Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8463 results about "Water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for monitoring and estimating energy resource consumption

ActiveUS20080224892A1Good estimateEasy to understandEnergy efficient ICTElectric signal transmission systemsElectricityEngineering

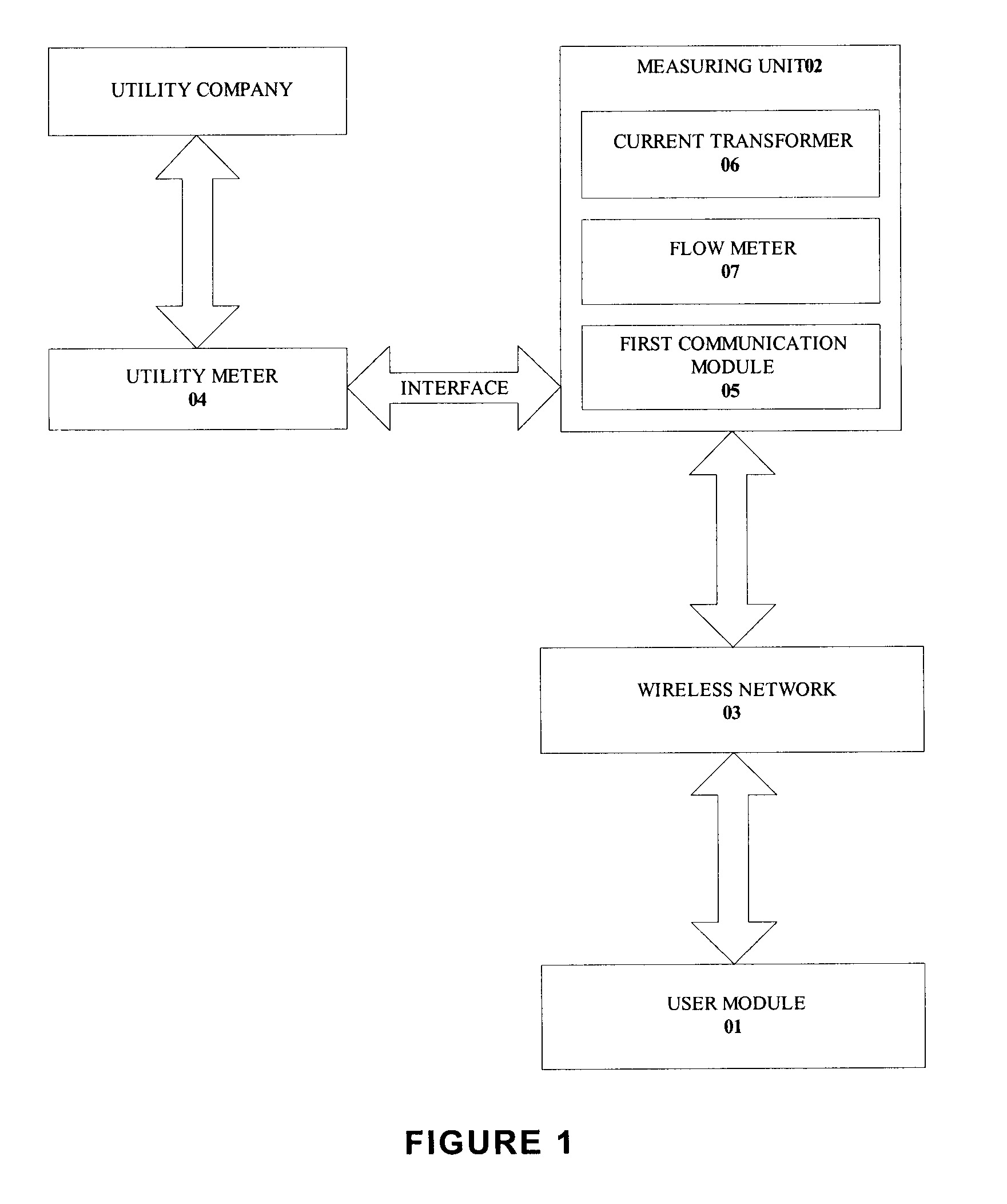

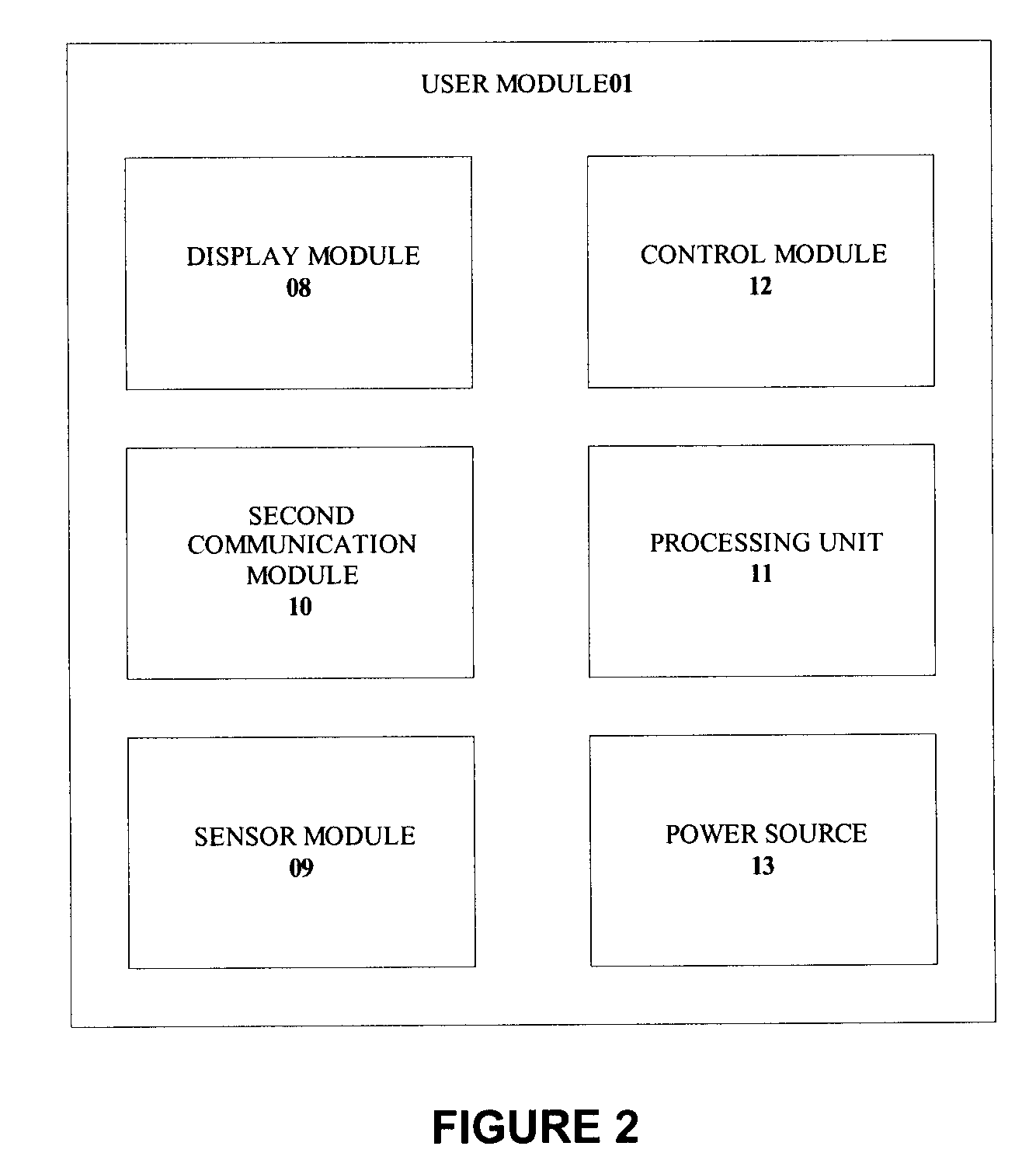

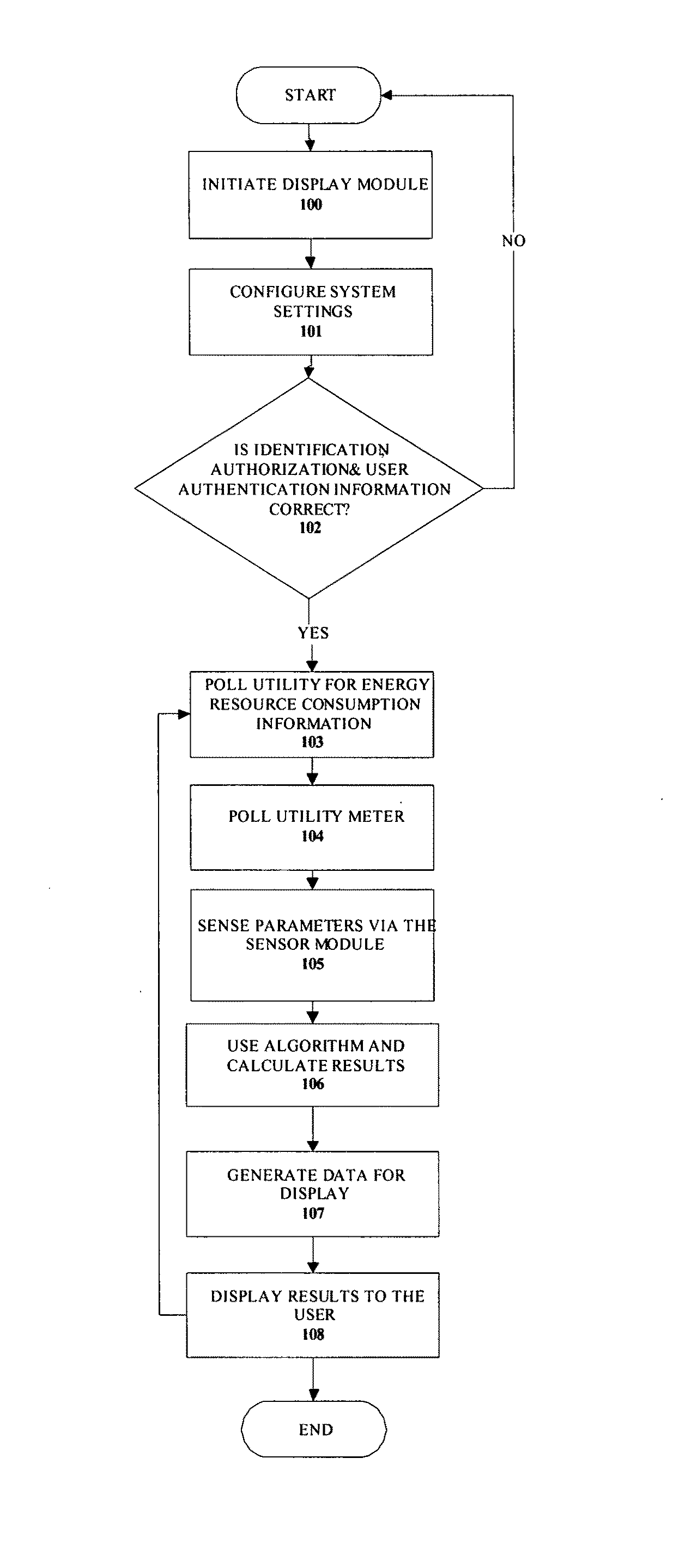

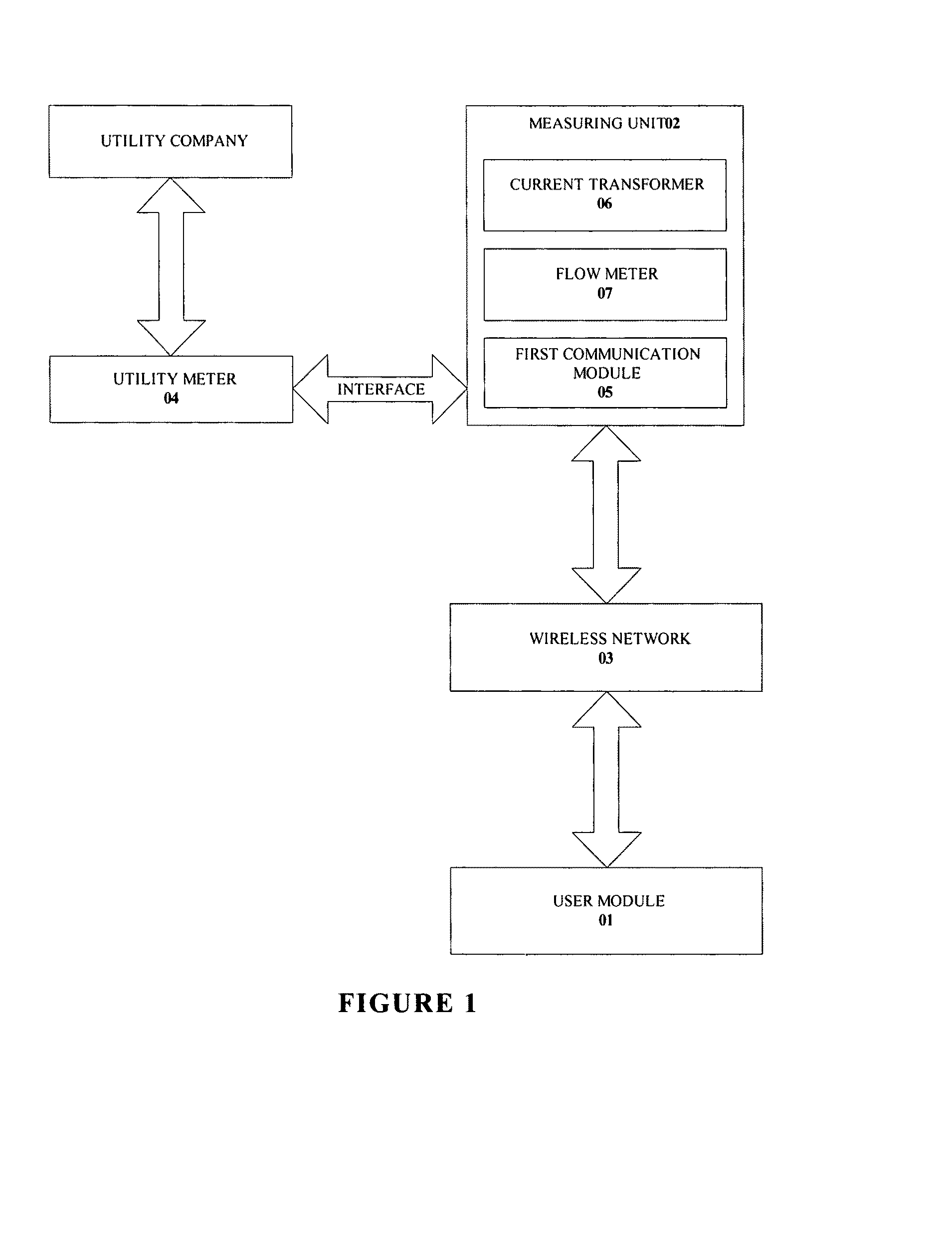

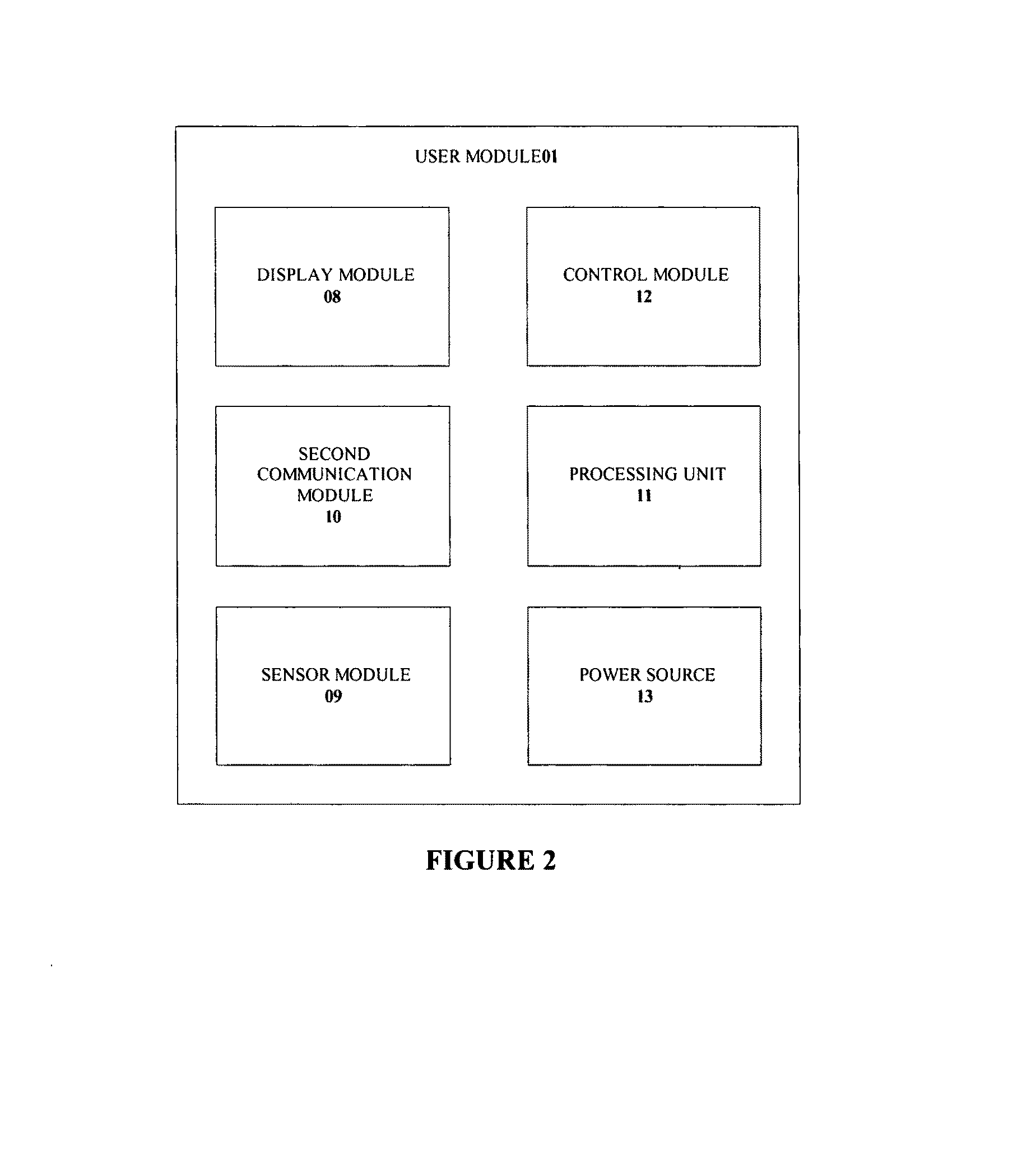

The present invention discloses a system for monitoring and estimating the consumption of energy resources in real-time. The system includes an interactive user module, a measuring unit and a wireless network. The measuring unit is interfaced to a utility meter. Optionally, the measuring unit can also function as a stand alone device. The measuring unit is further connected to the interactive user module via the wireless network. The system monitors energy resource consumption such as electricity, gas or water consumption in real-time, generates and displays graphs of energy resource consumption over user selected time periods and enables communication with at least one utility company. The system increases the users' awareness of their energy consumption and aids users in dynamic or deregulated pricing environments to shed load when the energy resource is most expensive. With knowledge of their energy use, the users can take proactive steps to control their energy consumption and save money. A method of estimating the energy resource consumption over a period of time is also provided.

Owner:ITRON NETWORKED SOLUTIONS INC

System and method for monitoring and estimating energy resource consumption

ActiveUS7541941B2Good estimateEasy to understandEnergy efficient ICTElectric signal transmission systemsElectricityEngineering

The present invention discloses a system for monitoring and estimating the consumption of energy resources in real-time. The system includes an interactive user module, a measuring unit and a wireless network. The measuring unit is interfaced to a utility meter. Optionally, the measuring unit can also function as a stand alone device. The measuring unit is further connected to the interactive user module via the wireless network. The system monitors energy resource consumption such as electricity, gas or water consumption in real-time, generates and displays graphs of energy resource consumption over user selected time periods and enables communication with at least one utility company. The system increases the users' awareness of their energy consumption and aids users in dynamic or deregulated pricing environments to shed load when the energy resource is most expensive. With knowledge of their energy use, the users can take proactive steps to control their energy consumption and save money. A method of estimating the energy resource consumption over a period of time is also provided.

Owner:ITRON NETWORKED SOLUTIONS INC

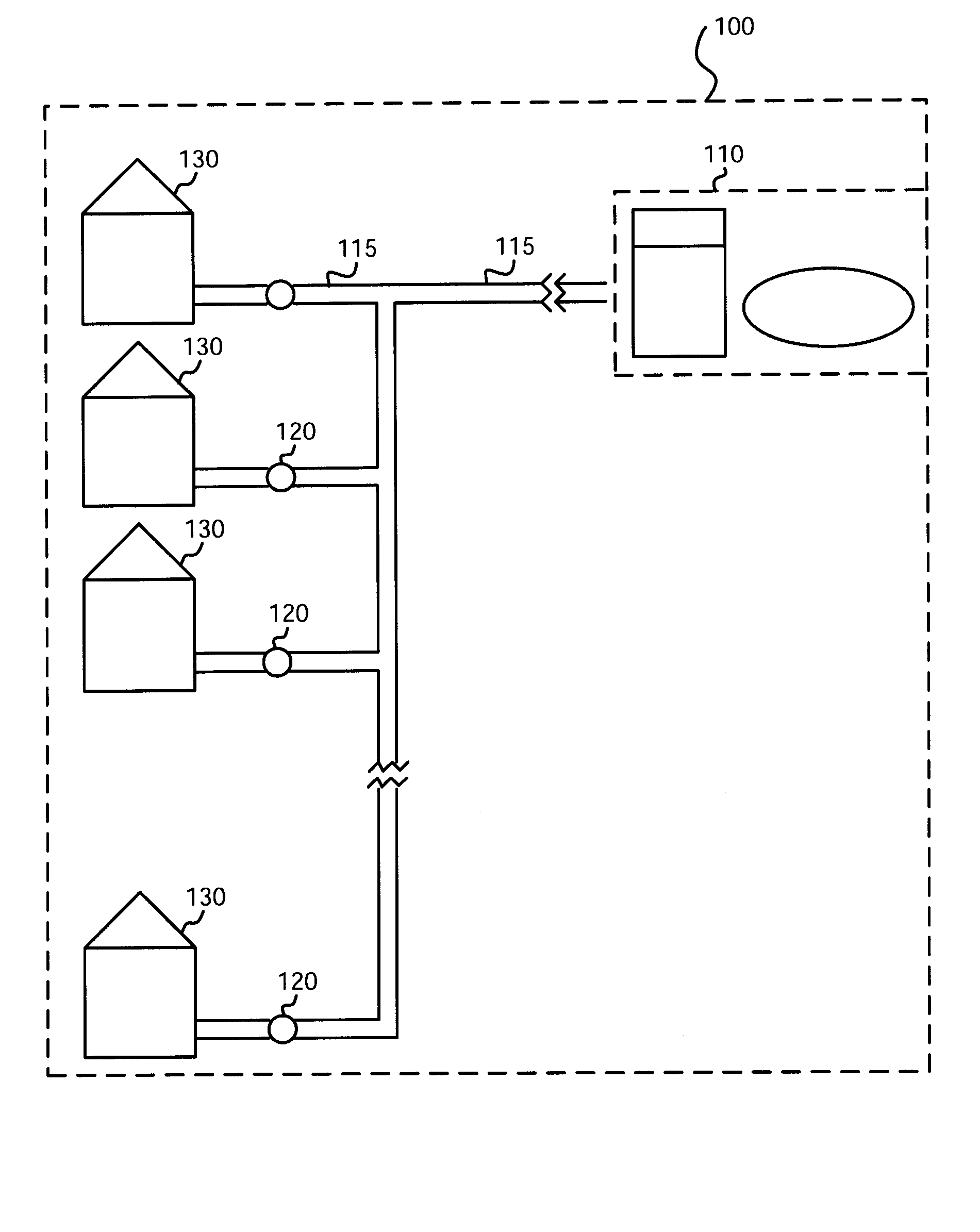

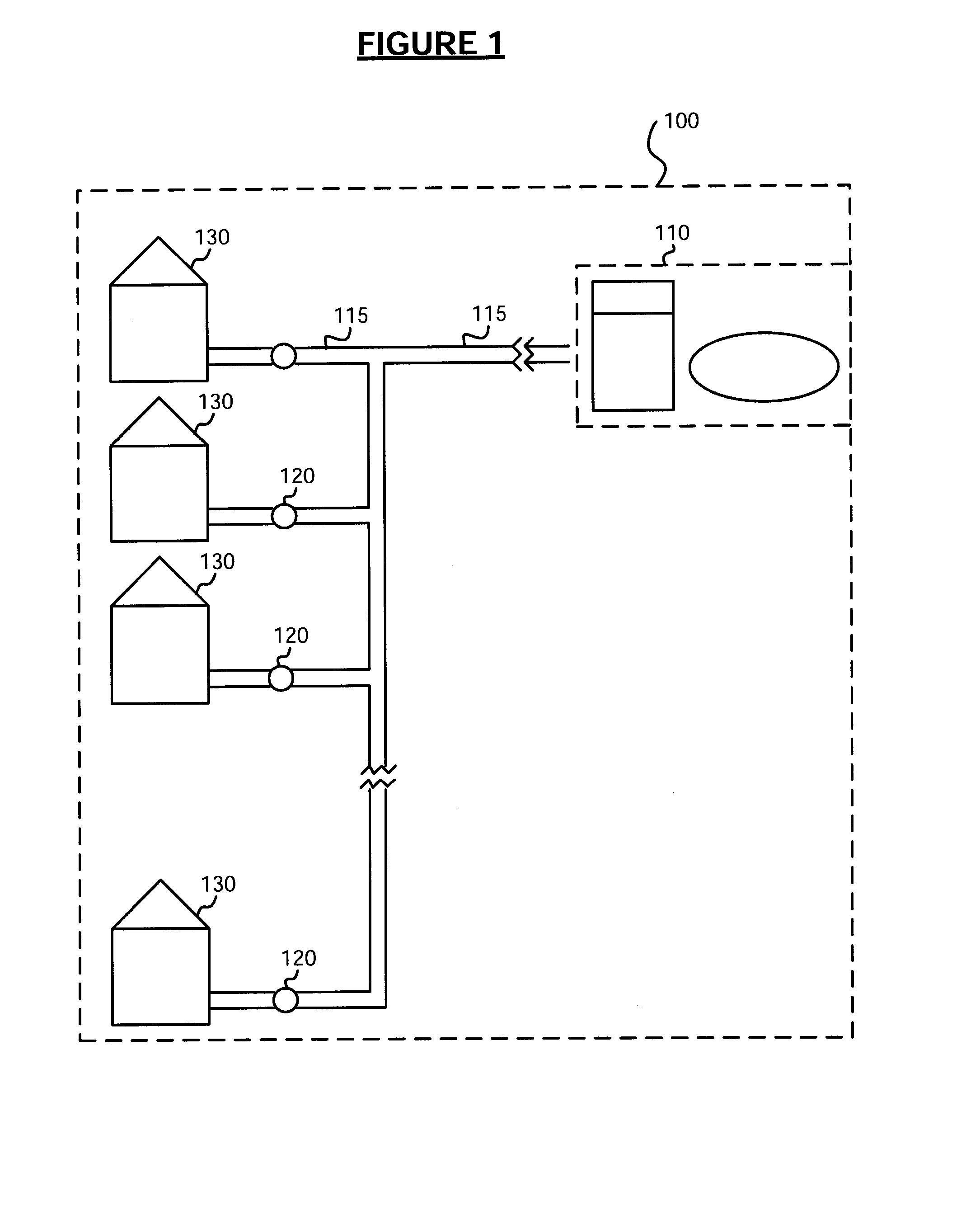

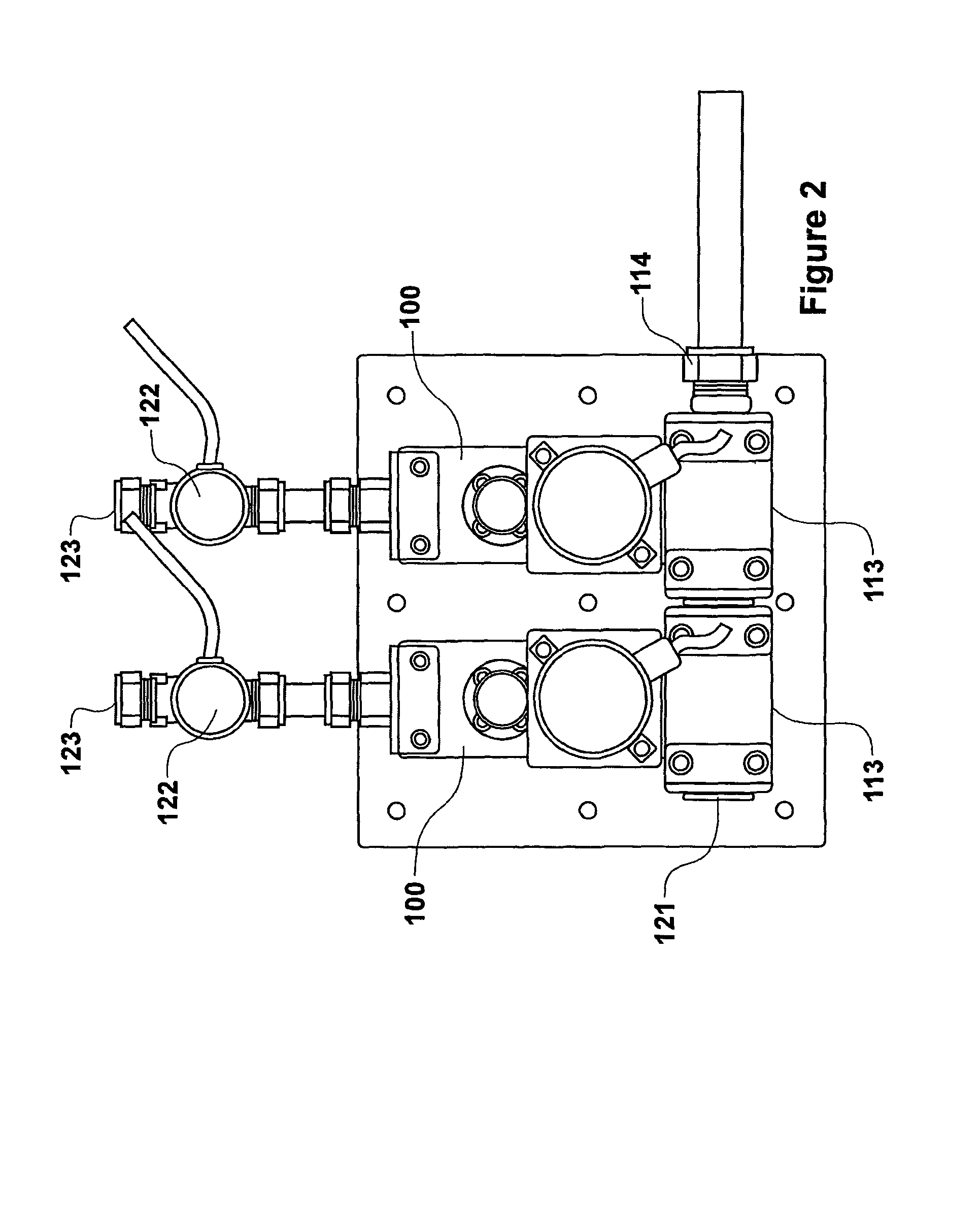

Systems and methods for monitoring and controlling water consumption

InactiveUS20060272830A1Save energyReduce energy costsProgramme controlWater treatment parameter controlFluid controlControl signal

Systems and methods for monitoring and controlling fluid consumption in a fluid-supply system are disclosed using one or more sensors for generating signals indicative of the operation thereof. In one embodiment, a method of preventing freezing of a conduit for fire suppression fluid in a fire sprinkler system includes sensing, with a temperature sensor, a temperature at a location; and if the sensed temperature falls below a predetermined threshold, sending, to at least one fluid control device interfaced with the conduit, at least one control signal to impede a flow of fire suppression fluid through the conduit.

Owner:R GIOVANNI FIMA

Systems and methods for remote utility metering and meter monitoring

ActiveUS20070284293A1Electric signal transmission systemsVolume/mass flow measurementTransceiverMechanical energy

A remote water meter monitoring system is provided. A mesh network-type transceiver unit is coupled to a water meter housing having a water counting mechanism inside to transmit water consumption information as well as other sensor information, such as backflow detection, water pressure, and water metrics (e.g., residual chlorine and temperature) to a central server system via a bridge device and a corresponding mesh network. Mechanical energy from the water flowing through the water meter housing is converted to electrical energy via an energy conversion unit. An electrically powered shut off valve is remote addressable via the transceiver unit.

Owner:MUELLER INT LLC

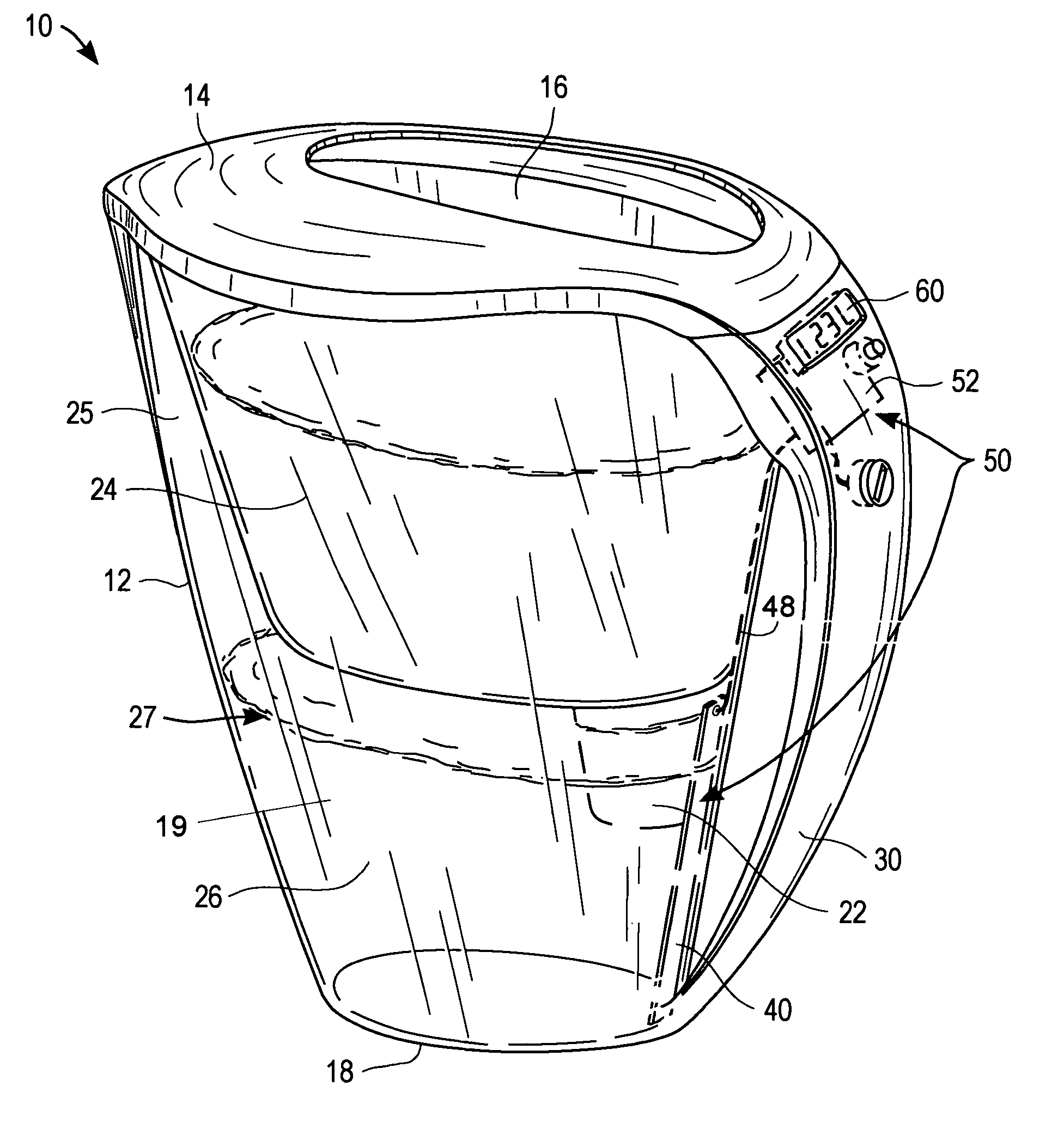

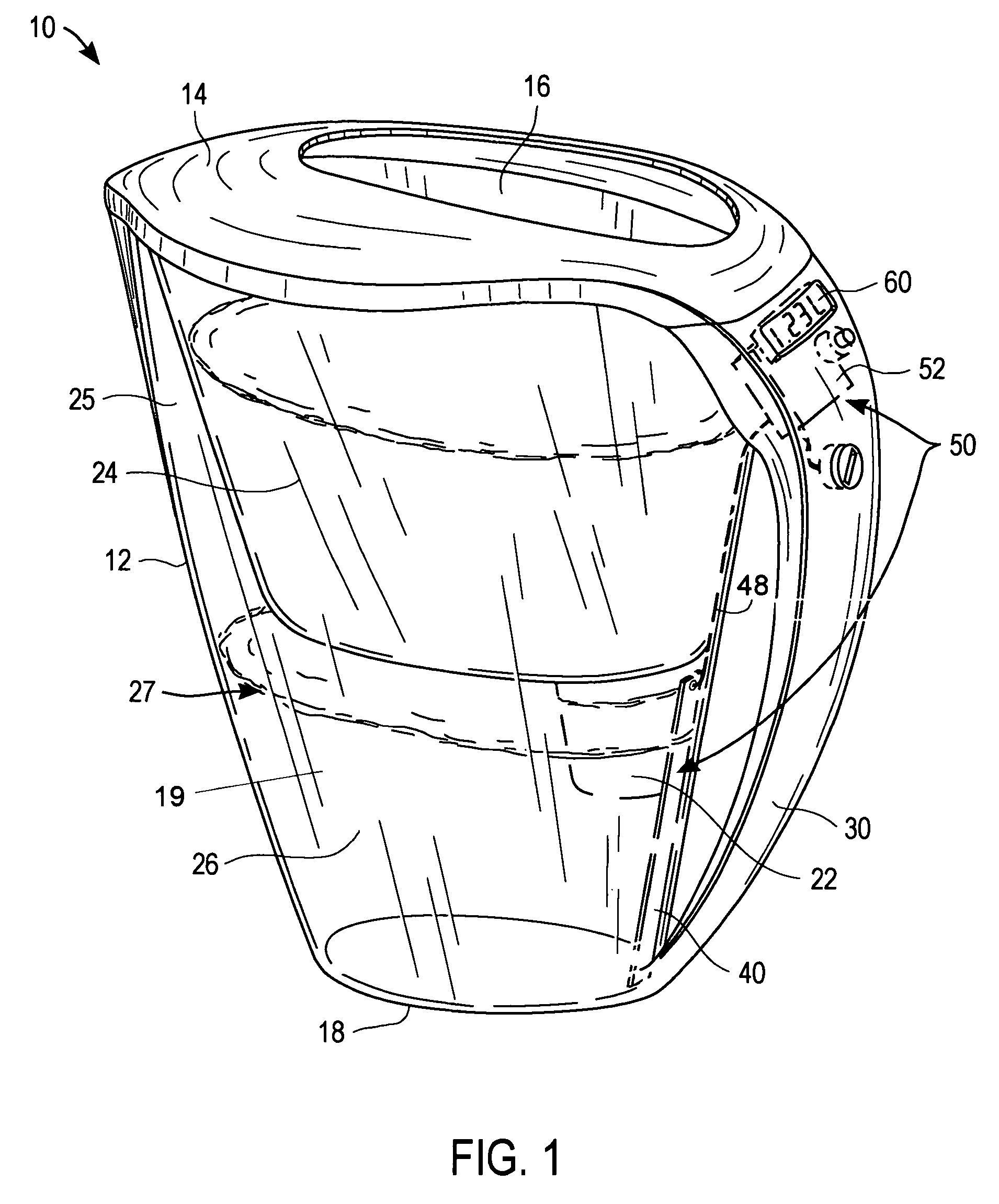

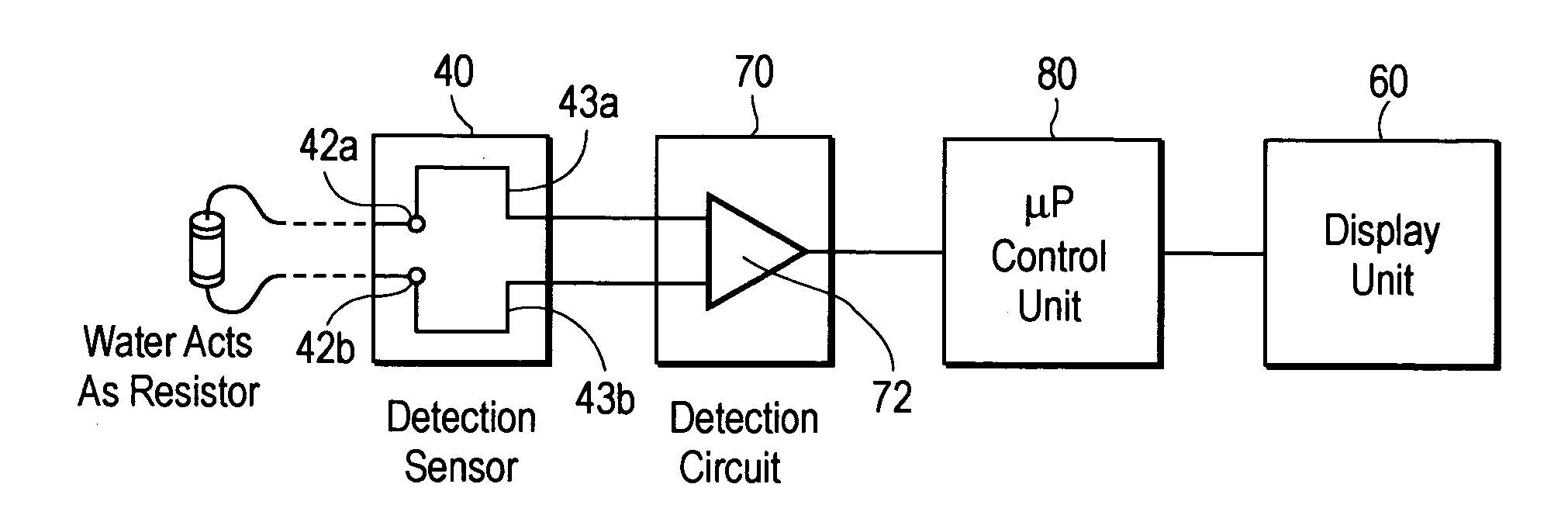

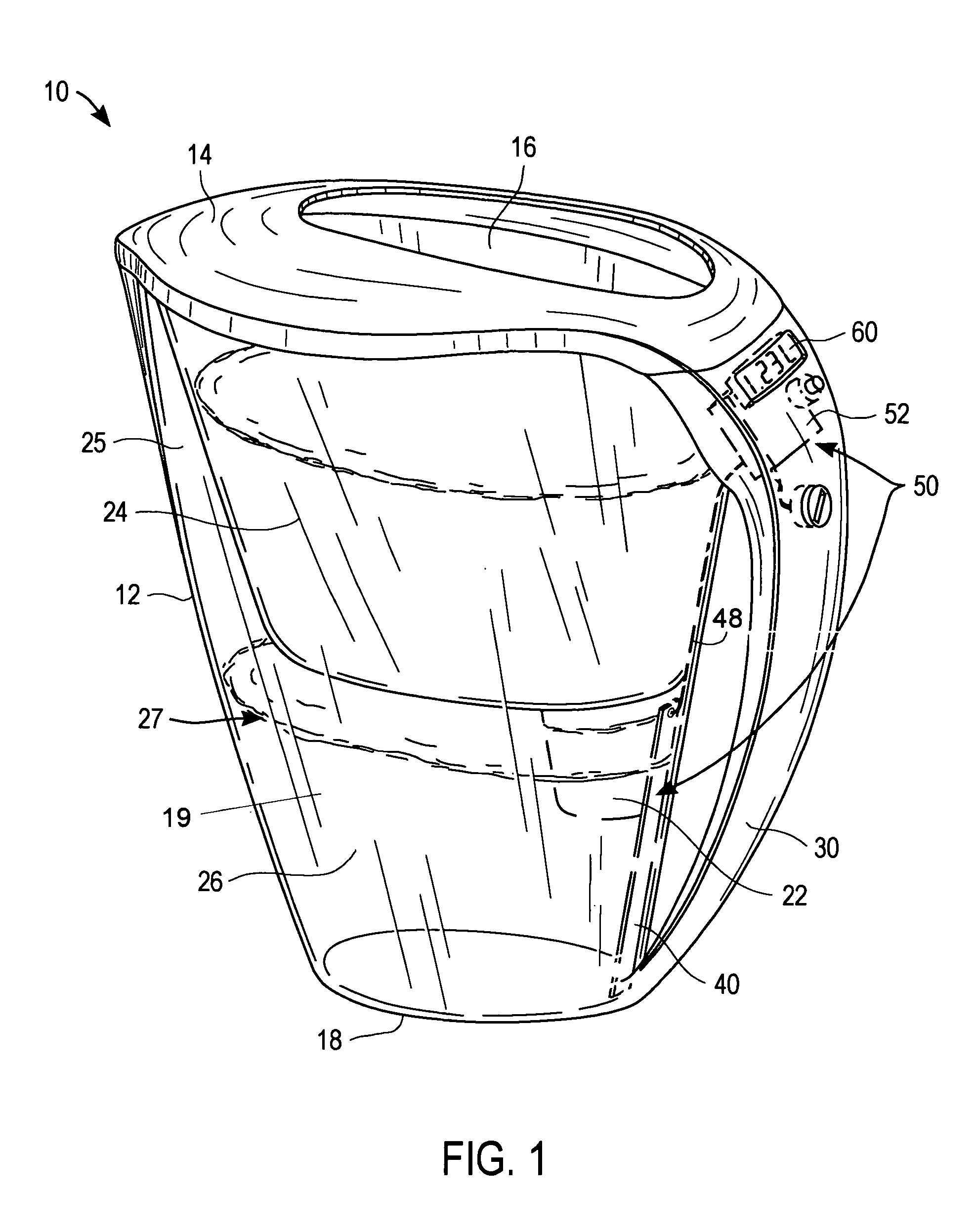

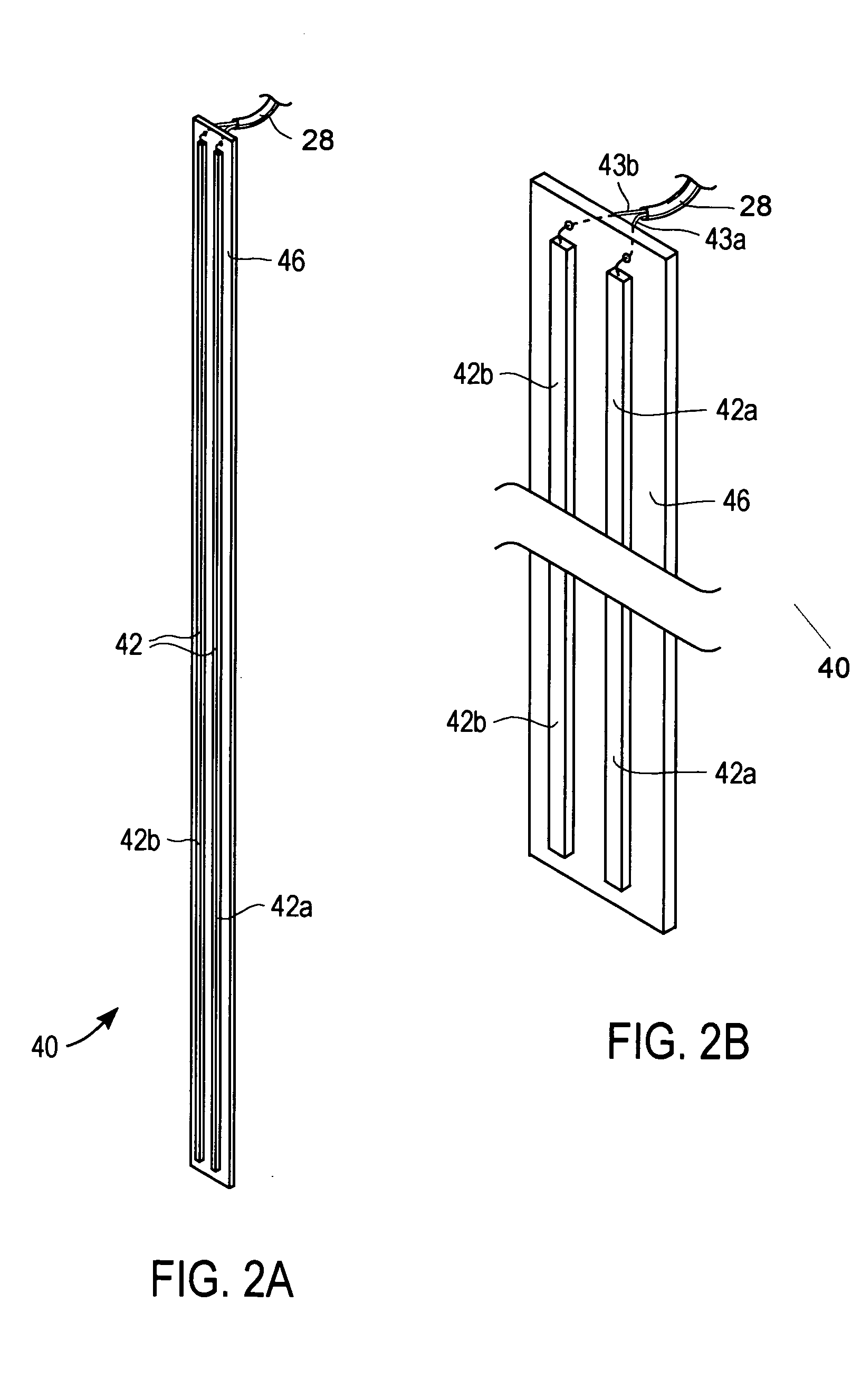

Apparatus and methods for monitoring water consumption and filter usage

InactiveUS7107838B2Water treatment parameter controlSpecific water treatment objectivesFilter mediaEnvironmental engineering

Apparatus and methods for employing electrical properties of water to indicate the level of filtered water in a filtered water container. The container is fitted with a hopper that holds unfiltered water. The hopper is fitted at its base with a removable and replaceable filter cartridge. Water is filtered by draining through the filter medium contained in the filter cartridge into the lower portion of the container. The water level in the lower portion of the container is monitored by means of one or more water level detector strips in the lower portion of the container. The detector strips are in electrical communication with a detection circuit and a control unit. The control unit uses the detection strips to monitor water level and uses such data to track filtered water consumption and to determine when the filter cartridge should be replaced.

Owner:FOOK TIN TECH

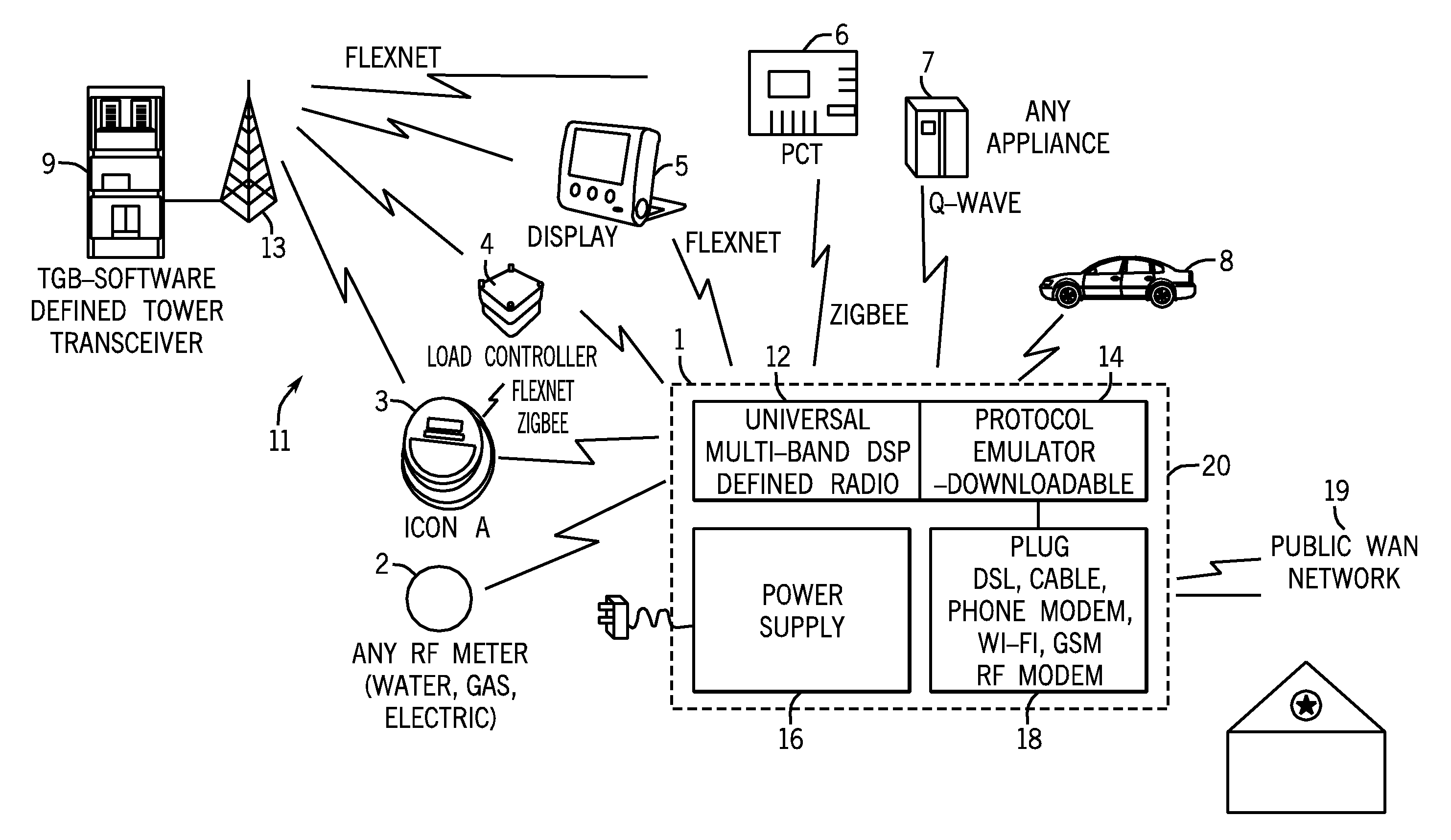

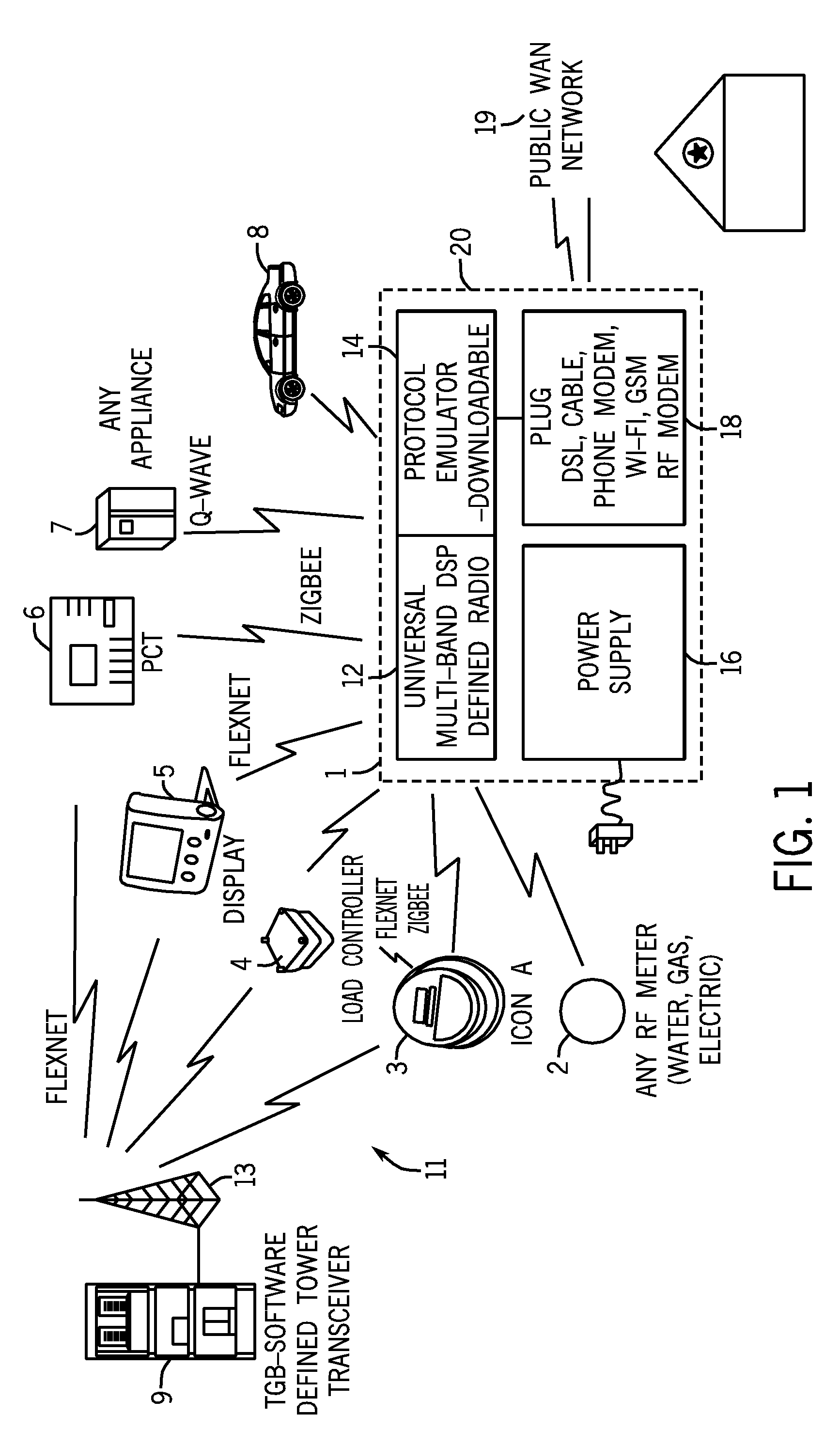

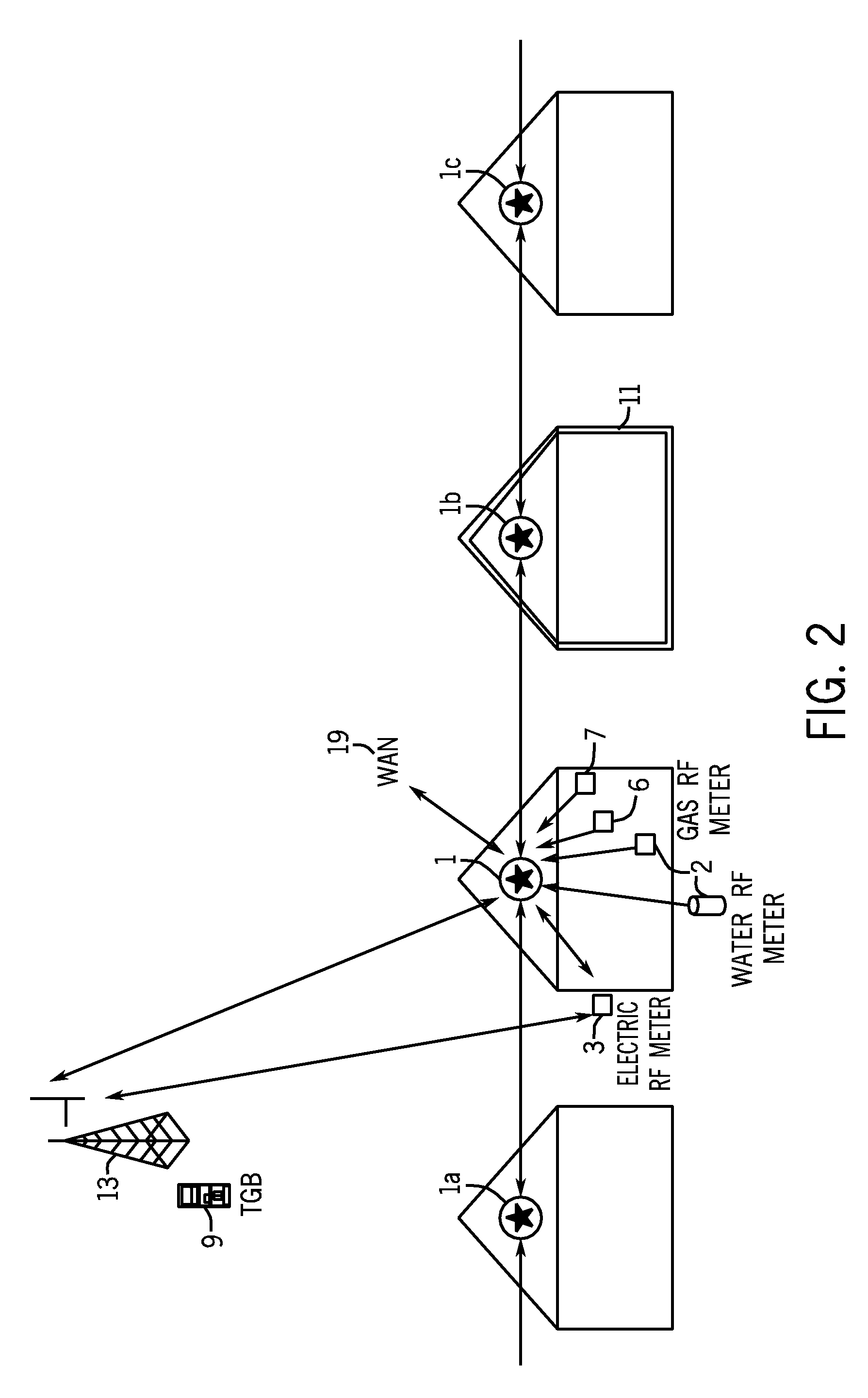

Universal software defined home gateway

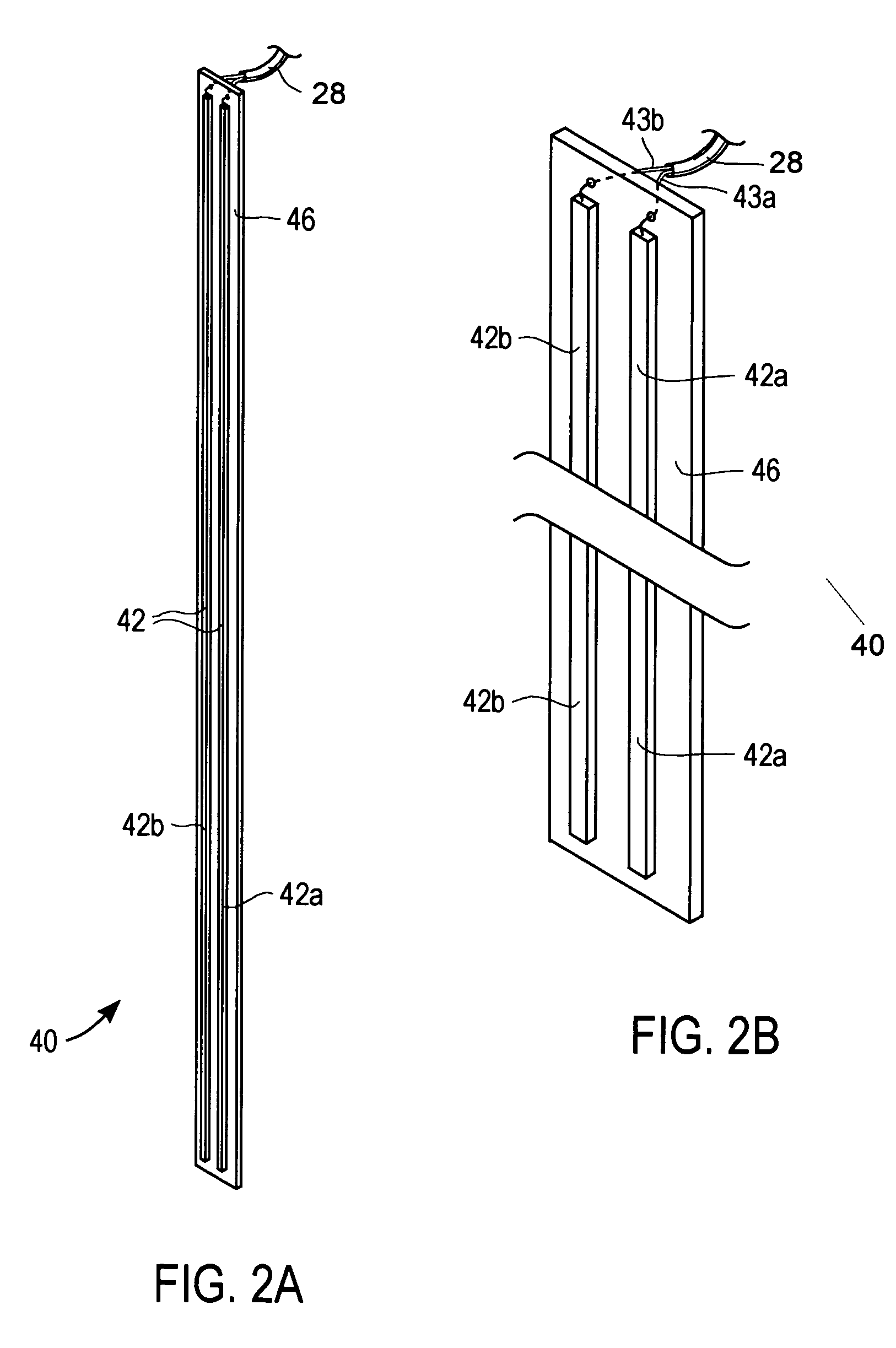

A system and method for communicating energy or water consumption related information from a plurality of RF enabled peripheral devices in a home, such as utility meters, thermostats, appliances and load controllers. The system includes a home gateway that enables wireless RF peripheral devices in a home to communicate to a WAN network, such as the internet. The home gateway contains a RF multi-band software defined radio that is fully programmable and configurable so that it is capable of emulating, transmitting, and receiving any of a plurality of RF protocols over multiple RF channels. The home gateway supports commonly used interfaces for communicating to the public WAN network. The system also supports future peripherals that do not exist today due to the flexibility of the home gateway.

Owner:M & FC HLDG LLC

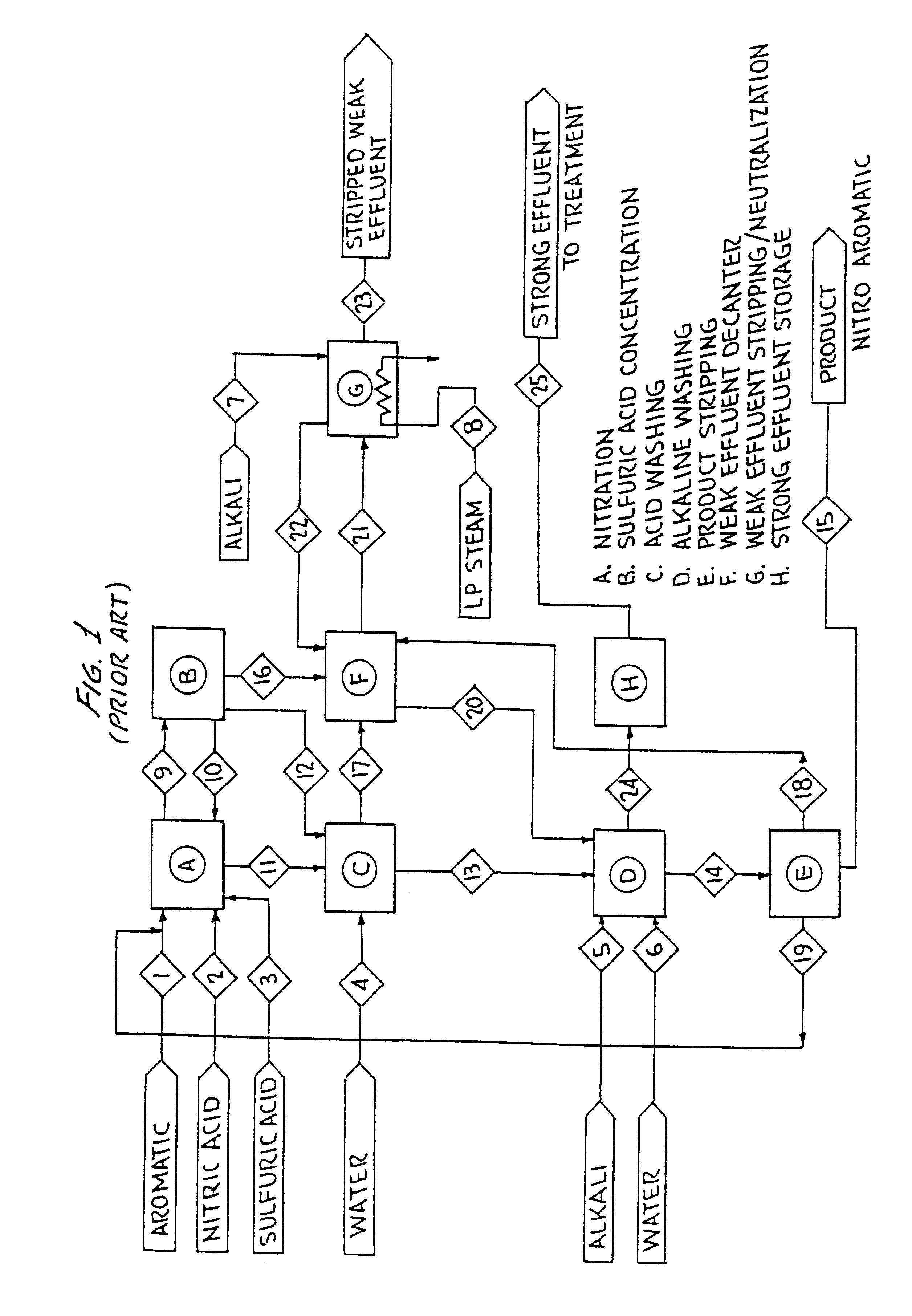

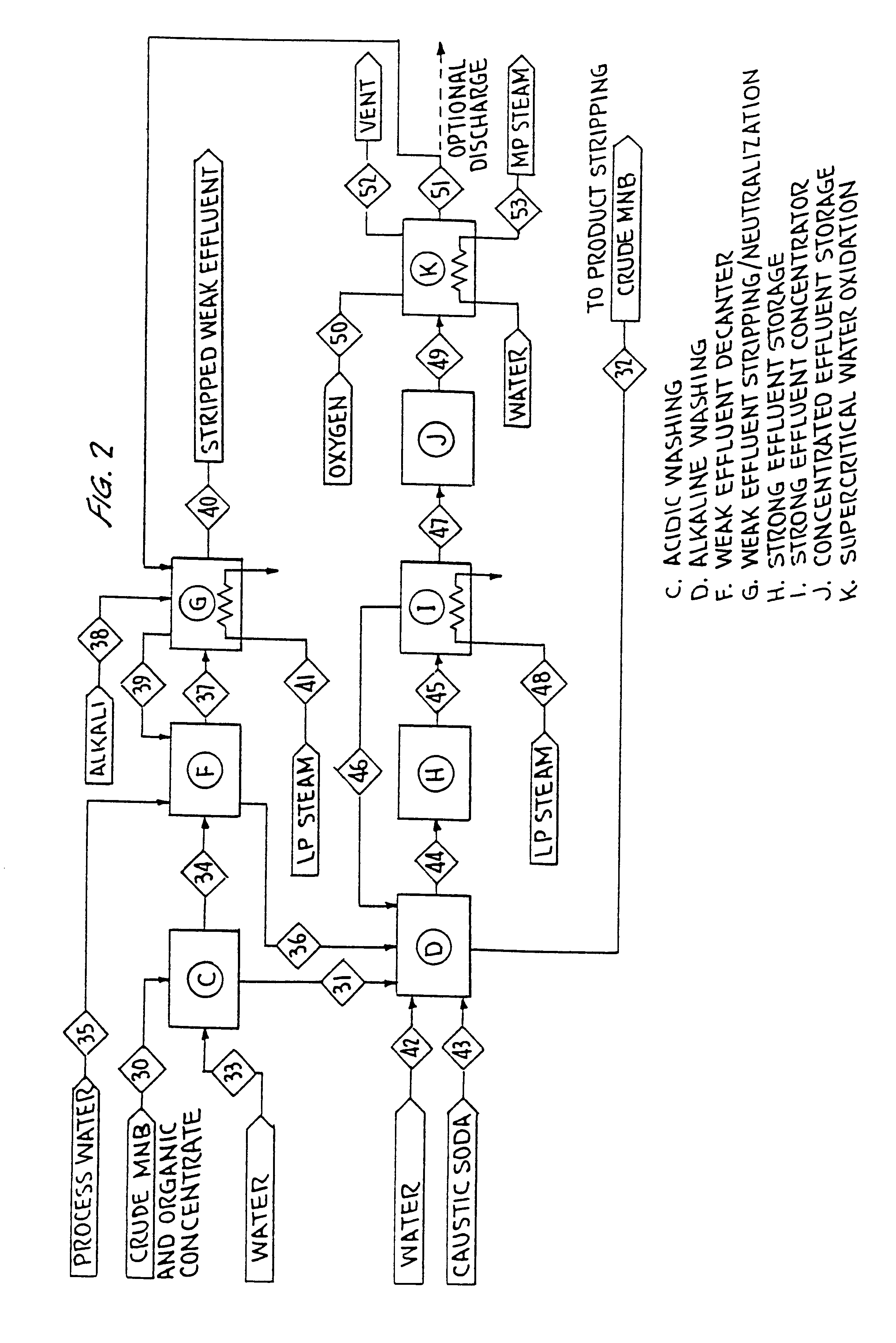

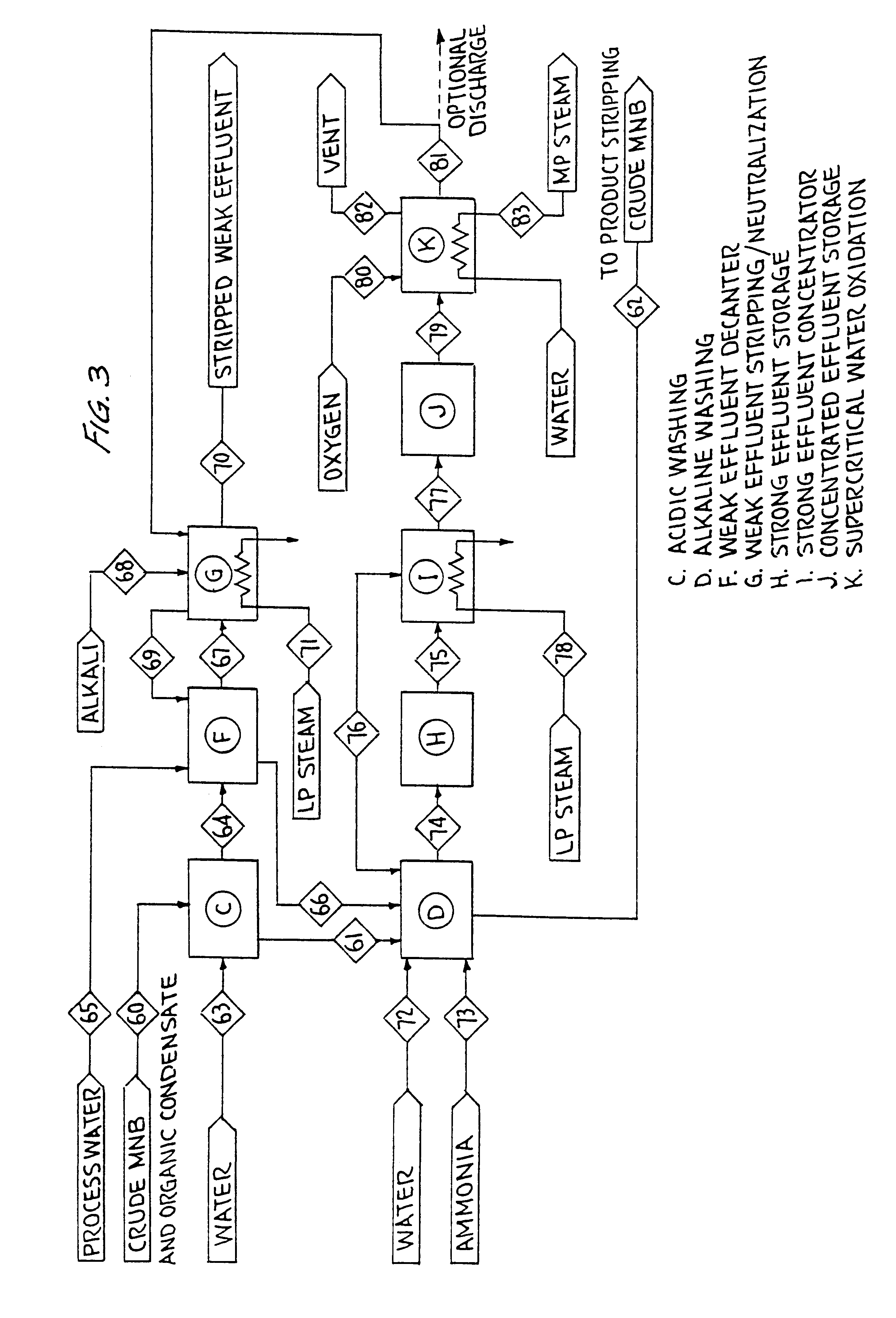

Integrated effluent treatment process for nitroaromatic manufacture

InactiveUS6288289B1Highly destructiveReduce consumptionOrganic chemistrySludge treatment by oxidationWash waterSupercritical water oxidation

An integrated process for treating alkaline wash water effluent from nitroaromatic manufacture, principally containing nitro-hydroxy-aromatic compounds is described. The integrated process concentrates the alkaline wash water to recover chemicals and water prior to treating the concentrate through supercritical water oxidation. The supercritical water oxidation step consists of treating the concentrate in the presence of an oxygen source at conditions, which are supercritical for water to cause a substantial portion of the organic component of the concentrate to oxidize. The product effluent includes a gaseous component and a clean water component, and in the event that insoluble ash is formed, an ash component. The new integrated process results in reduced chemical and water consumption compared to existing processes. In addition, the treated wash water effluent can be recycled to process or directly discharged.

Owner:NORAM INT

Systems and methods for monitoring and controlling water consumption

InactiveUS20060168611A1Save energyReduce energy costsGeneral water supply conservationSpace heating and ventilationFluid controlControl signal

Systems and methods for monitoring and controlling water consumption in a water-supply system are disclosed using one or more sensors for generating signals indicative of the operation thereof. In one embodiment, a method of preventing freezing of a water conduit in a water-supply system comprises sensing, with a temperature sensor, a temperature at a location; and, if the sensed temperature falls below a predetermined threshold, sending, to at least one fluid control device interfaced with the conduit, at least one control signal to impede a flow of water through the conduit and to drain water from the conduit.

Owner:FIMA R GIOVANNI

Irrigation system with wireless control

InactiveUS20100179701A1Watering devicesFlow control using electric meansWireless controlChemical composition

A disclosed method of weather forecasting with respect to a set of irrigation criteria includes enabling an irrigation system controller operating on a user defined schedule to wirelessly receive soil condition information from an environmental sensor, evaluate the soil condition information for satisfaction of an irrigation criterion, and activate an irrigation valve associated with the environmental sensor when the irrigation criterion is satisfied. The soil condition information may indicate a chemical composition or moisture content of the soil. The irrigation system controller is further enabled to generate a warning message based on the soil condition. The irrigation system controller is further enabled to send the warning message to a lawn care service. The irrigation system controller is further enabled to generate a report of the soil condition. The irrigation system controller is further enabled to generate a report indicative of water consumption per irrigation valve.

Owner:AT&T INTPROP I L P

Apparatus and methods for monitoring water consumption and filter usage

InactiveUS20050229699A1Accurate and robust methodWear is exacerbatedWater treatment parameter controlSpecific water treatment objectivesElectricityFilter media

Apparatus and methods for employing electrical properties of water to indicate the level of filtered water in a filtered water container. The container is fitted with a hopper that holds unfiltered water. The hopper is fitted at its base with a removable and replaceable filter cartridge. Water is filtered by draining through the filter medium contained in the filter cartridge into the lower portion of the container. The water level in the lower portion of the container is monitored by means of one or more water level detector strips in the lower portion of the container. The detector strips are in electrical communication with a detection circuit and a control unit. The control unit uses the detection strips to monitor water level and uses such data to track filtered water consumption and to determine when the filter cartridge should be replaced.

Owner:FOOK TIN TECH

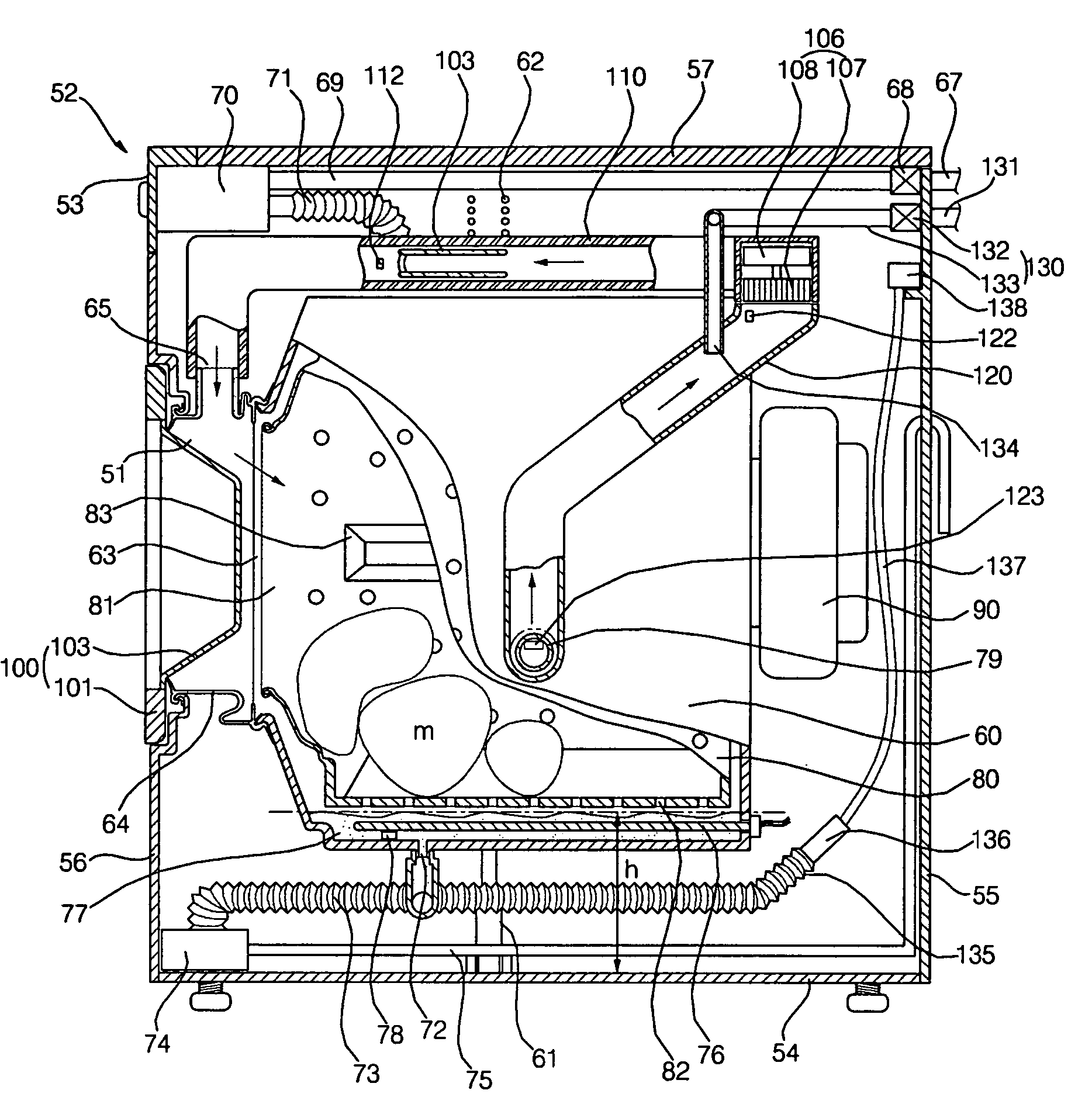

Drying control apparatus and method of washing and drying machine

InactiveUS20060137105A1Improve condensation effectMinimizing rateOther washing machinesWashing machine with receptaclesCold airProcess engineering

A drying control method and apparatus of a washing and drying machine, in which cooling water dropped from a condensation duct to a tub accelerates the condensation of moisture contained in circulated air so as to improve condensing capability, a cold air drying time is differently set according to load so that when the load is small, a drying time is shortened, and the drying of laundry is rapidly performed, a power consumption rate is minimized, or a cooling water consumption rate is minimized according to user's desire, and a drying operation is controlled using a difference between a temperature of air and a temperature of cooling water so that the drying operation is efficiently performed according to load conditions so as to improve the drying capability.

Owner:LG ELECTRONICS INC

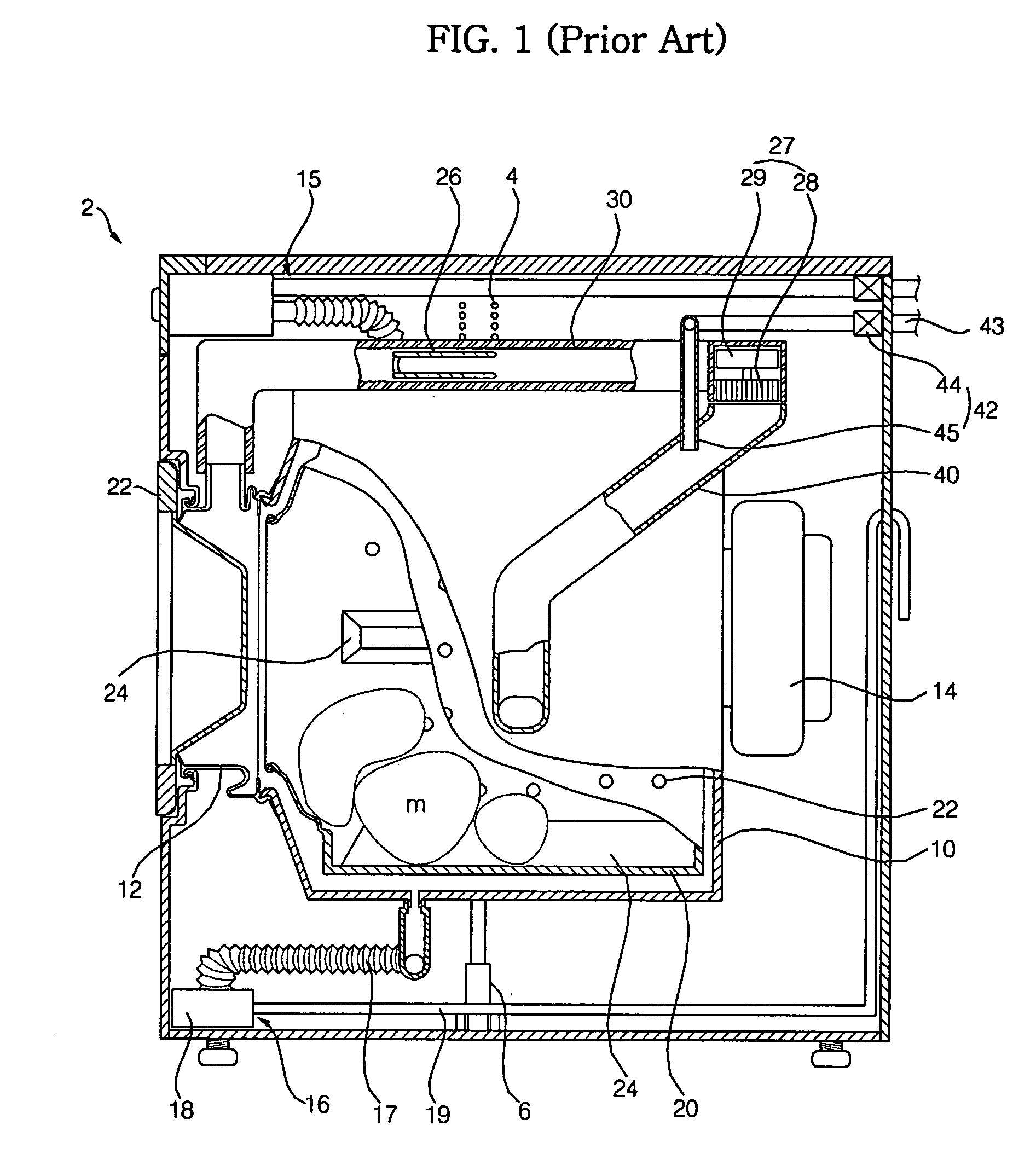

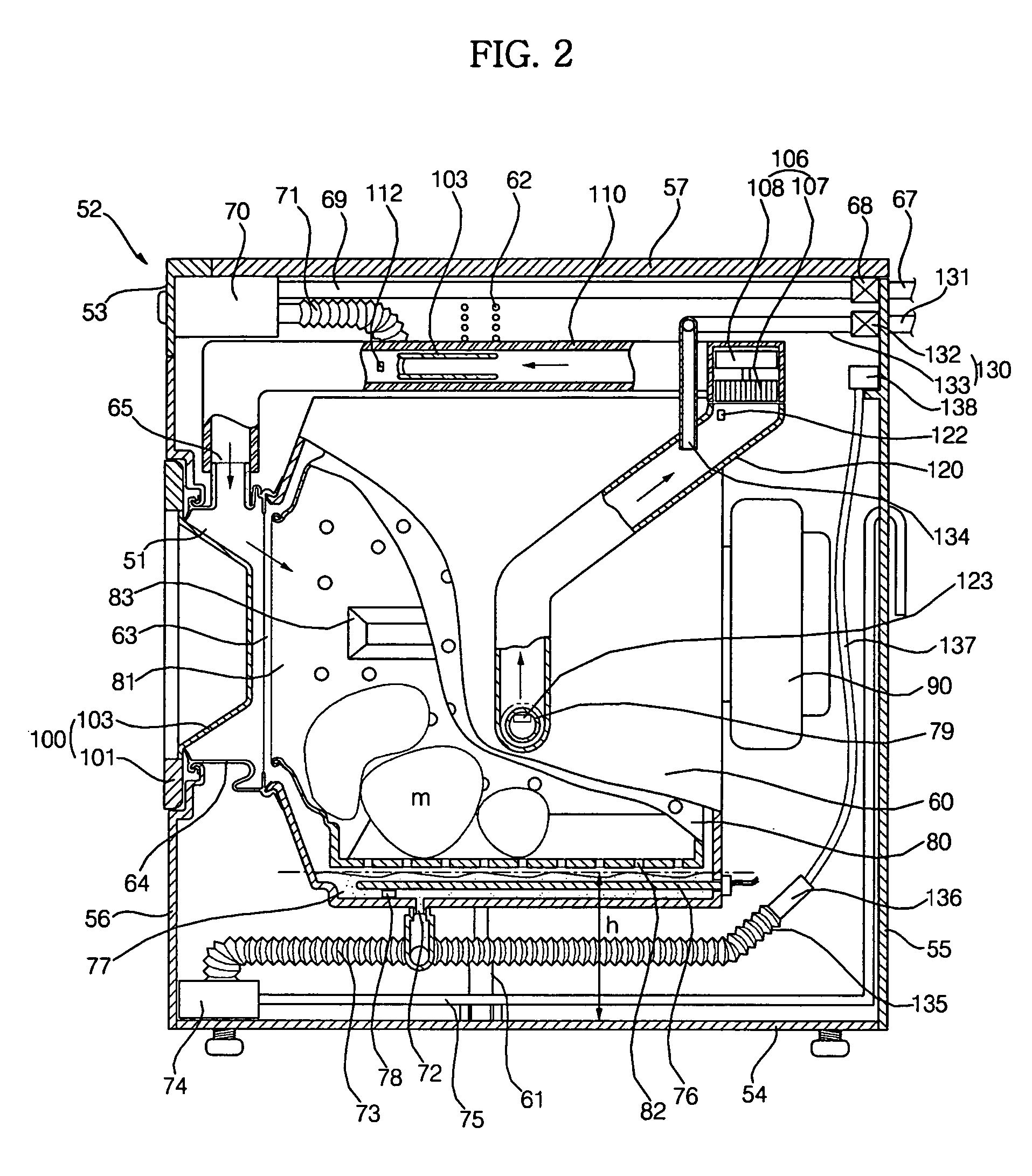

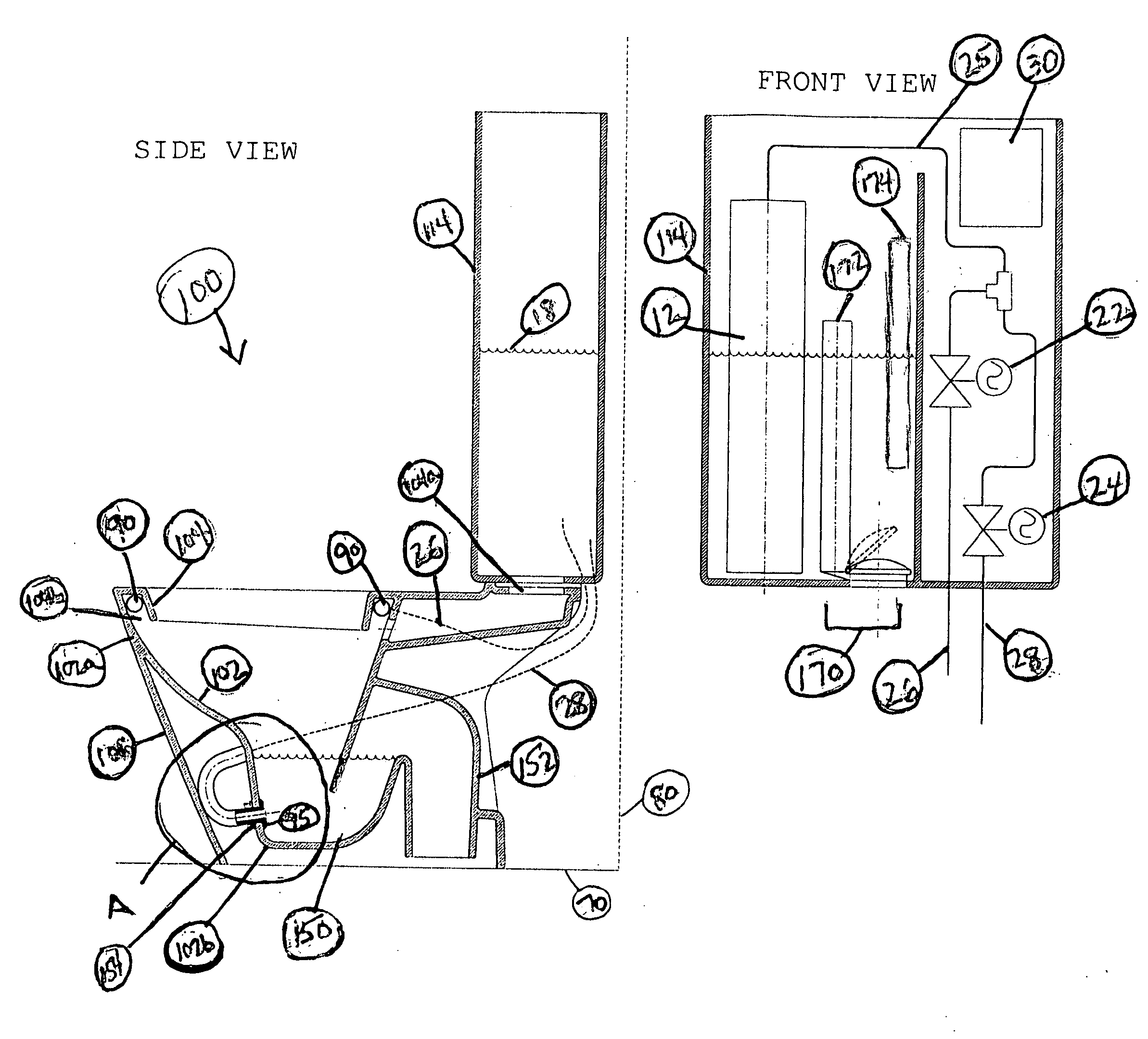

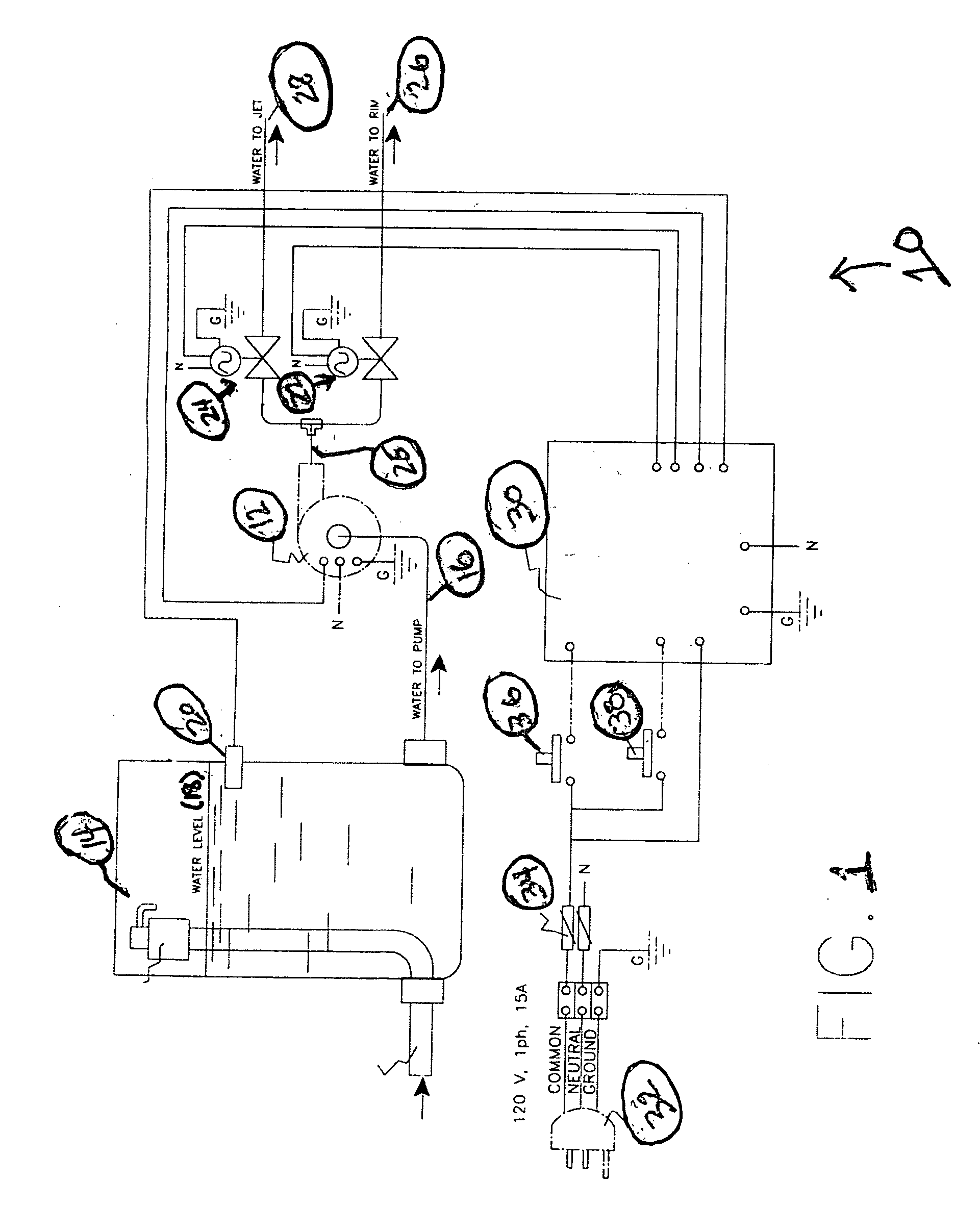

Method of operating a multi-phase, high energy flushing system for optimal waste removal and bowl cleaning within a prescribed water consumption range

ActiveUS20070113331A1Elevating cleaning performanceImprove flushing performanceUrinalsWater closetsHigh energyBiological activation

The present invention provides a method of operating a flushing system for efficient waste removal from and cleaning of a toilet bowl. In the disclosed method, a flushing system is provided that includes a pumping means having each of a rim diverter means and a jet diverter means in fluid communication therewith; a sensor means; a control means; a switching means; and a spray means. Activation of the switching means initiates at least a single flush schedule that comprises the steps of initiating operation of the pumping means; opening the jet diverter means for delivery of water to a jet delivery means in fluid communication therewith; subsequently closing the jet diverter means and simultaneously opening the rim diverter means; and directing water from the rim diverter means to a toilet rim in fluid communication therewith for terminal delivery of the water through the spray means.

Owner:IDEAL STANDARD INT

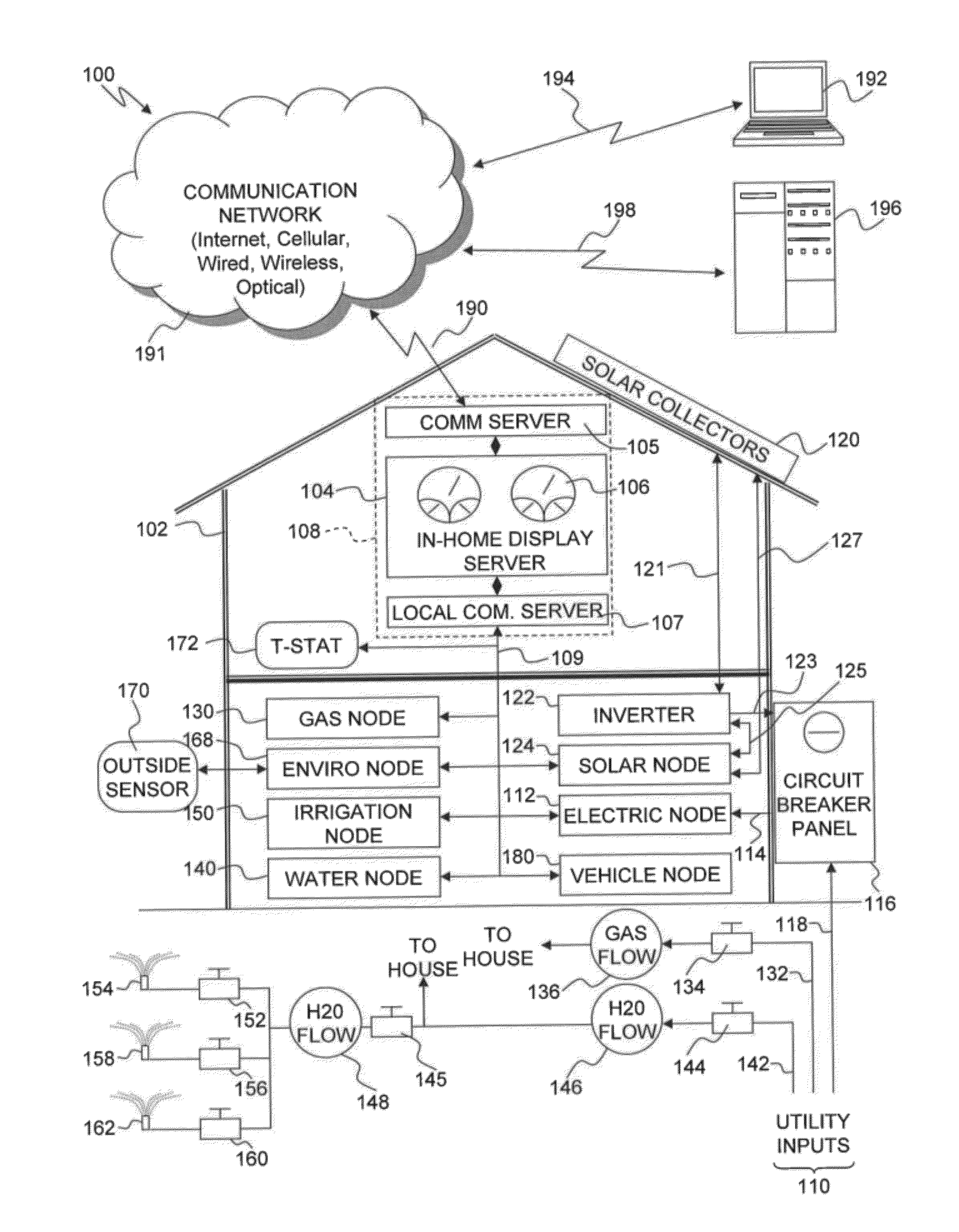

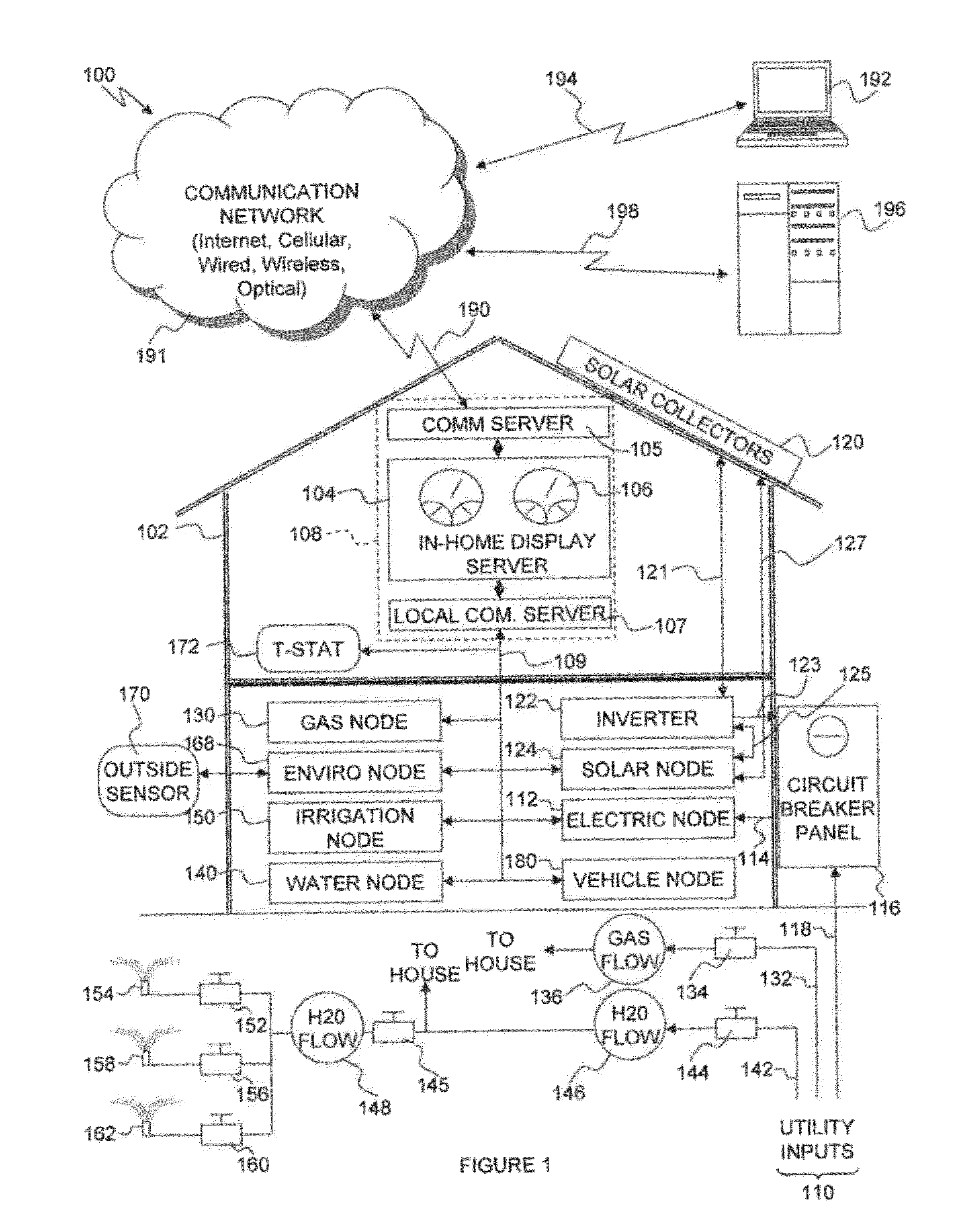

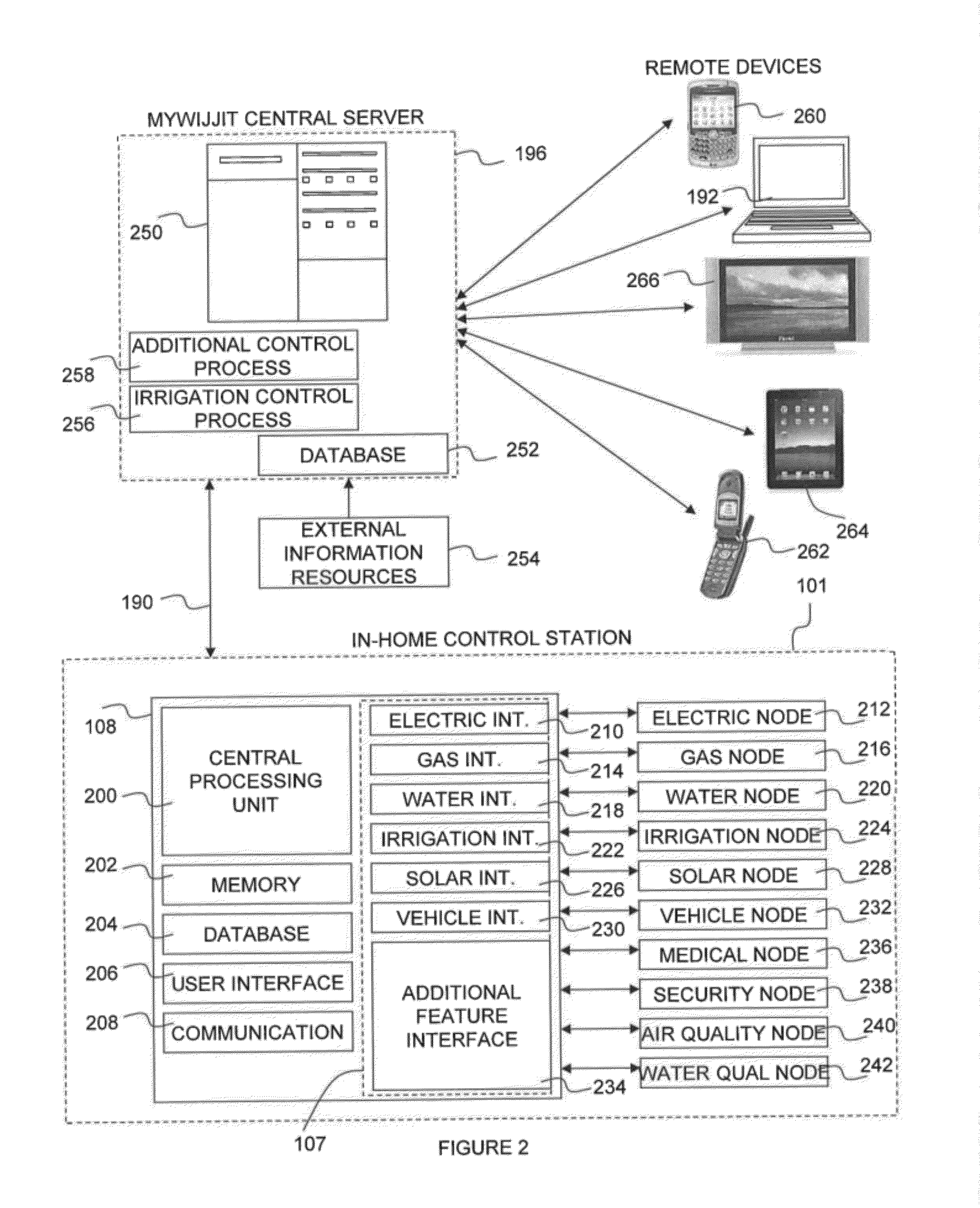

Resource management and control system

InactiveUS20120054125A1Easy to useSave effortProgramme controlData processing applicationsWater useService-level agreement

A resource management and control system includes real-time visibility to energy and water consumption. The resource management platform is flexible and allows users to create a system to suit their individual needs, and to make changes to that platform as their needs change and new needs arise. The resource management and control system monitors electricity and gas consumption, solar production, and water use in real time. The control system includes a number of wireless access nodes for interfacing with the various systems within a property, and also includes monitoring, diagnostic and alerting capabilities. Billing system integration provides historical data for the cost of resource usage and production relative to time, geography and consumer service level agreements and allows the user the ability to directly correlate consumption behaviors with cost implications. Autonomously operating control processes are incorporated to automatically configure and control devices for optimal resource consumption and application.

Owner:CELEVATORON ERIC DOUGLASS +1

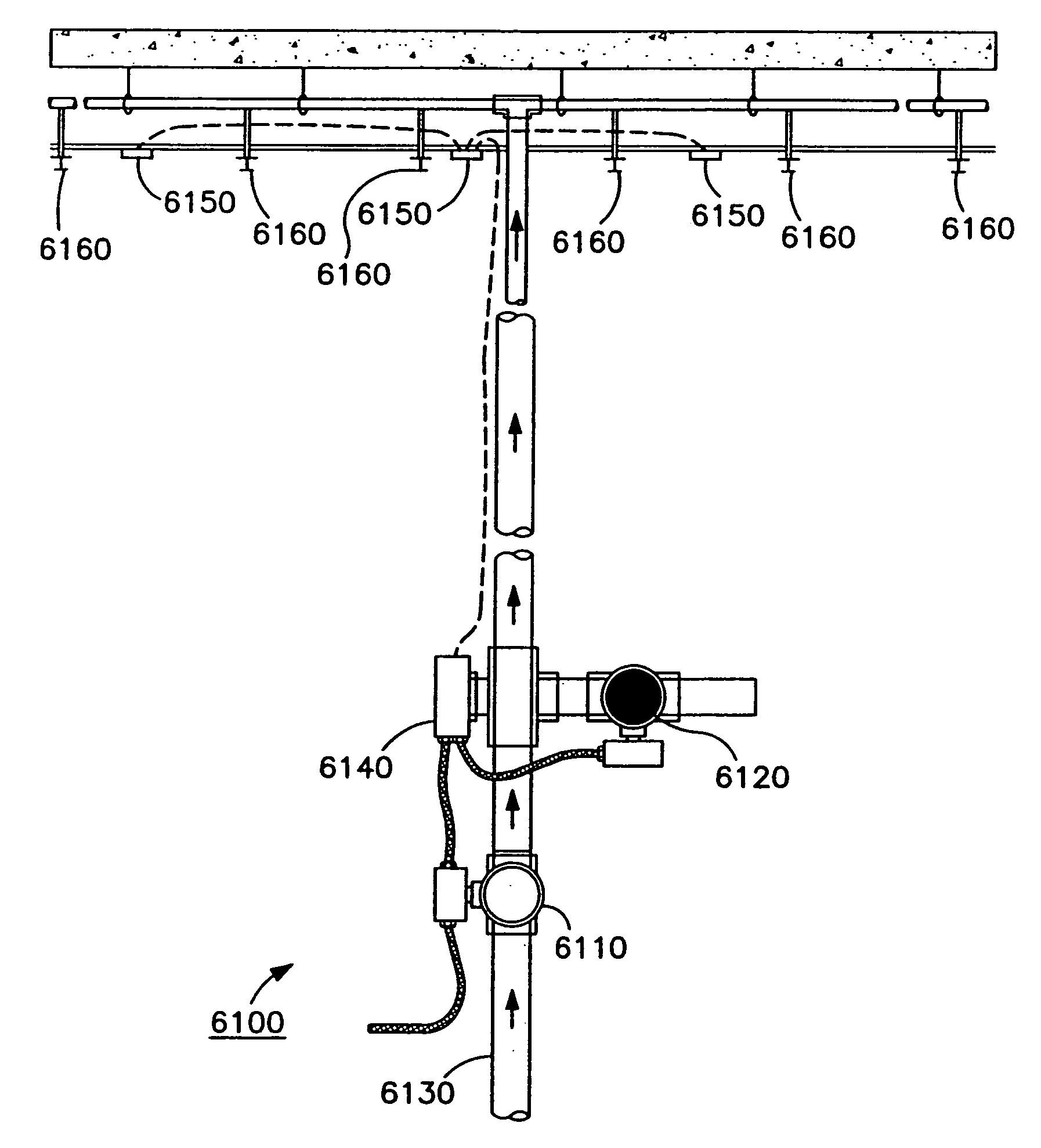

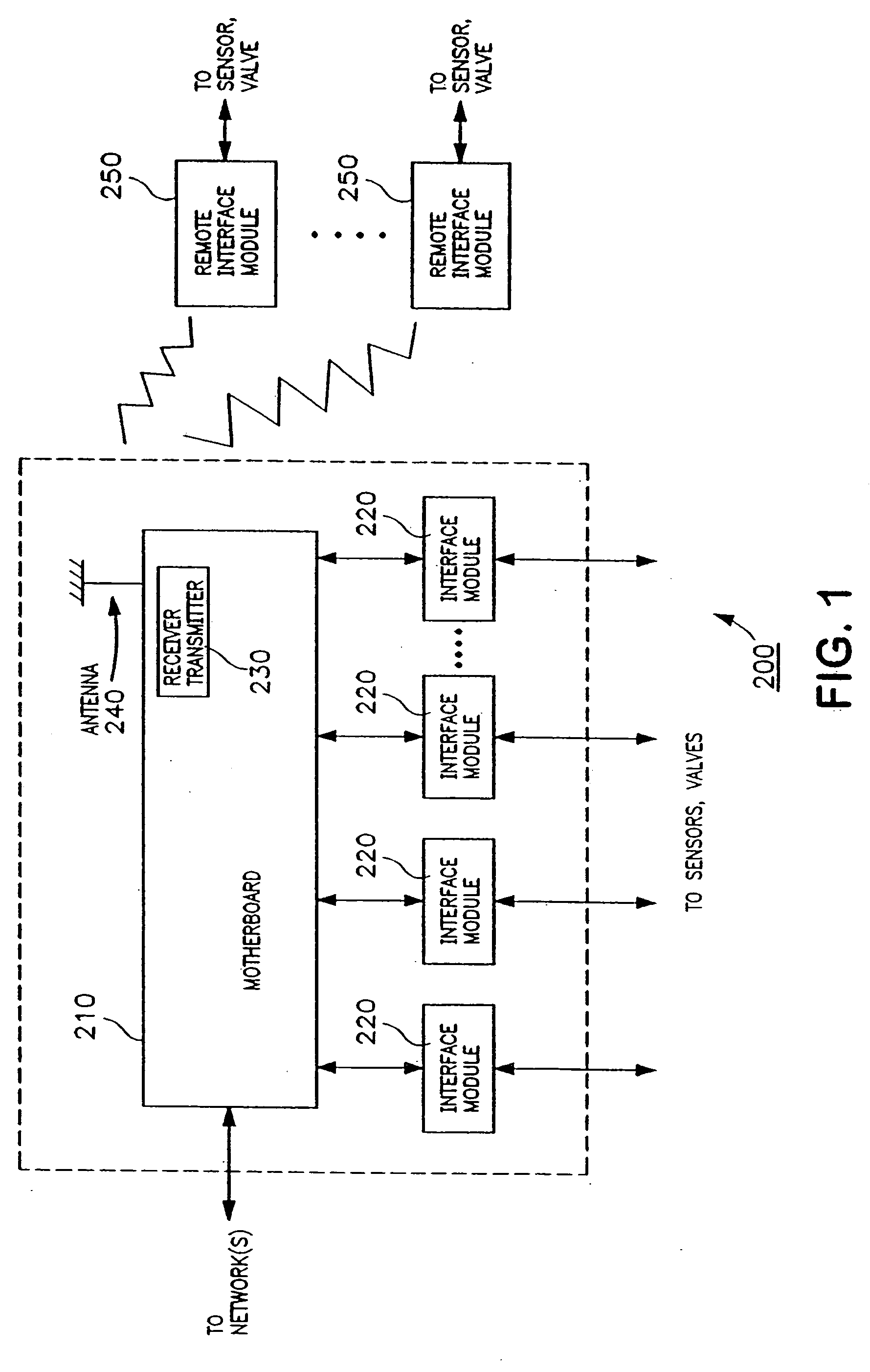

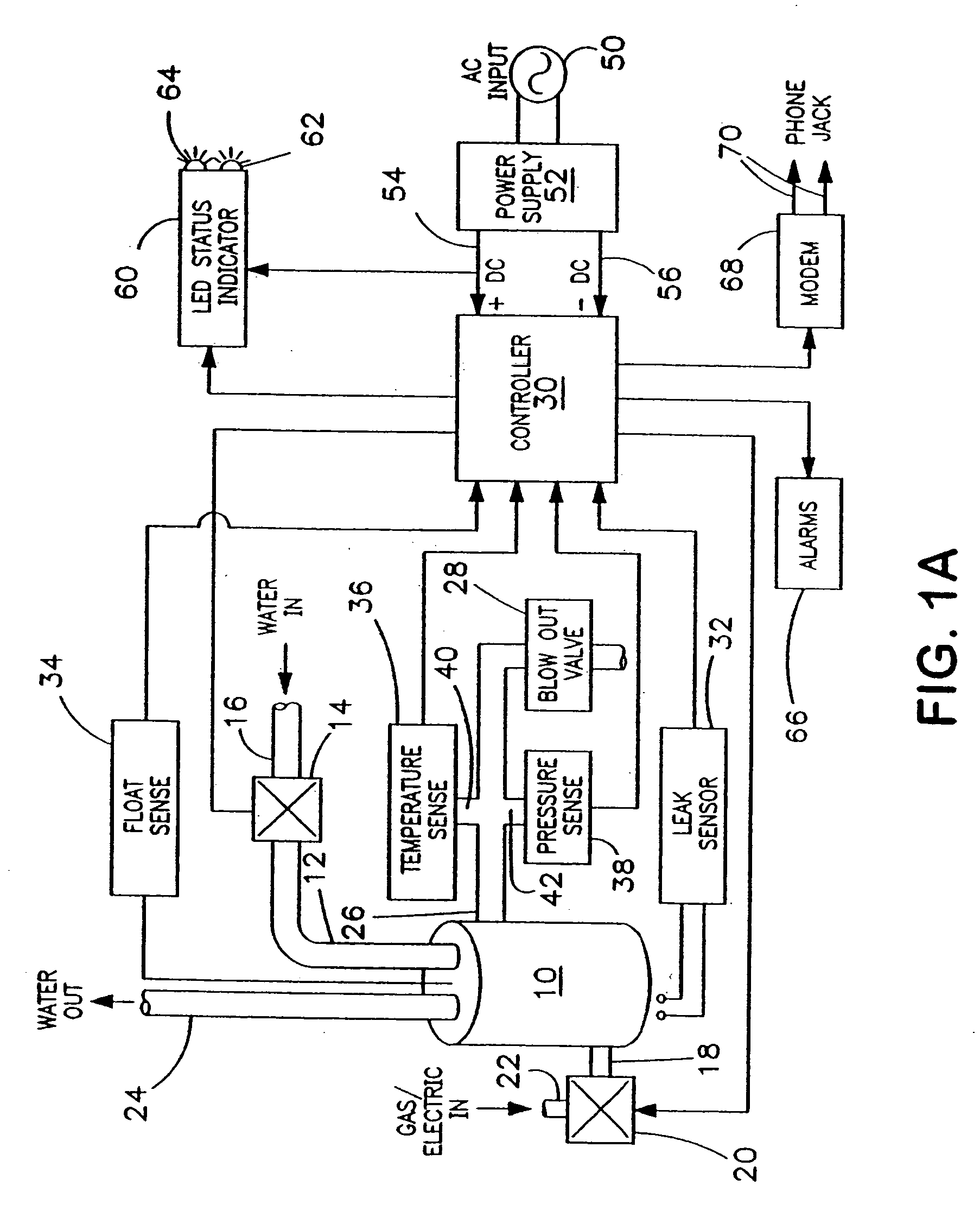

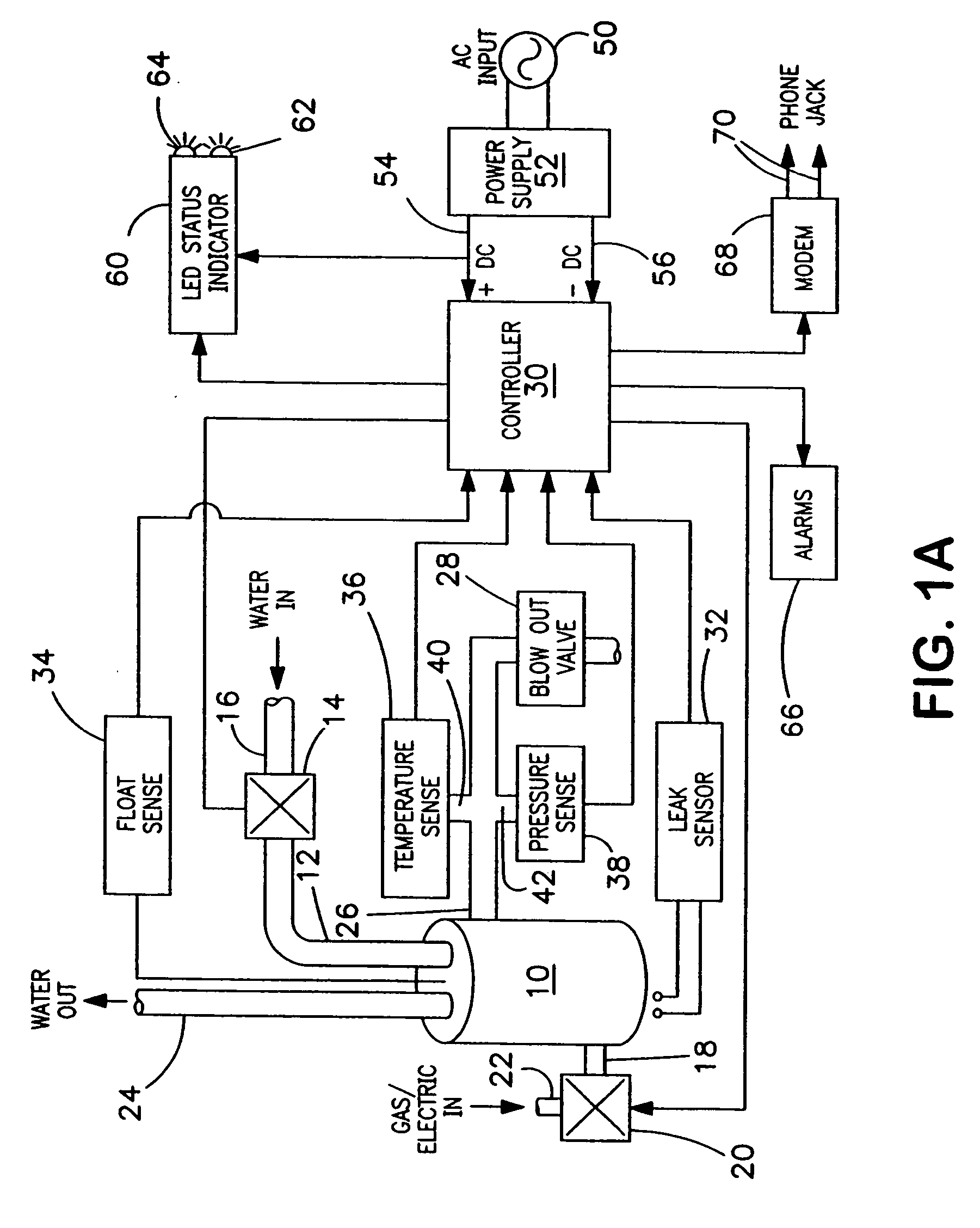

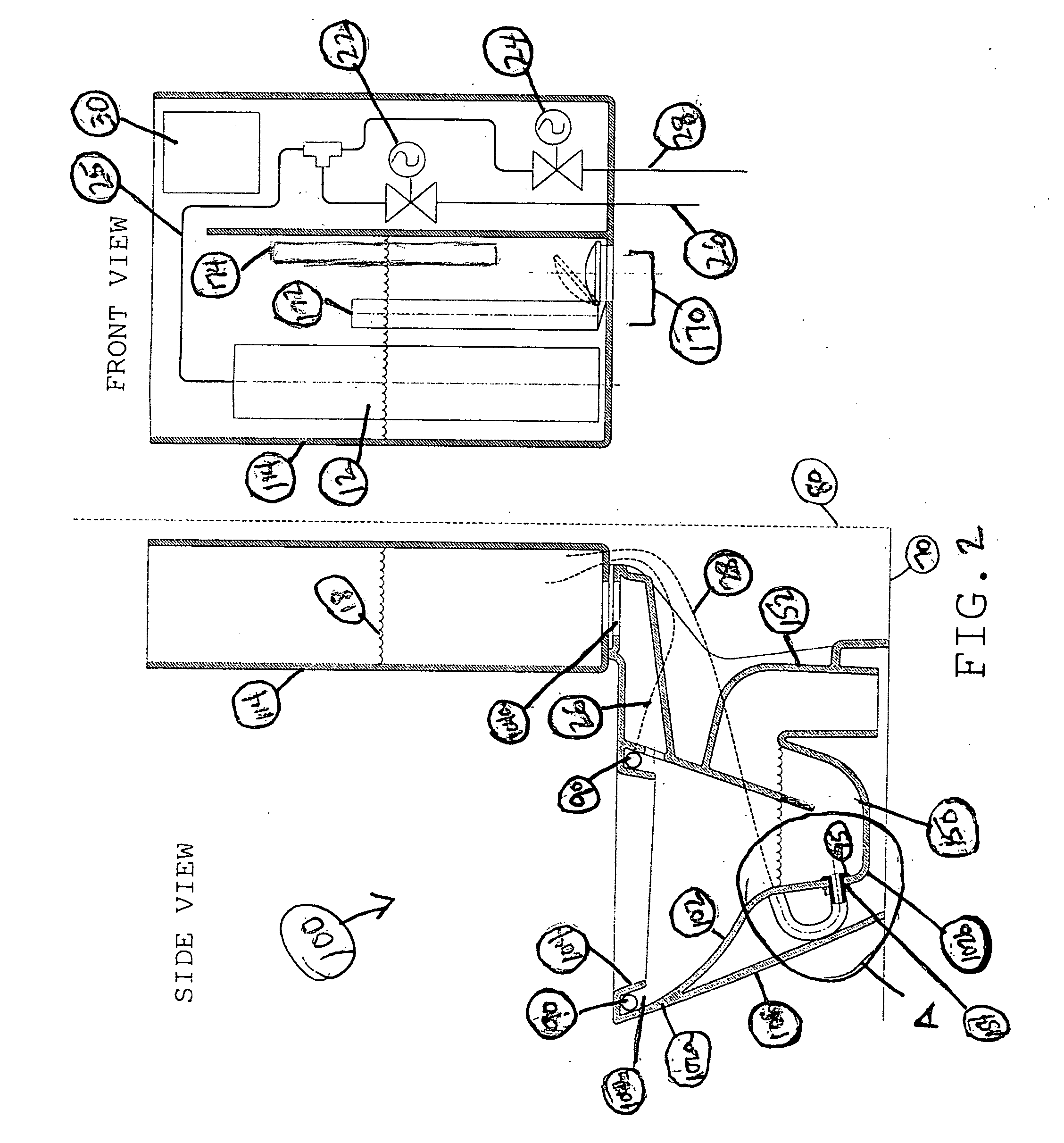

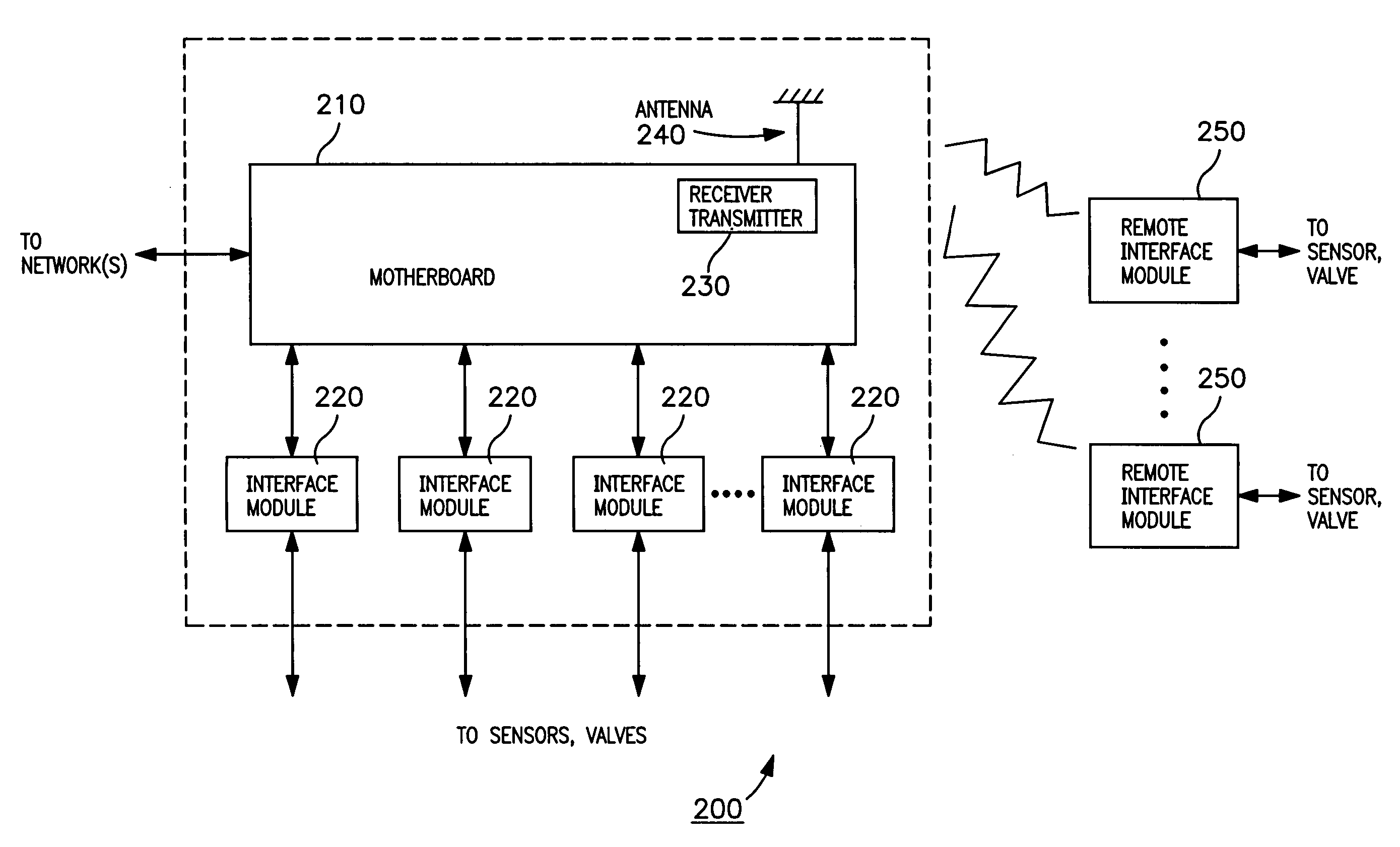

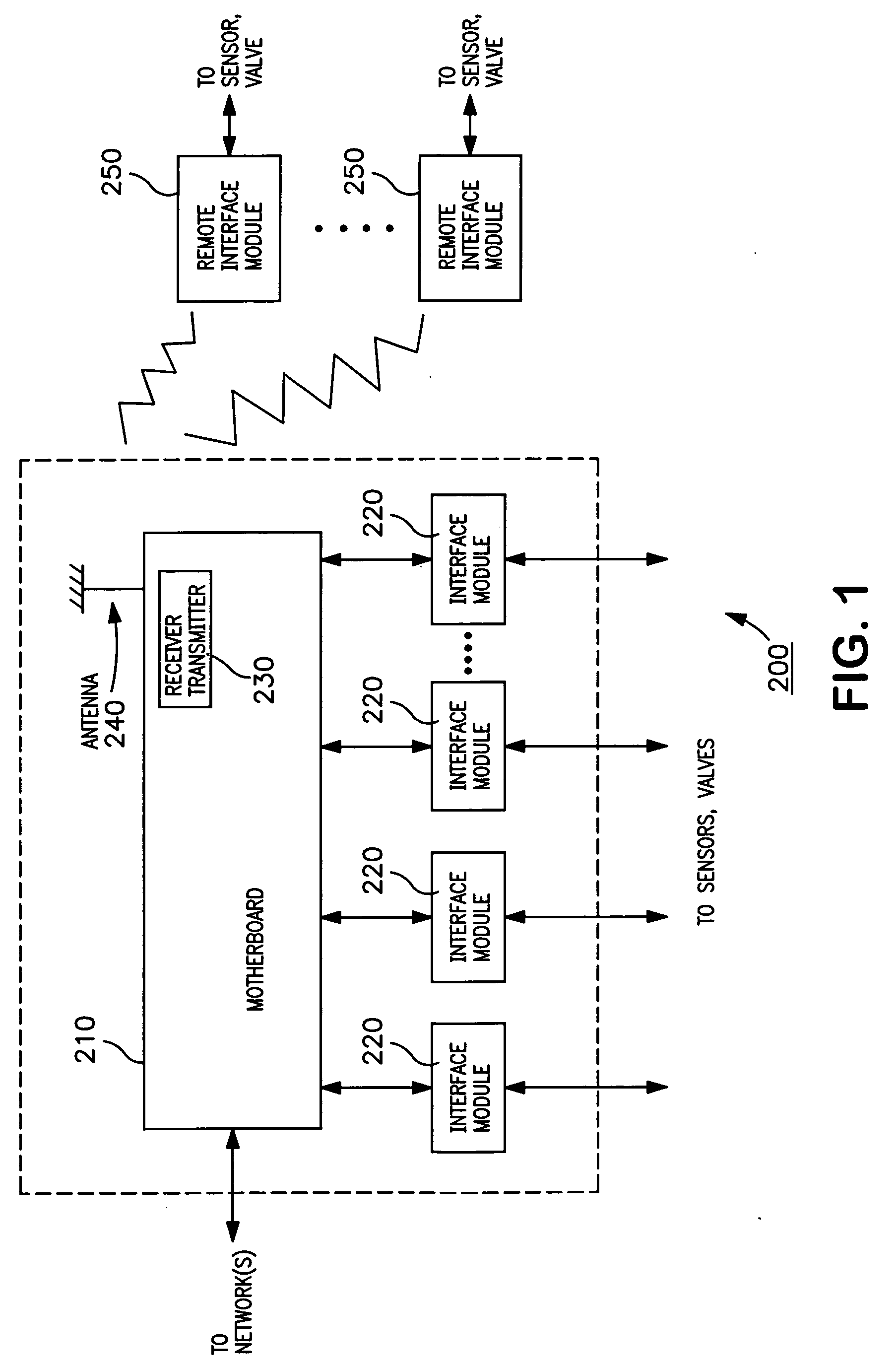

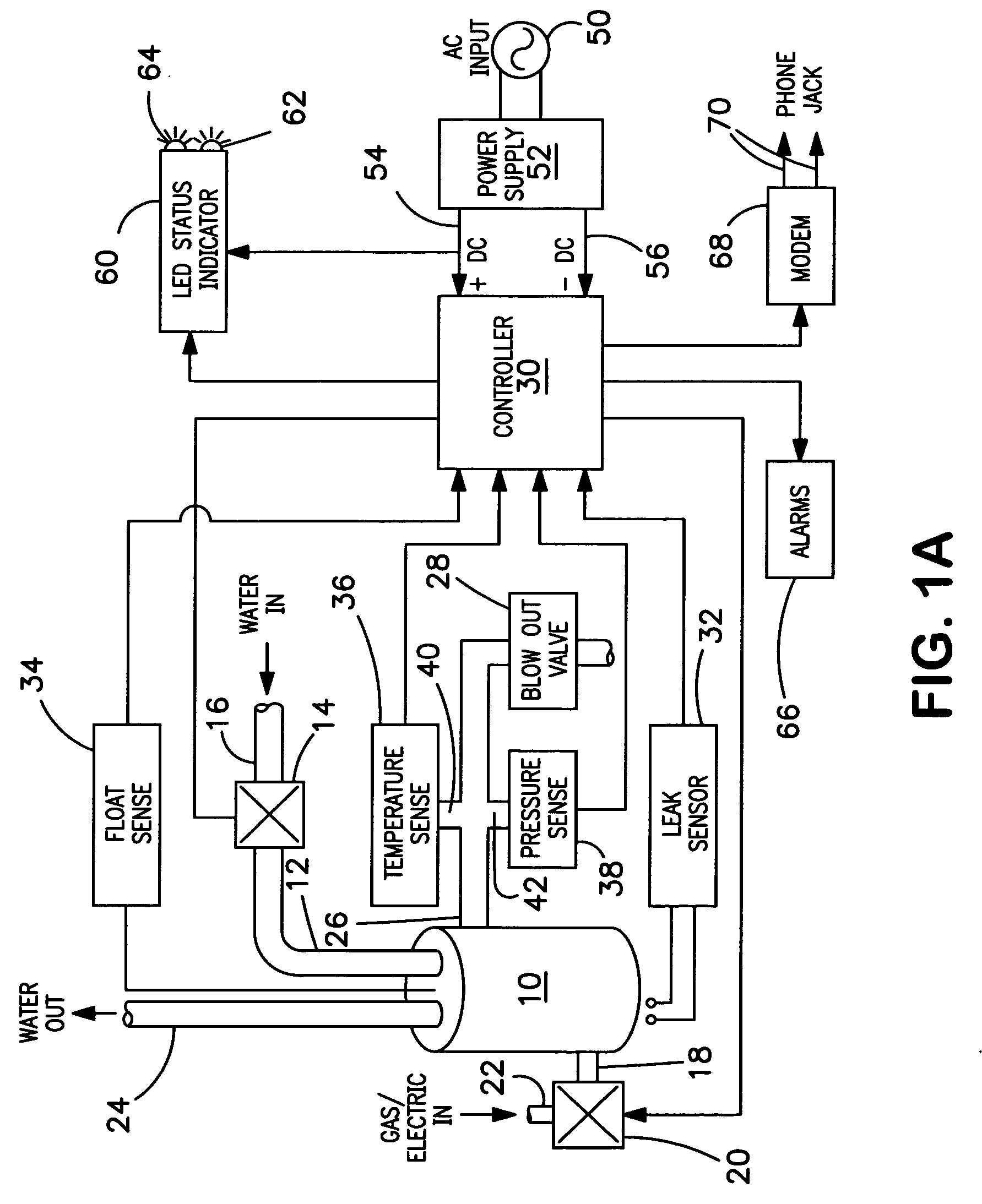

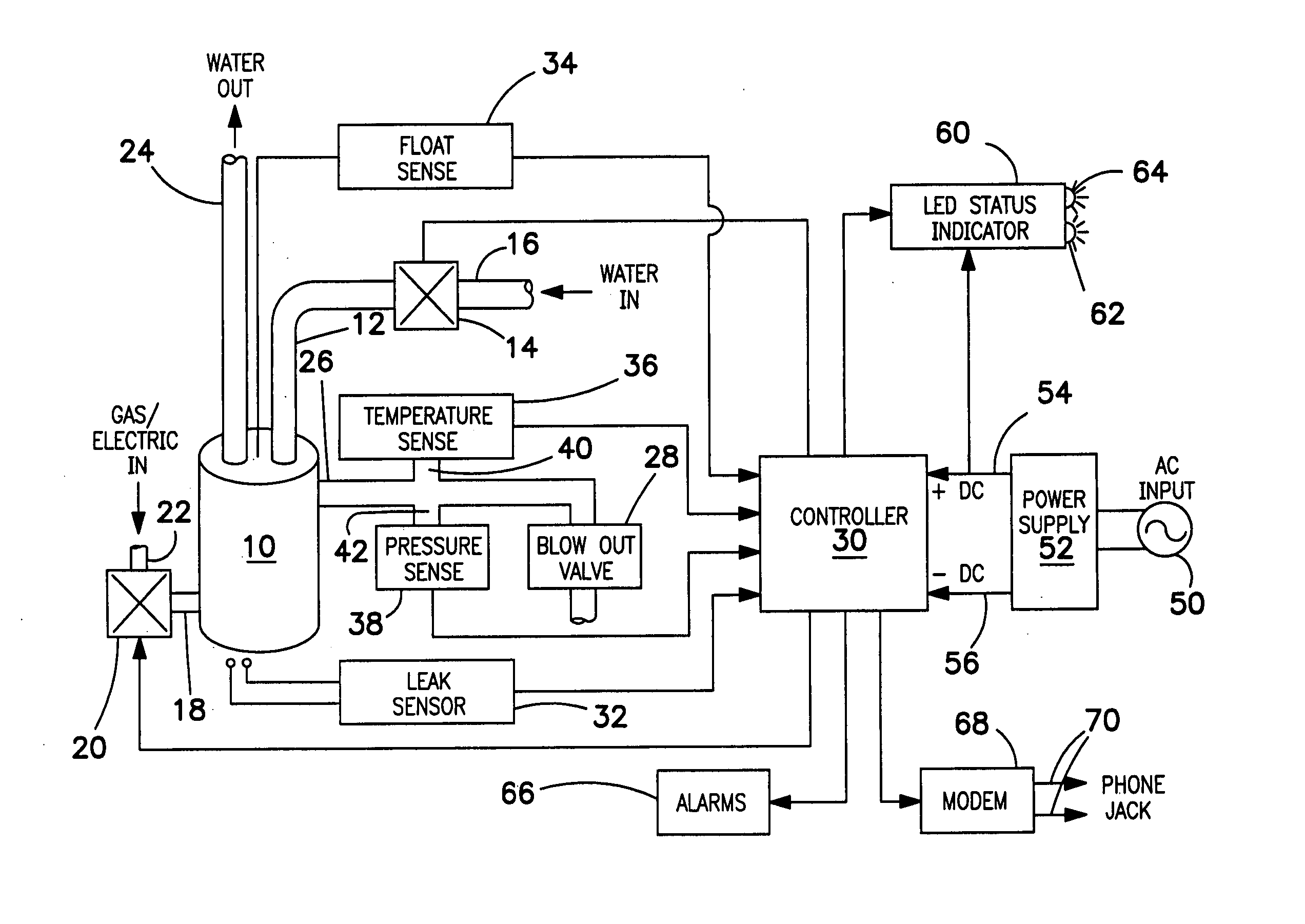

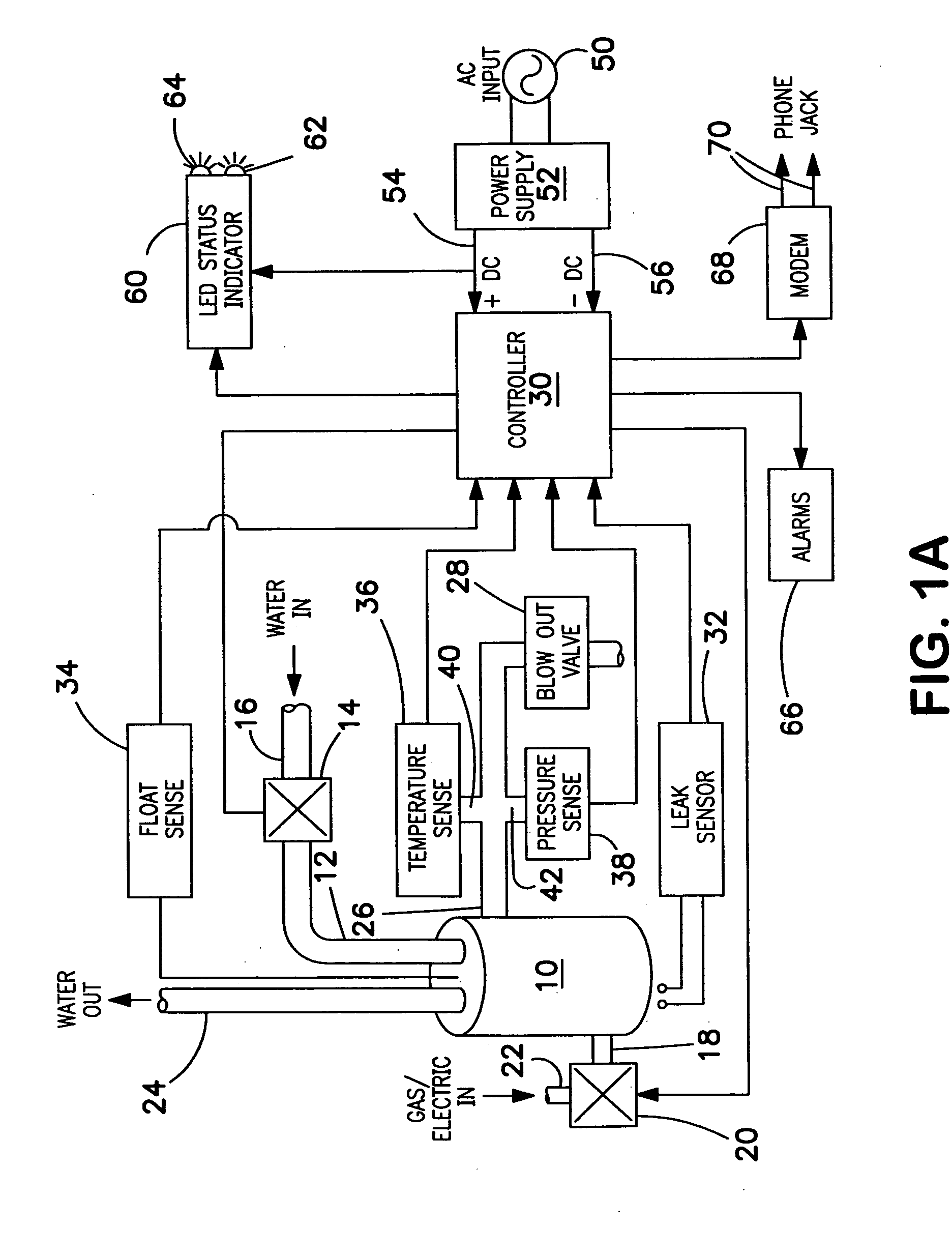

Systems and methods for monitoring and controlling water consumption

InactiveUS20050235306A1Save energyReduce energy costsGeneral water supply conservationSpace heating and ventilationInformation processingWater based

Systems and methods for monitoring and controlling water consumption in a water-based system are disclosed using one or more sensors for generating signals indicative of the operation thereof. One or more interface modules are provided as breaker circuits for receiving the generated signals, and a fluid control device is operable for limiting the water consumption. A motherboard receives the interface modules and provides communication therebetween for information processing. Signals from the various sensors are supplied to a controller, which provides signals to status indicators, and also operates to provide alarm signals via network interfaces to remote locations. In an alternate embodiment, a water monitoring system is designed to shut off the water supply to the water device and to shut off either the electrical supply or the gas supply to the heating unit of the water device in response to sensing a malfunction through one or more sensed parameters.

Owner:FIMA R GIOVANNI

Systems and methods for monitoring and controlling water consumption

InactiveUS20050067049A1Monitor and control daily water consumption flowProtection malfunctionDetection of fluid at leakage pointMeasurement of fluid loss/gain rateInformation processingWater based

Systems and methods for monitoring and controlling water consumption in a water-based system are disclosed using one or more sensors for generating signals indicative of the operation thereof. One or more interface modules are provided as breaker circuits for receiving the generated signals, and a fluid control device is operable for limiting the water consumption. A motherboard receives the interface modules and provides communication therebetween for information processing. Signals from the various sensors are supplied to a controller, which provides signals to status indicators, and also operates to provide alarm signals via network interfaces to remote locations and to operate an alarm. In an alternate embodiment, a water monitoring system is designed to shut off the water supply to the water device and to shut off either the electrical supply or the gas supply to the heating unit of the water device in response to sensing a malfunction through one or more of a number of different sensed parameters. These parameters include a water leak detector located beneath the water device, a water level float sensor, a temperature sensor to sense excess temperature, and a pressure sensor located in line.

Owner:FIMA RAOUL G

Method and system for estimating an agricultural management parameter

InactiveUS20060030990A1For easy referenceAnalogue computers for trafficComputations using stochastic pulse trainsData processing systemAgricultural management

A system and method for estimating agricultural parameters for growing crops is well suited for promoting efficient utilization of agricultural inputs (e.g., water consumption). Sensors collect data via one or more vehicles equipped with location-determining receivers. A transmitter transmits the collected environmental data to a data processing system. The data processing system applies the collected environmental data to an agronomic model for determining an agricultural management parameter. A prescription is made available for application of an agricultural input (e.g., water) to a crop in a particular location consistent with the collected environmental data and the agronomic model.

Owner:DEERE & CO

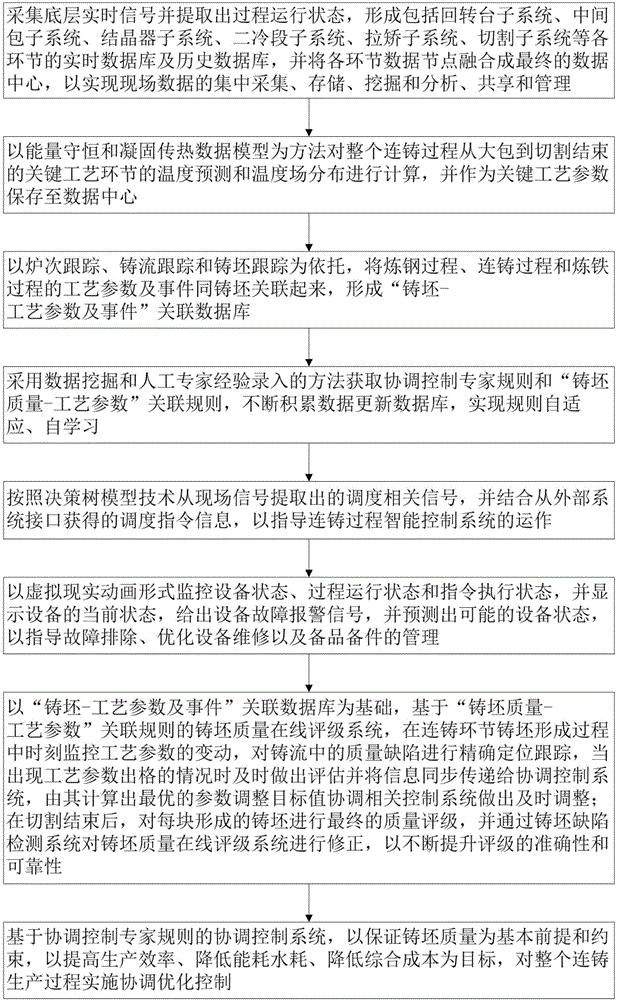

System method for intelligent control over continuous-casting process

The invention discloses a system method for intelligent control over the continuous-casting process. Firstly, signals are collected to form a data center; then a temperature field model is designed to calculate the temperatures of continuous-casting key process nodes, and the temperatures of the continuous-casting key process nodes are stored into the data center; then logistics tracking of the continuous-casting process is achieved, and a 'casting blank-technological parameter and event' related database is formed; then rules and dispatching command information are obtained through data mining and artificial expertise, and virtual reality animation displaying of the equipment state, process operation state and command execution state is conducted; then a casting blank quality online grading system is built and casting blank grading is achieved; and finally, a coordination control system is built, energy consumption and water consumption are optimized, and large-closed-loop quality control and underlying loop control are achieved. Energy conservation and consumption reduction are achieved by optimizing the related parameters of energy consumption and water consumption while the effects that the continuous casting blank quality is stable and the quality is improved continuously are ensured, so that the yield is improved, the cost of per ton of steel is reduced, the comprehensive production cost is reduced continuously, and normal and efficient operation of continuous casting is ensured.

Owner:HUNAN CHAIRMAN IOT INFORMATION TECH CO LTD

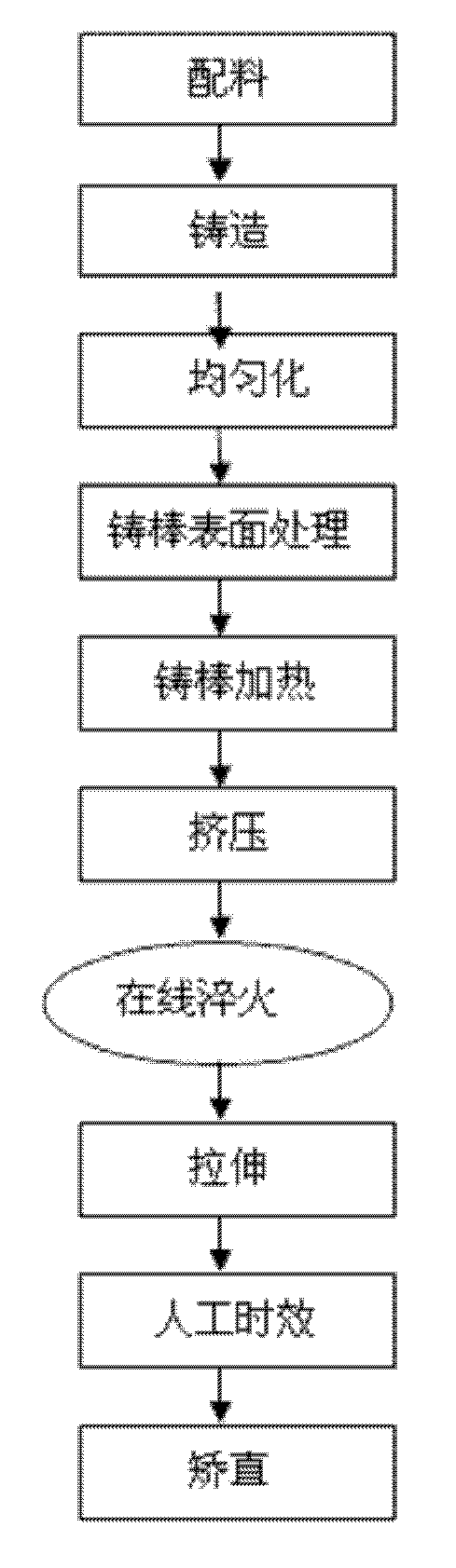

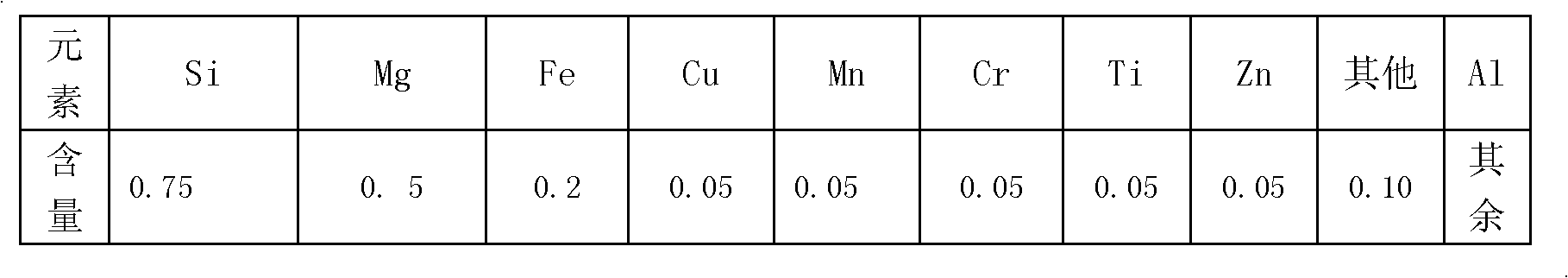

Extruding processing technology of aluminium alloy tubing with large diameter

InactiveCN102492877AReduce residual stressHigh strength propertiesExtrusion control devicesFailure rateHigh energy

The invention discloses an extruding processing technology of an aluminium alloy tubing with large diameter. The method comprises steps of a. proportioning, b. casting, c. uniformization, d. surface treatment on casting rod, e. casting rod heating, f. extrution, g. on-line quenching, h. stretching, i. artificial aging and j. straightening, etc. Strict control on each parameter can solve problems of extruding production of tubing with large diameter, eliminate disadvantages of long production period, low production efficiency, high energy consumption, huge environmental pollution and expensiveauxiliary equipment of rolling and drawing, save cost, simplify arrangement of auxiliary equipment and further reduce failure rate of an apparatus. The energy consumption of the present invention is merely 1 / 4 that of rolling and drawing, and water consumption is 1 / 8 that of a steam jet pump set; therefore, the invention brings obvious economic effects.

Owner:CHINA ZHONGWANG

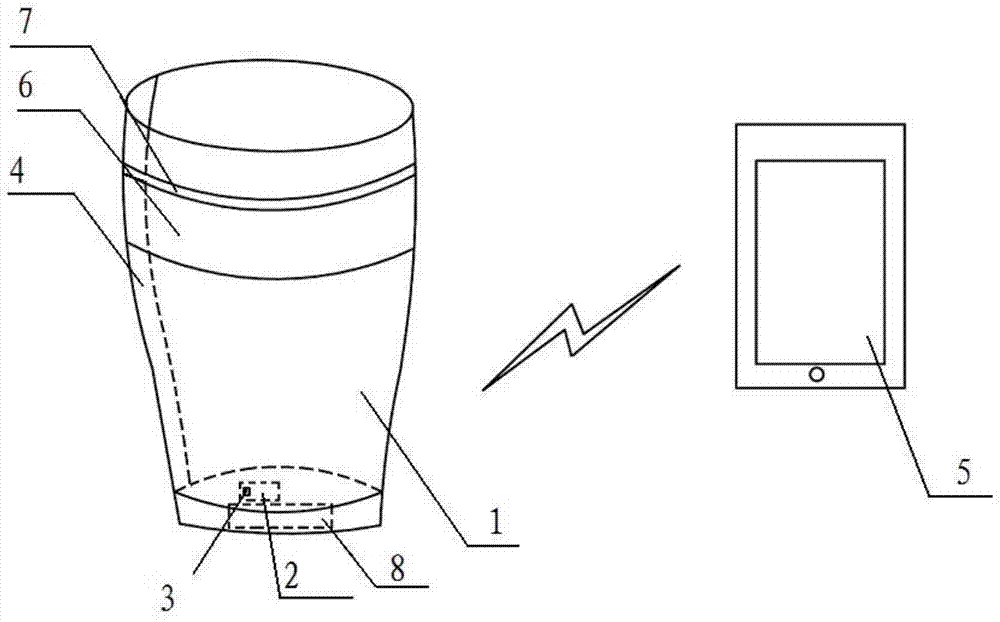

Intelligent cup

ActiveCN103519639AEasy to carryElectric vehicle charging technologyDrinking vesselsElectricityWireless transmission

The invention relates to the field of tableware, in particular to an intelligent cup which comprises a cup body, a controller, a wireless transmission module, a mobile terminal and a measuring instrument used for measuring water consumption. The controller and the wireless transmission module are arranged on the cup body, the controller is electrically connected with the measuring instrument, and the wireless transmission module is electrically connected with the controller and wirelessly connected with the mobile terminal. Acquired signals are transmitted to the controller through the measuring instrument used for measuring water level, the controller converts the signals into data and transmits the data to the mobile terminal through the wireless transmission module, and a water drinking person is prompted to drink water through the mobile terminal. The mobile terminal is convenient to carry and is an electronic product essential to people's life and work, so that the water drinking person can be prompted to drink water at any time.

Owner:张申

Method and device for repairing contaminated soil with persistent organic pollutants

ActiveCN103272838AAvoid condensationAchieving Removal EfficiencyContaminated soil reclamationAir filterCyclonic spray scrubber

The invention relates to a method for repairing contaminated soil, and aims at providing a method and a device for repairing contaminated soil with persistent organic pollutants. The device comprises a separator, a material hopper, a material feeder and an indirect-heating thermal desorbing device which are connected with one another in sequence, wherein a soil emission device is connected to the bottom of the heating thermal desorbing device; a combustion system, a waste heat utilization device and an inert gas generator are respectively connected with the indirect-heating thermal desorbing device; the combustion system is connected with an outer barrel, and the inert gas generator is connected with an inner barrel; and a tail gas processing component comprises a cyclone dust extractor, a primary spray tower, a secondary regulating spray tower, a dehumidifier, a plasma reactor, an air filter, an induced draft fan and an exhaust barrel which are connected with one another in sequence. According to the method and the device for repairing contaminated soil with persistent organic pollutants disclosed by the invention, the amount of exhaust gas needing processing is less, water consumption is low, the persistent organic pollutants are thoroughly removed, the operation cost is reduced by 30%-60%, and the contaminated soil with persistent organic pollutants can be economically and effectively processed.

Owner:ZHEJIANG UNIV

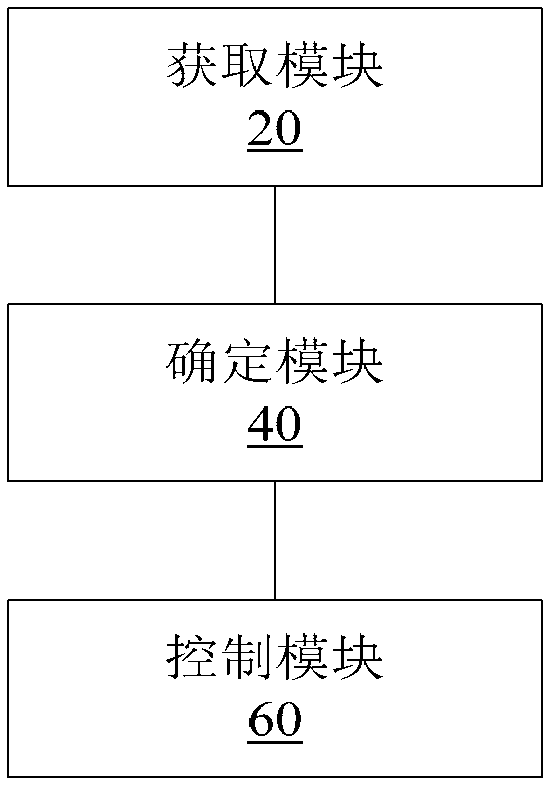

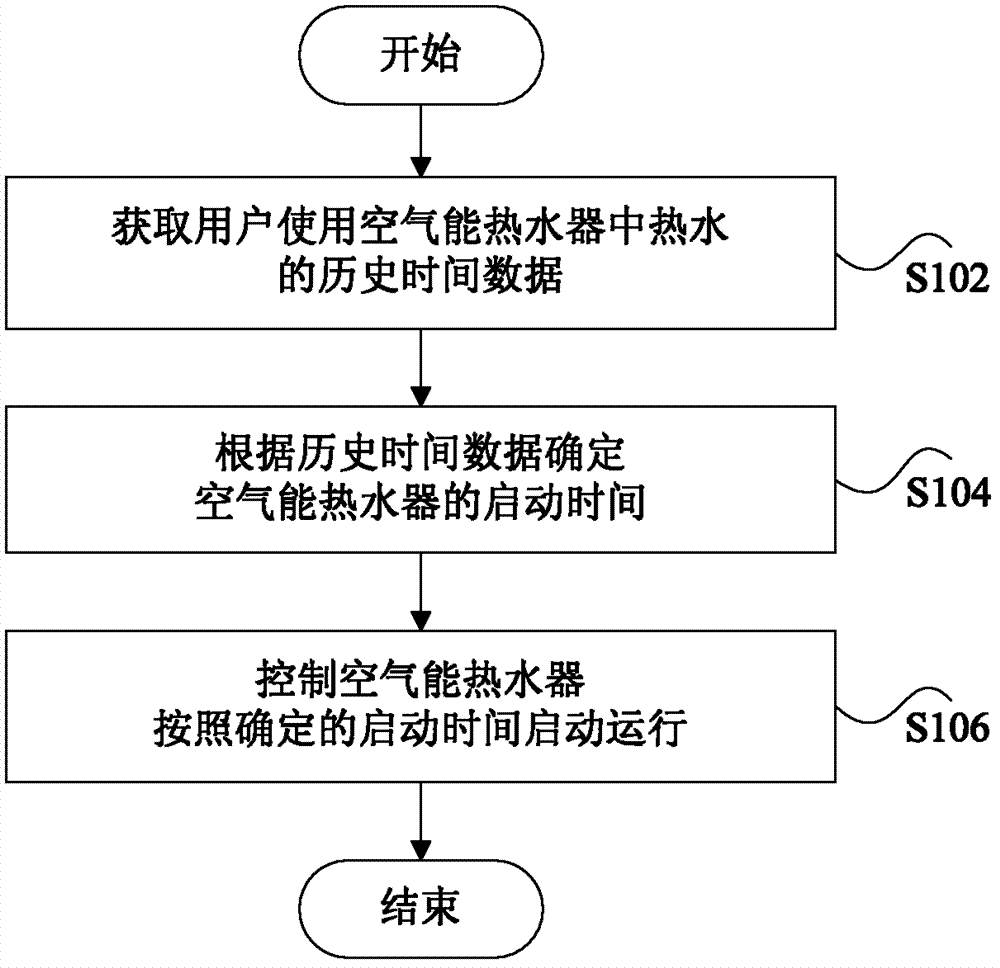

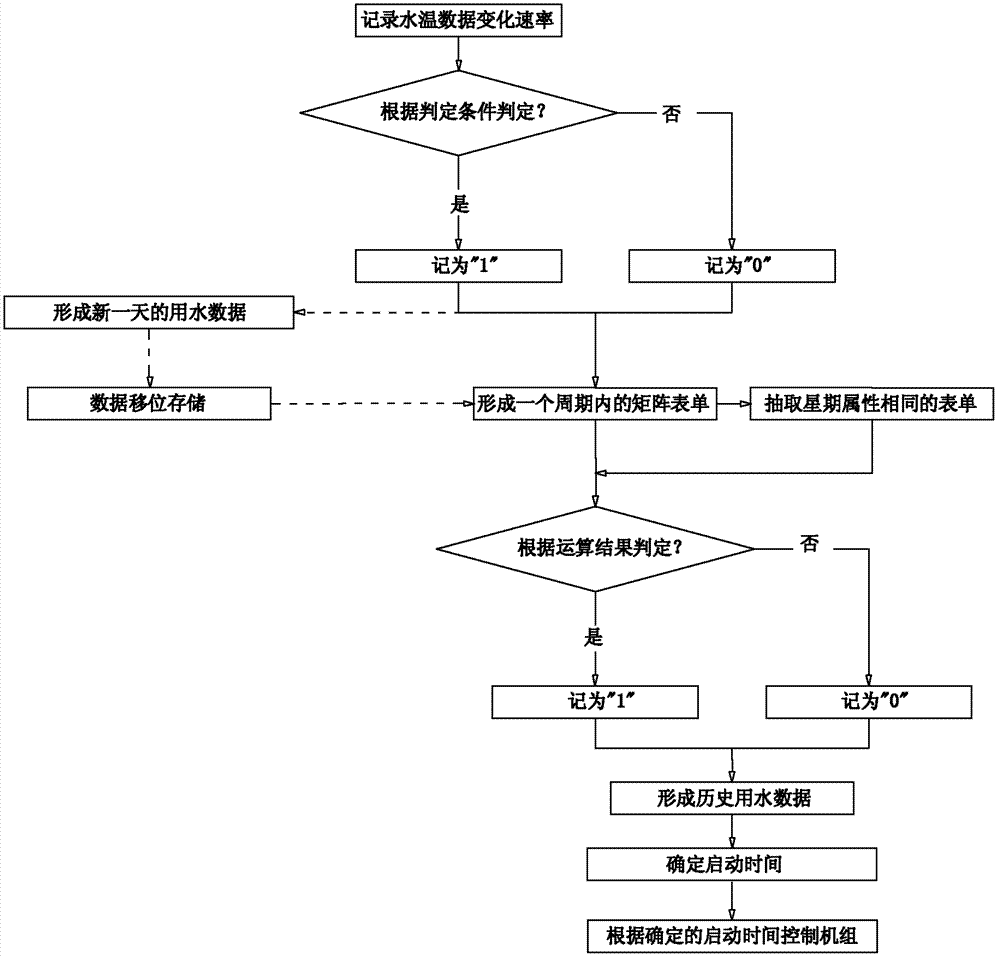

Air energy water heater and control method and device for same

ActiveCN103363670ASolve the problem of high energy consumptionRealize energy-saving controlFluid heatersStart timeEngineering

The invention provides an air energy water heater and a control method and device for the same. The control method comprises obtaining historical time data of utilization of hot water in the air energy water heater by users; determining starting time of the air energy water heater according to the historical time data; controlling the air energy water heater to be started to operate according to the determined starting time. By means of the air energy water heater and the control method and device for the same, the air energy water heater can be controlled to be started to operate according to user own water consumption habits, so that hot water can be provided as user required, frequent heating is not required, and energy-saving control is effectively achieved.

Owner:GREE ELECTRIC APPLIANCES INC

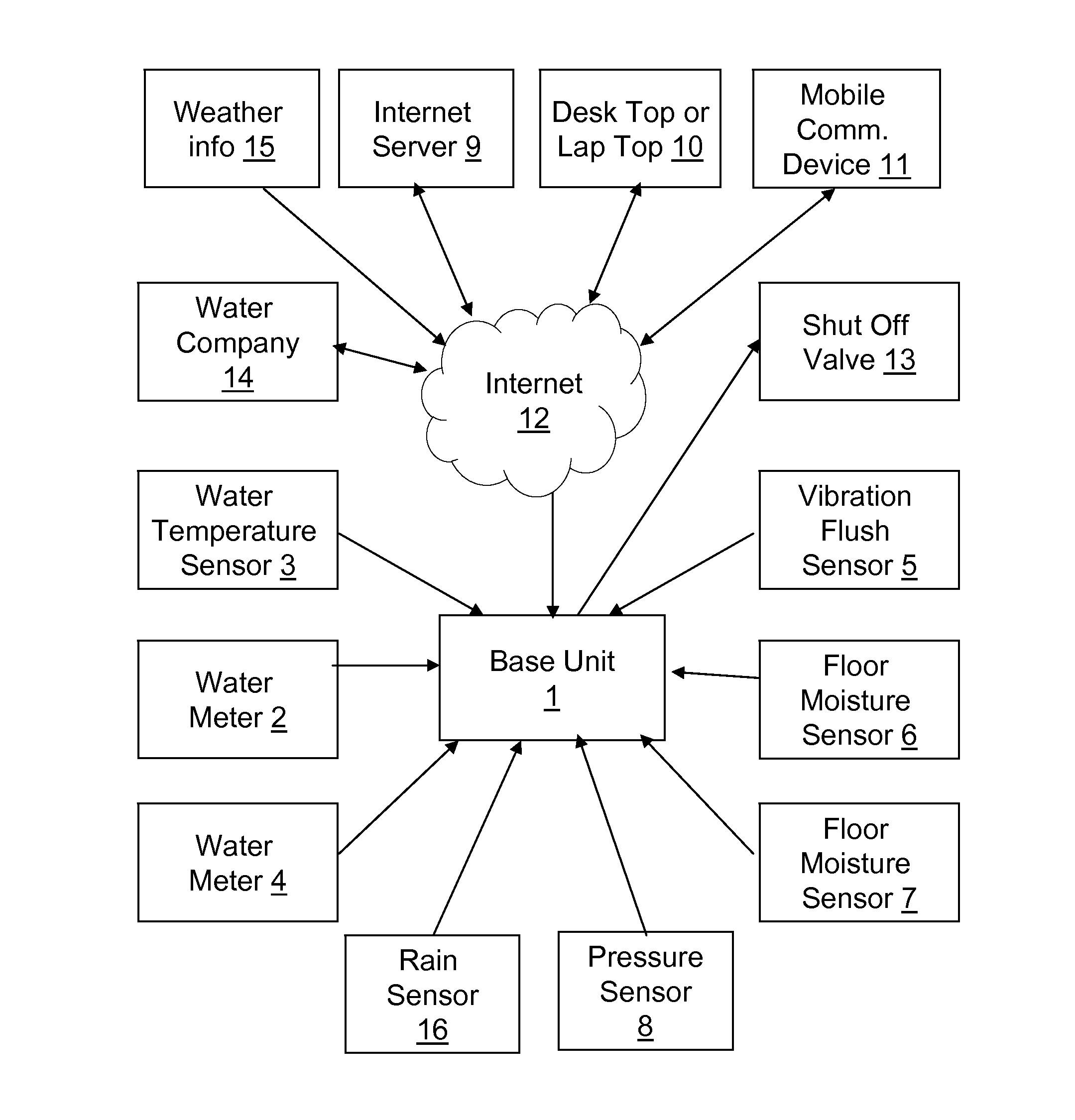

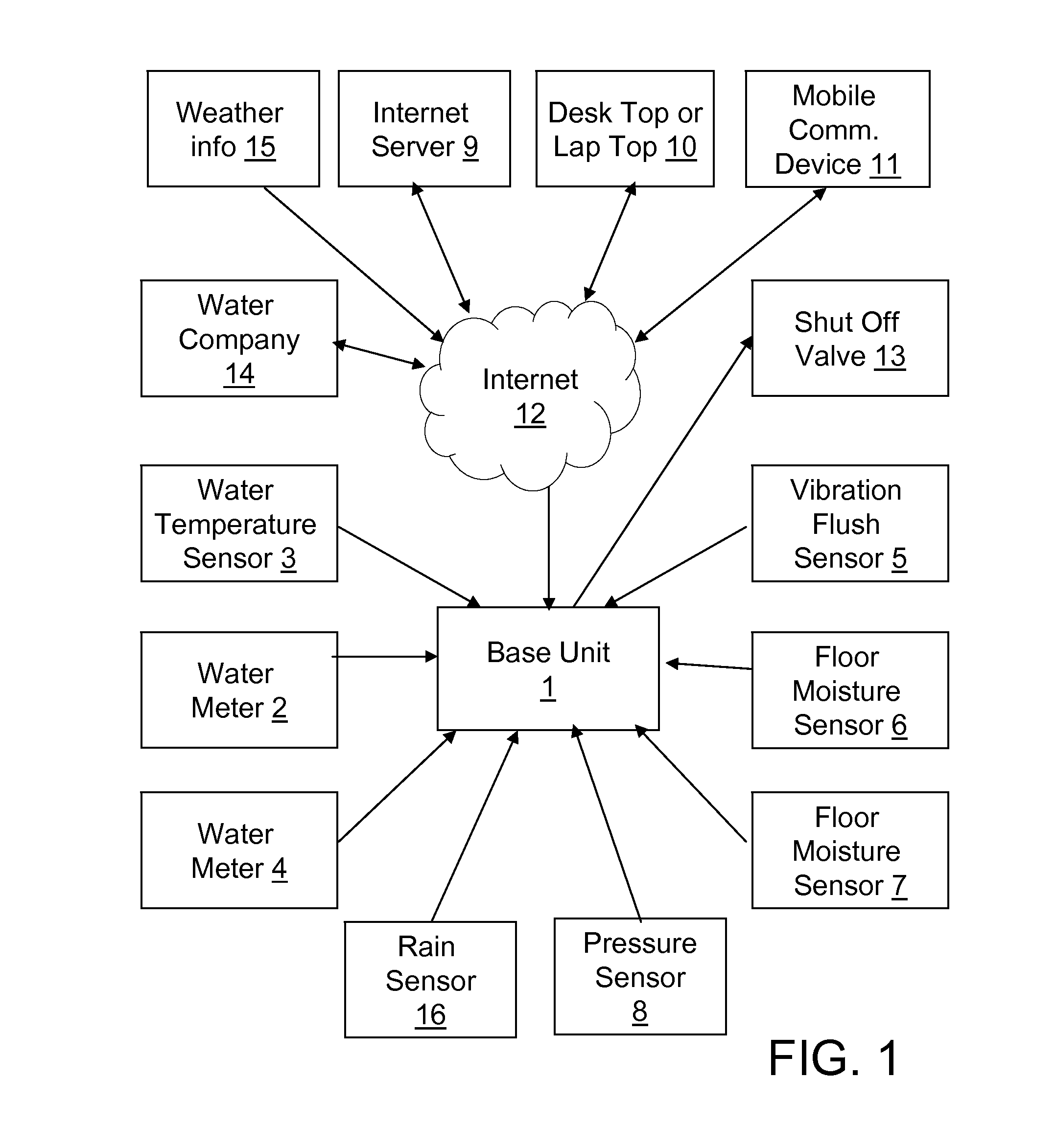

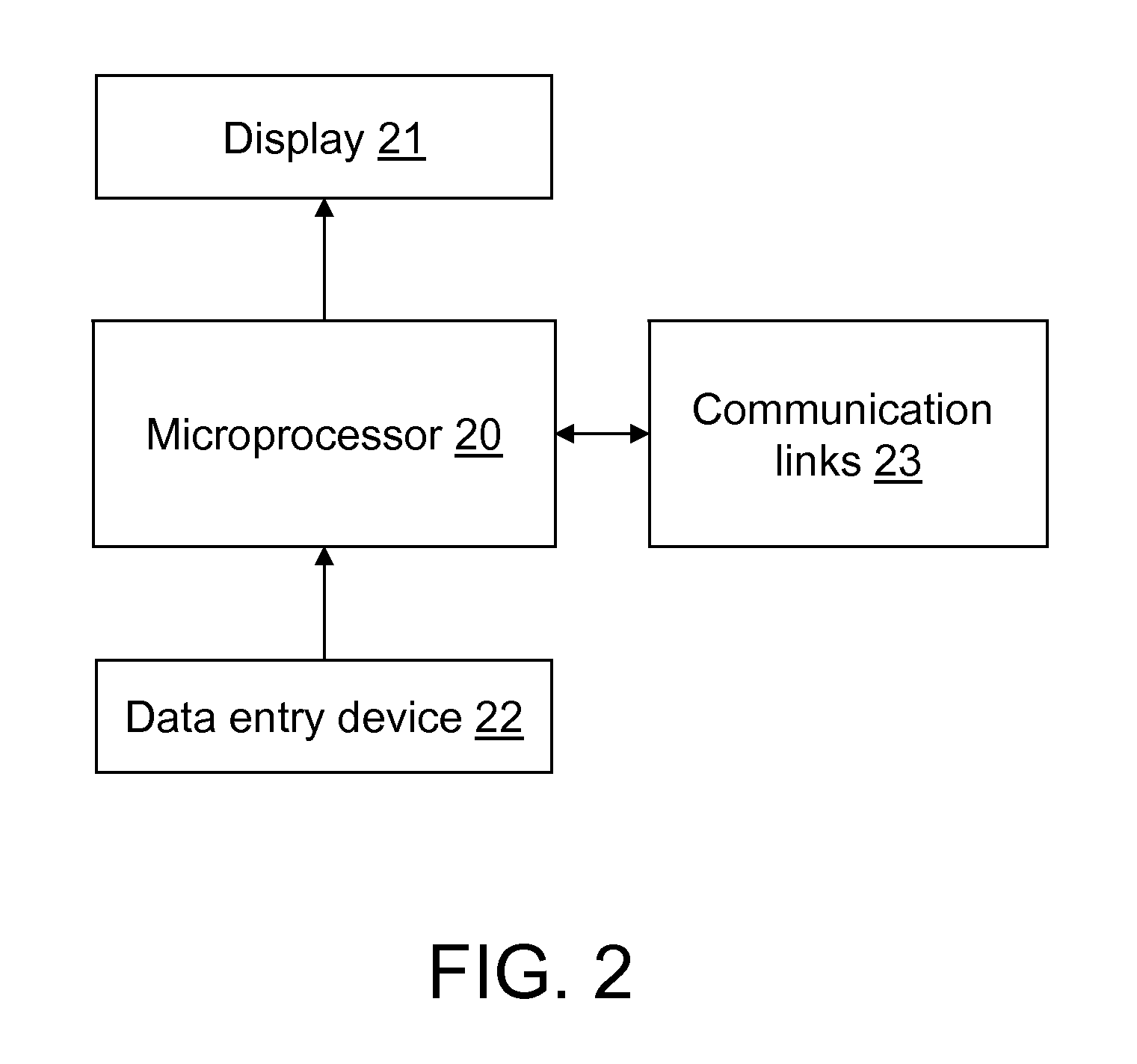

Water Management System

InactiveUS20110035063A1Facilitate water conservationData processing applicationsElectric devicesTelecommunications linkDisplay device

This invention is a water consumption monitoring and control system comprised of a base unit, itself comprising a display and a data entry device, a microprocessor, a communication link to water meters, pressure sensors, temperature sensors, flush toilet vibration sensors and shut-off valves. In addition the base unit has access to the Internet and can access a server which holds a database of water conservation information. This database includes watering advisories from the local government, and weather information from the weather office. The server runs an algorithm and generates control data which is sent to the base unit.

Owner:PALAYUR SAJU ANTONY

Wet method transfer printing method for natural fiber and polyamide fibre

InactiveCN101105006AHigh color yieldReduce consumptionTransfer printing processDyeing processPolyamidePrinting ink

The invention provides a wet-method transfer printing process of natural fiber and nylon, which mainly comprises the following steps: (1) selecting acidic printing ink or active printing ink; (2) printing: printing the surface of PET or BOPP film with the selected printing ink to obtain a transfer printed film; (3) transfer printing: treating natural fiber and nylon with a soaking liquid, subjecting the transfer printed film and printed fabric simultaneously to the compression by a rolling machine; and (4) oven-drying: oven-drying the fabric after the transfer printing is completed and baking to allow color fixation. The invention has the advantages of high transfer printing rate, high color yield of fabric, bright color, good color fastness, less pollution, reduced water consumption, simple process, high production efficiency, low cost, and success in non-paper transfer printing.

Owner:常州涵源新印花有限公司

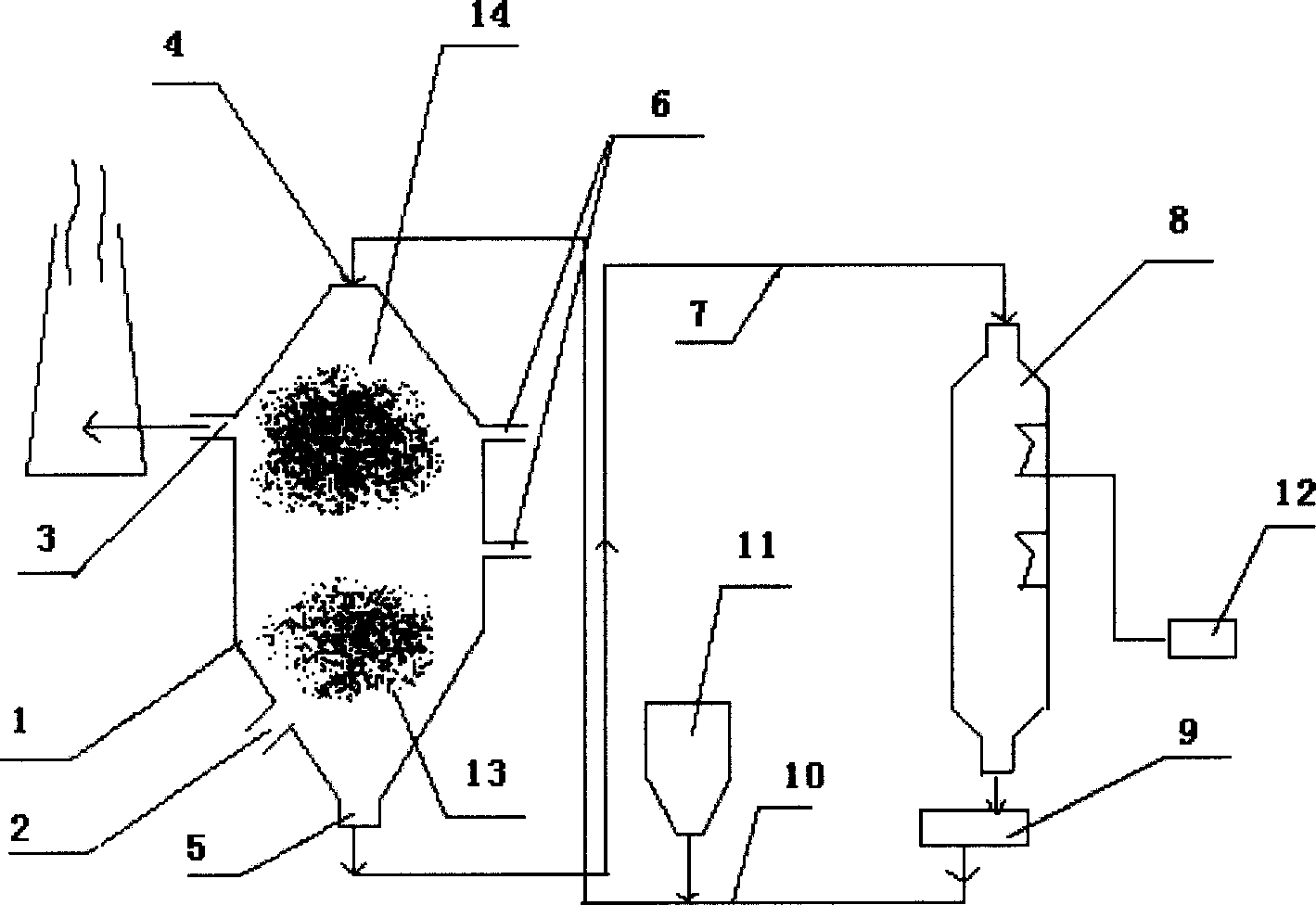

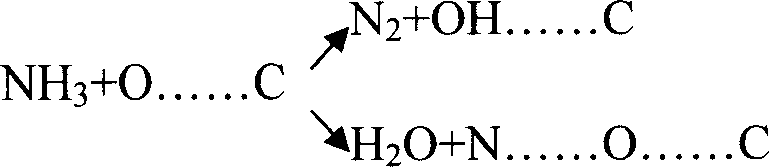

Moving bed smoke desulfur denitrate and dust removal technology

InactiveCN1911491ASimple processImprove efficiencyDispersed particle separationAir quality improvementSulfatePhysical chemistry

The present invention relates to fume desulfurizing, denitrating and dedusting process in moving bed. During the reverse contact between fume and active coke, the fume first has its adsorbed SO2 eliminated in the desulfurizing layer and then has its NOx reacted with injected NH3 to produce N2, H2O and other harmful products. The active coke after finishing desulfurization and denitration is regenerated in a regenerator physically through heating to decompose and desorb sulfuric acid and sulfate and chemically through the reaction between the created SO3 and the inner surface of the active coke to produce surface functional group. Experiment shows that the technological scheme of the present invention has the advantages of simple process, high efficiency, low cost, low power consumption, low water consumption and other advantages.

Owner:长春惠工净化工业有限公司

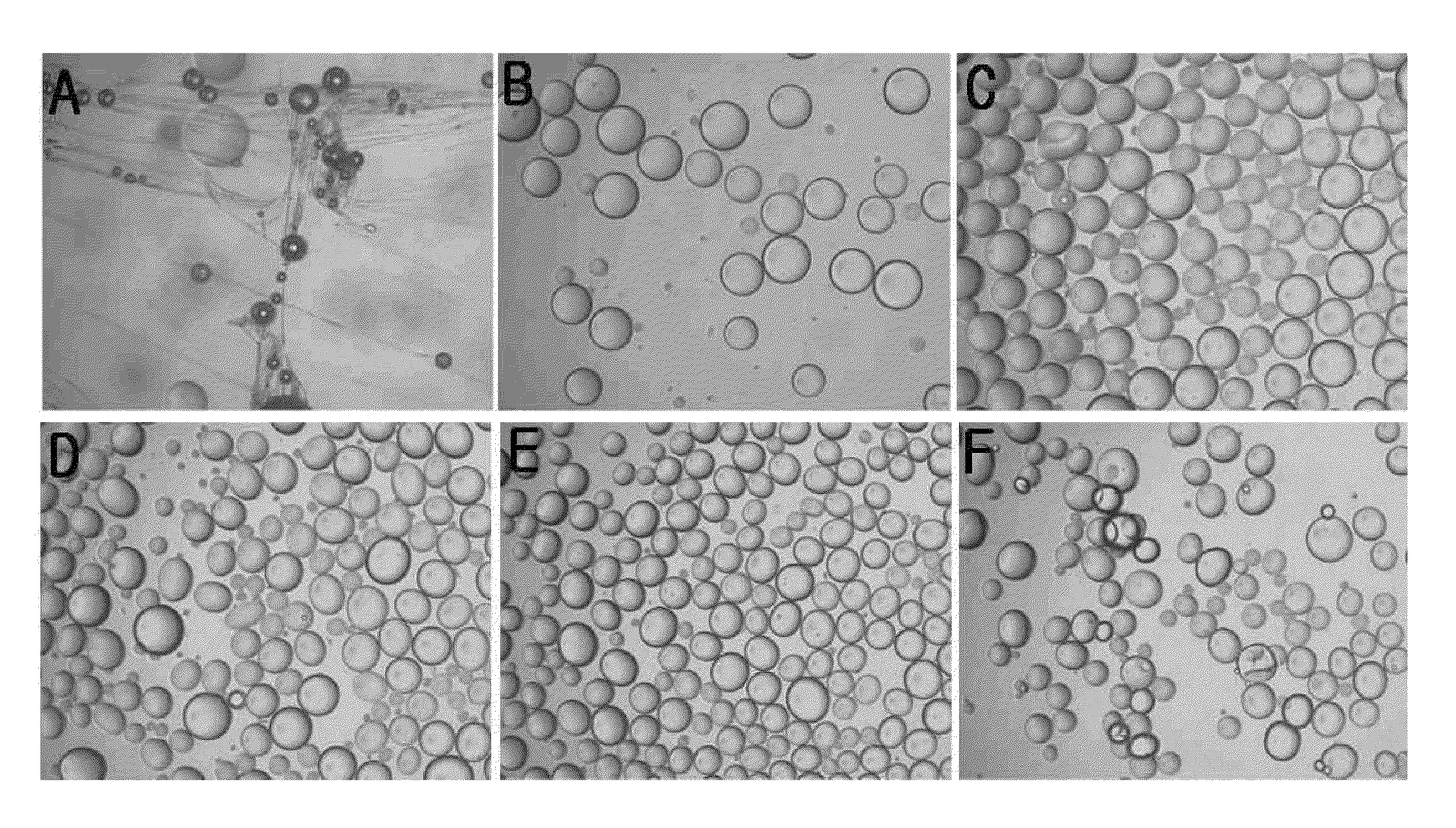

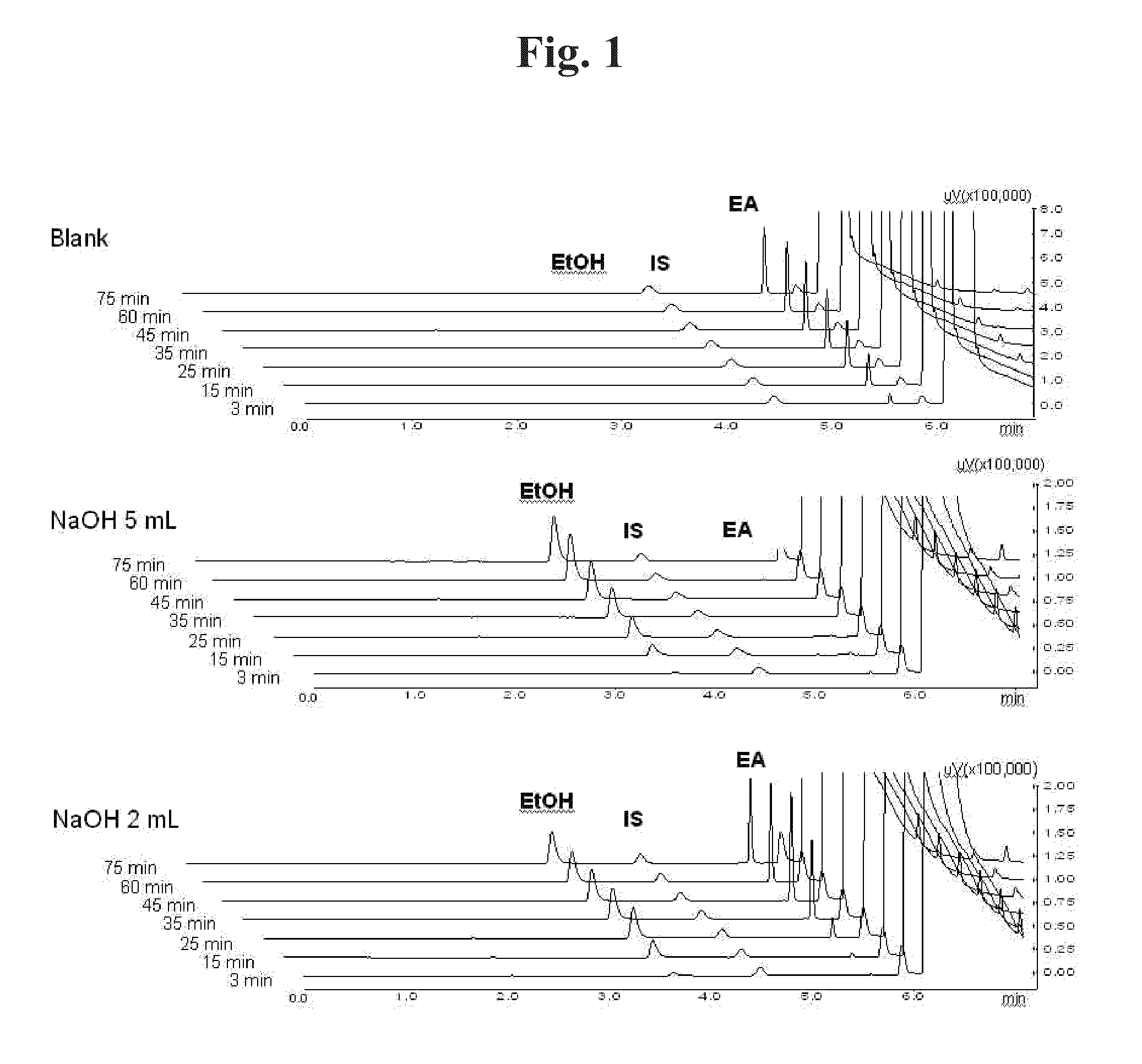

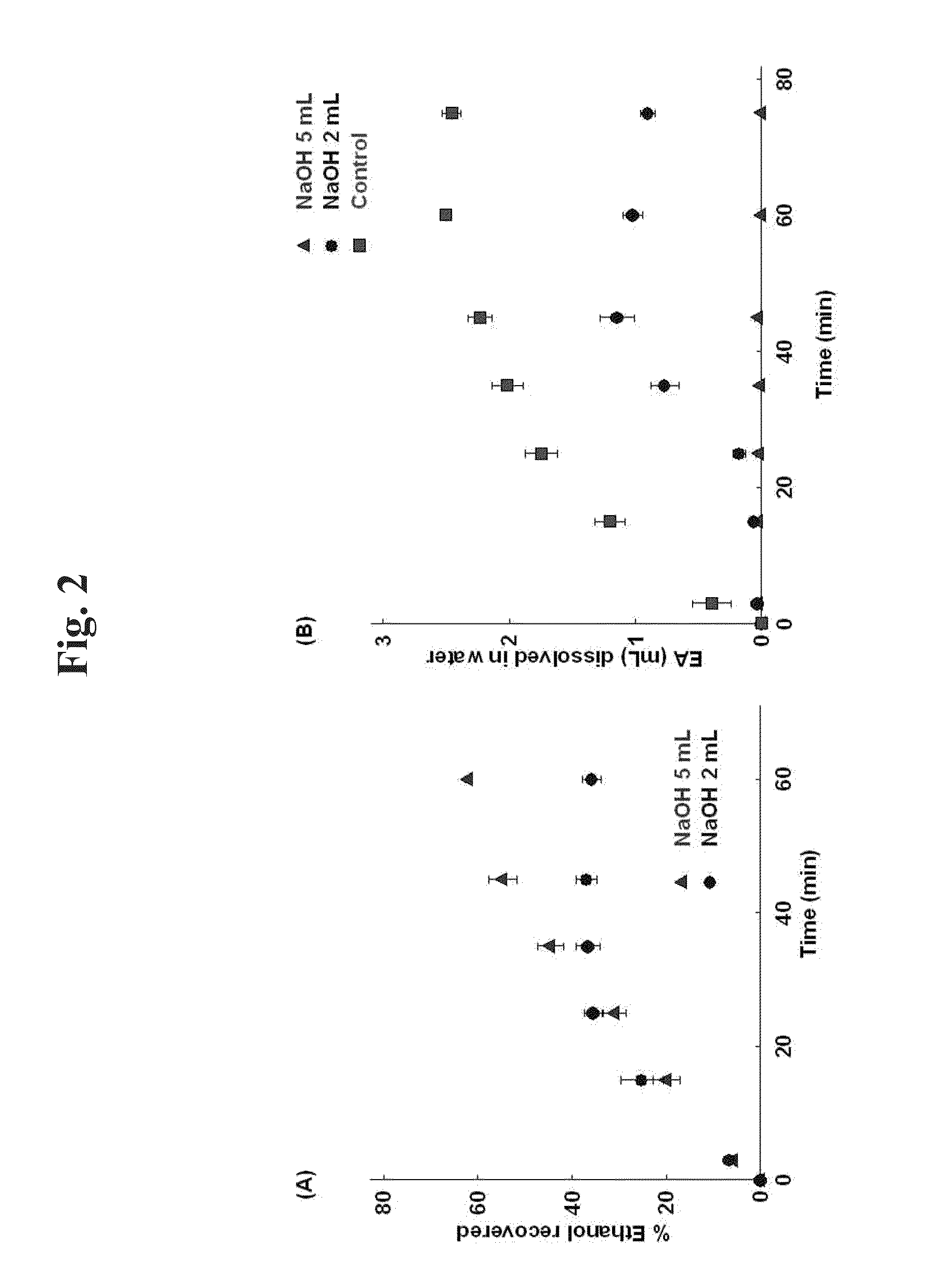

Method for preparing microspheres and microspheres produced thereby

Owner:EWHA UNIV IND COLLABORATION FOUND +1

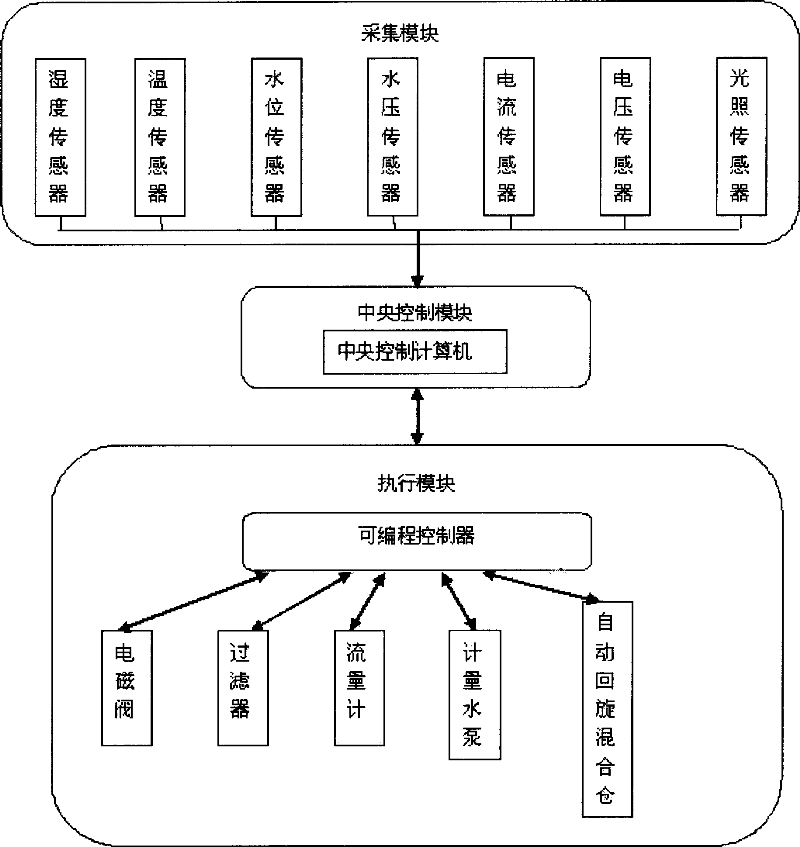

Remote and intelligent irrigation and fertilization system

InactiveCN101040581AMeet the needs of large-scale productionScientificWatering devicesPressurised distribution of liquid fertiliserAutomatic controlWater level

The invention discloses a remote intelligent irrigating fertilizing system, comprising a collecting module, a central controlling module and an executing module, wherein the collecting module uses a sensor to collect field on-site humidity, inlet and outlet water levels, weather, temperature and lightness, the central controlling module receives the collected data from the collecting module, via a central control computer to calculate out the fertilize formula and the water consumption, to be sent to the executing module, the executing module comprises a programmable controller exchanging data with the central controlling module to control the switches of an electromagnetic valve, a filter, a flux meter, a metering water pump, and an automatic rotary mixing chamber. The invention can calculate out the fertilizer formula and water consumption according to the basic information of field, so as to automatically control the inferior devices to intelligently irrigate and fertilize, with real-time property, high efficiency and wide application.

Owner:SHANGHAI YUZHILING INFORMATION SCI & TECH

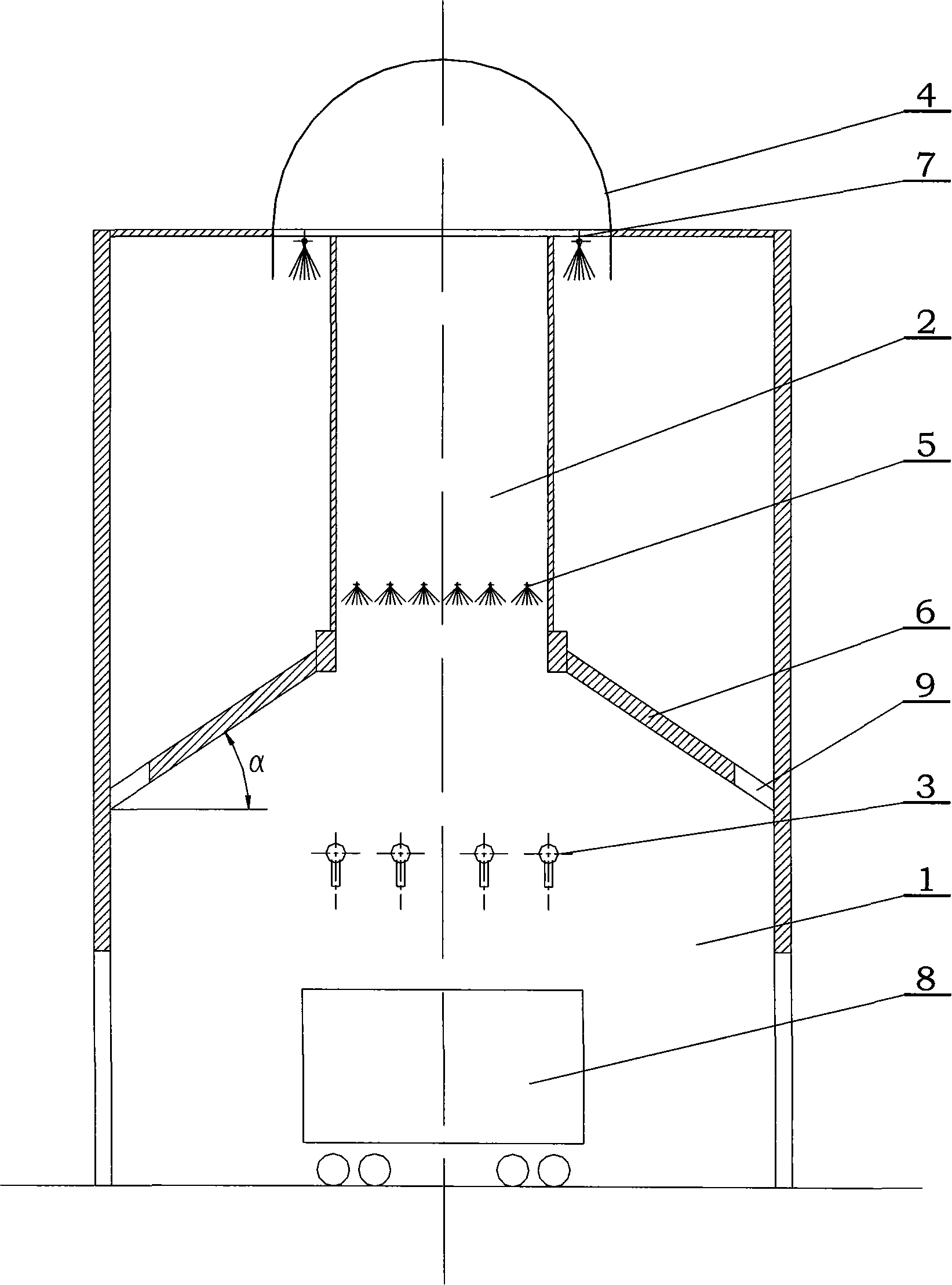

Dome type dust removing coke quenching machine

The invention relates to a dome-like dedusting coke quenching tower, which comprises the following parts: a coke quenching procedure at the bottom and a deduesting procedure at the top, wherein the coke quenching procedure is equipped with a coke quenching injecting pipe; the dedusting procedure is divided into three lattices; the bottom of two side lattices sealed by a tipping plate; the bottom of the tipping plate is equipped with blow-off hole; the included angle alpha of the tipping plate and the horizontal surface is 10-75 degree; the top of the coke quenching injecting pipe and the middle lattice entrance of the dedusting procedure are equipped with a plurality of washing and cooling devices; the top of washing and cooling devices and the top of the coke quenching tower are equipped with dome-like dedusting device which covers the middle lattice and two side lattices of the coke quenching tower dedusting procedure. The invention reduces the dust content after washing the polluting vapor with the water fog, cooling the polluting vapor, settling the polluting vapor gravitively and changing the direction of the gas flowing, which reduces the water consumption.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

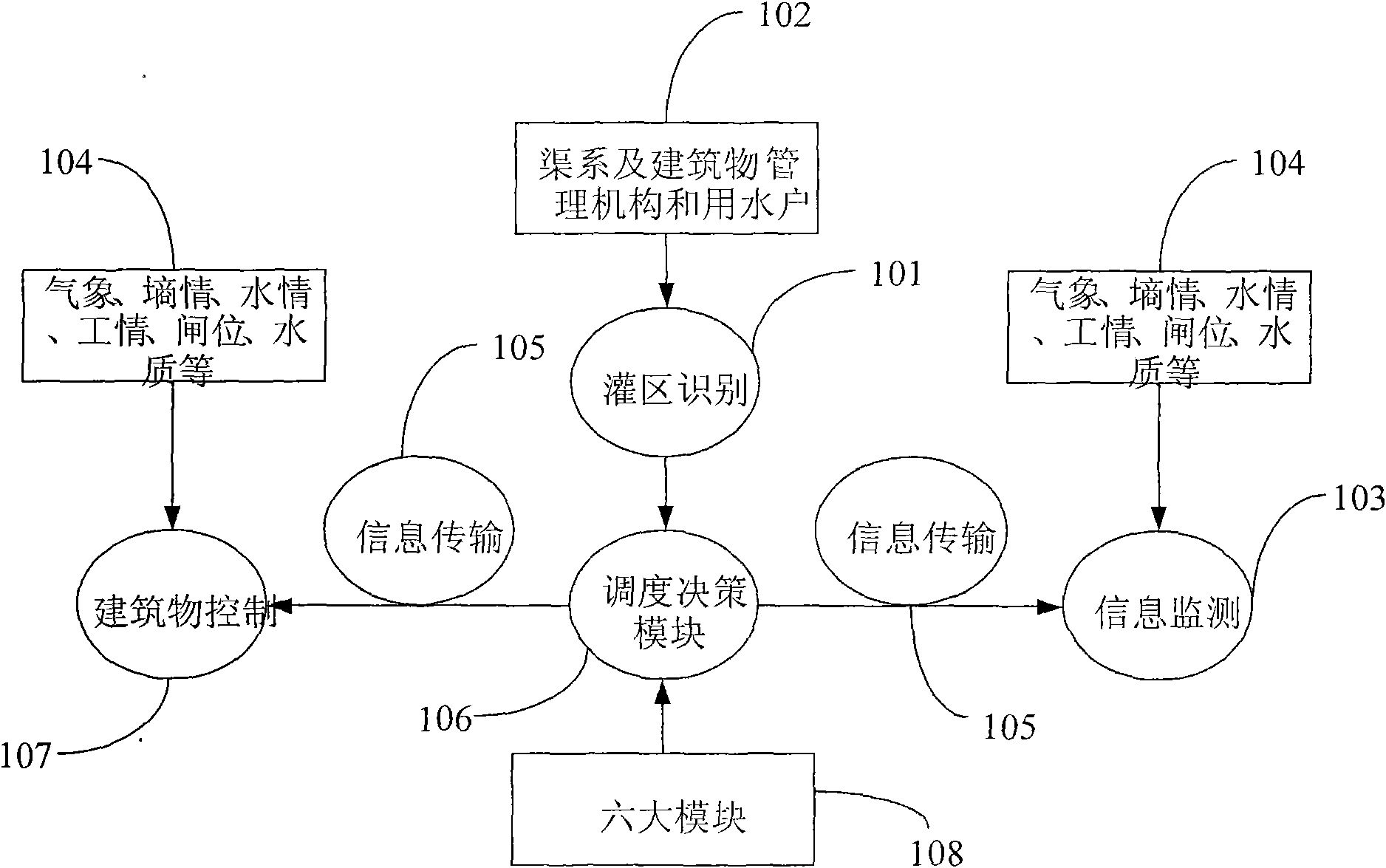

Water management informatization structure system of irrigation district

InactiveCN101622952AReduce management costsOptimize schedulingWatering devicesCultivating equipmentsInformatizationInformation transmission

The invention discloses a water management informatization structure system of an irrigation district, which comprises irrigation district identification, information monitoring, information transmission, building control and a scheduling decision module. The irrigation district identification is used for identifying an irrigation district canal system, buildings, management mechanisms and water users; the information monitoring is used for acquiring and outputting irrigation district information; the information transmission is used for transmitting the information to the scheduling decision module in time and transmits water demand information to the building control through the scheduling decision module; the building control is used for dynamically scheduling gates and pumping stations of the irrigation district; and the scheduling decision module is used for providing a decision basis and a decision plan for an irrigation district administrator and controlling the water consumption of the irrigation district. According to the actual condition of the water management informatization of the irrigation district, the invention constructs the water management informatization structure system of the irrigation district, which conforms to reality by a method of the attribute classification of information technology. The water management informatization structure system of the irrigation district has the advantages of no repetition and intersection, easy understanding and prominent water management informatization of the irrigation district.

Owner:CHINA IRRIGATION & DRAINAGE DEV CENT +1

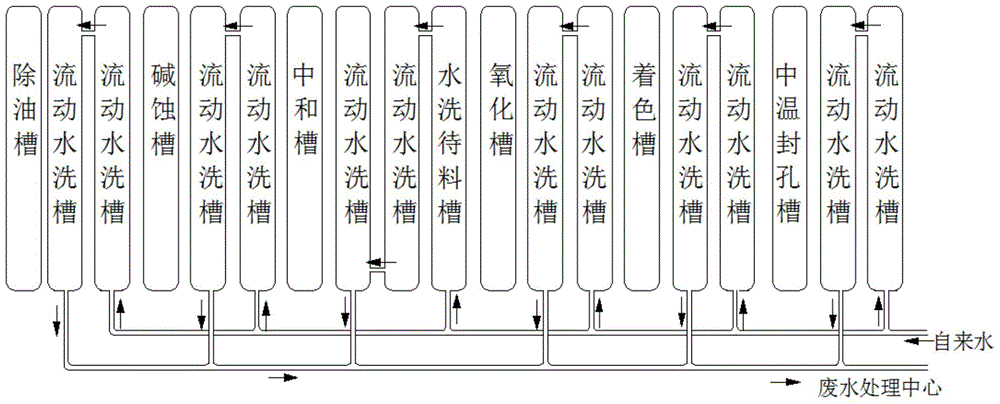

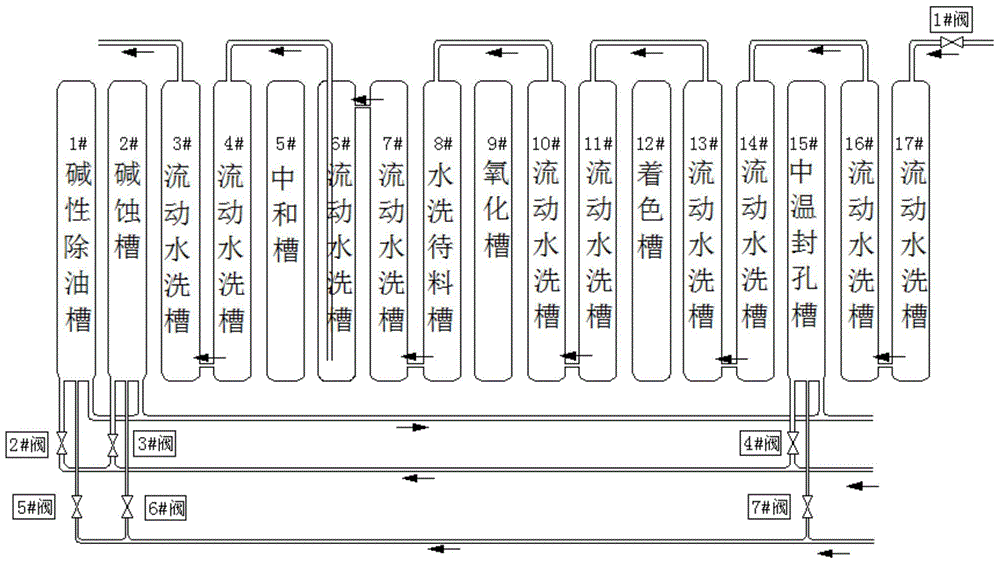

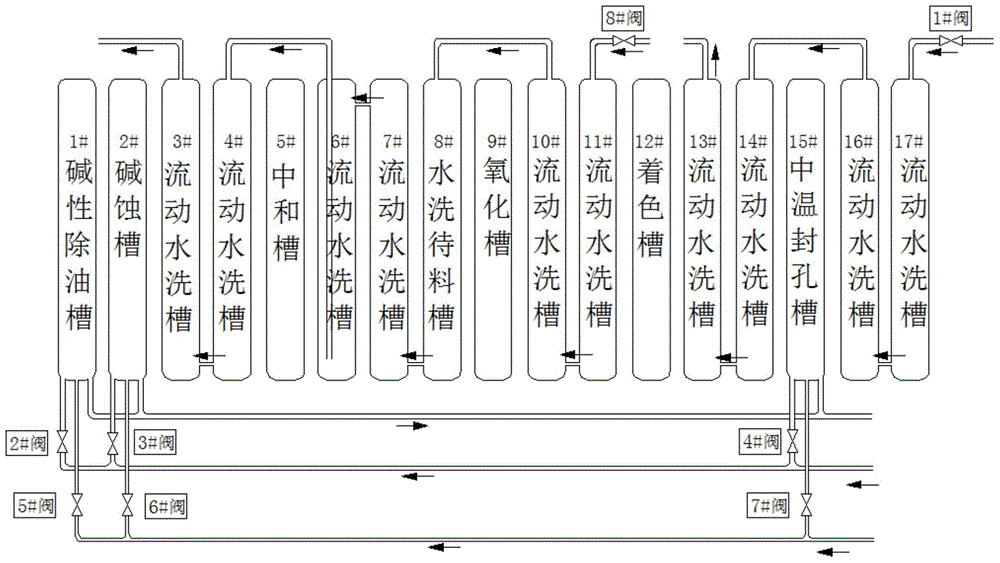

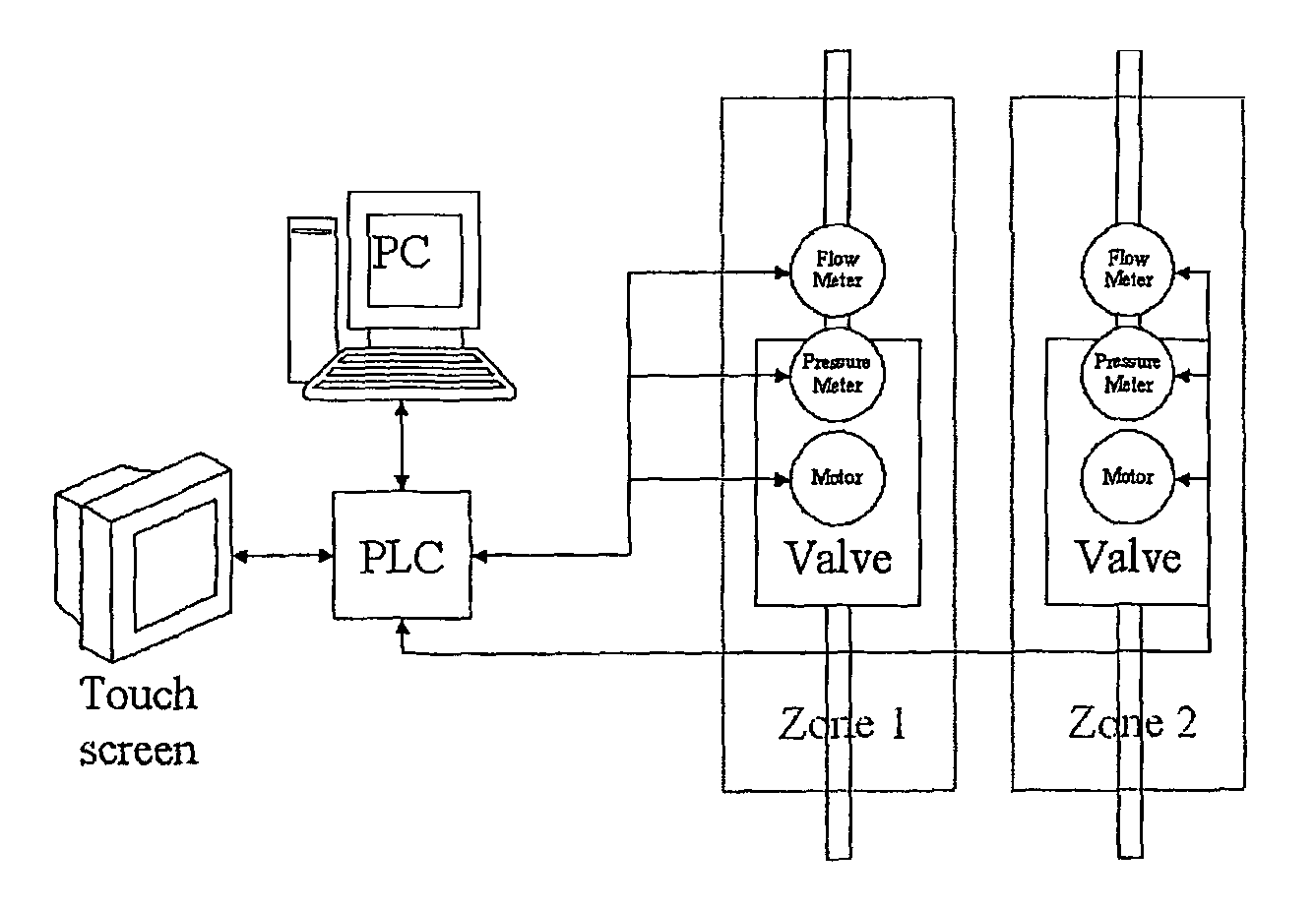

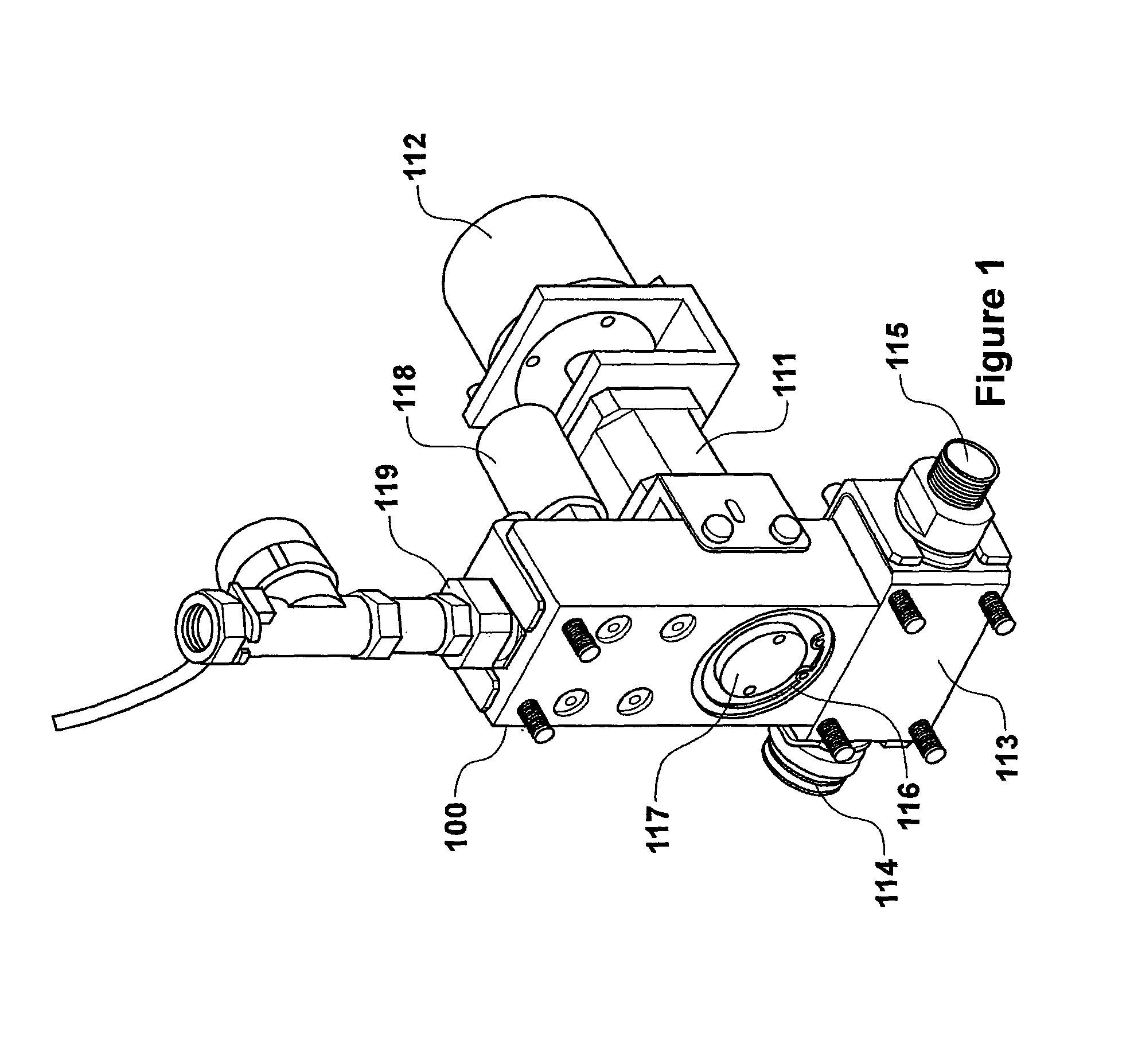

Aluminum alloy anodizing line treatment process

ActiveCN103952741AAchieve large-scale water conservationAvoid pollutionAnodisationAnodizingMaterials science

The invention relates to an aluminum alloy anodizing line treatment process. The aluminum alloy anodizing line treatment process comprises a functional trough system and water washing trough systems arranged between functional troughs. The functional trough system is arranged along the flow direction of washing water in a manner that an upstream functional trough is compatible with a downstream functional trough, and the water washing trough systems are arranged in an overall phase-reversing in-series-connection manner. According to the aluminum alloy anodizing line treatment process, a mode in which a flowing water washing tank is separately configured for each functional trough in the traditional anodizing line is changed. Since all water washing troughs are connected in series in a phase-reversing manner, the number of the water inlets and outlets is greatly reduced and the water consumption is decreased from 25.0-35.0 tons per ton material to 5.0-6.0 tons per ton material and the water is saved by more than 80%. The treatment process disclosed by the invention has the advantages of low production cost, high efficiency and environmental friendliness and is suitable for industrial application.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

Water management system

InactiveUS8606413B2Detection of leakageLevel controlGeneral water supply conservationWater management systemWater flow

A method of managing and conserving water at a point of use, by installing a control panel and at least one electrically operated valve in a plumbing line, which valve can monitor at least pressure and flow rate, and allow the calculation of the total volume of flow in a particular line. The valve being controlled by a controller programmed to prevent water loss by monitoring the pressure and flow rate in a particular line to detect and prevent water consumption outside controlled parameters by shutting off the valve if the system detects an uncontrolled flow, such as faucet being left on, or a leaky toilet cistern, or the water flow in a zone exceeding a predetermined quota.

Owner:PICTON DAVID JOHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com