Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1211 results about "Sea bottom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

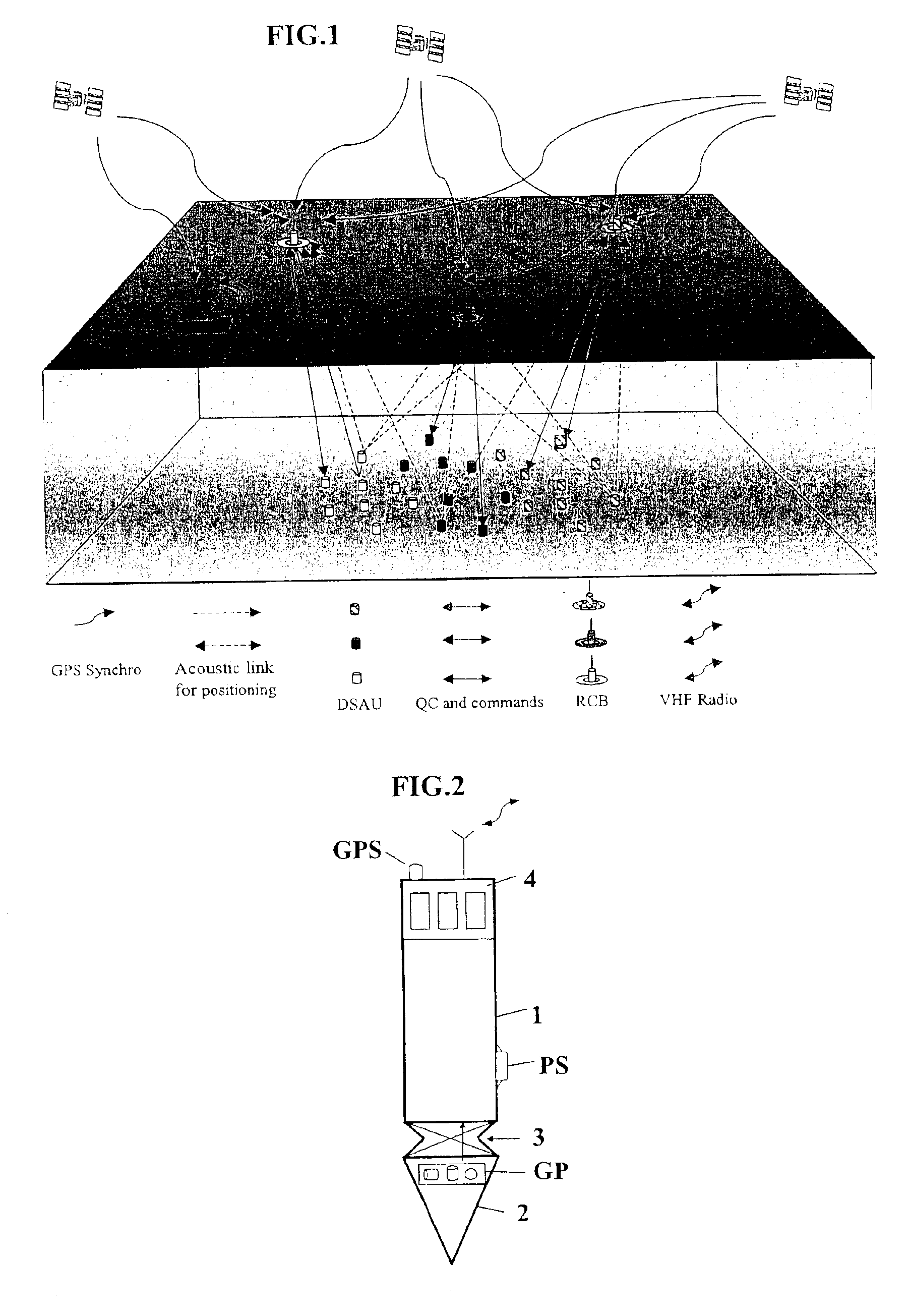

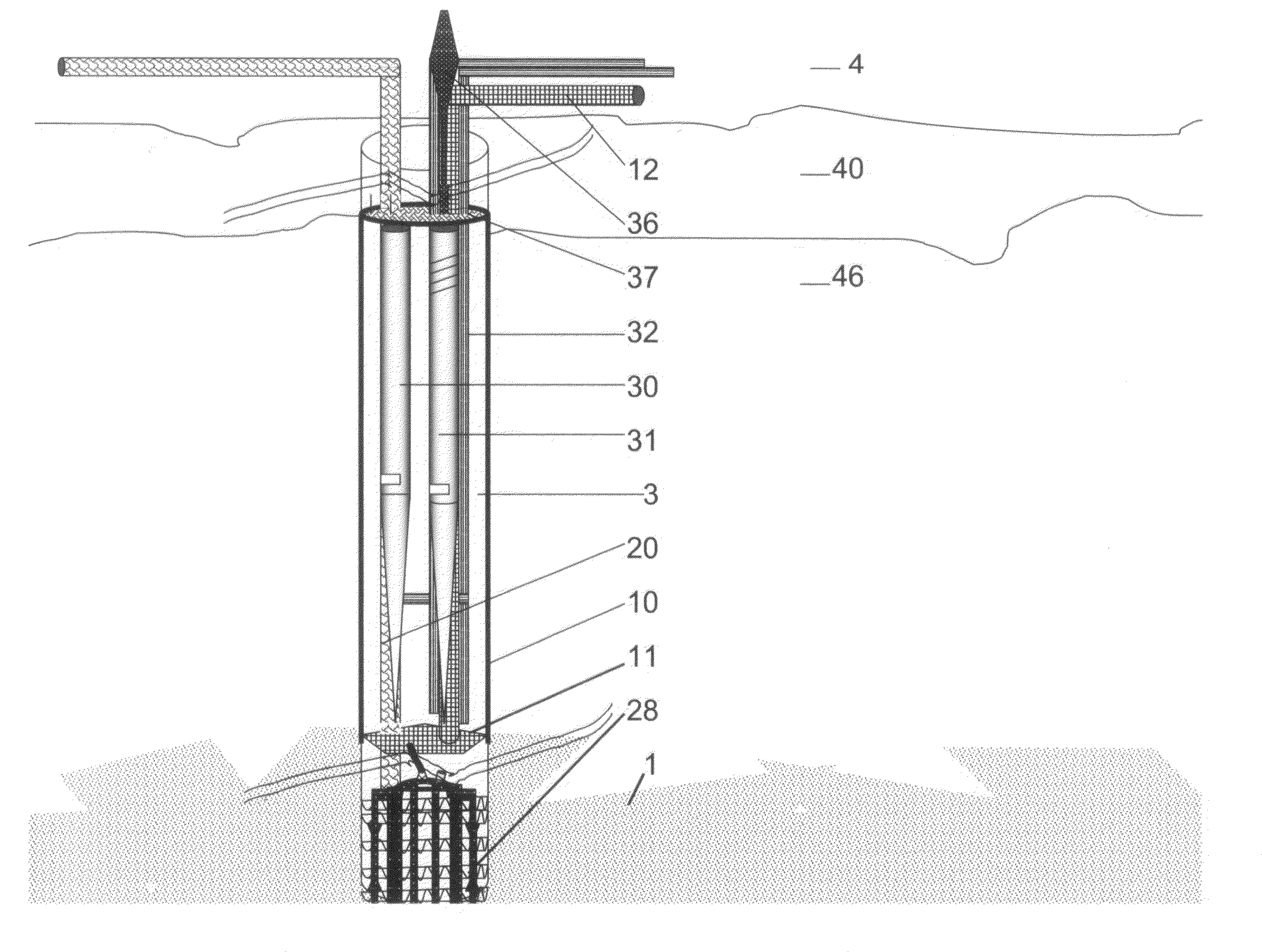

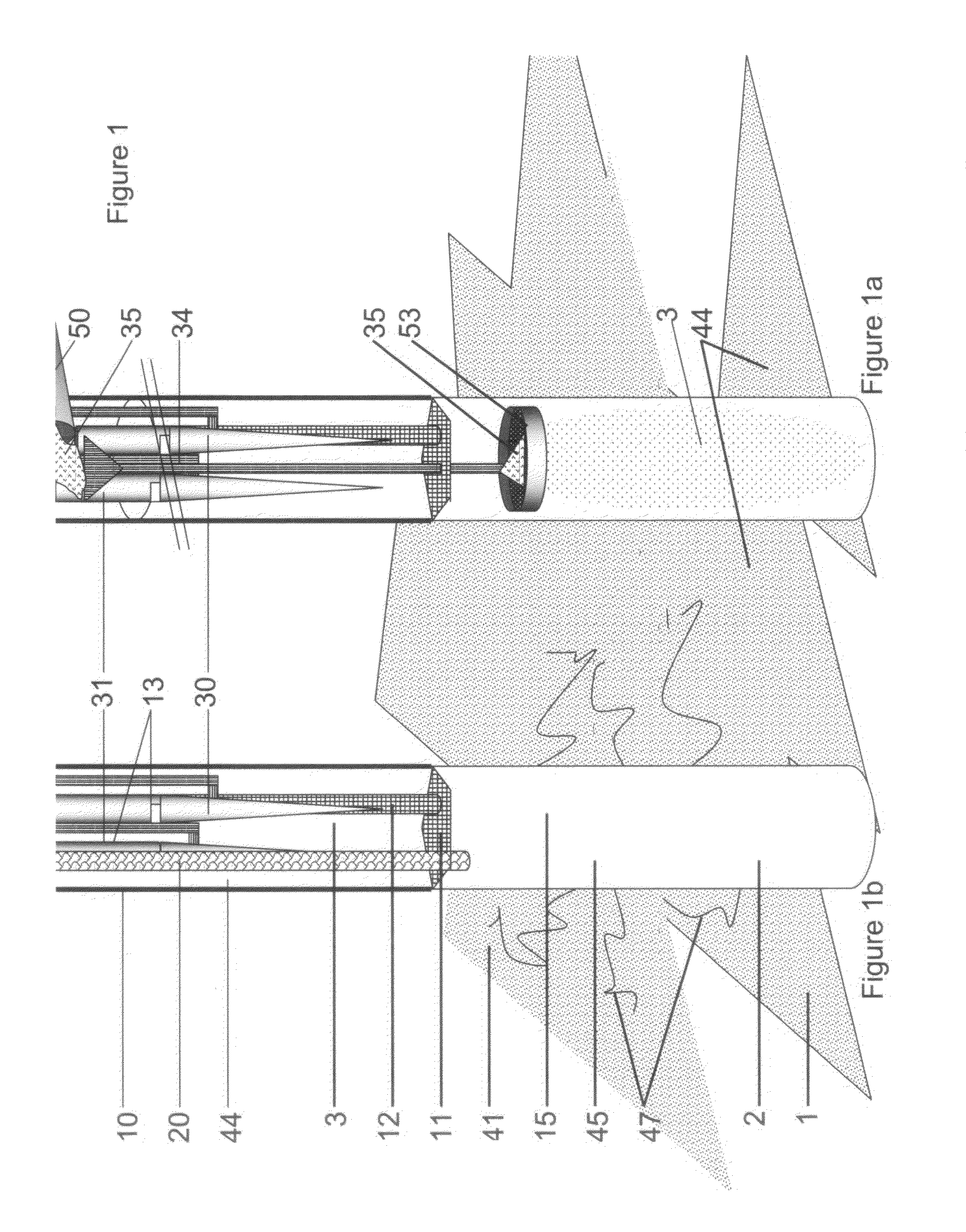

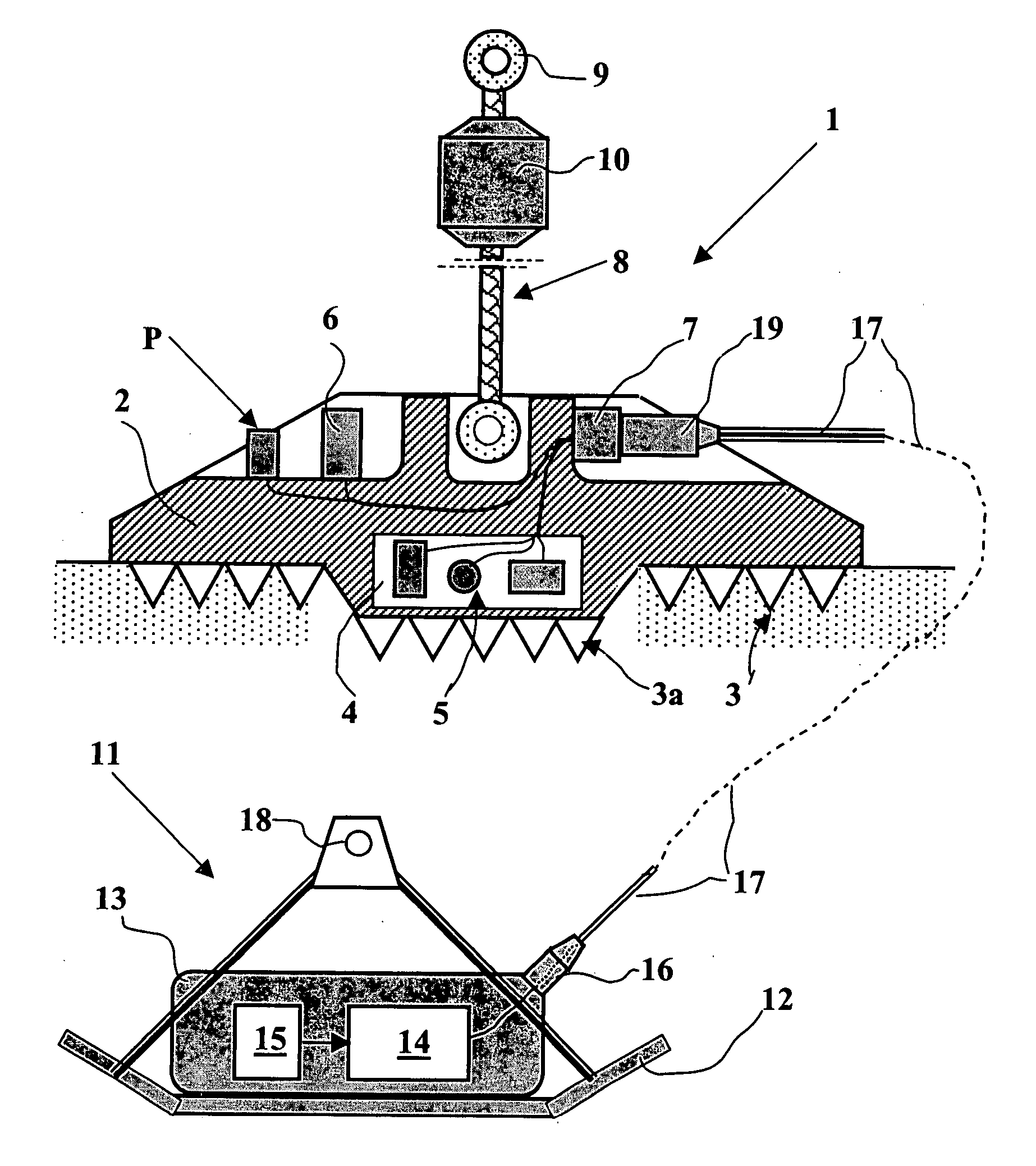

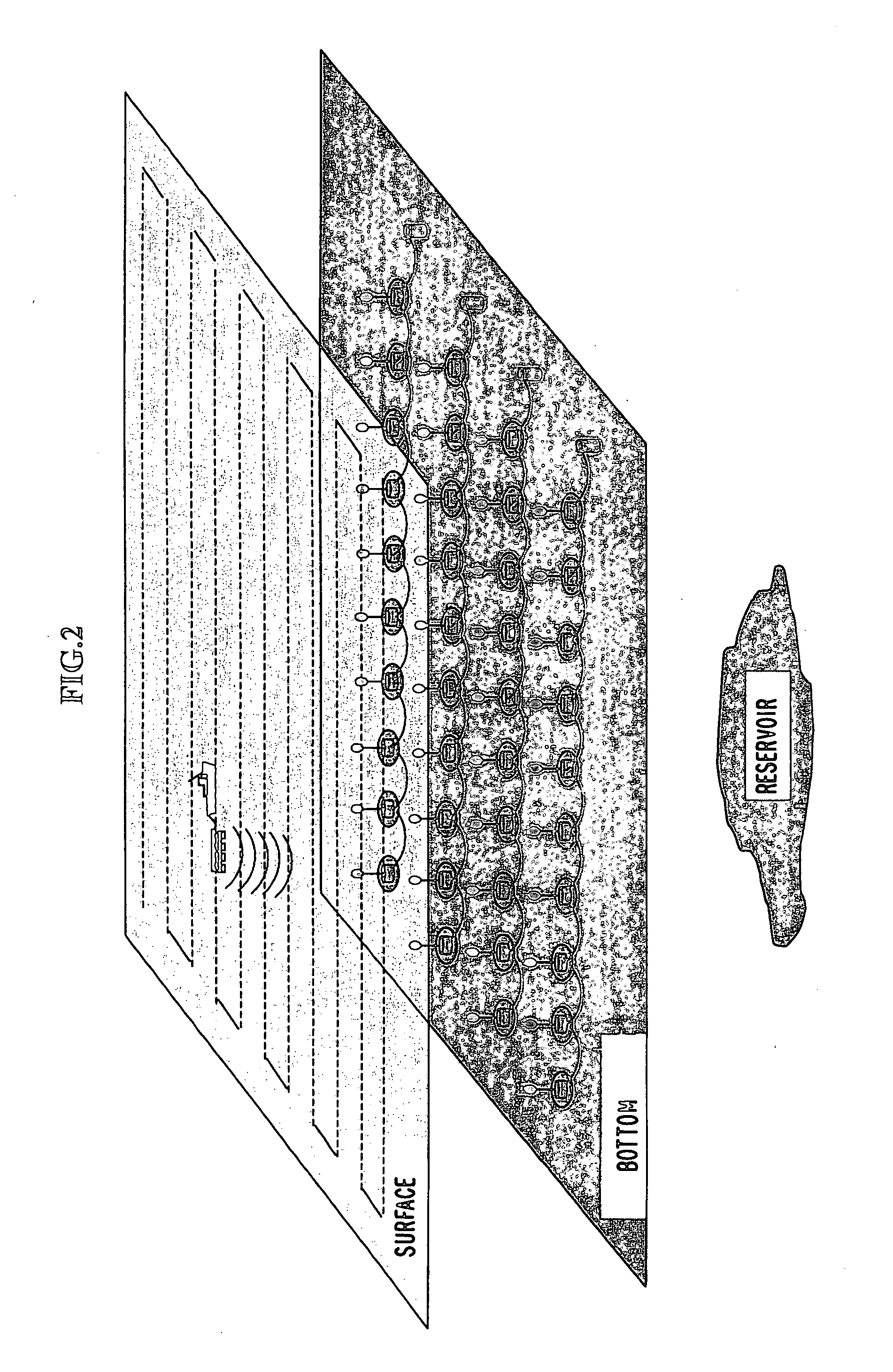

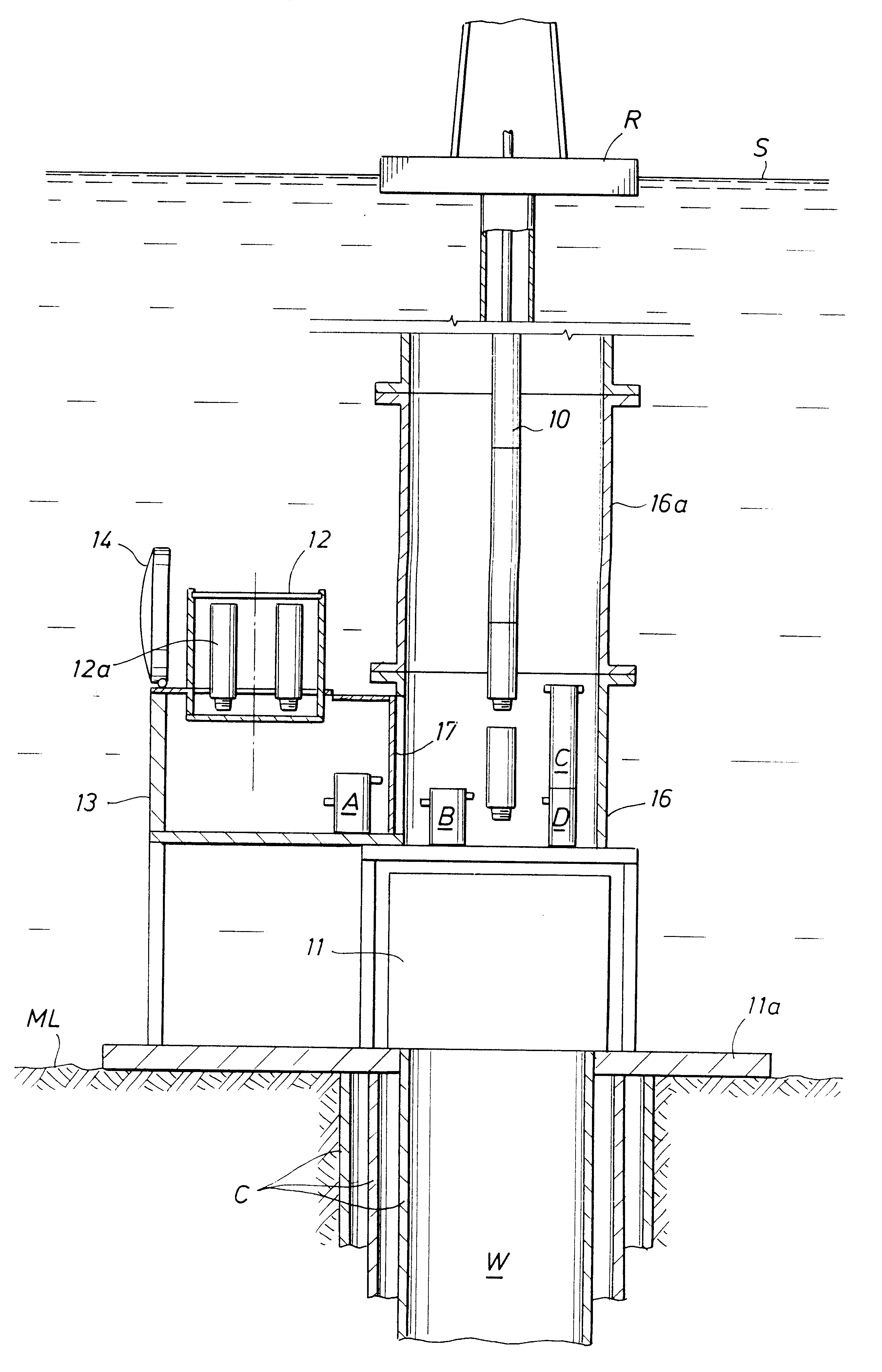

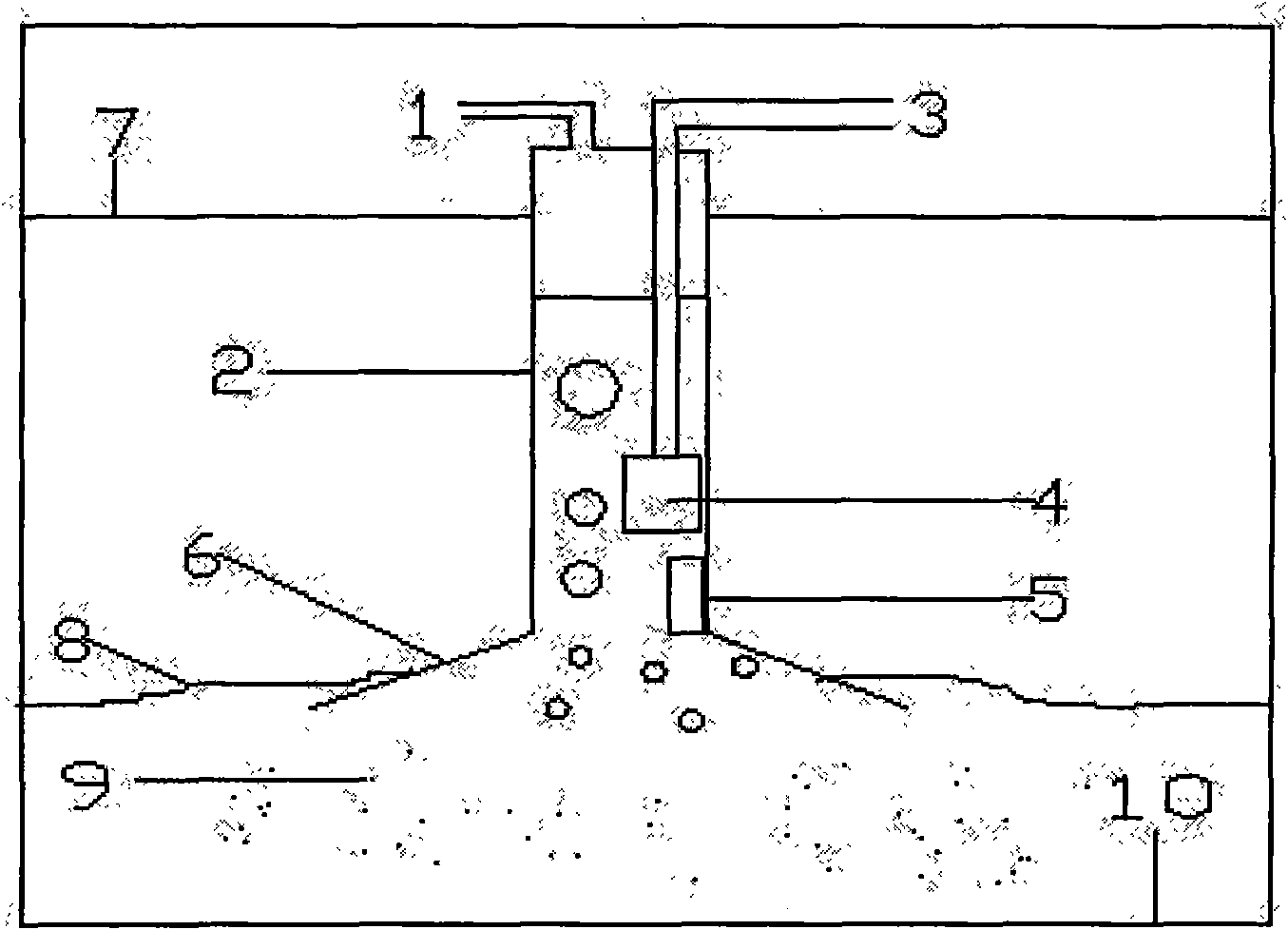

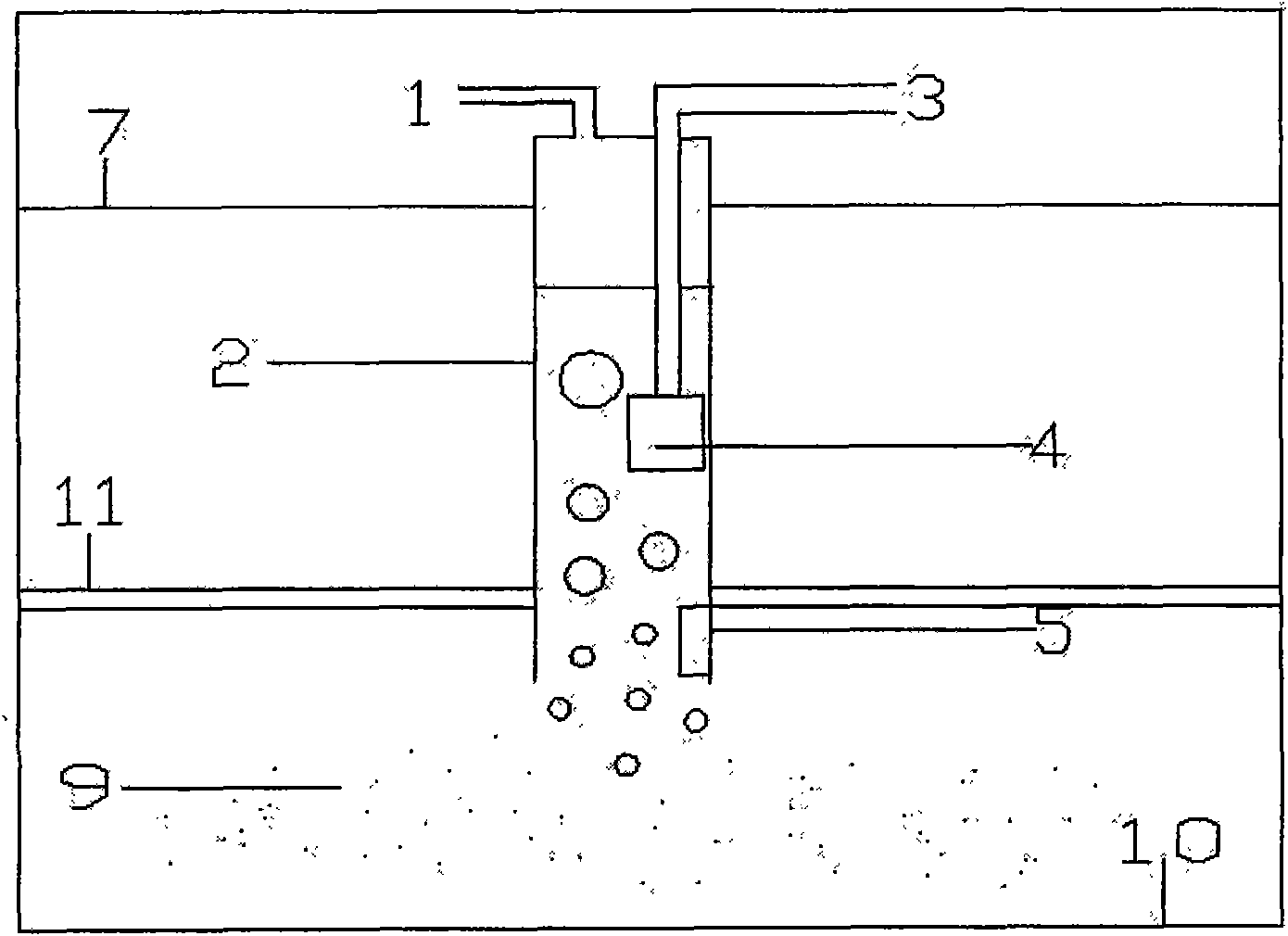

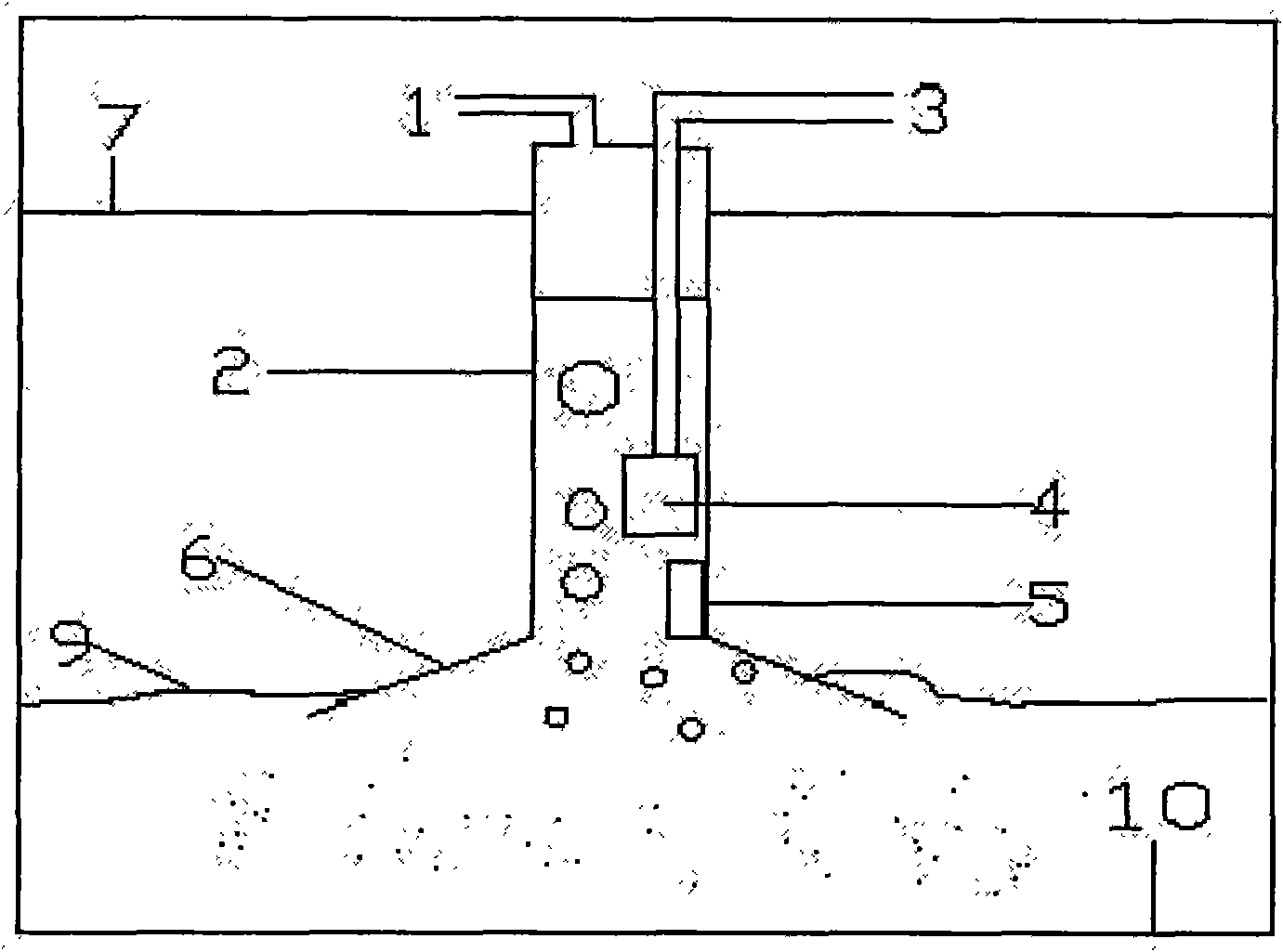

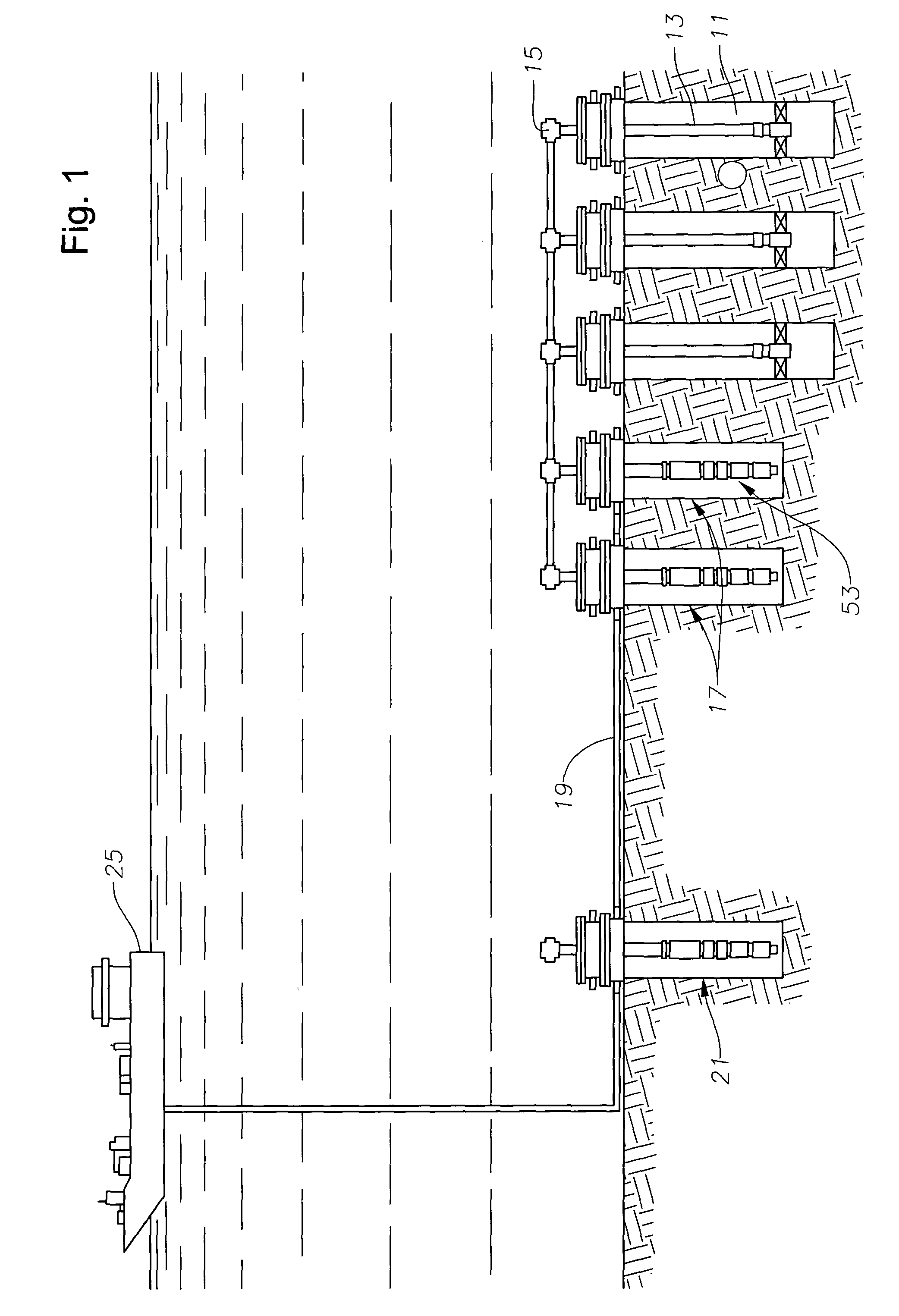

Acquisition method and device for seismic exploration of a geologic formation by permanent receivers set on the sea bottom

InactiveUS6932185B2Good flexibilityFine divisionSeismic energy generationSeismic signal receiversGeophoneHydrophone

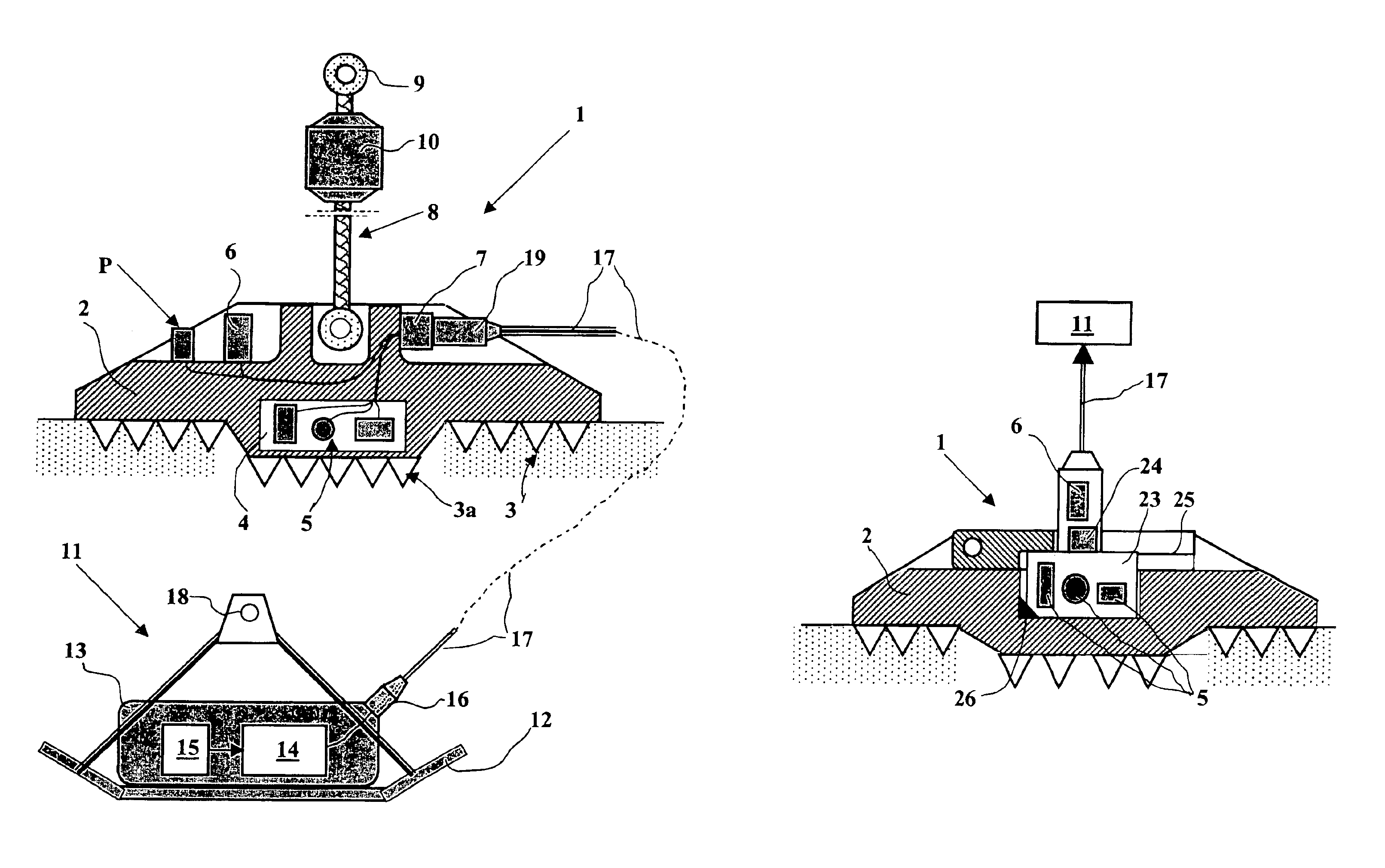

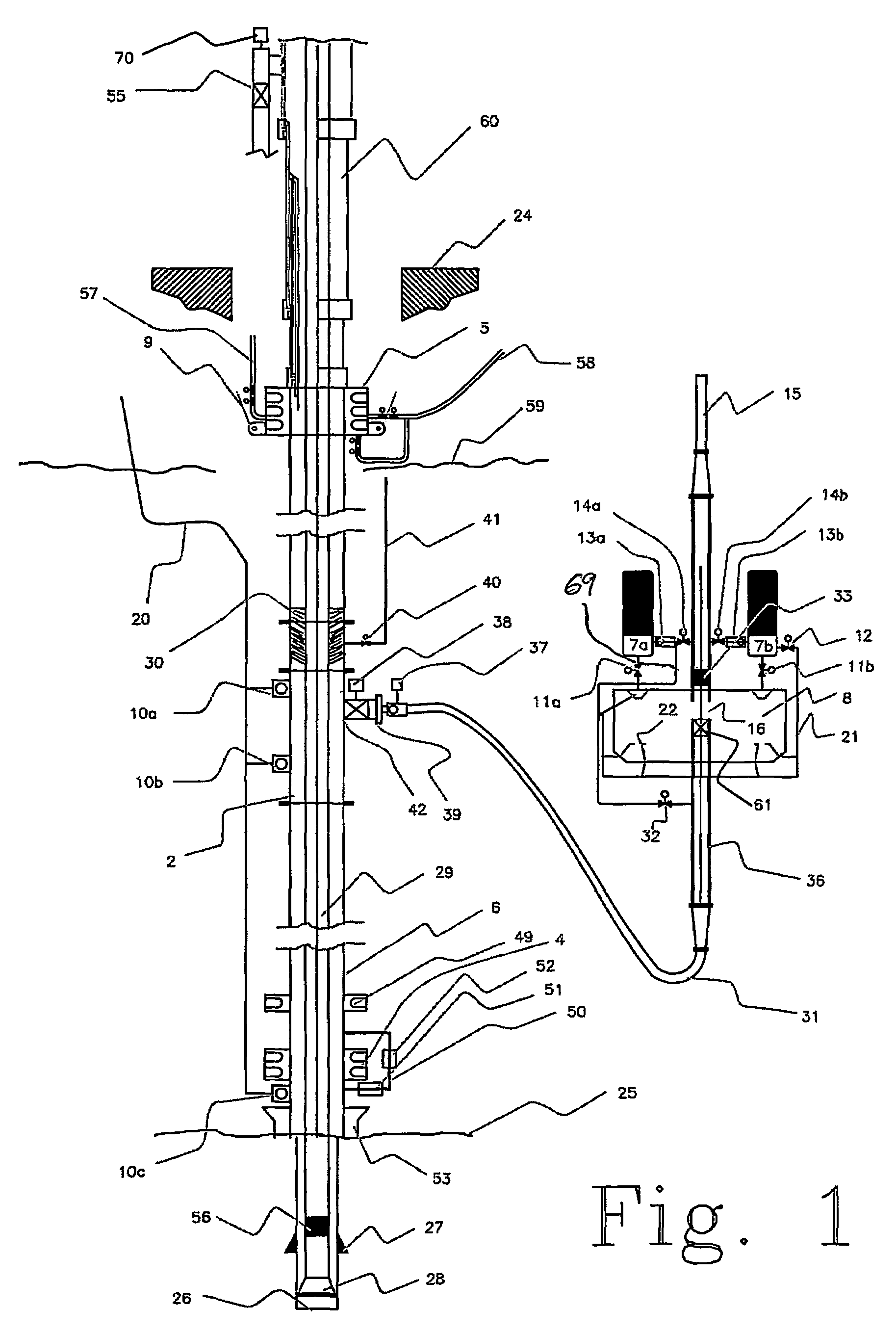

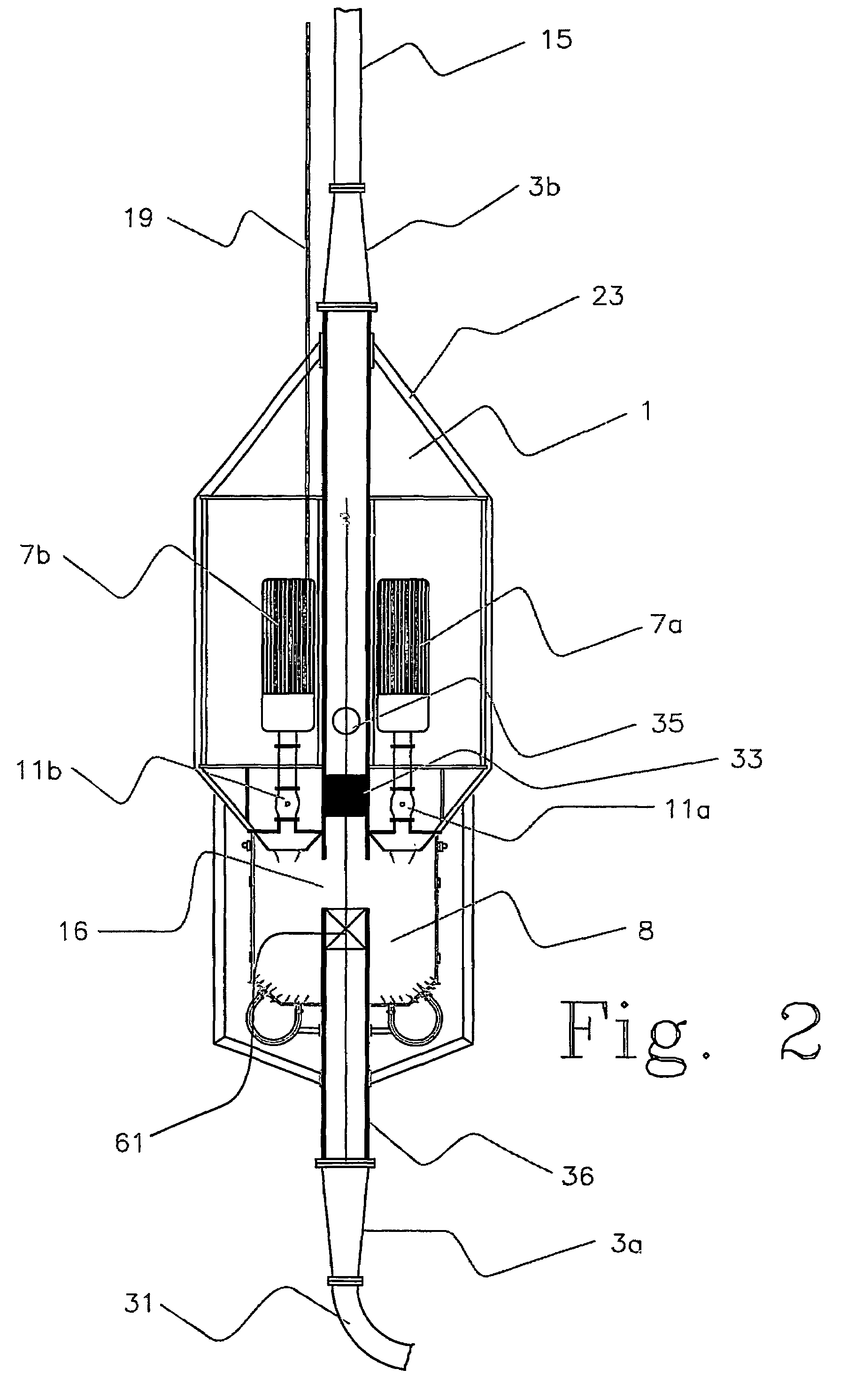

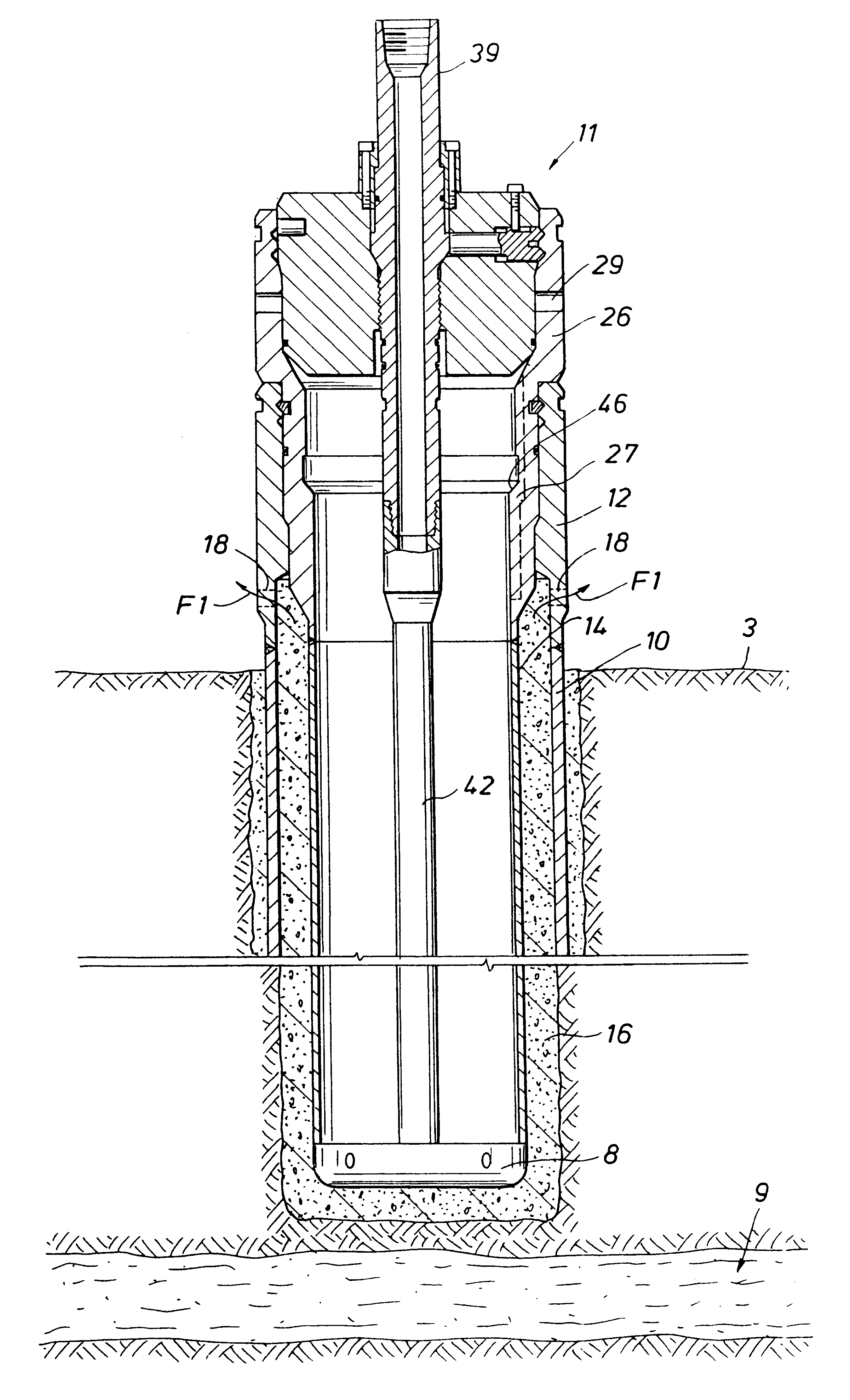

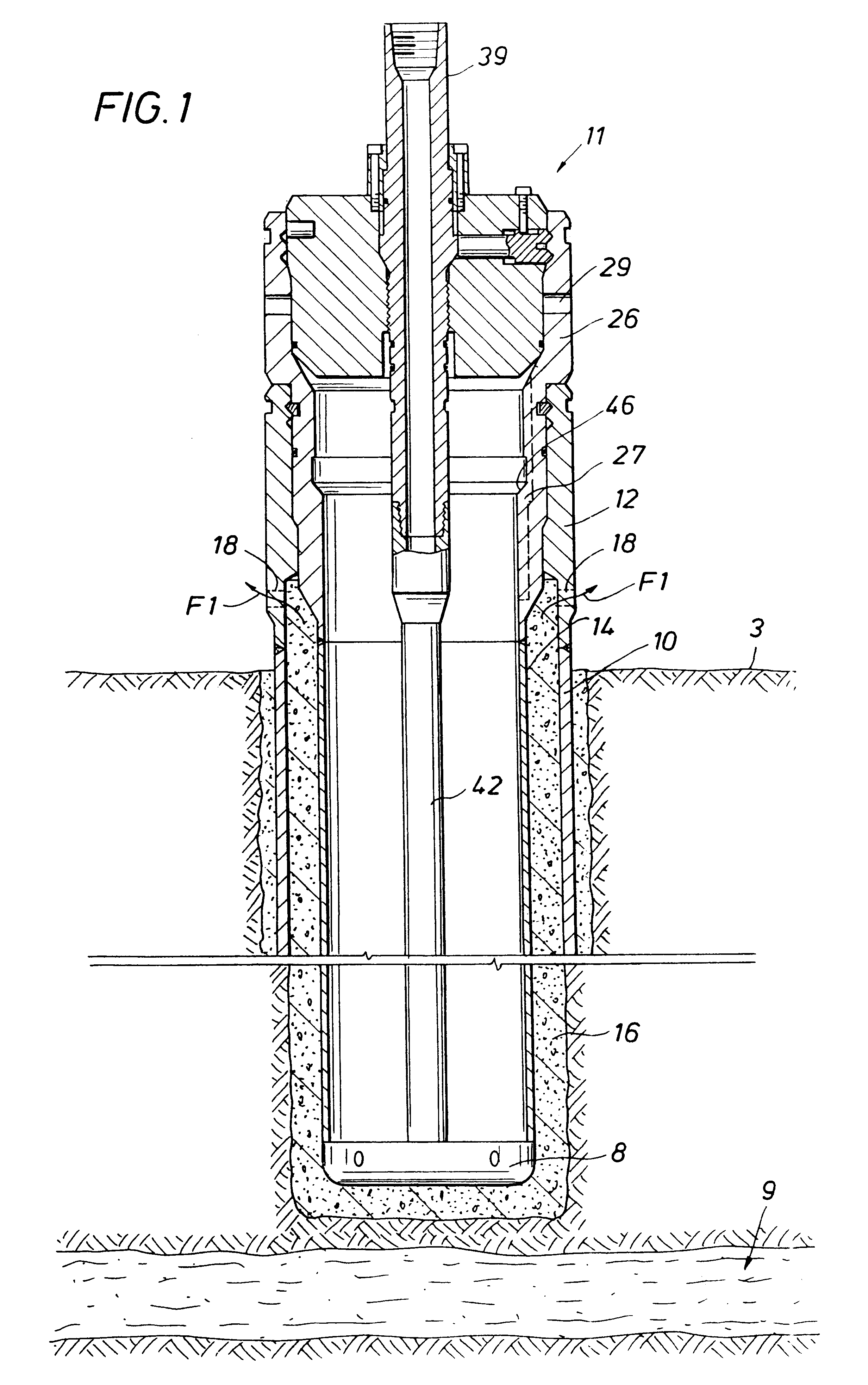

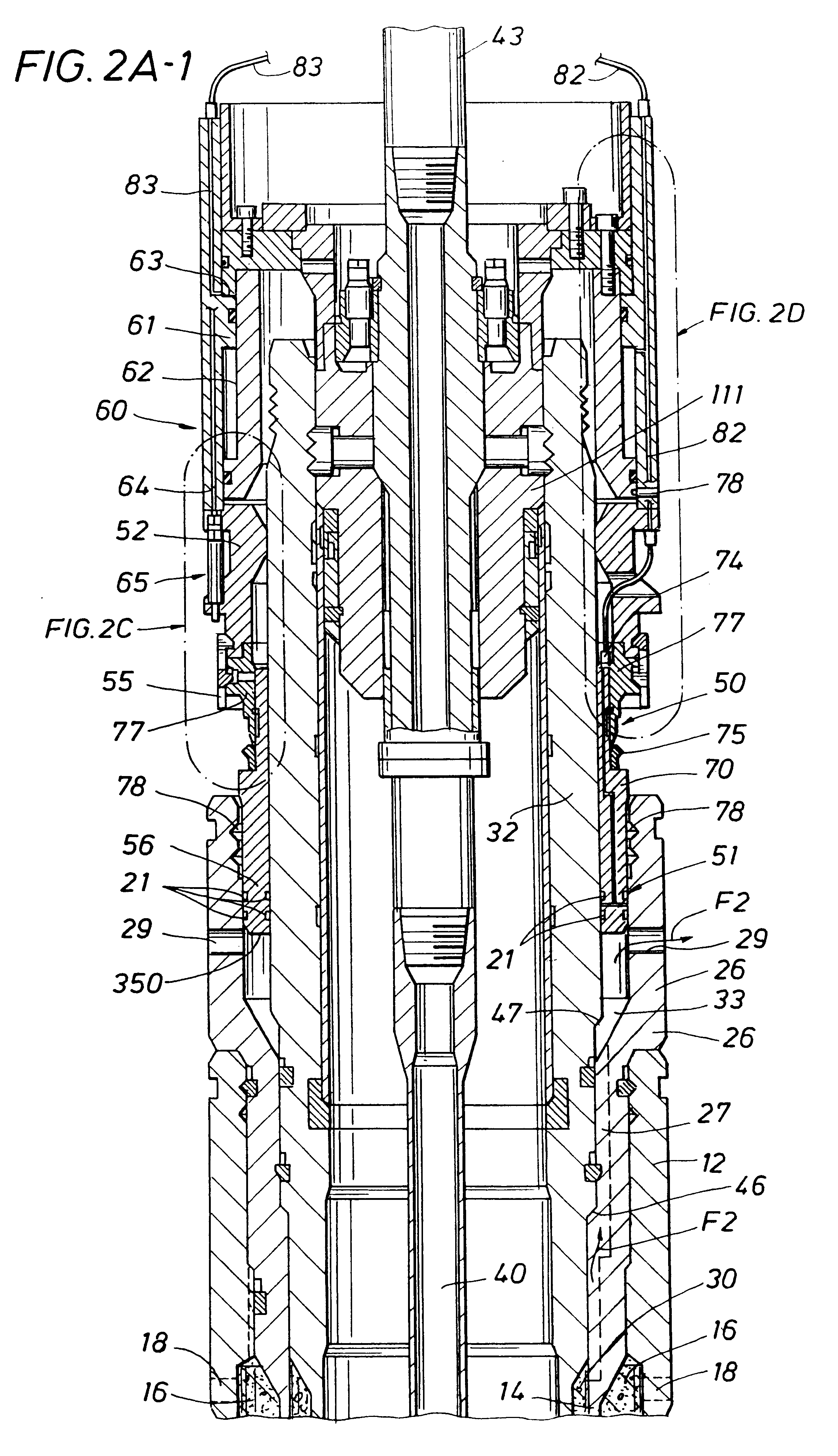

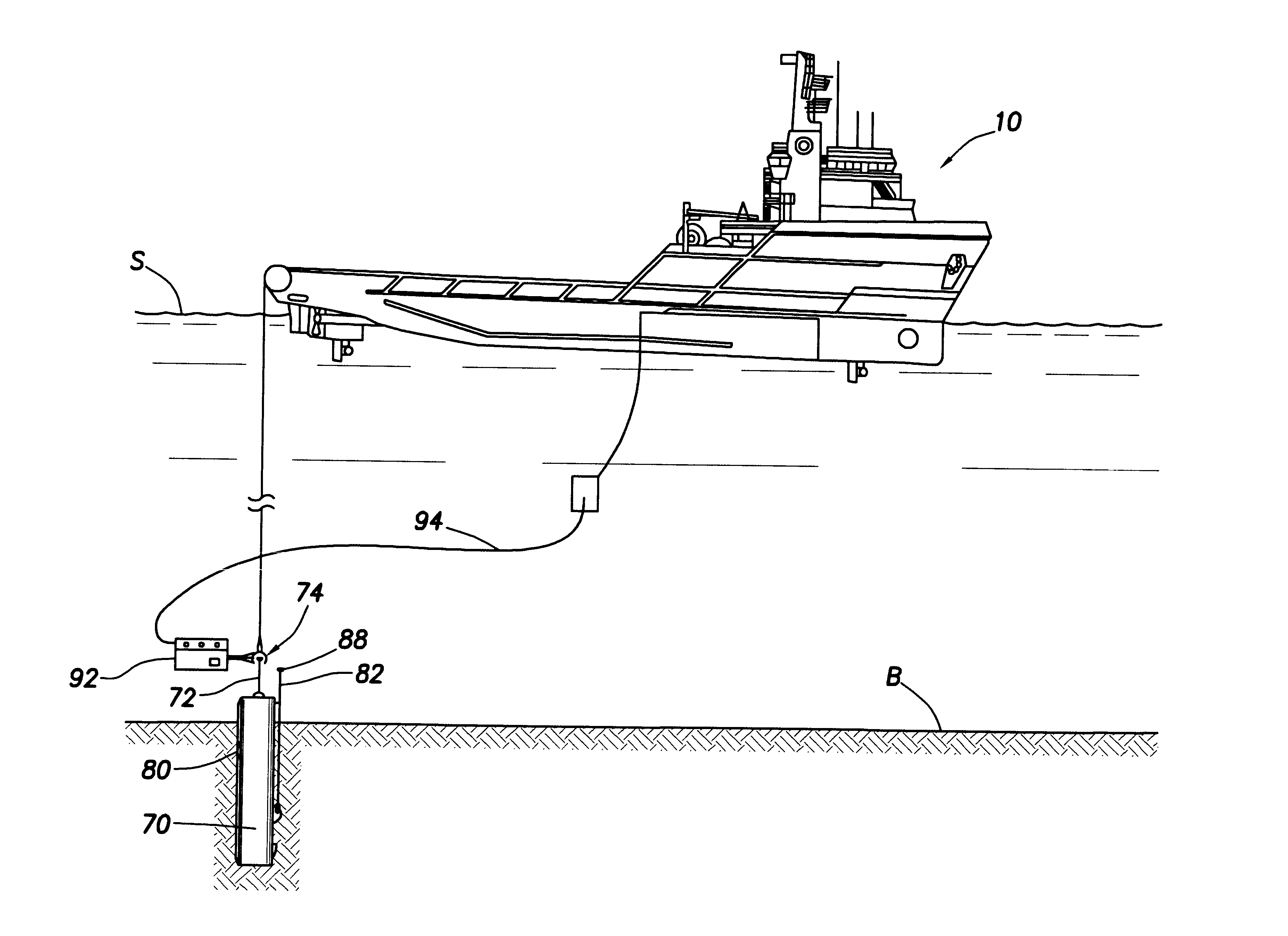

A method and device for seismic exploration of a subsea geologic formation by pickups set on the sea bottom and intermittently connectable to active data acquisition stations (11) brought nearby. Permanent passive reception stations (1) comprising a heavy pedestal provided with housings for seismic pickups (geophones (6), hydrophone (7) which receive acoustic or seismic signals from the underlying formation are arranged at the bottom of the water body. When collection sessions for the signals received by the pickups are scheduled, mobile active acquisition stations (11) connected to permanent passive reception stations (1) are positioned at the bottom of the water body. The signals picked up are then recorded, for the time required to carry out at least one session of acquisition and recording of the acoustic or seismic signals received by the passive stations in response to the emission of seismic waves by one or more seismic sources. The mobile active acquisition stations (11) are thereafter recovered at the surface and the records acquired by each one are transferred to a central collection laboratory.

Owner:INST FR DU PETROLE

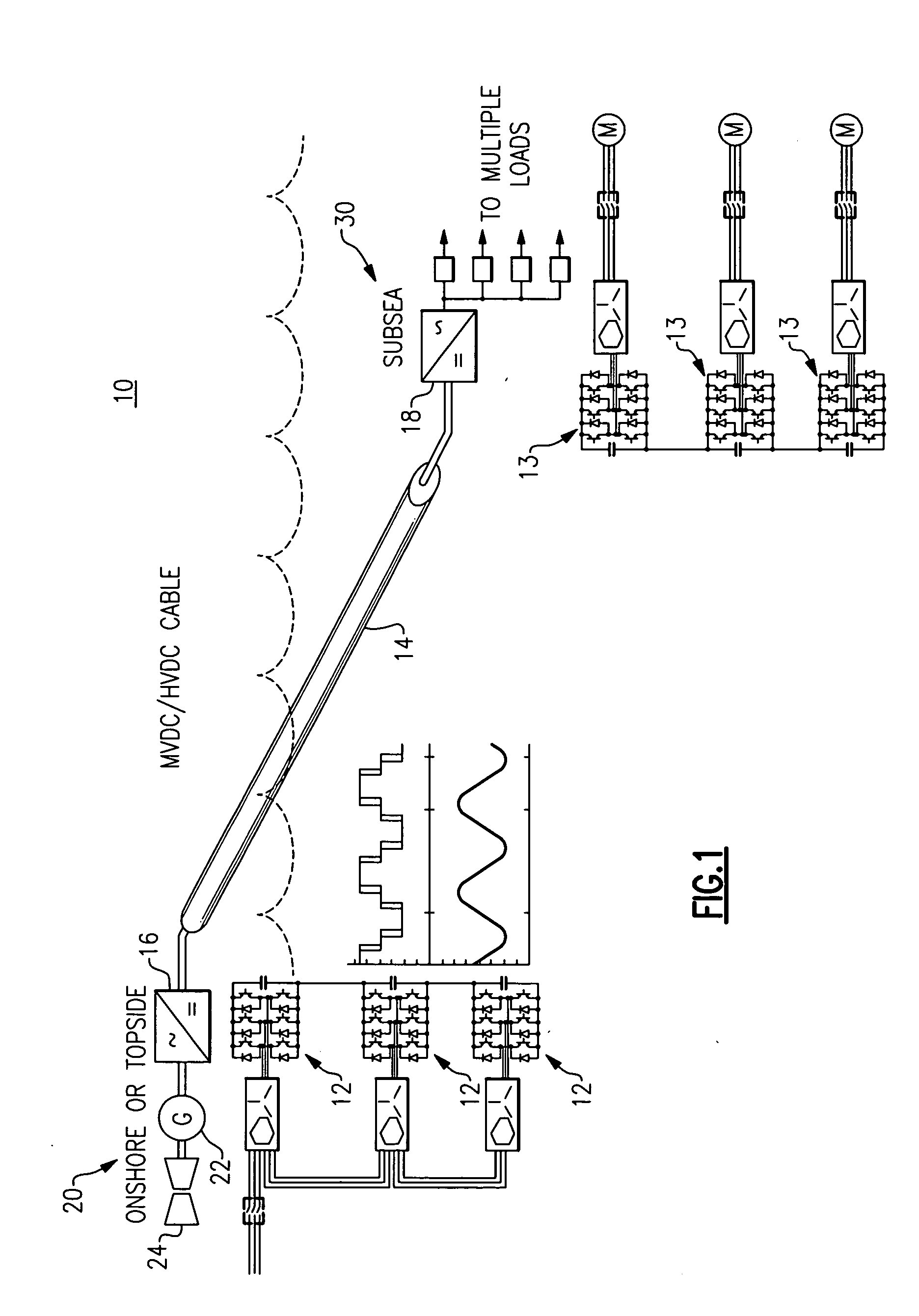

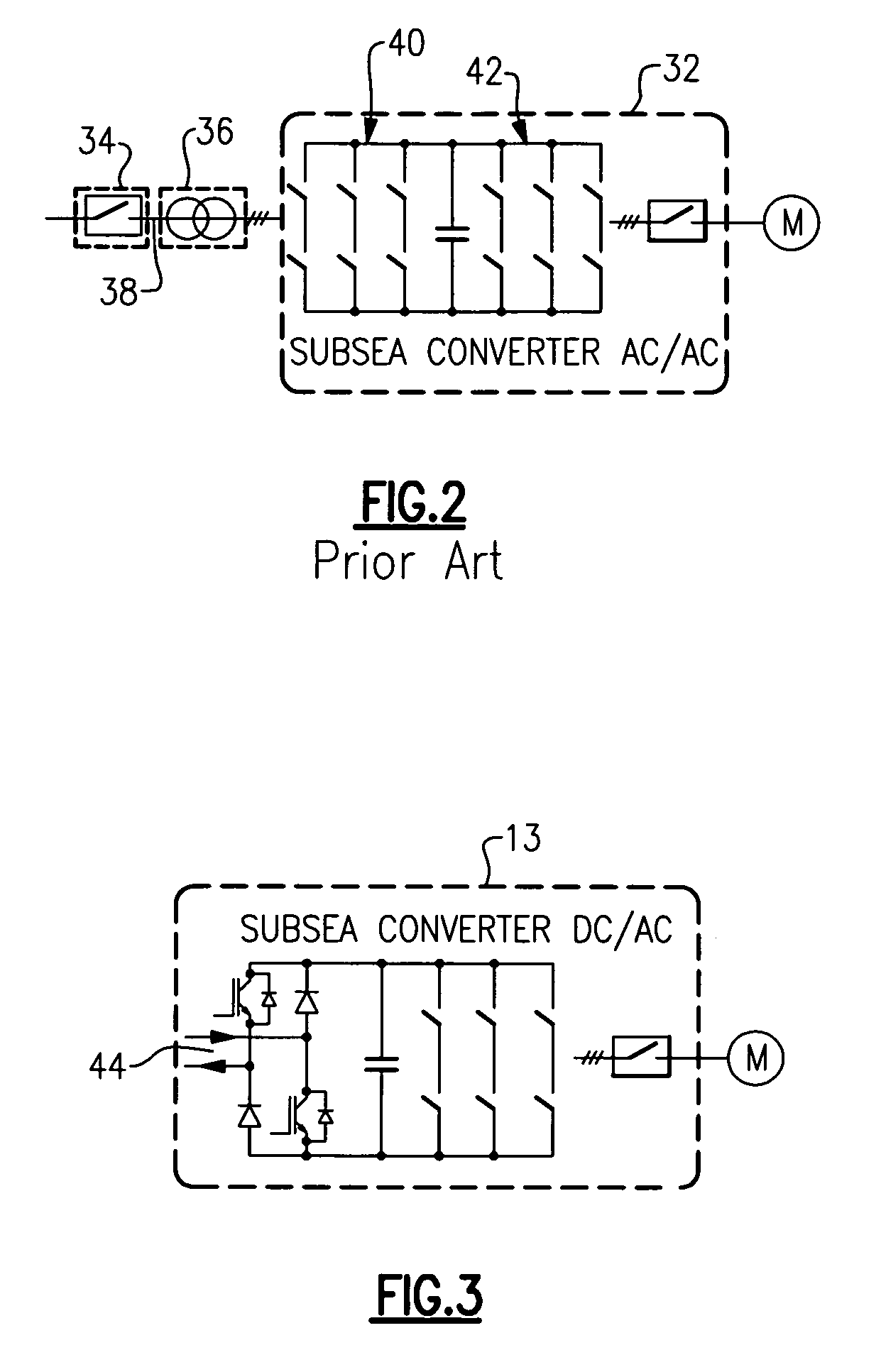

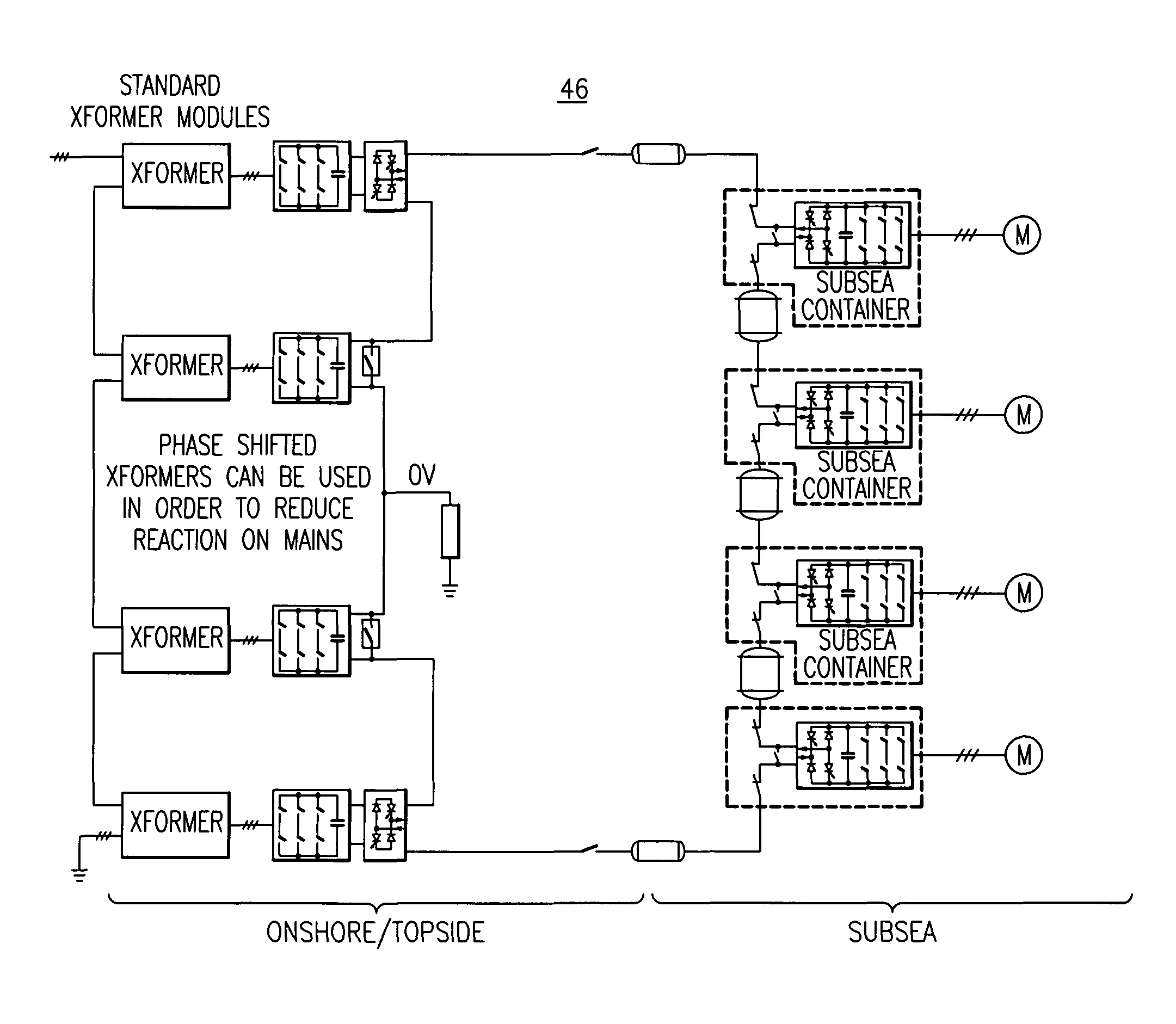

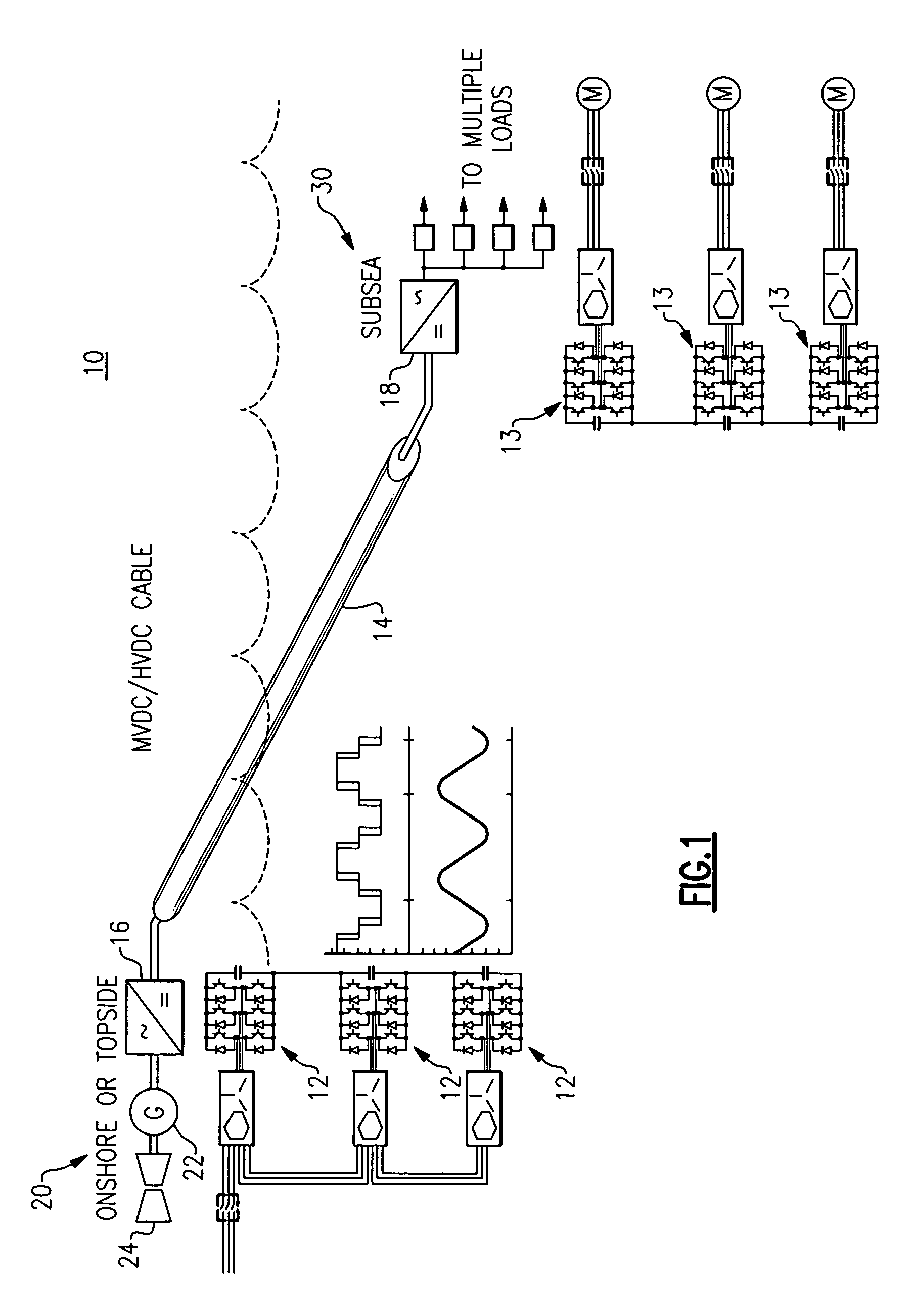

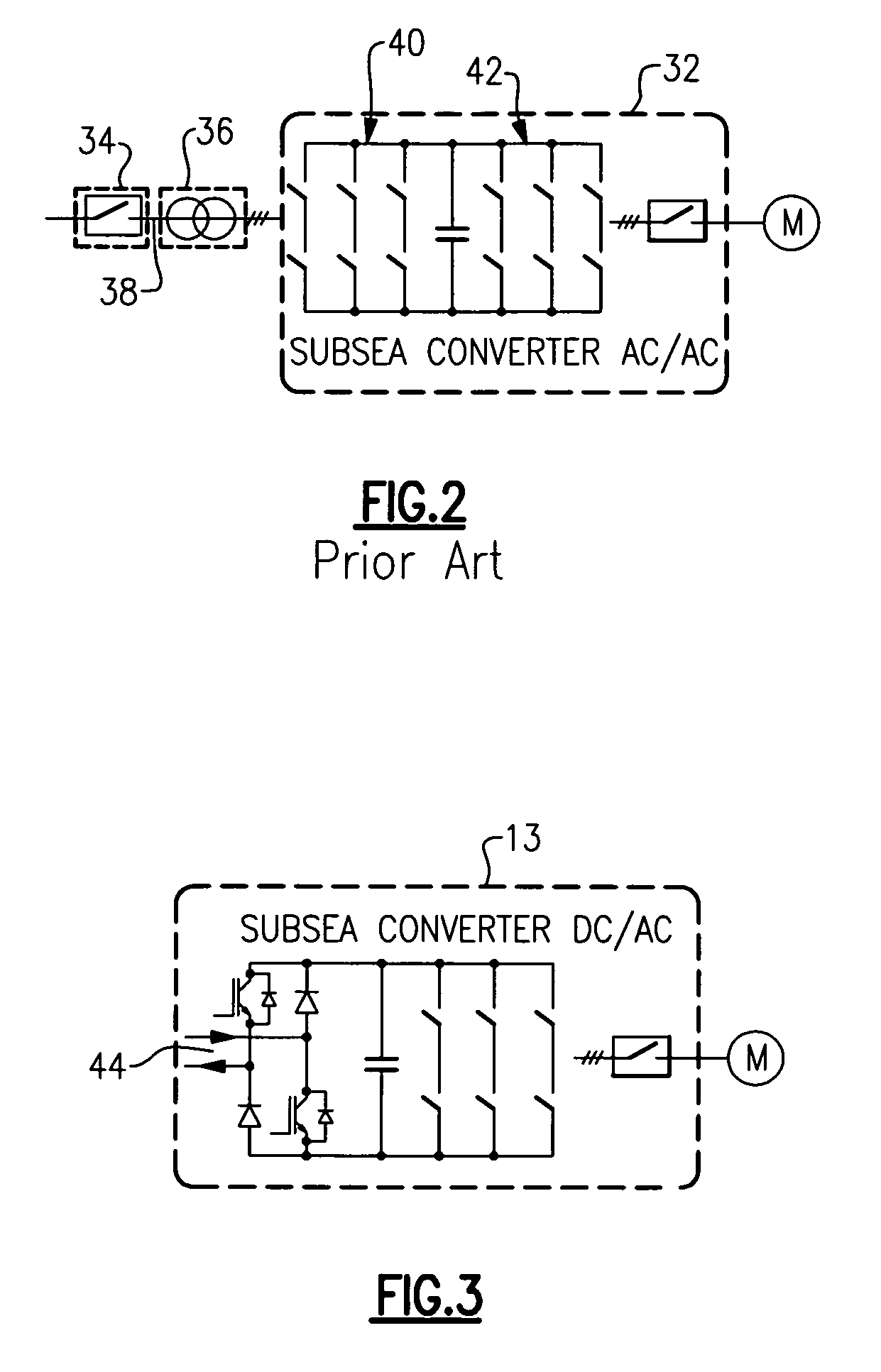

Modular stacked subsea power system architectures

InactiveUS20100133901A1Dc network circuit arrangementsAc-dc conversion without reversalModularityShore

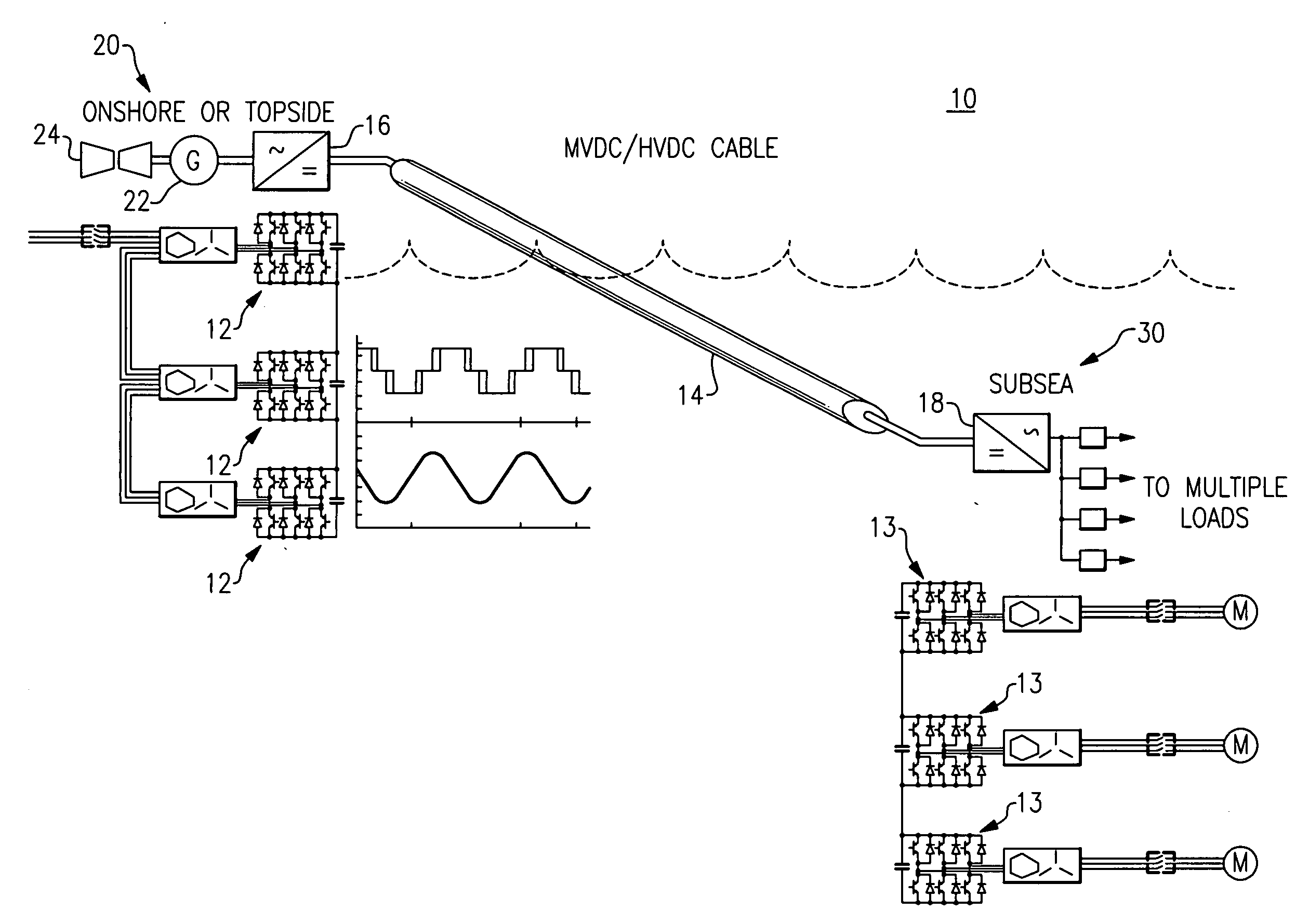

A sub-sea power delivery system includes a plurality of modular power converter building blocks on each of the power source side and the sub-sea load side that are stacked and interconnected to meet site expansion requirements and electrical load topologies. The power delivery system comprises a system DC transmission link / bus, wherein the system DC link is configured to carry HVDC or MVDC power from an onshore utility or topside power source to multiple sub-sea load modules. The stacked modular power converter topology on the sub-sea side of the sub-sea power delivery system is symmetrical with the stacked modular power converter topology on the on-shore / top-side of the sub-sea power delivery system.

Owner:GENERAL ELECTRIC CO

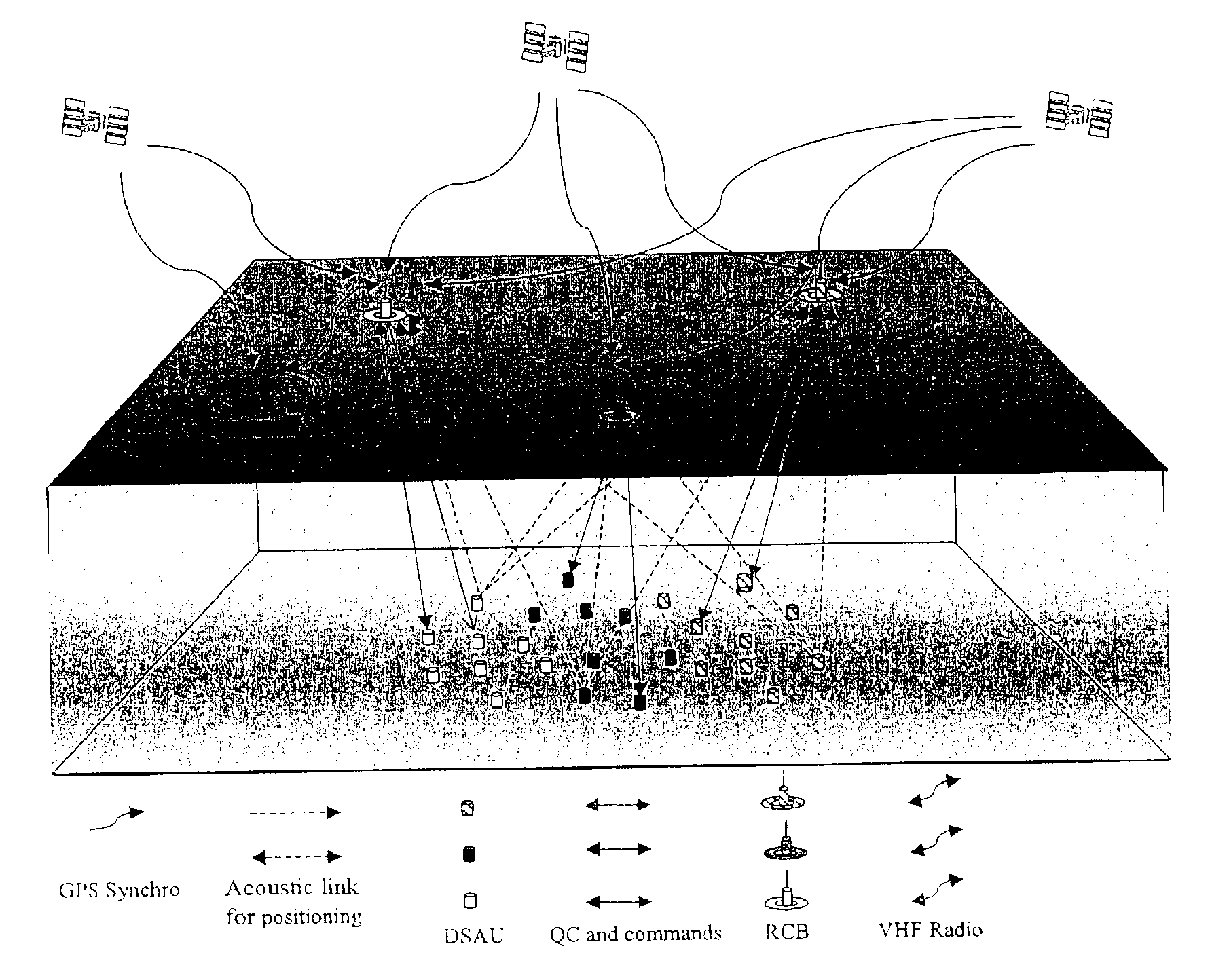

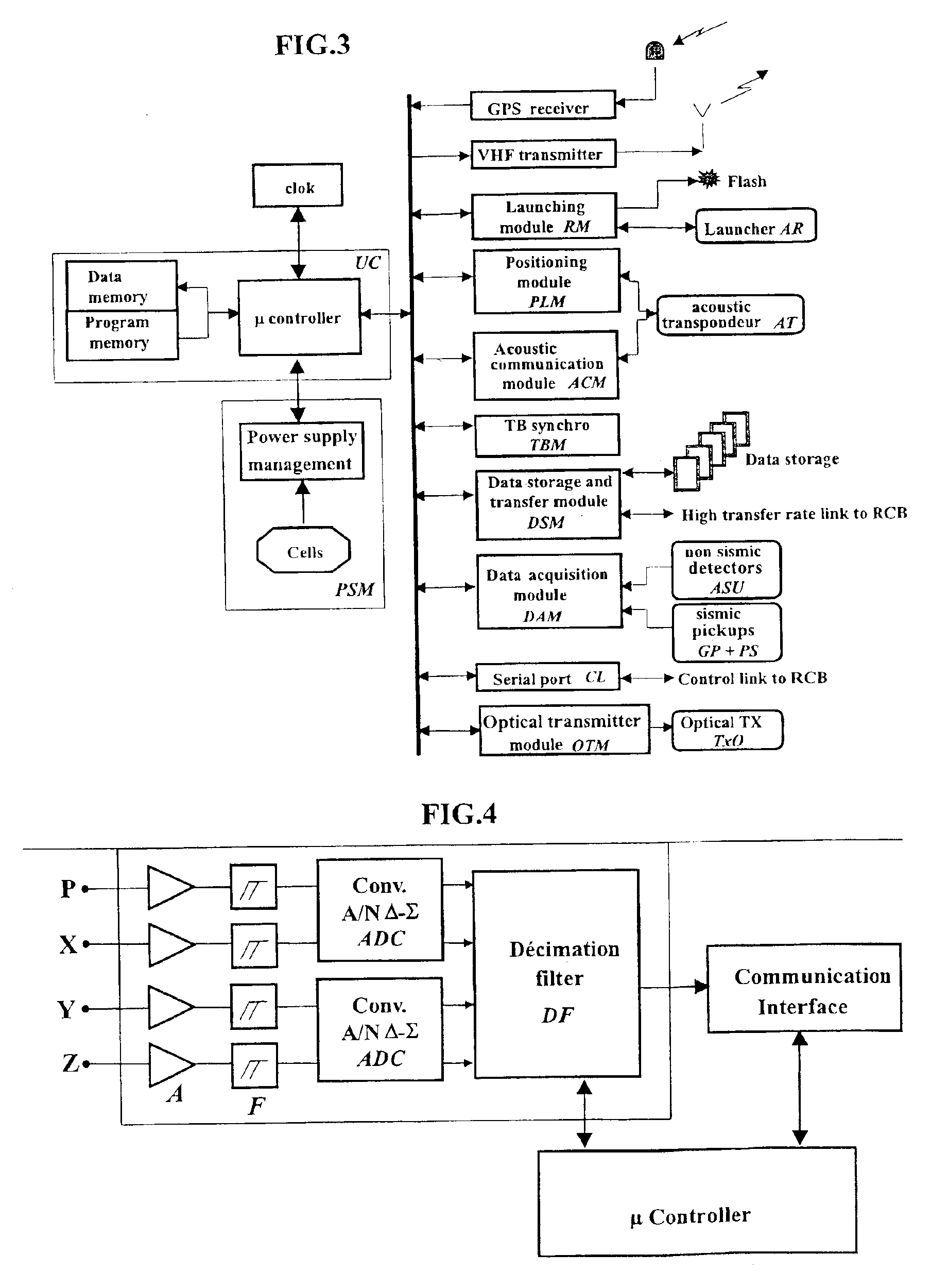

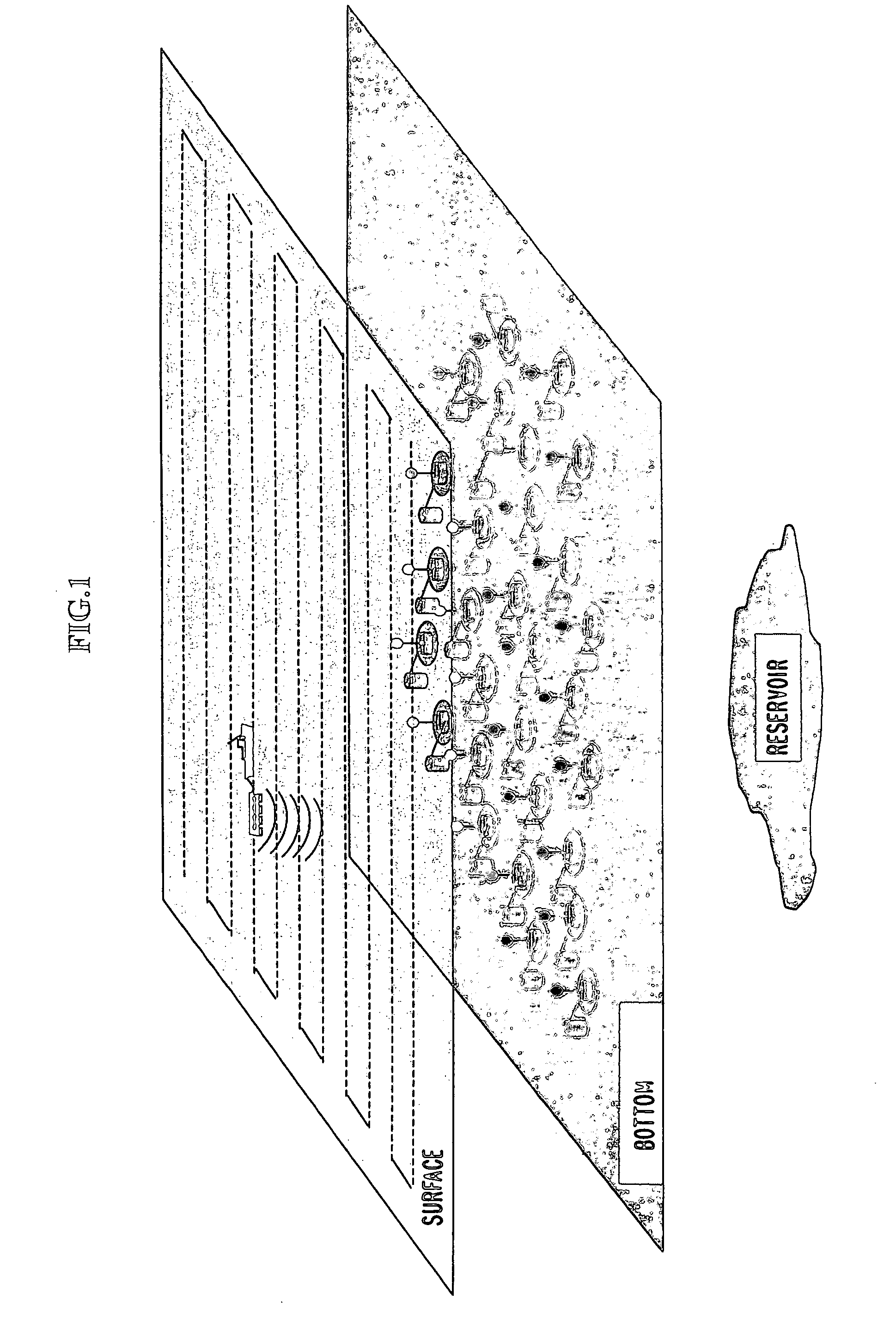

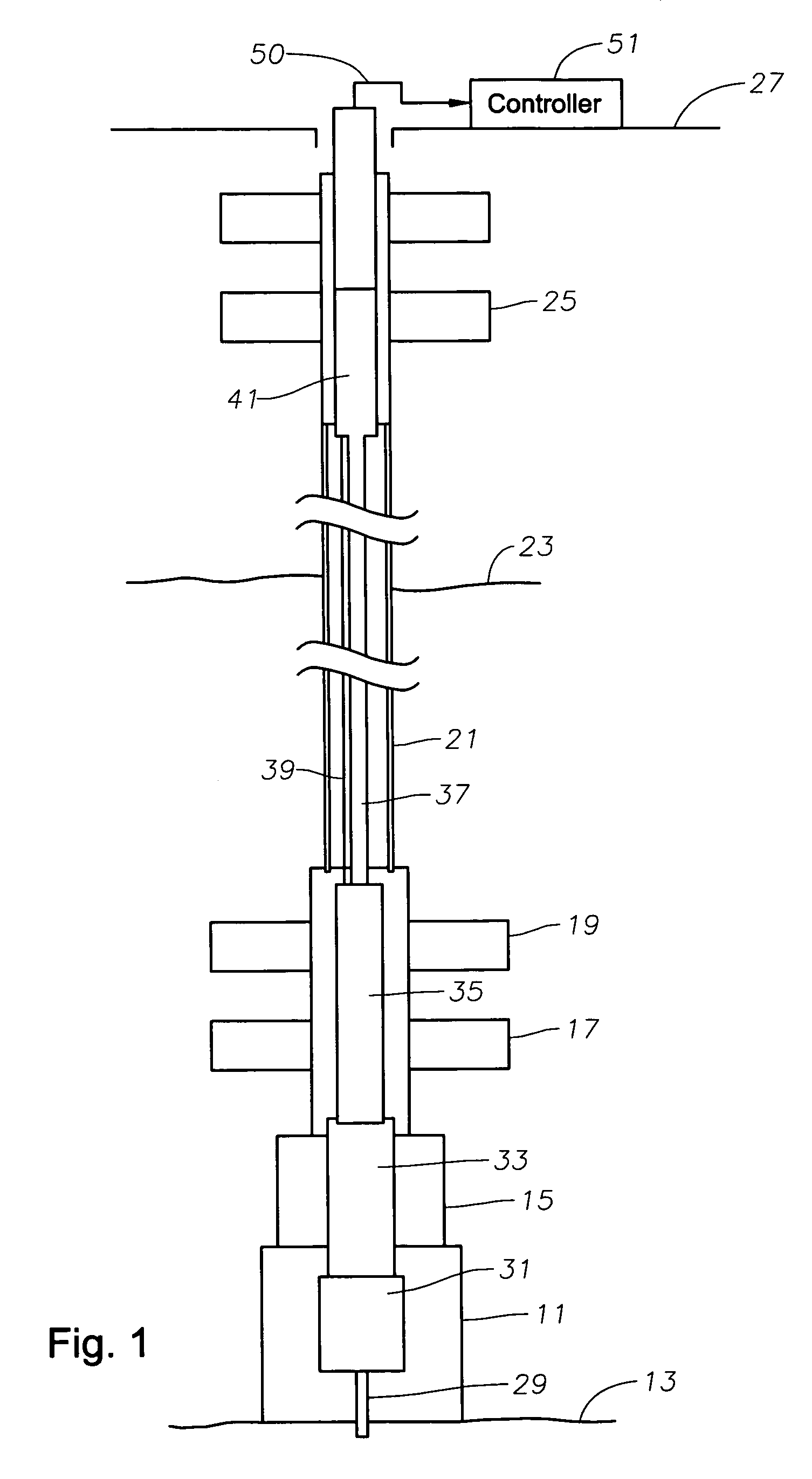

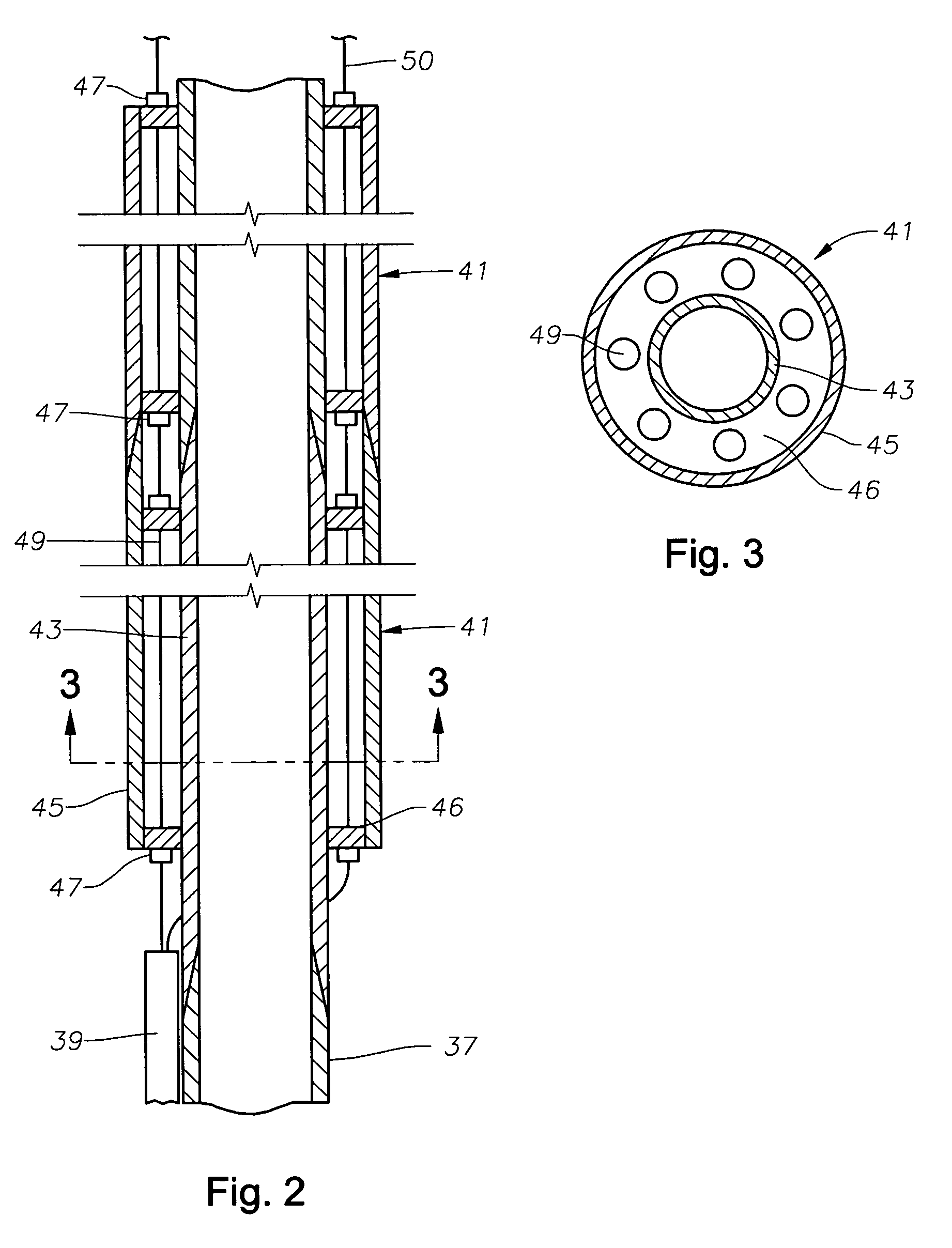

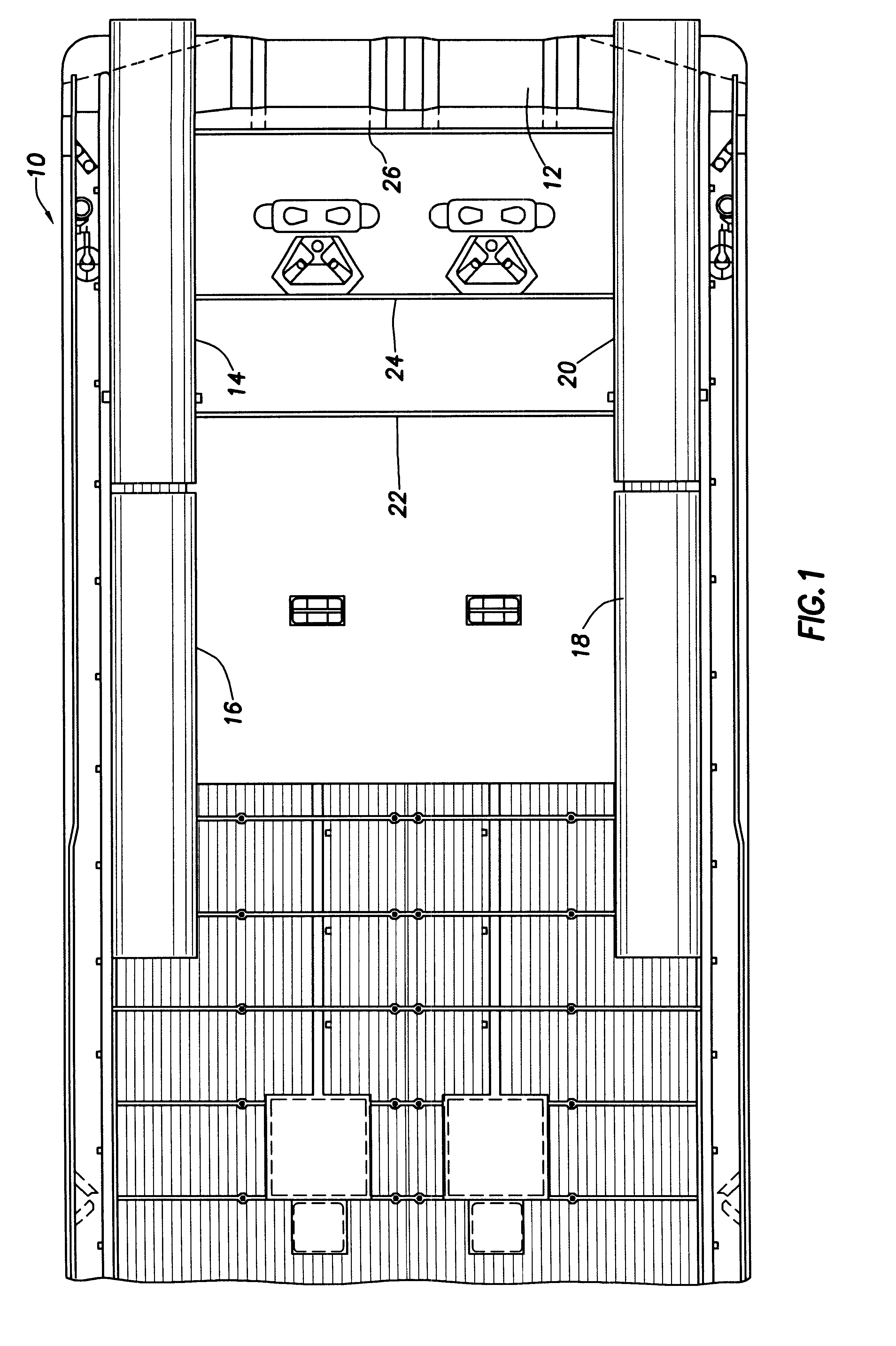

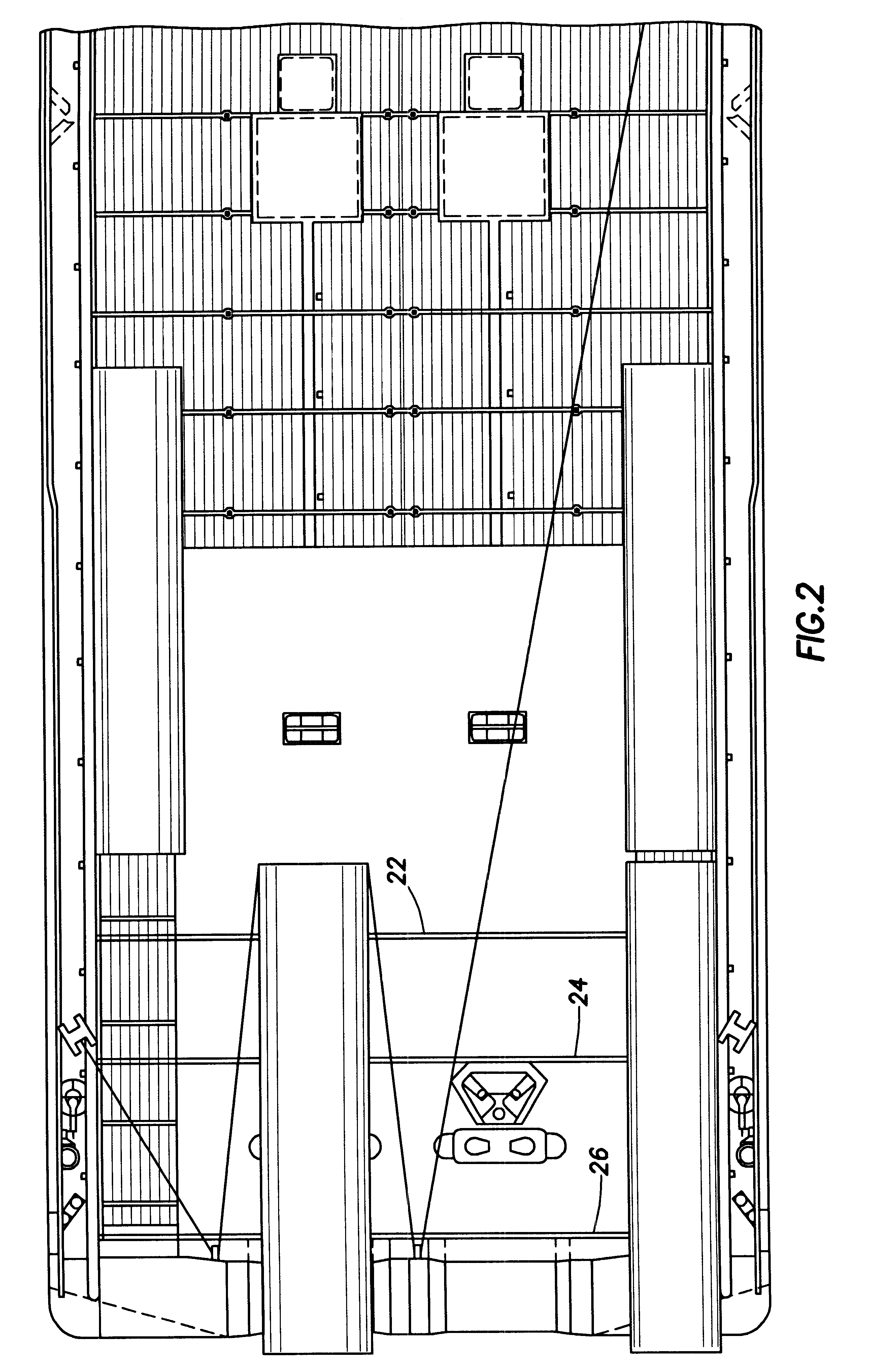

Seismic data acquisition system using acquisition stations set on the sea bottom

InactiveUS7016260B2Good synchronizationTelemetry/telecontrol selection arrangementsTransmission systemsSystems designData acquisition

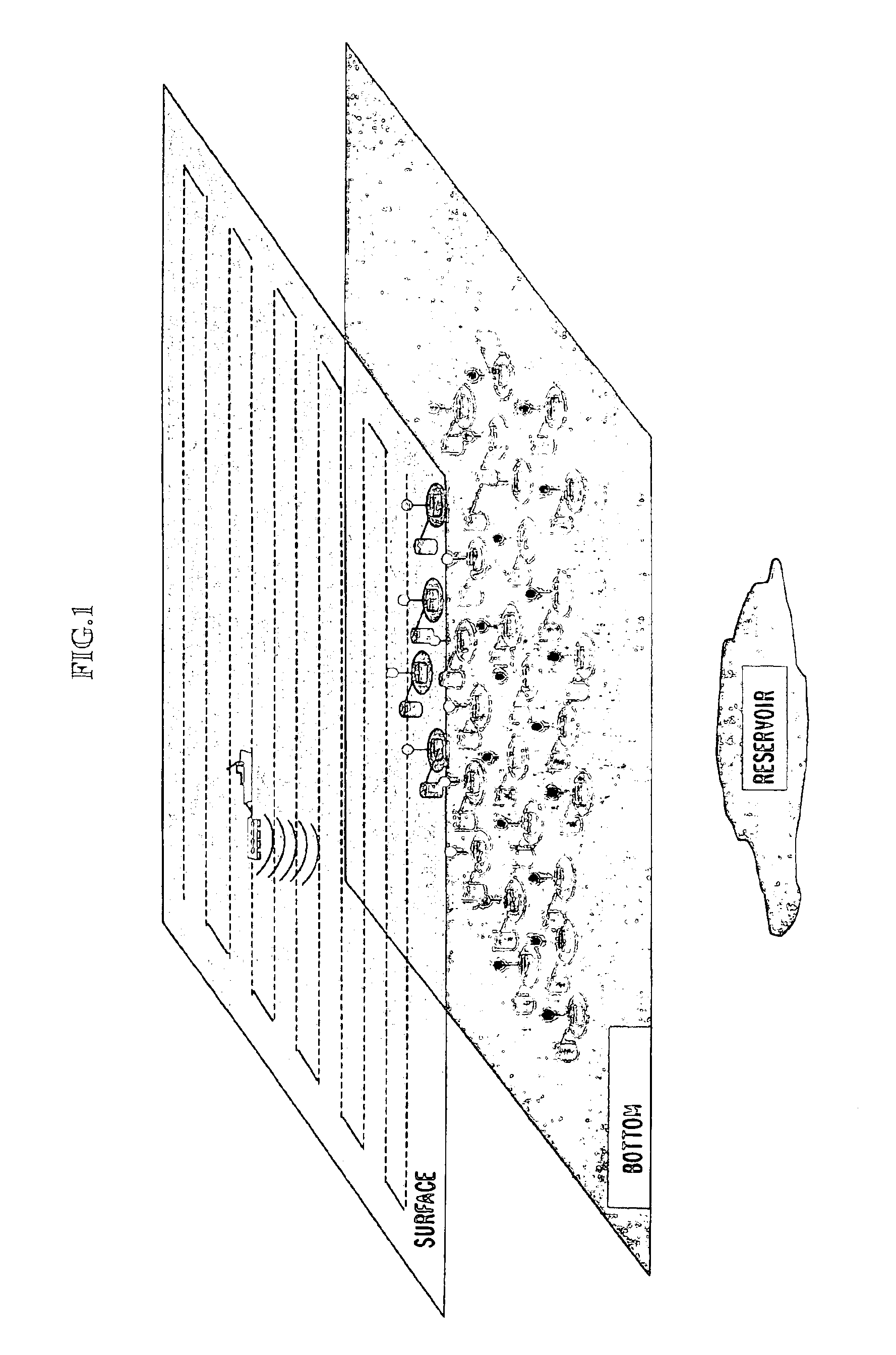

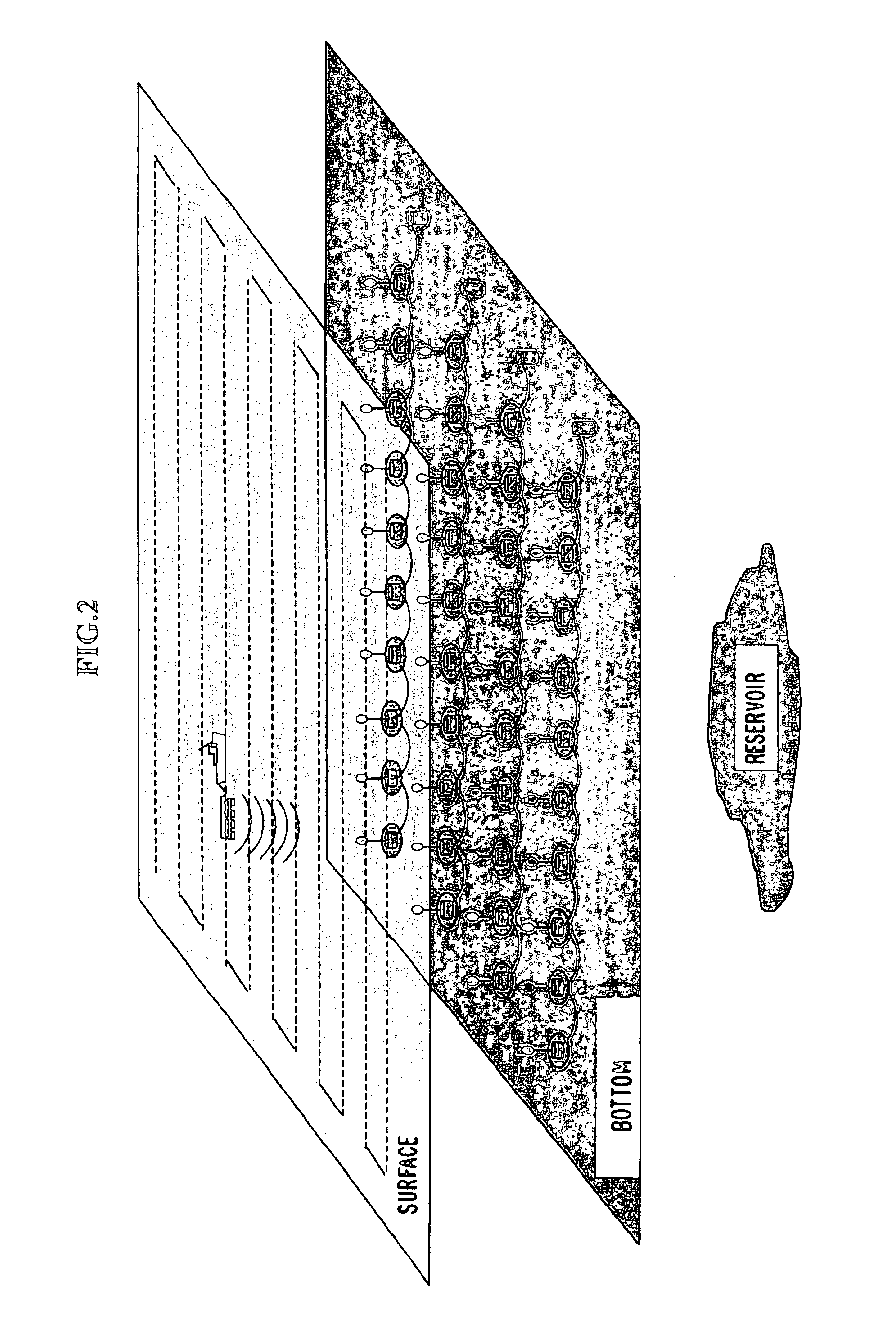

The invention is a system designed for acquisition of seismic data by means of acquisition stations set on water bottom of a water body. The system comprises acquisition stations (DSAU) combining a streamlined boom suited to penetrate the bottom and thus couple seismic receivers with the underlying formation, a sealed body for electronic data acquisition and communication modules. These acquisition stations (DSAU) are placed in the water and drop to the bottom under the effect of gravity. Relay buoys (RCB) are positioned at the surface, each with a GPS positioning module, a radio link with a central station (CCRU), on a ship for example, and modules providing acoustic communication with bottom acquisition stations (DSAU), which are used to determine the position of the stations in relation to the relay buoys and to exchange control data and seismic data (good running order data or possibly seismic traces acquired if the conditions lend themselves thereto) to provide seismic prospecting or monitoring of an underground formation.

Owner:INST FR DU PETROLE

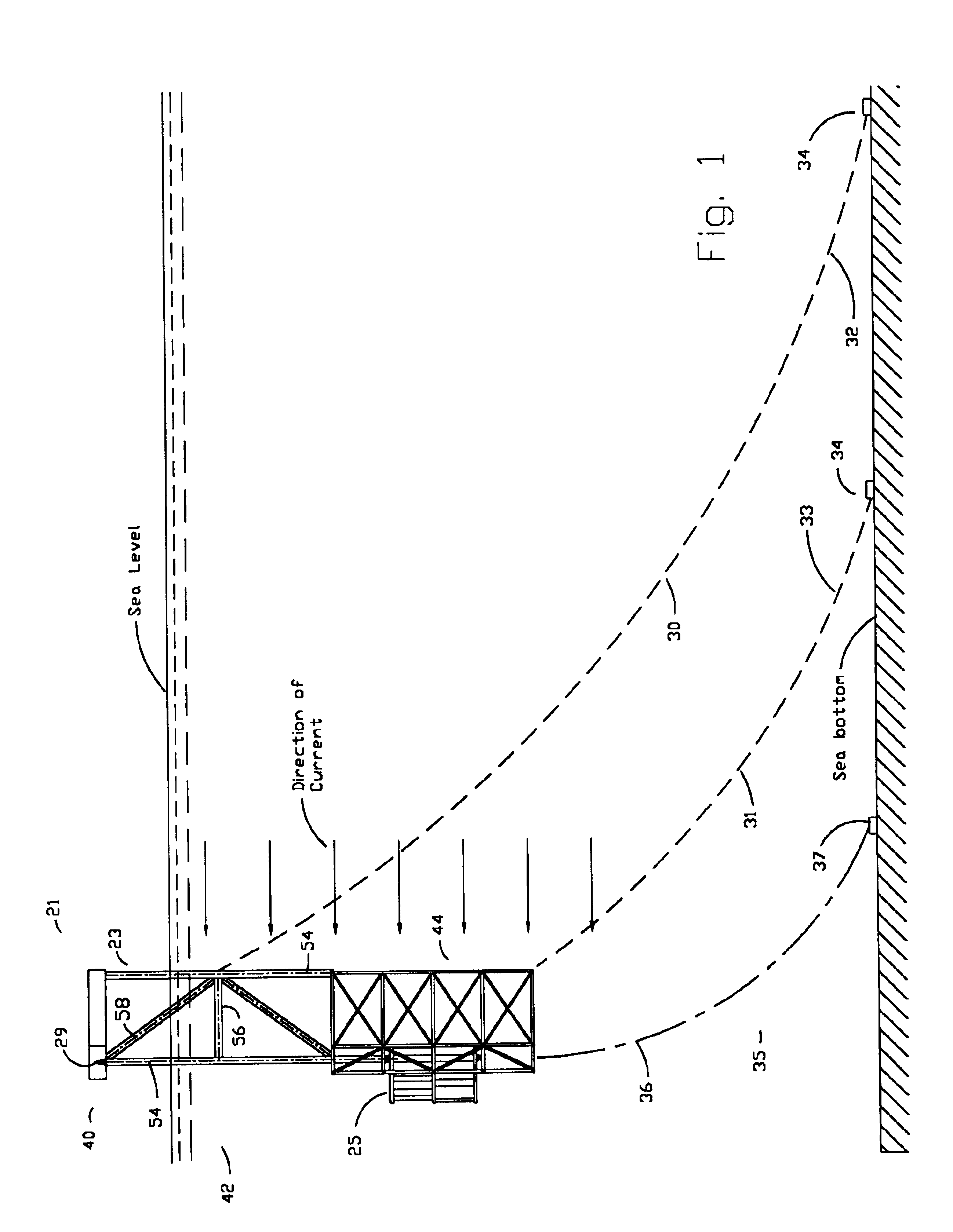

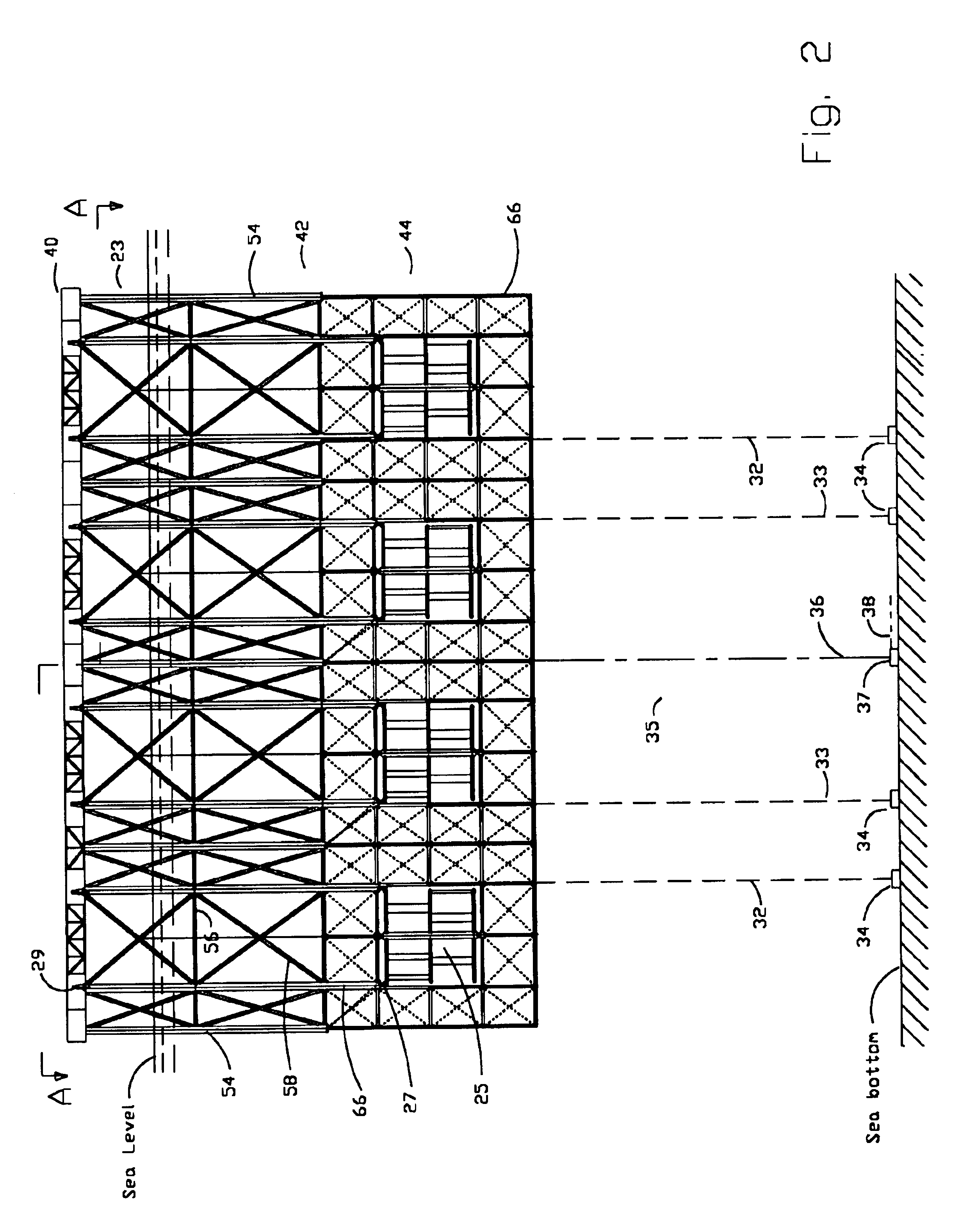

Installation for harvesting ocean currents (IHOC)

Installation for harvesting kinetic energy of ocean currents in deepwaters is based on utilization of a semisubmersible platform and the multiple of vertically oriented Darrieus type hydraulic turbines with funnels. The turbines are located bellow sea level on distance sufficient to exclude them from being affected by wave actions. The electric power generators are located on a structure above water and transmit electric power to the shore utilizing flexible cable from semisubmersible to the sea bottom and underwater cable going to the shore, where it connected to the power distributing network. One of the Embodiments of this invention is designed to harvest energy of tides in deepwaters.

Owner:BELINSKY SIDNEY IRVING

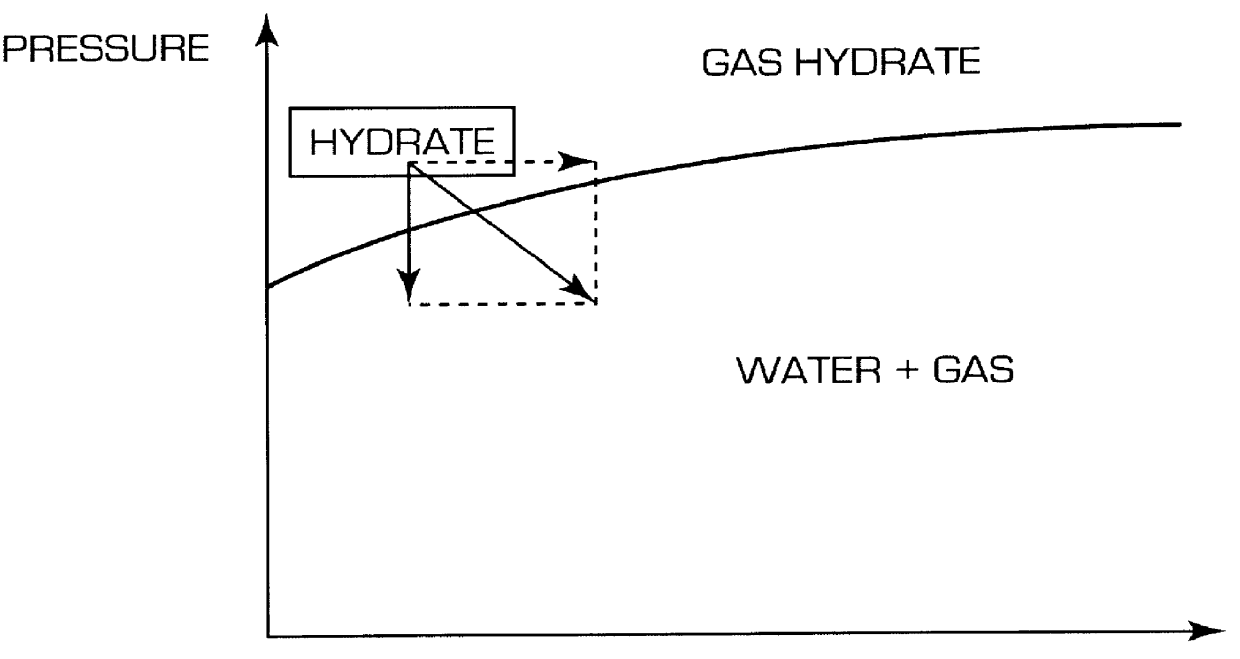

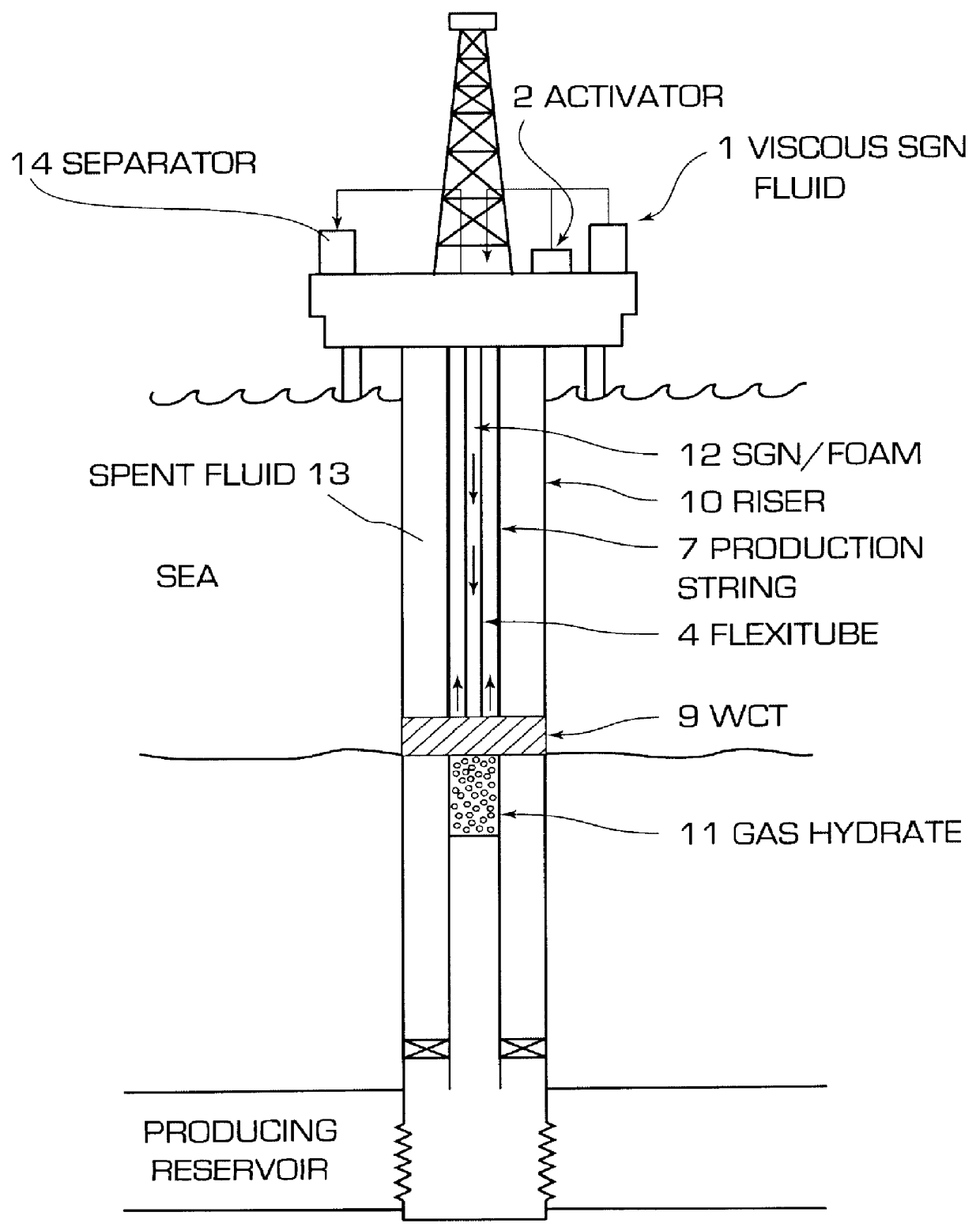

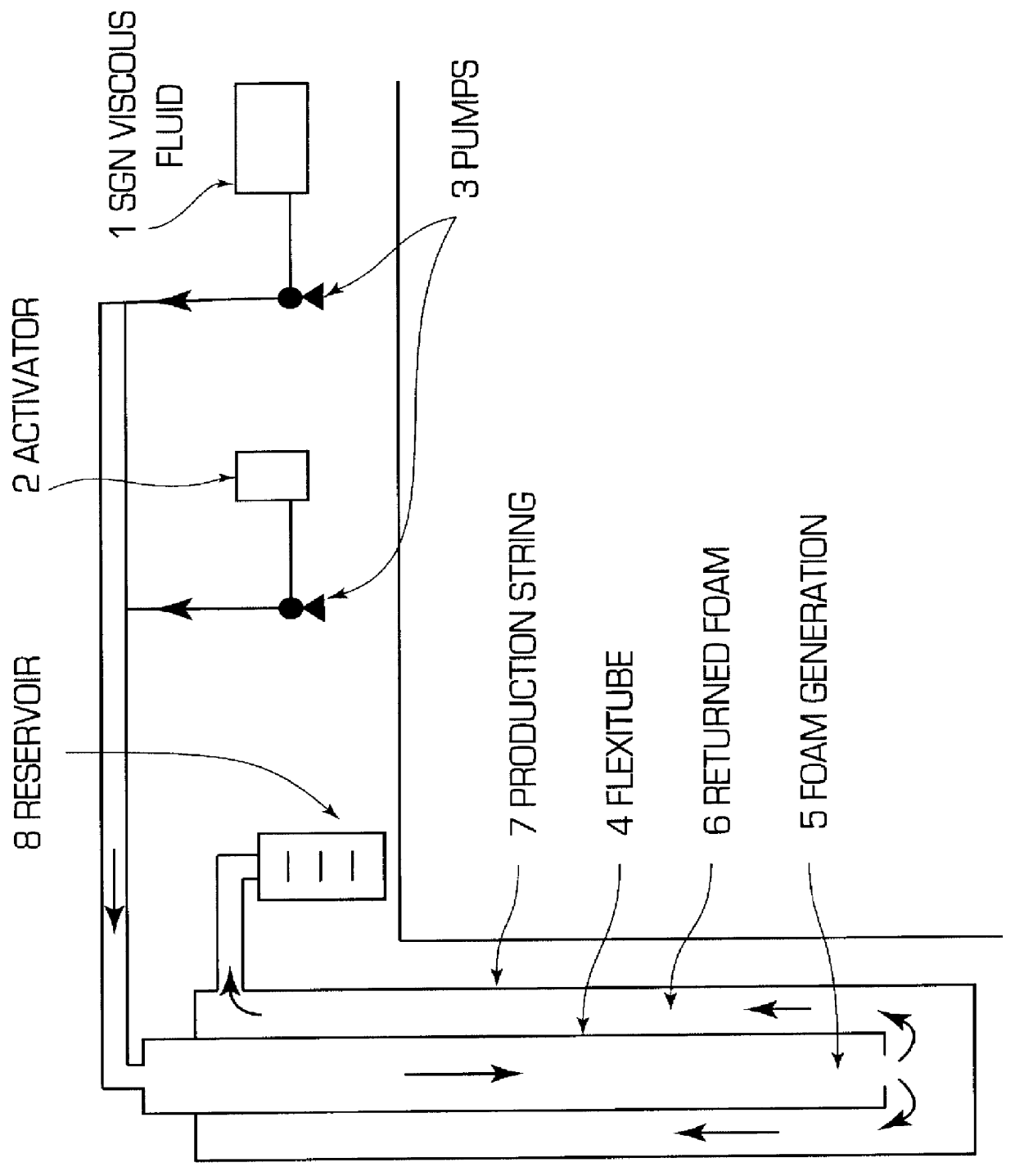

Process for the thermo-hydraulic control of gas hydrates

InactiveUS6035933AInhibition formationPipeline systemsDifferential sedimentationForming gasGas phase

A process for the thermo-hydraulic control of gas hydrates in subsea production and injection wells as well as pipelines which transport liquid or gaseous hydrocarbons is described, the process making use of a Nitrogen Generating System foamed or in solution. The control may signify the prevention of the formation of the gas hydrates or the dissolution of the gas hydrate plug already formed. Under conditions of use designed for the prevention of the formation of gas hydrates the SGN fluid prevents the thermal conditions leading to the gas hydrate plugs. Under conditions of use designed to dissolve the already formed gas hydrate plugs, the SGN fluid alters the thermo-hydraulic conditions which favor the gas hydrate plugs, so that they are dissolved and return to the water+gas phase.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

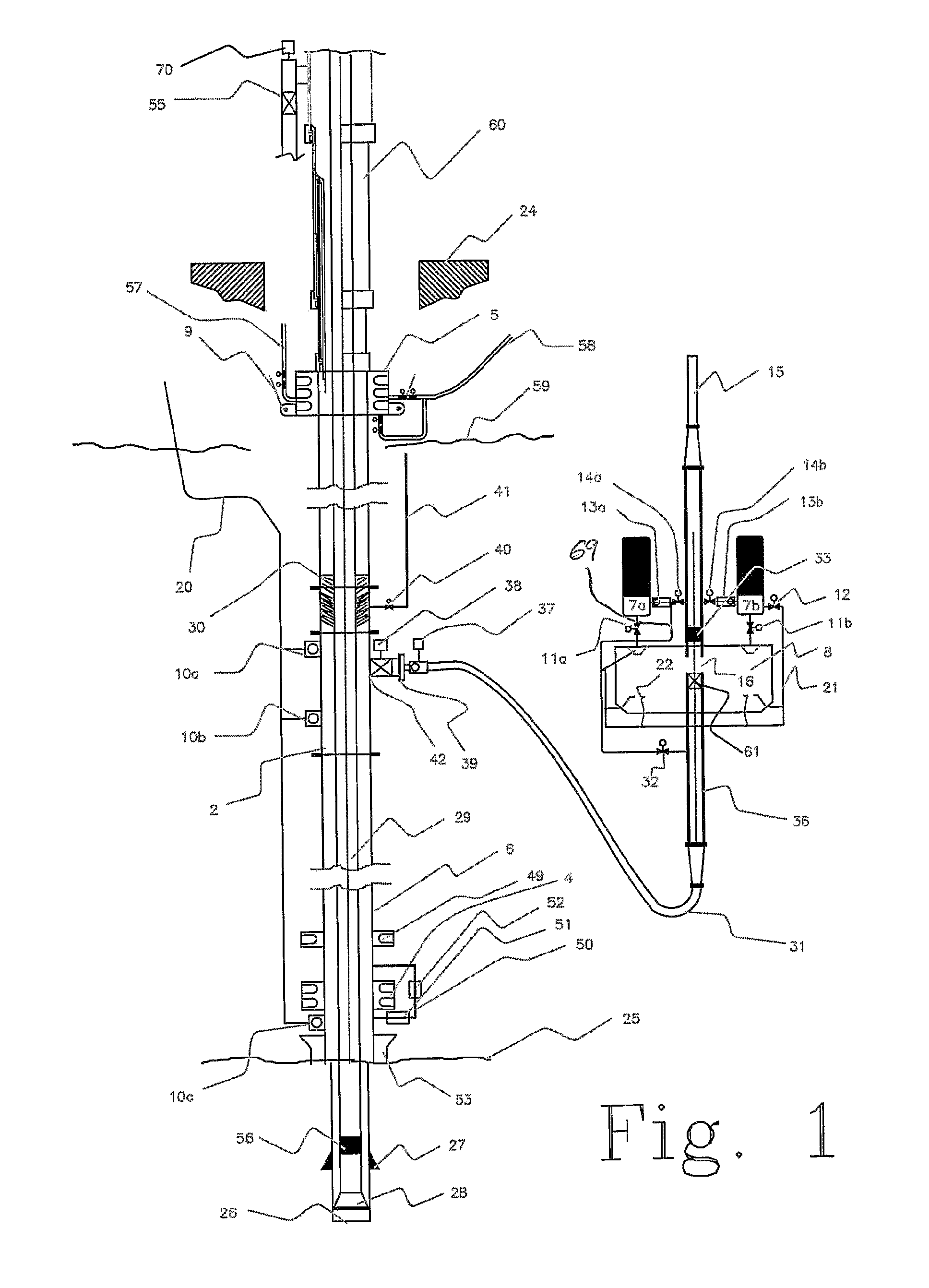

Arrangement and method for controlling and regulating bottom hole pressure when drilling deepwater offshore wells

InactiveUS7497266B2Handling is restrictedReduce pressureDrilling rodsConstructionsBottom hole pressureLine tubing

An arrangement and method for controlling and regulating bottom hole pressure in a well during subsea drilling in deep water involves adjustment of a liquid / gas interface level in a high pressure drilling riser up or down to change the slope and offset of the pressure gradient in the well. The arrangement may include a surface BOP and gas bleeding outlet at the upper end of the drilling riser, a lower BOP with a by-pass line, and an outlet at a depth below the water surface that is connected to a pumping system with a flow return conduit running back to a drilling vessel or platform.

Owner:ENHANCED DRILLING

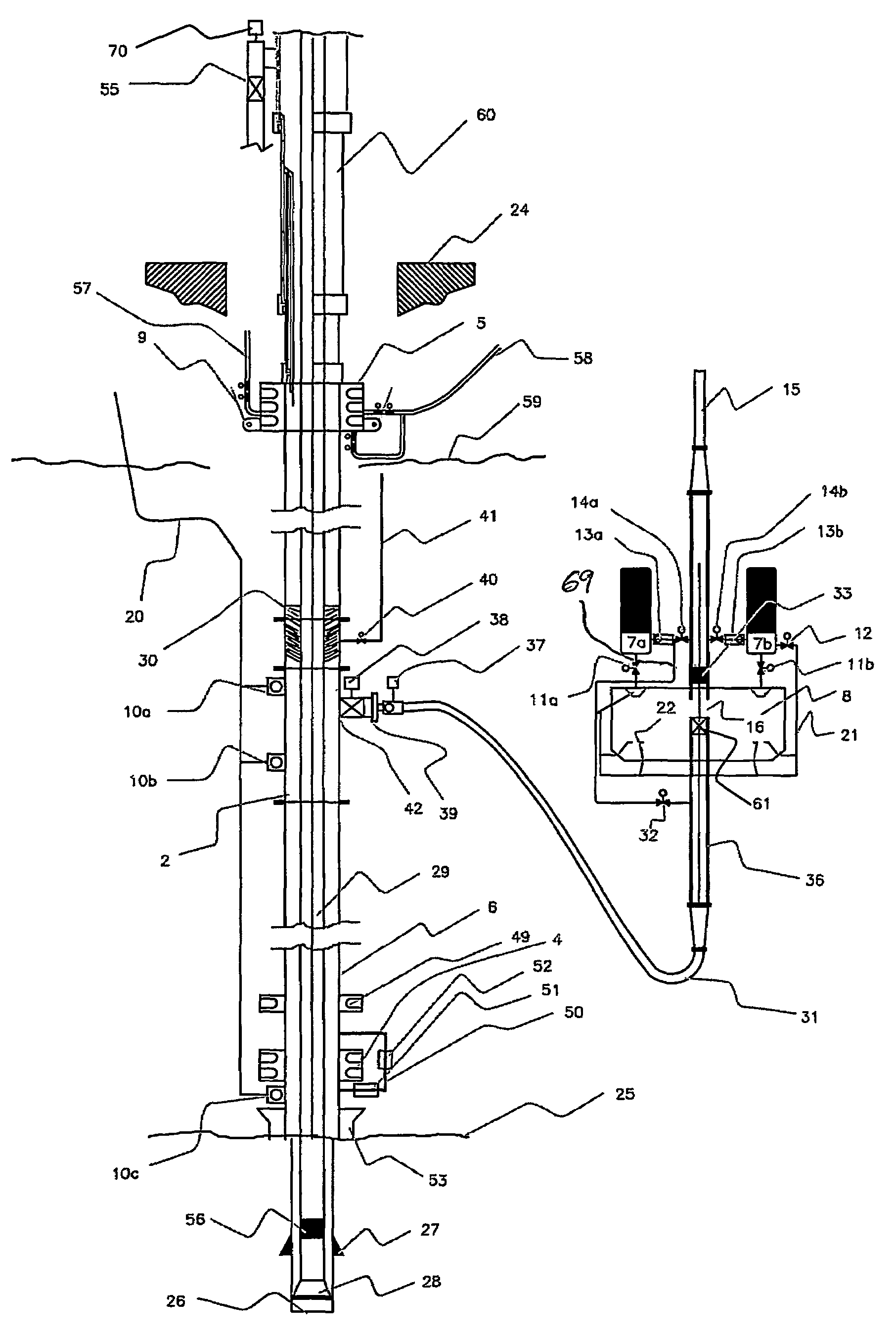

Arrangement and method for regulating bottom hole pressures when drilling deepwater offshore wells

InactiveUS7264058B2Improve abilitiesChange densityDrilling rodsConstructionsBottom hole pressureLine tubing

An arrangement and a method to control and regulate the bottom hole pressure in a well during subsea drilling at deep waters: The method involves adjustment of a liquid / gas interface level in a drilling riser up or down. The arrangement comprises a high pressure drilling riser and a surface BOP at the upper end of the drilling riser. The surface BOP havs a gas bleeding outlet. The riser also comprises a BOP, with a by-pass line. The drilling riser has an outlet at a depth below the water surface, and the outlet is connected to a pumping system with a flow return conduit running back to a drilling vessel / platform.

Owner:ENHANCED DRILLING

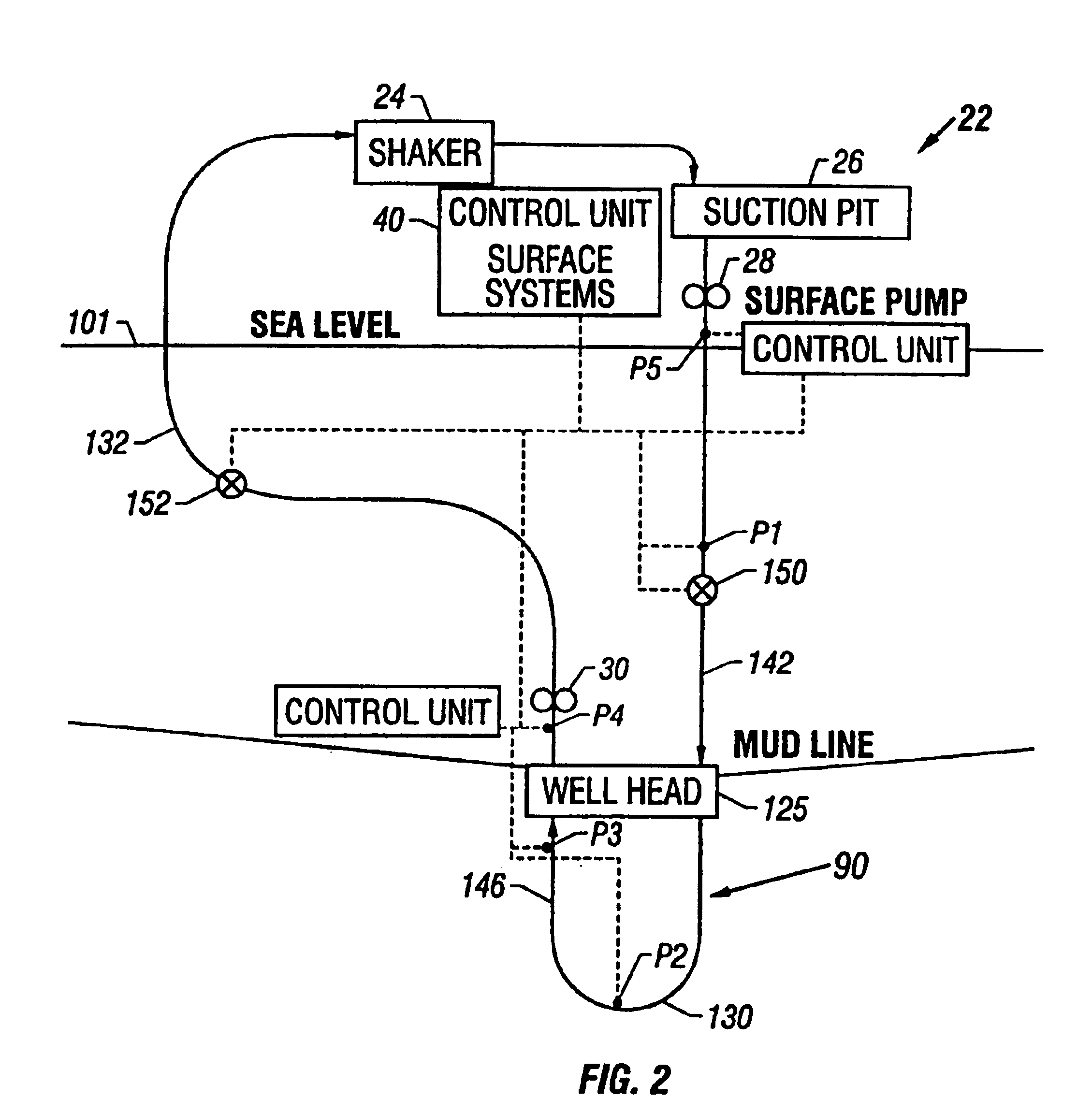

Subsea wellbore drilling system for reducing bottom hole pressure

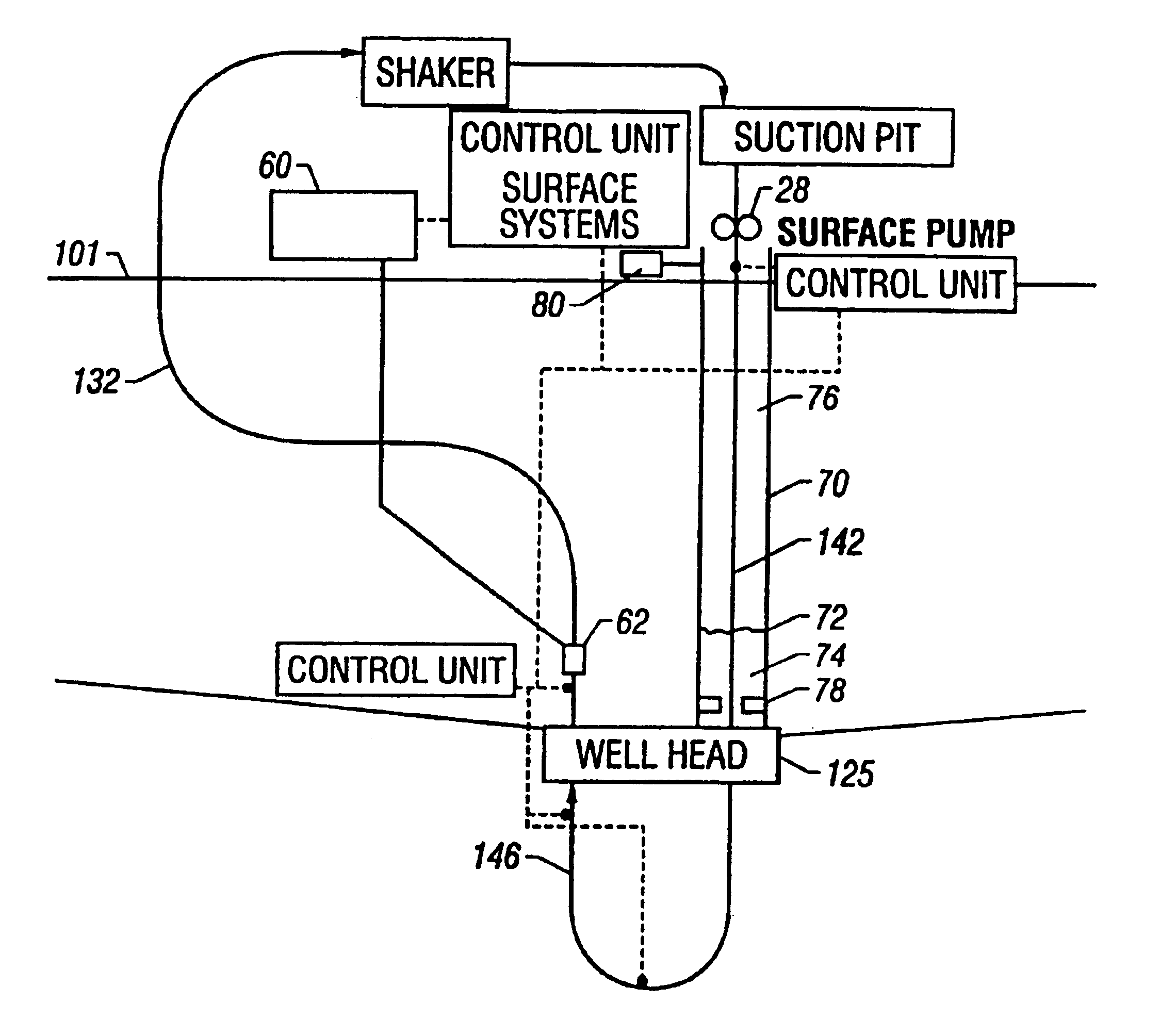

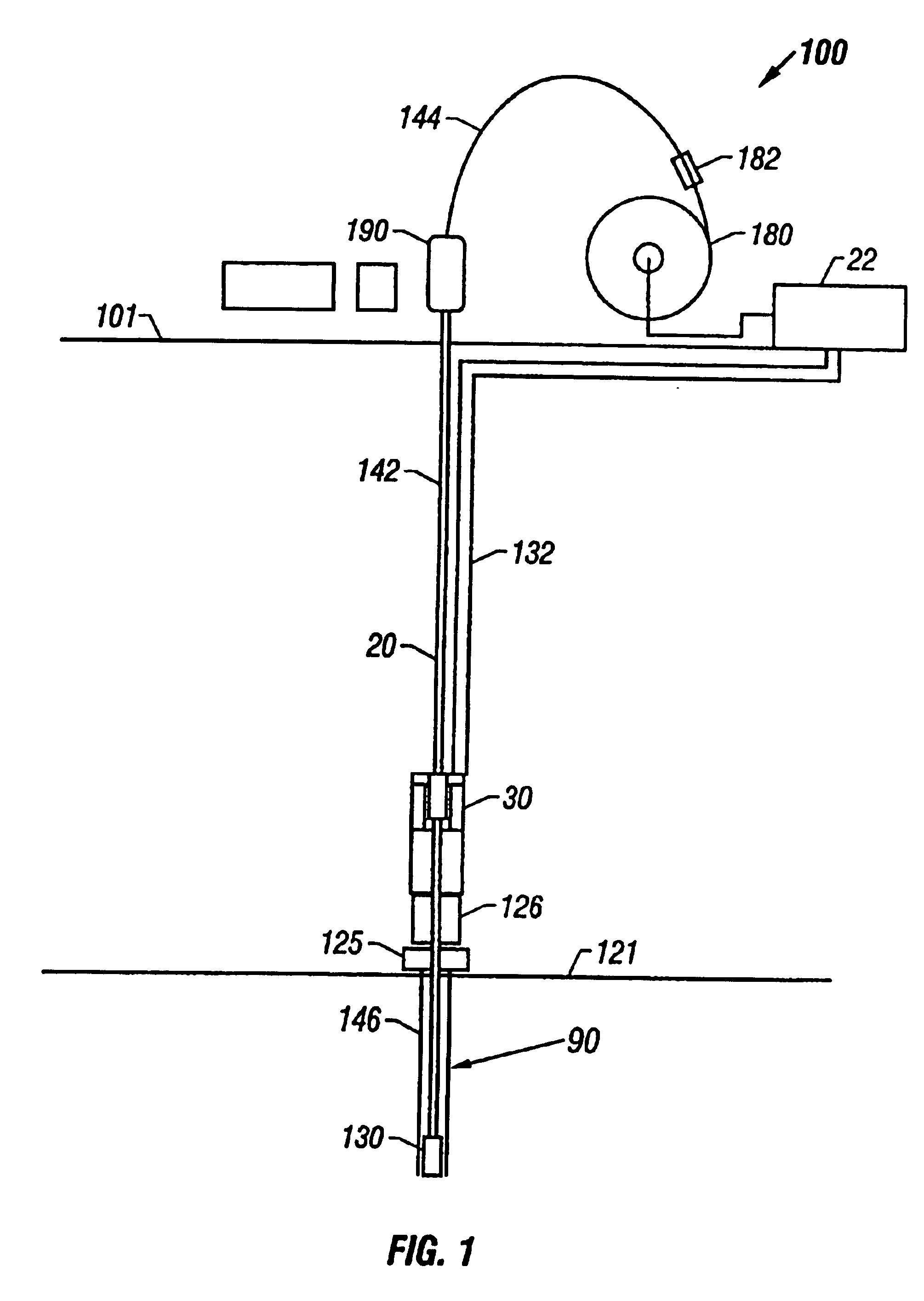

InactiveUS6854532B2Easy to deployFaster and effective subsea downhole operationDrilling rodsConstructionsDelivery systemBottom hole assembly

The present invention provides drilling systems for drilling subsea wellbores. The drilling system includes a tubing that passes through a sea bottom wellhead and carries a drill bit. A drilling fluid system continuously supplies drilling fluid into the tubing, which discharges at the drill bit bottom and returns to the wellhead through an annulus between the tubing and the wellbore carrying the drill cuttings. A fluid return line extending from the wellhead equipment to the drilling vessel transports the returning fluid to the surface. In a riserless arrangement, the return fluid line is separate and spaced apart from the tubing. In a system using a riser, the return fluid line may be the riser or a separate line carried by the riser. The tubing may be coiled tubing with a drilling motor in the bottom hole assembly driving the drill bit. A suction pump coupled to the annulus is used to control the bottom hole pressure during drilling operations, making it possible to use heavier drilling muds and drill to greater depths than would be possible without the suction pump. An optional delivery system continuously injects a flowable material, whose fluid density is less than the density of the drilling fluid, into the returning fluid at one or more suitable locations the rate of such lighter material can be controlled to provide supplementary regulation of the pressure. Various pressure, temperature, flow rate and kick sensors included in the drilling system provide signals to a controller that controls the suction pump, the surface mud pump, a number of flow control devices, and the optional delivery system.

Owner:BAKER HUGHES INC

Hybrid riser configuration

Hybrid riser configuration comprising a plurality of steel riser pipes substantially inserted in aluminium guide conduits, with buoyancy means and tethering tension means, the guide conduits and riser pipes being rigidly connected to a base anchored to the ocean floor. The guide conduits serve as the tethering tension means and as radial constraint for the respective riser pipe therein to allow the riser pipe to buckle in elastic deformation (Euler) to form a spiral when expanding due to service pressure and temperature. A method for installing the riser configuration is also disclosed.

Owner:AKER RISER SYST

Intervention device for a subsea well, and method and cable for use with the device

A device for intervention of a subsea oil and / or gas well by means of a tool (8) suspended by a cable (9), fed from or withdrawn to a vessel (1) and driven by a drive mechanism (12) located on the vessel. The device comprises a lubricator (5) having a tool housing for the insertion of the tool into the well, and a stuffing box (40) sealing around the cable after the tool is inserted into the well. According to the invention an injector which drives the cable in the well is located on the lubricator, and is controllable independently of the drive mechanism for the cable located on the vessel. The drive mechanism and the injector may be synchronized in a manner, among others, providing that the cable is hanging in a predetermined arc during the intervention, whereby the vessel may be moved from the well. Moreover, the invention relates to a method and a cable used together with the device.

Owner:FMC KONGSBERG SUS

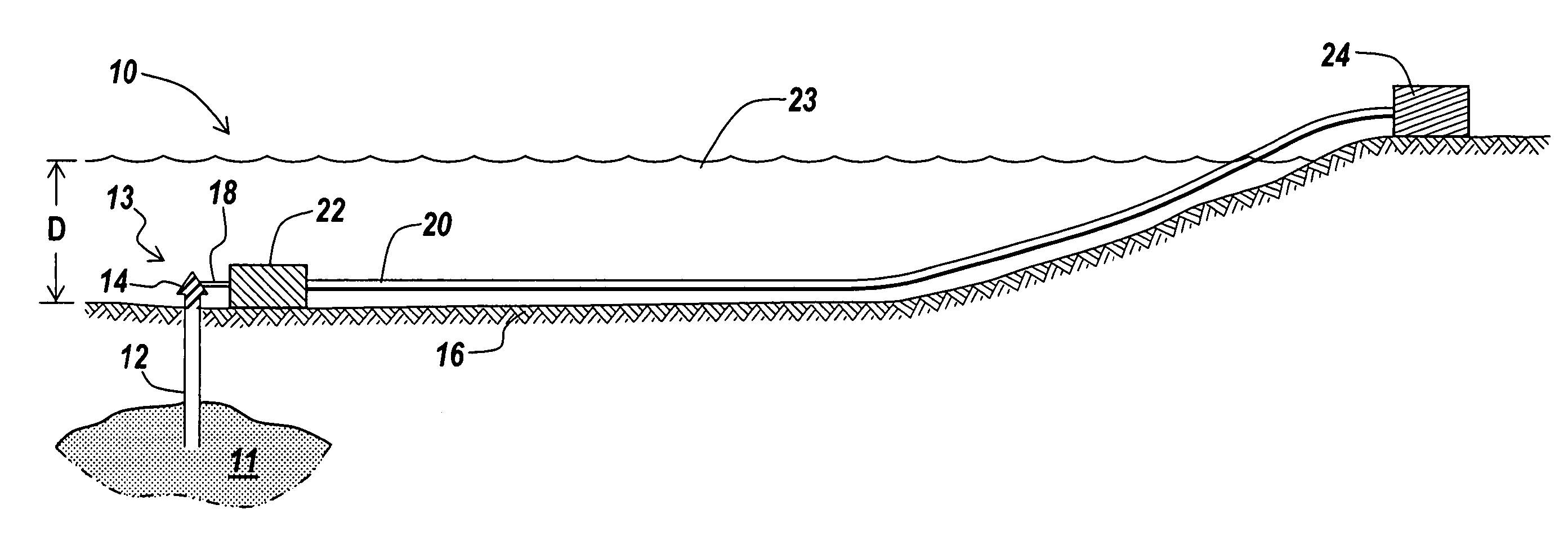

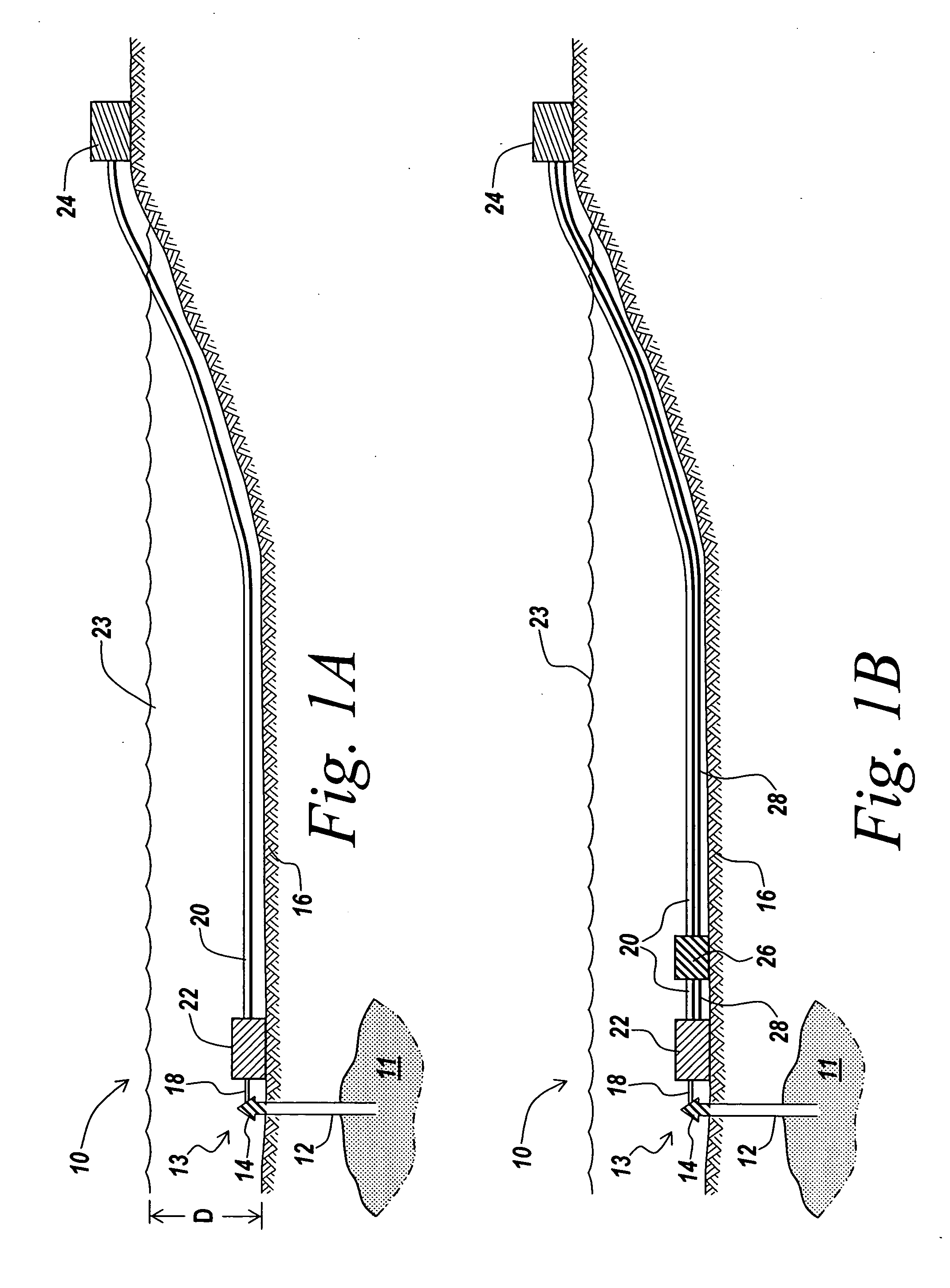

Undersea well product transport

InactiveUS20060175062A1Reduce and eliminate needEliminate and minimizeDrilling rodsInsulationHydrocotyle bowlesioidesShore

An apparatus and corresponding method of use extracts, cools, and transports effluents from subterranean, sub-sea oil formations to distant shore based processing facilities. The effluents, mostly crude oil, are conveyed rapidly to a cold flow generator near the oil wellhead on the sea bottom using the cold seawater to chill the effluents to a dispersed mixture including generated solids. The mixture is transported close to sea bottom temperatures, slowly, with small pressure drops, in low-cost submerged bare pipes over long distances to on or near shore processing facilities that can produce useful hydrocarbon products more cost effectively than at sea processing facilities. The apparatus eliminates or minimizes the need for heated or insulated pipe, the need for large floating processing structures, the need for sub-sea processing equipment, and / or the need for chemical additions to production flow.

Owner:BENSON ROBERT A

Float collar

The present invention relates to a float collar apparatus for regulating the passage of fluid through a drilling / production liner or sub-sea casing. Apparatus of the present invention is fabricated using plastic flapper valves and valve-actuating sleeve components in contrast to prior art float collar components which are fabricated almost entirely of hard metals. Particularly, the plastic may be nylon, phenolic, or a phenolic-nylon laminate. The use of plastic components in the float collar apparatus of the present invention provides a substantial reduction in time and resources expended during drilling out of the float collar once cementing operations are completed. Additionally, the float collar apparatus of the present invention is fabricated from a pre-determined combination of plastic components and metal components thereby ensuring that the improved float collar can still endure substantial hydrostatic stresses encountered during casing liner running in and cementing operations.

Owner:ALLAMON JERRY P +2

Harvesting hydrocarbons and water from methane hydrate deposits and shale seams

InactiveUS20100006281A1Low extraction temperatureLess waterConstructionsMultiple-effect/fractional condensationNoble gasKerosene

A method of extraction of fuels, organic pollutants, and elements from Methane hydrate deposits, shale seams and the soil is described which freezes the zone and heats the center carrying the fuel, chemicals and water in these deposits and seams from where they are found, be it deep in the sea or on land, and carries them into the condensing unit in inert Nitrogen gas. Required drilling on the surface or sea bottom includes a main shaft and with auxiliary narrow drillings widely spaced from the shaft. The extraction zone, which is first cooled to brittle cold using the evaporation of Liquid Nitrogen and fractured with vibrations, is heated to the highest temperature of the hydrocarbon fraction desired to be extracted. The evaporating hydrocarbons are extracted in a Nitrogen gas carrier, a recognized fire suppressant (NFPA Code 2000). To speed the extraction rate, tonal input from two or more sounding units vibrates the seam structure freeing the evaporated hydrocarbons allowing more rapid escape into the shaft. To prevent air loss in aquifers, ice barriers seal the zone periphery. These hydrocarbons are separated into the hydrocarbons fractions, into fuel fractions as heating oil, kerosene, gasoline, ethers, and fuel gas including methane, Argon / Oxygen and rare gas segments, or, if pollutants, into the separate chemicals by boiling point. The thermal gradient of the extraction pipe is implemented by sourcing the Nitrogen from Liquid Nitrogen and bundling those pipes with the extraction pipe condensing its contents by hydrocarbon fractions into vessels and gas drums depending on boiling points of fractions. Water is separated from the gasoline segment and purified first by separation and then by freezing. The extraction of deep deposits layer the extraction zones as well as work neighboring extraction zones covering many acres. Fuel gases can be liquefied or burned in an on-site electric generating plant.

Owner:AIR WARS DEFENSE

Tensioner/slip-joint assembly

A tensioner / slip-joint module for providing a conduit from a floating vessel at the surface of the ocean to the blowout preventer stack, or production tree, which is connected to the wellhead at the sea floor. The tensioner / slip-joint module compensates for vessel motion induced by wave action and heave and maintains a variable tension to the riser string alleviating the potential for compression and thus buckling or failure of the riser string. The tensioner / slip-joint module preferably includes at least one mandrel having at least one hang-off donut; at least one upper flexjoint swivel assembly, at least one radially ported manifold, at least one tensioning cylinder, and at least one slip-joint assembly combined in a single unit.

Owner:CONTROL FLOW

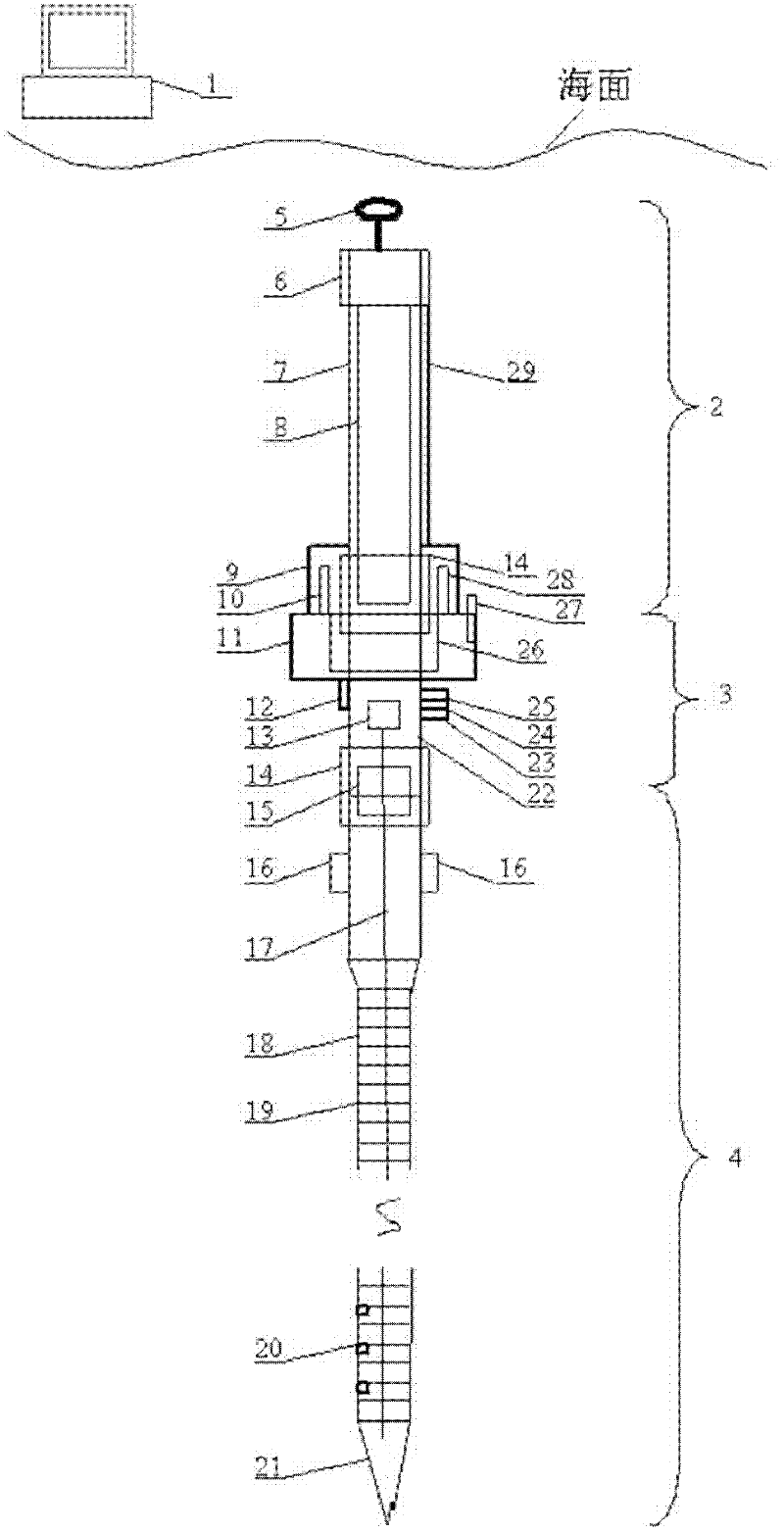

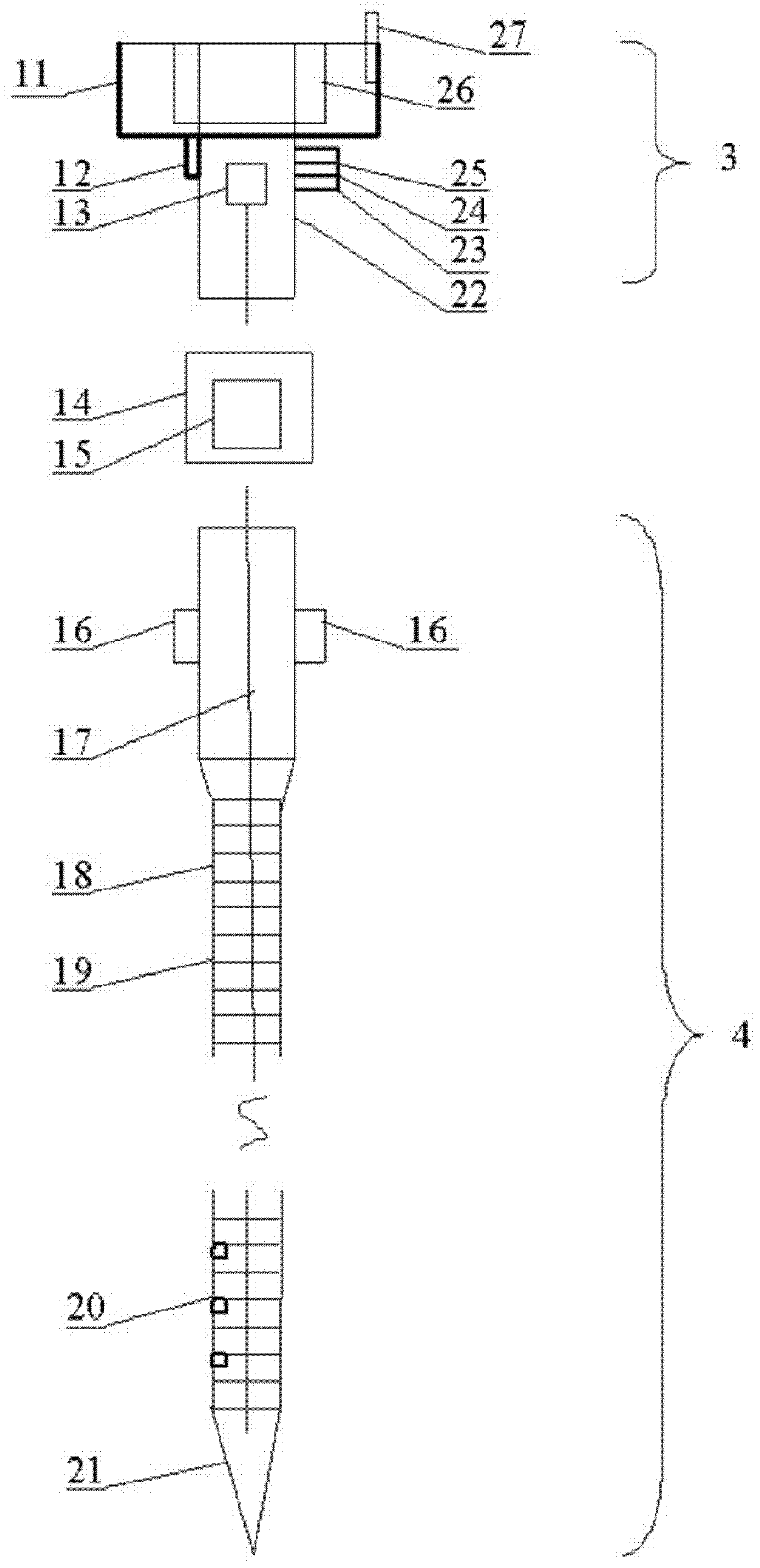

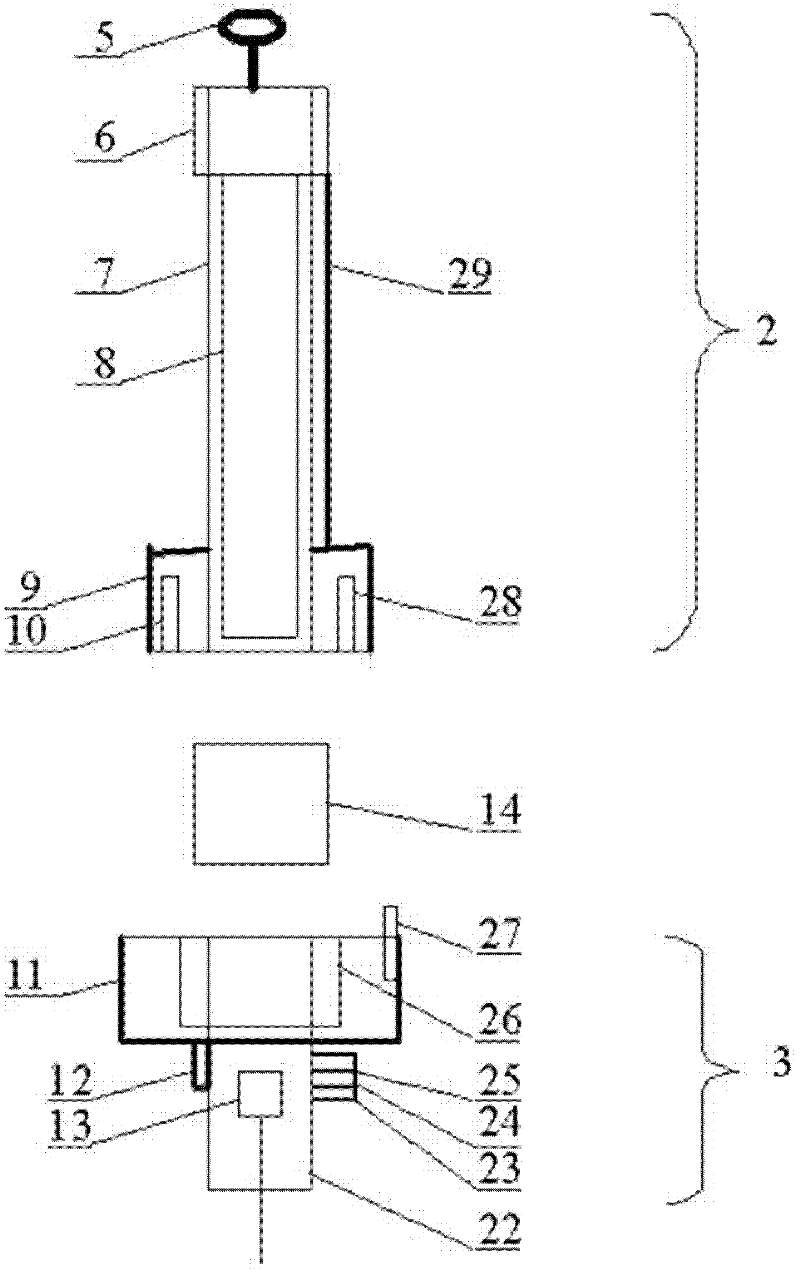

Penetration probe-based deep sea multi-element comprehensive observation system

ActiveCN102331275ARealize synchronous automatic observation recordSimple structureMeasurement devicesTransceiverPore water pressure

The invention discloses a penetration probe-based deep sea multi-element comprehensive observation system, which comprises an upper computer and a data recovery cabin, wherein the upper end and the lower end of the data recovery cabin are connected with a probe rod through a hydraulic separation releaser and a launching device respectively; a small-sized pile driver is arranged in the launching device; the launching device is provided with an underwater search light, an underwater camera and an underwater acoustic communication transceiver; the top of the data recovery cabin is provided with a floating body; a central controller is included in the data recovery cabin; the outer side face of the data recovery cabin is provided with an underwater acoustic transducer; and the outer surface of the probe rod is provided with more than 10 annular electrodes and more than 2 pore water pressure sensors which are connected with the central controller. The system has a simple structure, is reliable in work and accurate in control, can carry various sensors and adapt to a deep sea high pressure environment, and can synchronously and automatically observe and record states and changes of sea water and sediments within a 10m depth range close to a sea water-sediment interface with over 2,000m water depth, including the state of sediments of 6-7m below a sea bottom surface, the condition ofsea water of a bottom layer of 3-4m above the sea bottom surface and the dynamic change in position of the sea bottom surface.

Owner:OCEAN UNIV OF CHINA

Modular stacked subsea power system architectures

InactiveUS8692408B2Electric signal transmission systemsAc-dc conversion without reversalModularityEngineering

A sub-sea power delivery system includes a plurality of modular power converter building blocks on each of the power source side and the sub-sea load side that are stacked and interconnected to meet site expansion requirements and electrical load topologies. The power delivery system comprises a system DC transmission link / bus, wherein the system DC link is configured to carry HVDC or MVDC power from an onshore utility or topside power source to multiple sub-sea load modules. The stacked modular power converter topology on the sub-sea side of the sub-sea power delivery system is symmetrical with the stacked modular power converter topology on the on-shore / top-side of the sub-sea power delivery system.

Owner:GENERAL ELECTRIC CO

Acquisition method and device for seismic exploration of a geologic formation by permanent receivers set on the sea bottom

InactiveUS20050098377A1Increases in lifetimeImprove reliabilitySeismic energy generationSeismic signal receiversGeophoneHydrophone

A method and device for seismic exploration of a subsea geologic formation by pickups set on the sea bottom and intermittently connectable to active data acquisition stations (11) brought nearby. Permanent passive reception stations (1) comprising a heavy pedestal provided with housings for seismic pickups (geophones (6), hydrophone (7)) which receive acoustic or seismic signals from the underlying formation are arranged at the bottom of the water body. When collection sessions for the signals received by the pickups are scheduled, mobile active acquisition stations (11) connected to permanent passive reception stations (1) are positioned at the bottom of the water body. The signals picked up are then recorded, for the time required to carry out at least one session of acquisition and recording of the acoustic or seismic signals received by the passive stations in response to the emission of seismic waves by one or more seismic sources. The mobile active acquisition stations (11) are thereafter recovered at the surface and the records acquired by each one are transferred to a central collection laboratory.

Owner:INST FR DU PETROLE

Underwater pipeline connection joined to a riser

InactiveUS6854930B2Low costIncreased complexityPipe laying and repairDrilling rodsTowerSubmarine pipeline

The present invention relates to an installation providing a bottom-to-surface connection for an undersea pipe resting on the sea bottom, in particular at great depth, the installation being of the hybrid tower type having a static base placed on the sea bottom. In the installation of the present invention, said pipe resting on the sea bottom is connected by a flexible pipe element constituting a bend to a vertical riser whose bottom end is held in fixed position relative to said base.

Owner:SAIPEM SA

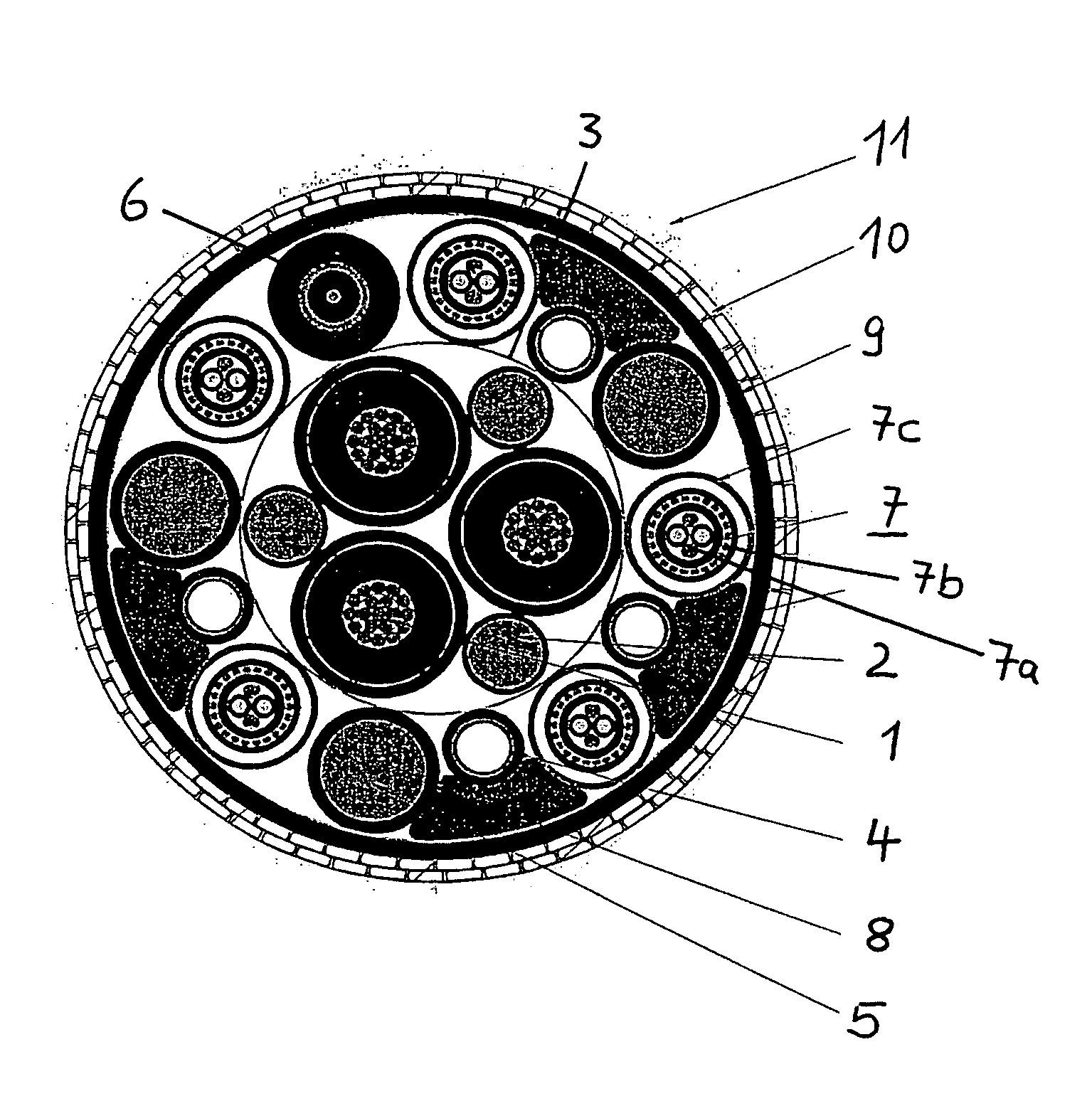

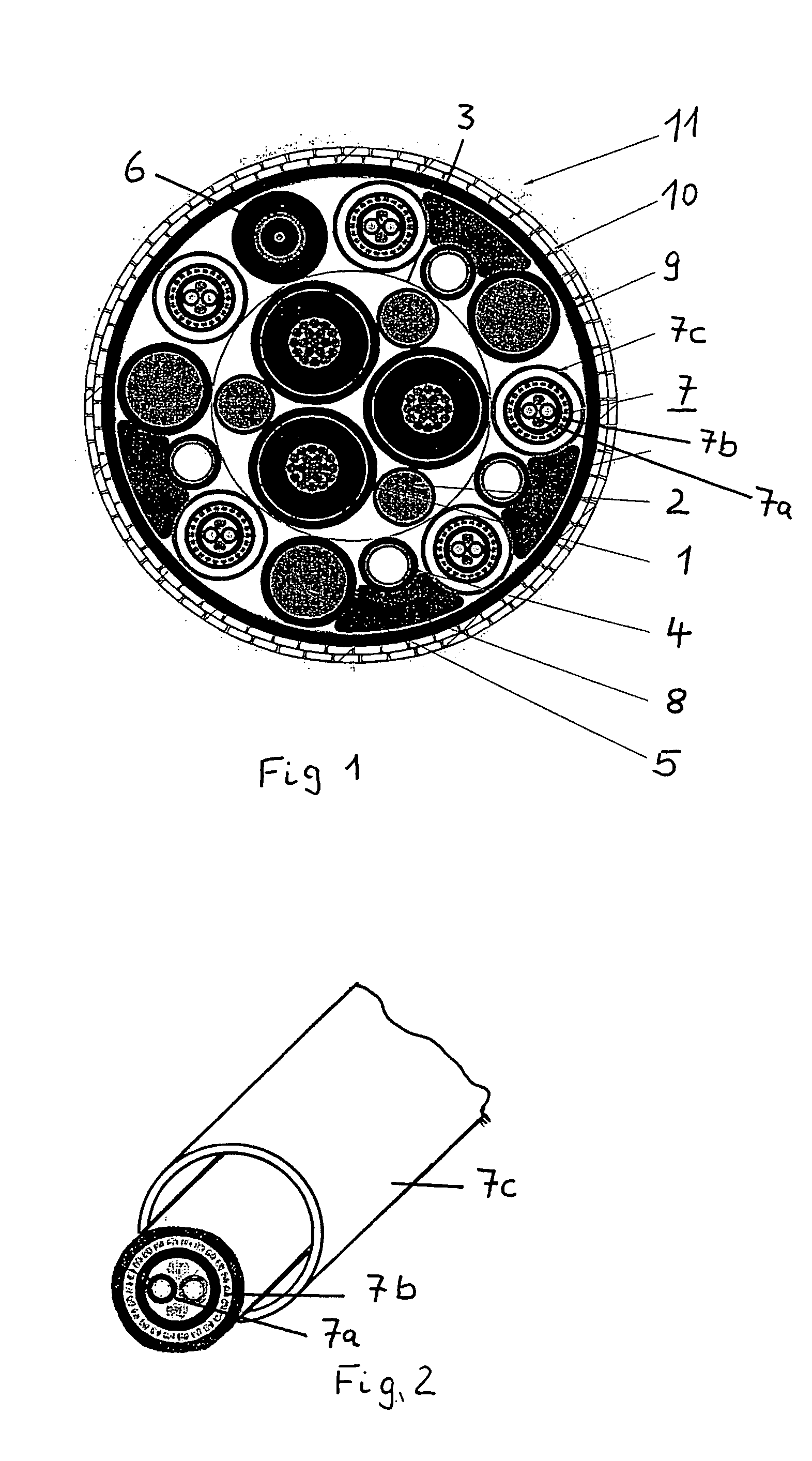

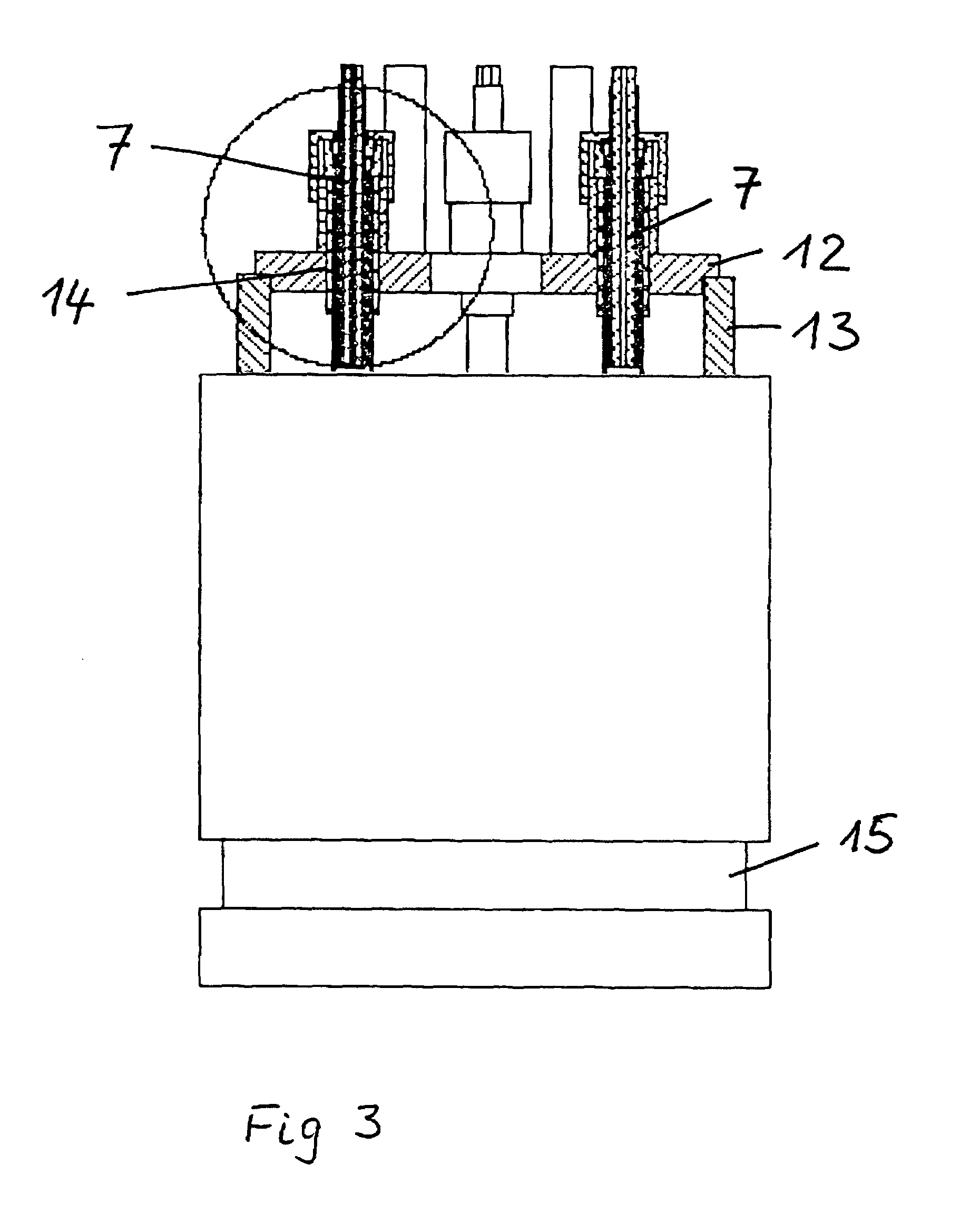

Power umbilical for deep water

InactiveUS7158703B2Power cables including communication wiresPower cables including electrical controlElectricityFiber

A subsea umbilical includes electrically insulated power conductors, fiber optic elements, electrical signal cables, and fillers within a common outer cover. At least one of the electrical signal cables is enclosed within a dedicated metal tube, and the umbilical is hung off on an offshore platform or the like and the metal tube containing the electrical signal cable is hung off separately from the umbilical.

Owner:NEXANS

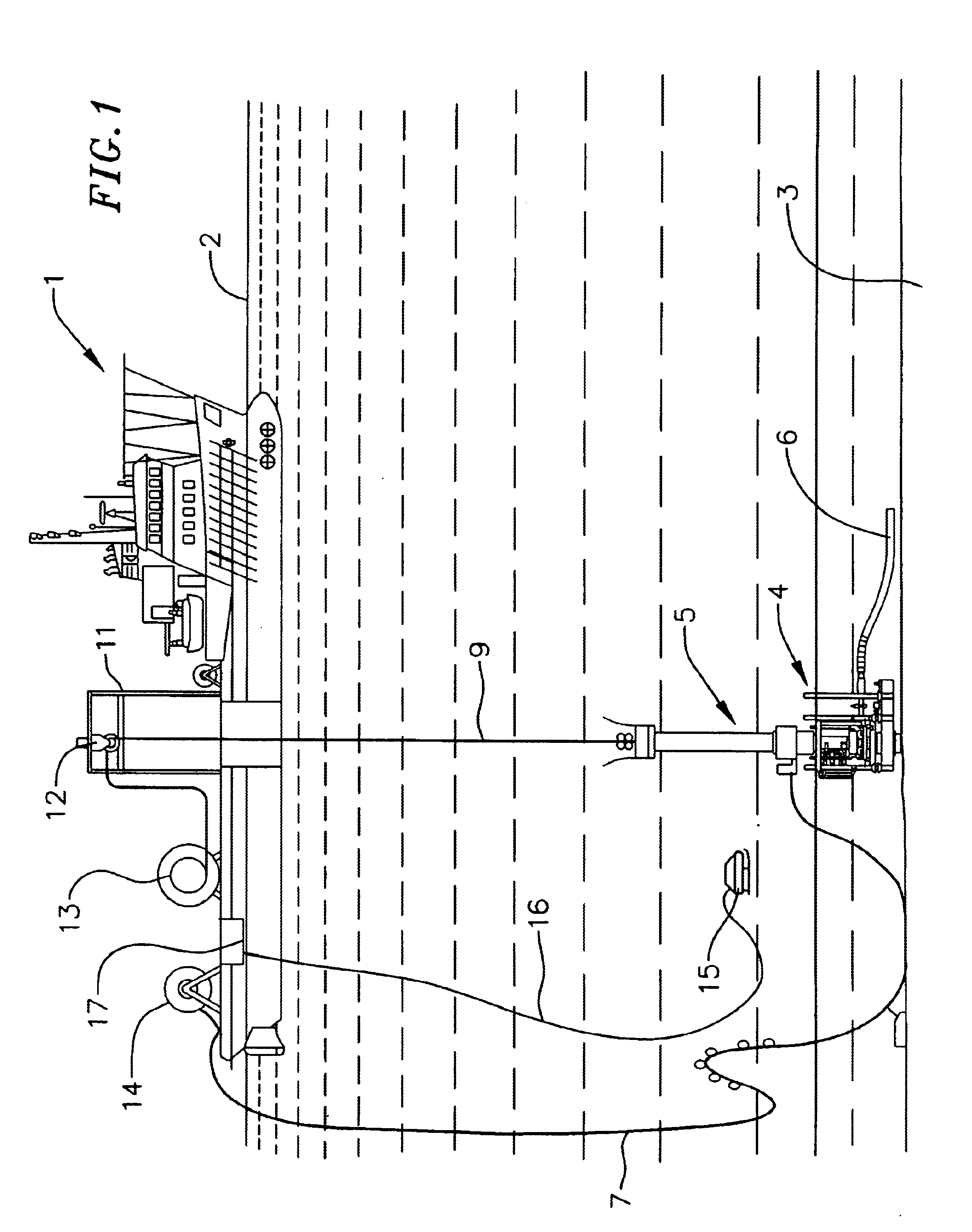

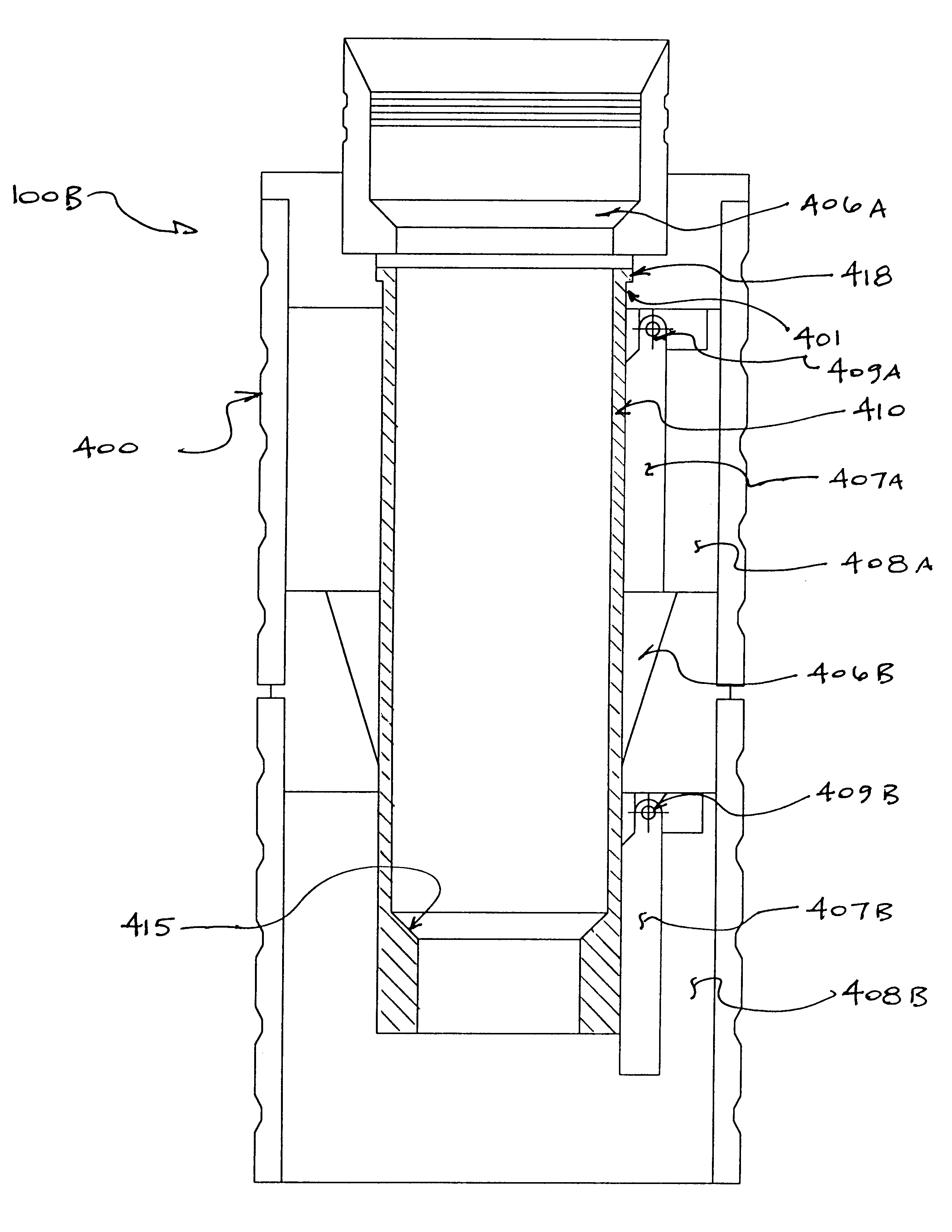

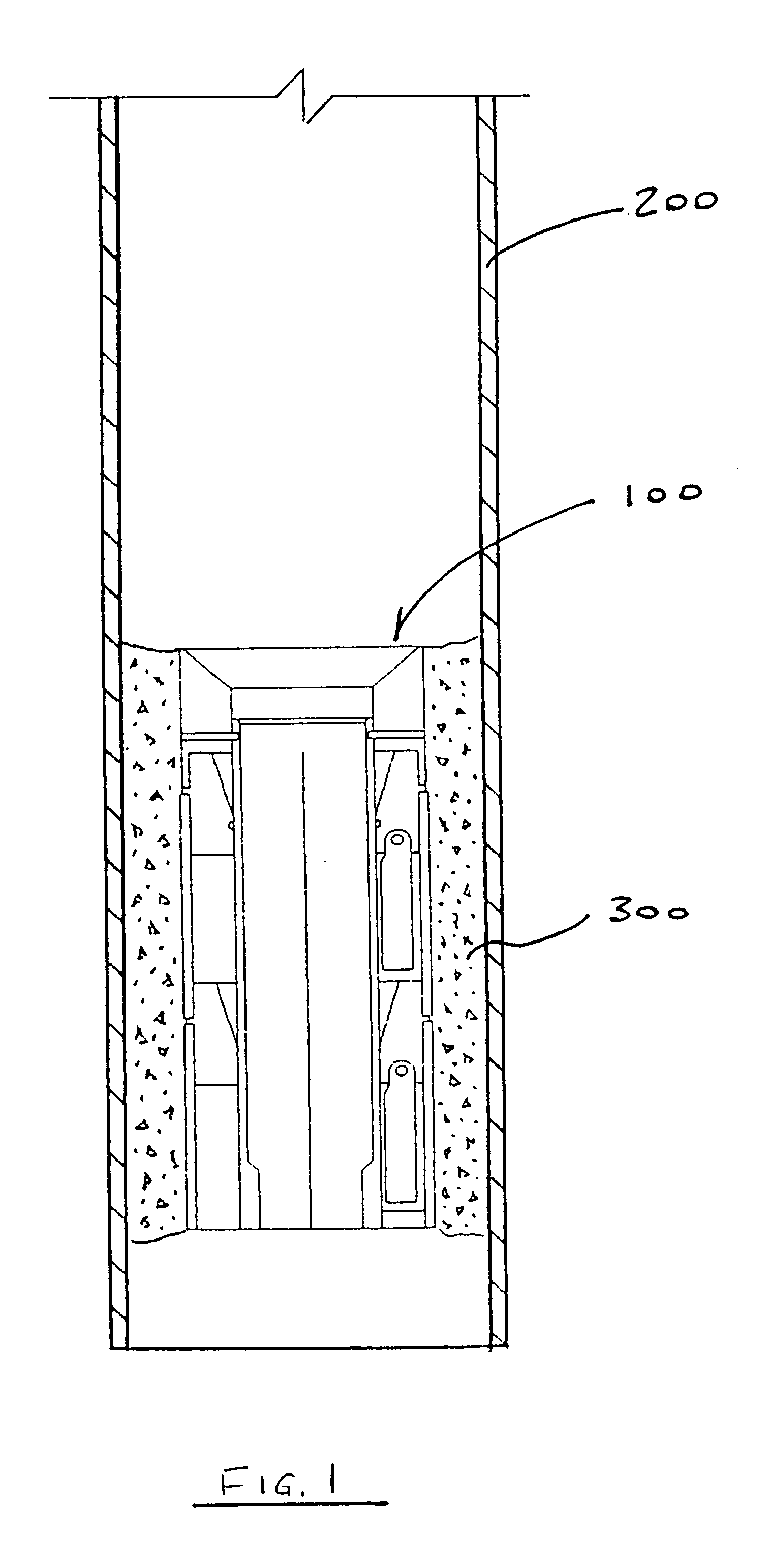

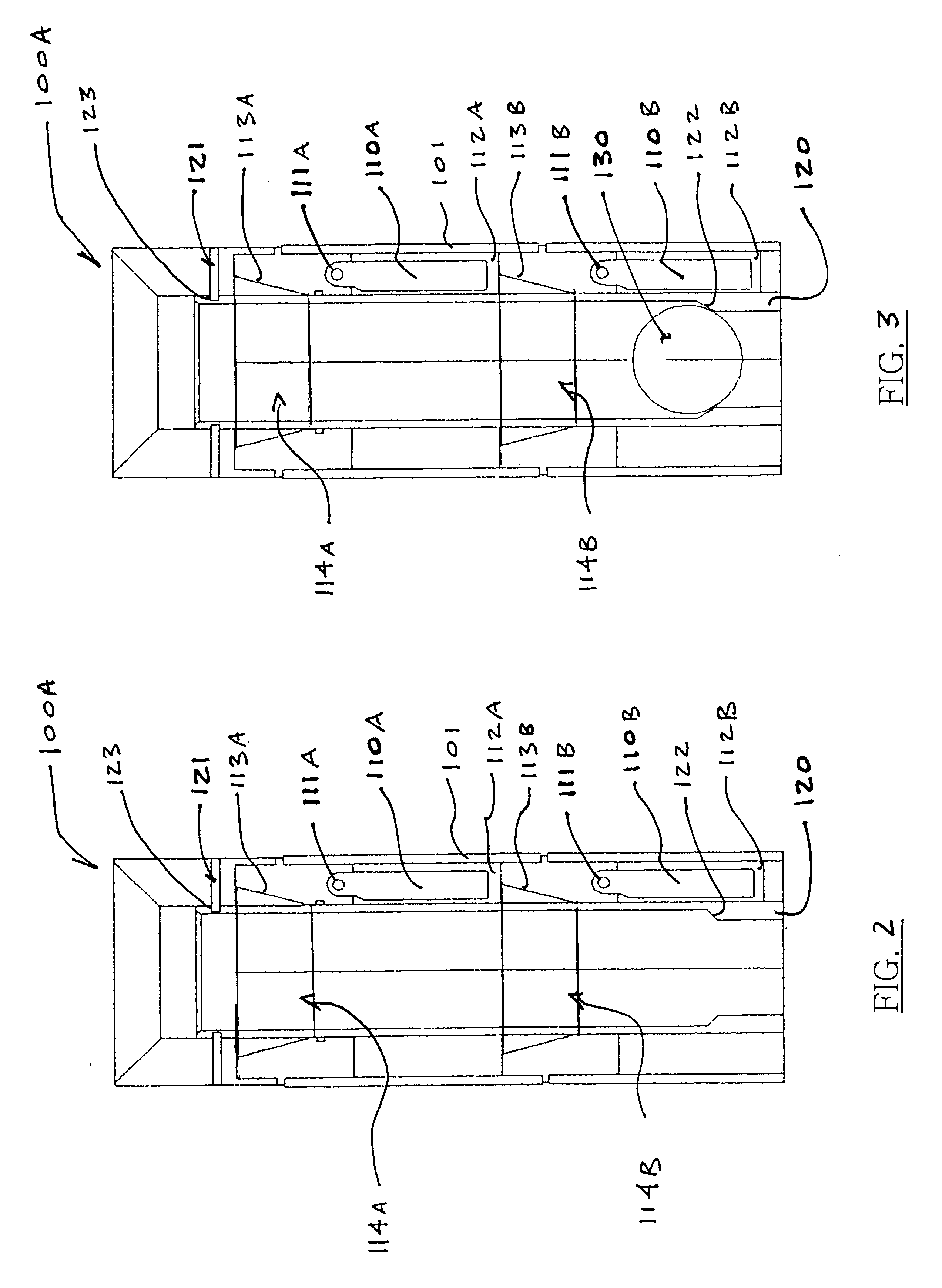

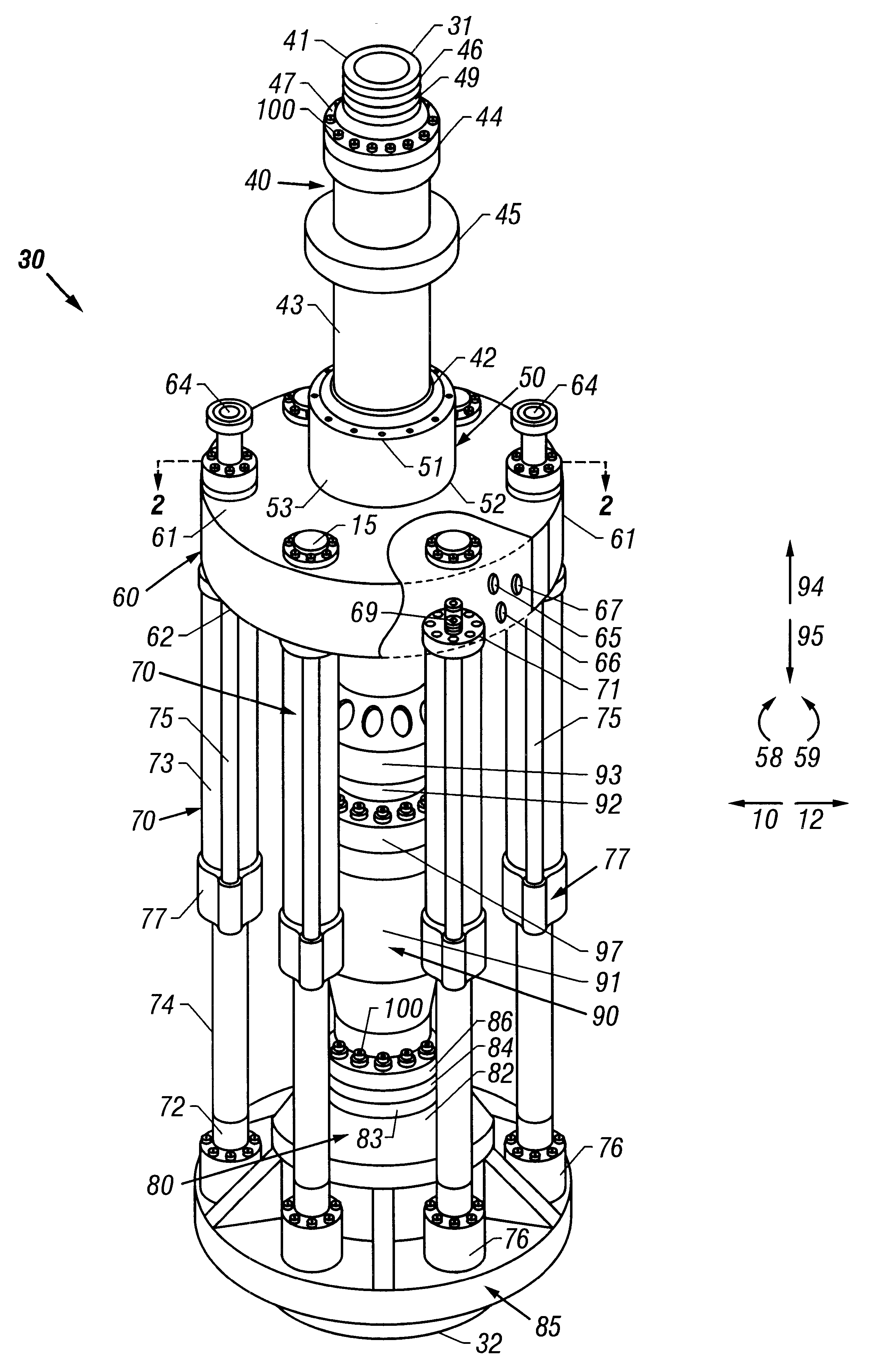

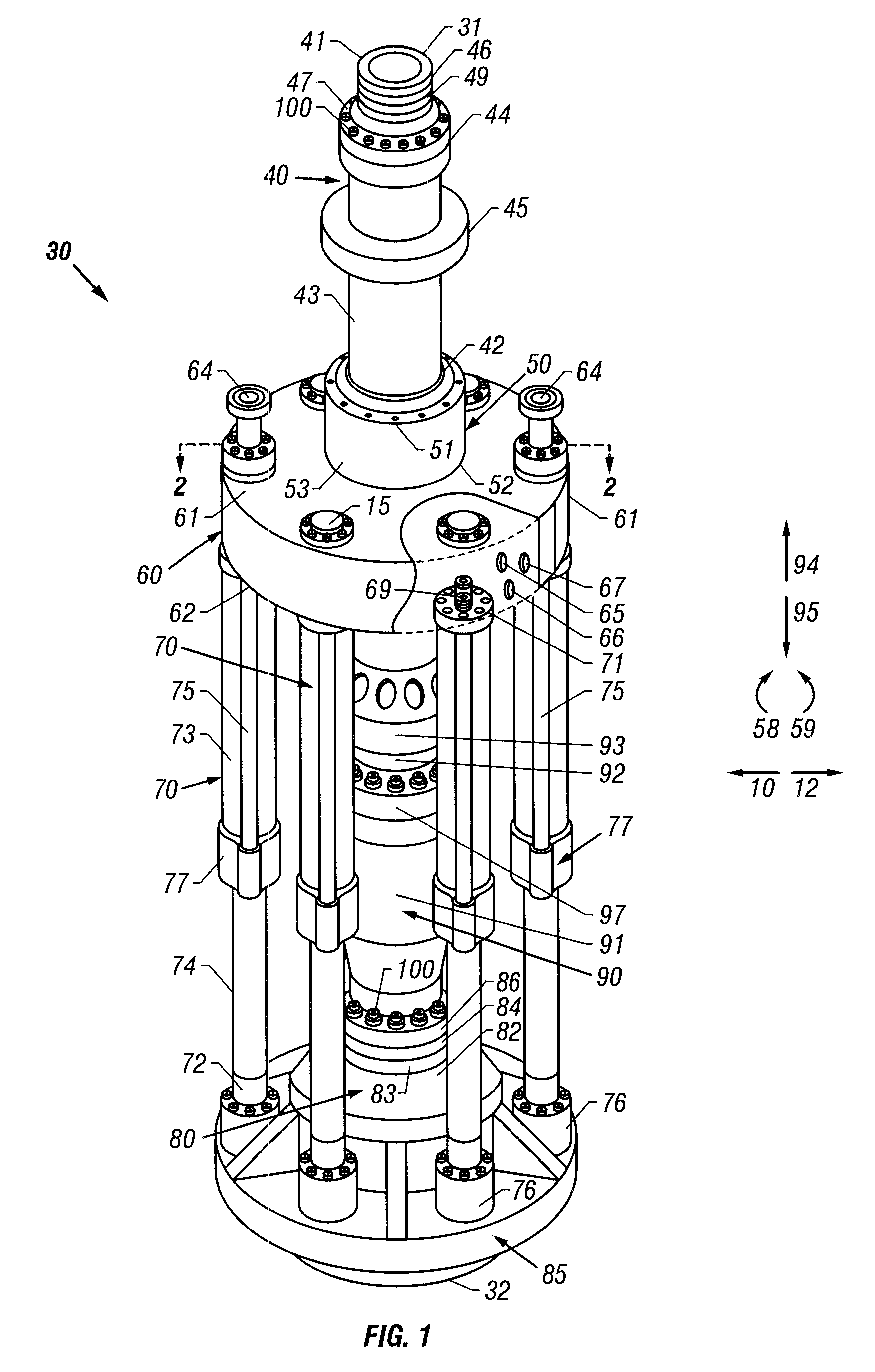

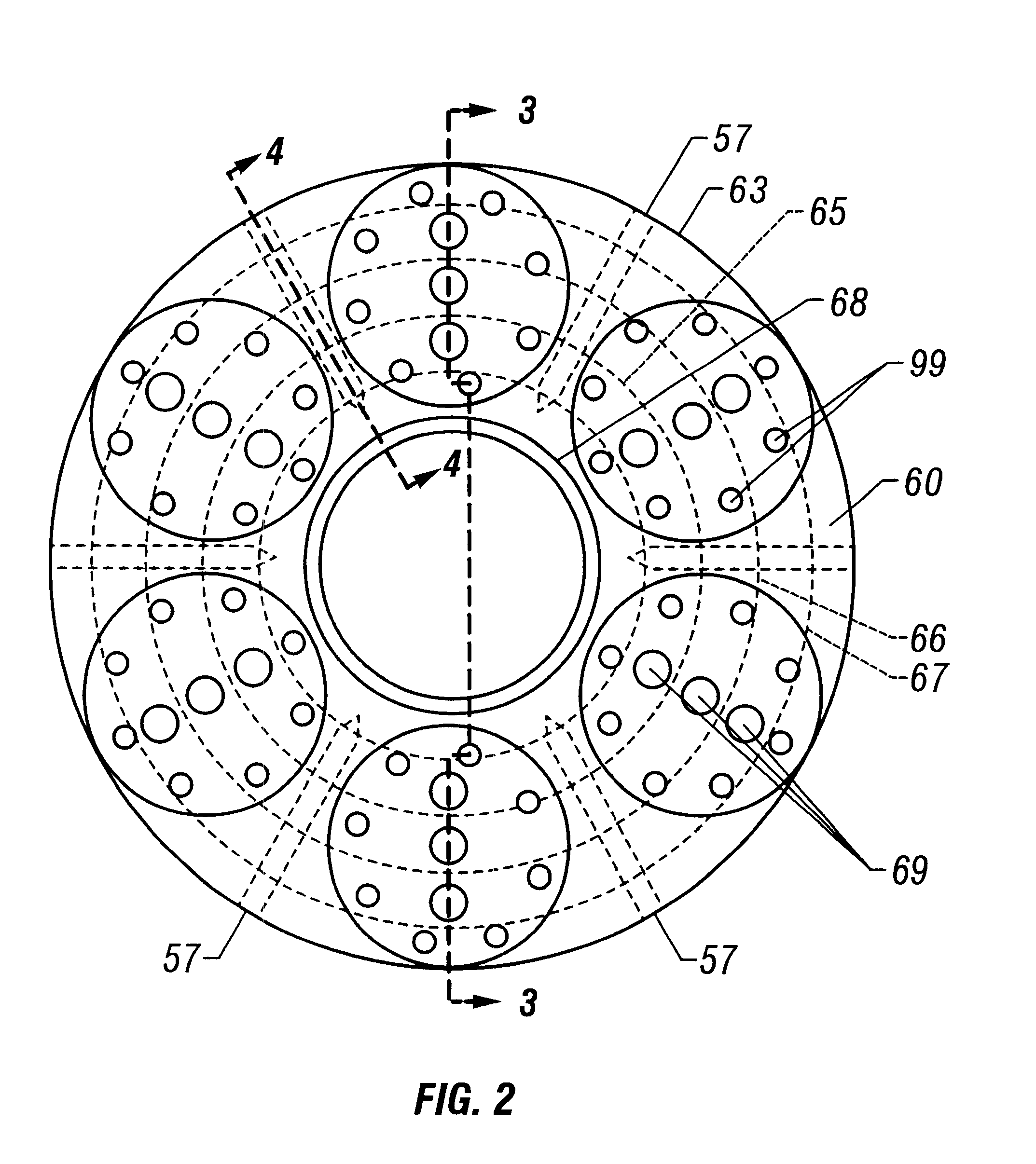

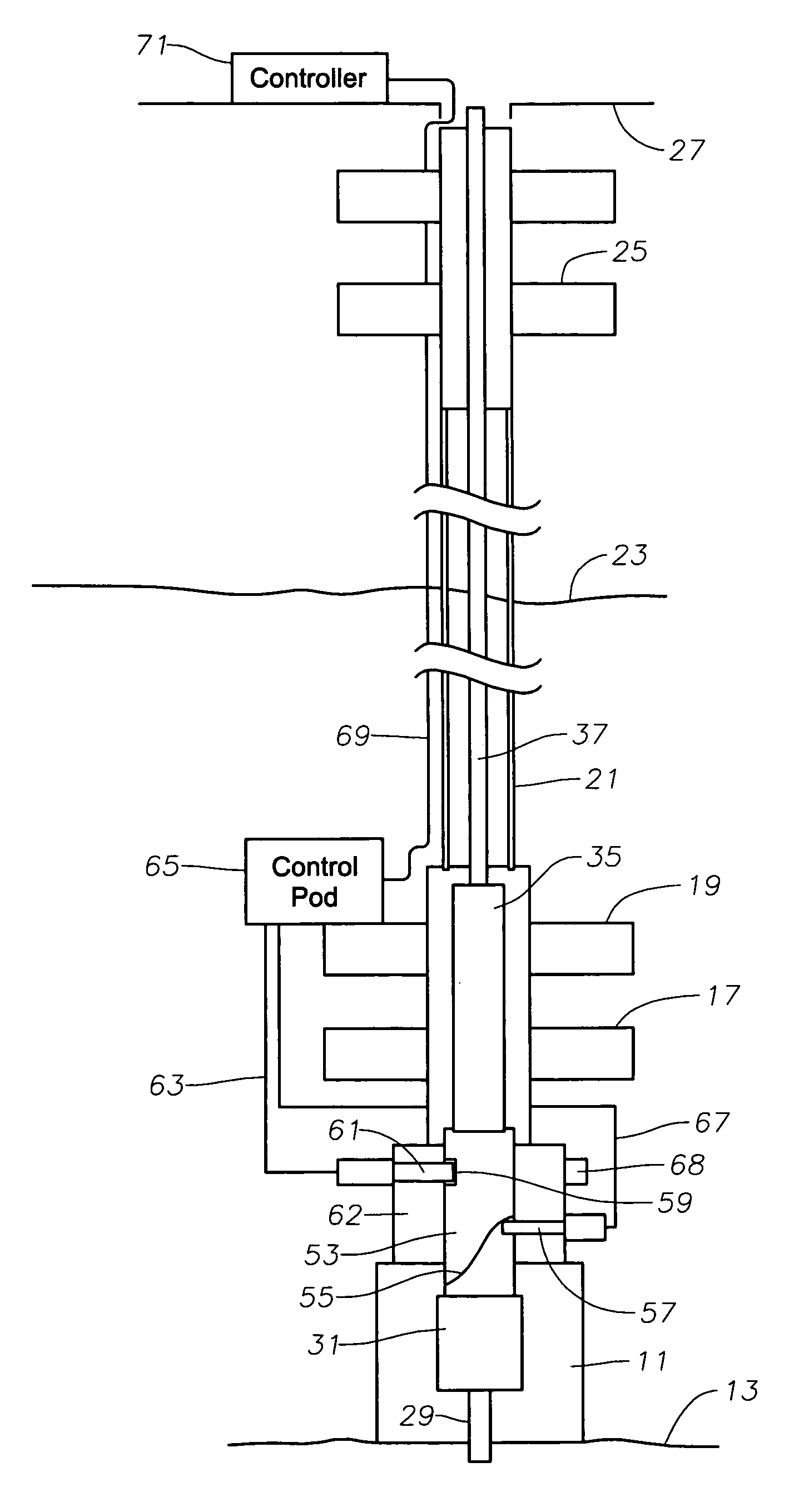

Sub sea bottom hole assembly change out system and method

The components required for changing out a bottom hole assembly are stored within a submerged storage chamber adjacent the lower end of a riser extending up from the bottom of a body of water. A vertical, revolving magazine holds the bottom hole assembly components within the storage chamber. A pressure lock between the storage chamber and the interior of the riser is opened to permit the bottom hole assembly components in the chamber to be exchanged with those forming the drilling string assembly within the riser. The storage chamber may be selectively sealed from the body of water and the internal riser area as the bottom hole assembly components are moved into and out of the chamber. A remotely operated mechanism assembles and disassembles the bottom hole assembly components of the drilling string assembly.

Owner:HALLIBURTON ENERGY SERVICES INC

Seabed gas hydrate mining methods and device

The present invention provides a method and a device for exploiting the submarine natural gas hydrate. The present invention transfers the natural gas hydrate on the submarine surface to a dredge and then to a large-volume container after being ground; a water pump is used to add sea water appropriately into the large-volume container. As the temperature of the sea water keeps about 20 DEG C, the temperature of the sea water makes the mixture of ground hydrate and sandstone fully decomposed in the large-volume container so as to separate the natural gas, water and sandstone. The separated natural gas is drained and then directly connected with a user terminal. The present invention with convenient operation and simple device can conveniently, economically and effectively achieve the exploitation of the submarine natural gas hydrate.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Extraction device for undersea gas hydrate and extraction method thereof

ActiveCN101555797AAchieve miningMining technology is simpleConstructionsMineral miningGas collecting tubeEngineering

The invention discloses an extraction device for undersea gas hydrate and an extraction method thereof, which is characterized in that the device is directly communicated with undersea (10) gas hydrate layer (9) through a hollow rigid body (2); or the hollow rigid body is communicated with undersea (10) gas hydrate layer (9) through layers of sand and clay (8) or impermeable bed (11); a water pump (4) and a test and supervisory equipment (5) are provided on one side of the hollow rigid body, the water pump is connected with a drain pipe (3) which is above the sea level (7) through a pipe, the test and supervisory system is connected with an image pickup system and a pressure testing system, and a gas collecting pipe (1) is arranged on the top of the inside of the hollow rigid body. The extraction method comprises the following steps: 1) a hollow rigid body is built on the sea separated with water, and the hollow rigid body is communicated with undersea gas hydrate layer; 2) water in the hollow rigid body is drained out via a water pump to lower the water height in the hollow rigid body and reduce the pressure acting on the gas hydrate layer and the gas hydrate is decomposed into gas and water when the pressure acting on the gas hydrate layer is less than the balance pressure; 3) the decomposed gas escapes upward, is discharged through the gas collecting pipe and is collected.

Owner:SICHUAN UNIV

High resolution bathymetric sonar system and measuring method for measuring the physiognomy of the seabed

InactiveUS20050036404A1Improve discriminationEasy to detectAcoustic wave reradiationPhysiognomyLinear arrays

A high resolution bathymetric sidescan sonar system for measuring micro-geomorphy of the sea bottom having an underwater vehicle, an underwater electronic subsystem mounted on the underwater vehicle and containing a transmitter and a receiver, and two sonar arrays mounted symmetrically on two sides of a lower part of the underwater vehicle and being connected to the underwater electronic subsystem through a cable. Each sonar array has a transmitting linear array and three or more parallel receiving linear arrays. The parallel receiving linear arrays are arranged at equal spaces, and the space d between two adjacent parallel receiving linear arrays is λ>d≧λ / 2, in which λ is a wavelength of an acoustic wave, and an operation frequency of the parallel receiving linear arrays ranges from 30 kHz to 1200 kHz.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

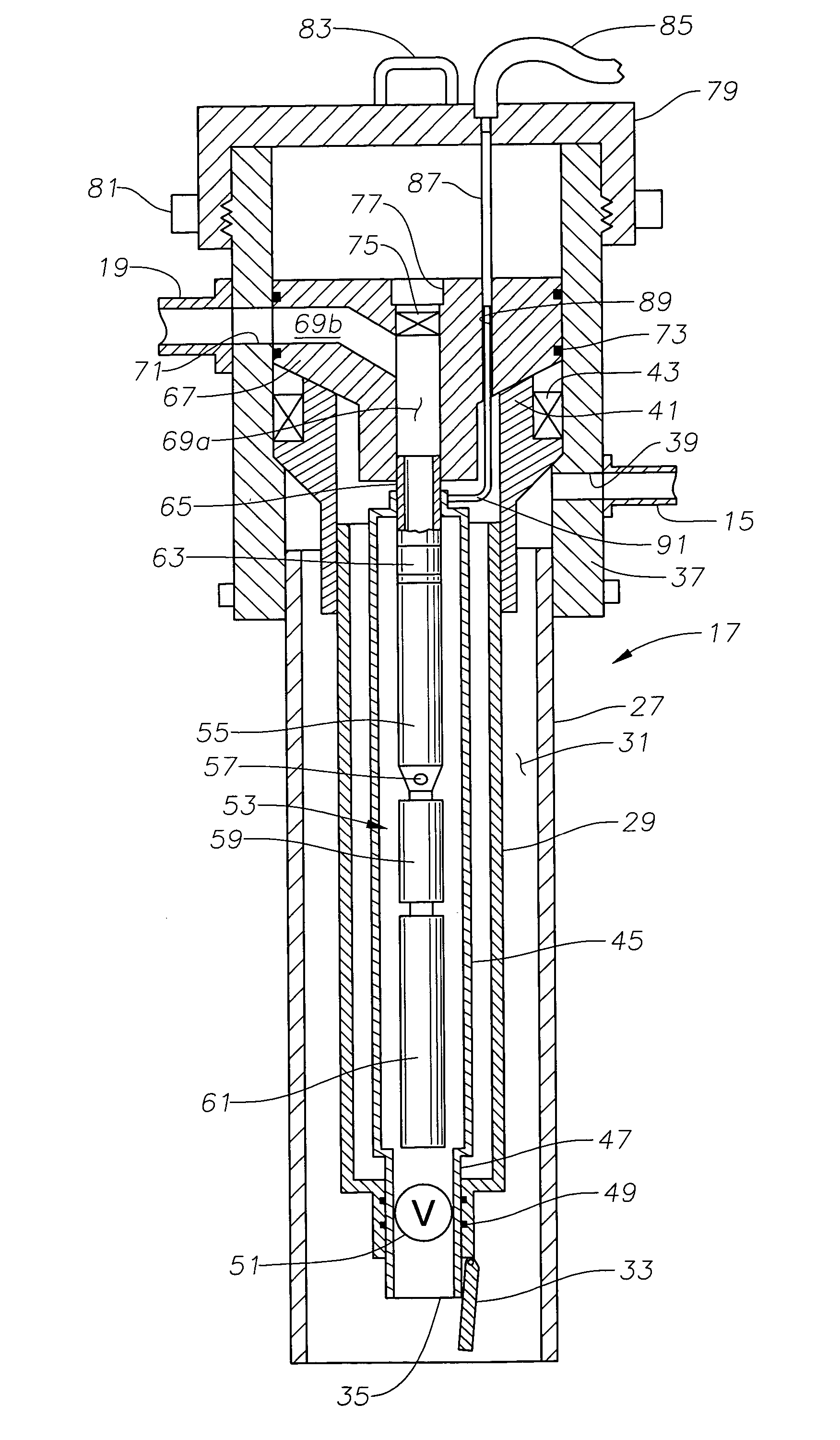

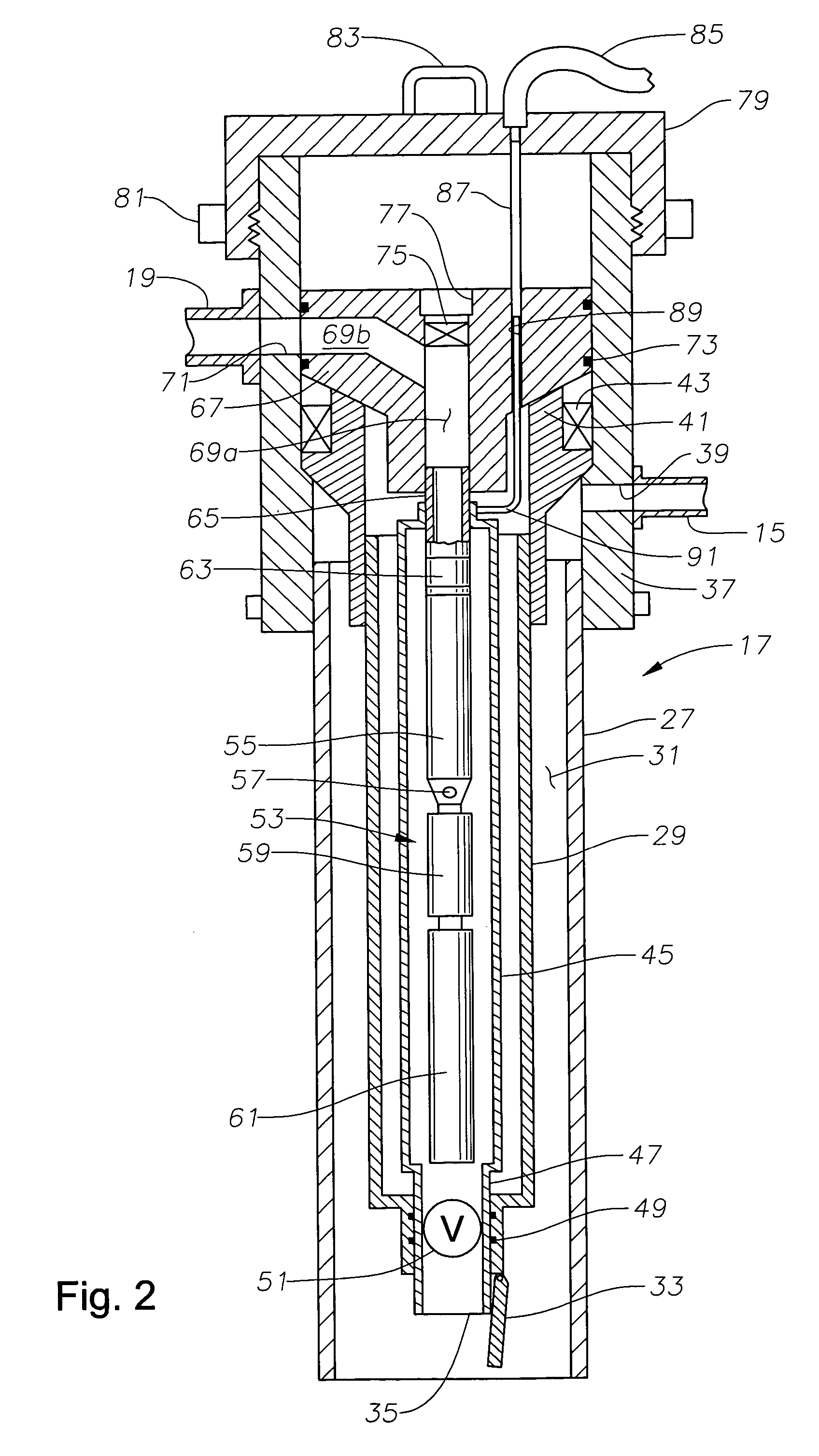

ROV retrievable sea floor pump

A subsea pumping assembly locates on a seafloor for pumping well fluid from subsea wells to the level. The pumping assembly has a tubular outer housing that is at least partially embedded in the seafloor. A tubular primary housing locates in the outer housing and has a lower end with a receptacle. An annular space surrounds the primary housing within the outer housing for delivering fluid to a receptacle at the lower end of the primary housing. A capsule is lowered in and retrieved from the primary housing. The capsule sealingly engages the receptacle for receiving well fluid from the annular space. A submersible pump is located inside the capsule. The pump has an intake that receives well fluid and a discharge that discharges the well fluid exterior of this capsule. The capsule has a valve in its inlet that when closed prevents leakage of well fluid from the capsule. The capsule may be retrieved through open sea without a riser.

Owner:BAKER HUGHES INC

Subsea well production facility

A method and system for separating and treating water produced from a subsea well includes separating the water subsea, and then separating the water from residual hydrocarbons on a surface vessel. The water treated at the surface, can be dumped to sea or injected into other subsea wells. The residual hydrocarbons separated on the vessel can be conveyed subsea for transportation to a processing facility along with hydrocarbons from the subsea separator. Also, the residual hydrocarbons from the surface separator can be used to fuel gas powered equipment in order to drive other equipment or to generate electricity for the vessel.

Owner:ABB OFFSHORE SYST INC

Tubing running equipment for offshore rig with surface blowout preventer

A method performing an operation in a subsea wellhead assembly through a riser extending between the wellhead assembly and a surface platform includes the step of connecting a surface blowout preventer to an upper portion of the riser. Then a tool is connected to a string of conduit. A control line is then connected to the tool, extended alongside the conduit. The tool and control line are lowered through the blowout preventer and riser. The method also includes the step of mounting a slick joint to an upper end of the conduit when the tool is near the wellhead assembly. The control line is then linked through the slick joint and extends to the surface platform. The method also includes the step of communicating with the tool via the control line and performing an operation in the wellhead assembly with the tool.

Owner:VETCO GRAY LLC

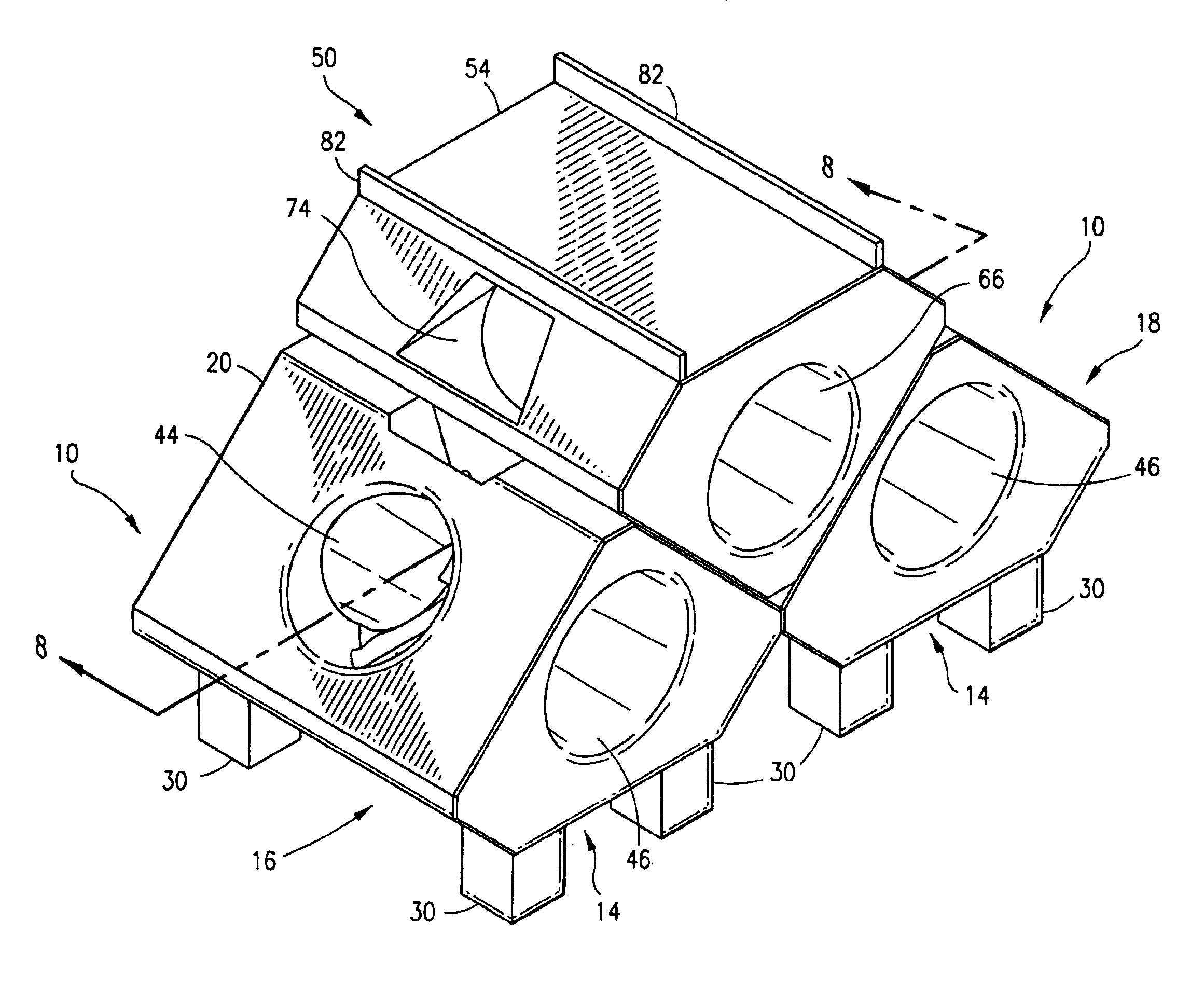

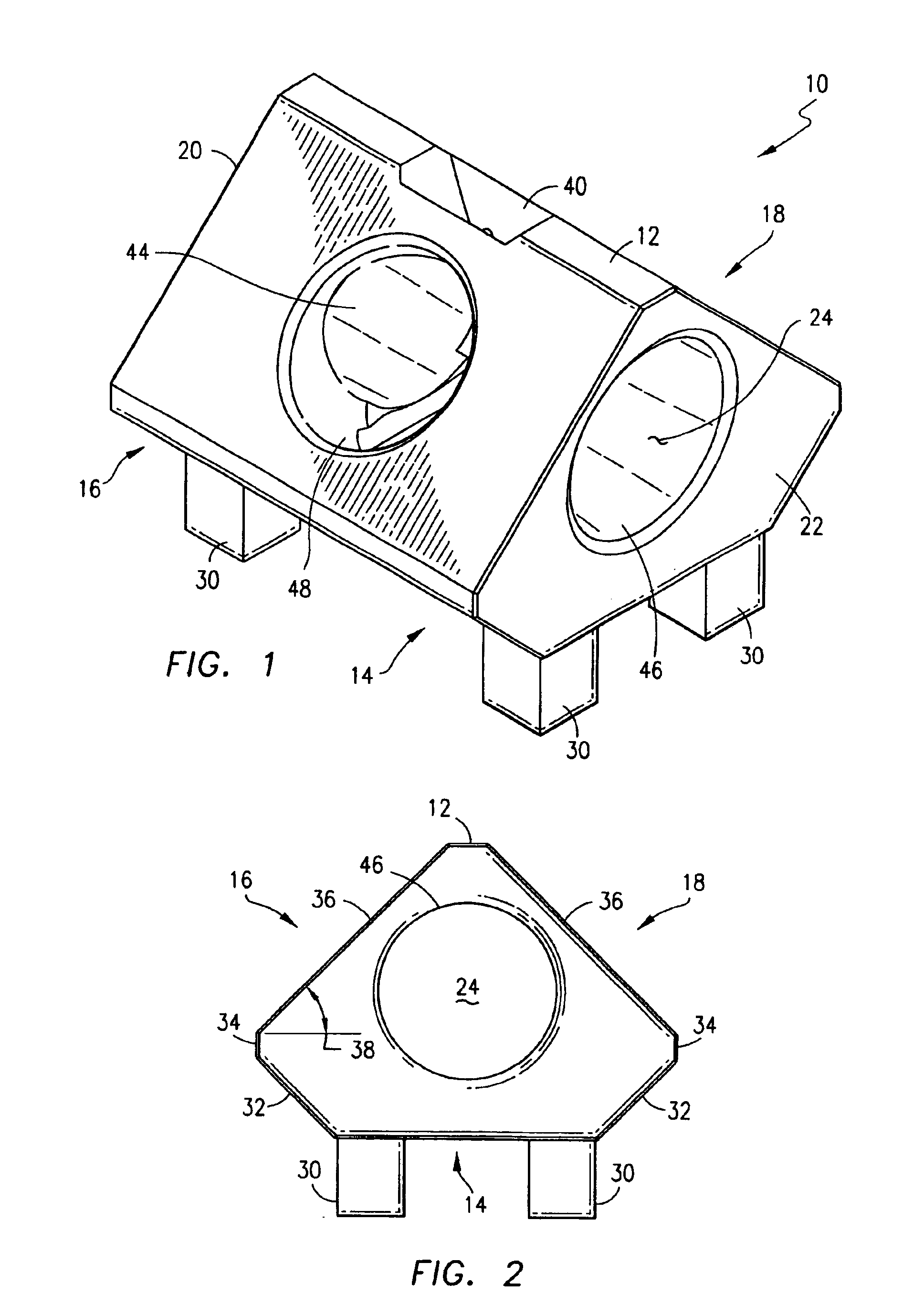

Modular artificial reef, sea wall and marine habitat

InactiveUS6896445B1Improve stabilityReduce porosity and absorptionBreakwatersQuaysSurface oceanModular unit

A modular unit intended for use as an artificial reef, marine habitat and / or sea wall which can be placed in stacked structures along the floor of an ocean, bay, or other body of water comprises a top wall, bottom wall, opposed side walls and opposed end walls which are interconnected to form a hollow interior. Each of the walls is formed with one or more openings whose position and size is designed to allow access of marine life into the interior of the units, permit the passage of sunlight therein, direct the flow of sea water into and through the units in a way which increases stability of the units when placed on the ocean floor, and permit alignment of the holes of one unit with those of another when stacked together.

Owner:ENGLER ERIC

Subsea wellhead system and method for drilling shallow water flow formations

A shallow water flow subsea drilling system is disclosed. A wellhead system is provided with a 36'' conductor pipe in which a 26'' casing and 26'' wellhead housing are landed. The 26'' casing extends to a depth above a shallow water flow zone. A borehole through the shallow water flow zone is sized to accept a 20'' casing to the top of which is secured an 18¾'' wellhead housing. An annulus between the 26'' and 18¾'' housings communicates with cement returns from the 20'' casing. Flow-by holes in the 26'' wellhead housing are sealed with a retrievable seal assembly and actuating mechanism run on the same running tool with the 20'' casing and 18¾'' wellhead housing. A hydraulic feedback mechanism is provided to sense at the service vessel whether or not the seal assembly has been correctly positioned in the annulus. The seal assembly is pressure tested in the same trip while in its pack-off condition and can be retrieved with a second running tool trip.

Owner:FMC CORP

Method and apparatus for suction anchor and mooring deployment and connection

A method and apparatus for deployment of mooring systems for buoyant marine structure such as mobile offshore drilling units (MODU's) and for connecting the same to the mooring lines thereof. An anchor handling vessel carries one or more anchors each having a deployment connection and a mooring connection and individually moves each anchor over its stern roller and deploys it to the sea bottom for installation. A handling line is disconnected by ROV from the deployment connection and is moved from the deployment connection to the mooring connection so as to become the main mooring line. Syntactic buoys are then mounted on the main mooring line for elevating it above the sea bottom for recovery. When MODU stationing is desired the anchor handling vessel then recovers the surface buoy and connects to the rig mooring line using a short section of mooring chain. A J-chaser stopper device is then installed in the mooring string and is connected to the mooring line of the MODU by a short section of chain. The J-chaser lowers the mooring string, completing the mooring connection between the anchor and the MODU. A plurality of mooring strings, typically eight, are deployed in this manner to properly station the MODU. Disconnection of the MODU is accomplished essentially by the reverse of the above deployment procedure.

Owner:DELMAR SYST

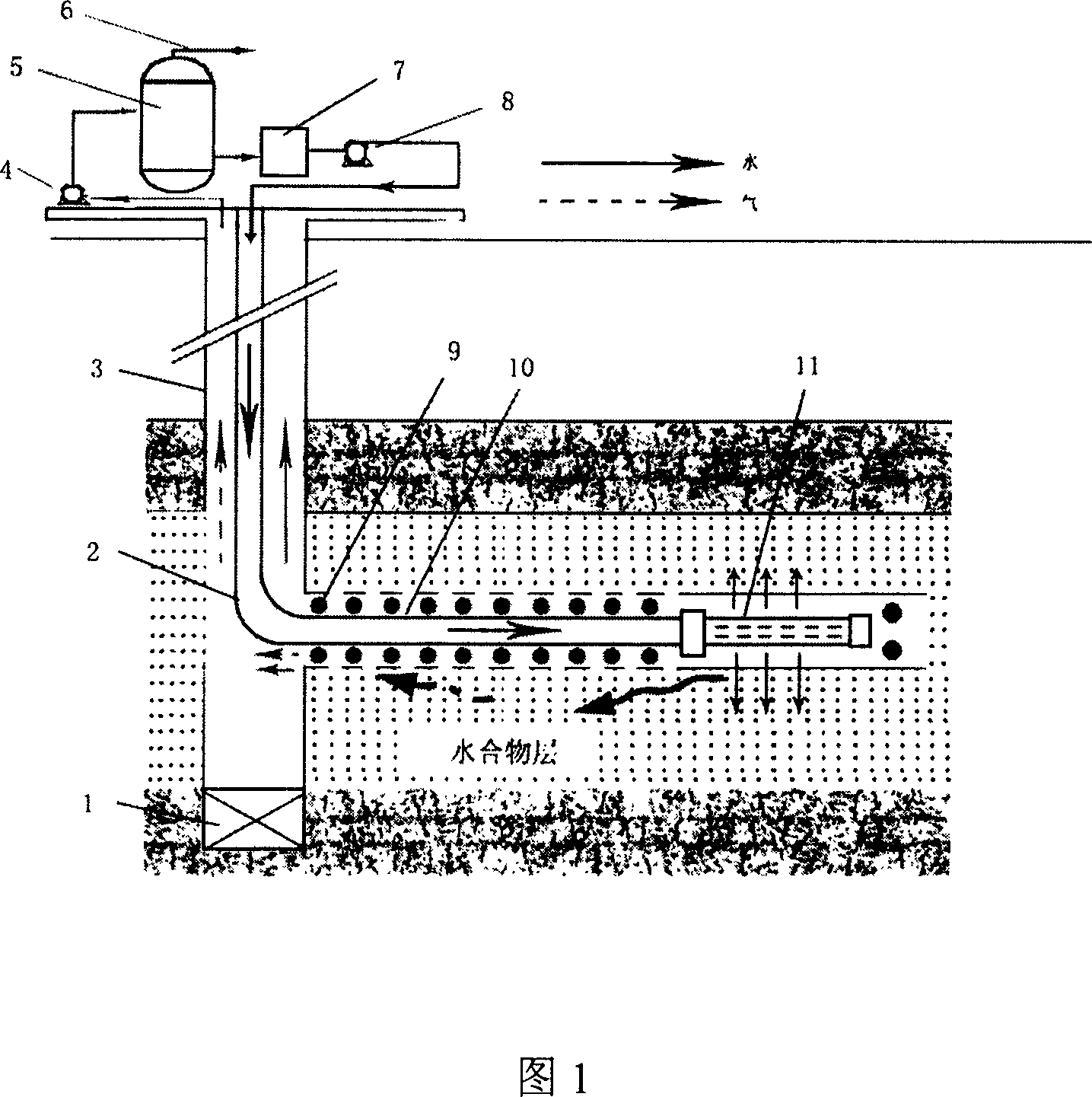

Method for recovering sea bottom hydrate by single well heat injection circulation

InactiveCN1944949AAvoid sewageEasy to operateConstructionsMineral miningHydrate decompositionThermal water

The single well operation process for exploiting hydrate from sea bottom includes the following steps: drilling one horizontal section in the top of hydrate layer to expand the hydrate layer exposing area; connecting slotted pipe to the end of the horizontal section to increase the passage area of the recirculated medium; forming one circulation with the oil pipe and the annular space and with water as the circulating medium; injecting hot water into oil pipe from the platform and returning hot water to the vertical section to exchange energy with stratum and to decompose the hydrate; backing upwards the mixed liquid through the annular space; adopting sand preventer in the horizontal section to leave sand in the storing layer; and treating the exploited water and reinjetting to underground for reuse and separating from sea water to avoid environmental pollution.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com