Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Fluffy guaranteed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyamide yarn production technology

InactiveCN104674366AImprove performanceImprove dyeing effectFilament forming substance formingMelt spinning methodsPolyamidePulp and paper industry

The invention discloses a polyamide yarn production technology. The polyamide yarn production technology comprises the following steps of treating raw materials, drying, preparing POY yarns, preparing DTY yarns, carrying out net treatment, classifying and packaging. According to the technology, an anti-oxidant, an anti-static agent and an antibacterial agent are added in the raw materials, so that the performances of a chinlon 66 finished product is improved, and the produced chinlon yarns have the anti-bacterial and anti-static effects; a easily dyeable agent is also added in the raw materials, so that the dyeing performance of the finished product is improved; by utilizing the production processes of the POY and DTY net yarns, yarn floating is prevented, and net breaking is low, so that the fluffy property and the good elasticity of the chinlon yarns are kept, the chinlon yarns also have the cycle property and net points, the stability is good, the compactness of the long yarns is improved, and the handfeel and the comfort of the finished product are effectively improved.

Owner:ZHEJIANG YINAN FIBER TECH

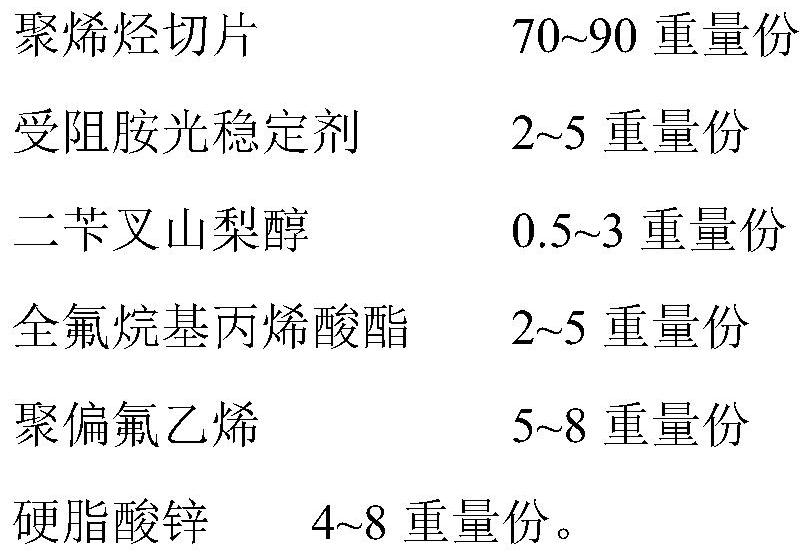

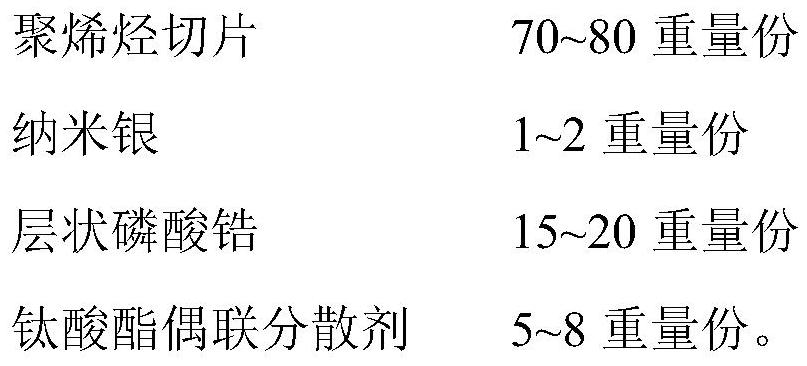

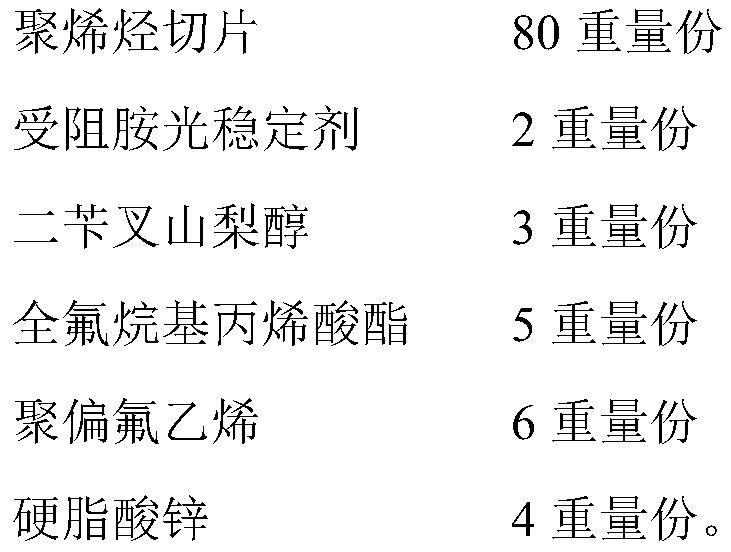

Polyamide-6 filament production technology

InactiveCN105088387AImprove performanceFluffy guaranteedFilament/thread formingArtifical filament manufacturePolyamideYarn

The invention discloses a polyamide-6 filament production technology. The Polyamide-6 filament production technology comprises the steps of preparation and drying of raw materials, preparation of POY yarns, preparation of DTY yarns and preparation of polyamide-6 filaments. As a modified antibacterial uvioresistant functional master batch is added into the raw materials to improve the performance of the finished polyamide-6 filaments, the produced polyamide-6 filaments has the antibacterial and uvioresistant functions. As the POY-DTY production process is adopted, the fluffiness and favorable elasticity of the polyamide-6 filaments are maintained, the compactness of the filaments is improved and the comfort degree of the end product is effectively improved.

Owner:TAICANG HONGYI CHEM FIBER

Planting method of sugarcane

InactiveCN107517686AGuaranteed NutrientsIncrease the sugar contentBiocidePlant growth regulatorsSoil depthLivestock manure

A method for planting sugarcane, comprising the following steps: 25-35 days before planting, carry out deep plowing with a soil depth of 40-45cm, and dry the soil for 3-5 days, and apply straw decomposing fertilizer according to 400-500KG per mu; 15-35 days before planting. Carry out 30-35cm intertillage in 20 days, and open ditches every 1.5-2m, dig a planting ditch with a depth of 28-32cm and a width of 20-25cm along the length of the ditch, and evenly lay 1-3cm thick poultry in the planting ditch. Decomposed livestock manure; sugarcane soaked in 1-2% carbendazim solution for 18-24 hours, washed with distilled water, soaked in a mixture of traditional Chinese medicine extract and gibberellin for 40-60 minutes, washed to obtain the processed sugarcane buds After 10-15 days of base fertilizer application, sugarcane buds are planted and 3-5 cm of decomposed straw fertilizer and poultry decomposed fertilizer are applied, trenches are filled, film-covered, and sealed; after emergence, the plastic film is removed, weeding, deep plowing, drainage, and poultry and livestock decomposed manure are applied. Spray insect repellant and strip leaves. The sugarcane planting method of the invention uses green and environment-friendly fertilizers, reduces farmers' costs, is convenient and saves resources.

Owner:NANJING JIANGNING TAIWAN PEASANTS INNOVATION PARKDEV

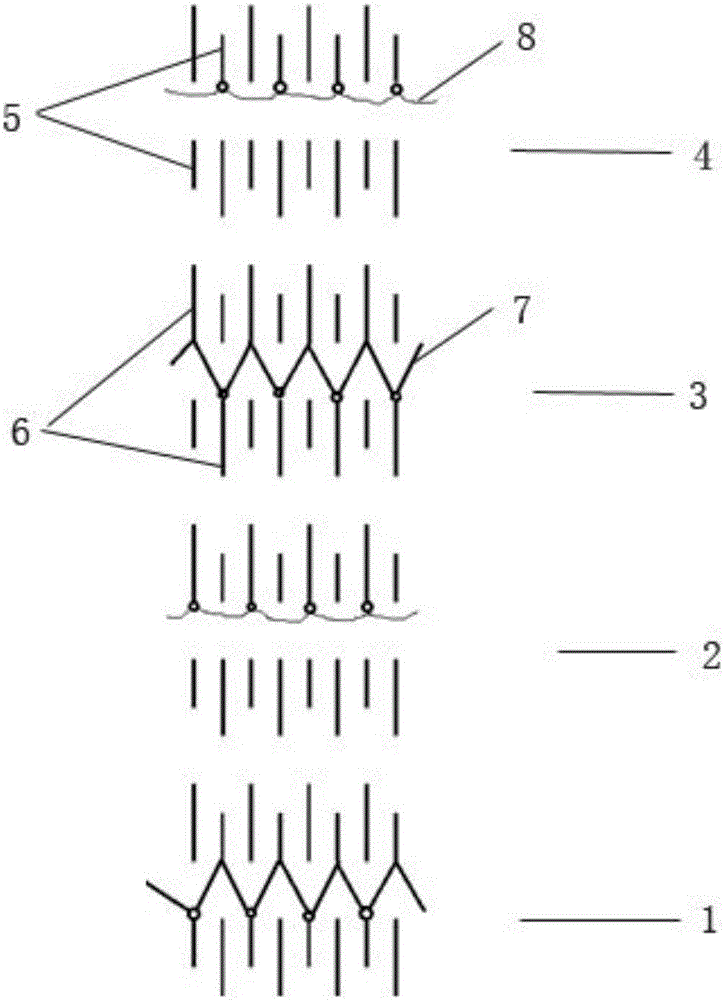

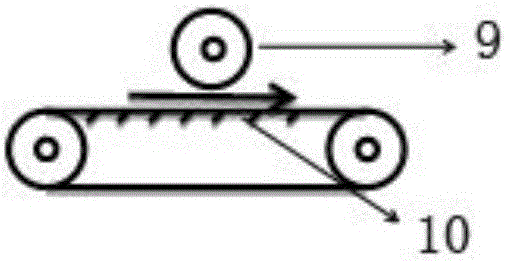

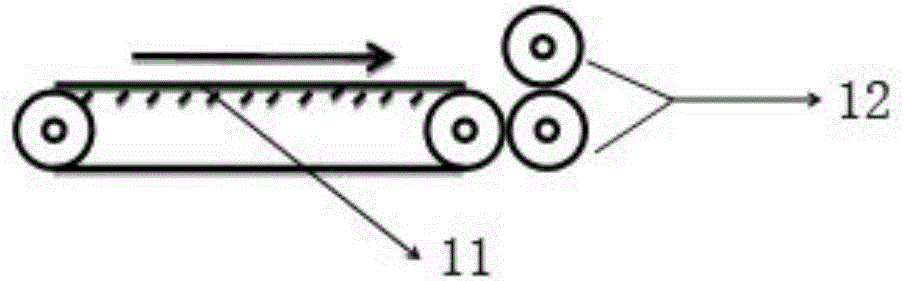

Washable polylactic acid fiber material quilt and manufacturing process thereof

The invention relates to the technical field of household appliances, and particularly discloses a washable polylactic acid fiber material quilt and a manufacturing process thereof. The quilt comprises a quilt cover and quilt filler. The quilt cover is manufactured with polylactic acid fiber as the weaving material and comprises a quilt surface layer and a fluff layer. The directions of the fluff layer on the surface of the quilt cover are the same. The quilt filler comprises polylactic acid short fiber endless tows with high crimpness. The manufacturing process of the polylactic acid fiber material quilt includes the steps of weaving of the quilt cover, combing of the quilt surface, preparing of the quilt filler and manufacturing of the quilt. The problem that a traditional quilt is not washable is solved, and the filler in the quilt keeps fluffiness and overall heat retention property for a long time.

Owner:美东生物科技(东莞)有限公司

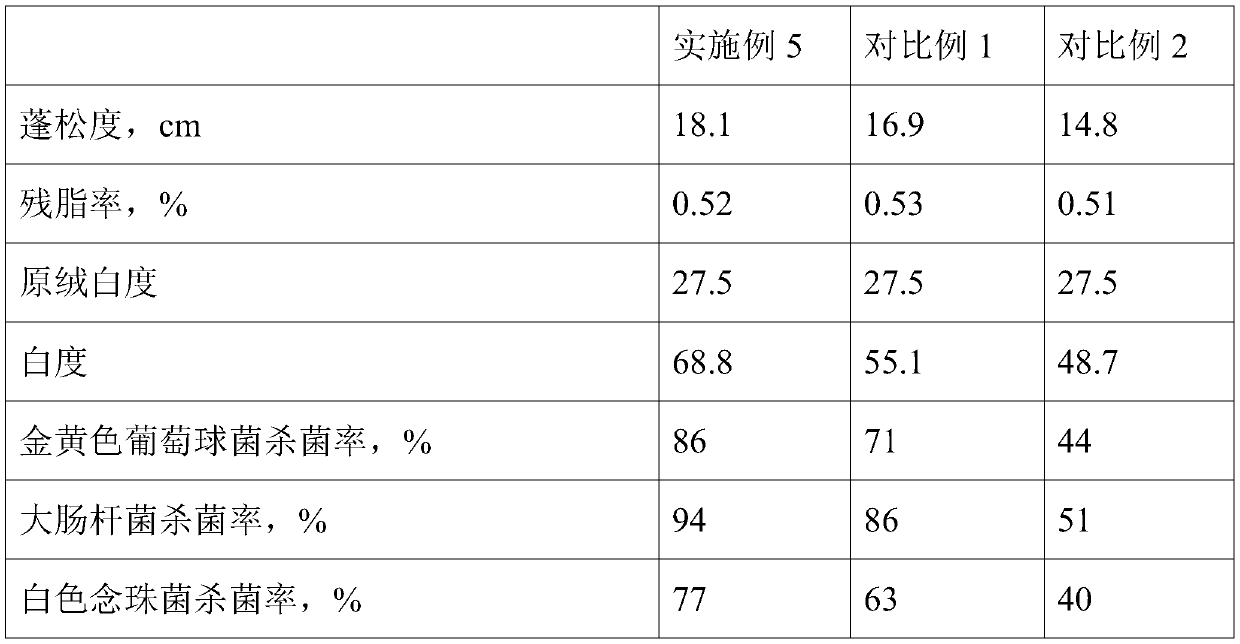

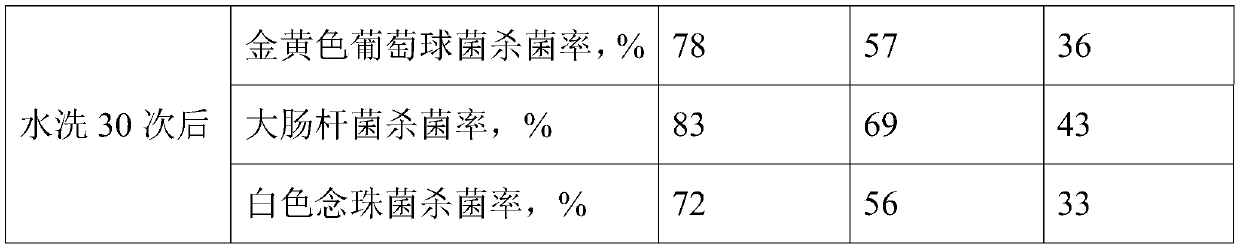

Preparation method for washable and antibacterial down feathers

InactiveCN110904690AGood antibacterial functionReduce dust contentBiochemical fibre treatmentFreeze-dryingAntibacterial property

The invention discloses a preparation method for washable and antibacterial down feathers. The method comprises the following steps of washing, dewatering and drying raw feathers, and removing residual dust and sand to obtain pretreated down feathers; adding a detergent into the pretreated down feathers for fine washing, then rinsing the pretreated down feathers with clear water, performing dewatering, adding a humic acid compound and chitosan to be uniformly mixed, and performing dipping, filtering, washing, drying and cooling to obtain the washable and antibacterial down feathers. The humicacid compound is prepared by adopting the following process of mixing humic acid and a sodium hydroxide solution, performing heating and stirring, adding disproportionated rosin and carbon nanotubes,performing shaking, adding soybean protein, adjusting the pH value of a system to be 8.8-9.4, adding monoepoxy-terminated polysiloxane to be continuously stirred, then carrying out microwave processing, performing distilling to remove the water, and performing freeze drying to obtain the humic acid compound. The obtained washable and antibacterial down feathers are good in fiber fluffiness and excellent in antibacterial function; and after the washable and antibacterial down feathers are washed with the water for multiple times, the antibacterial performance is not reduced, the original elasticity and compression performance can be restored, and the fluffiness of the down feathers is guaranteed.

Owner:六安市皖西羽绒有限公司

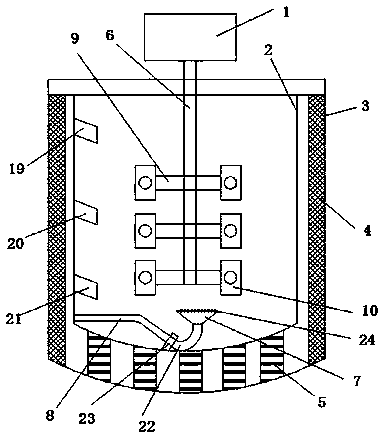

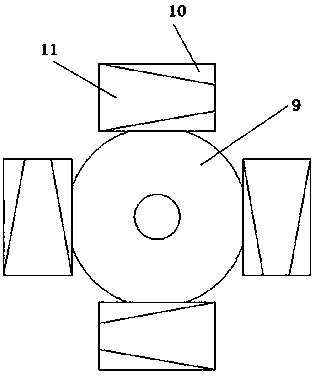

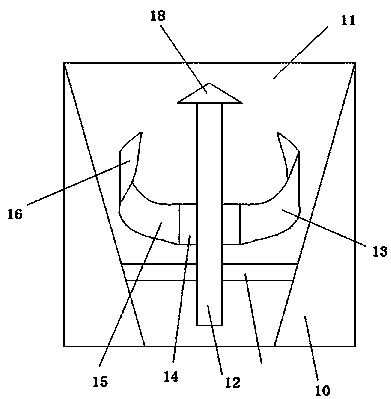

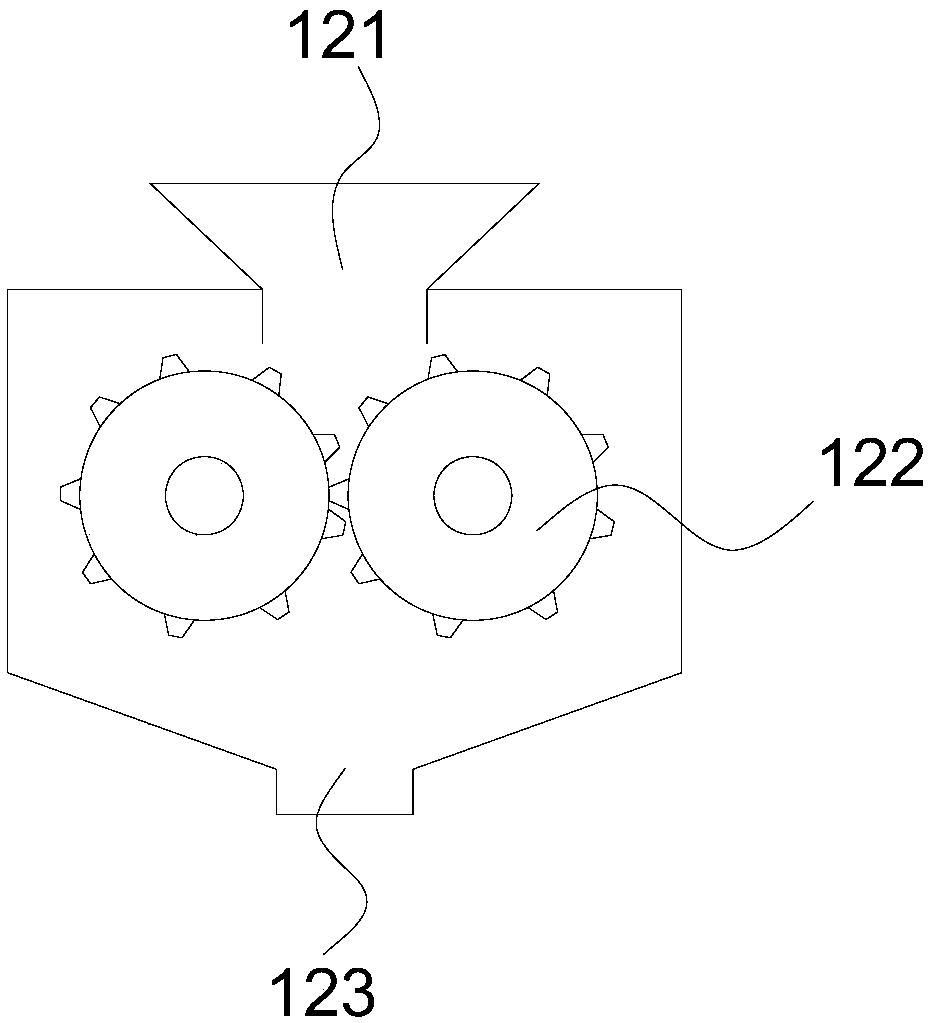

Chicken manure fermentation system and chicken manure fermentation method

PendingCN107686382ASimple structureStir wellBio-organic fraction processingExcrement fertilisersInsulation layerPulp and paper industry

The invention relates to a chicken manure fermentation system. The chicken manure fermentation system comprises a fermentation tank consisting of an inner tank body and an outer tank body, a stirringcomponent and a gas guiding component are arranged in the fermentation tank, a driving device with a stirring driving component is arranged above the fermentation tank, a heat insulation layer is sandwiched between the inner tank body and the outer tank body, heating components are arranged below the inner tank body symmetrically and are fixedly connected with the inner portion of the outer tank body, the stirring component comprises a stirring shaft and at least one disk stirring mechanism arranged along the axial direction of the stirring shaft, and the stirring shaft is connected with the driving device. The chicken manure fermentation system has the advantages that chicken manure and bubbles can be stirred and dispersed once through horizontal guide ports and interior stirring blades of stirrers and secondary stirring is achieved through rotation of the stirrers, so that stirring uniformity is improved substantially and fermentation efficiency is improved.

Owner:惠东县华昊生物科技有限公司

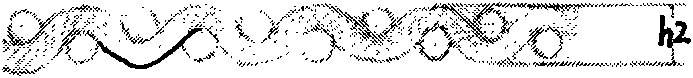

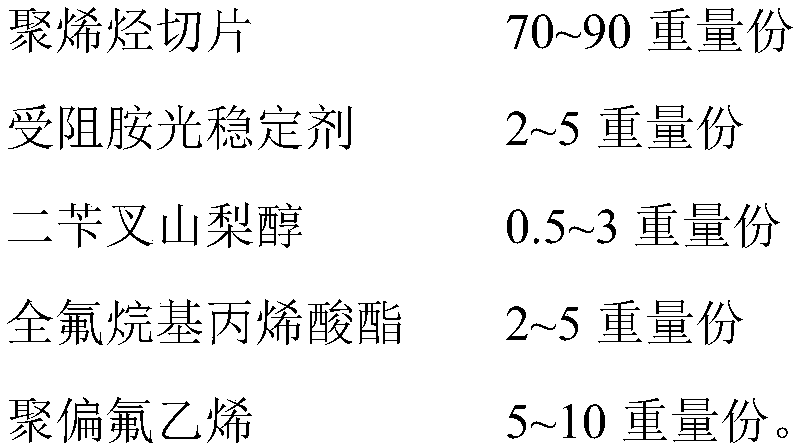

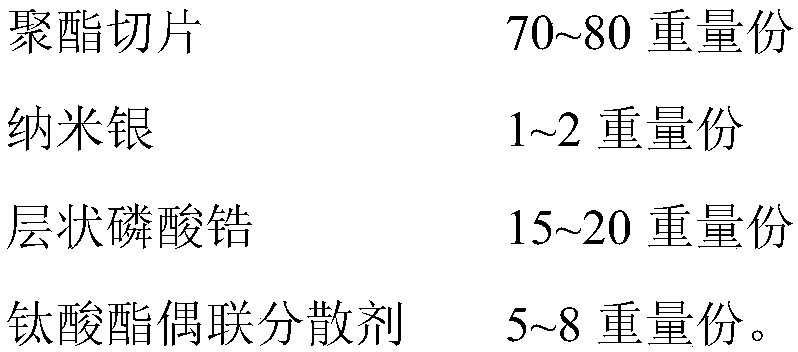

Spunbond filament electrostatic skeleton filtering material and preparation method and application thereof

InactiveCN111334935ASimple manufacturing processGood for direct discountsFibre typesFilament/thread formingPolymer scienceMelt spinning

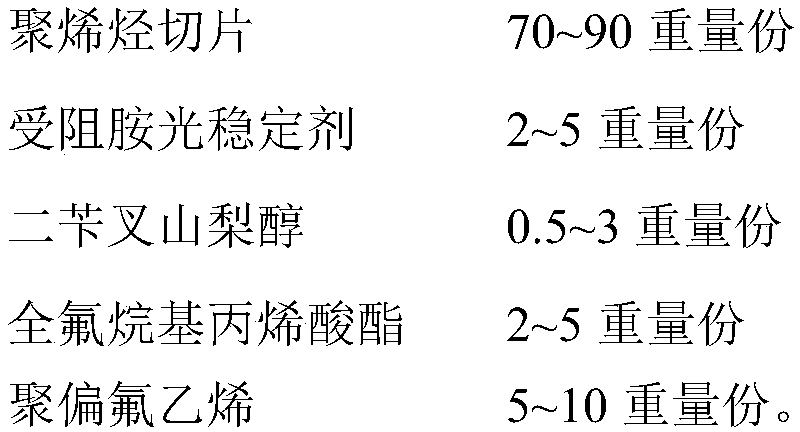

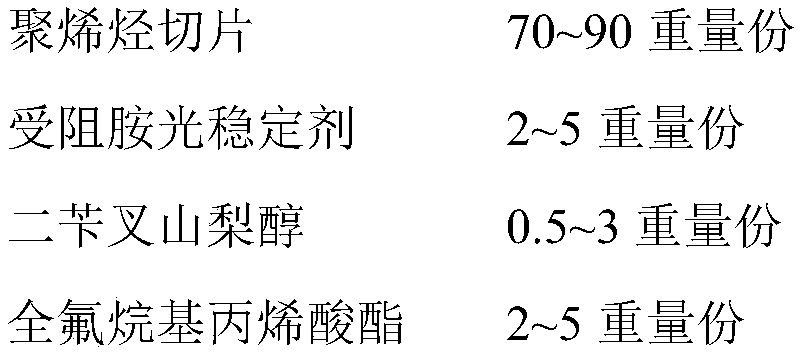

The present invention provides a spunbond filament electrostatic skeleton filtering material and a preparation method and application thereof. The preparation method comprises the following steps of 1) melt spinning, wherein a component A and a component B are subjected to melt spinning to form continuous double-component composite filaments with skin-core structures, the component A and / or the component B contains high polymers and functional mediums with the electricity storage functions, and the high polymers in the component A and the component B are two types of fiber-forming polymers with different melting point temperatures; 2) web forming, wherein the continuous double-component composite filaments with the skin-core structures are split to form a web; 3) reinforcement forming, wherein a non-woven material is formed by hot air melt bonding; and 4) high-voltage electrostatic treatment, wherein the non-woven material is charged. The filtering material has double filtering functions of physical blockage and electrostatic adsorption, and can directly folded, the filtering efficiency can reach the level H11, and the filtering resistance is lower than 10 Pa.

Owner:上海精发实业有限公司

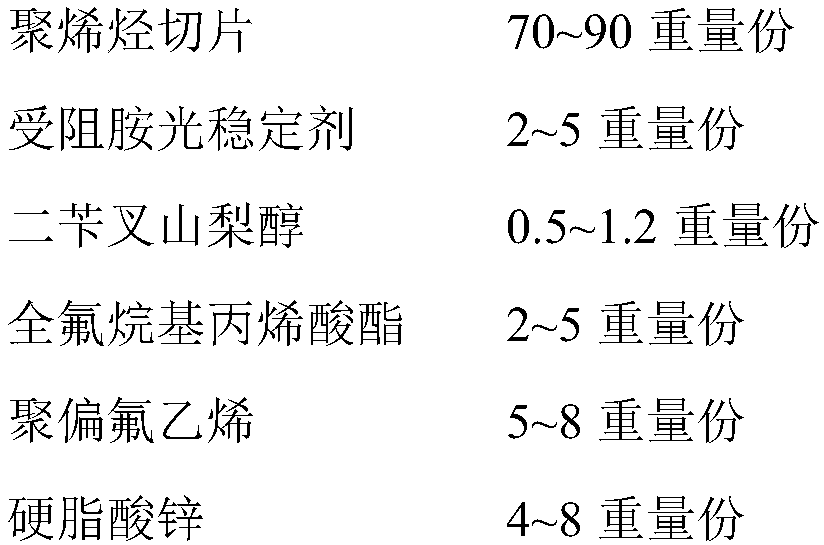

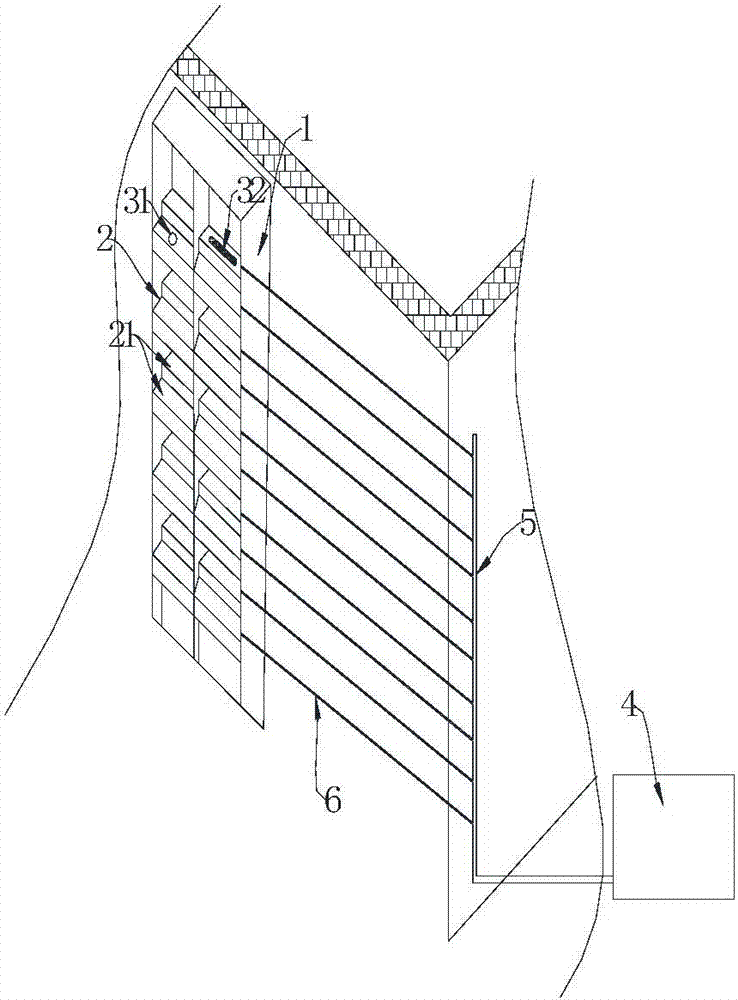

Soil repairing device

InactiveCN108672486AImprove adaptabilityImprove repair efficiencyContaminated soil reclamationSoil remediationEngineering

The invention discloses a soil repairing device. The soil repairing device comprises a soil turning component, a supporting arm, a repairing component and a control center, wherein the soil turning assembly is used for retreading the soil in a target position; the supporting arm is used for guiding the soil turning assembly to reach the target position; and the repairing component is used for mixing a predetermined repairing agent when the soil turning component is used for retreading the soil of the target position; and the control center comprises a control platform, a base and a power system, wherein the control platform is used for controlling the supporting arm, the base is used for bearing the whole device, and the power system is used for providing power for the whole device. Through the supporting arm, the soil turning assembly is pulled to reach the target position, the repairing component cooperates to mix the predetermined repairing chemical agent to the retreaded soil, so that the soil remediation treatment of the target position is realized; and through controlling of the control center, the adaptability of various target position environments and the soil remediationefficiency are improved while the labor cost investment is reduced, moreover, secondary rolling of the restored soil is avoided in the repairing process, and the fluffiness of the repaired soil is ensured.

Owner:安徽省大地园林股份有限公司

Argon bleaching and dyeing technology of acrylic yarn

InactiveCN102965906AFluffy guaranteedSoft touchDry-cleaning apparatus for textilesBleaching apparatusYarnSodium chlorite

The invention relates to the technical field of argon bleaching and dyeing technology in the textile industry, and in particular relates to an argon bleaching and dyeing technology of the acrylic yarn. The argon bleaching and dyeing technology of the acrylic yarn comprises the following steps: (1) placing the acrylic yarn into water, and then sequentially adding auxiliaries which are respectively 1g of chelating disperse agent per liter of water, 1g of oxalic acid per liter of water, 1g of sodium chlorite per liter of water, 0.5g of sodium nitrate per liter of water, and 1g of sodium thiosulfate per liter of water; and (2) heating the water solution with the auxiliaries at speed of 1 DEG C per minute until reaching 95 DEG C, and maintaining the temperature for 30 minutes. According to the argon bleaching and dyeing technology of the acrylic yarn, the sodium chlorite is used as the main auxiliary for oxygen bleaching and can be used for enhancing the oxidability, therefore, high bleaching effect can be realized, and the whiteness of the yarn can be improved; and the yarn is slowly cooled and washed by hot water after the oxidization, and are washed by hot water again after the oxygen bleaching, so that the problem caused by hardening in cold water can be avoided, and the oxidized acrylic yarn is fluffy, soft, full and not hard, and as a result, the quality of the acrylic yarn is improved.

Owner:江苏富邦纺织集团有限公司

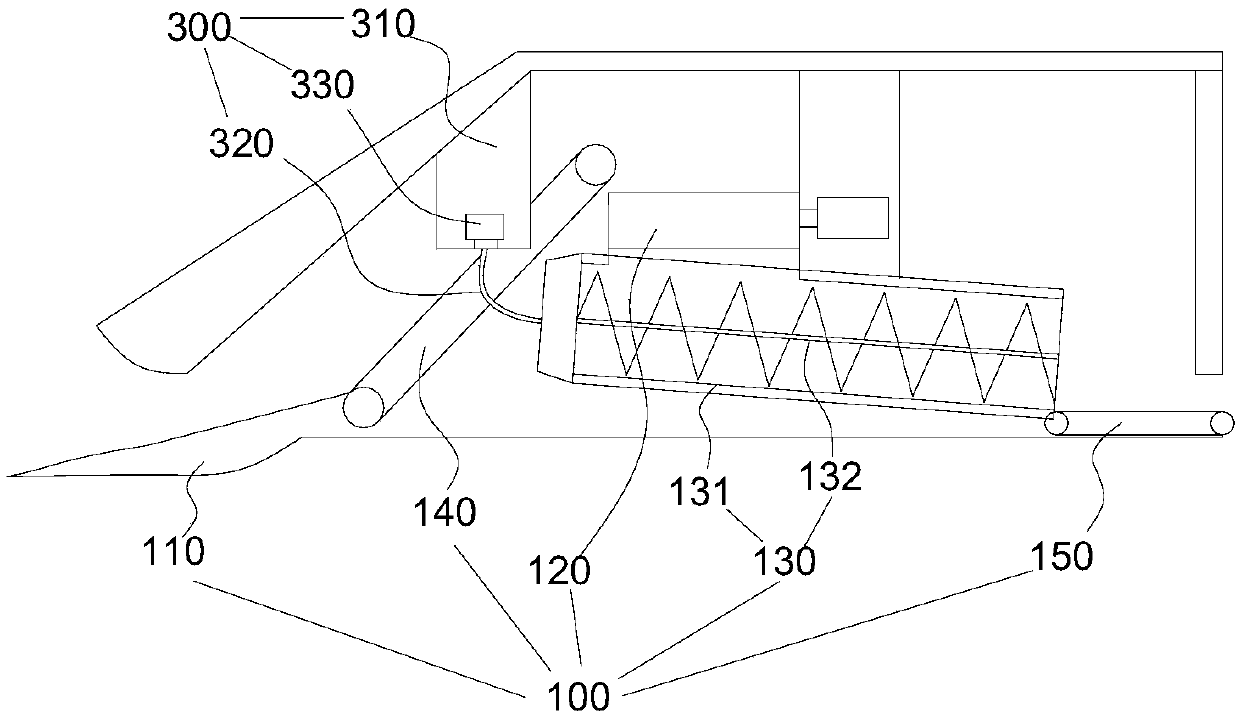

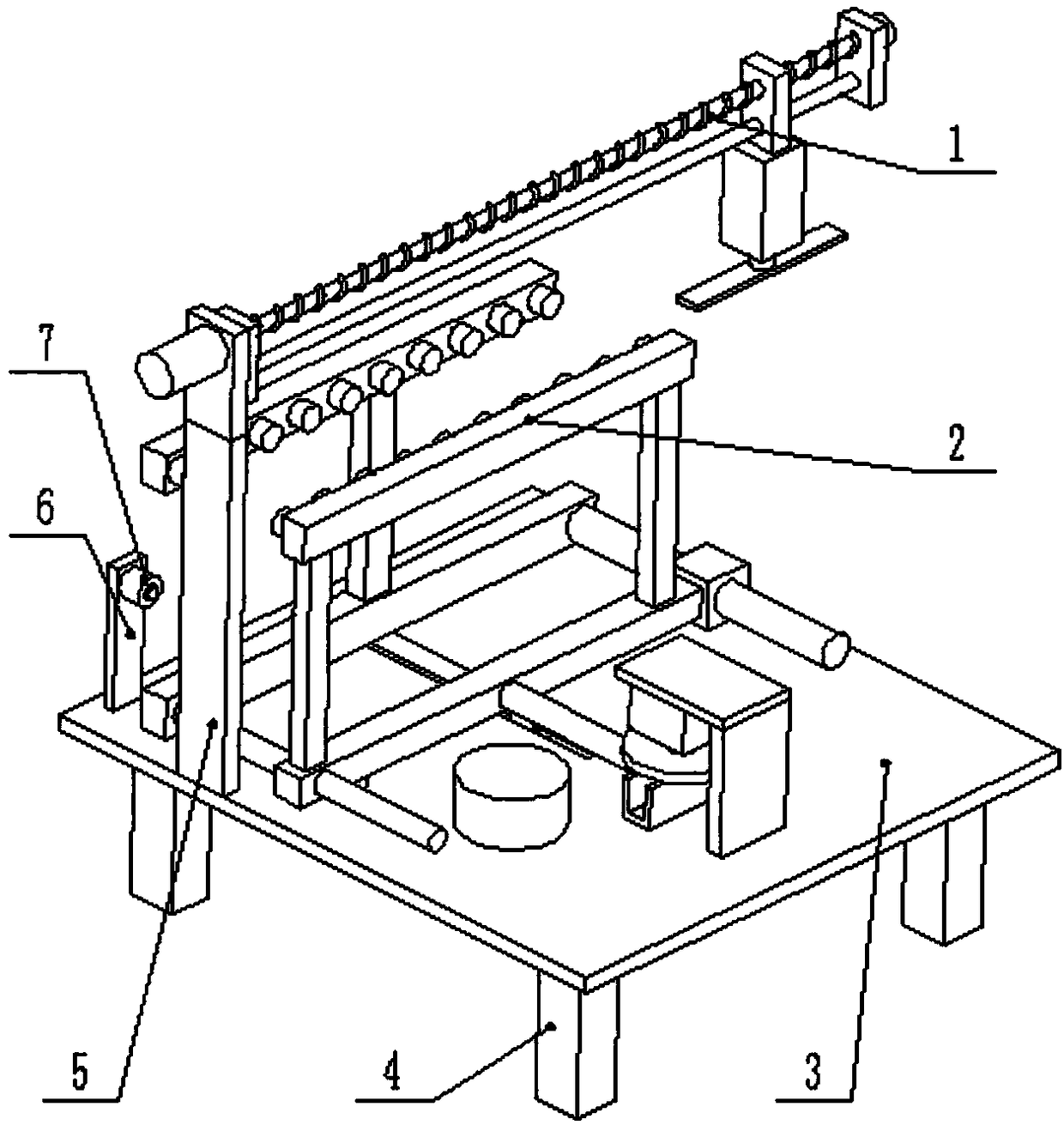

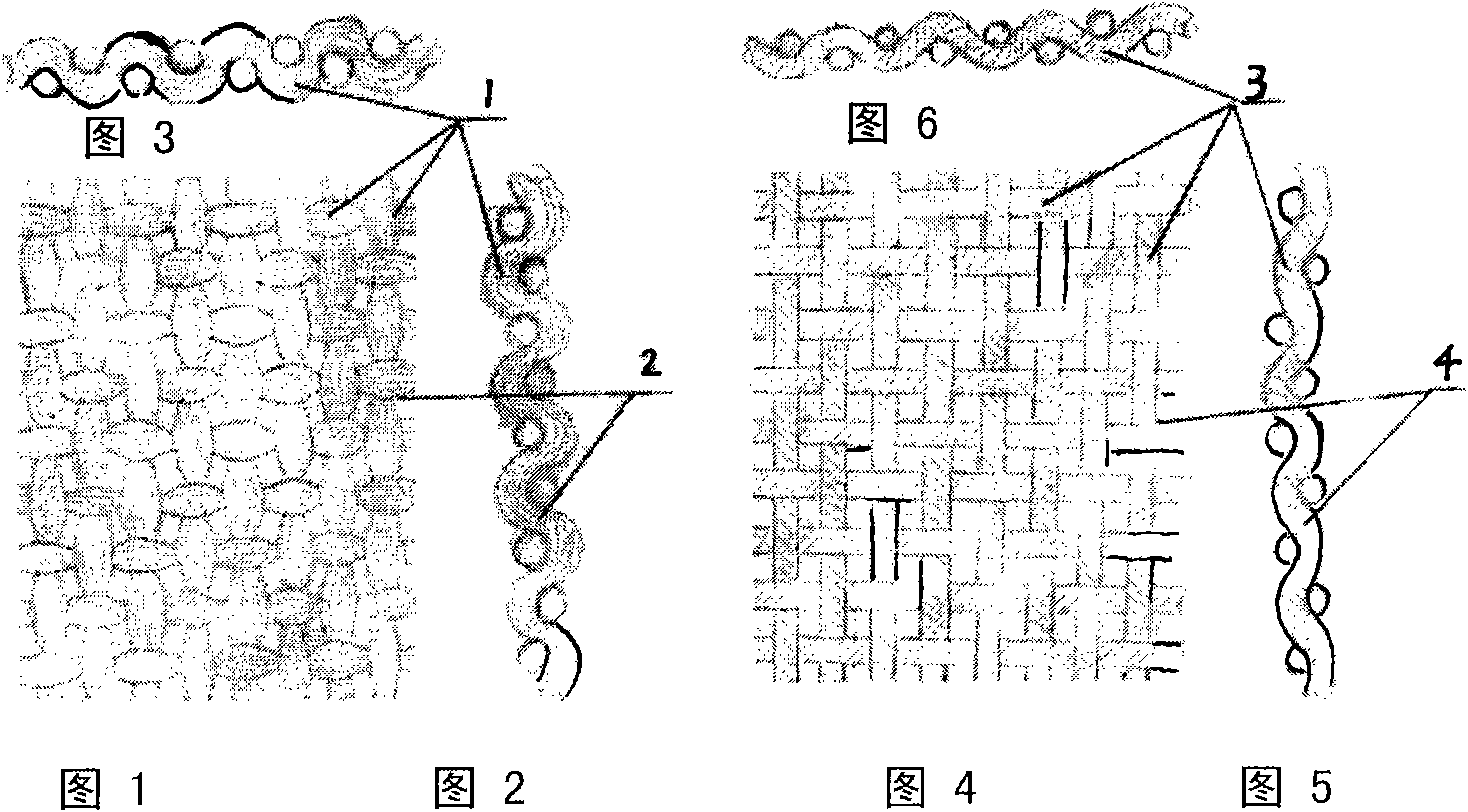

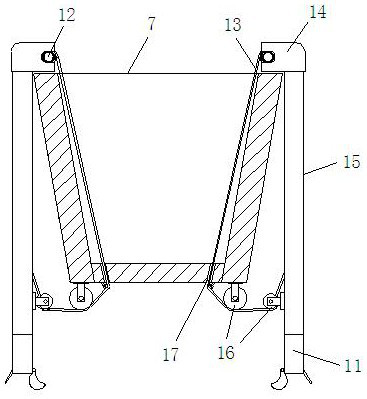

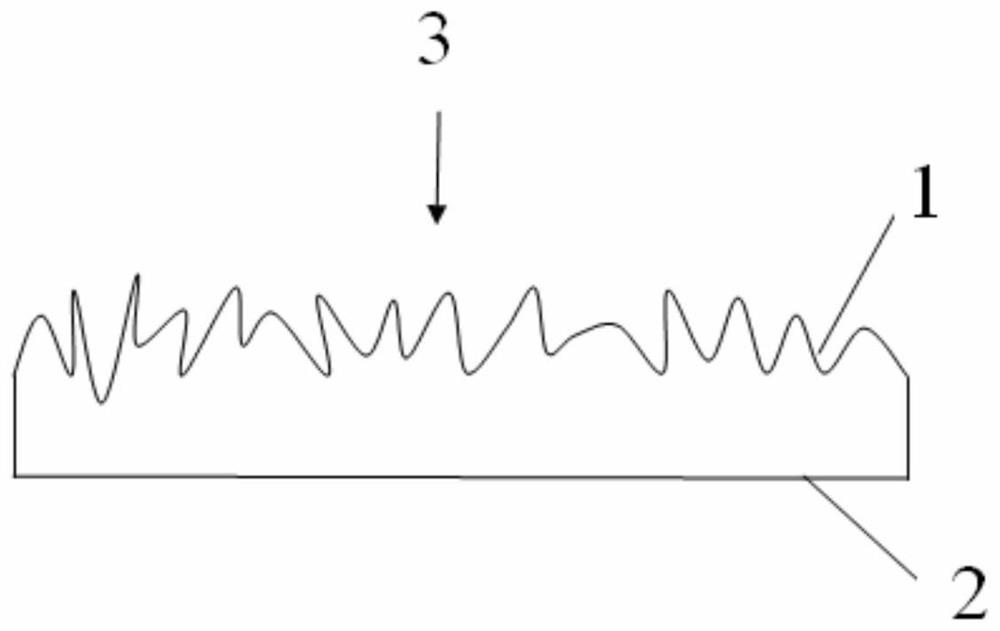

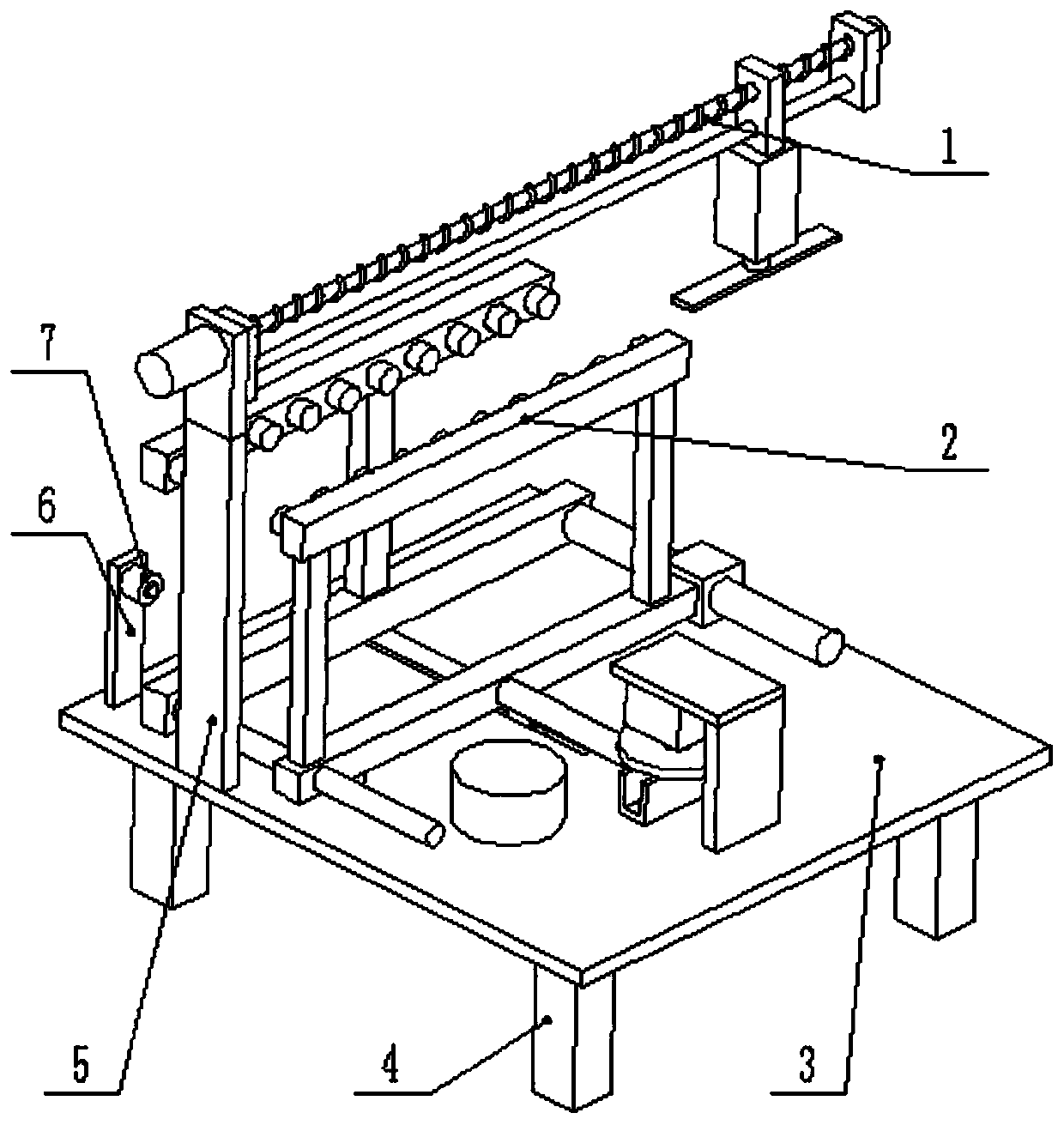

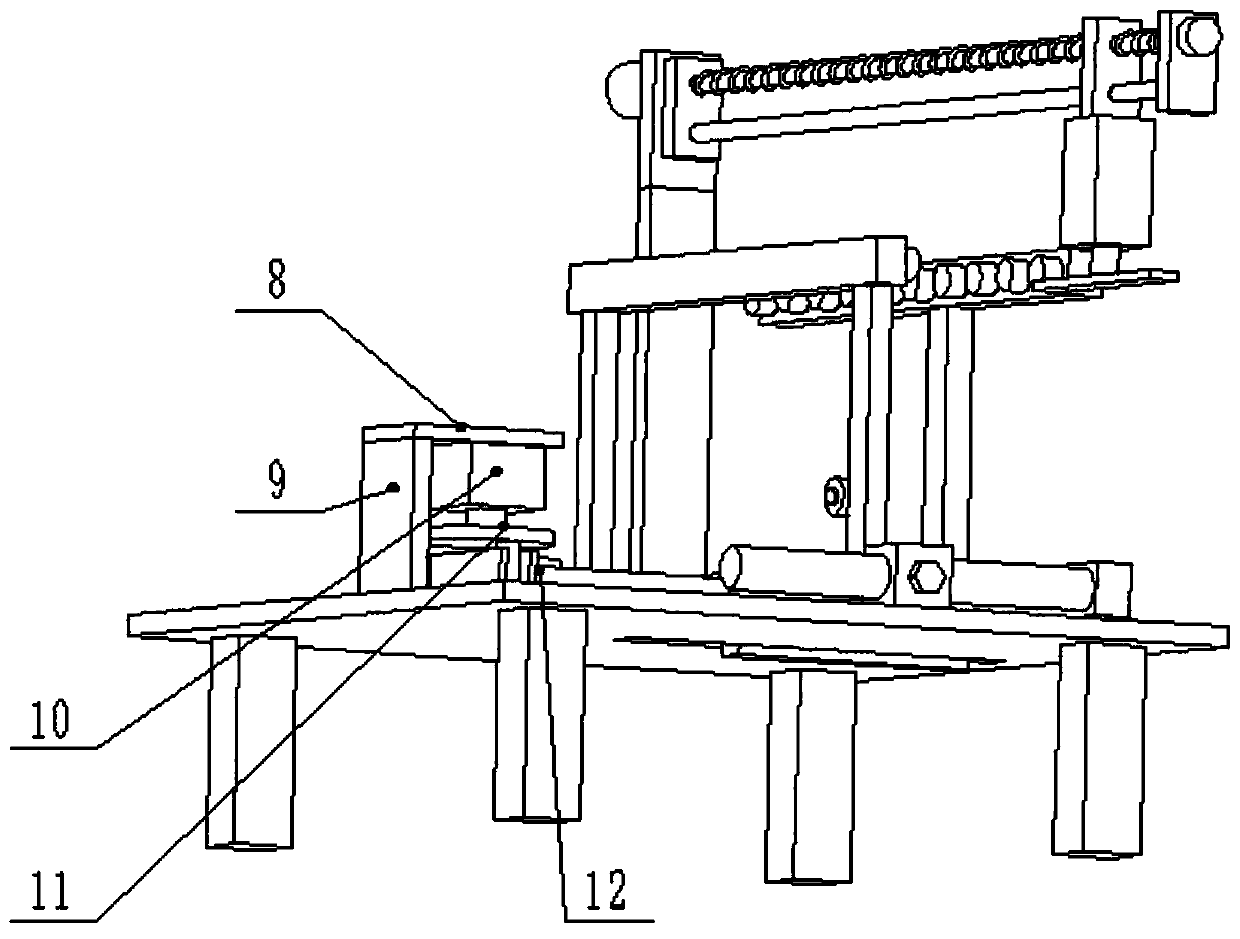

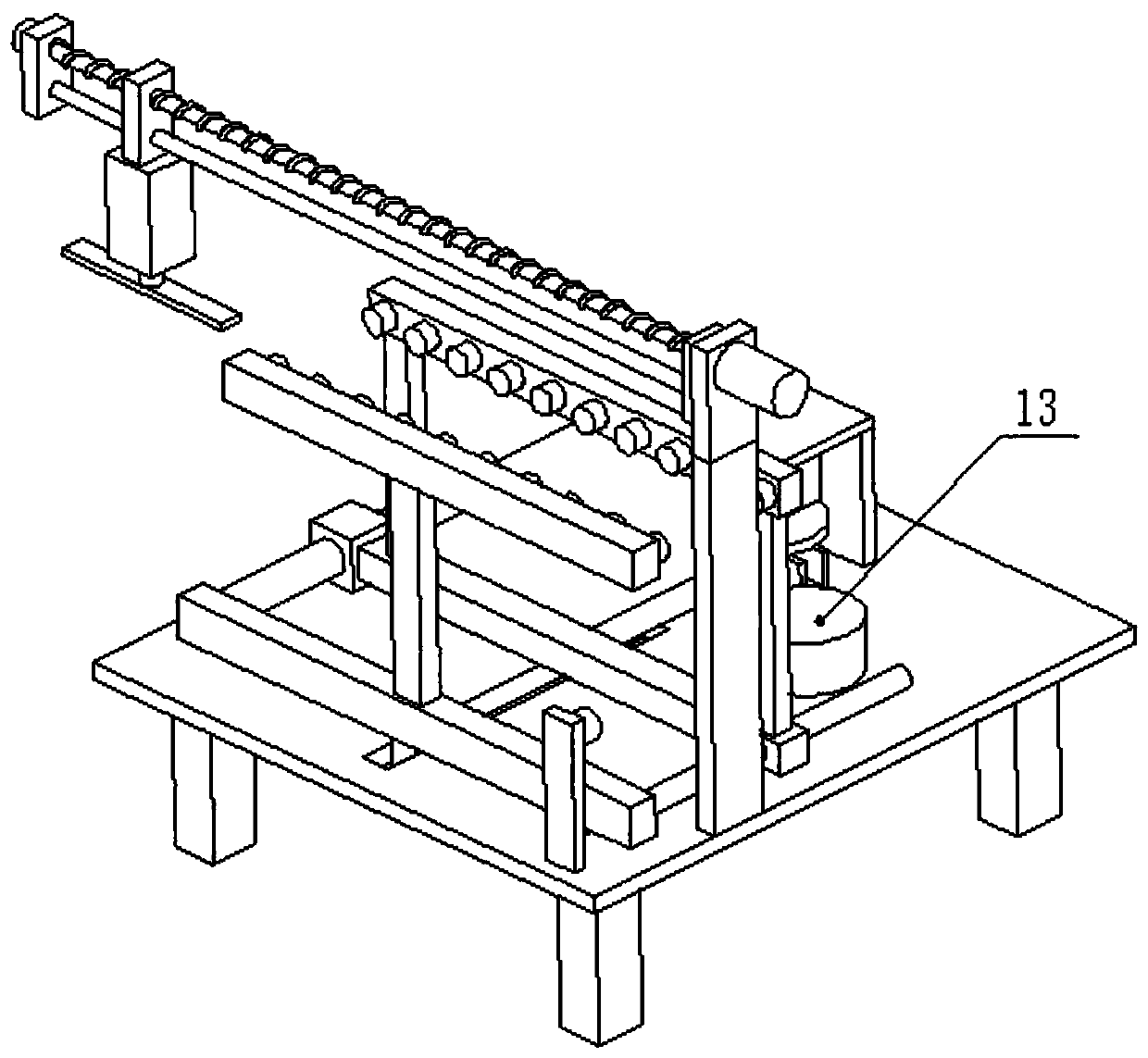

Laundry clothes beating device for fluffing

ActiveCN108252071AGuaranteed to be verticalFluffy guaranteedTextiles and paperConditioning apparatusEngineeringLaundry

Disclosed is a laundry clothes beating device for fluffing. The device belongs to the field of living equipment. A transmission device is fixed on the top of a first supporting frame, a power device is fixed on a sliding rod and located in the center of a working platform, four supporting legs are fixed on four corners below the working platform respectively, the first supporting frame is vertically fixed on the edge of the left side of the working platform, the second supporting frame is fixed on the upper left corner of the working platform, a photoelectric sensor is installed on the top ofthe second supporting frame, a third supporting frame is fixed in the center of the front side of the working platform, a first motor is fixed below the base of a first motor, an eccentric wheel is installed on the main shaft of the first motor, the sliding rod is installed on the eccentric wheel, and a controller is fixed on the working platform. According to the device, clothes are beaten through the back-and-forth movement of the moving supporting frames to make the clothes fluffy, the process of manual beating is replaced, the working efficiency is improved, and the damage on the clothes is avoided.

Owner:平邑经发科技服务有限公司

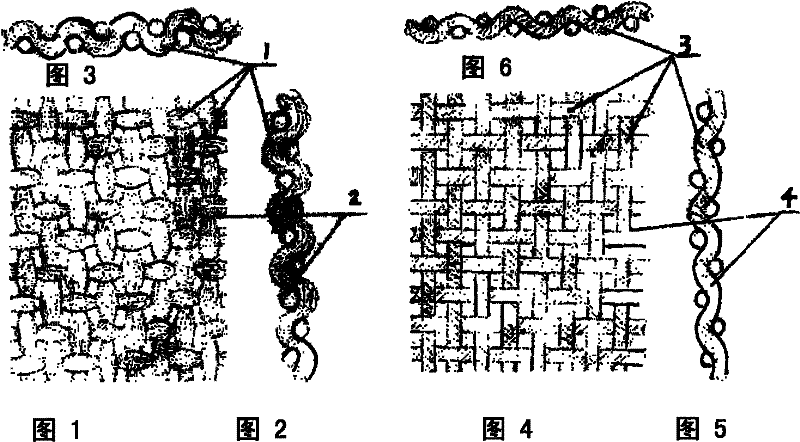

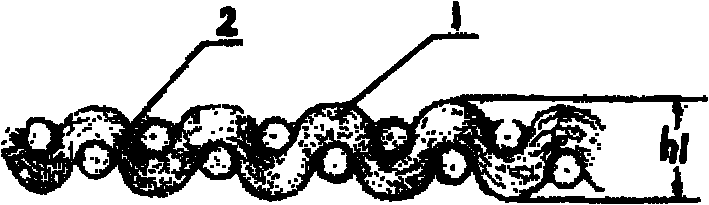

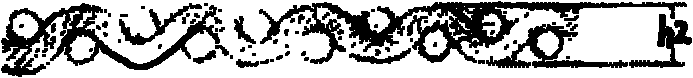

Manufacturing method of twistless fabric and product thereof

InactiveCN101929021ASimple finishing processImprove tensile capacityWoven fabricsYarnDyeingWeft yarn

The invention discloses a manufacturing method of twistless fabric and a product thereof. The method comprises the following working procedures: using a fibre rod prepared by medium staple fibre and staple fibre; taking the fibre rod as wrap and weft yarn after wrapped by Vitron; and dyeing, warping, starching, weaving and tidying according to design of pattern and flower color, wherein the weight ratio of Vitron yarn for wrapping to fibre rod body is within 10-35%, the tension at the time of beaming is not more than 8-13% of warp breaking tenacity, and weaving machine speed at the time of weaving is 15-20% lower than speed for weaving the traditional twisted fabric.

Owner:马玉成

Antibacterial ultraviolet-proof cotton yarn

InactiveCN110820113APlay the role of antibacterial and UV protectionFluffy guaranteedYarnHollow fibreYarn

The invention discloses an antibacterial ultraviolet-proof cotton yarn which comprises cotton fibers, hollow fibers, carbon fibers, bamboo fibers and acrylic fibers. The bamboo fibers and the acrylicfibers are spun on the cotton fibers in a mixed manner, antibacterial ultraviolet-proof functions can be achieved according to structural characteristics, the cotton fibers are enclosed on the hollowfibers, the carbon fibers penetrate the whole hollow fibers in an S-shaped manner, so that the bulkiness of the yarn can be ensured, and the tensile strength of the yarn is enhanced.

Owner:盐城市海威棉业有限公司

Stereoscopic cultivation method for flowers

InactiveCN107371679AMaximize utilizationTake advantage ofCultivating equipmentsPlant cultivationGrowth managementGreenhouse

The invention provides a stereoscopic cultivation method for flowers, and belongs to the field of plant cultivation. The cultivation method comprises construction of a stereoscopic cultivation greenhouse, construction of an automatic watering system, laying of cultivation substrates, planting of the flowers and growth management. The greenhouse comprises a plurality of trapezoidal planting platforms, each trapezoidal planting platform is provided with a plurality of steps, and planting areas are arranged on the steps. A black soil layer is laid on each planting area and comprises black soil and sand soil with the weight ratio of 3:1, and the cultivation substrates are laid on the black soil layers. The flowers are planted on the trapezoidal planting platforms, wherein the heliophilous flowers are planted on the upper-layer steps, and the sciophilous flowers are planted on the lower-layer steps. According to the stereoscopic cultivation method, the heliophilous flowers and the sciophilous flowers are planted in a cooperative mode, the outer sunlight and the inner space are fully utilized, and the aesthetic appearance is improved.

Owner:GUANGXI MODERN GARDEN GREENING ENGINEERING SEEDLING CO LTD

Production technology for menswear casual lining cloth

The invention discloses a production technology for menswear casual lining cloth. The production technology includes the steps that terylene grey cloth woven by DIY middle-elasticity network yarns serves as a base-cloth raw material, the number of single fibers of the DIY middle-elasticity network yarns is 96 F to 144 F, and the three-upper-and-one-lower rip weave structure is adopted in the base-cloth weaving process; double faces are soaked with rolling liquid, the base-cloth raw material is soaked into treating liquid, the remaining time is 0.5 s to 1 s, the liquid feeding amount is kept ranging from 1.8 g / m<2> to 2 g / m<2>, and liquid is dried and solidified to form a film; grey cloth is coated, coating is carried out through a micro-pore circular net, and coating slurry is high-viscosity bottom slurry; powder is dispersed, wherein high-strength hot melt adhesive powder is dispersed on the surface of the lining cloth, the adhesive feeding amount is controlled to be 14 g / m<2> to 16 g / m<2>, and the adhesive powder and the base cloth are integrated; powder is sucked, wherein the redundant adhesive powder which is not combined with the bottom slurry and located between points is sucked away through a powder suction device; infrared sintering and drying are carried out. By means of the production technology, the raw yarn material of the base cloth is changed, and the elasticity and the recovery degree of the base cloth are improved; meanwhile, the network technology is adopted, and the bulkiness and the good elasticity of the cloth are guaranteed.

Owner:维柏思特衬布(南通)有限公司

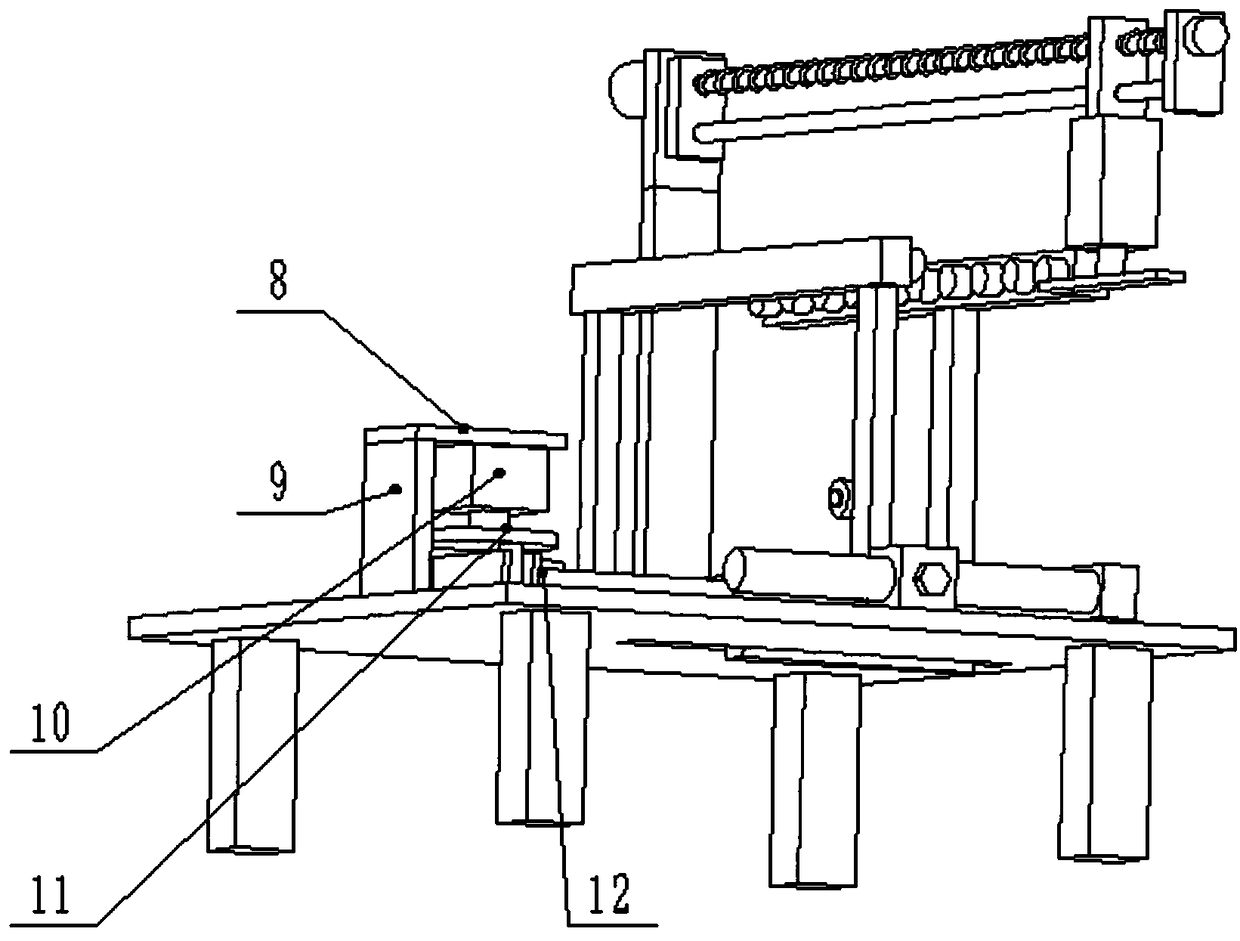

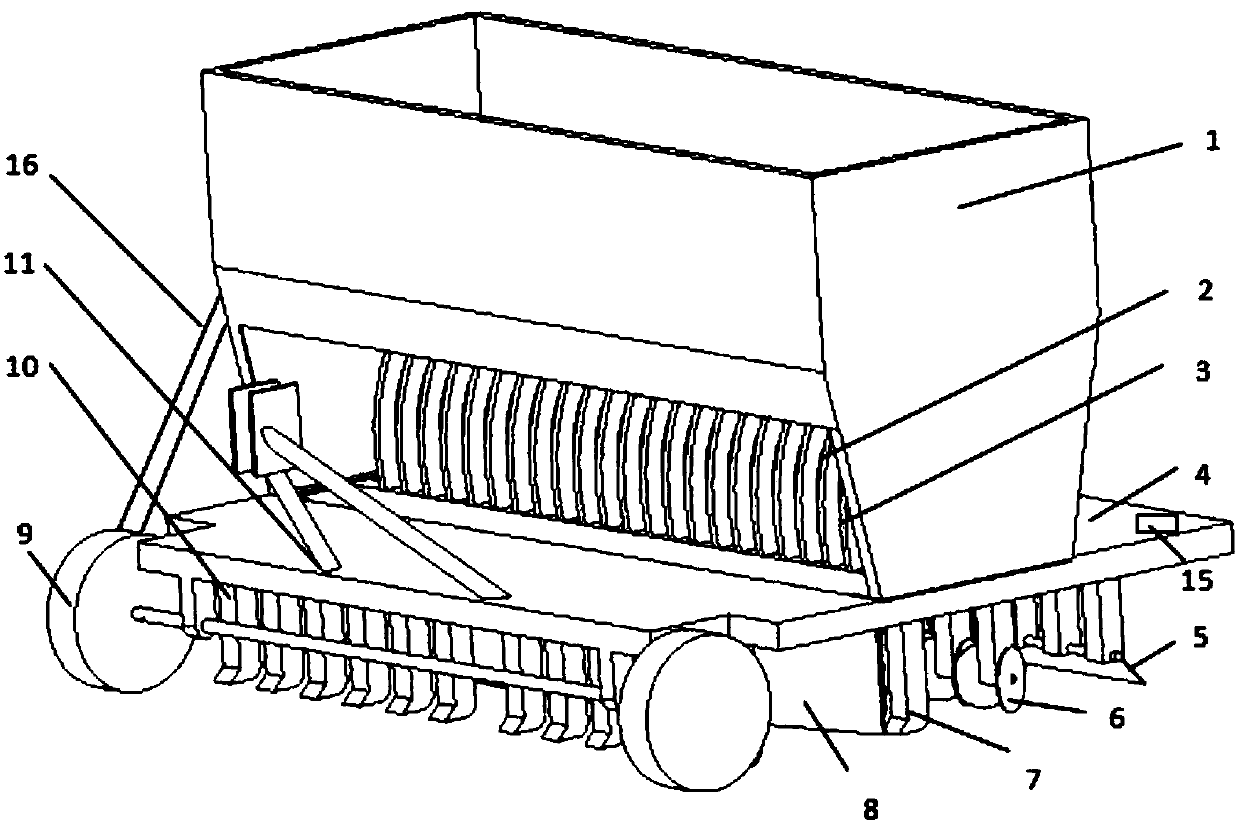

Efficient garlic sowing machine

PendingCN111670653AFluffy guaranteedGuarantee fluffy demandSpadesPloughsSeederAgricultural engineering

The invention discloses an efficient garlic sowing machine. The efficient garlic sowing machine comprises a bottom frame, a soil press roller is fixedly mounted at the back end of the bottom frame through a fixed shaft seat, a first discharge hopper is fixed in the middle position of the bottom frame, a soil ridging roller is also mounted at the bottom of the front end of the bottom frame, fixed pipes are uniformly mounted on front and back sides of the first discharge hopper respectively, a sowing mechanism is arranged on the fixed tubes, a drag fixed frame is welded and fixed to the front end of the bottom frame, a fixed frame is welded and supported at the top of the back end of the bottom frame, a second discharge hopper is welded on the fixed frame, and a guide plate welded at the bottom of the second discharge hopper extends into the second discharge hopper. A receiving spoon for receiving garlic seeds is fixed to a chain, meanwhile, the chain is driven by a rotating rod to rotate, the rotating rod is driven to rotate together with the soil press roller and the soil ridging roller, so that consistence of soil turning, planting and soil pressing is guaranteed, and the garlic seeding effect is enhanced.

Owner:王恩保

Multifunctional self-reinforced type double-component filament electrostatic filter material as well as preparation method and application thereof

InactiveCN111364164ASimple manufacturing processThe manufacturing process is simplified compared with the off-line composite filter material manufacturing process of the same filtration gradeSpinning solution de-aeratingUltrasonic/sonic fibre treatmentComposite filterAnti bacteria

The invention provides a multifunctional self-reinforced type double-component filament electrostatic filter material as well as a preparation method and application thereof. The preparation method ofthe filter material comprises the following steps that 1) melt spinning is carried out, wherein a component A and a component B are adopted to form a skin-core structure continuous double-component composite filament after being subjected to melt spinning, the component A comprises a skin layer polymer and a functional medium with an electricity storage effect, and the component B comprises a core layer polymer and a functional medium with an antibacterial and mildew-proof effect; 2) a net is formed, and specifically the skin-core structure continuous two-component composite filament form thenet after being split; 3) reinforced forming is carried out, and specifically hot air is adopted for fusion, adhesion and curing; and 4) high voltage electrostatic treatment is carried out, and specifically the material is charged. According to the self-reinforced type double-component filter material, single-layer medium-efficiency and high-efficiency filter materials can achieve the same filtering efficiency as a composite filter material, meanwhile, the effects of being antibacterial, mildew-proof, high in stiffness and electrostatic adsorption are achieved, and the GB / T21551 antibacterialstandards are met.

Owner:上海精发实业有限公司

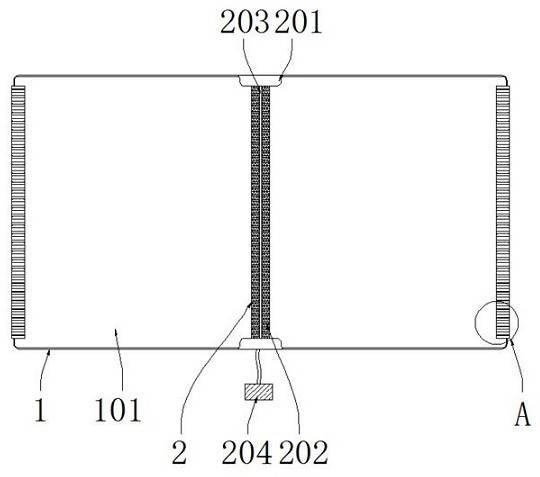

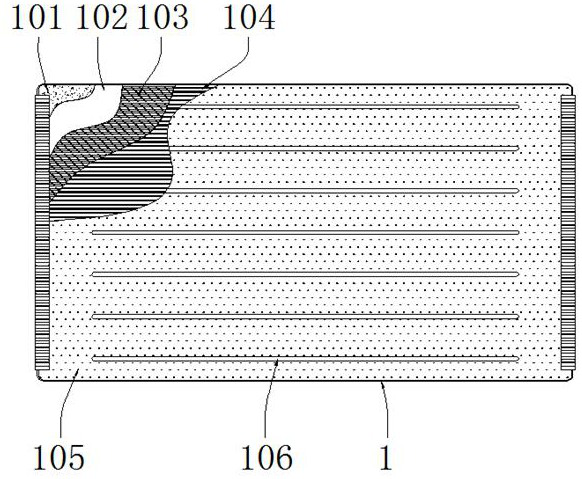

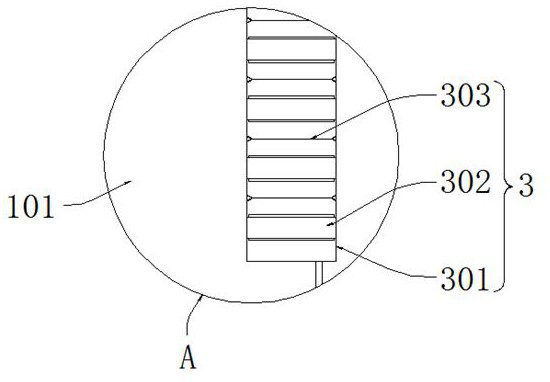

Oil guide cotton with preset assembly structure and processing technology of oil guide cotton

InactiveCN114190598AQuick tightenAdjust the tightening strengthTobaccoAgricultural engineeringElectronic cigarette

The invention discloses oil guide cotton with a preset assembly structure and a processing technology of the oil guide cotton, and relates to the technical field of electronic cigarettes, the oil guide cotton comprises oil guide cotton and preassembly assemblies, a tightening assembly is installed in the middle of the oil guide cotton, the preassembly assemblies are installed on the two sides of the oil guide cotton, and the tightening assembly comprises closing-in cotton, a tightening net, marking lines and hook velvet. The tightening net is arranged on the surface of the closing-in cotton, the marking lines are arranged on the surface of the tightening net, the hook velvet is arranged on the back face of the tightening net, the pre-assembling assembly comprises a storage frame, protruding blocks and creases, and the protruding blocks are arranged on the surface of the storage frame. According to the oil guiding device, the multiple assemblies are arranged in a matched mode, the oil guiding cotton can be rapidly tightened, the tightening force can be adjusted by tensioning the tightening net, the two ends of the oil guiding cotton can be tightly tightened in cooperation with the arrangement of the pre-assembling assembly, and therefore the oil guiding cotton and the heating wire can be conveniently installed, and the oil guiding device is convenient to use.

Owner:深圳市辉鸿达电子科技有限公司

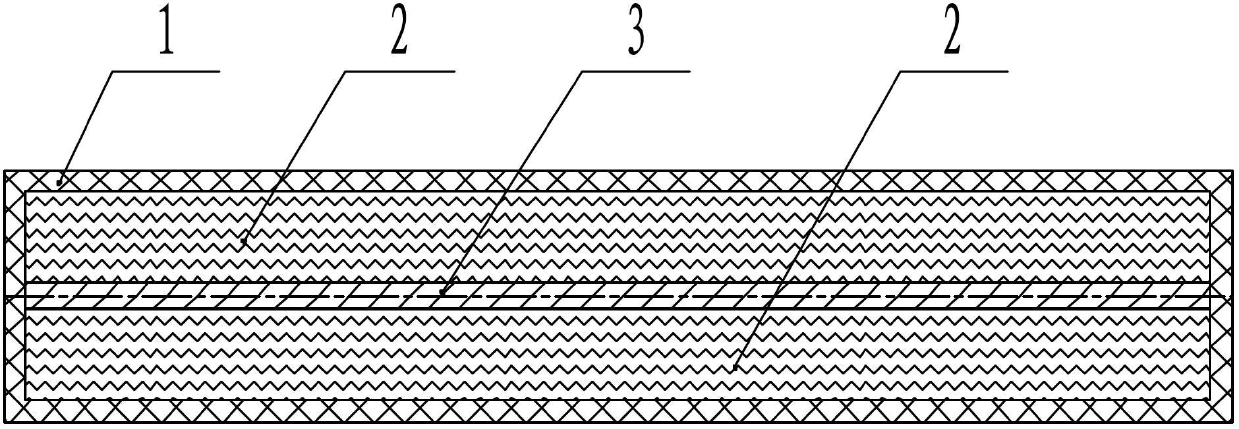

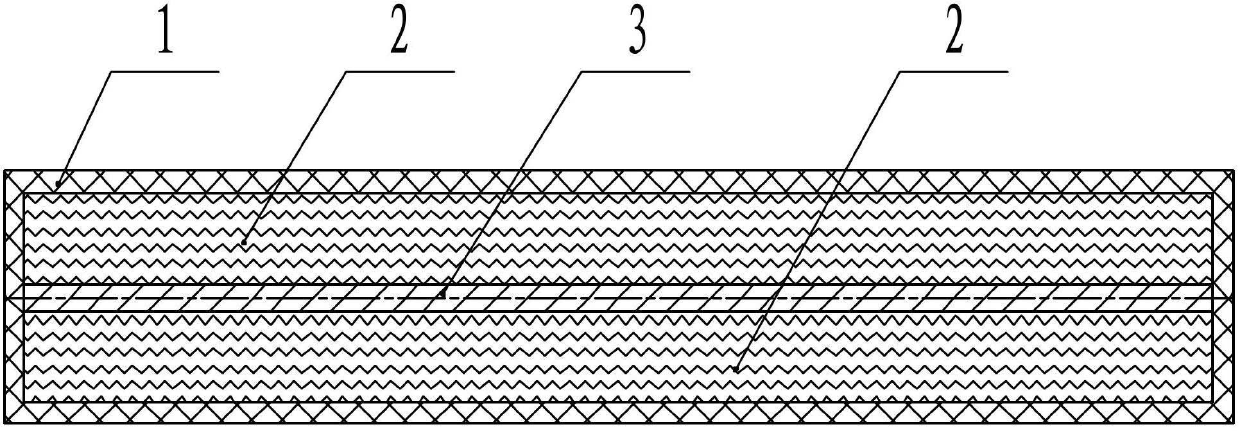

Radiation-proof silk cotton quilt core and making method thereof

InactiveCN102670009AGuaranteed breathabilityFluffy guaranteedBed-coversEngineeringElectromagnetic radiation

The invention relates to a radiation-proof silk cotton quilt core for human body. The silk cotton quilt core is characterized in that a radiation-proof layer is arranged in the silk cotton quilt core. The making method comprises the following steps of: when silk cotton sheets are put to half of total layers of silk cotton sheets, putting stainless steel fiber screen sheets of the radiation-proof layer which is slightly smaller than the required vertical amplitude of the silk cotton quilt core, downwards patting the stainless steel fiber screen sheets of the radiation-proof layer by using smooth thin bamboo strips or thin plastic strips, and lightly brushing the surfaces of the stainless steel fiber screen sheets of the radiation-proof layer by using a special brush till a small amount of velvet of the silk cotton sheets is exposed out of meshes of the stainless steel fiber screen sheets of the radiation-proof layer so as to avoid layering. The radiation-proof layer is arranged in the middle of the silk cotton quilt core, so the silk cotton quilt core has good radiation-proof and antistatic functions, and the health-care function of the silk cotton quilt core on the human body is not affected; and crowds in a habit of watching television on bed, particularly pregnant women or infants can be prevented from being harmed by electromagnetic radiation produced by household appliances.

Owner:YANCHENG SILIDE COCOON SILK

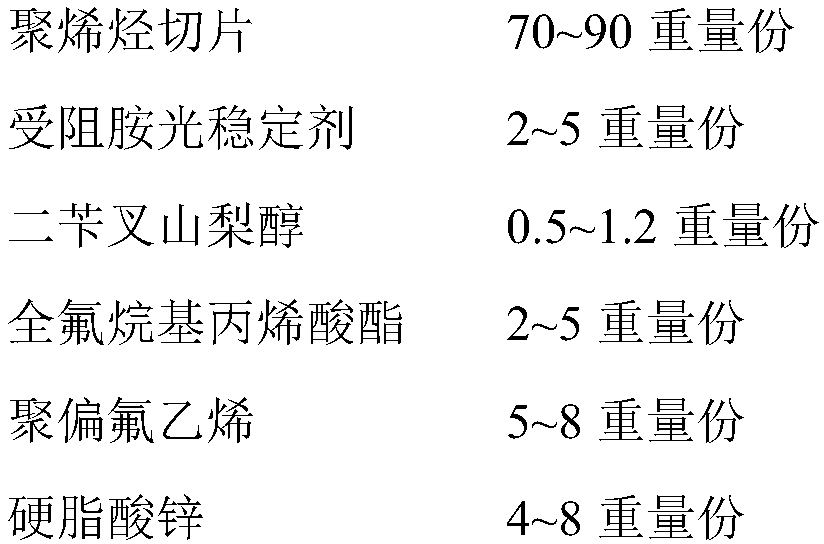

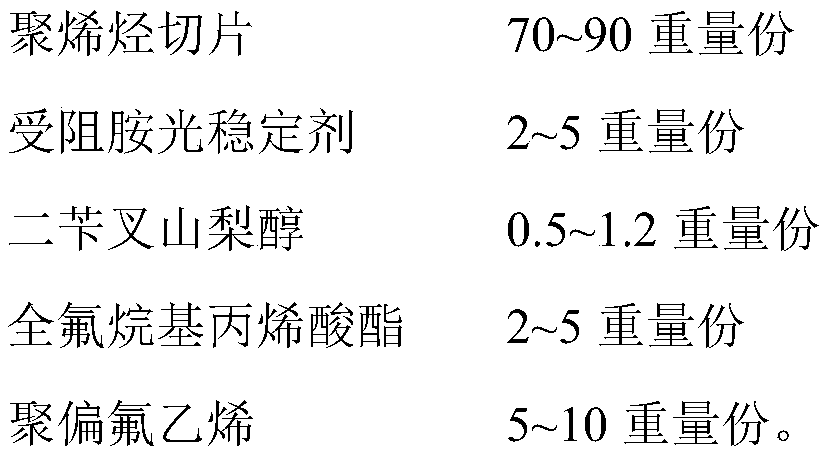

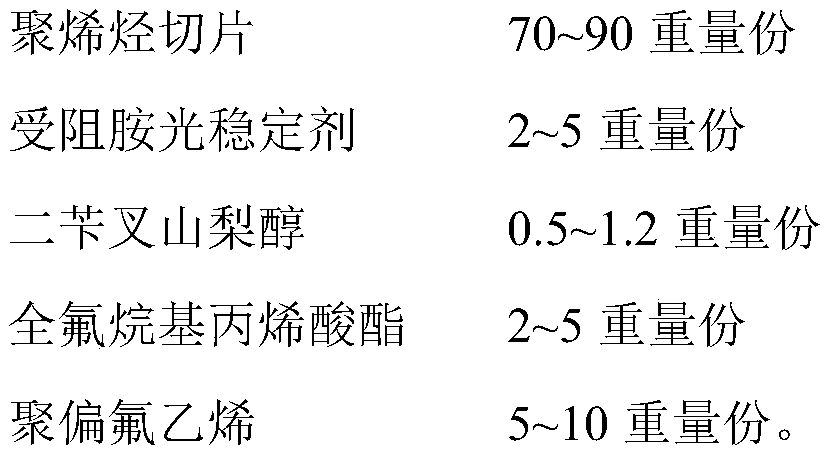

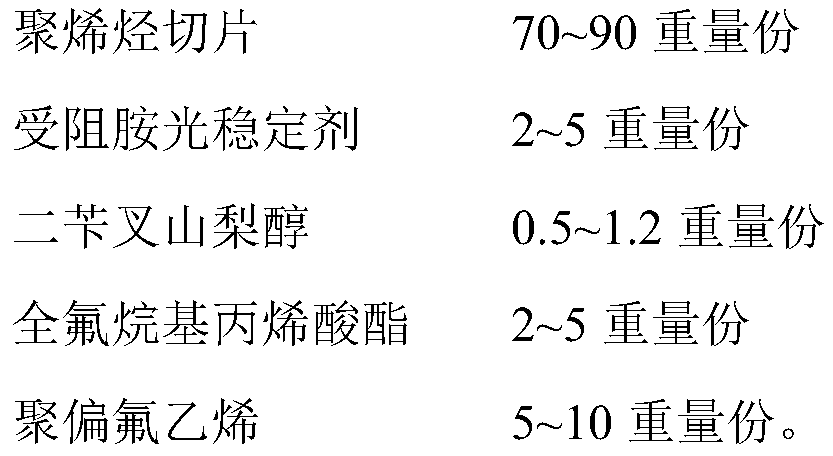

A kind of electrostatic filter material with flame retardant function and its preparation method and application

ActiveCN111203054BSimple manufacturing processImprove mechanical propertiesCombination devicesPolyesterPolymer science

The invention provides an electrostatic filter material with flame-retardant function and its preparation method and application. The preparation method includes the following steps: 1) Melt spinning: use A component and B component to form a sheath core after melt spinning Continuous bicomponent composite filament of structure, wherein component A includes at least polyolefin polymer and functional medium with electricity storage function, component B includes at least polyester polymer and functional medium with flame retardant effect or group B Divided into polyester polymers with flame retardant properties; 2) Web formation: continuous skin-core structure bi-component composite filaments are divided into webs; 3) Reinforcement molding: hot air fusion bonding is used to form a double group 4) High-voltage electrostatic treatment: charge the two-component spunbond material. In this application, the electrostatic filter material is a single-layer medium-high-efficiency filter material, which can achieve the same filtration performance as the composite filter material, and can meet the flame-retardant standard FMVSS302 of the US automotive interior materials and the Chinese GB8410 standard.

Owner:上海精发实业有限公司

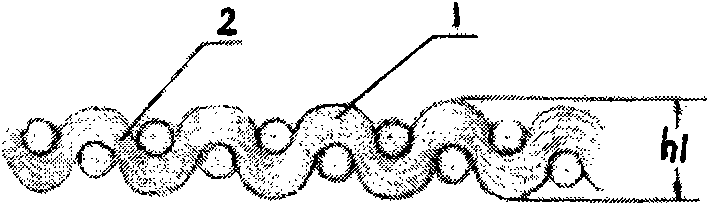

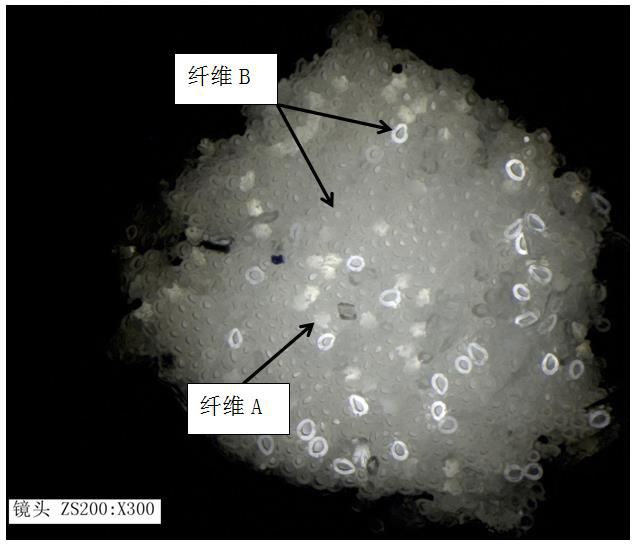

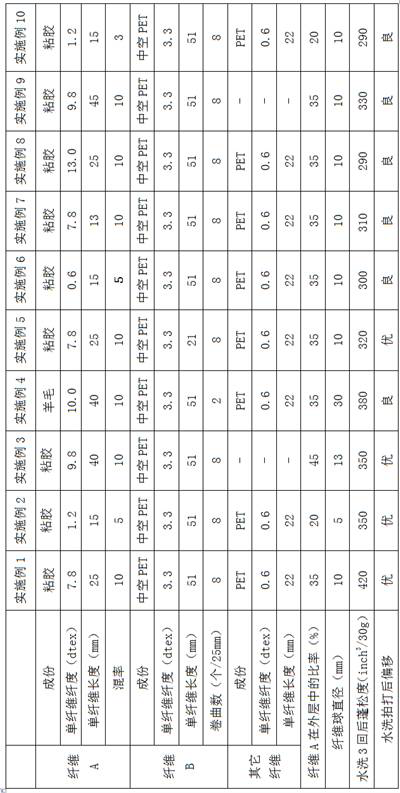

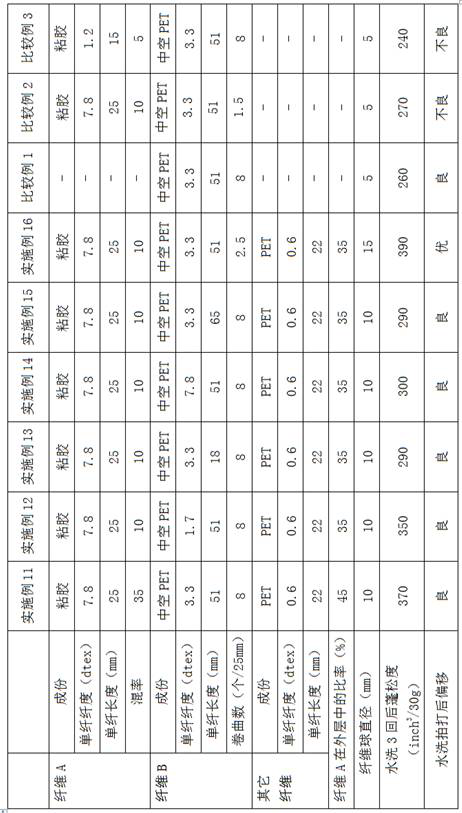

Fiber ball

PendingCN114162774AFluffy goodFluffy guaranteedProtective garmentUpholstery fillingComposite materialEngineering

The invention discloses a fiber ball. The fiber ball comprises a fiber A and a fiber B, the diameter of the fiber ball is 5-30 mm, an inner layer and an outer layer are sequentially arranged on the cross section from inside to outside, and less than 45% of the fiber A is distributed on the outer layer; and the fiber B has a three-dimensional crimp form, and the crimp number is 2-8 / 25mm. The fiber ball is high in fluffiness, soft in hand feeling and washable.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

A kind of non-woven filter medium and its preparation method and application

ActiveCN107385683BImprove uniformityDiameter adjustable and controllableFilament/thread formingFiltration separationPolymer scienceFilter media

Owner:上海精发实业有限公司

Electrostatic filter material with flame-retardant function as well as preparation method and application thereof

The invention provides an electrostatic filter material with a flame-retardant function as well as a preparation method and application thereof. The preparation method comprises the following steps: 1) melt spinning: carrying out melt spinning on a component A and a component B to form a continuous double-component composite filament with a sheath-core structure, wherein the component A at least comprises a polyolefin polymer and a functional medium with an electricity storage effect, and the component B at least comprises a polyester polymer and a functional medium with a flame retardant effect, or the component B is a polyester polymer with a flame retardant property; 2) net forming: splitting the continuous double-component composite filament with a sheath-core structure to form the net; 3) reinforcing and forming: forming a two-component spun-bonded material by hot air melting, bonding and solidifying; and 4) high-voltage electrostatic treatment: charging the double-component spun-bonded material. According to the electrostatic filter material, the electrostatic filter material is a single-layer medium-efficient filter material, so that the filter efficiency equivalent to thatof a composite filter material can be achieved, and the flame retardant standard FMVSS302 of American automobile interior trim materials and the standard of GB8410 in China can be met.

Owner:上海精发实业有限公司

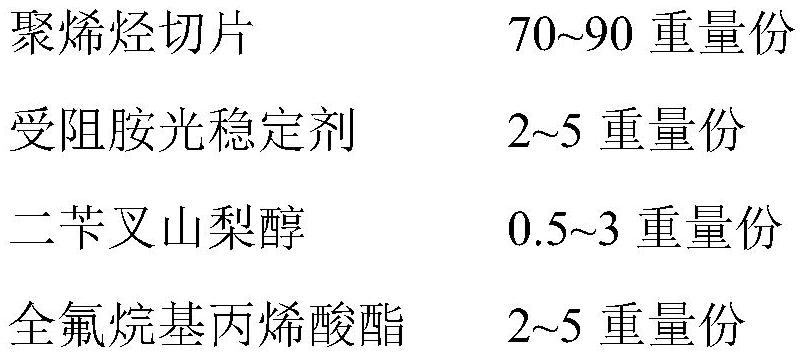

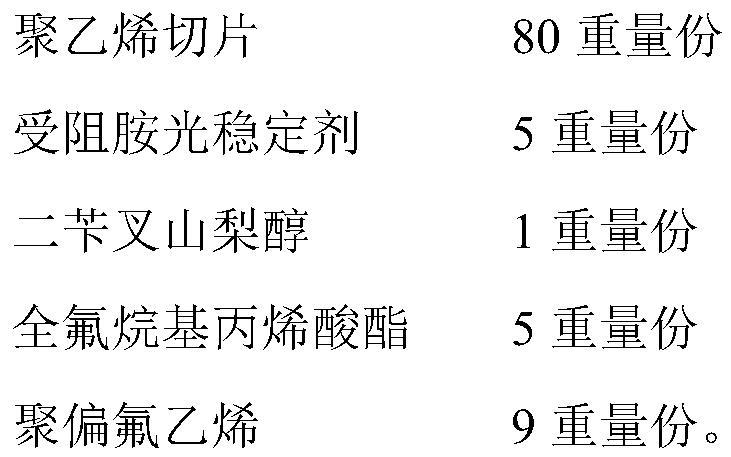

A polyolefin spunbonded filament electrostatic skeleton filter material with antibacterial and antifungal functions and its preparation method and application

ActiveCN111359316BSimple manufacturing processImprove mechanical propertiesDispersed particle filtrationFiltration separationParticulatesPolymer science

The invention provides a polyolefin spunbonded filament electrostatic skeleton filter material with antibacterial and antifungal functions and its preparation method and application. After viscose melt spinning, a continuous two-component composite filament with a sheath-core structure is formed; component A includes polyethylene and a functional medium with electricity storage, and component B includes polypropylene and a functional medium with antibacterial and antifungal effects; or A component includes polyethylene and a functional medium with antibacterial and antifungal effects, and B component includes polypropylene and a functional medium with electricity storage; 2) Forming a web: continuous skin-core structure two-component composite filament through the sub-filament 3) Reinforcement forming: use hot air fusion bonding to form a two-component spunbond material; 4) High-voltage electrostatic treatment: charge the two-component spunbond material. The electrostatic filter material of the present invention has the effects of particulate matter filtration, electrostatic adsorption, broad-spectrum antibacterial and anti-mildew at the same time.

Owner:上海精发实业有限公司

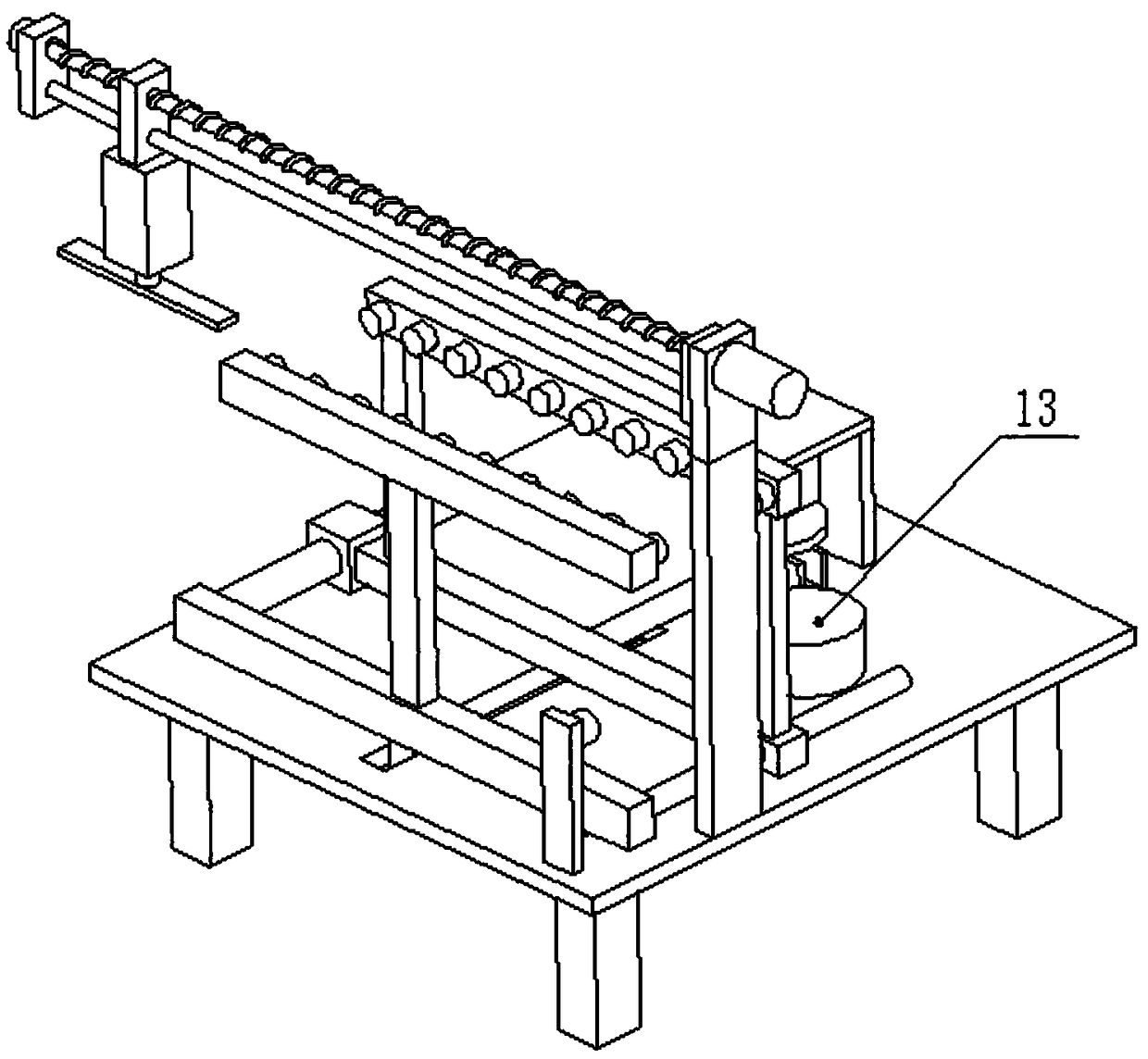

Synchronous fertilizing and seeding machine and operating method thereof

PendingCN107667628ASave materialSimple structurePlantingFurrow making/coveringAgricultural scienceAgricultural engineering

The invention discloses a synchronous fertilizing and seeding machine and an operating method thereof. The synchronous fertilizing and seeding machine comprises a seed and fertilizer tank, fertilizingpipes, seeding pipes, a bottom plate, double drill legs and a furrow plough. The seed and fertilizer tank is arranged on the upper surface of the bottom plate, and a partition is arranged in the seedand fertilizer tank to partition the seed and fertilizer tank into a fertilizer tank and a seed tank. Each double drill leg is formed by welding of two abreast drill legs, and the double drill legs in a row are arranged in the middle of the lower surface of the bottom plate. A plurality of fertilizer dischargers and seed dischargers are arranged at the bottom of the seed and fertilizer tank and staggered at intervals on a same transmission shaft. Each double drill leg is connected to one fertilizer discharger and one seed discharger through one fertilizing pipe and one seeding pipe. The seeddischargers are communicated with the seed tank, and the fertilizer dischargers are connected with the fertilizer tank. By design of the partition in the middle of the seed and fertilizer tank, fertilizing and seeding can be realized through one shaft, so that structural simplification is realized. Due to adoption of the double drill legs, fertilizing and seeding can be performed by use of the drill legs in a row, and structural simplification and size reduction are realized.

Owner:CHANGAN UNIV

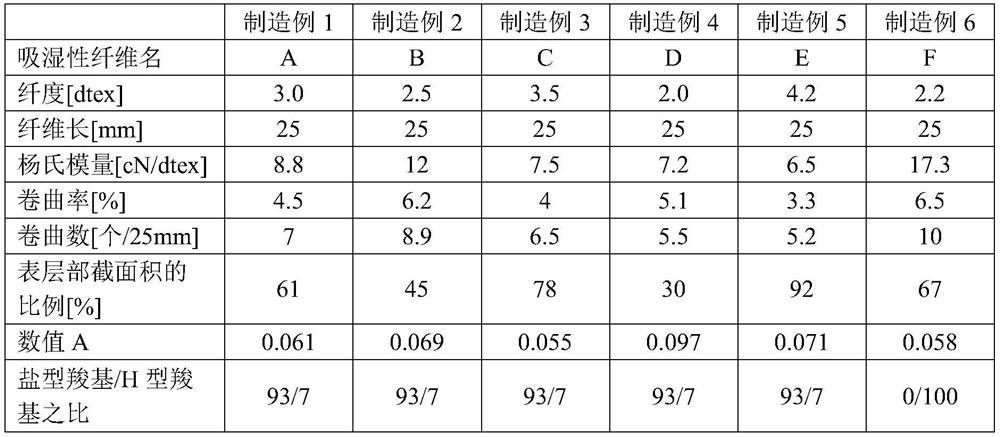

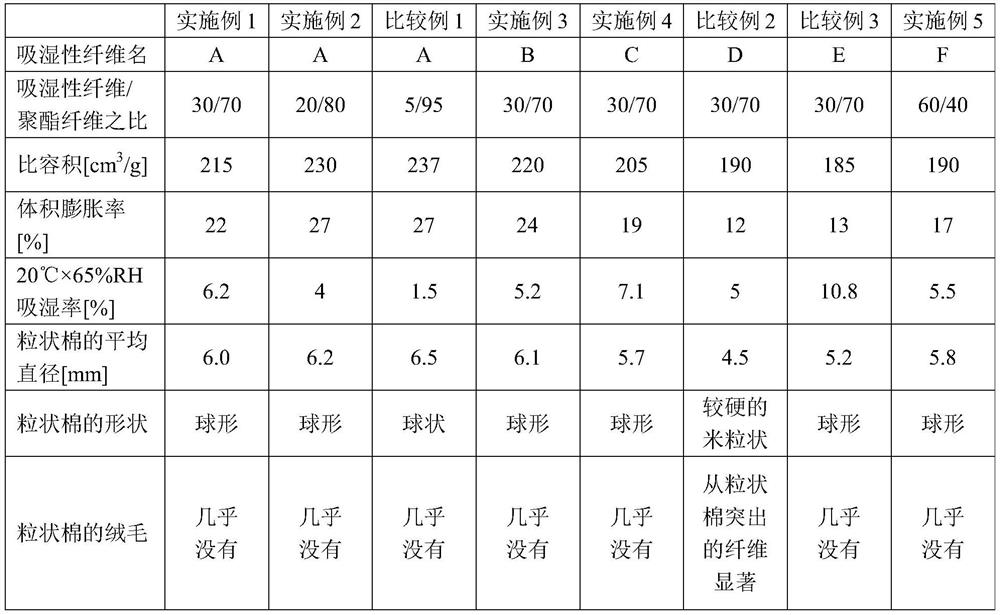

Hygroscopic granular cotton and filling cotton containing the granular cotton

ActiveCN110446808BFluffy guaranteedNot easy to stuffyFibre typesNon-woven fabricsFiberPolymer science

[Problems] The bulkiness and resiliency of moisture absorbing and desorbing fibers are low, and it becomes a problem in terms of development to filling cotton. Some techniques for improving bulkiness are known, but they only stop at securing the initial bulkiness, and the bulkiness tends to gradually decrease due to moisture absorption, repeated use, and passage of time. The present invention is made in view of the present state of the prior art, and an object of the present invention is to provide hygroscopic granular cotton having both hygroscopicity and continuous bulkiness, and filling cotton containing the granular cotton. [Solution] A hygroscopic granular cotton characterized in that it contains hygroscopic fibers composed of a surface layer made of a polymer having a cross-linked structure and a carboxyl group, and a center part made of propylene Formed from a nitrile polymer, the hygroscopic granular cotton has a volume expansion rate of 15% or more and a moisture absorption rate of 4% or more in an environment of 20°C and a relative humidity of 65%. The expansion of the volume under, the volume after the load is removed.

Owner:JAPAN EXLAN CO LTD

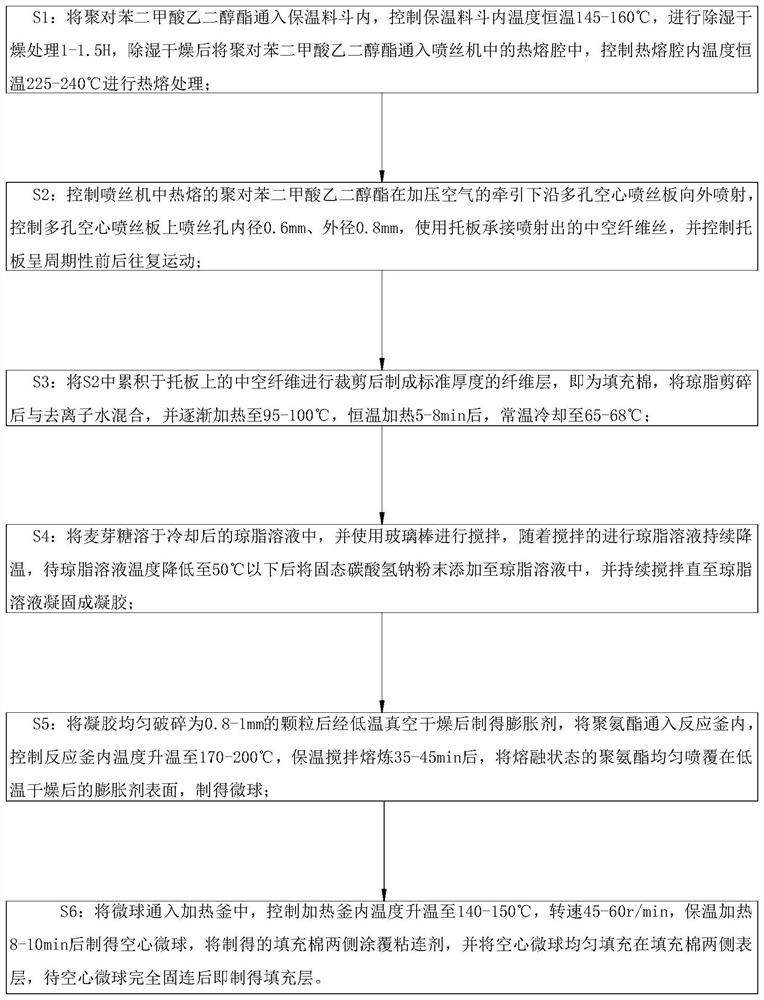

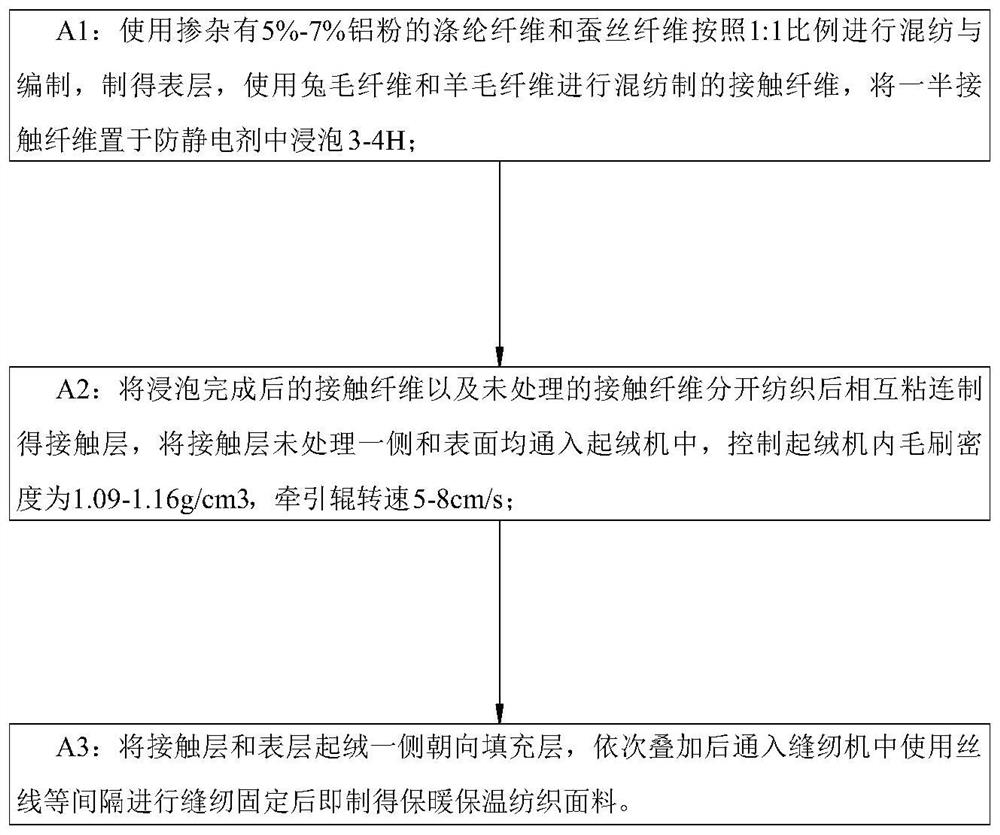

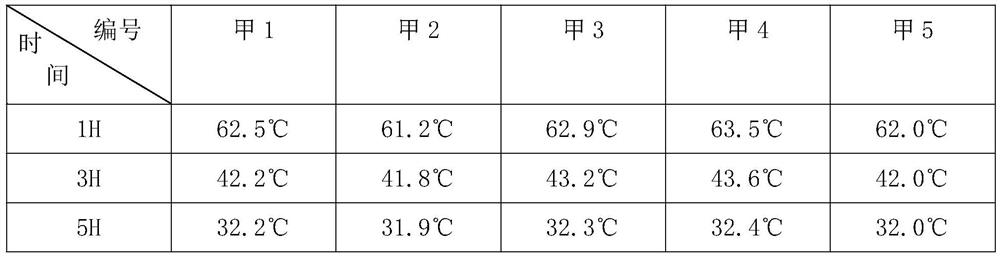

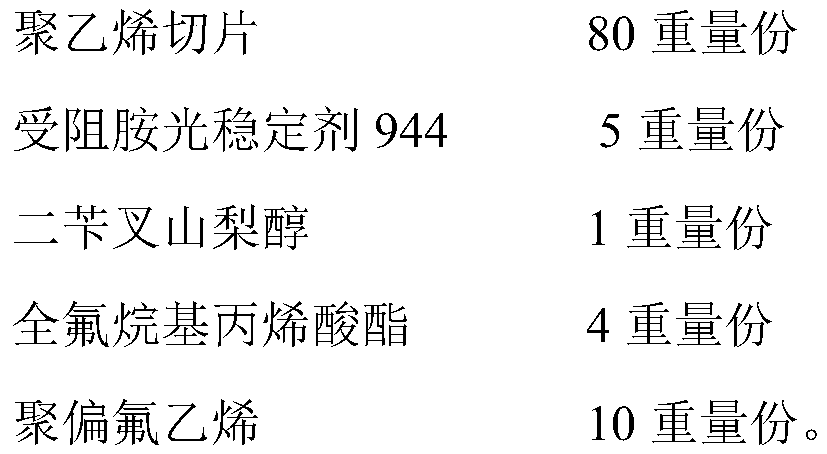

Warm-keeping and heat-preservation textile fabric and preparation method thereof

ActiveCN113978051AExtended service lifeIncrease elasticitySynthetic resin layered productsMonocomponent polyesters artificial filamentFiberPolymer science

The invention belongs to the technical field of textiles, and particularly relates to a warm-keeping and heat-preservation textile fabric and a preparation method thereof. The warm-keeping and heat-preservation textile fabric comprises a surface layer, a filling layer and a contact layer, the surface layer, the filling layer and the contact layer are sequentially arranged from outside to inside, the surface layer is made of a chemical fiber material with hydrophobic property, the contact layer is a fiber layer with soft and smooth characteristics, the filling layer is a fiber layer with warm-keeping and heat-preservation characteristics, and the warm-keeping and heat-preservation characteristics refer to that the filling layer isolates heat emitted by a human body from external air by increasing the content of internal static air, so that heat emission is reduced. According to the invention, the filling layer is divided into the filling cotton and the filling balls, the filling balls are evenly distributed on the two sides of the filling cotton, a large amount of standing air is stored in cavity type structural bodies in the filling balls, and the double-layer structure can effectively cooperate with the filling cotton to prevent heat from diffusing to the outside, so that the effects of keeping warm, preserving heat, supporting and preventing collapse are effectively achieved.

Owner:深圳市珂莱蒂尔服饰有限公司

Clothes percussion fluffing device for laundry

ActiveCN108252071BGuaranteed to be verticalFluffy guaranteedTextiles and paperConditioning apparatusLaundryPower apparatus

Disclosed is a laundry clothes beating device for fluffing. The device belongs to the field of living equipment. A transmission device is fixed on the top of a first supporting frame, a power device is fixed on a sliding rod and located in the center of a working platform, four supporting legs are fixed on four corners below the working platform respectively, the first supporting frame is vertically fixed on the edge of the left side of the working platform, the second supporting frame is fixed on the upper left corner of the working platform, a photoelectric sensor is installed on the top ofthe second supporting frame, a third supporting frame is fixed in the center of the front side of the working platform, a first motor is fixed below the base of a first motor, an eccentric wheel is installed on the main shaft of the first motor, the sliding rod is installed on the eccentric wheel, and a controller is fixed on the working platform. According to the device, clothes are beaten through the back-and-forth movement of the moving supporting frames to make the clothes fluffy, the process of manual beating is replaced, the working efficiency is improved, and the damage on the clothes is avoided.

Owner:平邑经发科技服务有限公司

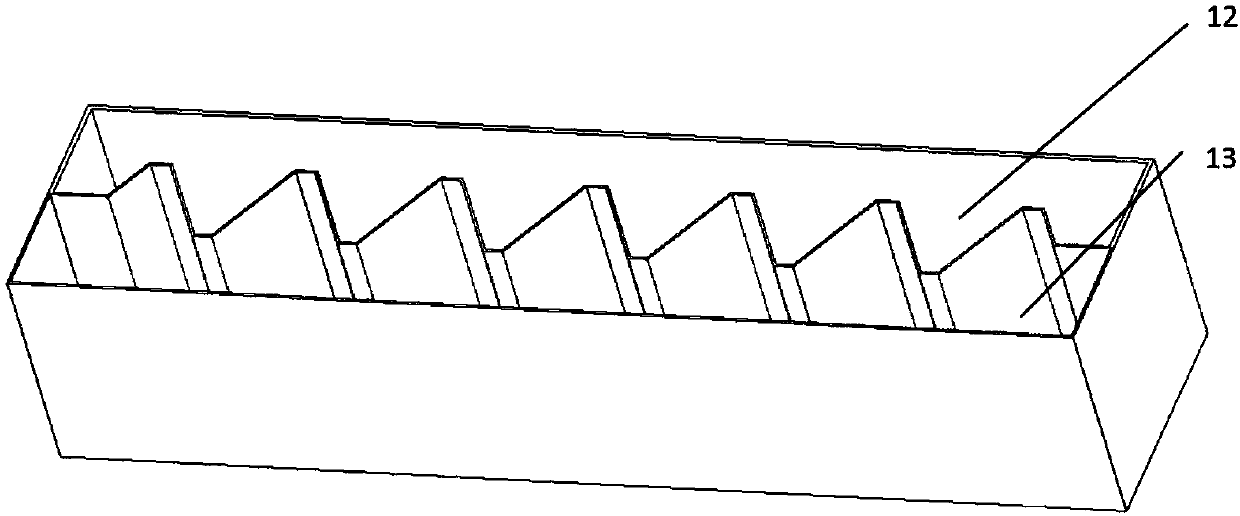

Pleated two-component filter material, and preparation method and use thereof

InactiveCN111206293ASimple manufacturing processEasy to operateSpinning solution de-aeratingUltrasonic/sonic fibre treatmentPower efficientEngineering

The invention provides a pleated two-component filter material, and a preparation method and use thereof. The preparation method thereof comprises the steps of: (1), performing melt spinning: performing melt spinning by adopting an A component polymer and a B component polymer, and then, forming skin-core structure continuous type two-component composite filaments, wherein a skin layer or / and a core layer contains a functional medium having the electricity storage function; (2), forming a net: forming a net after dividing the skin-core structure continuous type two-component composite filaments; (3), reinforcing and forming: performing melt gluing and solidification by adopting hot air; and (4), performing high-voltage electrostatic treatment: charging the material. According to the pleated two-component filter material in the invention, a single-layer medium-efficiency filter material can have the filtration efficiency, which is the same as the filtration efficiency of a composite filter material; simultaneously, the single-layer medium-efficiency filter material has dual filtering functions of physical blocking and electrostatic adsorption; furthermore, relatively are mechanicalstrength and stiffness are also achieved; furthermore, the filter material has very low filtration resistance and relatively high air permeability; and thus, the filter material in the invention can completely replace corresponding medium and high-efficiency filtering composite material products in the present market.

Owner:上海精发实业有限公司

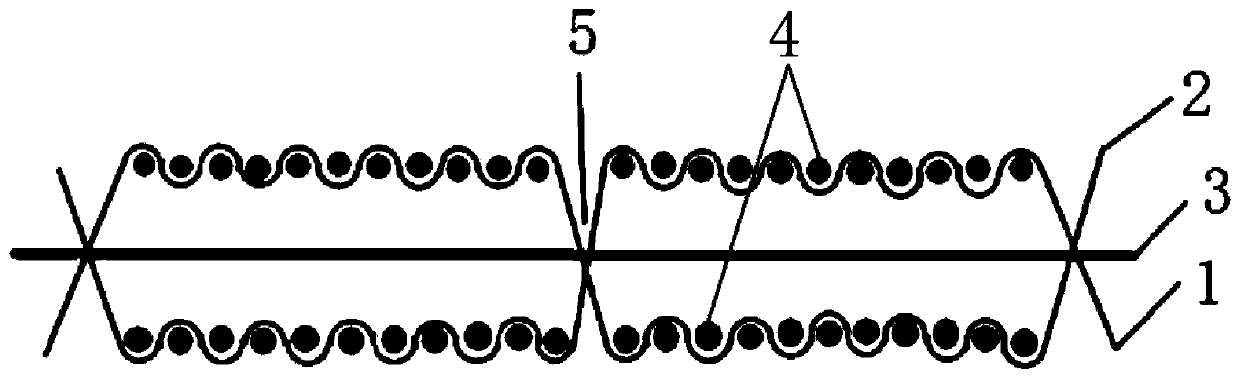

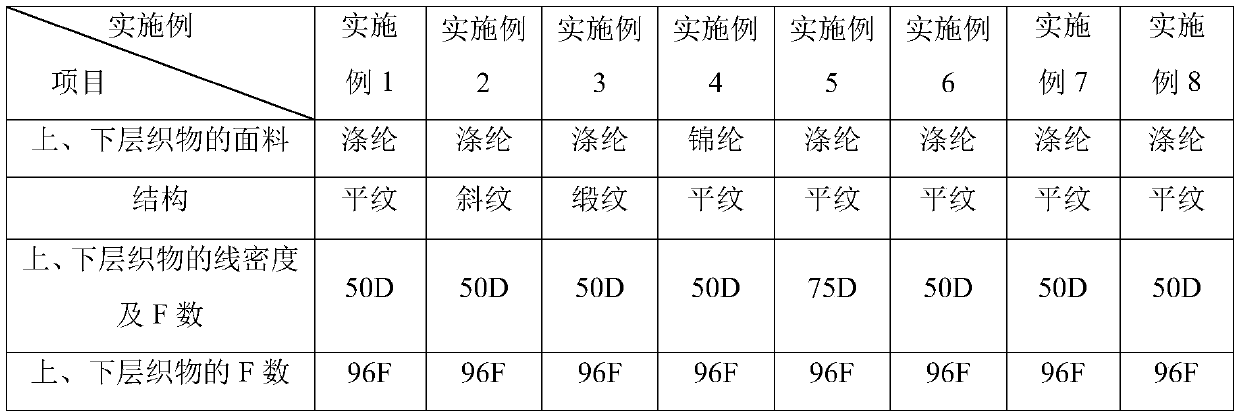

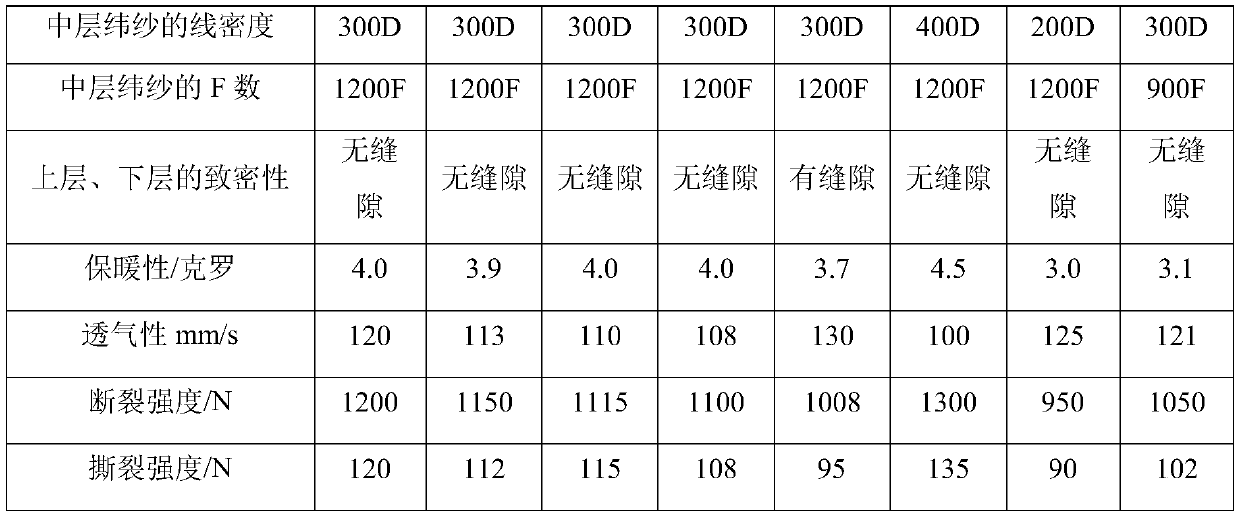

Weaving and post-processing method of three-layer non-filling cotton clothing fabric

ActiveCN108239812BFluffy guaranteedGood warmth retentionTextile storage in superimposed formFibre typesFiberPolymer science

The invention relates to the technical field of clothing fabrics, in particular to a method for weaving and post-processing a three-layer integrated non-filling cotton clothing fabric. Wherein said weaving method comprises (1) raw material preparation; (2) warping; (3) sizing; (4) drafting, denting; (5) uniaxial weaving; ) cold pile; (2) desizing; (3) dyeing and finishing; (4) setting; (5) alkali reduction fiber opening treatment. The synergy of the upper, middle and lower layers of the fabric prepared by this process can not only make the bulkiness of the fabric easy to maintain, but also make the weft yarn in the middle layer fixed firmly, without fleece, and it is not easy to flow and shrink under the action of external force. Even, the fabric has good warmth retention and air permeability, and has strong resistance to breaking and tearing. Moreover, the preparation process is simple, mass production can be realized, dyeing and finishing is worry-free, the product is elegant in appearance, novel and unique, and has great market potential.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

Manufacturing method of twistless fabric and product thereof

InactiveCN101929021BSimple finishing processGuaranteed moisture absorptionWoven fabricsYarnEngineeringUltimate tensile strength

Owner:马玉成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com