Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113 results about "Retinal Prosthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Retinal prosthesis have been translated from the laboratory to the clinical over the past two decades. Currently, two devices have regulatory approval for the treatment of retinitis pigmentosa.

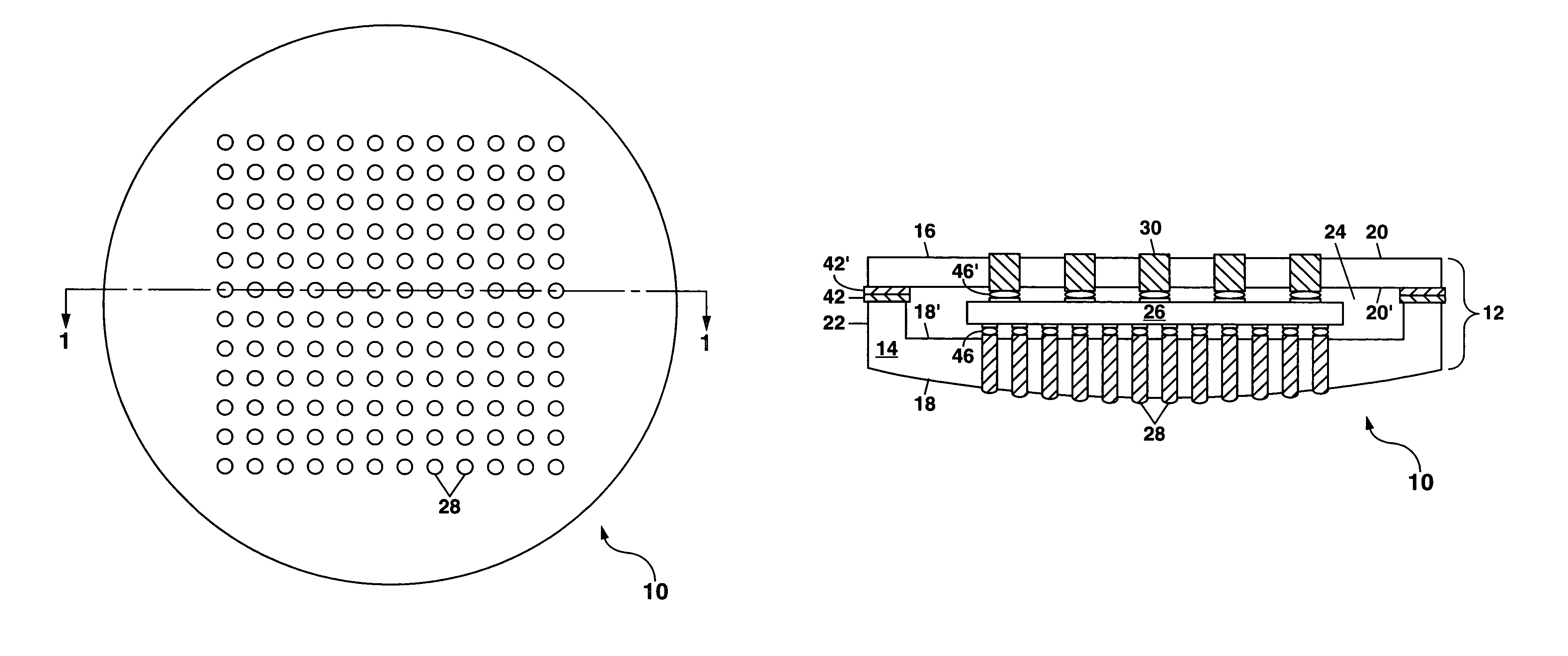

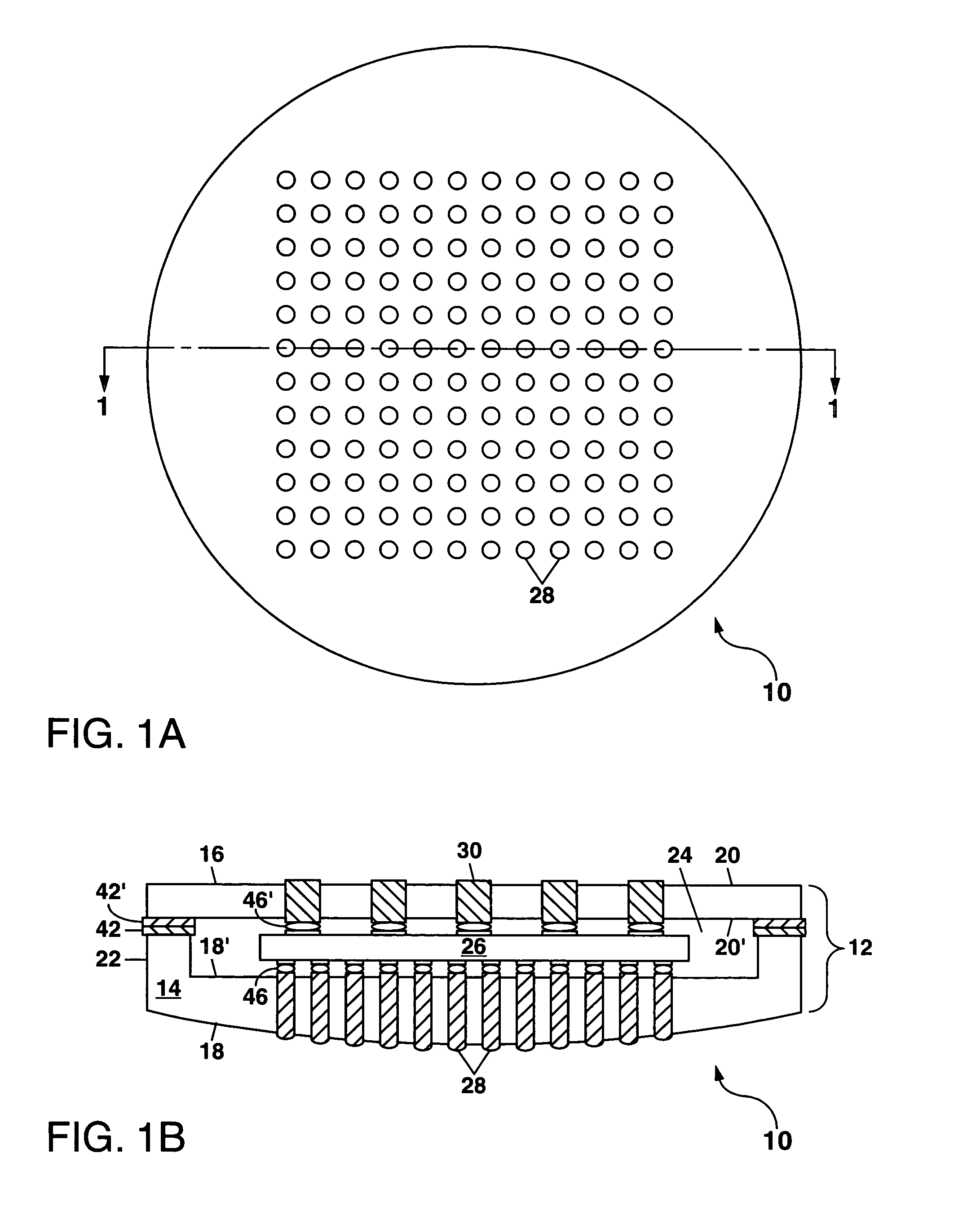

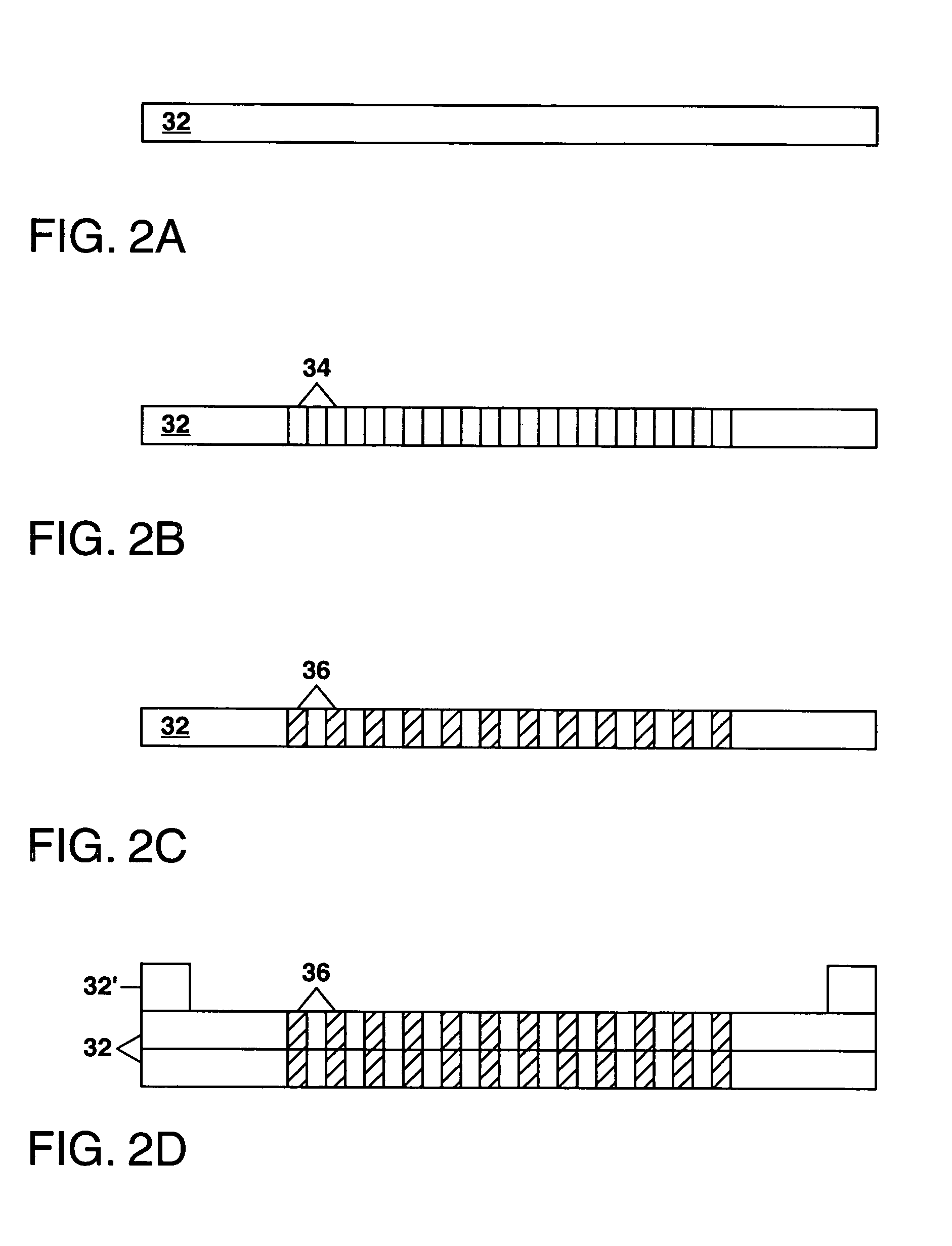

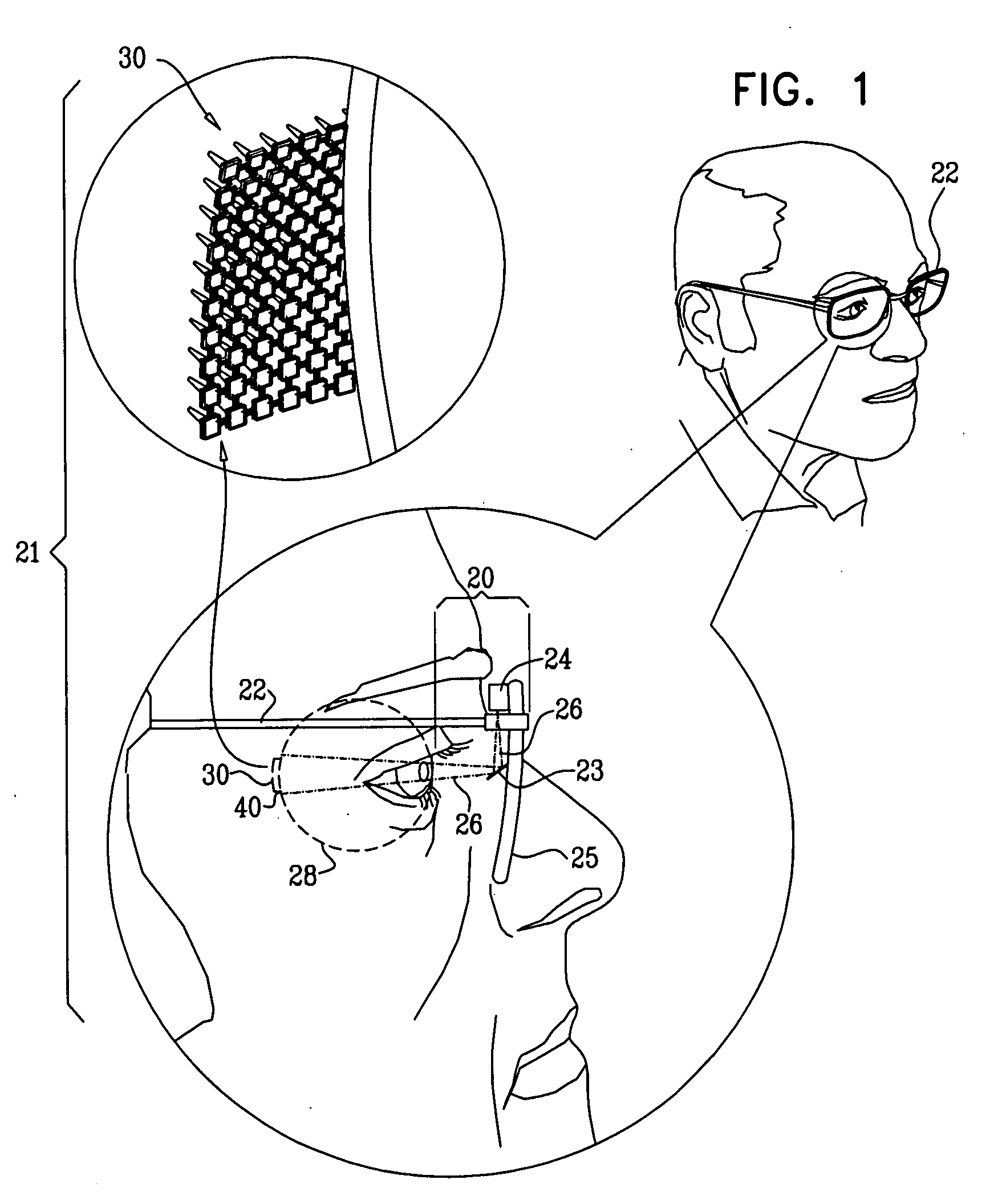

Electrode array for neural stimulation

An electrode array for neural stimulation is disclosed which has particular applications for use in a retinal prosthesis. The electrode array can be formed as a hermetically-sealed two-part ceramic package which includes an electronic circuit such as a demultiplexer circuit encapsulated therein. A relatively large number (up to 1000 or more) of individually-addressable electrodes are provided on a curved surface of a ceramic base portion the electrode array, while a much smaller number of electrical connections are provided on a ceramic lid of the electrode array. The base and lid can be attached using a metal-to-metal seal formed by laser brazing. Electrical connections to the electrode array can be provided by a flexible ribbon cable which can also be used to secure the electrode array in place.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

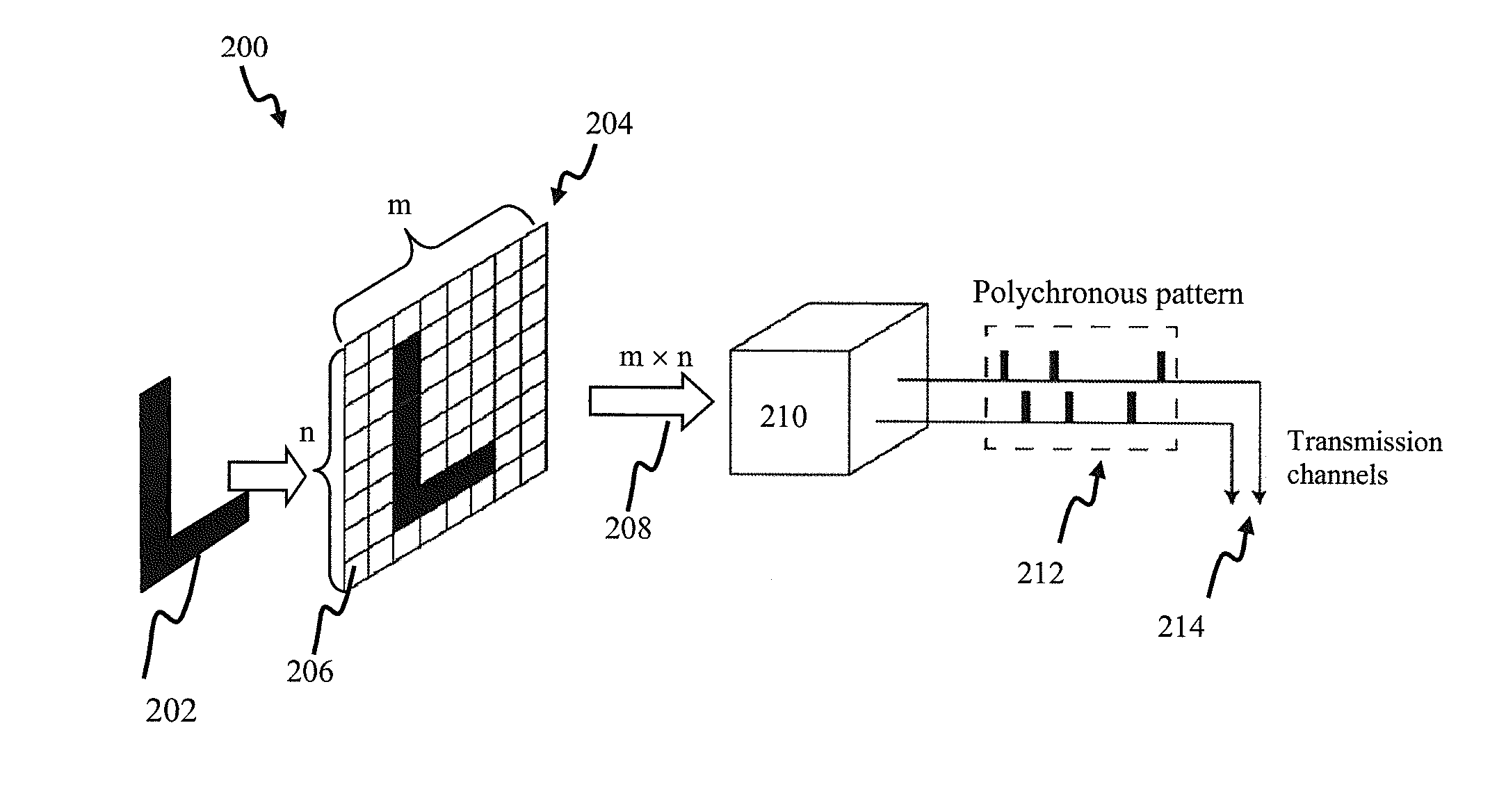

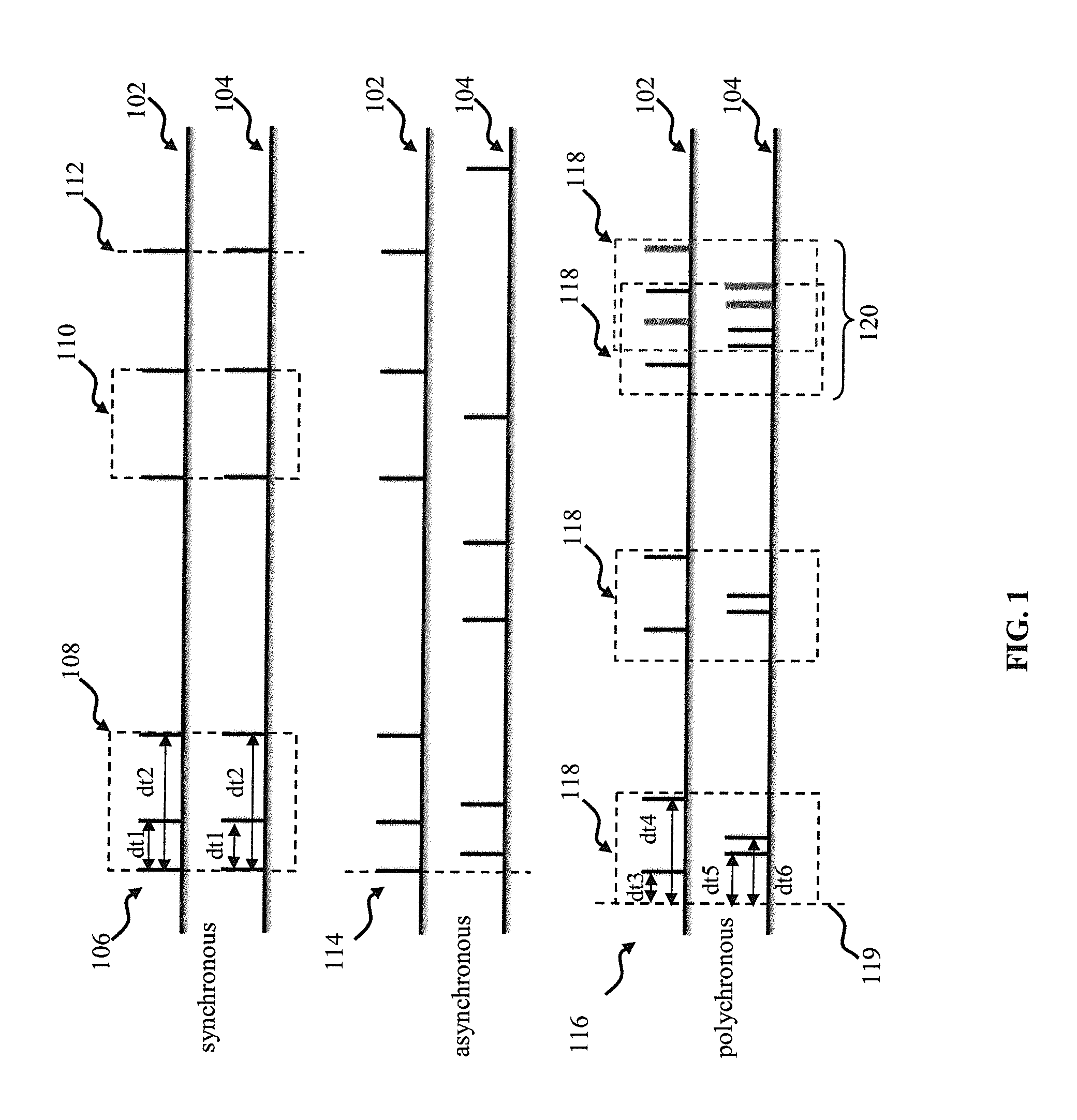

Apparatus and methods for polychronous encoding and multiplexing in neuronal prosthetic devices

Apparatus and methods for encoding sensory input information into patterns of pulses and message multiplexing. In one implementation, the patterns of pulses are polychronous (time-locked by not necessary synchronous), and a retinal prosthetic encodes the input signal into the polychronous patterns for delivery via stimulating electrodes. Different polychronous patterns simultaneously encode different sensory signals; (such as different features of the image), thus providing for message multiplexing. Increasing data transmission capacity allows for a reduction in the number of electrodes required for data transmission. In one implementation, an adaptive feedback mechanism is employed to facilitate encoder operation. In another aspect, a computer vision system is described.

Owner:BRAIN CORP

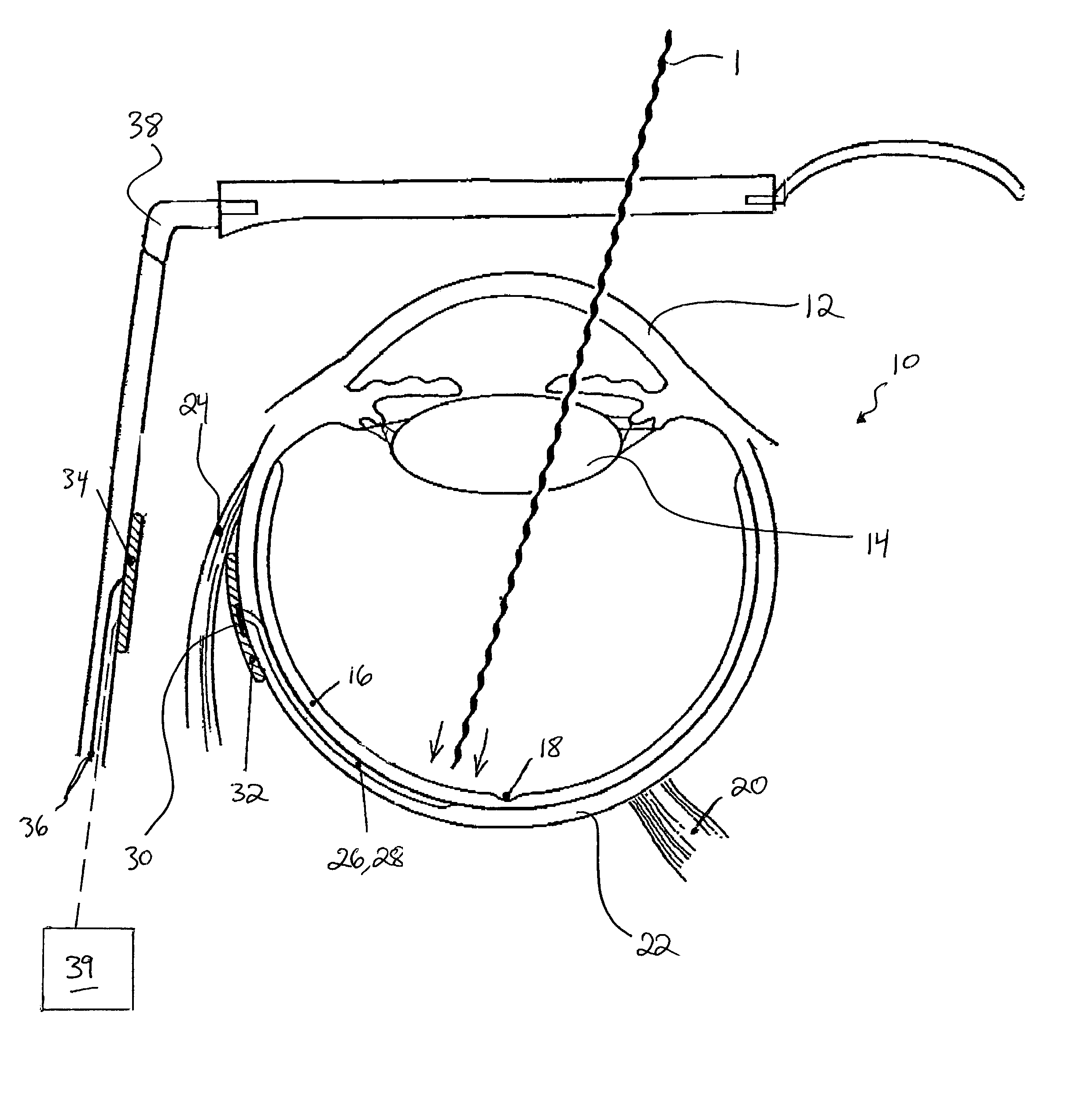

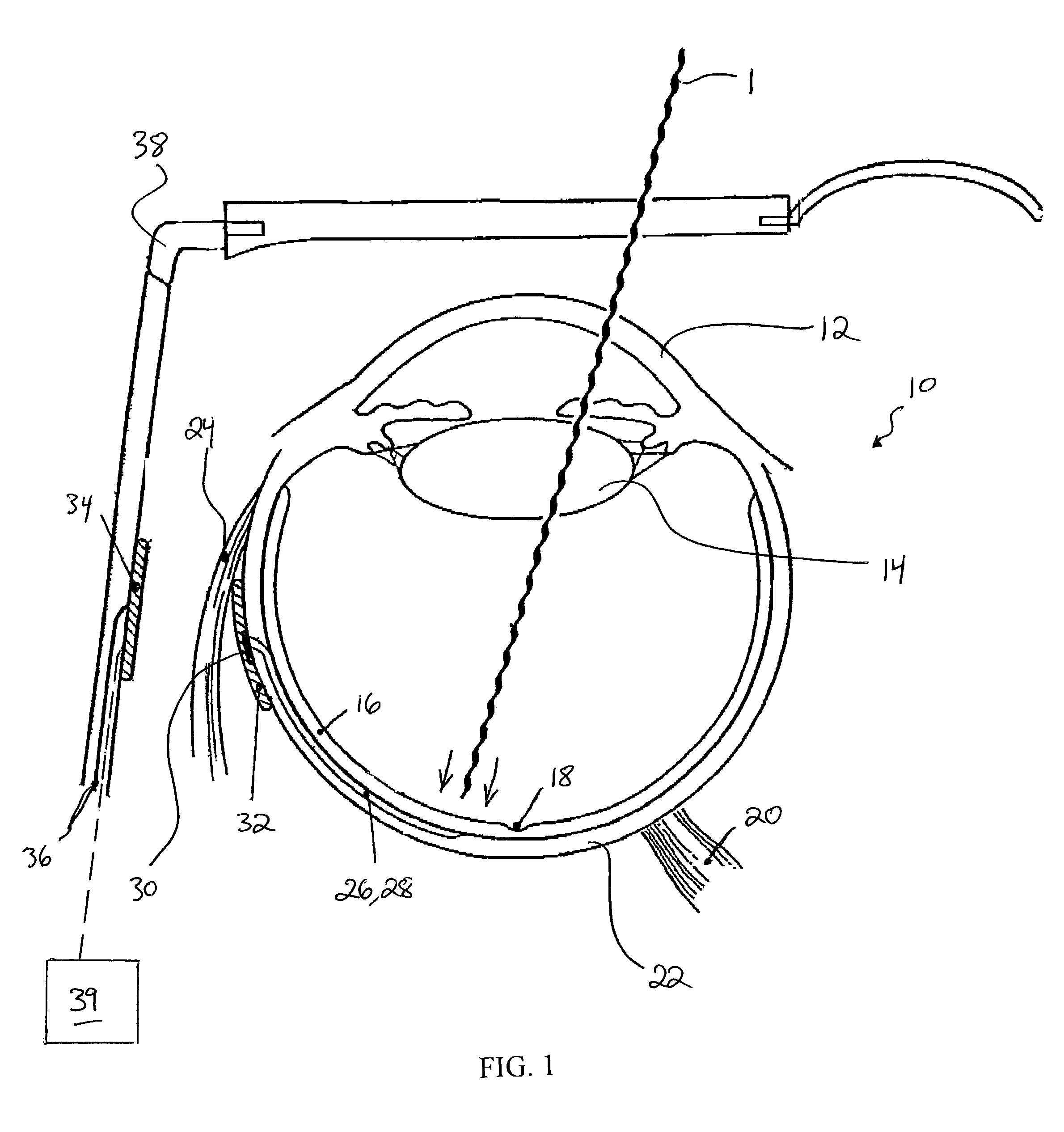

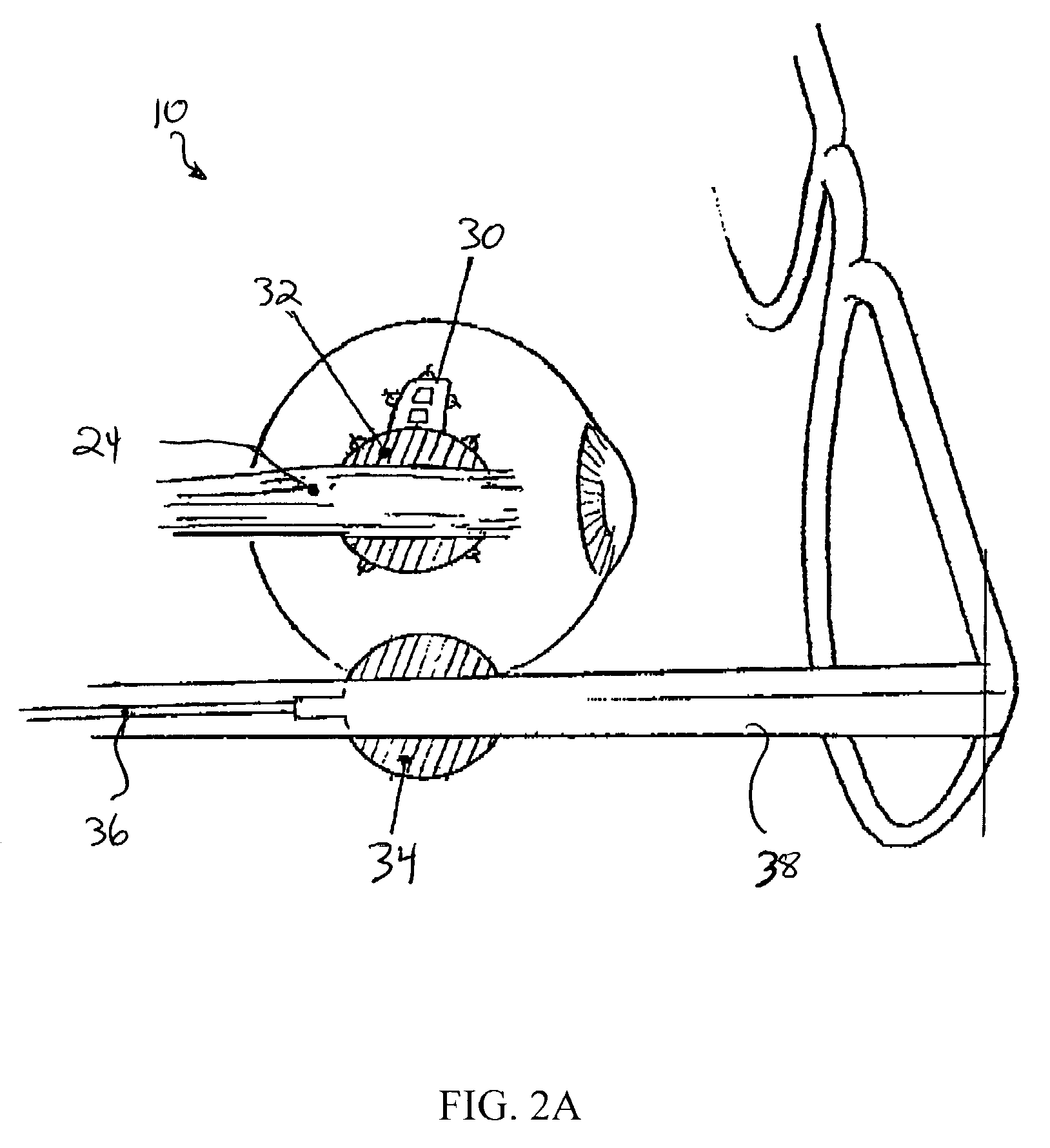

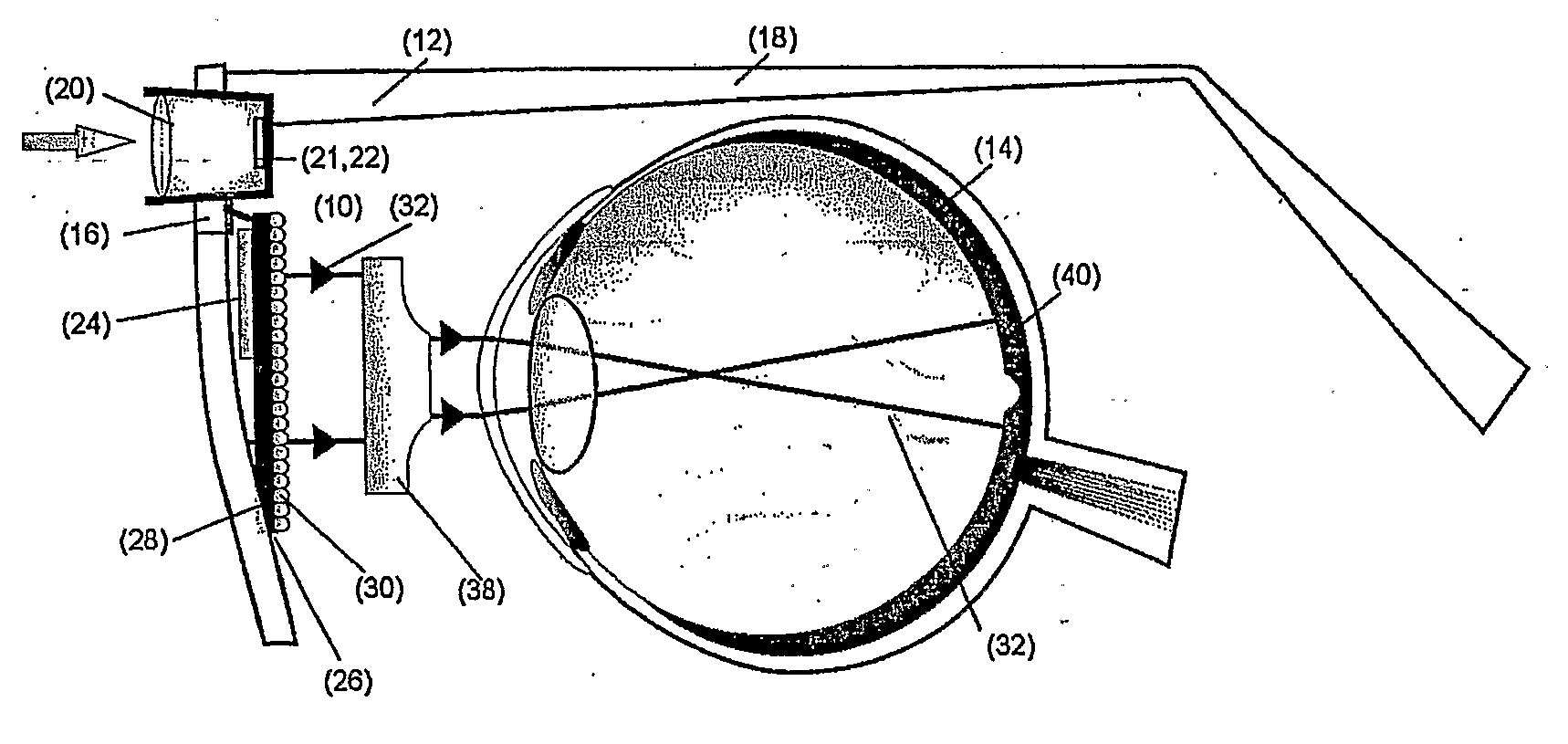

Minimally invasive retinal prosthesis

InactiveUS6976998B2Safely and effectively performInfluence functionHead electrodesEye treatmentProsthesisRetinal Prosthesis

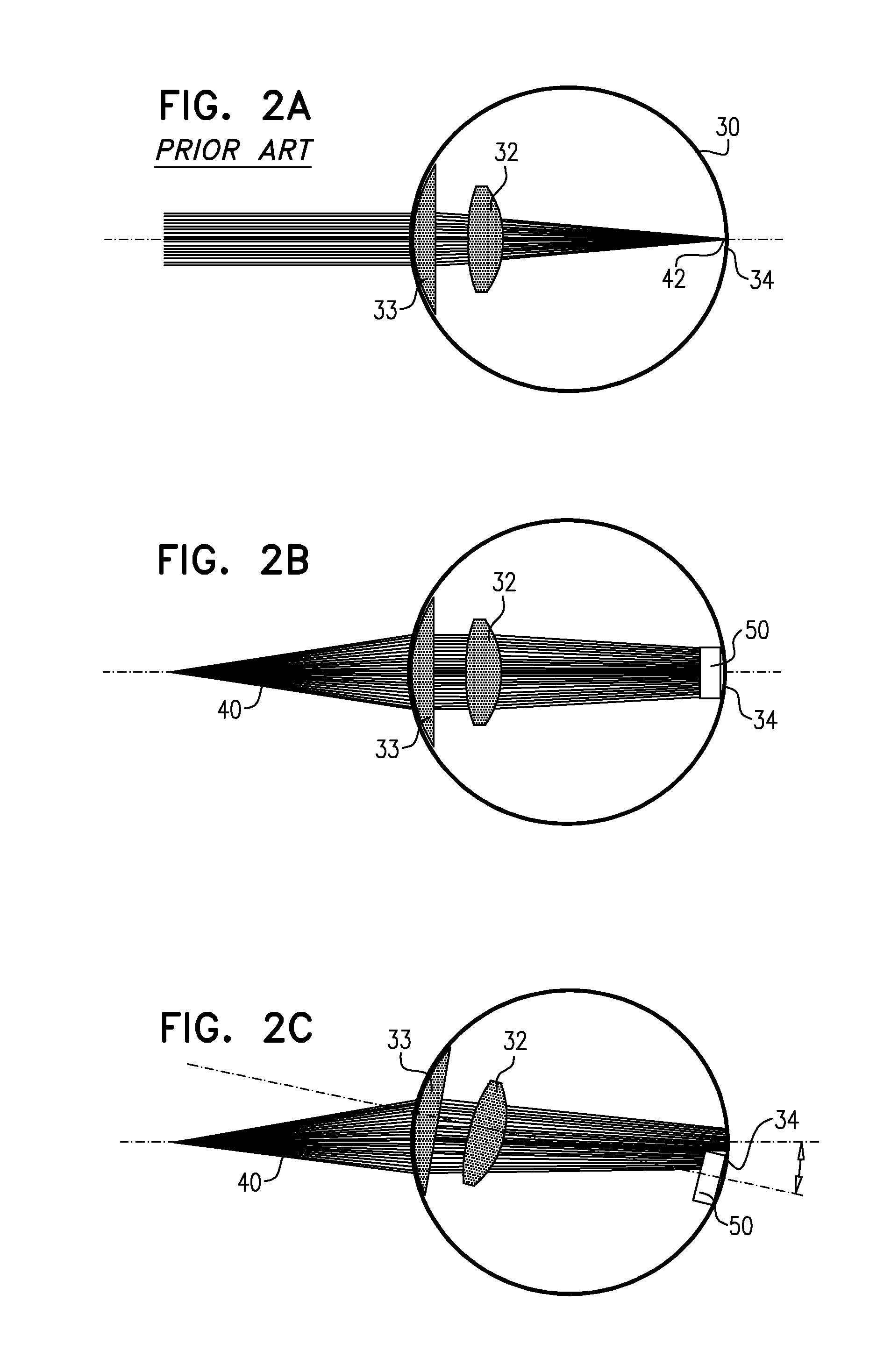

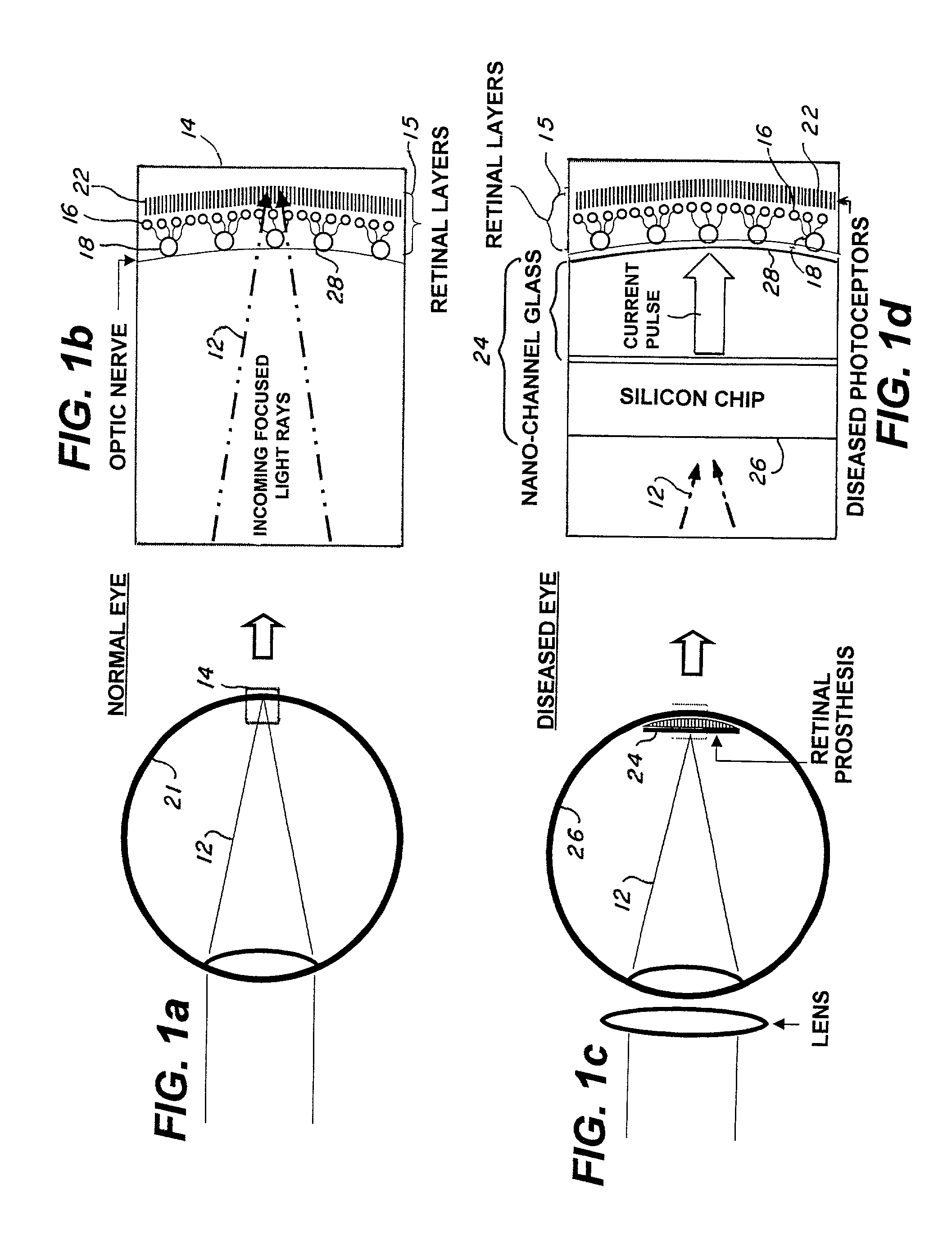

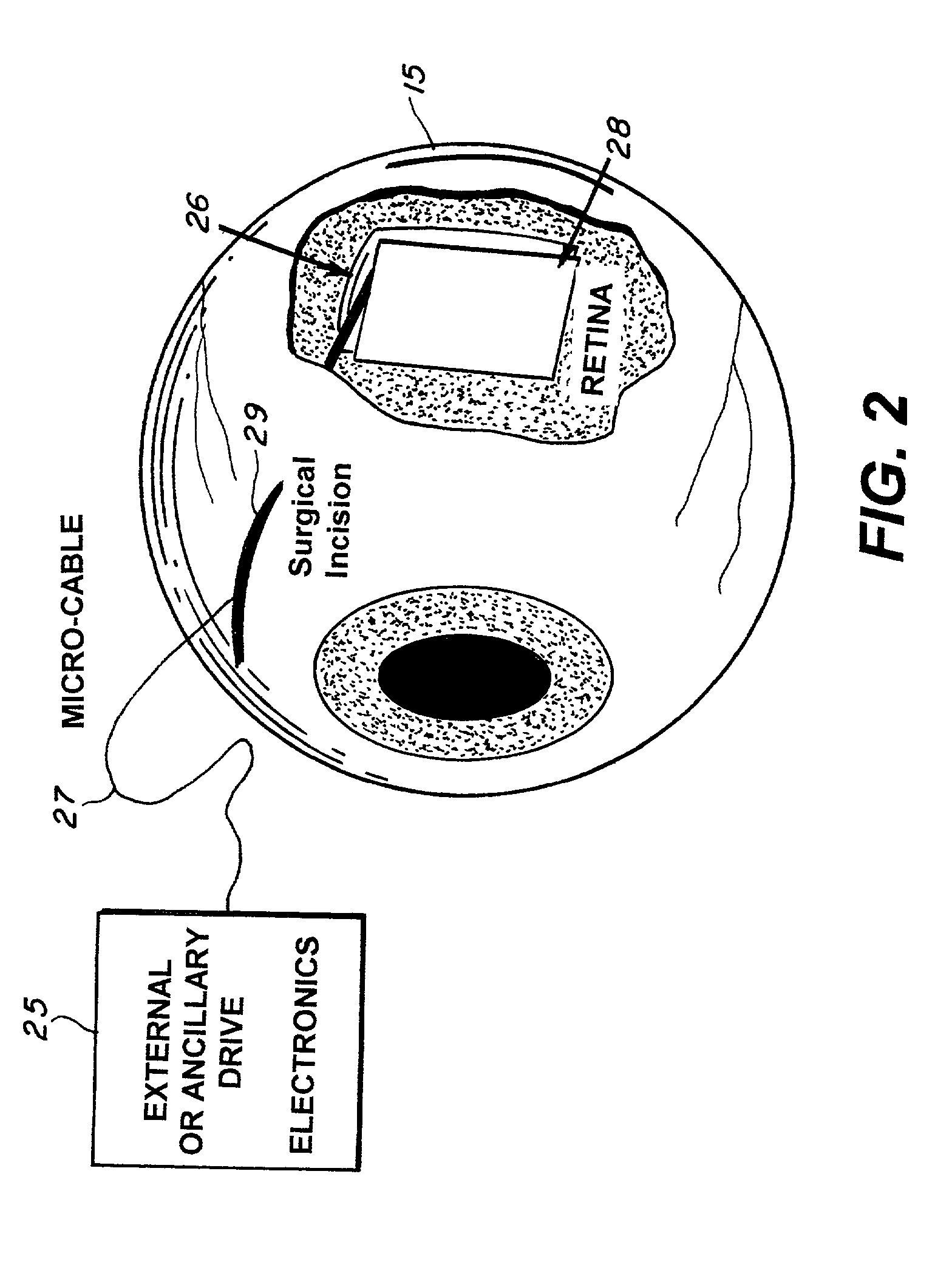

An ocular device that can more safely and effectively perform all functions needed of a retinal prosthesis with electronic components that are placed outside the wall of an eye, are powered wirelessly provided by an external power source, and which provide a patient with a view determined by natural motion of the eye and triggered by natural incident light converging at the retina. In one aspect, the invention is an externally powered, light-activated, sub-retinal prosthesis in which natural light entering the eye conveys visual details to the sub-retinal prosthesis, while wireless radiofrequency transmission provides the power needed to stimulate the retina, which would be insufficient if it were obtained from the intensity of incoming light alone.

Owner:MASSACHUSETTS EYE & EAR INFARY +1

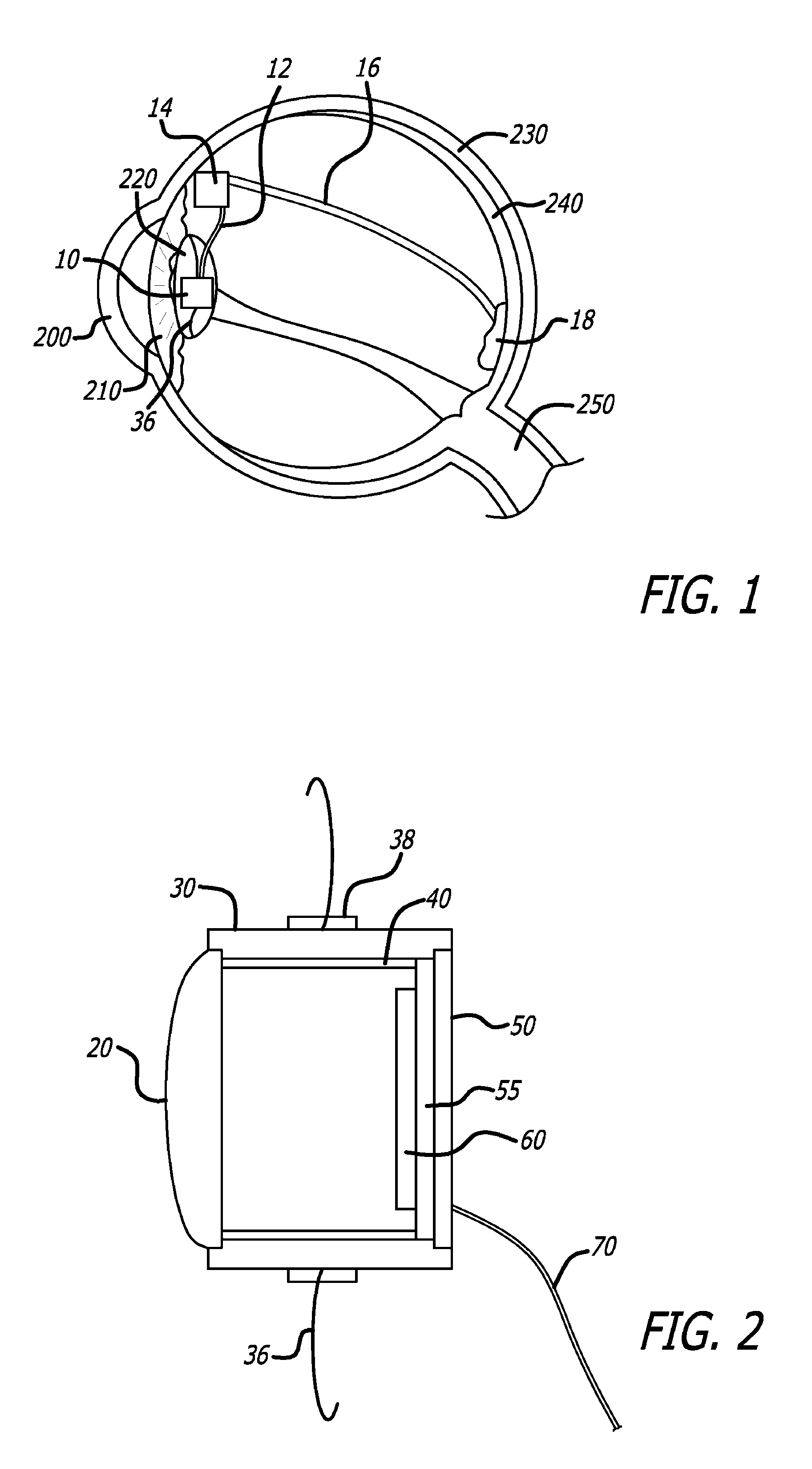

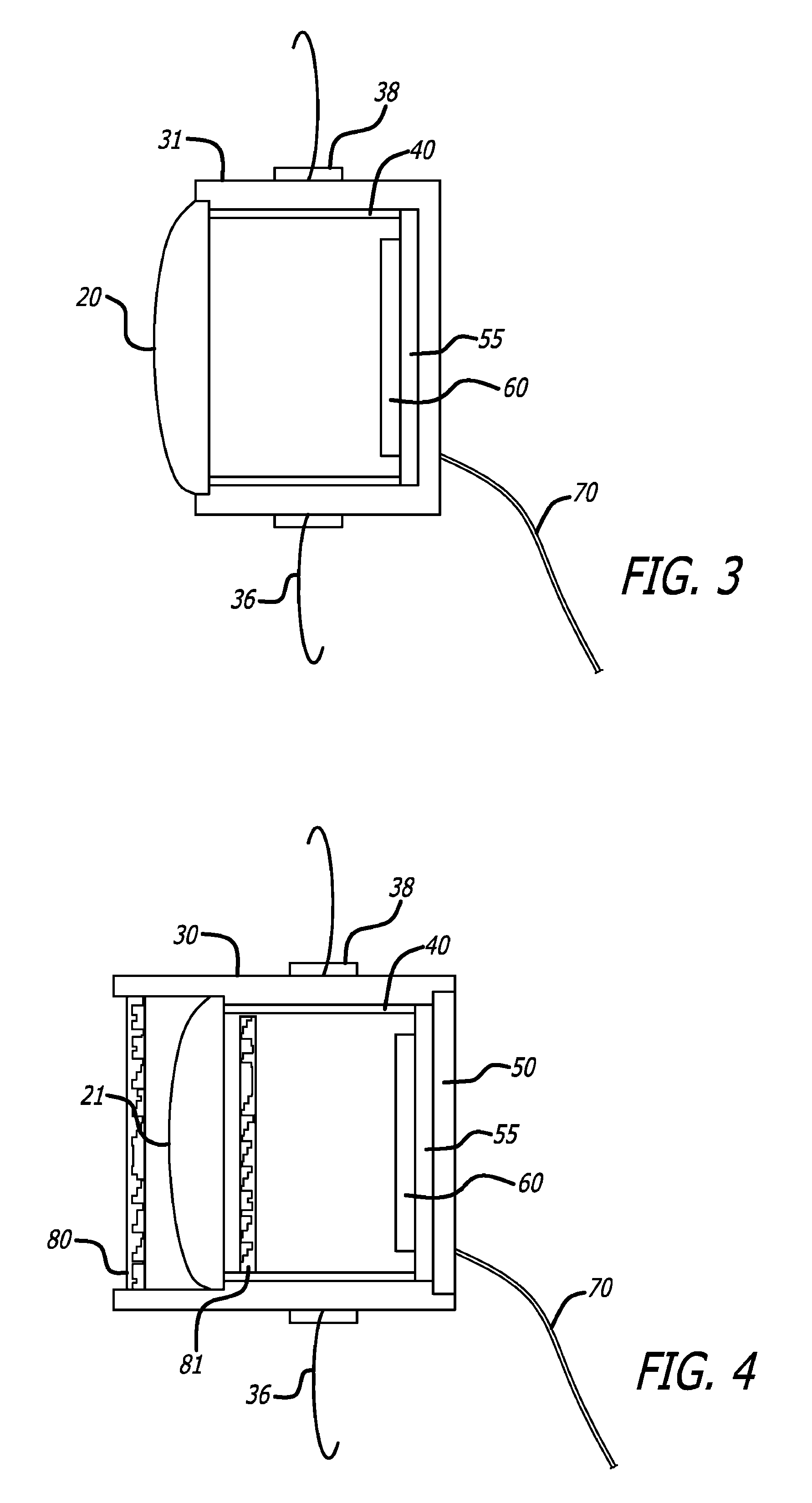

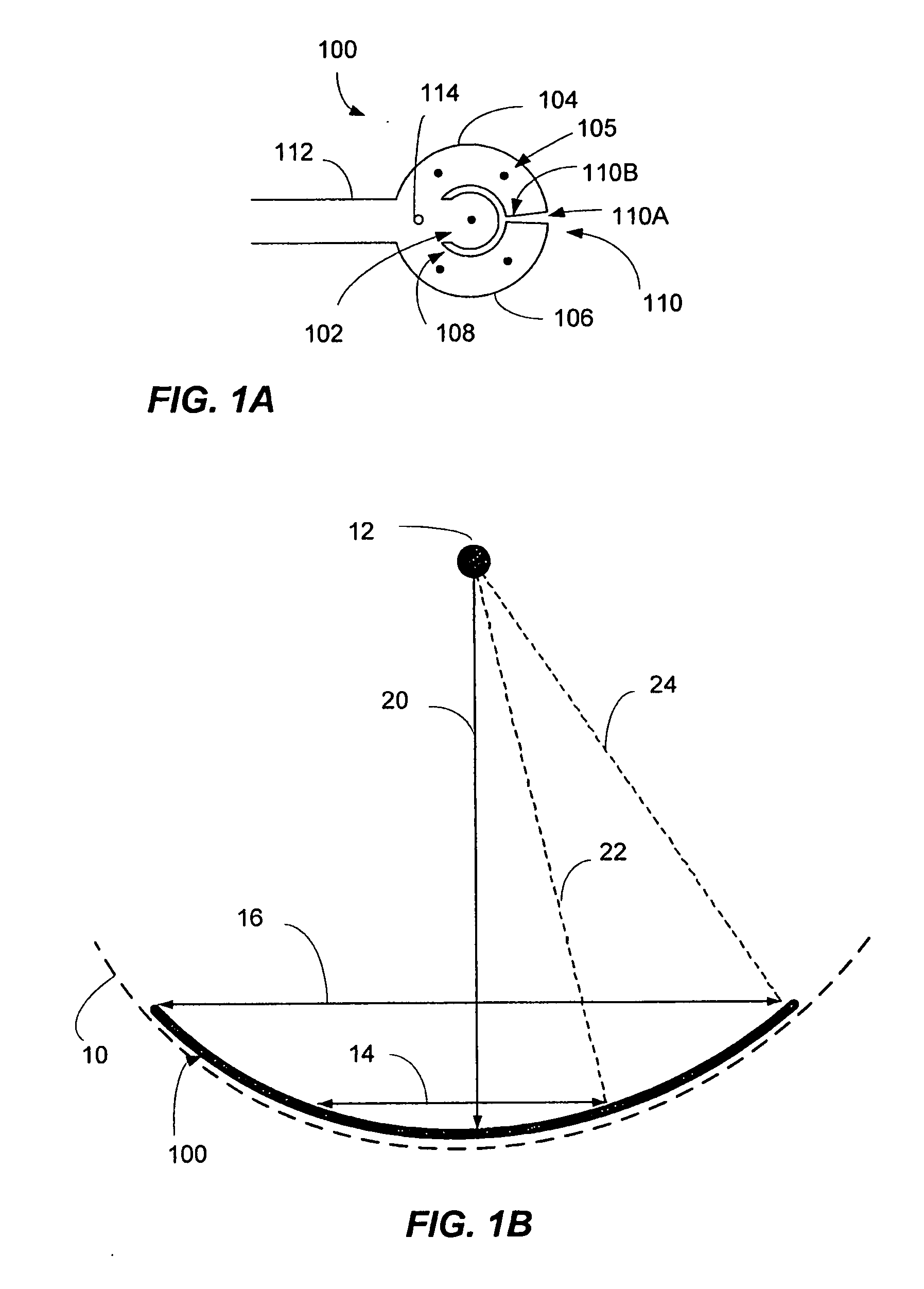

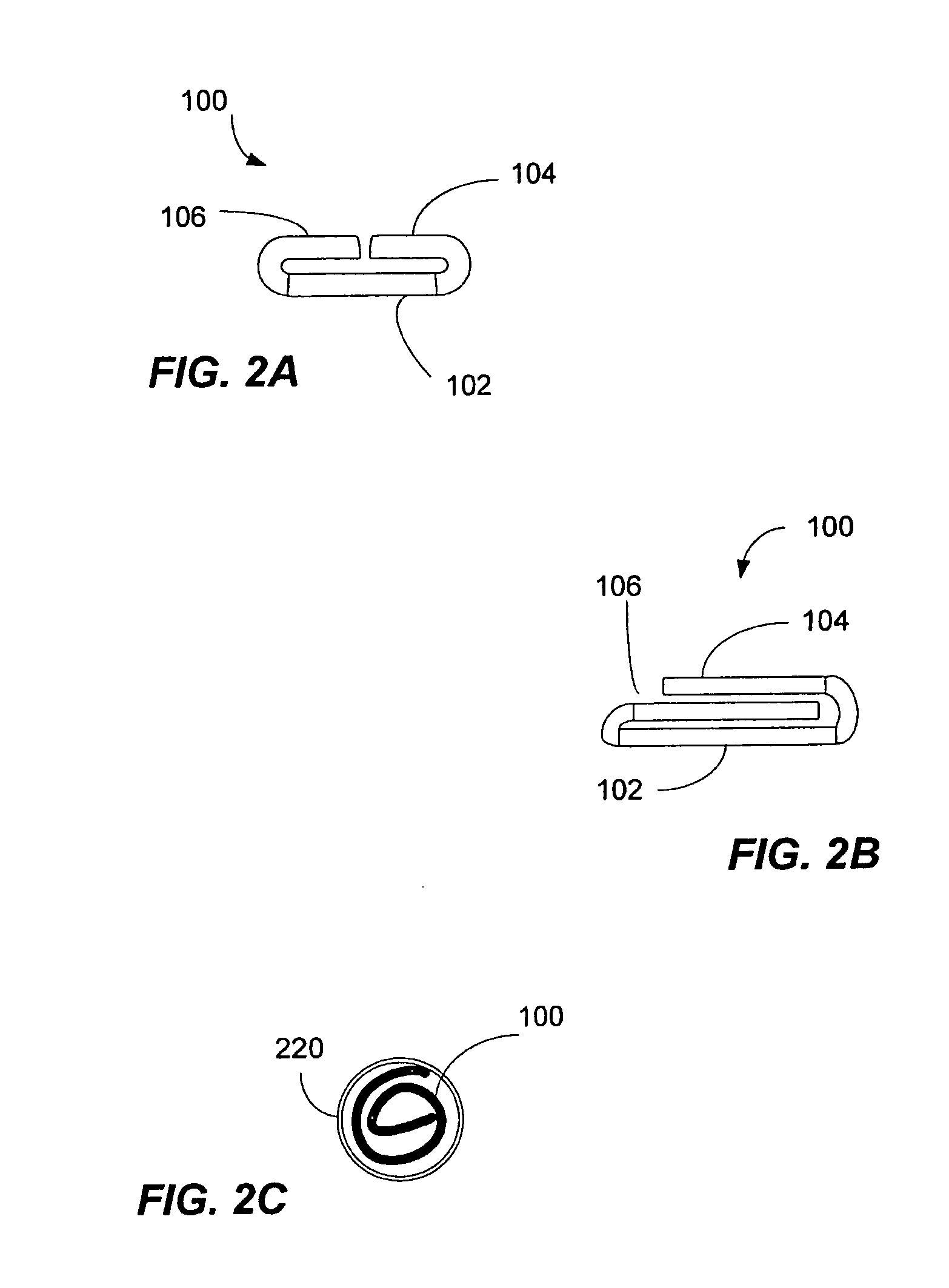

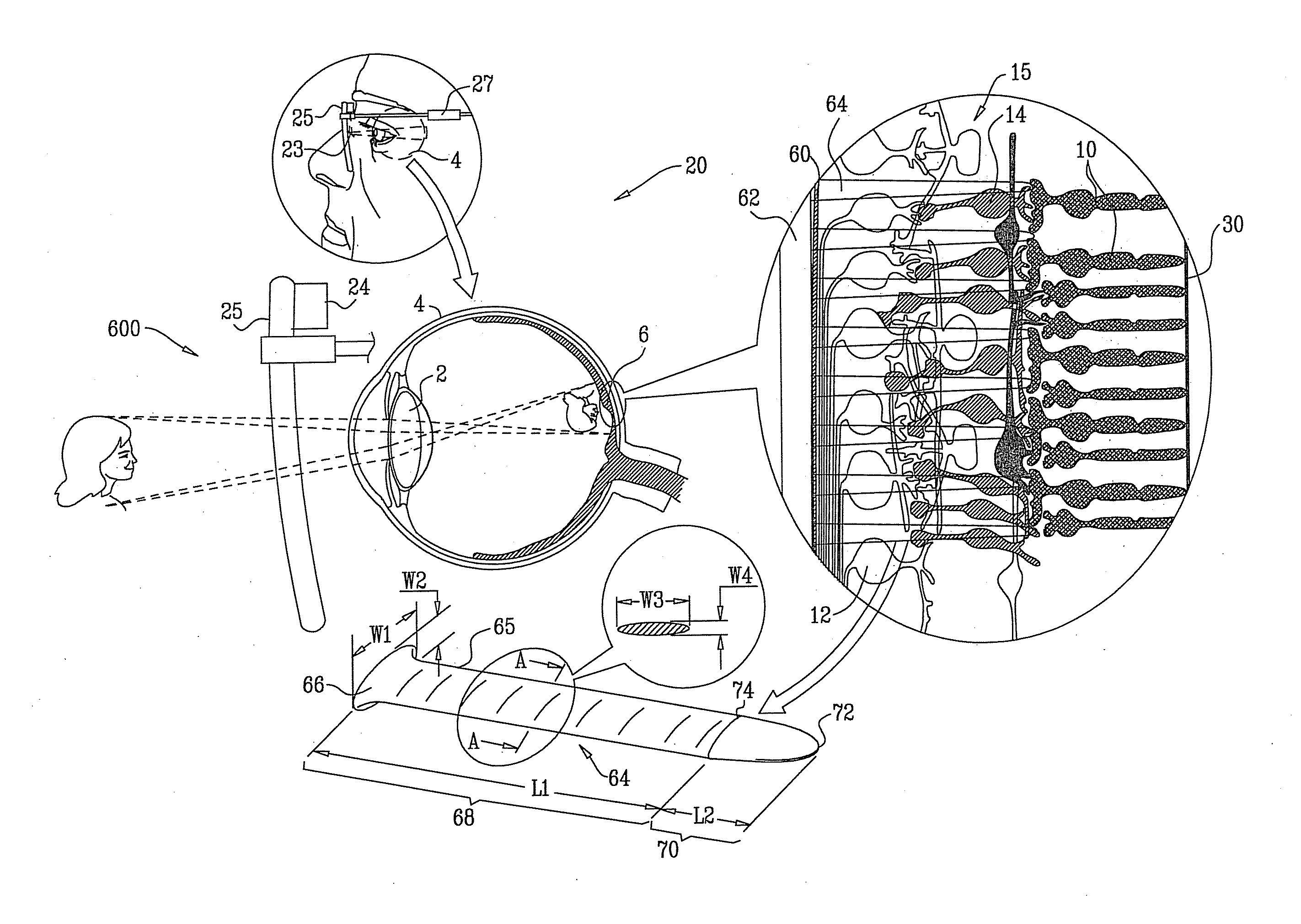

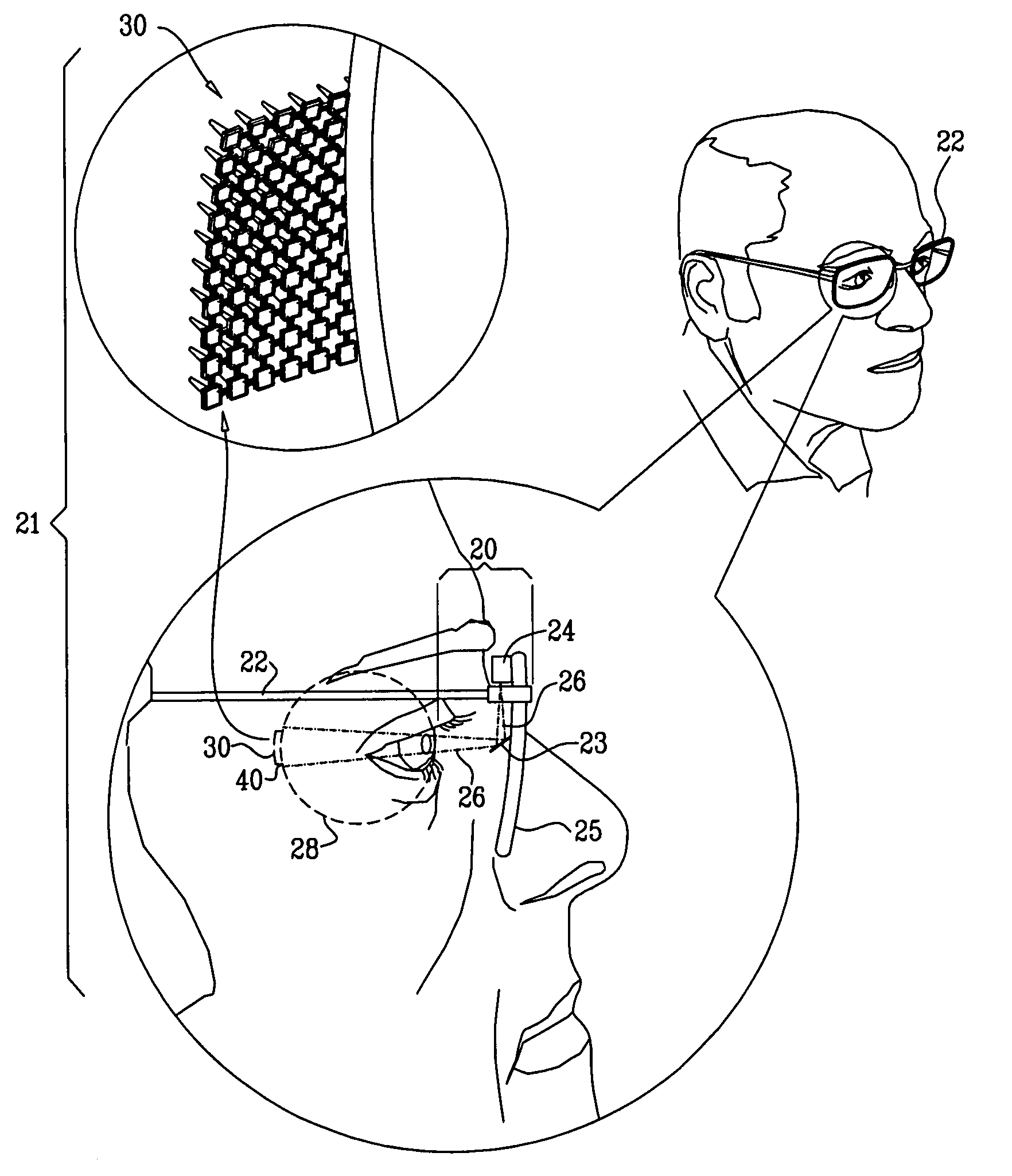

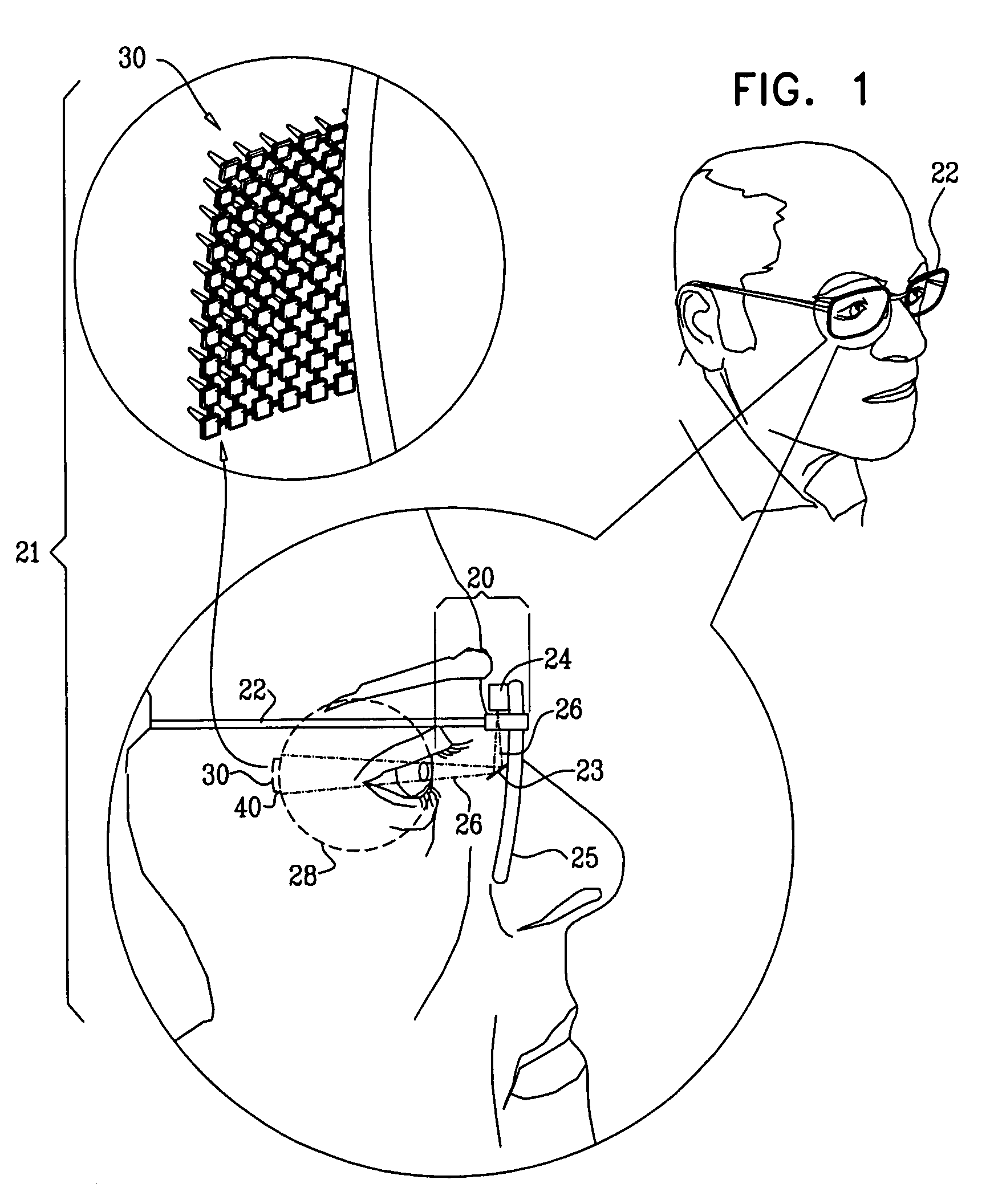

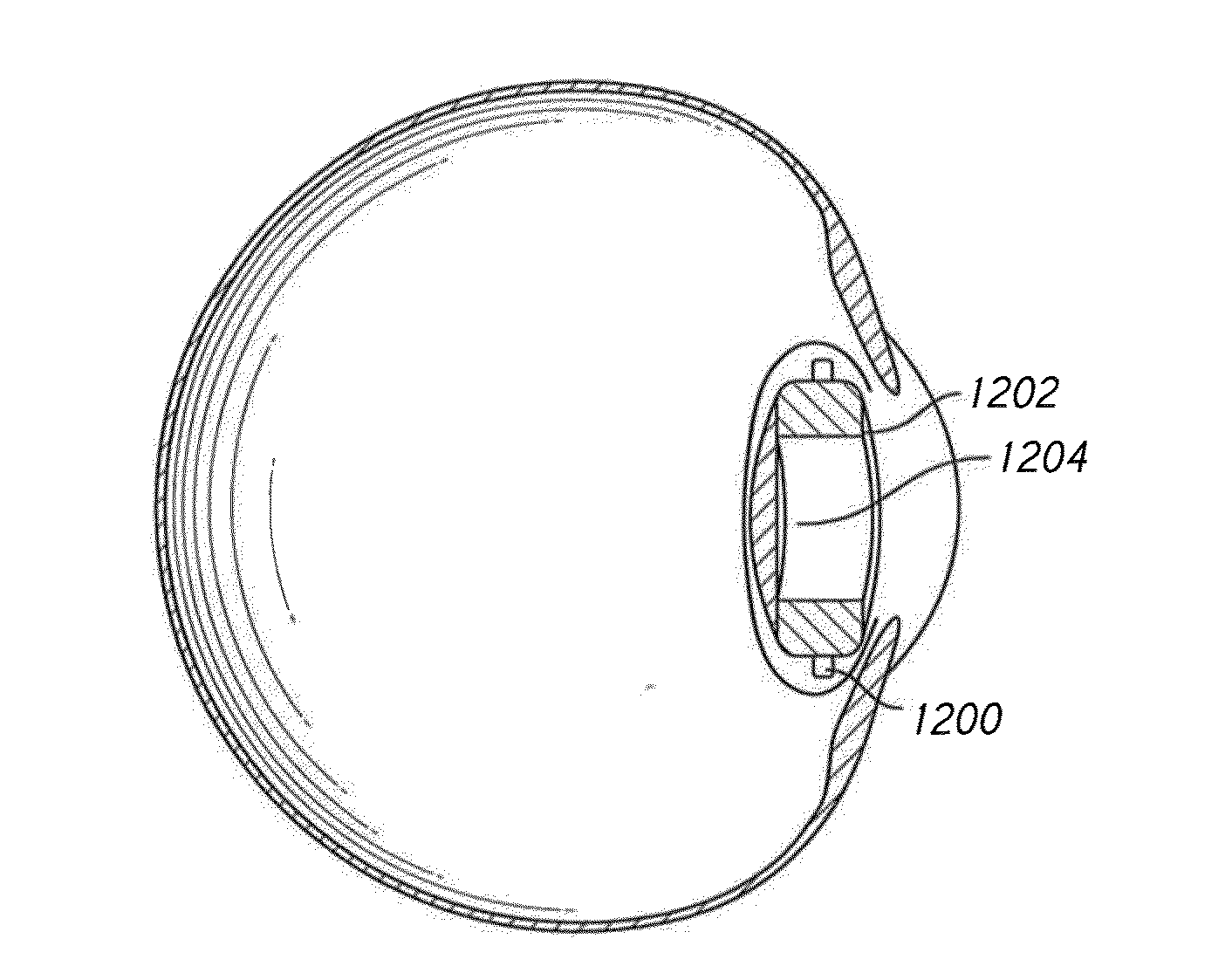

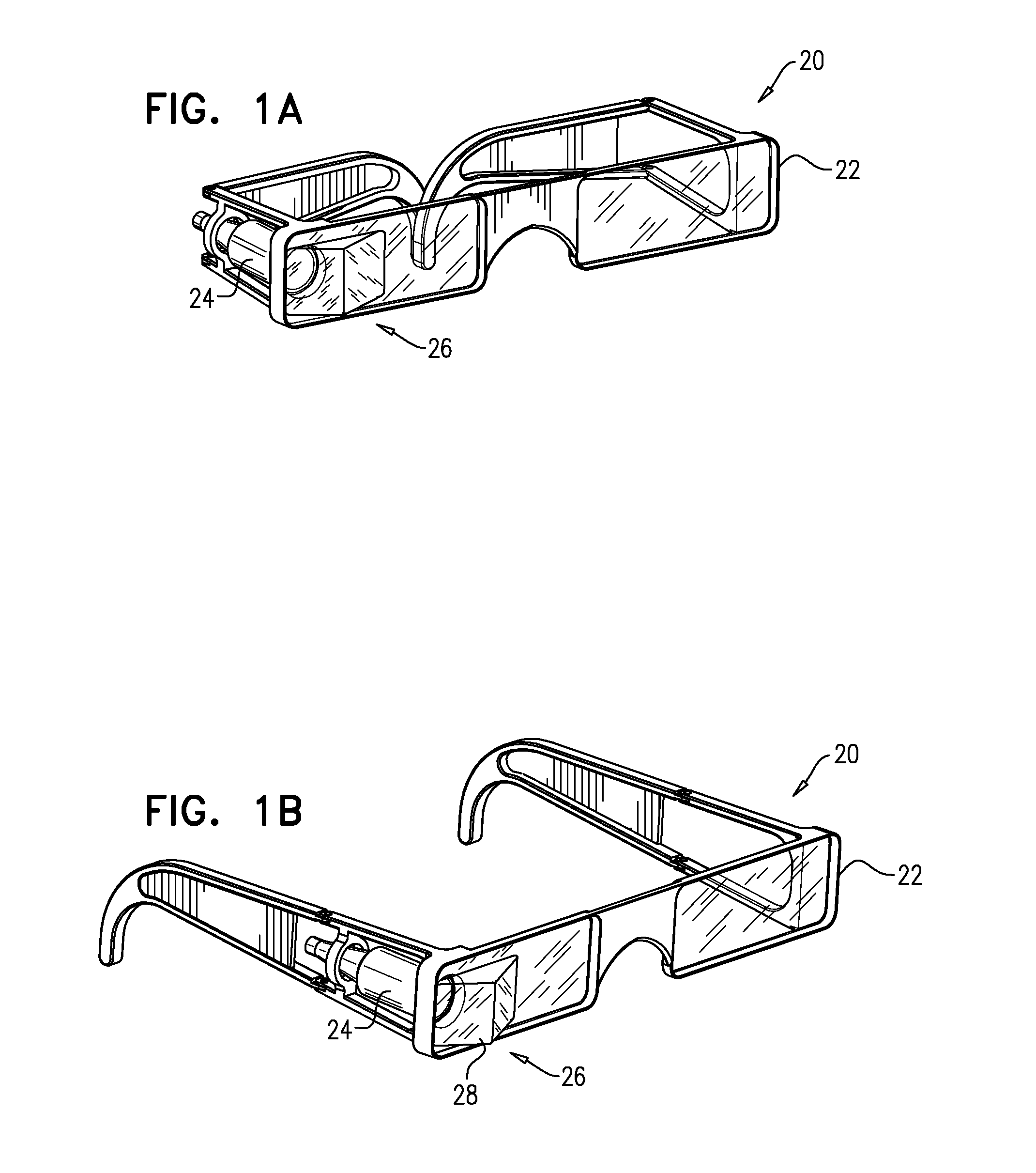

Intraocular Camera for Retinal Prostheses

ActiveUS20080086206A1Enhanced patient acceptabilityAdd depthHead electrodesEye treatmentControl signalRetinal Prosthesis

An intraocular camera for retinal prostheses may include an optical imaging system comprising a set of optical elements for forming an image of the external world on an image sensor array, wherein the optical elements and the image sensor array may be enclosed in an implantable biocompatible housing that may employ haptic elements for stabilization within the eye. The set of optical elements may be designed to have a short focal length and to provide adequate resolution images that can be transformed into a set of stimulation signals applied to a pixellated microstimulator array. Transmission of the signals from the intraocular camera to a microstimulator driver circuit may be accomplished either by a wired or wireless communication device. Power and control signals may be provided to the intraocular camera by a wired or wireless communication device, or optically by means of ambient illumination or an optical beam.

Owner:UNIV OF SOUTHERN CALIFORNIA

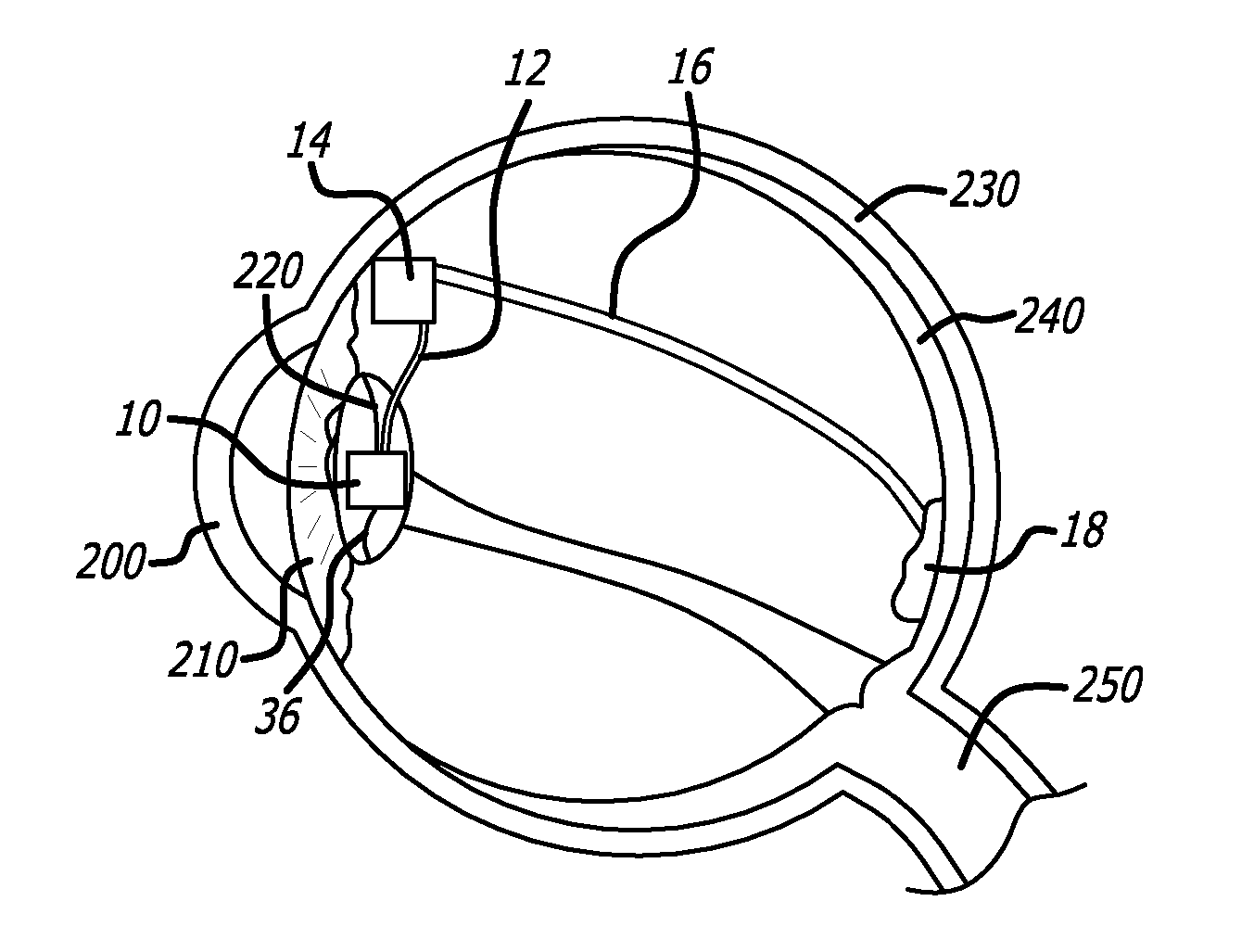

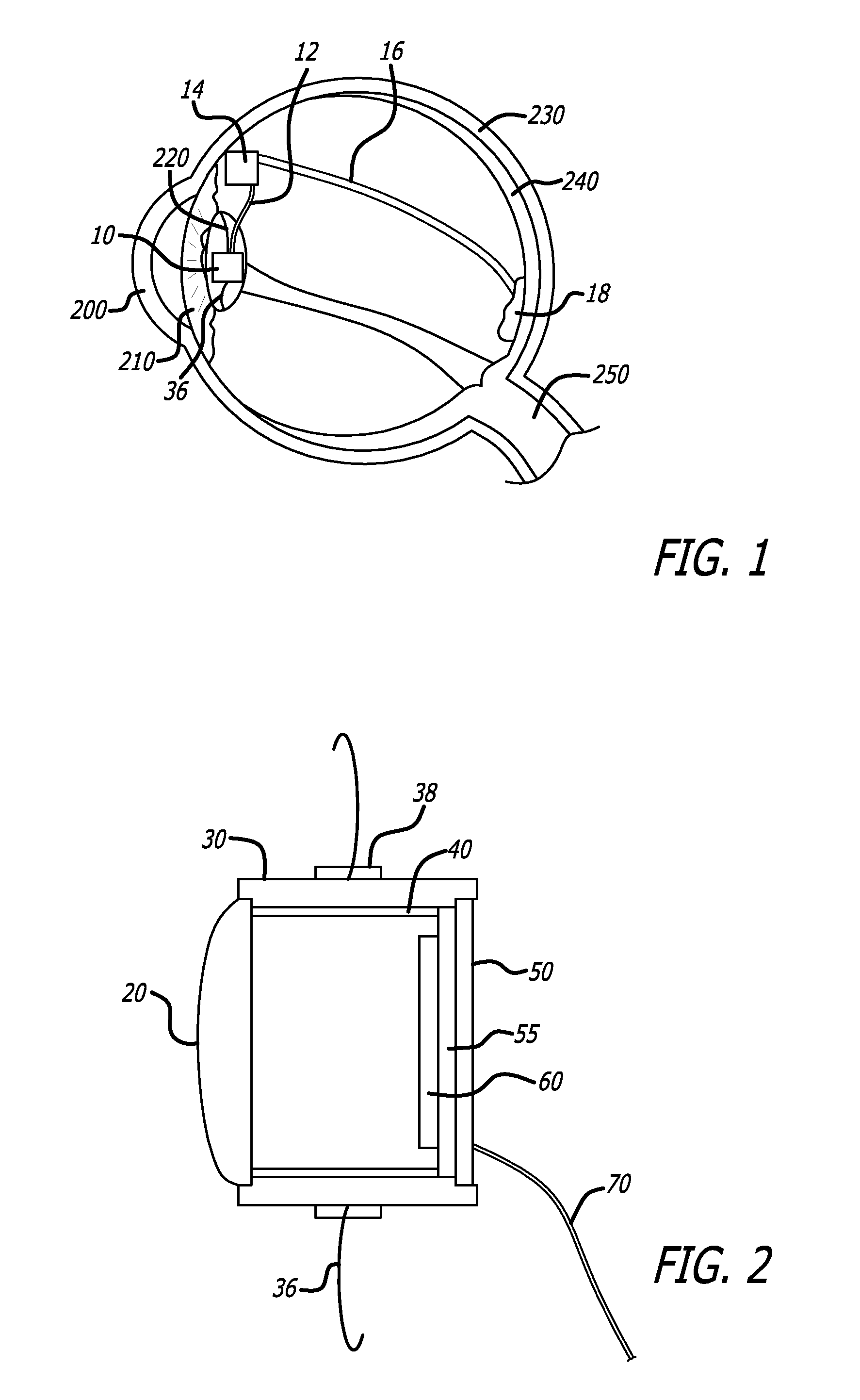

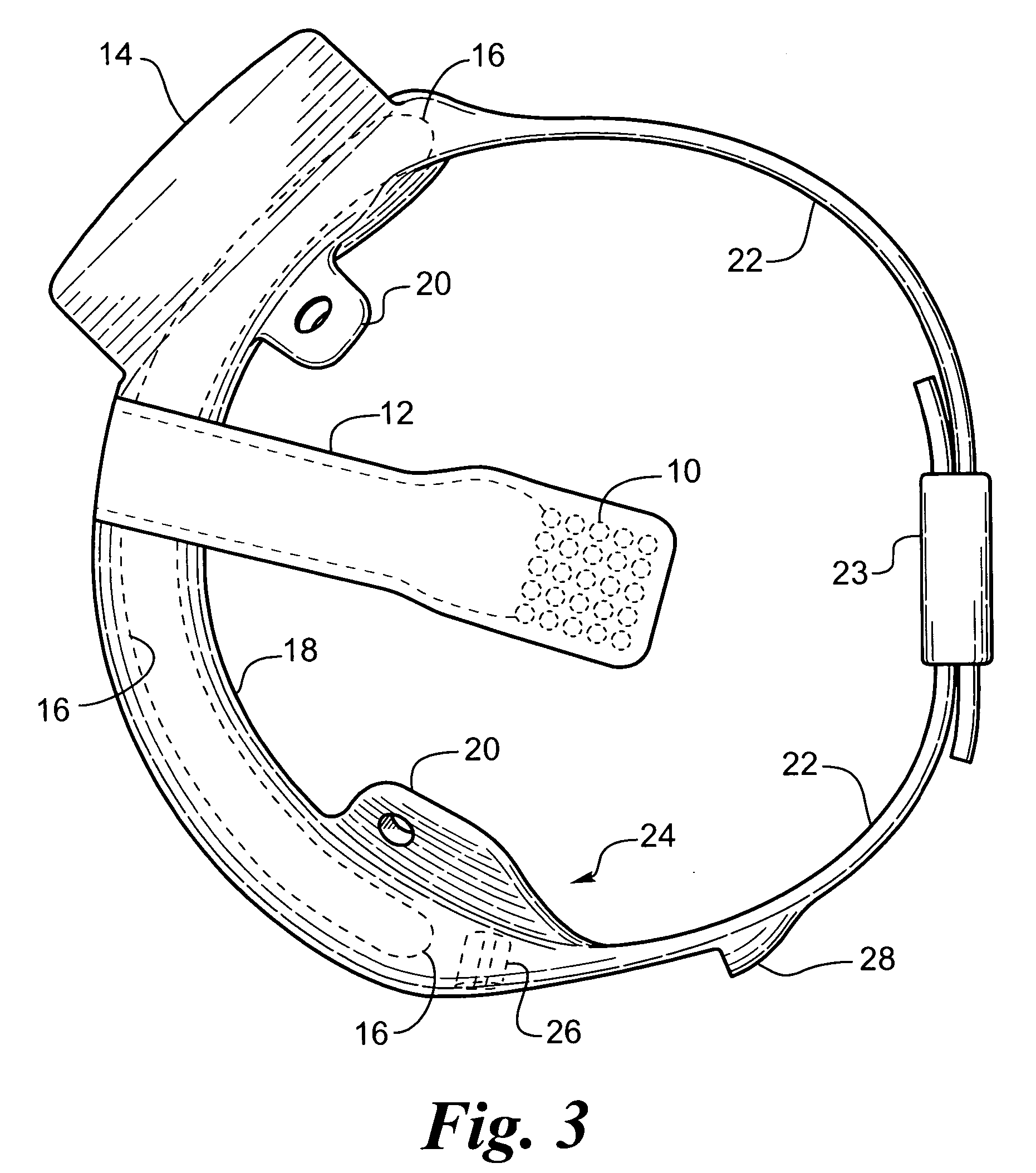

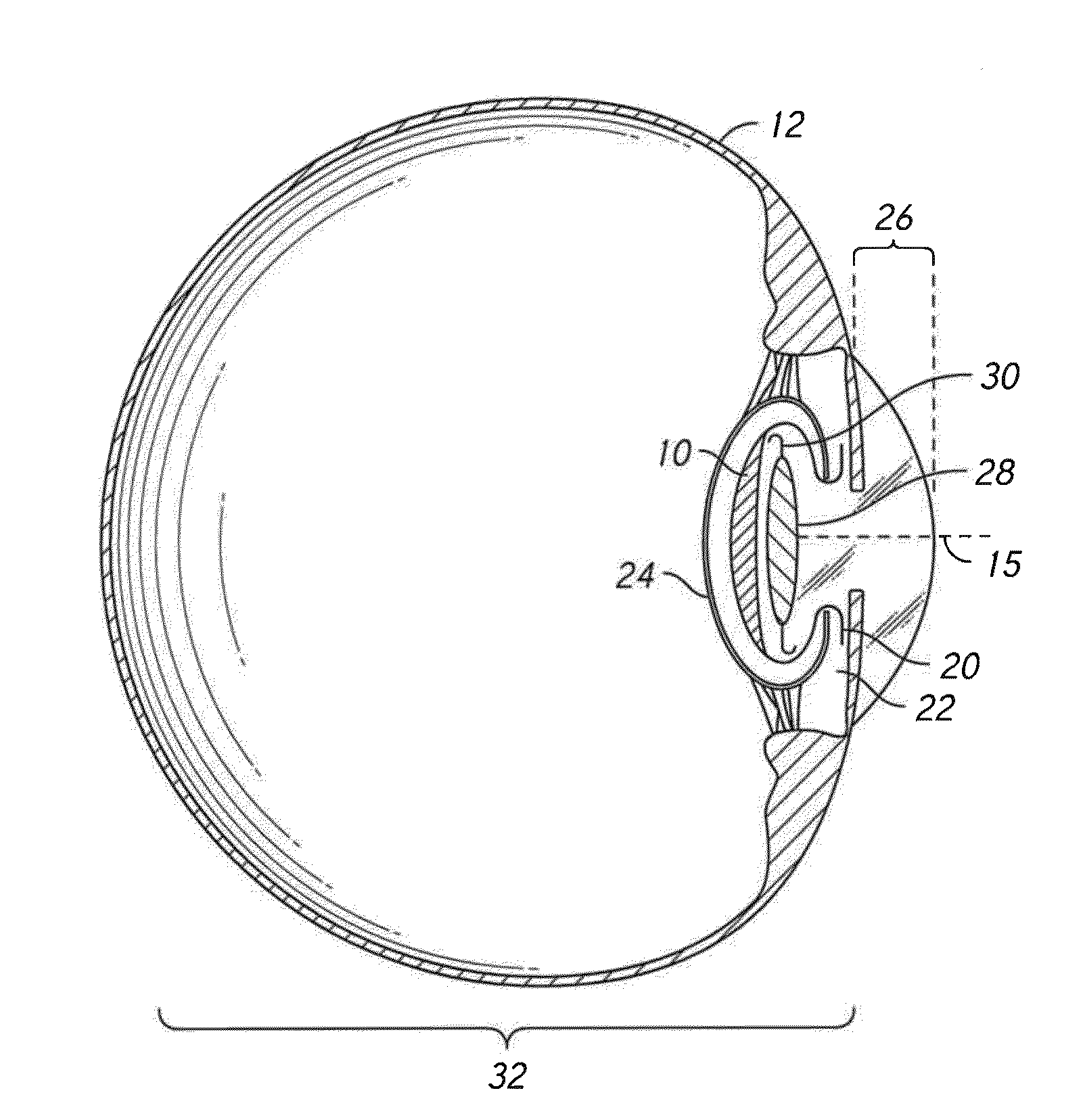

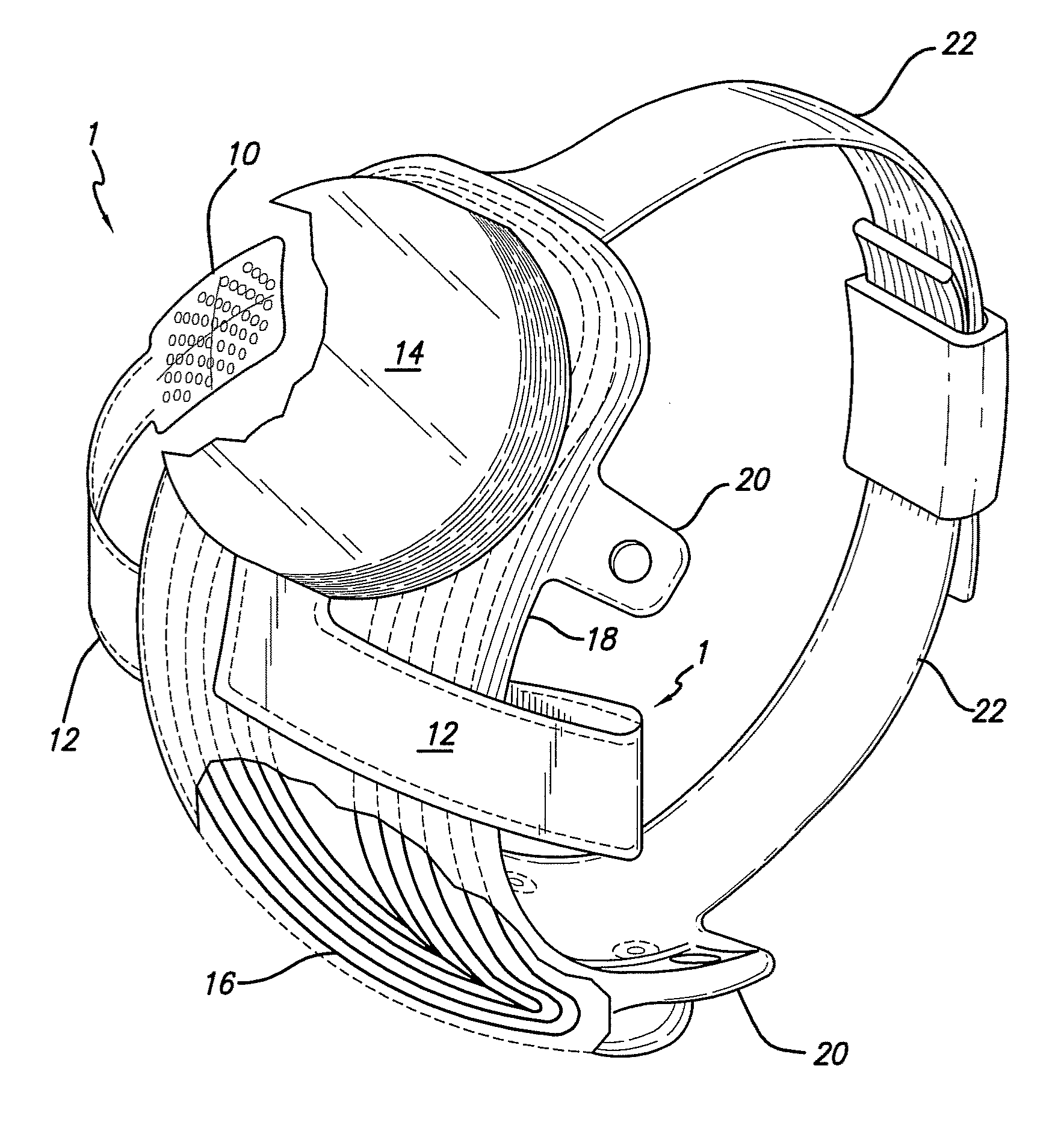

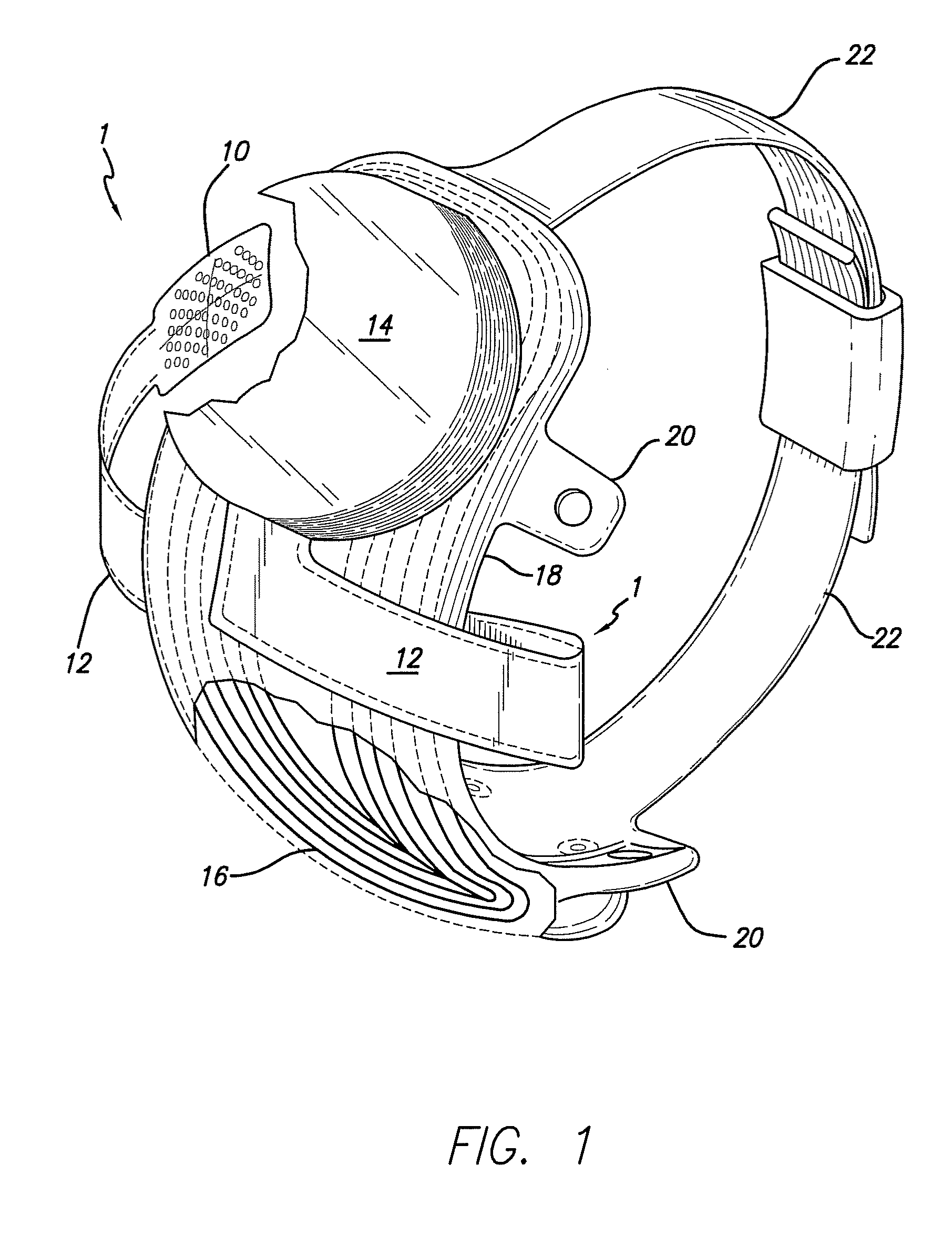

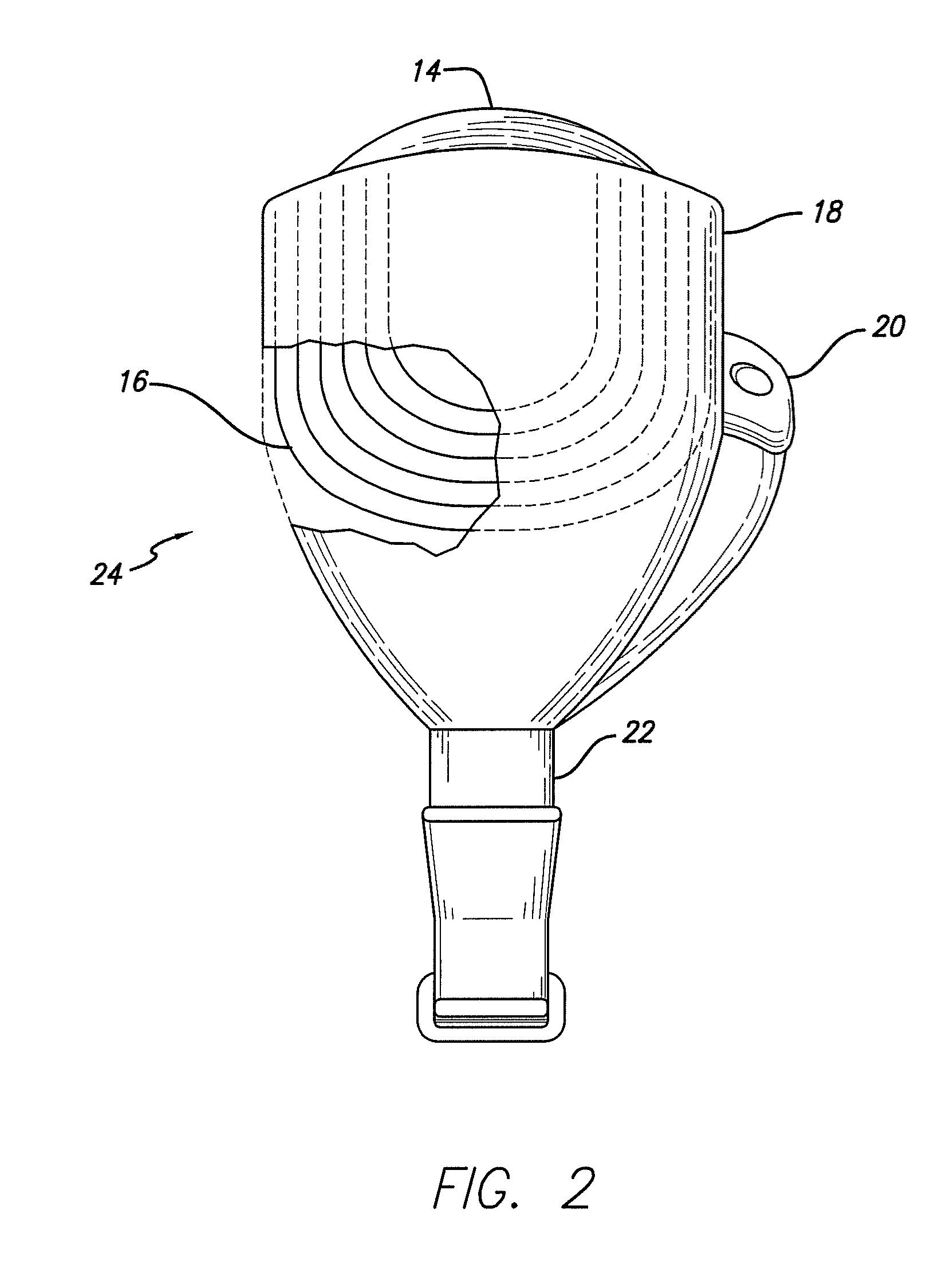

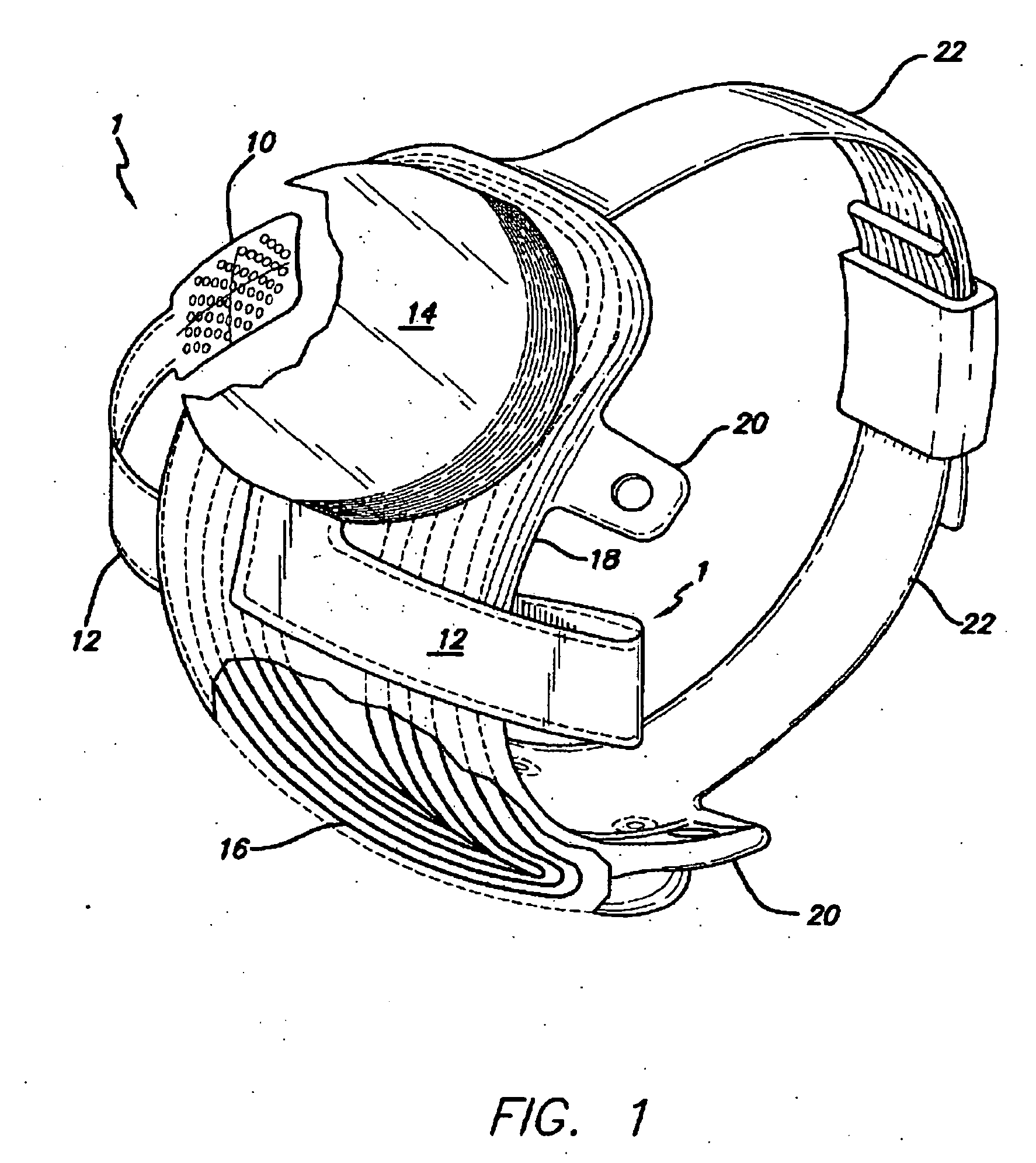

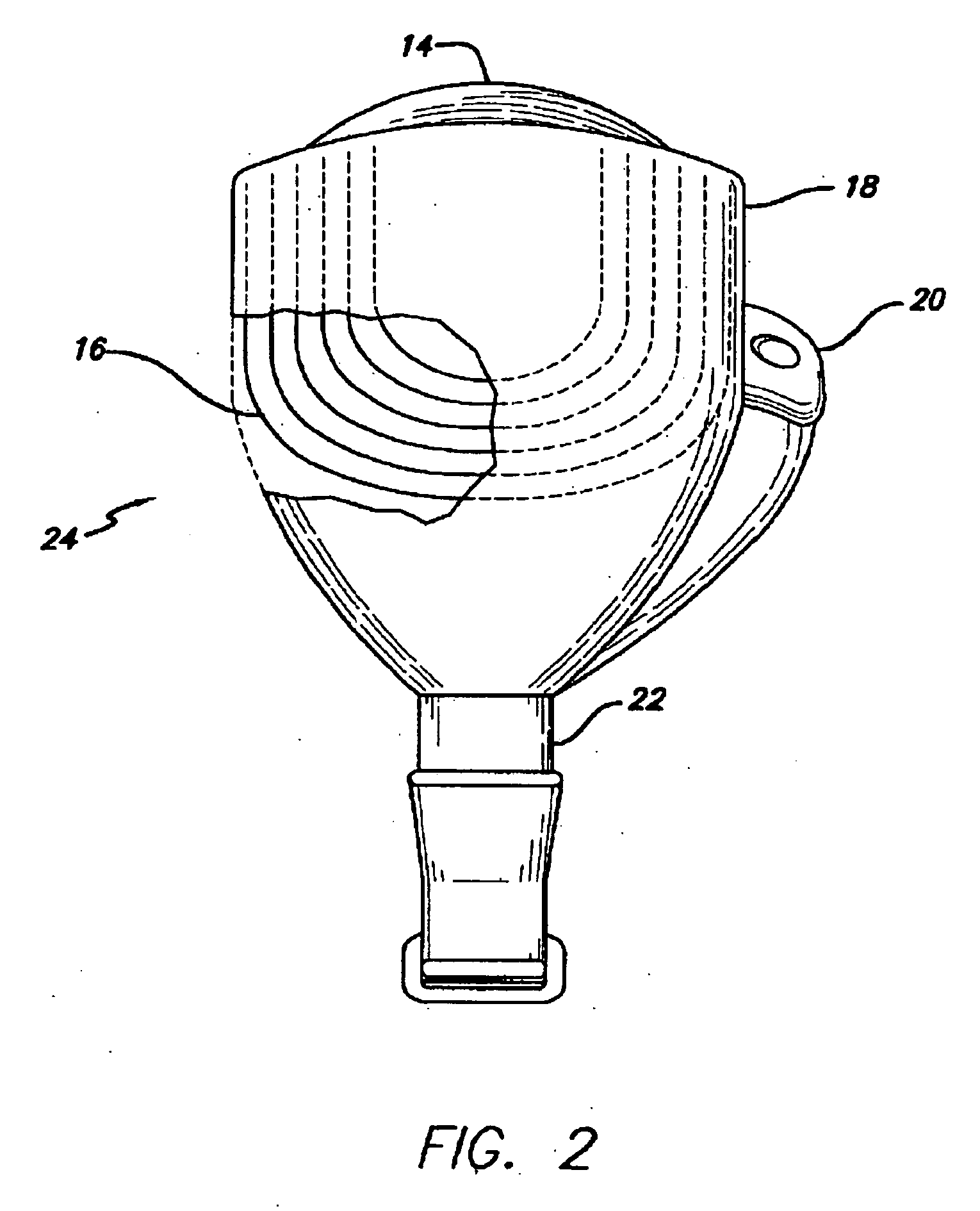

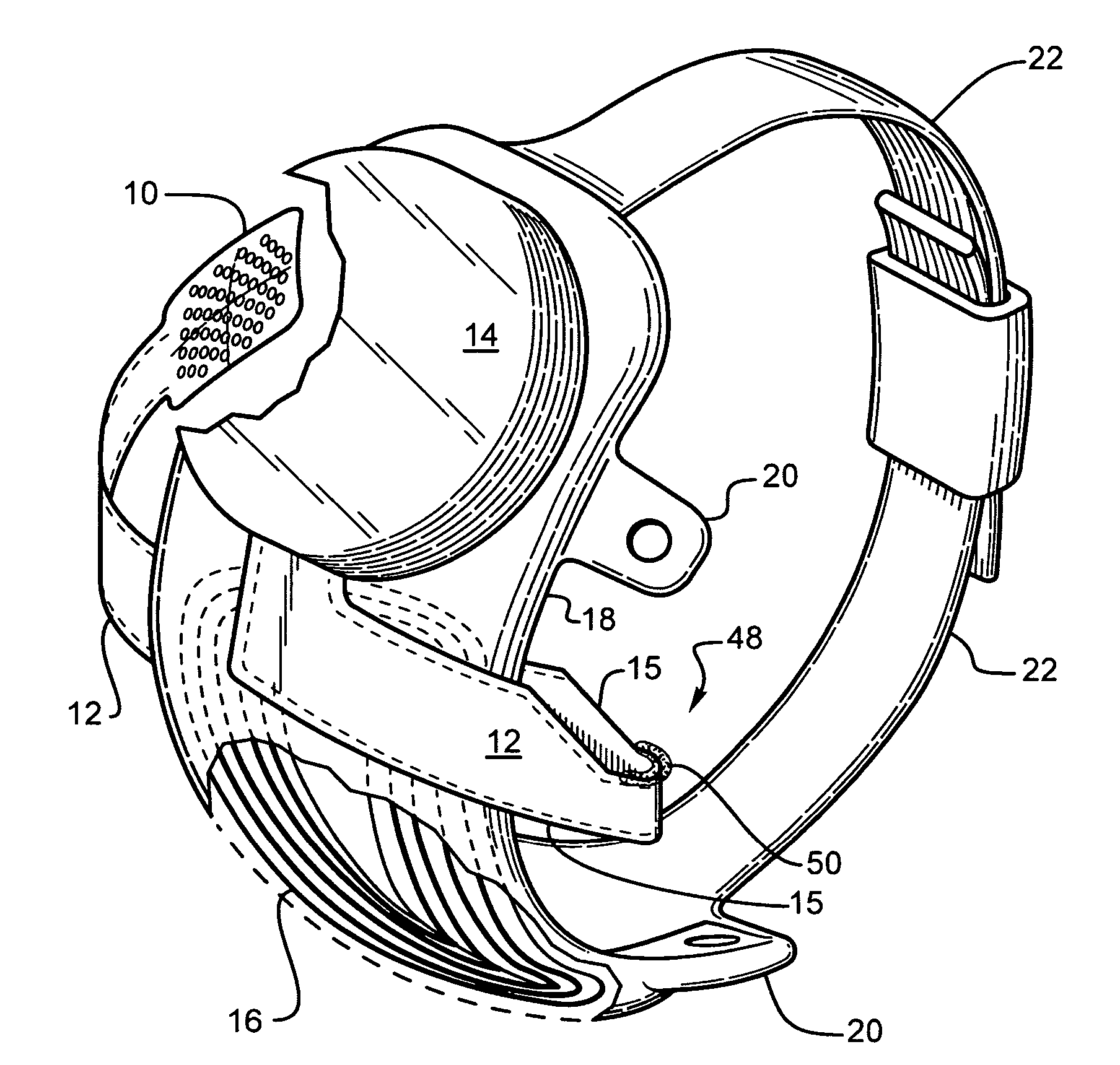

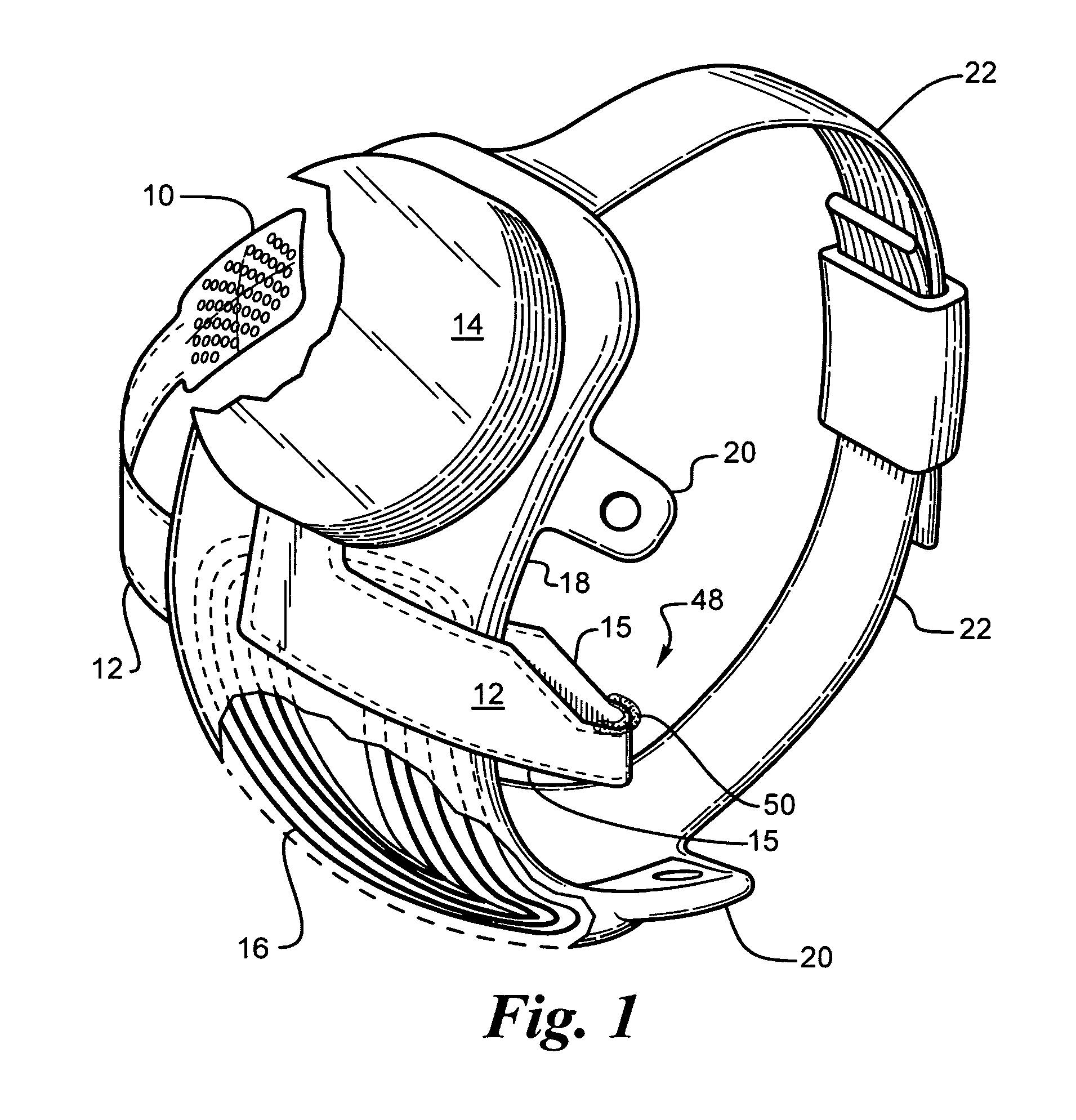

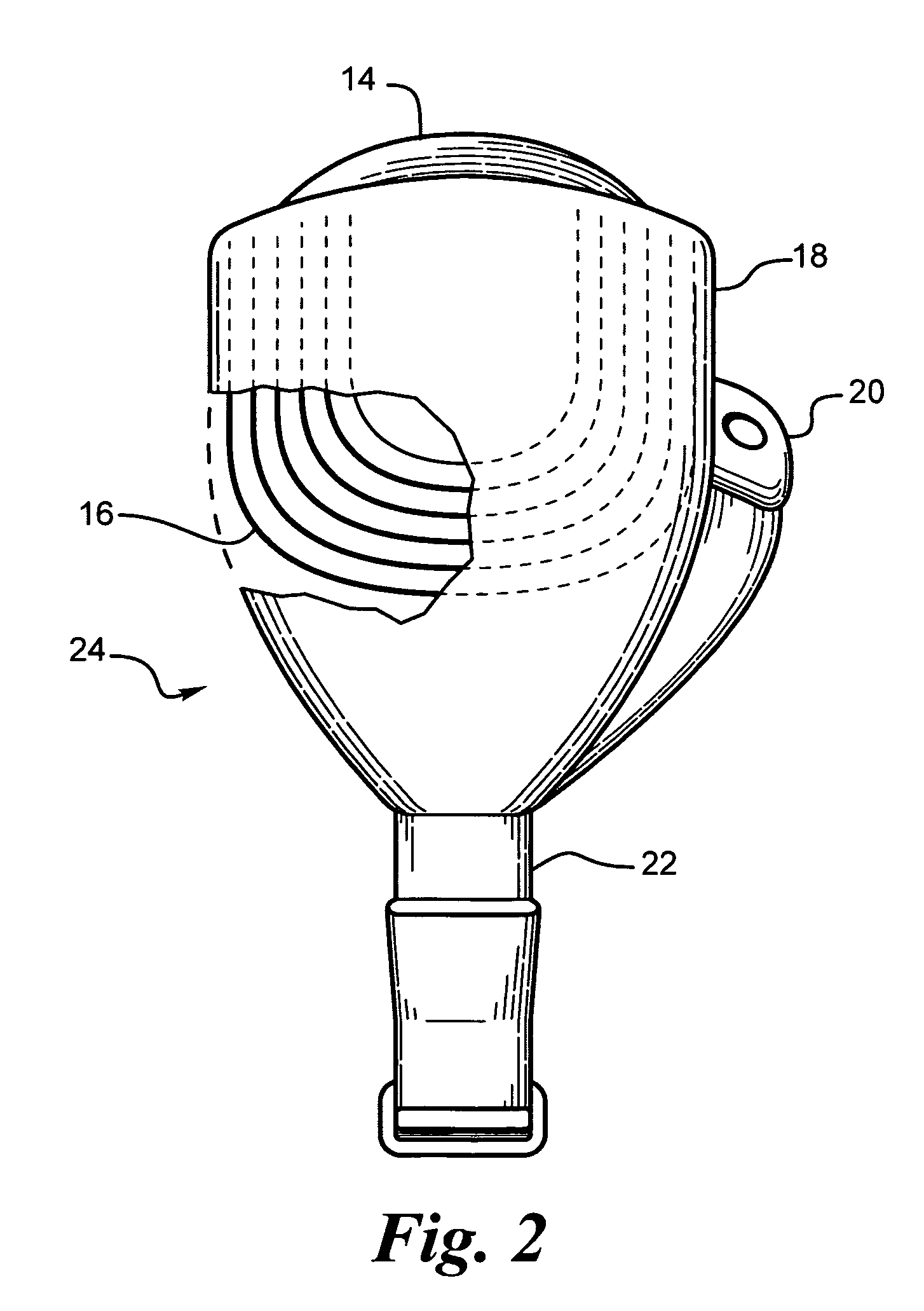

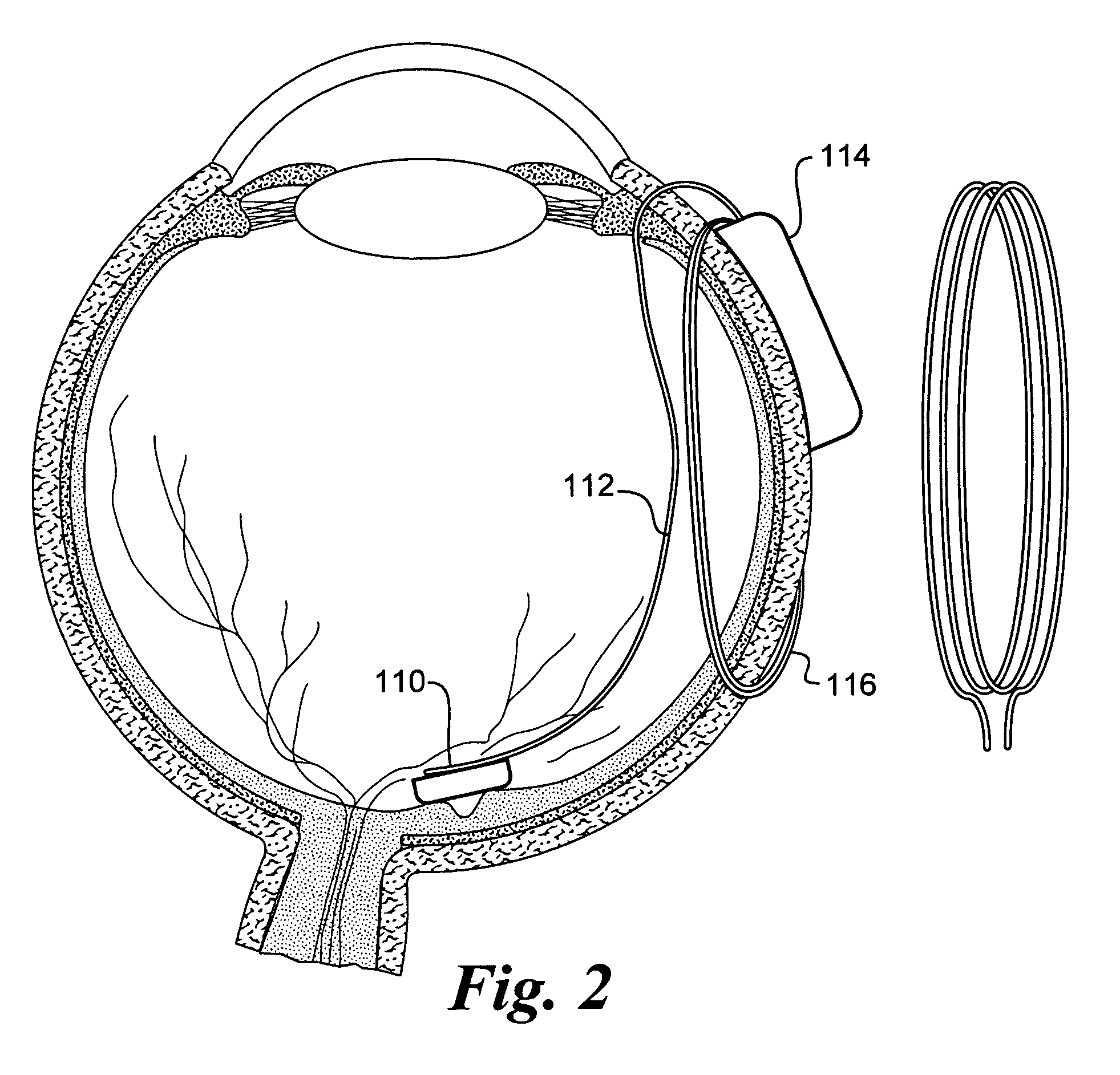

Retinal prosthesis with side mounted inductive coil

The invention is a retinal prosthesis with an inductive coil mounted to the side of the eye by means of a strap around the eye. This allows for close coupling to an external coil and movement of the entire implanted portion with movement of the eye ball.

Owner:SECOND SIGHT MEDICAL PRODS +2

Intraocular camera for retinal prostheses

ActiveUS8197539B2Enhanced patient acceptabilityEliminate needHead electrodesEye treatmentSensor arrayDriver circuit

Owner:UNIV OF SOUTHERN CALIFORNIA

Retinal prosthesis

ActiveUS20100204754A1Facilitating refraction of visible lightHead electrodesSolid-state devicesMedicineVoltage drop

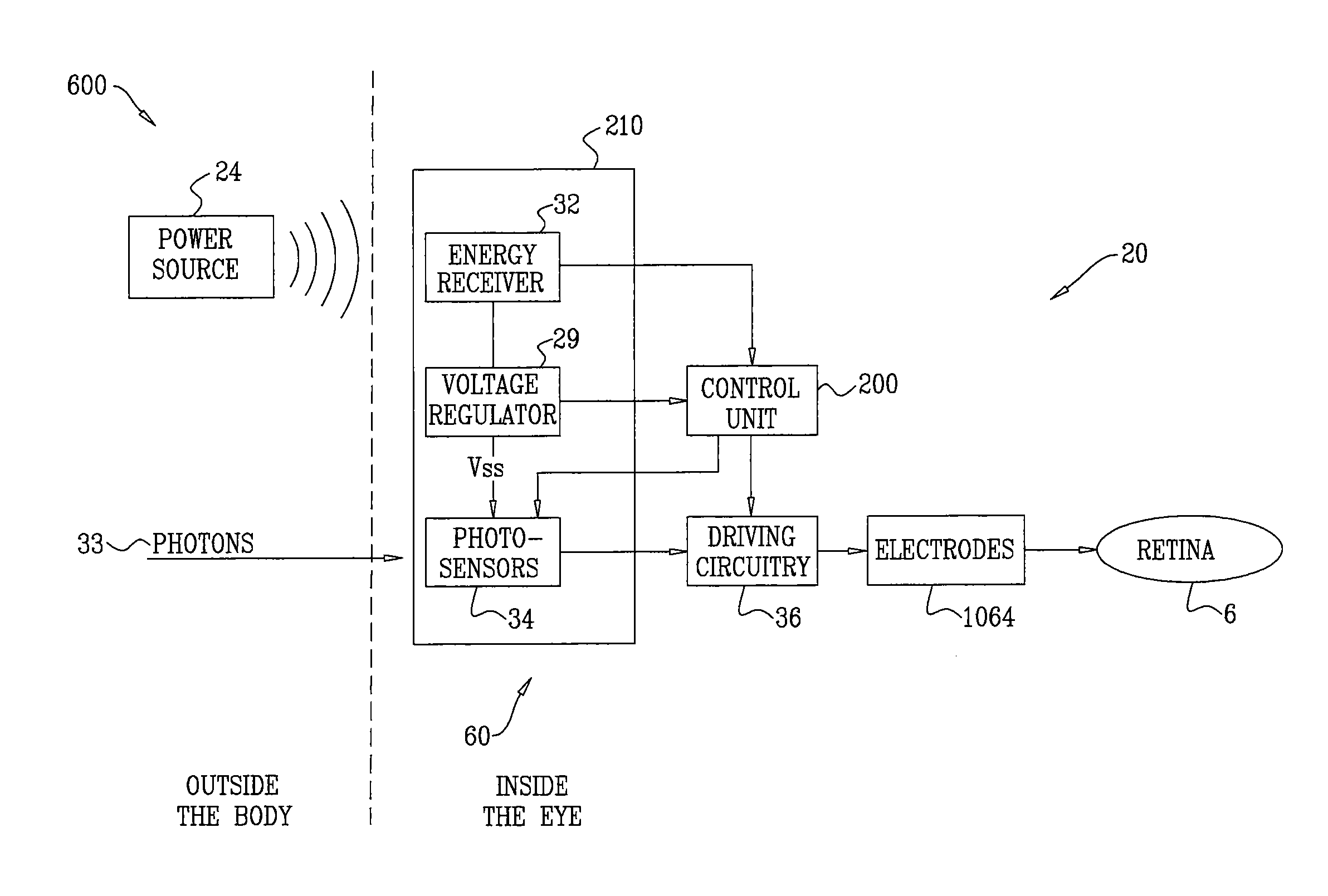

Apparatus is provided, including an external device, including a mount, which is placed in front of an eye of a subject. A laser is coupled to the mount and configured to emit toward the eye radiation that is outside of 380-750 nm. A partially-transparent mirror is coupled to the mount. An intraocular device is implanted entirely in the subject's eye, and includes a plurality of stimulating electrodes, and an energy receiver, which receives the radiation from the laser and generates a voltage drop in response thereto. A plurality of photosensors detect photons and generate a signal in response thereto. Driving circuitry is coupled to the energy receiver and to the photosensors, and receives the signals from the photosensors and utilizes the voltage drop to drive the electrodes to apply currents to the retina in response to the signals from the photosensors. Other embodiments are also described.

Owner:NANO RETINA INC

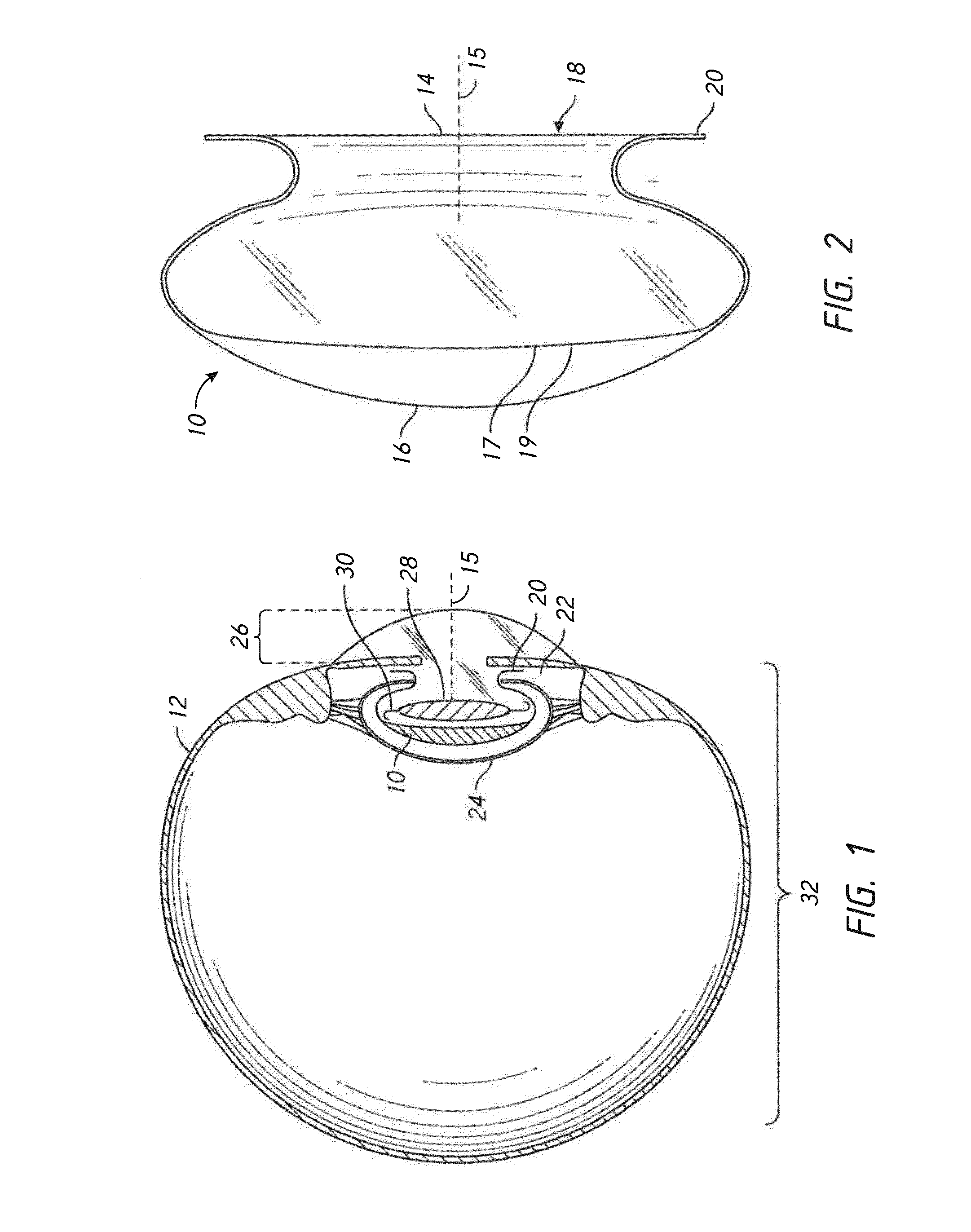

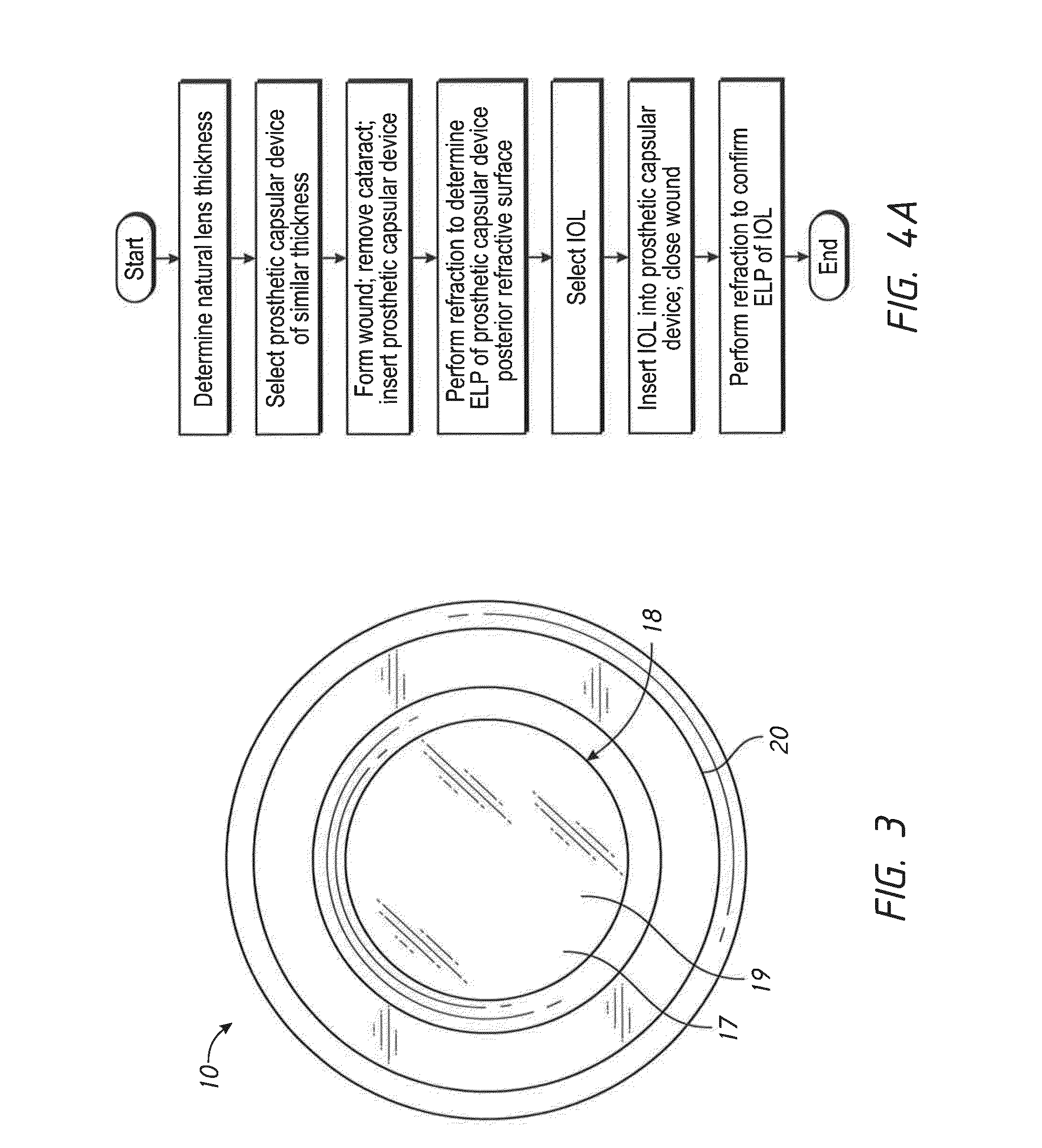

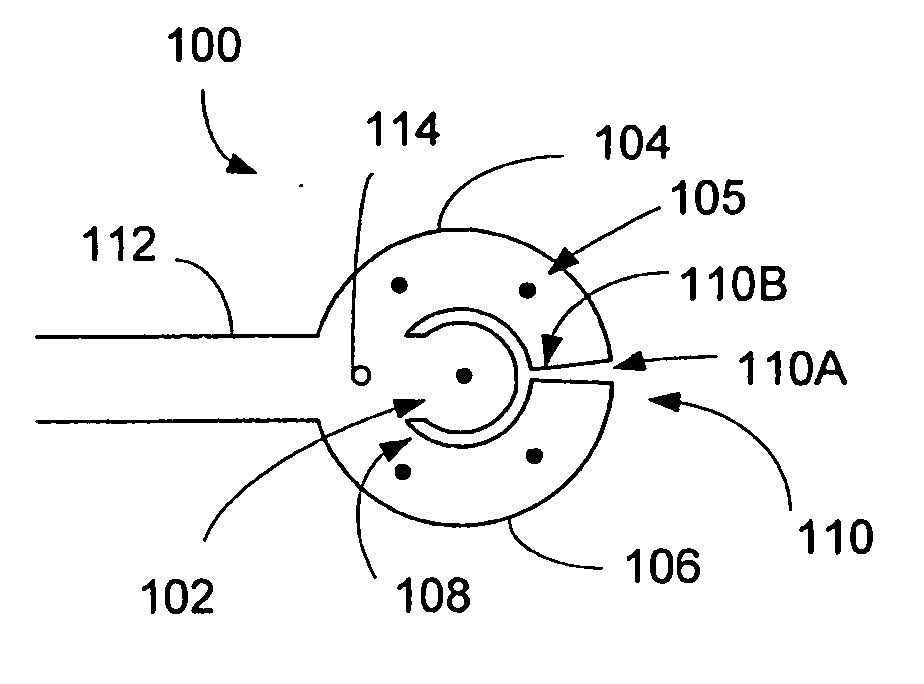

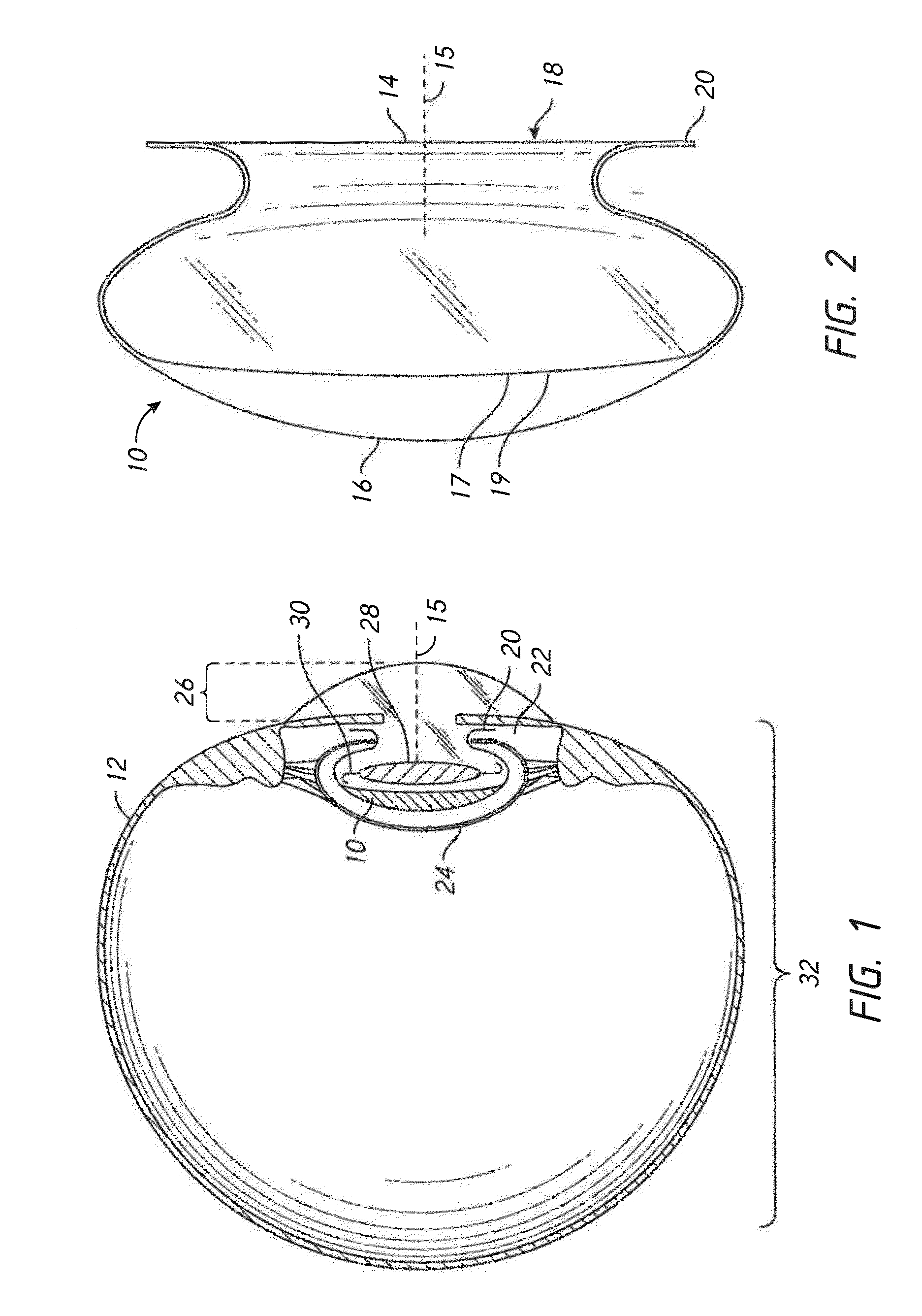

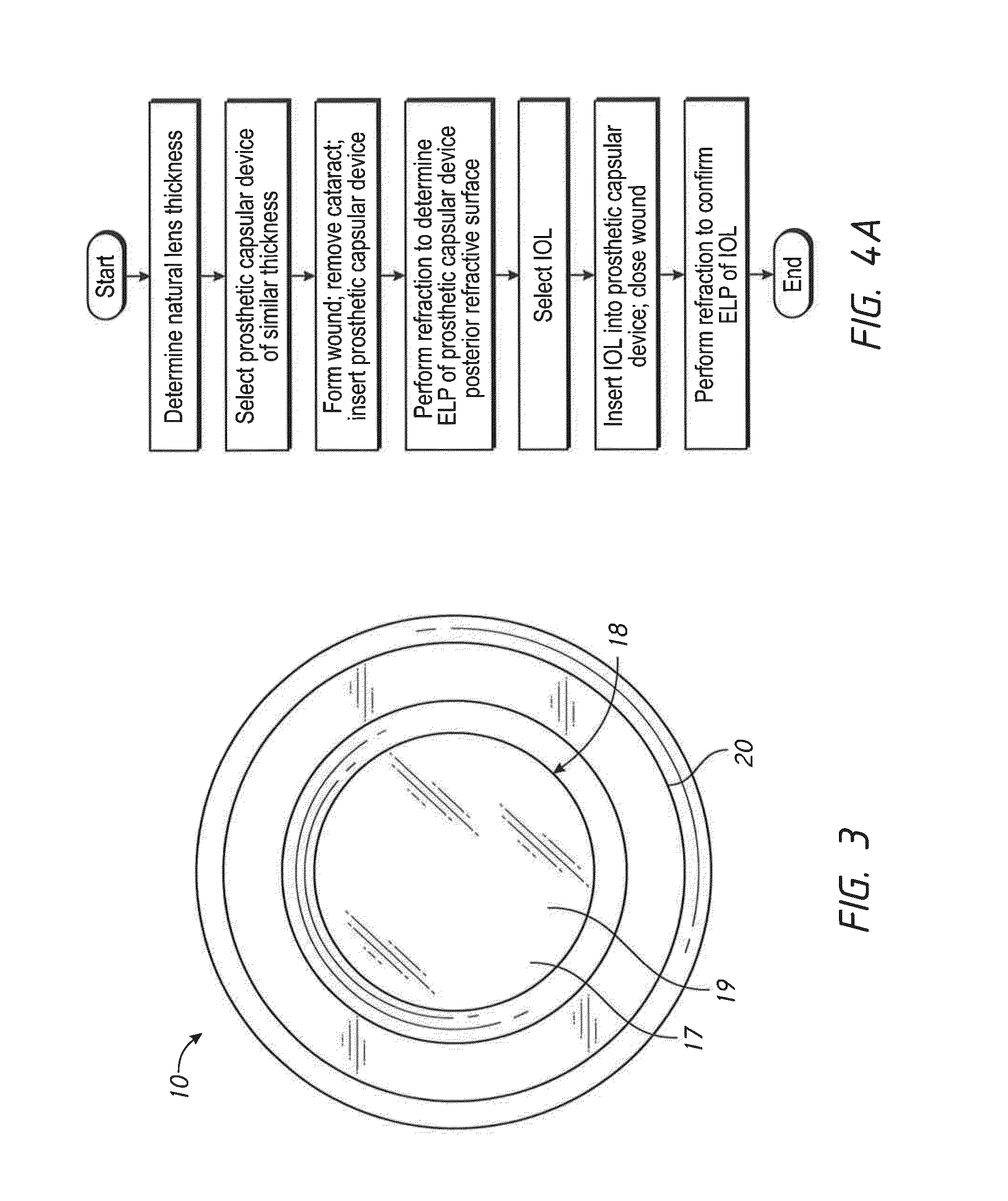

Prosthetic capsular devices, systems, and methods

Prosthetic capsular devices (e.g., bag, bowl, housing, structure, cage, frame) include technology devices such as a computer, virtual reality device, display device, WiFi / internet access device, image receiving device, biometric sensor device, game device, image viewers or senders, GPSs, e-mail devices, combinations thereof, and / or the like. The technology devices can be used in combination with an intraocular lens. The output from the technology device(s) can be fed to the retina of the user to provide a visual image, can be otherwise connected to the user, and / or can be used to control the properties of the intraocular lens or of the prosthetic capsular device. Wearable technology that provides biometric data, such as blood glucose levels, body temperature, electrolyte balance, heart rate, EKG, EEG, intraocular pressure, sensing ciliary muscle contraction for accommodation stimulus, dynamic pupil change and retinal prostheses, combinations thereof, and the like can assist in technology-assisted health care functions.

Owner:OMEGA OPHTHALMICS

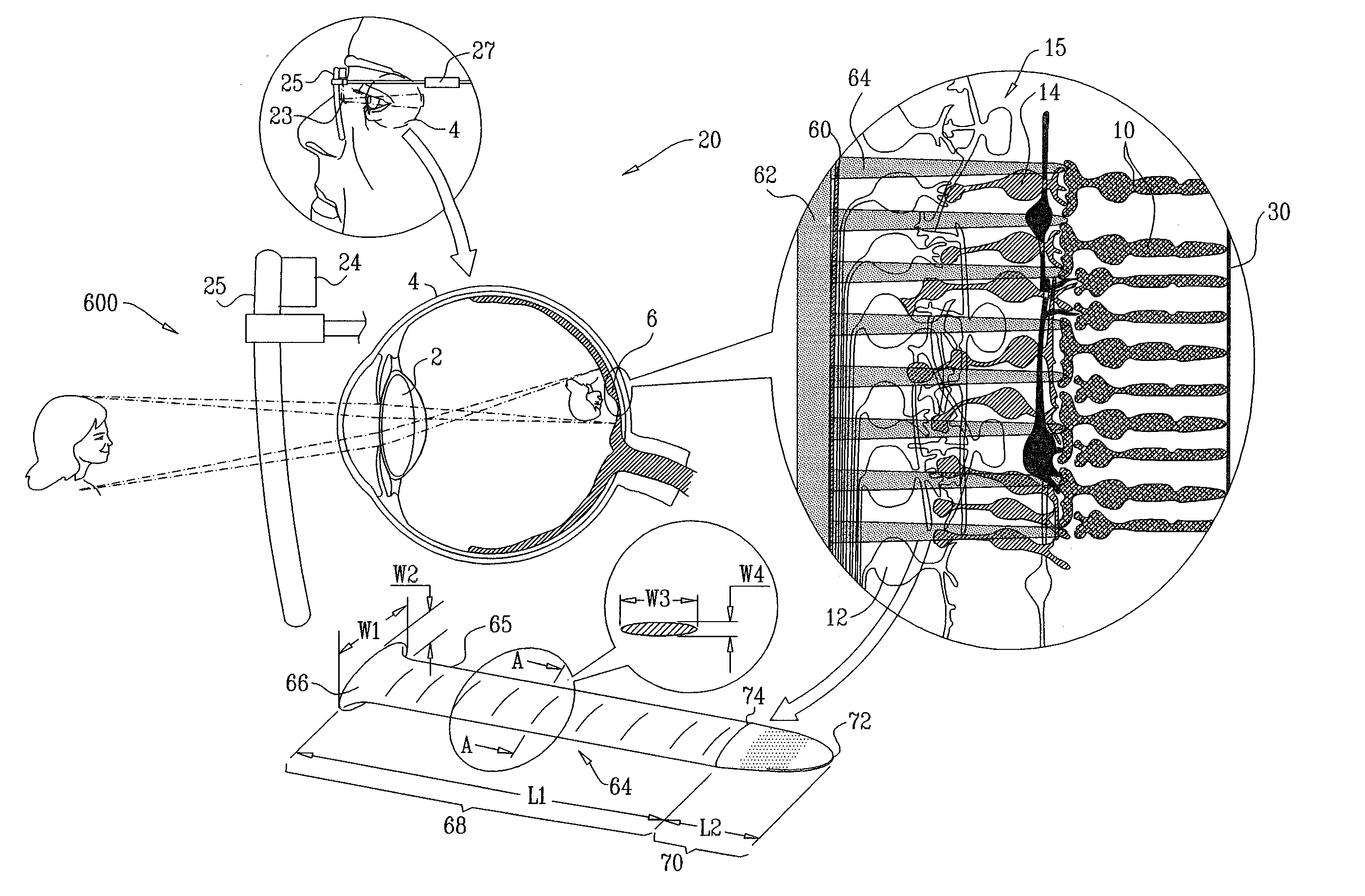

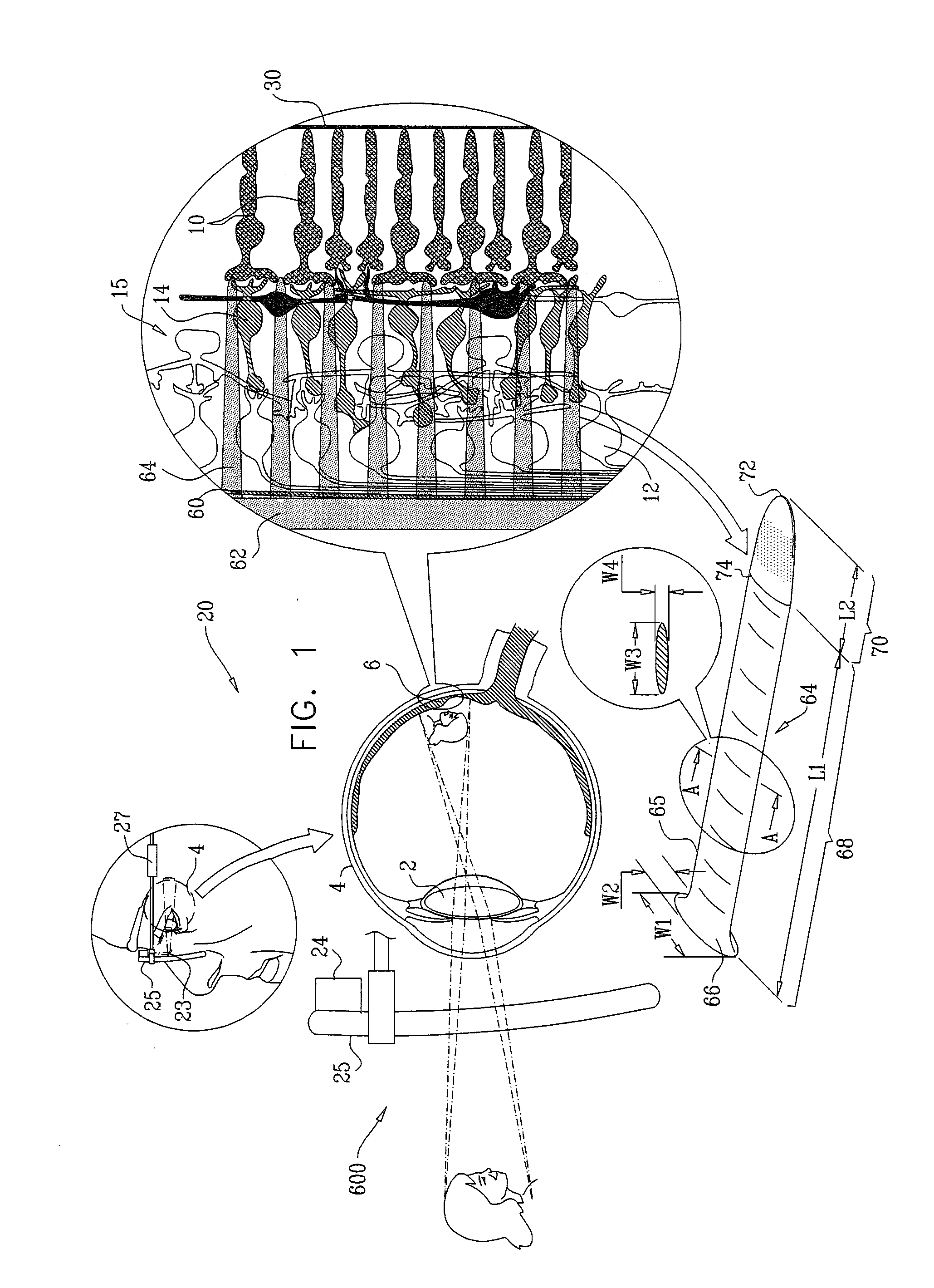

Wide-field retinal prosthesis

InactiveUS20070191909A1Stimulate visionHead electrodesDiagnostic recording/measuringWide fieldProsthesis

A wide-filed retinal prosthesis enables an increased field of vision with a relatively small scleral incision. The retinal prosthesis includes a flexible substrate comprising a central member and at least one wing, with an array of electrodes disposed therein that are configured to stimulate the central and peripheral nerves of the retina.

Owner:DOHENY EYE INST

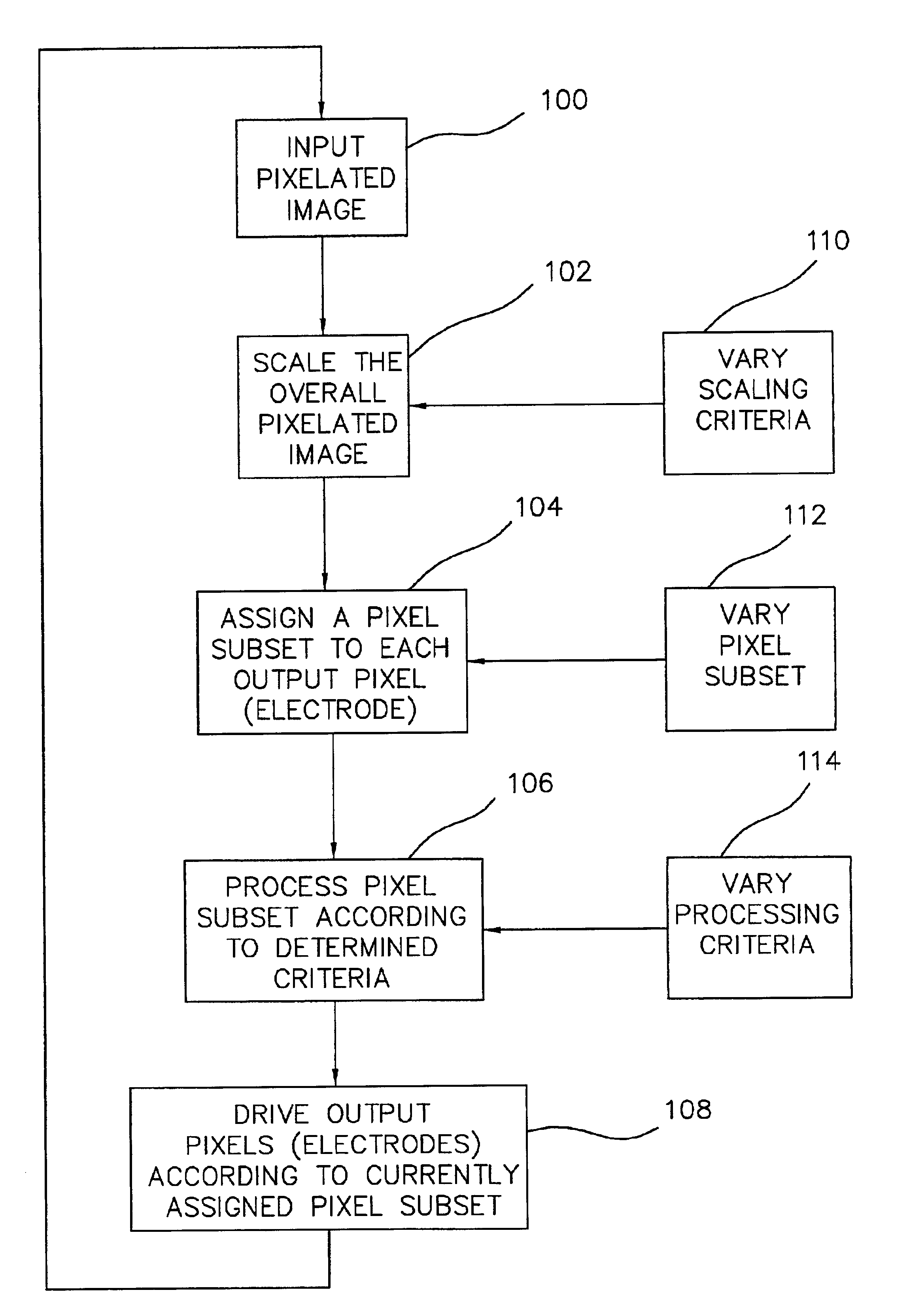

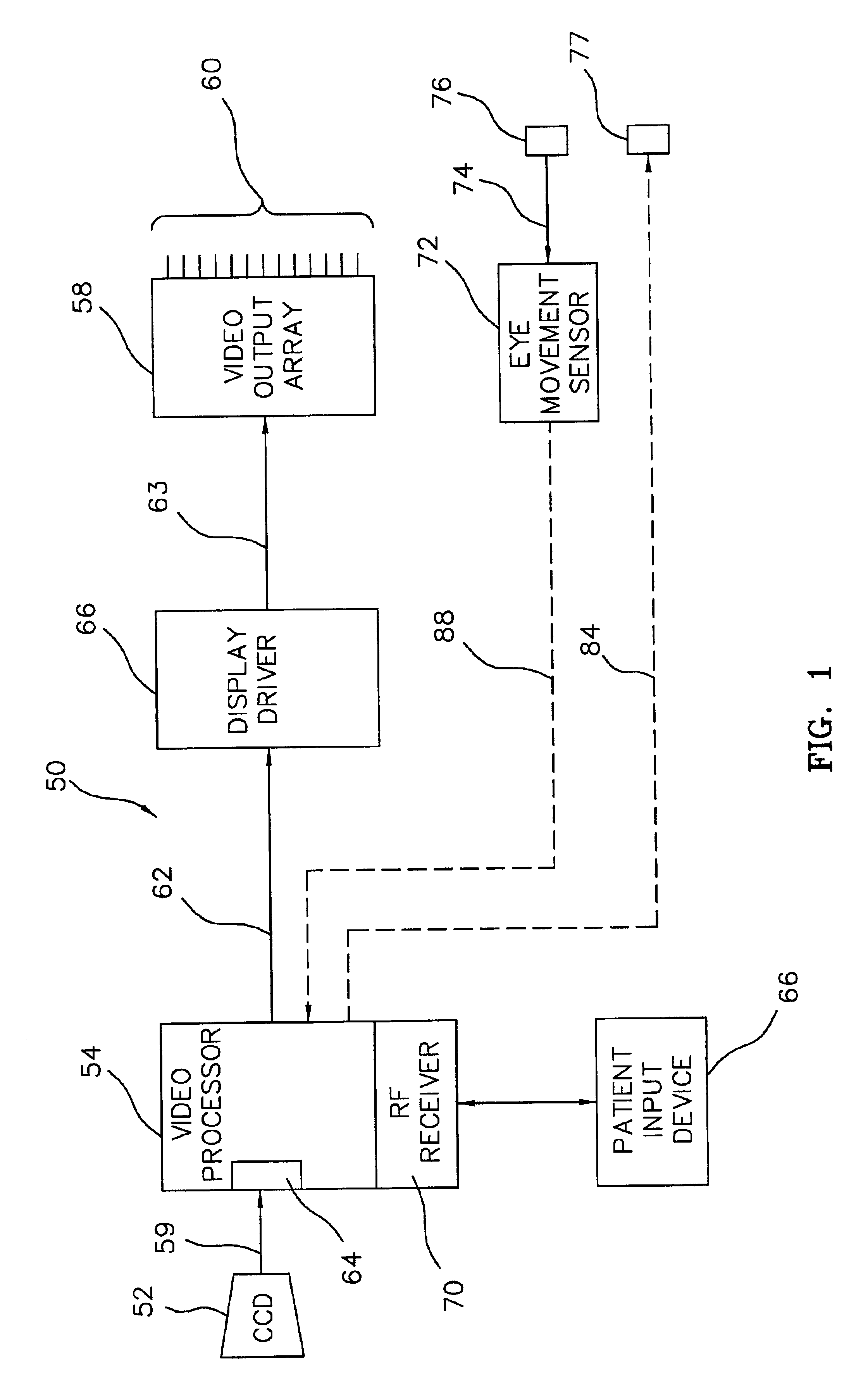

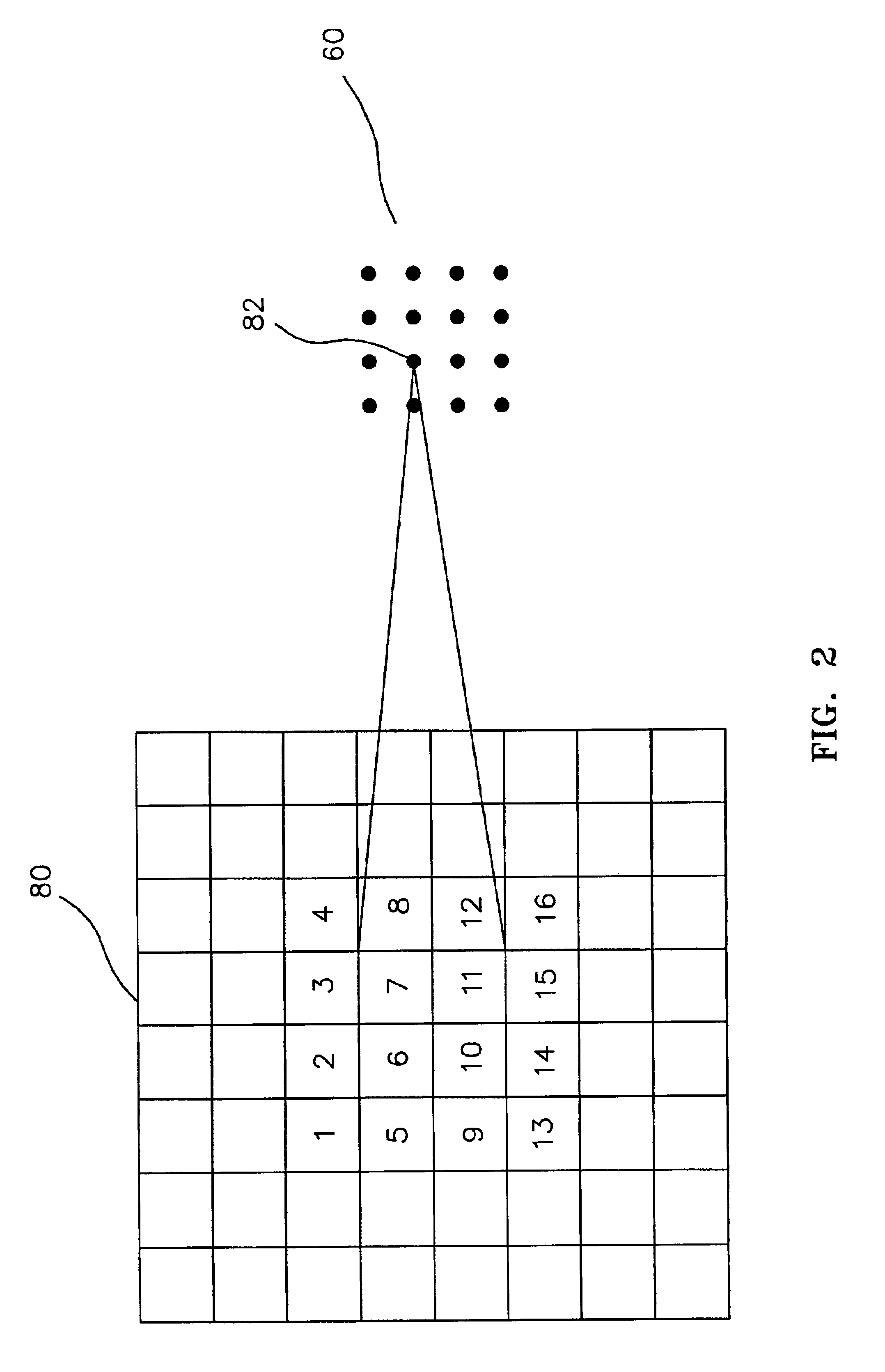

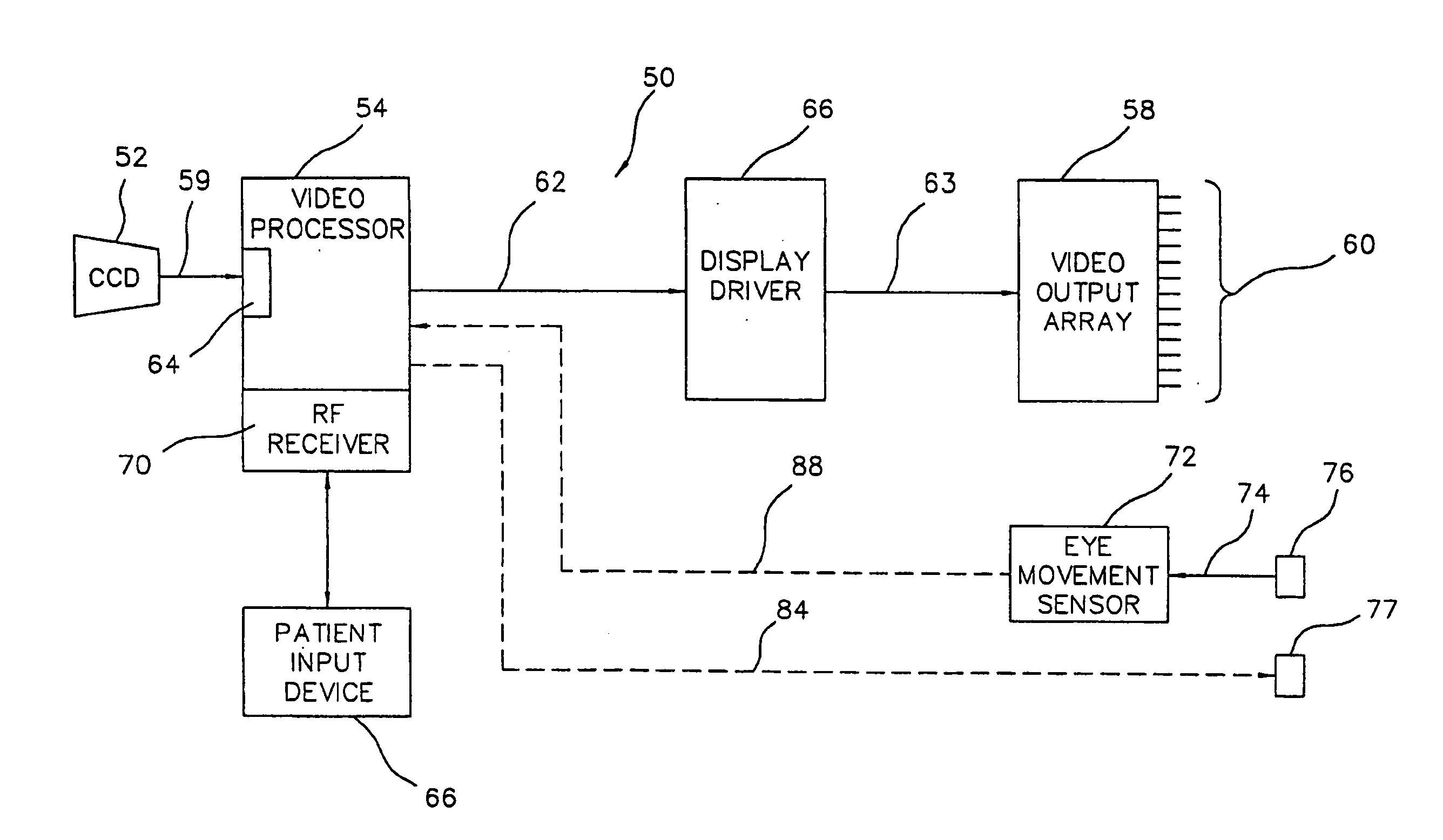

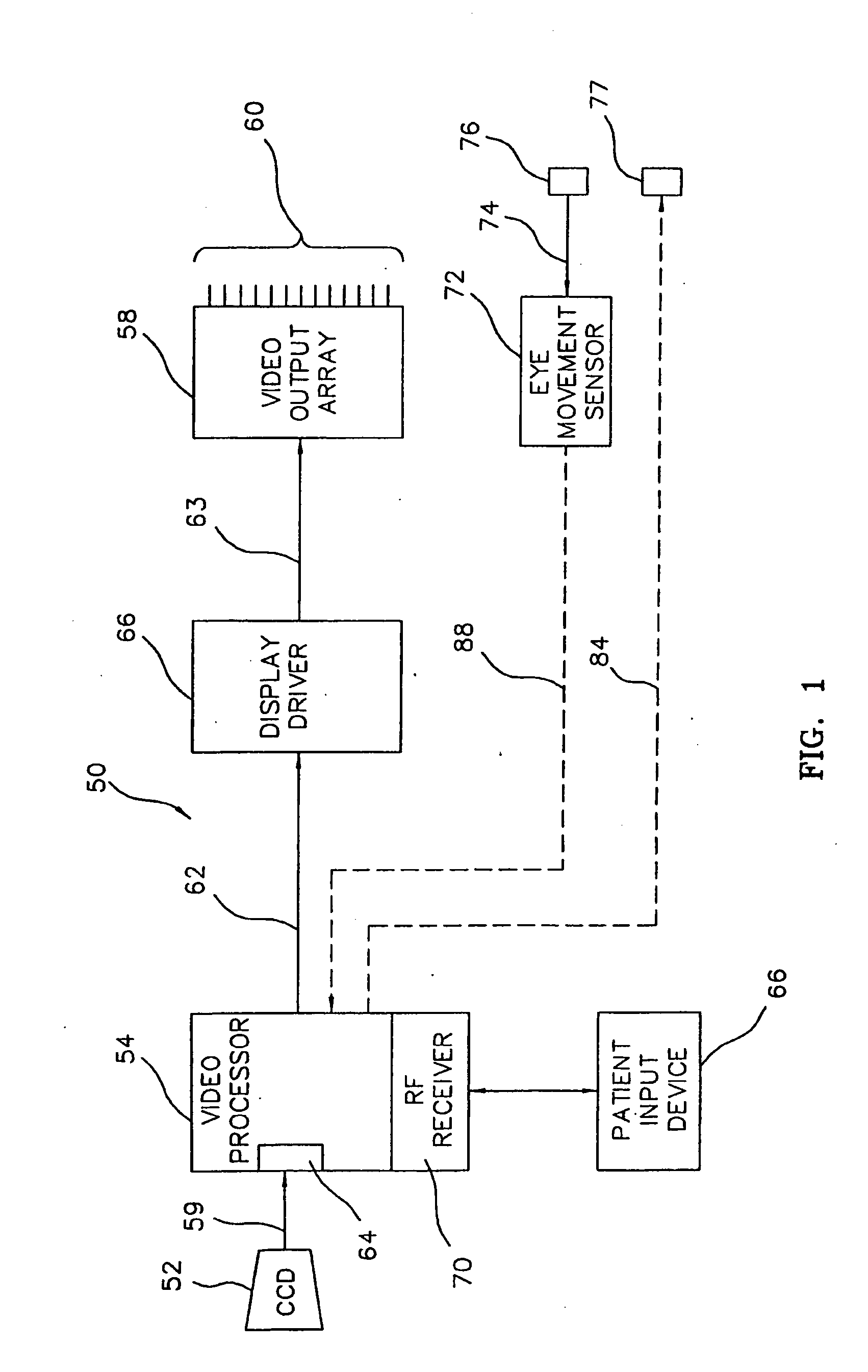

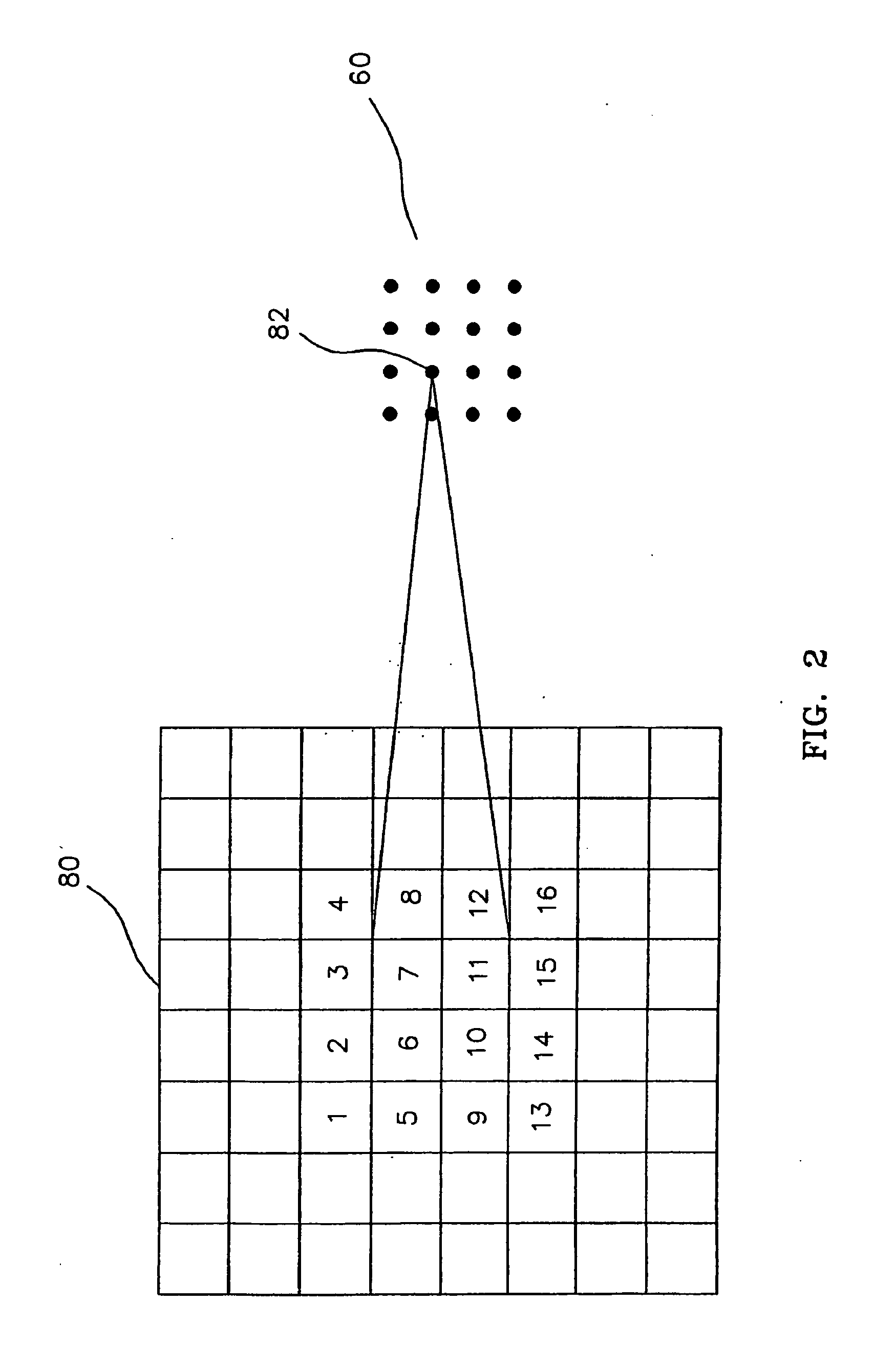

Video processing methods for improving visual acuity and/or perceived image resolution

InactiveUS6920358B2Improve eyesightEliminate and severely degrade visionGeometric image transformationInternal electrodesVisually impairedRetinal Prosthesis

A method and apparatus for improving visual acuity when providing a visual image from a “high” resolution input device to a “low” resolution output device. The described invention is of particular use when the output device is an array of electrodes as part of a retinal prosthesis used to restore vision to a visually-impaired patient. In that various limitations may, within the foreseeable future, limit the density of such an electrode array (and thus the resolution of the output image), the present invention teaches techniques to assign processed pixel subsets of a higher resolution image to a single electrode. By varying the pixel subsets, e.g., by jittering, and / or altering the processing criteria, the perceived visual acuity may be further improved. Alternatively and additionally, such processing may be further extended to drive neighboring electrodes in combination to thus stimulate virtual electrode sites and thus further enhance visual acuity.

Owner:SECOND SIGHT MEDICAL PRODS

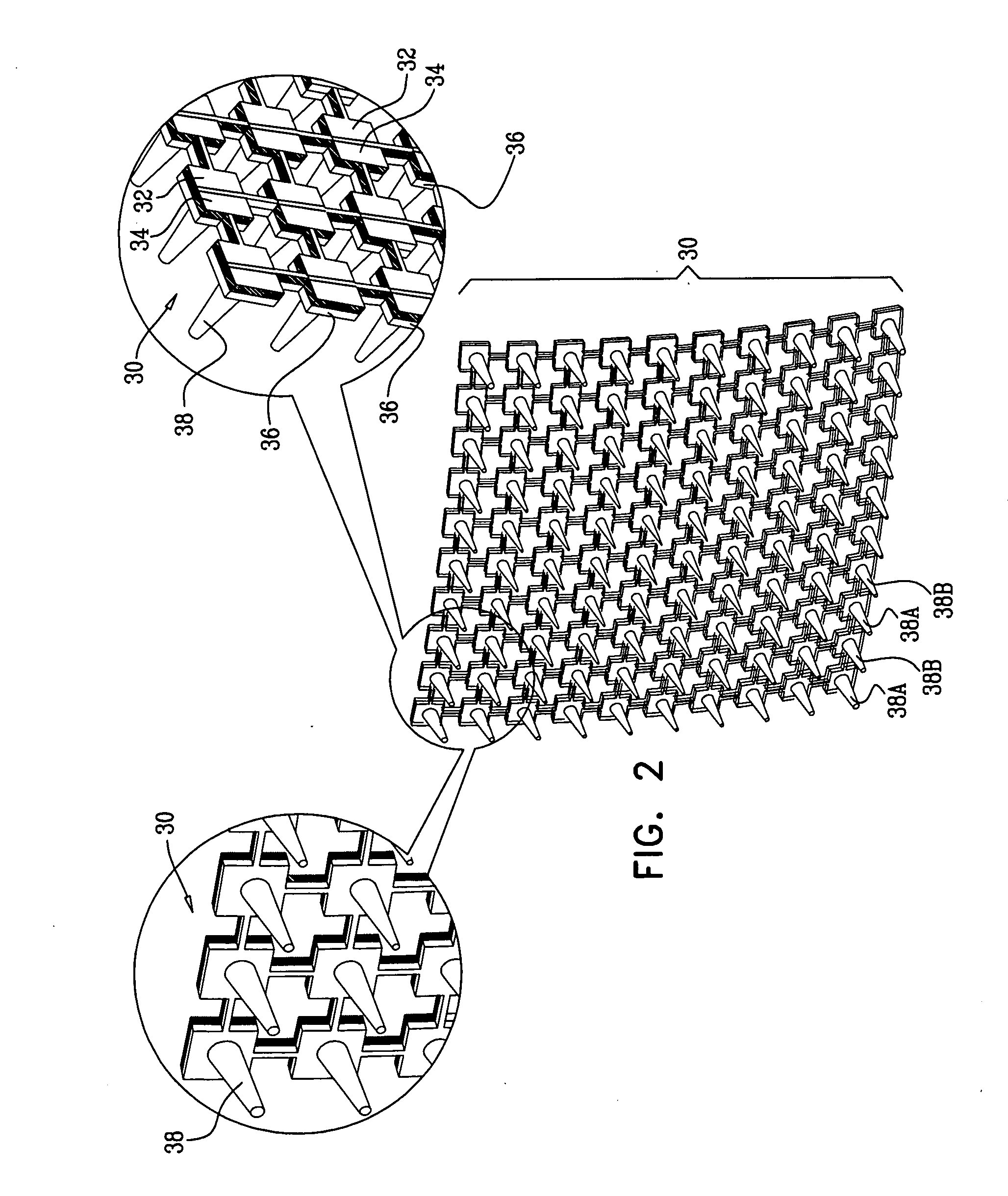

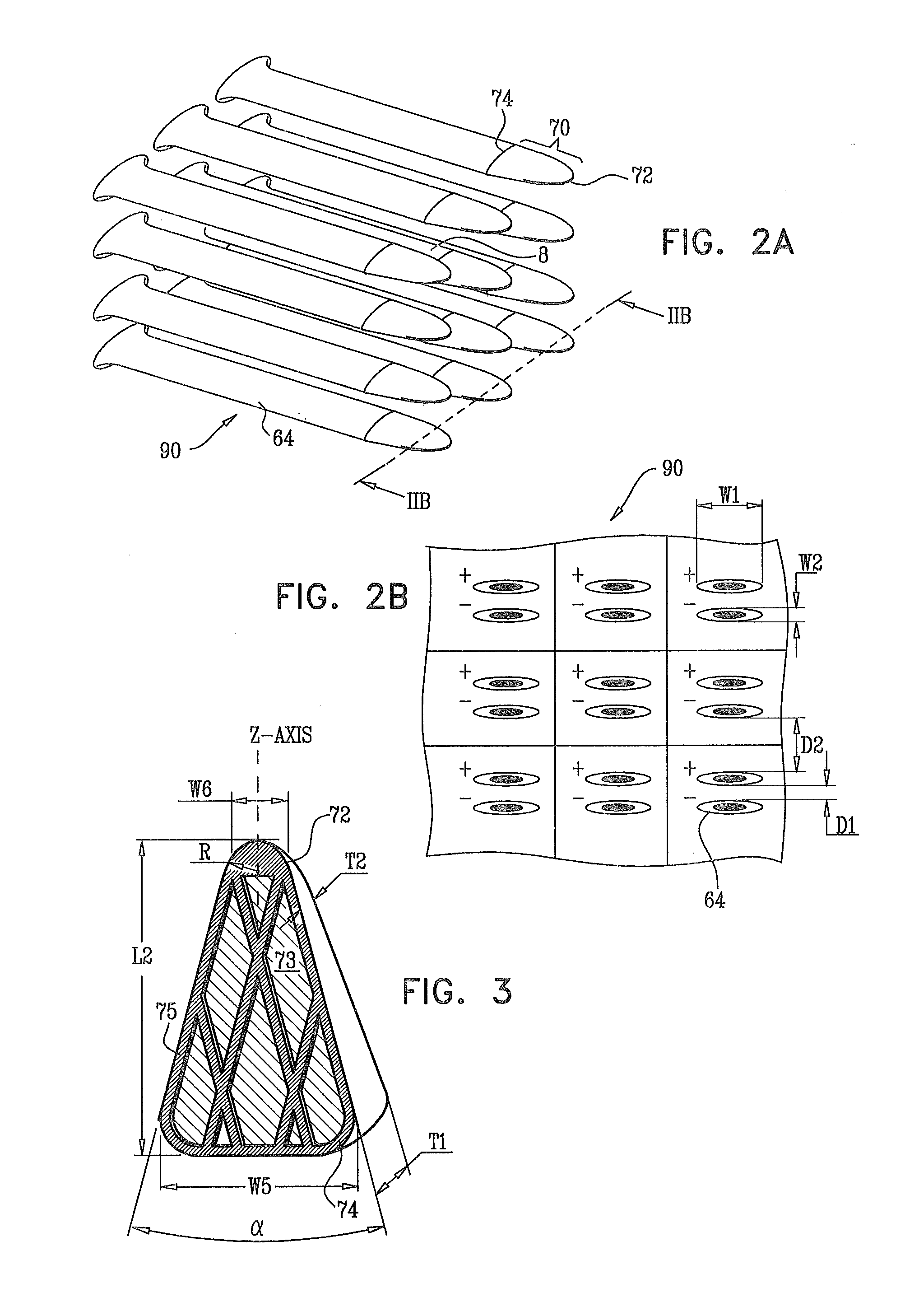

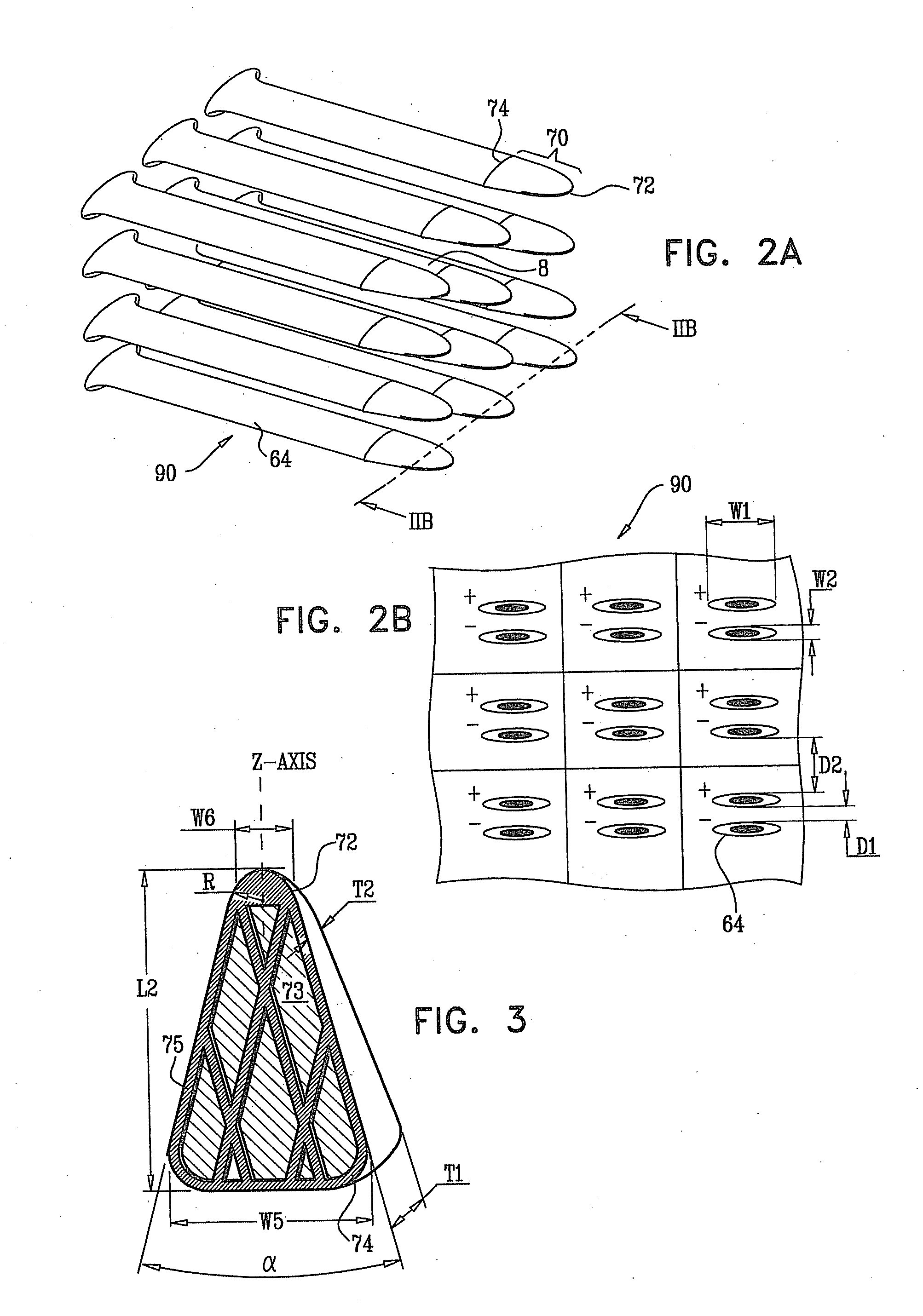

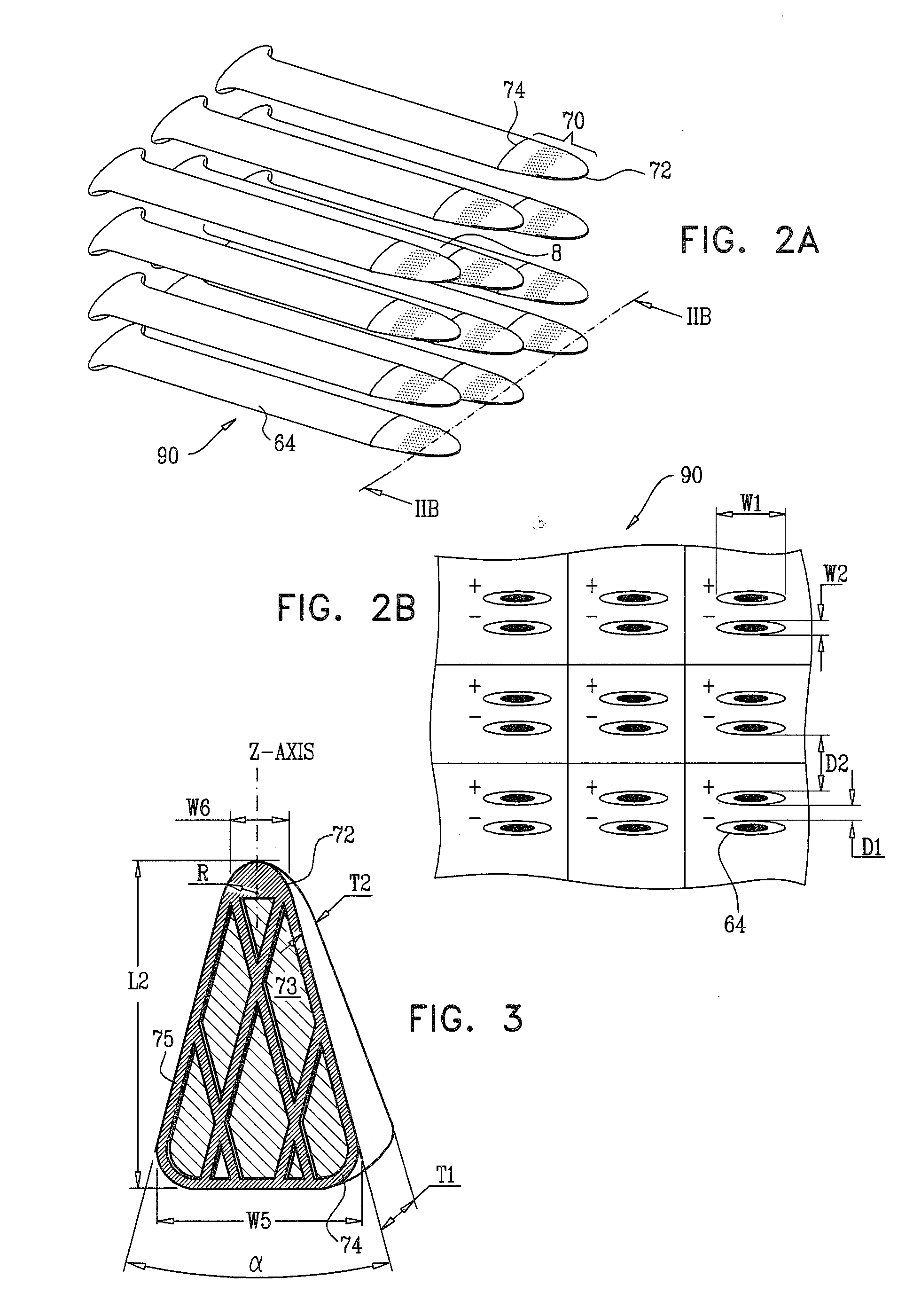

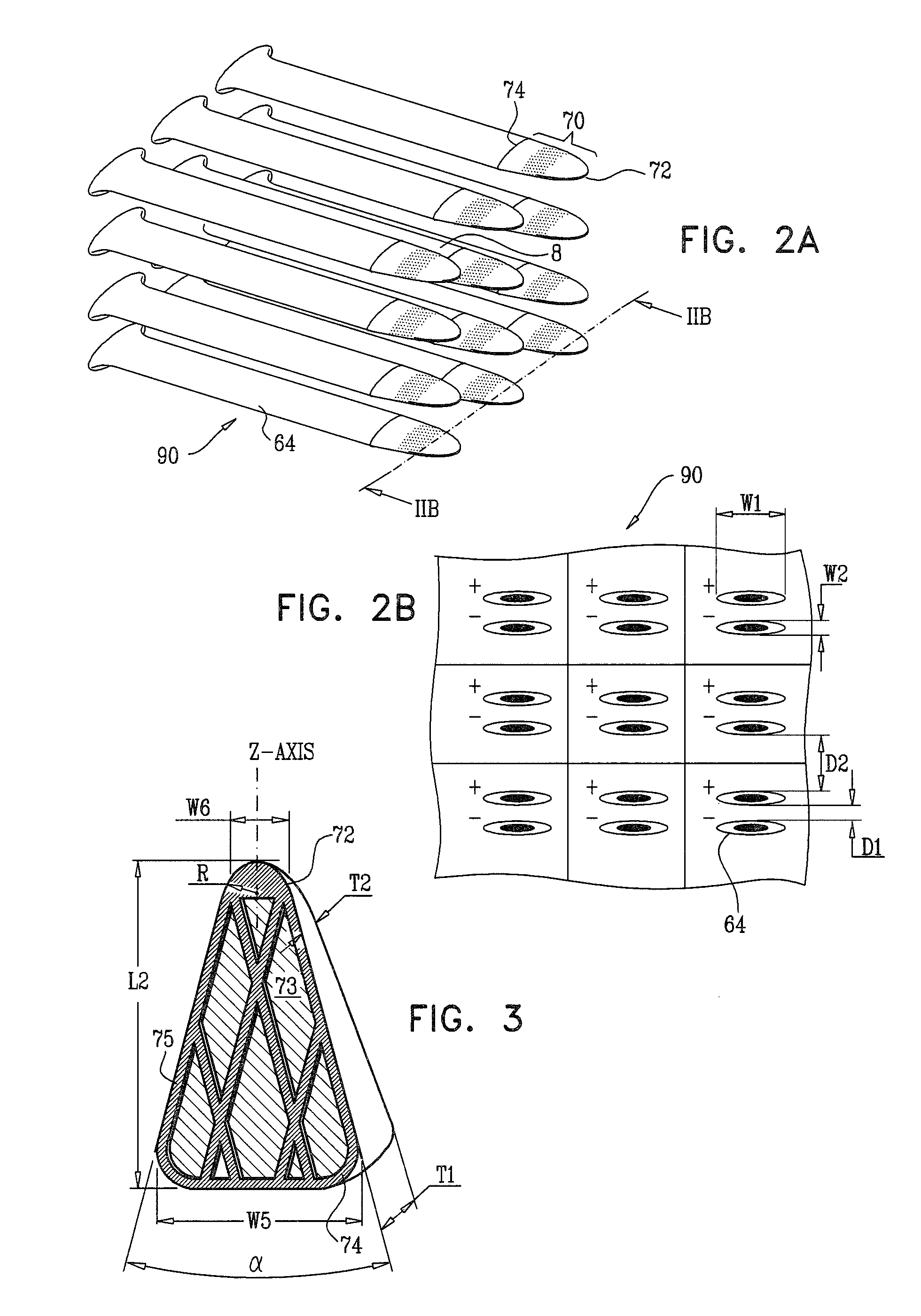

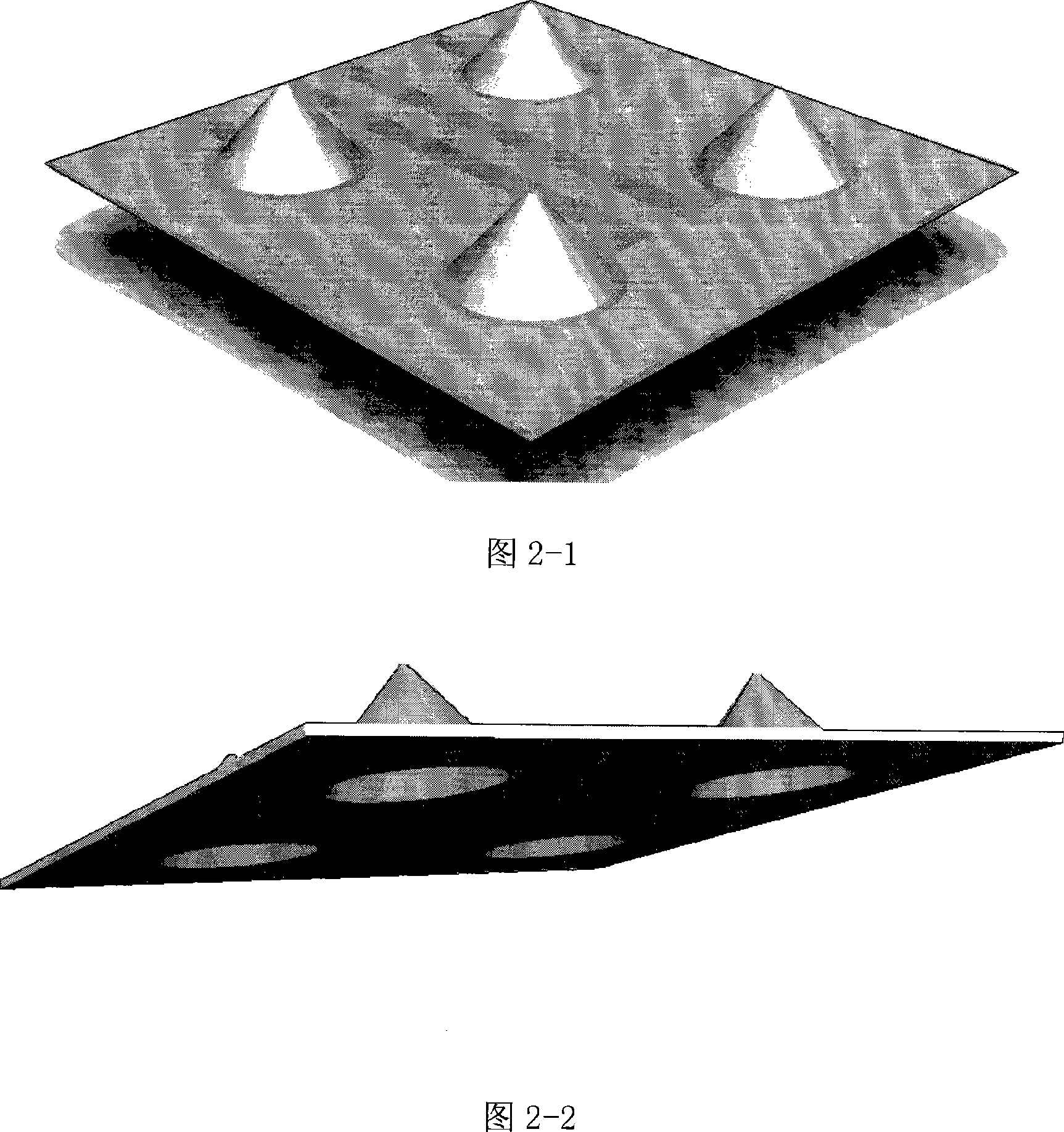

Retinal Prosthesis with a New Configuration

ActiveUS20080275527A1Improve the immunityCut the delicate retinal tissueCircuit bendability/stretchabilityHead electrodesFlexible circuitsRetinal Prosthesis

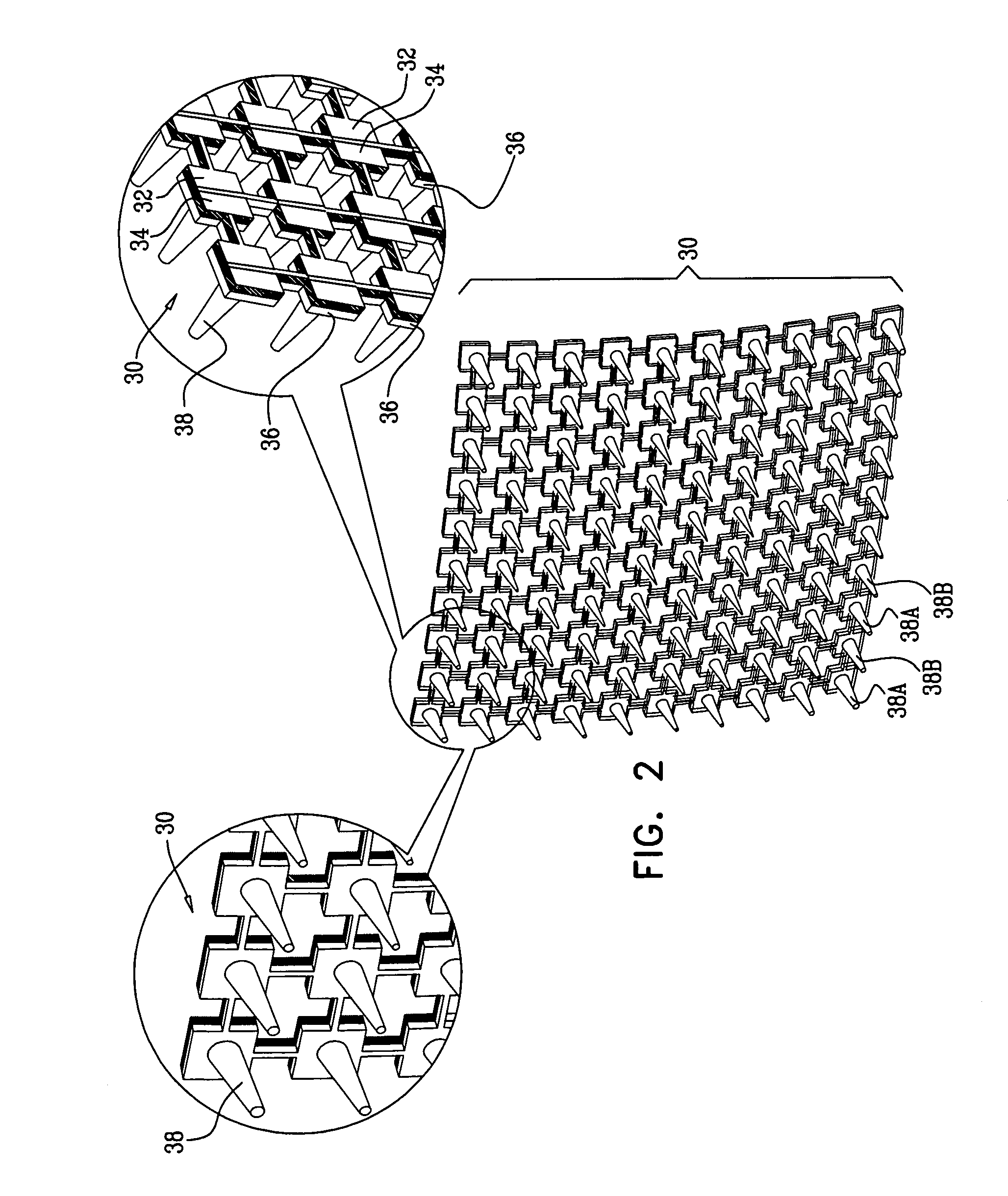

Polymer materials are useful as electrode array bodies for neural stimulation. They are particularly useful for retinal stimulation to create artificial vision, cochlear stimulation to create artificial hearing, and cortical stimulation, and many related purposes. The pressure applied against the retina, or other neural tissue, by an electrode array is critical. Too little pressure causes increased electrical resistance, along with electric field dispersion. Too much pressure may block blood flow. Common flexible circuit fabrication techniques generally require that a flexible circuit electrode array be made flat. Since neural tissue is almost never flat, a flat array will necessarily apply uneven pressure. Further, the edges of a flexible circuit polymer array may be sharp and cut the delicate neural tissue. By applying the right amount of heat to a completed array, a curve can be induced. With a thermoplastic polymer it may be further advantageous to repeatedly heat the flexible circuit in multiple molds, each with a decreasing radius. Further, it is advantageous to add material along the edges. It is further advantageous to provide a fold or twist in the flexible circuit array. Additional material may be added inside and outside the fold to promote a good seal with tissue.

Owner:SECOND SIGHT MEDICAL PRODS +1

Retinal prosthesis techniques

ActiveUS20120035726A1Increase the areaIncrease roughnessHead electrodesIntraocular lensMedicineProsthesis

Apparatus for use with an external non-visible light source is provided. The apparatus comprises an intraocular device configured for implantation in a human eye, and comprising an energy receiver. The energy receiver is configured to receive light emitted from the external non-visible light source, and extract energy from the emitted light for powering the intraocular device. The intraocular device is configured to regulate a parameter of operation of the intraocular device based on a modulation of the light emitted by the external non-visible light source and received by the energy receiver. Other embodiments are also described.

Owner:NANO RETINA INC

Retinal prosthesis with a new configuration

ActiveUS20070055336A1CutImprove the immunityCircuit bendability/stretchabilityHead electrodesFlexible circuitsBlood flow

Polymer materials are useful as electrode array bodies for neural stimulation. They are particularly useful for retinal stimulation to create artificial vision, cochlear stimulation to create artificial hearing, and cortical stimulation, and many related purposes. The pressure applied against the retina, or other neural tissue, by an electrode array is critical. Too little pressure causes increased electrical resistance, along with electric field dispersion. Too much pressure may block blood flow. Common flexible circuit fabrication techniques generally require that a flexible circuit electrode array be made flat. Since neural tissue is almost never flat, a flat array will necessarily apply uneven pressure. Further, the edges of a flexible circuit polymer array may be sharp and cut the delicate neural tissue. By applying the right amount of heat to a completed array, a curve can be induced. With a thermoplastic polymer it may be further advantageous to repeatedly heat the flexible circuit in multiple molds, each with a decreasing radius. Further, it is advantageous to add material along the edges. It is further advantageous to provide a fold or twist in the flexible circuit array. Additional material may be added inside and outside the fold to promote a good seal with tissue.

Owner:SECOND SIGHT MEDICAL PRODS +1

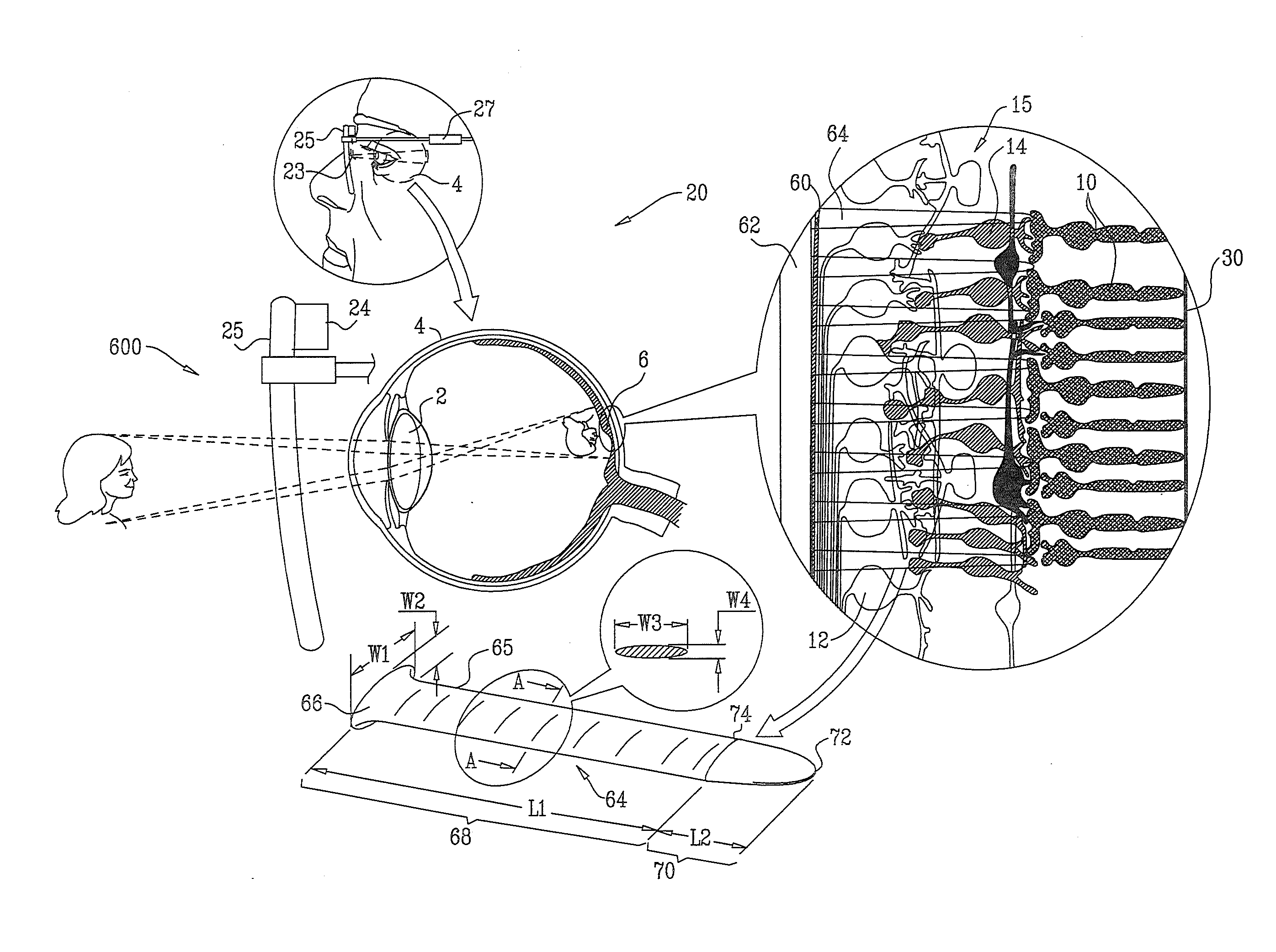

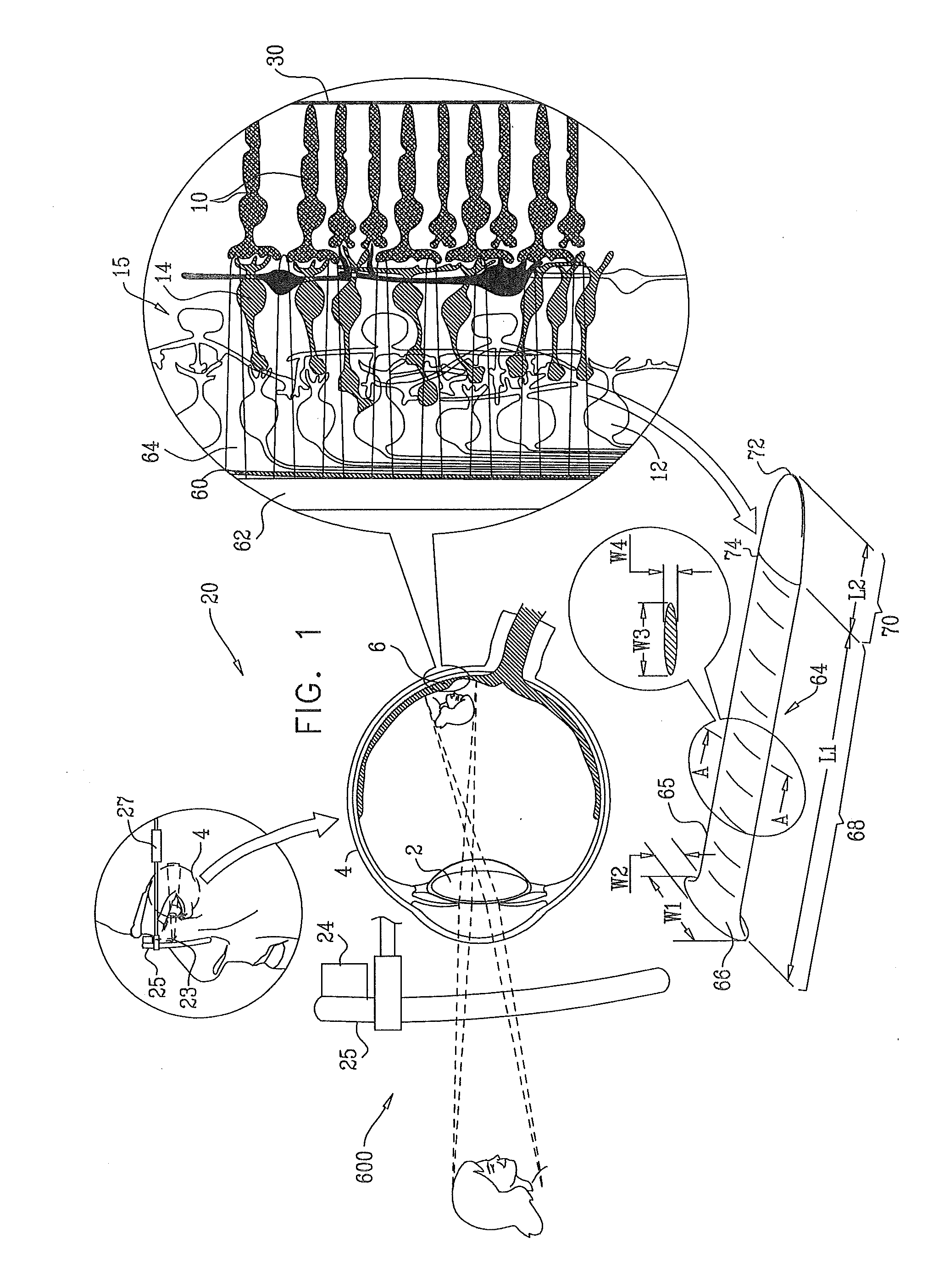

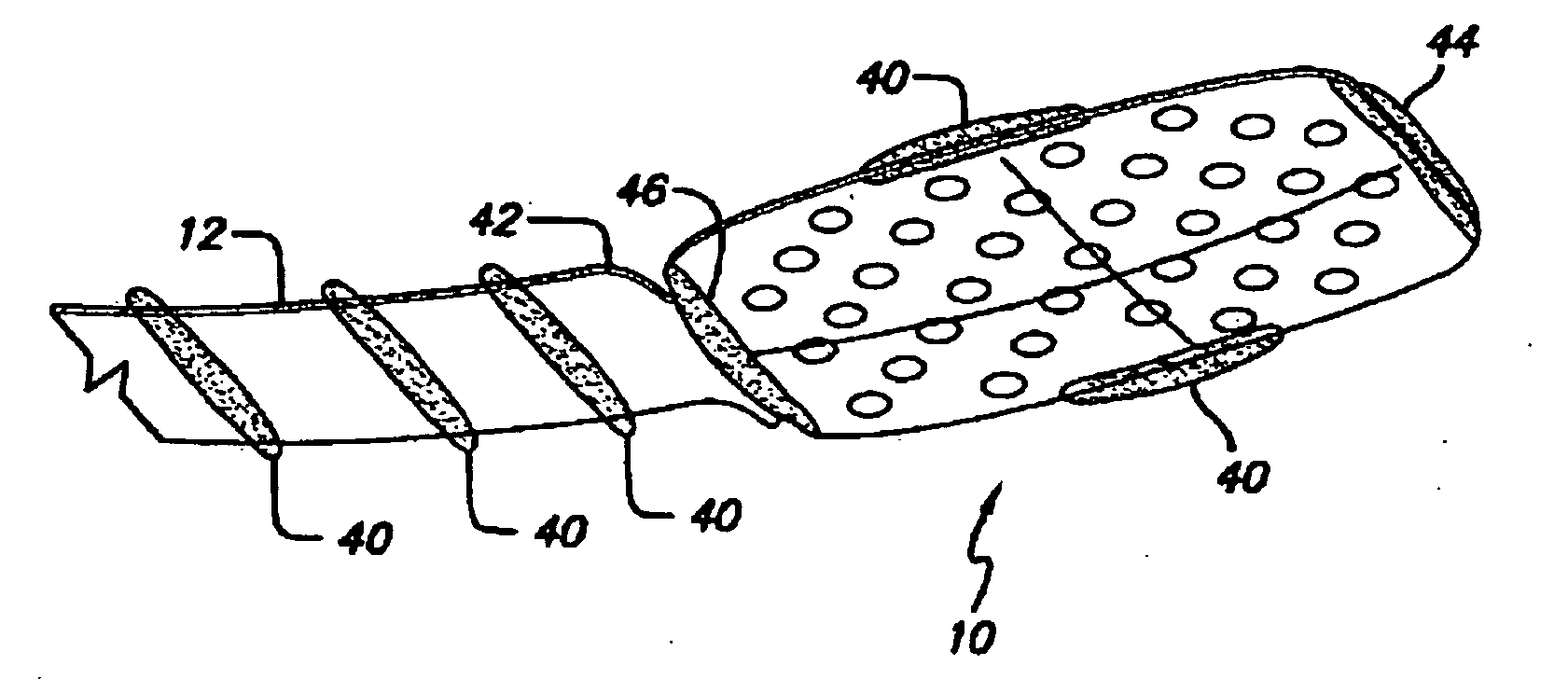

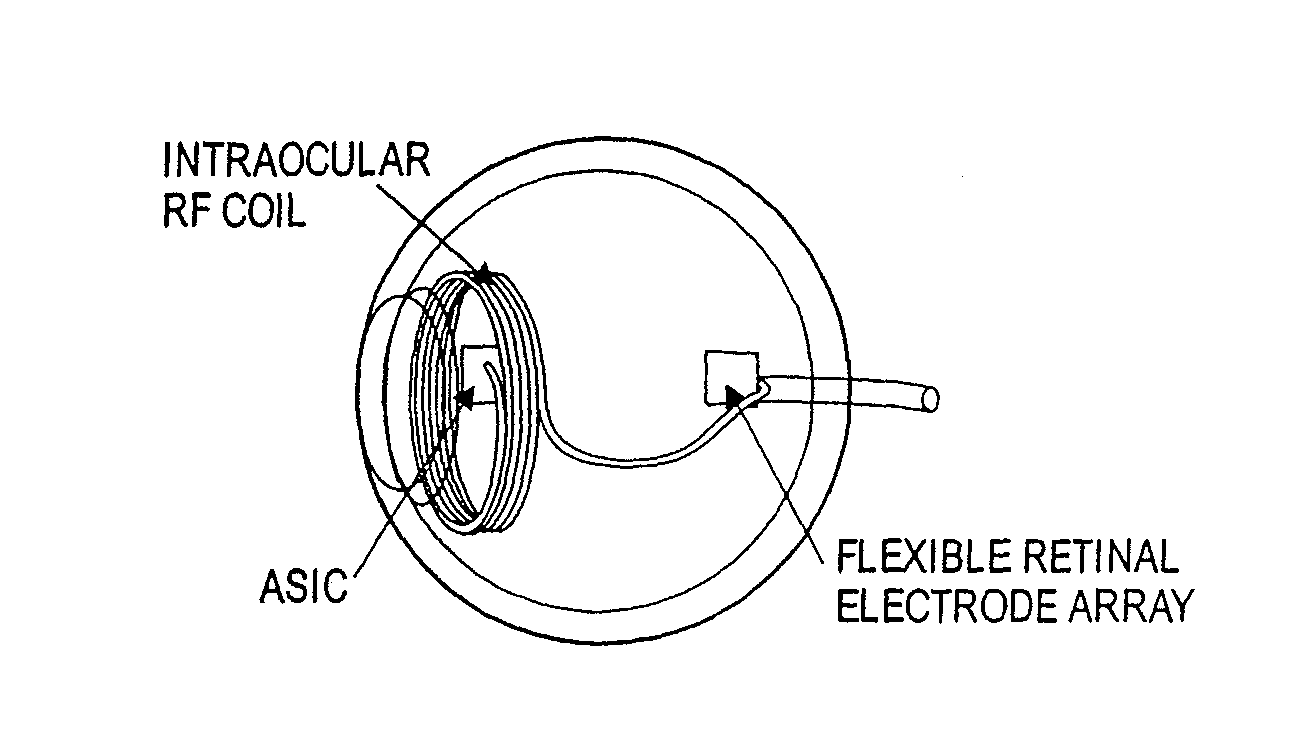

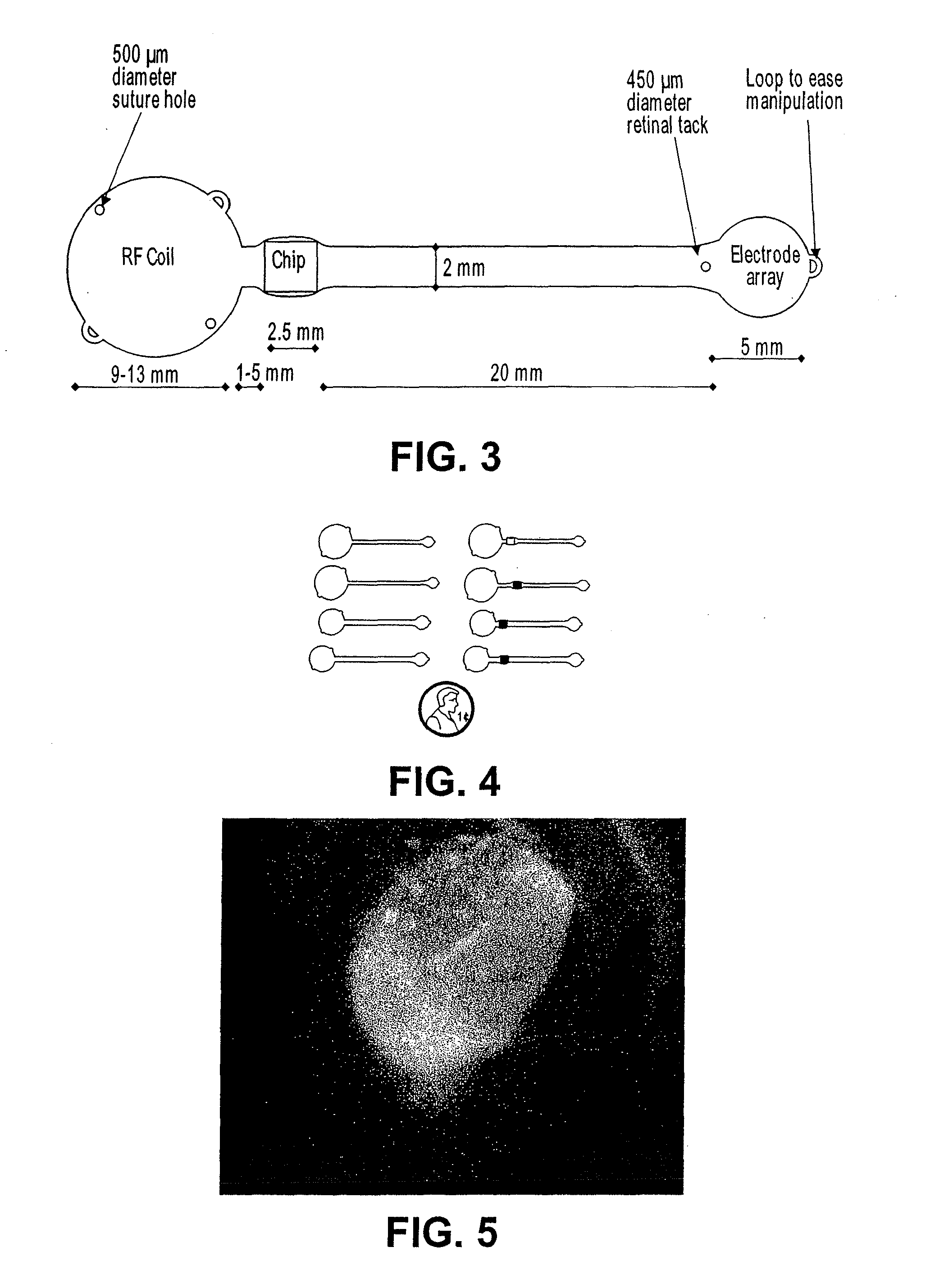

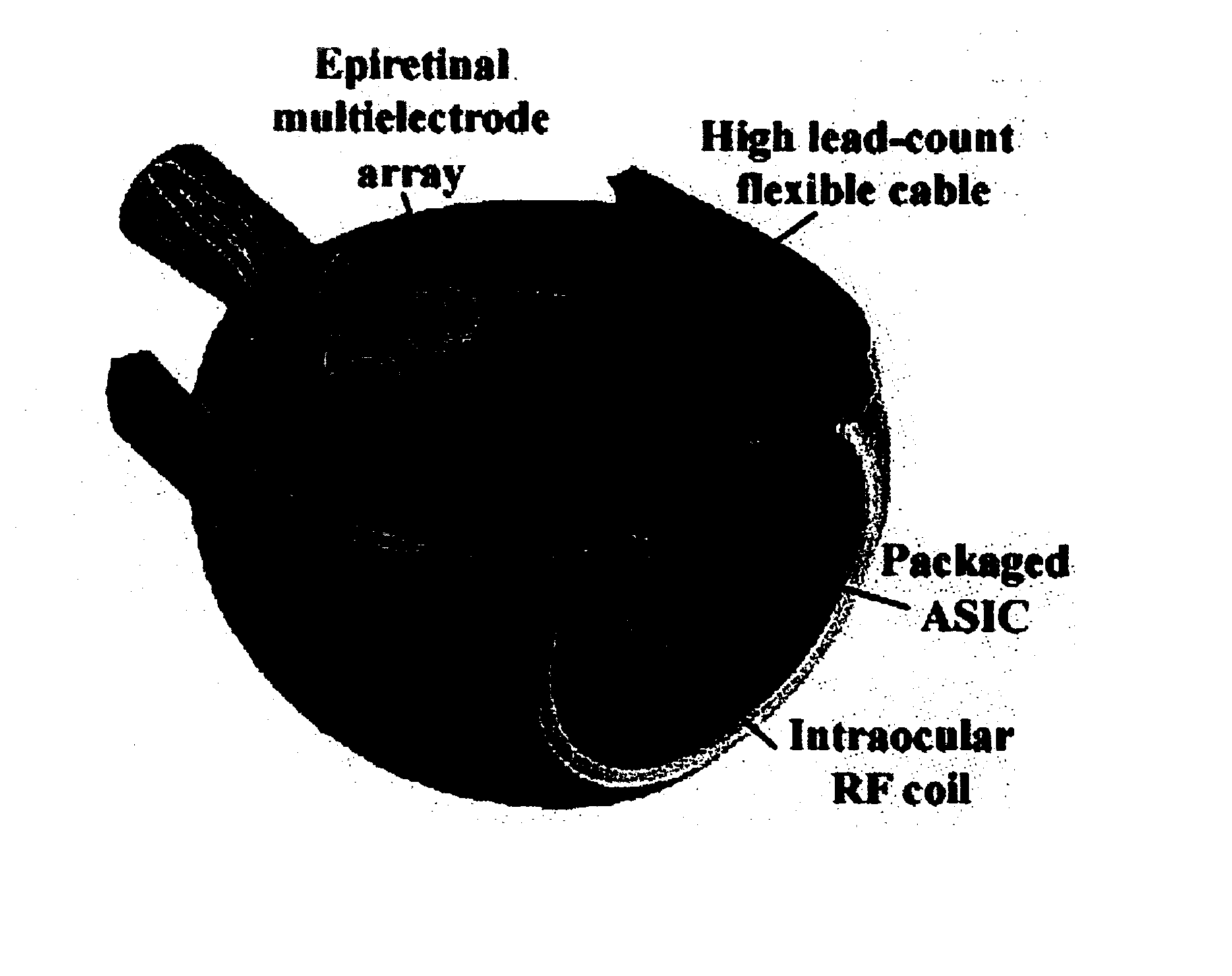

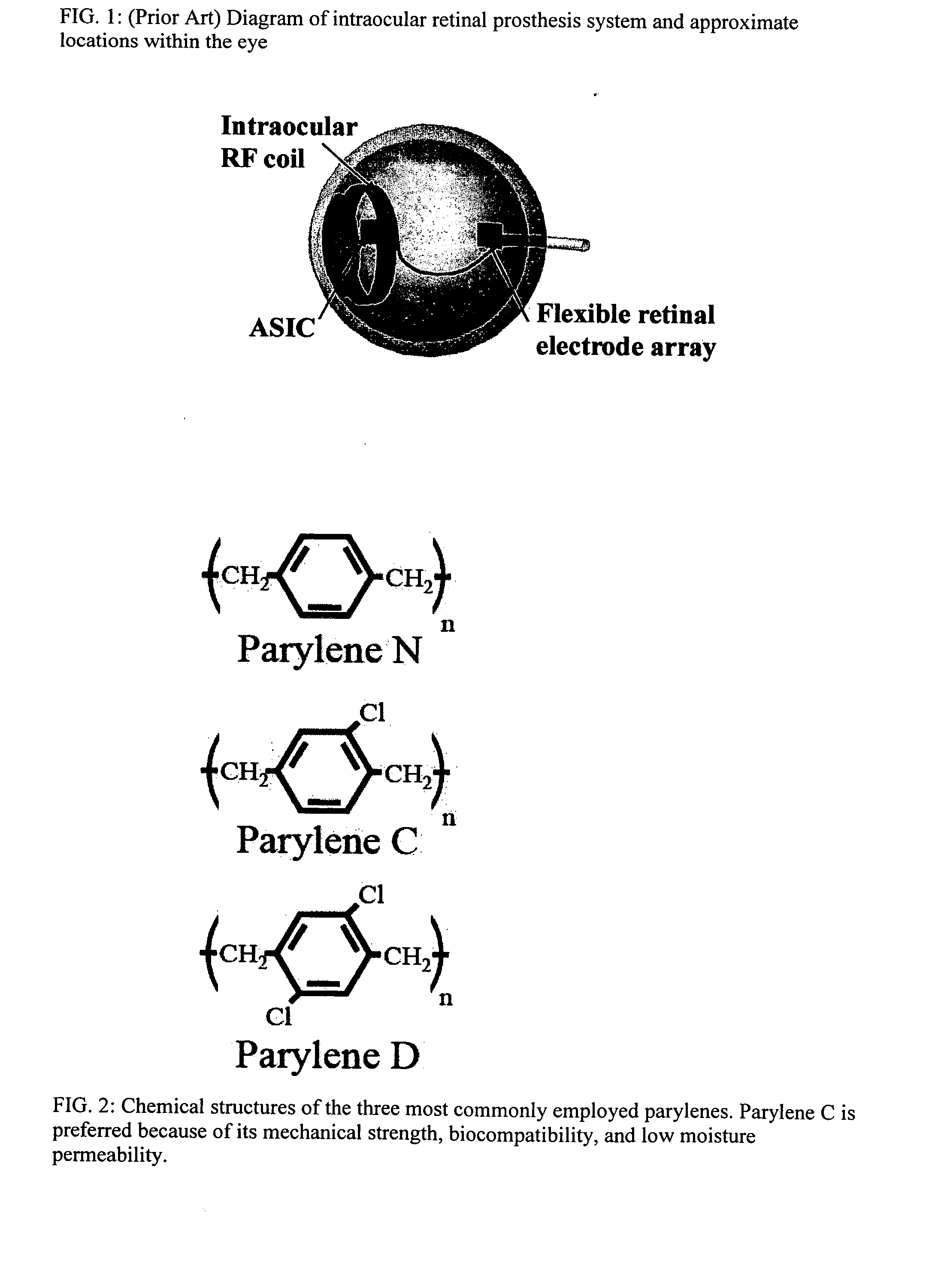

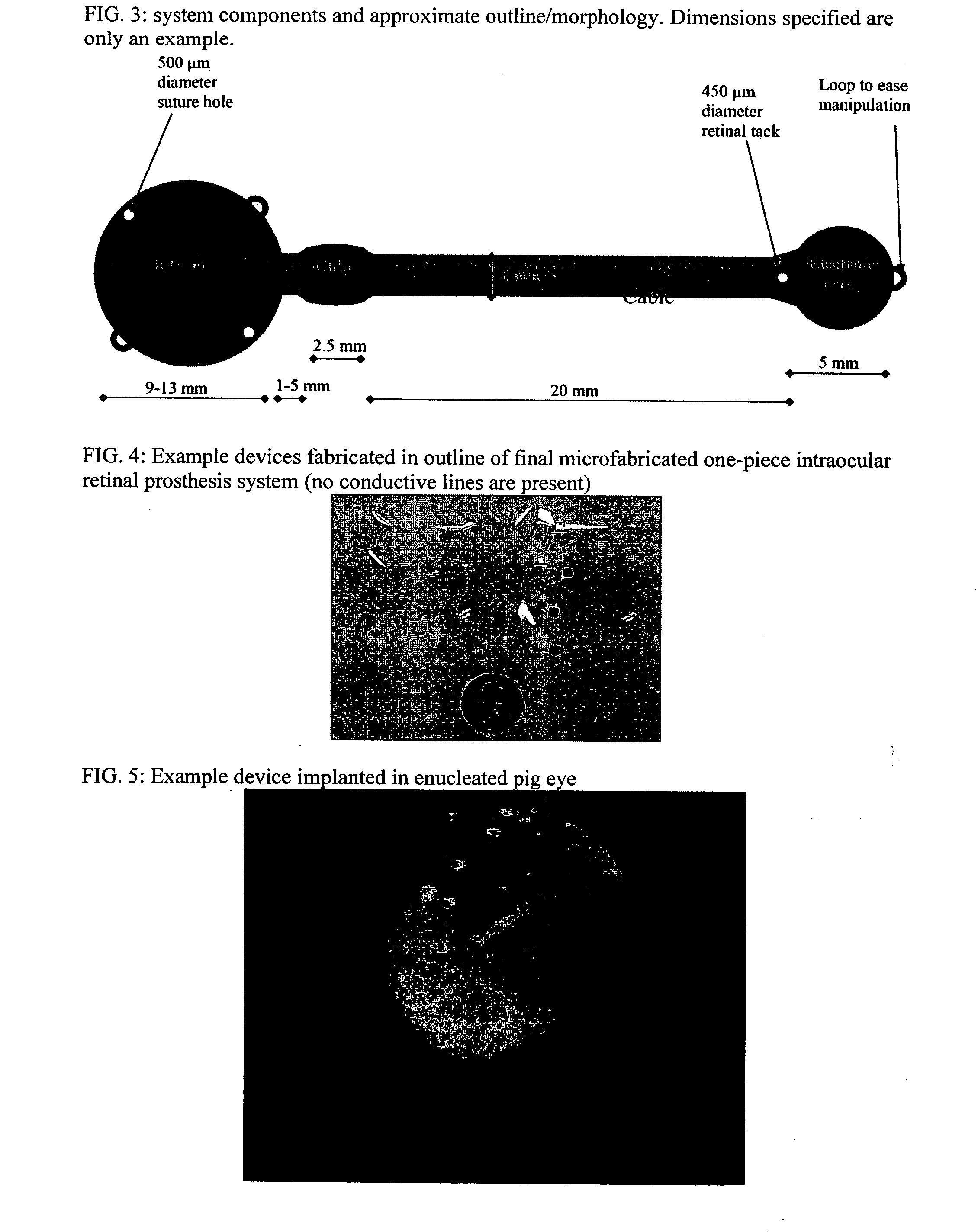

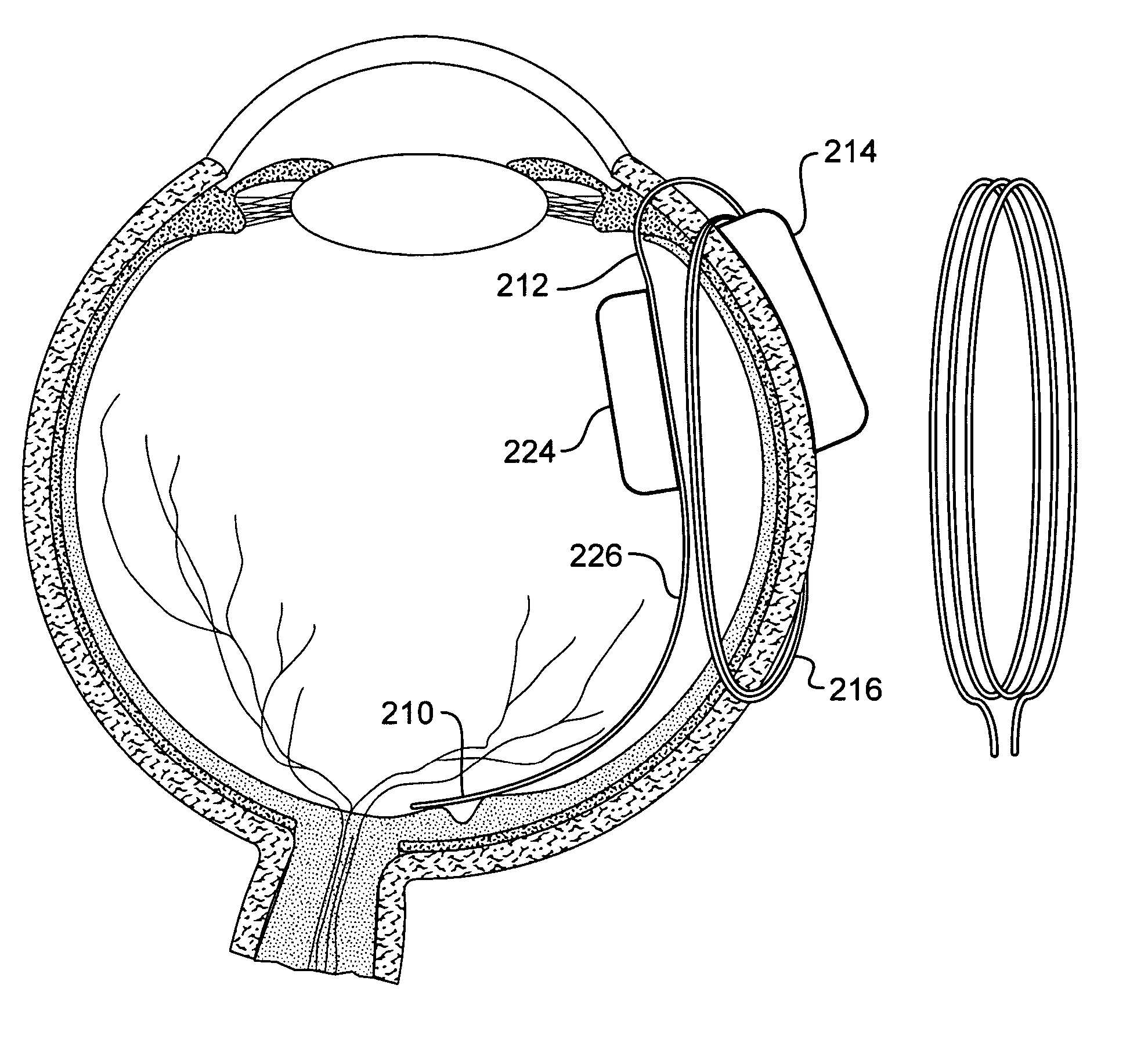

Method of fabricating an integrated intraocular retinal prosthesis device

ActiveUS7774931B2Function increaseDecrease traction and pullingPrinted circuit assemblingLine/current collector detailsProsthesisData management

Intraocular retinal prosthesis devices and methods for fabricating the same. A prosthesis device includes a cable region that connects an electrode array region with a power and data management region. The electrode array region includes one or more arrays of exposed electrodes, and the power and data management region includes various power and control elements. The power and data management elements, in one aspect, include an RF coil or coils and circuit arrangements and / or chips configured to provide drive signals to the electrodes via a cable and receive power and signals from the RF coil or coils. Each region includes elements fabricated on or in a single polymer layer during the same fabrication process.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

Retinal Prosthesis Techniques

ActiveUS20120259410A1Facilitating refraction of visible lightIncrease the areaLaser surgeryHead electrodesMedicineProsthesis

Apparatus for use with an external non-visible light source is provided. The apparatus comprises an intraocular device configured for implantation in a human eye, and comprising an energy receiver. The energy receiver is configured to receive light emitted from the external non-visible light source, and extract energy from the emitted light for powering the intraocular device. The intraocular device is configured to regulate a parameter of operation of the intraocular device based on a modulation of the light emitted by the external non-visible light source and received by the energy receiver. Other embodiments are also described.

Owner:NANO RETINA INC

Retinal prosthesis

ActiveUS8150526B2Facilitating refraction of visible lightHead electrodesSolid-state devicesPower flowMedicine

Apparatus is provided, including an external device, including a mount, which is placed in front of an eye of a subject. A laser is coupled to the mount and configured to emit toward the eye radiation that is outside of 380-750 nm. A partially-transparent mirror is coupled to the mount. An intraocular device is implanted entirely in the subject's eye, and includes a plurality of stimulating electrodes, and an energy receiver, which receives the radiation from the laser and generates a voltage drop in response thereto. A plurality of photosensors detect photons and generate a signal in response thereto. Driving circuitry is coupled to the energy receiver and to the photosensors, and receives the signals from the photosensors and utilizes the voltage drop to drive the electrodes to apply currents to the retina in response to the signals from the photosensors. Other embodiments are also described.

Owner:NANO RETINA INC

Retinal prosthesis and method of manufacturing a retinal prosthesis

Owner:CORTIGENT INC

Retinal prosthesis techniques

ActiveUS20120035725A1Increase the areaIncrease roughnessHead electrodesIntraocular lensDriver circuitProsthesis

Apparatus is provided including an external device including, a mount, which is placed in front of an eye of a subject. A power source is coupled to the mount and emits energy toward the eye. An intraocular device is implanted entirely in the subject's eye, and includes a control unit, a plurality of stimulating electrodes, and an energy receiver, which receives the energy from the power source and generates a voltage drop in response thereto. A plurality of photosensors detect photons and generate a signal in response thereto. Driving circuitry is coupled to the energy receiver and to the photosensors, and drives the electrodes to apply electrical charges to a retina in response to the signals from the photosensors. The external device modulates the emitted energy, and the control unit demodulates the modulated energy to regulate an operation parameter of the intraocular device. Other embodiments are also described.

Owner:NANO RETINA INC

Prosthetic capsular devices, systems, and methods

Prosthetic capsular devices (e.g., bag, bowl, housing, structure, cage, frame) include technology devices such as a computer, virtual reality device, display device, WiFi / internet access device, image receiving device, biometric sensor device, game device, image viewers or senders, GPSs, e-mail devices, combinations thereof, and / or the like. The technology devices can be used in combination with an intraocular lens. The output from the technology device(s) can be fed to the retina of the user to provide a visual image, can be otherwise connected to the user, and / or can be used to control the properties of the intraocular lens or of the prosthetic capsular device. Wearable technology that provides biometric data, such as blood glucose levels, body temperature, electrolyte balance, heart rate, EKG, EEG, intraocular pressure, sensing ciliary muscle contraction for accommodation stimulus, dynamic pupil change and retinal prostheses, combinations thereof, and the like can assist in technology-assisted health care functions.

Owner:OMEGA OPHTHALMICS

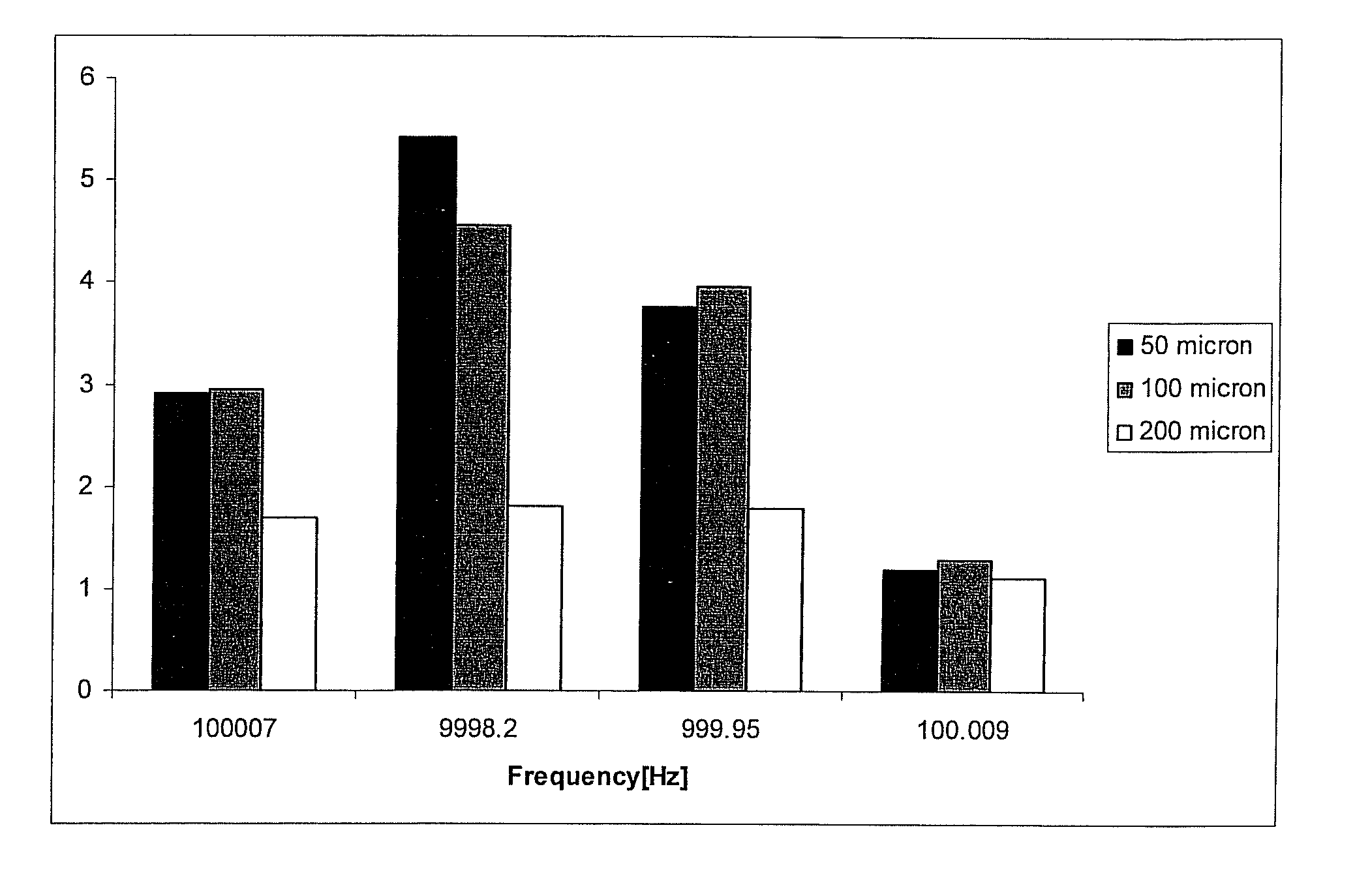

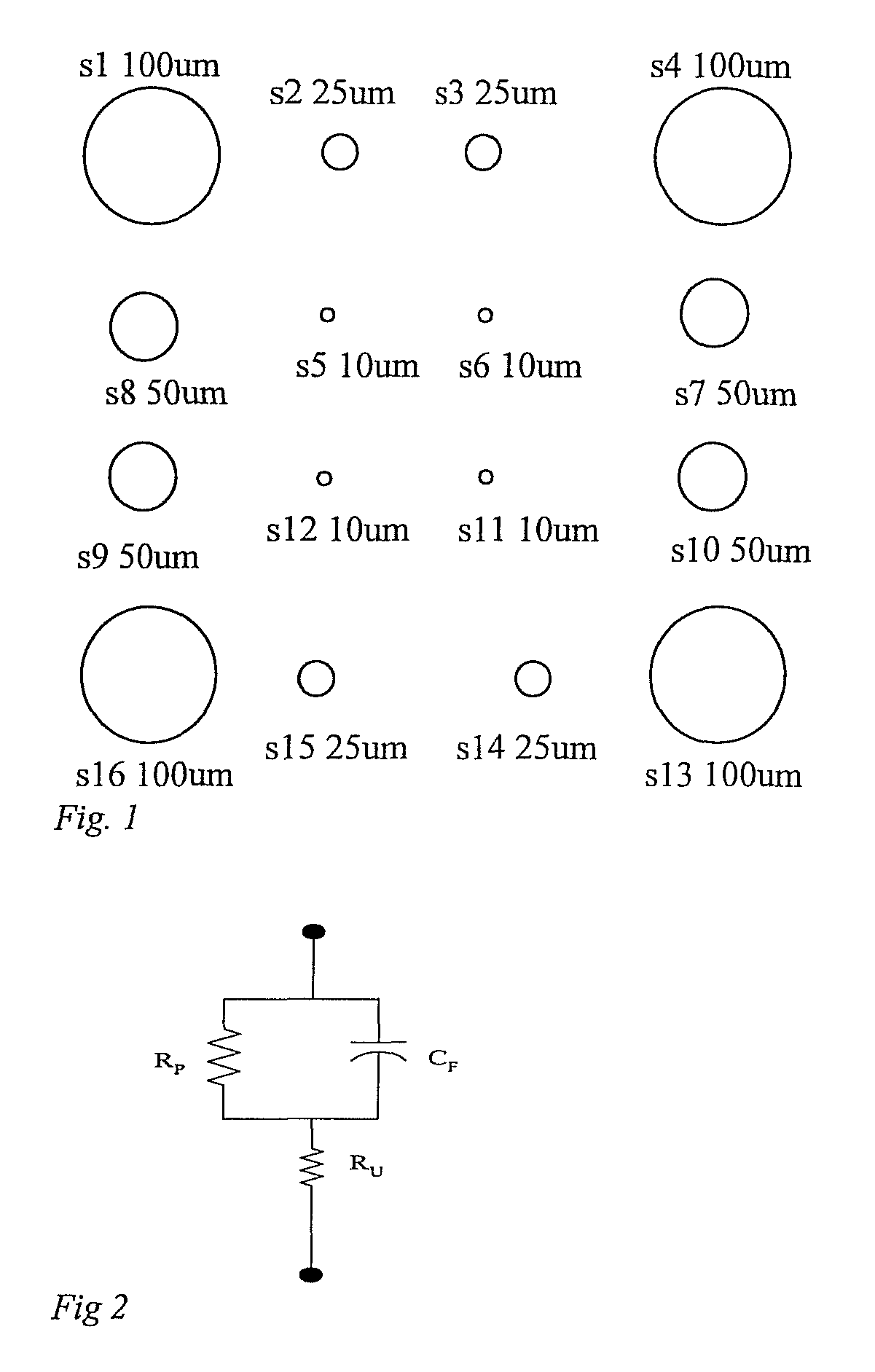

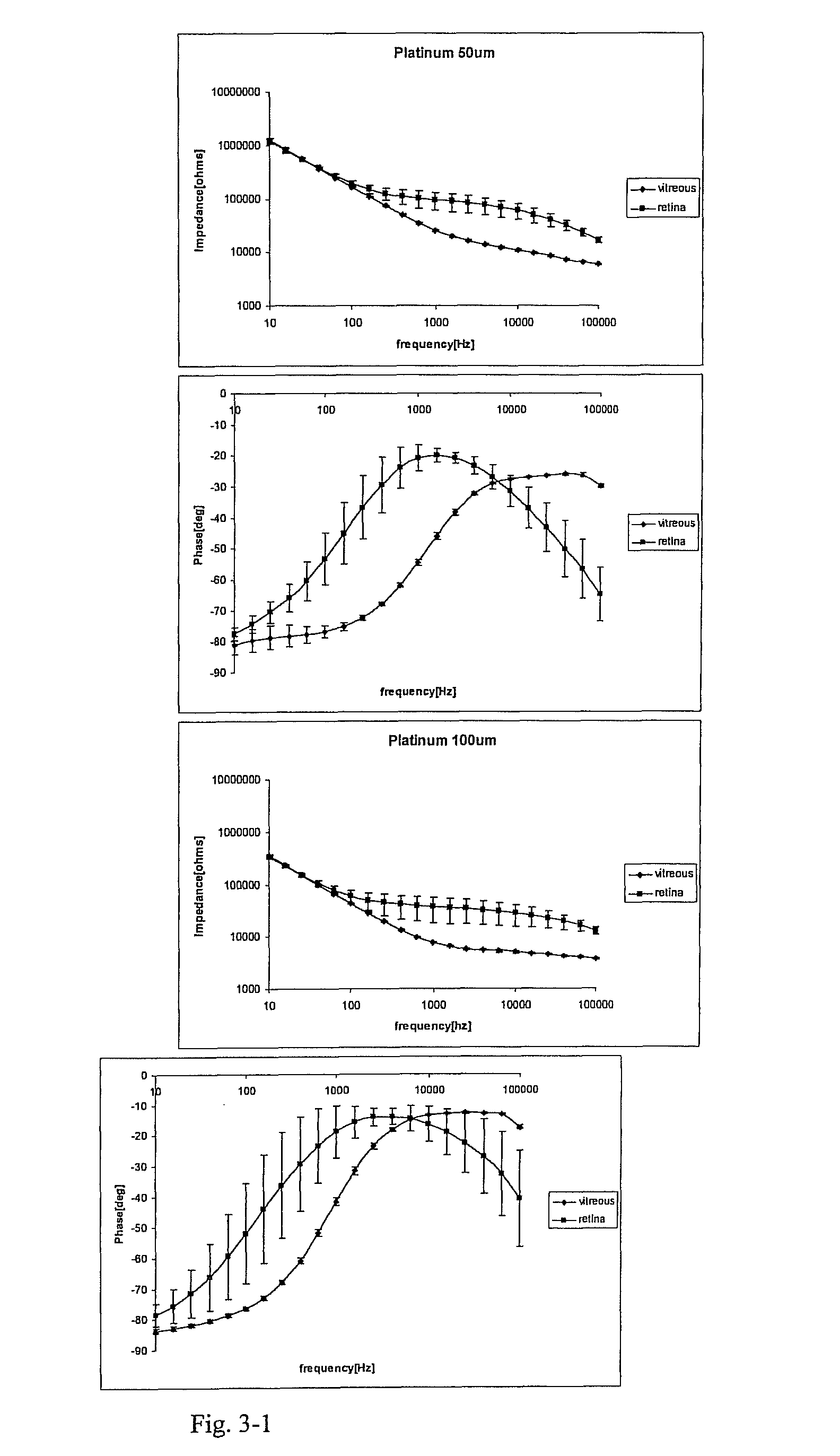

Method of improving electrode tissue interface

A critical element of a retinal prosthesis is the stimulating electrode array, which is placed in close proximity to the retina. It is via this interface that a retinal prosthesis electrically stimulates nerve cells to produce the perception of light. The impedance load seen by the current driver consists of the tissue resistance and the complex electrode impedance. The results show that the tissue resistance of the retina is significantly greater than that of the vitreous humor in the eye. Circuit models of the electrode-retina interface are used to parameterize the different contributors to the overall impedance.

Owner:CORTIGENT INC +2

Batch-fabricated flexible intraocular retinal prosthesis system and method for manufacturing the same

ActiveUS20060282128A1Function increaseReduce tractionPrinted circuit assemblingLine/current collector detailsMicrofabricationProsthesis

Intraocular retinal prosthesis systems and methods for fabricating the same are provided. In one aspect, fabrication of all or multiple components of a prosthesis device or system are combined into a single monolithic fabrication process. Also, many such entire systems can be fabricated simultaneously in a single microfabrication processing run. A prosthesis device includes a cable region that connects an electrode array region with a power and data management region. The electrode array region includes one or more arrays of exposed electrodes, and the power and data management region includes various power and control elements. The power and data management elements, in one aspect, include an RF coil or coils and circuit arrangements and / or chips configured to provide drive signals to the electrodes via a cable and receive power and signals from the RF coil or coils. Each region includes elements fabricated on or in a single polymer layer during the same fabrication process.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

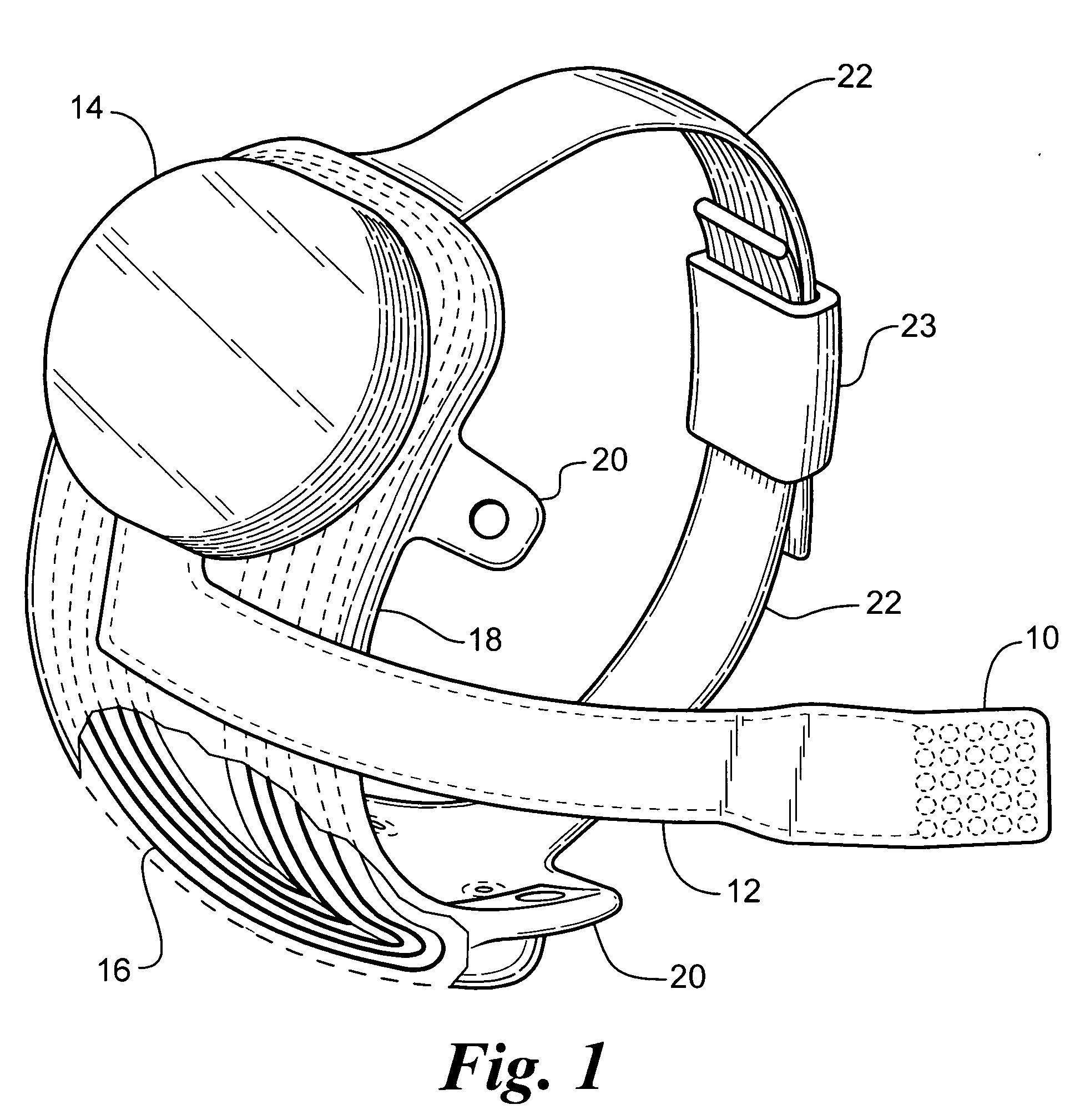

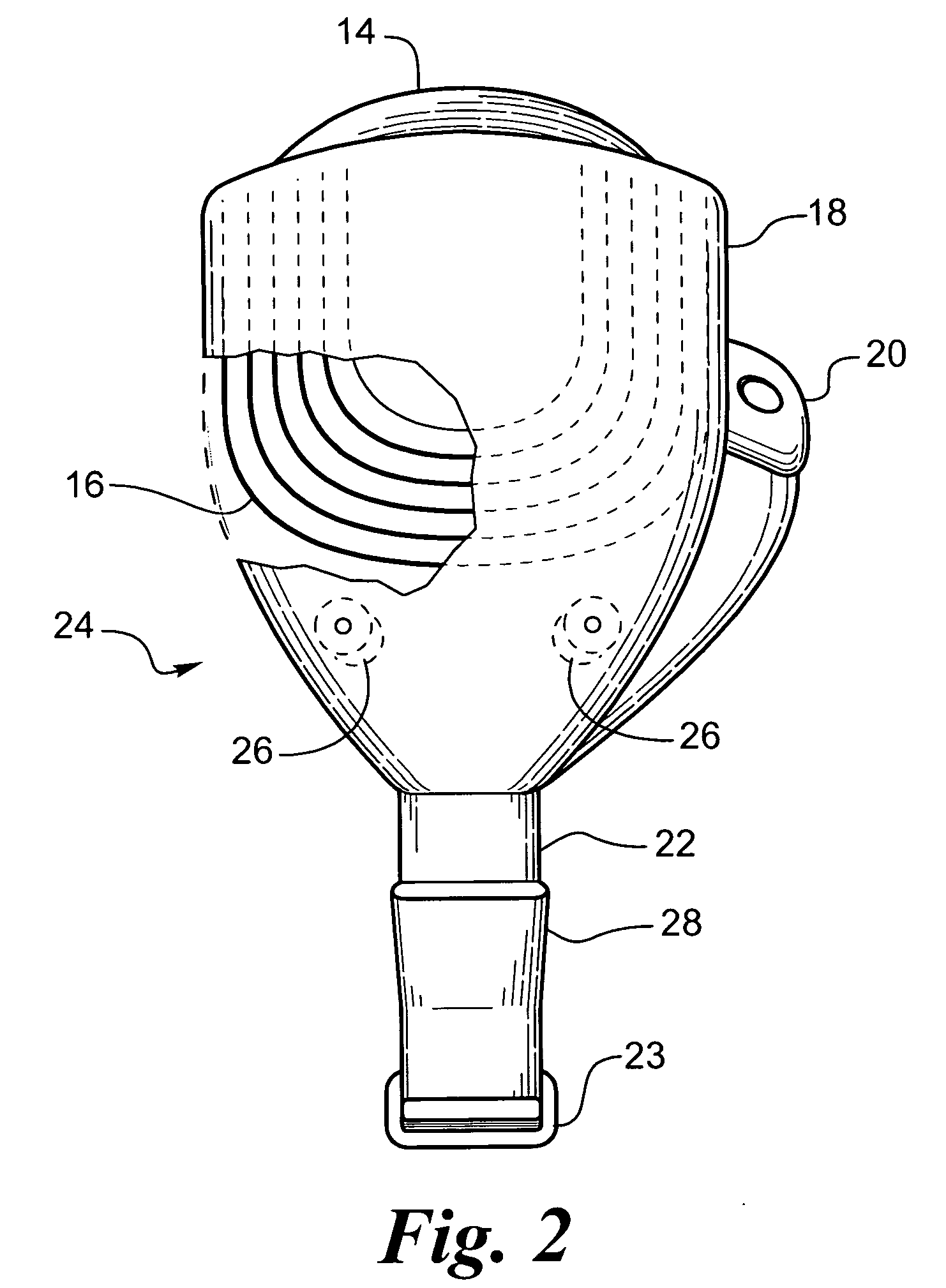

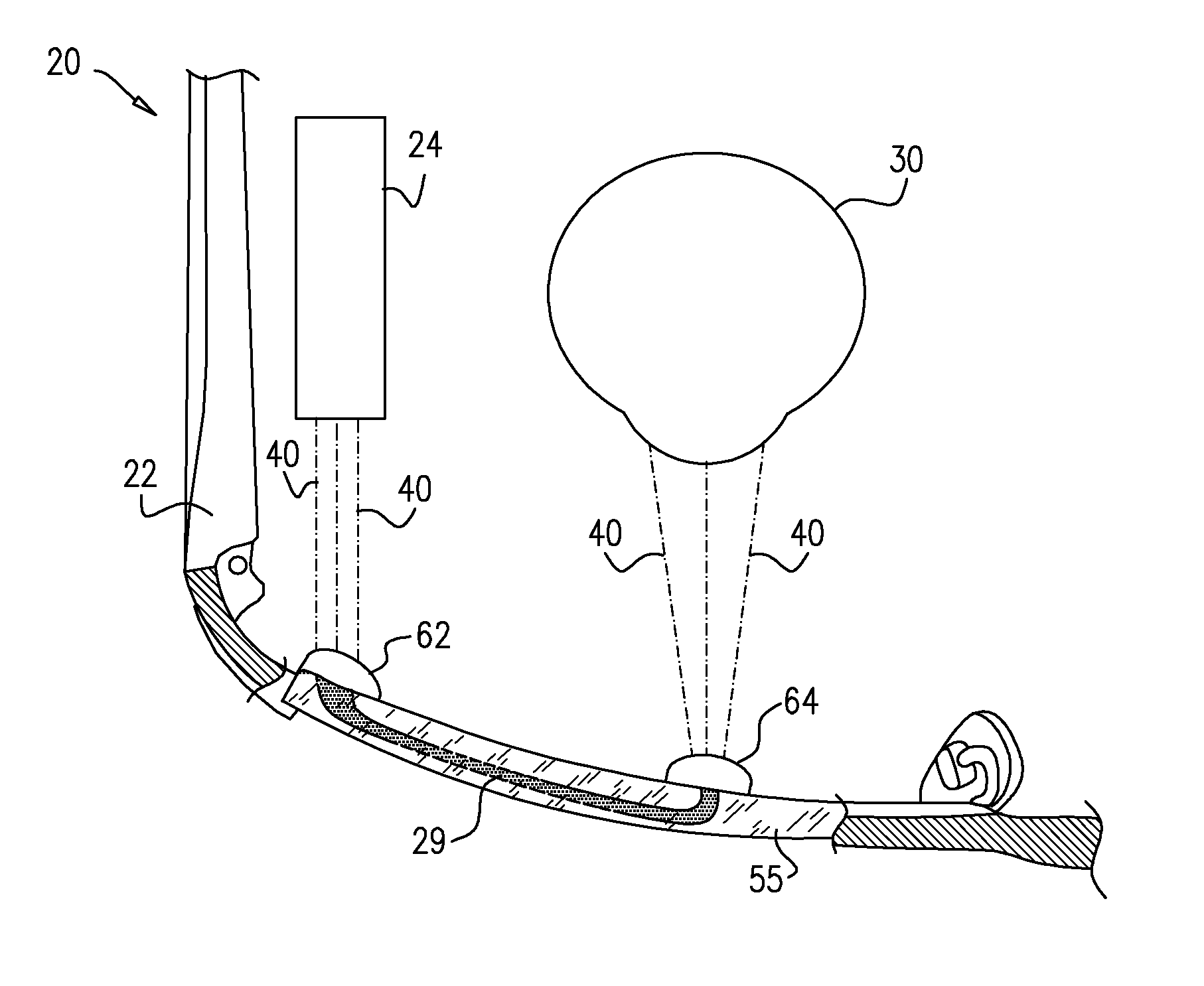

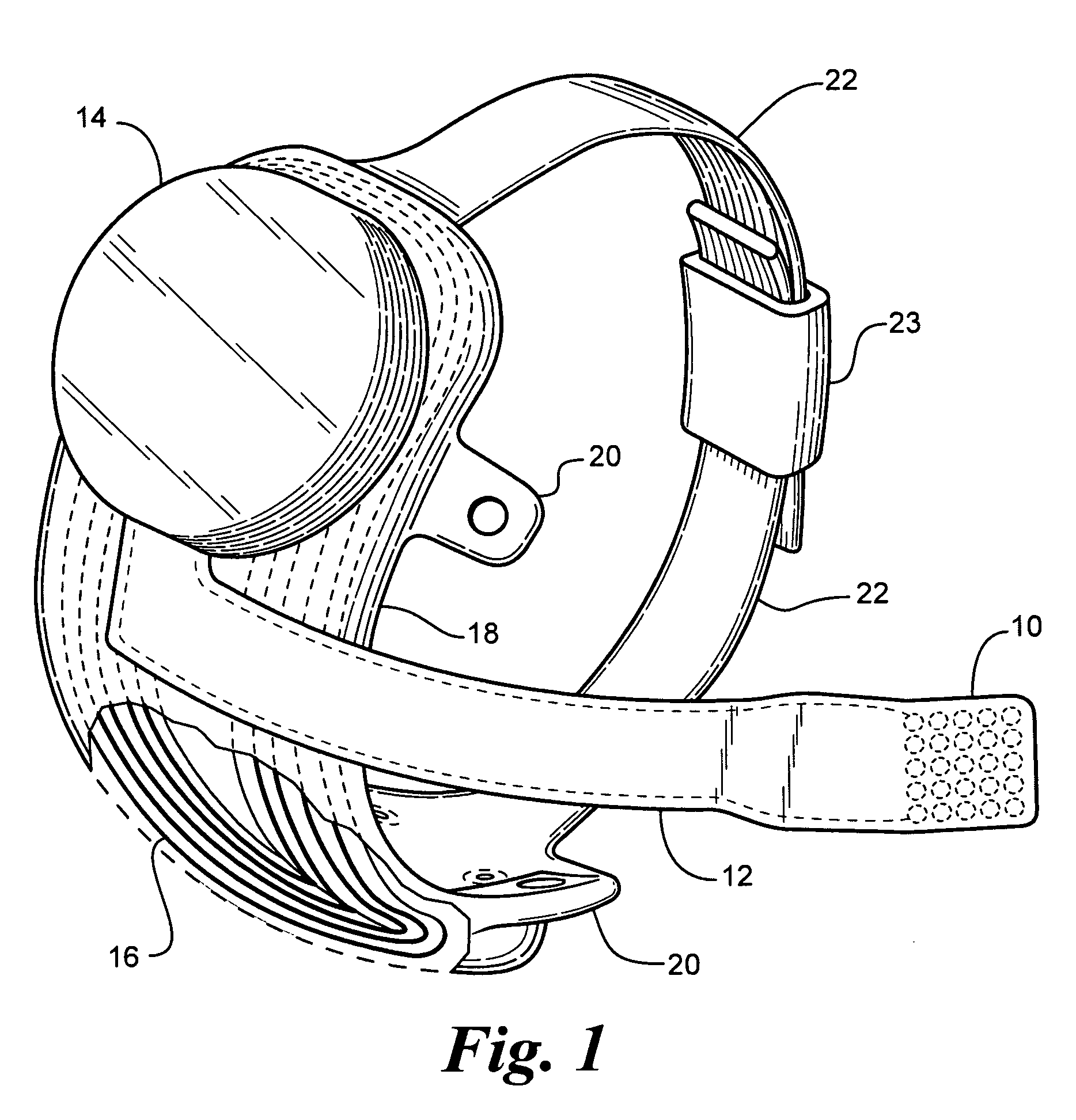

Wearable apparatus for delivery of power to a retinal prosthesis

Apparatus is provided including an extraocular device, which includes an eyeglasses frame, which is placed in front of an eye of a subject, and a power source coupled to the eyeglasses frame and configured to emit a beam of light that is outside of 380-750 nm. A light-guiding element is coupled to the eyeglasses frame and at least one optical coupling-in element and at least one optical coupling-out element are optically coupled to the light-guiding element. The coupling-in element is positioned such that the beam of light is directed into the light-guiding element via the coupling-in element, and the coupling-in and coupling-out elements are positioned such that the beam diverges from a focal point located within 3 mm of the coupling-out element. Other applications are also described.

Owner:NANO RETINA LTD

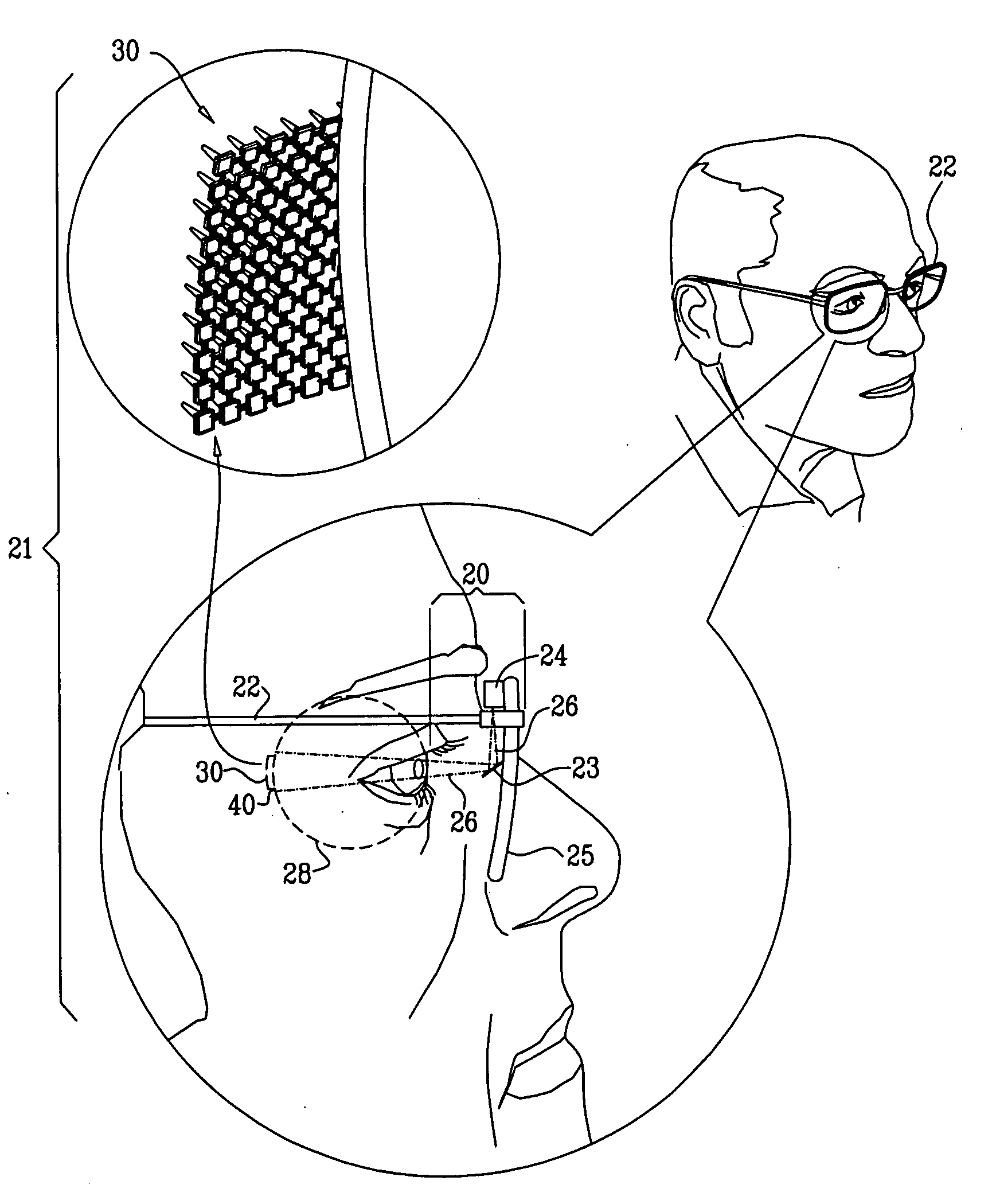

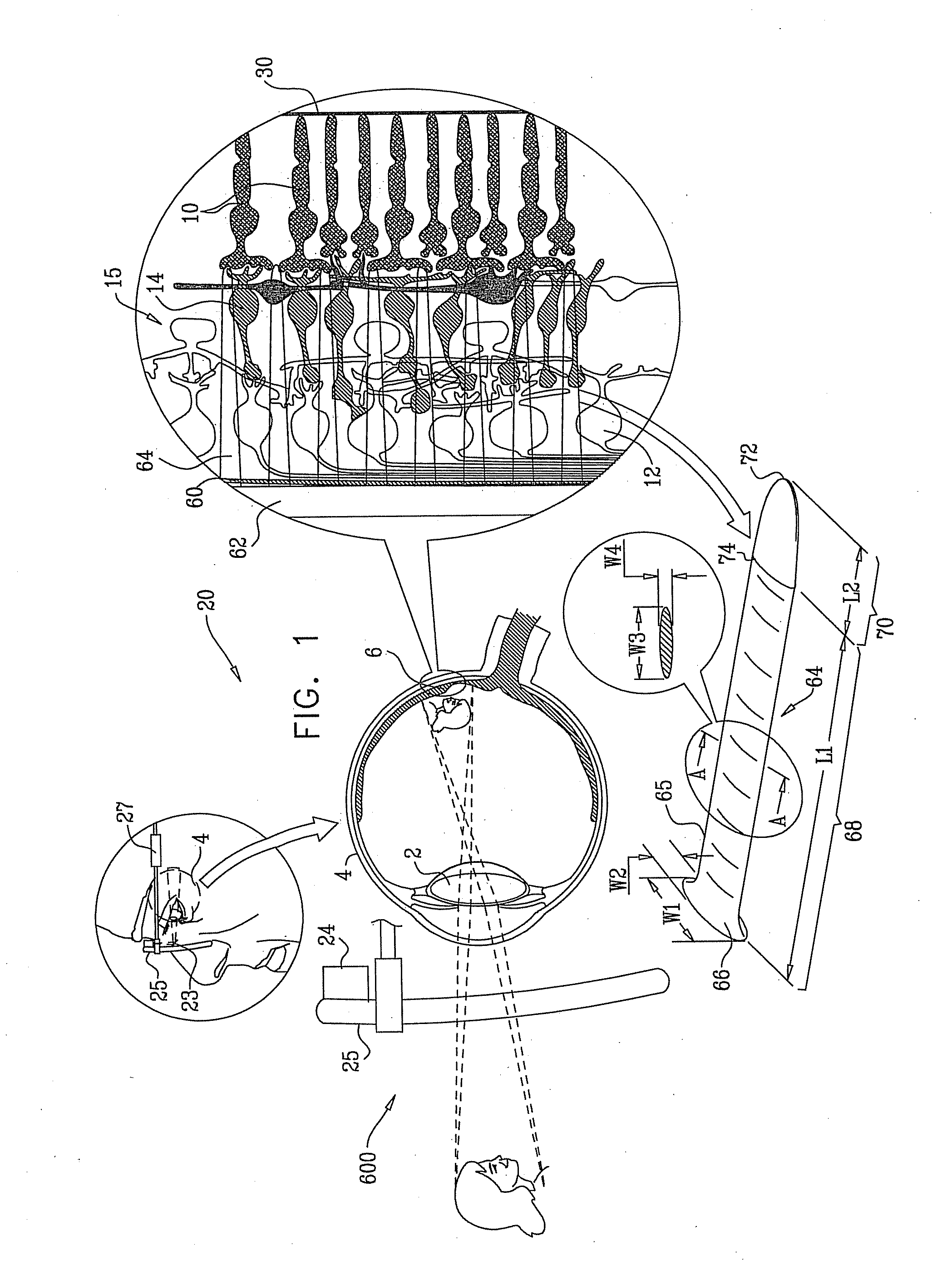

Microelectronic stimulator array for stimulating nerve tissue

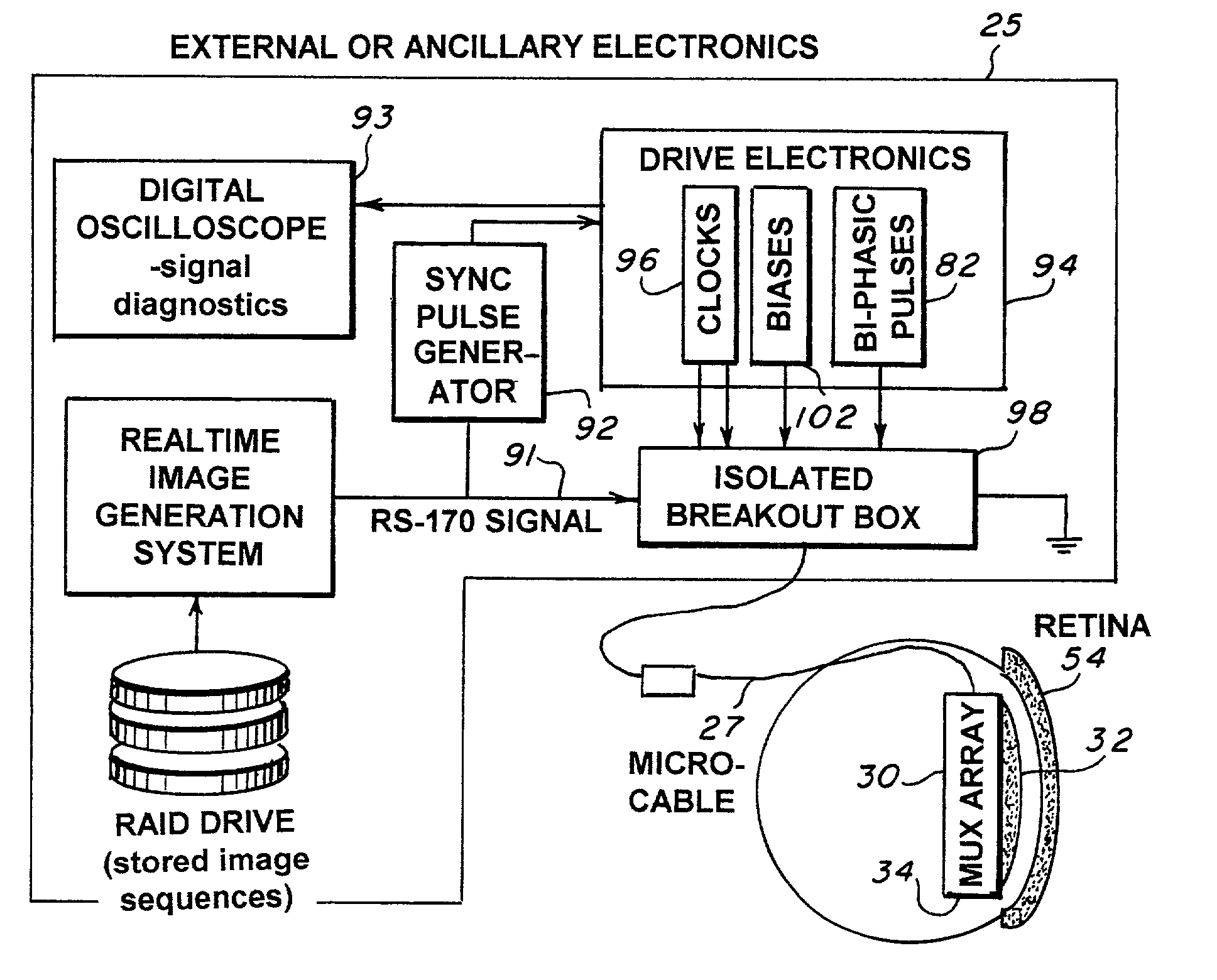

The retinal prosthesis test device is comprised of a thin wafer of glass made from nanochannel glass (NGC) with very small channels perpendicular to the plane of the wafer filled with an electrical conductor forming microwires. One surface of the glass is ground to a spherical shape consistent with the radius of curvature of the inside of the retina. The NGC is hybridized to a silicon de-multiplexer and a video image is serially input to a narrow, flexible micro-cable and read into a 2-D array of unit cells in a pixel-by-pixel manner which samples the analog video input and stores the value as a charge on a MOS capacitor. After all unit cells have been loaded with the pixel values for the current frame, a biphasic pulse is sent to each unit cell which modulates the pulse in proportion to the pixel value stored therein. Because the biphasic pulses flow in parallel to each unit cell from a global external connection, the adjacent retinal neurons are all stimulated simultaneously, analogous to image photons stimulating photoreceptors in a normal retina. A permanent retinal implant device uses a NGC array hybridized to a silicon chip, the image is simultaneously generated within each cell through a photon-to-electron conversion using a silicon photodiode. The photons propagate directly through into the backside of the device. Electrical power and any control signals are transmitted through an inductively driven coil or antenna on the chip. The device collects the charge in storage capacitors via the photon-to-electron conversion process, stimulates the neural tissue with biphasic pulses in proportion to the stored charges, and resets the storage capacitors to repeat the process.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Method for preparing ball-shaped bump biological microelectrode array

InactiveCN101149559ASimple processEasy to operateSemi-permeable membranesEye implantsLacquerRetinal Prosthesis

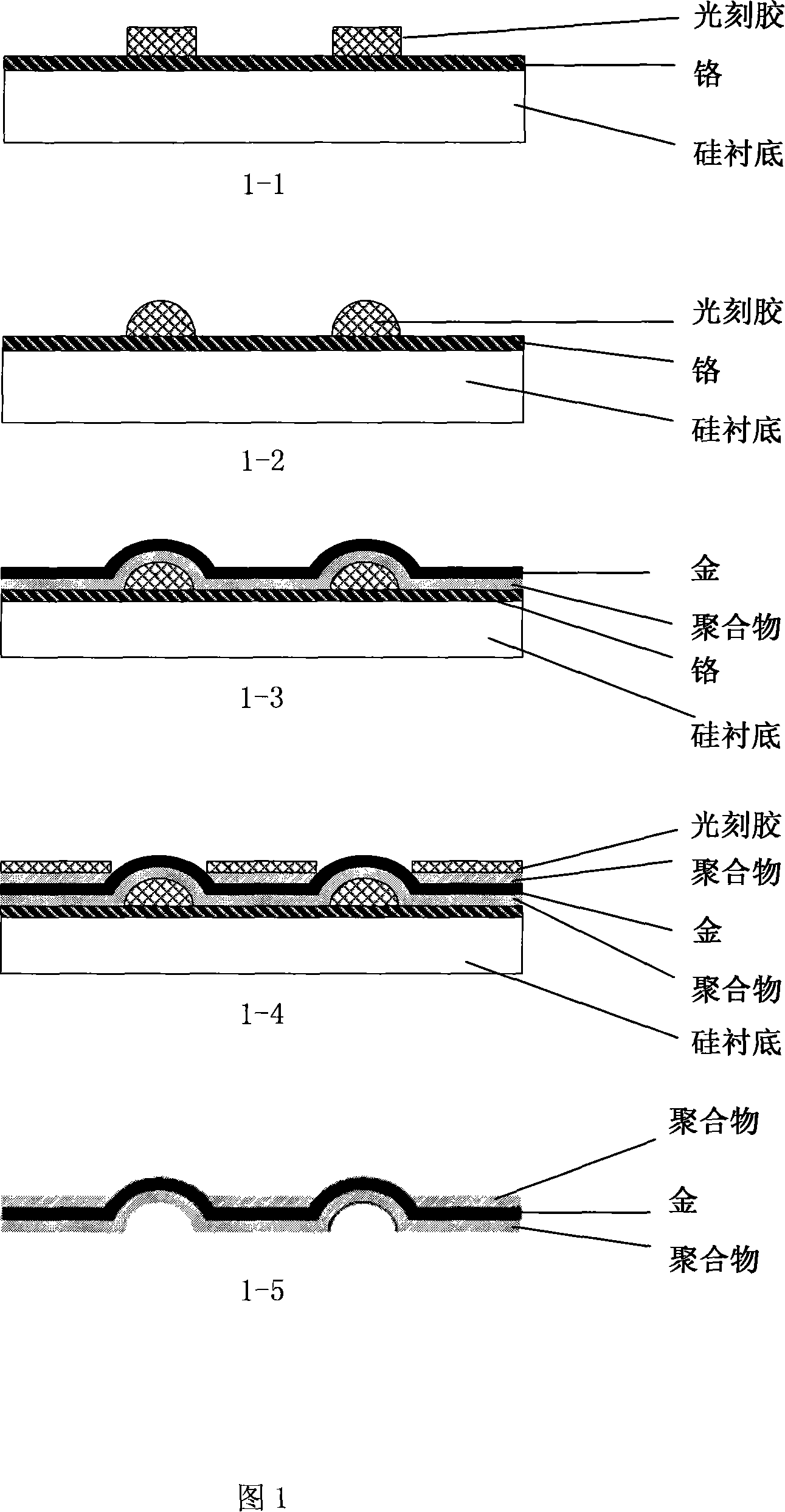

This invention discloses a sort of method that it uses the light-sensitive lacquer hot-melt method to prepare the roundness heave biologic micro-electrode array. It uses the light-sensitive lacquer technique to prepare the heave cylindrical light-sensitive lacquer, and it adopts the hot-melt circumfluence light-sensitive lacquer to form the roundness salient point. A bed of polymer which is covered in the underlay is used for the protecting material of the bottom of the device, and the presented in figures forms the metal electrode point and the lead, and then that it covers the polymer to be the protecting material of the top of the device. The presented in figures reveals the electrode point and the weld point, and it gets the needed roundness heave smooth micro-electrode array. The cost of the invention is low, also the technical process is simple, and it has the upper irritant effect. It is used for the preparation of the biologic micro-electrode array which has the nerve-cell stimulation of the retina prosthesis and so on.

Owner:SHANGHAI JIAO TONG UNIV

Retinal prosthesis techniques

ActiveUS8428740B2Increase the areaIncrease roughnessHead electrodesIntraocular lensDriver circuitProsthesis

Apparatus is provided including an external device including, a mount, which is placed in front of an eye of a subject. A power source is coupled to the mount and emits energy toward the eye. An intraocular device is implanted entirely in the subject's eye, and includes a control unit, a plurality of stimulating electrodes, and an energy receiver, which receives the energy from the power source and generates a voltage drop in response. A plurality of photosensors detect photons and generate a signal in response. Driving circuitry is coupled to the energy receiver and to the photosensors, and drives the electrodes to apply electrical charges to a retina in response to the signals from the photosensors. The external device modulates the emitted energy, and the control unit demodulates the modulated energy to regulate an operation parameter of the intraocular device. Other embodiments are also described.

Owner:NANO RETINA INC

Retinal prosthesis

ActiveUS20060111757A9Easy to configure and installReduce widthHead electrodesExternal electrodesElectrical conductorMultiplexer

Owner:CORTIGENT INC

Method of fabricating flexible artificial retina devices

ActiveUS20120107999A1High resolutionReduce electrical distanceHead electrodesSolid-state devicesProsthesisRetinal Prosthesis

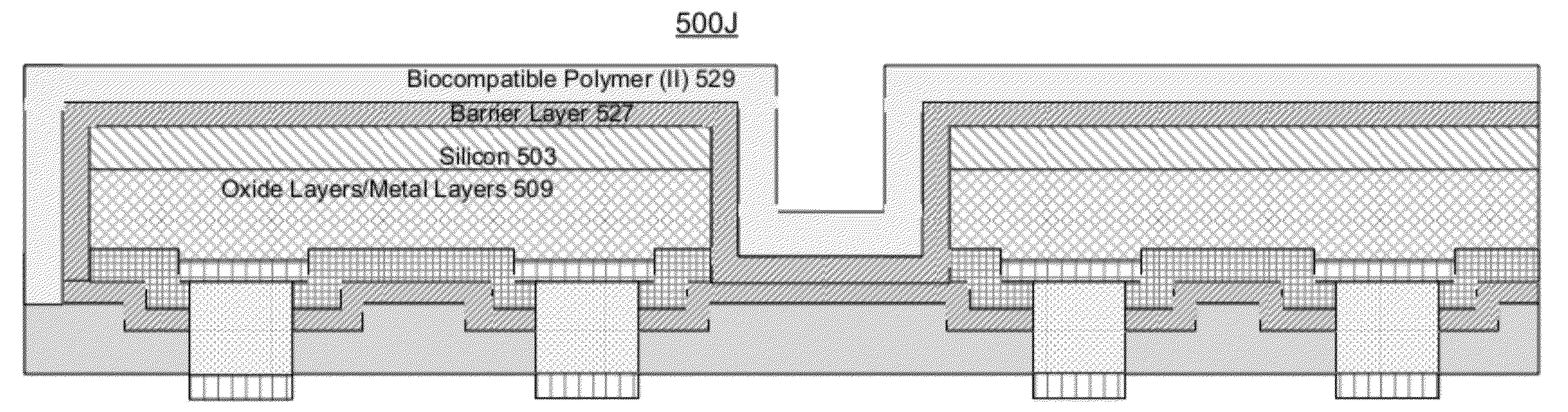

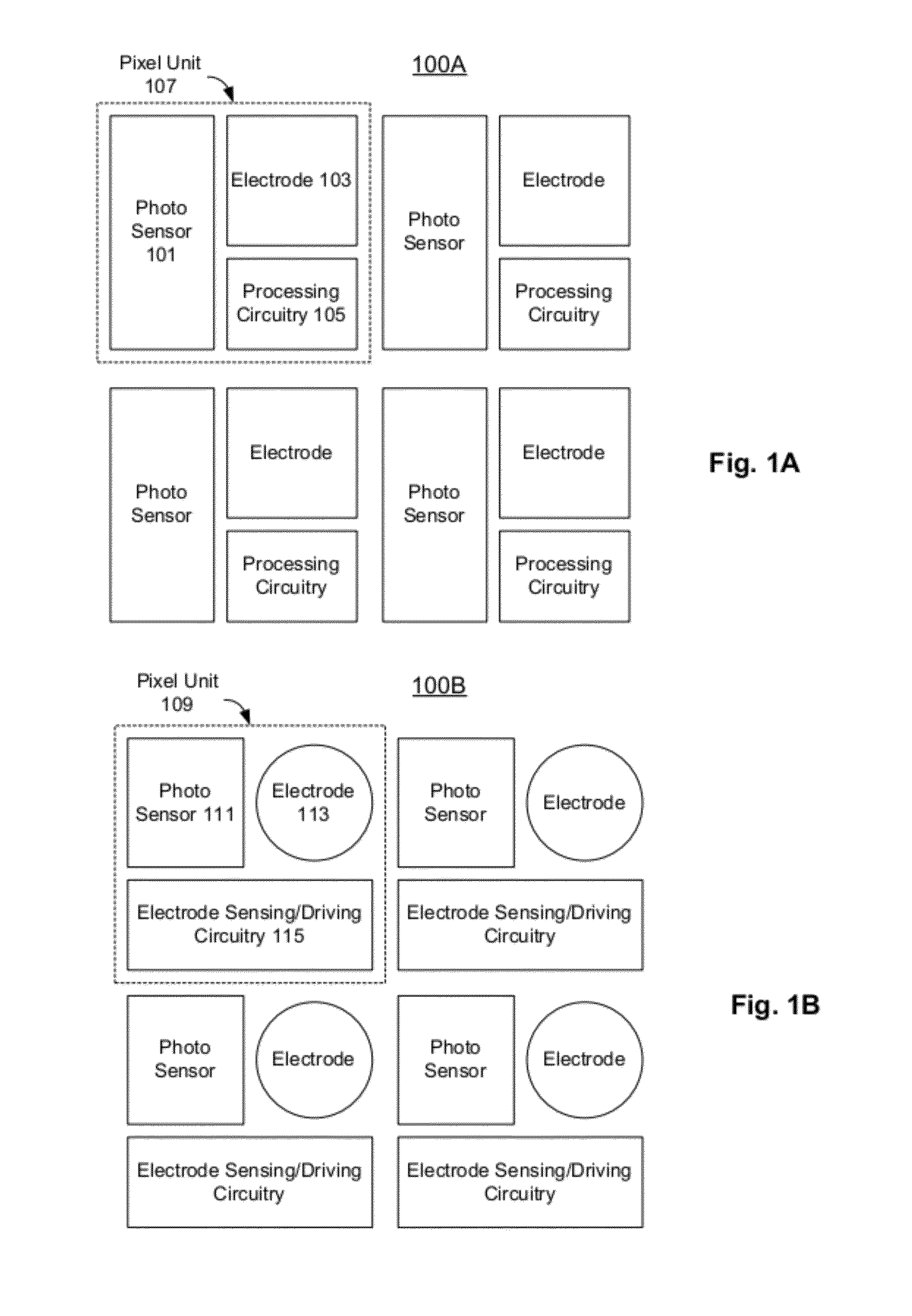

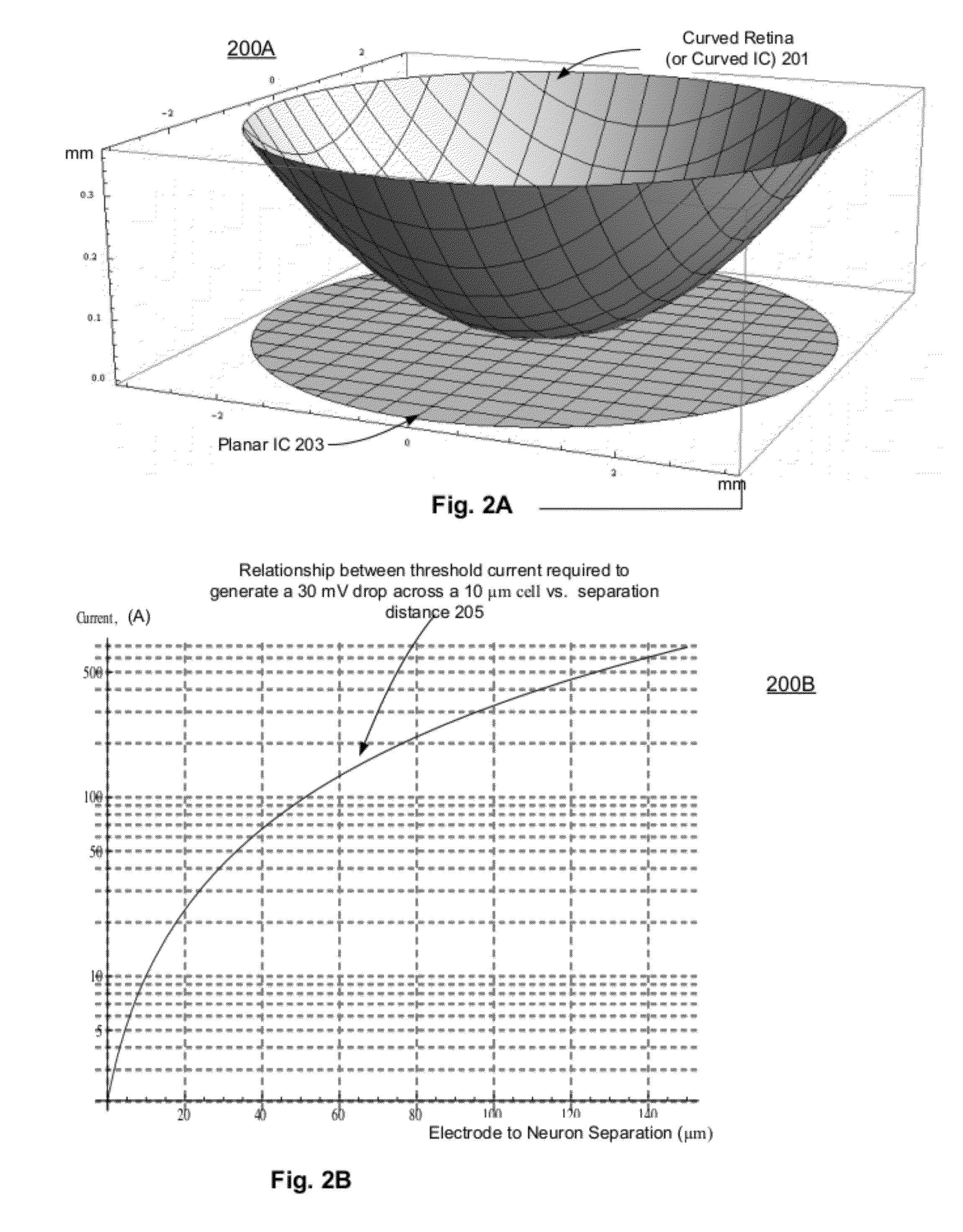

Fabrication methods for a flexible device for retina prosthesis are described. Layered structures including an array of pixel units may be formed over a substrate. Each pixel unit may comprise a processing circuitry, a micro electrode and a photo sensor. A first set of biocompatible layers may be formed over the layered structures. The substrate may be thinned down to a controlled thickness of the substrate to allow bending of the substrate to the curvature of a retina. A second set of biocompatible layers may be formed over the thinned substrate. The second set of biocompatible layers may be in contact with the first set of biocompatible layers to form a biocompatible seal wrapping around the device to allow long-term contact of the device with retina tissues. Micro electrodes of the pixel units may be exposed through the openings of these biocompatible layers.

Owner:IRIDIUM MEDICAL TECH

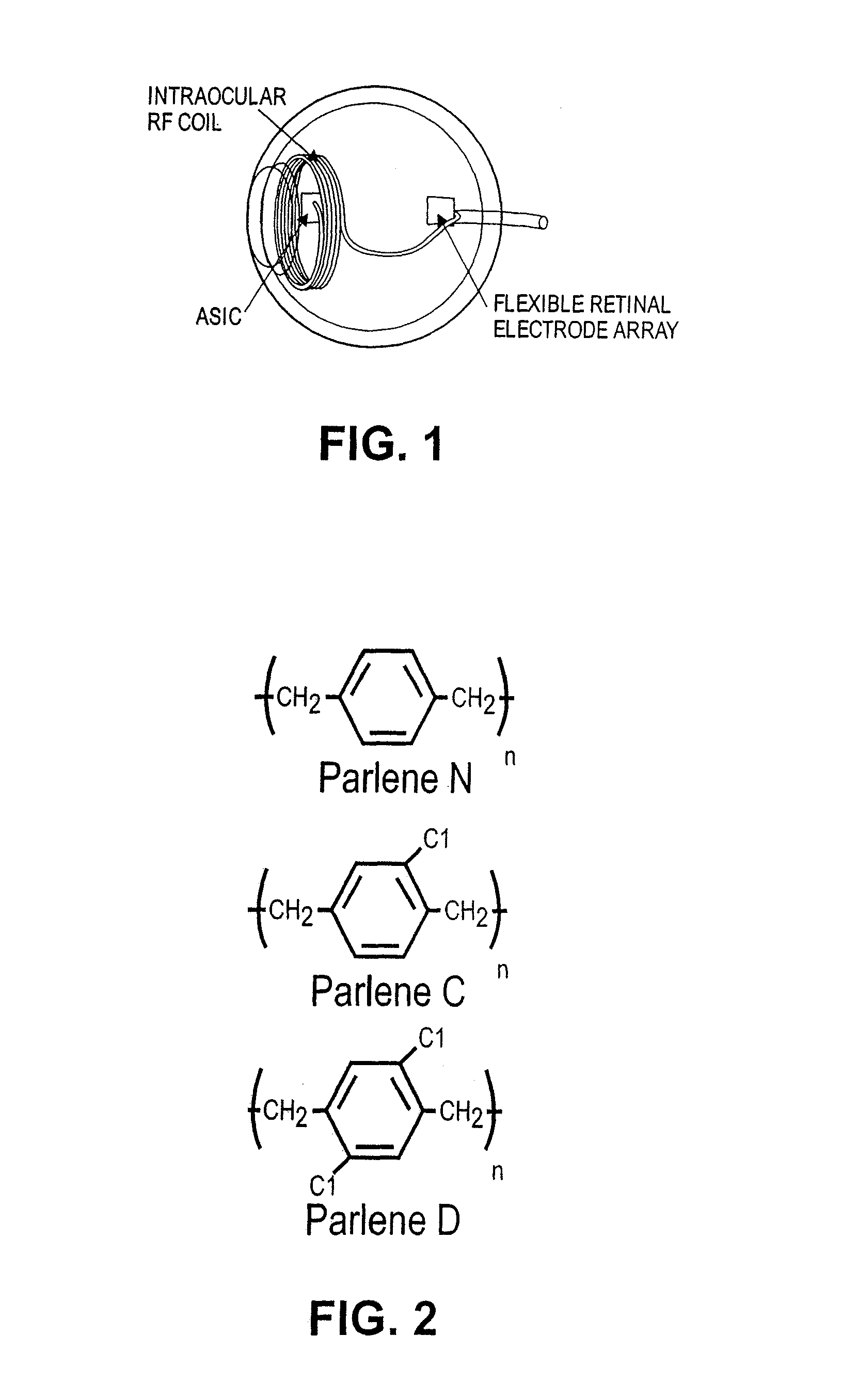

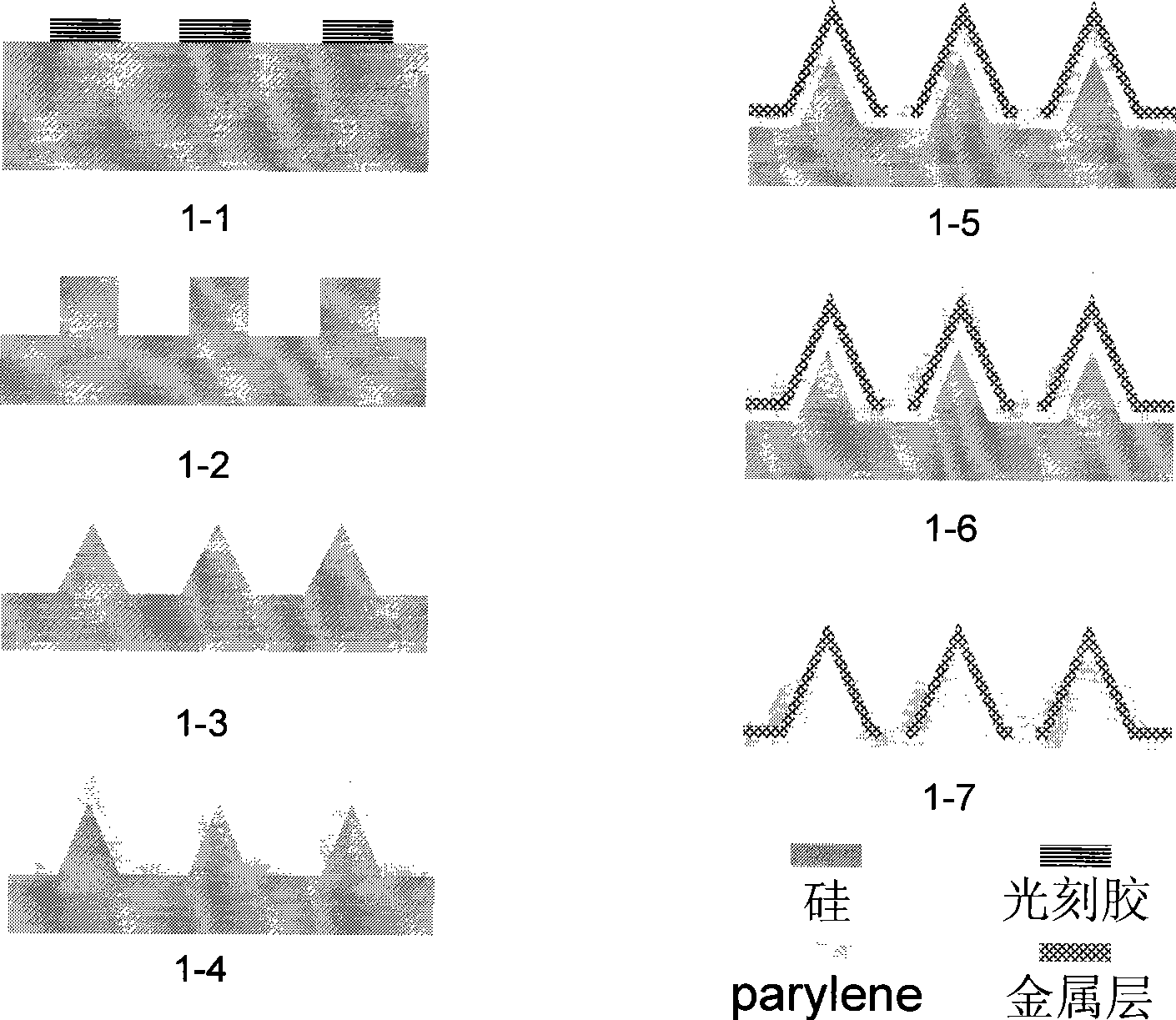

Method for making three-dimensional needlepoint electrode array based on parylene

InactiveCN101398614AReduce process stepsReduce processing costsSemi-permeable membranesEye implantsParyleneVolumetric Mass Density

A fabricating method for a Parylene-based 3D pinpoint electrode array is characterized in that 3D pinpoint electrode array based on the Parylene flexible substrate is prepared by a 3D silicon pinpoint array, and the electrode array is a three-layer structure similar to a sandwich structure (Parylene- metal layer-Parylene) and can be used for subretinal implantation surgery for artificial retinal prosthesis. The 3D pinpoint electrode array fabricated by the method can effectively improve the density of a chip electrode array, reduce the power consumption and the area of the chip, strengthen the rehabilitation effect of the retinal chip, and better adapt to the requirements of the subretinal implantation surgery.

Owner:PEKING UNIV

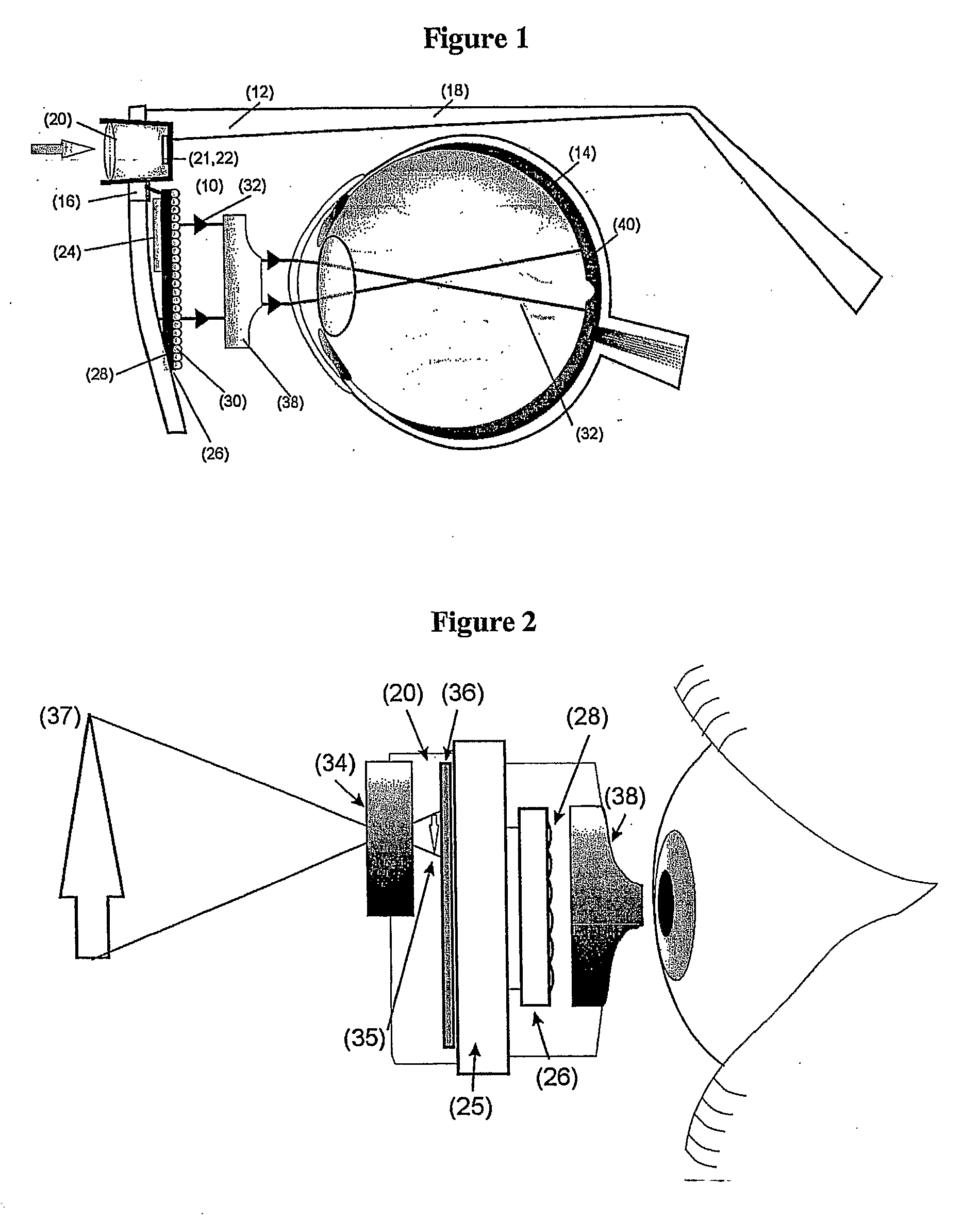

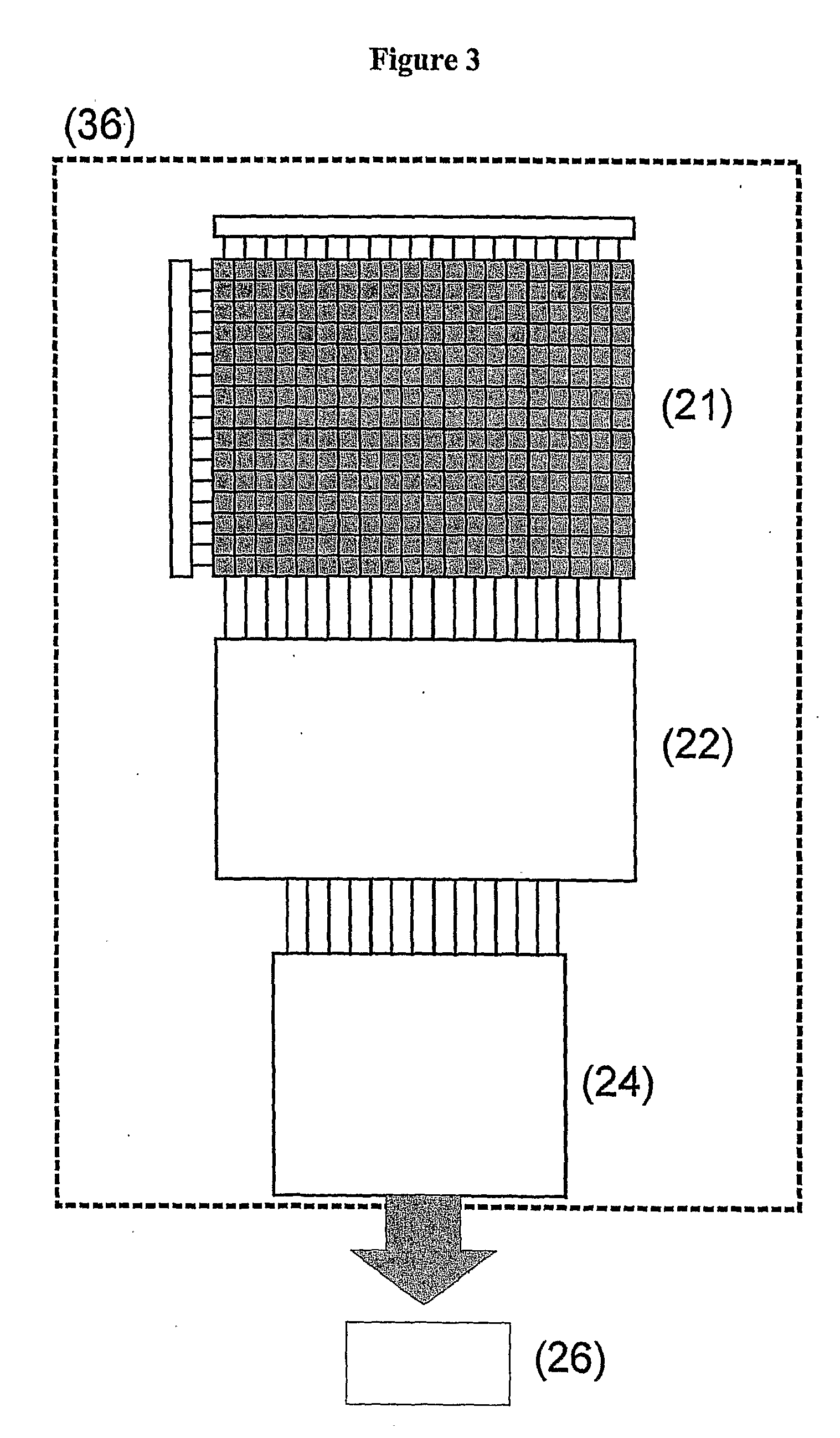

Retinal prosthetic devices

InactiveUS20100152849A1Easy to controlSimple processEye treatmentIntraocular lensLight beamProsthesis

A retinal prosthetic device comprises image capture means (20) arranged to capture an image, light producing means (30) arranged to define a plurality of light paths along each of which a light beam can be directed towards a respective position on a retina, and control means (24) arranged to process the captured image and control the light producing means so as to produce a stimulating array of light beams along a group of the light paths, the group being dependent upon the captured image.

Owner:IMPERIAL INNOVATIONS LTD

Video processing methods for improving visual acuity and/or perceived image resolution

InactiveUS20080021516A1Eliminate and severely degrade visionLow densityElectrotherapyVisually impairedOutput device

Owner:SECOND SIGHT MEDICAL PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com