Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165results about How to "Improve creep strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

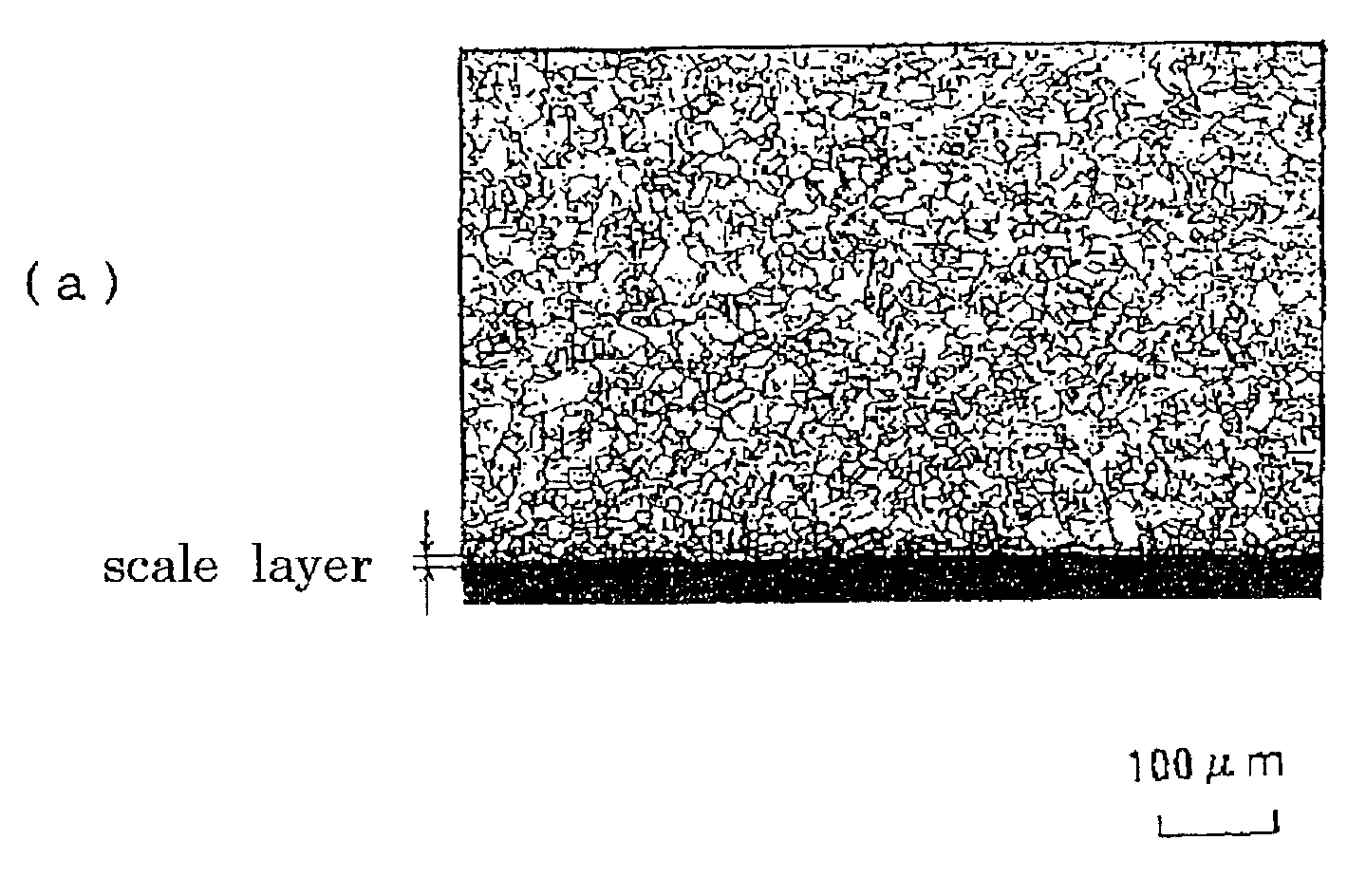

Austenitic stainless steel tube excellent in steam oxidation resistance and a manufacturing method thereof

InactiveUS7014720B2Excellent in steam oxidation resistanceHigh-temperature bendingFurnace typesHeat treatment furnacesAustenite grainOxygen

The present invention provides an austenitic stainless steel tube with a uniform fine grained structure of regular grains, which is not changed to a coarse structure and the steam oxidation resistance is maintained even if the tube is subjected to a high temperature reheating during welding and high temperature bending working. The austenitic stainless steel tube consists of, by mass %, C: 0.03–0.12%, Si: 0.1–0.9%, Mn: 0.1–2%, Cr: 15–22%, Ni: 8–15%, Ti: 0.002–0.05%, Nb: 0.3–1.5%, sol. Al: 0.0005–0.03%, N: 0.005–0.2% and O (oxygen): 0.001–0.008%, and the balance Fe and impurities, the austenitic stainless steel tube having austenitic grain size number of 7 or more and a mixed grain ratio of preferably 10% or less.

Owner:NIPPON STEEL CORP

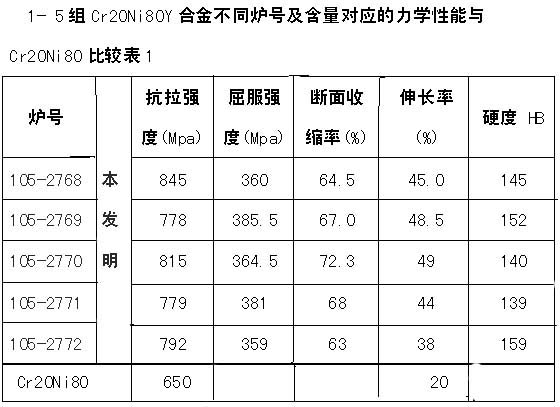

New high-resistance electrical heating alloy material and preparation method thereof

ActiveCN102191409AReasonable component designSimple manufacturing processHigh resistivityHigh resistance

The invention discloses a new high-resistance electrical heating alloy material and a preparation method thereof. The material comprises the following components by weight percent: 0.01-0.06% of C, 1.0-1.5% of Si, 0.1-0.6% of Mn, less than or equal to 0.02% of P, less than or equal to 0.015% of S, 20-23% of Cr, 74.0-78.0% of Ni, 0.1-0.25% of Al, 0.2-1.0% of Fe, 0.01-0.2% of Ti, 0.2-0.8% of Zr and the balance of inevitable impurities. The preparation method comprises the steps of smelting, forging, wiring, annealing, rinsing, drawing and the like. Compared with Cr20Ni80, the prepared new high-resistance electrical heating alloy material has better oxidation resistance and is an electrical heating alloy material with low thermal expansion coefficient, good high temperature strength, long service life and high resistivity.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

High-resistance electrothermal alloy material and preparation method thereof

The invention discloses a high-resistance electrothermal alloy material, which comprises the following components in percentage by weight: 0.02 to 0.08 percent of C, 0.75 to 1.6 percent of Si, 0.1 to 0.5 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.015 percent of S, 20 to 23 percent of Cr, 0.1 to 0.5 percent of Al, 0.2 to 0.8 percent of Y, 0.2 to 1.0 percent of Fe, and the balance of Ni and inevitable impurities. The preparation method for the high-resistance electrothermal alloy material comprises the following steps of: smelting; forging; coiling; annealing; rinsing; mold drawing, and the like. Compared with Cr20Ni80, the high-resistance electrothermal alloy material has higher antioxidation performance, and is an electrothermal alloy material with small thermal expansion coefficient, high high-temperature strength and processability, long service life and high resistivity.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

Alloy vermicular cast iron glass mold material and preparation method thereof

The invention relates to an alloy vermicular cast iron glass mold material and a preparation method thereof, and belongs to the field of glass mold manufacturing. The alloy vermicular cast iron glass mold material comprises the following chemical elements in percentage by mass: 3.5-3.6% of carbon, 2.9-3.0% of silicon, 0.4-0.5% of manganese, 0.4-0.5% of molybdenum, less than 0.15% of vanadium, less than 0.10% of titanium, 0.3-0.4% of chromium, 0.4-0.5% of nickel, less than 0.05% of phosphorus, less than 0.03% of sulfur and the balance of iron. The invention has the following advantages: the reasonable selection of the metal elements and the mass percents thereof is beneficial to saving noble metal materials and reducing the variety of the used noble metal elements; the selected alloy elements have a favorable solution strengthening effect, thereby being beneficial to enhancing the strength of the iron element under a high-temperature environment and then prolonging the service life of the glass mold; and the preparation method provided by the invention is beneficial to the dispersion and distribution of second-phase carbides in grain boundaries, so that the grain boundaries can be strengthened, and the creep strength can be improved.

Owner:ORI MOLD TECH SUZHOU

Heat resistant austenitic stainless steel

InactiveUS6485679B1High creep rupture strengthGood steam oxidation resistanceRigid pipesHeat exchange apparatusAustenitic stainless steelTungsten

A heat resistant austenitic stainless steel with high strength at elevated temperatures, good steam oxidation resistance, good fire side corrosion resistance, and a sufficient structural stability, suitable for use in boilers operating at high temperatures has a composition (by weight) of. 0.04 to 0.10% carbon (C), not more than 0.4% silicon (Si), not more than 0.6% manganese (MN), 20 to 27% chromium (Cr), 22.5 to 32% nickel (Ni), not more than 0.5% molybdenum (Mo), 0,20 to 0.60% niobium (Nb), 0.4 to 4.0% tungsten (W), 0.10 to 0.30% nitrogen (N), 0.002 to 0.008% boron (B), less than 0.05% aluminium (Al), at least one of the elements Mg and Ca in amounts less than 0.010% Mg and less than 0.010% Ca, and the balance being iron and inevitable impuities.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Austenitic heat resistant alloy

InactiveCN101864531APrevent liquefaction cracksPrevent embrittlement cracksSteam boilersSteam boilers componentsLiquationUltimate tensile strength

An austenitic heat resistant alloy, which comprises, by mass percent, C<=0.15%, Si<=2%, Mn<=3%, Ni: 40 to 80%, Cr: 15 to 40%, W and Mo: 1 to 15% in total content, Ti<=3%, Al<=3%, N<=0.03%, O<=0.03%, with the balance being Fe and impurities, and among the impurities P<=0.04%, S<=0.03%, Sn<=0.1%, As<=0.01%, Zn<=0.01%, Pb<=0.01% and Sb<=0.01%, and satisfies the conditions [P1=S+{(P+Sn) / 2}+{(As+Zn+Pb+Sb) / 5}<=0.050], [0.2<=P2=Ti+2Al<=7.5-10P1], [P2<=9.0-100O] and [N<=0.002P2+0.019] can prevent both the liquation crack in the HAZ and the brittle crack in the HAZ and also can prevent defects due to welding fabricability, which occur during welding fabrication, and moreover has excellent creep strength at high temperatures.

Owner:NIPPON STEEL CORP

Austenitic stainless steel and manufacturing method thereof

ActiveUS6939415B2Reliably obtainedImprove high temperature strengthLavatory sanitoryFurnace typesMetallurgyUltimate tensile strength

An austenitic stainless steel excellect in high temperature strength and creep rupture ducitility which comprises, on the percent by mass basis, C: 0.03-0.12%, Si: 0.2-2%, Mn: 0.1-3%, P: 0.03% or less, S: 0.01% or less, Ni: more than 18% and less than 25%, Cr: more than 22% and less than 30%, Co: 0.04-0.8%, Ti: 0.002% or more and less than 0.01%, Nb: 0.1-1%, V: 0.01-1%, B: more than 0.0005% and 0.2% or less, sol. Al: 0.0005% or more and less than 0.03%, N: 0.1-0.35% and O (Oxygen): 0.001-0.008%, with the balance being Fe and impurities. The austenitic stainless steel may contain a specified amount of one or more element(s) of Mo and W, and / or a specified amount of one or more element(s) of Mg, Zr, Ca, REM, Pd and Hf.

Owner:NIPPON STEEL CORP

Oxidation resistant superalloy and article

InactiveUS20050271886A1Increased uncoatedIncreased coated oxidation resistanceBlade accessoriesSolid state diffusion coatingOxidation resistantTurbine

An oxidation resistant, nickel base superalloy is described. The combination of alloy and a thermal barrier coating can be used to fabricate turbine components with good high temperature strength and good oxidation resistance, while maintaining other relevant properties.

Owner:UNITED TECH CORP

Machining process of engine crankshafts in heavy trucks

InactiveCN103447778AHigh tensile strengthImprove fatigue strengthMetal-working apparatusNumerical controlMachined surface

The invention discloses a machining process of engine crankshafts in heavy trucks. The process includes the steps of blanking, forging, shot blasting, rough turning, numerical control correction, rough grinding, drilling, enhanced surface treatment, accurate grinding, dynamic balancing, finishing and the like. Metal bar blanks are bent and forged in a forging hammer die; forging blanks are subjected to surface grinding and shot blasting prior to machining and enhanced surface treatment; finally, finishing, grinding and final inspection are performed. The machining process has the advantages that the produced crankshafts in compact in structure, fine in metal streamline, high in tensile strength, fatigue strength and hardenability; little deformation occurs during enhanced treatment; creeping strength at high temperature is high; product qualification rate and product quality are high; the process is available for large-scale production, and productivity is improved greatly.

Owner:ZHEJIANG WEILIN MECHANICAL

Welding material for ni-based heat-resistant alloy, and welded metal and welded joint each using same

InactiveCN102947048AResistant to stress relaxation crackingExcellent heat crack resistanceWelding/cutting media/materialsWelding/soldering/cutting articlesCrack resistanceAlloy

Disclosed is a welding material for an Ni-based heat-resistant alloy, which has a chemical composition that contains 0.06-0.18% of C, 0.5% or less of Si, 1.5% or less of Mn, 46-56% of Ni, 10-15% of Co, 20-25% of Cr, more than 10.0% but 14.0% or less of Mo, 0.01-0.5% of Ti, 0.1-1.0% of Al and 0.006% or less of N, and additionally if necessary, 0.1% or less of Nd with the balance made up of Fe and impurities, while controlling O, P and S contained as impurities to 0.02% or less, 0.008% or less, and 0.005% or less, respectively. The welding material for an Ni-based heat-resistant alloy exhibits excellent high-temperature cracking resistance during the welding. A welded metal that has high-temperature cracking resistance during the welding, stress relaxation cracking resistance when in use for a long period of time at high temperatures, and good creep strength can be provided using the above-described welding material. In addition, a welded joint can be provided using the above-described welding material, said welded joint being composed of a base of an Ni-based heat-resistant alloy that has excellent high-temperature strength and a welded metal that has high-temperature cracking resistance during the welding, stress relaxation cracking resistance when in use for a long period of time at high temperatures, and good creep strength.

Owner:NIPPON STEEL CORP

Nickel-based high-temperature alloy used for ultra-supercritical boiler and preparation method and application of nickel-based high-temperature alloy

The invention discloses nickel-based high-temperature alloy used for an ultra-supercritical boiler and a preparation method and application of the nickel-based high-temperature alloy and belongs to the technical field of high-temperature alloy materials. The alloy comprises, by weight, 0.02-0.08% of C, 21-25% of Cr, 10-16% of Co, 1.0-3.0% of Mo, 1.0-3.0% of Nb, 1.0-1.8% of Al, 1.5-2.5% of Ti, 0.002-0.008% of B, 0.002-0.03% of Si, 0-10% of Fe and the balance Ni and inevitable impurities. The alloy is high in creep strength, excellent in structure stability and good in oxidation resistance and corrosion resistance within the applicable temperature range; meanwhile, the cold and hot machining performance is excellent, and the alloy can serve for a long time at the temperature of 600-800 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

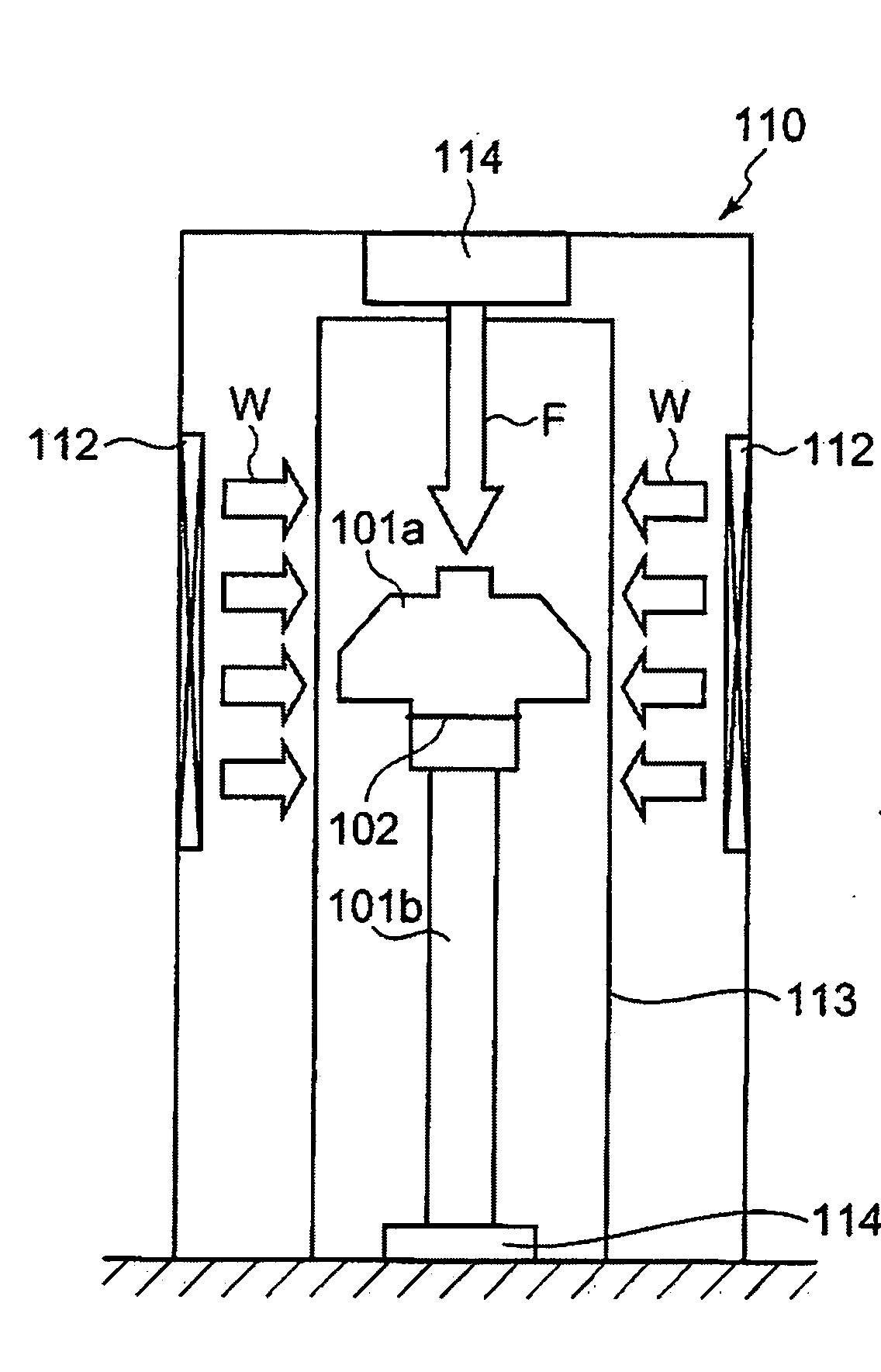

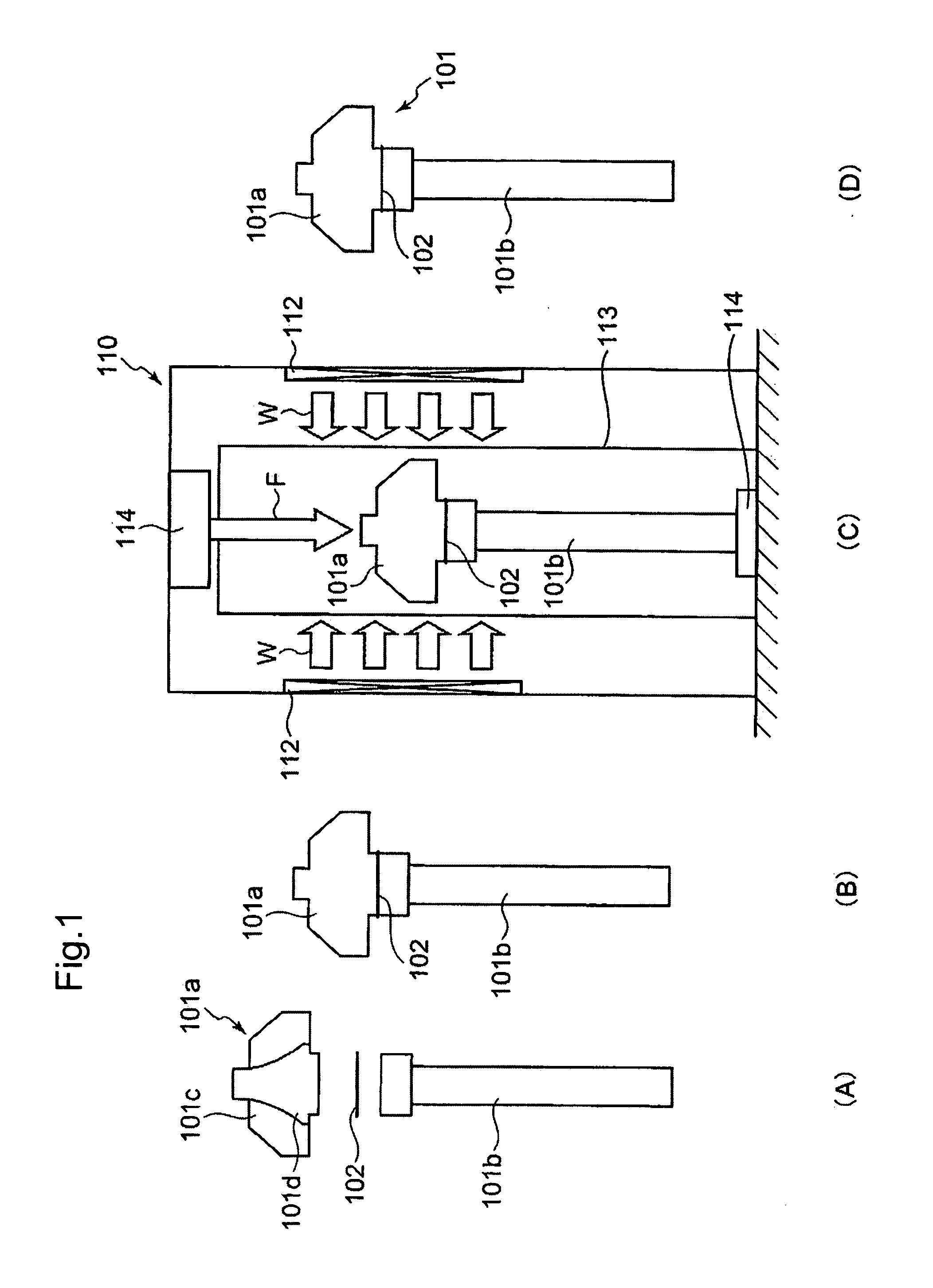

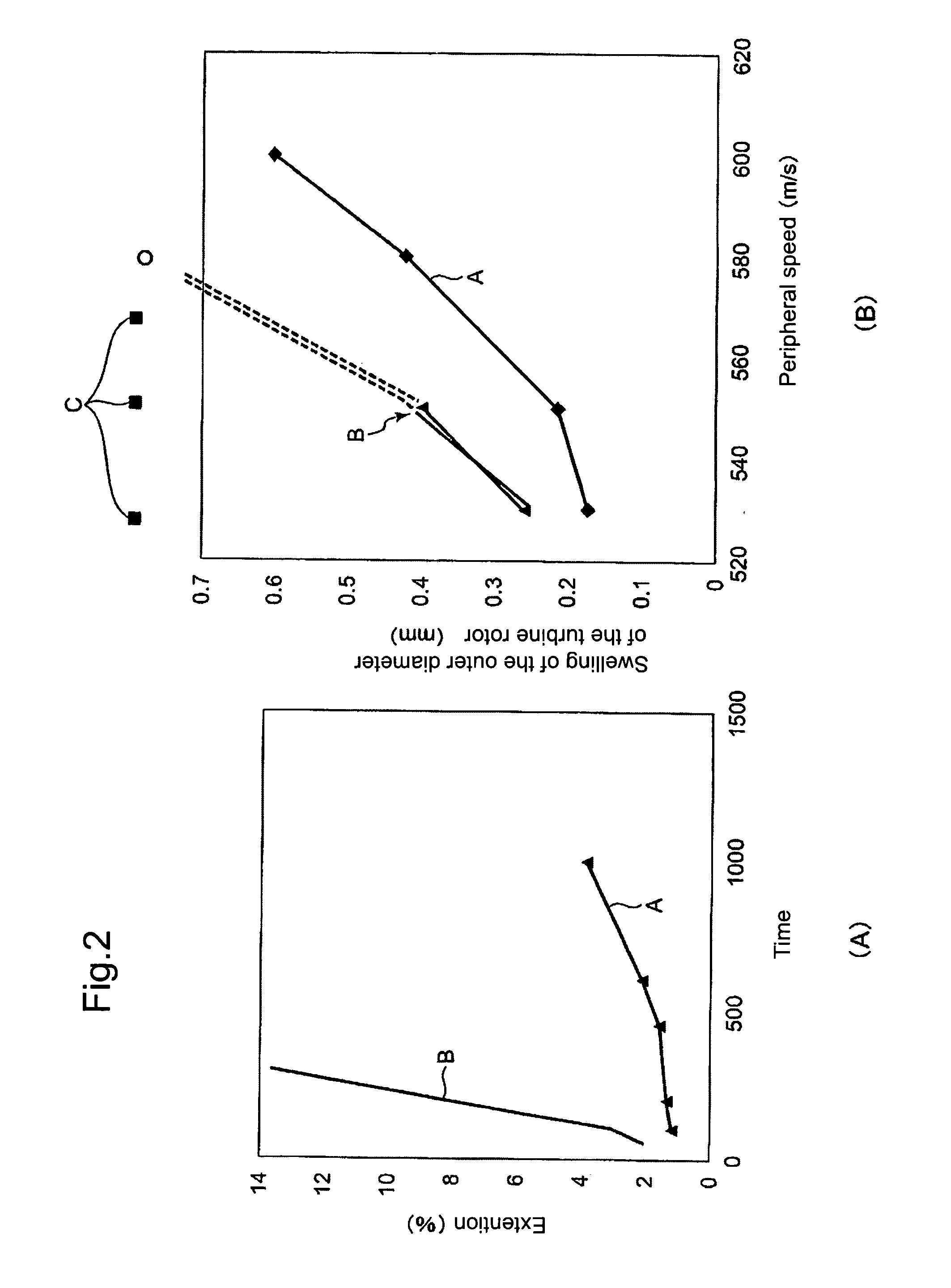

Method of manufacturing rotor and exhaust turbo-supercharge incorporating the rotor

InactiveUS20080199313A1High strengthInhibition strengthPropellersPump componentsCircular discTurbocharger

Provided are a method of manufacturing a brazed rotor composed of a wheel and a shaft joined to the former by brazing, having a durability and a reliability which can be enhanced without increasing the manufacturing man hours, and a turbine rotor for an exhaust turbo-supercharger. The wheel having a disc portion formed at its outer periphery with blades, and a rod-like shaft are arranged in a furnace, being opposed to each other at their surfaces to be joined with a brazing solder being interposed therebetween, and infrared radiation is irradiated onto a side part of the wheel so as to heat the surfaces to be joined up to a temperature in a range from 1,000 to 1,080 deg. C. in order to melt the brazing solder, thereby the wheel and the shaft are joined by brazing to each other at their surfaces to be joined.

Owner:MITSUBISHI HEAVY IND LTD

Austenitic stainless steel welded joint and austenitic stainless steel welding material

ActiveUS20100062279A1Reduce sensitivitySolidification cracking is reducedWelding/cutting media/materialsThin material handlingRare earthAustenite

An austenitic stainless steel welded joint, whose base metal and weld metal each comprises, by mass percent, C: not more than 0.3%, Si: not more than 2%, Mn: 0.01 to 3.0%, P: more than 0.04% to not more than 0.3%, S: not more than 0.03%, Cr: 12 to 30%, Ni: 6 to 55%, rare earth metal(s): more than 0.2% to not more than 0.6%, sol. Al: 0.001 to 3% and N: not more than 0.3%, with the balance being Fe and impurities, and satisfies the formula of (Cr+1.5×Si+2×P) / (Ni+0.31×Mn+22×C+14.2×N+5×P)<1.388, in spite of having a high P content and showing the fully austenitic solidification, has excellent resistance to the weld solidification cracking. Therefore, the said austenitic stainless steel welded joint can be widely used in such fields where a welding fabrication is required. Each element symbol in the above formula represents the content by mass percent of the element concerned.

Owner:NIPPON STEEL CORP

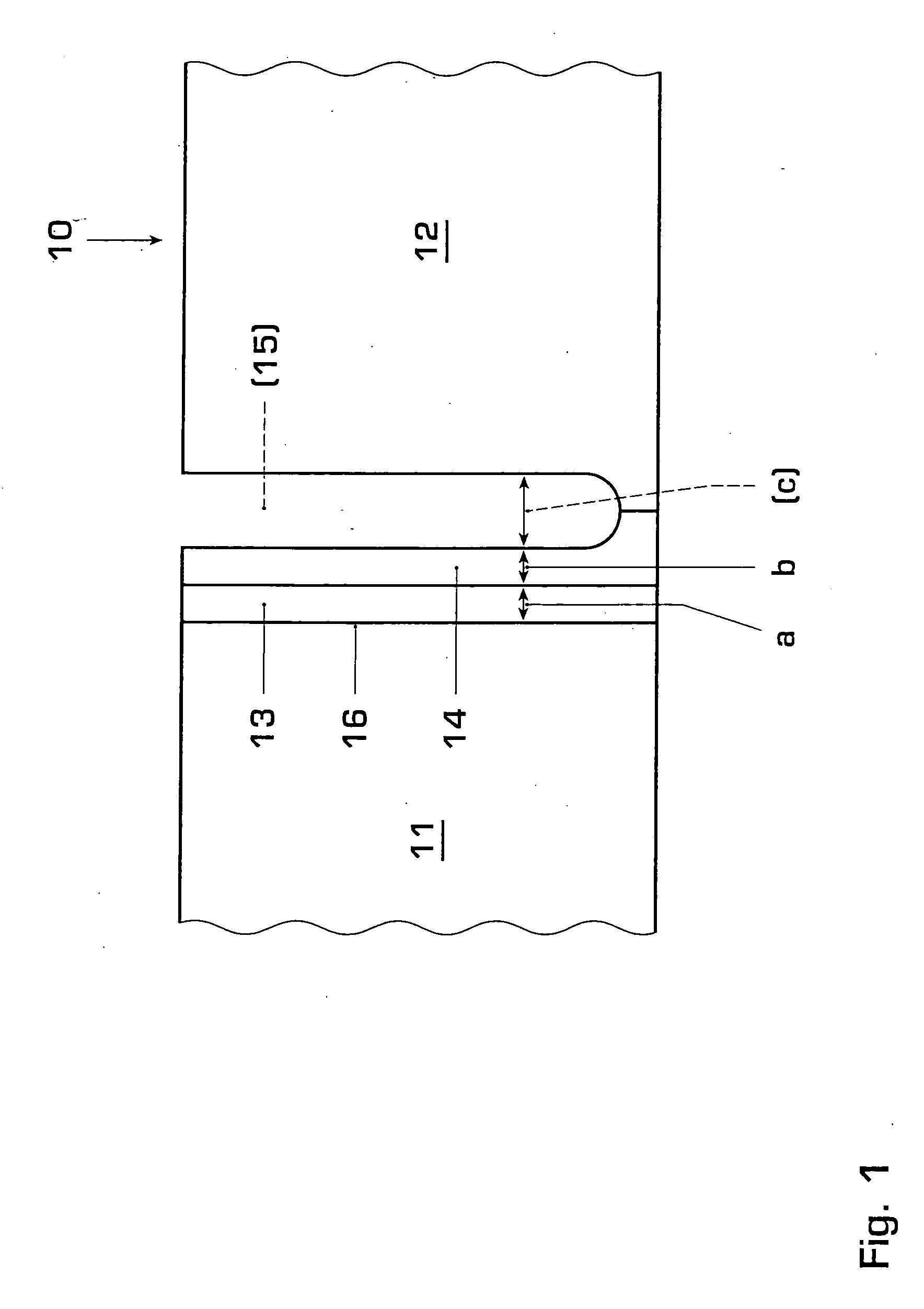

Welded component

ActiveUS20050255333A1Improve creep strengthImprove toughnessWind motor controlArc welding apparatusCompound (substance)Toughness

A welded component includes at least one high temperature segment of a high alloy Cr steel with high creep strength and a low temperature segment of a low alloy steel with high toughness and / or a high yield strength which are connected materially to one another via a weld joint. In one such component a gradual transition of chemical, physical and mechanical properties in the joining area is achieved in that between the weld joint and the high temperature segment there are at least two successive clad layers of at least two lower alloy weld metals with a total content of elements which increase the creep strength, such as for example Cr, Mo, W and V, which total content decreases toward the weld joint, and / or an increasing total content of elements which increase the toughness and / or yield strength, such as for example Ni and Mn, which total content increases toward the weld joint.

Owner:GENERAL ELECTRIC TECH GMBH

Ni-based single crystal super alloy

The object of the present invention is to provide an Ni-based single crystal super alloy capable of improving strength by preventing precipitation of a TCP phase at high temperatures. This object is achieved by an Ni-based single crystal super alloy having a composition consisting of 5.0-7.0 wt % Al, 4.0-8.0 wt % Ta, 2.9-4.5 wt % Mo, 4.0-8.0 wt % W, 3.0-6.0 wt % Re, 0.01-0.50 wt % Hf, 2.0-5.0 wt % Cr, 0.1-15.0 wt % Co and 1.0-4.0 wt % Ru in terms of its weight ratio, with the remainder consisting of Ni and unavoidable impurities.

Owner:NAT INST FOR MATERIALS SCI +1

Austenitic heat-resistant alloy and method for manufacturing same

Provided is an austenitic heat-resistant alloy having high creep strength and high toughness even in a high-temperature environment. This austenitic heat-resistant alloy has a chemical composition containing, in terms of mass%, 0.03 to less than 0.25% C, 0.01-2.0% Si, 2.0% or less of Mn, 10 to less than 30% Cr, more than 25% to 45% Ni, more than 2.5% to less than 4.5% Al, 0.2-3.5% Nb, and 0.025% or less of N, the remainder comprising Fe and unavoidable impurities, and P and S being 0.04% or less and 0.01% or less, respectively, of the impurities. The gross moment of precipitates 6 [mu]m or larger in the structure of the austenitic heat-resistant alloy is 5% or less.

Owner:NIPPON STEEL CORP

Fan blade and attaching means therefor

ActiveUS8827652B2High tensile strengthWeight morePropellersPump componentsFan bladeUltimate tensile strength

In order to disclose attaching means (3) for attaching a blade section (2) of a fan blade (1), in particular of a smoke extractor fan, to a fan hub, as well as a fan blade (1), which guarantee a high tensile strength even at high temperatures, wherein the attaching means (3) and fan blades (1) are to be produced so as to save as much weight as possible, it is proposed that the attaching means (3) have a connecting section (5) embodied to produce a high-tensile connection to a blade section (2) of a fan blade (1), which connecting section can be arranged essentially in the interior of the blade section (2).

Owner:W & S MANAGEMENT

Low silver oxidation resistance active leadless solder

InactiveCN101214588AReduced activityImprove reliabilityWelding/cutting media/materialsSoldering mediaWettingWelding

A lower-Ag anti-oxidation lead-free solder relates to a lead-free solder. The invention solves the problems of high Ag content, high manufacture cost and poor wettability of the existing lead-free solder. The invention consists of the following components according to a weight percentage of 0.5 to 2.5 percent of Ag, 0.3 to 1.5 percent of Cu, 0.002 to 0.2 percent of P, 0.01 to 1.0 percent of Zn, 0.02 to 3.0 percent of Ti, 0.01 to 2.5 percent of Zr, 0.01 to 3.5 percent of Ni, 0.02 to 1.5 percent of mixed RE and the rest is Sn. Compared with the existing Sn-Ag-Cu solder under a same condition, the wetting angle of the lower-sliver anti-oxidation lead-free solder of the invention is reduced by 5 to 7 degrees, the anti-oxidation performance is improved by 14 to 20 percent and the creep strength is improved by 6 to 10 percent; thereby being able to acquire a joint with higher reliability from braze welding. The invention has the advantages of few Ag content and low manufacture cost.

Owner:HARBIN INST OF TECH

Ascalloy and manufacturing method thereof

The invention discloses ascalloy which comprises the following chemical components by weight percentage: 0.05 to 0.15 of C, 0.1 to 0.5 of Si, 0.1 to 1.0 of Mn, 11.0 to 13.0 of Cr, 0.1 to 1.0 of Mo, 0.10 to 0.30 of V, 0.01 to 0.20 of Nb, 0.1 to 3.0 of W, 0.5 to 3.0 of Co, 0.1 to 1.0 of Cu, 0.001 to 0.008 of B, 0.01 to 0.11 of N, less than or equal to 0.03 of Al, less than or equal to 0.030 of P, less than or equal to 0.015 of S and the balance of Fe and inevitable of impurities. The chemical components meet a relational expression: Cr+2Mo+W-40C-30N-Co-0.5Cu is less than 7.5. The preparation method comprises the steps that high-temperature deformation processing is performed at the upper limitation of the temperature of 1200 DEG C, and the total elongation percentage is more than or equal to 3. The ascalloy obtained by the invention has favorable ageing rear toughness, heat oxidation resistance and steam etching.

Owner:BAOSHAN IRON & STEEL CO LTD

21/4Cr-1Mo-1/4V steel forging and automatic temperature-control inflation three-dimensional circulating water rapid cooling thermal treatment method thereof

InactiveCN101831595AHigh tensile strengthImprove creep strengthFurnace typesHeat treatment furnacesAutomatic controlHydrogen damage

The invention discloses an improved 21 / 4Cr-1Mo-1 / 4V steel forging which is characterized by comprising the following components in percent by weight: 0.11-0.15 percent of carbon, not more than 0.10 percent of silicon, 0.30-0.60 percent of manganese, not more than 0.01 percent of phosphorus, not more than 0.01 percent of sulfur, 2-2.5 percent of chromium, 0.9-1.10 percent of molybdenum, not more than 0.20 percent of nickel, not more than 0.15 percent of copper, 0.25-0.35 percent of vanadium, not more than 0.30 percent of titanium, not more than 0.002 percent of boron, not more than 0.07 percent of niobium, not more than 0.015 percent of calcium and the balance of iron. The invention also discloses an automatic temperature-control inflation three-dimensional circulating water rapid cooling thermal treatment method of the steel forging, which comprises the steps of: 1, an after-forging thermal treatment process: normalizing at a temperature of 890-990 DEG C, air-cooling after constant temperature is not less than 1h / 100mm, tempering at a temperature of 680-720 DEG C, furnace-cooling after constant temperature, and cooling at a limited speed at a temperature of below 400 DEG C; 2, a thermal refining process: quenching at a temperature of 900-980 DEG C, carrying out constant temperature with 1h / 100mm, rapidly cooling and quenching and tempering at a temperature of 680-720 DEG C, carrying out constant temperature with 1h / 100mm and air-cooling thickness of the forging, wherein the water temperature of thickness of the forging is not more than 10 DEG C; and 3, adopting a three-dimensional automatic control circulating water periphery inflation method. The forging has higher tension strength, temper brittleness resistance, hydrogen damage resistance and lower long-term high-temperature damage sensitivity.

Owner:抚顺加氢炼化设备有限公司

Heat-resistant steel for ultra-supercritical steam turbine rotor

The invention provides heat-resistant steel for an ultra-supercritical steam turbine rotor, which can solve the problem that an ultra-supercritical steam turbine rotor manufactured by adopting X12CrMoWVNbN10-1-1 ferrite heat-resistant steel can not satisfy the demand of an ultra-supercritical steam turbine unit with the temperature of 620 DEG C, and is characterized by comprising the following elements by mass percent: 0.1-0.15 percent of carbon (C), 0.15-0.25 percent of manganese (Mn), 10.00-11.00 percent of chromium (Cr), 2.0-4.0 percent of cobalt (Co), 0.6-1.1 percent of molybdenum (Mo), 1.0-3.0 percent of wolfram (W), 0.15-0.25 percent of nickel (Ni), 0.15-0.25 percent of vanadium (V), 0.07-0.09 percent of niobium (Nb), 0.02-0.04 percent of nitrogen (N), and the balance of Fe and impurity elements.

Owner:WUXI TURBINE BLADE

Titanium alloy, polish sucker rod made of titanium alloy and application of polish sucker rod

ActiveCN103667789AImprove performanceImprove fatigue strengthDrilling rodsDrilling casingsMetallurgyAlloy

The invention relates to titanium alloy, which is characterized by comprising the following ingredients in percentage by weight: 4 to 8 weight percent of Al, 2 to 5 weight percent of Mo, 2 to 4 weight percent of V, 0.5 to 3 weight percent of Zr, 0.1 to 1 weight percent of Si, 0.02 to 1 weight percent of Fe, 0 to 0.4 weight percent of other impurities and the balance Ti. The invention also relates to a polish sucker rod made of the titanium alloy and an application of the polish sucker rod to oil well equipment.

Owner:BEIJING GRAND TITANIUM TRADE

Third-generation nickle base monocrystal high temperature alloy with stable texture and preparation method

ActiveCN111455220AImproved creep propertiesEnsure organizational stabilityPolycrystalline material growthAfter-treatment detailsSingle crystal superalloyDirectional solidification

The invention discloses third-generation nickle base monocrystal high temperature alloy with a stable texture and a preparation method thereof. The third-generation nickle base monocrystal high temperature alloy is composed of Al, Ta, W, Re, Mo, Cr, Co, Hf and Ni; and W and Ni are added in the form of Ni-W intermediate alloy. Directional solidification is adopted to prepare monocrystal alloy; through multistep high temperature long-time solid solution homogenization treatment, high temperature aging treatment and low temperature aging treatment, the third-generation nickle base monocrystal high temperature alloy is free of incipient melting and precipitation of TCP phase to lower the TCP precipitation tendency, so that alloy reducing Re content reaches the performance level of the third-generation nickle base monocrystal high temperature alloy, and the obtained nickle base monocrystal high temperature alloy has higher intermediate and high temperature strength, excellent instant tensile property and creep property and high texture stability.

Owner:苏州高晶新材料科技有限公司

High-chromium heat-resistant steel

ActiveUS20160102856A1Improve propertiesEconomic efficiency is excellentBoiler water tubesWater-tube boilersChromiumMartensitic microstructure

The present invention provides a high-chromium heat-resistant steel. The steel contains in mass %, C: 0.08% to 0.13%; Si: 0.15% to 0.45%; Mn: 0.1% to 1.0%; Ni: 0.01% to 0.5%; Cr: 10.0% to 11.5%; Mo: 0.3% to 0.6%; V: 0.10% to 0.25%; Nb: 0.01% to 0.06%; N: 0.015% to 0.07%; B: ≦0.005%, and Al: ≦0.04%. The balance consists of Fe and inevitable impurity elements. The steel shows a martensitic microstructure.

Owner:TENARIS CONNECTIONS

Carbon-silicon-tungsten-yttrium lamellar structure high-niobium titanium-aluminum alloy and preparation method thereof

Owner:NANJING UNIV OF SCI & TECH

Ni-BASED SINGLE CRYSTAL SUPERALLOY AND TURBINE BLADE INCORPORATING THE SAME

ActiveUS20120034098A1Improve creep strengthIncrease temperaturePropellersRotary propellersTurbine bladeSingle crystal superalloy

A Ni-based single crystal superalloy which has the following composition: Co: 0.0 wt % or more to 15.0 wt % or less, Cr: 4.1 to 8.0 wt %, Mo: 2.1 to 4.5 wt %, W: 0.0 to 3.9 wt %, Ta: 4.0 to 10.0 wt %, Al: 4.5 to 6.5 wt %, Ti: 0.0 to 1.0 wt %, Hf: 0.00 to 0.5 wt %, Nb: 0.0 to 3.0 wt %, Re: 8.1 to 9.9 wt % and Ru: 0.5 to 6.5 wt % with the remainder including Ni and unavoidable impurities. As a result, the Ni-based single crystal superalloy which includes more than 8 wt % of Re in the composition ratio and has excellent specific creep strength and the turbine blade incorporating the Ni-based single crystal superalloy may be made.

Owner:IHI CORP

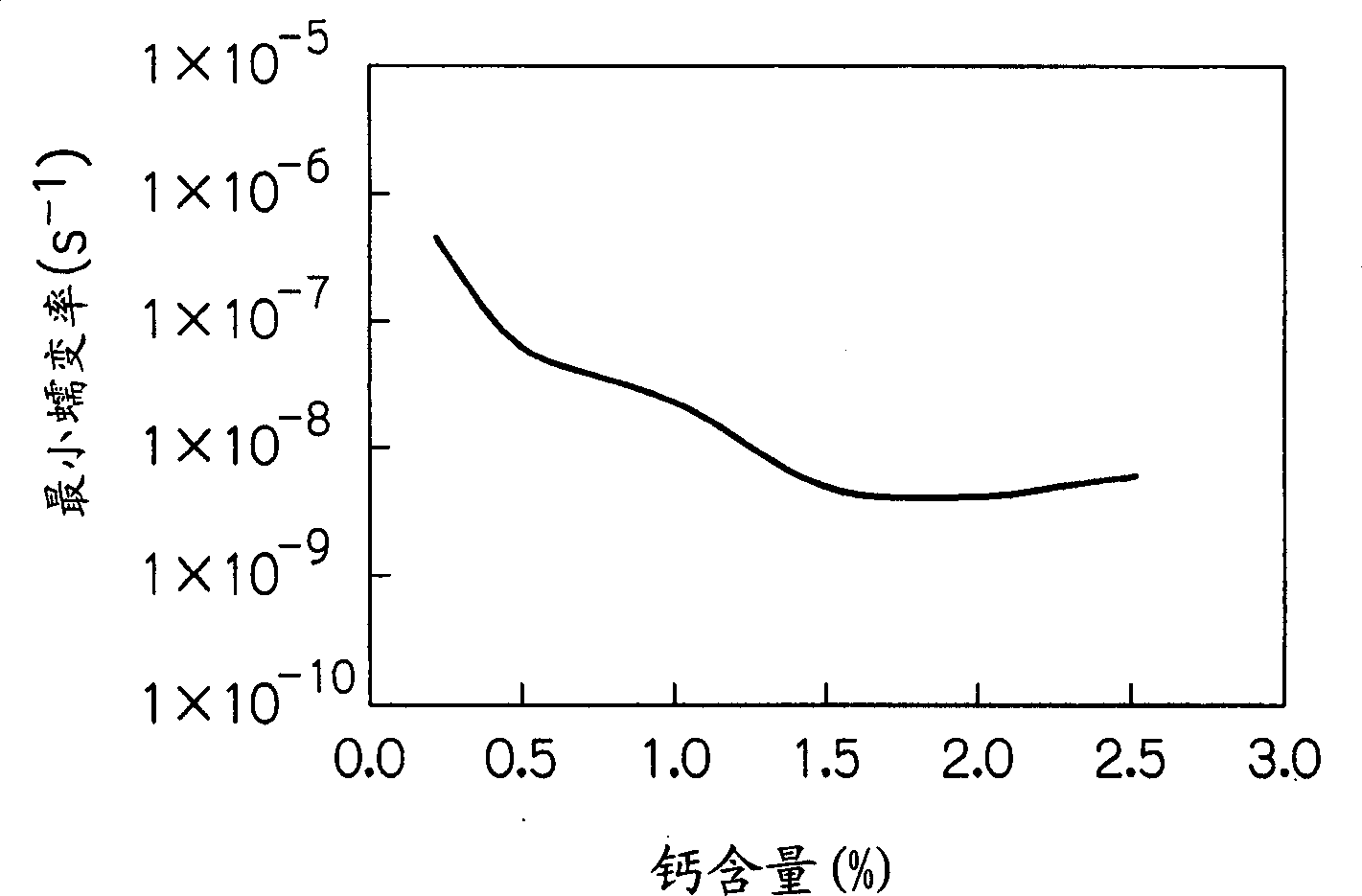

Mould casting magnesium alloy

InactiveCN1434143AImprove mechanical propertiesHigh tensile strengthRare-earth elementHeat resistance

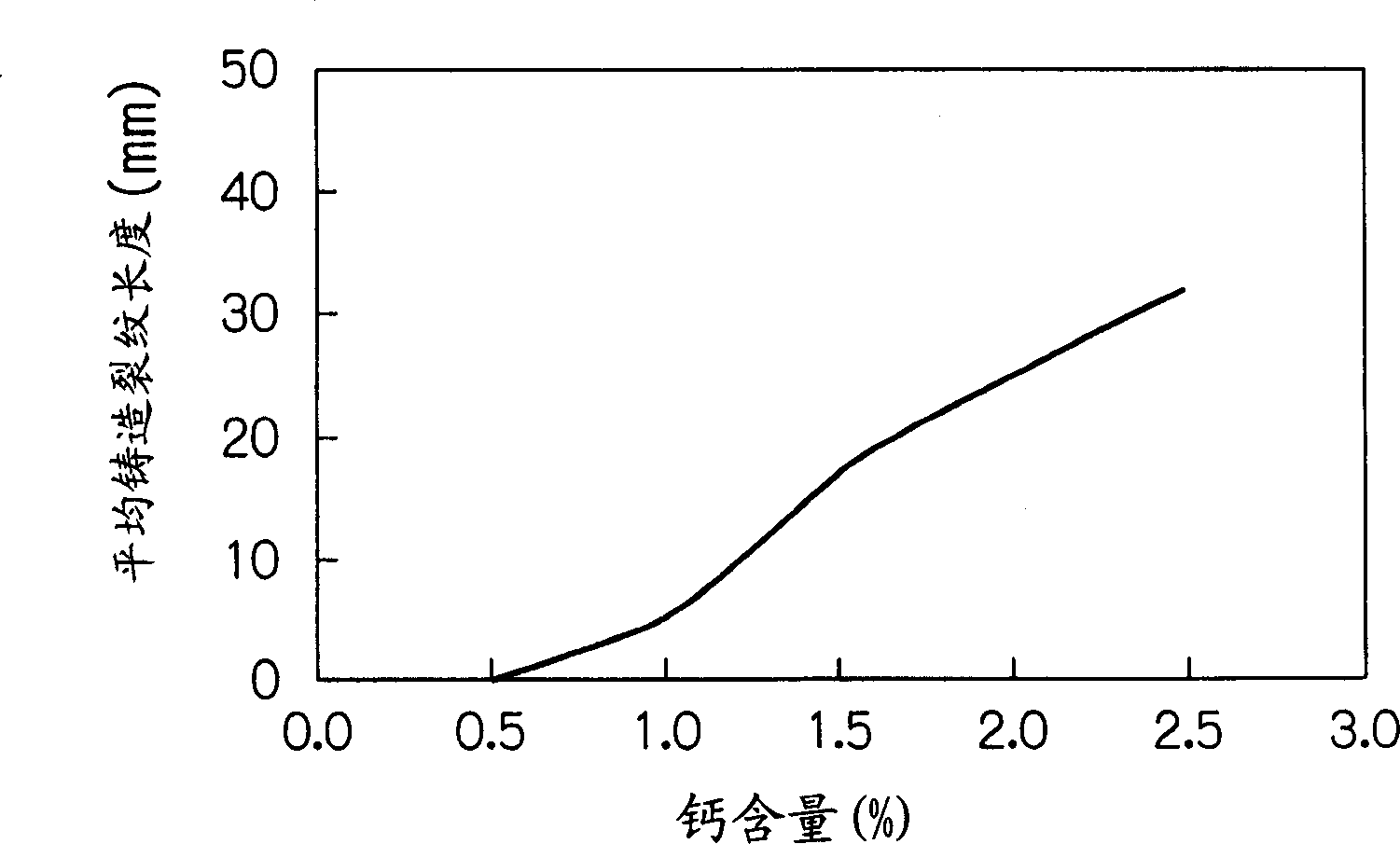

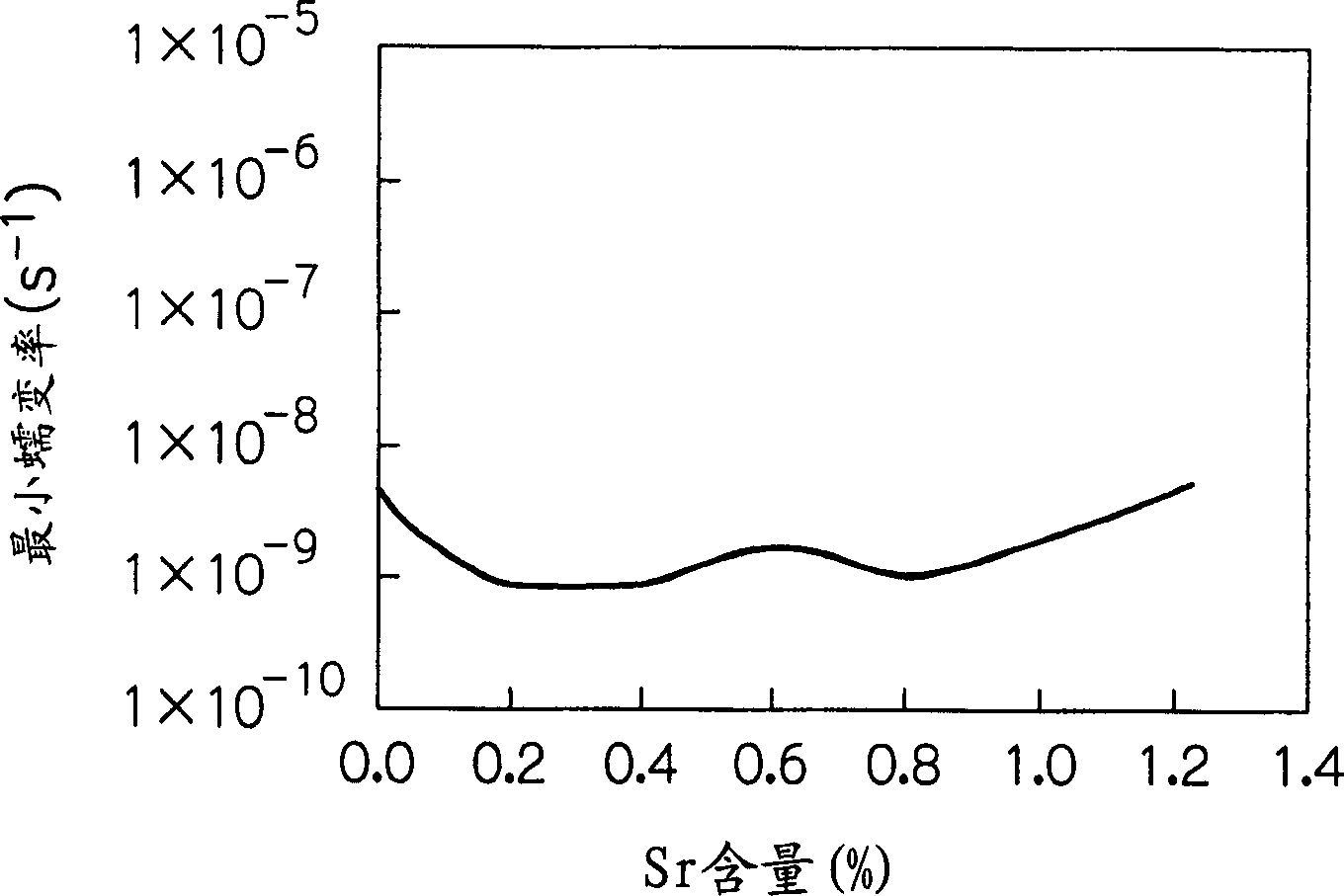

The present invention provides a magnesium die cast alloy with excellent heat resistance and casting property, and its composition contains (wt%) 1.5-6% of aluminium, 0.3-2% of calcium, 0.01-1% of strontium, 0.1-1% of manganese and the rest is magnesium and inevitable impurity. According to said invention in the above-mentioned composition a rare earth element composition can be added, it can obtain better effect.

Owner:MITSUBISHI ALUMINUM CO LTD

Method for producing platinum material reinforced with dispersed oxide

InactiveCN1383456AFine and evenly dispersedImprove creep strengthGlass furnace apparatusPlatinumIngot

The present invention aims to provide a method for manufacturing oxide dispersion-enhanced platinum material, which enables zirconia to be more finely dispersed in the platinum material, thereby further improving the creep strength of the oxide dispersion-enhanced platinum material. The invention provides a method for producing a platinum material in which zirconia is finely dispersed in platinum and oxide dispersion is enhanced. The platinum powder is poured into water to prepare a platinum powder suspension; zirconium nitrate solution and Urea solution, adjust the suspension to a given pH value of precipitated zirconium hydroxide, and form platinum powder loaded with zirconium hydroxide; collect platinum powder loaded with zirconium hydroxide, and then make it into a pressed product; in the platinum crystal Sintering and forging pressed products under the condition that secondary recrystallization growth occurs in medium to form platinum ingots; cold rolling the platinum ingots at a processing rate of at least 70%, and then subjecting the products to thermal recrystallization treatment.

Owner:TANAKA PRECIOUS METAL IND

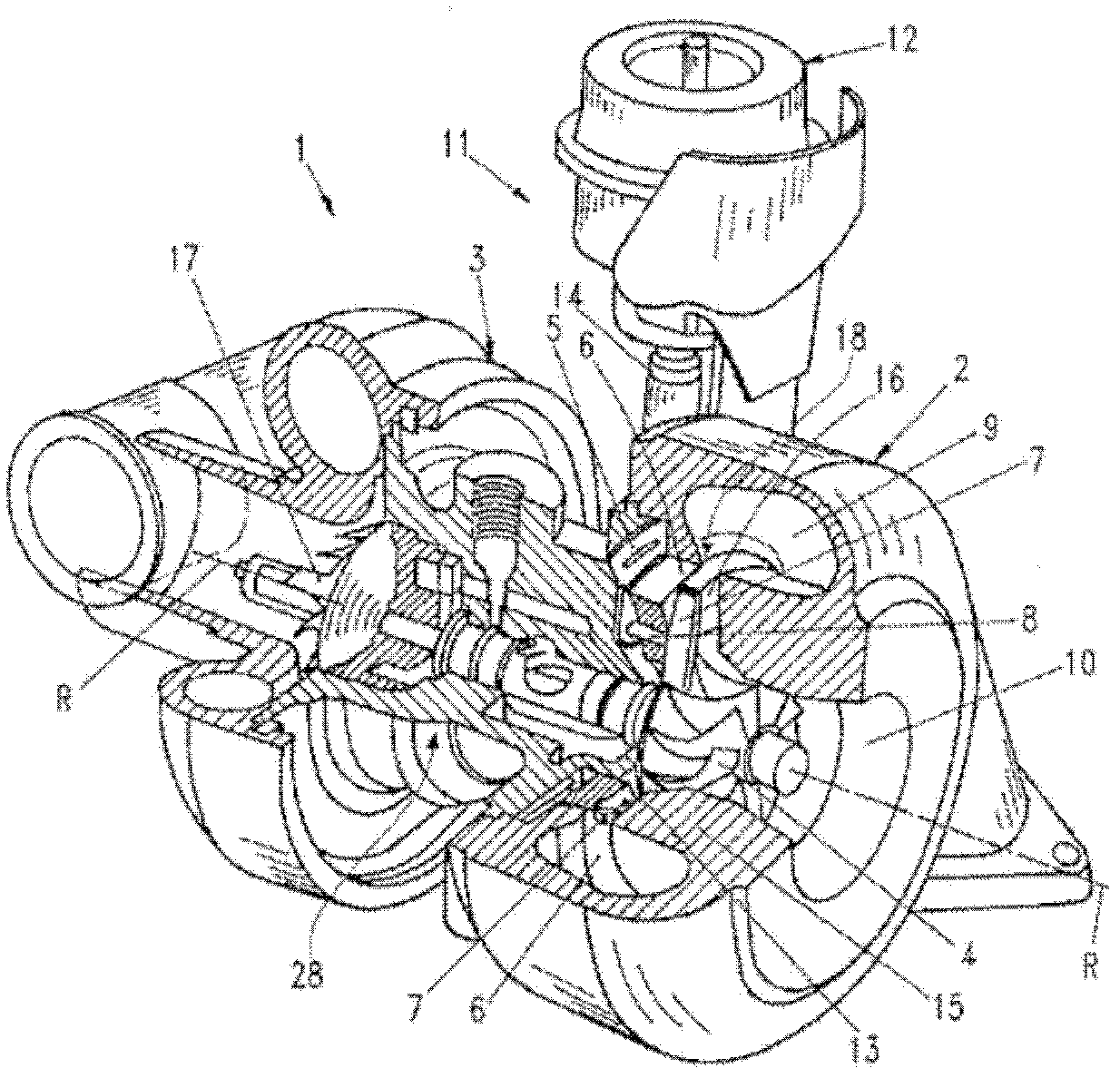

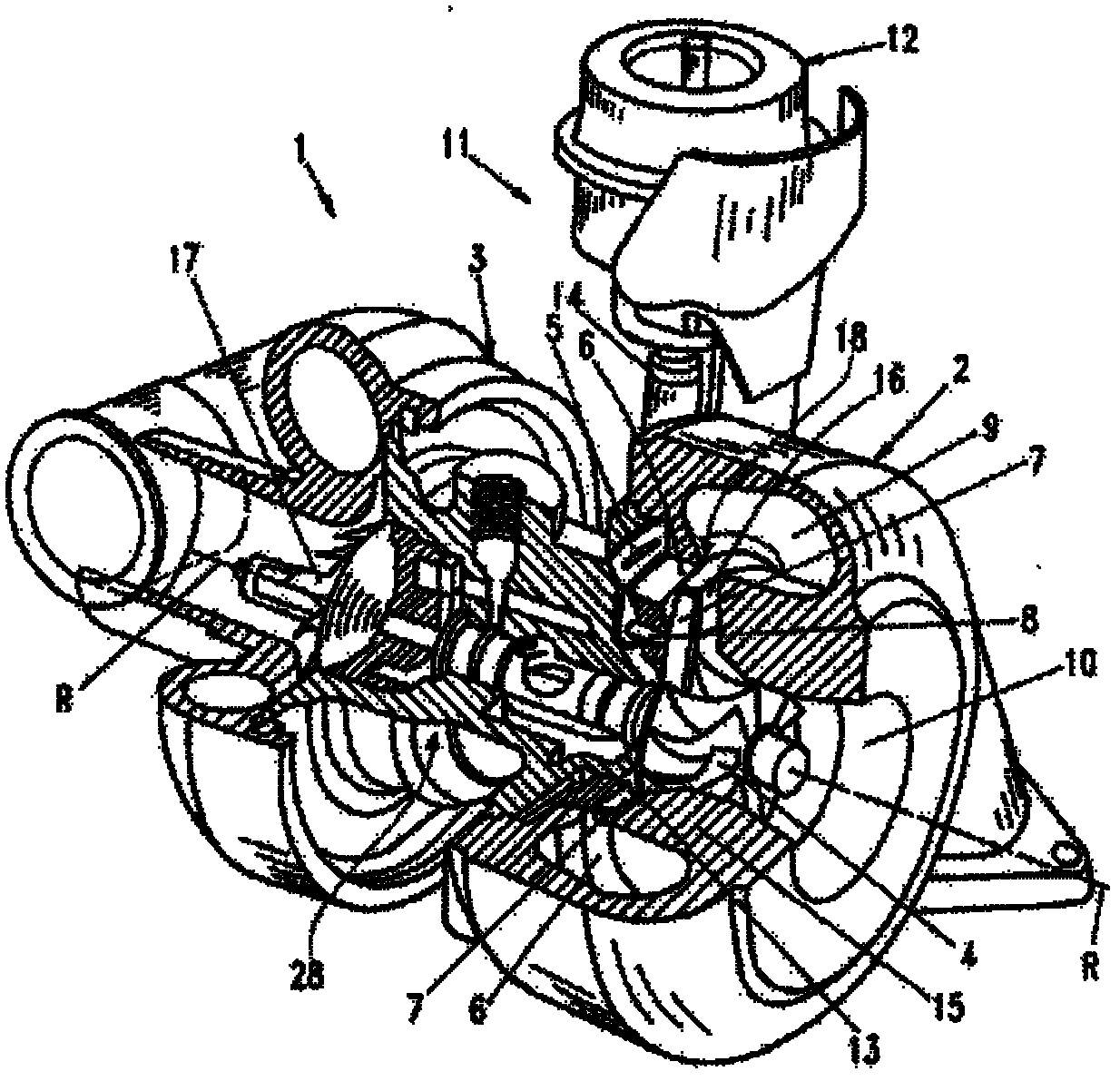

Turbocharger and compressor wheel therefor

InactiveCN102472162AImprove heat resistanceHelp stabilizeTurbinesInternal combustion piston enginesImpellerTurbocharger

Owner:BORGWARNER INC

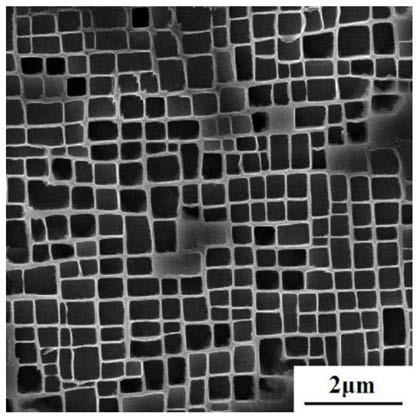

Austenitic heat-resistant alloy

An austenitic heat-resistant steel containing, by mass, 0.05-0.16% of C, 0.1-1% of Si, 0.1-2.5% of Mn, 0.01-0.05% of P, less than 0.005% of S, 7-12% of Ni, 16-20% of Cr, 2-4% of Cu, 0.1-0.8% of Mo, 0.1-0.6% of Nb, 0.1-0.6% of Ti, 0.0005-0.005% of B, 0.001-0.15% of N, and 0.005% or less of Mg and / or 0.005% or less of Ca, the amounts of Nb and Ti being 0.3% or above in total, with the remainder being made up by Fe and unavoidable impurities. The cumulative number density of a precipitate has a particle diameter of over 0 nm to 100 nm being 0.1-2.0 / [mu]m2, the precipitate particle diameter corresponding to half of the cumulative number density in the distribution of the cumulative number density and the precipitate particle diameter is 70 nm or less, the average hardness is 160 Hv or less, and the grain size number is 7.5 or above.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com