Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

336results about How to "Crystal fine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcination process of active lime

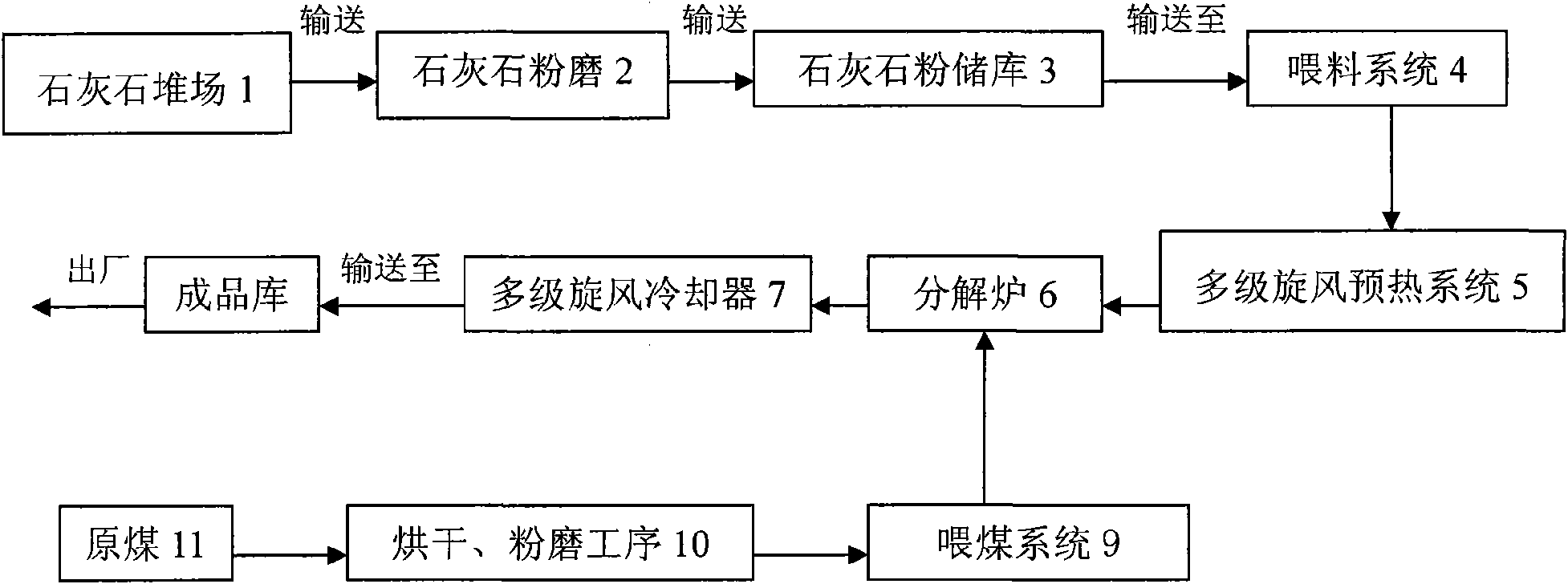

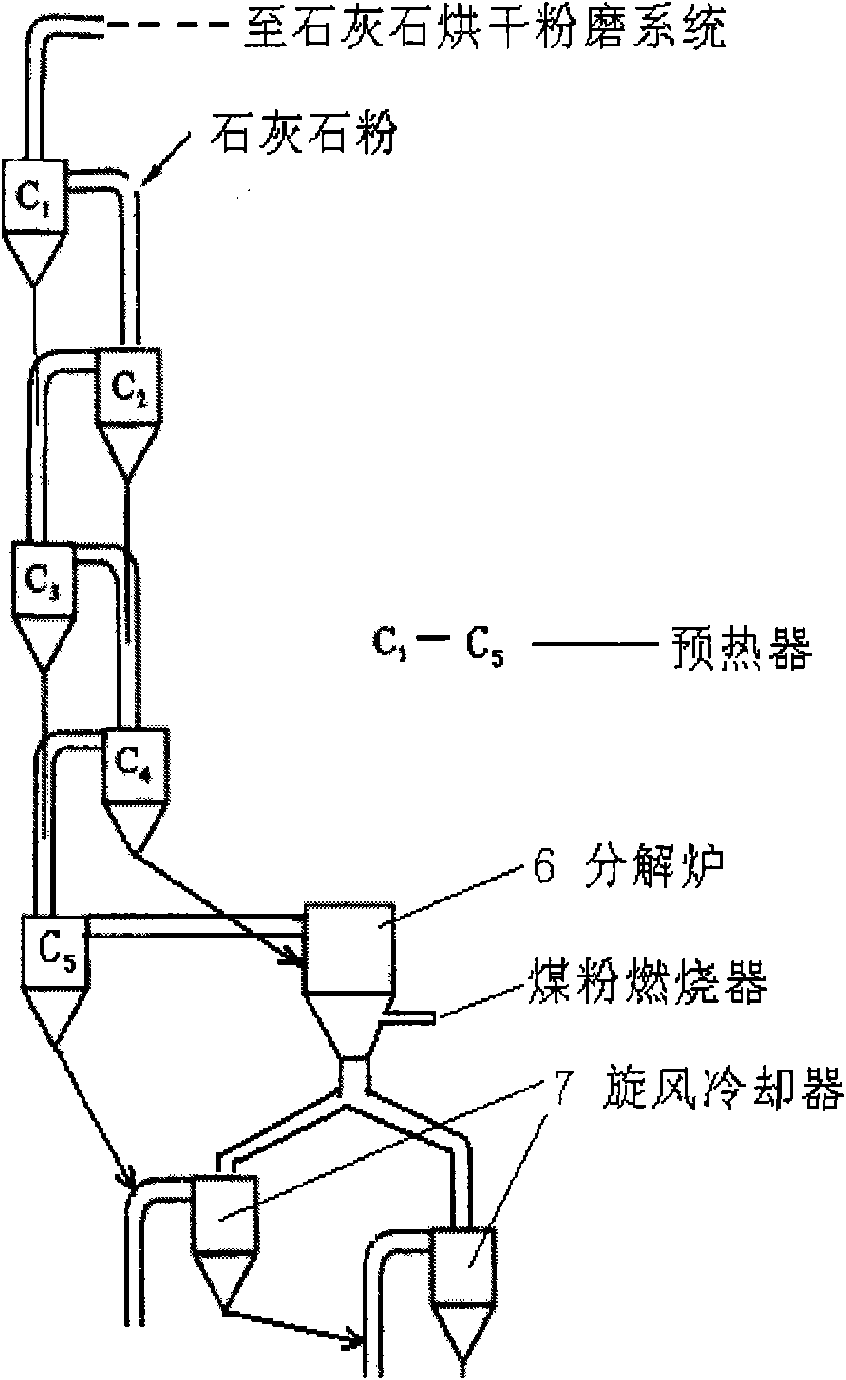

The invention discloses a calcination process of active lime. The calcination process adopts a preheating-suspension calcination device comprising a multi-stage cyclone preheating system, a decomposing furnace and a multi-stage cyclone cooler. The calcination process is characterized in that limestone powder which is broken and homogenized into blocks is ground into fine powder, the fine powder is placed in a storage tank for homogenization, then preheated by the multi-stage cyclone preheating system and sent to the decomposing furnace for calcination, thereby preparing the active lime, and the active lime is further cooled by the multi-stage cyclone cooler for obtaining the active lime; wherein the main control temperature of the decomposing furnace is 850-950 DEG C; and the calcination time is 3-5 seconds. The calcination process utilizes the preheating-suspension calcination reaction method for calcining the active lime, and fuel can use low-grade fuel-biluminous coal. Compared with the traditional process, the calcination time is short, the effective utilization rate of the lime product is high, the product quality is stable, the energy consumption is low, and a production region has no environmental pollution; meanwhile, the calcined active lime is the fine powder, the use is very convenient, and the range of applications is broader in comparison with the active lime calcined by the traditional process, thereby being conductive to promotion and implementation.

Owner:BEIJING LIULIHE CEMENT

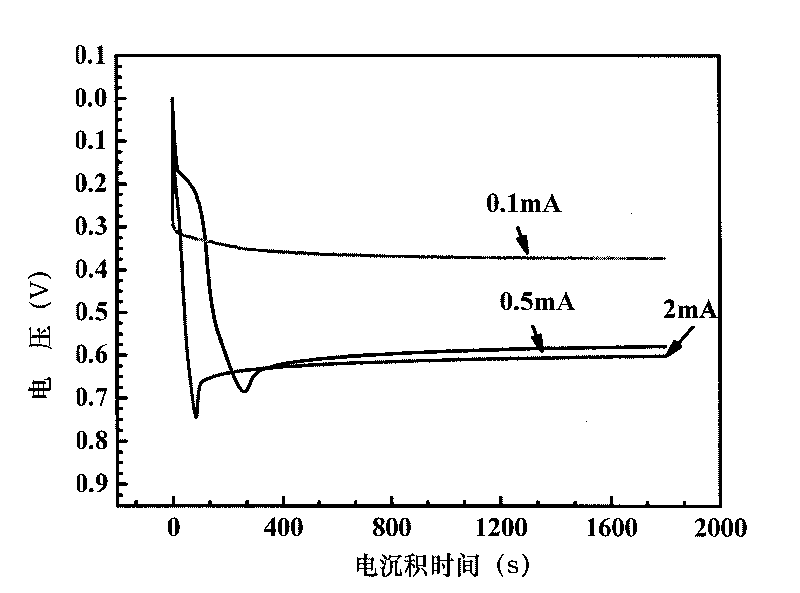

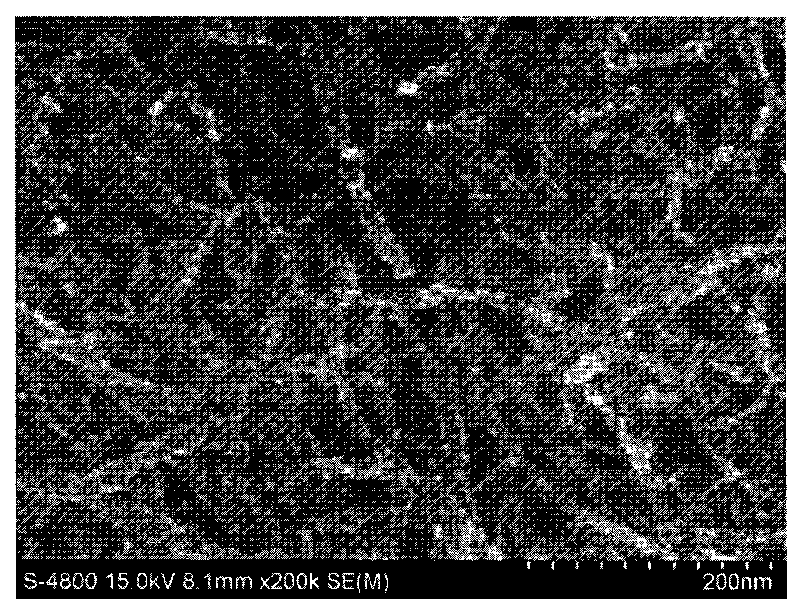

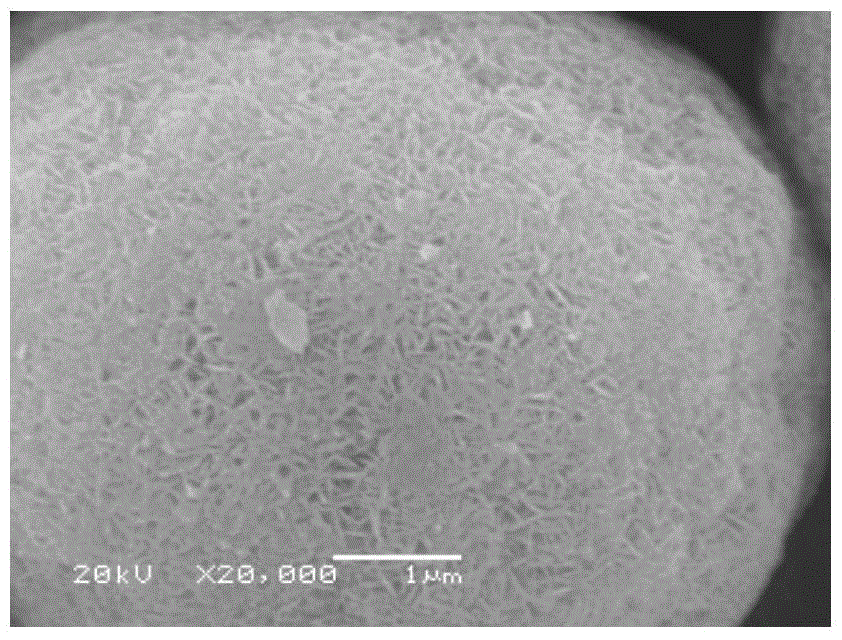

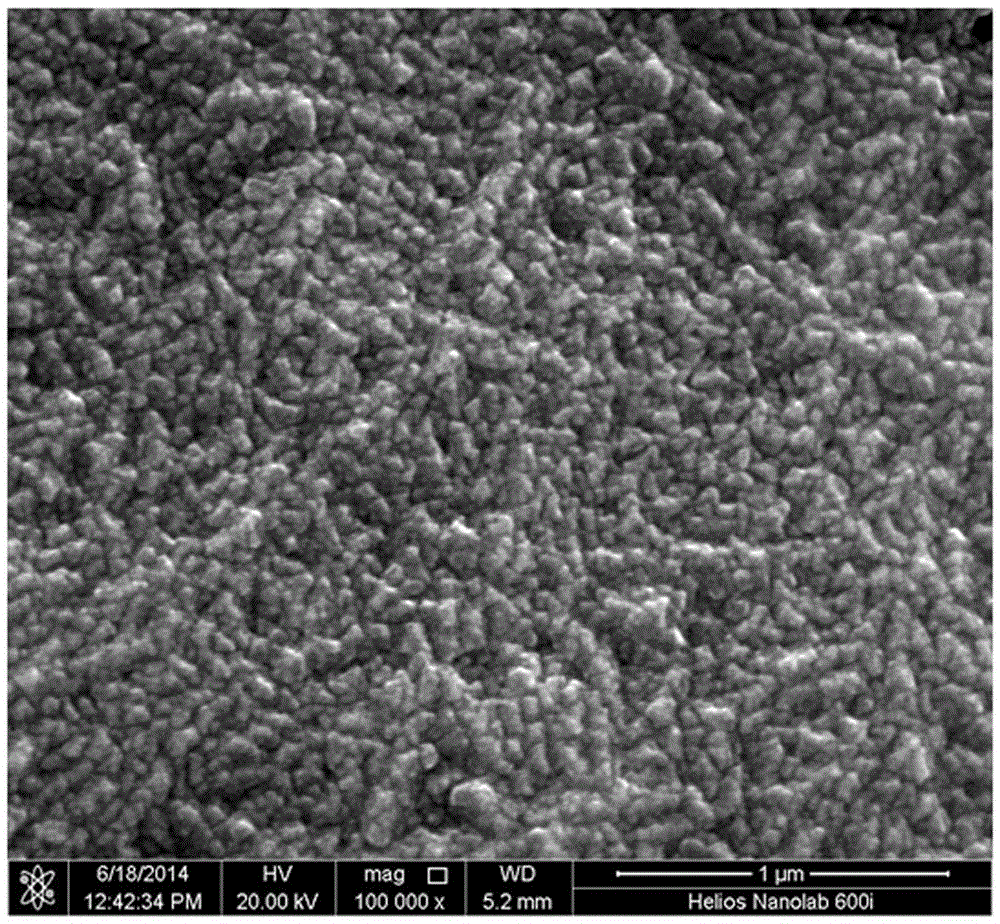

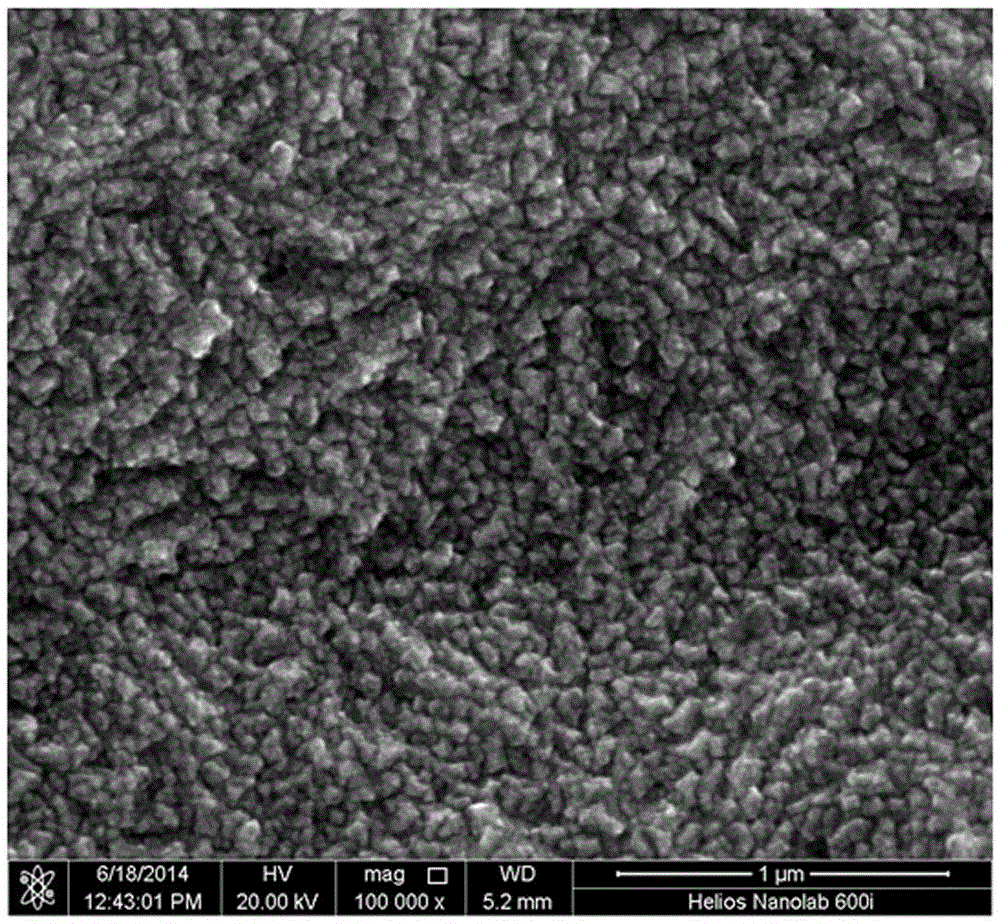

Method for preparing stannic oxide battery anode material on carbon nano tube by using electro-deposition process

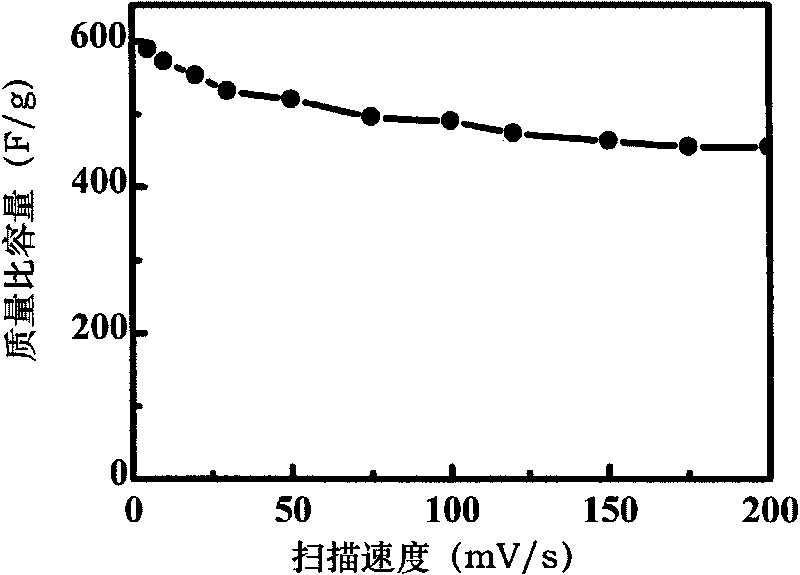

The invention discloses a method for preparing a stannic oxide battery anode material on a carbon nano tube by using an electro-deposition process. The method comprises the steps of: making electro-deposition solution, treating the solution with water bath, preparing the carbon nano tube pole piece, pressing on a foam nickel base, putting the base carrying the carbon nano tube pole piece into the electro-deposition solution so as to perform vacuum treatment, and then perform the electro-deposition treatment under a constant current on the vacuumized pole piece so as to acquire the battery anode material on the carbon nano tube carrying the stannic oxide. The battery anode material prepared by using the method has higher power property and has a quality specific capacity kept between 350 and 450 F / g under a high scanning speed of 200 mV / s. The material applied in a super capacitor has higher volumetric properties, excellent cycling stability and long cycling life, first discharging specific capacity ranged between 410 and 588 F / g under a constant current density of 15 A / g, cycling times more than 5000 times and specific capacity retention rate ranged between 90 to 95 percent.

Owner:BEIHANG UNIV

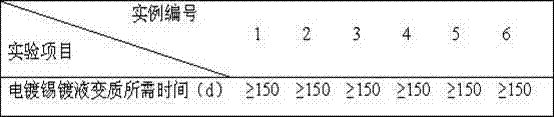

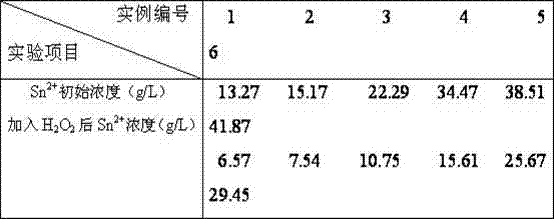

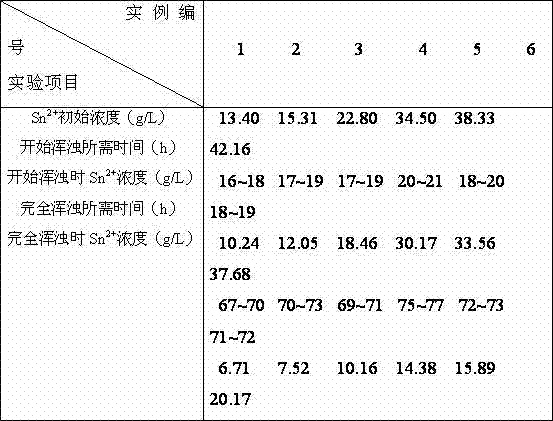

Methyl sulfonate tinning electrolyte and tinning method of steel strip or steel plate

The invention discloses methyl sulfonate tinning electrolyte using cerium salt as an additive. The electrolyte comprises the following components: 30 to 120 g / L of stannous methyl sulfonate, 60 to 180 g / L of methylsulfonic acid, 1 to 10 g / L of cerium sulfate, 0.1 to 2 g / L of antioxidant, 5 to 10 g / L of brightening agent and 5 to 10 g / L of surfactant. The invention also discloses a method for tinning a steel strip or a steel plate by adopting the electrolyte. During plating, the cerium salt in the electrolyte lightens the harm degree of 'hydrogen brittleness', and plays roles of the antioxidant and the brightening agent. On the basis of adaptability to the environment, the electrolyte meets the requirements that the process is simple, the solution is stable, the maintenance is easy and the quality of a coating is high.

Owner:张家港市凤凰科技开发有限公司

Chemical-copper plating liquid and copper plating production process

ActiveCN101654797AImprove bindingApplicable functionLiquid/solution decomposition chemical coatingPorosityCopper plating

The invention relates to chemical-copper plating liquid and a copper plating production process, which are used for copper plating of tubular steel and iron pieces and non-metal pieces, and are characterized in that: the chemical-copper plating liquid consisting of copper sulphate, a retarder, a complexant, a reductant and deionized water is used to pretreat a workpiece and then the workpiece is subjected to chemical-copper plating; an anode is 0.3 percent phosphor-containing copper plate; the area ratio of the anode and the cathode is 2:1; the current intensity in the cathode is 0.5 to 4A / dm<2>; the pH value of the copper plating liquid is 1.0 to 3.0; the temperature of the copper plating liquid is normal temperature; and the carrying capacity is 1 to 4dm<2> / kg; the copper plating time is8 to 10 minutes. The liquid and the process have the advantages of firm bonding between cladding and a substrate, stable process, high impurity resistance, long service life, crystalline simple copper cladding, fine cladding crystallization, low porosity, high anticorrosion performance, simple operation, convenient maintenance, no formaldehyde, no damages to human bodies and environment and environmentally-friendly product.

Owner:河北聚贤环保科技股份有限公司

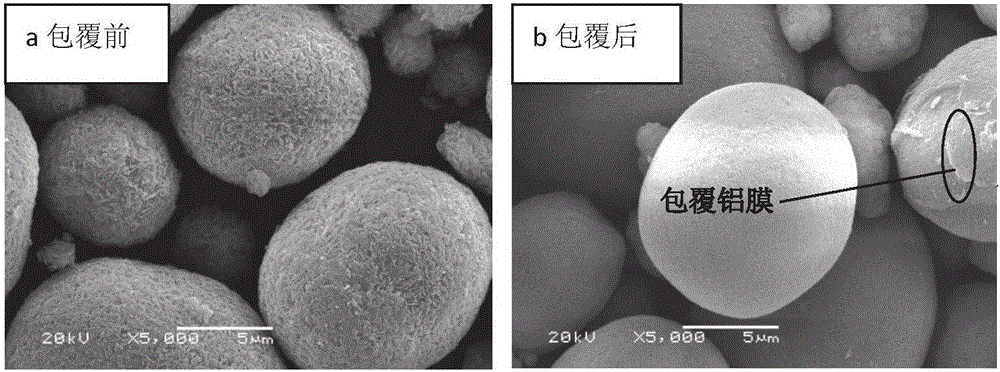

Neodymium-iron-boron magnet of aluminum or aluminum alloy composite coating and preparation method thereof

ActiveCN102031522AImprove processing efficiencyLow costVacuum evaporation coatingSputtering coatingHigh humidityAlloy composite

The invention discloses a neodymium-iron-boron magnet of an aluminum or aluminum alloy composite coating and a preparation method thereof. An aluminum or aluminum alloy film is deposited on the neodymium-iron-boron magnet by adopting multi-arc ion plating technology, and then phosphate treatment is performed. The coating is uniform and dense, and is well combined with a matrix. The neodymium-iron-boron magnet applied with the aluminum composite coating with thickness of 10 to 20 microns tolerates high pressure and high humidity (100 to 130 DEG C, 2 to 2.6atm, and 95 to 100 percent RH) for over 200 hours, and tolerates NaCl salt fog corrosion (3.5 to 5 weight percent of NaCl and 25 to 35 DEG C) for over 500 hours. The coating process has high efficiency and low cost; and the prepared composite coating has good corrosion resistance and adhesion performance, and has no influence on the magnetism of the neodymium-iron-boron matrix (mainly small-size magnet).

Owner:北京钐元新材料股份有限公司

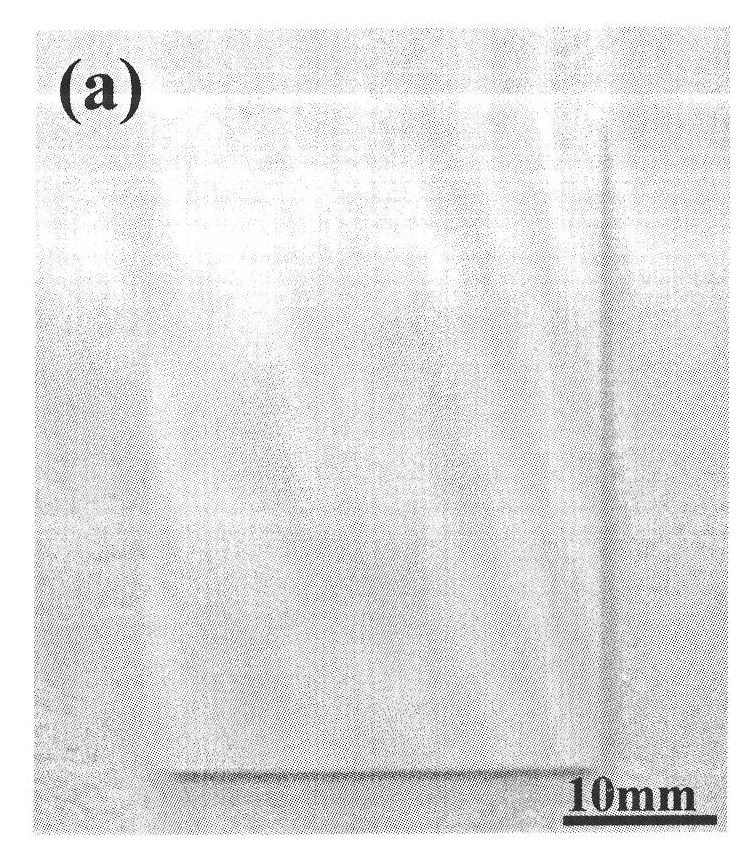

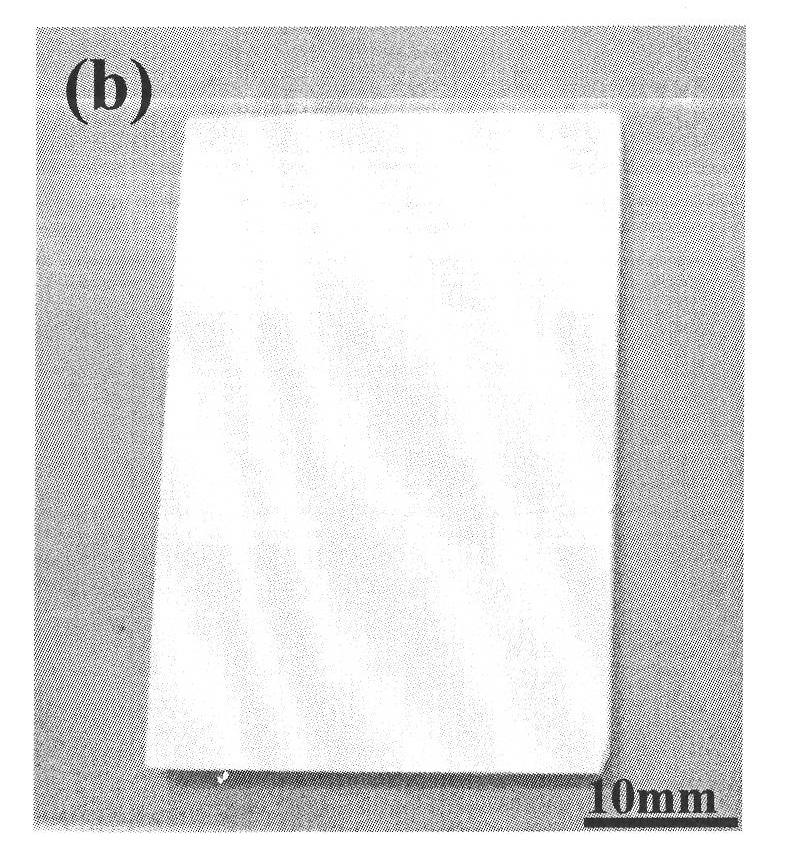

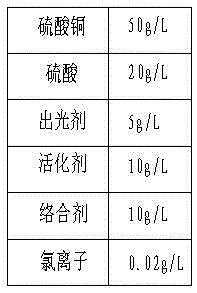

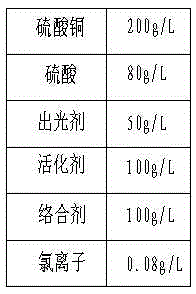

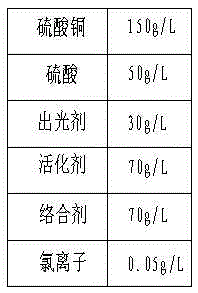

Copper plating liquid and process for direct cyanide-free acid copper plating on steel substrate

The invention relates to a copper plating liquid and process for direct cyanide-free acid copper plating on a steel substrate, belonging to the technical field of copper plating. The copper plating liquid comprises copper sulphate, sulfuric acid, deionized water, chloride ion, a desmutting agent, an activator and a complexing agent, wherein concentrations of the copper sulphate, the sulfuric acid, the chloride ion, the desmutting agent, the activator and the complexing agent are 50 to 200 g / L, 20 to 80 g / L, 0.02 to 0.08 g / L, 5 to 50 g / L, 10 to 100 g / L and 10 to 100 g / L, respectively, and the weight of deionized water is 400 to 900 g. Compared with the prior art, the invention has the following advantages: the copper plating liquid can realize direct copper plating on the steel substrate without pre-plating; an obtained plating is fine and shiny and has good bonding strength; after continuous electroplating on a steel band copper plating production line for 10 years, the copper plating liquid can still be normally used; and the copper plating liquid can be used for continuous electroplating of steel bands, steel wires and steel pipes and for rack plating, barrel plating and the like of steel members.

Owner:张志梁

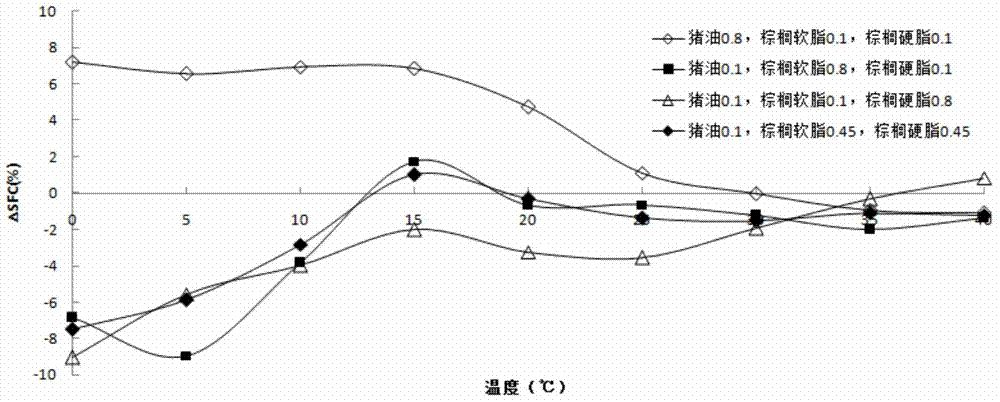

Method for preparing shortening/margarine base stock oil commonly used by lard oil base

InactiveCN102578485ASFC curve smoothingCrystal fineEdible oils/fatsCream substitutesFatty acid compositionEdible oil

A method for preparing shortening / margarine base stock oil commonly used by lard oil base belongs to the technical field of edible oil processing and comprises the steps of using lard oil and parts of hydrogenated oil, extreme hydrogenated oil or high-melting-point palm oil extract as raw materials, adopting immobilized lipase (Lipozyme IM-20, Lipozyme IM-60 and Chirazyme L2) to perform catalysis and enzymic method transesterification, adopting solid fat content (SFC) and melting point change of a system before and after reaction at the temperatures of 20 DEG C and 25 DEG C to investigate influence of the temperatures, enzyme adding amount and time to the transesterification and obtain ideal technical parameters, wherein the reaction temperature is 50-80 DEG C, the Lipozyme IM-20 adding amount is 3%-11% or the Lipozyme IM-60 adding amount is 3%-11% or the Chirazyme L2 adding amount is 5%-11%, and the reaction time is 1-6 hours. The SFC curves, crystal habit, fatty acid, triacylglycerol composition and esterization changes of a mixed system after ester exchange are analyzed, and results show that after the ester exchange, the SFC curves of mixed oil products are smooth, crystallization is fine and smooth, fatty acid composition does not change obviously, triglyceride distribution is even, esterization is enhanced remarkably, the method has good processing characteristics, and prepared shortening / margarine is superior to commercially available shortening in bread baking application. The method for preparing the shortening / margarine base stock oil commonly used by the lard oil base widens the application range of the lard oil and can enable domestic excess lard oil resources to be utilized completely.

Owner:JIANGNAN UNIV

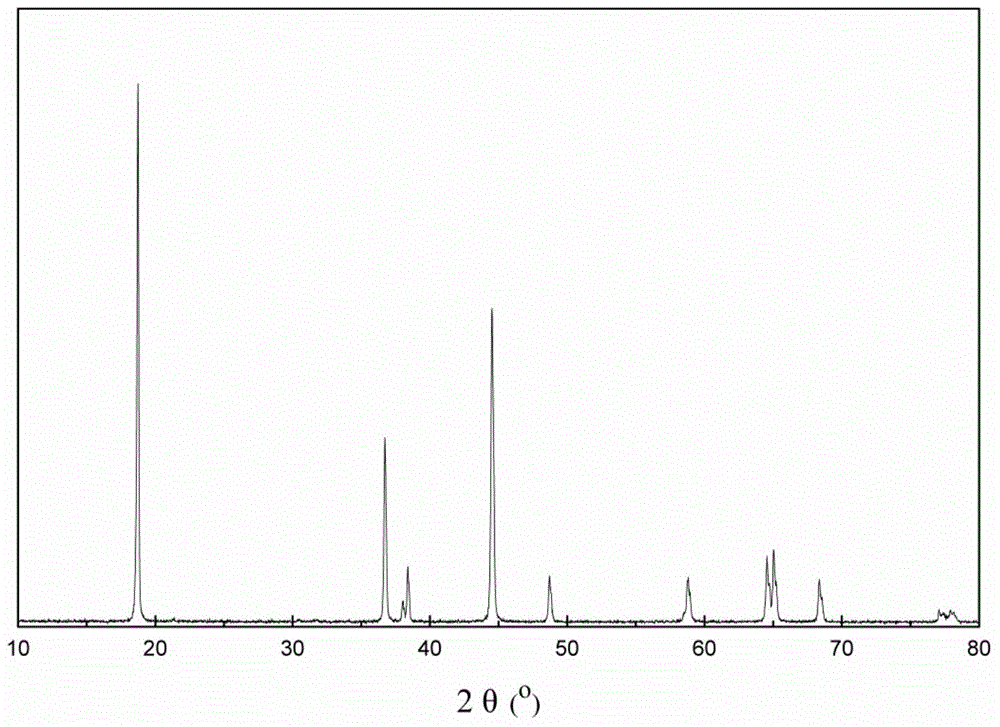

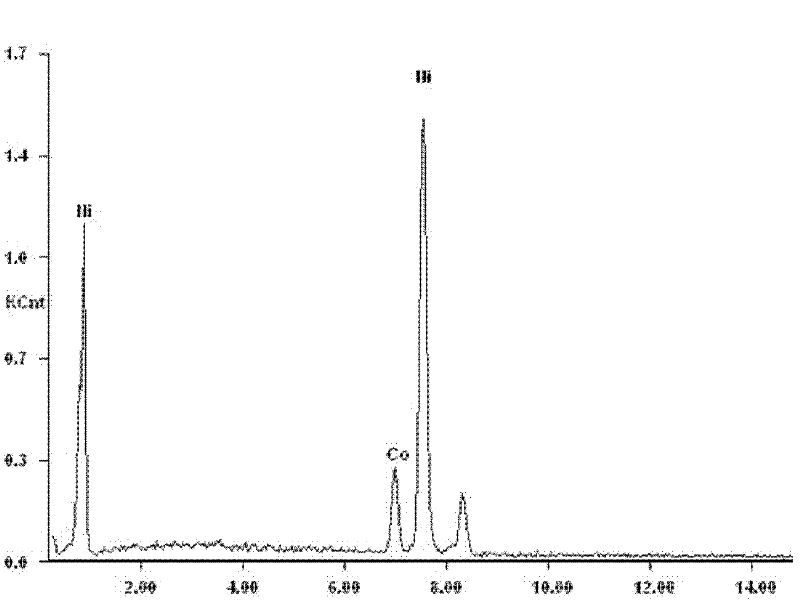

Lithium-ion battery precursor material, composite positive electrode material and preparation method thereof

InactiveCN104966820AEasy to processIncrease storage capacityCell electrodesSecondary cellsHigh densityCobalt

The present invention relates to a lithium-ion battery positive electrode material precursor material with high-voltage charge and discharge stability, a composite positive electrode material synthetic method and a composite positive electrode material prepared by the method. The precursor material has the advantages of good sphericity, high density, strong lithium source adaptability, gentle mixing environment, and the like, the synthesized composite material has high tap density, compared with ordinary lithium nickel-cobalt-aluminum material, the composite material sensitivity to ambient moisture and carbon dioxide is reduced, and the composite material has good processing performance and storage performance, and exhibits high specific capacity and high stability characteristics when the composite material is charged and discharged in 2.8-4.4V and 2.8-4.5V voltage windows.

Owner:GUANGZHOU LIBODE NEW MATERIAL

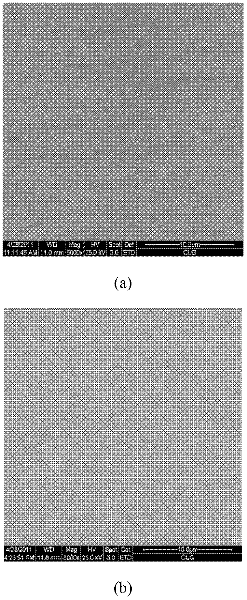

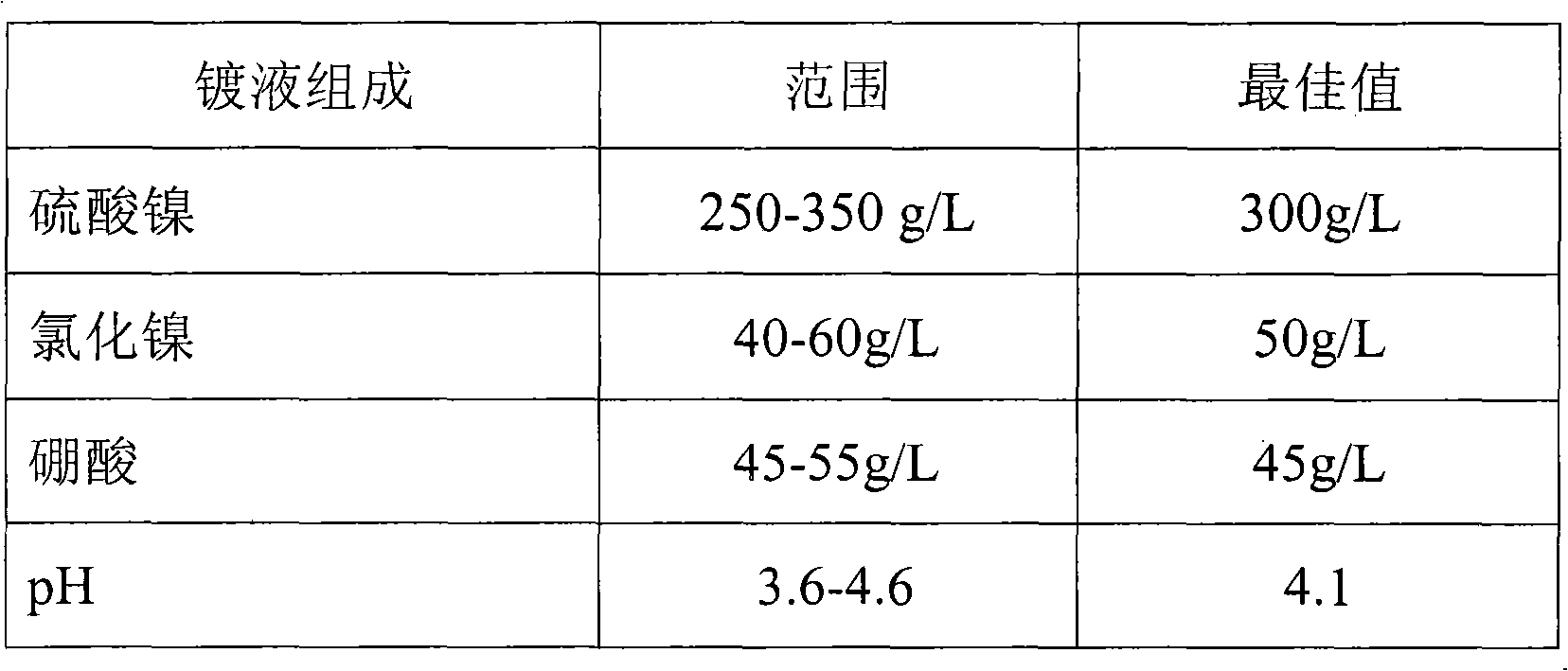

Method for double-pulse electrodeposition of nanocrystalline nickel-cobalt alloy

InactiveCN102260891AUniform crystallizationCrystal fineMaterial nanotechnologyPhotography auxillary processesElectroplatingNickel ions

The invention relates to a method for electrodepositing a nanocrystalline nickel-cobalt alloy by double-pulse. The method for electrodepositing the nanocrystalline nickel-cobalt alloy by double-pulse is characterized by comprising the following processing steps: in a plating solution with a pH value of 5-6, a nickel ion concentration of 0.68-0.95 mol / L and a cobalt ion concentration of 1.9*10<-2>to 3.8*10<-2> mol / L, taking a soluble nickel plate after the soluble nickel plate is subjected to surface treating as a anode, taking an iron sheet after the iron sheet is subjected to surface treating as a cathode and electroplating a nanocrystalline nickel-cobalt alloy layer by using double-pulse electrodepositing technology, wherein the time for electrodepositing is 15-20 min, the positive-going pulse current density is 1.0-2.0 A / dm<2>, the positive-going duty ratio is 60-80%, the working time of the positive-going pulse is 50-100 ms and the positive-going cycle is 40-60 ms; and the negative-going pulse current density is 0.1-0.2 A / dm<2>, the negative-going duty ratio is 60-80%, the working time of the negative-going pulse is 10-20 ms, the negative-going cycle is 1-2 ms and the workingtime of the positive-going pulse is 5-10 times of that of the negative-going pulse. The nickel-cobalt alloy coating prepared by the method has the advantages of smooth surface, compact structure, fine and even crystal, good smoothness, no crack and excellent corrosion resistance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

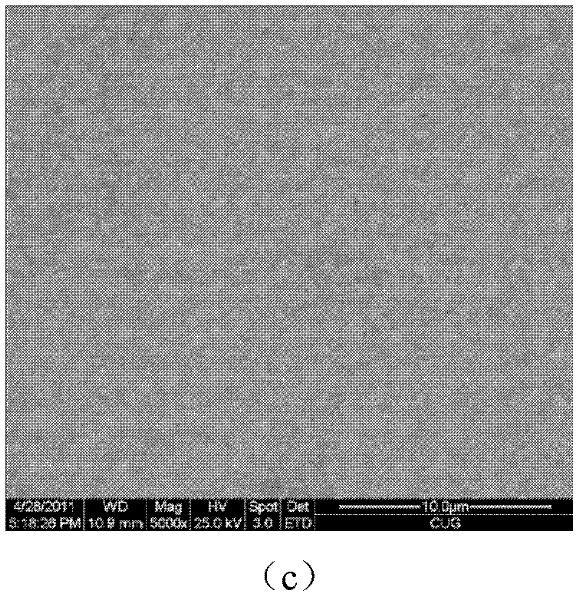

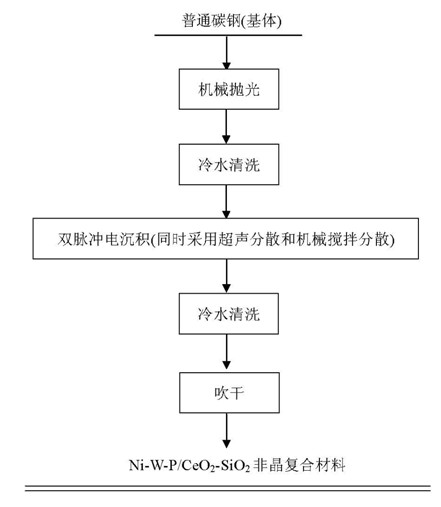

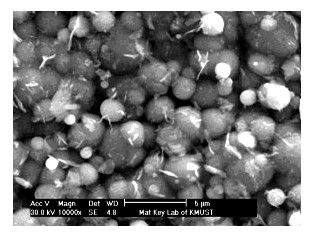

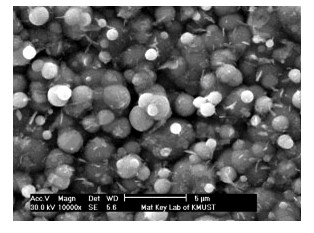

Nanometer granule reinforced metal-based amorphous composite material and preparation method thereof

InactiveCN102400066APrevent precipitationImprove stabilityElectrolytic coatingsElectrolytic agentChemical industry

The invention provides a nanometer granule reinforced metal-based amorphous composite material and a preparation method thereof. In the method, the Ni-W-P / CeO2-SiO2 amorphous composite material of which the thickness is between 54 and 251 micrometers is prepared on the surface of ordinary carbon steel in electrolyte by utilizing dipulse electrolytic deposition for 1.5 to 6 hours under the action of ultrasound, mechanical stirring and the common dispersion of two surfactants. In the nanometer granule enhanced metal-based amorphous composite material, the electrolyte is high in stability, homogeneous plating capacity, current efficiency and deposition rates. CeO2 and SiO2 nanometer granule reinforced phases in the amorphous composite material are dispersed, the sizes of matrix metal granules ranges from 1 to 2 micrometers, and the composite material has a compact tissue structure, a thick deposition layer and high plating microhardness, is combined with a matrix firmly and can be used as surface functional plating layers of equipment parts of metallurgy, chemical industries, tobaccos, machines and the like.

Owner:KUNMING UNIV OF SCI & TECH

Low-concentration weakly alkaline cyanide-free copper plating and bath solution preparing method

The invention relates to a bath solution preparing method and a low-concentration weakly alkaline cyanide-free copper plating which can ensure that the bonding force exists between a plating layer and a matrix, the plating solution has best stability, better dispersing capacity and deep plating capacity and simple process maintenance. The low-concentration weakly alkaline cyanide-free copper plating comprises a main salt, a conductive salt, a main complexing agent and a secondary complexing agent, wherein the main salt is copper chloride, the conductive salt comprises a mixture of sodium chloride, potassium chloride and ammonium chloride, the main complexing agent is a mixture of tartrate, citrate, nitrilotris(methylene)]tris-phosphonic acid salt, (1-Hydroxyethylidene)bis-phosphonic acid tetrasodium salt and ethylenediamine tetra(methylenephosphonic acid) salt; and the secondary complexing agent is a mixture of ortho-hydroxybenzoic acid, succinimide and derivatives thereof and dimethyl hydantoin. The invention has the advantages of capability of ensuring the bonding force of the plating and the matrix, best stability and better dispersing capacity and deep plating capacity and simple process maintenance.

Owner:HANGZHOU HAISHANG TECH

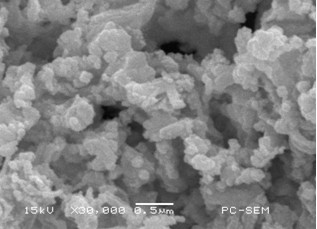

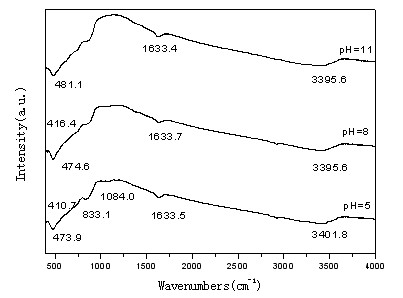

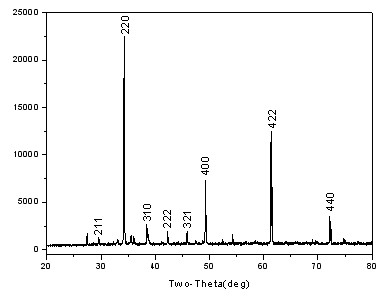

Preparation method of perovskite-like varistor ceramic material CaCu3Ti4O12 with high dielectric constant

ActiveCN102432062AOvercome energy consumptionOvercome granularityTitanium compoundsNitrateVaristor ceramics

Belonging to the technical field of preparation and application of electronic ceramics, the invention relates to a preparation method of a perovskite-like varistor ceramic material CaCu3Ti4O12 (CCTO) with a high dielectric constant. With nitrates of Cu and Ca as well as Ti (OC4H9)4 as starting materials, the method of the invention combines a hydrothermal method for preparing nanometer CCTO powder so as to prepare high performance CCTO varistor ceramics, thus realizing the purposes of lowering temperature, and improving varistor as well as dielectric properties.

Owner:江苏津沂菊源生物健康产业研究院有限公司

Non-cyanide zinc-deposited solution and non-cyanide plating method of aluminum wheel boss using non-cyanide zinc-deposited solution

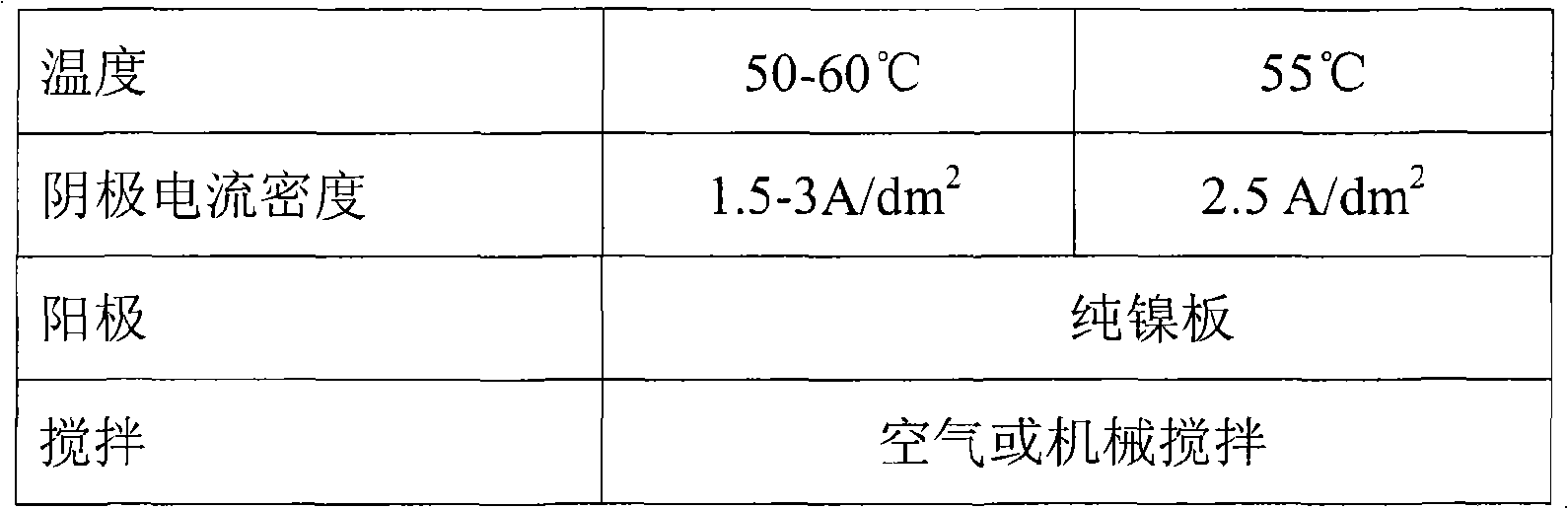

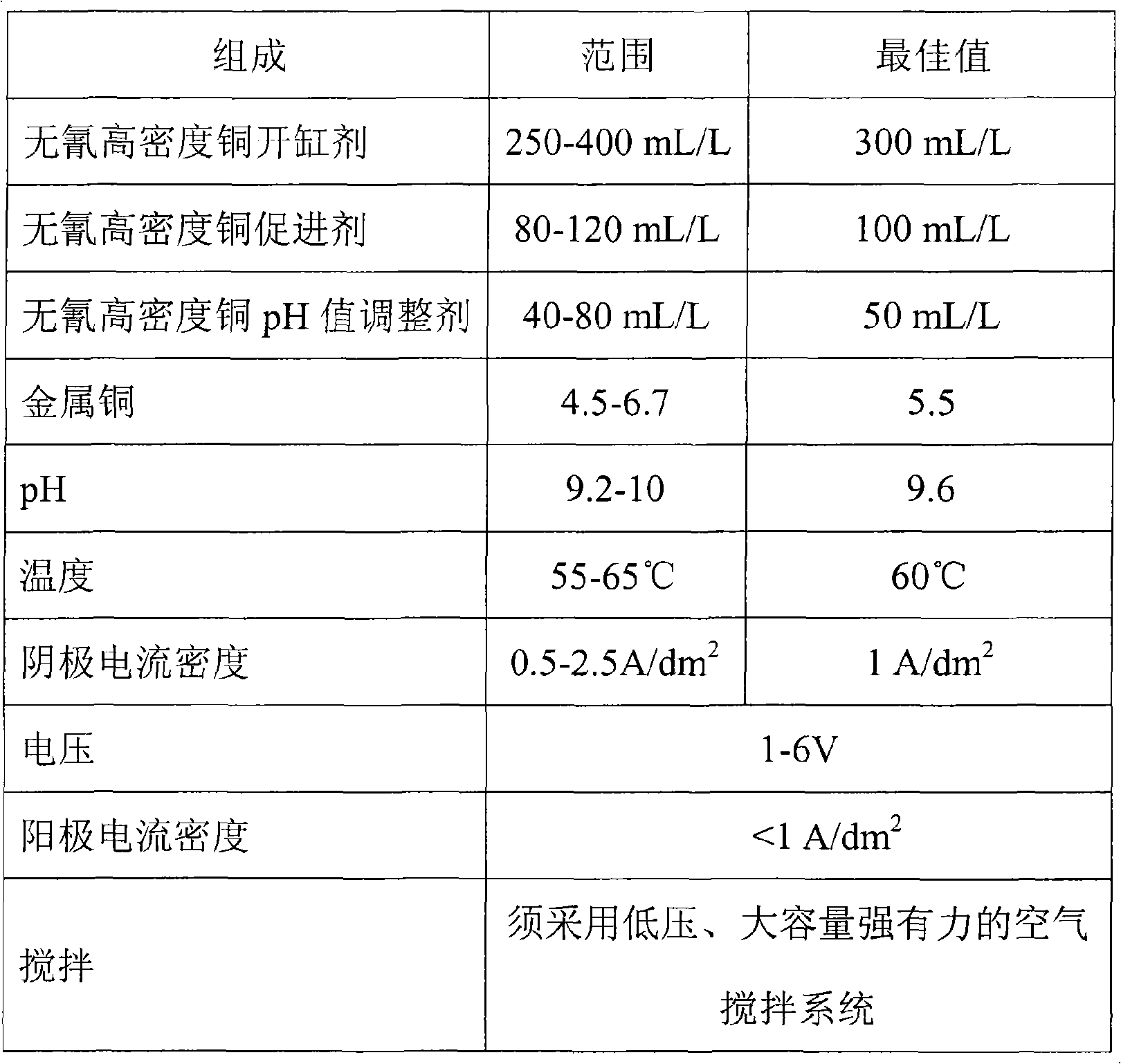

The invention relates to electroplating of aluminum wheel boss, in particular to non-cyanide zinc-deposited solution and a non-cyanide plating method of the aluminum wheel boss using the non-cyanide zinc-deposited solution. The non-cyanide zinc-deposited solution is mainly prepared from the following components: 350 to 450 mL / L cylinder opening agent, 8 to 12 mL / L regulator, 120 to 130 mL / L extender, and the balance of water. The cylinder opening agent contains quaternionic metallic ions of copper, iron, nickel and zinc. The non-cyanide plating method comprises the steps of preplating treatment, zinc deposition for two times, nickel preplating / high-density non-cyanide copper preplating, acid bright copper plating, polishing, pretreatment and multilayer nickel chromium plating; and the non-cyanide zinc-deposited solution is used in the twice zinc deposition. The electroplating technology adopts the process of substituting cyanide with a multielement composition additive, does not contain the cyanide and a strong complexing agent, is non-toxic and harmless, is simple in wastewater disposal and belongs to the process of cleaner production.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH

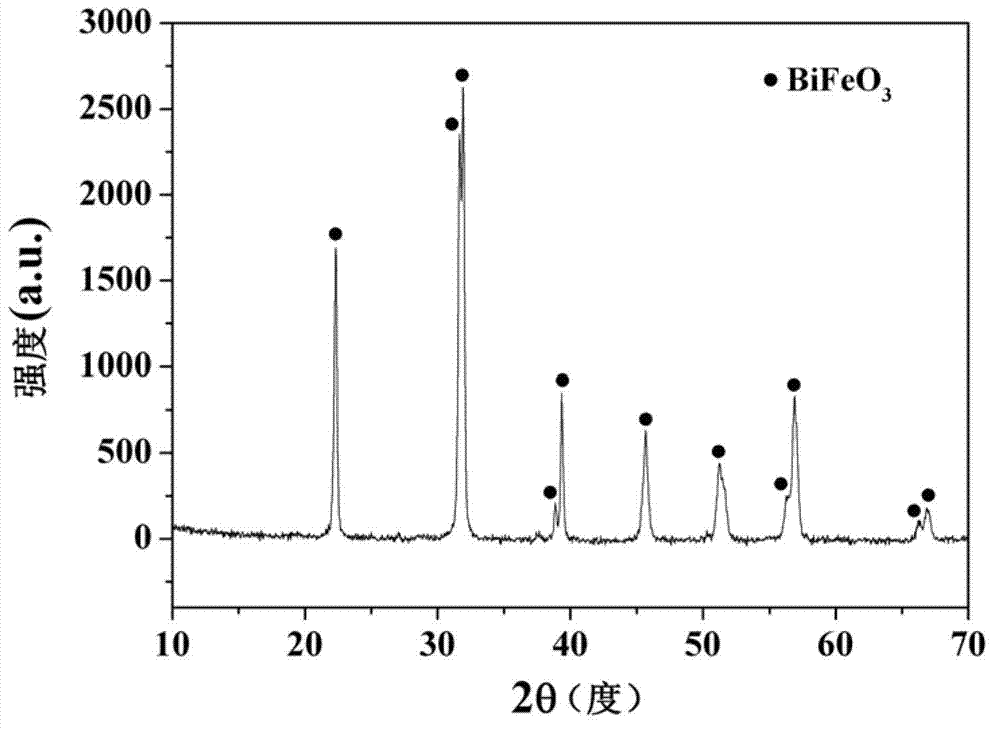

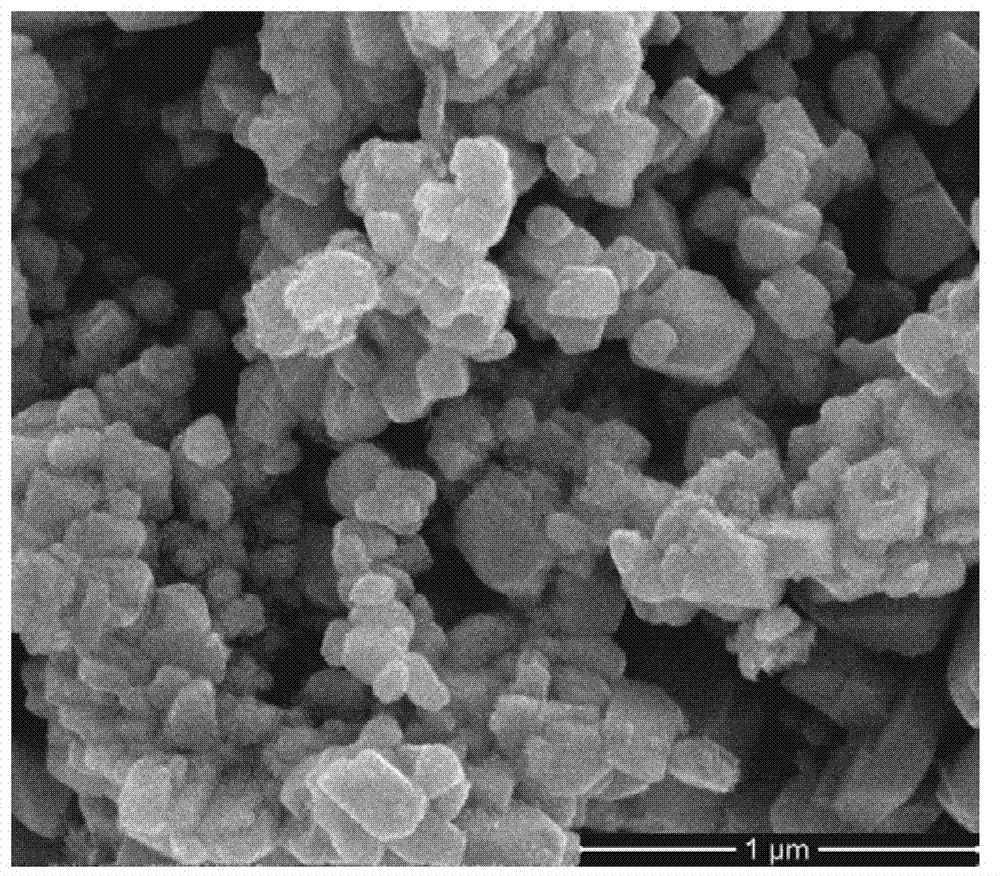

Method for preparing bismuth ferrite powder by solvothermal method

InactiveCN102826608AEnergy savingSimple equipmentChemical industryIron compoundsSolventHydrothermal reaction

The invention discloses a method for preparing bismuth ferrite powder by a solvothermal method. The method comprises the following steps of: (1) weighing and analyzing pure Fe(NO3)3.9H2O and Bi(NO3)3.5H2O according to a molar ratio of 1:1, dissolving the Fe(NO3)3.9H2O and the Bi(NO3)3.5H2O into a nitric acid solution, and stirring through magnetic force to prepare a uniform mother salt solution; (2) dropping an KOH solution into the mother salt solution, stirring through the magnetic force to obtain a precipitate, and washing and drying the precipitate to obtain a hydrothermal reaction precursor; (3) putting the hydrothermal reaction precursor into a hydrothermal kettle, adding a mixture of absolute ethyl alcohol and water as a solvent, and taking the KOH as a mineralizing agent; (4) sealing the reaction kettle, putting the reaction kettle into an oven with a temperature of 120-130 DEG C, taking out a product in the reaction kettle after reacting, and filtering to obtain a precipitate; and washing and drying the precipitate to obtain the bismuth ferrite powder. The method for preparing the bismuth ferrite powder by the solvothermal method has the advantages of low preparation temperature, energy saving, good bismuth ferrite crystallization and simple process control and apparatus required by synthesis.

Owner:SOUTH CHINA UNIV OF TECH

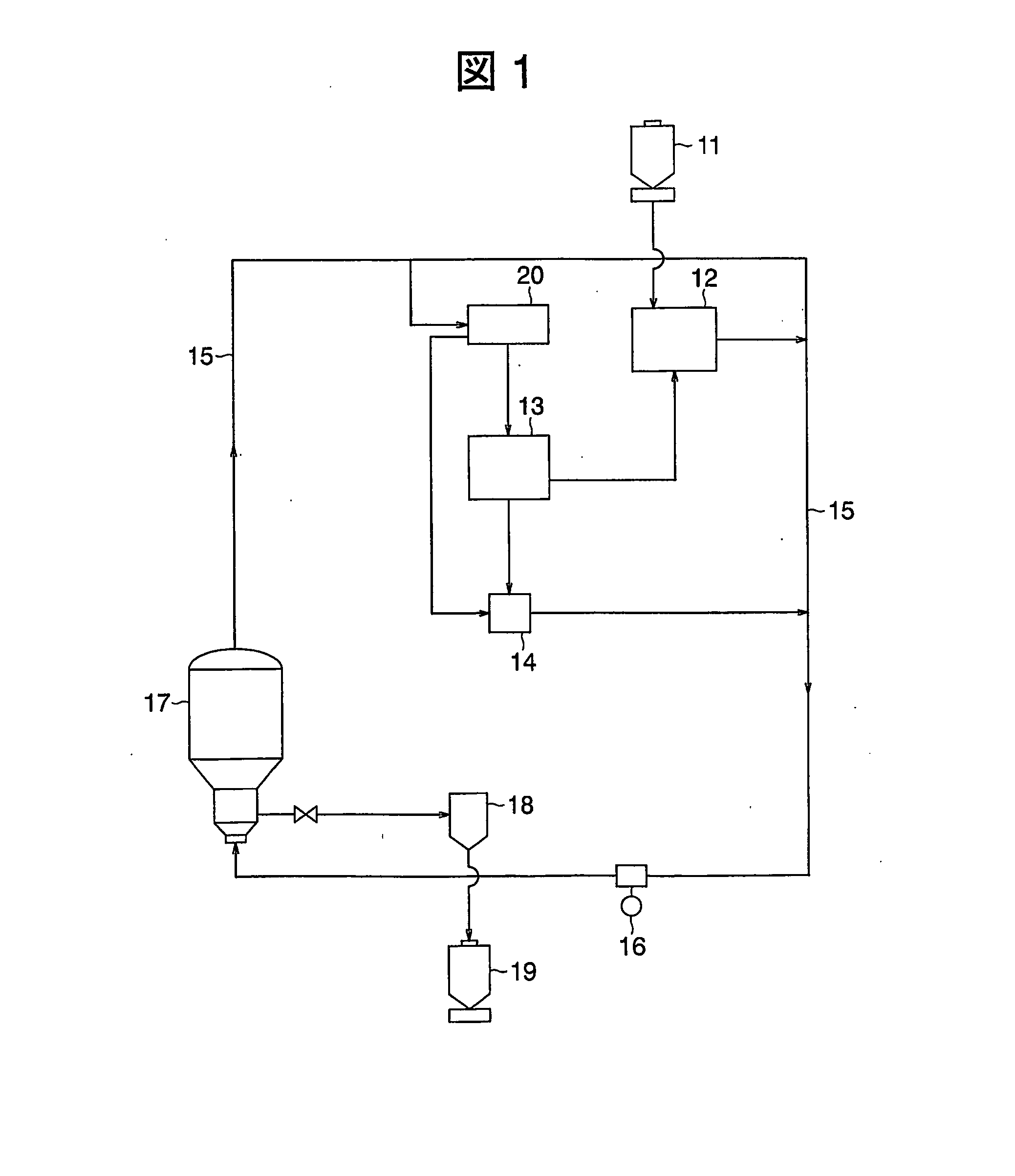

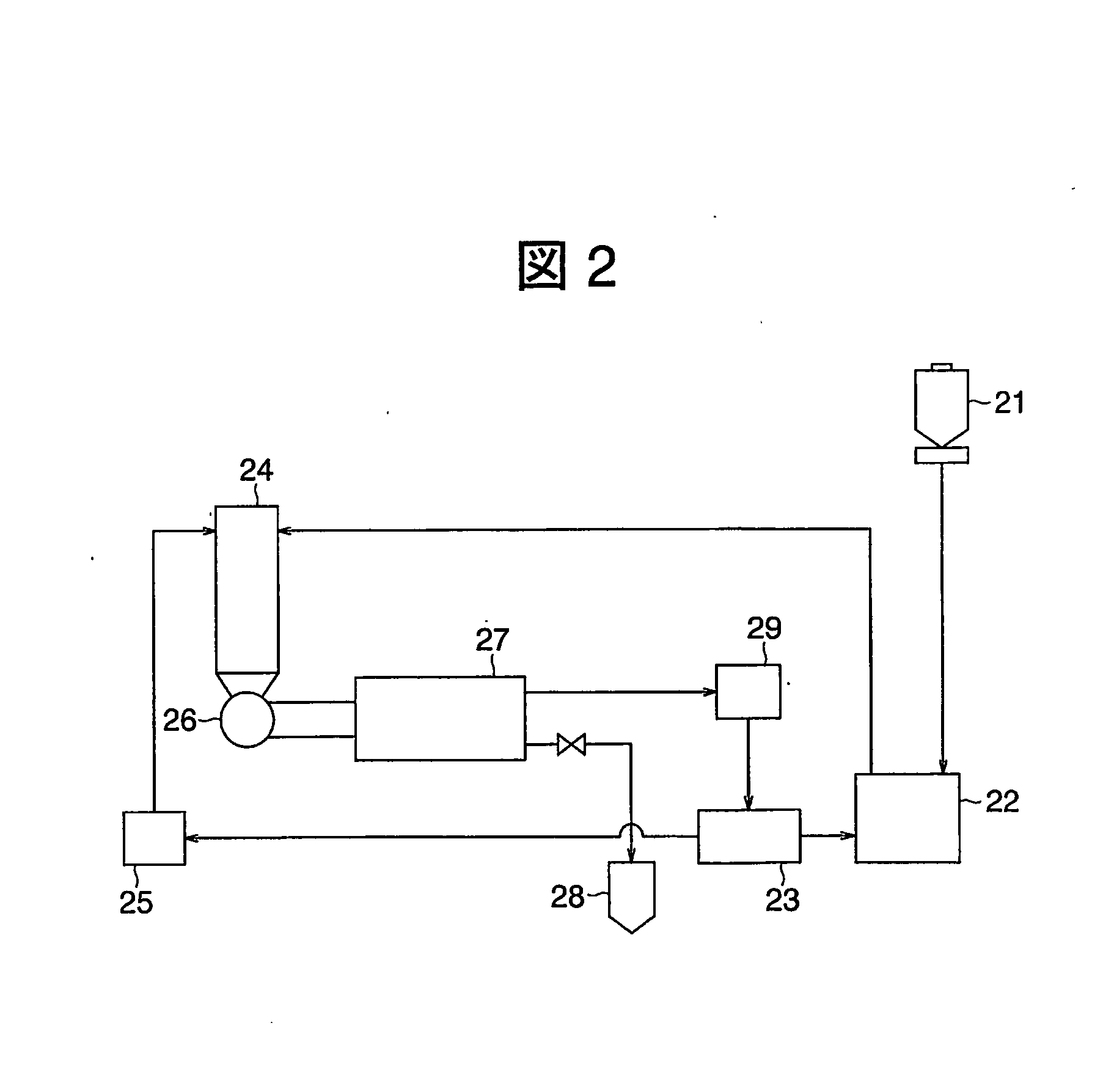

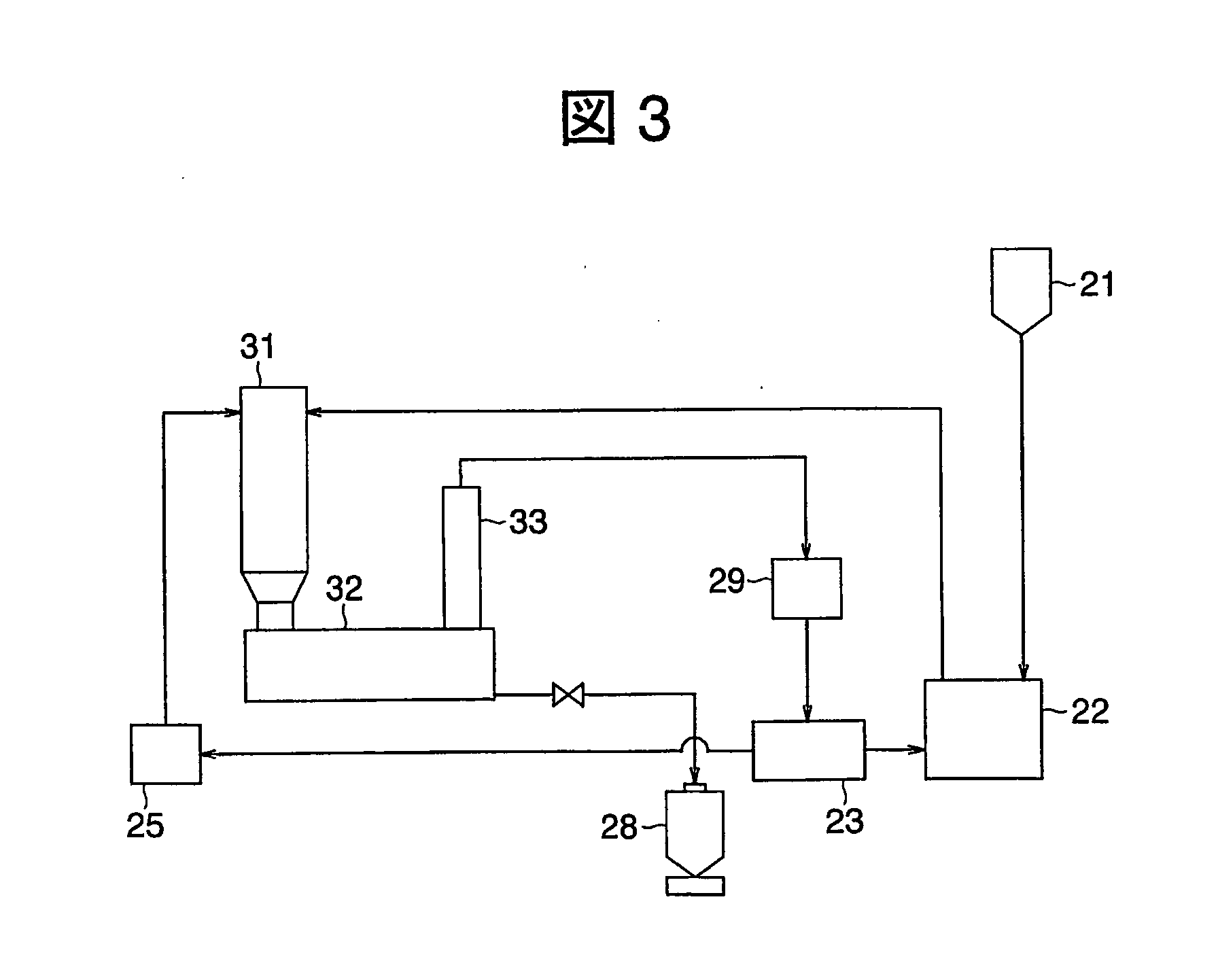

Process for producing high-purity silicon and apparatus

InactiveUS20060270199A1Crystal fineImprove reaction efficiencyPolycrystalline material growthSilicon halogen compoundsMolten stateGas phase

When high purity silicon is produced through a gas-phase reaction between silicon tetra-chloride and zinc in a reaction furnace, the produce silicon is obtained as block or molten state. after the reaction in which the silicon is not in contact with air and reaction temperature is maintained at melting point of the silicon or less.

Owner:ASAHI GLASS CO LTD

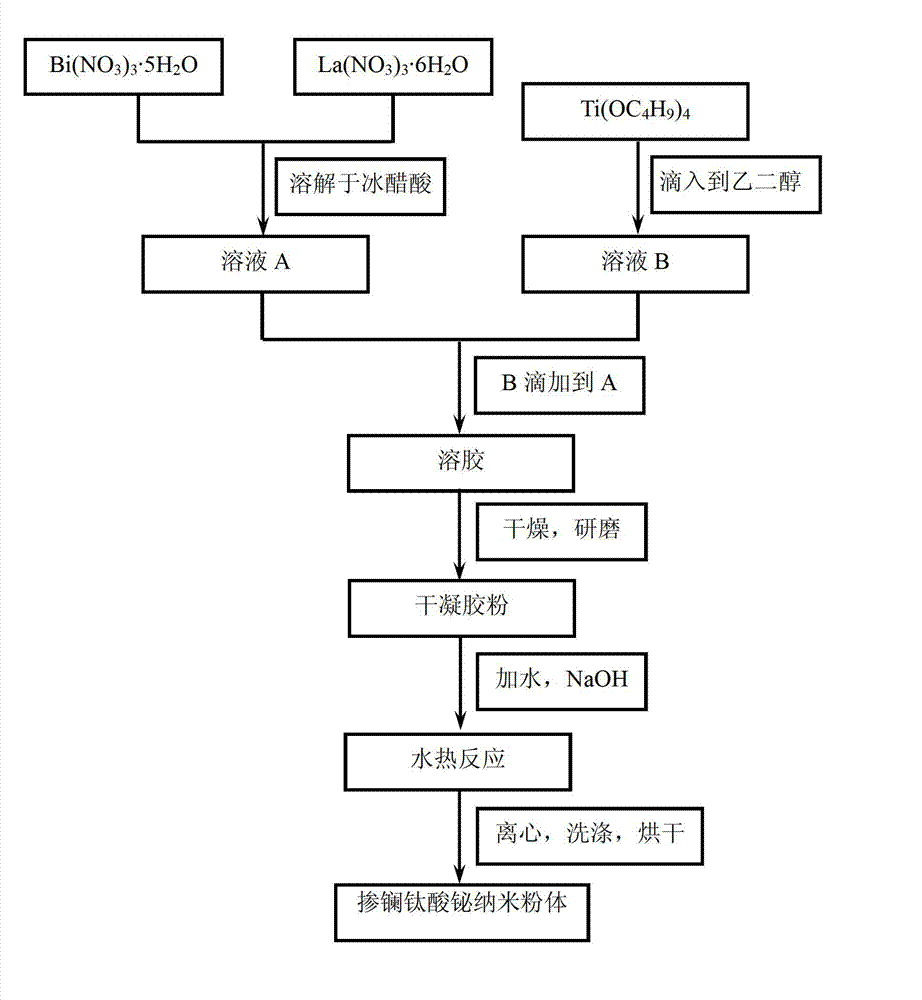

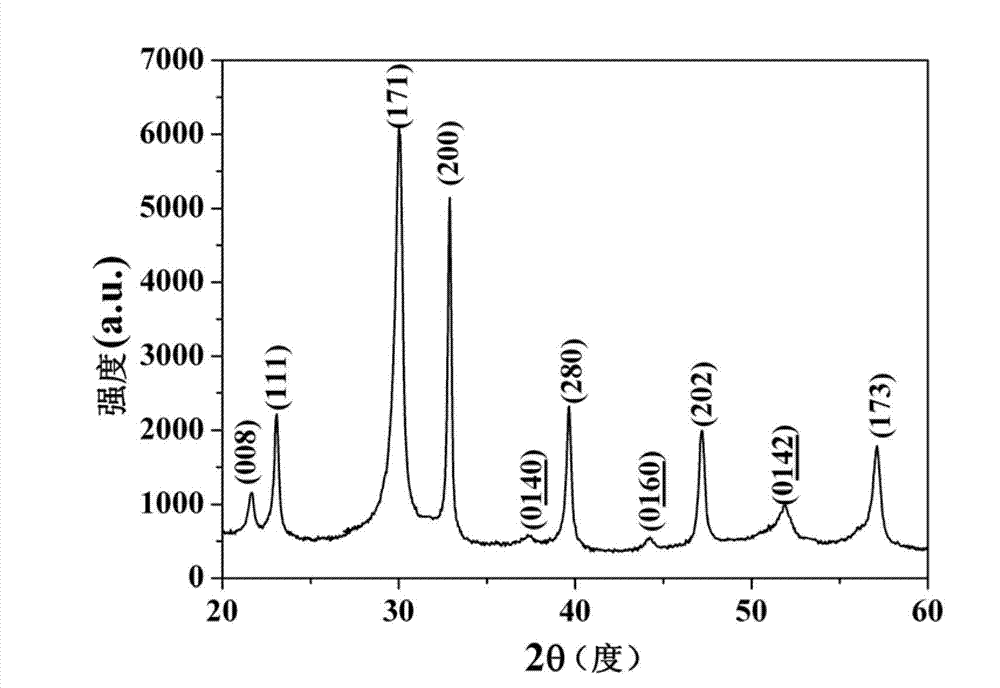

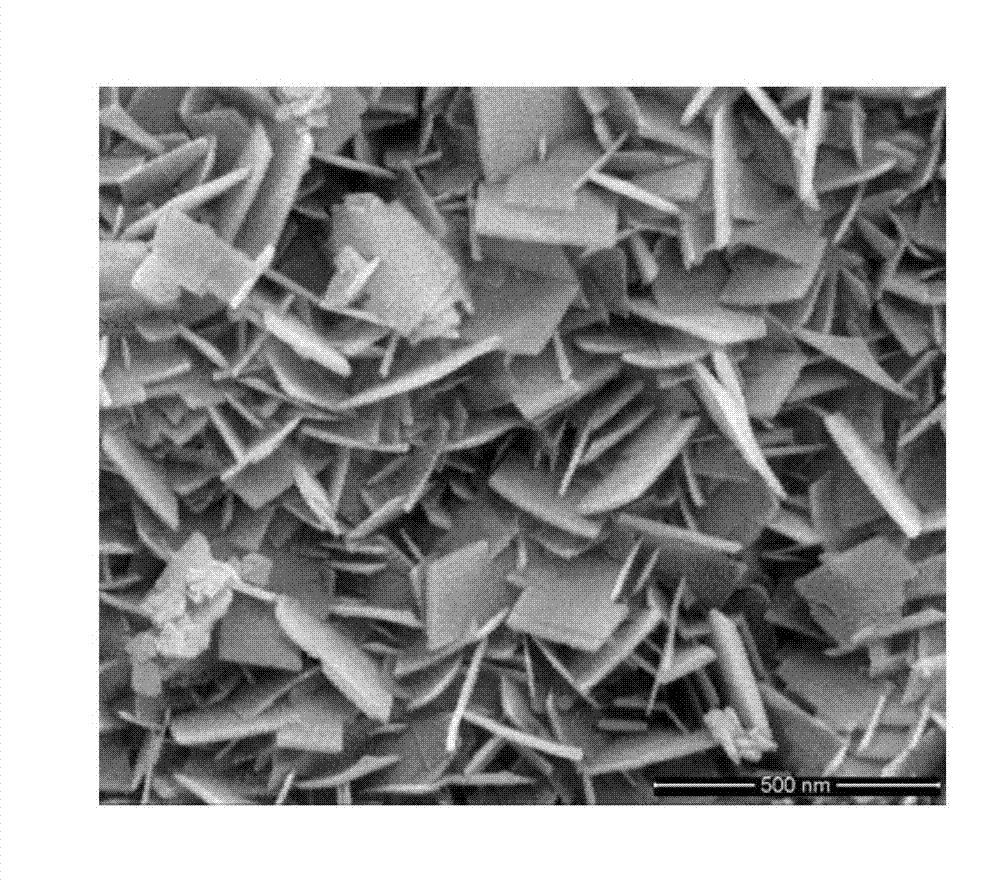

Method for preparing lanthanum-doped bismuth titanate nano powder by sol-gel hydrothermal method

ActiveCN102963929ASave energySimple equipmentMaterial nanotechnologyChemical industryOrganic solventAcetic acid solution

The invention discloses a method for preparing lanthanum-doped bismuth titanate nano powder by a sol-gel hydrothermal method, which comprises the following steps of: dissolving Bi (NO3) 3.5H2O and La (NO3) 3.6H2O into glacial acetic acid solution to obtain solution A; dropwise adding Ti (OC4H9) 4 into organic solvent to obtain solution B; dropwise adding the solution B into the solution A, and preparing even sol by magnetic stirring; putting the sol into a drying oven, and drying to obtain xerogel; grinding to obtain powdered hydrothermal reaction precursor; putting the hydrothermal reaction precursor into a hydrothermal kettle, and adding pure water taken as solvent and NaOH taken as mineralizer into the hydrothermal kettle; sealing the reaction kettle, and putting the reaction kettle into the drying oven at 160-170 DEG C; taking out products after reaction, and filtering to obtain precipitate; and finally, washing and drying the precipitate to obtain the lanthanum-doped bismuth titanate nano powder. The method can be used for preparing the lanthanum-doped bismuth titanate nano powder under the condition of low temperature, so that the energy is saved, and lanthanum-doped bismuth titanate is perfect in crystallization.

Owner:SOUTH CHINA UNIV OF TECH

Thermoplastic composition, preparation method and application thereof

The invention discloses a thermoplastic composition, a preparation method and an application thereof. The thermoplastic composition comprises 25-87% of a thermoplastic resin, 8%-35% of a laser direct pattern additive, 0.5%-10% of a high dielectric additive, 2-10% of an inorganic filler, 1-10% of a rubber solubilizing polymer, 1-10% of a surface modification agent and 0.1-0.5% of an antioxygen. The obtained thermoplastic composition is used in a laser direct pattern method and is good in dispersibility, excellent in mechanical property and chemical plating performance, good in plating performance and processing shaping performance, capable of achieving fine lines with sizes below 100 mu m, and wide in application prospects in the aspect of weak current circuits of communication devices such as notebook computers, portable computers, mobile phones and hand-held terminals, medical treatment, a radio frequency identification (RFID) technology, automobiles, sensors, connectors and the like.

Owner:邓文 +2

Cyanogen-free silver-plating brightener and method for preparing the same

The preparation method for cyan-free silver plating lustre-coating agent comprises: adding 0.1-1mol / L heliotropin into saturated 0.1-2mol / L NaHSO3 solution for ultrasonic oscillating; dissolving 0.1-2mol / L triethanolamine and 0.1-1mol / L butynediol into the solution, adding solvent to dilute to 1L. This invention overcomes the defects in prior art withnot sulfur-containing compound, and has well dispersion.

Owner:HARBIN INST OF TECH

Anodic phosphorous copper balls and preparation method thereof

InactiveCN101914801AImprove qualityPhosphorus is evenly distributedElectrodesCopper platingInduction furnace

The invention discloses anodic phosphorous copper balls and a preparation method thereof. The method comprises the following steps of: (1) after yellow phosphorus or red phosphorus and oxygen-free copper are melted by adopting a medium-frequency induction furnace, stirring the melt uniformly through a magnetic stirring tank to obtain phosphorous copper solution; (2) producing a phosphorous copper bar with a diameter of 20 to 50 millimeters by using the phosphorous copper solution prepared in the step (1) and an up-draw process, and continuously stamping the phosphorous copper bar to obtain copper balls of different sizes in different dies; and (3) performing polishing, burr removal, cleaning and drying treatment on the copper balls obtained in the step (2) in turn to obtain the anodic phosphorous copper balls. The anodic phosphorous copper balls have the advantages of compact crystal, thin and small crystal grain, high phosphorous copper film generating speed, exquisite and firm phosphorous copper film texture and dropping resistance, and can reduce the cleaning frequency of an anode, effectively improve the utilization rate of the anode and remarkably improve the copper plating effect.

Owner:金峰电路(惠州)有限公司

Phosphating liquid of high corrosion resistance black phosphating production process

ActiveCN101864563ACrystal fineFirmly attachedMetallic material coating processesO-Phosphoric AcidOptical instrumentation

The invention relates to phosphating liquid of a phosphating process, in particular to phosphating liquid of a high corrosion resistance black phosphating production process for steel piecec, which is characterized in that: the phosphating liquid comprises the following components: 25 to 35 g / L zinc oxide (ZnO), 120 to 135 g / L phosphoric acid H3PO4, 100 to 150 g / L zinc nitrate Zn(NO3)2.6H2O, 5 to 8 g / L nitric acid HNO3, 3 to 5 g / L citric acid, 0.5 to 1 g / L tartaric acid and 5 to 10 g / L nickel nitrate. The phosphating liquid ensures the fineness and smoothness of the phosphating film crystal of the steel piece, has firm attachment, good blackness and high abrasion resistance, and is particularly applicable to the steel components of the optical instrument.

Owner:西安北方光电有限公司

Additive for electrolytic copper foils and application thereof, electrolytic copper foil and preparation method and application thereof, and lithium ion battery

ActiveCN109267111AUniform thicknessReduce warpageFinal product manufactureElectrode carriers/collectorsElectrolysisMetallurgy

The invention provides an additive for electrolytic copper foils and application thereof, an electrolytic copper foil and a preparation method and application thereof, and a lithium ion battery, and belongs to the technical field of electrolytic copper foils. The additive herein comprises additive A and additive B, wherein the additive A includes a grain refiner and a polyvinyl alkylimine compoundin a weight ratio of (5-20):(1-10); the additive B includes collagen and carboxymethyl chitosan in a weight ratio of (8-20):(1-10). The additive containing the additive B and the additive B can be used to prepare an electrolytic copper which is a double-side photo-electrolytic foil having thickness of only 5-8 mu m; the prepared electrolytic copper foil has low warpage, uniform thickness, zero edge tearing and fine crystal.

Owner:HUBEI ZHONGYI TECH

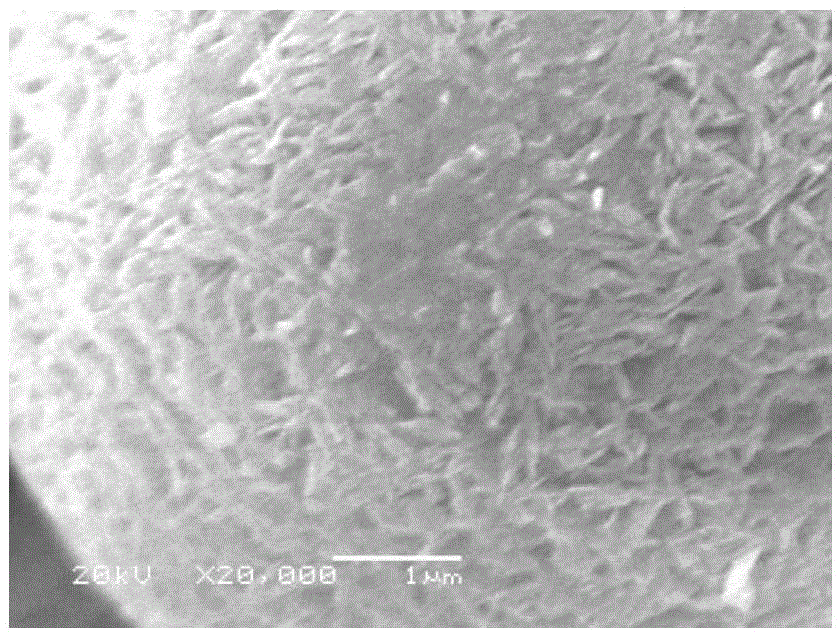

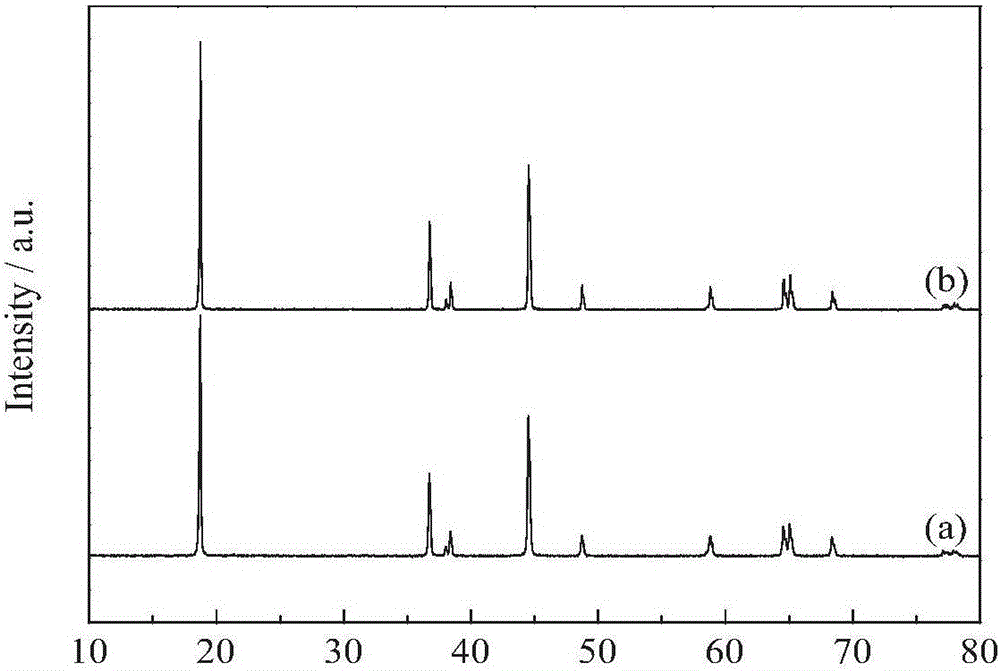

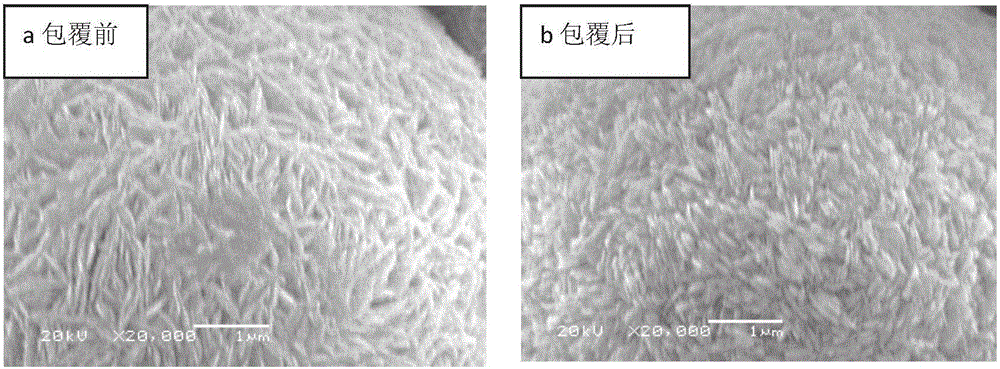

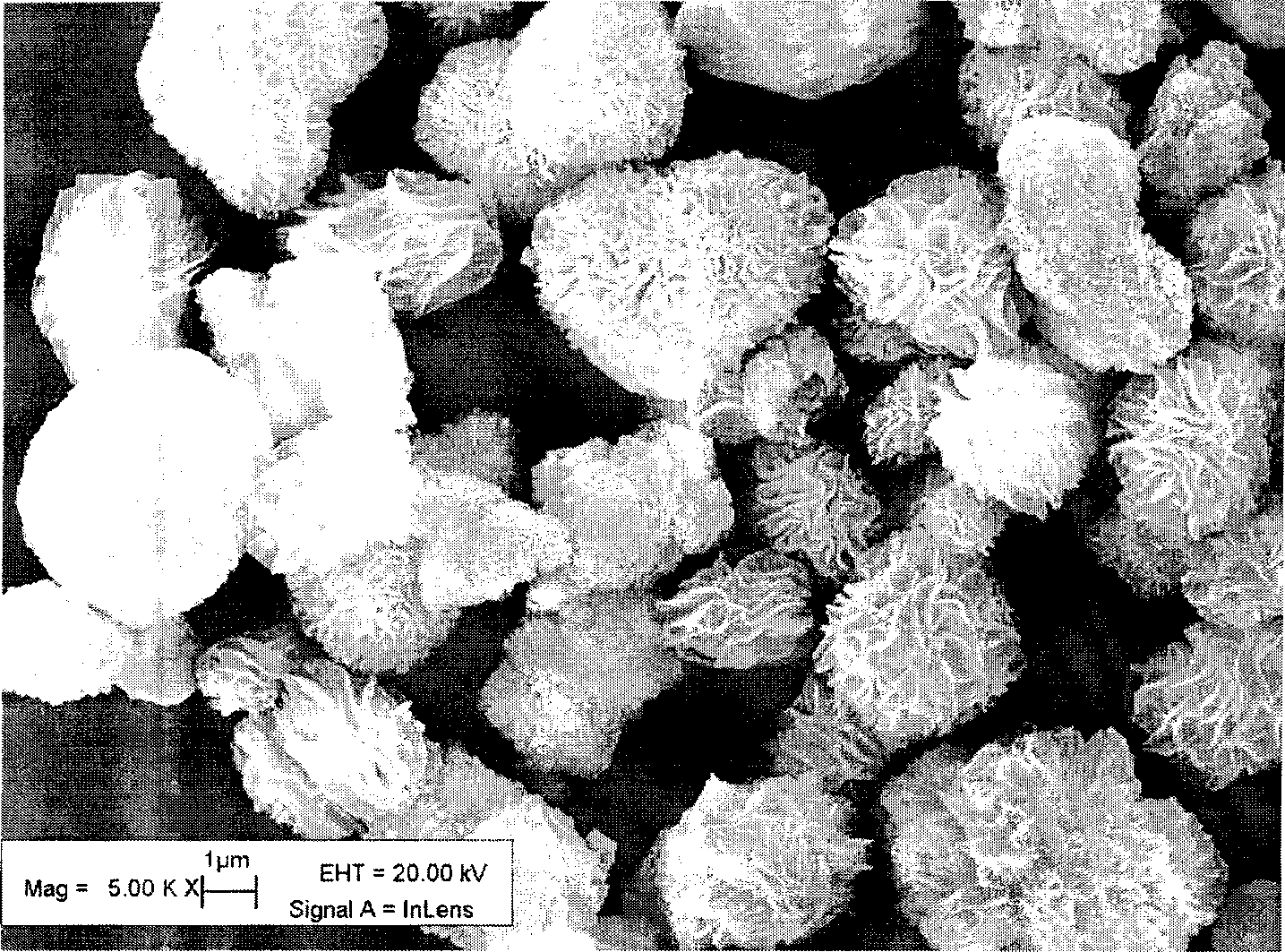

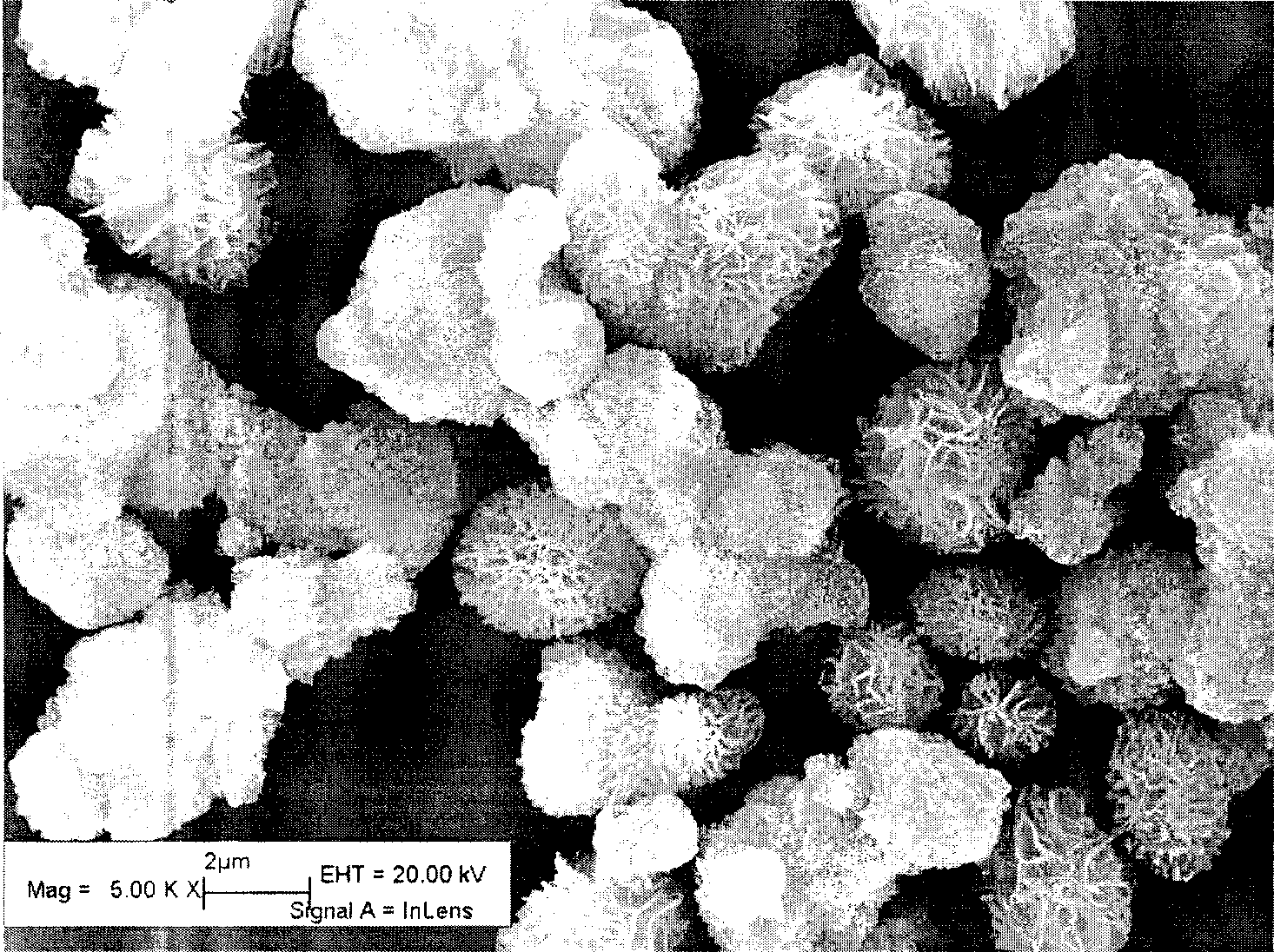

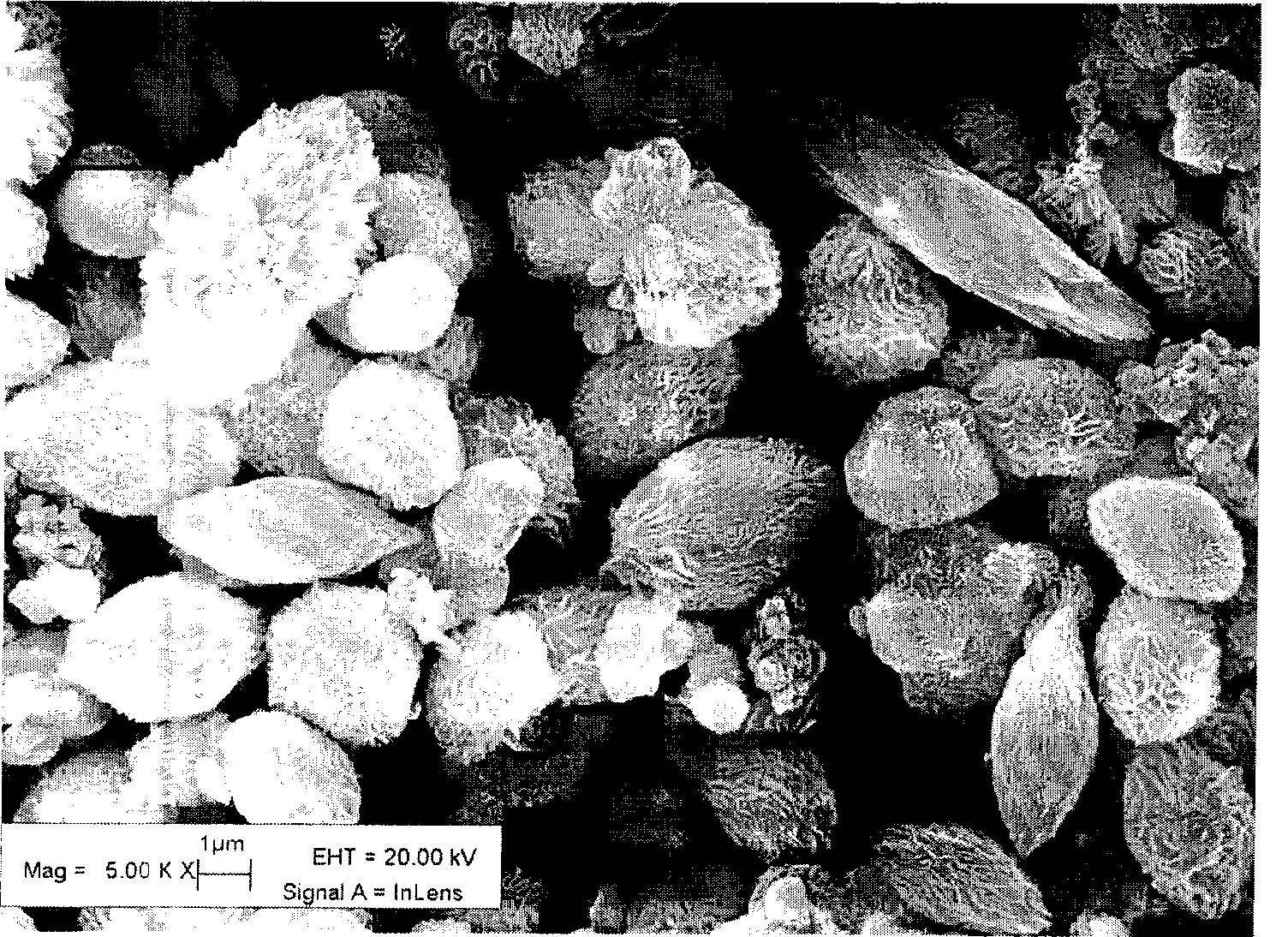

Lithium ion battery composite cathode material LiNi1-x-yMxAlyO2 with core-shell structure and preparation method of lithium ion battery composite cathode material LiNi1-x-yMxAlyO2

The invention discloses a lithium ion battery composite cathode material LiNi1-x-yMxAlyO2 with a core-shell structure and a preparation method of the lithium ion battery composite cathode material LiNi1-x-yMxAlyO2. The preparation method comprises the following steps that precursor powder is dispersed into a reaction still containing a base solution of a certain volume; a sodium metaaluminate solution is added into the reaction still, a precipitator is added at certain flow speed, the reaction conditions are controlled, and aluminum slowly deposits to the surface of the precursor powder; slurry is aged, washed and filtered, and a precursor with the core-shell structure is obtained after drying; the precursor and lithium salt are mixed to be uniform and calcined in oxygen shield to form the composite cathode material LiNi1-x-yMxAlyO2. The method has the advantages of being low in equipment requirement, easy to operate, environmentally friendly, high in element utilization rate, even in coating, good in product quality and the like.

Owner:CENT SOUTH UNIV

Process for producing flower shaped indium hydroxide powder having high specific surface area

InactiveCN101508462AHigh specific surface areaControllable sizeGallium/indium/thallium compoundsUreaChemistry

The invention relates to a method for preparing flower indium hydroxide with high specific surface area, which belongs to the technical field of inorganic material preparing process. The method uses In water soluble salt as an indium source, urea as an alkali source and sodium dodecyl sulfate as a surfactant to prepare indium hydroxide powder by a hydro-thermal method, wherein the compositions react at a constant temperature for 12 to 24 hours under a low-temperature hydrothermal condition of between 90 and 105 DEG C; and precipitate is obtained through filtration after the reactant is cooled to room temperature, and is washed, centrifugally precipitated and dried to obtain the flower high specific surface area indium hydroxide assembled by nanometer flakes. The method has the advantages that the method prepares the flower indium hydroxide by the low-temperature hydro-thermal method, not only can make crystal sufficiently grow under unrestricted condition with advantages of high specific surface area, controllable appearance and size of the crystal, perfect crystal and the like, but also can obtain powder body with specific surface area of between 20 and 40 mg; and XRD diffraction indicates that a main crystal phase is In(OH) and grows with preferred orientation along (100) direction, and impurity phase is InOOH with content totally less than 12 percent. The system has excellent application prospect in microelectronics, photoelectricity, sensing devices, catalysts, alkaline cells and other fields.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Alkaline non-cyanide zinc plating nickel alloy plating solution and electroplating process thereof

The invention discloses an alkaline non-cyanide zinc plating nickel alloy plating solution and an electroplating process thereof. The plating solution is prepared with hydantoin or a hydantoin derivative as a main coordination agent by adding an auxiliary coordination agent, zinc sulfate, nickel sulfate, potassium carbonate and water. The plating solution comprises 20 g-400 g / L of the main coordination agent, 5 g-300 g / L of the auxiliary coordination agent, 5 g-200 g / L of the zinc sulfate, 1 g-150 g / L of the nickel sulfate and 5 g-435 g / L of the potassium carbonate. The electroplating process of the plating solution comprises the steps of substrate pretreatment and zinc-nickel alloy electroplating. A constant current electroplating mode is adopted for zinc-nickel alloy electroplating. The electric current density is 0.5 A-5 A / dm2. The temperature of the plating solution is 30 DEG C-60 DEG C. The distance between a cathode and an anode is 0.5 cm-25 cm. The stirring speed of the plating solution is 0 rpm-3000 rpm. The electroplating time is 1 min-120 min. According to the plating solution and the electroplating process thereof, the hydantoin or the hydantoin derivative serves as the main coordination agent for the first time, and zinc-nickel alloy with the nickel content of 10 wt.%-13 wt.% is obtained through electro-deposition by using the main coordination agent and the auxiliary coordination agent in a combination mode. An obtained coating is good in corrosion resistance. The stability of the plating solution is improved immensely compared with using of a single coordination agent.

Owner:宏正(福建)化学品有限公司

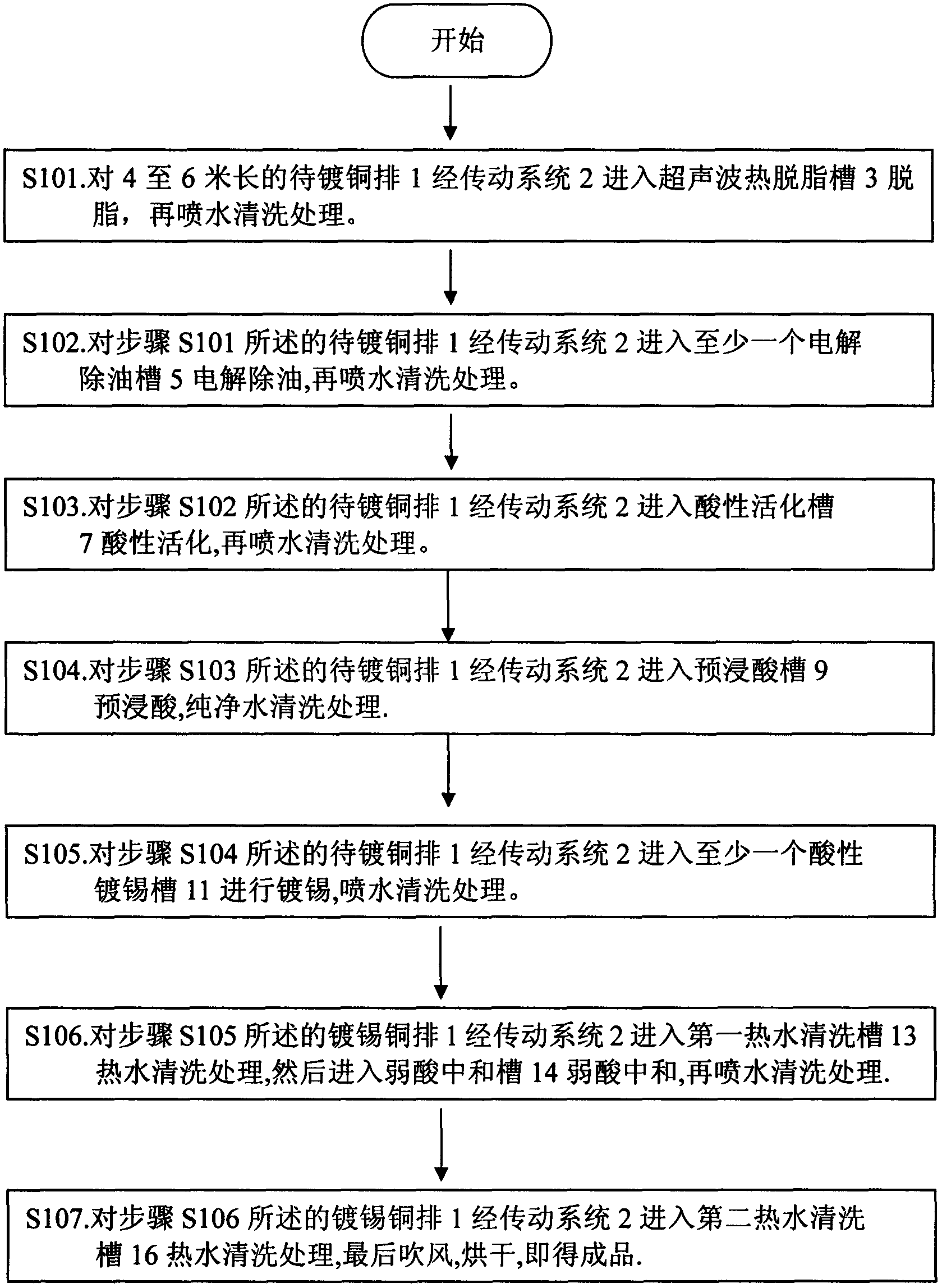

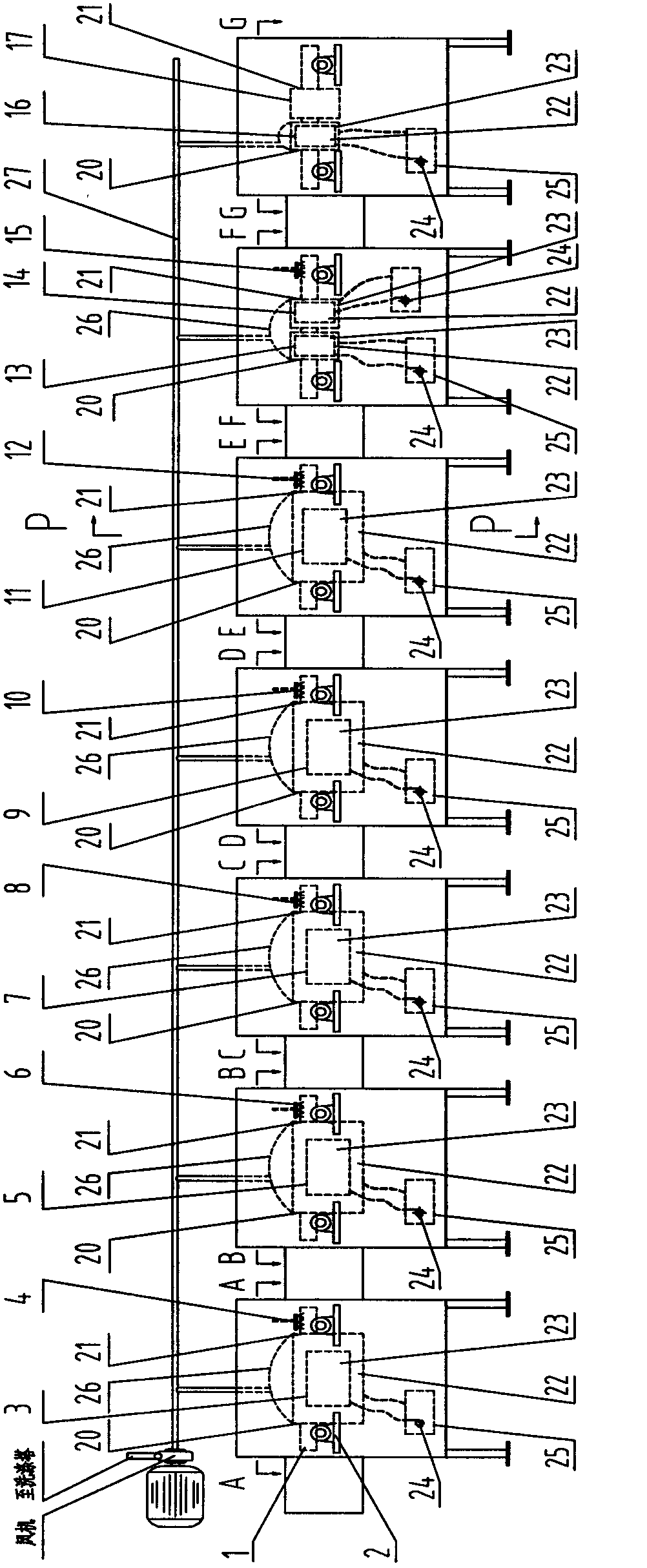

Copper bar continuous travelling tinning method and equipment

ActiveCN102703959ABright surfaceUniform crystallizationElectrolysis componentsTinningHigh current density

The invention discloses a copper bar continuous travelling tinning method and equipment, which includes the follows steps: step S101 is that a to-be-tinned copper bar of 4 to 6 meters in length undergoes ultrasonic thermal bebinding and water-spray washing through a transmission system; step S102 is that the to-be-tinned copper bar undergoes electrolytic degreasing and water-spray washing; step S103 is that to-be-tinned copper bar undergoes acid activating and water-spray washing; step S104 is that the to-be-tinned copper bar undergoes pre-pickling and purified water washing; step S105 is that the to-be-tinned copper bar undergoes tinning and connected with a conducting wheel in a sliding way, and the flowing cooling water pipe on the upper side of the conducting wheel performs water-spray washing after the tinning; step S106 is that the tinned copper bar undergoes hot water washing, weak acid neutralization and water-spray washing; and step S107 is that the tinned copper bar undergoes hot water washing and drying through blowing, so as to obtain the finished product. The method and equipment enable the to-be-tinned copper bar to continuously travel at a uniform speed in the electroplating baths through the transmission system, can electroplate under high current density, and improve the tinning efficiency; the surface of the tinned surface is uniform, smooth and is highly anti-corrosive, the harmful waste gases as alkali and acid mist produced during the tinning process can be purified by the equipment, and the equipment doesn't pollute the environment.

Owner:周建元

Method for separating aluminum and iron in high-iron bauxite

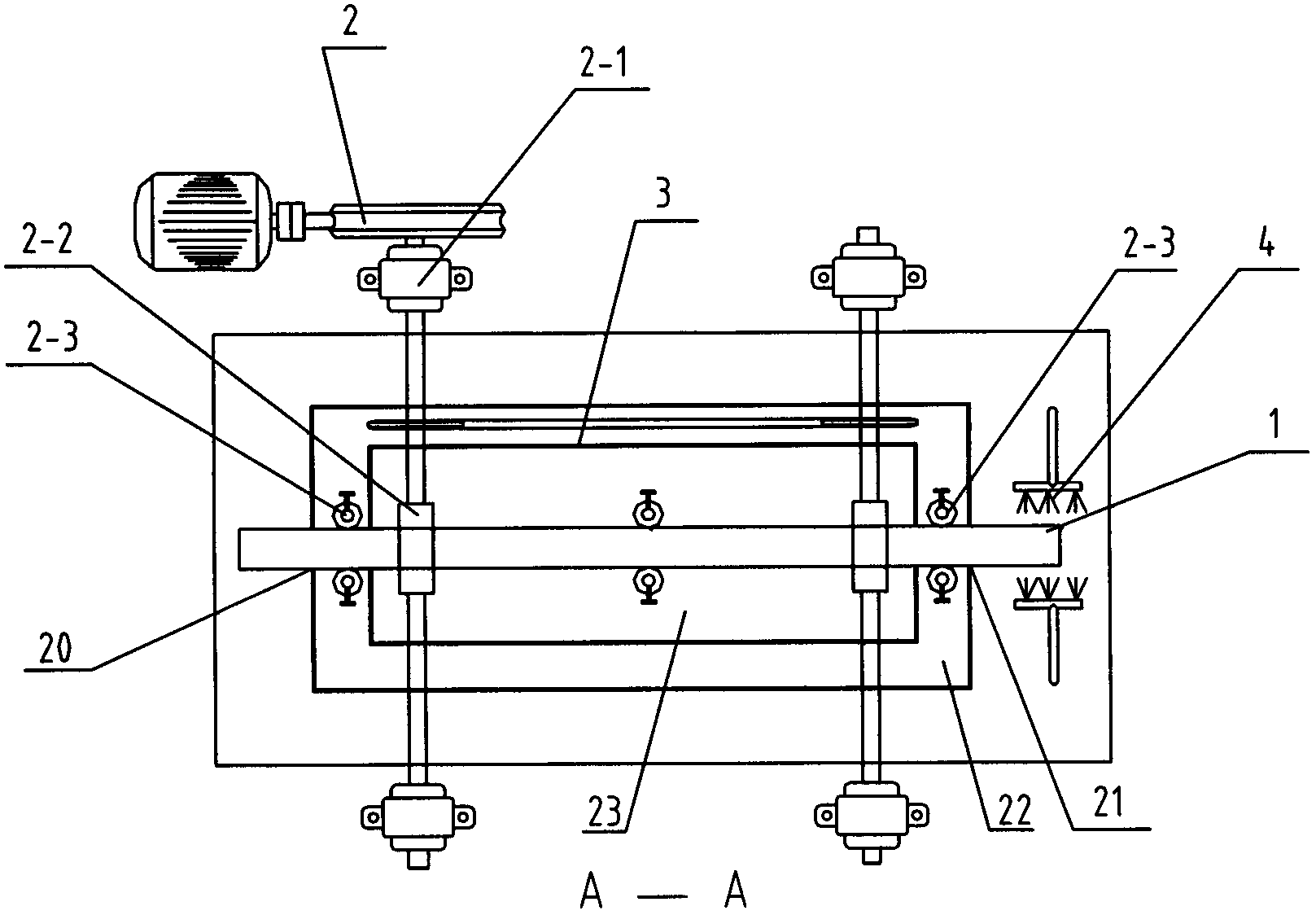

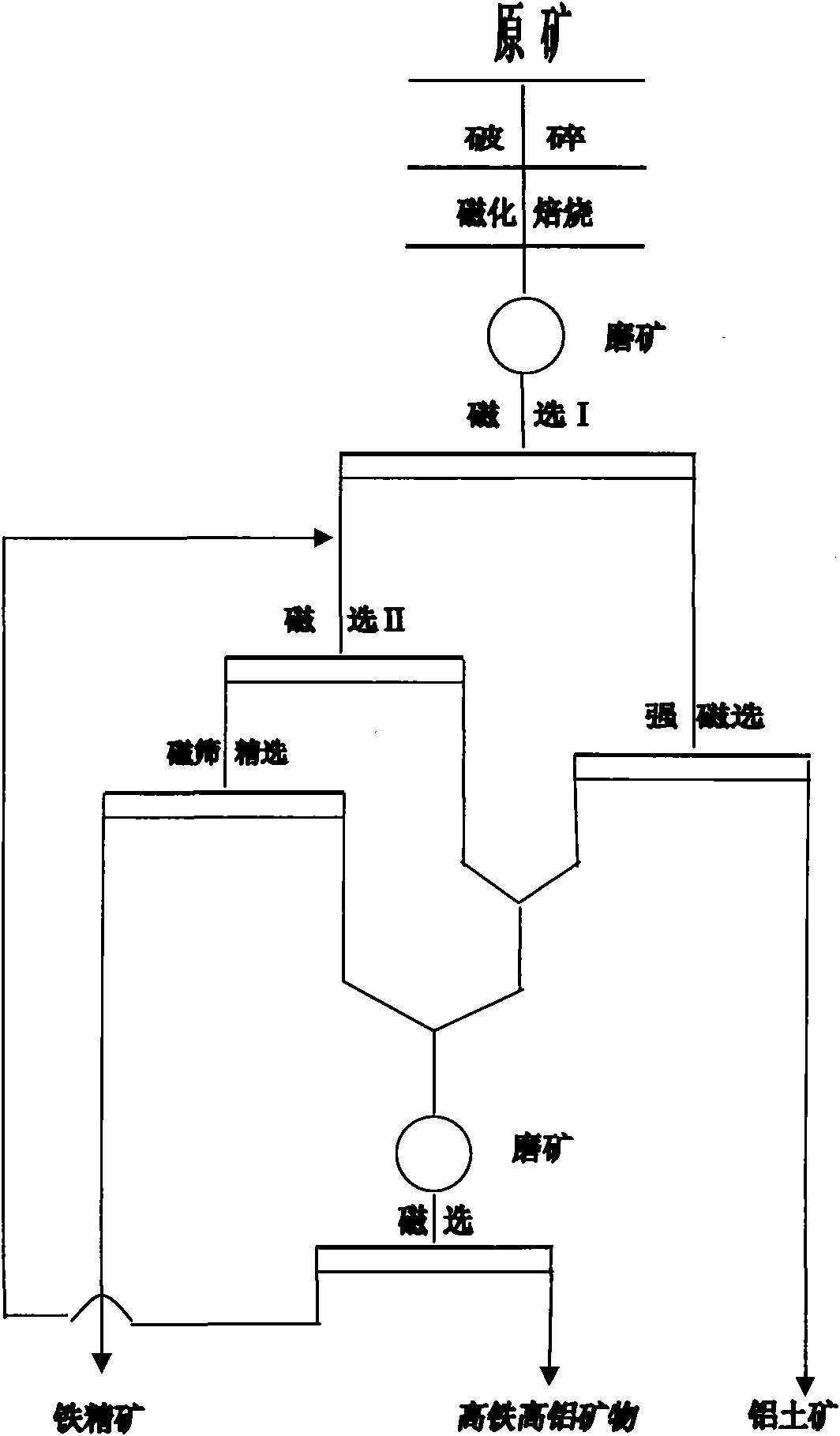

The invention discloses a method for separating aluminum and iron in high-iron bauxite, which comprises the following steps: (1) breaking high-iron bauxite; (2) carrying out magnetic roasting for the broken high-iron bauxite; (3) milling; and (4), separating the bauxite from iron minerals through weak magnetic separation, and respectively obtaining the bauxite and the iron minerals. Before the high iron bauxite is dissolved out, the magnetic roasting - magnetic separation process is adopted, so that the iron is separated from the bauxite containing high iron through the magnetic roasting - magnetic separation process, and the iron is removed from the bauxite after the magnetic separation through strong magnetic separation so as to obtain qualified bauxite concentrate, so that the high-iron bauxite is utilized well, and the bauxite and the iron minerals can be comprehensively utilized. The invention has the advantages of simple process, low cost, high yield, good product quality, safety and environment protection and the like.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Chemical deposition preparation method of piezoelectric composite metal electrode

InactiveCN103938192ANo disengagementUniform coarseningLiquid/solution decomposition chemical coatingPolymeric surfaceChemical plating

The invention relates to a chemical deposition preparation method of a piezoelectric composite metal electrode. The chemical deposition preparation method particularly aims at a PZT ceramic and polymer coexisting composite material and comprises the following preparation steps: preparing a piezoelectric composite, cleaning, removing oil, wetting, carrying out primary coarsening, reducing, carrying out secondary coarsening, activating a colloid target, peptizing, carrying out chemical plating and passivating. According to the chemical deposition preparation method, a metal coating chemically deposited on the surface of the piezoelectric composite has a bright surface, is fine in crystallization, can uniformly cover the surfaces of ceramics and polymers and has good binding force with the ceramics and polymers. An adopted medium and low temperature technology is capable of ensuring that the piezoelectric composite metal electrode is free of deformation and material separation. The chemical deposition preparation method does not need expensive equipment and is low in cost and suitable for large scale production.

Owner:XIAMEN UNIV

Method of monopulse cyanide-free silver electroplating

The invention discloses components and a technology of a monopulse cyanide-free silver electroplating solution. The components and the technology are characterized in that: cyanide-free silver electroplating solution mainly comprises silver nitrate, hydantoin and derivatives thereof, potassium pyrophosphate, potassium sulfate, hydrochloric acid, deionized water, and the like. Operation conditions are that the pH value of the electroplating solution is 6-10 and that the temperature of the electroplating solution is 20-40 DEG C. A finely crystallized silver plating can be obtained through electroplating on pure copper or a copper alloy by utilizing of monopulse electroplating and by controlling the pulse width, the pulse duty cycle, the average pulse current density and the pulse working time. The electroplating solution is simple in formula, easy to control, strong in throwing power and in covering power and high in batch production stability. The plating is finely crystallized, and is good in appearance color. The plating is free from peeling, falling off and stripping. The technology can replace cyanide silver electroplating technologies, is environmental-friendly and pollution-free, and reduces damage of silver electroplating to operators.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Method for filling PCB blind hole by electroplating copper

InactiveCN106757194AGood dispersion ability of plating solutionCoating crystal finePrinted element electric connection formationIonChemical plating

The invention discloses a method for filling a PCB blind hole by electroplating copper, and belongs to the field of circuit board manufacturing. The method is characterized by comprising the following steps of: (i) taking CuSO4.5H2O and dissolving CuSO4.5H2O into deionized water, then, adding 44 mL of concentrated sulfuric acid, starting to sequentially add chloride ions, an inhibitor, an accelerator and a leveling agent after a solution is cooled to the room temperature, and uniformly stirring for later use; (2) transferring a plating solution into an electroplating bath, separately inserting a copper plate and a phosphor copper plate as a cathode and an anode, and performing small-current electrolytic treatment; (3) performing PCB sample pre-treatment; and (4) switching on a power supply, and switching off after controlling current density to perform electroplating. According to the method disclosed by the invention, a layer of thin copper is deposited on a hole wall through a chemical plating method, and hole filling treatment is performed by electroplating copper in an acidic copper sulfate plating solution containing an additive until the whole blind hole or buried hole is filled with a deposited copper layer, so that dispersing power of the plating solution is good, crystals of a coating are fine, and binding force is good.

Owner:SHAANXI HUANKE BIOLOGICAL TECH CO LTD

Special grease for refrigeration and prepared by mixing lard oil and palm oil and preparation method thereof

The invention discloses special grease for refrigeration and prepared by mixing lard oil and palm oil and a preparation method thereof. The preparation method of the special grease for refrigeration includes the steps of heating and melting the lard oil, the palm olein and palm stearin, adding a food-grade emulsifier and water into a totally melt oil phase, carrying out emulsification, then carrying out cooling and kneading, and finally curing to obtain the special grease for refrigeration. The special grease for refrigeration comprises, by weight, 8-12 parts of the lard oil, 10-80 parts of the palm olein, 10-80 parts of the palm stearin and 1-2.5 parts of the food-grade emulsifier. An obtained special grease product for refrigeration is in a beta crystal form, the SFC curve of the product is smooth, crystals are fine, the product has good processing characteristics and certain plasticity, compatibility of the grease is good at low temperature, and the oil separation phenomenon can be prevented from occurring.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com