Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

333results about How to "Good thermal shock resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature resistant ceramic matrix composite material and preparation method thereof

The invention relates to an ultra-high temperature resistant ceramic-based composite and a preparation method, which adopts carbon or boron nitride fabric cloth as reinforcing phases, ceramic powders of high melting point or high-temperature resistant metal powders as the stuffing, and carbon / silicon carbide as the base. Through the blending and ball milling of the adhesives and the powder stuffing, the sizing agent thus acquired is coated on the reinforcing phase fabric cloth, and then overlapping, molding, cross-bonding, high-temperature pyrolysis, and repeated densification are carried out in preparing the composite. The ultra-high temperature resistant ceramic composite has the advantages of excellent thermal shock resistance, low density, and low ablating rate under ultra-high temperature.

Owner:NAT UNIV OF DEFENSE TECH

Epoxy mortar adapted in bridge expansion joint and construction method thereof

ActiveUS20170121918A1High strengthSimple construction processSolid waste managementBridge structural detailsEpoxyHeat resistance

An epoxy mortar material for a bridge expansion joint structure and a construction method thereof are provided. The epoxy mortar material includes a liquid A, a liquid B and a filler, wherein diamines D2000 and D230 are mixed to act as the epoxy resin curing agent. The curing agent has low viscosity, good compatibility with epoxy resin, long usable life, high bonding strength, and good flexible and heat shock resistance, so that it is suitable for the epoxy mortar material capable of absorbing the stress. Furthermore, the silicone adhesive is made into the sealing waterstop band, so that the present invention has good water resistant performance; the color of the expansion joint structure is the same as that of the adjacent concrete or asphalt, so that the bridge has beautiful appearance; the expansion joint structure has no tremors while vehicles passing through, noise generated by vehicle driving is lower.

Owner:HEERON TECH (WUHAN) NEW MATERIALS CO LTD

High transmittance fine household porcelain and production technology thereof

ActiveCN101973758AGood thermal shock resistanceHigh light transmittanceClaywaresPotassium feldsparAluminium oxide

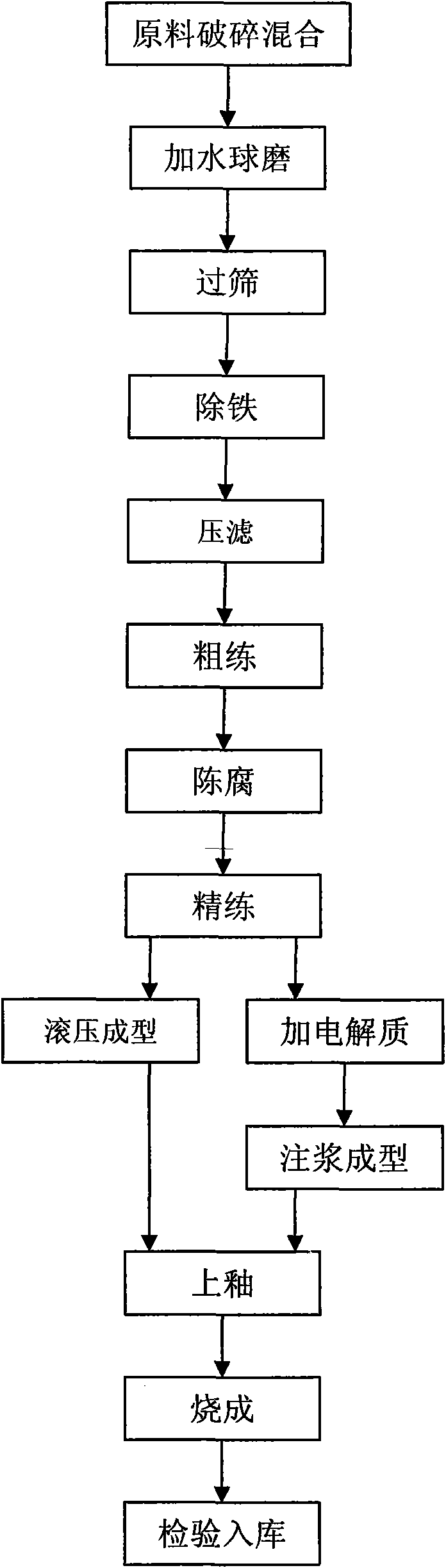

The invention discloses a kind of high transmittance fine household porcelain and a production technology thereof. The porcelain clay in Guangxi is added in the common raw materials and bone meal and talcum powder are not needed to add. The green body comprises the following components by weight percent: 20-35% of porcelain clay in Guangxi, 5-20% of potassium feldspar, 10-20% of quartz powder, 5-10% of alumina, 30-50% of kaolin, 5-10% of clay and 4-12% of bentonite. The production technology of the high transmittance fine household porcelain comprises the following steps: crushing and mixing the raw materials, performing ball-milling, sieving, deironing, performing filter-pressing, smelting, aging, refining, rolling or performing slip casting, enameling, and using an oxidizing atmosphere for single firing in a kiln. By adopting the formulation selected by the invention, the mud has extremely good plasticity so that the mud can be used to form the thinner eggshell porcelain and be suitable to prepare various irregular products with peculiar shapes. The products have high transmittance and strength, and smooth and delicate porcelain glaze.

Owner:GUANGDONG SITONG GROUP

Zirconium oxide sandwich composite calcining-endure plate and preparation process thereof

The invention discloses a zirconium oxide sandwich composite calcining-endure plate. The zirconium oxide sandwich composite calcining-endure plate comprises a matrix mullite calcining-endure plate and zirconium oxide paint. The matrix mullite calcining-endure plate comprises the following raw materials in percentage by mass: 20 to 25 percent of andalusite with thickness degree between 1 and 1.5 mm, 5 to 10 percent of andalusite with thickness degree between 0.5 and 1 mm, 5 to 8 percent of andalusite with thickness degree less than 0.5 mm, 10 to 15 percent of plate-shaped corundum with thickness degree between 0.5 and 1 mm, 5 to 10 percent of plate-shaped corundum with thickness degree less than 0.5 mm, 5 to 10 percent of electrical melting mullite with thickness degree between 0.5 and 1 mm, 8 to 12 percent of sillimanite powder, 15 to 20 percent of alpha-aluminium oxide (Al2O3) powder, 2 to 3 percent of silica micropowder, 3 to 4 percent of clay and 3 to 4 percent of binding agent. The zirconium oxide paint comprises the following raw materials in percentage by mass: 75 to 80 percent of zirconium oxide with granularity less than or equal to 600 meshes and 20 to 25 percent of silicasol. In addition, the invention also provides a process for preparing the zirconium oxide sandwich composite calcining-endure plate. The zirconium oxide sandwich composite calcining-endure plate has the advantages of high-temperature resistance, high mechanical strength, stable chemical properties, high stability of thermal shock resistance, long service life and high anti-stripping property.

Owner:夏卫平

Method for producing silicon mullite abrasive brick

ActiveCN101712551AReduce kiln maintenance timesHigh softening temperature under loadTunnel kilnBrick

The invention discloses a method for producing a silicon mullite abrasive brick, comprising the following steps of: firstly, selecting 4 parts of bauxite granules, 2 parts of brown aluminum oxide granules, 0.4 part of carborundum granules, 2.5 parts of bauxite powder, 0.8 part of carborundum powder, 0.2 part of metallic silicon powder, 0.2 part of silicon powder and 0.5 part of clay powder in parts by weight; secondly, adding the bauxite granules, the brown aluminum oxide granules and the carborundum granules into an edge runner wet mill and premixing, then adding lignin liquor accounting for 4-5 percent of the total weight of materials and premixing, adding the bauxite powder, the carborundum powder, and the metallic silicon powder and mixing, adding the clay powder and the silicon powder, mixing and discharging ground ageing mixture; and thirdly, pressing the pug into semi-finished products, feeding the semi-finished products into a drying chamber, drying, feeding semi-finished products into a high-temperature tunnel kiln and sintering to form a finished brick body. The brick body has long service life, can keep synchronous running with a kiln liner in a firing zone, reduces the maintenance times for users to close down the kiln, and simultaneously has the advantages of high softening temperature for load, favorable thermal shock resisting stability, favorable wear-resisting performance and the like.

Owner:郑州真金耐火材料有限责任公司

Lightweight calcium hexaluminate-magnesia alumina spinel composite microporous refractory aggregate and preparation method thereof

The invention discloses a lightweight calcium hexaluminate-magnesia alumina spinel composite microporous refractory aggregate for lightweight refractory castables and a preparation method thereof. The lightweight calcium hexaluminate-magnesia alumina spinel composite microporous refractory aggregate is obtained by taking 3 to 7 weight percent of lime, 12 to 18 weight percent of magnesite and 75 to 85 weight percent of industrial aluminum hydroxide as initiative materials, adding a binding agent in an amount which is 3 to 6 percent of the total weight of the initial materials, performing wet co-grinding and machine molding, drying a green body and then calcining the green body, and crushing a product obtained after calcination. The lightweight microporous aggregate has the advantages of high stability in reducing atmosphere and alkaline environment, excellent thermal shock resistance and thermal insulation property and the like, so that the service life of the material is prolonged andthe loss of energy consumption is reduced.

Owner:HENAN UNIV OF SCI & TECH

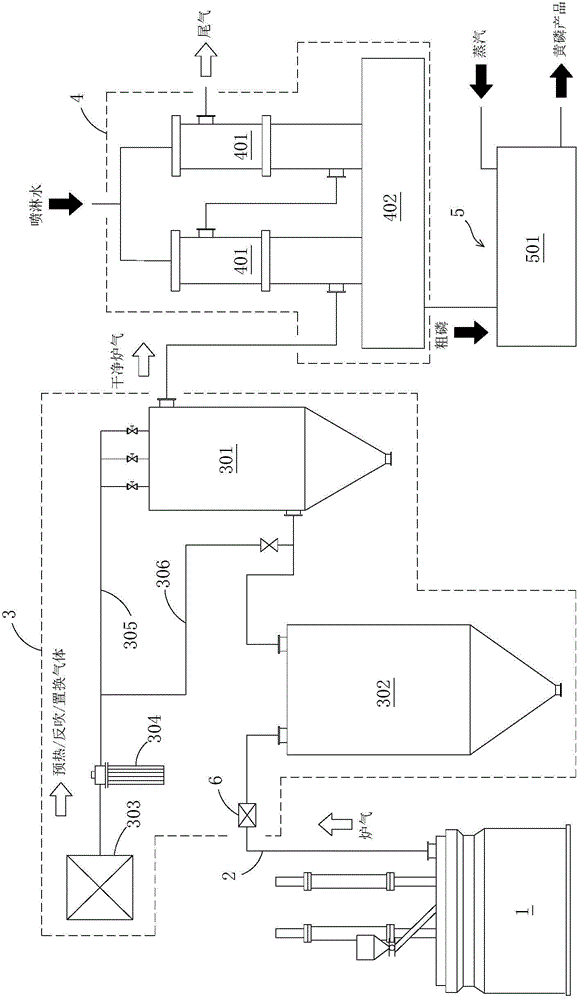

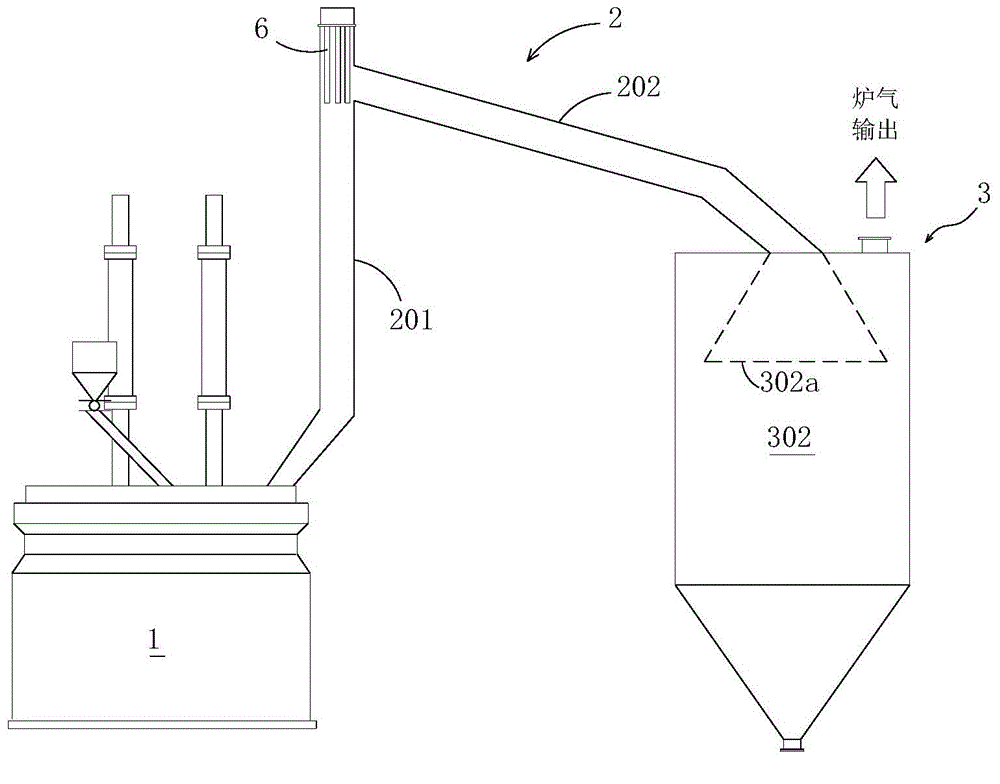

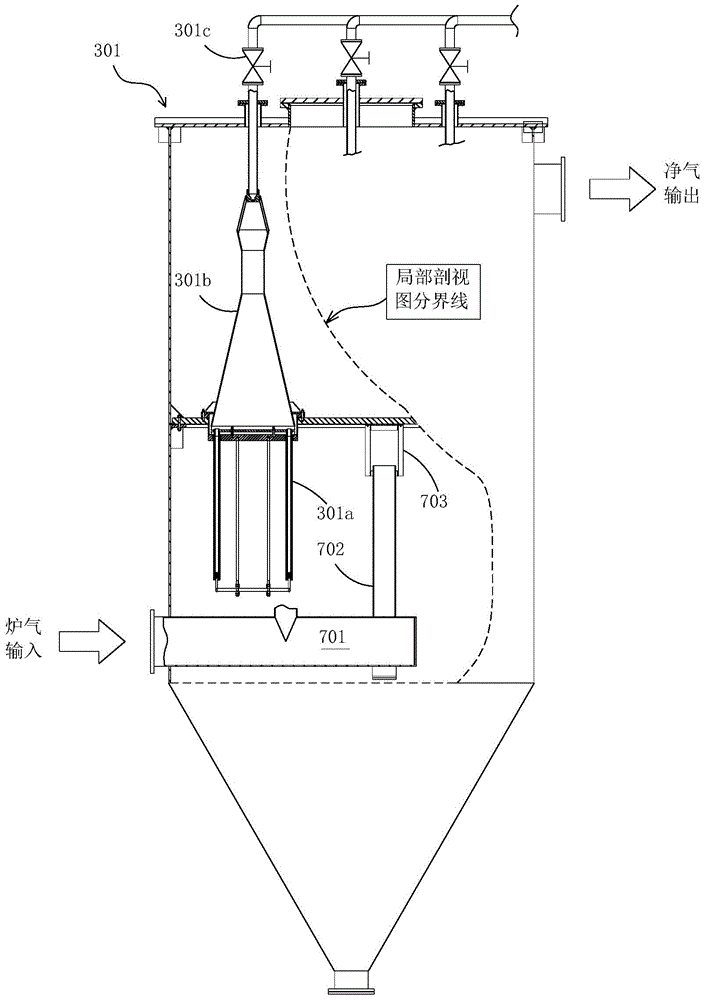

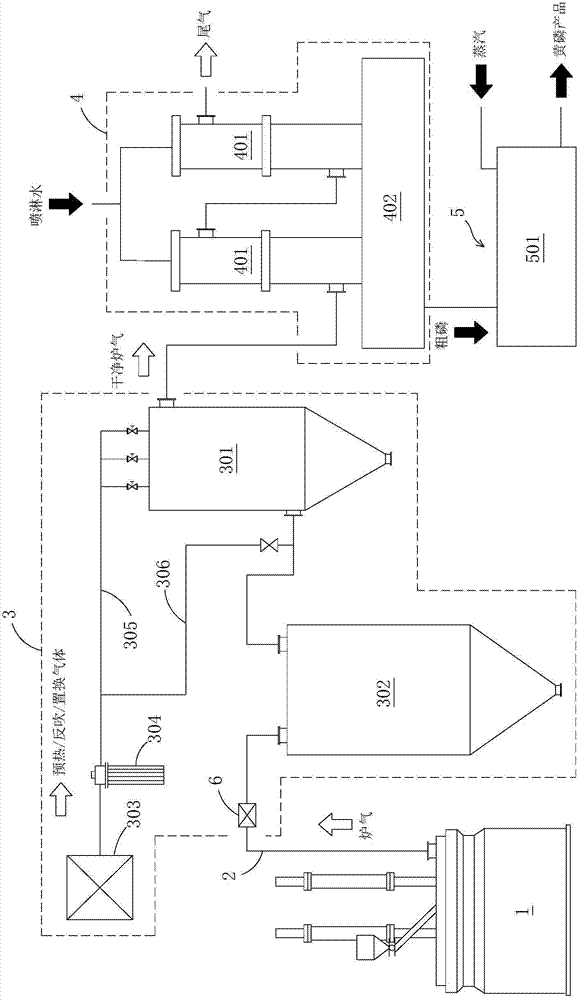

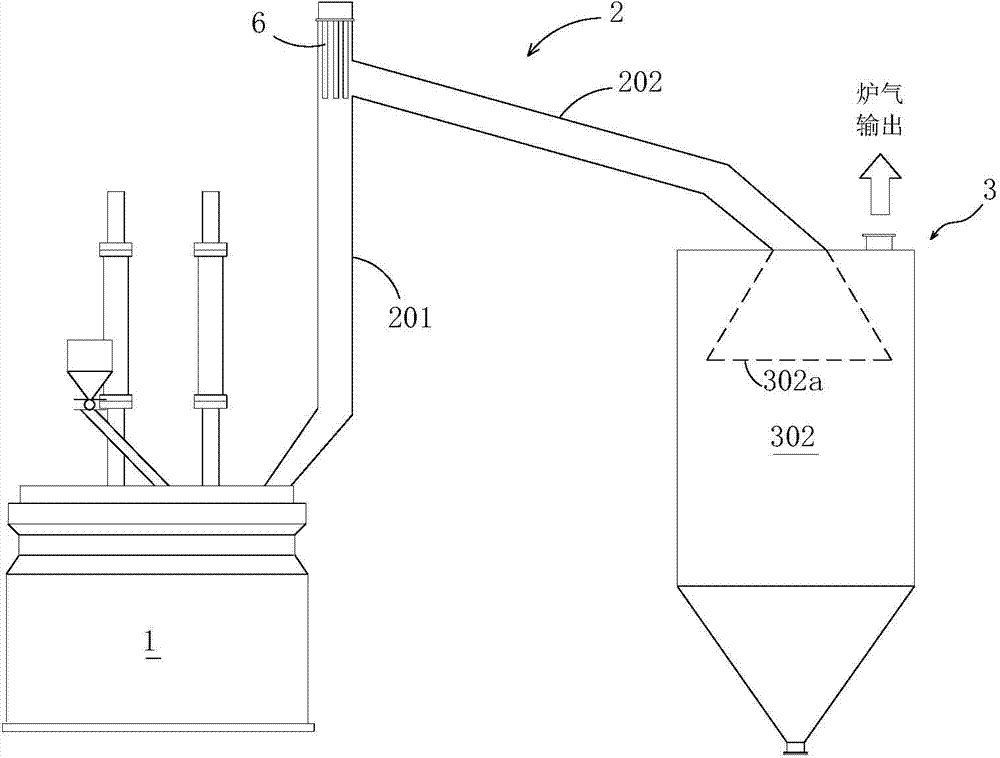

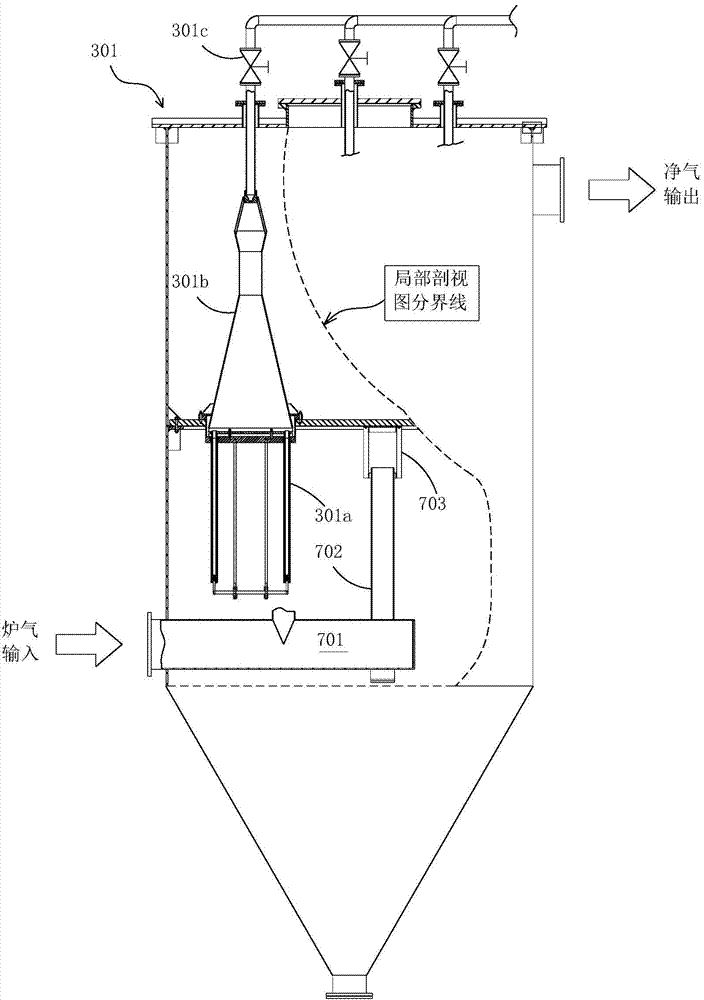

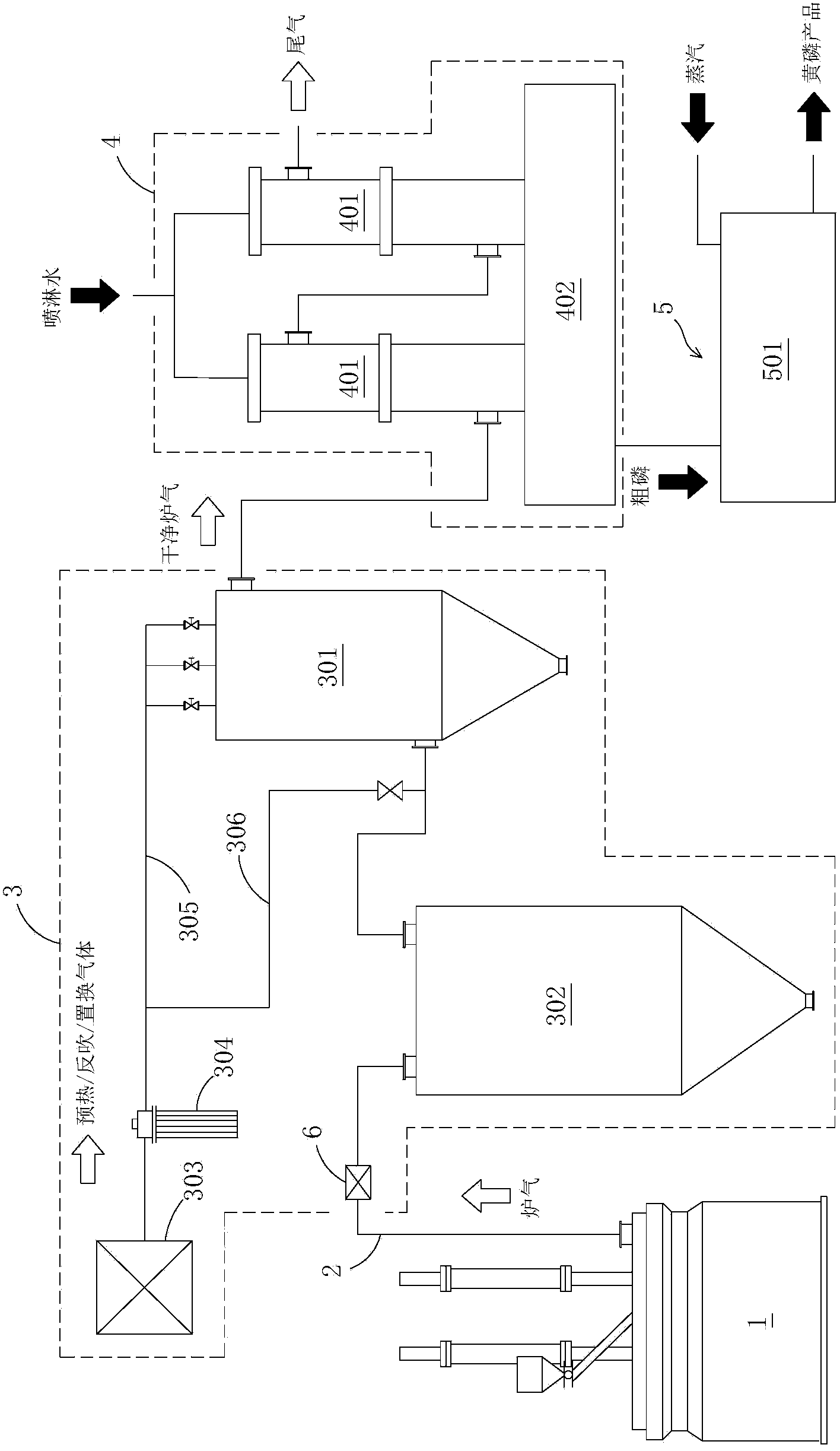

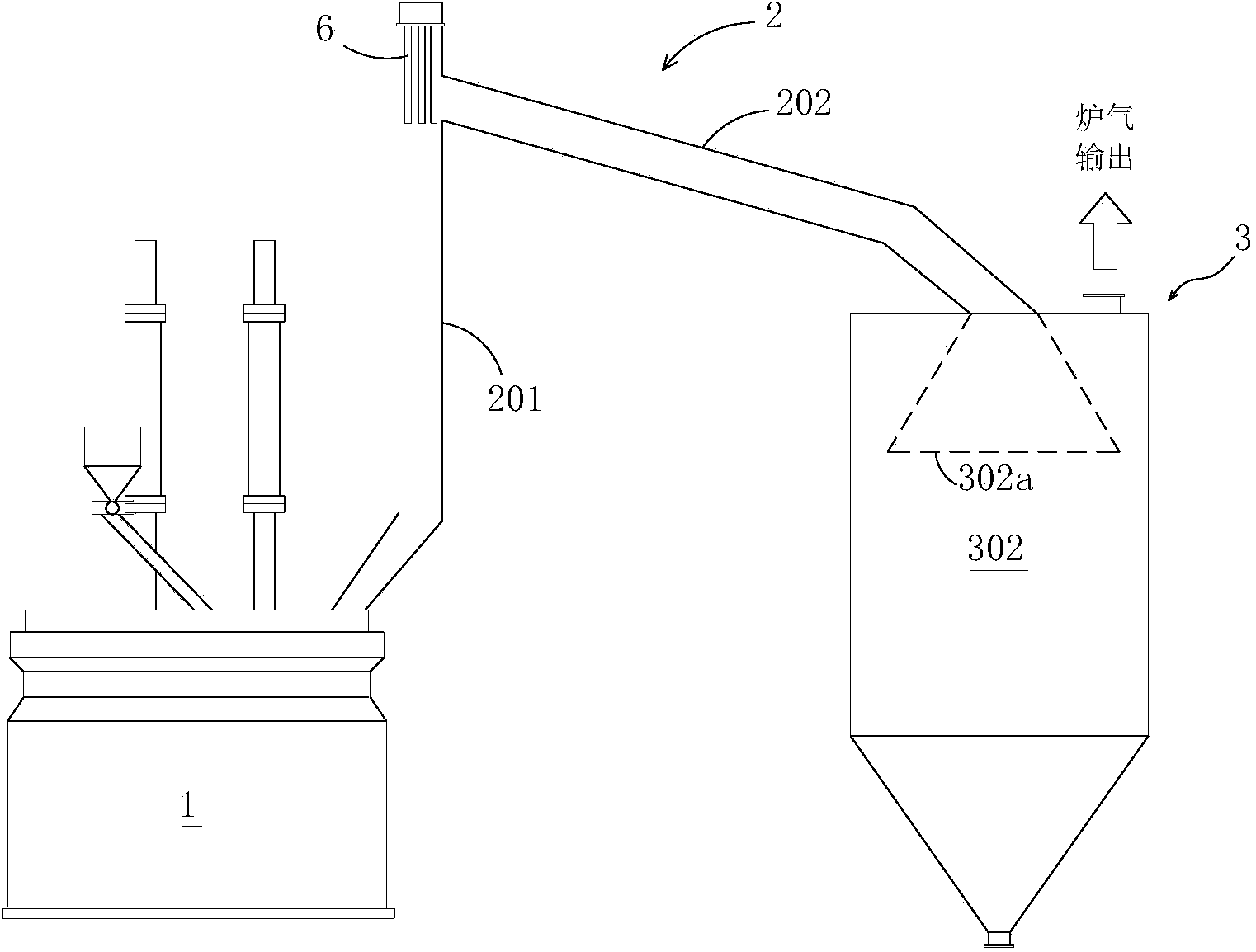

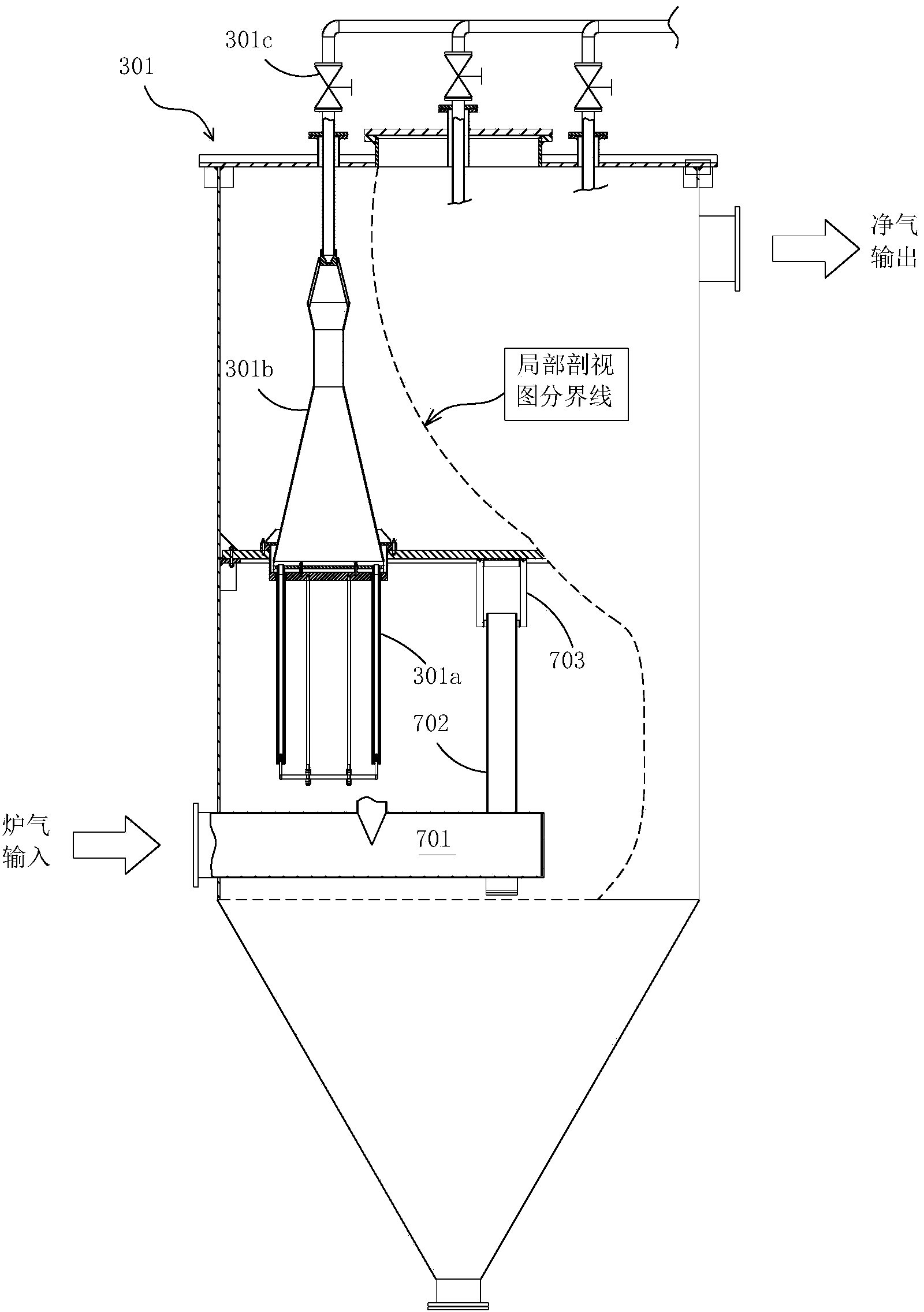

Yellow phosphorus preparation method and yellow phosphorus preparation equipment

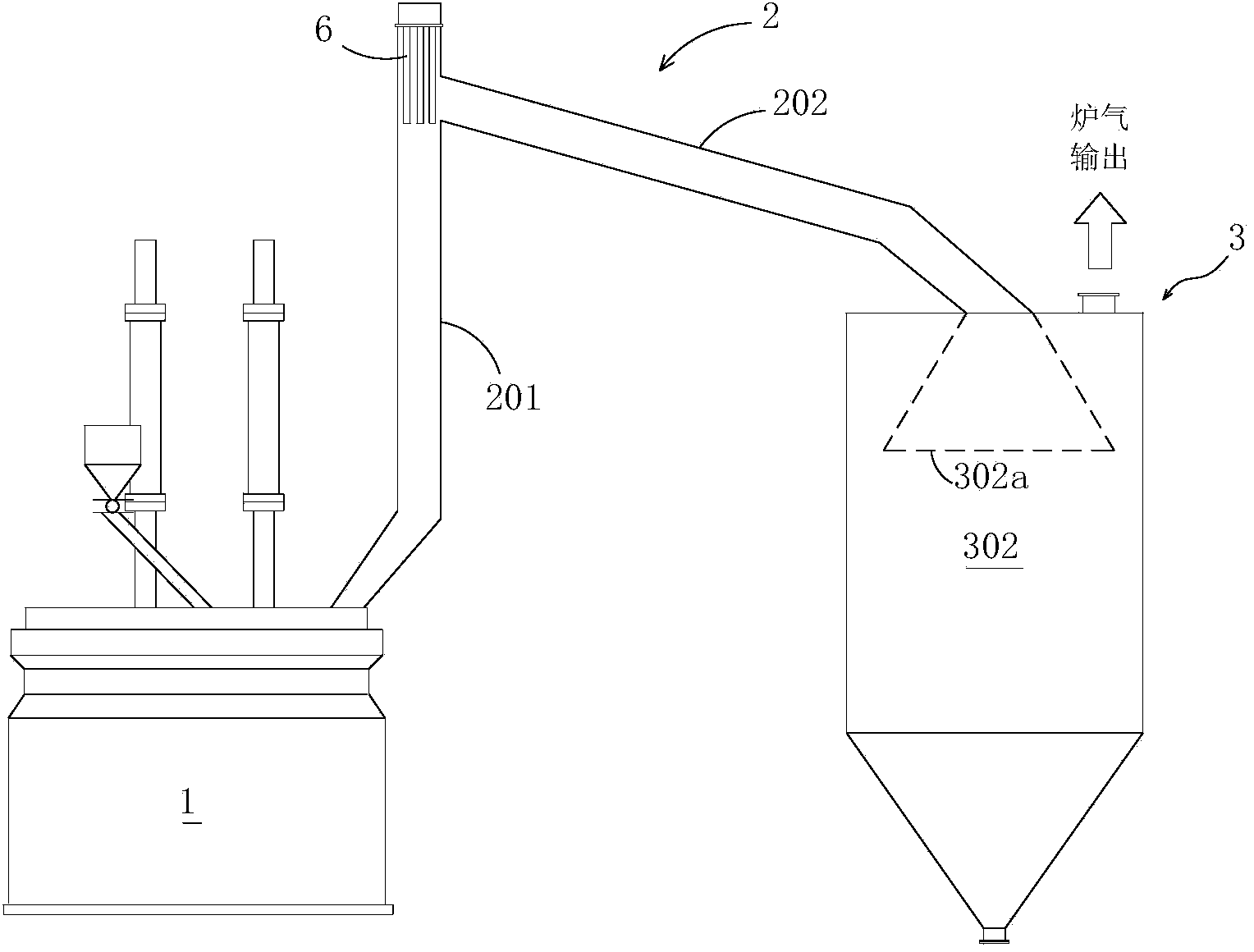

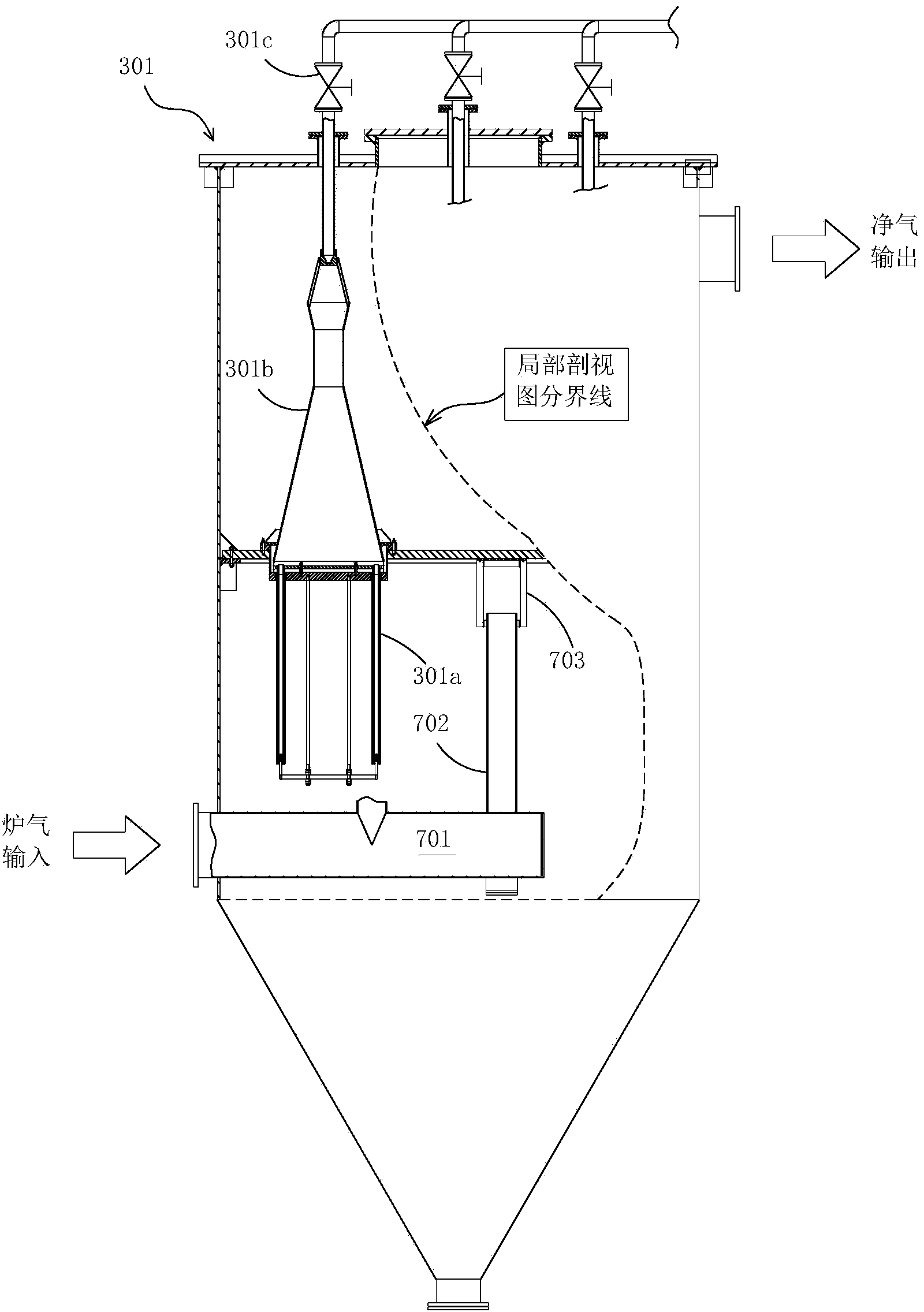

ActiveCN103508429AHigh filtration precisionGood thermal shock resistancePhosphorus compoundsProcess engineeringSlurry

The invention discloses a yellow phosphorus preparation method and yellow phosphorus preparation equipment, which produce no phosphorous slurry and reduce the dust content of tail gas. The yellow phosphorus preparation method comprises the technological processes of electric furnace smelting, furnace gas purifying and phosphorus collecting and refining. In the process of furnace gas purifying, the furnace gas discharged out from an electric furnace is guided into a furnace gas dust-collection system through a smoke discharge pipeline, the furnace gas dust-collection system at least comprises a filter for filtering the furnace gas, the filter is provided with a sintering inorganic porous material filter element meeting the following working conditions, and the operations executed on the filter comprise the operation executed during starting a machine, the operation executed during normal operation, the operation executed during back flowing and the operation executed during stopping the machine; in the operation executed during starting the machine, pre-heated inertia gas is injected into the filter so as to preheat the sintering inorganic porous material filter element in the filter to the temperature of more than 187.5 DEG C, and in the operation executed during the normal operation, the to-be-filtered furnace gas of which the temperature is kept at 420-590 DEG C is input into the filter and the dust content of the filtered clean furnace gas is lower than 10-20 mg / m<3>.

Owner:CHENGDU INTERMENT TECH

Non-oxide composite refractory materials for molten iron chute

The invention relates to a technology for preparation of refractory material, and especially to a composite refractory of non-oxidized substance used in a hot-metal launder of consecutive pre-processing. The composite refractory of non-oxidized substance used in a hot-metal launder is characterized in that it contains (wt %) 50-70 % of corundum material, 15-30 % of silicon carbide, 3-10 % of silicon nitride, 3-10 % of silicon nitride tiny powder, 1-5 % of charcoal material, 1-3 % of silicon anti-oxidization agent, 6-15 % of additional silicasol astringent, and a few additives containing anti-knock agent and dispersing agent with 0.15-1.5 % by wt. The refractory material of the said invention can resist the erosion of the hot-metal and the molten ash and is of strong erosion ability, uniform and high-integrity structure, high intensity at a medium-high-temperature, strong stability of resistance to heat shocks and of volume of material, and strong resistance to oxidation, so it adapts to the process requirement of the desired hot-metal launder of consecutive pre-processing.

Owner:BAOSHAN IRON & STEEL CO LTD

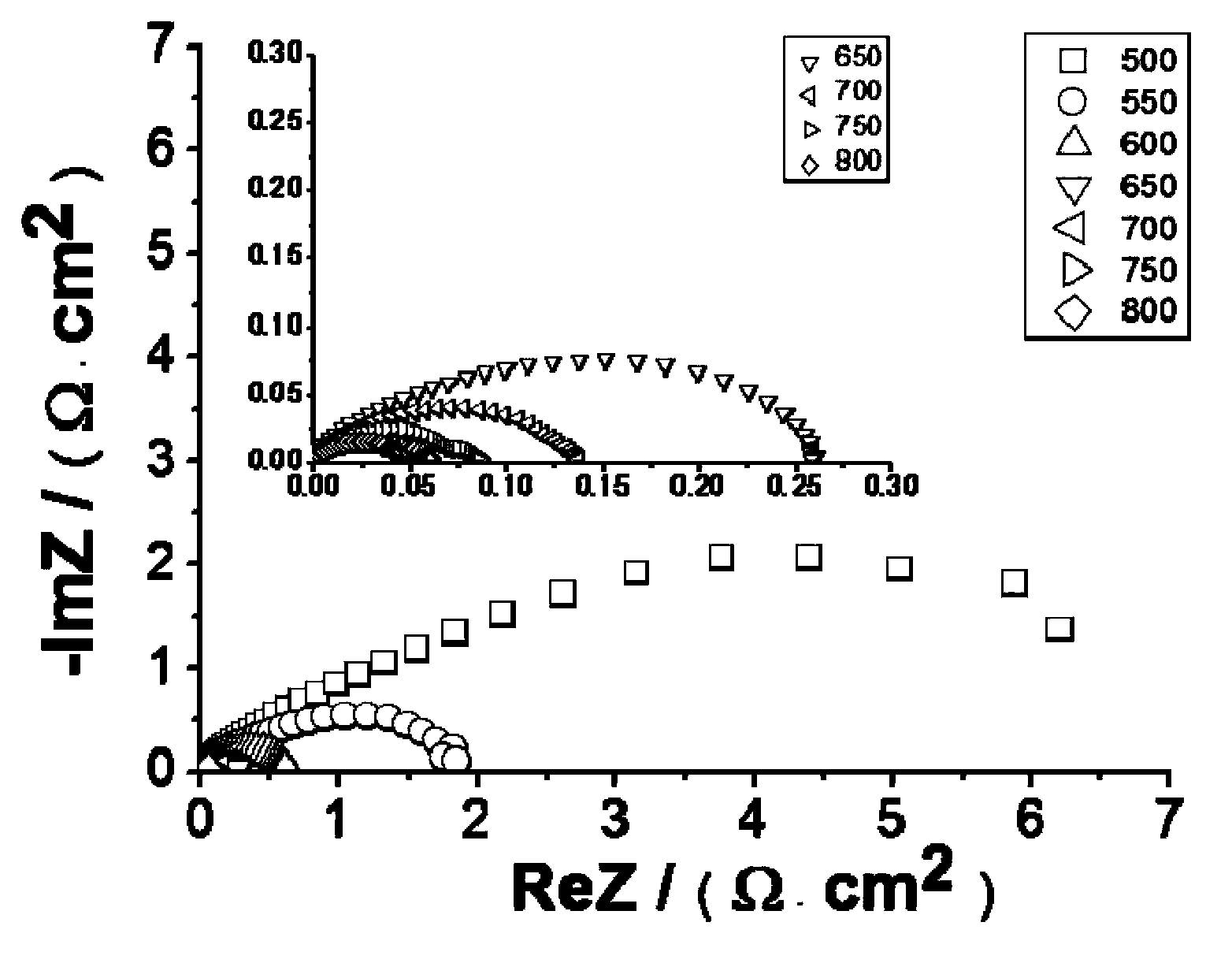

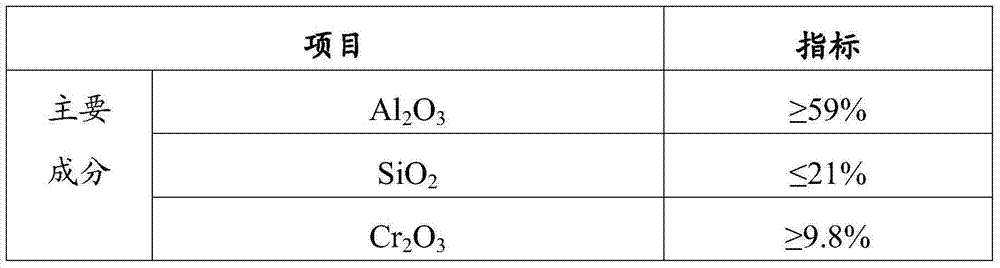

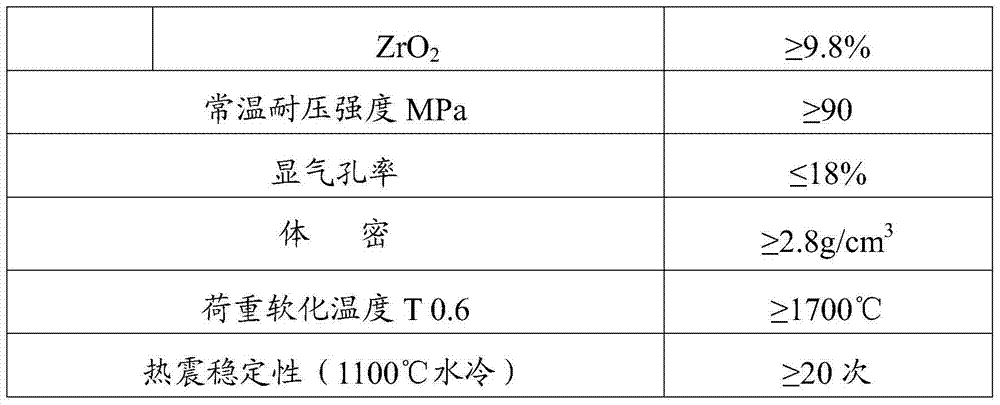

Solid oxide fuel cell with symmetrical electrodes, and preparation method and application thereof

InactiveCN103811789AGood thermal expansion matching performanceGood thermal shock resistanceCell electrodesSolid electrolyte fuel cellsChemistryThermal shock

The invention discloses a solid oxide fuel cell with symmetrical electrodes and a preparation method and application thereof. The solid oxide fuel cell has the following symmetrical structure: an electrocatalysis membrane electrode deposited on the inner wall of the pore of a porous electrolyte, a compact electrolyte layer and another electrocatalysis membrane electrode deposited on the inner wall of the pore of the porous electrolyte. The preparation method comprises the following steps: preparing a porous electrolyte / compact electrolyte / porous electrolyte skeleton structure and an electrocatalysis membrane electrode infiltration precursor solution; infiltrating the prepared porous electrolyte / compact electrolyte / porous electrolyte skeleton structure in the electrocatalysis membrane electrode infiltration precursor solution by using an impregnation method; and carrying out heat treatment. The cell provided by the invention has the advantages of good thermal expansion coupling performance, good thermal shock resistance, low cost, a short preparation period, etc.; and when hydrocarbon is used as a fuel, carbon deposition on the positive electrode of the cell can be effectively prevented, and the cell can be used as an electrolytic bath and has commercialization prospects.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Silicon carbide bonded carbon-containing fireproof material and preparation method thereof

The invention relates to a carbon-containing fireproof material with excellent oxidation resistance and high intensity. The fireproof material comprises an aluminum-carbon fireproof material, a magnesium-carbon fireproof material and a zirconium-carbon fireproof material. The fireproof material is mainly applied to an inner lining of a smelting furnace, a molten metal flow guiding pipe or a flow controller during metallurgy and casting. During preparation of the carbon-containing fireproof material, polycarbosilane is used as a bonding agent, and a cracking reaction is performed during a sintering process to generate silicon carbide fibers and to form a silicon carbide bonded component. The silicon carbide bonded component has better oxidation resistance than a resin carbon bonded component and has a quite high bonding strength with fireproof aggregates; in addition, bonded carbon formed after the silicon carbide fibers and phenolic resin are carbonized has similar thermal conductivity and thermal expansion coefficients, so the silicon carbide bonded carbon-containing fireproof material has thermal shock resistance equivalent to the thermal shock resistance of a resin carbon bonded carbon-containing fireproof material. The polycarbosilane is a polymer which can be pyrolyzed to obtain the silicon carbide and comprises a main chain or branched chains mainly containing Si and C, and the amount of the added polycarbosilane is 8-12 percent of the weight of raw materials.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Chromium zirconium mullite refractory material and preparation method thereof

ActiveCN103496992AGood thermal shock resistanceHigh temperature slag resistanceRefractoryMelting furnace

The invention relates to a chromium zirconium mullite refractory material and a preparation method thereof. The chromium zirconium mullite refractory material takes fused mullite or sintered mullite as an aggregate and takes zirconite powder, corundum powder and chromium oxide green as product matrix parts. The raw materials of the refractory material comprise 65% of mullite, 10% of corundum powder, 15% of zirconite powder and 10% of chromium oxide green by weight. The sintered chromium zirconium mullite refractory product is mainly used in glass melting furnaces, glass fiber melting furnaces and steel and chemical kilns, and has the high temperature use characteristics of excellent thermal shock resistance, strong high temperature cracking and slag resistance, no stripping and the like.

Owner:ZHENGZHOU HRD NEW MATERIAL CO LTD

Corundum breathable seat brick with high thermal shock resistance and production method thereof

The invention discloses a corundum breathable seat brick with high thermal shock resistance. The brick consists of mixed corundum, a magnesium-containing material, a binding agent, chromium oxide, a water reducing agent and an explosion-proof agent. The production method of the corundum breathable seat brick comprises the following steps: dosing, and mixing to prepare mud; placing the mud in a mould, performing shake densification, demoulding, and drying to obtain a breathable seat green brick; and heating the breathable seat green brick, and roasting to obtain the corundum breathable seat brick with thermal shock resistance. The component ratio is reasonable, the production and preparation method is simple, the prepared breathable seat brick has good high-temperature strength and thermal shock resistance; and the service life of the breathable seat brick can be effectively prolonged, the use security of the breathable brick can be increased, the replacement times of the breathable brick can be reduced, the production cost of enterprises can be reduced and the production efficiency of ferrous metallurgy can be increased. The corundum breathable seat brick can replace the existing breathable seat brick and be suitable for industrial production.

Owner:CENT SOUTH UNIV

Plastic refractory and use thereof

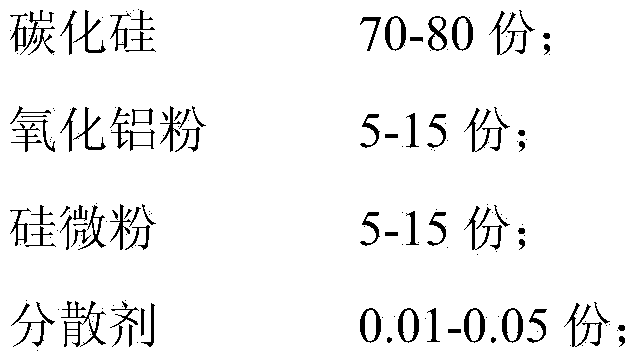

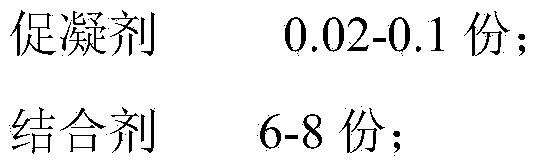

The invention relates to the field of a refractory matter, and particularly relates to a plastic refractory and use thereof. The invention provides a plastic refractory. The plastic refractory comprises the following raw materials in parts by weight: 70-80 parts of silicon carbide, 5-15 parts of alumina powder, 5-15 parts of silica powder, 0.01-0.05 part of dispersing agents, 0.02-0.1 part of coagulant, and 6-8 parts of binding agents, wherein the silicon carbide comprises powder SiC and aggregate SiC; and the weight ratio of the powder SiC to the aggregate SiC is 1:(1.8-1.9). Compared with the prior art, the plastic refractory disclosed by the invention not only has the advantages of being good in workability and moderate in hardening speed, but also has good using performances, such as high strength, good abrasive resistance, good corrosion-resistance, good thermal shock stability, and good heat-conducting property, and can completely meet the operating requirements of a burner of a pulverized coal fired steam boiler.

Owner:BAOJIUHE REFRACTORY

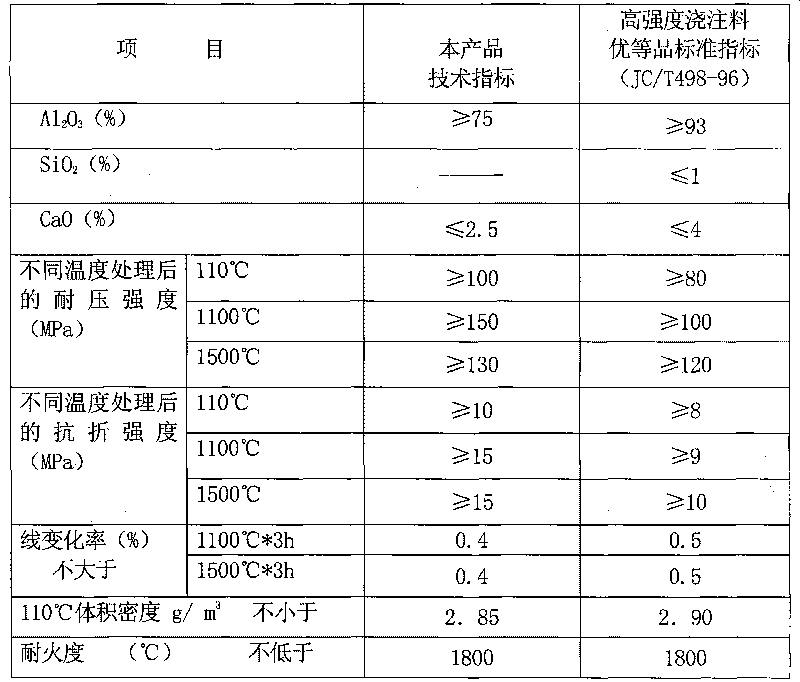

High-strength steel fibre castable

The invention discloses a high-strength steel fibre castable which is prepared by the following raw materials in parts by weight: 2.5 parts of bauxite material with the granularity of 8-5mm, 2.3 parts of bauxite material of which the granularity is more than 0.075mm and is less than 5mm, 2 parts of brown aluminium oxide particle material with the granularity of 3-1mm, 0.8 part of bauxite material of which the granularity is less than or equal to 0.075 mm, 0.4 part of alumina submicron powder of which the granularity is less than or equal to 0.025 mm, 0.6 part of carborundum powder of which the granularity is less than or equal to 0.075 mm, 0.3 part of silica micropowder of which the granularity is less than 0.019 mm, 0.6 part of CA-70 cement, 0.5 part of brown aluminium oxide powder of which the granularity is less than 0.053 mm, 0.2 part of No. 446 heat-resistant steel fiber, 0.02 part of anti-explosion steel fiber, sodium tripolyphosphate accounting for 0.1% of total material weight and sodium hexametaphosphate accounting for 0.08% of total material weight. The product has high compression strength, high breaking strength, high refractoriness under load and favorable thermal shock resistance stability, has the characteristic of microdilatancy at high temperature and has the advantages of favorable wear-resisting property and the like.

Owner:郑州真金耐火材料有限责任公司

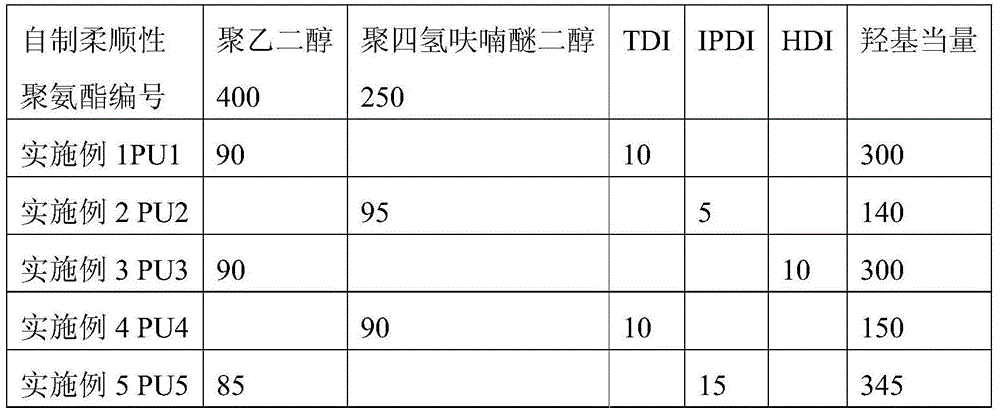

Insulation packaging material of high capacity film capacitor

ActiveCN104130547AGood resistance to heat and humidityGood thermal shock resistanceFilm capacitorCapacitance

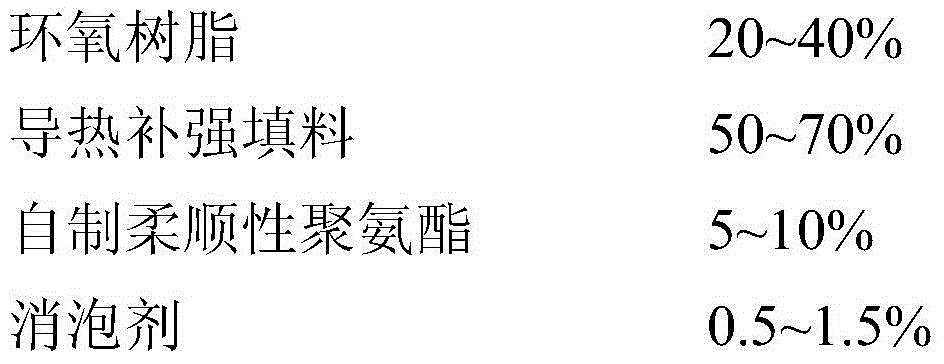

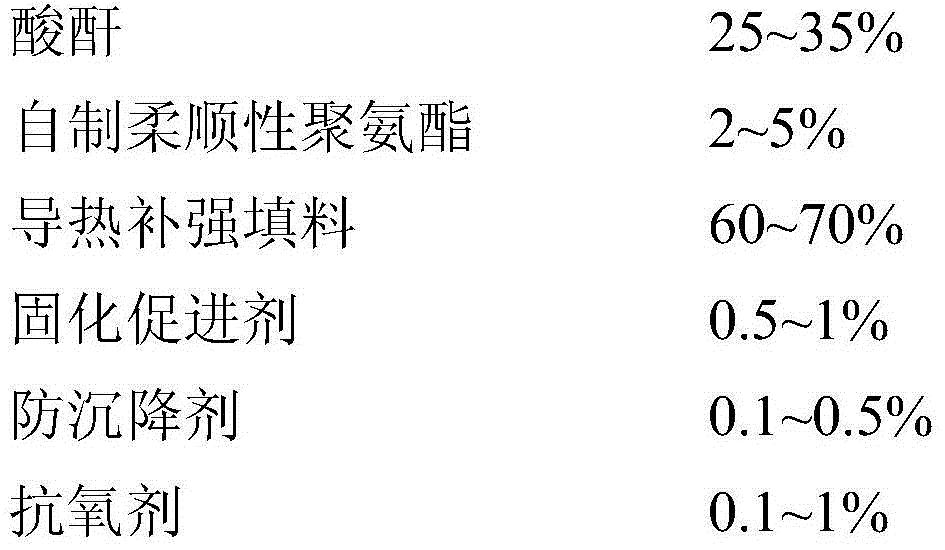

An insulation packaging material of a high capacity film capacitor comprises a component A and a component B, wherein raw materials of the component A comprise 20-40wt% of epoxy resin, 50-70wt% of a heat conduction reinforcing filler, 5-10wt% of a self-made compliant polyurethane and 0.5-1.5wt% of an antifoaming agent; and raw materials of the component B comprise 25-35wt% of acid anhydride, 2-5wt% of the self-made compliant polyurethane, 60-70wt% of the heat conduction reinforcing filler, 0.5-1wt% of a curing accelerant, 0.1-0.5wt% of an anti-settling agent and 0.1-1wt% of an antioxidant. The curing packaging material is obtained through the steps of mixing the component A with the component B according to a weight ratio of 100:90-100, uniformly stirring, carrying out vacuum defoaming, filling, curing at 70-80DEG C for 2-3h, and ageing at 100-110DEG C for 6-8h. The packaging material has the advantages of excellent weatherability, hot and cold impact resistance, good bonding force with metals and plastics, and solving of the insulation packaging problem of the high capacity film capacitor.

Owner:无锡东润电子材料科技有限公司

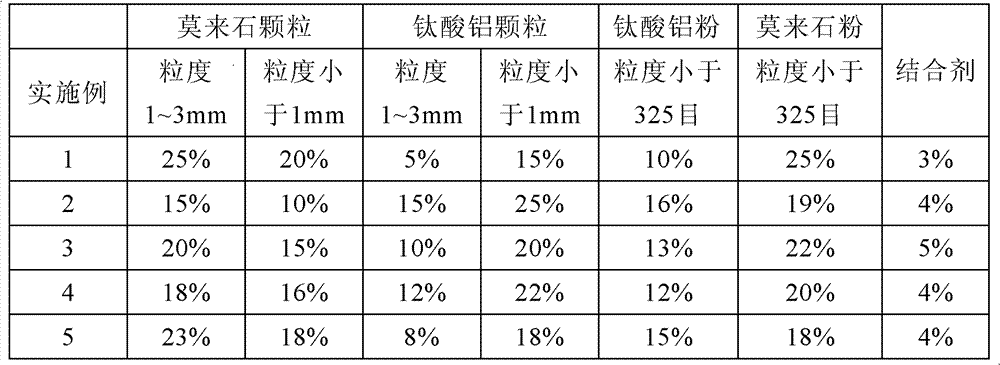

Aluminium titanate mullite composite monoblock stopper and preparation method thereof

The invention relates to an aluminium titanate mullite composite monoblock stopper and a preparation method thereof. The stopper body and the stopper head of the monoblock stopper are prepared by the same materials. The mass percentages of the materials are as follows: 15-25% of mullite particles with the granularity of 1-3 mm, 5-15% of aluminium titanate particles with the granularity of 1-3 mm, 10-20% of mullite particles with the granularity less than or equal to 1 mm, 15-25% of aluminium titanate particles with the granularity less than or equal to 1 mm, 10-16% of aluminium titanate powder with the granularity less than or equal to 325 meshes, 19-25% of mullite powder with the granularity less than or equal to 325 meshes and 3-5% of an additional binding agent. The monoblock stopper has excellent whole structural properties, prevents the oxidation problem produced by using carbon-containing materials, has relatively high liquid erosion resistance and relatively long service life, can solve the problems of falling off of sleeve brick-type stopper head and stopper cracking, simultaneously creates conditions for casting high oxygen and ultra-low carbon steel, and provides conditions for guarantee of the service life of the stopper after a submerged nozzle is changed quickly.

Owner:BAOSHAN IRON & STEEL CO LTD

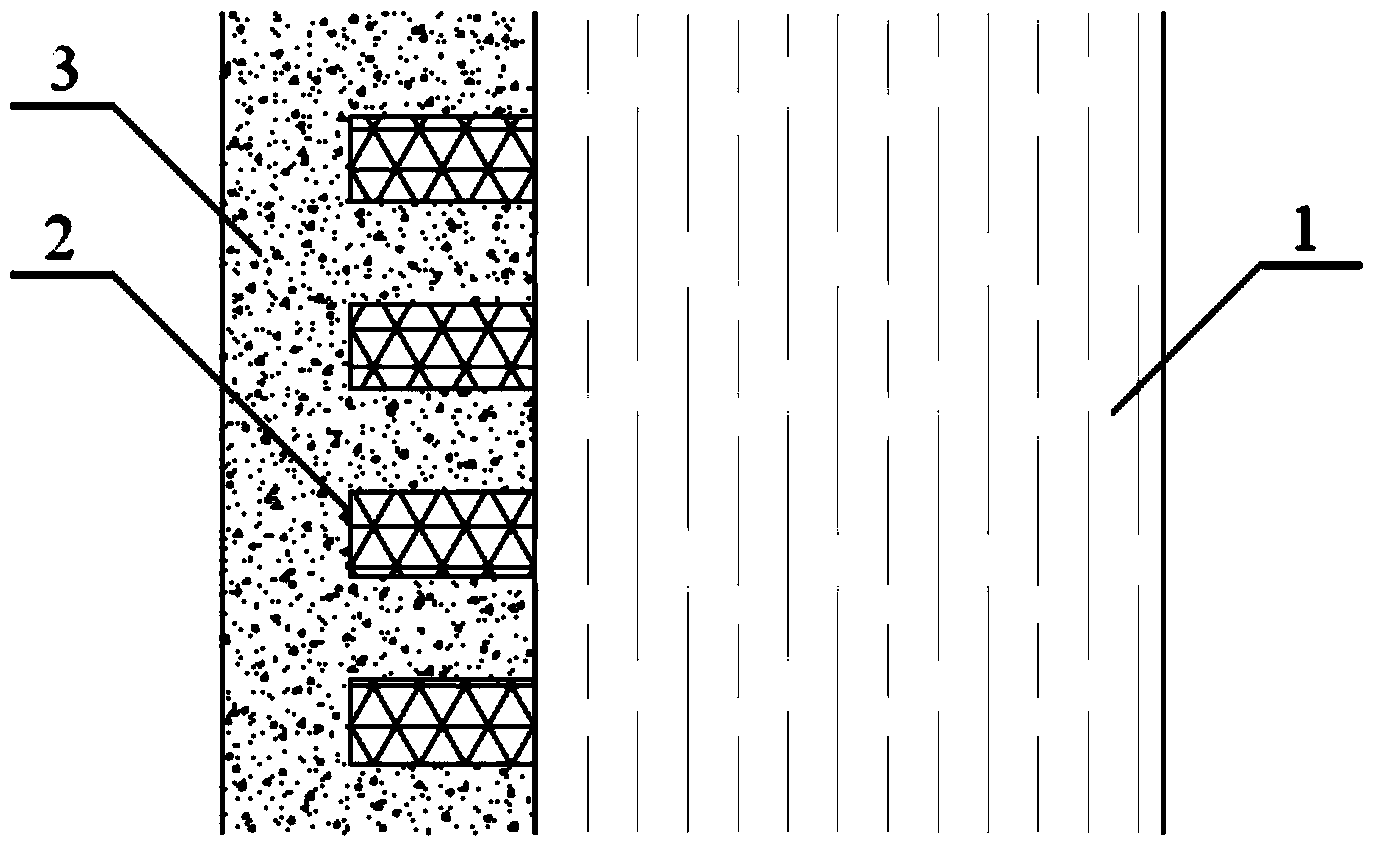

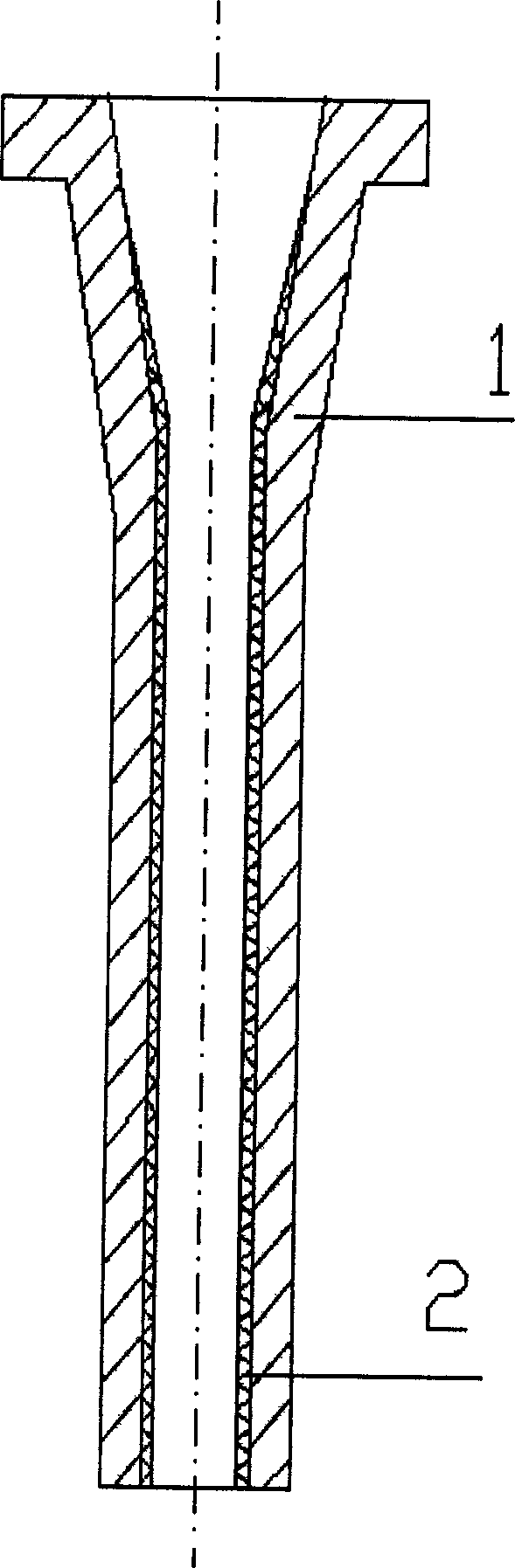

Long nozzle in composite structure free from prewarming

ActiveCN1796025AGood thermal shock resistanceResistance to molten steel erosionMelt-holding vesselsComposite structureNozzle

The present invention belongs to a functional refractory material for continuous casting process, and provides a non-preheating long sprue with composite structure. It includes an external layer made of Al2O3-C material and a lining which contains no carbon material and is combined on the inner wall of said external layer. Said lining material is formed from metal powder additive, three-component system Al2O3-MgO-TiO2 synthetic material with low expansion coefficient, sintered or electrofused spinel and corundum, in which the content of spinel and corundum is 25-70wt%, content of Al2O3-MgO-TiO2 synthetic material is 25-70 wt% and the content of metal powder is 2-10 wt%.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Fireproof spraying coating for steel ladle working lining and preparation method of fireproof spraying coating

The invention relates to a fireproof spraying coating for a steel ladle working lining. The fireproof spraying coating is prepared from the following raw materials in parts by weight: 20-50 parts of sintered bauxite clinker, 10-20 parts of fused magnesite, 8-20 parts of fused magnesia-alumina spinel, 5-12 parts of fused white corundum, 5-10 parts of active alumina micropowder, 3-10 parts of andalusite, 3-7 parts of silicon dioxide micropowder, 2-5 parts of a sintering agent, 0.1-0.2 part of externally added explosion-proof fibre, and 0.1-0.3 part of an externally added compound water-reducing agent. The fireproof spraying coating disclosed by the invention is simple in preparation method and simple and convenient to construct; rapid construction maintenance and rapid use of the steel ladle working lining can be realized; because of being compounded by adopting a carbon-free material, the fireproof spraying coating is environment friendly and free from pollution; therefore, molten steel can be purified effectively; the characteristics of high-temperature molten steel to the steel ladle working lining, such as washing resistance, slag corrosion resistance, thermal shock resistance and product comprehensive benefits, can be sufficiently improved; and the service life of the steel ladle working lining can be increased and prolonged effectively.

Owner:HUANGHE S & T COLLEGE

Yellow phosphorus preparation method and yellow phosphorus preparation equipment

ActiveCN103508429BHigh filtration precisionGood thermal shock resistancePhosphorus compoundsElectric arc furnaceSlurry

The invention discloses a yellow phosphorus preparation method and yellow phosphorus preparation equipment, which produce no phosphorous slurry and reduce the dust content of tail gas. The yellow phosphorus preparation method comprises the technological processes of electric furnace smelting, furnace gas purifying and phosphorus collecting and refining. In the process of furnace gas purifying, the furnace gas discharged out from an electric furnace is guided into a furnace gas dust-collection system through a smoke discharge pipeline, the furnace gas dust-collection system at least comprises a filter for filtering the furnace gas, the filter is provided with a sintering inorganic porous material filter element meeting the following working conditions, and the operations executed on the filter comprise the operation executed during starting a machine, the operation executed during normal operation, the operation executed during back flowing and the operation executed during stopping the machine; in the operation executed during starting the machine, pre-heated inertia gas is injected into the filter so as to preheat the sintering inorganic porous material filter element in the filter to the temperature of more than 187.5 DEG C, and in the operation executed during the normal operation, the to-be-filtered furnace gas of which the temperature is kept at 420-590 DEG C is input into the filter and the dust content of the filtered clean furnace gas is lower than 10-20 mg / m<3>.

Owner:CHENGDU INTERMENT TECH

Yellow phosphorus production method and equipment

ActiveCN103523762BHigh filtration precisionGood thermal shock resistancePhosphorus compoundsEngineeringYellow phosphorus

The invention discloses a yellow phosphorus production method and equipment which do not produce mud phosphorus and can reduce the dust content in tail gas. The method comprises the technology links as follows: 1, electric furnace smelting; 2, furnace gas purification, furnace gas discharged from an electric furnace is guided into a furnace gas dust collecting system through an exhaust pipeline, the furnace gas dust collecting system comprises at least a filter used for filtering the furnace gas, the filter is provided with a sintering inorganic porous material filter element capable of meeting following work conditions, and the operation performed according to the filter comprises the steps as follows: 1), the operation executed during driving: inert preheating gas is injected into the filter, and the sintering inorganic porous material filter element in the filter is heated to 187.5 DEG C or above; 2), the operation executed during normal operation: to-be-filtered furnace gas with the temperature maintained to be 187.5-280 DEG C is input into the filter, and the dust content in the filtered clean furnace gas is below 10-20 mg / m <3>; and 3), the operation executed during reverse blowing and 4) the operation executed during parking; and 3, phosphorus collecting and refining.

Owner:CHENGDU INTERMENT TECH

Preparation method of in-situ generated mullite whisker ceramic material

The invention discloses a preparation method of an in-situ generated mullite whisker ceramic material. According to the preparation method, coal gangue and high bauxite are used as raw materials, polycrystal mullite fibers are added and used as seed crystals, chlorine trifluoride is added and used as a whisker growth catalyst, and generation of mullite whiskers in the sintering process is promoted; the crystal structure of acidized potassium feldspar is damaged, the liquid-phase formation temperature of a ceramic blank system is lowered, fusion of substances in ceramic blank is promoted, formation and growth of mullite crystals are promoted, the aim of lowering the ceramic sintering temperature is achieved, and energy consumption is lowered; through gel injection molding and two-segment high-temperature sintering, in-situ generated mullite whiskers develop completely, a three-dimensional network structure is formed in the ceramic material, the ceramic material has high porosity, a gelinjection molding technology is adopted at the same time, the pore distribution state of final ceramic can be adjusted and controlled, and the light heat insulation performance of the ceramic materialis improved.

Owner:马鞍山科润冶金材料有限公司

Inorganic anti-radiation coating for lining of radiation chamber of ethylene cracking furnace and preparation method of inorganic anti-radiation coating

InactiveCN104109407AGood thermal shock resistanceImprove efficiencyChemical industryReflecting/signal paintsCobalt oxideSodium silicate

The invention discloses an inorganic anti-radiation coating for a lining of a radiation chamber of an ethylene cracking furnace. The inorganic anti-radiation coating comprises the following components in parts by weight: 15-20 parts of cobalt oxide, 1-10 parts of zirconium oxide, 3-10 parts of aluminum oxide, 1-5 parts of silica powder, 8-12 parts of silicon carbide, 3-7 parts of chromium oxide, 0-8 parts of manganese oxide, 0-5 parts of carborundum, 2-10 parts of sodium silicate, 5-8 parts of aluminum dihydrogen phosphate, 1-5 parts of quartz powder, 1-5 parts of feldspar powder, 10-15 parts of phosphorus pentoxide, 0-3 parts of chrome iron ores, 0-2 parts of zircon sand, 0-1 part of cerium oxide, 1-4 parts of graphite powder, 0.5-1.0 part of boron oxide and 0.1-0.5 part of carclazyte, wherein the particle of each solid component is not smaller than 350 meshes. The invention also discloses a preparation method of the inorganic anti-radiation coating for the lining of the radiation chamber of the ethylene cracking furnace. By using the inorganic anti-radiation coating disclosed by the invention, the high temperature resistance and thermal shock resistance of the coating can be effectively improved, the utilization ratio of radiant energy can be increased, and the binding force of the coating and the lining material of the cracking furnace can be enhanced.

Owner:上海乐恒石油化工集团有限公司

Refractory materials and refractory equipment for aluminum alloy melt casting, and method for preparing refractory equipment

The invention discloses a fire-resisting material used for aluminum alloy fusion casting, and a fire-resisting apparatus made of the fire-resisting material and a method for preparing the fire-resisting apparatus, wherein the fire-resisting material comprises aluminum silicate fiber powder, talcum powder, mullite powder, zirconite powder and a silica sol solution. The fire-resisting material has the advantages of no aluminum adhesion and no chemical reaction with an aluminum liquid, no addition of asbestos, rapid deslagging and no damage after using a prefabricated molding assembling part, better thermal-shock resistance, durability, controllable concentration, intensity and thermal-shock resistance, and small shrinkage mass of a cooling process after use to effectively prevent the assembling joint of the prefabricated molding part from cracking. The corresponding fire-resisting apparatus has the advantages of heat shock resistance, washing resistance, corrosion resistance, and small heat expansion coefficient.

Owner:SOUTHWEST ALUMINUM GRP +1

Bottom bonding material used in preservative treatment of chimney and flue

ActiveCN101602927AReduce load requirementsStrong weather resistanceNon-macromolecular adhesive additivesWeather resistanceStrong acids

The invention relates to a bottom bonding material used in preservative treatment of a chimney and a flue. The bottom bonding material is modified silicon rubber (M50), and surface modified polytetrafluoroethylene (DS1) of a surface preservative material is bonded to the inner walls of the chimney and the flue; the modified silicon rubber (M50) is formed by modifying room-temperature vulcanized silicon rubber through nano SiOx and TiO2 additives, and the weight ratio of the room-temperature vulcanized silicon rubber to the nano SiOx to the TiO2 is 100:2-6:1-3; and x in the nano SiOx is 1.2 to 1.6. The bottom bonding material can provide effective bonding for DS1 (surface modified polytetrafluoroethylene board) with temperature resistance and strong corrosion resistance in the preservative treatment of the chimney and the flue so that an integral preservative layer has good temperature resistance, strong adhesive force, super-strong acid resistance, good thermal shock resistance, good weather resistance, strong permeability resistance, strong pollution resistance and good scouring resistance.

Owner:重庆大众防腐股份有限公司

Rafractory for molten iron discharge channel of blast furnace

InactiveCN1465548AGood thermal shock resistanceImprove corrosion resistanceDischarge devicesMetallic aluminumPhysical chemistry

The composition of refractory material for tapping spout includes (by weight portion) brown corundum aggregate formed from 12-14 portions of 8-5 mm aggregate, 16-18 portions of 5-3 mm aggregate, 23-25 portions of 3-1 mm aggregate and 13-15 portions of 1-0 mm aggregate, 14-16 portions of SiC (No.90), 3-5 portions of micropowder, 0.15 portion of metal aluminium powder, 1 portion of white mud, 6 portions of cement, 0.2 portion of sodium tripolyphosphate and 5-5.5 portions of water. Said invention fealures good erosion resistance, thermal shock-resisting stability and long service life, etc.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Yellow phosphorus production method and equipment

ActiveCN103523762AHigh filtration precisionGood thermal shock resistancePhosphorus compoundsEngineeringYellow phosphorus

The invention discloses a yellow phosphorus production method and equipment which do not produce mud phosphorus and can reduce the dust content in tail gas. The method comprises the technology links as follows: 1, electric furnace smelting; 2, furnace gas purification, furnace gas discharged from an electric furnace is guided into a furnace gas dust collecting system through an exhaust pipeline, the furnace gas dust collecting system comprises at least a filter used for filtering the furnace gas, the filter is provided with a sintering inorganic porous material filter element capable of meeting following work conditions, and the operation performed according to the filter comprises the steps as follows: 1), the operation executed during driving: inert preheating gas is injected into the filter, and the sintering inorganic porous material filter element in the filter is heated to 187.5 DEG C or above; 2), the operation executed during normal operation: to-be-filtered furnace gas with the temperature maintained to be 187.5-280 DEG C is input into the filter, and the dust content in the filtered clean furnace gas is below 10-20 mg / m <3>; and 3), the operation executed during reverse blowing and 4) the operation executed during parking; and 3, phosphorus collecting and refining.

Owner:CHENGDU INTERMENT TECH

Low-activity vitreous barrier layer capable of preventing hydrogen or hydrogen isotopic from permeation and preparation thereof

InactiveCN101274818AGood thermal shock resistanceSimple preparation processLow activityMetal substrate

The invention relates to a low activity glass barrier layer for restraining the penetration of hydrogen or hydrogen isotopes and a preparation method thereof, pertaining to the technique of functional coating on metal surfaces. The glass barrier layer is characterized in that: the surface of a metal substrate is fixedly coated with the glass barrier layer of 50 to 180 Mum; the mismatch degree between the linear thermal expansion coefficient of glass powder and the metal substrate is smaller than 5 percent; components by weight percentage are one of or a plurality of 56 to 61 percent of SiO2, 3 to 10 percent of Cr2O3, TiO2 and WO3, one of or a plurality of 13 to 20 percent of Na2O, K2O and Na3AlF6, one of or a plurality of 5-12 percent of ZrO2 and ZnO, and one of or a plurality of the left percent of Cao, MgO and SrO. The preparation method of the invention has the advantages of being simple and easy for operation with low cost, being applicable to industrialized production, having extremely small mismatch degree of thermal expansion and good combination, preventing the deterioration of mechanical capacity of materials and deterioration of working environment and waste of resources by effectively restraining the penetration of the hydrogen or the hydrogen isotopes to the metal substrate, reducing the absorption of neutrons and the release of harmful rays after nuclear radiation when the coating is in use and enhancing the use temperature of the coating.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

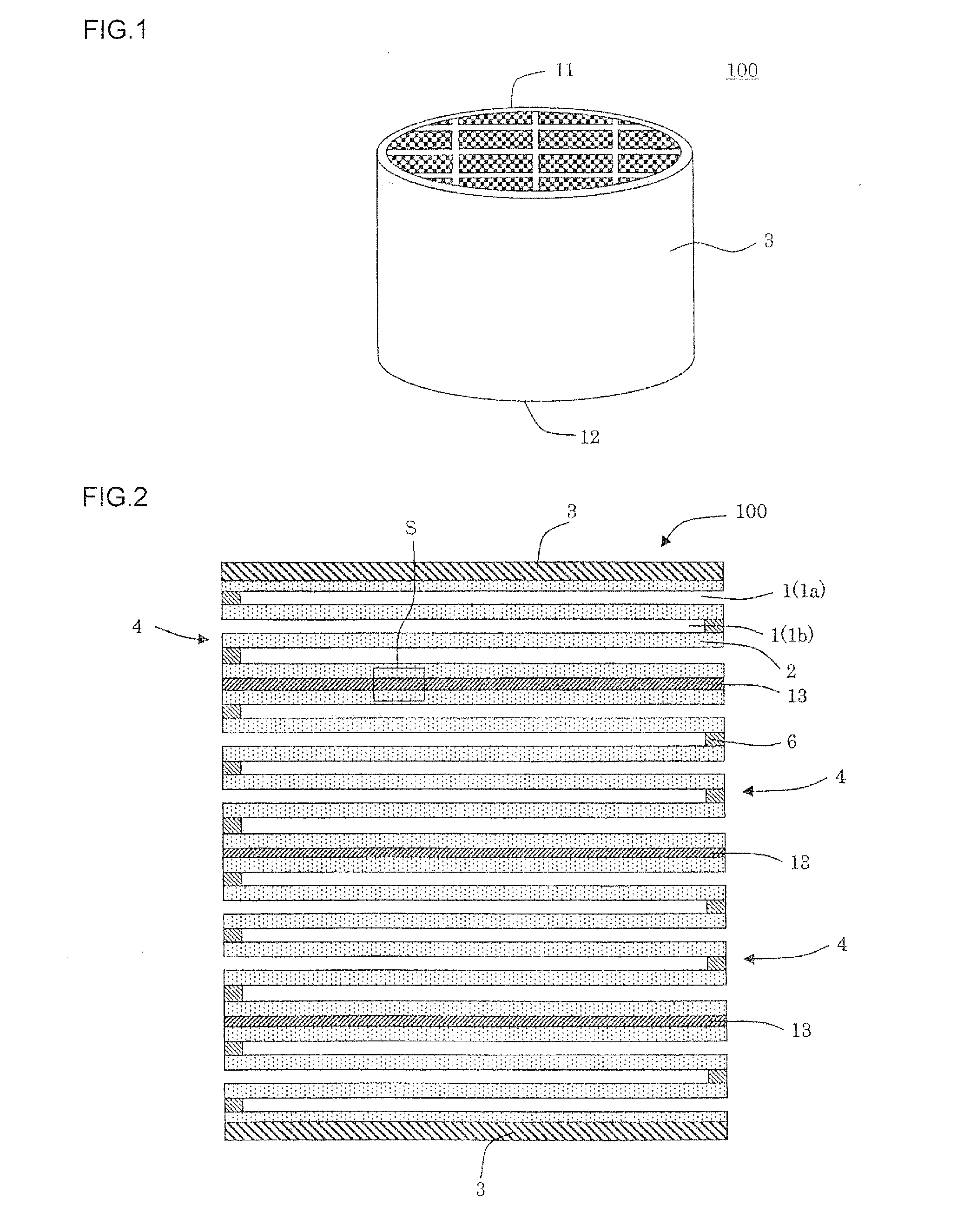

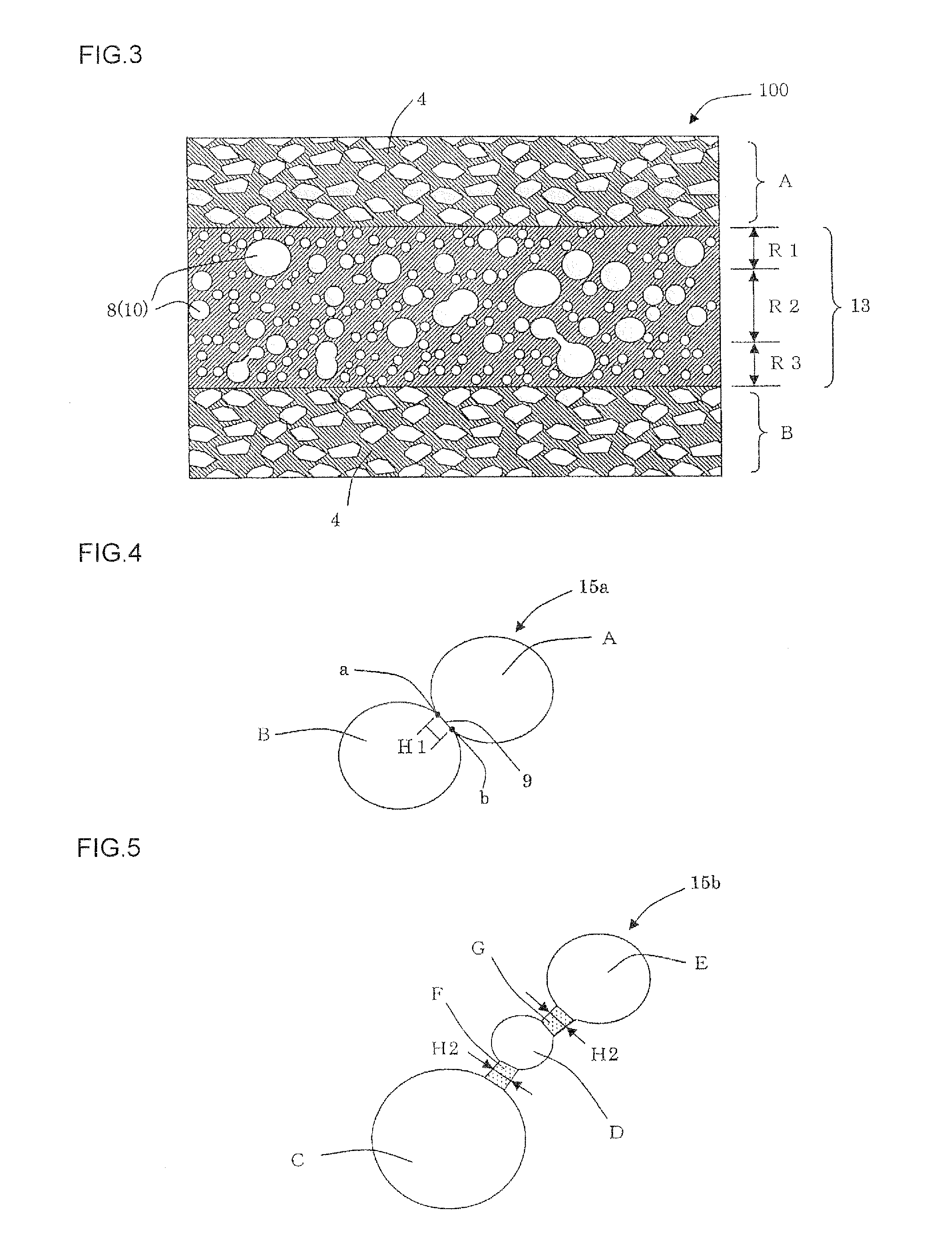

Honeycomb structure body

ActiveUS20130316130A1Good thermal shock resistanceInternal combustion piston enginesDispersed particle filtrationMaximum diameterStress relaxation

There is disclosed a honeycomb structure body having joining material layers of a stress relaxing function and joining strength equivalent to those of joining material layers of a conventional honeycomb structure body, and having an excellent heat shock resistance. A honeycomb structure body includes a plurality of honeycomb segments and joining material layers having a plurality of pores and joining the plurality of honeycomb segments in a state where the honeycomb segments are arranged adjacent to each other so that side surfaces of the honeycomb segments face each other. A ratio of the number of pores having a value of 1.2 or less which is obtained by dividing a maximum diameter of each of the pores by a minimum diameter of the each of the pores is 60% or more of the number of all the pores of each of the joining material layers.

Owner:NGK INSULATORS LTD

Metal alloy composite ceramic board and preparation technology thereof

The invention provides a metal alloy composite ceramic board and a preparation technology thereof. The metal alloy composite ceramic board comprises a plurality of metal alloy composite ceramic board base bodies, and ceramic connectors II which wrap the metal alloy composite ceramic board base bodies, wherein each metal alloy composite ceramic board base body comprises a ceramic connector I, a ceramic base body and a metal alloy body; each ceramic connector I is positioned between the corresponding ceramic base body and the corresponding metal alloy body; each ceramic base body and the corresponding ceramic connector I are connected by filling a ceramic connector solution; each metal alloy body comprises at least two types of metal powder; the ceramic connectors I and the ceramic connector II are composed of 75-90 parts by weight of raw ceramic material components of the ceramic base bodies, 0.5-1 part by weight of nickel powder, and 9-24 parts by weight of raw material components of the metal alloy bodies. The metal alloy composite ceramic board has outstanding performance such as relativelyhigh durability, relativelyhigh strength, relativelyhigh hardness and relativelyhigh toughness, so that the ceramic alloy composite ceramic board can be applied to each industry.

Owner:洛阳鹏飞耐磨材料股份有限公司

High-strength castable

The invention discloses a high-strength castable, which is prepared from the following raw materials in part by weight: 4.8 parts of bauxite aggregate, 2 parts of brown aluminium oxide granules, 0.8 part of bauxite powder, 0.4 part of alumina super-micro powder, 0.6 part of silicon carbide powder, 0.3 part of silicon micro powder, 0.6 part of CA-70 cement, 0.5 part of brown aluminium oxide powder, sodium tripolyphosphate accounting for 0.1 percent of weight of the total material, and sodium hexametaphosphate accounting for 0.08 percent of the weight of the total material. The castable has the advantages of high compression strength, high breaking strength, high load softening temperature, good thermal shock resistant stability, micro-expansion property at high temperature, good abrasion resistance and the like; the cost is reduced by about two fifth compared with that of the conventional high-strength castable; and the castable can be widely applied to kilns of cement kiln eyes, pre-heaters, grate coolers and the like with high strength requirement and severe using conditions, and is an ideal new product for replacing a high-strength corundum castable.

Owner:郑州真金耐火材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com