Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2741 results about "Magnesite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesite is a mineral with the chemical formula MgCO₃ (magnesium carbonate). Iron, manganese, cobalt and nickel may occur as admixtures, but only in small amounts.

Magnesia-calcia dry type working liner for tundish and preparation thereof

The invention relates to a magesia-calcia tundish dry working lining refractory and a method for preparing the same. The technical scheme comprises mixing 55-65wt% of particle material with a grain size of 3-0mm, 22-35wt% of powder with a grain size less than 0.088mm, 0 or 0.5-8wt% of additives and 6-12wt% of binding agent according to a theoretical content of MgO 55-85wt% and CaO 10-40wt%, baking at 200-350 DEG C after stirring and vibration molding, getting the tundish dry working lining after demoulding, wherein the particle material is one or a mixture more than one selected from the magnesia, magnesite, limestone and dolomite; the powder is one or a mixture more than one selected from the magnesia, hydrated lime, limestone, dolomite and magnestie. The invention has advantages of simple technology, convenient construction, low cost, environment friendly and saving energy, and the magesia-calcia tundish dry working lining has a good metallurgical effect and the feature of easy disintegration after use.

Owner:WUHAN UNIV OF SCI & TECH

Non-oxide composite low-carbon magnesia-carbon brick

A non-oxide compound magnesite-graphite brick containing carbon less than 6% belongs to a fire resisting material. The material contains magnesia of 75-94%, carbon of 1-5%, non-oxide such as nitride and boride of 0.4-20%, additive of 0-5%, and binder containg carbon. Such magnesite-graphite brick with low carbon has a low heat conductivity, a small acierating to the molten steel and less pollution to the low carbon steel compared to the common magnesite-graphite brick. The magnesite-graphite brick has a good slag resistance because the magnesia is the primary component. And it also has a good heat shock capacity because the carbon is one of the primary components. The carbon prevents said non-oxide from being oxidated. The brick maintains a good heat and shock resistance and slag resistance when reducing the proportion of the carbon because said non-oxide has a low heat expansion and a wet resistance to the slag.

Owner:江苏苏嘉集团新材料有限公司

Reduction of coal-fired combustion emissions

ActiveUS20060034743A1Efficiently and economically capturedReduce in quantityUsing liquid separation agentSolid fuel pretreatmentBruciteMagnesite

A process for mitigation of fouling deposits within a combustion zone, capturing of toxic metal emissions, and reduction of visible sulfur emissions attributable to sulfuric acid mist during coal combustion. SO3 formed during coal combustion is reduced by the addition to the coal of raw, unprocessed magnesium-containing minerals such as magnesite ore or brucite ore. The minerals are pulverized to a fine particle size and combined with pulverized coal to provide a mixture of the particles. The mixture is combusted and the ore particles calcine and decrepitate to very fine magnesium oxide particles that have a significant particle surface area. The magnesium oxide particles react with the SO3 produced during combustion of the coal and also capture toxic metals to reduce the quantity of undesirable stack discharge components.

Owner:PREMIER MAGNESIA

Periclase-magnesium aluminate spinel composite refractory brick and technique for producing the same

The invention relates to an alkaline composite refractory brick, which consists of a periclase-magnesium aluminate spinel flame retardant coating and a periclase-forsterite thermal-protective coating. The proportion of the alkaline composite refractory brick is as follows: 1) the proportion of the flame retardant coating is as follows: 29 to 48 percent of magnesite of between 5 and 1 millimeter, 7 to 16 percent of the magnesium aluminate spinel of between 3 and 1 millimeter, 6 to 20 percent of the magnesite of between 1 and 0.088 millimeter, 0 to 4 percent of desilicated zirconia granules of between 0.4 and 0.088 millimeter, 16 to 25 percent of the magnesite of less than 0.088 millimeter, 0 to 10 percent of magnesite micropowder of less than 0.020 millimeter, 0 to 5 percent of desilicated zirconia micropowder of less than 0.020 millimeter, 0 to 3 percent of calcium carbonate micropowder less than 0.020 millimeter, 0 to 6 percent of lanthanum oxide of less than 0.020 millimeter, and 0 to 0.3 percent of additional water reducing agent (sulfonated naphthaldehyde polymer, sulfonated melamine polymer and polycarboxylic acid or sodium salt thereof); and 2) the proportion of the thermal-protective coating is as follows: 0 to 20 percent of the magnesite of between 3.2 and 1.0 millimeter, 35 to 45 percent of the forsterite of between 3.2 and 1.0 meter, 5 to 15 percent of the magnesite of between 1.0 and 0.088 millimeter, 5 to 15 percent of the forsterite of between 1.0 and 0.088 millimeter, and 30 to 40 percent of grinding powder of the magnesite and the forsterite of less than 0.088 millimeter. The material has the advantages that the material improves the erosion resistance of the flame retardant coating by micropowder technology, and allows the sintering temperature of the flame retardant coating to be matched with that of the thermal-protective coating, thereby producing the periclase-magnesium aluminate spinel alkaline composite refractory brick which has excellent.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD +1

Preparation method for wear resistant fire-retardant coating

ActiveCN101570650AImprove working environmentImprove work efficiencyFireproof paintsO-Phosphoric AcidSodium phosphates

The invention provides a preparation method for wear resistant fire-retardant coating with simple construction process, good wear resistance and relatively low cost. The raw material of the wear resistant fire-retardant coating selects plate-shaped tabular alumina, brown alumina and high-quality bauxite chamotte as aggregate, selects plate-shaped tabular alumina powder, flint clay powder, alpha-Al2O3 micropowder and ceramic powder as fine powder, selects 42.5 mass percent industrial phosphoric acid solution, solid aluminium dihydrogen phosphate and clay powder as bonding agents, selects fused magnesite as a curing agent and selects sodium borate and sodium hexametahposphate as sintering aids. The wear resistant fire-retardant coating can be directly smeared on the surfaces of a wear resistant fire-retardant material liner and a water cooling wall pipe, fills up technical blank of resisting the wear on metal by using a non metal coating at a high temperature of 900 DEG C, provides a new repairing method for a non metal wear resistant fire-retardant material liner, has simple construction process, can obviously improve working environment of workers, reduce the labor intensity and improve the working efficiency of maintaining a circulating fluid bed boiler heated surface metal pipe wall and the wear resistant fire-retardant material liner.

Owner:TONGDA REFRACTORY TECH CO LTD

Porous refractory material and preparation method thereof

InactiveCN105481464ALow costSimple process equipmentSolid waste disposalCeramicwarePorosityThermal insulation

The invention relates to a porous refractory material and a preparation method, and relates to the technical field of refractor materials. The preparation method is characterized in that fly ash and a natural mineral material magnesite are adopted as main raw materials; and the porous refractory material is prepared through the processes such as blending and mixing, molding, drying, sintering and the like. Among the raw materials, the addition amount of fly ash is 10.0-90.0wt%, the addition amount of magnesite is 5.0-85.0wt%, the addition amount of a pore-forming agent is 5-15.0wt%, and the addition amount of a binding agent is 1-8wt%. A main phase of the porous refractory material prepared through high-temperature sintering is forsterite. The material has the characteristics of high porosity, low volume density, high strength, good thermal insulation effect, low cost and the like. According to the invention, a novel technical approach is provided for high-efficiency value-added exploitation of solid wastes such as fly ash and magnesite.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

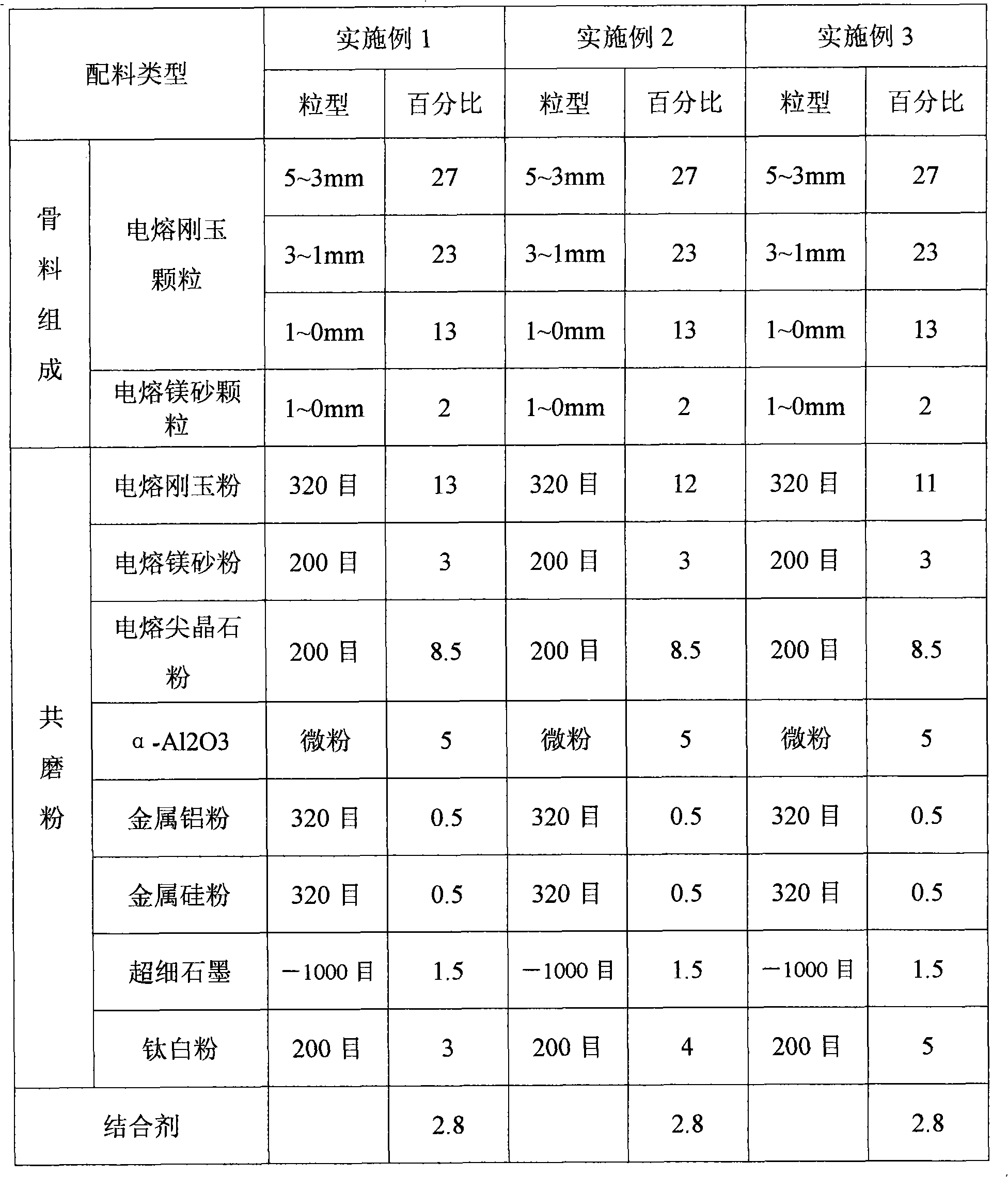

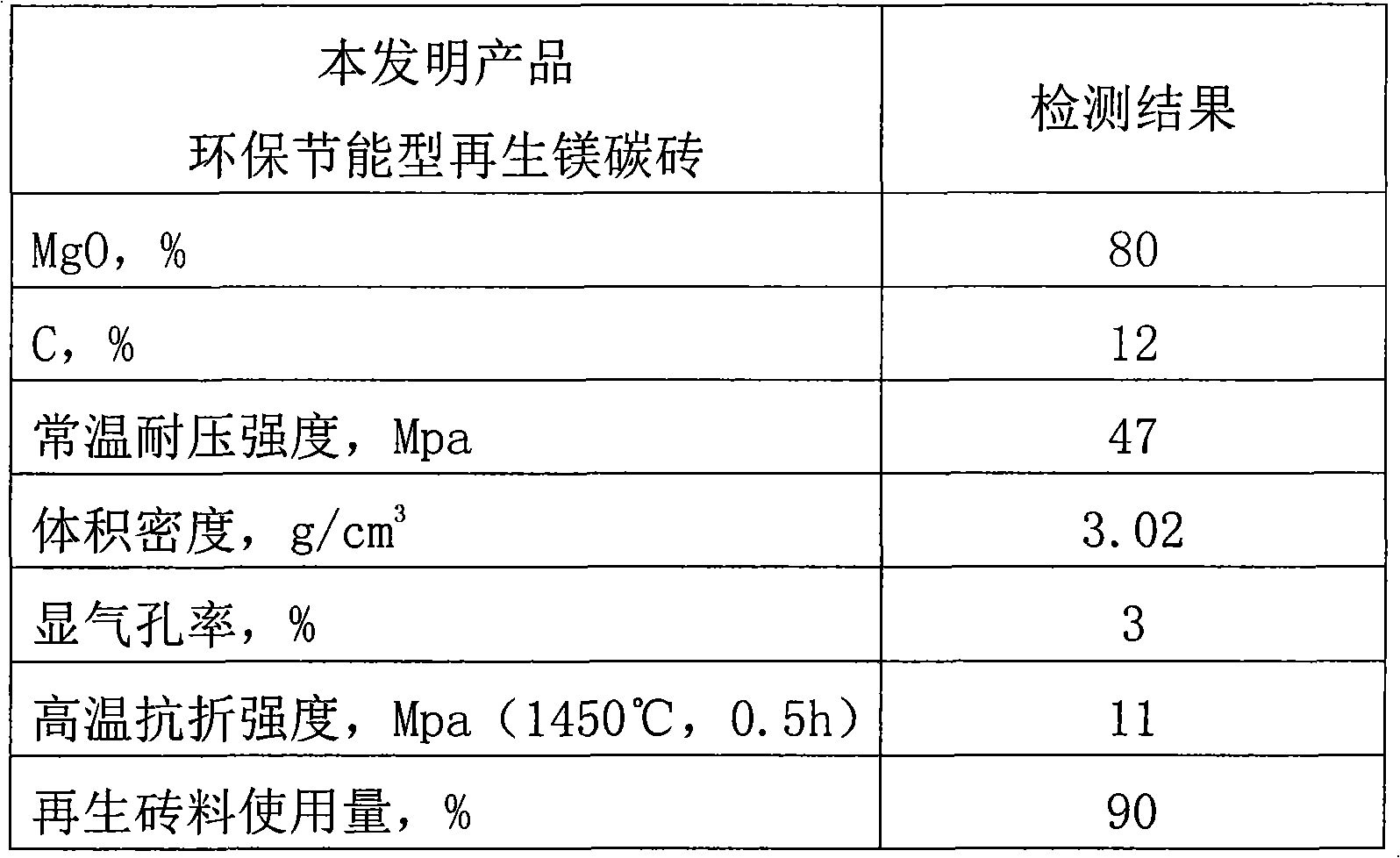

Low-carbon corundum spinelle brick for refined steel ladles and preparation method thereof

The invention relates to a low-carbon corundum spinelle brick for refined steel ladles and a preparation method thereof for overcoming the defect of overhigh carbon content in the prior carbon-contained fireproof material technology. The low-carbon corundum spinelle brick for refined steel ladles comprises the following components in percentage by weight: 60-70 fused corundum particles, 2-6 fused magnesite particles, 10-20 fused corundum fine powder, 2-10 fused magnesite fine powder, 5-15 fused spinelle fine powder, 3-6 alpha-Al2O3 micro powder, 0-2.0 metal aluminum fine powder, 0-2.0 metal silicon fine powder, 2-6 bond, 1-2 superfine graphite and 2-6 titanium white powder. The invention has good thermal stability at high temperature, resists high temperature and the erosion of molten steel and slag and has high mechanical strength, good thermal shock stability and high under-load softening point, thereby being widely applied to various steel ladles, in particular to steel ladles of refined low-carbon steel and ultra-low-carbon steel.

Owner:海城利尔麦格西塔材料有限公司 +2

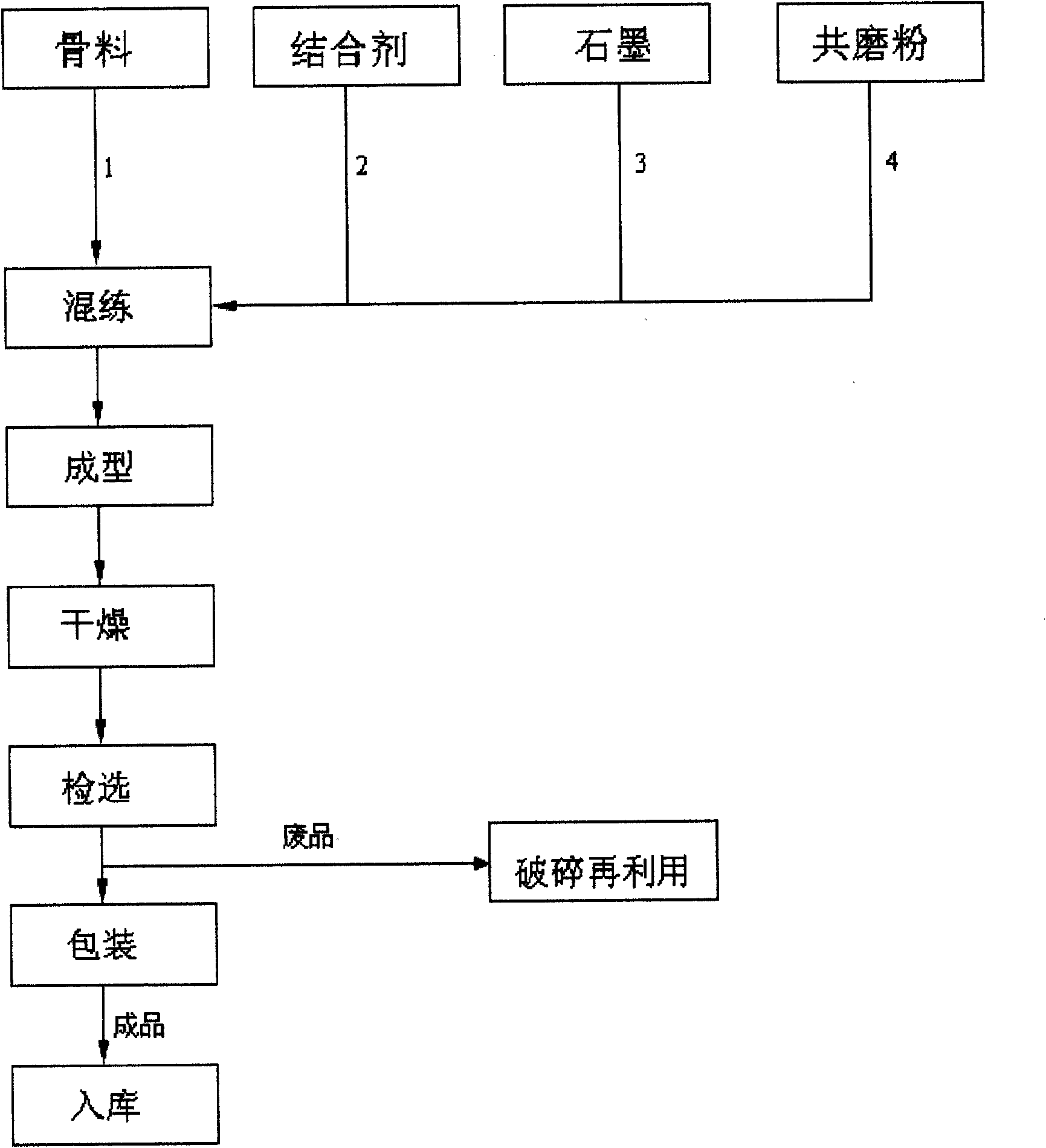

Production method of environment-friendly and energy-saving type regenerative magnesia-carbon brick

InactiveCN101851103AImprove recycling ratesSolve the problem of unstable performanceSolid waste managementBrickResonance

The invention discloses a production method of an environment-friendly and energy-saving type regenerative magnesia-carbon brick, comprising the following production steps: (1) sorting and crushing waste magnesia-carbon bricks; (2) powdering with weak acid aqueous solution; (3) carrying out high-temperature drying to dehydrate and electromagentic resonance to homogenize; (4) carrying out crushing, particle shaping, iron removing and screening; (5) mixing materials: mixing regenerative aggregates, fine powder and newly-added and electrically-fused magnesite aggregates, and fine powder; and (6)forming. The mixed material is added with a bonding agent, is treated by high-speed constant-temperature mixing, hydraulic forming and electric heating drying and obtains a regenerative magnesia-carbon brick product. The production method solves the problem that the product in the prior art has unstable performance, can retain usable components such as electrically-fused magnesite, crystalline flake graphite and the like in the raw material furthest, has high recovery and utilization rate and is energy-saving and environment-friendly.

Owner:吴钦合

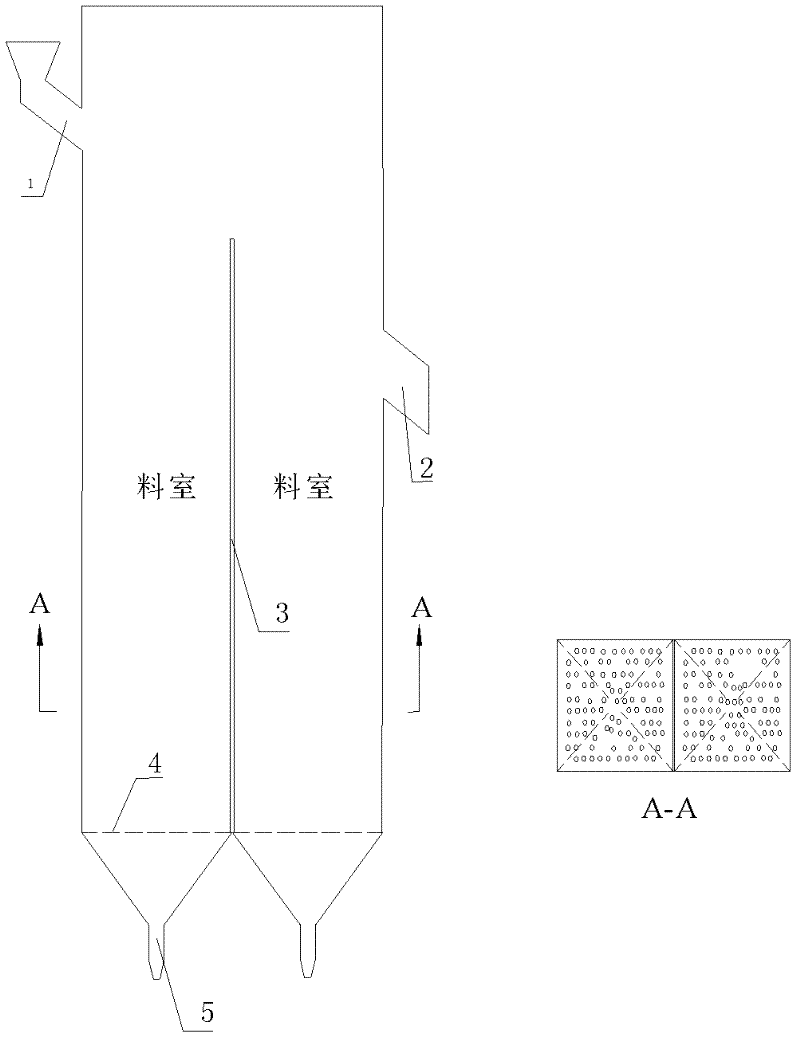

Air brick for magnesia carbon ladle and method for producing the same

The invention discloses an air brick used for a magnesium and carbon ladle, and a producing method thereof, aiming at producing high-quality air bricks used for the ladles. The mass percentage of the chemical compositions of the air brick is: 55 to 99 percent of MgO, 0 to 20 percent of C, 0 to 20 percent of AI2O3, 0 to 5 percent of ZrO2, 0 to 5 percent of AI, 0 to 5 percent of AI-Mg alloy, 0 to 5 percent of CaB6, and 0 to 2 percent of B4; the physical property indexes are: volume density (g / cm<3>): 3.00 to 3.15, apparent porosity (%): 1.5 to 5.0, cold compressive strength (MPa): 40 to 65, and distortion resistance at high temperature (MPa): 14.0 to 25.0. Raw materials adopted by the invention comprise fused magnesite, magnesite clinker, crystalline flake graphite, corundum, zirconia and oxidation inhibitor. The raw materials are added into a pug mill and externally added with a bonding agent for mulling. Mulled pug is added into a mould, and molded by utilizing isopressing equipment or a friction brick press or a hydraulic press. The invention obviously reduces the apparent porosity of the air brick, not only can improve the basic slag corrosion resistant capability of the air brick, but also can reduce the cost of the raw materials by more than two thirds.

Owner:UNIV OF SCI & TECH LIAONING

Slag adhesion resistant gunning refractory for converter

The invention provides a slag adhesion resistant gunning refractory for a converter. The gunning refractory comprises the following components in percentage by weight: 35 to 45 percent of magnesia carbon refractory crushed brick recycled aggregate, 5 to 16 percent of magnesite clinker, 18 to 25 percent of fused magnesite, 5 to 8 percent of silicon carbide, 8 to 13 percent of graphite, 1 to 3 percent of alumina cement, 1 to 3 percent of silicon micro powder, 1 to 3 percent of alpha-Al2O3 micro powder, and 3 to 4 percent of sodium hexametahposphate. On the basis of the raw materials, 0.2 to 0.4 percent of calcium lignosulfonate and 0.05 to 0.15 percent of polypropylene fiber are added; the magnesia carbon refractory crushed brick recycled aggregate has two granularities, namely comprises 30 to 40 weight percent of aggregate with the granularity of 3 to 1 mm and 60 to 70 weight percent of aggregate with the granularity of 1 to 0.15mm; the granularity of the magnesite clinker is 1 to 0.15mm; the fused magnesite has two granularities, namely comprises 40 to 60 percent weight percent of fused magnesite with the granularity of 180 meshes and 40 to 60 weight percent of fused magnesite with the granularity of 325 meshes; and the granularity of the silicon carbide is 180 meshes.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite

InactiveCN101525690AImprove leaching rateHigh dissolution rateProcess efficiency improvementSlagLaterite

A method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite is disclosed; nickel, cobalt, magnesium and iron therein are leached out by using high-temperature peracid, leachate is pre-neutralized via serpentine powder, after the pre-neutralization, the leachate is neutralized by magnesite powder for de-ironing, and the scum is delivered for ironmaking after being dewatered by smoke gases in a fluidized bed furnace for making sulfuric acid, the de-ironed clear nickel liquid uses magnesite powder to precipitate nickel carbonate, and the precipitated liquid is concentrated and crystallized to obtain magnesium sulfate heptahydrate. The leached slag mainly contains silicon and can be used for making white carbon black. The invention can sufficiently recover and utilize nickel, cobalt, magnesium, iron and silicon in the nickel-bearing laterite, and the invention is simple in technology, low in energy consumption and pollution-free on environment.

Owner:广西冶金研究院有限公司 +1

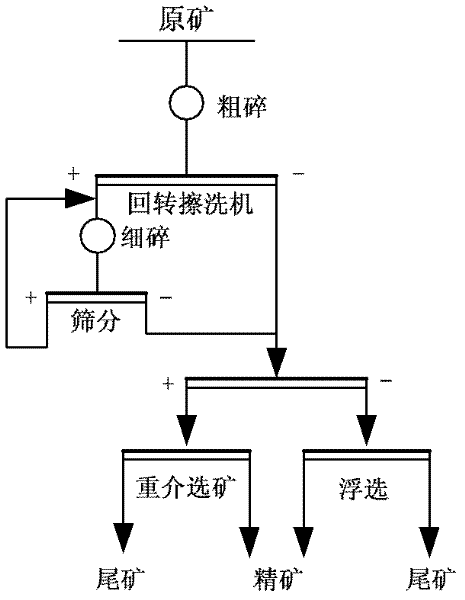

Integrated utilization method of low grade magnesite

InactiveCN102515213ASave raw materialsSimple processCarbon compoundsAmmonium carbonates/bicarbonatesElectrolysisMagnesium salt

The invention belongs to the fields of integrated utilization technology of magnesite and environmental protection, and relates to an integrated utilization method of low grade magnesite. The method comprises steps of: magnesite fragmentation; ore grinding; ore dressing; ore dressing product calcining; conversion of calcined useful components into magnesium salt to prepare high purity magnesium oxide or direct electrolysis of the calcined useful components into magnesium metal or preparation of refractory material; and recovery utilization of gas generated by calcination. The invention comprehensively utilizes useful ingredients in the magnesite, realizes zero discharge of magnesite mine tailing, increases utilization rate of low grade magnesite and efficiently utilizes ore resource; and especially, fluidized roasting by a horizontal fluidized bed saves energy consumption and maximize economic benefit.

Owner:UNIV OF SCI & TECH BEIJING

Environmental friendly sustained-release long-acting compound fertilizer and method of preparing the same

The invention discloses an environment-friendly slow-releasing long-standing compound fertilizer which belongs to polyelement compound fertilizer and a production method thereof. The fertilizer comprises the following raw material ingredient (by parts by weight): 10-40 parts of powdered rock phosphate, 10-40 parts of potassium feldspar, 15-40 parts of coal gangue, 10-20 parts of magnesite powder, 10-30 parts of nitrogenous fertilizer, 8-18 parts of swell soil, 1-3 parts of kieselguhr and 0.3-1 part of trace element; the powdered rock phosphate, the coal gangue and proper amount of coke are roasted for 8-16 hours at 500-800 DEG C, cooled, crushes and screened by a 60-mesh sieve. The invention provides an environment-friendly energy-saving fertilizer capable of improving soil with comprehensive effective fertilizer composition, slow releasing and high fertilizer utilization ratio. Meanwhile, the environment-friendly slow-releasing long-standing compound fertilizer is suitable for various soils and growth of various crops and the preparation method thereof is provided. The problems of low fertilizer utilization ratio, environment pollution, hardening soil, high production cost and the like in the prior art are solved.

Owner:吕庆淮

Phosphate base cementing agent

The invention discloses phosphate base cementing agent which is formed by uniformly mixing phosphate cementing mixture and water. The phosphate cementing mixture comprises the following component according to mass percent: 65 to 80 percent of phosphate cementing mixture and 20 to 35 percent of water; the phosphate cementing mixture comprises the following components according to mass percent: 20 to 60 percent of dihydric phosphate, 20 to 40 percent of magnesite, and 0 to 40 percent of inorganic mineral filler, wherein the mass of retarder occupies 5 to 15 percent of that of the magnesite; and the mass of sand occupies 0 to 30 percent of that of the phosphate cementing mixture. Phosphate gelling slurry can be served as structural adhesive to prepare fibrous composite material for concrete reinforcement, to improve the compatibility between the phosphate gelling slurry and concrete, and can also be served as gelling material to prepare artificial composite board material, self-leveling slurry, protective paint and the like.

Owner:SHENZHEN UNIV

Lightweight periclase-magnesium aluminate spinel refractory material for rotary cement kiln and preparation method thereof

The invention relates to a lightweight periclase-magnesium aluminate spinel refractory material for a rotary cement kiln and a preparation method thereof. According to the scheme, the preparation method comprises the following steps of: uniformly dispersing 0.2 to 4wt% of magnesite micro powder and 0.2 to 4wt% of active alpha alumina micro powder into 5 to 8wt% of binding agent to obtain a modified binding agent; adding 50 to 70wt% of porous periclase-magnesium aluminate spinel ceramic particles to a vacuum agitating machine; vacuumizing to be below 2.5kPa; maintaining the constant pressure for 3 minutes; adding the modified biding agent to the vacuum agitating machine; agitating for 10 minutes; closing a vacuumizing system; then adding 10 to 25wt% of porous periclase-magnesium aluminate spinel ceramic fine powder, 4 to 20wt% of fine magnesia powder, and 1.5 to 4wt% of magnesium aluminate spinel fine powder to the vacuum agitating machine; uniformly agitating; mechanically pressing and modeling; drying; and maintaining the temperature of 1,500 to 1,650 DEG C for 2 to 10 hours. The lightweight periclase-magnesium aluminate spinel refractory material for the rotary cement kiln has the advantages of being low in heat conductivity, high in intensity, high in thermal shock resistance, high in kiln coating performance, and high in resistance to medium erosion.

Owner:WUHAN UNIV OF SCI & TECH

Magnesium gunning refractory for copper smelting-furnace

A magnesium gunning refractory used in copper smelting furnace can be used to gun and repair large area or partial erosive part of the furnace lining of nonferrous metals smelting furnace, the material thereof comprises aggregate, powder, binding agent and additive; the material of aggregate and powder comprises fused magnesite chrome sinter, fused magnesia, sintered magnesia and forsterite; the critical particle size of the aggregate is 0.1-5mm, and the particle size of the powder less than 0.088mm; the weight ratio is that fused magnesite chrome sinter 0-20%, sintered magnesia 10-30%, forsterite 0-20% for particle size of 3-5mm; sintered magnesia10-40%, forterite 10-40% for particle size of 1-3mm; fused magnesia 0-20%, sintered magnesia 5-20%, forsterite 5-20% for particle size of 0.1-1mm; fused magnesia 6-20%, forsterite 0-15% for particle size less than 0.088mm; binding agent 5%-15%; additive 6%-20%. The invention has the advantages of delaying the date of retirement, increasing the service life of the whole furnace lining, decreasing the repairing expenses and working intensity, and ensuring the continuity of production.

Owner:河南荣耀产业管理有限公司 +1

Phenolic resin containing nano-carbon powder, nano-carbon modified low carbon magnesium carbon brick and production method thereof

The invention relates to a low-carbon MgO-C brick containing modified phenolic resin and nanocarbon which are produced by nano carbon powder and a preparation method thereof. Phenolic resin bonding agent containing nano carbon powder is produced by ohenol, formaldehyde, a dispersant and nano carbon powder; the low-carbon MgO-C brick is produced by adopting fused magnesite, graphite, phenolic resin and an antioxidant as raw materials. The ultrasonic dispersion method adopted by the invention replaces partial graphite with the nano carbon powder and leads the nano carbon powder into the low-carbon MgO-C brick, thus obviously improving the anti-erosion ability and the oxidation resistance of the MgO-C brick. The brick has comparatively low thermal expansion coefficient, low thermal conductivity, low oxidative mass loss and thinner decarburized layer; a slag resistance experiment under conditions of 1600 DEG C, 3h heat preservation and carbon sequestration shows that erosion and osmosis phenomenon of the brick are not obvious, thereby being applicable to sites of converters, electric furnaces and ladle working linings, external scouring of furnaces, key components for continuous castings and refractories for blast furnace ironmaking etc., thus having comparatively large application range.

Owner:ZHENGZHOU UNIV +1

Ceramic tile capable of releasing negative oxygen ions and preparation method thereof

The invention discloses a ceramic tile capable of releasing negative oxygen ions and a preparation method thereof. The ceramic tile is prepared from the following raw materials in parts by weight: 38-56 parts of river sand, 22-34 parts of fluorite, 18-26 parts of volcanic, 10-20 parts of dolomite, 24-36 parts of modified clay, 15-25 parts of magnesite ore, 12-18 parts of tourmaline, 10-15 parts of hexacyclic stone, 8-14 parts of medical stone, 5-10 parts of stove ash residue, 6-12 parts of talcum powder, 4-8 parts of shell powder, 3-6 parts of barium carbonate and 2-4 parts of zinc oxide. The tourmaline, the hexacyclic stone, the medical stone and the like are added into the ceramic tile, so that the ceramic tile can release negative oxygen ions beneficial to human health for a long time, can obviously enhance blood circulation, promote metabolism, improve immunity and soothe mind and body, has an effect of bacteriostat and sterilization and has an obvious deodorization function, the indoor air can be purified, and the indoor air quality is improved.

Owner:安徽省亚欧陶瓷有限责任公司

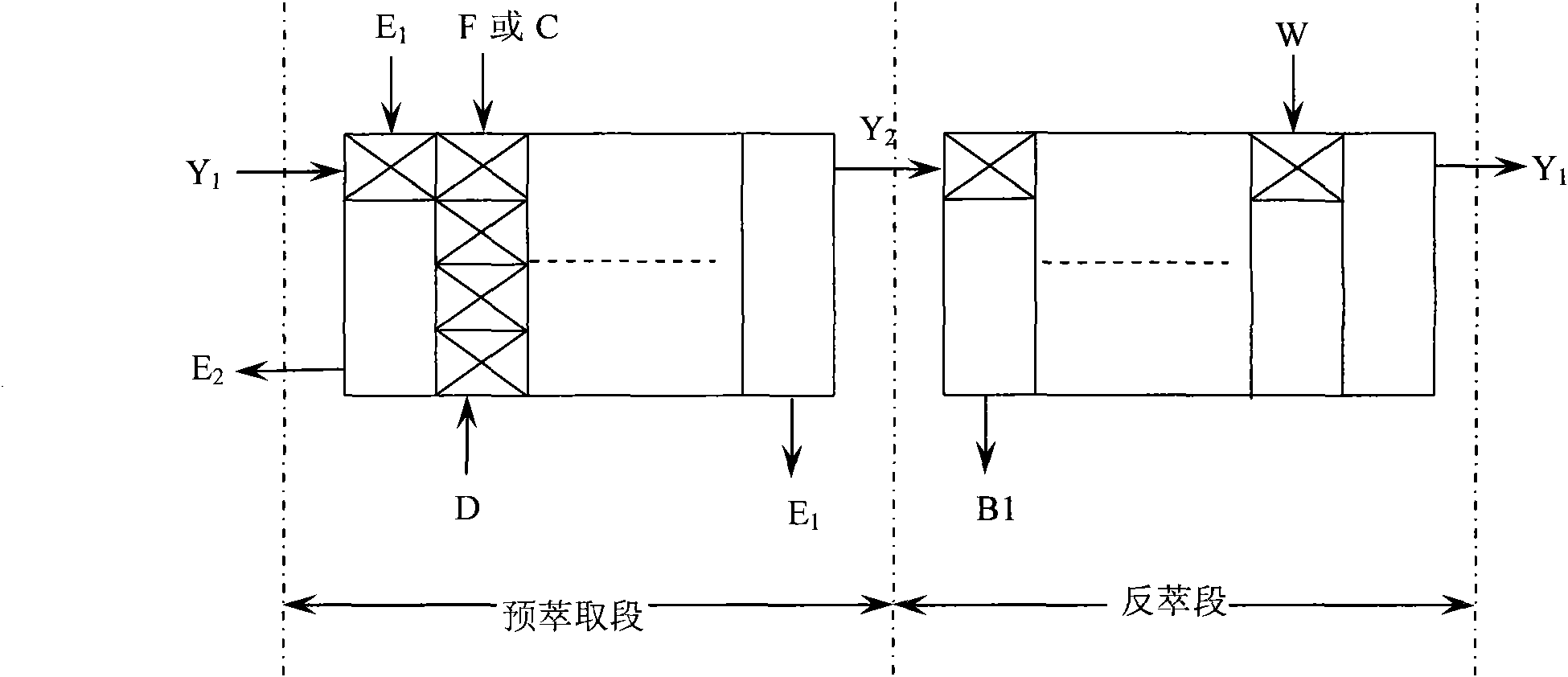

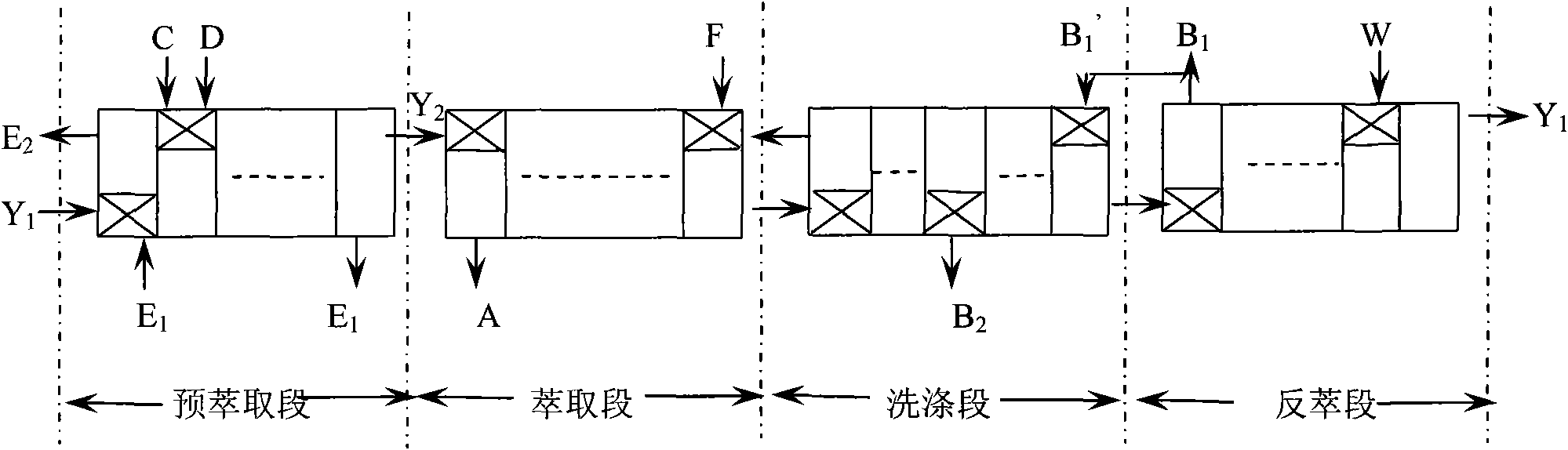

Process for separating rare-earth element by extraction

InactiveCN101781706ALow impurity contentEliminate pollutionProcess efficiency improvementRare-earth elementCalcium bicarbonate

The invention mixes and pre-extracts the mixed solution of acidic organic extractants such as P507, P204, C272, and naphthenic acid with magnesium bicarbonate and / or calcium bicarbonate solution and rare-earth solution. The rare-earth ions are extracted into the organic phase, then the loaded organic phase containing rare-earth ions are obtained through clarification, and can be used for the extract separation of the mixed rare-earth feed liquid. After a plurality of different levels of extraction, washing, stripping, single rare-earth compounds or rare-earth elements-containing enrichments can be obtained. The magnesium bicarbonate and / or calcium bicarbonate solution are prepared by roasting, digesting, carbonizing magnesite, limestone, calcite, dolomite and similar minerals, so that the content of impurities, such as silicon, iron, aluminum is lower. Ternary phase sediment is not produced in the pre-extraction and extraction separation process, so that the purity of the rare-earth products are not affected. The organic phase does not need ammonia saponification and does not produce ammonia-nitrogen wastewater. By adopting the invention, the production cost of rare-earth products is greatly lowered and the cost for three waste disposal is also greatly saved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for preparing lightweight magnesium-aluminum spinel raw material

The invention provides a process for preparing lightweight magnesia-alumina spinel brick raw material, belonging to the production technique of fireproof materials. The process employs Gamma-Al2O3 fine powder and magnesite fine powder as main raw materials, the two are formulated according to the mass ratio of aluminum oxide and magnesium oxide of 2.7-4.0, and organic bond and water are additionally added to uniformly mix. By employing semidry process to mold, green bodies after being baked are calcined at a temperature of 1650-1800DEG C and then heat-insulated for 2-4 hours. The lightweight magnesia-alumina spinel brick raw material provided by the invention can be used for preparing heat-proof fireproof products and heat-proof amorphous fire-proof materials of magnesia-alumina spinel brick. Compared with the heat-proof corundum bricks, the heat-proof bricks prepared by employing lightweight magnesia-alumina spinel brick raw material have lower heat conductivity.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Low-temperature steel flux-cored wire

InactiveCN101450426AExcellent Oxygen Content Diffusion Hydrogen ContentOxygen Diffusion Good Hydrogen ContentWelding/cutting media/materialsSoldering mediaArc stabilitySlag

The invention discloses a low-temperature steel flux cored wire. Flux core of the flux cored wire comprises the following raw materials by weight percentage: 28 to 33 percent of rutile, 1 to 3 percent of aedelforsite, 14 to 18 percent of silicon-manganese alloy, 16 to 21 percent of ferrous powder, 2 to 4 percent of nickel powder, 1 to 2 percent of cryolite, 5 to 7 percent of feldspar, 1.5 to 2.5 percent of ferrotitanium, 0.5 to 1 percent of ferroboron, 5 to 6 percent of mid-carbon ferromanganese, 2.5 to 4 percent of magnesite, 4 to 6 percent of quartz and 1.5 to 3.5 percent of fluorite. Compared with the similar product of the prior art, the flux cored wire belongs to the meta-acid slag series, and has the advantages of good electric arc stability, less splash, easy slag removal, good low-temperature impact ductility, good low-temperature crack resisting performance, high efficiency and low cost.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

High-viscosity continuous casting protective slag for solving slag inclusion on surface of low-carbon steel

The invention discloses high-viscosity continuous casting protective slag for solving slag inclusion on the surface of low-carbon steel. The protective slag comprises the following raw materials by weight percent: 0%-7% of glass powder, 50%-70% of premelting material, 5.5%-8.5% of fluorite, 4%-8% of dietary alkali, 3% of N330 carbon black, 3.5% of graphite, 0%-3% of R agent, 0.5-2% of lithium carbonate, 2%-5% of manganese carbonate, 2%-5% of magnesite, 3%-7% of bauxite, 1%-3% of cryolite, 1%-3% of adhesive, and 0.3%-1% of water-reducing agent. By utilizing the high-viscosity continuous casting protective slag, mainly on the basis of CaO and SiO2, a certain amount of fluxing agents such as the lithium carbonate, the fluorite, the dietary alkali and the like and a certain amount of carbon materials such as carbon black and graphite are externally added, thus the viscosity is improved and the surface tension is increased; and under the same technique condition, slag inclusion on the surface of a steel billet can be effectively prevented.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Steam hot aerosol fire-extinguishing composite and application method and fire extinguishing device thereof

ActiveCN101554520AWide variety of sourcesLess corrosiveFire rescueFire extinguisherSodium bicarbonateEpoxy

The invention provides a steam hot aerosol fire-extinguishing composite which contains 30-80wt percent of oxidant, 10-60wt percent of fuel additive and 2-30wt percent of cohesion solidification molding auxiliary agent. The oxidant can be one or more of the following substances: potassium salt, strontium salt, ammonium salt, magnesium salt, nitrocellulose and nitroglycerin; the fuel additive can be one or more of the following substances: azos, azoles, amino-guanidine nitrate, sodium bicarbonate, melamine, cyanoguanidine, carbamide, hexamine, triaminoguanidine nitrate, olefin, saccharose, aluminium powder, magnesite powder and magnesium-aluminium alloy power; the cohesion solidification molding auxiliary agent can be one or more of the following substances: phenol formaldehyde resin, ethoxyline resin, glycidyl azide, urethane rubber, hydroxyl-terminated polybutadiene, polyisobutylene, acetyl tributyl citrate, carboxymethyl cellulose, polyvinyl alcohol phenolic resin and acrylic resin. The invention also provides a fire extinguishing method and a fire extinguishing device adopting the composite. The invention has strong fire extinguishing capacity and fewer hazardous materials and can be applied to different places.

Owner:JIANGXI TSINGHUA IND CO LTD

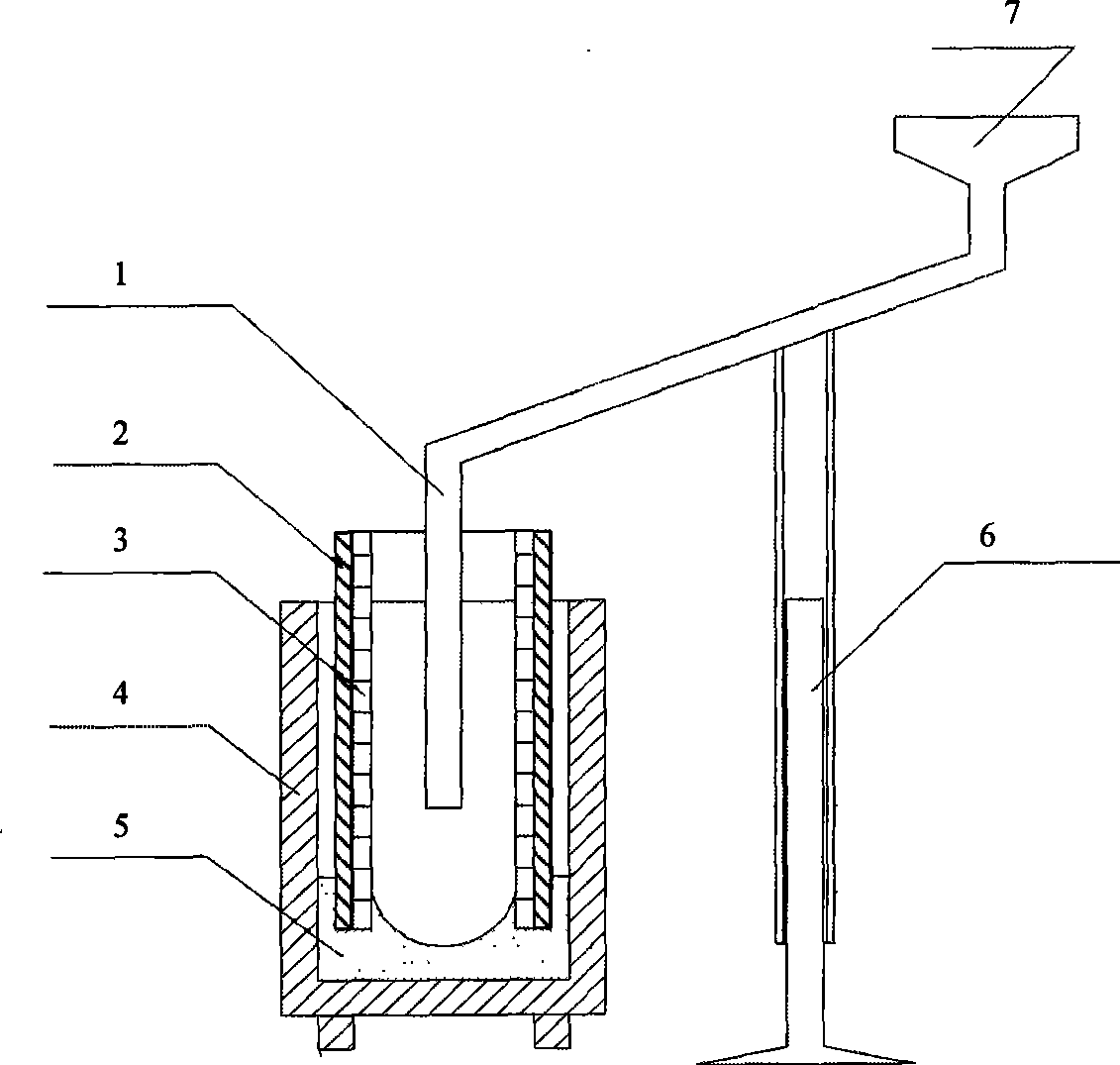

Method and device for preparing high quality high ferrotitanium alloy based on aluminothermy reduction

A method for preparing high-quality high ferrotitanium based on aluminothermic reduction and a device thereof belong to the technical field of metallurgy. The method comprises the following steps: (1) preheating an aluminothermic reducing agent into a liquid state; and ball milling and baking a titanium-containing substance, an iron-containing substance and a slagging medium, and then continuously adding an obtained mixture to a molten metal bath to perform high-temperature smelting; (2) blowing a particle reducing agent to perform smelting; and (3) cooling, obtaining ingot, removing impurities and obtaining the high-quality high ferrotitanium. The device comprises a charging device and a smelting device; the charging device comprises a charging hopper and a charging tube; and the smelting device comprises a resistance furnace, a magnesite bottom socket, a heat-resistant steel tube, a refractory material and a magnesite lining. The method has the advantages of short process, low production cost, low energy consumption, high product quality and the like, and the device has the advantages of simple structure, convenient operation and good application prospect.

Owner:NORTHEASTERN UNIV

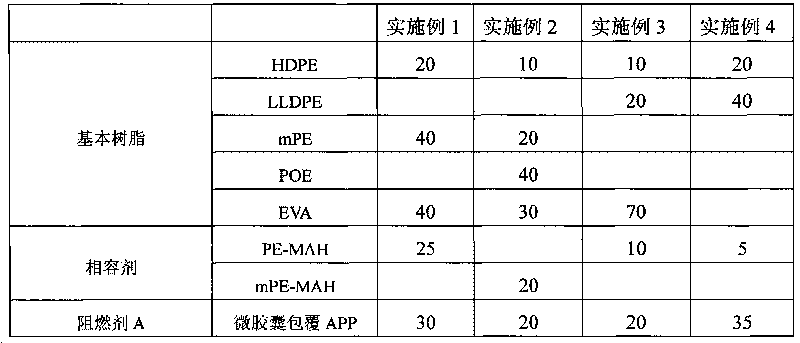

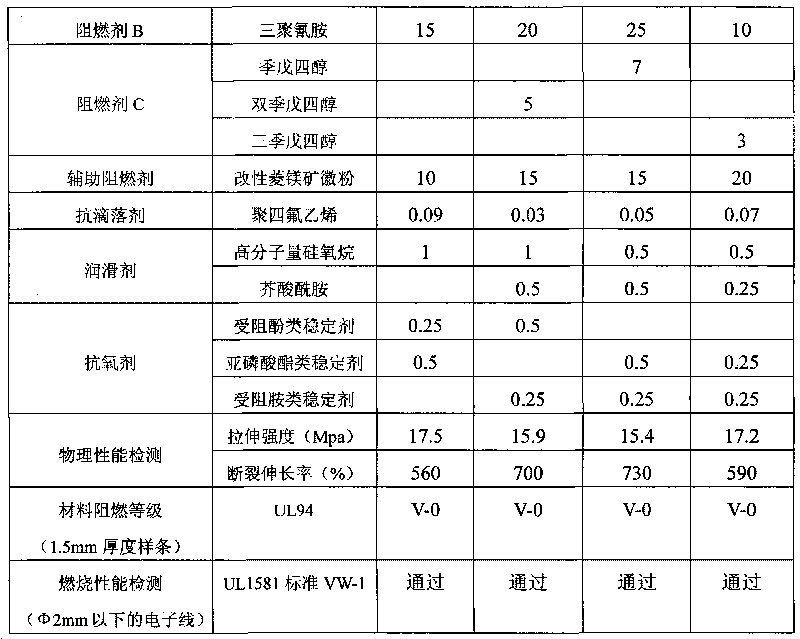

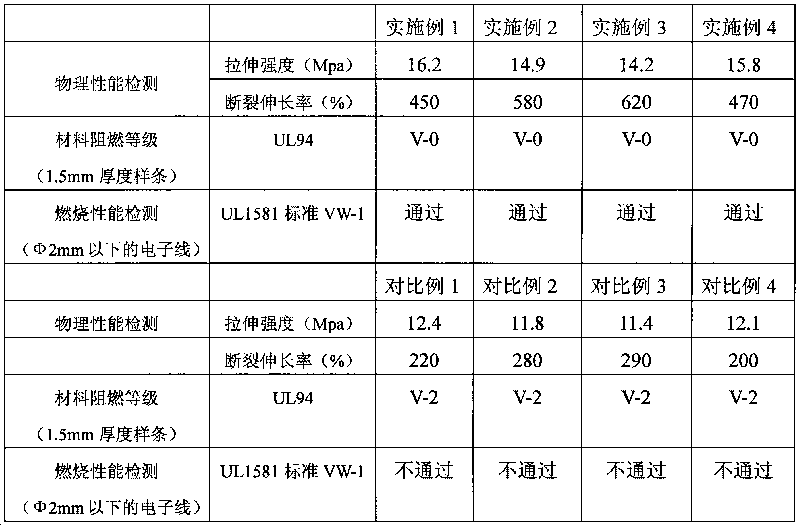

Magnesite micro powder-assisting flame-resistant expanded halogen-free flame-resistant electronic wire-coated material and preparation method thereof

InactiveCN101717534ALow priceRapid industrializationPlastic/resin/waxes insulatorsInsulated cablesMicrometerMagnesite

The invention discloses a magnesite micro powder-assisting flame-resistant expanded halogen-free flame-resistant electronic wire-coated material and a preparation method thereof. The material consists of 100 parts of basic resin, 5-25 parts of compatilizer, 20-40 parts of fire retardant A, 10-30 parts of fire retardant B, 0-10 parts of fire retardant C, 5-25 parts of assistant fire retardant, 0-0.1 part of anti-dripping agent, 0.1-2 parts of lubricating agent and 0.1-1 part of antioxygen, wherein the fire retardant A is microcapsule-coated ammonium polyphosphate, the microcapsule takes phenolic resin as capsule wall, and the assistant fire retardant is modified micrometer-level magnesite micro powder. The material has good physical performance, does not obtain poisonous and harmful substances, does not release poisonous gas when burning, has good flame resistance, higher extension-resistant and breaking elongation ratio than congeneric products, higher flame-resistant effect than the congeneric halogen-free flame-resistant electric wire and cable material, greatly reduce the price, and particularly can be fast popularized in an industrialization way and applied in a marketization way due to the low price as high-grade magnesite resource is abundance in China.

Owner:NINGBO SHIP PLASTIC CO LTD

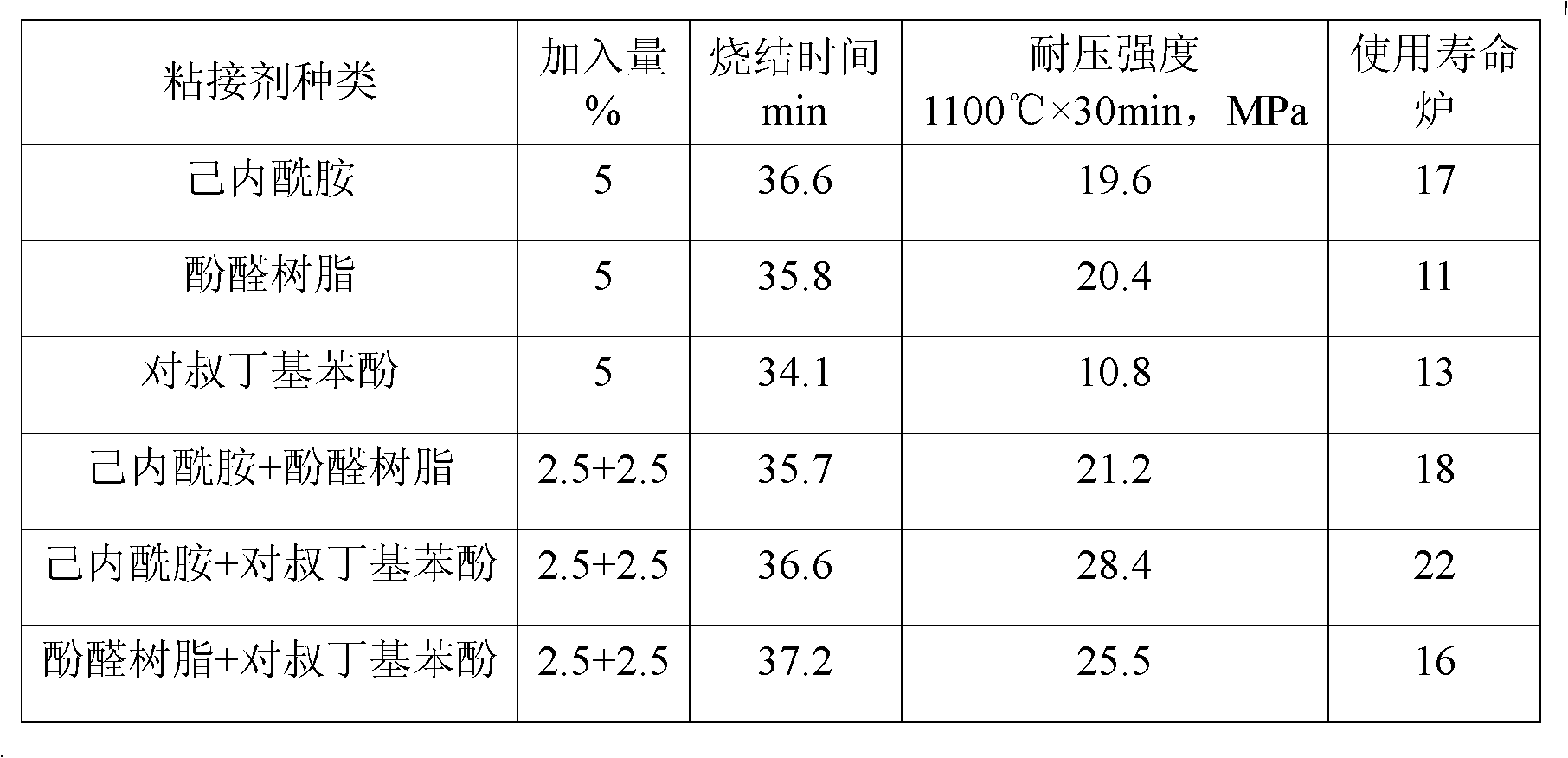

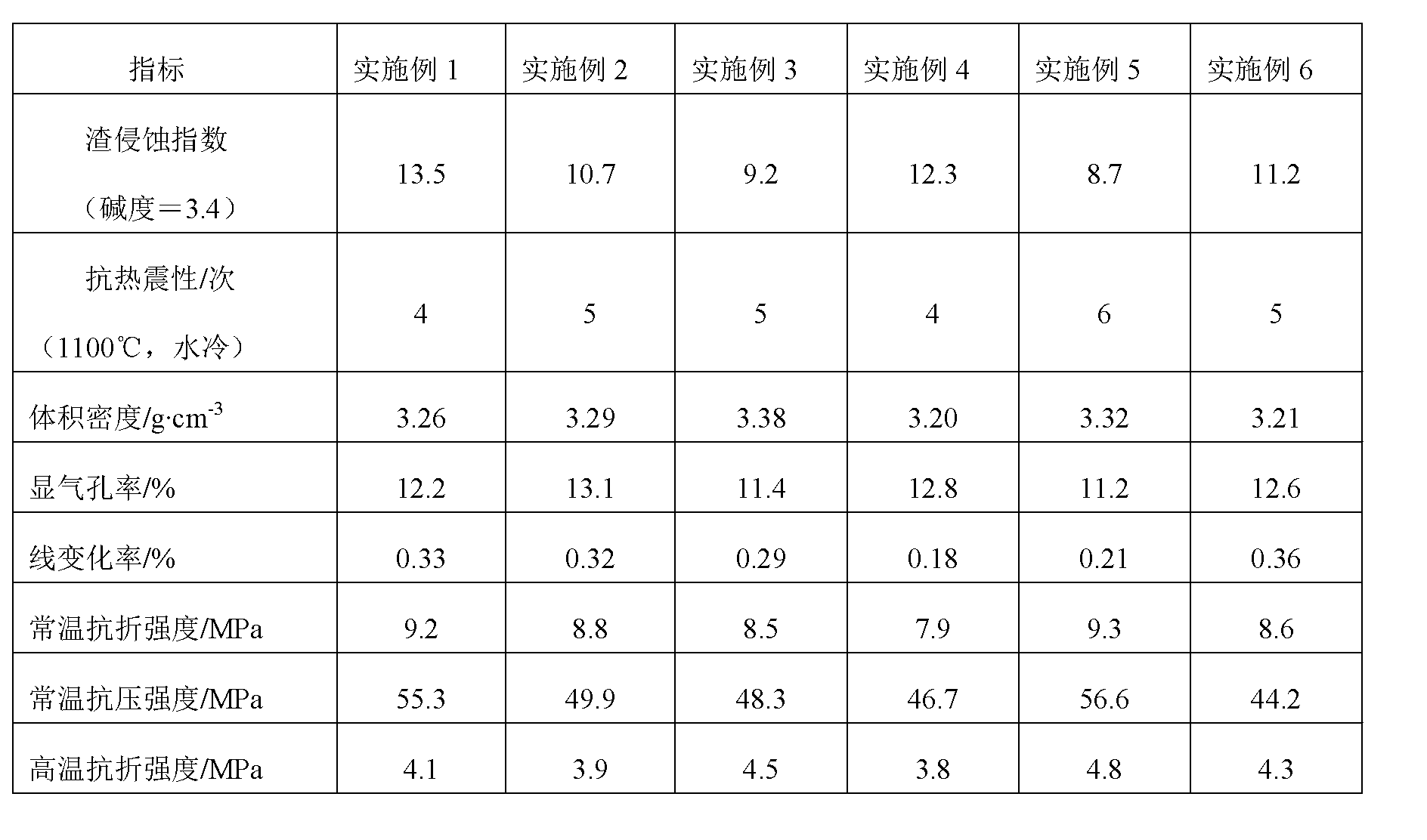

Repairing mass and preparation method thereof

The invention relates to a repairing mass for repairing in the converter production process of steel making and vanadium extracting of steel enterprises, in particular to a repairing mass used for a converter lining made of magnesia carbon bricks and a preparation method thereof, and provides a repairing mass having the advantages of short sintering time and long service life for meeting the requirement of production. The repairing mass per 100 weight parts comprises the following raw materials in parts by weight: 48-60 parts of fused magnesia, 22-28 parts of magnesite clinker, 10-16 parts ofmodified asphalt, 1-5 parts of metallic aluminum powder, 1-4 parts of ferric oxide powder and 2-10 parts of adhesive. The preparation method of the repairing mass is simple and convenient, i.e. all the raw materials are mixed. In the fettling production process of the vanadium extracting converter, when a local breakage appears on the converter lining, the repairing mass is coated on the part to be repaired; the repairing mass is sintered by utilizing the wall temperature of the converter, and production by blending with iron can be carried out after sintering; and under the conditions of lowsmelting temperature (1,360-1,400 DEG C) of the vanadium extracting converter and shorter smelting period (5-10 minutes), the repairing mass still can be quickly sintered with a working lining to form an organic combination with higher strength so as to prolong the service life of the repairing mass.

Owner:攀枝花钢城集团瑞矿工业有限公司

Corundum-spinel casting material for dip pipe of RH refining furnace

The invention discloses a corundum-spinel casting material for a dip pipe of an RH refining furnace, which is composed of a main material and an admixture, wherein the main material comprises the following components in percentage by weight: 35-60% of fused white corundum, 10-25% of fused compact corundum, 1-10% of fused magnesite powder, 1-10% of ultrafine spinel micropowder, 3-10% of active aluminum oxide powder, 3-10% of calcium aluminate cement group and 1-5% of zirconium oxide sol; and the admixture comprises an FDN water-reducing agent and explosion-proof organic fibers. Practice proves that the casting material is high in slag corrosion resistance and fine in thermal shock resistance and can effectively prolong the service life of an inserted pipe.

Owner:武汉钢铁有限公司

High-performance magnesium-aluminum-chromium composite spinel brick and manufacturing method thereof

The invention relates to a high-performance magnesium-aluminum-chromium composite spinel brick for RH refining furnace dip pipes and non-ferrous smelting furnaces. The high-performance magnesium-aluminum-chromium composite spinel brick is characterized by comprising the following raw materials: 14.0-20.0 parts of low-chromium fused magnesium chromium sand (6-8% of Cr2O3, at least 78% of MgO), 71.6-82.0 parts of high-purity fused magnesite, 2.0-4.4 parts of nano Cr2O3 powder, 2.0-4.0 parts of uf-Al2O3 micropowder and 2-4 parts of binder. The manufacturing method comprises the following steps: mixing, molding, drying, firing and the like. The magnesium-aluminum-chromium composite spinel brick provided by the invention has the advantages of high sintering tendency, high crystal compactness, low porosity (at most 10%), high compressive strength (at least 100 MPa), high thermal shock stability (at least 18 times by 1100 DEG C water cooling) and the like. The Cr2O3 content of the product isat most 6%, thereby reducing the Cr2O3 content in the brick, lowering the production cost and finally effectively reducing the environmental pollution of waste magnesium-chromium bricks after use.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Hot patching material for large face of converter

The invention relates to a hot patching material for a large face of a converter. The technical scheme is that: a uniform and loose aggregate is prepared by mixing and stirring 80 to 85 weight percent of magnesite or forsterite serving as a main raw material, 10 to 15 weight percent of lactose or maltose serving as a binder, 0 to 5 weight percent of graphite serving as a carburant, and 0 to 5 weight percent of silica powder, ferrosilicon powder, aluminum powder and the like serving as combustion improvers. The hot patching material is mainly applied to patching the large face part of the converter, and has the characteristics of short sintering time, no toxic gas emission, high adhesive force with a converter body, long service life and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

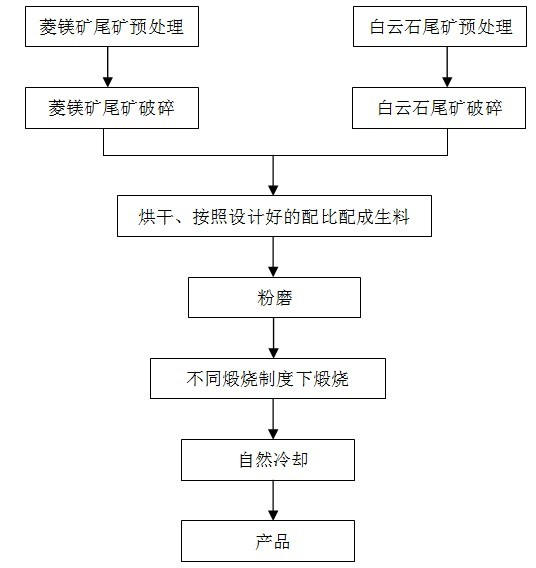

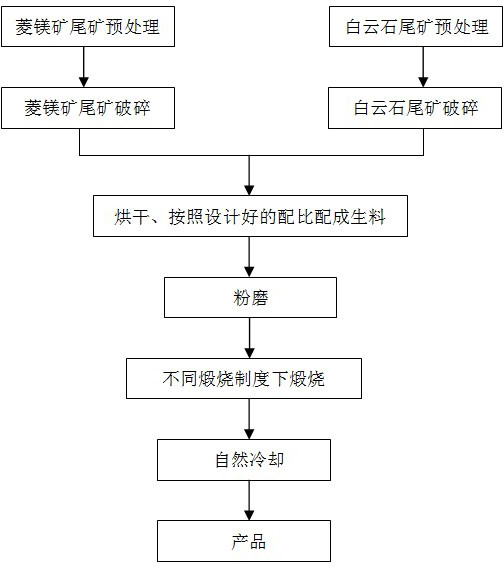

Mass eco-concrete expansive agent and preparation method thereof

ActiveCN102092976ASimple manufacturing processReduce pollutionSolid waste managementThermal expansionPre treatment

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com