Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

990 results about "Shrinkage porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The reason of shrinkage porosity is that shrinkage happen when melted alloy turn into solid from liquid.The casting become solid from inner to outer,therefor,there will be shrinkage porosity if wall thickness of casting is big. All above,it is really impossible to fully solve the gas porosity for casting that have big wall thickness.

Low pressure casting process for aluminum alloy cylinder part

The invention discloses a low pressure casting process for an aluminum alloy cylinder part. The aluminum alloy used by the method comprises the following materials in percentage by mass: 6.0 to 7.0 percent of Si, 0.3 to 0.5 percent of Mg, 0.1 to 0.2 percent of Ti, 0.05 to 0.15 percent of Fe and the balance of Al. After melting, thining, modification, and refining, the materials are subjected to low pressure casting and pouring; and after low pressure casting process of liquid lifting, filling, pressure maintaining and pressure releasing, the materials form a cast in a die cavity; and after a cast blank is subjected to solution treatment, and heat treatment of incomplete artificial aging, the cast has the advantages that: the texture is compact, casting defects such as pores, shrinkage porosity, shrinkage cavity, slag inclusion, and the like are avoided, the quality of the cast is improved; meanwhile, the working allowance of the cast is less, so the material utilization is improved and the production cost is reduced.

Owner:王宏波

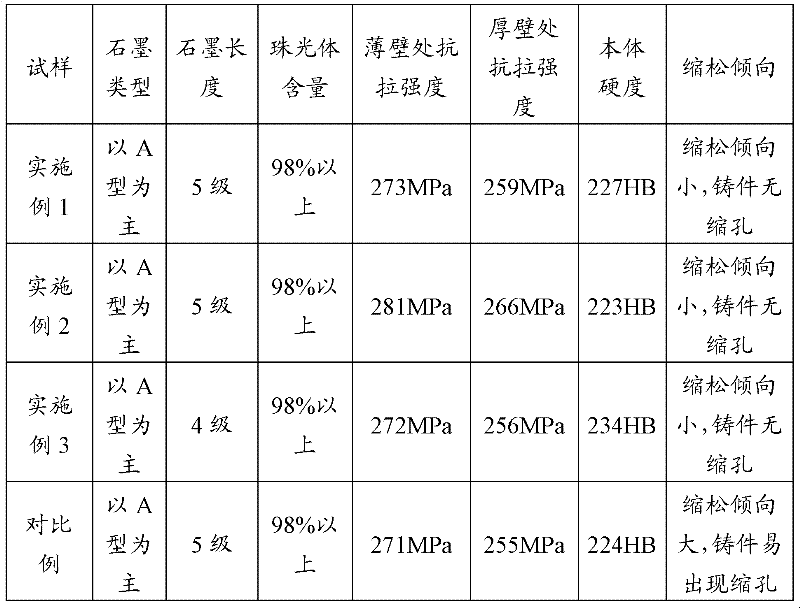

Synthetic cast iron for production of hydraulic piece and preparation method thereof

The invention discloses a synthetic cast iron for hydraulic member production, the mass percentage of the compositions is as follows: 1.8 percent to 3.3 percent of C, 1.8 percent to 2.0 percent of Si, 0.4 percent to 0.7 percent of Mn, 0 percent to 0.3 percent Cr, 0 percent to 0.5 percent of Cu and the rest is Fe. The percentage of the compositions of the charging is as follows: 50 percent to 75 percent of scrap steel, 10 percent to 30 percent of foundry returns, pig iron of 10 percent to 20 percent of pig iron and 1.5 percent to 2.6 percent of recarbonizer. The molten iron is added carbon at low temperature and compensated carbon at high temperature to reach the required ingredients during smelting. The invention can effectively remove the fault of shrinkage porosity inside the high strength gray cast iron; therefore the body strength is greatly improved. The invention has petty microscopic constitution and the casting has compact texture.

Owner:CSIC NO 12 RES INST

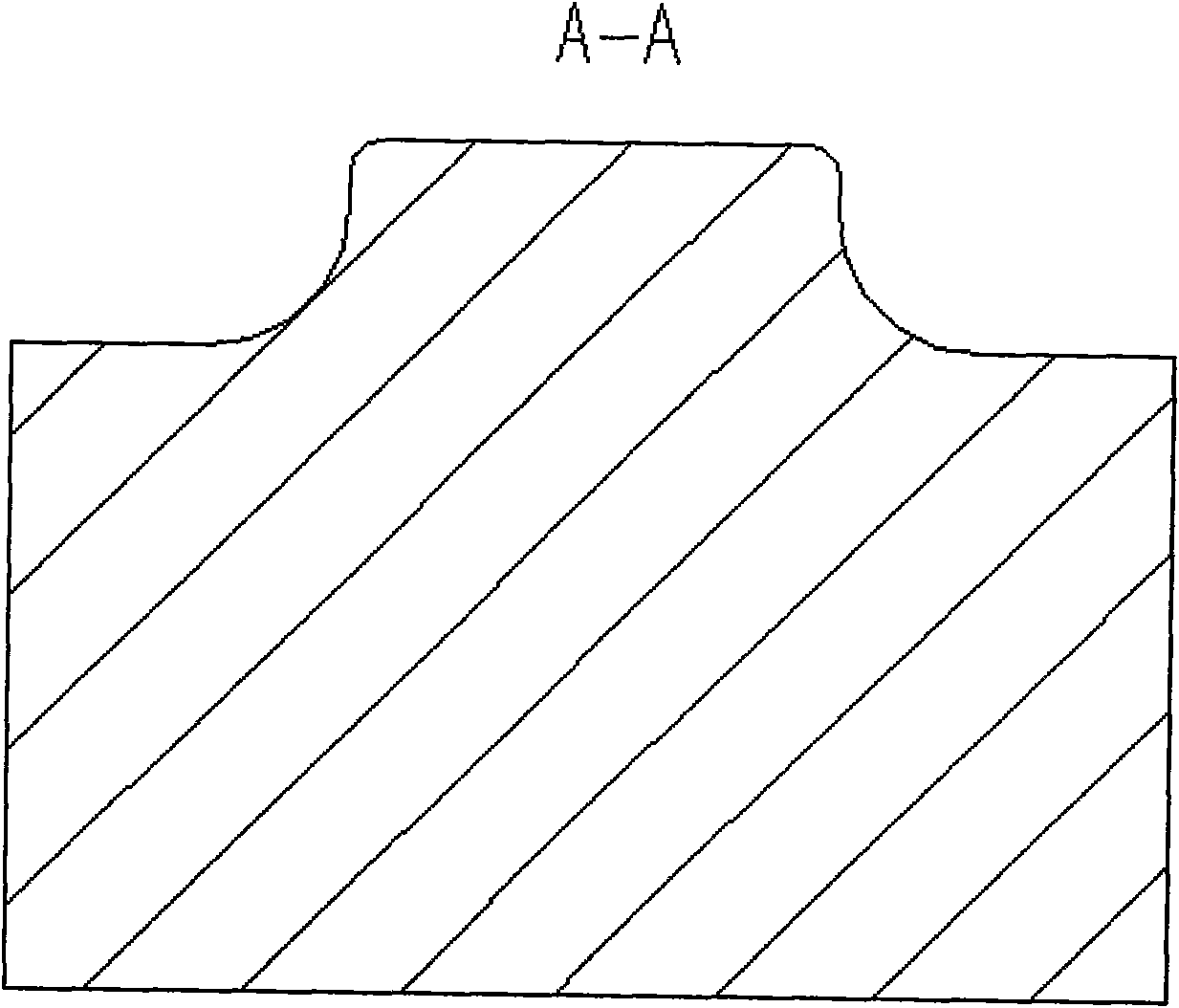

Forging method of coupler knuckle for railway vehicle

InactiveCN101559555AGood mechanical propertiesAvoid air holesOther manufacturing equipments/toolsMaterials preparationToughness

The invention discloses a forging method of a coupler knuckle for railway vehicles. The coupler knuckle for railway vehicles is formed by forging, and coupler knuckle products for railway vehicles with qualified performance and size are forged by the working procedures of material preparation, heating and blank forming, die forging and forming, trimming, heat treatment, preliminary processing, heat treatment, shot blasting, fault detecting and machining. The forging method of the coupler knuckle for railway vehicles, in which the coupler knuckle for railway vehicles has compact texture, high toughness and good fatigue performance, solves the defects of air pore, shrinkage porosity, inclusion, crack, short service life and the like of the coupler knuckle of the existing cast steel vehicle coupler.

Owner:CHONGQING CHANGZHENG HEAVY IND

Nodular graphite cast iron crankshaft of diesel engine and its non-feedhead casting process

ActiveCN101429615APrevent shrinkage and shrinkage defectsImprove product qualityDuctile ironHeavy load

The invention discloses a diesel nodular cast iron crankshaft, which comprises the following components in mass percentage: 3.80 to 3.90 percent of w(C), 2.10 to 2.40 percent of w(Si), more than 0 and less than or equal to 0.30 percent of w(Mn), more than 0 and less than or equal to 0.060 percent of w(P), more than 0 and less than or equal to 0.020 percent of w(S), 0.60 to 0.80 percent of w(Cu), 0.20 to 0.30 percent of w(Mo), 0.020 to 0.040 percent of w(RE), 0.030 to 0.050 percent of w(Mg), and the balance being Fe. The nodular cast iron crankshaft can bear heavy load and constantly changing bending moment and torque actions, and has good mechanical property. The invention also provides a feederless casting process for the crankshaft, and cast parts produced by the casting process do not have the defect of shrinkage porosity at the root part and have reliable mechanical property and high yield.

Owner:GUANGZHOU DIESEL ENGINE FACTORY

Clay molding sand for cast steel and preparation method thereof

The invention discloses clay molding sand for cast steel and a preparation method thereof. The clay molding sand is prepared from the following raw materials in parts by weight: 60-80 parts of quartz sand, 20-30 parts of forsterite sand, 8-12 parts of bentonite, 5-8 parts of composite powder, 4-6 parts of talcum powder, 2-3 parts of nanometer aluminum oxide, 3-5 parts of pine sawdust, 2-4 parts of alpha-starch, 1-2 parts of dextrin, 3-6 parts of calcium phosphate, 1.5-2.5 parts of sulfite lye and 4-8 parts of water. The molding sand is high-temperature resistant, high in strength and high in impact resistance, can be used for overcoming the defects on hot spot parts and avoiding sand adhesion, and a phenomenon that the sand mold is broken due to impact force of liquid steel casting is avoided. Moreover, the clay molding sand is low in air release amount, good in air permeability effect and high in liquidity, the defects of air holes, cold shut and shrinkage porosity in the casting can be effectively overcome, and the yield of the casting is improved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

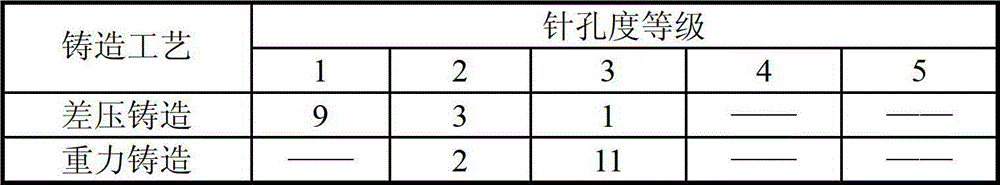

Counter-pressure casting process for ZL424 aluminum alloy castings

ActiveCN102873301AIncrease the speed of solidificationNot easy to precipitateCounter pressureShrinkage porosity

The invention relates to a counter-pressure casting process for ZL424 aluminum alloy castings. The process includes the steps: (1) alloy burdening; (2) using secondary refining and intermediate purifying for smelting alloy; (3) using a counter-pressure casting method for preparing ZL424 aluminum alloy castings; (4) cleaning the ZL424 aluminum alloy blank castings prepared at the step (3) before heat treatment; (5) checking the ZL424 aluminum alloy blank castings subjected to heat treatment. Blank castings prepared by the counter-pressure casting process overcome defects of ZL424 aluminum alloy castings obtained by traditional gravity casting methods, internal pinholes, microscopic shrinkage porosity and microcracks of castings are eliminated, and chemical component acceptability, mechanical performance and compactness of the castings are improved. In addition, the process has the advantages of high efficiency, high casting yield, low manufacturing cost and the like.

Owner:TIANJIN NAVIGATION INSTR RES INST

Gray pig iron and production process thereof

The invention provides a gray pig iron, which comprises the following elements in percentage by weight: 3.1 to 3.4 percent of C, 1.5 to 2.1 percent of Si, 0.5 to 0.8 percent of Mn, 0 to 0.06 percent of P, 0.05 to 0.15 percent of S, 0.15 to 0.50 percent of Cr, 0.3 to 0.8 percent of Cu, 0 to 0.12 percent of Sn, 0.20 to 0.60 percent of Ni, and the balance of Fe. In the production process of the gray pig iron, the Cu, the Cr, the Ni and the Sn are added into molten iron to perform alloying, so the defect of large shrinkage porosity tendency caused by using molybdenum to perform the alloying can be overcome, the obtained gray pig iron has excellent casting property, shrinkage cavities are not generated on casts, the requirements on materials of key casts of cylinder bodies and cylinder covers of high-performance engines at present can be met; and the price the Ni and the Sn is lower than that of the molybdenum, so the cost of the casts is low.

Owner:WEICHAI POWER CO LTD

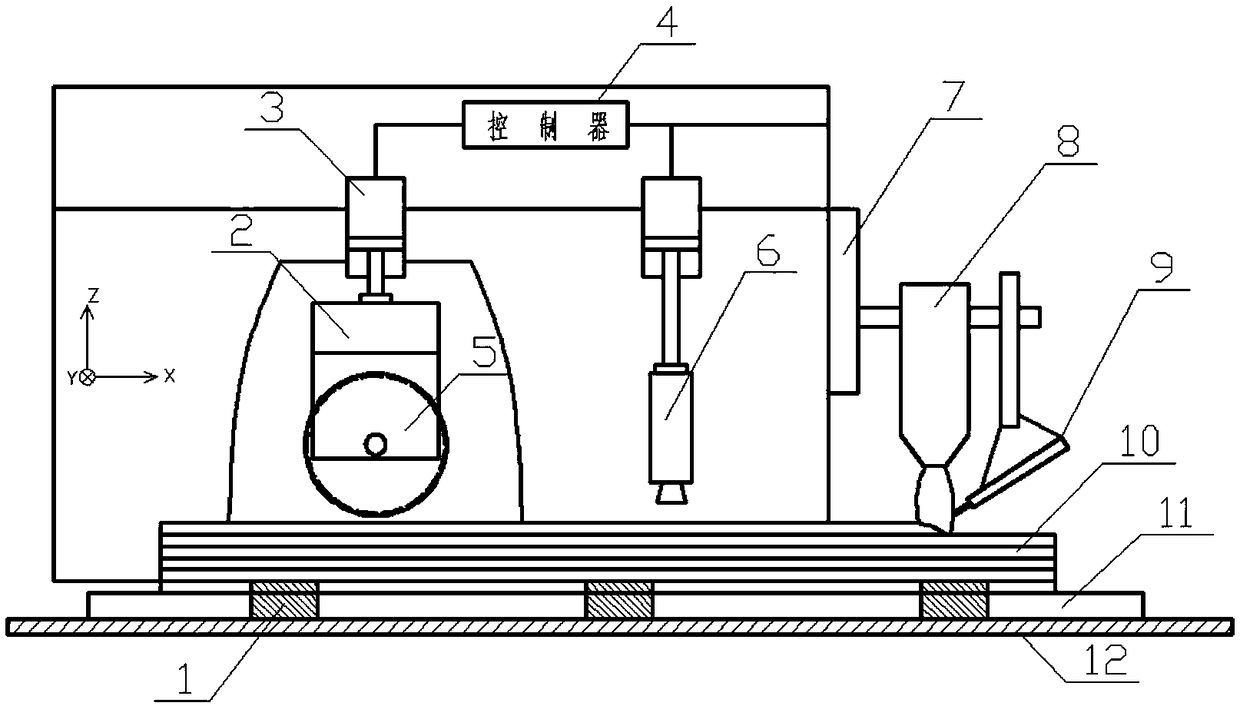

Electric arc wire filling and rolling combined material additive manufacturing method and device

InactiveCN108637504AImprove wear resistanceImprove corrosion resistanceWelding apparatusSurface roughnessEngineering

The invention relates to a material additive manufacturing method and device, in particular to an electric arc wire filling and rolling combined material additive manufacturing method and device. During operation of the device, a substrate is fixed to a welding platform; a welding gun is controlled to move in cooperation with a wire feeding mechanism to conduct electric arc wire filling to form aweld layer; meanwhile, the temperature of the weld layer is collected through a temperature sensor; collected data are transmitted to a controller; the controller controls a rolling wheel to conduct synchronous rolling strengthening on the surface of the weld layer. In the workpiece manufacturing process, metal grains are refined. A residual compressive stress layer is introduced to reduce the surface roughness. The wear resistance, corrosion resistance and compatibility of the surface of a workpiece are improved. The internal defects such as pores, non-fusion and shrinkage porosity possibly occurring to metal parts manufactured through a common electric arc material additive manufacturing method are avoided. Meanwhile, the comprehensive mechanical properties of metal workpieces are improved.

Owner:JIANGSU UNIV

Process for casting thick and large nodular cast iron valve plate

The invention provides a process for casting a thick and large nodular cast iron valve plate. The process comprises the following steps of: (1) manufacturing a mould; (2) manufacturing a casting mould and a sand core; (3) drying and integrating; (4) smelting; (5) pouring; and (6) shaking out and cleaning. In the process, a large number of external chilling blocks and sand separation chilling blocks are used on upper and lower surfaces of a casting for chilling, appropriate placing positions and thickness are selected, and shrinkage cavity and shrinkage porosity of the casting are effectively avoided; meanwhile, a good graphite balling state is ensured by quickly chilling, a feeding head is avoided, the casting is easy to clean, 5 percent of molten iron using amount is saved, and production cost is reduced; a semi-closed casting system is adopted by a casting system, an ingate is uniformly distributed around the casting mould, and the casting mould is slightly scoured, and a good residue stopping effect is achieved; and under the action of chilling of chilling blocks, the thick and large nodular cast iron casting which is smelted by a cupola furnace is good in moulded surface, and meets production requirements, offscourings and sand are avoided, and process yield is improved by 5.9 percent.

Owner:TIJIN YIJI MACHINERY

Low pressure casting wheel cooling technology

The invention discloses a mist-spraying cooling technology, which utilizes an electromagnetic type quantitative pump to pump water into an air and water mixing cooling channel so as to form water mist to be used as cooling medium, and is used for cooling a die by aiming at different air ducts via utilizing water mist cooling or air cooling, so the die is cooled to 430 DEG C-410 DEG C from 490 DEG C-470 DEG C within 40-60 seconds, and the temperature of the die is reduced about 40-80 DEG C. The invention utilizes the mist-spraying cooling technology to control the cooling rate so as to quench the die and can crystallize according to the progressive solidification principle, so an R angle is generated, and the shrinkage porosity defect probability of a rim part is smaller; and the cooling medium is the mixture of water and air and is directly acted on the surface of the die, so the mechanical property of a blank is correspondingly improved, the pinhole scrappage and rework rate are reduced, and the service life of the die is obviously prolonged at the same time.

Owner:BAODING CITY LIZHONG WHEEL MFG

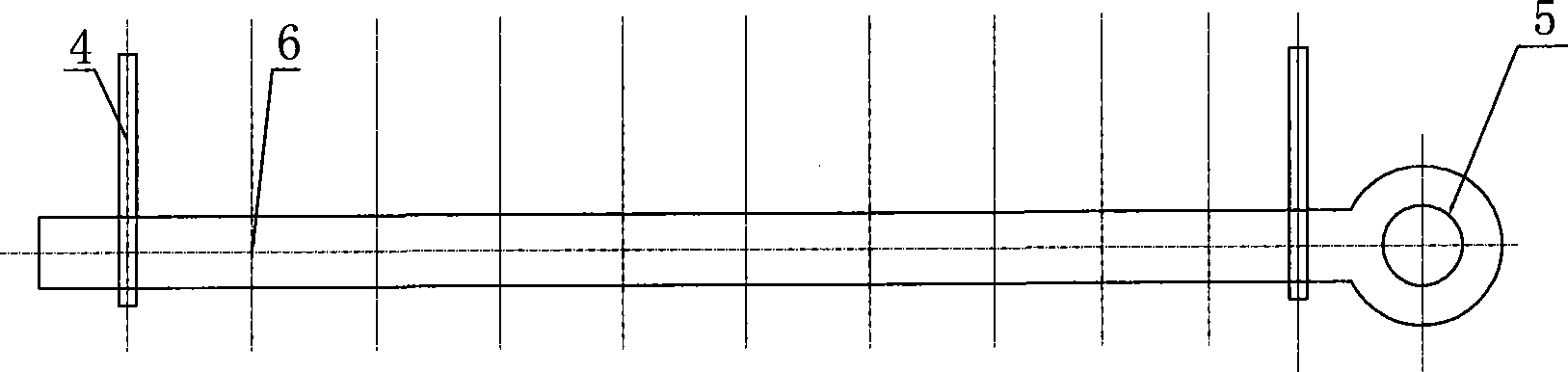

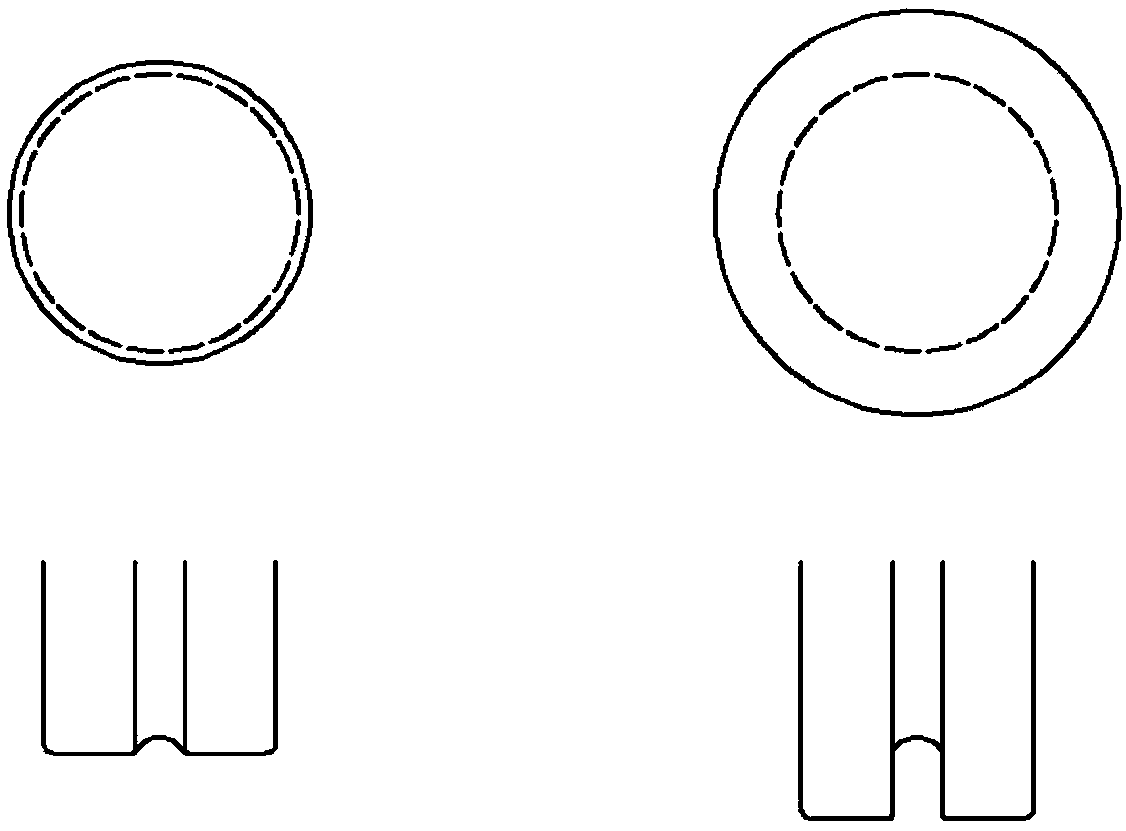

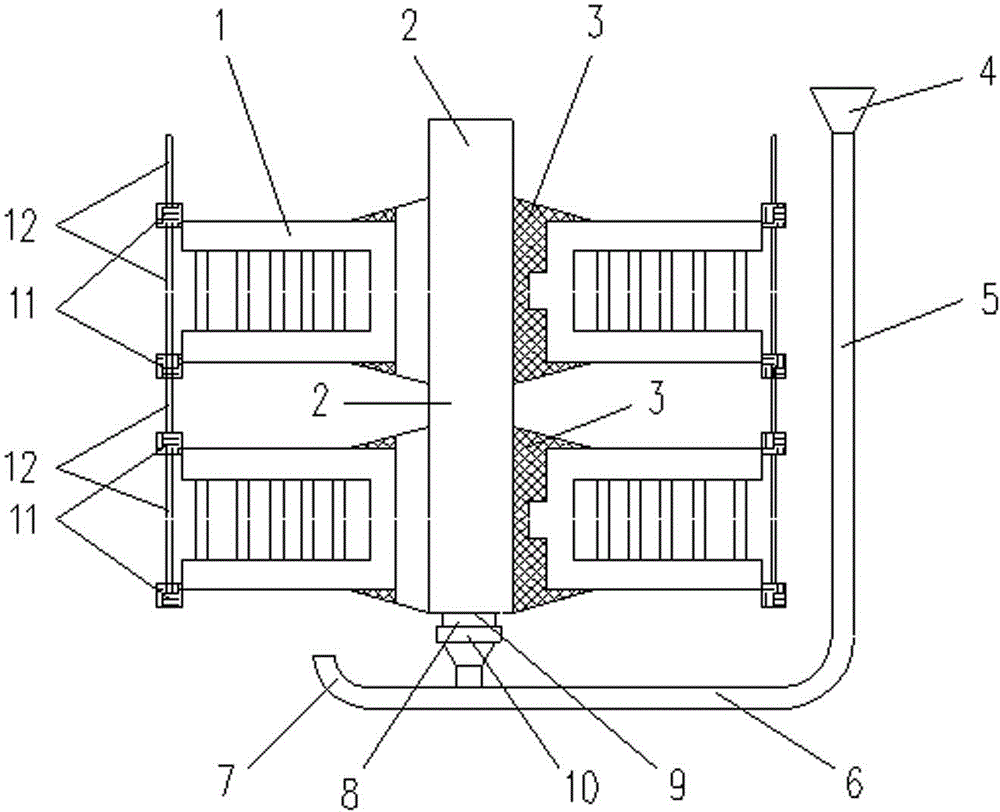

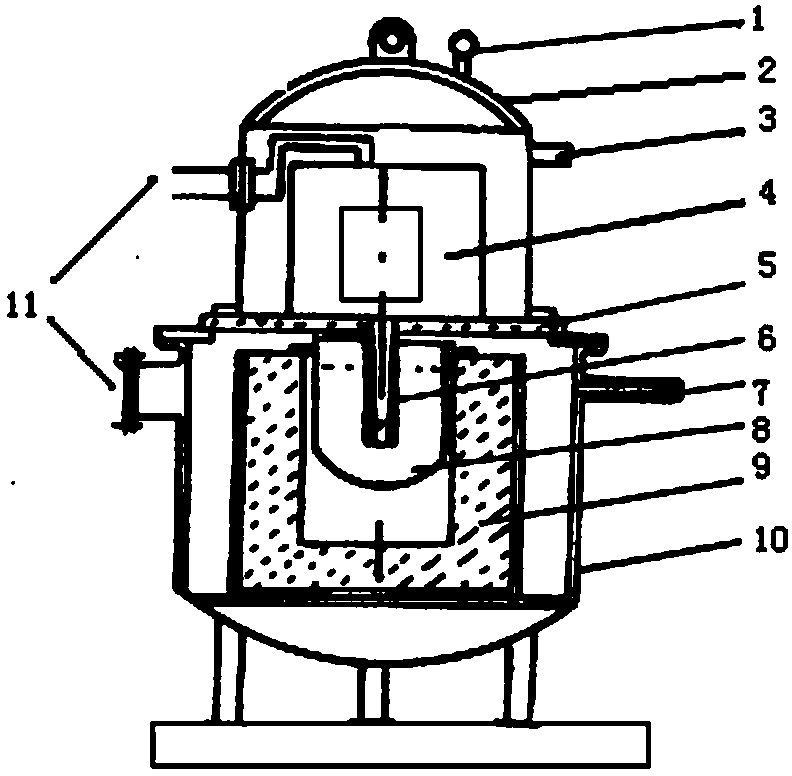

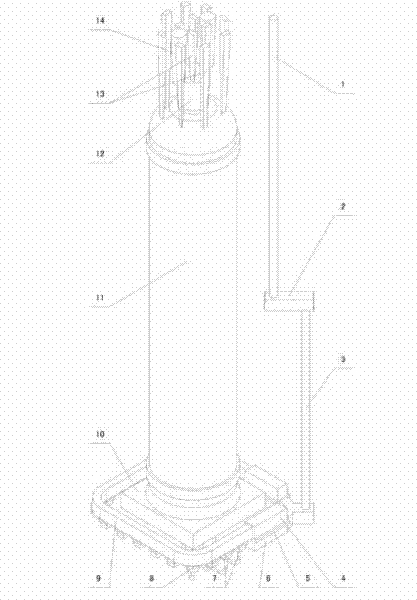

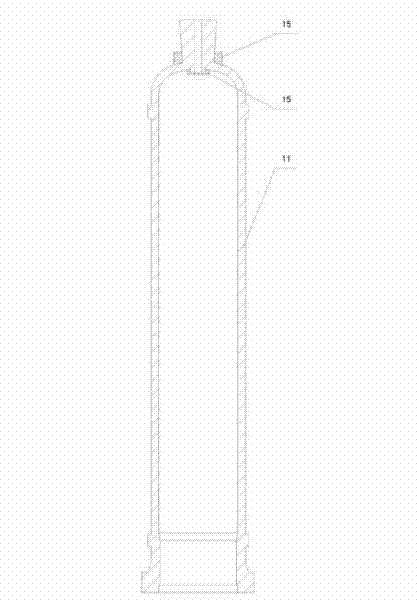

Continuous casting method of large-length hollow ductile cast iron sections and method for arcing hollow ductile cast iron sections after local continuous heating

InactiveCN101638748ASolve technical problems that are difficult to produceCorrosion resistancePhysical fieldVolumetric Mass Density

The invention relates to a continuous casting method of large-length hollow ductile cast iron sections and a method for arcing the hollow ductile cast iron sections after local continuous heating. Thesection comprises the following components by weight percent: 3.4-3.6% of C, 2.8-3.2% of Si, 0.40-0.60% of Mn, S less than or equal to 0.1%, P less than or equal to 0.1% and the balance Fe. Molten iron is subjected to shaping and continuous casting under multiple physical fields to become the hollow sections. The molten iron in heat preserving furnaces is separated from dross, sand and gas in twoways, thus completely solving the defects of dross inclusion, sand inclusion and pores; liquid column cores in a crystallizer carry out continual feeding on condensing tube shells, thus eliminating the possibility of shrinkage porosity inside the tube walls, obtaining highly dense cast structure of (ferritic matrix+spherical graphite) and eliminating crack initiation origins in thermoplastic deformation to be carried out later. The intense cooling speed in the crystallizer enables the volumes of eutectic cells to be only 1 / 15-1 / 25 of the volumes of traditional sand mould casts. The density ofthe graphite balls reaches around 500 / mm<2>. In plastic deformation, the micro slip orientation is increased and the ductility is enhanced, therefore, the hollow cast iron sections can be arced by medium frequency induction heating and bending.

Owner:SHAN XI TONGXIN LIANZHU PIPE IND

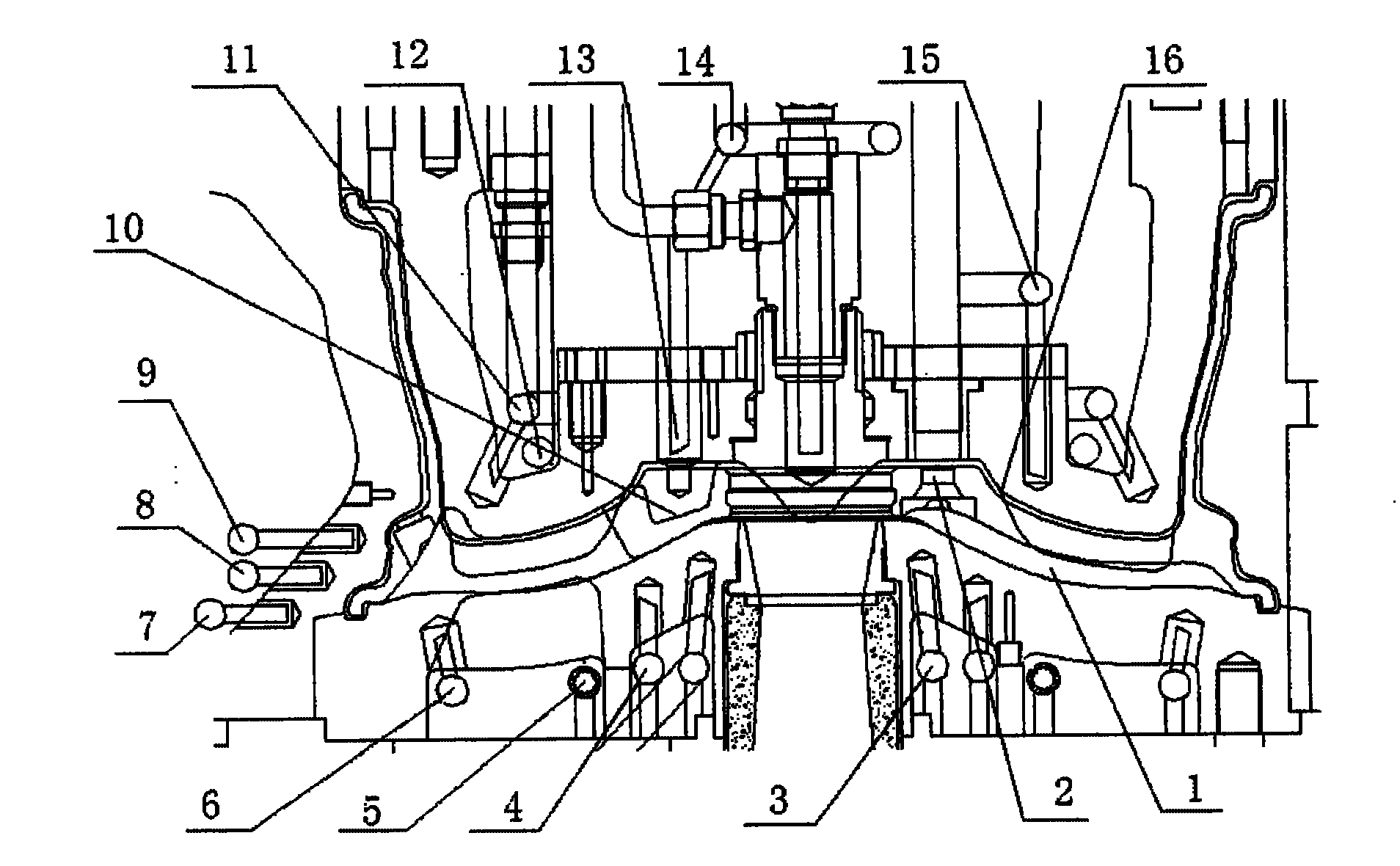

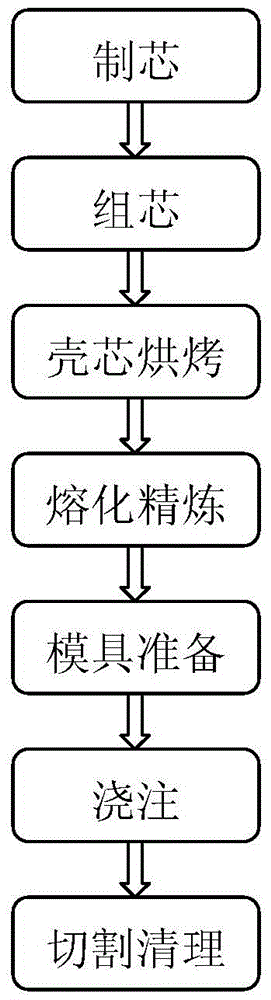

Casting method of turbine housing

ActiveCN105458182AIncrease productivityEffective control of solidification sequenceFoundry mouldsFoundry coresSlagTurbine

The invention provides a casting method of a turbine housing. The casting method includes the following steps of firstly, core manufacturing, secondly, core assembly, thirdly, shell core baking, fourthly, smelting and refining, fifthly, mold preparation, sixthly, casting and seventhly cutting and cleaning. In the core manufacturing process, a riser sand core mold is arranged on a core shooting machine, the core shooting machine is powered on to heat the mold, a layer of precoated sand is cured on a cavity of the riser sand core mold, and a riser sand core is obtained after mold opening. In the core assembly process, the riser sand core and a turbine housing core are assembled and bonded. In the shell core baking process, shell cores painted with coatings are put into a baking kiln. In the smelting and refining process, raw materials are added to a melting and heat preservation furnace, and the melting and heat preservation furnace is powered on for melting. In the casting process, the shell cores are put in a mold, and tilt casting is conducted after mold combination. In the cutting and cleaning process, a casting is cut, the riser is cast, and burrs and fins of the casting are ground and cleaned. The metal tilt casting method of an aluminum alloy turbine housing body can solves the problems of shrinkage porosities and cavities and slag holes in a big flange face of the aluminum alloy turbine housing; open risers and blind risers are arranged, in combination with the riser sand core, an ideal temperature field is formed after the casting is cast, and solidification can be conducted from the casting to the risers in sequence.

Owner:XIAN AERO ENGINE CONTROLS

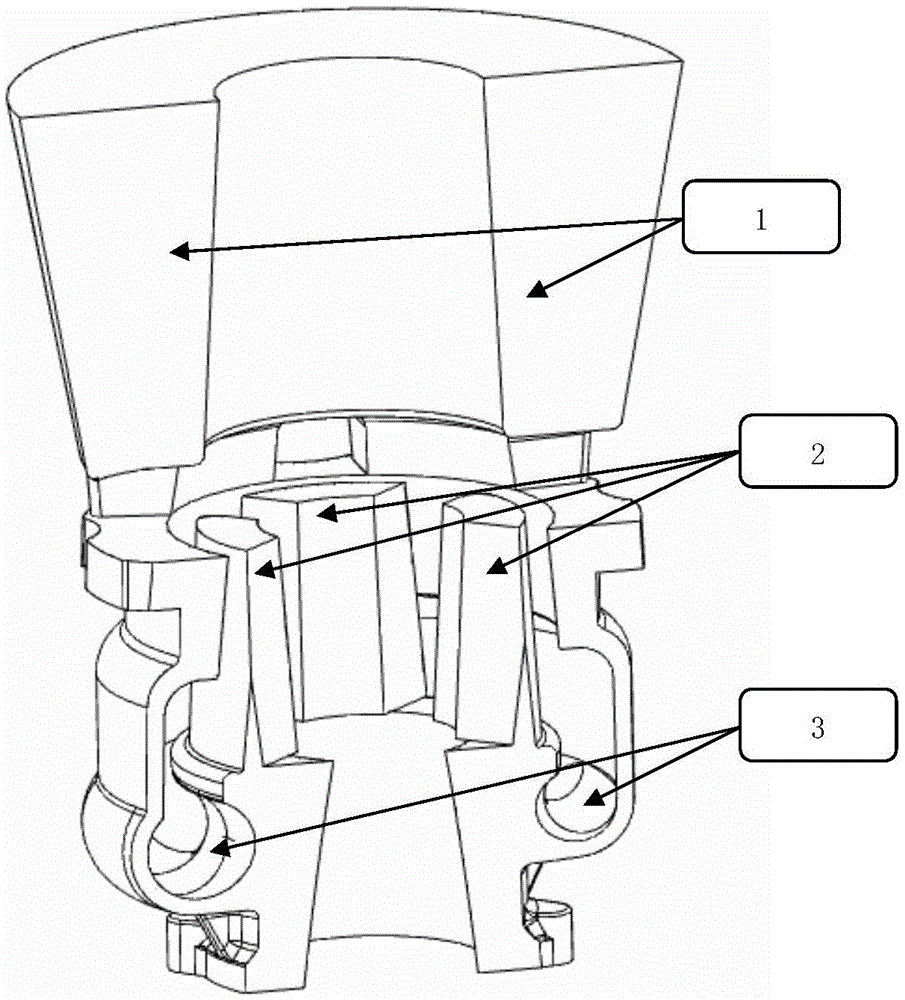

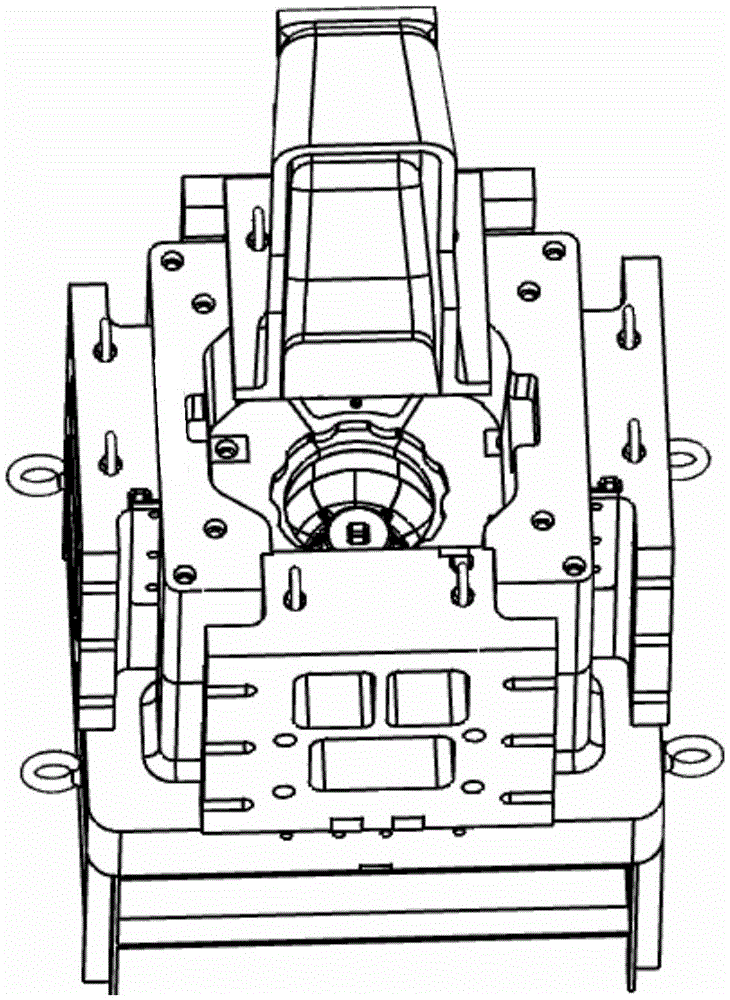

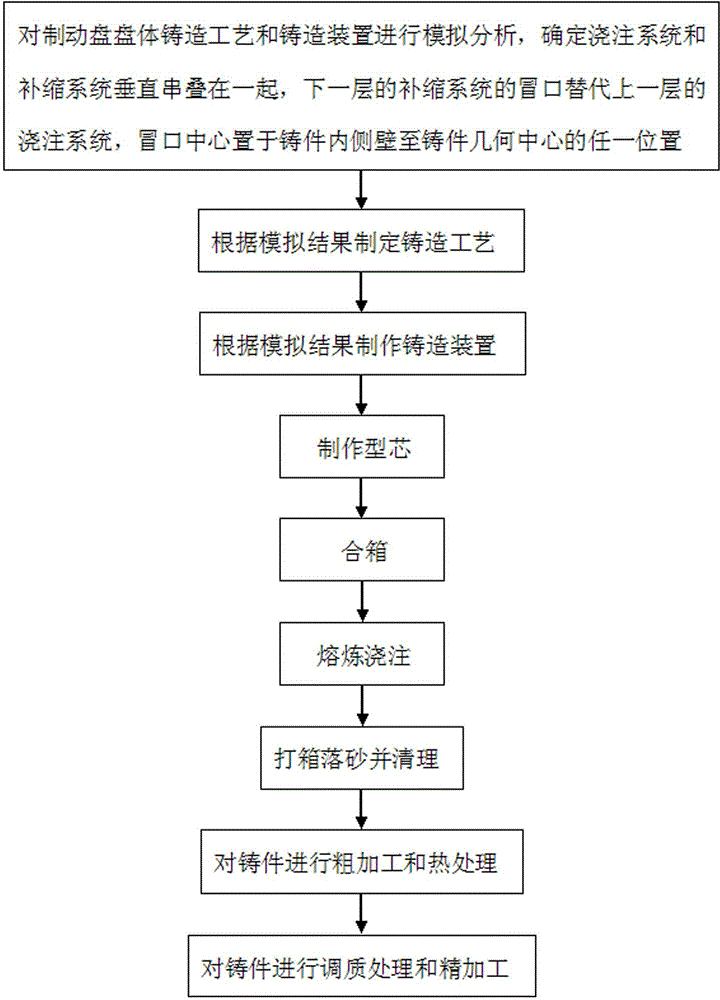

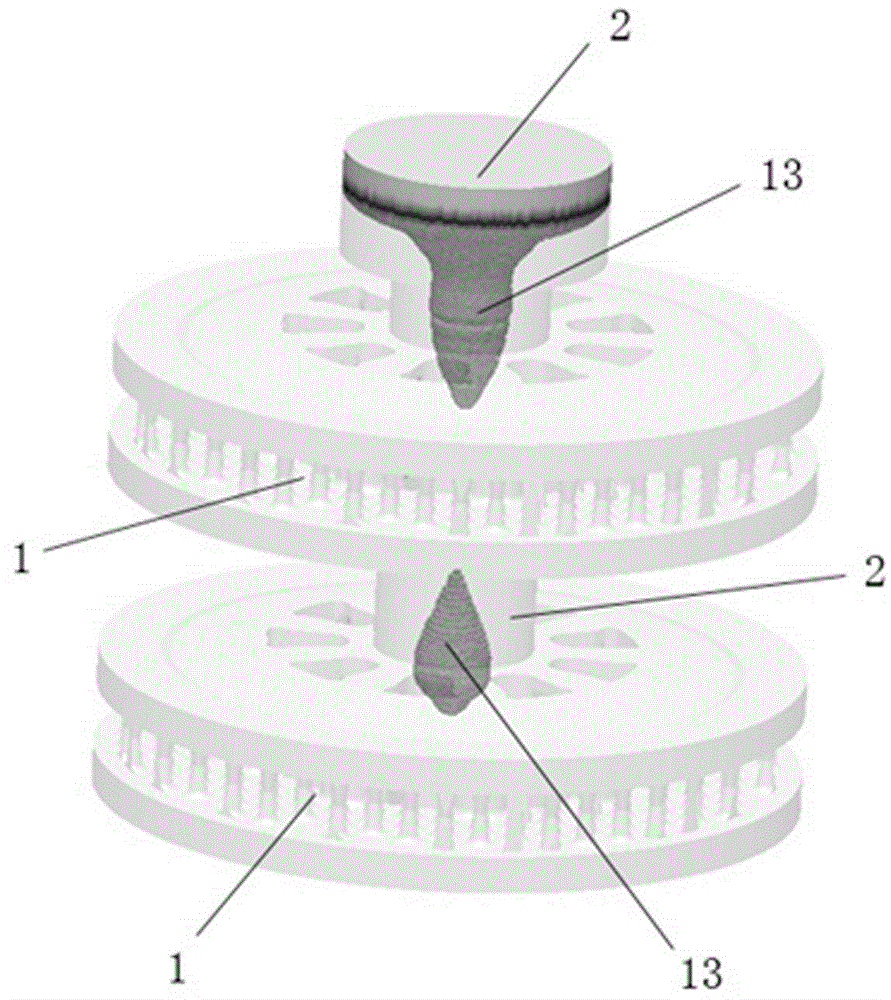

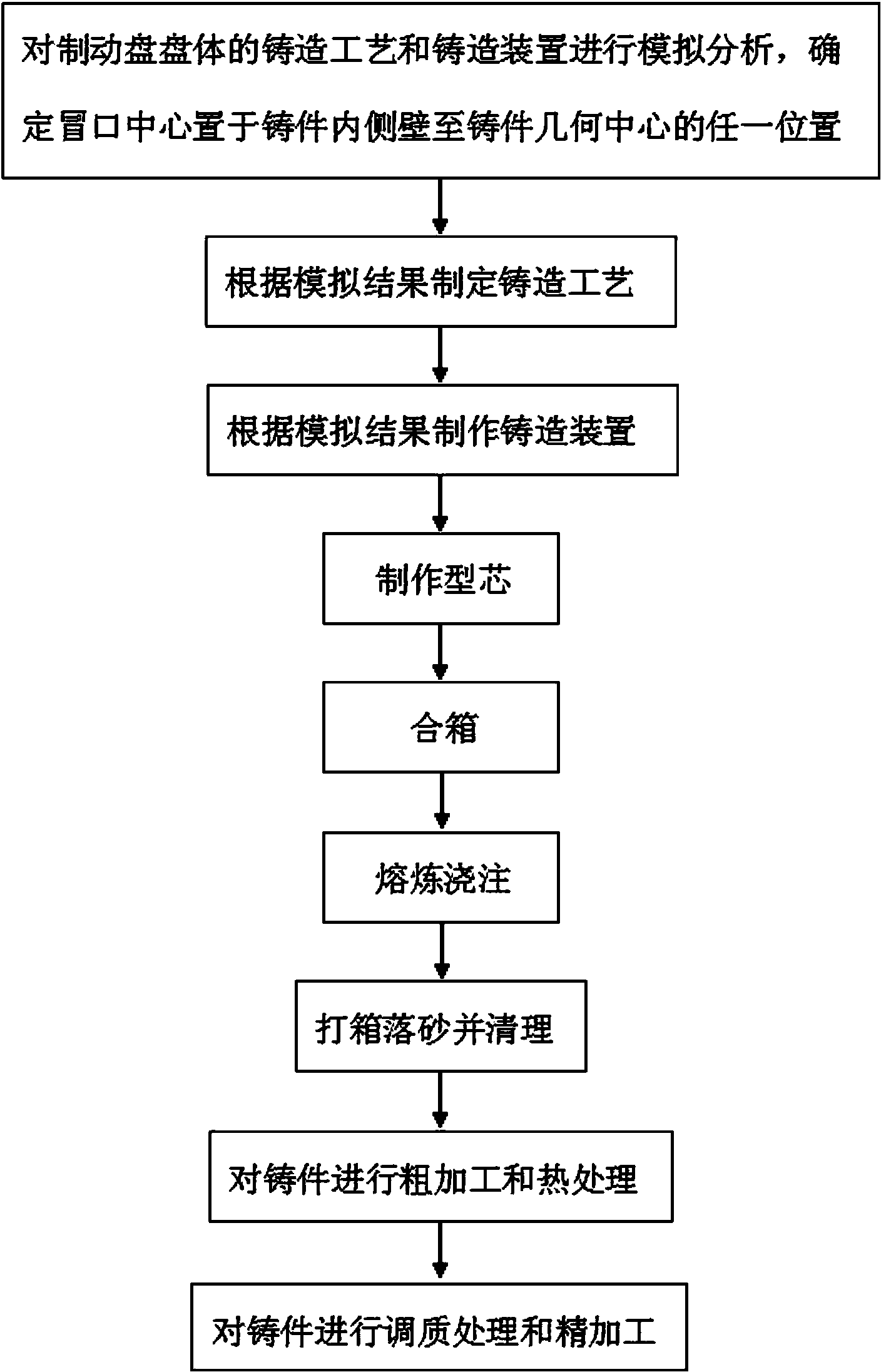

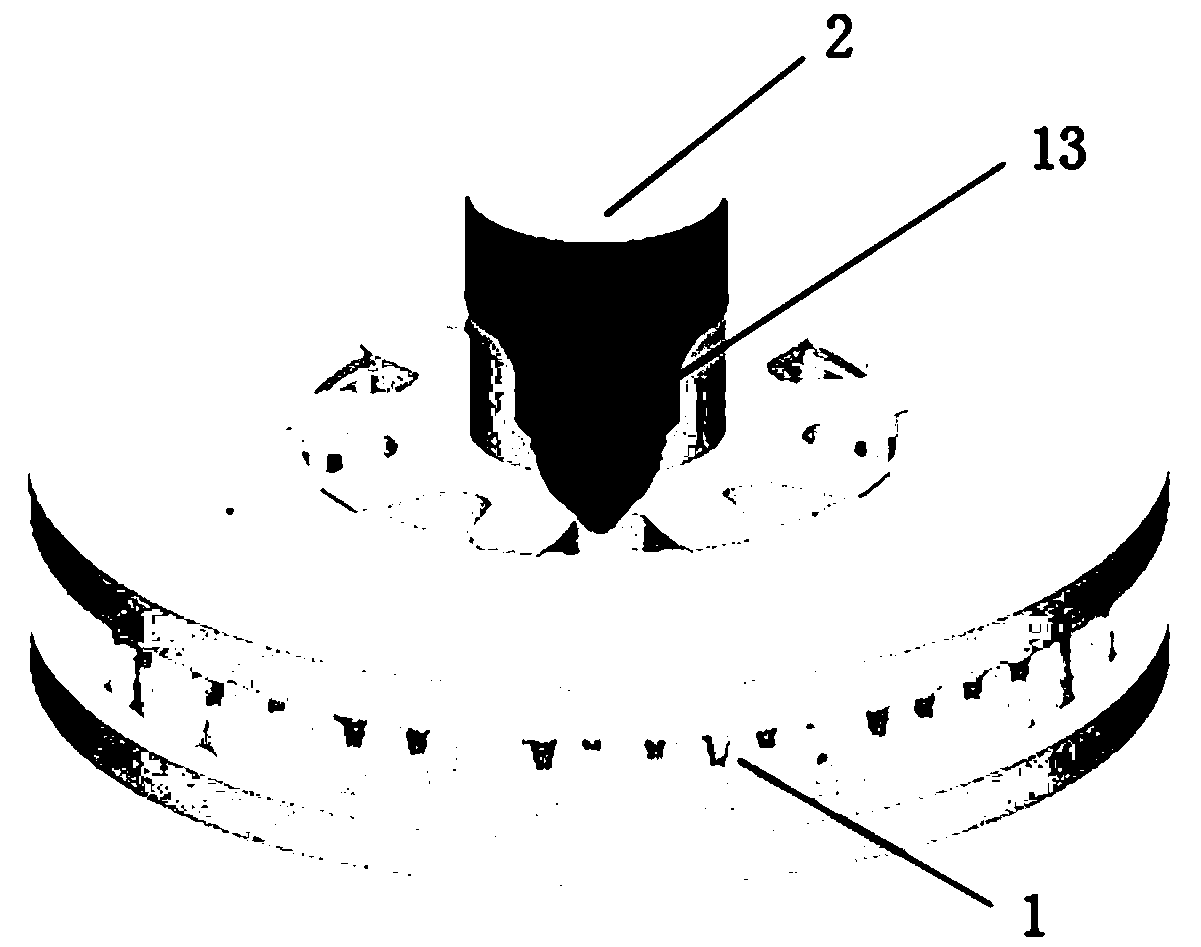

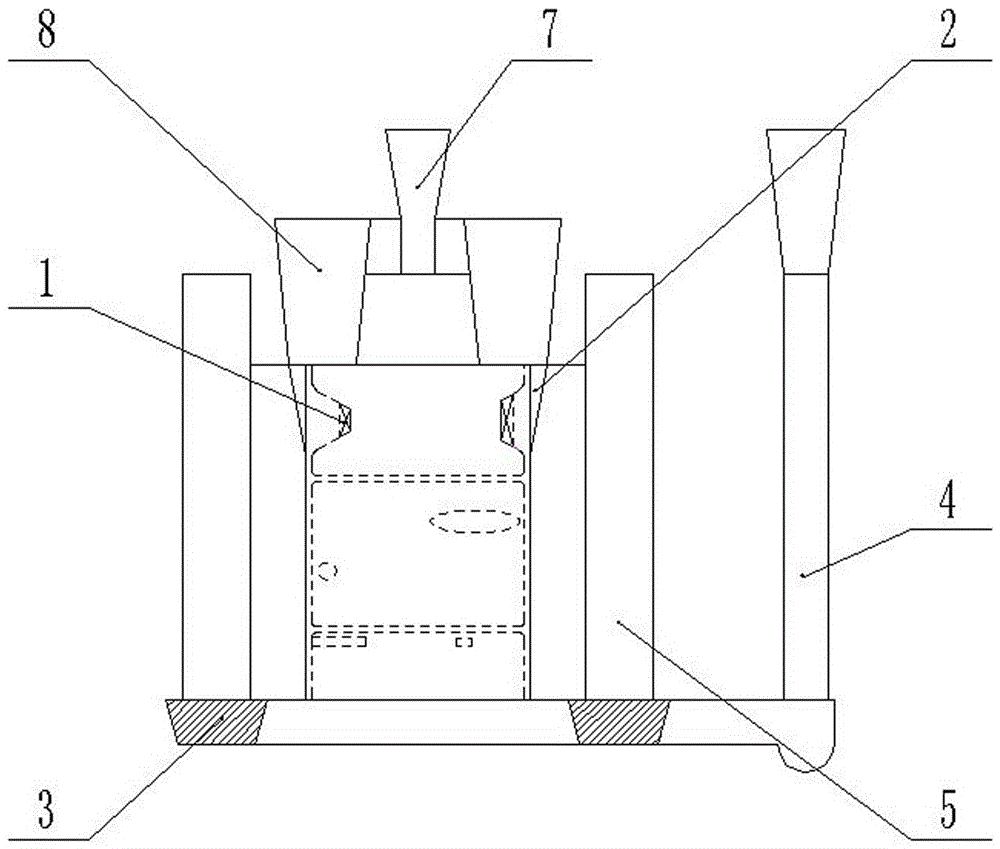

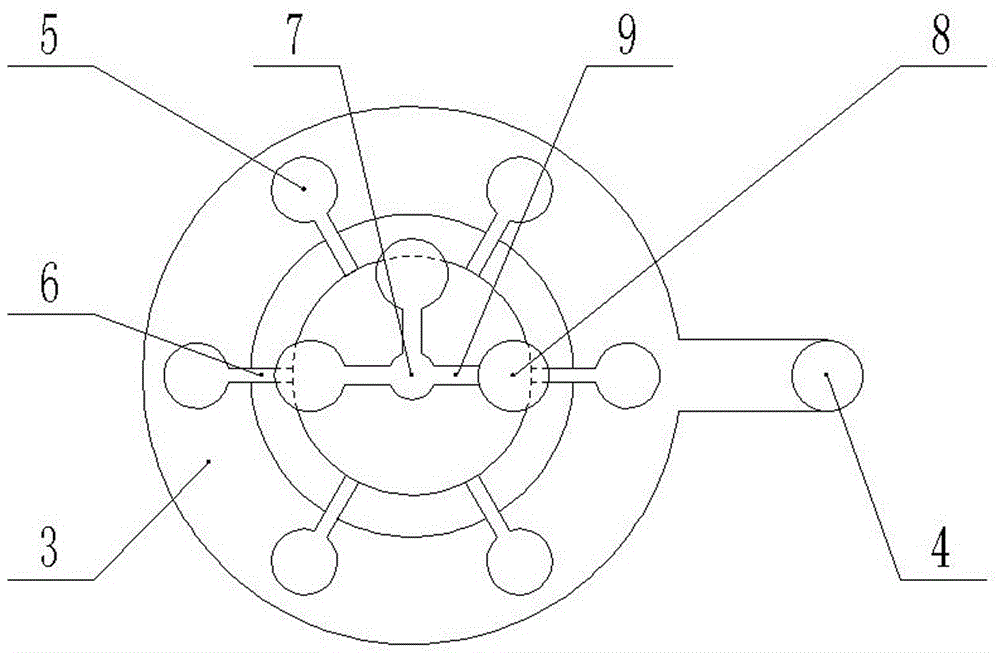

Method and device for casting brake disc body and manufactured brake disc body

ActiveCN104148587AStable and balanced fillingPrevent shrinkageBraking discsFoundry mouldsHigh volume manufacturingSlag

The invention discloses a method and device for casting a brake disc body, and the brake disc body manufactured through the method and device. A casting system and a feeding system are perpendicularly stacked together in a cluster mode, the casting system on the upper layer is replaced with a feeder head on the lower layer, the center of the feeder head is arranged at any position from the inner side wall of a casting to the geometric center of the casting, a mode that metal liquid is introduced in a bottom returning mode is adopted to perform cluster casting, the metal liquid enters a cavity in the upper layer from the bottom of the lower layer, and after the cavity in the upper layer is filled with the metal liquid, the metal liquid enters a cavity in the upper layer from the feeder head on the lower layer. According to the casting method, sequential solidification and complete feeding of the casting can be achieved, defects of shrinkage holes, shrinkage porosity, sand holes, air holes, slag holes, cracks and the like are effectively prevented from appearing in the casting process of the casting, isotropy of performance of the casting is ensured, meanwhile, the method is suitable for large-scale production of the high-quality brake disc body under the large-ladle casting, the use rate of metal is improved by 30 percent to 60 percent, the production cost is reduced by 30 percent to 60 percent, and the working efficiency is improved by 40 percent to 60 percent.

Owner:CHINA MACHINERY IND PROD +1

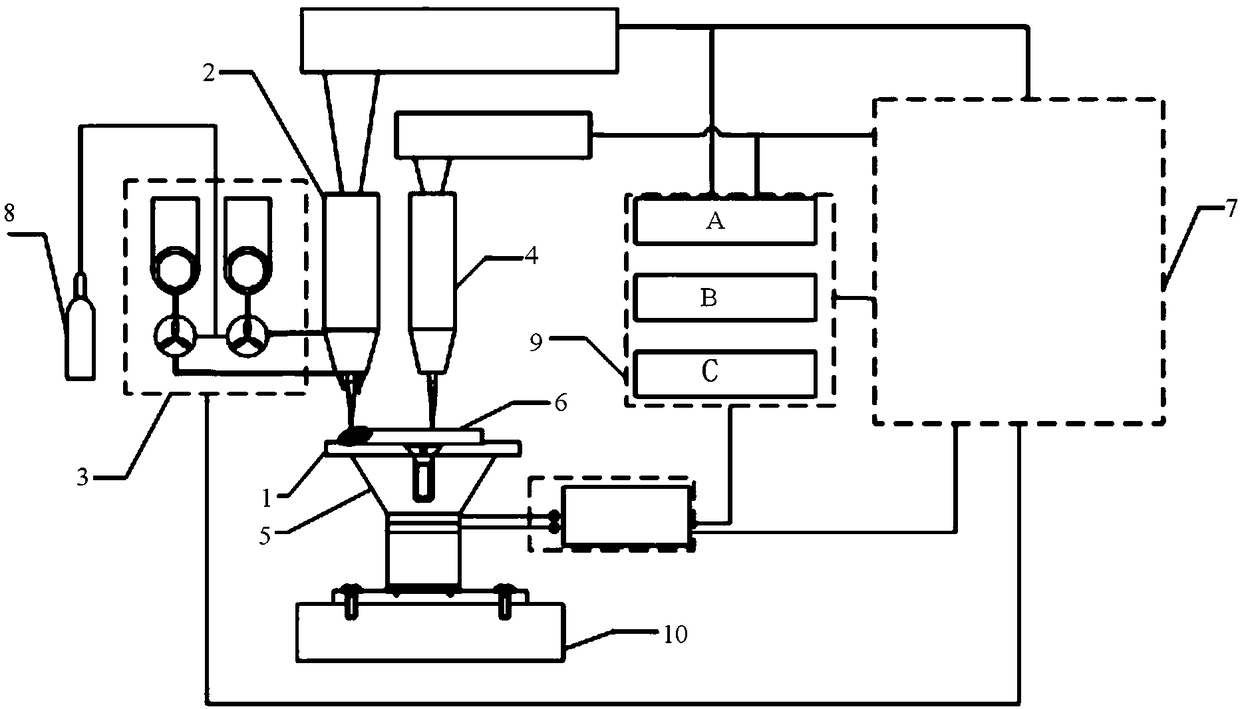

Method and device for carrying out 3D (Three-Dimensional) printing and composite manufacturing on metal

PendingCN108176857AImprove internal qualityImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyShock waveUltrasonic vibration

The invention belongs to the technical field of 3D (Three-Dimensional) printing, and particularly relates to a method and a device for carrying out 3D printing and composite manufacturing on metal. The method for carrying out the 3D printing and the composite manufacturing on the metal comprises the following steps: S101, fusing metal powder under the action of an ultrasonic vibration energy fieldaccording to a preset 3D printing and filling scanning path, thus forming cladding layers of a workpiece; S102, simultaneously carrying out laser shock processing on the cladding layers under the action of the ultrasonic vibration energy field, and impacting and forging the cladding layers through ultrasonic vibration waves and shock waves induced by laser shock; S103, stacking the cladding layers layer by layer, thus obtaining the workpiece. Aiming at the problem existing when an existing metal 3D printing technology is used for manufacturing metal parts, the method disclosed by the invention has the advantages that internal defects of pores, poor fusion, shrinkage porosity and cracks of metal cladding layers and thermal stress can be removed to the maximum, the internal quality and themechanical dynamical comprehensive performance of the metal parts can be increased, and the problems of macroscopic deformation and cracking can be effectively controlled.

Owner:GUANGDONG UNIV OF TECH

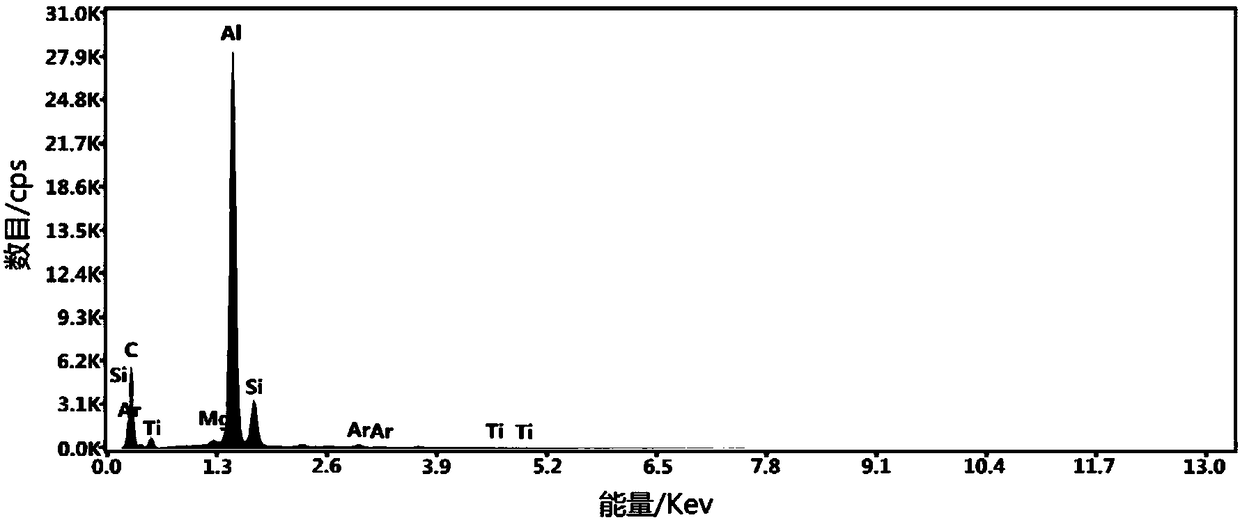

Preparation method of graphene-reinforced aluminum matrix composite

The invention relates to a preparation method of a graphene-reinforced aluminum matrix composite. Aiming at the conditions that graphene is nonuniformly dispersed in an aluminum alloy matrix and is difficult to combine with the matrix, the preparation method adopts a semi-solid squeeze casting method, and comprises the steps of smelting in a smelting and stirring atmosphere oven, electromagnetically stirring, pouring, and conducting squeeze casting to obtain the graphene-reinforced aluminum matrix composite. The preparation method is advanced in process, accurate and detailed in data, and precise in process; a slurry is pure; a metallographic structure is good in compactness without the phenomenon of shrinkage porosity; the prepared graphene-reinforced aluminum matrix composite has the hardness reaching to 87 HB, the tensile strength reaching to 255 MPa, the elongation reaching to 8%, and the compactness reaching to 99.6%; and the preparation method is the advanced preparation method of the graphene-reinforced aluminum matrix composite.

Owner:ZHONGBEI UNIV

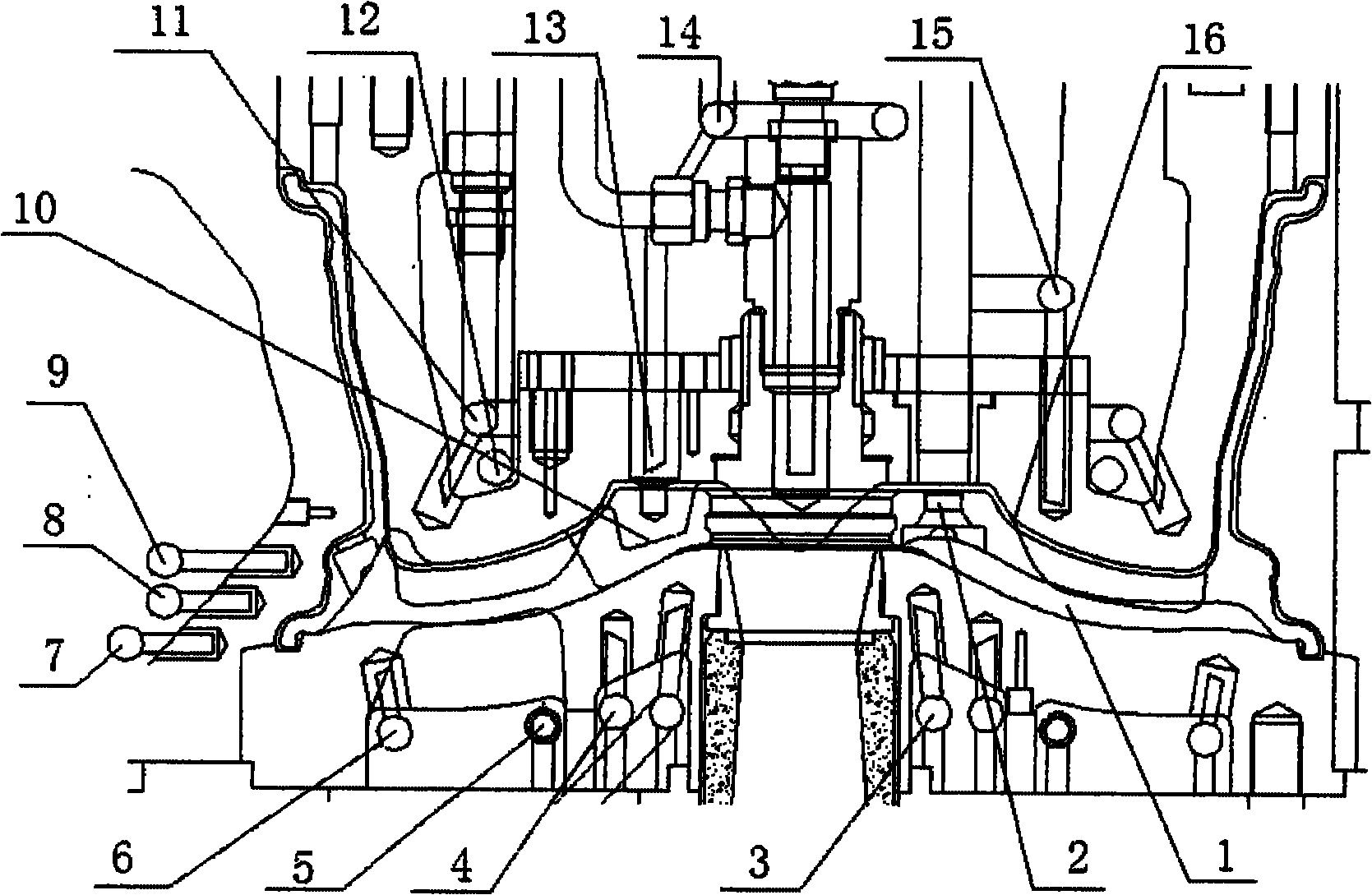

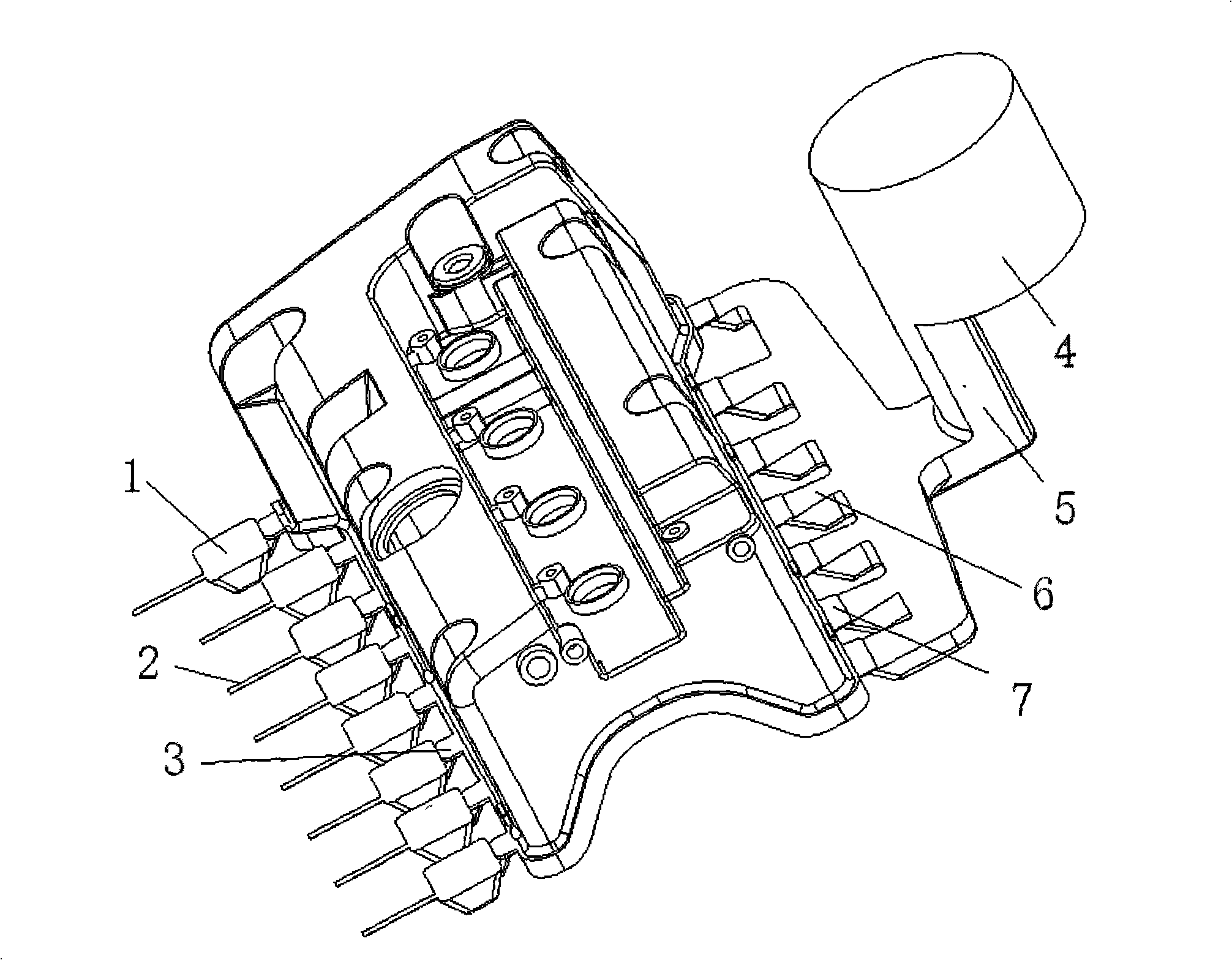

Die-casting die casting system for magnesium alloy automobile engine cylinder head casing

InactiveCN101537478AReduce energy consumptionEvenly filledCylinder headsCylindersCylinder headDie casting

The invention discloses a die-casting die casting system for a magnesium alloy automobile engine cylinder head casing. The casting system is a passage for metal liquid to enter a cylinder head casing die cavity and comprises a main channel, a straight channel, a transversal channel and an inner casting opening; the casting opening is an inlet of a passage between the rear end of a transversal casting channel and a casting before the metal liquid enters the cylinder head casing die cavity and is connected with the transversal casting channel which is connected with the straight channel, and the straight channel is connected with the main channel; each displacement system comprises an overflow groove and an exhaust groove, a plurality of displacement systems are uniformly distributed at both sides of the die cavity, wherein one side of each overflow groove is connected with the cylinder head casing die cavity, and the exhaust groove is connected with the other side of each overflow groove. The invention can realize stable filling and smooth demolding in the die-casting process, has the advantages of simple structure, strong maneuverability, and the like, can lessen defects such as shrinkage porosities, shrinkage cavities, air holes, coldshut, insufficient casting, and the like on the size design of the displacement system to a great extent and can reduce the casting size to a great extent.

Owner:SOUTH CHINA UNIV OF TECH

Brake disc body and casting method and device for manufacturing same

The invention discloses a brake disc body and a casting method and device for manufacturing the same. The method comprises the following steps: firstly performing simulation analysis on a casting process and the casting device of the brake disc body by computer simulation software to determine the positions of a pouring system and a feeding system, wherein the center of a riser of the feeding system is located at any position from the inner sidewall of a cast piece to the geometrical center of the cast piece; and performing bottom pouring in a manner of introducing metal liquid from the bottom, wherein the metal liquid enters a cavity from the bottom of a rectifier filter device. The casting device and the casting method of the brake disc body disclosed by the invention can be used for performing sequential condensation and complete feeding on the cast piece, effectively preventing defects of shrinkage cavities, shrinkage porosity, sand holes, air holes, slag blowholes, cracks and the like, guaranteeing the performance isotropy of the cast piece and guaranteeing the production of the high-quality brake disc body.

Owner:CHINA MACHINERY IND PROD +1

Solidification and feeding method for complicated annular thin-wall shell steel casting

The invention discloses a solidification and feeding method for a complicated annular thin-wall shell steel casting. By means of the solidification and feeding method, the problem that in the casting process of existing complicated annular thin-wall steel castings, shrinkage porosity, shrinkage cavities and crack defects are prone to occur is resolved. The solidification and feeding method comprises the following steps that a, steel casting sand mold cavity is made; b, annular transverse runners and a straight runner are made on the steel casting sand mold cavity, slag collecting cylinders are arranged on the upper surfaces of the annular transverse runners, gap inner runners are arranged between the slag collecting cylinders and the outer wall of the steel casting sand mold cavity, a feeding auxiliary sprue and top risers are arranged on the upper portion of the steel casting sand mold cavity, and a gap auxiliary runner is arranged between each top riser and the feeding auxiliary sprue; c, during pouring, the film forming pouring temperature of molten metal is 1500 DEG C-1520 DEG C; and d, when the molten metal level reaches the upper portions of the top risers, melt metal pouring is stopped on the straight runner, and the molten metal enters the steel casting sand mold cavity through the feeding auxiliary sprue until pouring is completed. The whole mold filling process is stable, no disturbance exists, and the phenomena of pores and dreg inclusion defects are avoided.

Owner:SHANXI PINGYANG IND MACHINERY

Method for casting thin-shell nodular-cast-iron turbocharger

The invention relates to a method for casting a thin-shell nodular-cast-iron turbocharger, in particular to a method for casting the thin-shell nodular-cast-iron turbocharger and the like products, which is characterized by comprising the following steps of: process method design, three-dimensional model design of the casting process, mold-filling / solidifying simulation, analysis treatment for a simulated result, selection of mold materials, mold assembling simulation, molding, core making, mold assembling, molten iron melting, spheroidizing inoculation, and pouring. The process method provided by the invention is unique, which can solve the problem of shrinkage porosity because the partially overlarge part of an inner cavity cannot be fed by a riser, and can ensure the dimensional accuracy of air cavity, water cavity and oil cavity which are intersected one another in the inner cavity of the casting shell.

Owner:KOCEL EQUIP +1

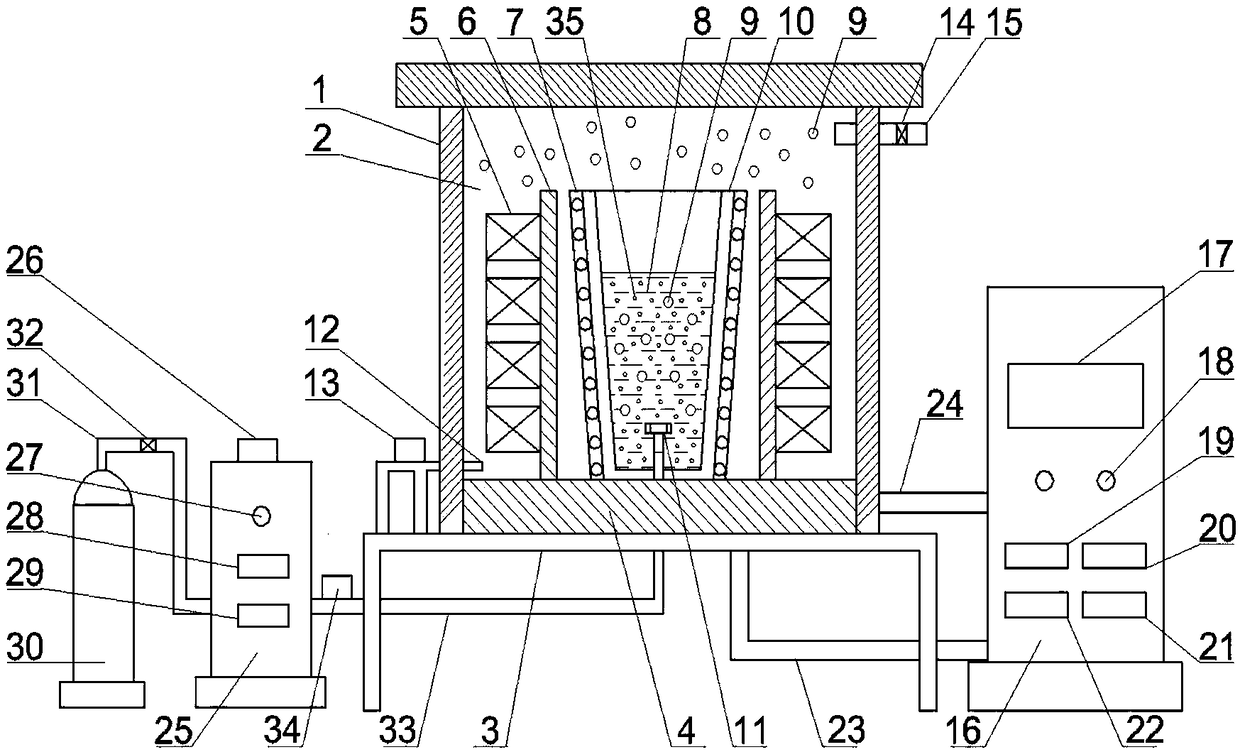

Plaster casting method for large-sized complex thin-walled magnesium alloy part

ActiveCN104209497ASolve Oxidation ProblemsImprove filling abilityFoundry mouldsFoundry coresVacuum castingMold filling

The invention relates to a plaster casting method for a large-sized complex thin-walled magnesium alloy part. The method comprises the following steps of coating the surface of an assembled form with a coating in situ, and arranging shapeless cold iron on a hot spot part, wherein a mixture for manufacturing the shapeless cold iron comprises the following components in percentage by mass: 1.25 percent of phenolic resin, 0.4 percent of toluenesulfonic acid, 1 to 1.5 percent of boric acid, 2 percent of bentonite and the balance of 70 to 140-mesh chromite sand; pouring a casting in an adjustable pressure casting device, arranging a plaster mold poured by the form at the casting position of the adjustable pressure casting device, filling a tank with dry air or a CO2 atmosphere with SF6 content of 0.1 to 1.0 percent, and performing vacuum casting and pressurized solidification, wherein the casting temperature is 710 to 750 DEG C, vacuum degree for primary mold filling is minus 0.6Mpa to minus 0.8Mpa, and the solidification pressure is 0.020 to 0.025Mpa. According to the method, oxidization can be prevented, the mold filling capability can be improved, shrinkage cavities and shrinkage porosities in the casting are reduced, and the obtained magnesium alloy casting is higher in density.

Owner:山西银光华盛镁业股份有限公司

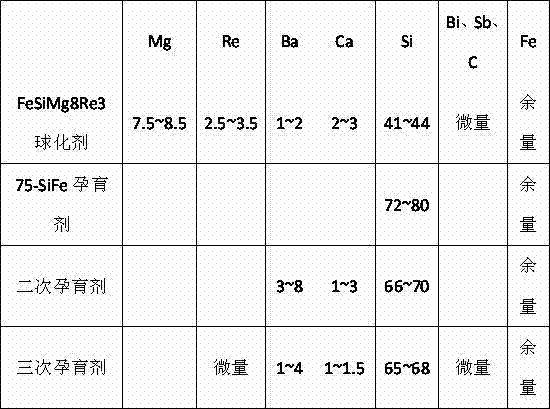

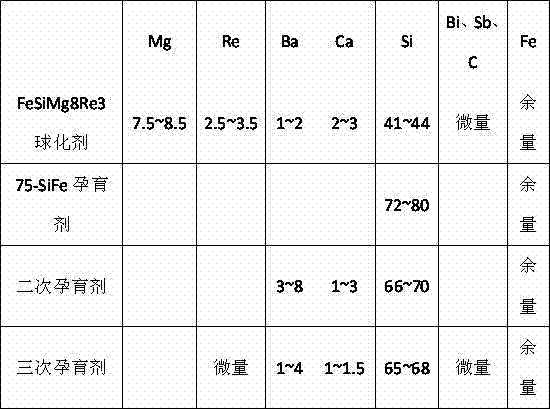

Manufacturing method of spheroidal graphite cast iron casting of wind power yaw variable-pitch device

The invention discloses a manufacturing process of a spheroidal graphite cast iron casting of a wind power yaw variable-pitch device. The process comprises the following processes of mould making, foaming and moulding, paint brushing, boxing and shaping, electric furnace smelting, tundish-covering nodulizing treatment, vacuum-assist pouring and three-time inoculation treatment, wherein the boxing and shaping process is a layered assembling process, so that the production efficiency can be improved and the process yield can be increased; cold iron is vibrated and reasonably arranged, so that the compactness of tissues in the casting can be improved and the defect of shrinkage porosity can be avoided; by virtue of the processes of electric furnace smelting and tundish-covering nodulizing treatment, the nodulizing rate of the casting can be stabilized and increased and the mechanical properties of the casting can meet the technical quality requirements of wind power castings; the spheroidal graphite cast iron casting manufactured by the process is compact and uniform in tissue, hardly has defects, has good surface quality and high size precision; the casting forming of multiple layers of castings can be realized; and the production efficiency and the process product yield are improved.

Owner:CHTC HEAVY IND

Method for casting large stamping cylinder casting

InactiveCN102248132AAvoid Casting DefectsImprove pass rateFoundry mouldsFoundry coresSlagCasting defect

The invention discloses a method for casting a large stamping cylinder casting, comprising the following steps of: 1) making a mould; 2) making a sand mould; and 3) pouring and moulding; when the sand mould is made, an upper core cover (19) is embedded in the center of a casting cavity (11) of an upper box, a lower core cover (17) with the same shape and size with the upper core cover (19) is embedded in a sand core (16) inside the casting cavity (11), and a mandril (18) made of iron is sheathed between the upper core cover (19) and the lower core cover (17). By adopting the structure, a gating system, arrangement of a dead head, laying of an cold iron, control of pouring temperature, control of chemical ingredients, control of spheroidization and inoculation and the like are all designed according to the characteristics of the casting, thus the casting defect that slag inclusion, an air hole and the like are produced can be overcome; and the probability that a shrinkage cavity and shrinkage porosity are caused can be reduced, thus the yield of casting finished products can be greatly improved.

Owner:RIYUE HEAVY IND

Monolithic multi-way valve body casting piece casting method

ActiveCN105903910ADefect control such as sticky sandAvoid overheatingFoundry mouldsFoundry coresCasting defectLinearity

The invention discloses a monolithic multi-way valve body casting piece casting method which comprises the following steps: preparing a core preparing mold, and checking and cleaning the mold; preparing a main core by mold sand, and after the shape of the main core is finalized, spraying a mold release agent, and demolding; preparing small cores, and drilling exhaust holes in the small cores; finishing to remove burrs on the main core and the small cores, and removing a transition jet nozzle on the main core; fixing the main core by a sand core bonding preparation tooling, firstly assembling the small core at one side, and then assembling the small core at the other side; mounting the assembled sand core into a shell body; and casting a valve body: performing a pouring process at two sides of a side thin gate at the same time, using an exothermic riser with the diameter of 120 mm and the height of 220 mm, and placing special cold iron at the bottom face of the shell body. The monolithic multi-way valve body casting piece casted by the casting method has the advantages that the linearity of a main valve hole casting blank is controlled to be less than or equal to 1.0 mm, and the valve hole linearity is ensured; the casting piece pore shrinkage, shrinkage porosity, internal gas holes and other casting defects, especially defects of micropores in the casting piece, are solved; and the compactness of the internal structure is improved.

Owner:南通华东油压科技有限公司

Casting molding sand and preparation method thereof

The invention discloses casting molding sand which is prepared from the following raw materials in parts by weight: 250-270 parts of silica sand powder, 40-50 parts of coal ash, 9-12 parts of aluminum hydroxide, 40-45 parts of rice bran, 20-30 parts of iron-ore slag, 20-30 parts of calcium carbonate powder, 1-2 parts of polycarboxylic acid water reducing agent, 1-2 parts of polyacrylamide, 1-2 parts of tung oil, 45-50 parts of aluminum silicate, 30-40 parts of maize straw powder, 22-30 parts of bamboo carbon, 30-40 parts of clay, 14-18 parts of corn meal, 3-4 parts of silane coupling agent KH-550 and a proper amount of water. Due to adoption of coal ash, the fineness and smoothness degree of the molding sand is improved, the formation is easy, and the energy is saved; due to adoption of the straw powder, the corn meal and the like, the air permeability and the high temperature collapsibility are improved; as the stone powder is sintered and is combined with organic binding agents, the plasticity, the dispersity and the air permeability are improved. The casting molding sand is easy to form and make a core, the shrinkage cavity and shrinkage porosity of a cast piece is reduced by more than 91%, and the finished product rate of the cast piece is improved.

Owner:海安苏博机器人科技有限公司

Evanescent mode pouring system of speed changing box body

The invention discloses an evanescent mode pouring system of a speed changing box body. The evanescent mode pouring system is provided with a sprue, wherein the sprue is sequentially communicated with a pouring cup, a first cross gate and a second cross gate from top to bottom, and the first cross gate and the second cross gate are respectively communicated onto the sprue along the radial direction of the sprue; the end part, away from of the sprue, of each of the first cross gate and the second cross gate is respectively provided with a first inner gate pouring port and a second inner gate pouring port. The pouring system is adopted for pouring a casting, so that the mold filling time is shortened, and the heat loss is reduced; moreover, the shrinkage porosity and cavity weakness can be greatly reduced, and the casting quality can be effectively improved.

Owner:HEFEI UNIV OF TECH

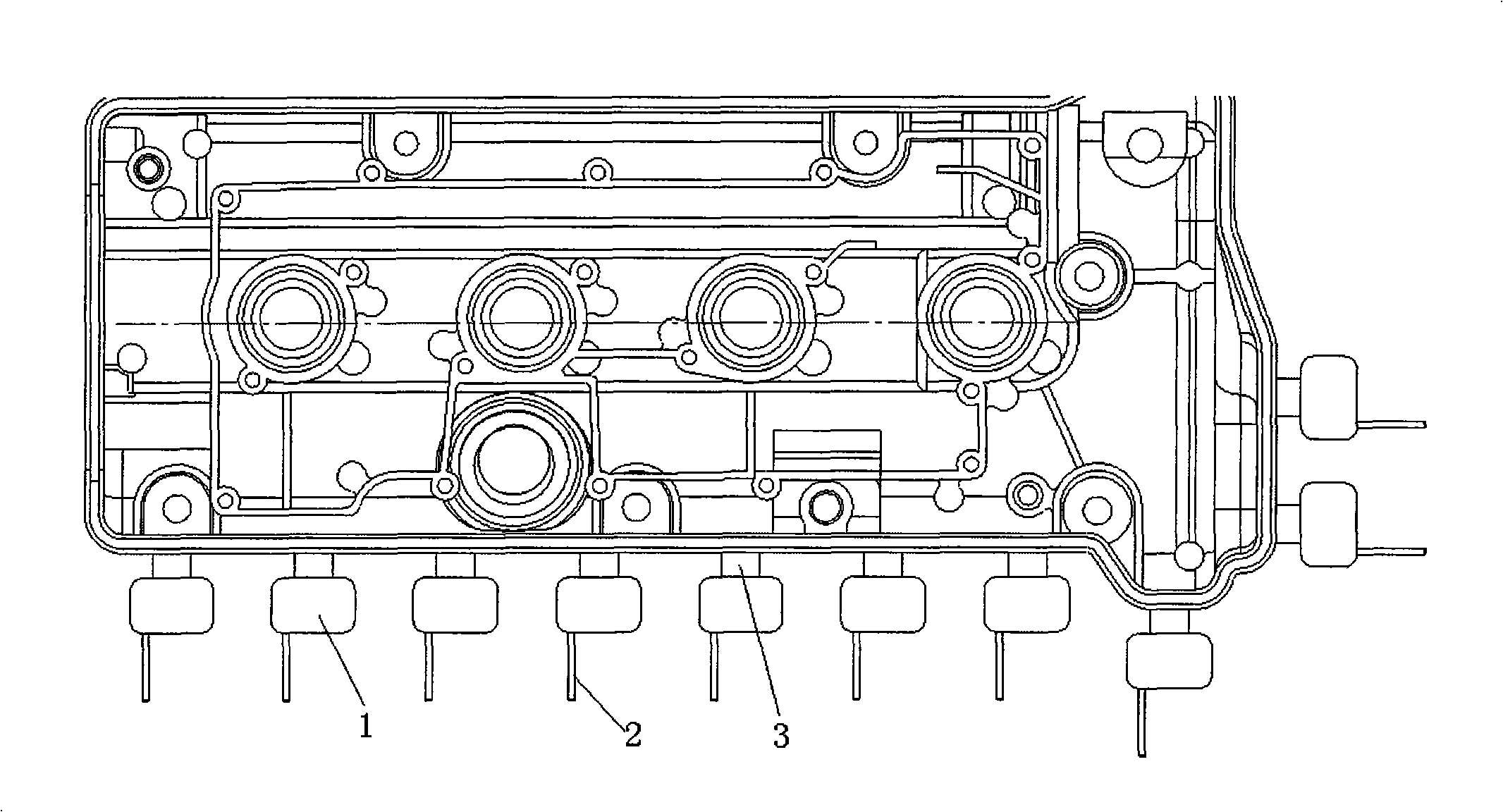

Process of casting cylinder head of diesel engine

InactiveCN101066557AImprove pass rateEasy to operateFoundry mouldsFoundry coresCylinder headDiesel engine

The present invention belongs to the field of casting technology, and is especially process of casting cylinder head of diesel engine. The process is one bottom pouring one including molten iron introduction from the bottom for smooth filling and fluent air exhaustion, applying iron chills in the heat centers to homogenize the cooling speed of different parts, and self shrink feeding of the casting to reduce inside shrinkage porosity and raise inherent quality of the casting. The present invention has high casting quality.

Owner:CSSC MARINE POWER

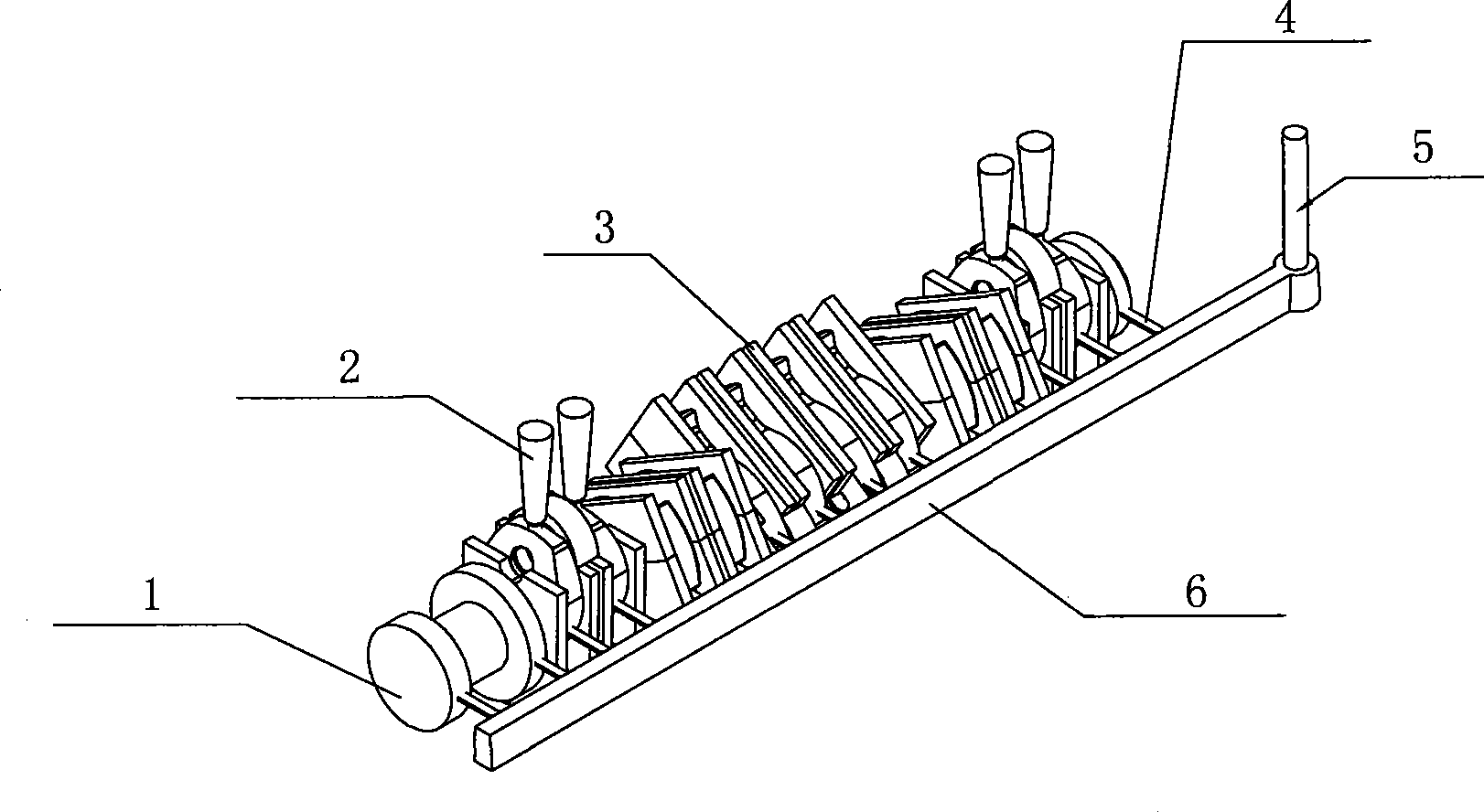

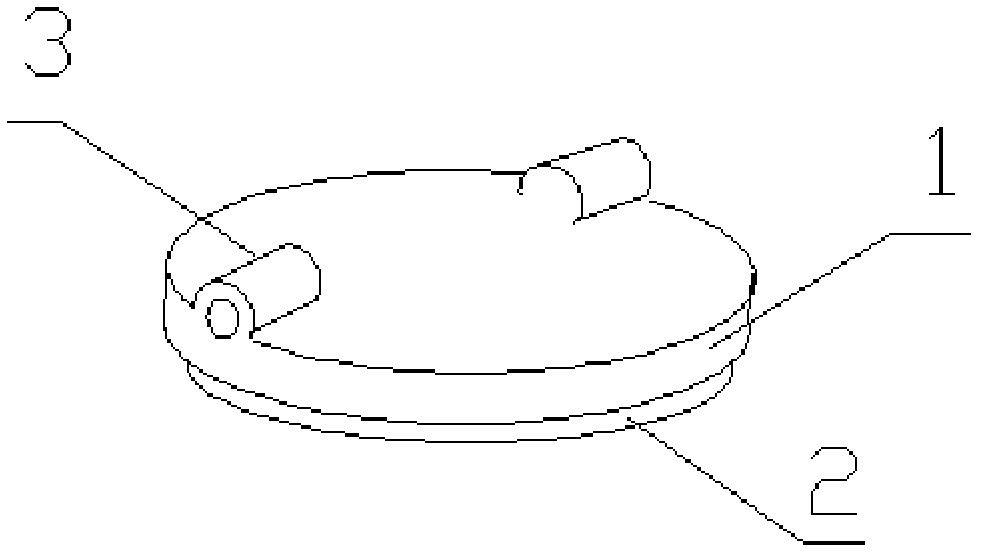

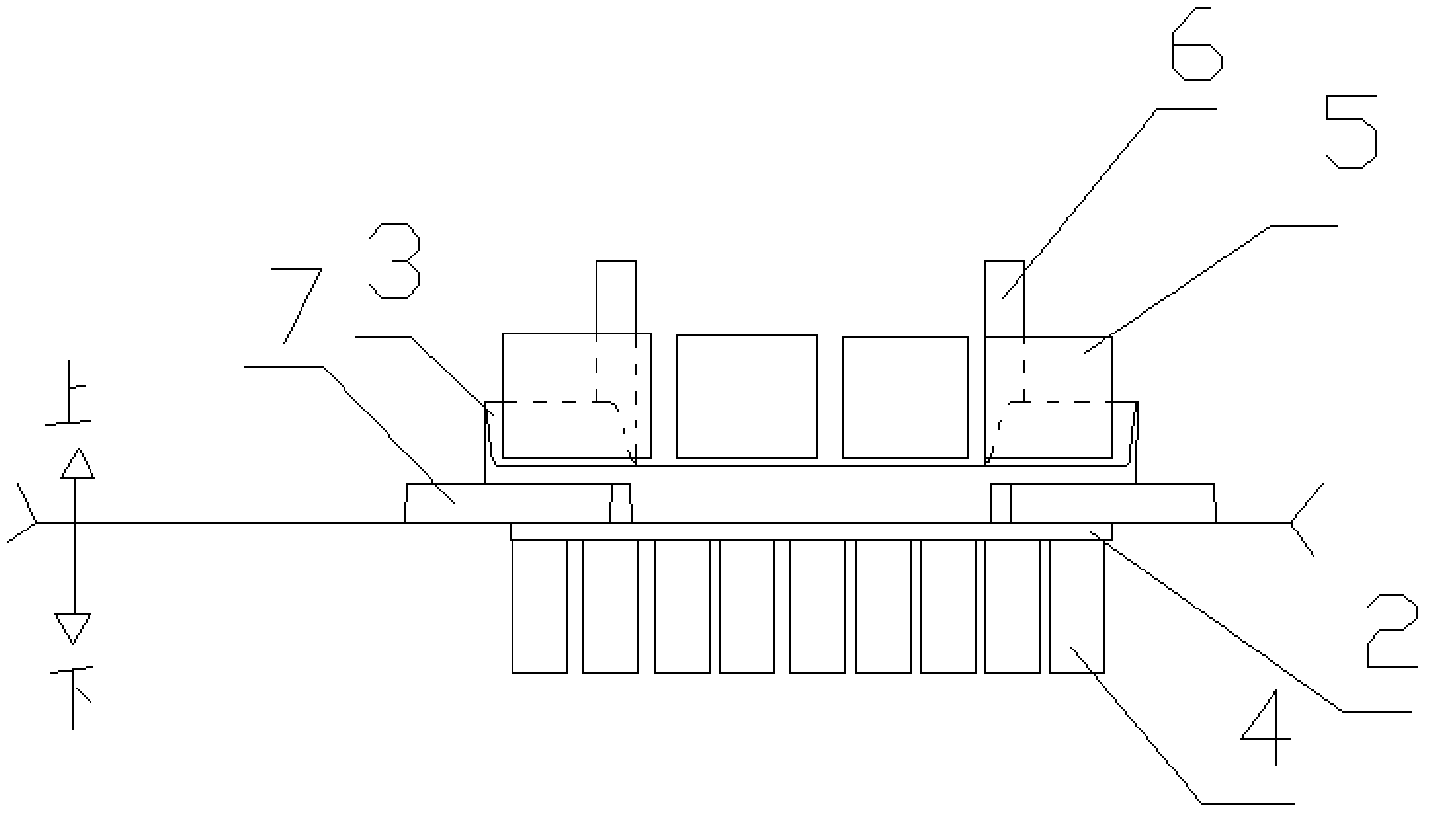

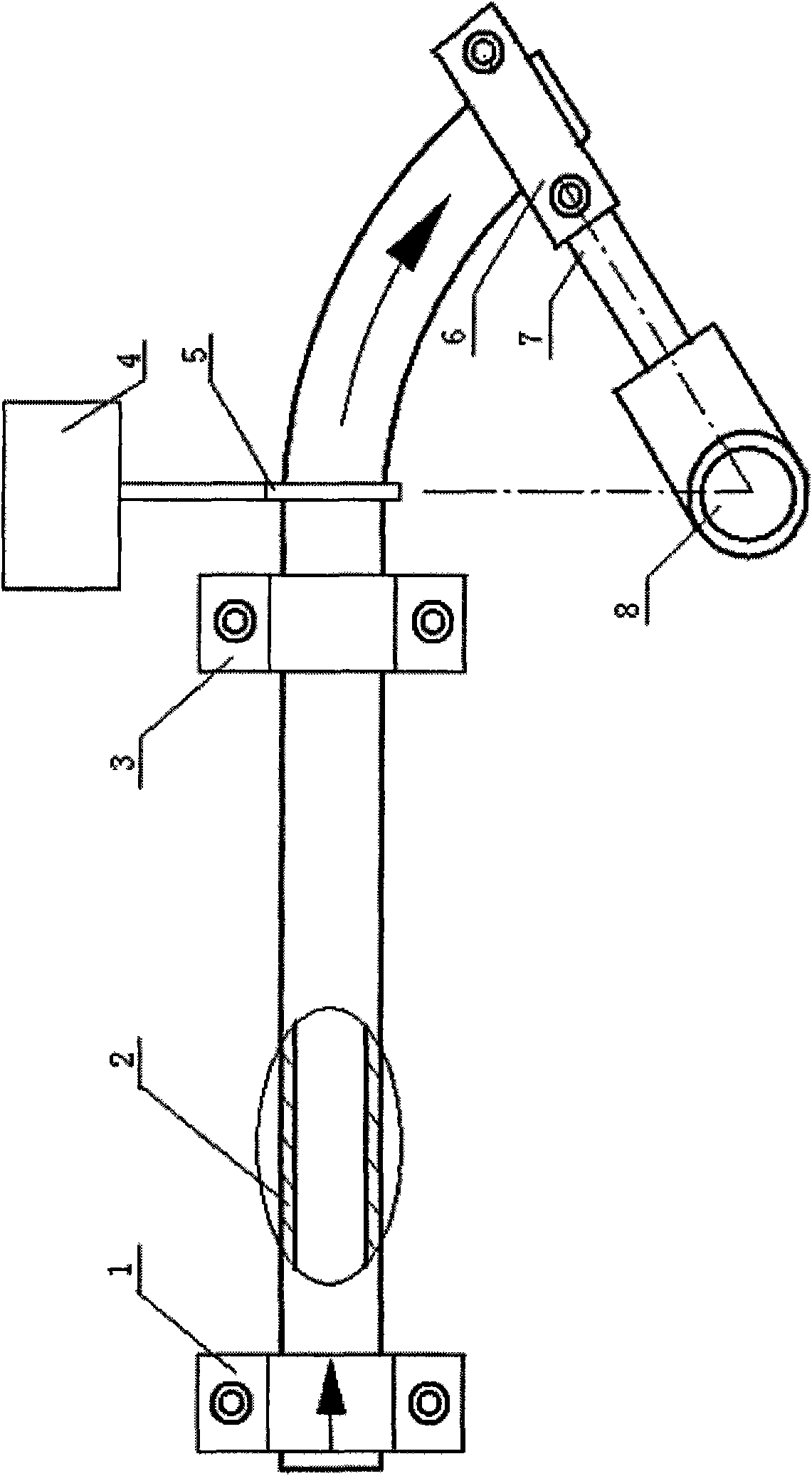

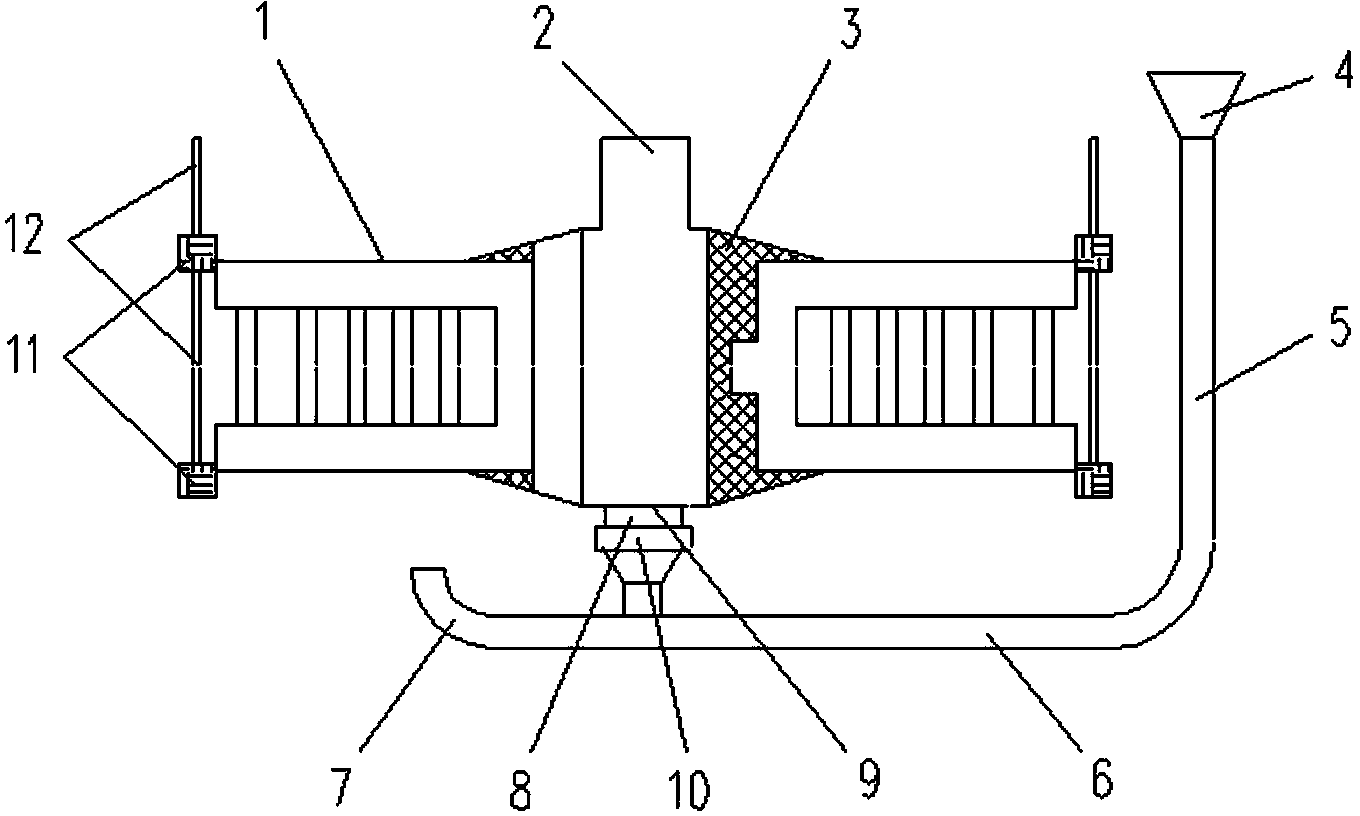

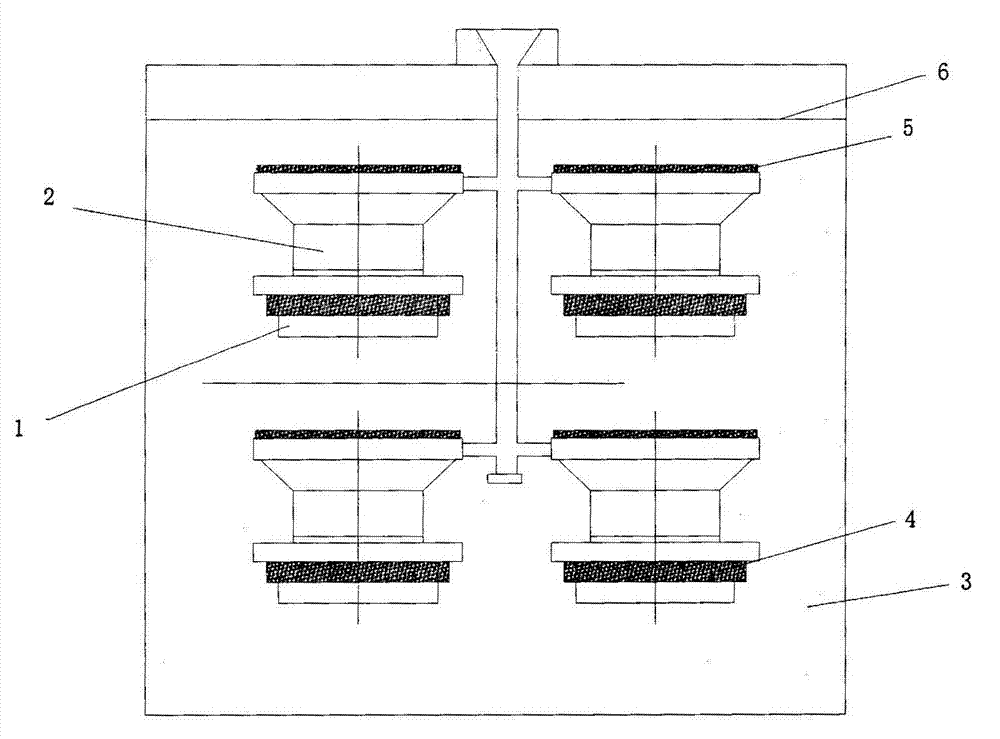

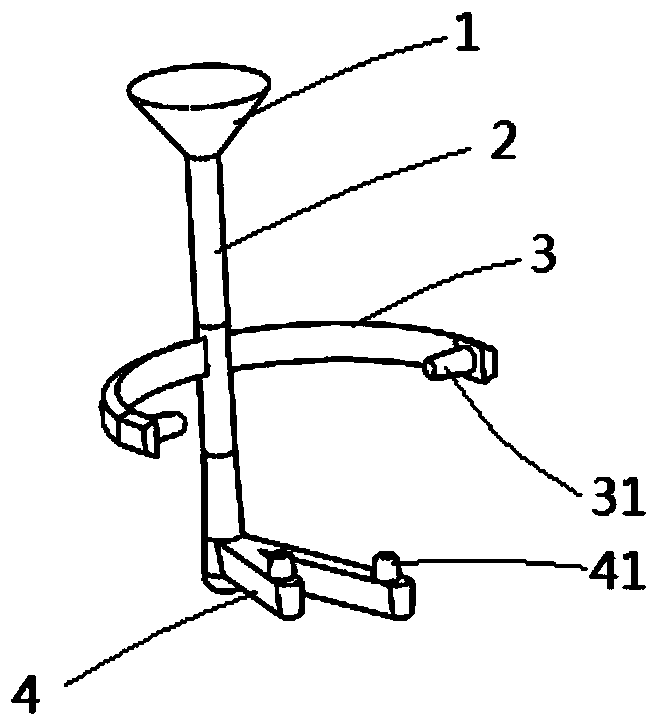

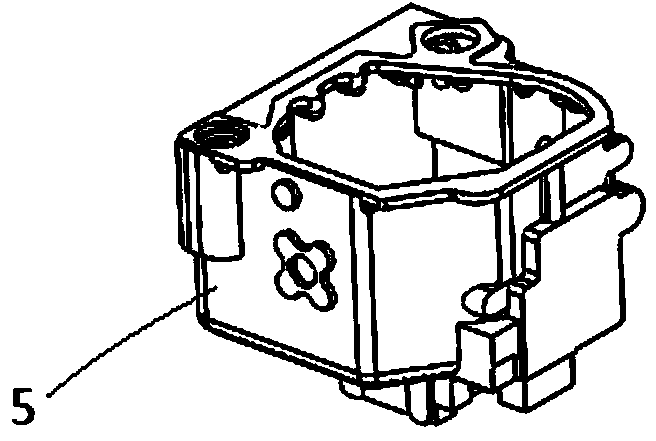

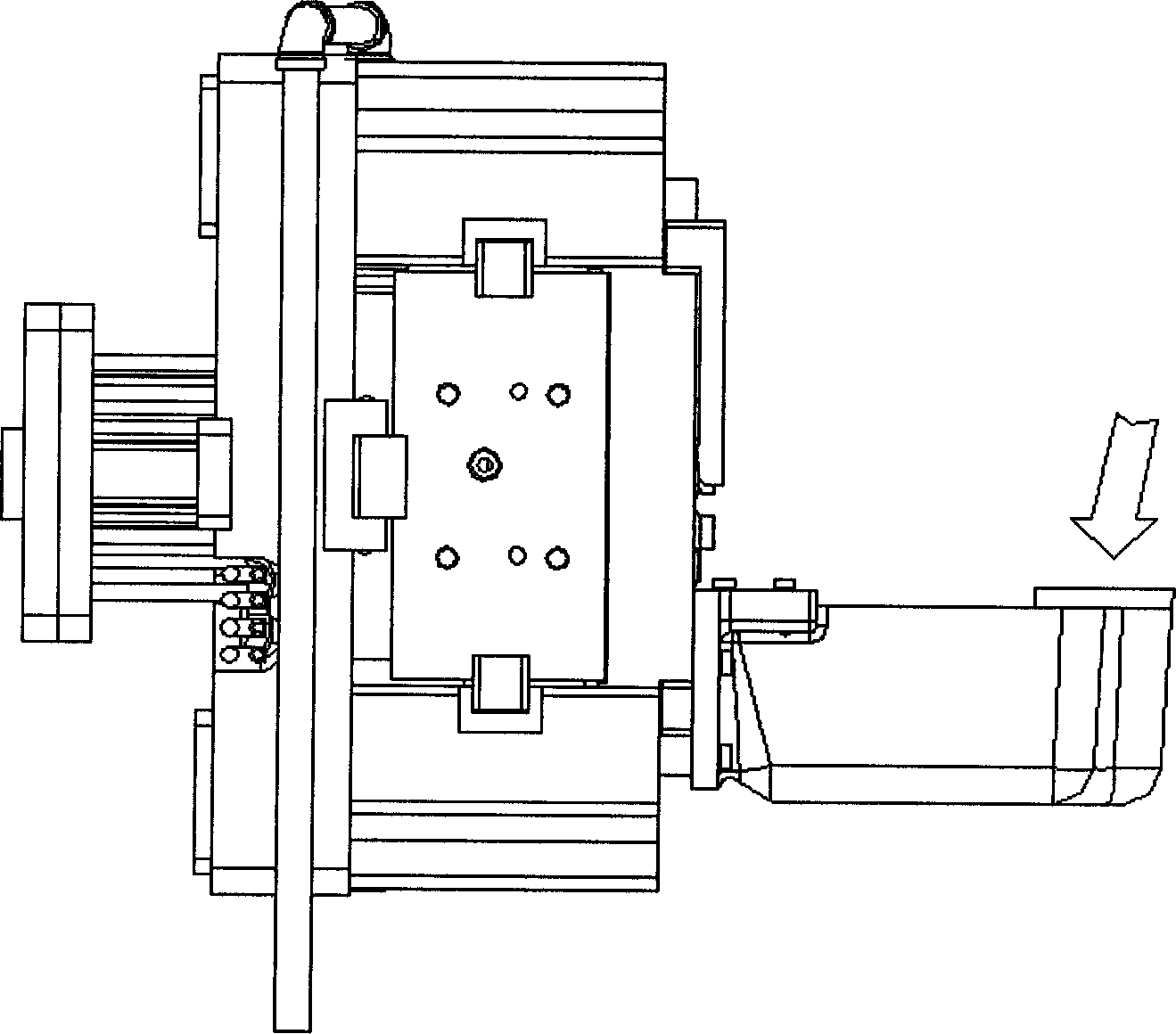

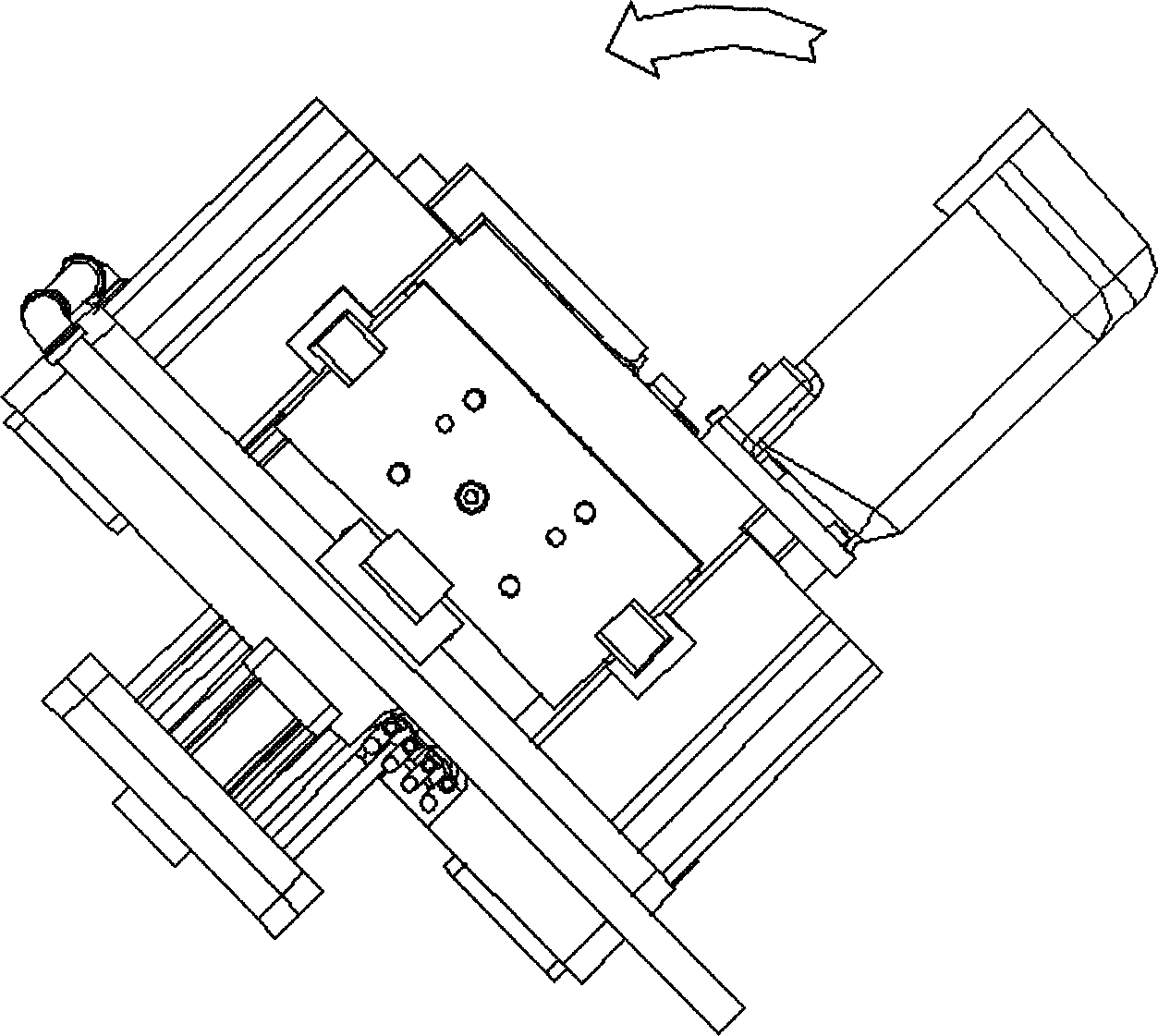

Metal section mould with controllable cross section and gravity slantingly-rotated foundry technique of aluminum alloy cylinder cover of metal section mould

The invention discloses a metal section mould with a controllable cross section and a gravity slantly-rotated foundry technique of an aluminum alloy cylinder cover of the metal section mould. The metal section mould comprises a pouring cup (1), a dead head sand core (2), a molding module (3), an ejector device (4), a water cooling device (5) and a negative pressure air extractor (6), and a control cross section retaining plate (7) is installed at the intersection position of the pouring cup and the dead head sand core on the lower portion of the pouring cup (1). Molten aluminum can only enter a casting cavity from a dead head beside an air inlet lateral cover due to retaining functions of the control cross section retaining plate in a slantingly-rotated pouring process, then the molten aluminum is discharged from a dead head at the position of a middle spark plug and a dead head beside an air discharge lateral cover, stable molten aluminum mold filling in a mold filling process is achieved, a principle of mold filling sequence and air inlet and air outlet in sequence is followed, the whole mold filling speed and time of a casting piece are controlled by controlling the minimum mold filling cross section of the pouring cup, defects such as air holes, shrinkage holes and shrinkage porosities produced by an original piece are obviously overcome, and accordingly product yield, acceptability and quality of the metal casting piece are improved.

Owner:WENZHOU RUIMING IND

Mould melting-deposition forming and laser impact forging composite additive manufacturing method and device

InactiveCN107520449AQuality improvementImprove efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyMetal powderMetal mold

The invention discloses a mould melting-deposition forming and laser impact forging composite additive manufacturing method. The mould melting-deposition forming and laser impact forging composite additive manufacturing method comprises the following steps that (1) a mould blank body is cast; (2) the melting-deposition forming thickness is calculated; (3) metal powder is subjected to melting deposition through a heat source to form cladding layers, a controller controls a laser generator to conduct impact forging on a melting-deposition metal area at the plastic deformation temperature synchronously, the cladding layers are stacked layer by layer till the thickness of the cladding layers reach the thickness value in the step (2), and thus a workpiece is formed; and (4) the surface of the workpiece is treated. The invention further provides a mould melting-deposition forming and laser impact forging composite additive manufacturing device. The method adopts melting-deposition forming and laser impact forging composite manufacturing, melting-deposition forming and impact forging are conducted simultaneously, parameters are mutually coordinated and restrained in the process, thus, thermal stress, deformation and cracking can be avoided, the microstructure of a metal part is optimized, internal defects of pores, non-fusion, shrinkage porosity and the like are avoided, and the forming quality and efficiency of additive manufacturing of a metal mould are improved.

Owner:GUANGDONG UNIV OF TECH

Molten iron of hundred-tonnage ferritic nodular cast iron casting and preparation method of molten iron

ActiveCN103882282ANot easy to produce sticky sandNot easy to produce shrinkage and other defectsDuctile ironShrinkage porosity

The invention discloses a molten iron of a hundred-tonnage ferritic nodular cast iron casting. The molten iron comprises the following elements in percentage by weight: 3.50-3.90 percent of C, 2.30-2.70 percent of Si, 0.20-0.5 percent of Mn, less than or equal to 0.050 percent of P, less than or equal to 0.020 percent of S, 0.010-0.020 percent of Re, 0.03-0.040 percent of Mg, 0.002-0.008 percent of Sb and the balance of Fe and trace impurity elements. The hundred-tonnage molten iron provided by the invention can be used for manufacturing the hundred-tonnage ferritic nodular cast iron casting, is excellent in performance, and meets the requirement of GB / T1348-2009; by adopting the hundred-tonnage ferritic nodular cast iron casting manufactured according to a process, defects of sand burning, shrinkage porosity and the like are difficultly generated.

Owner:RIYUE HEAVY IND

Casting method for valve body of expansion valve

InactiveCN104646635AEliminate shrinkageUnsmooth solutionFoundry mouldsFoundry coresQuality control systemEngineering

The invention provides a casting method for a valve body of an expansion valve. An insulating riser is installed at the part of a central flange of a sand core, blind risers are installed at the tail of the valve body of the sand core and the part of a drain hole of the valve body, the insulating riser is used for feeding on the central flange, the insulating riser of the central flange is used for feeding at the part of a valve belly by adopting the form of a feeding rib, and the blind risers are used for feeding at the tail of the valve body and the part of the drain hole of the valve body; the lower parts of a lower molding pit external mold real sample and an inner cavity sand core assembly are scraped to be planes by using a shaft rod scraper, and an upper molding cover core and a riser are calculated based on rod-shaped parts and divided into an upper layer and a lower layer. The casting technology for the main valve body of the expansion valve, provided by the invention, adopts a combination of the inner layer and the outer layer of open and blind risers with an external chill quenching process, so that the problems of shrinkage cavity and shrinkage porosity of a thin-walled steel casting in a production process are effectively eliminated, namely a complete set of inner quality control system is formed by the process.

Owner:夏平桂 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com