Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

256 results about "Program calculation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of simplifying & automating enhanced optimized decision making under uncertainty

InactiveUS20060117303A1Simple interfaceSuccessful applicationOffice automationSpecific program execution arrangementsProgram calculationSensitivity analyses

Many business problems involve too many complex and interacting variables for a person to solve them, unassisted. Linear programming, statistical and probability analyses provide effective tools for solving such problems, but until now, use of these tools has not been practical for persons without extensive mathematical training. The present invention provides an understandable user interface to these tools, enabling even mathematically unsophisticated users to effectively solve complex problems. The invention also incorporates sensitivity analyses, thereby permitting the user to explore how changes in input data would affect the results of the program calculations. In addition to a data-input program module, respective program modules are disclosed for managing a company product line, a securities portfolio, and a short-selling portfolio.

Owner:GIZINSKI GERARD H

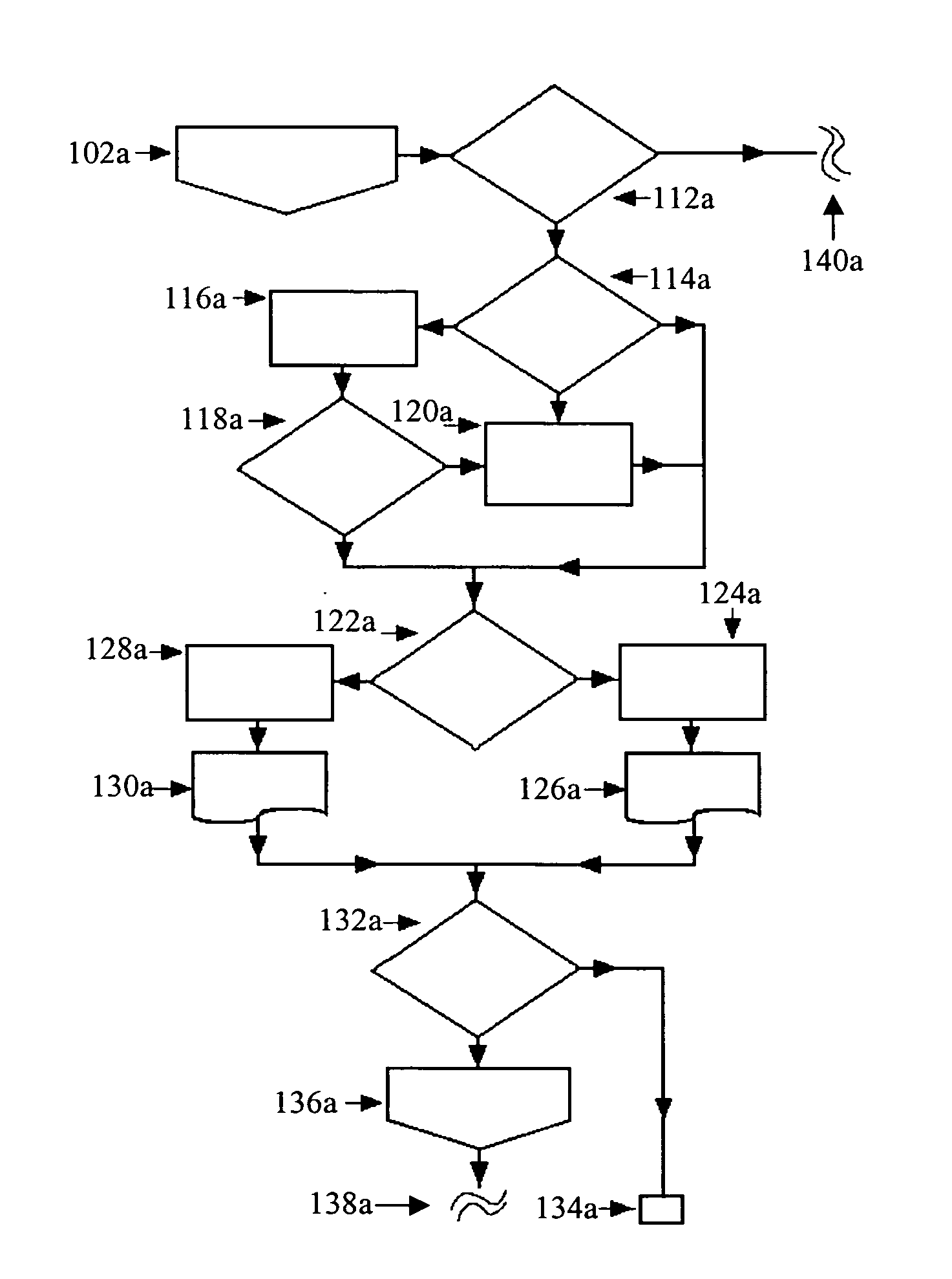

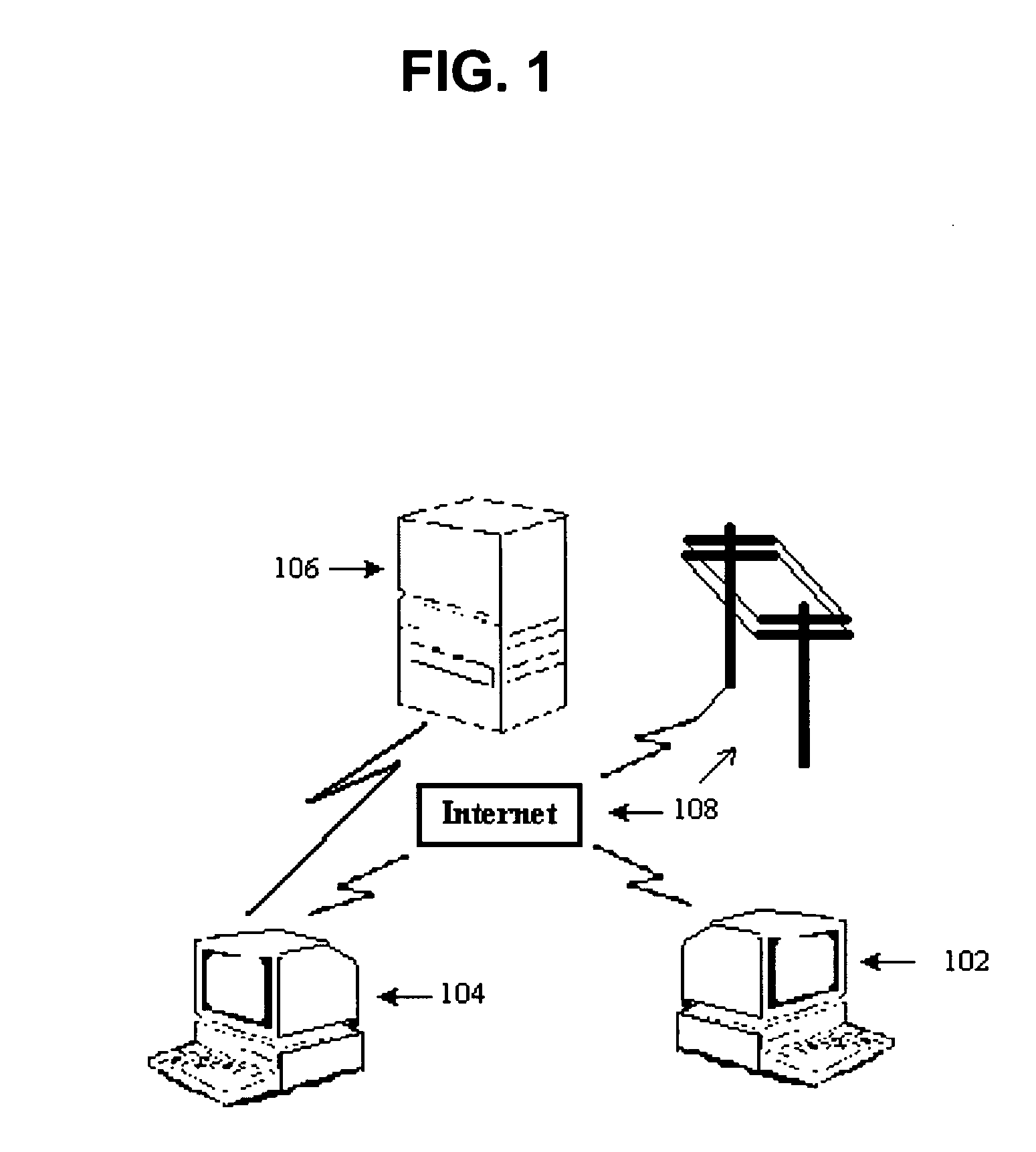

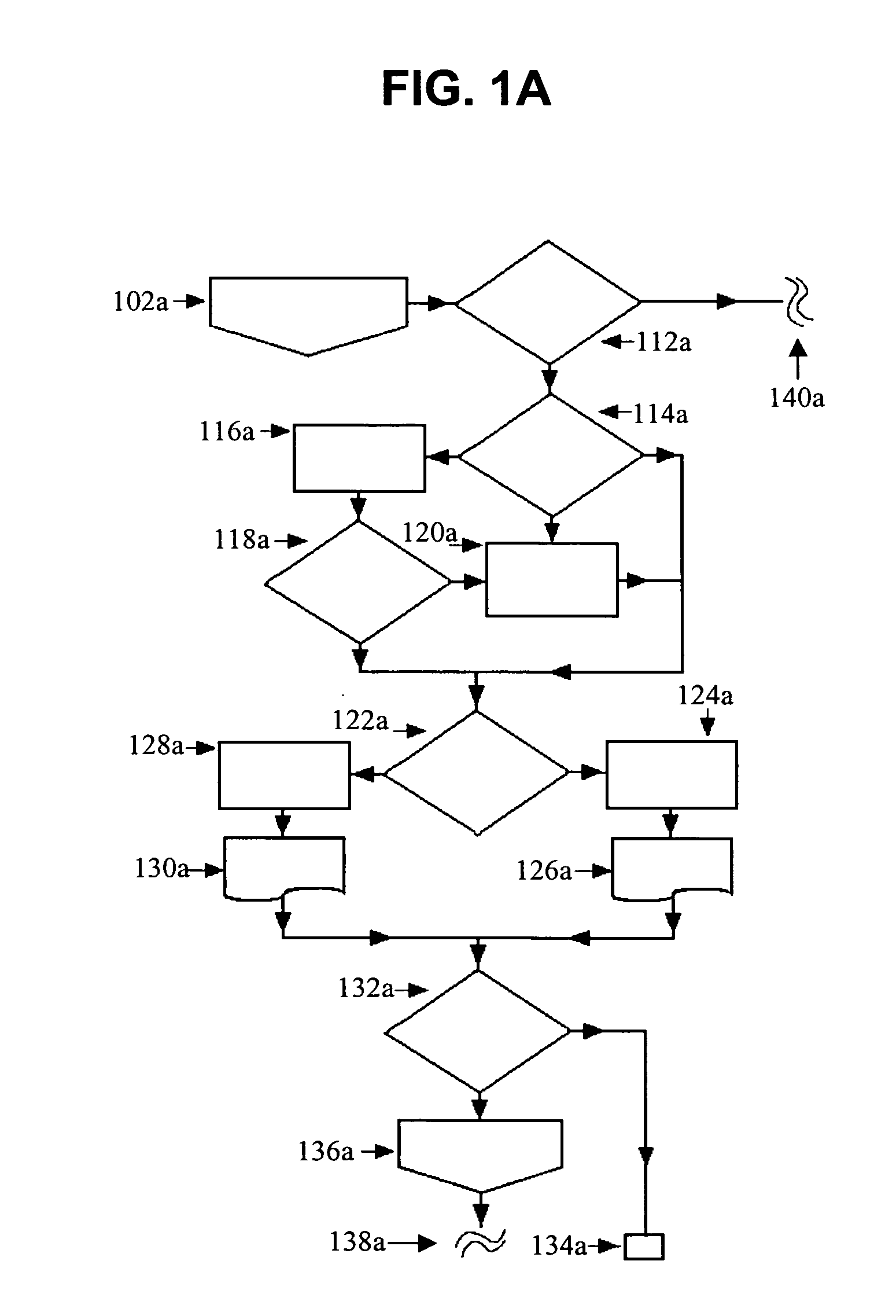

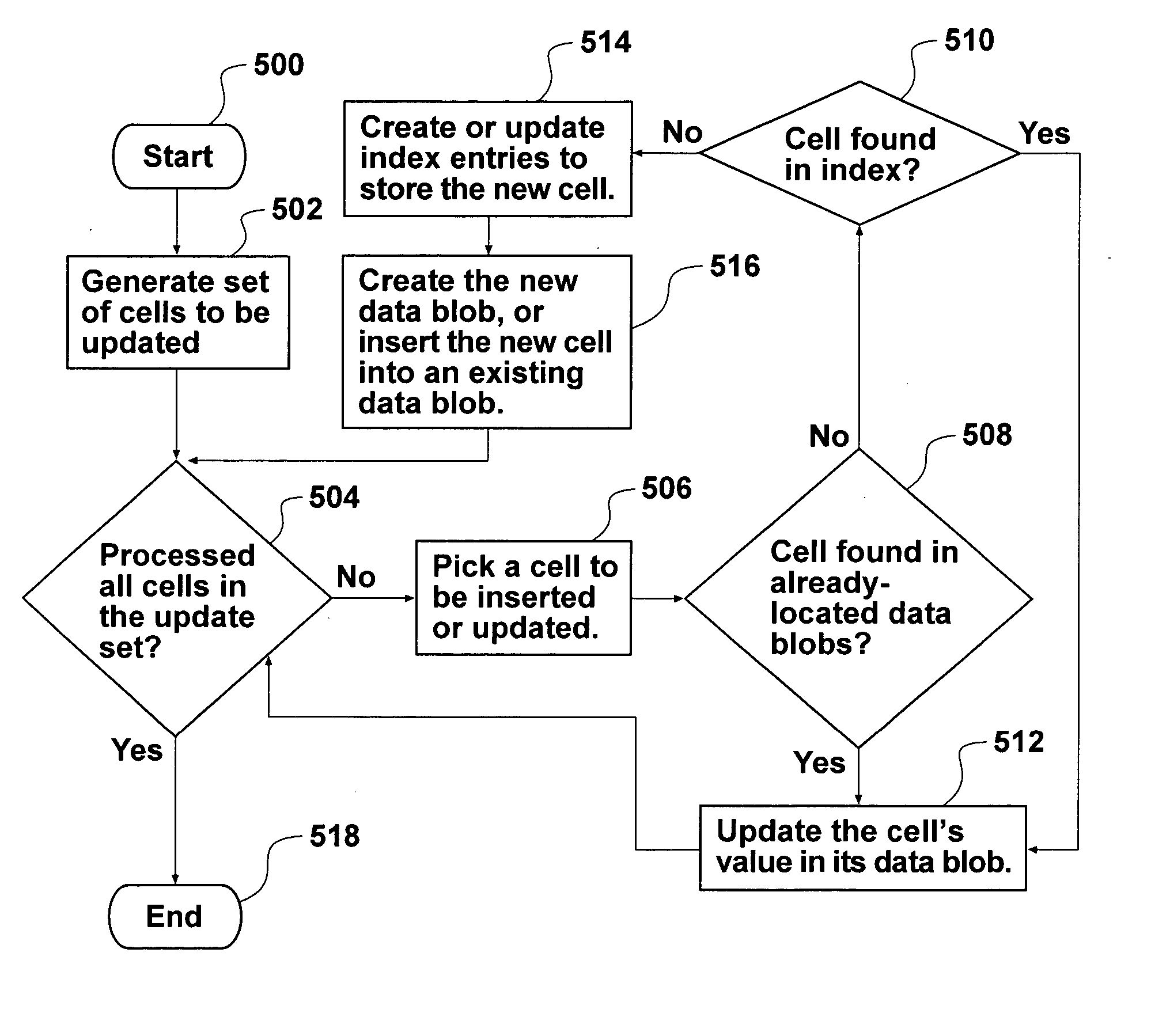

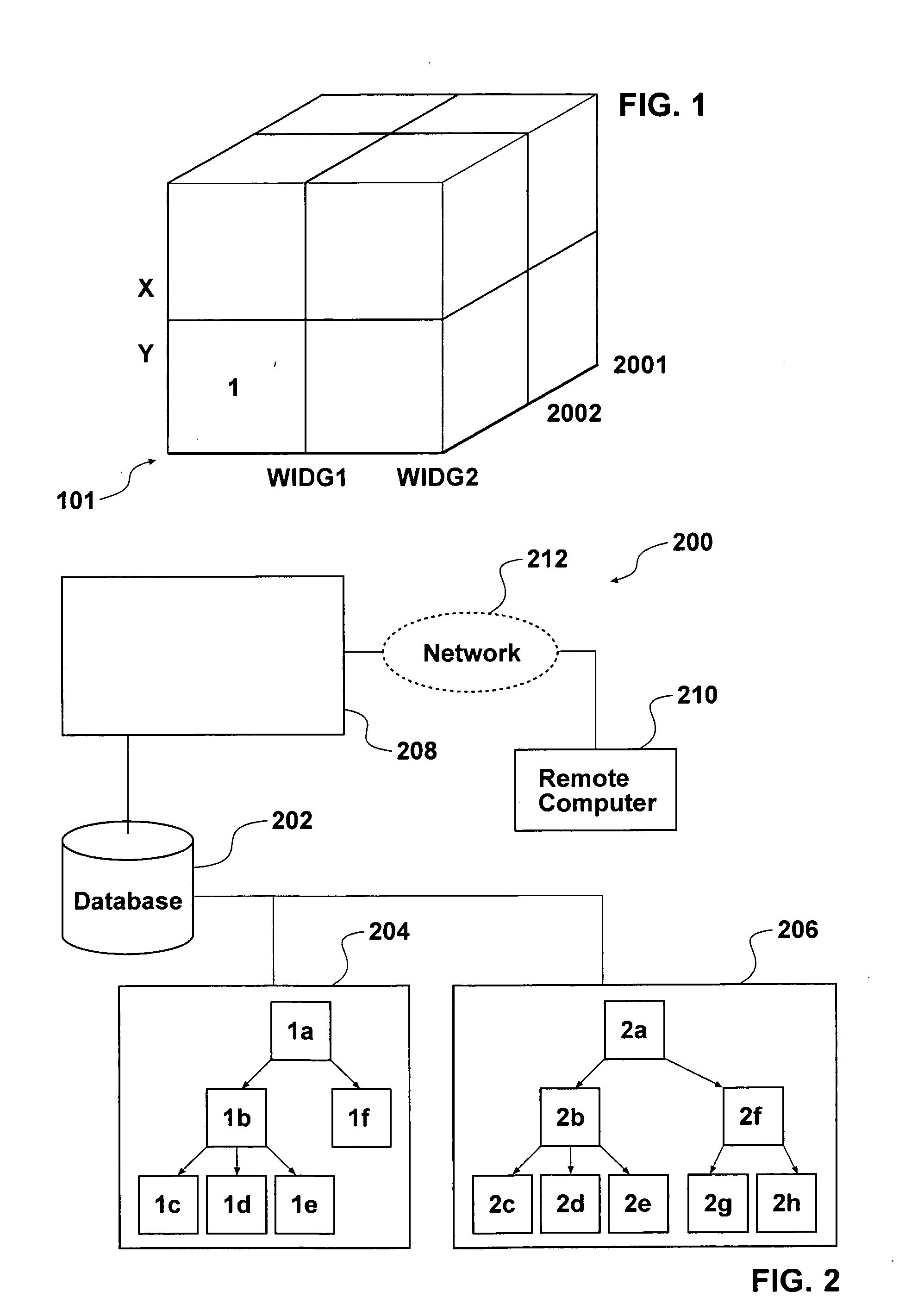

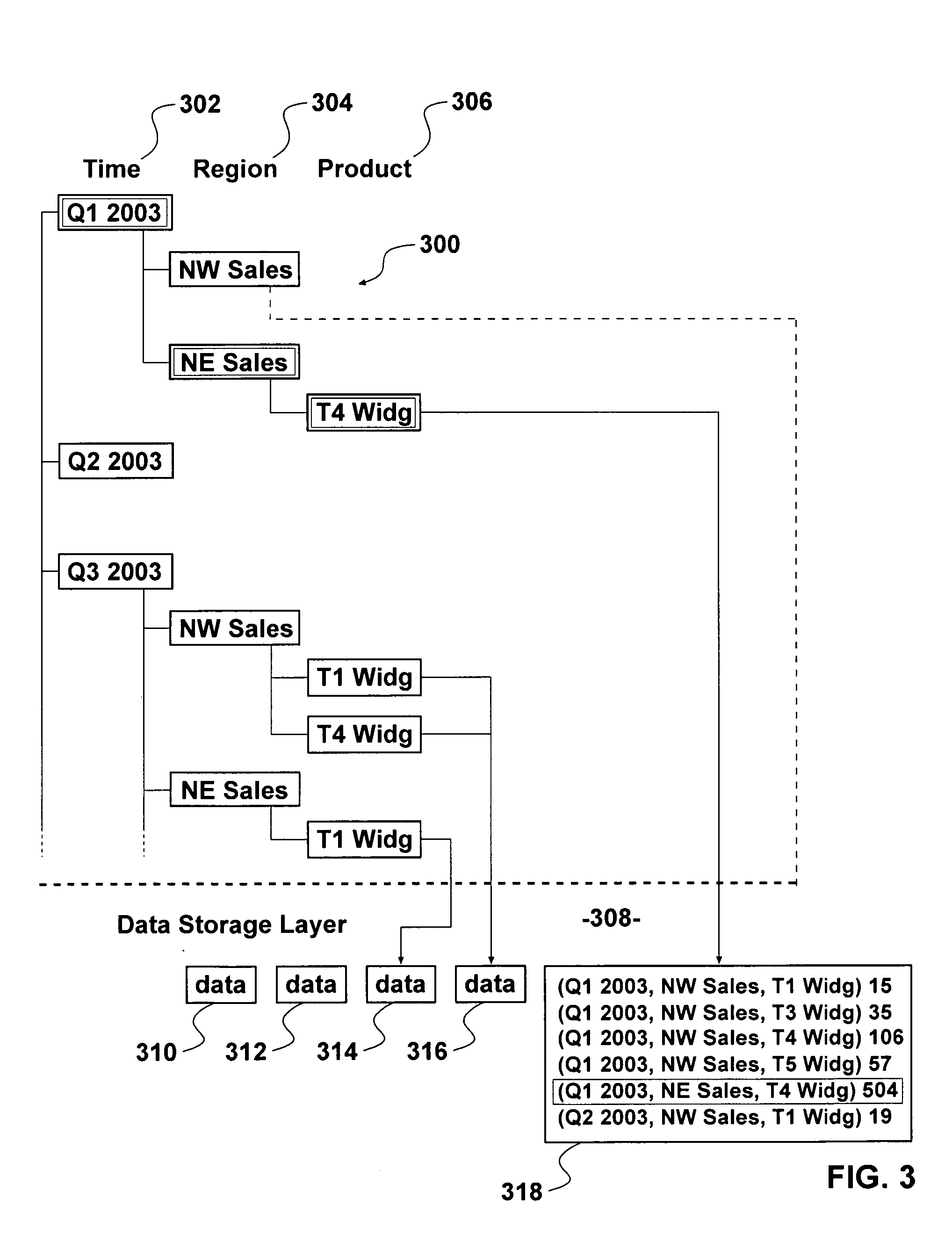

Method and apparatus for accessing multidimensional data

InactiveUS20050071349A1Shorten the timeDigital data processing detailsStatic storageData accessStorage model

A method of indexing data in a multidimensional database includes creating a multidimensional logical access model, creating a multidimensional data storage model in which data is located in cells that are stored and retrieved in blocks, gathering data access information derived from one or more user queries of the database, and reorganizing one or more selected cells in the multidimensional data storage model based on the data access information to reduce the time taken to access the one or more selected cells in response to a user query of the database. A computerized apparatus in communication with a multidimensional database includes a program to perform the method. A computer readable medium contains instructions to cause a computer to perform the method.

Owner:DESCISYS

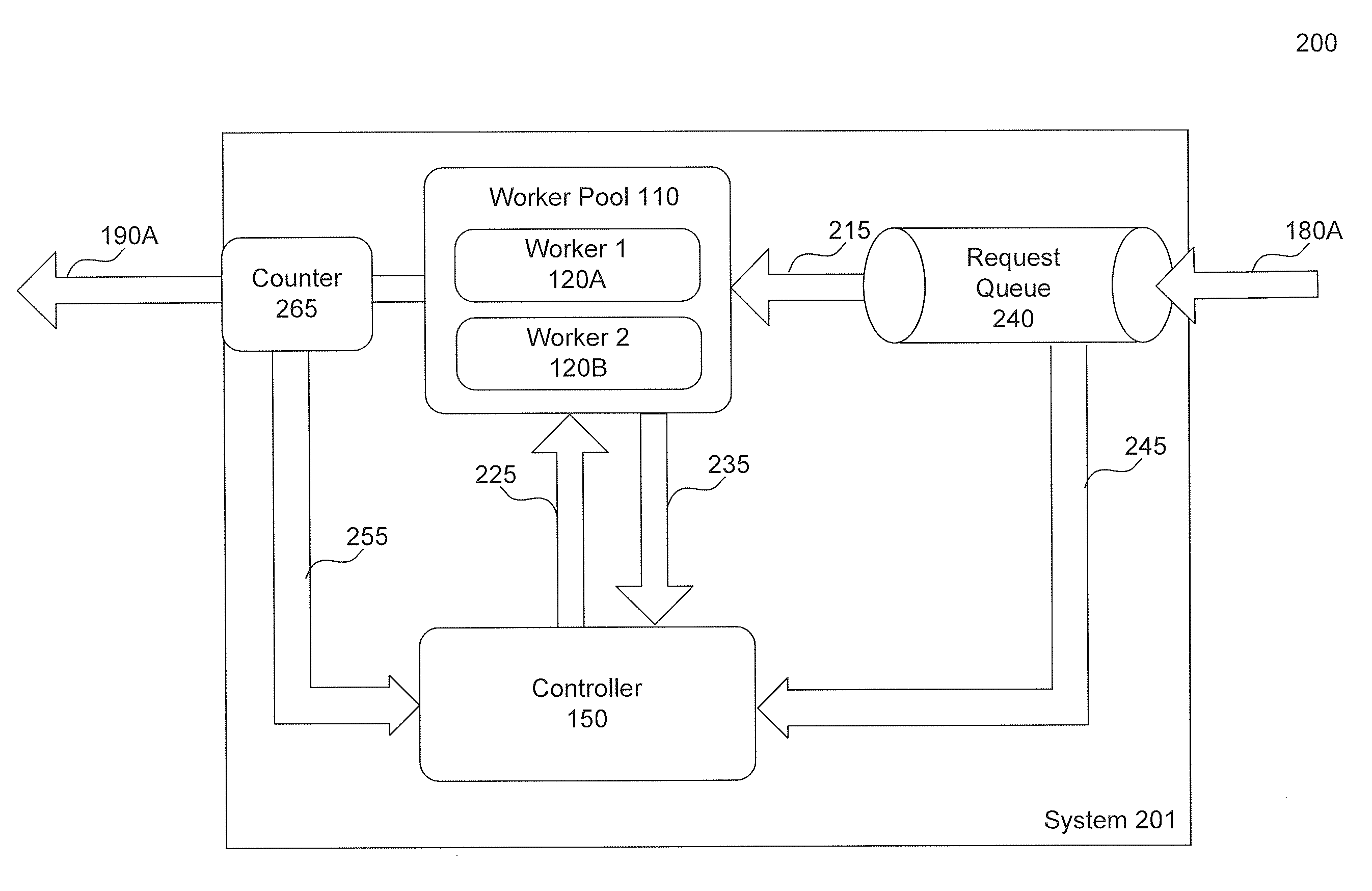

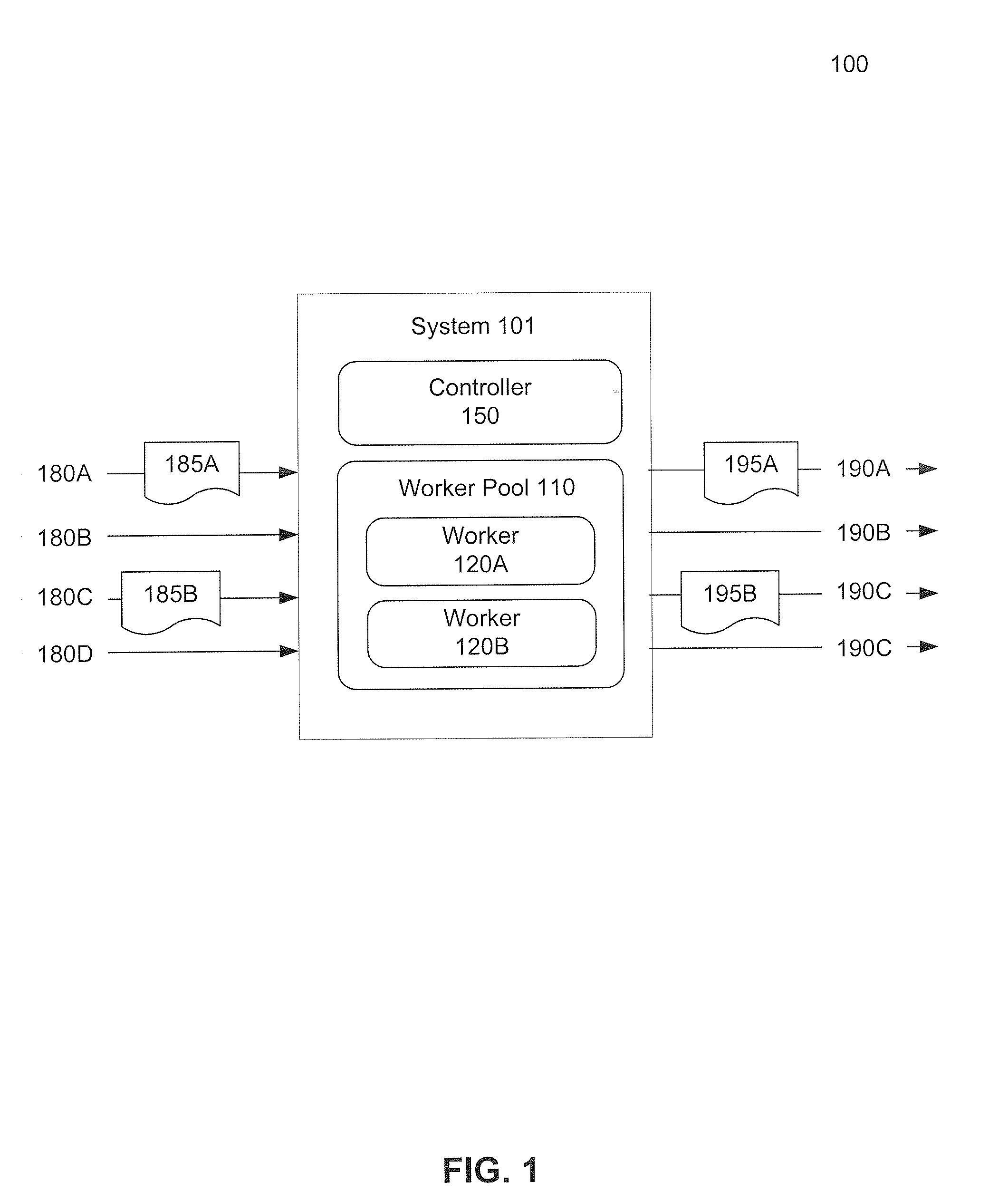

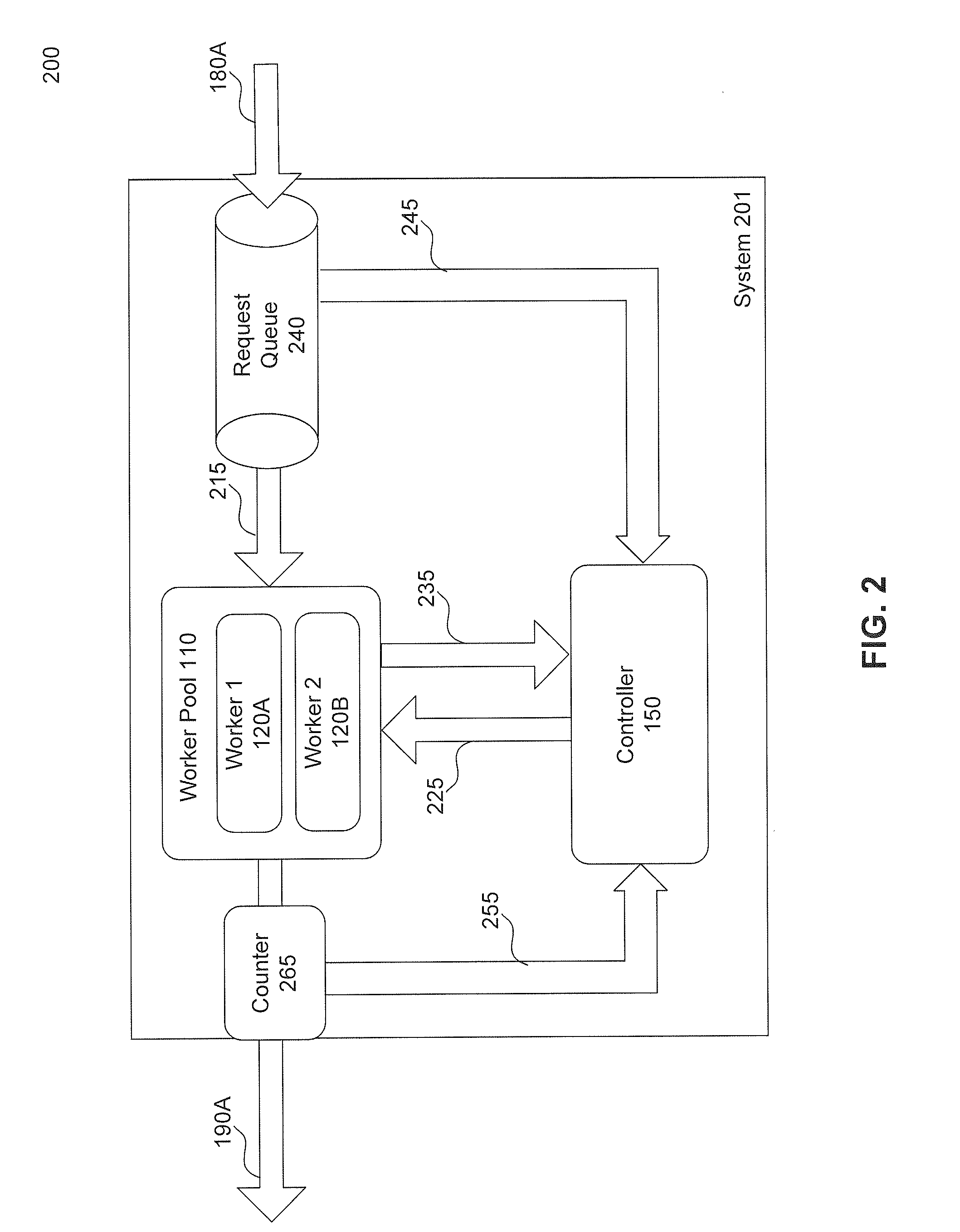

Dynamically Tuning A Server Multiprogramming Level

Methods, apparatus and computer program products for allocating a number of workers to a worker pool in a multiprogrammable computer are provided, to thereby tune server multiprogramming level. The method includes the steps of monitoring throughput in relation to a workload concurrency level and dynamically tuning a multiprogramming level based upon the monitoring. The dynamic tuning includes adjusting with a first adjustment for a first interval and with a second adjustment for a second interval, wherein the second adjustment utilizes data stored from the first adjustment.

Owner:IANYWHERE SOLUTIONS

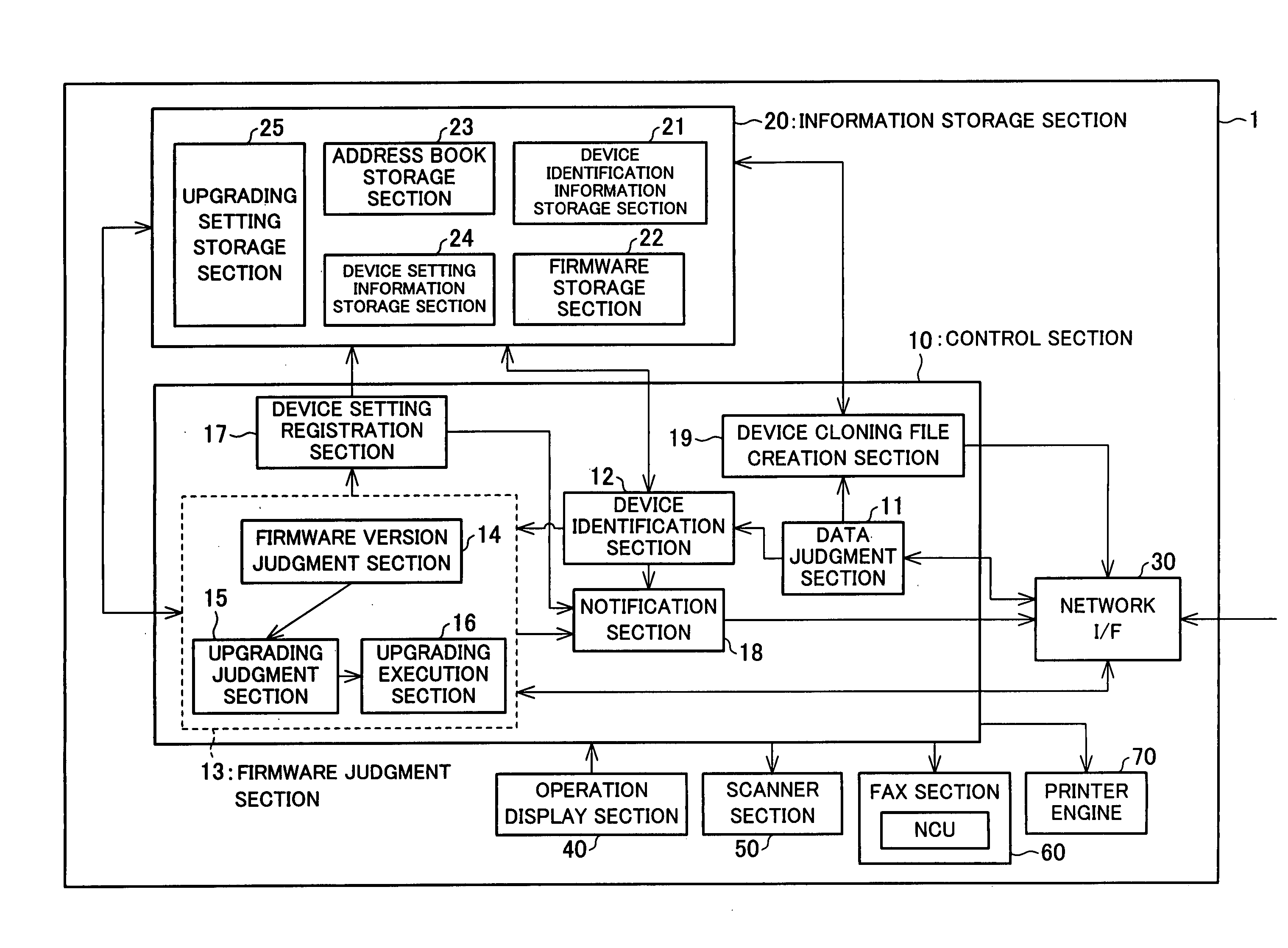

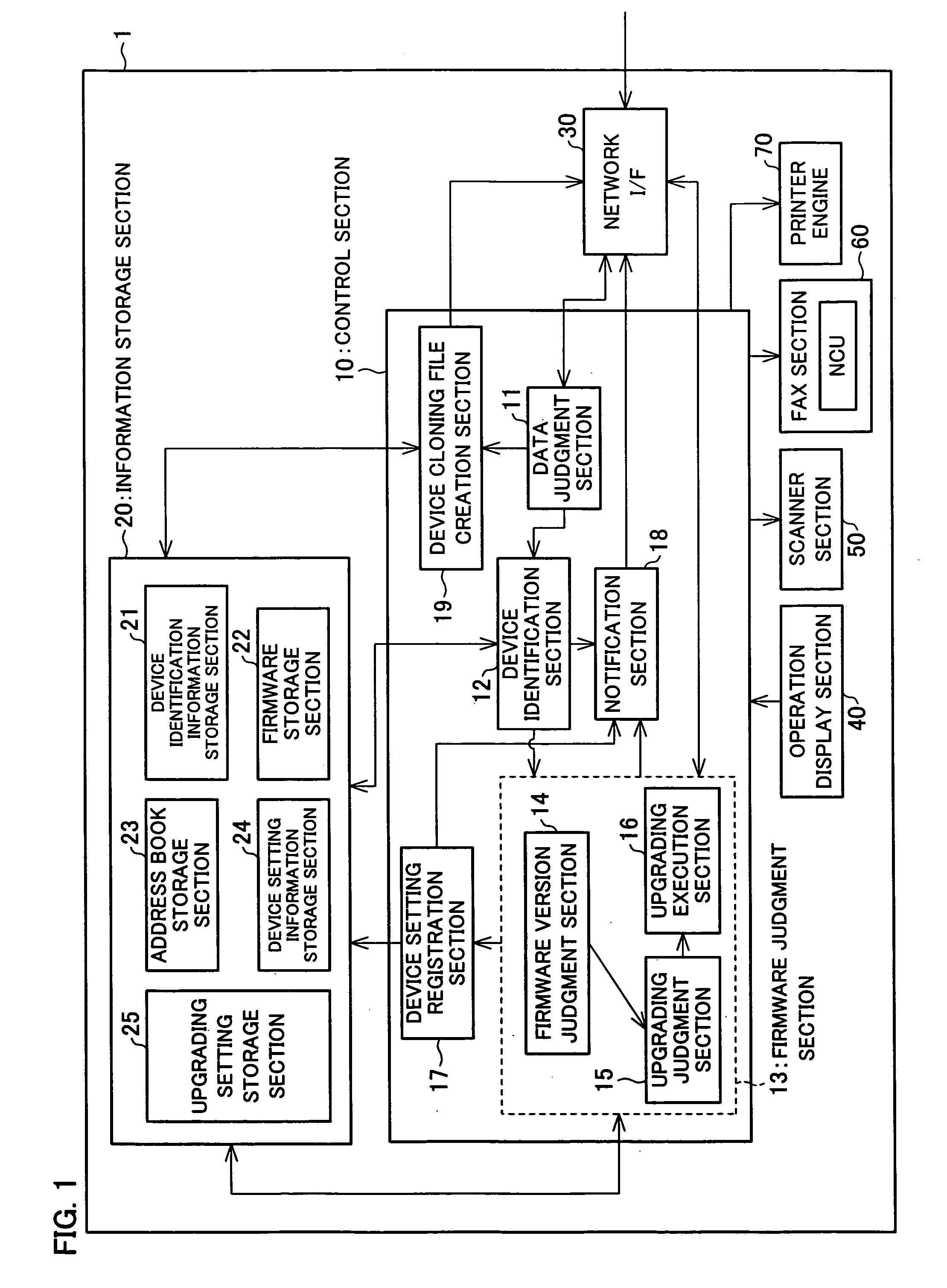

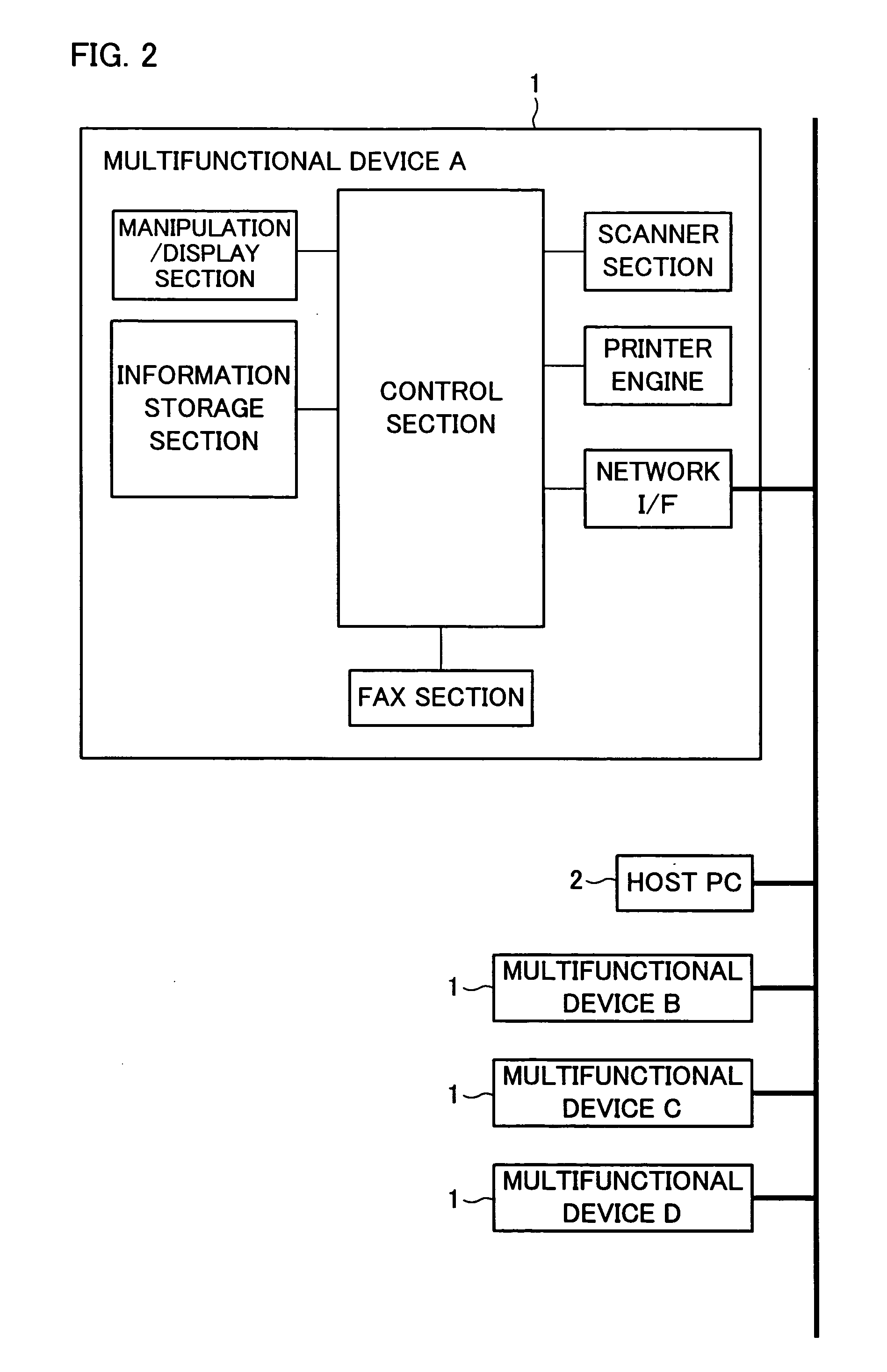

Information processing device and control method for the same, control program, computer-readable storage medium

InactiveUS20050132091A1Avoid failureError detection/correctionDigital computer detailsInformation processingInformation storage

The present invention provides an information processing device that comprises an information storage section for storing device setting information of the information processing device and a program for bringing the information processing device into operation; a firmware version judgment section for comparing, upon reception of updating data that includes device setting information and version information, the version information of a program contained in the updating data and version information of the program stored in the storage section; wherein: an upgrading judgment section brings the acquirement section into operation to obtain a program corresponding to the version information of a program contained in the updating data so as to update the program stored in the storage section and the device setting information when the version information of a program contained in the updating data and the version information of the program stored in the storage section are not identical, and updates the device setting information when the version information of a program contained in the updating data and the version information of the program stored in the storage section are identical.

Owner:SHARP KK

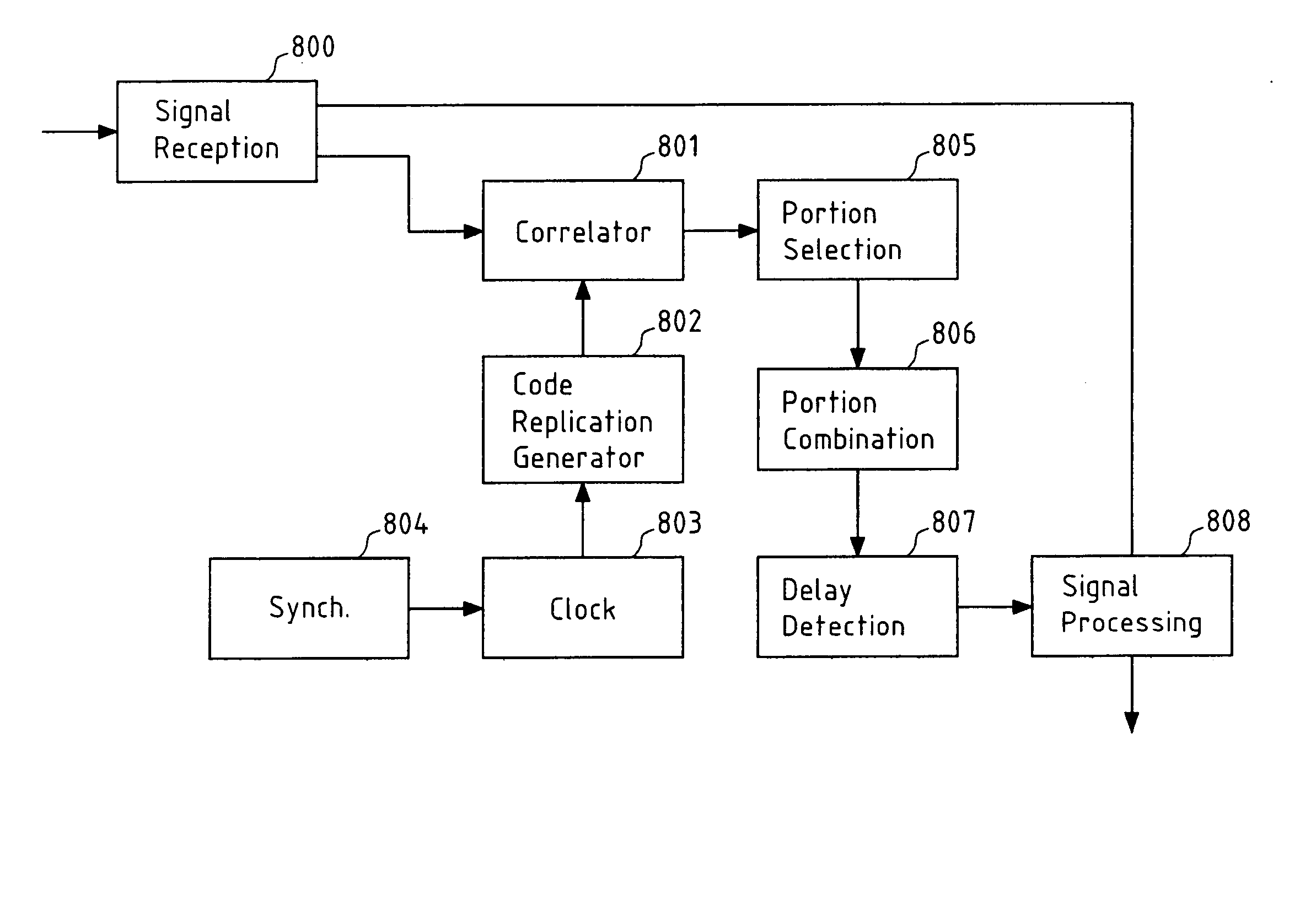

Multiple access using different codes lengths for global navigation satellite systems

InactiveUS20050129096A1Reduce impactEnhance the auto-correlation peaksCode division multiplexBeacon systemsParallel computingCorrelation function

A method for determining a delay of a spread data symbol stream comprises the steps of at least partially correlating a signal, which comprises at least first and second spread data symbol streams (300, 301) that are obtained by spreading at least a first and second data symbol stream with a respective first (302) and second code, with said first code (302) to obtain at least two portions (303-1, 303-2) of a Cross-Correlation Function CCF (303), and combining said at least two portions (303-1, 303-2) of said CCF (303) to obtain a combined CCF portion from which a first delay of said first spread data symbol stream is determined, wherein said first code (302) and said second code are composed of chips and wherein the number of chips of said first code (302) is different from the number of chips of said second code. The invention further relates to a computer program, a computer program product, a device and a system.

Owner:NOKIA CORP

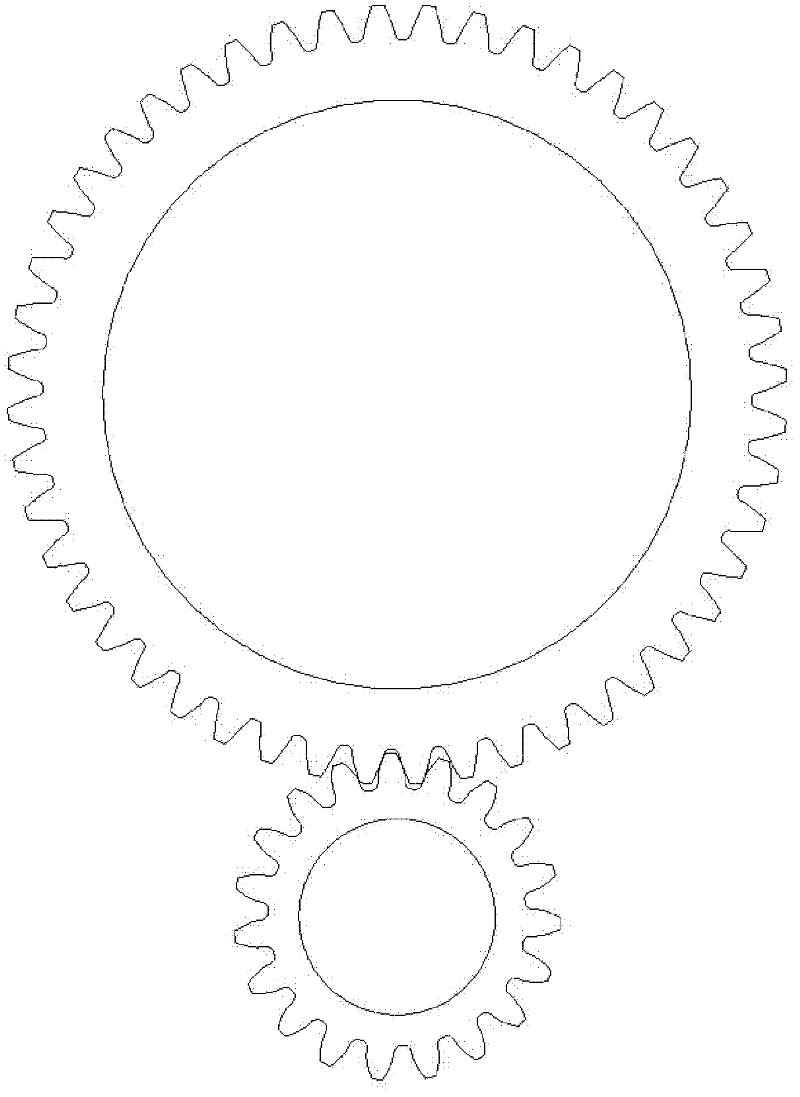

Gear crack propagation simulated wavelet extension finite element simulation analysis method

InactiveCN102332046AConvenient researchAvoid difficultiesSpecial data processing applicationsFinite element equationComputer-aided

The invention relates to a finite element analysis method for crack propagation, in particular to a numerical value analysis method using wavelet extension as a new finite analysis unit. The method comprises the following steps that: based on a computer-aided drawing software, a gear meshing model containing any crack failure is built; the module is imported into a finite element analysis software ABAQUS, and geometric data of a finite element mesh is obtained by combination of ABAQUS meshing and data output functions; according to the obtained data, a mathematics-assisted calculation software is applied to a program to calculate the element stiffness matrix of a wavelet extension unit, and then according to the mesh of the analyzed structure, the overall stiffness matrix of an integratedstructure is arranged; and after boundary constraint conditions and loads are introduced, a finite element equation is solved to obtain the numerical value solution of crack propagation. In the invention, the growth conditions of cracks can be tracked, and the difficulty brought by highly concentrated stress is also solved; and the method has higher computational accuracy and higher computationalefficiency, and facilitates the study of fault diagnosis of mechanical equipment.

Owner:BEIJING UNIV OF TECH

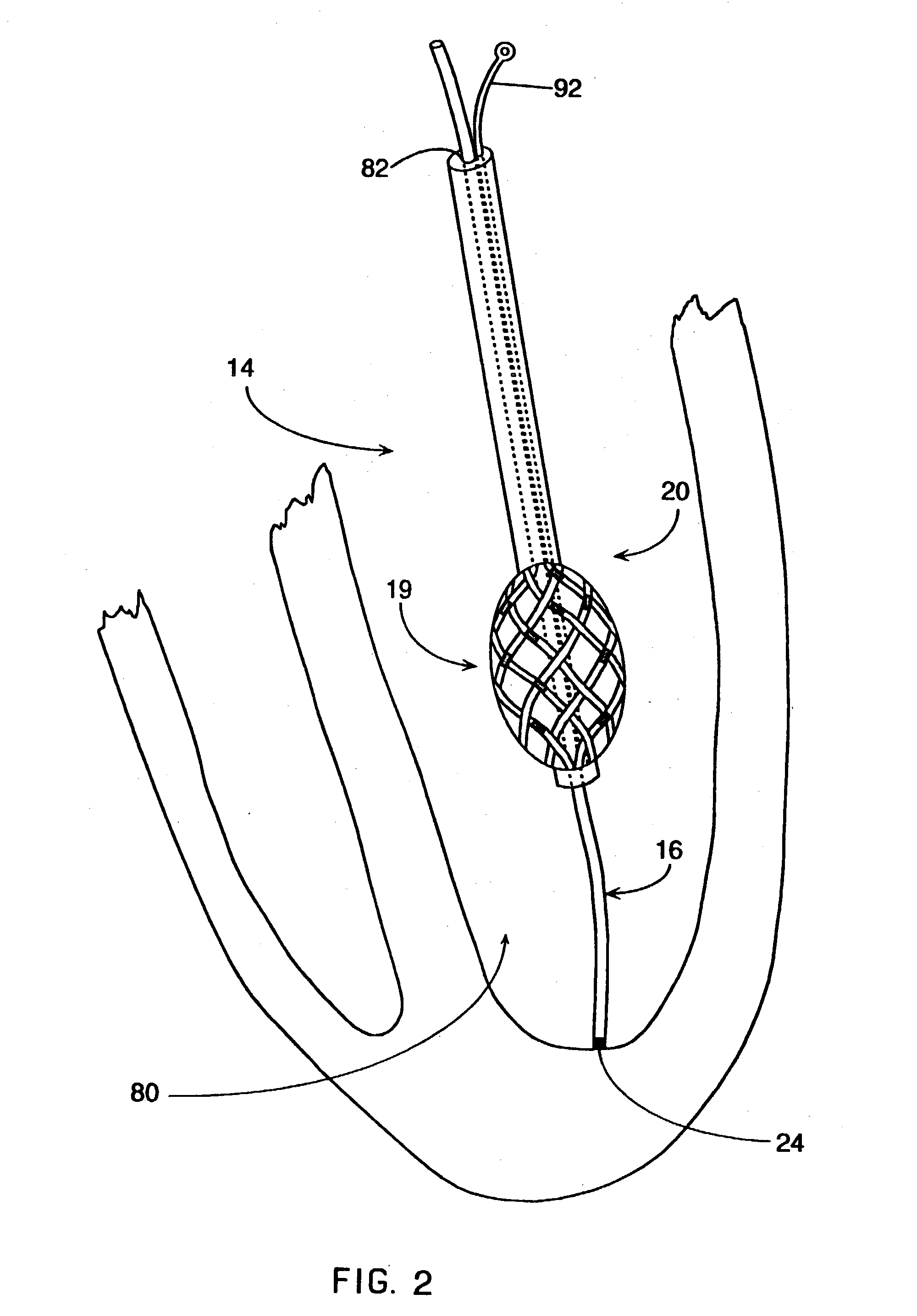

Software for mapping potential distribution of a heart chamber

A computer software program is described that maps the electrical activity of a patient's heart. The software program utilizes inputs from electrodes contained within a heart chamber. Inputs from the electrodes cause the program to calculate the heart chamber volume, and then to determine the position of the electrodes within the heart chamber. The program then utilizes inputs from the electrodes to calculate the three-dimensional volumetric electrical field distribution of said heart chamber. This calculation is accomplished using a spherical harmonic series expression. Finally, the computer program displays the electrical field distribution of the heart chamber.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

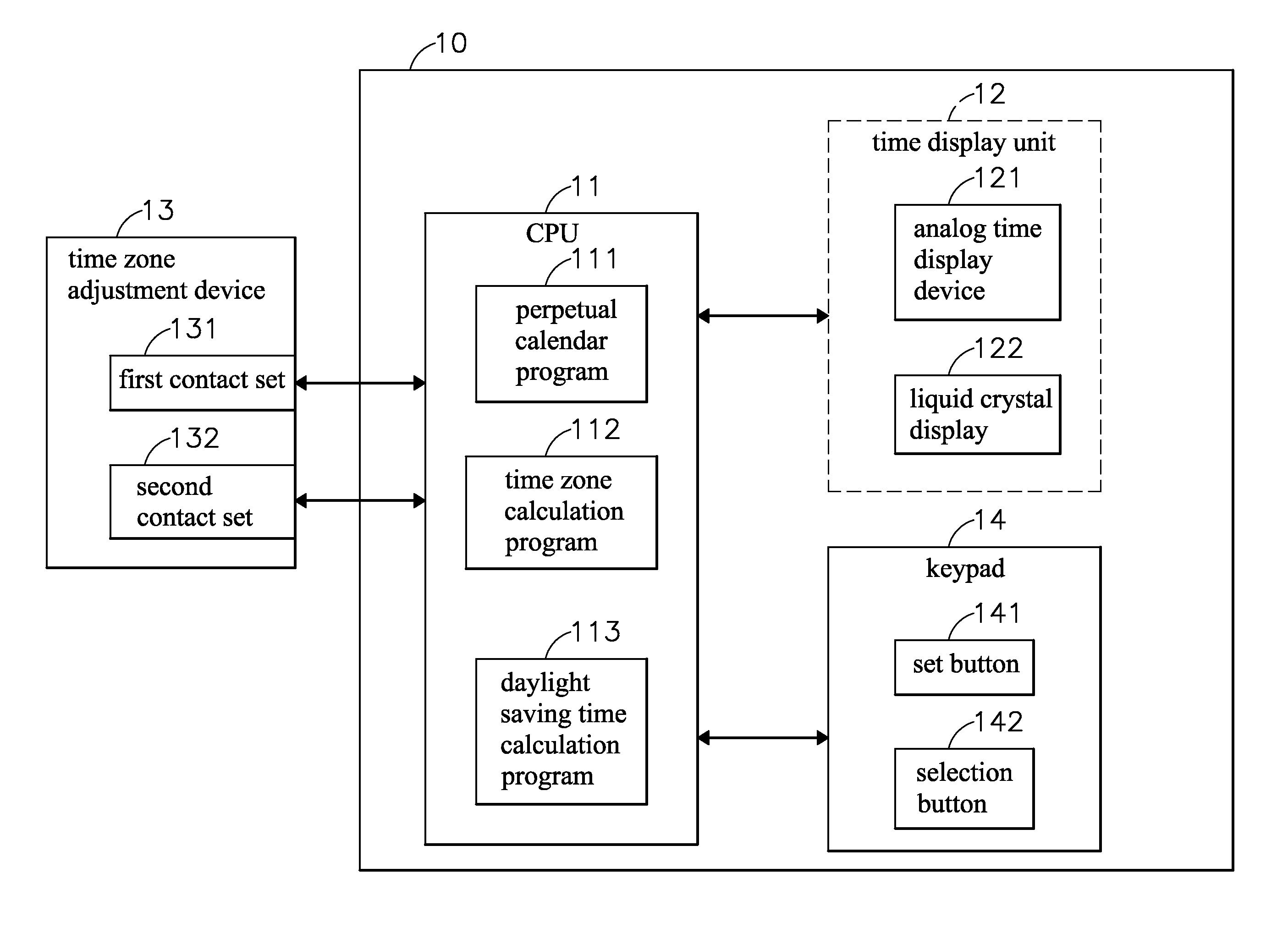

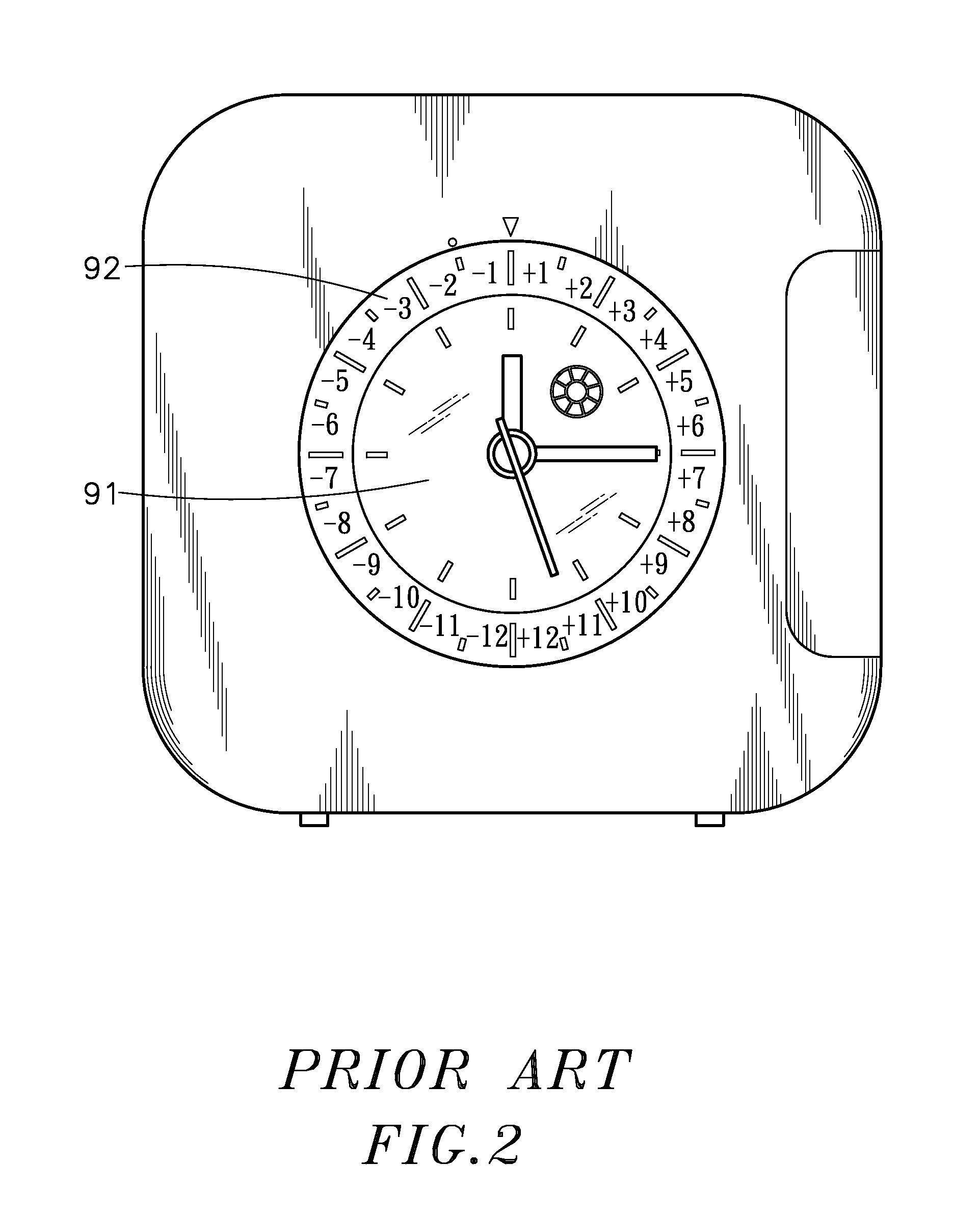

Daylight saving time automatic adjustment method and timepiece using same

A timepiece time having installed in the movement thereof a CPU, a time zone adjustment device and a time display unit, the CPU having installed therein a perpetual calendar program, a time zone calculation program, and a daylight saving time calculation program, the time zone adjustment device being operable to input a time zone signal to the CPU for enabling the time zone calculation program to calculate the conversion time corresponding to the set time zone and for enabling the daylight saving time calculation program to determine whether the set time zone has applied daylight saving time, such that the time display unit is controllable by the CPU to automatically adjust displayed time and to automatically enter / withdraw from the daylight saving time cycle of the corresponding time zone subject to calculation of the time zone calculation program and the daylight saving time calculation program.

Owner:DUTECK INDAL

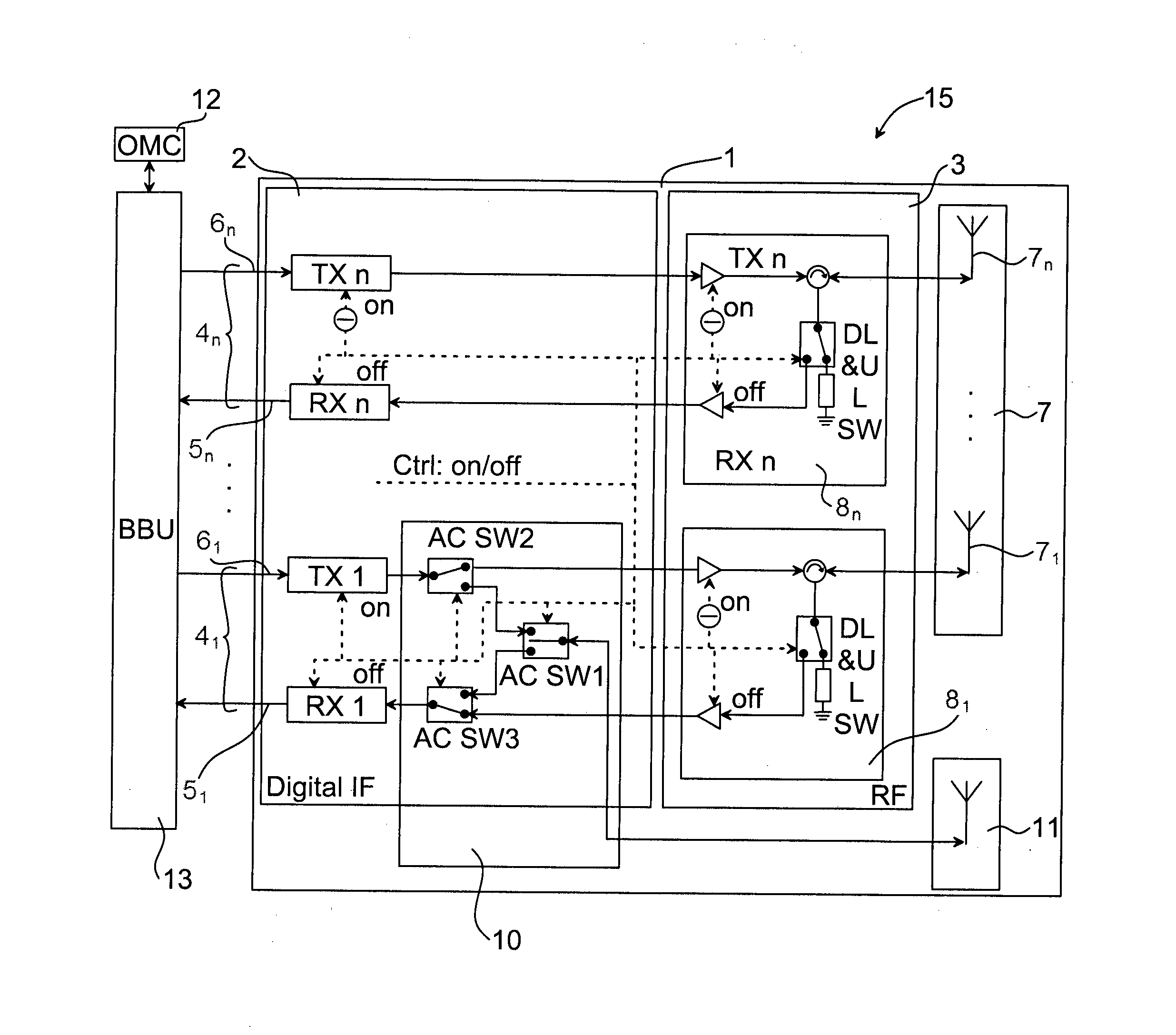

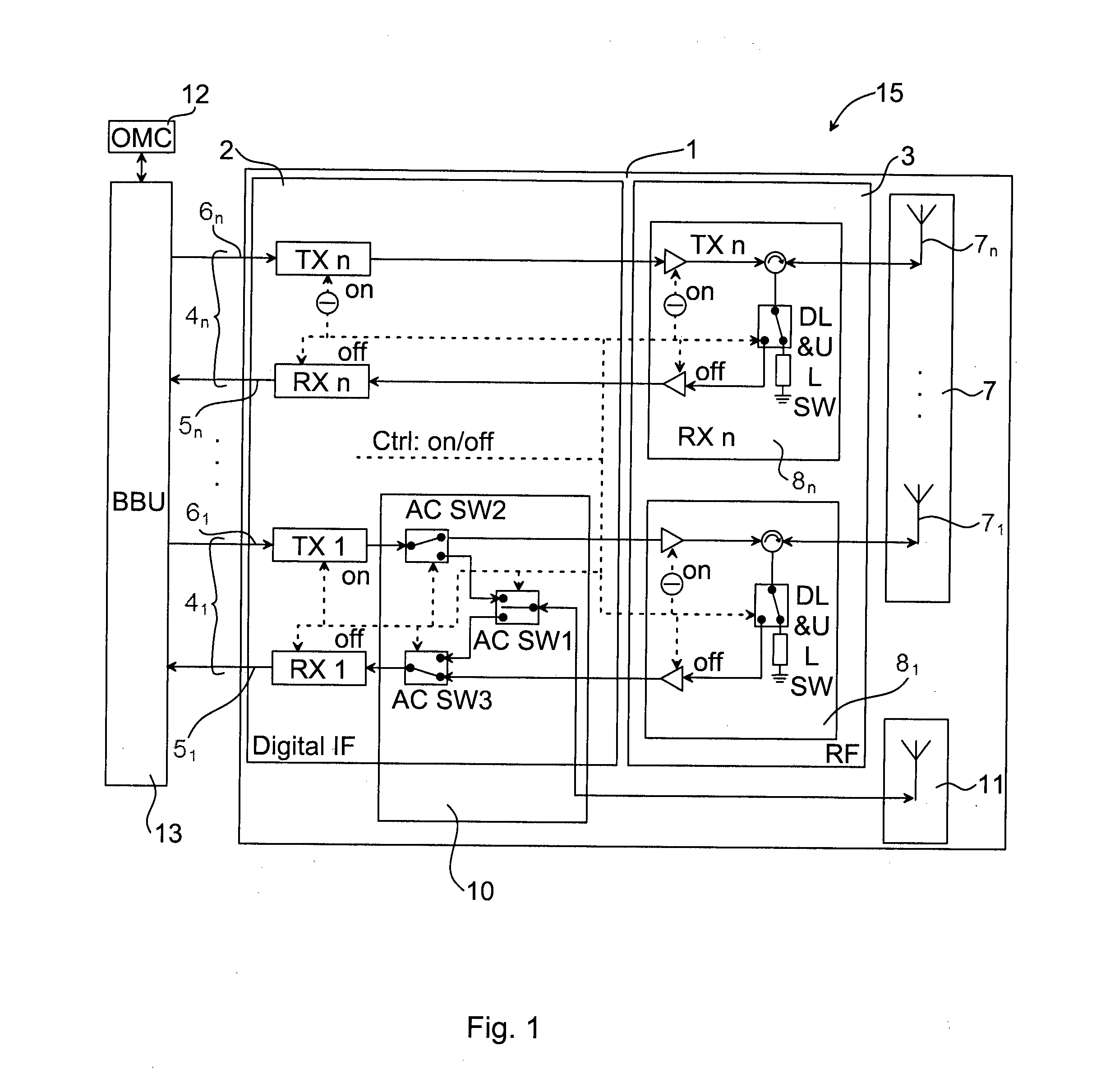

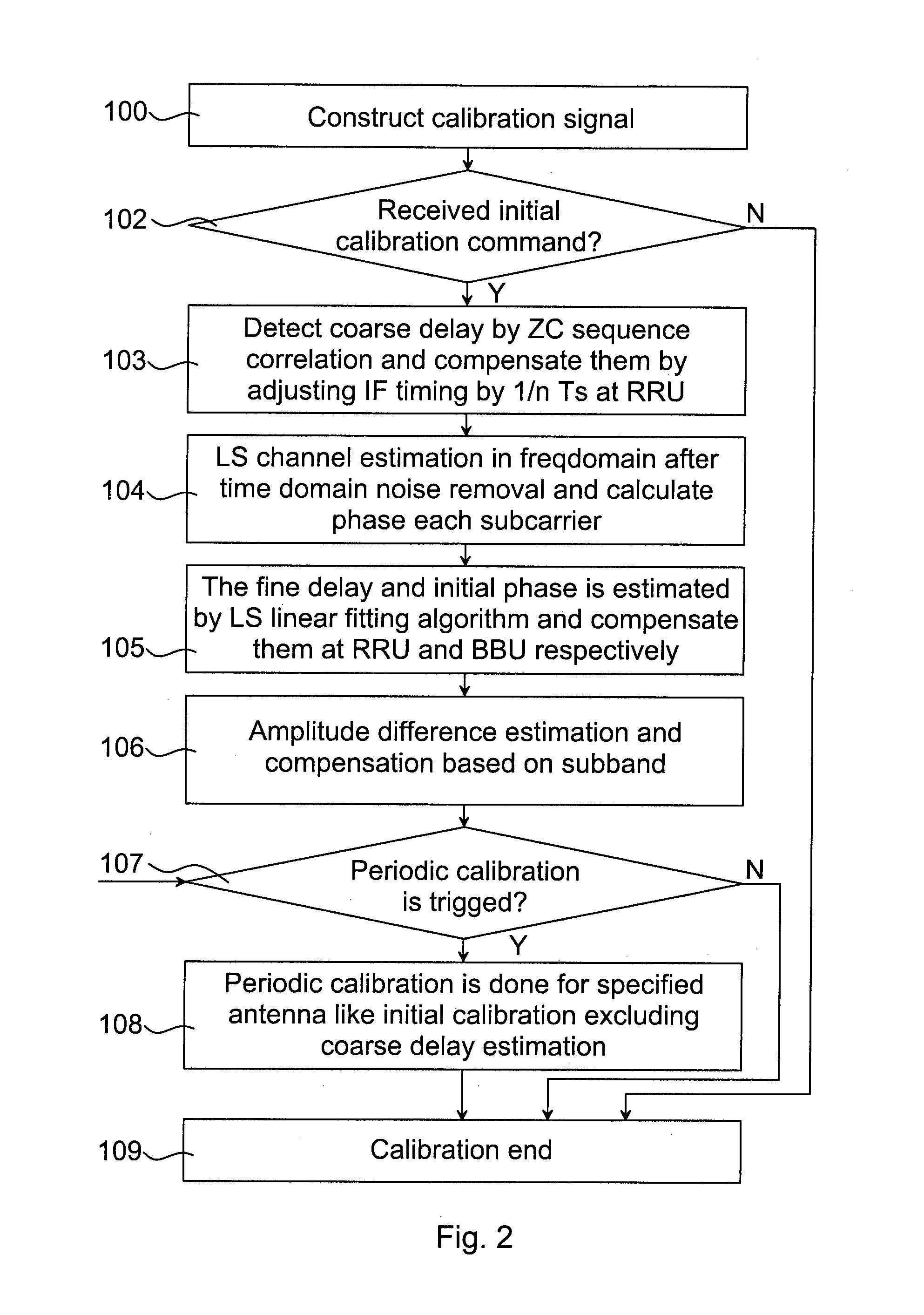

Methods, processing device, computer programs, computer program products, and antenna apparatus for calibration of antenna apparatus

InactiveUS20140370823A1Improved antenna calibrationLess processor loadTransmitters monitoringReceivers monitoringIntermediate frequencyTransceiver

The invention relates to a method 20 in an antenna array system 15 for calibration of an antenna apparatus 1. The method 20 comprises: estimating 21 coarse receive delays for the receive chains 51, . . . , 5n and coarse transmit delays for the transmit chains 61, . . . , 6n; adjusting 22 a timing of the receive chains 51, . . . , 5n based on the estimated coarse receive delays so that the receive chains 51, . . . , 5n align with the maximum coarse receive delay difference and adjusting a timing of the transmit chains 61, . . . , 6n based on the estimated coarse transmit delays so that the transmit chains 61, . . . , 6n align with the maximum coarse transmit delay difference; estimating 23 a fine delay and initial phase for the receive chains 51, . . . , 5n and the transmit chains 61, . . . , 6n based on their phase-frequency characteristics; adjusting 24 an intermediate frequency timing of the antenna apparatus 1 based on the estimated fine delay; compensating 25 initial phase and residual delay at base band frequency-domain signal; estimating 26 amplitude-frequency characteristics of the transceiver chains 41, . . . , 4n; and compensating 27 the estimated amplitude-frequency characteristics at base band frequency-domain signal.

Owner:OPTIS CELLULAR TECH LLC

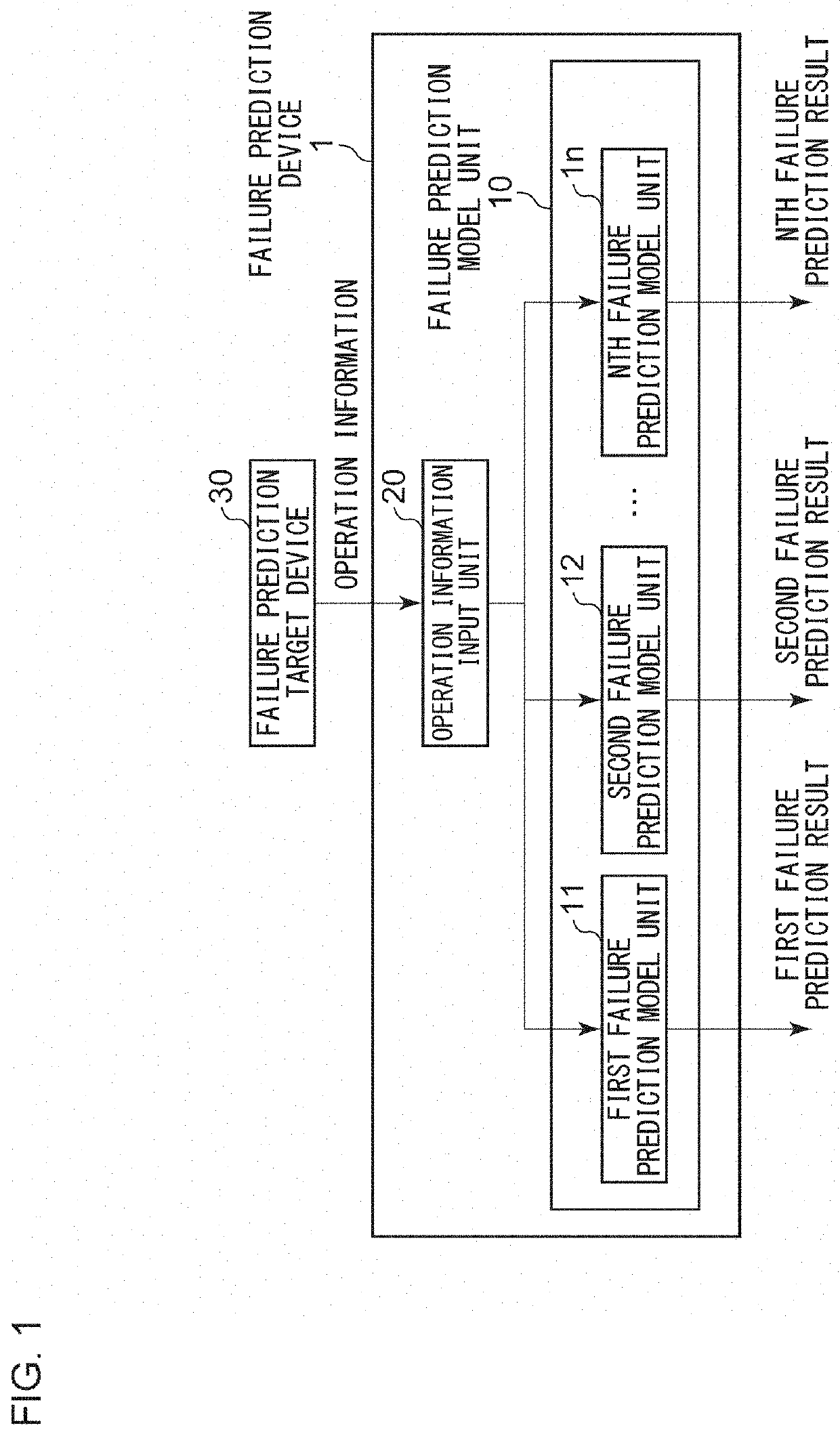

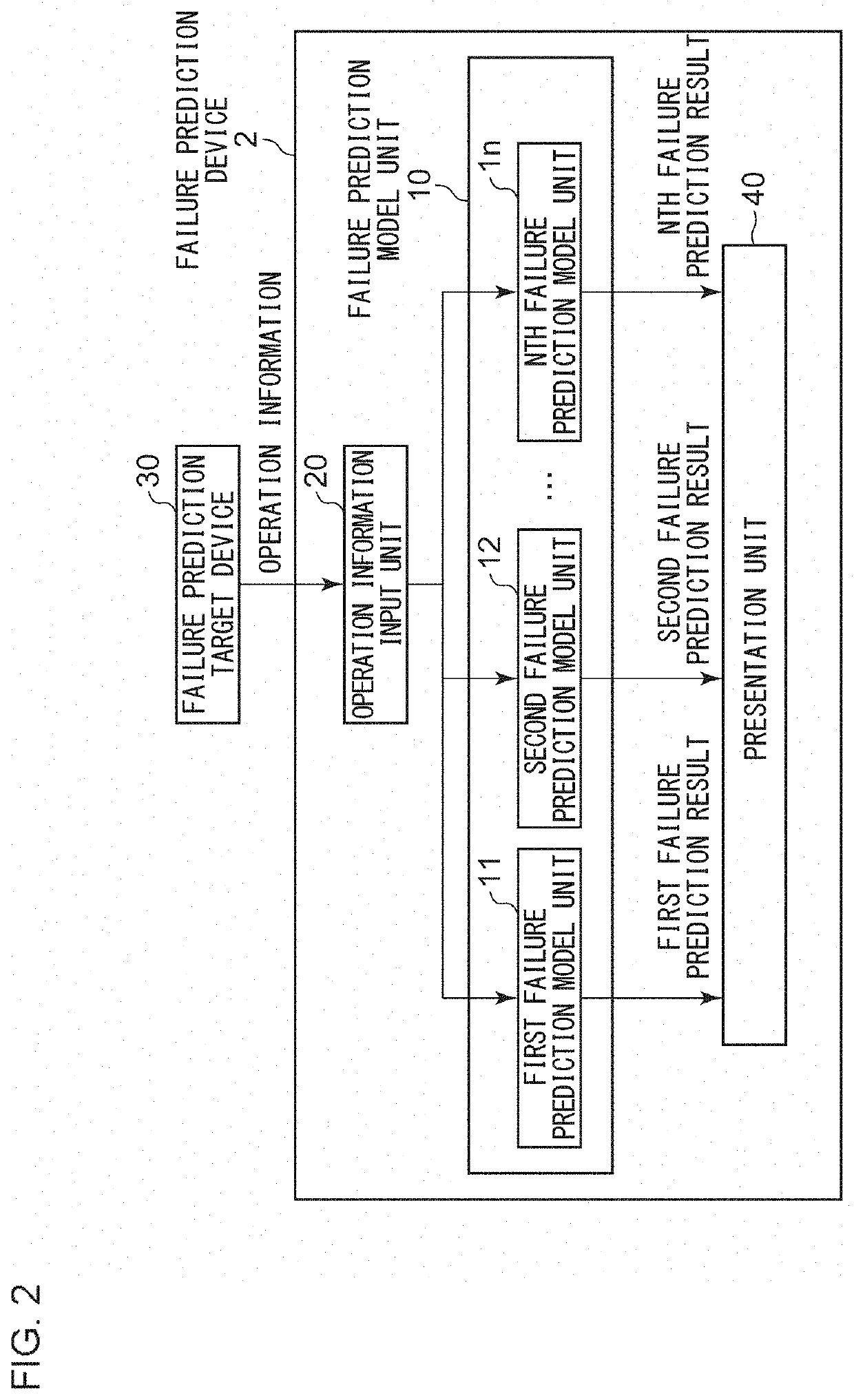

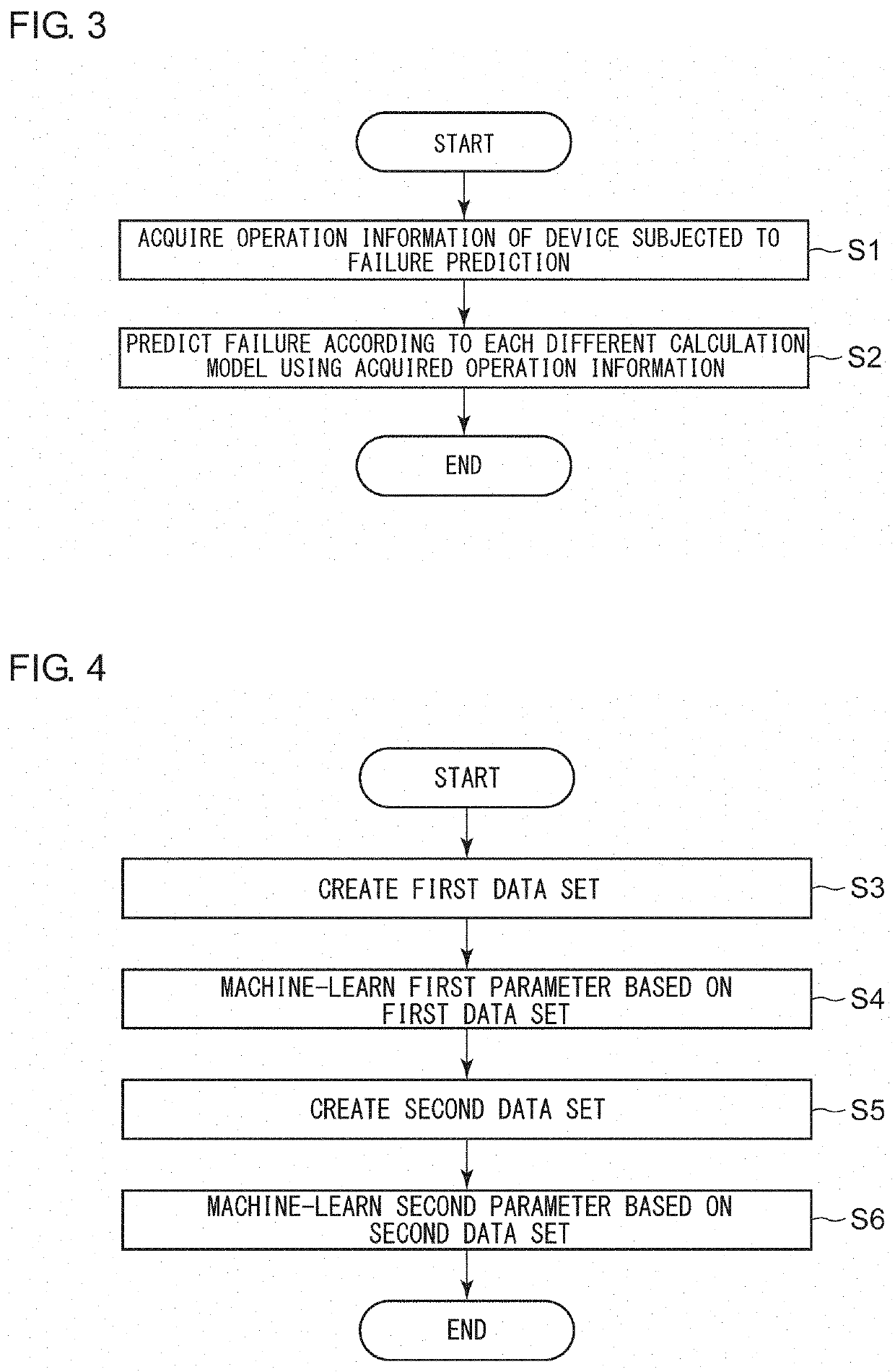

Failure prediction device, failure prediction method, computer program, calculation model learning method, and calculation model generation method

InactiveUS20200326698A1Improve accuracyElectric testing/monitoringForecastingComputational modelProgram calculation

Owner:NABLESCO CORP

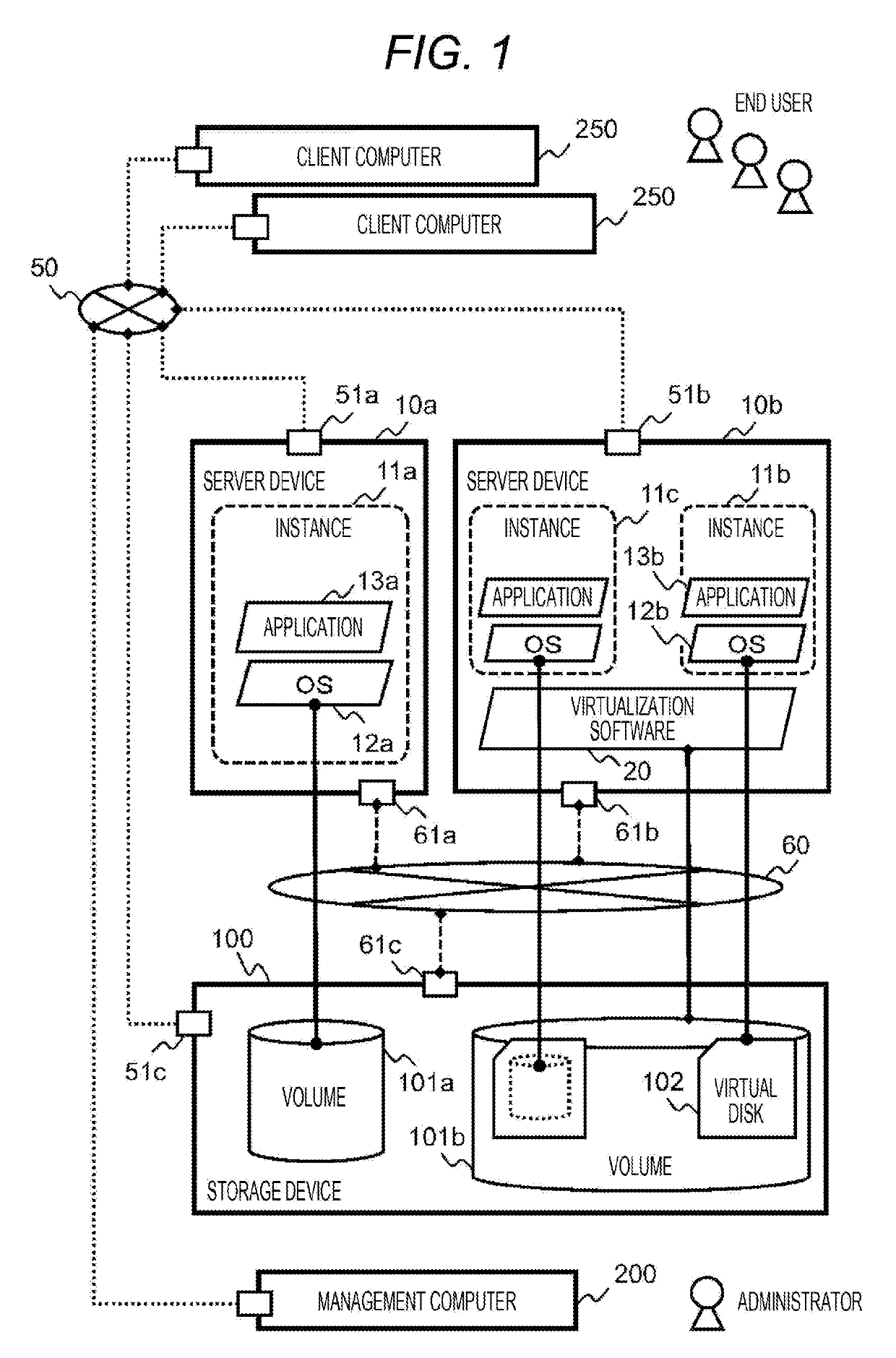

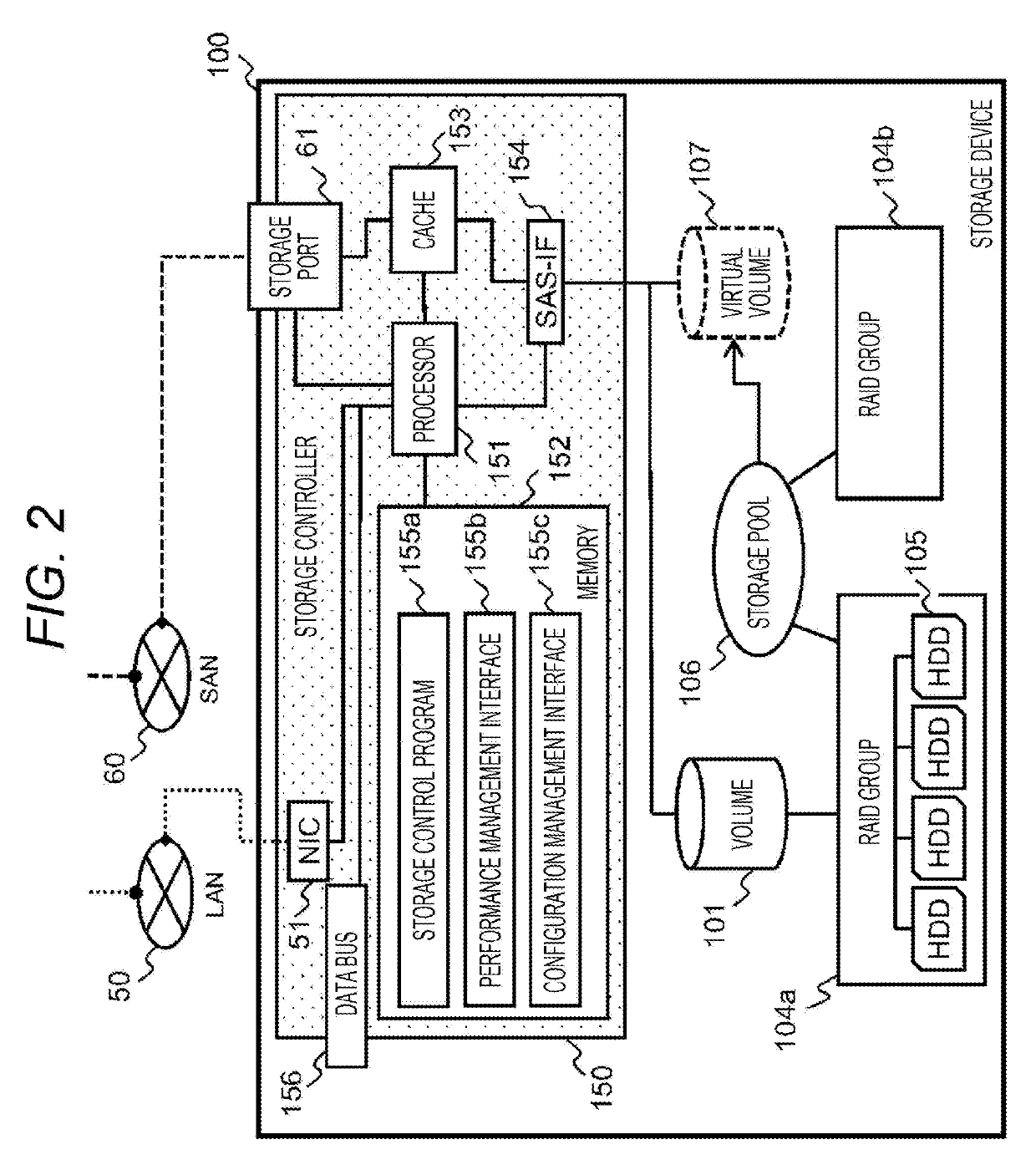

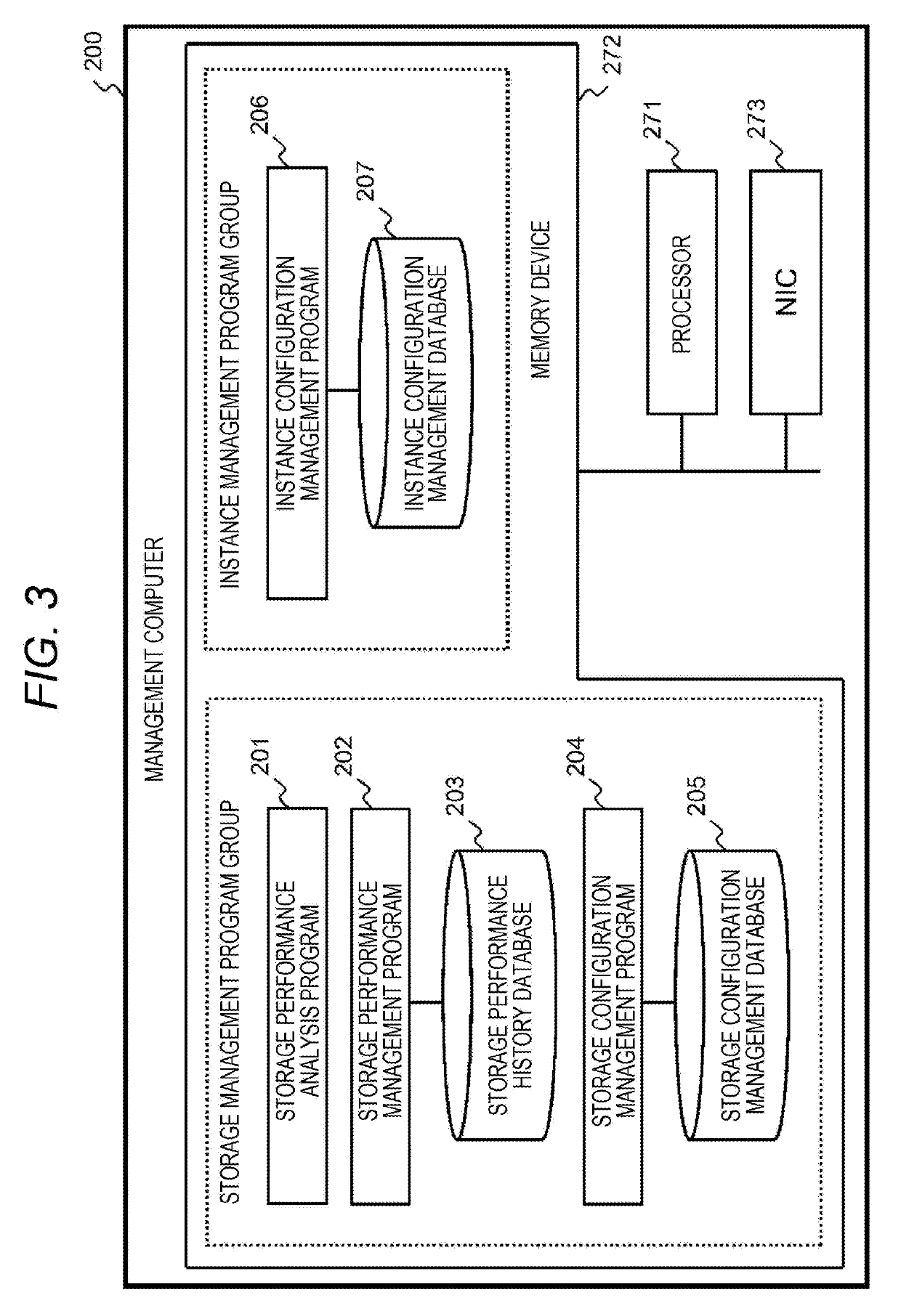

Performance analysis method and management computer

A performance analysis method of a computer system using a management computer. The management computer includes: a processor; and a memory device in which a program to be executed by the processor is stored. The computer system is constituted by a plurality of resources. The processor divides the plurality of resources into a plurality of resource groups based on a correlation of changes in performance data between the resources, and analyzes the performance data for each of the divided resource groups.

Owner:HITACHI LTD

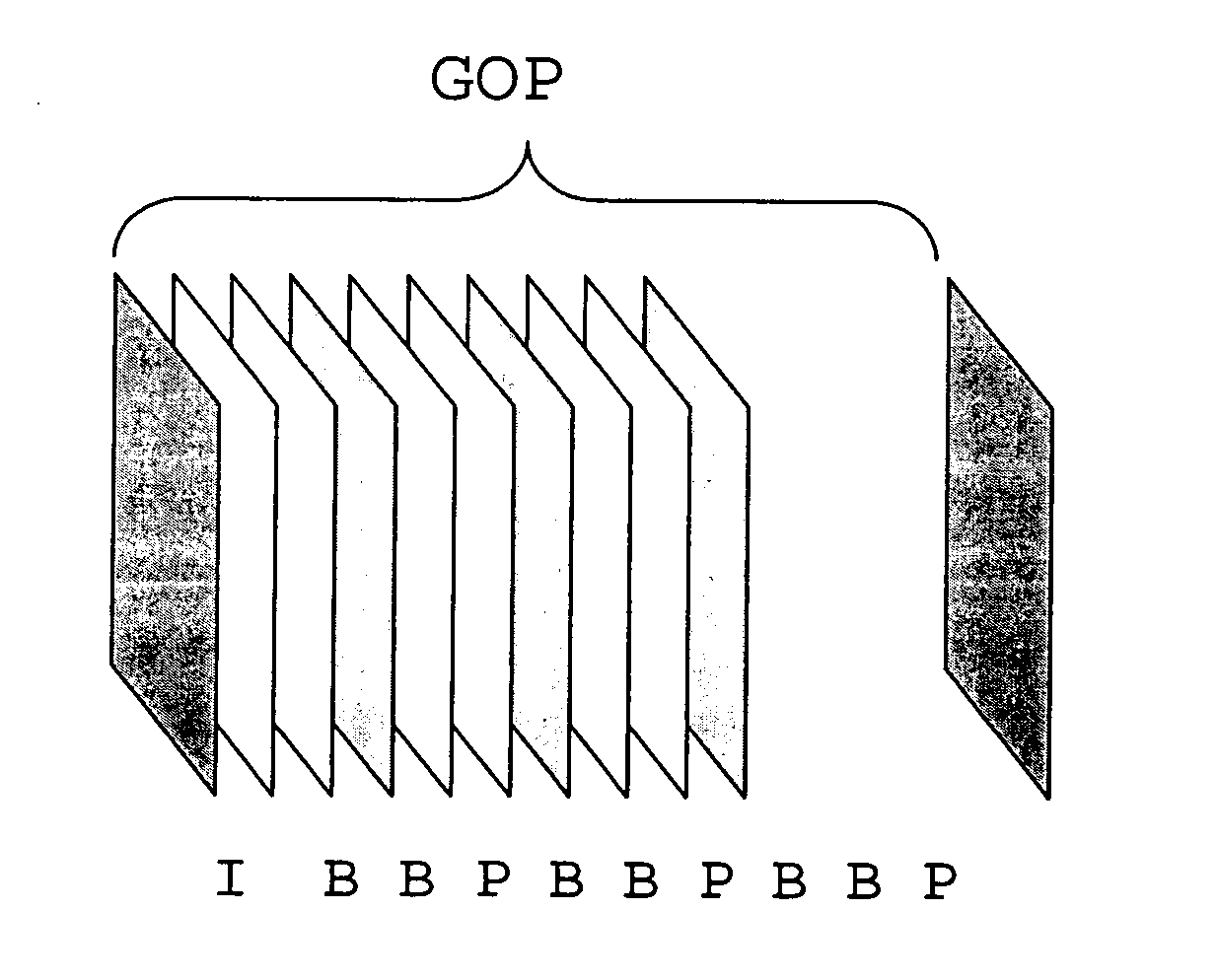

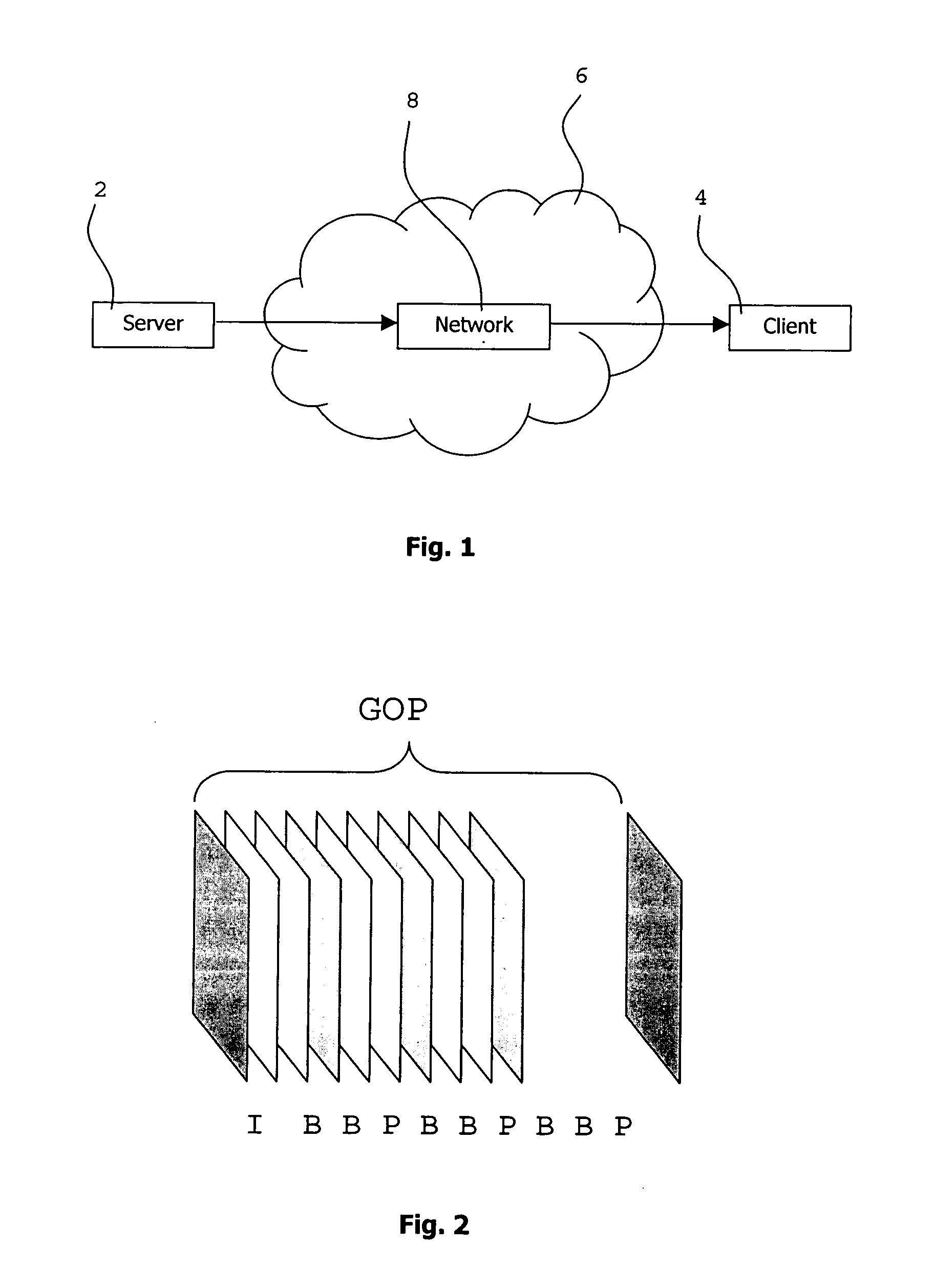

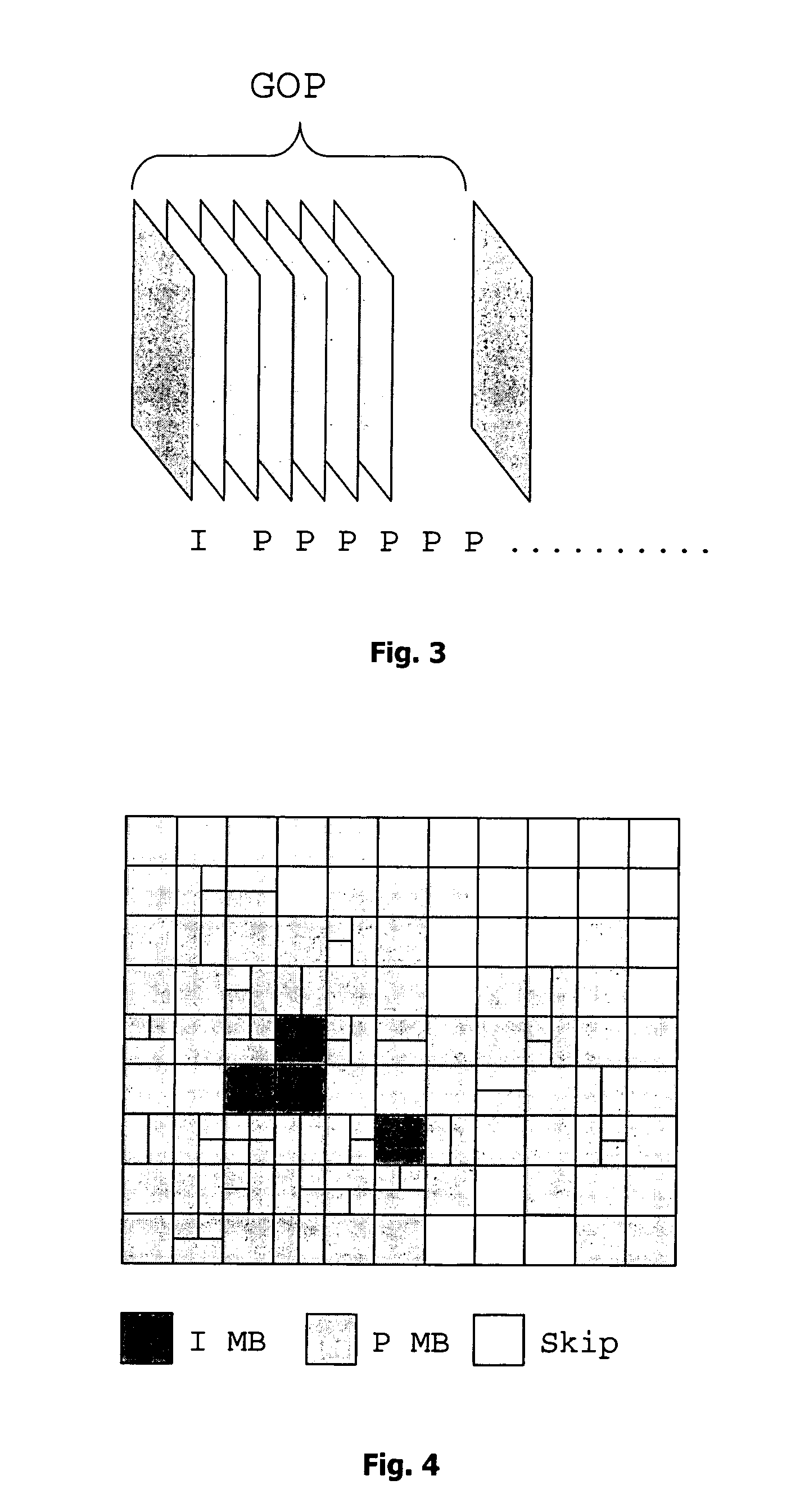

Technique for video quality estimation

ActiveUS20120281142A1Satisfactory accuracyConsumes few computational resourceTelevision system detailsColor television detailsVideo bitstreamVideo encoding

An objective video quality estimation technique is disclosed. The technique may be based on a video bitstream model, using parameters taken from the video coding layer of the bitstream for estimating the quality of the video. The technique can be implemented as a method, a computer program, a computer program product, a device, or any one of a server node, a client terminal and a network node comprising the device. As a method embodiment, the technique comprises receiving a video bitstream comprising a series of picture frames; determining an error occurrence in a picture frame of the video bitstream; determining at least one of a temporal propagation and a spatial propagation of the error; and estimating the quality of the video bitstream based on result of the determination.

Owner:TELEFON AB LM ERICSSON (PUBL)

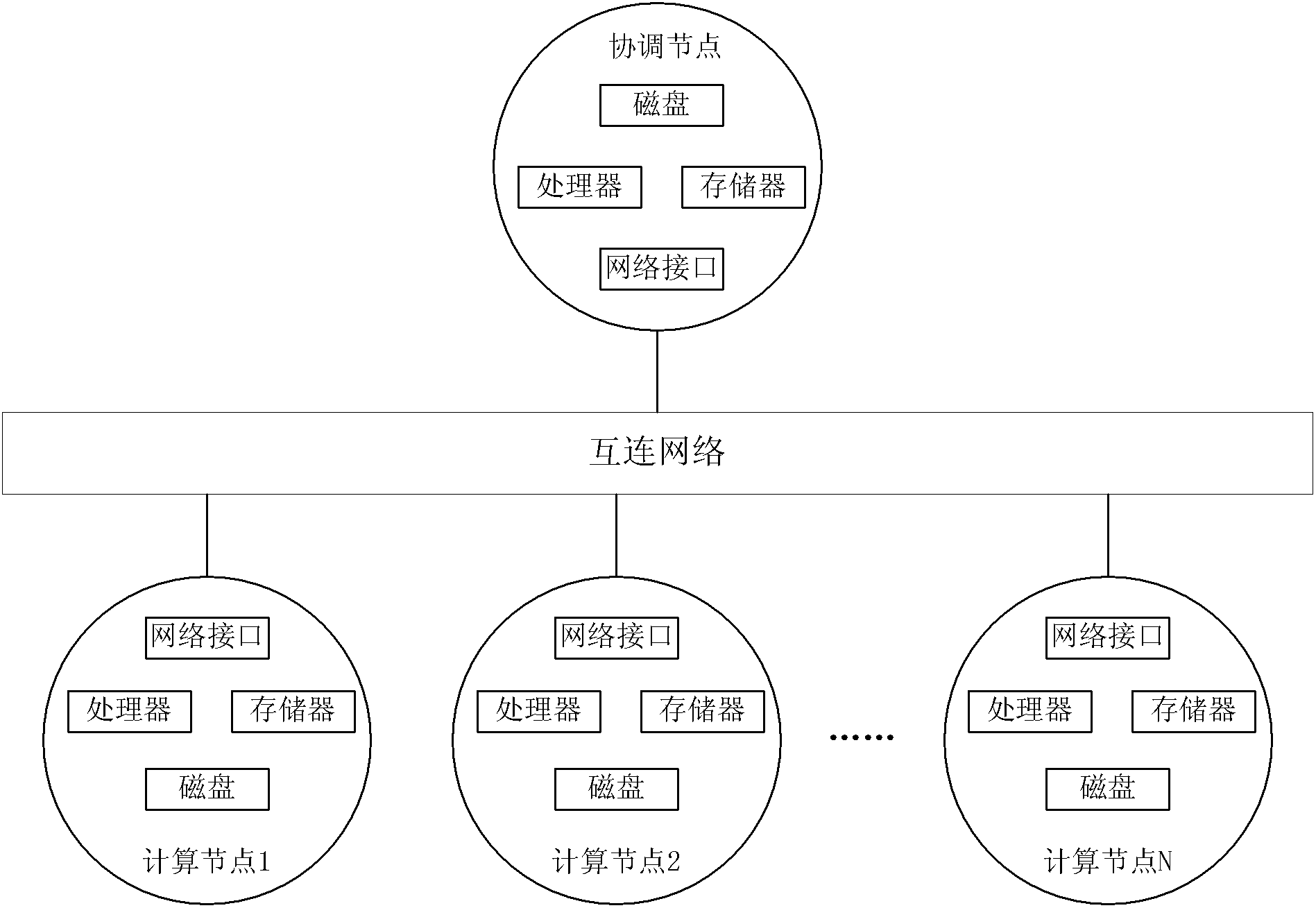

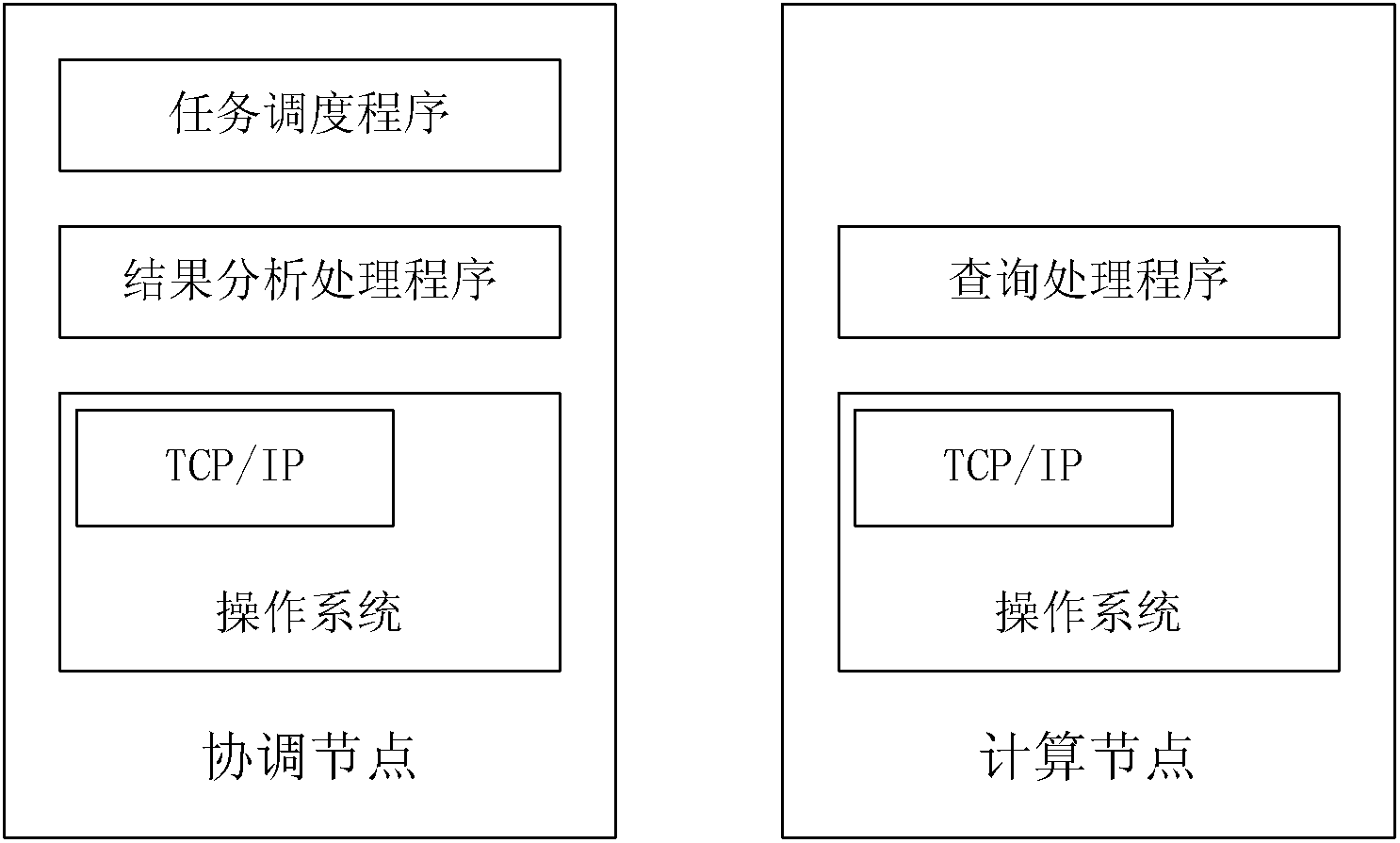

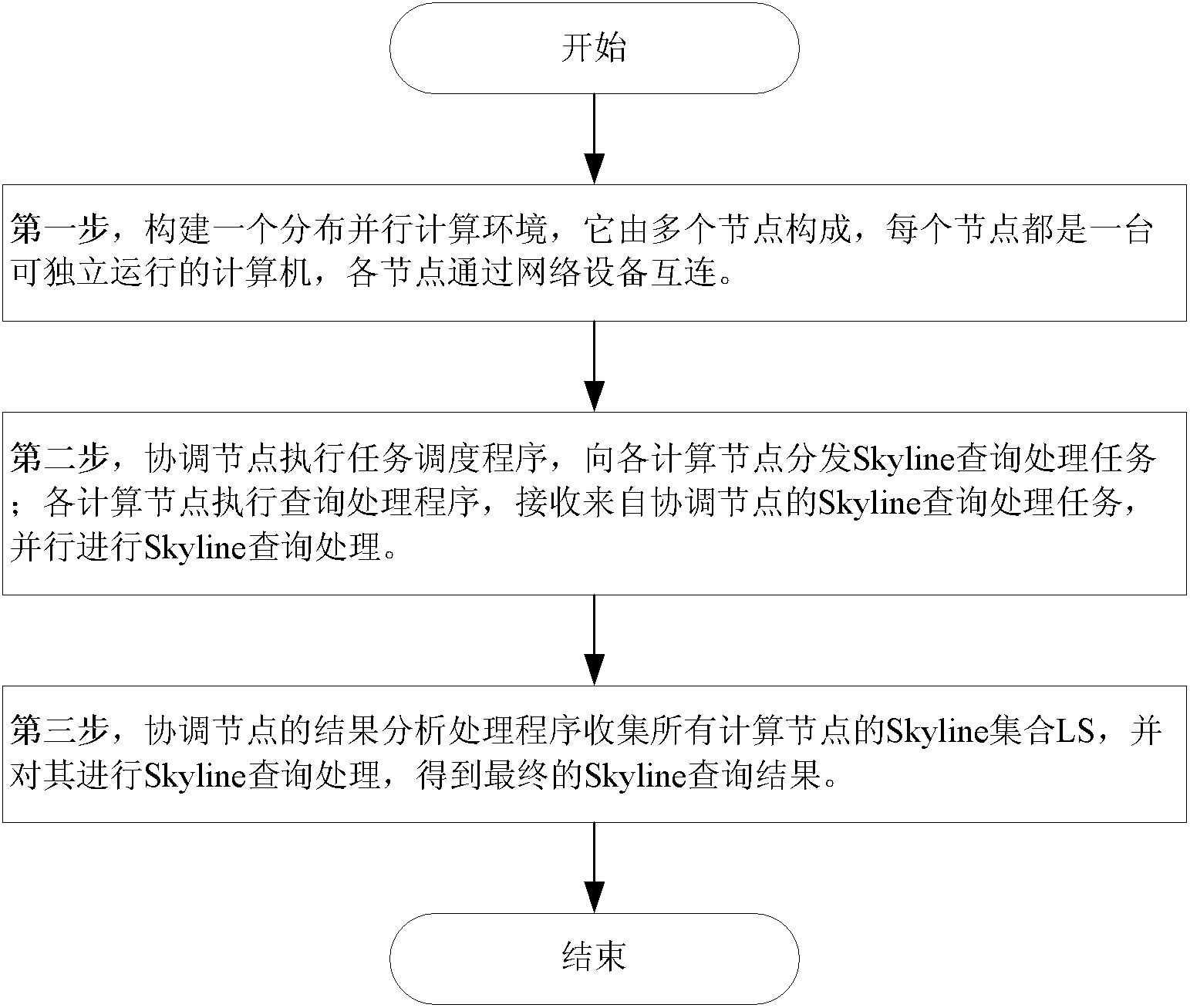

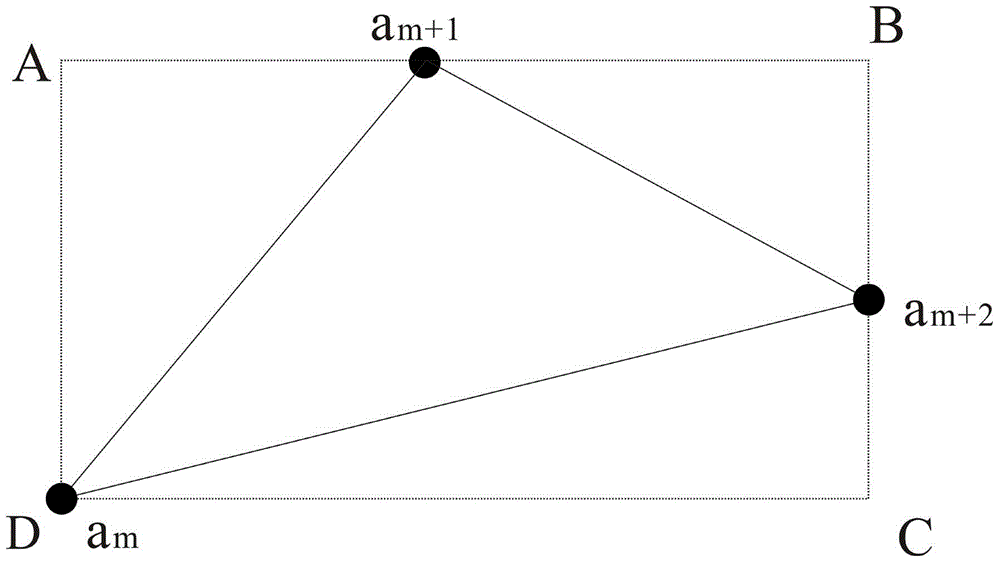

Distributed parallel Skyline query method based on vertical dividing mode

ActiveCN102323957ALoad balancingImprove query processing efficiencySpecial data processing applicationsFully developedParallel computing

The invention discloses a distributed parallel Skyline query method based on a vertical dividing mode and aims to provide a new Skyline query method for fully developing the parallelism of Skyline query processing and improving efficiency. The invention adopts the technical scheme that: the method comprises the following steps that: a distributed parallel computing environment which consists of a coordination node and N computing nodes is constructed, wherein the coordination node has a task scheduling program and a result analysis processing program, and the computing nodes have query processing programs; the coordination node executes the task scheduling program and distributes a Skyline query processing task to each computing node; each computing node executes the query processing program, receives the Skyline query processing task from the coordination node and performs Skyline query processing; and the coordination node executes the result analysis processing program to collect a Skyline set LS of all computing nodes and performs Skyline query processing on the Skyline set LS to obtain a final Skyline query result. By adoption of the method, load balancing between the computing modes can be effectively guaranteed, the accuracy of the Skyline query result is guaranteed, and query efficiency is improved.

Owner:NAT UNIV OF DEFENSE TECH

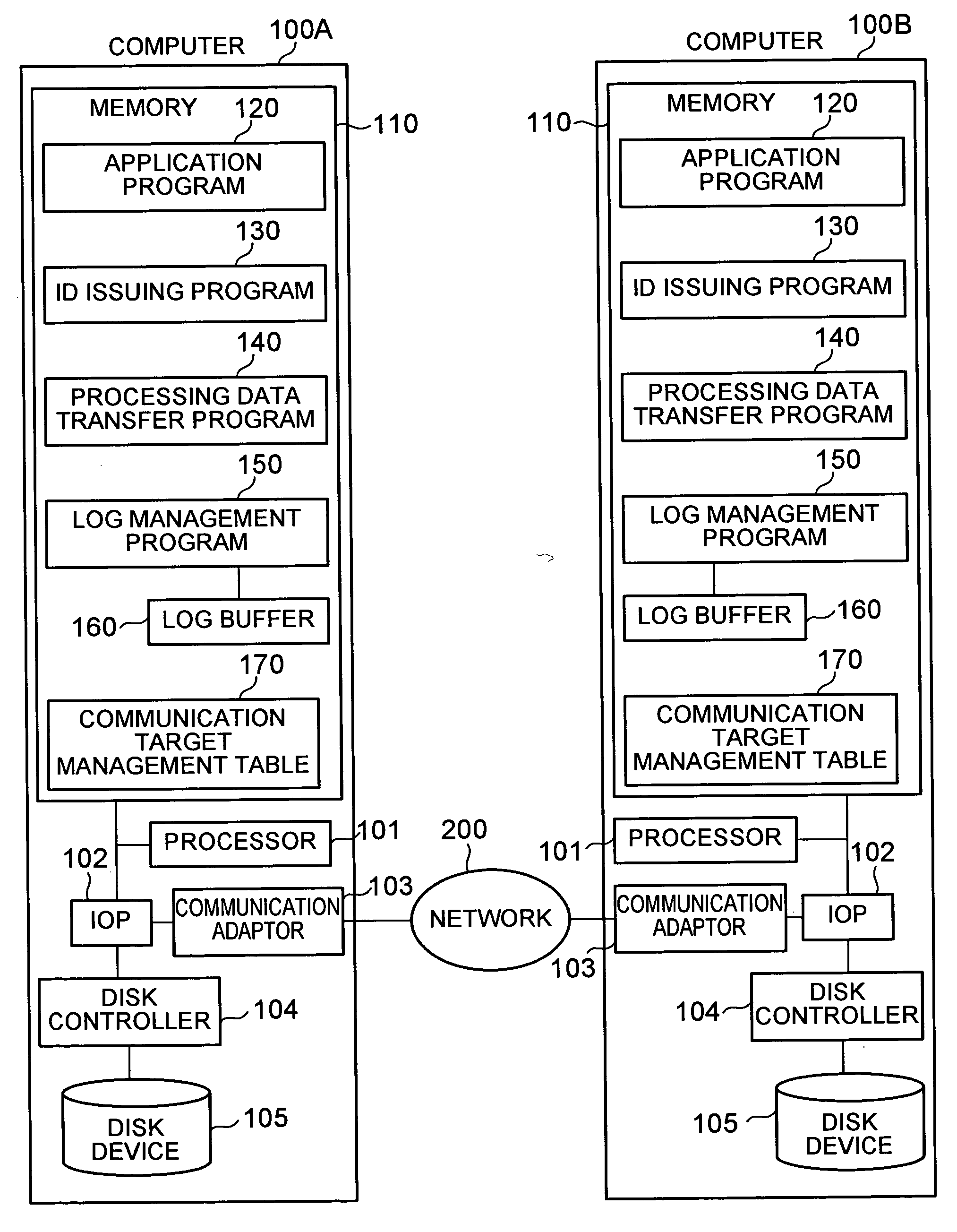

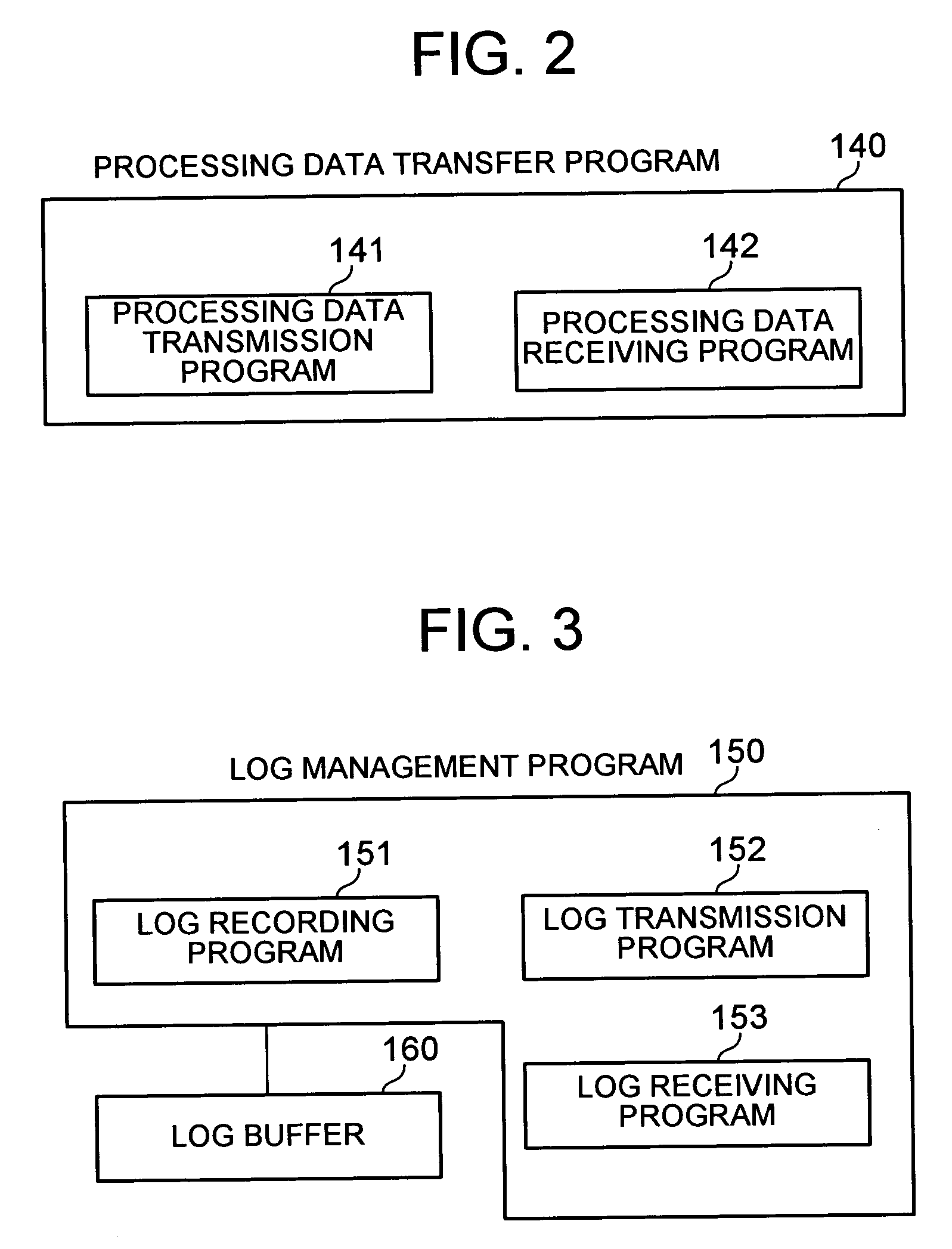

Log management program of a computer, log management method thereof, and computer system

InactiveUS20070050425A1Non-redundant fault processingSpecial data processing applicationsLog managementSoftware engineering

According to the present invention, even when any one of the computers constituting a computer system becomes inoperable, a series of flow of distributed processing can be traced. Application program 120 in computer 100A requests computer 100B to perform a part of the series of the processes (S106). Log information items in the computer 100A, to which an ID issued to a series of processes is attached, are transmitted to the computer 100B by the log transmission program 152 in the computer 100A (S110). The log information receiving program 153 of the computer 100B receives these log information items and stores them in logbuffer 160 (S221, S222). The application program 120 in the computer 100B executes thus requested processing, and returns the process result to the computer 100A (S206). The log information items of the computer 100B each having the above ID, generated by executing the processing, are transmitted to the computer 100A by the log transmission program 152 of the computer 100B (S210) , and the log information receiving program 153 of the computer 100A receives this log information items and stores them in the log buffer 160 (S121, S222).

Owner:HITACHI LTD

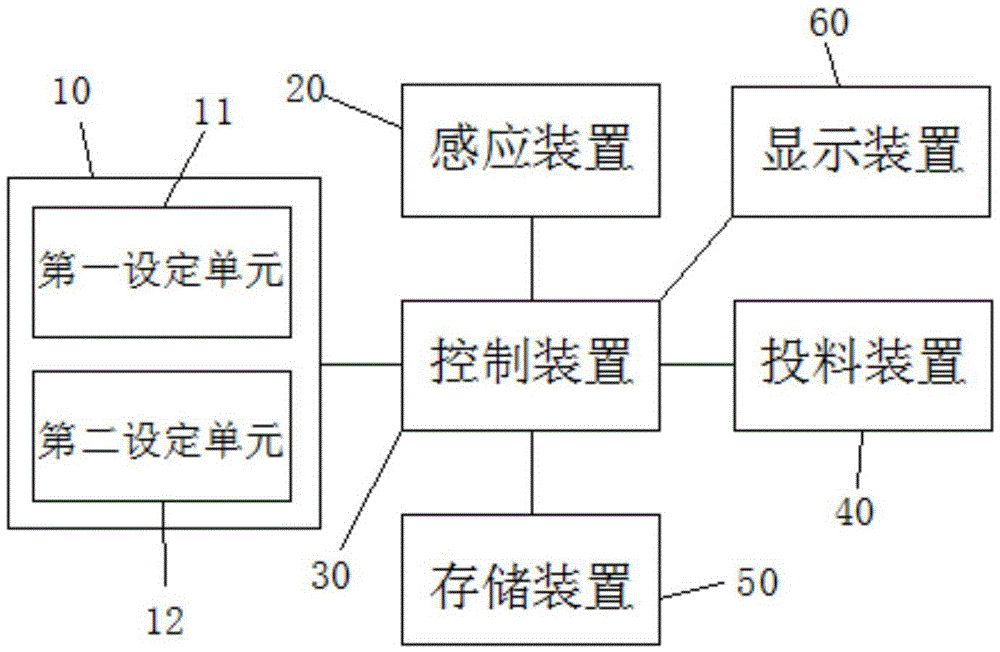

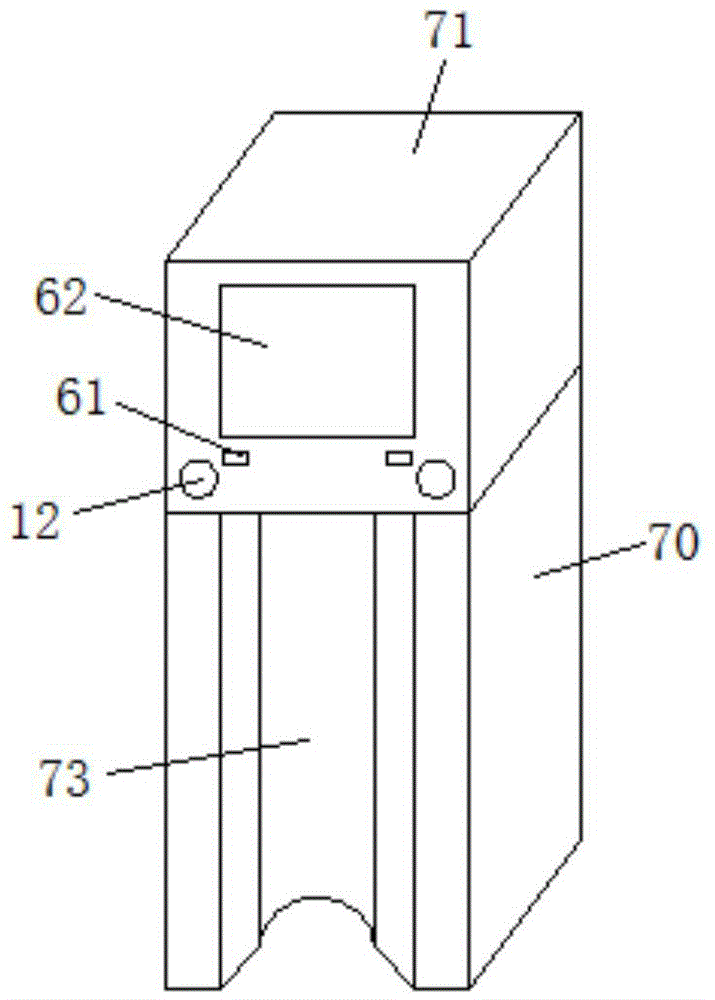

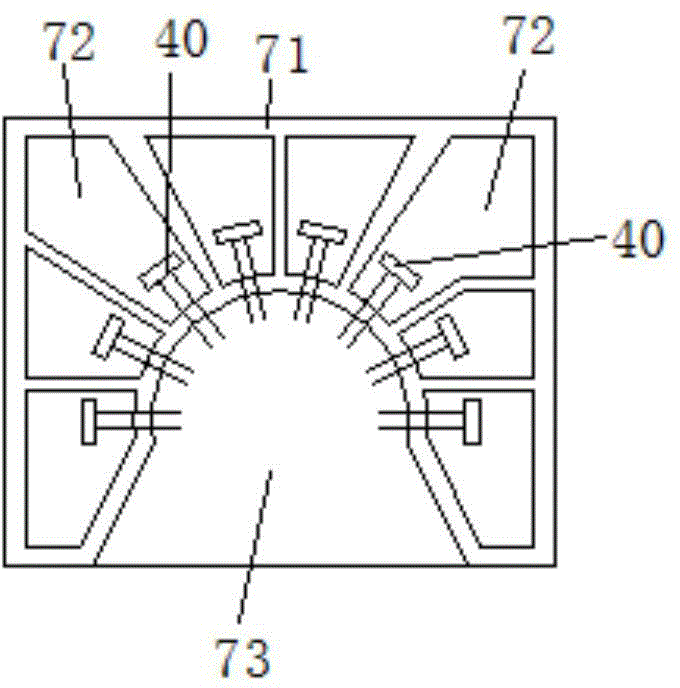

Seasoning adding control system and seasoning adding device

InactiveCN104688097AAvoid standardizationAvoid procedural workKitchen equipmentFlavorAutomatic control

The invention relates to a seasoning adding control system. A setting device sets a current processed dish and a required flavor and sends information to a control device, the control device acquires a seasoning ratio matched with the dish and the flavor by means of program calculation, a sensing device sends signals to the control device after sensing a cooking spoon put by a cook, the control device sends control instructions to the seasoning adding device, the seasoning adding device adds seasonings according to the seasoning ratio, and seasoning adding time, types and quantities can be controlled automatically. The invention further provides the seasoning adding device with the control system. The seasoning adding control system and the seasoning adding device have the advantages that dish processing efficiency can be improved evidently, time cost is reduced for catering enterprises, and competitiveness is promoted.

Owner:欧阳亮

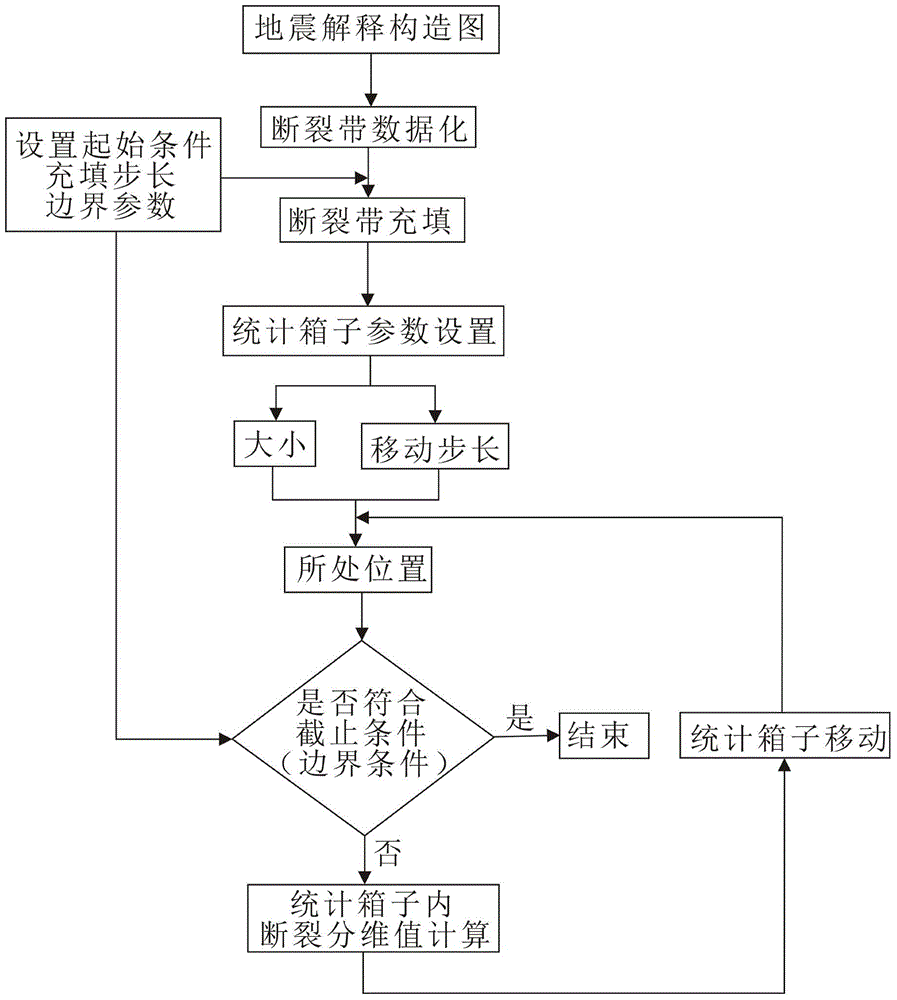

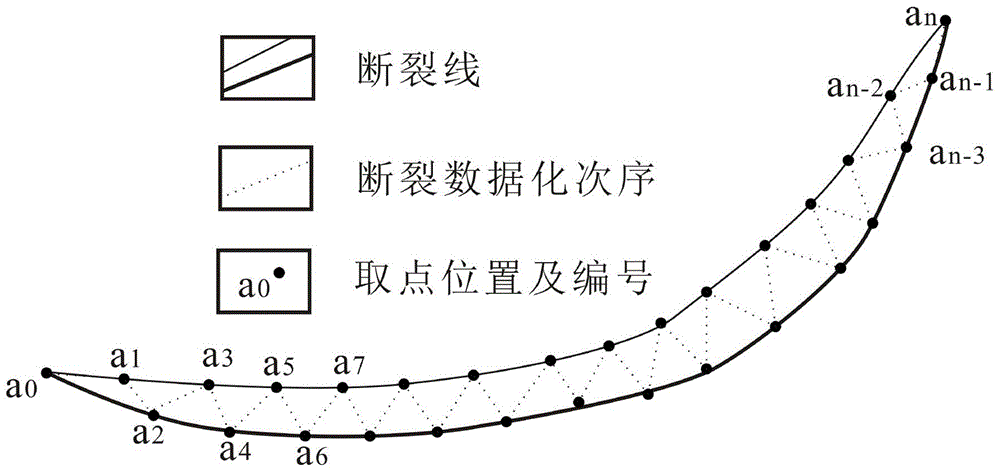

Fracture fractal characteristic optimization computation method

InactiveCN104459776AReduce spendingHigh utility valueSeismic signal processingEvaluation resultDatafication

The invention relates to the field of exploration and development of oil and gas fields, in particular to a fracture fractal characteristic optimization computation method. After datamation of a facture zone, parameters of statistical boxes are defined by setting boundary parameters and initial positions, the statistical boxes are moved constantly through program writing, fractal dimension values of the positions where the statistical boxes are located are calculated, and therefore programmed calculation of fracture fractal characteristics is realized. The fracture fractal characteristic optimization computation method has high practical value on the aspects of fracture fractal characteristic quantitative evaluation, fracture fractal characteristic quantitative description and the like, is low in prediction cost and high in operability, and greatly reduces the expense of manpower; evaluation results have certain guiding significance in the aspects of predicting the distribution characteristics of oil and gas exploration and development key areas, fracture dominant distribution areas and low-level-sequence faults and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

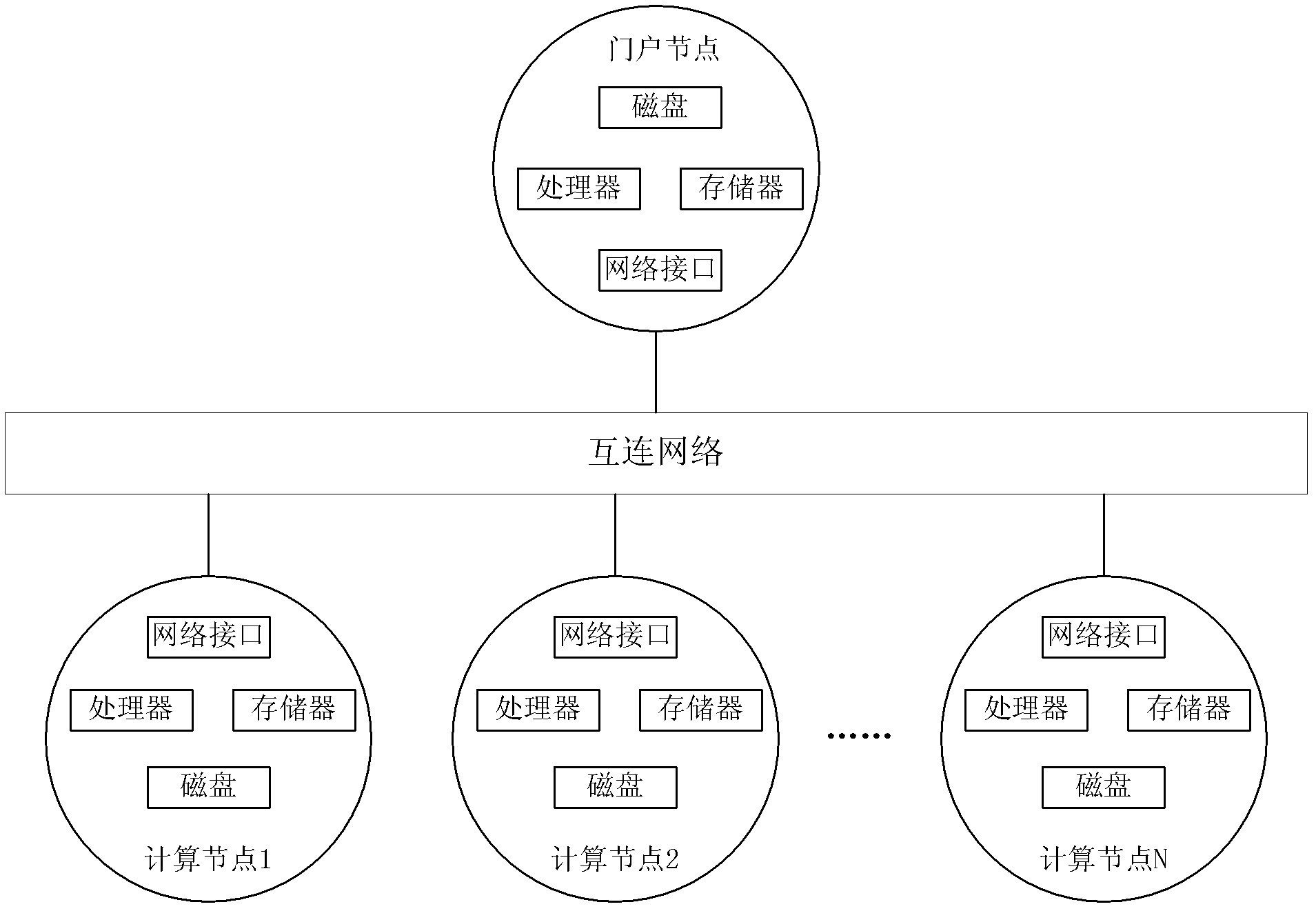

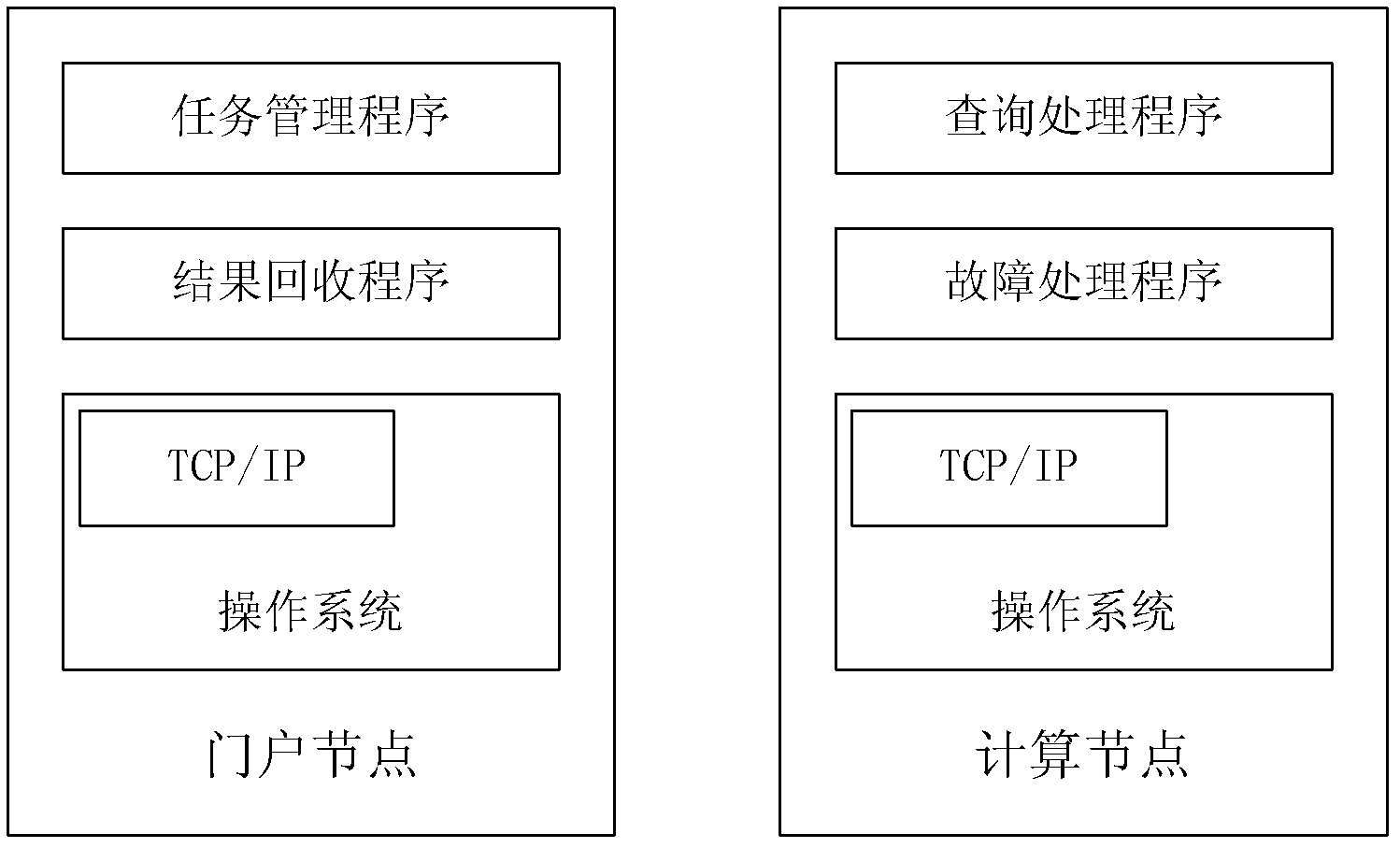

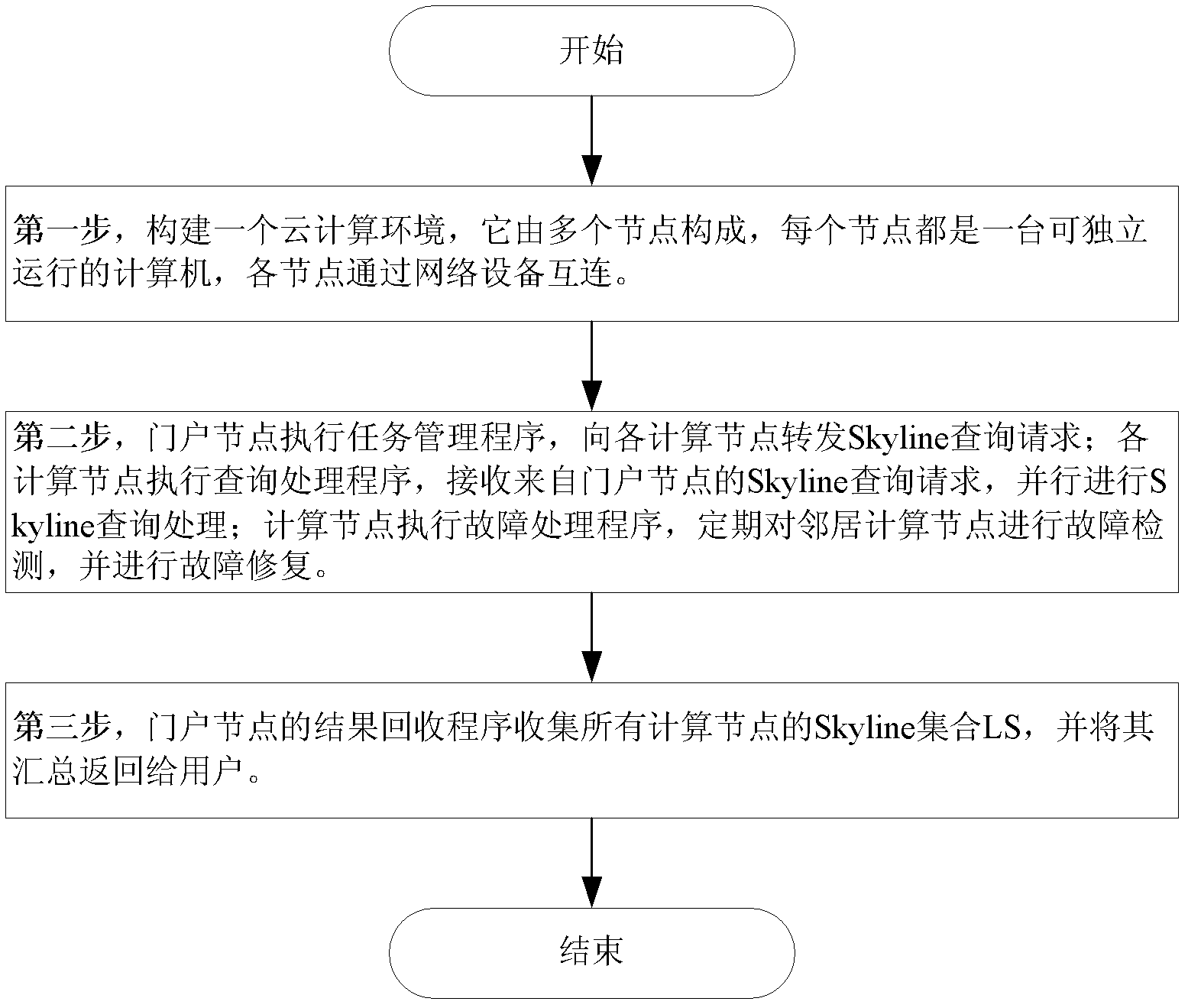

Distributed parallel Skyline inquiring method based on cloud computing environment

ActiveCN102314521AFully exploit parallelismEfficient parallel processingTransmissionSpecial data processing applicationsParallel computingDependability

The invention discloses a distributed parallel Skyline inquiring method based on a cloud computing environment, aiming at effectively preventing a node failure from influencing inquiring and processing processes of the distributed parallel Skyline. The technical proposal comprises the steps as follows: firstly, the clouding computing environment which consists of a portal node and N computer nodes is constructed, wherein a task management program and a result recovery program are arranged on the portal node, an inquire processing program and a fault processing program are arranged on the computer nodes; the portal node executes the task management program and transfers the Skyline inquiring request to each computer node; each computer node executes the inquire processing program and implements Skyline inquire processing; each computer node executes the fault processing program, and periodically detects and repairs the fault for the neighbor nodes; the portal node executes the result recovery program, collects a Skyline set of all the computer nodes, gathers the Skyline set and returns the Skyline set to users. By adopting the invention, the influences to the inquire processing process of the distributed parallel Skyline caused by the node failure can be effectively controlled, and high efficiency, reliability and accuracy of the Skyline inquire processing can be guaranteed.

Owner:NAT UNIV OF DEFENSE TECH

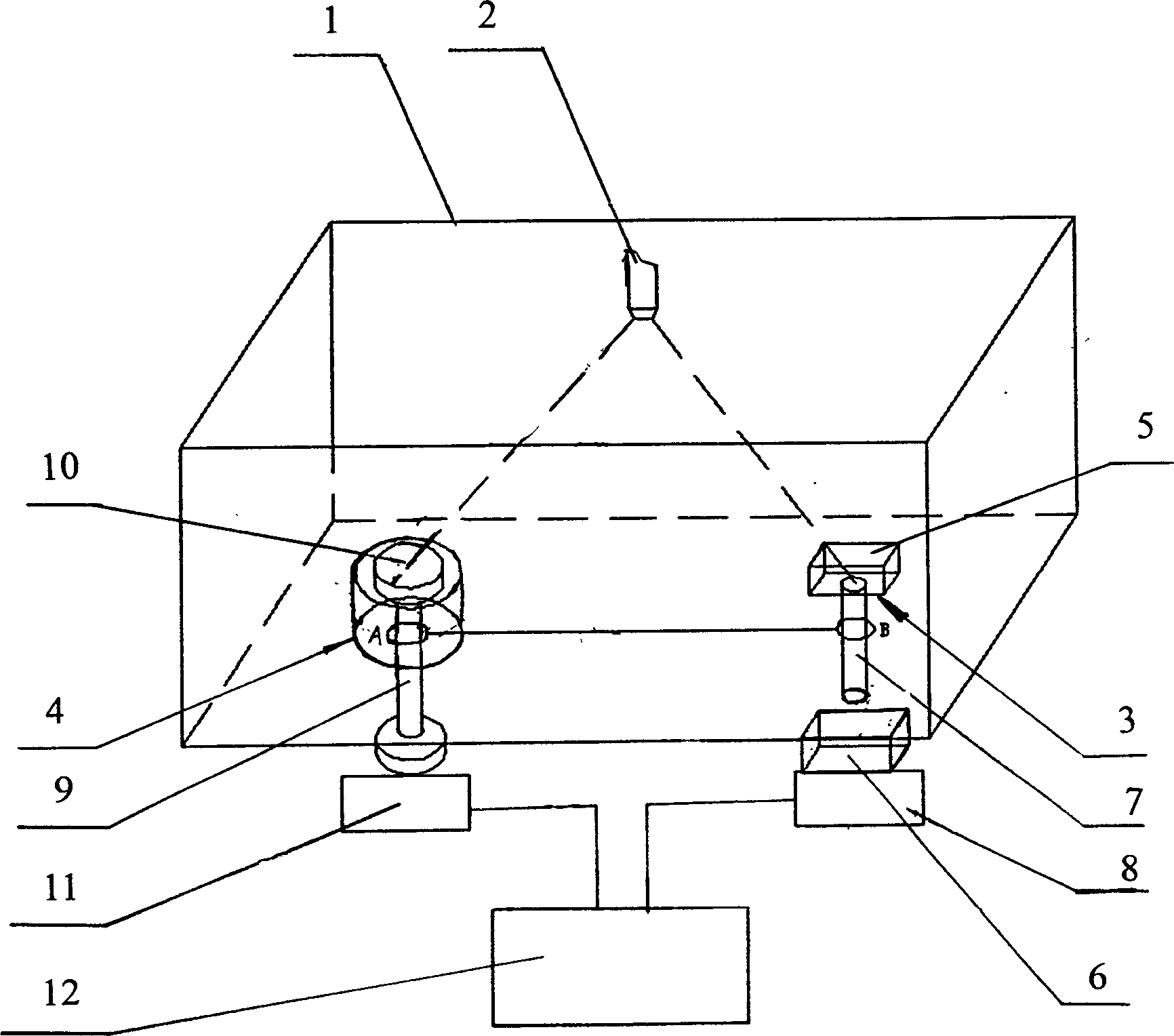

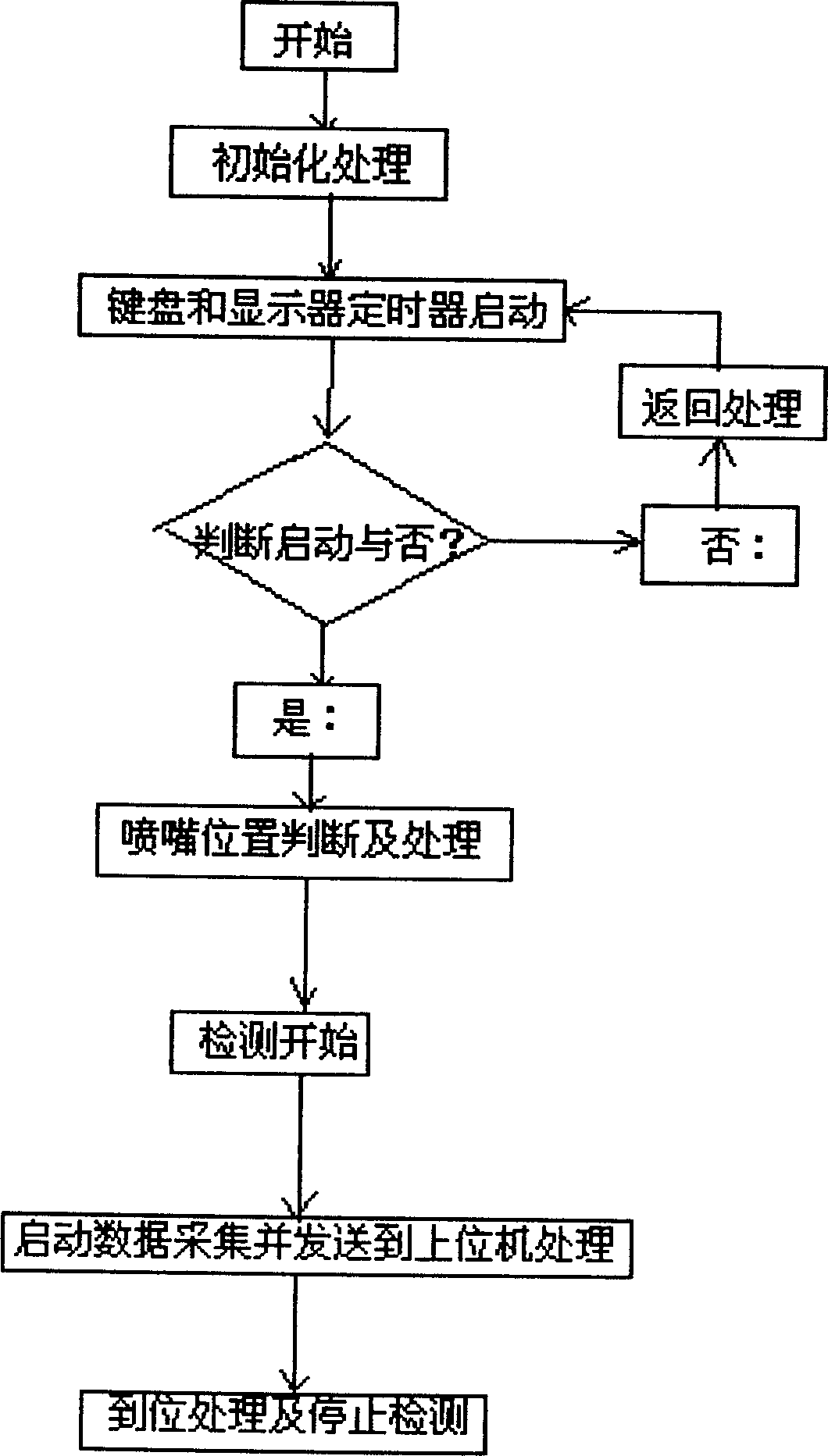

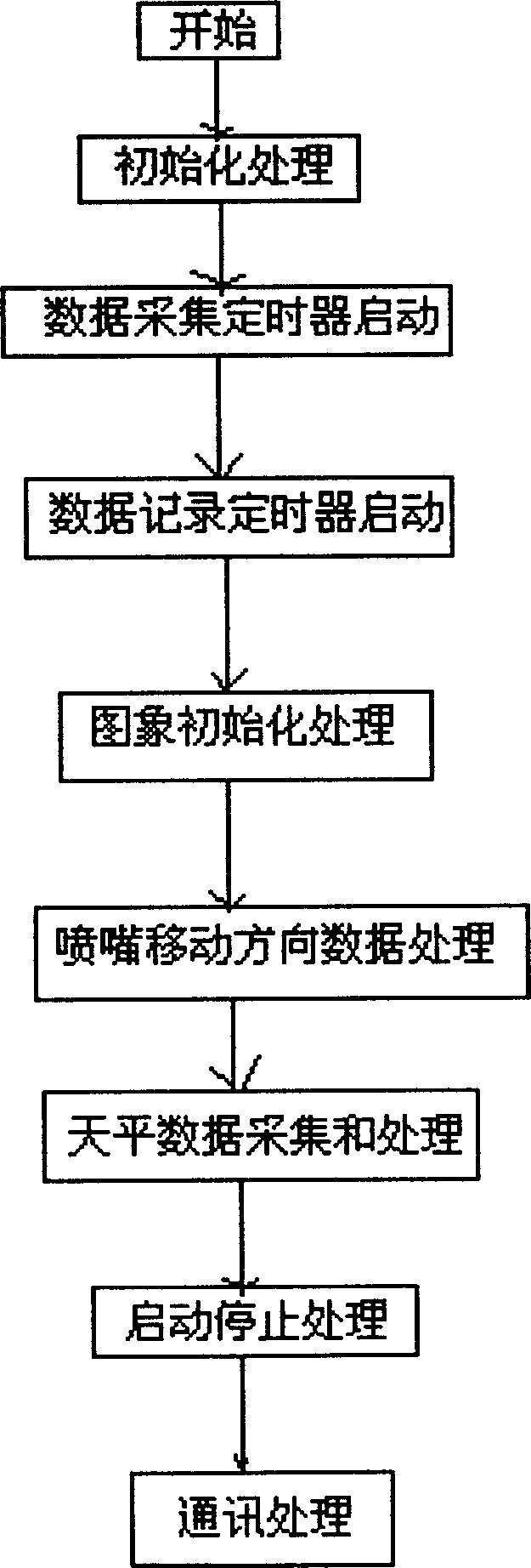

Method and apparatus for testing spraying characteristic of secondary cooling nozzle of continuous casting

InactiveCN1789951AHigh degree of automationSuitable nozzleFluid pressure measurement by electric/magnetic elementsStructural/machines measurementSprayerWater flow

The invention discloses a spray character test method and device of continuous casting two-cold-sprayer, which comprise the following steps: 1. the moving sprayer sprays water through the water-spray quality sensor and water-spray bunch pressure sensor on the downward moving gathering point; 2. the water-spray quality sensor and water-spray bunch pressure sensor transmits the real-time gathered spray quantity and increment and spray bunch pressure value to the computer; 3. the computer calculates the flow density value and bunch pressure value according to the setting parameter and program, which generates the distribution graph of spray flow density and bunch pressure. The entire course can be controlled by computer automatically, which improves the automatic degree greatly to finish the test by one person. The test result can be printed at the report pattern, which displays the distribution graph of spray flow density and bunch pressure.

Owner:CHONGQING UNIV +1

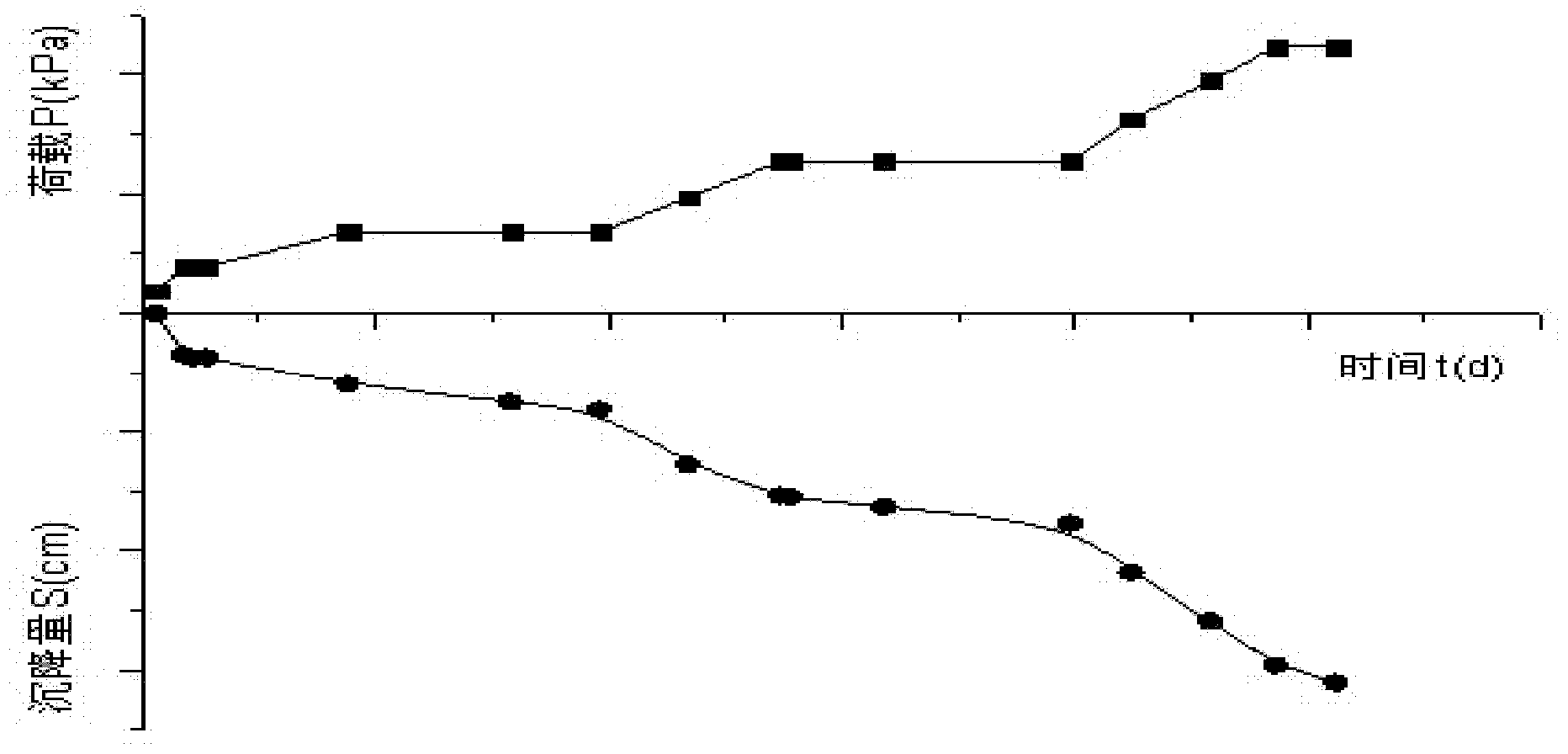

A Method of Calculating the Height of Precompacted Soil Based on the Measured Settlement Data

ActiveCN102289602AStrong targetingOptimize data processingSpecial data processing applicationsData treatmentMATLAB

The invention discloses a method for calculating the height of pre-pressed soil based on actually measured sedimentation data. The method is established over calculation of foundation average concreting degree through a Gaomujunjie method. Various parameters are obtained by calculating the actually measured sedimentation data. The method comprises the following steps of: firstly, calculating the foundation concreting degree under an instantaneous loading condition through the actually measured sedimentation data; then, calculating concreting coefficients by operating a least square method through the foundation concreting degree under the instantaneous loading condition; and finally, calculating the pre-pressed height by calculating the foundation average concreting degree according to the Gaomujunjie method. Compared with the traditional method for determining pre-pressed height, the method disclosed by the invention has the advantages that: various calculation parameters are obtained through the actually measured sedimentation data and closer to engineering practice; the method is capable of calculating the height of the pre-pressed soil in the section according to various observation section sedimentation data so that the method has strong pertinence; simultaneously, programming calculation of software, such as MATLAB and the like, can be carried out; and the data is simpleand convenient to process and convenient to popularize and apply.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

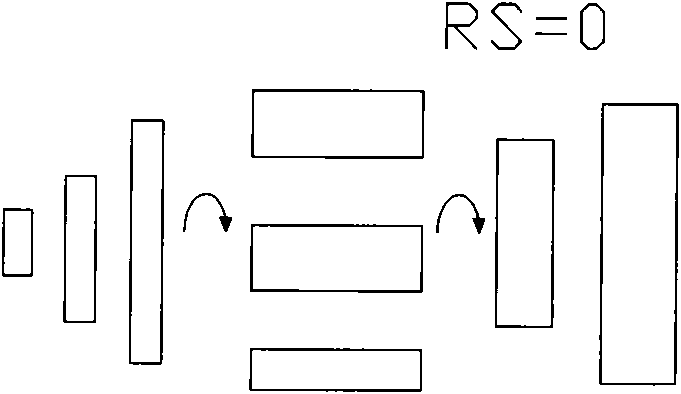

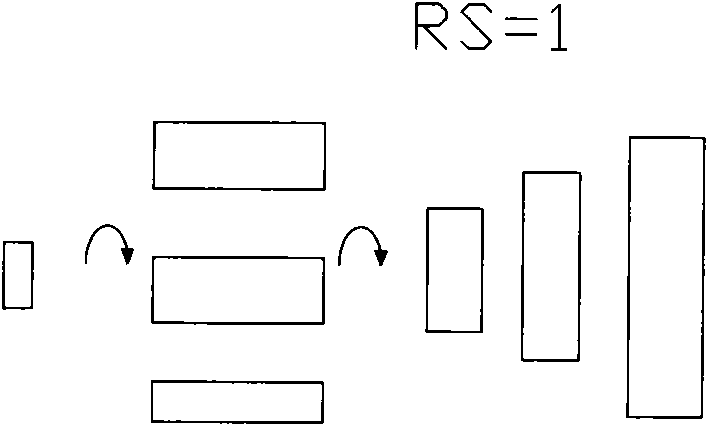

Opening degree control method of side guide plate of heavy plate mill

ActiveCN101585050AShorten the timeShorten production timeRoll mill control devicesMetal rolling arrangementsSheet steelEngineering

The invention relates to an opening degree control method of a side guide plate of a heavy plate mill. The opening degree of a side guide plate before rolling is preset according to a rolling method code RS and the size of a plate blank so that the opening degree of the side guide plate before the rolling is preset to a proper position; as for the plate blanks with RS=0, 3 and 4, the preset opening degree of the side guide plate before the rolling is determined according to the width of the plate blanks; as for the plate blanks with RS=1 and 2, the opening degree of the side guide plate before the rolling is set according to the length and the width of the plate blanks; and the opening degree of the side guide plate during the rolling is set according to the length and the width of a steel plate at the time of steel rotation. The opening degree control method solves the problem that the opening degree of the side guide plate influences the rolling speed and sets the opening degree of the side guide plate with the assistance of program calculation; and during the rolling, the side guide plate does not need man adjustment, thereby improving the rolling speed and increasing the productivity of the mill. The production time of each steel plate can be reduced by over 15 s, and the productivity of the mill can be improved by 7 percent.

Owner:BAOSHAN IRON & STEEL CO LTD

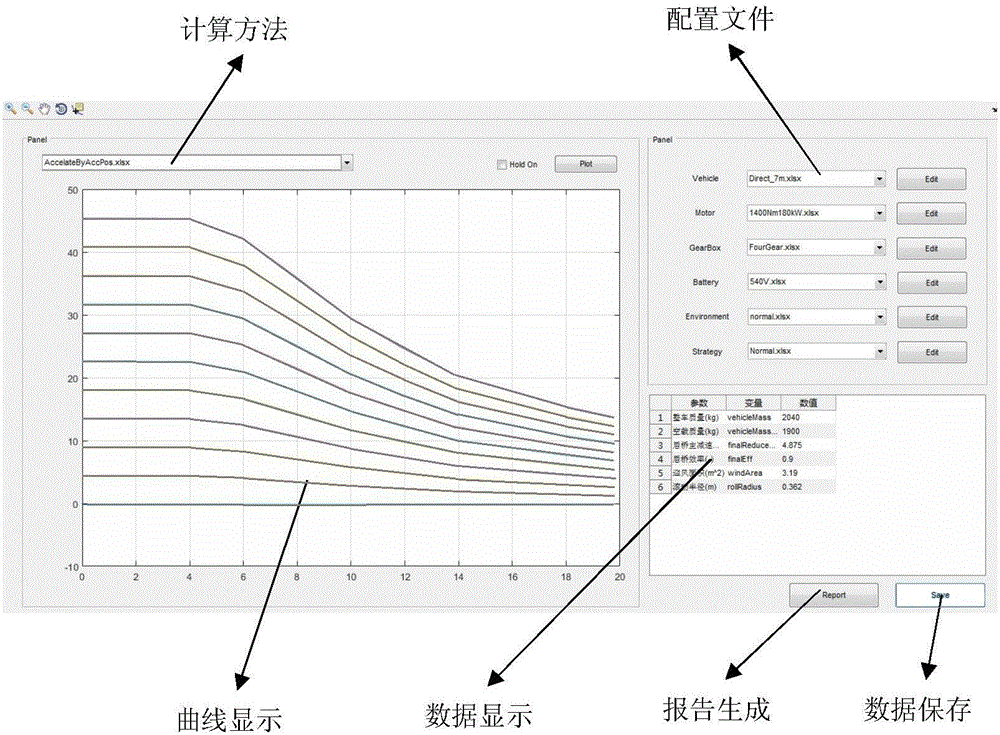

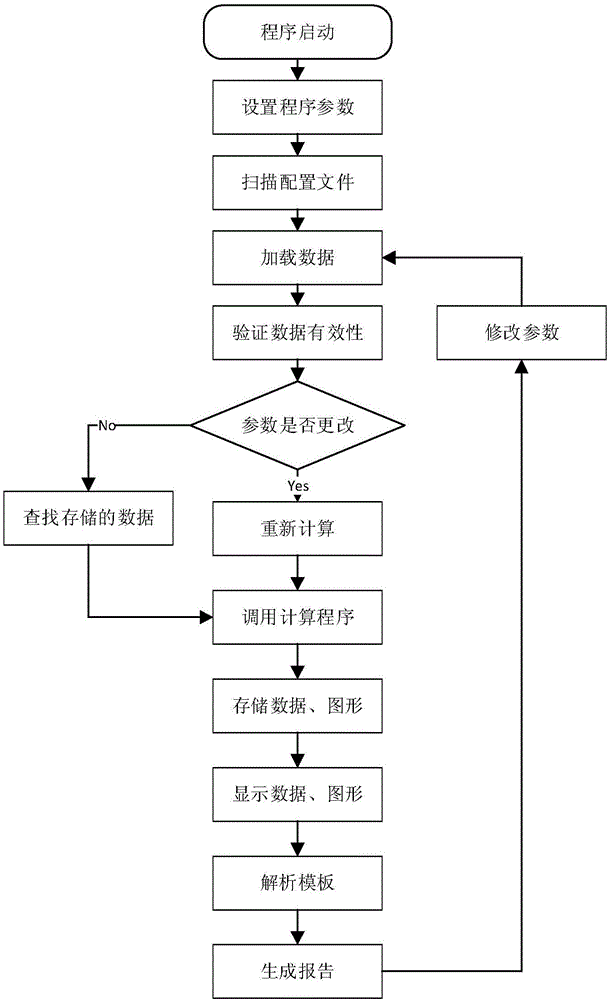

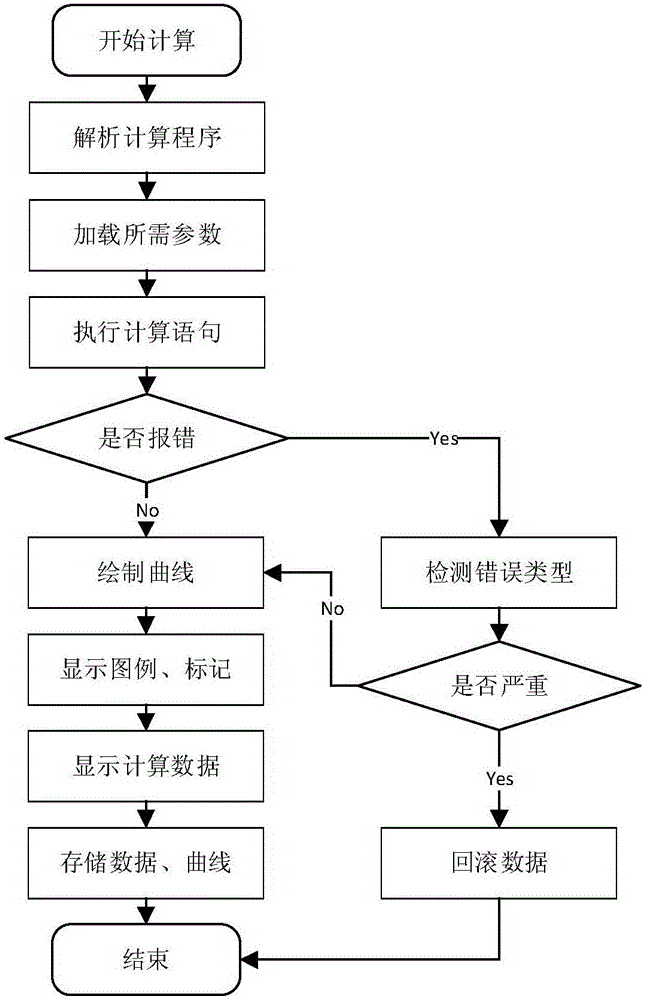

Matlab-based vehicle performance simulation and calculation method for automobile

ActiveCN106650059AFlexible definitionEasy to changeGeometric CADDesign optimisation/simulationData displayNew energy

The invention discloses a Matlab-based vehicle performance simulation and calculation method for an automobile. The method comprises a first step of program calculation, a second step of file configuration, a third step of curve display, a fourth step of data display, a fifth step of data saving and a sixth step of report generation. The method is used for calculating vehicle basic performance data of the automobile and provides a basic theoretical basis for vehicle performance analysis and simulation of the automobile. When the method is applied to a new energy automobile, vehicle parameters of the automobile can be calculated through a Matlab, parameters of all parts of the whole automobile are input into software, the vehicle performance of the automobile is simulated and calculated through a program, the vehicle performance of the automobile can be calculated just through a computer without the need for a real automobile, specific professional knowledge does not need to be grasped, and therefore a large amount of time is saved.

Owner:NANJING YUEBOO POWER SYST CO LTD

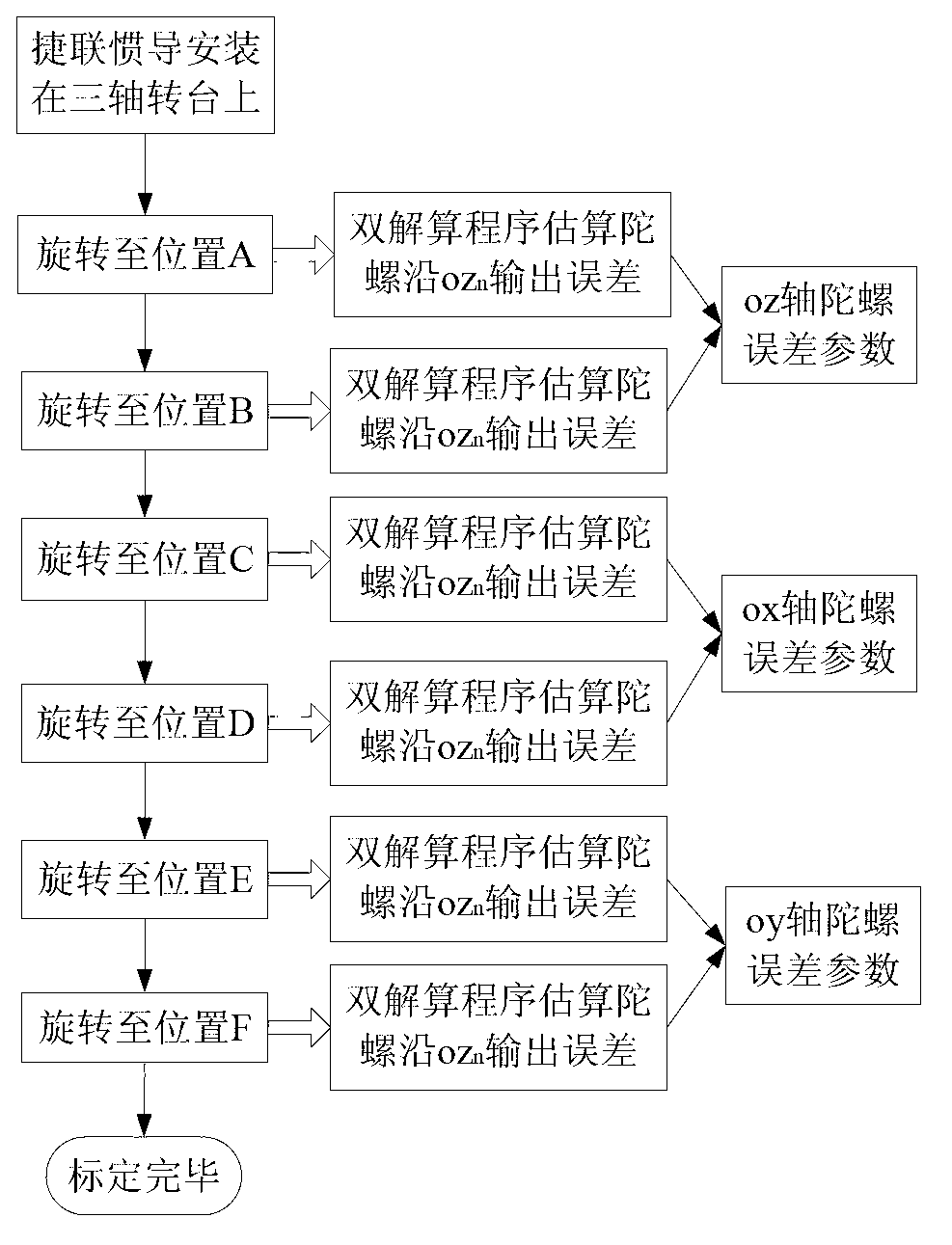

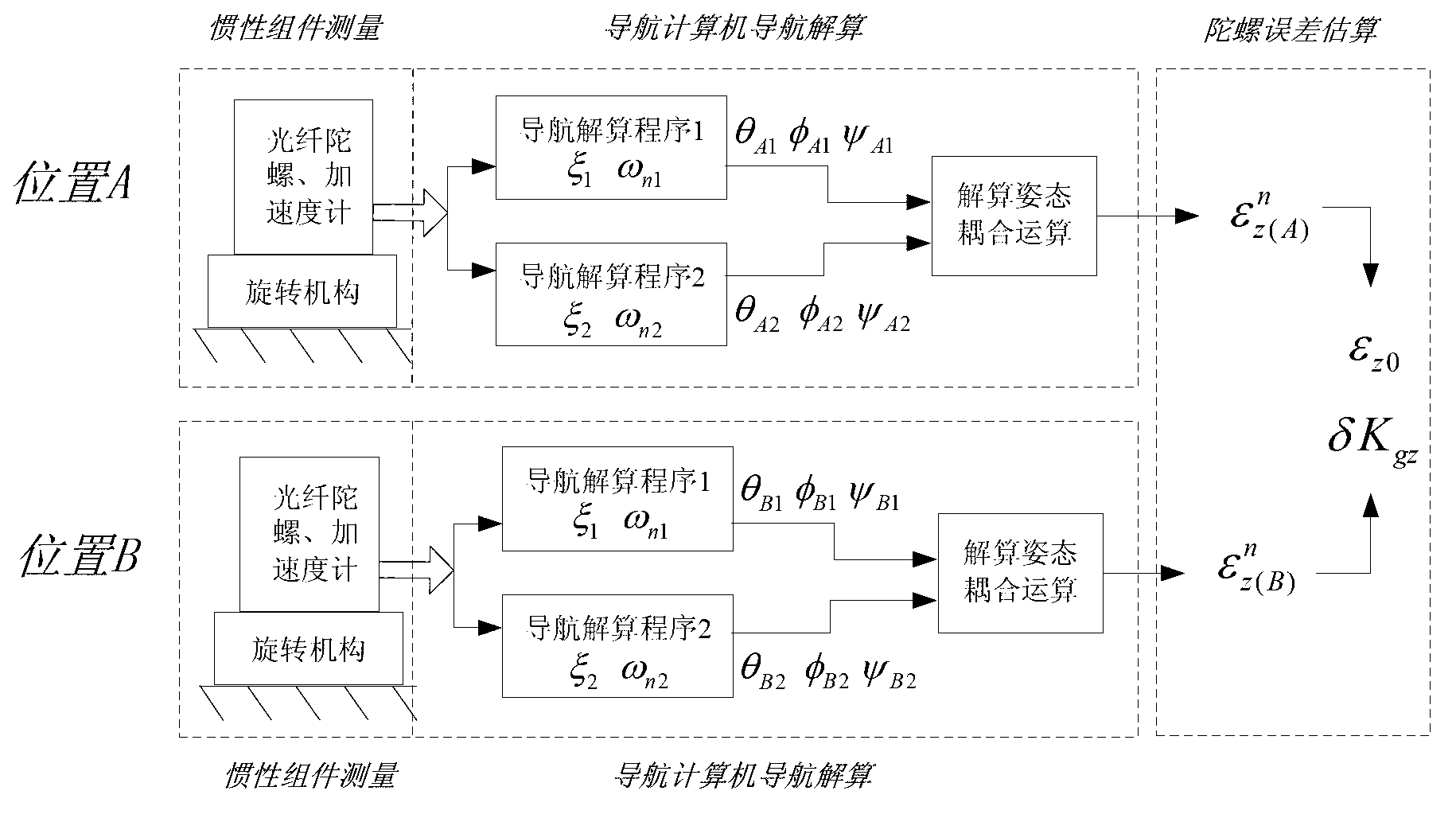

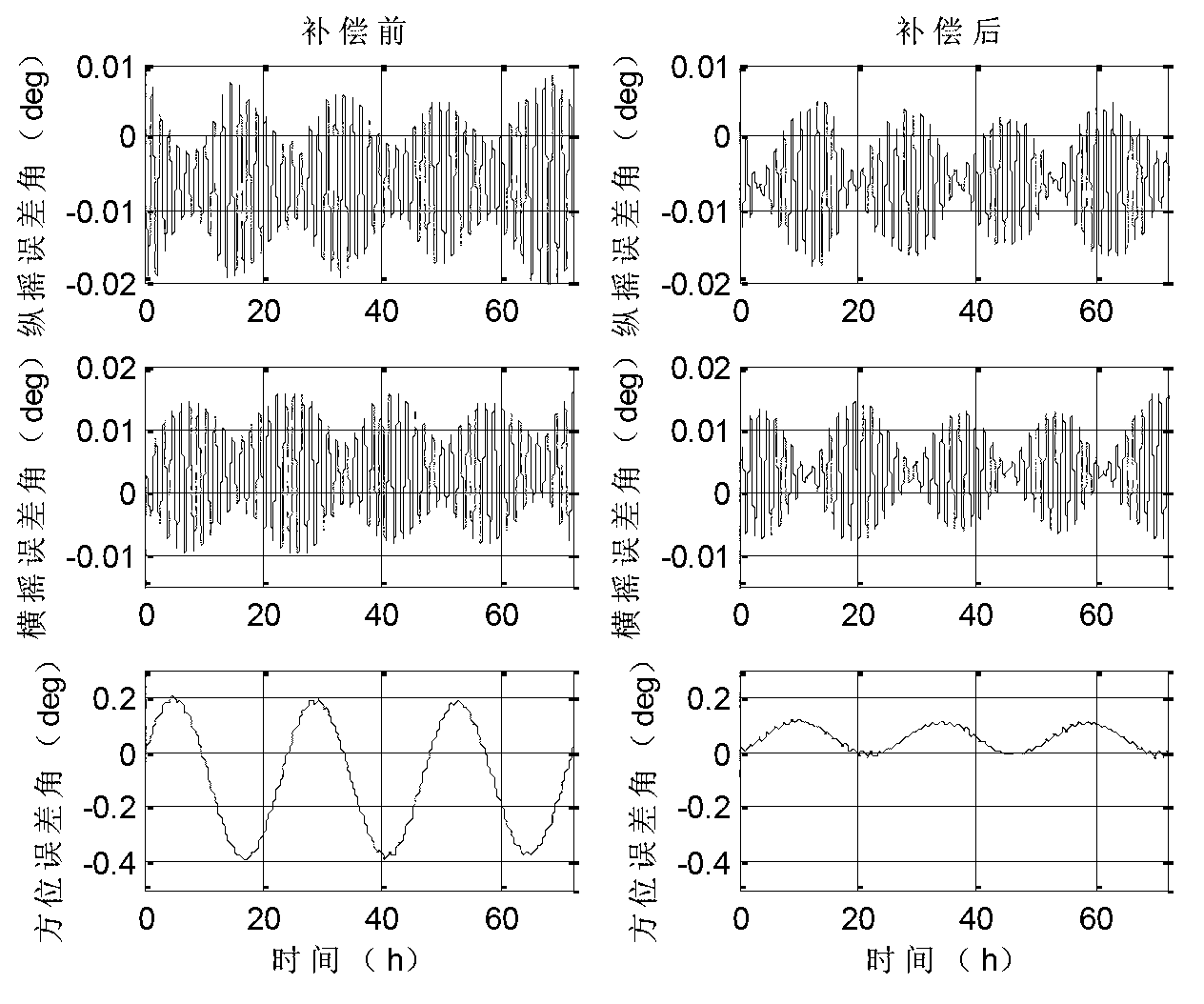

Constant error calibration method of fiber-optic gyroscope based on double-calculation program

The invention discloses a constant error calibration method of a fiber-optic gyroscope based on a double-calculation program. The method utilizes a rotating mechanism to drive inertia components to rotate to six positions of each axis gyroscope in the forward direction and reversed direction of Z-axis of a navigation system respectively, wherein during the stay process of each position, measure values of a group of the inertia components are simultaneously served as input values of two groups of navigation calculation programs, and the navigation parameter setpoint values of the two groups of programs are different. Then the two groups of calculation posture information are further coupled and calculated, and constant drift and scale factor error of each axis gyroscope is estimated. The invention provides the scheme that measure values of one group of the inertia components are used as input in a navigation computer, the two groups of navigation program calculation are performed simultaneously, and the two groups of calculation results are utilized to further estimate the device error; no external criteria information is required, the calculation amount is small, and the operation is simple and easy; and the two groups of navigation calculation programs have same input information, no installation deviation and time delay exist, and output information has relativity.

Owner:HARBIN ENG UNIV

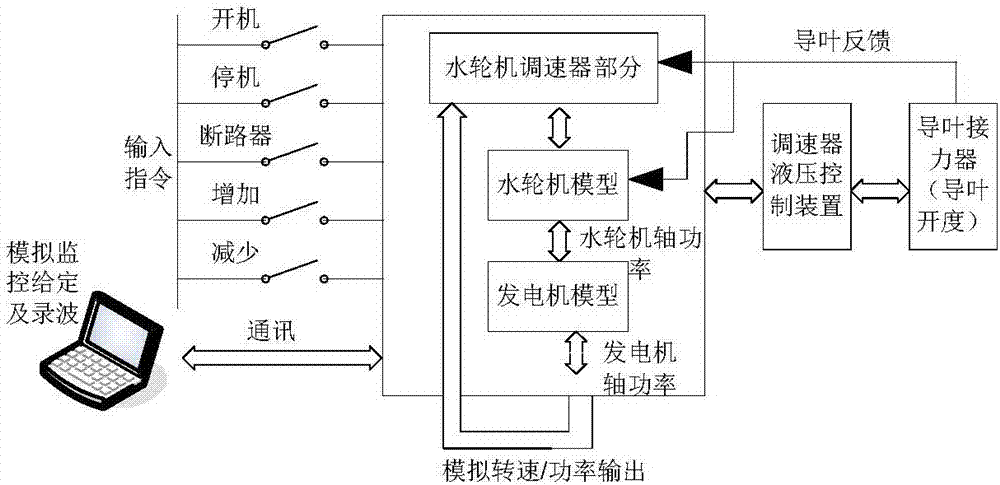

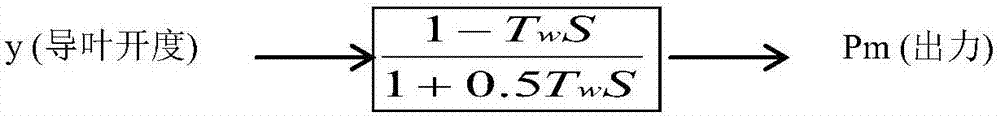

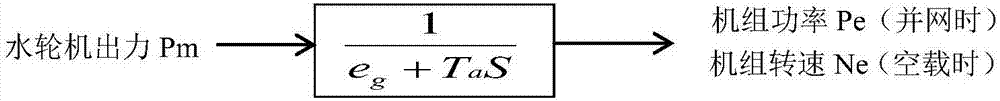

Water turbine speed regulator embedded control object model simulation method

The invention discloses a water turbine speed regulator embedded control object model simulation method. A water turbine model, a generator model and a fault diagnosis module are embedded in a water turbine speed regulator; through acquiring basic parameters of an actual controlled water turbine and a generator set, the water turbine model and the generator model are respectively abstracted into Laplace transfer function expressions; differential discrete transformation of the Laplace transfer function expressions is carried out for program calculation, water turbine guide vane relay feedbackis acquired to input to the water turbine model, output of the water turbine model is inputted to the generator model, the generator rotation speed and the active power output are calculated; the generator rotation speed and an active power signal are fed back to an actual speed regulator cabinet, and rotation speed and power closed loop control on a speed regulation system is realized. The methodis advantaged in that the method is independent from external simulation equipment, the simulation test and fault diagnosis of the speed regulation system can be realized through utilizing self resources of the speed regulator, and factory test integrity of the speed regulator equipment is improved.

Owner:NANJING NARI GROUP CORP

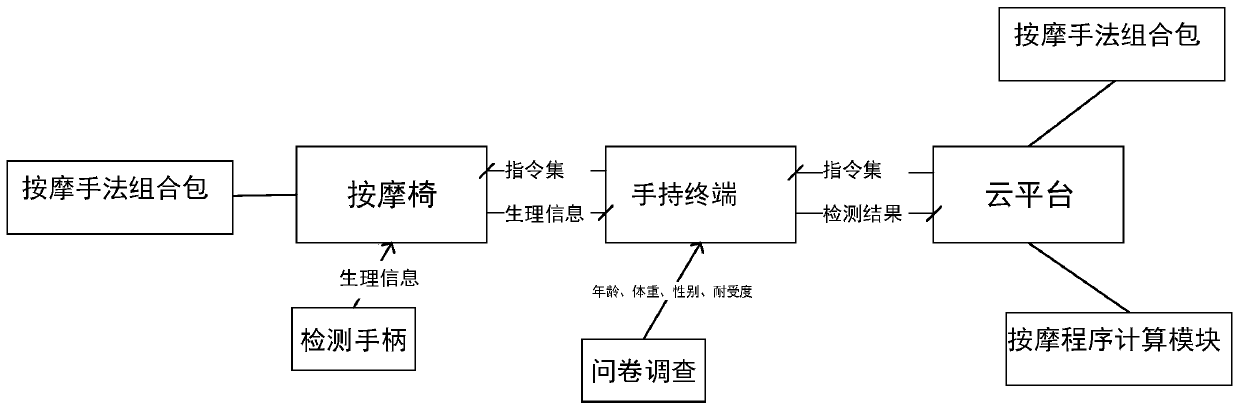

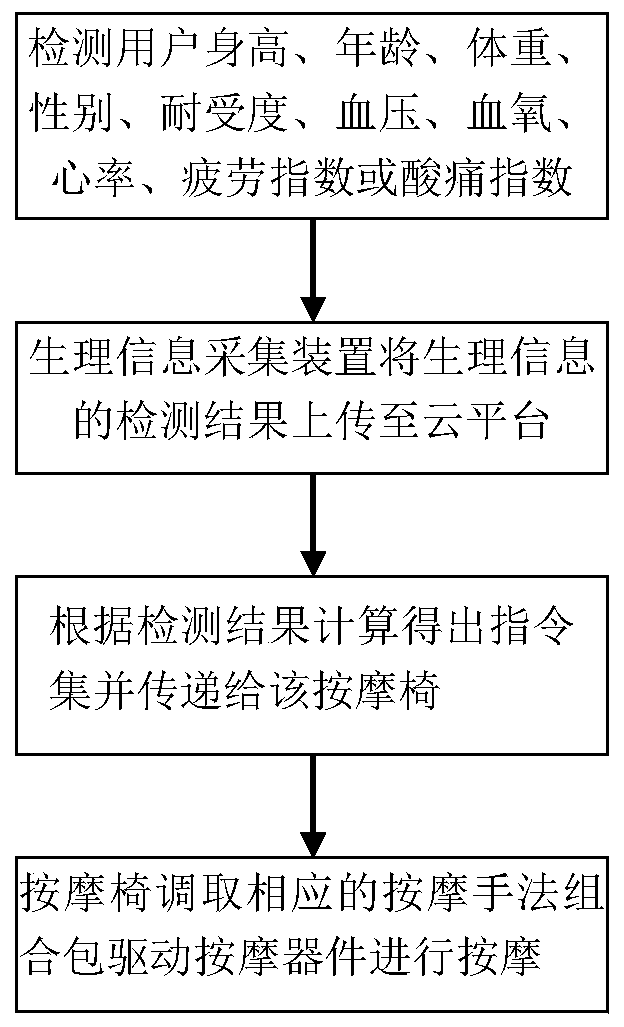

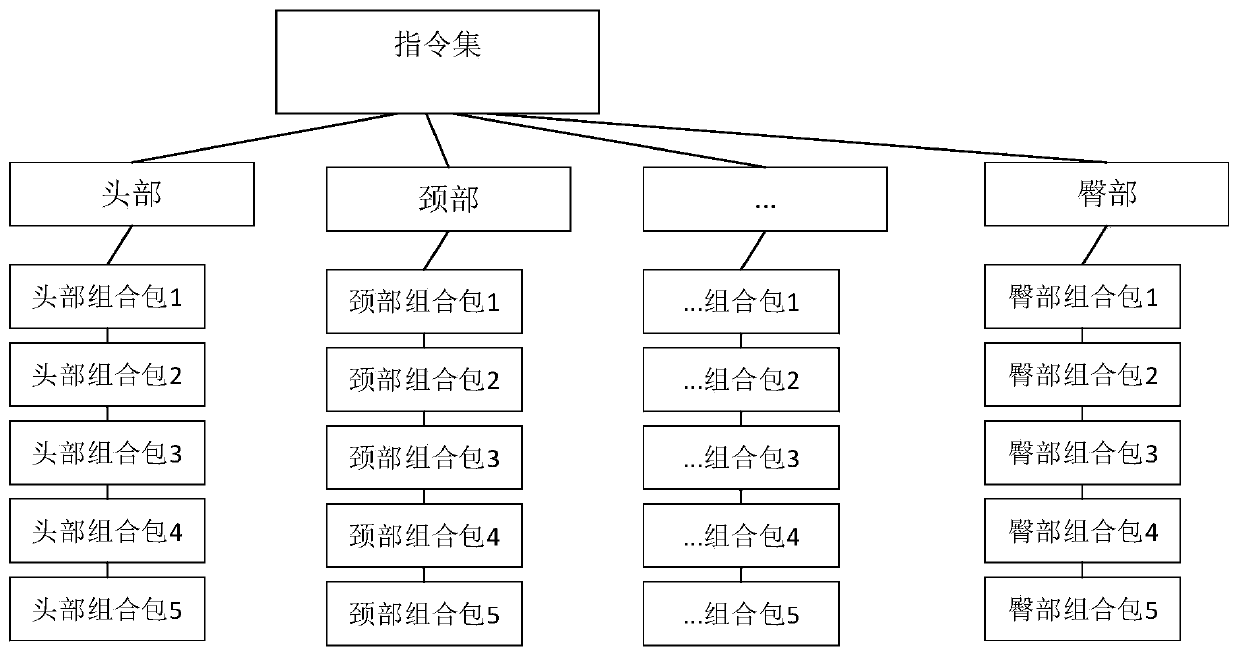

Intelligent massaging chair cloud platform control system and method

PendingCN110473620AAchieve customized massage effectTakes up little storage spacePhysical therapies and activitiesDiagnosticsControl systemMassage

The invention discloses an intelligent massaging chair cloud platform control system and method. The system comprises a massaging chair provided with a control panel and a plurality of massaging devices, a physiological information collection device used for detecting physiological information of a user and sending the information to a cloud platform, and the cloud platform provided with a massageprogram calculation module, wherein a plurality of massage manipulation combined packages are stored in the control panel, and all the massage manipulation combined packages are used for respectivelycontrolling motion of different massaging devices; an instruction set is obtained through calculation by the massaging program calculation module according to the physiological information and transmitted to the massaging chair, so that the corresponding massage manipulation combined packages are utilized for working so as to drive the corresponding massaging devices to massage the user. According to the system and method, precise recommendation for the user can be achieved, massaging is more personalized, and customized massaging effects on all kinds of people can be achieved.

Owner:XIAMEN COMFORT SCIENCE & TECHNOLOGY GROUP CO LTD

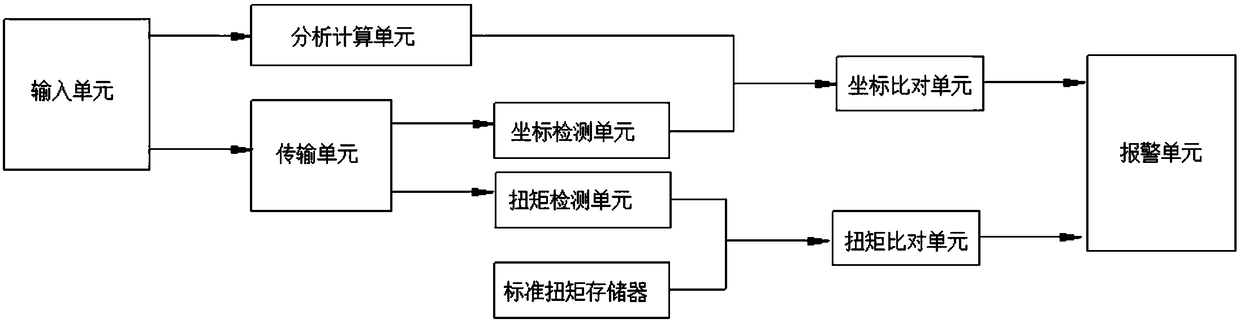

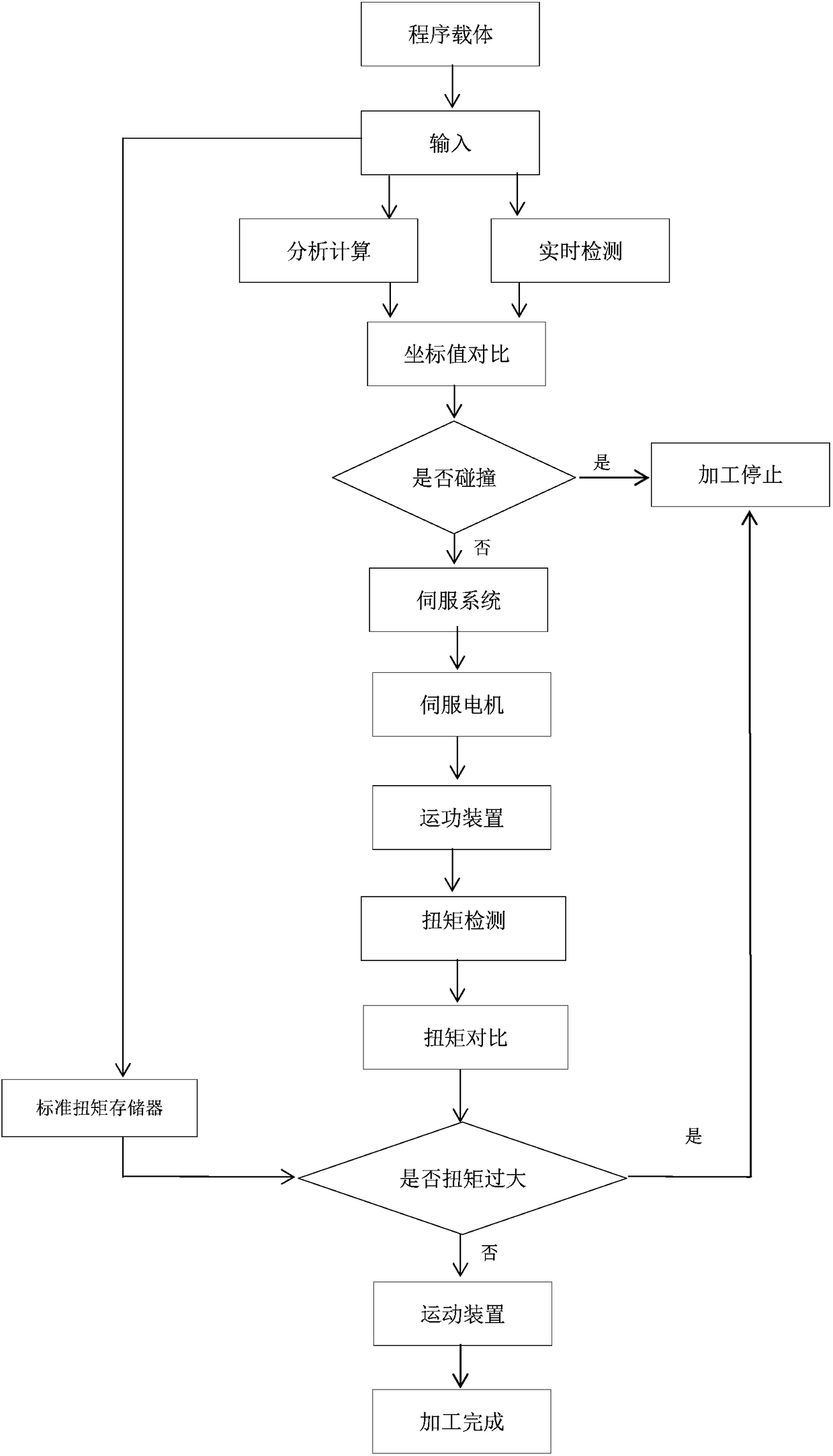

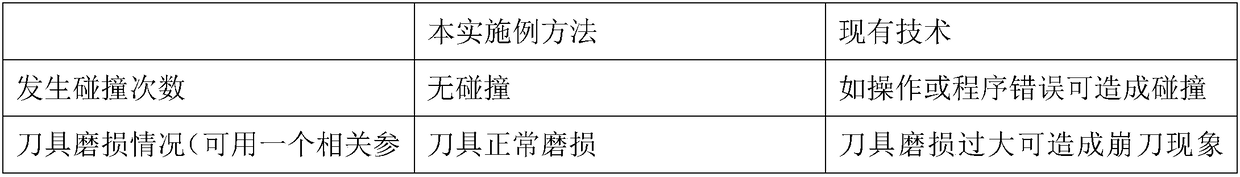

Automatic detection and early warning system for numerical control machine tool and operation method of automatic detection and early warning system

ActiveCN108388201AAvoid collisionEasy to adjustProgramme controlComputer controlNumerical controlEarly warning system

The invention relates to an automatic detection and early warning system for a numerical control machine tool and the operation method of the automatic detection and early warning system. The automatic detection and early warning system comprises an input unit, a transmission unit, an analysis and calculation unit, a coordinate detection unit, a coordinate comparison unit and an alarm unit. The input unit is used for reading a processing program into a machine tool, andconverting the processing program into a readable analog signal. The analysis and calculation unit is used for reading the processing program, andcalculating a theoretical coordinate value. The transmission unit is used for driving the mechanical part of the machine tool to move through the readable analog signal. The coordinate detection unit is used for detecting the actual coordinate value of the mechanical part of the machine tool in real time. The coordinate comparison unit is used for comparing the theoretical coordinate value with the actual coordinate value. If the difference value between the theoretical coordinate value and the actual coordinate valueis within the range of a threshold value A, the numericalcontrol machine tool works normally. Otherwise, the alarm unit is started to give an alarm. According to the invention, the program data can be analyzed in advance when the system works normally. Theon-line real-time detection is carried out, and the machining state is monitored in real time. The tool damage of the numerical control machine tool can be effectively prevented, and the operation safety and the operation reliability are improved.

Owner:WEIFANG UNIVERSITY

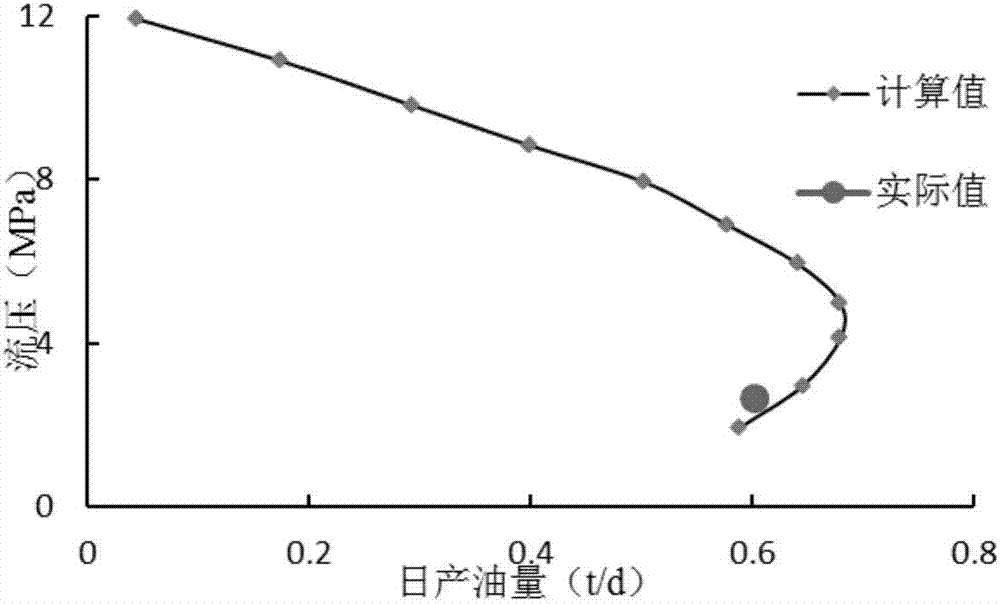

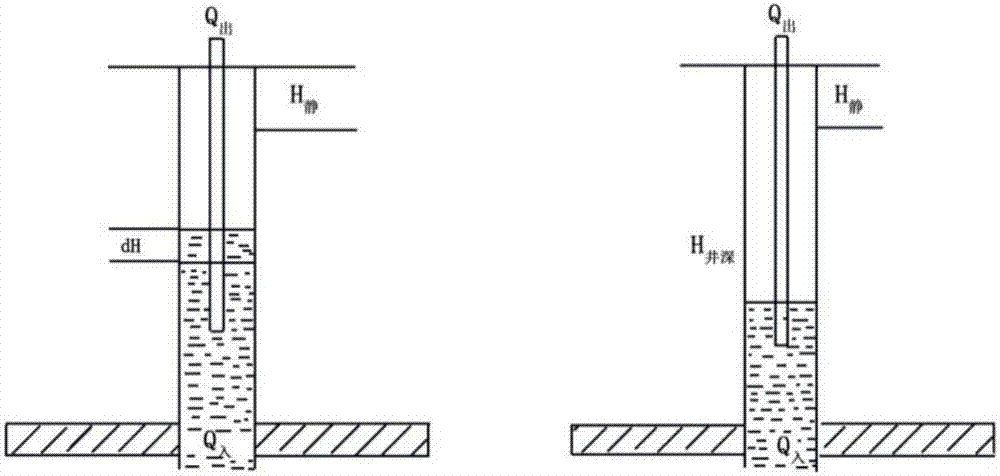

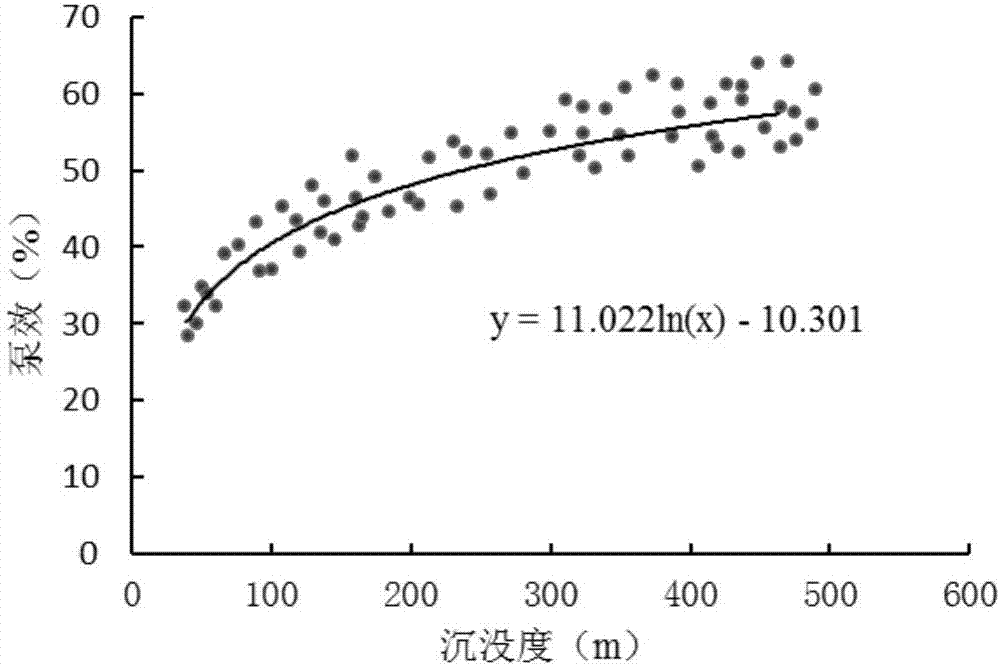

Method for optimizing low-permeability reservoir intermittent mining working system based on model coupling exhaustion method

ActiveCN107578342ATruly reflect the law of seepageQuantitative precisionData processing applicationsSpecial data processing applicationsDynamic modelsEngineering

The invention discloses a method for optimizing a low-permeability reservoir intermittent mining working system based on a model coupling exhaustion method. Aiming at the input and output characteristics of a low-permeability and low-yield well, through the combination of the flow-in dynamic characteristics of the low-permeability reservoir, the liquid level change rule of an intermittent mining well shaft and the pump efficiency analysis, and based on the relation between the stratum liquid supply capacity and the pumping and suction capacity, a stratum flow-in dynamic model and a well shaftoutflow dynamic model are established, a coupling model is established through the coupling parameters of the bottom flow pressure and the pump efficiency, a computer solution model is established onthis basis, and the optimization of the low-permeability reservoir intermittent mining working system determination method is carried out by means of an exhaustion method. The method can accurately describe the low-permeability reservoir seepage law, realizes the real-time dynamic changes of the bottom flow pressure and the pump efficiency during the intermittent mining, and realizes the accuratequantified intermittent mining limit. The exhaustion method has better optimization precision, and the program calculation efficiency is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

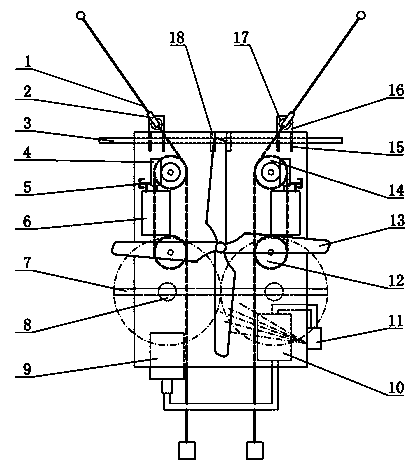

Double-flexible-cable-driven glass curtain wall cleaning robot

InactiveCN103445731AImprove motion stabilityRealize self-lockingCarpet cleanersFloor cleanersDrive motorProgram calculation

The invention relates to a double-flexible-cable-driven glass curtain wall cleaning robot used for cleaning glass curtain walls of low-rise and mid-rise buildings. A double-cable driving mechanism in a double-cable driving mode realizes cable winding and unwinding by depending on friction between cables and rollers, then driving rollers are driven to rotate through roller driving motors, and the cleaning robot moves in a cleaning plane by depending on coordinated winding and unwinding of the double cables. A deflection angle detecting mechanism is used for detecting an included angle between each cable and a guide sliding rod and then feeding the included angles back to a single chip microcomputer, and needed running speed and revolution number of the roller driving motors are worked out through program calculation, so that the two roller driving motors can move in a coordinated manner, the cleaning robot is enabled to reach the target position along a straight track more accurately, movement distance is shortened, and rapidness and accuracy are improved. By the combination of the double-cable driving mechanism and the deflection angle detecting mechanism, the cleaning robot can move at optional positions in the cleaning plane and can be adjusted rapidly, and thereby cleaning efficiency is improved.

Owner:HARBIN UNIV OF SCI & TECH

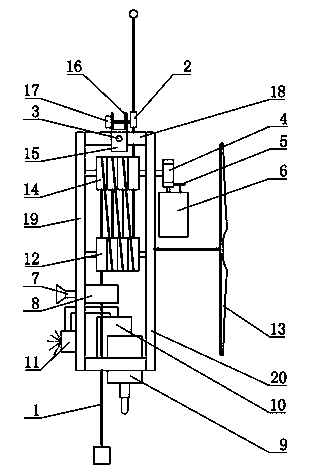

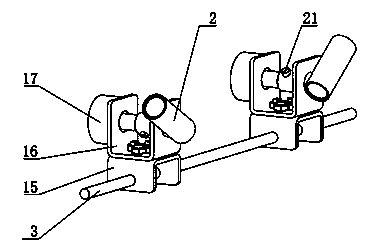

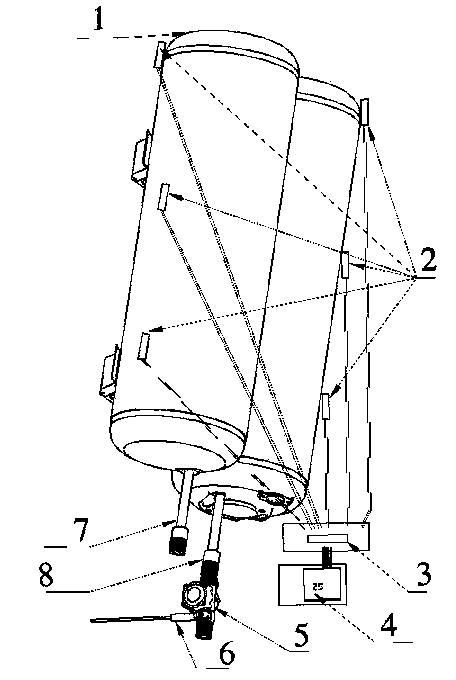

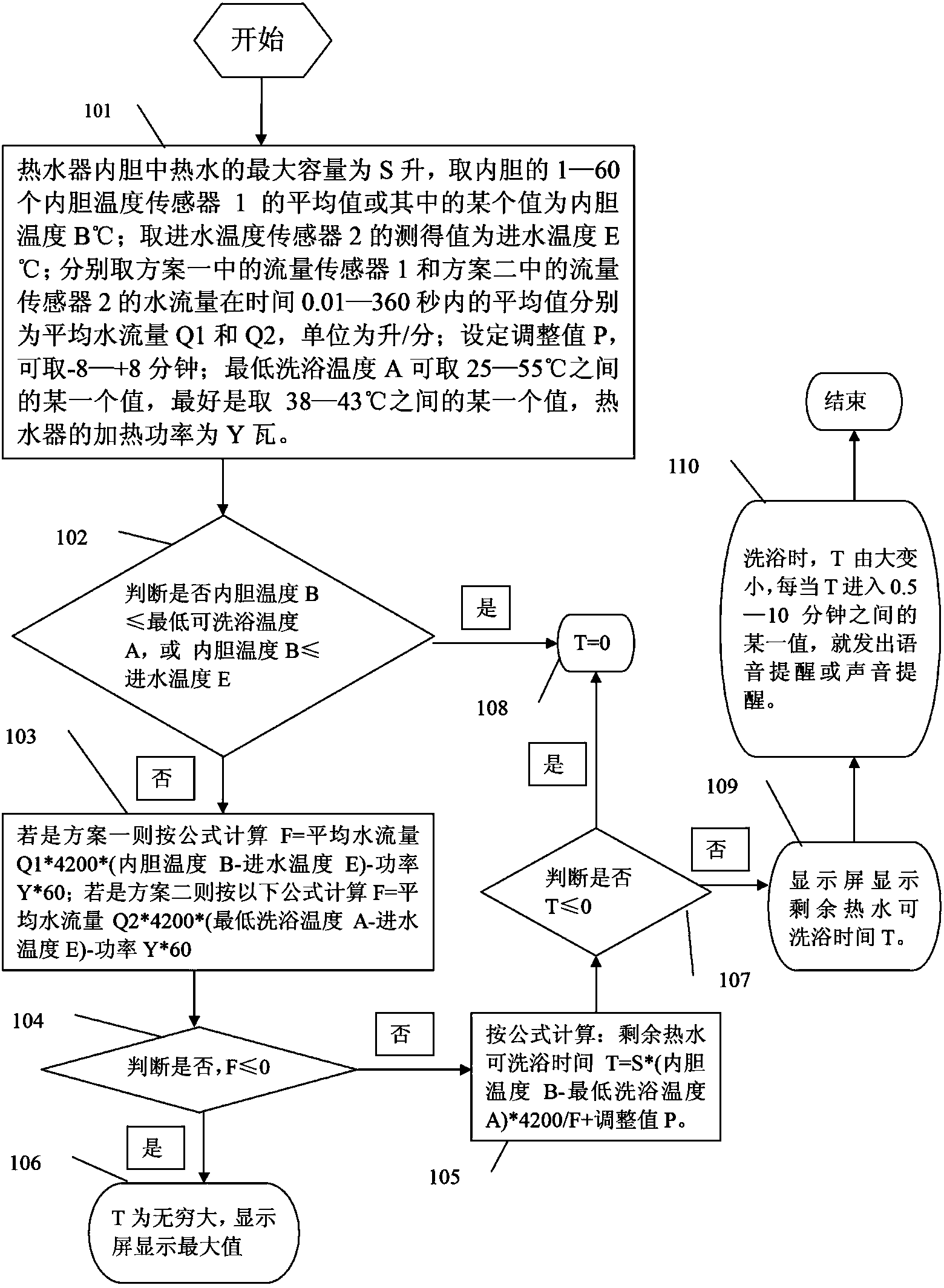

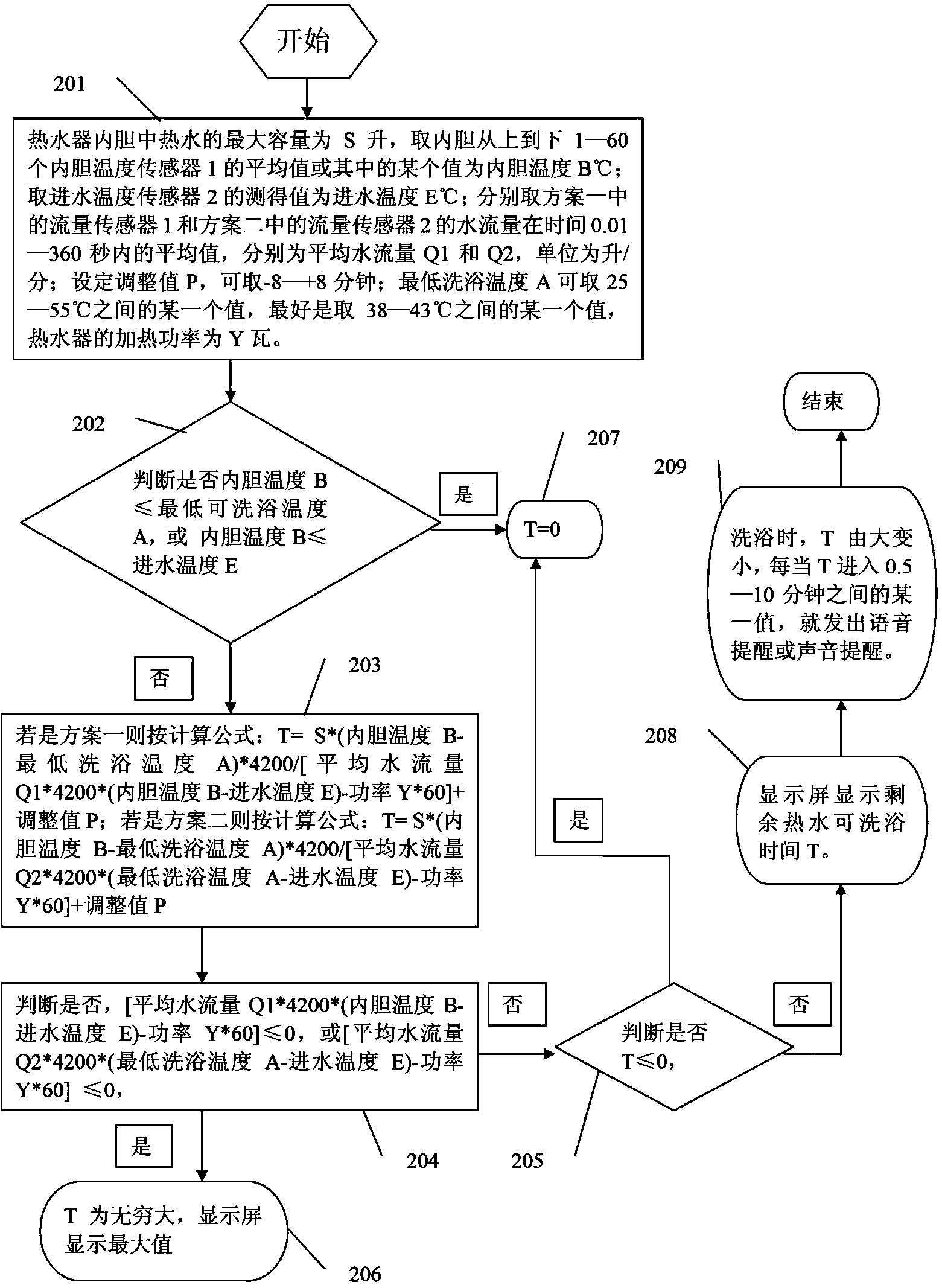

Water heater

InactiveCN104075452ARemind attention timeEasy to masterFluid heatersSolar heat devicesSolar waterEngineering

The invention relates to water heaters, in particular to a solar water heater, an electric water heater, a heat pump water heater and a programming method thereof. 1 to 60 first liner temperature sensors are arranged in positions of a water heater liner, and one first liner temperature sensor can be arranged at the top of the liner. An income water temperature sensor is arranged in a water income pipe of the liner according to two arrangement schemes; according to the first arrangement scheme, a first flow sensor is arranged in the water income pipe or water drainage pipe of the liner; according to the second arrangement scheme, a pipe is connected to the water income pipe to connect an electric flow adjusting valve to the water drainage pipe and is connected to the second flow sensor; the flow sensors can be Hall flow sensors or infrared flow sensors and used for measuring the water income or drainage flow and transmitting electric signal data to a single chip, the temperature signals of each temperature sensor can be transmitted to the single chip, calculation is performed according to the program calculating method, a hot water bathing time T is acquired and is displayed on a display screen, and the time for the remaining hot water for bathing in the water heater can be accurately calculated and displayed.

Owner:蓝军梅

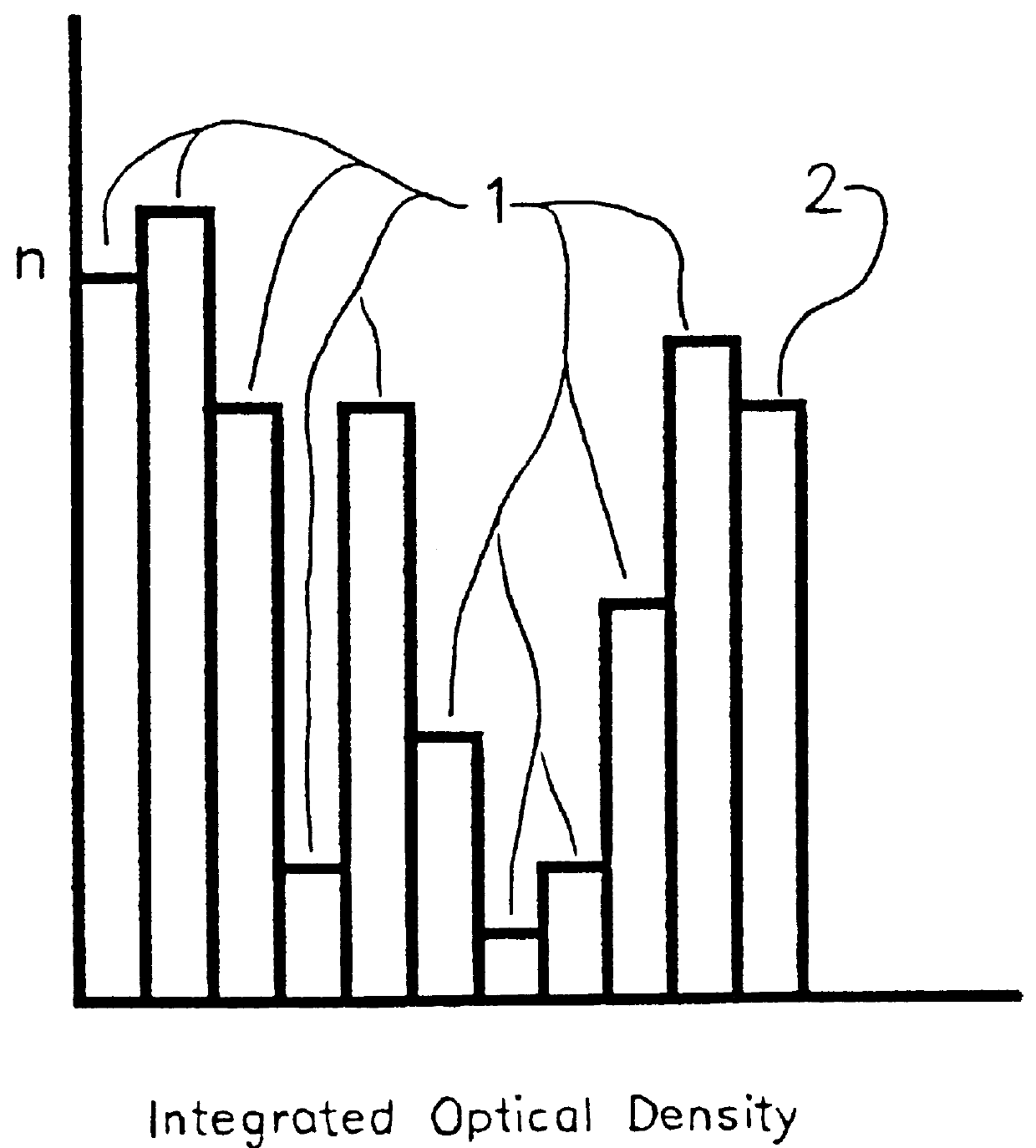

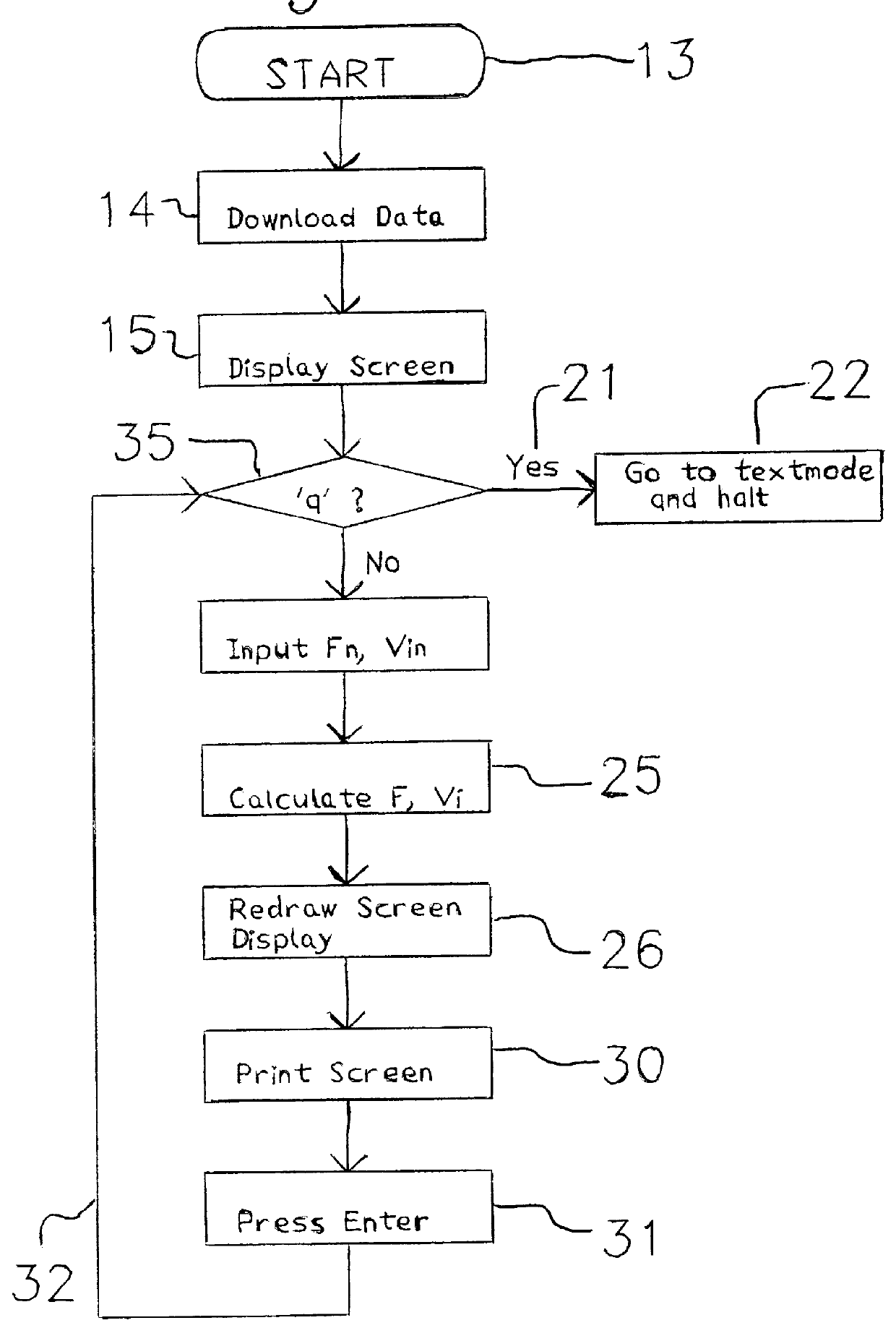

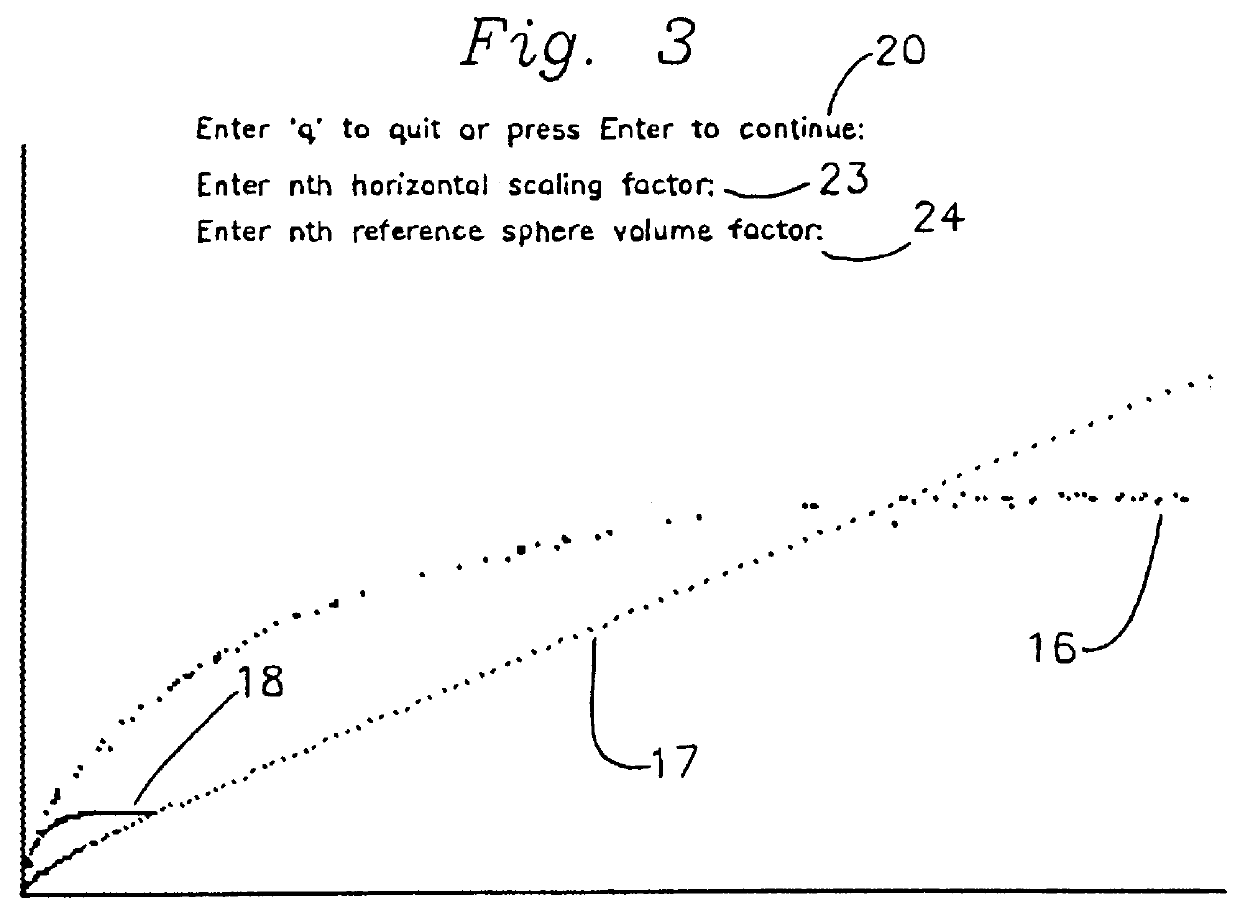

Method for correction of quantitative DNA measurements in a tissue section

InactiveUS6035258AAnalogue computers for chemical processesColor/spectral properties measurementsRandom access memoryFeulgen stain

The operator downloads, from a data file into the random access memory of a personal computer, integrated optical density and profile area data for a plurality of nuclei and partial nuclei in a Feulgen-stained histologic tissue section; the thickness of the section; and the integrated optical density of an intact diploid nucleus. The operator then operates a computer program which plots the data curve together with a reference line and a reference curve. The data curve is scaled and the reference curve is recalculated and redrawn through a number of iterations until the operator is satisfied that the scaled data curve terminates on the reference line, and the scaled data curve is as nearly congruent as possible with the latest reference curve. The program calculates and displays the corrected DNA index on a video screen, the contents of which the operator may print on a printer.

Owner:FREED JEFFREY A

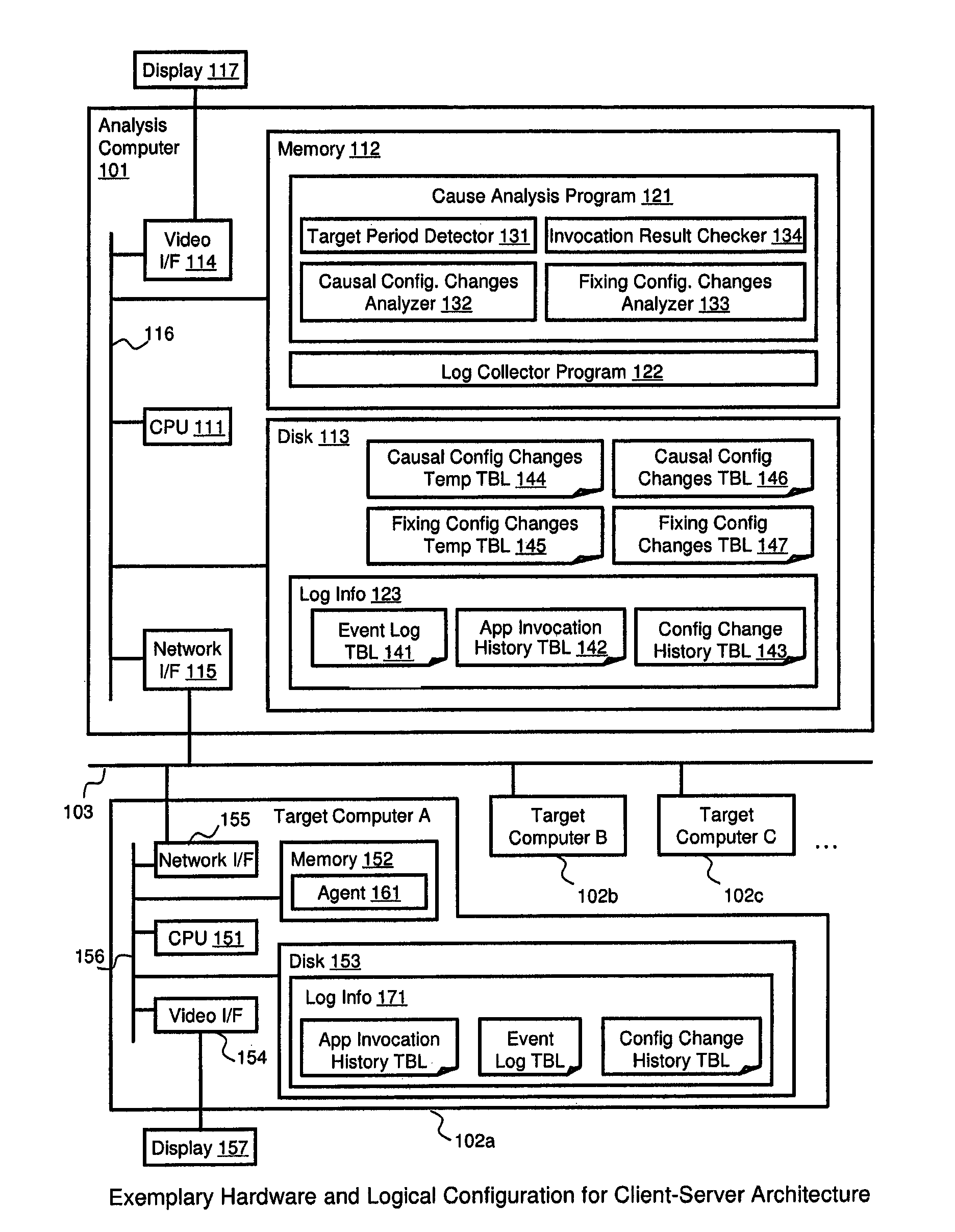

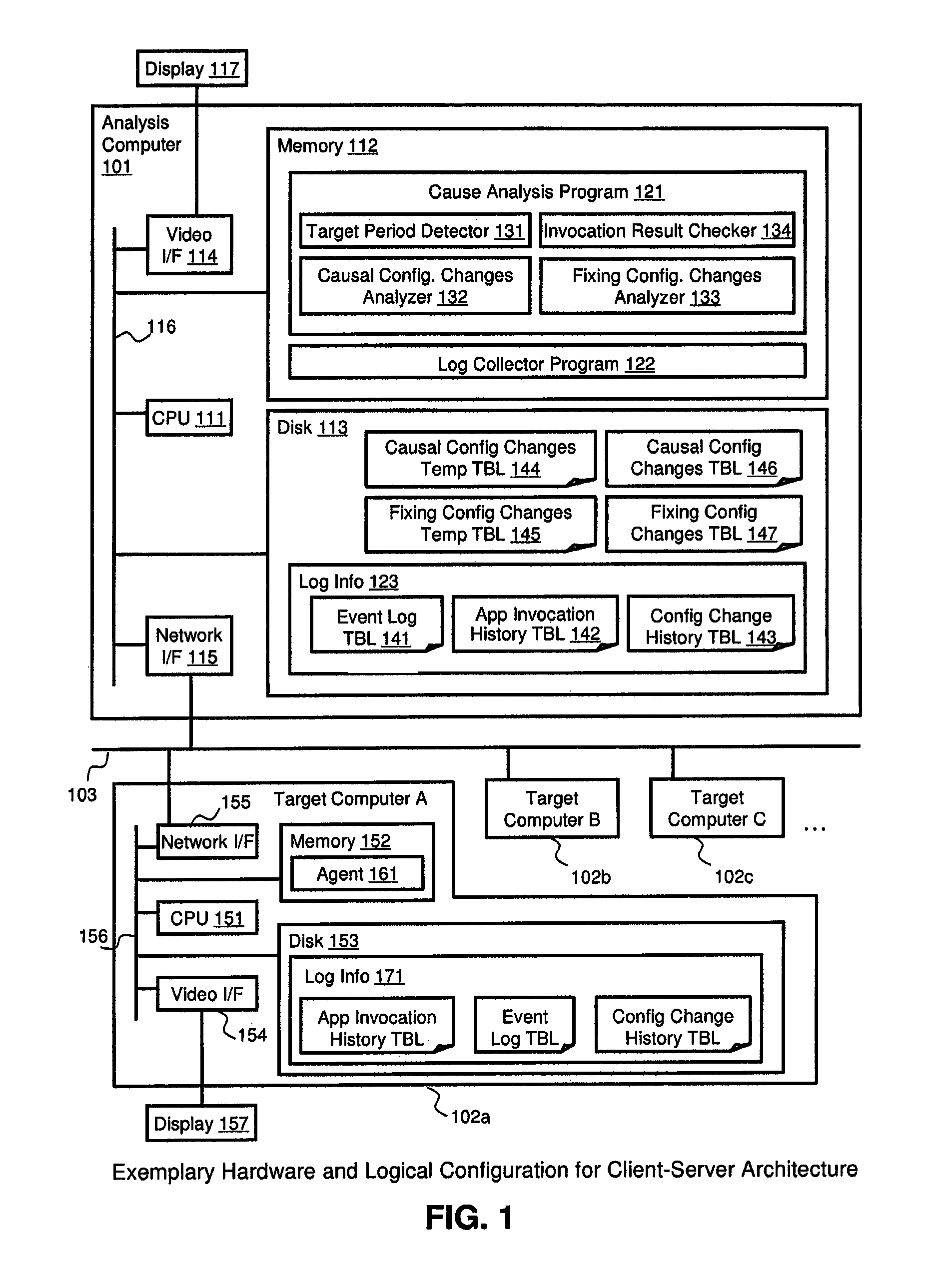

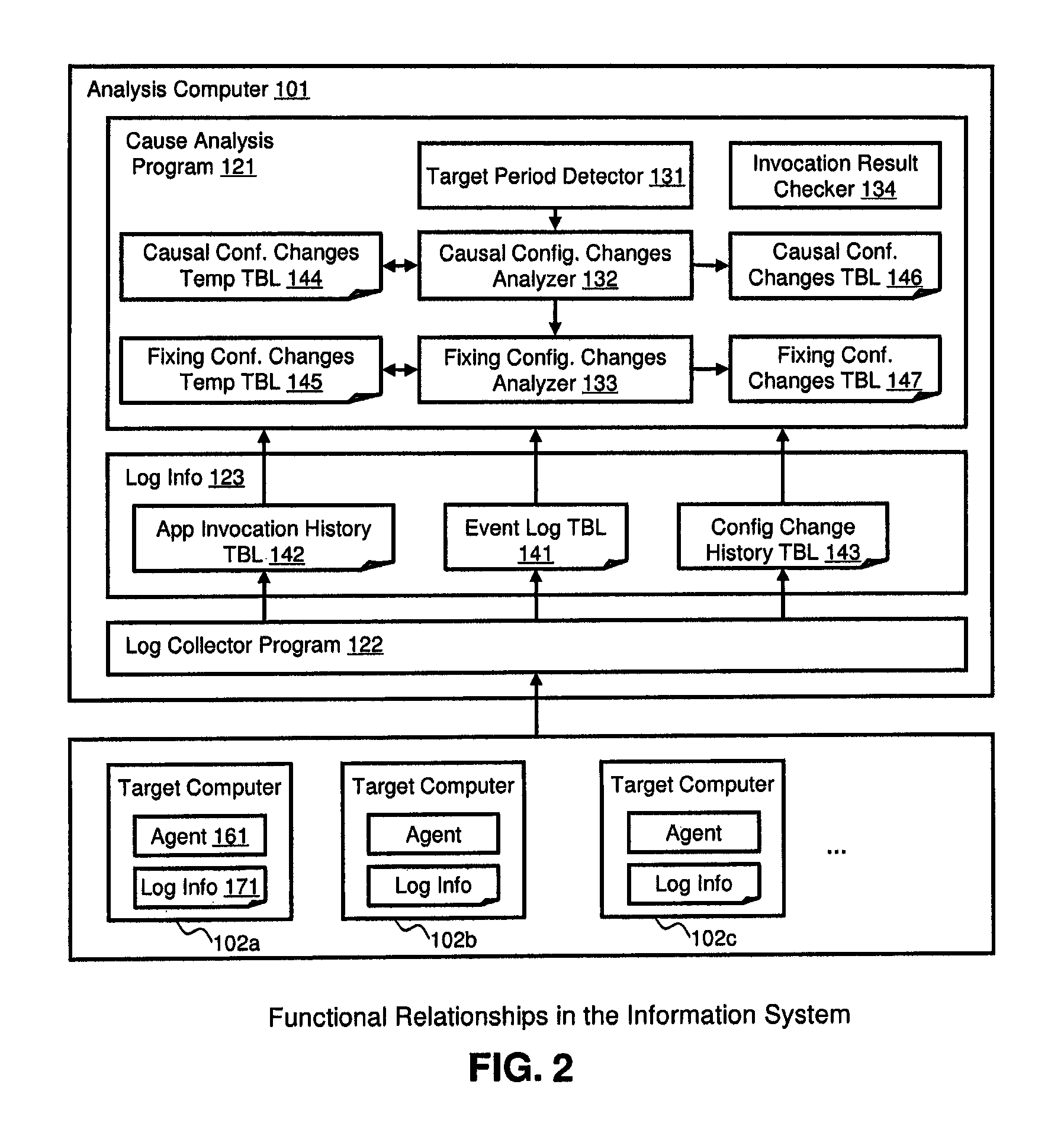

Method and apparatus for cause analysis involving configuration changes

InactiveUS8024617B2Non-redundant fault processingTransmissionTheoretical computer scienceSoftware engineering

A technique determines which configuration change(s) caused an application invocation failure of a computer application without the need for a knowledge database. To determine which configuration change is the most likely cause, the cause analysis program (121) checks other computers (102) that have experienced the same configuration changes. The cause analysis program checks and counts the application invocation results before and after each configuration change is done. If the same configuration changes are found in the other computers, the program checks whether each configuration change caused or cured the same problem in that computer. The program counts the similar cases for all of the computers. Subsequently, the program calculates the ratio of those instances involving a change from success to failure and the ratio of those instances involving a change from failure to success out of all instances for each configuration change.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com