Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

229 results about "Volcano" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A volcano is a rupture in the crust of a planetary-mass object, such as Earth, that allows hot lava, volcanic ash, and gases to escape from a magma chamber below the surface. Earth's volcanoes occur because its crust is broken into 17 major, rigid tectonic plates that float on a hotter, softer layer in its mantle. Therefore, on Earth, volcanoes are generally found where tectonic plates are diverging or converging, and most are found underwater. For example, a mid-oceanic ridge, such as the Mid-Atlantic Ridge, has volcanoes caused by divergent tectonic plates whereas the Pacific Ring of Fire has volcanoes caused by convergent tectonic plates. Volcanoes can also form where there is stretching and thinning of the crust's plates, e.g., in the East African Rift and the Wells Gray-Clearwater volcanic field and Rio Grande Rift in North America. This type of volcanism falls under the umbrella of "plate hypothesis" volcanism. Volcanism away from plate boundaries has also been explained as mantle plumes. These so-called "hotspots", for example Hawaii, are postulated to arise from upwelling diapirs with magma from the core–mantle boundary, 3,000 km deep in the Earth. Volcanoes are usually not created where two tectonic plates slide past one another.

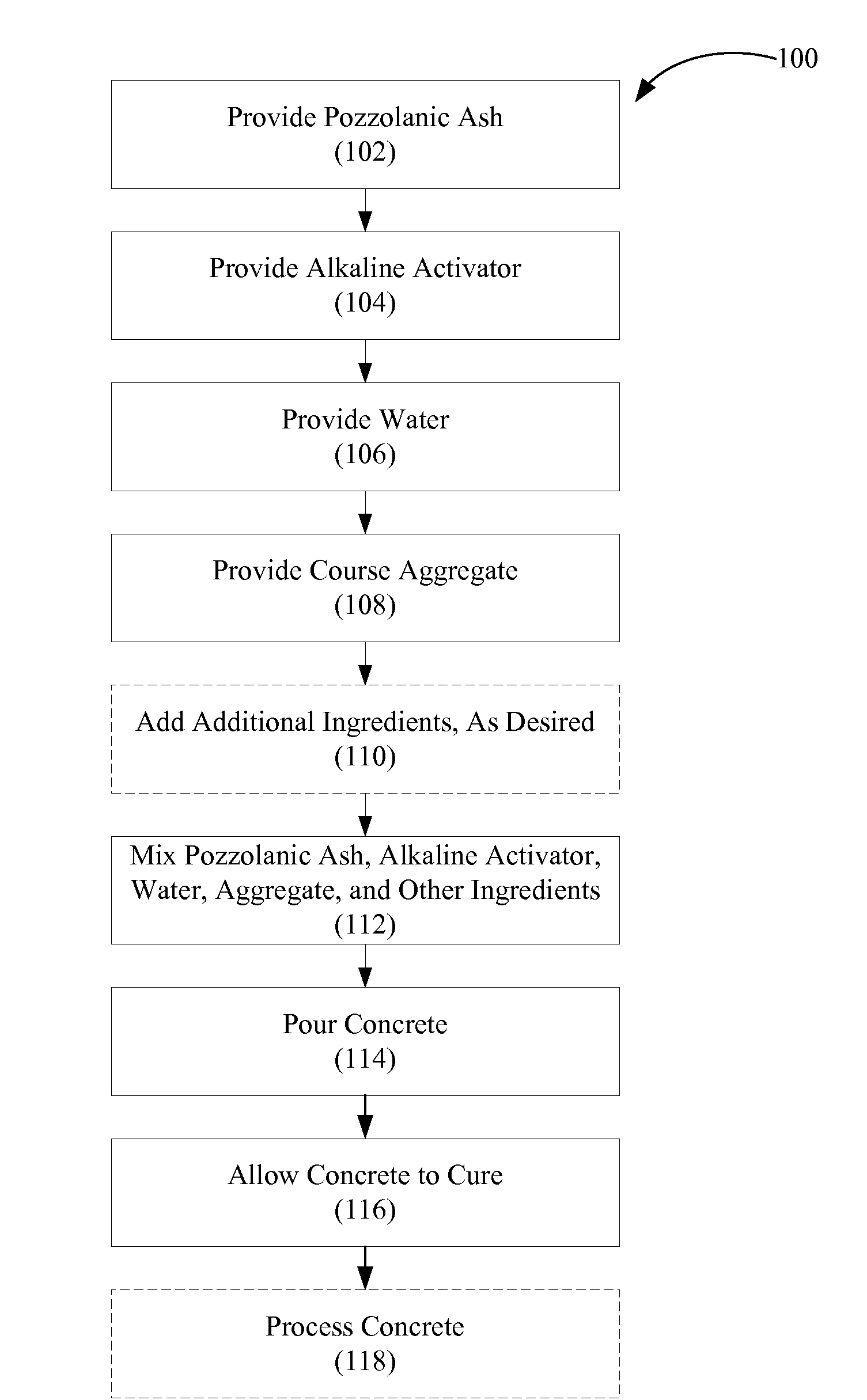

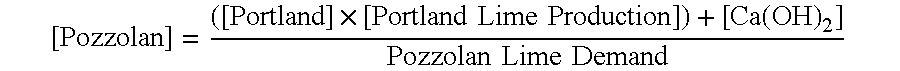

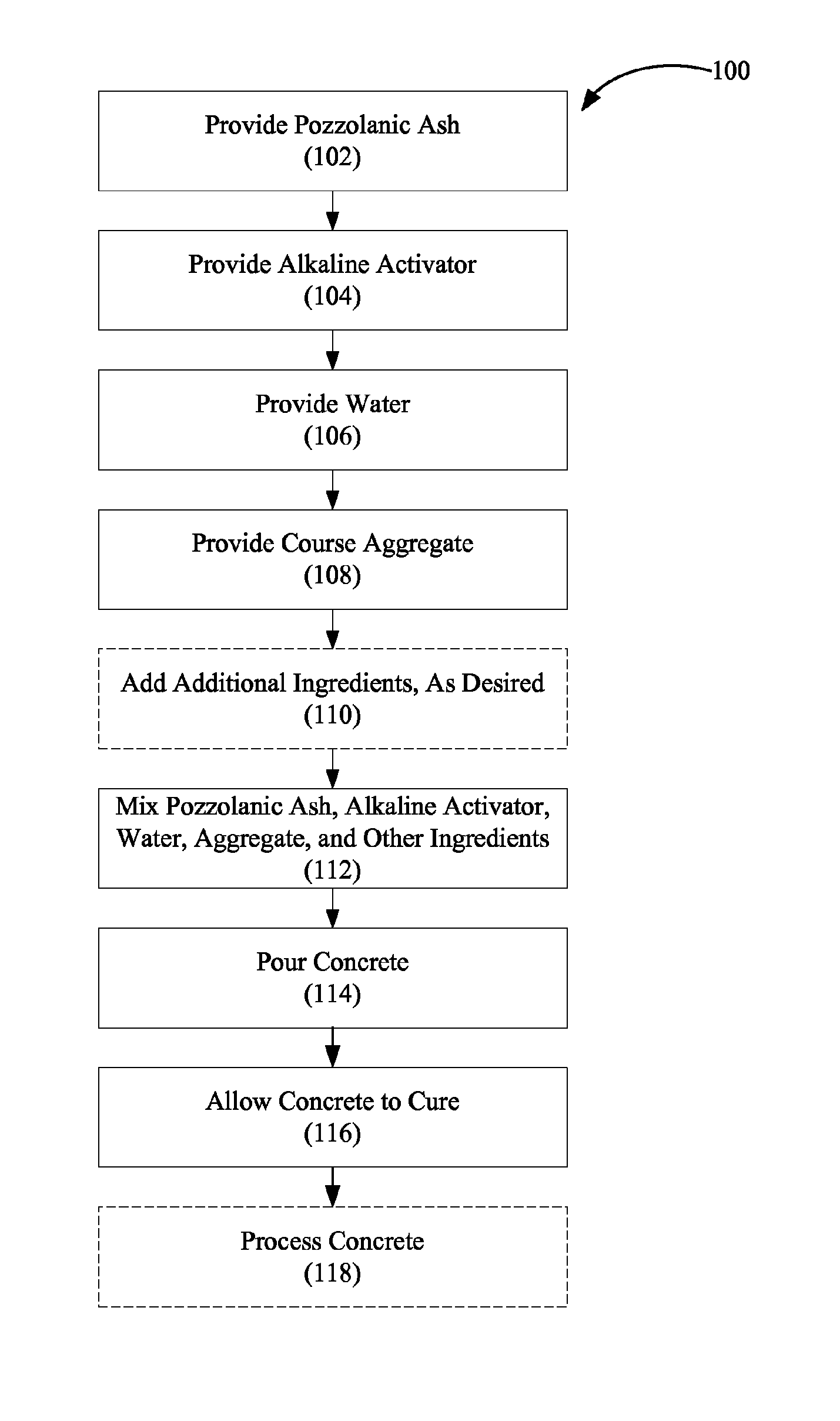

Previous concrete comprising a geopolymerized pozzolanic ash binder

ActiveUS20100058957A1Low costImprove performanceSolid waste managementCement productionAluminateCombustion

A process for making a pervious concrete comprising a geopolymerized pozzolanic ash. Generally, the process includes mixing a solid aggregate and a geopolymerized pozzolanic ash binder together to form a pervious concrete mixture. Some examples of suitable aggregates comprise recycled carpet, recycled cement, and aggregates of coal-combustion byproducts. The geopolymerized pozzolanic ash binder is made by combining a pozzolanic ash, such as fly ash, with a sufficient amount of an alkaline activator and water to initiate a geopolymerization reaction. The activator solution may contain an alkali metal hydroxide, carbonate, silicate, aluminate, or mixtures thereof. In some aspects, the final concrete forms a solid mass in the form of pavement or a pre-cast concrete shape. The solid mass of concrete may have a void content of between about 5% and about 35%.

Owner:CERAMTEC

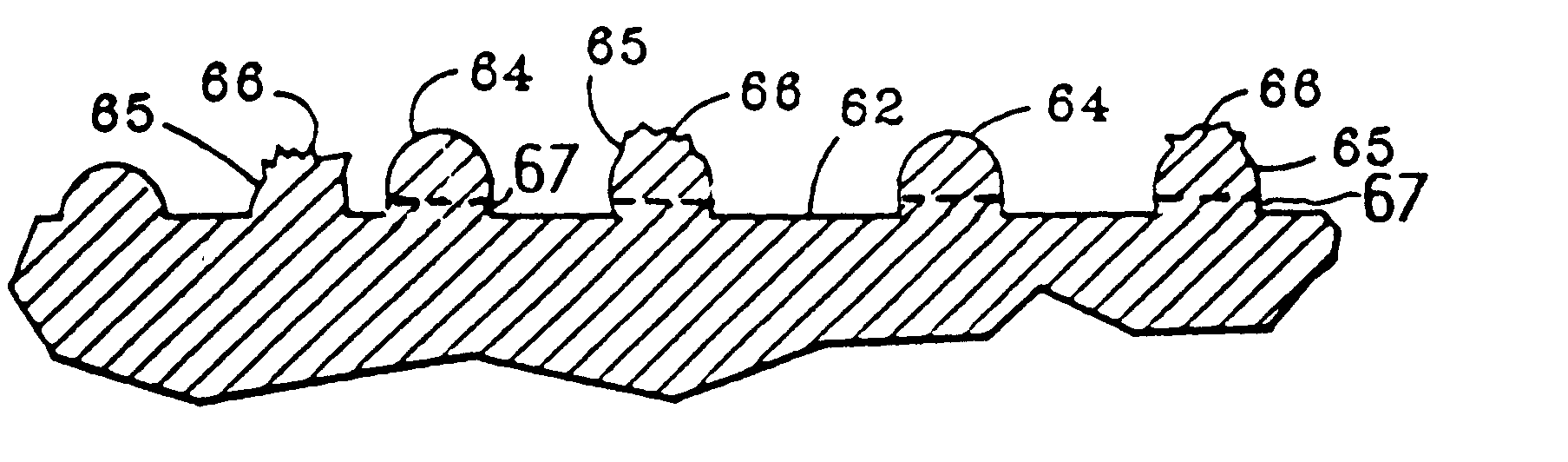

Thermoplastic products having antislip surfaces

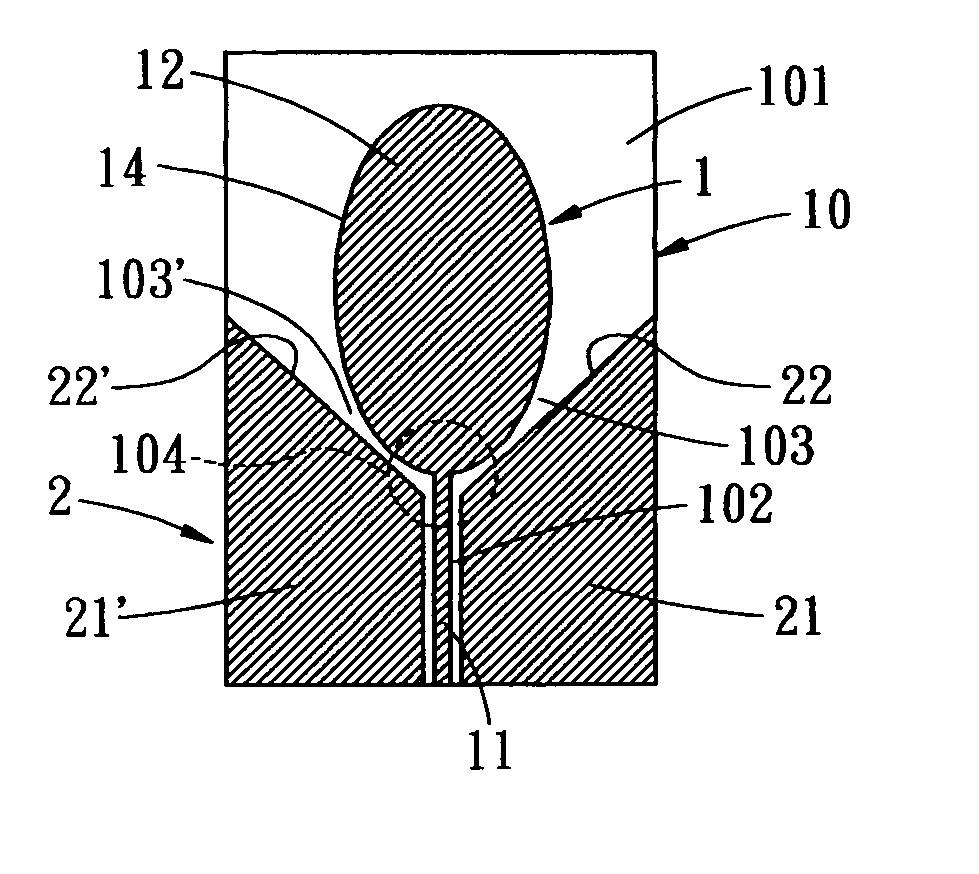

InactiveUS6509084B2Effective antislip surface propertyGood adhesion and durability and wearabilityKitchenware cleanersCleaning machinesEngineeringVolcano

Thermoplastic products such as vehicle cargo area liners, floor mats, recreational and playground equipment, cargo pallets, and wet area walking surfaces are provided with an antislip surface treatment. The antislip surface is made up of individual non-interconnected asperities of an antislip polymer material, which do not form a continuous film over the surface of the thermoplastic product. The thermoplastic product is especially made of high density polyethylene. The antislip polymer is preferably a thermoset polymer, and most particularly is a polyurea / isocyanate polymer. The antislip polymer is preferably applied by spraying, and then the product is heat treated at a temperature in the range from 100 to 200° F., or is thermoformed at a temperature in the range from 250 to 550° F. The antislip asperities are durably bonded onto the thermoplastic base material, and provide a significantly increased coefficient of friction. The asperity size, height, and hardness can be controlled by adjusting the processing conditions. The asperities may have an increased surface relief due to a so-called "moth effect" and an increased surface roughness due to cratering as a result of a so-called "volcano effect" in the process using thermoforming.

Owner:CUSTOM PLASTICS MOLDING

Blended fly ash pozzolans

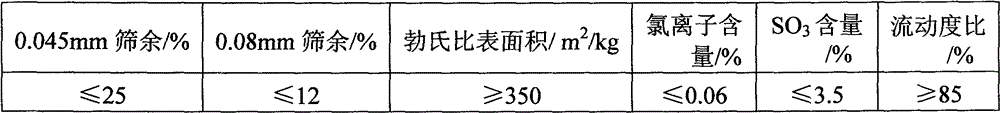

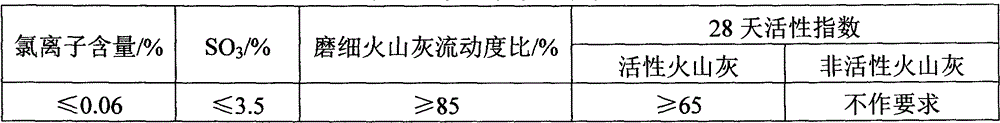

InactiveUS20060201395A1Improved sulfate resistanceReduce penetrationSolid waste managementVolcanoCoal

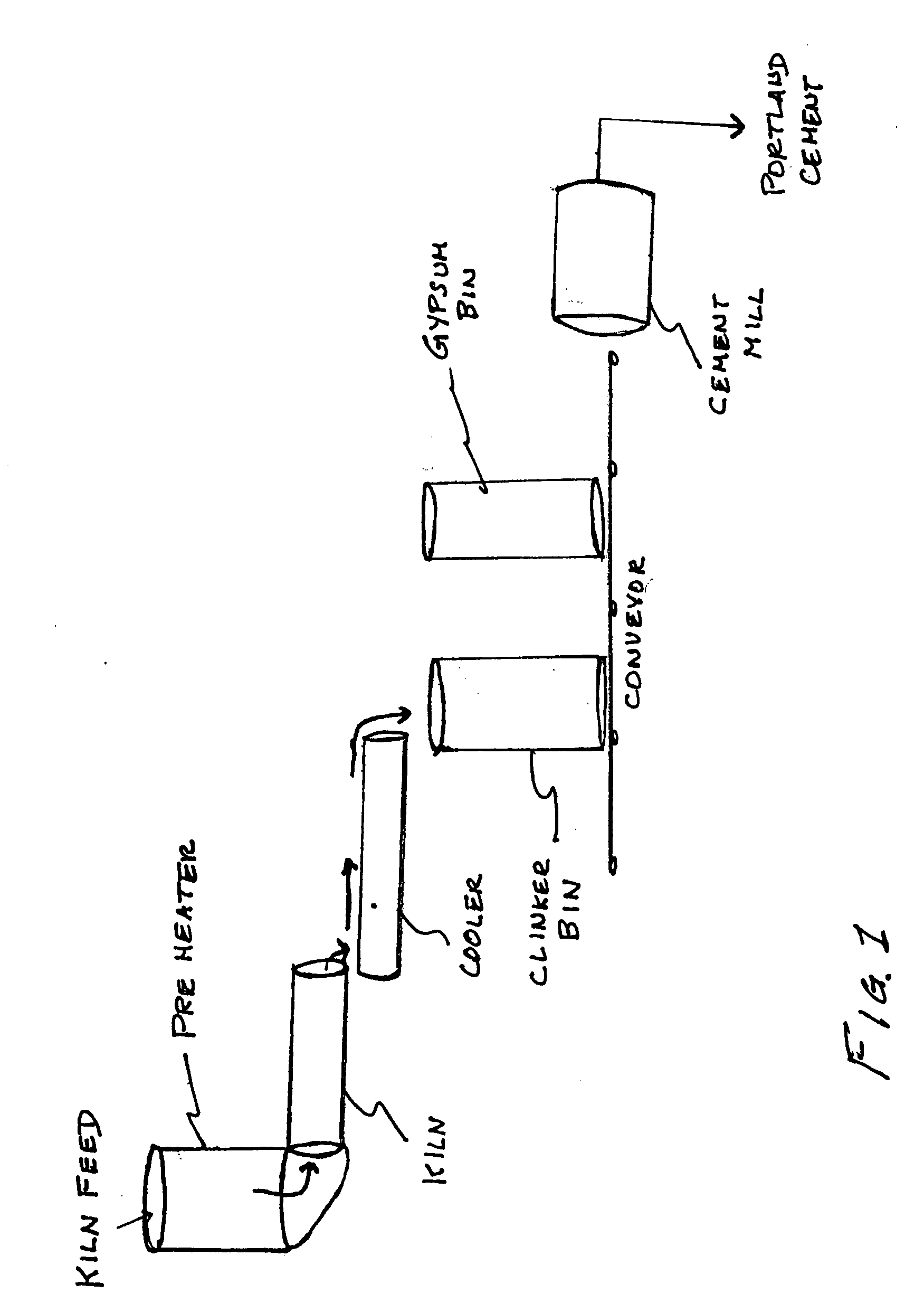

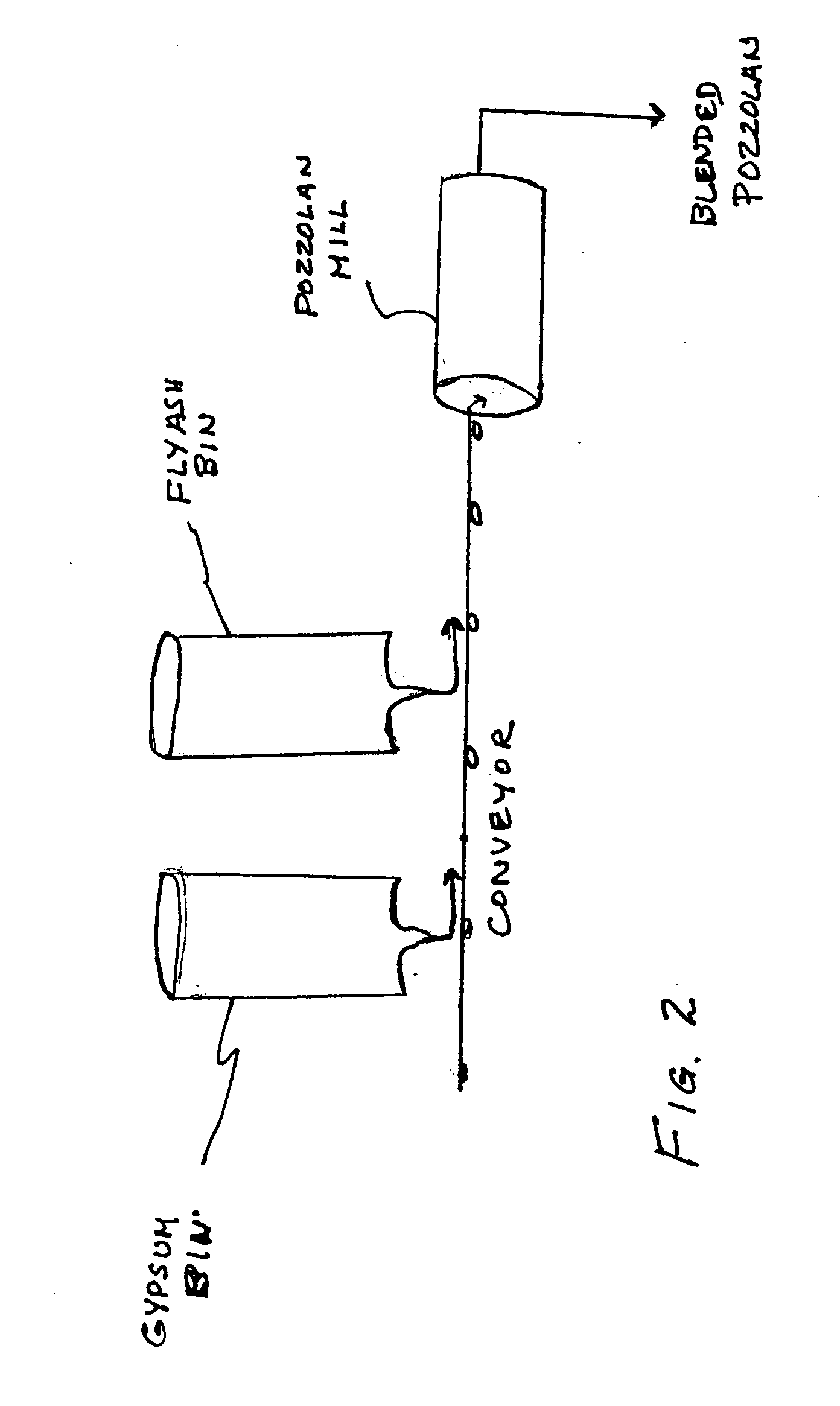

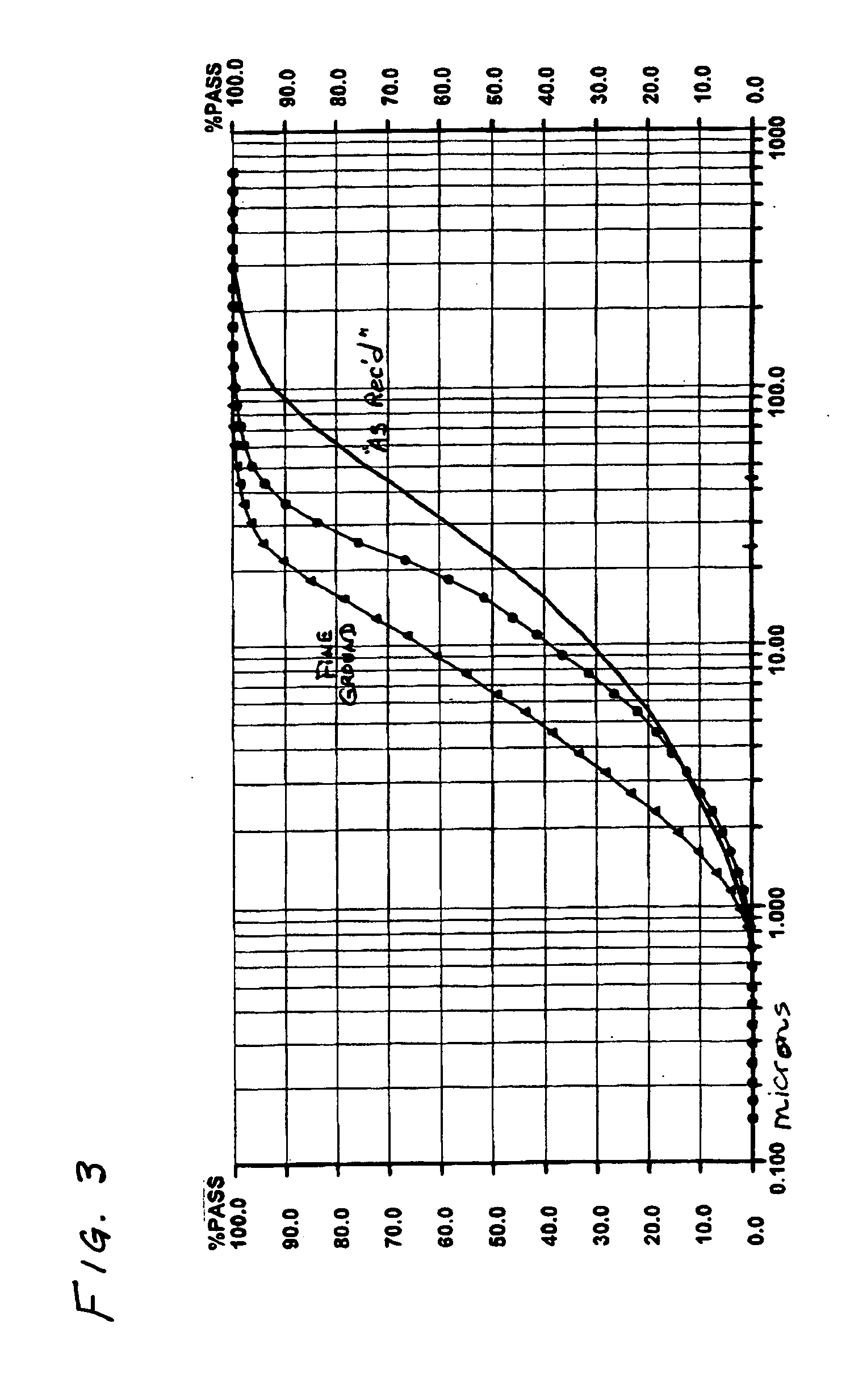

Novel premium blended pozzolans for use with hydraulic cement are created by intergrinding an ASTM Class F or Class C coal fly ash and a source of calcium sulfate, such as gypsum, so that the resultant mixture has a fineness of at least 90% passing through a 45 micron sieve. The novel mixture meets the requirements of ASTM C 618. Alternately, a novel concrete composition can be formed using the blended pozzolan with a hydraulic cement, aggregate and water so as to produce a concrete having improved strength, ASR mitigation, improved sulfate resistance and lowered permeability. The novel pozzolans not only reduce production costs by decreasing fuel and raw material consumption per ton of cement, but they also use by-product waste materials from another industry to create a premium product for the construction industry.

Owner:ASH GROVE CEMENT

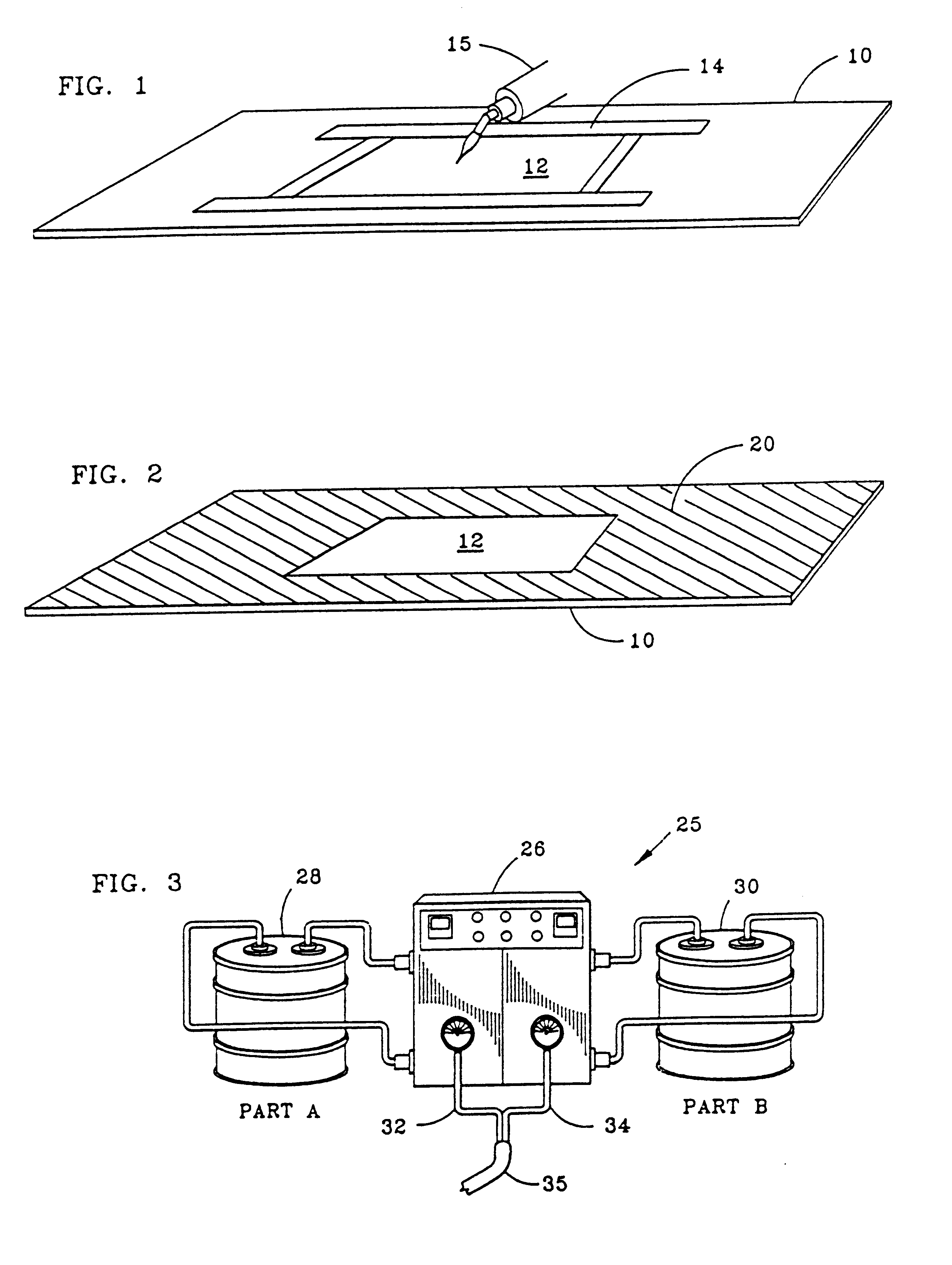

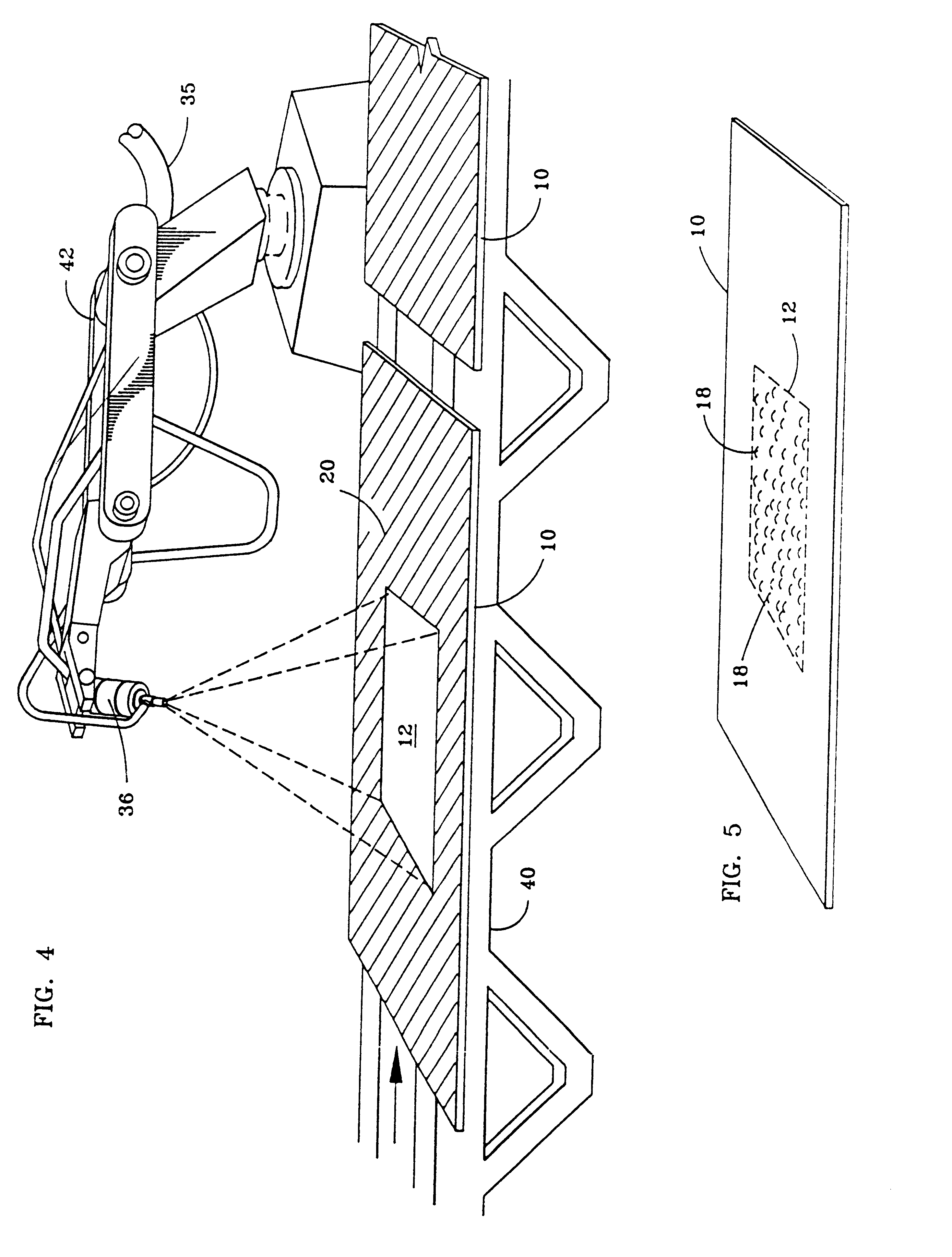

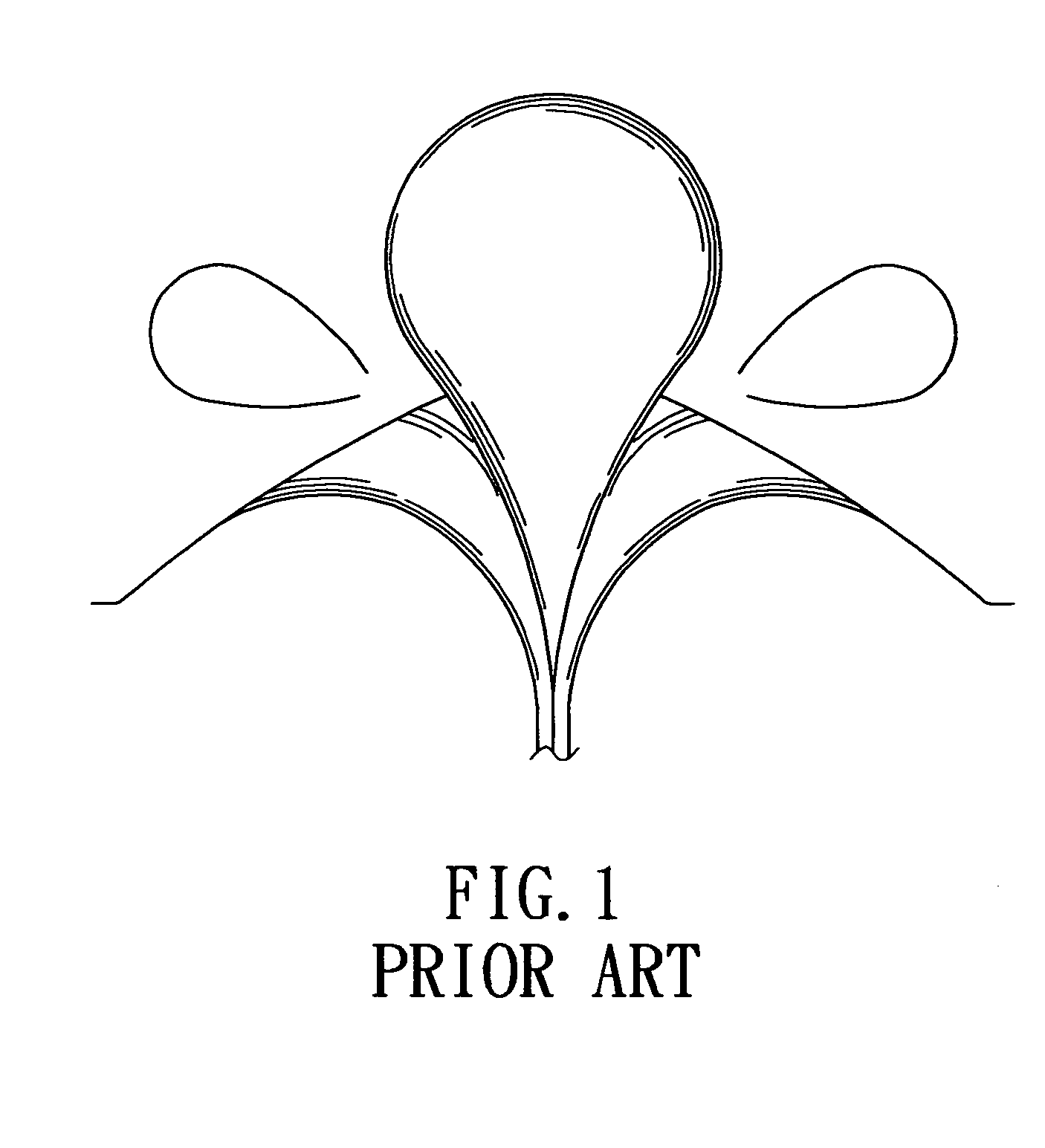

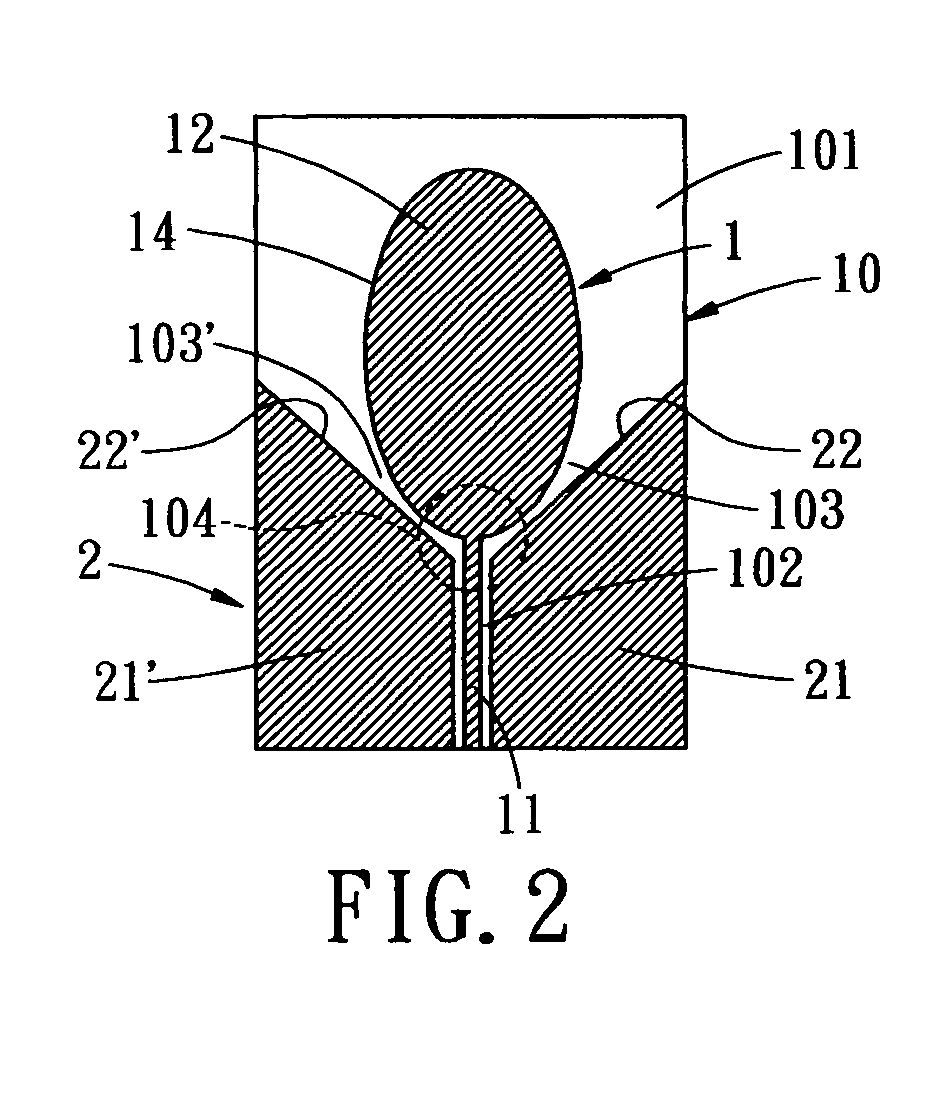

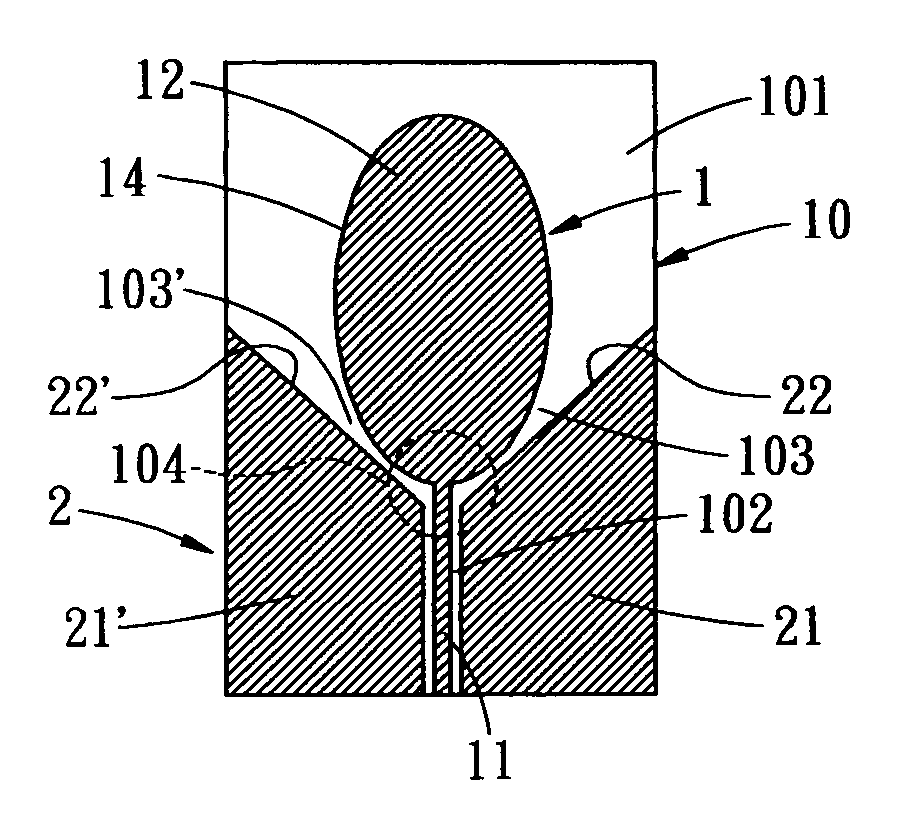

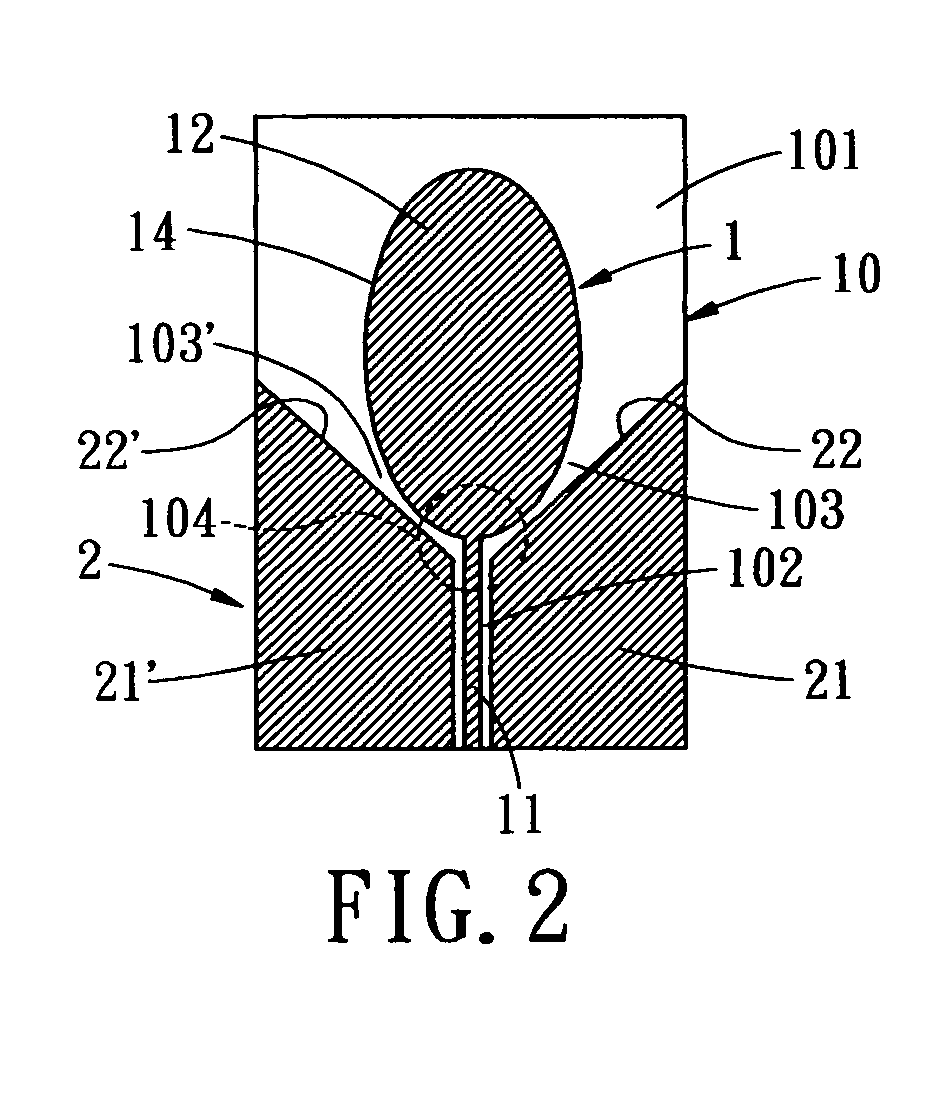

Ultra wideband planar printed volcano antenna

InactiveUS20050156788A1Easy to manufactureLow costSimultaneous aerial operationsRadiating elements structural formsUltra-widebandEngineering

An ultra wideband planar printed volcano antenna, which not only complies with the UWB bandwidth standard (3.1 GHz˜10.6 GHz) but also is lightweight, compact, inexpensive, easy to manufacture, high performance, and highly integrated. The ultra wideband planar printed volcano antenna has an antenna unit and a grounding unit formed on one or two printed circuit board by means of etching. The antenna unit includes an electrically conductive radiating element. The rest of the printed circuit board forms an electrically nonconductive open area. The grounding unit has at least one electrically conductive grounding element. The rest of the printed circuit board also forms an electrically nonconductive open area. The overlapping of the two open areas of the printed circuit board forms the adjustable space which has a gradually narrowing shape. By adjusting the size of the adjustable space, the antenna may acquire a best frequency range.

Owner:LIN DING FU

Earthquake and Displacement Early Warning System

Novel solutions, which can include devices, systems, methods, than can measure earthquakes and other displacement events. Some solutions feature the integration of real-time, high-rate global navigation satellite system (“GNSS”) displacement information with acceleration and / or velocity data within a single device to create very high-rate displacement records. The mating of these two instruments allows the creation of a new, very high-rate displacement measurement device that has the full-scale displacement characteristics of GNSS and high-precision dynamic motions of seismic technologies. Such a device can be used for earthquake early warning studies and other mission critical applications, such as volcano monitoring, building, bridge and dam monitoring systems.

Owner:TRIMBLE INC

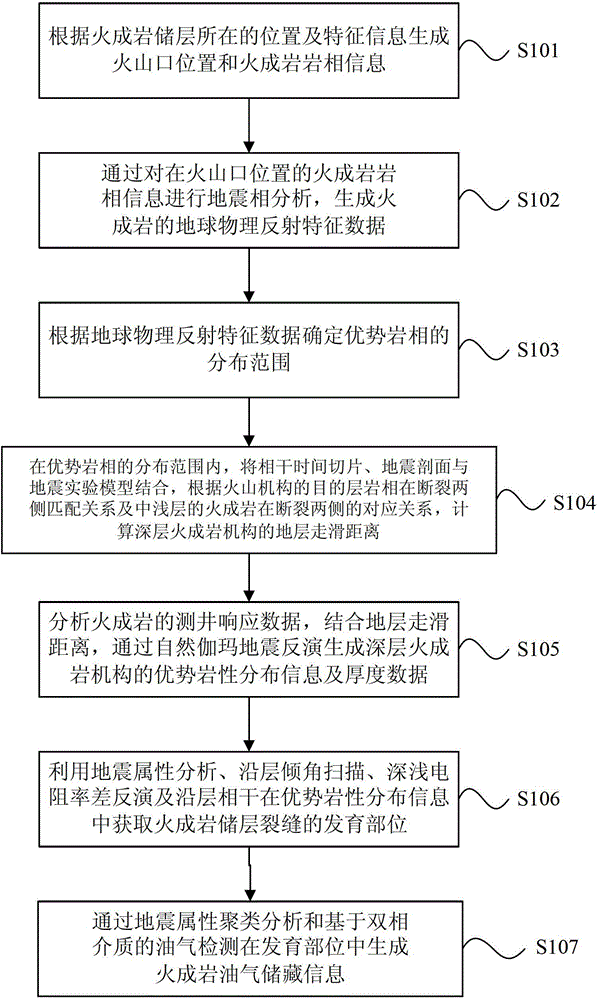

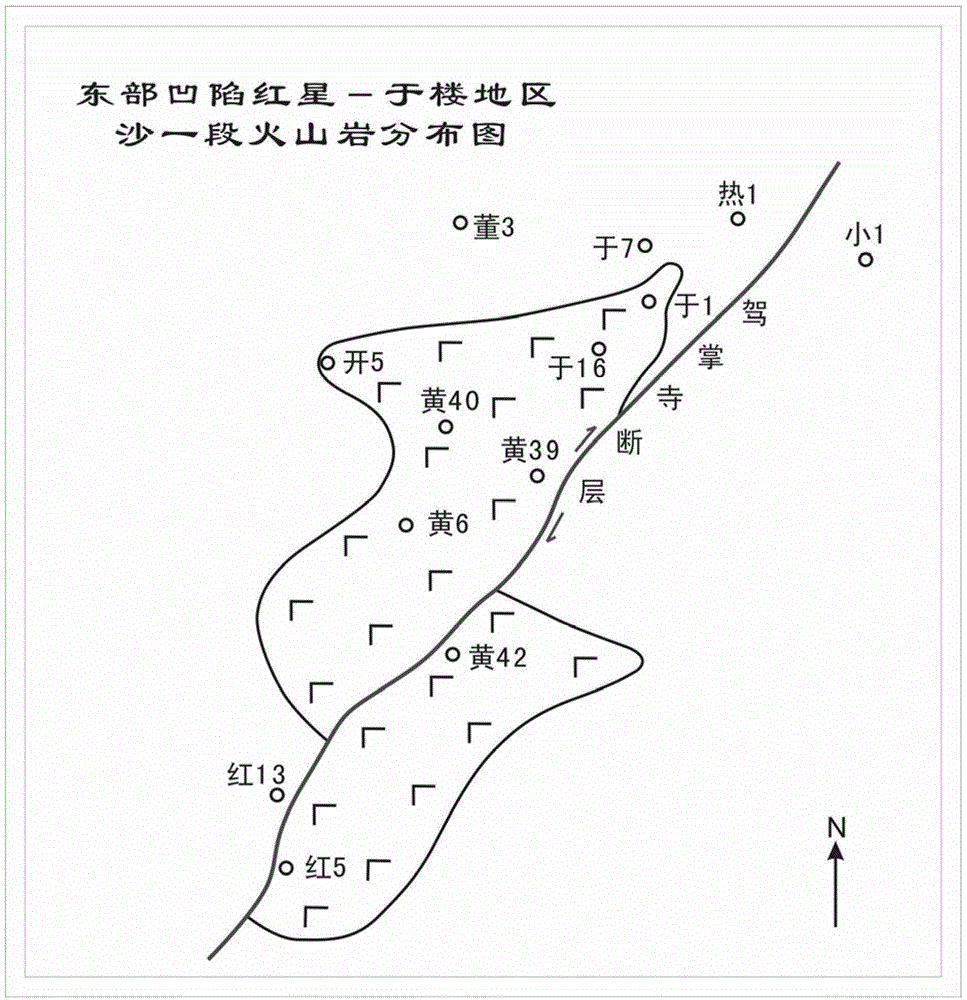

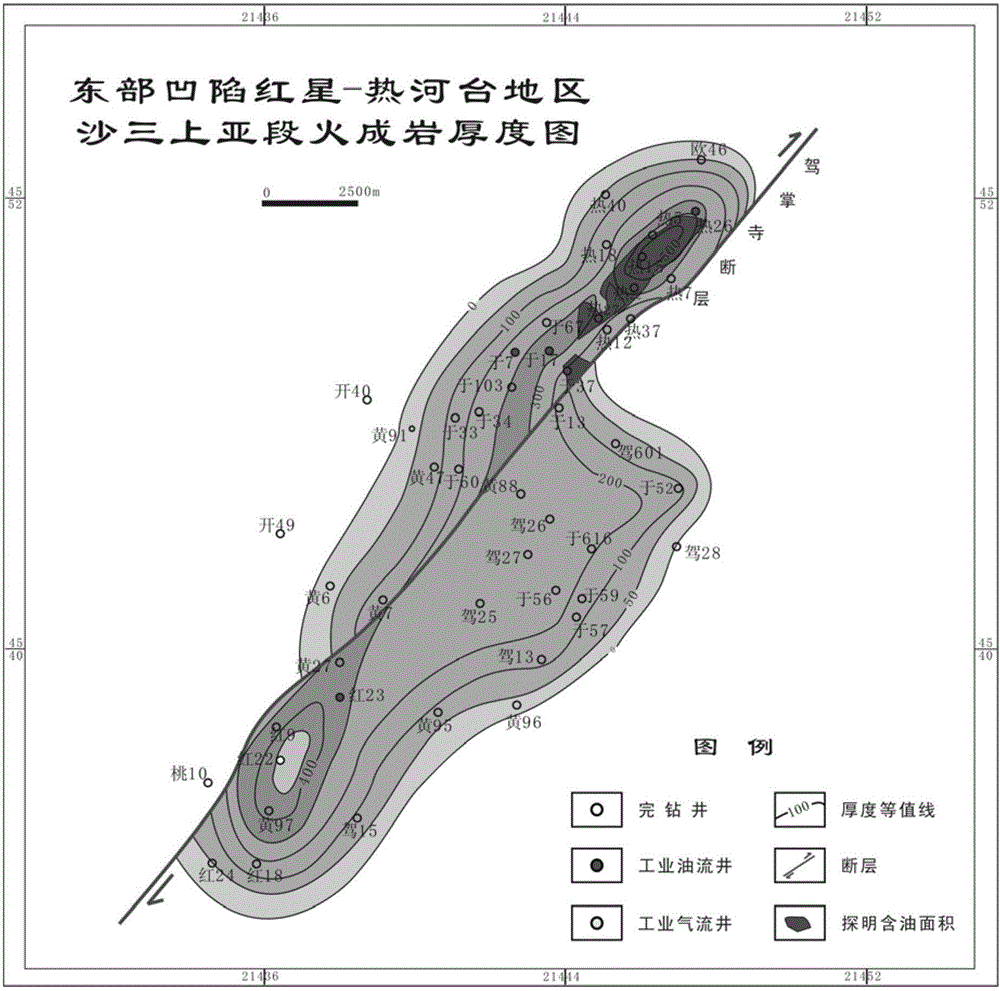

Igneous rock oil and gas exploration method and device

ActiveCN103149589AHigh precisionIncrease success rateSeismic signal processingLithologySeismic attribute

The invention provides an igneous rock oil and gas exploration method and an igneous rock oil and gas exploration device. The method comprises the following steps of generating crater position and igneous rock lithofacies information according to the position of an igneous rock reservoir and characteristic information; generating geophysical reflection characteristic data according to seismic facies analysis, and determining a distribution range of advantageous lithofacies; calculating a stratigraphic strike-slip distance of a deep igneous rock mechanism according to a matching relation of target stratum lithofacies of a volcanic edifice on two sides of a fracture and a corresponding relation of igneous rocks of a middle-shallow layer on the two sides of the fracture; analyzing logging response data of the igneous rocks, and generating advantageous lithology distribution information and thickness data of the deep igneous rock mechanism through natural gamma seismic inversion; acquiring a development part of the fracture of the igneous rock reservoir by using means such as deep and shallow resistivity difference inversion; and generating igneous rock oil and gas reservoir information in the development part through cluster analysis of seismic attributes and two-phase media-based oil and gas detection. By the invention, the accuracy of exploring and predicting the igneous rock oil and gas reservoir and the drilling success rate can be improved.

Owner:PETROCHINA CO LTD

Thermoplastic products having antislip surfaces

InactiveUS20010046588A1Effective antislip surface propertyImprove adhesionLayered productsAbrasion apparatusEngineeringVolcano

Thermoplastic products such as vehicle cargo area liners, floor mats, recreational and playground equipment, cargo pallets, and wet area walking surfaces are provided with an antislip surface treatment. The antislip surface is made up of individual non-interconnected asperities of an antislip polymer material, which do not form a continuous film over the surface of the thermoplastic product. The thermoplastic product is especially made of high density polyethylene. The antislip polymer is preferably a thermoset polymer, and most particularly is a polyurea / isocyanate polymer. The antislip polymer is preferably applied by spraying, and then the product is heat treated at a temperature in the range from 100 to 200° F., or is thermoformed at a temperature in the range from 250 to 550° F. The antislip asperities are durably bonded onto the thermoplastic base material, and provide a significantly increased coefficient of friction. The asperity size, height, and hardness can be controlled by adjusting the processing conditions. The asperities may have an increased surface relief due to a so-called "moth effect" and an increased surface roughness due to cratering as a result of a so-called "volcano effect" in the process using thermoforming.

Owner:CUSTOM PLASTICS MOLDING

Masonry, mortar, and stucco cement compositions

This invention pertains to a process of making ASTM quality masonry cement, mortar cement, and stucco cement (also called plastic cement) and to the products themselves which are useful in making ASTM quality mortar for masonry construction or ASTM quality stucco for plastering construction. These cements are classified as hydraulic cements and are made using selected pozzolan(s), such as natural pozzolan and fly ashes, Portland Cement, hydrated lime, and an air-entraining agent. Other additives, such as fibers, may be added to further modify its properties. The pozzolans act as functional ingredients in the mix rather than as a filler. As a result, concentrations of greater than 25 wt. % and more pozzolan can be produced.

Owner:OLDCASTLE ARCHITECTURAL

Volcanic material-enriched source rock organic carbon recovery method

InactiveCN103983746APotential awarenessFlesh out the theory of evaluationFuel testingRecovery methodKerogen

The invention discloses a volcanic material-enriched source rock organic carbon recovery method. The recovery method comprises the following steps: selecting a sample; determining content Z of volcanic materials in source rock; implementing source rock residual organic carbon analysis and kerogen treatment; dividing volcanic material-enriched source rock organic matter types through an element analysis method; calculating an organic carbon recovery coefficient Kc by combining numerical simulation with experiment; fitting related functions Kc=f(Z) of Kc and volcanic material content Z. The method disclosed by the invention, by recovering residual organic carbon of source rocks differing in volcanic material content, can greatly improve precision of recovering source rock organic carbon; meanwhile, on the basis of researching a research area test data recovery method, the reliability of resource quantity evaluation is improved; the technology fills the blank of volcanic materials in a complex sedimentary structure environment on organic matter abundance recovery, and enriches source rock evaluation theory; according to results, progress of next resource evaluation is greatly promoted.

Owner:中国石油化工股份有限公司胜利油田分公司勘探开发研究院西部分院

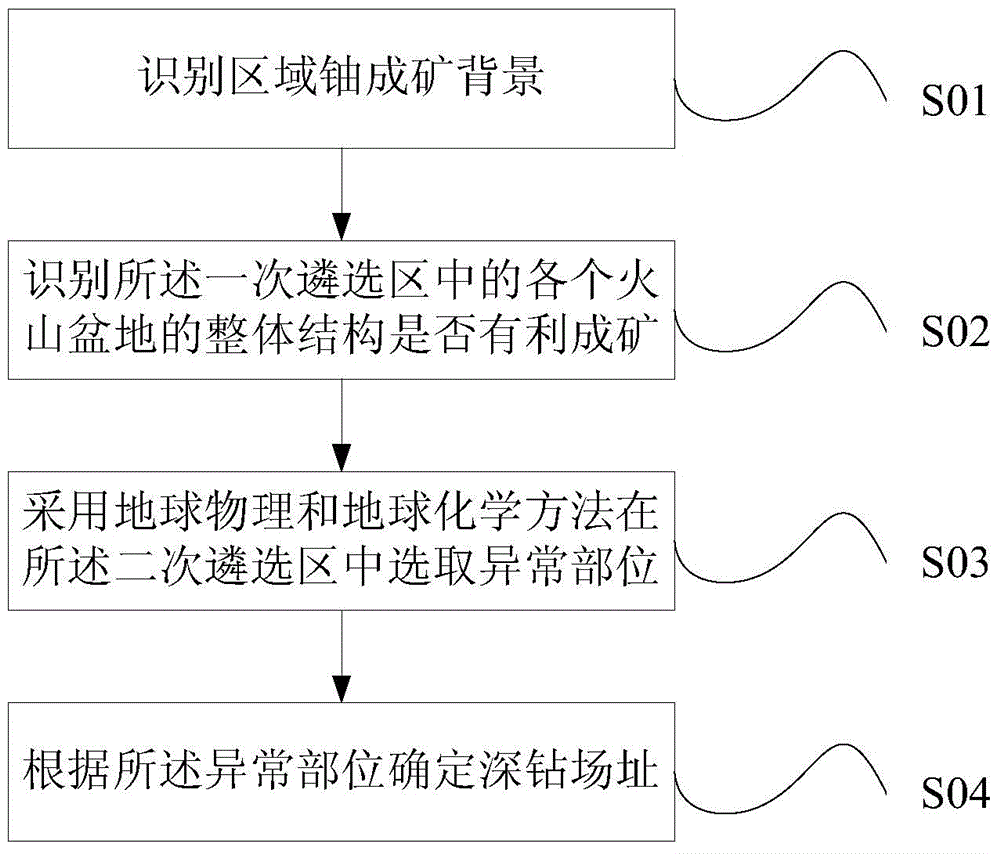

Scientific deep drilling site selection method of volcanic type uranium ore field

ActiveCN105549113ASmooth surveySuccessful research workGeological measurementsAbnormal positionsUranium mineralization

The invention discloses a scientific deep drilling site selection method of a volcanic type uranium ore field. The method includes following steps: S01: recognizing an area uranium mineralization background, and screening an area with good uranium mineralization background as a primary selection area via the recognition of the area uranium mineralization background; S02: recognizing whether the overall structure of each volcanic basin in the primary selection area is good for mineralization, and recognizing at least one volcanic basin whose overall structure is good for mineralization in the primary selection area as a secondary selection area; S03: selecting abnormal positions in the secondary selection area by employing geophysical and geochemical methods; and S04: determining the deep drilling site according to the abnormal positions. According to the selection method, the range is gradually reduced from large to small, the deep drilling site is determined, the process is clear, the implementation is convenient, and the deep drilling construction of the deep drilling site determined by the method can strongly guarantee smooth operation of uranium ore exploration and research work.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

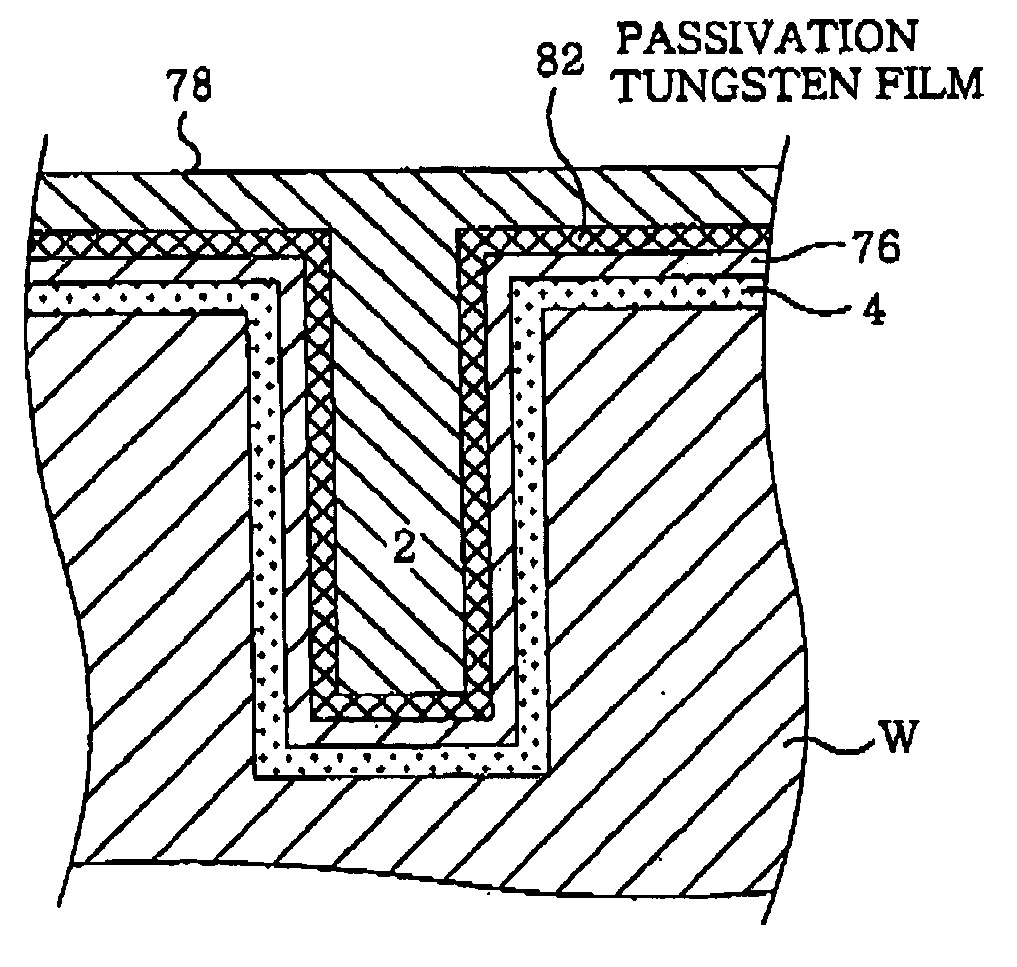

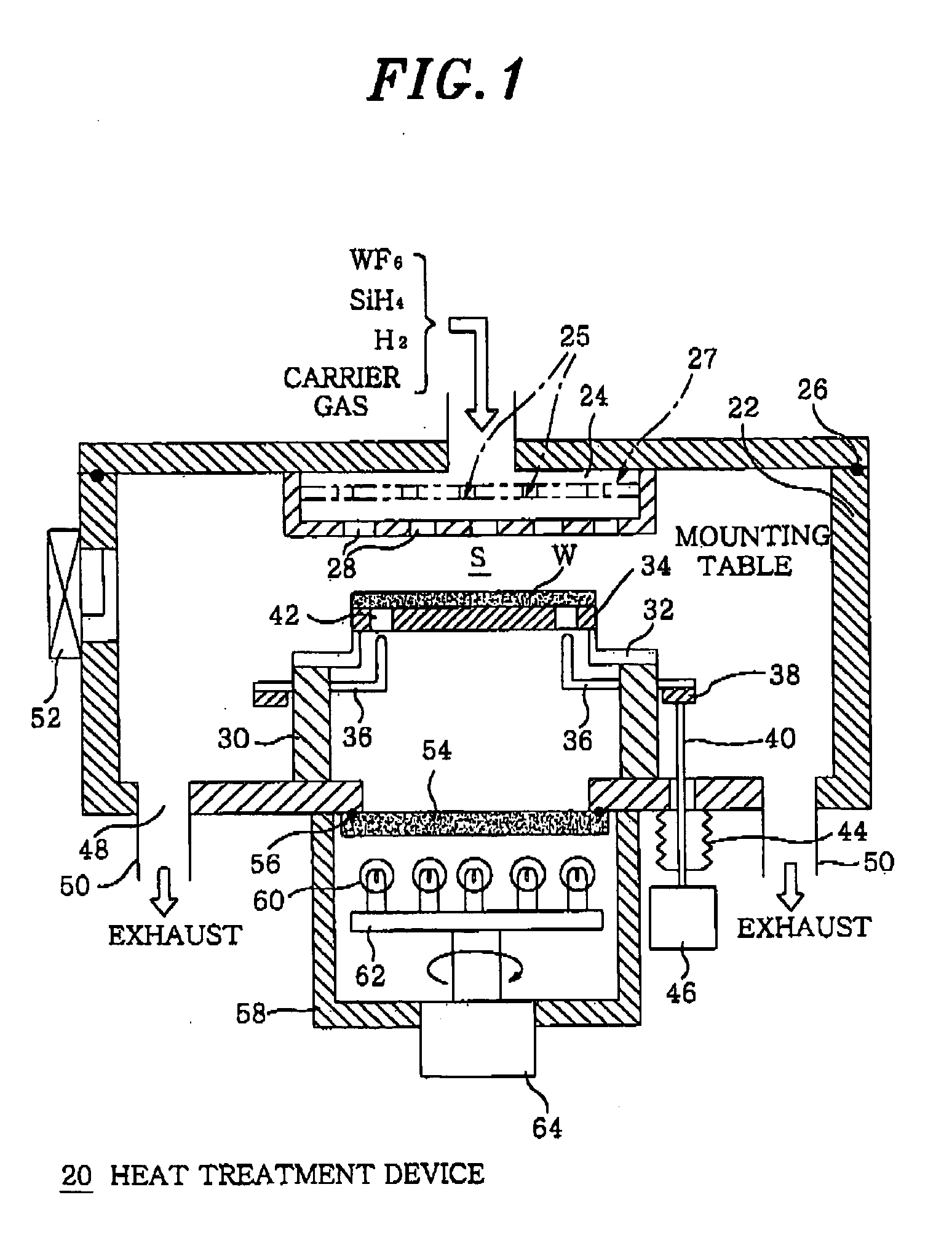

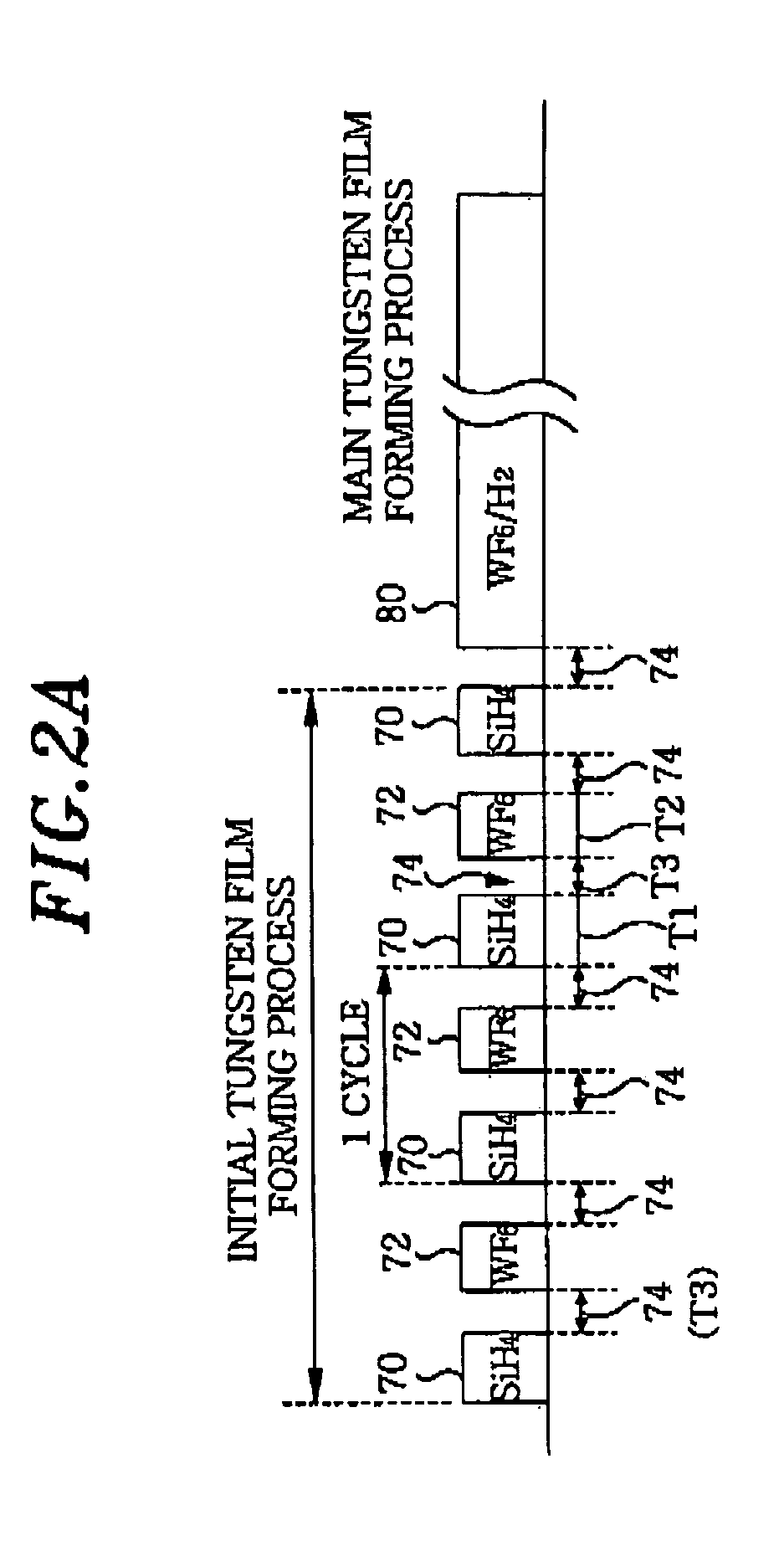

Method of forming tungsten film

InactiveUS20050032364A1Satisfactory characteristicAvoid it happening againSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNucleationVolcano

A method of forming a tungsten film, capable of restricting voids and volcanoes as large as adversely affecting characteristics despite the small diameter of a buried hole, and providing good burying characteristics. When forming a tungsten film on the surface of an object of treating (W) in a vacuumizing-enabled treating vessel (22), a reduction gas supplying process 70 and a tungsten gas supplying process 72 for supplying a tungsten-containing gas are alternately repeated with a purge process 74, for supplying an inert gas while vacuumizing, intervened therebetween to thereby form an initial tungsten film 76. Therefore, an initial tungsten film can be formed as a nucleation layer high in film thickness uniformity; and, accordingly, when main tungsten films are subsequently deposited, it is possible to restrict voids and volcanoes as large as adversely affecting characteristics despite the small diameter of a buried hole, and provide good burying characteristics.

Owner:TOKYO ELECTRON LTD

Agglomerated perlite

Perlite, a volcanic glass, is used in a variety of horticultural, construction and industrial applications. In order to be put to such uses, mined perlite ore is crushed and screened to size and then expanded by being passed through a flame at high temperature. During the expansion phase, up to 50% of the perlite may be unintentionally fractured, resulting in very fine perlite material with little or no commercial application. The method and product of the present invention converts saleable expanded perlite, as well as fine perlite material (which is of such a size and quality that it is of no value to a manufacturer and is difficult to dispose of) into a relatively dust free product with numerous end applications, some of which are new uses for perlite.

Owner:BODYCOMB FREDERICK M +1

Hyaloclastite pozzolan, hyaloclastite based cement, hyaloclastite based concrete and method of making and using same

ActiveUS9822037B1Improved propertyWater demandLiquid ingredients supply apparatusVolcanoPolymer chemistry

The invention comprises a composition comprising hyaloclastite having a volume-based mean particle size of less than or equal to 40 μm. The invention also comprises a cementitious material comprising a hydraulic cement and hyaloclastite, wherein the hyaloclastite has a volume-based mean particle size of less than or equal to approximately 40 μm. The invention further comprises a cementitious-based material comprising aggregate, a cementitious material comprising a hydraulic cement and hyaloclastite, wherein the hyaloclastite has a volume-based mean particle size of less than or equal to approximately 40 μm and water sufficient to hydrate the cementitious material. A method of using the composition of the present invention is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

Pervious concrete comprising a geopolymerized pozzolanic ash binder

InactiveUS8038789B2Low costImprove performanceSolid waste managementCement productionAluminateRoad surface

Owner:CERAMTEC

Ultra wideband planar printed volcano antenna

InactiveUS7132985B2Easy to manufactureImprove performanceSimultaneous aerial operationsRadiating elements structural formsUltra-widebandWide band

Owner:LIN DING FU

Oil-well cement additive for preventing corrosion of hydrogen sulfide as well as preparation method and application thereof

The invention provides an oil-well cement additive for preventing corrosion of hydrogen sulfide as well as a preparation method and an application thereof, belonging to the field of oil-well cement well cementation. The oil-well cement additive mainly comprises the following components in percent by weight: 20-75% of volcano cinerea mineral, 2-35% of silica powder, 5-30% of aluminum salt mineral,2-35% of pitch organic material, 1-10% of gangue, and the like. By adding 15-60 parts of the oil-well cement additive in the well cementation cement slurry system with 100 parts of cement, the invention can enhance the tightness of a cement loop pillar, has low gas permeability and strong ability for resisting the corrosion of hydrogen sulfide, is suitable for different temperatures in the bad well cementation environment and has wider application range.

Owner:CHINA PETROLEUM & CHEM CORP +1

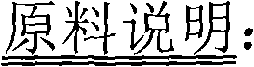

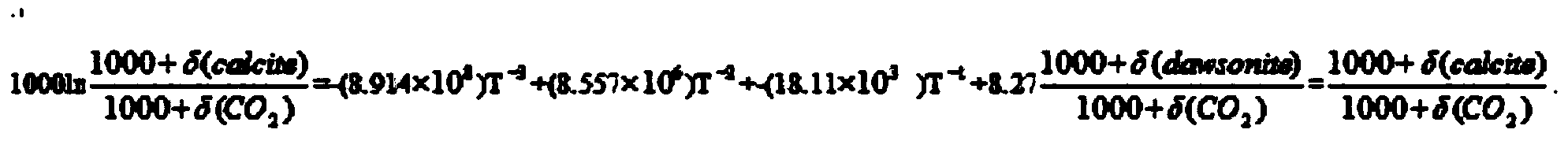

Method for judging mantle-derived CO2 charging time

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Water enhancement fire retardant

InactiveUS7087105B1Improve returnReduce erosionFireproof paintsAntifouling/underwater paintsAnimal lifeAdditive ingredient

An air-droppable wildfire retardant composition including Lassenite N pozzolan is a natural siliceous (amorphous) mineral, consisting of the layers of diatoms and volcanic tuffs of Northern California's Cascade Range. The Lassnite pozzolan is mixed with a thickener such a Bentonite clay, a measured volume of water forming a slurry-type mixture capable of suspending the particles of pozzolan in a mixture having a viscosity sufficient to avoid solids separation. The inventive fire retardant contains substantially three innocuous ingredients which have no harmful effects to the atmosphere, plant, or animal life.

Owner:HARRY H CHAPPELL TRUST +6

Modified soft sandstone baking-free brick

The invention discloses a modified soft sandstone baking-free brick, and belongs to the field of a building material. The baking-free brick comprises the following components by mass percent: 10-50% of diagenetic admixture with cinerite activity or latent hydraulicity, 10-15% of universal portland cement, 0.5-40% of diagenetic agent, 8-12% of water and 45-70% of soft sandstone. The method comprises the following steps: mixing the components according to the ratio; carrying out compression molding the components; naturally maintaining, maintaining in a green house under the condition at 30-60 DEG C; carrying out standard maintenance under the conditions that the temperature is 20-30 DEG C and the humidity is greater than 90% or carrying out steam maintenance at the temperature of 60-210 DEG C, so as to obtain the modified soft sandstone baking-free brick. The modified soft sandstone baking-free brick has a good market prospect in the locality, and is low in price, convenient to obtain raw materials, applicable to local promotion, and conducive to promotion of new rural policy of the country.

Owner:DALIAN UNIV OF TECH

Method of making cement from tailings or rock fines containing silicate or siliceous compounds

InactiveUS20020033120A1Eliminate riskSolve the real problemSolid waste managementCompound aCrushed stone

A method of making cement from tailings or rock fines containing silicate or siliceous compounds includes grinding the tailings or rock fines to a size in the range of from about -250 to about 425 mesh to produce ground pozzolan. The ground pozzolan is mixed with Type 1 normal Portland cement or Type 3 high early strength Portland cement in a ratio of at least about 0.1:1 by weight to produce a blended cement.

Owner:FENICEM MINERALS

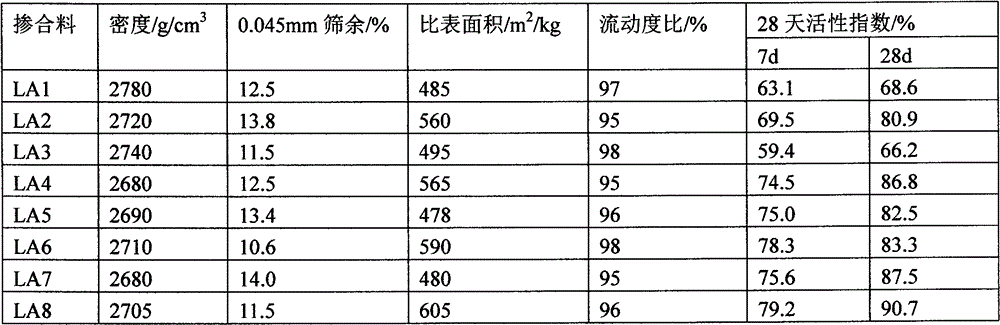

Preparation method and application of PD composite mineral admixture containing silica fume

The present invention provides a preparation method and application of a PD composite mineral admixture containing silica fume. The PD composite mineral admixture comprises components of, by weight percentage, 0%-95% of volcano ash, 0%-95% of mountain flour, 5%-30% of silica micropowder (silica fume) and 0-8% of gypsum, wherein the volcano ash content and mountain flour content can not be zero at the same time, and the gypsum content can be zero according to the requirements. A double-mixing admixture, a ternary-mixing admixture and a quaternary-mixing admixture are prepared by utilizing superimposed effect and interaction effect generated by a quaternary system of ''volcano ash-mountain flour-silica fume-gypsum''. Admixtures with different performance characteristics can be prepared by only adjusting the proportion of the components in the PD composite mineral admixture provided by the invention; the admixture can substitute 15%-50% of cement in concrete and mortar, with equal or excessive amount, and realizes a better effect than an admixture mixed with single volcano ash or mountain flour; and the admixture can be prepared by using local raw materials, or waste stone slag and mountain flour. Therefore, the admixture has good application prospect and promotion value in places lack of conventional admixture.

Owner:张仲 +1

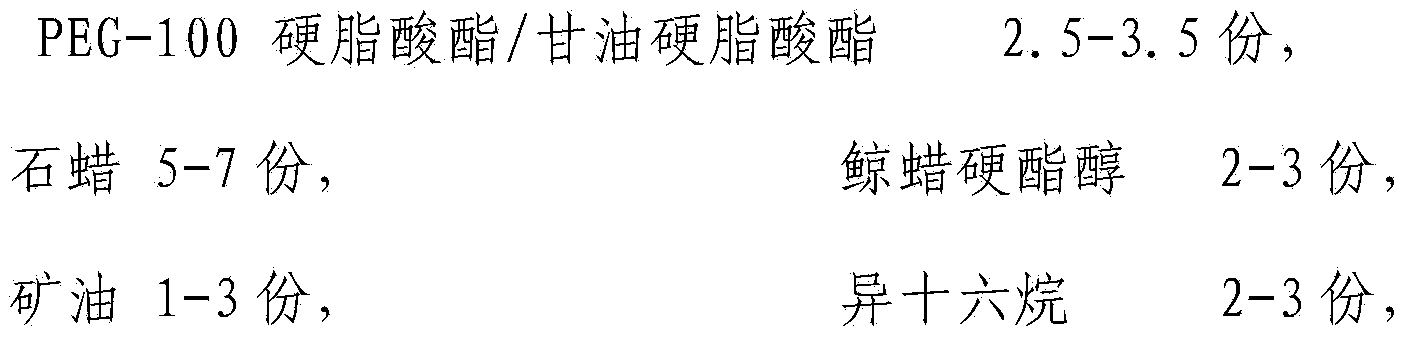

Muddy facial mask containing natural volcanic mineral mud powder

InactiveCN104042511ALow costGood effectCosmetic preparationsToilet preparationsParaffin waxSide effect

The invention discloses a muddy facial mask containing natural volcanic mineral mud powder. The muddy facial mask comprises PEG-100 stearate / glycerol stearate, paraffin wax, cetearyl alcohol, mineral oil, isohexadecane, phenyl isopropyl polydimethylsiloxane, butylated hydroxytoluene, cyclohexasiloxane / cyclopentasiloxane, glycerin, sodium hyaluronate, EDTA disodium, allantoin, panthenol, volcanic mud, paeonia suffruticosa root extract, portulaca oleracea extract, preservatives and a flavouring agent. The muddy facial mask is prepared from simple and easily available raw materials, simple in production preparation operation, and low in production cost, and required mineral mud powder is natural and easily available; the muddy facial mask is compounded of three kinds of mud powder for different purposes, integrates all different functions of the three raw materials and brings out the best in one another; and the muddy facial mask has no side effect and has high safety and good stability. Users do not has dependence after the muddy facial mask is used many times.

Owner:NOX BELLCOW COSMETICS CO LTD

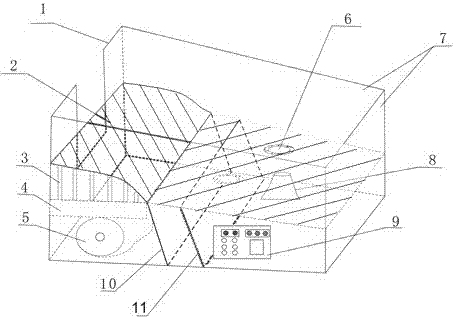

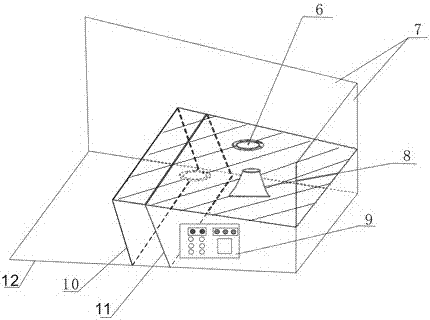

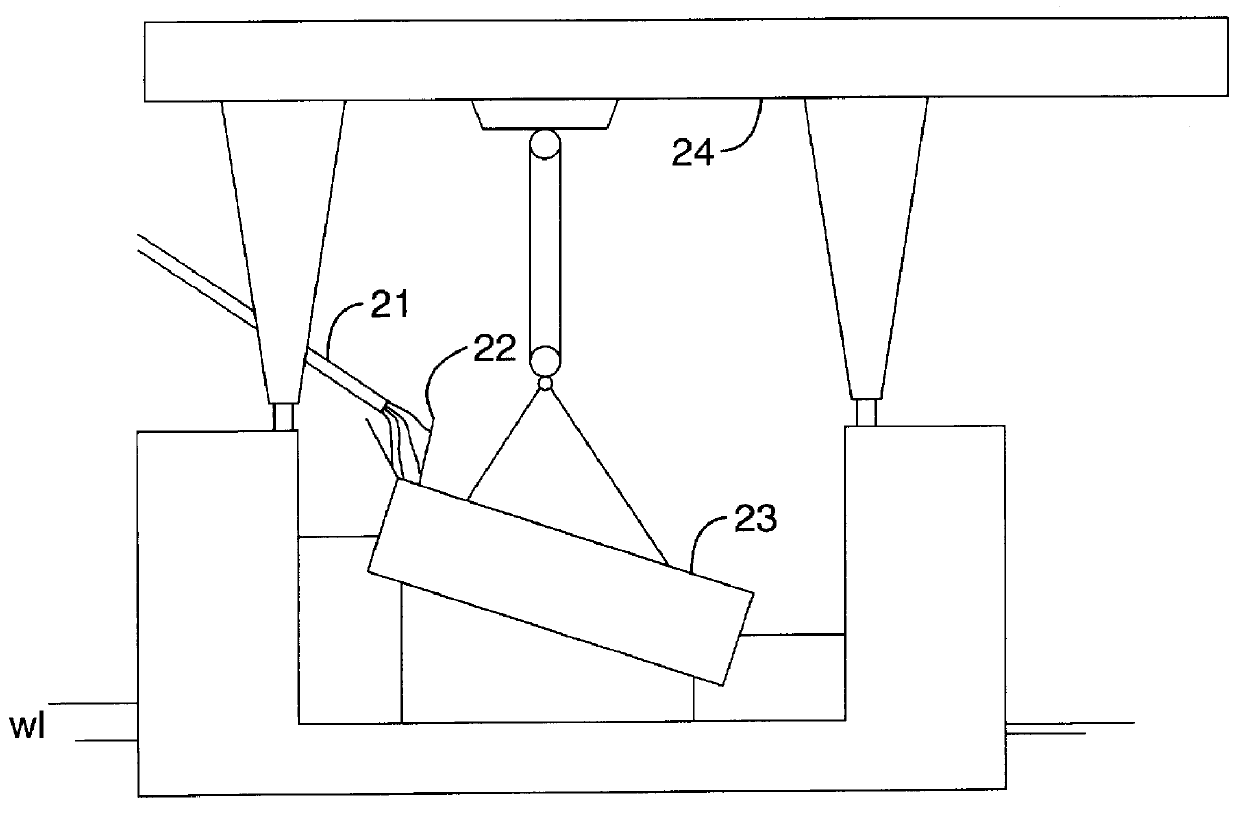

Multifunctional sedimentary water tank experiment device and method

ActiveCN107219061AImplement the spread featureHigh degree of automationHydrodynamic testingMaterial analysisOcean bottomControl system

The invention relates to a multifunctional sedimentary water tank experiment device and method. The technical scheme is that the device comprises four parts of a water tank external wall, a variable-gradient slope system, a seabed or lakebed system and a power and control system. The power and control system supplies power to other parts. The variable-gradient slope system comprises a sedimentary slope, elevating columns, a column house and a cylinder. The lower side of the sedimentary slope realizes elevating through the elevating columns and the column house, and scaling and shortening of the sedimentary slope are realized through the cylinder. The seabed or lakebed system is provided with a volcano model, an inclined plane I and an inclined plane II. The water tank external wall comprises a baffle plate having a notch and a transparent baffle plate. The beneficial effects are that the sedimentary environments of the simulation sea, lake and desert are integrated, the slope toe of the sedimentary basin can be freely changed, the sedimentary base can automatically elevate and sedimentation of earthquake, volcano and other special events can be simulated so that the degree of automation is high.

Owner:山东石油化工学院

Hyaloclastite pozzolan, hyaloclastite based cement, hyaloclastite based concrete and method of making and using same

ActiveUS10047006B1Improved propertyWater demandLiquid ingredients supply apparatusVolcanoPolymer chemistry

The invention comprises a composition comprising hyaloclastite having a volume-based mean particle size of less than or equal to 40 μm. The invention also comprises a cementitious material comprising a hydraulic cement and hyaloclastite, wherein the hyaloclastite has a volume-based mean particle size of less than or equal to approximately 40 μm. The invention further comprises a cementitious-based material comprising aggregate, a cementitious material comprising a hydraulic cement and hyaloclastite, wherein the hyaloclastite has a volume-based mean particle size of less than or equal to approximately 40 μm and water sufficient to hydrate the cementitious material. A method of using the composition of the present invention is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

Simulated lunar soil for engineering and its preparation process

InactiveCN102288472AGuaranteed preparationMeet the requirements of the preparation cycle (complete the preparation of 700 tons of simulated lunar soil within three months)Preparing sample for investigationLunar soilVolcano

The invention discloses a simulated lunar soil for engineering and a preparation process thereof. Cinerite in Jinchuan District, Huinan County, Jilin Province is selected as the raw material of the simulated lunar soil; the simulated lunar soil is prepared from nine types of cinerite of 3 meshes, 4 meshes, 8 meshes, 10 meshes, 18 meshes, 40 meshes, 60 meshes, 160 meshes and 200 meshes according to respective weight percentages. The preparation process of the simulated lunar soil comprises the steps of raw material selection, scoria air-drying, scoria coarse crushing and drying, scoria pulverization and finished product preparation. The simulated lunar soil prepared through the preparation process of the invention meets the requirements of the simulated lunar soil for engineering in both preparation cycle and control indexes.

Owner:JILIN UNIV

Building external wall thermal insulation material and preparation method thereof

InactiveCN106396535AHigh compressive strengthImprove insulation effectCeramicwareCarbon fibersPolyvinyl alcohol

The invention discloses a building external wall thermal insulation material and a preparation method thereof, and the building external wall thermal insulation material comprises the following components by weight: 70-90 parts of Portland cement, 8-15 parts of nano calcium carbonate, 20-30 parts of aminopropyltriethoxysilane, 5-15 parts of water glass, 1-5 parts of carbon fiber, 5-7 parts of polyvinyl alcohol, 6-11 parts of expanded perlite, 4-8 parts of mastra veneriformis shell powder, 2-4 parts of stannous chloride, 6-10 parts of polypropylene, 10-15 parts of phenolic resin, 8-14 parts of silicone modified epoxy resin, 6-12 parts of polystyrene resin, 4-10 parts of volcano ash, 8-12 parts of butyl acetate, 3-9 parts of magnesium oxide, 2-4 parts of magnesium chloride, 3-8 parts of calcite powder, 6-10 parts of graphite, 2-6 parts of mordenite powder, 2-5 parts of mica powder, 1-6 parts of aluminite powder, 2-4 parts of talc powder, 2-5 parts of bauxite, 1-3 parts of vanadium carbide, 1-5 parts of molybdenum disulfide, 1-3 parts of a foam stabilizer, 1-2 parts of a foaming agent and 100-260 parts of water. The building external wall thermal insulation material can save the amount of cement, reduces the construction cost, and reduces the environmental damage, and the compressive strength and the fireproofing thermal insulation performance of the material are improved.

Owner:ANQING CITY JIN YING NEW BUILDING MATERIALS TECH

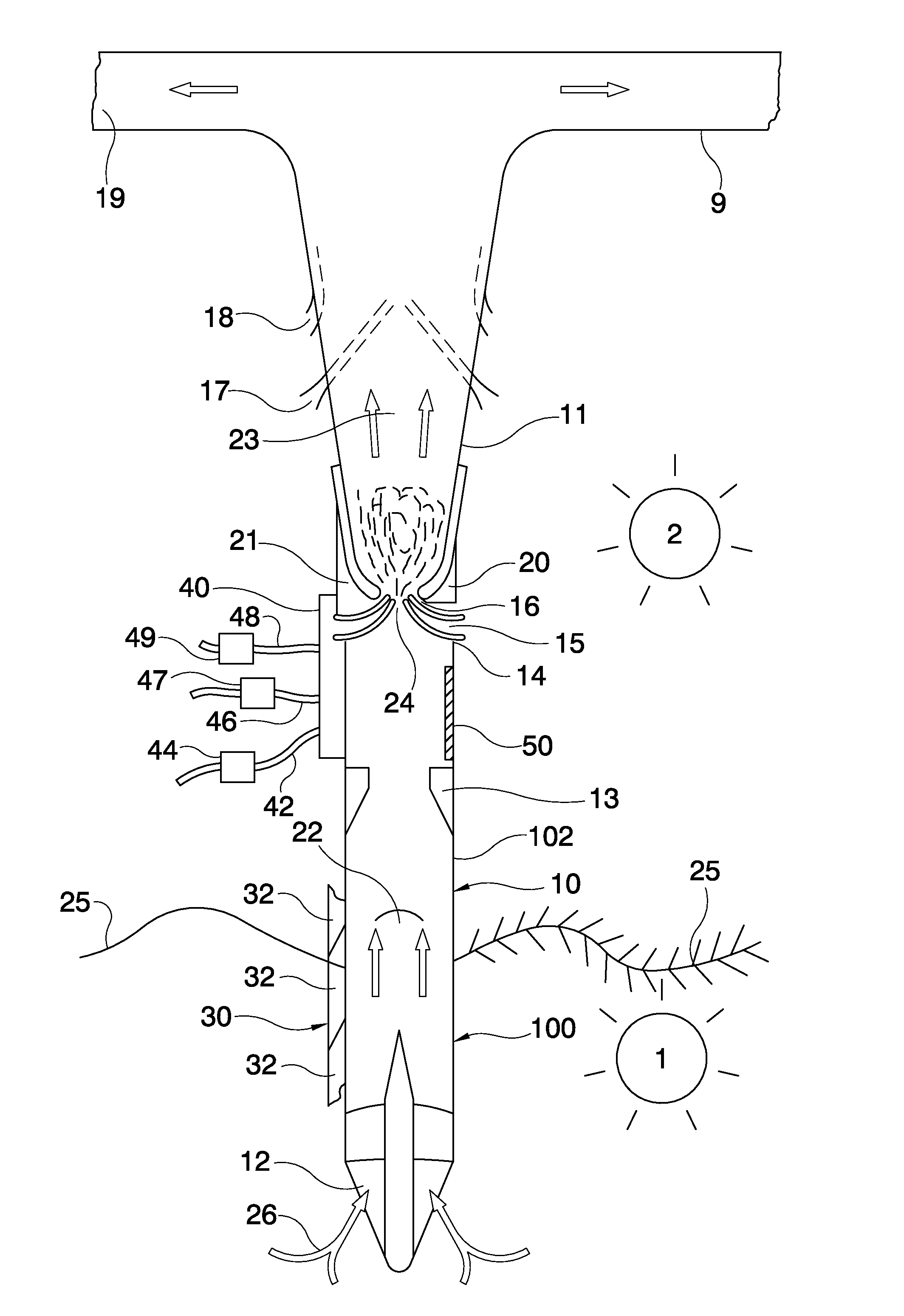

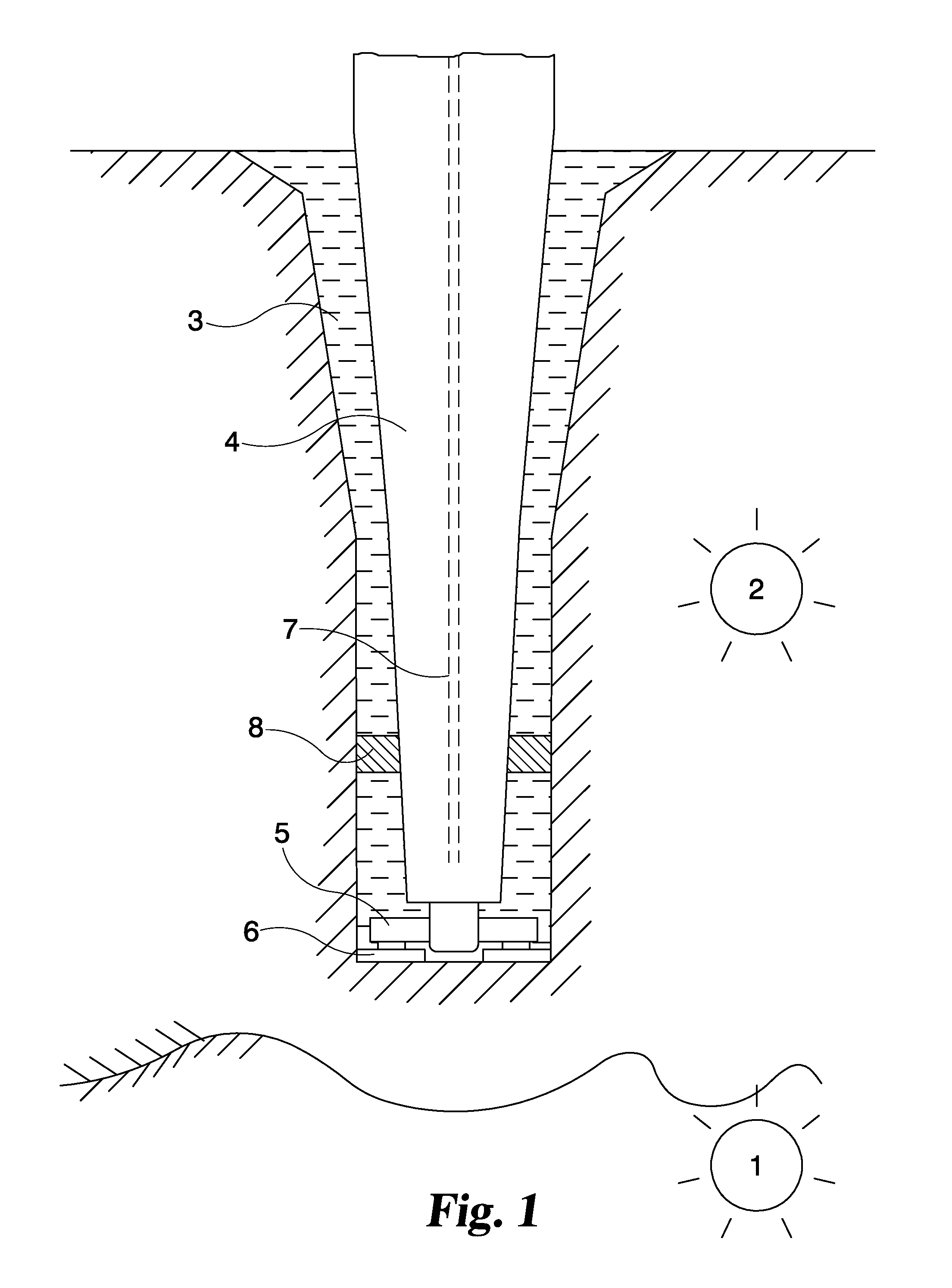

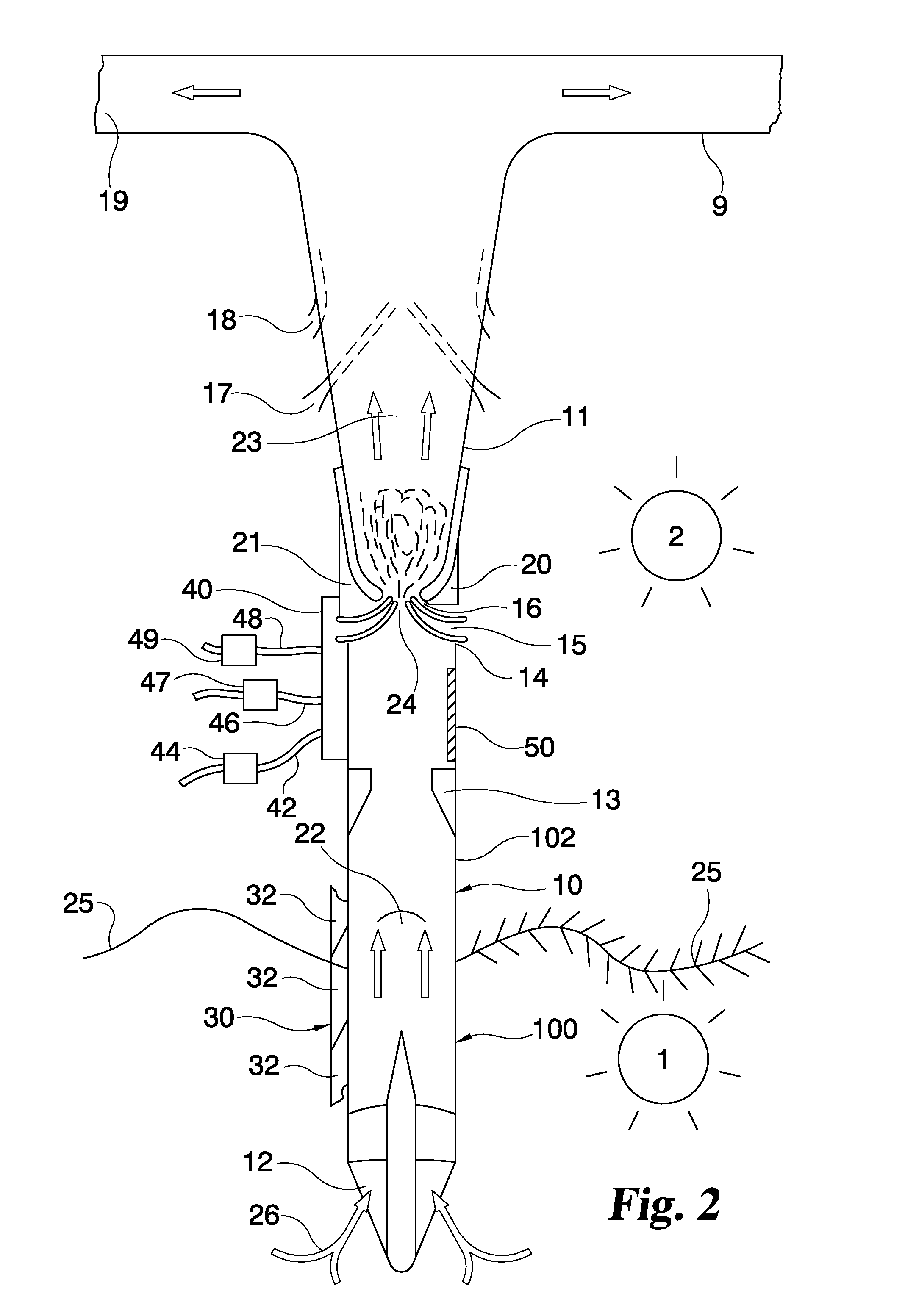

Magma evacuation systems for the prevention of explosions from supervolcanoes

InactiveUS7284931B2Avoid explosionOther heat production devicesGeothermal energy generationMagmaCombustion chamber

An apparatus controls the evacuation of volcanic magma to prevent explosions. Magma evacuation is through a single evacuation tube that heats the magma flow within the tube to prevent stickiness of the magma in the tube. The heating may use small combustion chambers to heat steam, which in turn heats and stabilizes the magma flow. Stability is aided by central cooling, where needed, using water jets from nozzles located at the wall of the tube.

Owner:STRATFORD BRIAN STAPLETON

System and Method of Control of the Terrestrial Climate and its Protection against Warming and Climatic Catastrophes Caused by Warming such as Hurricanes

InactiveUS20090032214A1Reduce intensityMinimal costOther heat production devicesAir heatersParticulatesAtmospheric air

This system of the control and protection of the terrestrial climate relies mainly on civilian airlines burning (preferably price-subsidized) sun-shading (sun-blocking / sun-reflective) fuels in the high levels of the atmosphere in order to reduce the intensity of the solar radiation reaching the Earth's surface. The use of sun-blocking airline fuels for the protection of the Earth from solar radiation parallels the use of sun-blocking skin-creams for the protection of the individual. The invention parallels the cooling effect on the Earth's climate caused by major volcanic eruptions, collisions of the Earth with asteroids, or the cooling effect one could expect after a major nuclear war. This invention proposes the creation of a controlled mini “nuclear winter”, in other words of a cooling caused by the increased refraction of the atmosphere or by the increased shading of the terrestrial surface by particulates in the high levels of the atmosphere.

Owner:HUCKO MARK

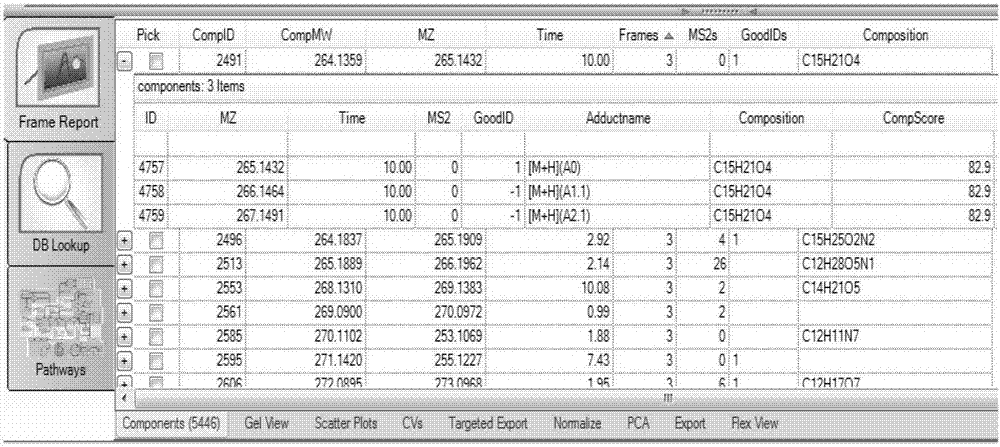

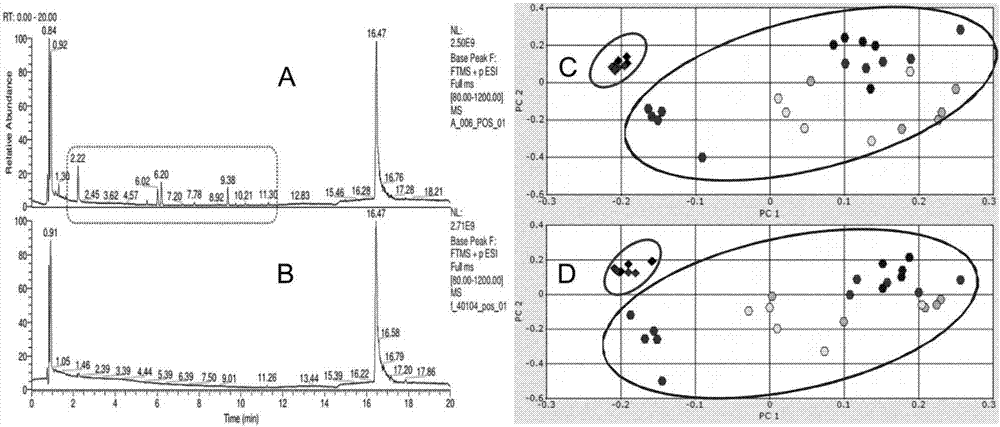

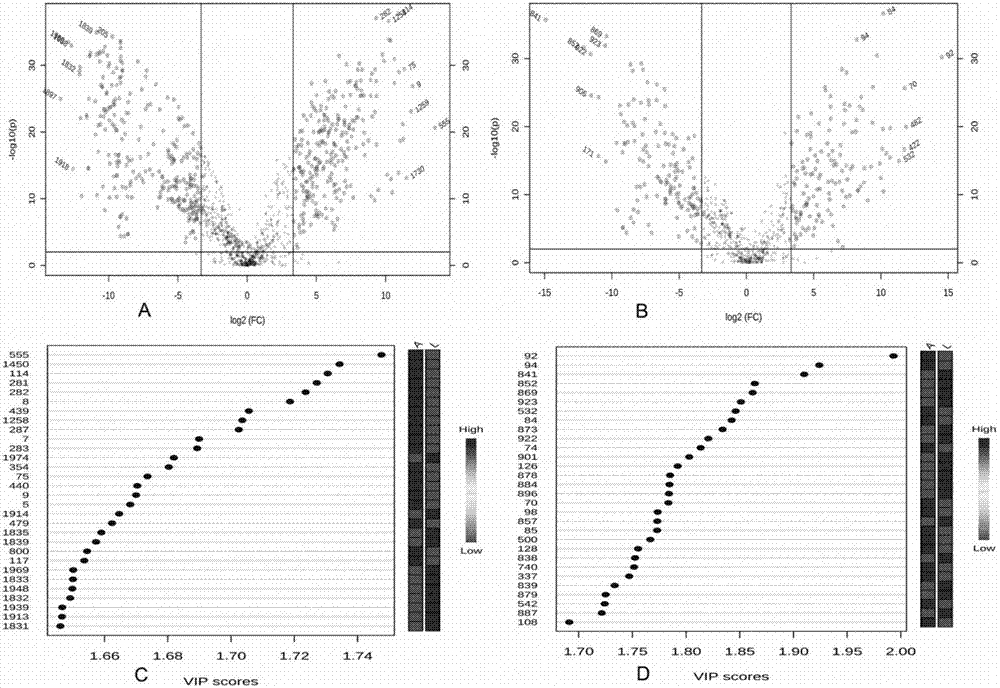

Method for identifying variety of honey by use of non-target metabonomics technology

ActiveCN106855552AKeep healthyImprove honey qualityComponent separationPrincipal component analysisQuadrupole

The invention relates to a method for identifying the variety of honey by use of a non-target metabonomics technology. The method is characterized in that through a simple sample pre-treatment process, then lots of high-resolution mass spectrometric data are acquired through an ultra-high performance liquid chromatography-quadrupole / electrostatic field orbitrap high-resolution mass spectrometry method, interference caused by deviation and variation in experimental data through background deduction, chromatographic peak extraction, normalization, data conversion and data scaling, and after that, a real feature marker capable of distinguishing the variety of honey can be discovered and confirmed through principal component analysis, t-checkout, volcano plots and variable importance projection drawings. When the feature marker is utilized to identify the quality of honey, the identification results are objective and accurate. The method is used for not only source-tracing identification of the variety of honey but also variety source tracing and origin tracing identification of other agricultural products.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

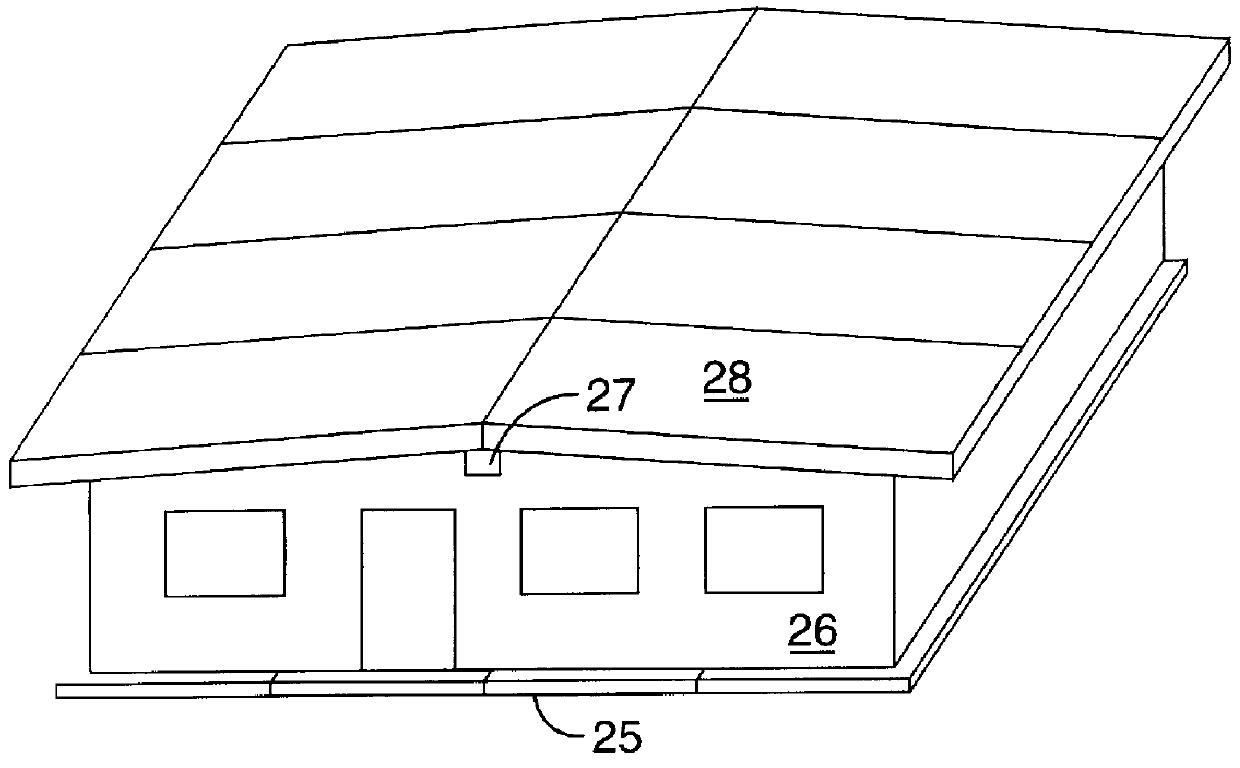

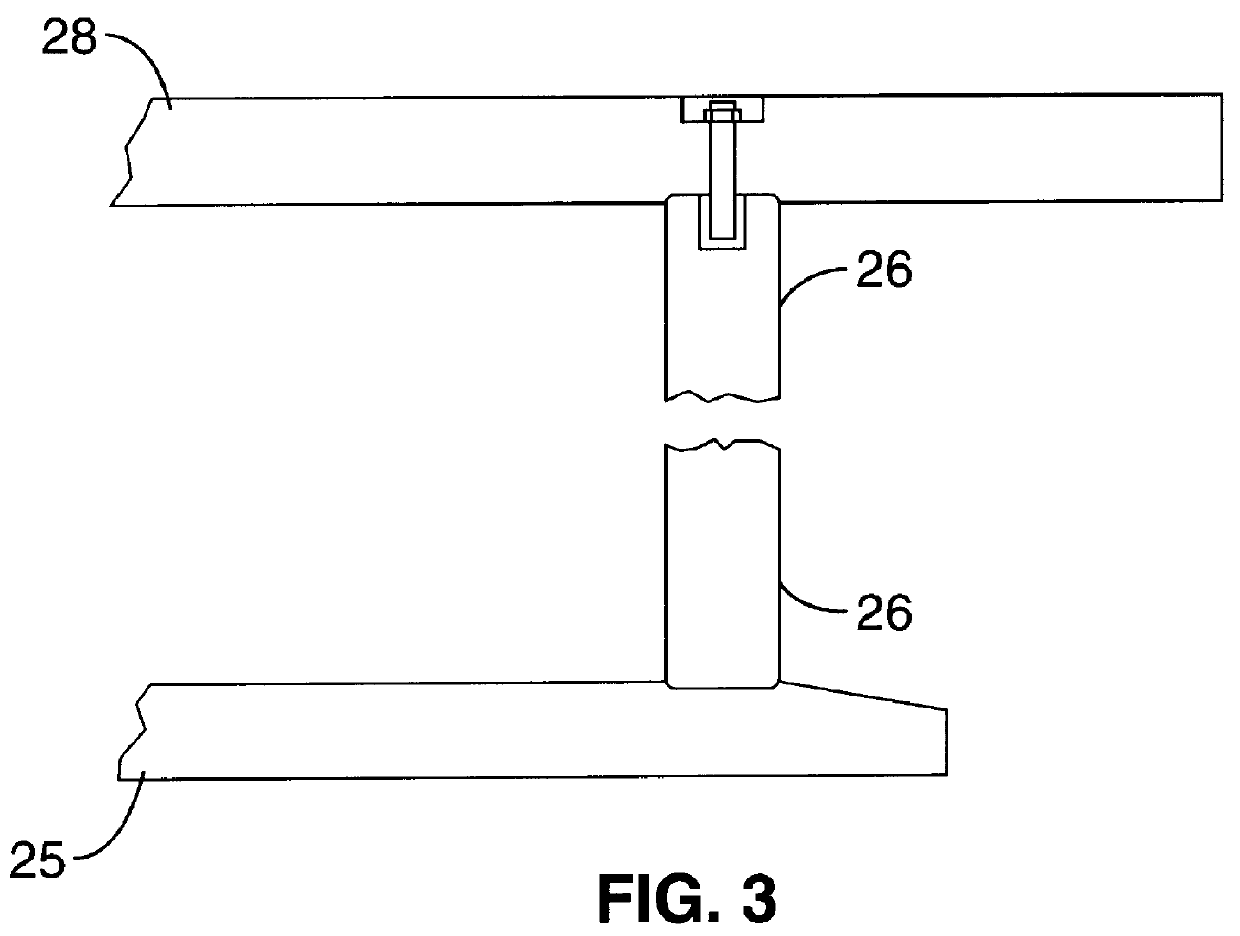

Method of manufacturing a building material from volcanic magma

A method of manufacturing a building material includes the steps of directing molten volcanic magma from an underwater volcanic magma vent to a level above sea level via a tube formed from the magma; directing the molten volcanic magma into a mold on a floating barge; cooling the magma in the mold to form a building material; and removing the building material from the mold. The tube is formed by lowering a cap assembly over an underwater flowing volcanic magma vent and raising the cap such that the magam solidifies inside the cap perimeter where it is cold.

Owner:WATSON LOUIS L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com