Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

779 results about "Wet-milling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet-milling is a process in which feed material is steeped in water, with or without sulfur dioxide, to soften the seed kernel in order to help separate the kernel’s various components. For example, wet-milling plants can separate a 56-pound bushel of corn into more than 31 pounds of cornstarch (which in turn can be converted into corn syrups or corn ethanol), 15 pounds of corn gluten meal for use in animal feed, and nearly 2 pounds of corn oil.

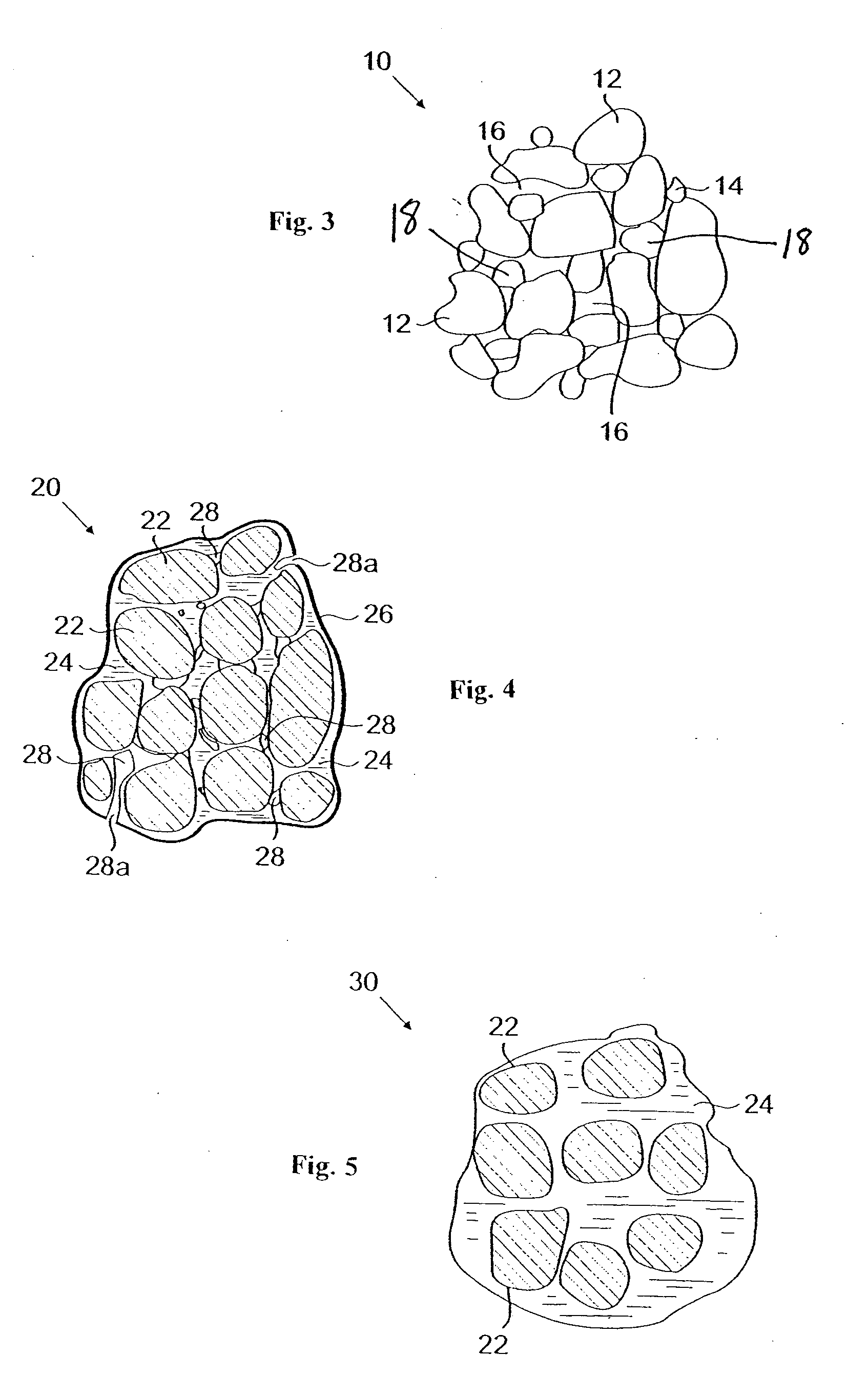

Orally disintegrating tablets and methods of manufacture

ActiveUS20050232988A1Effective taste-maskingOptimal size distributionPowder deliveryGranular deliveryOrally disintegrating tabletAlcohol sugars

A tablet that rapidly disintegrates in the oral cavity comprising a compressed blend of rapidly dispersing microgranules prepared by granulating a sugar alcohol or a saccharide or a mixture thereof having an average particle size less than about 30 microns and a disintegrant, and a taste-masked microcapsule containing at least one drug, the microcapsule being prepared by granulating a pharmaceutically acceptable formulation comprising at least one drug in a therapeutically effective amount and at least one polymeric binder that improves resilience of the microgranules, wet milling the granulated mass, and microencapsulating the milled granules to provide microcapsules.

Owner:ADARE PHARM INC

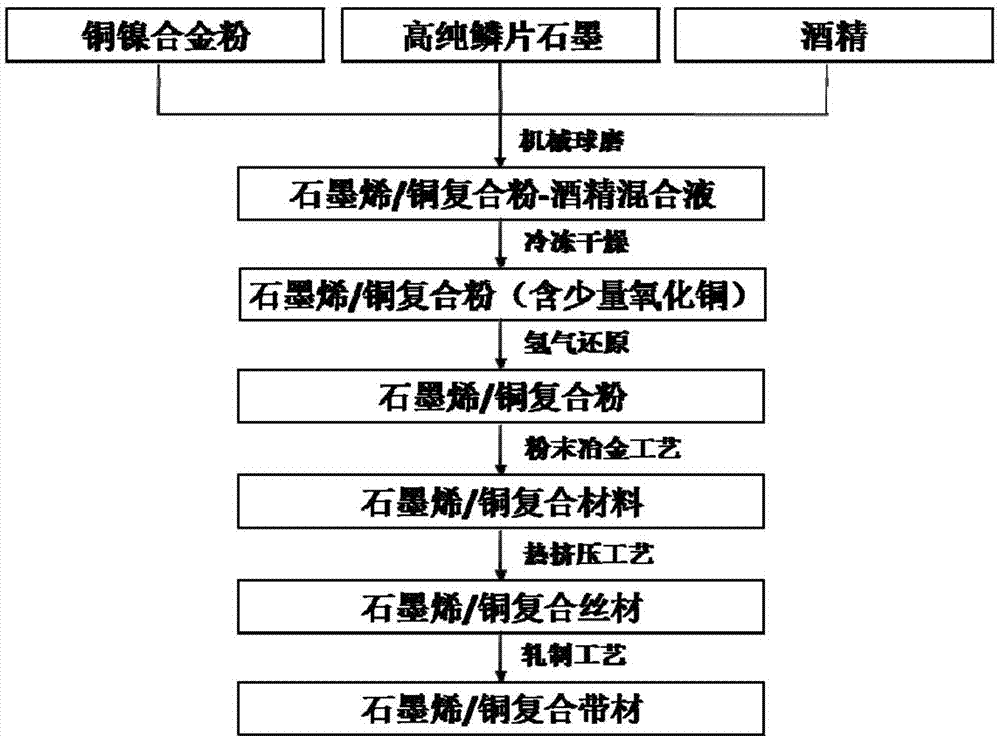

Graphene/copper composite and preparation method thereof

The invention provides a graphene / copper composite and a preparation method of the graphene / copper composite. Copper-nickel alloy powder and crystalline flake graphite are ball-milled mechanically jointly, alcohol is added as a wet milling medium during mechanical ball milling, and copper powder oxidation can be avoided. Graphene is stripped from the graphite by virtue of a mechanical force; at the same time, due to the presence of copper-nickel micro powder, a stripping process of the graphite is promoted; the spherical copper-nickel alloy powder is changed into sheeted powder by the action of the ball milling to obtain graphene / copper composite powder preliminarily; and a graphene / copper composite block, a composite wire and a composite tape are obtained by powder metallurgy, hot extrusion and rolling technologies. According to the composite, the graphene is dispersed uniformly; interface bonding between a matrix and a reinforcement; and the graphene / copper composite has excellent physical properties. According to the composite and the method, a technology is simple, a process is easy to control, and a scale production application is easy to achieve.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

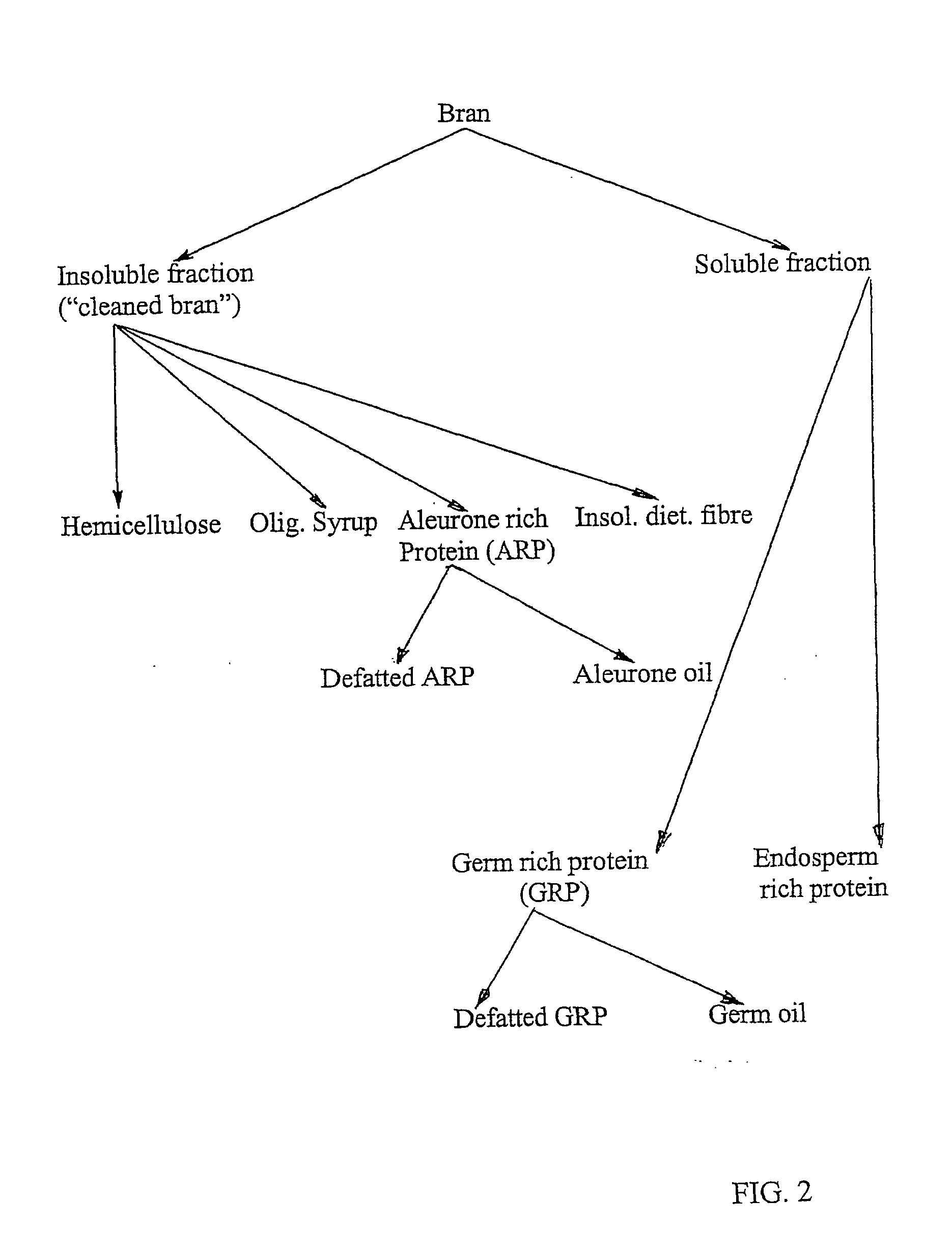

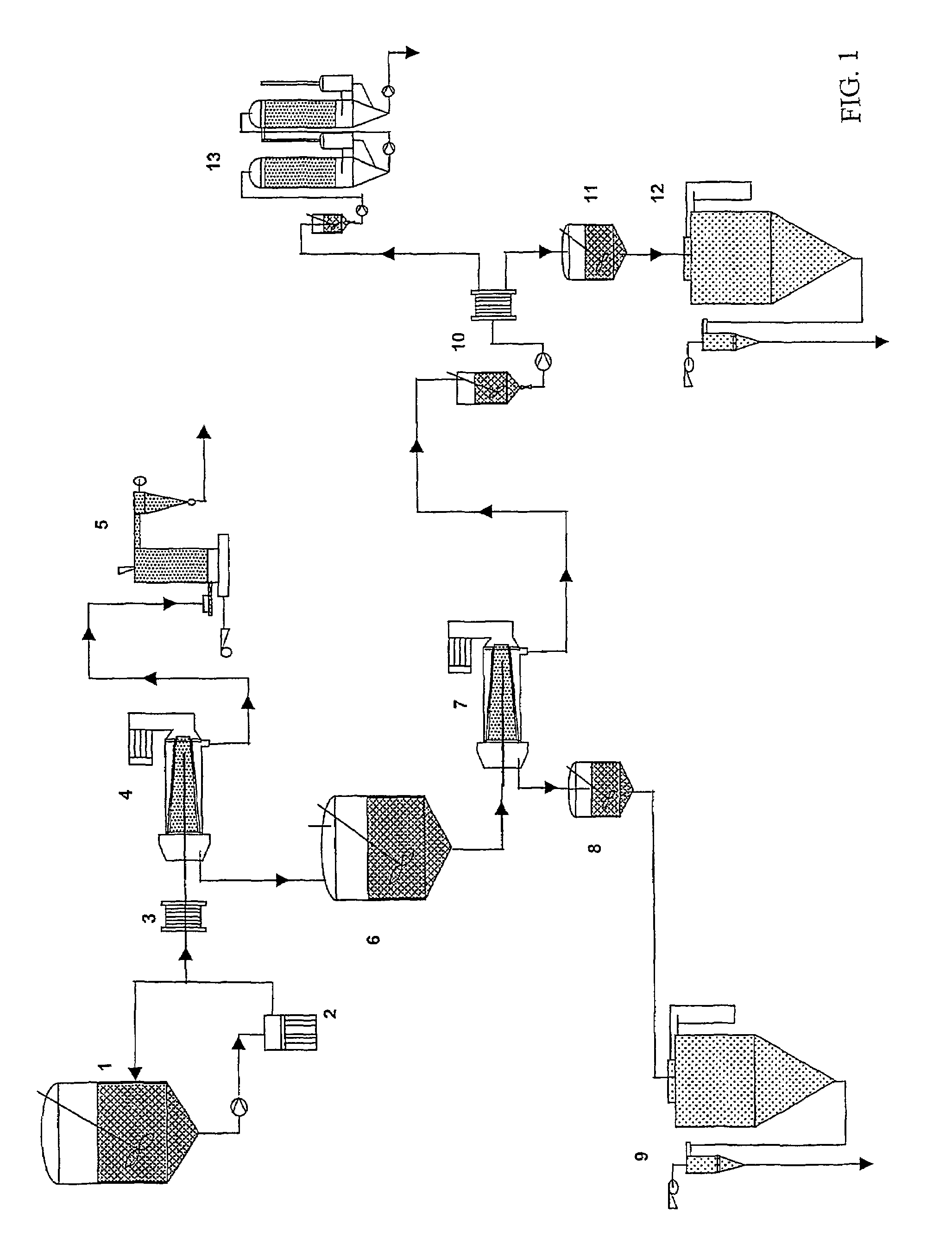

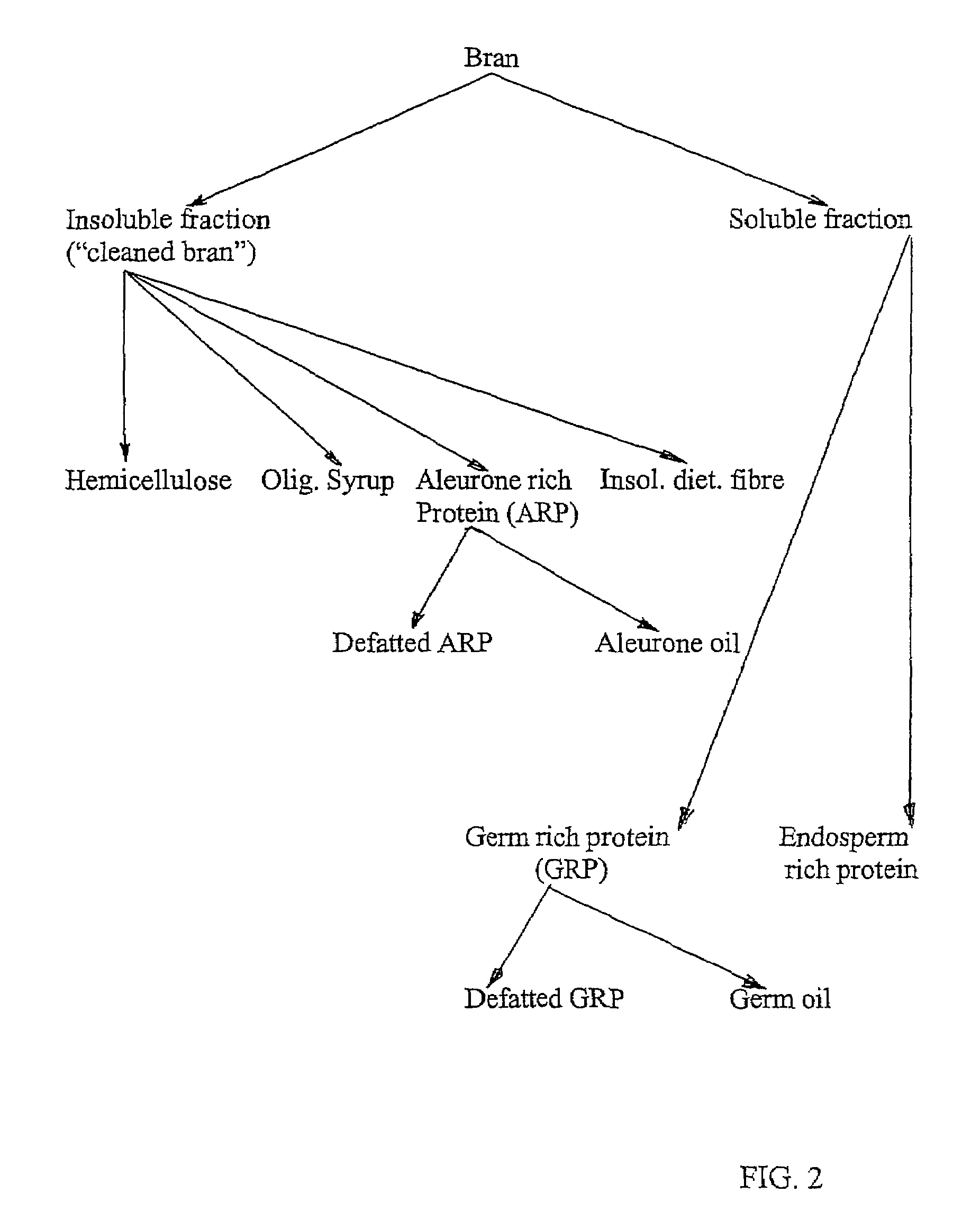

Process for the fractionation of cereal brans

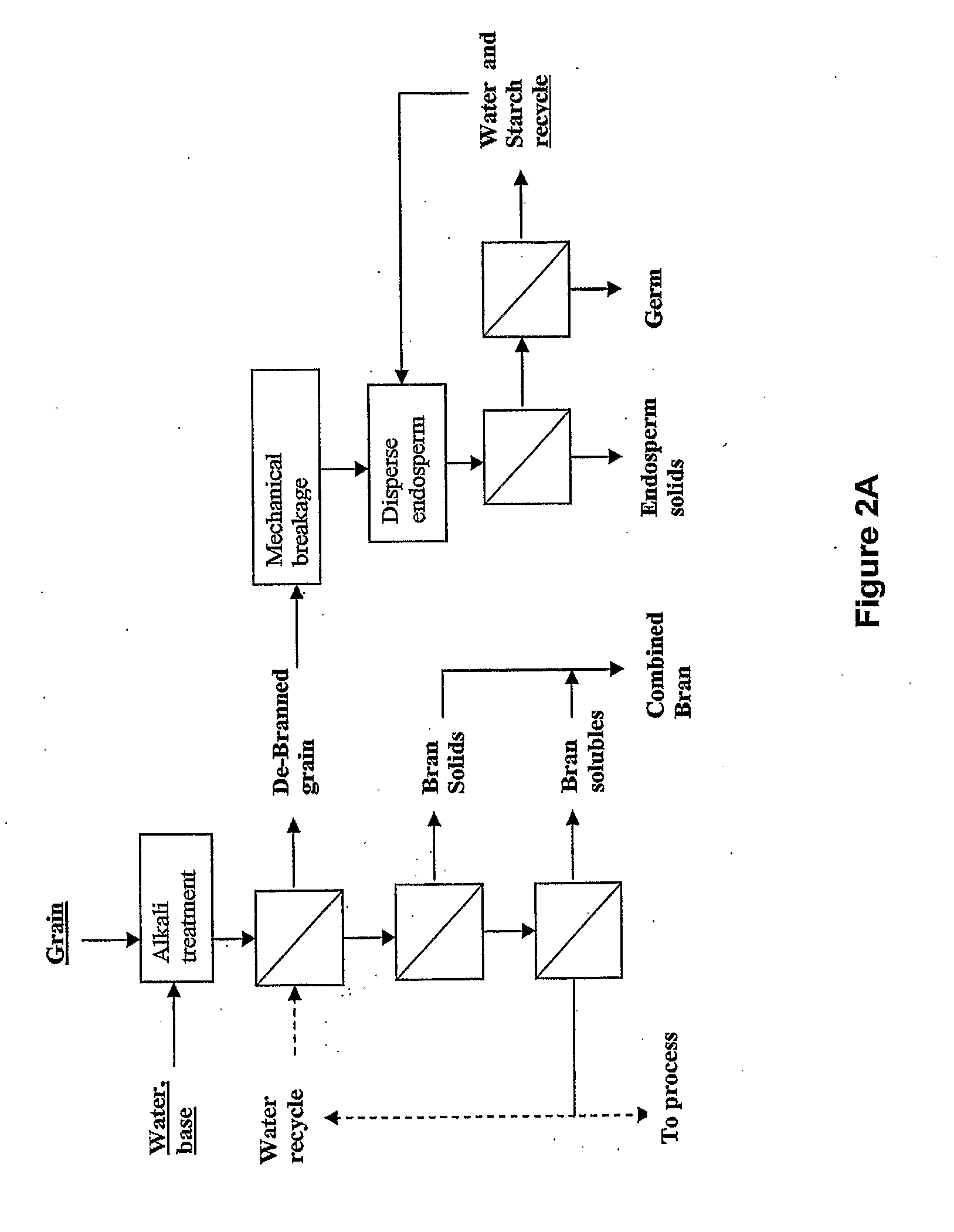

InactiveUS20050089602A1Minimal contaminationImprove efficiencyTea extractionProtein composition from vegetable seedsUltrafiltrationHordeum vulgare

A process for the fractionation of valuable fractions from cereal brans (e.g. wheat, barley and oat brans, and rice polish) is described. In particular, this invention describes a two step process, in which the said bran is first subjected to a combination of enzymatic treatment and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main bran factions, i.e. insoluble phase (pericarp and aleurone layer), germ-rich fraction, residual endosperm fraction and soluble sugars. A second step consists of fractionating cereal brans substantially free of soluble compounds, hence insoluble phase from the above-mentioned first step, by enzymatic treatment with xylanases and / or beta-glucanase and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main fractions, i.e. insoluble phase (remaining cell wall components), protein-rich fraction, soluble hemicellulose and oligosaccharide, and therefore maximizes the extraction rate of valuable cell wall components and aleurone cells from previously cleaned bran.

Owner:LANTMANNEN OATS AB

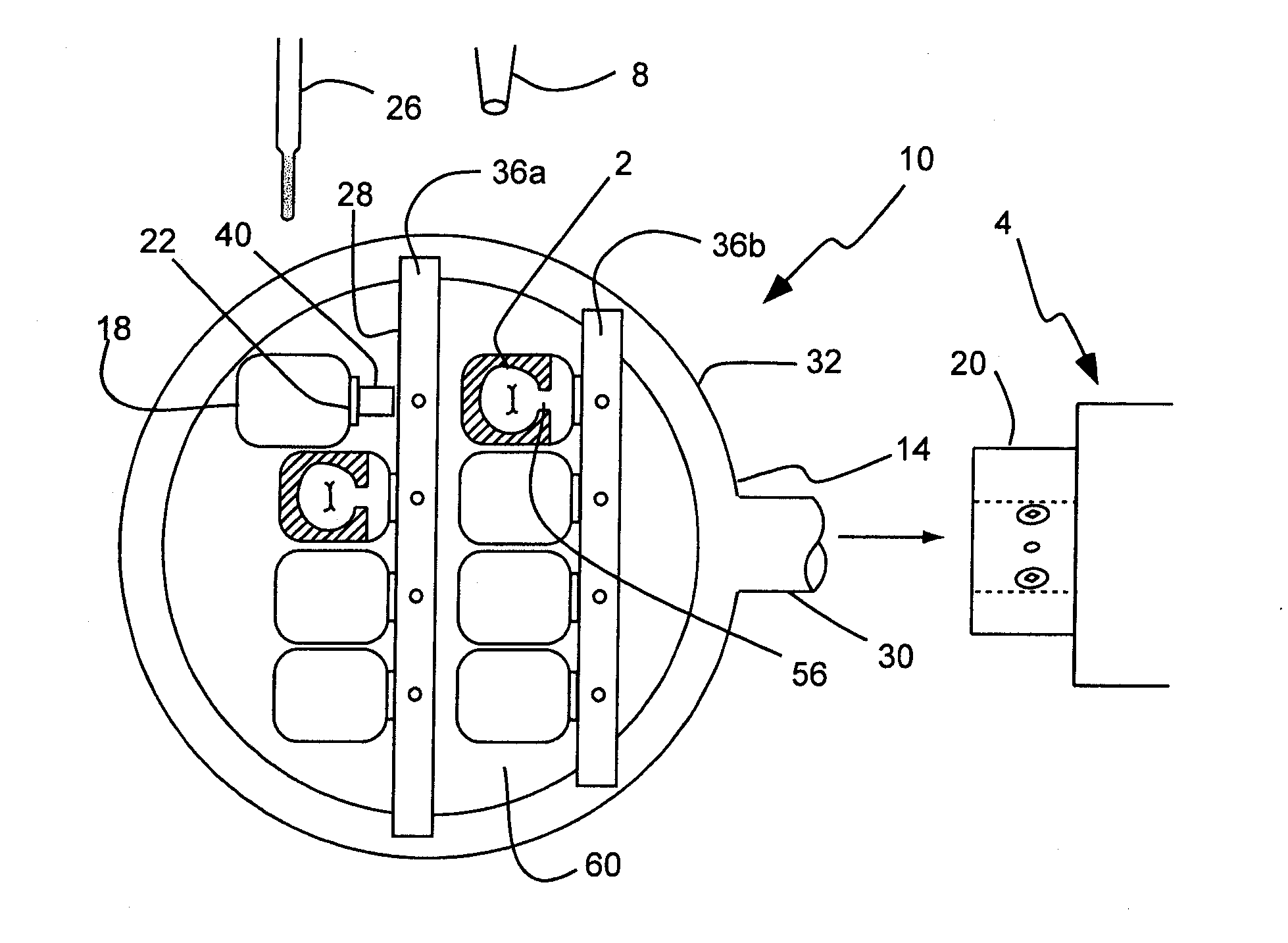

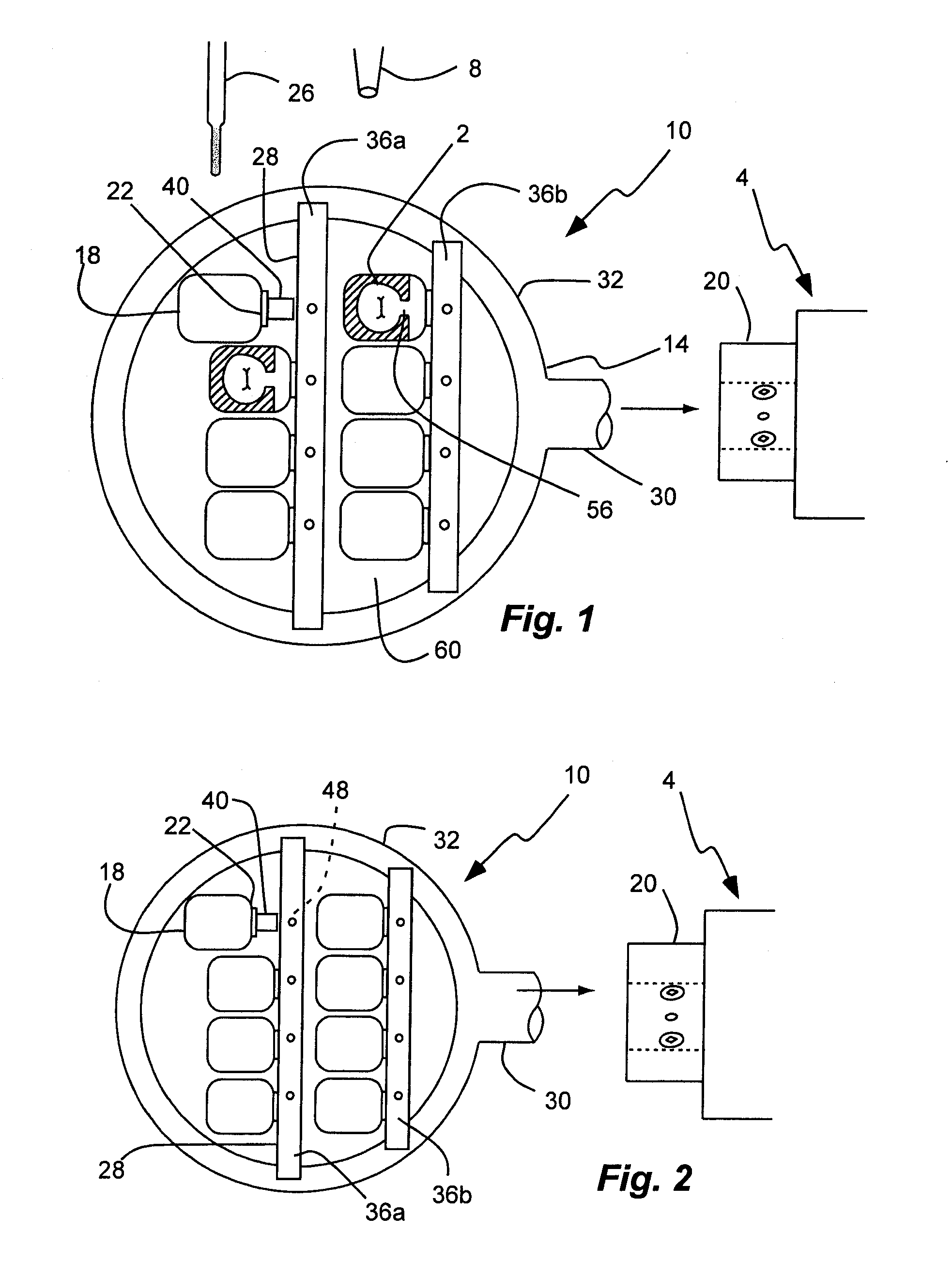

Processes and Apparatuses for the Production of Crystalline Organic Microparticle Compositions by Micro-Milling and Crystallization on Micro-Seed and Their Use

InactiveUS20090087492A1Large specific surface areaIncrease ratingsBiocideNervous disorderMicroparticleOrganic compound

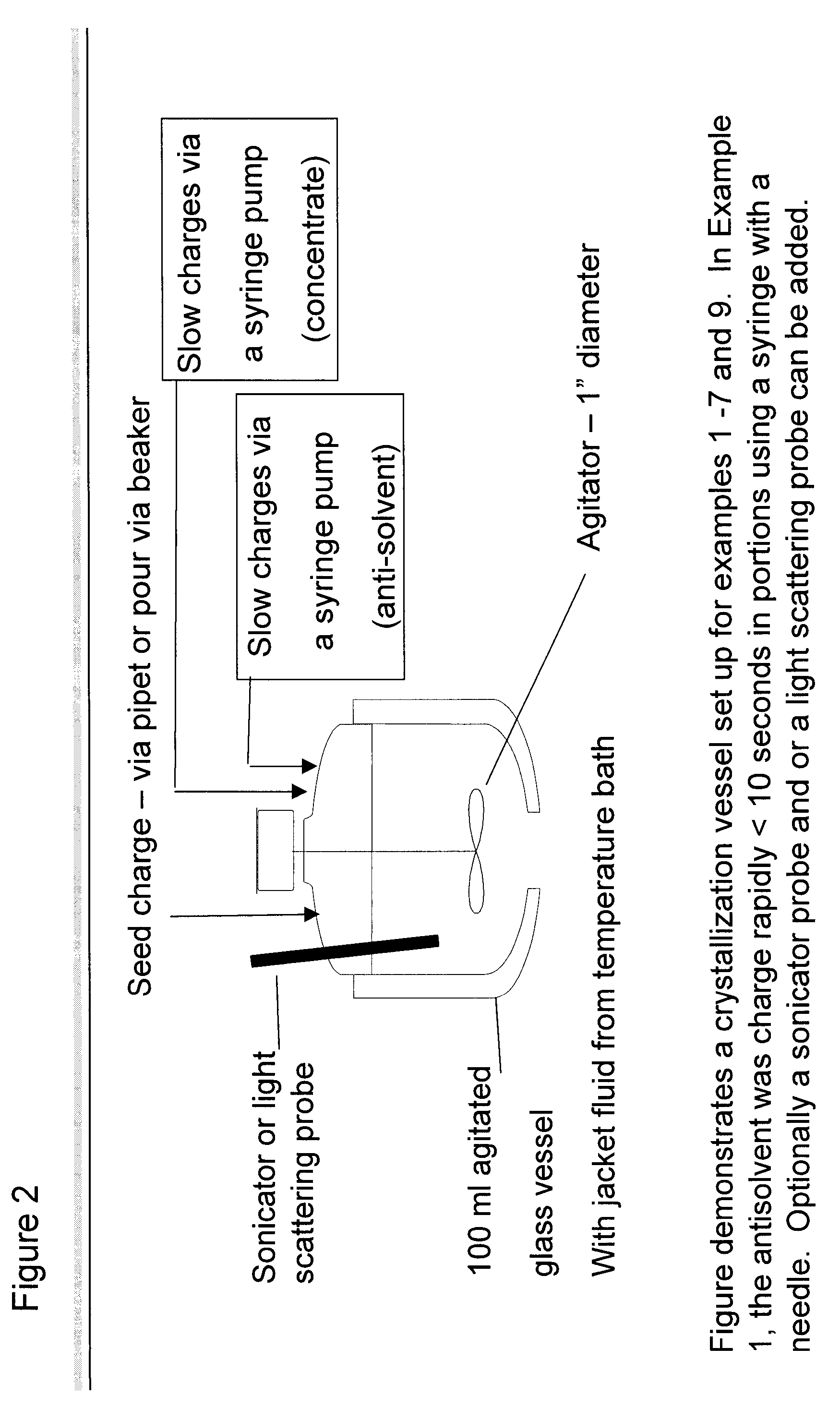

The present invention relates to a process, for the production of crystalline particles of an active organic compound The process includes the steps of generating a micro-seed by a wet-milling process and subjecting the micro-seed to a crystallization process. The resulting crystalline particles have a mean particle size of less than about 100 μm. The present invention also provides for a pharmaceutical composition which includes the crystalline particles produced by the method described herein and a pharmaceutically acceptable carrier.

Owner:MERCK SHARP & DOHME CORP

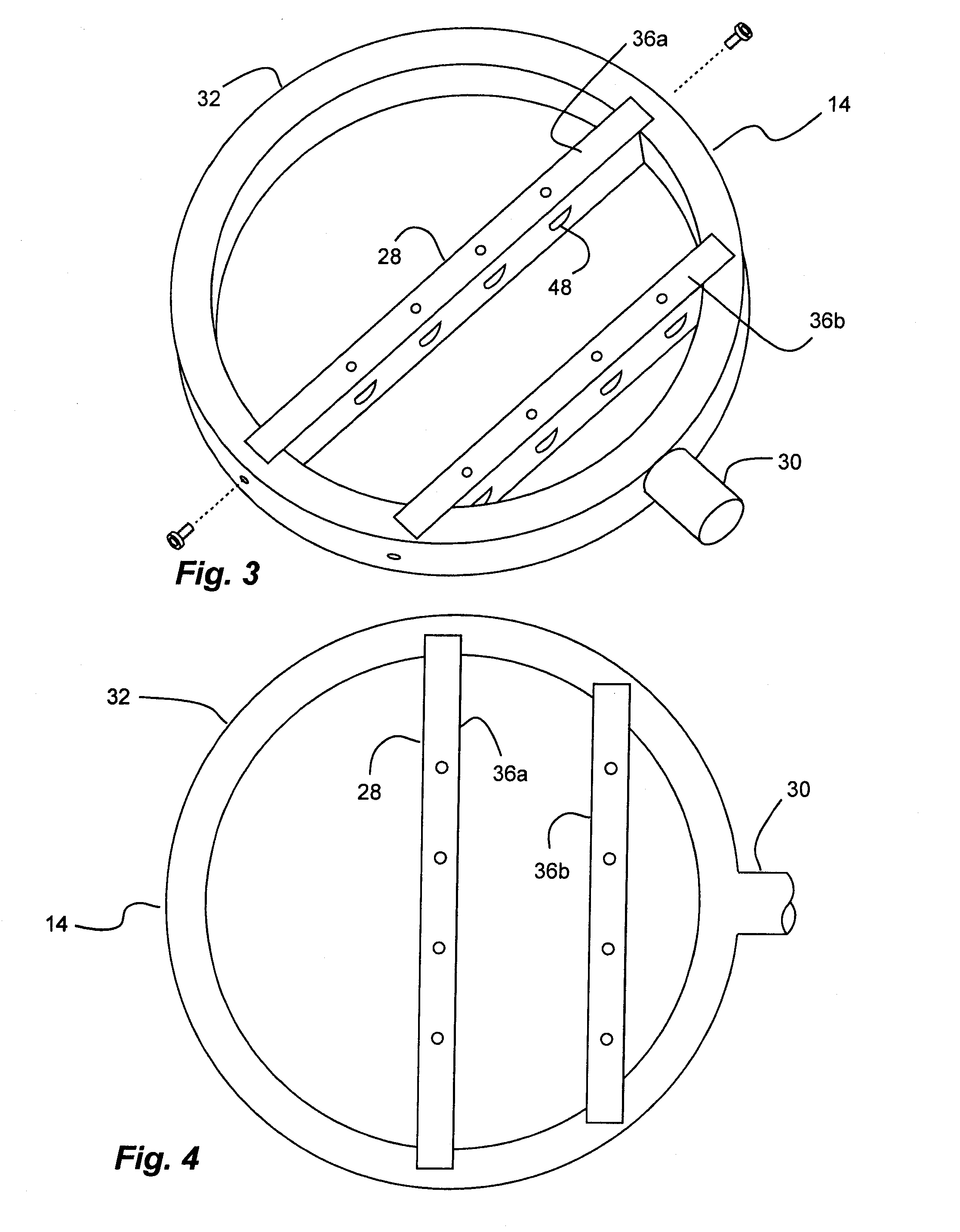

System and Method for Securing Multiple Ceramic Dental Blocks for Milling

A system and method for milling dental prostheses in a CNC milling includes affixing a lateral side of each of a plurality of ceramic millable dental blanks to a lateral wall of a fixture; securing the fixture to a chuck of the milling machine; wet milling a single dental prosthesis in each of the plurality of ceramic millable dental blanks with a diamond burred cutter; and removing the plurality of ceramic millable dental blanks from the fixture.

Owner:JUNG YUNOH +1

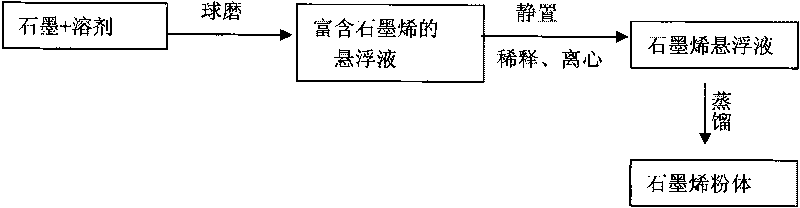

Method for producing graphene

ActiveCN101704520AAvoid damageIncrease frictionMaterial nanotechnologySingle layer grapheneState of artOrganic solvent

The invention discloses a method for producing graphene, which comprises the step that: graphite powder is subjected to wet ball milling in organic solvent, wherein the surface tension of the organic solvent is 30 to 45 mNm-1; and the surface of a milling ball used for the wet ball milling is wrapped with soft polymer. After adopting the scheme, the method selects and uses a ball milling process widely applied in the actual production to peel off graphite. Compared with the prior art, the method has the following advantages that: 1) the damage of rigid collision between the milling balls to the graphite crystal structure is effectively reduced by adopting the soft polymer to wrap the hard milling balls, meanwhile, the soft polymer has stronger friction force with the graphite so as to greatly improve the milling and peeling effects, and the yield of the graphene can reach 30 to 50 weight percent; 2) the adopted ball milling process is easier to expand the scale and implement industrialized production; 3) except little defect at the edge part, the graphene crystal structure is kept intact; and 4) the graphene product has even thickness which is kept between 1 and 2 carbon atom layers.

Owner:HUAQIAO UNIVERSITY +1

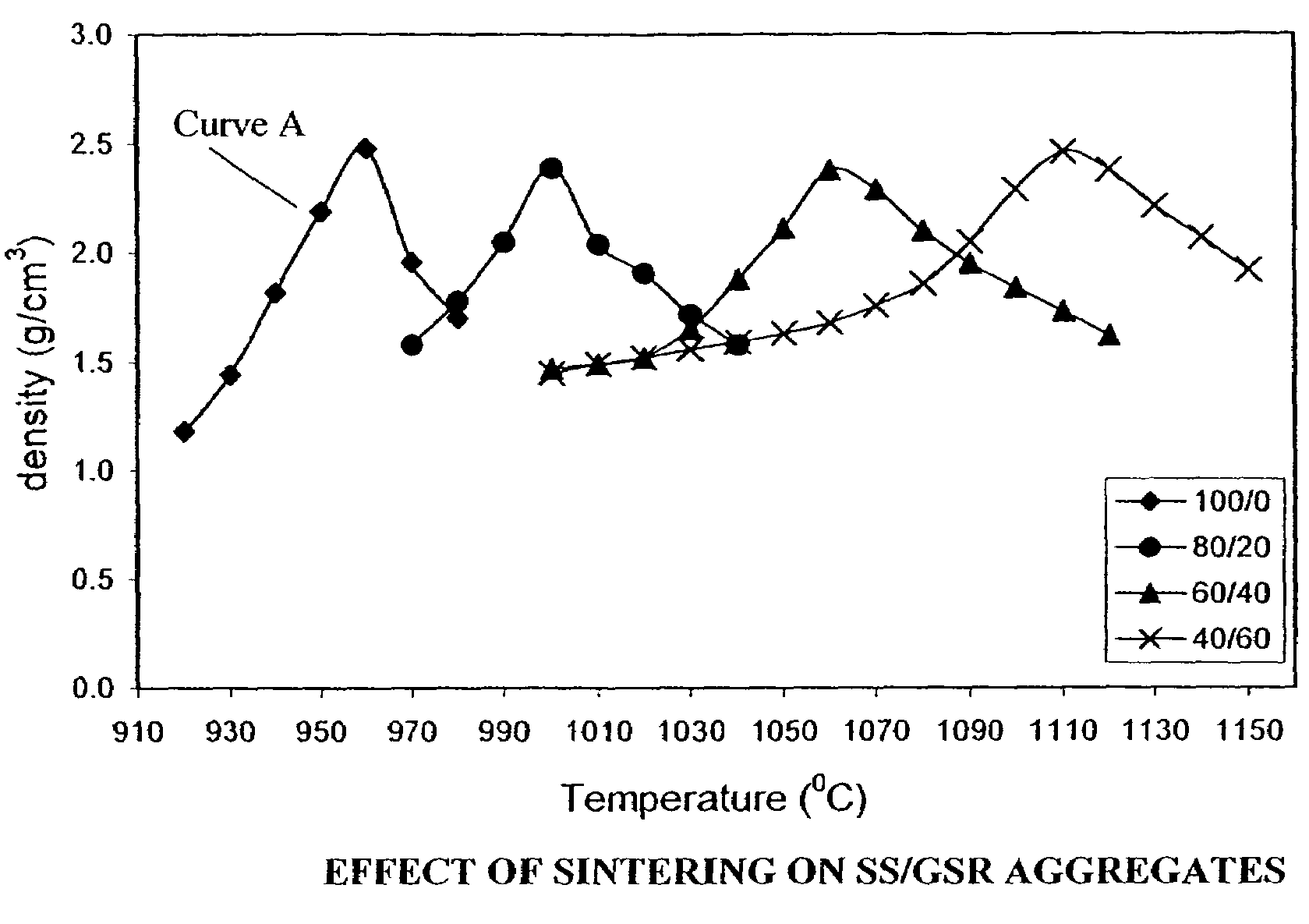

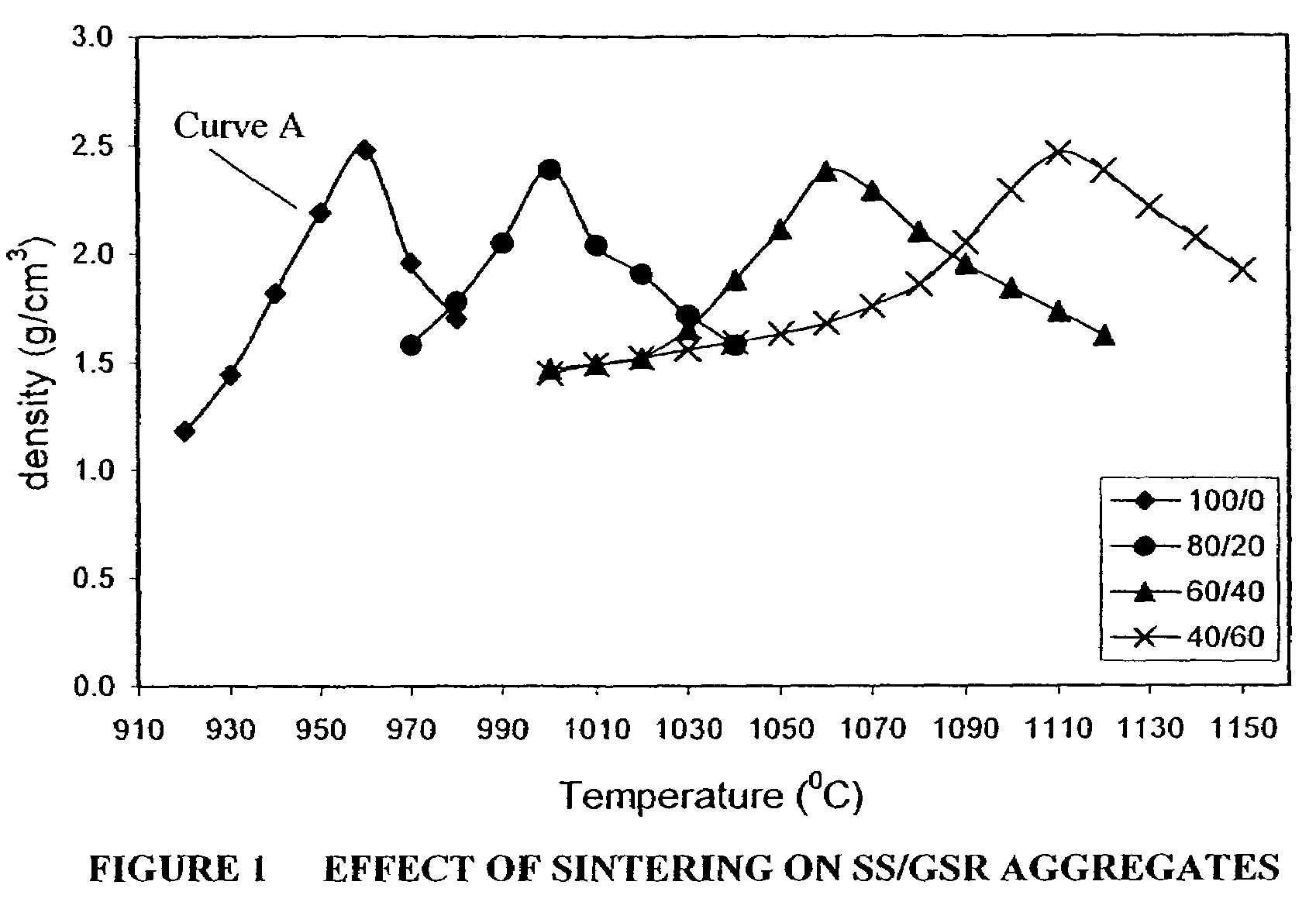

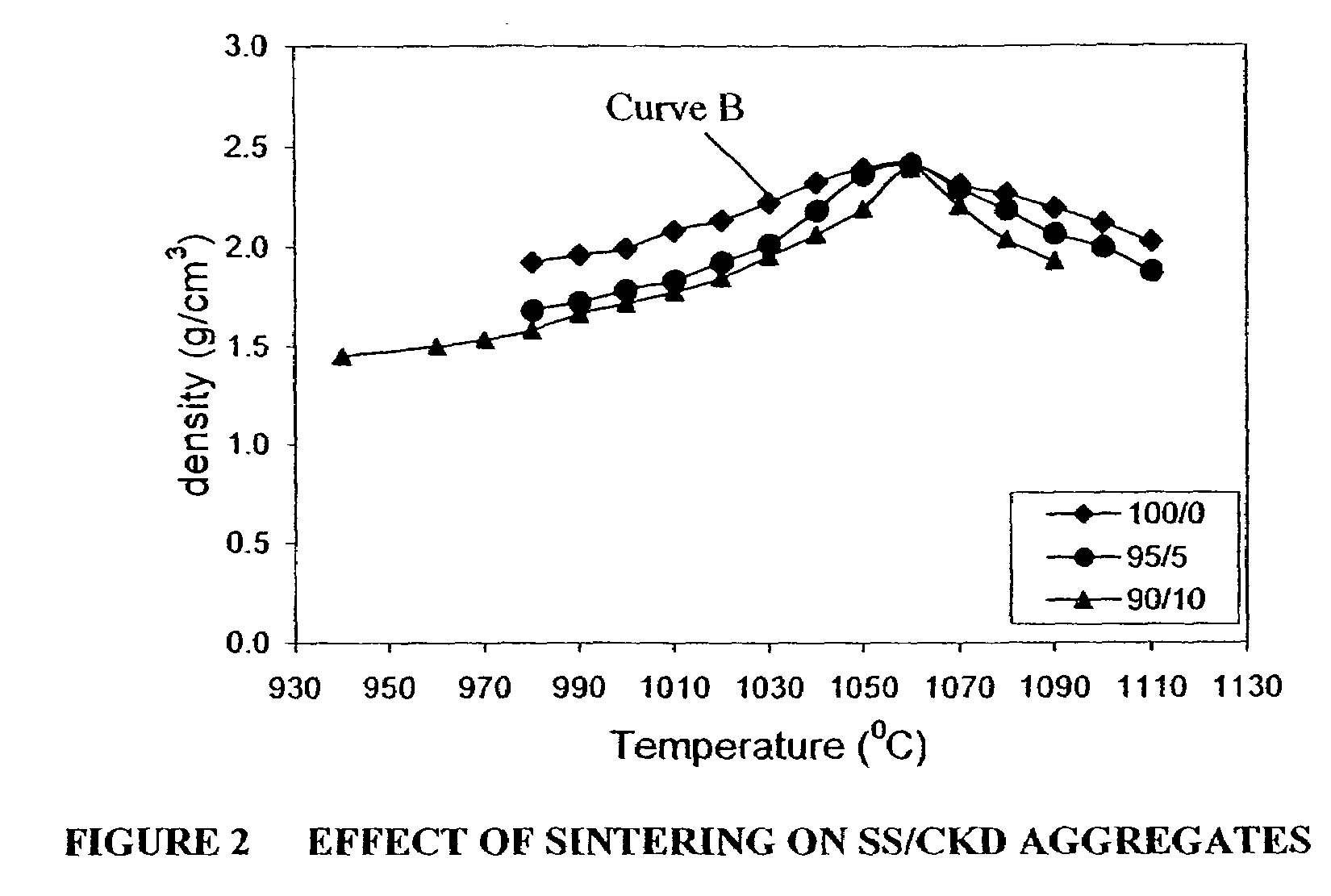

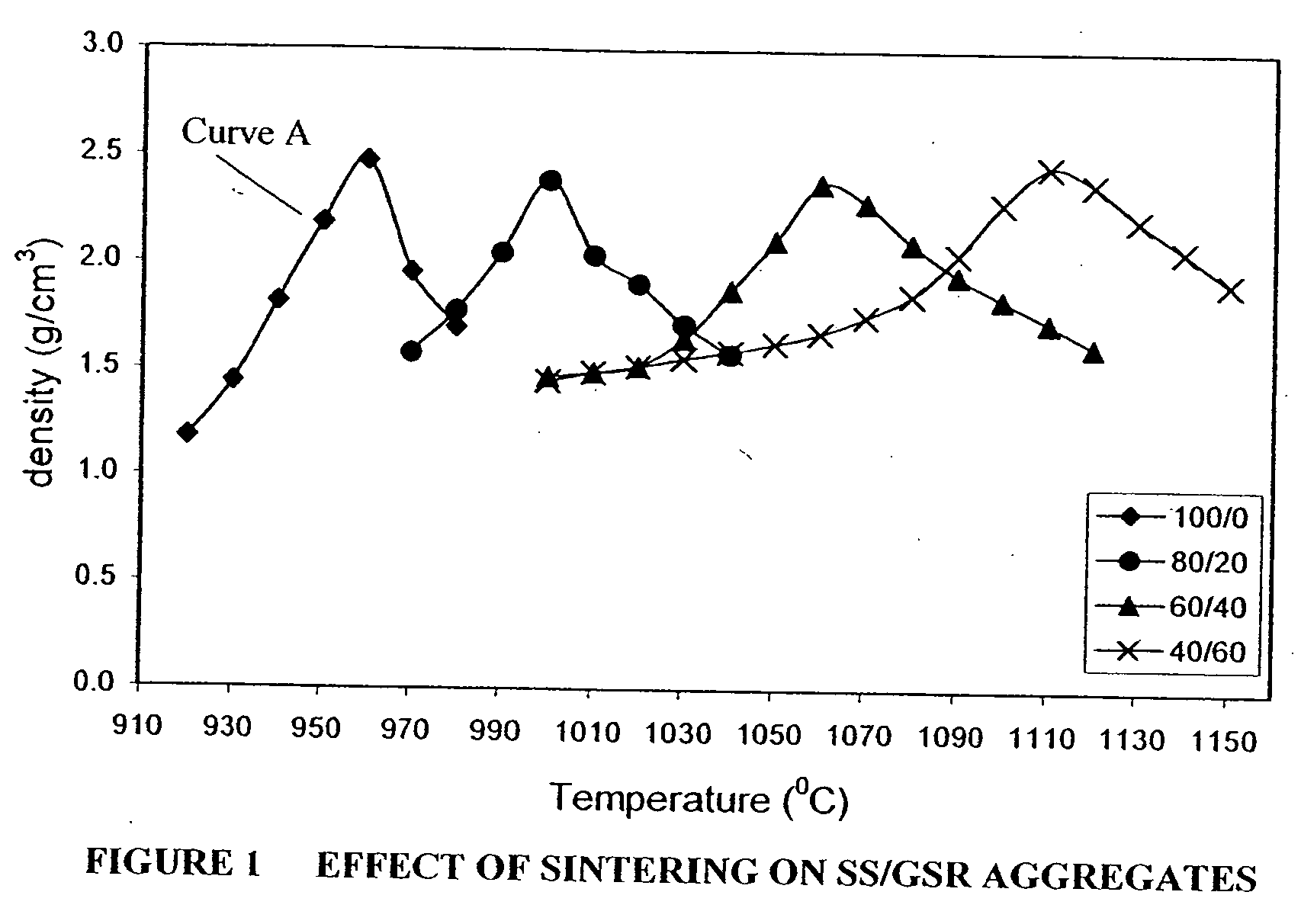

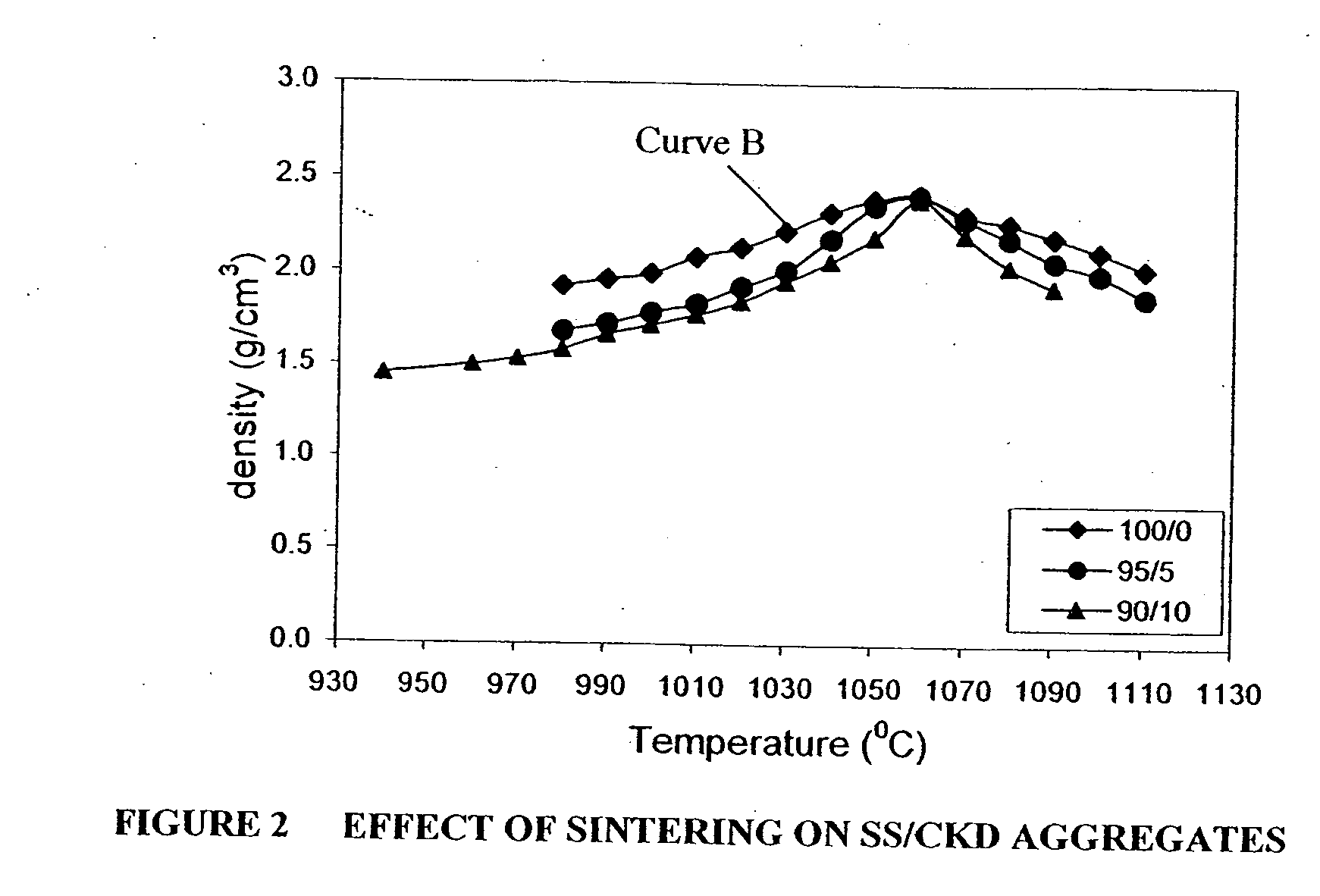

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

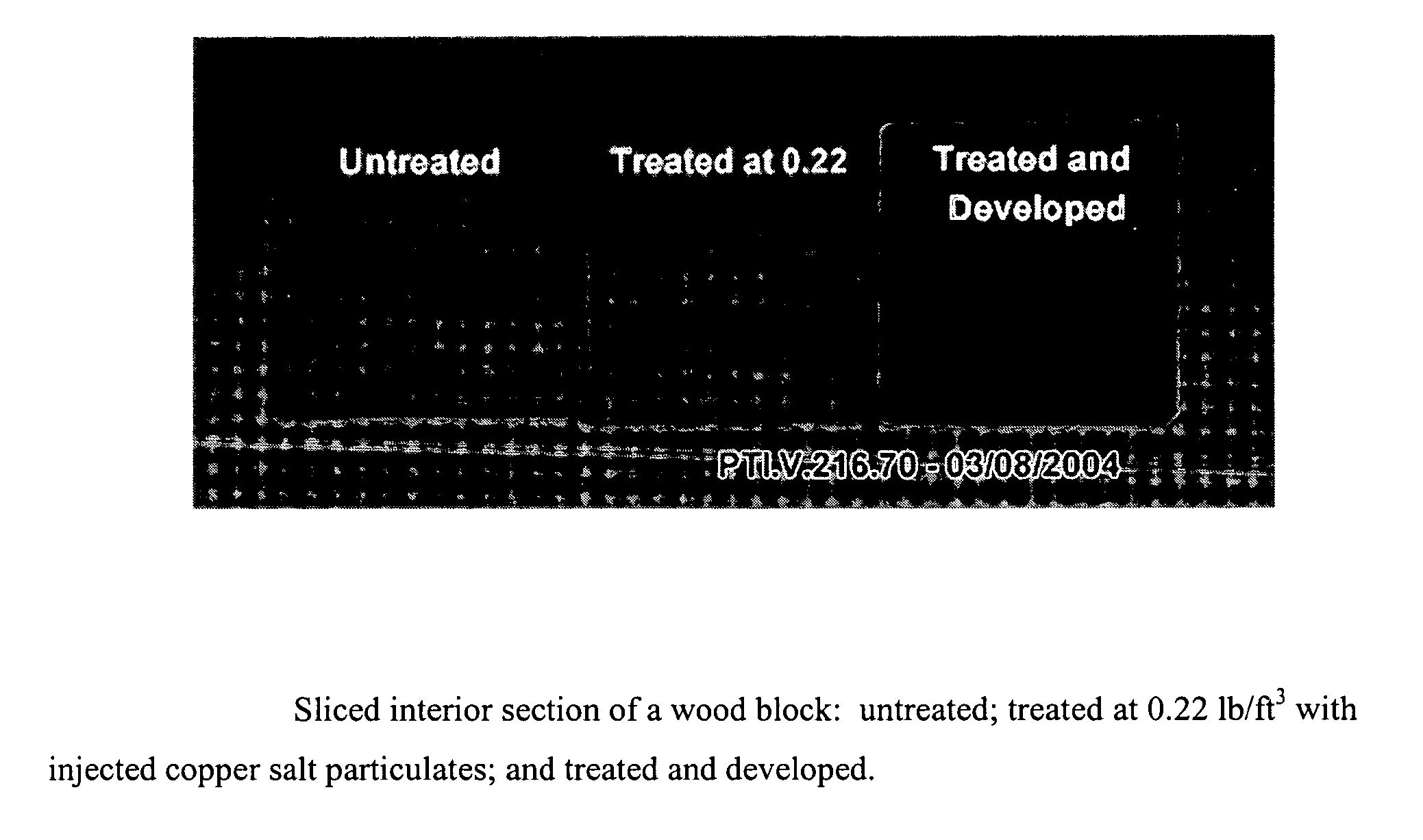

Milled submicron organic biocides with narrow particle size distribution, and uses thereof

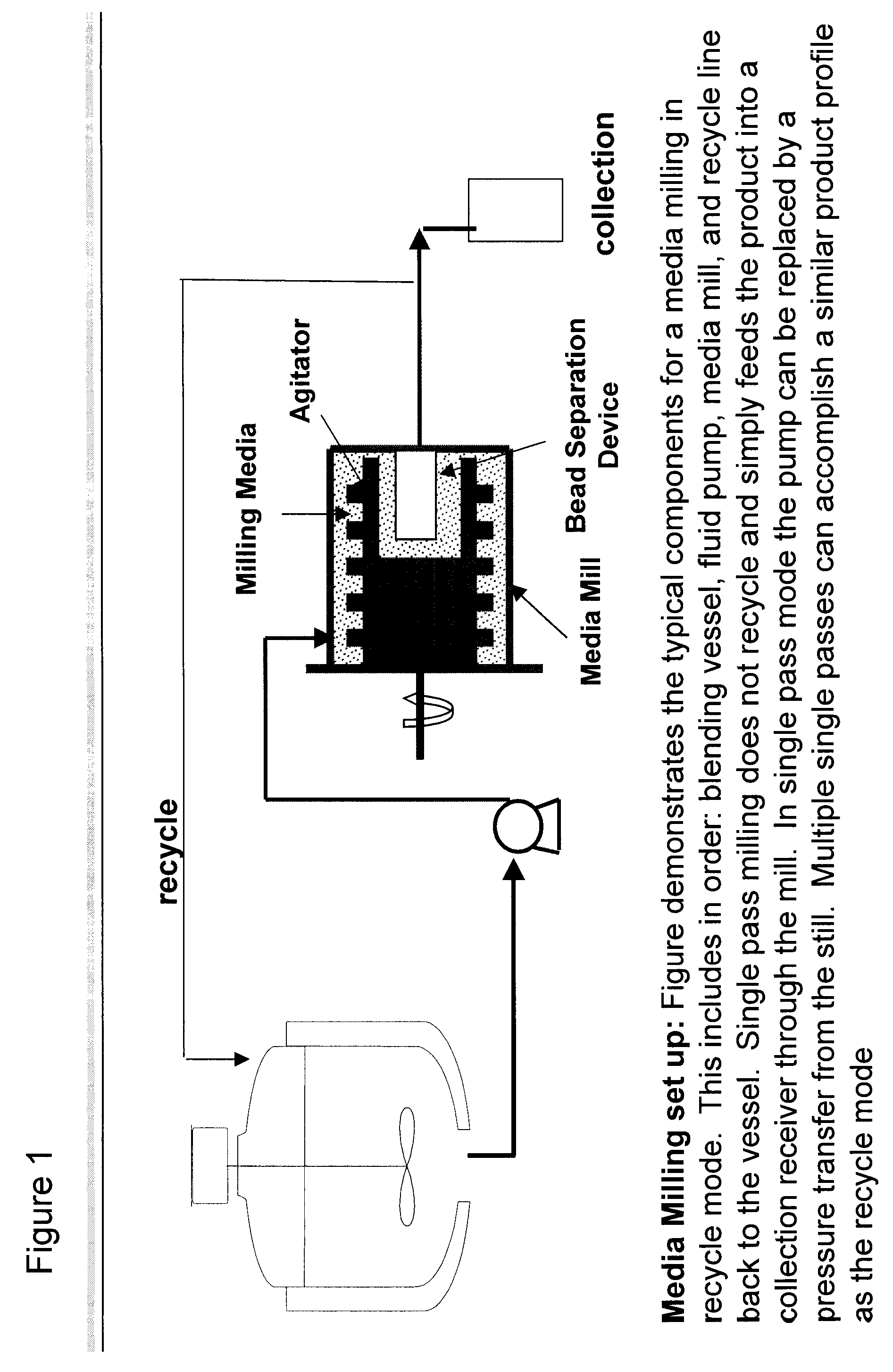

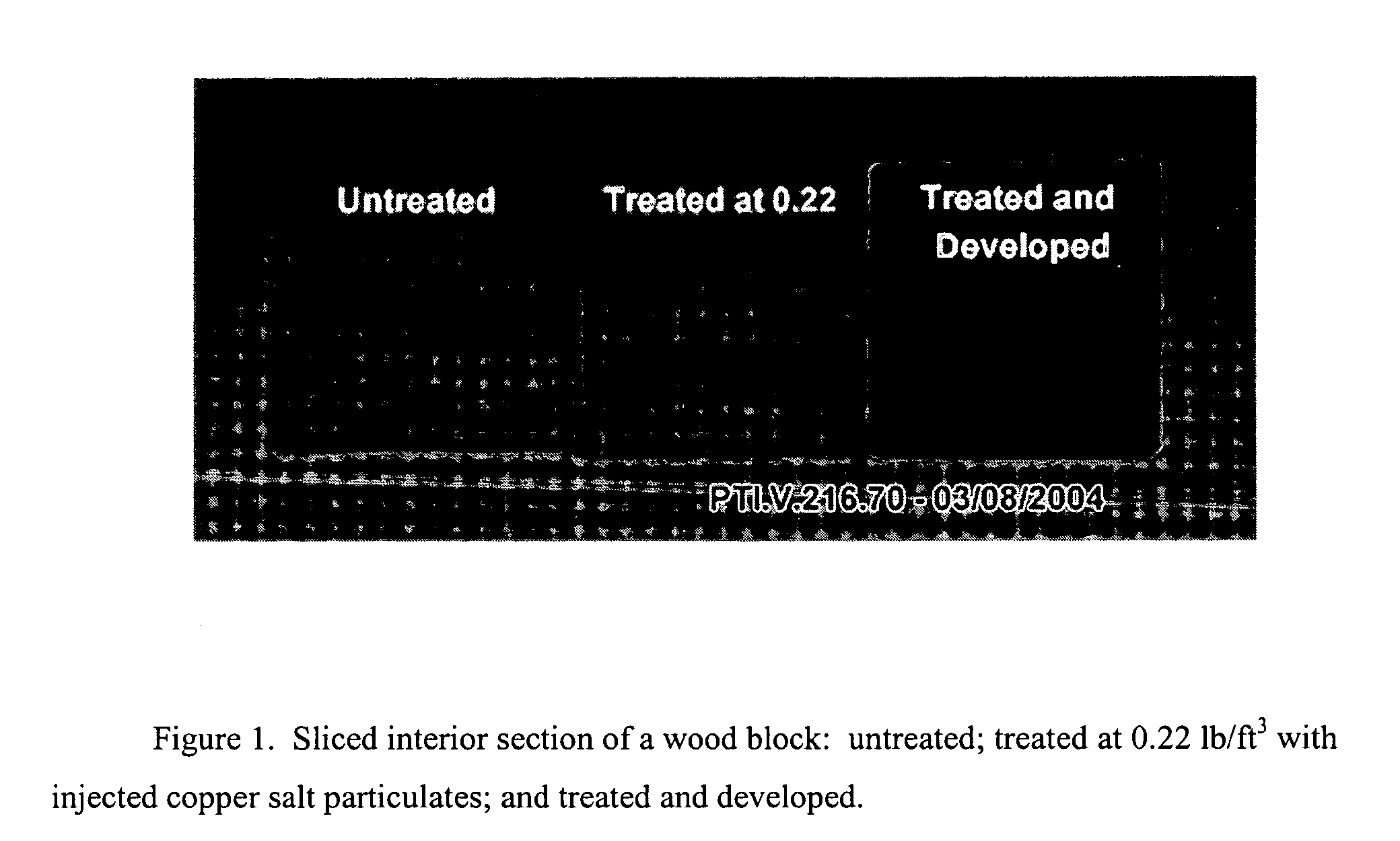

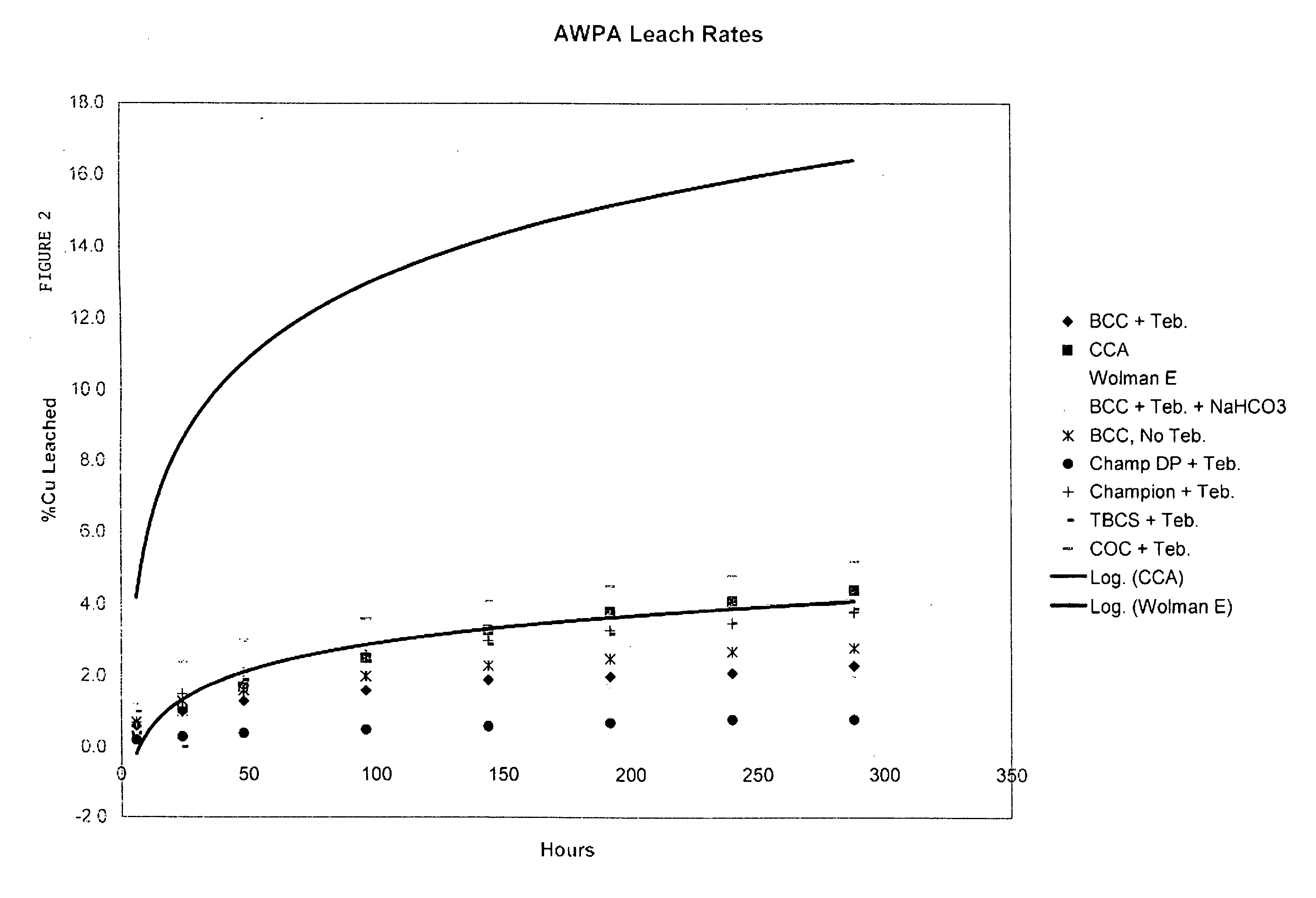

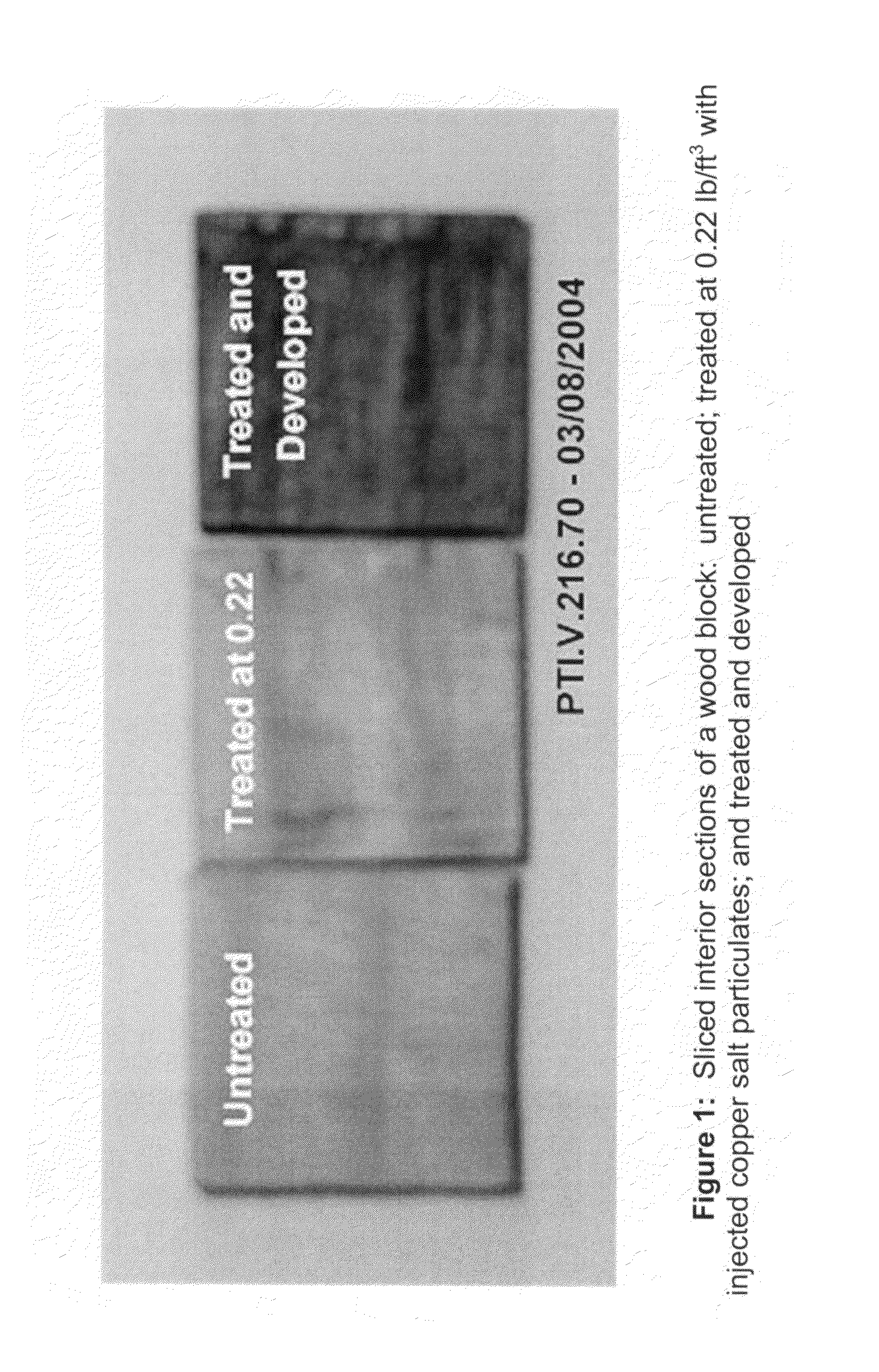

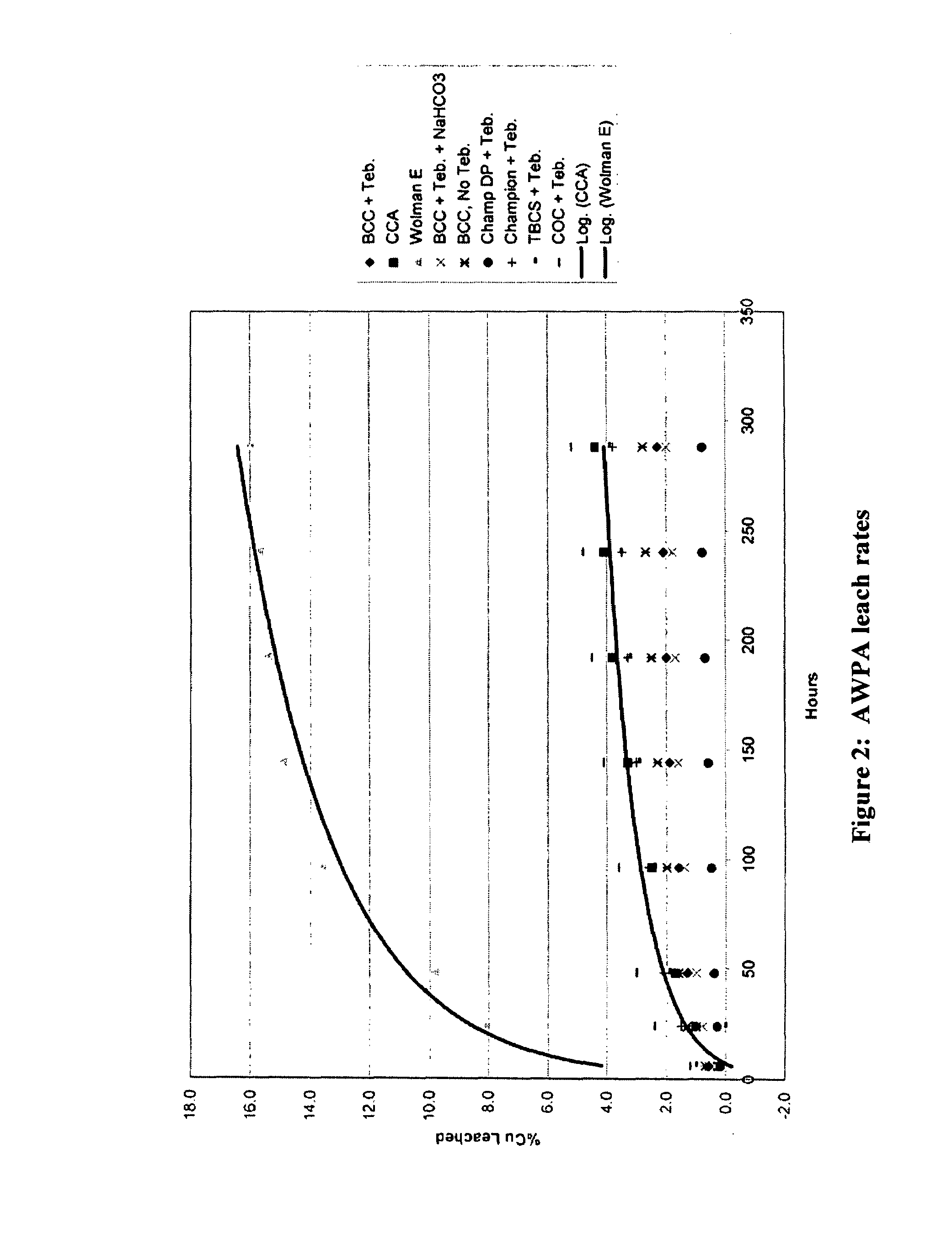

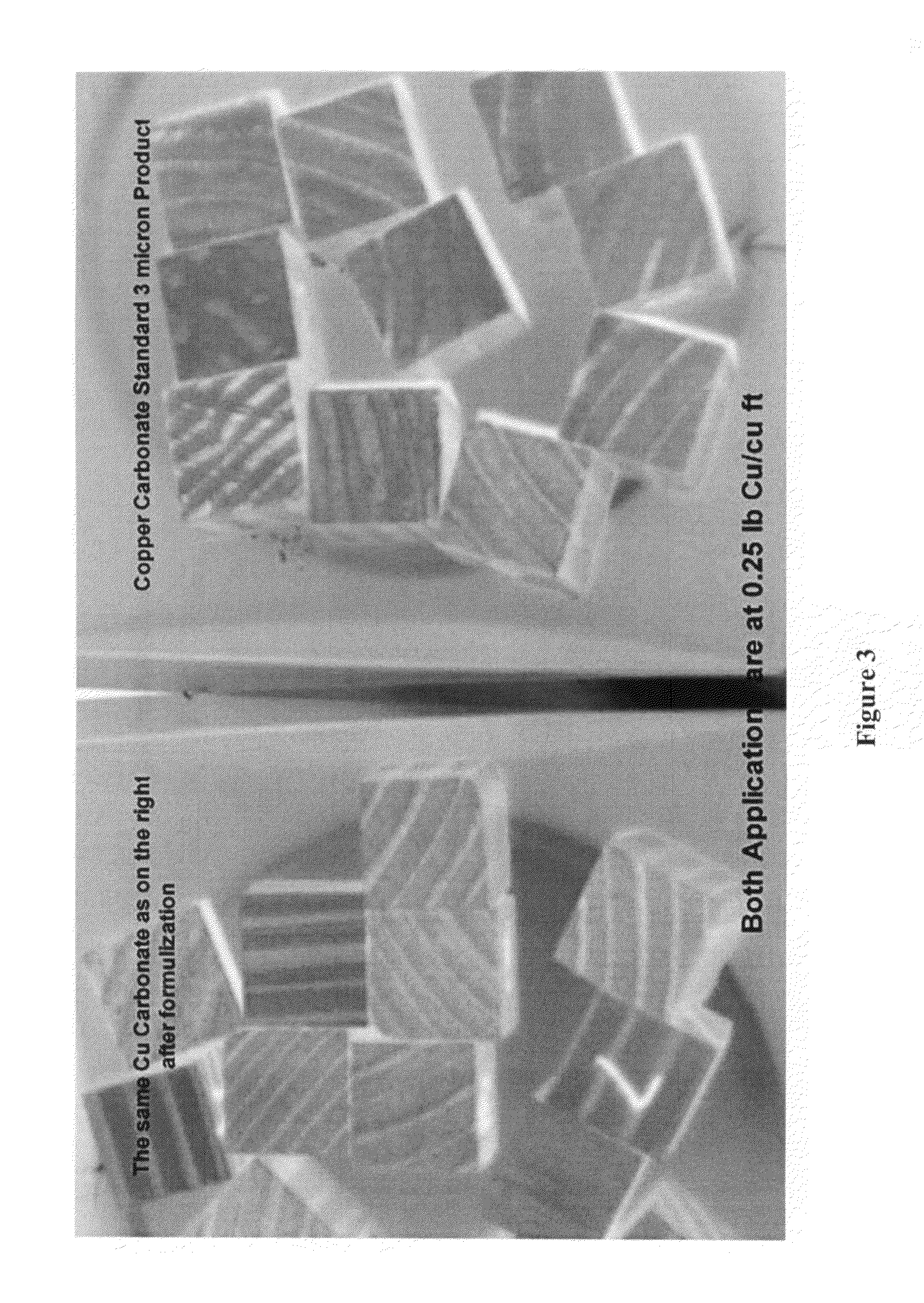

A method of milling substantially insoluble solid organic biocides to form a micron or sub-micron product having a narrow particle size distribution is presented. The milling involves wet milling of the organic biocide with high density milling media having a diameter between 0.1 mm and 0.8 mm, preferably between 0.2 mm and 0.7 mm, and a density equal to or greater than 3.8 g / cc, preferably greater than 5.5 g / cc, in a ball mill using between about 40% and 80% loading of the mill volume with milling media, and having the organic biocide suspended in an aqueous milling liquid which comprises one or more surface active agents. The milling speed is preferably high, for example from about 1000 rpm to about 4000 rpm. The milled product can be used in foliar applications at a lower effective dosage than prior art formulations, can be used in improved antifouling paint formulations, and can be used in new applications such as the direct injection of solid organic biocide particulates in wood to act as a long lasting wood preservative.

Owner:KOPPERS PERFORMANCE CHEM

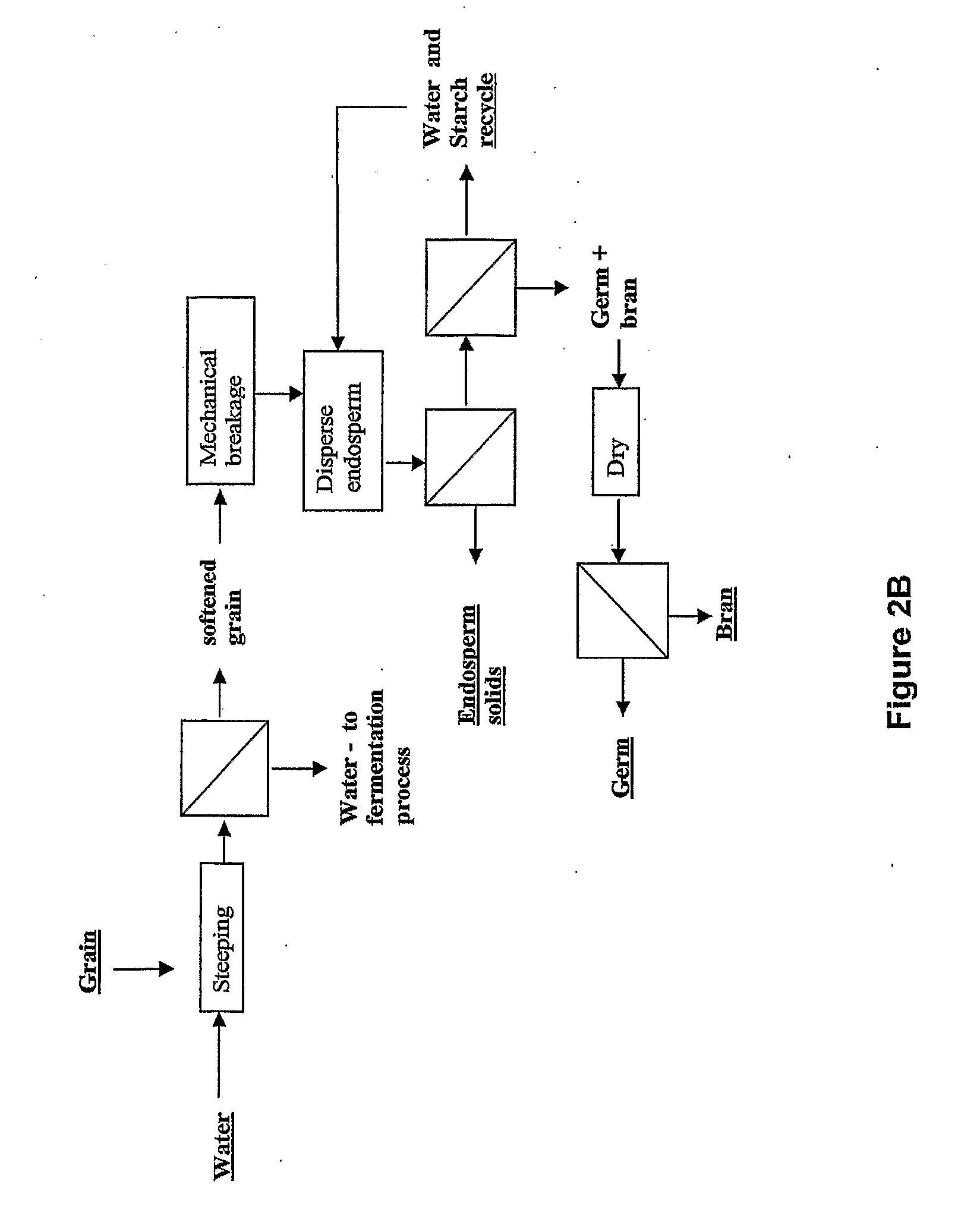

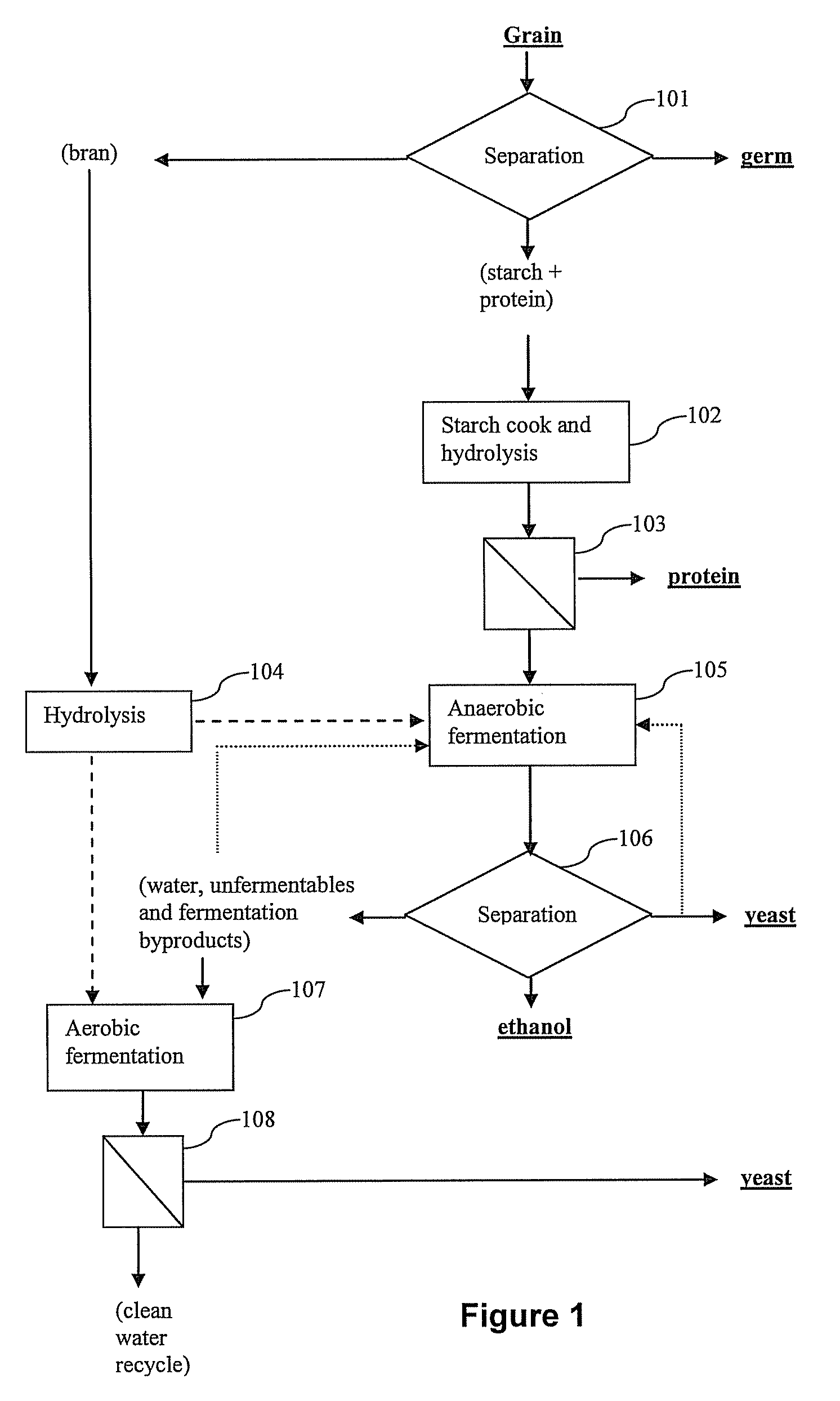

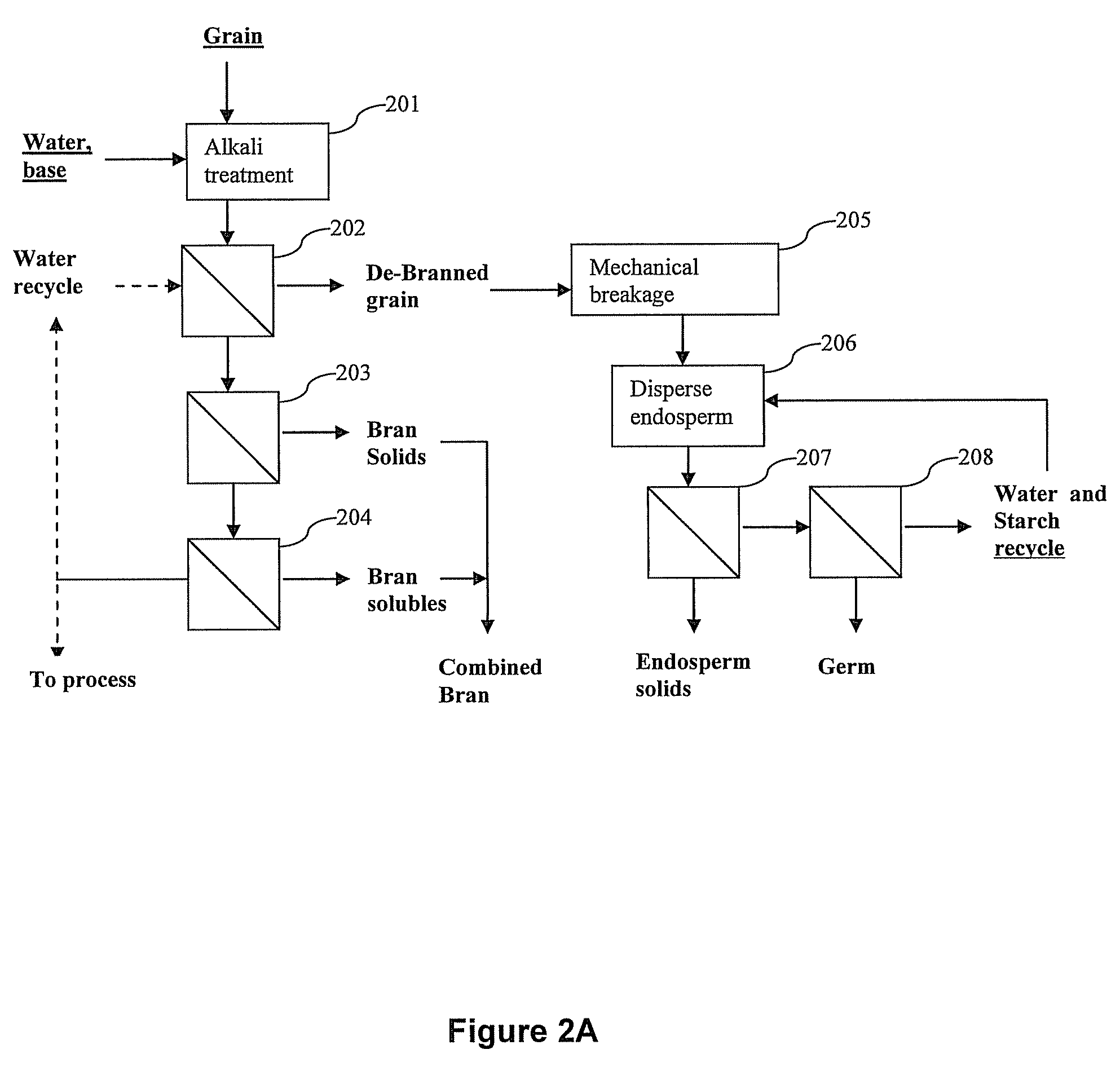

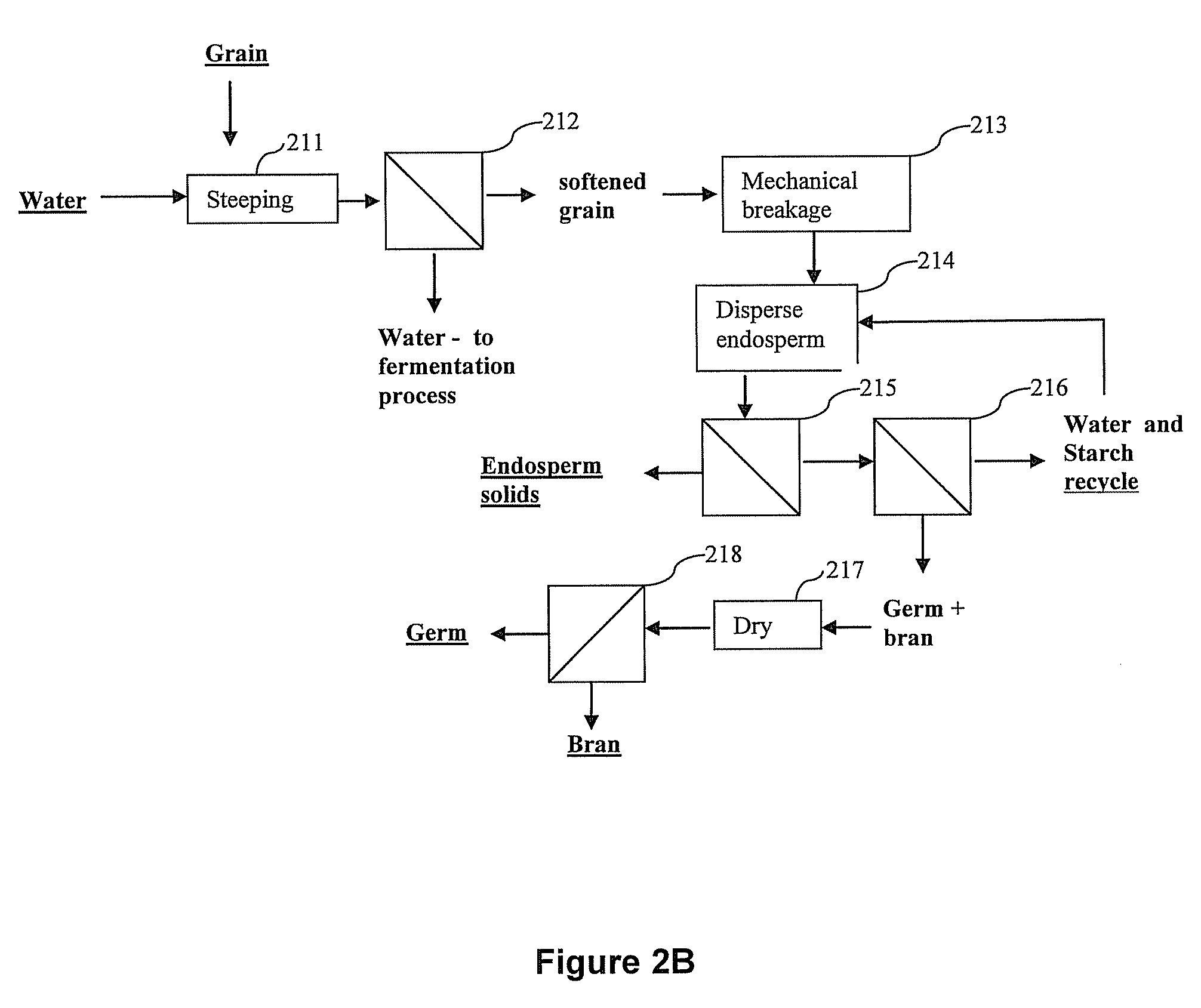

Corn fractionation method

InactiveUS20070184541A1Avoid fermentationContributing to air pollutionMicroorganismsBiofuelsFractionationFermentable sugar

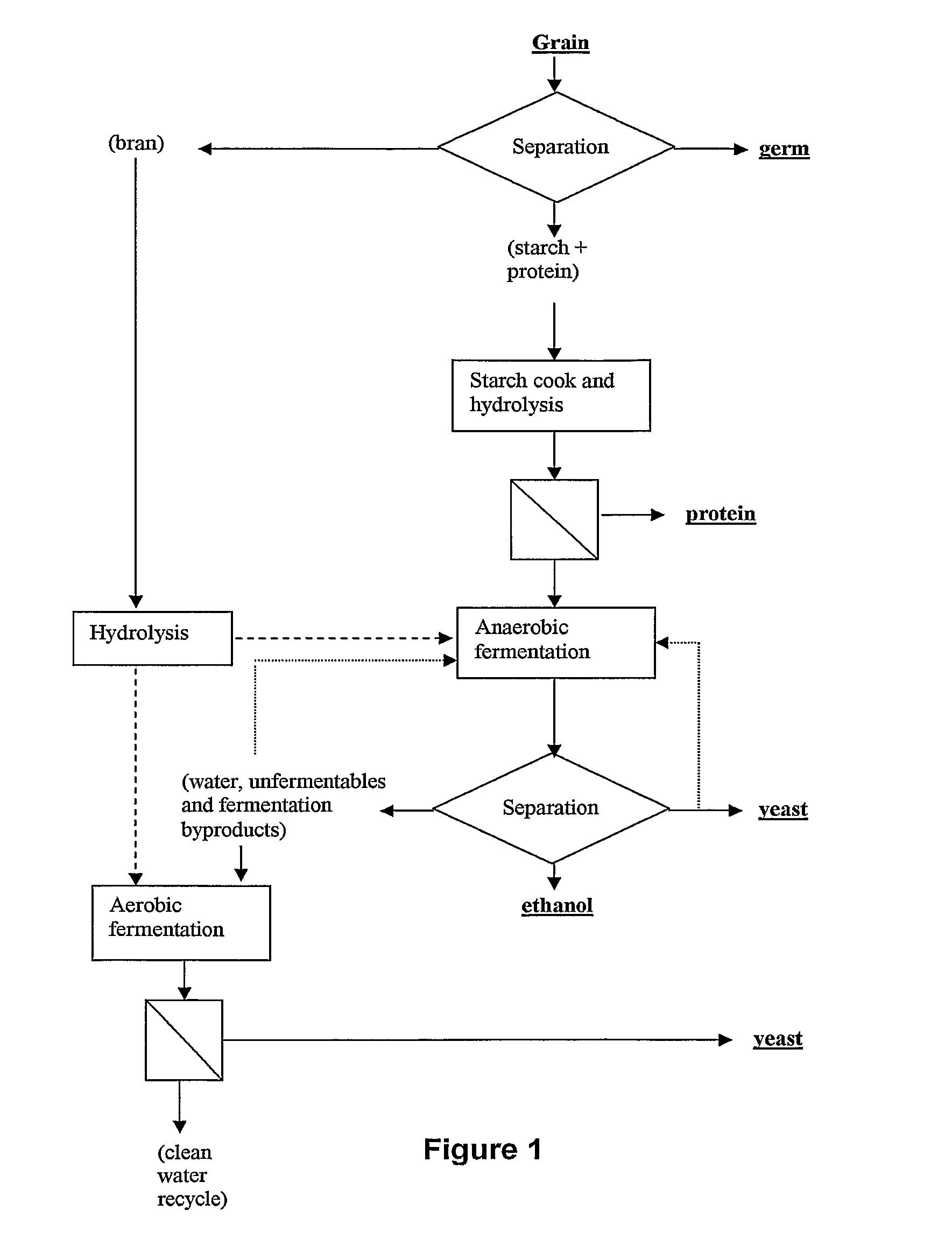

An improved method for processing corn into ethanol and other valuable co-products. The invention generally involves a multi-step process which produces germ (or oil), protein, and feed yeast as its co-products while maintaining or enhancing the provision of fermentable sugar to ethanol fermentation. This is accomplished by fundamentally altering the way the corn is fractionated, disrupting the cell walls rather than the protein matrix as is done in conventional wet milling.

Owner:GRAINVALUE

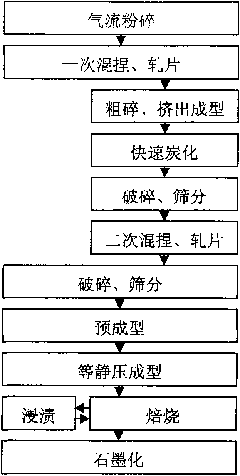

Technical method for producing isostatic pressure graphite

The invention provides a technical method for producing isostatic pressure graphite, which comprises the following steps: using refinery coke or pitch coke as raw materials; crushing raw materials to 5 to 20 mum through airflows; then, carrying out treatment through work procedures such as primary mixing squeezing and sheet milling, extrusion forming, fast carbonization, crushing, sieving, secondary mixing squeezing and sheet milling, crushing, sieving, pre-forming, isostatic pressure forming, calcination, impregnating, graphitization and the like; and obtaining fine particle isostatic pressure isotropical graphite materials. Compared with traditional coarse particle graphite materials, the invention has the characteristics of fine and compact structure, good uniformity, excellent mechanical property, isotropy and the like, and is particularly suitable for the production of large-specification graphite products.

Owner:SICHUAN GUANGHAN SHIDA CARBON +1

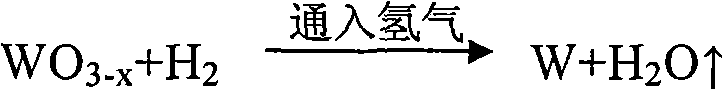

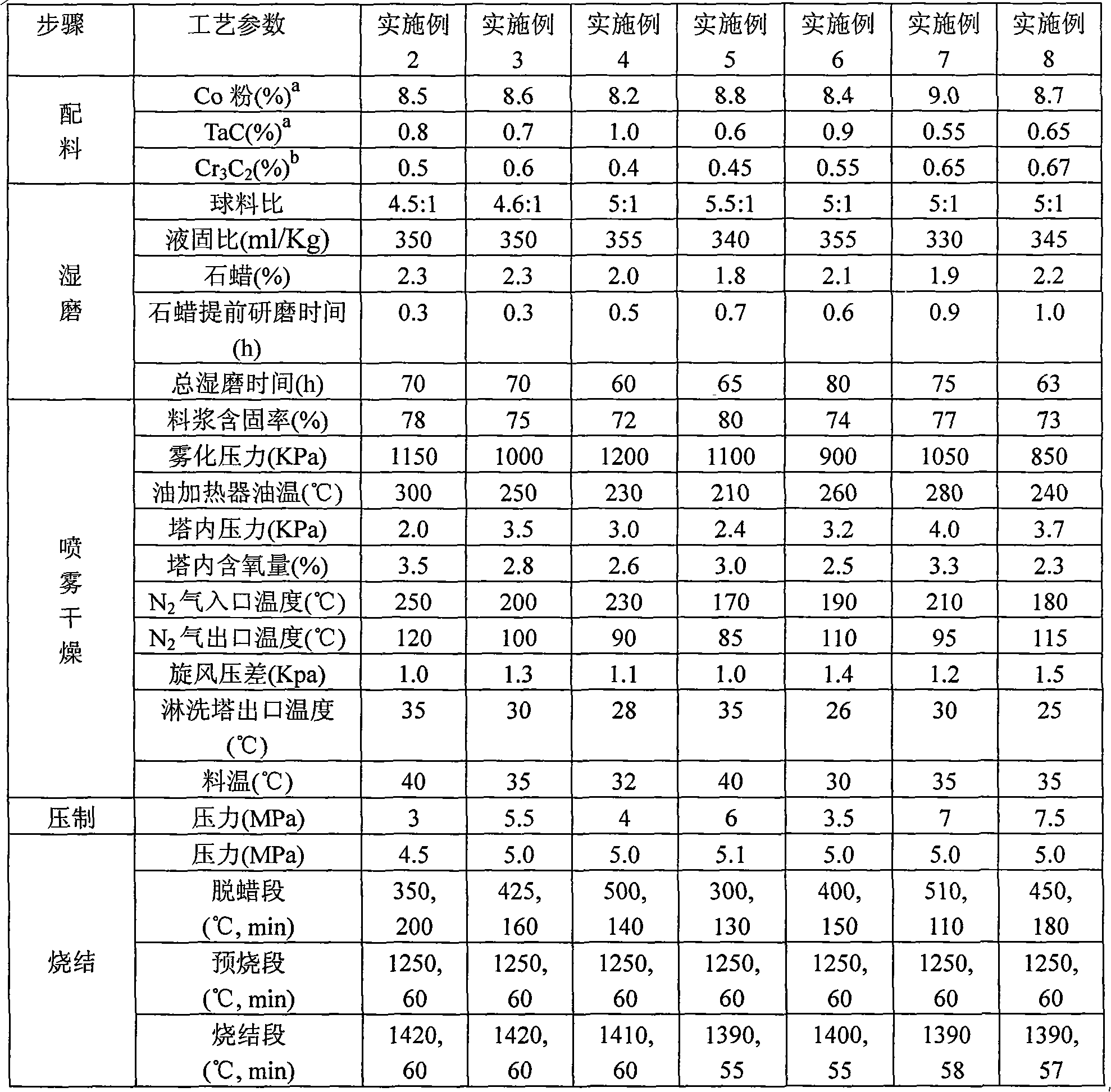

Ultrafine cemented carbide and preparation method and application thereof

The invention discloses ultrafine cemented carbide which comprises the following components in raw materials in percentage by weight: 8.0-9.0 percent of Co, 0.5-1.0 percent of TaC and the balance of WC including 0.3-2.0 percent of Cr3C2; and the preparation method comprises the steps of blending, wet milling, spray drying, pressure molding and sintering. The invention definitely limits the optimized technical conditions of all the components in the raw materials and the optimized process conditions of all the steps of preparation; the ultrafine cemented carbide has good hardness property and good strength property: the transverse rupture strength is equal to or higher than 2800 MPa, the hardness is equal to or higher than 92.5 HRA, the coercive force is 26-35 KA / m and the average grain size of the WC is 200-400 nm. And the invention also discloses application of the ultrafine cemented carbide in the preparation of cemented carbide tools.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

Method for preparing porcelain granules by using fly ash

InactiveCN101585698AImprove protectionSave natural resourcesFluid removalCeramic materials productionExpanded clay aggregateSlurry

The invention discloses a method for preparing porcelain granules by using fly ash, which comprises the following steps: putting fly ash, potassium feldspar and quartz as raw materials into a ball mill respectively, dry-milling the raw materials, sieving the milled raw materials respectively, removing iron from the sieved fly ash, putting the fly ash after iron removal, the sieved potassium feldspar and quartz and kaolin into the ball mill, and wet-milling and evenly mixing the materials to form mixed slurry; and granulating the mixed slurry by adopting a pressure type spray granulator, putting the granules into an alumina crucible, placing the alumina crucible into a silicon-carbon rod resistance furnace, sintering and naturally cooling the granules, and taking out the granules to obtain the high-strength porcelain granules. The method for preparing the porcelain granules by using the fly ash is not only favorable for saving natural resources and reducing the production cost, but also favorable for environmental protection. The fly ash does not need to be crushed by a high-power crusher, and the fly ash is mixed evenly. The production process is easy to control, and has little energy consumption; the strength of the prepared fly ash porcelain granules can reach 60 to 120MPa; and the porcelain granules have good properties of light weight, high temperature resistance, corrosion resistance and the like, and can be used as a fracturing propping agent for middle and deep layer oil-gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

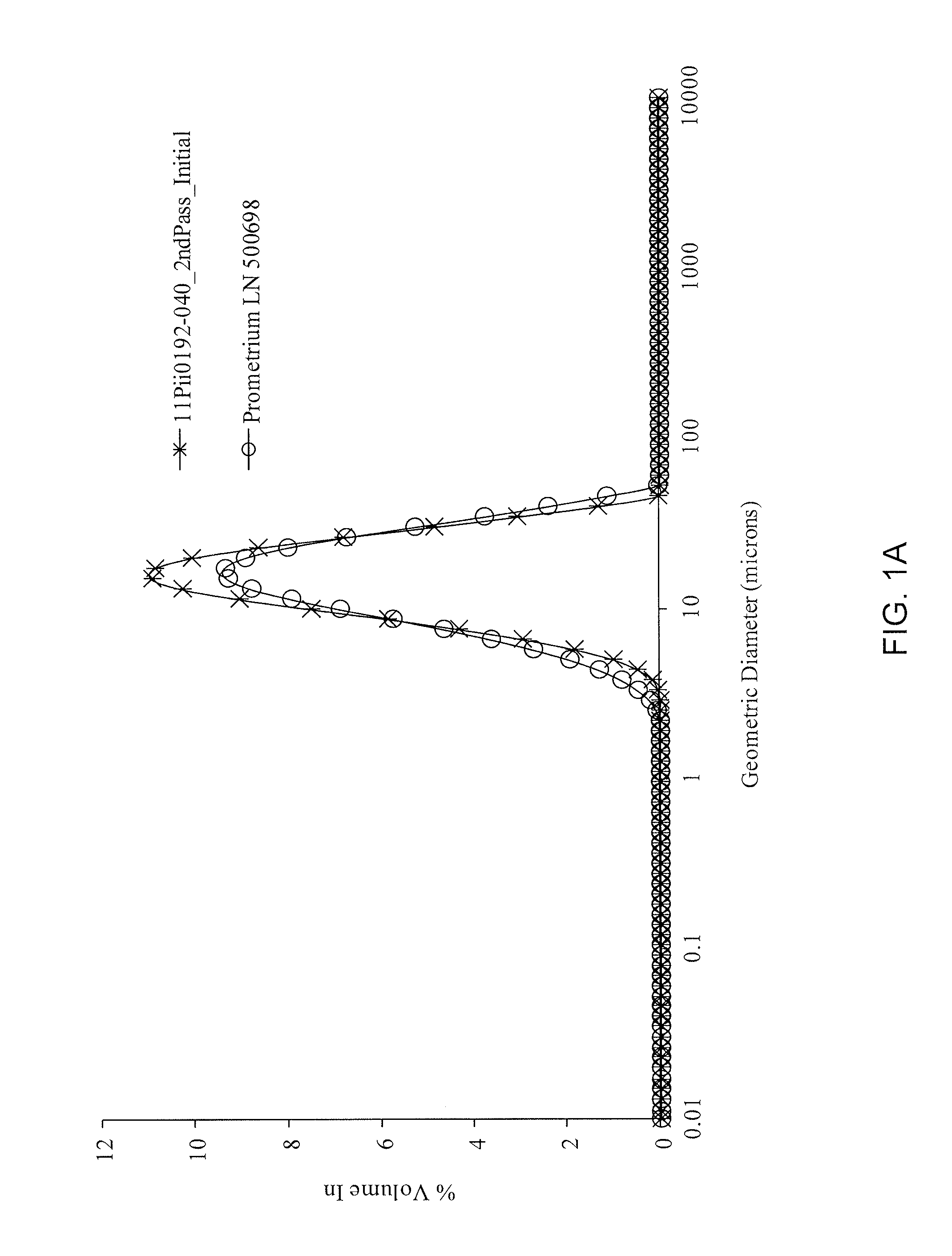

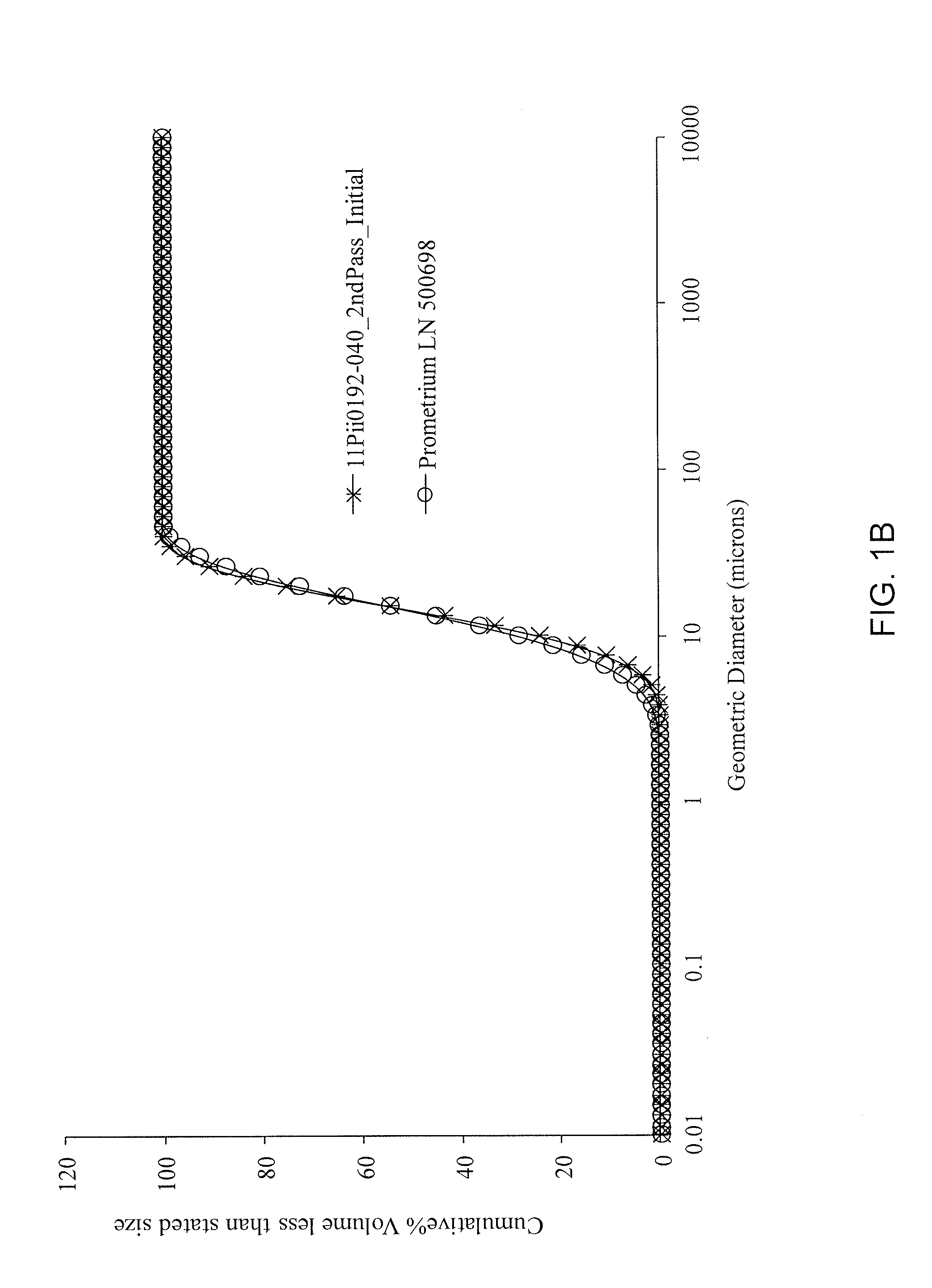

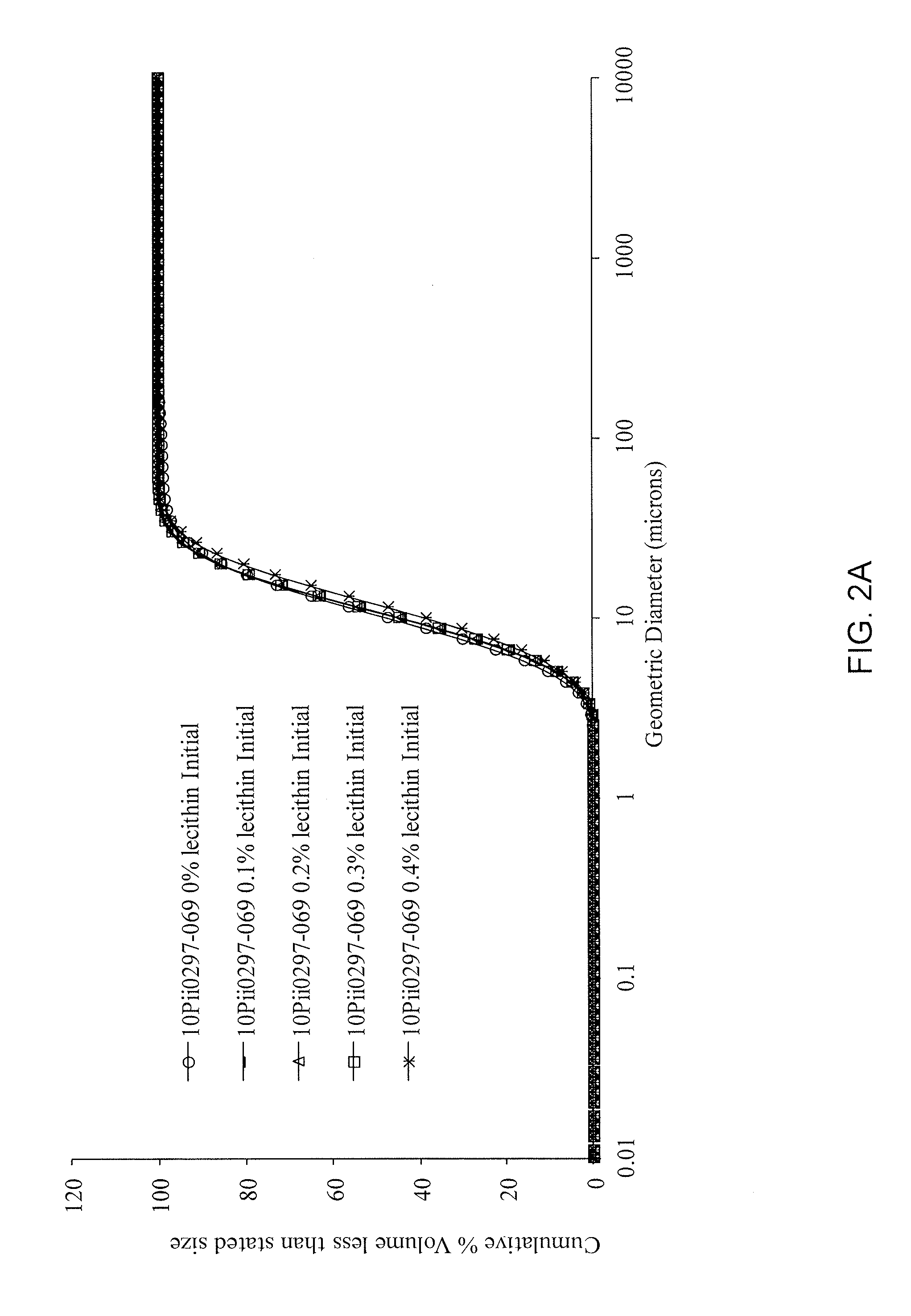

Methods of preparing progesterone pharmaceutical compositions

The invention provides a method of preparing a pharmaceutical composition comprising: (a) combining progesterone particles with a liquid carrier to provide a mixture; (b) wet-milling the mixture to provide a wet-milled progesterone composition; and (c) processing the wet-milled progesterone composition to provide a pharmaceutical composition. Pharmaceutical compositions prepared by the method are also provided.

Owner:PHARMA INT INC

High evenness negative temperature coefficient heat-sensitive resistance material and its preparation method

ActiveCN101127266AImprove uniformityGood repeatabilityNegative temperature coefficient thermistorsMetal/alloy conductorsNegative temperatureHeat sensitive

The utility model relates to a thermistance material with high uniformity and negative temperature coefficient. The main formulation is one in the six systems of Mn-Ni-Cu, Mn-Co-Cu, Mn-Co-Ni-Cu, Mn-Co-Fe-Cu, Mn-Co-Ni or Mn-Co-Fe. The combination of at least two of the oxides as CaO, ZnO, SiO2, Al2O3, Fe2O3, MgO, Cr2O3, TiO2, Sb2O3, Bi2O3, SrO, Nb2O5 and B2O3 are added to the main formulation. The utility model also relates to a preparation method for preparing the thermistance material with high uniformity and negative temperature coefficient, comprising the following steps: mixture making, primary wet milling, drying, calcining, and secondary wet milling, drying and granulating, pressing and forming, and sintering. The utility model has the advantages that: the thermistance material with negative temperature coefficient (NTCR) made by the method has high uniformity and high repeatability; the specific resistance uniformity of the same batch material is all better than plus or minus 1%; the specific resistance error of different batches does not exceed plus or minus 2%; the error of value B does not exceed plus or minus 1%; the utility model is suitable for mass and large-scale production.

Owner:山东中厦电子科技有限公司

Alumina abrasive for chemical mechanical polishing

InactiveUS20050194358A1Reduce amountSlowing rate of settlingPigmenting treatmentOther chemical processesCompound (substance)Slurry

Methods of manufacturing alumina abrasive for use in chemical mechanical polishing are described, wherein the abrasive is in a slurry having gamma alumina formed in a low temperature fuming process, water, an acid sufficient to maintain the pH below about 7, wherein the slurry does not settle appreciably in an 8 to 24 hour period. Advantageously, the alumina is wet-milled without the use of wet-milling salt additives.

Owner:VERSUM MATERIALS US LLC +1

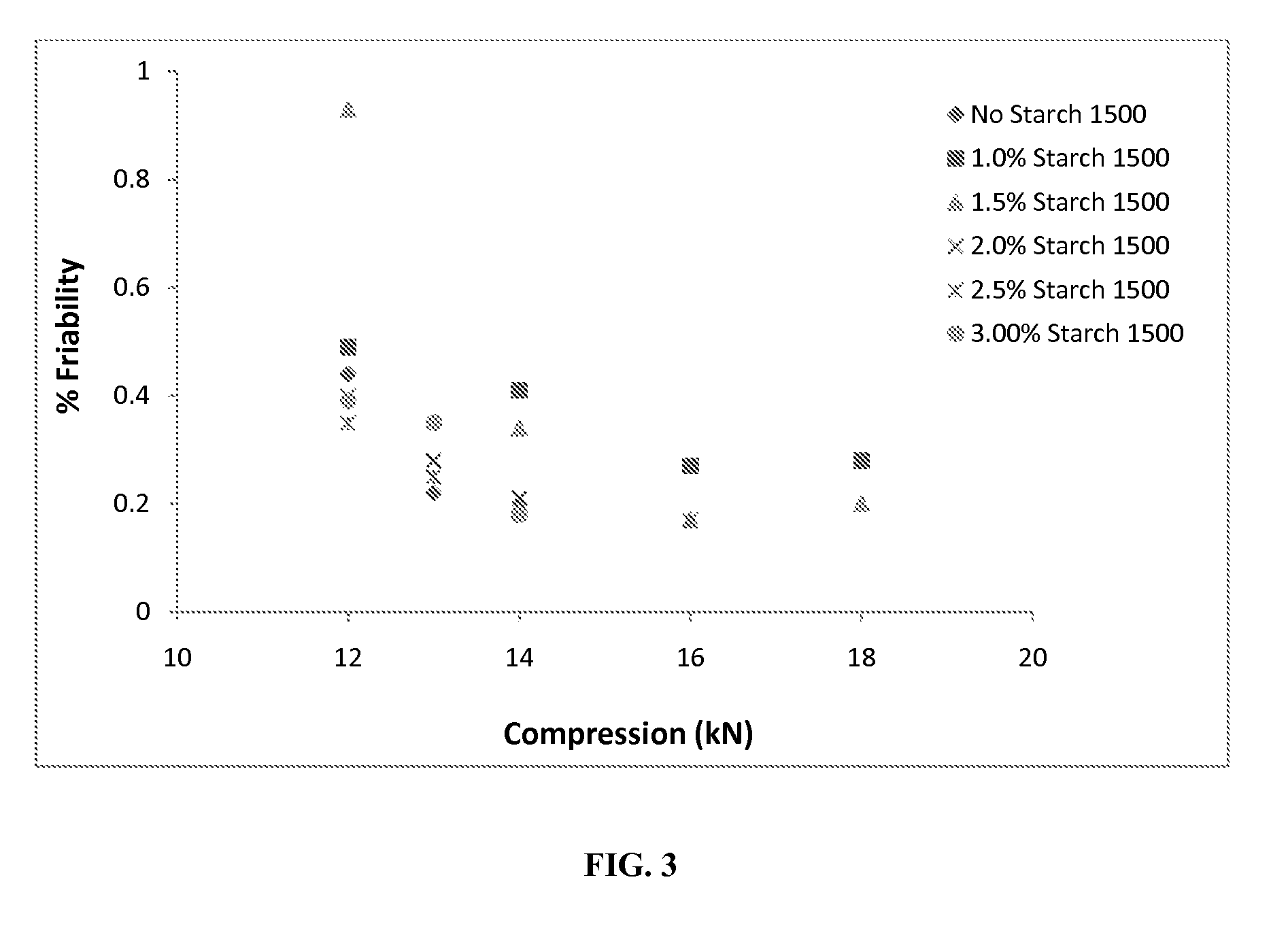

Rapidly dispersing granules, orally disintegrating tablets and methods

InactiveUS20120282335A1High mechanical strengthDisintegrates quicklyAntibacterial agentsBiocideControlled releaseOrally disintegrating tablet

This invention relates to rapidly dispersing microgranules comprising at least one sugar alcohol or saccharide, at least one super disintegrant, and a pharmaceutically acceptable additive with multi-functionality (e.g., starch acting as a binder, disintegrant, diluent / filler, glidant, etc) at a low level, which can be formed by not only eliminating a wet milling step but also avoiding an extensive dry milling step. Furthermore, such rapidly dispersing microgranules could also comprise a pharmaceutically active agent thereby providing for a pharmaceutical composition, or the rapidly dispersing microgranules thus produced are suitable for blending with a pharmaceutically active agent that is optionally taste-masked and / or controlled release coated microparticles to also provide for a pharmaceutical composition and the invention is also directed to a method for manufacturing such rapidly dispersing microgranules in a high useable yield, as well as orally disintegrating tablets comprising such rapidly dispersing microgranules. The rapidly dispersing microgranules are also free flowing.

Owner:ADARE PHARM INC

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

Milled submicron chlorothalonil with narrow particle size distribution, and uses thereof

A method of milling chlorothalonil to form a sub-micron product having a narrow particle size distribution is presented. The milling involves wet milling of the chlorothalonil with high density milling media having a diameter between 0.1 mm and 0.8 mm, preferably between 0.2 mm and 0.7 mm, and a density equal to or greater than 3.8 g / cc, preferably greater than 5.5 g / cc, in a ball mill using between about 40% and 80% loading of the mill volume with milling media, and having the chlorothalonil suspended in an aqueous milling liquid which comprises one or more surface active agents. The milling speed is preferably high, for example from about 1000 rpm to about 4000 rpm. The milled product can be used in foliar applications at a lower effective dosage than prior art formulations, can be used in improved antifouling paint formulations, and can be used in new applications such as the direct injection of solid chlorothalonil particulates in wood to act as a long lasting wood preservative.

Owner:KOPPERS PERFORMANCE CHEM

Production method for hard carbide with graded distributed cobalt content

The hard alloy producing process includes compounding material, wet milling, adding glue, molding to form, loading the plain blank into boat, covering with pure carbon black, sintering in sintering furnace under the protection of hydrogen, and post-treatment to eliminate internal stress and to obtain the hard alloy with gradiently distributed Co content. Owing to the sintering and carburizing with pure carbon black as carburizing agent and the increased post-treatment step, the advanced technological process has high reliability, strong carburizing reaction activity, simple operation process, obvious Co content gradient in the hard alloy product, high comprehensive mechanical performance, low production cost, and other advantages.

Owner:ZIGONG CEMENTED CARBIDE CORP

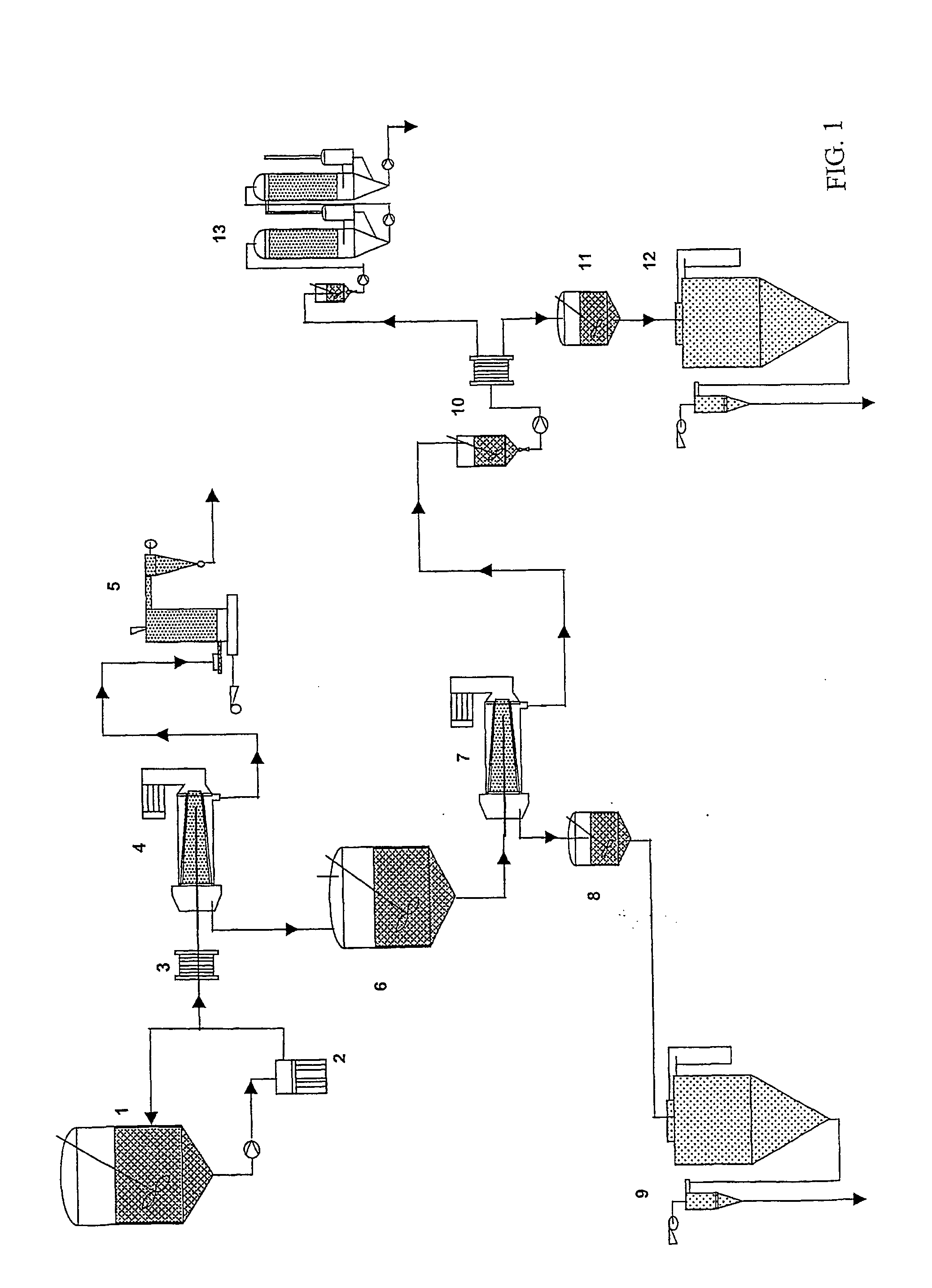

Corn fractionation method

InactiveUS7820418B2Good amino acid balanceAvoid fermentationMicroorganismsBiofuelsFractionationFermentable sugar

An improved method for processing corn into ethanol and other valuable co-products. The invention generally involves a multi-step process which produces germ (or oil), protein, and feed yeast as its co-products while maintaining or enhancing the provision of fermentable sugar to ethanol fermentation. This is accomplished by fundamentally altering the way the corn is fractionated, disrupting the cell walls rather than the protein matrix as is done in conventional wet milling.

Owner:GRAINVALUE

Method for directly producing high-purity electronic level cobaltous sulfate by using cobalt-containing waste

ActiveCN102061390AMeet high purity requirementsImprove overall recoveryProcess efficiency improvementTotal recoveryGoethite

The invention provides a method for directly producing high-purity electronic level cobaltous sulfate by using cobalt-containing waste, in particular a process for producing cobaltous sulfate by using cobalt-containing waste. The method comprises the steps of: checking and classifying raw materials, wet-milling and size-mixing, acid-decomposing, filtering, washing, separating, and extracting copper sponge. The method is characterized by also comprising the steps of: removing iron with a goethite process, extracting P2O4 and removing impurities, separating nickel from cobalt, extracting N235, purifying, concentrating and crystallizing. The high purity electron level cobaltous sulfate is directly regenerated by using various kinds of cobalt wastes, the requirement of the modern high-technology industry on high purity of the cobaltous sulfate is met; the total recovery of the cobalt is higher than or equal to 98 percent; various usable elements can be comprehensively recycled, and coppersponge, tungsten carbide, iron hydroxide and nickel carbonate can be regenerated while the electronic level cobaltous sulfate as a main product is regenerated. The invention has the advantages of comprehensively utilizing waste cobalt resources, recycling the wastes, improving the enterprise benefit, and being beneficial to the development of energy conservation, emission reduction, environment protection and circular economy.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

Process for the fractionation of cereal brans

InactiveUS7709033B2Improve efficiencyEasy to separateTea extractionProtein composition from vegetable seedsUltrafiltrationFractionation

A process for the fractionation of valuable fractions from cereal brans (e.g. wheat, barley and oat brans, and rice polish) is described. In particular, this invention describes a two step process, in which the said bran is first subjected to a combination of enzymatic treatment and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main bran factions, i.e. insoluble phase (pericarp and aleurone layer), germ-rich fraction, residual endosperm fraction and soluble sugars. A second step consists of fractionating cereal brans substantially free of soluble compounds, hence insoluble phase from the above-mentioned first step, by enzymatic treatment with xylanases and / or beta-glucanase and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main fractions, i.e. insoluble phase (remaining cell wall components), protein-rich fraction, soluble hemicellulose and oligosaccharide, and therefore maximizes the extraction rate of valuable cell wall components and aleurone cells from previously cleaned bran.

Owner:LANTMANNEN OATS AB

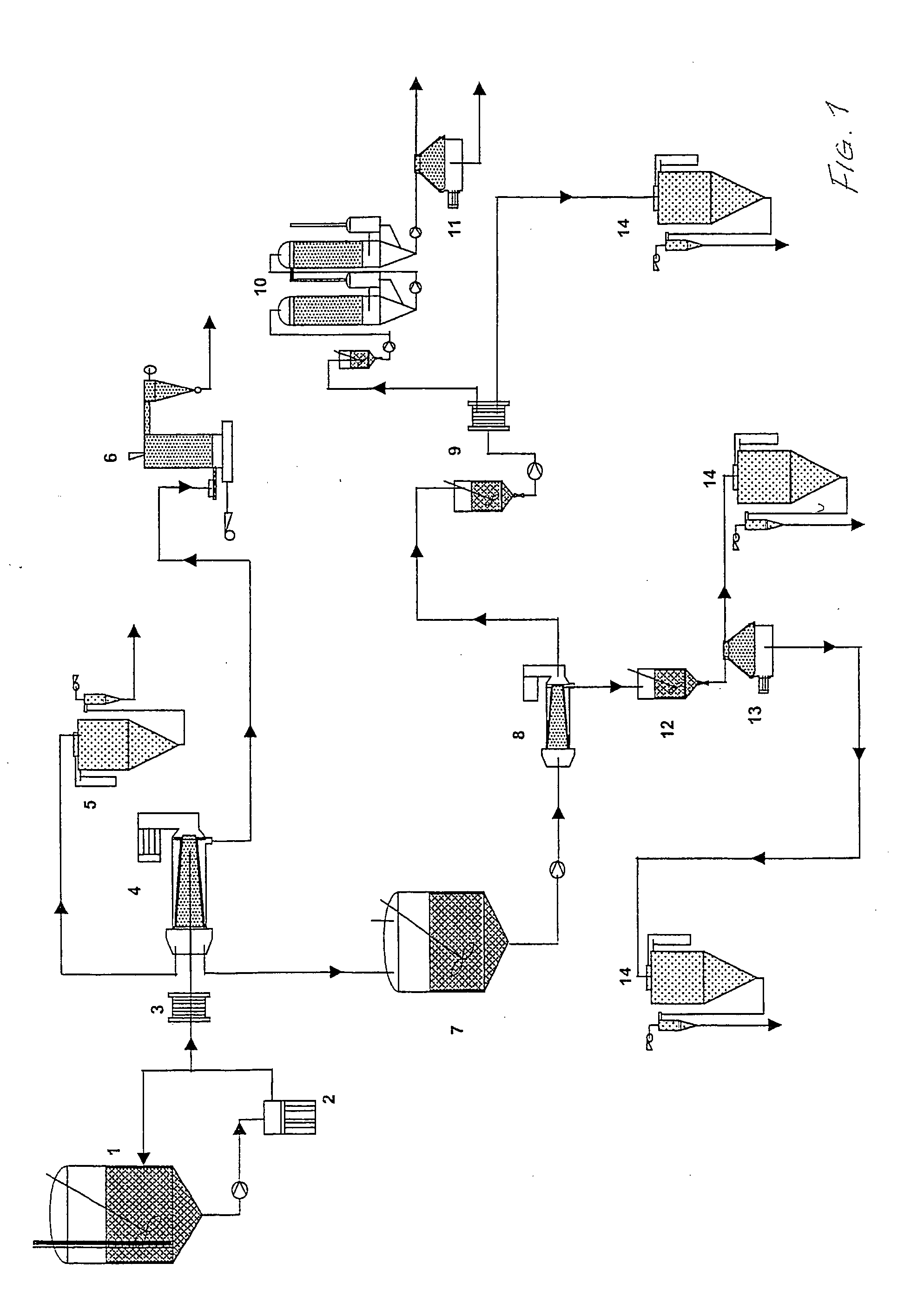

Process for the fractionation of oilseed press cakes and meals

A process for the fractionation of oilseed cakes and meals (e.g. rapeseed cake, soybean meal, and cottonseed cake) is disclosed. This invention describes a fractionation process, in which the said cake or meal is subjected to enzymatic treatment with polysaccharidases with intermittent wet milling, followed by heat treatment to facilitate separation of insoluble from soluble phase by centrifugal forces. Sequential centrifugation and ultrafiltration steps are carried out in order to yield a fibre-rich fraction, at least three protein-rich fractions, in the case of oilseed cakes at leas one emulsified oil fraction, a sugar-rich fraction, and a phytate-rich fraction. This invention also describes the use of the above-mentioned fractions in food, feed, nutraceutical and pharmaceutical applications.

Owner:BIOVELOP INT

Preparation method for cemented carbide mixture

A preparation method for producing cemented carbide mixture is disclosed, the raw materials of which comprises WC powder, WC-TiC solid solution and Co powder; adopting paraffin as forming agent, absolute alcohol as the medium of rubbing and adding oleic acid and stearic acid into the rubbing medium as dispersing agent. The technical process comprises the following steps: accurate batching, loading the heated molten and filtered paraffin into a ball mill for pre-rubbing; wet milling, putting the prepared material into the ball mill, adding right amount alcohol as the ball milling medium, simultaneously, adding dispersing agent, and then turning on the machine for wet milling; slurries filterring, unloading the slurries and filtering for 200-320 meshes; spray drying and pelletizing, spray drying and pelletizing the slurries by using spray drying equipment; and sieving, producing mixture material grain suitable for various kinds of pressing requirements. The method has the advantages of short production process flow, reliable and stable product quality and high production efficiency, which is suitable for large scale production operation and can be widely used for preparing cemented carbide mixture.

Owner:株洲江钨博大硬面材料有限公司

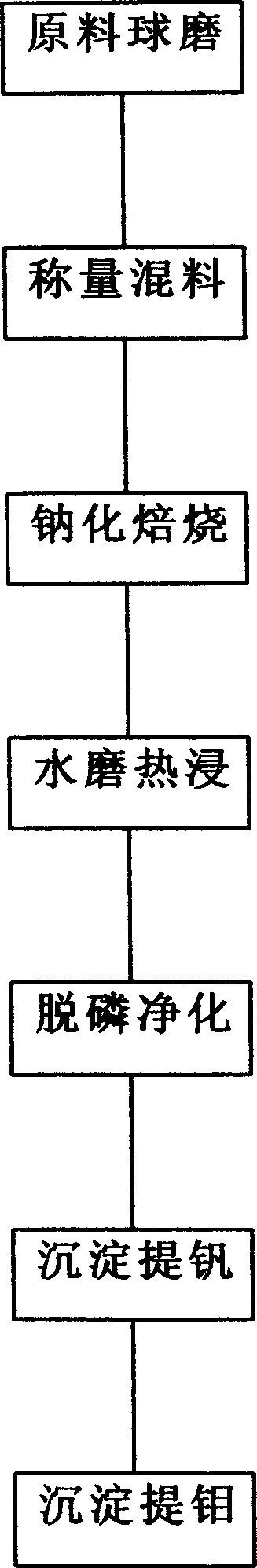

Production technology for extracting vanadium and molybdenum from spent aluminum base molybdenum catalyzer using wet method

The wet production process of extracting vanadium and molybdenum from waste aluminum-base molybdenum catalyst includes successively ball milling material, mixing material, roasting to sodidize, wet milling and hot soaking, dephoshorization to purify, deposition to extract vanadium and molybdenum successively. The present invention is developed on the basis of weight vanadiuim extracting process and apparatus and realizes the simultaneous extraction of valuable vanadium and molybdenum.

Owner:四川川投峨眉铁合金(集团)有限责任公司

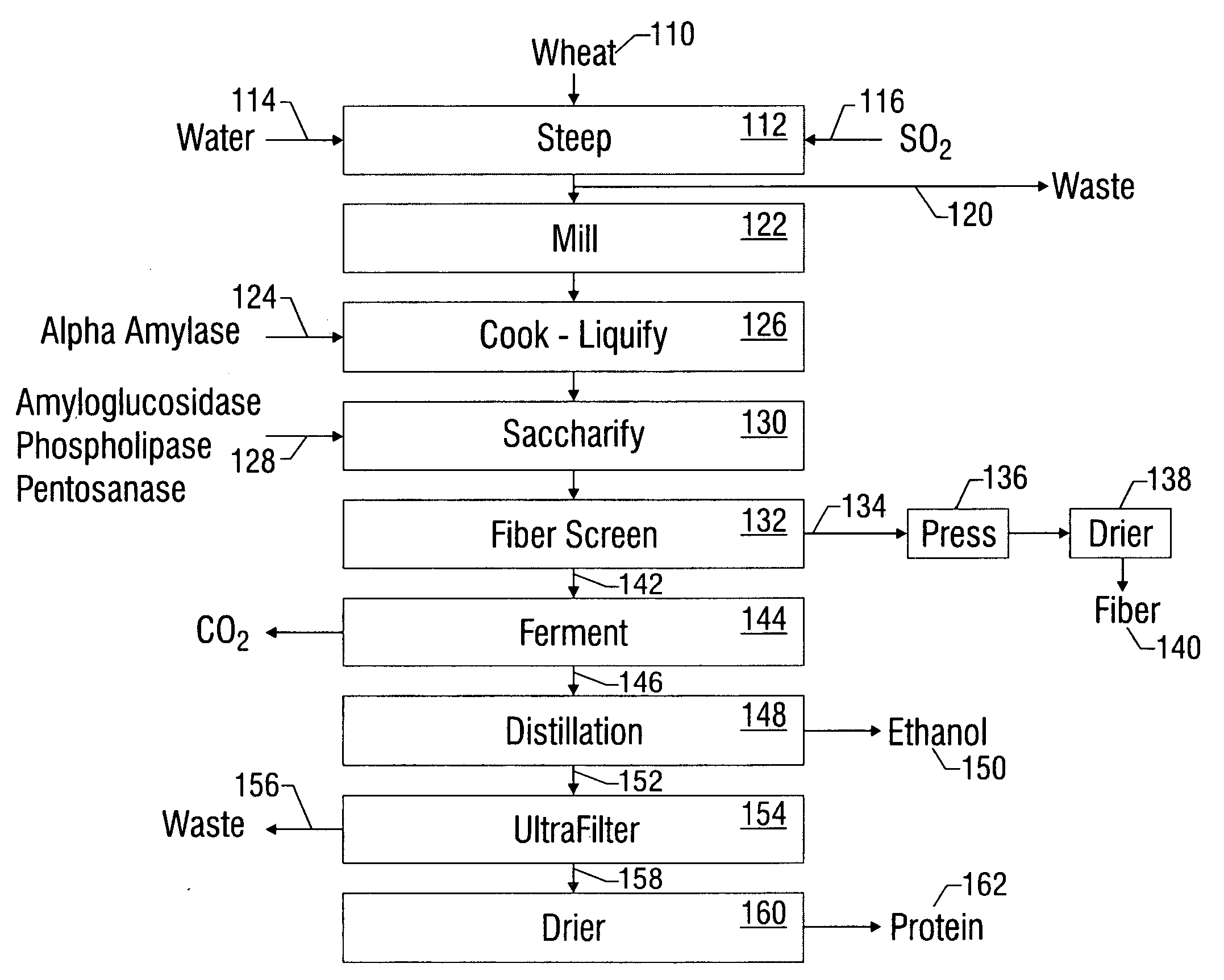

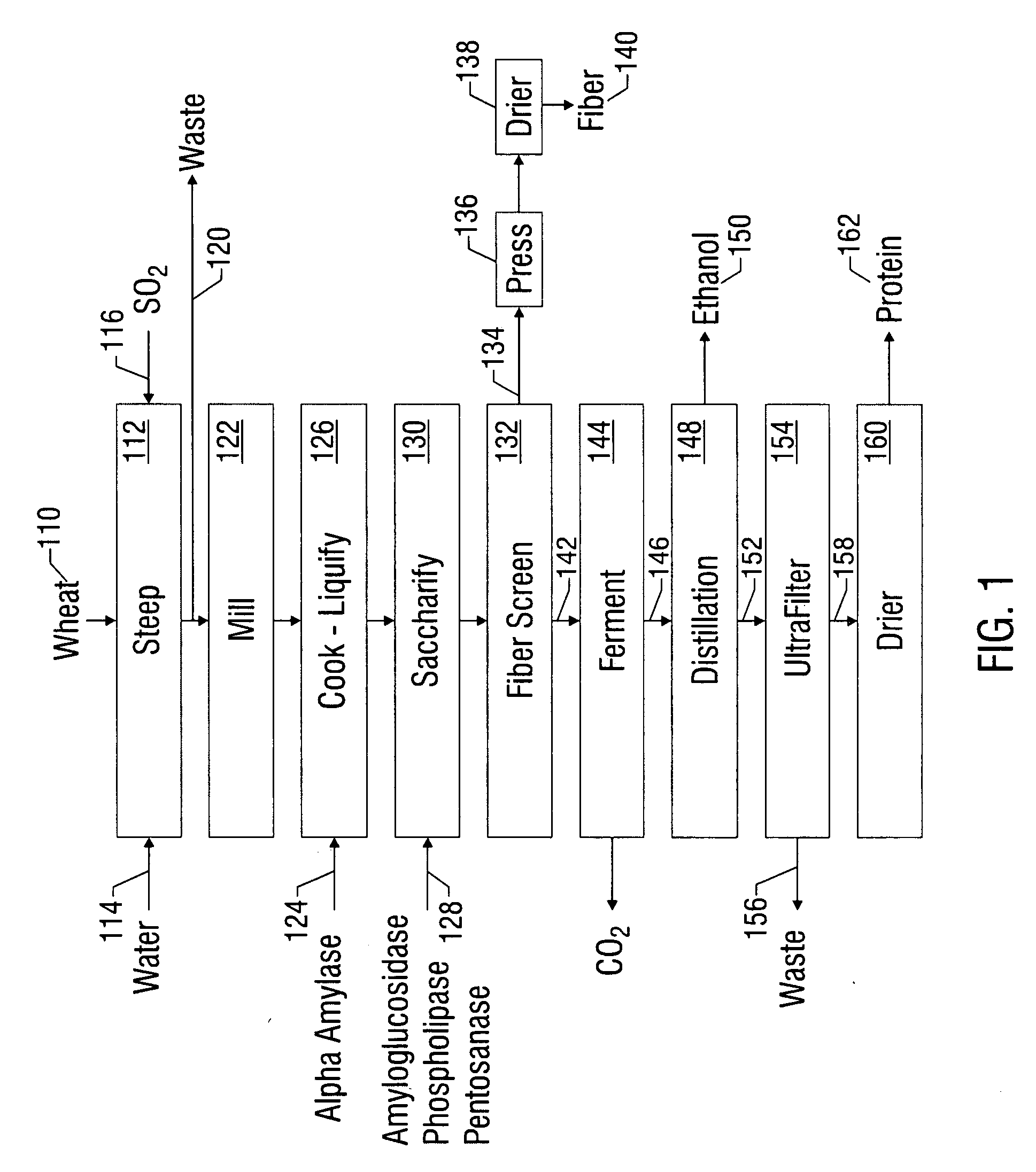

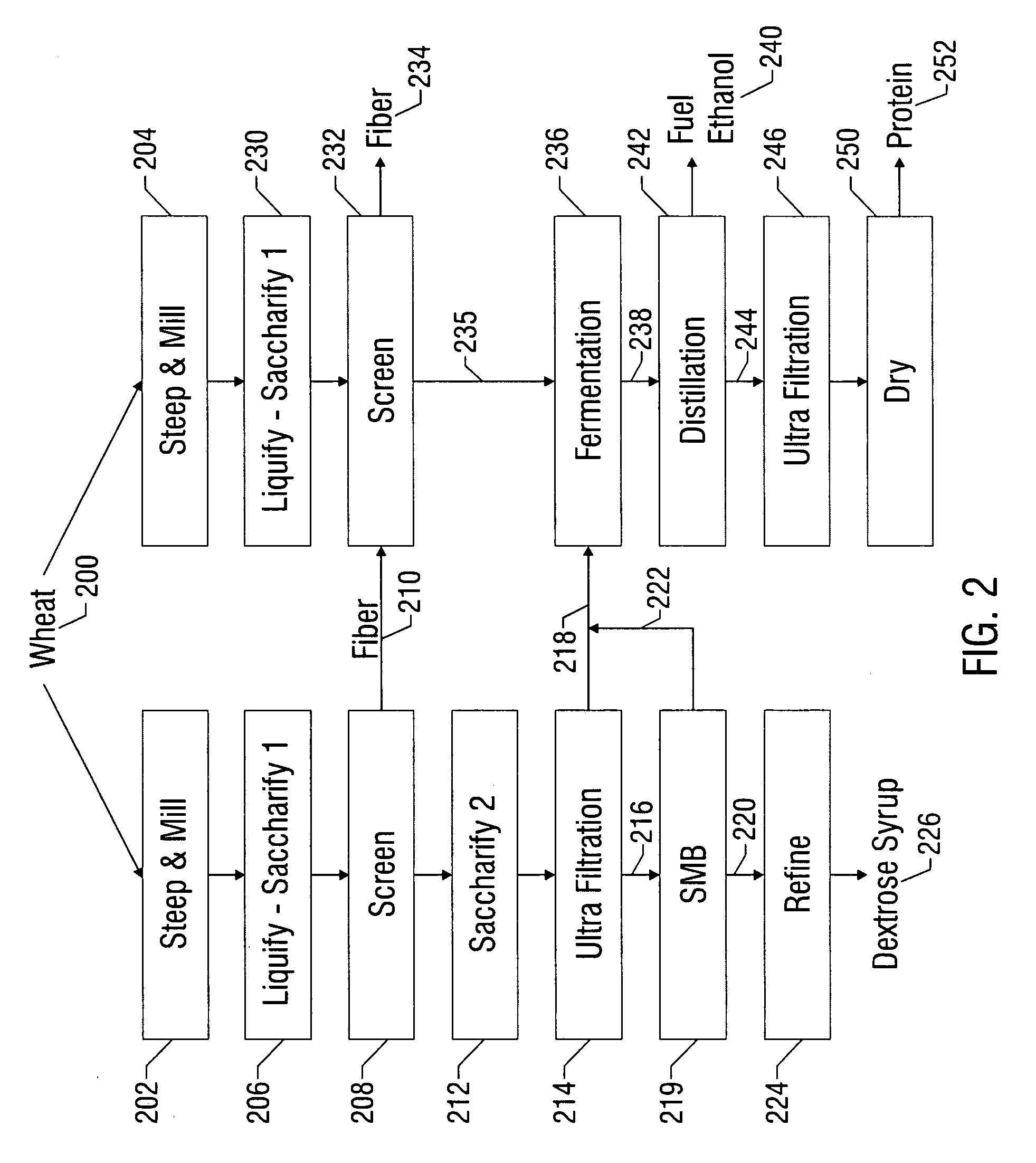

Grain wet milling process for producing ethanol

Whole grain, such as wheat, barley, rye, and / or rice, can be processed by (a) steeping the grain in an aqueous liquid to produce softened grain, (b) milling the softened grain to produce milled grain, (c) liquefying the milled grain by contacting it with amylase and heating it to a temperature of at least about 50° C., producing a liquefied material, (d) at least partially saccharifying the liquefied material by contacting it with amyloglucosidase at a temperature of at least about 50° C., producing a first saccharified material, and (e) separating fiber and germ from the first saccharified material, producing a screened material that is substantially free of fiber and germ. The process also includes the steps of (f) further saccharifying and fermenting the screened material with a microorganism that produces ethanol, thereby producing a broth that comprises ethanol, soluble protein, and insoluble protein, and (g) separating ethanol from the broth. A protein-rich product can be recovered from the broth that comprises both gluten from the grain and microorganism from the fermenting step.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

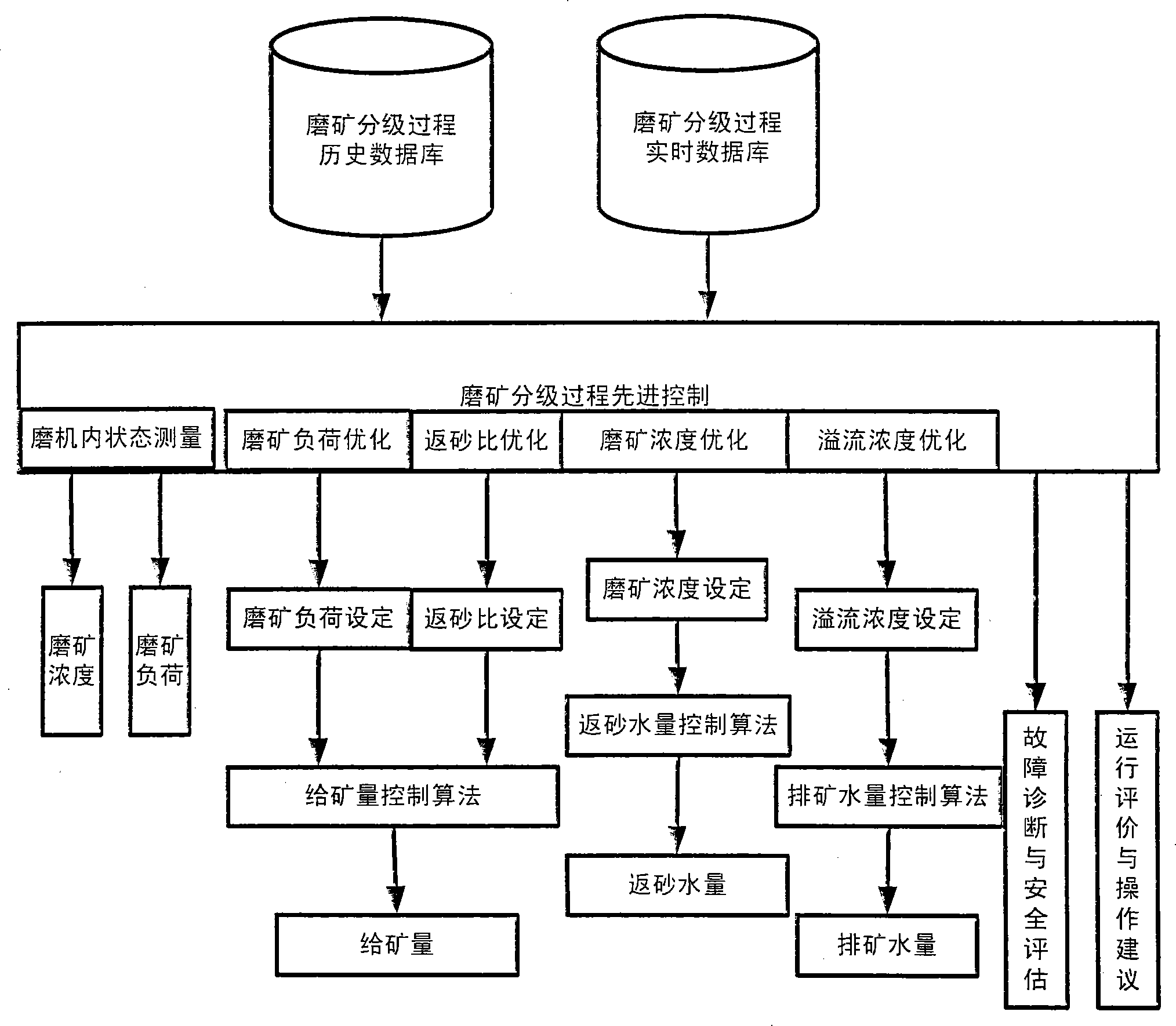

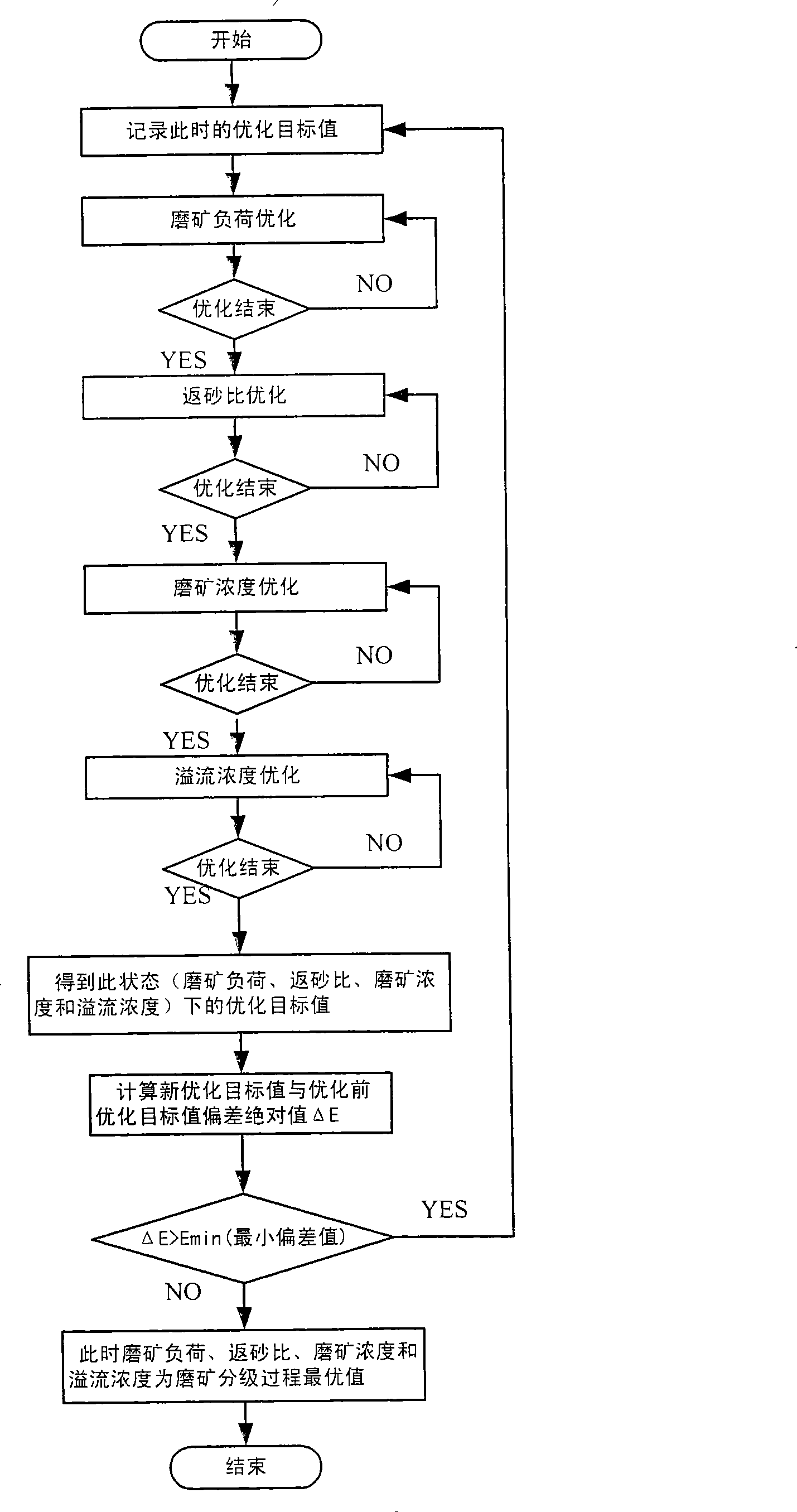

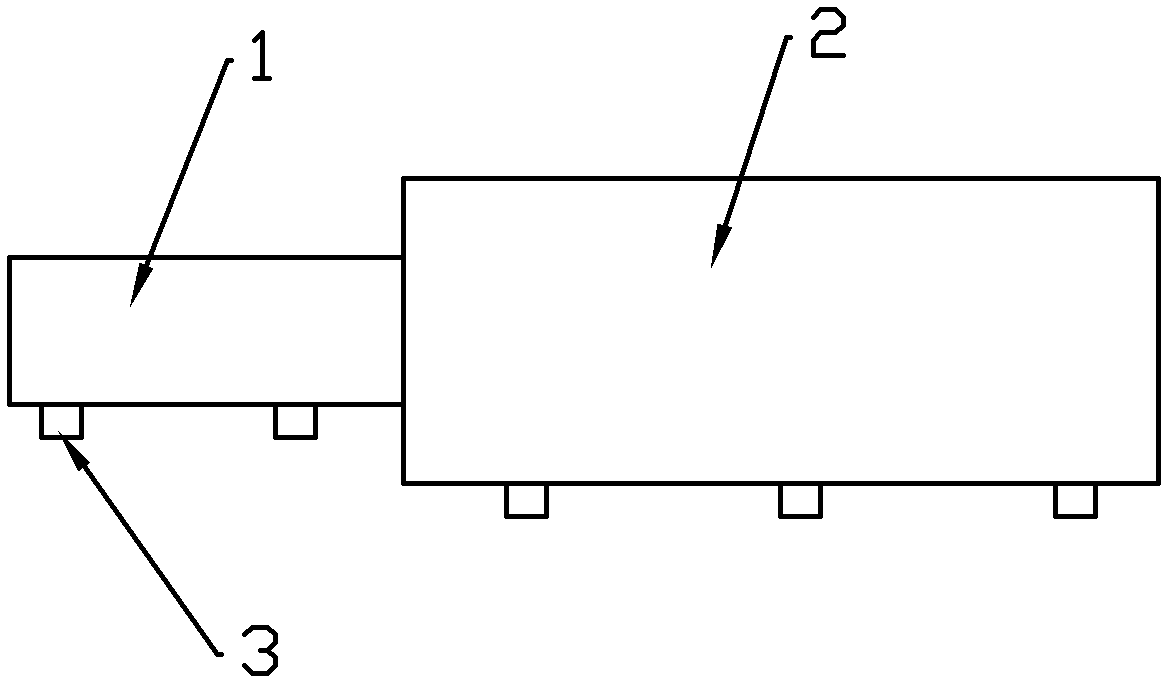

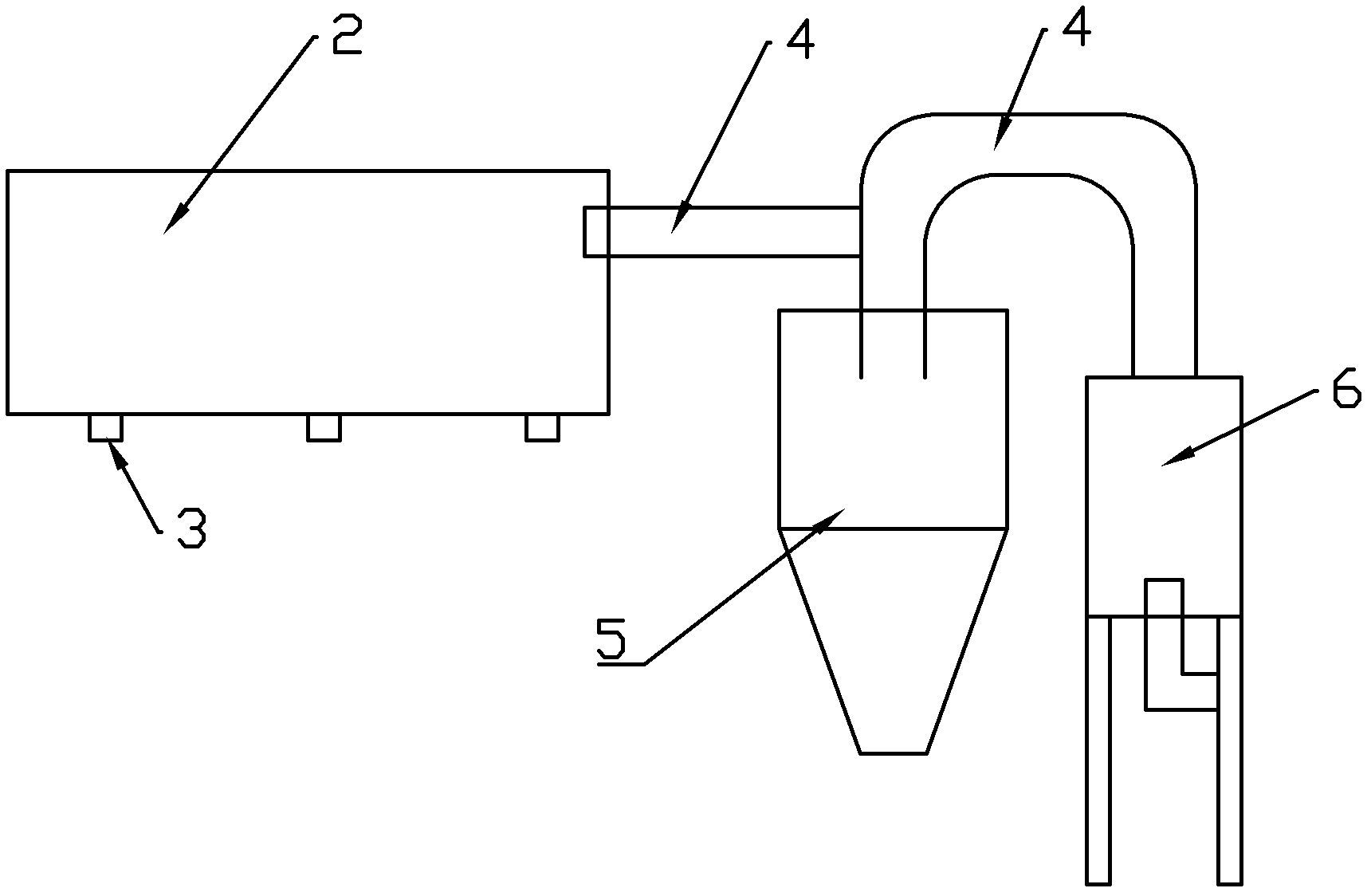

Optimization control method for grind grading process

InactiveCN101244403ARealize online measurementImprove pass rateElectric testing/monitoringGrain treatmentsComing outWater volume

The invention discloses an optimal control method for grinding and grading mineral powder, which is characterized in that: the grinding load and grinding concentration is obtained by sampling grinding-grading process signal, with the help of the advanced control and through testing the state in the grinder; the optimal grinding load, the optimal sand-returning ratio, the optimal grinding concentration and the optimal overflow concentration are obtained through the grinding load optimization, the sand-returning ratio optimization, the grinding concentration optimization and the overflow concentration optimization; the feeding quantity is obtained through the control algorithm of the feeding quantity ; the sand-returning water volume is obtained through the control algorithm of the sand-returning water volume; the discharging water volume is obtained through the control algorithm of the discharging water volume. The optimal control method has advantages that: the global optimization to the grinding-grading process is realized; and meanwhile the diagnosis is done to reveal the fault of the grinding-grading process; the appraisal and analysis is executed in the grinding-grading process; reasonable advice is come out; continuous, stable, safe and economic running is ensured; so the method is widely used in the grinding-grading process and similar wet milling process in other industry crafts.

Owner:徐宝平

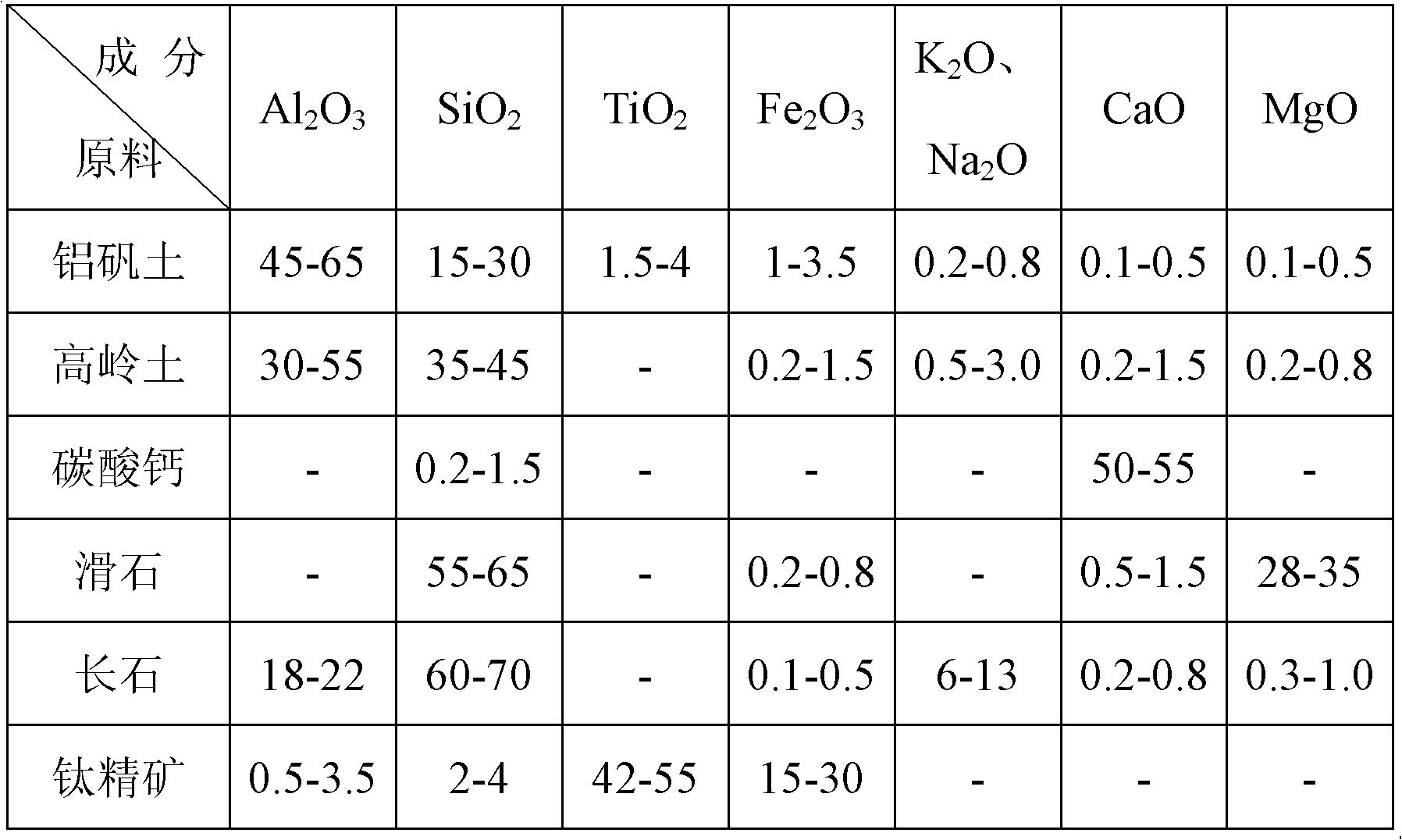

Production process for preparing ceramsite by using low-grade bauxite

The invention discloses a production process for preparing ceramsite by using low-grade bauxite, comprising the steps of: crushing low-grade bauxite ore and then mixing with auxiliary materials to form a mixture; carrying out secondary wet milling until the granularity of slurry is 5-20 microns; after mustiness, pumping the slurry into a spray drying tower for drying granulating to form loose granules and then scattering the granules; after further spray rolling granulation, feeding into a drying-firing comprehensive system for drying and firing; and extracting out the afterheat generated in the firing process to the spry drying tower for utilization. According to the invention, the low-grade bauxite ore is used as the main material, so that the positive roles in rationally utilizing resources and reducing energy consumption are played; a wet ball milling process is adopted, so that the granularity distribution and mixing uniformity of mixed powder can be remarkably improved; by meansof the process of scattering spray granulated powder, the proportions of the pseudo granules and hollow granules in the spray granulated powder are decreased; and through the equipment integration design of the drying and firing processe, the damage rate of the semi-finished granules are decreased.

Owner:JINGANG NEW MATERIALS

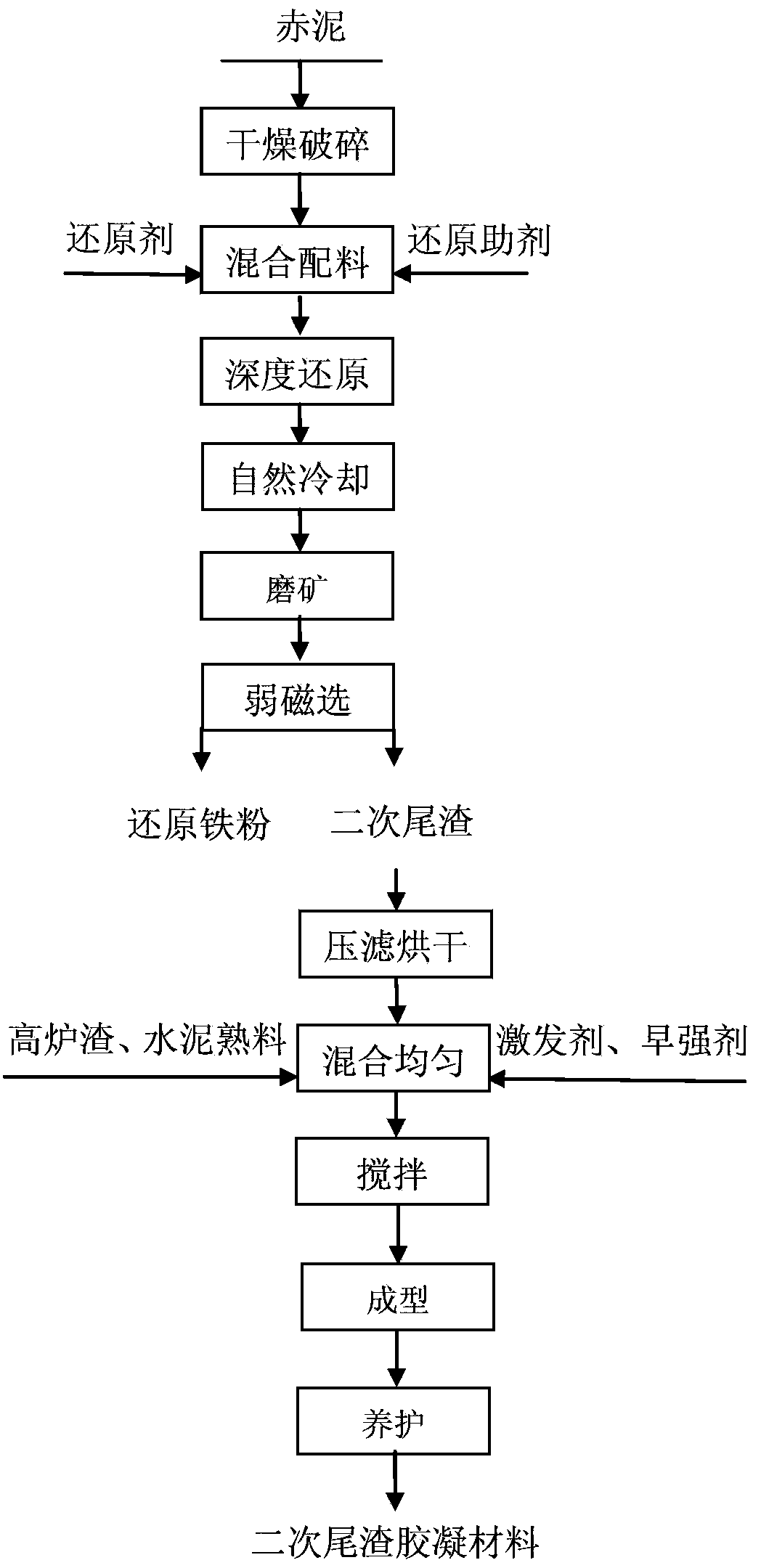

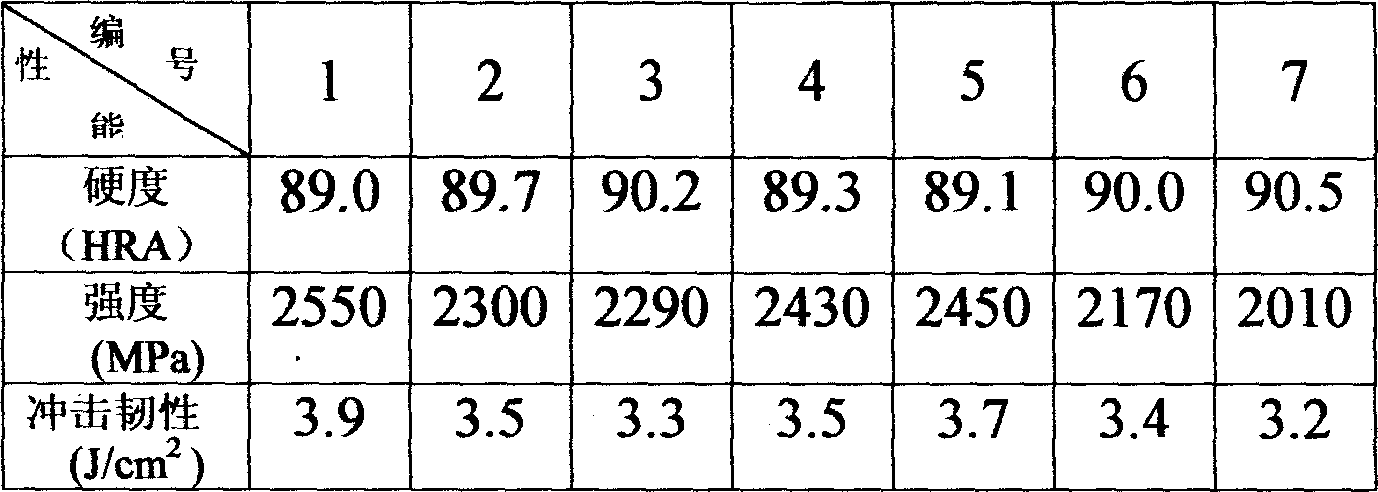

Method used for extracting iron from red mud by drastic reduction and method used for preparing gel material from secondary tailings

ActiveCN103397128ASolve storage problemsAchieve recyclingCement productionMagnetic separationSlagRed mud

The invention discloses a method used for extracting iron from red mud by drastic reduction and a method used for preparing a gel material from secondary tailings, and belongs to the field of comprehensive utilization of resources. The method used for extracting iron from red mud by drastic reduction comprises following steps: Bayer process red mud is dried and crushed; the crushed red mud is mixed uniformly with a reducing agent and an auxiliary agent; the mixture is subjected to drastic reduction in a sealed container in a kiln with oxidizing atmosphere or reducing atmosphere; and the cooled material prepared by reduction reaction is subjected to wet milling and magnetic separation so as to obtain the iron powder of drastic reduction with iron grade of 90% or more, and iron recovery rate of 90% or more. The method used for preparing the gel material from secondary tailings comprises following step: the secondary tailings obtained after magnetic separation is dried, and are mixed uniformly with blast furnace slag, cement clinker, an exciting agent and an early strength agent; and then the secondary tailing gel material is prepared, wherein compressive strength and breaking strength of the secondary tailing gel material both meet the requirements of composite Portland cement 325 standard. According to the methods of the invention, the large amount of residual iron is recycled from the red mud, and the secondary tailings are used for preparation of the gel material, so that waste is transformed into valuables, the recovery of red mud iron resource is realized, and a problem of accumulation of red mud is solved.

Owner:UNIV OF SCI & TECH BEIJING +1

Process for preparing tungsten-cobalt hard alloy

The process of preparing hard W-Co alloy includes compounding material with WC powder and Co powder in 4-6 wt%, wet milling, drying, pelletizing after mixing with excipient, pressing to form, eliminating excipient, sintering and other steps. During compounding material, two kinds of WC powder, including great granularity component of 20-30 micron and fine granularity component of 1.2-1.8 micron in the weight ratio of 1.5-4.0, are used. The said process can compromise the wear resistance and toughness of hard alloy effectively to raise the comprehensive performance of alloy and expand the application range.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com