Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Effective prolapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

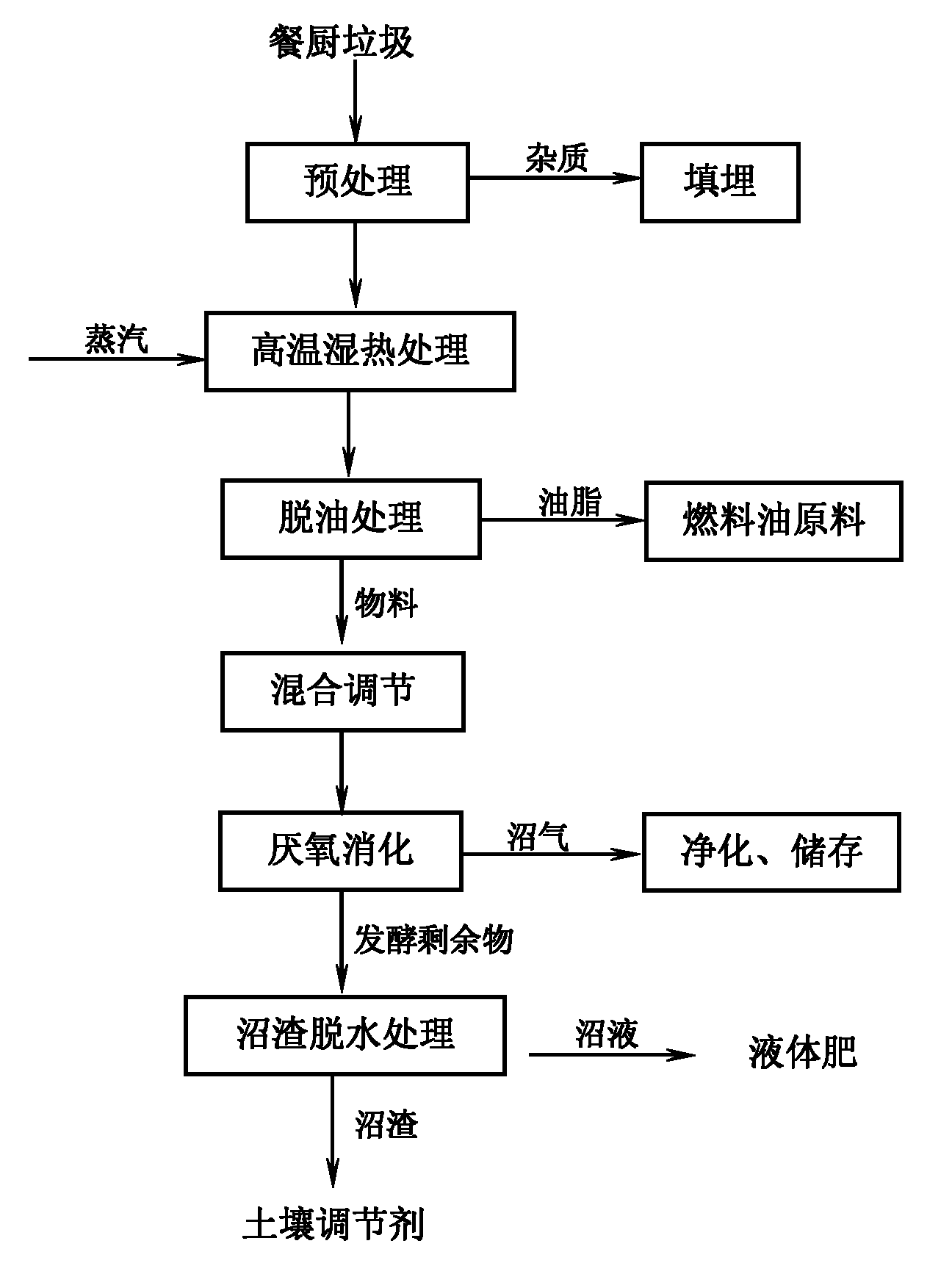

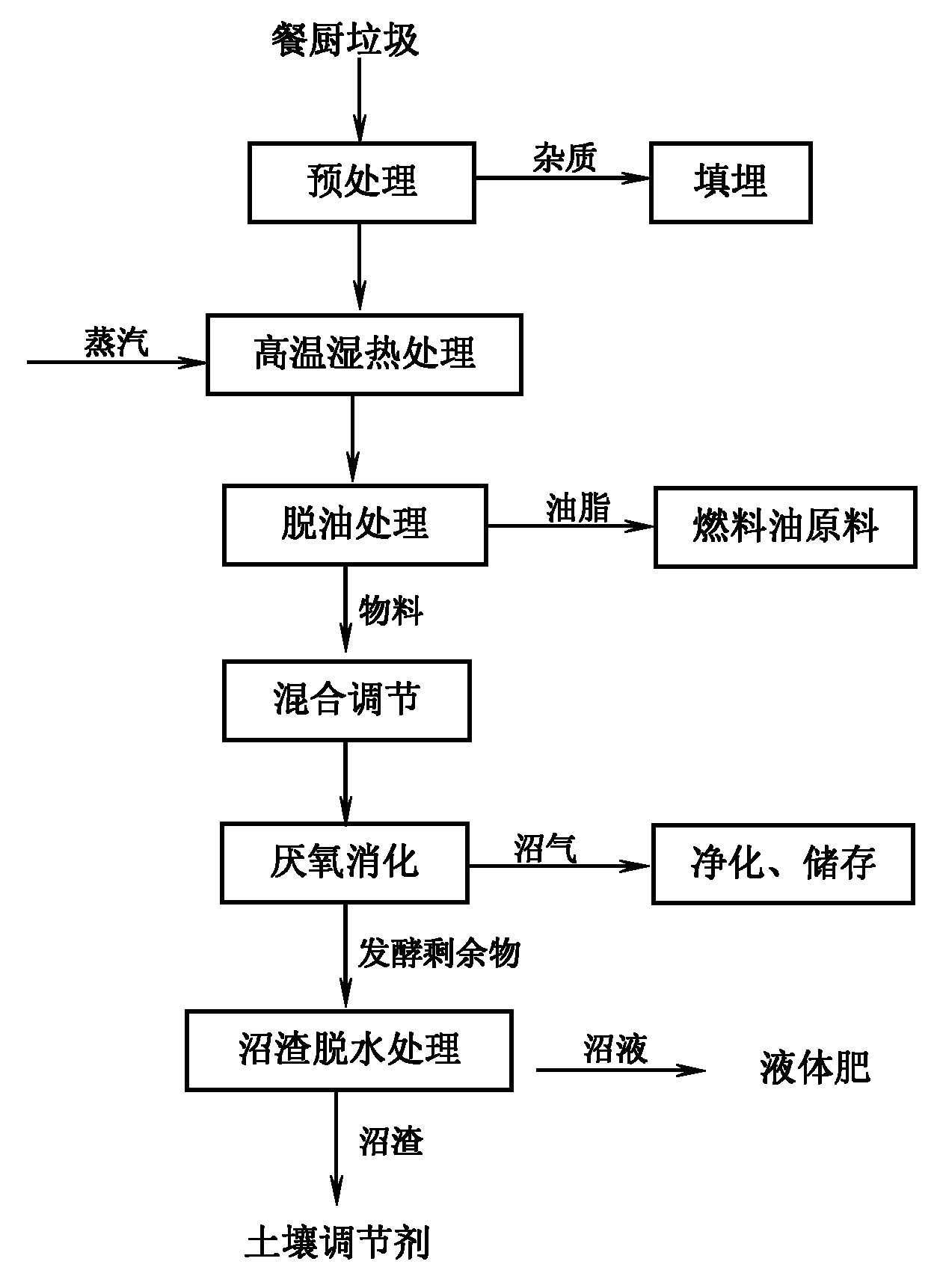

Method for carrying out anaerobic digestion on kitchen waste after heat-moisture treatment

InactiveCN102489496APrevent acidificationEffective saltSolid waste disposalOil and greaseSalt content

The invention relates to a method for carrying out anaerobic digestion on kitchen waste after heat-moisture treatment, belonging to the technical fields of harmless resource treatment and disposal of solid waste. The method comprises the following steps of: pre-treatment, high-temperature heat-moisture treatment, de-oiling, anaerobic digestion, biogas residue dehydration treatment of the kitchen waste, and the like. The method disclosed by the invention has the following advantages that: (1) the kitchen waste ia sterilized before the anaerobic digestion; (2) the kitchen waste can be effectively de-oiled and the occurrence of oil acidification is prevented so that the follow-up anaerobic digestion process is more stable and the oil recovery is improved; and (3) salt content in the kitchen can be effectively desalinated so that the salt content in the biogas residue is decreased and the treated kitchen waste can be used as a good soil conditioner.

Owner:BMEI

Preparation method of acrylamide-polyvinyl alcohol-acrylic acid-calcium chloride three-network compound hydrogel

The invention relates to a preparation method of acrylamide-polyvinyl alcohol-acrylic acid-calcium chloride three-network compound hydrogel. The preparation method comprises the following steps: firstly, proportionally dissolving acrylamide, acrylic acid, calcium chloride and polyvinyl alcohol into water for mixing; secondly, sequentially adding a cross-linking agent and an initiator; and after argon oxygen displacement treatment is performed, adding a catalyst; and thirdly, carrying out vacuumizing and ultrasonic treatment on the obtained mixture solution and then carrying out a heating reaction to obtain the acrylamide-polyvinyl alcohol-acrylic acid-calcium chloride three-network compound hydrogel with a certain shape. The prepared hydrogel is frozen at the temperature of 20 DEG C belowzero for 12 hours, is unfrozen at room temperature for 8 hours and is repeatedly frozen and unfrozen for three times. The acrylamide-polyvinyl alcohol-acrylic acid-calcium chloride three-network compound hydrogel prepared by the preparation method disclosed by the invention has relatively-high tensile strength and compression strength; the water absorption expansion rate can be controlled by controlling the use amounts of polyvinyl alcohol and calcium chloride; and in addition, the acrylamide-polyvinyl alcohol-acrylic acid-calcium chloride three-network compound hydrogel has a potential application value in biomedicine, such as non-load artificial cartilage.

Owner:SHANDONG UNIV

Method for preparing blueberry juice beverage with high anthocyanin content

The invention discloses a method for preparing a blueberry juice beverage with a high anthocyanin content. The method comprises using frozen or fresh blueberry as raw materials, selecting, cleaning, adding citric acid and some pure water and smashing in an ultrafine way to get the smashed blueberry juice, filtering by using a ceramic ultrafiltration membrane to degerming at a low temperature, and then homogenizing, degassing and filling to get the finished product of the blueberry juice. The method is advantageous by greatly increasing the content and a transfer rate of the anthocyanin in the blueberry juice, preventing denaturation of anthocyanin caused by high-temperature disinfection, the denaturation causing an acerb taste, stabilizing the beverage by adding mycose and a small amount of pectin finally, reducing stability of the anthocyanin in the beverage, and improving mouthfeel of the beverage. The method is simple, and the juice is good in mouthfeel and relatively high in nutritional value.

Owner:GUIZHOU INST OF BIOLOGY

Processing method of high-purity aloe acetylated polysaccharide

The invention provides a processing method of high-purity aloe acetylated polysaccharide, comprising the steps of: peeling and crushing the aloe, filtering to obtain the aloe juice, adding the pectinase in the aloe juice according to the additive amount of 50-70 ml / ton of aloe juice, adding the active carbon in the aloe juice according to 0.1-0.3 of the mass of the aloe juice, then stirring for 20-40 min for enzymolysis and decolorization, and standing until the aloe juice is clear; thereafter, filtering by the microfiltration membrane with filtration aperture of 10 mu m, the filtration membrane with filtration aperture of 0.2 mu m and the ultrafiltration membrane with filtration aperture of 0.001 mu m, concentrating by the reverse osmosis membrane and drying to obtain the aloe powder, the mass content of the aloe acetylated polysaccharide reaches 15%. The invention realizes continuous separation at the normal temperature and enables various functional compositions in the aloe to be fully separated without adding any assistant, thereby the purity of the aloe acetylated polysaccharide is guaranteed and the extraction and separation costs are reduced.

Owner:YUNNAN TIANMEI TIANKANG BIOTECH CO LTD

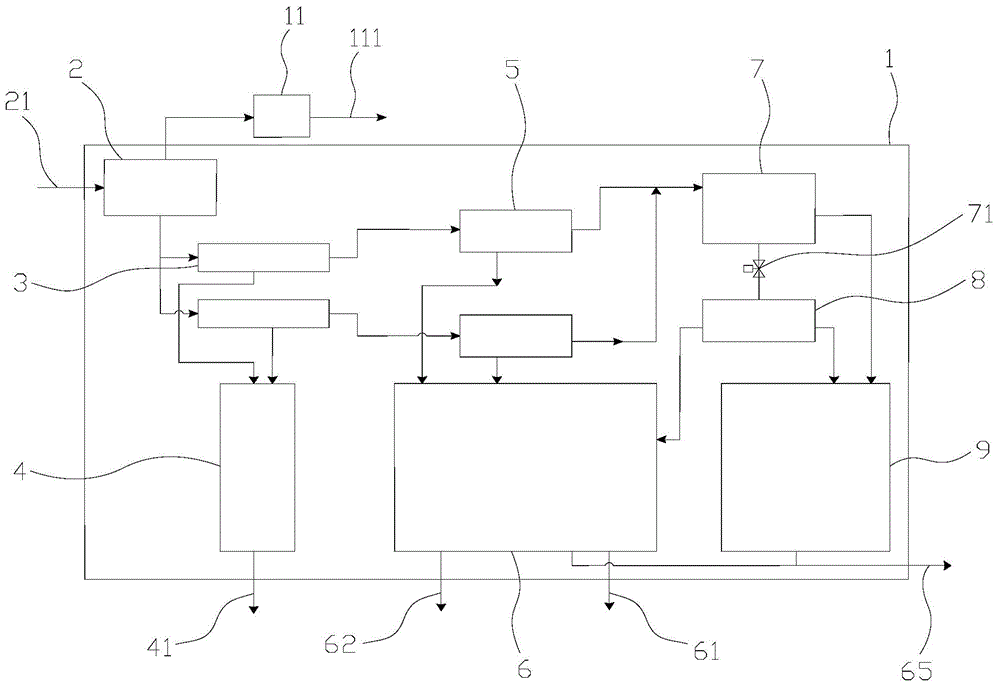

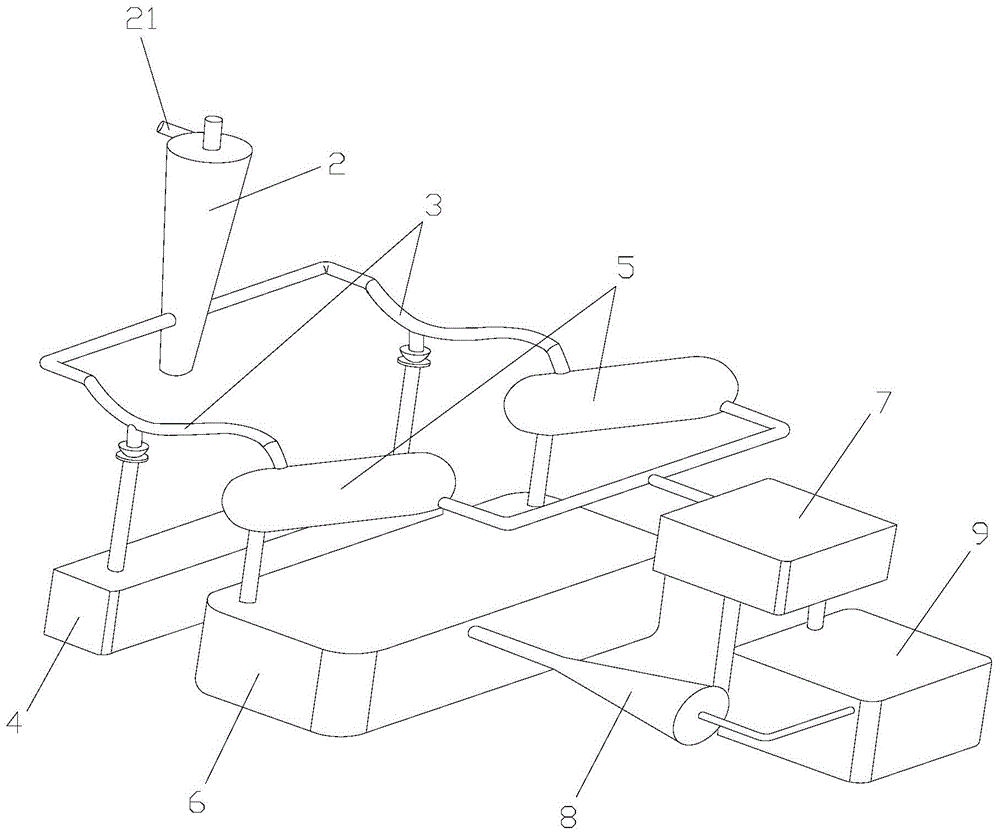

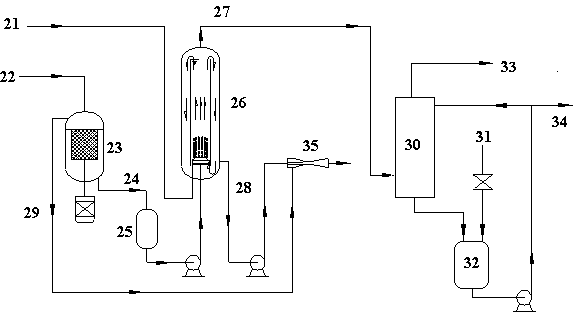

Oil-gas-water-solid three-level separation sled device

InactiveCN104150632ASimple structural designReasonable structural designWaste water treatment from quariesMultistage water/sewage treatmentThree levelCyclone

The invention relates to an Oil-gas-water-solid three-level separation sled device, comprising a sled shell, a cyclone bin, a sand settling diversion pipe, a sand settling bin, an inclined settling chamber, a water-gathering chamber, an oil-mixing bin, a cyclone and an oil-gathering chamber. The cyclone bin, the sand settling diversion pipe and the inclined settling chamber form a first separation system for primary separation of the oil-gas-water-solid four phases; the oil-mixing bin, a control valve and the cyclone form a second separation system for cyclone separation of oil-water two phases; and the oil-gathering chamber and the water-gathering chamber form a third separation system for gravity settling separation of the oil and water. Under a synergistic effect of the three separation systems, efficient separation of the oil, gas, water and solid is realized. The oil-gas-water-solid three-level separation sled device is simple and reasonable in structure design, has large processing capacity, occupies small floor area, is suitable for change of moisture content in a produced liquid of an oilfield, can separate oil, gas, water and solid phases in a liquid coming from the oilfield, is convenient for discharging the separated oil, gas, water and solid phases in time, has high efficiency and is simple to maintain.

Owner:SOUTHWEST PETROLEUM UNIV

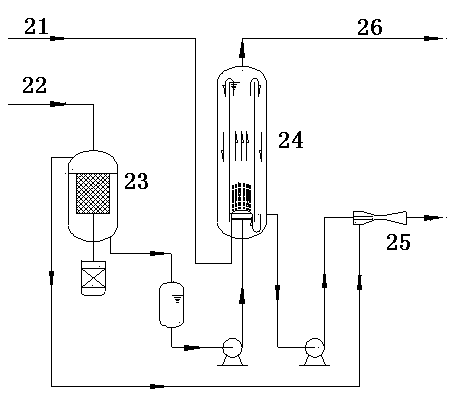

Treating method for waste gas containing sulfur and hydrocarbons

The invention discloses a treating method for waste gas containing sulfur and hydrocarbons. The method comprises the following steps that: crude diesel or crude kerosene enters a rotating packed bed for devolatilization pretreatment; a material discharged from the liquid phase outlet of the rotating packed bed enters absorption equipment as an absorbent and contacts and reacts with waste gas containing sulfur and hydrocarbons, and hydrocarbons in the waste gas are recovered; waste gas discharged from the absorption equipment enters an alkali liquor absorption device for removal of the sulfur-containing compounds in the waste gas, and a rich absorption solvent discharged from the absorption equipment directly enters a hydrogenation device; and waste gas discharged from the alkali liquor absorption device meets national standard and is discharged. The treating method for the waste gas containing sulfur and hydrocarbons provided by the invention adopts the rotating packed bed for pretreatment of the crude diesel or crude kerosene so as to remove foreign matters like hydrogen sulfide and volatile components in the crude diesel or crude kerosene, thereby preventing the waste gas from producing secondary pollution; and the method has the advantages of simple process, economical performance and reasonability and is applicable to absorption treating process for the waste gas containing sulfur and hydrocarbons.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEM +1

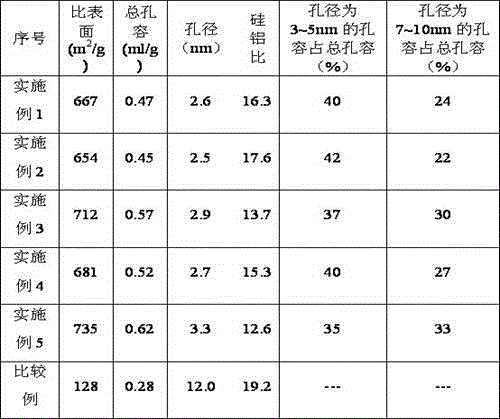

System and method for regenerating reactivating and recovering FCC balance catalyst

InactiveCN101168137AEffective prolapseIncreased microreactivityCatalyst regeneration/reactivationAutomatic controlMetal device

The invention belongs to the technical field of petrochemical industries, in particular to a regenerative recovery system used to balance catalysts in a fluid catalytic cracker (FCC) and a method for preparing same. The regenerative revived recovery system used to balance catalysts in a fluid catalytic cracker (FCC) of the invention comprises that to-be-processed discarded equilibrium catalysts enter a multi-stage magnetic separator (A) via a material delivery system, sorted low magnetic E-cats enter an acidification demetalization device (B), high magnetic E-cats are unloaded from a sack, serous fluid after being processed by the acidification demetalization device (B) enter an activating device (C), and water and activating agents are added in the serous fluid which is acid-reacted. After a certain time of reaction, the serous fluid is processed to form filter cakes via a filter dehydration device (D) and enter a drier (E). The filter cakes are baked in a rotary baker (F) to be completed products of recovery catalysts which continuously flow out from a revolving furnace, and the recovery catalysts are just sifted and packed. The whole process flow is controlled and displayed by an automatic control device (G).

Owner:BEIJING LIKONPEC TECH

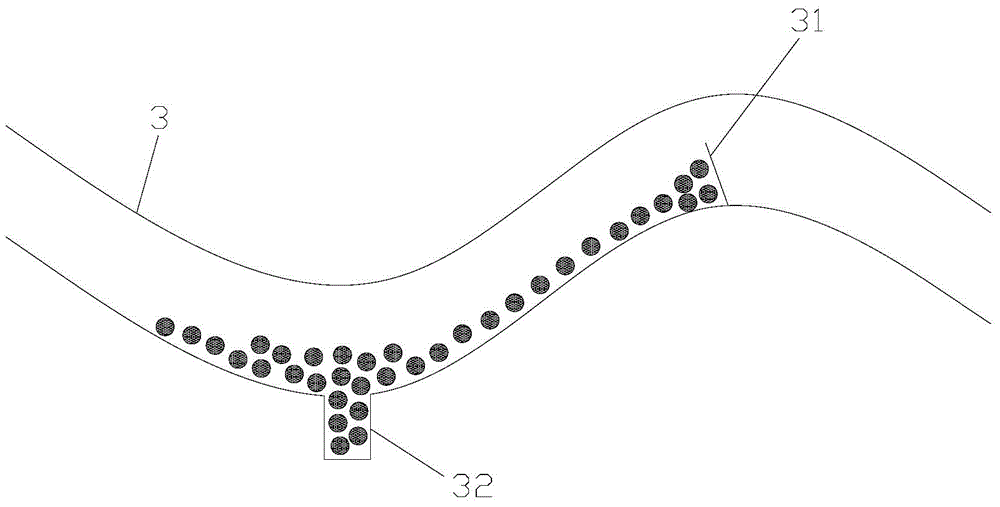

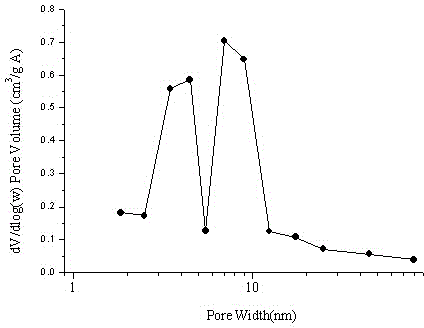

Y-Beta composite molecular sieve having double mesoporous structure, and preparation method thereof

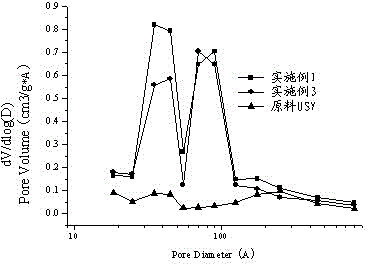

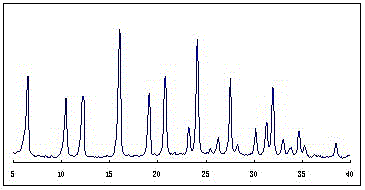

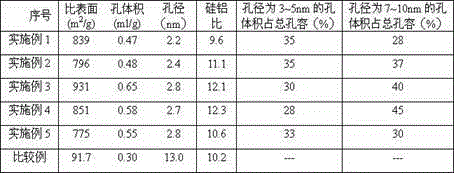

ActiveCN105540608AReduce the ratio of silicon to aluminumIncrease acidityFaujasite aluminosilicate zeoliteMolecular sieveHydrogen

The present invention discloses a Y-Beta composite molecular sieve having a double mesoporous structure, and a preparation method thereof. The Y-Beta composite molecular sieve has two mesoporous structures such as 3-5 nm mesopores and 7-10 nm mesopores, wherein the pore volume of the mesopores with the pore size of 3-5 nm accounts for 20-50% of the total pore volume, the pore volume of the mesopores with the pore size of 7-10 nm accounts for 15-40% of the total pore volume, a molar ratio of silica to alumina is 7-25, a specific surface area is 480-780 m<2> / g, the total pore volume is 0.39-0.70 ml / g, and the average pore size is 1.7-3.8 nm. The preparation method comprises: (1) dissolving an inorganic alkali and an organic alkali in water to form a mixed solution; and (2) adding a hydrogen type Y-Beta composite molecular sieve to the mixed solution, carrying out a constant temperature treatment, filtering, washing, drying, calcining, and carrying out ammonium exchange on the calcined product to obtain the Y-Beta composite molecular sieve having the double mesoporous structure. The Y-Beta composite molecular sieve of the present invention can provide more reaction spaces for macromolecules so as to improve the catalytic performance of the composite molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

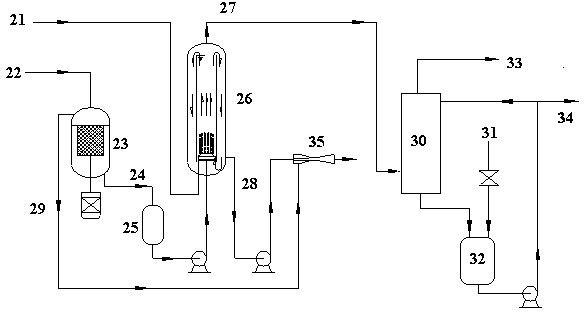

Treating method for waste gas containing sulfur and hydrocarbons

ActiveCN104587814AEffective prolapseIncrease concentrationDispersed particle separationRefining by centrifugal forceForeign matterKerosene

The invention discloses a treating method for waste gas containing sulfur and hydrocarbons. The method comprises the following steps that: crude diesel or crude kerosene enters a rotating packed bed for devolatilization pretreatment; a material discharged from the liquid phase outlet of the rotating packed bed enters absorption equipment as an absorbent and contacts and reacts with waste gas containing sulfur and hydrocarbons, and hydrocarbons in the waste gas are recovered; waste gas discharged from the absorption equipment enters an alkali liquor absorption device for removal of sulfur-containing compounds in the waste gas, and a rich absorption solvent discharged from the absorption equipment directly enters a hydrogenation device; and waste gas discharged from the alkali liquor absorption device meets national standard and is discharged. The treating method for the waste gas containing sulfur and hydrocarbons provided by the invention adopts the rotating packed bed for pretreatment of the crude diesel or crude kerosene so as to remove foreign matters like hydrogen sulfide and volatile components in the crude diesel or crude kerosene, thereby preventing the waste gas from producing secondary pollution; and the method has the advantages of simple process, economical performance and reasonability and is applicable to absorption treating process for the waste gas containing sulfur and hydrocarbons.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Method and device for burning petroleum coke by use of circulating fluid bed

InactiveCN1415890AControl and reduce emissionsInhibition formationSolid fuel combustionCombustion apparatus

This invention relates to a method and device for using oil coke as fuel in circulation fluidized bed solving the difficulties of burned-out in burning, desulfurization and lumping, slag-bonding appearing in end flue pipe and cyclone separator in the circulation fluidized bed. This invented oil coke combined fuel includes oil coke, coal and desulfurizer which can effectively removed SO2 and eliminate lumping and slag-bonding phenomenon and big mesh sieving is applied for oil coke particles to form thicken or thin phase beds in firing chamber, suitable for subjects balance in bed; warm scuff-resistant coating is designed under the circulation fluidized bed to form high temperature zone good for firing of oil coke and burning-out, stepped burning is good for reducing NOx exhaust.

Owner:TSINGHUA UNIV +1

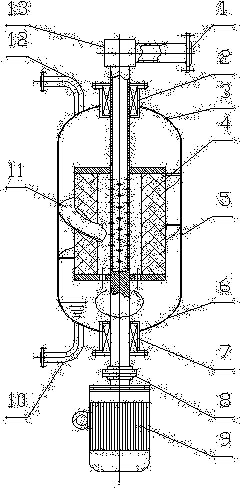

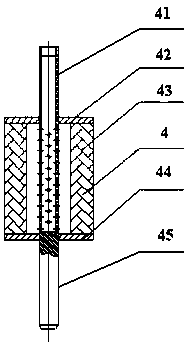

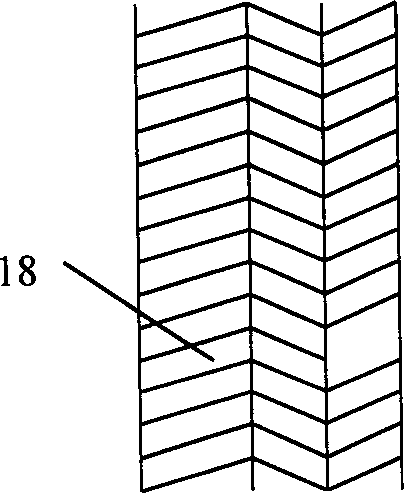

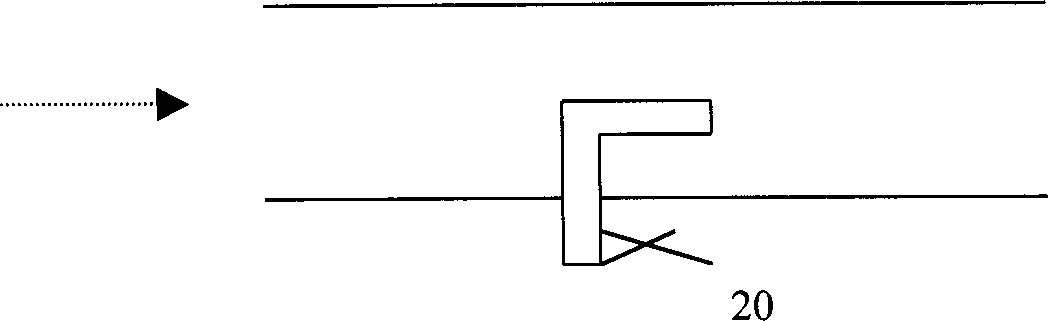

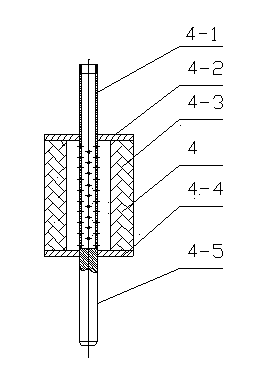

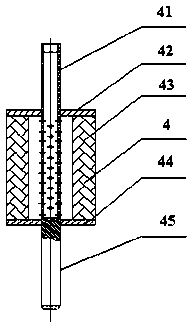

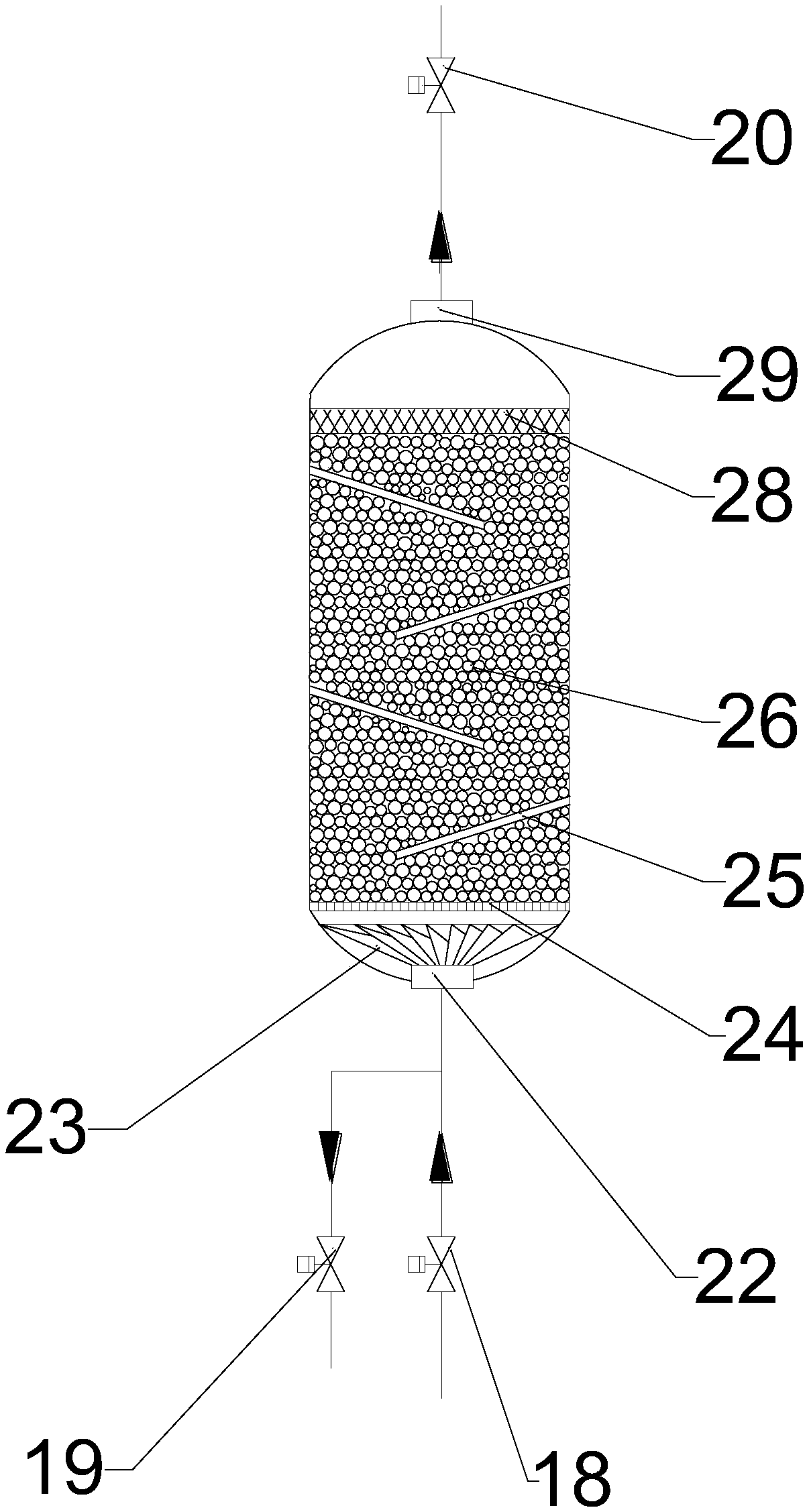

A rotary bed and a recovery method of hydrocarbon-containing exhaust gas

ActiveCN103789000AEffective prolapseEfficient removalLiquid hydrocarbon mixture recoveryDispersed particle separationRecovery methodKerosene

The invention discloses a rotary bed. The rotary bed comprises a cylinder, a bed layer assembly, an upper head and a lower head. A spiral plate is fixed to the inner wall of the cylinder. The spiral plate and a bed layer are in a clearance fit. The bed layer assembly is an integrated structure formed by an upper cover plate, the bed layer, a lower cover plate and a rotating shaft. The upper cover plate and the lower cover plate are respectively fixed to the upper part and the lower part of the rotating shaft. The bed layer is sandwiched between the upper cover plate and the lower cover plate. The lower cover plate is provided with a through hole. The part of the rotating shaft in the bed layer and the part of the rotating shaft above the bed layer are hollow tubular structures. The tube wall of the rotating shaft, in the bed layer, is provided with a plurality of through holes, namely, the part of the rotating shaft is also a liquid distributing tube. The invention relates to a recovery method of hydrocarbon-containing exhaust gas. Crude diesel or crude kerosene is pretreated by utilization of the rotary bed. Materials discharged from a liquid phase outlet of the rotary bed are adopted as an absorbent and used for adsorption treatment of the hydrocarbon-containing exhaust gas. The recovery method is simple in process, economic, reasonable, and free of secondary pollution, and is suitable for adsorption recovery processes of the hydrocarbon-containing exhaust gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treating method for waste gas containing sulfur and hydrocarbons

ActiveCN104587815AAvoid secondary pollutionEffective prolapseDispersed particle separationExhaust fumesKerosene

The invention discloses a treating method for waste gas containing sulfur and hydrocarbons. The method comprises the following steps that: crude diesel or crude kerosene enters a rotating packed bed for devolatilization pretreatment; a material discharged from the liquid phase outlet of the rotating packed bed enters absorption equipment as an absorbent and contacts and reacts with waste gas containing sulfur and hydrocarbons, and hydrocarbons in the waste gas are recovered; waste gas discharged from the absorption equipment enters an alkali liquor absorption device for removal of the sulfur-containing compounds in the waste gas, and a rich absorption solvent discharged from the absorption equipment directly enters a hydrogenation device; and waste gas discharged from the alkali liquor absorption device meets national standard and is discharged. The treating method for the waste gas containing sulfur and hydrocarbons provided by the invention adopts the rotating packed bed for pretreatment of the crude diesel or crude kerosene so as to remove foreign matters like hydrogen sulfide and volatile components in the crude diesel or crude kerosene, thereby preventing the waste gas from producing secondary pollution; and the method has the advantages of simple process, economical performance and reasonability and is applicable to absorption treating process for the waste gas containing sulfur and hydrocarbons.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEM +1

USY molecular sieve with double meso-structures and preparation method thereof

ActiveCN105712370AReduce the ratio of silicon to aluminumIncrease acidityFaujasite aluminosilicate zeoliteMolecular sieveSilicon oxide

The invention discloses a USY molecular sieve with double meso-structures. The volume of pores with pore sizes of 3 to 5 nm in the USY molecular sieve accounts for 15 to 40% of the total pore volume of the USY molecular sieve; the volume of pores with pore sizes of 7 to 10 nm accounts for 25 to 50% of the total pore volume of the USY molecular sieve; a mol ratio of silicon oxide to alumina in the molecular sieve is in a range of 7 to 15; and the USY molecular sieve has a specific surface area of 680 to 980 m<2> / g, a pore volume of 0.42 to 0.75 ml / g and an average pore size of 1.9 to 3.1 nm. The USY molecular sieve prepared in the invention has meso pores of two pore sizes, can provide more reaction space for large molecules and has improved catalysis performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for comprehensively recovering selenium, mercury, lead and silver from acid mud

InactiveCN111926187ARealize phase reconstructionAchieve recyclingProcess efficiency improvementElemental selenium/telluriumSlagWater chlorination

The invention relates to a method for comprehensively recovering selenium, mercury, lead and silver from acid mud, and belongs to the technical field of metallurgical acid mud treatment. The method comprises the steps that carbonate is added to subjected to phase transformation reaction with the acid mud to obtain a transformation solution and transformation slags; dilute acid is added to selectively leach the lead in the transformation slags, and sodium chloride is added after leaching to obtain lead-containing leachate and selenium-mercury-silver enriched slags correspondingly so as to realize separation of lead from the selenium, the mercury and the silver; an oxidizing agent and acid are added to chloridize and leach selenium-mercury enriched slags to obtain selenium-mercury leachate and silver-containing slags; sulfur dioxide is introduced into the selenium-mercury leachate for reduction, and crude selenium and a mercury-containing solution are obtained; sulfuric acid is added into the lead-containing leachate for a reaction to generate lead sulfate and the dilute acid, the dilute acid and the pure lead sulfate are obtained, and the dilute acid is recycled; and a vulcanizing agent is added into the mercury-containing solution for reaction to obtain mercury sulfide and vulcanized residual liquid. The method for comprehensively recovering the selenium, the mercury, the leadand the silver from the acid mud treats the smelting acid mud through a full-wet method, is low temperature and environmentally friendly, the mercury yield in the whole process is larger than 99.5%, the lead yield is larger than 95.0%, the selenium yield is larger than 98.0%, related treatment equipment is mature and easy to engineer, and the application prospect is good.

Owner:CHUXIONG DIANZHONG NON FERROUS METALS LLC +1

Purification method for coal pitch with high softening point

InactiveCN104232135AReduce energy consumptionEffective prolapseWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by solidifying/disintegratingPurification methodsMetal impurities

The invention discloses a purification method for coal pitch with a high softening point and belongs to the technical field of tar deep processing. The purification method comprises the following steps: mixing pitch with small-molecule aromatic hydrocarbons and obtaining pitch particles by using a granulator and a cutting-off machine; extracting the pitch particles with a solvent to obtain porous pitch particles; extracting the porous tar particles with alkali solution and acid solution to obtain the content of silicon and the content of metal and performing solid-liquid separation; washing the extracted particles with deionized water and performing solid-liquid separation; drying the substances in an inert atmosphere or vacuum environment to obtain purified pitch. The purification method disclosed by the invention has the benefits that the porous pitch particles are extracted by using low-temperature alkali and acid of 30-80DEG C, so that silicon and other metal impurities in the coal pitch are effectively removed; the total ash content of the obtained purified pitch is less than 0.005 percent, the content of the silicon is less than 0.001 percent and the content of the metal impurities is less than 0.002 percent; higher use requirement can be met; besides, the purification method is simple in process step and lower in energy consumption.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

Coal dealkalization method

The invention discloses a coal dealkalization method. The method comprises the following steps: (1) grinding raw coal to be dealkalized to obtain coal powder; (2) mixing the coal power obtained in the step (1) with eluent to obtain a mixed solution of coal and water, wherein the eluent is a water solution of a water-soluble organic solvent and the volume fraction of the water-soluble organic solvent is in a range of 5 to 20%; introducing gas containing carbon dioxide into the coal-water mixed solution obtained in the step (2), stirring the mixed solution to soak and wash the coals for 3 to 24 hours at a temperature of 20 to 60 DEG C to make carbon dioxide become excess; (4) subjecting the coal-water mixed solution, which has been processed in the step (3) to solid-liquid separation to obtain solids, and finally drying the solids to obtain the dealkalized coal. The provided method has the advantages of good dealkalization effect, mild reaction conditions, simple technology, and low cost.

Owner:HUAZHONG UNIV OF SCI & TECH

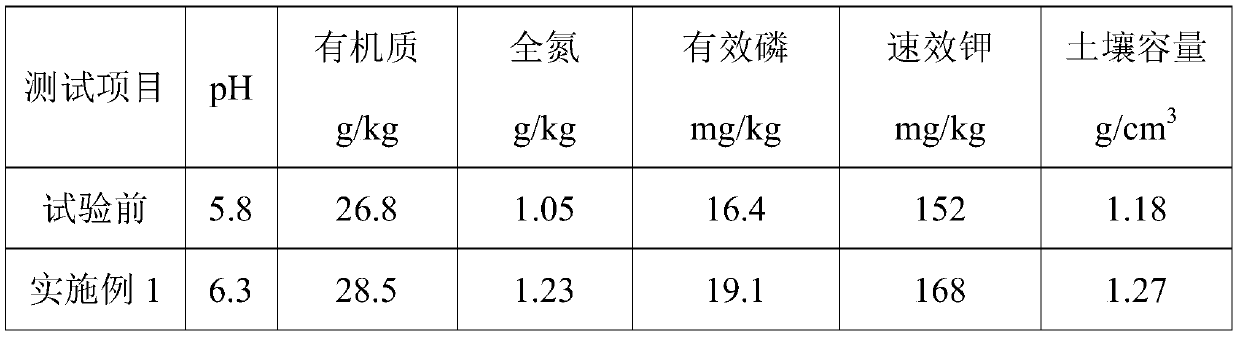

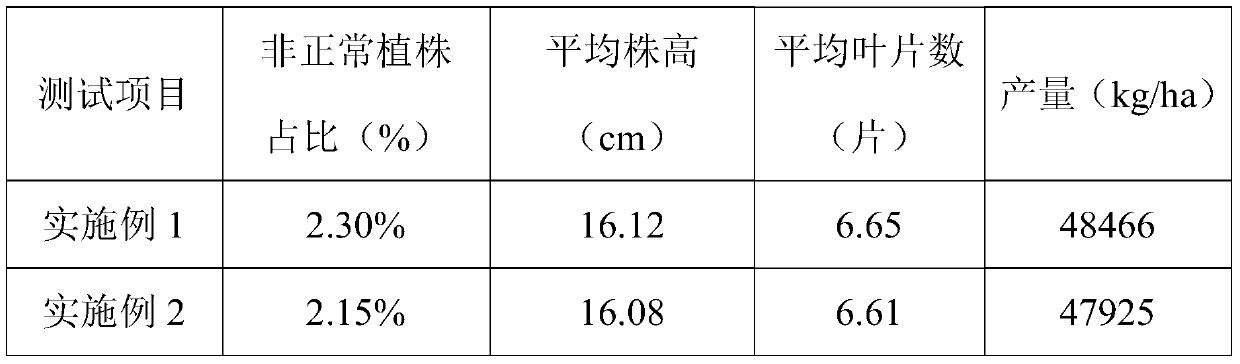

Soil remediation fertilizer prepared from kitchen waste as well as preparation method and application thereof

InactiveCN111320497AShort processing timeHigh recovery rateClimate change adaptationOrganic fertilisersBiological propertySoil remediation

The invention provides a soil remediation fertilizer prepared from kitchen waste as well as a preparation method and an application of the soil remediation fertilizer. The soil remediation fertilizeris prepared from kitchen waste subjected to anaerobic heat treatment, a complex microbial inoculant and a synergistic component. The soil remediation fertilizer prepared from the kitchen waste can reduce resource waste and effectively improve the problems of grease, germs and worm eggs of the kitchen waste, so that the physical, chemical and biological properties of soil are effectively improved,soil nutrients are maintained, and the utilization rate of the soil nutrients is increased.

Owner:时科生物科技(上海)有限公司

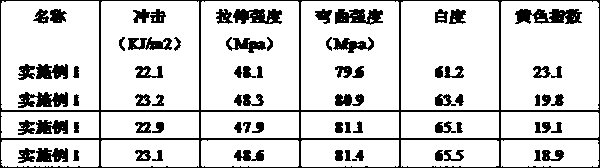

Preparation method of yellowing-resistant abs resin

PendingCN109608782AGood yellowing resistanceImprove thermal stabilityPolymer scienceFunctional monomer

The invention discloses a preparation method of yellowing-resistant ABS (acrylonitrile butadiene styrene) resin, and belongs to the technical field of synthetic resin and plastic. The invention specifically relates to a preparation method of ABS (acrylonitrile butadiene styrene) resin with high whiteness and low yellow index. According to the invention, the ABS resin with the whiteness value greater than 66, the yellow index lower than 19 and the excellent mechanical property can be prepared. According to the invention, the technical problem is solved, and the preparation method is provided inthe synthesis process of an ABS (acrylonitrile butadiene styrene) graft emulsion, and a functional monomer with an epoxy group is introduced into the shell layer of the ABS grafted powder, by utilizing an epoxy group and a cyano group, so that the cyclization reaction between the acrylonitrile groups in the ABS resin in the heating process is relieved, so that the apparent performance of the ABSresin can be improved, for example, the whiteness can be improved, and the yellow index and the like can be reduced. The ABS resin prepared by the method can be preferentially used in a household appliance shell, automobile apparent parts and the like, and has a wide market prospect.

Owner:CHANGCHUN UNIV OF TECH

A rotary bed and an adsorption method of hydrocarbon-containing exhaust gas

ActiveCN103785343APromote prolapseIntegrated structure realizationDispersed particle separationChemical/physical/physico-chemical stationary reactorsRecovery methodGas phase

The invention discloses a rotary bed. The rotary bed comprises a cylinder, a bed layer assembly, an upper head and a lower head. A gas-phase outlet is disposed in the lower part of the cylinder and a liquid phase outlet is disposed in the lower head. A spiral plate is fixed to the inner wall of the cylinder. The spiral plate and a bed layer are in a clearance fit. The bed layer assembly is an integrated structure formed by an upper cover plate, the bed layer and a lower cover plate. The upper end of the bed layer assembly is fixed in a rotatable manner to the upper part in the cylinder through a support. The bed layer is sandwiched between the upper cover plate and the lower cover plate. The middle part of the bed layer is a cylindrical cavity. A liquid distributing tube stretches from the upside into the cylindrical cavity in the middle part of the bed layer. The invention relates to a recovery method of hydrocarbon-containing exhaust gas. Crude diesel or crude kerosene is pretreated by utilization of the rotary bed. Materials discharged from the liquid phase outlet of the rotary bed are adopted as an absorbent and used for adsorption treatment of the hydrocarbon-containing exhaust gas. The recovery method is simple in process, economic, reasonable and free of secondary pollution, and is suitable for adsorption recovery processes of the hydrocarbon-containing exhaust gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Casting residual steel slag recycling method

InactiveCN105132626ASpeed up the flowImprove cleanlinessManufacturing convertersProcess efficiency improvementSteelmakingMolten steel

The invention discloses a casting residual steel slag recycling method, and particularly provides a casting residual steel slag recycling method applied to the technical field of ferrous metallurgy. By means of the casting residual steel slag recycling method, phosphorus in semisteel can be effectively removed, the cleanliness of molten steel can be improved, the temperature drop generated during converter steel tapping is small, and the consumption of semisteel covering agents and the consumption of steelmaking converter cold slag materials are effectively reduced. The casting residual steel slag recycling method includes the following steps: a, molten steel casting is carried out; b, casting residual steel slag generated after molten steel casting is poured into a semisteel tank on a spanning part crossing trolley; c, the semisteel tank on the spanning part crossing trolley is delivered to a vanadium extracting spanning part; d, semisteel tapping is carried out on the semisteel tank at a vanadium extracting furnace; e, the casting residual steel slag generated after semisteel tapping is carried out is delivered to a steelmaking converter to be smelted; f, furnace post-treatment is carried out on the casting residual steel slag; g, the casting residual steel slag is refined; and h, the steps are sequentially repeated. By means of the casting residual steel slag recycling method, the phosphorus in the semisteel can be effectively removed, the cleanliness of the molten steel can be improved, and the consumption of steel materials can be greatly reduced.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Underground water dissolved gas on-site sampling device

PendingCN106769244AEffective prolapseEfficient collectionWithdrawing sample devicesGas cylinderEnvironmental engineering

The invention relates to an underground water dissolved gas on-site sampling device. The on-site sampling device comprises a degassing bottle, a gas collecting bottle, a water supplementing bottle, a vacuum pump and an inflating pump. Three ports are arranged on the degassing bottle, a bottle plug is arranged on the first port and provided with a gas guide pipe, a gas bag is arranged at one end of the gas guide pipe, and the other end of the gas guide pipe is connected with the inflating pump; a second bottle plug is arranged on the second port and provided with a water guide pipe, one end of the water guide pipe stretches deeply into the degassing bottle, and the other end of the water guide pipe is connected with the bottom of the water supplementing bottle; a third bottle plug is arranged on the third port, an inner cavity in the third bottle plug is communicated with a vacuum pipe and a gas collecting pipe, the free end of the vacuum pipe is connected with the vacuum pump, and a gas collecting needle head is arranged at the free end of the gas collecting pipe and is communicated with the gas collecting bottle. The on-site sampling device is simple in structure, low in cost and convenient to operate and effectively degasses and collects gas dissolved in underground water, which is beneficial for assay research in the next step.

Owner:山东省地质矿产勘查开发局第一地质大队

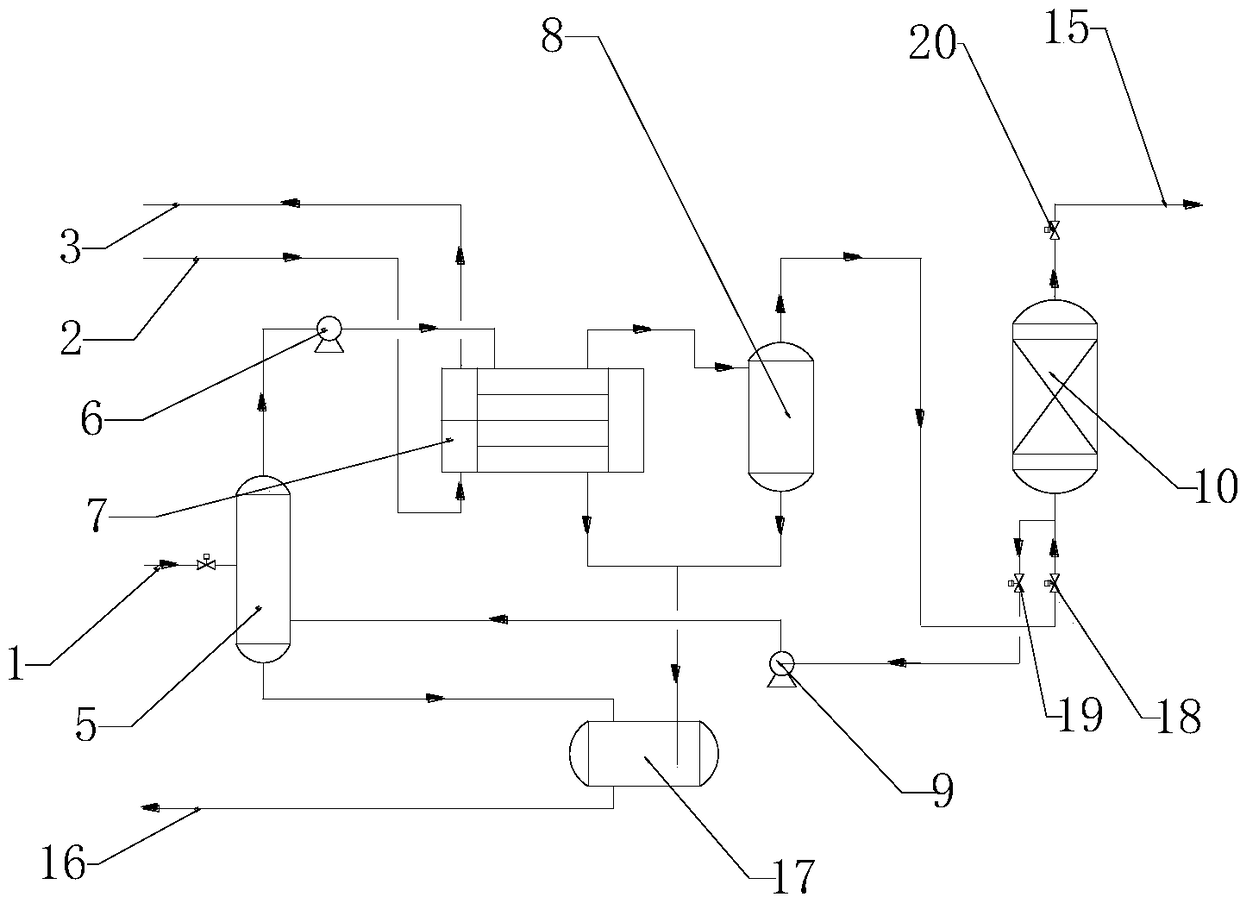

Device used for high-efficiency processing and fugitive emission of VOCs

PendingCN108722104AEfficient governanceGuaranteed uptimeGas treatmentDispersed particle separationLiquid wasteDesorption

The invention discloses a device used for high-efficiency processing and fugitive emission of VOCs. The device comprises a buffer tank, a blower fan, a condenser, a gas-liquid separation tank, and anadsorption tower unit which are connected successively; the adsorption tower unit and a vacuum pump are connected through a desorption pipeline; the desorption pipeline is provided with a desorption valve; the vacuum pump is connected with the buffer tank; the vacuum pump is used for conveying desorption gas from the desorption tower unit into the buffer tank from bottom to top; a presser sensor is arranged in the buffer tank; the condenser and the gas-liquid separation tank are connected with a liquid storage tank; and the liquid storage tank is provided with a waste liquid outlet. The devicecomprises the advantages of condensing method and adsorption method, a high efficiency stable operation comprehensive treatment technology process is formed, the newest national emission standards are achieved at relatively low investment and operation cost, and no secondary pollution is caused.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

A kind of aging oil demulsifier and preparation method thereof

ActiveCN103666542BEffective prolapseImprove dehydration efficiencyDewatering/demulsification with chemical meansDemulsifierLauroyl peroxide

Owner:河南鼎源化工科技有限公司

Magnesium lithium silicate pre-lithiated silicon monoxide negative electrode material as well as preparation method and application thereof

PendingCN112331854ALower pHImprove the first Coulombic efficiencyNegative electrodesSecondary cellsCarbon coatingLithium oxide

The invention discloses a preparation method of a magnesium lithium silicate pre-lithiated silicon monoxide negative electrode material, which comprises the following steps: (1) proportioning: obtaining silicon monoxide negative powder which is silicon monoxide powder without disproportionation treatment; preparing lithium oxide powder, wherein the lithium oxide powder is analytically pure and anhydrous lithium oxide powder; preparing magnesium oxide powder, wherein the magnesium oxide powder is analytically pure; (2) mixing: adding the silicon monoxide powder, the lithium oxide powder and themagnesium oxide powder into a mixer according to a certain proportion, and stirring and mixing at normal temperature to obtain uniform mixed powder A; (3) heat treatment: carrying out heat treatmentreaction on the mixed powder A in the step (2) under inert gas to obtain an intermediate product B; and (4) CVD carbon coating: carrying out carbon coating on the intermediate product B obtained in the step (3) under carbon source gas through a chemical vapor deposition method, wherein the prepared product has relatively high initial coulombic efficiency and good cycling stability.

Owner:浙江锂宸新材料科技有限公司

Comprehensive treatment method of shale gas extraction water

InactiveCN106032301AEffective prolapseReduce Chloride ContentMultistage water/sewage treatmentShale gasImpurity

The invention discloses a comprehensive treatment method of shale gas extraction water. The method is characterized by comprising: (1) adjusting the pH value of shale gas extraction water to 2.5-5; (2) performing contacting of the pH value-adjusted material, a catalyst and an oxidant under microwave irradiation, and carrying out a microwave catalysis oxidation reaction; (3) adjusting the pH value of the material obtained through the microwave catalysis oxidation to 7.5-12 so as to obtain a suspension; (4) carrying out solid-liquid separation on the suspension to obtain a supernatant and a solid; and (5) carrying out a microwave pressure reducing treatment on the obtained supernatant, and carrying out a harmless treatment on the solid and the remaining residue obtained through the microwave pressure reducing treatment. With the technical scheme of the present invention, the shale gas extraction water can be efficiently treated, the contents of the chlorine ions and other impurities in the treated extraction water are substantially reduced, the treated extraction water can meet the discharge standard or can be recovered and utilized, and the treatment process is simple and effective.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-carbon source high-ammonia nitrogen high-organic phosphor waste water combined type biological bed treatment technology

ActiveCN109354314ASolve the problem of meeting emission standardsImprove biochemical treatment efficiencyWater contaminantsMultistage water/sewage treatmentSocial benefitsElectrolysis

The invention provides a low-carbon source high-ammonia nitrogen high-organic phosphor waste water combined type biological bed treatment technology. Five steps of raw water regulation, iron-carbon-internal Fenton treatment, struvite treatment, A2O treatment and Fenton deep processing are included, a first flocculating agent and a second flocculating agent are added to the iron-carbon-internal Fenton treatment and the Fenton deep treatment steps respectively. The low-carbon source high-ammonia nitrogen high-organic phosphor waste water combined type biological bed treatment technology is takenas the primary treatment manner of low-carbon source high-ammonia nitrogen high-phosphor waste water, the biochemical treatment efficiency is greatly improved, the problem of standard meeting emission of the low-carbon source high-ammonia nitrogen high-phosphor waste water is solved, and the technology has better social benefits and economical benefits; the Fenton effect is improved by the combination of internal Fenton, iron-carbon, micro electrolysis and Fenton, and the operation cost and operation working intensity are reduced.

Owner:XINJIANG LVFENG ENVIRONMENT PROTECTION ENG CO LTD

An inorganic all-solid-state electrochromic device and its preparation method

ActiveCN103365017BFast injectionQuick releaseVacuum evaporation coatingSputtering coatingOptoelectronicsElectrochromism

The invention relates to an inorganic all-solid electrochromic device adopting an optimized structure, which structurally comprises a glass substrate, a transparent conducting layer A, an electrochromic layer, an ionic conducting layer and a transparent conducting layer B, wherein the transparent conducting layer A, the electrochromic layer, the ionic conducting layer and the transparent conducting layer B are deposited on the glass substrate in sequence; both the transparent conducting layer A and the transparent conducting layer B are Al-doped ZnO (ZAO) thin films; the electrochromic layer is a tungsten oxide (WO3) thin film; the ionic conducting layer is a lithium titanate (Li4Ti5O12) thin film. The thin film structure of the electrochromic device is simplified from the traditional five layers into four layers, so that the performance of the electrochromic device is optimized while the technology is simplified and the cost is reduced.

Owner:天津南玻节能玻璃有限公司 +1

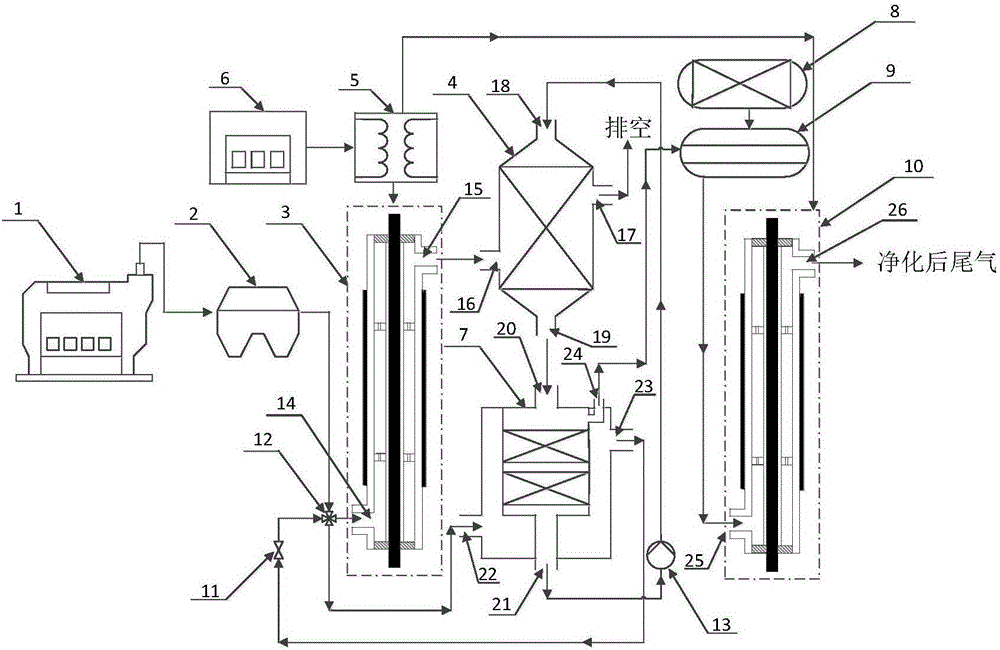

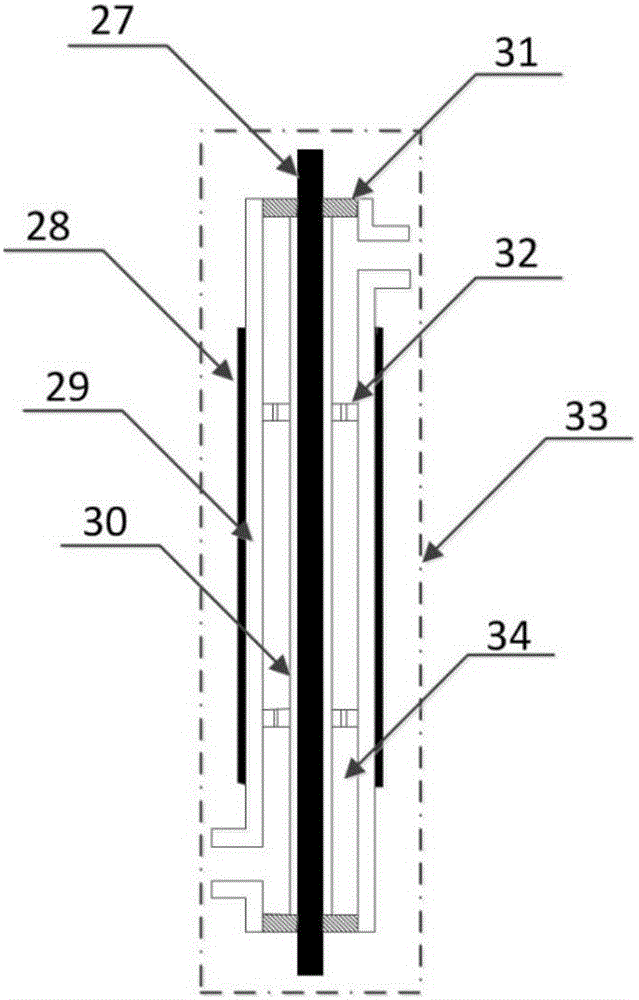

Apparatus for removing nitrogen oxide in tail gas of marine diesel engine and removal method thereof

ActiveCN107433132ASuitable for chemical reactionsThe discharge process is easy to controlGas treatmentInternal combustion piston enginesNitrogen oxidesProduct gas

The invention discloses an apparatus for removing nitrogen oxide in tail gas of a marine diesel engine and a removal method thereof, which belong to the technical field of exhaust-gas treatment of the marine diesel engine. The main fuel oil of the marine diesel engine is heavy fuel oil, and the tail gas contains a lot of nitrogen oxide. Through a mode by combining plasma and an adsorption phase, the novel technical design and the method are employed for processing NOx in the tail gas. A packed bed reactor is used for cyclic adsorption, at the same time, a low-temperature plasma technology is used for processing the tail gas, the NOx gas in the tail gas of the marine diesel engine can be effectively processed under normal temperature, and a final product is the elemental harmless gas. According to the invention, participation of a catalyst is not required for a tail gas processing method, secondary processing is not required for the final product, the equipment investment and equipment land occupation area are reduced, and the effective processing requirement on the tail gas of the marine diesel engine under dynamic complex condition is satisfied.

Owner:HARBIN ENG UNIV

Novel excrement and urine treatment device

PendingCN113511789AFully contactedImprove dehydration rateWater treatment parameter controlSludge treatment by de-watering/drying/thickeningUrine collectionFeces urine

The invention discloses a novel excrement and urine treatment device, and relates to the technical field of excrement and urine treatment. The novel excrement and urine treatment device comprises a source separation sanitary ware, an excrement collection box and a urine collection box, a urine outlet of the source separation sanitary ware is connected with the urine collection box, and an excrement outlet of the source separation sanitary ware is connected with the excrement collection box; the excrement collection box is connected with a drying device through a controller, a filtering device and a urine treatment device are arranged in the urine collection box, the urine collection box is divided into a first area chamber and a second area chamber by the filtering device, a urine outlet of the source separation sanitary ware communicates with the first area chamber, the urine treatment device is arranged in the second area chamber, and the second area chamber is provided with a discharge port; and the controller, the drying device and the urine treatment device are all connected with a circuit control device. According to the invention, the treated excrement can be used as a fertilizer raw material, the safety of the treated urine is ensured, and cross infection is avoided.

Owner:BEIJING JIAOTONG UNIV

Method and device for burning petroleum coke by use of circulating fluid bed

InactiveCN1178021CControl and reduce emissionsInhibition formationSolid fuel combustionCombustion apparatus

This invention relates to a method and device for using oil coke as fuel in circulation fluidized bed solving the difficulties of burned-out in burning, desulfurization and lumping, slag-bonding appearing in end flue pipe and cyclone separator in the circulation fluidized bed. This invented oil coke combined fuel includes oil coke, coal and desulfurizer which can effectively removed SO2 and eliminate lumping and slag-bonding phenomenon and big mesh sieving is applied for oil coke particles to form thicken or thin phase beds in firing chamber, suitable for subjects balance in bed; warm scuff-resistant coating is designed under the circulation fluidized bed to form high temperature zone good for firing of oil coke and burning-out, stepped burning is good for reducing NOx exhaust.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com