Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1457results about How to "Achieve regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

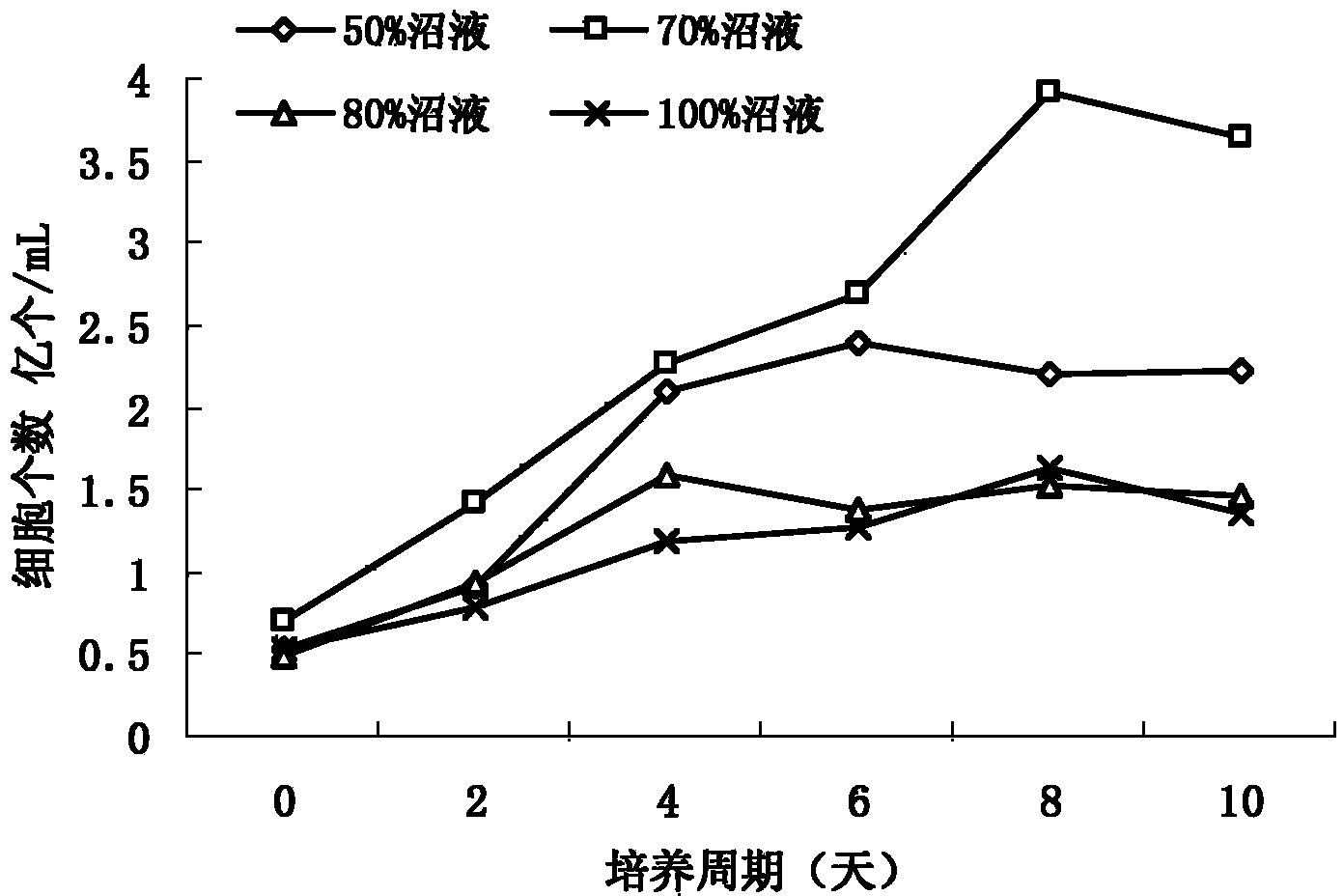

Biogas slurry ecological purification method based on microalgae cultivation

ActiveCN103396950AImprove photosynthetic efficiencyFast growthUnicellular algaeMicroorganism based processesSocial benefitsPurification methods

The invention discloses a biogas slurry ecological purification method based on microalgae cultivation. The method comprises the following steps: (1) biogas slurry pretreatment; (2) habituated culture of autotrophic microalgae, namely, obtaining algae strains capable of rapidly growing in 70%-100% biogas slurry; (3) preparation of a seed solution; (4) a biogas slurry purification method during growing of microalgae, namely, after expanded cultivation, inoculating the habituated algae species into an open photobioreactor for cultivation, obtaining chlorella biomass growing by high density through a semi-continuous culture method and optimized methods such as fed-batch cultivation, and purifying the biogas slurry; (5) biochemical breaking of microalgae cell walls, namely, introducing the microalgae cells into a biochemical wall breaking pool, putting freshwater fish into the pool, and obtaining algae slurry subjected to wall breaking; and (6) collection of the microalgae cells and recycling of the biogas slurry. According to the method, not only is a method provided for purifying the biogas slurry, but also the obtained algae cells and the biogas slurry can be recycled, so that ecologicalization treatment of the biogas slurry is realized, the environment is improved, and furthermore, the economic and social benefits are produced.

Owner:湖南瑞藻生物科技有限公司

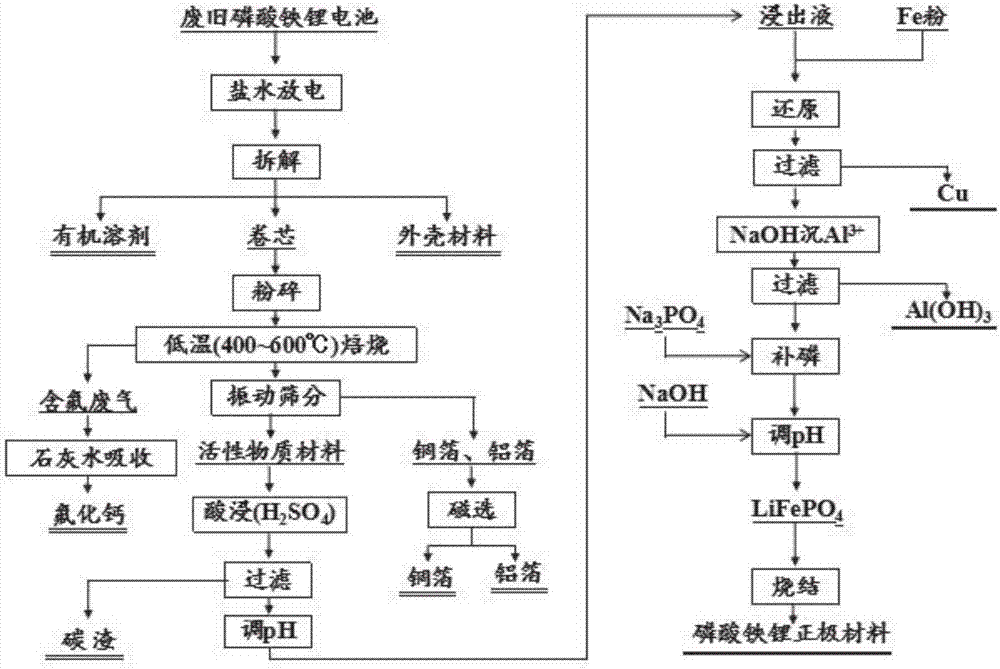

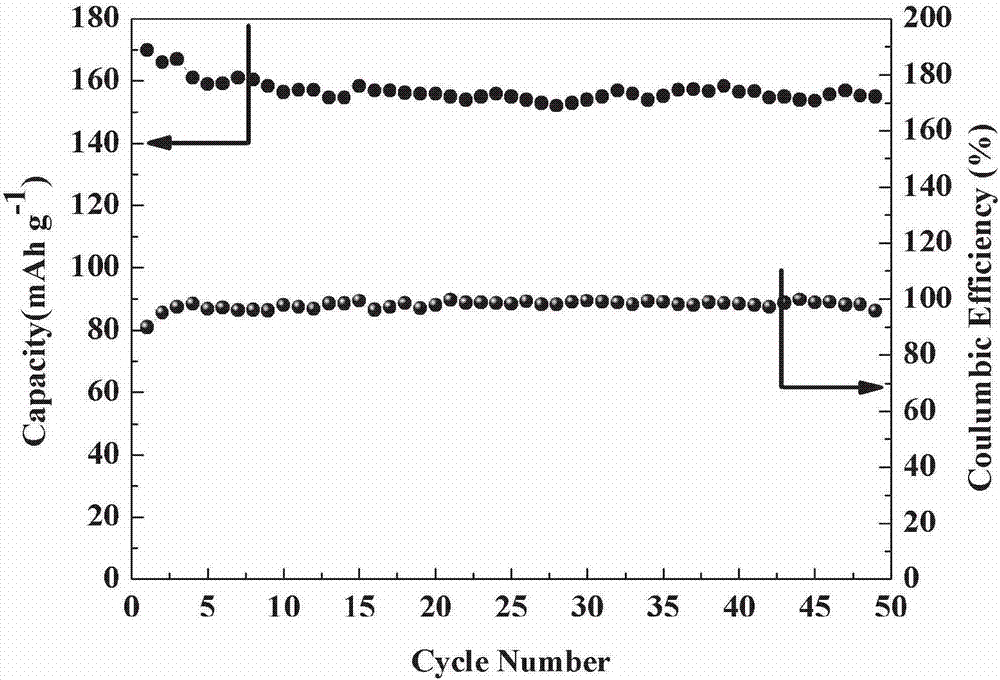

Method for regenerating positive active material from waste lithium iron phosphate batteries

ActiveCN106910889ARealize combination generationQuality assuranceCell electrodesWaste accumulators reclaimingFiltrationCopper foil

The invention discloses a method for regenerating a positive active material from waste lithium iron phosphate batteries. The method comprises the steps as follows: 1) waste lithium iron phosphate batteries are discharged in saline water, and organic solvents, roll cores and casing materials are disassembled; 2) the roll cores are subjected to crushing, calcination and other steps, and active materials, copper foil and aluminum foil are separated through vibrating screening. Fluorine-containing waste gas is absorbed with lime water, the copper foil and the aluminum foil are separated with a magnetic separation method, the active materials are leached out with sulfuric acid, and a leachate and carbon residues are obtained through separation; 3) Cu<2+> in the leachate is reduced to elementary copper by adding iron powder, meanwhile, Fe<3+> is reduced to Fe<2+>, copper and excessive iron residues are filtered out, aluminum is removed through precipitation with an alkaline liquid, the filtrate is supplemented with a phosphorus source after filtration, the pH value is adjusted by adding the alkaline liquid, coarse lithium iron phosphate precipitates are produced, and finally, battery-grade lithium iron phosphate is obtained through sintering. Comprehensive utilization of the waste lithium iron phosphate batteries and regeneration of the active materials are realized with a simple, practical, economical and feasible method, no secondary pollution is produced, and the method is suitable for industrial production.

Owner:CENT SOUTH UNIV

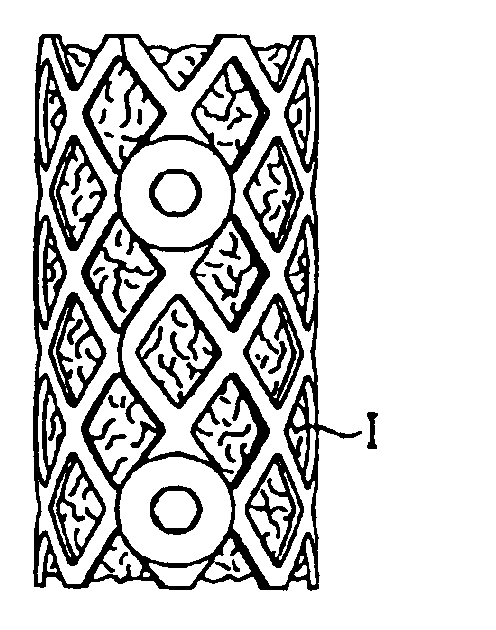

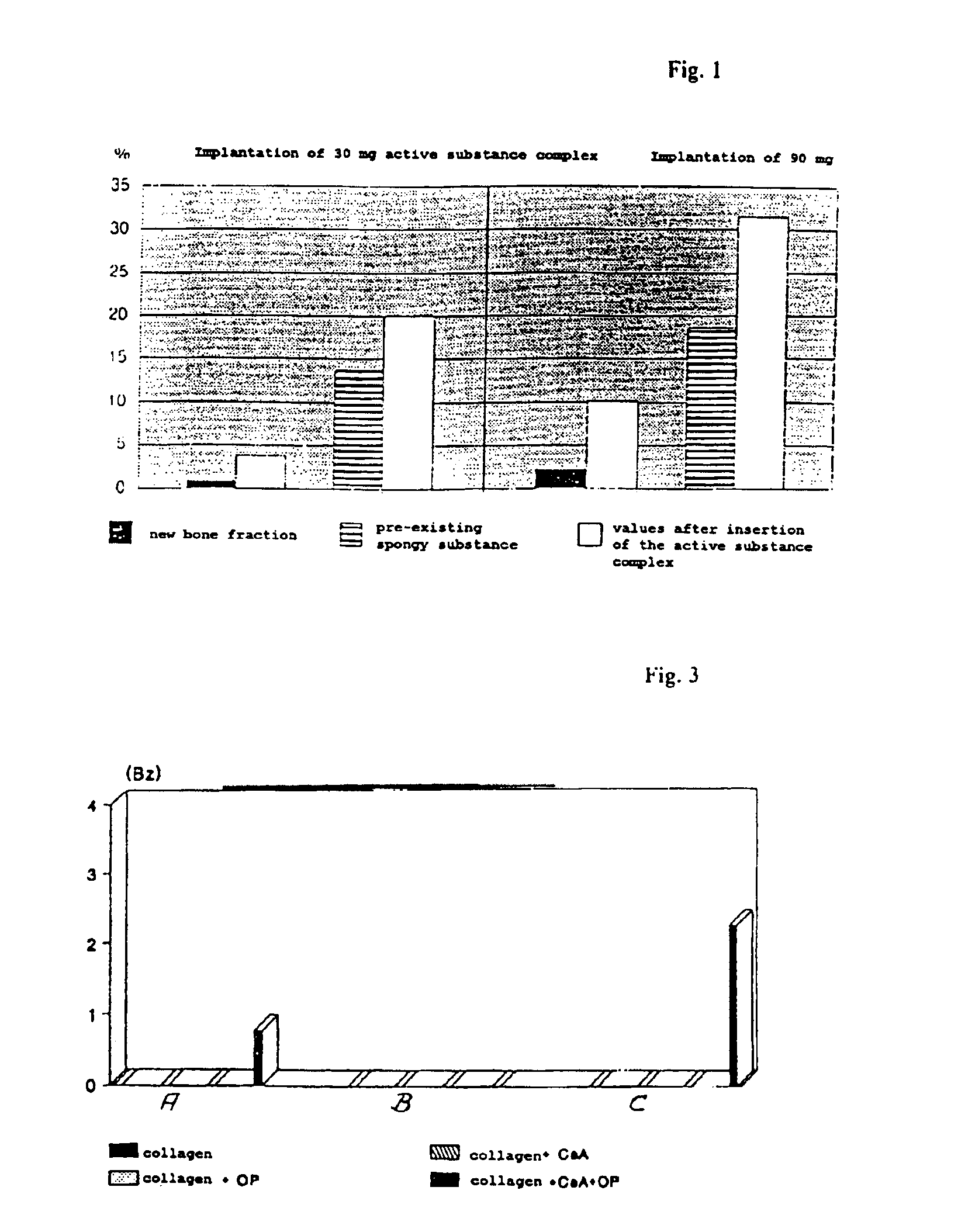

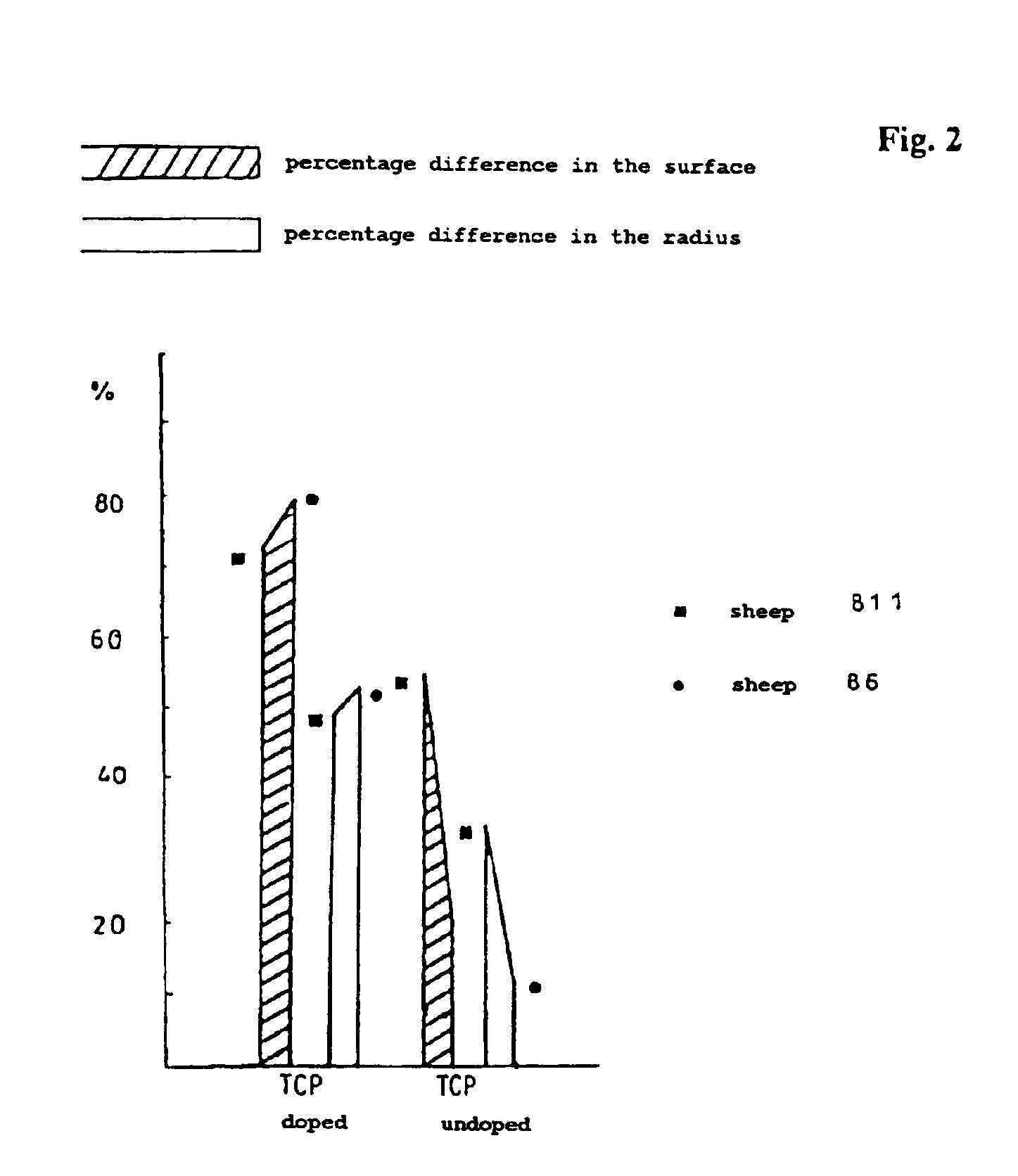

Implant for recreating verterbrae and tubular bones

InactiveUS6989033B1High mechanical strengthExtend range of possible usBone implantSpinal implantsExtracellular materialBiomedical engineering

The invention relates to an implant for at least partially creating, recreating or stabilizing vertebral bodies or tubular bones. In said implant, a metallic, nonmetallic or ceramic hollow body is coated with an active substance complex or comprises said active substance complex. This active substance complex comprises the following components which differ from one another and which are specifically adapted for creating bone: at least one structural component based on extracellular material which is specifically adapted to the cells of the bone which is to be created, at least one recruiting component, at least one adhesion component, and at least one growth and / or maturation component.

Owner:OSSACUR +1

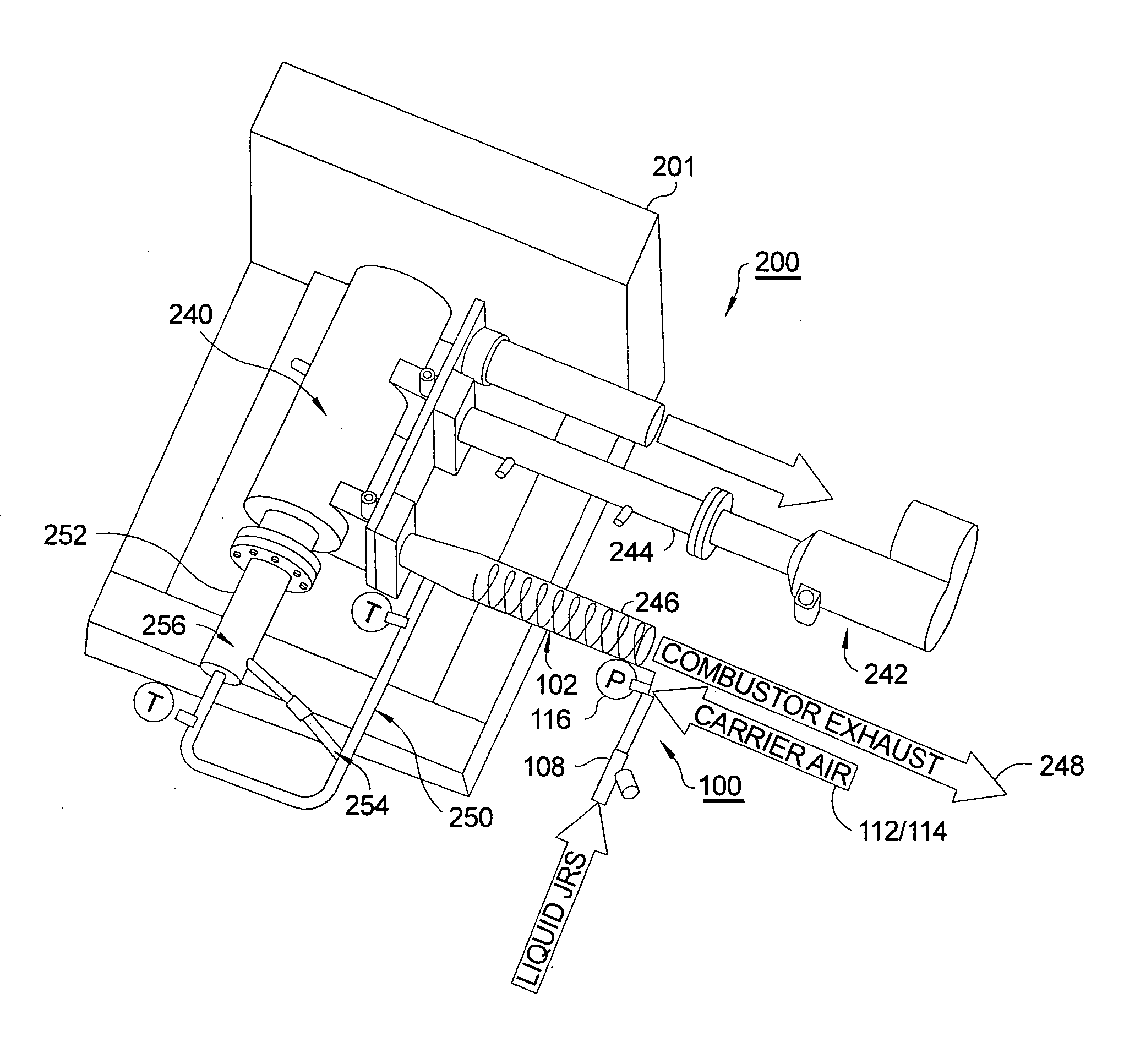

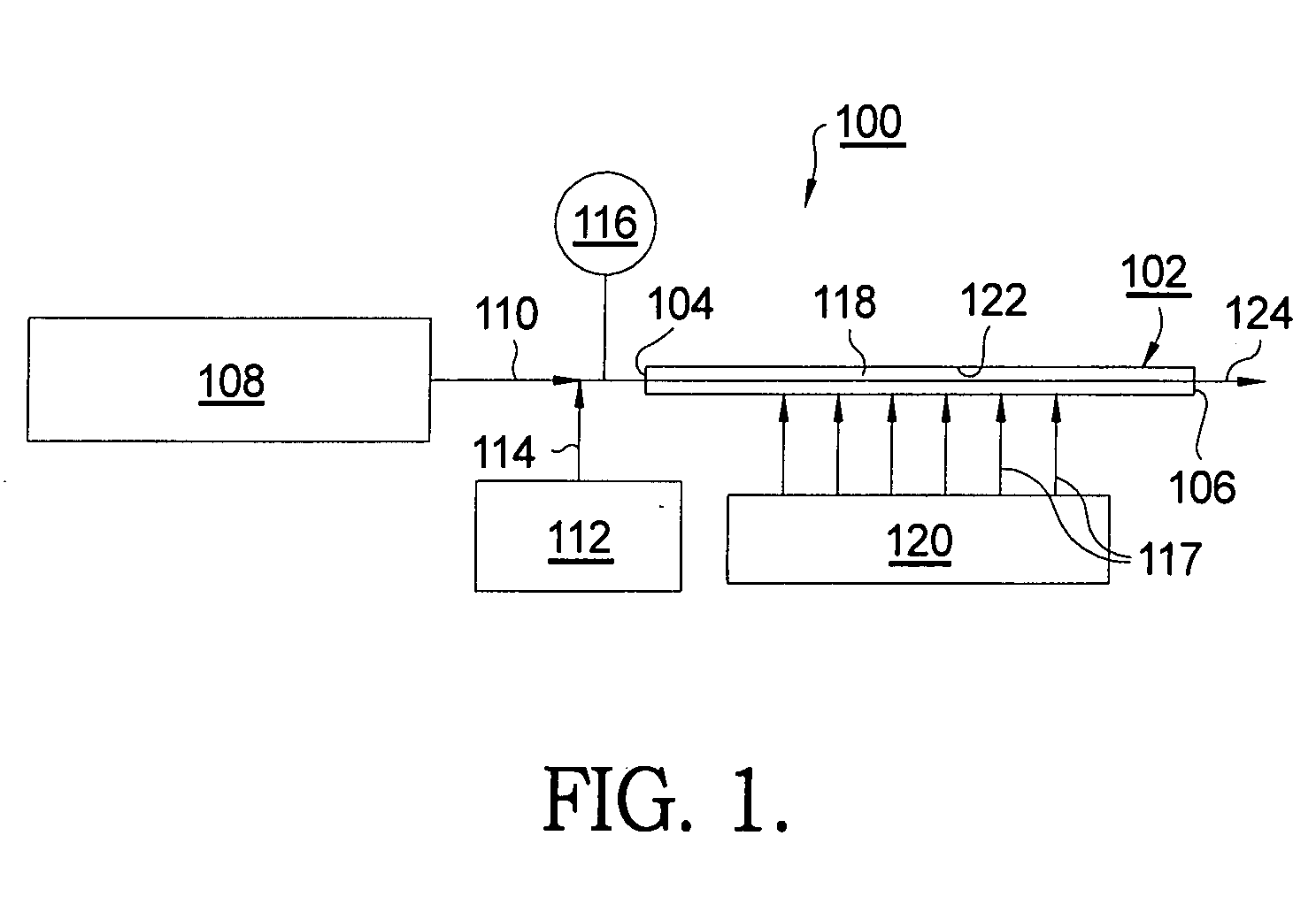

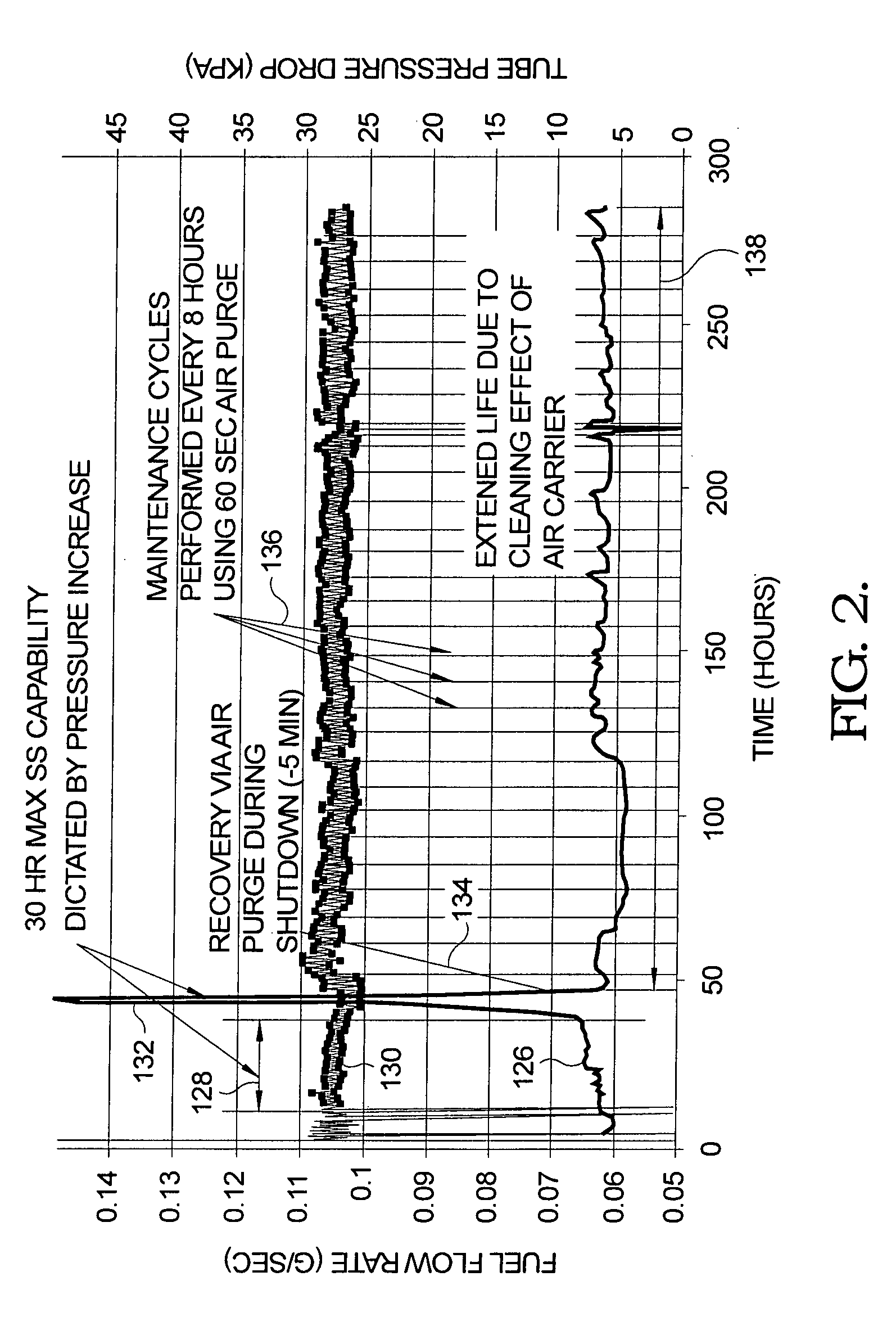

Continuous liquid fuel vaporizer

InactiveUS20080230039A1Reduce rateEasy to disassembleLiquid fuel feeder/distributionMachines/enginesEngineeringVaporization

A tubular vaporizer for vaporizing volatile liquids, and especially hydrocarbon fuels. Liquid fuel is passed into the vaporizer tube, is vaporized by heat transferred through fuel contact with the hot walls, and vaporized fuel exits the vaporizer tube. A hot carrier air stream is passed through the vaporizer with the vaporized fuel, greatly reducing the rate of buildup of deposits on the vaporizer walls; however, fueling of the vaporizer eventually must be shut down to remove the deposits. The deposits are easily removed, and the vaporizer tube completely regenerated, by passing hot air alone through the tube for a period of time. In a preferred embodiment, two parallel-path vaporization tubes and switching means therebetween are provided for alternate use and regeneration cycles, affording a continuous flow of vaporized fuel from the apparatus. The vaporizer is especially useful in providing gaseous fuel for a catalytic hydrocarbon reformer.

Owner:DELPHI TECH INC

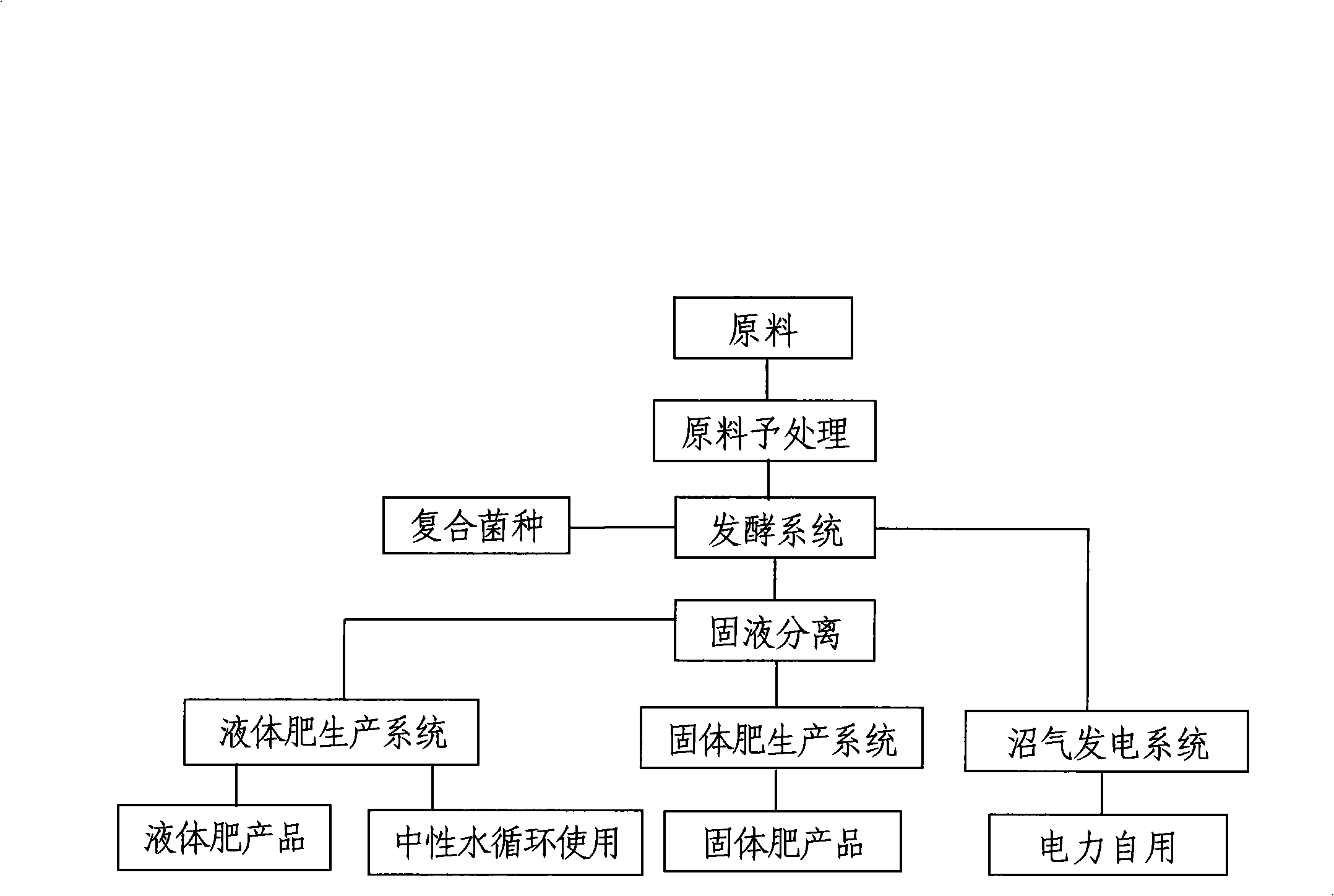

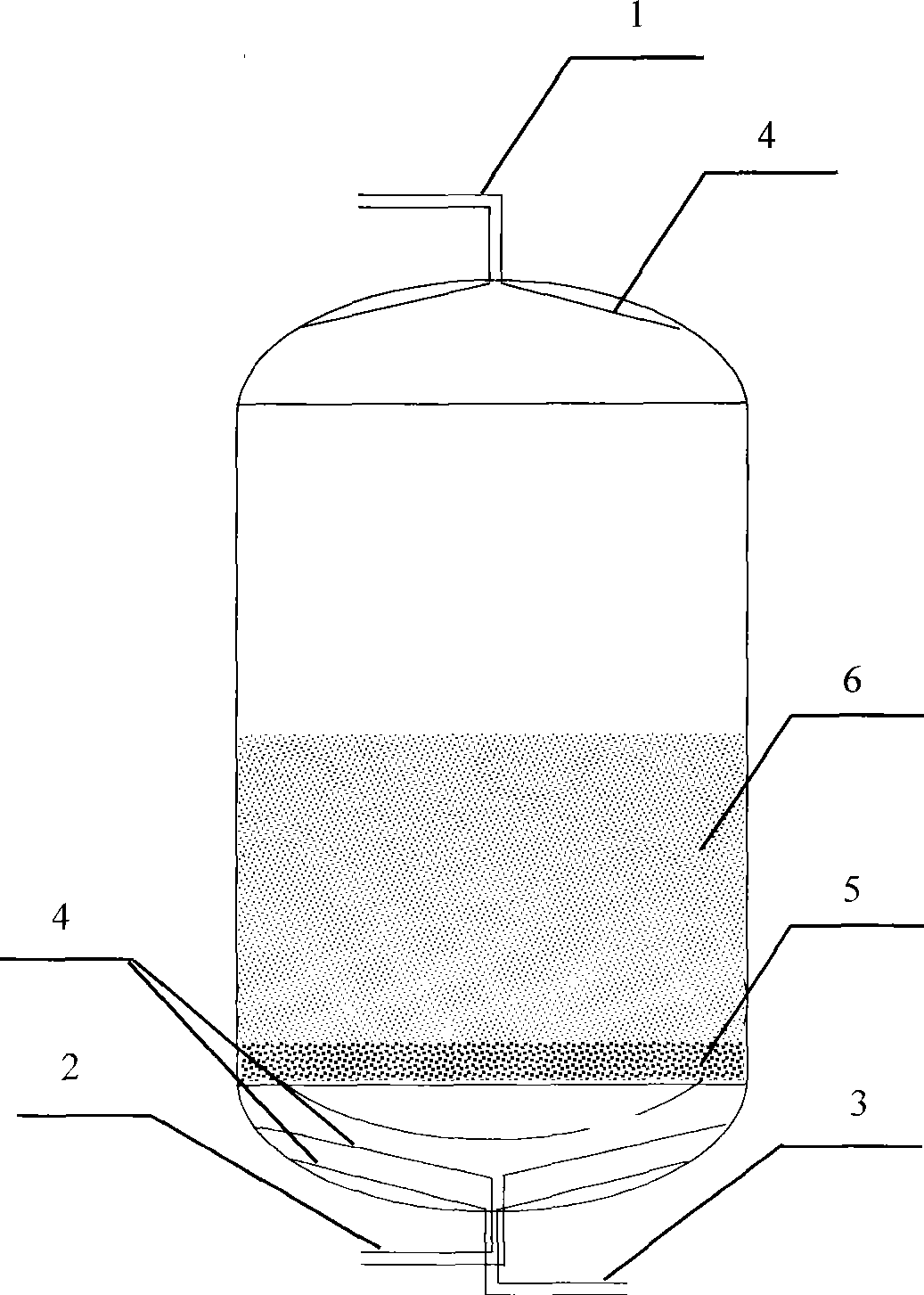

Innocent comprehensive approach method for human feces by biotechnology

InactiveCN101307332AThoroughly deodorizedElectricity for own useBio-organic fraction processingSolid waste disposalElectricityFiltration

The invention relates to a method for realizing harmless comprehensive treatment of human excrements through adopting biotechnology, in particular to a comprehensive technology used for the harmless centralized treatment of human excrements in urban areas. The method comprises the following steps that: (1) human excrements, aquatic plants and terrestrial plants are added in a fermenter, and then a composite strain mixed solution of microzyme, bacillus and lactobacillus is fed into the fermenter so as to carry out aerobic fermentation and anaerobic fermentation in turn; (2) the biogas generated during fermentation is fed into a biogas generating set so as to generate electricity; (3) the products after fermentation undergoes solid-liquid separation, and the solid fermentation products are made into solid organic fertilizer through dewatering, drying, preparation and regranulation; (4) the liquid fermentation products is obtained after solid-liquid separation undergo decoloring, filtration and settlement layering, in the liquid, the sublayer liquid in the solution is made into liquid organic fertilizer through coarse filtration, secondary filtration, sterilization and preparation and the supernatant is made into rinsing meeting effluent standard through aeration and settlement filtration. The method can realize clean, environment-friendly and energy-saving ecological production.

Owner:昆明伽得科贸有限公司

Defluorination absorbing material based on aluminum base composite oxides and its preparation method and use and special device of the preparation method

ActiveCN101507911AExcellent adsorption and defluorination performanceGood defluoridation effectOther chemical processesChemical reactionWater source

The invention belongs to the field of materials for removing fluorine in water, and in particular relates to a fluorine-removal adsorption material based on alanate and aluminum-based composite oxide, a preparation method and uses of the same, and a special device for the preparation method. The fluorine-removal adsorption material based on the aluminum-based composite oxide, which is prepared by a heterotopic preparation method or an in-situ preparation method, comprises two parts of an active composition and a porous supported substrate, wherein the active composition is the aluminum-based composite oxide prepared from an aluminum salt solution and an inorganic alkaline solution by chemical reaction; and the aluminum-based composite oxide is loaded on the surface of the porous supported substrate by an in-situ loading method, and the mass ratio of the aluminum-based composite oxide to the porous supported substrate is 0.25-25:100. The fluorine-removal adsorption material based on the aluminum-based composite oxide can be used for the adsorption of fluorine pollutants in the water and particularly common fluorine in underground drinking water sources. In addition, the material can also be used for removing pollutants such as arsenic, iron, manganese, phosphate, and the like in the water.

Owner:清华苏州环境创新研究院

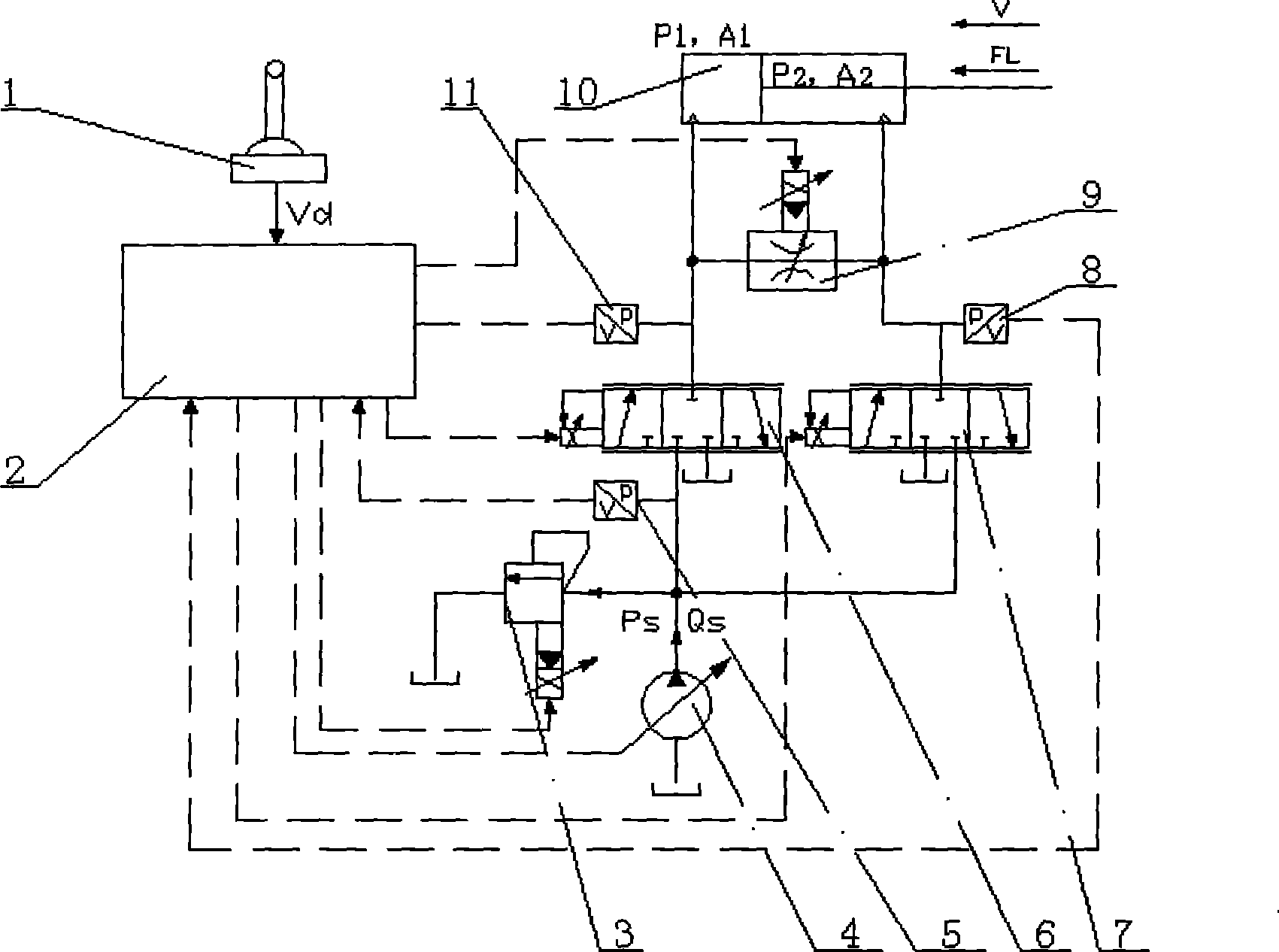

Independent electrohydraulic load sensitive energy regeneration hydraulic system of engineering machinery load port

InactiveCN101413522AAchieve regenerationReduce lossFluid-pressure actuator componentsLoad sensingElectrical connection

The invention discloses an independent electrohydraulic load sensing energy regeneration hydraulic system of an actuator port of an engineering machine. An oil outlet of a variable pump is connected with an oil inlet of a proportional relief valve, a first pressure sensor, an oil inlet of a first proportional directional valve, and an oil inlet of a second proportional directional valve respectively. An oil outlet of the first proportional directional valve is connected with a second pressure sensor, the oil inlet of a proportional throttle valve and a rodless cavity of a hydraulic cylinder respectively. An oil outlet of the second proportional directional valve is connected with an oil outlet of the proportional throttle valve, a third pressure sensor and a rod cavity of the hydraulic cylinder. A Controller is in electrical connection with a control handle, the variable pump, the proportional relief valve, two proportional directional valves, the proportional throttle valve and three pressure sensors. The system adopts the pressure sensors to detect working conditions, selects control policies according to the working conditions, reduces energy loss in flow restriction and realizes overload energy regeneration under the control of an actuator. Speed and energy-conservation control is realized through the combination of pump control and valve control.

Owner:ZHEJIANG UNIV

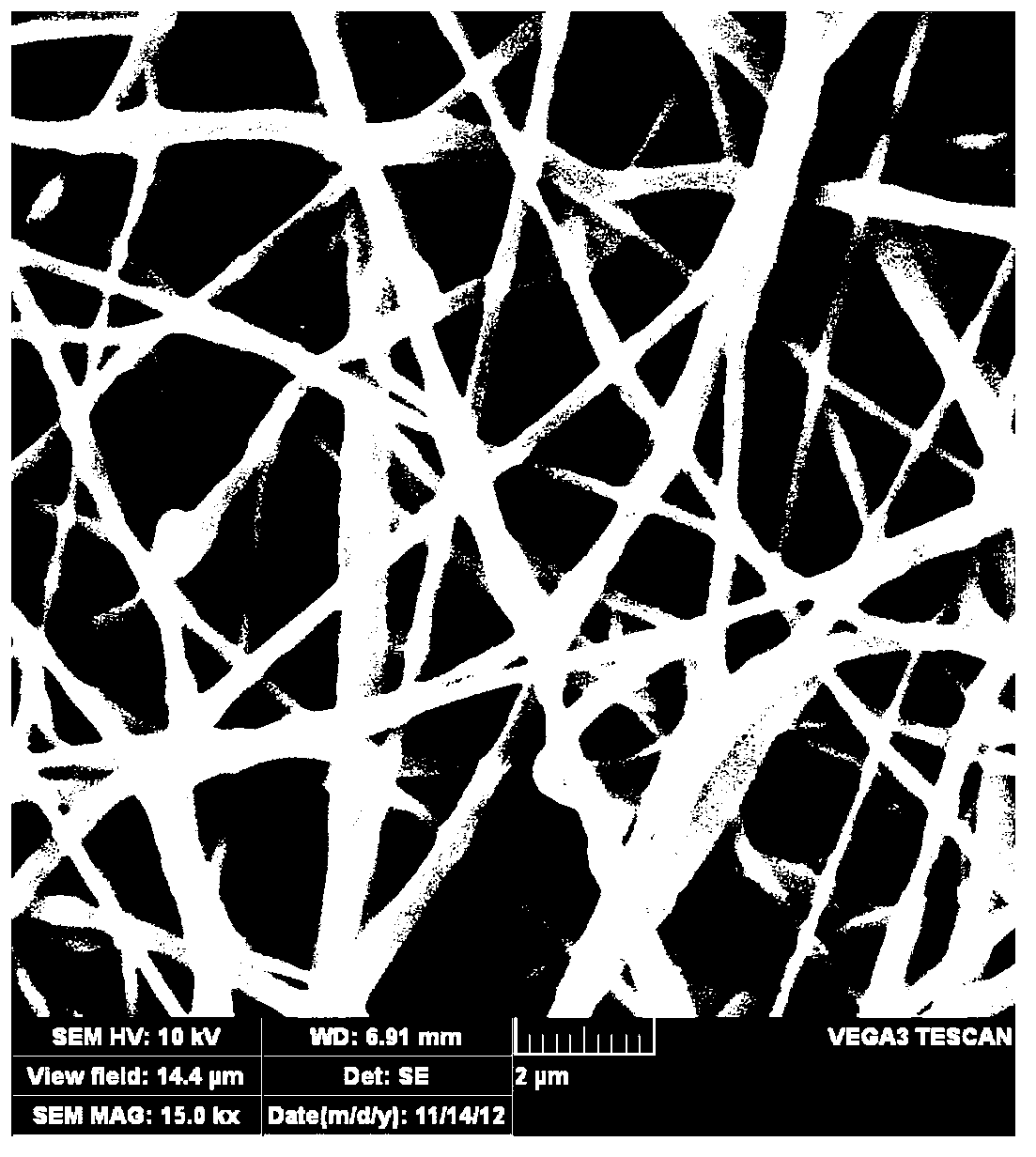

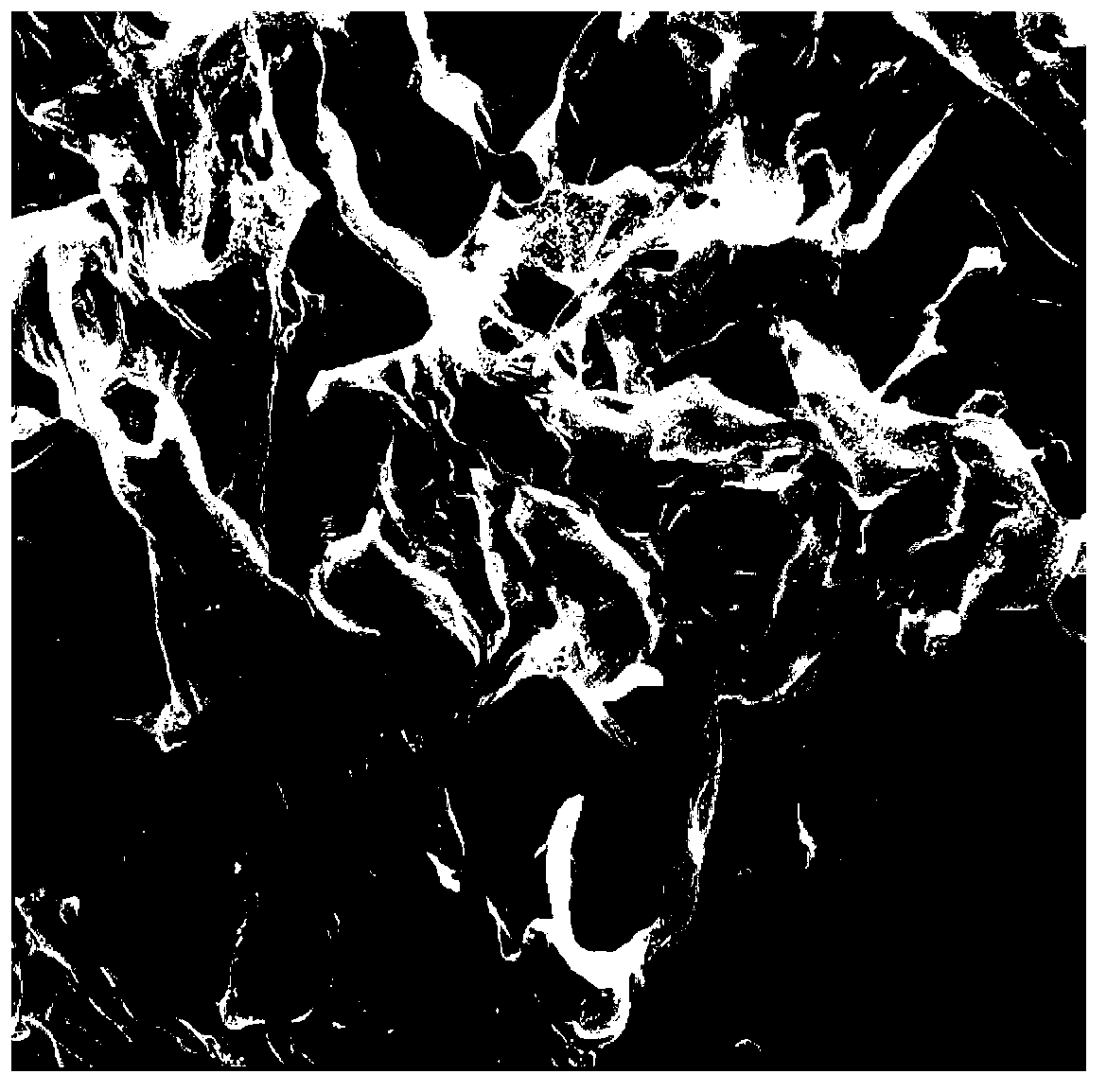

Bionic three-dimensional tissue engineering scaffold and preparation method thereof

InactiveCN103006359APromote proliferationImprove regenerative functionStentsProsthesisDirected differentiationComposite scaffold

The invention discloses a bionic three-dimensional tissue engineering scaffold, which is formed by high molecular fibrous membrane-loaded active growth factors, or active growth factors loaded on a composite scaffold formed by a high molecular fibrous membrane and a macropore spongy layer. With the adoption of the bionic three-dimensional tissue engineering scaffold, the problem that the concentration of active molecules loaded with an emulsion electricity texture fibrous membrane is low; the emulsion electricity texture fibrous membrane is combined with a macropore spongy or a mixed electricity texture process, so that the load rate of the active factors can be greatly improved; parts of factors are retained in the fiber through an emulsion electricity texture core-shell structure, so that the effective control of releasing time is realized, and a repairing process is monitored for a long time; and the introduction of active molecules in the scaffold plays guiding and promoting functions for proliferating regenerative cells, directionally differentiating, migrating and adhering cells, and capturing stem cells to introduce regenerative functions of newly born tissues, so that a new path is provided for development of regenerative medicine industries.

Owner:江西欧芮槿生物科技有限公司 +1

Method for using modified soy protein tackiness agent to prepare bamboo fiberboard

InactiveCN101186047AWide variety of sourcesEasily biodegradableDomestic articlesFlat articlesFiberQuality level

The invention discloses a bamboo fiberboard manufacturing method adopting a modified soy protein bond. The method includes the following steps: 1) glue mixing: 1 part of polyoxypropylene glycerin ether is added to 88 parts of modified reagent solution, and then 10 parts of soy proteins are added; then the solution is stirred for 2 to 3 hours; then 1 part of potassium sorbate is added as antiseptic and the solution is evenly stirred; 2) gluing: the bamboo fibers and the modified soy proteins are evenly mixed; 3) hot-pressing: a water-content of the acquisition of the step 2) is regulated to 24 to 27 percent to get a plate blank; then the plate blank is hot-pressed for shaping so as to get the bamboo fiber board. The adoption of the method of the invention can realize non-formaldehyde production, thus enhancing the quality level of fiberboard products.

Owner:ZHEJIANG UNIV

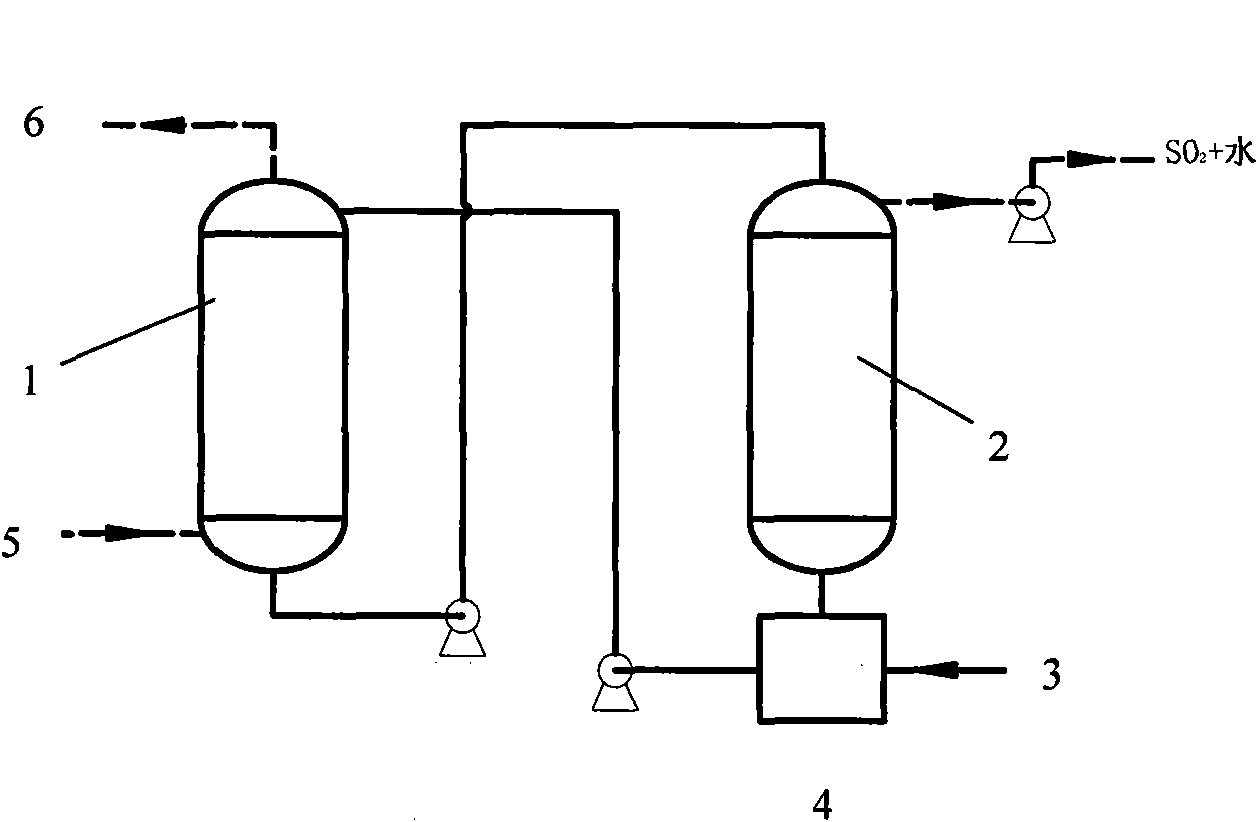

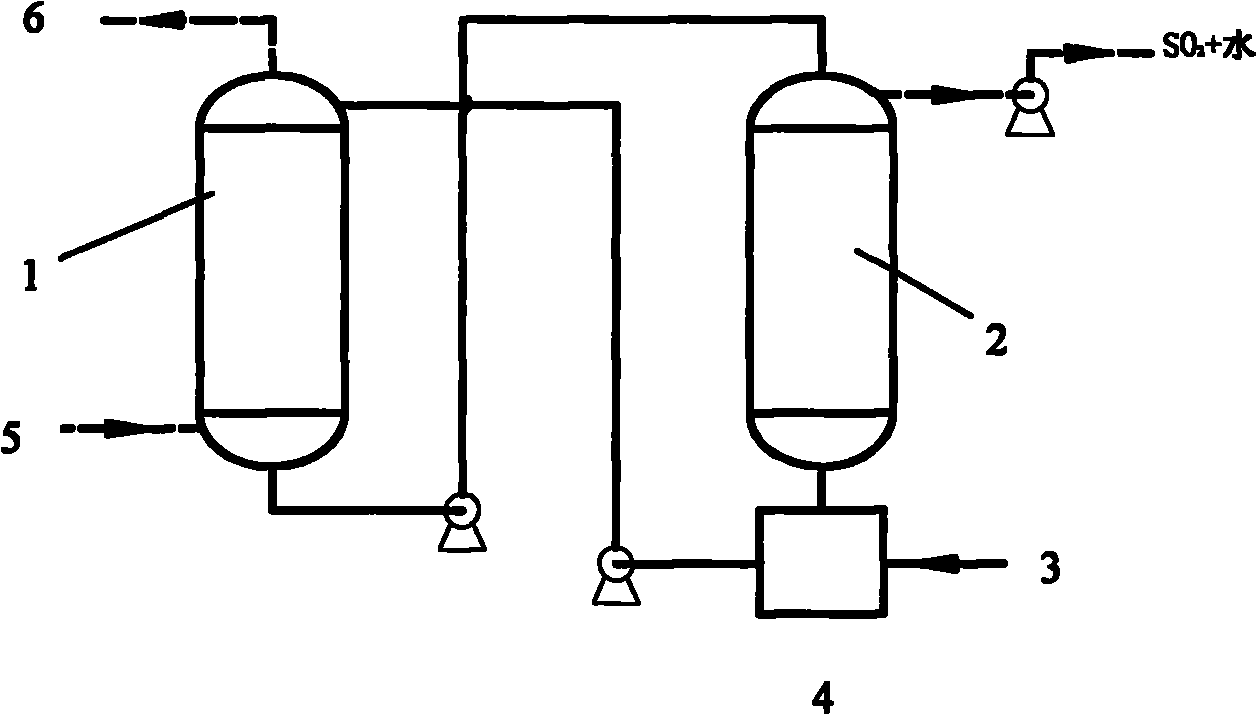

Flue gas desulfurization process

InactiveCN102068876AEasy to recycle and reuseRealize resourcesDispersed particle separationFlue gasTower

The invention provides a flue gas desulfurization process employing an ionic liquid. In the process, the ionic liquid is used as an absorbent, different types of absorption towers are adopted to absorb SO2 in the flue gas at the temperature of 0-200 DEG C under the pressure of 0.09-5.0 MPa, wherein gas-liquid countercurrent contact is adopted, various types of towers are adopted to improve a mass transfer effect so as to realize the emission of flue gas reaching the standard. The ionic liquid after absorbing the SO2 is pumped into a desorber through a pump and is subjected to deabsorption by adopting a heating and / or decompressing method, and SO2 is recovered. The desorbed ionic liquid enters the absorption towers to be reused. The process provided by the invention can be used for effectively removing the SO2 in the flue gas and recovering the SO2.

Owner:BEIJING UNIV OF CHEM TECH

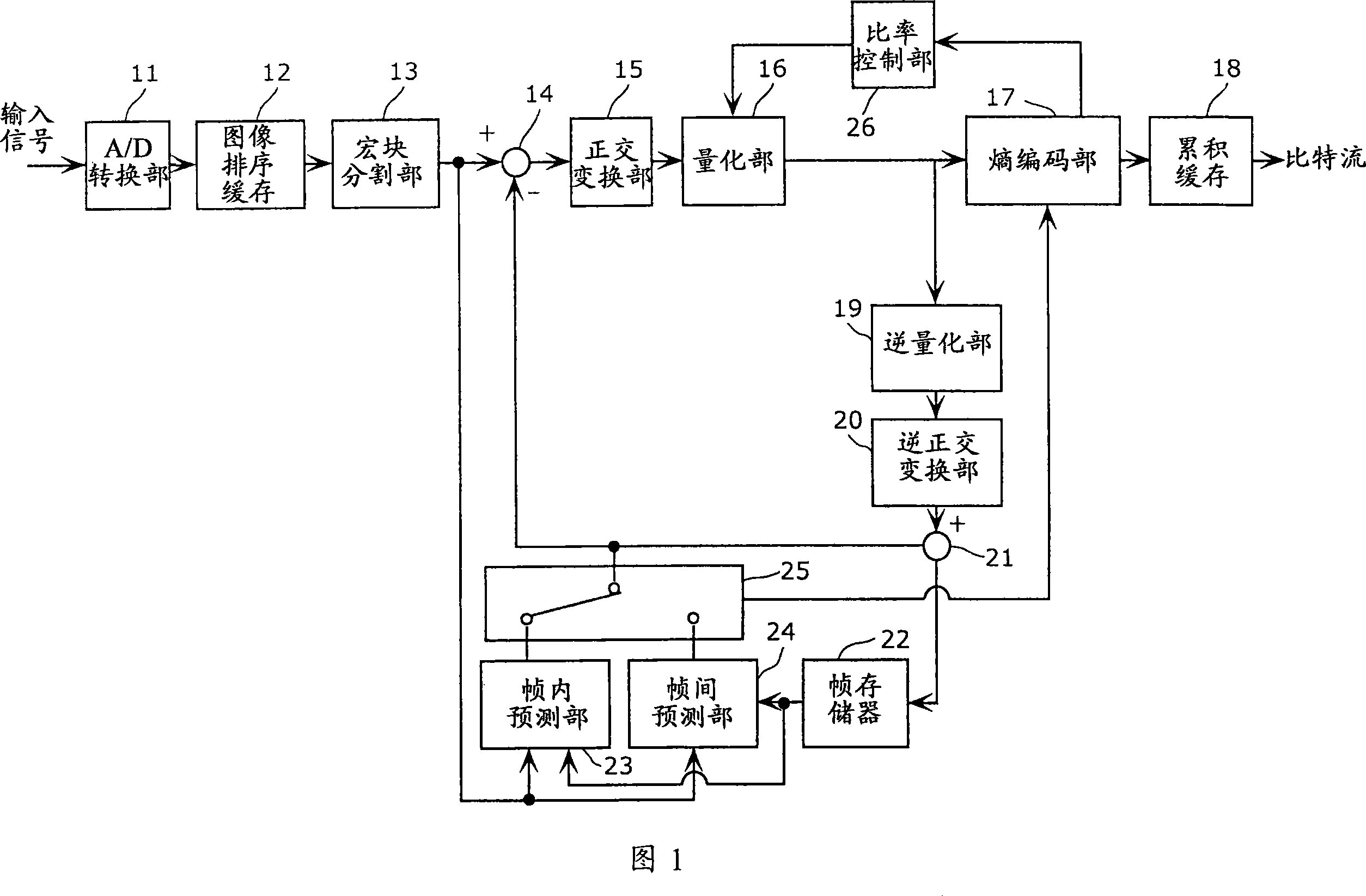

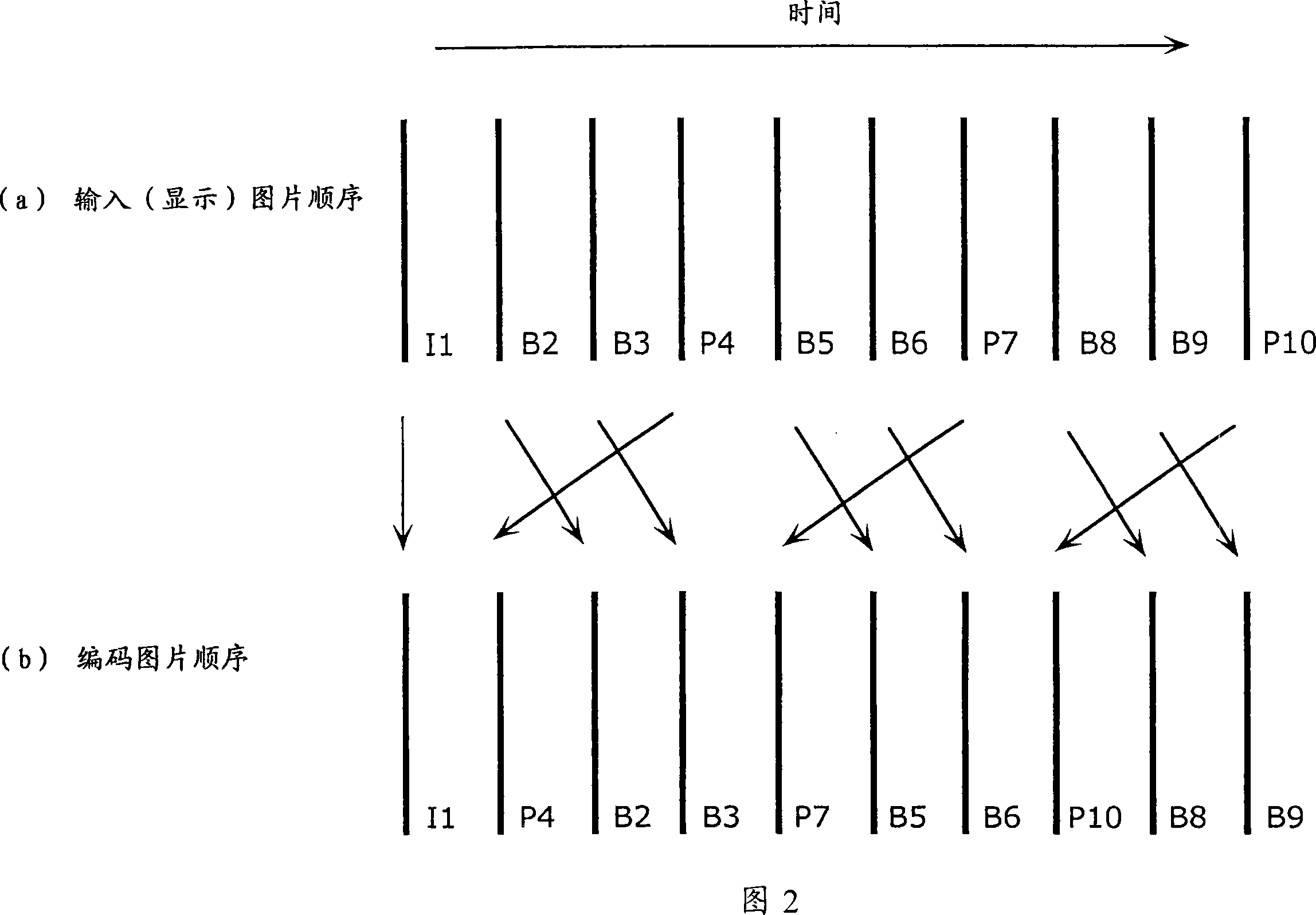

Image coding/recording apparatus and image coding/recording method

InactiveCN101087408AAddress processing load issuesSolve processingTelevision system detailsPulse modulation television signal transmissionComputer hardwareImage code

The invention provides an image coding / recording apparatus which can solve problems of large processing loads due to the real-time re-coding and problems of complicated controls and circuits for returning processing. The image coding / recording apparatus according to an aspect of the invention codes and records image data. The image coding / recording apparatus includes: a coding unit operable to code the image data; a recording unit operable to record the coded data; and a re-coding control unit operable to control said coding unit to re-code the coded data recorded by said recording unit and does not satisfy a predetermined condition, so that the re-coded data satisfies the predetermined condition, and control said recording unit to record the re-coded data, so that the re-coded data and non-re-coded data are reproduced consecutively.

Owner:PANASONIC CORP

Tissue engineering bracket material capable of physically embedding active substances and preparation method thereof

The invention relates to a tissue engineering bracket material capable of physically embedding active substances and a preparation method thereof. The tissue engineering bracket material capable of physically embedding the active substances is prepared from 100 weight parts of biodegradable macromolecular substance and 0 to 20 weight parts of active substances, wherein the weight part of the active substances is not equal to zero; 100 weight parts of biodegradable macromolecular substance consists of 50 to 100 weight parts of synthetic macromolecular substance and 0 to 50 weight parts of natural macromolecular substance; the macromolecular substances and the active substances form a micromolecular nanofiber membrane or a composite macromolecular nanofiber membrane; and the active substances are bonded on the surface of the fiber membrane uniformly. The tissue engineering bracket material capable of physically embedding the active substances has high biocompatibility and sufficient mechanical strength, can be biodegraded, is suitable for proliferation and directed differentiation of stem cells, and has the functions of promoting cell migration adhesion and capturing the stem cells so as to induce regeneration of tissues such as bones, cartilages, nerves, skin and the like.

Owner:汪泱

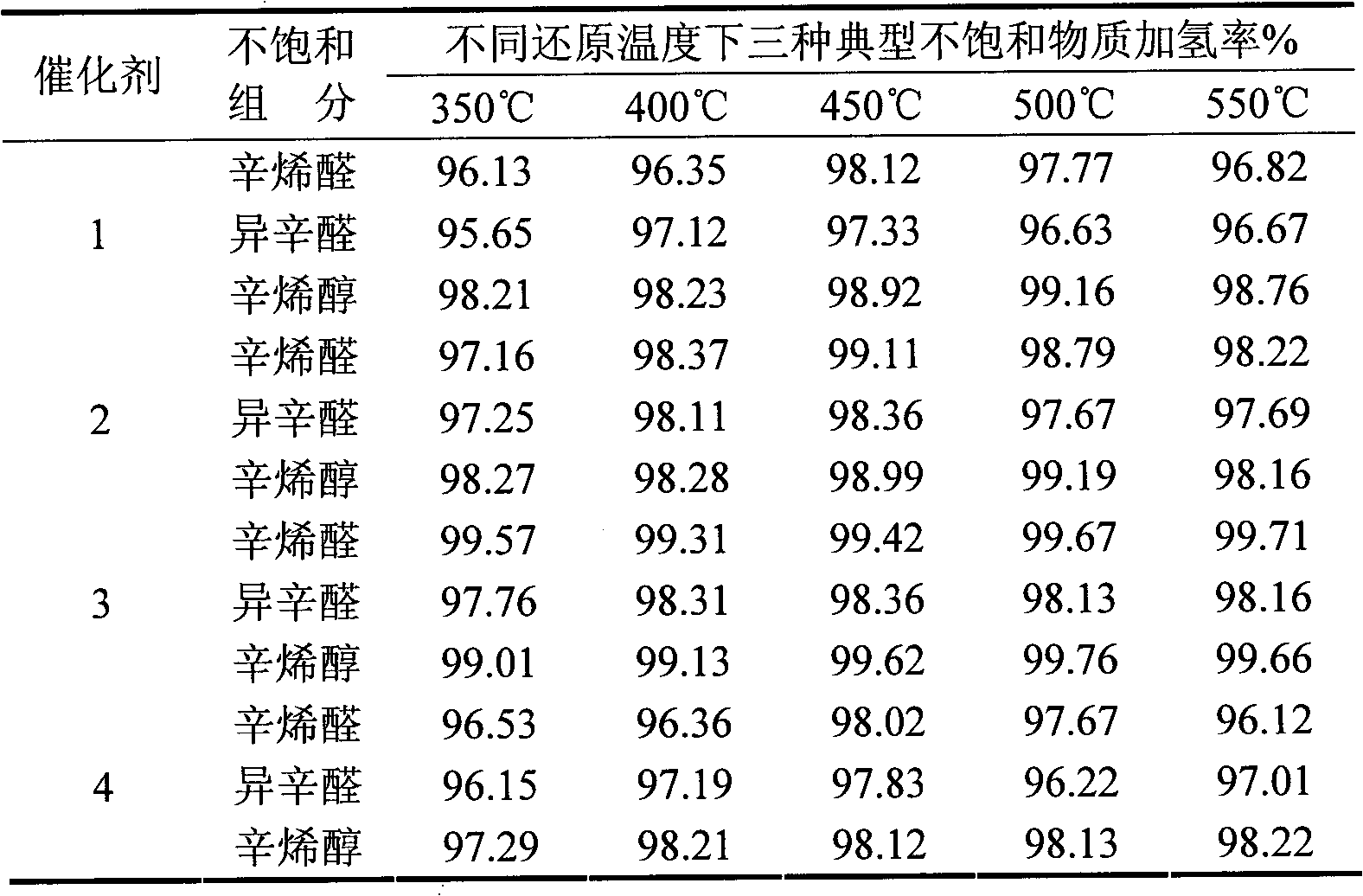

Lanthanum-modified nickel-copper octanol hydrorefining catalyst, preparation and application thereof

ActiveCN102059121AReduce generationReduce coalescenceOrganic compound preparationHydroxy compound preparationReaction temperatureOctanol

The invention relates to a lanthanum-modified nickel-copper octanol hydrorefining catalyst, preparation and application thereof. The catalyst is prepared by taking Gamma-Al2O3 as a carrier, taking lanthanum as an auxiliary agent, taking nickel-copper as a active component and adopting an immersion method; and the aluminum oxide accounts for 40-90%in the terms of 100% by mass, the content of nickel is 1-40% in the terms of NiO, the content of copper is 1-30% in the terms of CuO, and the lanthanum as the auxiliary agent is 0.1-10% in the terms of La2O3; and a hydrogenation evaluation result indicates that the catalyst is reduced at a temperature of 350-550 DEG C, and under the conditions that the reaction temperature is 120 DEG C, the reaction pressure is 2.5MPa, the volume ratio of hydrogen to liquid is 8:1 and the volume air speed is 3.0h<-1>, the hydrogenation rates of unsaturated substances such as octylene aldehyde, isooctyl aldehyde and octylene alcohol are all more than 95%.

Owner:PETROCHINA CO LTD +1

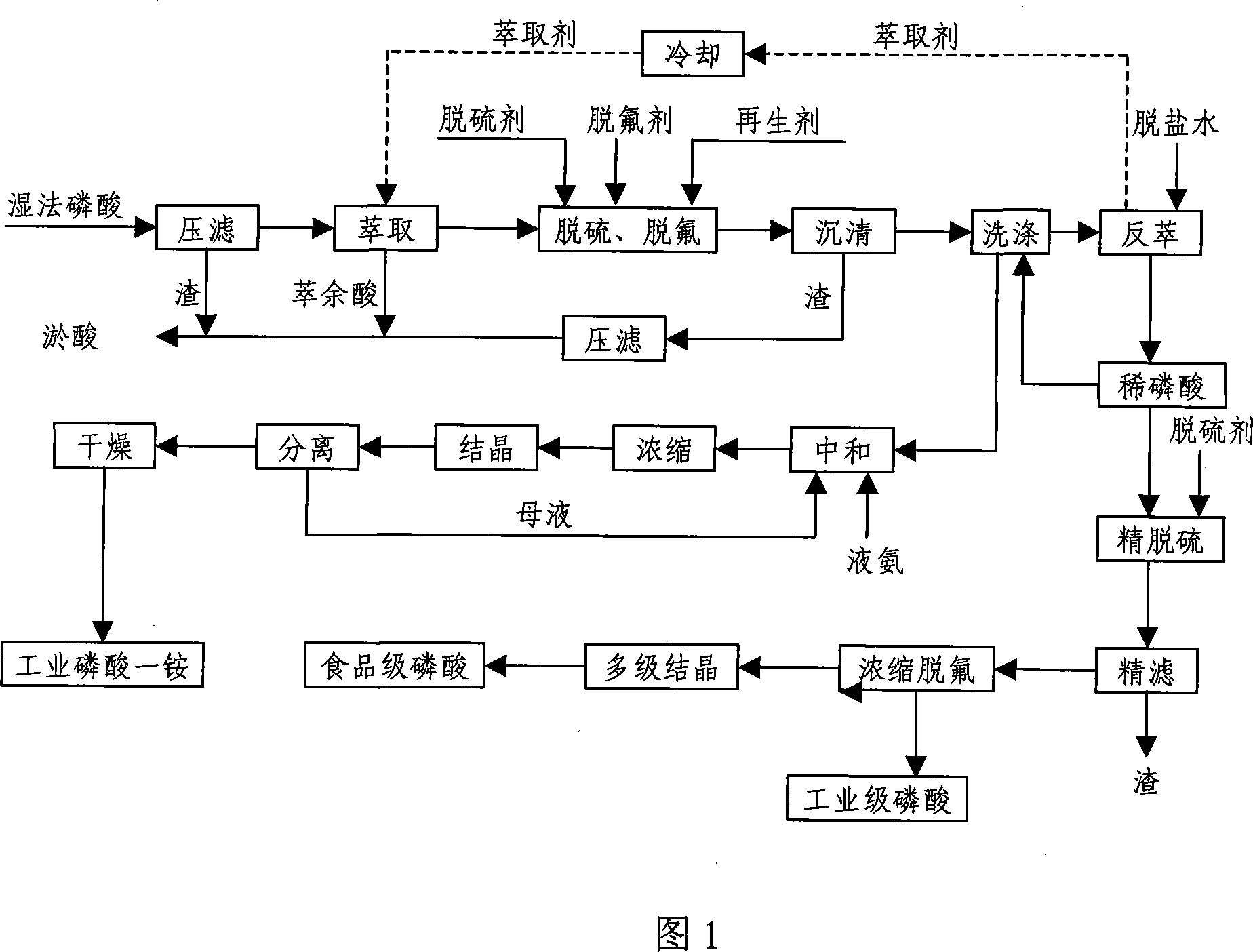

Method for producing technical grade ribose phosphate, food grade ribose phosphate and industry ammonium diacid phosphate using wet-process ribose phosphate

The invention discloses a method of using wet phosphoric acid to prepare industrial grade phosphoric acid, food grade phosphoric acid and industrial ammonium diacid phosphate, which is characterized in using wet phosphoric acid as the material, and preparing industrial grade phosphoric acid and food grade phosphoric acid respectively by using a series of compound purifying technologies such as chemical sedimentation and extracting by organic solvent and concentration and recrystallization and other technologies; meanwhile, the invention uses a part of purified diluted phosphoric acid to prepare industrial ammonium diacid phosphate. The invention has the advantages of reasonable cascade utilization of the wet phosphoric acid, high additional value of phosphorus, and further exploitation of the lower industrial and food grades phosphate.

Owner:中化重庆涪陵化工有限公司

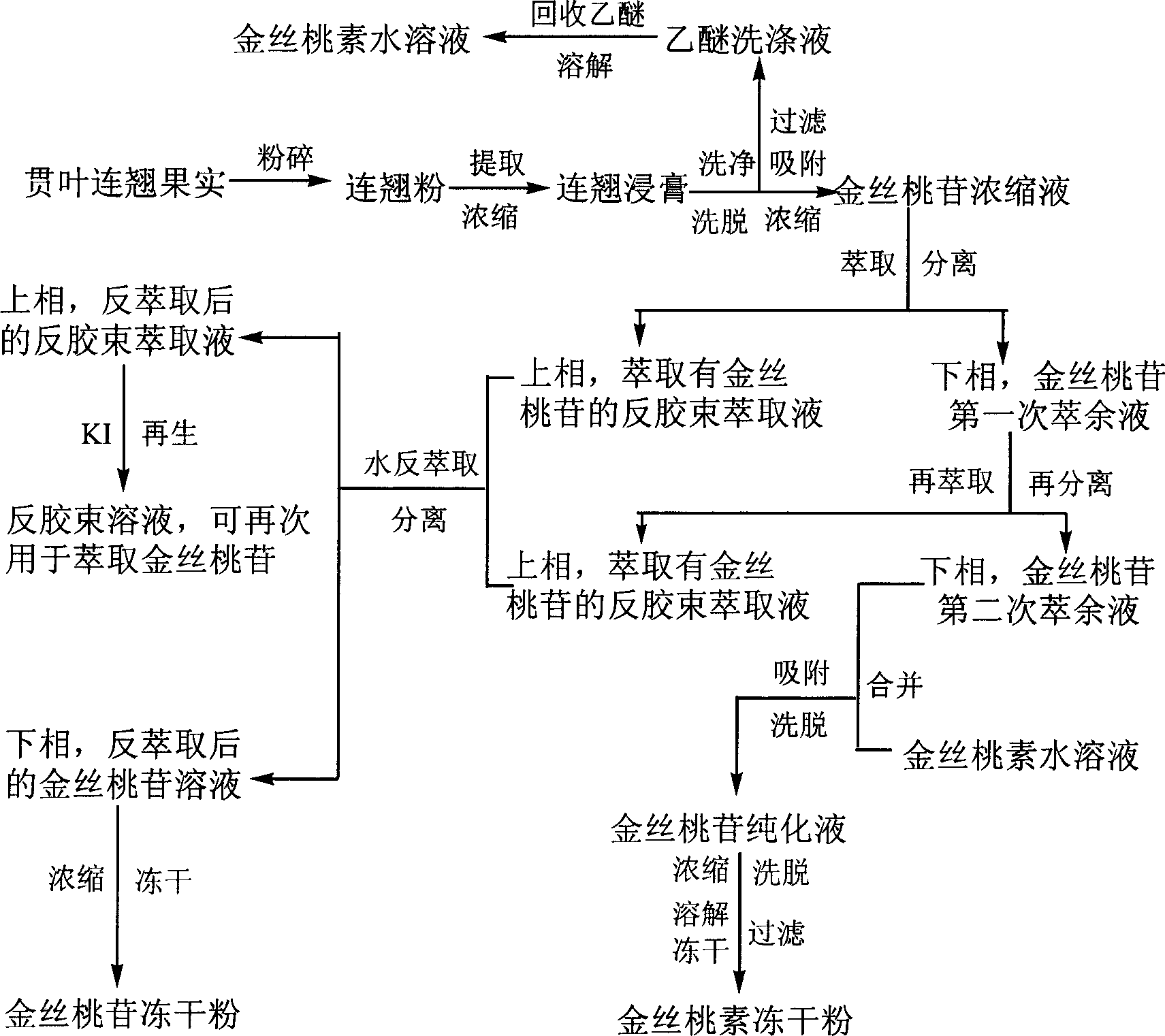

Preparation method of hyperin and hypericin of Hypericum perforatum

InactiveCN1880328AHigh yieldReduce manufacturing costOrganic active ingredientsSenses disorderHypericum perforatumHyperoside

This invention relates to a method for producing Hypericum perforatum hyperoside and hypericin. This invention comprehensively utilizes Hypericum perforatum fruits which are rich in our country to produce both hyperoside and hypericin pharmaceutical active components with high recovery rate, high product purity, and low cost. During the producing process, it achieves the recovery and cycling use of many solvents like ethanol and ethyl ether, and also achieves the regeneration and cycling use of micelle reextracting agent and absorption resin. The plant biological active compounds produced by this invention can be broadly used in heat-clearing and detoxifying, astringing to arrest bleeding and promote diuresis, and antidepressant drug.

Owner:CHONGQING UNIV

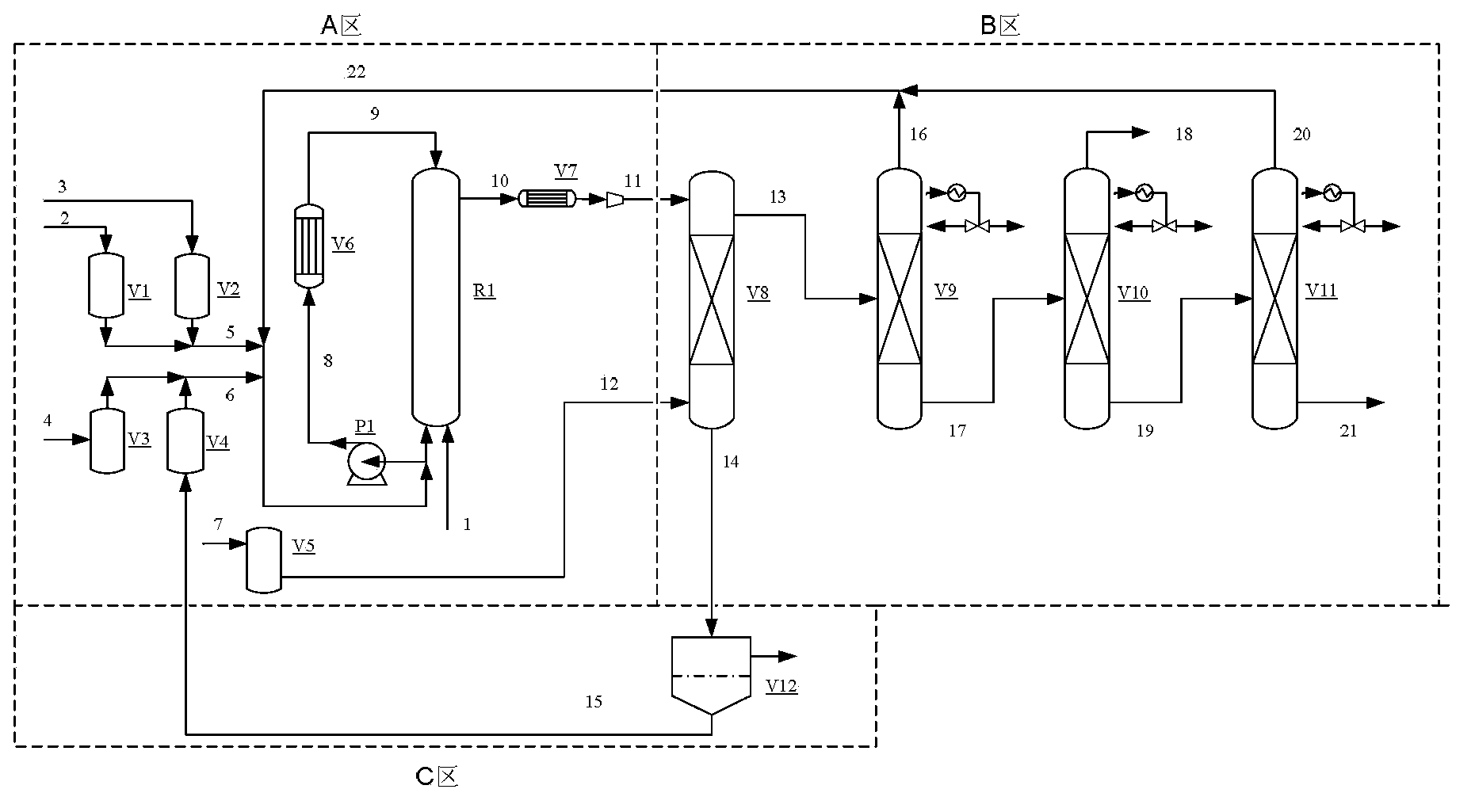

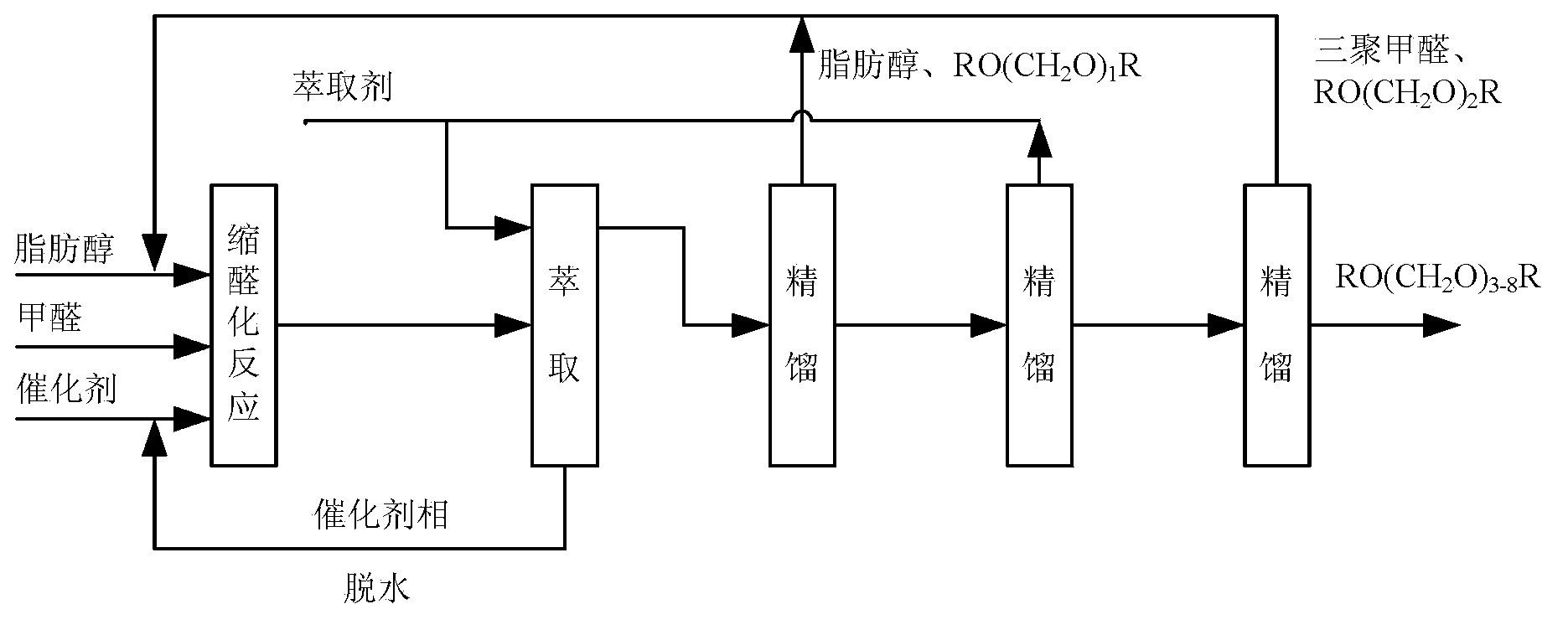

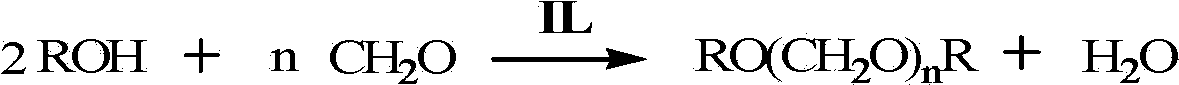

Reaction system for continuously preparing polyoxymethylene dialkyl ether, and process thereof

InactiveCN103772164AAchieve separationAchieve regenerationOrganic compound preparationChemical/physical/physico-chemical processesProcess equipmentAlcohol

The invention discloses a process apparatus system for preparing polyoxymethylene dialkyl ether (RO(CH2O)nR, n=1-8) through a continuous acetalation reaction of formaldehyde and fatty alcohol under the catalysis of an acidic ionic liquid, and a process thereof. A process apparatus used in the method comprises an acetalation reaction unit, a product separation unit and a catalyst regeneration unit. The adoption of the extraction and rectification combined separation mode in the invention effectively realizes the separation of circulating materials and the above catalyst and makes the recovery rate of the catalyst reach above 99%; the separation of byproduct water from the reaction system is realized, and the azeotropy of water, alcohol, aldehyde and RO(CH2O)nR is destroyed, so the product separation is simple; and a catalyst regeneration technology is simple, so catalytic cycle is realized.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

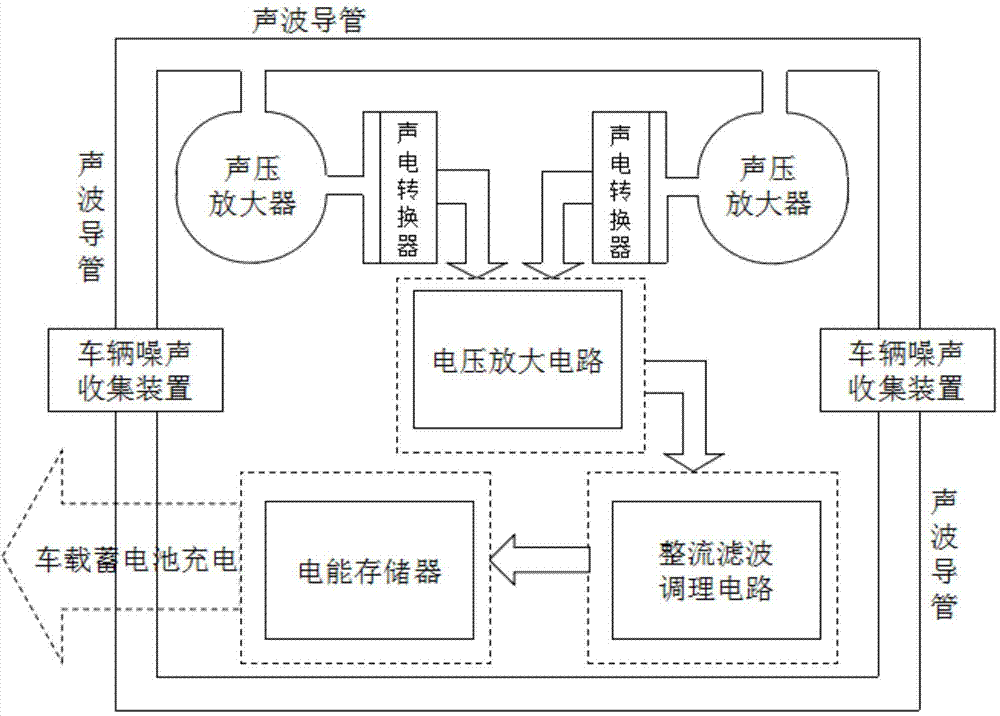

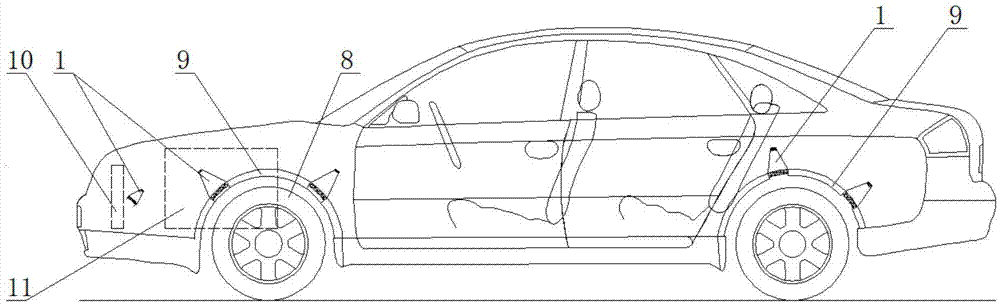

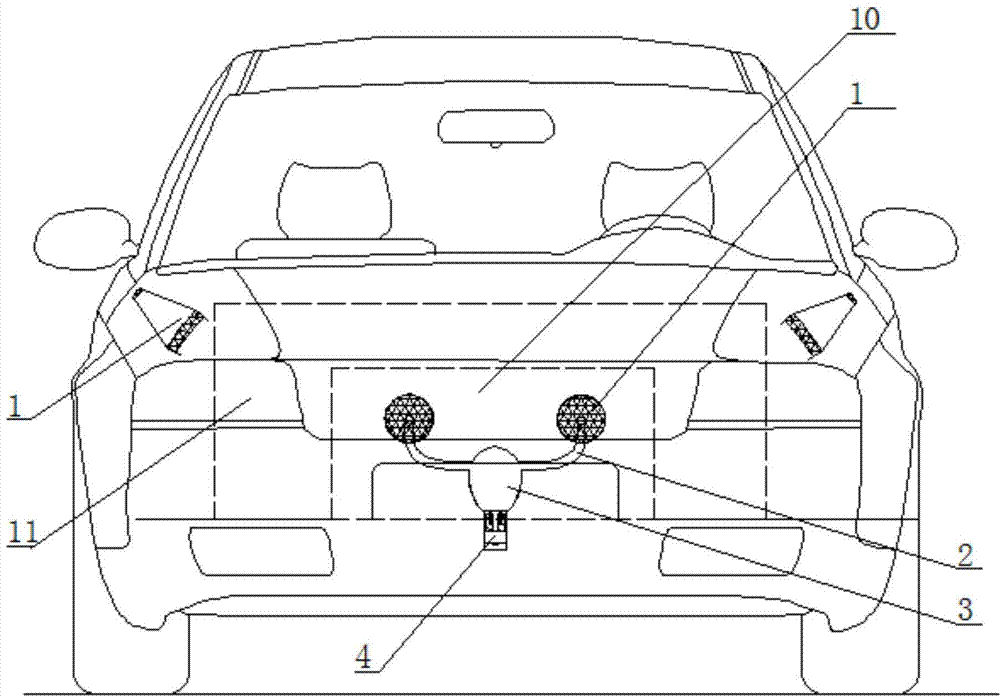

Automobile-mounted noise generating set

ActiveCN103501041AAchieve recyclingHigh feasibilityBatteries circuit arrangementsElectric powerElectricityPower flow

The invention provides an automobile-mounted noise generating set. The automobile-mounted noise generating set comprises an automobile-mounted noise collecting unit, a sound-electricity conversion unit and an electric energy storing unit, wherein different arrangement ways and collecting devices are adopted according to the noise and structural characteristics of different positions of the automobile. The main structure of the set comprises a noise collector and a sound wave conduit in the automobile noise collecting unit, a sound pressure amplifier and a sound-electricity converter in the sound-electricity conversion unit, and a current conditioning circuit, an electric energy storage and an automobile-mounted storage battery in the electric energy storing unit. According to the automobile-mounted noise generating set, the aim of converting the noise energy of the automobile into usable electric energy is fulfilled on the premise of not influencing the normal running performance of the automobile, and waste energy is recycled. The automobile-mounted noise generating set further has the advantages of high power generation efficiency, simple structure, convenience in installing, high practicability, small occupied size, high reliability and the like.

Owner:WUHAN UNIV OF TECH

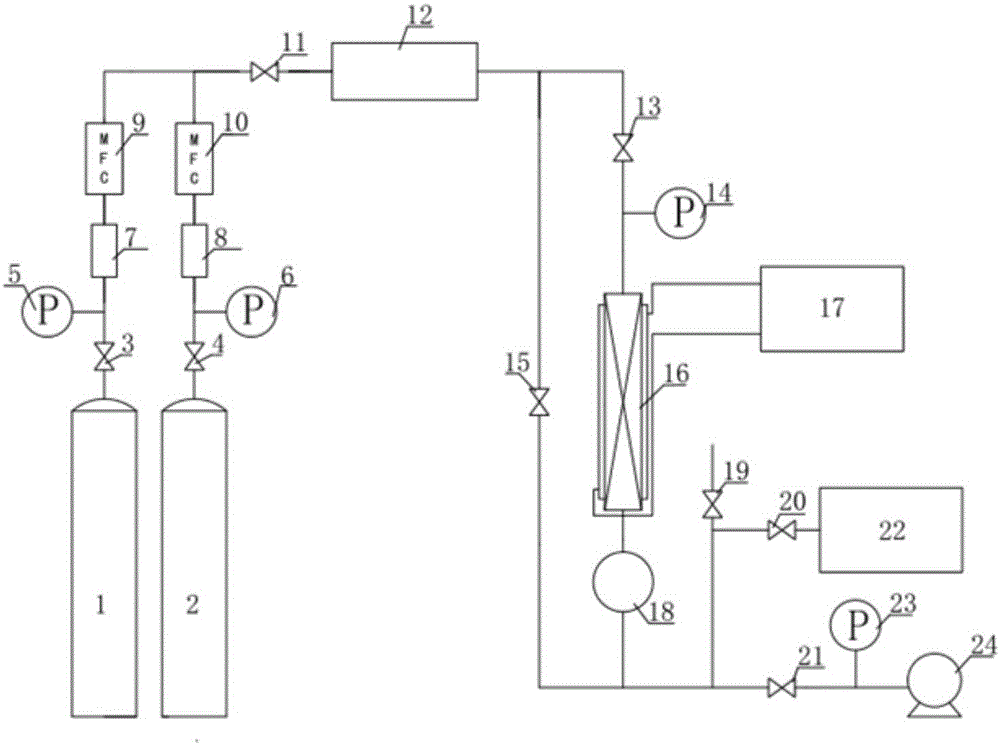

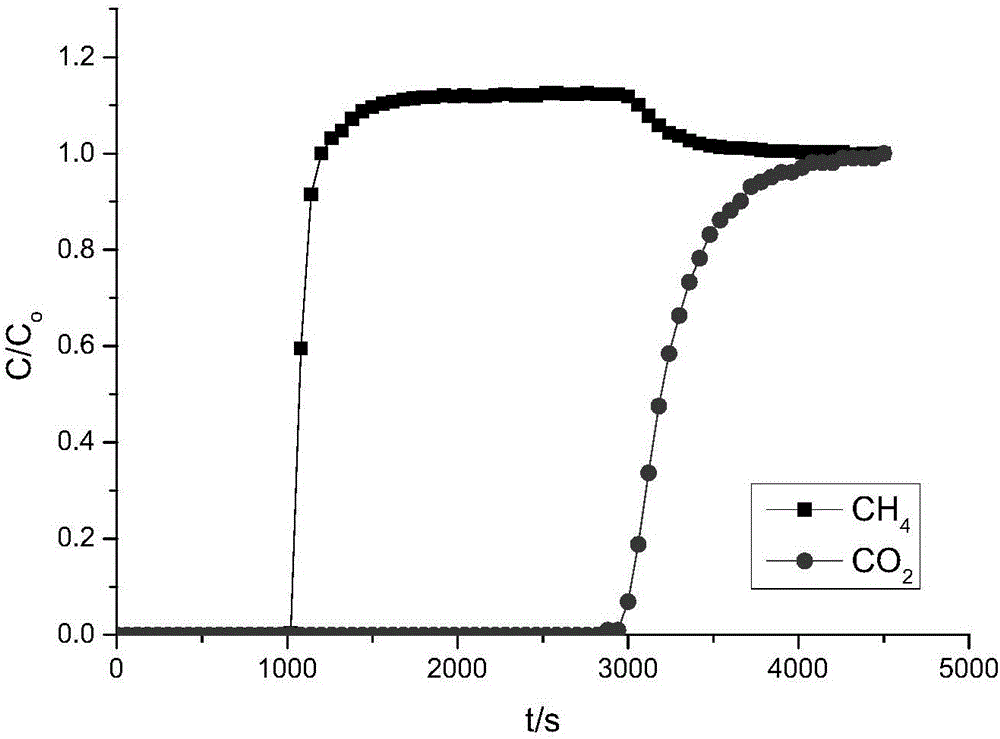

Apparatus of purifying CO2 in natural gas through low-temperature pressure swing adsorption (PSA) technology and method thereof

ActiveCN105132060ALarge adsorption capacityConducive to separationGaseous fuelsDispersed particle separationChemistryLiquefied natural gas

The invention belongs to the technical field of gas separation and purification and provides an apparatus of purifying CO2 in natural gas through a low-temperature pressure swing adsorption (PSA) technology and a method thereof. In the invention, by means of cooling capacity generated in liquefaction of natural gas, a low-temperature environment is formed to control the temperature within the range of -70 - 25 DEG C, and meanwhile, through change of pressure within the range of 0-10 MPa, an absorption process of CO2 at a low temperature with the solid absorbent is achieved. By means of increase of the temperature and reduction of the pressure of the low-temperature PSA natural gas purifying system, the CO2 in the solid absorbent is desorbed, thereby regenerating the absorbent and finally achieving the object of continuously purifying the natural gas and regenerating the absorbent. The solid absorbent can be regenerated through increase of temperature and change of pressure, thereby recycling the solid absorbent and further reducing the use of the absorbent. The apparatus is simple and available in operation process. The process can complete purification of natural gas and achieve adsorption, enrichment and capture of CO2, and also has significant practical significance in environment protection.

Owner:DALIAN UNIV OF TECH

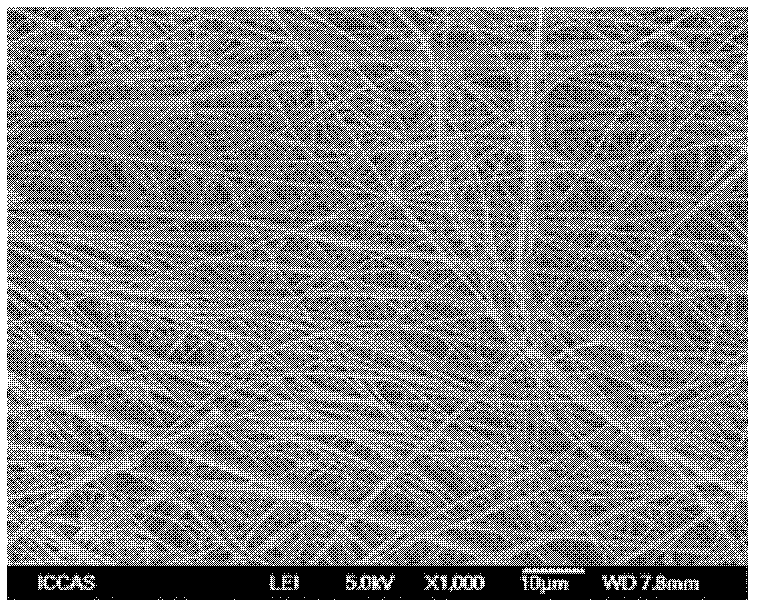

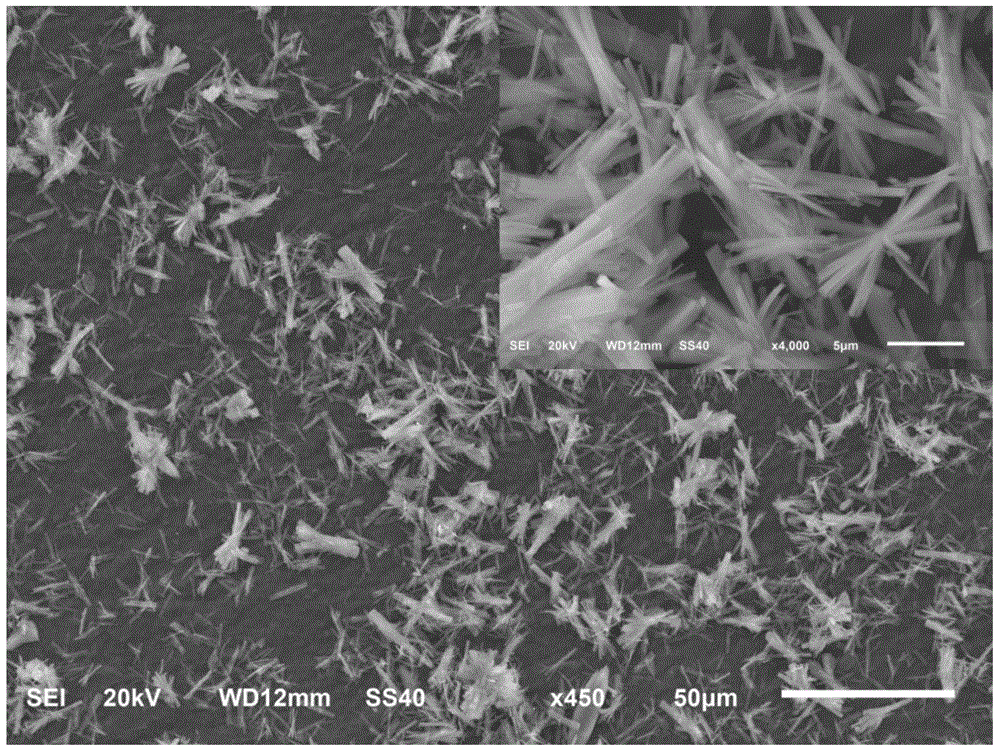

S-1 full-silicon molecular sieve and preparation method thereof as well as application of S-1 full-silicon molecular sieve in caprolactam preparation

The invention discloses an S-1 full-silicon molecular sieve and a preparation method thereof as well as application of the S-1 full-silicon molecular sieve in caprolactam preparation. The S-1 full-silicon molecular sieve is prepared by the method comprising the following steps: (1) synthesizing a tetrapropylammonium hydroxide template agent; and (2) synthesizing a molecular sieve: carrying out a reaction on tetrapropylammonium hydroxide liquor and tetraethoxysilane and ethanol, filtering, washing with deionized water, drying reaction liquid, roasting, so as to obtain molecular sieve raw powder; adding silica sol, polyethylene glycol 2000, and stronger ammonia water, sesbania powder and activated carbon powder in the molecular sieve raw powder, kneading in a kneader, then carrying out extrusion; roasting, immersing the roasted product in a NH3-NH3NO3 mixing solution and a hydrofluoric acid solution respectively, washing with deionized water, drying, roasting again so as to obtain the S-1 full-silicon molecular sieve. In the invention, the template agent is cheap; the conversion rate of the cyclohexanone and selectivity of the caprolactam are extremely high; a catalyst can be easily and fast regenerated; and the use of concentrated sulphuric acid is avoided, thus the S-1 full-silicon molecular sieve and the preparation method thereof are environment-friendly.

Owner:CHINA TIANCHEN ENG +1

Gasoline desulfurization method

InactiveCN104673376ARealize deep desulfurizationLow component contentTreatment with hydrotreatment processesGasolineRaw material

The invention provides a gasoline desulfurization method. The gasoline desulfurization comprises the following steps: cutting a gasoline raw material into a light gasoline fraction and a heavy gasoline fraction; performing adsorption desulfurization on the light gasoline fraction to obtain desulfurized light gasoline fraction; and performing selective hydrogenation desulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction, wherein the cutting temperature of the light gasoline fraction and the heavy gasoline fraction is 70-110 DEG C. By adopting the gasoline desulfurization method, not only can deep desulfurization of gasoline be realized, but also the octane loss is low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

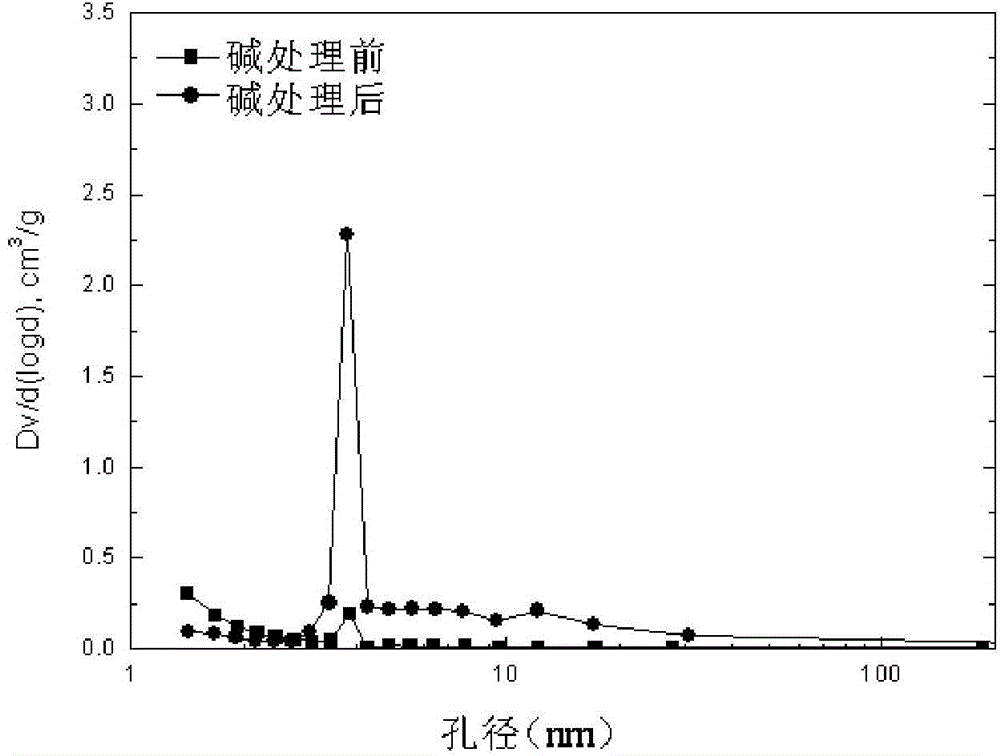

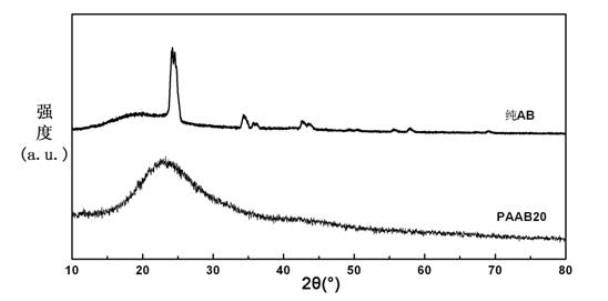

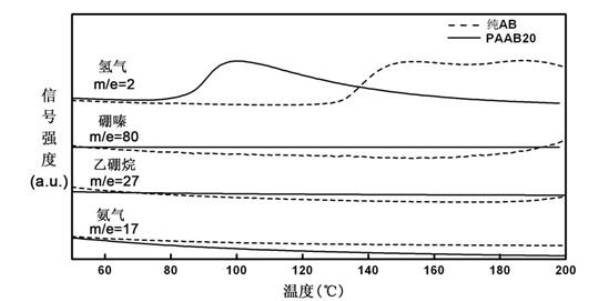

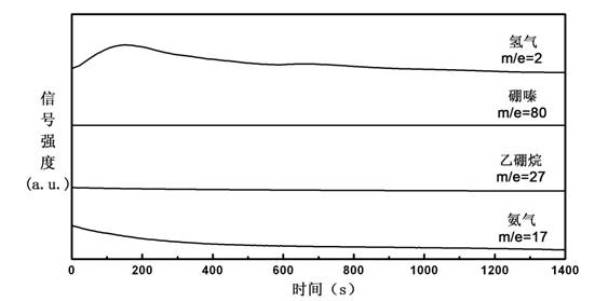

Organic matter and ammonia borane compounded hydrogen storage material and preparation method thereof

ActiveCN102030313ALowering the temperature of thermally liberated hydrogenInhibitionMonoborane/diborane hydridesPolyethylene oxideSolvent

The invention relates to an organic matter and ammonia borane compounded hydrogen storage material. The hydrogen storage material is prepared by compounding the organic matter and the ammonia borane, wherein the organic matter is phthalic anhydride, polyethylene oxide, dextrose, mannitol or mannitol hexaacetic ester. The preparation method comprises the following steps: 1) adding the organic matter to the purified acetonitrile solvent, and stirring for dissolving; 2) dissolving the ammonia borane into the mixing solvent comprising acetonitrile and methanol, and stirring at the temperature of 20 to 70 DEG C to obtain a uniform solution; and 3) carrying out vacuum drying, and removing the solvent, thus obtaining the hydrogen storage material. The invention has the advantages that the ammonia borane and the organic matter are taken as raw materials to prepare the hydrogen storage material at the lower hydrogen discharge temperature; the thermal decomposition and hydrogen discharge temperature of the ammonia borane can be effectively reduced; the generation of harmful gas impurities of borazole, diborane, ammonia and the like is effectively inhibited; the hydrogen storage material has quicker hydrogen discharge kinetics; in addition, the heat discharge amount is less in the hydrogen discharge course; and the enthalpy change of a decomposition reaction approaches to thermal neutrality; and the hydrogen storage material is beneficial to realizing the regeneration of reaction products through a solid-gas reaction or a chemical process under the relatively mild condition.

Owner:NANKAI UNIV

Regeneration treatment method for waste cathode carbon blocks of aluminum electrolytic cell

The invention discloses a regeneration treatment method for waste cathode carbon blocks of an aluminum electrolytic cell and belongs to the technical field of solid waste treatment in the aluminum electrolysis industry. The main treatment process comprises the steps of crushing, screening, toxicity inhibition, batching and pressure-controlled heat treatment. After waste cathode carbon block materials of the aluminum electrolytic cell are crushed and screened, toxic inhibitors of hydrogen peroxide, potassium permanganate, hypochlorite and the like are added, then carbonaceous materials of anthracite, calcined petroleum coke, waste anode carbon blocks, anode scraps and the like are blended to serve as furnace-in raw materials, and the furnace-in raw materials are placed in a resistance furnace to be subjected to heat treatment at the ordinary pressure (1200-1800 DEG C) or the control pressure (1000-1600 DEG C and 0.01-0.5 atm). Fluoride volatilized from flue gas can be used for producingfluoride salt electrolytes after being cooled and crystallized, treated materials do not contain any contaminant, the carbon content is up to 99%, the conductivity is good, the specific surface areais large, the treated materials can be used for producing various carbon products, waste is turned into wealth, and environment-friendly resource application of overhaul of the waste cathode carbon blocks of the aluminum electrolytic cell is achieved.

Owner:UNIV OF SCI & TECH BEIJING

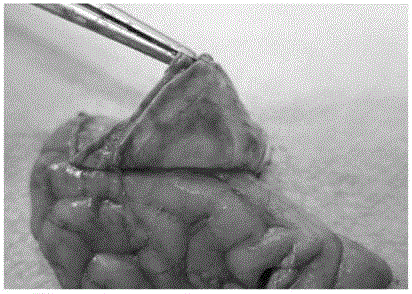

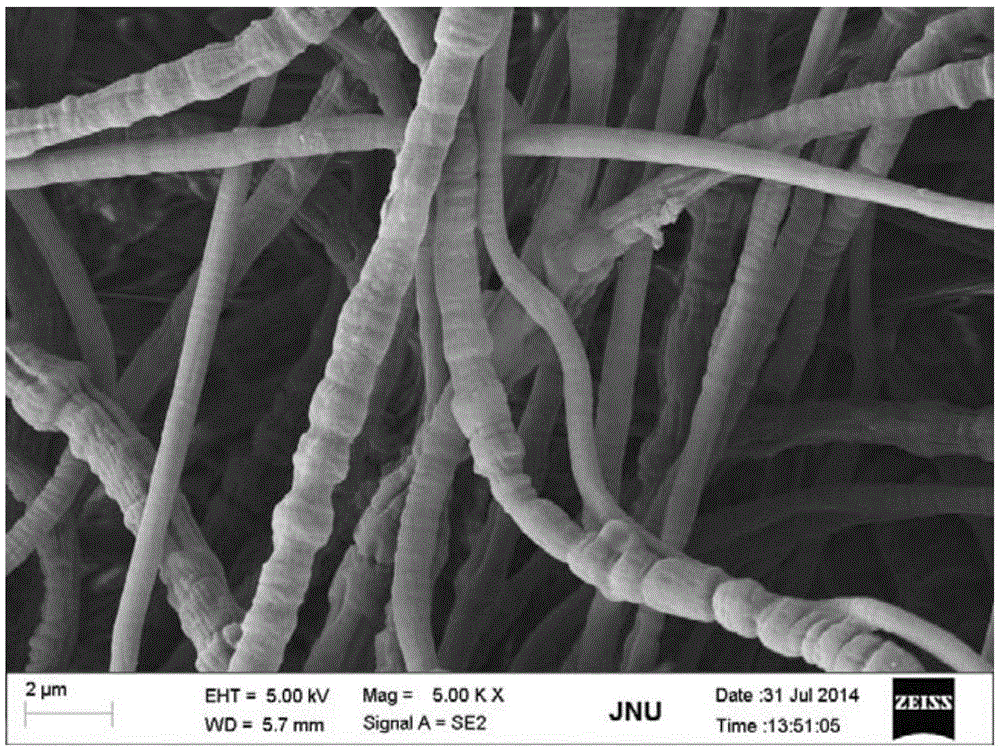

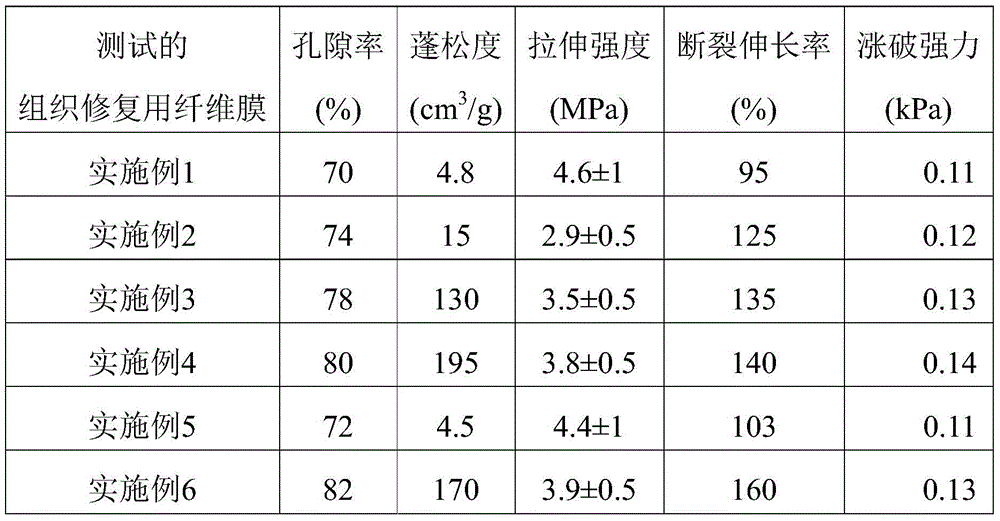

Tissue restoration fiber membrane, production method and application thereof, and tissue restoration product

ActiveCN106492272AHigh specific surface areaHigh porosityHeating/cooling textile fabricsTissue regenerationChemistryMembrane configuration

The invention relates to a tissue restoration fiber membrane, a production method and an application thereof, and a tissue restoration product. The tissue restoration fiber membrane is formed by interlacing fiber yarns with the diameter of 10 nm to 100 [mu]m, the fiber membrane has a pore structure formed by interlacing the fiber yarns, every fiber yarn is provided with an annular projection structure in a radial direction, and the bulkiness of the fiber membrane is not less than 2 cm<3> / g and less than 200 cm<3> / g. The invention also discloses the production method of the tissue restoration fiber membrane, the application of the tissue restoration fiber membrane in the production of the tissue restoration product, and the tissue restoration product produced by using the fiber membrane.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

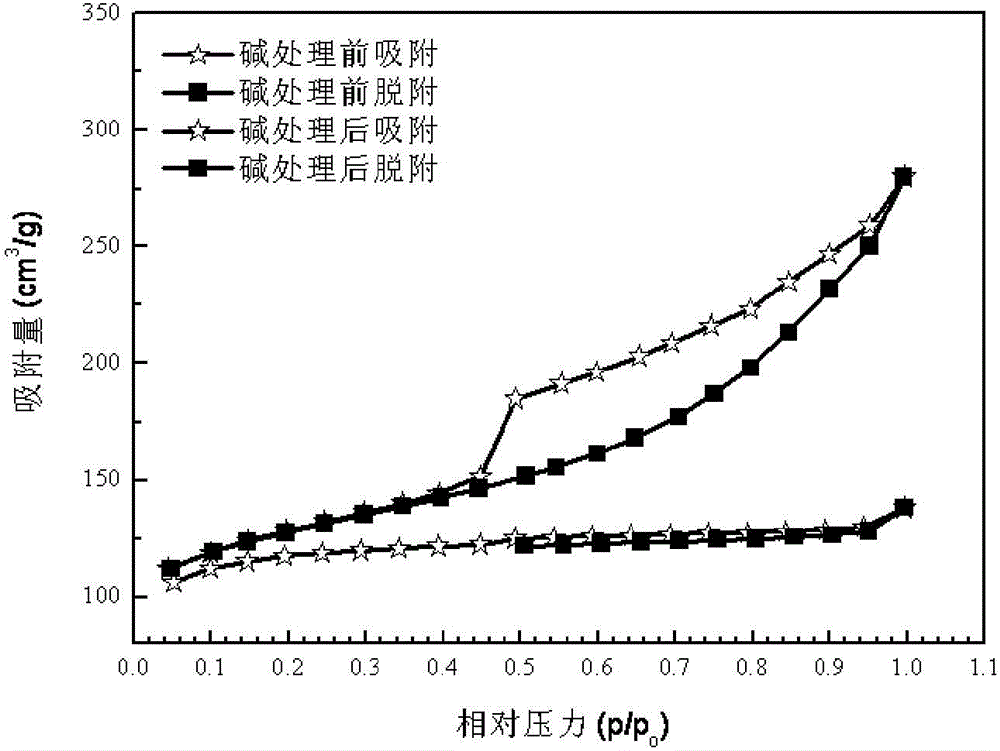

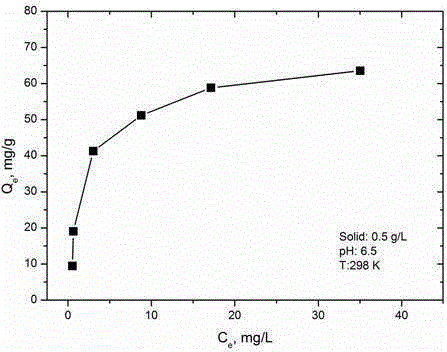

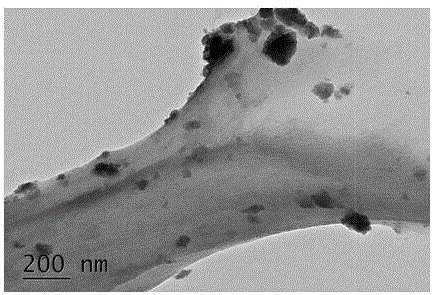

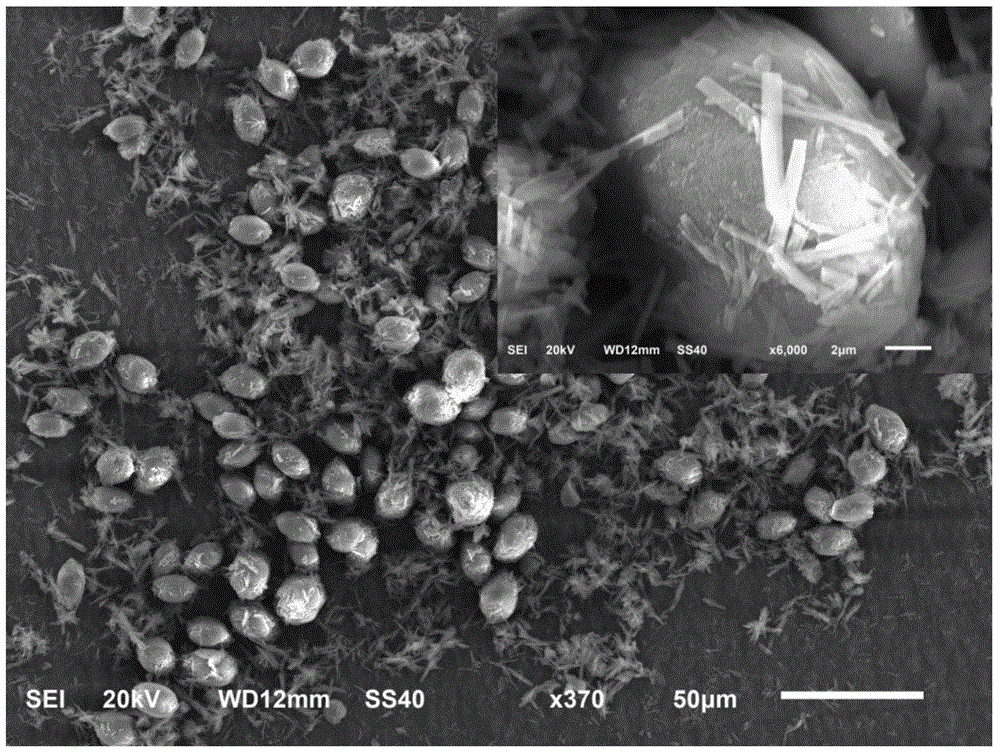

Biomass-based nanometer lanthanum oxide dephosphorization composite adsorbent and preparation method thereof

InactiveCN105214629ASynthesis process is simple and cleanLow costOther chemical processesWater/sewage treatment by sorptionRice strawBiomass

The invention discloses a biomass-based nanometer lanthanum oxide dephosphorization composite adsorbent and a preparation method thereof. According to the composite adsorbent, biomass anion exchange resin is taken as a matrix, and nanometer lanthanum oxide is loaded on the biomass anion exchange resin; the load of the nanometer lanthanum oxide is 0.5 to 22.6 percent by weight percentage of lanthanum; the biomass anion exchange resin is alkali quaternary ammonium group-contained biomass anion exchange resin, and is prepared by performing aminated modification on a biomass material by taking N,N-dimethylformamide as solvent, epichlorohydrin as an etherifying agent and trimethylamine or triethylamine or urea as an aminating agent; the biomass material is selected from maize straw, soybean straw, cassava straw, rice straw, wheat straw, bamboo reed, saw dust or a mixture thereof. The composite adsorbent disclosed by the invention is low in cost and high in adsorption capacity.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

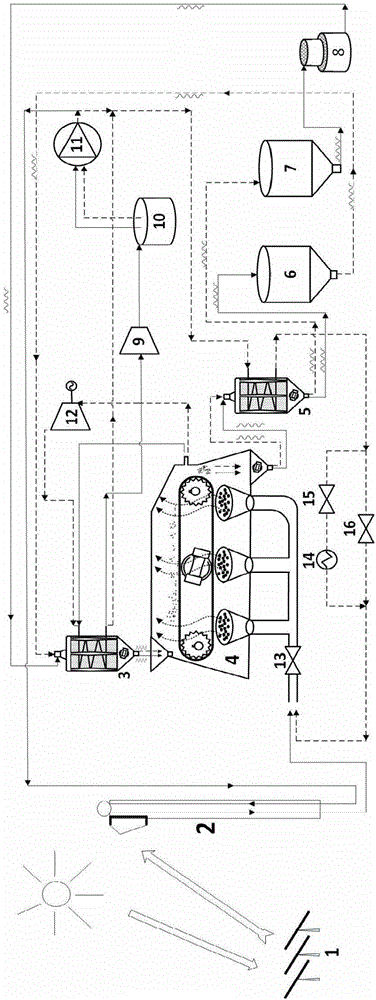

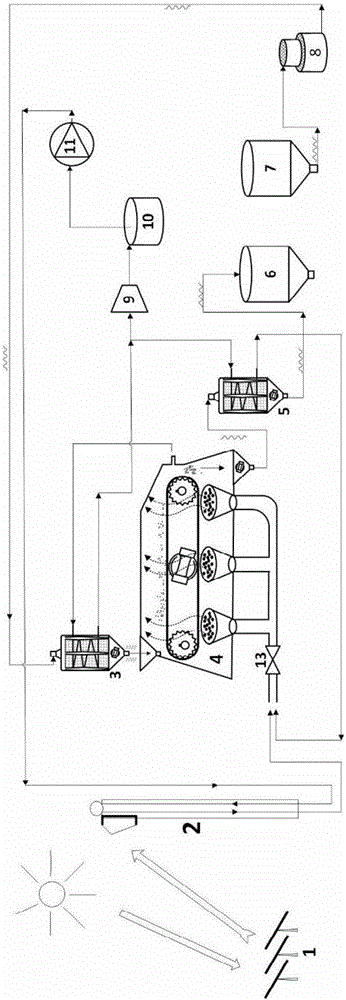

Medium-and-low temperature calcium cycling thermochemical energy storage device and method

ActiveCN106813402AAchieve regenerationAchieve continuous power supplySolar heating energySolar heat devicesThermal energyChemical reaction

The invention relates to a medium-and-low temperature calcium cycling thermochemical energy storage device and method. The device comprises a solar heat collection device, an energy storage system and a power generation system. According to the Ca(OH)2 / CaO thermochemical energy storage system, energy storage is conducted through interconversion between thermal energy and chemical energy, when solar irradiation is sufficient, Ca(OH)2 solid particles are subjected to an endothermic decomposition reaction under the action of high-temperature water vapor generated by solar energy, and received heat is stored in decomposition products, namely CaO and H2O, in a chemical energy form; when the heat is released, CaO and H2O are subjected to a backward thermochemical reaction at normal pressure, and the chemical energy stored in CaO and H2O are inversely converted into the thermal energy and released out. The device and method are high in energy storage density, high in cycle efficiency and environmentally friendly, the structure is simple, and flexible control and application under variable working conditions are achieved.

Owner:NANJING UNIV OF TECH

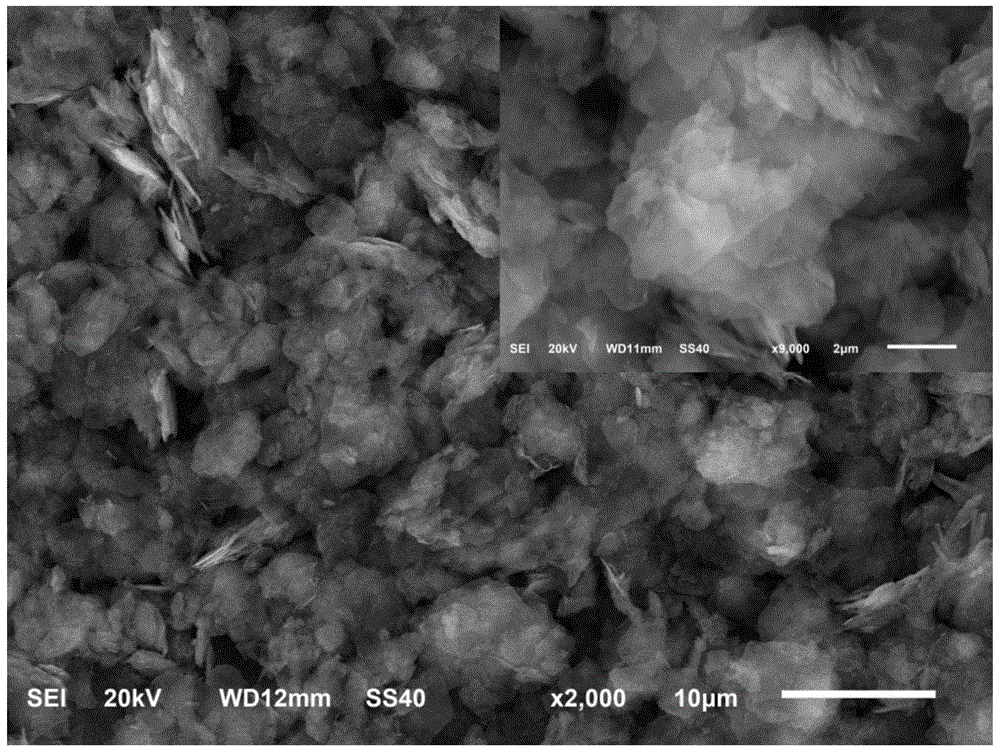

Preparation method of grading magnesium and aluminum hydrotalcite capable of adsorbing Cr(VI)

InactiveCN103551104AVarious shapesImprove adsorption capacityOther chemical processesCombustible gas purificationMagnesium saltBULK ACTIVE INGREDIENT

The invention discloses a preparation method of grading magnesium and aluminum hydrotalcite capable of adsorbing Cr(VI) and recycling. The method comprises the steps of firstly, sequentially adding a certain amount of sodium polyacrylate, Pluronic block copolymer P123 or F127 and a urea precipitating agent into magnesium salt solution and aluminum salt solution, stirring and dissolving and transferring to a hydrothermal kettle for performing hydrothermal treatment, naturally cooling, filtering, washing, vacuum drying and roasting a hydrothermal product to obtain magnesium and aluminum hydrotalcite with excellent Cr(VI) property. The method has the advantages of low-cost active ingredients, simple preparation technology, mild conditions, diversified product shapes and the like, and the prepared grading magnesium and aluminum hydrotalcite has good adsorption property on the Cr(VI) in a water body, and can be regenerated and recycled.

Owner:WUHAN UNIV OF TECH

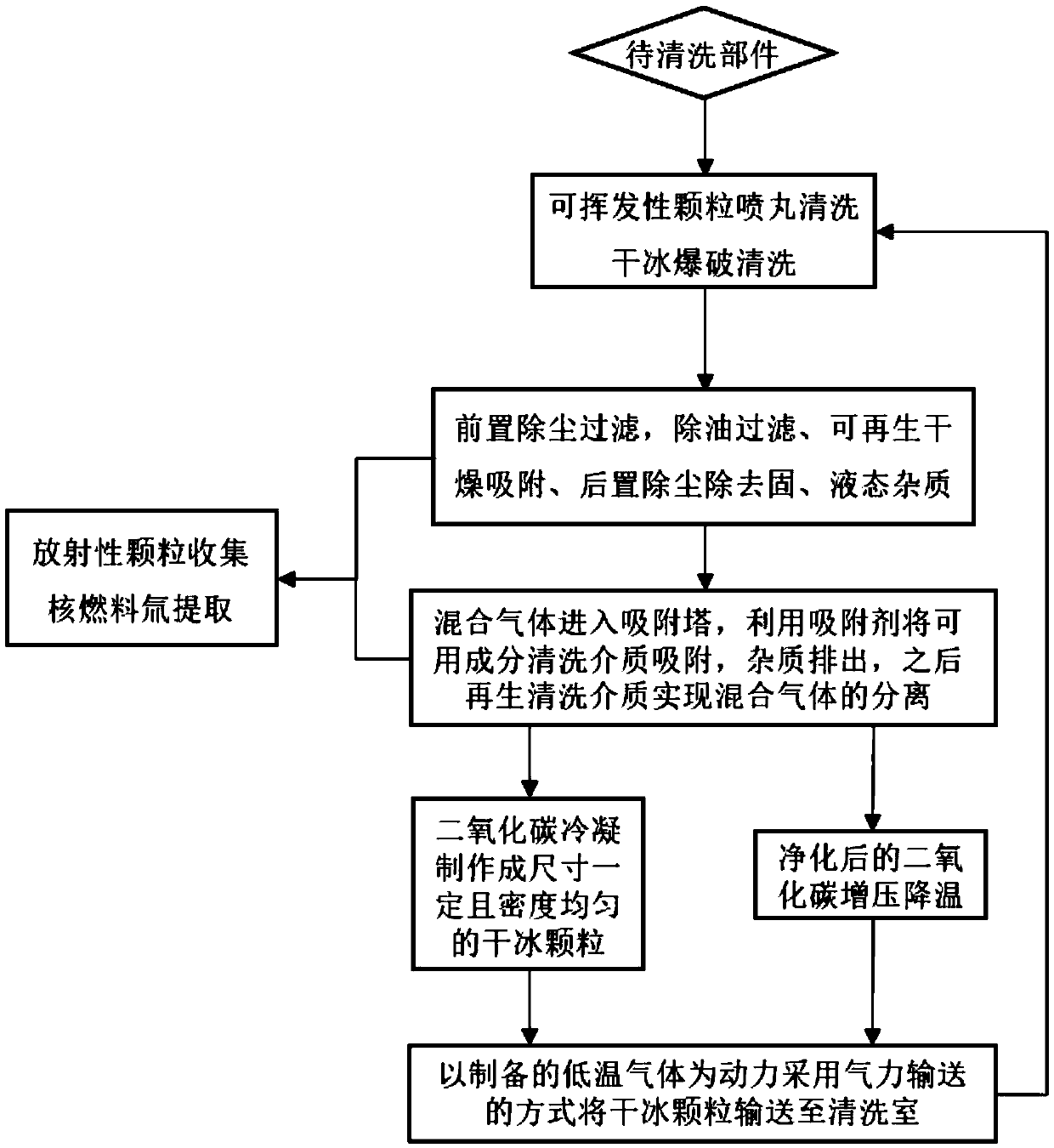

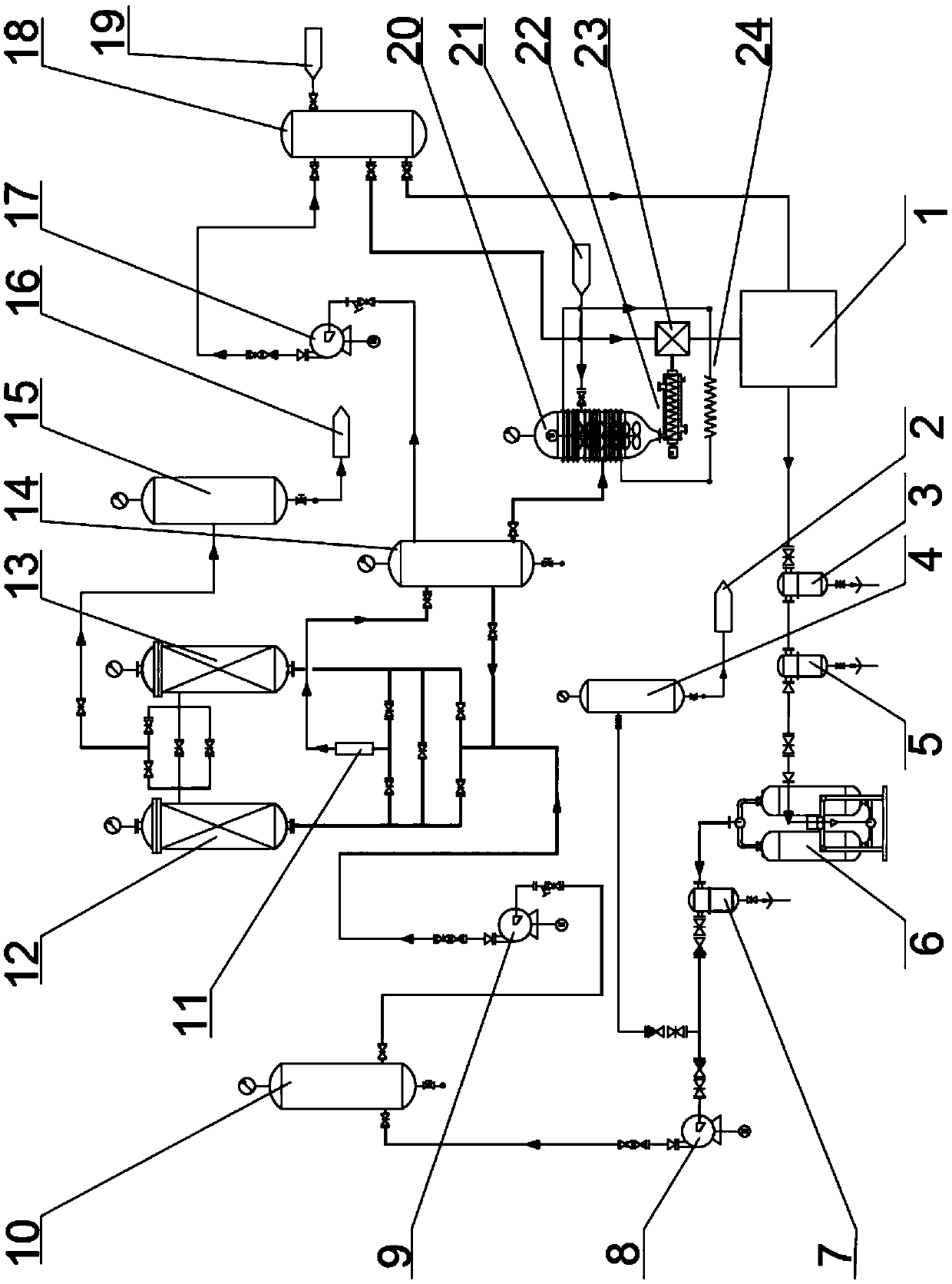

Cleaning waste gas pressure swing adsorption purification and recycling method and device for fusion reactor hot room

ActiveCN105513661AMinimize wasteAchieving classification of by-productsGas treatmentDispersed particle filtrationRadioactive gasCarbon dioxide

The invention relates to a cleaning waste gas pressure swing adsorption purification and recycling method and device for a fusion reactor hot room. The method includes the technological process of cleaning and contaminating, solid and liquid impurity filtration and purification, cleaning medium adsorption separation and regeneration, low-temperature power gas preparation, volatilizable particle regeneration and volatilizable particle remote-distance pneumatic transport. Fusion reactor hot room cleaning waste gas containing radioactive particles and radioactive gas is processed in a low-risk mode through a multiple filtration and pressure swing adsorption method, and separation, classified collection and recycling of radioactive particles, radioactive gas tritium and a cleaning medium carbon dioxide gas are achieved. The purity of regenerated products is high, no external heat source heating is needed, the gas temperature change range is small, the device is more economical and saves more energy, the service life of adsorbent is long, the device maintenance is easy and convenient, automatic production can be completely achieved, and the method and the device are suitable for the hot room environment remotely controlled and operated.

Owner:UNIV OF SCI & TECH OF CHINA

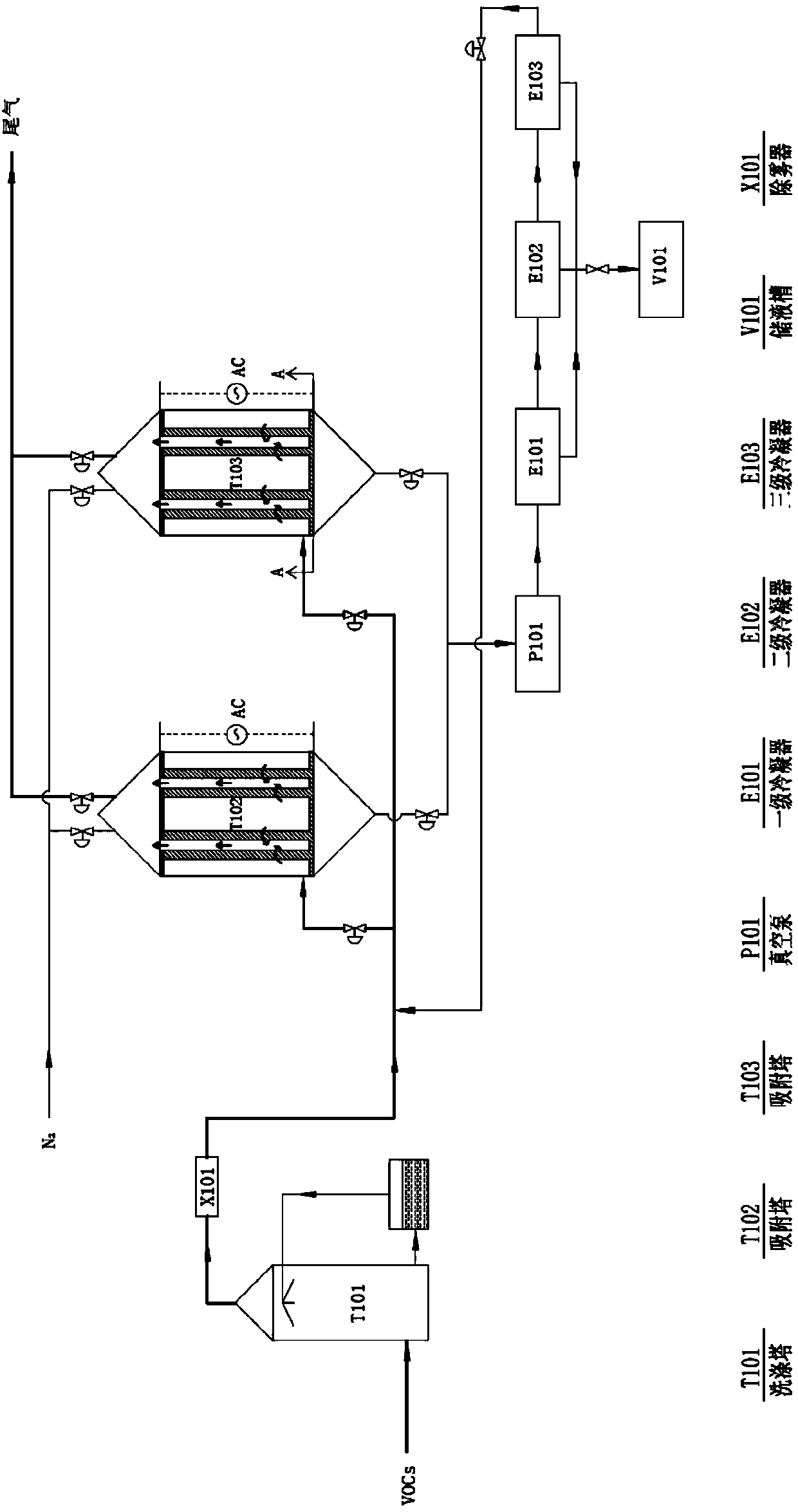

Device and process for recycling volatile organic gas in adsorption-desorption manner

ActiveCN103736359AHigh recovery rateComplete regenerationDispersed particle separationVapor condensationOrganic moleculesChemistry

The invention discloses a device for recycling a volatile organic gas in an adsorption-desorption manner and a utilization method of the device. The device comprises activated carbon fiber adsorption towers, a vacuum pump, a condenser and a liquid storage pot, wherein an activated carbon fiber adsorption column as well as an upper fixing rack and a lower fixing rack which are used for fixing the activated carbon fiber adsorption column are arranged in each adsorption tower; the activated carbon fiber adsorption column is formed by a hollow insulating pipe which has an airtight bottom and an upper opened end and activated carbon fiber fabric which wraps the wall of the side surface of the hollow insulating pipe; air through holes are formed in the wall of the side surface of the hollow insulating pipe; the wall of the side surface of the hollow insulating pipe is completely wrapped by the activated carbon fiber fabric; two ends of the activated carbon fiber adsorption column are connected with an electrode in which a current can be conducted. According to the device, organic molecules adsorbed by a plurality of activated carbon fiber adsorption towers are recycled in a desorption condensation manner through the combination of electric-heating and vacuum technologies. According to the process of the device, the continuous adsorption-desorption recycling of the organic waste gas can be realized, so that the recycling rate of the organic waste gas is high and the activated carbon fiber can be completely regenerated.

Owner:ZHEJIANG UNIV OF TECH

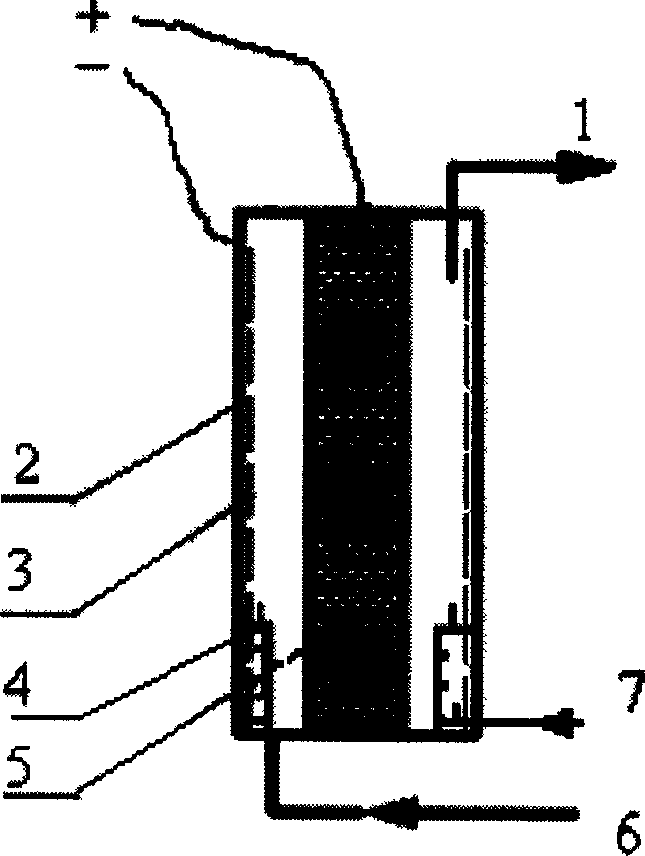

Equipment and method for treating organic waste water through electrocatalysis of cathode in combination with anode

InactiveCN1600699AEase of industrial applicationEasy to zoom inWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationIron sulfateElectrochemical response

In the invention, positive pole is fit at center of reaction casing, negative pole is fit surround inwall of reaction casing, a cyclic microporous aeration unit is fit near negative pole on bottom of the reaction casing, waste water charging pipe intercommunicated with waste water storage tank is fit on bottom part of the reaction casing, water discharging pipe is fit on the super part. In waste water treatment, 0.1-5mM iron sulfate and 1-10g / L sodium sulfate electrolyte are added in waste water, adjusting pH value of waste water is 2.0-5.0, the waste water is pumped from storage tank to electrochemical reactor, at same time, turn on electrochemical DC power and sending gas in, controlling flow of waste water is 10-50ml / s, electric current is 0.1-2A, aeration speed is 1-30ml / s-1.

Owner:ZHEJIANG UNIV

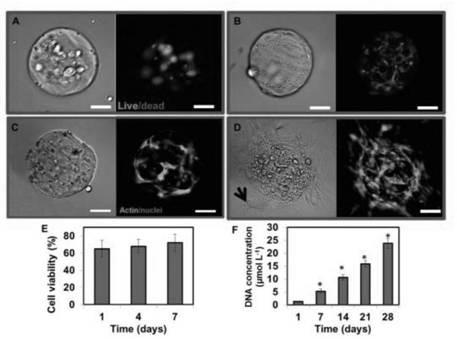

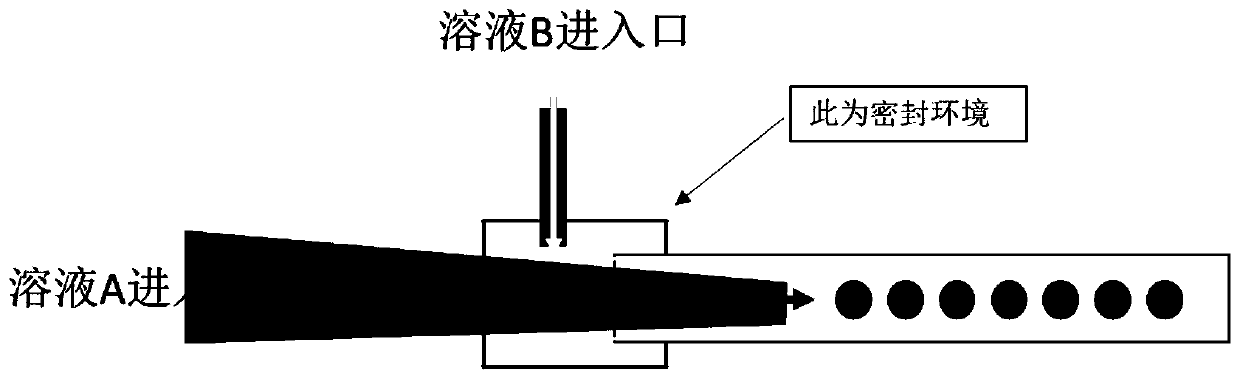

Preparation method of hydrogel porous microspheres and porous scaffold material

InactiveCN109880151AQuick buildGuaranteed survival rateMicroballoon preparationProsthesisFreeze-dryingPorous scaffold

The invention provides a preparation method of hydrogel porous microspheres. The preparation method comprises the following steps: a, a hydrogel material, a buffer solution and a photoinitiator are mixed to obtain a hydrogel solution, and an oily material is mixed with a surfactant to obtain an oily solution; b, a first container is partially nested in a second container, the inner diameter of theinlet end of the first container is larger than the inner diameter of the outlet end of the first container, and the inner diameter of the outlet end of the first container is smaller than the innerdiameter of the second container; the hydrogel solution is injected into the first container, the oily material is injected into the intersection of the first container and the second container, and the oily solution and the hydrogel solution form water-in-oil droplets under the action of a flowing shear force; c, ultraviolet irradiation is performed on the water-in-oil droplets, and crosslinkingis performed to obtain hydrogel microspheres; and d, freezing and freeze-drying are performed on the hydrogel microspheres to obtain the hydrogel porous microspheres. According to the invention, uniform and stable hydrogel porous microspheres are obtained by utilizing a micro-fluidic technology.

Owner:上海市伤骨科研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com