Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Increase acid concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

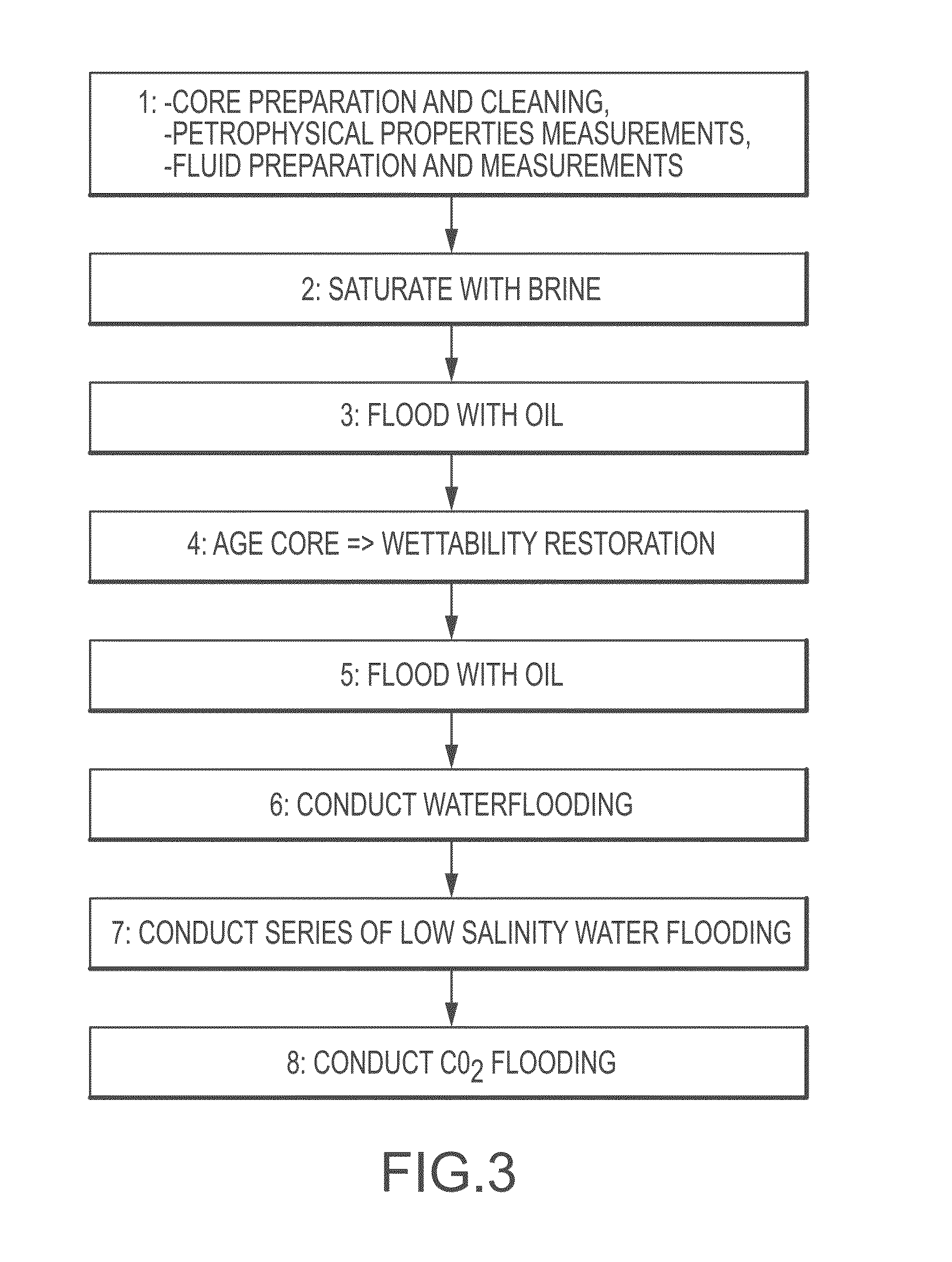

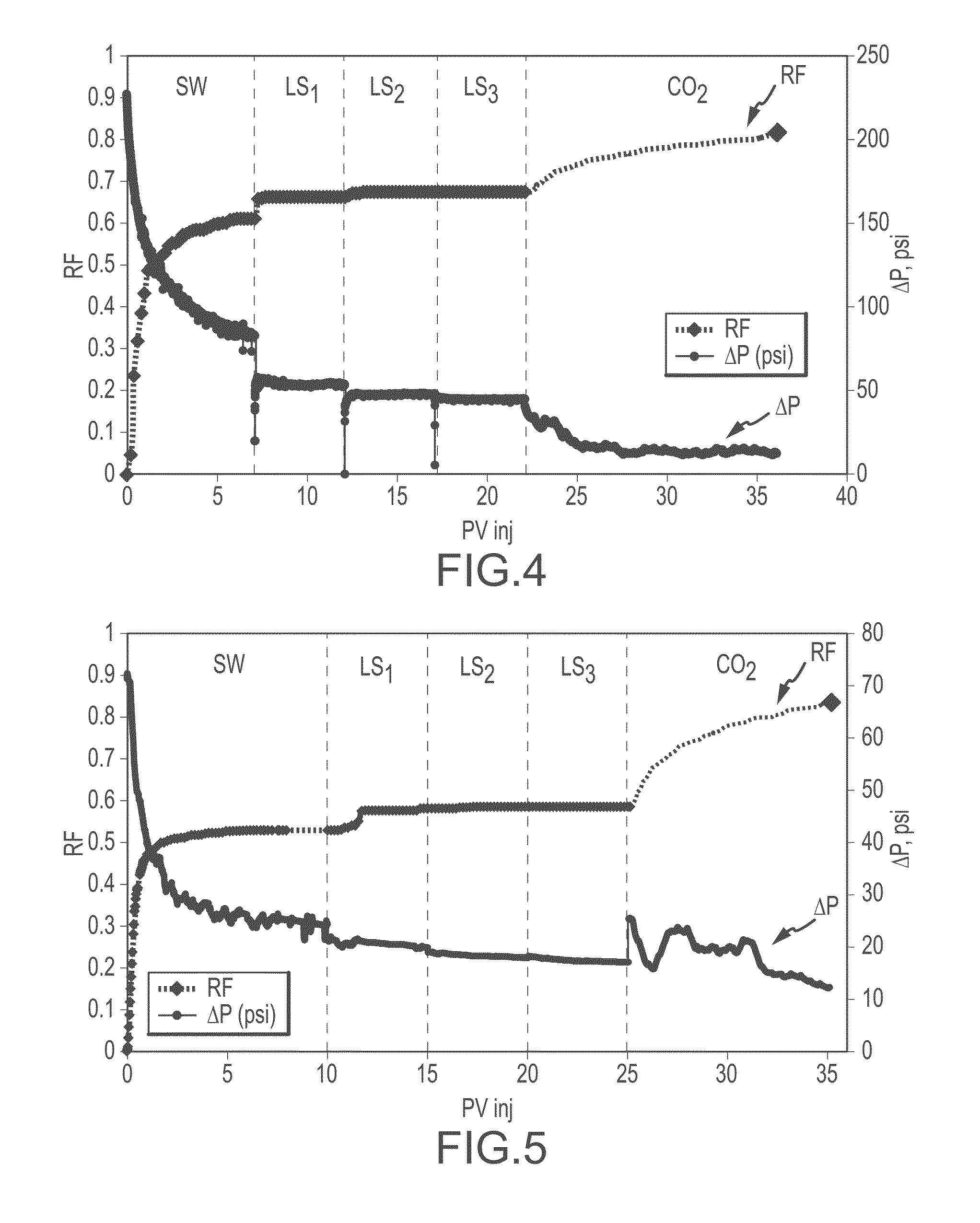

Enhanced oil recovery process to inject low salinity water and gas in carbonate reservoirs

InactiveUS20150233222A1Speed up recoverySignificant amount of additionalFluid removalDrilling compositionLow salinityEnvironmental engineering

The present invention relates to a method to enhance oil recovery from a hydrocarbon reservoir. One aspect of the invention includes injecting high salinity water into the reservoir followed by alternating the injection of low salinity water and gas.

Owner:COLORADO SCHOOL OF MINES

Colloidal composite sol gel formulation with an expanded gel network for making thick inorganic coatings

InactiveUS20040258611A1Inhibition formationRelieve pressurePretreated surfacesCatalyst activation/preparationColloidSol gel coating

Owner:DATEC COATING CORP

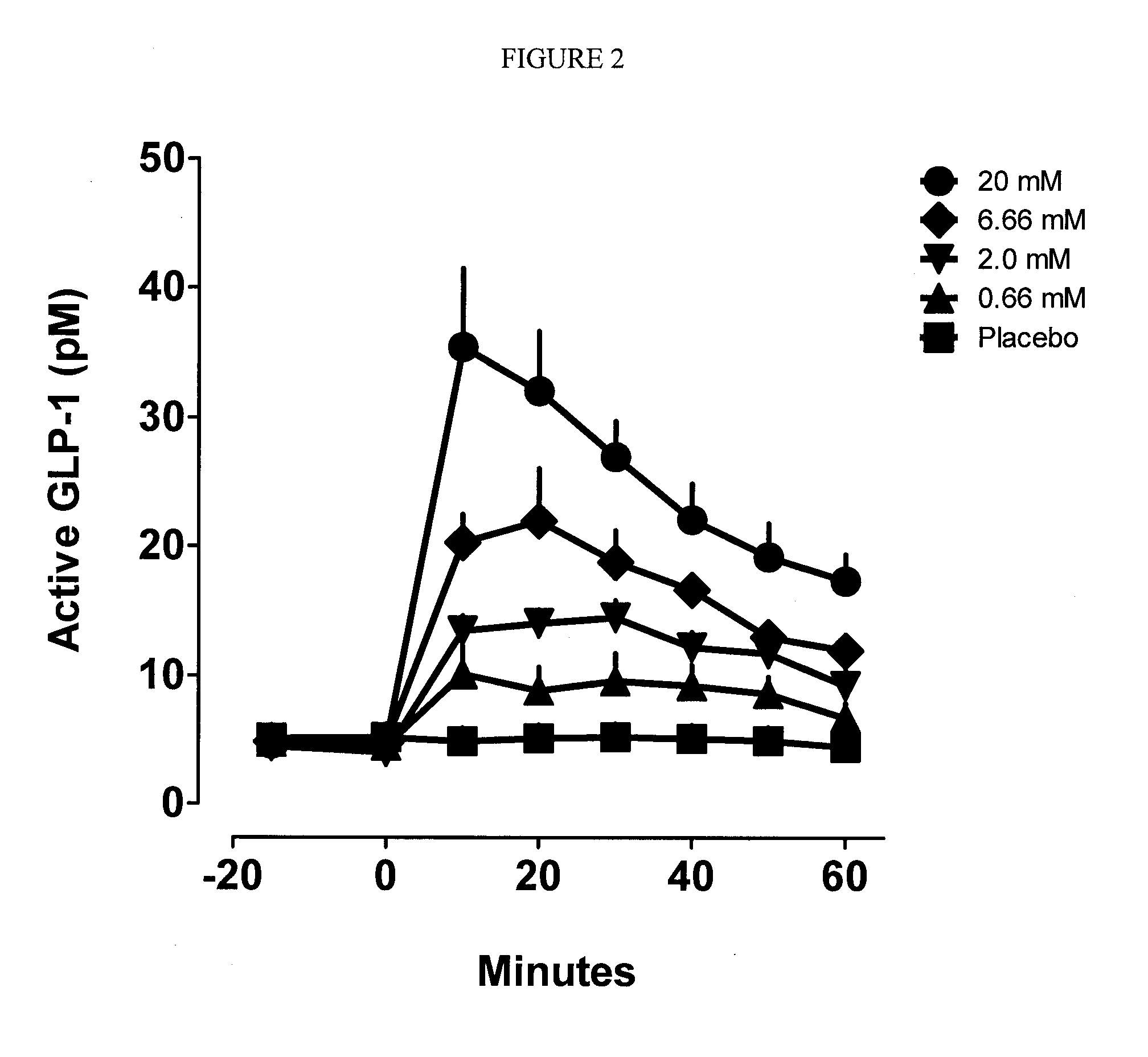

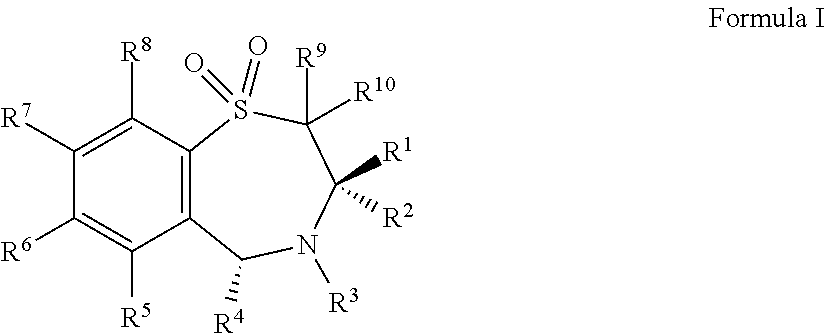

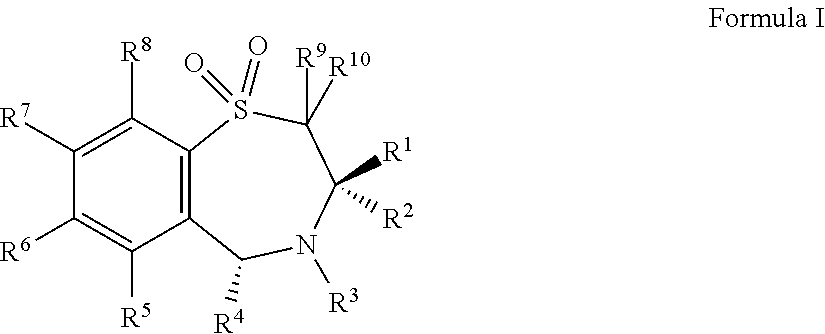

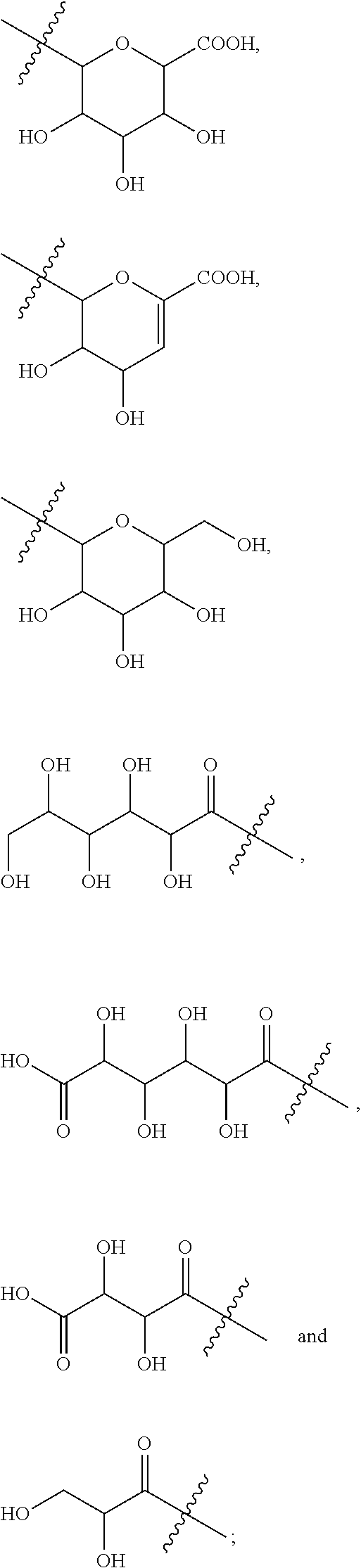

Bile Acid Recycling Inhibitors for Treatment of Pancreatitis

Provided herein are methods and compositions comprising bile acid transport inhibitors and / or enteroendocrine peptide enhancing agents and / or FXR agonists for the treatment of pancreatitis or prevention of pancreatitis.

Owner:LUMENA PHARMA INC

Bile acid recycling inhibitors for treatment of primary sclerosing cholangitis and inflammatory bowel disease

InactiveUS20140275090A1Reduce erosionExtension of timeBiocideOrganic chemistryApical sodium-dependent bile acid transporterInflammatory bowel disease

Provided herein are methods of treating or ameliorating primary sclerosing cholangitis and inflammatory bowel disease by administering to an individual in need thereof a therapeutically effective amount of an Apical Sodium-dependent Bile Acid Transporter Inhibitor (ASBTI) or a pharmaceutically acceptable salt thereof. Also provided are methods for treating or ameliorating primary sclerosing cholangitis comprising administering to an individual in need thereof a therapeutically effective amount of ASBTI or a pharmaceutically acceptable salt thereof.

Owner:LUMENA PHARMA INC

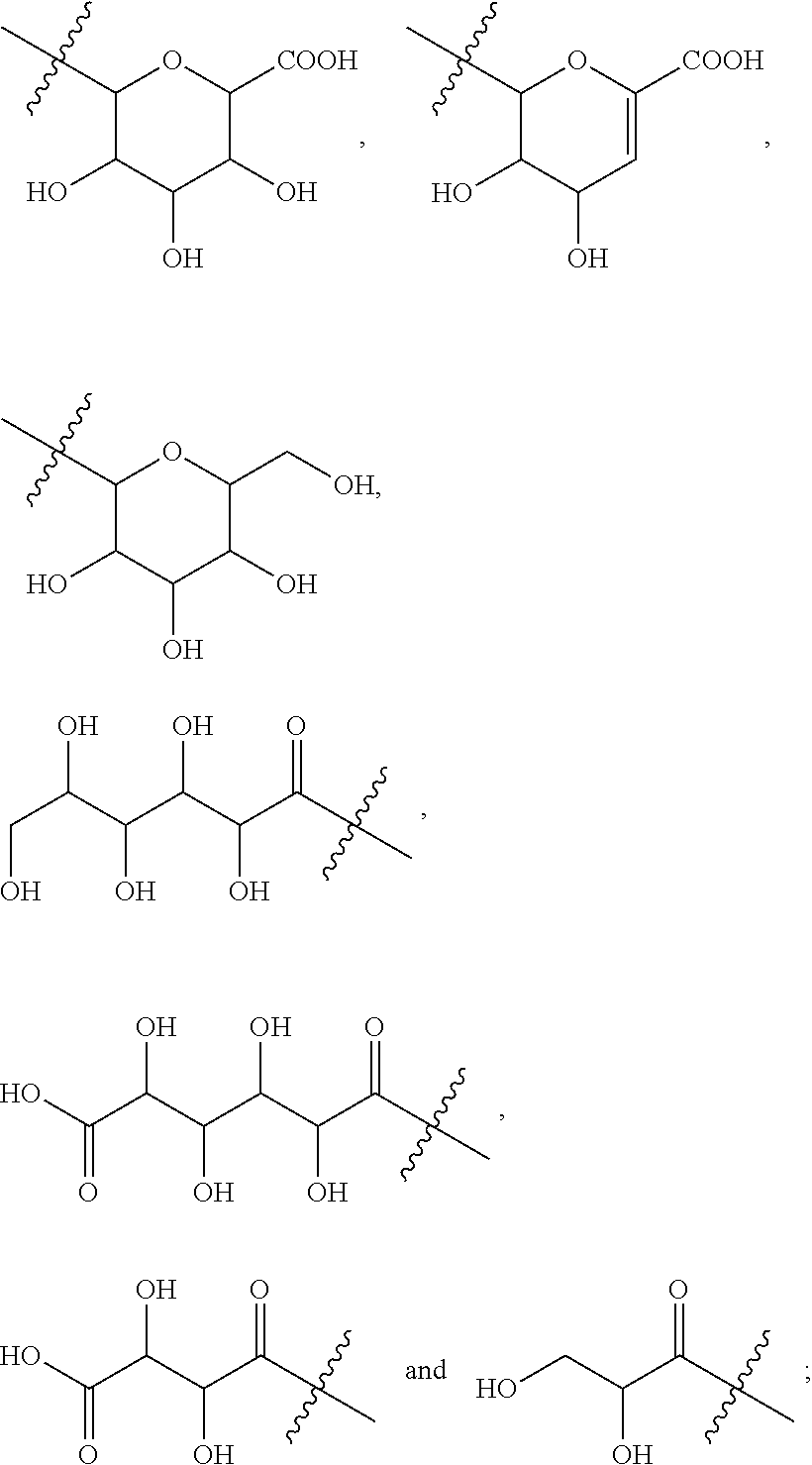

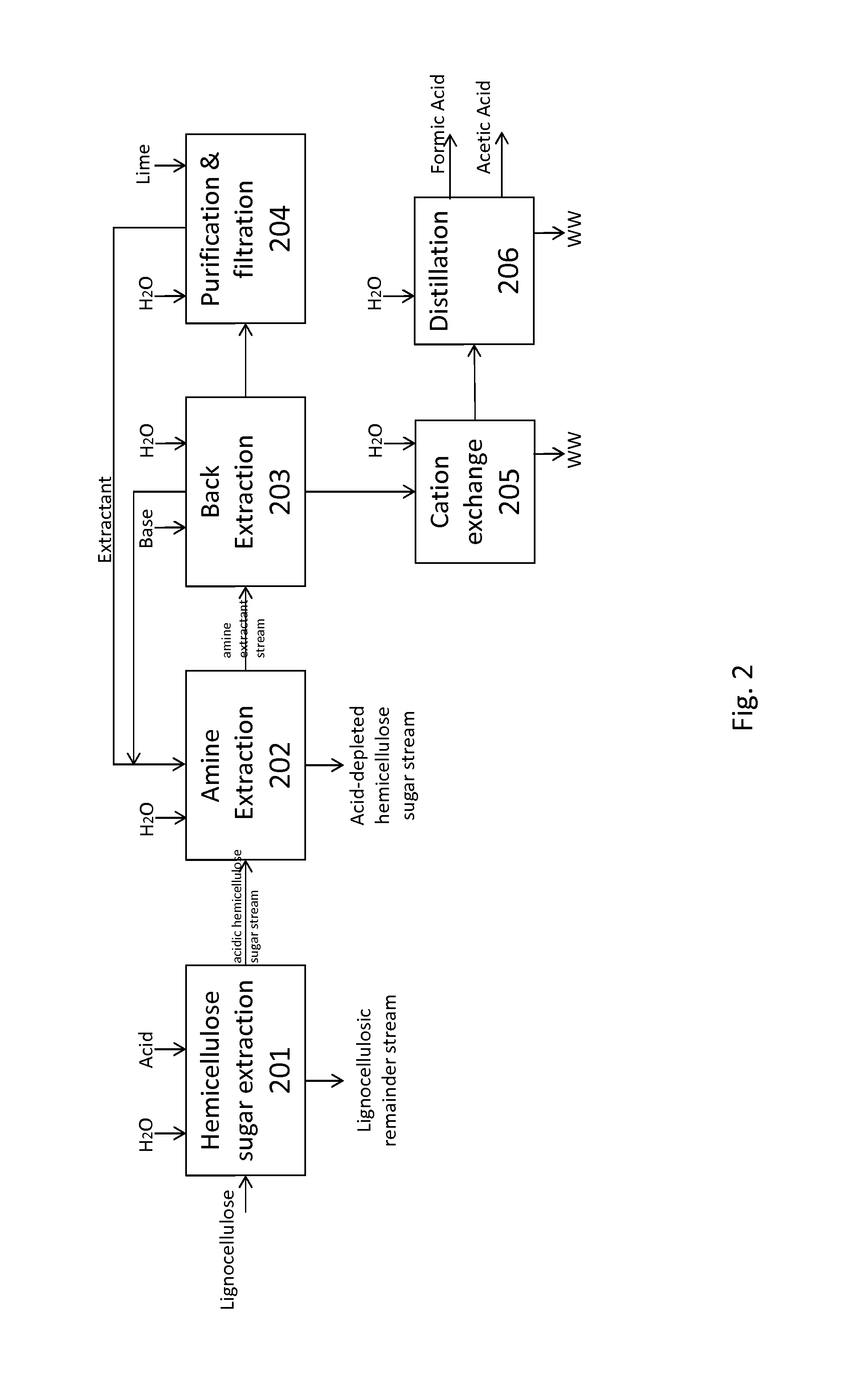

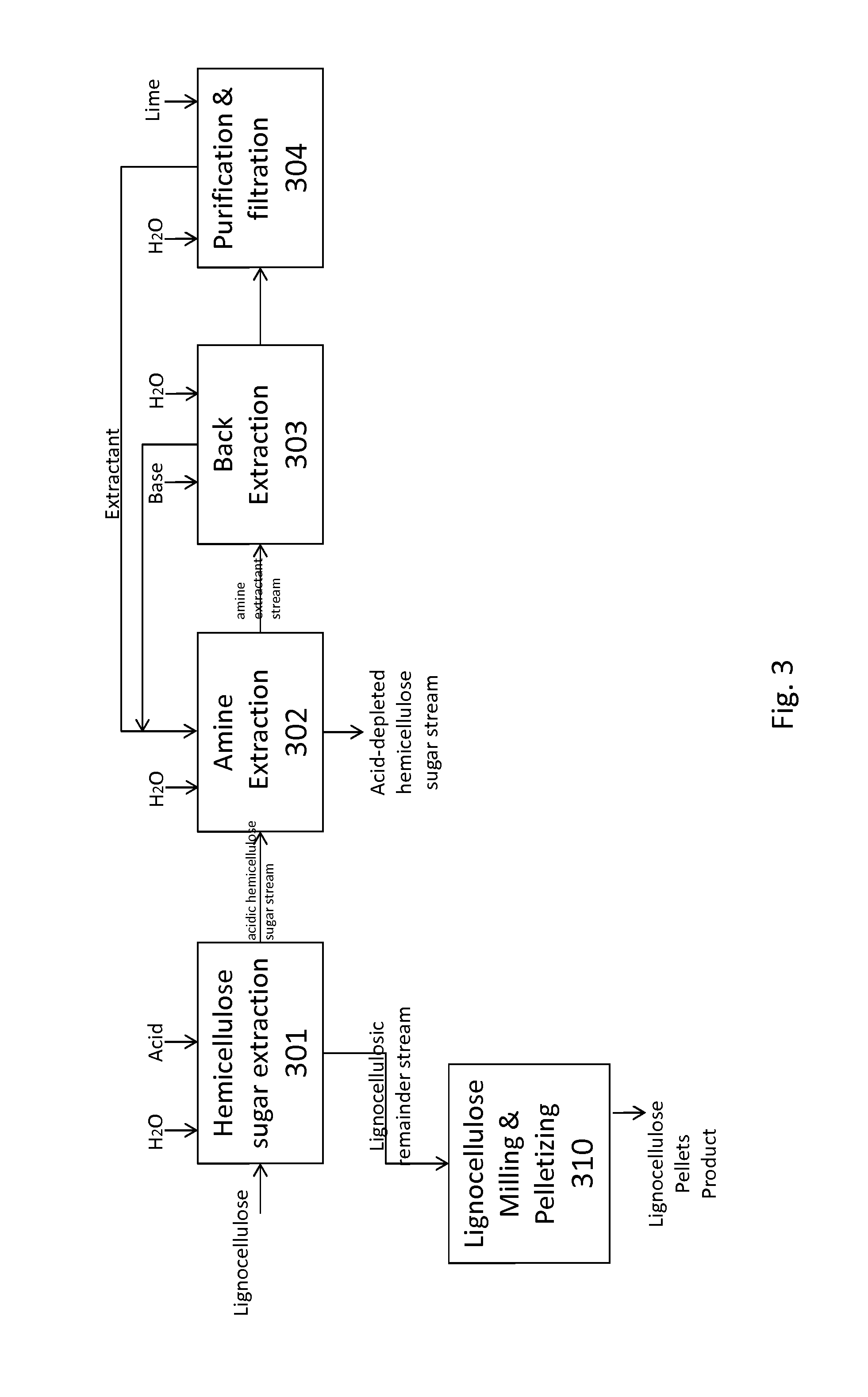

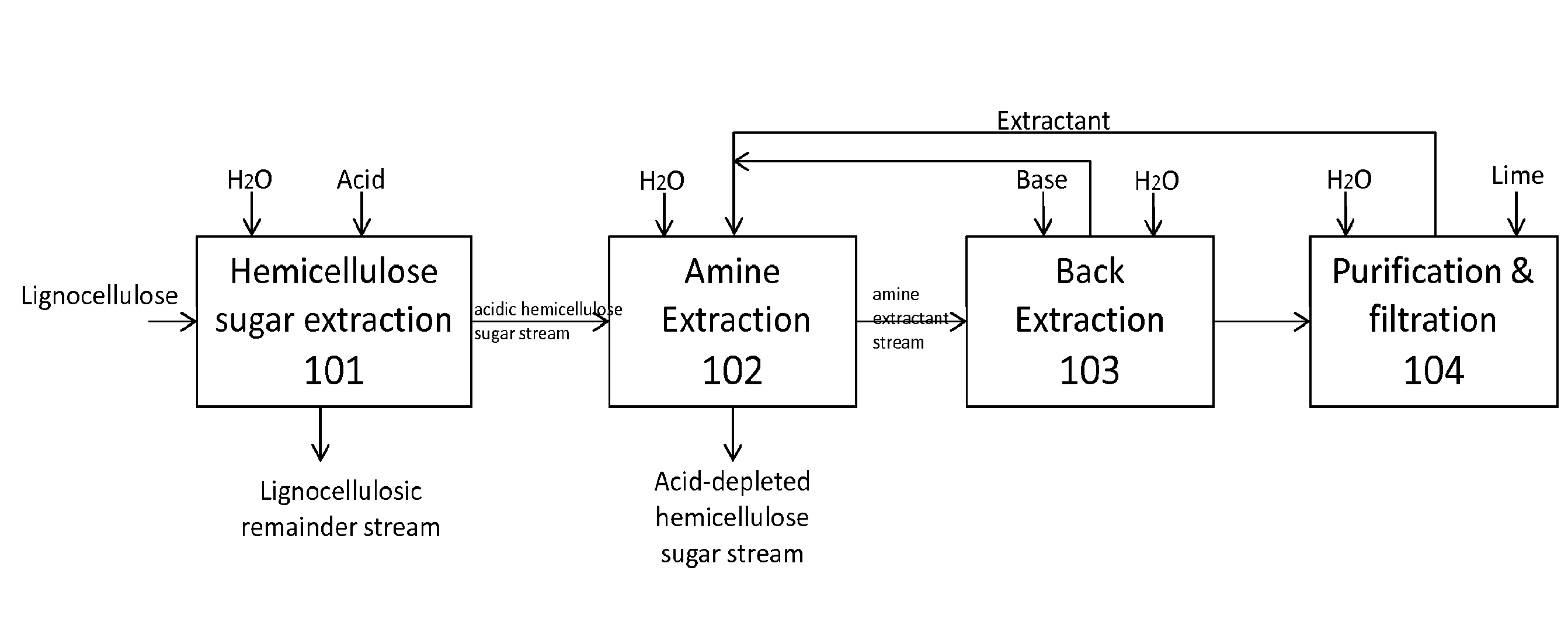

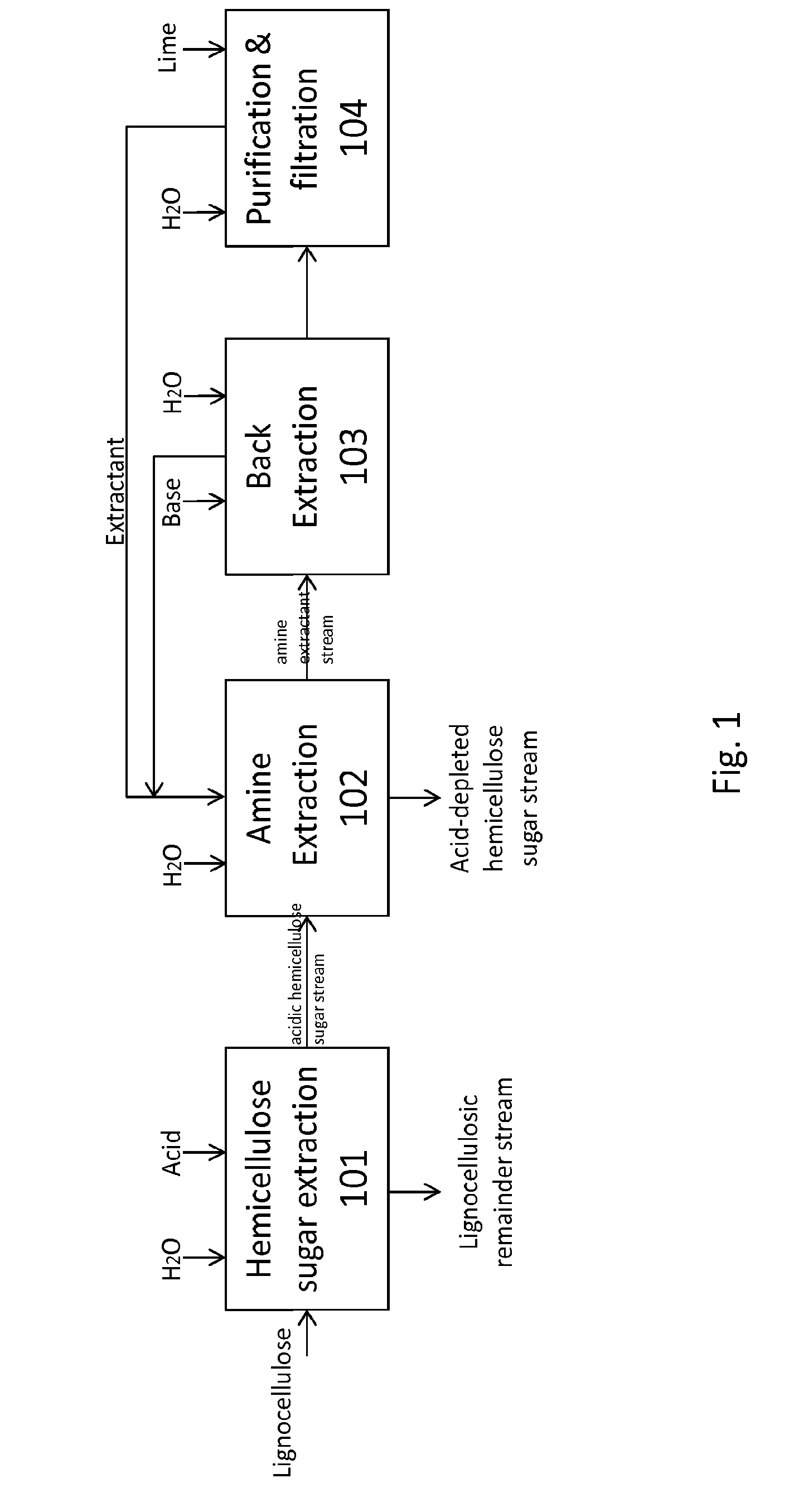

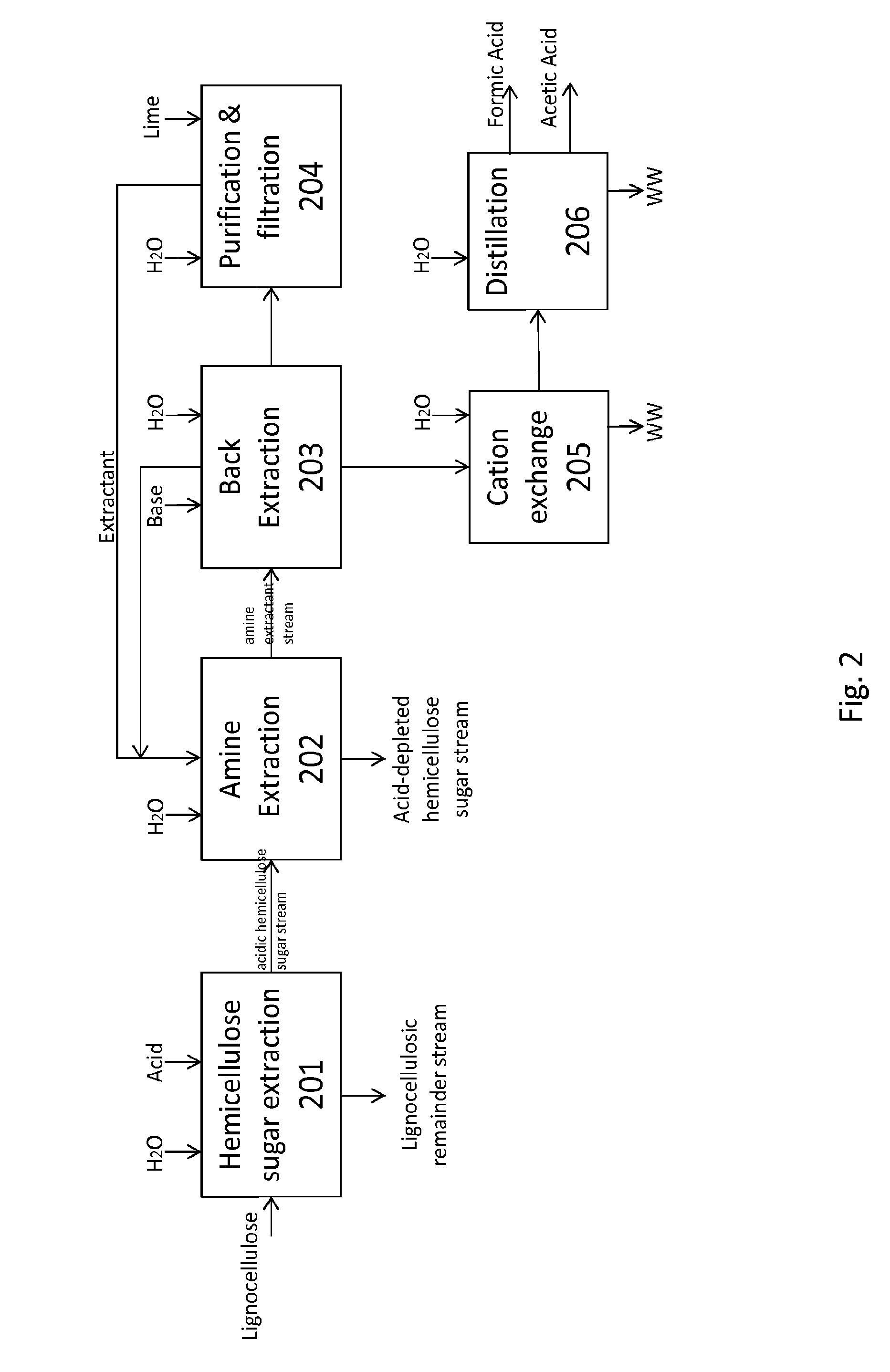

Methods for treating lignocellulosic materials

The present invention relates to methods of processing lignocellulosic material to obtain hemicellulose sugars, cellulose sugars, lignin, cellulose and other high-value products. Also provided are hemicellulose sugars, cellulose sugars, lignin, cellulose, and other high-value products.

Owner:VIRIDA

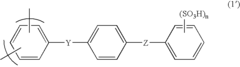

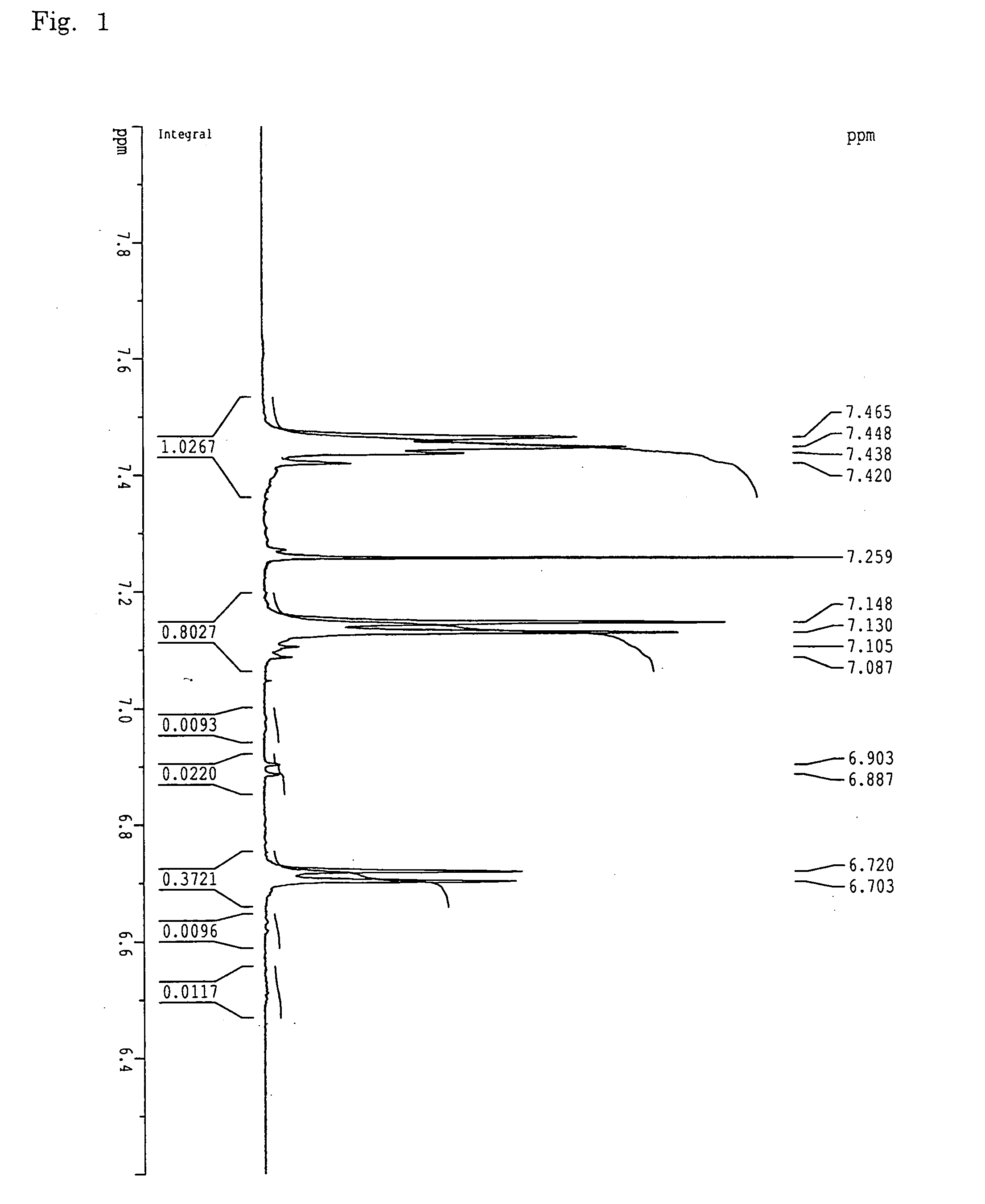

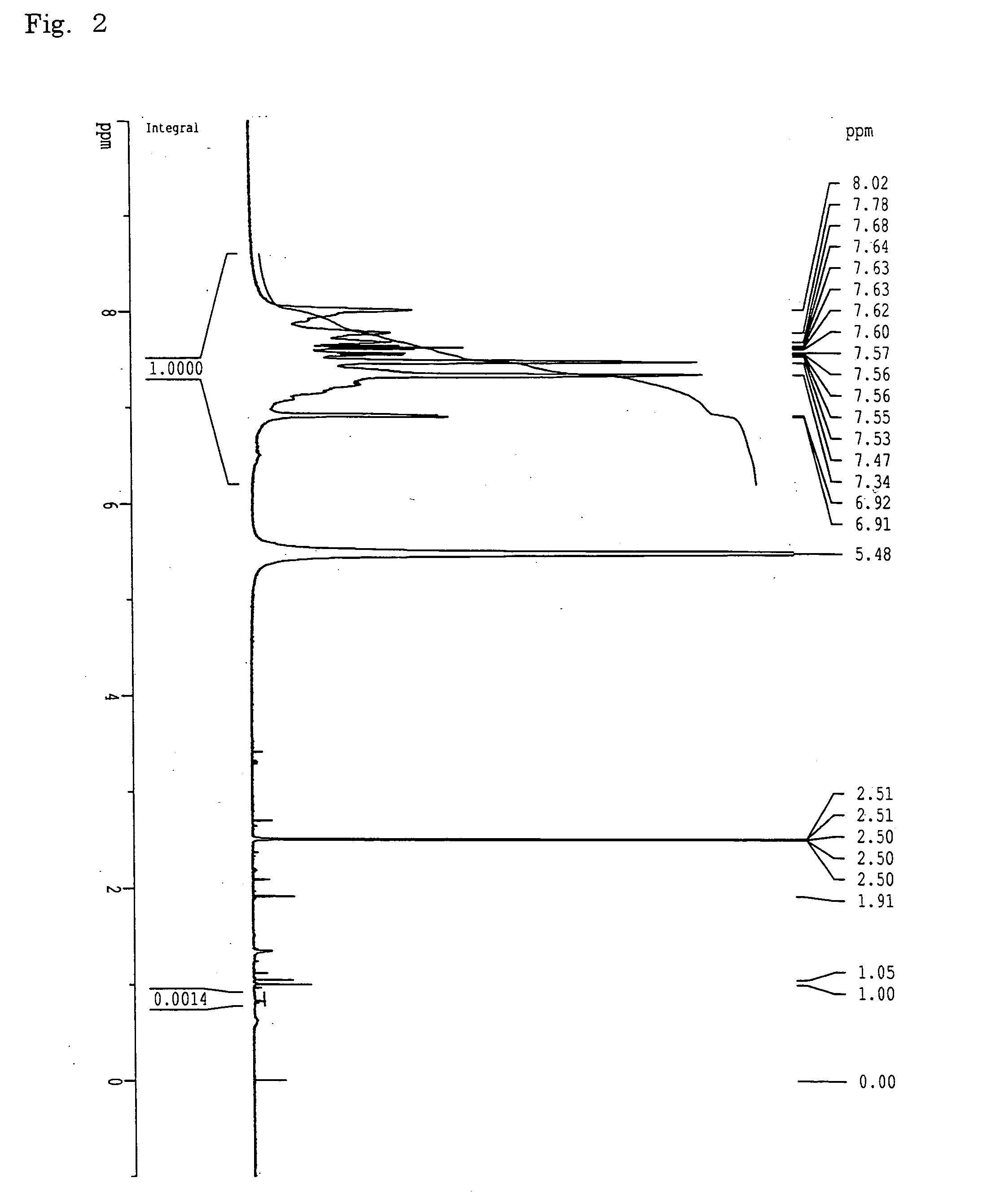

Sulfonated polymer having nitrile-containing hydrophobic block and solid polymer electrolyte

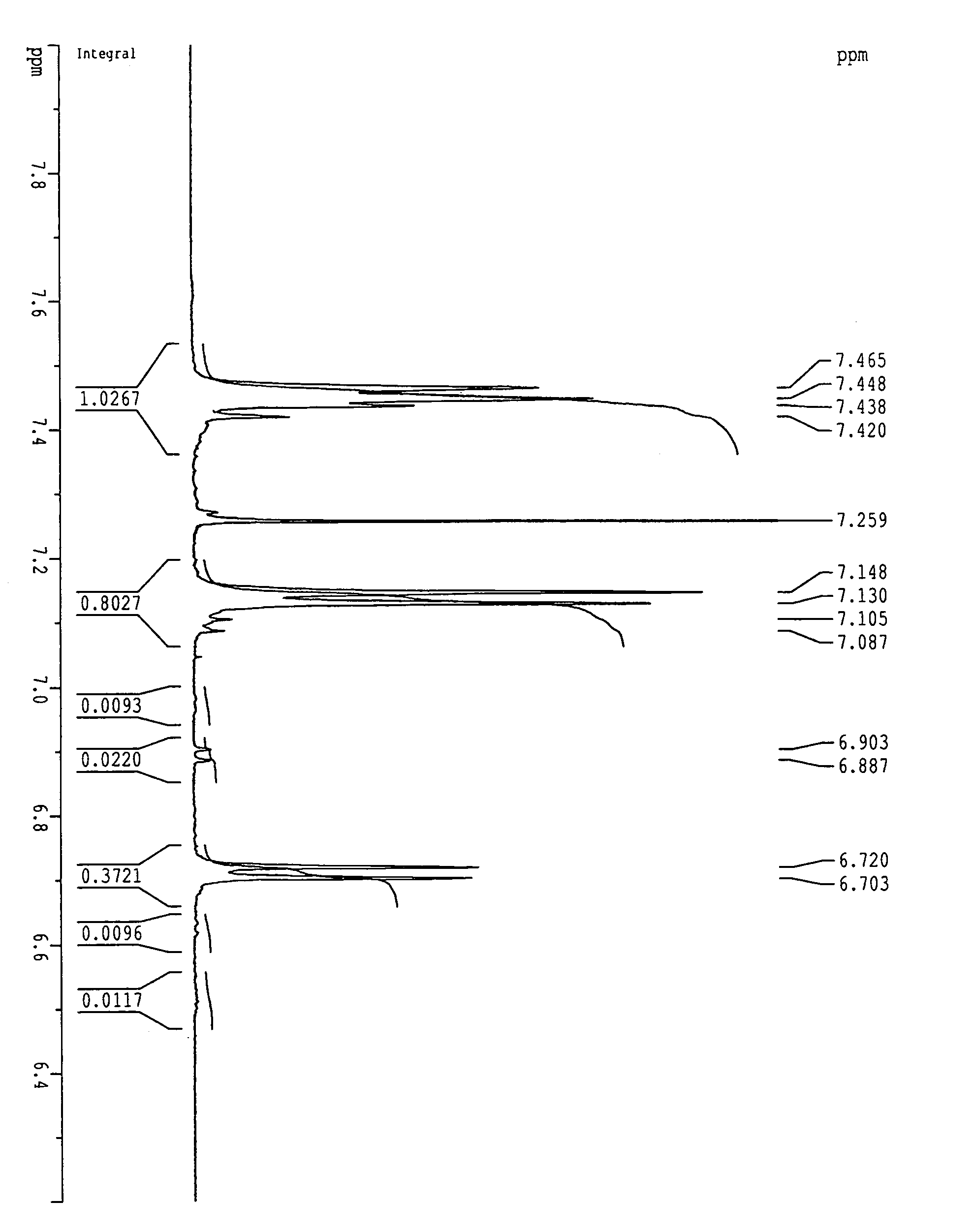

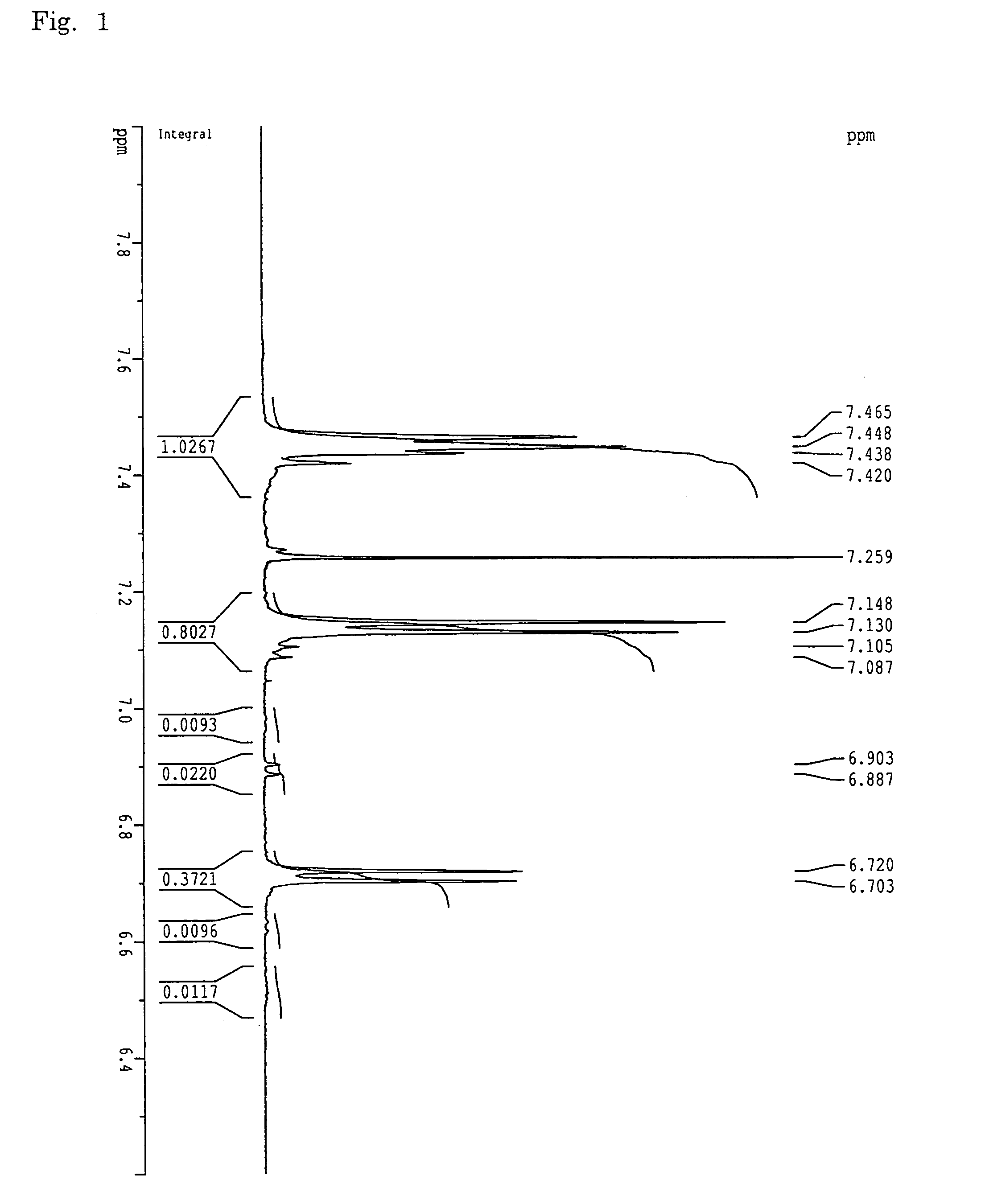

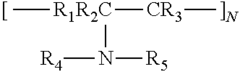

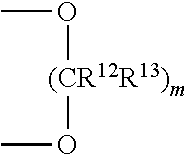

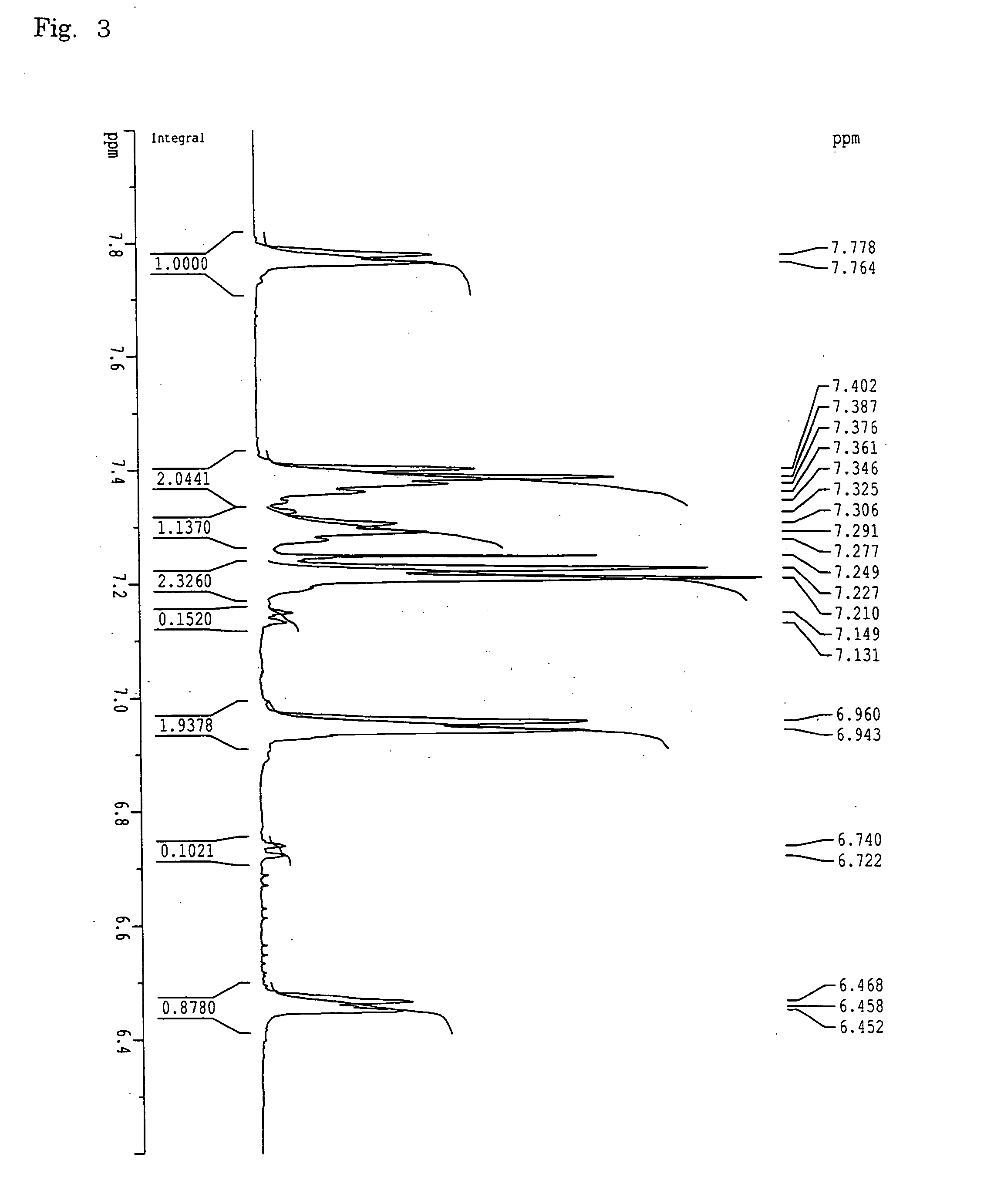

ActiveUS7115699B2Excellent hot water resistanceIncrease acid concentrationNon-metal conductorsSolid electrolytesPolymer electrolytesAryl

Provided are a sulfonated polymer capable of high hot water resistance even if it has an increased amount of the sulfonic groups introduced therein, and a solid polymer electrolyte containing the sulfonated polymer that has high proton conductivity and excellent generating performance.The sulfonated polymer has repeating units represented by the formula (1′):wherein B's are each independently an oxygen or a sulfur atom, R1 to R3 may be the same or different and are selected from a hydrogen atom, a fluorine atom, a nitrile group and an alkyl group, n is an integer of 2 or greater, and Q is a structure represented by the formula (q):wherein A is independently a divalent atom or organic group or a direct bond, and R4 to R11 may be the same or different and are selected from a hydrogen atom, a fluorine atom, an alkyl group and an aromatic group.

Owner:JSR CORPORATIOON

Method for absorbing acrylic acid and method for purifying acrylic acid

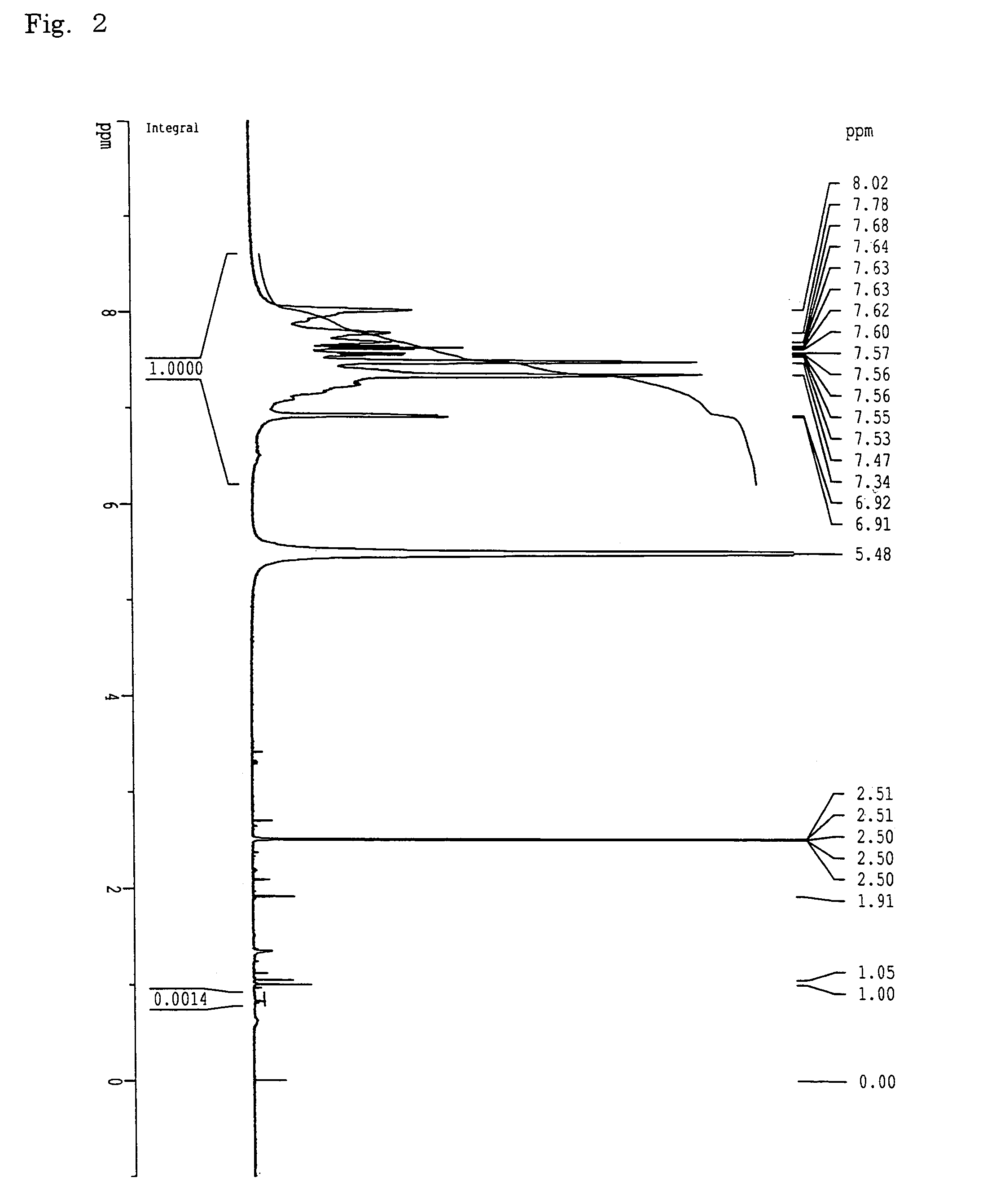

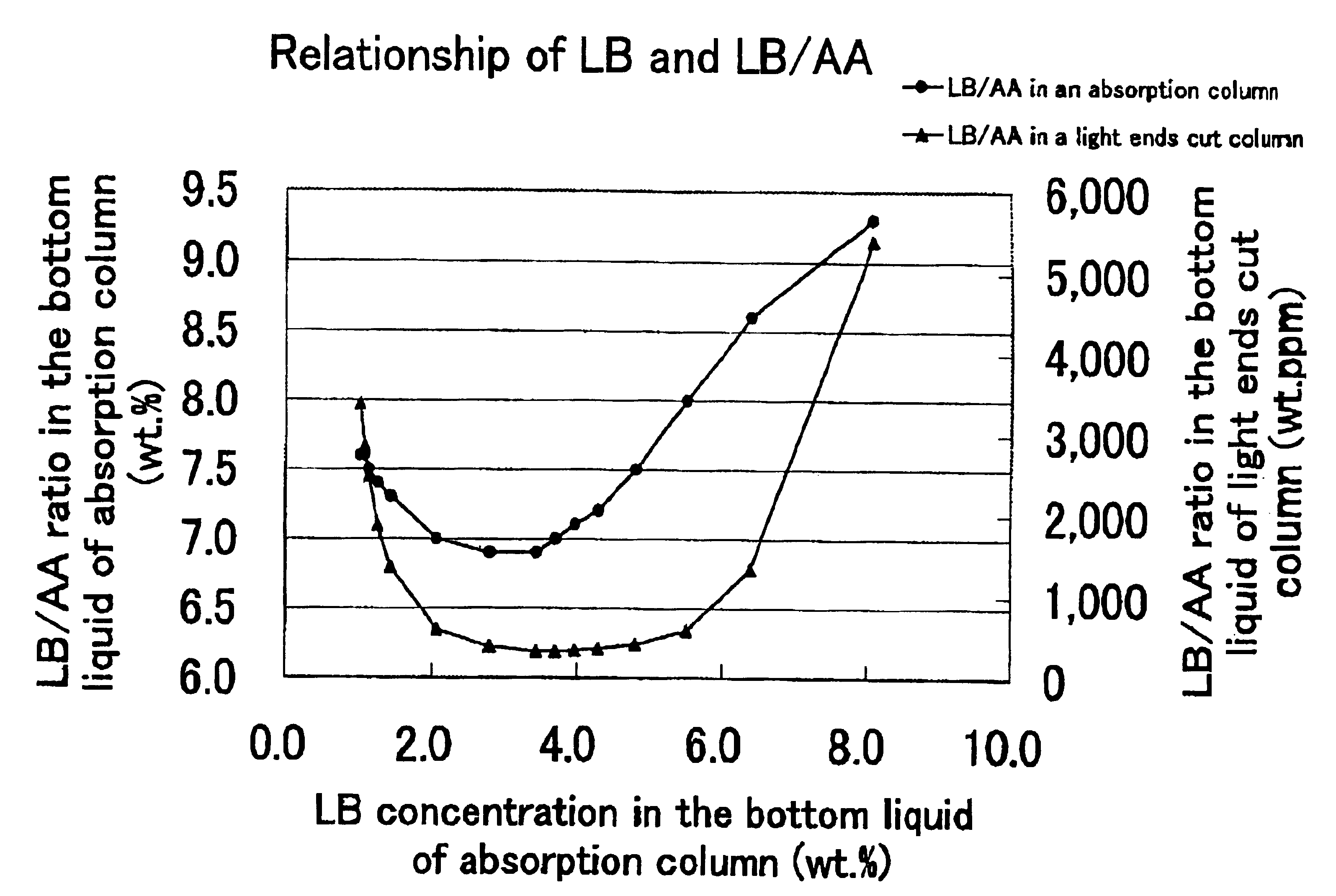

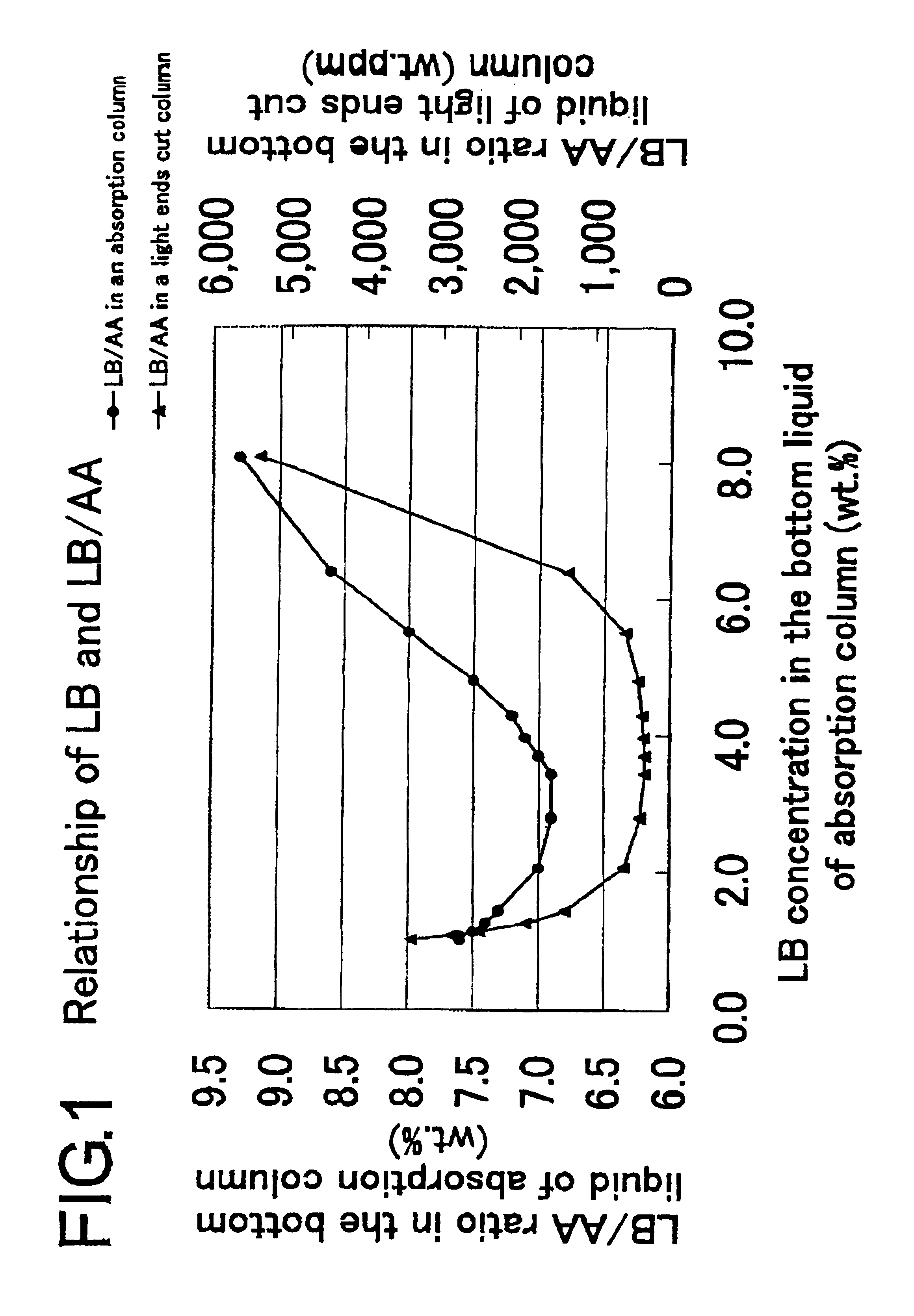

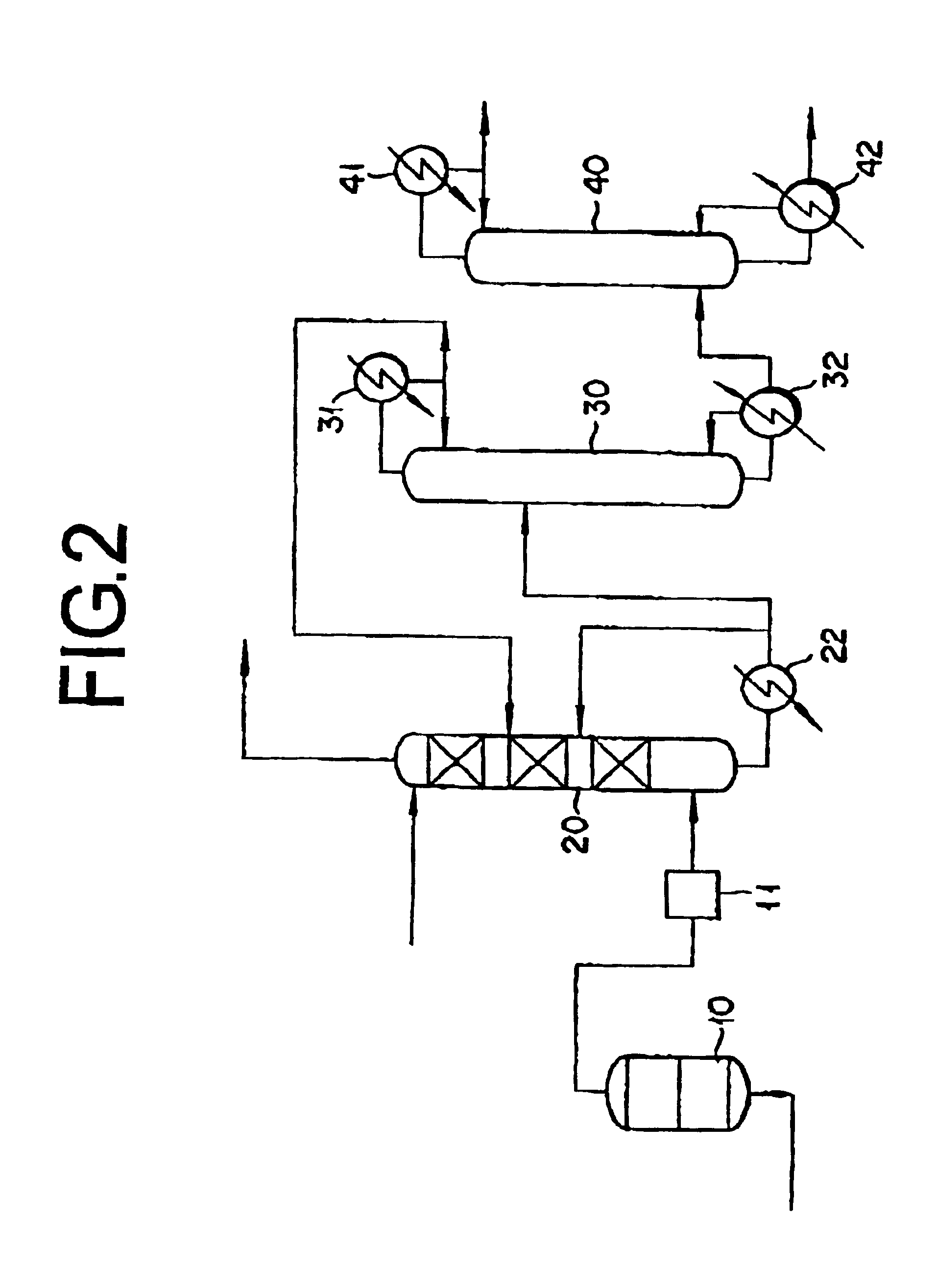

InactiveUS6888025B2Absorption coefficientLow related substancesOrganic compound preparationDistillation separationCounter flowAbsorption column

This invention concerns a method for absorbing acrylic acid, characterized by supplying an acrylic acid-containing reaction gas component obtained by the reaction of catalytic gas phase oxidation to an acrylic acid absorption column and advancing a high boiling inert hydrophobic organic liquid into counter-flow contact with said reaction gas in said acrylic acid absorption column with the mass flow rate of the organic liquid fixed in the range of 0.2-7.0 times the mass flow rate of the acrylic acid in the reaction gas thereby absorbing acrylic acid in said organic liquid and obtaining an acrylic acid-containing solution including a low boiling substance in the range of 0.7-7.5 wt % based on the weight of bottom liquid of absorption column.

Owner:NIPPON SHOKUBAI CO LTD

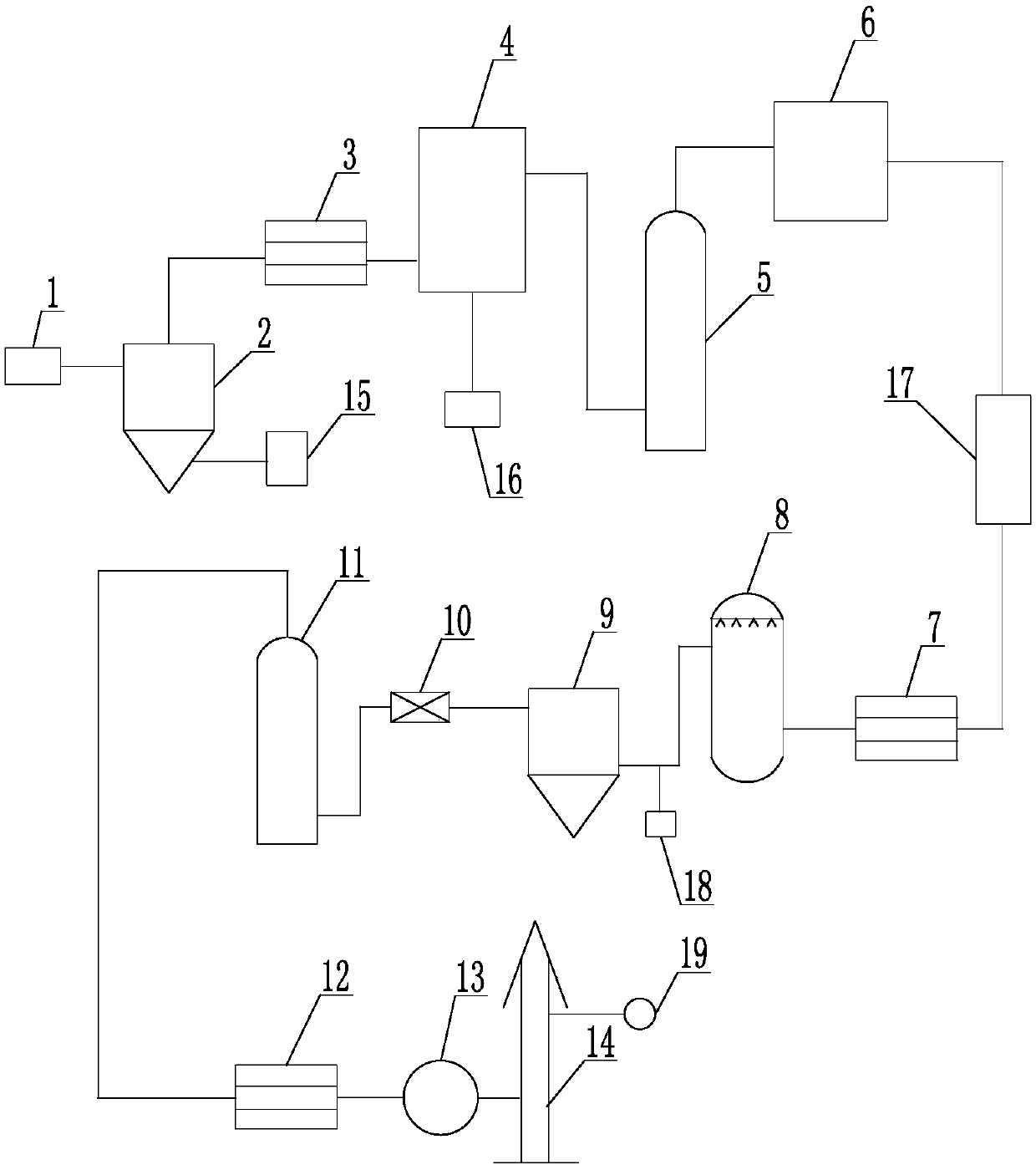

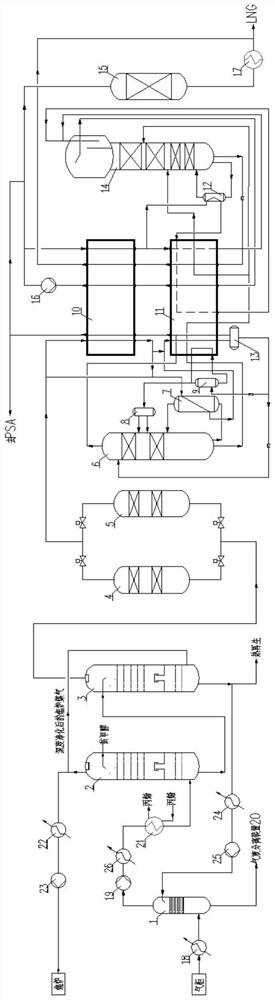

Resource recycling process and system for high-temperature plasma of chlorine-containing waste

InactiveCN109539272AFully harmless treatmentEfficient recyclingDispersed particle filtrationEmission preventionCombustion chamberDecomposition

The invention belongs to the technical field of industrial waste treatment, and particularly relates to a resource recycling process and system for high-temperature plasma of chlorine-containing waste. The method comprises the steps that (1) the chlorine-containing waste is conveyed into a plasma gasifier through a feeding system; (2) synthesis gas produced through splitting decomposition is cooled by a first-stage waste heat exchanger; (3) after entering an acid absorption system to absorb acid, the synthesis gas enters an alkaline tower to be further deacidified; (4) the deacidified synthesis gas enters a secondary combustion chamber to be combusted, and generated high-temperature flue gas is cooled by a second-stage waste heat exchanger; (5) after the cooled flue gas enters a quench cooler to be subjected to quenching, the flue gas enters a bag-type dust remover for dust removal; (6) the flue gas with dust removed enters a flue heater to be warmed; (7) the flue gas enters an SCR catalytic tower to remove nitric oxide in the flue gas; and (8) after the flue gas subjected to SCR treatment enters the heat exchanger for heat exchange, the flue gas is drawn out by an induced draft fan, and the flue gas is discharged into the atmosphere through a chimney. By means of the resource recycling process and system, resource, harmless, reducing and stabilizing treatment of the chlorine-containing waste is achieved, and the system operation cost is low.

Owner:SHANDONG BO RUN IND TECH

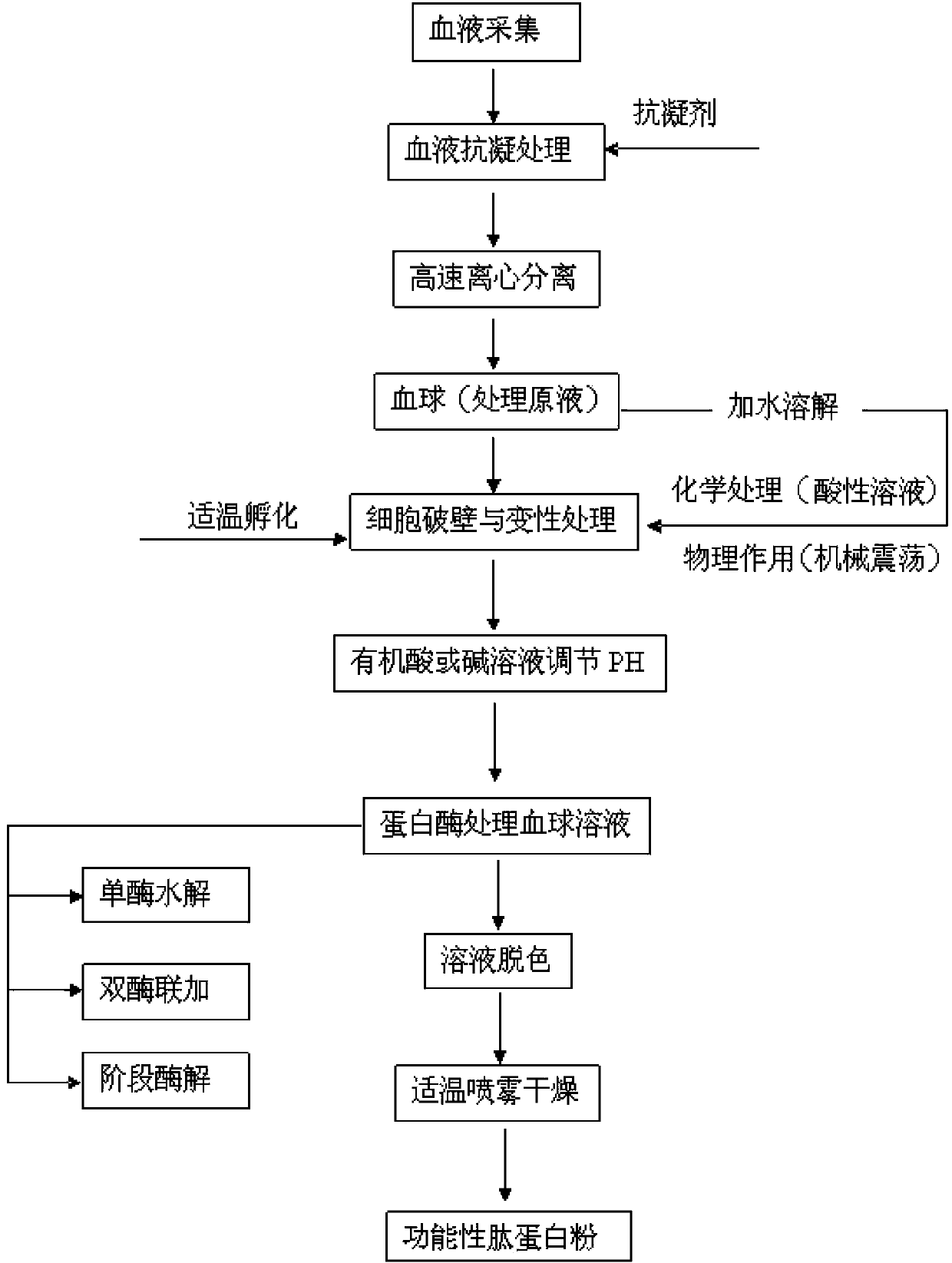

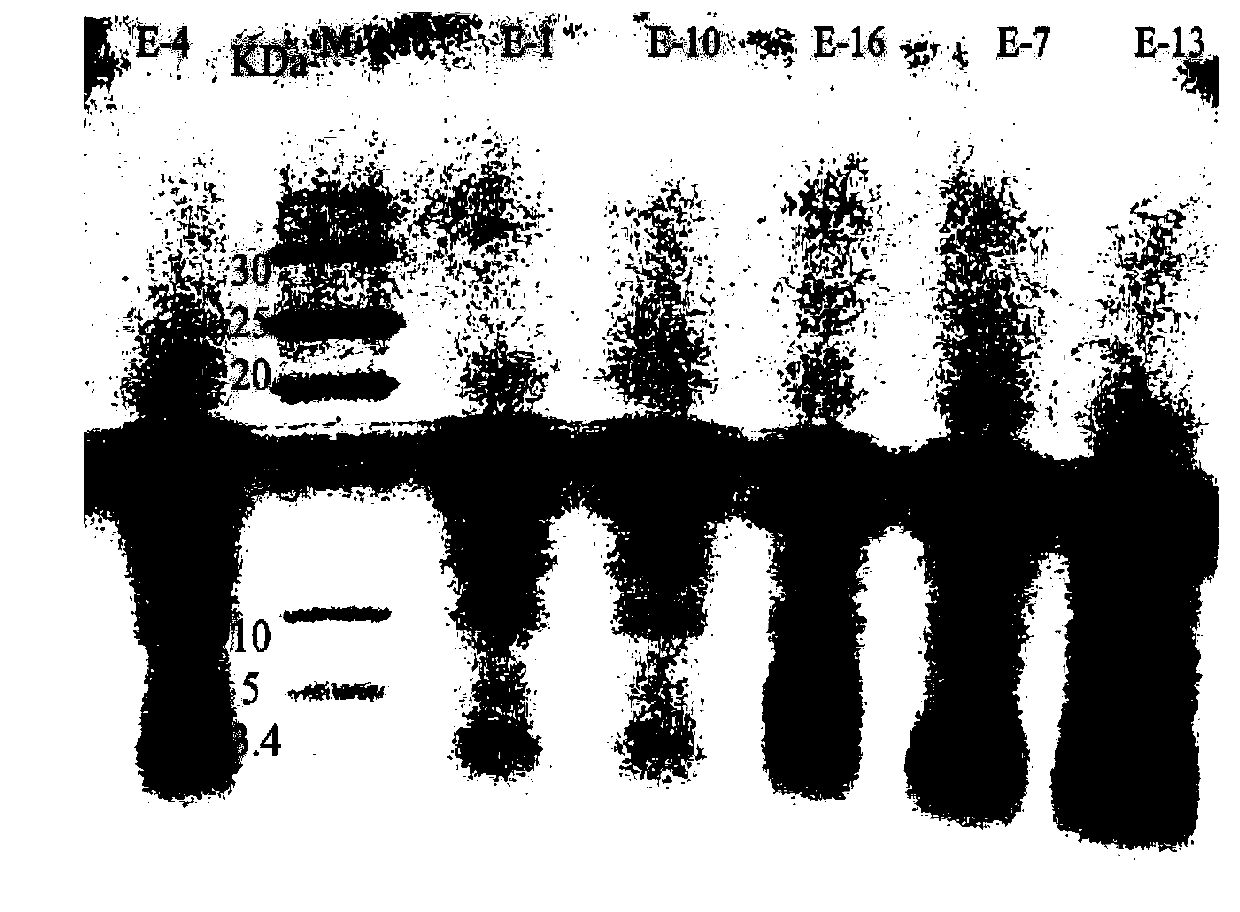

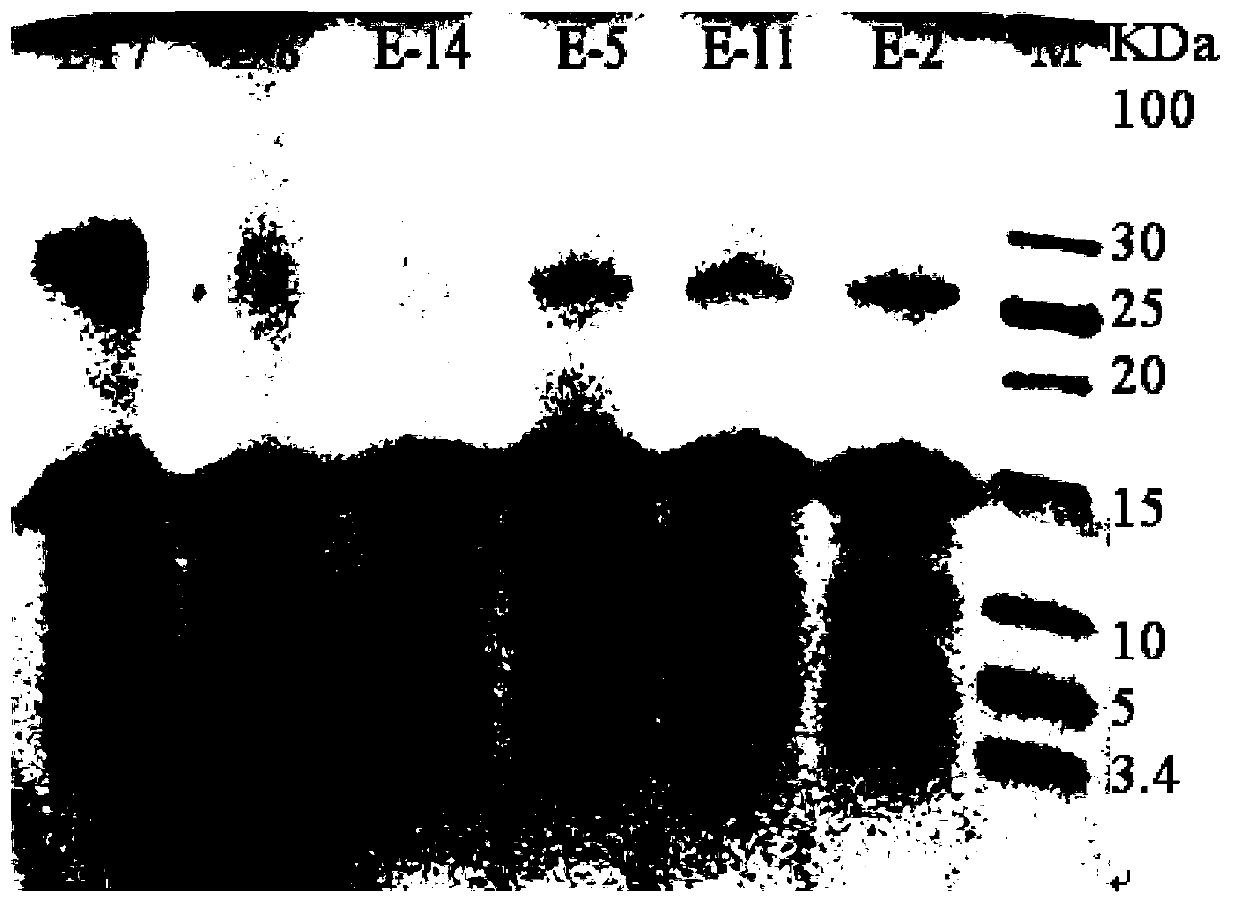

Functional peptide protein powder, and preparation method and applications thereof

ActiveCN104171260AShorten centrifugation timeShorten production timeProtein composition from bloodClimate change adaptationDiseaseProtease preparation

The present invention discloses a method for preparing functional peptide protein powder using blood cells of livestock and poultry as raw materials. The method is as follows: continuously centrifuging fresh blood of livestock and poultry to separate blood plasma and blood cells; processing the blood cells by physical and chemical methods to break cell membranes and denature intracellular protein; after the membrane breaking and denaturing process, adding acid (or base) and a protease preparation into the blood cell solution to enzymatically hydrolyze the blood cell protein into small peptides and amino acids containing functional ingredients; then centrifuging the products of enzymolysis and adding acid and a decolorizer to performing decoloration; and finally performing spray drying on the decolorized blood cell solution. The present invention also provides functional peptide protein powder prepared by the method. The functional peptide protein powder has a high protein content, a high essential amino acid content, a high bioactive peptide content, a high digestion and absorption rate, and a strong antioxidant capacity, can improve the disease resistance of livestock and poultry, protein deposition and production performance, can be widely used for livestock, poultry and aquatic animals, and can also be used as a substitute for fish meal and soybean meal.

Owner:北京澳龙港生物技术研究中心

Process for surface treatment of metals

InactiveUS20110056516A1Reducing eliminate releaseAvoid attackOrganic detergent compounding agentsDetergent mixture composition preparationImpurityNuclear chemistry

An environmentally acceptable and comparatively safe acid cleaning solution containing sulfuric acid, water and amine containing inhibitors that adequately remove oxidation or contaminants from surfaces without excessively damaging equipment. The sulfuric acid is effective in removing impurities and contaminants, while the amine moieties or amine salts reduce the otherwise damaging effect of sulfuric acid on equipment and on human skin and tissue.

Owner:JOT HLDG

Methods for treating lignocellulosic materials

ActiveUS20150141628A1Increase acid concentrationChromatographic cation exchangersSugar derivativesChemistryHigh value products

The present invention relates to methods of processing lignocellulosic material to obtain hemicellulose sugars, cellulose sugars, lignin, cellulose and other high-value products. Also provided are hemicellulose sugars, cellulose sugars, lignin, cellulose, and other high-value products.

Owner:VIRDIA

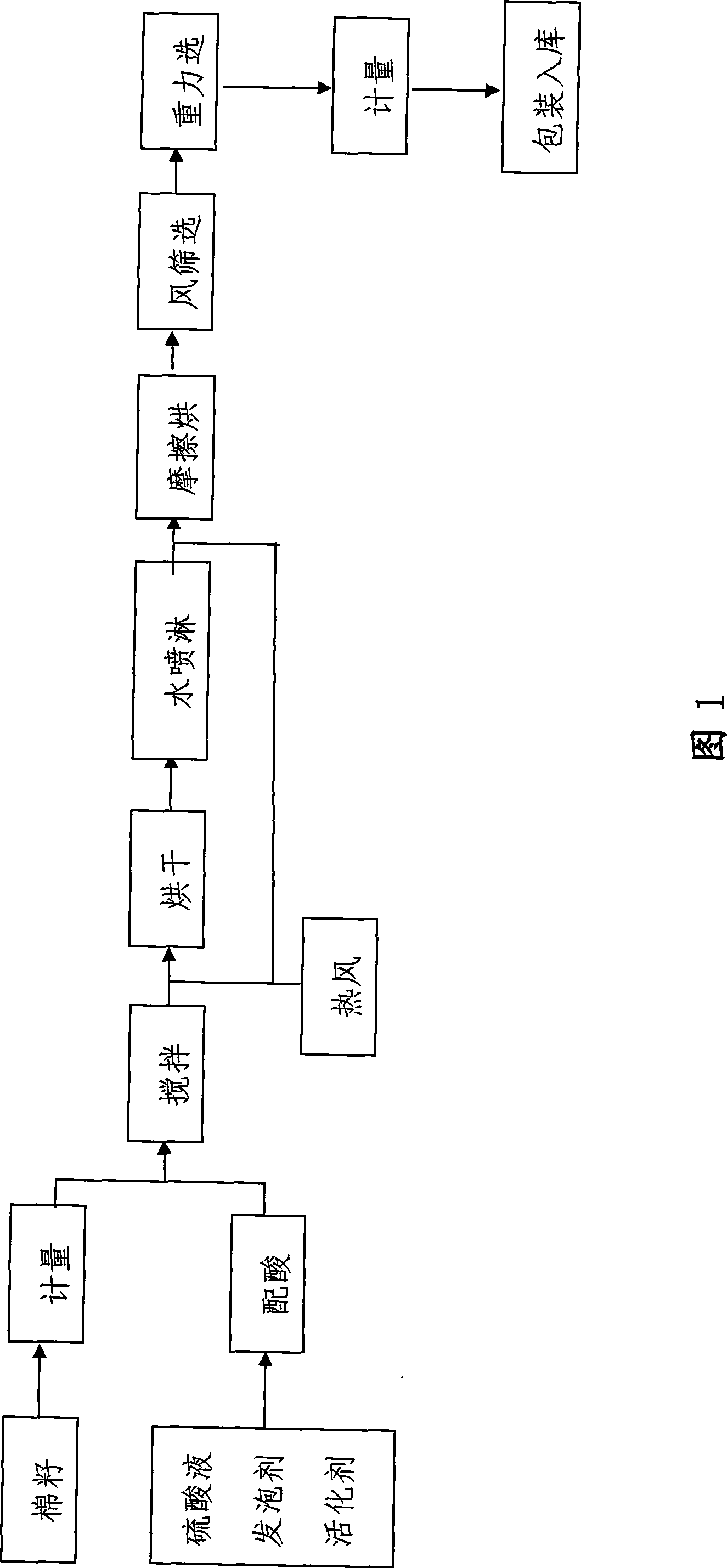

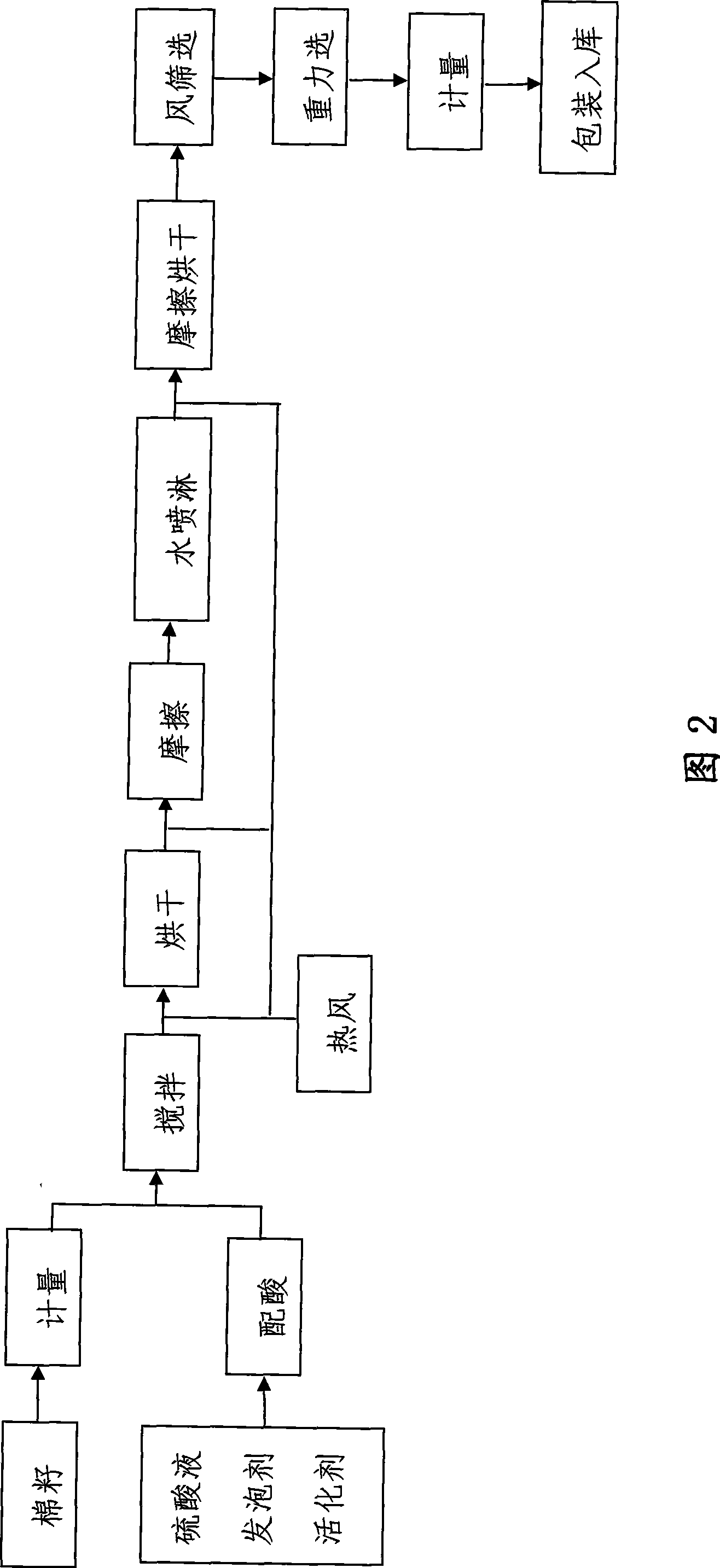

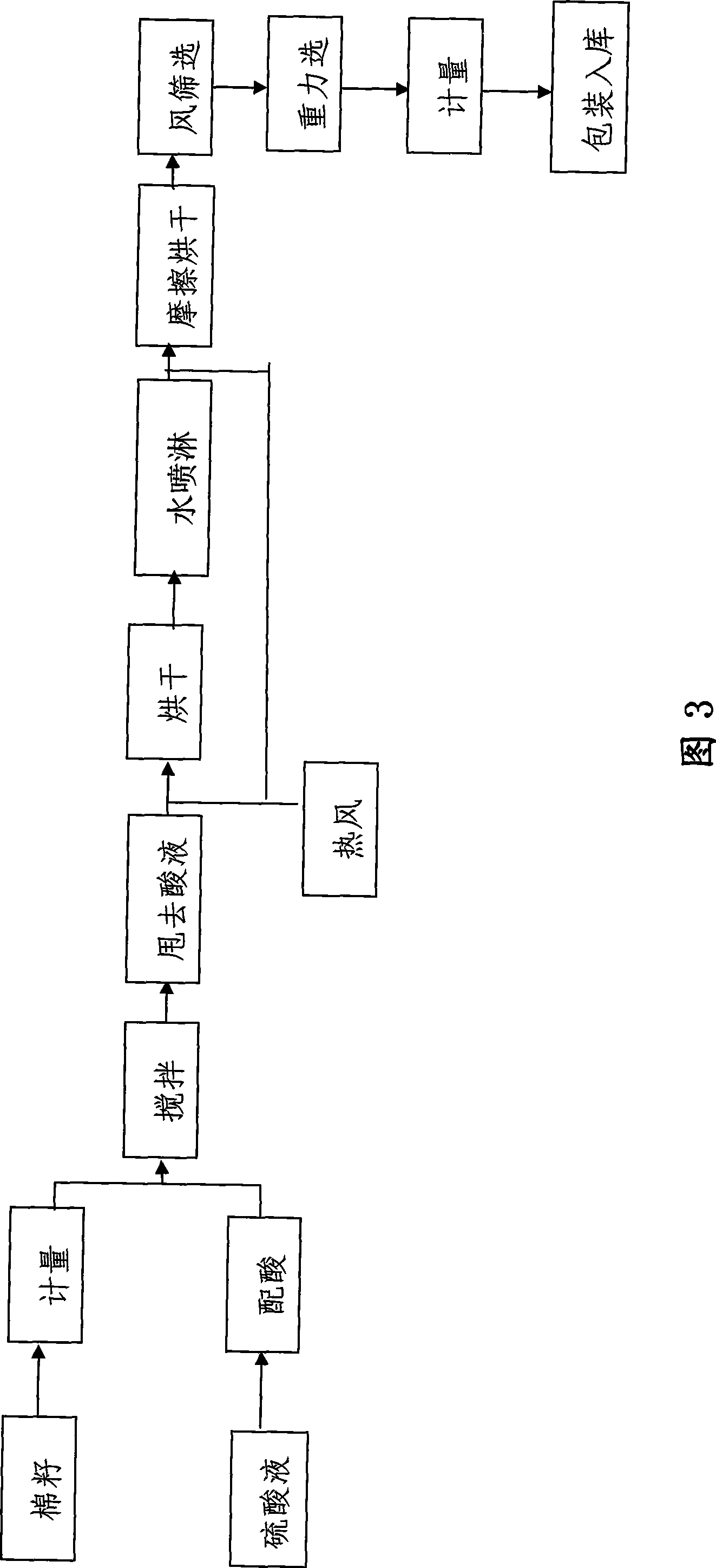

Cotton seeds processing technique

The invention discloses a processing technique for cotton seeds, pertaining to the technical filed of seed preparation before planting. Currently, an acid treatment technology is adopted to remove the residual velvet of the cotton seeds, and in order to protect the seeds against damage, strict control can be carried out on the concentration of the acid and the charing temperature of the residual velvet, as the sprouting rate and appearance of the cotton seeds can be affected due to any negligence. Therefore, the invention adds a water spray cleaning device and the working procedures thereof on the basis of the original processing technique. At the same time, the concentration of sulphuric acid in acid treatment solution is increased to 7.0-10.0 percent and the content of a foaming agent and an activating agent is reduced, wherein, the total content of the foaming agent and the activating agent is below 0.35 percent. The invention has the advantages of no residual acid, no residual velvet, lower cost, higher sprouting rate, less damage to the cotton seeds, higher safety and reliability, and glabrous appearance of the cotton seeds.

Owner:张卫东

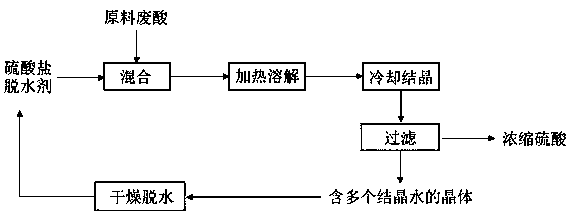

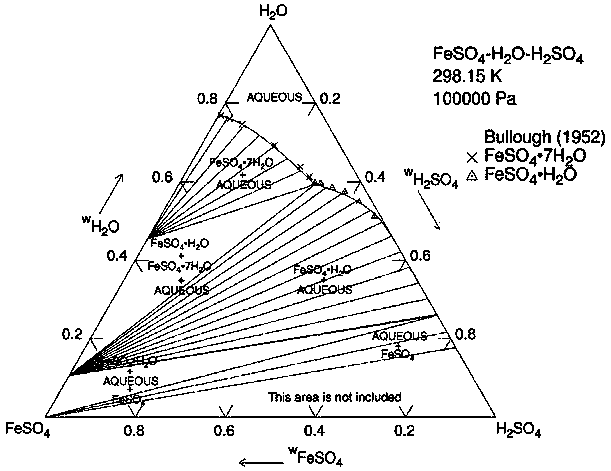

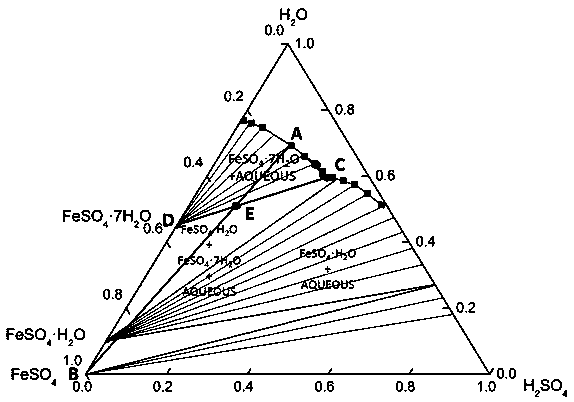

Process for concentrating titanium white waste acid through generation of crystalline hydrate by utilizing phase equilibrium principle

InactiveCN109368604AAvoid introducingAvoid it happening againSulfur-trioxide/sulfuric-acidResource utilizationCopper sulfate

The invention provides a process for concentrating titanium white waste acid through generation of crystalline hydrate by utilizing the phase equilibrium principle. According to the process, ferrous sulfate, copper sulfate or other sulfate capable of forming crystalline hydrates are added into titanium white waste acid, the phase equilibrium process is controlled by utilizing the equilibrium relationship among sulfuric acid, water and sulfate, moisture is brought out by generating sulfate hydrates containing different crystal water and crystallizing and separating the sulfate hydrate from diluted sulfuric acid, and the diluted sulfuric acid can be concentrated; and the separated ferrous sulfate and other crystalline hydrates can be recycled after being dried to remove crystal water; different concentration degrees can be realized by controlling the mode of generated crystalline hydrate and can be adjusted according to requirement, and a concentrated sulfuric acid product having an acidconcentration of higher than 60 percent can be obtained; and anhydrous ferrous sulfate and other sulfates capable of forming crystalline hydrate can be utilized as raw materials, and the raw materials have wide sources. The process is simple, has low operation temperature, small equipment investment and weak corrosion, moisture of waste acid is not needed to be directly evaporated, energy consumption is low, and resource utilization of titanium white waste acid can be realized.

Owner:SICHUAN UNIV

Laminated polyester film for protective material for protecting back surface of photovoltaic cells

InactiveUS20130065063A1Improve hydrolysis resistanceImprove adhesionSynthetic resin layered productsElectrical equipmentPolyesterHydrolysis

The present invention provides a polyester film for a protective material for protecting a back surface of photovoltaic cell which exhibits a good hydrolysis resistance and an excellent adhesion property to a sealing resin for photovoltaic cells. The present invention relates to a polyester film for a protective material for protecting a back surface of photovoltaic cells which is in the form of a laminated polyester film comprising the below-mentioned polyester (A) layer as at least one of outermost layers of the film and at least one below-mentioned polyester (B) layer, the laminated polyester film having a terminal carboxyl group content of not more than 26 equivalents / t, and the polyester (A) layer being provided on at least one surface thereof with a coating layer formed of a polyurethane having at least one of a polycarbonate skeleton and a polyether skeleton, and a crosslinking agent:Polyester (A) layer: Layer formed of a polyester comprising an aromatic polyester as a main constitutional component and having a white pigment content of less than 8% by weight; andPolyester (B) layer: Layer formed of a polyester comprising an aromatic polyester as a main constitutional component and having a white pigment content of not less than 8% by weight.

Owner:MITSUBISHI PLASTICS INC

Bile acid recycling inhibitors for treatment of gastrointestinal infections

InactiveUS20150119345A1Reduce erosionExtension of timeEsterified saccharide compoundsBiocideIntestinal structureLiver infection

Provided herein are methods for treating or preventing gastrointestinal and / or liver infections utilizing bile acid transport inhibitors and / or enteroendocrine peptide enhancing agents and / or FXR agonists. Also provided herein are methods for increasing the levels of an enteroendocrine peptide or hormone in an individual suffering from a gastrointestinal infection or liver infection utilizing bile acid transport inhibitors and / or enteroendocrine peptide enhancing agents and / or FXR agonists.

Owner:LUMENA PHARMA INC

Dilute nitric acid production process

ActiveCN110550614AReduce emission concentrationImprove absorption rateEnergy inputNitric oxideChemical industryEvaporation

The invention belongs to the field of chemical industry, and in particular, relates to a dilute nitric acid production process. The process includes the following steps: after ammonia evaporation andheating, adjusting the flow quantity, allowing gas ammonia to enter an ammonia-air mixer and uniformly mixing the gas ammonia with compressed air; allowing the ammonia-air mixture after mixing to enter an oxidation furnace, carrying out catalytic oxidation reaction on a platinum mesh surface, oxidizing ammonia into nitric oxide, recycling waste heat from process gas leaving the catalyst through awaste heat boiler and tail gas respectively, and then condensing by a low-pressure quick cooler, after separation of dilute acid, mixing the process gas with air from a bleaching tower, and then allowing the mixed gas to enter an oxidation nitrogen compressor; further increasing the temperature of gas through the compressed process gas; recycling waste heat of the compressed process gas, cooling,and then allowing the cooled process gas to enter an absorption tower; and carrying out a reaction of oxide of nitrogen in the absorption tower after absorption with water to generate nitric acid. Theprocess has the advantages of high nitrogen oxide absorption rate, low ammonia consumption, high acid concentration and low tail gas emission concentration, and can reach the standard without furthertreatment.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

Compositions for raising uric acid levels and methods of using same

InactiveUS20020045580A1Improve the level ofImprove solubilityBiocideNervous disorderDiseaseAntioxidant

Compositions for the treatment of uric acid deficiency are disclosed. The compositions generally comprise either a precursor or derivative of uric acid, which, when administered to a patient, will result in a raising of the uric acid levels in that patient. The compositions can optionally comprise one or more additional active ingredients such as antioxidants, glutathione precursors, or inhibitors of NO synthase or homocysteine. Methods for raising uric acid levels in a patient are also disclosed. These methods are useful for in the treatment of various illnesses, such as cancer, infectious disease, Alzheimer disease and neurodegenerative diseases. Use of improved solutions comprising the present compositions in organ preservation is also disclosed.

Owner:SACKS MEIR S

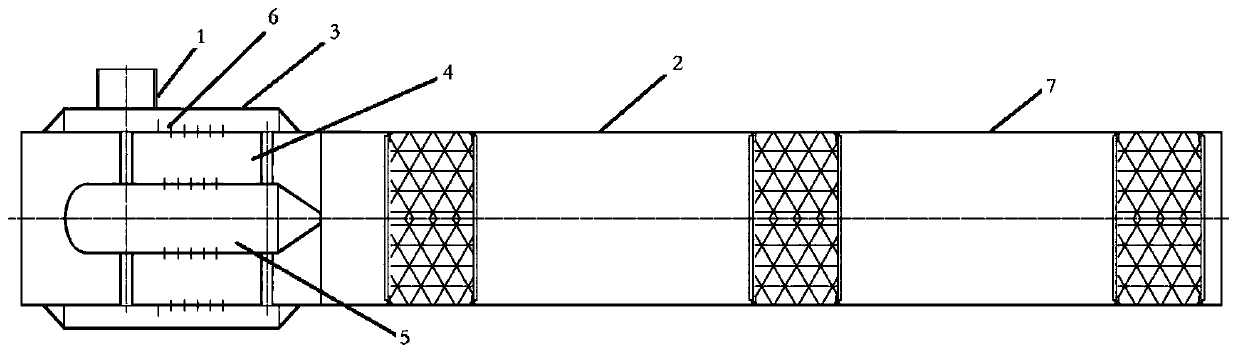

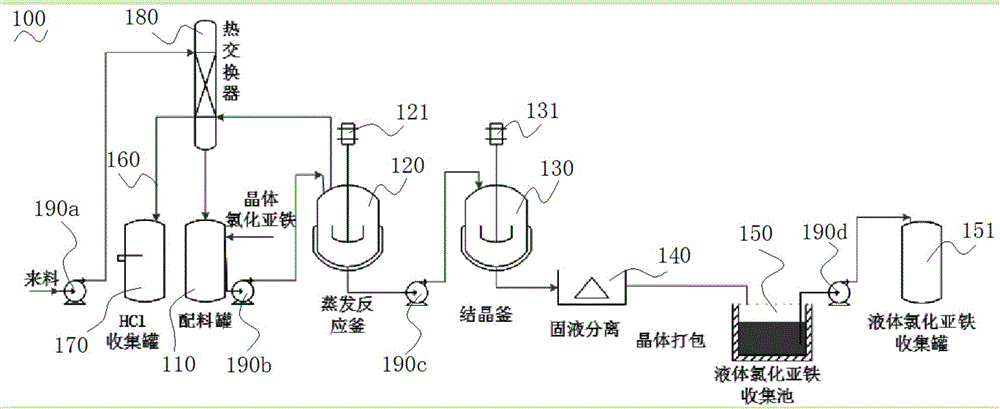

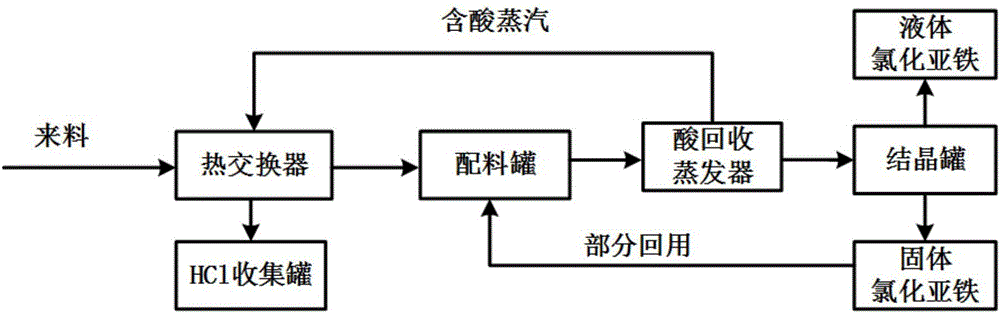

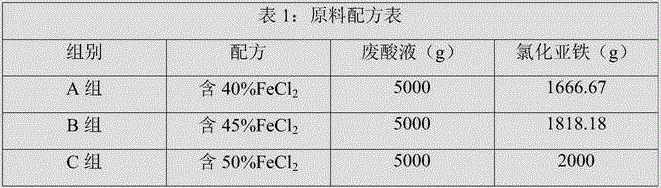

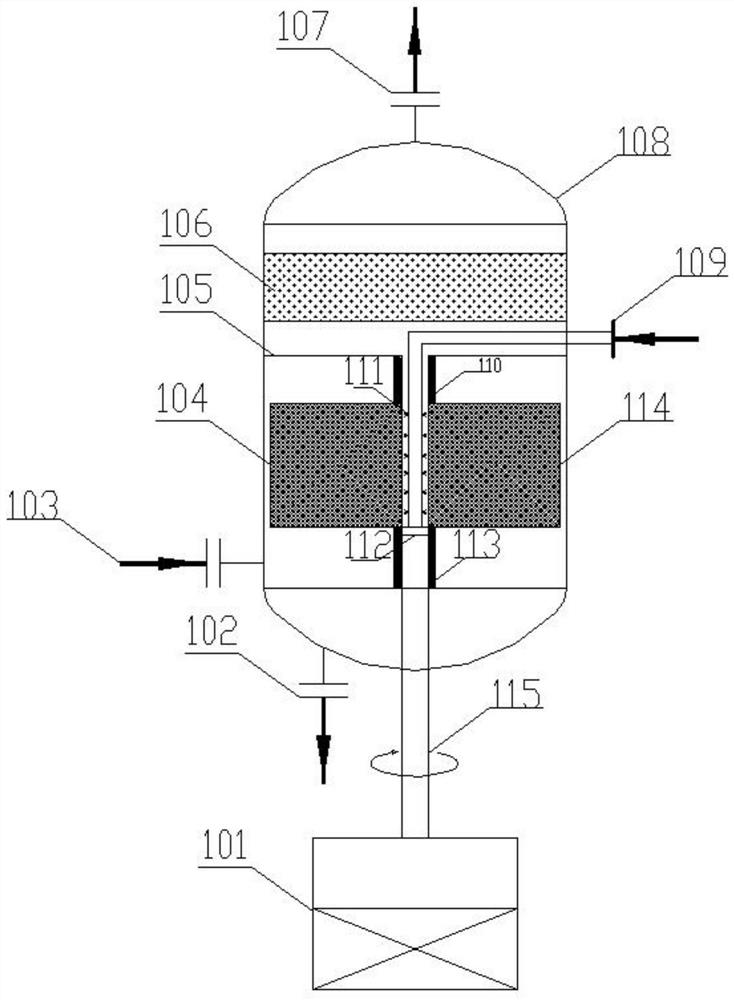

Continuous-production reduced pressure distillation device and process for recovering iron-containing waste acid liquid

ActiveCN106430100AAchieve separationEnable recyclingChlorine/hydrogen-chloride purificationDistillationResource utilization

The invention relates to the field of the recovery of waste acids, and particularly relates to a continuous-production reduced pressure distillation device and a continuous-production reduced pressure distillation process for recovering iron-containing waste acid liquid. The continuous-production reduced pressure distillation device comprises a blending tank, an evaporation reaction kettle, a crystallization kettle, a solid-liquid separation tank, a ferrous chloride solution collection pool and a ferrous chloride solution collection tank, and also comprises an exhaust pipe and a HCl collection tank, wherein the blending tank is used for blending a ferrous chloride solution; the evaporation reaction kettle is connected with an output end of the blending tank and is used for evaporating the ferrous chloride solution to be concentrated liquid; the crystallization kettle is connected with an output end of the evaporation reaction kettle and is used for separating out a ferrous chloride crystal from the concentrated liquid; the solid-liquid separation tank is connected with an output end of the crystallization kettle and is used for separating the crystallized ferrous chloride crystal from the ferrous chloride solution; the ferrous chloride collection pool and the ferrous chloride collection tank are connected with an output end of the separation tank and are used for collecting the separated ferrous chloride solution; the exhaust pipe is connected with the top of the evaporation reaction kettle and is used for outputting evaporated acid-containing steam; the HCl collection tank is connected with the exhaust pipe and is used for collecting the acid-containing steam. The continuous-production reduced pressure distillation device and the continuous-production reduced pressure distillation process for recovering the iron-containing waste acid liquid are low in treatment cost, high in treatment efficiency, low in safety production requirement and free from secondary pollution; the resource utilization rate can be improved.

Owner:江门市崖门新财富环保工业有限公司

Membrane-electrode assembly for solid polymer electrolyte fuel cell

InactiveUS20080241628A1Increase acidityImprove proton conductivitySolid electrolytesSolid electrolyte fuel cellsProtonStructural unit

An object of the present invention is to provide a membrane-electrode assembly for solid polymer electrolyte fuel cells, which can impart high electrical properties by increasing the introduction amount of the sulfonic acid group, has excellent swell suppression effect even under the humidified condition of high-temperature, and which has excellent electrical properties even under the condition of high-temperature and low-humidity. By using sulfonated polyarylene having specific constitutional units as a proton conductive membrane, a membrane-electrode assembly for solid polymer electrolyte fuel cells can be provided which has excellent swell suppression effect even under the humidified condition of high-temperature, and which has excellent proton conductivity even under the condition of high-temperature and low-humidity.

Owner:HONDA MOTOR CO LTD

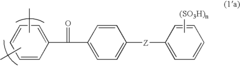

Method for producing phosphoric acid and low-silicon gypsum by middle-low-grade phosphorus ore

ActiveCN109573972AReduce consumptionIncrease acid concentrationCalcium/strontium/barium sulfatesPhosphorus compoundsSlagPhosphoric acid

The invention relates to a method for producing phosphoric acid and low-silicon gypsum by a middle-low-grade phosphorus ore. According to the method, ferrous-iron-containing waste acid is diluted by magnesium removal waste liquid, the diluted ferrous-iron-containing waste acid and the phosphorus ore react, easily decomposed components such as carbonate in the phosphorus ore are decomposed, so thatacid consumption of subsequent phosphate leaching reaction is reduced, the quality of the phosphorus ore is improved, production cost is reduced, the gypsum is screened to remove part of silicon, phosphorus content is reduced, so that the gypsum serves as a good cement raw material, application approaches are provided for wide comprehensive utilization of phosphogypsum, filter flushing water of wet phosphoric acid slurry is recycled after being filtered to remove slag, water consumption is reduced, and phosphoric acid concentration is improved.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

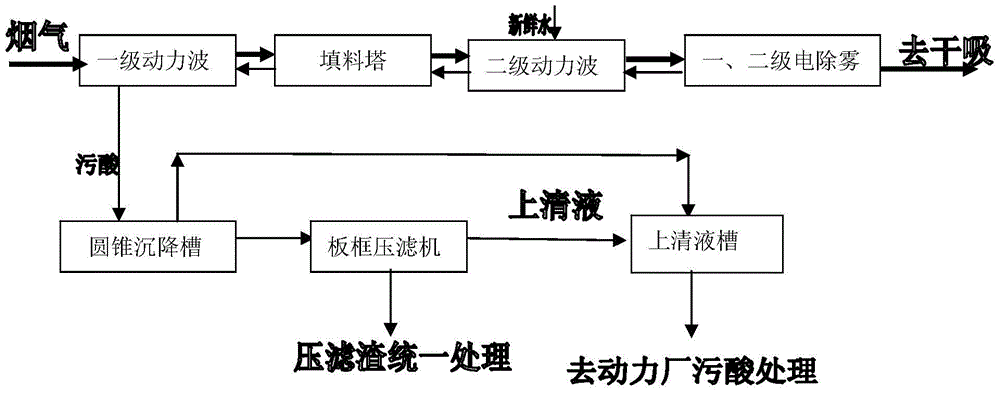

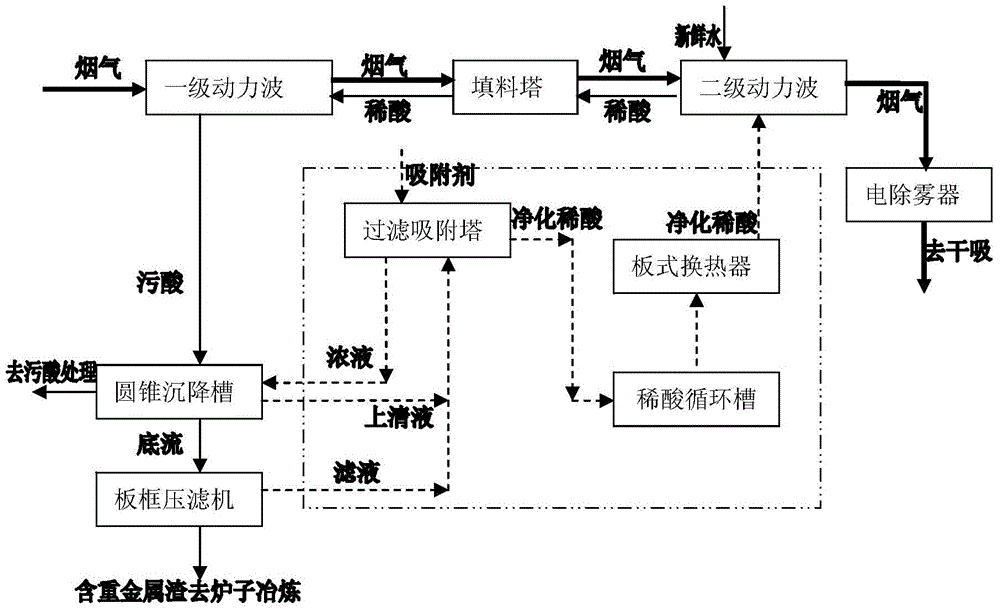

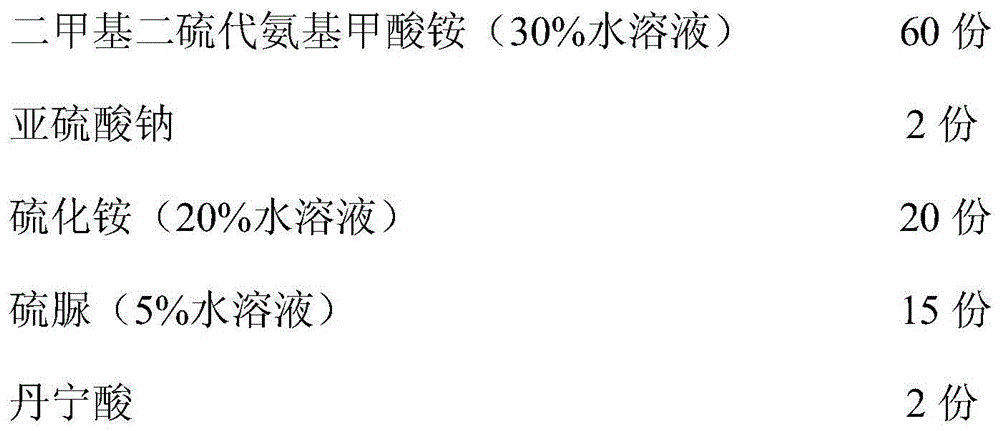

Heavy metal adsorbent for purifying dilute acid and application thereof

ActiveCN106215863AFully removedOvercoming Poor Processing EffectsOther chemical processesWater contaminantsSorbentThiourea

The invention discloses a heavy metal adsorbent for purifying a dilute acid and application thereof. The heavy metal adsorbent is prepared by mixing the following components in order: 50-70 parts of a 30% ammonium dimethyldithiocarbamate aqueous solution, 2-5 parts of sodium sulfite, 10-30 parts of a 17%-20% ammonium sulfide aqueous solution, 10-20 parts of a 5% thiourea aqueous solution and 2-5 parts of tannic acid. The heavy metal adsorbent is filled into a filtration adsorption tower, waste acid is introduced into the filtration adsorption tower, purified dilute acid enters a plate-type heat exchanger for cooling via a dilute acid circulation tank, and after cooling, the cooled dilute acid is introduced into a two-level dynamic wave washing tower for flue gas washing. The product can effectively remove heavy metal ions from the waste acid, and overcomes the problem of poor treatment effect of a conventional DTC heavy metal adsorbent in acidic environment. The heavy metal adsorbent is combined with a dilute acid purifying reuse method, the acid concentration of the cyclic dilute acid can be significantly enhanced without affection of the process conditions, dilute acid emission can be reduced, the consumption of water in purification process can be reduced, and the water saving emission reduction effect is remarkable.

Owner:云南兴贤环保科技有限公司

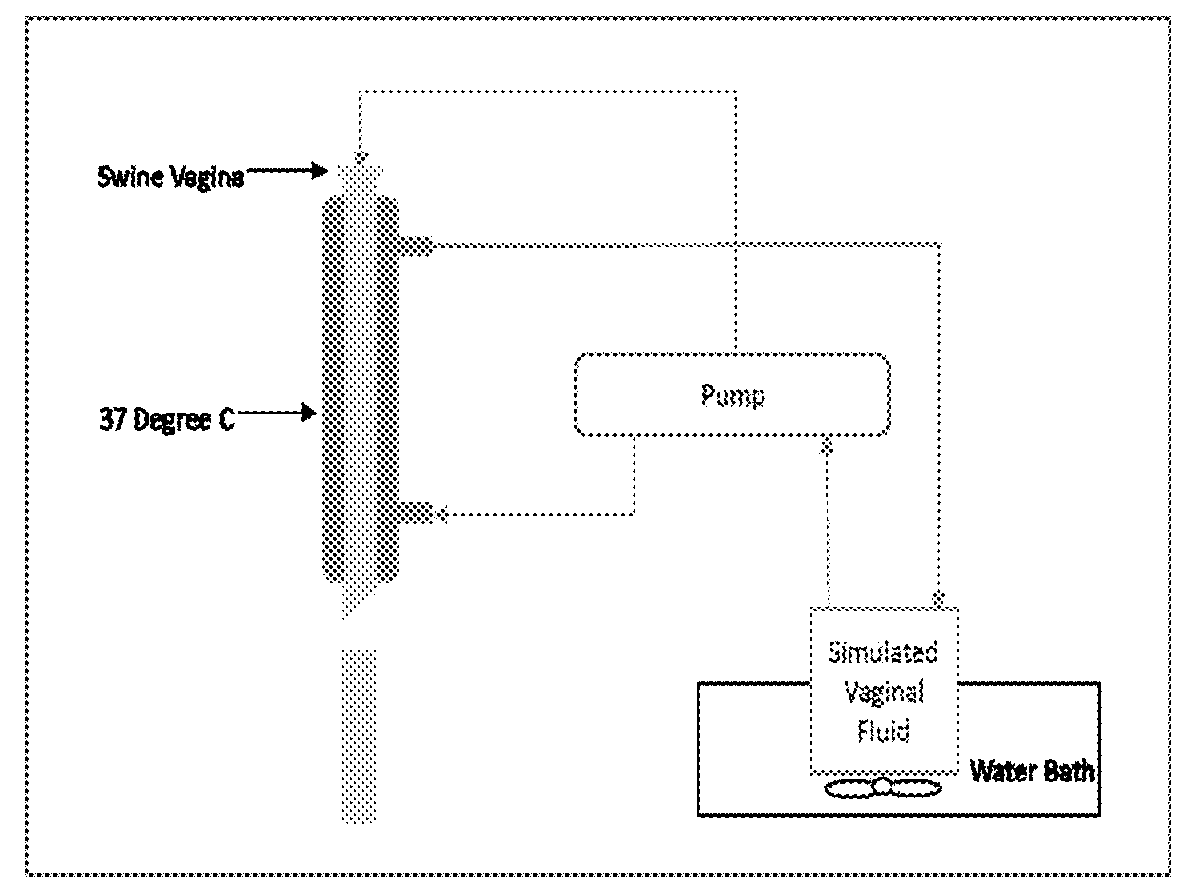

Vaginal Bioadhesive Boric Acid Formulation and Its Preparation Method

InactiveUS20180104346A1More manageableMore comfortableInorganic boron active ingredientsPharmaceutical delivery mechanismHigh concentrationBioadhesive

This invention discloses a bioadhesive boric acid formulation and its preparation method. Specifically, preferred vaginal bioadhesive boric acid formulation mainly comprises chitosan, carbopol 974 , polycarbophil, boric acid, and purified water as a gel. The main performance characteristic of this vaginal boric acid preparation is the ability of the formulation to retain and release boric acid in the vagina by using a combination of carbopol 974 and polycarbophil as preferred bioadhesive polymers. It was proved experimentally that boric acid as the antibacterial component of this gel can be maintained at a relatively high concentration (>10 mg / mL) in vagina for an extended period of time (>2 hours) with the use of a combination of polyacrylic acid polymers, i.e. carbopol 974 and polycarbophil. In order to prepare a gel of the said formulation with uniform continuity, boric acid was dissolved in water at the beginning of the process to make an aqueous solution and the bioadhesive polymers were added portion-wise into the aqueous solution with vigorous stirring. Further, it was demonstrated that the said vaginal bioadhesive boric acid formulation had a dynamic viscosity >100000 cps, pH value of 2 to 5, good moisture-retention capability. The formulation was non-allergenic, non-vaginal irritative, and capable of inhibiting bacteria and fungi.

Owner:YUAN XUDONG

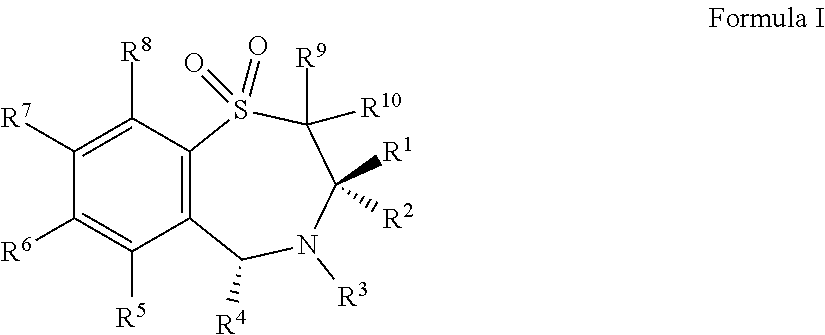

Sulfonated polymer having nitrile-containing hydrophobic block and solid polymer electrolyte

ActiveUS20050080220A1Excellent hot water resistanceIncrease acid concentrationNon-metal conductorsSolid electrolytesPolymer scienceOxygen

Provided are a sulfonated polymer capable of high hot water resistance even if it has an increased amount of the sulfonic groups introduced therein, and a solid polymer electrolyte containing the sulfonated polymer that has high proton conductivity and excellent generating performance. The sulfonated polymer has repeating units represented by the formula (1′): wherein B's are each independently an oxygen or a sulfur atom, R1 to R3 may be the same or different and are selected from a hydrogen atom, a fluorine atom, a nitrile group and an alkyl group, n is an integer of 2 or greater, and Q is a structure represented by the formula (q): wherein A is independently a divalent atom or organic group or a direct bond, and R4 to R11 may be the same or different and are selected from a hydrogen atom, a fluorine atom, an alkyl group and an aromatic group.

Owner:JSR CORPORATIOON

Parakeratosis inhibitor, pore-shrinking agent and skin preparation for external use

InactiveUS20050152930A1Increase acid concentrationBiocideCosmetic preparationsInhibitory cellN-Methyl-D-aspartic acid

It is intended to provide a substance having an effect of shrinking pores by analyzing the mechanism of making pores perceptible and compositions such as a skin preparation for external use which exerts the above effect to thereby make pores imperceptible. As means for solving these problems, there are provided a parakeratosis inhibitor and a pore-shrinking agent comprising an antagonist to an excitatory cell receptor, for example, a glutamate receptor such as N-methyl-D-aspartic acid receptor or an ATP receptor such as P2X receptor, or an agonist to an inhibitory cell receptor such as a γ-aminobutyrate receptor such as bicuculline-sensitive receptor having the Cl— channel therein or glycine receptor, as well as a skin preparation for external use aiming at inhibiting parakeratosis and a skin preparation for external use aiming at shrinking pores each containing such an antagonist to an excitatory cell receptor or an agonist to an inhibitory cell receptor as described above. Owing to the effects of inhibiting parakeratosis and shrinking pores, the skin can be maintained in a healthy state without perceptible pores.

Owner:SHISEIDO CO LTD

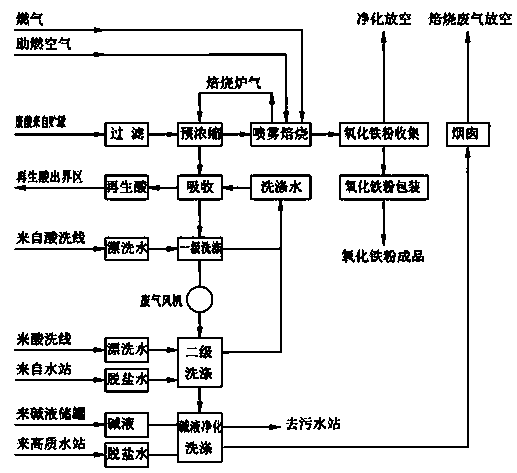

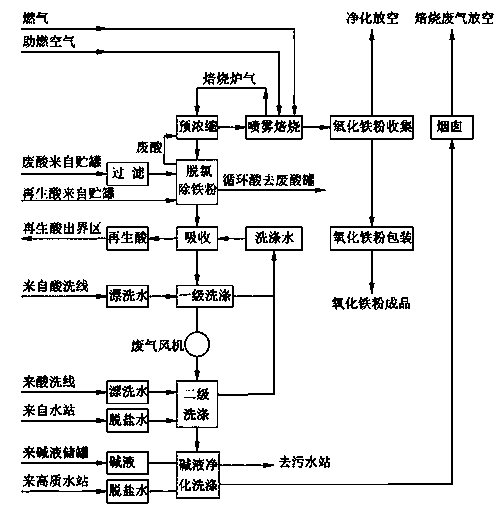

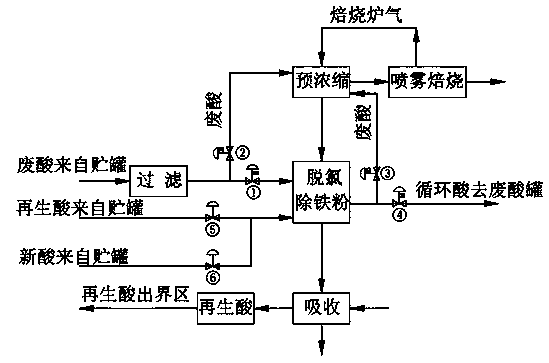

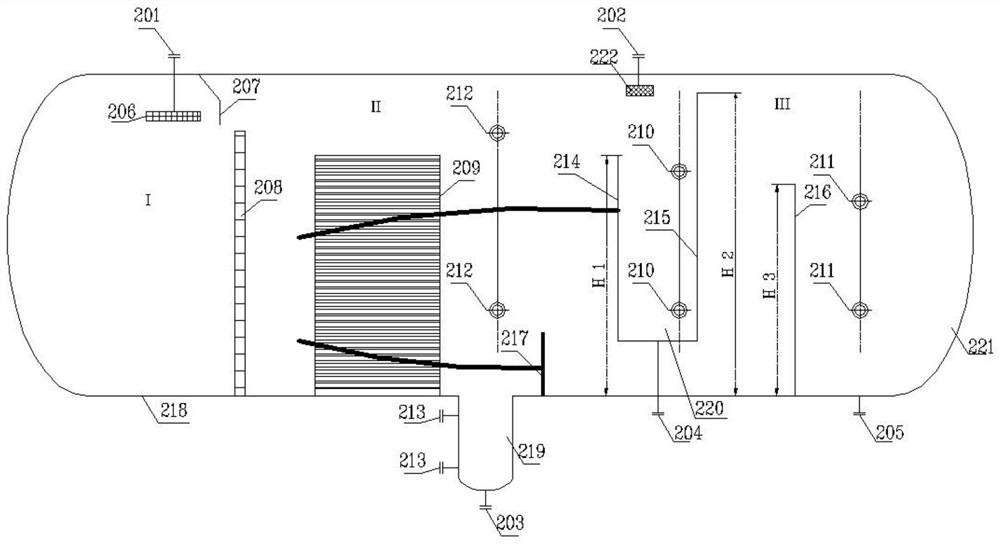

Process for eliminating red fume discharged from waste acid regenerating device

ActiveCN103668269AHCl content has no adverse effectAvoid the "red smoke" phenomenonAcid waterEmission standard

The invention discloses a process for eliminating red fume discharged by a waste acid regenerating device and aims to solve the problem that the waste acid regenerating device has the phenomenon of discharging the red fume in the acid water conversion process in the prior art. According to the process, as a dechlorinating tower is added between a preconcentrator and an absorption tower, and new acid and regenerated acid are introduced into the dechlorinating tower, on one hand, the acid concentration of the preconcentrator is increased, and the purpose that a ferric oxide powder is fully reacted with free acid in the preconcentrator is reached; on the other hand, ultrafine ferric oxide powder enters the dechlorinating tower and is removed, so that the phenomenon that the acid regenerating device discharges the red fume can be completely avoided, and discharged tail gas of a roasting furnace can be fully ensured to reach Emission Standard of Air Pollutants for Steel Rolling Industry GB28665-2012 which is newly issued by the country. Therefore, the process is suitable for popularization and application.

Owner:CHENGDU HUAXI CHEM TECH CO LTD

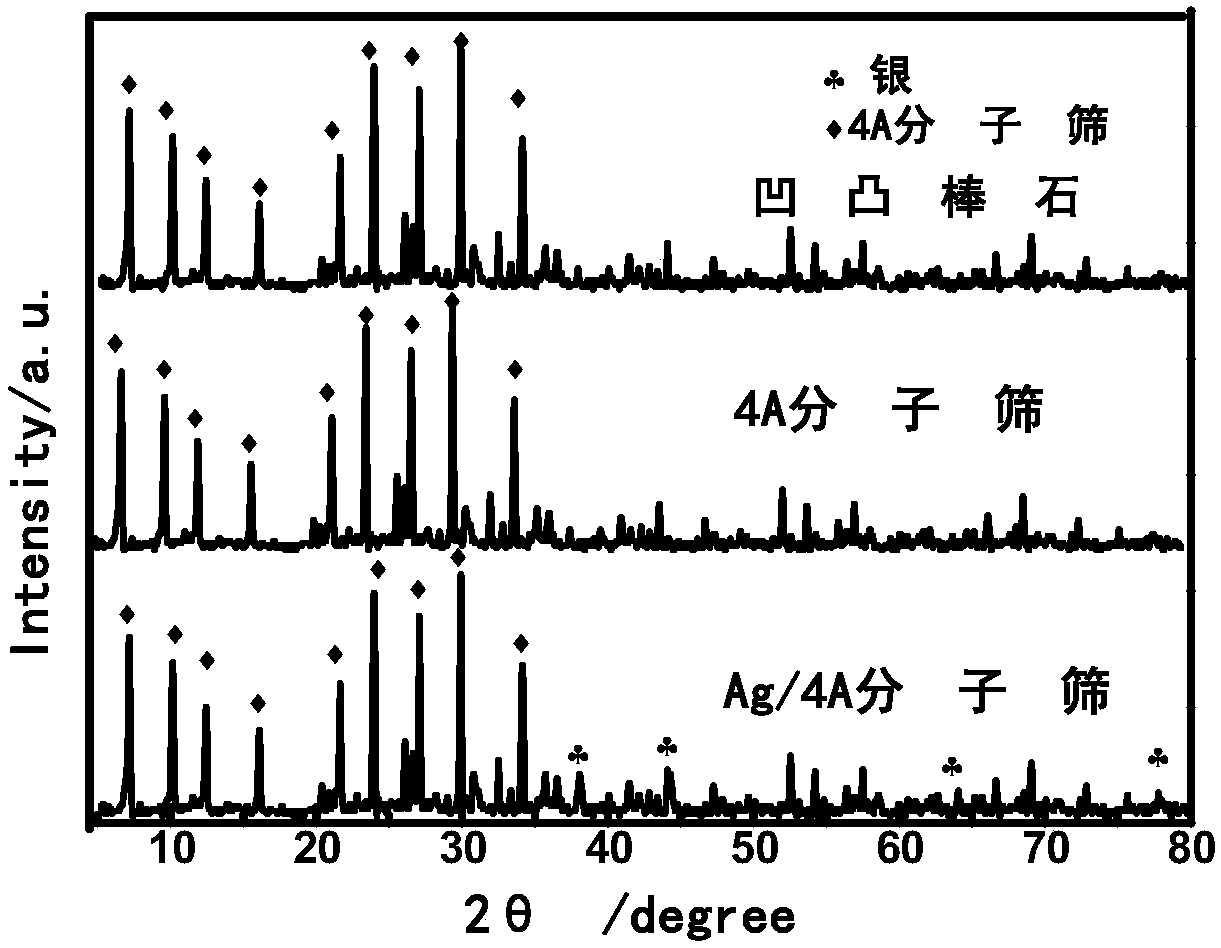

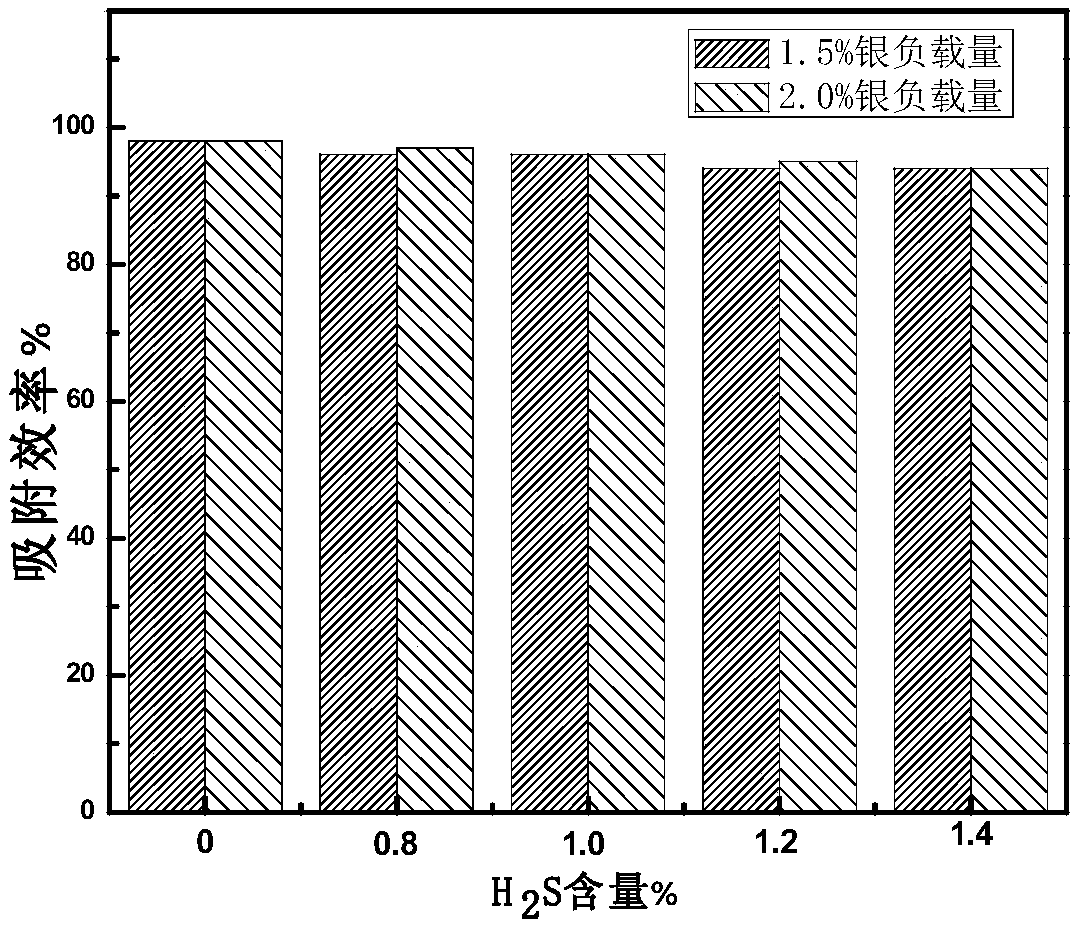

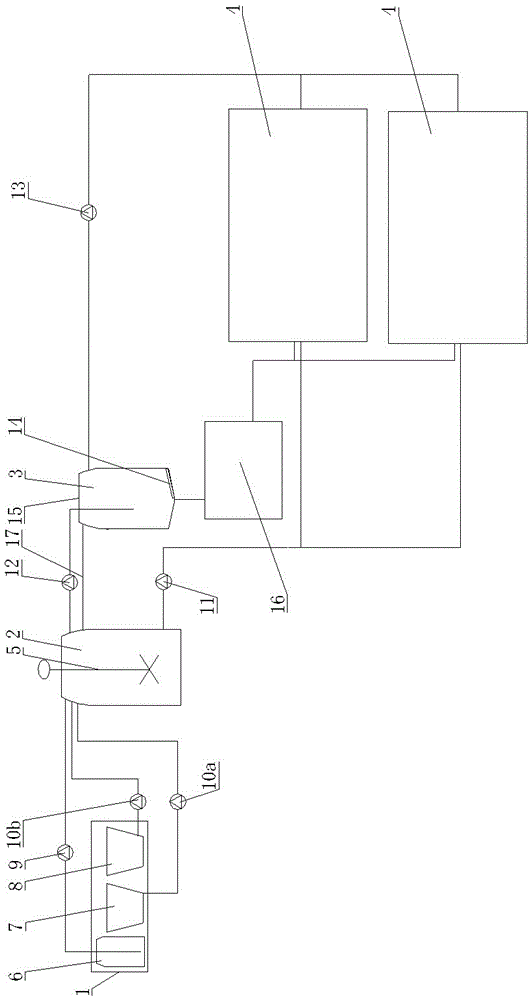

Method for preparing silver-loaded hydrogen sulfide poisoning-resistant 4A molecular sieve from attapulgite serving as raw material

ActiveCN108455624AFully dispersedEvenly dispersedGas treatmentOther chemical processesMolecular sieveHydrogen sulfide poisoning

The invention discloses a method for preparing a silver-loaded hydrogen sulfide poisoning-resistant 4A molecular sieve from attapulgite serving as a raw material, and belongs to the technical field ofpreparation of a molecular sieve. The method comprises the following steps: firstly, pretreating the attapulgite; mixing the pretreated attapulgite and an alkali liquid and performing microwave heating; preparing a sodium aluminate solution, performing crystallization, and performing silver loading on the 4A molecular sieve obtained through crystallization through supercritical carbon dioxide; and finally obtaining the silver-loaded 4A molecular sieve. The silver-loaded 4A molecular sieve prepared by the method is applied to mercury removing experiment under the simulated natural gas atmosphere, and the 4A molecular sieve with the silver loaded quantity of 1.5 percent is selected. The silver is loaded by other loading methods, the mercury removing efficiency experiment is conducted underthe atmosphere of different H2S concentration through comparison, and the experiment proves that the silver-loaded 4A molecular sieve has high mercury removing efficiency and has H2S poisoning resistance. The silver-loaded molecular sieve can maintain high mercury removing efficiency under the atmosphere containing H2S.

Owner:SHANDONG UNIV OF SCI & TECH

Acid solution, device and process for cleaning sludge plate-frame dewatering filter cloth

ActiveCN105670836AReduce concentrationDoes not affect resource utilizationDetergent mixture composition preparationMembrane filtersLiquid wasteSludge

The invention provides acid solution, device and process for cleaning sludge plate-frame dewatering filter cloth.The acid solution for cleaning sludge plate-frame dewatering filter cloth is environmental friendly and can effectively remove scales on the filter cloth with low damage to the same.The device for cleaning sludge plate-frame dewatering filter cloth comprises an acid solution tank, a dilute acid return tank, at least two plate-frame pressure filters, an acid injection pump, a dilute acid reflux pump, a supernatant acid reflux pump and an acid storage compartment; in the acid storage compartment, the acid solution is prepared by dissolving acetic acid, oxalic acid and citric acid according to the mass ratio of 3:2:1-4:3:1 in water, and acid concentration of the acid solution is less than or equal to 10%; a sludge scraper is arranged at the bottom of the dilute acid reflux tank, an alkali feed inlet is arranged on the dilute acid reflux tank which is further connected with a sludge quenching and tempering tank.The device for cleaning sludge plate-frame dewatering filter cloth has the advantages of short time for cleaning, good cleaning effect, capability of producing and running continuously, no discharge of waste liquid and no secondary pollution.

Owner:WUXI HUAGUANG BOILER

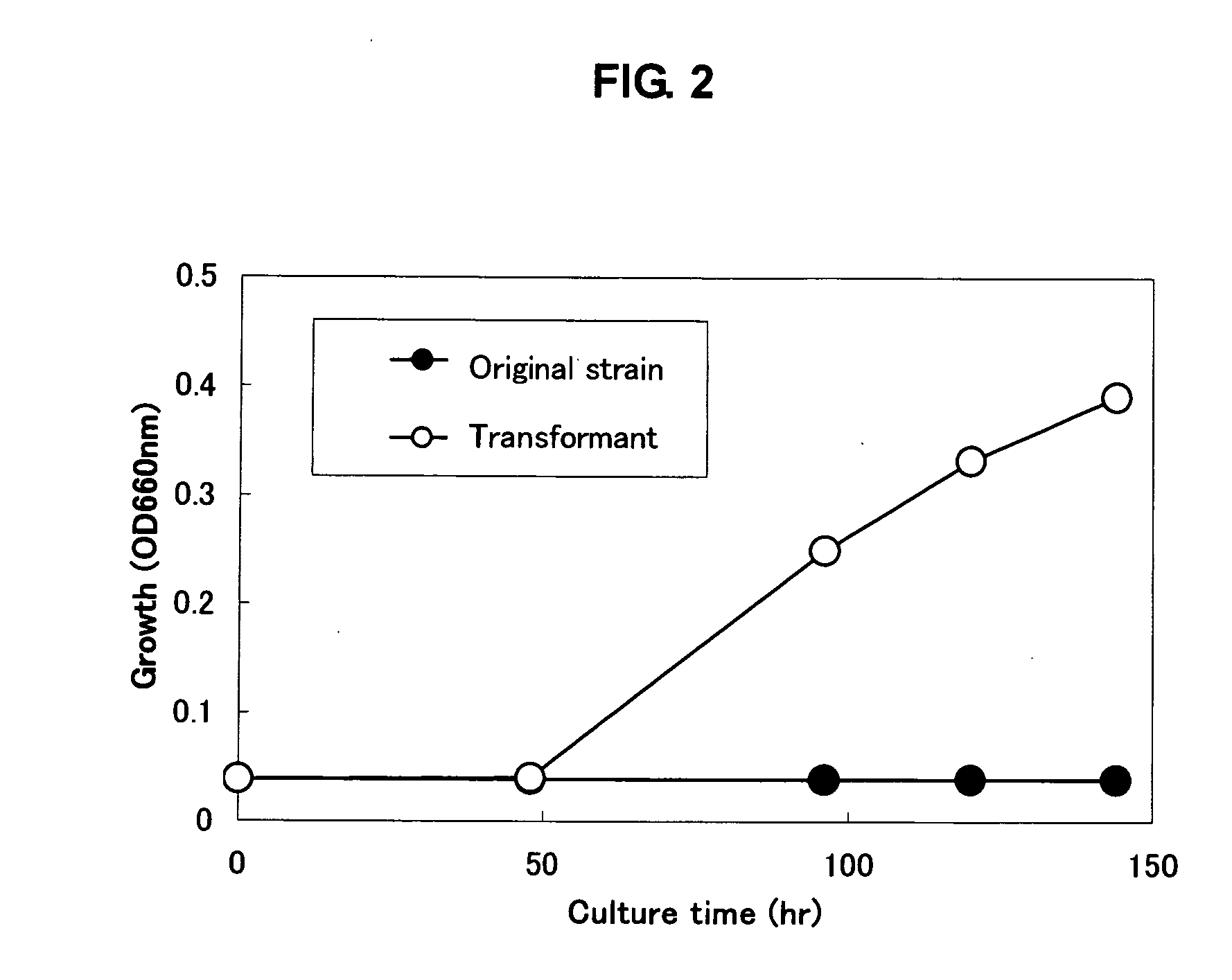

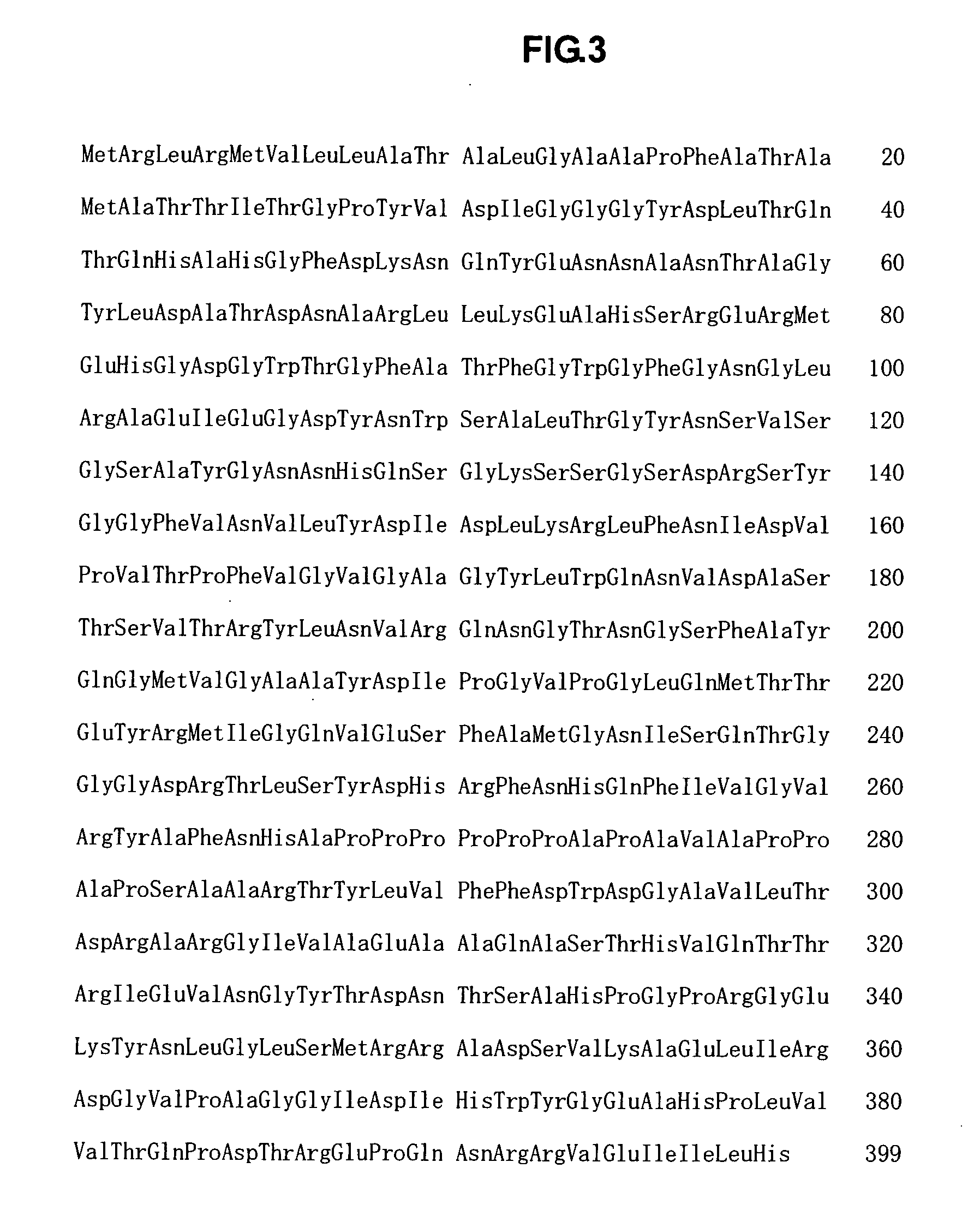

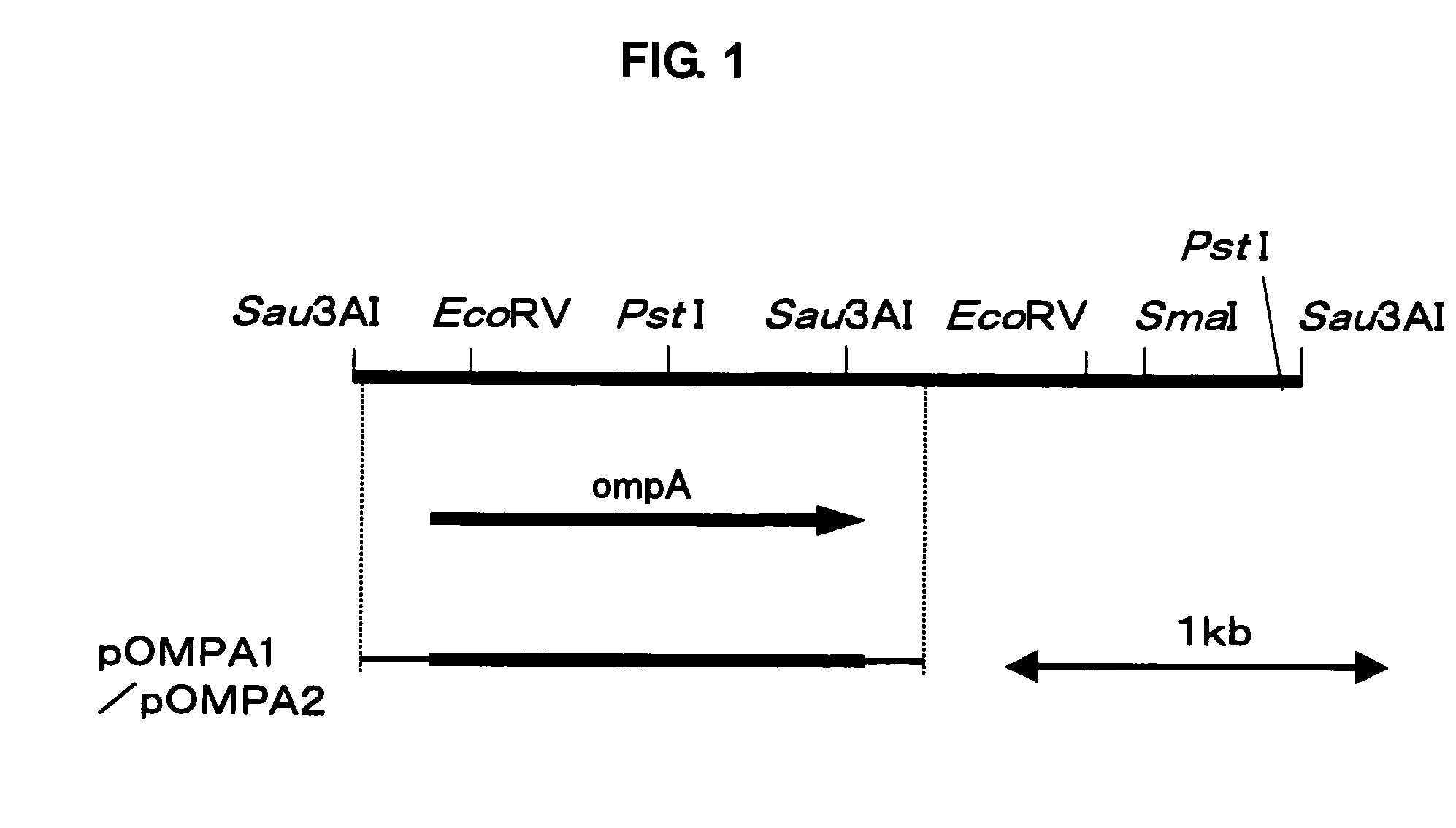

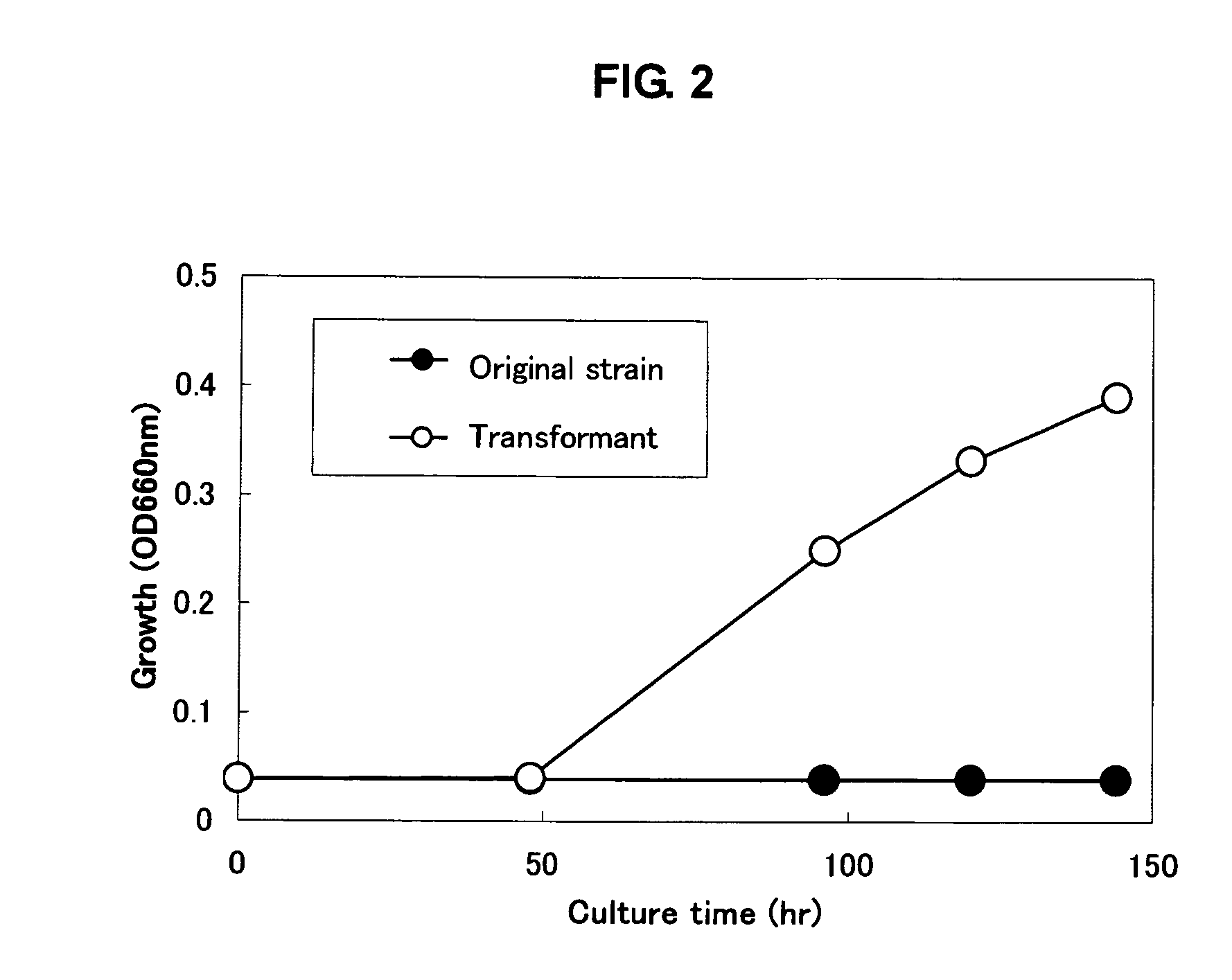

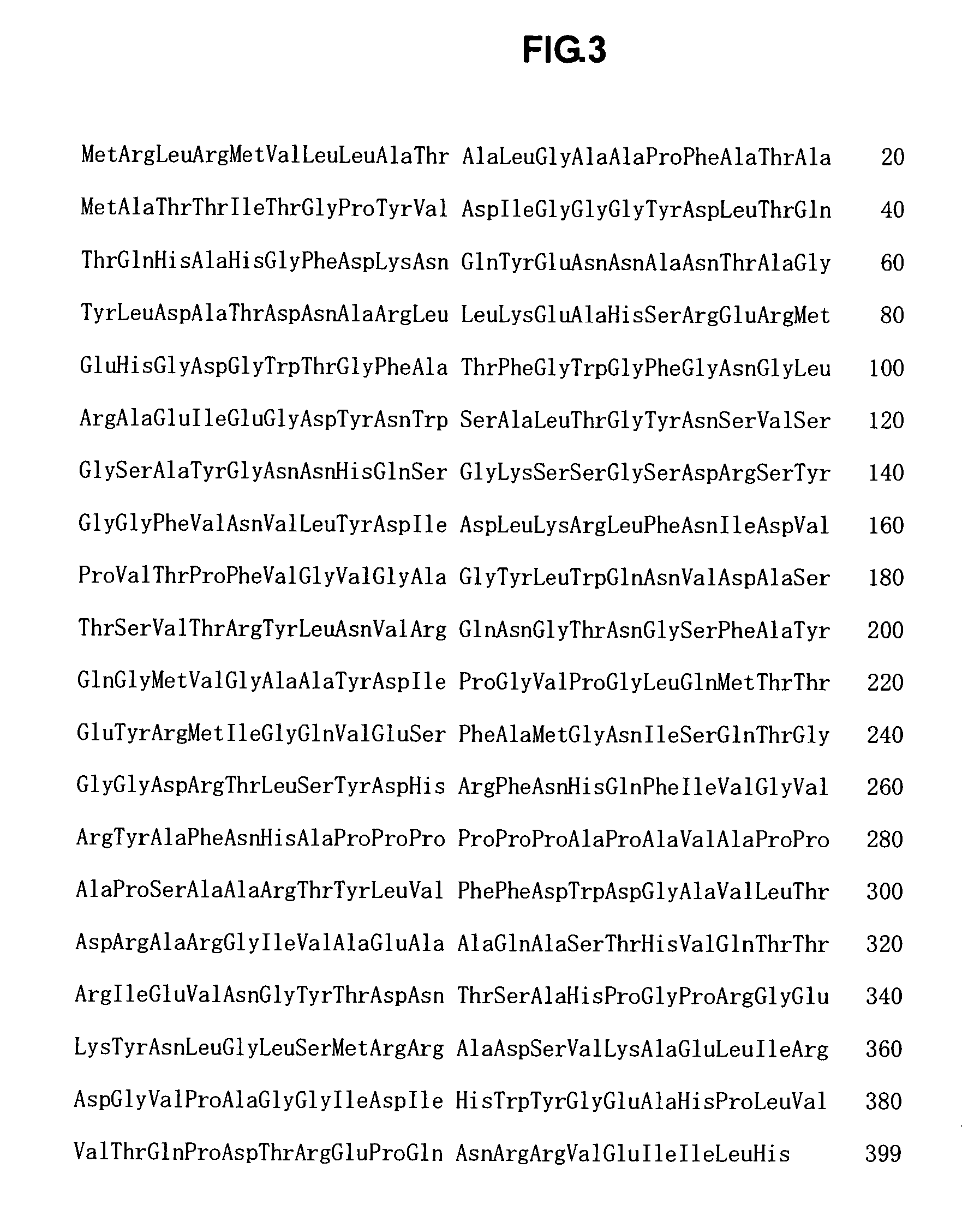

Gene participating in growth promoting function of acetic acid bacterium and utilization of the same

InactiveUS20060228445A1Extended maintenance periodFunctionSugar derivativesBacteriaBacteroidesHigh concentration

The present invention provides a novel gene involved in the growth-promoting function of acetic acid bacteria and a microorganism containing the gene. In particular, the present invention provides a method for enhancing the growth-promoting function of acetic acid bacteria and a method for efficiently producing vinegar containing acetic acid at a high concentration in a short time using such acetic acid bacteria having an enhanced growth-promoting function.

Owner:MIZKAN HLDG +1

System and method for preparing LNG and co-producing hydrogen by deeply purifying coke oven gas

ActiveCN112961712AImprove cleanlinessSolve the blockageSolidificationLiquefactionBenzeneThermodynamics

The invention provides a system and a method for preparing LNG and co-producing hydrogen by deeply purifying coke oven gas, and belongs to the field of coke oven gas purification. A pre-washing tower is arranged as a supergravity rotating device, so that the coke oven gas subjected to benzene removal can be subjected to primary impurity removal in the pre-washing tower through a supergravity rotating technology, and harmful substances such as dust, benzene, tar, naphthalene, ammonia and sulfur in the coke oven gas subjected to benzene removal are deeply removed; and the problems that sulfur and ammonia in the coke oven gas exceed the standard to influence stable operation of a system, tar and naphthalene in the coke oven gas can cause blockage of a compression system, and the operation cost is increased due to the fact that a desulfurization adsorbent for fine desulfurization loses efficacy in advance due to abnormal coarse desulfurization are solved. Through pretreatment, the coke oven gas does not need to be desulfurized after returning to the coke oven, so that the investment and desulfurization waste liquid can be reduced. CH4, CO and H2 are separated out through coke oven gas cryogenic separation, then LNG is prepared through methanation reaction, and meanwhile, a high-purity hydrogen product is produced as a byproduct.

Owner:SEDIN ENG

Gene involved in growth-promoting function of acetic acid bacteria and uses thereof

The present invention provides a gene involved in the growth-promoting function of acetic acid bacteria and a microorganism containing the gene. In particular, the present invention provides a method for enhancing the growth-promoting function of acetic acid bacteria and a method for efficiently producing vinegar containing acetic acid at a high concentration in a short time using such acetic acid bacteria having an enhanced growth-promoting function.

Owner:MIZKAN HLDG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com