Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2813 results about "Surface grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface grinding is used to produce a smooth finish on flat surfaces. It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, making a face of it flat or smooth.

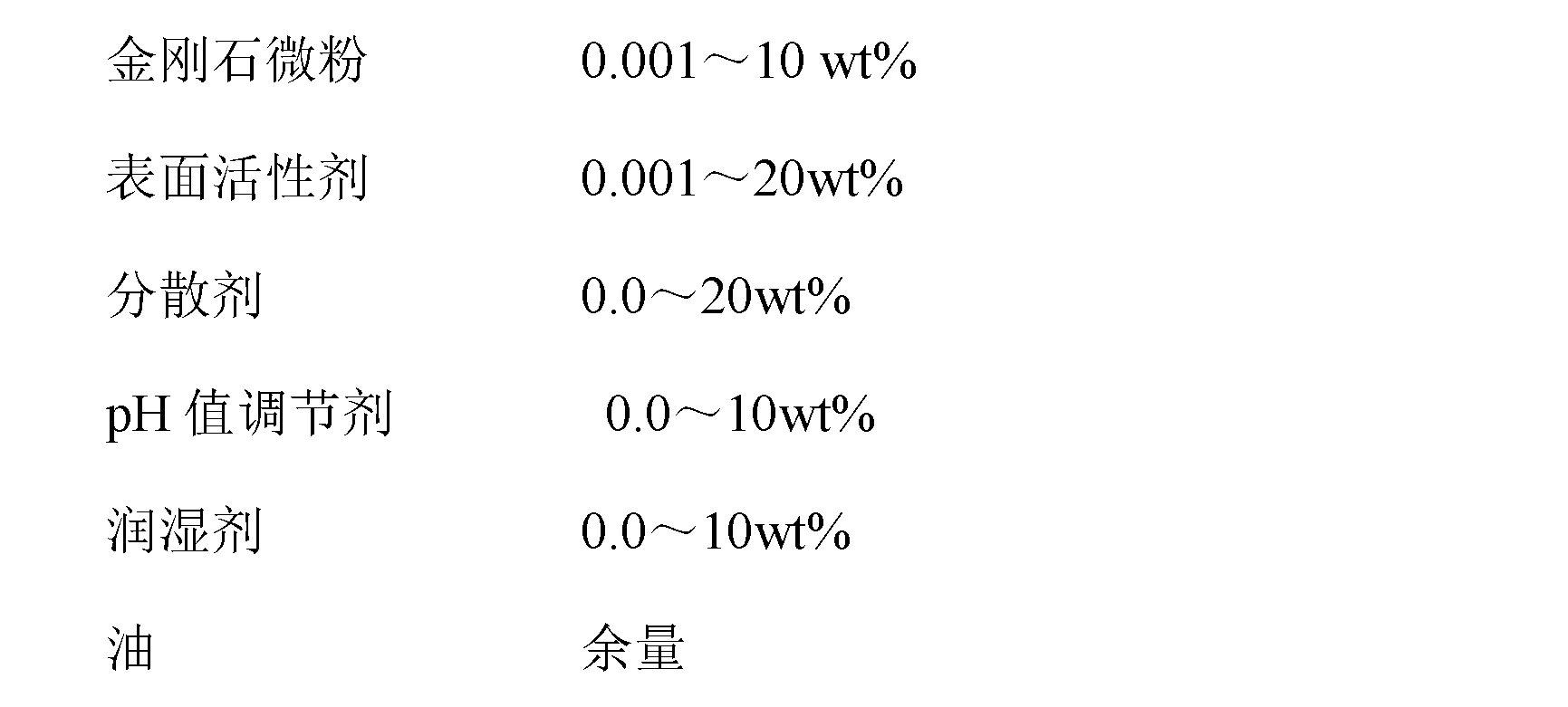

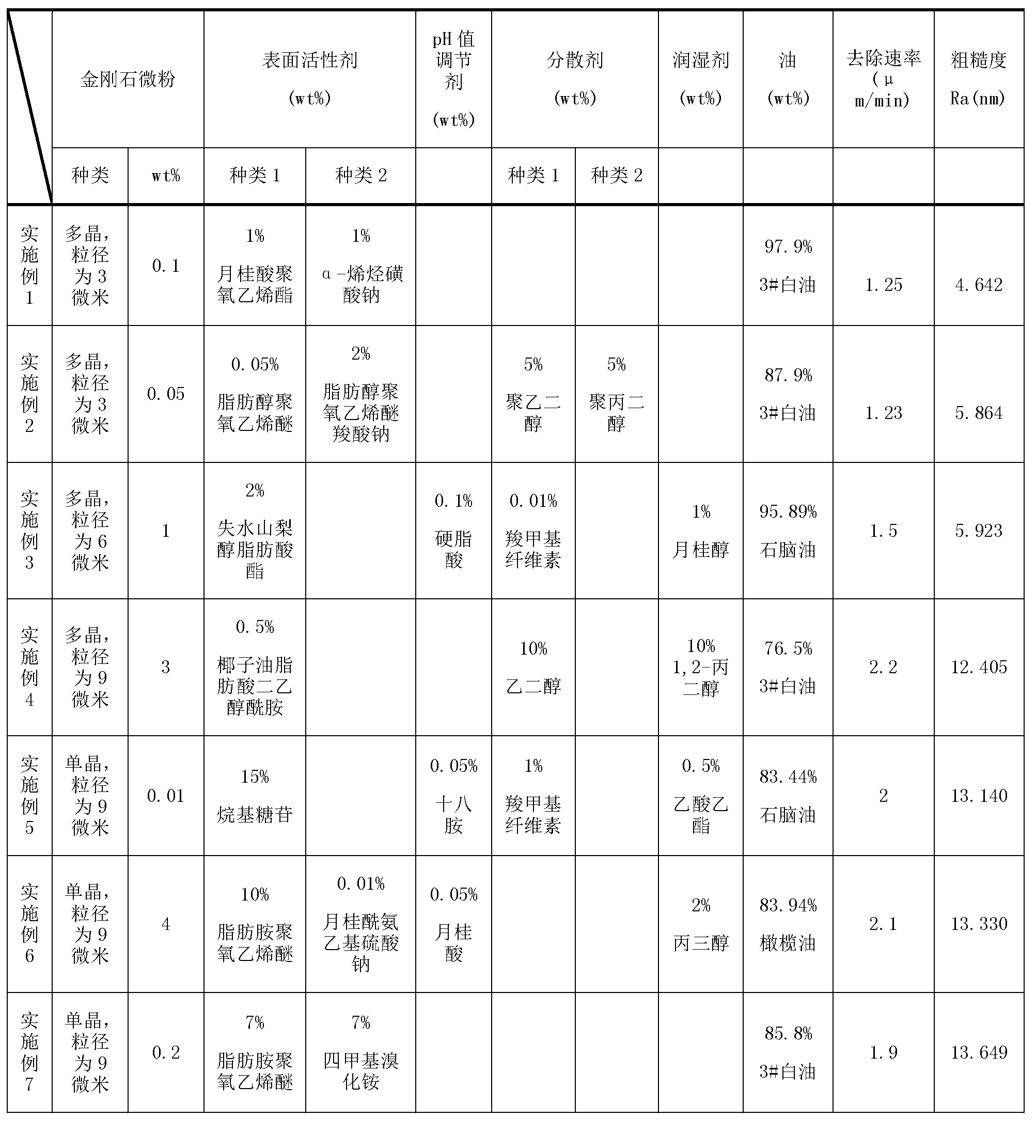

Oily diamond grinding liquid and preparation method thereof

InactiveCN103013345AImprove polishing efficiencyImprove matchPolishing compositions with abrasivesStable stateEnvironmental resistance

The invention discloses an oily diamond grinding liquid and a preparation method thereof, and belongs to the technical field of surface superfine grinding. The grinding liquid comprises the following components by weight percent: 0.001%-10% of diamond micro powder, 0.001%-20% of surface active agent, 0-20% of dispersant, 0-10% of pH value regulator, 0-10% of wetting agent and oil in balancing amount. The oily diamond grinding liquid is mainly applied to surface grinding and polishing of silicon carbide wafers, LED sapphire substrate slices, ceramic, optical fiber, dies, semi-conductor compound wafers and the like. By the use of the oily diamond grinding liquid provided by the invention, the polishing efficiency can be greatly improved; the dispersing performance is good; a uniform and stable state can be kept for a long time; the degree of finish of products polished with the oily diamond grinding liquid is high; the polishing effect is good; no ingredient harmful to human body is contained; the cleaning is easy; and the environmental protection is facilitated.

Owner:TSINGHUA UNIV +2

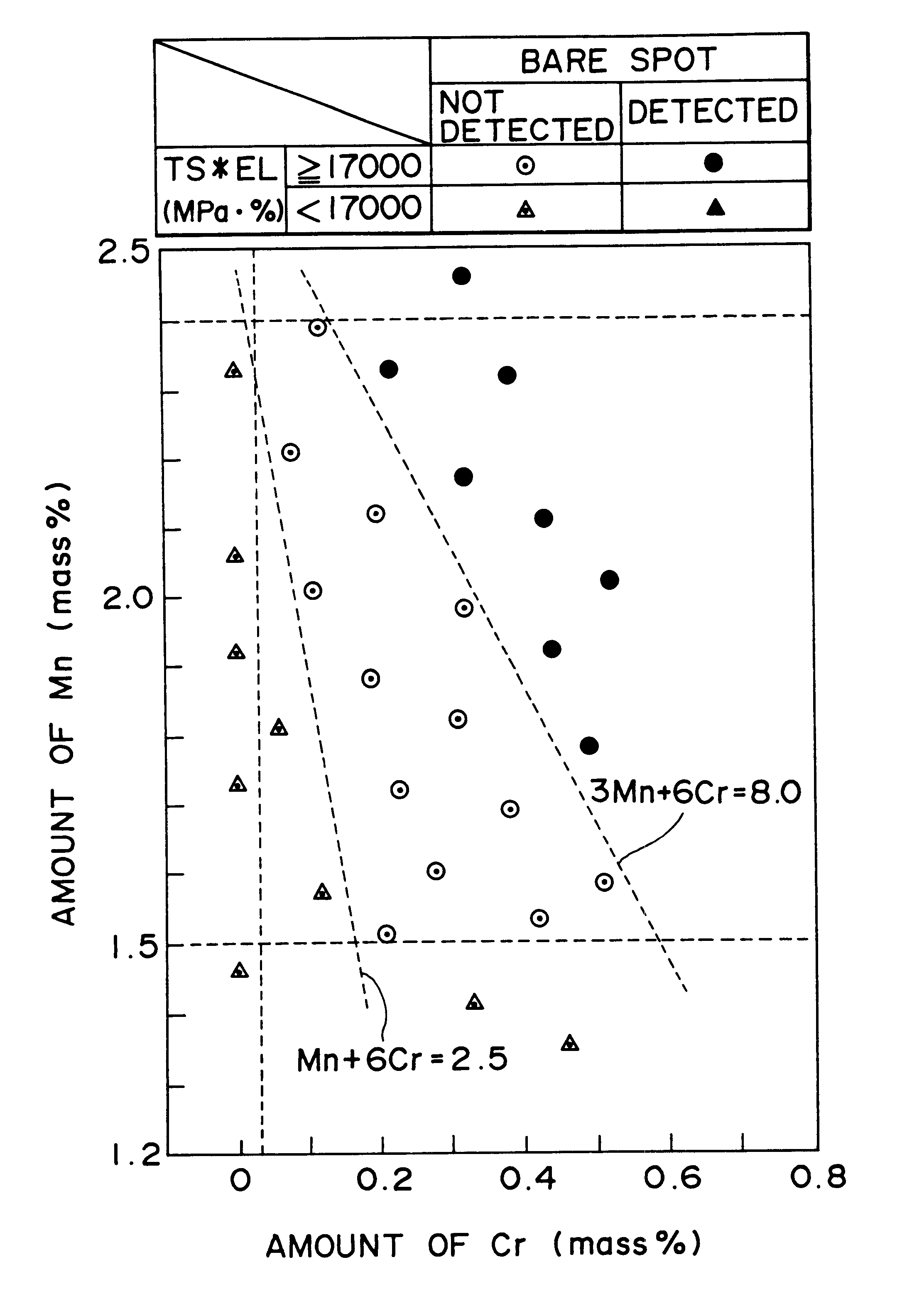

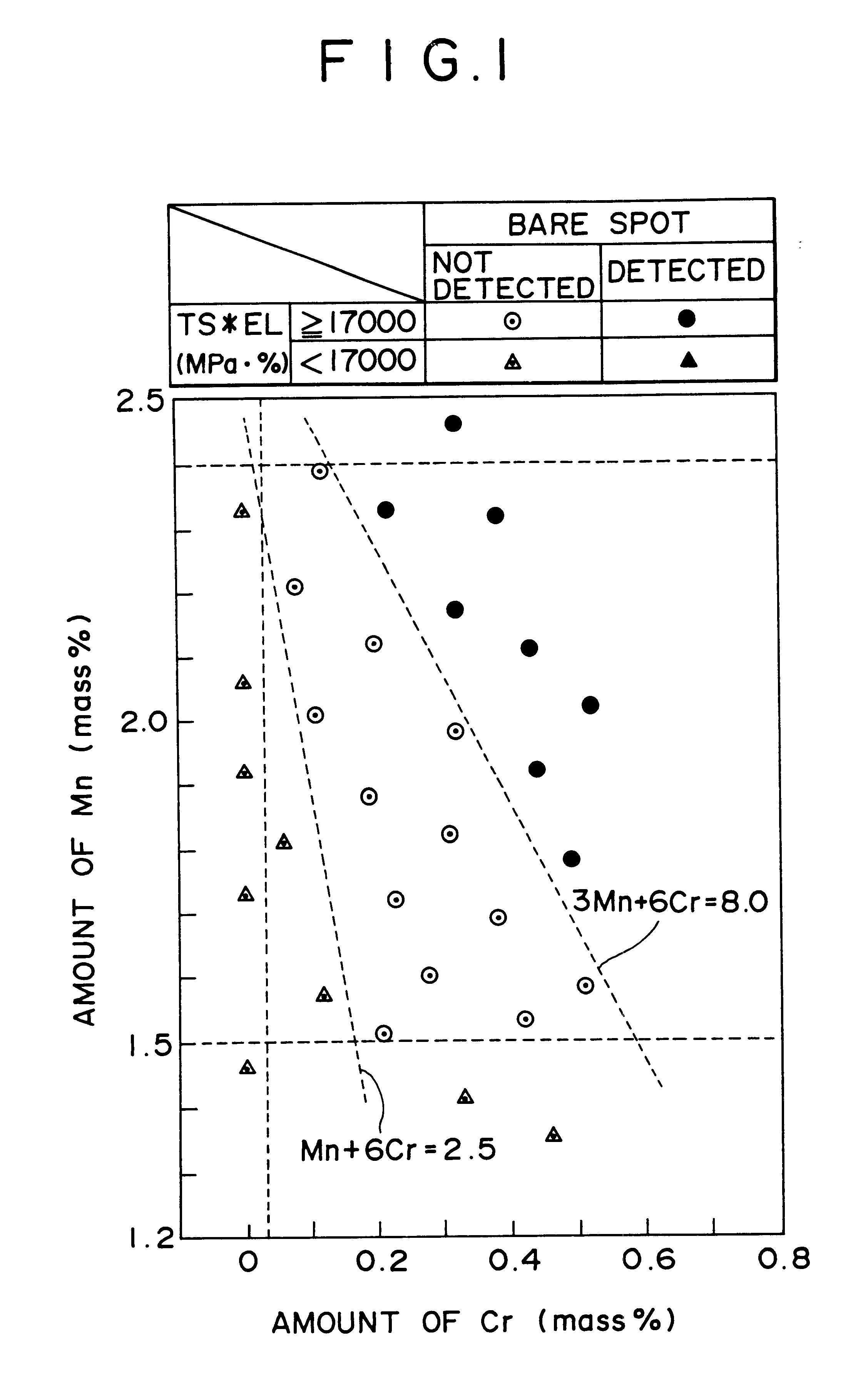

Hot-dip galvanized steel sheet and production thereof

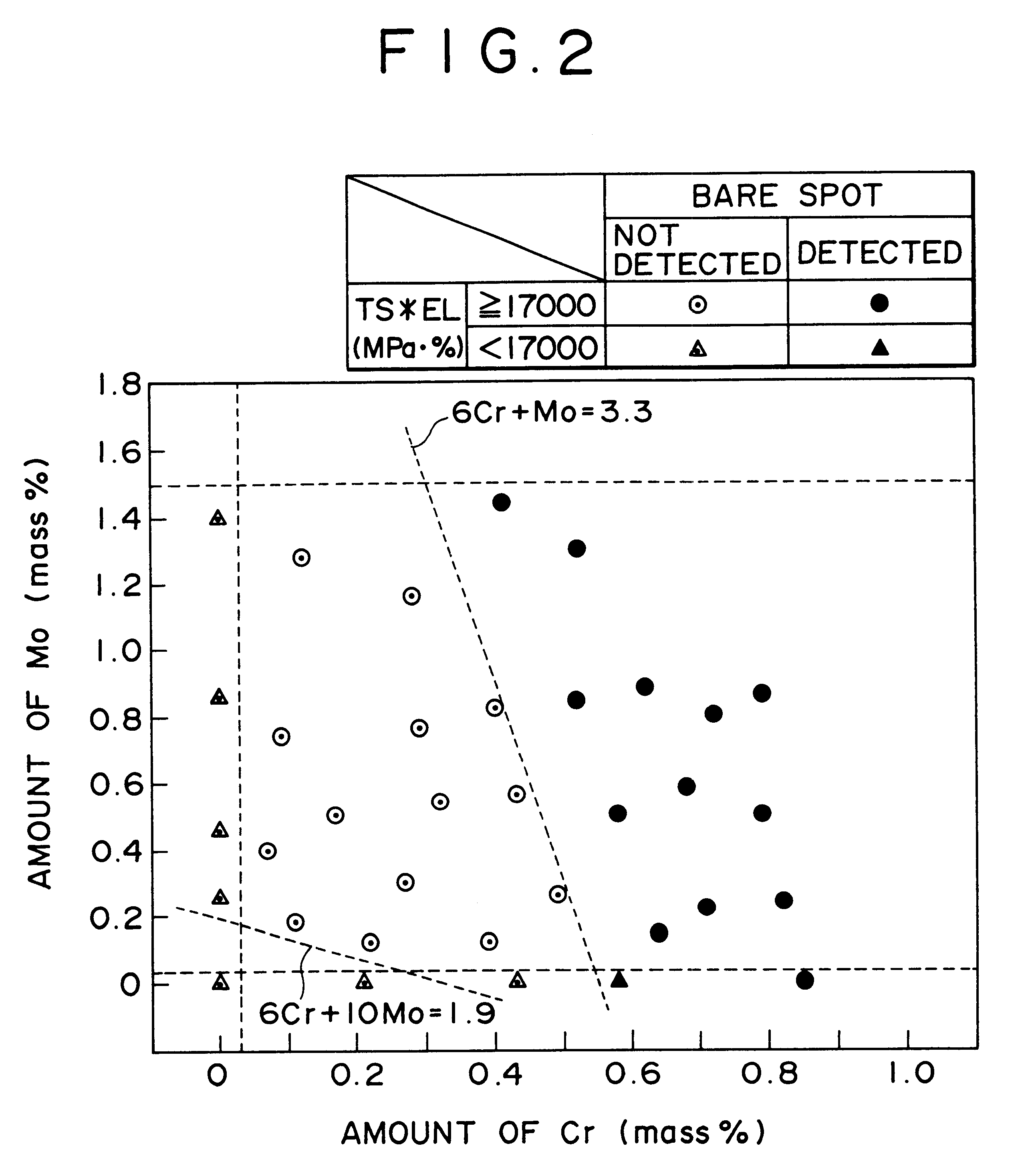

InactiveUS6312536B1High strengthGood formabilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

A hot-dip galvanized steel sheet having both high strength and good formability. A process for producing said hot-dip galvanized steel sheet without requiring additional steps of surface grinding and pre-plating.The hot-dip galvanized steel sheet is produced by forming a hot-dip galvanizing layer on a base cold-rolled steel sheet composed of C (0.02-0.20 mass %), Mn (1.50-2.40 mass %), Cr (0.03-1.50 mass %), Mo (0.03-1.50 mass %), 3Mn+6Cr+Mo (no more than 8.1 mass %), Mn+6Cr+10 Mo (no less than 3.5 mass %), Al (0.010-0.150 mass %), and Fe as the principal component, with Ti limited to 0.01 mass % or less, Si limited to 0.04 mass % or less, P limited to 0.060 mass % or less, and S limited to 0.030 mass % or less, and said base steel sheet having the composite microstructure composed mainly of ferrite and martensite.

Owner:KOBE STEEL LTD

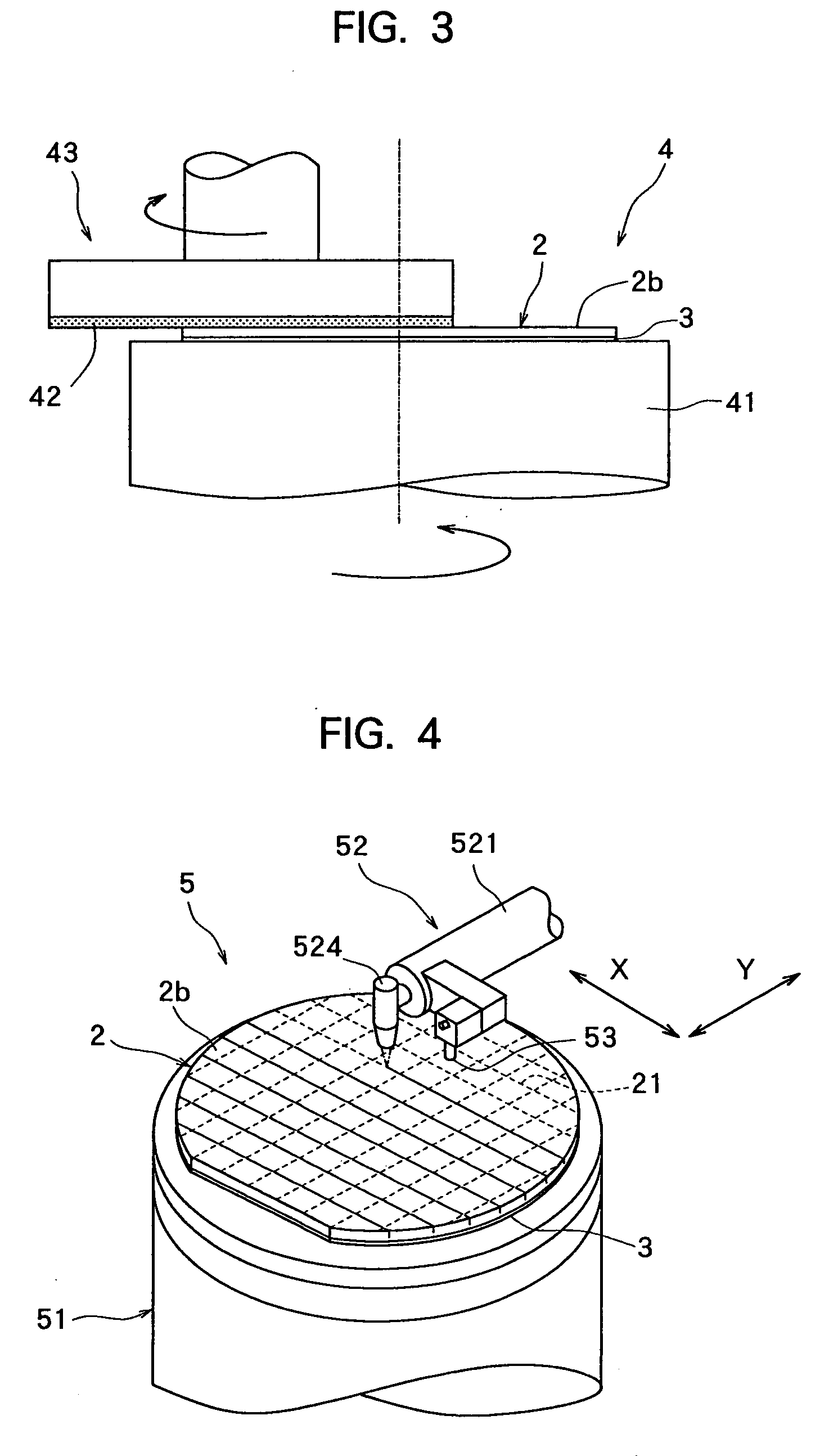

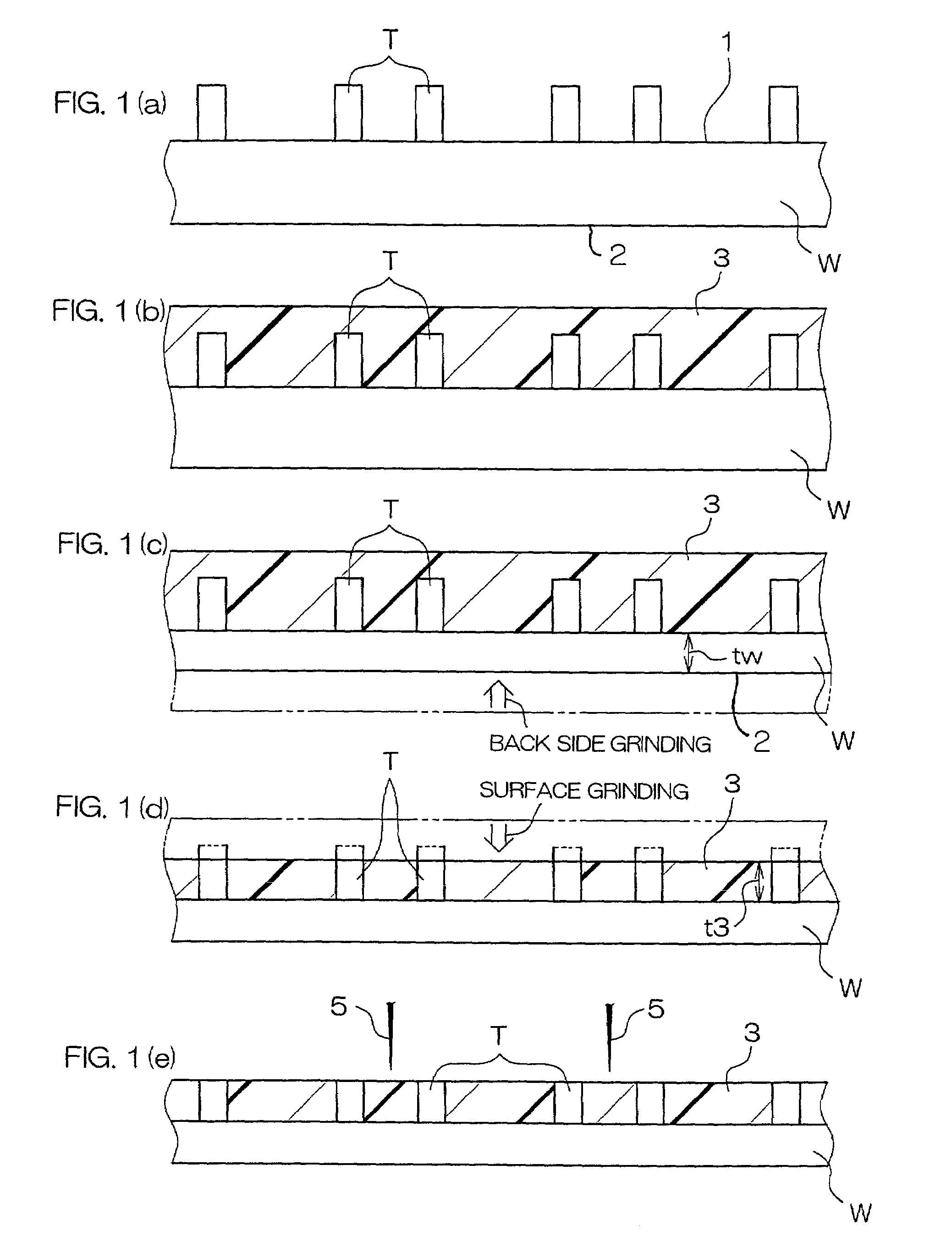

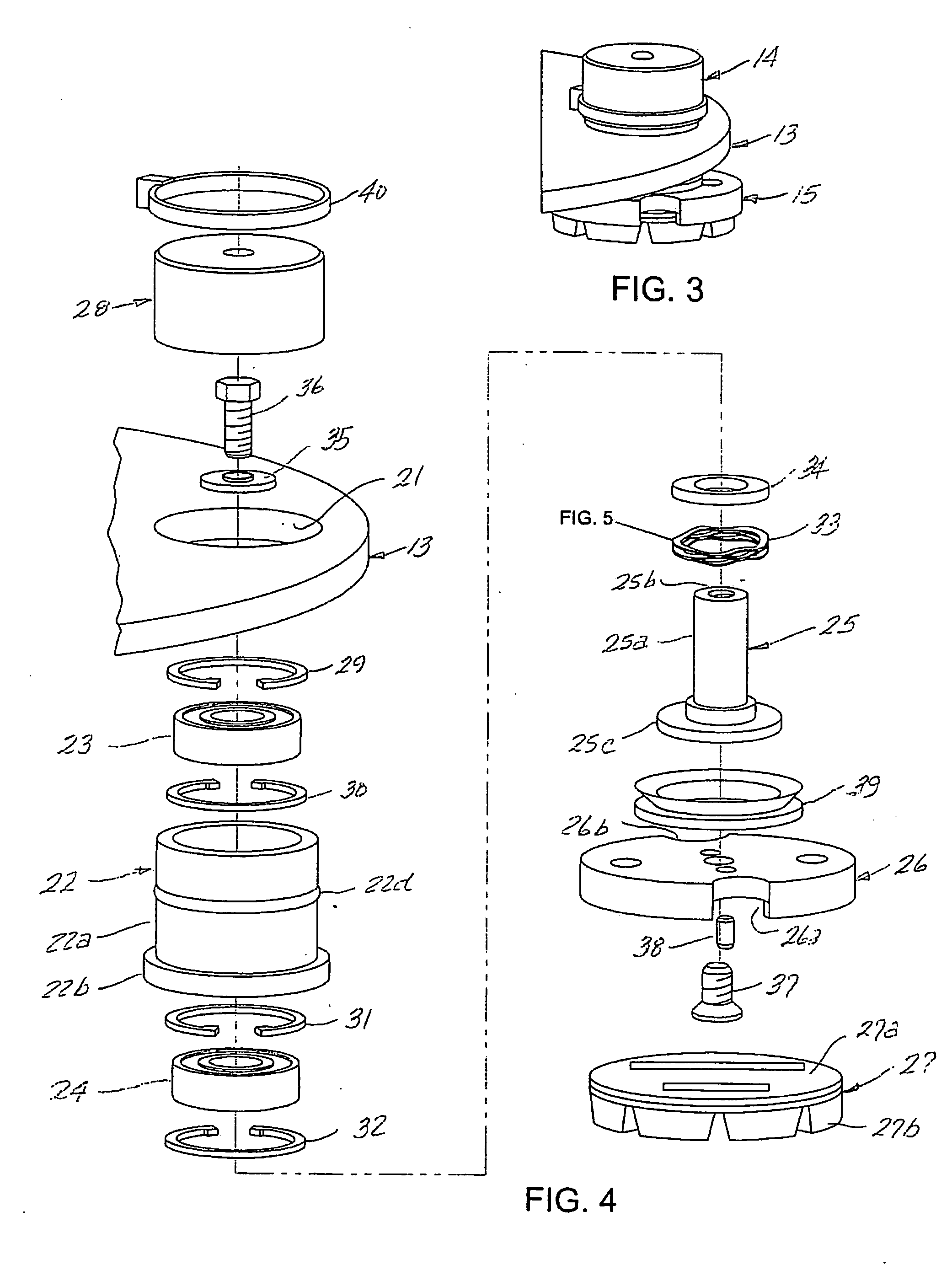

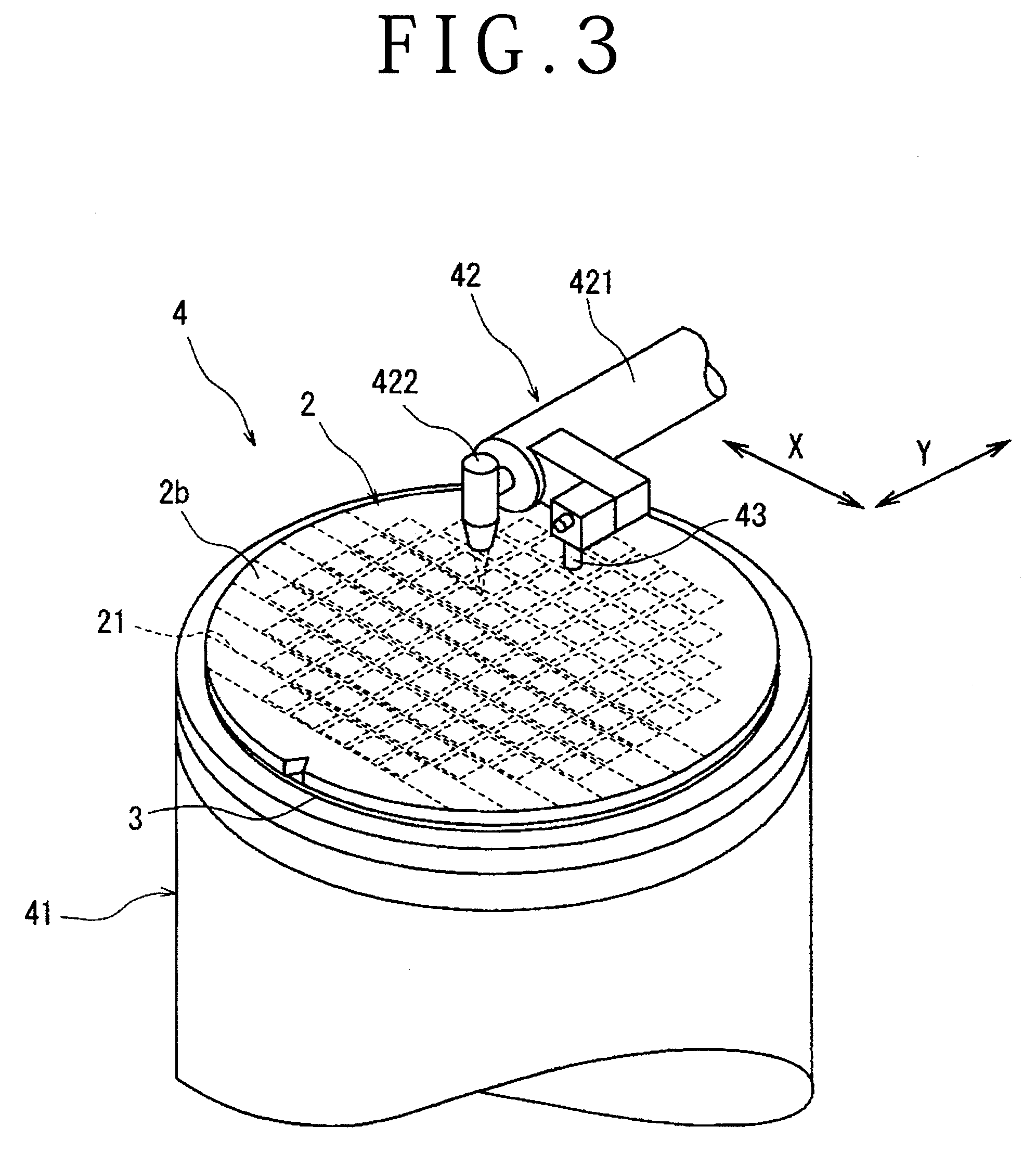

Wafer processing method

ActiveUS20050282359A1Transverse rupture strength of does not lowerHigh strengthSolid-state devicesSemiconductor/solid-state device manufacturingSplit linesWafer backgrinding

A wafer processing method for dividing a wafer having function elements in area sectioned by dividing lines formed on the front surface in a lattice pattern into individual chips along the dividing lines, comprising a deteriorated layer forming step for forming a deteriorated layer on the side of the back surface of a position at a distance corresponding to the final thickness of the chip from the front surface of the wafer by applying a laser beam capable of passing through the wafer along the dividing lines from the back surface of the wafer; a dividing step for dividing the wafer into individual chips along the dividing lines by applying external force to the wafer in which the deteriorated layer has been formed along the dividing lines; and a back surface grinding step for grinding the back surface of the wafer divided into individual chips to the final thickness of the chip.

Owner:DISCO CORP

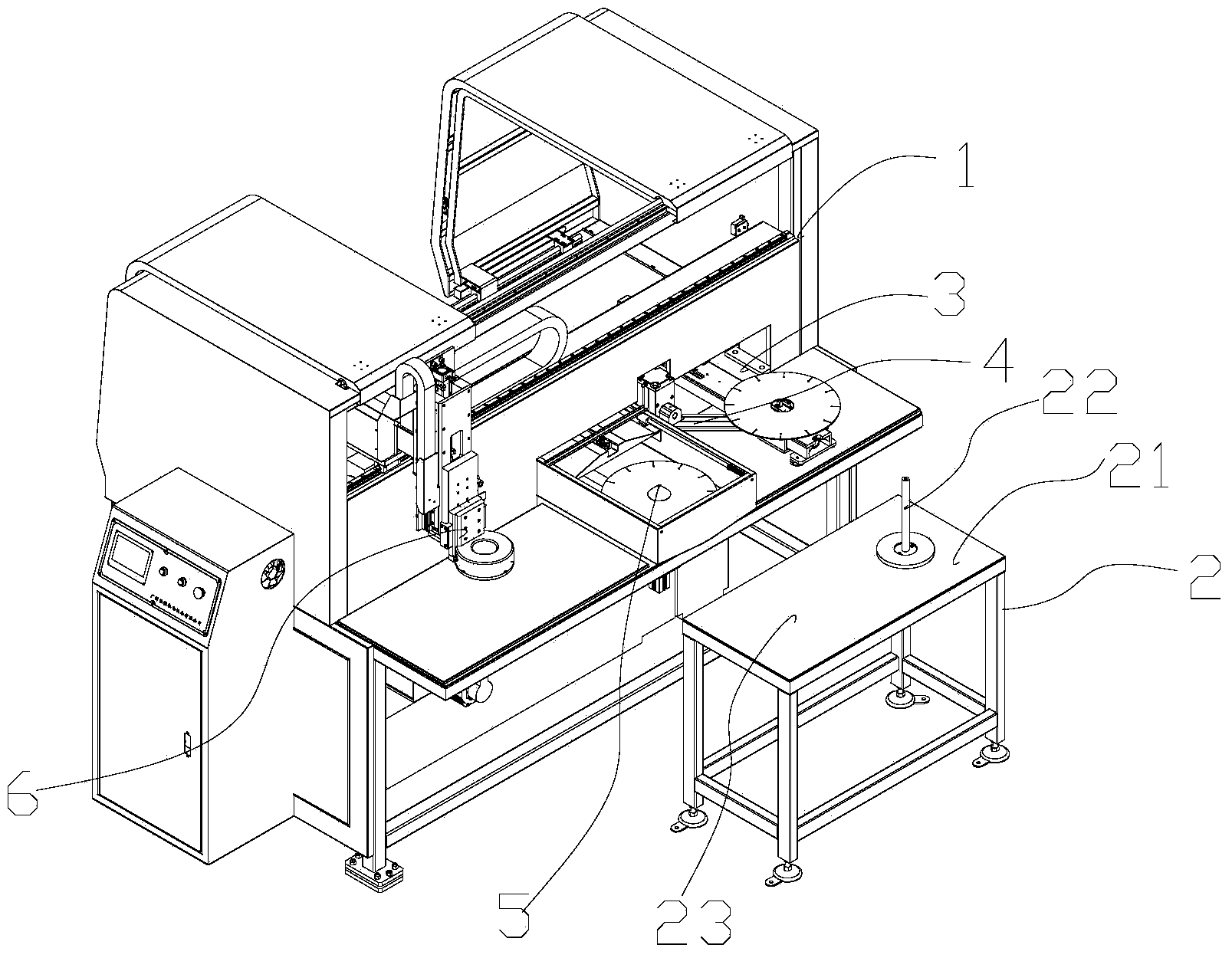

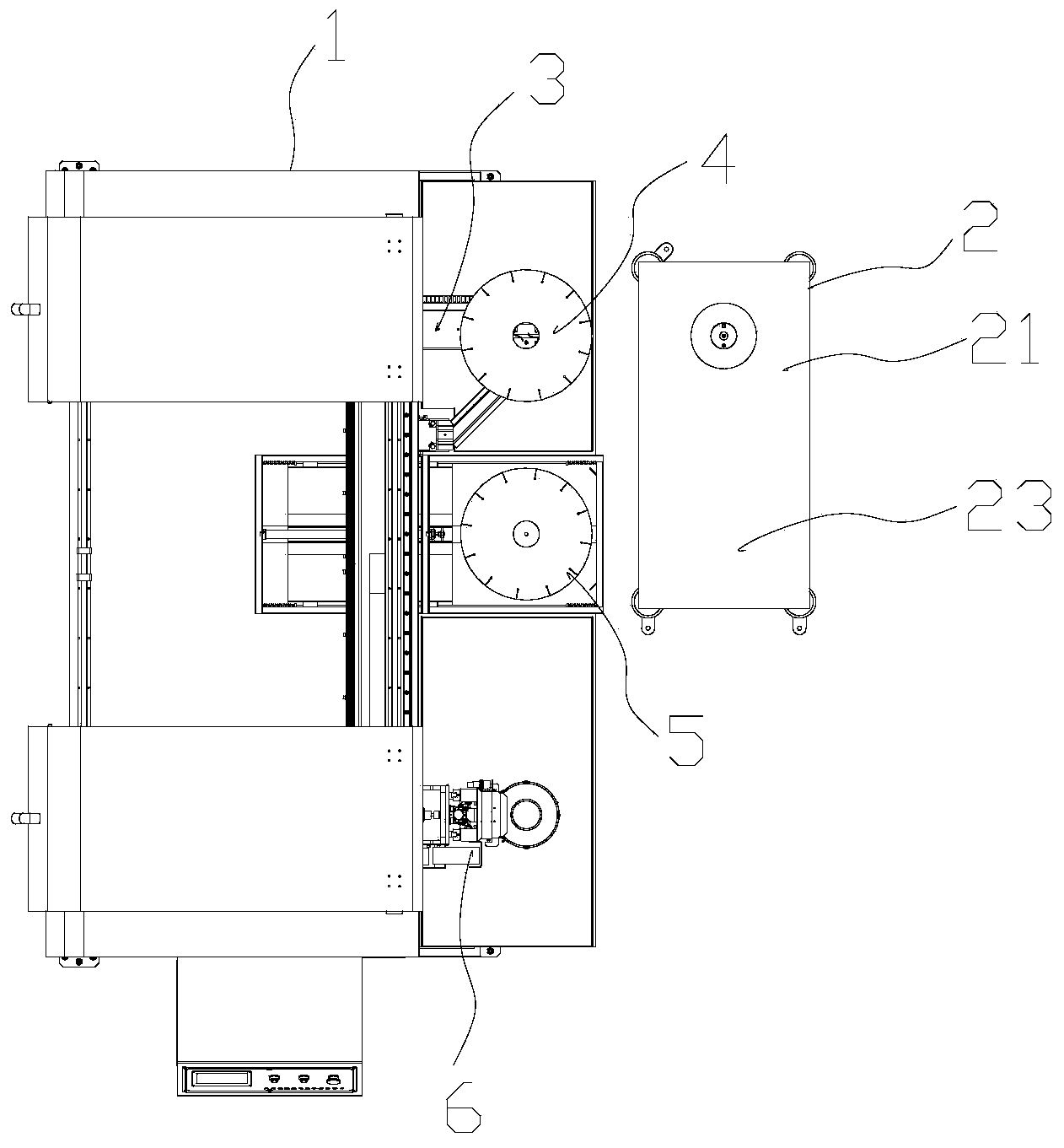

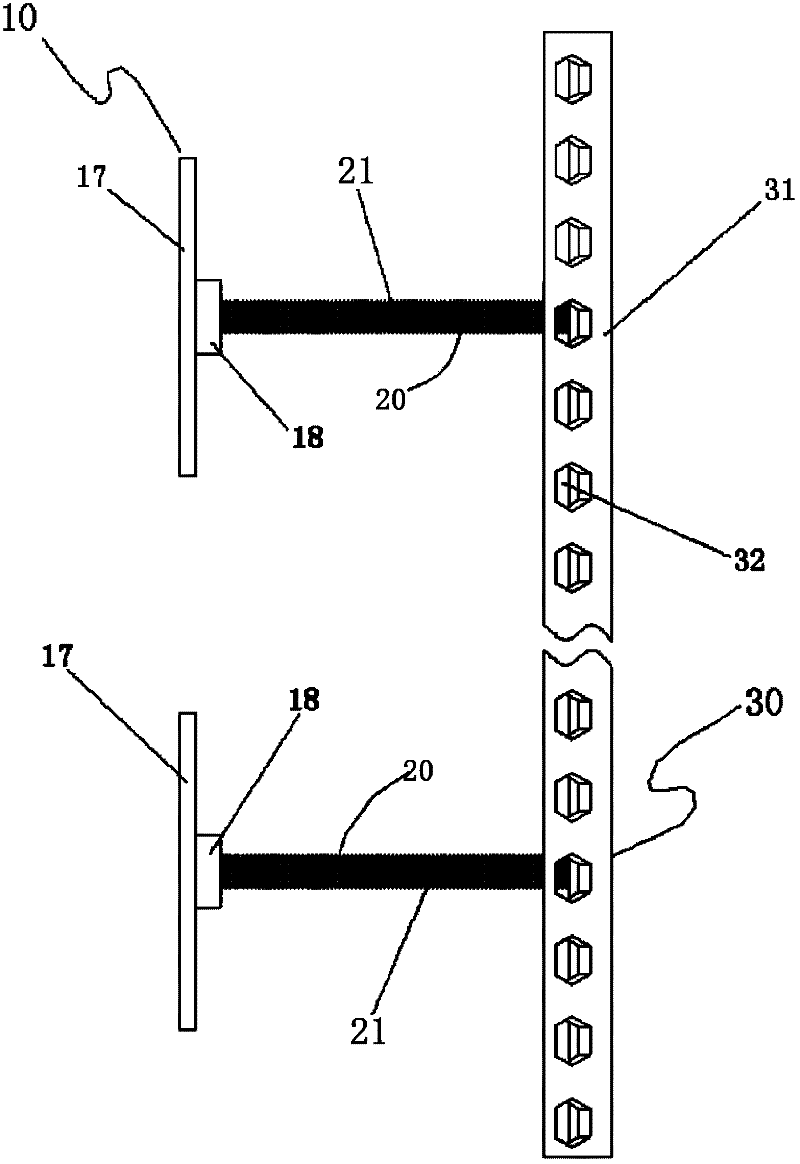

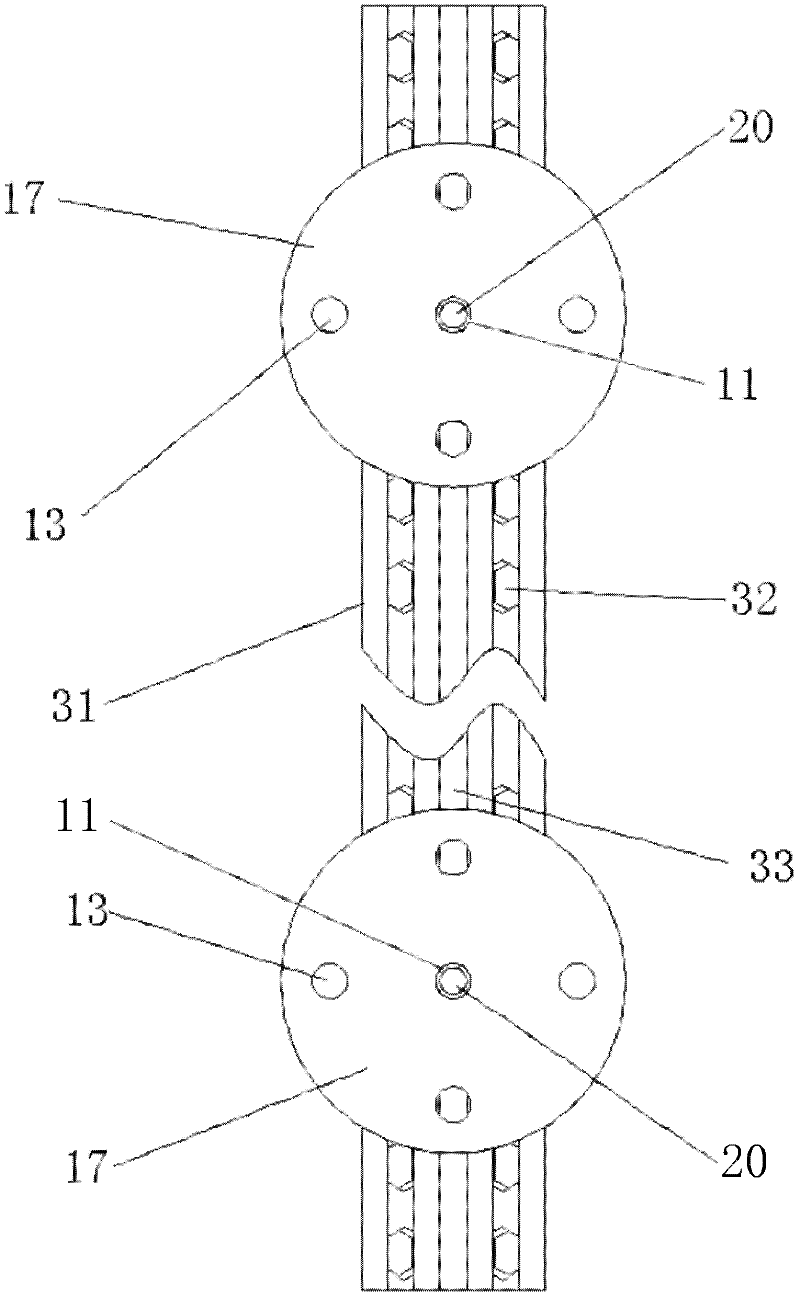

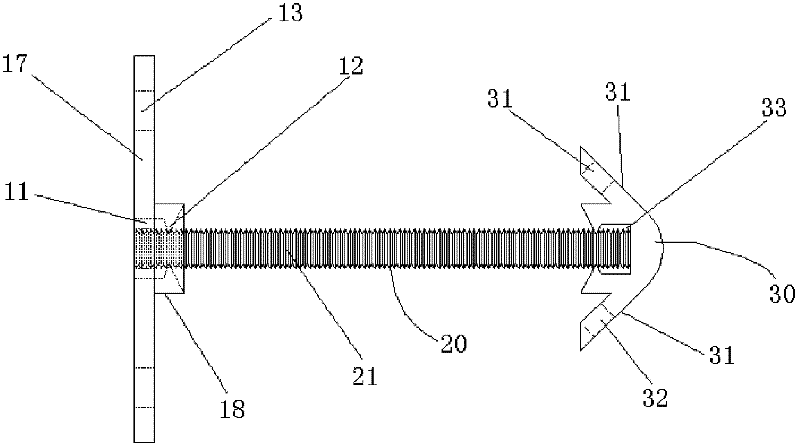

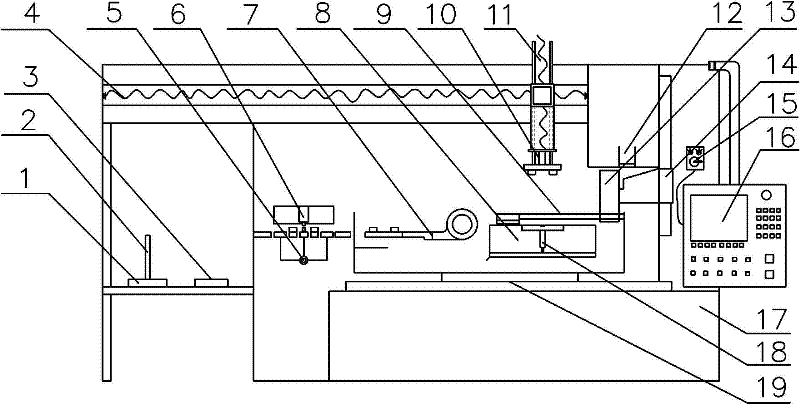

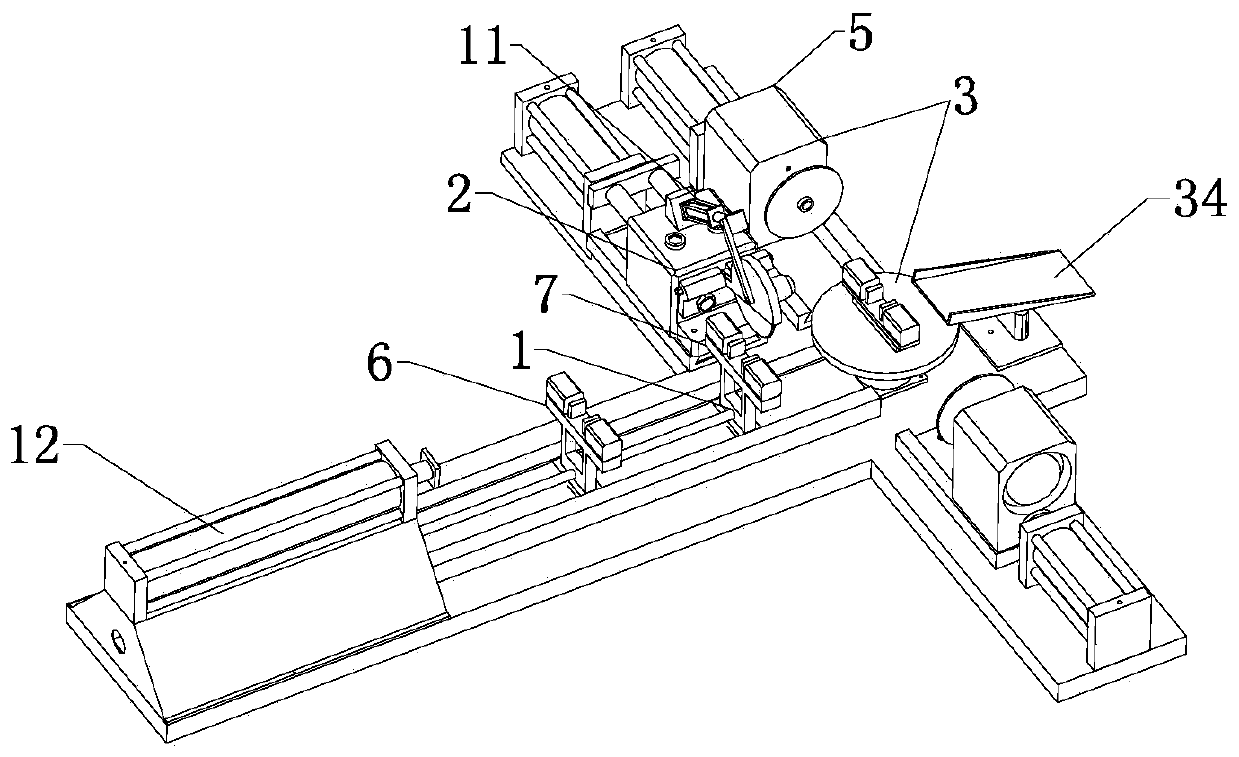

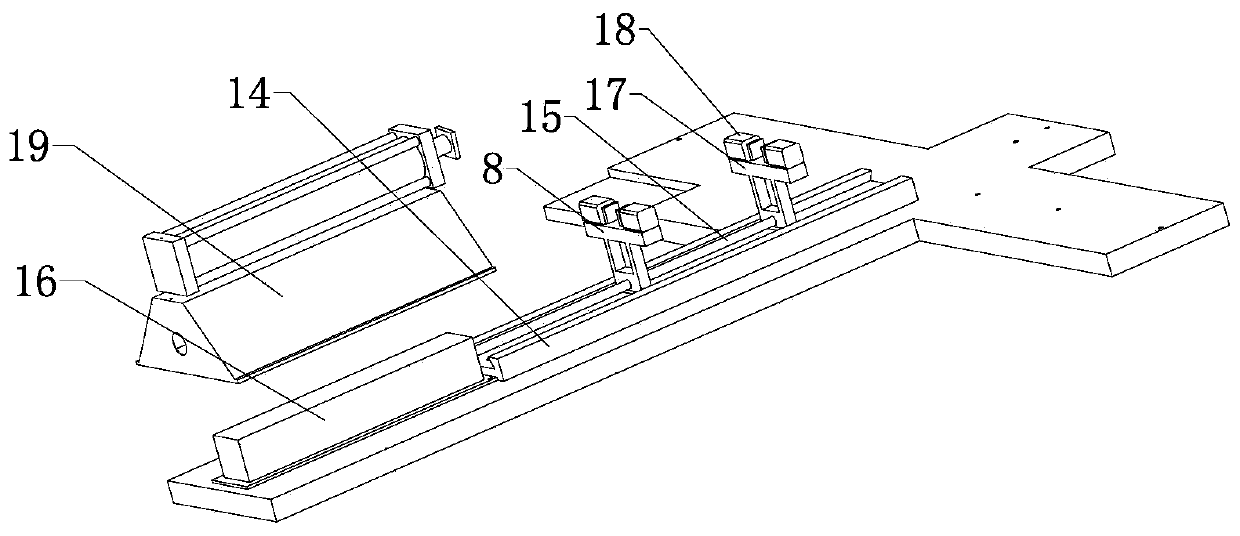

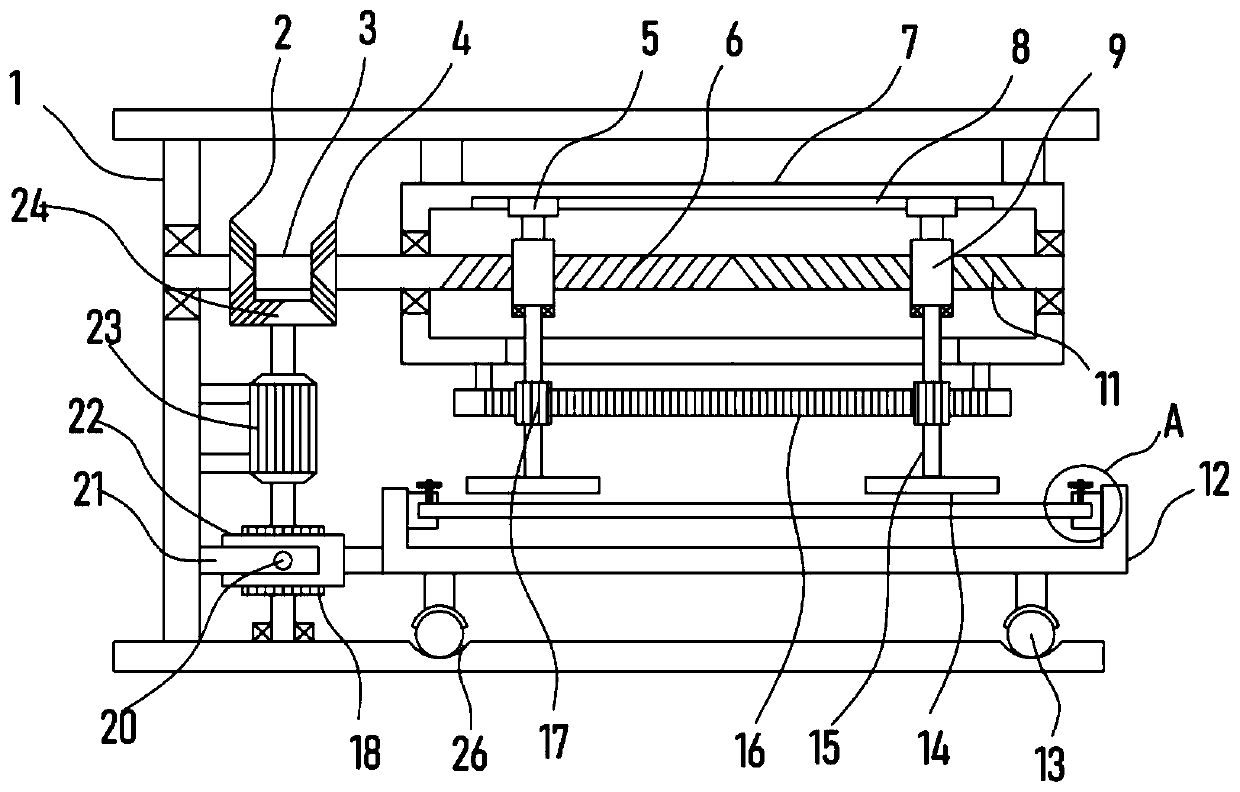

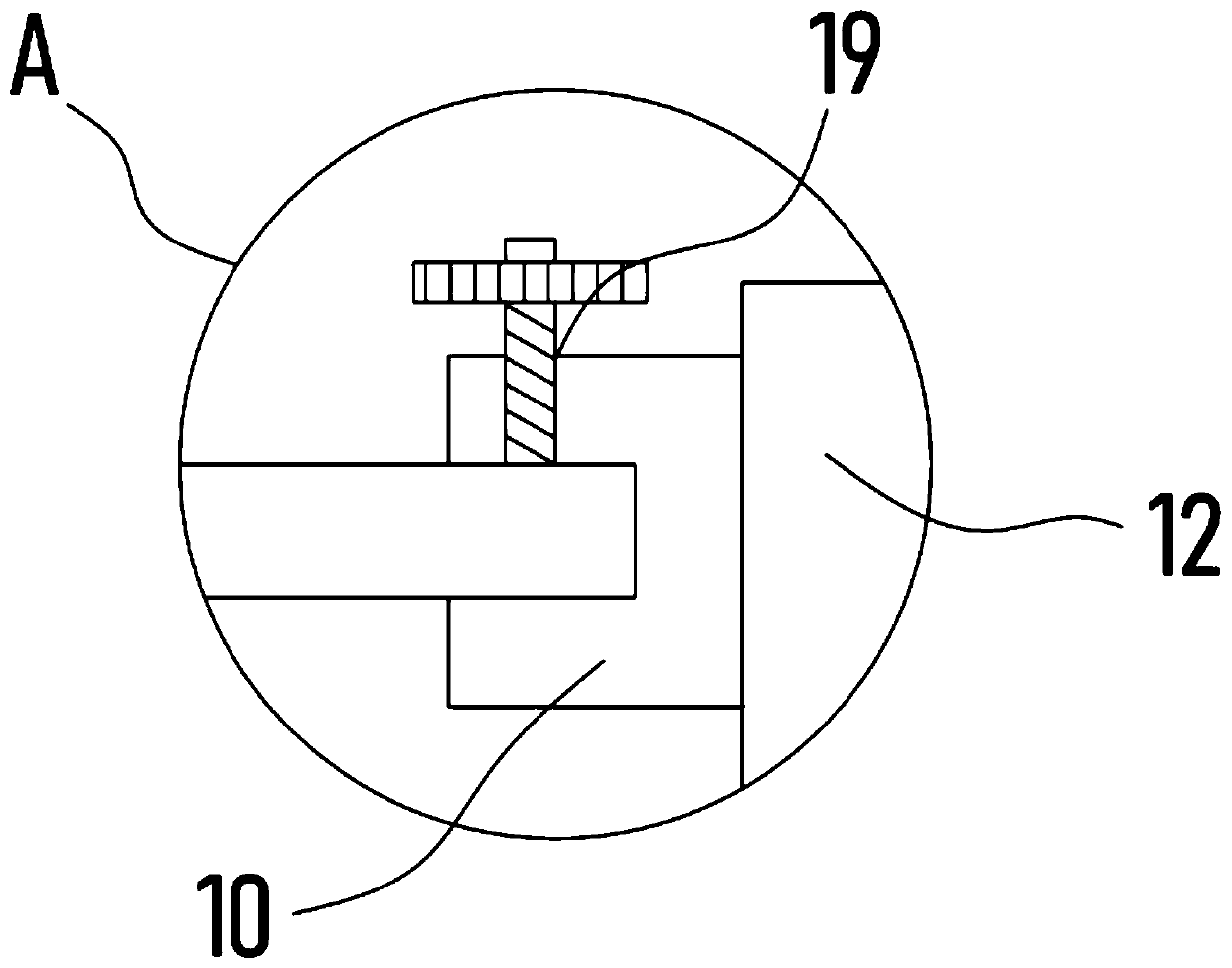

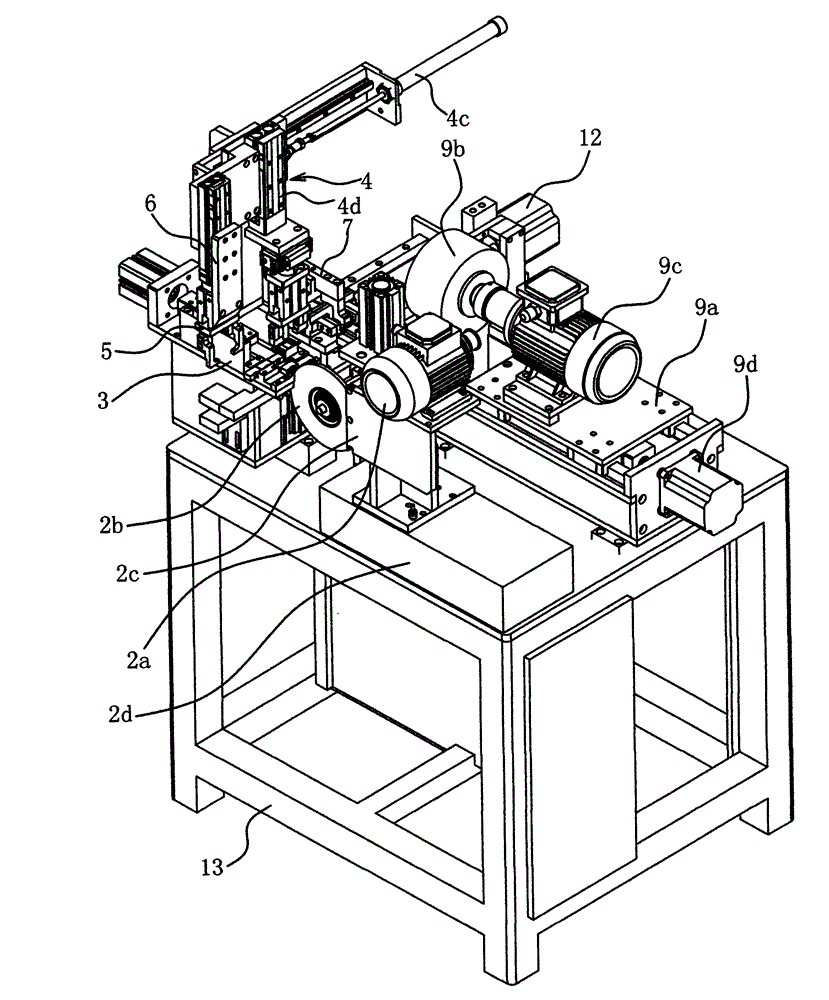

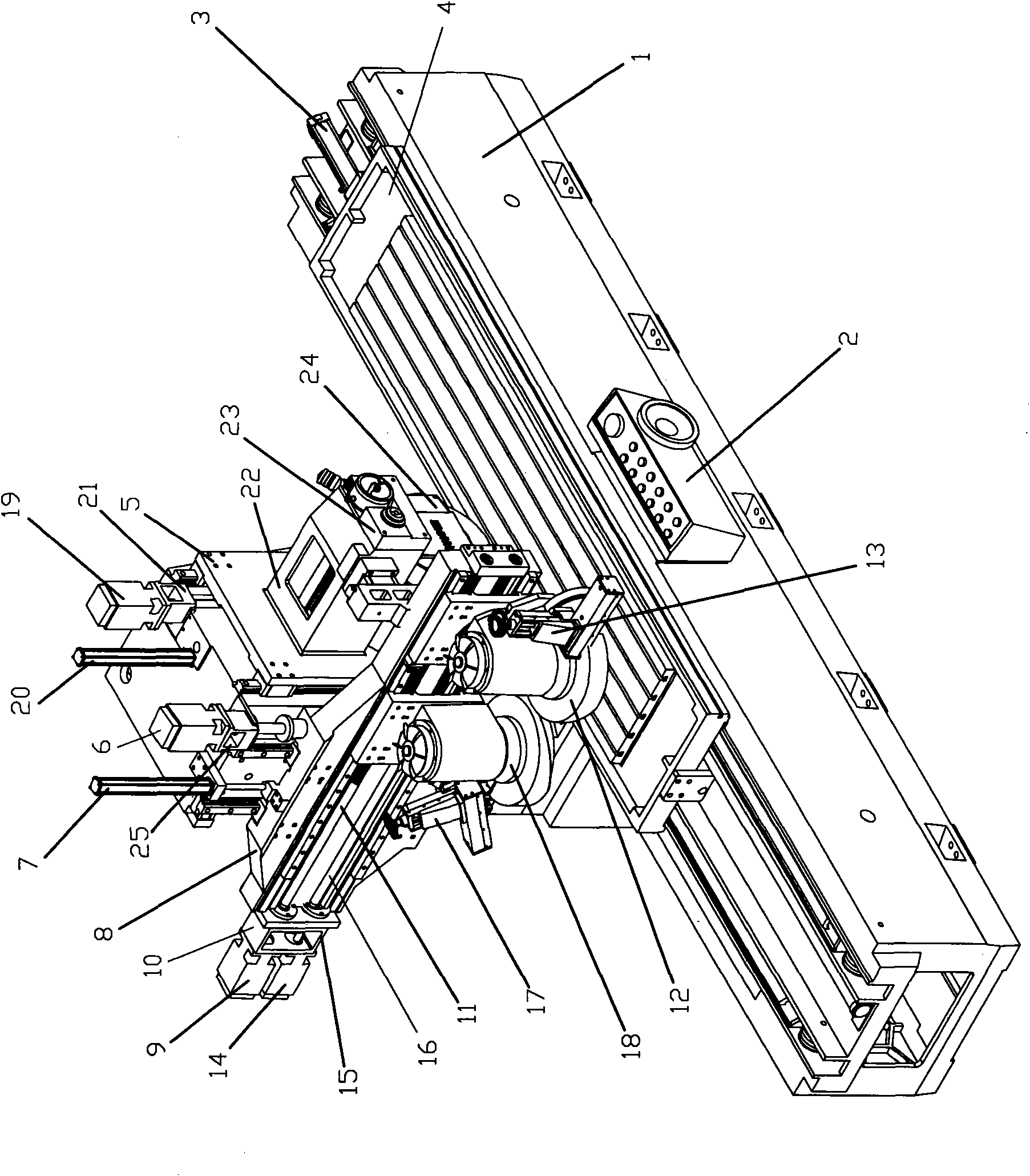

Full-automatic horizontal surface grinding machine mechanical arm

ActiveCN103831680AReduce labor costsImprove pass rateProgramme-controlled manipulatorGripping headsWork periodNumerical control

The invention discloses a full-automatic horizontal surface grinding machine mechanical arm which comprises a machine table and a product containing table. An automatic detection device, a turning device, a cleaning device and a grabbing mechanical arm body are arranged on the machine table. The product containing table and the machine table are arranged side by side. The automatic detection device, the turning device, the cleaning device and the grabbing mechanical arm body are all installed on the machine table, and an automatic grinding machine device is connected with the machine table. By means of the automatic detection device, the turning device, the cleaning device, the grabbing mechanical arm body and the automatic grinding machine device, saw blades are fed, discharged, detected, cleaned and ground in a full-automatic mode, full-automatic operation of the whole process is achieved, and labor cost of an enterprise is greatly reduced; by means of accurate numerical control operation, cost is reduced, the yield is improved, and the production loss rate is reduced; production efficiency is improved, and working time is shortened; by means of full-automatic production, guarantees can be provided for workers on the aspects of mechanical contusion, tiny dust and exhaust gas inhalation and metal dirty water corrosion to human bodies.

Owner:GUANGZHOU HENGWEI ELECTROMECHANICAL EQUIP CO LTD

Double-surface grinding and double-surface polishing high-efficiency ultraprecise processing method for large-sized A-directional sapphire mobile phone screen

ActiveCN104669106AQuality improvementReach processing costOther chemical processesLapping machinesManufacturing technologySurface layer

The invention discloses a double-surface grinding and double-surface polishing high-efficiency ultraprecise processing method for a large-sized A-directional sapphire mobile phone screen. The method comprises the steps of crystal ingot orientation, crystal plate slicing, crystal plate double-surface grinding, crystal plate cleaning, crystal plate annealing, crystal plate double-surface polishing, secondary crystal plate cleaning, laser drilling, crystal plate chamfering, triple crystal plate cleaning and crystal plate film plating. According to the method, optimal parameters, including constituents of polishing liquid, of the optimal processing technology and all the steps can be obtained by screening by a large quantity of experiments. By the method, the manufacturing technology of the large-sized (10 inches) sapphire mobile phone screen can be simplified, the processing stress on the surface layer can be effectively eliminated, the mechanical processing damaged layers can be eliminated, and the ultrasmooth surface with a complete surface crystal lattice, the flatness being less than 5 microns and the polishing surface roughness (RMS) being less than 0.2 nanometers can be obtained; the processing quality is high, the cost is low, and the efficiency is high; compared with the prior art, the method disclosed by the invention has the advantage that an extremely high technical progress is achieved.

Owner:江西伟嘉晶创光电科技有限公司

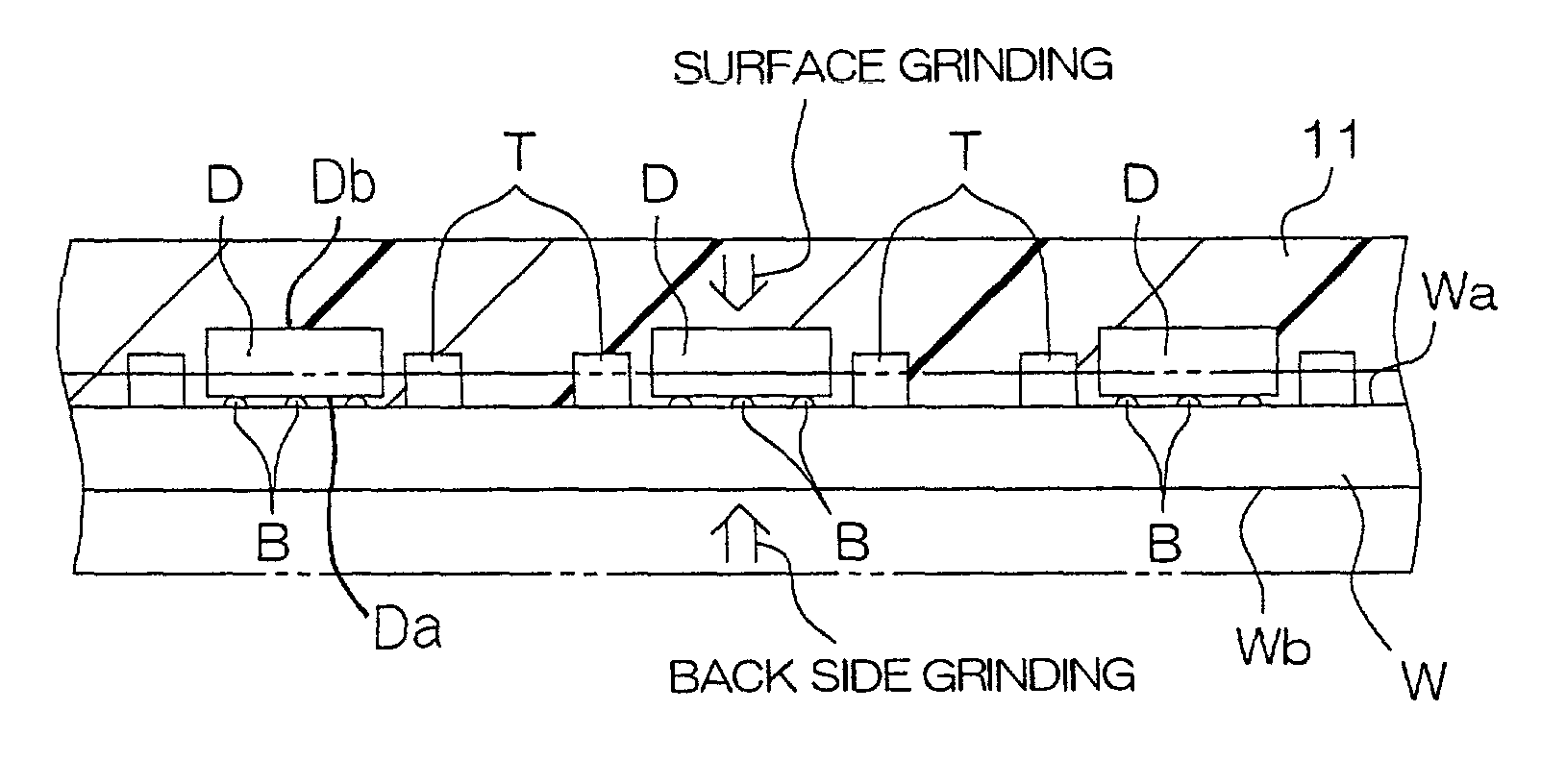

Semiconductor device and method for manufacturing the same

InactiveUS7129110B1Simplify manufacturing stepsEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesSurface grindingSemiconductor

A method for manufacturing a semiconductor device having projection electrodes on the surface of a semiconductor substrate. This method include an electrode forming step of forming the projection electrodes on the surface of the semiconductor substrate, a step of forming a protective resin layer on the whole surface of the semiconductor substrate provided with the projection electrodes, a back side grinding step of thinning the semiconductor substrate by polishing or grinding the back side of the semiconductor substrate, and a surface grinding step of exposing the projection electrodes by polishing or grinding the surface side of the semiconductor substrate.

Owner:TAIWAN SEMICON MFG CO LTD

Method for architectural decoration plastering construction

The invention provides a method for architectural decoration plastering construction. The method comprises the following steps: firstly, base treatment, secondly, screeding, thirdly, plastering, and fourthly, wall surface grinding; screeding in the second step means that construction positioning paying-off is performed according to required plastering height, screeding templates are longitudinally installed along a wall surface subjected to base treatment in the first step according to the paying-off height, and the lateral distance between adjacent screeding templates is 1.3 to 1.8 meters. Wall surface grinding in the fourth step means that the wall surface subjected to plastering in the third step is subjected to standing for 12 to 24 hours till plastering mortar on the wall surface is at a half-dried compact hardened state, and teeth of a saw blade are used for grinding the mortar along the two adjacent screeding templates through a rule till the mortar is even. Due to the method, the plastering construction efficiency can be improved, the construction quality is guaranteed, the large-area construction efficiency is further improved with the matching of mechanized construction, and the defects of low efficiency of traditional manual construction and high technical requirements on constructors are overcome.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Multi-angle synchronous efficient grinding equipment for automobile brake disc

ActiveCN112025432AEffective positioningSynchronous and efficient grinding equipment can be positioned accurately and efficientlyRevolution surface grinding machinesGrinding drivesEngineeringSurface grinding

The invention relates to the technical field of automobile brake disc grinding machining, in particular to multi-angle synchronous efficient grinding equipment for an automobile brake disc. The equipment further comprises a machining platform, a clamping rotating assembly, a top surface grinding assembly and a side wall chamfering and grinding assembly, wherein the clamping rotating assembly comprises a mounting disc, a transmission disc, a positioning disc, a clamping jaw and a pressing mechanism; the top surface grinding assembly comprises a first lifting mechanism, a first horizontal displacement mechanism and a top end horizontal grinding mechanism, and the top end horizontal grinding mechanism comprises a horizontal grinding disc capable of grinding the top surface of the automobile brake disc; and the side wall chamfering and grinding assembly comprises a second lifting mechanism, a second horizontal displacement mechanism, an angle adjusting mechanism and a side wall chamferingand grinding mechanism, and the side wall chamfering and grinding mechanism comprises a side wall grinding disc. The equipment shown can precisely and efficiently position and clamp the automobile brake disc, and the surface, the side wall and the edge of the brake disc are synchronously and accurately ground, such that the working efficiency is greatly improved, and repositioning is avoided.

Owner:浙江杭万汽车零部件实业有限公司

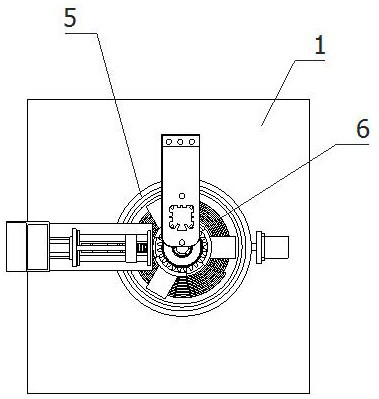

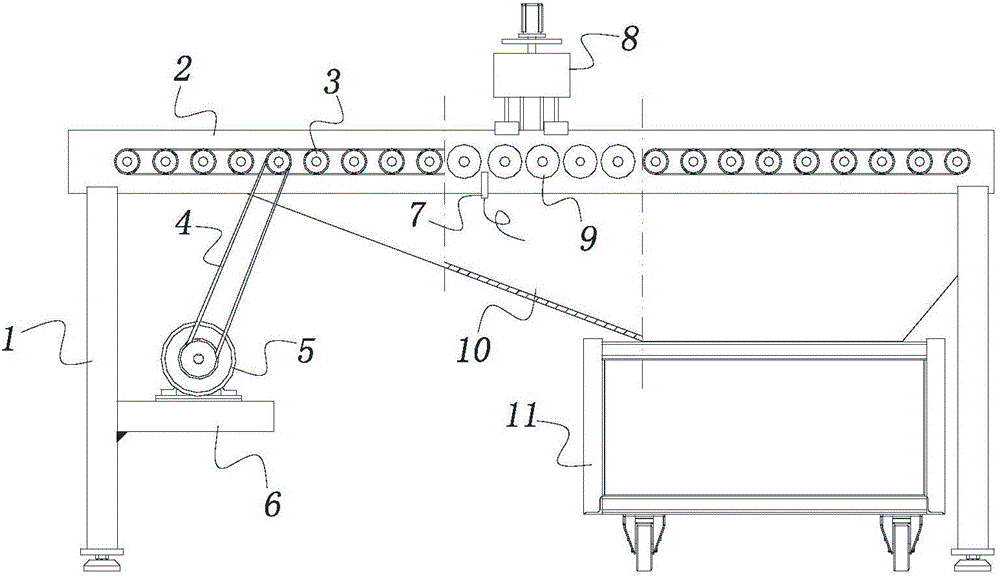

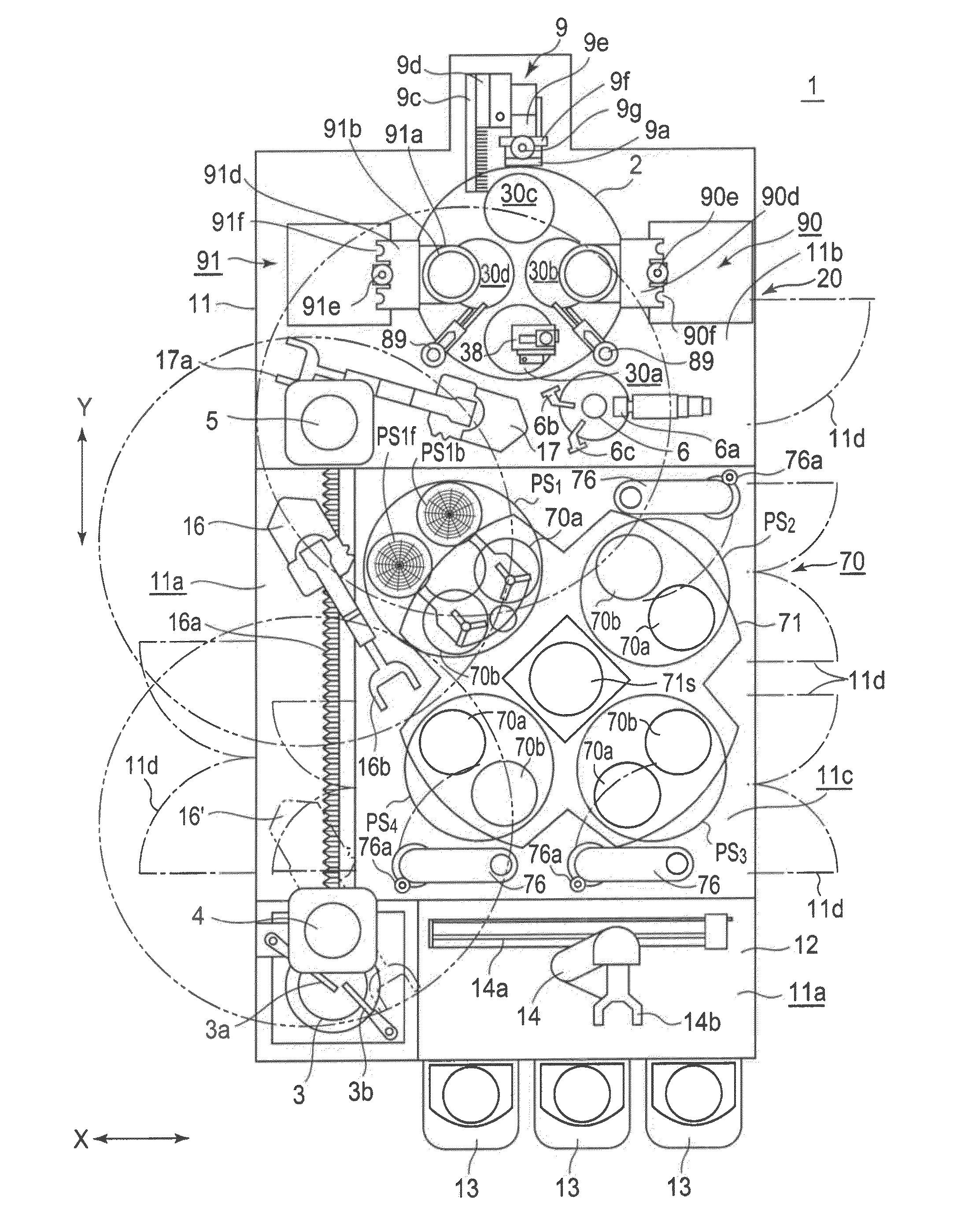

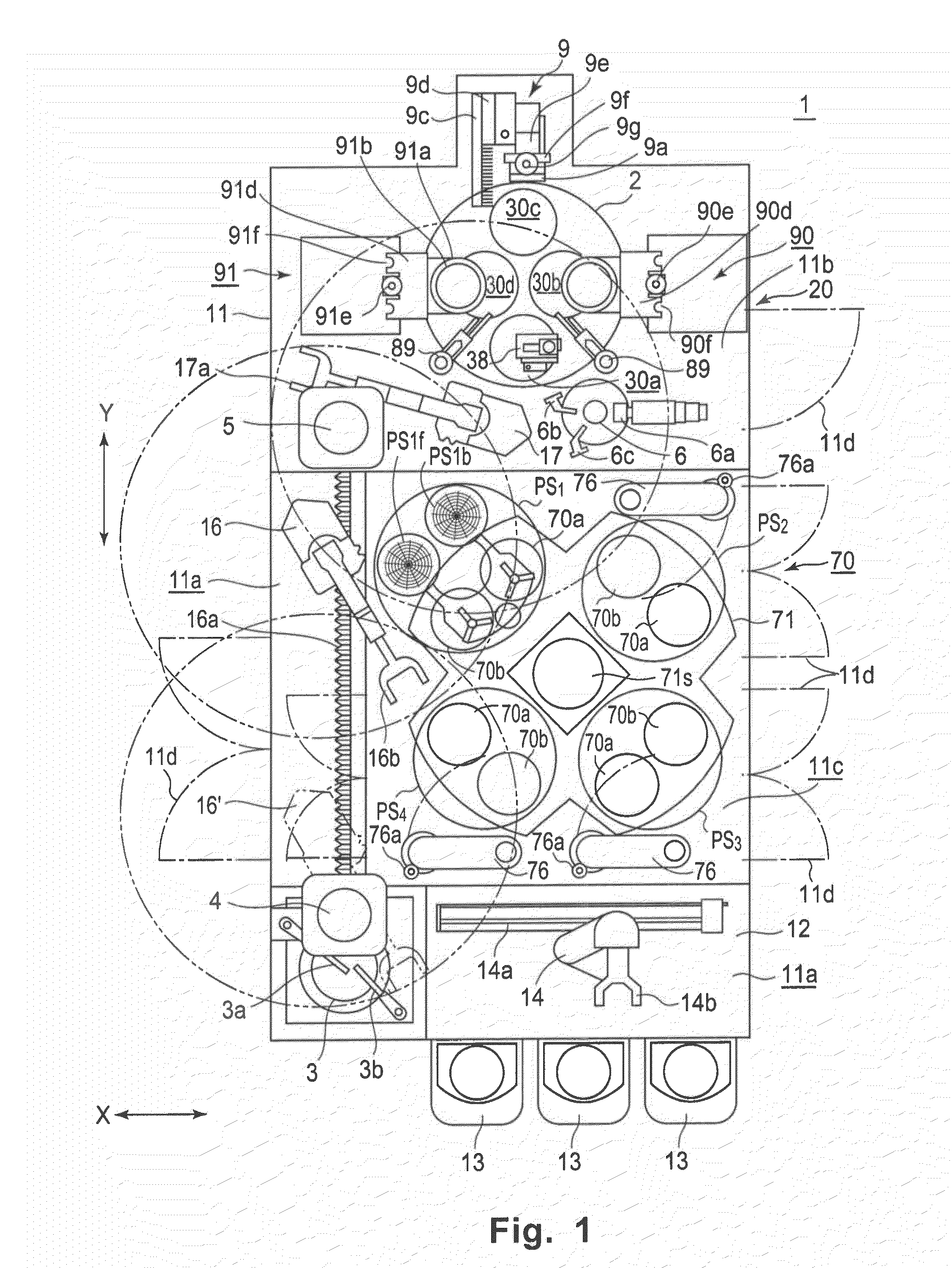

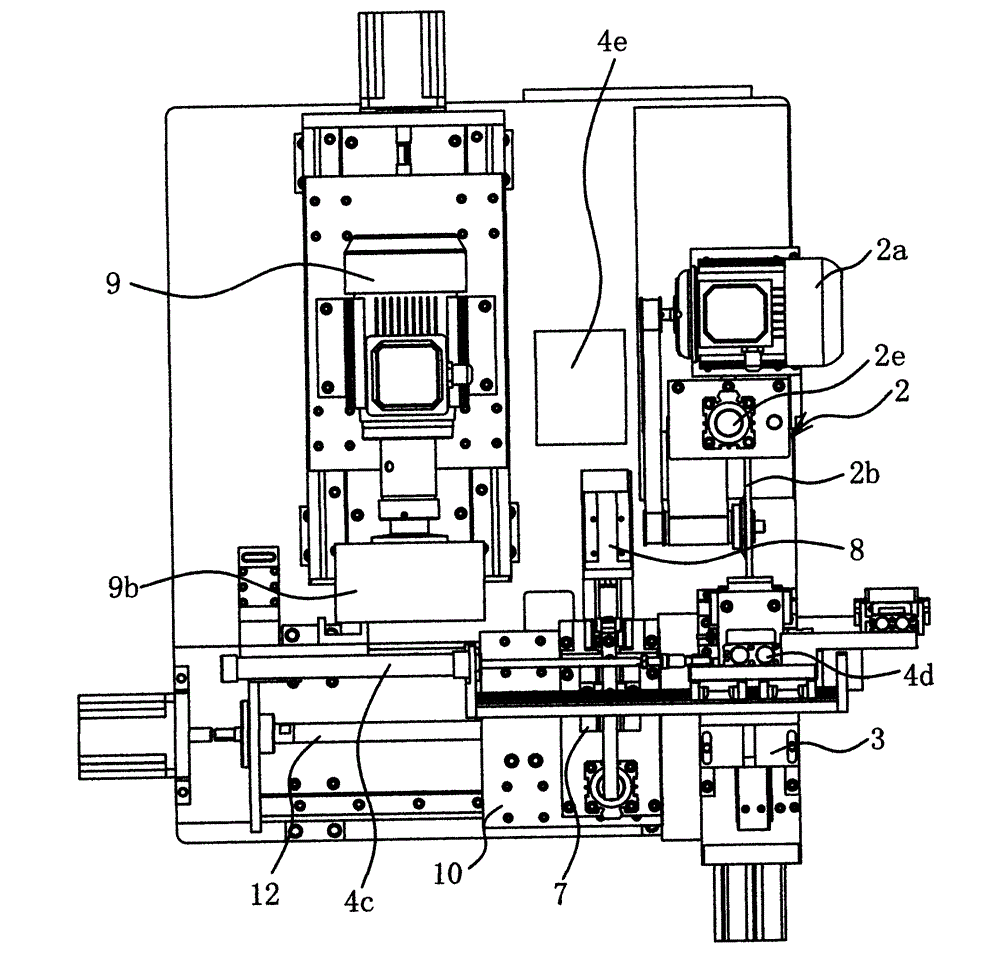

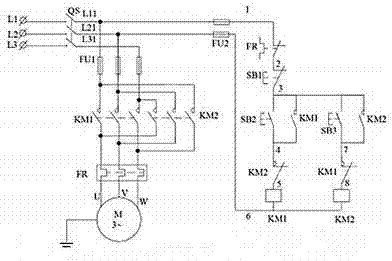

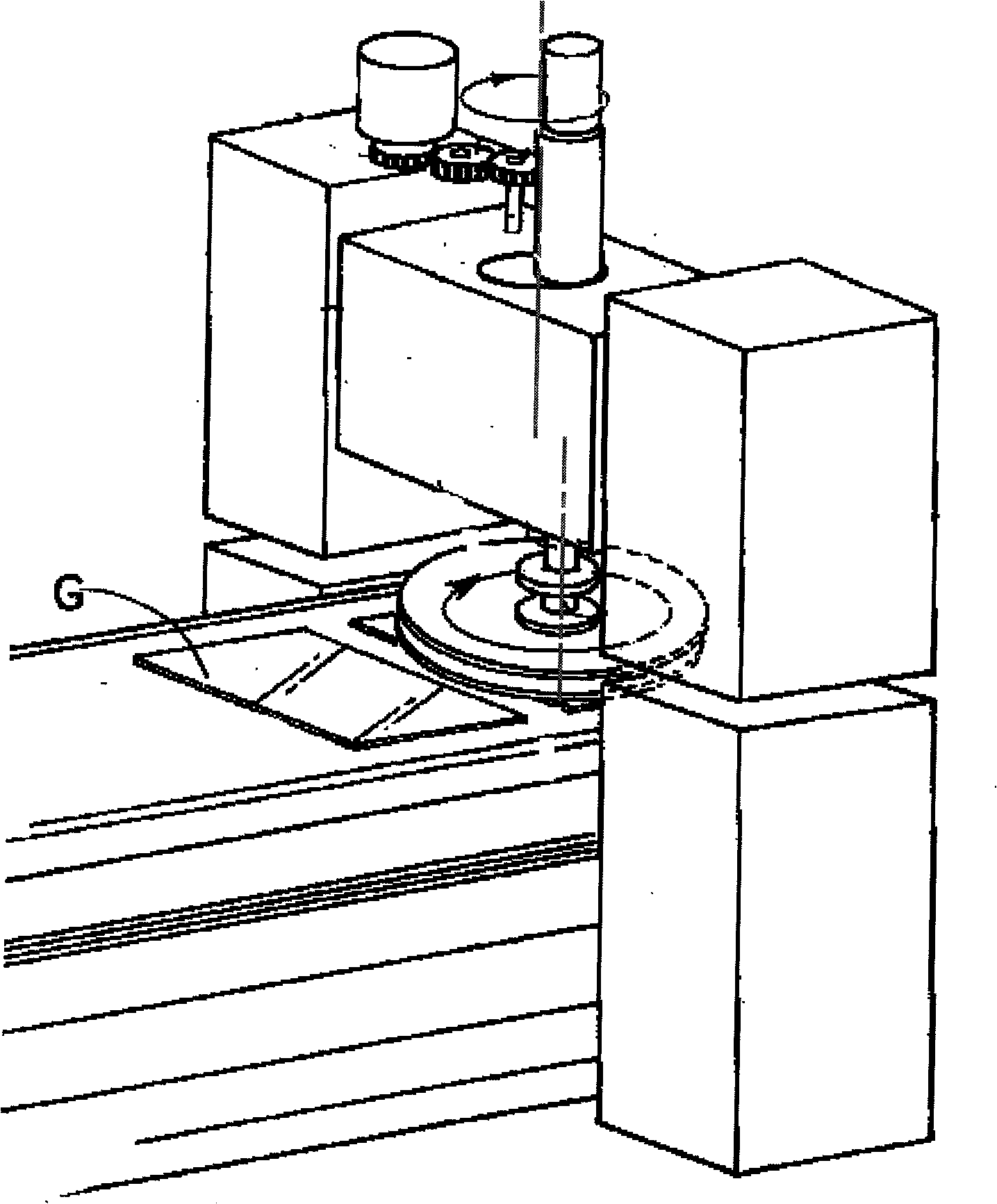

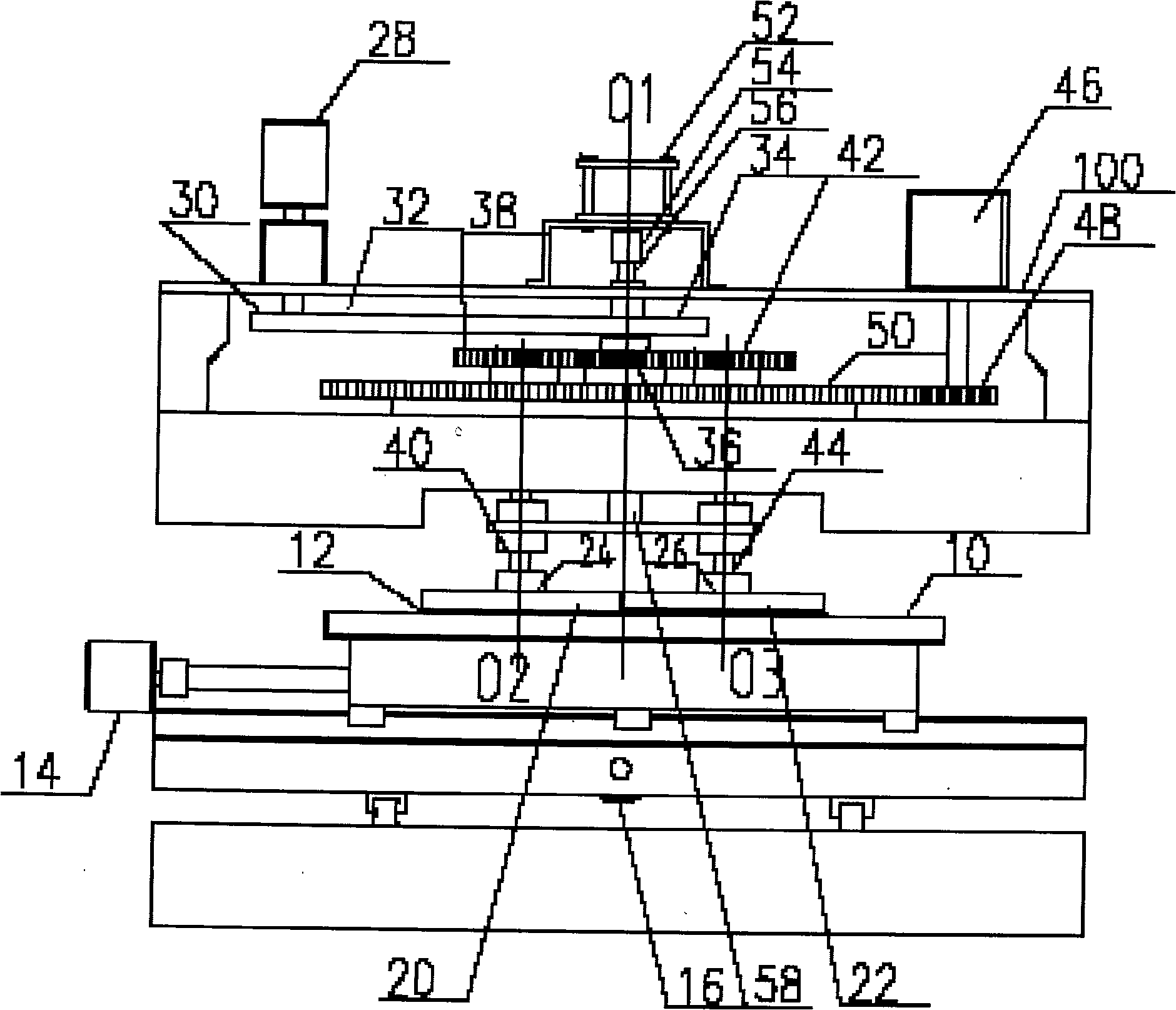

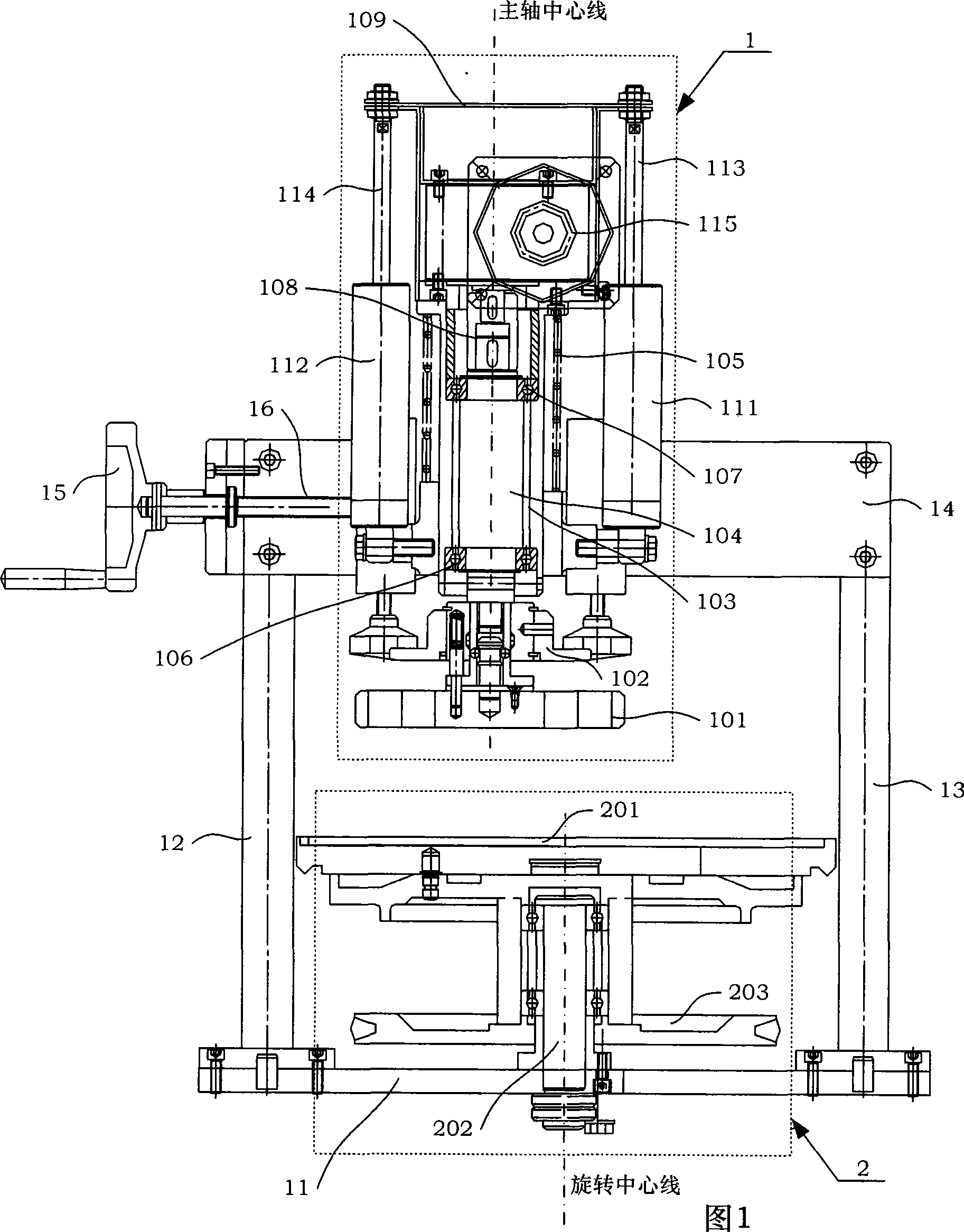

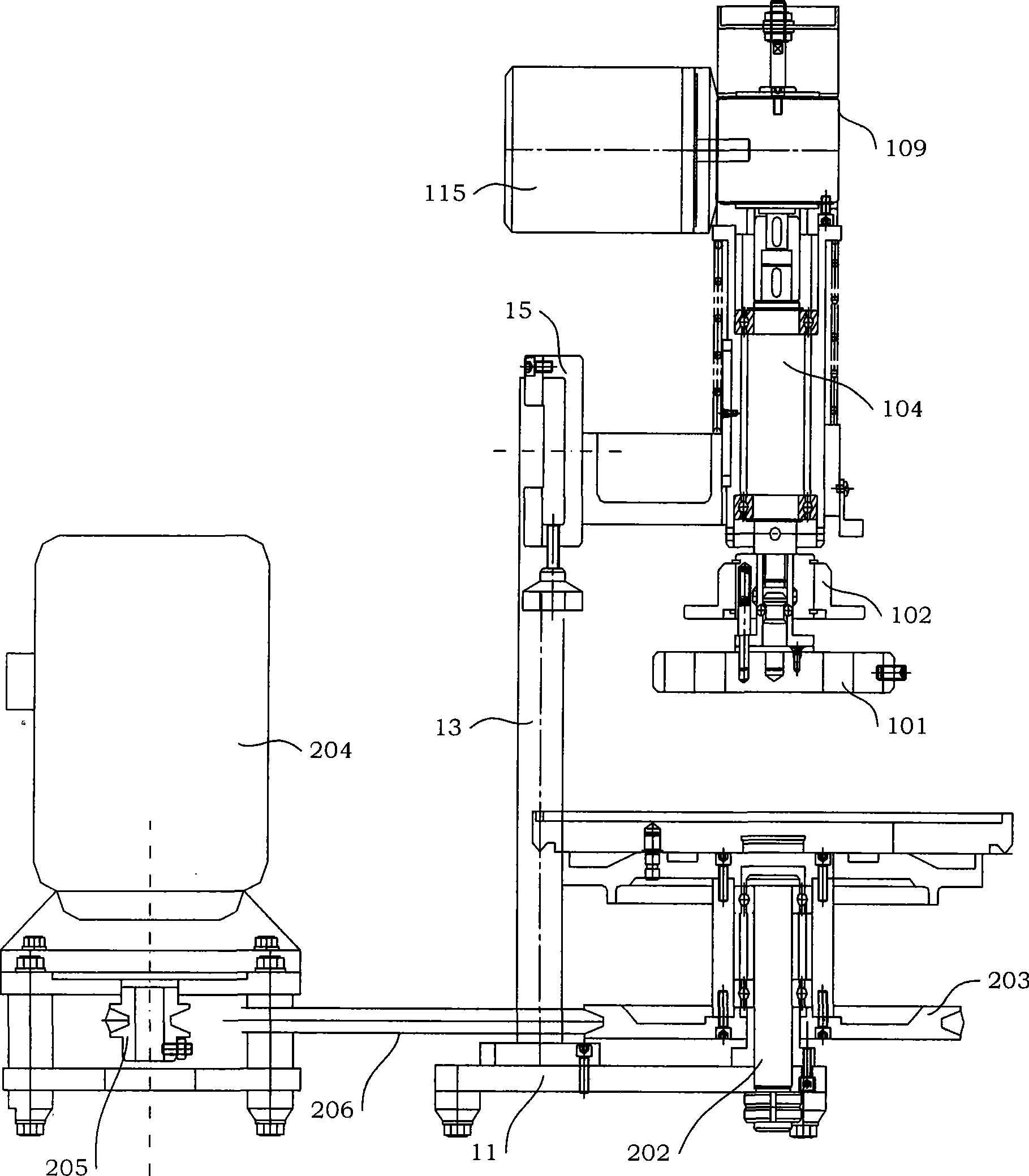

Intelligent surface grinding machine with horizontal spindle and rotary table

ActiveCN102328251AQuality improvementIncrease productivityGripping headsPlane surface grinding machinesEngineeringManipulator

The invention provides an intelligent surface grinding machine with a horizontal spindle and a rotary table, which comprises a grinding machine body and a worktable, wherein one side of the worktable is provided with a turn-over device, an automatic thickness measuring device, a workpiece and worktable cleaning device and a workpiece storage site; and a mechanical arm is arranged above the worktable, the turn-over device and the workpiece storage site. By adopting the intelligent surface grinding machine with the horizontal spindle and the rotary table, both surfaces of a saw bit matrix are automatically processed without manual interference through the arranged turn-over device, automatic thickness measuring device and mechanical arm, and the production efficiency is greatly improved. Moreover, as all steps are controlled by a program, the human error is also reduced, and the workpiece quality is improved.

Owner:YICHANG DISEN MACHINERY

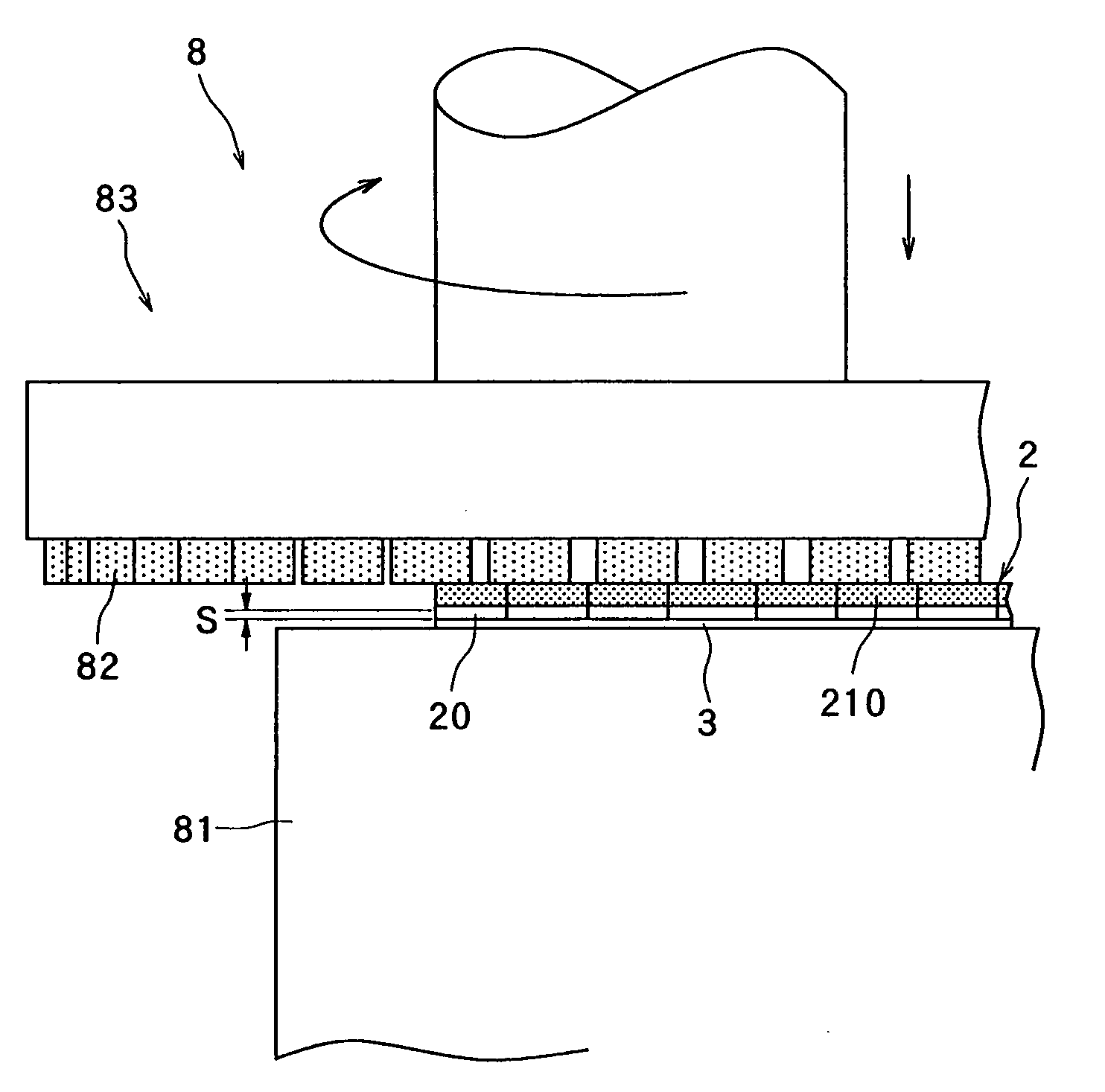

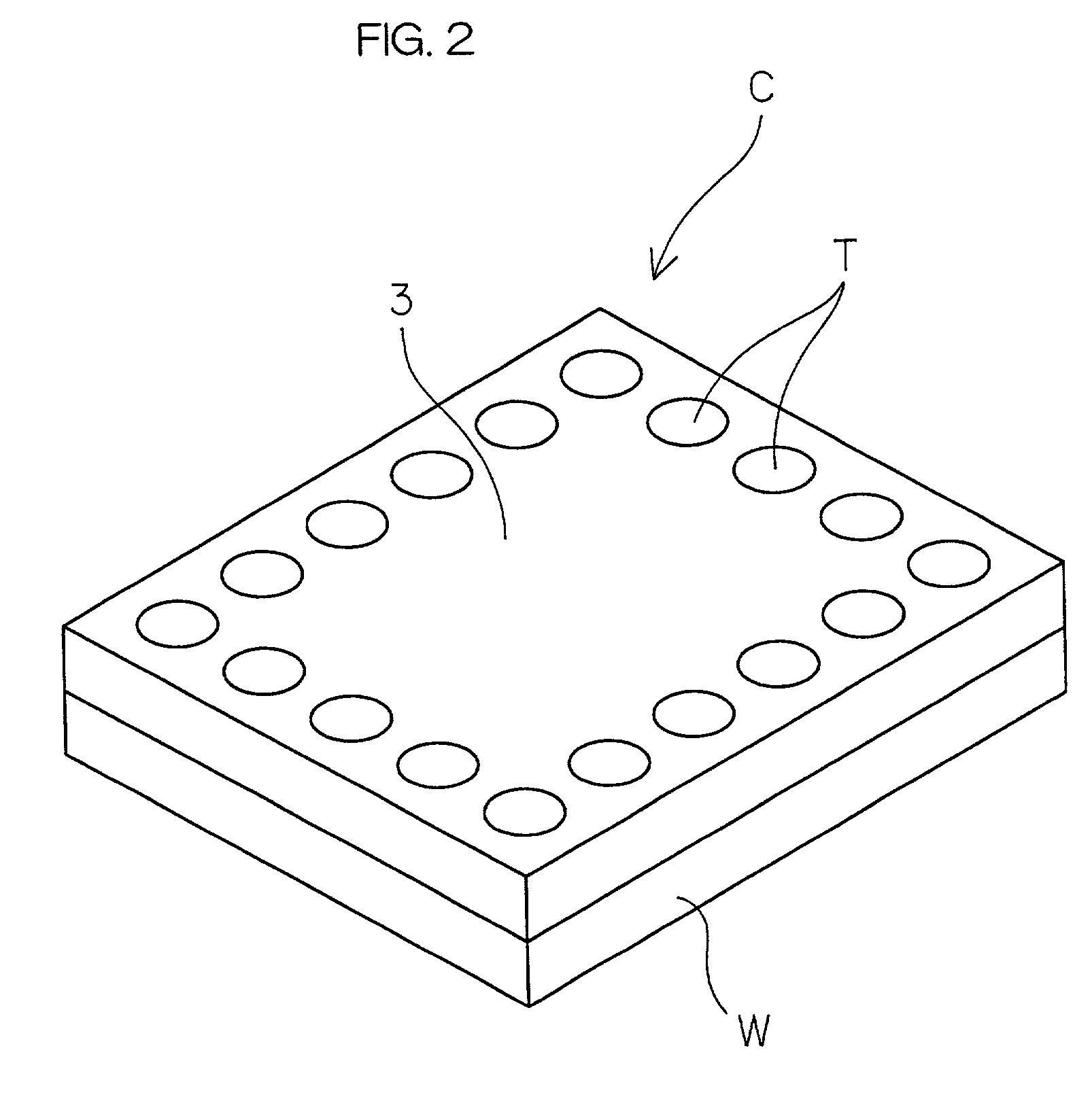

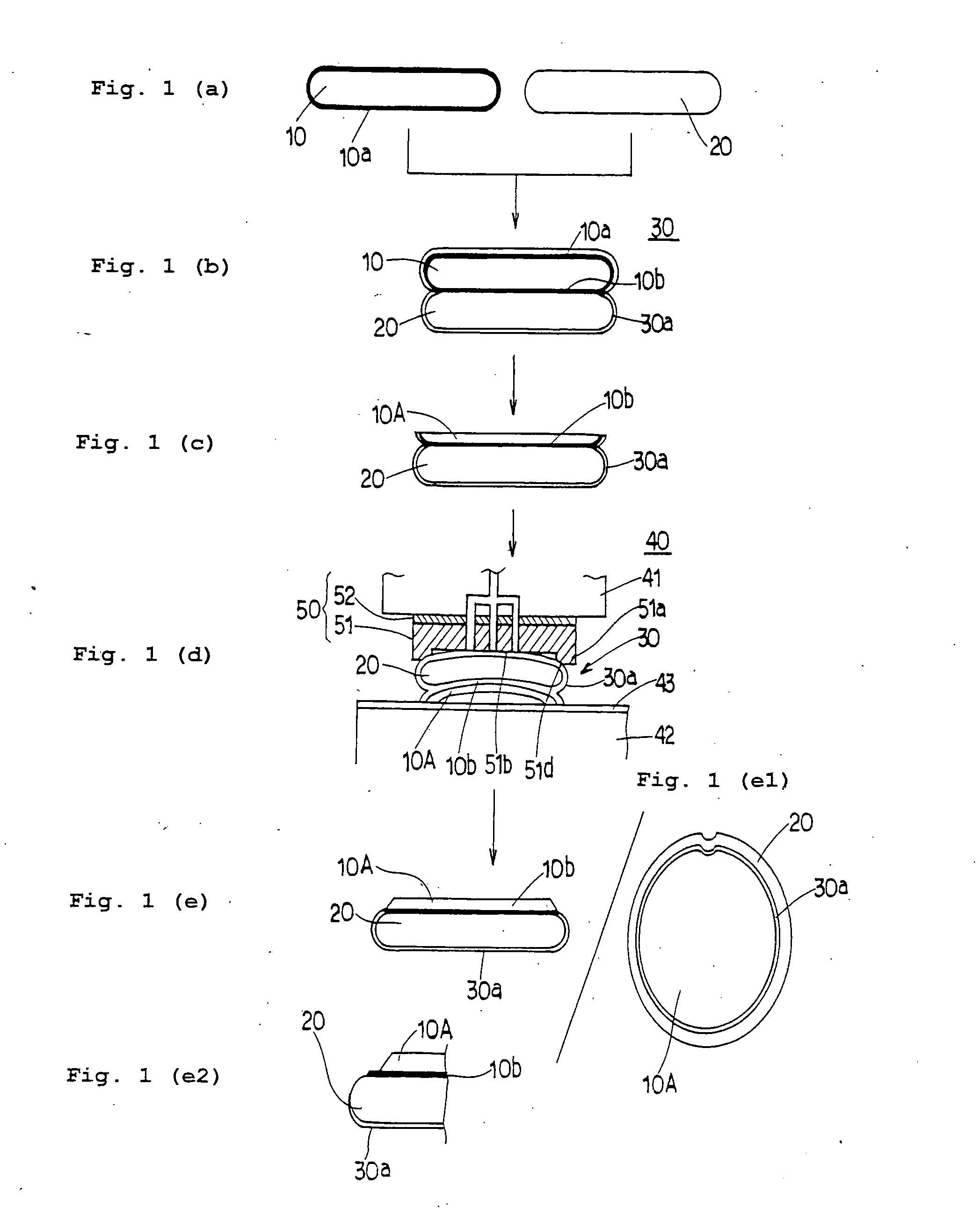

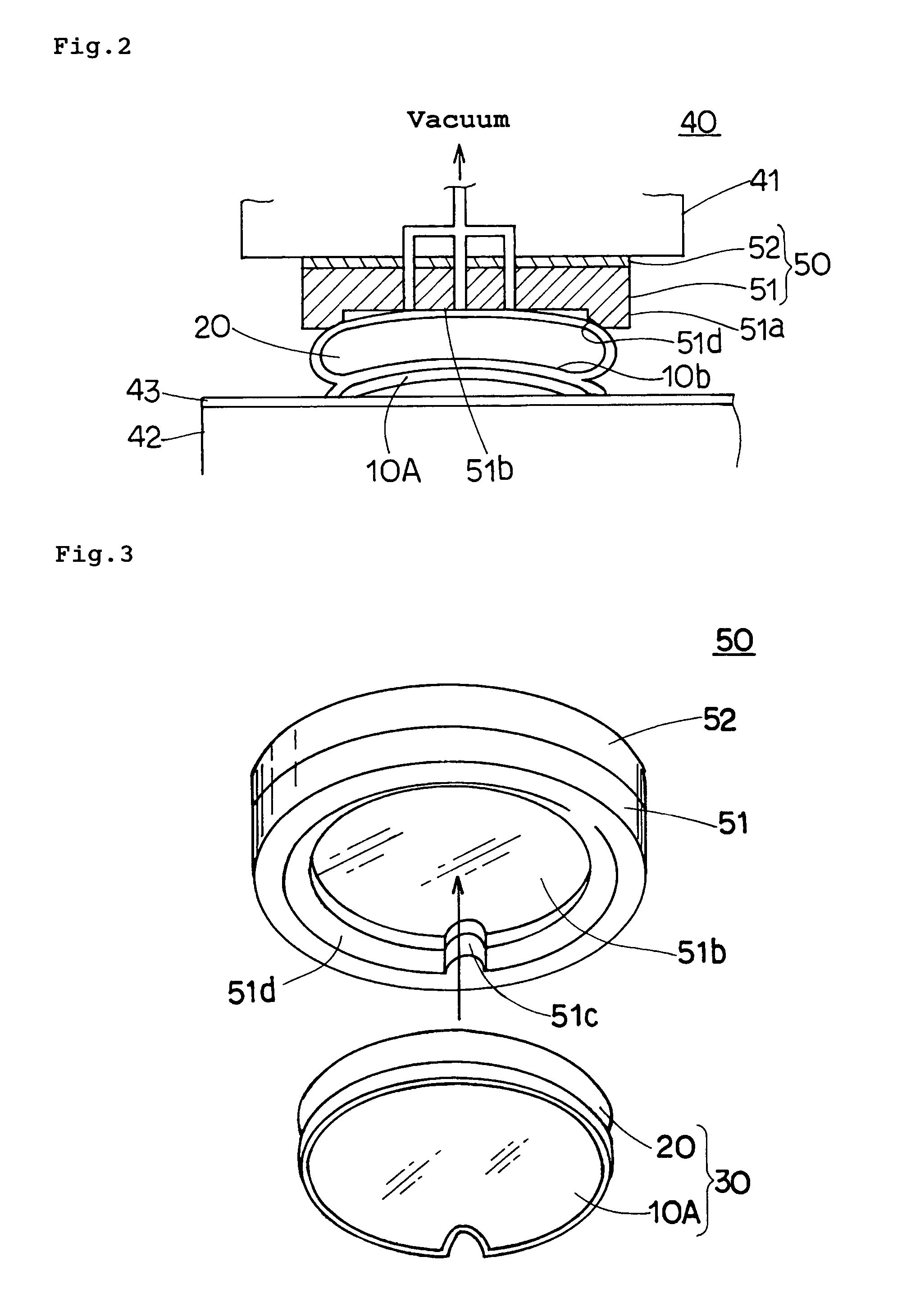

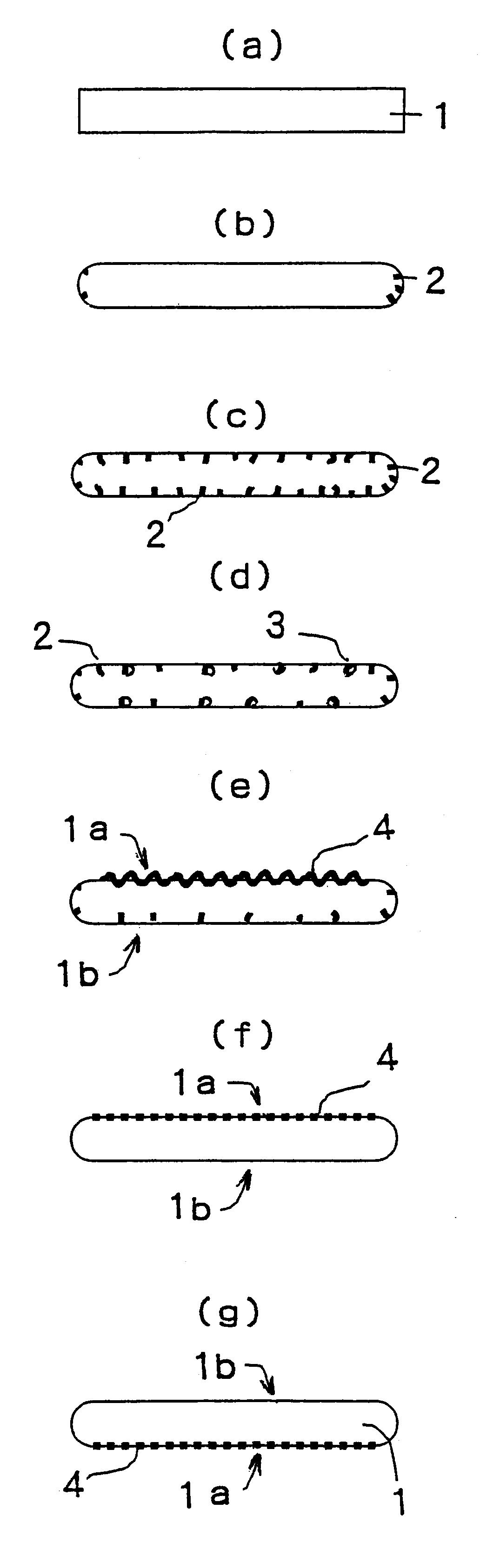

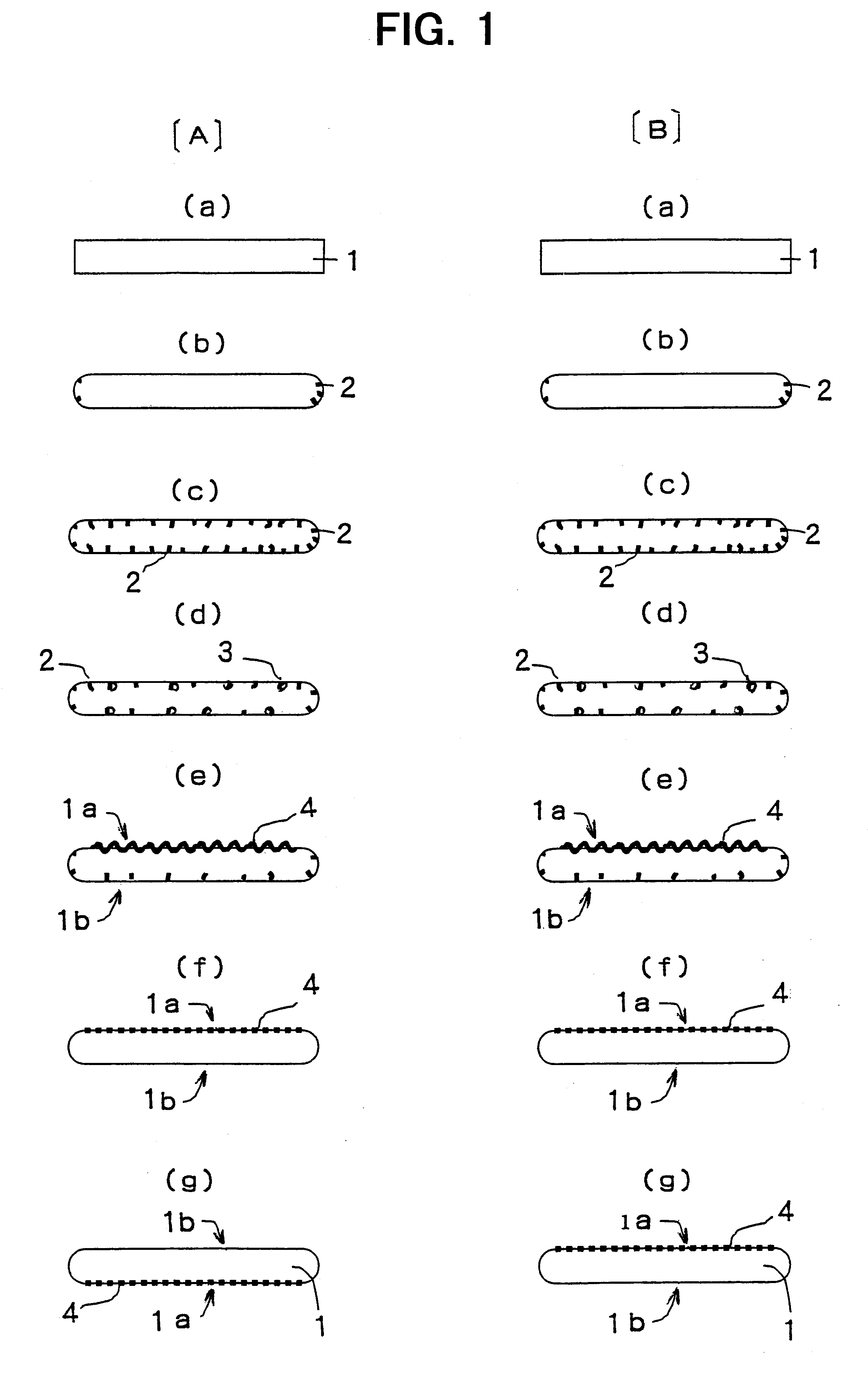

Laminated substrate, method of manufacturing the substrate, and wafer outer periphery pressing jigs used for the method

ActiveUS20050014347A1Reduce in quantityShorten production timeSemiconductor/solid-state device manufacturingWork carriersState of artEtching

Provided are a bonding substrate whose defective bonding portion in a peripheral region of an active layer has been removed by a polishing applied thereto after a surface grinding, a manufacturing method of the same substrate and wafer periphery pressing jigs. After the surface grinding, a periphery removing polishing is applied from an active layer wafer side of a bonding wafer so that a peripheral region of the active layer may be removed and a central region thereof may be left un-removed. Consequently, a periphery grinding and a periphery etching according to the prior art can be eliminated. Furthermore, an etch pit on a circumferential face of a wafer which could be caused by the periphery etching and a contamination or a scratching in an SOI layer which could be caused by a silicon oxide film left un-ground-off can be prevented, thereby achieving high yield and low cost.

Owner:SUMITOMO MITSUBISHI SILICON CORP

Method for machining thin-wall bearing housing part

The invention relates to the field of machining, in particular to a method for machining a thin-wall bearing housing part. The method comprises the following steps that a blank is forged, and a process construction chuck is reserved; rough turning is carried out, wherein the appearance of a workpiece is roughly turned on a common lathe, a ladder hole of the workpiece is roughly turned, stabilizing treatment is carried out, and the internal stress of the workpiece is eliminated; finish turning is carried out, finish turning is carried out on the workpiece on a numerically controlled lathe, the working allowance of 0.9 mm is reserved on the single side of the outer circle and the single side of an inner hole; rough grinding is carried out, wherein the two end faces of the workpiece are ground on a surface grinding machine, and the depth of parallelism between the two end faces is kept within 0.05 mm; rough grinding is carried out, wherein the construction chuck end face of the workpiece is sucked by a suction cup on a universal grinding machine, alignment is carried out according to the outer circle, and the outer circle, the inner hole and the end faces of the workpiece are ground roughly. The machining process is simple, the scheme is simple and practical, clamp design is reasonable, application is convenient, manufacturing cost is low, the part is easy to dismount, the use effect is good, the machining quality of the workpiece can be ensured, workpiece efficiency can be improved, and the method is suitable for batch production of the large-diameter thin-wall part.

Owner:祝云

Semiconductor wafer and method for fabrication thereof

InactiveUS6352927B2Easily causedImprove flatnessSemiconductor/solid-state device manufacturingEngineeringSurface grinding

There is disclosed a semiconductor wafer obtained, at least, by removing a mechanical damage layer by etching both surfaces of the wafer, flattening one of the surfaces by a surface-grinding means, polishing both of the surfaces, and then subjecting a front surface of the wafer to a finishing mirror-polishing when defining the surface subjected to surface-grinding as a back surface of the wafer, and a method for fabricating it. There can be provided a method for fabricating a semiconductor wafer wherein grinding striations which remain on a semiconductor wafer even when double side polishing and finishing mirror-polishing are conducted after a conventional step of surface-grinding of the front surface or the both surfaces, are eliminated to improve quality of the front surface of the wafer, and the back surface having a quality suitable for the device process can be obtained, and a semiconductor wafer obtained thereby.

Owner:SHIN-ETSU HANDOTAI CO LTD

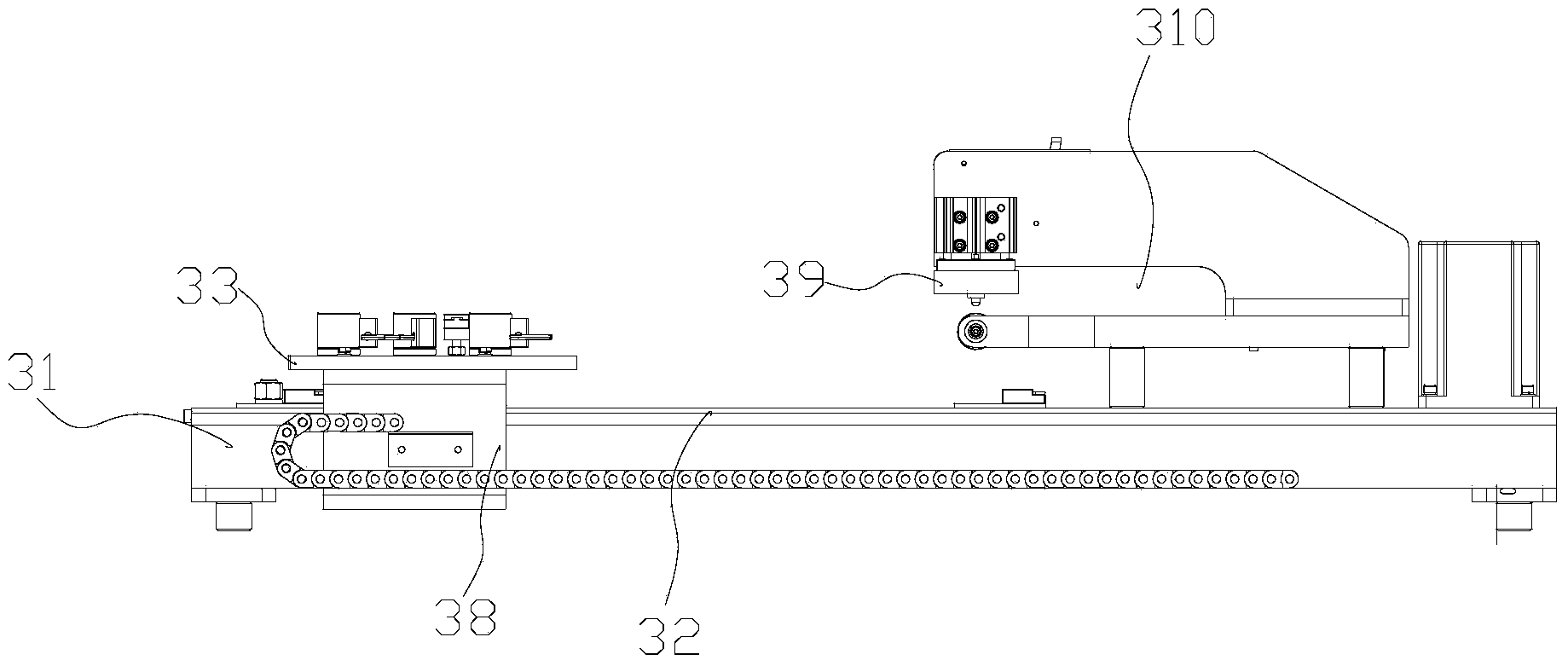

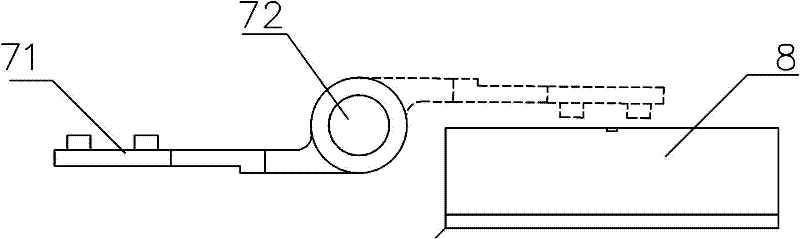

Square tube cutting and end surface grinding integrated equipment

InactiveCN110421356ADisadvantages of realizing that it cannot be completed at one timeWork clamping meansOther manufacturing equipments/toolsCircular sawEngineering

The invention relates to the field of cutting and grinding machines, in particular to square tube cutting and end surface grinding integrated equipment. The equipment comprises a feeding component, acutting component and an end grinding component, wherein the end grinding component comprises a rotary table and two grinding mechanisms symmetrically arranged on the two sides of the rotary table, the feeding component comprises a first fixed clamp and a movable clamp, the cutting component comprises a movable base and a circular saw blade, an angle adjusting mechanism connected with a free end of a supporting arm is arranged at the top of the movable base, a horizontal pushing air cylinder is arranged at the top of the starting end of the feeding component in a horizontal state, the horizontal pushing air cylinder, the first fixed clamp, the movable clamp and the rotary table are linearly arranged in sequence, and a second fixed clamp is arranged on the top of the rotary table. Accordingto the square tube cutting and end surface grinding integrated equipment, the cutting component carries out cutting on a square tube, and the end grinding component carries out grinding on the squaretube, so that the cutting and end surface grinding integrated equipment is realized, and a large amount of manpower and financial resources are reduced.

Owner:吴丽平

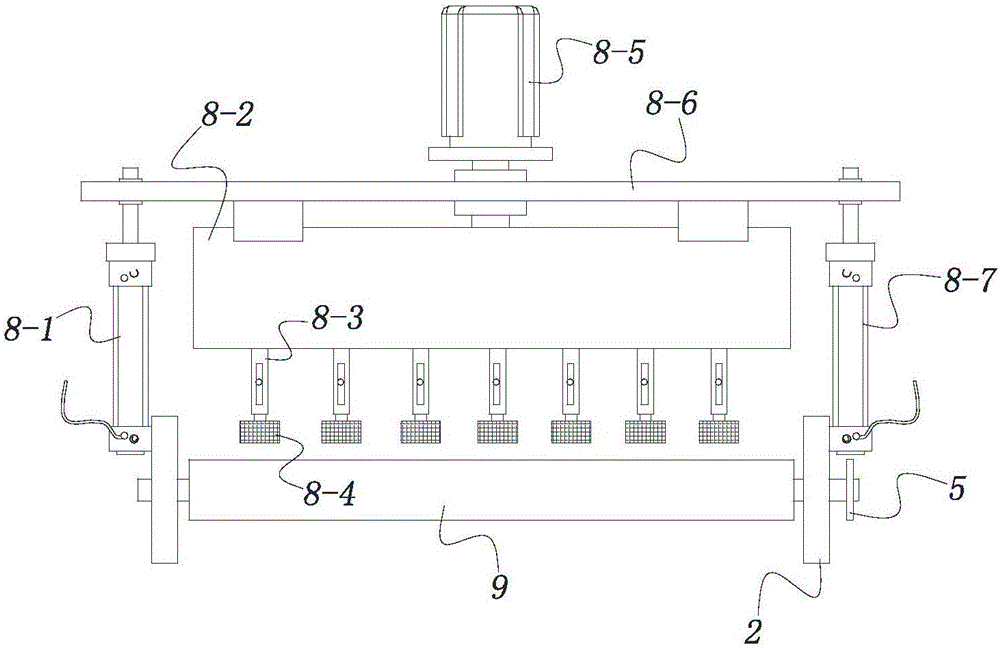

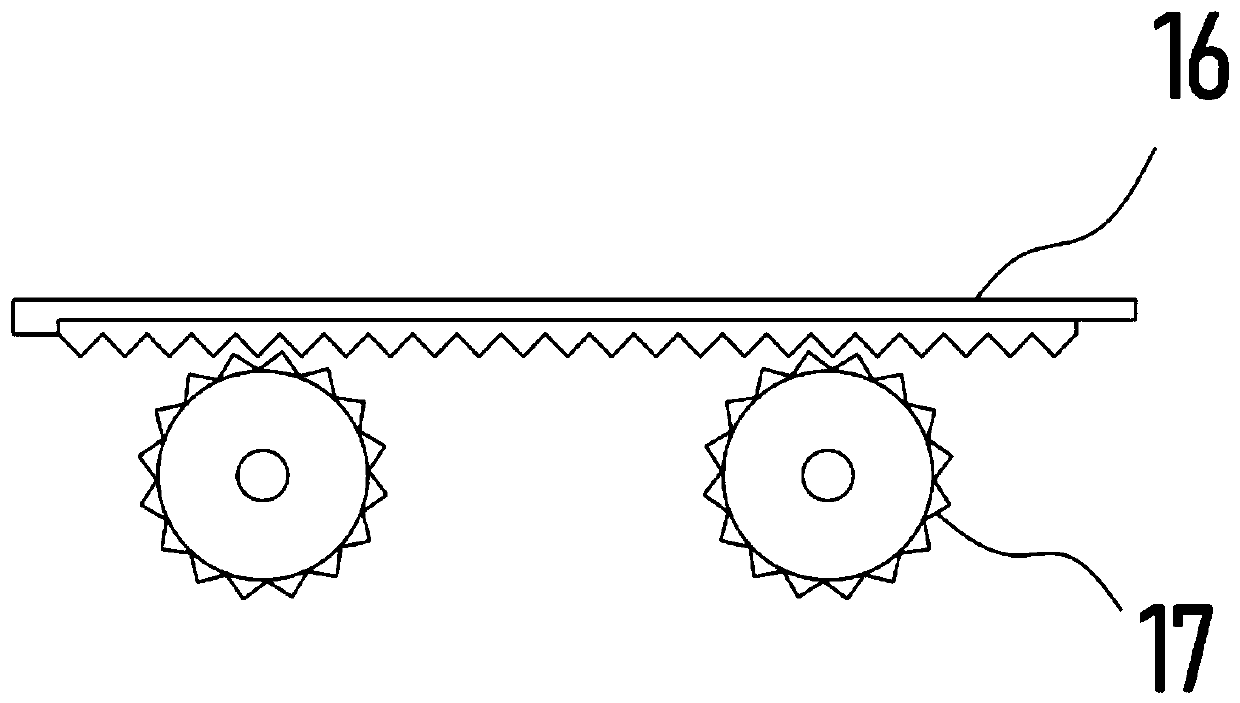

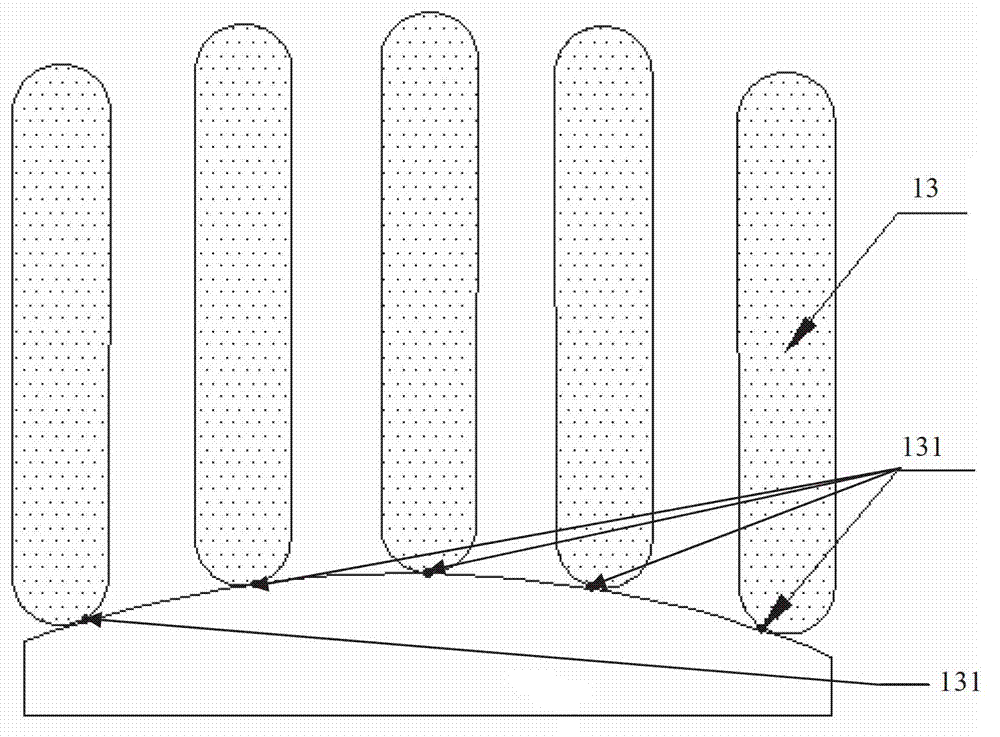

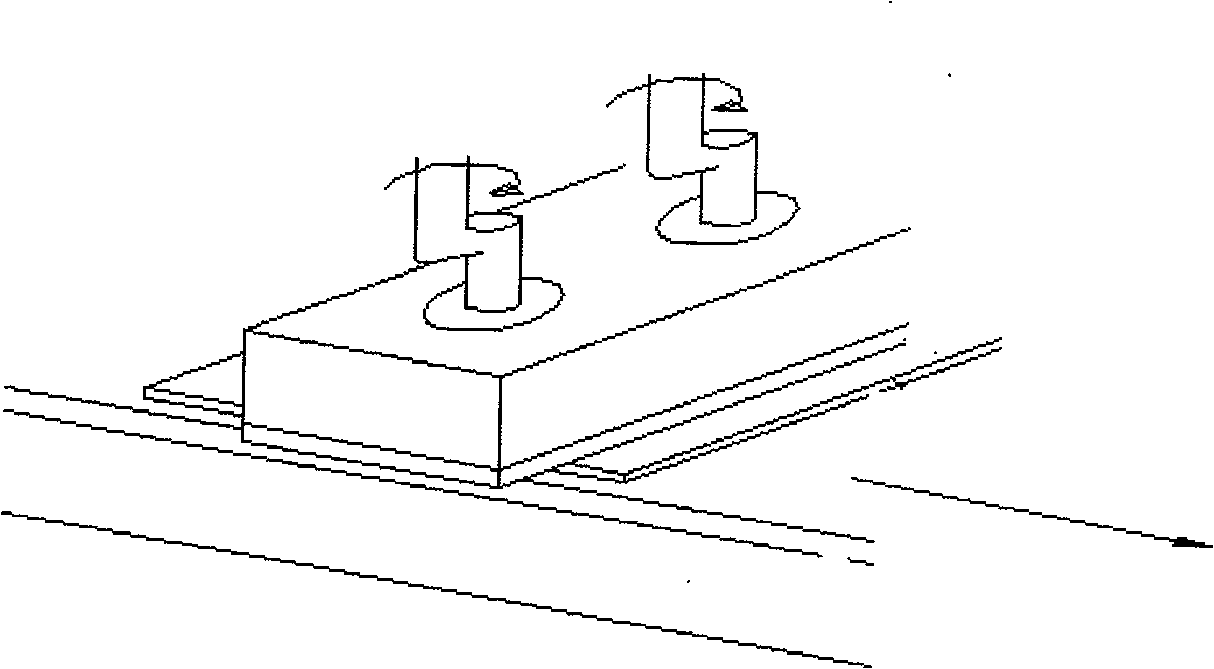

Plate surface grinding equipment

InactiveCN105127851ASimple structural designHigh degree of automationGrinding drivesAutomatic grinding controlHydraulic cylinderSprocket

The invention relates to plate surface grinding equipment. The plate surface grinding equipment is composed of a front lateral plate and a rear lateral plate which are supported by vertical pillars and arranged oppositely. A plurality of carrier rollers at the same height are erected between the two lateral plates in the length direction. Driven sprockets are arranged at the ends, on the same side, of all carrier roller core shafts. A cross beam is fixedly connected with one of the vertical pillars, and a speed reducer used for driving the driven sprockets to rotate synchronously is installed on the cross beam. A grinding mechanism is installed between the middles of the two lateral plates and comprises a first hydraulic cylinder and a second hydraulic cylinder vertically and fixedly installed in the middles of the two lateral plates respectively. A lifting plate is erected between the upper ends of pistons of the two hydraulic cylinders, a shaft sleeve is arranged in the middle of the lifting plate, a single-input and multi-output gearbox is fixedly installed at the bottom of the lifting plate, and an input shaft of the gearbox is located in the shaft sleeve. The plate surface grinding equipment further comprises a motor used for driving the input shaft, output shafts fall into a front row and a rear row, the intervals between the output shafts in each row are the same, the output shafts of the two rows are arranged in a staggered mode, and grinding heads are installed at the bottoms of all the output shafts.

Owner:天津市帝标建材有限公司

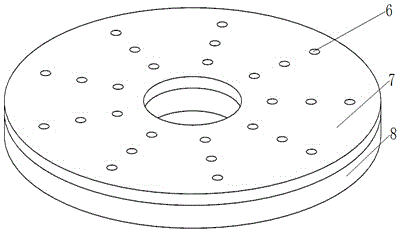

Semiconductor substrate planarization apparatus and planarization method

InactiveUS20110165823A1Easy to polishUniform film thickness distributionEdge grinding machinesPolishing machinesEngineeringSurface grinding

A planarization apparatus and method that thins and planarizes a substrate by grinding and polishing the rear surface of the substrate with high throughput, and that fabricates a semiconductor substrate with reduced adhered contaminants. A planarization apparatus that houses various mechanism elements in semiconductor substrate loading / unloading stage chamber, a rear-surface polishing stage chamber, and a rear-surface grinding stage chamber. The throughput time of the rear-surface polishing stage that simultaneously polishes two substrates is typically about double the throughput time of the rear-surface grinding stage that grinds one substrate.

Owner:OKAMOTO MACHINE TOOL WORKS LTD

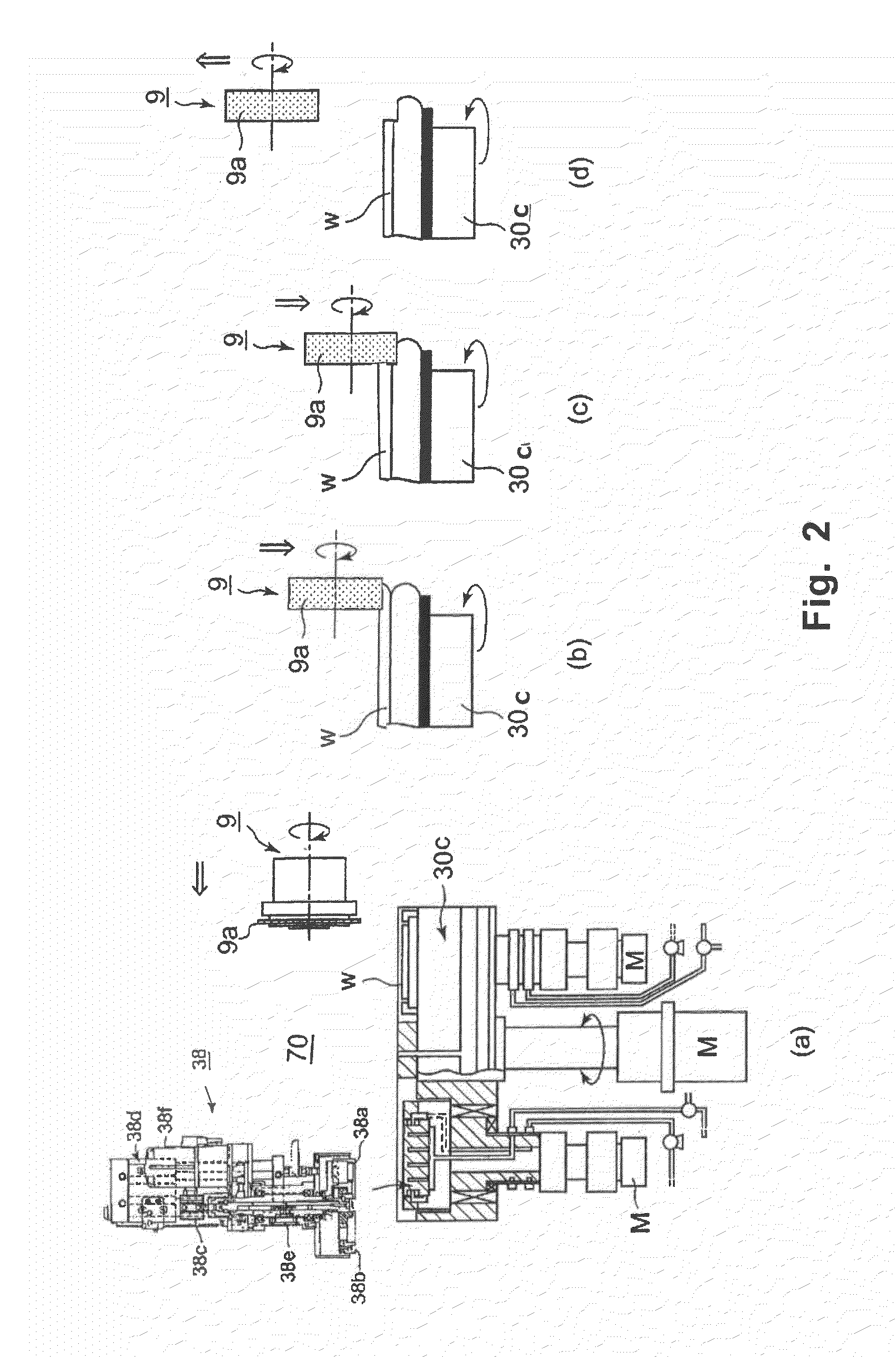

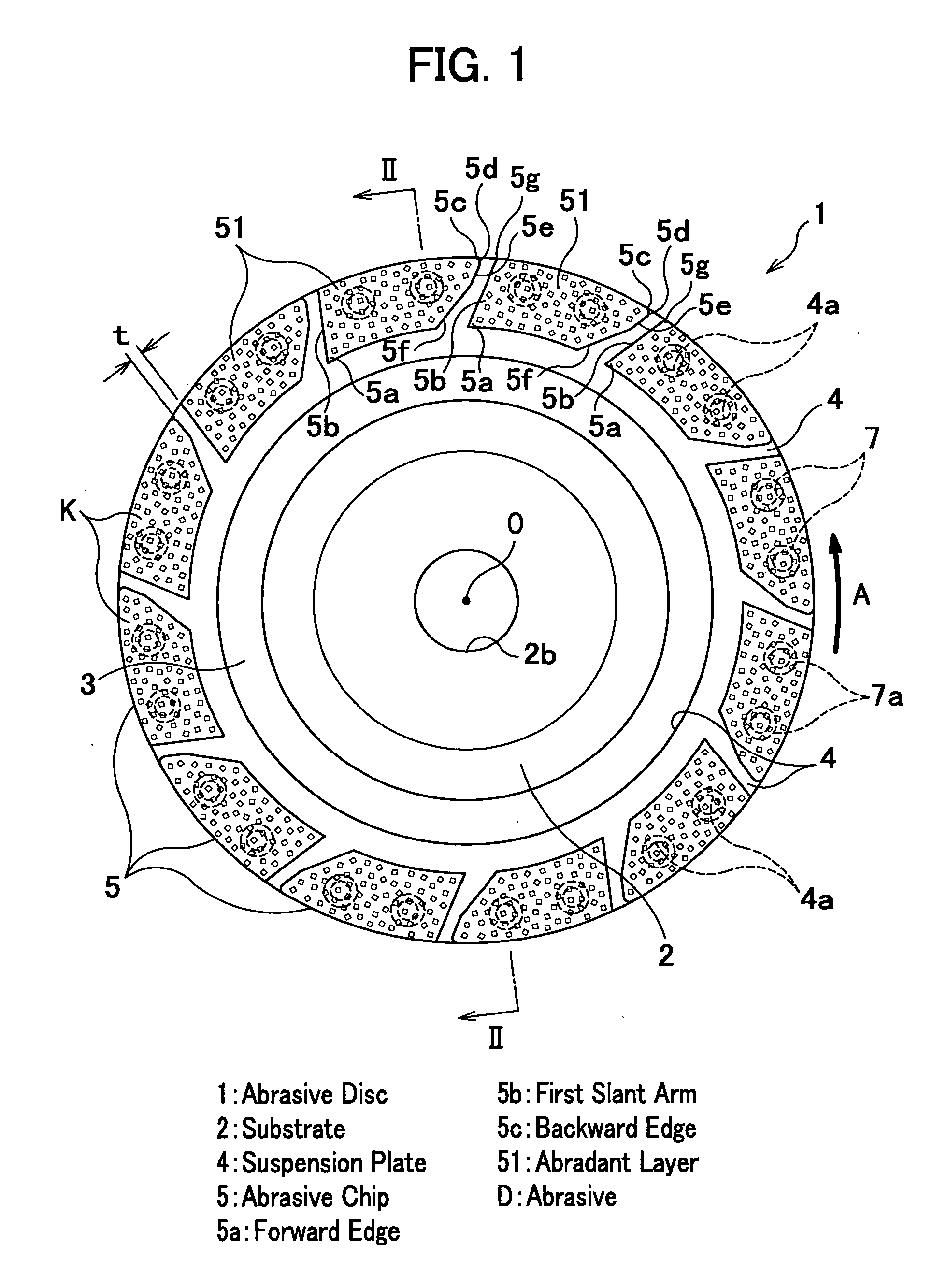

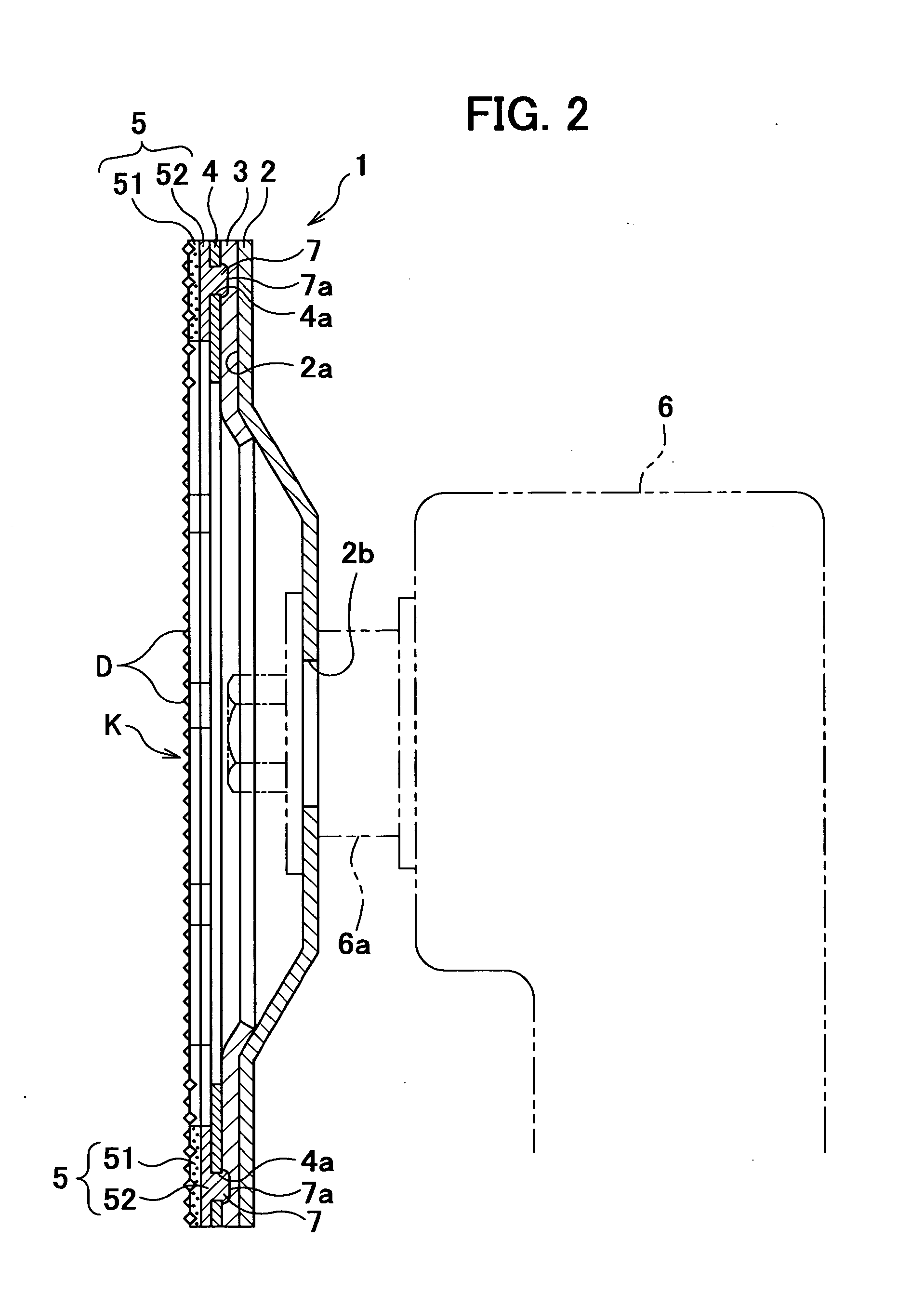

Abrasive disc

InactiveUS20060211353A1Maintain strengthEasy to removeEdge grinding machinesRevolution surface grinding machinesFiberSurface grinding

An abrasive disc which has plural abrasive chips having an abrasive layer on a metal piece and being arranged in a peripheral portion of a disc substrate with a predetermined space comprises a suspension plate placed between the disc substrate and abrasive chips and an elastic sheet placed between the disc substrate and the suspension plate, wherein the disc substrate consists of a plastic resin including fiber, the abrasive chips have stakes therein and the suspension plate has through-holes to which the stakes are deformed therein. Each of the abrasive chips has abrasive surfaces including a top abrasive surface and peripheral surfaces and the outer peripheral portion and the inner peripheral portion are declined to the top surface. The abrasive discs have a combination of different abrasive chips fabricated by different bonding metals for the fabrication of the abrasive chips.

Owner:GOEI

Basketball stand backboard surface grinding device

InactiveCN109732421AAchieve rotary grindingAchieve grindingGrinding drivesGrinding work supportsReciprocating motionEngineering

The invention discloses a basketball stand backboard surface grinding device, and relates to the technical field of backboard machining. The basketball stand backboard surface grinding device comprises a supporting frame, a movable frame is slidably mounted on the supporting frame, clamping blocks used for clamping the backboard are symmetrically arranged on the movable frame, the top of the supporting frame is fixedly provided with an operation box, the supporting frame is fixedly provided with a double-shaft motor, and one output shaft is coaxially and fixedly provided with an incomplete bevel gear meshed with a bevel gear I or a bevel gear II. According to the grinding device, a grinding plate rotates along with a rotating shaft, so that rotary grinding of the surface of the backboard can be realized, meanwhile, the grinding plate can perform transverse reciprocating motion, so that the grinding effect of the backboard is further promoted, the grinding range is wider; and an incomplete gear is arranged to be alternately meshed with two inner racks to achieve reciprocating movement of the movable frame, so that the backboard on the movable frame can move in a reciprocating mode,and the movement direction is perpendicular to the translation direction of the grinding plate, therefore the grinding efficiency is greatly improved, and comprehensive grinding of the backboard is realized.

Owner:李智伟

Ultra-precise processing integrated platform for large caliber optical mirror surface

ActiveCN102756316AEasy to moveAchieve multi-axis ultra-precision grindingOptical surface grinding machinesOptical processingSurface grinding

An ultra-precise processing integrated platform for a large caliber optical mirror surface solves the problem that processing and detection are not integrated while processing the large caliber optical mirror surface in the conventional optical processing technical field. The platform integrates grinding, detection and milling for processing the large caliber optical mirror surface, and comprises a base, a horizontal moving device, a rotation device, an ultra-precise grinding device, a mirror surface detection device and a milling device, wherein the horizontal moving device drives the rotation device to move to a workpiece mounting position, a grinding position, a surface shape detection position and a milling position in a horizontal direction; a vertical moving device drives a spindle system and a diamond grinding wheel to move up and down in a vertical direction; the spindle system can adjust the inclined angle of the diamond grinding wheel; the diamond grinding wheel has a cambered surface; when in the workpiece mounting position, the rotation device can conduct cambered surface grinding on a workpiece; when in the surface shape detection position, the rotation device can conduct surface shape detection on the workpiece; when in the surface shape detection position, the rotation device can mill the workpiece.

Owner:SHANGHAI JIAO TONG UNIV

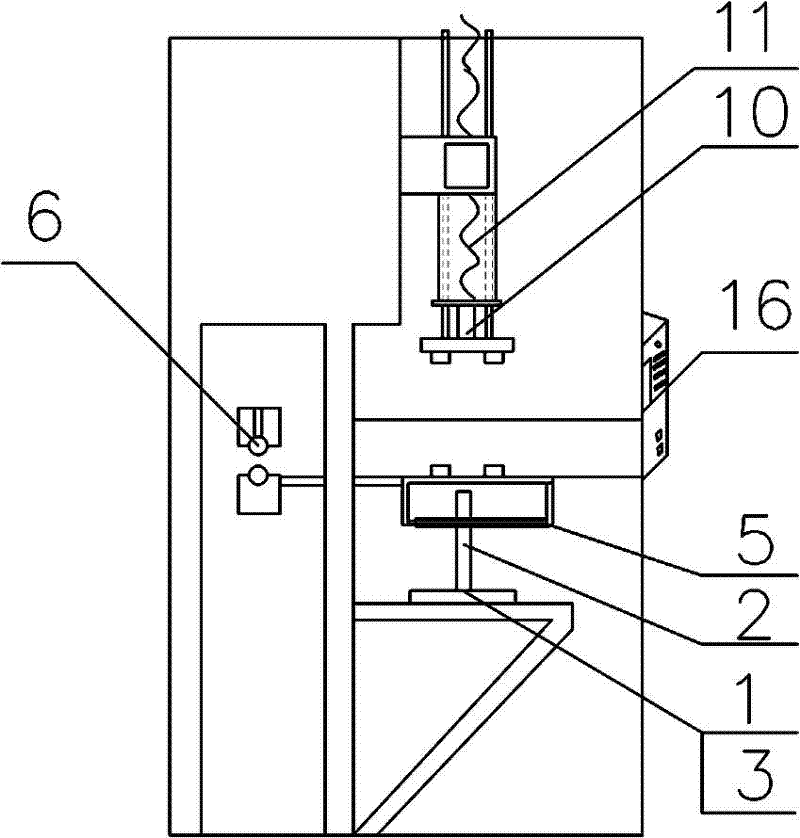

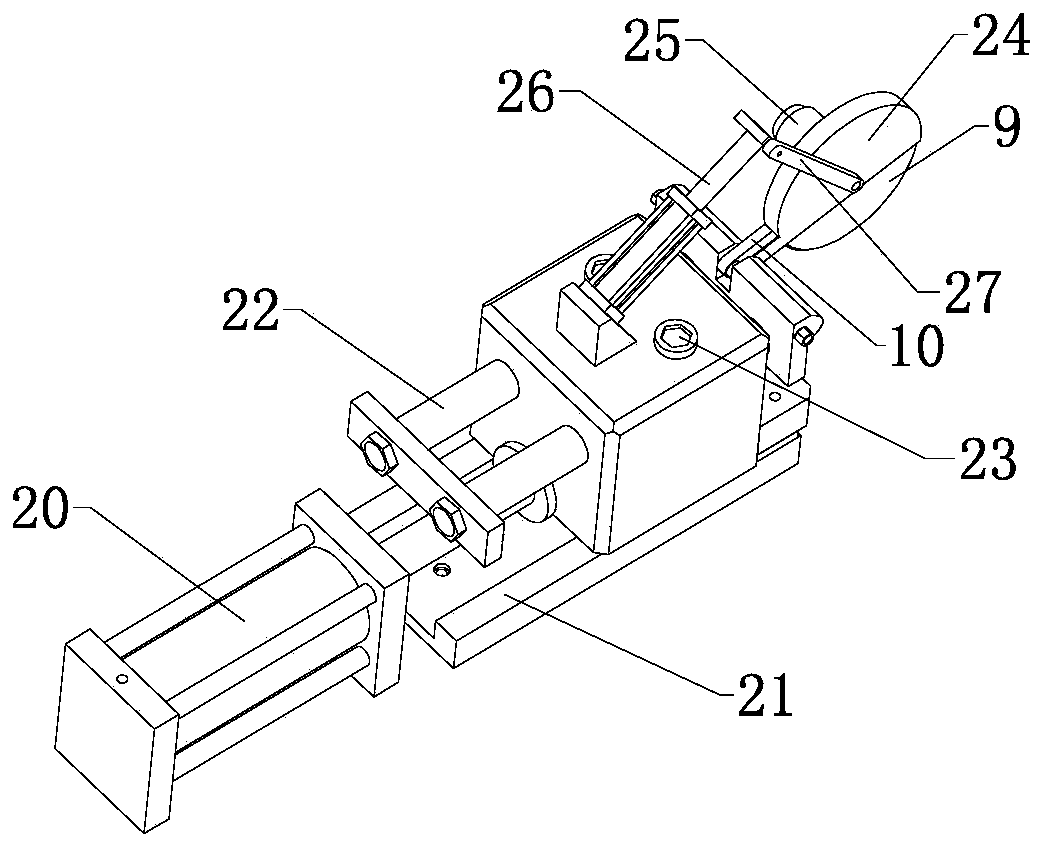

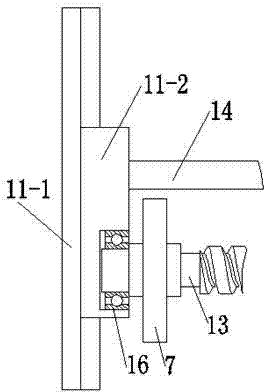

Diamond tool bit bottom surface grinding device

ActiveCN103331488AEasy to produceLabor savingSawing tools dressing arrangementsDrilling toolsTool bitSurface grinding

The invention provides a diamond tool bit bottom surface grinding device, which belongs to the technical field of the operation. The problem that the traditional diamond tool bit bottom surface grinding has low production efficiency because of grinding by a common machine tool is solved. The diamond tool bit bottom surface grinding device comprises a rack, wherein the rack is provided with a first grinding mechanism, a transfer discrimination mechanism and a second grinding mechanism, wherein the first grinding mechanism can be used for grinding the certain end surface of a diamond tool bit into a bright surface; the transfer discrimination mechanism can be used for transferring out the diamond tool bit capable of grinding the certain end surface of the diamond tool bit into the bright surface, can be used for judging whether the bright surface is positioned on the bottom surface or a tool surface and enables the diamond tool bit to face to the same direction according to the judgment result; and the second grinding mechanism can be used for bearing the diamond tool bit with the same facing direction of the transfer discrimination mechanism and can be used for grinding the diamond tool bit bottom surface. The diamond tool bit bottom surface grinding device has the advantages of convenience in production, labor force saving, high automation degree and high efficiency. According to the test, the diamond tool bit bottom surface grinding device can be used for grinding ten diamond tool bit bottom surfaces in one minute.

Owner:ZHEJIANG BANNINGER FLUID CONTROL CO LTD

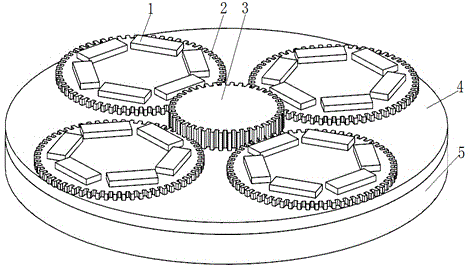

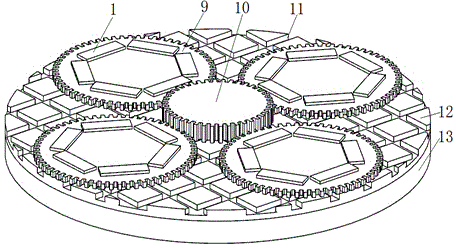

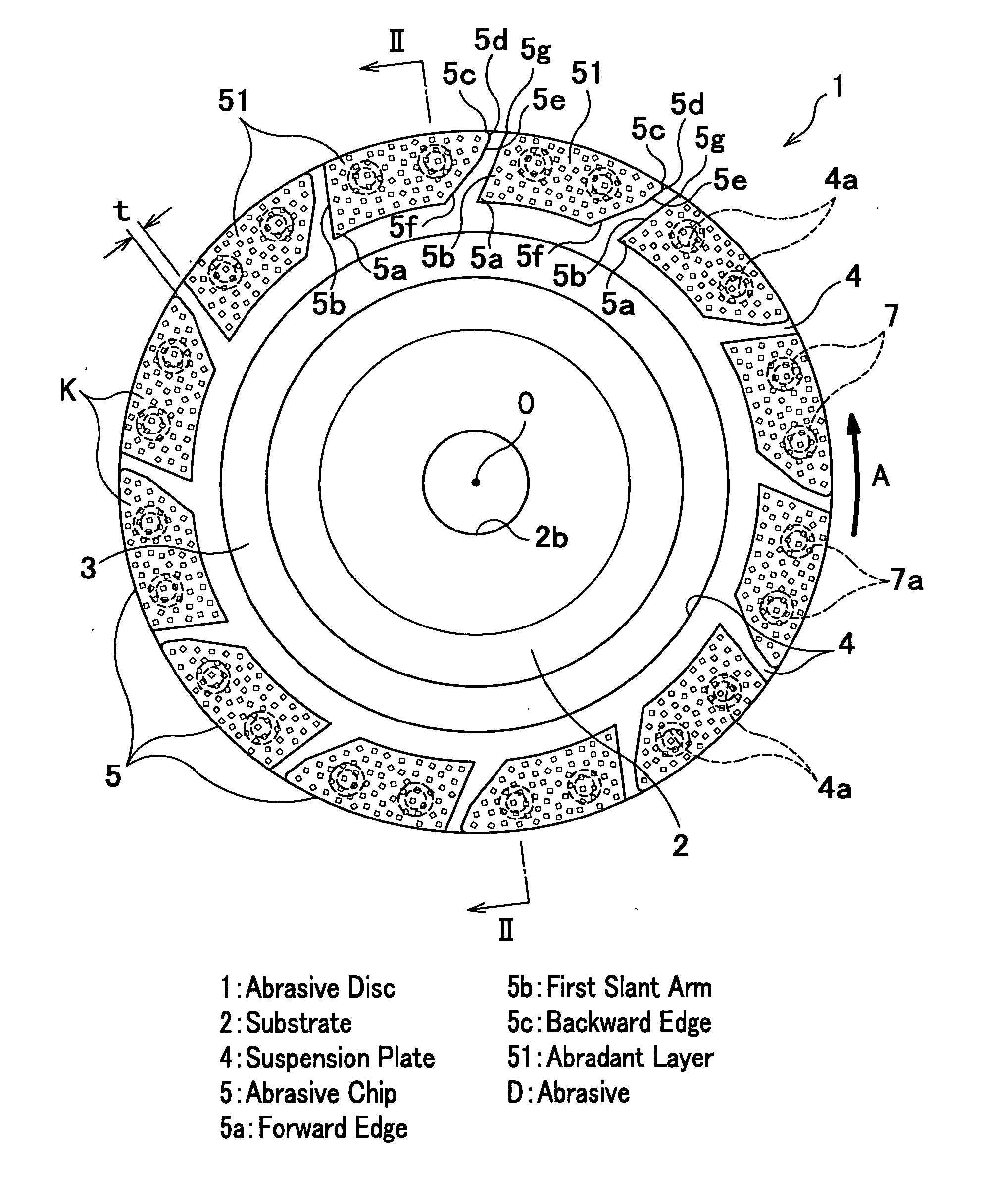

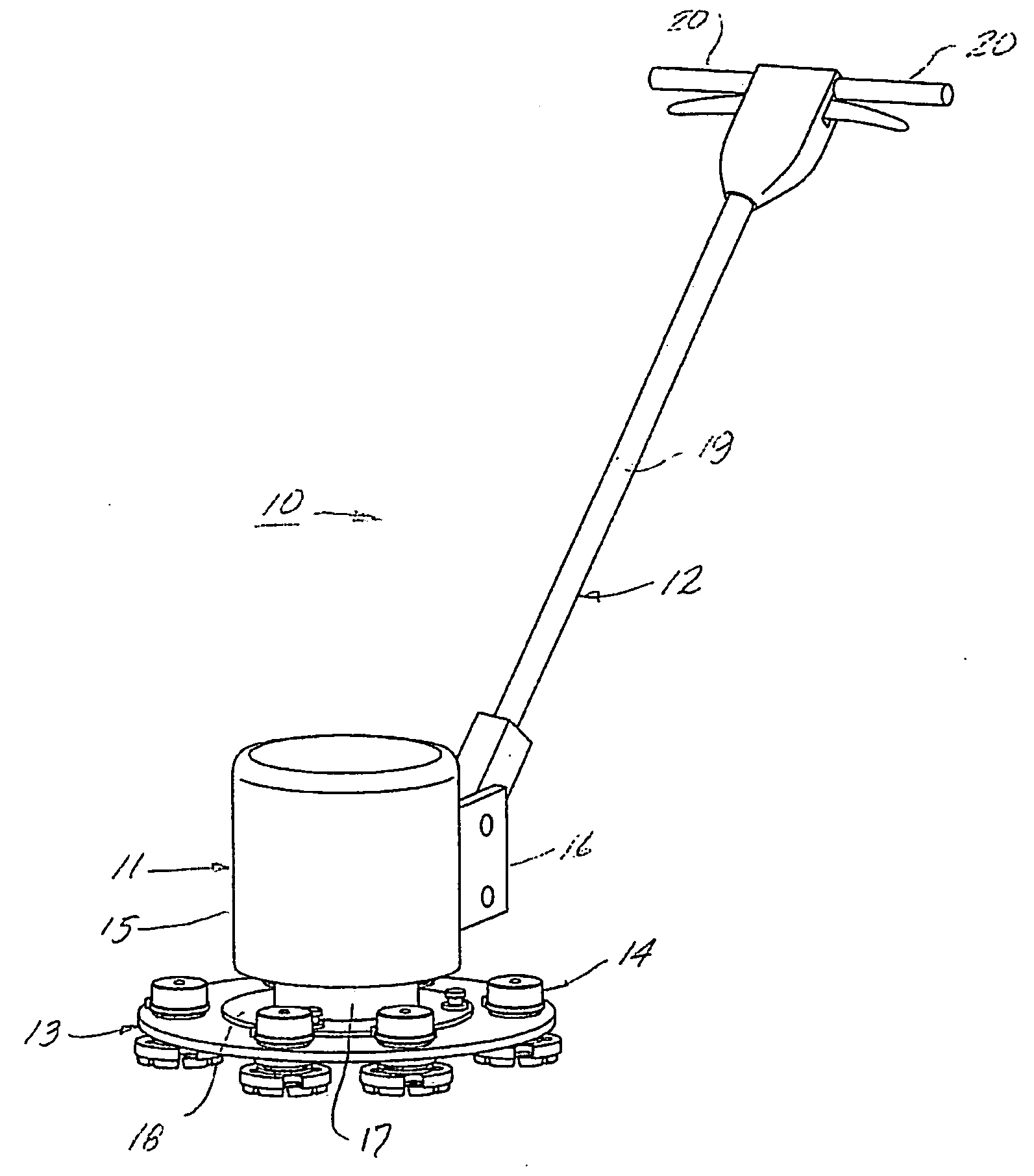

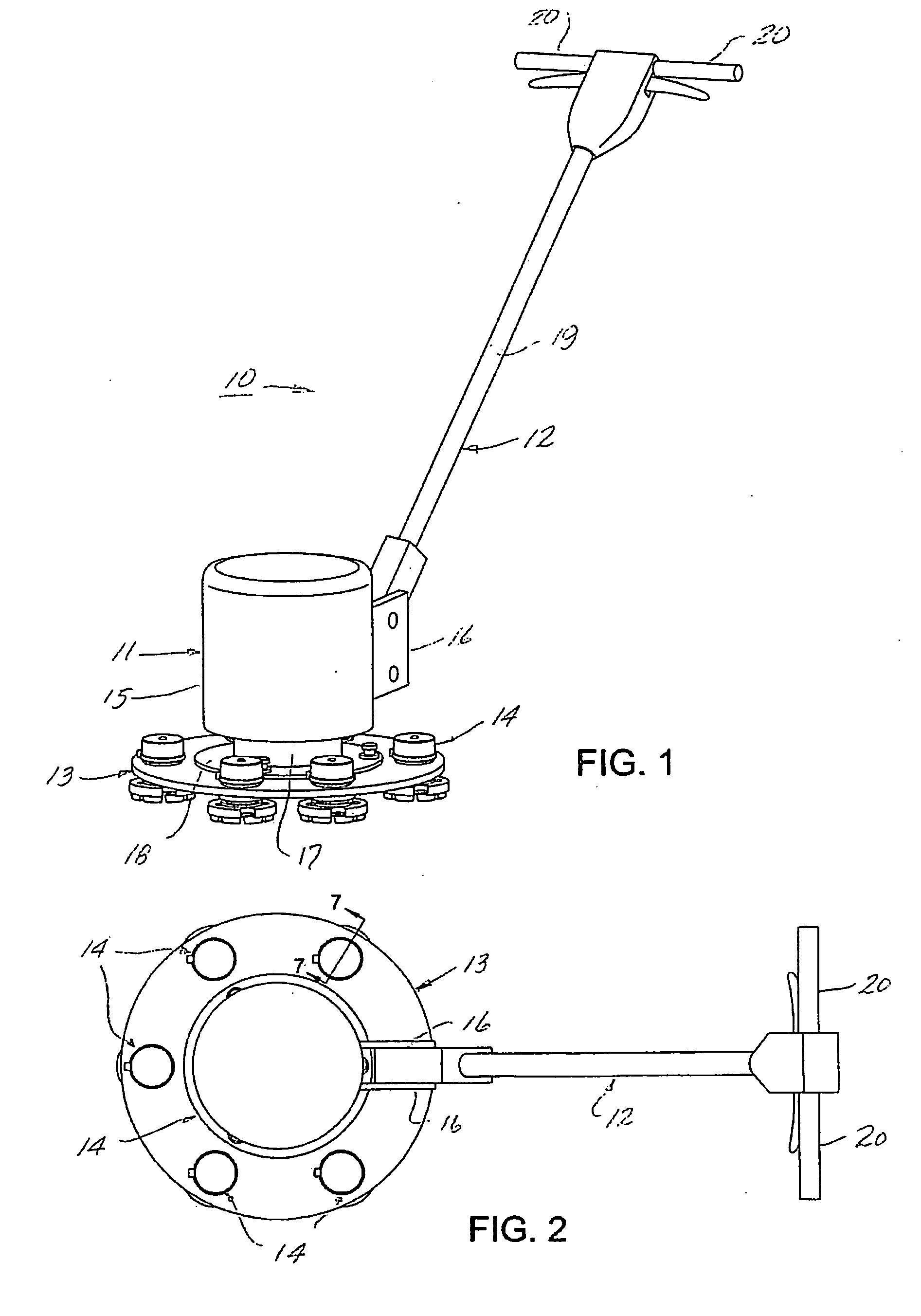

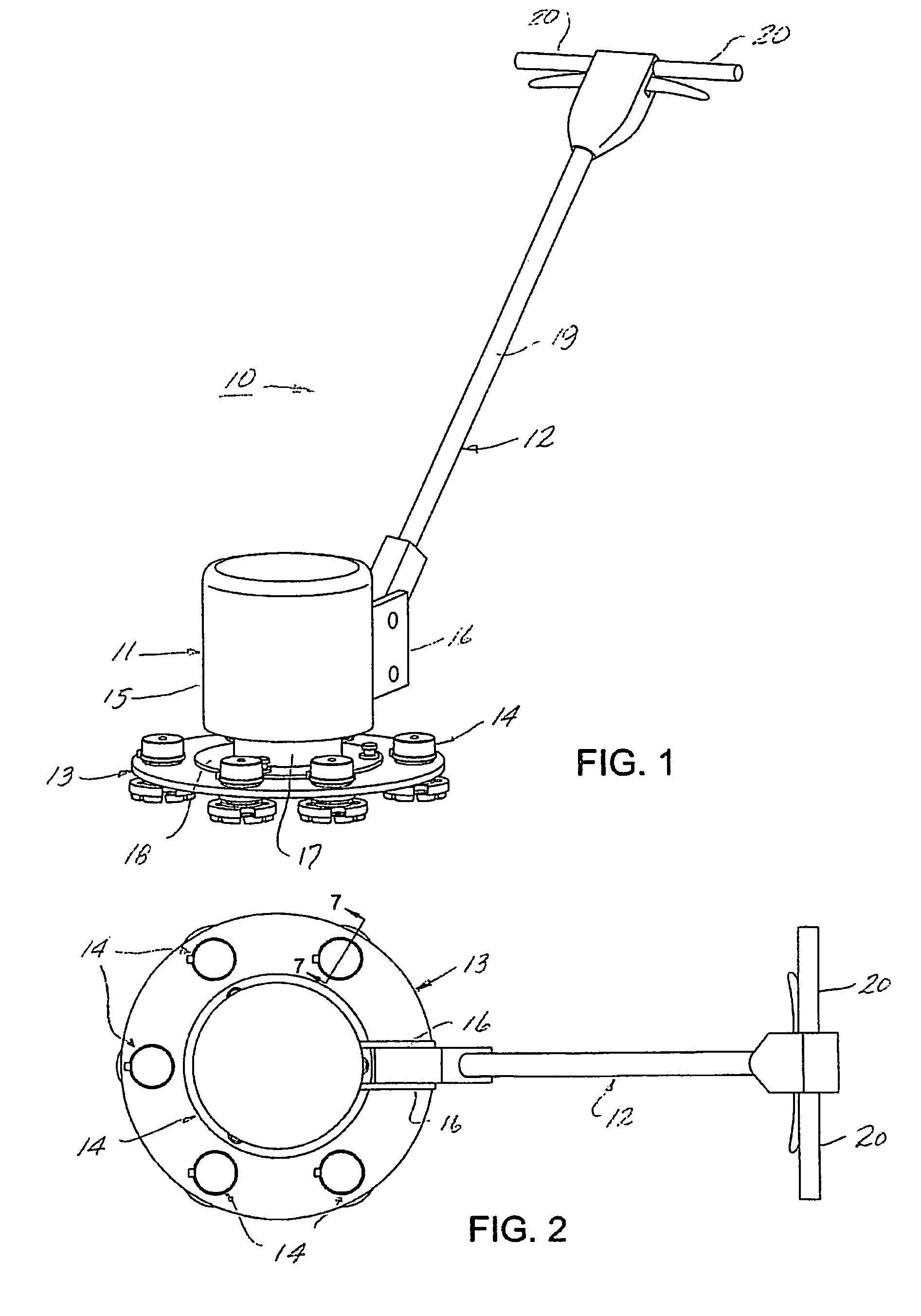

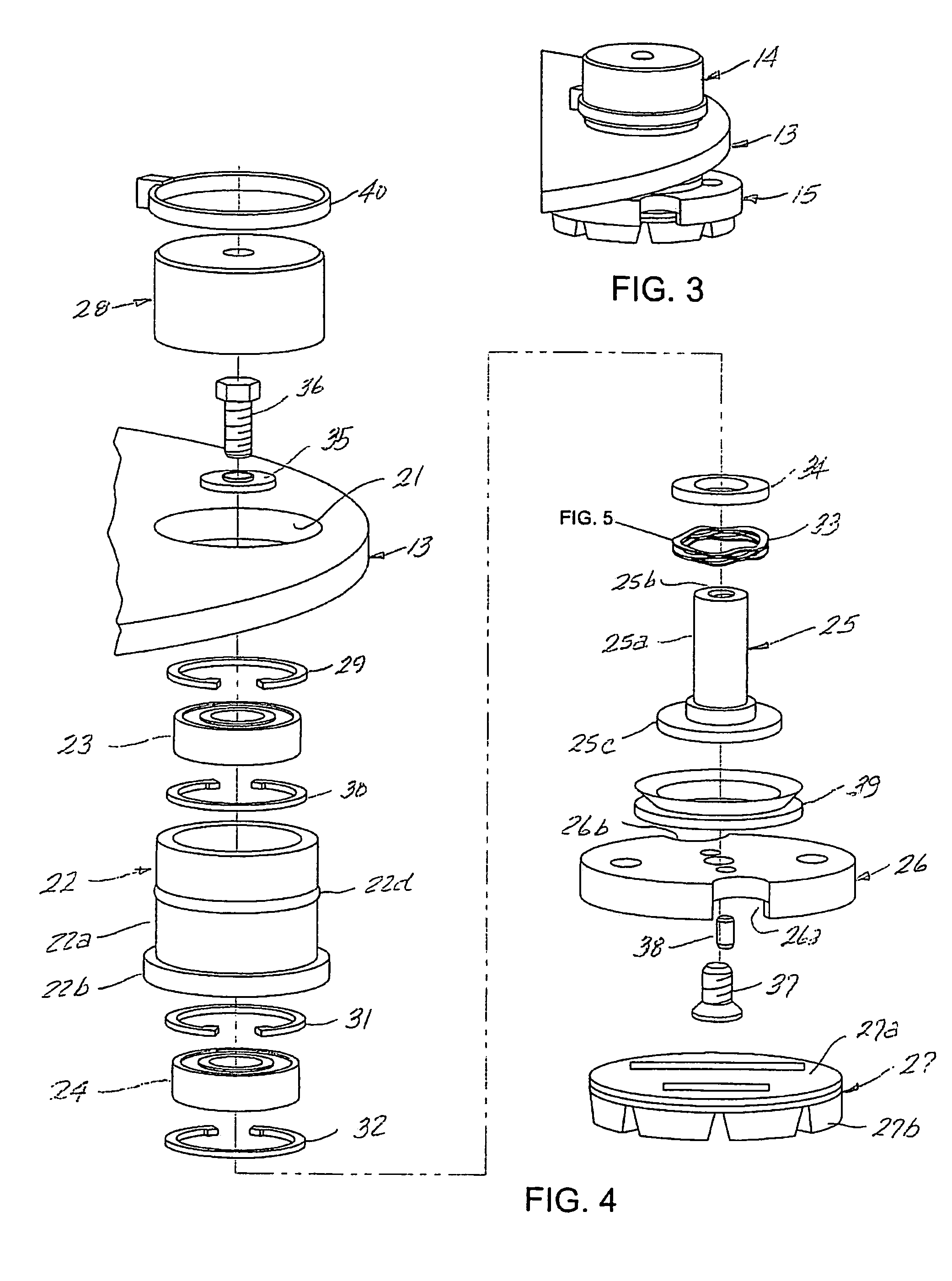

Surface Grinding Machine and Grinding Head Therefor

InactiveUS20100190421A1Edge grinding machinesRevolution surface grinding machinesEngineeringSurface grinding

A surface grinding machine generally consisting of a drive means provided with an output shaft; a planetary disk mounted on the shaft; and at least two grinding head units mounted on the planetary disk, each including a housing mounted on the planetary disk, a shaft having a flange portion, journaled in the unit housing, resilient means interposed between the housing and the flange portion of the unit shaft and a disk provided with a grit surface disposed on an outer side of the flange, portion of the unit shaft.

Owner:AMANO PIONEER ECLIPSE CORP

Wafer dividing method

InactiveUS20080280421A1Small thicknessFormed surelySolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeEngineering

A wafer dividing method that includes a modifying layer forming step in which a laser beam with a wavelength that can pass through the wafer is focused on the inside of the wafer from a rear surface side thereof, and applied along the street to form a modifying layer having a thickness corresponding to at least a device-finishing thickness from the front surface of the wafer; a rear surface grinding step in which an area, corresponding to the device area, of the rear surface of the wafer subjected to the modifying layer forming step is ground and formed to have a thickness corresponding to the device-finishing thickness and to have an annular reinforcing section at an area corresponding to the outer circumferential redundant area; a reinforcing section cutting step in which the wafer is cut along the inner circumference of the annular reinforcing section; a wafer support step in which the rear surface of the wafer whose annular reinforcing section is cut is stuck to a dicing tape attached to an annular frame; and a wafer rupture step in which an external force is applied to the wafer stuck to the dicing tape to rupture it along the street formed with the modifying layer.

Owner:DISCO CORP

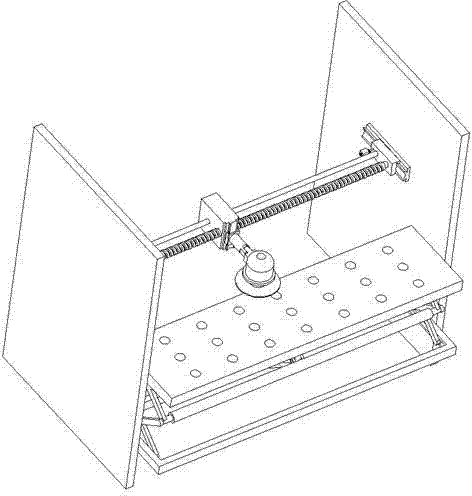

Panel surface grinding device and grinding method with multi-degree of freedom

ActiveCN104723185ARealize multi-degree-of-freedom grindingImprove grinding limitationsGrinding drivesPlane surface grinding machinesMulti degree of freedomEngineering

The invention relates to a panel surface grinding device and grinding method with multi-degree of freedom. The panel surface grinding device with the multi-degree of freedom comprises a left side plate and a right side plate, a transmission mechanism, a driving mechanism, a grinding mechanism and a lifting table mechanism; the transmission mechanism and the lifting table mechanism are both fixedly connected with the inner sides of the left side plate and the right side plate, and the driving mechanism and the grinding mechanism are connected with the transmission mechanism. By means of the adjustment of the mechanisms, position adjustment is achieved in the directions of X, Y and Z; by means of own characteristics of an articulated mechanism, and the adjustment of different grinding angles on a panel surface is achieved. The grinding direction can be adjusted according to the own characteristics of products and the grinding requirements, the grinding direction is adjusted, the grinding of a panel with the multi-degree of freedom is achieved, the grinding limitation of an existing automatic grinder is improved, manual operation is replaced by automatic processing by using a machine, the labor intensity of workers is relieved, the production efficiency is improved, and the production quality of the products is guaranteed.

Owner:安徽金大进重工机床有限公司

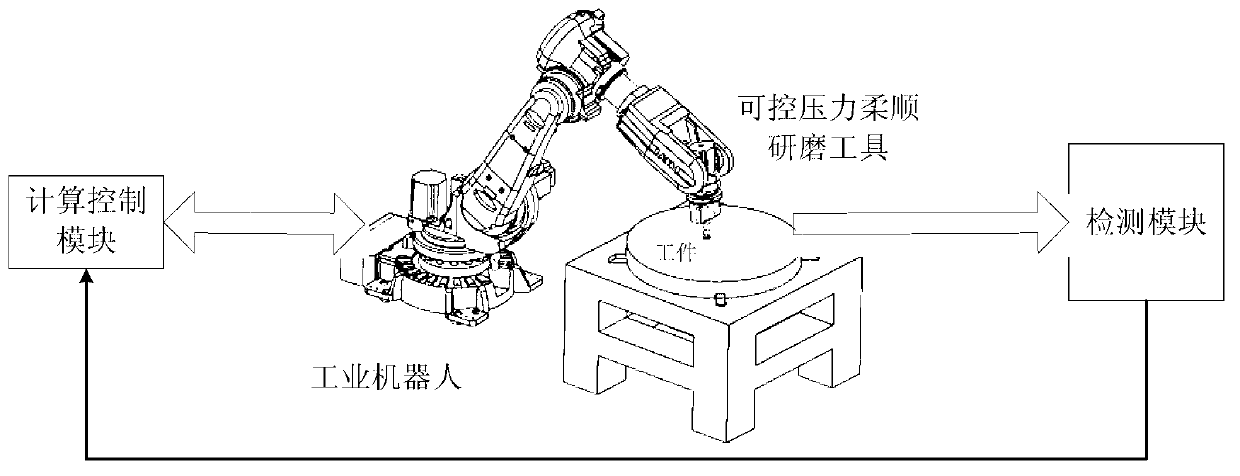

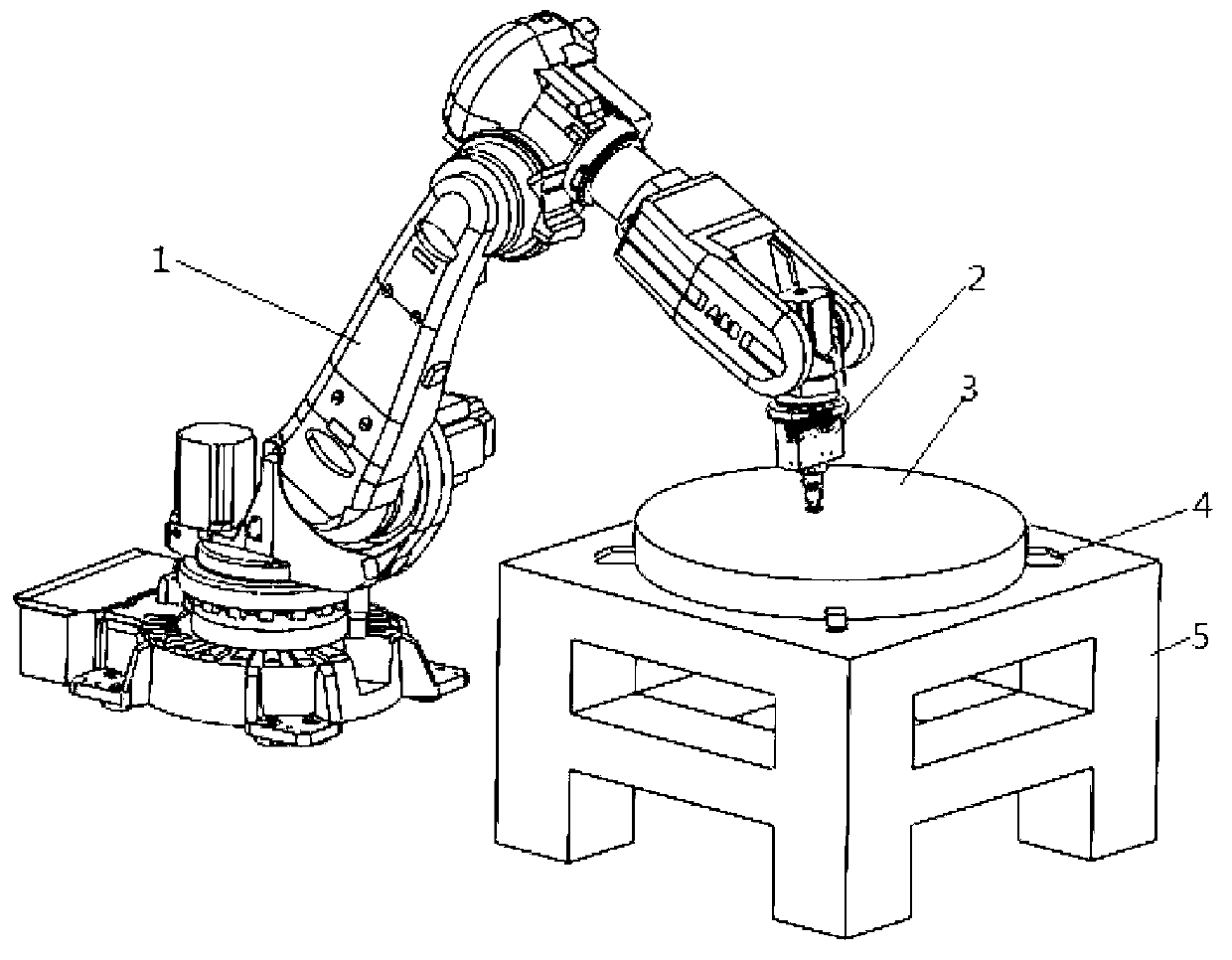

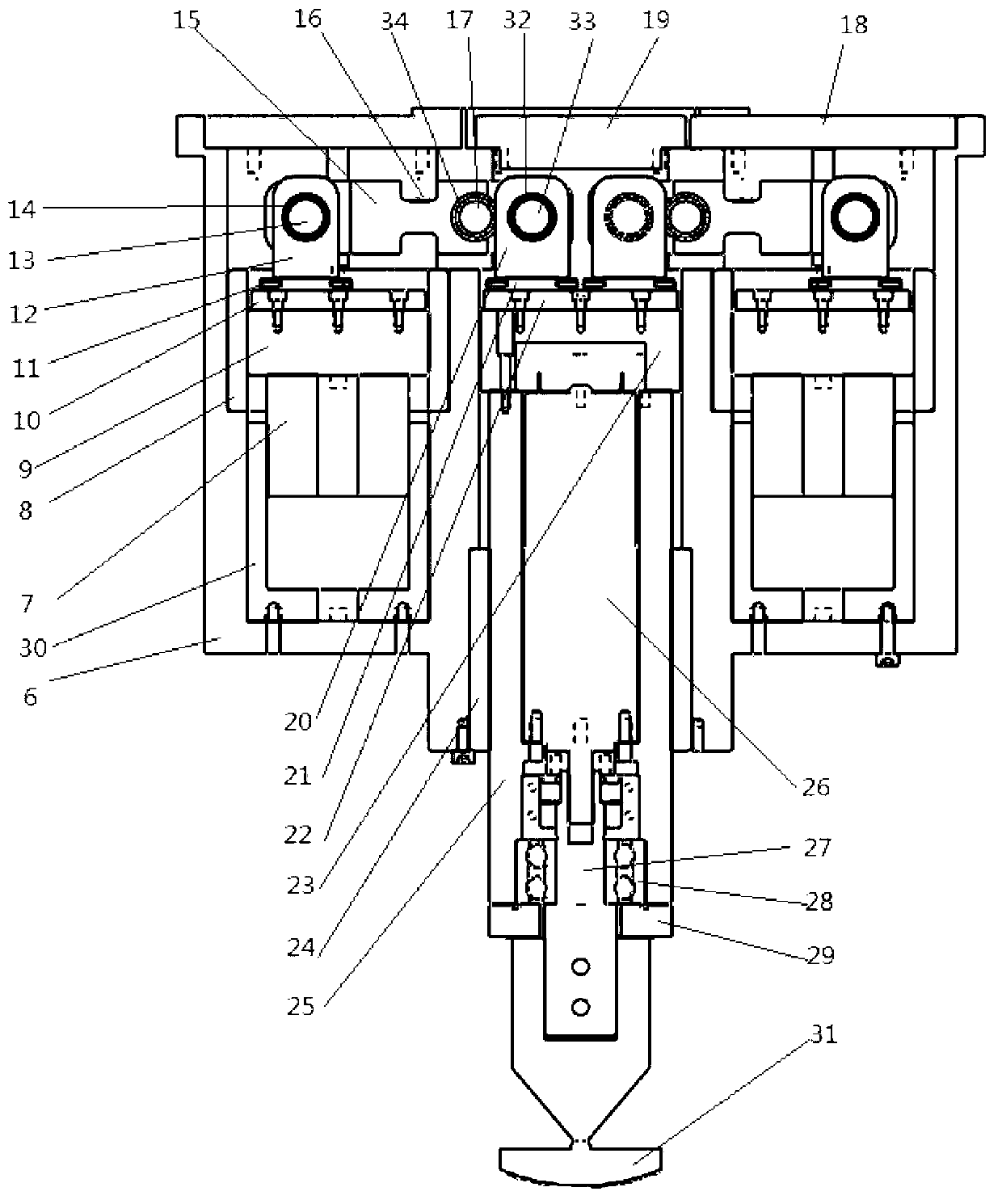

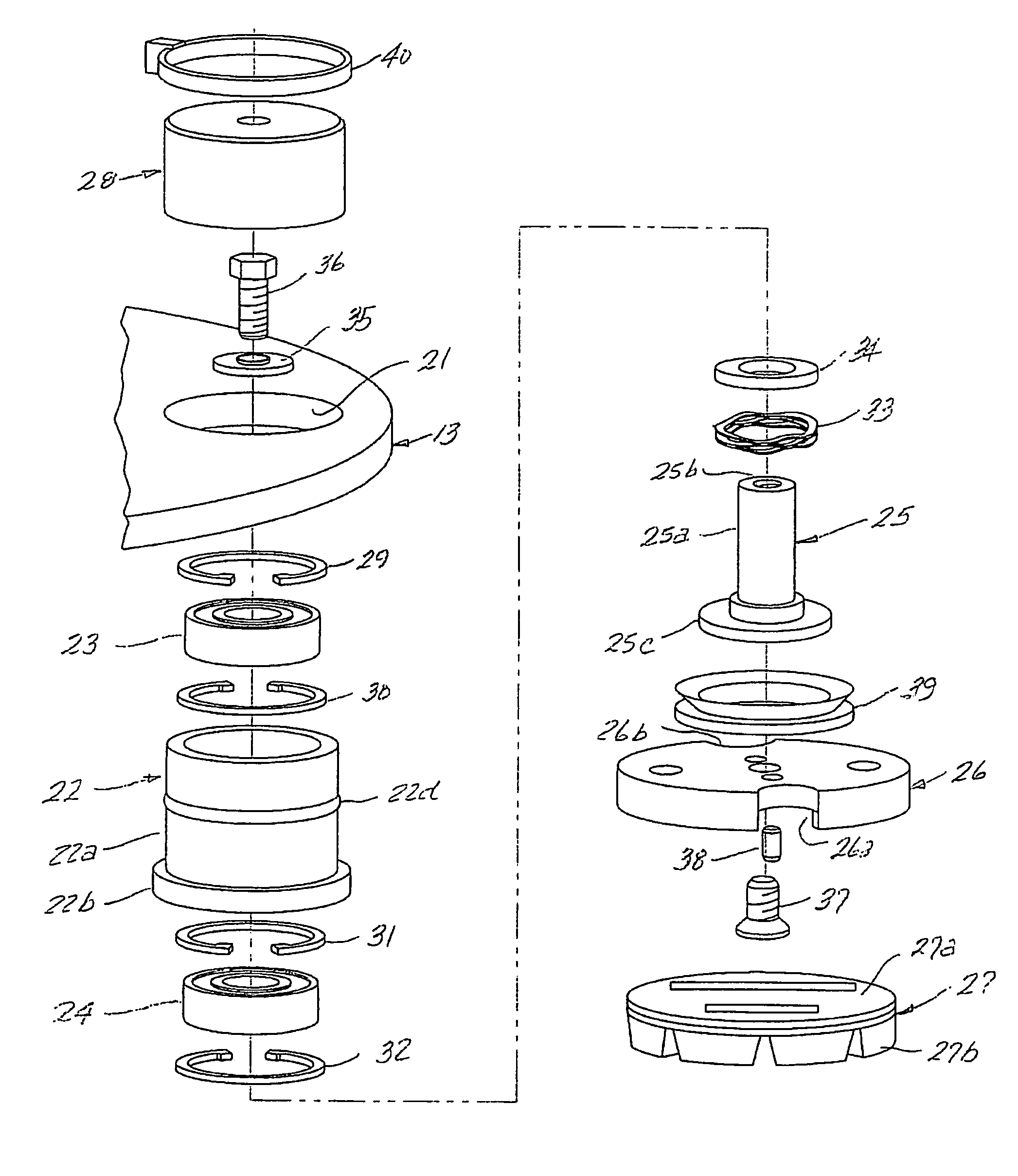

Active compliance robot grinding system with controlled pressure and changeable speed and method

ActiveCN103128645AReal-time monitoring of actual surface shapeAvoid nonlinear distortion errorsLapping machinesLapping toolsTarget surfaceThree-dimensional space

The invention discloses an active compliance robot grinding system with controlled pressure and changeable speed. The active compliance robot grinding system with the controlled pressure and the changeable speed comprises an industrial robot, a controlled pressure compliance grinding tool, a detection module and a computing control module. The industrial robot moves and locates the controlled pressure compliance grinding tool in a three-dimensional space. An optical mirror surface is compliantly grinded by the controlled pressure compliance grinding tool with the controlled pressure and the changeable speed. An actual surface shape of the optical mirror surface is measured by the detection module. The computing control module plans a grinding track, a pressure, a rotating speed and a dwell time according to comparing the actual surface shape and a target surface shape to obtain an error curved surface, and the industrial robot and the controlled pressure compliance grinding tool are controlled to carry out complicated optical mirror surface grinding which is high in rate of convergence.

Owner:SHANGHAI JIAO TONG UNIV

Novel wood plastic anticorrosive wallboard and production method thereof

InactiveCN102234439AImprove antibacterial and antiseptic effectGood shear mixing effectCovering/liningsFireproofingAntibacterial agent

The invention relates to a novel wood plastic anticorrosive wallboard for outdoor wall decorations and a production method thereof. The wood plastic anticorrosive wallboard consists of PE or PP plastic, wood powder or bamboo powder, calcium carbonate, coupling agent, lubricant, antiaging agent, antibacterial agent and colouring agent. The production method comprises the following steps that: the raw materials are subject to mixing, granulation and extrusion molding to obtain a baseplate, and the baseplate is subject to cooling, cutting, surface grinding, and embossing to obtain a product. The side of the baseplate is a slot structure, and the water absorption of the baseplate in 24h is 0.2%. The wallboard used in the field of outdoor decorations has the advantages of graceful appearance, lifelike pattern, reasonable structural design, being easy to install, fireproofing, waterproofing, insect preventing, sun protection, aging resistance, no formaldehyde, good sound-absorbing effect, good antibacterial and anticorrosive effects and the like, and being 100% recyclable. Compared with other wallboard decorative materials and production technologies existed in the prior art, the novel wood plastic anticorrosive wallboard disclosed in the invention has reasonable structure, and graceful and beautiful appearance, and the production method is advanced and scientific, with high production efficiency, and good performance of the produced products.

Owner:HUANGSHAN MEISEN NEW MATERIAL TECH

Surface grinding machine and grinding head therefor

A surface grinding machine generally consisting of a drive means provided with an output shaft; a planetary disk mounted on the shaft; and at least two grinding head units mounted on the planetary disk, each including a housing mounted on the planetary disk, a shaft having a flange portion, journaled in the unit housing, resilient means interposed between the housing and the flange portion of the unit shaft and a disk provided with a grit surface disposed on an outer side of the flange portion of the unit shaft.

Owner:AMANO PIONEER ECLIPSE CORP

Numerically controlled multi-functional surface grinding machine

InactiveCN101559575AIncrease productivityGood value for moneyGrinding drivesGrinding headsReciprocating motionClosed loop

The invention relates to the field of grinding machine used for mechanical processing, in particular to a numerically controlled multi-functional surface grinding machine which comprises an upright post, a vertical grinding wheel head mechanism, a horizontal grinding wheel head mechanism, an operation box, a worktable mechanism and a base; both the vertical grinding wheel head mechanism and the horizontal grinding wheel head mechanism are arranged on the upright post; and the upright post, the operation box and the table mechanism are all arranged on the base. Compared with the prior art, the invention adopts the matched use of the vertical grinding wheel head mechanism and the horizontal grinding wheel head mechanism which are linked with the reciprocating motion of a worktable and form fully closed loop control by being matched with the information of related position of the feedback of a precise linear scale, and realizes the grinding of planes, curved surfaces or guide surfaces and the like after one-time clamping of the workpiece, thus having higher production efficiency and higher cost performance.

Owner:洪清德

Plate glass surface grinding device and method

InactiveCN101357447AGrind fully and evenlyImprove flatnessPlane surface grinding machinesFlat glassGear wheel

The invention relates to a flat glass surface grinding device which can meet the processing requirement of large-area flat glass and a grinding method thereof; the grinding device comprises a grinding worktable, a base and a frame, wherein, the grinding worktable is arranged on the guide rail, independently moves along the X direction or along the Y direction and is used for mounting a glass substrate; the base is used for bearing a guide rail; the frame spans over the two sides of the grinding worktable and is fixedly connected with the base; two or more grinding heads are arranged on the frame above the grinding worktable and is driven by a power device to rotate; all grinding heads are arranged on a revolution bracket which is connected with a rotation shaft of a revolution bull gear; the revolution bull gear is meshed with a gear on an output shaft of a revolution driving motor; the rotation shaft of the revolution bull gear is connected with an ascending-descending cylinder of the grinding heads and is driven by the ascending-descending cylinder to ascend and descend; the grinding pressure of the grinding heads are adjusted by the ascending-descending cylinder; even grinding is achieved by the rotation and revolution of a plurality of grinding discs and the motion of the worktable. The grinding device and the grinding method have good grinding efficiency and can be applied to a surface polishing process in the field of liquid crystal glass substrate.

Owner:HENAN ANFEI ELECTRONICS GLASS

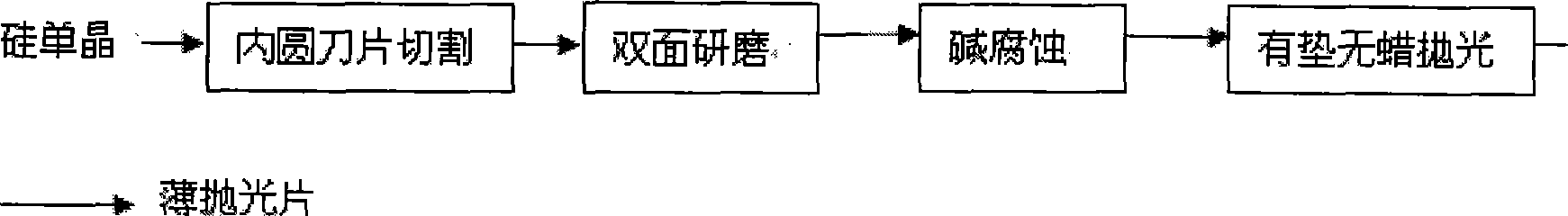

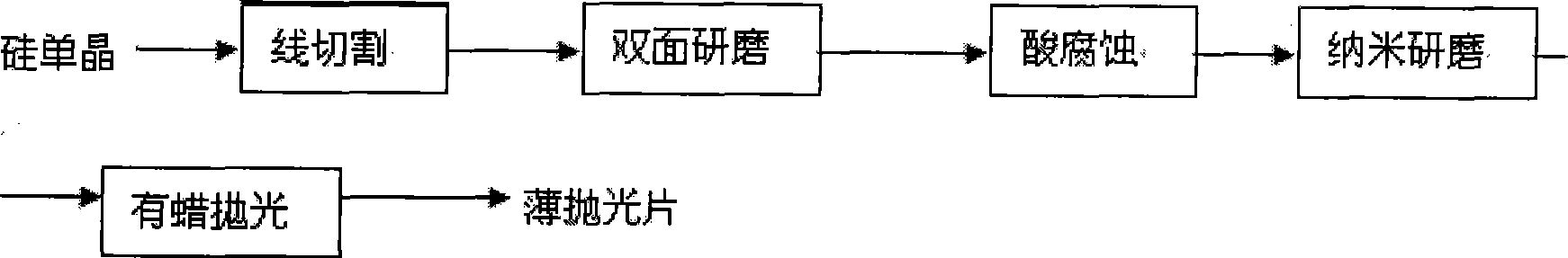

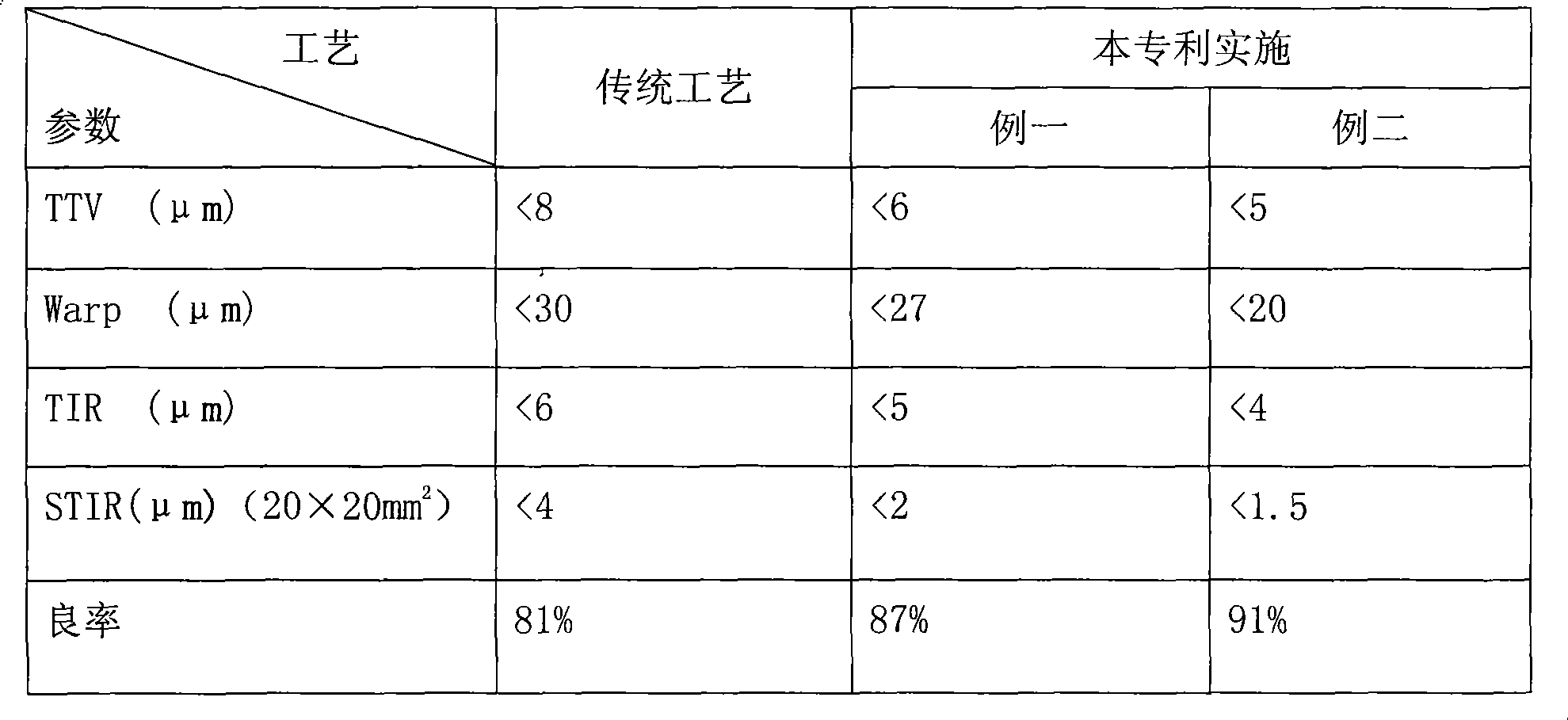

Processing method of thin silicon monocrystal polished section

ActiveCN101431021AImprove productivityImprove qualitySemiconductor/solid-state device manufacturingRubber ringWax

The invention relates to a method for producing thin monocrystalline silicon polished wafer. The method comprises the following steps: Step 1, monocrystalline silicon is sliced up by adopting wire cutting; Step 2, a slotting double-face grinder which adopts a stainless steel planetary sheet with an internal circle inlaid with a soft rubber ring is adopted to carry out double-surface grinding on the sliced monocrystalline silicon; Step 3, a technique of acid corrosion thinning is adopted, wherein, the removal amount resulted from acid corrosion is 10 micrometers to 60 micrometers; Step 4, a nanometer grinding technique is adopted, wherein, the removal amount resulted from nanometer grinding is 1 micrometer to 25 micrometers; and Step 5, a wax polishing technique is adopted, wherein, the removal amount resulted from wax polishing is 5 micrometers to 30 micrometers. By adopting a new technical route and a new technical procedure for producing new thin monocrystalline silicon polished wafer, the invention effectively improves TTV level, WARP level, TIR level, STIR level and other levels as well as the finished product rate of the thin monocrystalline silicon polished wafer.

Owner:JINGHUA ELECTRONICS MATERIAL

Metallic phase automatic grinding and polishing device

InactiveCN101417406AReduce gapImprove grinding precisionGrinding drivesGrinding machinesElectrical controlEngineering

Owner:BEIHANG UNIV

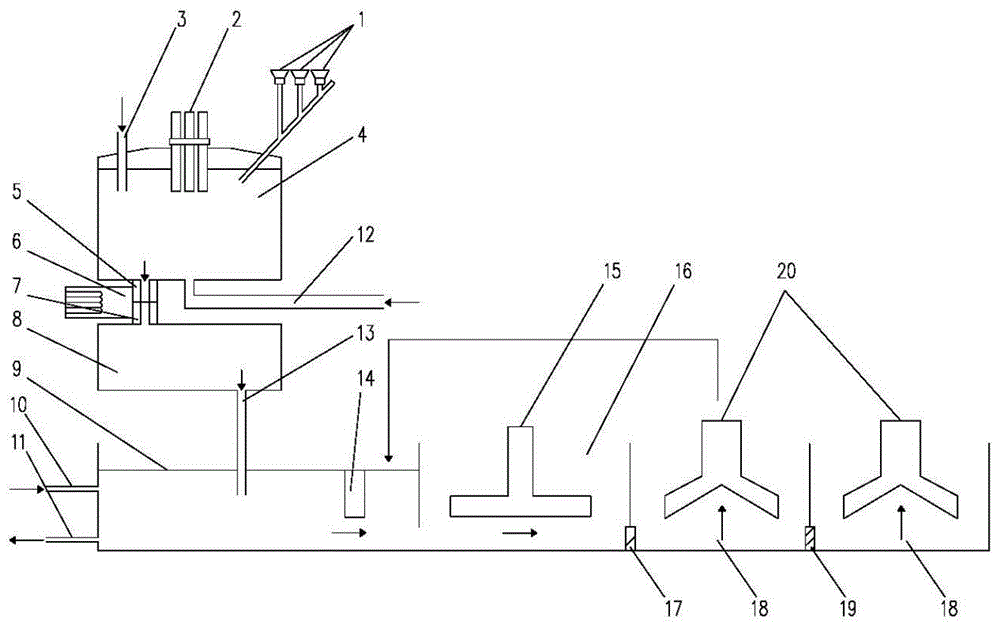

Sintering process method and device for producing microcrystalline glass by using blast furnace slag

The invention discloses a sintering process method and device for producing microcrystalline glass by using blast furnace slag, belonging to the field of metallurgical and inorganic non-metallic materials. The process method comprises the following main steps that: (1) blast furnace slag is transferred to a composition hardening, tempering and stirring tank, a modifier, a coloring agent and a nucleating agent are added into the tank, the obtained mixture is uniformly stirred, and the temperature of the slag is ensured; (2) the slag enters a water quenching pond through a slag inlet and is quenched with water so as to form glass particles; (3) after the glass particles are finely ground and screened, qualified glass particles are dried; (4) the dried glass particles are distributed on a shelf board and enter a nucleating area; (5) after the temperature of the nucleating area arises to 700-800 DEG C, the glass particles are subjected to heat preservation; (6) after entering a crystallization area, the glass particles are heated to 900-1100 DEG C and then subjected to heat preservation; and (7) the glass particles enter a cooling area to be cooled, thus obtaining products; and then the qualified products are subjected to surface grinding and polishing, thus obtaining a finished product microcrystalline glass. According to the invention, blast furnace slag and solid waste resources are fully used, and the product microcrystalline glass has the advantages of high strength, corrosion resistance, multiple colors and the like and has remarkable economic benefits and environmental protection benefits.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com