Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Good sheeting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing sheet silver powder with high dispersibility

ActiveCN101279369AGood dispersionMeet different performance requirementsShaking/oscillating/vibrating mixersApparent densityMetallurgy

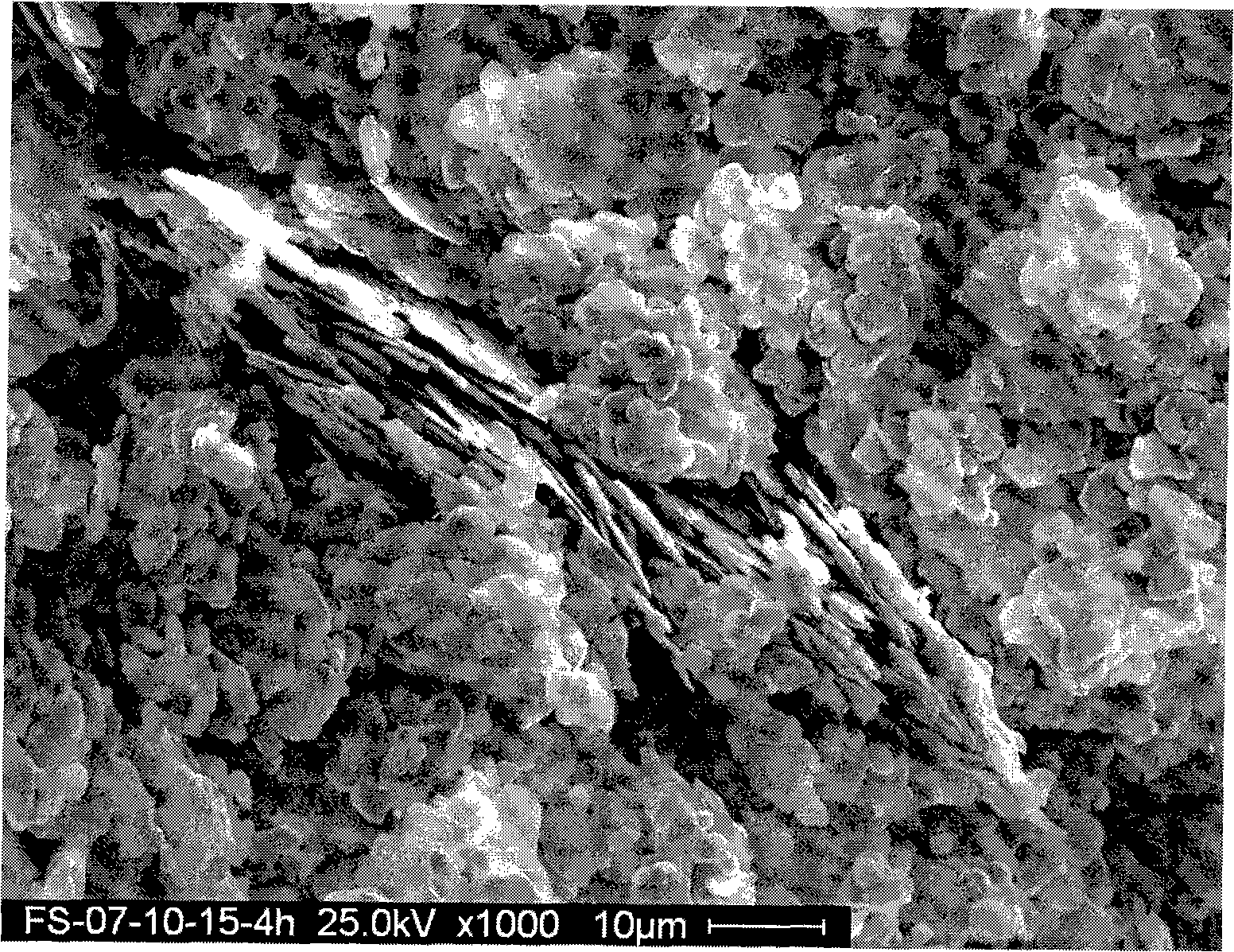

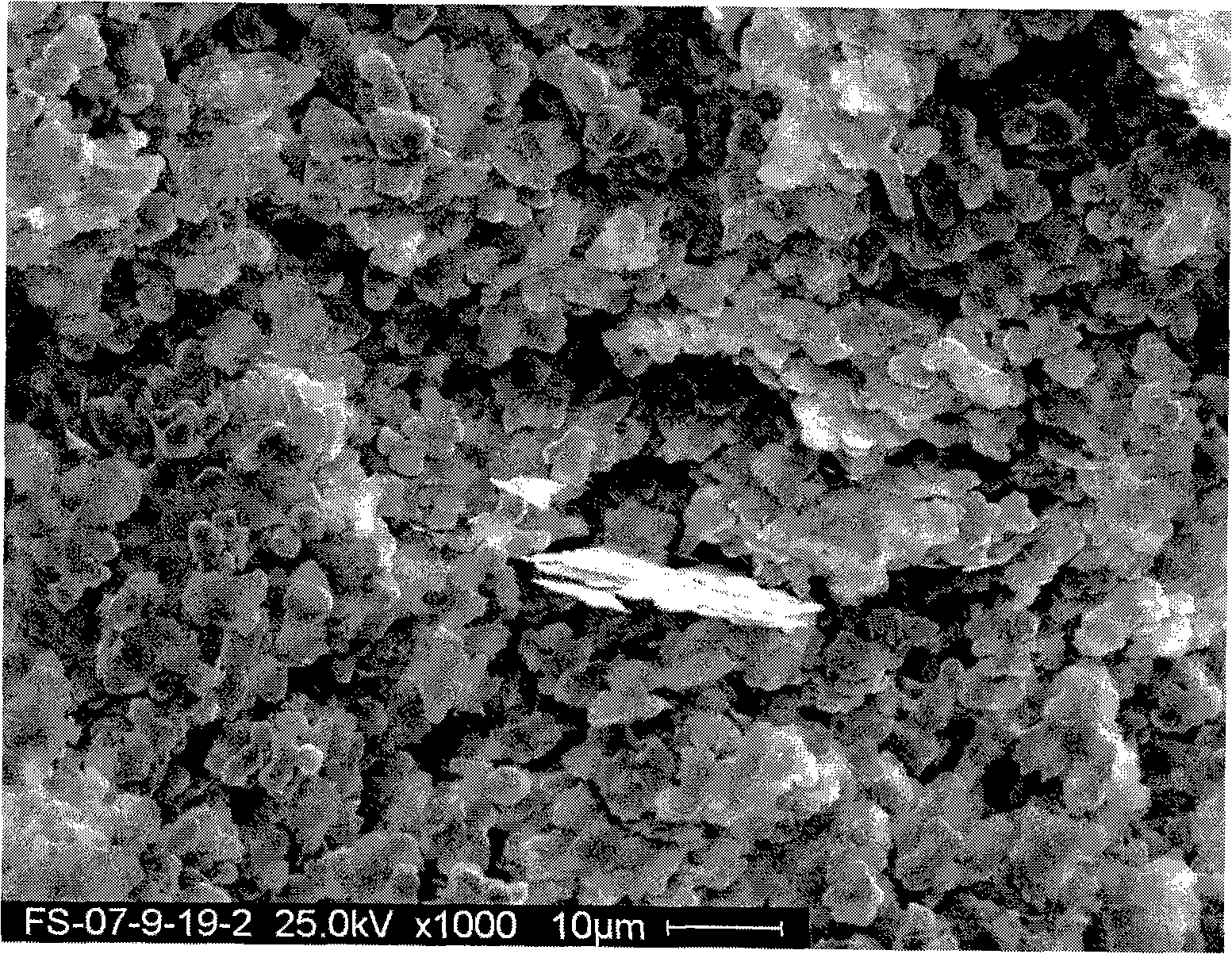

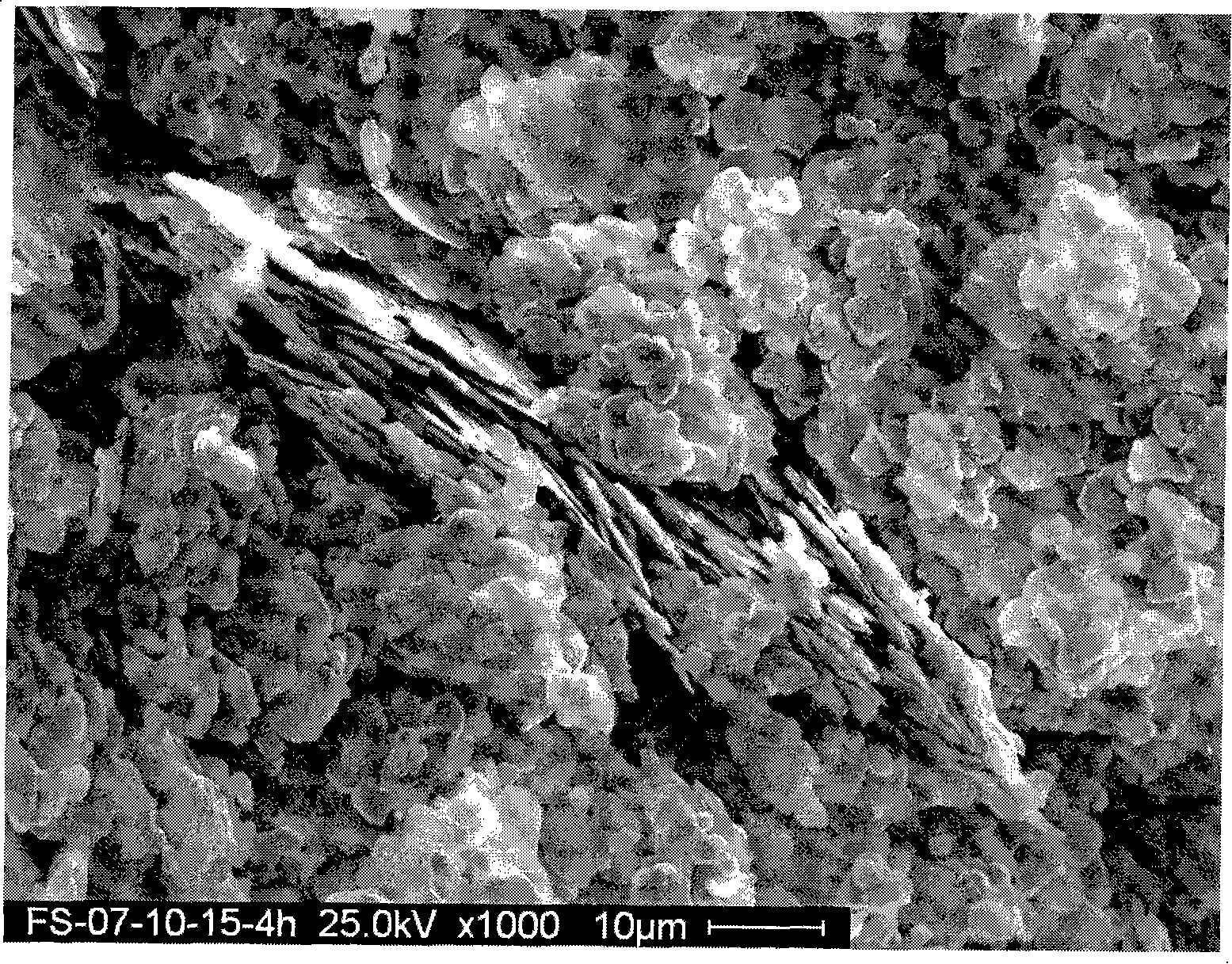

The invention discloses a preparation method of high-dispersion flake silver powder, which is characterized in that spherical raw material silver powder with the1 to 3Mum of particle size D50 and the more than 99.95 percent of silver content is ground into the flake silver powder by adopting a grinding machine, the dispersion is then improved by ultrasonic dispersion and airflow dispersion, and the high-dispersion flake silver powder with the 3 to 25Mum of flake diameter D50 and the apparent density of 0.5 to 1.8g / cm<3> is obtained. The preparation process has simple process flow, which is applicable to the industrial mass production of flake silver powder.

Owner:JINCHUAN GROUP LIMITED

Nutrition-enriched recombinant translucent meat slices and preparation method thereof

The invention discloses nutrition-enriched recombinant translucent meat slices and a preparation method thereof. The translucent meat slices comprise the raw materials of meat stuffing, cane sugar, mixed powder of puffed peanut powder, puffed sesame powder and puffed tartary buckwheat flour or a pulp-powder mixture of mashed fruit and melon earthnut pulp and puffed tartary buckwheat flour, edible salt and food additives. The preparation method comprises the steps of mincing of meant, puffing, pulping, chopping, emulsifying, slicing of the quick-frozen meat and then curing, thus obtaining the recombinant translucent meat slices. The method is capable of preparing the translucent meat slices from the minced meat fully; tartary buckwheat, peanuts and semen sesami nigrum, or fruit and melon earthnut can be added into the meat slices as binding agent or seasoning materials, and the tartary buckwheat also covers meat taint, so that the prepared recombinant nutrition-enriched translucent meat slices are thicker in taste, and balanced and rich in nutrition; the preparation process is exquisite; and the types of products are varied to meet the requirements of different people. Besides, after being baked, the translucent meat slices are crisper, are more balanced in nutritional ingredient and do not generate harmful substances.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES +1

Method for preparing noodles dough with oxidase

InactiveUS20110091599A1Increase the amount of waterImproves elasticity and smoothnessDough treatmentWort preparationFood science

Owner:DSM IP ASSETS BV

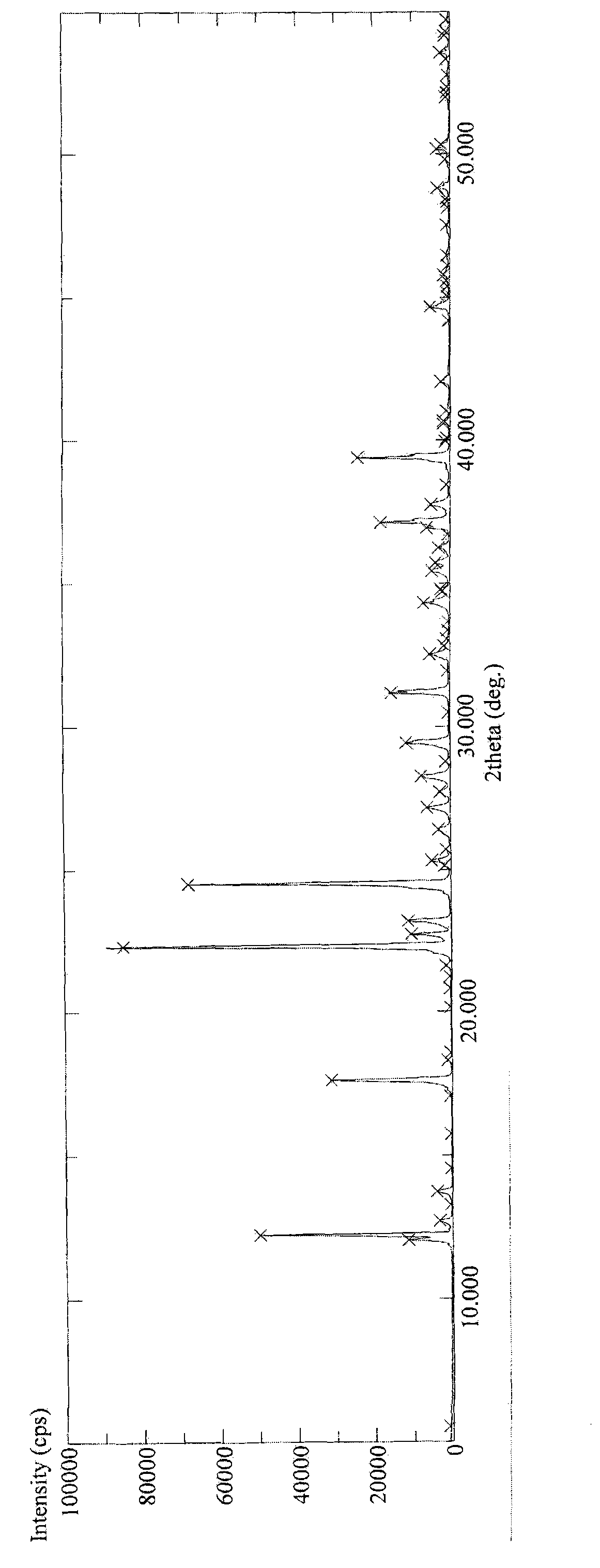

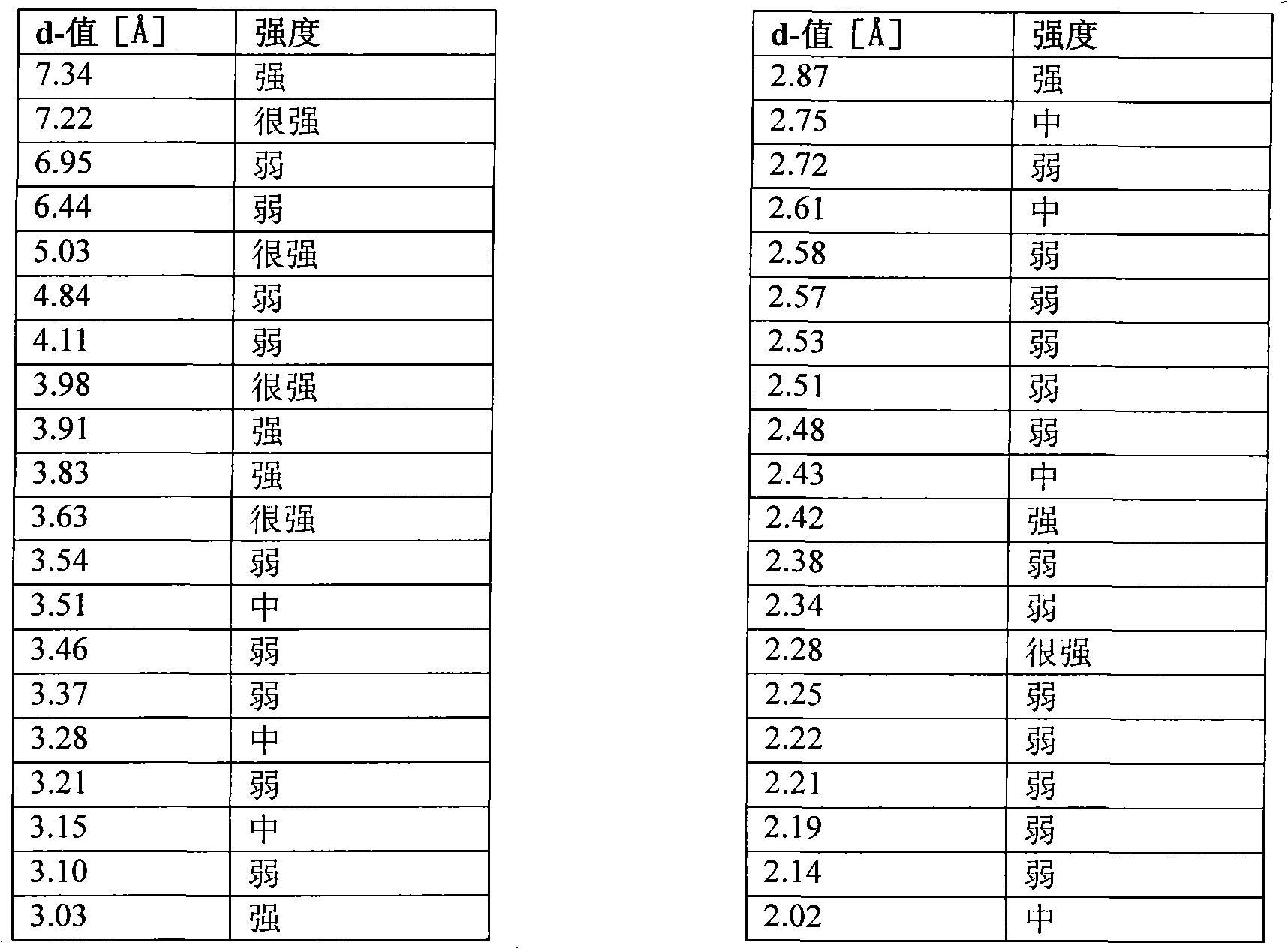

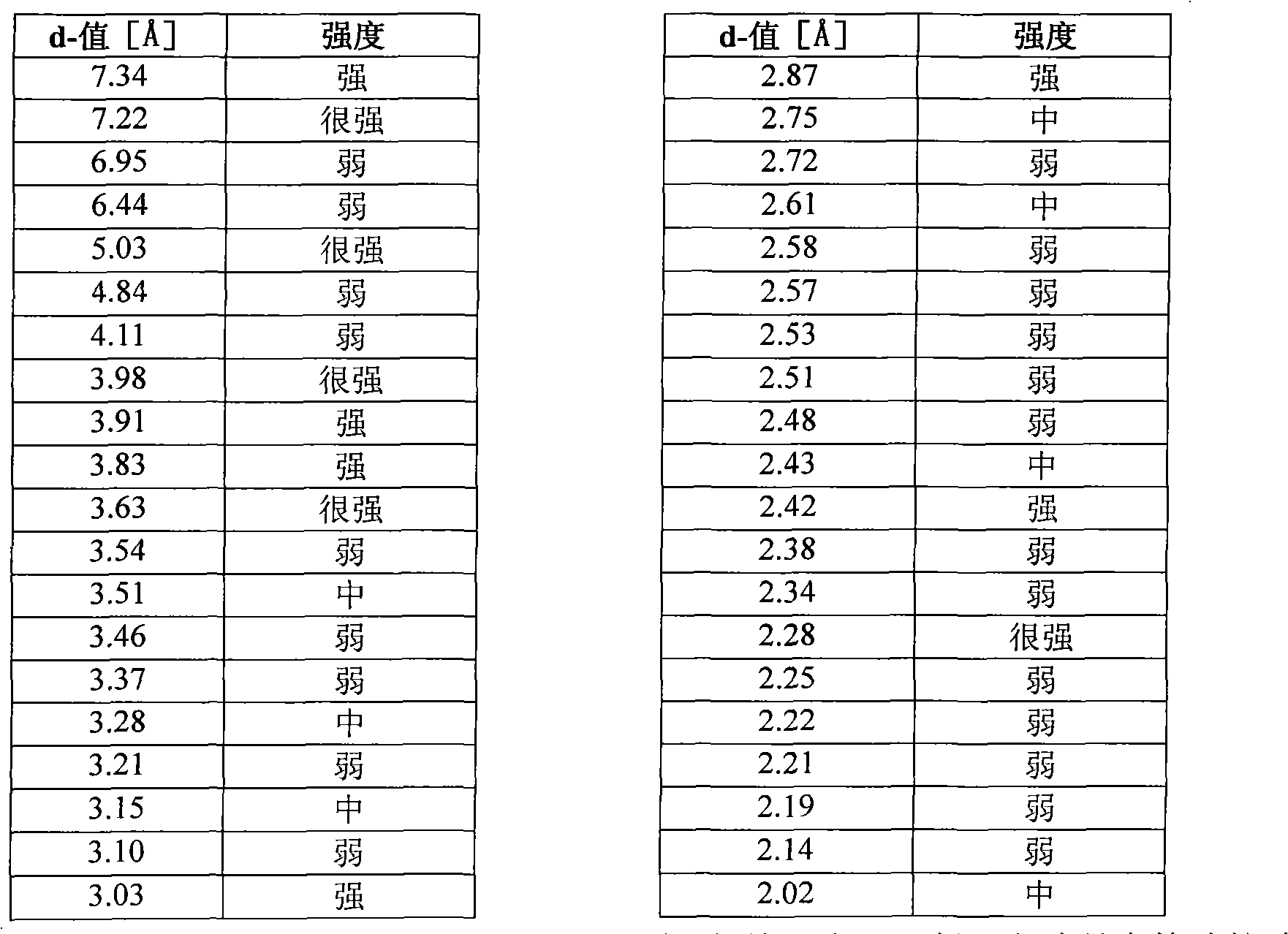

Novel crystal form of metformin hydrochloride and preparation method thereof

InactiveCN102153489AReduce contentGood sheetingOrganic chemistryOrganic compound preparationMetformin HydrochlorideCrystallization

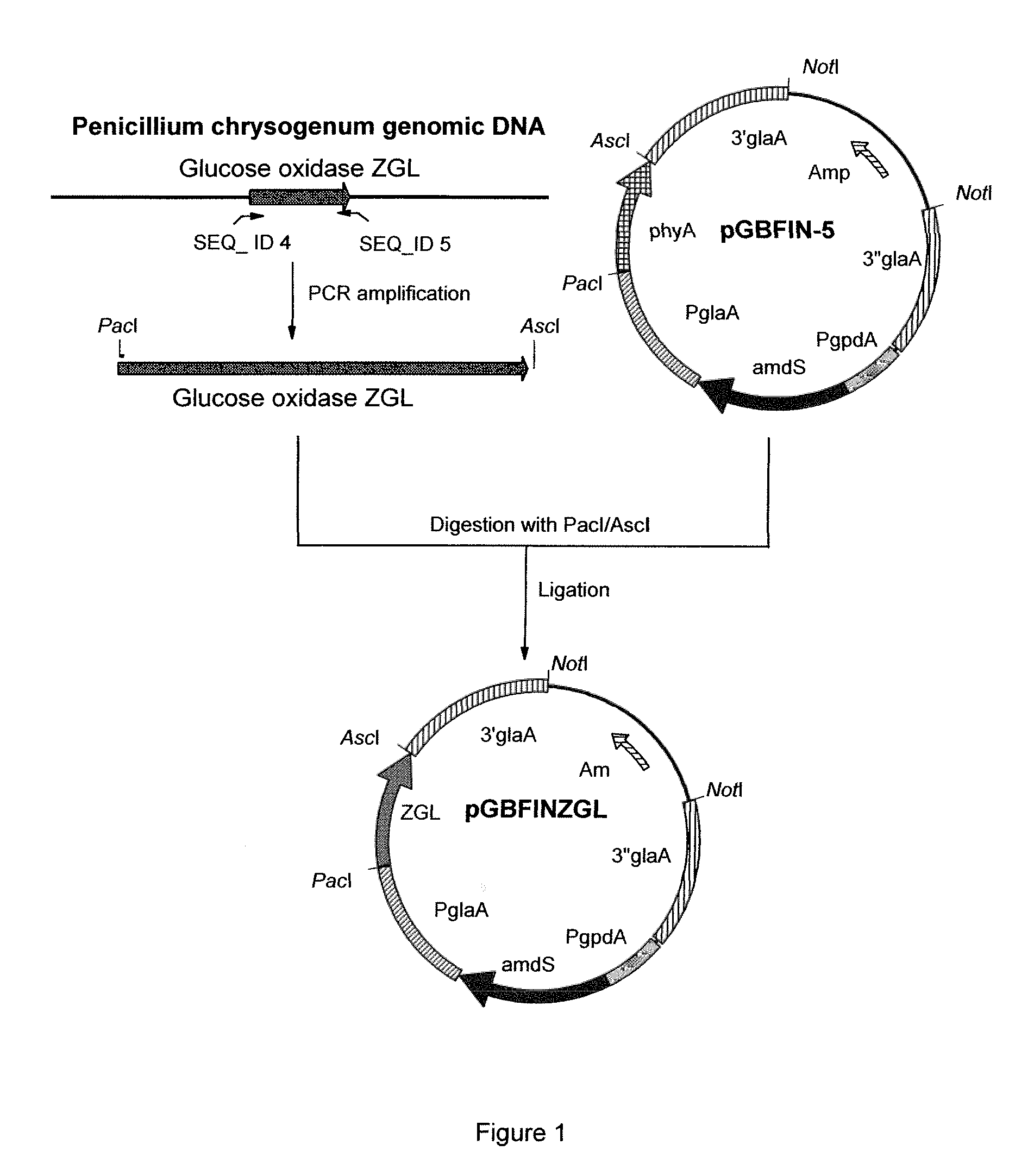

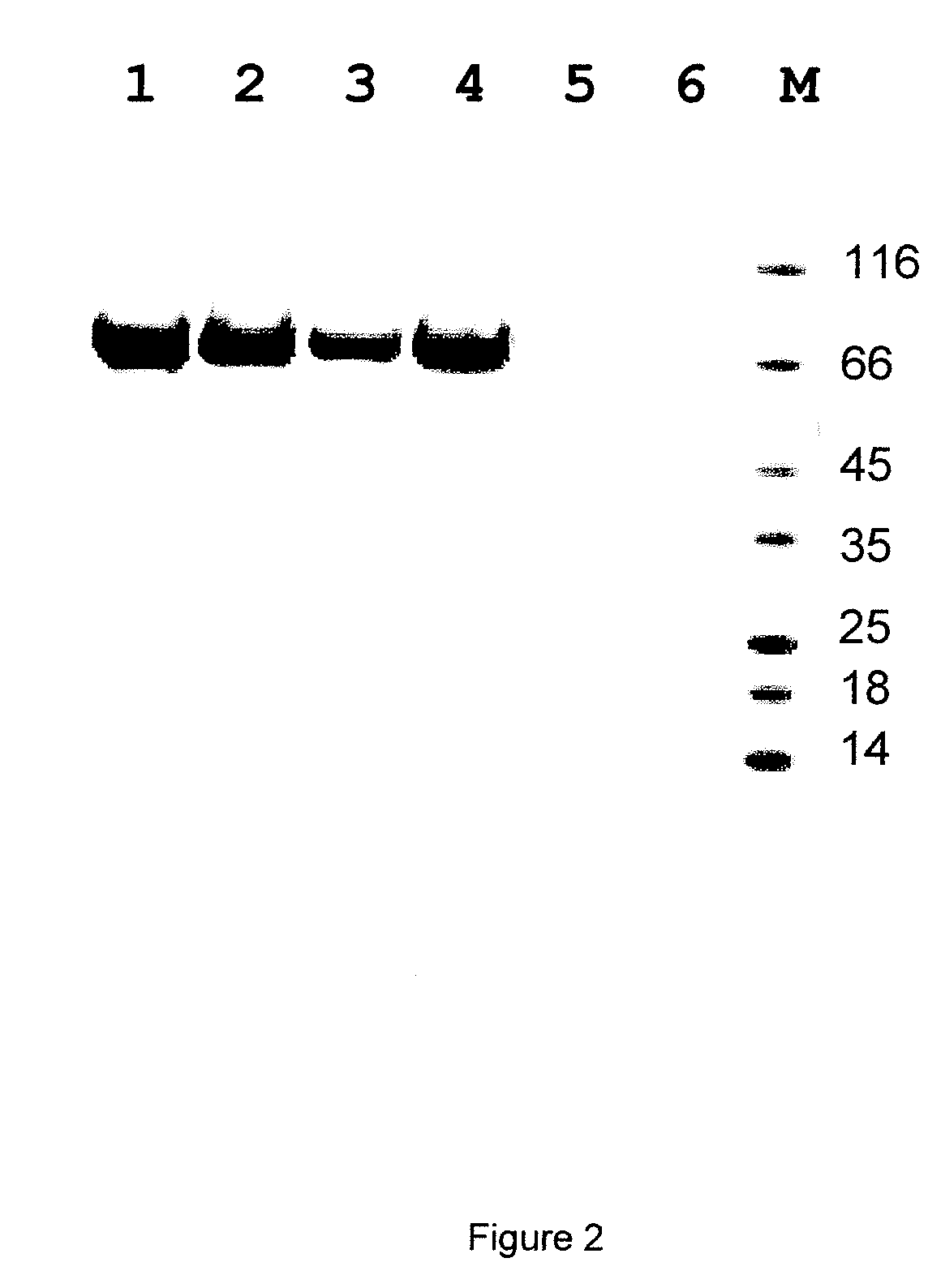

The invention relates to a novel crystal form of metformin hydrochloride and a preparation method thereof. The preparation method comprises the following steps of: in a cylindrical flow barrel crystallization tank body serving as special crystallization equipment, dissolving crude metformin hydrochloride in an ethanol solution with the concentration of 70-80 percent; and cooling in the control process to obtain the novel crystal form of the metformin hydrochloride.

Owner:SHOUGUANG FUKANG PHARMA

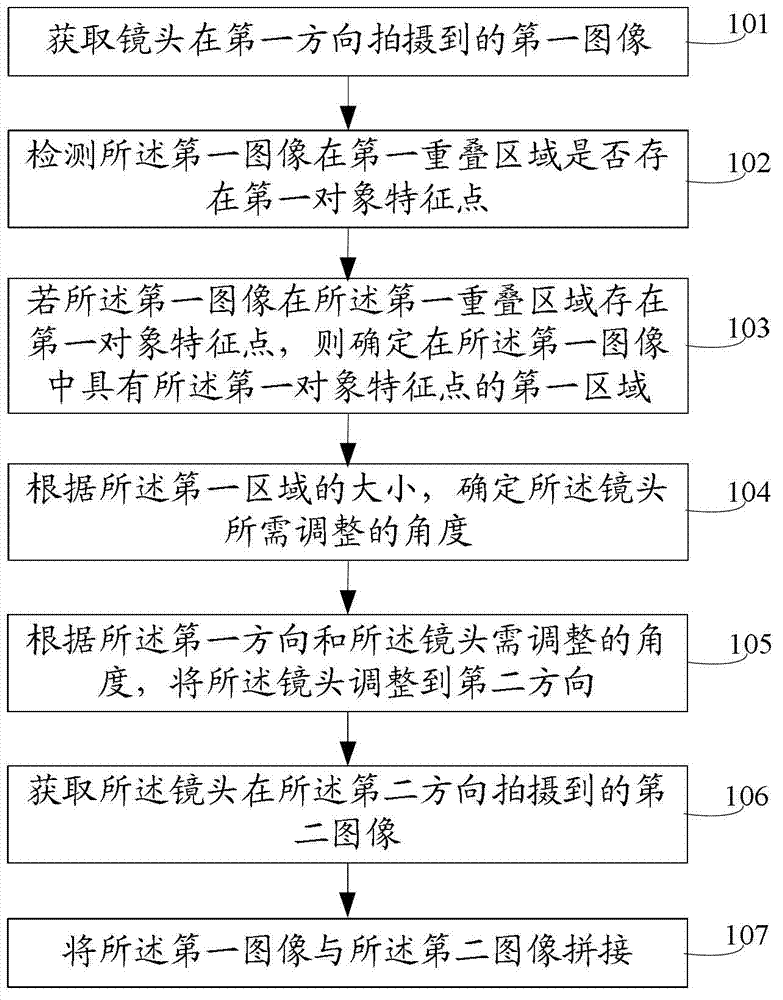

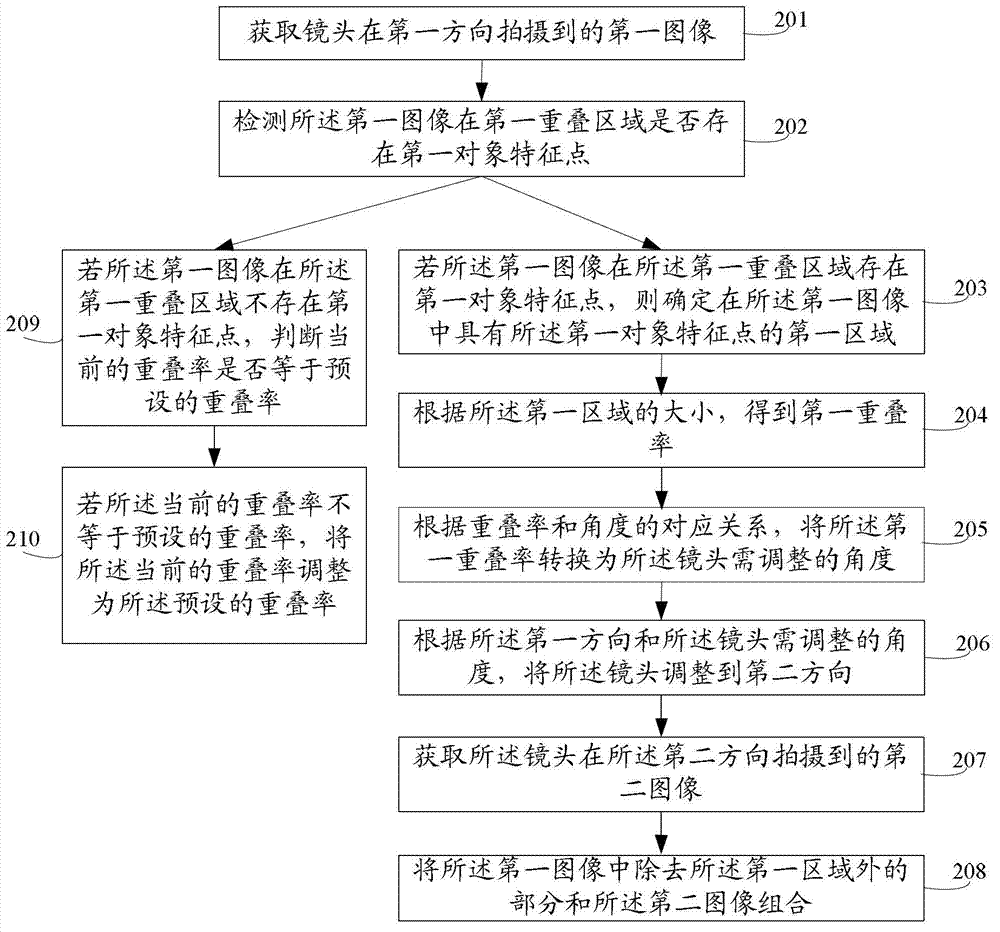

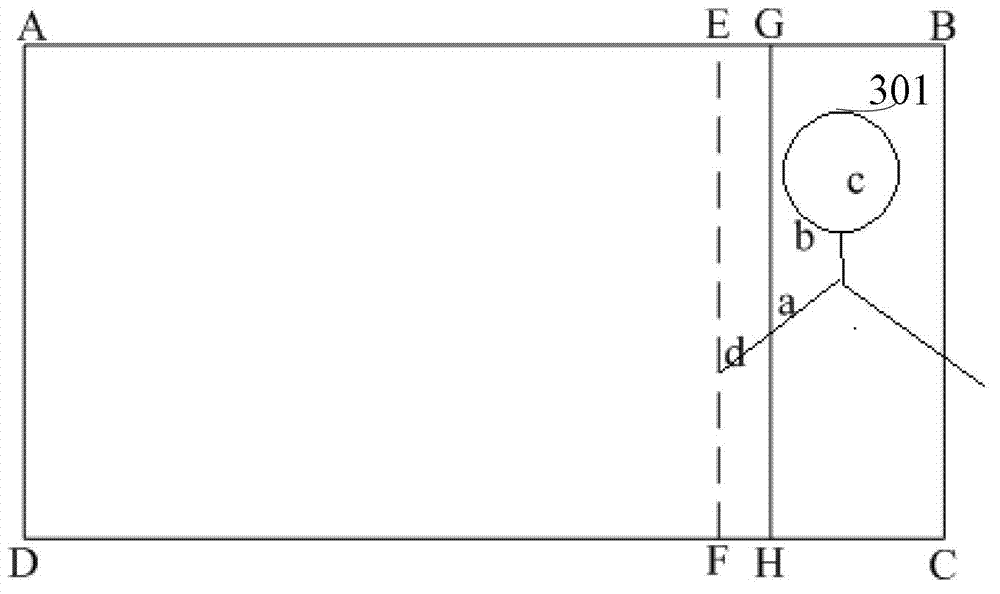

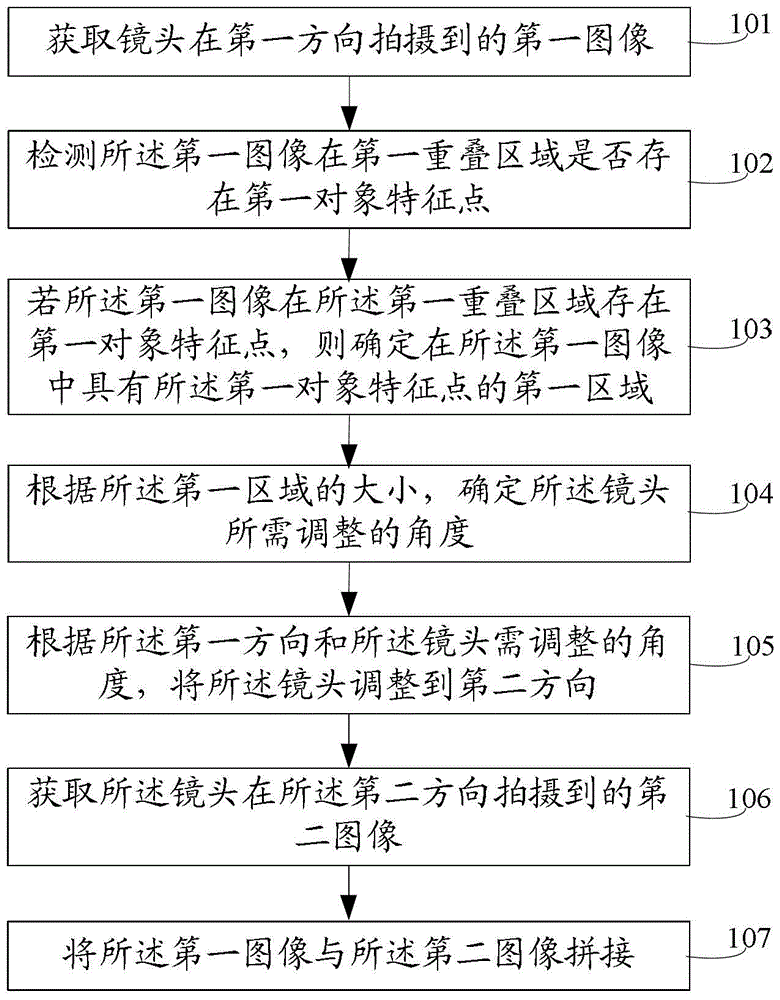

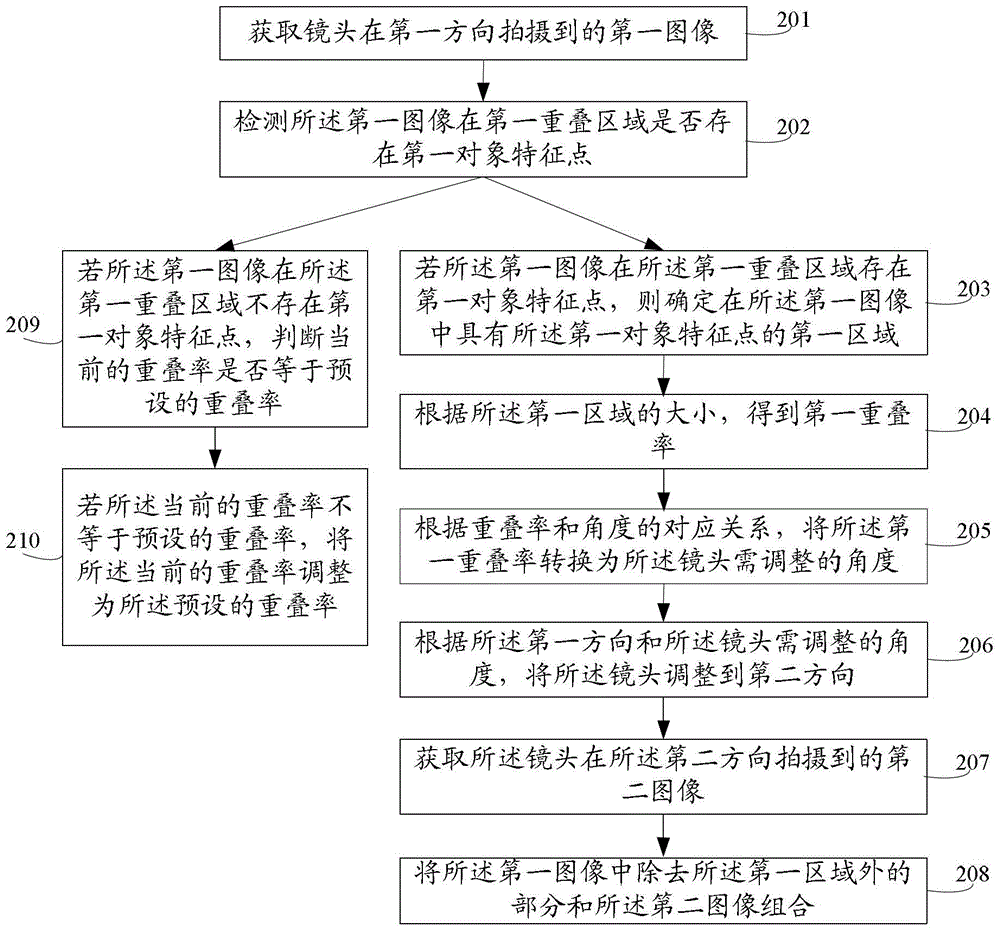

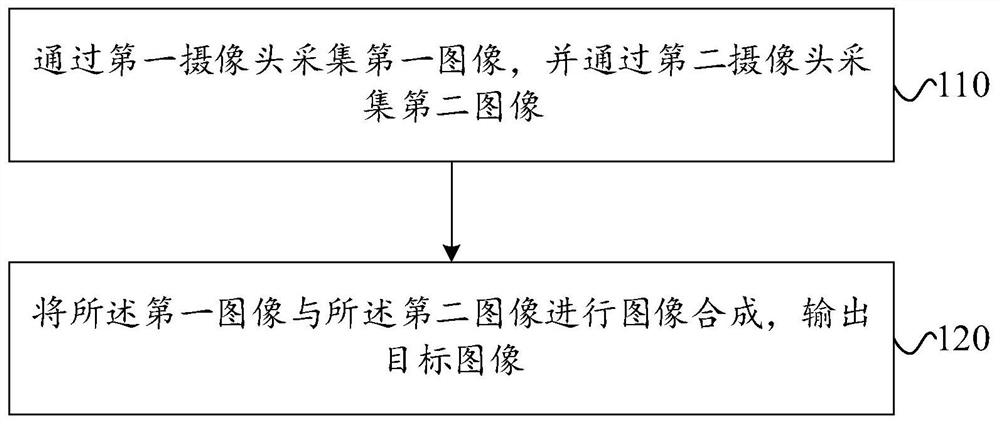

Image processing method and apparatus

ActiveCN103927728AImprove experienceGood sheetingImage enhancementGeometric image transformationCamera lensElectronic information

The embodiments of the invention provide an image processing method and apparatus. The method is applied to imaging equipment for optimizing imaging effect and improving user experience. The method comprises: first of all, after a first image shot by a lens in a first direction is obtained, detecting whether a first object characteristic point exists for the first image in a first overlapping area, if the first object characteristic point exists for the first image in the first overlapping area, determining a first area provided with the first object characteristic point in the first image, then according to the size of the first area, determining an adjustment angle needed by the lens so as to enable the lens to be adjusted to a second direction according to the first direction and the adjustment angle needed by the lens, and finally, obtaining a second image shot in the second direction by the lens, and splicing the first image with the second image. The image processing method and apparatus are applied to the field of electronic information.

Owner:LENOVO (BEIJING) CO LTD

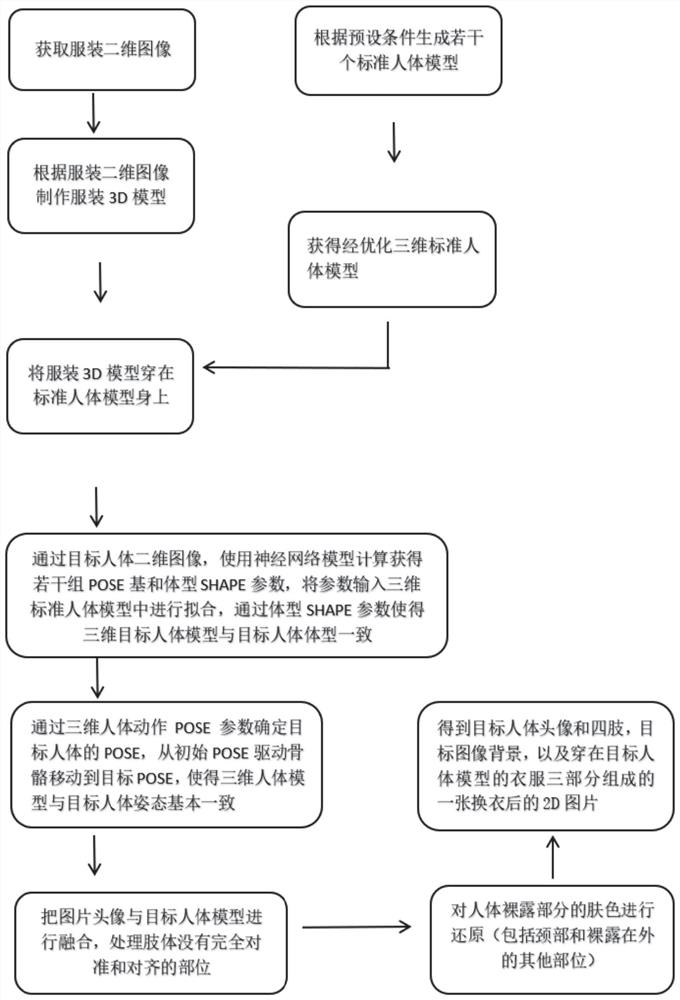

Human body model image fusion processing method and device, and storage medium

The invention discloses a human body model image fusion processing method. The method comprises the following steps: making a basic mannequin; obtaining a three-dimensional clothing model; fitting the three-dimensional clothing model to the basic mannequin; acquiring secondary information of the human body model according to the target human body two-dimensional image; performing regression prediction to obtain posture and body shape parameters of the target human body model; obtaining a target attitude and a target body type; driving the human body model to move from the initial posture to the target posture; obtaining a target human body model of which clothes replacement is completed; fusing the picture head portrait with the target human body model image; restoring the skin color of the exposed part of the human body; and obtaining a 2D picture after clothes changing. According to the method, the animation sequence is generated through frame insertion, so that the effect of the whole fitting and driving process is better, the image effect after model generation is optimized, and the film forming effect is improved.

Owner:北京陌陌信息技术有限公司

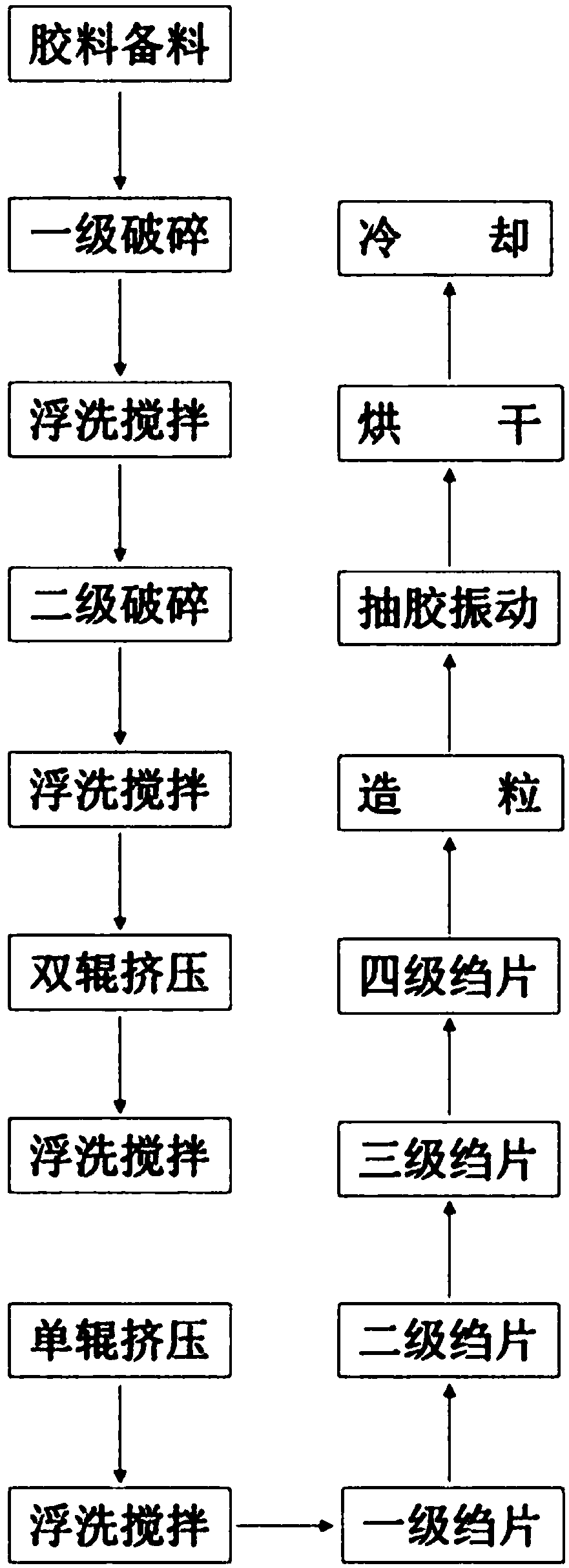

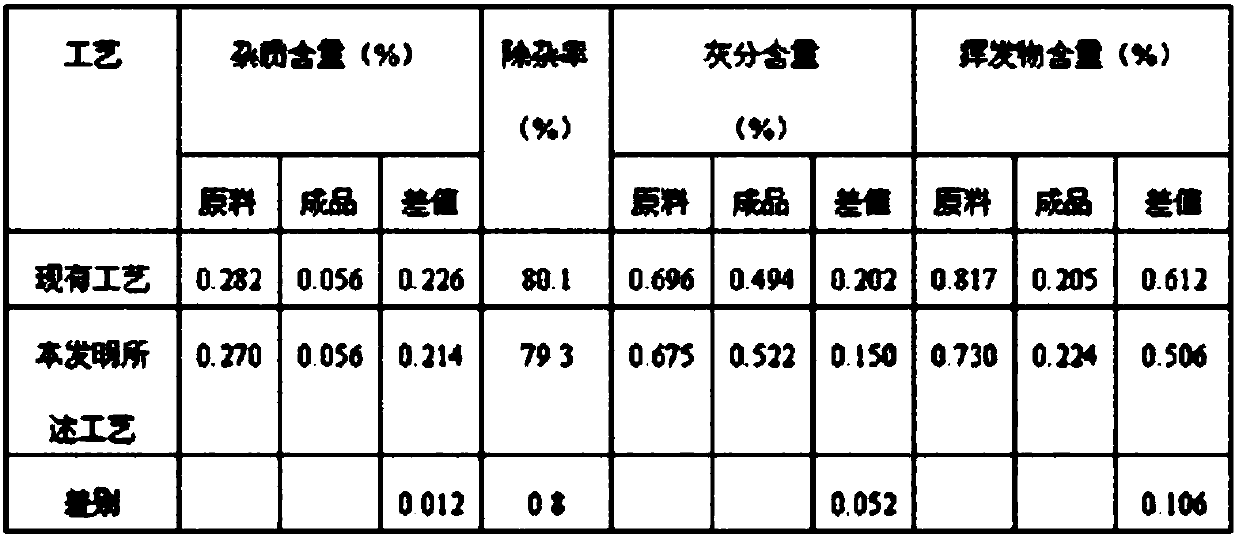

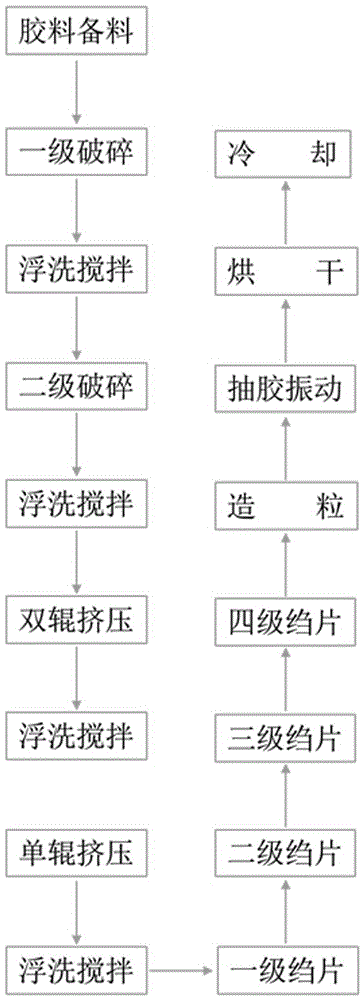

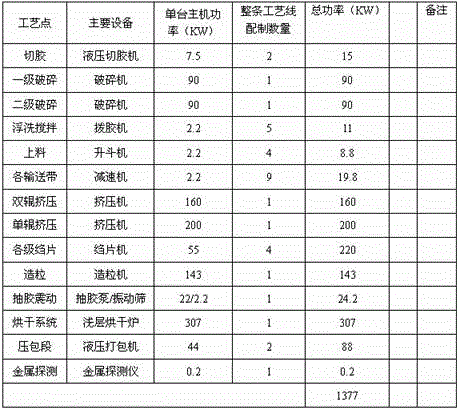

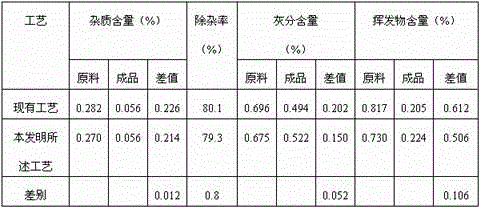

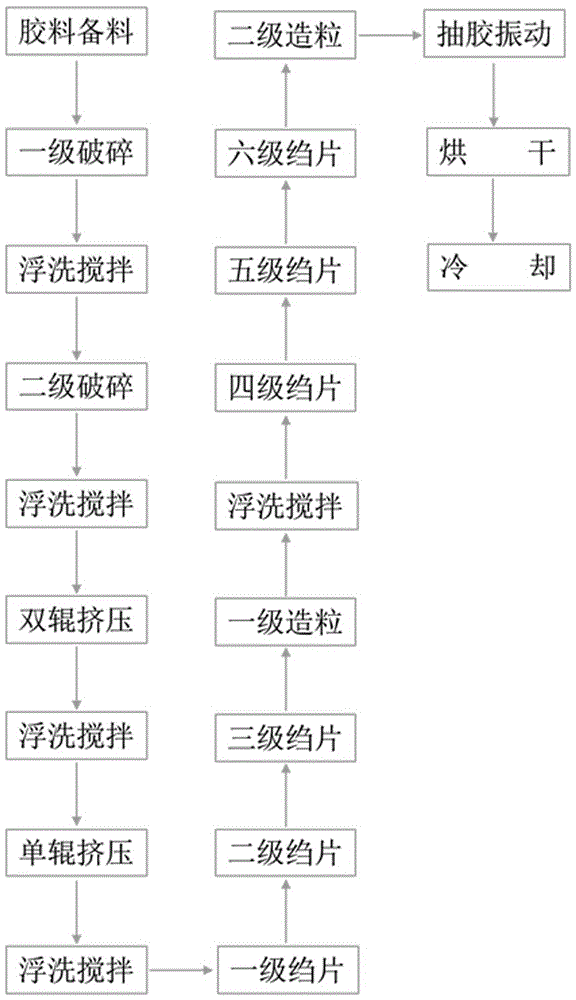

Processing technology for special rubber for radial tire

The invention discloses a processing technology of special rubber for radial tires. The process first divides the recovered rubber raw materials into two grades according to the evaluation results of the enterprise quality inspection standards, and breaks them into rubber blocks of 40cm×10cm×8cm~50cm×15cm×20cm respectively, and divides the graded rubber raw materials after removal of impurities by 1 ~3:1~3 weight ratio mixing. The mixed rubber material is crushed in the first stage, floated and stirred, and the secondary crushed, floated and stirred, the floating washing time must be ≥ 20min, and then the mixed rubber material is subjected to two-stage extrusion floating washing, and the floating washing time must be ≥ 12min, Make the rubber into a gelatinous mass. The rubber material is treated with one to four stages of creping to make the rubber material into a continuous sheet with a thickness of 6-12mm, and the creped rubber material is granulated to make rubber particles with a diameter of 6-12mm. The colloidal particles are pumped and vibrated, dried at 82-108°C according to the standard of 4-6t / h rubber material, and then cooled to room temperature. The process improves the impurity removal rate of the equipment, avoids damage to the rubber structure due to excessive processing, simplifies the equipment configuration of the production line, reduces the overall failure rate, reduces the amount of crushed rubber, and improves production efficiency.

Owner:南通通江橡胶制品有限公司

Preparation method of antibacterial silk painting canvas

The invention discloses a preparation method of an antibacterial silk painting canvas. The preparation method comprises the following steps of S01, immersing silk in an antibacterial solution, then taking out the silk, and carrying out airing, wherein the antibacterial solution is a solution of a broad-spectrum antibiotic, S02, coating the lower surface of the dried silk obtained by the step S01 with a dry layer, wherein the dry layer comprises a main material and accessory materials, the main material comprises 80-130 parts by weight of microcrystalline cellulose, the accessory materials comprise a binder, a wetting agent, a surfactant, an anti-oxidant, a lubricant and an antiseptic, and the main material and the accessory materials are uniformly mixed and coat the lower surface of the silk, and S03, after the dry layer is dried, adhering a chemical dye adsorption layer to the lower surface of the dry layer. The silk painting canvas obtained by the preparation method has high quality and good glossiness, can be preserved easily and does not mildew even if hands touches the surface of the silk.

Owner:SUZHOU WEIDU SILK

Nutritional food with nutrition characteristics of germinated brown rice developed by applying biotechnology and preparation method of nutritional food

InactiveCN106036485AIncrease profitImprove gelatinizationVitamin food ingredientsFood hydrolysisGerminationSalt water

The invention relates to a nutritional food with nutrition characteristics of germinated brown rice developed by applying a biotechnology and a preparation method of the nutritional food. The preparation method mainly comprises the following steps of selecting fresh organic rice produced in present year, and performing husking and impurity removal to obtain brown rice; performing ozone sterilizing, saline soaking, brown rice germination accelerating, aeration-drying and secondary crushing on the brown rice to obtain superfine germinated brown rice powder; then adding milk powder, white granulated sugar, fructo-oligosaccharide and trace elements; performing gelatinizing, enzymolysis, roller drying, crushing, filling and the like to obtain the nutritional food. According to the nutritional food and the preparation method disclosed by the invention, the content of GABA (Gamma Amino Acid Butyric Acid) is improved by using a biotechnology method, the health-care function of a product is improved, the flavor is improved, added value of brown rice germs can be greatly improved, and economic benefits are increased.

Owner:广东东泰乳业有限公司

Machining process for rubber special for radial tire

ActiveCN106217679ARaise the compound temperatureReduce loadPlastic recyclingMechanical material recoveryPelletizingRadial tire

The invention discloses a machining process for rubber special for a radial tire. According to the machining process, firstly, recycled rubber raw materials are divided into two grades according to evaluation results of enterprise quality detection standards and smashed into 40 cm x 10 cm x 8 cm-50 cm x 15 cm x 20 cm rubber blocks correspondingly, and the cleaned graded rubber raw materials are mixed according to the weight ratio being 1-3:1-3. The mixed rubber materials are subjected to primary smashing, flotation and stirring, secondary smashing and flotation and stirring, flotation needs larger than or equal to 20 min of time, then the mixed rubber materials are subjected to two-stage extrusion flotation, flotation needs larger than or equal to 12 min of time, and the rubber materials are made into a rubber ball shape. The rubber materials are subjected to one to four stage crepe treatment to be made into a continuous sheet shape, the thickness is 6-12 mm, and the rubber materials obtained after crepe treatment are subjected to granulation treatment to be made into rubber particles being 6-12 mm in diameter. The rubber particles are subjected to rubber drawing vibration treatment, dried at the temperature being 82-108 DEG C according to the standard being 4-6 t / h of the rubber materials, and then cooled to the room temperature. Through the machining process, the equipment impurity removing ratio is increased, the condition that the rubber structure is damaged due to over-machining is avoided, equipment arrangement of a production line is simplified, the total failure rate is lowered, rubber smashing quantity is reduced, and the production efficiency is improved.

Owner:德宏滇源橡胶有限公司

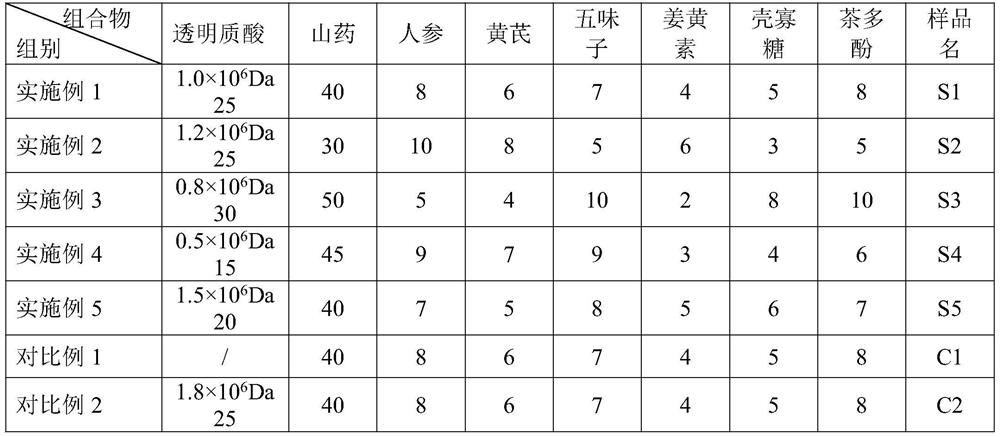

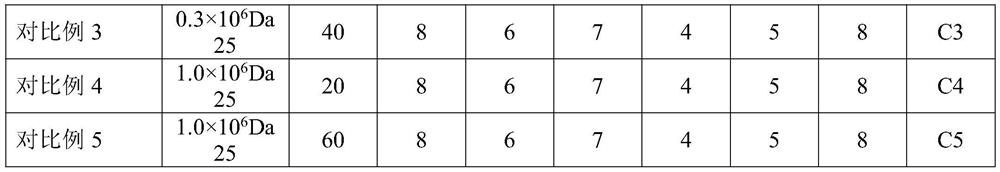

Composition having effects of protecting livers and eyes, and preparation method and applications of composition

ActiveCN111903965ASolve the limited amount of additionSolve more precipitationSenses disorderDigestive systemBiotechnologyForest yam

The invention discloses a composition having effects of protecting livers and eyes. The composition is characterized in that the composition includes, by weight, 10-40 parts of hyaluronic acid, 20-60parts of common yam rhizome, 3-15 parts of radix ginseng, 2-10 parts of radix astragali, 2-10 parts of Chinese magnoliavine fruits, 2-10 parts of curcumin, 3-10 parts of chitosan oligosaccharide and 3-10 parts of tea polyphenol. As the hyaluronic acid with specific molecular weight is compounded with the common yam rhizome in proper proportion, and components that can protect the livers and eyes are added to prepare into rice flour, the problems of restricted addition of the hyaluronic acid,more precipitation, poor taste and easy caking during brewing due to lots of Chinese herbal medicines inthe components capable of protecting the livers and eyes when the composition is prepared into oral solutions, tablets and brewing powder particles can be solved; and the formula is good in flake forming, strong in toughness and easy to scrape during roller drying, and damage to flakes cannot be caused.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

Method for preparing sheet silver powder with high dispersibility

ActiveCN101279369BGood dispersionMeet different performance requirementsShaking/oscillating/vibrating mixersApparent densityMetallurgy

The invention discloses a preparation method of high-dispersion flake silver powder, which is characterized in that spherical raw material silver powder with the1 to 3Mum of particle size D50 and the more than 99.95 percent of silver content is ground into the flake silver powder by adopting a grinding machine, the dispersion is then improved by ultrasonic dispersion and airflow dispersion, and the high-dispersion flake silver powder with the 3 to 25Mum of flake diameter D50 and the apparent density of 0.5 to 1.8g / cm<3> is obtained. The preparation process has simple process flow, which is applicable to the industrial mass production of flake silver powder.

Owner:JINCHUAN GROUP LIMITED

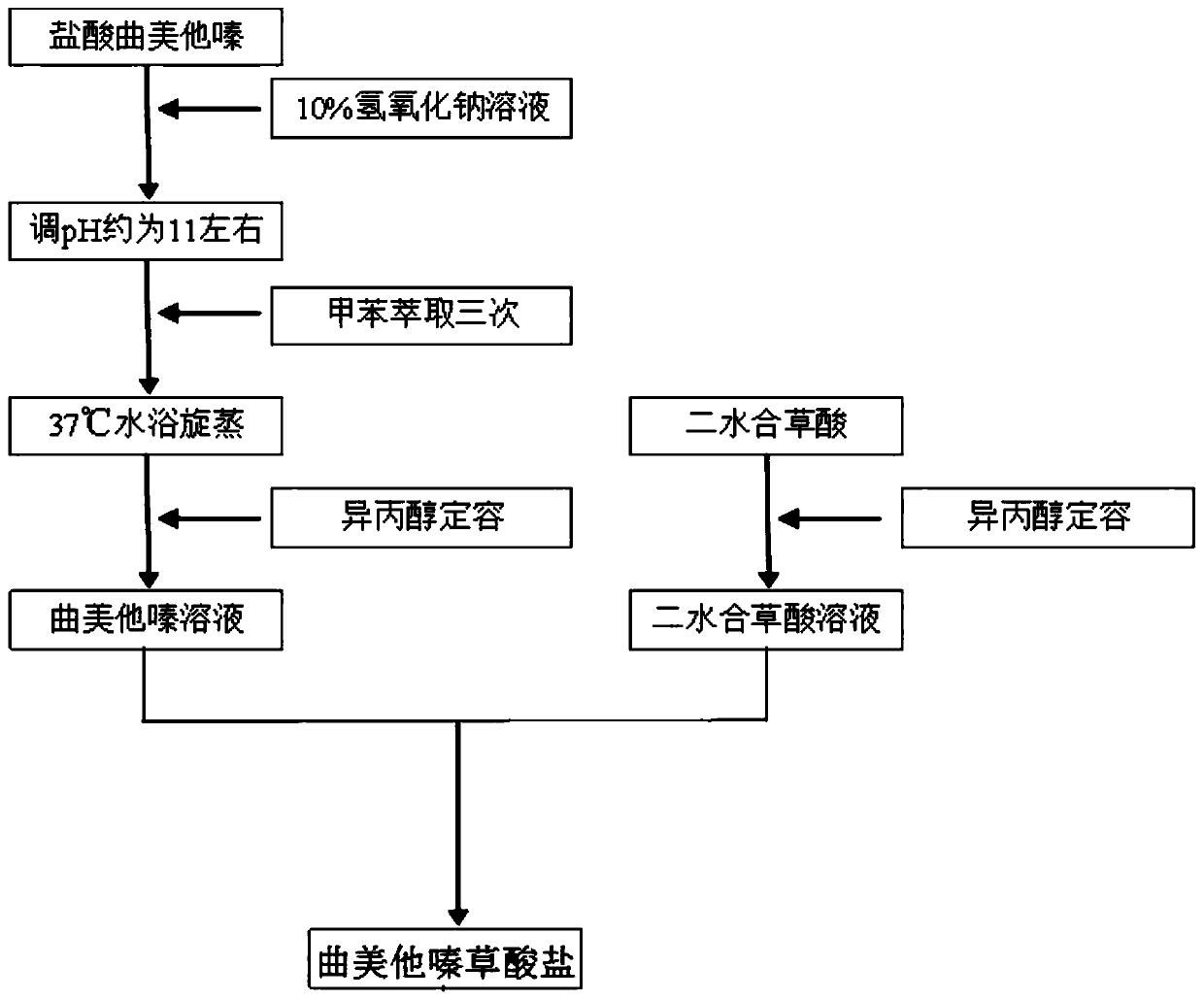

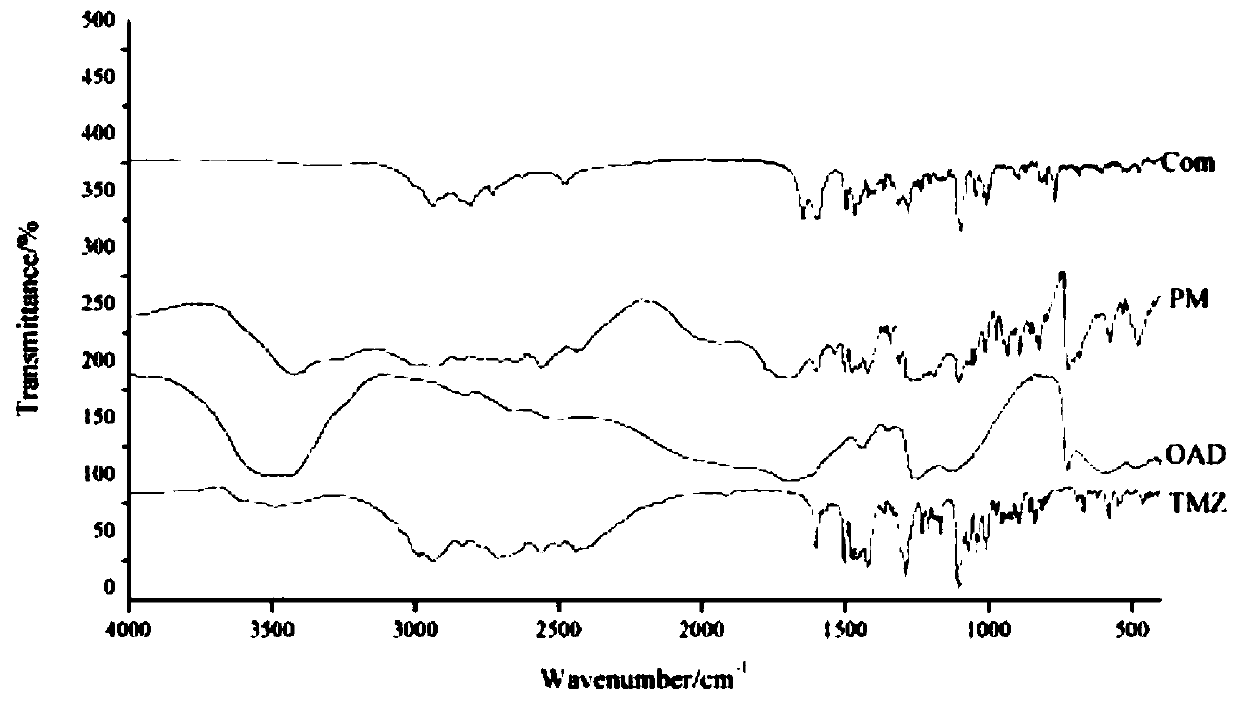

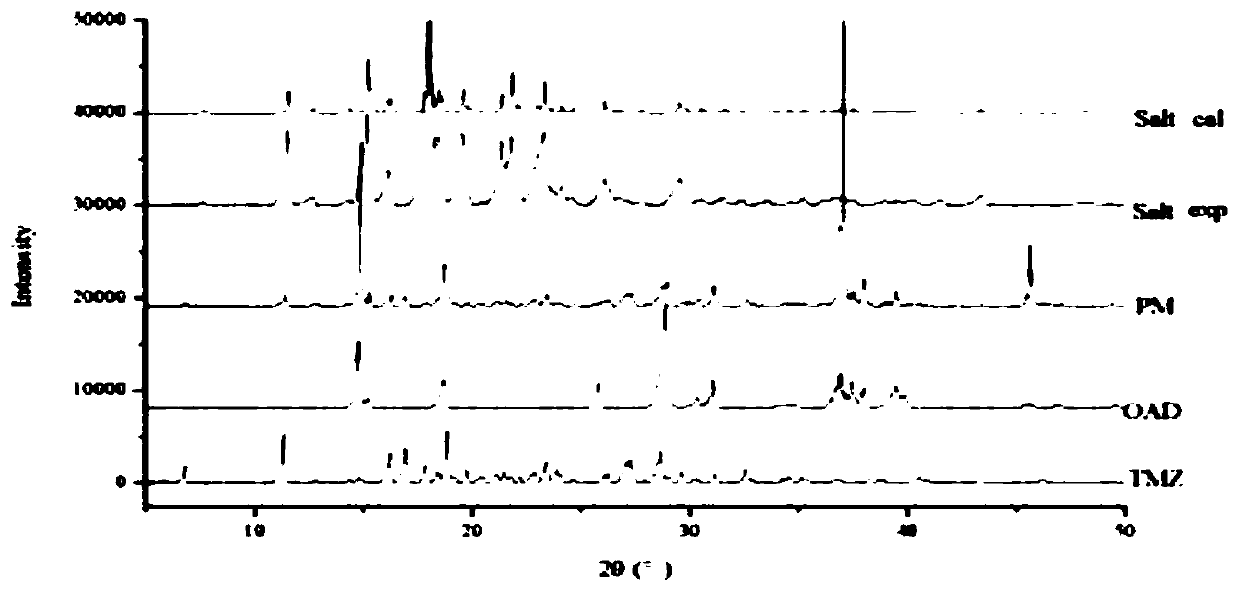

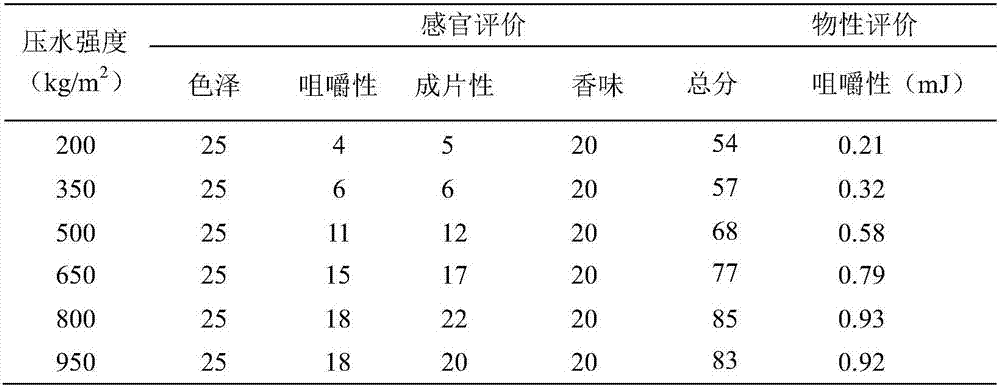

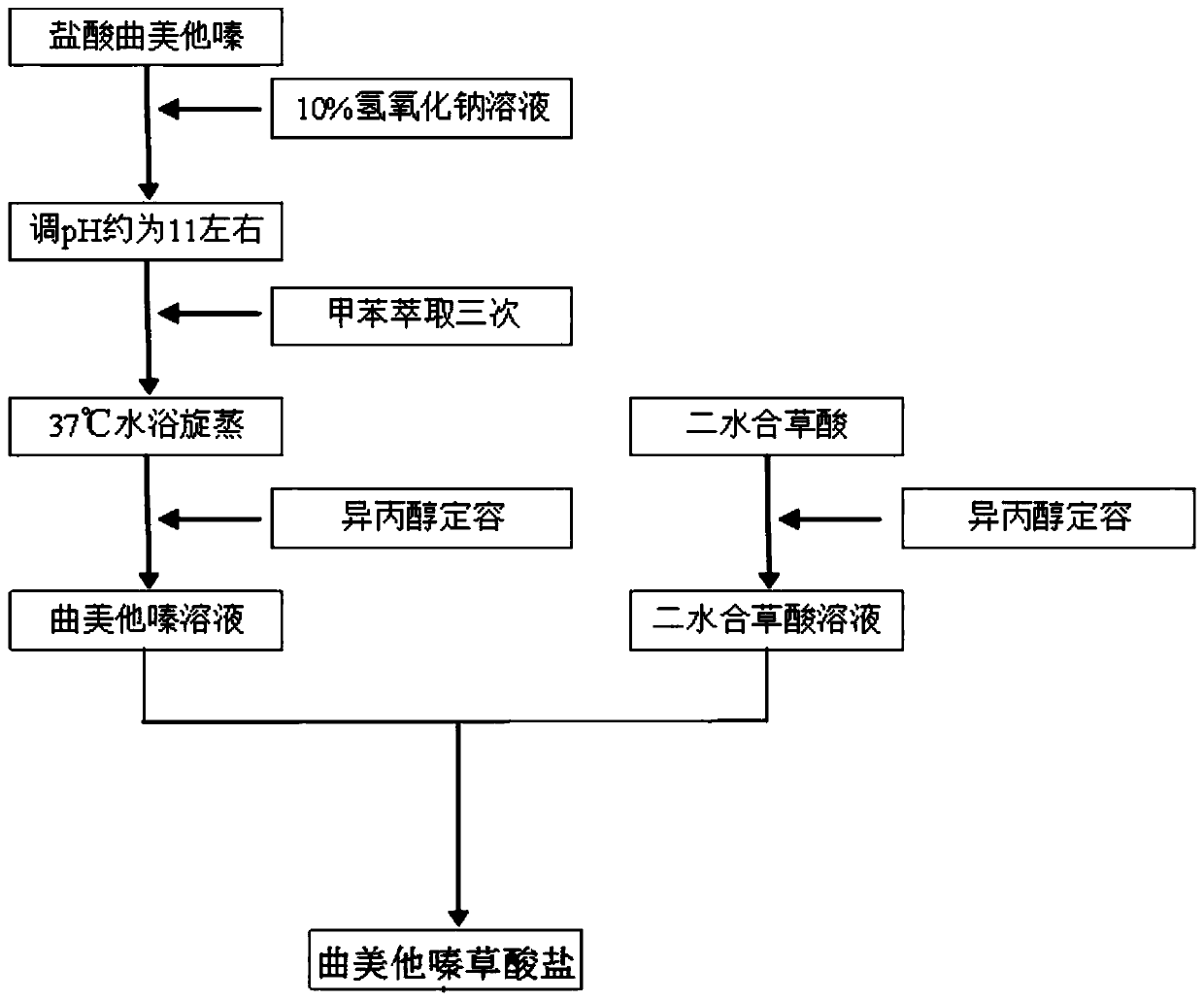

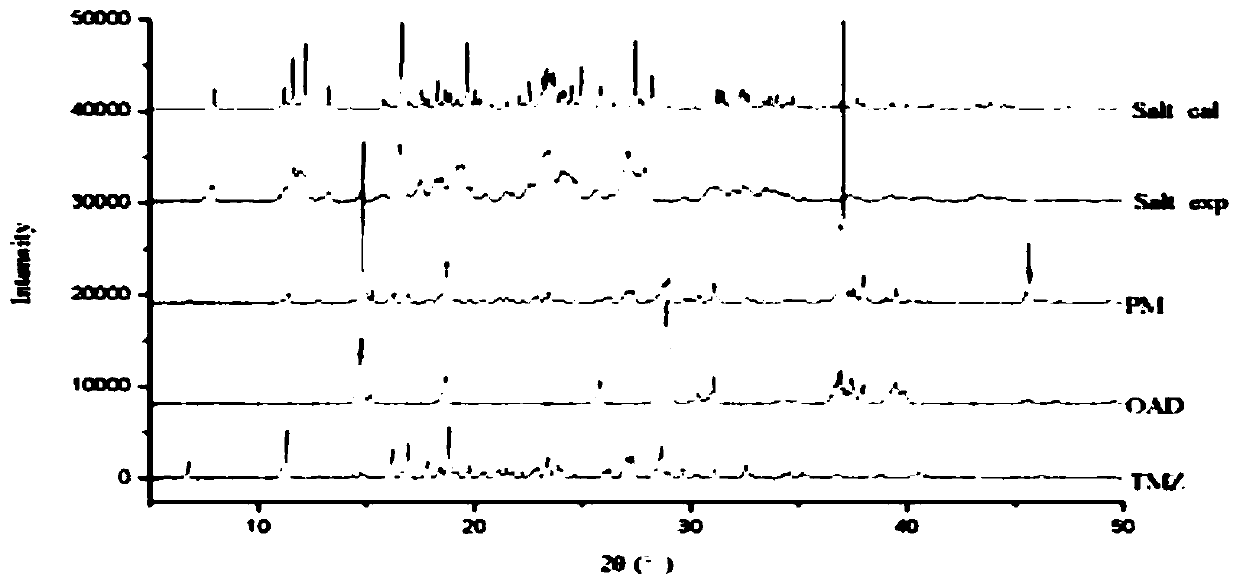

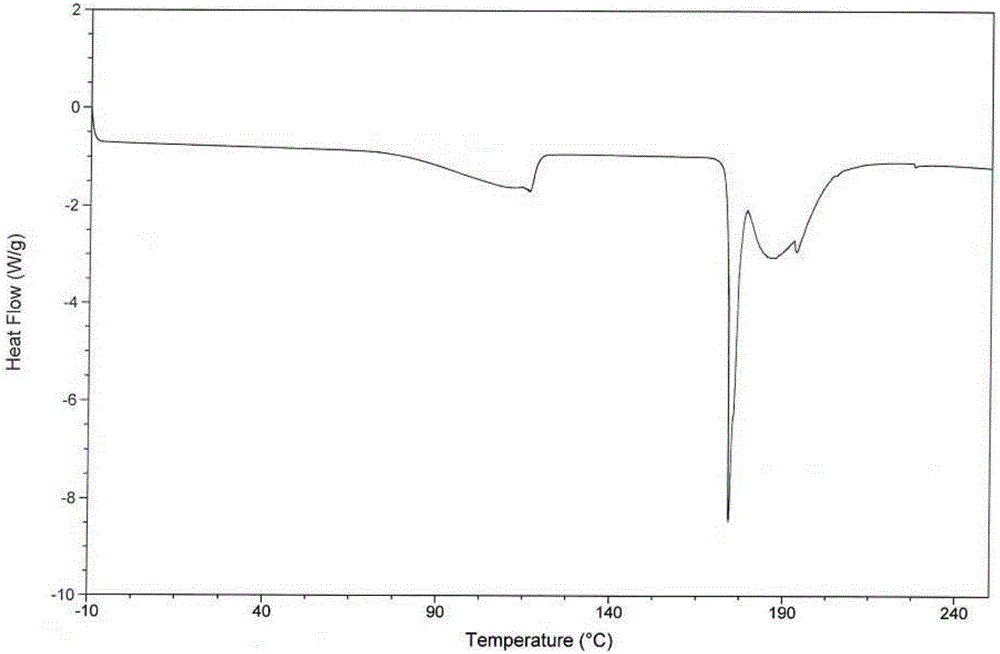

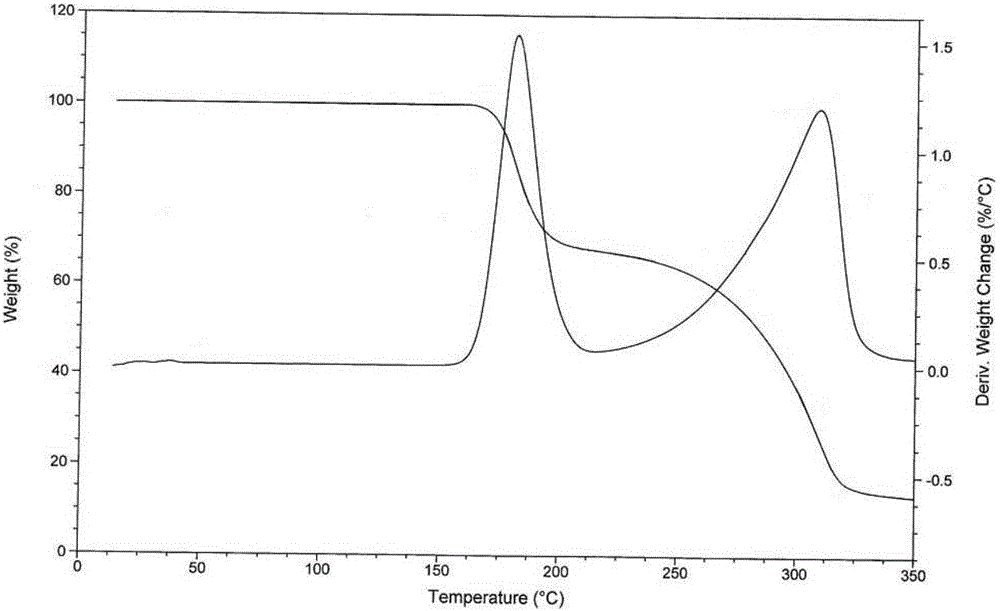

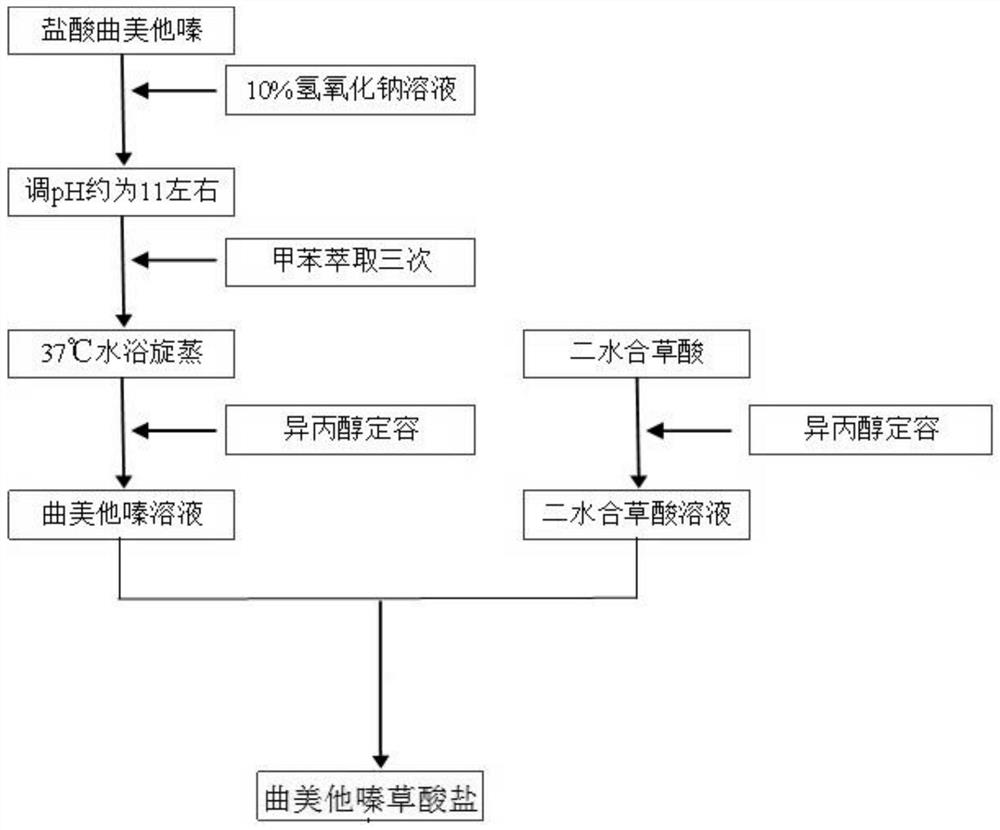

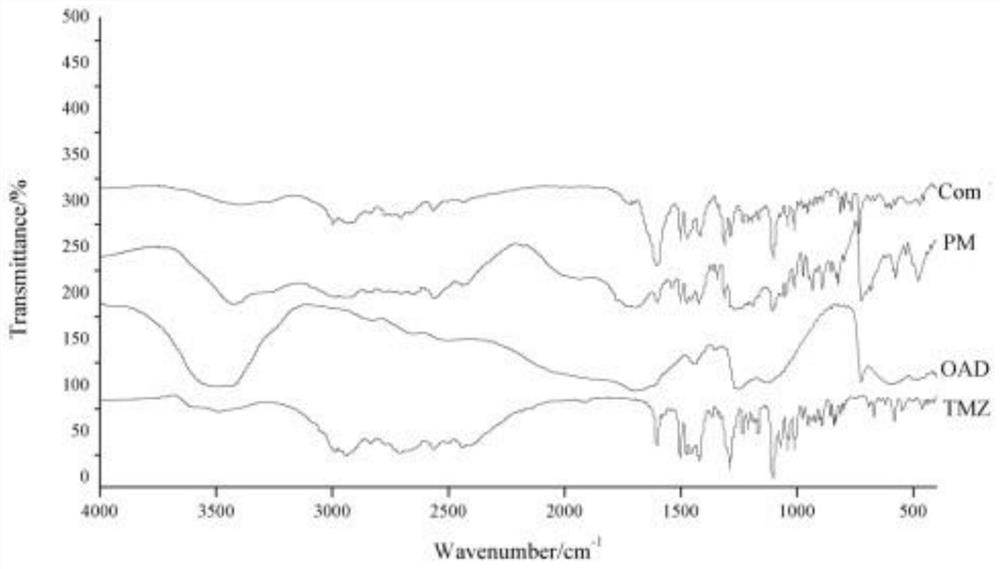

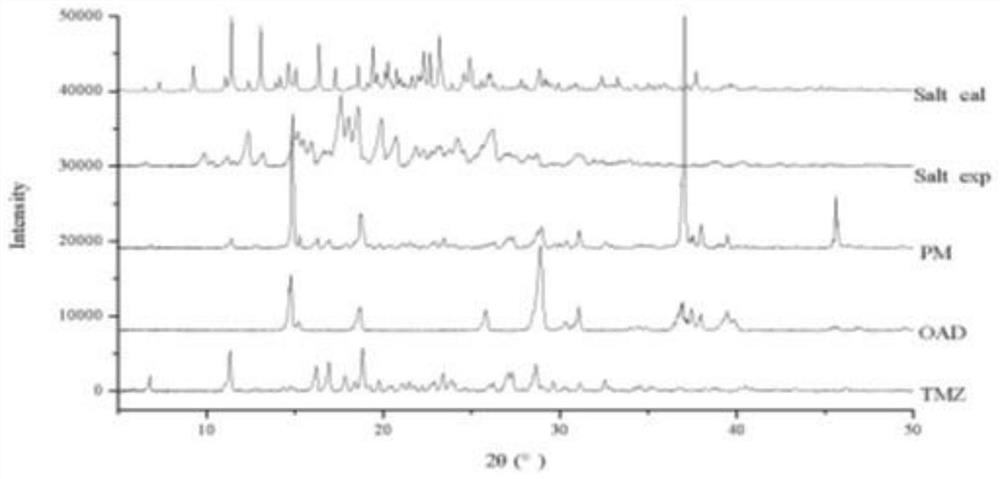

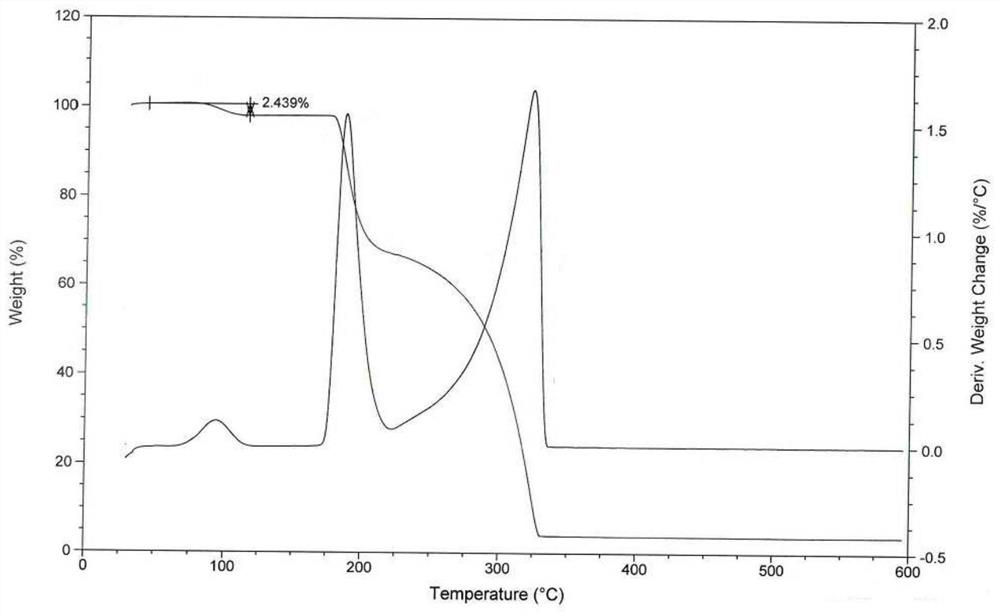

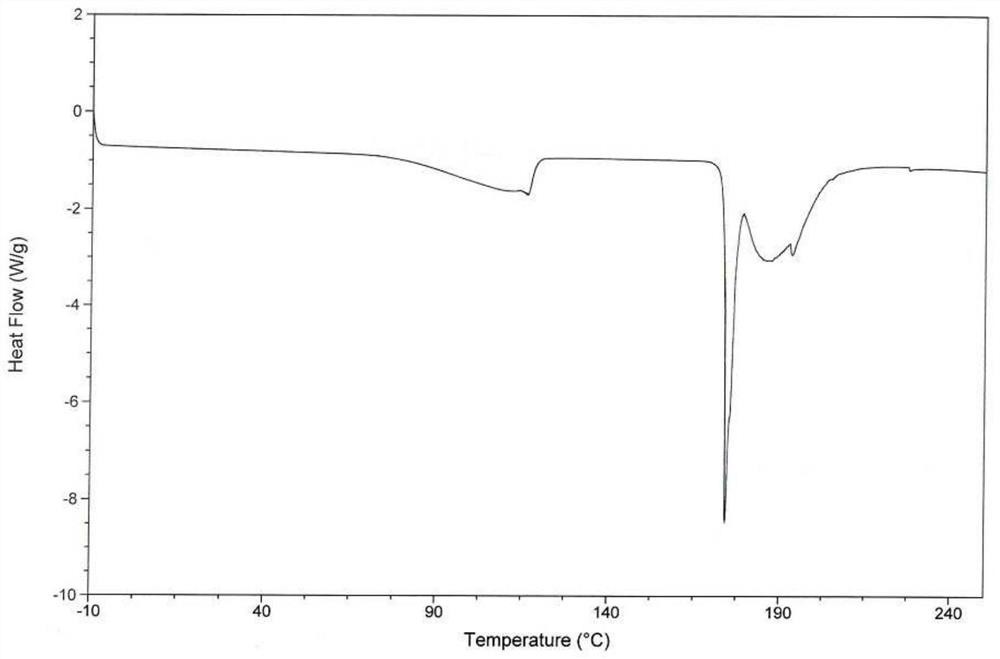

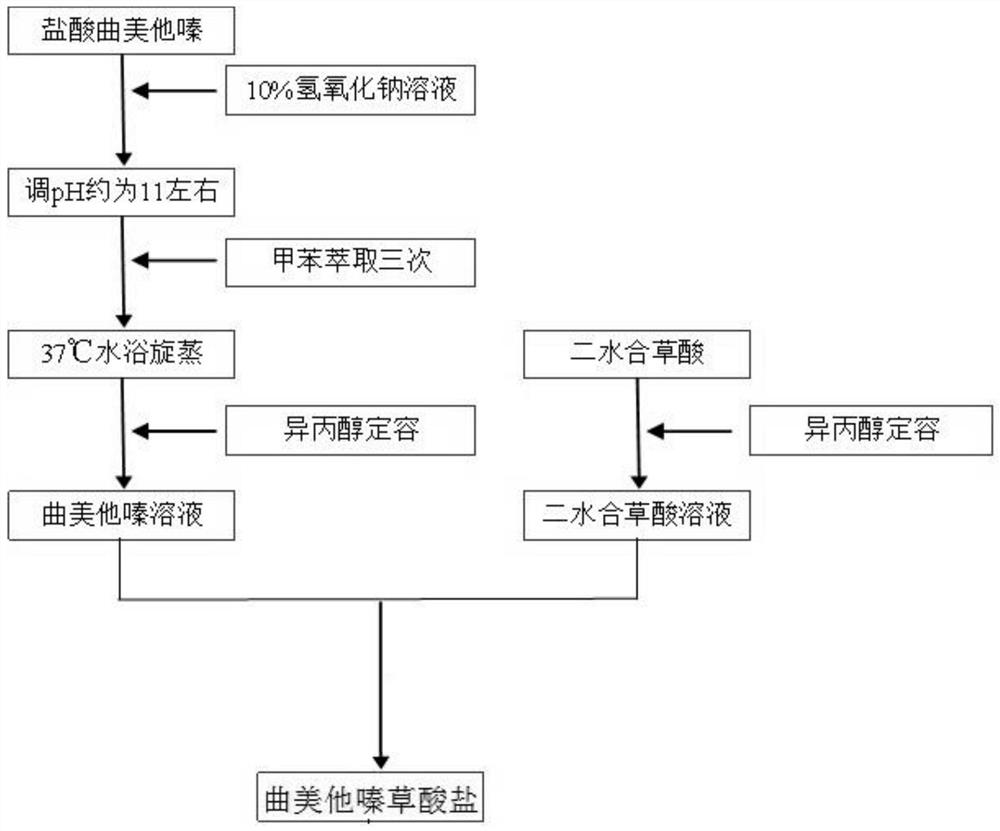

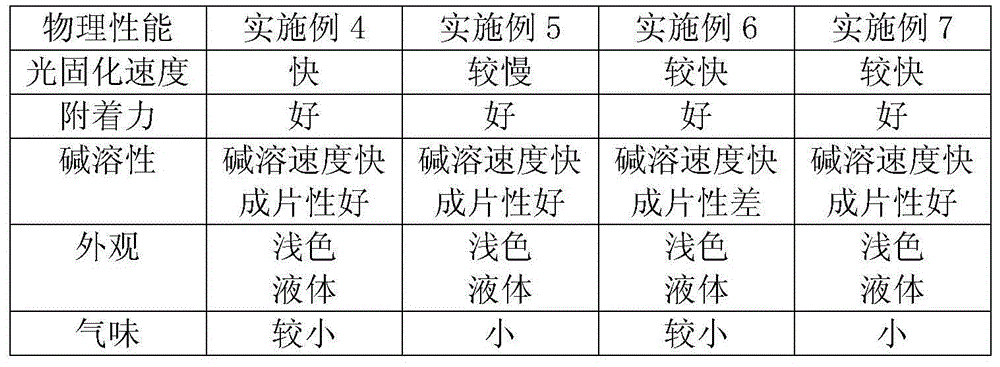

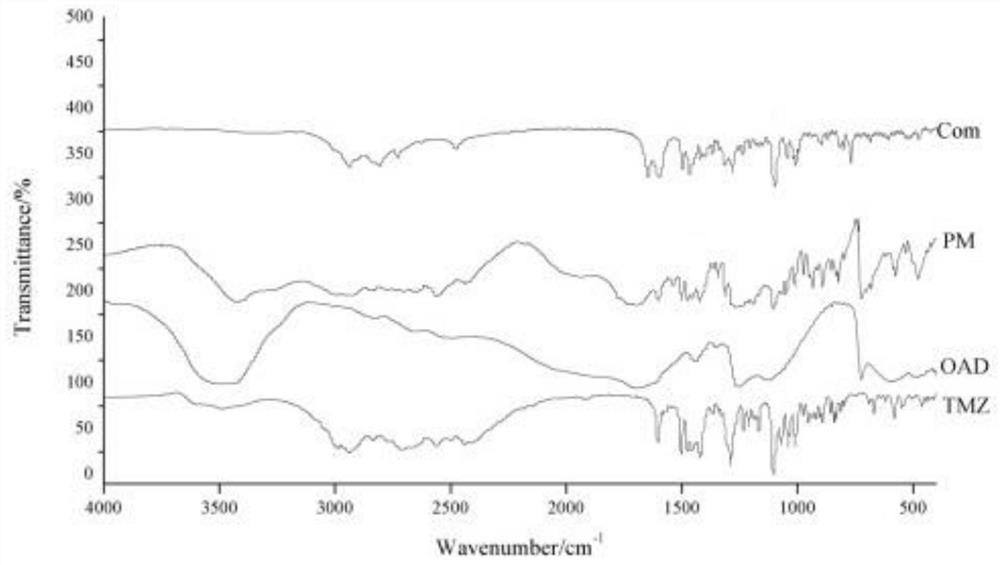

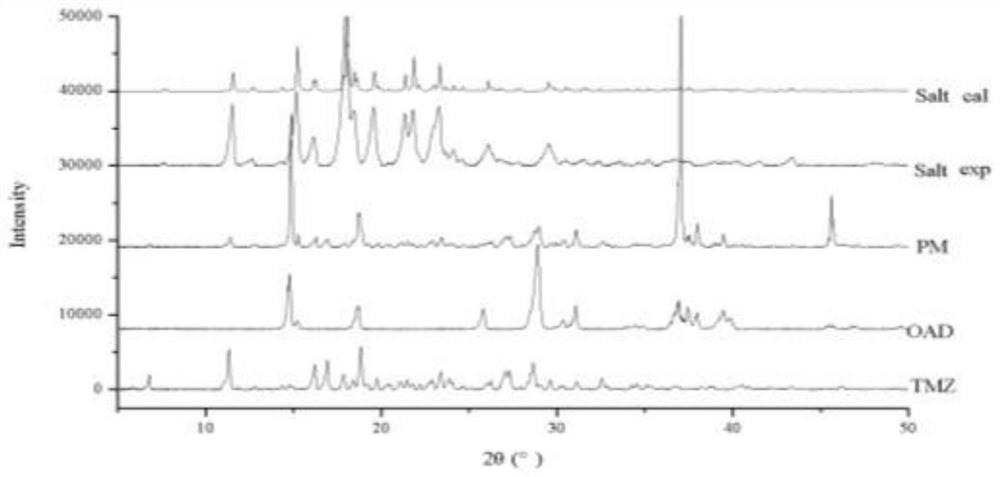

Trimetazidine oxalate and preparation method and application thereof

ActiveCN110105307ALarge specific surface areaImprove mobilityOrganic active ingredientsOrganic compound preparationChemistryAngle of repose

The invention provides trimetazidine oxalate. The molecular formula of the trimetazidine oxalate is C15H23N2O5, and the trimetazidine oxalate is obtained through a reaction of trimetazidine and oxalicacid in a molar ratio of 2:1. The angle of repose of the trimetazidine oxalate is smaller than that of trimetazidine hydrochloride, the surface appearance of the trimetazidine oxalate is flaky, and compared with a prismatic crystal of the trimetazidine hydrochloride bulk drug, the fluidity and hygroscopicity of the drug are improved; the tensile strength of the trimetazidine oxalate reaches the maximum value of 2.60 MPa at 350 MPa, and is significantly higher than that of the trimetazidine hydrochloride under the same pressure, and the flake formation performance of the drug is improved.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

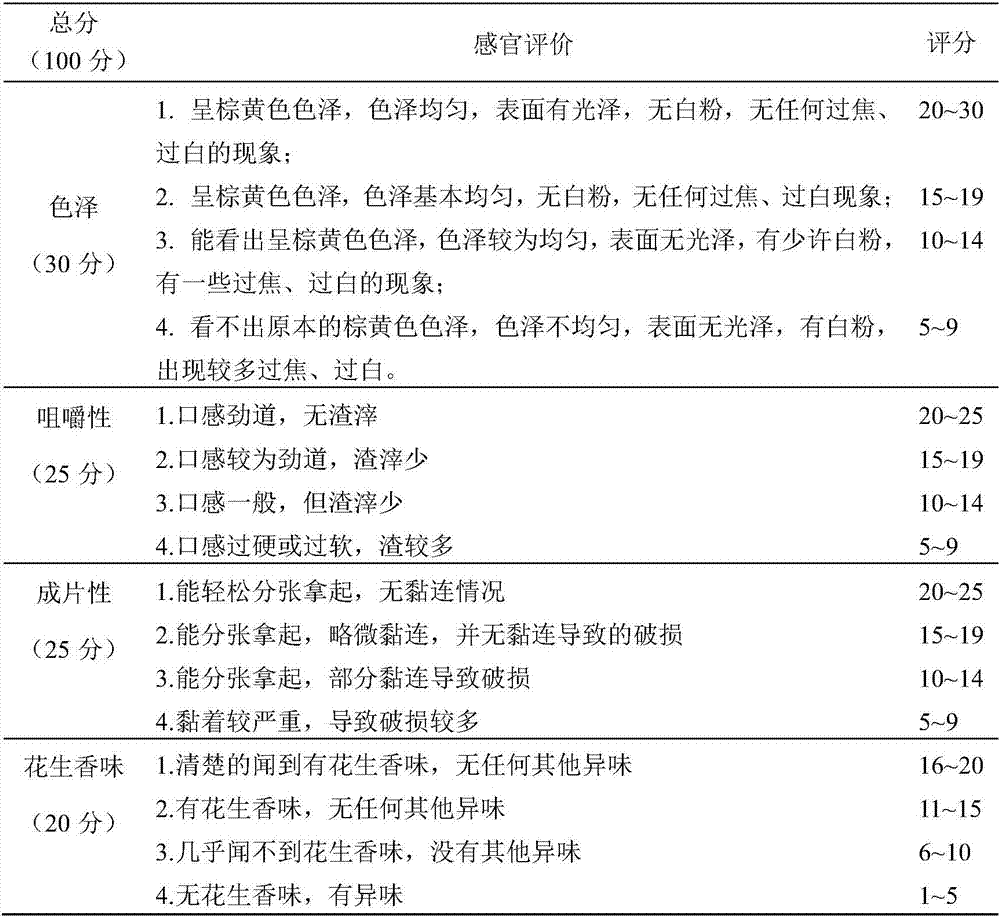

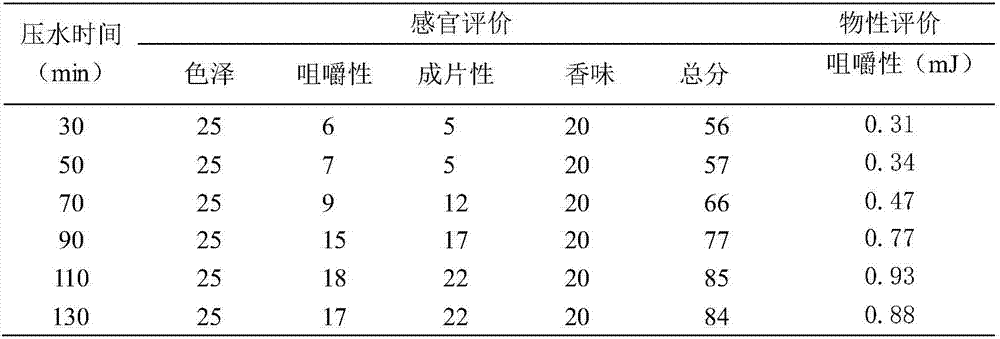

Peanut dried beancurd and production method thereof

InactiveCN106912619AIncrease added valueYellowish colorCheese manufactureFood scienceSlurryArachis hypogaea

The present invention relates to a peanut dried beancurd and a production method thereof, which belong to the technical field of food processing. According to the invention, the peanut dried beancurd comprises the following raw materials in parts by mass: 76-140 parts of soybeans, 4-50 parts of raw peanuts, 1-10 parts of cooked peanut, 4.5-6.5 parts of bittern, 14-17 parts of calcium carbonate, and 630-1500 ml of water. The production method comprises the following steps: a) performing pulp refining on immersed soybeans and raw peanuts, cooked peanut and water, filtering the materials to obtain peanut soybean slurry; b) adding a composite coagulating agent in the peanut soybean slurry while stirring, insulating the material and standing the material to obtain the peanut soybean jelly; wherein the composite coagulating agent is obtained by adding water in bittern and calcium carbonate according to the mass of 1:3; and c) crushing the peanut soybean jelly, layering the material on a bean curd cloth, and finally standing the material to obtain the product. The production technology is simple, the product has better flakiness performance and good chewing performance, can be fired and braised, has special fragrance of peanut and soybean, and has considerable market prospect.

Owner:JILIN UNIV

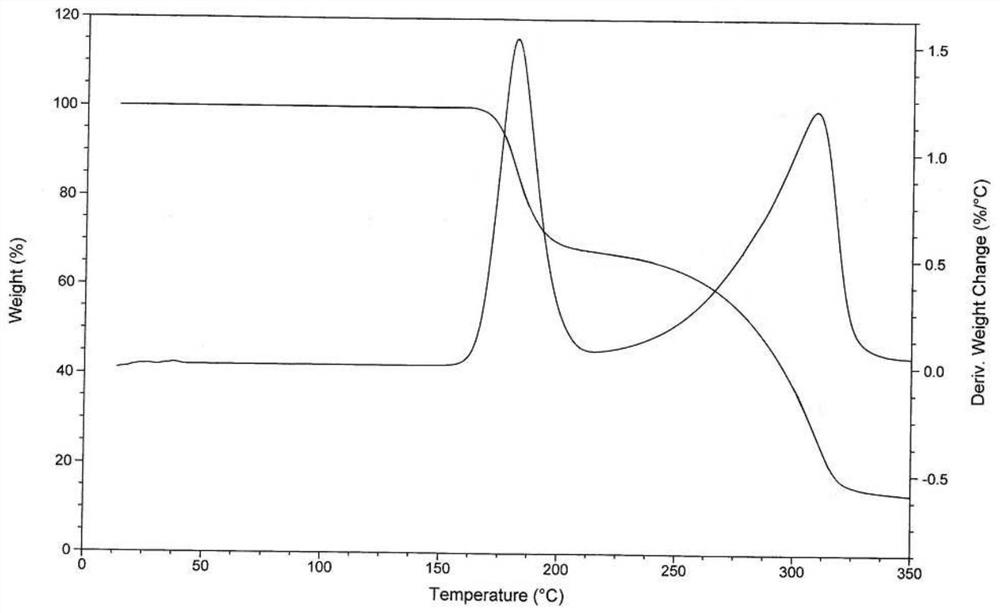

Trimetazidine oxalate, preparation method thereof and application of oxalate

ActiveCN110054599AChange melting pointChange solubilityOrganic active ingredientsOrganic chemistry methodsOxalateMole ratio

The invention provides trimetazidine oxalate. A molecular formula of the trimetazidine oxalate is C18H26N2O11, and trimetazidine and oxalate react according to mole ratio of 1:2 to obtain the trimetazidine oxalate. A repose angle of the trimetazidine oxalate is smaller than that of trimetazidine hydrochloride, the surface appearance of the trimetazidine oxalate is flaky, flowability and hygroscopicity of a medicine are improved as compared with those of a prismatic crystal medicine prepared from trimetazidine hydrochloride raw materials, the maximum tensile strength of the trimetazidine oxalate is 4.66MPa in the pressure of 150MPa and remarkably higher than that of the trimetazidine hydrochloride at the same pressure, and tablet forming performance of the medicine is improved.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Processing method of rubber special for radial tires

ActiveCN106217678ARaise the compound temperatureReduce loadPlastic recyclingMechanical material recoveryPelletizingScrap

The invention discloses a processing method of rubber special for radial tires. The method includes the steps that recycled raw rubber is divided into two grades according to assessment results of quality detection standards of enterprises and is crushed into rubber blocks with the sizes ranging from 40cm*10cm*8cm to 50cm*15cm*20cm, and the purified graded raw rubber is mixed according to the weight ratio of 1-3 to 1-3; the mixed rubber sequentially undergoes primary crushing, floatation stirring, secondary crushing and floatation stirring with the total floatation time greater than or equal to 20 minutes, then undergoes two-stage extrusion flotation with the floatation time greater than or equal to 12 minutes and finally forms micelles; the rubber undergoes crumpling treatment from the stage one to the stage three and undergoes primary granulating treatment, and manufactured rubber particles are made into rubber sheets with the thickness being 6-12 mm through crumpling treatment from the stage four to the stage six and then are made into rubber particles with the diameters being 6-12mm through secondary granulating treatment; and the rubber particles undergo rubber pumping and vibrating treatment, then are dried at 82-106 DEG C according to the 4-6 t / h standard of the rubber and finally are cooled to indoor temperature. According to the method, the purification rate of equipment is increased, the phenomenon that the structure of the rubber is damaged due to excessive processing is avoided, the equipment layout of a production line is simplified, the total failure rate is lowered, the amount of rubber scraps is reduced, and the production efficiency is improved.

Owner:德宏滇源橡胶有限公司

Image processing method and device

ActiveCN103927728BImprove experienceGood sheetingImage enhancementGeometric image transformationImaging processingElectronic information

The embodiments of the invention provide an image processing method and apparatus. The method is applied to imaging equipment for optimizing imaging effect and improving user experience. The method comprises: first of all, after a first image shot by a lens in a first direction is obtained, detecting whether a first object characteristic point exists for the first image in a first overlapping area, if the first object characteristic point exists for the first image in the first overlapping area, determining a first area provided with the first object characteristic point in the first image, then according to the size of the first area, determining an adjustment angle needed by the lens so as to enable the lens to be adjusted to a second direction according to the first direction and the adjustment angle needed by the lens, and finally, obtaining a second image shot in the second direction by the lens, and splicing the first image with the second image. The image processing method and apparatus are applied to the field of electronic information.

Owner:LENOVO (BEIJING) LTD

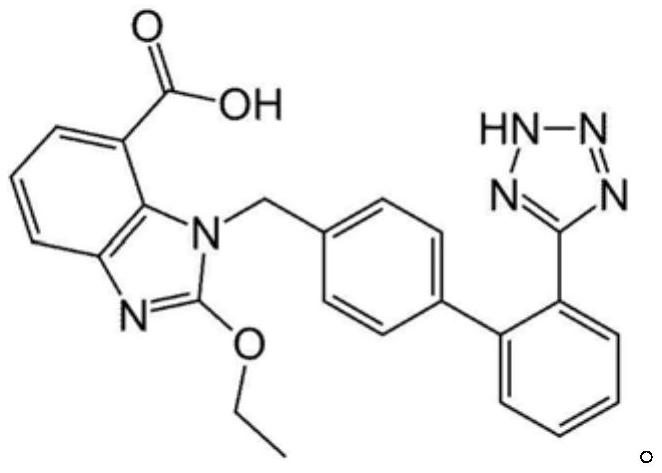

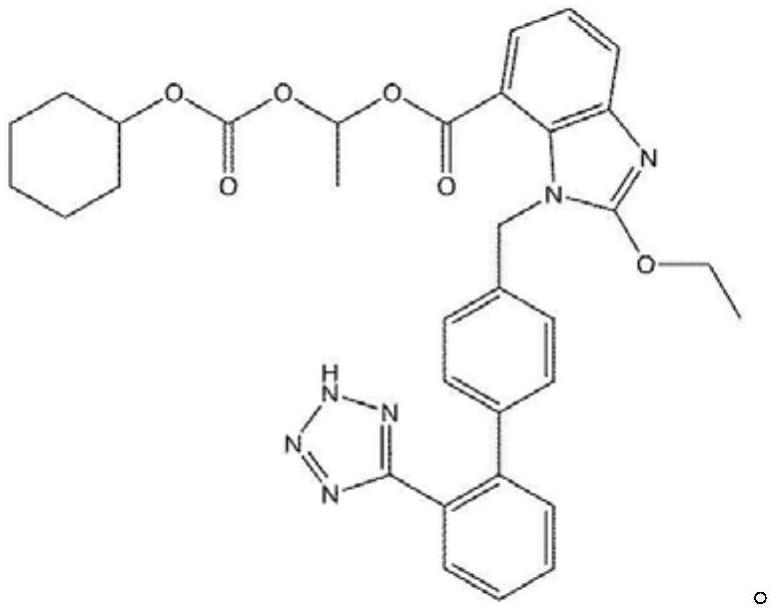

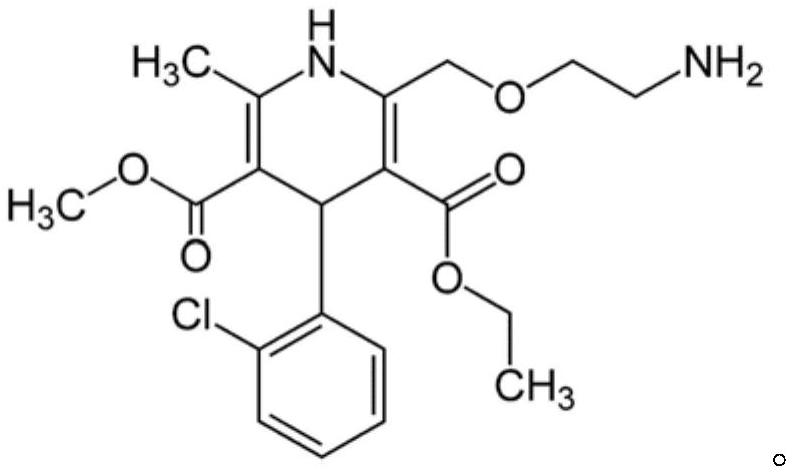

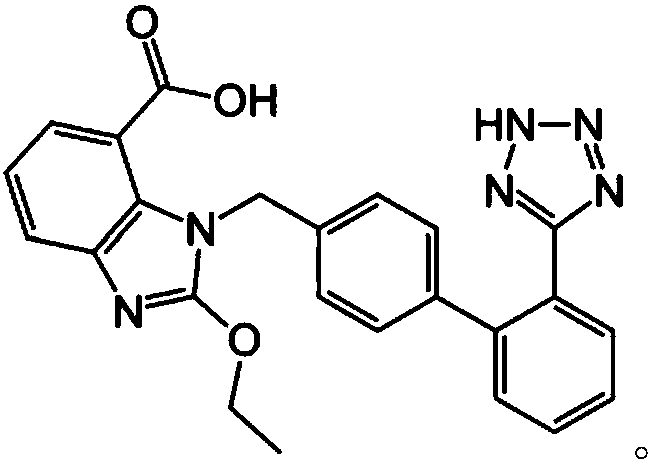

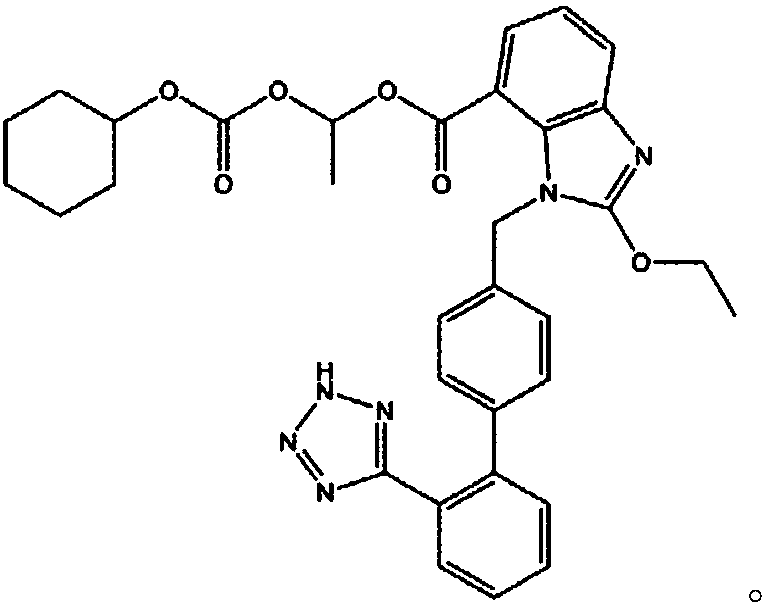

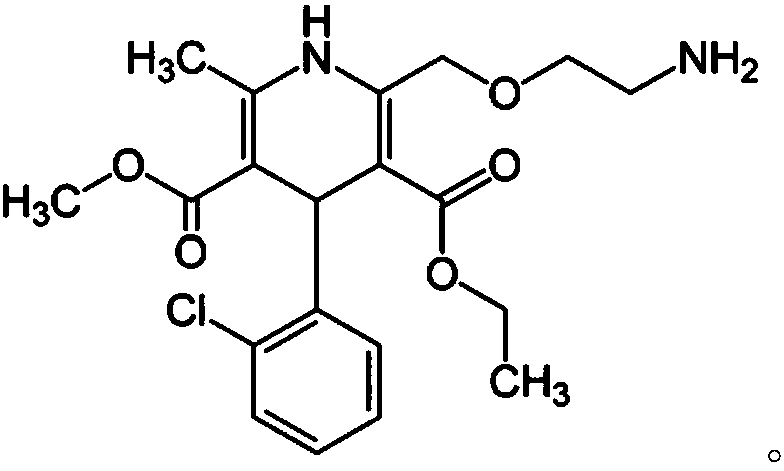

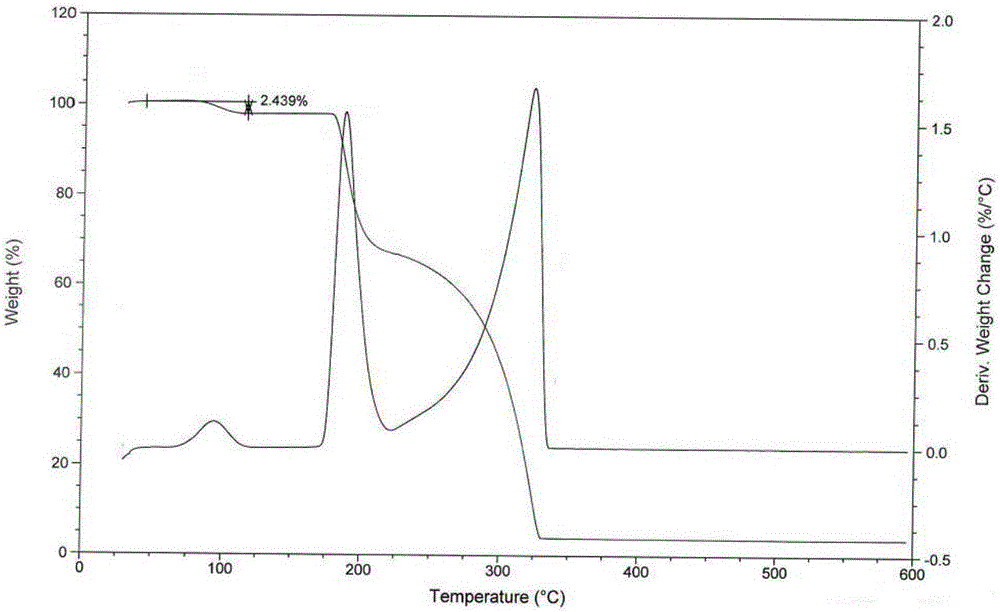

drug combination preparation

ActiveCN108472257BImprove stabilityKeep intactPill deliveryHeterocyclic compound active ingredientsCandesartanPharmaceutical medicine

Owner:SHIN POONG PHARMA CO LTD

Pharmaceutical composite preparation

ActiveCN108472257AImprove stabilityKeep intactPill deliveryHeterocyclic compound active ingredientsMedicineCandesartan

Owner:SHIN POONG PHARMA CO LTD

Almond slice processing technique

InactiveCN101310626BGood wet and dry effectGood flexibilityFood shapingFood preparationComputer scienceToughness

The invention relates to the technical filed of food processing, in particular to a processing technique of almond tablet. The processing technique of the almond tablet comprises the steps of soaking, peeling, primary roasting, slicing, screening, secondary roasting and packaging. After the almond kernel was carried out the process of hot-water soaking in the steps of the technique, peel and flesh are separated, a great deal of water is absorbed and toughness is enhanced, which brings convenience for the next step of peeling; the process of peeling produces crustless almond kernel; after the primary roasting, the water content of the almond kernel is proper, wet and dry effect is excellent and the almond kernel has excellent flexibility, therefore, flakiness effect during the slicing process of a slicer is good and the almond tablet is not easy to be brokedown. The technique of the invention can solve the problem that flakiness during the slicing process of the almond tablet is difficult, chip is little during the production process, raw materials are saved and the qualification rate of product is high.

Owner:东莞市利源贸易有限公司

A 5-hydroxytryptamine receptor agonist, a preparing method thereof and uses of the receptor agonist

ActiveCN106397411AImprove stabilityImprove solubilityOrganic active ingredientsSenses disorderSolubilityIsoindoles

The invention relates to a 5-hydroxytryptamine receptor agonist, a preparing method thereof and uses of the receptor agonist, particularly (3a[alpha],4[beta],7[beta],7a[alpha])-hexahydro-2-[4[4-(2-pyrimidinyl)-1-(piperazinyl)]-butyl]-4,7-methylene-1H-isoindole-1,3(2H)-dione citrate 4 / 5-hydrate, a preparing method thereof and uses of the 4 / 5-hydrate. The molecular formula of the 4 / 5-hydrate is C<21>H<29>N5O2.C6H8O<7>.(4 / 5)H2O. The 4 / 5-hydrate has advantages of high stability and good solubility, and therefore product quality control is facilitated and the 4 / 5-hydrate can be prepared into various dosage forms conveniently. The 4 / 5-hydrate has excellent compactibility and tabletting performance so that the 4 / 5-hydrate can be easily processed into tablets and is convenient to store and convey. The preparing method has advantages of few steps, simple and convenient operation, a high product yield, high purity, and the like and is particularly suitable for industrial application.

Owner:SICHUAN CREDIT PHARMA

A kind of trimetazidine oxalate and its preparation method and application

ActiveCN110183398BLarge specific surface areaImprove liquidityOrganic active ingredientsOrganic compound preparationOXALIC ACID DIHYDRATEOxalate

The invention provides a kind of trimetazidine oxalate, its molecular formula is C 16 h 24 N 2 o 7 , the trimetazidine oxalate is obtained by reacting trimetazidine and oxalic acid at a molar ratio of 1:1. The angle of repose of the trimetazidine oxalate is smaller than that of trimetazidine hydrochloride, and its surface morphology is flaky, which improves the fluidity and moisture absorption of the drug compared with the prismatic crystals of the trimetazidine hydrochloride bulk drug At the same time, the tensile strength of the trimetazidine oxalate reaches a maximum value of 3.99MPa at 150MPa, which is significantly higher than that of trimetazidine hydrochloride under the same pressure, which improves the tableting performance of the medicine.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Shooting method, shooting device and electronic equipment

ActiveCN112492209BEasy to operateAdd funTelevision system detailsPicture signal generatorsComputer graphics (images)Background image

Owner:VIVO MOBILE COMM CO LTD

5-hydroxytryptamine receptor agonist and its preparation method and use

ActiveCN106397411BImprove stabilityImprove solubilityOrganic active ingredientsSenses disorderHydroxylamineTryptamine Receptors

The invention relates to a 5-hydroxytryptamine receptor agonist, a preparing method thereof and uses of the receptor agonist, particularly (3a[alpha],4[beta],7[beta],7a[alpha])-hexahydro-2-[4[4-(2-pyrimidinyl)-1-(piperazinyl)]-butyl]-4,7-methylene-1H-isoindole-1,3(2H)-dione citrate 4 / 5-hydrate, a preparing method thereof and uses of the 4 / 5-hydrate. The molecular formula of the 4 / 5-hydrate is C<21>H<29>N5O2.C6H8O<7>.(4 / 5)H2O. The 4 / 5-hydrate has advantages of high stability and good solubility, and therefore product quality control is facilitated and the 4 / 5-hydrate can be prepared into various dosage forms conveniently. The 4 / 5-hydrate has excellent compactibility and tabletting performance so that the 4 / 5-hydrate can be easily processed into tablets and is convenient to store and convey. The preparing method has advantages of few steps, simple and convenient operation, a high product yield, high purity, and the like and is particularly suitable for industrial application.

Owner:SICHUAN CREDIT PHARMA

A kind of trimetazidine oxalate and its preparation method and application

ActiveCN110054599BLarge specific surface areaImprove liquidityOrganic active ingredientsOrganic chemistry methodsOXALIC ACID DIHYDRATEMedicine

The invention provides a kind of trimetazidine oxalate, its molecular formula is C 18 h 26 N 2 o 11 , the trimetazidine oxalate is obtained by reacting trimetazidine and oxalic acid in a molar ratio of 1:2. The angle of repose of the trimetazidine oxalate is smaller than that of trimetazidine hydrochloride, and its surface morphology is flaky, which improves the fluidity and moisture absorption of the drug compared with the prismatic crystals of the trimetazidine hydrochloride bulk drug At the same time, the tensile strength of the trimetazidine oxalate reaches a maximum value of 4.66MPa at 150MPa, which is significantly higher than the tensile strength of trimetazidine hydrochloride under the same pressure, which improves the tableting performance of the drug.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Imageable coating layer, thermal negative-working lithography printing plate, and platemaking method therefor

ActiveUS20190176460A1Prevent fluctuationSimple processPhotomechanical coating apparatusPhotomechanical exposure apparatusChemistryRadiation

The invention relates to an imageable coating layer, thermal negative-working lithography printing plate, and platemaking method. The coating layer includes constituents in parts by weight: a radically polymerizable compound 20-60 parts, a radiation-absorbing compound 0.5-12 parts, a free radical initiator 1-25 parts, a binding agent 10-70 parts, and a development accelerator 0.5-15 parts. The platemaking method includes the steps: S1, preparing a printing plate precursor that includes a substrate having a hydrophilic surface or is provided with a hydrophilic layer and imageable coating layer covering the substrate; S2, patternedly exposing the printing plate precursor, forming an exposed area and an unexposed area; and S3, removing the unexposed area via a development process. The employment of the imageable coating layer and the plate making method allows the implementation of a flexible development process of “on-press development” or “off-press development” and produces a printing plate provided with great printing performance.

Owner:ZHEJIANG KONITA NEW MATERIALS

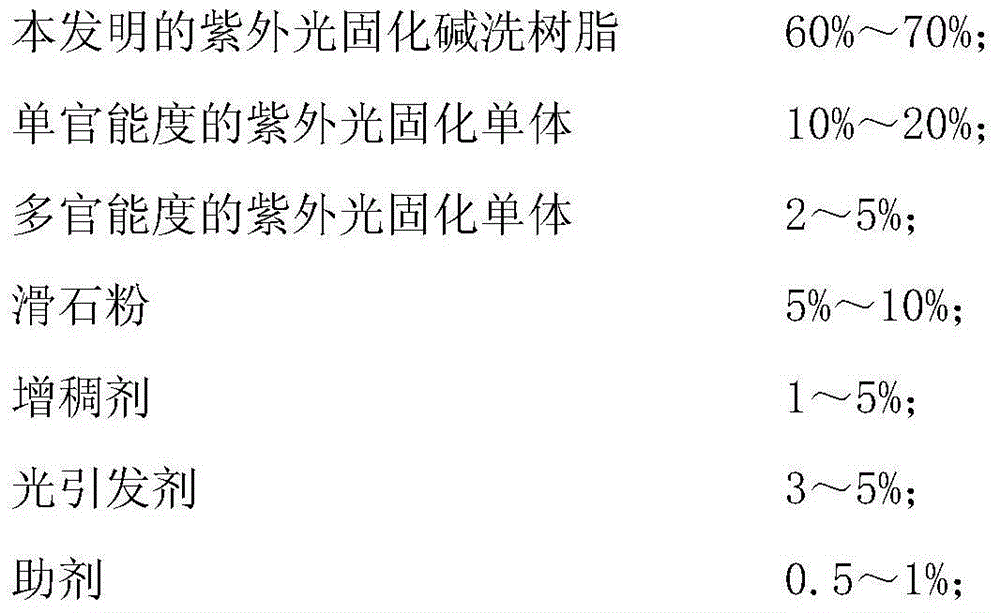

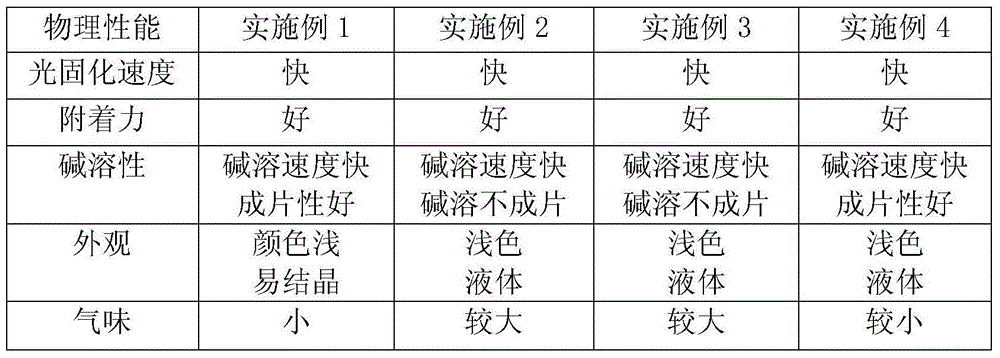

Ultraviolet curing alkali cleaning resin and its preparation method and the preparation method of matte ink

ActiveCN103755557BLight curing speed is fastImprove adhesionOrganic compound preparationCarboxylic acid esters preparationPhotosensitizerAcid value

The invention discloses an ultraviolet-cured alkali washing resin as well as a preparation method thereof and the preparation method of a frosted ink, and belongs to the field of ink preparation. The method is characterized by comprising the following steps: mixing 0.5mol% of anhydride and 0.5mol% of hydroxyl acrylate to obtain a mixture; preacting; adding a polymerization inhibitor accounting for 0.1% to 0.2% of the mass of the mixture and a catalyst accounting for 0.2% of the mass of the mixture into the mixture; heating and reacting; and measuring an acid value, thus obtaining the ultraviolet-cured alkali washing resin. The ultraviolet-cured alkali washing resin has the advantages of high ultraviolet curing speed, good adhesive force, rapid alkali dissolution speed, small odor, light color and the like, and cannot generate turbid substances. The ultraviolet-cured alkali washing resin can react with a monomer, talcum powder, an aiding agent and a photosensitizer so as to prepare the ultraviolet-cured alkali washing frosted ink.

Owner:HUNAN BANFERT NEW MATERIALS TECH

Nutrition-enriched recombinant translucent meat slices and preparation method thereof

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES +1

A kind of trimetazidine oxalate and its preparation method and application

ActiveCN110105307BLarge specific surface areaImprove liquidityOrganic active ingredientsOrganic compound preparationOXALIC ACID DIHYDRATEOxalate

The invention provides a kind of trimetazidine oxalate, its molecular formula is C 15 h 23 N 2 o 5 , the trimetazidine oxalate is obtained by reacting trimetazidine and oxalic acid in a molar ratio of 2:1. The angle of repose of the trimetazidine oxalate is smaller than that of trimetazidine hydrochloride, and its surface morphology is flaky, which improves the fluidity and moisture absorption of the drug compared with the prismatic crystals of the trimetazidine hydrochloride bulk drug At the same time, the tensile strength of the trimetazidine oxalate reaches a maximum value of 2.60MPa at 350MPa, which is significantly higher than that of trimetazidine hydrochloride under the same pressure, which improves the tableting performance of the medicine.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

A kind of processing technology of special rubber for radial tire

ActiveCN106217679BRub wellIncrease temperaturePlastic recyclingMechanical material recoveryRubber materialFailure rate

The invention discloses a machining process for rubber special for a radial tire. According to the machining process, firstly, recycled rubber raw materials are divided into two grades according to evaluation results of enterprise quality detection standards and smashed into 40 cm x 10 cm x 8 cm-50 cm x 15 cm x 20 cm rubber blocks correspondingly, and the cleaned graded rubber raw materials are mixed according to the weight ratio being 1-3:1-3. The mixed rubber materials are subjected to primary smashing, flotation and stirring, secondary smashing and flotation and stirring, flotation needs larger than or equal to 20 min of time, then the mixed rubber materials are subjected to two-stage extrusion flotation, flotation needs larger than or equal to 12 min of time, and the rubber materials are made into a rubber ball shape. The rubber materials are subjected to one to four stage crepe treatment to be made into a continuous sheet shape, the thickness is 6-12 mm, and the rubber materials obtained after crepe treatment are subjected to granulation treatment to be made into rubber particles being 6-12 mm in diameter. The rubber particles are subjected to rubber drawing vibration treatment, dried at the temperature being 82-108 DEG C according to the standard being 4-6 t / h of the rubber materials, and then cooled to the room temperature. Through the machining process, the equipment impurity removing ratio is increased, the condition that the rubber structure is damaged due to over-machining is avoided, equipment arrangement of a production line is simplified, the total failure rate is lowered, rubber smashing quantity is reduced, and the production efficiency is improved.

Owner:德宏滇源橡胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com