Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

219 results about "Set constraint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics and theoretical computer science, a set constraint is an equation or an inequation between sets of terms. Similar to systems of (in)equations between numbers, methods are studied for solving systems of set constraints. Different approaches admit different operators (like "∪", "∩", "\", and function application) on sets and different (in)equation relations (like "=", "⊆", and "⊈") between set expressions.

System and Method to Provide Custom Constraints for Faceted Exploration

InactiveUS20080086451A1Web data indexingDigital data processing detailsInteraction deviceData mining

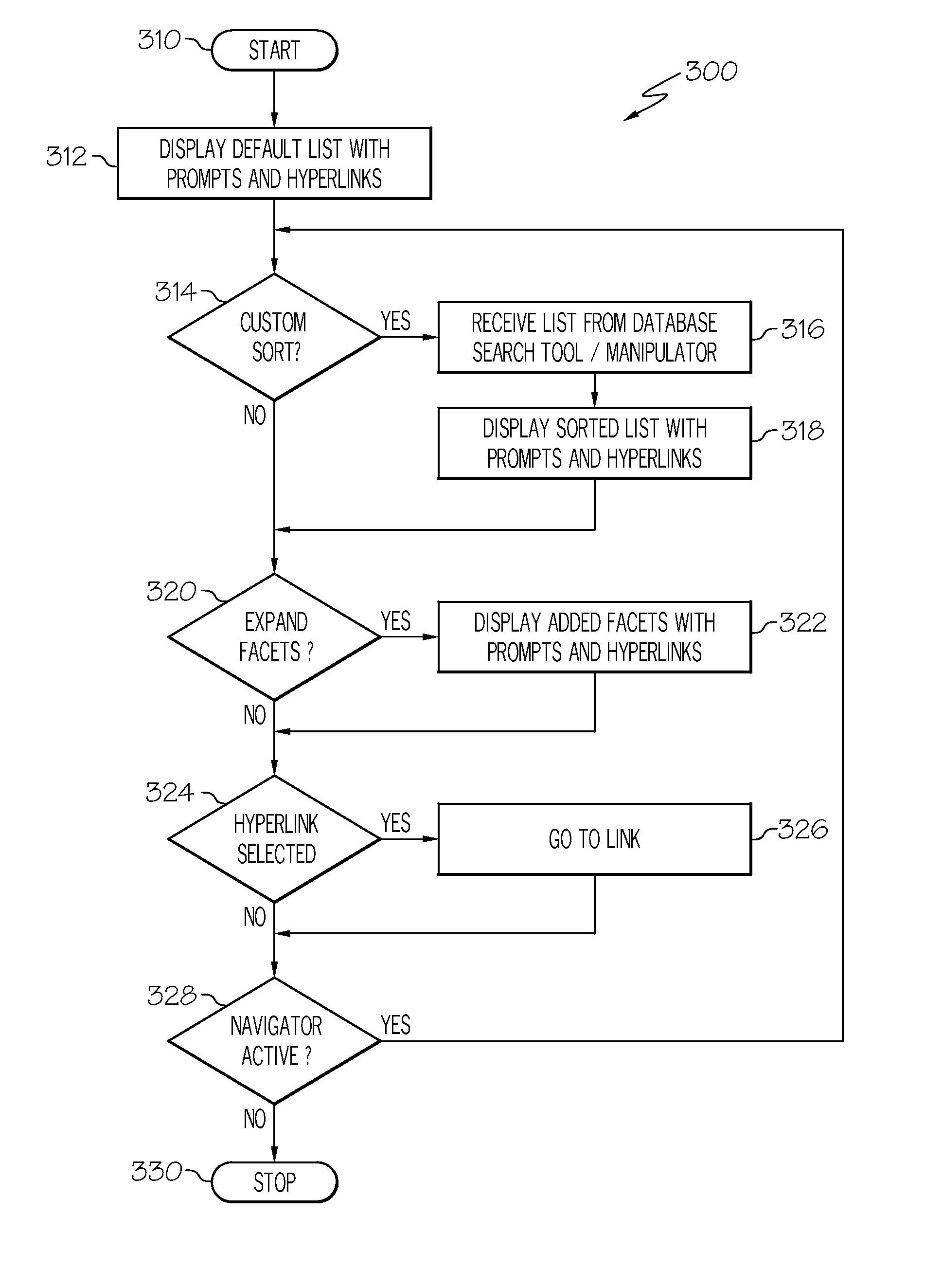

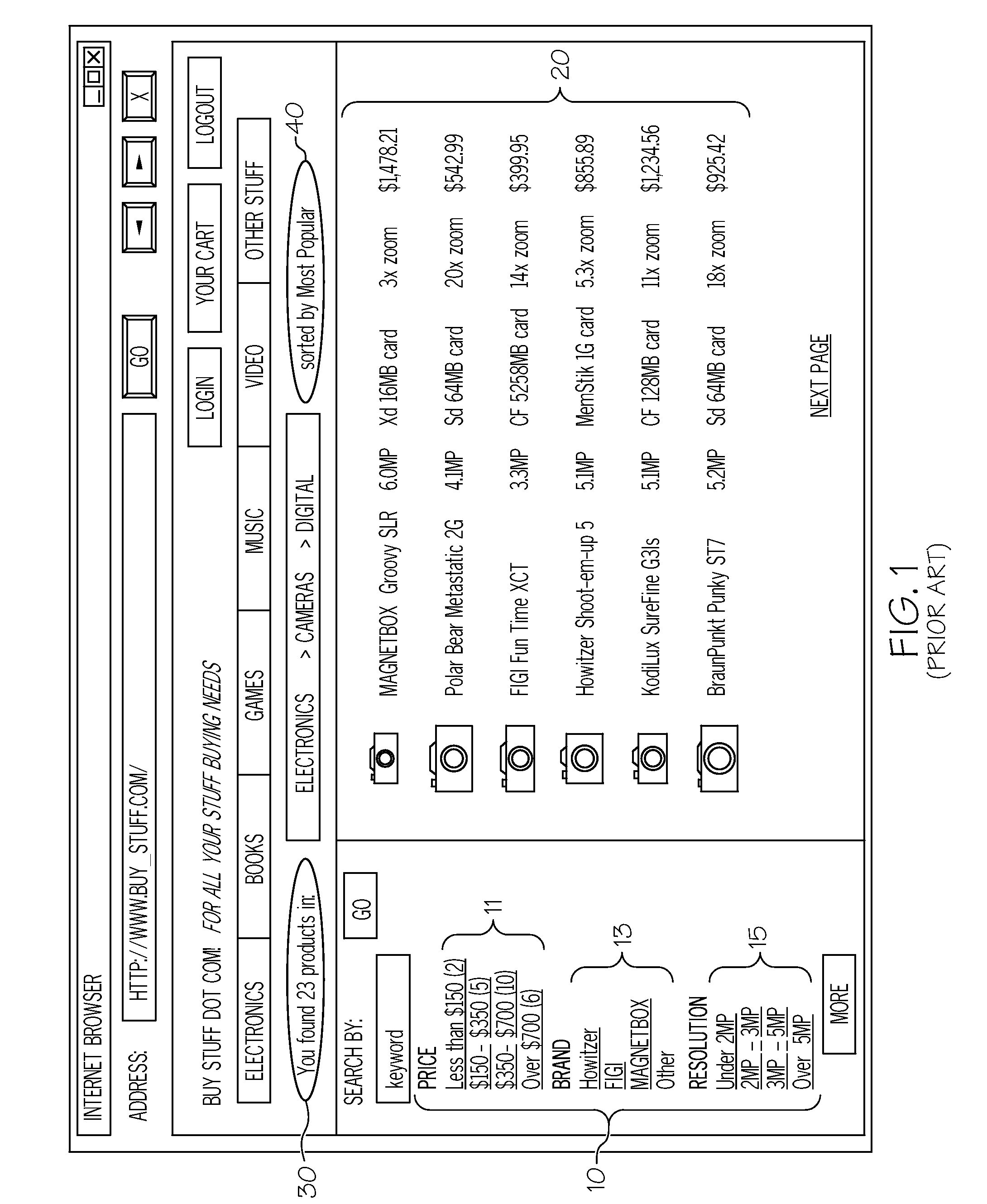

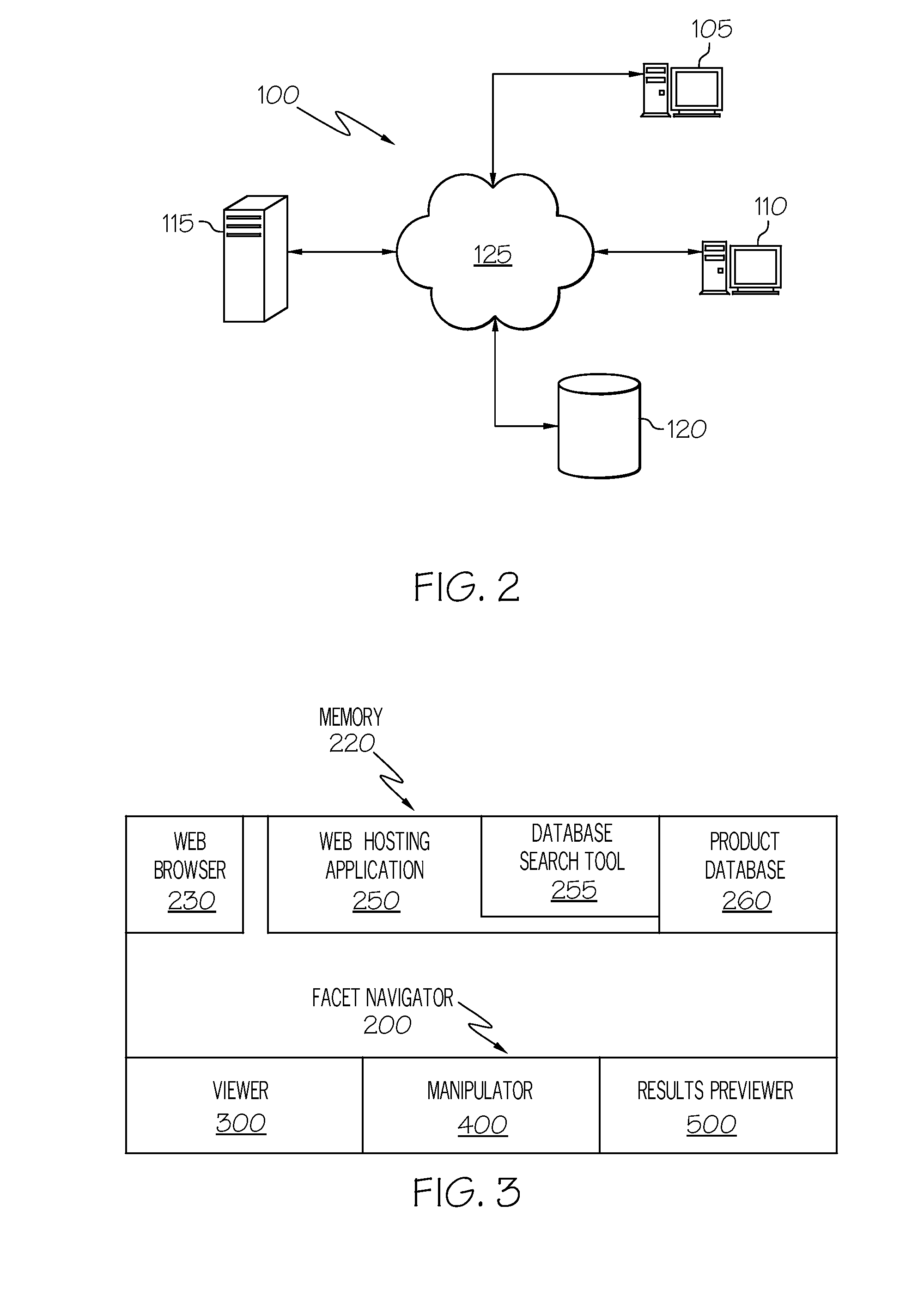

The Facet Navigator permits users to set custom constraints for searching databases by facet, displays facets representing fields in a database, and provides a manipulator for each facet. The manipulator may be a slider bar, or a drop-down menu, or some other interactive device known to persons skilled in the art. When a user sets constraints for a facet with the manipulator, the Facet Navigator searches the database based on the constraints and displays a list of items in the database that satisfy the constraints. The Facet Navigator displays a preview of interim results whenever a cursor is moved over an active region of the manipulator, where the preview includes details of database items meeting a search criteria based on the location of the cursor on the manipulator.

Owner:IBM CORP

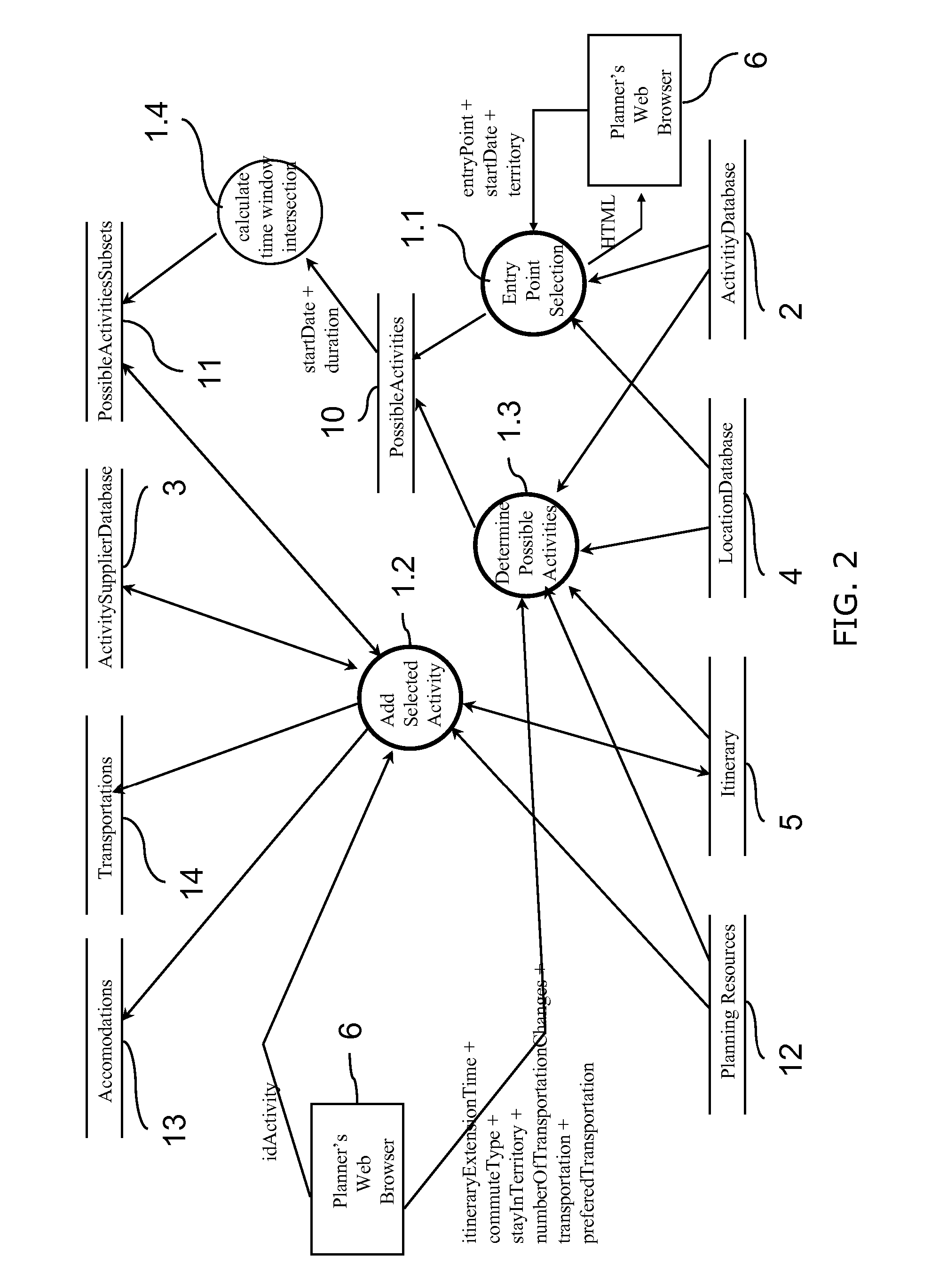

Itinerary planning tool, system, method, software, and hardware

InactiveUS20070078729A1Enough timeReduce the burden onReservationsMarketingProgram planningEntry point

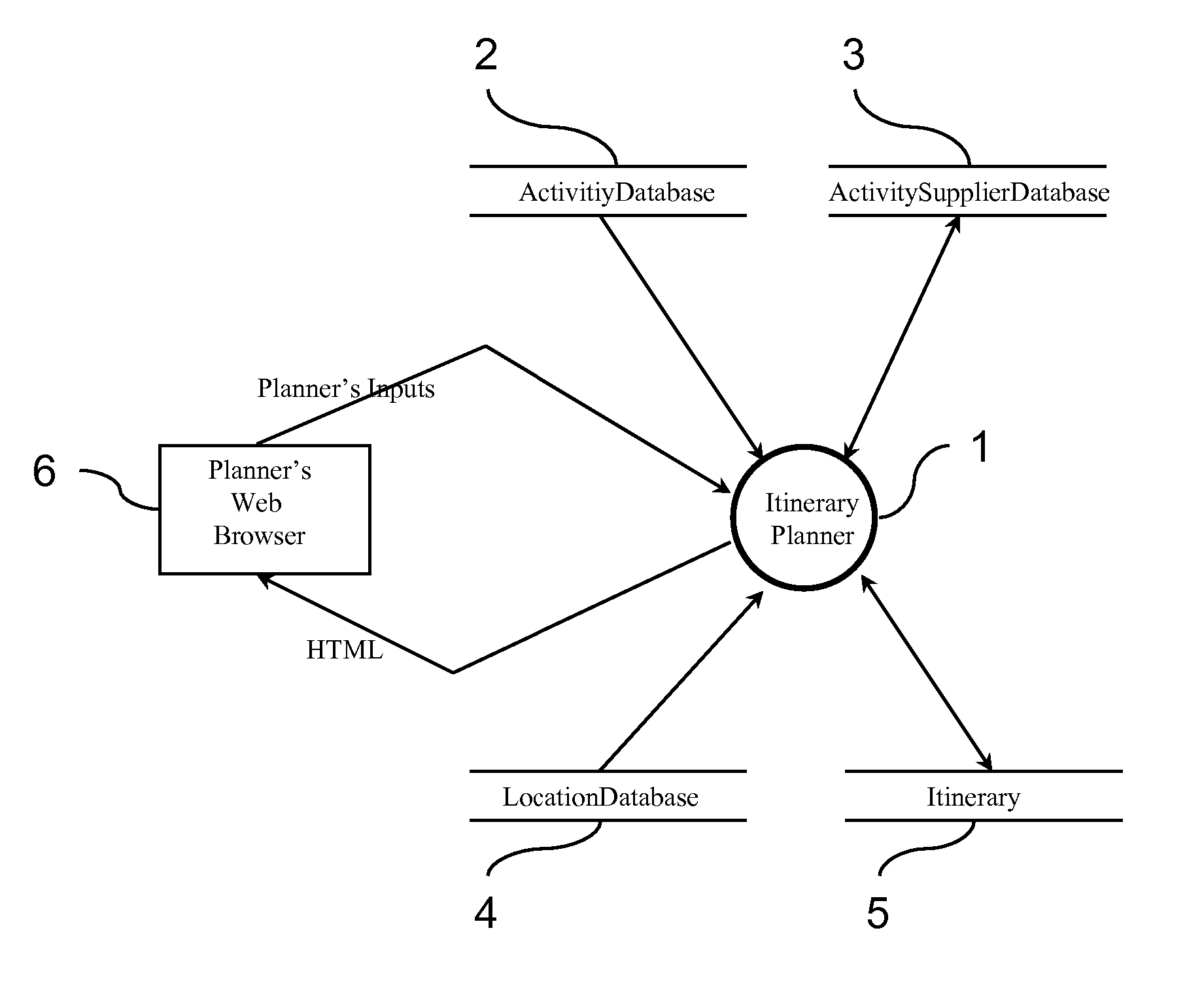

An activity-based itinerary planning tool permits a trip planner to incrementally build an itinerary, starting at a selected entry point and adding activities in a step-by-step manner, by taking into account commute times for different types of transportation and entry / exit conditions for particular activities / facilities, in order to present the user with lists of all activities / facilities that can be reached from the entry point or from already-selected activities / facilities. Also, an electronic marketplace for consumers and suppliers of activities to meet and exchange. Consumers are given search tools for narrowing all possible activities to those a consumer can actually perform and attend, based on their proximity and performance criteria. Suppliers are given tools to enter activities into a central repository, and set constraints to prevent unqualified consumers from purchasing. Detection change monitors the activities of the database for changes that will invalidate original recommendations, and provides consumer notification.

Owner:BROWN KEVIN LEE

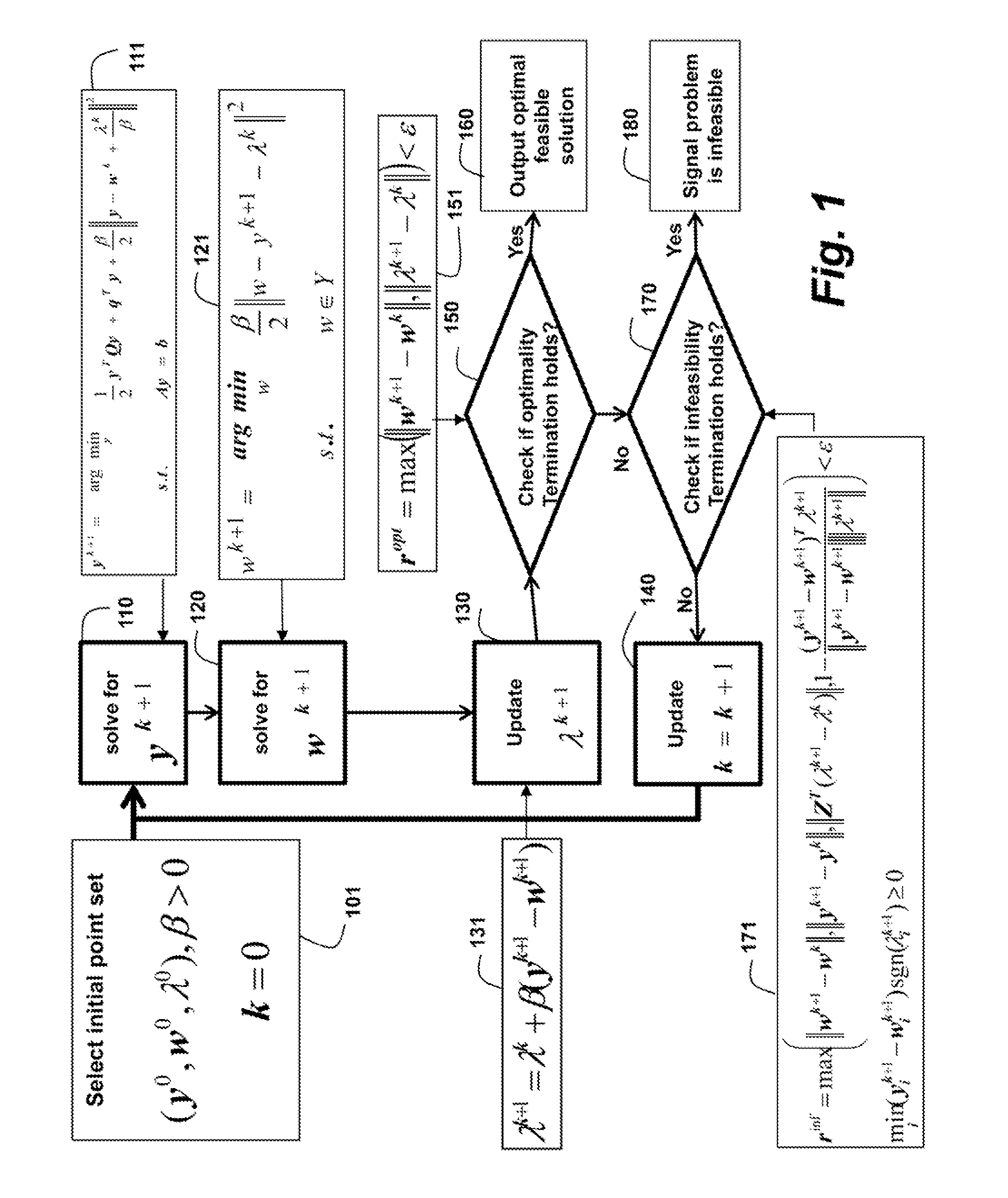

Method for Solving Quadratic Programs for Convex Sets with Linear Equalities by an Alternating Direction Method of Multipliers with Optimized Step Sizes

ActiveUS20150234779A1Minimizes violationMinimizes numberCode conversionComplex mathematical operationsAlgorithmEuclidean vector

Owner:MITSUBISHI ELECTRIC RES LAB INC

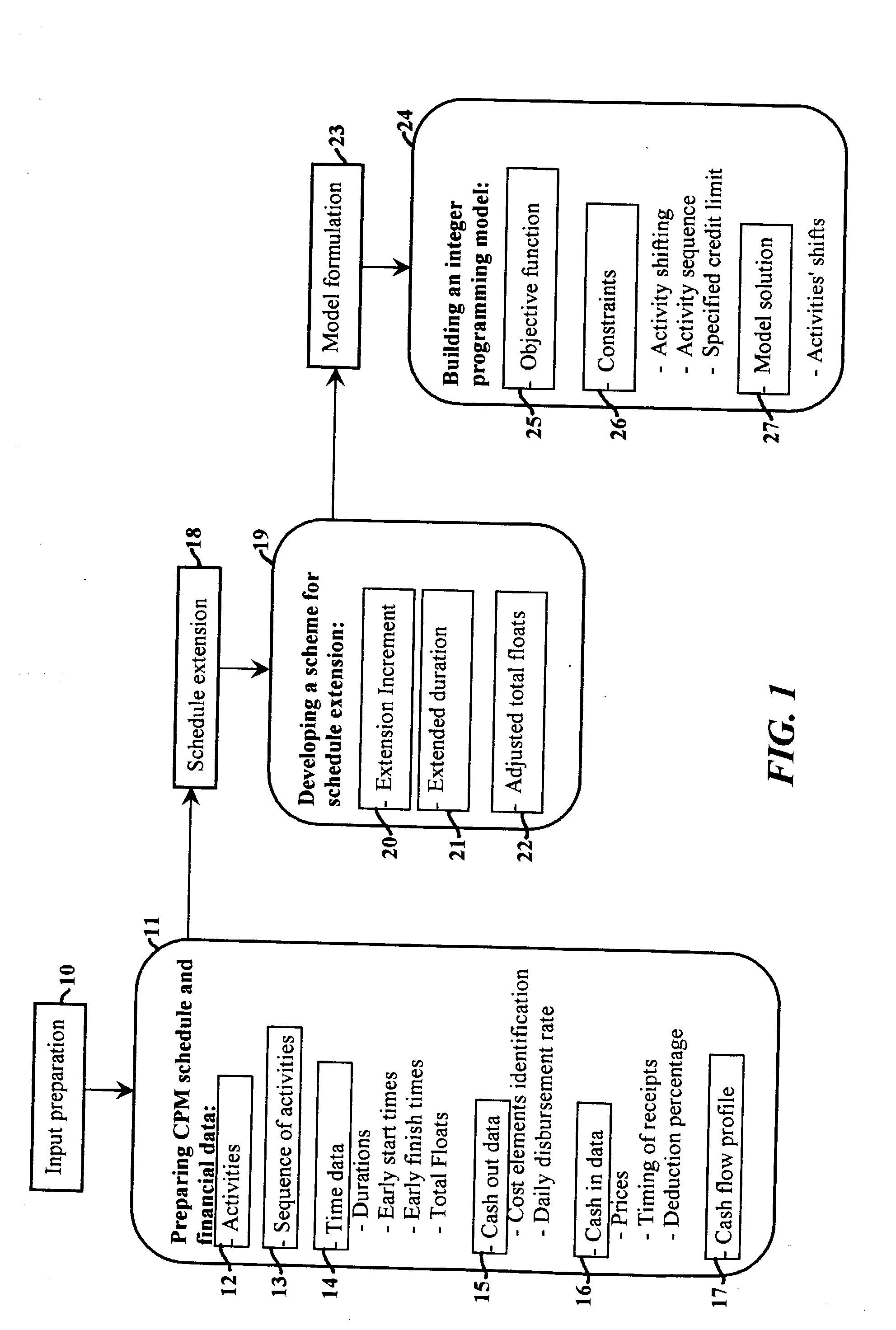

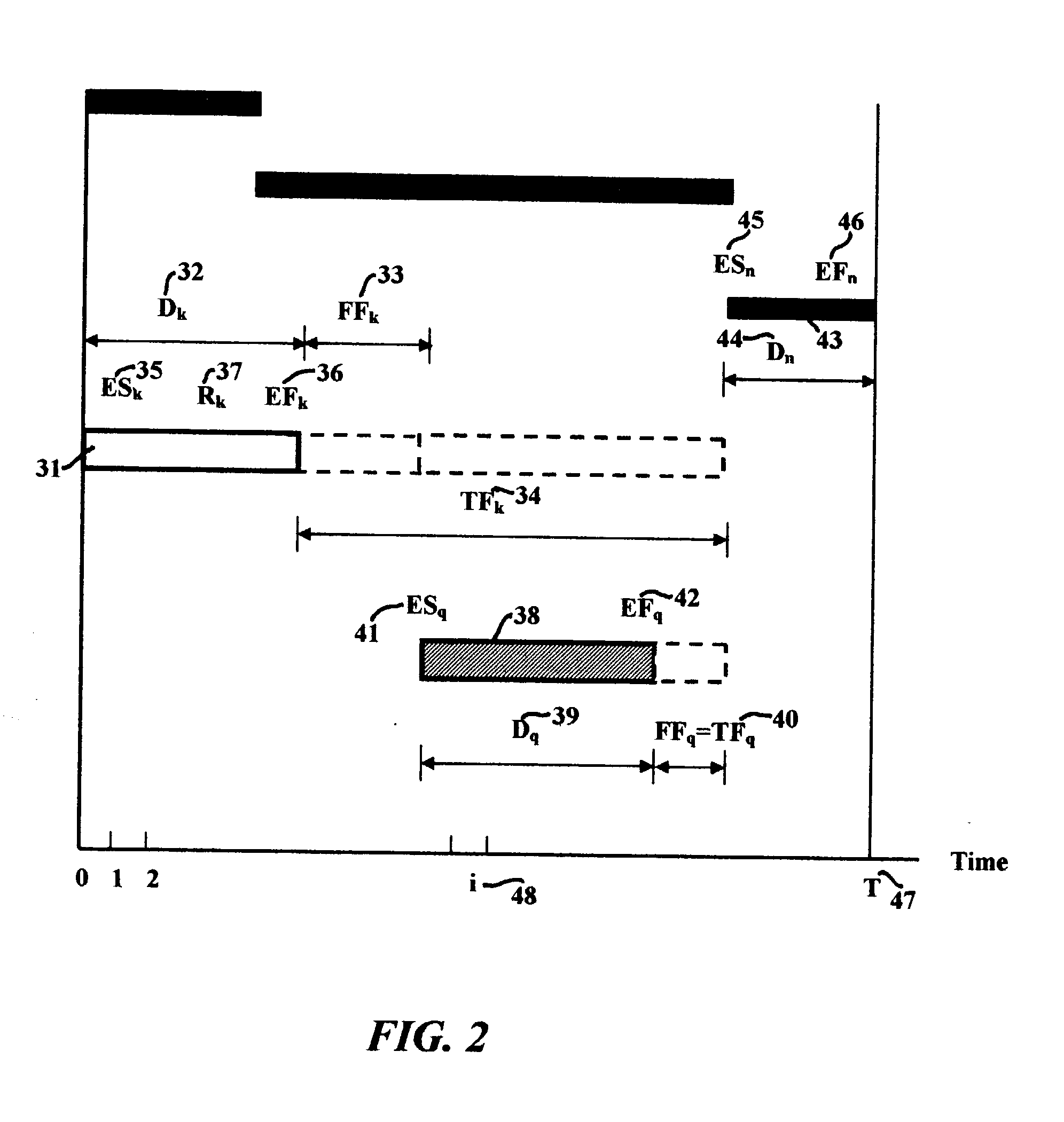

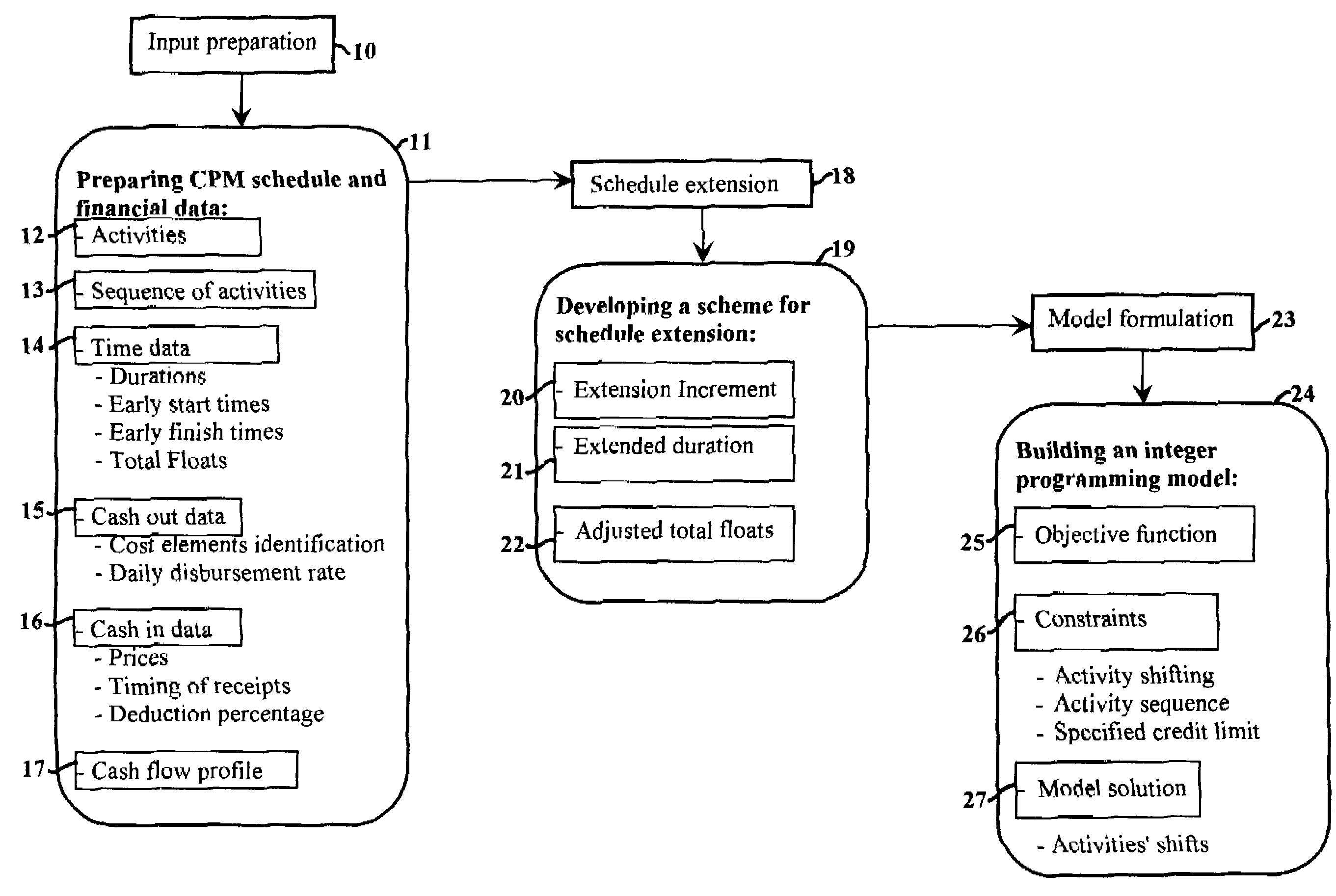

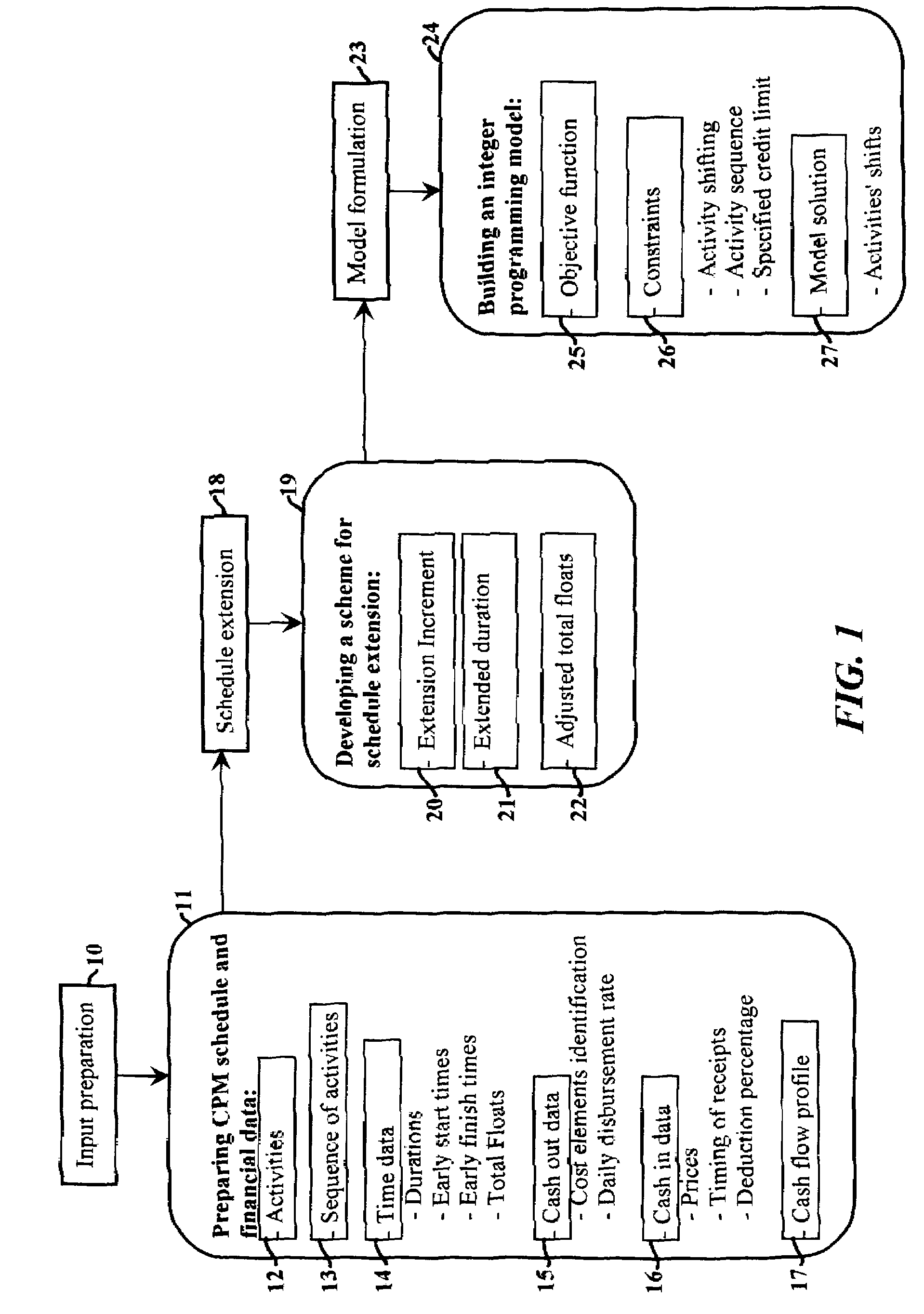

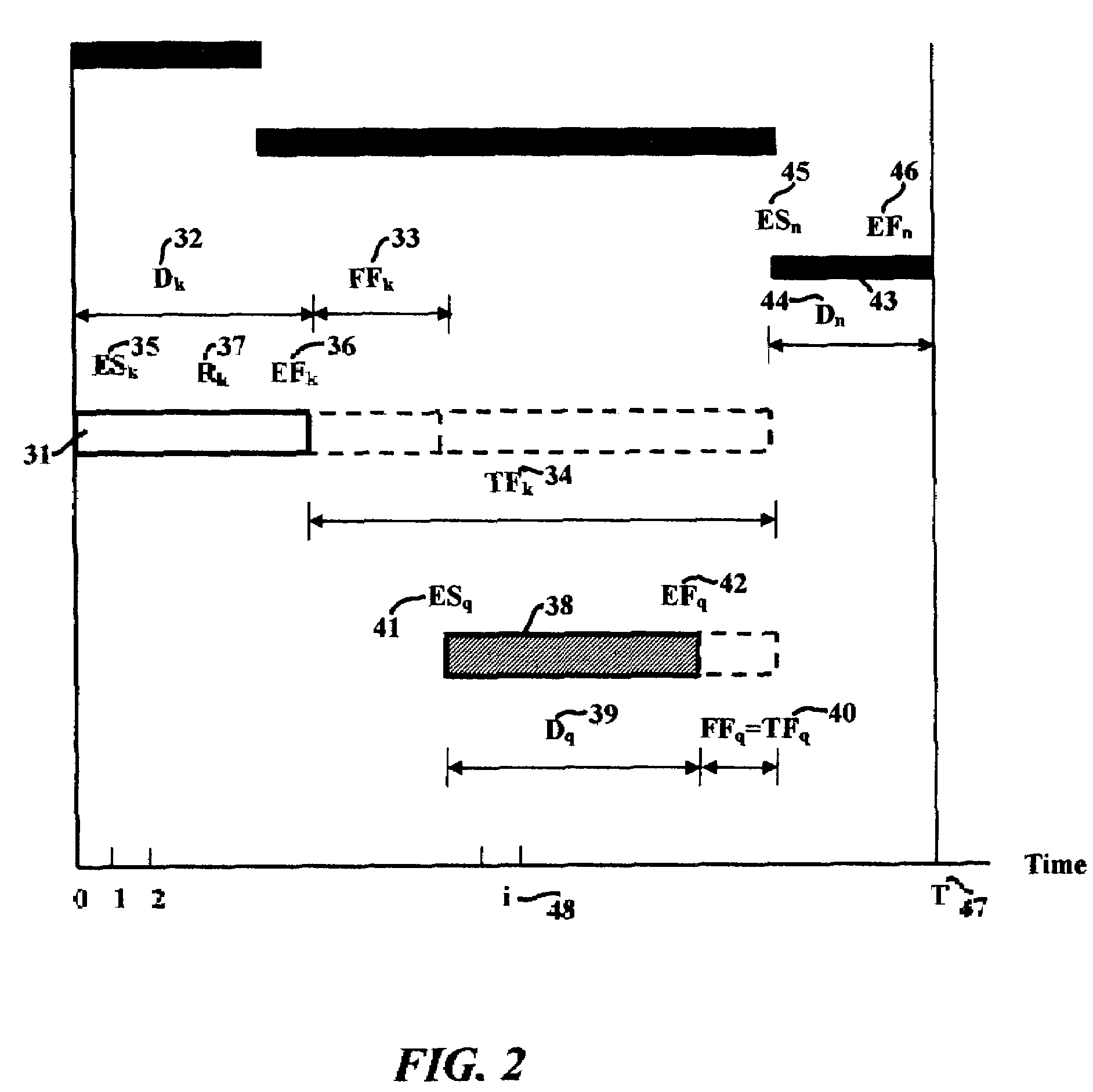

Method and apparatus for finance-based scheduling of construction projects

a method and apparatus is disclosed for scheduling construction projects based on the available finance using integer programming. This method renders CPM / PERT schedules of construction projects executable using bank overdrafts of specified credit limits. Conveniently, the method is organized in three stages; input preparation, schedule extension, and model formulation. Input preparation stage supports preparing CPM / PERT schedule and financial data of the project. Schedule extension stage supports developing a scheme for schedule extension. The scheme is a framework of the original schedule that allows a definite extension increment in the critical path of the CPM. Model formulation stage supports building an integer programming model for the scheme and involves the components of formulating an objective function, setting constraints, and searching for a model solution. The model solution determines the activities' shifts that fulfill the constraints of the specified credit limit while minimizing the schedule extension. A search for a solution of the model is performed. If no solution is found, a repetition of the last two stages of the method is performed after allowing longer extension increment.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

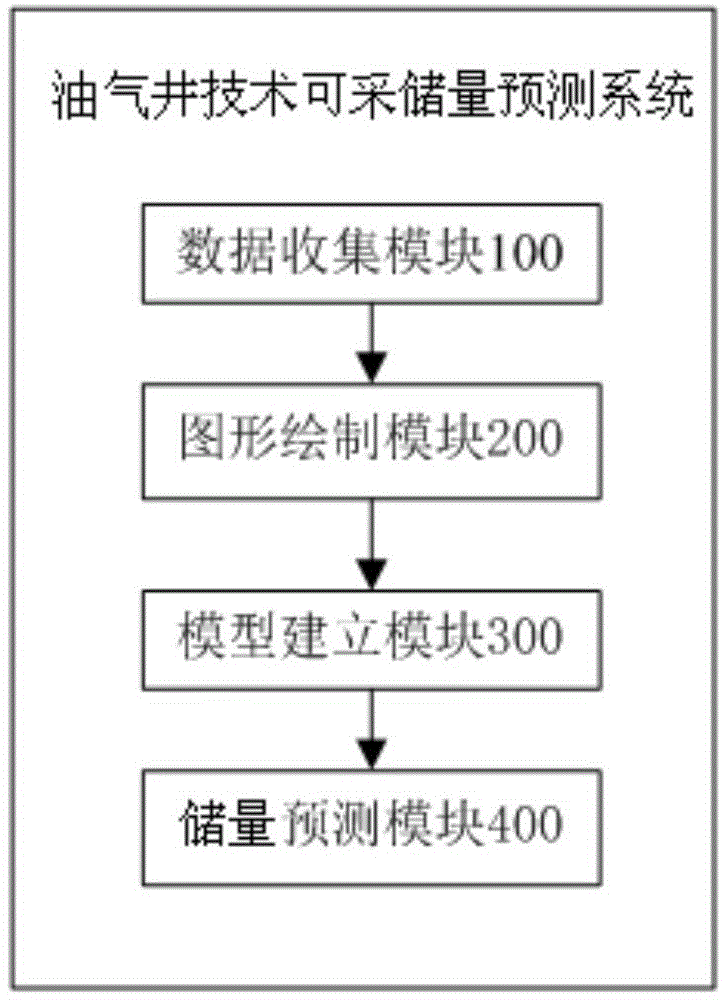

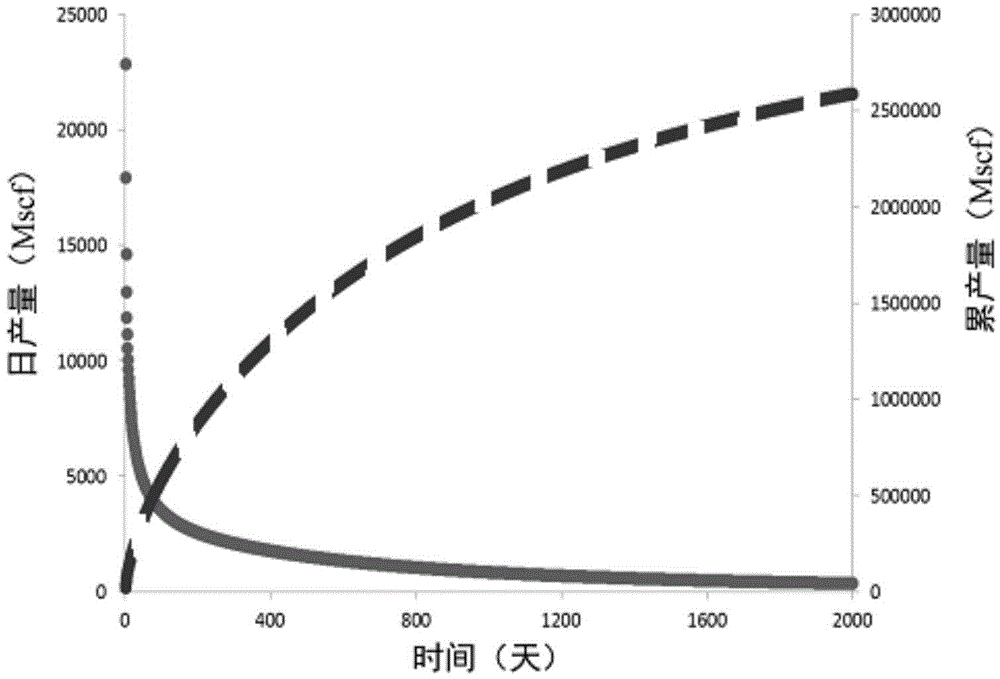

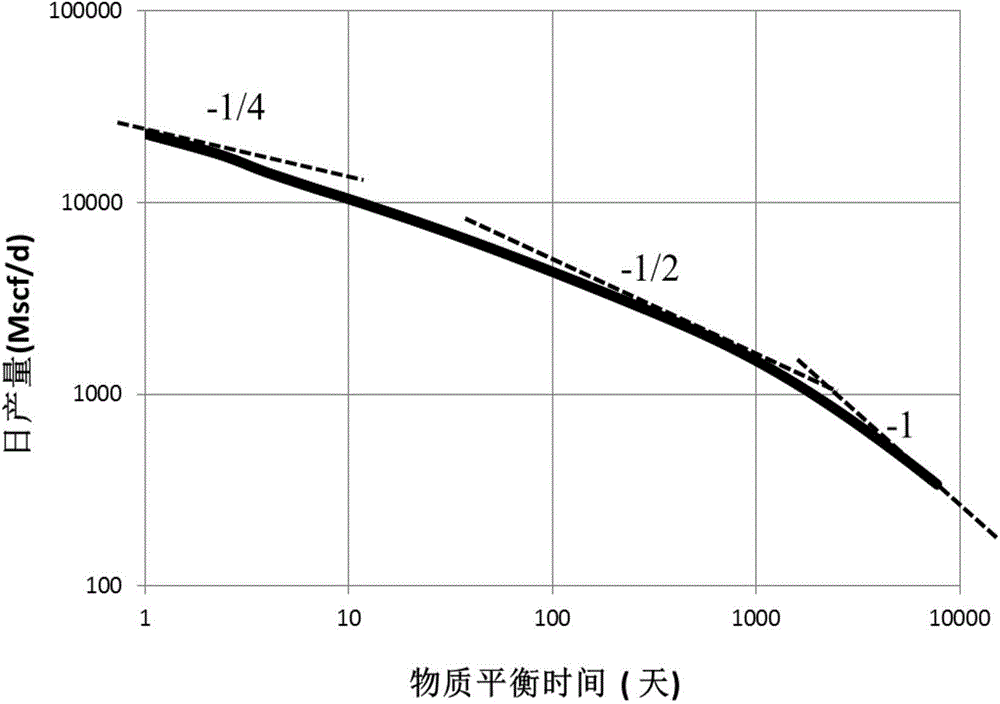

Oil and gas well technical recoverable reserves prediction method

ActiveCN105569646AImprove forecast accuracySolving Uncertain Technical IssuesBorehole/well accessoriesMaterial balanceComputer science

The invention provides an oil and gas well technical recoverable reserves prediction method. The method comprises: collecting daily output and accumulated output data; according to the daily output and accumulated output data, drawing a daily output and material balance time relation curve, the material balance time being ratio of accumulated output and daily output in corresponding time, then, through taking a derivative of the daily output and material balance time relation curve, drawing a feature segment, the feature segment being a segment whose slope is a special value; according to the distribution condition of the feature segment in the daily output and material balance time relation curve, determining a flow filed type, and then according to the flow filed type, establishing a corresponding production decline analysis model; finally, under a set constraint condition, according to the production decline analysis model, predicting technical recoverable reserves. In the method, the production decline analysis model is unified in the same decision rule, and analysis and selection of adaptability of the production decline analysis model are performed through flow field identification, so as to predict technical recoverable reserves. The method can solve technical problems in the prior art that a prediction result is not determined caused by blindly choosing a model, and the method improves prediction precision of the technical recoverable reserves.

Owner:CHINA PETROLEUM & CHEM CORP +1

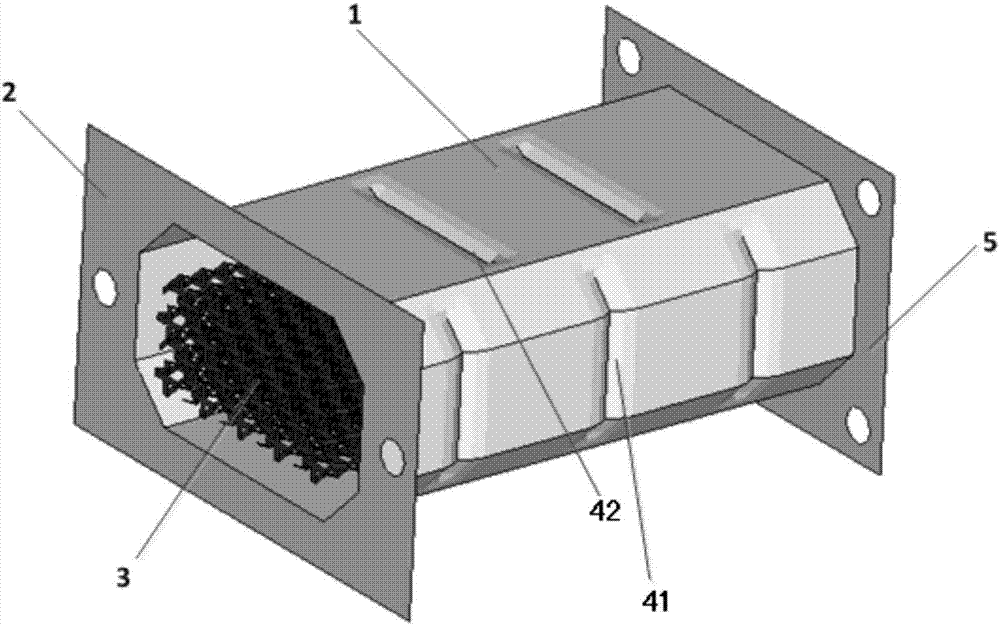

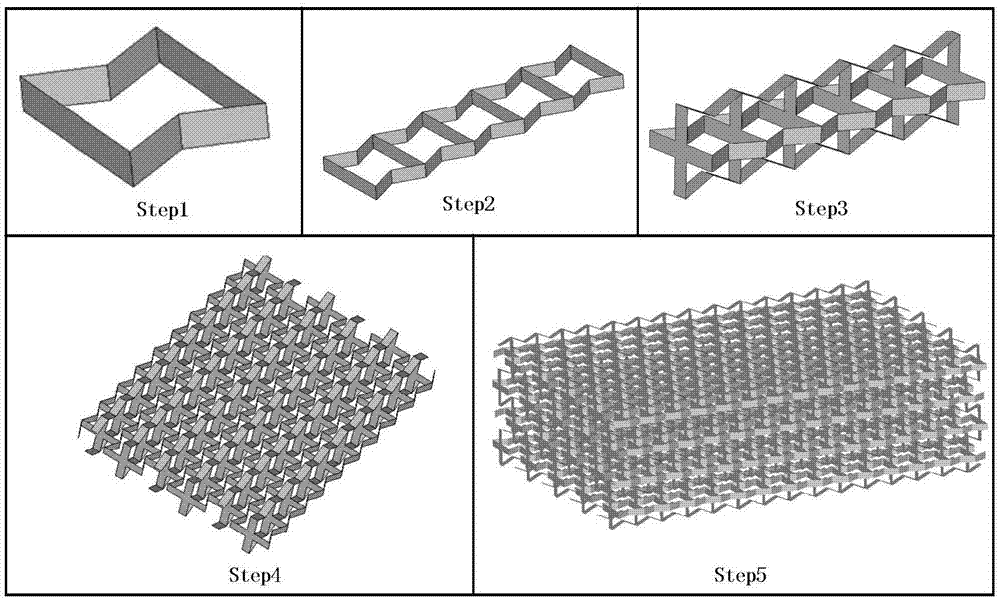

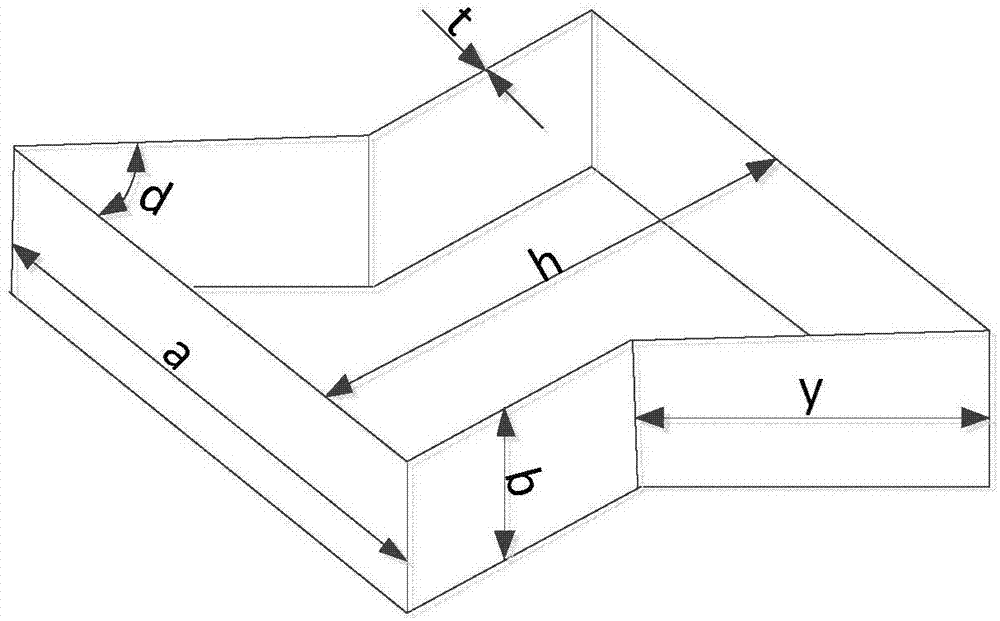

Negative-Poisson-ratio structure type energy absorption box and multi-objective optimization method therefor

PendingCN106934175AImprove energy absorptionGeometric CADMulti-objective optimisationEnergy absorptionEngineering

The invention discloses a negative-Poisson-ratio structure type energy absorption box and a multi-objective optimization method therefor. The negative-Poisson-ratio structure type energy absorption box consists of an energy absorption box body (1), a front mounting plate (2), a back mounting plate (5) and a three-dimensional negative-Poisson-ratio structure type inner core (3). The three-dimensional negative-Poisson-ratio structure type inner core consists of a large amount of negative-Poisson-ratio unit cell structures, so that parameters of the negative-Poisson-ratio unit cell structures have a great influence on energy absorption performance of the energy absorption box. The invention provides the multi-objective optimization method based on the negative-Poisson-ratio structure type energy absorption box. The method comprises the steps of establishing an objective function by taking the parameters of part of the negative-Poisson-ratio unit cell structures as optimization variables; setting constraint conditions; building a negative-Poisson-ratio structure type energy absorption box optimization model; and performing multi-objective optimization on the negative-Poisson-ratio structure type energy absorption box by adopting a multi-objective particle swarm optimization algorithm.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

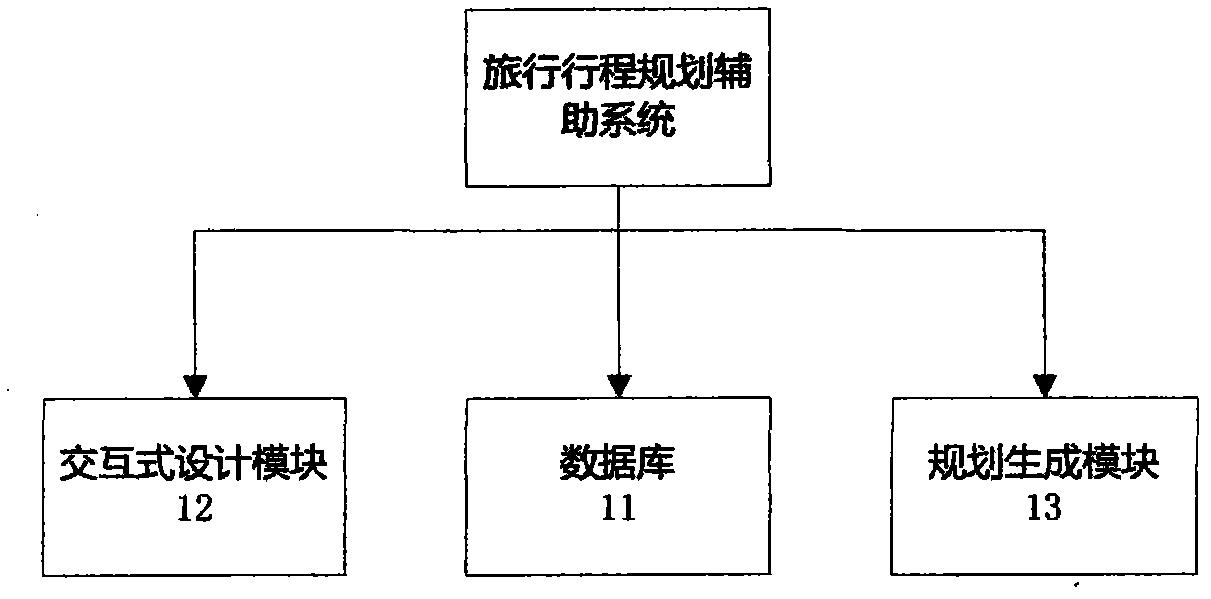

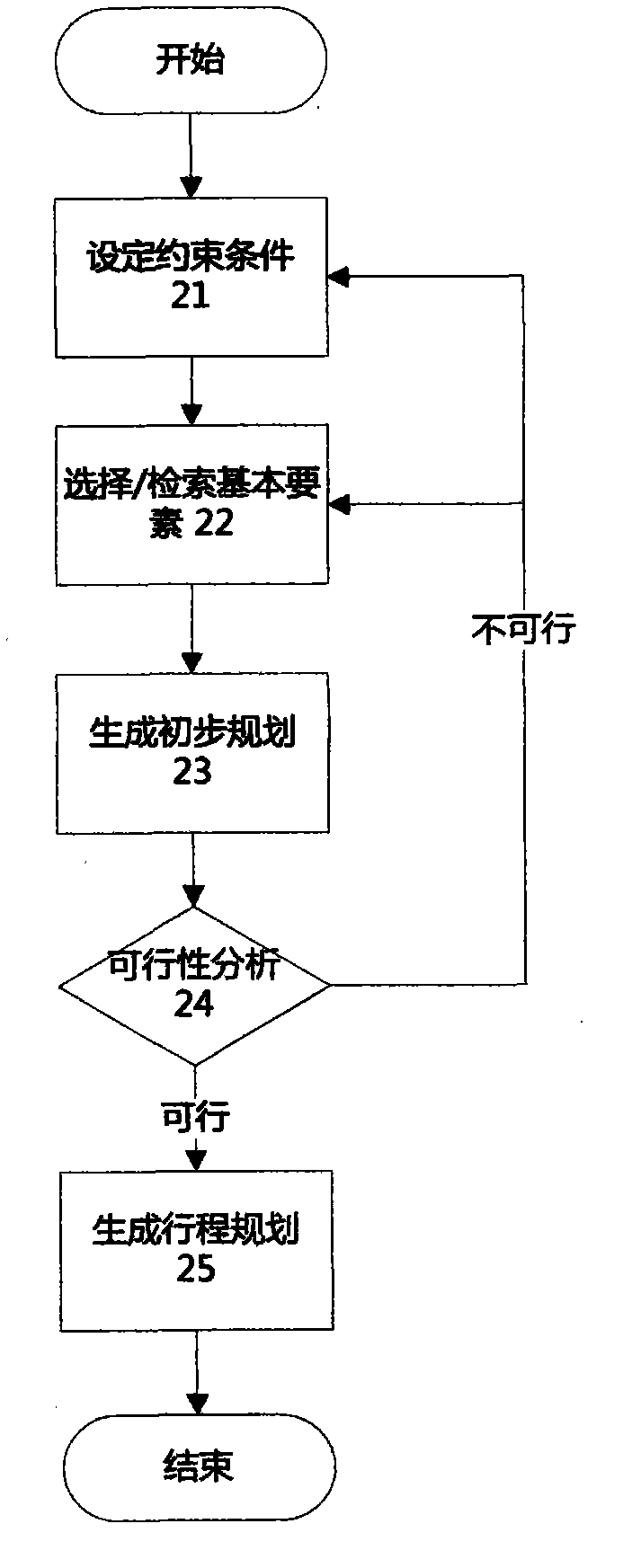

Auxiliary system and method for travel journey plan

InactiveCN102073696AFree from wantEasy to operateSpecial data processing applicationsPersonalizationChronological time

The invention belongs to the field of information technology and travel service. An auxiliary system for a travel journey plan structurally at least comprises a 'food, housing, transportation, traveling, entertainment and purchasing' database, an interactive journey design module and a plan generation module, wherein the 'food, housing, transportation, traveling, entertainment and purchasing' database contains geographic information; the interactive journey design module is combined with a map function; and the plan generation module is used for generating the travel journey plan according to set conditions. Meanwhile, the invention also discloses a method for a personalized journey plan on the basis of the auxiliary system for the travel journey plan. The method comprises the following implementing processes that: a user sets constraint conditions; the user selects or searches link elements of 'food, housing, transportation, traveling, entertainment and purchasing' and combines the selected elements according to a time sequence to generate a primary journey plan by the system; the system automatically carries out feasibility analysis according to the constraint conditions of space, time, cost and the like and feeds back a suggestion prompt; the user changes the elements or modifies the constraint conditions; and the system generates a journey plan scheme containing information of time, position and cost.

Owner:刘志

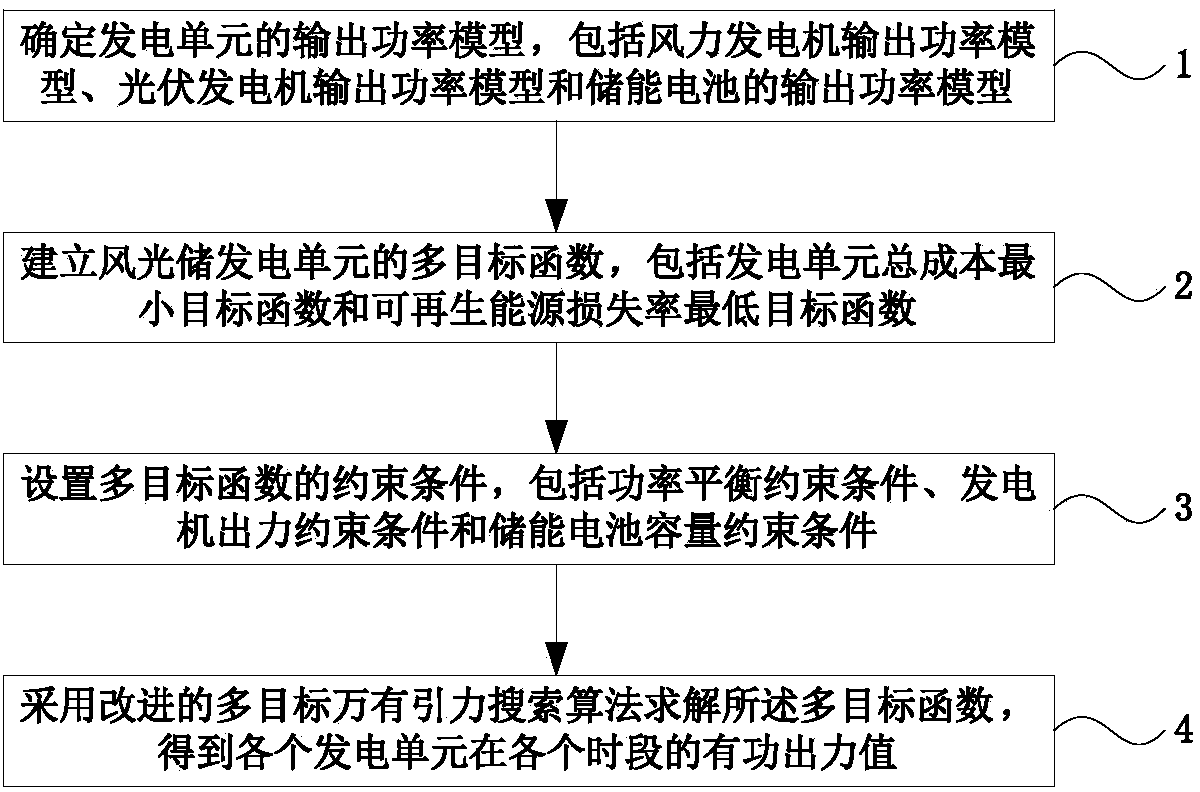

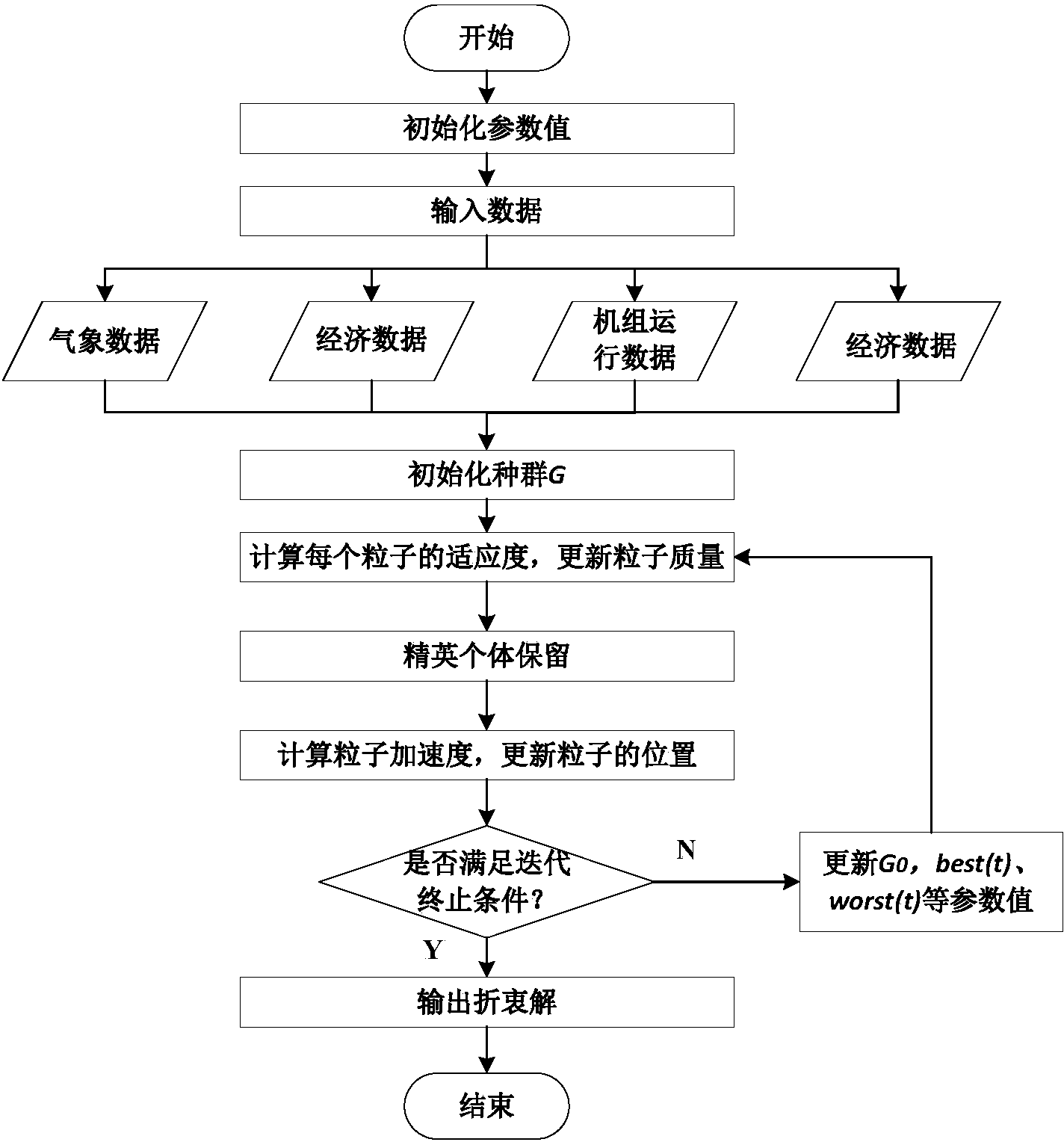

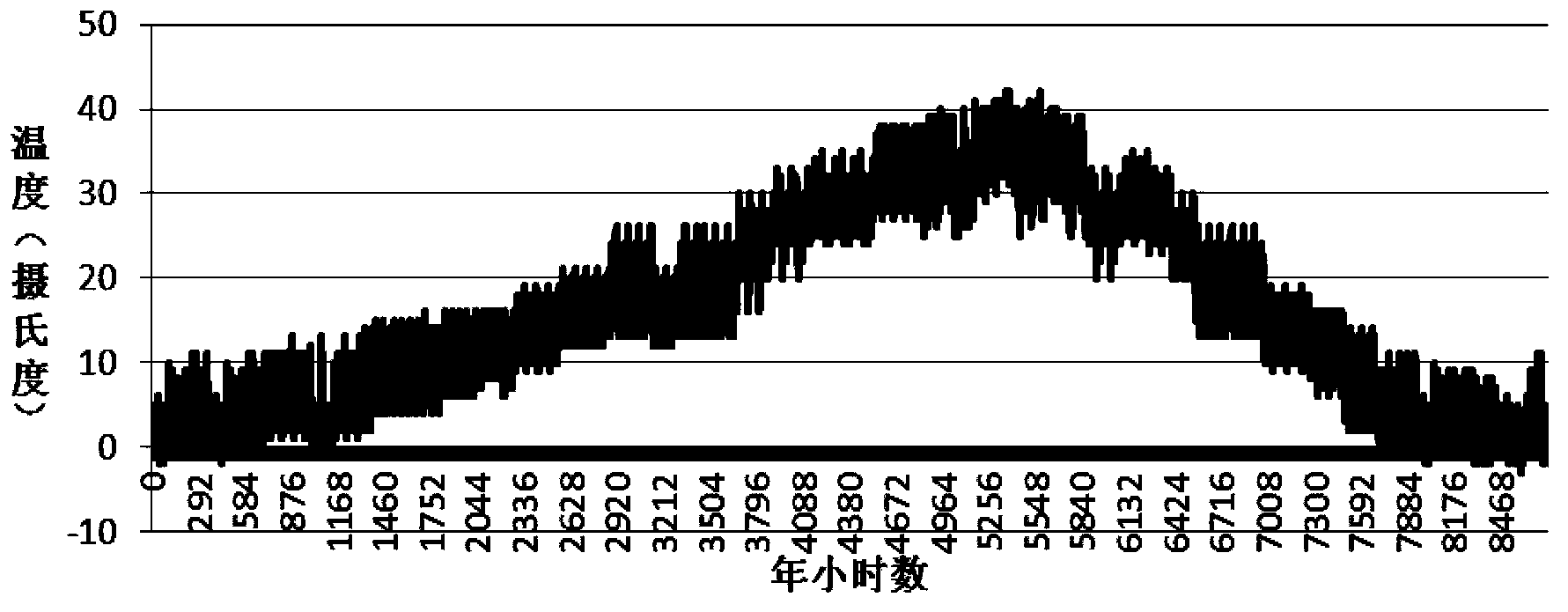

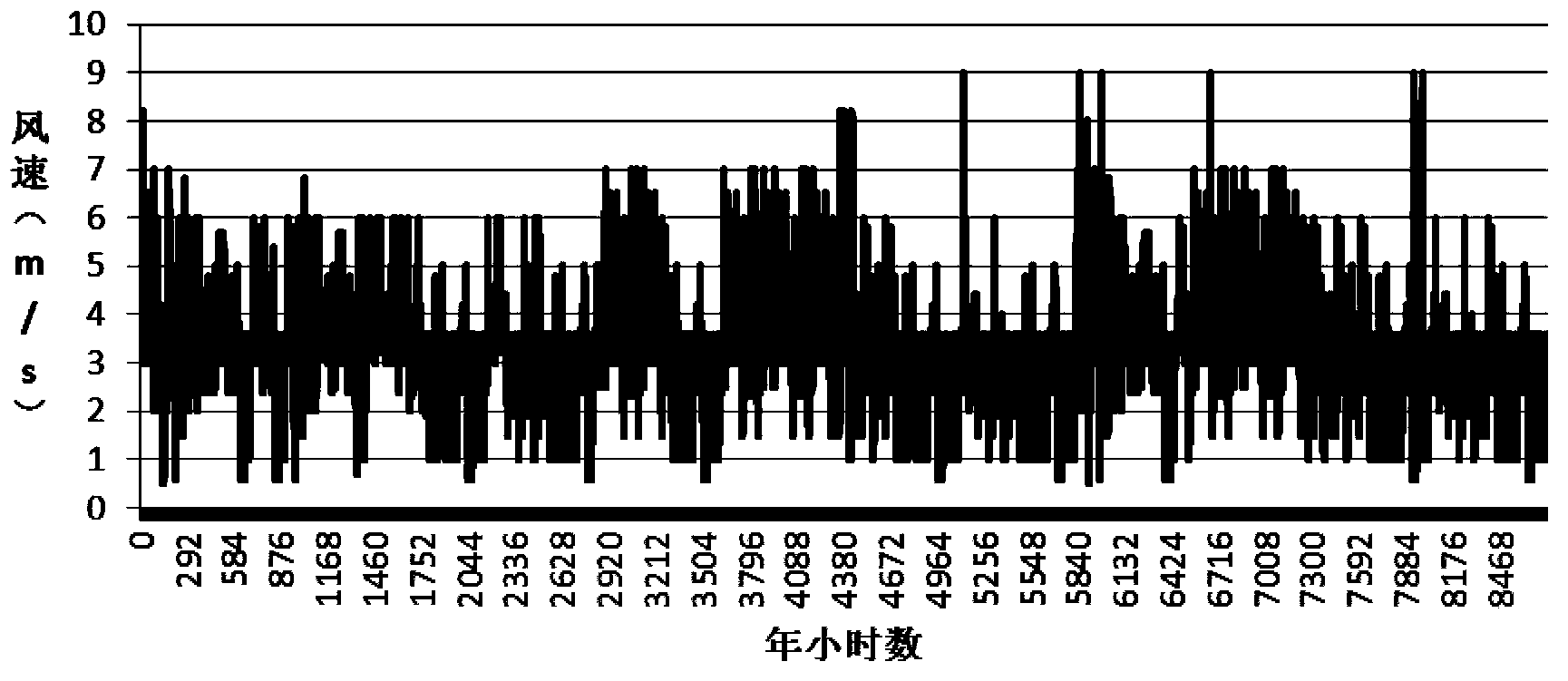

Multi-target coordinated operation optimization method of wind and photovoltaic storage electricity generation units

InactiveCN104022534AMaximum service lifeImprove operational efficiencyForecastingSingle network parallel feeding arrangementsWind drivenPower balancing

The invention discloses a multi-target coordinated operation optimization method of wind and photovoltaic storage electricity generation units and relates to the technical field of wind and solar storage electricity generation control. The method comprises the steps of determining output power models of the electricity generation units, wherein the output power models comprise the output power models of wind driven generators, the output power models of photovoltaic generators and the output power models of energy storage batteries; building multi-objective functions of the wind and photovoltaic storage electricity generation units, wherein the multi-objective functions comprise the electricity-generation-unit total-cost minimum objective functions and the renewable-energy-source loss-ratio minimum objective functions; setting constraint conditions of the multi-objective functions, wherein the constraint conditions comprise the power balance constraint conditions, the generator output constraint conditions and the energy-storage-battery capacity constraint conditions; solving the multi-objective functions through an improved multi-target universal gravitation search algorithm to obtain an active output value of each period of each electricity generation unit. On the basis that renewable energy sources are fully used, the longest service life of each storage battery is achieved, and therefore overall operating efficiency of the wind and photovoltaic storage electricity generation units is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

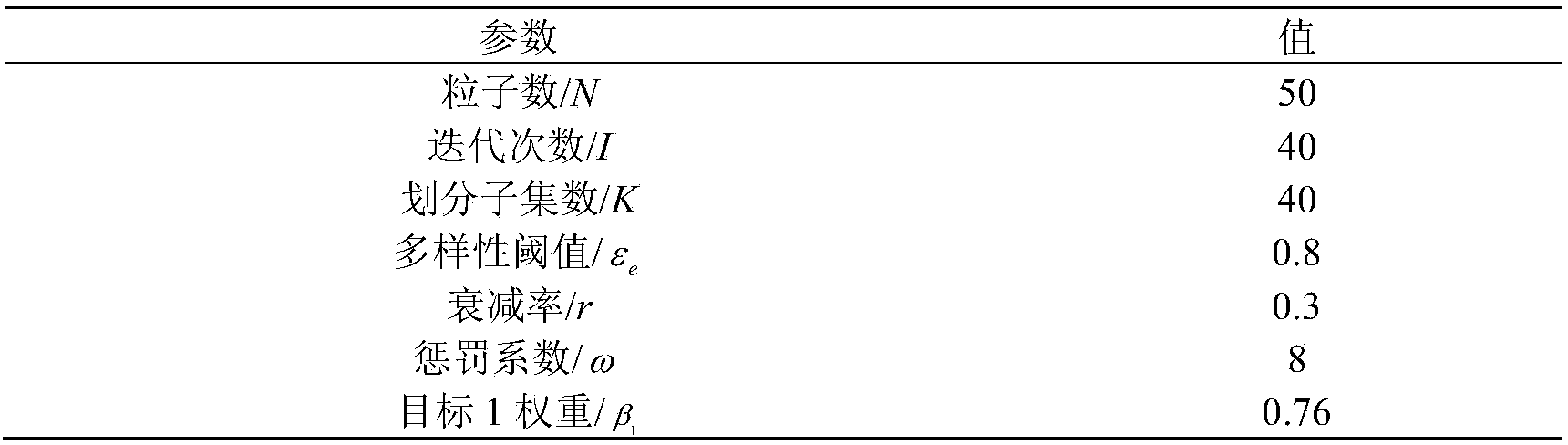

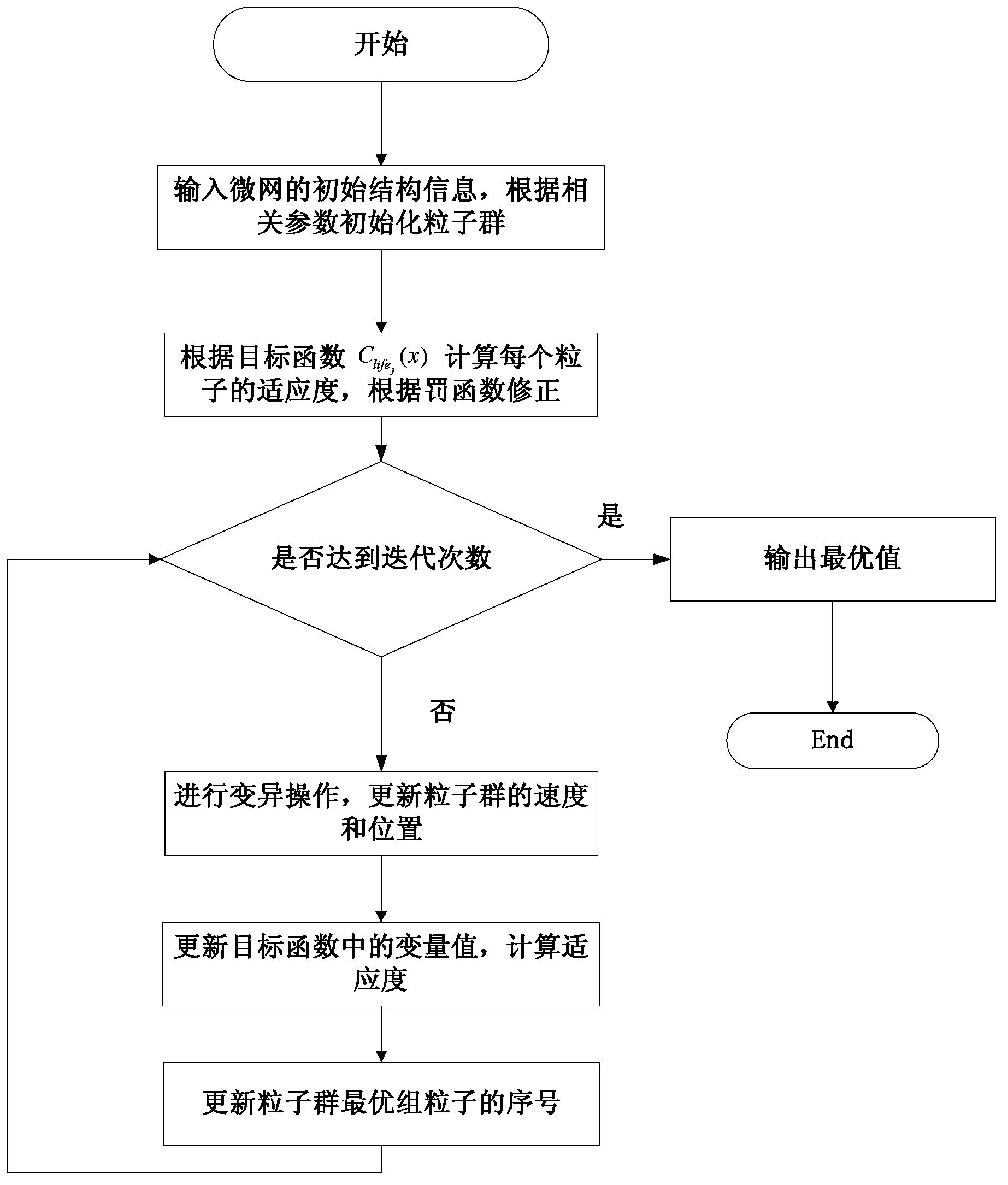

Power supply optimal configuration method for sea island type micro-grid

InactiveCN103414213ALow costLow investment costSingle network parallel feeding arrangementsResourcesFull life cyclePower grid

The invention discloses a power supply optimal configuration method for a sea island type micro-grid. Firstly, each referred power supply in the micro-grid serves as a particle, referred power supplies of various types in the number xi serve as a group of particles, and a particle swarm is established; construction cost at the beginning of a planning period, the electric quantity Eti generated within the planning period, generated fuel cost Oti and operating maintenance cost Mti of each group of particles are obtained; secondly, whether the construction cost, the electric quantity Eti, the fuel cost Oti and the operating maintenance cost Mti meet set constraint conditions or not is judged, and if the construction cost, the electric quantity Eti, the fuel cost Oti and the operating maintenance cost Mti meet the set constraint conditions, fitness of the particle swarm is calculated through a current objective function; if the construction cost, the electric quantity Eti, the fuel cost Oti and the operating maintenance cost Mti do not meet the set constraint conditions, the fitness of the current particle swarm is adjusted by the adoption of a penalty function, and the optimal particle group is picked out according to calculation of the fitness of the particle swarm; after the optimal particle group is picked out, the optimal solution is outputted until set iterations are achieved, and thus power supply optimal configuration of the sea island type micro-grid is obtained. An algorithm of the particle swarm is adopted to solve most preferably power supply optimal configuration capacity, so investment cost of the micro-grid within a full life cycle is reduced, and stability of the micro-grid is improved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD +1

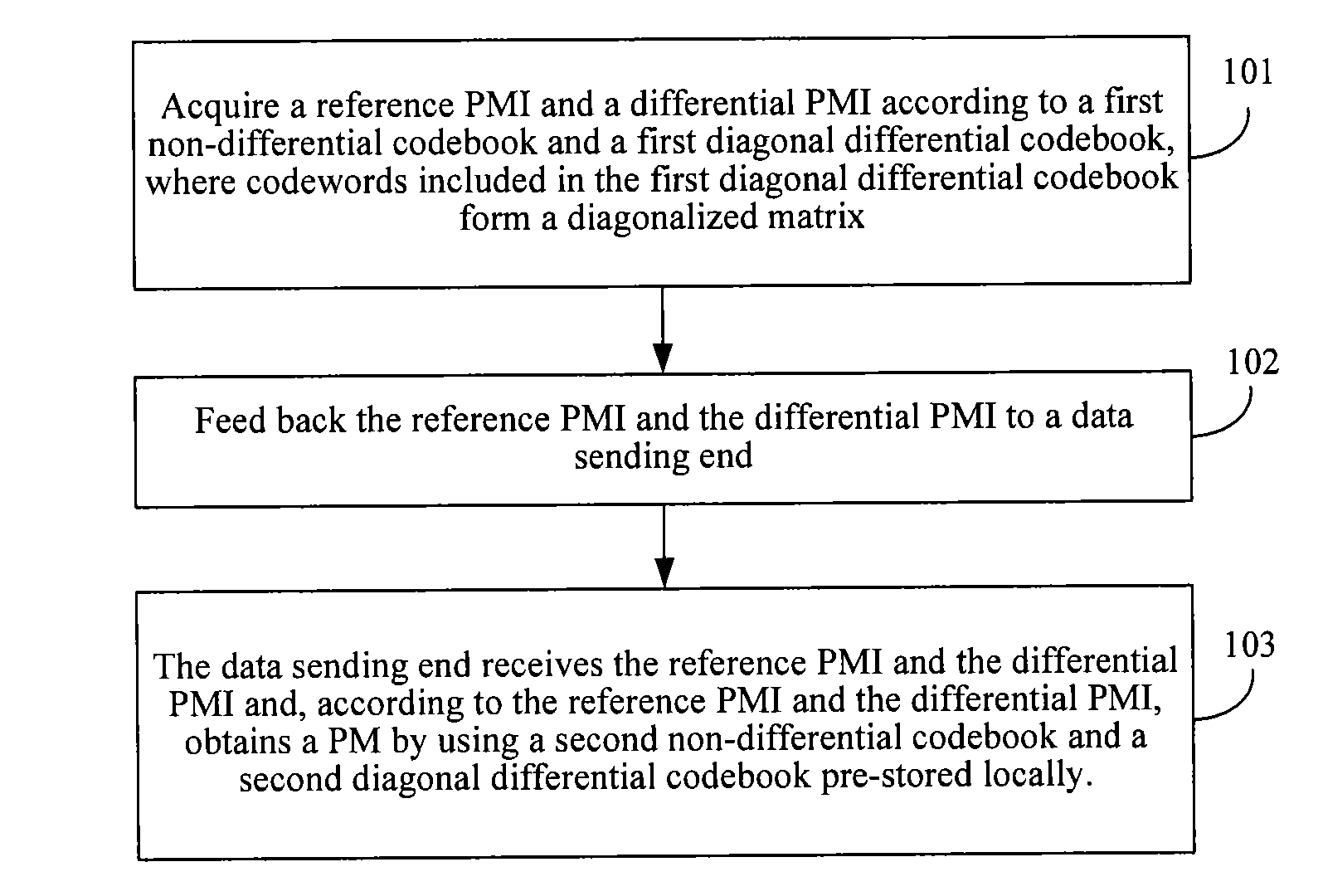

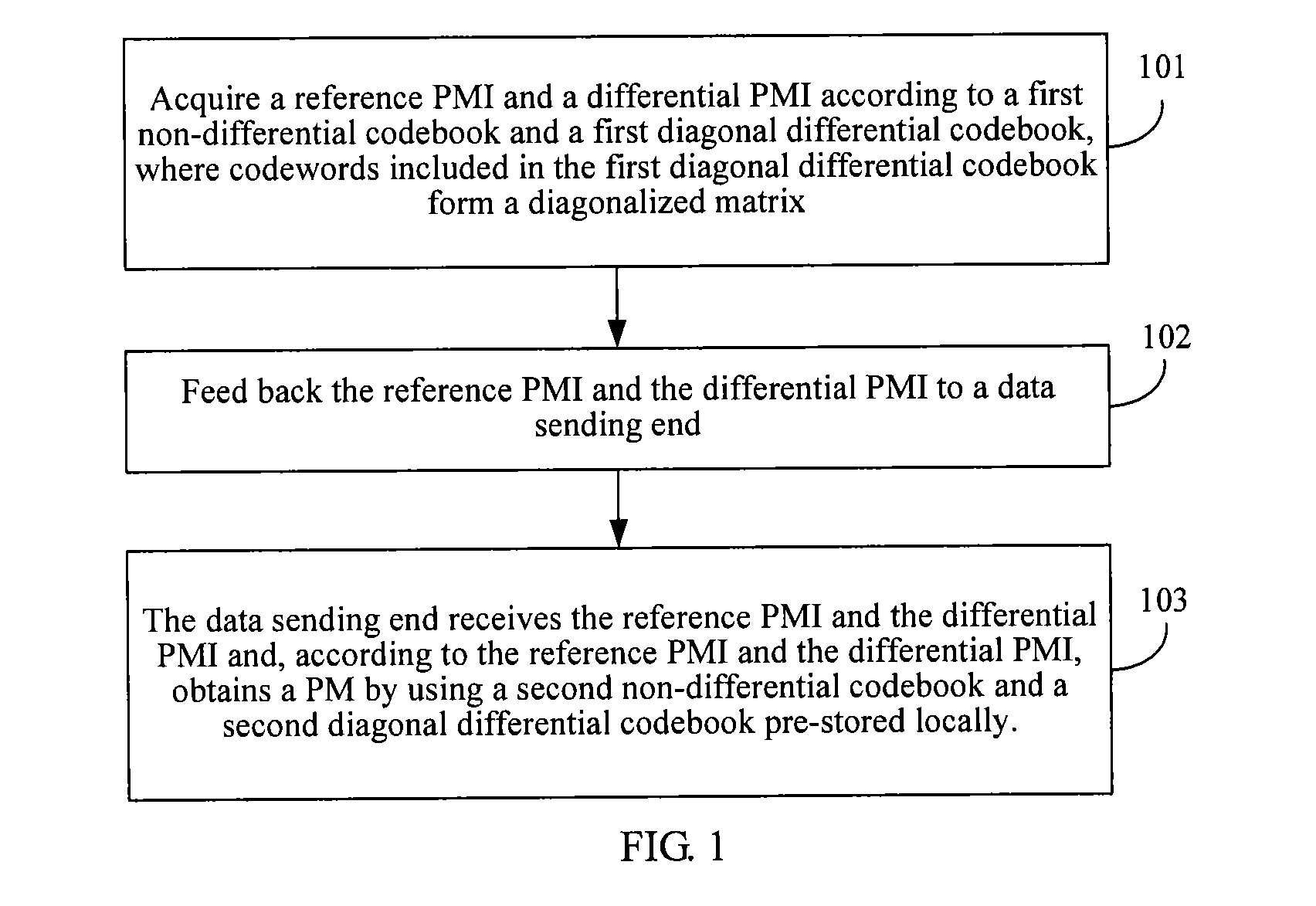

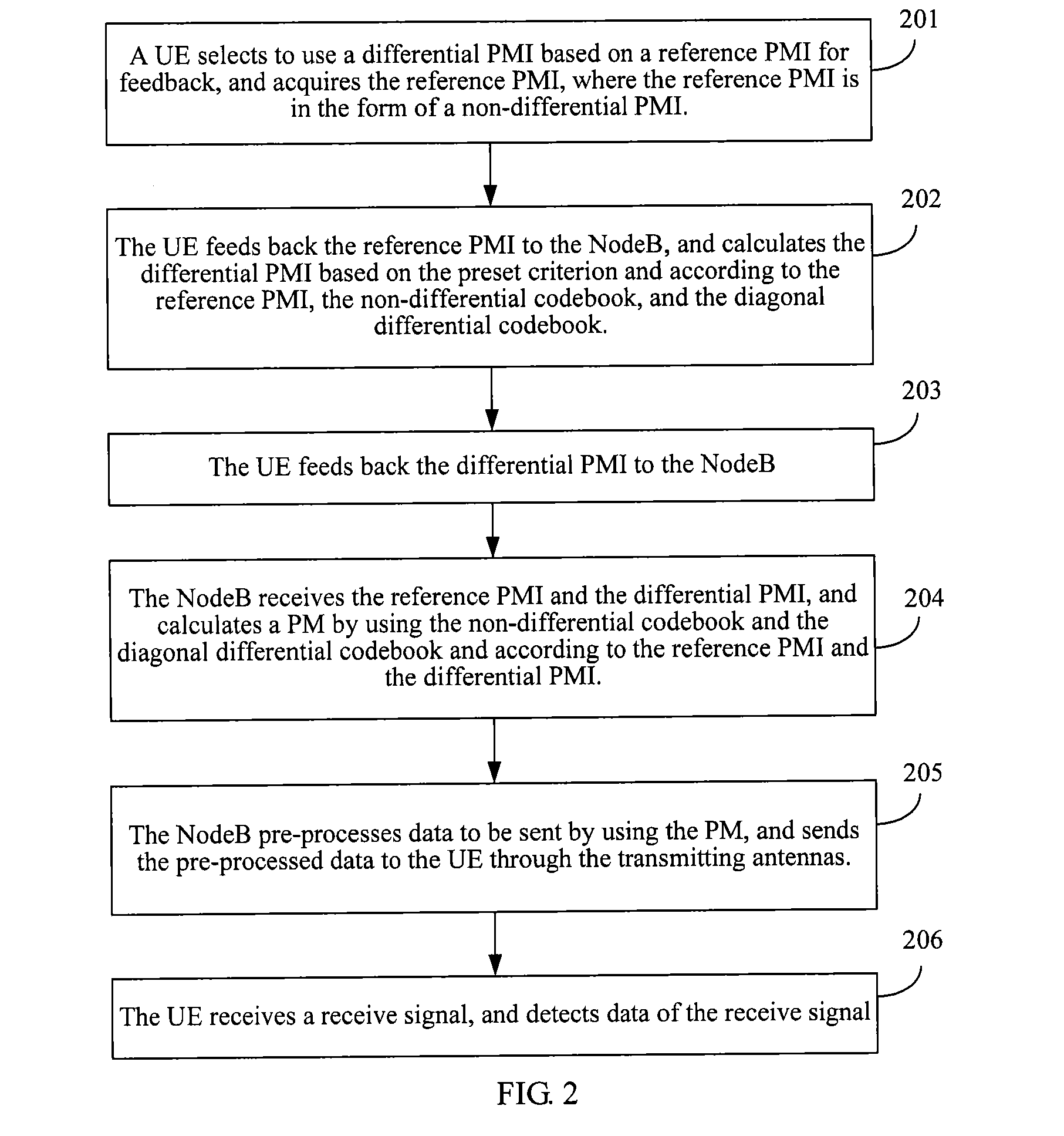

Method and apparatus for acquiring a precoding matrix indicator and a precoding matrix

ActiveUS20130121437A1Reduce Feedback OverheadImprove Feedback AccuracySpatial transmit diversityModulated-carrier systemsDiagonal matrixEngineering

In the field of communication technologies, a method and an apparatus for acquiring a Precoding Matrix Indicator (PMI) and a Precoding Matrix (PM) are provided. The method includes: acquiring a reference PMI and a differential PMI according to a first non-differential codebook and a first diagonal differential codebook, where codewords included in the first diagonal differential codebook form a diagonal matrix. The apparatus includes a PMI acquiring module. Acquiring a reference PMI and a differential PMI according to a non-differential codebook and a diagonal differential codebook can reduce the feedback overhead or improve the feedback precision; and the fact that codewords included in the diagonal differential codebook form a diagonal matrix can maintain amplitude characteristics (for example, a constant modulus characteristic, and a finite character set constraint characteristic) of elements of the non-differential codebook or facilitate power distribution among antennas.

Owner:HUAWEI TECH CO LTD

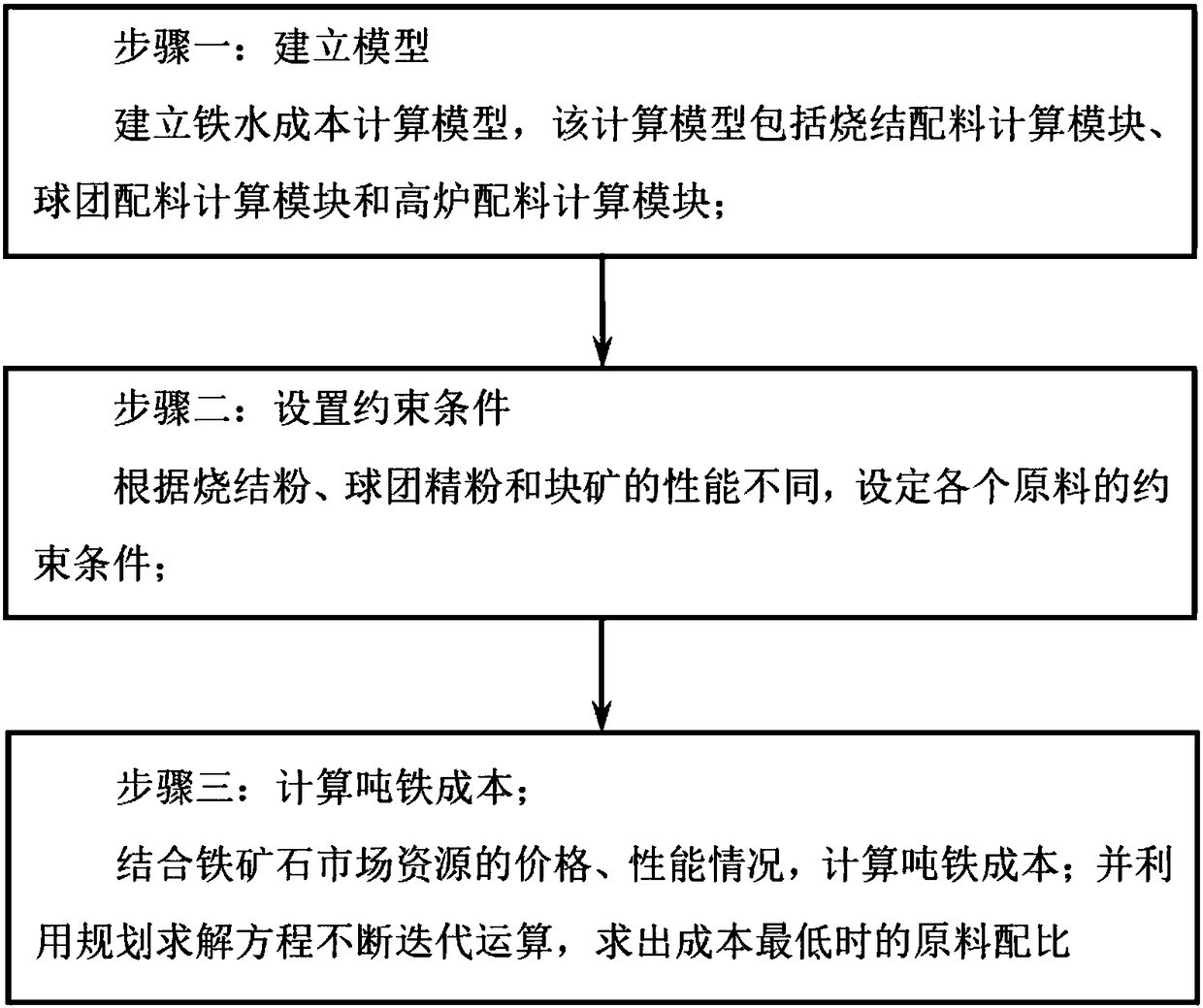

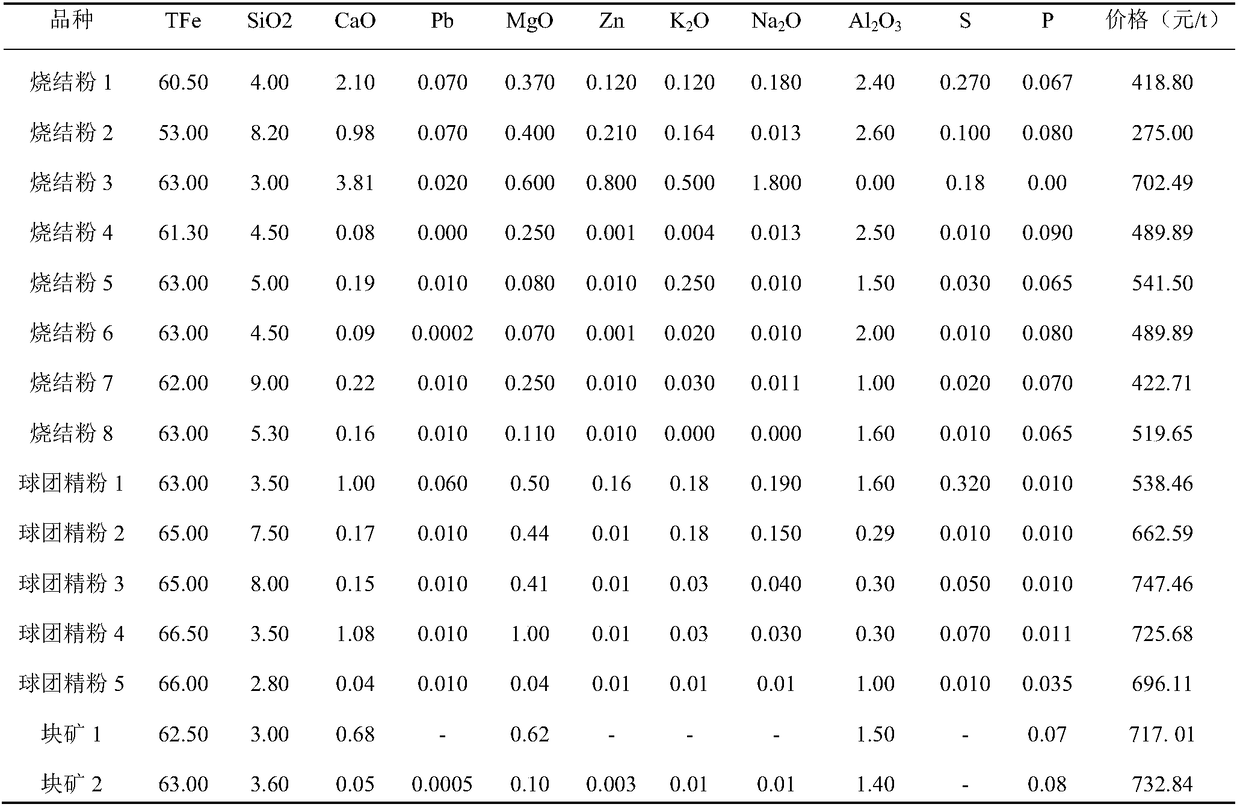

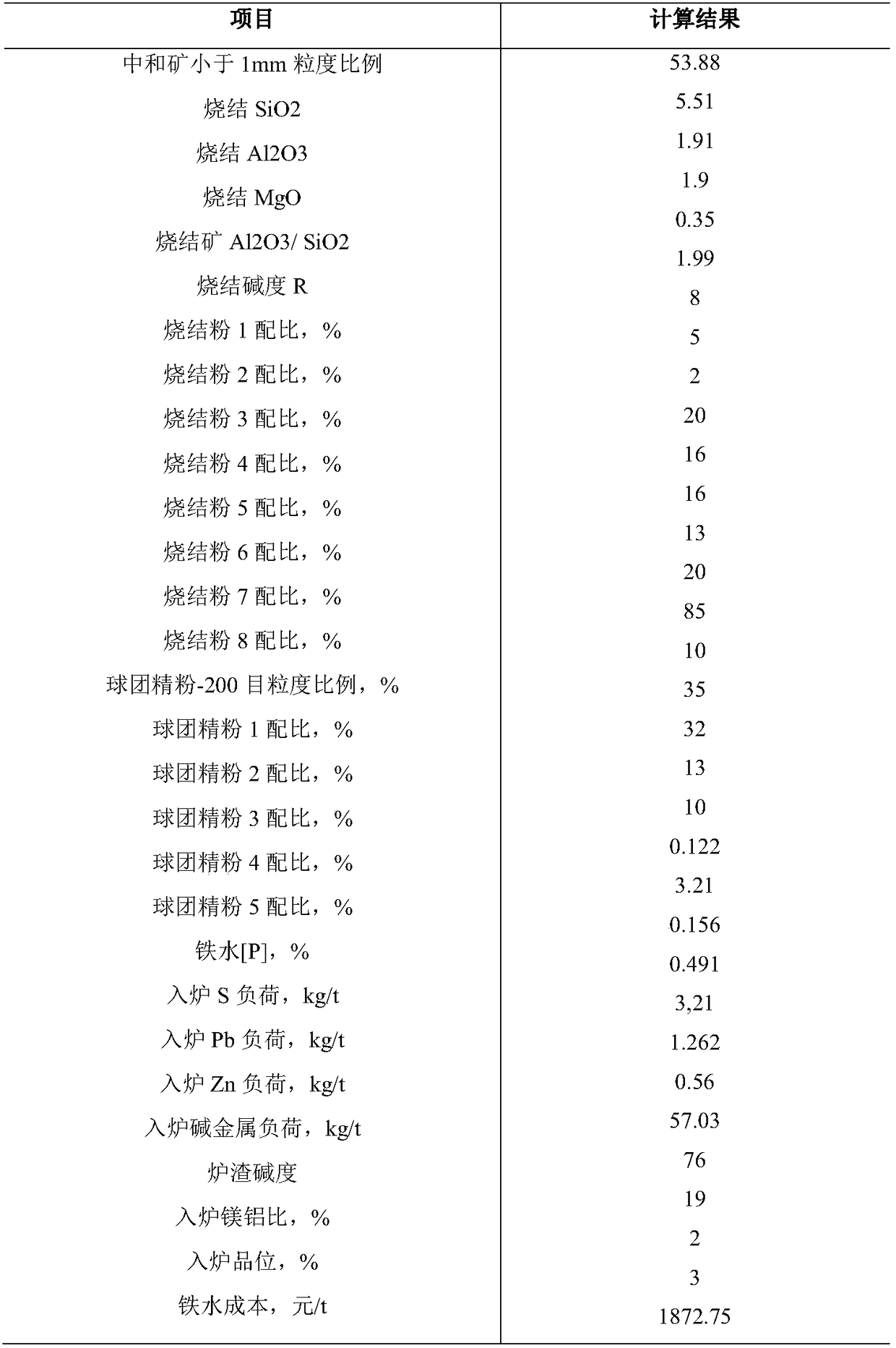

Optimized ore blending method based on sintering-pelletizing-ironmaking linkage

PendingCN108154295AReduce the ratioReduce the cost of hot metalResourcesManufacturing computing systemsChemical compositionShaft furnace

The invention discloses an optimized ore blending method based on sintering-pelletizing-ironmaking linkage, and belongs to the technical field of optimized ore blending before ironmaking. The method comprises the steps: 1, building a model, building a molten iron cost calculation model, wherein the calculation model comprises a sintering mixture calculation module, a pelletizing mixture calculation module and a shaft furnace mixture calculation module; 2, setting a constraint condition, and setting constraint conditions of all raw materials according to the performance difference of sinteringpowder, pelletizing fine powder and lump ore; 3, calculating the cost of iron per ton: calculating the cost of the iron per ton through combining with the price and performance conditions of the resources in the iron ore market, carrying out the continuous iteration calculation through a planning solving equation, and solving the raw material ratio when the cost is minimum. Through combining withthe conditions of resources in the iron ore market and the effective chemical components, the method takes the cost of molten iron as an optimization target, performs the continuous iteration calculation through the planning solving equation, solves the optimal raw material ratio, and achieves the purpose of optimizing the ore blending.

Owner:LIUZHOU IRON & STEEL +1

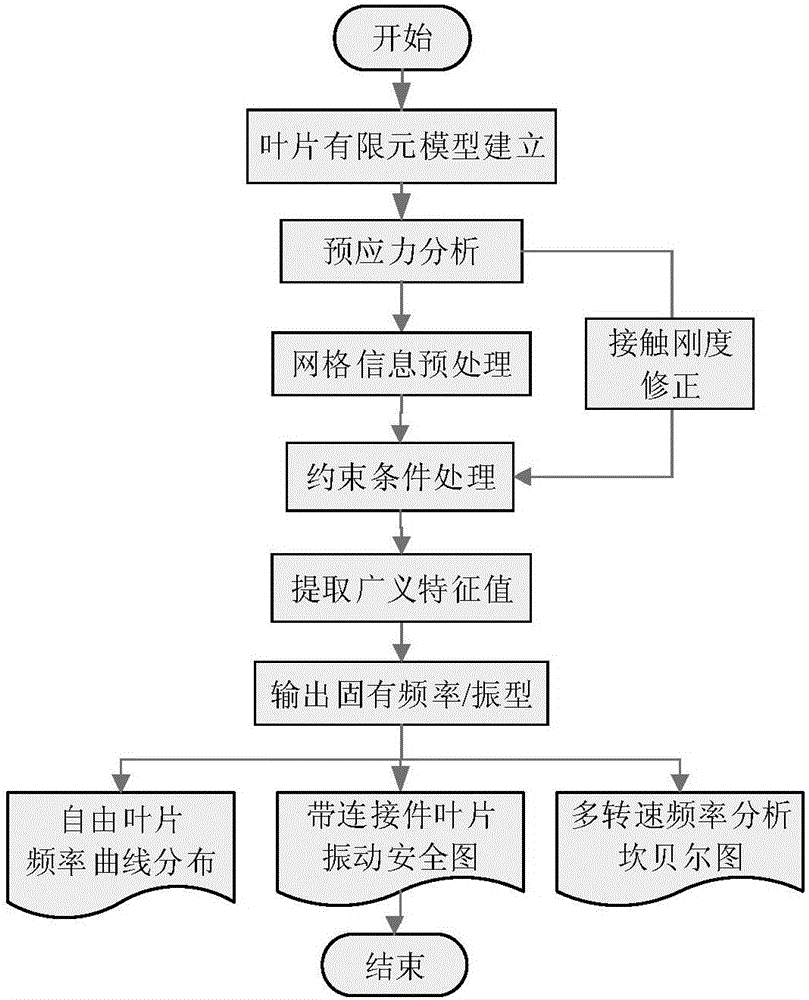

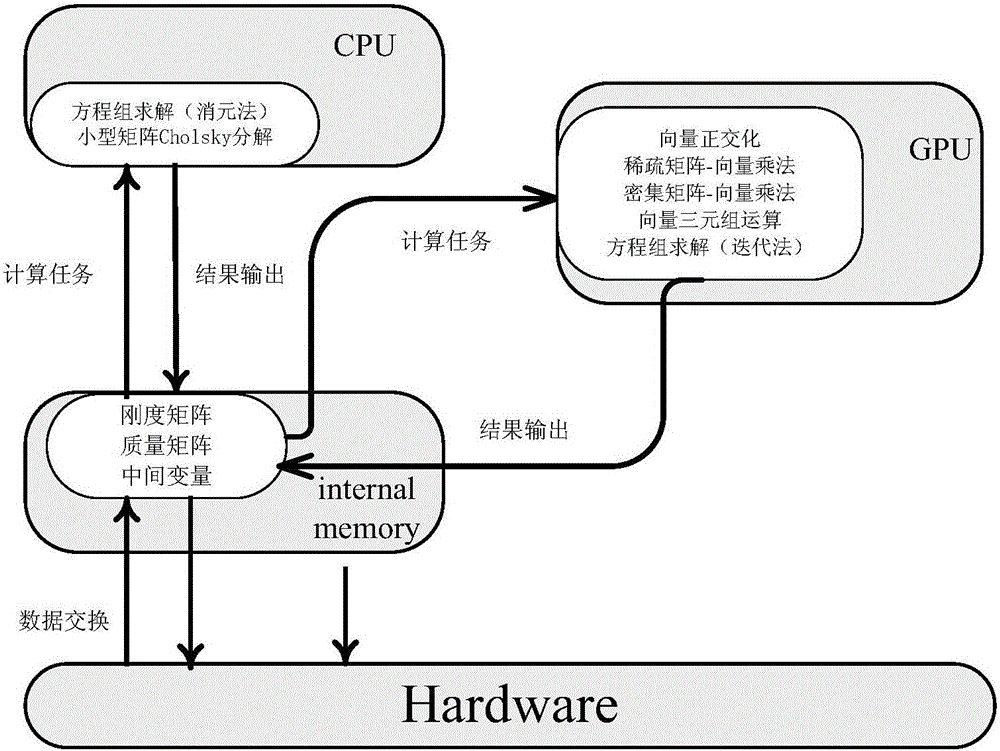

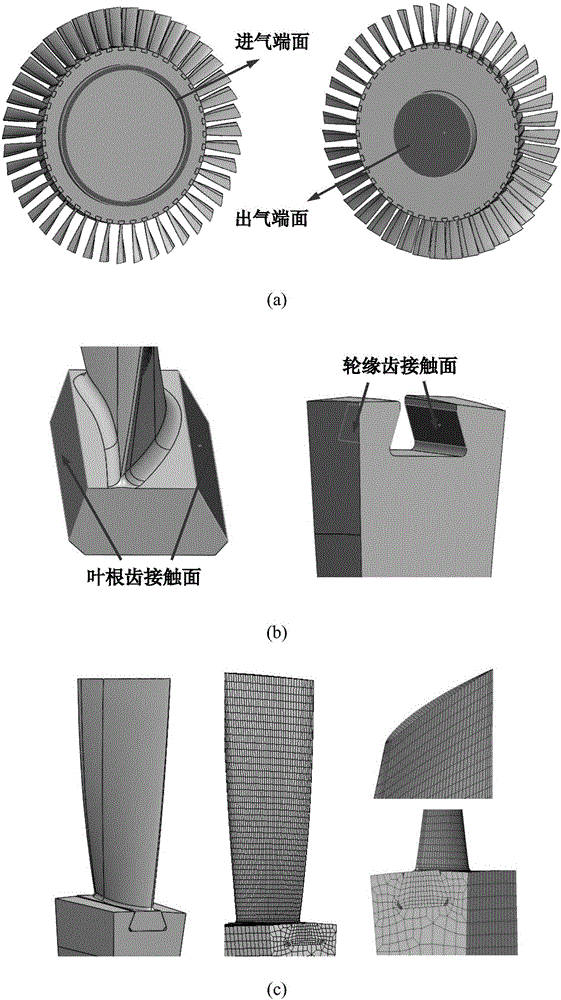

CPU+GPU heterogeneous parallel computing based natural frequency characteristic analysis method for turbomachinery blade

ActiveCN105808829AAvoid complex node selectionEasy to viewGeometric CADDesign optimisation/simulationElement modelParallel algorithm

The invention provides a CPU+GPU heterogeneous parallel computing based natural frequency characteristic analysis method for a turbomachinery blade. The method comprises the steps of firstly, establishing a finite element model according to a three-dimensional model and material parameters of a to-be-analyzed turbomachinery blade, and performing pre-stress analysis on the blade; secondly, performing blade grid data preprocessing, simultaneously calculating a rigidity matrix and a mass matrix of each unit in a CPU and a GPU, and assembling the rigidity matrix and the mass matrix into total rigidity and mass matrixes; setting constraint conditions of the blade and a rim, wherein the setting process comprises constraint of rigid and elastic displacement of a boundary, contact coupling of a blade root and the rim or contact coupling of connecting pieces and correction of the total rigidity matrix; thirdly, extracting generalized eigenvalues and eigenvectors of the total rigidity and mass matrixes by using a CPU+GPU heterogeneous parallel algorithm; fourthly, converting the eigenvalues and eigenvectors into a frequency and a vibration mode of the blade, and performing output; and finally, judging a vibration type of a natural vibration mode, and drawing frequency curve distribution, a vibration safety graph or a Campbell chart of the blade according to the vibration type.

Owner:XI AN JIAOTONG UNIV

Apparatus and method for automatically setting constraints within a document layout

ActiveUS7373593B2Efficient settingsEasy to operateProgram control using stored programsDigital computer detailsInformation processingComputer science

Owner:CANON KK

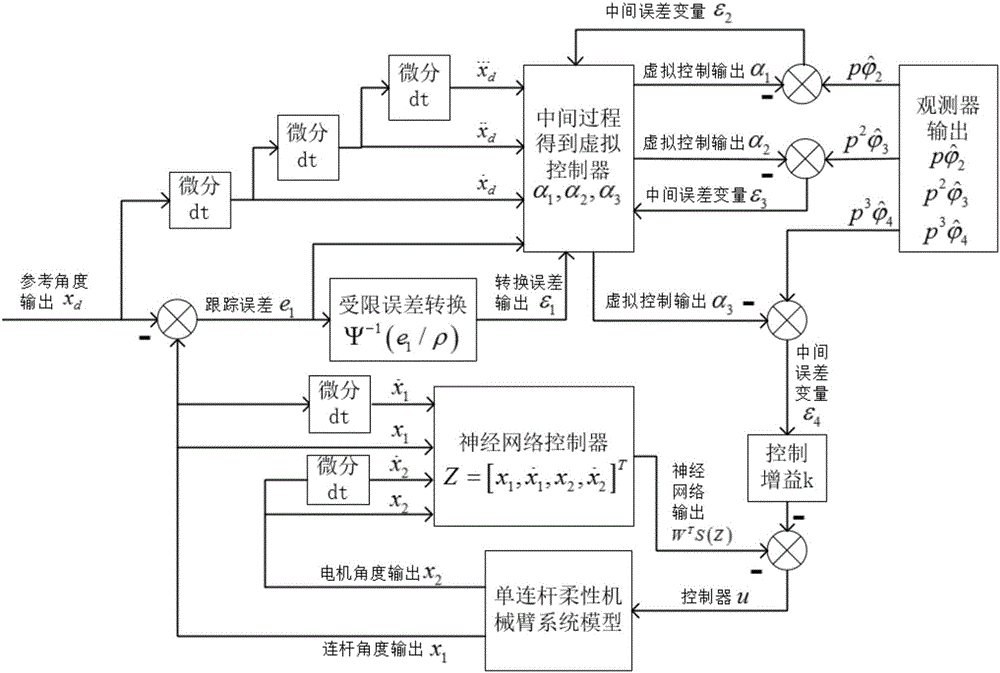

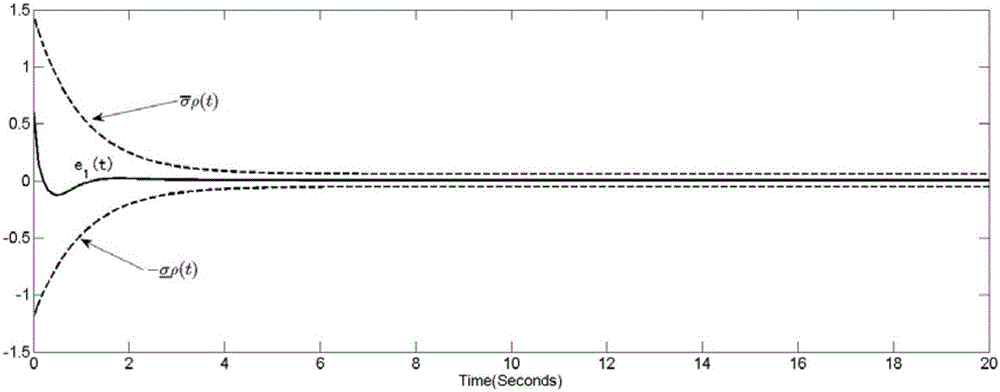

Performance limited flexible manipulator control method based on determining learning theory

ActiveCN106078741ASimple designRealize offline controlProgramme-controlled manipulatorNeural network controllerDynamic models

The invention discloses a performance limited flexible manipulator control method based on determining learning theory. Aiming at the indeterminacy of the dynamic model of the flexible manipulator, the method designs a tracking error to satisfy the limitation of constraint conditions, and forms an error controller. The method in the invention comprises the following steps: building a dynamic model of the flexible manipulator, building a system state observer, designing tracking error performance constraint conditions, designing a neural network controller based on the determining learning theory, and correcting the controller utilizing experiential knowledge. The method designed in the invention can realize the dynamic properties of rapid convergence and low overshoot, satisfy the limitation of set constraint conditions, avoid the on-line regulations to the neural network weights at the same time, and shorten the control time. In addition, the method can utilize the learned experiential knowledge to control the later same task rapidly.

Owner:SOUTH CHINA UNIV OF TECH

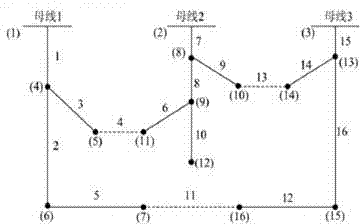

Power distribution network anti-error optimization method

ActiveCN103036234AEliminate overloadEliminate voltage violationsGenetic modelsSystems intergating technologiesComputer scienceRate of convergence

The invention provides a power distribution network anti-error optimization method. The power distribution network anti-error optimization method is characterized by comprising the following steps: 1, dividing a power distribution network topological system into a plurality of independent units according to a current running state, wherein each unit is provided with only one off switch and the number of the units is equal to the number of switches with off states; 2, performing real number encoding on the on-off state of each unit by a switch exchange algorithm, and connecting all the units into a chromosome; and 3, through a set objective function and set constraints, calculating the network by a chaos genetic algorithm so as to obtain an optimal solution. The invention has the advantages as follows: the power distribution network anti-error optimization method has certain theoretical study value and certain practical value; on the premise of meeting security constraints, the running way of a distributing line is changed by a switch operating method and the like, so that branch circuit overload and voltage out-of-limit are eliminated, feeder load is balanced and network loss is minimum; and the power distribution network anti-error optimization method has an obvious advantage in network loss improvement and convergence rate and is more suitable for on-site real-time application.

Owner:南京软核科技有限公司 +1

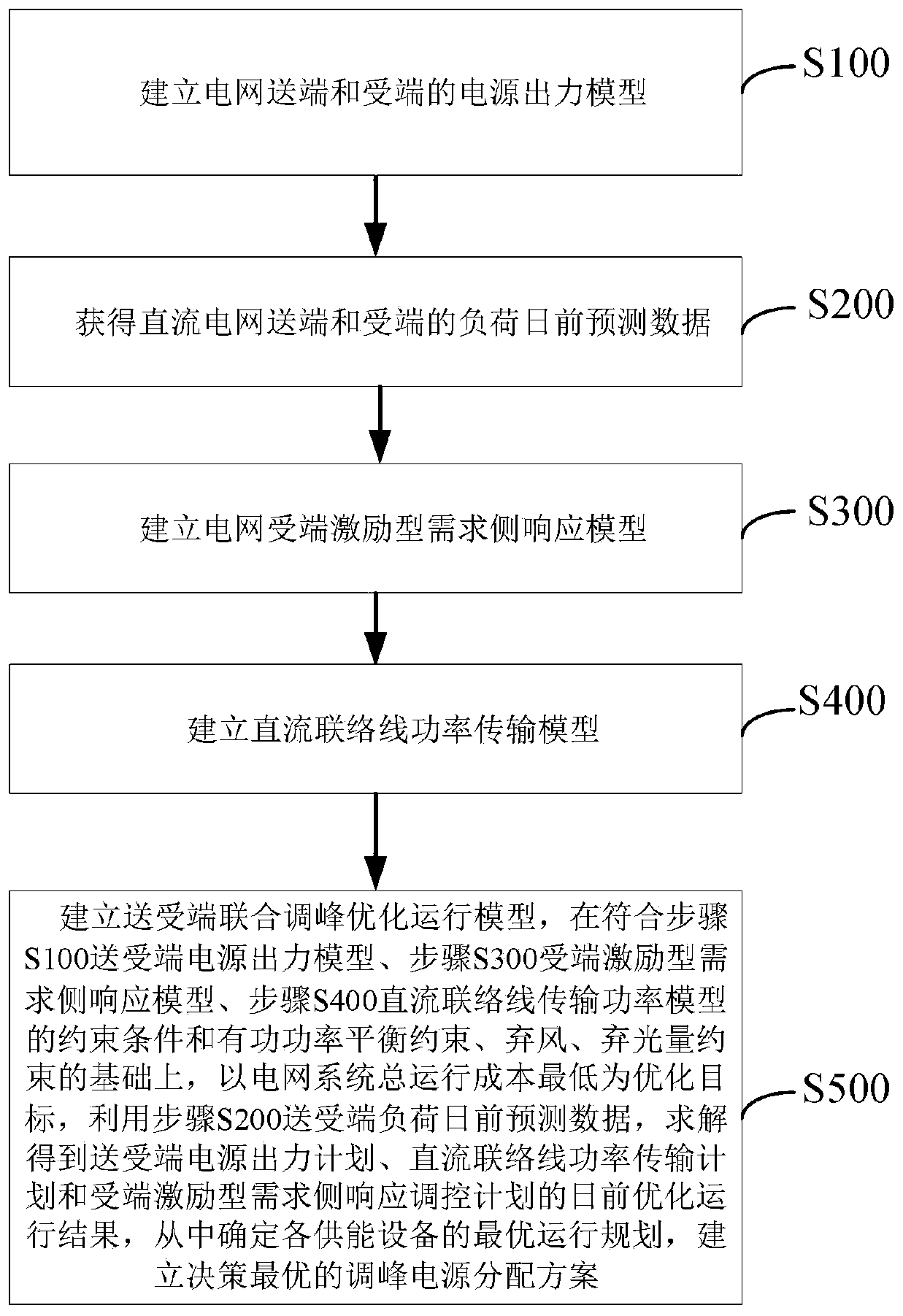

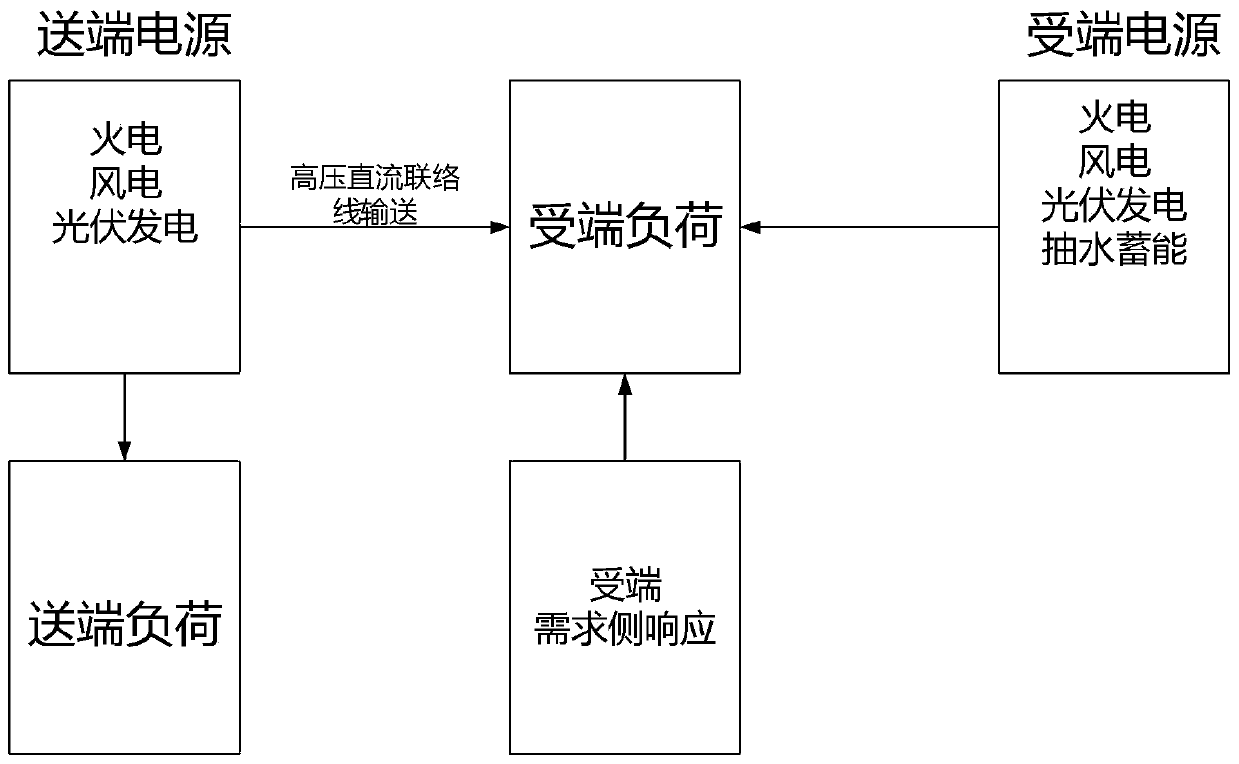

DC grid transmitting and receiving end combined peak regulation optimization method considering source network load constraints

ActiveCN110417048APromote digestionAchieve coordinated optimizationSingle network parallel feeding arrangementsWind energy generationPower balancingOperation mode

The invention discloses a dc grid transmitting and receiving end combined peak regulation optimization method considering source network load constraints, and can solve the technical problems that a 'linear' or 'reverse peak regulation' transmission plan often occurs in the prior art, which causes great difficulty in peak regulation, frequency modulation and operation mode arrangement of a receiving end grid. The method comprises the steps: firstly obtaining day-ahead output prediction data of a wind power plant and a photovoltaic power station; on the basis that a grid sending end power supply meets the requirement of local load power utilization, transmitting the generated surplus electric quantity to the grid receiving end through a high-voltage DC connecting line; taking the minimum total operation cost of a power grid system as an optimization target, taking the power balance constraint, the conventional generator set constraint, the wind curtailment and light curtailment constraint, the DC tie line constraint and the excitation type demand side response constraint as constraint conditions, establishing an optimization model, and obtaining operation power plans of each energysupply device which is accessed to DC, the high-voltage DC tie line and the excitation type demand side response of the receiving end. According to the invention, the energy consumption cost of a useris reduced, and the complementation and collaboration among various energy sources are improved.

Owner:中科海奥(黄山)储能科技有限公司

Comprehensive energy balance scheduling method for industrial park

ActiveCN109858759AImprove forecast accuracyAccurate energy storage strategyGenetic modelsResourcesEnergy balancingLoad following power plant

The invention discloses a comprehensive energy balance scheduling method for an industrial park, and the method comprises the steps: step 1, obtaining the starting moment of an optimization period, and determining the optimization period and each group of scheduling intervals; step 2, obtaining a topological structure and subsystem information of the energy system; obtaining the real-time price ofeach energy source, and calculating the average price of the energy sources in each scheduling interval; step 3, obtaining historical data of a demand side load; establishing a load prediction model;predicting future cold / heat and electricity demands by using a load prediction model; step 4, establishing an energy supply and storage model of each subsystem; step 5, determining an optimization variable; setting an objective function; setting constraint conditions; obtaining an optimized scheduling model; and step 6, calling a genetic algorithm to solve the optimal scheduling model to obtain ascheduling result. Compared with an existing scheduling method, the method is closer to the actual system operation condition, and the demand side load data prediction accuracy can be improved; And the energy storage strategy is more accurate and flexible. And the selection of the objective function is more flexible.

Owner:SHAANXI BLOWER GROUP

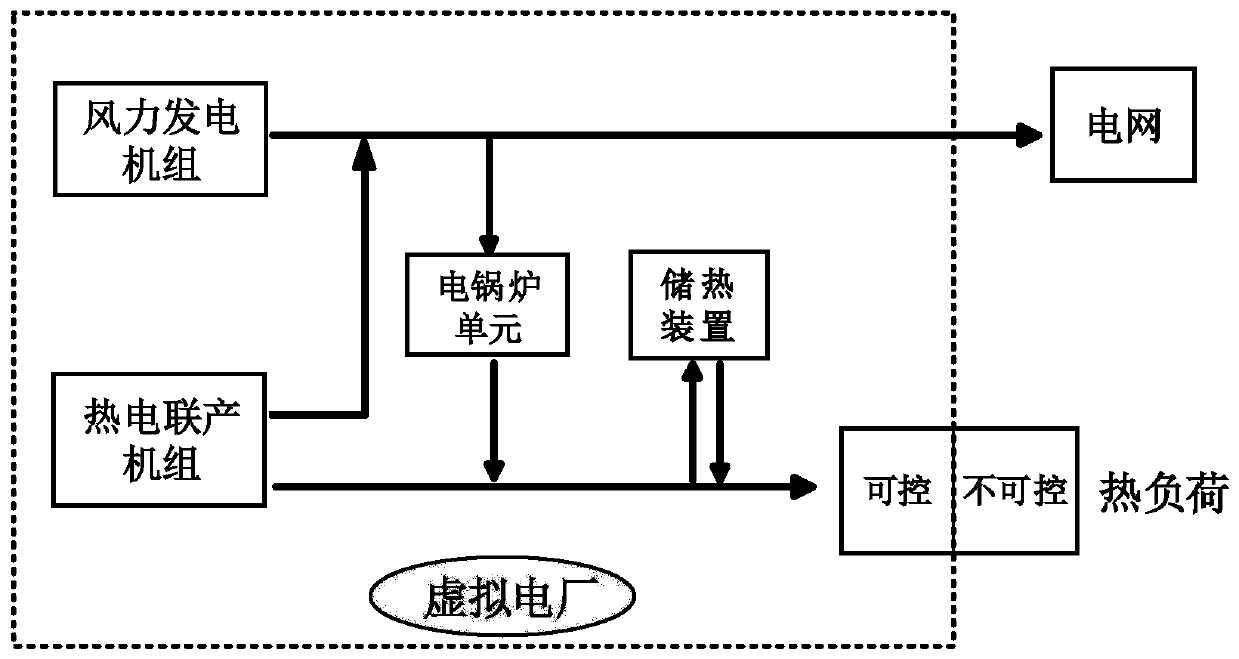

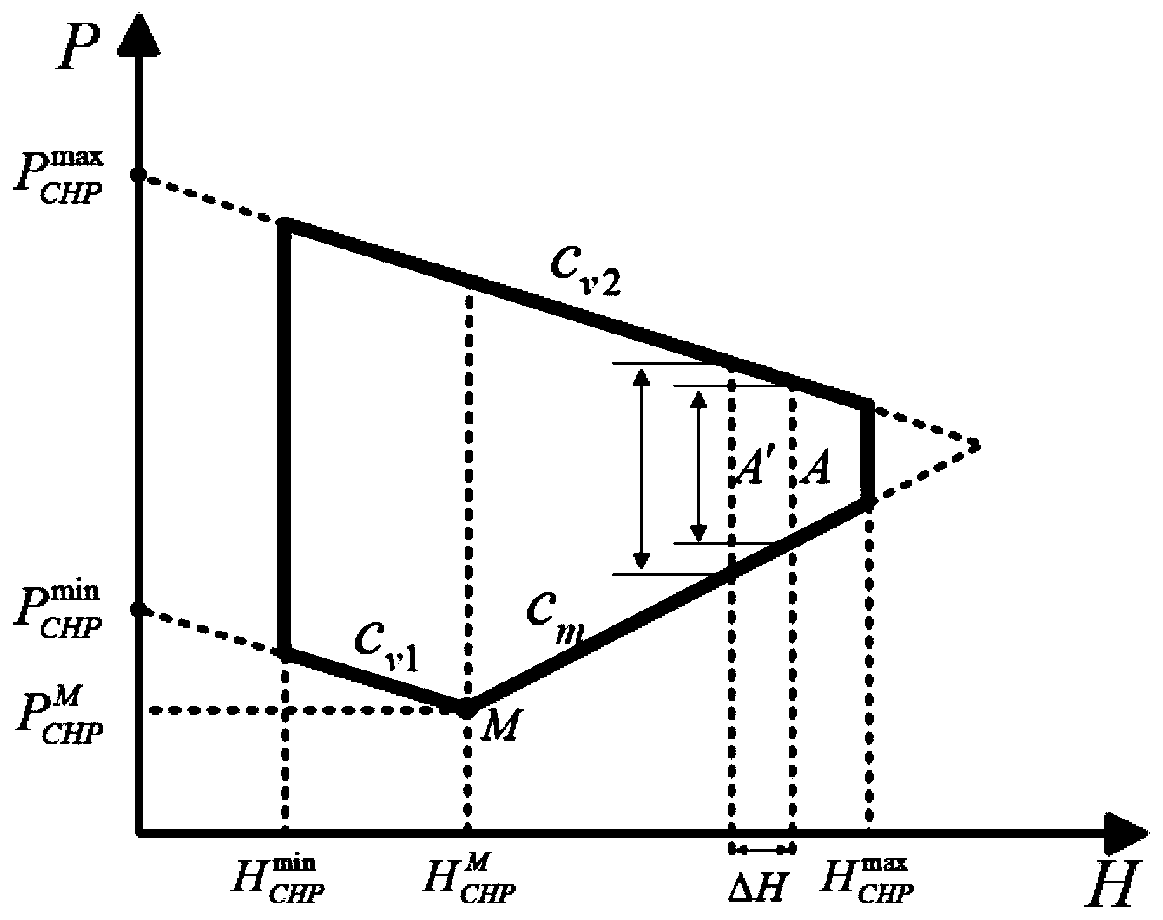

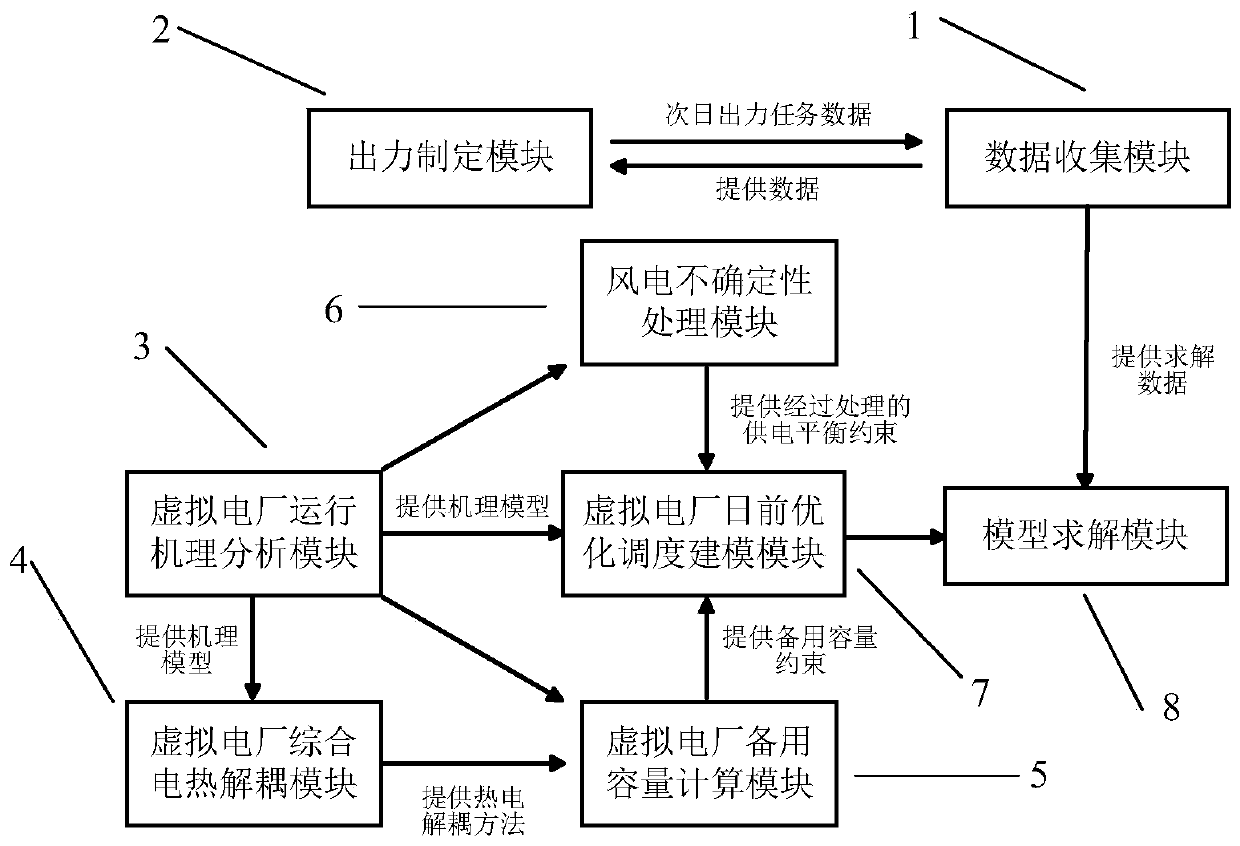

Virtual power plant day-ahead optimal scheduling system and method considering wind power uncertainty,

ActiveCN110571867AReduce external thermoelectric coupling relationshipElectric output adjustable range expandedSingle network parallel feeding arrangementsEnergy storageParticle swarm algorithmLoad following power plant

The invention discloses a virtual power plant day-ahead optimal scheduling system and method considering wind power uncertainty. The method comprises the steps: obtaining the next-day wind power fulloutput prediction of a virtual power plant and the next-day thermal load demand prediction of a borne region, formulating a next-day power generation plan, and reporting the next-day power generationplan to a power grid to obtain a next-day output task of the virtual power plant; establishing a virtual power plant energy supply balance model; determining a virtual power plant spinning reserve capacity of the heat reserve; performing wind power uncertainty processing on the virtual power plant power supply balance constraint to reduce the influence of wind power uncertainty on a day-ahead scheduling plan; establishing an objective function with the maximum daily income of the virtual power plant as an objective, setting constraints and enabling the spinning reserve capacity of the virtualpower plant to meet the wind power fluctuation requirement and all components of the virtual power plant to operate in a safe range; and solving the model by using a particle swarm algorithm to obtaina next-day operation scheduling plan and earnings of the virtual power plant. The external thermoelectric coupling relation of the virtual power plant is reduced, the adjustable range of the power output of the virtual power plant is expanded, and the reserve capacity of the power grid is released.

Owner:NORTHEASTERN UNIV

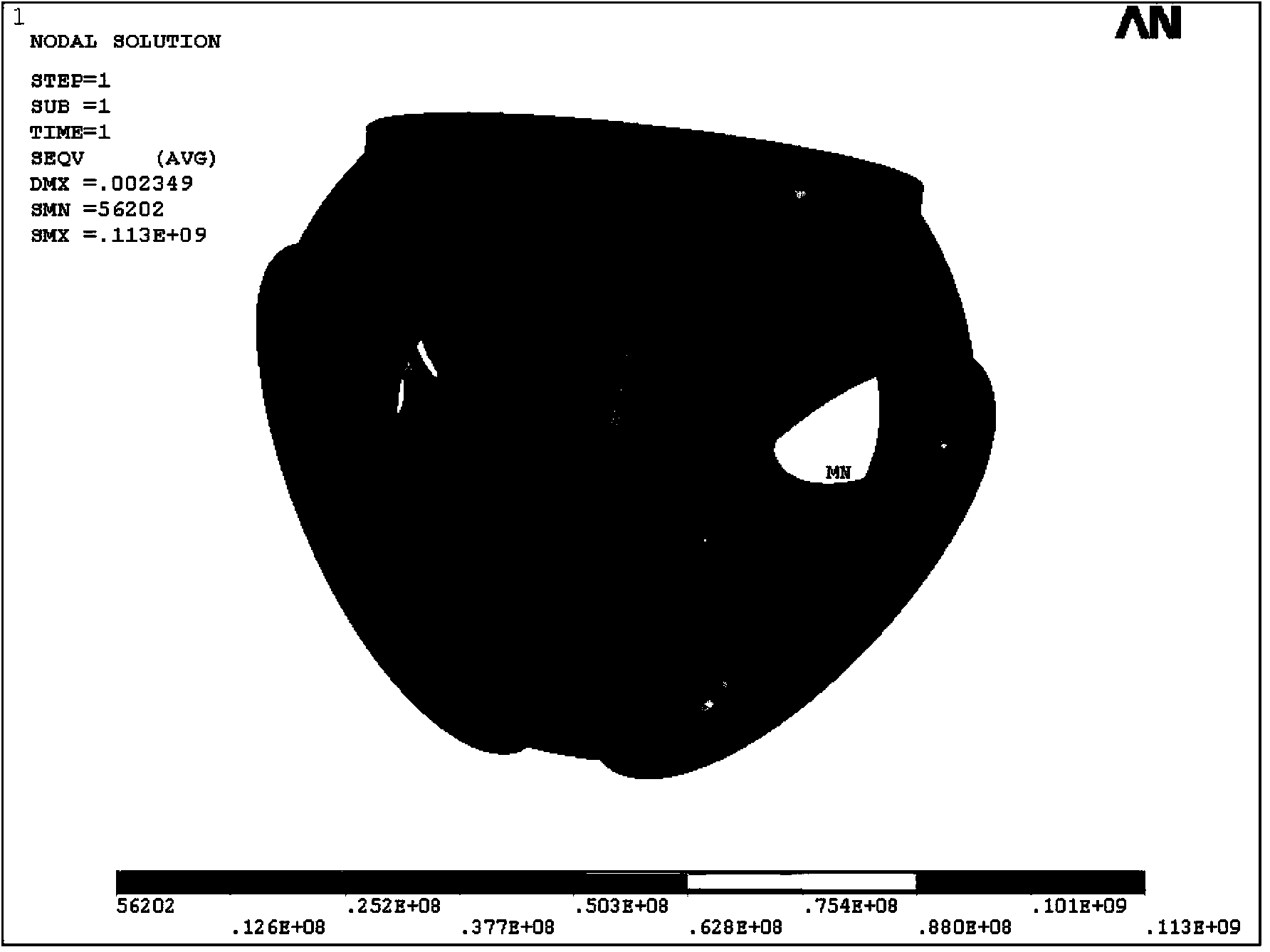

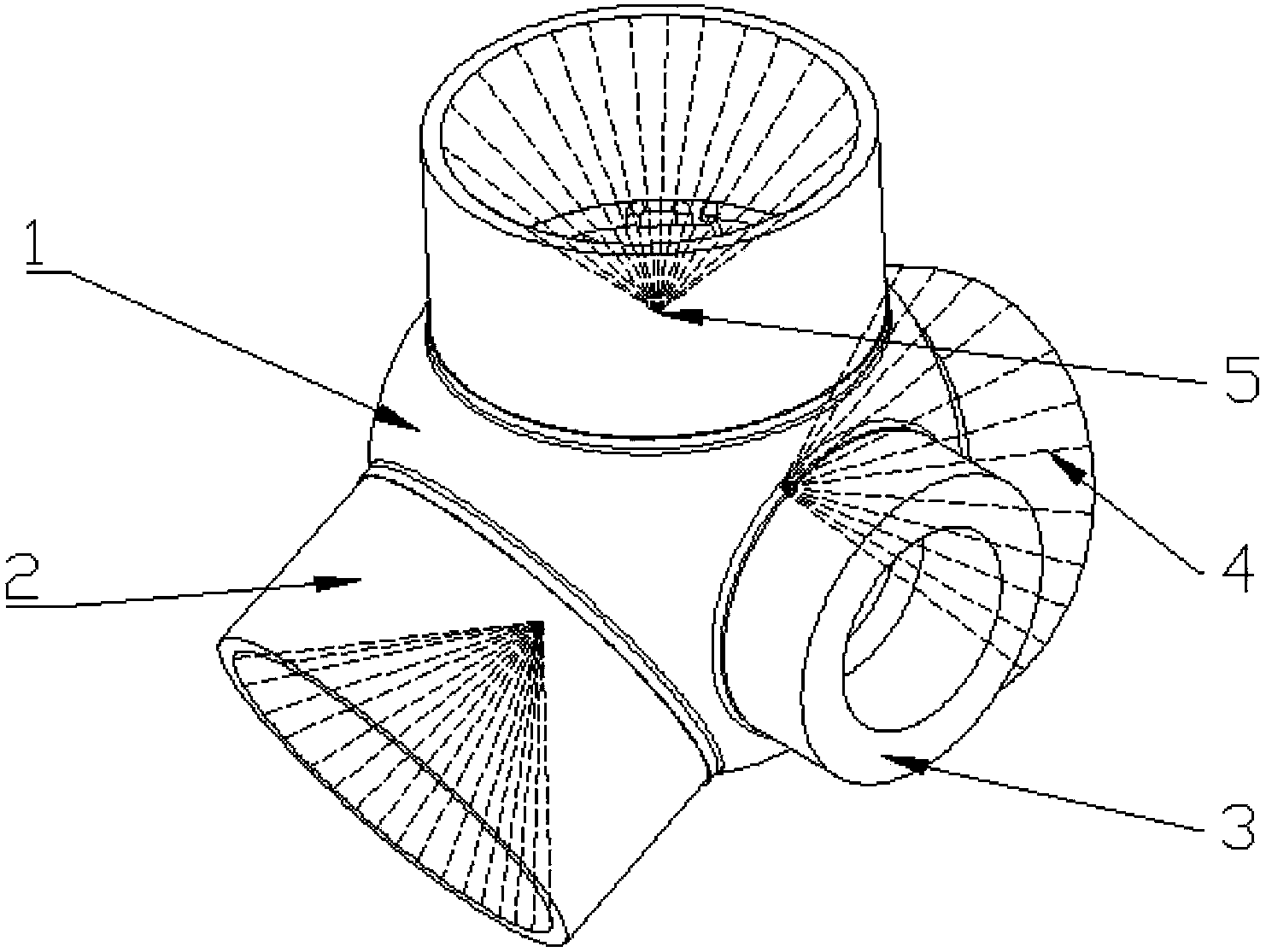

Computing method for hub ultimate strength of wind turbine generator system

InactiveCN103366049ACalculation intensityLow costSpecial data processing applicationsElement modelElement analysis

A computing method for hub ultimate strength of a wind turbine generator system belongs to the technical field of wind power generation, and comprises the following steps: modeling by adopting software of finite element analysis, performing finite element mesh generation, setting constraint conditions and computing to obtain a deformation and stress cloud chart. The modeling process is as follows: 1, drawing a 3D model for a hub, importing the 3D model into a finite element software platform, and drawing a 3D entity model for the connection part of blades and the hub and the connection part of a main shaft and the hub in the finite element software; 2, setting material attributes for the blades, the main shaft and the hub, establishing a finite element model thereof, rigidly coupling the blades, the main shaft and the hub, and determining an overall coordinate system of the hub; 3, establishing nodes at root parts of the hub and each blade, converting the nodes into a blade root coordinate system specified by Germanischer Lloyd, then rigidly coupling the nodes to the blades, so that the load can be transmitted to the hub through the blades. The computing method facilitates accurate computation of strength performance of the hub, saves the computing time and improves the computing efficiency.

Owner:CHINA CREATIVE WIND ENERGY +3

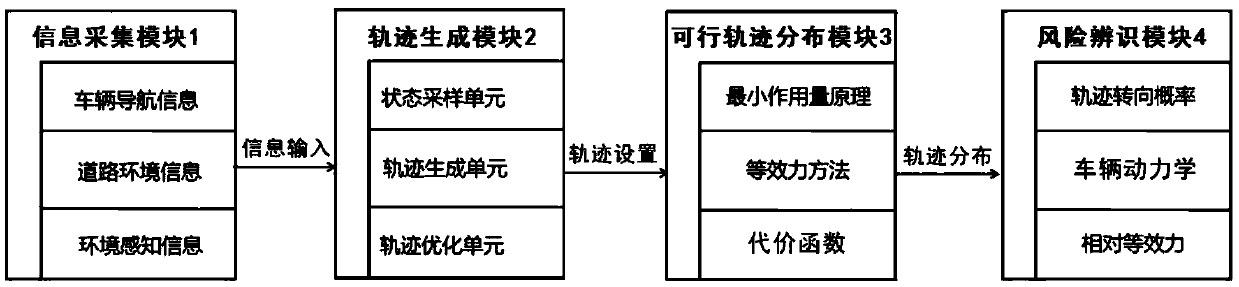

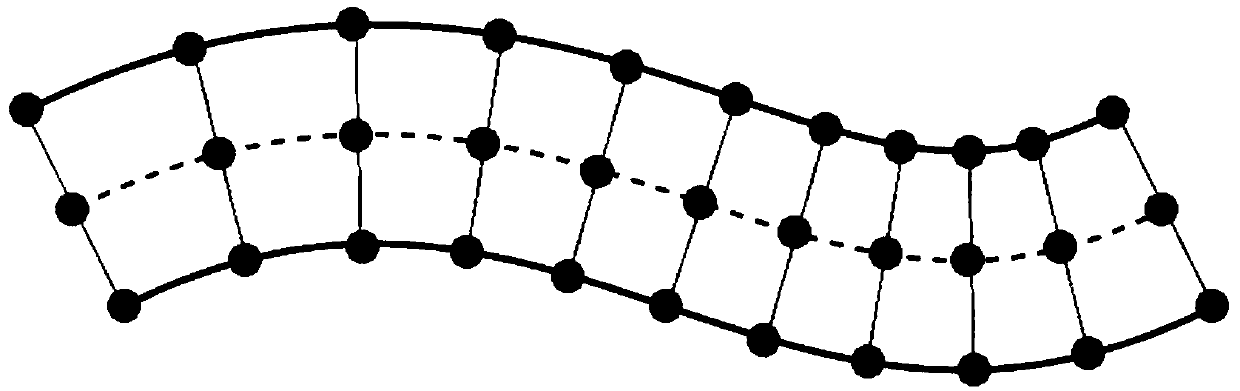

A driving risk identification method based on track prediction

ActiveCN109684702AProof of validityProof of feasibilityDesign optimisation/simulationSpecial data processing applicationsVehicle dynamicsDriving risk

The invention discloses a driving risk identification method based on track prediction, and the method comprises the following steps: S1, obtaining the GPS information in real time, and generating a reference track; S2, according to the reference trajectory and GPS information, in combination with a vehicle dynamics model and a control constraint condition, generating a feasible trajectory set which is dynamic and is connected with the initial end of the reference trajectory and the terminal and a speed corresponding to each feasible trajectory in the feasible trajectory set; S3, optimizing the feasible track and the corresponding speed; S4, calculating the cost values of the feasible tracks by using a cost function according to the optimized feasible tracks and speed in combination with avehicle dynamics model and a set constraint condition, and forming a probability distribution diagram of the own vehicle driving on each feasible track, thereby drawing a feasible track distributiondiagram; Wherein the cost function is obtained according to a minimum action principle and an equivalent force method; And S5, according to the feasible track distribution map, calculating a relativeequivalent force by using the vehicle dynamics model and the track steering probability, so as to identify the dynamic risk range in the driving process according to the relative equivalent force. Themethod comprehensively considers the coupling relationship among human, vehicle and road elements, can be suitable for accurate identification of the driving risk range, and provides support for driving decision.

Owner:TSINGHUA UNIV

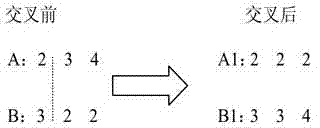

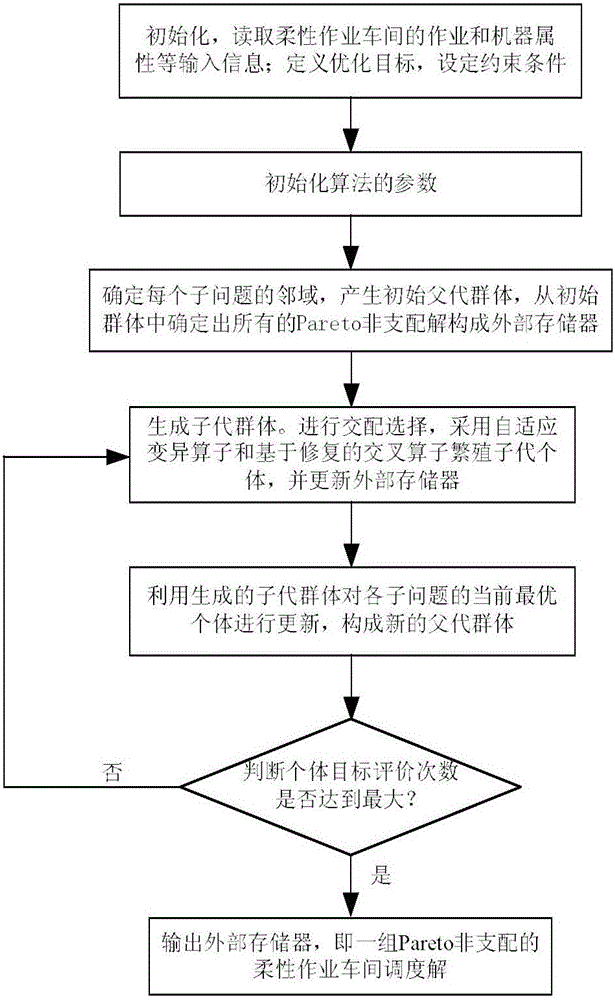

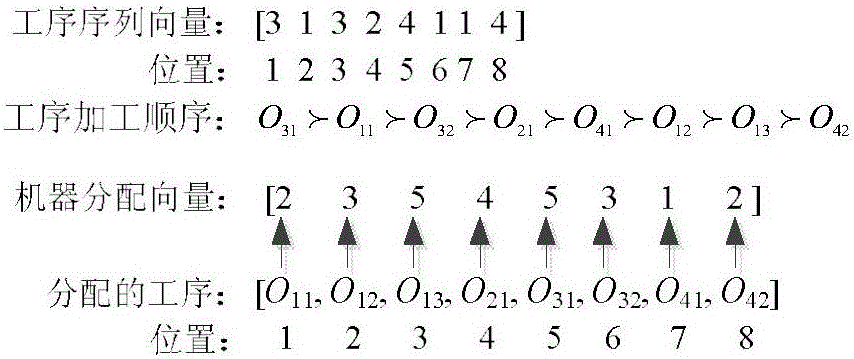

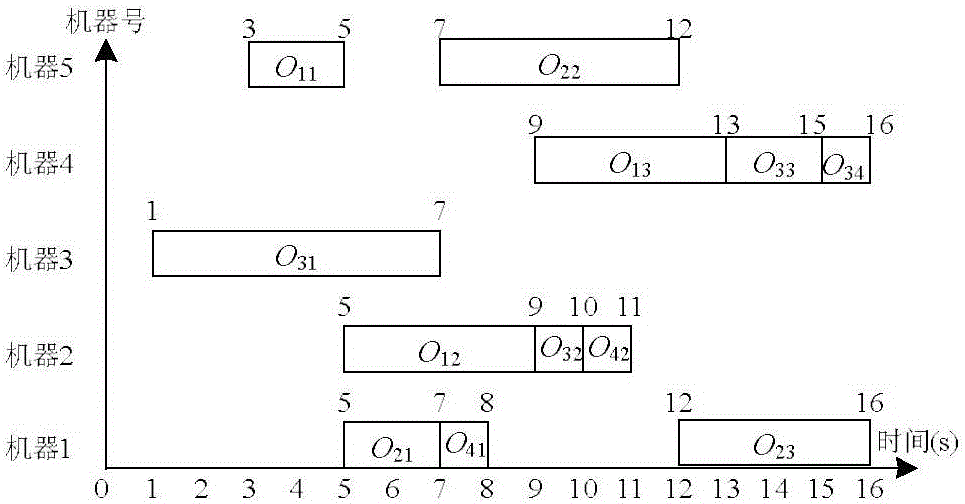

Flexible workshop robustness scheduling method based on decomposition multi-target evolution algorithm

The invention discloses a flexible workshop robustness scheduling method based on a decomposition multi-target evolution algorithm. The method comprises the following steps: 1, reading such input information as operation, machine attributes and the like of a flexible operation workshop, defining an optimization object, and setting constraint conditions; 2, initializing parameters of the algorithm; 3, determining an adjacent domain of each subproblem, generating an initial parent group, and determining all Pereto non-dominant solutions from the initial group so as to form an external memory; 4, generating a child group, carrying out mating selection, breeding child individuals by use of an adaptive variation operator and a restoration-based intersection operator, and updating the external memory; 5, by use of the generated child group, updating a current optimal individual of each subproblem, and forming a new parent group; and 6, when it is determined that the individual object evaluation frequency reaches the maximum, outputting the external memory, i.e., a group of Pareto non-dominant flexible operation workshop scheduling solutions, and if the frequency does not reach the maximum, skipping to the fourth step. According to the invention, scheduling tasks in a flexible operation workshop can be rapidly and efficiency realized.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Multi-source video editing method, device and storage medium

ActiveCN109257545AQuality improvementImprove user experienceTelevision system detailsCharacter and pattern recognitionRhythmVideo editing

The invention discloses a multi-source video editing method. The method comprises the following steps: obtaining target music and dividing the target music into at least two music segments; selectinga second number of video segments from at least one source video file according to a first number of music segments; judging whether the time length of the current music segment meets the set constraint conditions; based on the determination result, allocating the current music segment to a corresponding video segment until the at least two music segments are completely allocated to the corresponding video segment; determining a maximum time-length video frame interval not allocated in the video segment, and partitioning the maximum time-length video frame interval based on a set first ratio;based on the interval division result, each video segment is associated with the assigned music segment to generate an object video file having a music rhythm. The invention also discloses a multi-source video editing device and a storage medium.

Owner:MIGU CO LTD +1

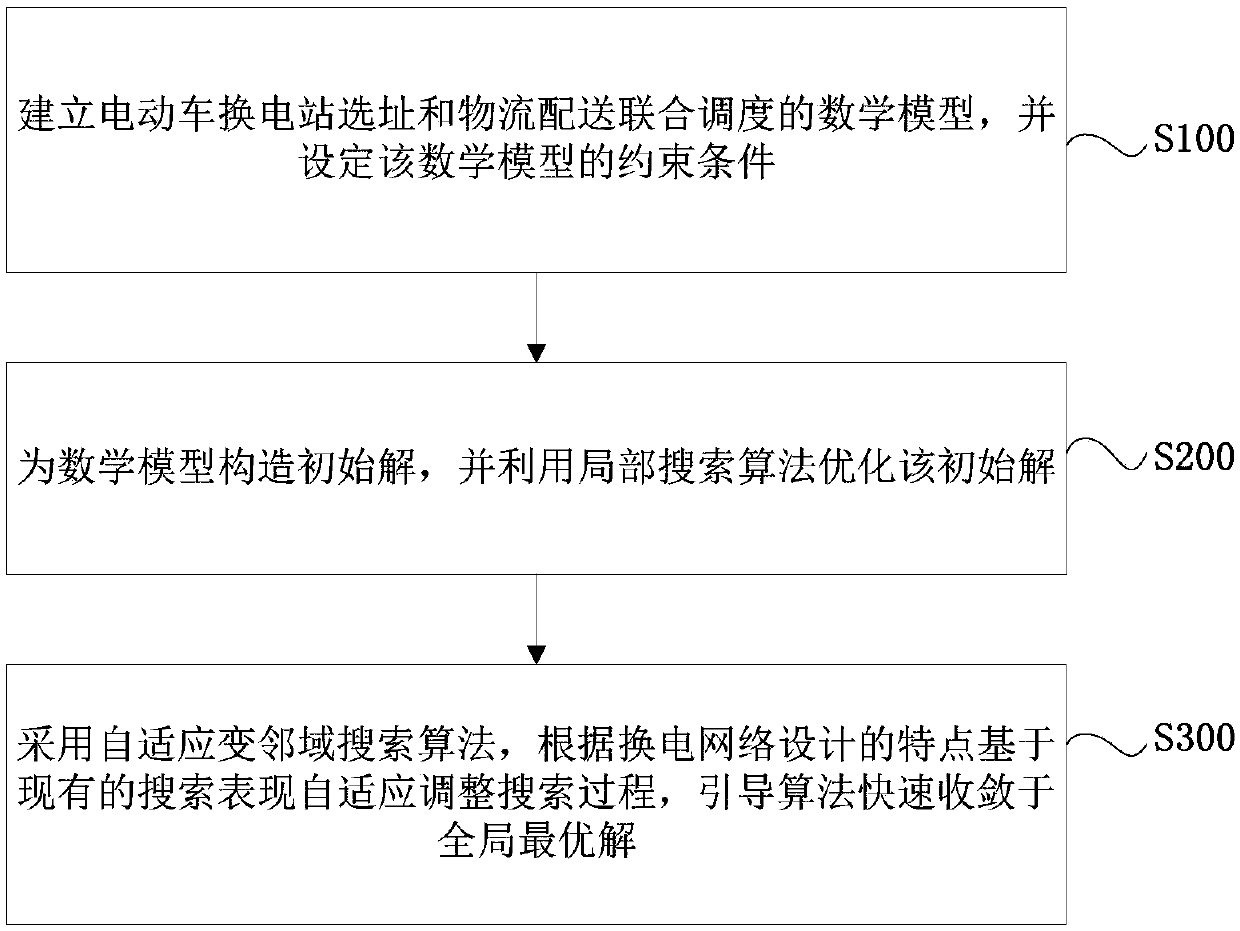

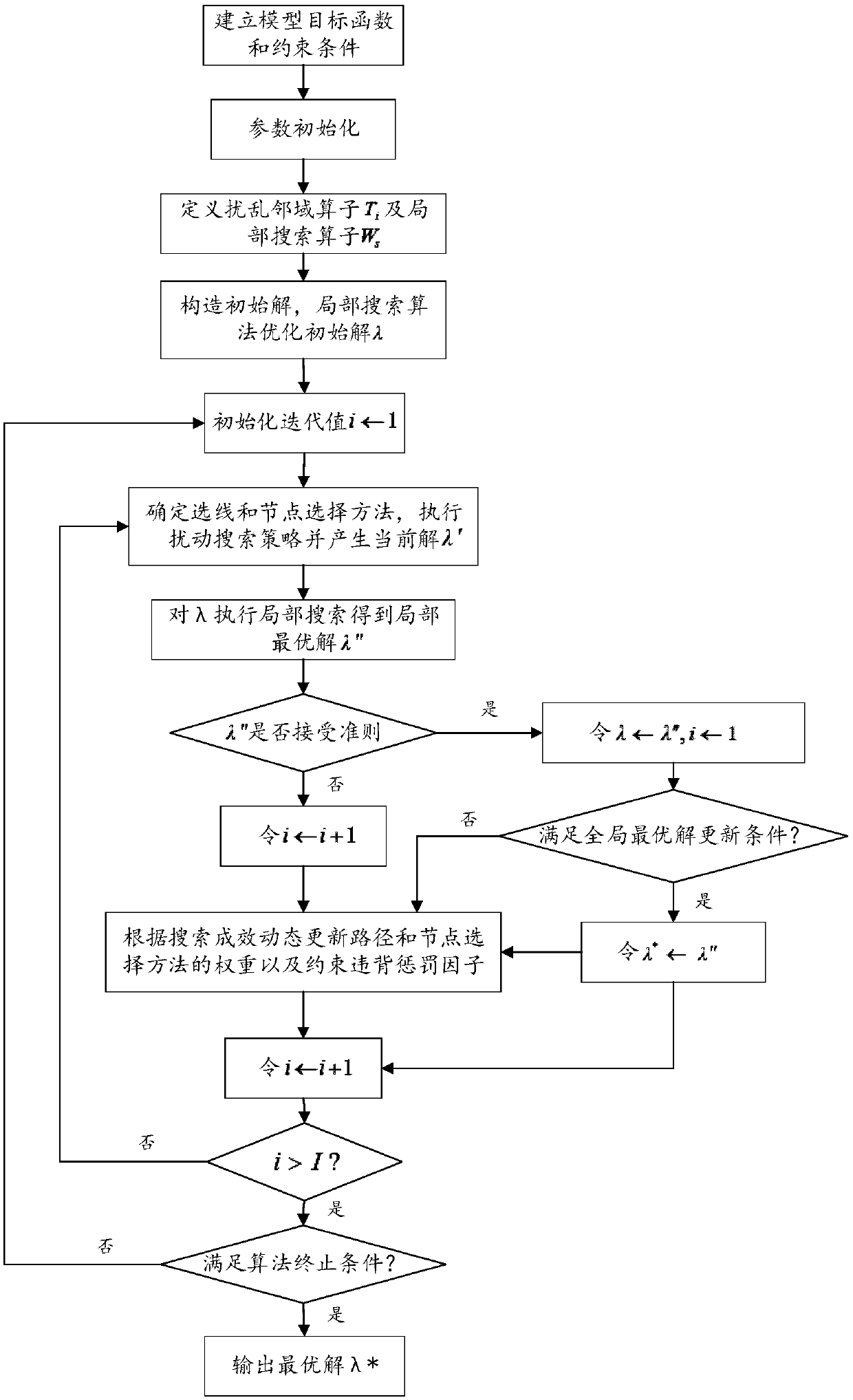

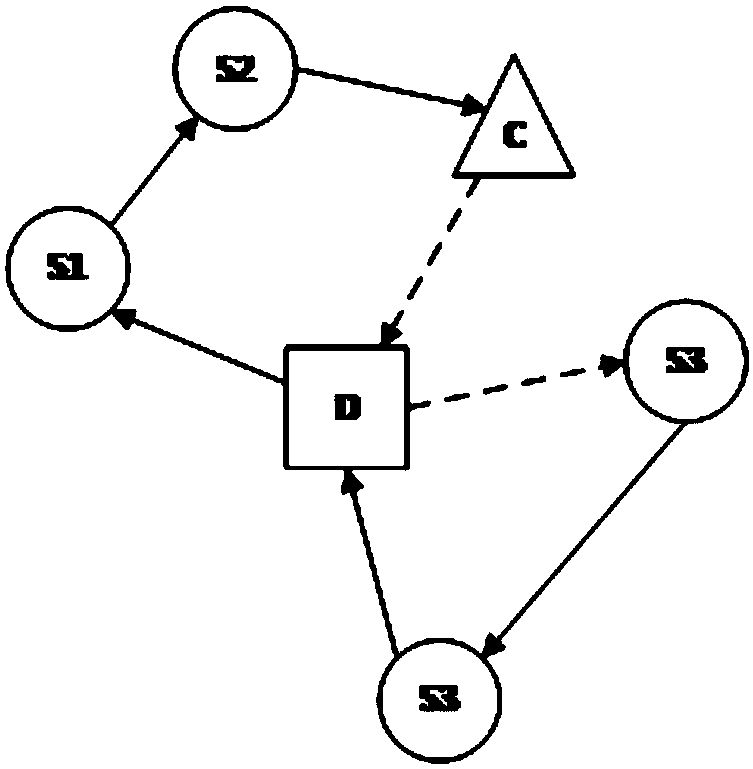

A joint scheduling method for site selection and logistics distribution of an electric vehicle battery swap station

ActiveCN109583650AFast convergenceImprove the efficiency of delivery servicesForecastingResourcesMathematical modelSimulation

The invention provides an electric vehicle battery swap station site selection and logistics distribution combined scheduling method, which comprises the following steps: establishing a mathematical model of electric vehicle battery swap station site selection and logistics distribution combined scheduling, and setting constraint conditions of the mathematical model; Constructing an initial solution for the mathematical model, and optimizing the initial solution by using a local search algorithm; And then adopting an adaptive variable neighborhood search algorithm, adaptively adjusting a search process based on the existing search performance according to the characteristics of the battery replacement network design, and guiding the algorithm to quickly converge to a globally optimal solution. According to the invention, the site selection position of the electric vehicle battery replacement station and the distribution route of the electric vehicle can be reasonably arranged, the efficiency of electric vehicle cargo distribution service is improved, the distribution time is shortened, the use of energy is reduced, and the pollution of carbon emission to the environment is furtherreduced.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

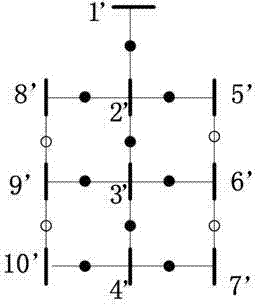

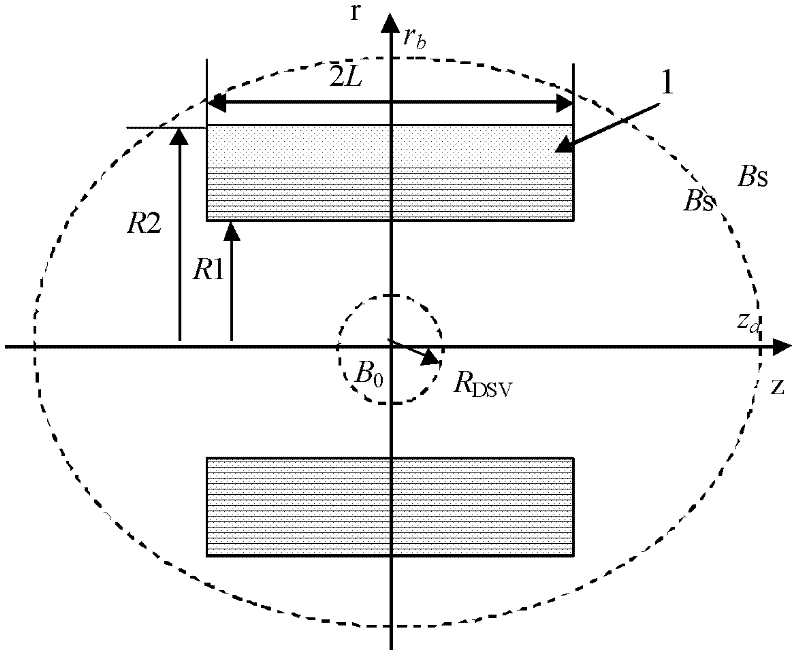

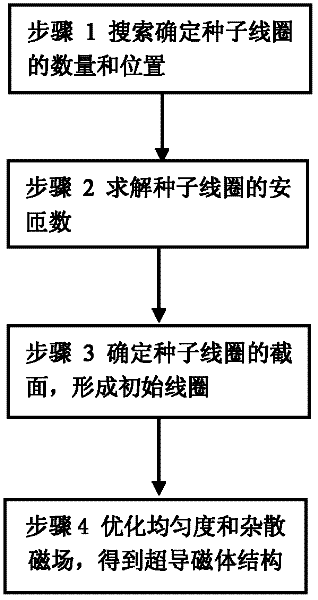

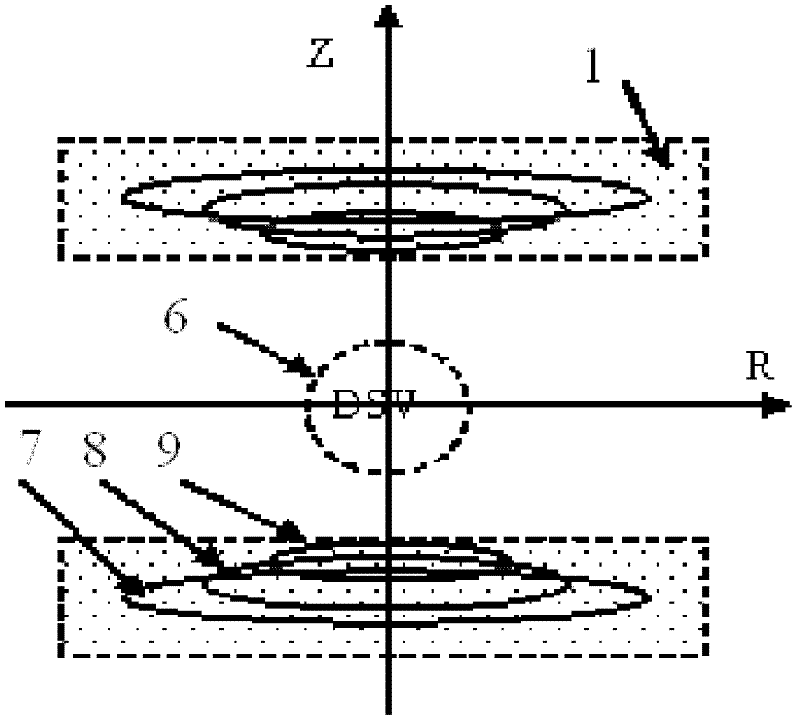

Design method for open magnetic resonance superconducting magnet

ActiveCN102376410AMagnetic measurementsInductances/transformers/magnets manufactureResonanceSuperconducting Coils

The invention discloses a design method for an open magnetic resonance superconducting magnet. The design method uses a method for searching a seed coil and comprises the following steps of: determining a solving region according to design parameters of the magnetic resonance superconducting magnet; searching from the solving region and calculating to obtain the quantity and the position of the seed coil according to set constraint conditions; then solving by using a regularization method to obtain ampere turns of the see coil; selecting work current density, determining the section of the seed coil and forming a structure of an initial coil; and with the initial coil as a main magnetic field coil, adding a shield coil and further optimizing to enable a magnetic filed generated by the magnetic resonance superconducting magnet to meet the requirements of the uniformity of the magnetic filed and a stray magnetic field in a uniform region ball domain of the magnet.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

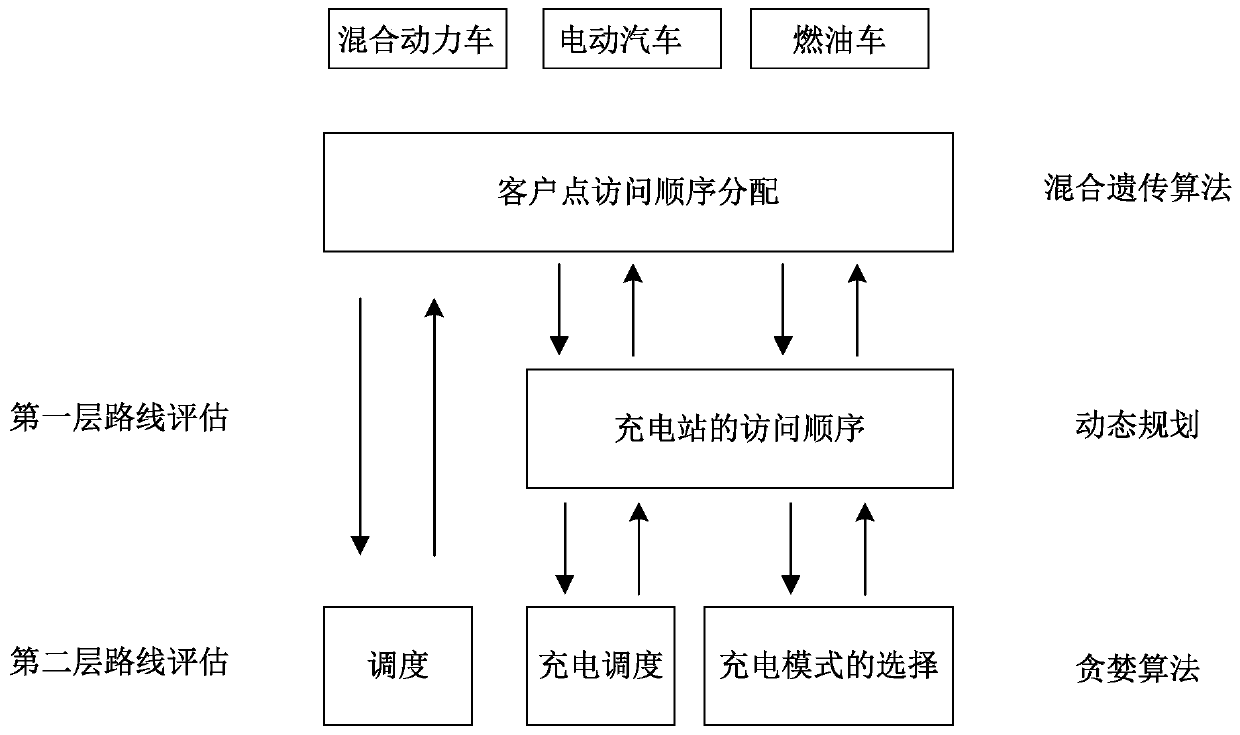

Fuel vehicle and new energy vehicle collaborative distribution scheduling method

InactiveCN110059934AReduce usageSolve the problem of accessInternal combustion piston enginesForecastingNeighborhood searchMathematical model

The invention discloses a fuel vehicle and new energy vehicle collaborative distribution scheduling method, and the method comprises the steps: building a basic mathematical model of a greedy algorithm in an electric vehicle mode, and setting constraint conditions of the basic mathematical model; based on the basic mathematical model, establishing a greedy algorithm model of the fuel vehicle and the new energy vehicle in a mixed mode; establishing an access insertion model of the charging station by utilizing a labeling algorithm, and setting constraint conditions; performing route evaluationon the basic mathematical model and the greedy algorithm model according to the access insertion model to obtain an optimized route solution; on the basis of a heuristic path search model of a geneticoptimization algorithm, searching a path solution in combination with a large-scale neighborhood search algorithm, and guiding an algorithm to be accurately converged to an optimal solution. The cooperative distribution route of the fuel vehicle and the new energy vehicle can be reasonably arranged, the access frequency of the charging station is reduced, and therefore pollution of carbon emission to the environment is reduced.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

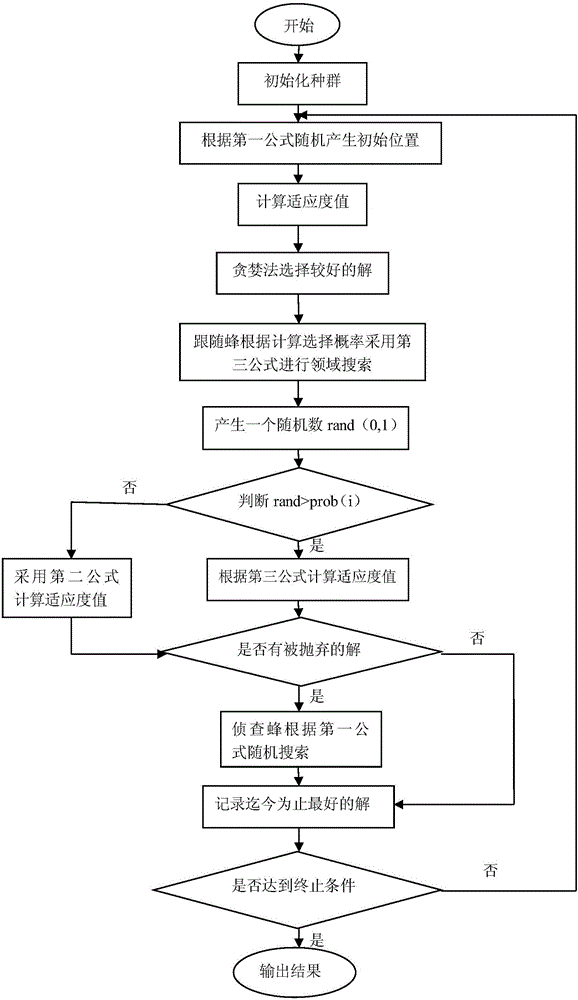

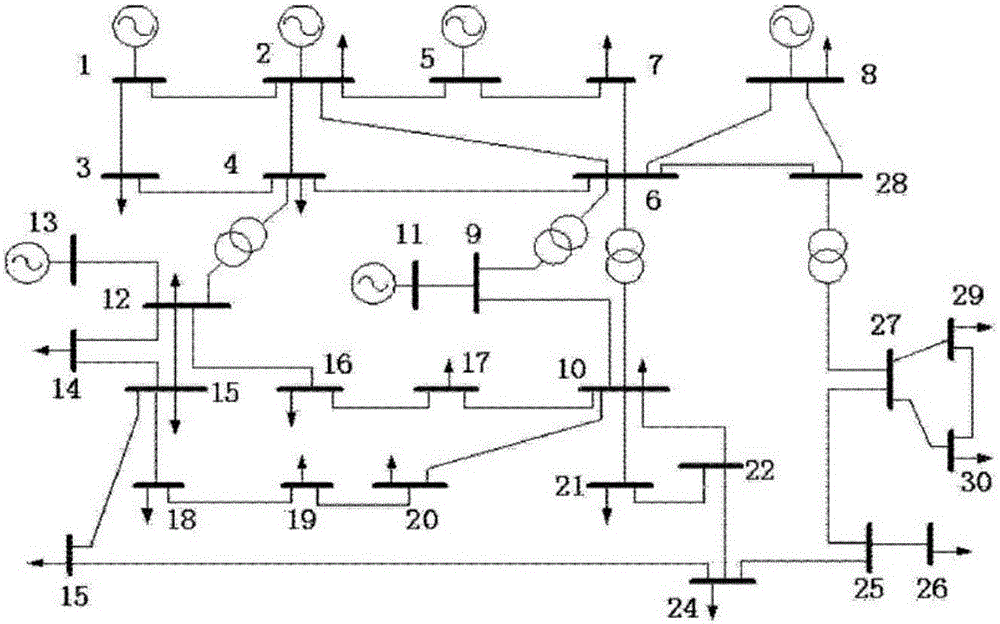

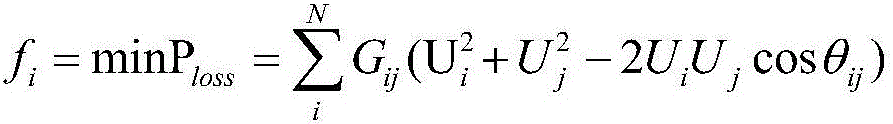

Distribution network reactive power optimization method based on improved artificial bee colony algorithm

InactiveCN105956706APrevent falling intoIncrease diversityForecastingArtificial lifeState variableDistribution power system

The invention puts forward a distribution network reactive power optimization method based on an improved artificial bee colony algorithm, specifically comprising the following steps: building a distribution network reactive power optimization model, and setting constraint conditions; setting a control variable and a state variable; initializing a population; randomly generating the initial position of the population, and calculating the fitting value; carrying out local optimization; updating the position of a nectar source, calculating the fitting value, and keeping an optimal solution; and judging the termination conditions, and outputting the optimal solution. The crossover and mutation mechanism in the difference algorithm is introduced into the artificial bee colony algorithm. The method is applicable to reactive power optimization of a distribution system. The convergence speed is increased. The local search ability of the artificial bee colony algorithm is improved. The effect of network loss is reduced. The operation cost of the power grid is lowered.

Owner:SUZHOU FANNENG ELECTRIC POWER TECH CO LTD

Program developing apparatus, program developing method and computer readable medium

There is provided a method including: dividing codes included in a first source code into a plurality of groups virtually; partitioning each arranged group into one or more sections made up of one or more codes which should be sequentially executed; store the sections in a storage; setting constraints of an execution order among the sections on a basis of the first source code; exhibiting contents of the storage to a user; exhibiting constraint information representing the constraints of the execution order to the user; editing the contents of the storage based on a first editing command from the user; editing the constraint information based on a second editing command from the user; and synthesizing the first source code and edited contents of the storage into a second source code according to edited constraint information.

Owner:KK TOSHIBA

Method and apparatus for finance-based scheduling of construction projects

a method and apparatus is disclosed for scheduling construction projects based on the available finance using integer programming. This method renders CPM / PERT schedules of construction projects executable using bank overdrafts of specified credit limits. Conveniently, the method is organized in three stages; input preparation, schedule extension, and model formulation. Input preparation stage supports preparing CPM / PERT schedule and financial data of the project. Schedule extension stage supports developing a scheme for schedule extension. The scheme is a framework of the original schedule that allows a definite extension increment in the critical path of the CPM. Model formulation stage supports building an integer programming model for the scheme and involves the components of formulating an objective function, setting constraints, and searching for a model solution. The model solution determines the activities' shifts that fulfill the constraints of the specified credit limit while minimizing the schedule extension. A search for a solution of the model is performed. If no solution is found, a repetition of the last two stages of the method is performed after allowing longer extension increment.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

QC-LDPC (Quasi-Cyclic Low Density Parity Check) code constructing method

InactiveCN101826878ABig and small circumferenceHigh Error Correction GainError correction/detection using multiple parity bitsParallel computingLow density

The invention relates to a QC-LDPC code constructing method which comprises the following steps of: initializing the line displacement values corresponding to all nonzero units of a basic matrix; traversing each column of the basic matrix according to the sequence from left to right and finding out all rings containing each nonzero unit of the current column; sequentially setting the line displacement value of each nonzero unit contained in each ring to satisfy a set constraint condition; selecting the nonzero unit with the minimum line displacement value in each ring, reserving the change of the line displacement value thereof and restoring the line displacement values of other nonzero units to original values; and when all the columns are traversed, finally determining the line displacement values corresponding to all the nonzero units of the basic matrix so as to construct a QC-LDPC code matrix. The method can maximize the minimum circumferential value of a QC-LDPC code, thereby enhancing the performance of the QC-LDPC code, so that the constructed QC-LDPC code can be more rapidly converged and achieve a lower error floor.

Owner:江苏创通电子股份有限公司

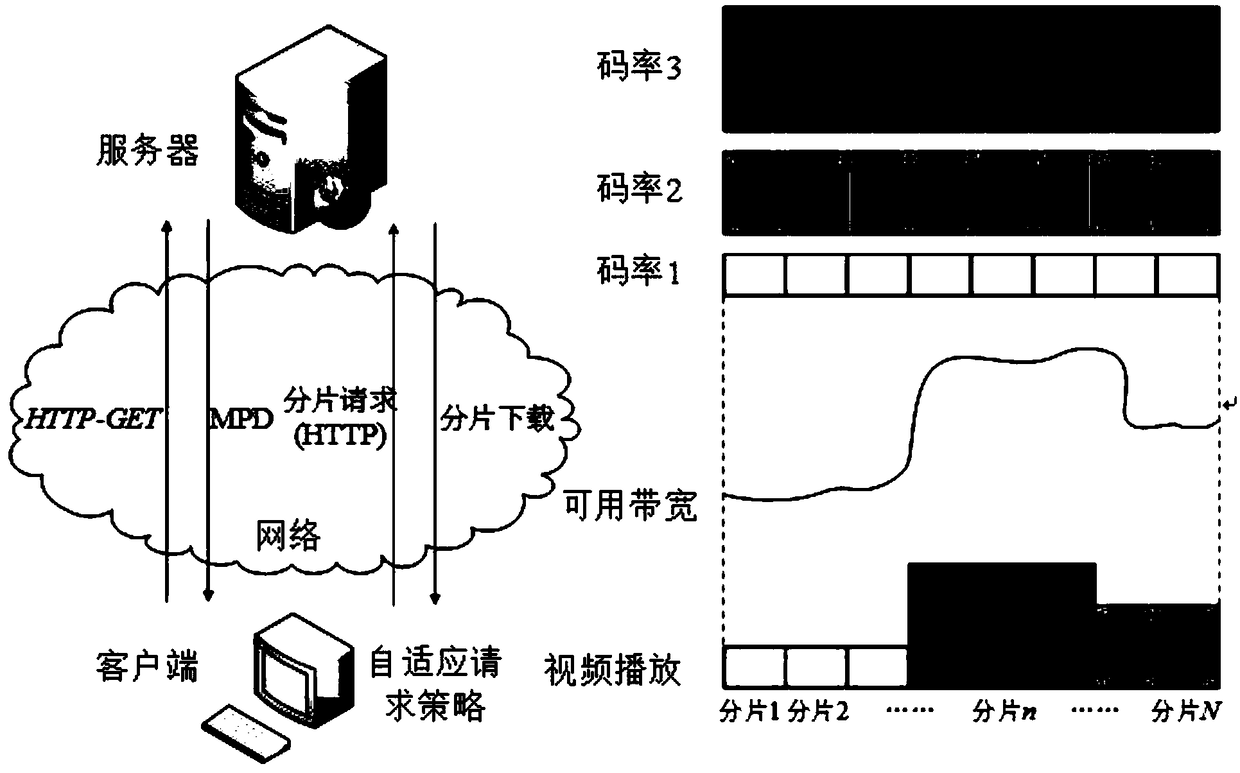

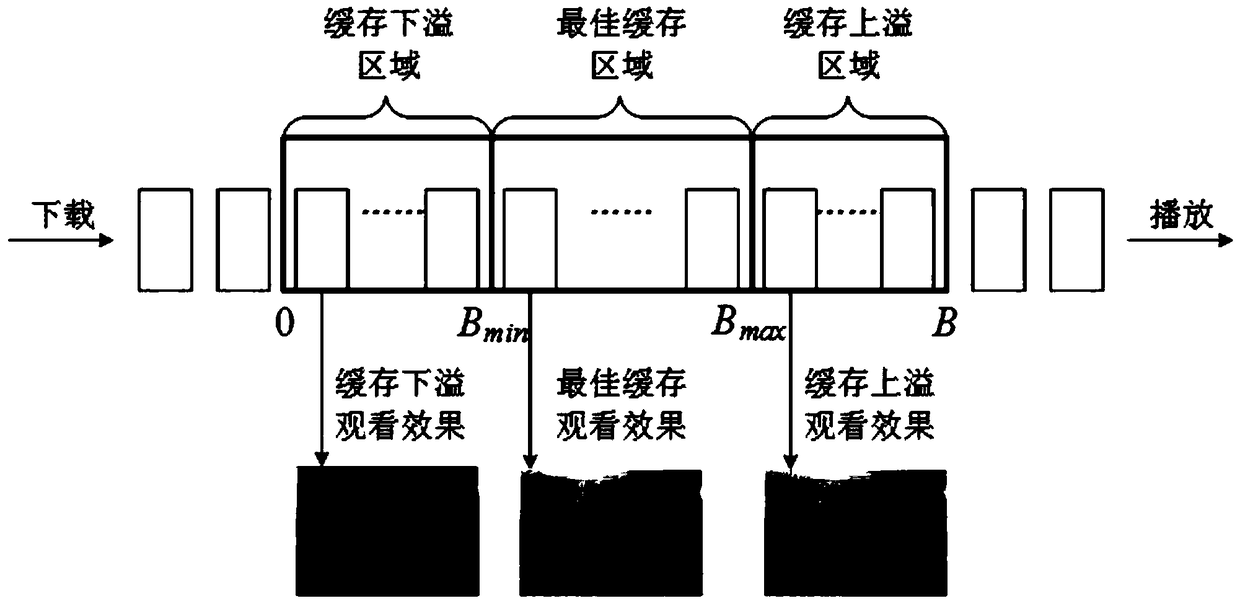

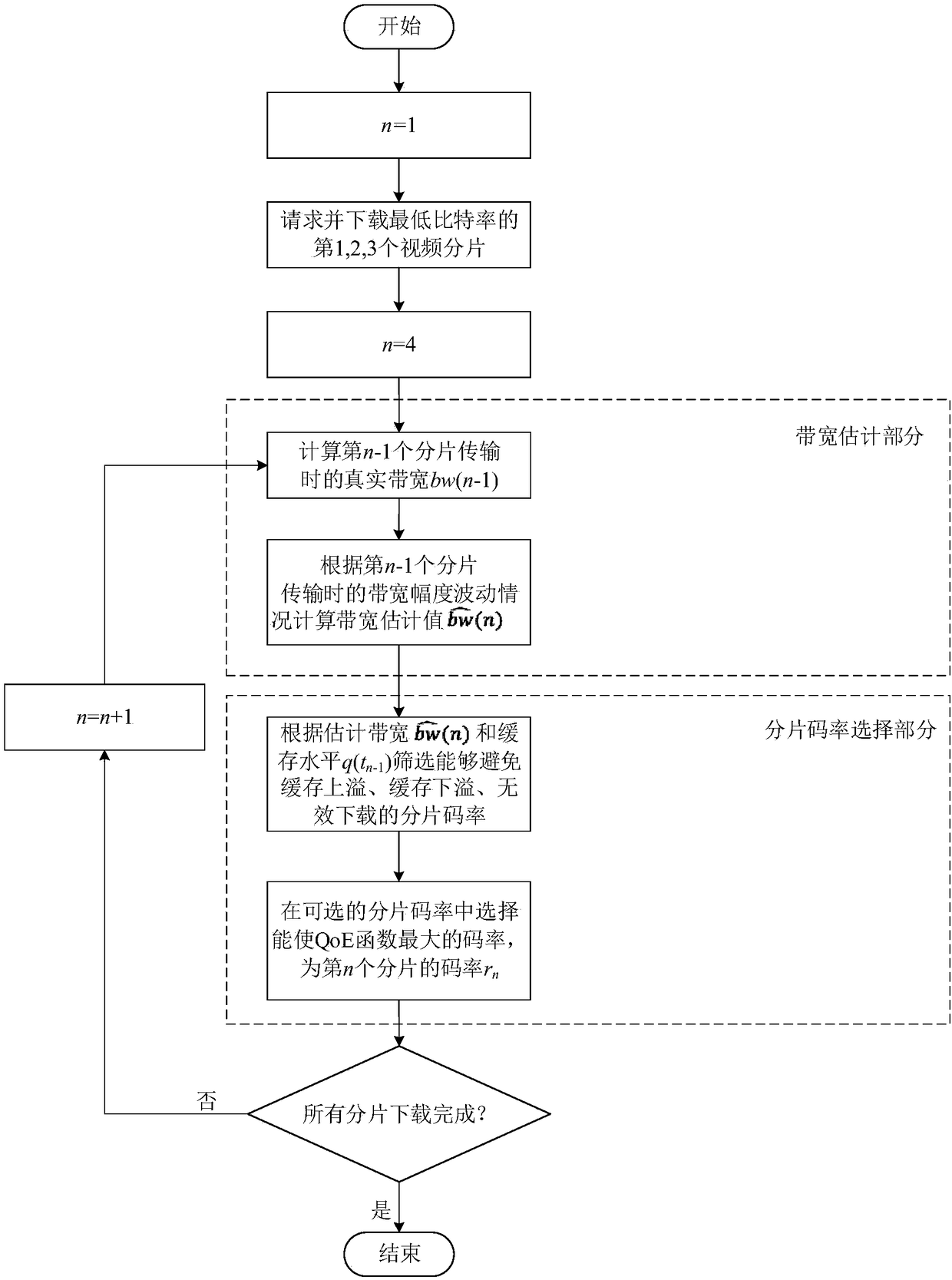

Available bandwidth adaptive video fragmentation request method supporting QoE maximization

ActiveCN108924667AImprove accuracyImprove quality of experienceSelective content distributionVideo transmissionAdaptive video

The invention discloses an available bandwidth adaptive video fragmentation request method supporting QoE maximization, and relates to the technical field of adaptive video transmission. The availablebandwidth adaptive video fragmentation request method provided by the invention comprises available bandwidth estimation and fragmentation code rate selection, the available bandwidth estimation comprises: dividing bandwidth fluctuation into slight fluctuation and severe fluctuation according to the severity of the variation of the bandwidth amplitude, and estimating the available bandwidths during the next fragmentation transmission for the slight fluctuation and the severe fluctuation by adopting different historical weighting methods; and the fragmentation code rate selection comprises: setting constraint conditions of avoiding cache underflow, cache overflow and invalid downloading according to the limitation of the cache and the estimated available bandwidth, expressing the fragmentation code rate selection as a QoE function, and requesting a video fragmentation that can maximize the QoE function. By adoption of the available bandwidth adaptive video fragmentation request methodprovided by the invention, the accuracy of bandwidth estimation is improved, the adaptive matching of a fragmentation request with the network bandwidth and the cache level is implemented, the video playing interruption times of the client are reduced, the cache level is improved, and the user experience quality is greatly improved.

Owner:阳雨哲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com