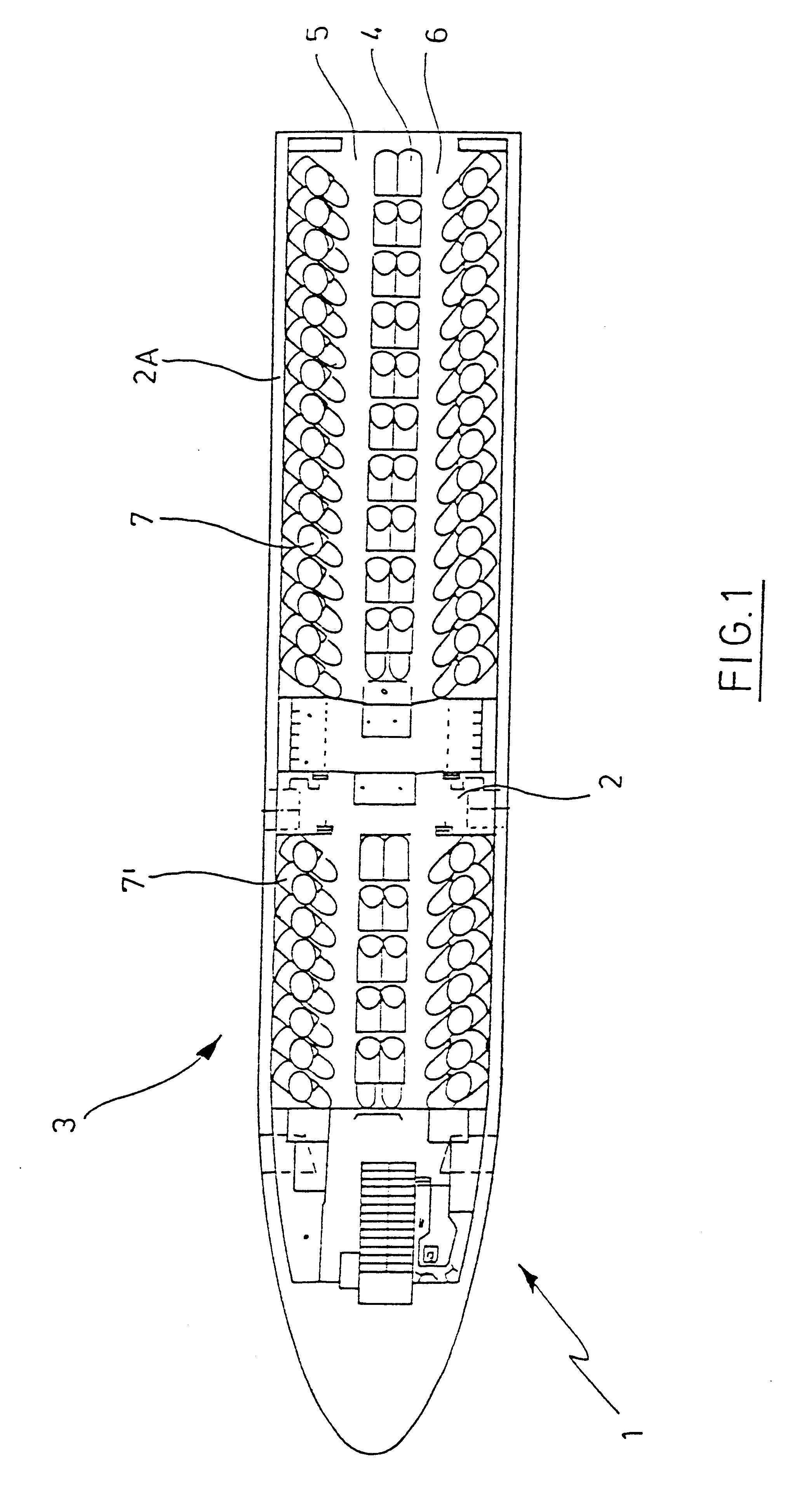

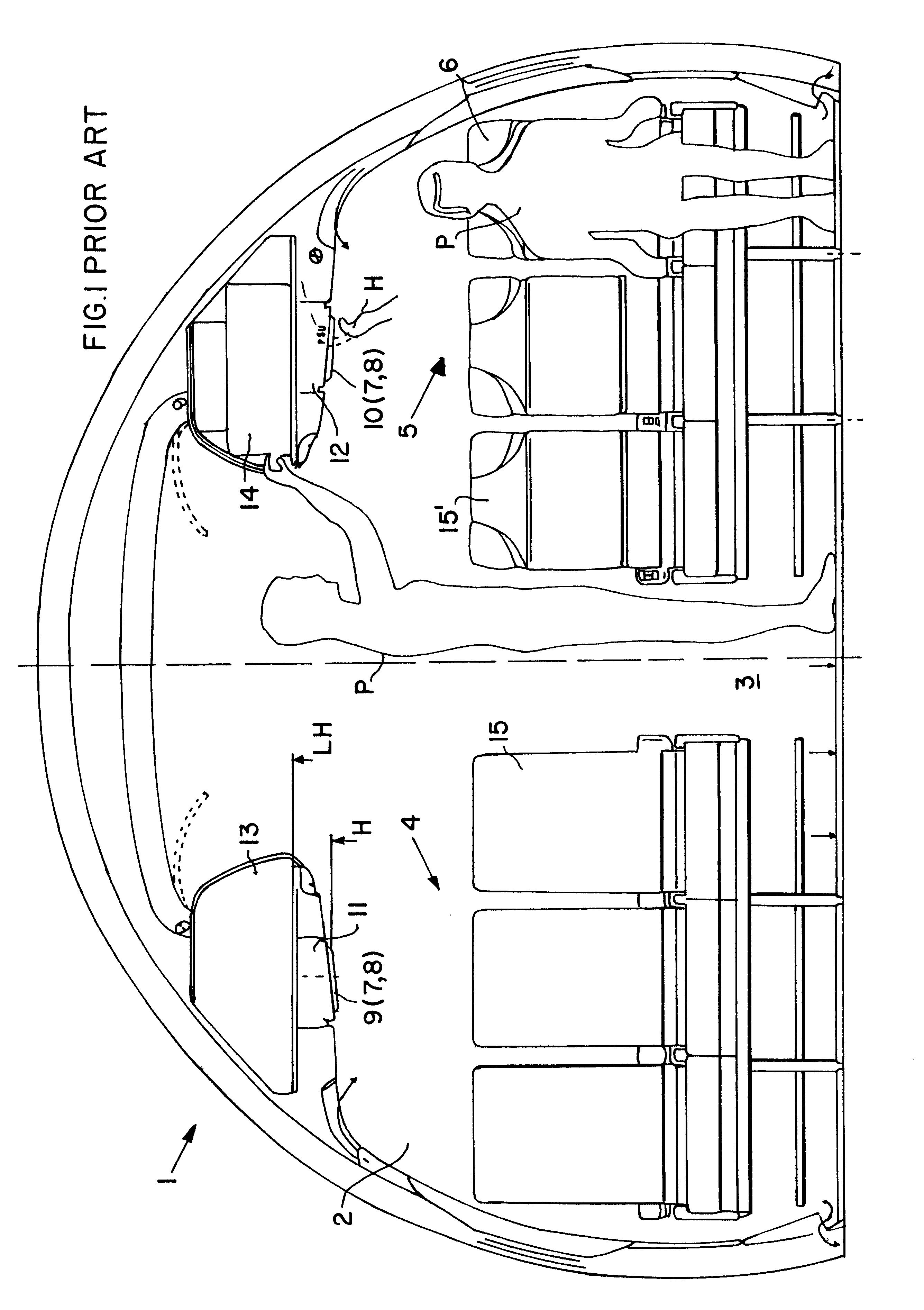

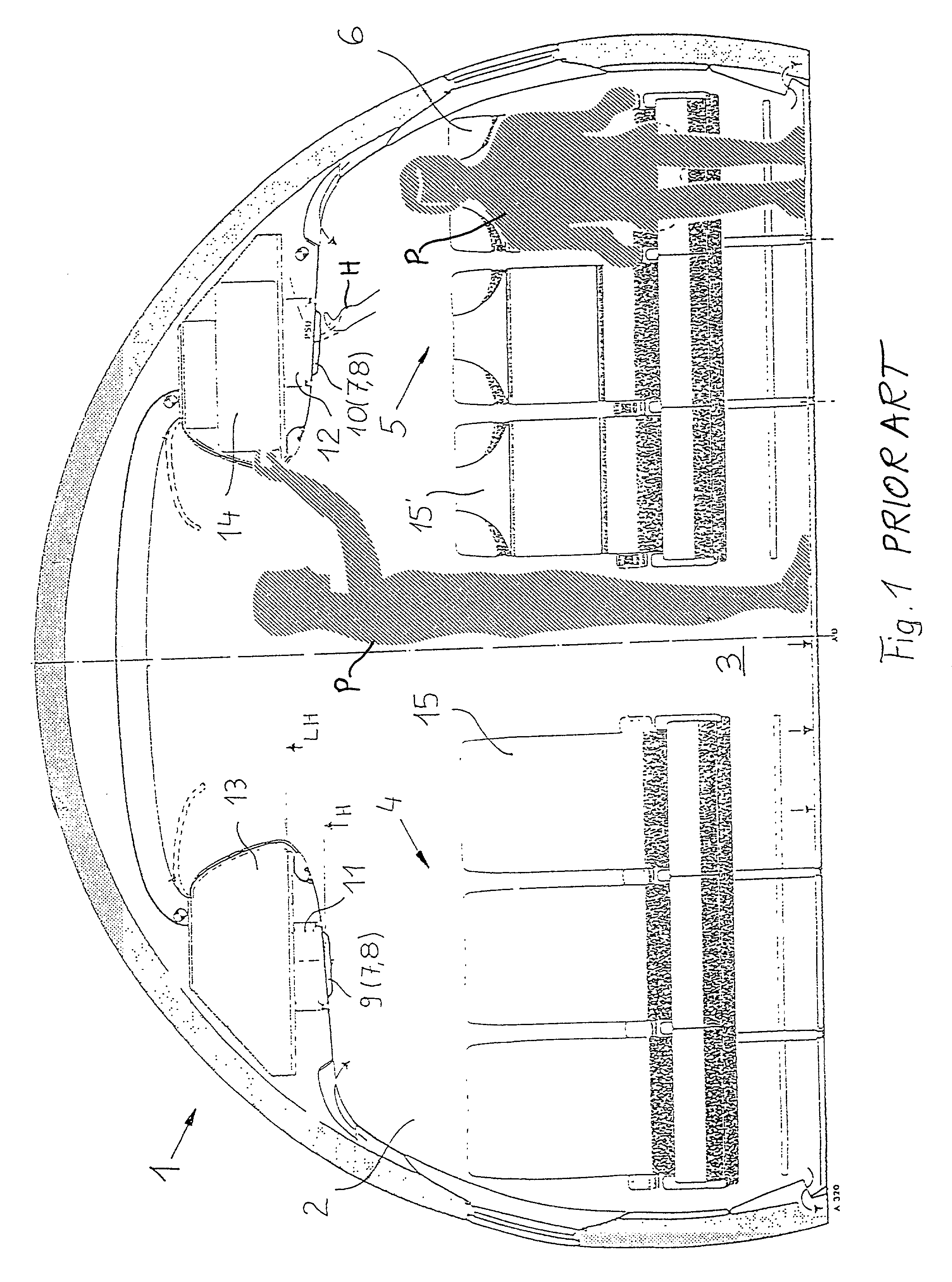

Aircraft passenger cabin with rotatable passenger seats

InactiveUS20020070314A1Seating arrangementsAir-treatment apparatus arrangementsSeating capacityPassenger train

A passenger cabin of a passenger transport vehicle such as an aircraft includes single passenger seats arranged between an aisle and an outside cabin wall. Each seat is tiltably adjustable between an upright seating configuration and a reclined lying configuration, and is rotatable between a forward-facing orientation facing 0 to 18° relative to the cabin longitudinal axis, and an inwardly-turned orientation facing 50 to 600 relative to the longitudinal axis. The forward-facing orientation is for upright seating during take-off and landing. The inwardly-turned orientation provides additional leg room and sufficient space for the reclined lying configuration. The pitch spacing between seats can be minimized, and total seating capacity is high, while providing substantial space and comfort for each passenger. Screening partitions adjacent to the cabin wall and the aisle provide privacy screening and define a personal space allocated to each seat.

Owner:AIRBUS OPERATIONS GMBH

Aircraft passenger cabin with rotatable passenger seats

Owner:AIRBUS OPERATIONS GMBH

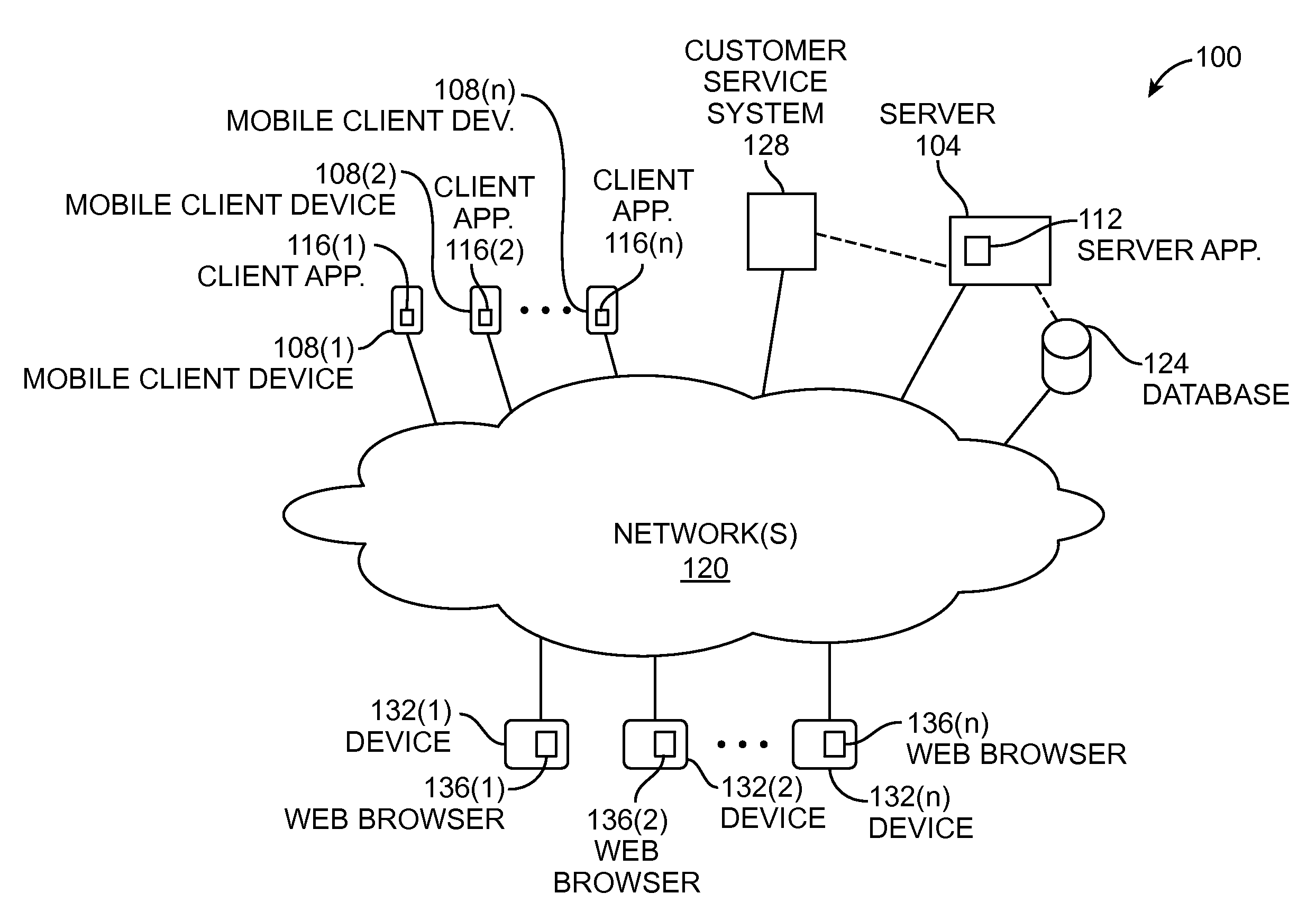

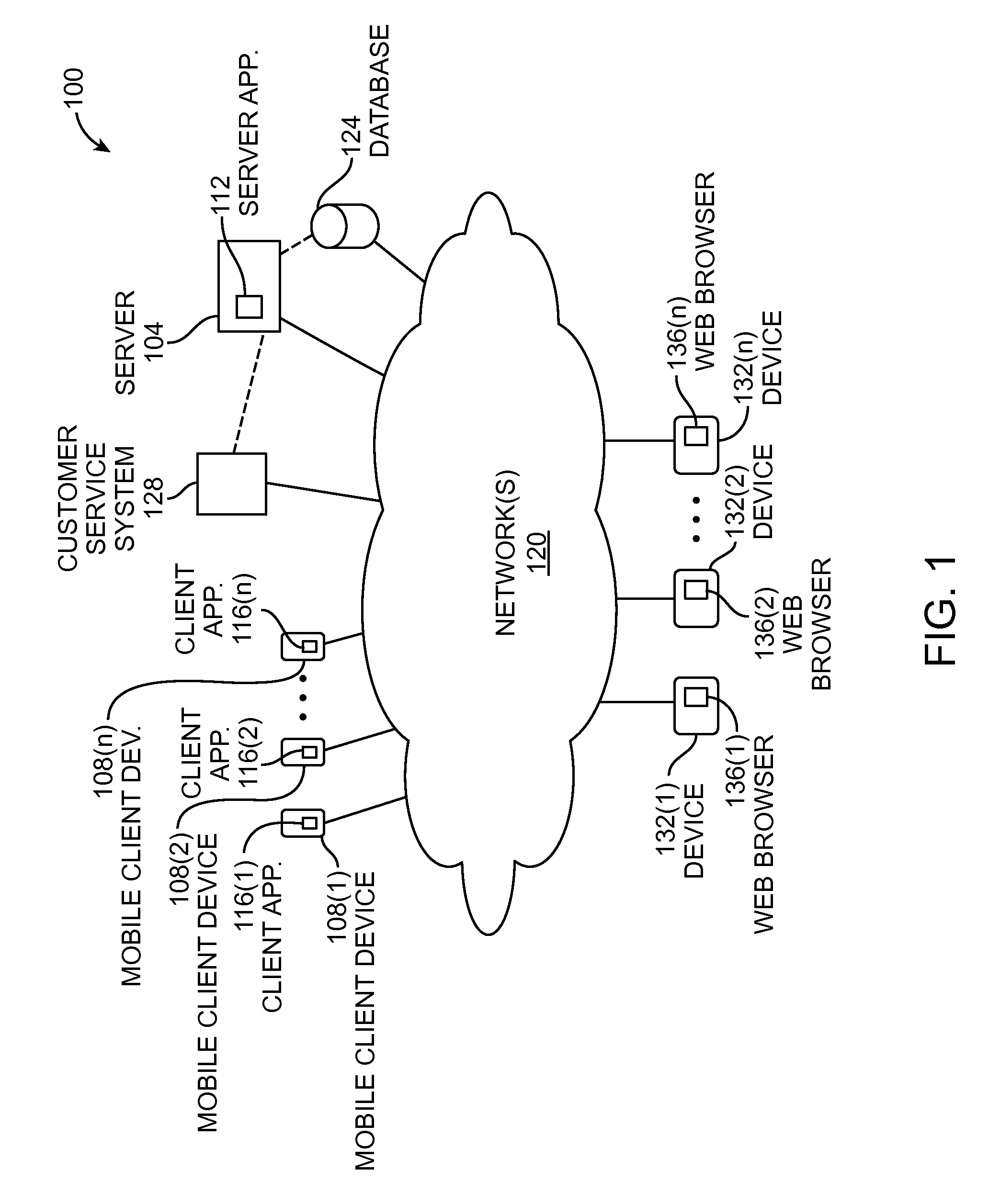

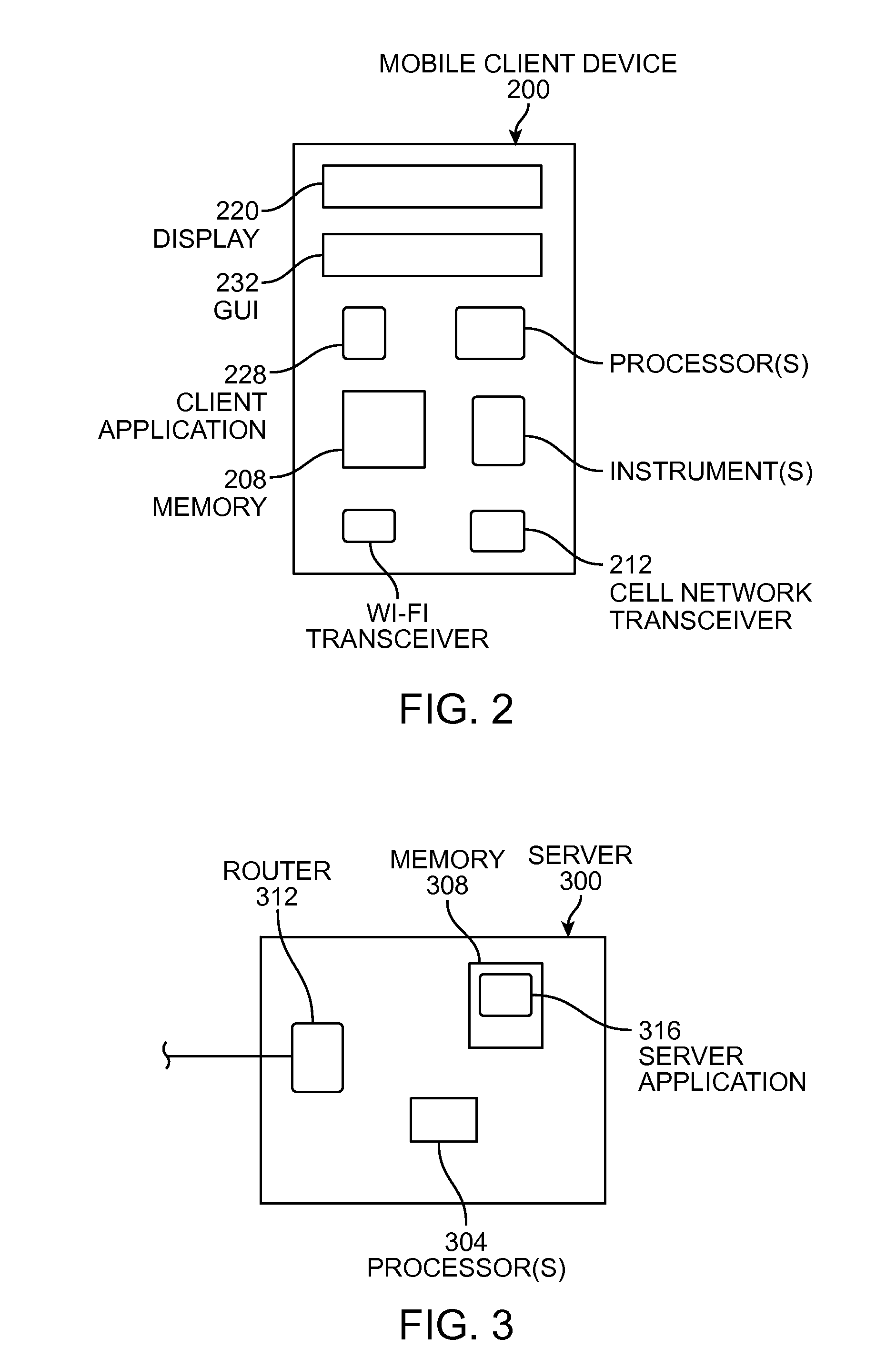

Crowd-Sourcing of Information for Shared Transportation Vehicles

InactiveUS20130041941A1Navigational calculation instrumentsRoad vehicles traffic controlCrowd sourcingArrival time

Systems, apparatuses, methods, and software for collecting and disseminating crowd-sourced information relating to one or more shared vehicles, such as buses, passenger trains, subway vehicles, streetcars, etc. The crowd-sourced information is collected via mobile client devices carried by users, such a riders of the shared vehicle at issue. Information collected includes tracing data for tracing the route and timing of each shared vehicles. The tracing data is used to update a computer model that helps predict arrival / departure times. The predicted arrival times can be conveyed to users and to allow people to arrange rendezvous events. Other information collected includes user-report information on items such as condition of the shared vehicle, fullness of the vehicle, and the user's experience with the vehicle and / or corresponding infrastructure. Collected user-report information can be shared with other users and / or a customer service system affiliated with the shared vehicle.

Owner:CARNEGIE MELLON UNIV

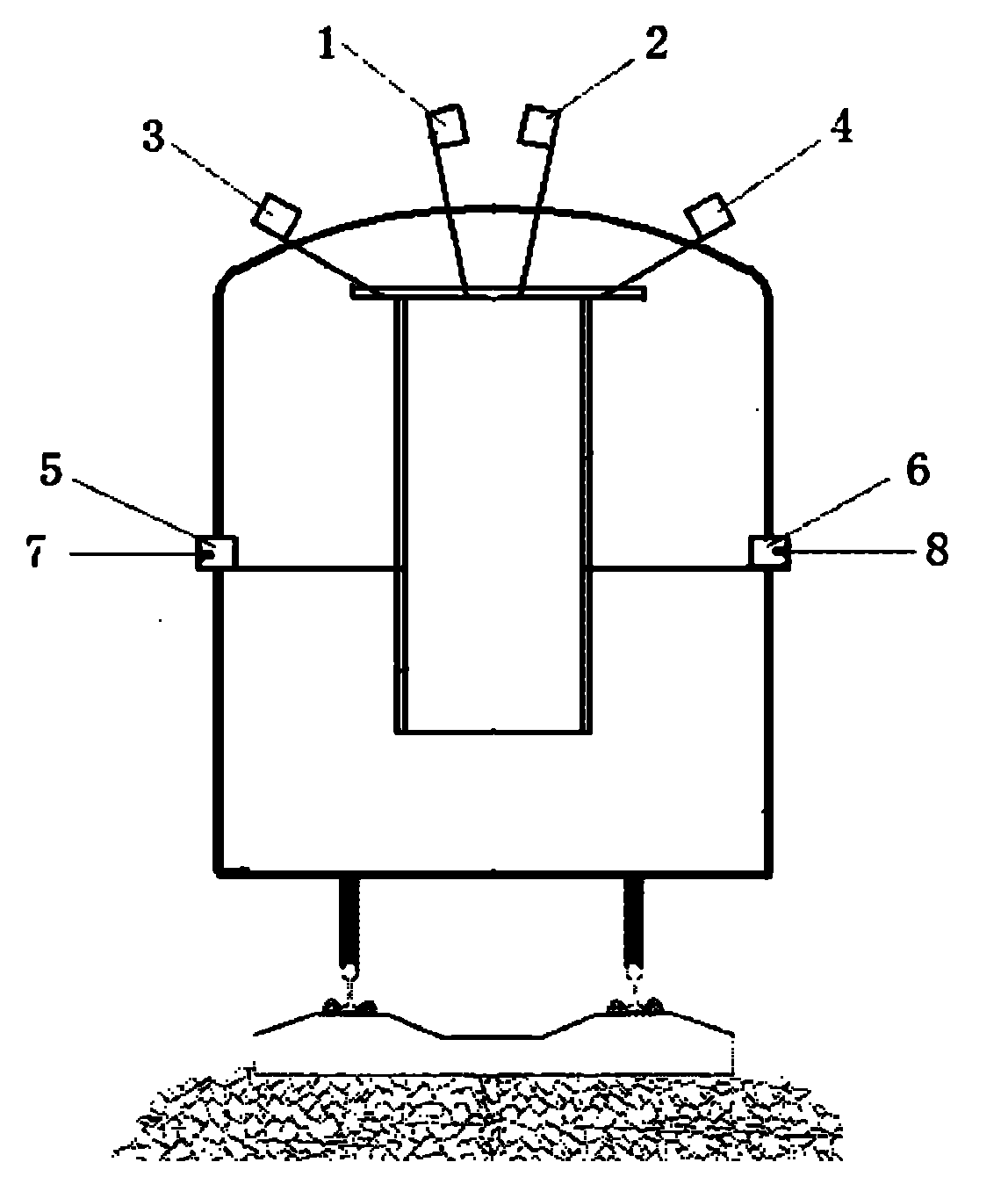

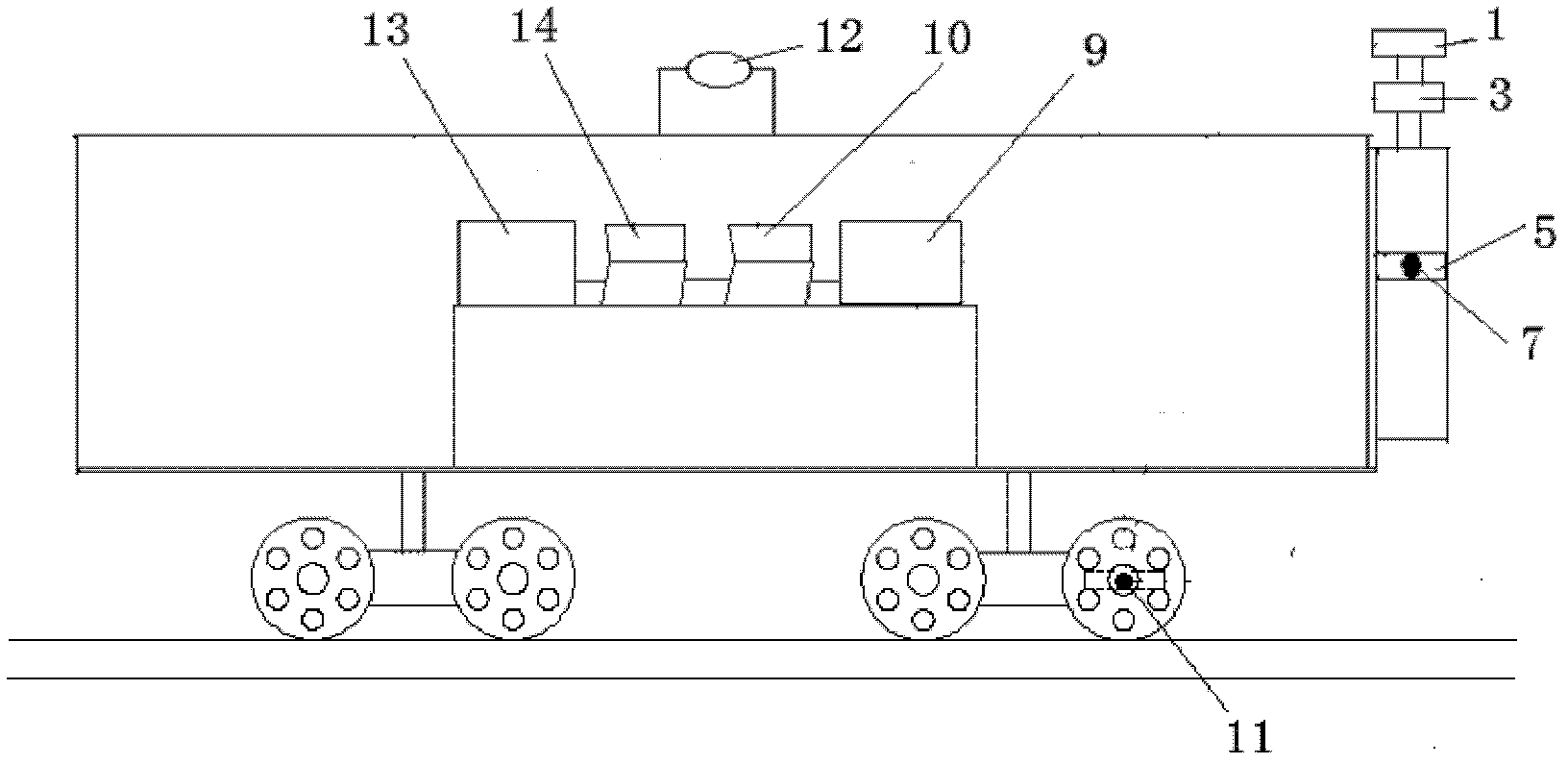

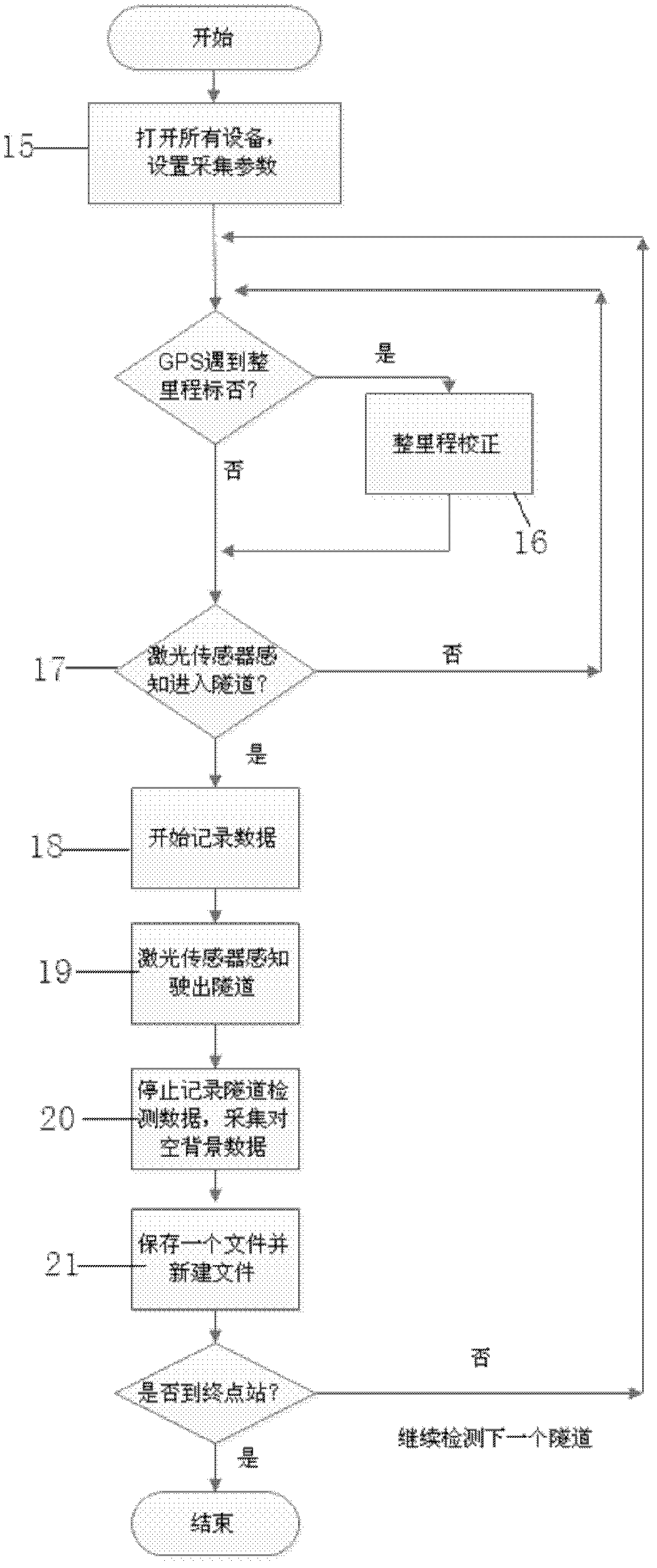

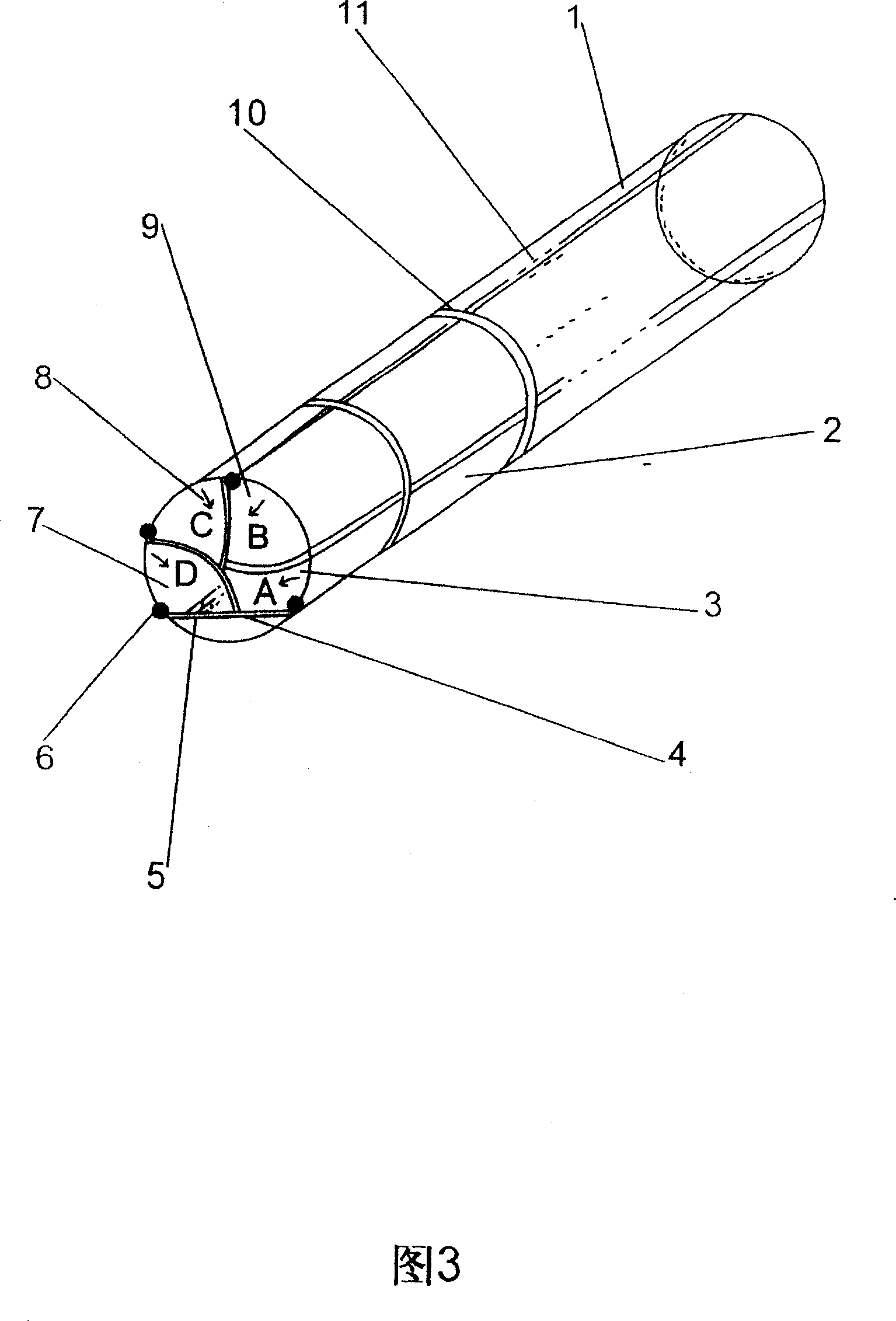

Full-face vehicular detection method for railway tunnel lining and device

ActiveCN102607477ARealize collection automationReduce data storageUsing wave/particle radiation meansMaterial analysis using radiation diffractionFace detectionRailway tunnel

A full-face vehicular detection method for a railway tunnel lining and a device aim to avoid collision of ground penetrating radar antennas with an overhead line system and a support of the overhead line system, the detection speed is a normal running speed of a train, the antennas in full-face detection are not interfered with each other, automatic positioning is realized during detection, only ground penetrating radar signals in a tunnel need to be acquired, and a penetrating radar signal processing and analyzing method in tunnel detection is modified. The vehicular device comprises a six-channel high-speed scanning penetrating radar, a positioning portion, a laser ranging portion and data acquisition and processing software. The pulse repetition frequency of the ground penetrating radar is 3MHz, the pulse repetition frequency of each channel is 500kHz, and the scanning rate is 976scan / s. The ground penetrating radar is provided with TEM (transverse electric and magnetic field) short-horn air coupled antennas, each group of antennas realizes a double-transmission and single-receiving function, and the center frequency of the antennas is 300MHz. The ground penetrating radar antennas are mounted outside passenger train connectors, radiation surfaces of the antennas respectively face to an arch crown, arch springing and side walls, and the full-face vehicular detection method and the device are used for automatically detecting to exam the railway tunnel lining.

Owner:SOUTHWEST JIAOTONG UNIV

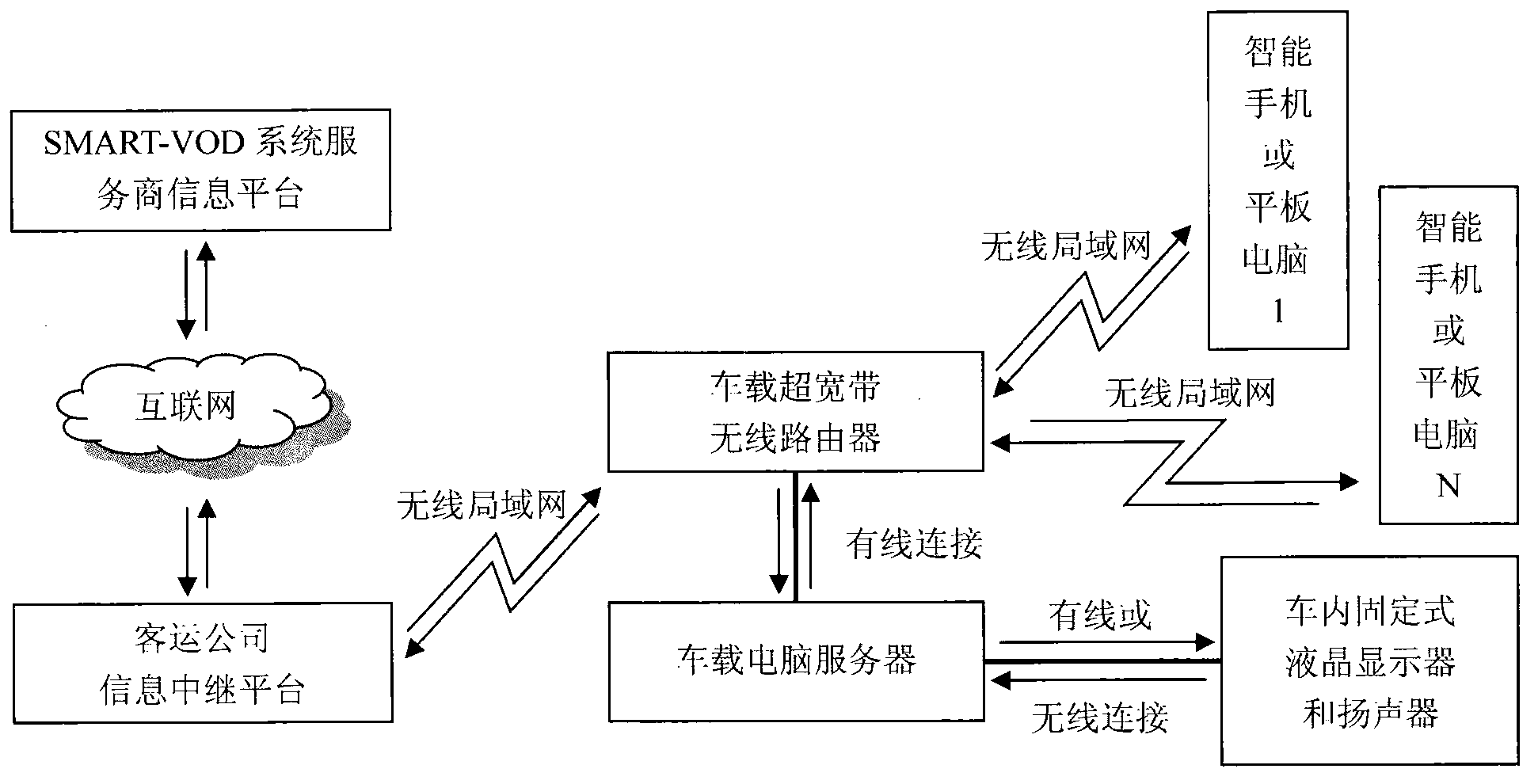

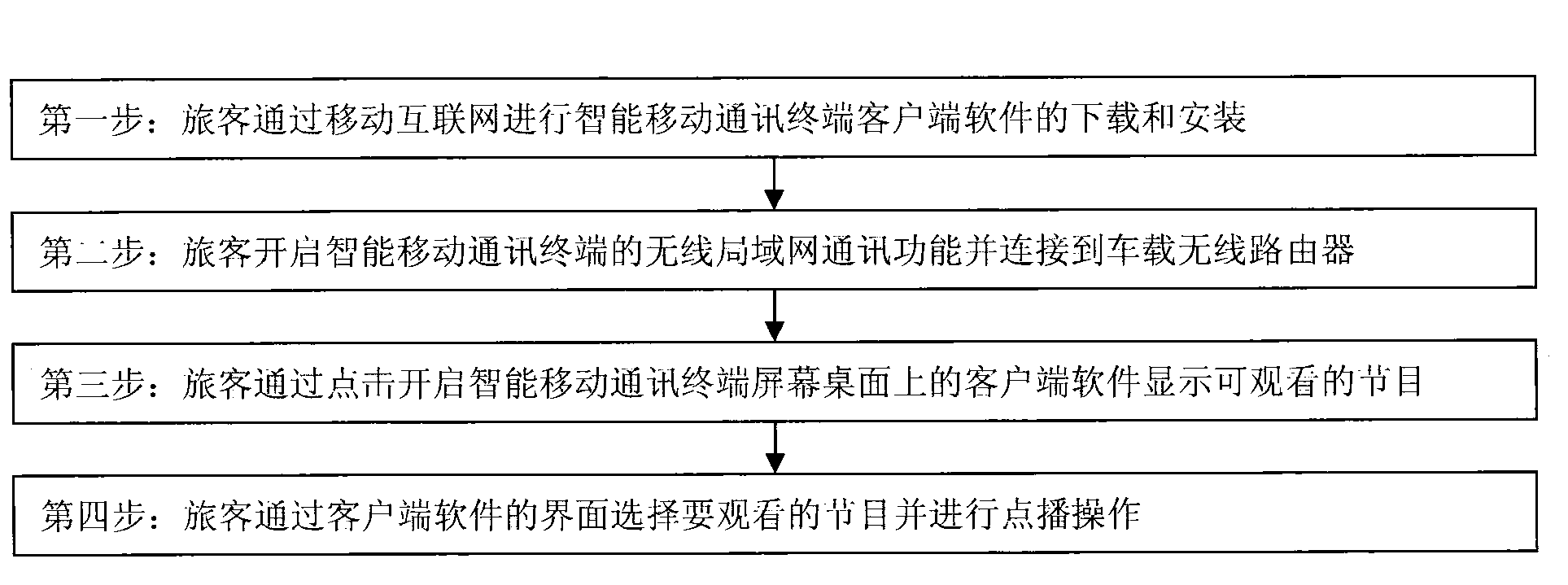

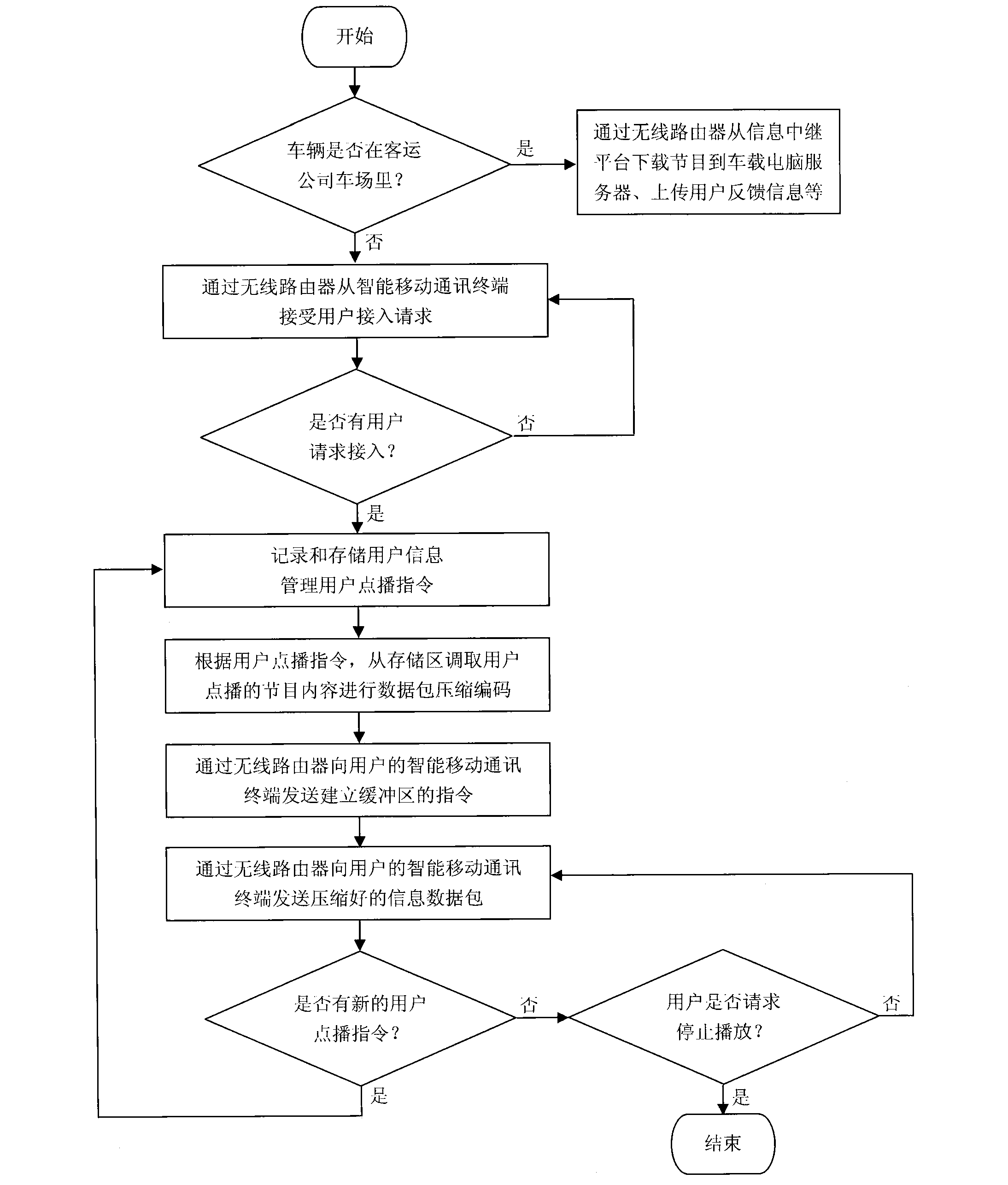

Method for achieving vehicle-mounted entertainment video information on demand by using intelligent mobile communication terminal

The invention provides a method for achieving vehicle-mounted entertainment video information on demand by using an intelligent mobile communication terminal. The method is characterized by comprising the following steps: S1, a vehicle-mounted video content storage computer server and an ultra wideband wireless router which are connected with each other are mounted on a highway passenger vehicle or a passenger train; S2, a passenger who gets on the highway passenger vehicle or the passenger train can choose the entertainment video information in the vehicle-mounted video content storage computer server with a vehicle-mounted entertainment video information on-demand client side of the intelligent mobile communication terminal carried by the passenger. Due to the fact that the cost of the intelligent mobile communication terminals of the passengers is not included in the cost of the system, the method for achieving vehicle-mounted entertainment video information on demand has the advantage that the purpose of video entertainment information on demand on the road by using the intelligent mobile communication terminals of the passengers in the highway passenger vehicle or the passenger train is achieved at low cost.

Owner:ACTIA SHANGHAI AUTOMOTIVE VEHICLE ELECTRONICS & DIAGNOSTICS CO LTD

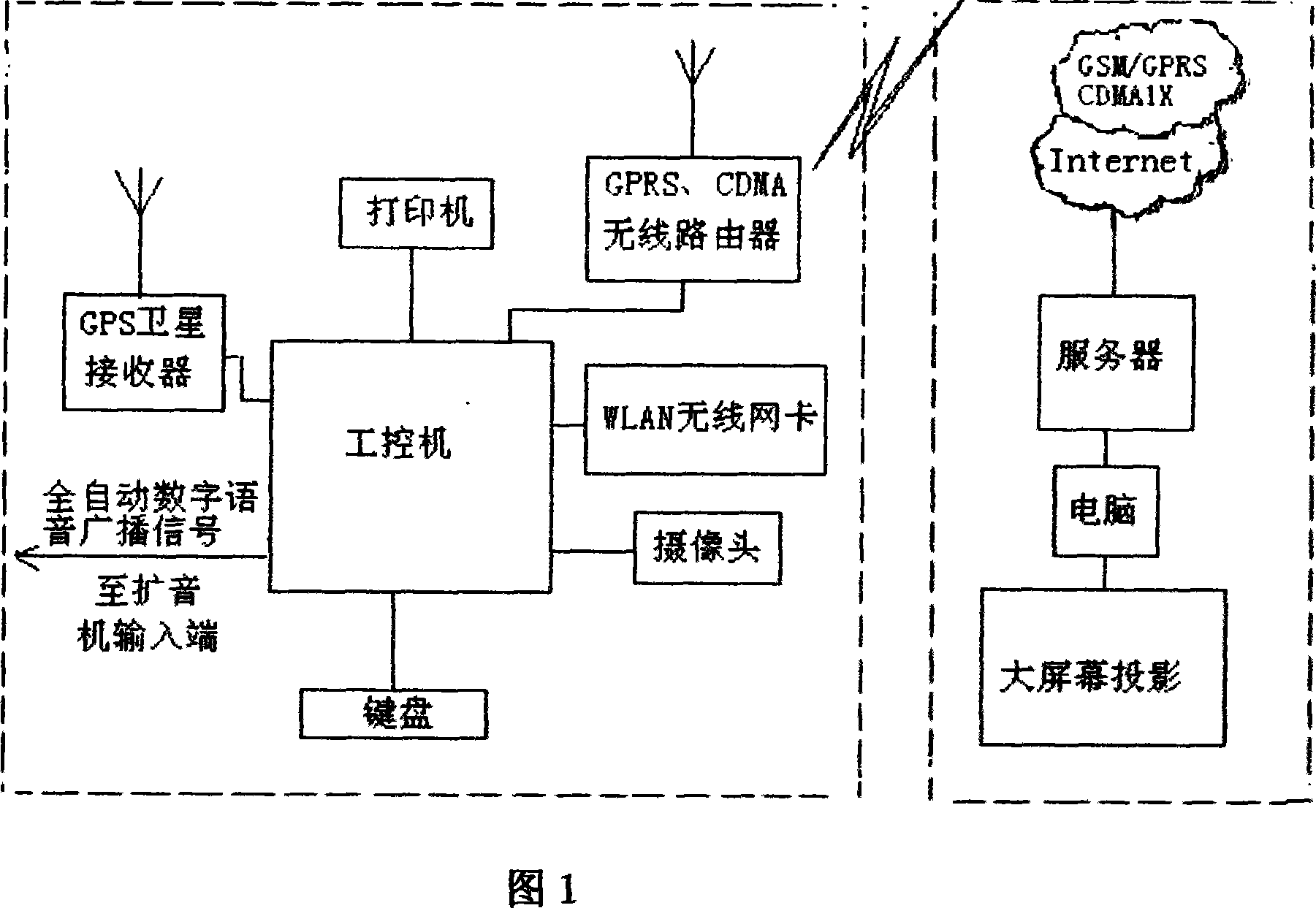

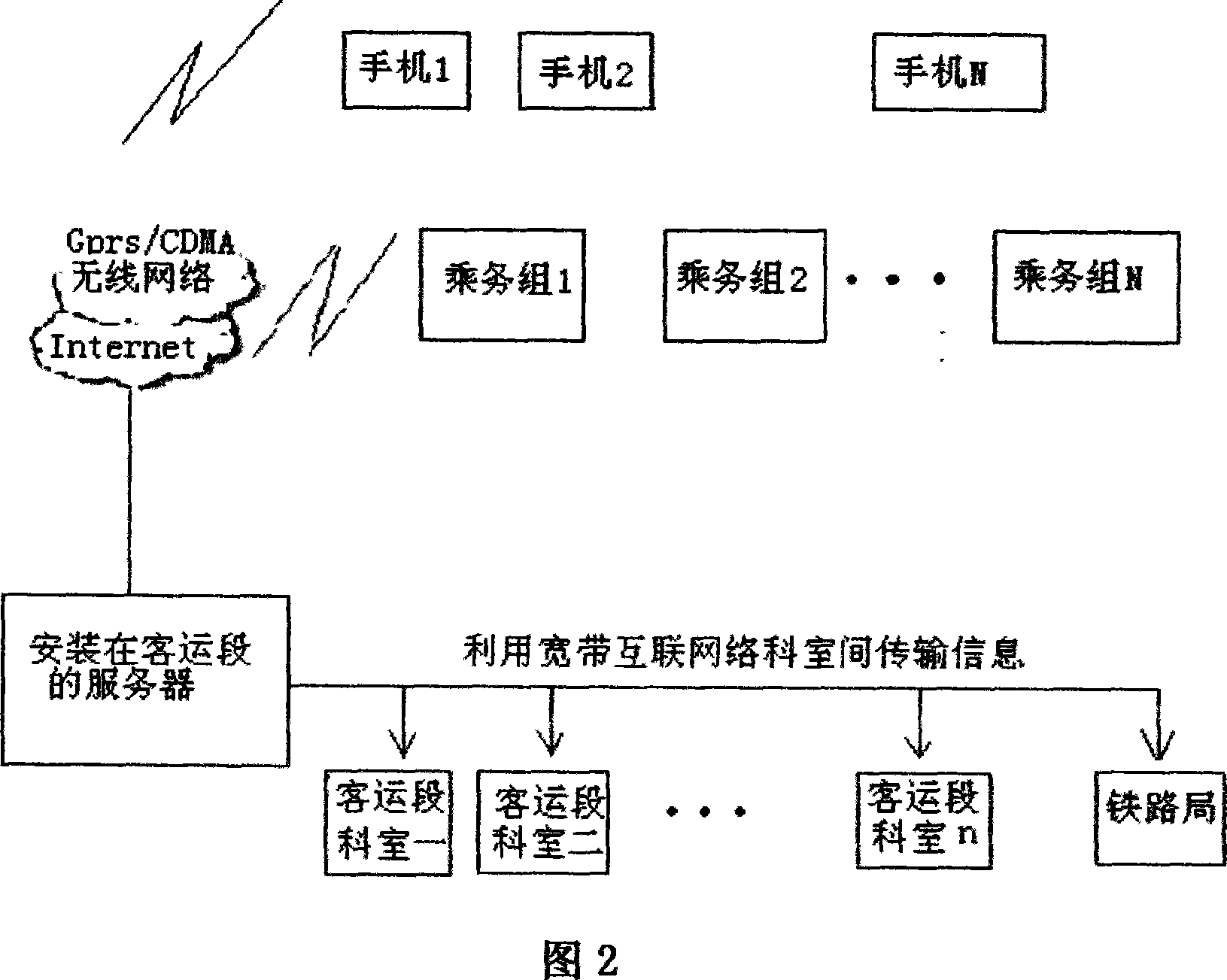

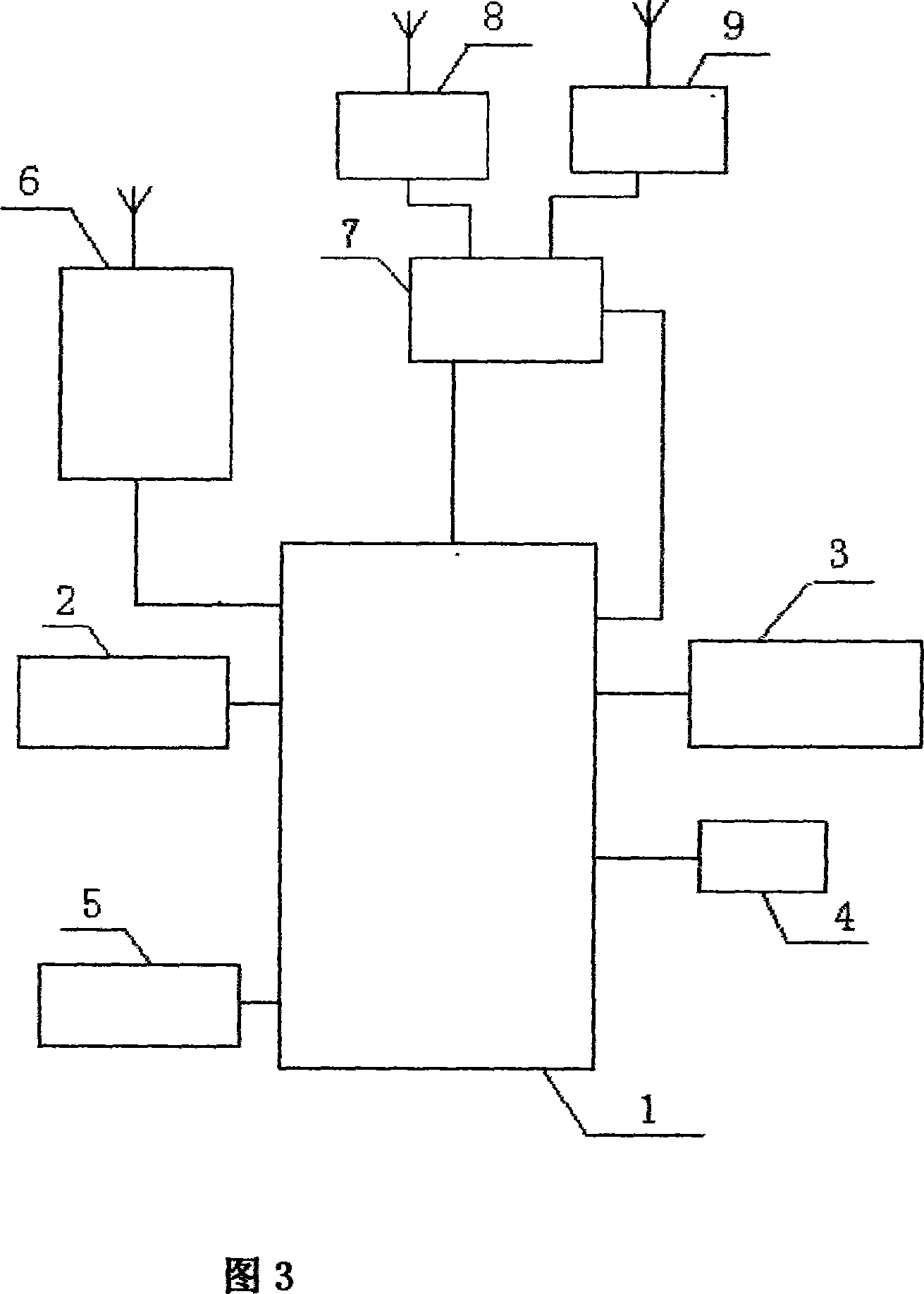

Digital information intelligence management system for passenger transport train

InactiveCN101032973ARealize mutual real-time transmissionReal-time transmissionAutomatic systemsData compressionRadio networks

The present invention belongs to the field of intelligent passenger train information management, and is especially intelligent passenger train digital information managing and intelligent passenger train digital information remote monitoring and managing system realized by means of computer control technology, phonetic synthesis technology, data compression technology, satellite positioning technology and radio data transmission technology. The system consists of on-train intelligent train information managing system, which consists of industrial control computer, printer, video camera, GPS satellite receiver, WLAN radio network card, GPRS and CDMA radio router, and sound card connected to loudspeaker; and intelligent passenger train digital information remote monitoring and managing system, which consists of server with control software and connected to Internet, computer and screen.

Owner:刘汉义

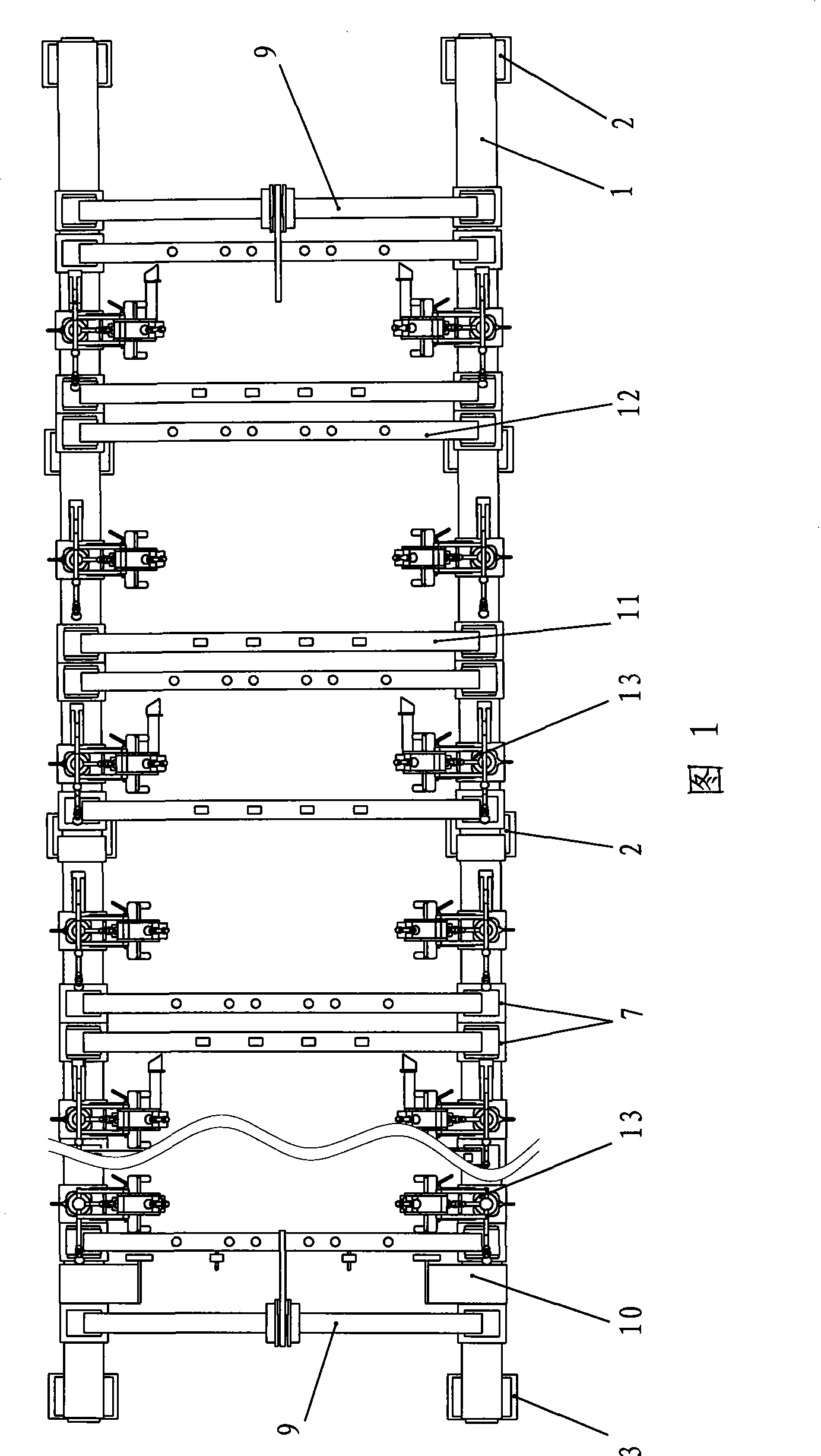

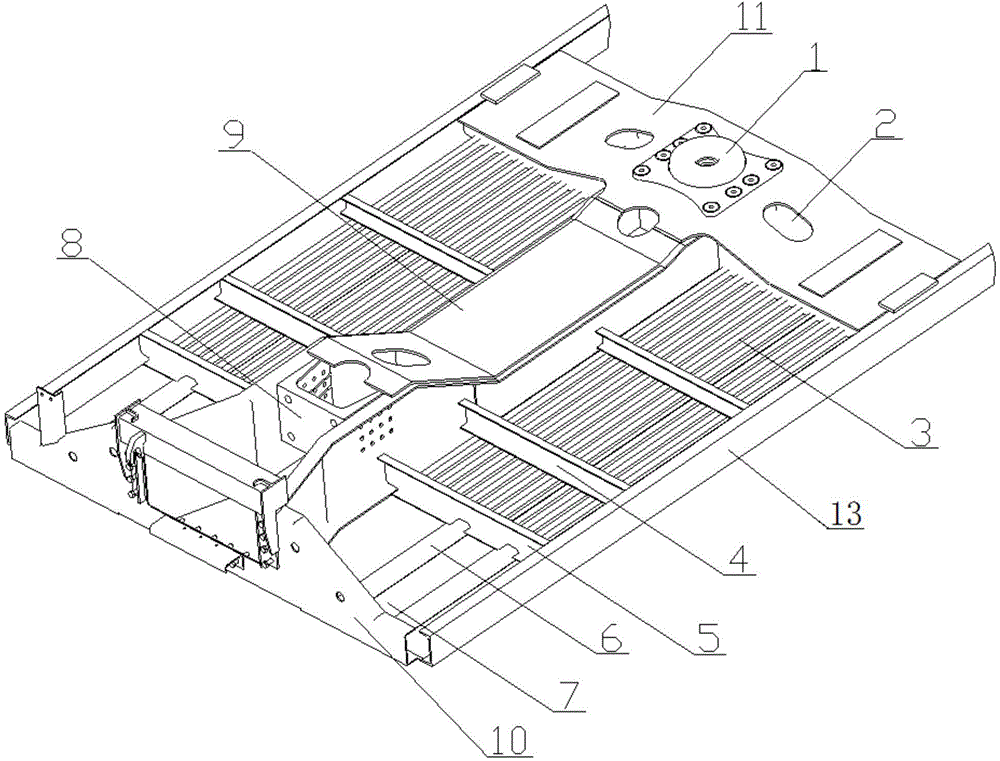

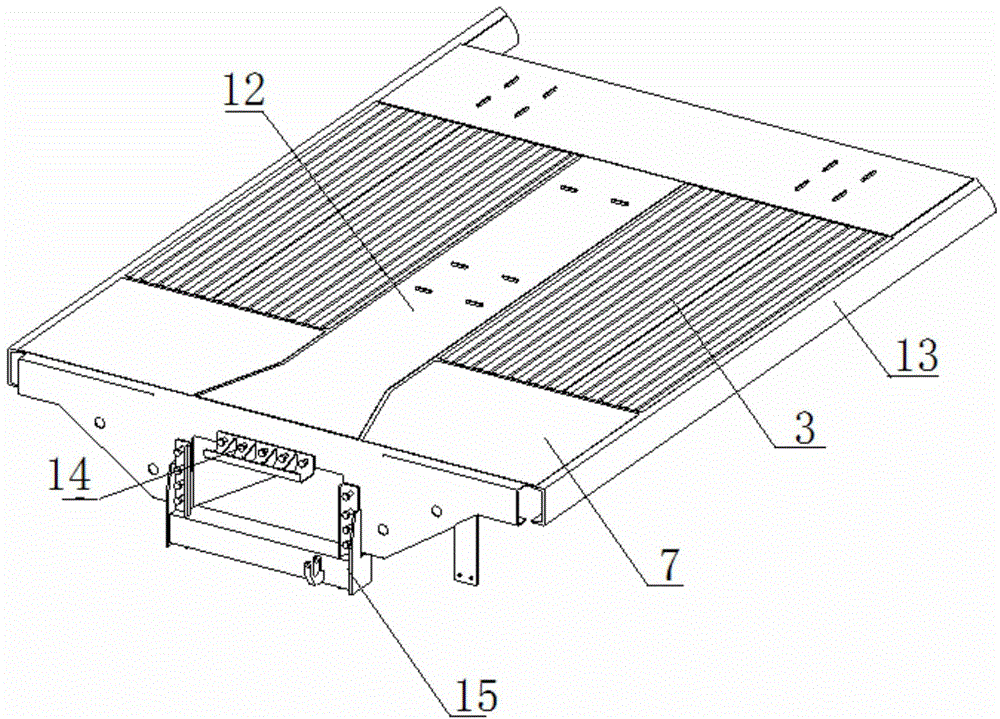

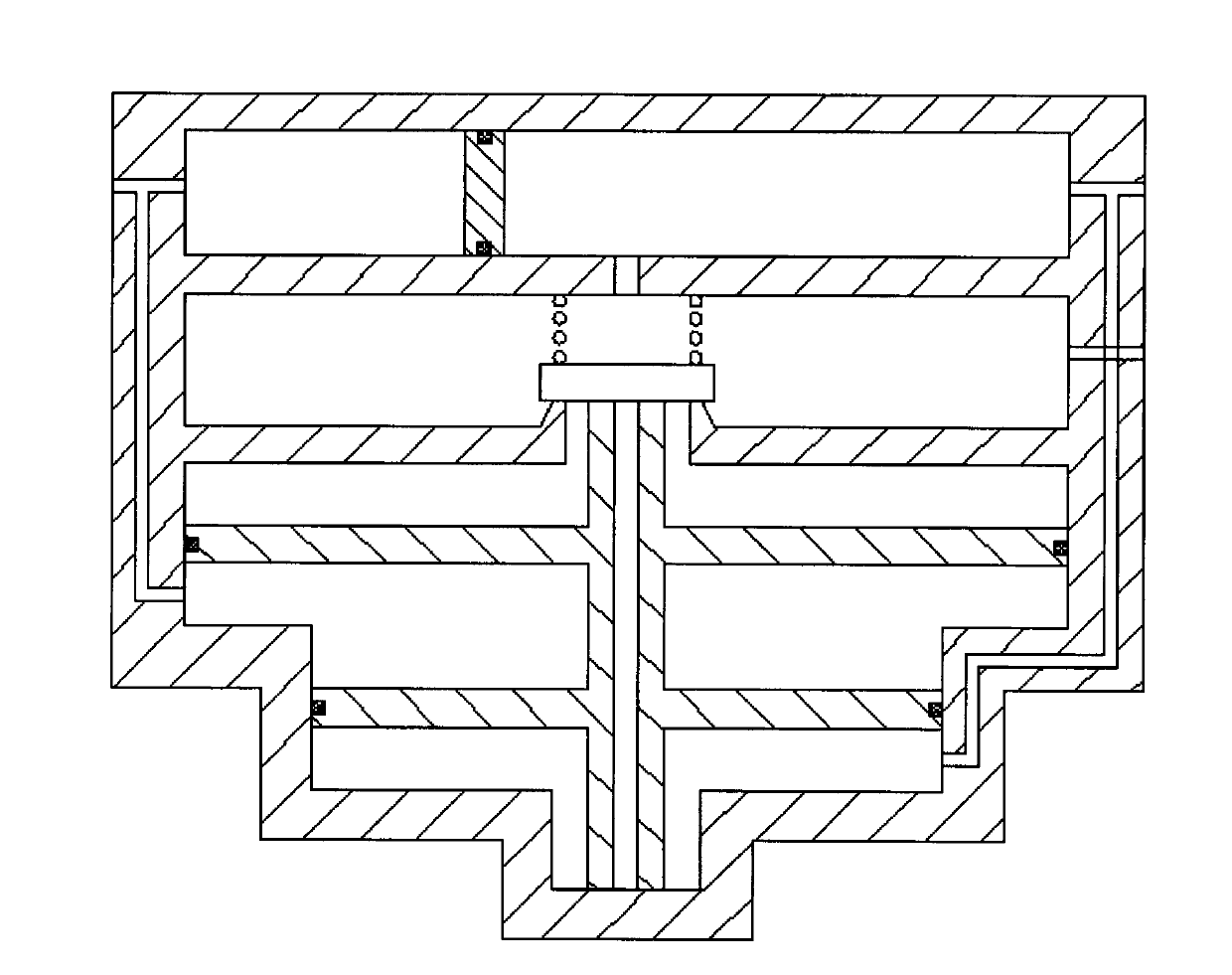

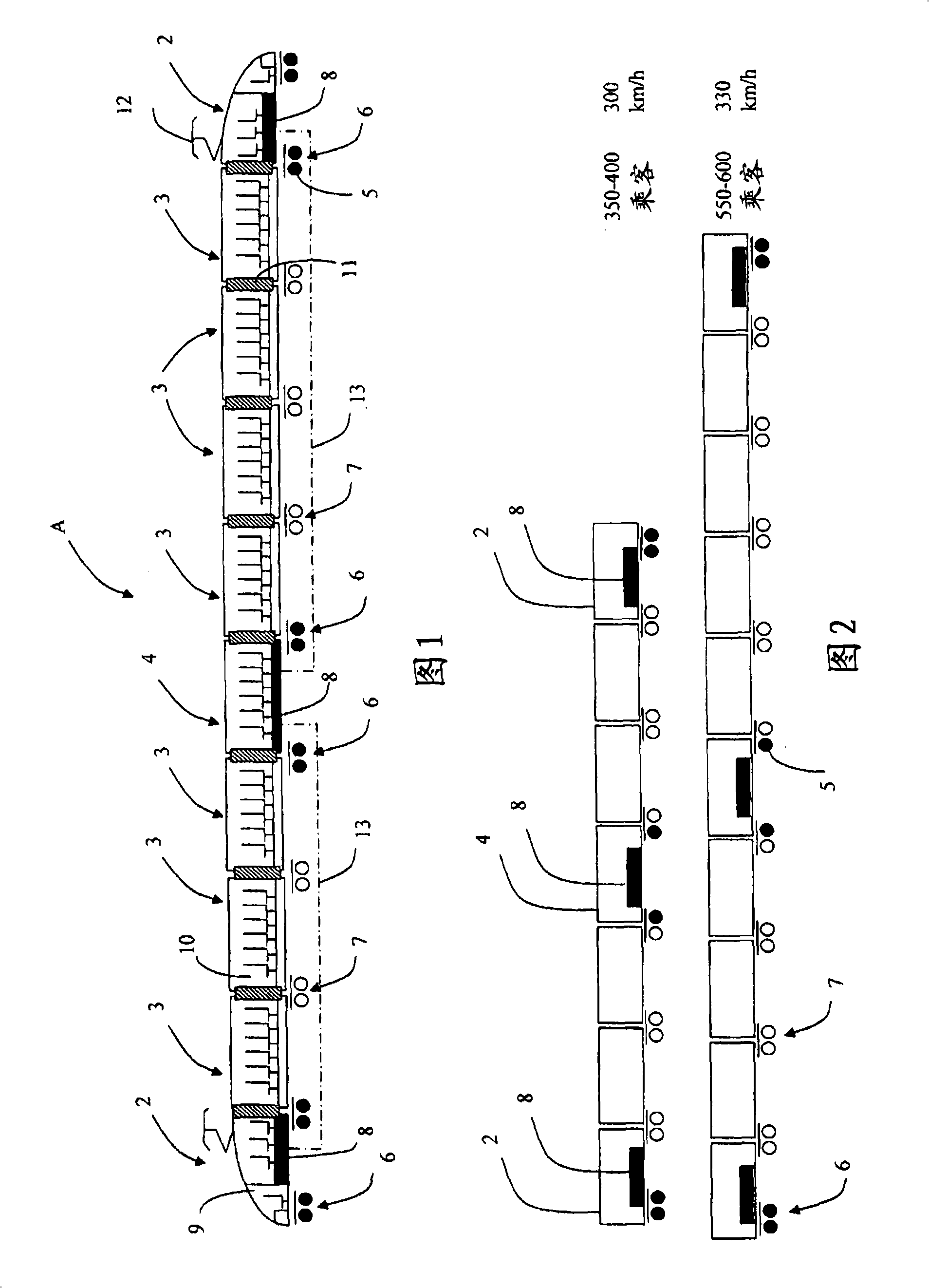

High speed motor train unit roof assembly-welding device

ActiveCN101456108AImprove space utilizationReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyEngineering

The invention discloses an assembly welding device for high-speed bullet train tops and belongs to the technical field of railway vehicle body manufacturing. The assembly welding device comprises two foundational beams which are arranged parallelly and a plurality of fixed plates arranged on the foundational beams, wherein the foundational beams are formed by a plurality of sections which have horizontal H-shaped cross sections and are connected by connecting pieces at two ends serially into a whole, and the bottom surfaces of the foundational beams are fixedly connected with two connecting plates pre-buried in a foundation; the fixed plates are provided with central positioning racks, top positioning racks, a plurality of flat-top supporting racks, round-top supporting racks and a plurality of pairs of clamping racks. Through full investigation and research and absorption of advantages of rail passenger train manufacturing technology at home and abroad, the welding device makes a structural break through and innovation in the prior mode, realizes the manufacturing of all of the five kinds of train tops of high-speed bullet trains, uses the cooperation of one set of tool and a welding mechanical arm and realizes the welding of the insides and the outsides of the train tops. In addition, the device reduces the area for welding operation, improves the utilization rate of plant space, saves capital, ensures welding quality, greatly improves working efficiency and reduces the labor intensity of operators.

Owner:CRRC TANGSHAN CO LTD

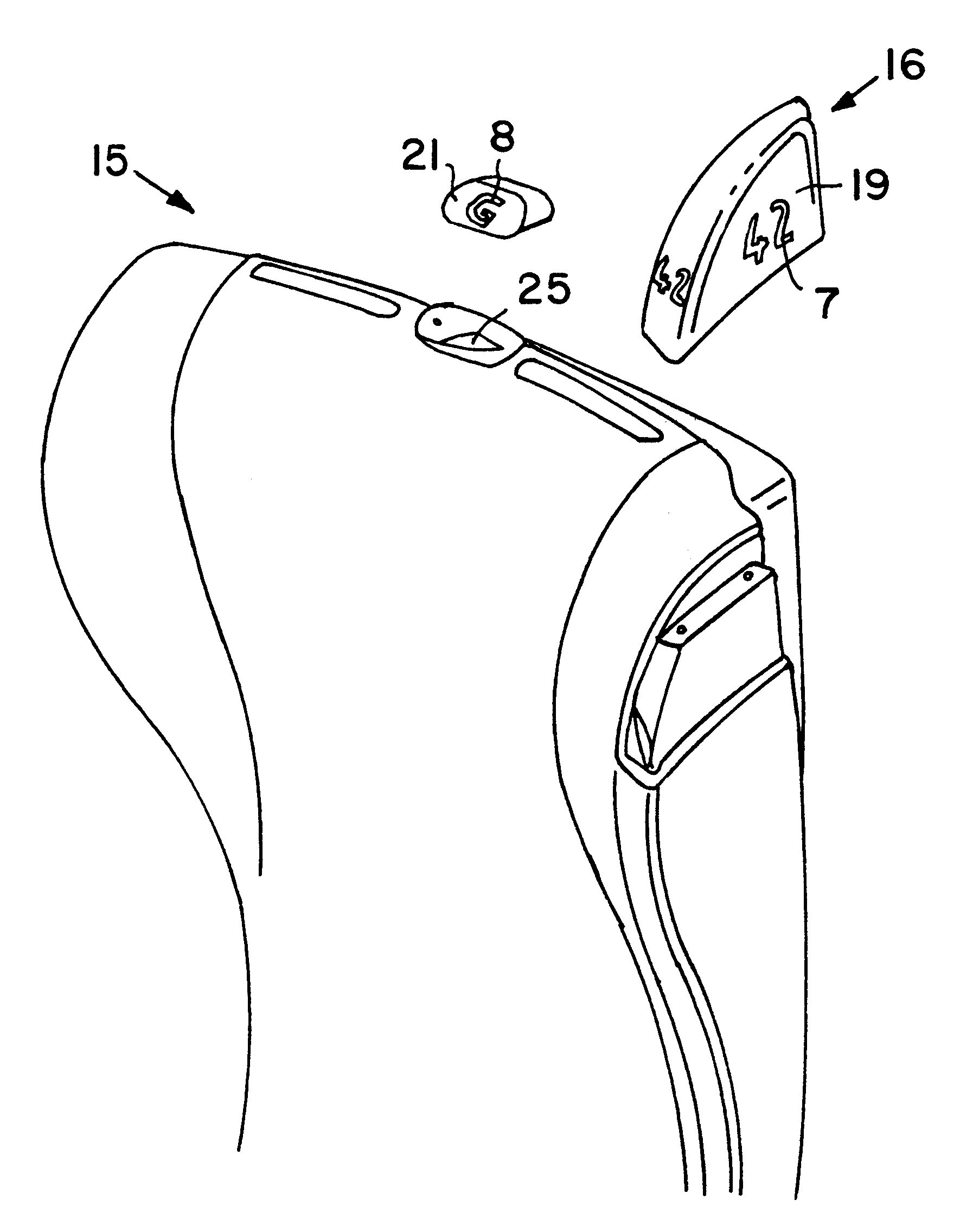

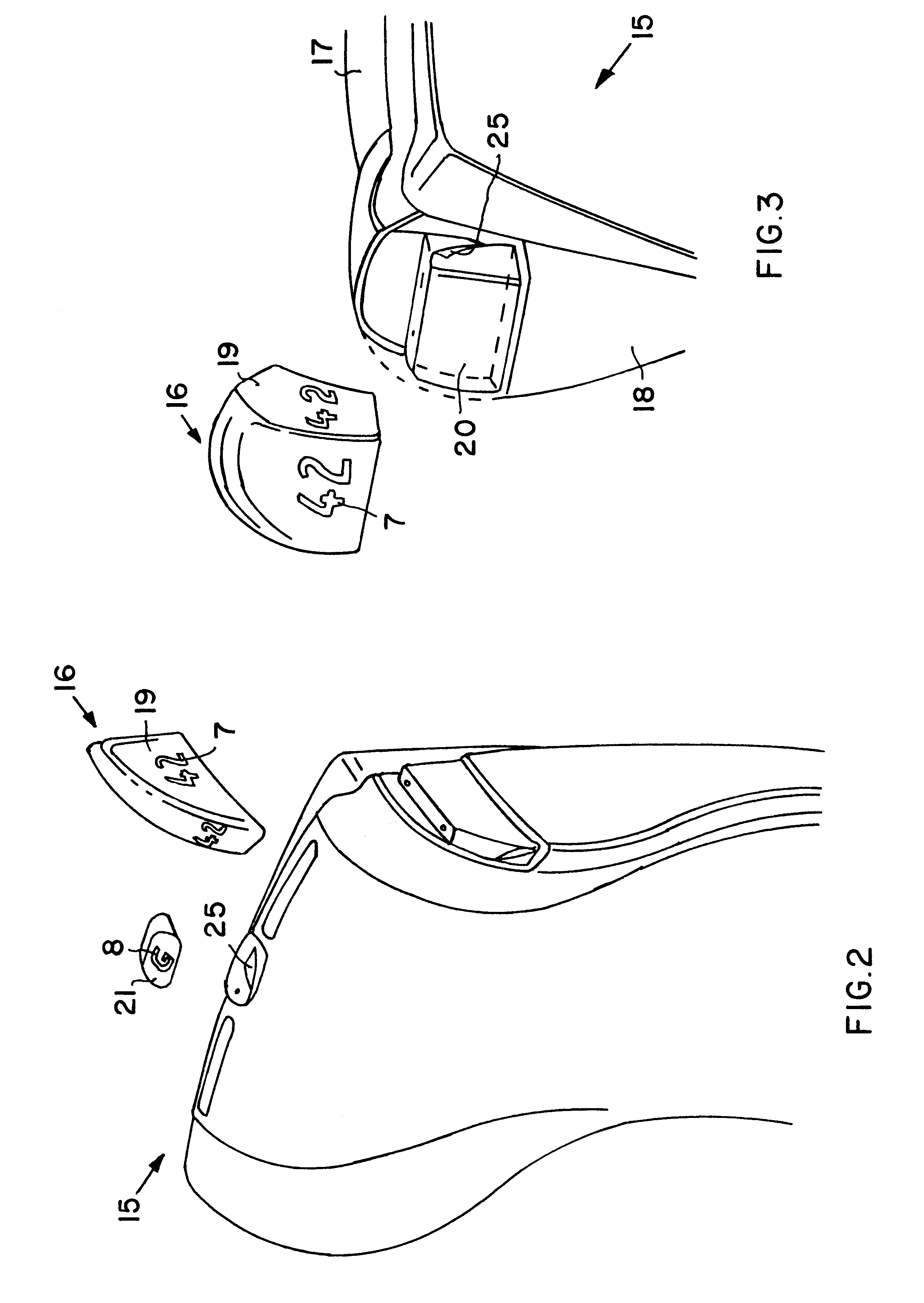

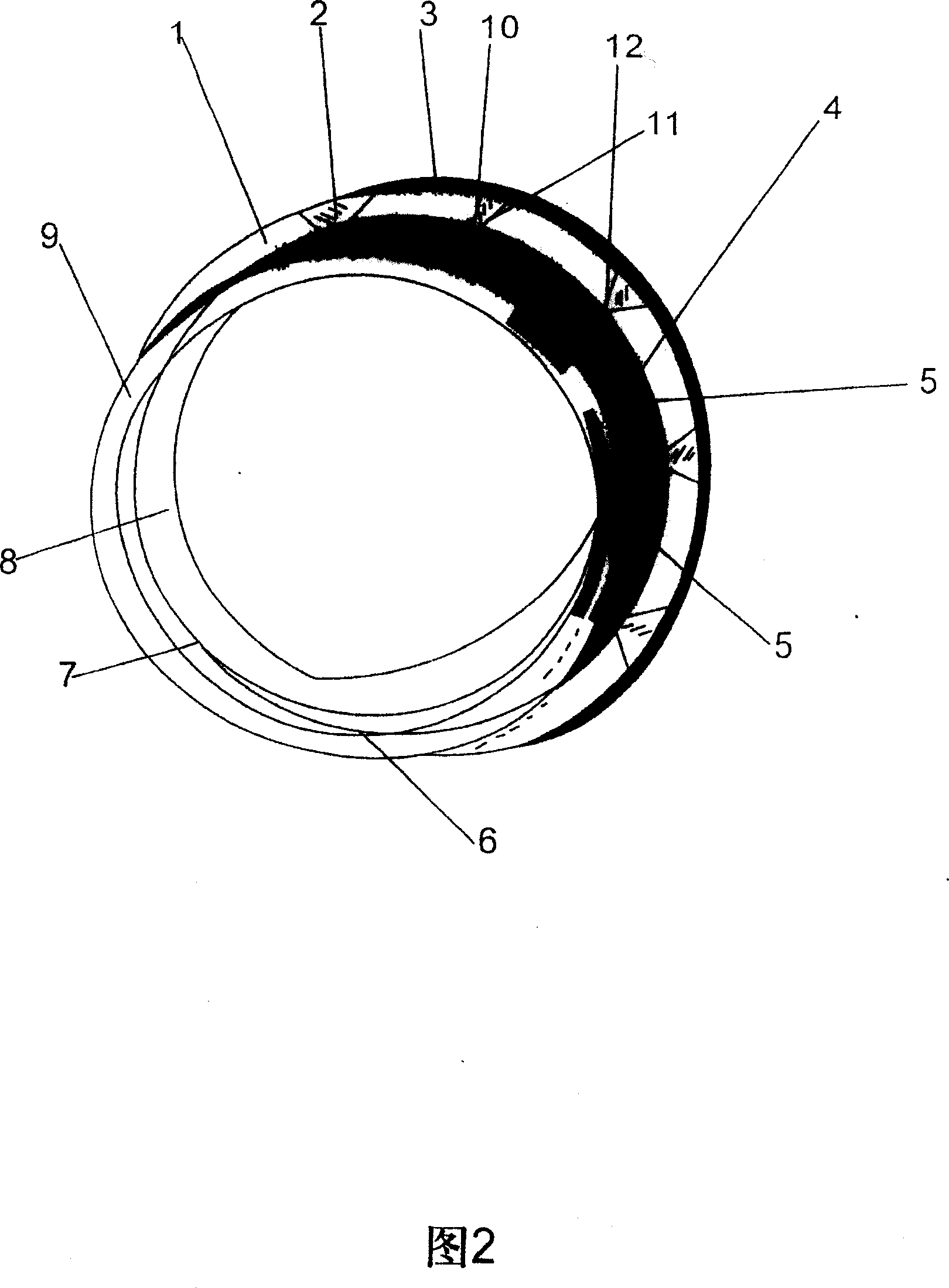

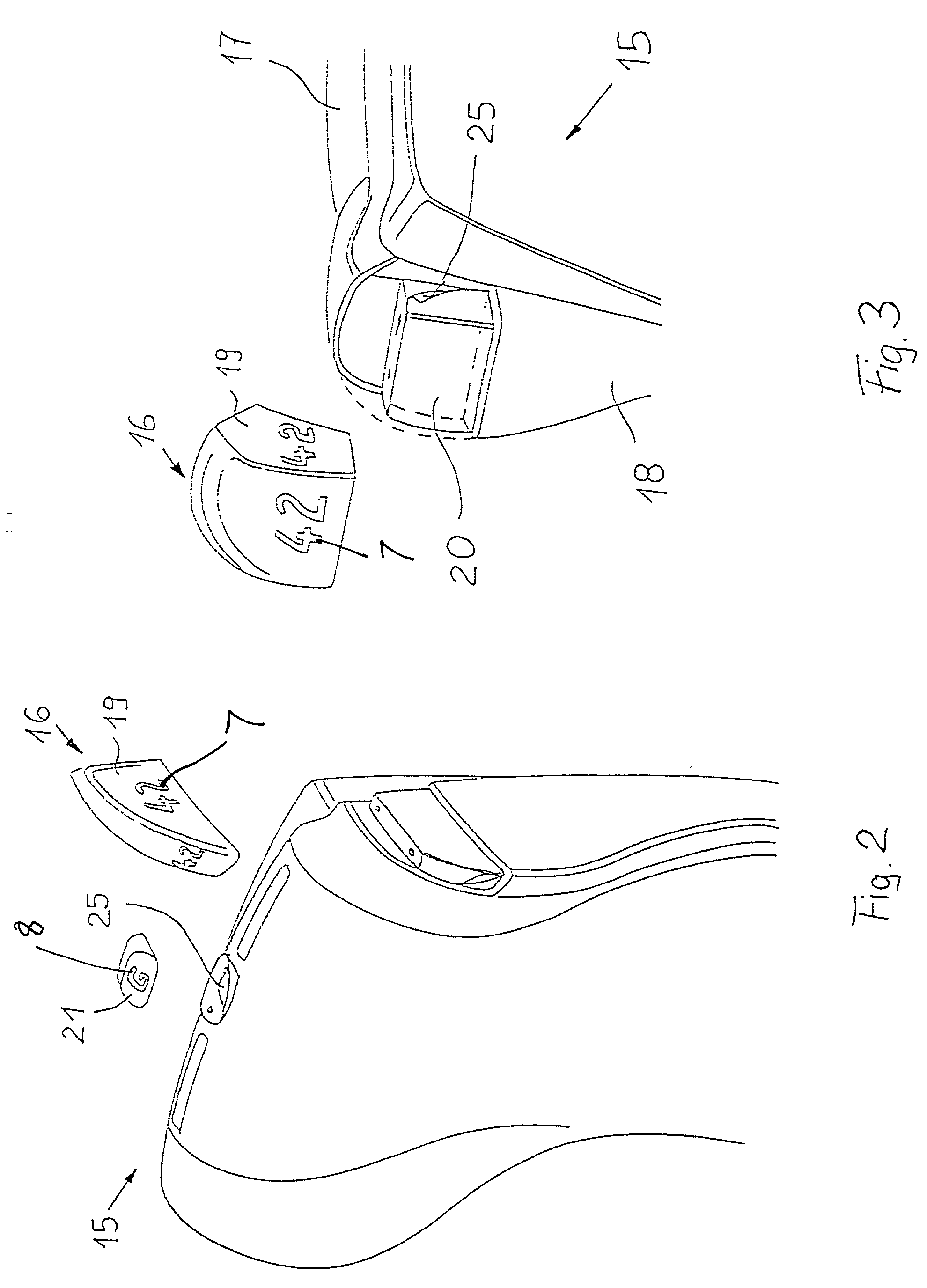

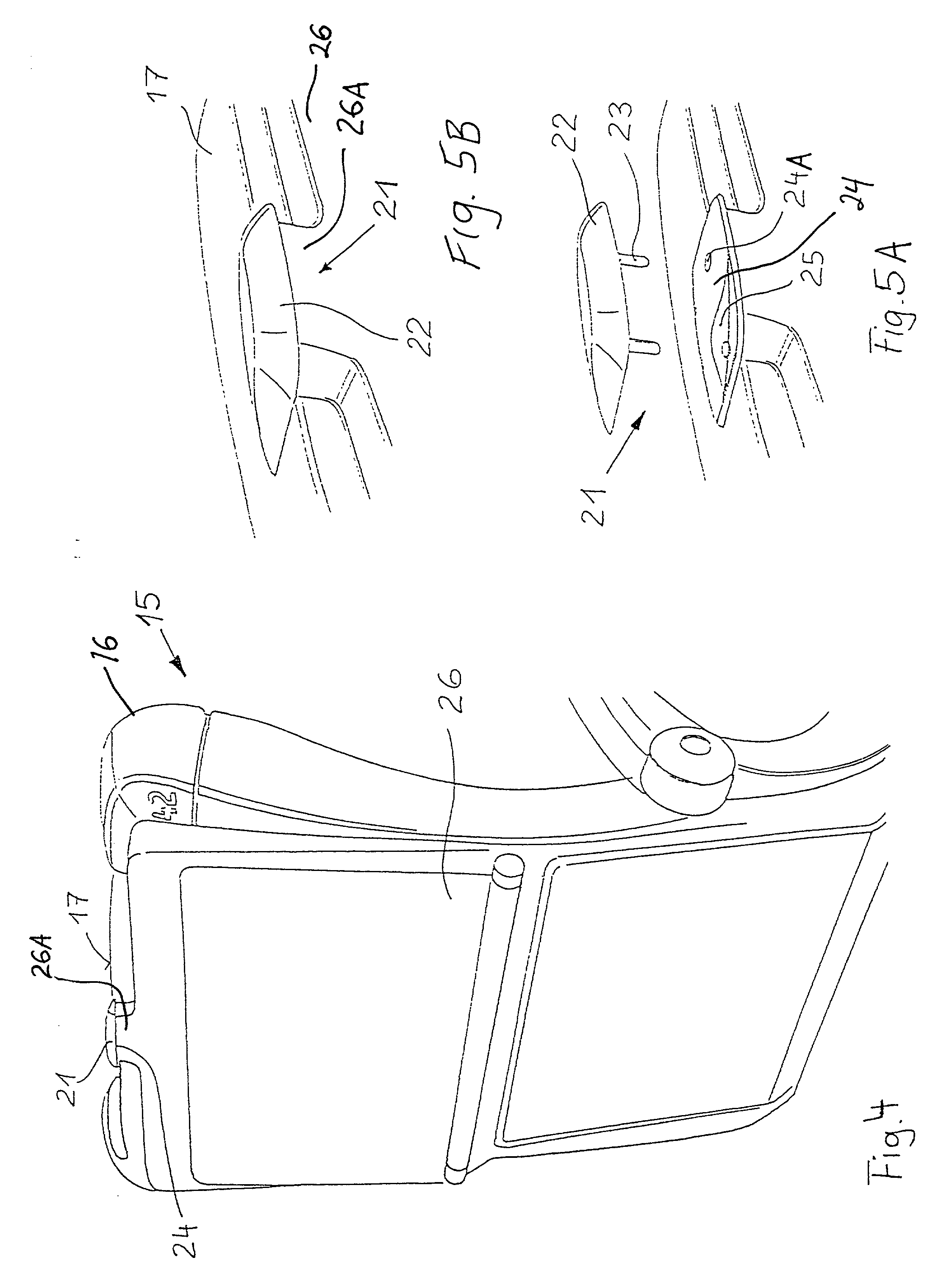

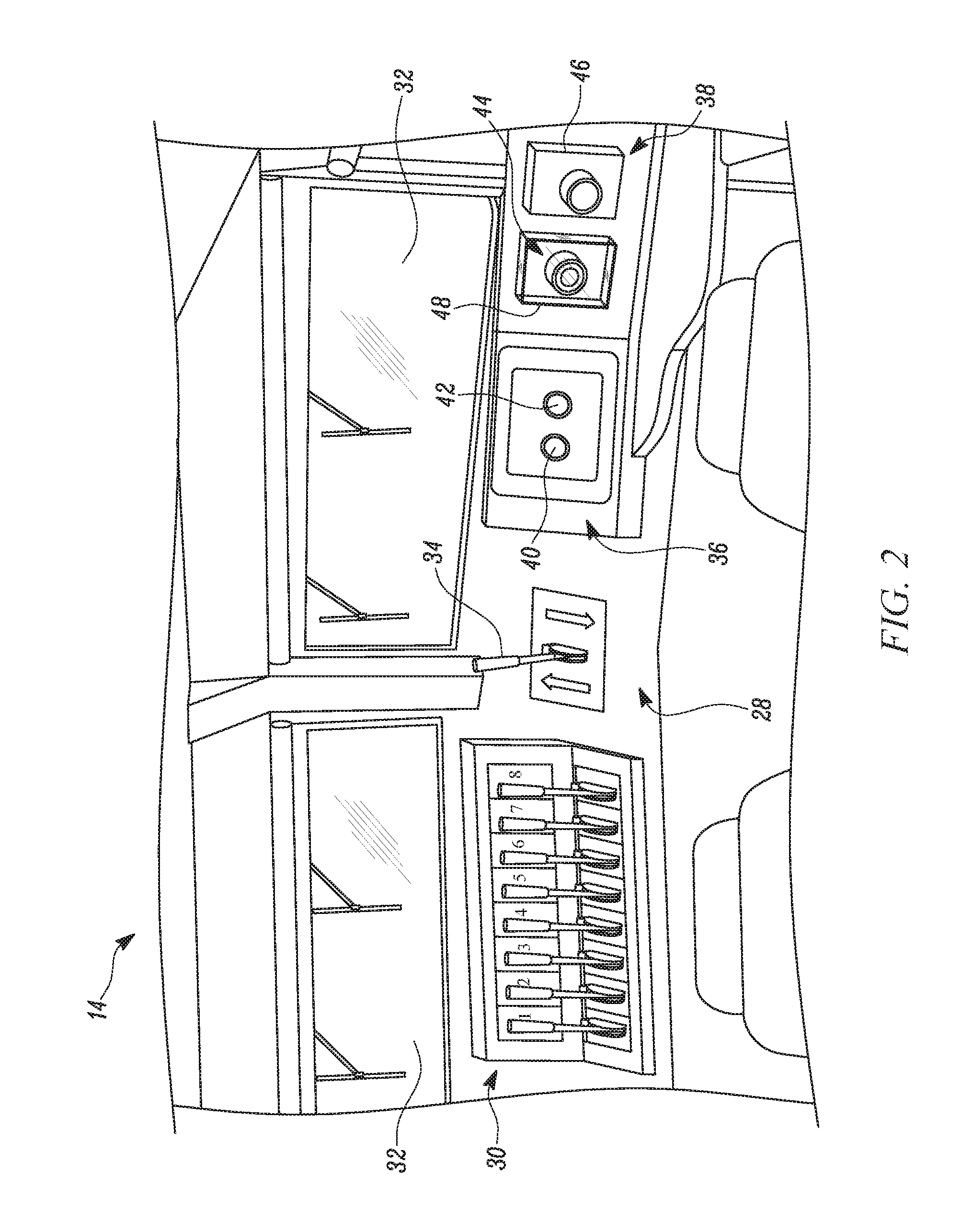

Passenger orientation arrangement in a passenger cabin

A seating space such as an aircraft passenger cabin has rows of seats along an aisle, identified by a row number and a seat location letter. A seat row indicator is arranged on the side flank of the seat back of each aisle seat, at the corner where the side flank and upper edge of the seat back meet. A seat location indicator is arranged at the middle of the upper edge of the seat back of each seat. The row numbers and seat letters are indicated on or in the indicators by paint, printing, engraving, inserts, illumination or tactile indicia. The indicators are conspicuous and easily visible to a passenger standing or walking in the aisle without bending or leaning over. Boarding of the aircraft is facilitated and expedited. Emergency evacuation is assisted by appropriate illumination of the indicators.

Owner:AIRBUS OPERATIONS GMBH

Heat treatment method of novel alloy steel hollow car axle material

ActiveCN102876860AGood mechanical propertiesWide range of water temperature allowedQuenching agentsPre treatmentPassenger train

The invention belongs to the technical field of heat treatment processes of alloy steel hollow car axle materials for high-speed passenger trains and particularly relates to a heat treatment method of a novel alloy steel hollow car axle material. The heat treatment method is characterized by pre-heating novel alloy steel with shaft blank sizes at the temperature of 910-950 DEG C, quenching the novel alloy steel at the temperature of 900-940 DEG and tempering the novel alloy steel at the temperature of 620-670 DEG C. The heat treatment method has the advantages that the developed novel alloy steel hollow car axle material for the high-speed passenger trains is domestically and independently developed, mechanical properties of axles which are treated by a heat treatment process matched with the material all exceed requirements of the European hollow car axle standard EN13261, the axles are good in obdurability matching, especially, high in smooth specimen fatigue strength and notch specimen fatigue strength and excellent in low temperature impact toughness, so that the axles can be used under various domestic weather conditions. According to the heat treatment method of the novel alloy steel hollow car axle material, heat treatment process technical assurance is provided for finally producing novel alloy steel hollow car axles at the speed of 200km / h-350km / h.

Owner:TSINGHUA UNIV +1

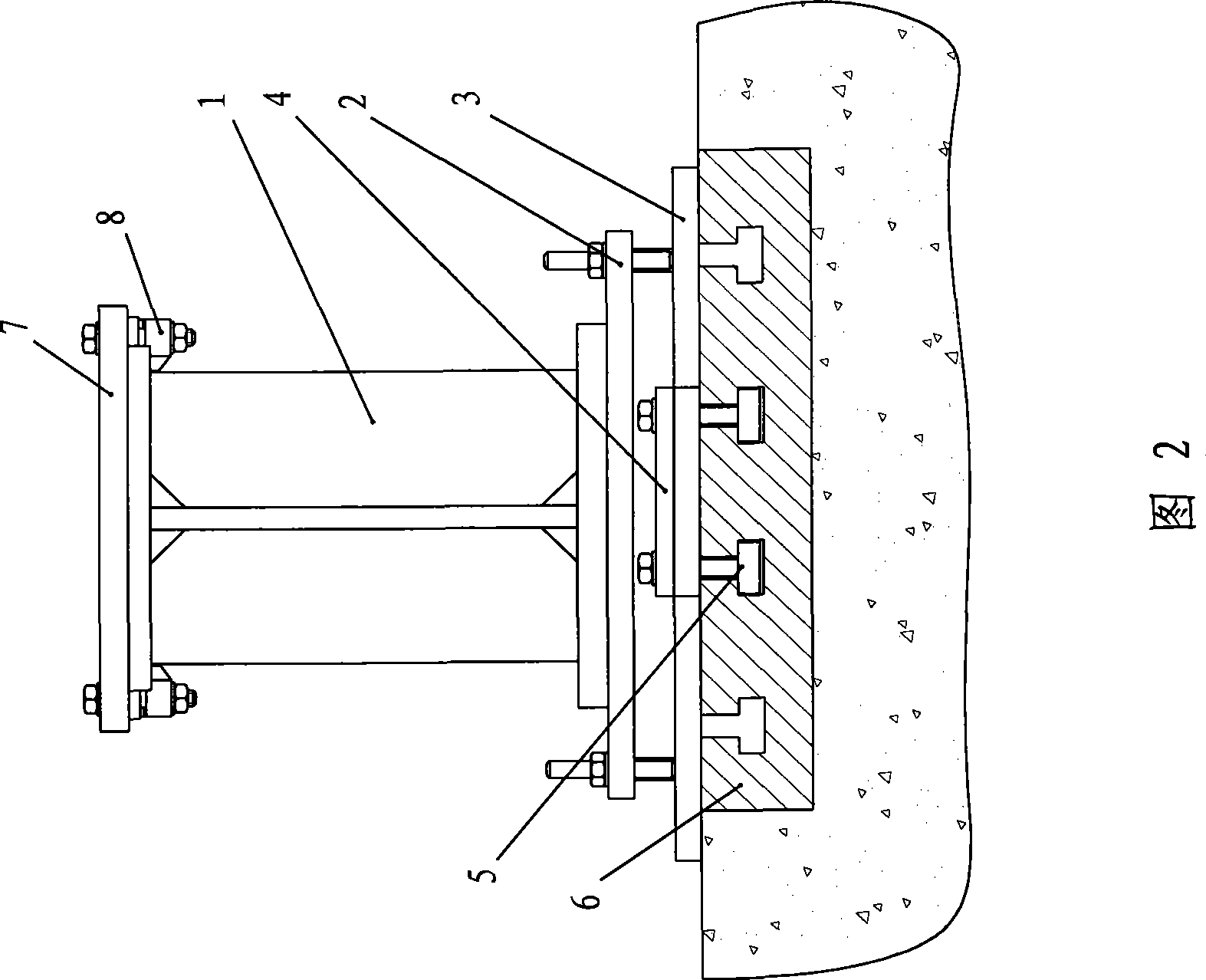

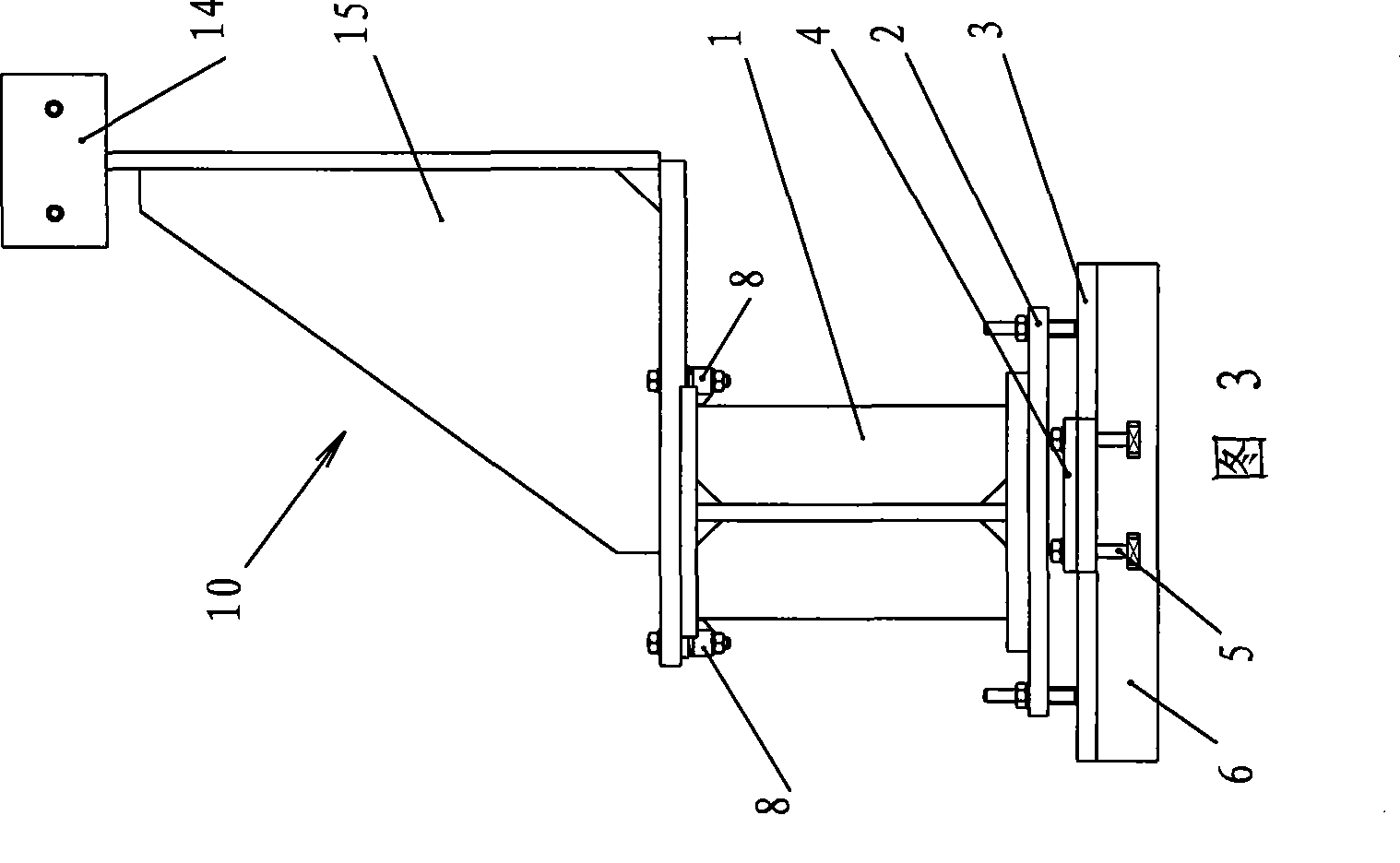

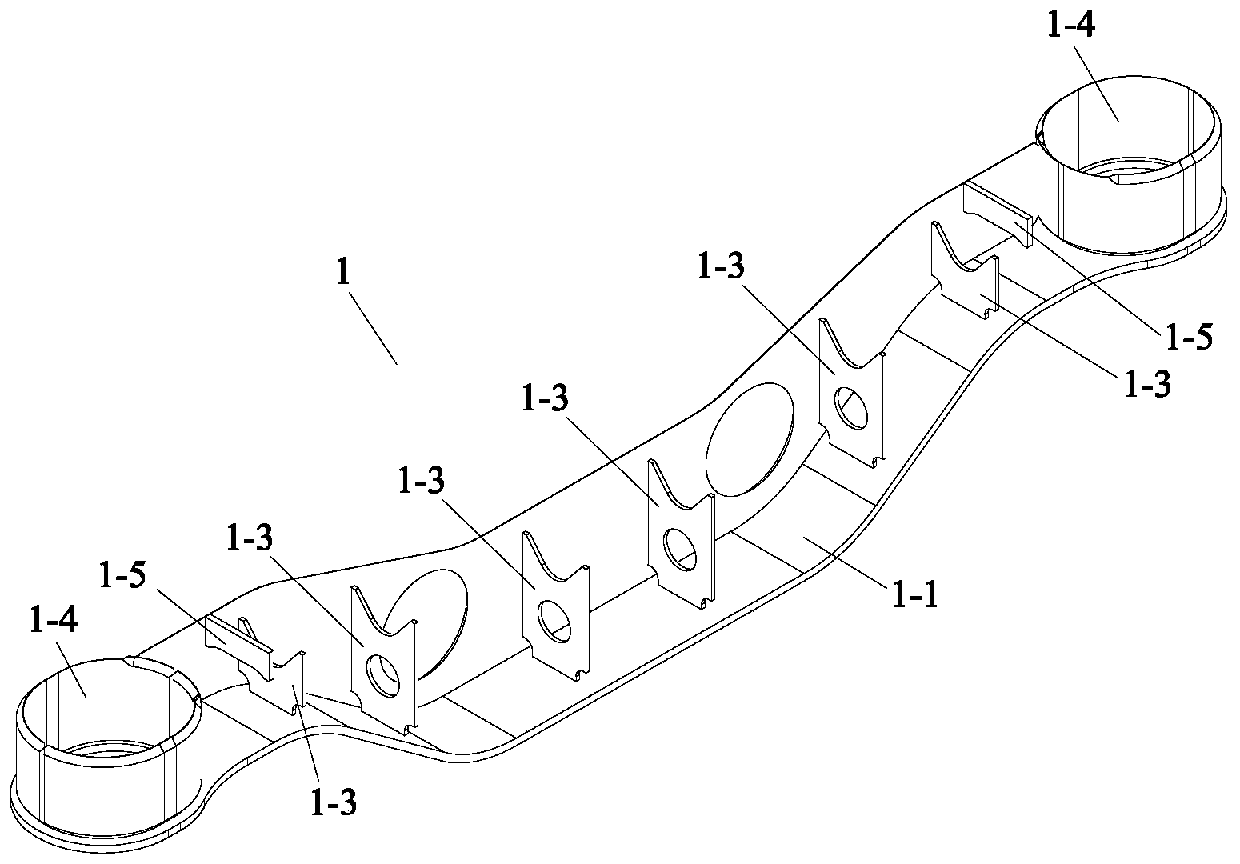

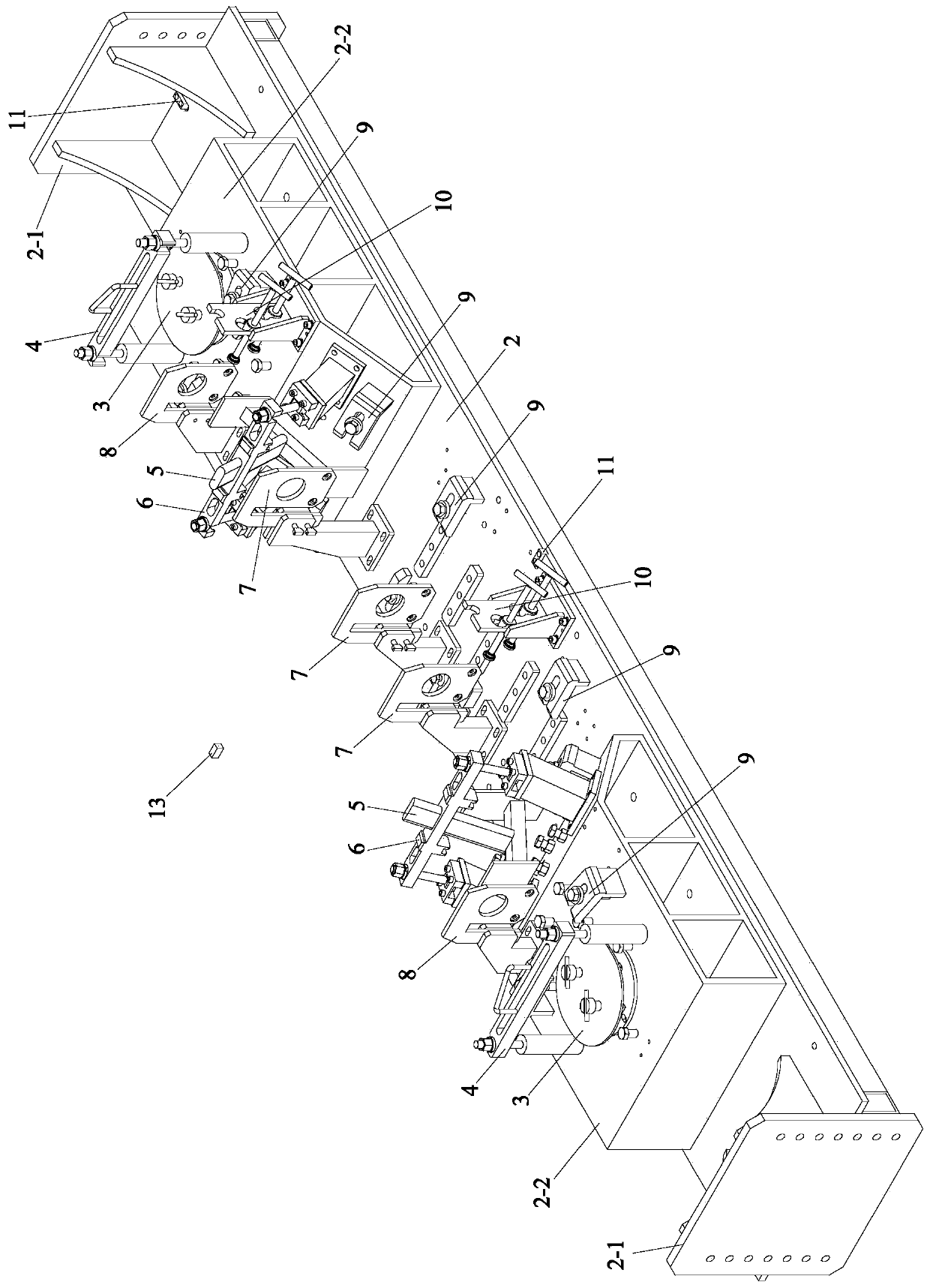

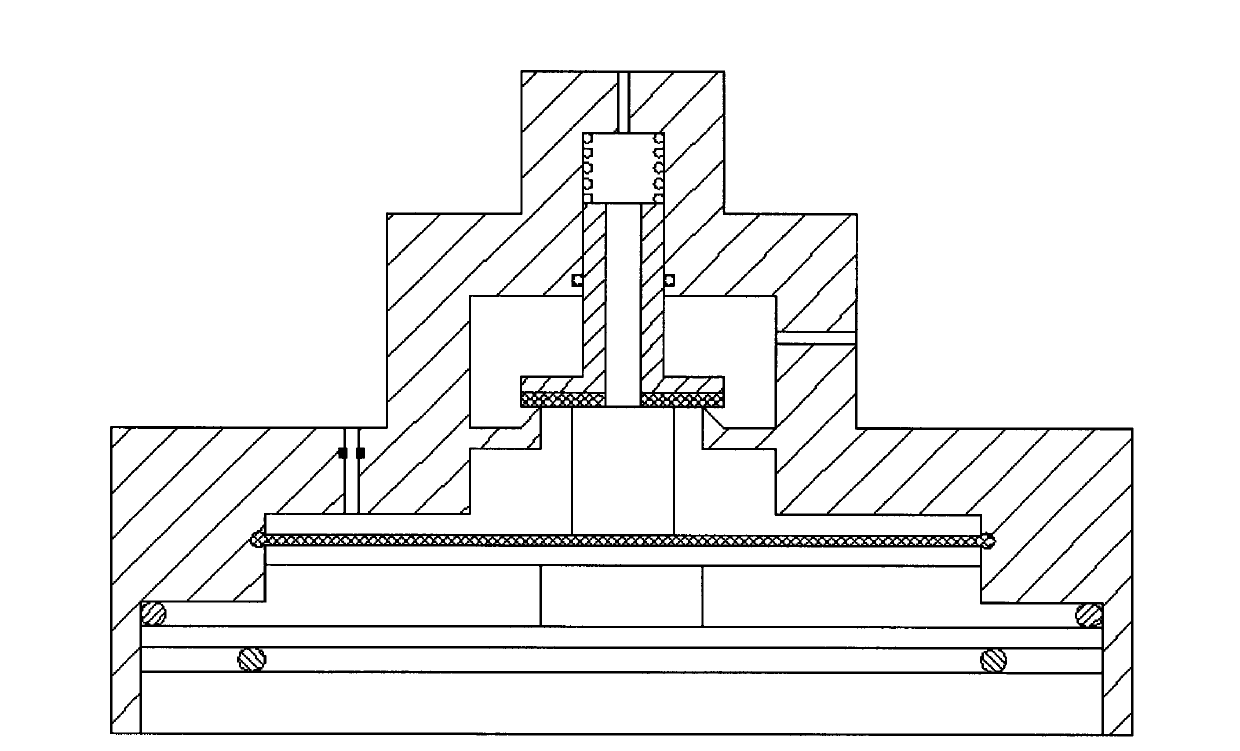

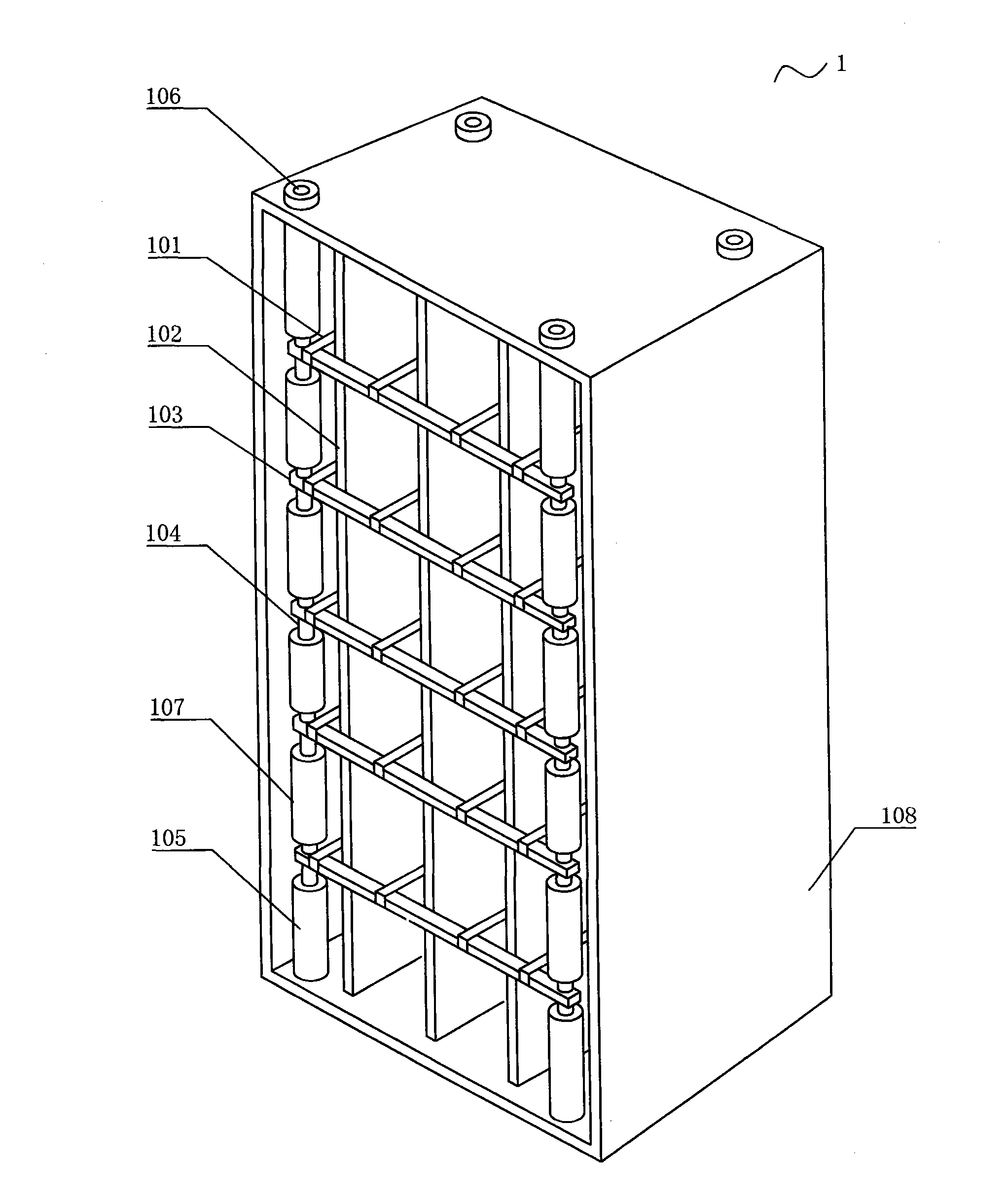

Passenger train framework side frame welding positioning tooling

ActiveCN110722319AReduce the difficulty of homeworkSimplify workloadWelding/cutting auxillary devicesAuxillary welding devicesPassenger trainManufacturing engineering

The invention provides a passenger train framework side frame welding positioning tooling, and belongs to the field of bogie welding of railway vehicles. The tooling includes a base, two cap tube centering mechanisms, two cap tube compacting mechanisms, two inclined plane stud positioning mechanisms, two vertical plate compacting mechanisms, three plane stud positioning mechanisms, two transversebar positioning mechanisms, a plurality of lower cover plate compacting mechanisms, two vertical plate lateral jacking mechanisms, four reference positioning blocks, a lower cover plate positioning block pressing pincer and a lower cover plate positioning block. According to the invention, the work load of the welding procedure of a side frame lower cover plate assembly is simplified, the operation difficulty in vertical plane calibration and deformation after welding is directly reduced, the overall working efficiency is improved; and the calibration mapping required for positioning adjustment is reduced, so that the labor intensity is reduced, the precision in assembly positioning is improved, and the production efficiency is improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Active powder concrete for railroad bridge cover plate

The invention discloses an active powder concrete for a railroad bridge cover plate, which is prepared by evenly mixing cement, silica powder, quartz sand, admixture, steel fiber, additive and water according to the weight ratio of 650-700:170-200:1,150-1,200:160-250:140-150:30-40:135-160, wherein the admixture is fly ash or slag, and the additive is a non-air-entraining type high-efficiency water reducing agent. The active powder concrete has the advantages of superior lasting quality, high-grade compression strength and rupture strength and simple preparation process, and a footway cover plate processed from the active powder concrete can completely satisfy the design requirement on special lines for passenger trains in China and has small workloads of later-period maintenance.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Railway vehicle outside-sleeper structure

The invention discloses a railway vehicle outside-sleeper structure. A center filler is fixed to a lower cover plate of a sleeper beam through a bolt, the back end of a traction beam and the sleeper beam are welded and fixed, a connector of a bogie is arranged between two webs of the sleeper beam, and the lower cover plate on the parts, on the two sides of the center filler, of the sleeper beam is provided with installing holes. The front section of the traction beam is provided with a vehicle hook installing base, a large beam is transversely arranged between the traction beam and side beams, the large beam is located near the vehicle hook installing base, a corrugated floor is laid between the large beam and the sleeper beam, a flat floor is laid between the large beam and an end beam, a panel is laid on the upper surface of the traction beam, and the front end of the traction beam is of a horn mouth structure. According to the outside-sleeper structure, a high load is achieved through a series of improvements and design, the maintaining frequency is low, manufacturing is easy, and the railway vehicle outside-sleeper structure can well adapt to the operation characteristics of meter-gauge rail intercity passenger trains due to the small curve radius.

Owner:CRRC NANJING PUZHEN CO LTD

Heat treatment method for materials of 25CrMo alloy steel hollow car axle for high-speed railway passenger trains

The invention belongs to the technical field of heat treatment, relating to a heat treatment method for materials of a 25CrMo alloy steel hollow car axle for high-speed railway passenger trains. The heat treatment method is characterized in that 900 to 930 DEG C pretreatment is carried out on 25CrMo steel of the size of an axle blank, quench treatment is carried out at 880 to 930 DEG C, and then tempering treatment is carried out at 630 to 680 DEG C. The invention has the advantages that the mechanical property of the developed 25CrMo alloy steel hollow car axle for the high-speed railway passenger trains meets the EN 13261 standard requirement, and especially the fatigue strength of a smooth sample and the fatigue strength of a notch sample are both higher than the standard values. The invention provides the technical assurance of the heat treatment technique for the final production of the hollow car axle with the high speed of 200 to 350 km / h.

Owner:TSINGHUA UNIV +2

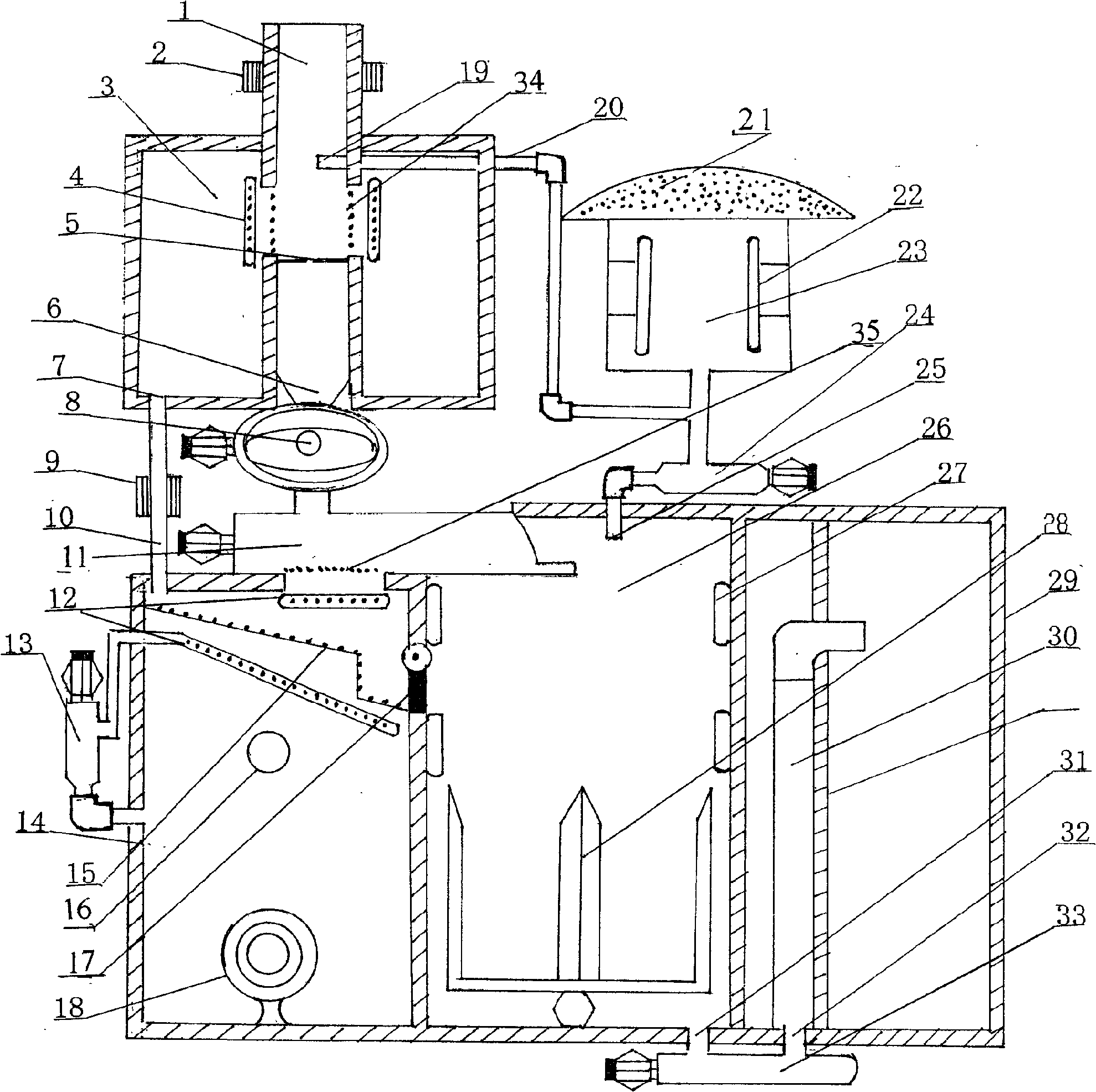

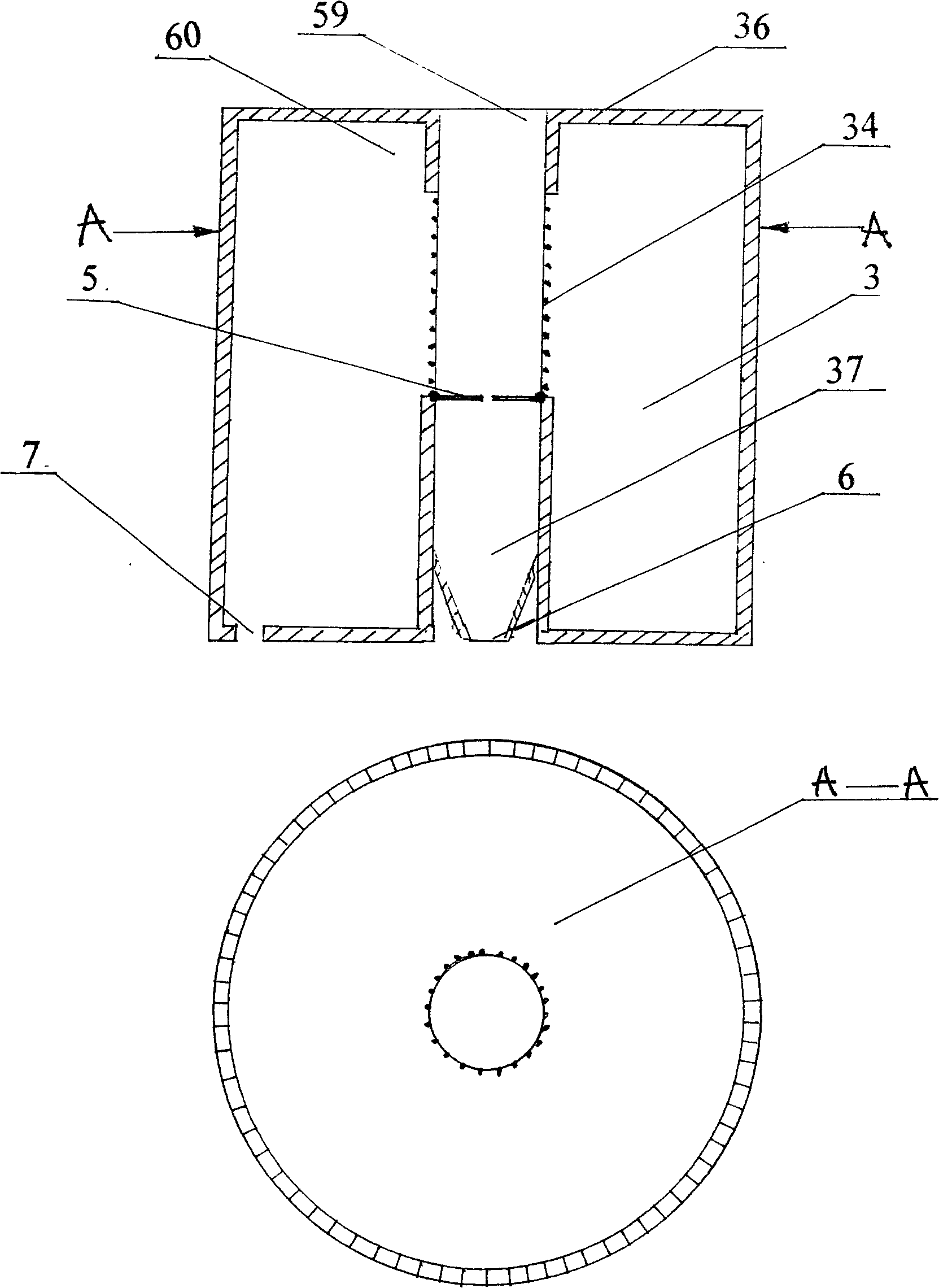

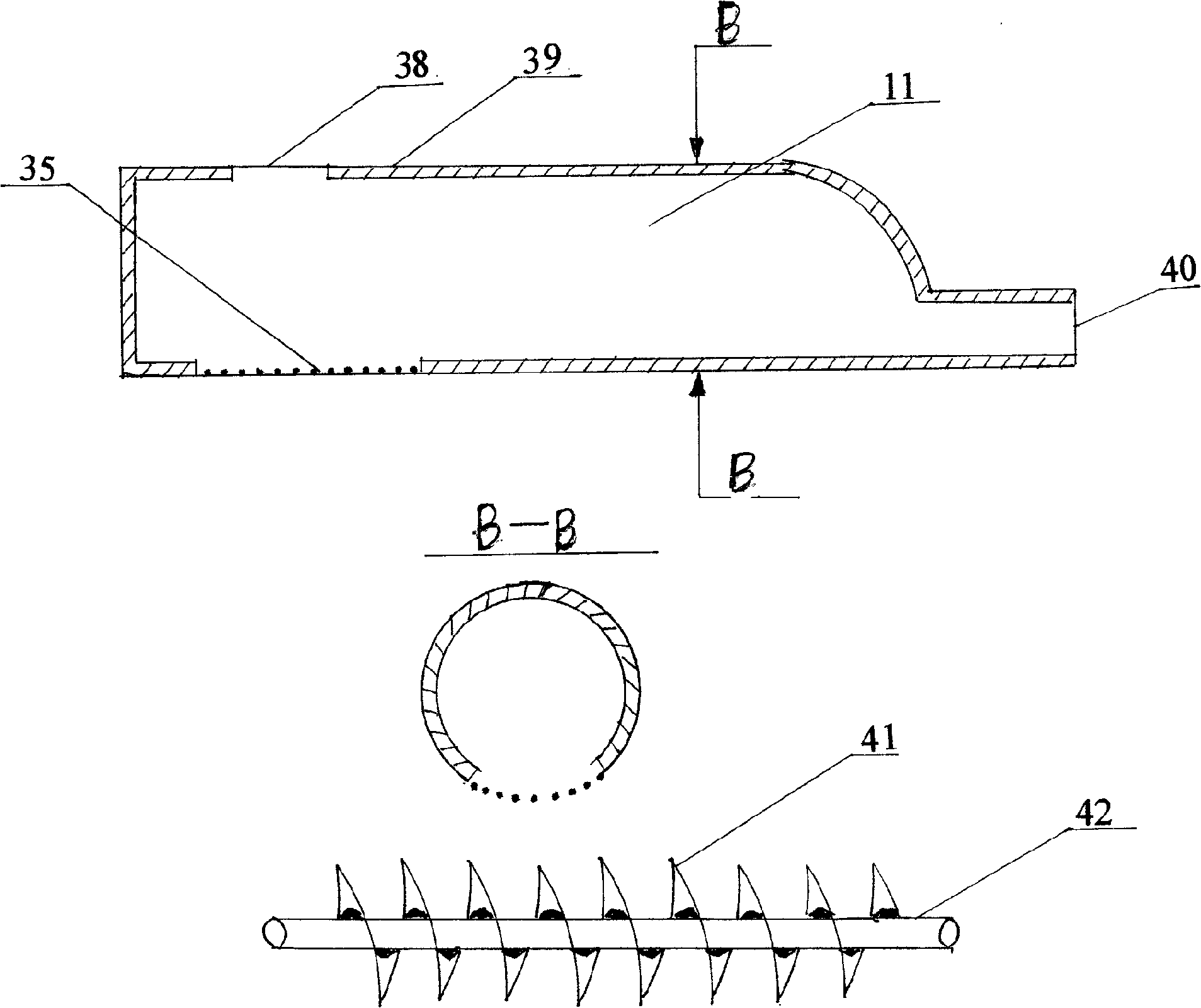

Environmental sanitation treating apparatus for fast decomposing, sterilizing and drying solid-liquid feculence dejection

InactiveCN101265004AKill eggs quicklyImprove sterilizationMaintainance for emmission reductionSludge treatmentHuman bodyDecomposition

The invention relates to a device for rapid decomposition, sterilization, drying and sanitary treatment of solid / liquid feces, aiming to solve the problems of human feces including environmental pollution, disease transmission and body health damage. The device comprises a solid-liquid separator, a semi-solid finishing machine, a secondary solid-liquid separation spiral pump, a urine treatment tank, a microwave sterilization drying chamber, a dry matter storage tank, and a deodorizing aeration tower. The feces can be rapidly sterilized, deodorized and dried after leaving human body, so as to become sterile and odorless dried particles in a short time, which can be used as fertilizer. The inventive device prevents transmission of pathogenic bacteria from source and solves fecal pollution problem. The inventive device has the advantages of low volume, light weight, and low energy consumption; and can be used in any places. Except fixed places, the device is more suitable for being installed and used in personal vehicles such as passenger train, passenger long-distance bus and passenger ship.

Owner:齐梓凡

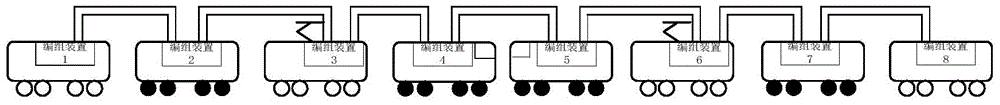

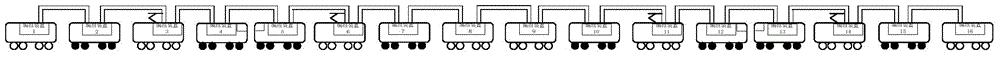

Intelligent train addressing and address finding method and dynamic cross-group reconnection networking method

The invention relates to the technical field of train address finding and train reconnection, in particular to an intelligent train addressing and address finding method and a dynamic cross-group reconnection networking method. The numbers of compartments and the direction of the train are recognized according to present current signals collected by grouping devices, when the train is electrified in the direction or the compartments are increased or reduced, reconfiguration is conducted on the network of the train, the address information of all the devices on the train is re-determined, the network attributes of the network nodes where the grouping devices are located are modified, the intelligent train addressing and address finding function and the dynamic cross-group reconnection networking function are achieved, and the demand for dynamic reconnection of a train network of a high-speed train, a locomotive, a passenger train and a city rail train is met.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

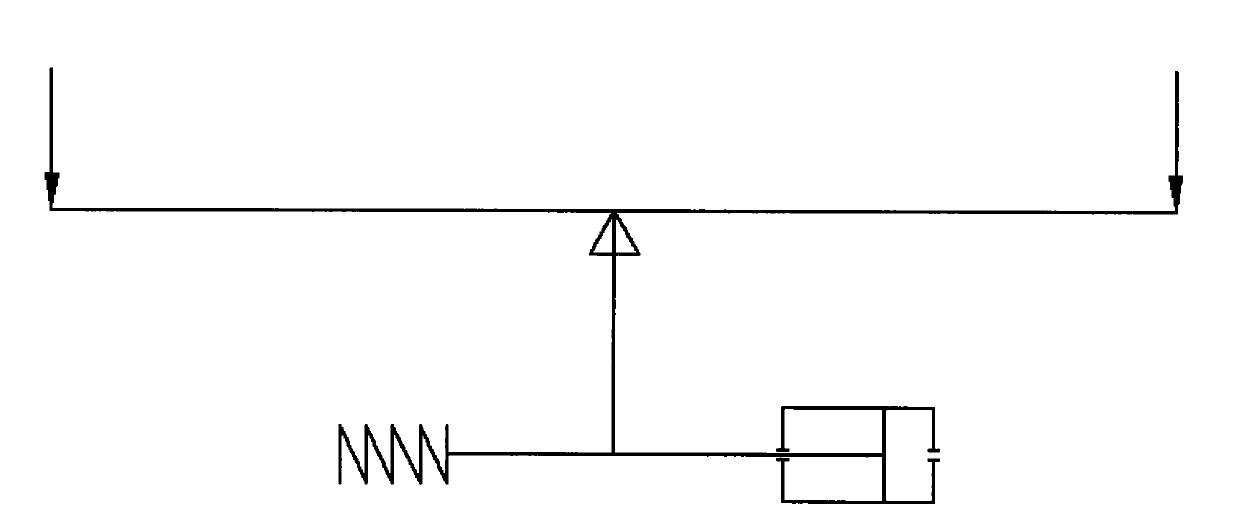

Method and device for braking quick railway freight car

InactiveCN102167021AImprove reliabilityImprove linearityAerodynamic brakesFluid braking transmissionTruckPassenger train

The invention relates to a method and system for braking a railway vehicle, which have the advantages of higher brake force, shorter idling braking time and brake cylinder boosting and relieving time and capabilities of shortening the braking distance, arranging passenger trains and adjusting the brake force according to the change of the weight of the vehicle. A high-friction-coefficient composition brake shoe with a higher friction coefficient is adopted, and the pressures of the brake cylinder and the brake shoe are controlled on the basis of measurement of the vehicle load by using a sensing valve, so that stepless control of the brake force of a quick freight car is realized; and the idling braking time and the brake cylinder relieving time are shortened by changing the inflation anddeflation time of the brake cylinder. The invention provides a method and system for braking a quick railway freight car. By adopting the method and system, the stepless change of the brake force canbe realized with the load increase and decrease change of the vehicle at the same time of improving the brake force and shortening the idling breaking time, therefore the safety traveling braking distance is ensured; meanwhile, the device has the advantages of high reliability, high vibration insulation, high dynamic performance, higher linearity and high sensitivity.

Owner:LOCOMOTIVE & CAR RES INST OF CHINA ACAD OF RAILWAY SCI

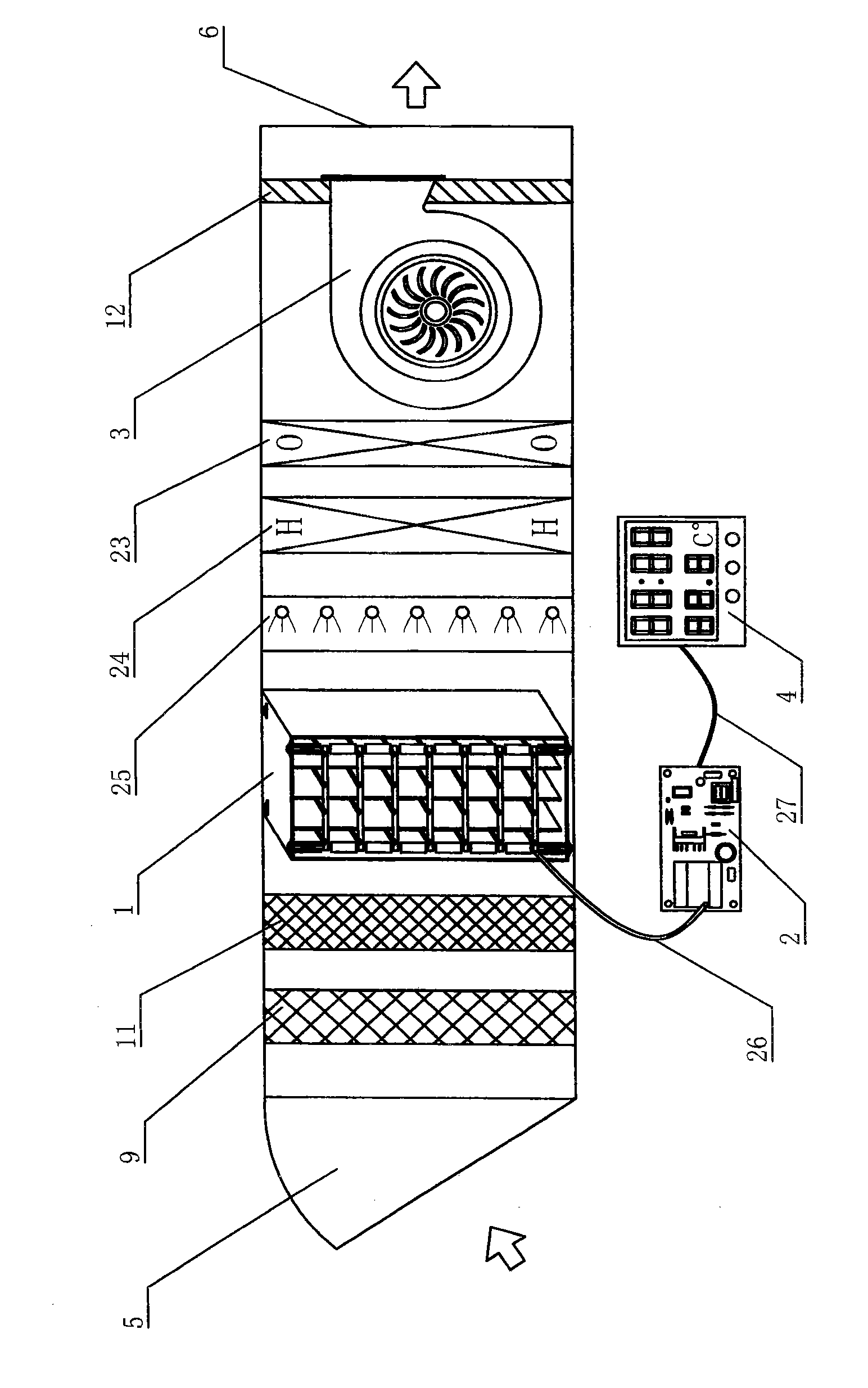

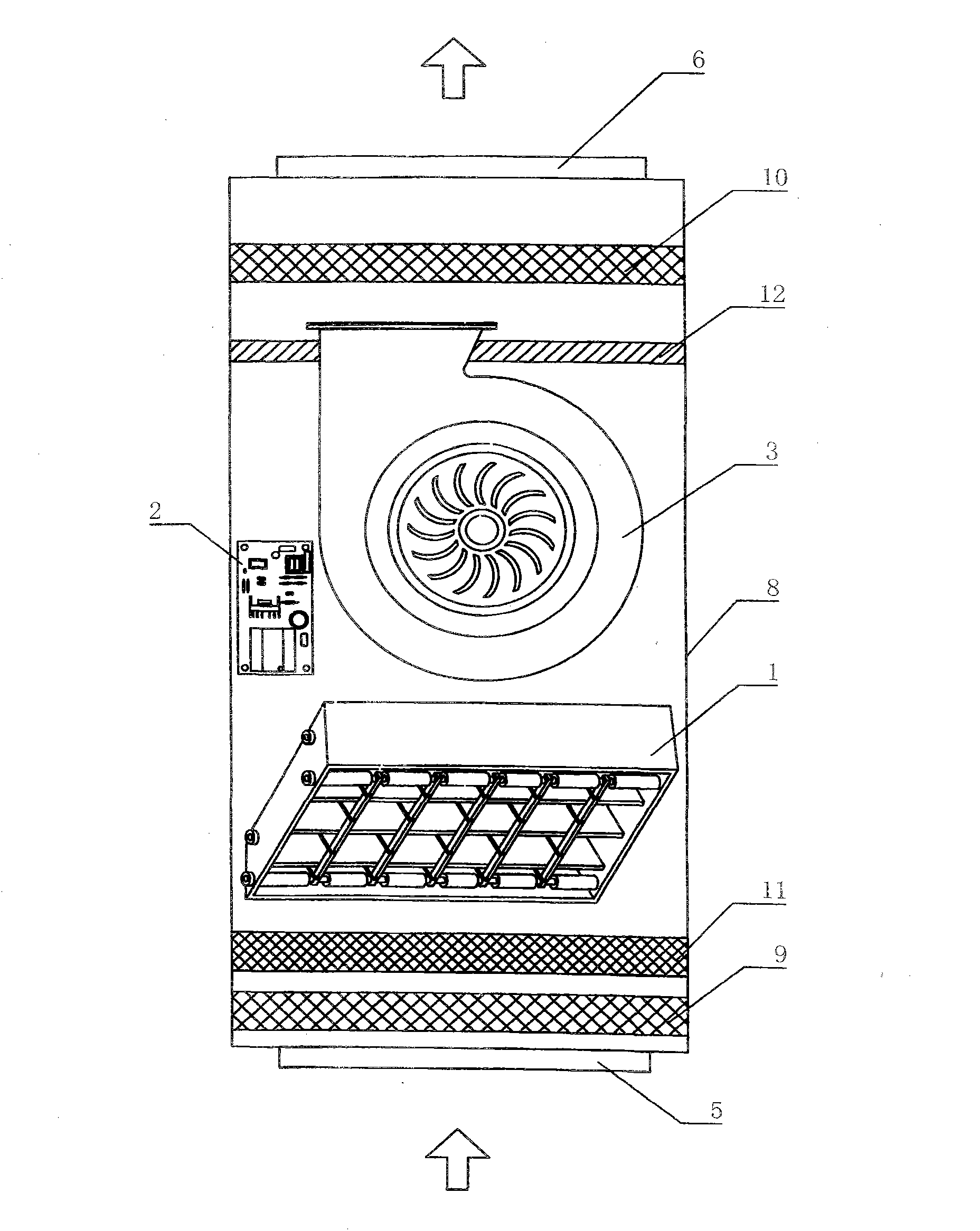

Plasma air sterilizing and purifying device for air-conditioned train

ActiveCN101920033AWill not affect normal workExtended service lifeAir-treating devicesDeodrantsSurface oxidationWorking life

The invention relates to a plasma air sterilizing and purifying device for an air-conditioned train, which comprises a plasma reactor, a pulse power source, a fan component, an air inlet, an air outlet and a shell and is characterized in that a positive electrode which is formed by arranging a plurality of nickel-chromium metal wires or nickel-chromium metal bands in the same plane at equal intervals in parallel is arranged in the plasma reactor; the positive electrode is arranged in the middle position of two adjacent negative electrodes; the two ends of the positive electrode are fixed in a groove or a convex part corresponding to a conductor rail for preventing micro-discharge; each negative electrode is made of an aluminum plate the surface of which is oxidized, and nano-TiO2 is respectively laid on the two surfaces of each negative electrode; and a pulse transformer and a pulse generator are arranged in the pulse power source and are arranged according to a single-ended flyback inverter. The device of the invention is arranged at the return air inlet or the air outlet of an air conditioner in a carriage, and the existing facilities of the air-conditioned train do not need to be changed. The device of the invention is the optimal combination of plasma and TiO2, has high dynamic sterilization and purification efficiency of a passenger train, and has the advantages of energy saving, good reliability, long working life, simple structure and convenient installation.

Owner:ZHEJIANG TIANQING ENVIRONMENTAL PROTECTION TECH CO LTD

System for ultrahigh speed railway train running in vacuum tunnel (pipeline)

InactiveCN101152866ASolve various problems that occur while drivingClear principleRailway tunnelsRailway transportUltra high speedLife quality

The present invention provides a railway train system in which passenger and cargo trains are arranged in a container train with a powerful driving force to run at a super-high speed; the container train runs in a vacuum or low vacuum or several branches (part) tunnel (pipe). A whole series of passenger trains or cargo trains are arranged in the container train. Passenger trains or cargo trains can enter or exit the container train automatically (with driving force) in stations; passengers can also enter each train carriage of the passenger train through an air outlet hermetic channel in a train platform. All along the train route emergency life-saving air pipelines, a plurality of hermetic doors and safety facilities are provided; hermetic doors and exhausting bags etc. are provided in and out of the train station. So that the vacuum environment and the in and out of passengers and cargo in the normal pressure environment are effectively and easily realized. The pressure in the carriage is normal pressure environment; a plurality of protective conditions are provided, (including two train shells (the container train shell, the passenger train shell), a middle layer and the related safety equipment and rescue channel). The system of the present invention is the first practical realization of long-distance transcontinental railway train passenger and cargo transporting with super-high speed in a vacuum condition. The present invention provides a significant meaning for saving traveling time, improving life quality and accelerating the passenger and cargo transporting.

Owner:杨福顺

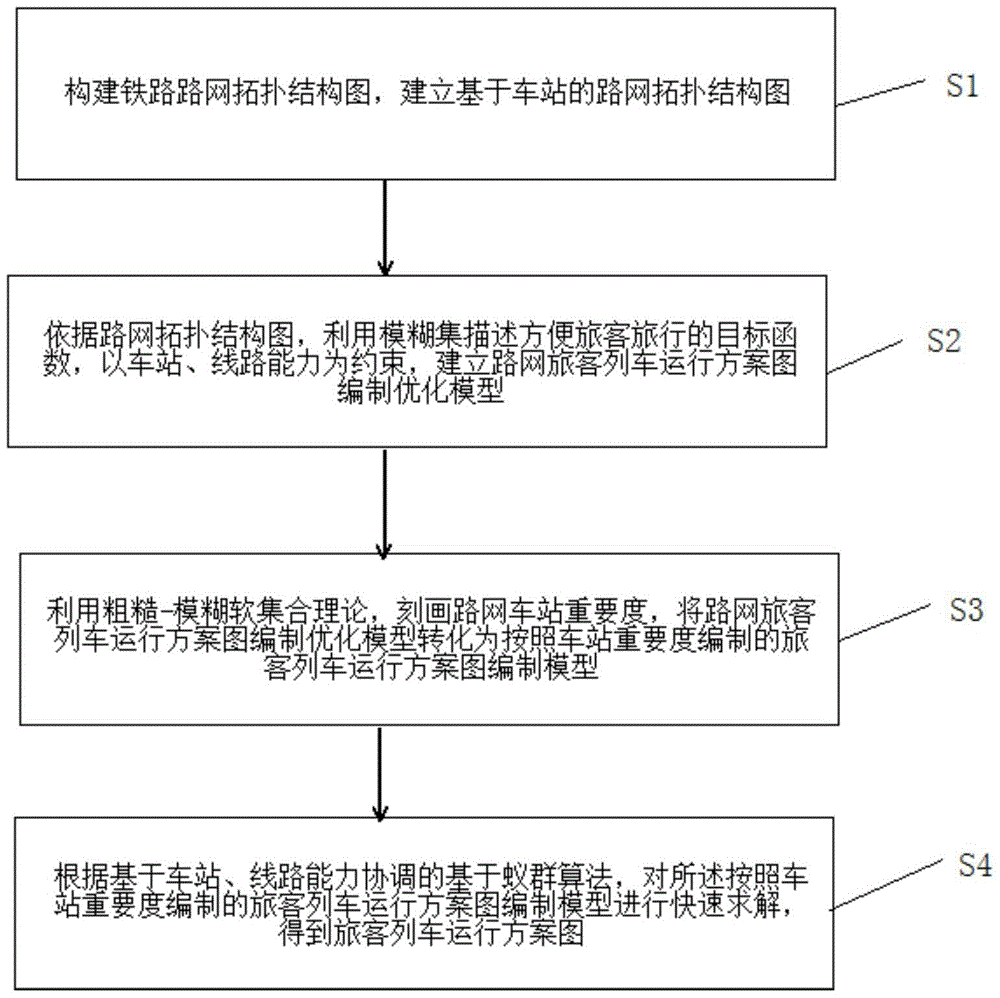

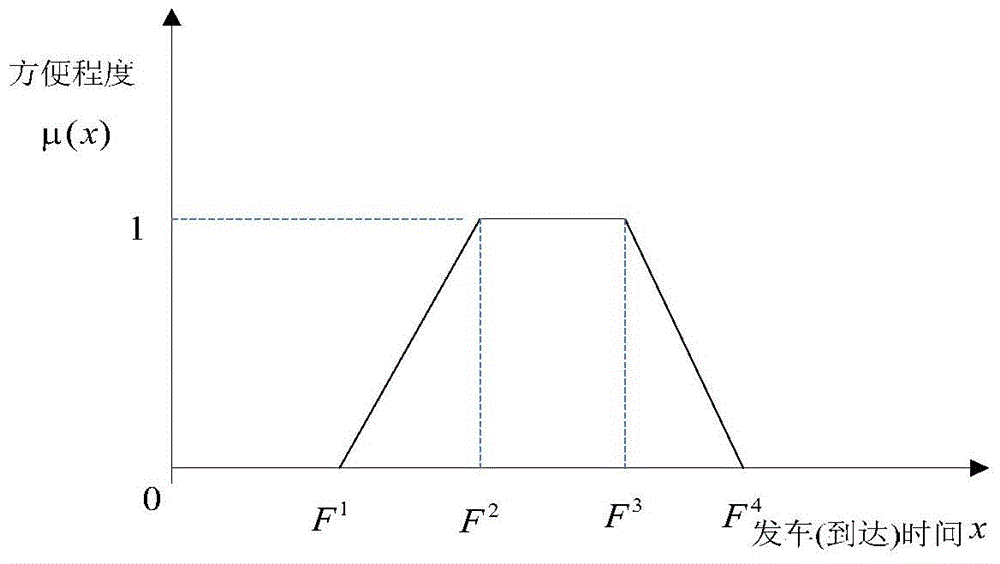

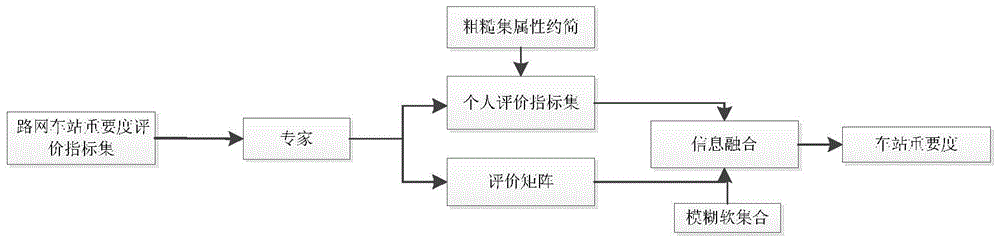

Passenger train operation scheme diagram drawing method

ActiveCN105678411AHigh implementabilityImprove computing efficiencyForecastingArtificial lifeRoad networksSimulation

A passenger train operation scheme diagram drawing method disclosed by the present invention comprises the steps of constructing a railway road network topological structure diagram, establishing a road network topological structure diagram based on stations; according to the road network topological structure diagram, utilizing a fuzzy set to describe a target function convenient for passengers to travel, and establishing a road network passenger train operation scheme diagram drawing and optimization model by taking the station and path capability as the constraint; utilizing a rough-fuzzy soft set theory to describe the important degrees of the road network stations, and transforming the road network passenger train operation scheme diagram drawing and optimization model into a passenger train operation scheme diagram drawing model which is drawn according to the important degrees of the stations; according to an ant colony algorithm based on the station and path capability cooperation, solving the passenger train operation scheme diagram drawing model which is drawn according to the important degrees of the stations rapidly to obtain a passenger train operation scheme diagram. By the technical scheme of the present invention, the implementation possibility of the passenger train operation scheme diagram is conducive to being improved.

Owner:SOUTHWEST JIAOTONG UNIV

Sizing formula of flame-retarding elastic support rubber product

The invention discloses a sizing formula of a flame-retarding elastic support rubber product. The sizing formula is characterized in that components of the rubber product are as follows (parts by mass of each component are shown in brackets): 21-type-322 neoprene (25-35), standard 1# natural rubber (65-75), zinc oxide (7-9), light magnesium oxide (4-6), sulfur (0.1-1.0), an accelerant CZ (1.3-1.7), an accelerant Na-22 (0.4-0.6), an ageing inhibitor 4,010 (0.8-1.2), 2,500-mesh diantimony trioxide (15-25), 2,500-mesh aluminium hydroxide (50-60) and semi-reinforcing carbon black (10-20). In the invention, unvulcanized rubber is a combination of the neoprene and the natural rubber, a vulcanizing system is a combination of metal oxide and the sulfur, a flame retardant is a combination of the diantimony trioxide and aluminium hydroxide, and the semi-reinforcing carbon black is used for reinforcing; therefore, the prepared rubber product has good physicochemical properties, especially has high oxygen index and low smoke index. The invention is applicable to preparing the elastic support rubber product used between a floor board and a floor board framework when floor boards are laid in a public place and on a passenger train, a subway as well as a bus.

Owner:铁岭华晨橡塑制品有限公司

Railcar vehicle for passenger transport

This railcar is of the type comprising: carriages including two driving carriages and intermediate carriages; carrier bogies, motor bogies comprising at least one motor axle; traction drives which are capable of supplying electrical energy to the motors of the motor bogies. According to one feature of the invention, all the carriages have passenger compartments, the railcar is completely articulated, the traction drives are arranged in three carriages and a motor bogie is arranged below at least one end of each carriage which receives a traction drive.

Owner:ALSTOM TRANSPORT TECH SAS

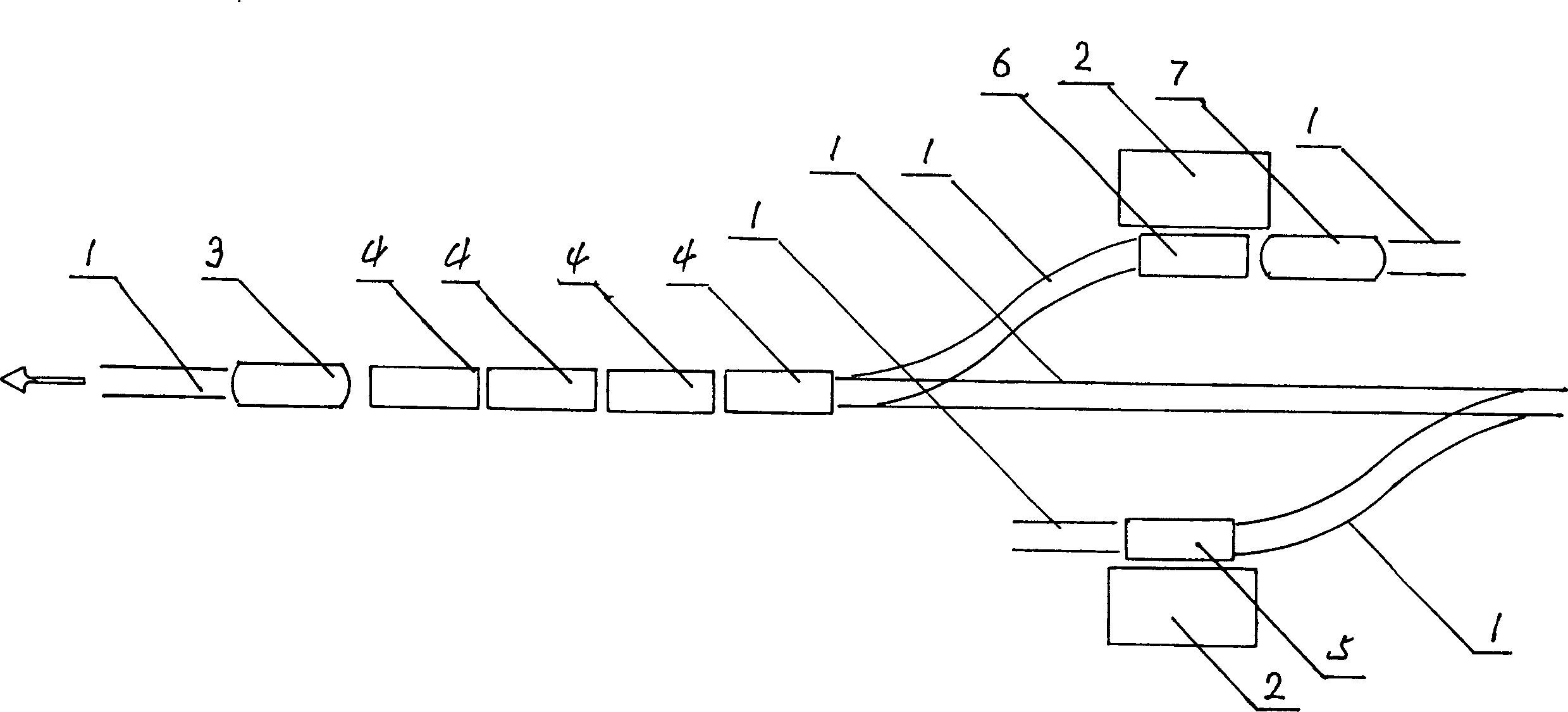

No-stop vehicle transfer method for passenger train

InactiveCN1781791AMake up for empty drivingMake up for the shortage of passengers waiting for buses along the wayRailway componentsRailway stationStop timePassenger train

The no-stop vehicle transfer method for passenger train includes arranging the passengers to be going to get off in some station in the tail carriage, or pulling-in carriage, in advance, separating the pulling-in carriage while the train body goes forwards, arranging boarding passengers in the outgoing carriage in advance, pushing the outgoing carriage with one assisting locomotive to connect with the train body, and transferring the boarding passengers to the main carriages. The present invention has separated pulling-in carriage and outgoing carriage, makes the getting on and getting off convenient, and results in saving in stop time and raised train transportation efficiency.

Owner:赵云祥

Halogen-free flame-retardant unsaturated polyester resin and preparation method of the halogen-free flame-retardant unsaturated polyester resin

InactiveCN102181016AReduce manufacturing costImprove flame retardant performancePolymer chemistryUnsaturated polyester

The invention relates to the technical field of preparation of high molecular materials, particularly relates to halogen-free flame-retardant unsaturated polyester resin and a preparation method of the halogen-free flame-retardant unsaturated polyester resin. The halogen-free flame-retardant unsaturated polyester resin is prepared by the following steps: by esterification and polycondensation of organic polyatomic alcohol, saturated or unsaturated polybasic acid or acid anhydride, and reactive flame retardant, a polymer is formed; and the polymer is dissolved in styrene containing polymerization inhibitor and then mixed with additive flame retardant. The advantages are as follows: (1) the halogen-free flame-retardant unsaturated polyester resin consists of materials with low price and the preparation cost is low; (2) combing the comprehensive effects of the reactive flame retardant and the additive flame retardant, the polyester resin is superior to similar products in flame retarding effect in the market; and (3) the product does not contain halogen and is low in smoke and toxicity, and excellent in constructability and settlement resistance. The halogen-free flame-retardant unsaturated polyester resin and the composite of the resin can be broadly applied to such products with high requirement for flame-retardant property as building materials, automobile parts and the like and especially applicable to such glass fiber reinforced plastic products with low-smoke and flame-retardant requirements as hand layup passenger trains.

Owner:CHANGZHOU HUAKE POLYMERS

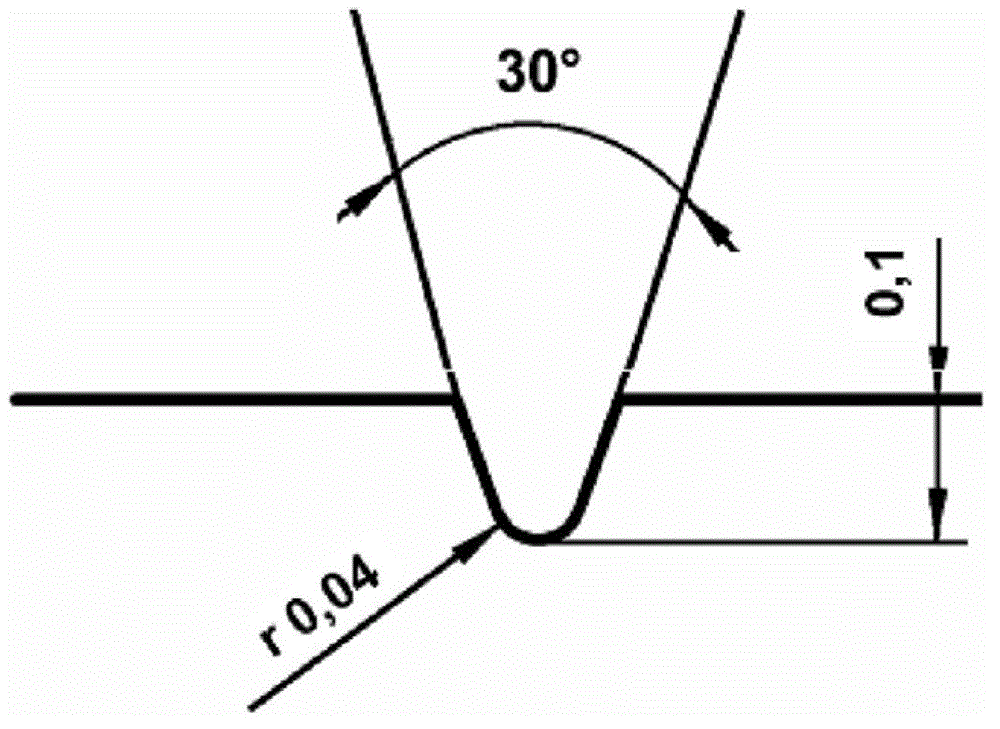

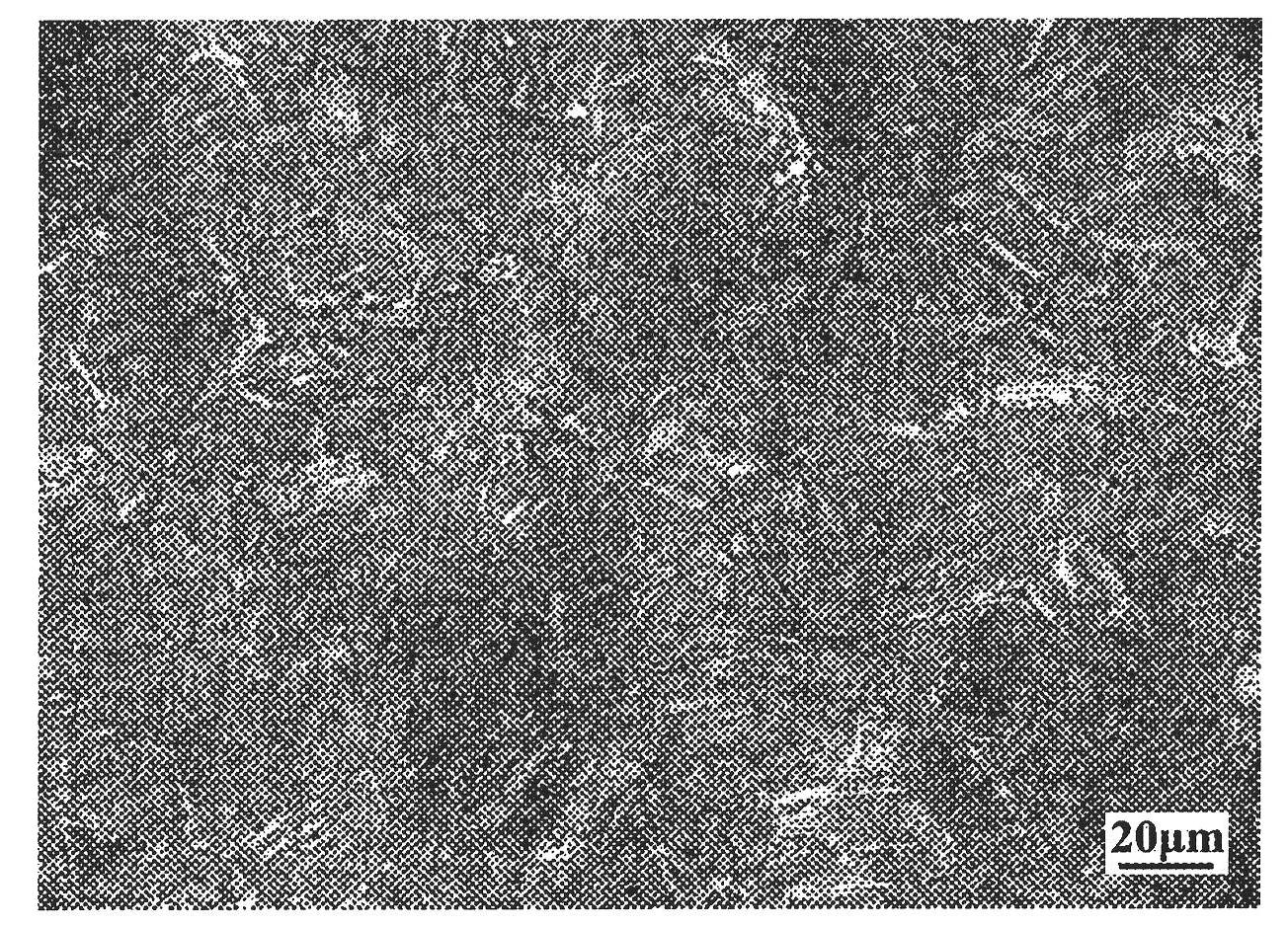

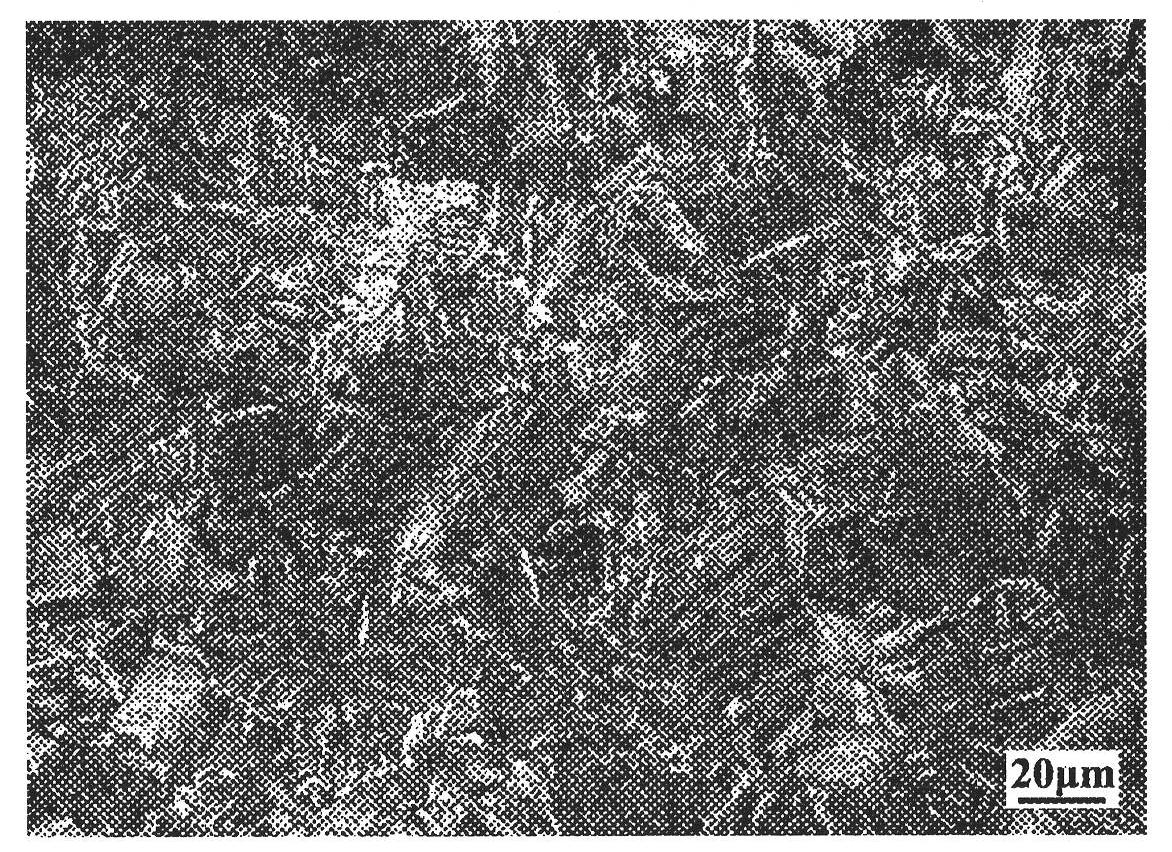

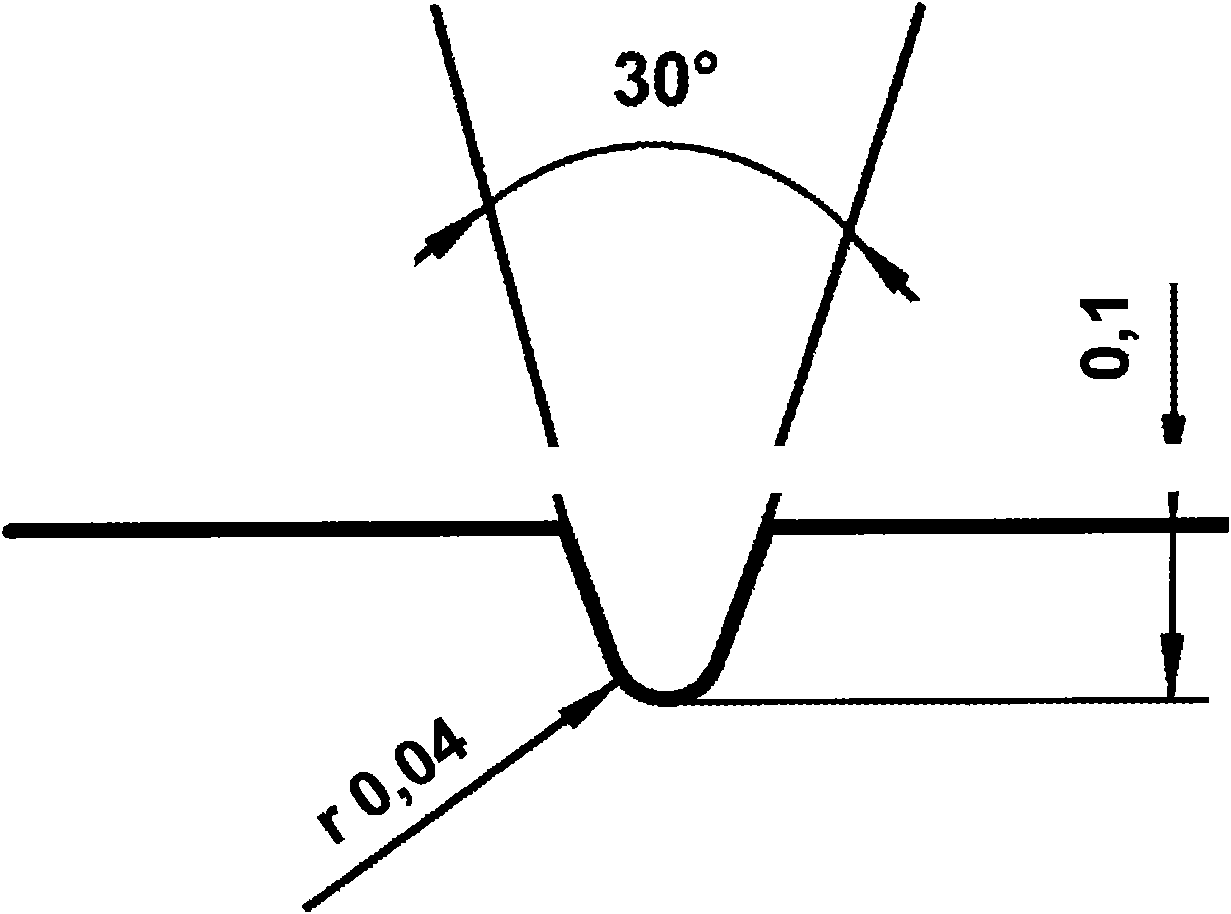

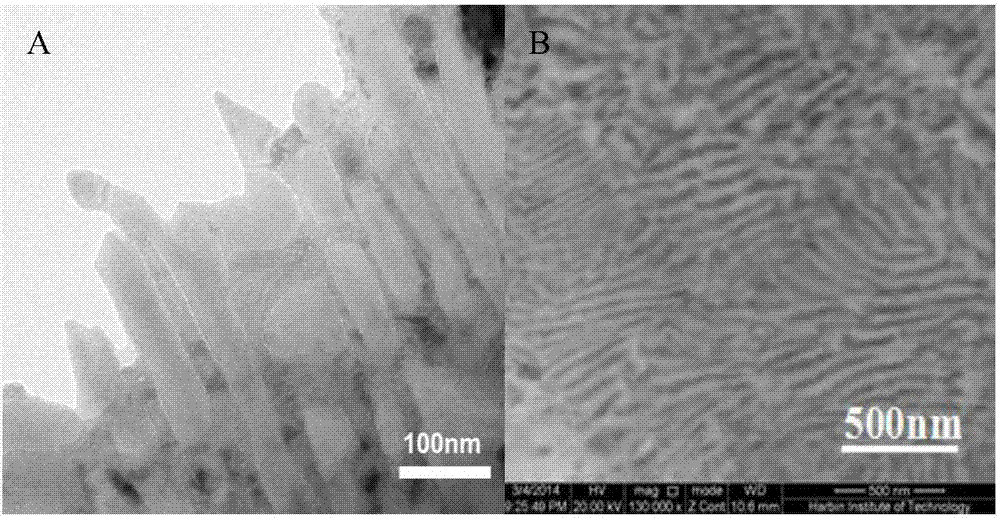

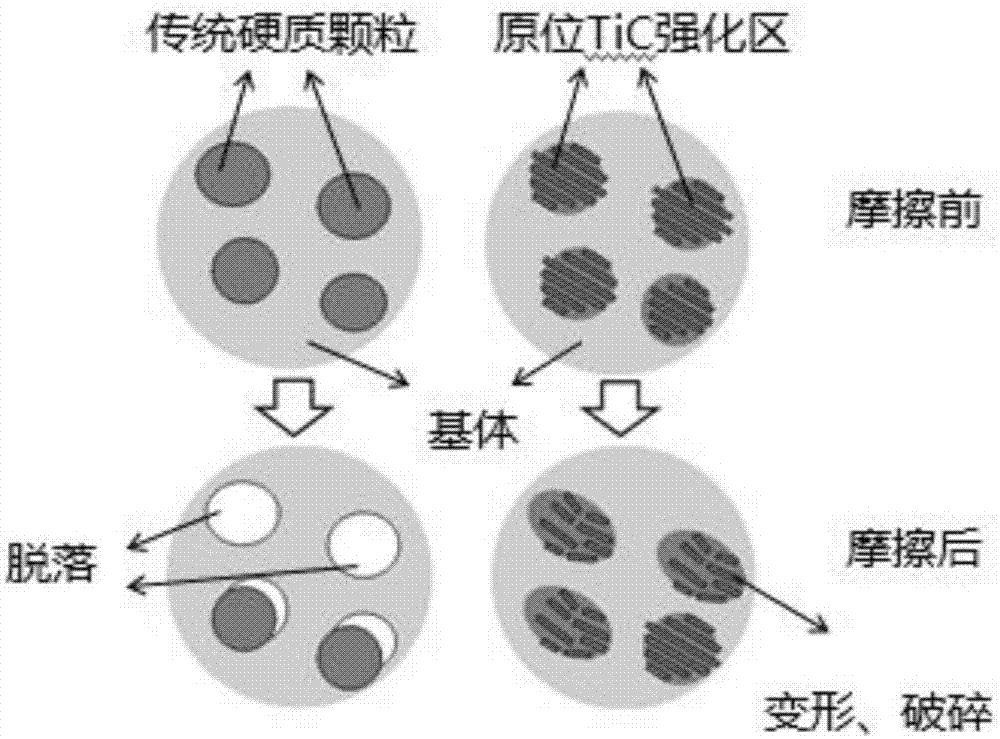

Brake pad material for high-speed railway passenger train and preparing method thereof

ActiveCN107460362ASolve the hardnessPoor ability to solve deformationTransportation and packagingMetal-working apparatusAdhesiveManganese

The invention discloses a brake pad material for a high-speed railway passenger train and a preparing method thereof and belongs to the technical field of powder metallurgy friction materials. The brake pad material is prepared by the following steps: after drying and sieving powdery raw materials, feeding the raw materials into a mixer, and spraying an adhesive; after mixing the materials, placing the materials in a steel mould, and carrying out pressing; and then, carrying out sintering at a reduction atmosphere, and then, carrying out heat treatment in a reduction atmosphere, wherein the powdery raw materials comprise copper powder, iron powder, Ti2AlC powder, chromium powder, nickel powder, manganese powder, silicon dioxide, graphite, boron nitride and molybdenum disulfate. The invention further provides the preparing method of the brake pad material. In the invention, in-situ TiC obtained through the Ti2AlC is used as a main friction component, the material of an in-situ nanometer TiC layered framework is prepared, the copper is accordingly used as a matrix, a small quantity of other metals is added, the content of lubricating components, such as the graphite, is regulated, and a novel material with a great brake effect and a low wear rate is finally obtained. The material is suitable for being used as the brake pad material for the high-speed railway passenger train.

Owner:哈尔滨新干线轨道交通科技有限公司

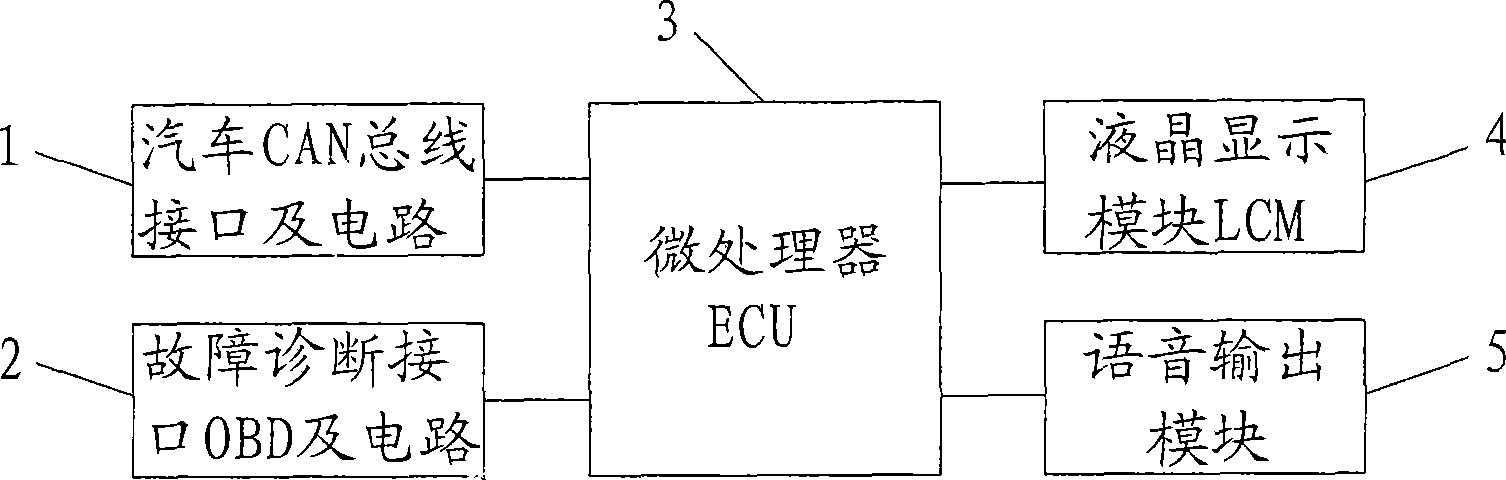

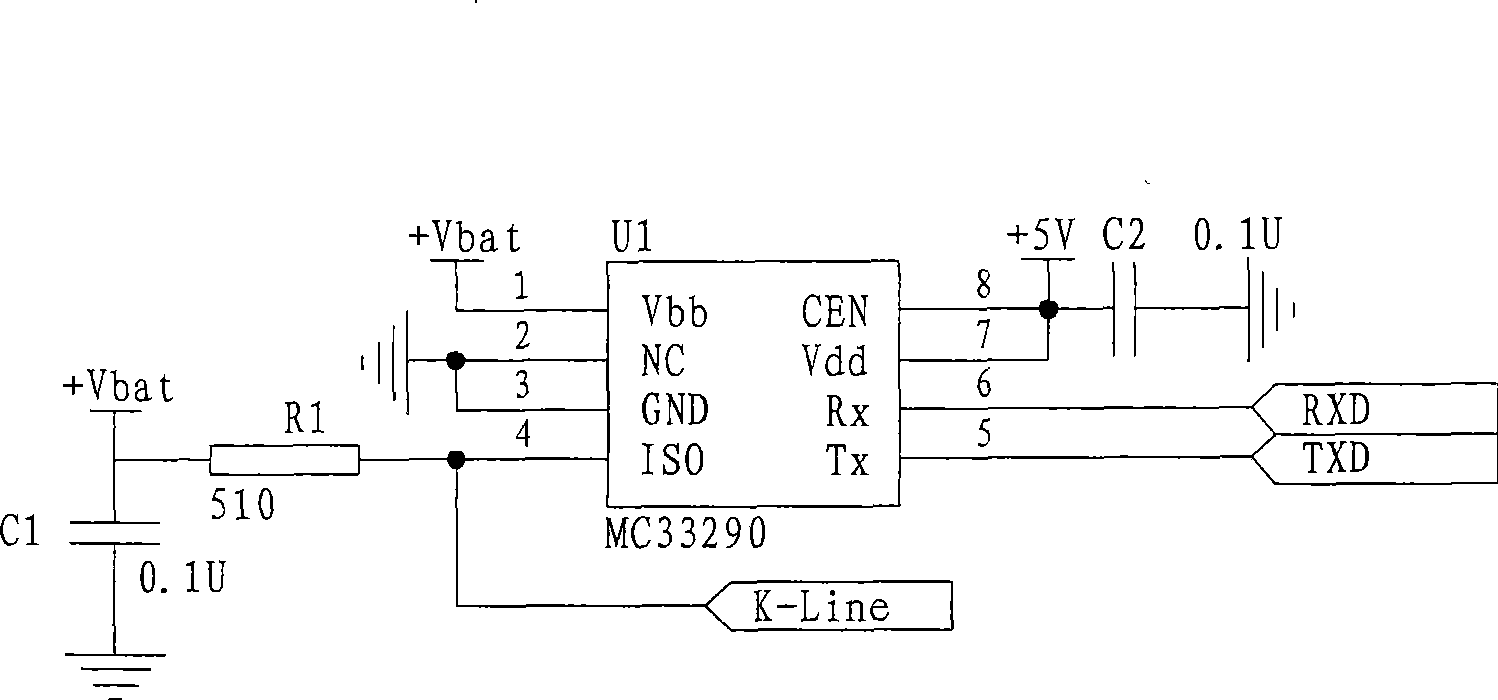

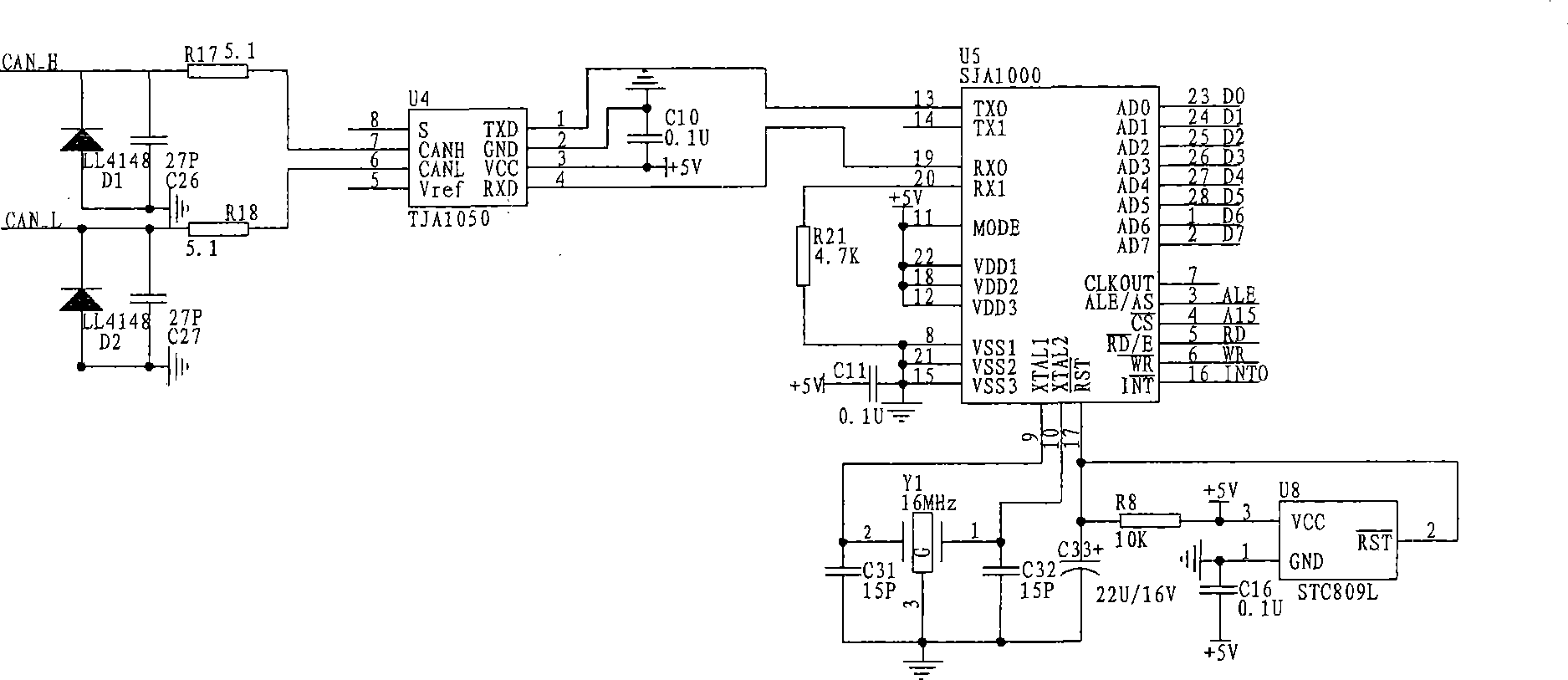

Bus line type passenger car fault alarm apparatus and method

InactiveCN101428595AImplement fault diagnosisEnsure driving safetyAcoustic signal devicesElectric/fluid circuitData streamDriver/operator

The invention discloses a bus type passenger train fault alarming device and the method thereof, and relates to a device mounted on passenger train and the method thereof capable of obtaining fault codes and data flow information of a passenger train electric control system for fault alarming through a fault diagnosis interface OBD and a passenger train CAN bus interface. Microprocessor ECU is connected to a passenger train CAN bus interface under a standard of J1939 protocol to obtain the data flow of the bus and the relevant fault information for fault diagnosis, and obtains the fault codes of a passenger train electric control unit through the fault diagnosis interface OBD. The obtained information can be displayed on a liquid crystal display module LCM, and important prompting messages can be output by a speech output module for effectively reminding a driver. The device alarms in mode of speech or LCM displaying when the faults are shown by the electric control system of the passenger train for reminding the driver, so as to improve the driving safety of the passenger car.

Owner:XIAMEN KING LONG UNITED AUTOMOTIVE IND CO LTD

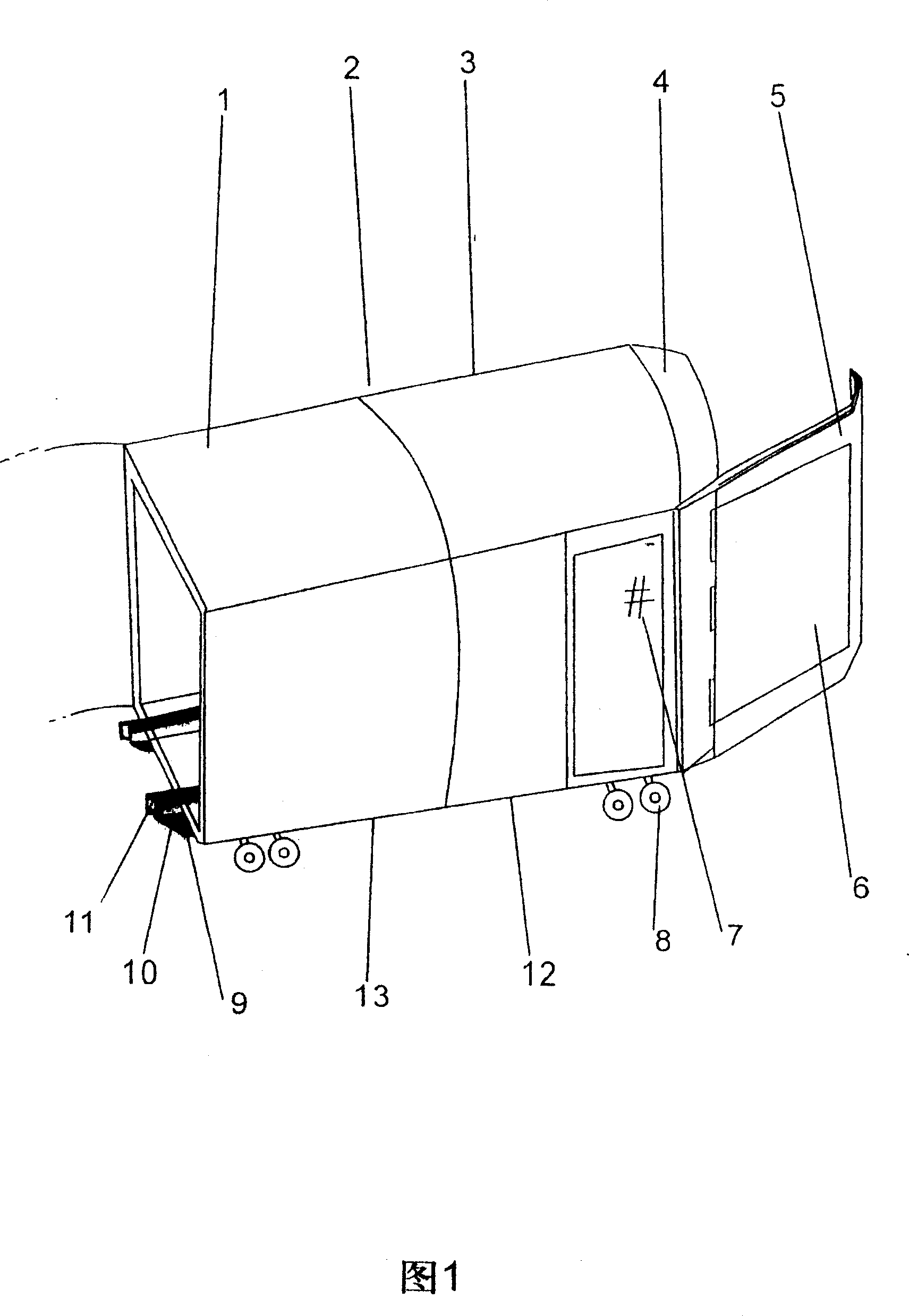

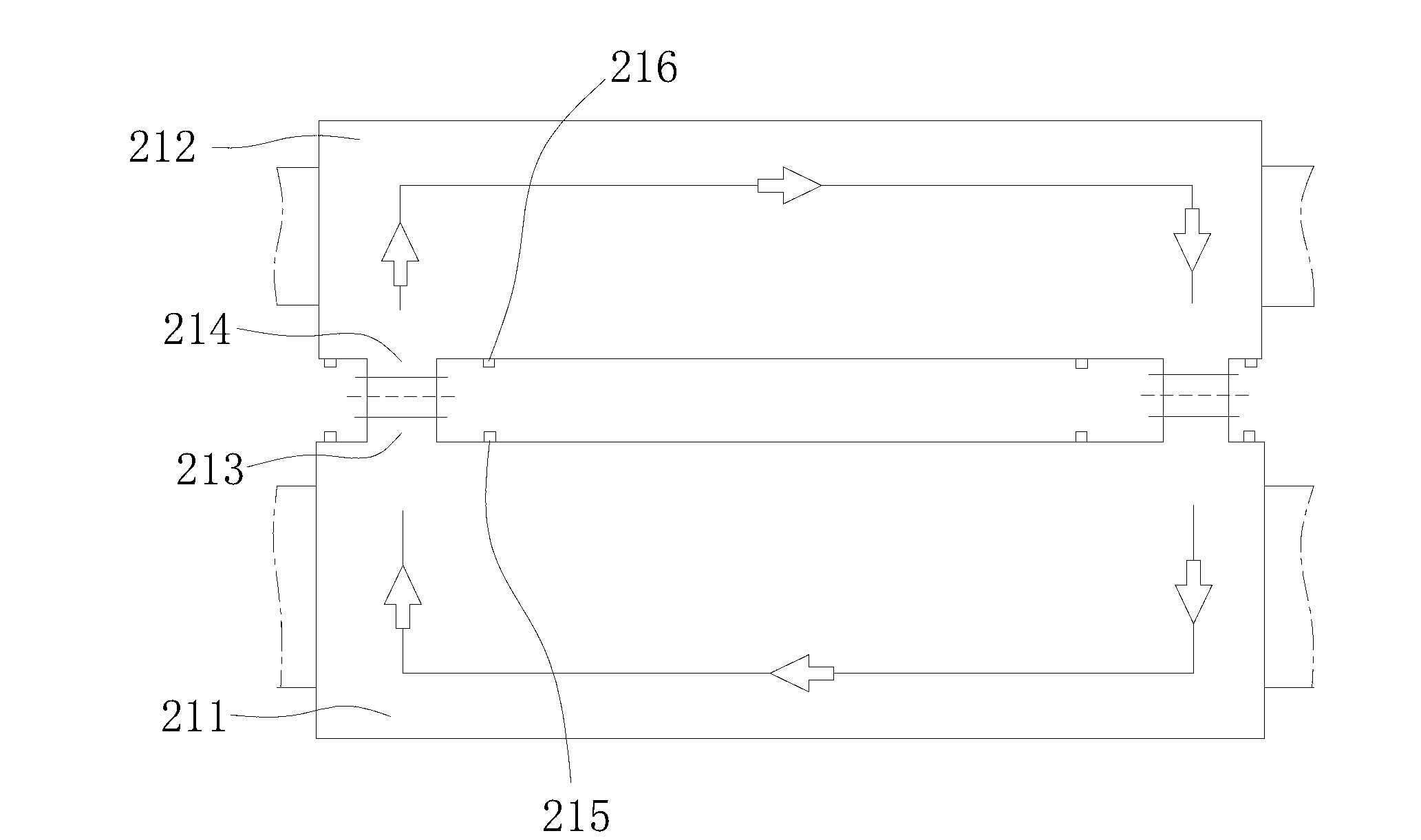

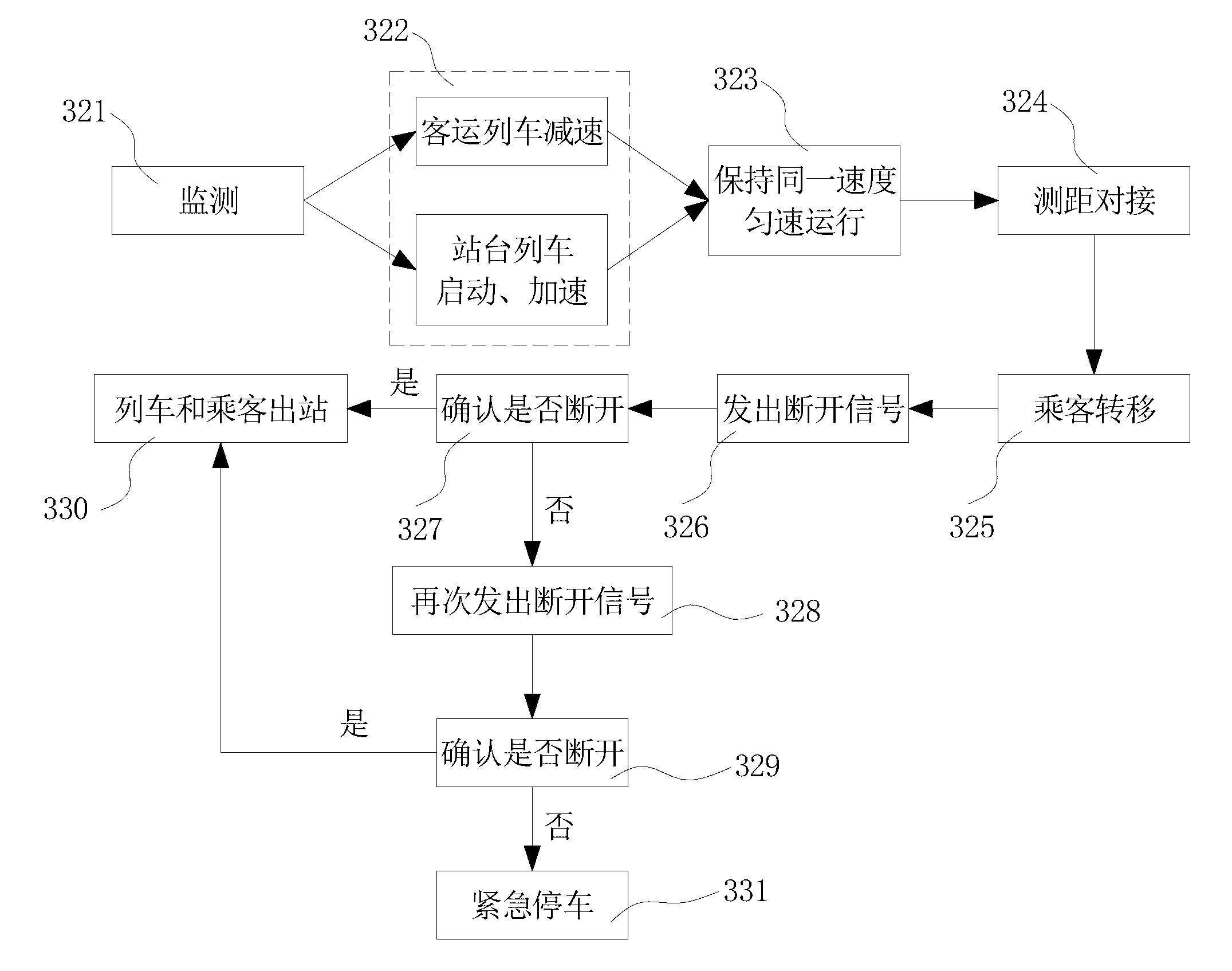

Device and method capable of realizing getting-on and getting-off of passengers without stopping of train when arriving at station

The invention relates to a device capable of realizing getting-on and getting-off of passengers without stopping of a train when arriving at a station, comprising a main train running on a main rail and an auxiliary train running on an auxiliary rail when the passengers get on or get off the train, and the main train and the auxiliary train are provided with a docking assembly which can butt the main train with the auxiliary train, and an a passenger on / off device. The invention also relates to a railway transportation method capable of realizing getting-on and getting-off of the passengers without stopping of the train when arriving at the station. The invention has the benefits of reducing the stopping waiting time, and the time excessively consumed by train deceleration and starting acceleration relative to train running with constant velocity, saves the total running time, and has remarkable effects; furthermore, the method is applicable to various passenger trains such as ordinary trains, motor train units and the like. In addition, the main train has high power and large load, and consumes a great amount of energy in the deceleration and the starting acceleration processes; the auxiliary train has low power and light load, carries the passengers to get on and get off the main train, replaces the deceleration and the starting acceleration processes of the main train, therefore, the energy consumption is remarkably reduced.

Owner:袁国庆

Passenger orientation arrangement in a passenger cabin

A seating space such as an aircraft passenger cabin has rows of seats along an aisle, identified by a row number and a seat location letter. A seat row indicator is arranged on the side flank of the seat back of each aisle seat, at the corner where the side flank and upper edge of the seat back meet. A seat location indicator is arranged at the middle of the upper edge of the seat back of each seat. The row numbers and seat letters are indicated on or in the indicators by paint, printing, engraving, inserts, illumination or tactile indicia. The indicators are conspicuous and easily visible to a passenger standing or walking in the aisle without bending or leaning over. Boarding of the aircraft is facilitated and expedited. Emergency evacuation is assisted by appropriate illumination of the indicators.

Owner:AIRBUS OPERATIONS GMBH

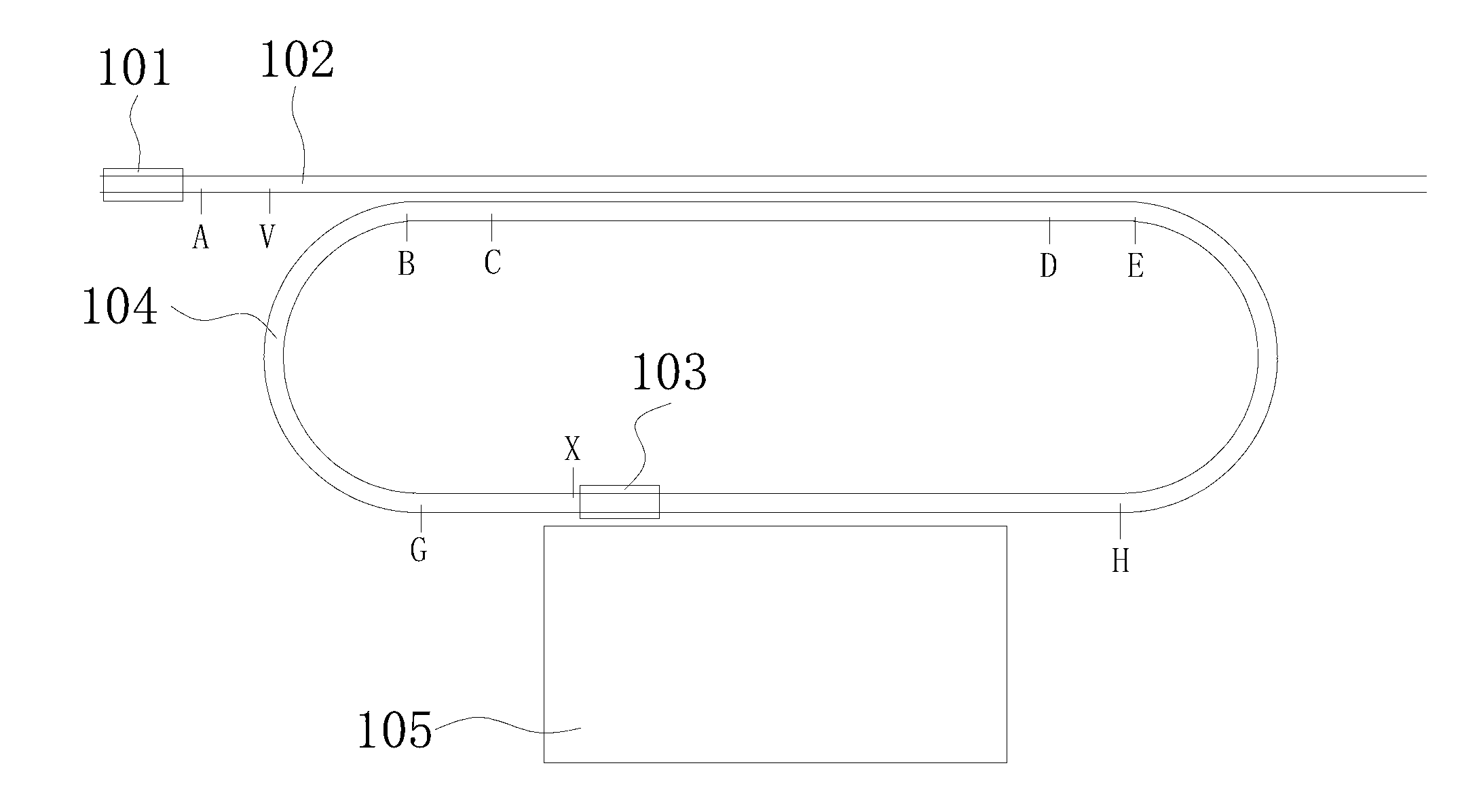

Station system based on synchronous operation of platform train and passenger train

ActiveCN103273923AImprove efficiencySimple structureRailway signalling and safetyRailway stationPassenger trainAerospace engineering

The invention discloses a station system based on synchronous operation of a platform train and a passenger train and a control method thereof. The station system comprises the passenger train, a passenger train track for the passenger train to operate, the station train operating in synchronous with the passenger train, a station track for the station train to operate and a station. The station system is high in efficiency, safe and simple in structure and enables passengers to get on or off the passenger train without parking the train close to the station.

Owner:魏宇科

Mold casting method for hollow axle steel of high-speed passenger train

The invention relates to a mold casting method for a hollow axle steel of a high-speed passenger train. The method comprises the following sequential steps of: I, setting the temperature of ingot molds to be 30-80 DEG C before casting; II, casting 2-3 discs for each furnace, preparing 4-6 ingot molds of which capacity is 5.8-8.4 tons, pumping inside of the mold to be clean before casting, purging the ingot molds with argon, and adding 12-16Kg of casting powder for each ingot mold; III, setting molten steel superheat degree before casting process to be 35-55 DEG C; IV, before the casting process, adding a cover for the steel ladle, covering a cap opening with an iron sheet, opening the steel ladle, discharging 1.0-1.5t of steel, after putting the steel stream in order, adding a central casting pipe for casting, carrying out argon sealing protection during the steel casting process, setting the ingot casting speed to be 125-165mm / min, setting the cap opening casting speed to be 35-65mm / min, when casting 1 / 2-2 / 3 of the cap opening, carrying out trickle filling, and adding 9-12Kg of heat generating agent for each ingot mold when casting to 2 / 3 height of the cap opening; and V, setting the time from the end of casting to demolding of the steel ingot to be not less than 4.5 hours. With the steel ingot formed by mold casting method provided by the invention, the general looseness and the central looseness of the macrostructure of the axle billet cogged by the blooming mill are not more than 0.5 level, and the pattern segregation is 0.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

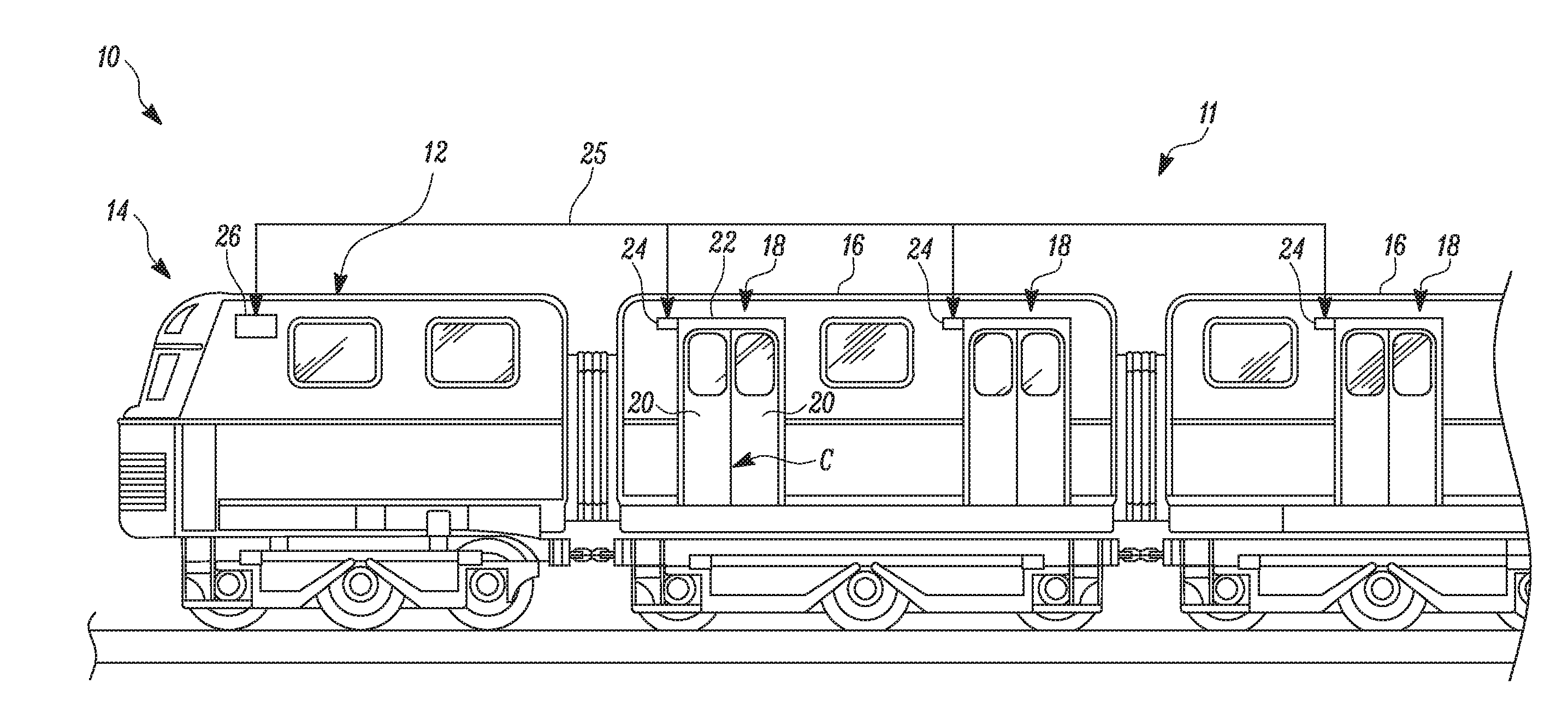

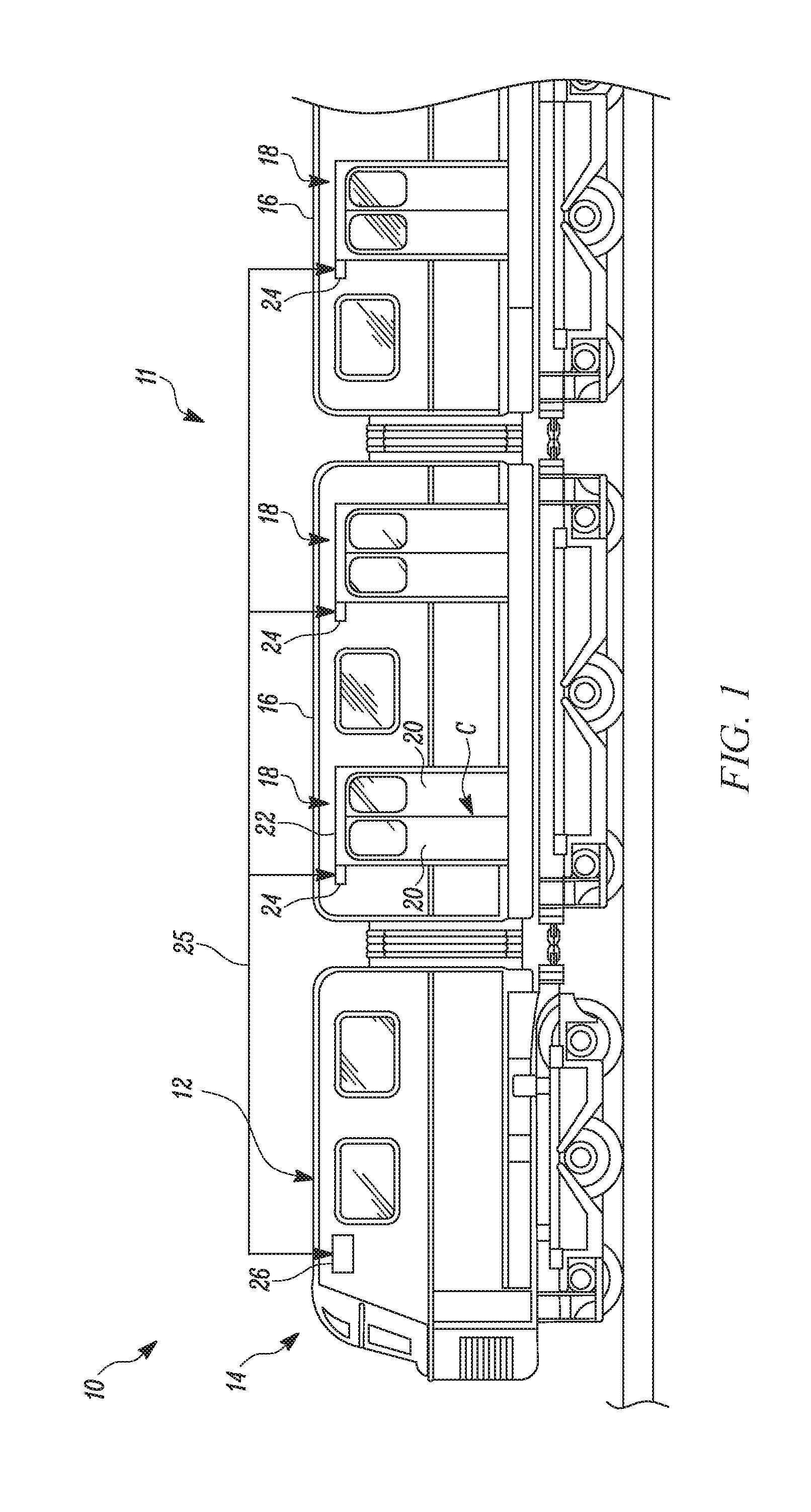

System for controlling movement of passenger train

A system for controlling movement of a passenger train having a locomotive and a plurality of doors is provided. The system includes a door status sensor to determine open and closed status of each door of the locomotive. The system further includes a first control module coupled to the door status sensor and a relay coil through a first diode. The relay coil is energized on receipt of input from the door status sensor, when all doors of the locomotive are closed, and the energized relay coil allows controlling movement of the locomotive. The system further includes a door override switch. In an actuated condition, the door override switch allows power to flow from a power source to the relay coil, thereby energizing the relay coil. The energized relay coil allows controlling movement of the locomotive.

Owner:ELECTRO-MOTIVE DIESEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com