Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Conducive to smelting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

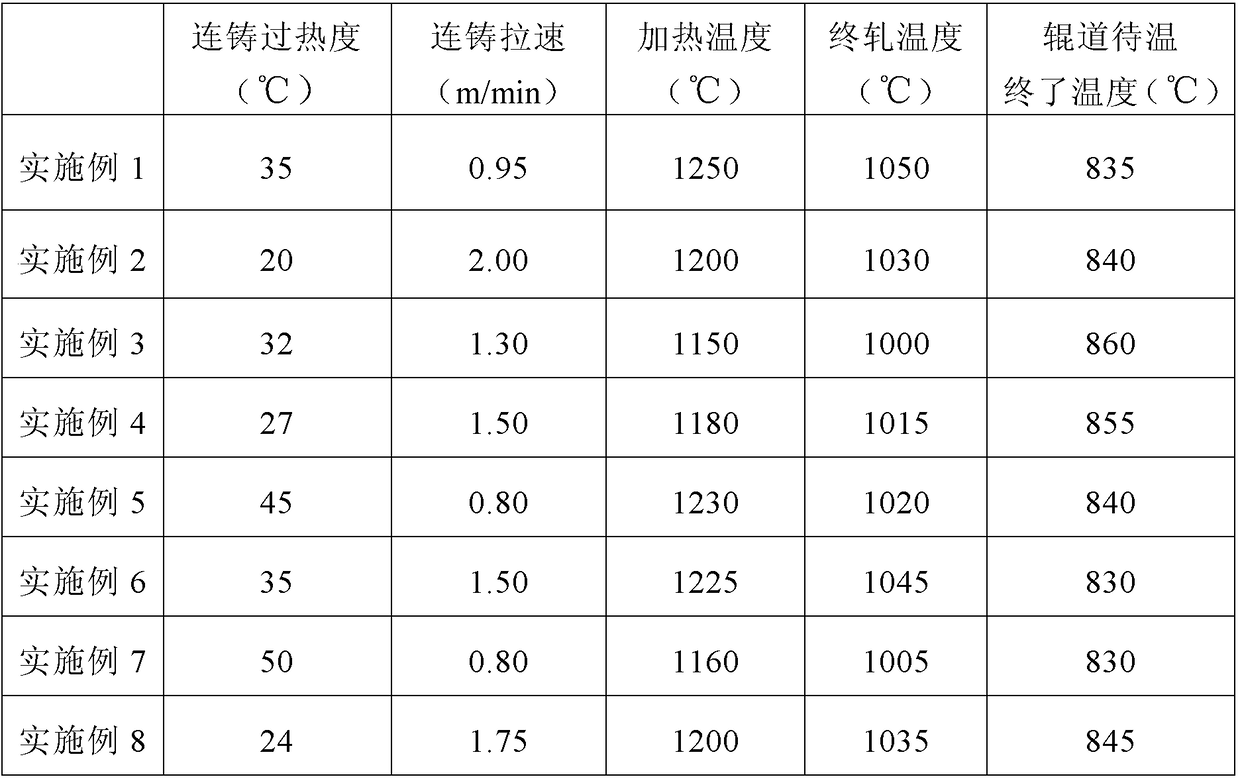

Method for extraction of potassium and sodium from iron ore and synchronous preparation of ironmaking burden

ActiveCN103397177AHigh removal rateLow in potassium and sodiumProcess efficiency improvementProcess engineeringSodium salt

The invention relates to a method for extraction of potassium and sodium from iron ore and synchronous preparation of ironmaking burden. The method includes: adding a reducing agent into an iron-containing raw material with high potassium and sodium content to prepare carbon-containing pellets of certain granularity, and subjecting an iron-containing raw material with low potassium and sodium content to mixing granulation so as to obtain a mixture; mixing the carbon-containing pellets with the mixture according to certain mass ratio, conducting material distribution and ignition, then circulating a low oxygen gas with a small CO content to perform sintering roasting, thus obtaining the ironmaking burden with certain reducibility and low potassium and sodium content, and gathering potassium and sodium in sintered precipitator dust; subjecting the precipitator dust rich in potassium and sodium to agglomeration and direct reduction to obtain a reduction product and volatile fume; further gathering compounds of potassium and sodium in the volatile fume, and carrying out sulfuric acid agitation leaching, filtering, impurity removing and evaporative crystallization, thus obtaining a potassium salt and a sodium salt. By means of the method provided in the invention, the high quality ironmaking burden can be prepared, the potassium and sodium content of the ironmaking burden can be reduced, the blast furnace alkali load can be alleviated, and extraction of potassium, sodium and other useful resources can be realized simultaneously.

Owner:CENT SOUTH UNIV

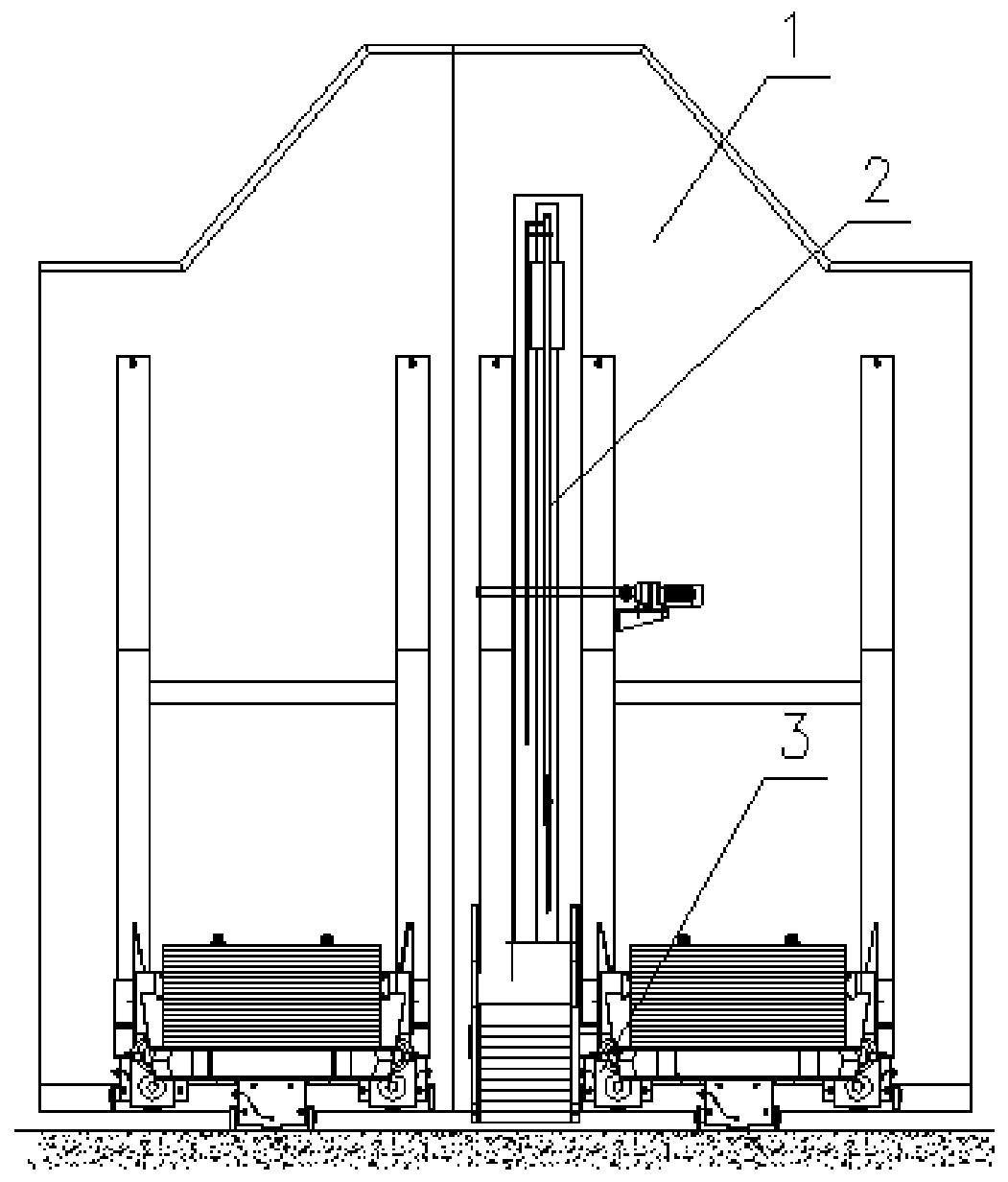

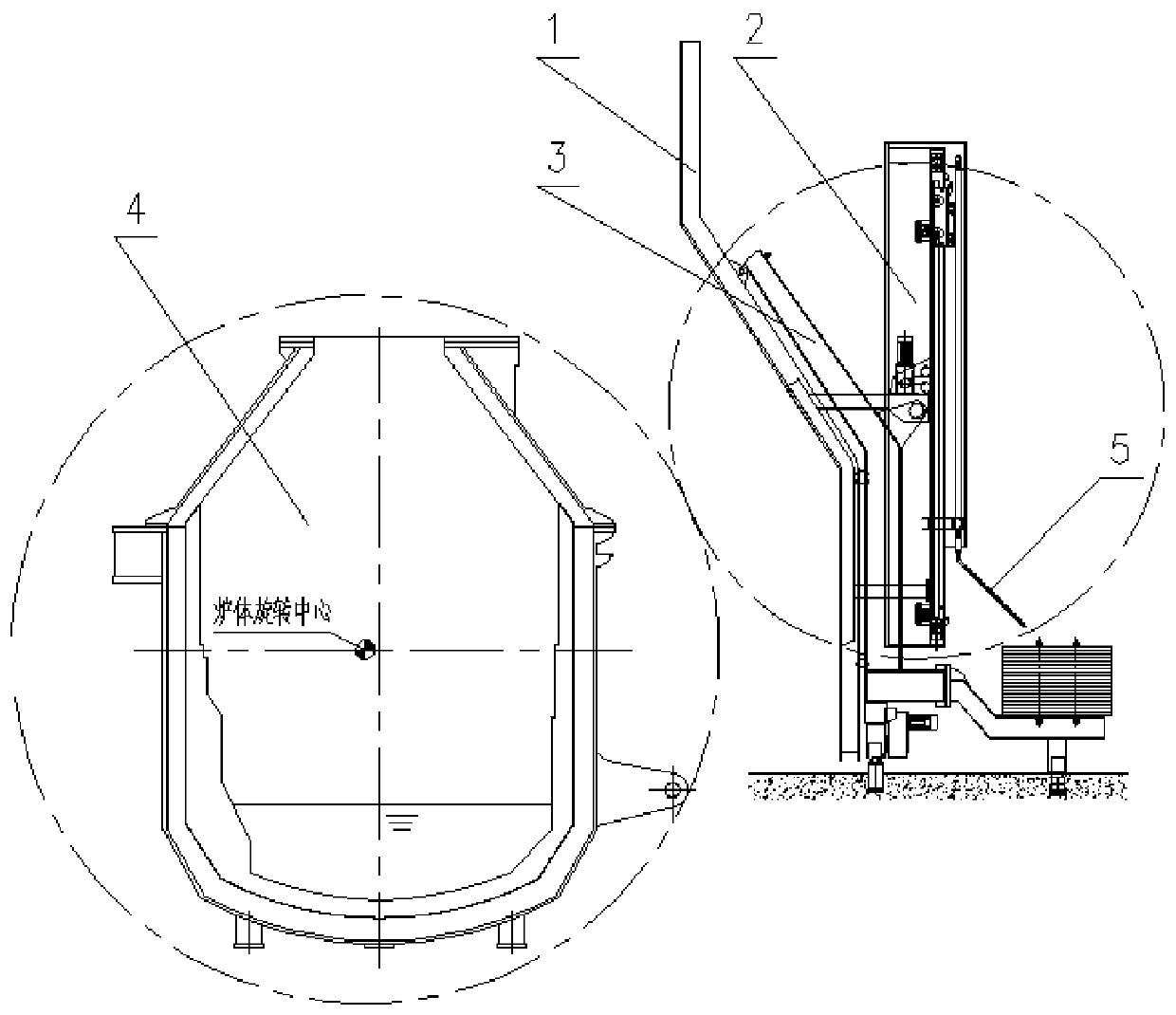

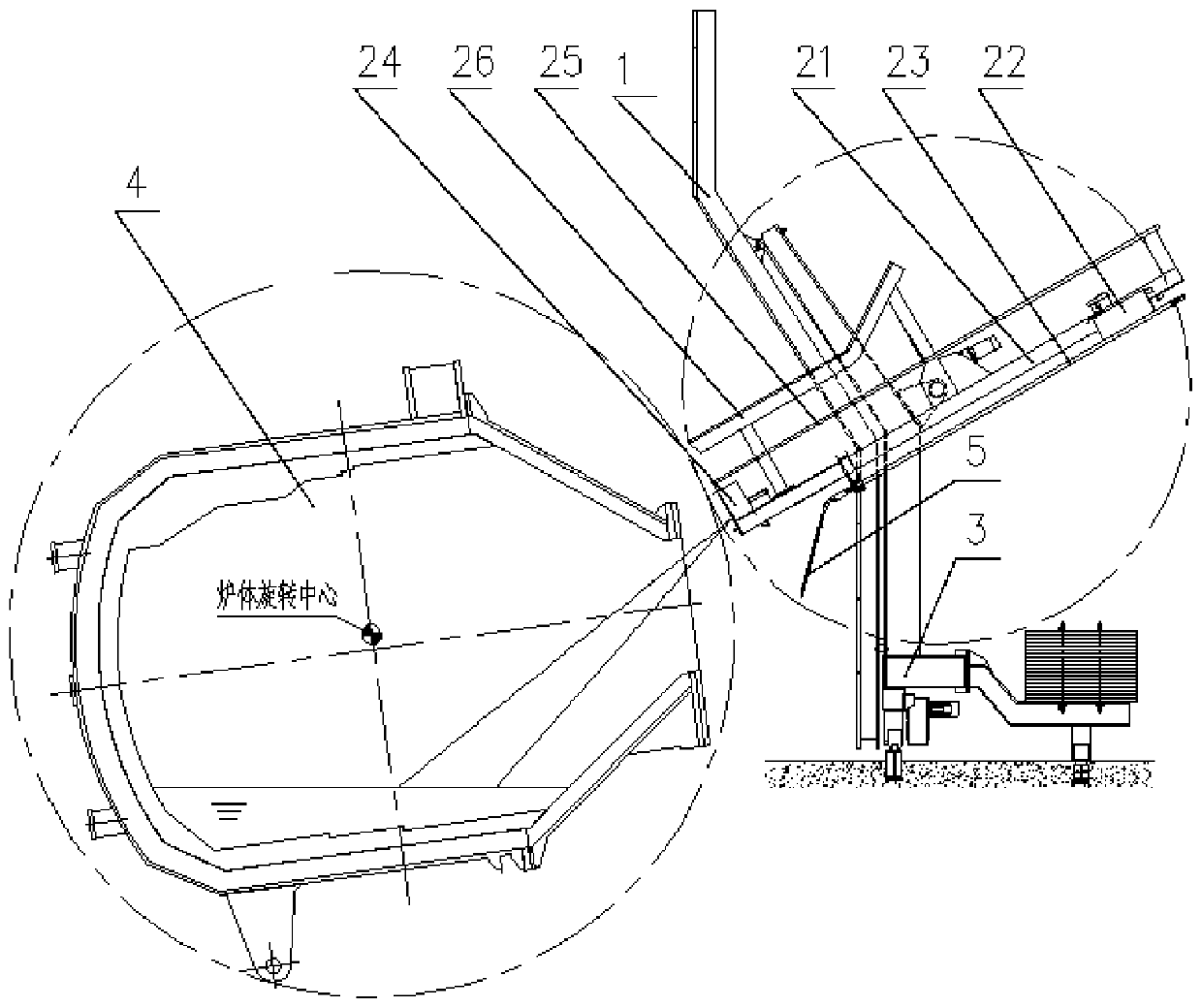

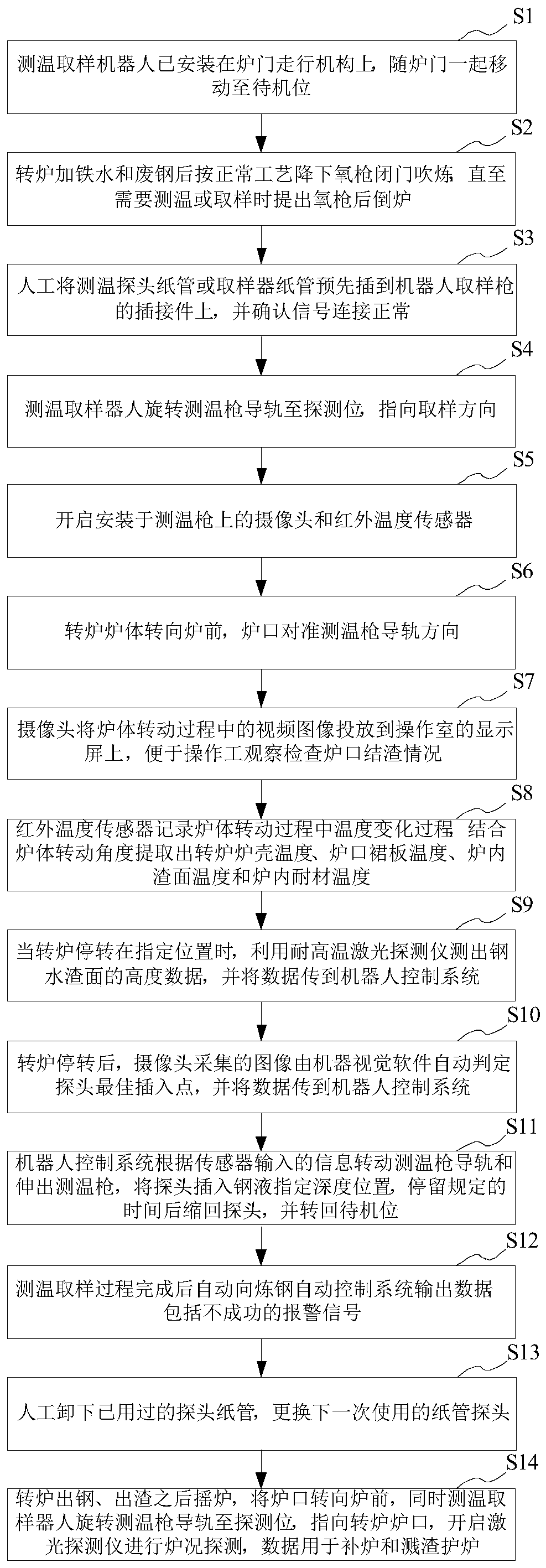

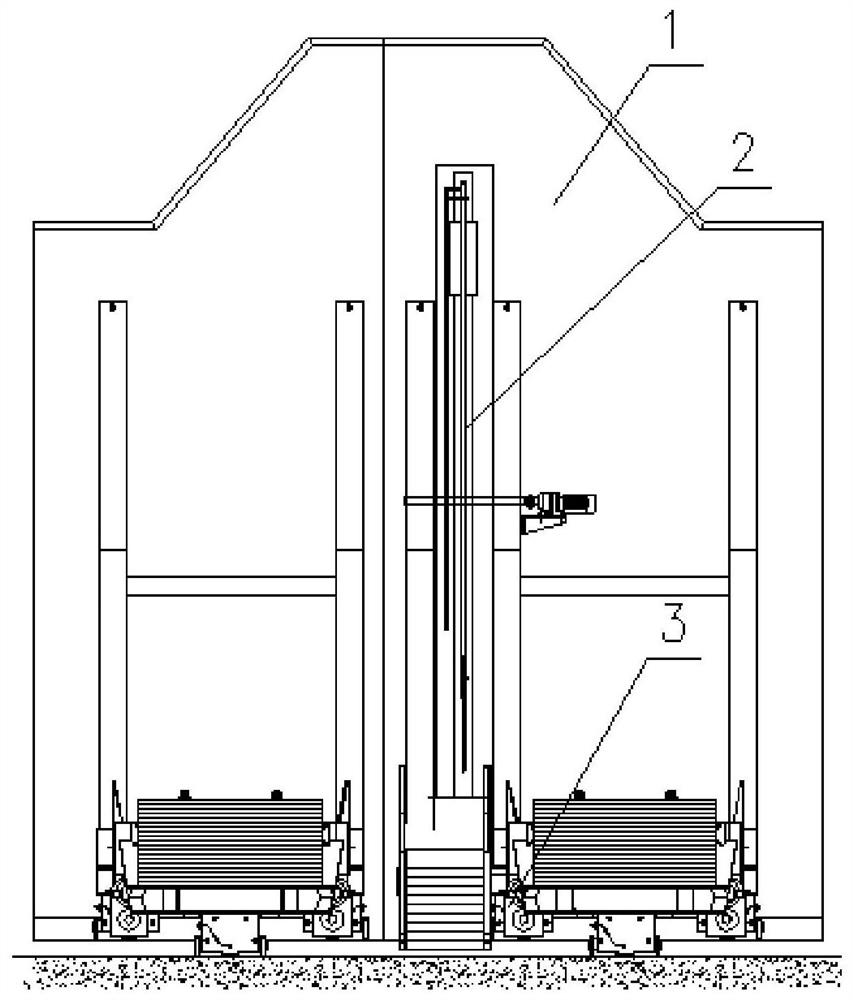

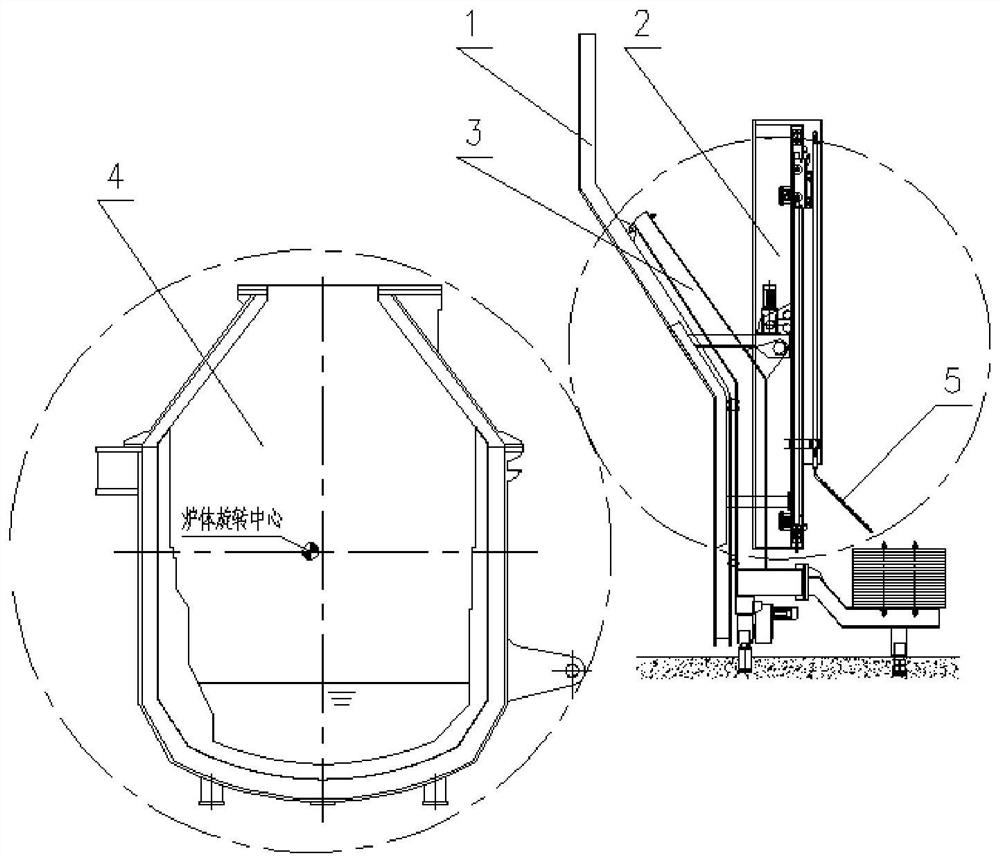

Converter door automatic temperature measuring sampling device

PendingCN110066901AEnd point carbon content judgment is stableJudgment is stableManufacturing convertersSlagEngineering

The invention provides a converter door automatic temperature measuring sampling device. The device comprises a moving mechanism which is moved on a track on the ground in front of the door of the converter and a suspension front fire blocking door and a temperature measuring sampling robot which are cooperatively installed on the moving mechanism, wherein a complete converted slag spattering andhigh-temperature radiation protecting baffle is formed by a steel slag spattering protecting plate and the suspension front fire blocking plate when the temperature measuring sampling robot is at a waiting position; converter mouth real-time image information is collected by the temperature measuring sampling robot to provide information for an operator when the operator maintains the converter, and self-decision is performed by the temperature measuring sampling robot according to collected molten steel and slag block position to control the extending range and inserting position of a temperature measuring sampling probe. The device has the advantages that the temperature measuring sampling robot is used for replacing operators to perform temperature measuring sampling, the operators canbe prevented from burning by spattered steel slag, the operation success rate is significantly improved, and the device is an advanced technology which has extensive application prospects.

Owner:CISDI ENG CO LTD +1

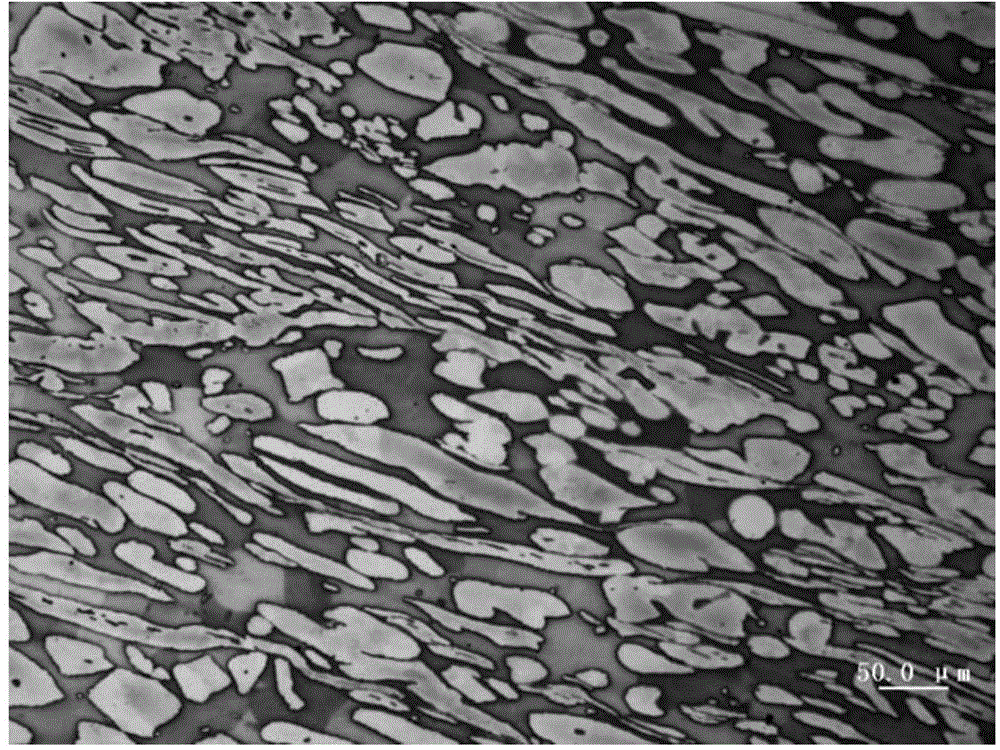

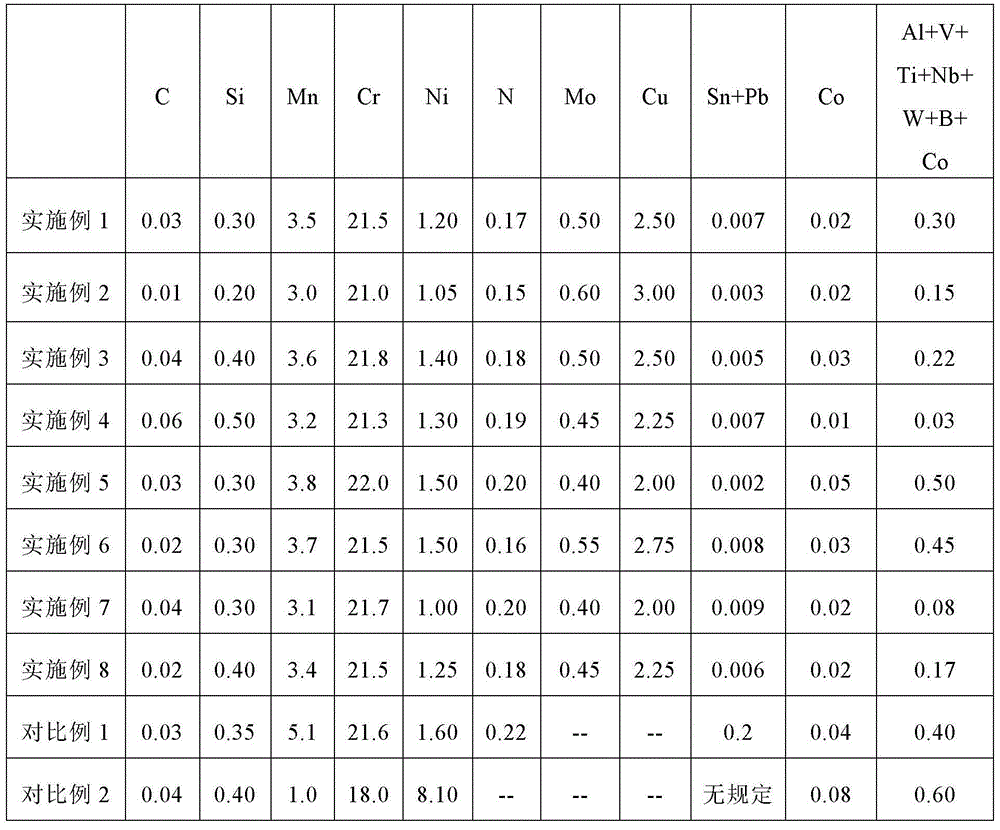

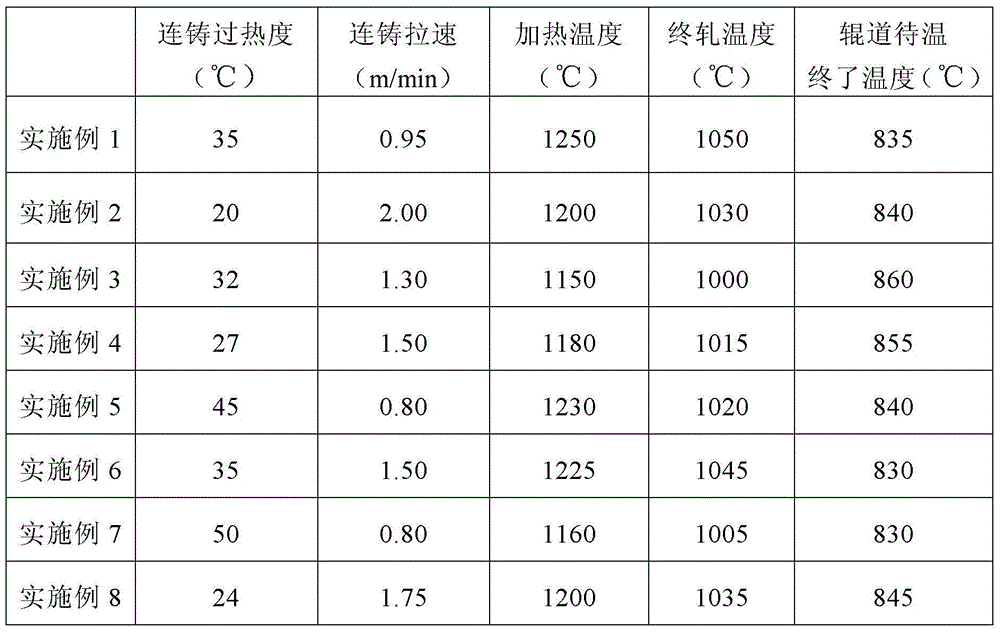

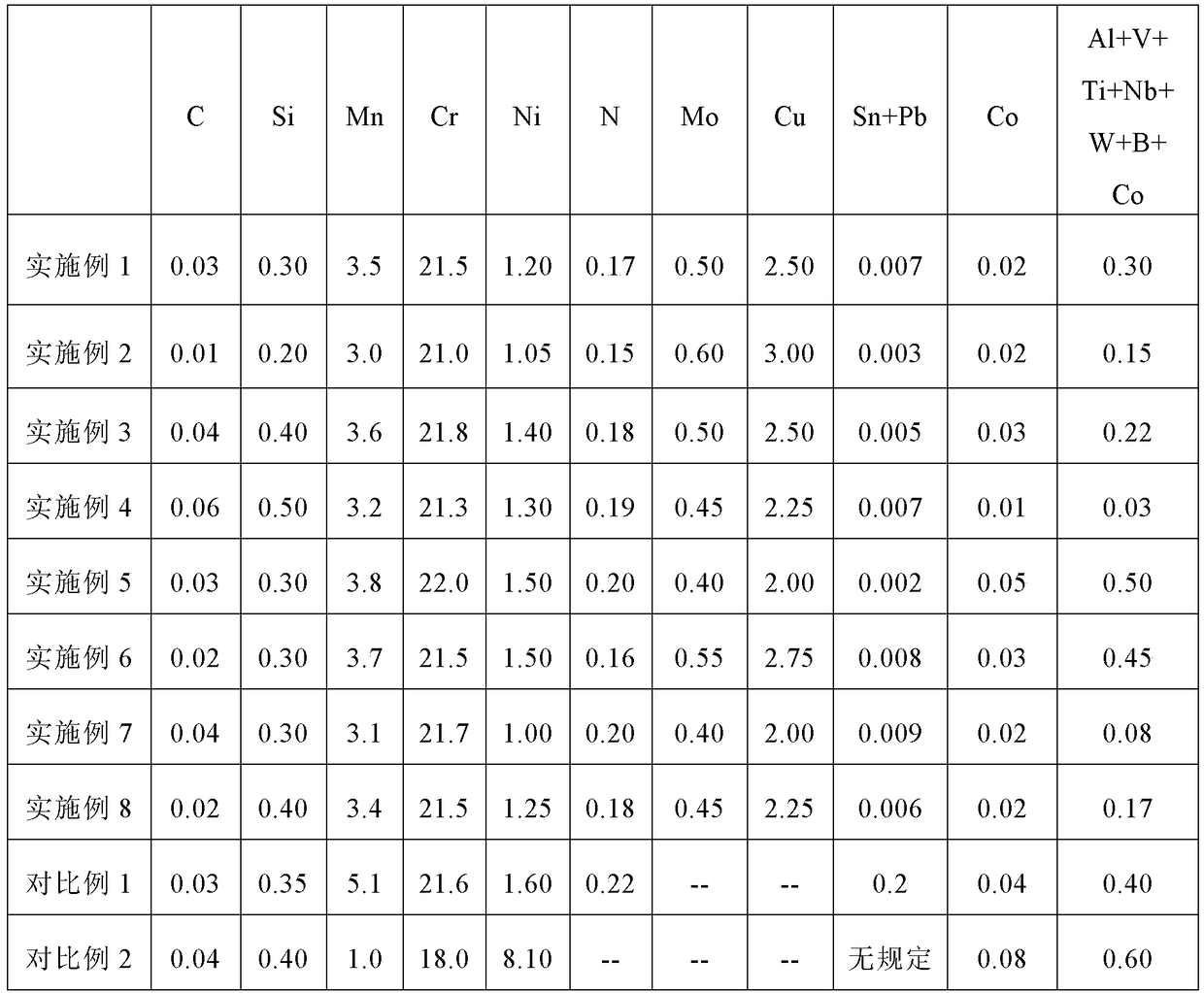

Acid-corrosion-resistant high-strength low-nickel duplex stainless steel and manufacturing method thereof

ActiveCN105441830AGood acid corrosion resistanceExcellent pickling corrosion resistanceNuclear powerAcid corrosion

Provided are acid-corrosion-resistant high-strength low-nickel duplex stainless steel and a manufacturing method thereof. The duplex stainless steel comprises the chemical components by the weight percentage: 0.01-0.06% of C, 0.20-0.50% of Si, 3.0-3.8% of Mn, 21.0-22.0% of Cr, 1.0-1.5% of Ni, 0.15-0.20% of N, 0.40-0.60% of Mo, 2.0-3.0% of Cu, less than or equal to 0.05% of Co, less than or equal to 0.01% of Sn, less than or equal to 0.01% of Pb, less than or equal to 0.5% of the total amount of W, B, Nb, Ti, Co, Al and V, and the balance Fe and inevitable impurities, wherein the ratio of Cu% to Mo% is 5 to 1. The duplex stainless steel has pitting corrosion resistance equivalent to that of S32101 and has acid corrosion resistance superior to that of the S32101, the corrosion resistance in boric acid and other acidic conditions is further improved, the risk of corrosion occurrence is reduced, and the yield strength is increased by 20% or more than that of the conventional S32101; the alloy cost is equivalent to that of the S32101; and ordinary raw materials can be used for smelting products satisfying nuclear power material standards.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

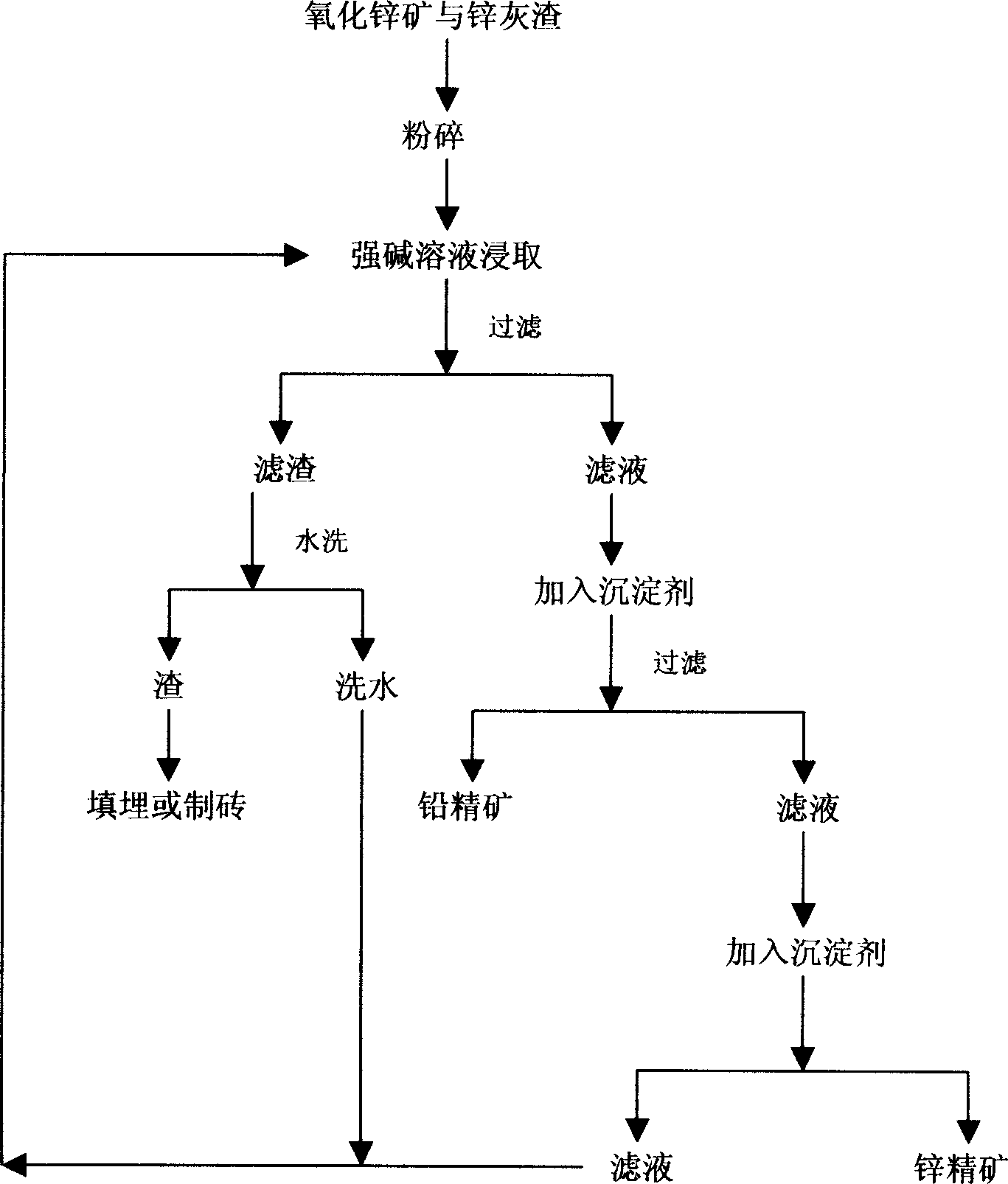

Mehtod for producing zinc concentrate and lead concentrate using zinc oxide ore and zinc slag

InactiveCN1858275AGood environmental and social benefitsSimple processProcess efficiency improvementSlagLow graded

The process of producing zinc concentrate and lead concentrate with zinc oxide and zinc slag includes the following steps: grinding material to granularity of 0.1-1mm, leaching in strong alkaline solution, stirring at 10-100deg.c for 60-100 min to leach out zinc and lead from the material; filtering, water washing filter residue, and producing slag brick or land filling of filter residue; adding precipitant in 0.5-3 times the lead content, stirring for 60 min, and filtering to obtain lead concentrate; adding precipitant in the amount of 0.5-5 times zinc content, stirring at 10-100 for 1-5 hr and filtering to obtain zinc concentrate; and returning filtrate and washing water for reuse. The present invention has simple technological process, low production cost and no environmental pollution, and can utilize zinc and lead resource, especially low grade resource, effectively.

Owner:TONGJI UNIV

Low carbon low silicon-aluminum killed steel converter refining production process

ActiveCN106884068AReduce consumptionShort processing cycleManufacturing convertersLiquid temperatureSlag

The invention relates to a low carbon low silicon-aluminum killed steel converter refining production process. Converter slag-making materials are added in two batches, and the steel tapping temperature of a converter is controlled between 1640 DEG C-1660 DEG C; in the blowing process, the lance position is controlled as low-high-low-high, and meanwhile it is guaranteed that the catch carbon time is larger than or equal to 2 minutes; after steel tapping of the converter is completed, a steel ladle is refined, then an argon bottom blowing flexible pipe is connected, strong argon blowing is adopted, when the steel liquid surface surges, the argon blowing flow is adjusted to be lower, and it is guaranteed that molten steel does not overflow the steel ladle; for the slag-making stage, the slag-making material are added for two times, after the slag-making materials are added, argon bottom blowing strong stirring is adopted, the argon blowing time is 3 min-10 min, and the slag sample taking frequency is 4-5 times; and when top slag is turned from original black to green, argon bottom blowing stirring is stopped, then steel liquid temperature measurement and sampling are conducted, and after steel liquid temperature measurement and sampling, the argon bottom blowing flow is adjusted to the weak blowing state. The production process is beneficial to smelting less slag of the converter, increasing the age of the converter, reducing consumption of refractory materials, reducing the oxygen content of molten steel of steel tapping in converter, increasing the ratio of scrap steel, and reducing production cost.

Owner:ANGANG STEEL CO LTD

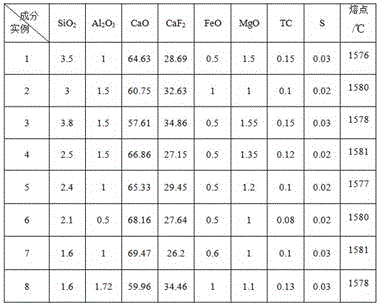

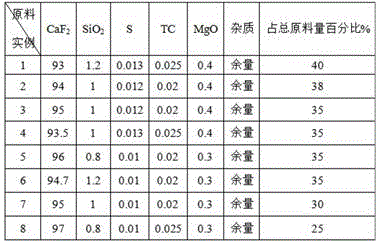

Desulfurizing agent for RH furnace

The invention belongs to the technical field of steel smelting and particularly relates to a desulfurizing agent for an RH furnace. The desulfurizing agent comprises, by weight, 1-4.0% of SiO2, less than or equal to 2.0% of Al2O3, 57-70% of CaO, 25-35% of CaF2, less than or equal to 1.0% of FeO, less than or equal to 2.0% of MgO, less than or equal to 0.15% of TC and less than or equal to 0.03% of S. The desulfurizing agent is low in melting point, beneficial to smelting of molten steel in the RH furnace, less in use amount, remarkable in desulfurizing effect and low in cost.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

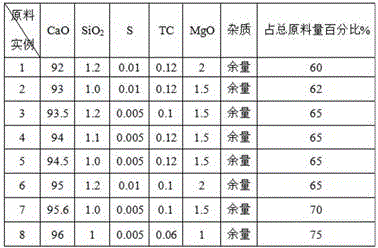

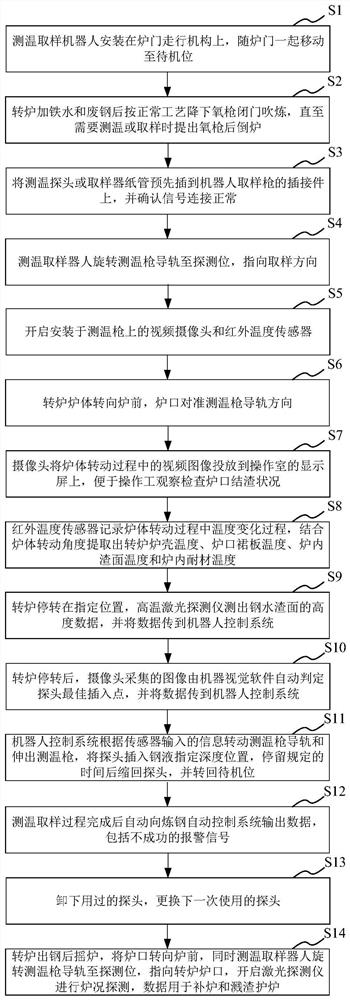

Automatic temperature measuring and sampling method for door of steelmaking converter

ActiveCN110146335AEnd point carbon content judgment is stableJudgment is stableWithdrawing sample devicesSensing heat from liquidsSteelmakingEngineering

The invention provides an automatic temperature measuring and sampling method for the door of a steelmaking converter. According to the method, a walking mechanism which moves on a rail on the groundin front of the door of the converter, a suspension type before-the-converter fire blocking door and a temperature measuring and sampling robot, wherein the suspension type before-the-converter fire blocking door and the temperature measuring and sampling robot are jointly arranged on the walking mechanism; at a standby position, the steel slag splashing protection plate of the temperature measuring and sampling robot and the suspension type before-the-converter fire blocking door form a complete converter slag splashing and high-temperature radiation protection baffle; the robot collects thereal-time image information of the mouth of the converter and provides the information for an operator in maintenance converter; and the robot collects molten steel and slag block position informationand can independently decide and control the stretching distance and insertion position of a temperature measuring and sampling probe. According to the method of the invention, the robot is used forreplacing manual operation to perform temperature measurement and sampling; and therefore, the operator can be protected from being scalded by splashing steel slag, and an operation success rate is remarkably improved. The method is an advanced technology with a bright application prospect.

Owner:CISDI ENG CO LTD +1

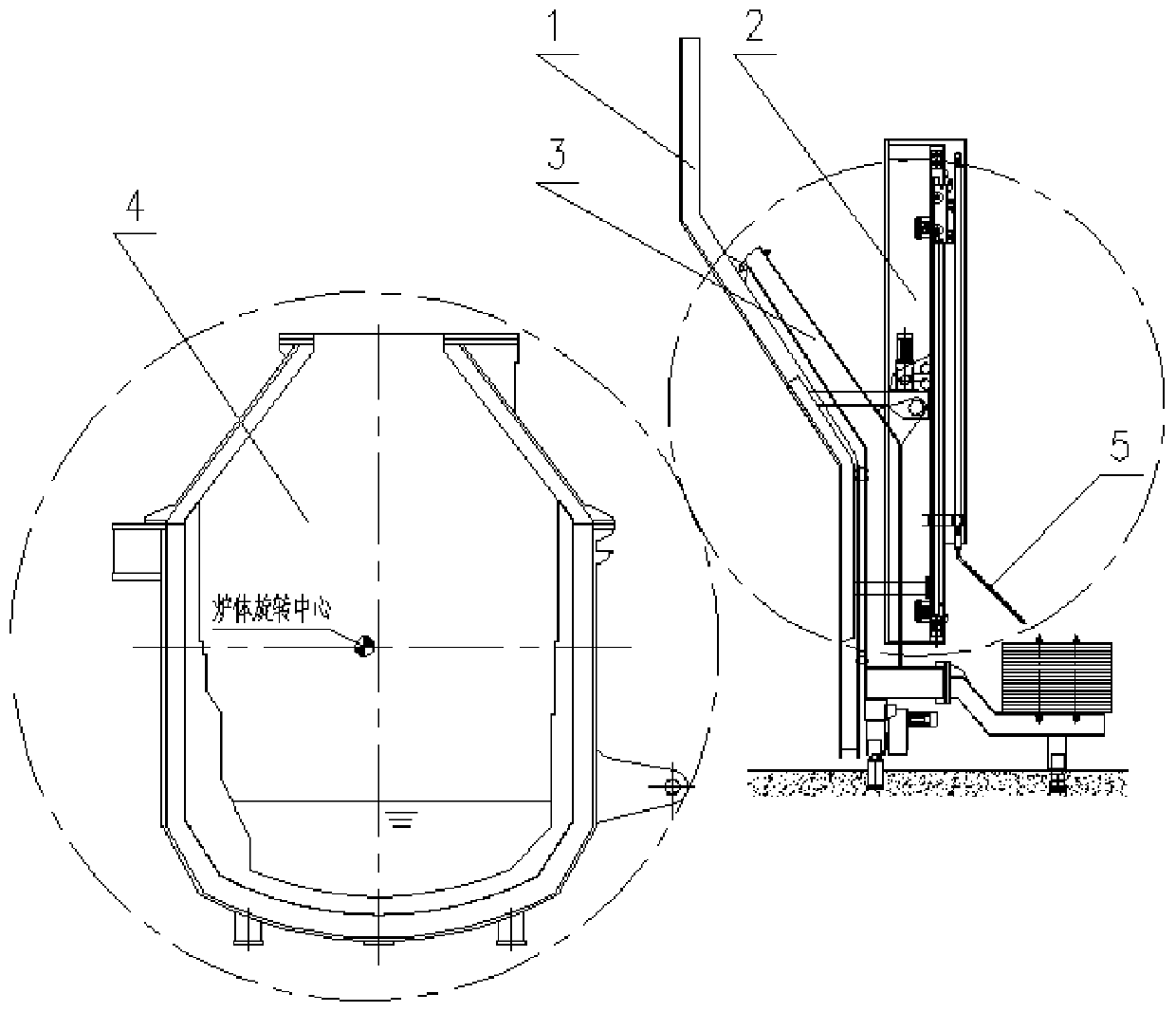

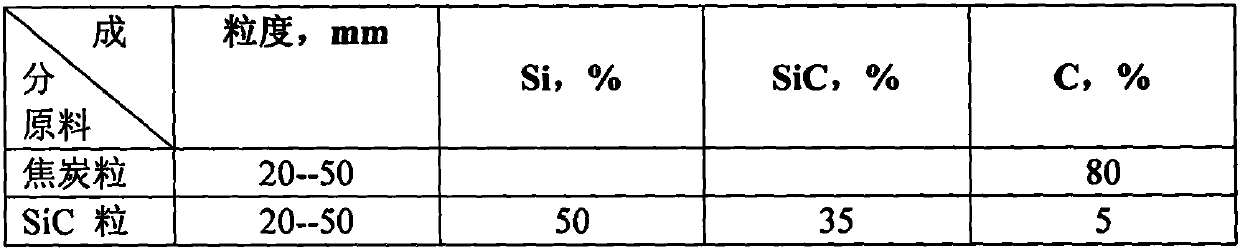

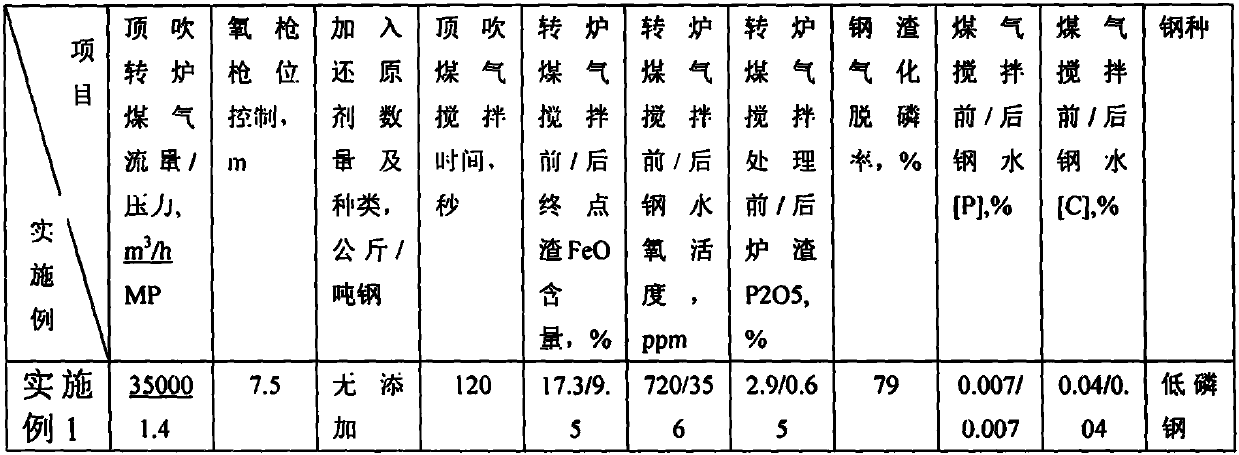

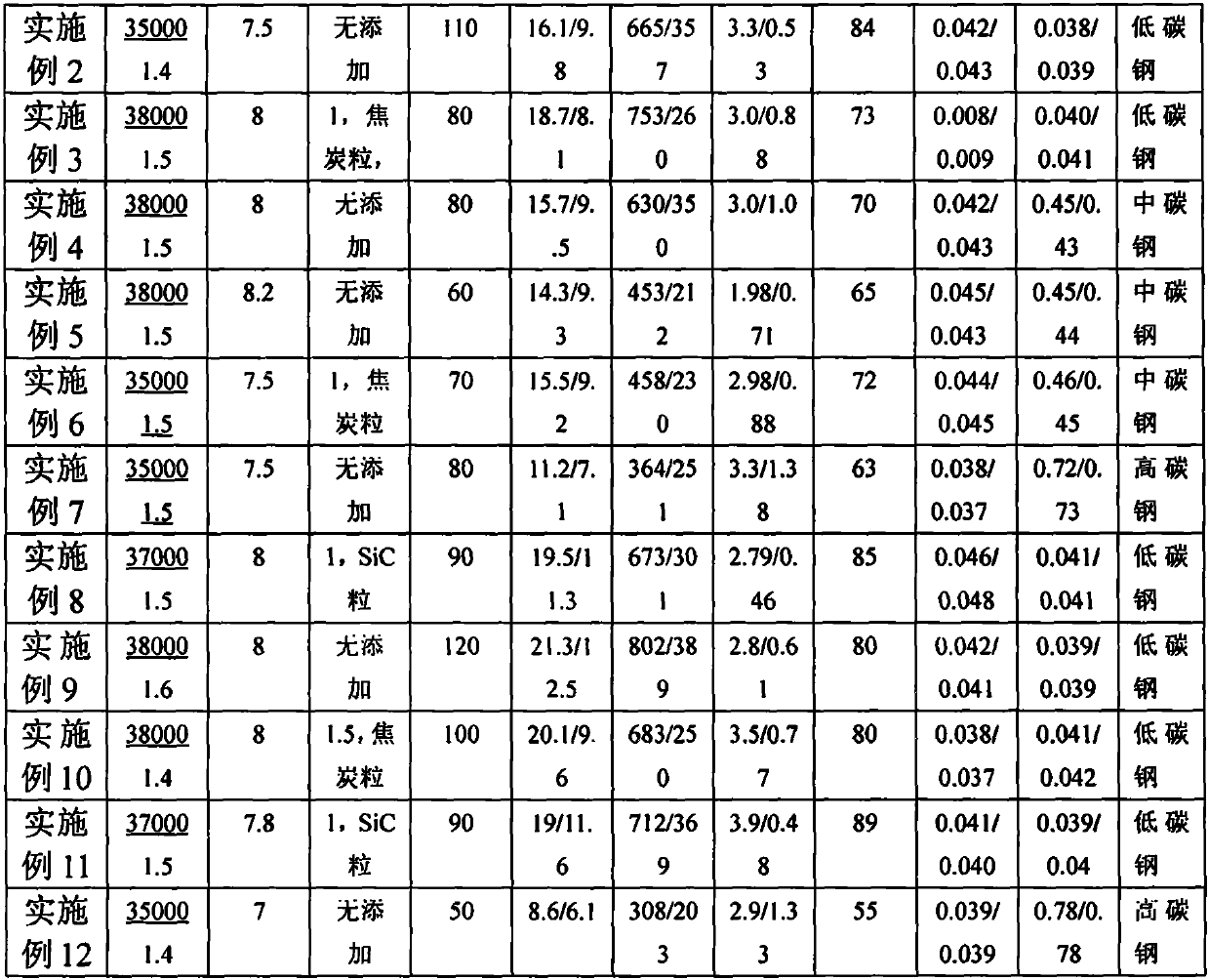

Novel pretreatment process for converter blowing end point steel slag

InactiveCN109593906AReduce iron oxide contentEmission reductionManufacturing convertersSteelmakingEconomic benefits

The invention discloses a novel pretreatment process for converter blowing end point steel slag. The process comprises the step of immediately blowing converter gas instead to the top slag surface for40-120 seconds at the end of the oxygen blowing at the converter blowing end point. With the technical solution, the process is simple and the cost is low. Steel slag is gasified and dephosphorized to obtain lower iron oxide content, the yield of molten steel is increased, and the consumption of a deoxidizer and alloy is reduced. The process is beneficial to the whole slag-retaining operation andslagless steelmaking, is beneficial to smelting low-phosphorus steel and ultra-low-phosphorus steel, is beneficial to slag stopping and slag splashing for protection of a converter, and has great economic benefits.

Owner:王虎

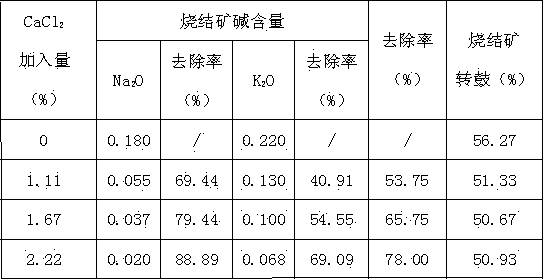

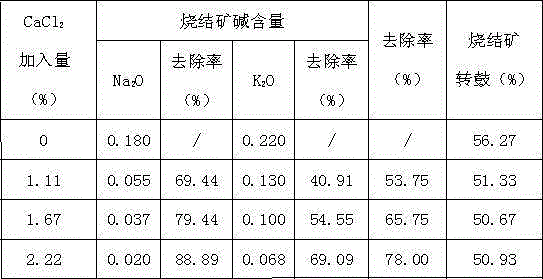

Method for removing alkali metals in sintering process

The invention discloses a method for removing alkali metals in a sintering process. CaCl2 powder is added in the sintering raw materials, and in the sintering process, CaCl2 powder is reacted with alkali metals existing in the form of silicate in the sintering raw materials to generate more stable NaCl and KCl; since the pressure in the furnace is in a negative pressure state during the sintering, the boiling points of NaCl and KCl are lower, so that NaCl and KCl are evaporated in the combustion layer and discharged to the outside of the reaction zone; simultaneously, the low-temperature reduction strength of the sintered ore is improved by spraying a CaCl2 solution on the cooled sintered ore; due to the adoption of the method, alkali metals contained in the metal ore are effectively removed, the alkali metal load in a smelting process is reduced, the service life of the blast furnace is prolonged and the harm of alkali metals is reduced, thereby being beneficial to the smelting of the blast furnace.

Owner:红河钢铁有限公司 +1

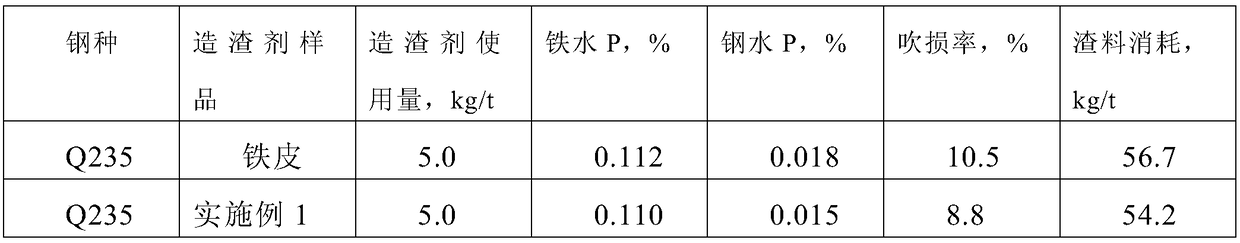

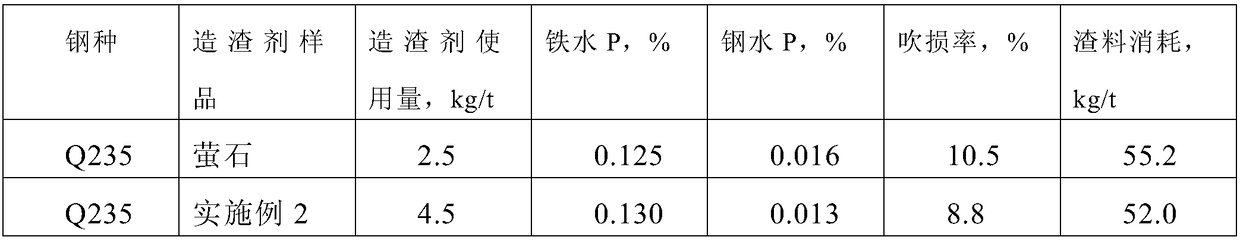

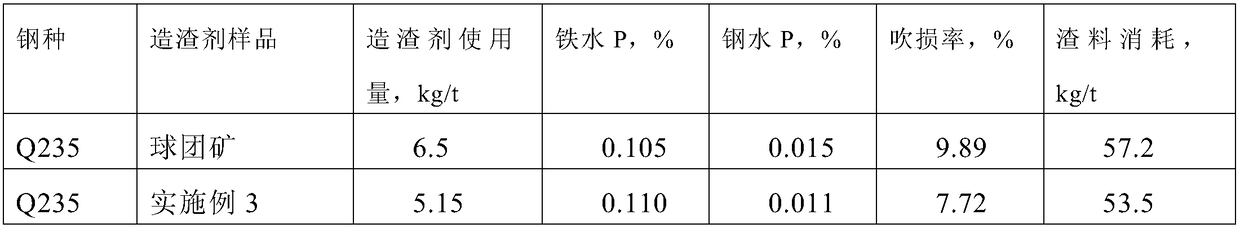

Premelting composite slugging agent for converter and preparation method thereof

InactiveCN109338027AConducive to smeltingResist drynessManufacturing convertersProcess efficiency improvementEnvironmental resistanceSlag

The invention relates to a premelting composite slugging agent for a converter and a preparation method thereof. The slugging agent comprises raw materials of lime, ferric oxide powder, activated aluminum oxide powder, low-sulfur cement, silica powder and an activating agent, wherein the raw materials comprise the following components in percentage by mass: 15-35% of CaO, 15-35% of Fe2O3, 5-15% ofAl2O3, 5-15% of MgO, and not greater than 15% of SiO; and the slugging agent contains not greater than 0.25% of impurity element S. According to the slugging agent, the raw materials are environmentally friendly; the melting point is low; the slagging speed is high; the breathability of slags can be obviously improved; the splashing in the converting process is reduced; and meanwhile, the slugging effect in the converting process can be effectively improved through the slugging agent, and the converting process is stable; the slugging agent avoids re-drying and gun adhering; in addition, theend point oxygen of a converter can be decreased after the converting slugging effect is improved, so that the oxidization of the slags can be reduced; the steel iron consumption is decreased; and theproduction cost is reduced.

Owner:武汉钢铁有限公司

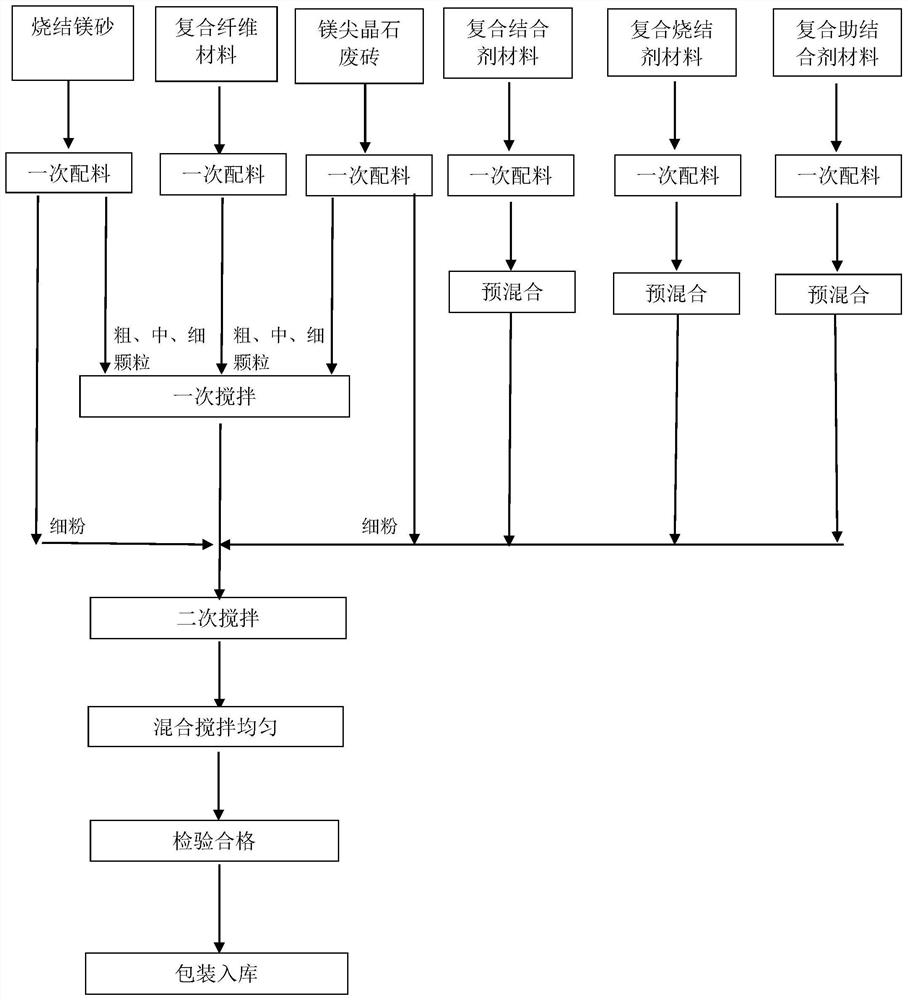

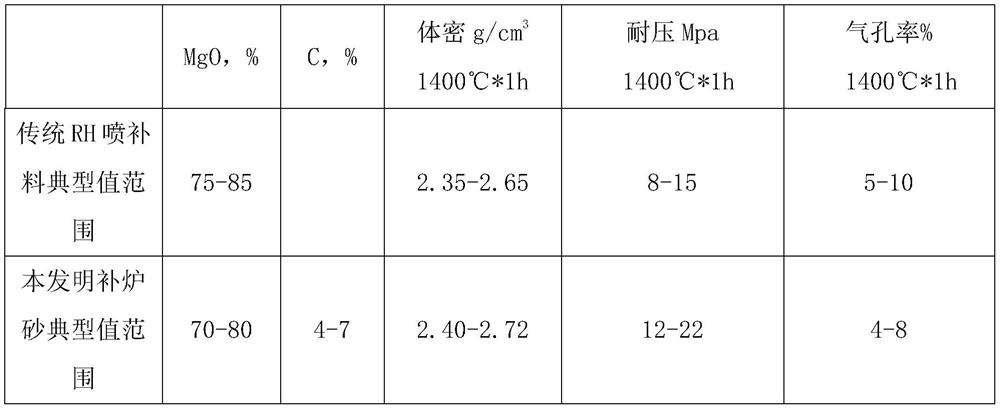

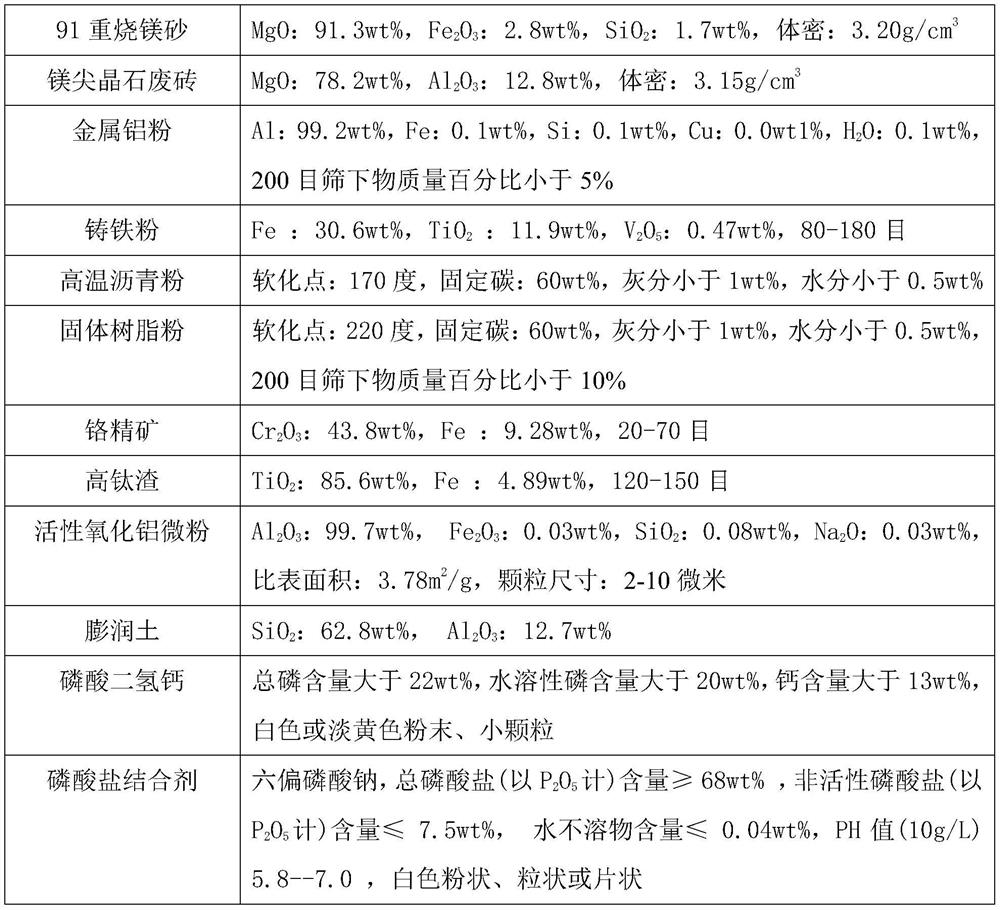

High-quality RH gunning mix added with large amount of cast iron powder and production method thereof

ActiveCN112479685AFully sinteredPromote sinteringProcess efficiency improvementCeramic materials productionFiberManufactured material

The invention relates to a high-quality RH gunning mix added with a large amount of cast iron powder and a production method thereof. The high-quality RH gunning mix is prepared from the following rawmaterials by weight: 35-60 parts of sintered magnesia, 10-30 parts of magnesia spinel waste bricks, 12-22 parts of a composite binding agent, 5-20 parts of a composite sintering agent, 3-10 parts ofa composite auxiliary binding agent and 0.1-2.0 parts of composite fibers. Compared with the prior art, the RH gunning mix has the beneficial effects that: the proportion of an existing RH gunning mixis optimally designed and improved, a large amount of cast iron powder is added for the first time in the domestic range, the sintering performance of the gunning mix is improved, so that the gunningmix meets the requirement for on-site rapid gunning maintenance of an RH dip pipe, the sintering speed is fast, the sintering strength is high, the adhesiveness is good, no resilience exists, the erosion resistance is good, meanwhile, the production method is simple and the raw material cost is lowered.

Owner:鞍山市和丰耐火材料有限公司

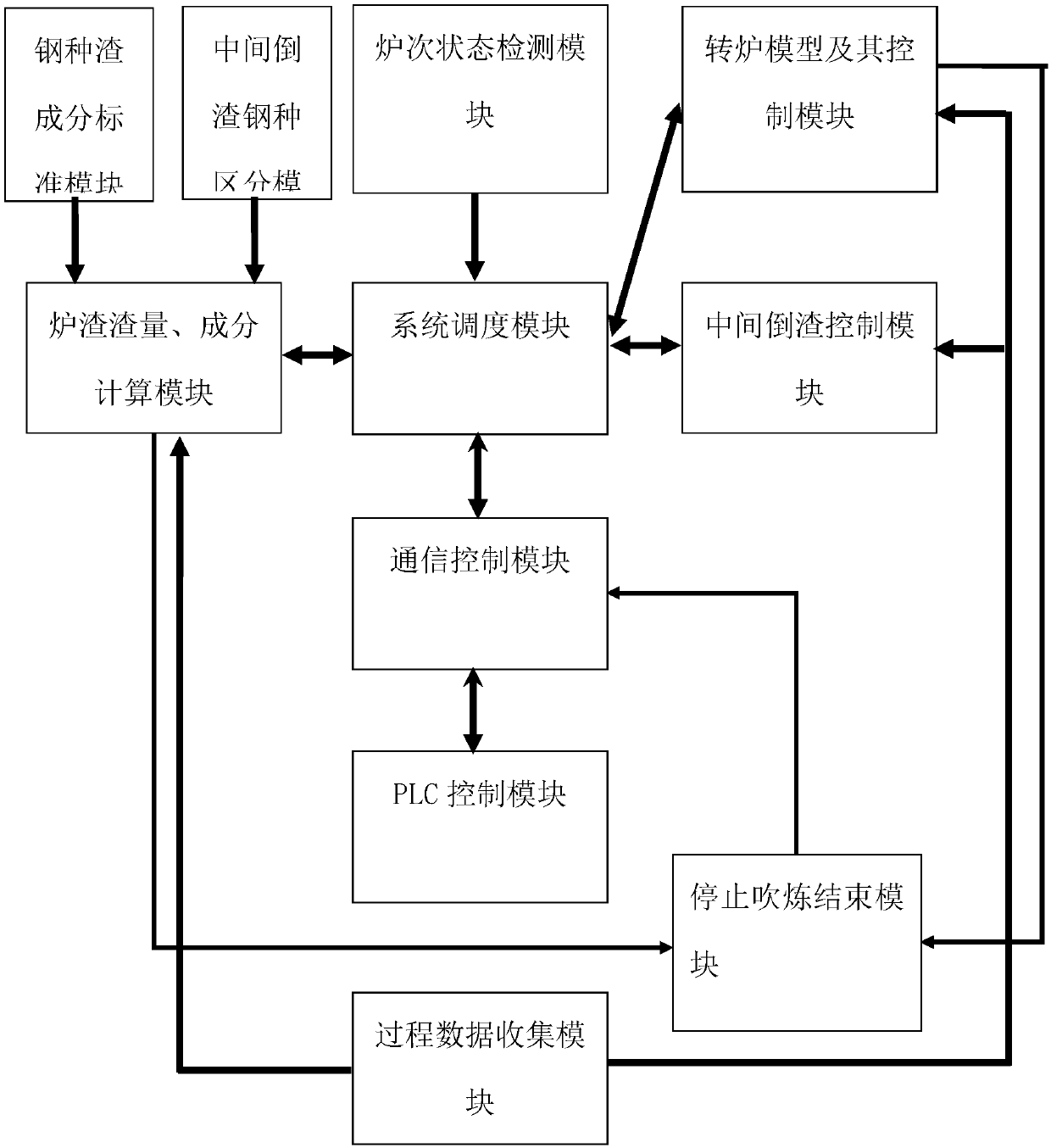

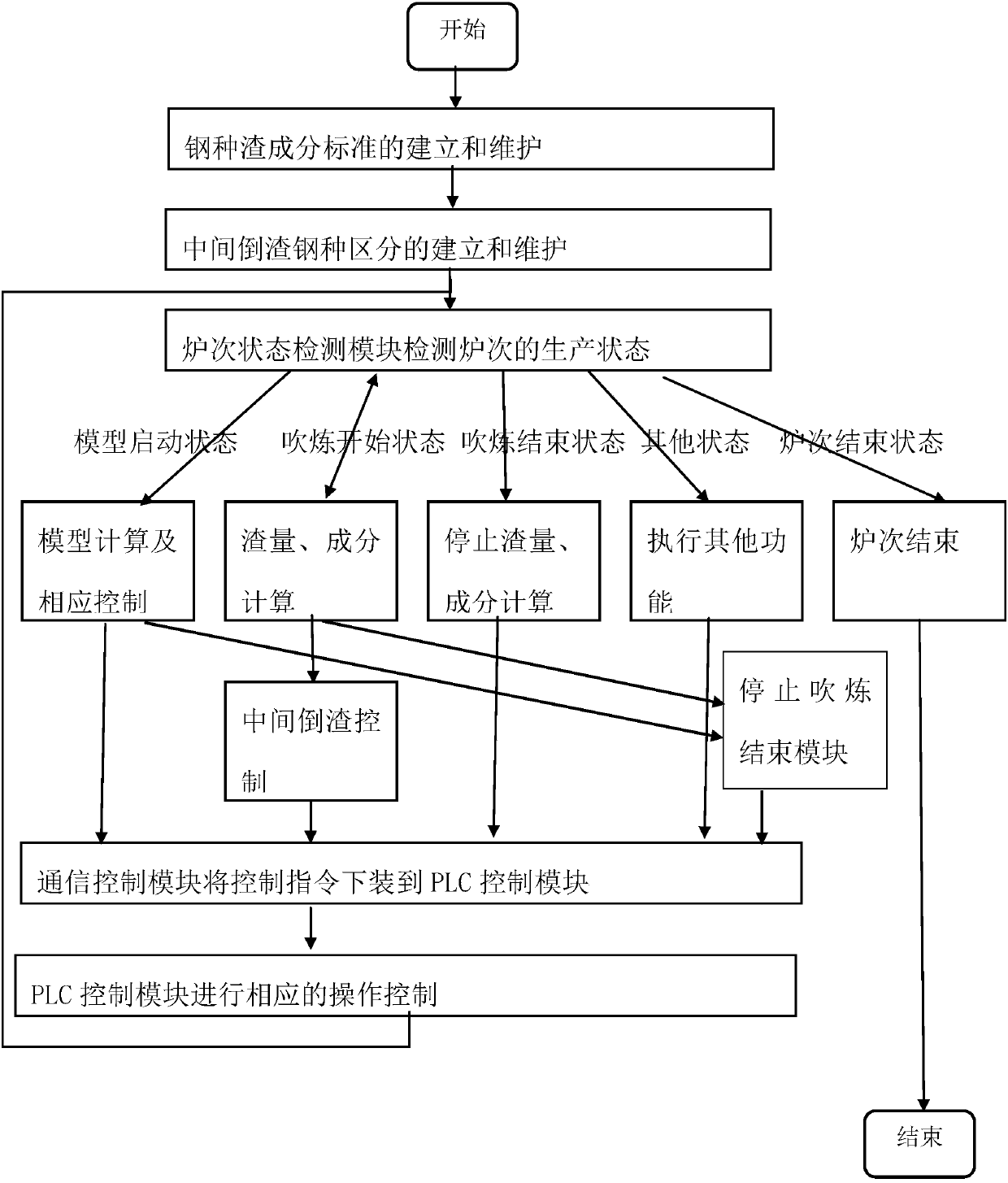

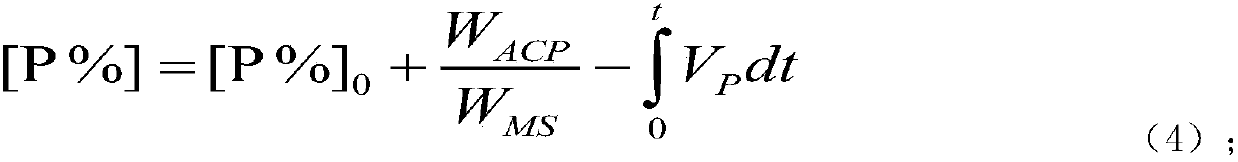

Converter smelting control method based on slag composition prediction

The invention relates to a converter smelting control method based on slag composition prediction. The control method includes the following steps that 1, establishment and maintenance of a steel typeslag composition standard are carried out; 2, establishment and maintenance of an intermediate deslagging steel type distinguishing are carried out; 3, a heat state detection module detects the heatproduction state; 4, slag quantity and composition calculation is carried out; 5, model calculation and corresponding control are carried out; 6, slag quantity and composition calculation is stopped;the step 3 is repeatedly executed; 7, intermediate deslagging control is carried out; 8, blowing operation is stopped; 9, a communication control module downloads control instructions to a PLC controlmodule; 10, the PLC control module performs corresponding operation control; the step 3 is repeatedly executed; and 11, operation is ended. By means of the technical scheme, related equipment does not need to be additionally arranged, and the real-time slag composition and weight are calculated by calculating the contents of various components contained in the molten steel slag quickly and accurately in real time.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Method for extracting nickel from high-grade matte nickel leaching residues

ActiveCN113755698AIncreased copper contentConducive to smeltingProcess efficiency improvementCopper sulfatesOrganic solventPhysical chemistry

The invention discloses a method for extracting nickel from high-grade matte nickel leaching residues. The method comprises the following steps of firstly, adding a crushed material of the high-grade matte nickel leaching residues into an organic solvent dissolved with sulfur, heating for reaction, carrying out solid-liquid separation to obtain first filtrate and first filter residues, adding the first filter residues into a copper sulfate solution, heating for reaction, carrying out solid-liquid separation to obtain second filtrate and second filter residues, carrying out evaporation condensation concentration on the second filtrate, and filtering to obtain copper sulfate crystals and nickel-containing filtrate. According to the method, Cu2S, Ni3S2, CuFeS2, a nickel-iron-copper alloy and the like in the high-grade matte nickel leaching residues are oxidized into CuS, NiS and FeS by utilizing the oxidability of elemental sulfur in the organic solvent, the elemental sulfur in the high-grade matte nickel leaching residues is dissolved in the solvent in the presence of the organic solvent, then NiS and FeS are replaced by more insoluble CuS by adopting a copper sulfate solution, nickel ions and ferrous ions enter the solution, and the copper content in the leaching residues is further improved. Only a small amount of sulfur and copper sulfate are consumed in the whole reaction, and the organic solvent can be recycled.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Calcium oxide material for clean steel smelting and preparation method thereof

The invention relates to a calcium oxide material for clean steel smelting and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: mixing 35-40 wt% of limestone particle, 30-35 wt% of limestone fine powder, 8-22 wt% of magnesium aluminum sol and 5-20 wt% of mixture, stirring uniformly, and painting or casting to form, thereby obtaining the calcium oxide material for clean steel smelting. The mixture is formed by mixing alumina micropowder, magnesite fine powder and calcium lignosulphonate in a mass ratio of 10:(3-5):(0.7-1.5); the particle size of the limestone particle is 7-0.1mm, the particle size of the limestone fine powder is 0.05-100 mu m, and the CaCO3 content of the limestone particle and limestone fine powder is greater than or equal to 92 wt%; and the mole ratio of magnesium to aluminum in the magnesium aluminum sol is 1:(0.4-2.2). The calcium oxide material has the advantages of low impurity content, proper strength and almost no influence on total oxygen content of molten steel, can adsorb oxide inclusions in the steel, and is suitable for preparing the working line of a tundish for clean steel smelting.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Preparation method of medium ferrovanadium

The invention provides a preparation method of medium ferrovanadium. The method comprises the following steps of: contacting a vanadium-extracting lixivium with a water-soluble ferric salt; controlling the pH value of a reaction system to be in a range of 1.8-2.8 through adding calcium hydroxide and / or calcium oxide in the contact process; carrying out solid-liquid separation on a product obtained after contact so as to obtain a solid containing ferric vanadate and calcium vanadate; calcining and dewatering the obtained solid and then evenly mixing the solid with aluminum powder, calcium oxide and magnesium oxide; and smelting the evenly mixed mixture in an induction furnace to obtain medium ferrovanadium. The method provided by the invention is a medium ferrovanadium preparation method which is simple in production process and low in cost.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

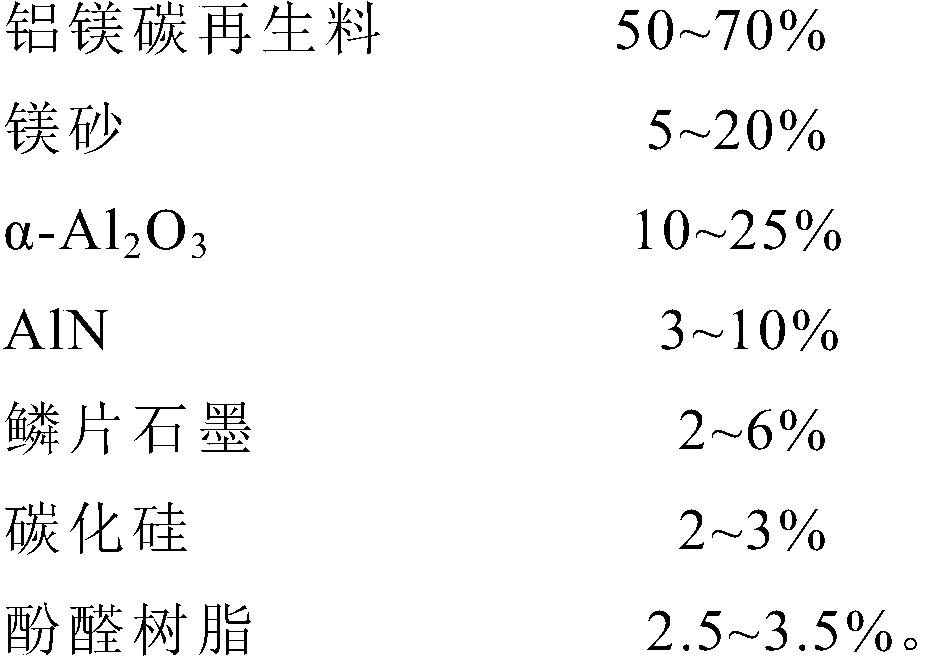

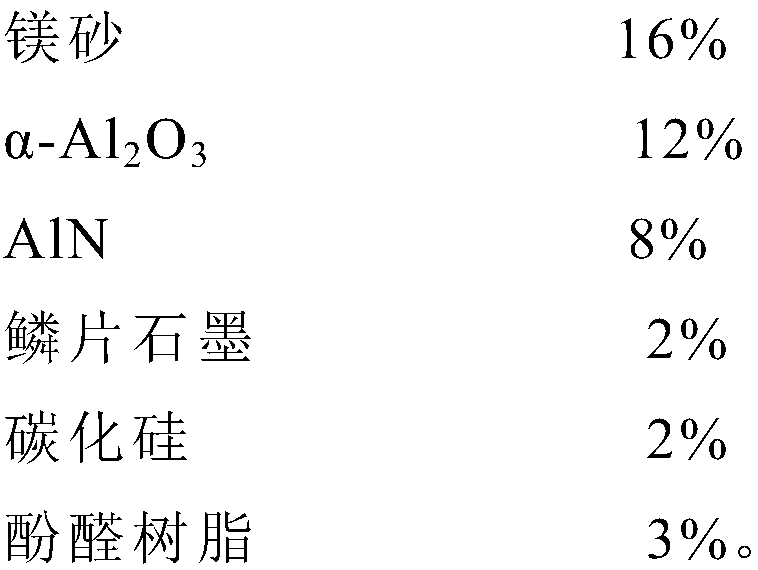

Al-Mg-C brick for steel ladle lining

The invention discloses an Al-Mg-C brick for a steel ladle lining. The Al-Mg-C brick is prepared from 50%-70% by weight of Al-Mg-C reclaimed materials, 5%-20% by weight of magnesia, 10%-25% by weightof alpha-Al2O3, 3%-10% by weight of AlN, 2%-6% by weight of crystalline flake graphite, 2%-3% by weight of SiC and 2.5%-3.5% by weight of phenolic resin. Due to addition of AlN, compared with a traditional Al-Mg-C brick, the Al-Mg-C brick is more resistant to high-temperature scouring, expansion coefficient of a brick body is reduced at the use temperature, volume stability is maintained, AlN is not corroded by molten metal, and slag resistance of the material is improved; a small amount of graphite is added, so that molten steel decarburization is facilitated, and the type of ultra-low carbonsteel is smelted; a large quantity of the Al-Mg-C reclaimed materials are adopted, therefore, the use quantity of high-bauxite clinkers or corundum particles is greatly reduced, the production cost is lower, and the Al-Mg-C brick has better social benefits and economic benefits.

Owner:WUGANG REFRACTORY CO LTD

Clean steel-refining slagging method

The invention relates to a clean steel-refining slagging method. The clean steel-refining slagging method includes the following steps in sequence: (I) converter end point control: the converter end point oxygen content is more than or equal to 600ppm, ferro-aluminium which is more than or equal to 2.0kg per ton steel is added in a steel ladle along with steel flow in the tapping process of a converter, and the amount of slag tapped from the converter is less than or equal to 9kg per ton steel; (II) in the refining process of the converter or a ladle furnace (LF), more than or equal to 3kg per ton steel of high alumina slag with Al2O3 with mass percentage being equal to or more than 70 percent is added, lime, the total amount of which is 6kg to 7kg per ton steel, is added, and fluorite which is less than or equal to 1.5kg per ton steel is added; (III) in the ladle furnace process, agitation is carried out with argon flow being 500Nl / min or more than 500Nl / min for 5 minutes or more than 5 minutes, and afterwards, the out furnace time is more than or equal to 15 minutes; and the weight percentage of the refining final slag is as follows: 35 to 40 percent of Al2O3, 41 to 45 percent of CaO and 6 percent or less of SiO2. The melting point of the target slag system of the clean steel-refining slagging method is low, and the usage amount of fluorite is less.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Environment-friendly water-based large fabric for converter fettling

The invention relates to an environment-friendly water-based large fabric for converter fettling. The fabric comprises the following components in parts by weight: 80-90 parts of magnesia, 6-10 partsof binding agent, 0.5-1 part of slaked lime and 0.5-1 part of bentonite. The preparation method comprises the steps: adding water into the supplementary material, stirring to form porridge, pouring the stirred material into a position needing to be repaired in the converter, burning for 15-25 minutes at 800-1350 DEG C, and finishing the repair when the supplementary material is large and the surface material turns red. Compared with a common converter large-area fettling material, the sintering time is shortened by about 30 minutes; during sintering, no smoke, no odor and no harmful volatile matter exist, and no harm is caused to human bodies and the environment; and during sintering, gunning operation can be carried out so that the steelmaking efficiency is improved.

Owner:鞍山赛诺新材料有限公司

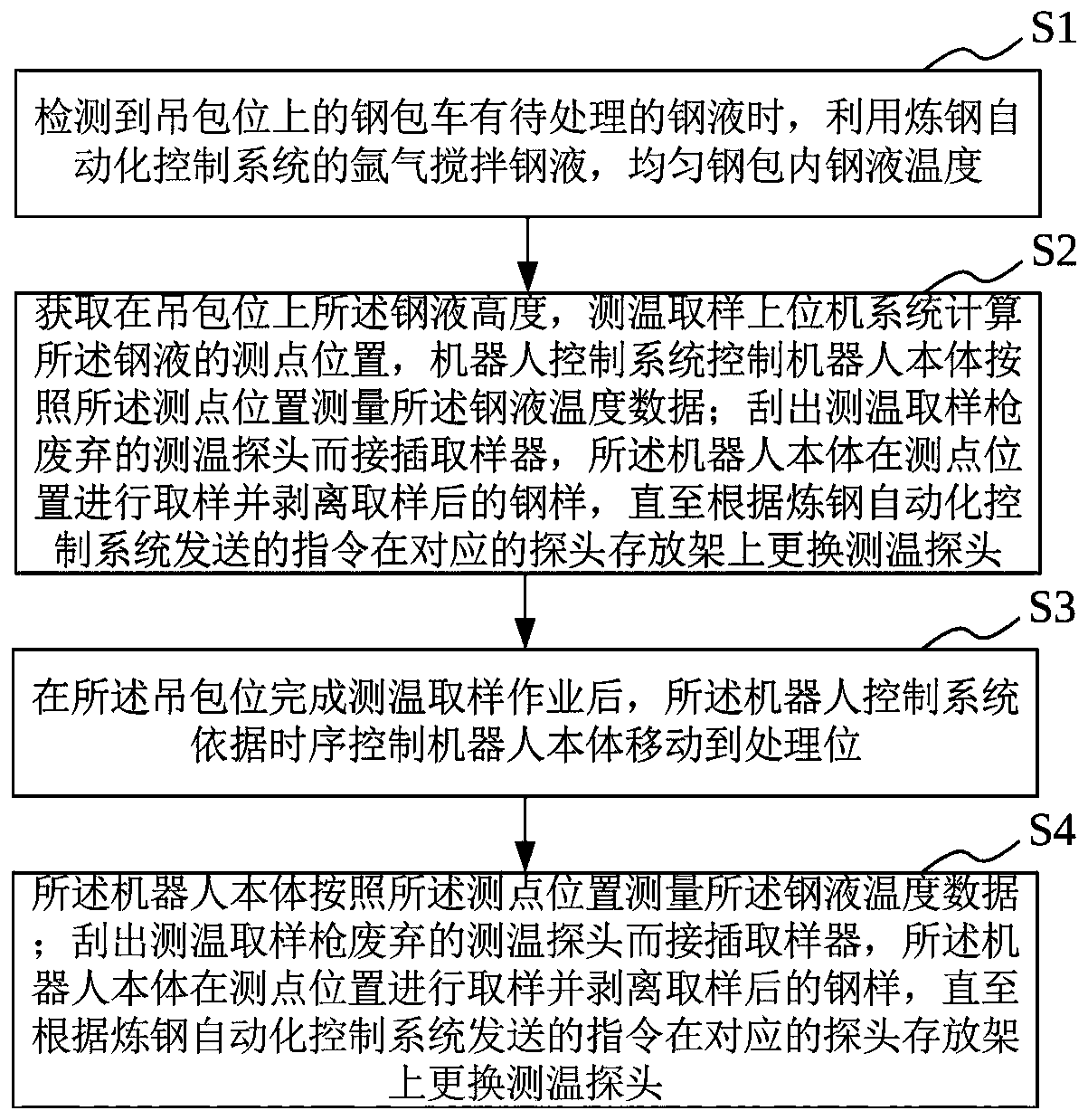

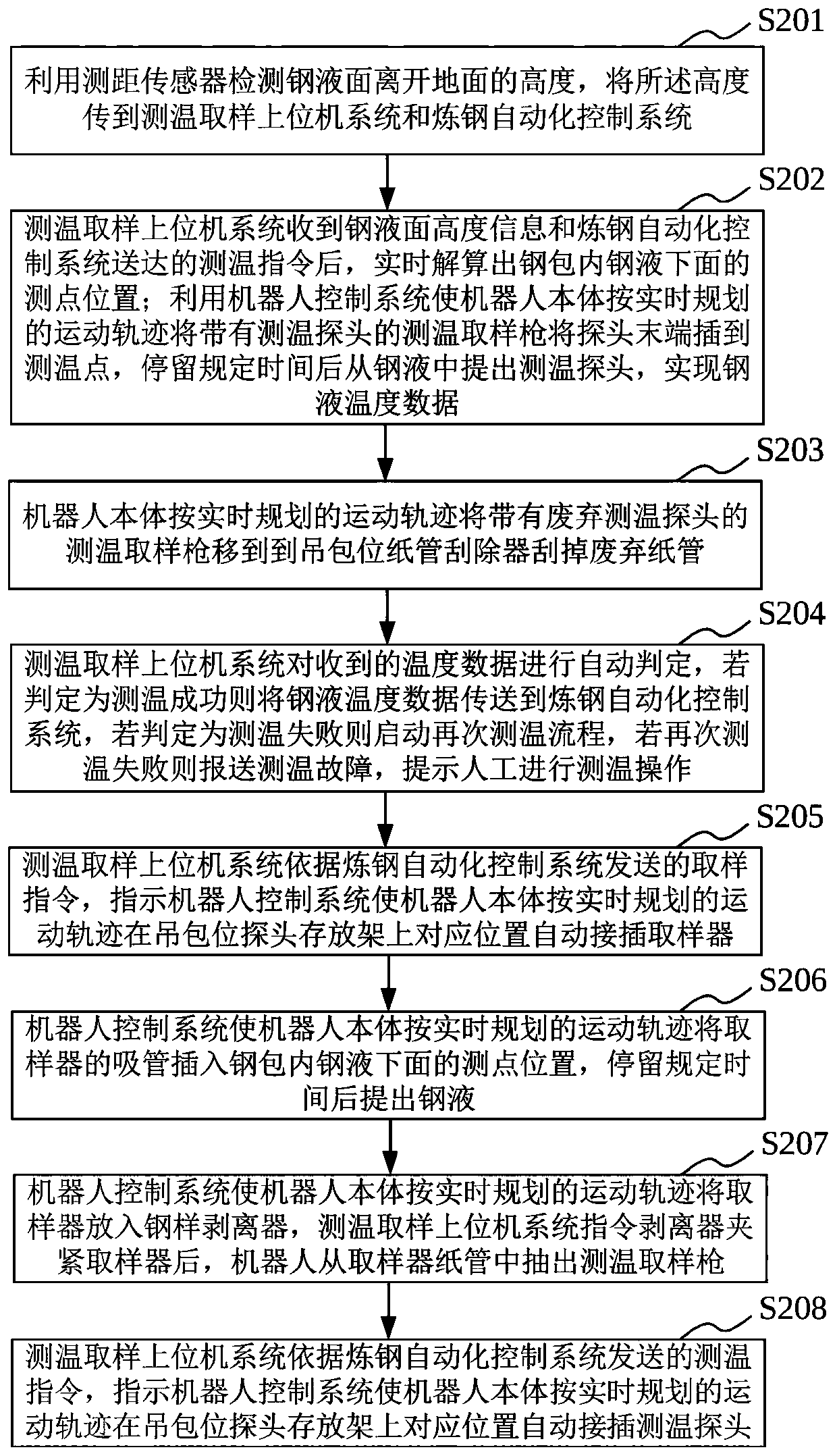

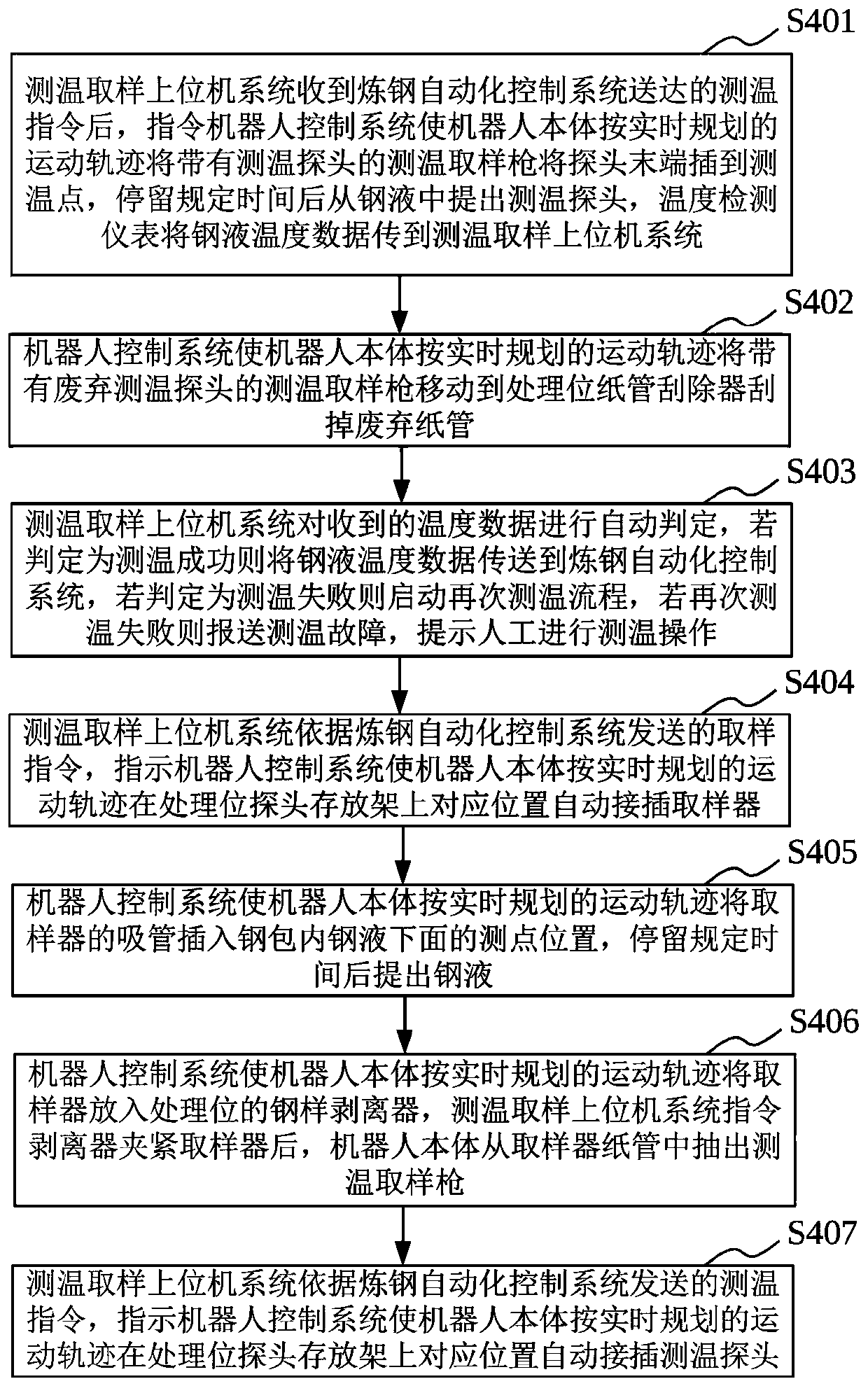

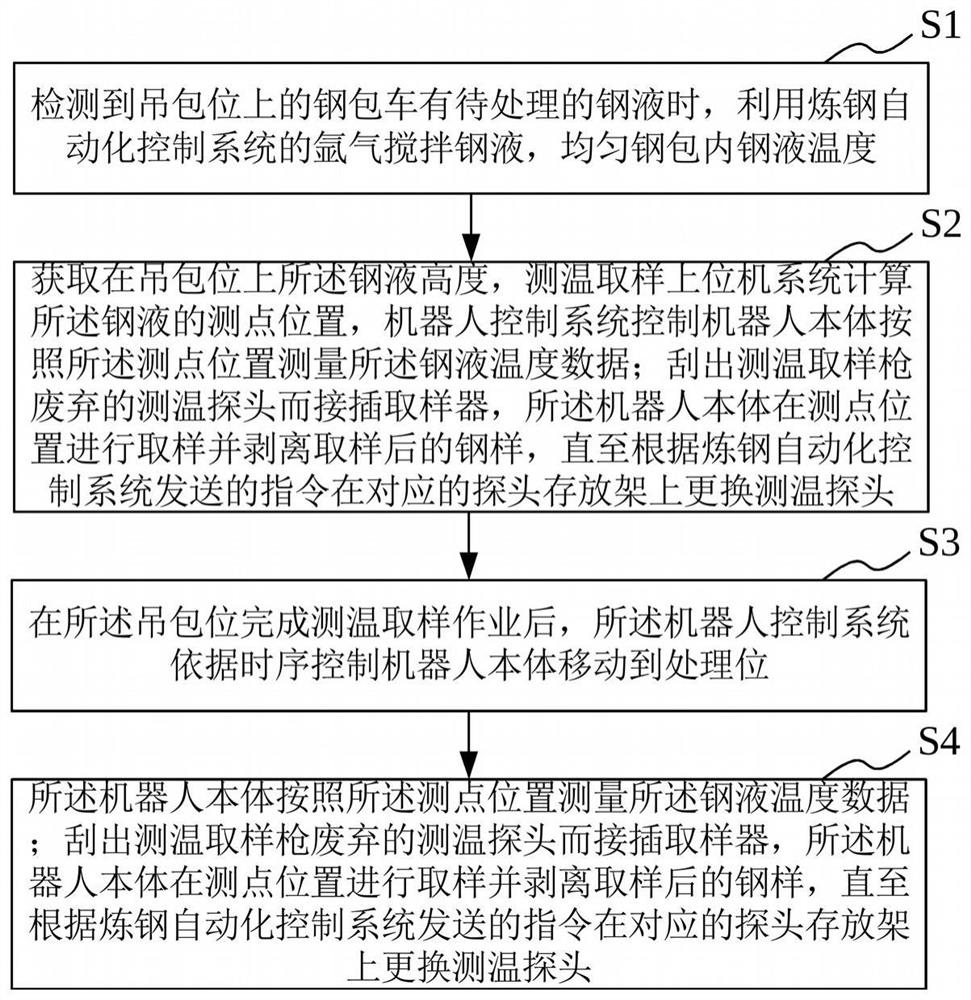

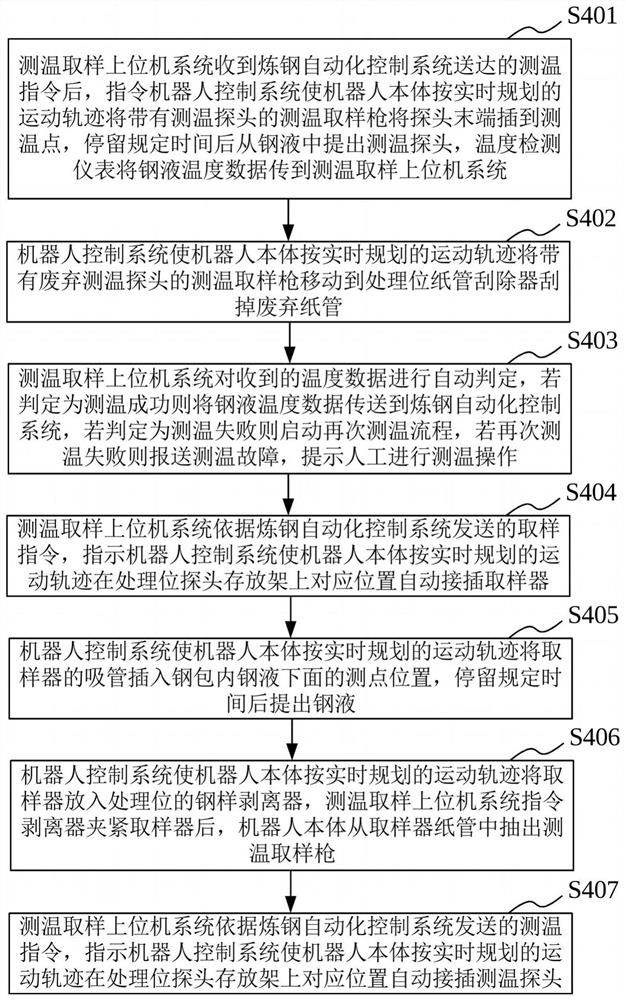

Temperature measurement sampling robot process arrangement and operation process for steelmaking production refining treatment

ActiveCN111272311AQuality assuranceEasy to controlWithdrawing sample devicesThermometer applicationsSteelmakingProcess engineering

The invention provides a temperature measurement sampling robot process arrangement and operation process for steelmaking production refining treatment. According to the method, a robot walking trackparallel to a buggy ladle track, a robot body, a temperature measurement sampling gun, a probe storage rack, a paper tube scraper and a steel sample stripping device are arranged on a main operation platform, the robot moves on the walking rail and can reach a plurality of stations, and the molten steel temperature measurement, molten steel sampling, paper tube probe insertion, paper tube probe scraping and other operations are completed at different stations. According to the present invention, the industrial robot is used for replacing the manual work for temperature measurement and sampling, operators are prevented from being scalded by the splashing of steel slag, meanwhile, the robot is used for automatic temperature measurement and sampling. The stability and consistency of the detection data are kept by controlling the consistency of the depth and position of a measuring point under the molten steel level, so that the process is an advanced technology for guaranteeing the quality of steel products.

Owner:CISDI ENG CO LTD +1

Calcium oxide material for clean steel smelting and preparation method thereof

The invention relates to a calcium oxide material for clean steel smelting and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: mixing 35-40 wt% of limestone particle, 30-35 wt% of limestone fine powder, 8-22 wt% of magnesium aluminum sol and 5-20 wt% of mixture, stirring uniformly, and painting or casting to form, thereby obtaining the calcium oxide material for clean steel smelting. The mixture is formed by mixing alumina micropowder, magnesite fine powder and calcium lignosulphonate in a mass ratio of 10:(3-5):(0.7-1.5); the particle size of the limestone particle is 7-0.1mm, the particle size of the limestone fine powder is 0.05-100 mu m, and the CaCO3 content of the limestone particle and limestone fine powder is greater than or equal to 92 wt%; and the mole ratio of magnesium to aluminum in the magnesium aluminum sol is 1:(0.4-2.2). The calcium oxide material has the advantages of low impurity content, proper strength and almost no influence on total oxygen content of molten steel, can adsorb oxide inclusions in the steel, and is suitable for preparing the working line of a tundish for clean steel smelting.

Owner:山东产研中科高端化工产业技术研究院有限公司

Method for smelting medium-low carbon ferromanganese

ActiveCN114574641AAvoid formingAvoid severe erosionBlast furnace detailsManufacturing convertersSmelting processBlast furnace

The invention relates to a method for smelting medium-low carbon ferromanganese, which is characterized in that the smelting cost of the medium-low carbon ferromanganese is further reduced by setting a blast furnace-converter process, and the smelting cost of the medium-low carbon ferromanganese is further reduced by mixing and blowing carbon dioxide and oxygen in different proportions in multiple directions in the converter process. The corrosion to equipment in the converter smelting process is reduced to the minimum, meanwhile, the volatilization loss of manganese is reduced, and the quality of a final product is guaranteed.

Owner:UNIV OF SCI & TECH BEIJING

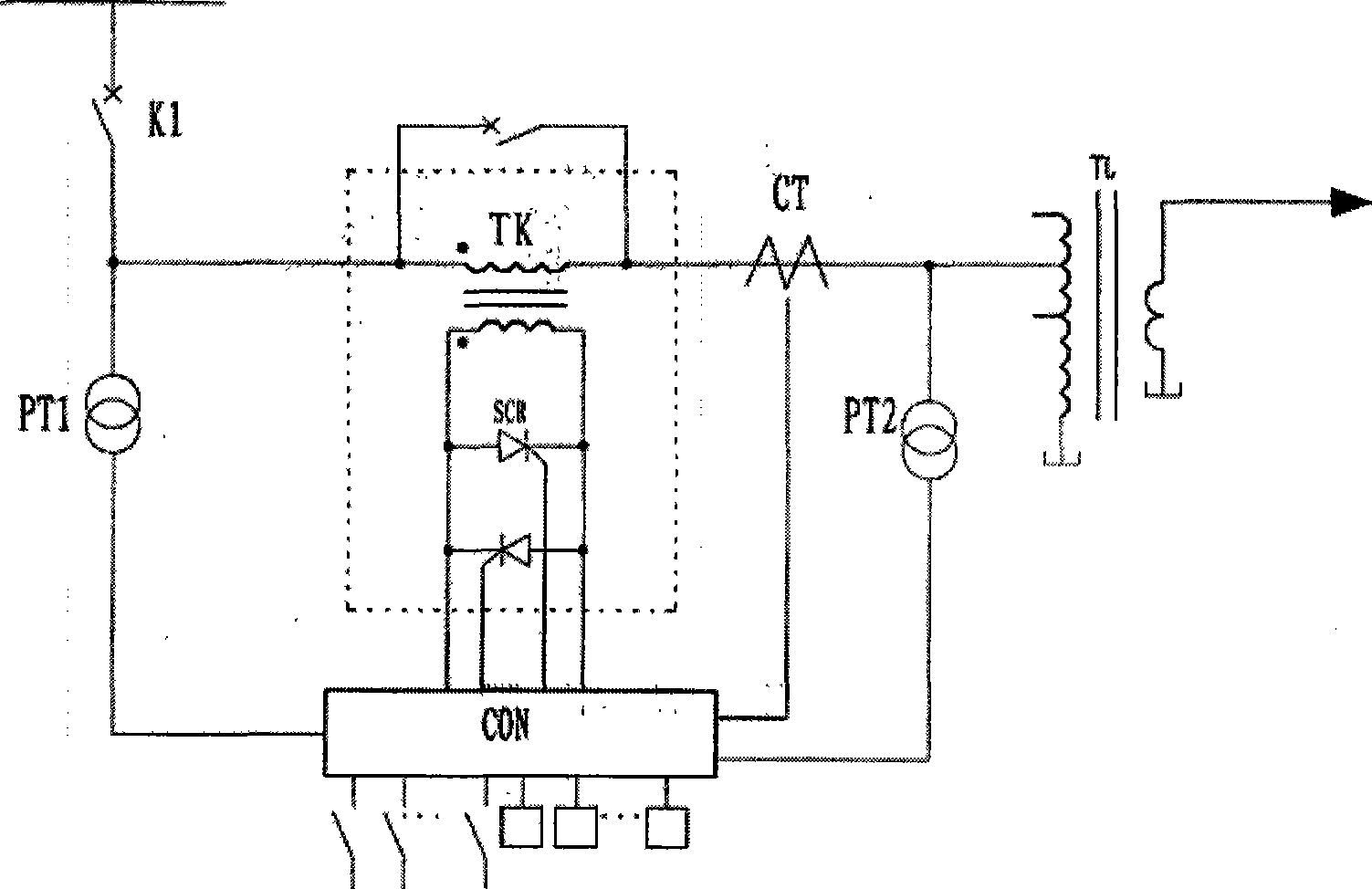

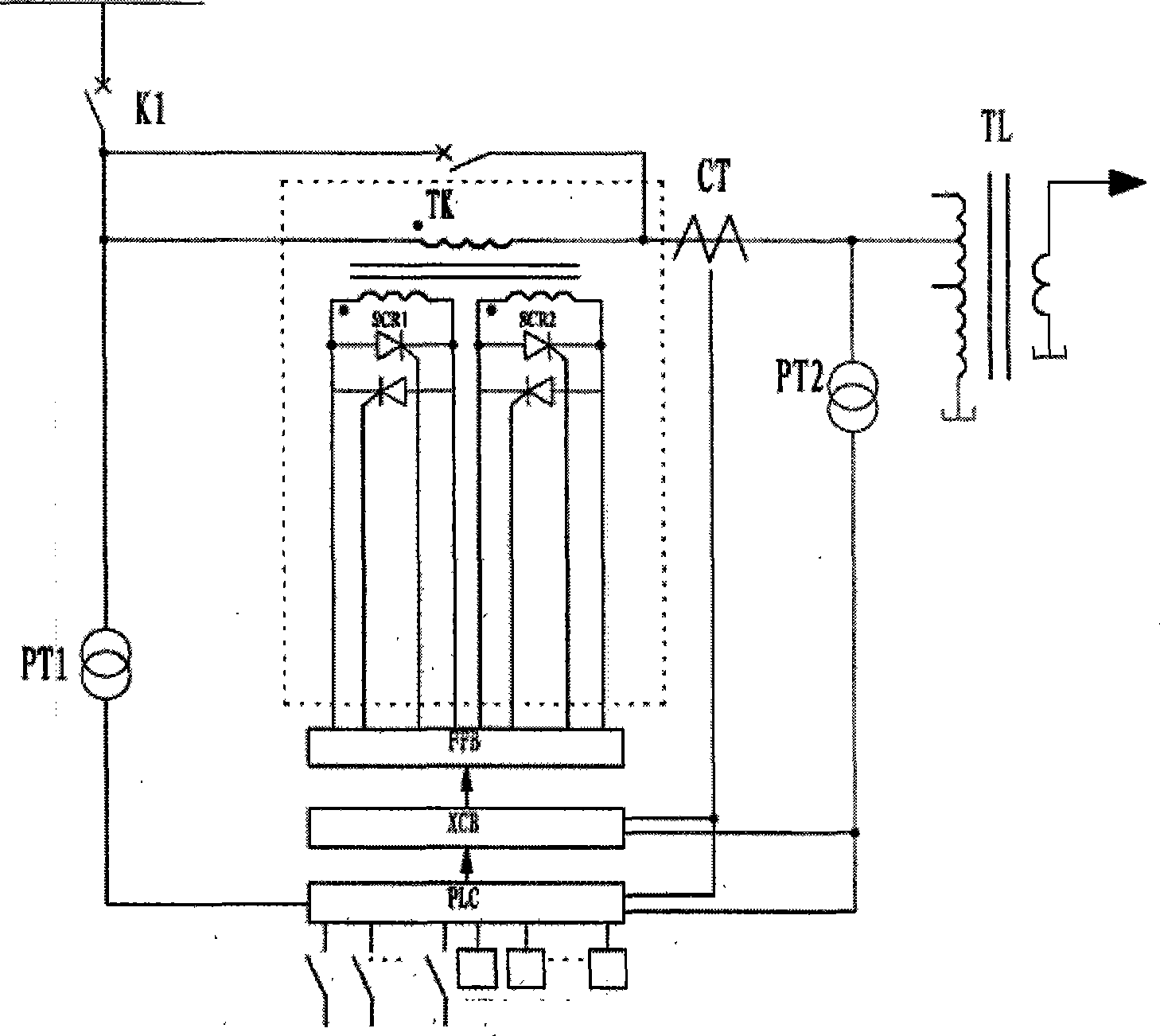

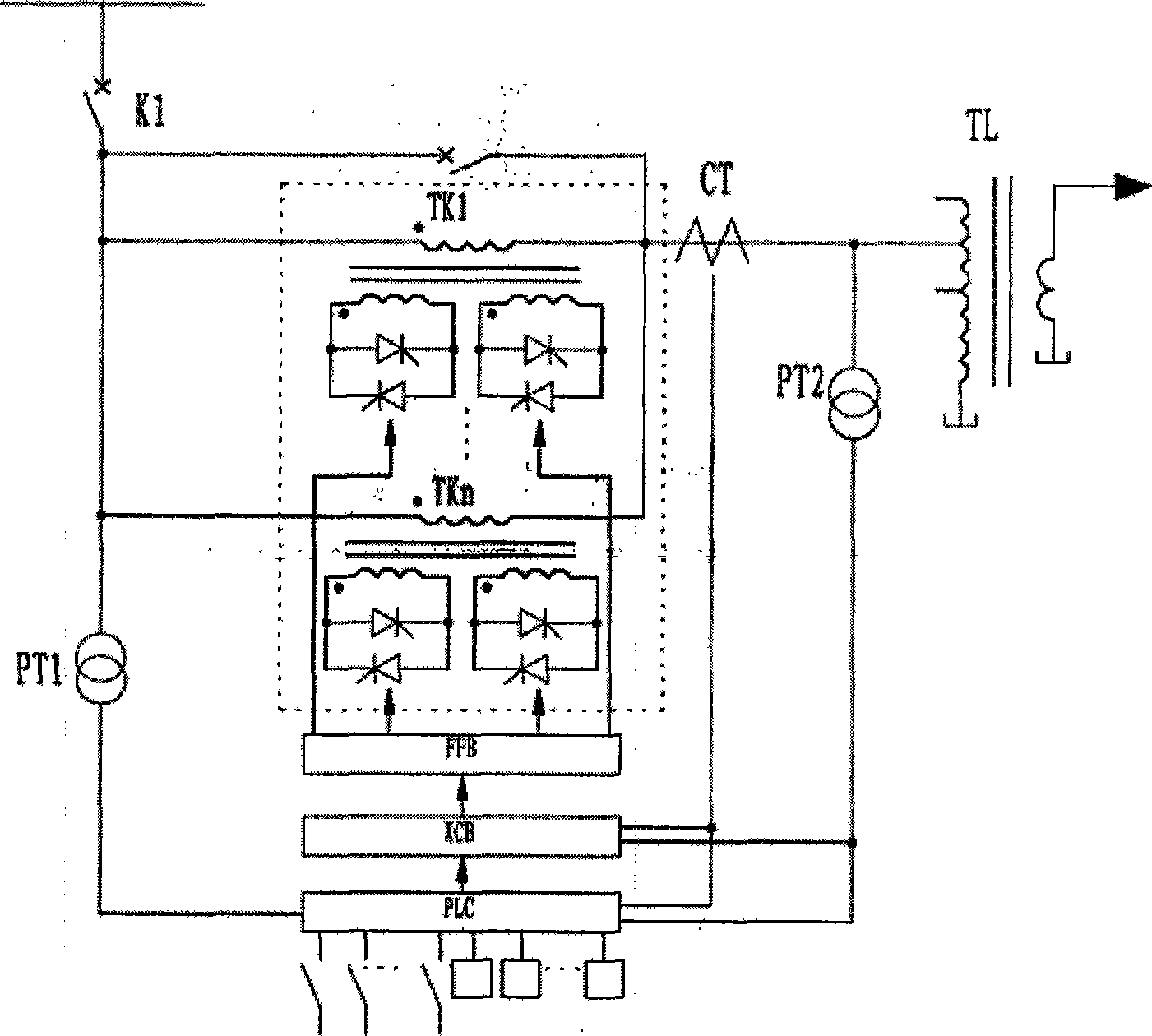

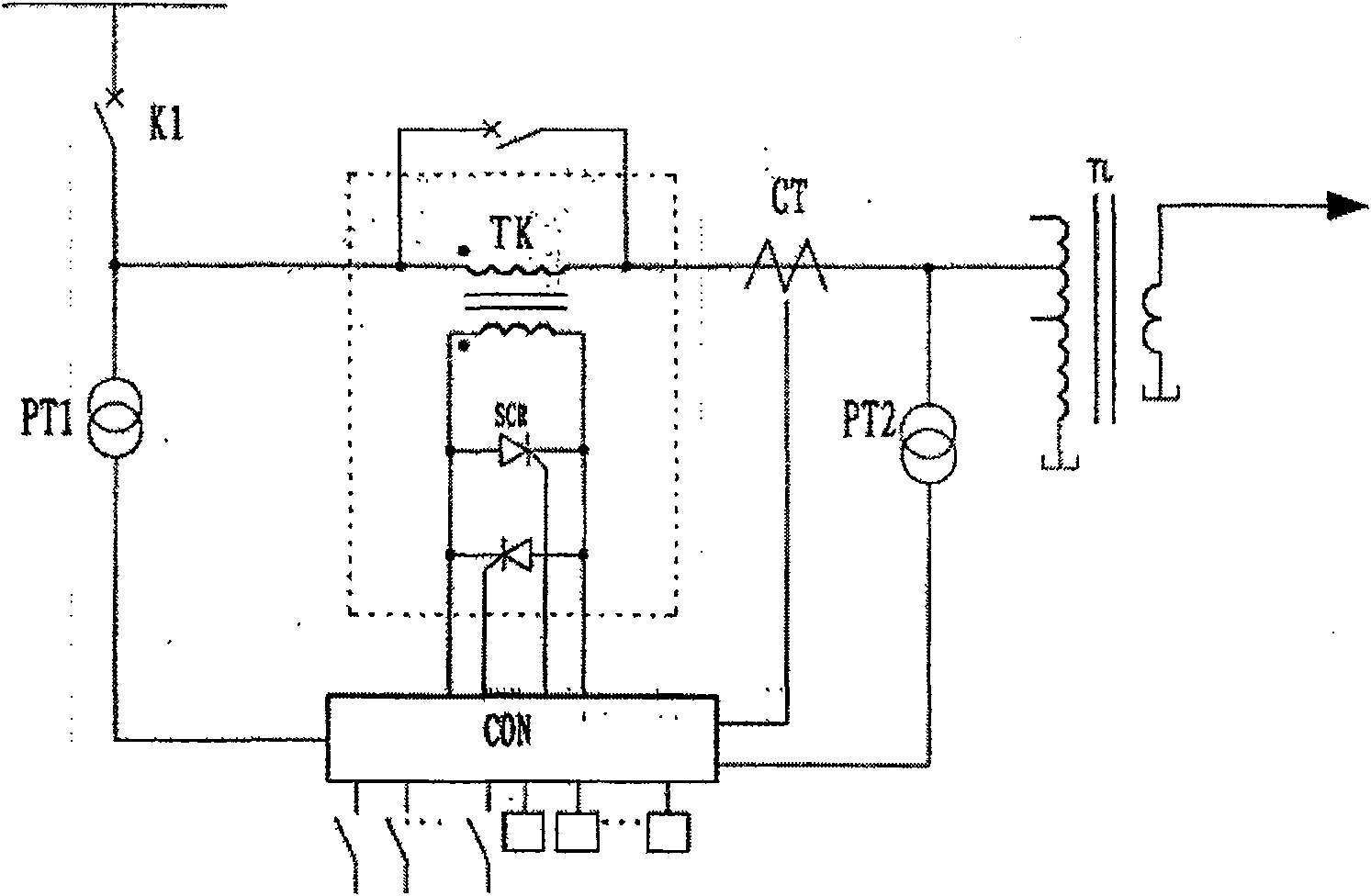

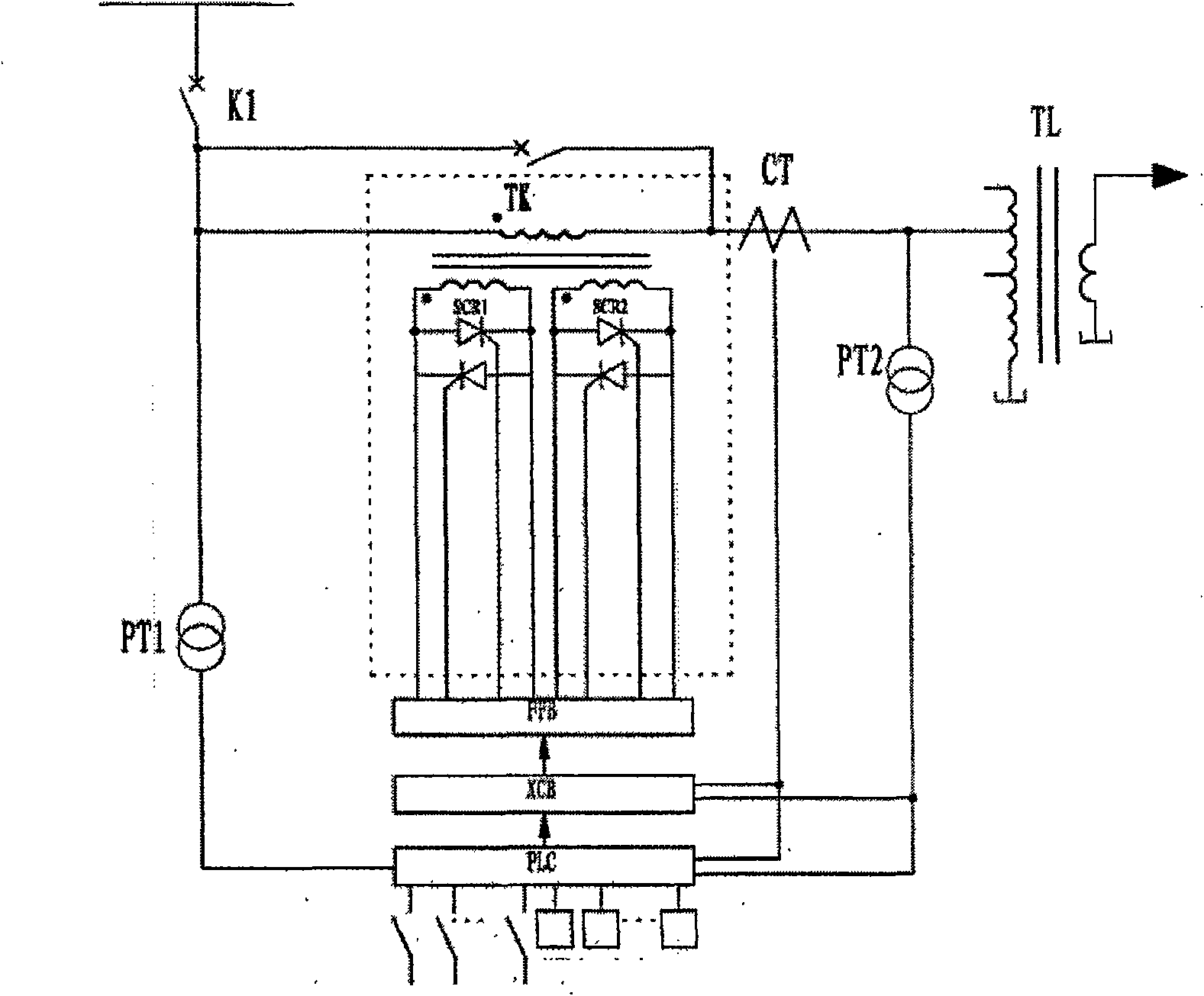

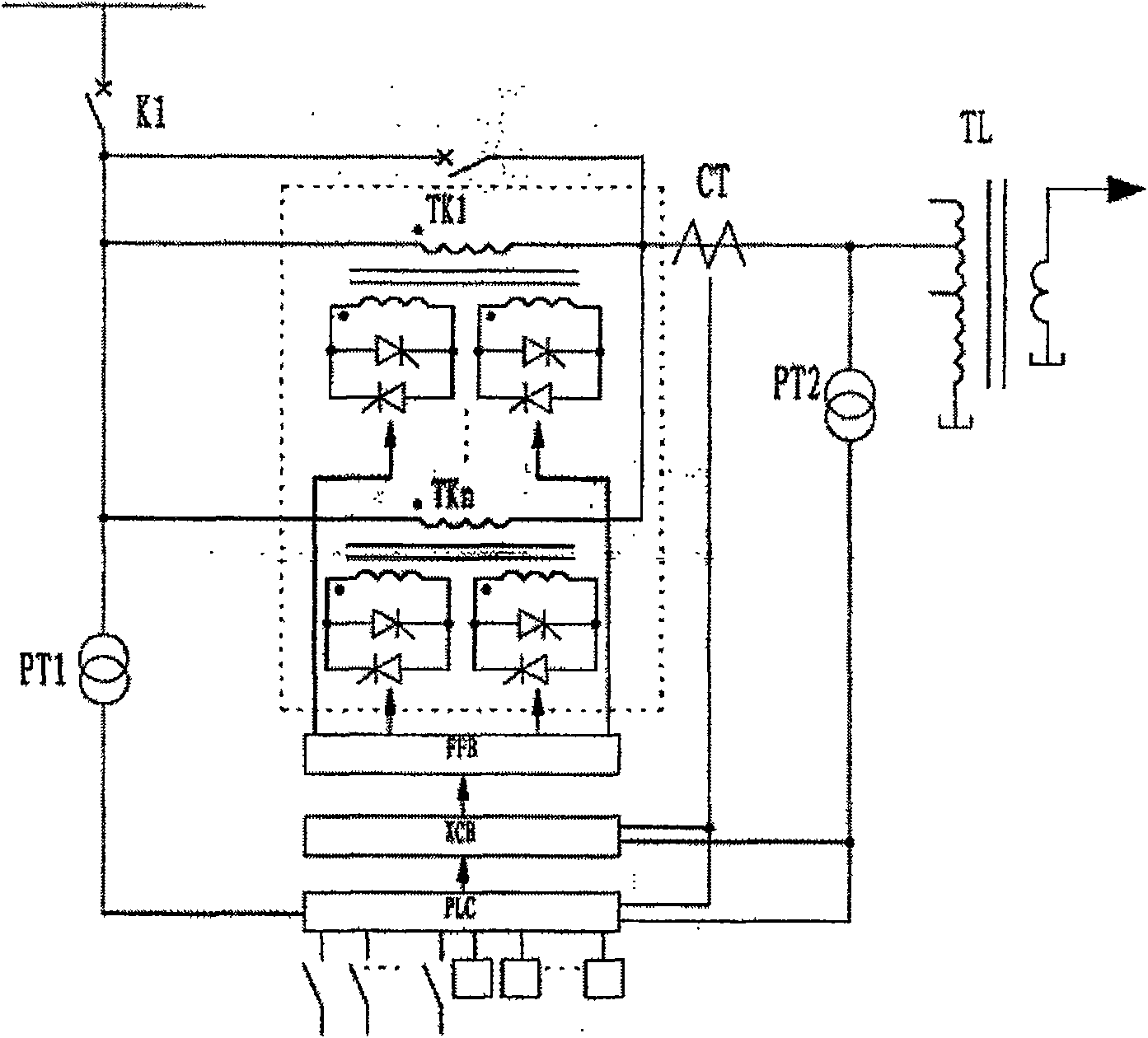

Environment-friendly energy-saving electric arc furnace control device

InactiveCN101430543AIncrease productivityReduce unit consumptionElectric controllersProgramme control in sequence/logic controllersElectric arc furnacePower grid

The invention relates to a green energy saving electric arc furnace controlling device, which can lead that the electric arc furnace has little influence on a power system, can increase production efficiency of the electric arc furnace and reduces unit consumption. The device has the technical proposal that the green energy saving electric arc furnace controlling device is characterized in that the device is also provided with a switch transformer, a main control unit circuit and a phase-control trigger element circuit; the beginning terminal of the primary side winding of the switch transformer is connected with a power supply by a breaker while the end is connected with the corresponding tap of an arc furnace transformer; two ends of the secondary side winding of the switch transformer are connected with thyristors which are positive and negative in parallel connection. The main control unit circuit and the signal input end of the phase-control trigger element circuit are connected with a current transformator, a pressure transformator. The given input end of the phase-control triggers element circuit is connected with the output end of the main control unit circuit output. The output end of the phase-control trigger element circuit is connected with the control end of the thyristors.

Owner:HARBIN PATEERN SCI & TECH

A method for automatic temperature measurement and sampling of steelmaking converter door

ActiveCN110146335BEnd point carbon content judgment is stableJudgment is stableWithdrawing sample devicesSensing heat from liquidsSteelmakingProcess engineering

The invention provides a method for automatic temperature measurement and sampling of a steelmaking converter door, which includes a running mechanism that moves on the ground track in front of the converter door, a suspended furnace front fire door and a temperature measuring and sampling robot that are jointly installed on the running mechanism. Among them, when the temperature measuring and sampling robot is in the standby position, its steel slag splash protection plate and the suspended furnace front fire door form a complete slag splash and high temperature radiation protection baffle; the robot collects real-time image information of the furnace mouth to provide information for operators to maintain the converter , the robot collects the position information of molten steel and slag blocks, and can independently decide and control the extension distance and insertion position of the temperature measurement sampling probe. The invention uses a robot to replace manual temperature measurement and sampling, which can prevent operators from being scalded by steel slag spray and significantly improve the success rate of operations, and is an advanced technology with wide application prospects.

Owner:CISDI ENG CO LTD +1

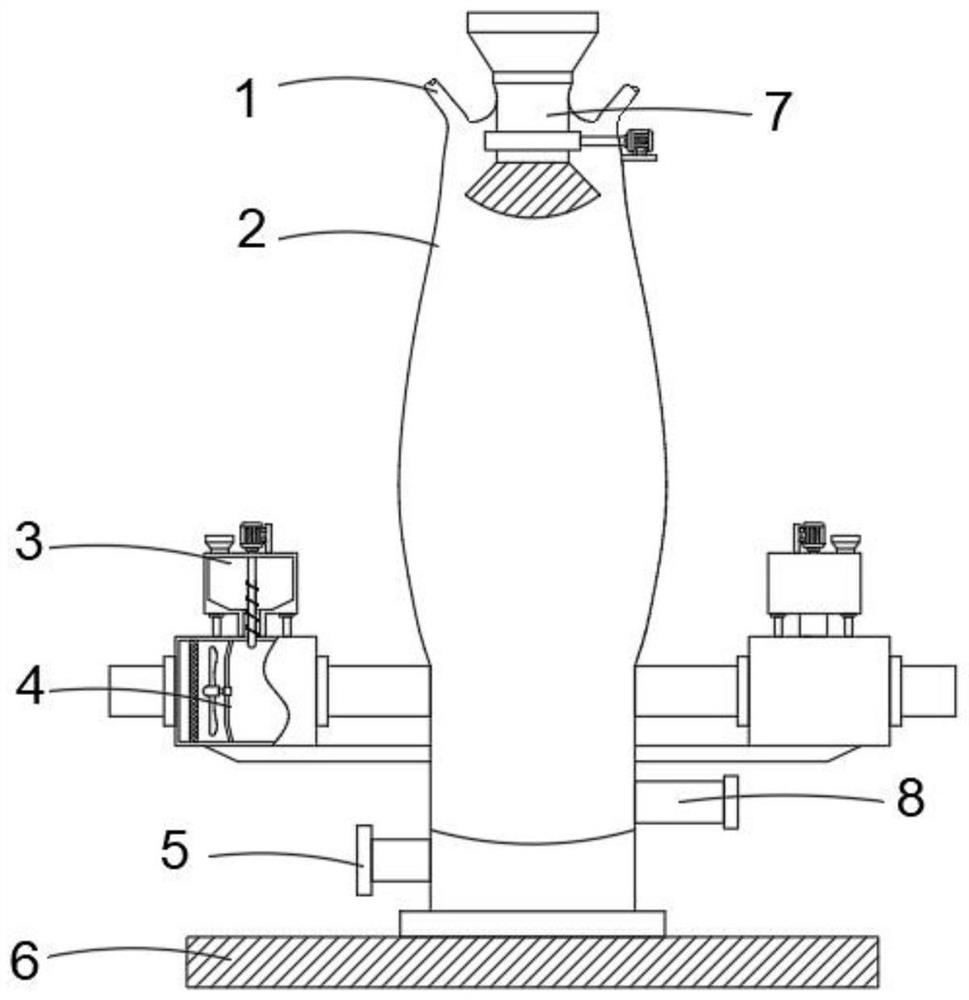

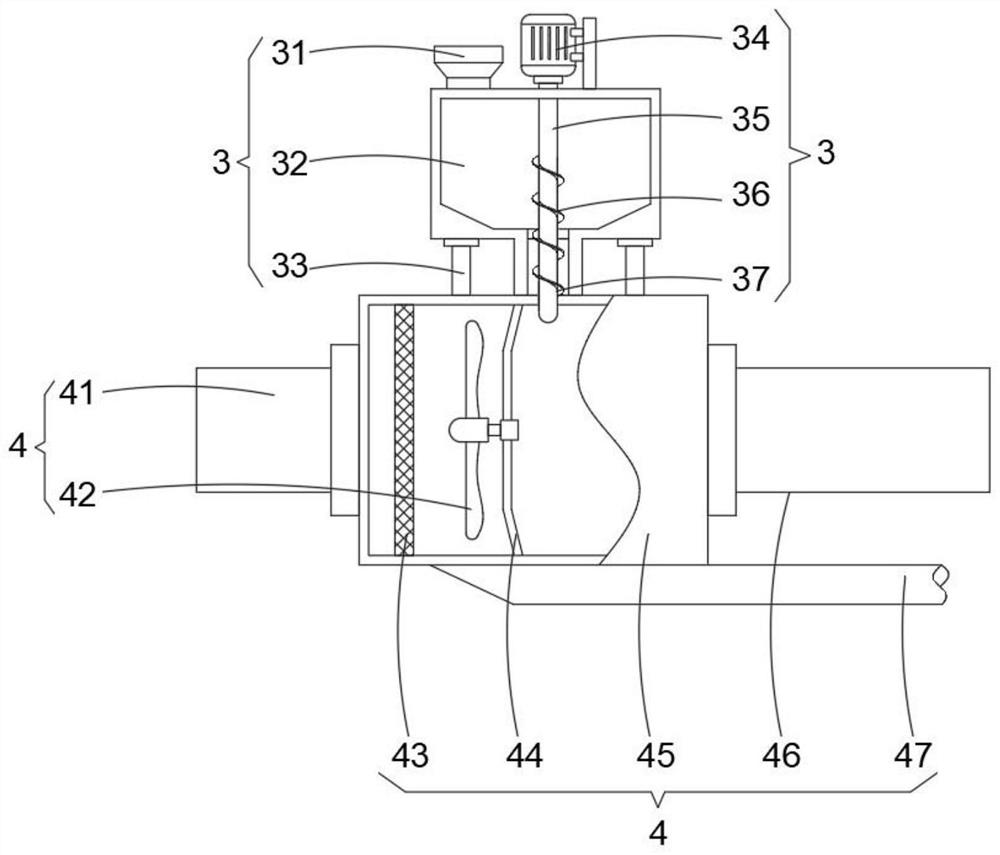

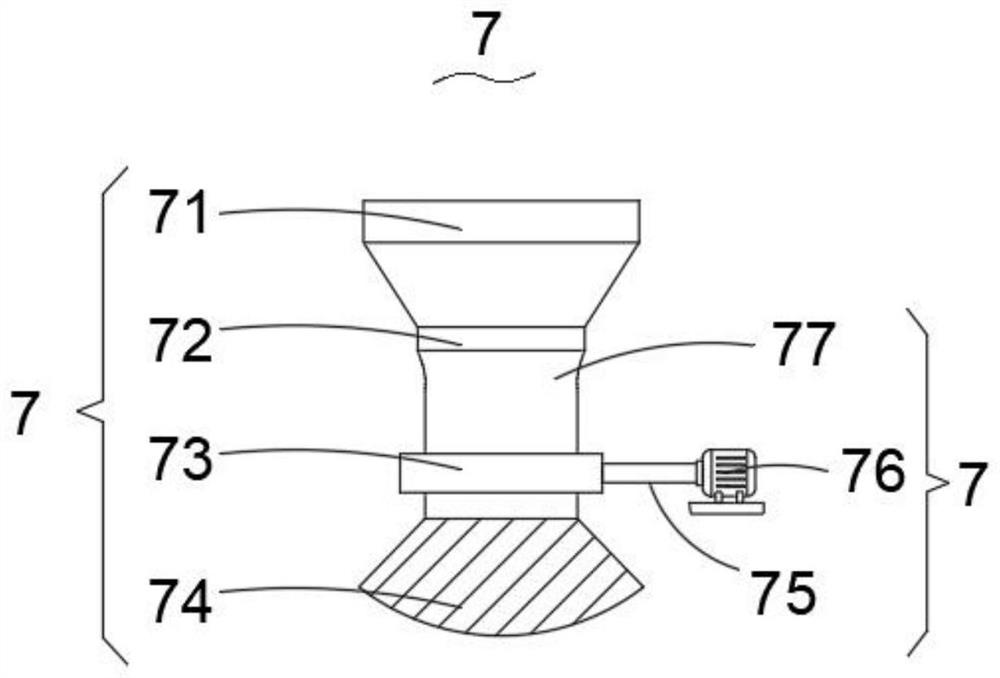

Smelting furnace for aluminum-titanium-boron wire production

InactiveCN113983812AReduce usageConducive to smeltingMaintainance of heating chambersCharge manipulationSlagCoke

The invention provides a smelting furnace for aluminum-titanium-boron wire production. The smelting furnace for aluminum-titanium-boron wire production comprises a blast furnace body, wherein the top of the blast furnace body is fixedly connected with two gas pipes communicating with the interior of the blast furnace body, and the bottom of the blast furnace body is fixedly connected with an aluminum outlet and a slag discharging opening which communicate with the interior of the blast furnace body; a feeding mechanism, wherein the top of the blast furnace body is connected with the feeding mechanism for feeding; two air inlet mechanisms, wherein the bottom of the blast furnace body is connected with two symmetrical air inlet mechanisms, each air inlet mechanism comprises a first air inlet pipe, a mixing box, a second air inlet pipe and a mounting plate, the outer surface of the bottom of the blast furnace body is fixedly connected with the mounting plate, and the upper surface of the mounting plate is fixedly connected with the mixing box, an air inlet in one side wall of the mixing box is connected with a first air inlet pipe, and an air outlet in the other side wall of the mixing box communicates with the blast furnace body through a second air inlet pipe. The smelting furnace for aluminum-titanium-boron wire production has the advantages that the coke ratio is reduced, and the inlet air temperature is increased.

Owner:湖南博溥立材料科技有限公司

Heating agent for metal smelting and preparing method of heating agent

A heating agent for metal smelting comprises components including, by mass, 21-25 parts of aluminum powder, 2-8 parts of zinc silicate, 5-10 parts of quartz sand, 2-5 parts of kieselguhr, 11-13 partsof silicon carbide, 3-10 parts of an additive, 2-8 parts of water glass, 3-6 parts of pulverized coal, 11-15 parts of nitrate, 3-6 parts of a stabilizer and 8-13 parts of a binding agent. A preparingmethod of the heating agent for metal smelting comprises the following steps that firstly, solid substances in the components are added in a reaction kettle, and ball milling and uniform mixing are conducted; secondly, liquid components are added in the mixture, and uniform mixing is conducted; thirdly, and after natural cooling, the mixture is scattered into powder. The components used in the obtained heating agent do not have harmful influences on the environment, the property of the contained components is stable, the duration of the heating effect is long, the heating effect can be effectively improved, the heat efficiency of heating can be effectively improved, and metal smelting is facilitated.

Owner:徐州宏阳新材料科技股份有限公司

Process layout and operation flow of temperature measurement and sampling robot for steelmaking production and refining treatment

ActiveCN111272311BQuality assuranceEasy to controlWithdrawing sample devicesThermometer applicationsSteelmakingProcess engineering

The invention provides a process layout and operation flow of a temperature measuring and sampling robot for steelmaking production and refining treatment, including: a robot running track parallel to the ladle car track, a robot body, a temperature measuring and sampling gun, and a probe storage rack are arranged on the main operating platform , paper tube scraper and steel sample stripping device, the robot moves on the traveling track, and can reach multiple stations, and complete steel temperature measurement, molten steel sampling, paper tube probe insertion, and paper tube scraping at different stations probes etc. The present invention uses industrial robots to replace manual temperature measurement and sampling, avoiding operators being scalded by steel slag spray, and at the same time, using robots to automatically measure temperature and sampling, by controlling the consistency of the depth and position of the measuring point under the liquid steel surface, the accuracy of the detection data is maintained. Stability and consistency are an advanced technology to ensure the quality of steel products.

Owner:CISDI ENG CO LTD +1

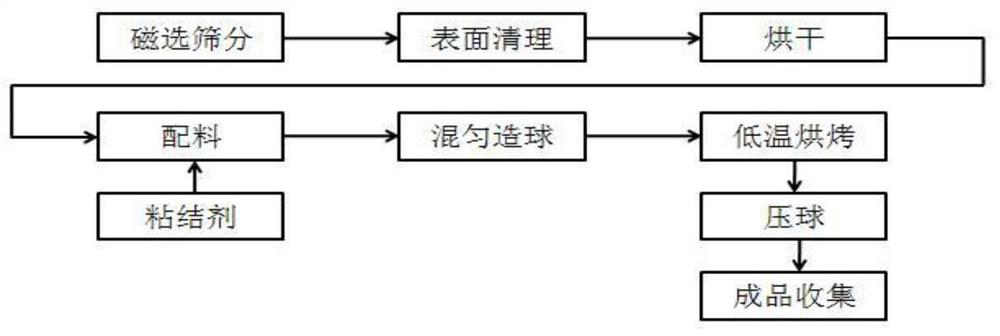

A kind of preparation method of spherical granular iron for steelmaking

ActiveCN111154972BEasy to useIncrease lossProcess efficiency improvementSteelmakingMaterials science

A method for preparing spherical granular iron for steelmaking, comprising the following steps: crushing and magnetically separating converter waste slag to screen out granular iron with a particle size of less than 15 mm; cleaning the surface of the granular iron; then air-drying or oven-drying; 75% to 90%, and the mass of the binder accounts for 10% to 25% for batching; put the small iron and binder into the mixer for mixing, and make a material ball of 45 to 65mm after mixing. Low-temperature baking; after the low-temperature baking, the temperature of the material ball drops to 35-45°C, and the material ball is pressed into spherical granular iron with a diameter of 40-60mm. The present invention bonds small grains of iron together, enlarges the size of small grains of iron, facilitates the coating of anti-high temperature oxidation materials on the surface of the grains of iron, and prevents the oxidation of small grains of iron in a high temperature environment of steelmaking, resulting in high loss of grain iron , and can be coerced by light and thin scrap steel in the recycling and processing process, so that small iron particles can be effectively recycled.

Owner:ANGANG STEEL CO LTD

A kind of acid corrosion-resistant high-strength low-nickel duplex stainless steel and its manufacturing method

ActiveCN105441830BGood acid corrosion resistanceExcellent pickling corrosion resistanceNuclear powerAcid corrosion

Owner:BAOSTEEL DESHENG STAINLESS STEEL

A method for removing alkali metals by sintering

The invention discloses a method for removing alkali metals in a sintering process. CaCl2 powder is added in the sintering raw materials, and in the sintering process, CaCl2 powder is reacted with alkali metals existing in the form of silicate in the sintering raw materials to generate more stable NaCl and KCl; since the pressure in the furnace is in a negative pressure state during the sintering, the boiling points of NaCl and KCl are lower, so that NaCl and KCl are evaporated in the combustion layer and discharged to the outside of the reaction zone; simultaneously, the low-temperature reduction strength of the sintered ore is improved by spraying a CaCl2 solution on the cooled sintered ore; due to the adoption of the method, alkali metals contained in the metal ore are effectively removed, the alkali metal load in a smelting process is reduced, the service life of the blast furnace is prolonged and the harm of alkali metals is reduced, thereby being beneficial to the smelting of the blast furnace.

Owner:红河钢铁有限公司 +1

Green energy-saving electric arc furnace control device

InactiveCN100582973CIncrease productivityReduce unit consumptionElectric controllersProgramme control in sequence/logic controllersElectric arc furnacePower grid

The invention relates to a green energy saving electric arc furnace controlling device, which can lead that the electric arc furnace has little influence on a power system, can increase production efficiency of the electric arc furnace and reduces unit consumption. The device has the technical proposal that the green energy saving electric arc furnace controlling device is characterized in that the device is also provided with a switch transformer, a main control unit circuit and a phase-control trigger element circuit; the beginning terminal of the primary side winding of the switch transformer is connected with a power supply by a breaker while the end is connected with the corresponding tap of an arc furnace transformer; two ends of the secondary side winding of the switch transformer are connected with thyristors which are positive and negative in parallel connection. The main control unit circuit and the signal input end of the phase-control trigger element circuit are connected with a current transformator, a pressure transformator. The given input end of the phase-control triggers element circuit is connected with the output end of the main control unit circuit output. The output end of the phase-control trigger element circuit is connected with the control end of the thyristors.

Owner:HARBIN PATEERN SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com