Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

169results about How to "Increase harvest" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

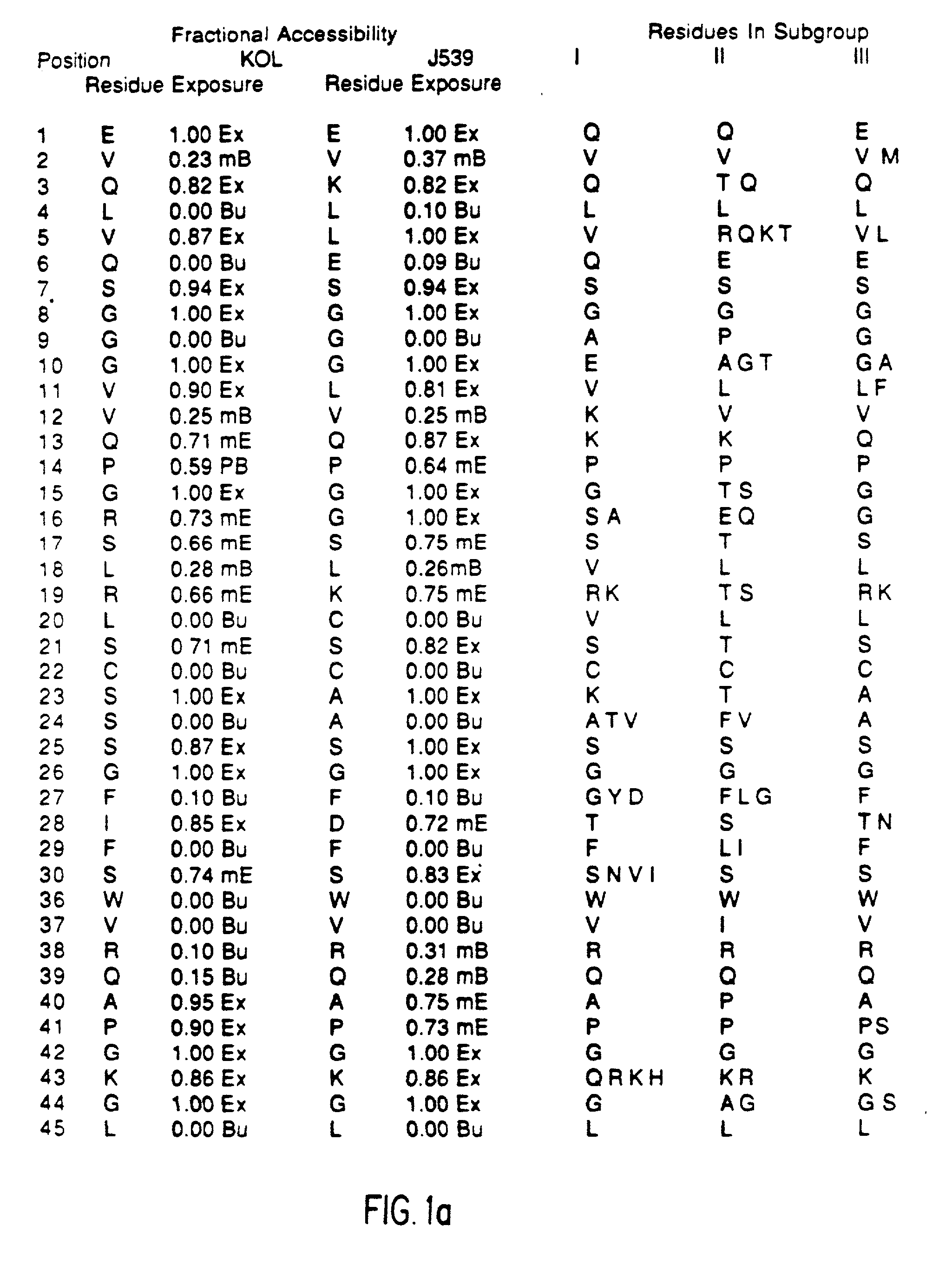

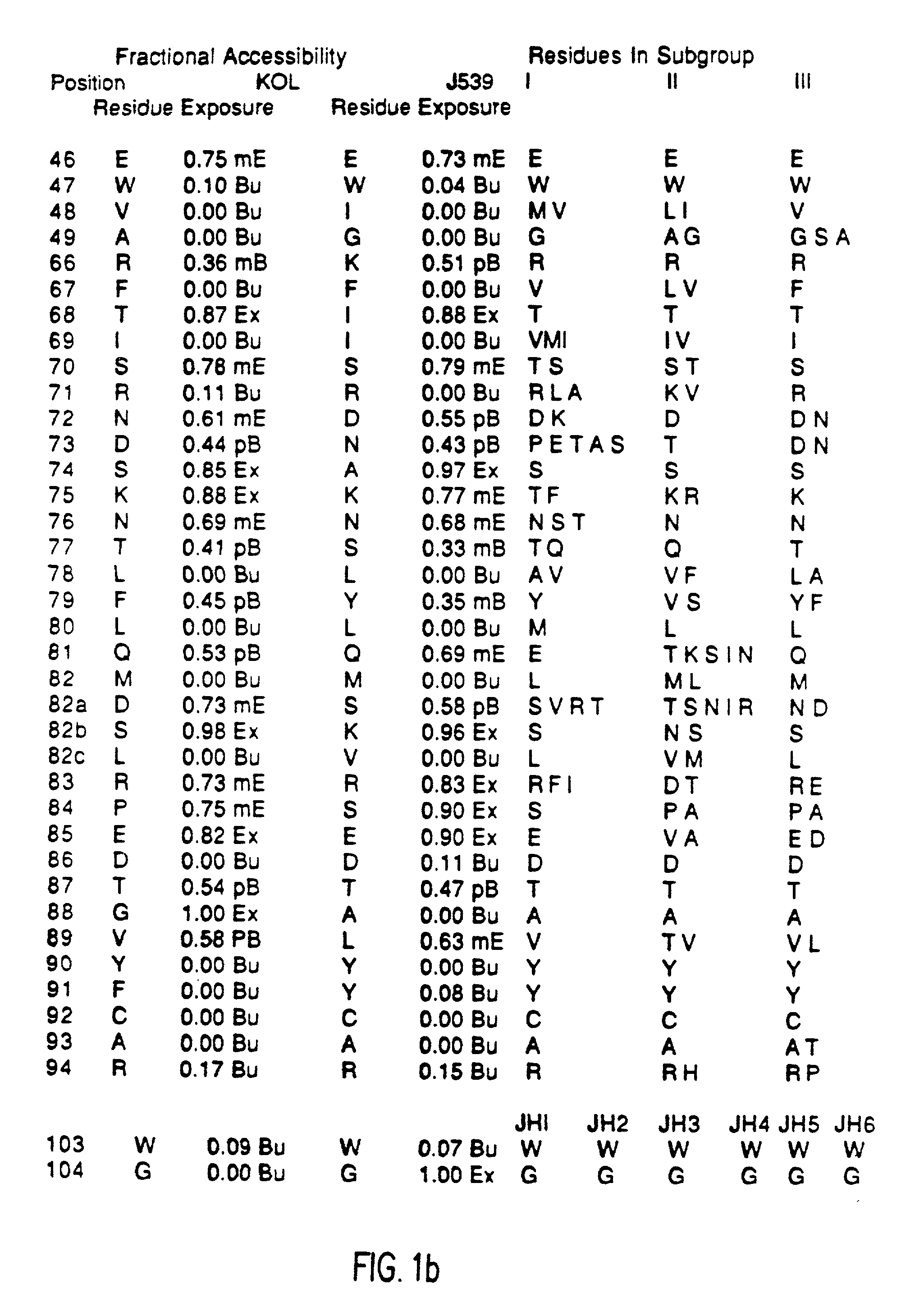

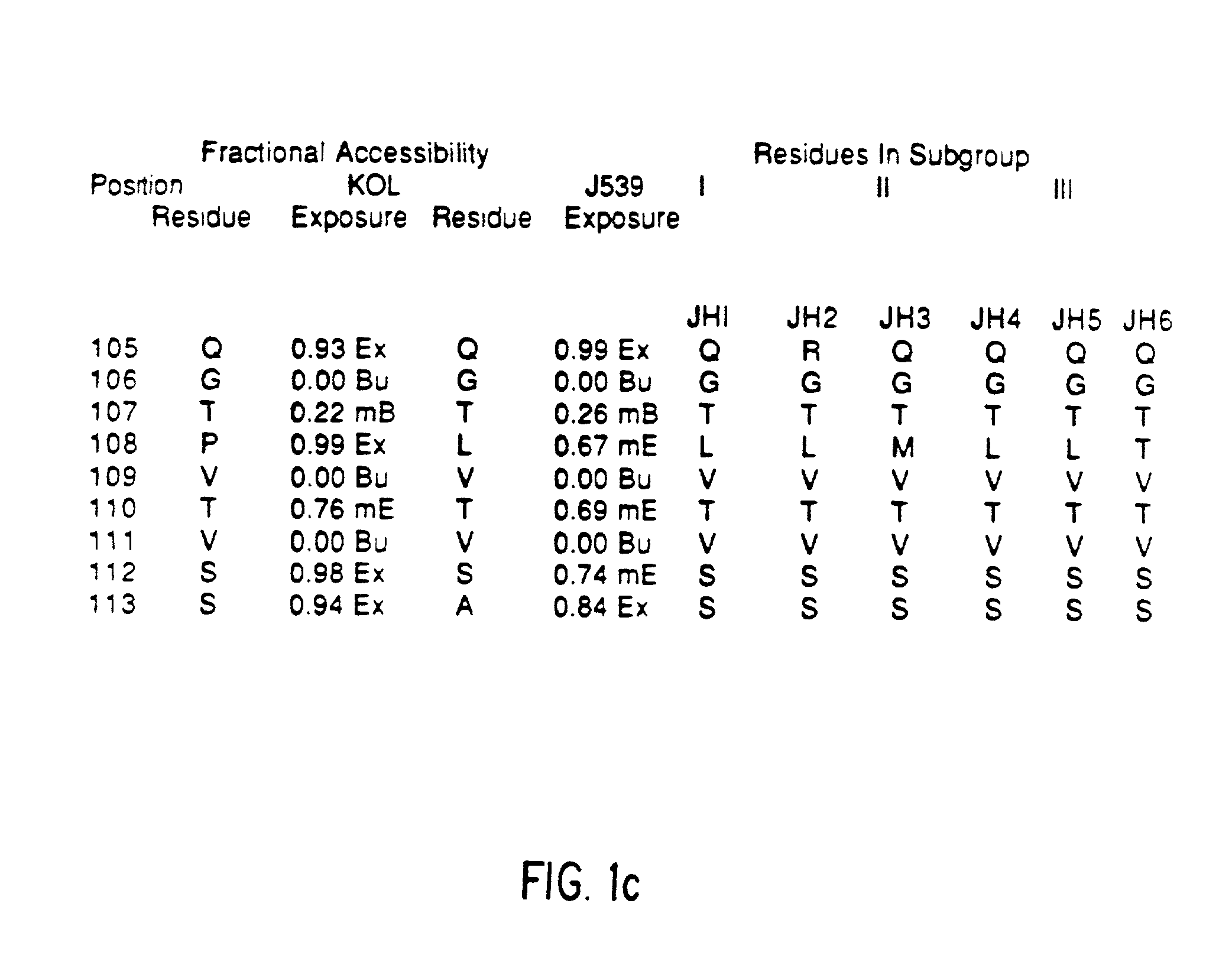

Method for reducing the immunogenicity of antibody variable domains

InactiveUS20020034765A1Altered immunogenicityLow immunogenicityHybrid immunoglobulinsBiological testingBound propertyVariable domain

A unique method is disclosed for identifying and replacing immunoglobulin surface amino acid residues which converts the antigenicity of a first mammalian species to that of a second mammalian species. The method will simultaneously change immunogenicity and strictly preserve ligind binding properties. The judicious replacement of exterior amino acid residues has no effect on the ligind binding properties but greatly alters immunogenicity.

Owner:DEPT OF HEALTH & HUMAN SERVICES US SEC THE +1

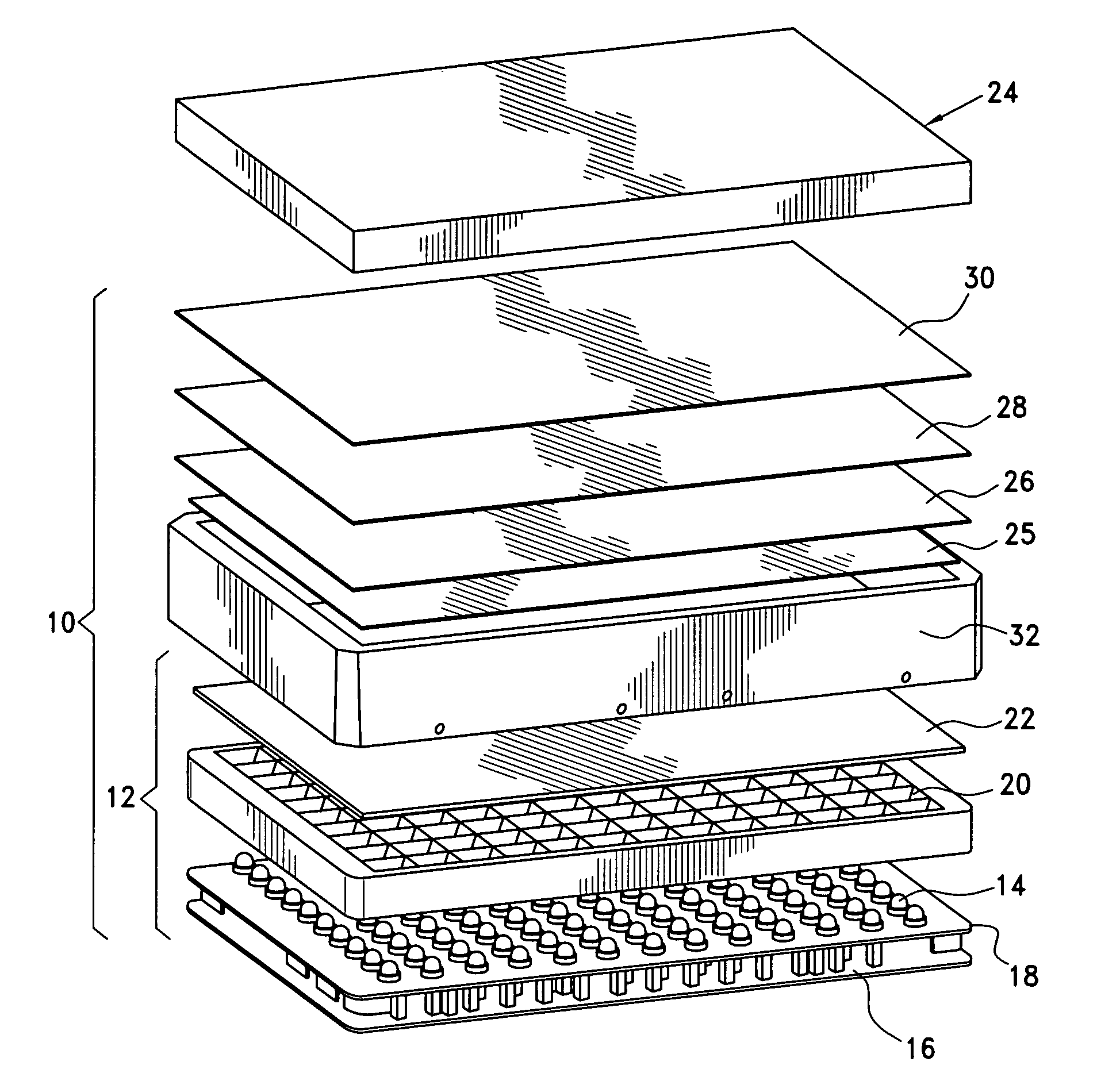

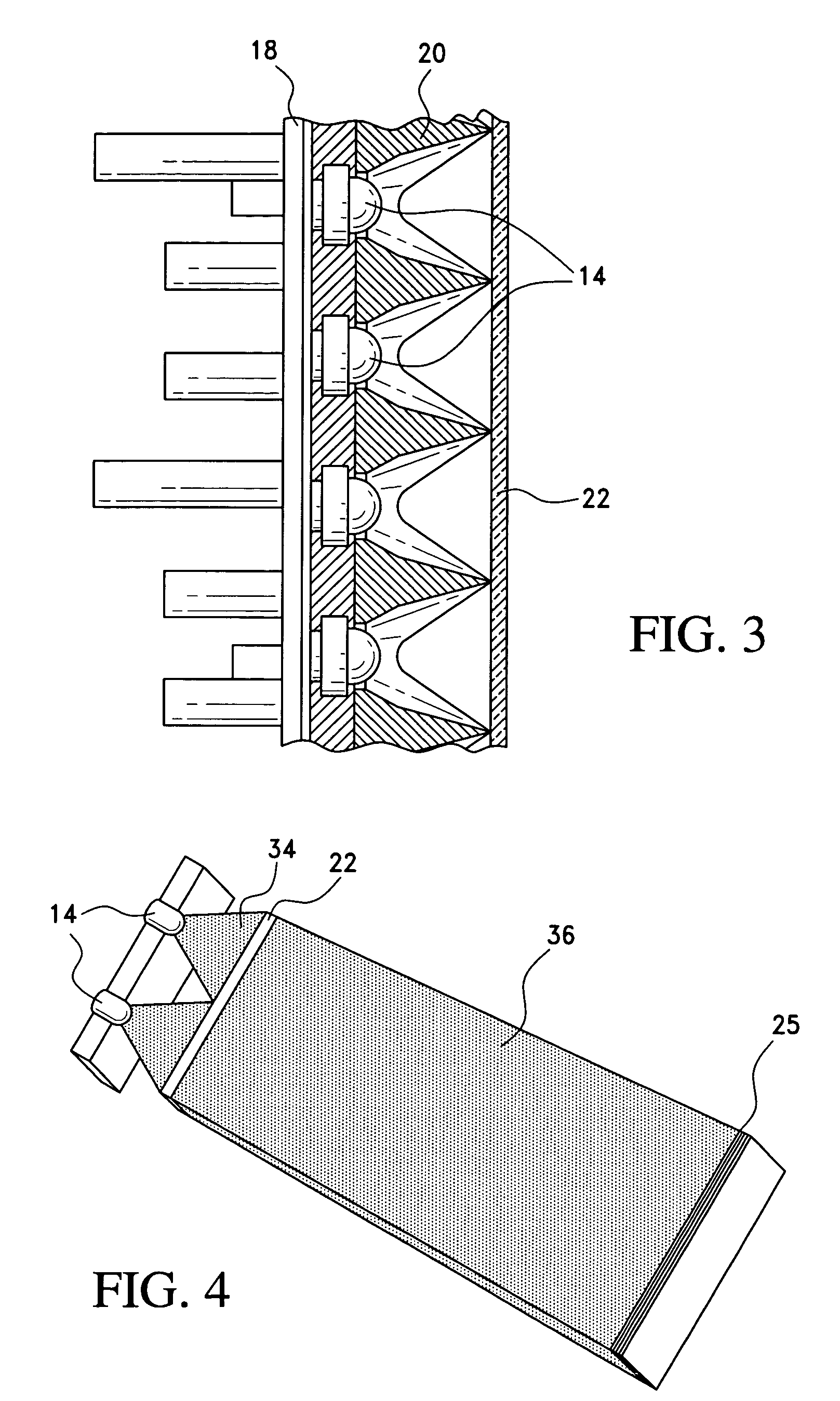

Illumination system for a head up display

ActiveUS7513668B1Increase harvestImprove system efficiencyThermometer detailsMeasurement apparatus componentsFresnel lensHead-up display

An illumination system for use in illuminating a spatial light modulator for a head up display system. The illumination system includes a high power light emitting diode (LED) array assembly; and, a Fresnel lens array operatively associated with the LED array assembly for receiving light produced by the LED and providing a nearly collimated light output for use by the spatial light modulator. Utilization of the ultra bright LED array and Fresnel lens array provides the capability of the illumination source to be made very thin, light weight, and efficient. The Fresnel lens array, which converges the light to be nearly collimated, enhances the harvest of the available flux thus increasing the system efficiency and providing a system that gives the illusion of having an image at infinity. Additional components such as holographic elements, optical compensation films, and brightness enhancement films can be used to tailor the light if required.

Owner:ROCKWELL COLLINS INC

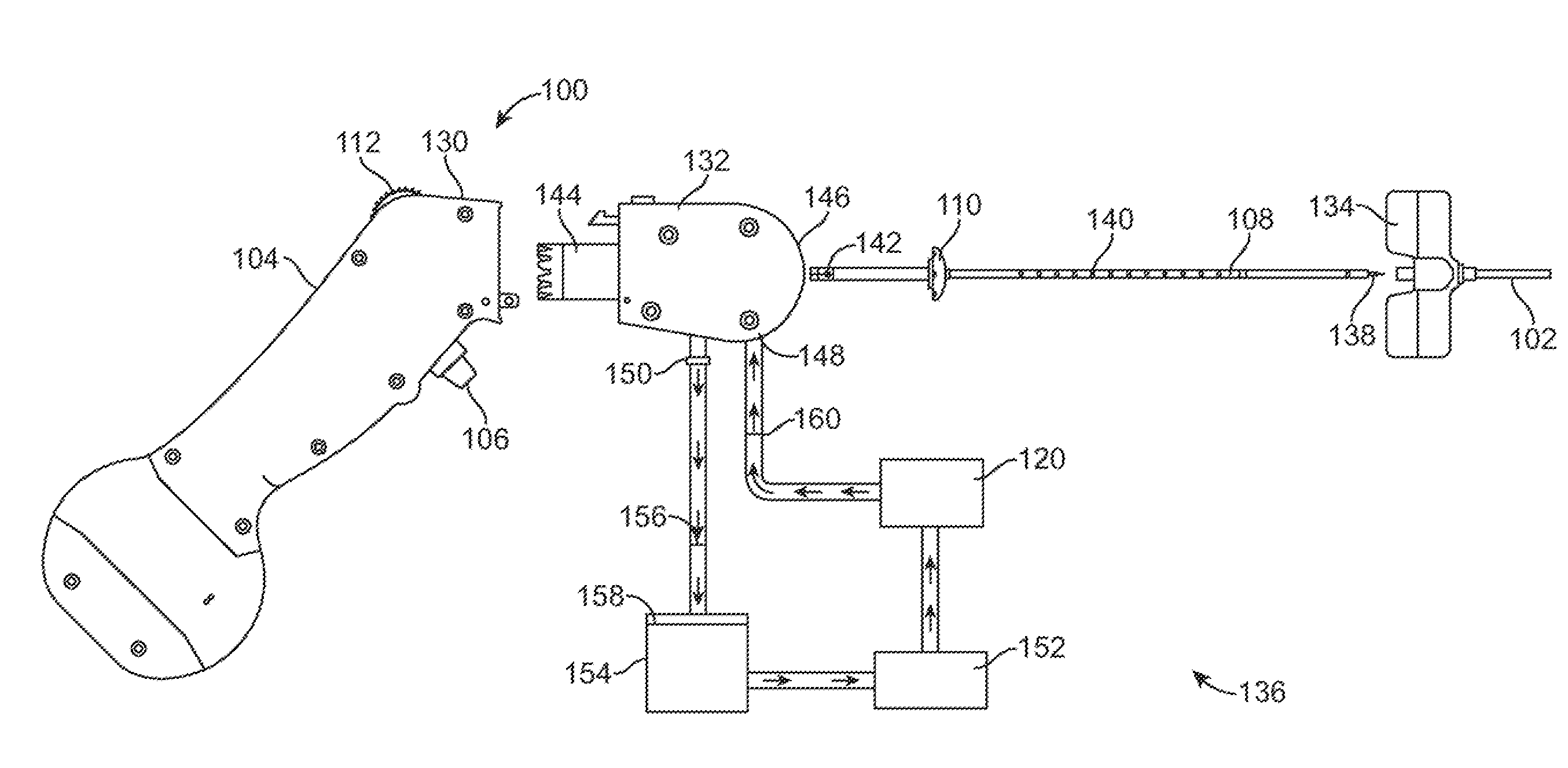

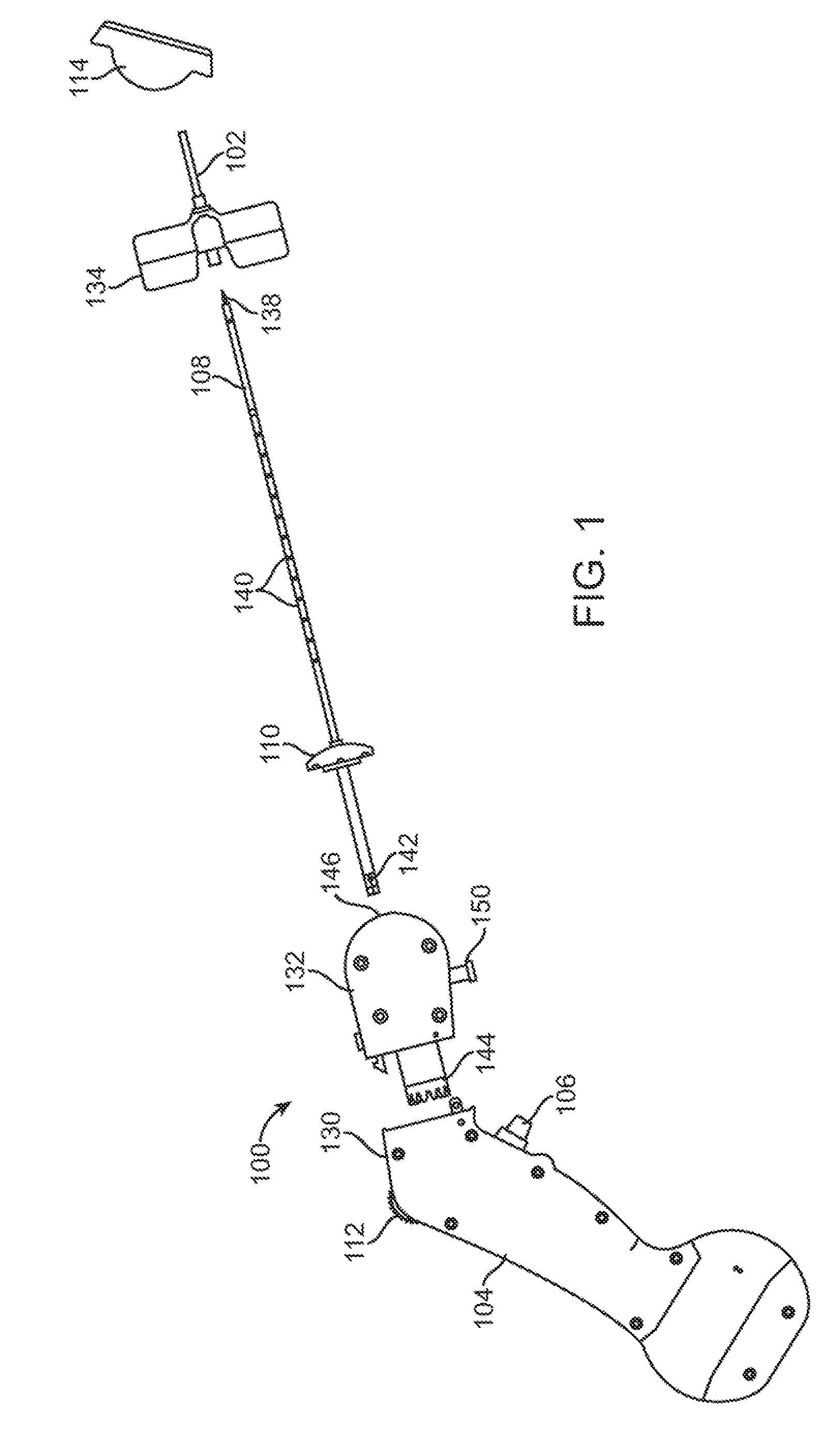

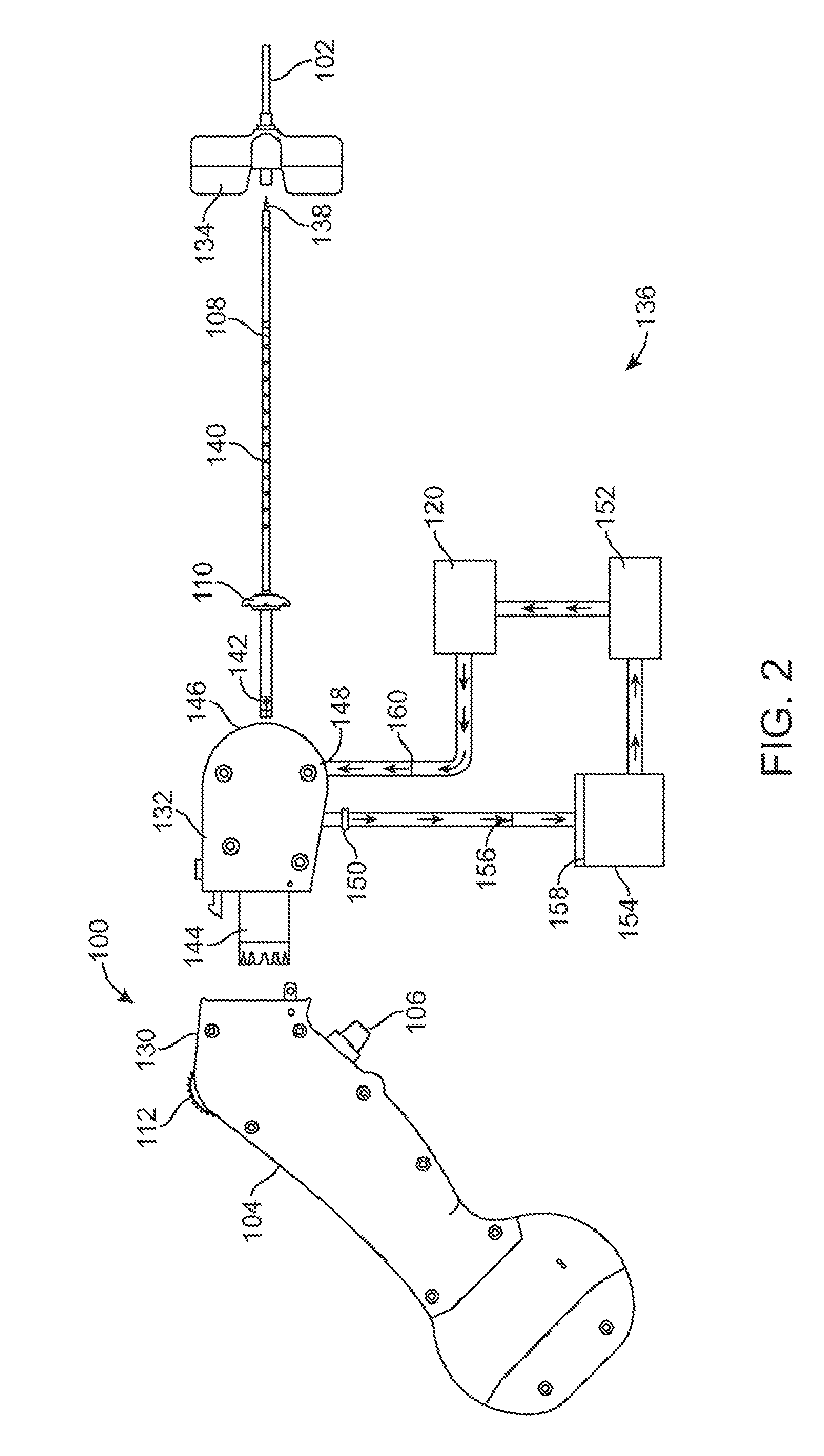

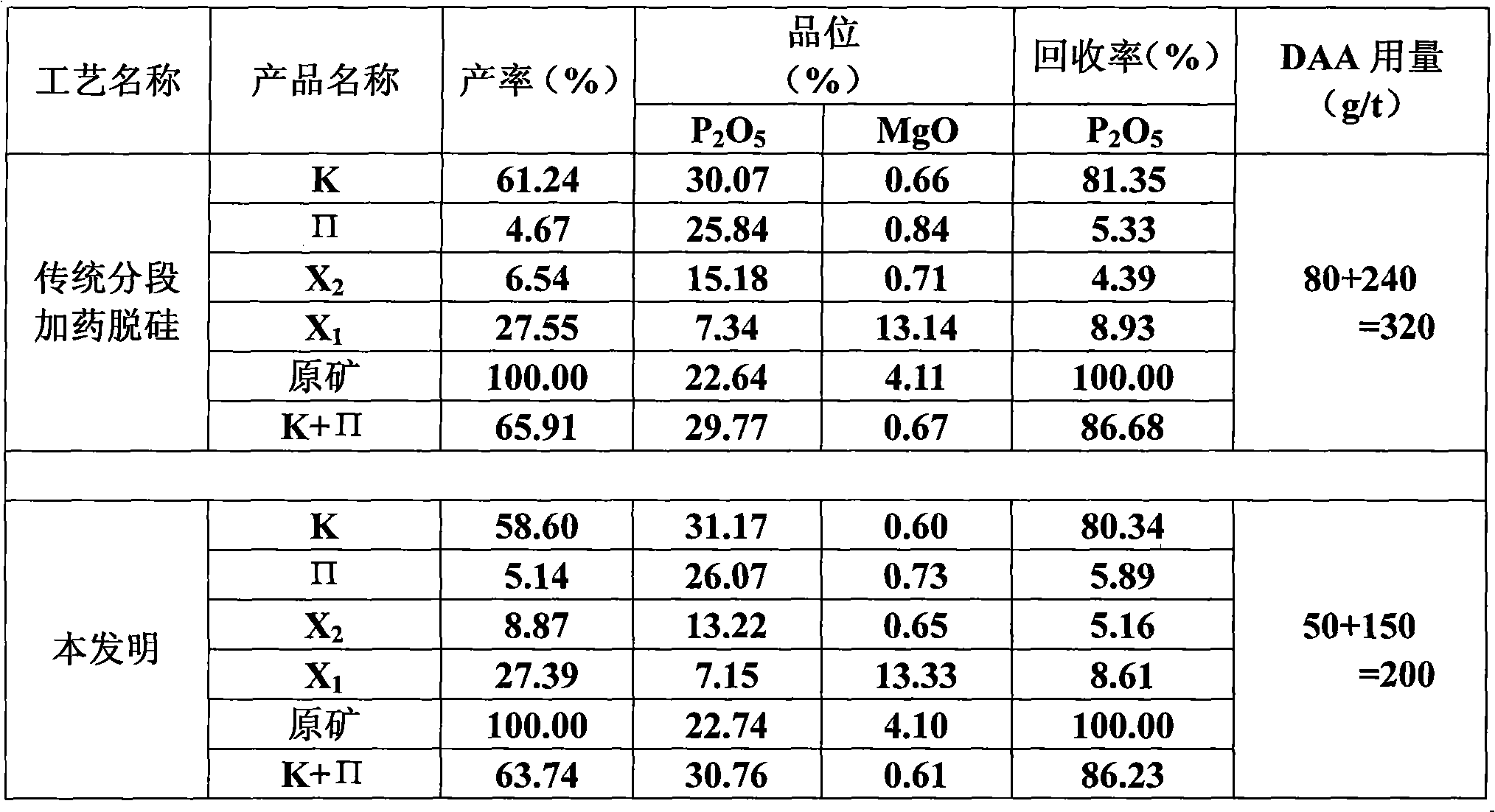

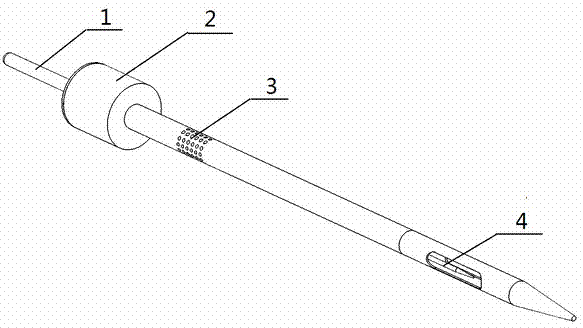

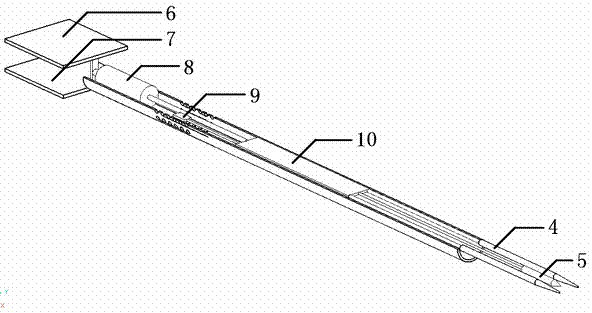

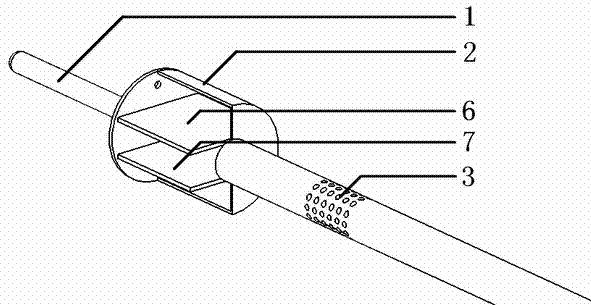

Apparatus and methods for tissue disruption

InactiveUS20090131827A1Increase harvestPrecise positioningCannulasSurgical needlesIn vivoWater irrigation

Apparatus and methods for tissue disruption are disclosed where a tissue disruptor may have various configurations extending from the distal end of a flexible aspiration cannula. The devices can have aspiration and / or irrigation systems configured to provide aspiration pressure and / or irrigate with fluid at the distal end of the cannula. The cannula can be configured to rotate or disrupt the matrix of bone marrow and extract the marrow in vivo through a single opening. The cannula shaft itself may be fabricated utilizing multiple layers of material such that the cannula is flexible yet sufficiently stiff to transmit a torque therealong.

Owner:STEMSOURCE LLC

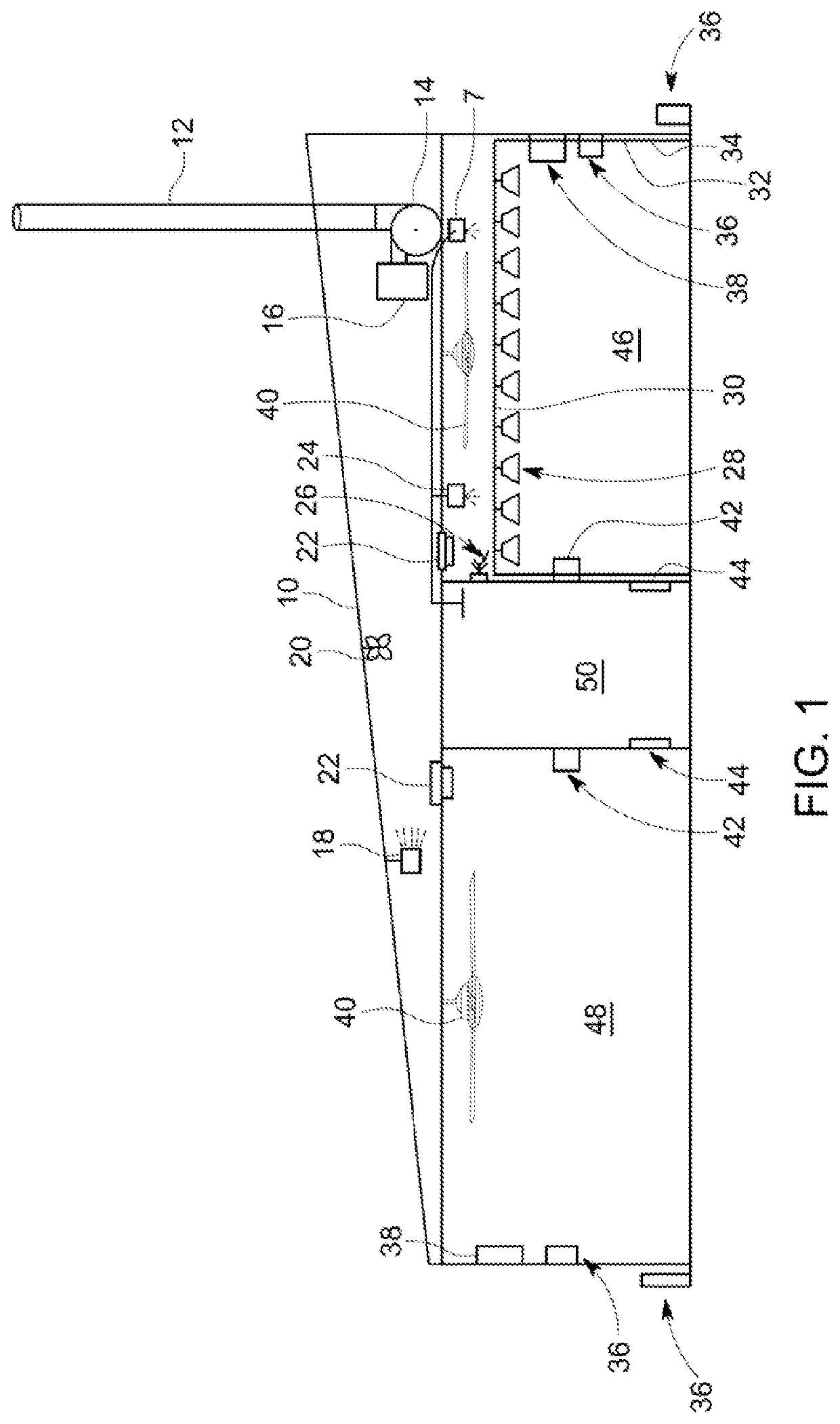

Travelling type automatic multifunctional field operation machine

InactiveCN102668758AEasy to operateSwap shortcutAgricultural undercarriagesElectricityMultiple function

The invention relates to a travelling type automatic multifunctional field operation machine which comprises a rail, a travelling rack and an operating system, wherein the travelling rack is arranged on the rail, the operating system is installed on the travelling rack, and various agricultural implements are installed at the lowest part of the operating system. The travelling type automatic multifunctional field operation machine can finish the following functions: 1, the travelling type automatic multifunctional field operation machine can travel on a lateral adjusting rail and a longitudinal operation rail; 2, the operating system can carry out longitudinal and lateral operation; 3, the operating system can rotate; 4, the operating system can lift; and 5, an operating stand and a crane rail are installed on the upper part of a travelling rack body. The travelling type automatic multifunctional field operation machine has the advantages as follows: (1), the energy is saved and emission is reduced, and the machine adopts electricity as the energy and does not generate environmental pollution; (2), a person does not enter the field during operation; (3), automatic production of agriculture is realized; (4), the operation quality is improved and the foodstuff yield is increased; and (5), the efficiency is improved and the labor is saved.

Owner:HUNAN CHUNYAN MACHINERY MFG

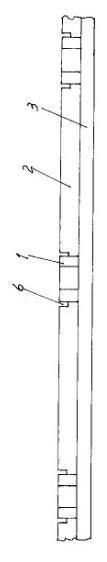

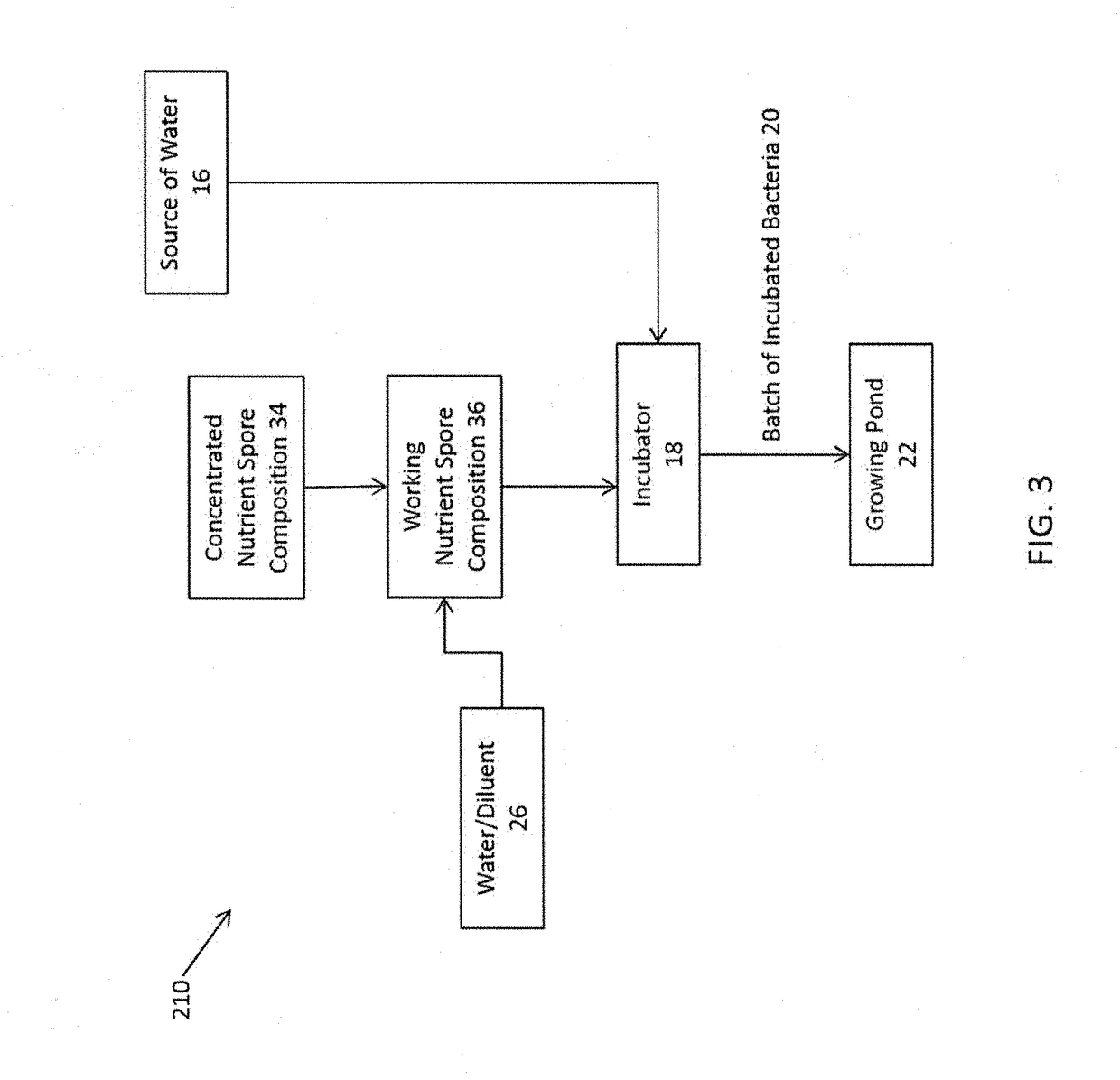

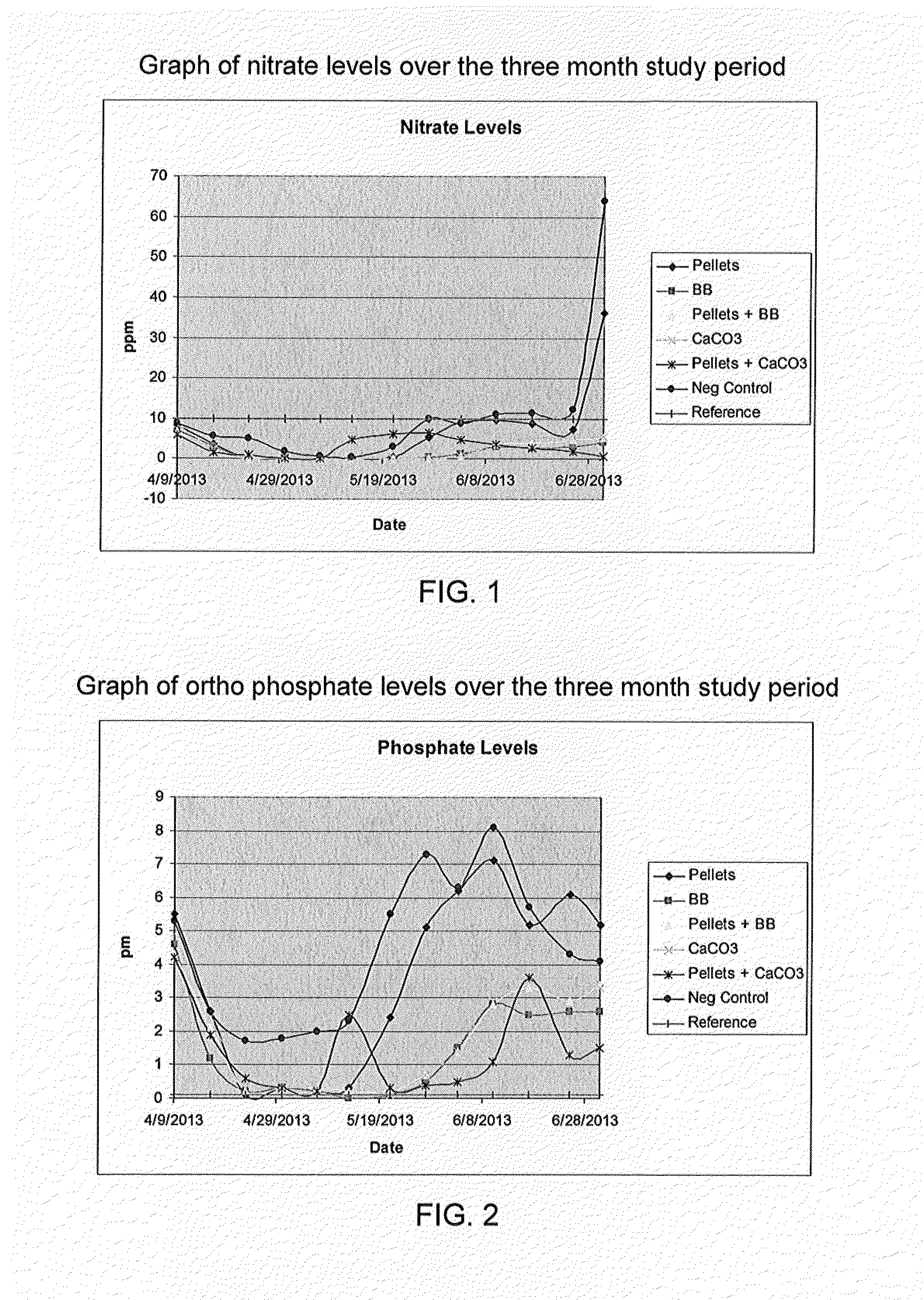

Method for Improving Quality of Aquaculture Pond Water Using a Nutrient Germinant Composition and Spore Incubation Method

ActiveUS20190071336A1Reduces disease pressureIncrease harvestWater contaminantsWaste water treatment from animal husbandrySpore germinationMetal particle

A method for improving the quality of pond water used in aquaculture applications by adding to the pond water active bacteria that are preferably germinated from spores on site using a nutrient-germinant composition and an incubation method for increased spore germination efficiency, in combination with a nitrification enhancement agent such as calcium carbonate or calcified seaweed, and an optional reaction surface area modifier such as calcified seaweed or plastic or metal particles or fragments. The nutrient-germinant composition comprises L-amino acids, D-glucose and / or D-fructose, a phosphate buffer, an industrial preservative, and may include bacteria spores (preferably of one or more Bacillus species) or they may be separately combined for germination. The incubation method comprises heating a nutrient germinant composition and bacteria spores, to a temperature range of 35° C. to 60° C. for around 2 to 60 minutes to produce an incubated bacteria solution that is discharged to the aquaculture application.

Owner:NCH CORP

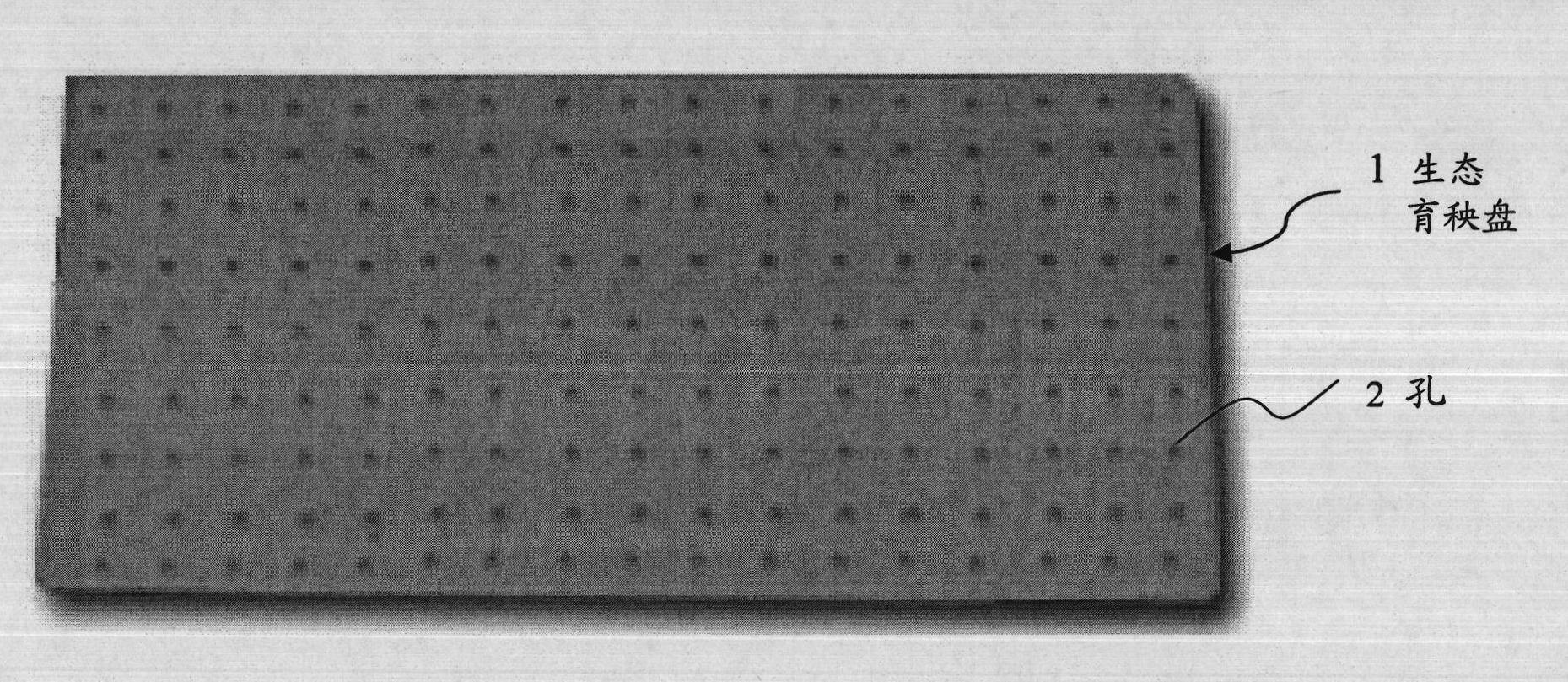

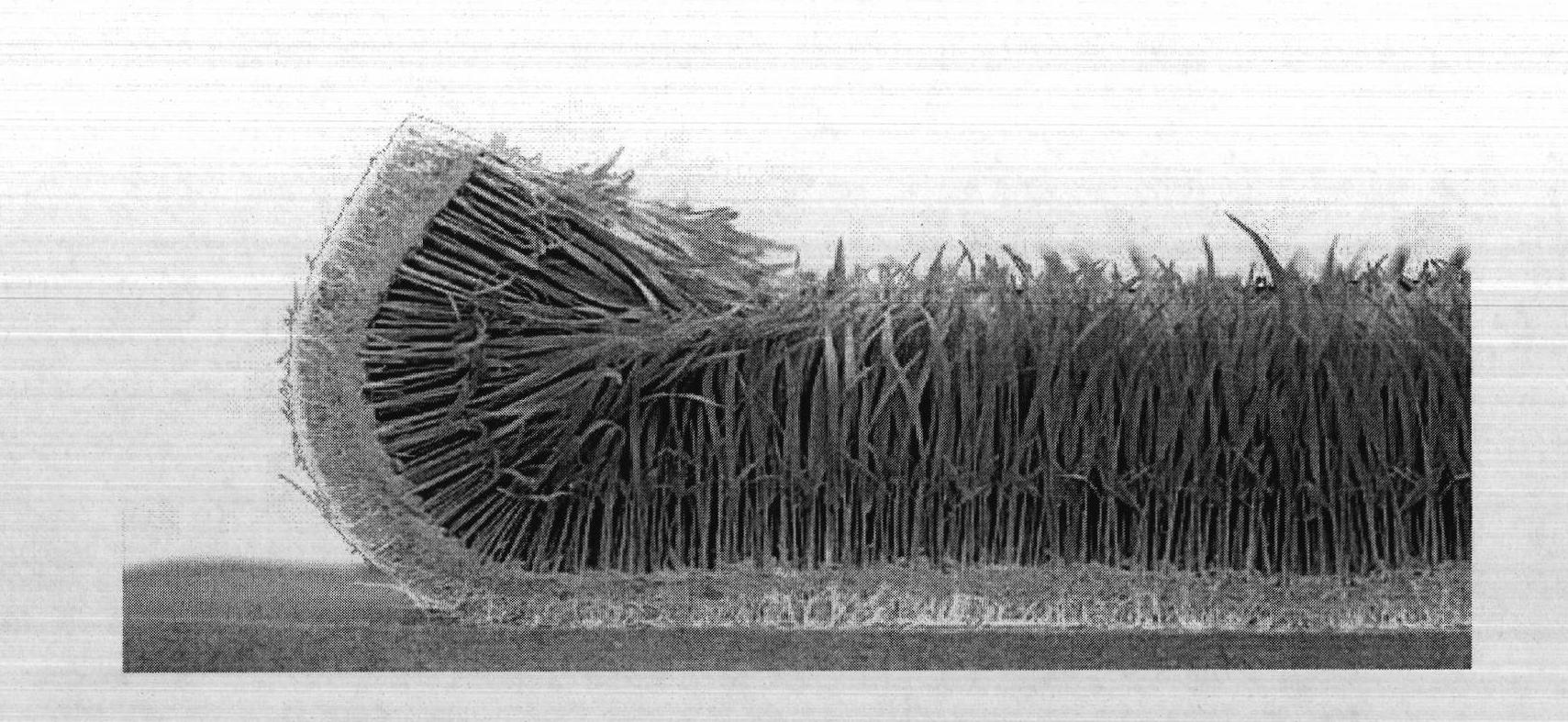

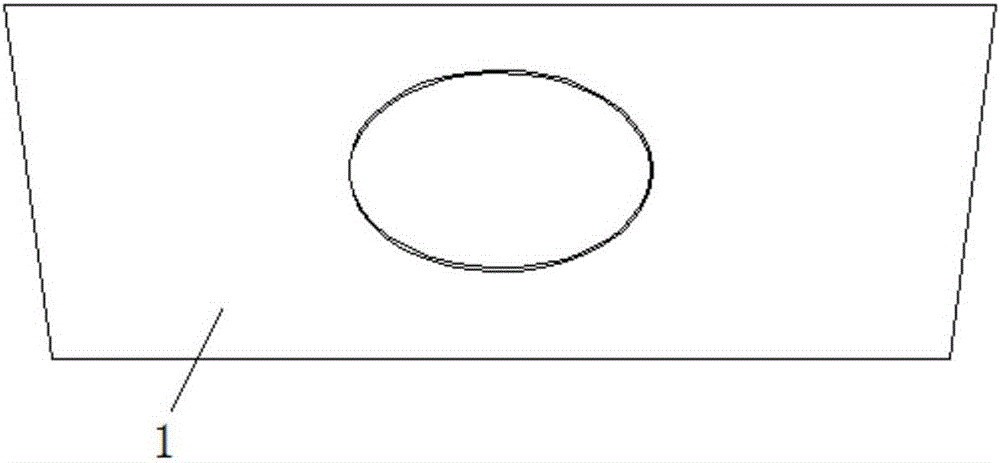

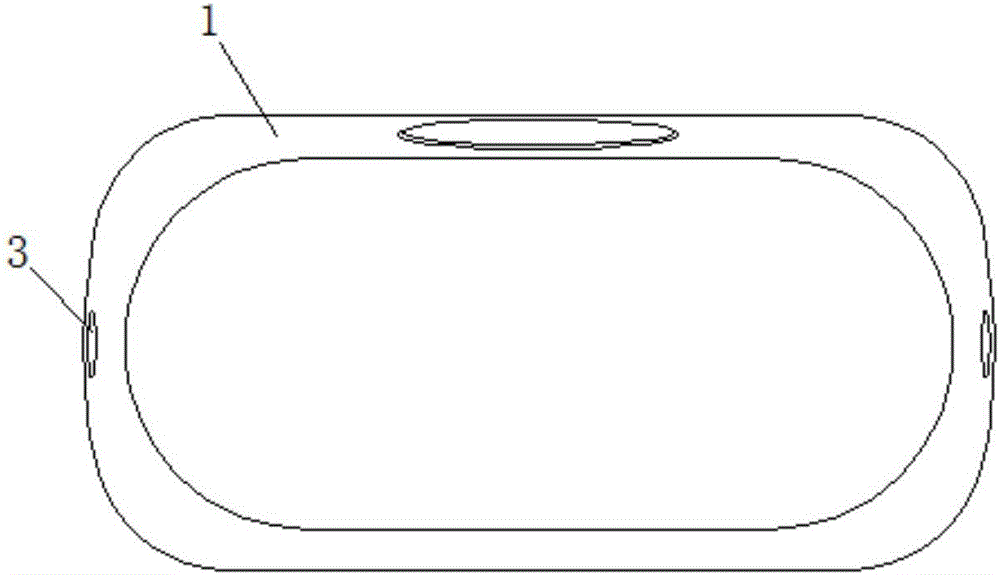

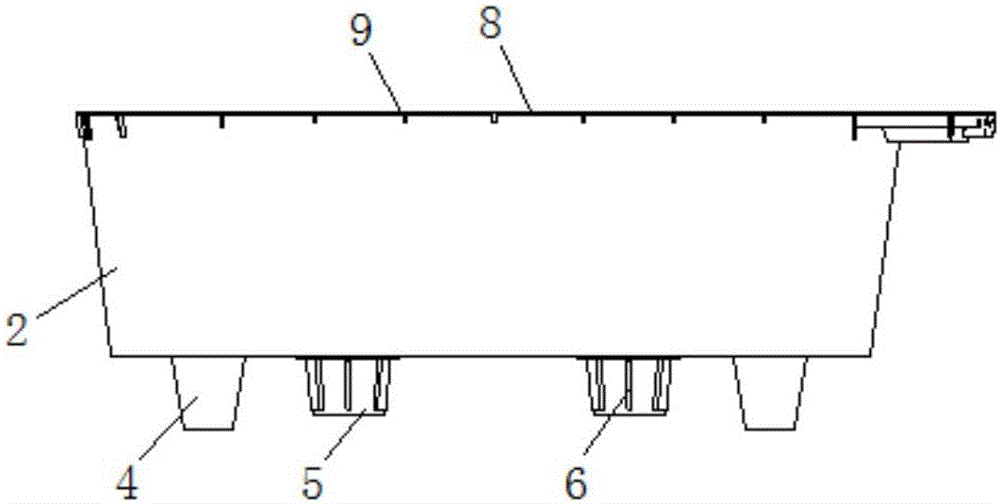

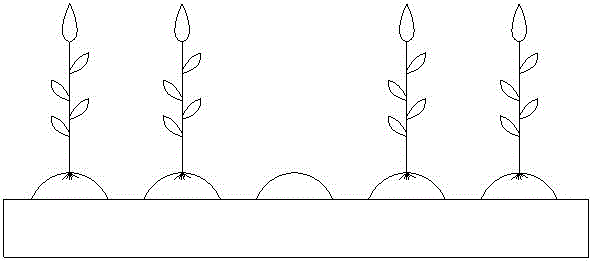

Ecological seedling tray and manufacturing method thereof

The invention provides an ecological seedling tray and a manufacturing method thereof. The ecological seedling tray comprises waste papers, expanded rice husks, and at least one selected from corn stalks and rice straws obtained by cutting, crushing, decomposing and fermenting operations. With respect to 100 wt% of the total weight of the waste papers and the expanded rice husks, the waste papers account for 20-35 wt%, the expanded rice husks account for 65-80 wt%, and the at least one selected from the corn stalks and the rice straws account for 25-35 wt%. By mixing them, shaping them according to the prescribed specification and drying them, the ecological seedling tray of the invention is obtained, which provides rich celluloses and nutrients and achieves improved water absorbability and permeability, so that seedlings take root and grow well. The ecological seedling tray of the invention allows easy control of the nutrients or water and eliminates barrier factors of successive plantation, thereby enhancing yield safety and mass production.

Owner:梁明俊

Planting method for pinellia ternata

The invention discloses a planting method for pinellia ternate, and belongs to the technical field of cultivation techniques of traditional Chinese medicinal materials. The planting method includes a, selecting seeds; b, ditching on a field surface to complete soil preparation; c, seeding around spring equinox in the lunar calendar, bedding fabrics or cloth-shaped materials at the bottom and on two lateral surfaces of the filed surface, placing seed stems or germination-accelerated seed stems on screens of ditches at the intervals of 3-8cm, and covering the seed stems with mixed fat soil with 4-5cm thickness; d, managing the field; and e, during harvesting, drawing back the fabrics or the cloth-shaped materials which contact with the bottoms and two lateral surfaces of the ditches and turn out from the upper edges of the ditches from one side, raking earthnuts, substantial fibres and pinellia ternate tubers with soil into containers, screening, sorting out, classifying, processing and storing the tubers, the earthnuts and the fibres. The width of the fabrics or the cloth-shaped materials can meet the requirement that the fabrics and the cloth-shaped materials can contact with the bottoms and the lateral sides of the ditches and turn out 2-6cm respectively from the two upper edges of the ditches. The planting method has the advantages that growth of weeds around the pinellia ternata plants can be prevented, and the pinellia ternata is convenient to harvest; and especially, the earthnuts can be sorted out, so that yield and income can be increased.

Owner:安徽振中农业科技有限公司

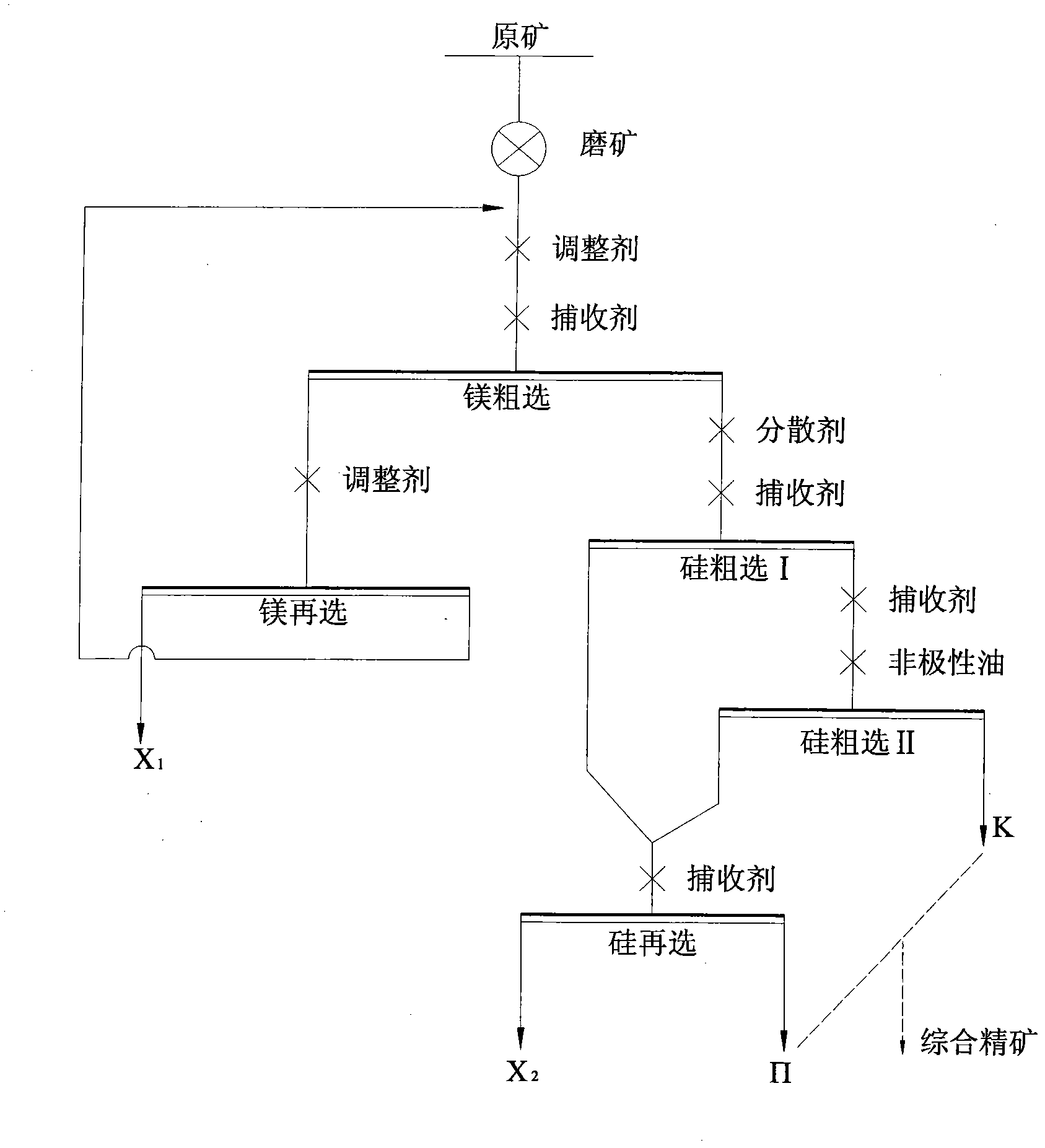

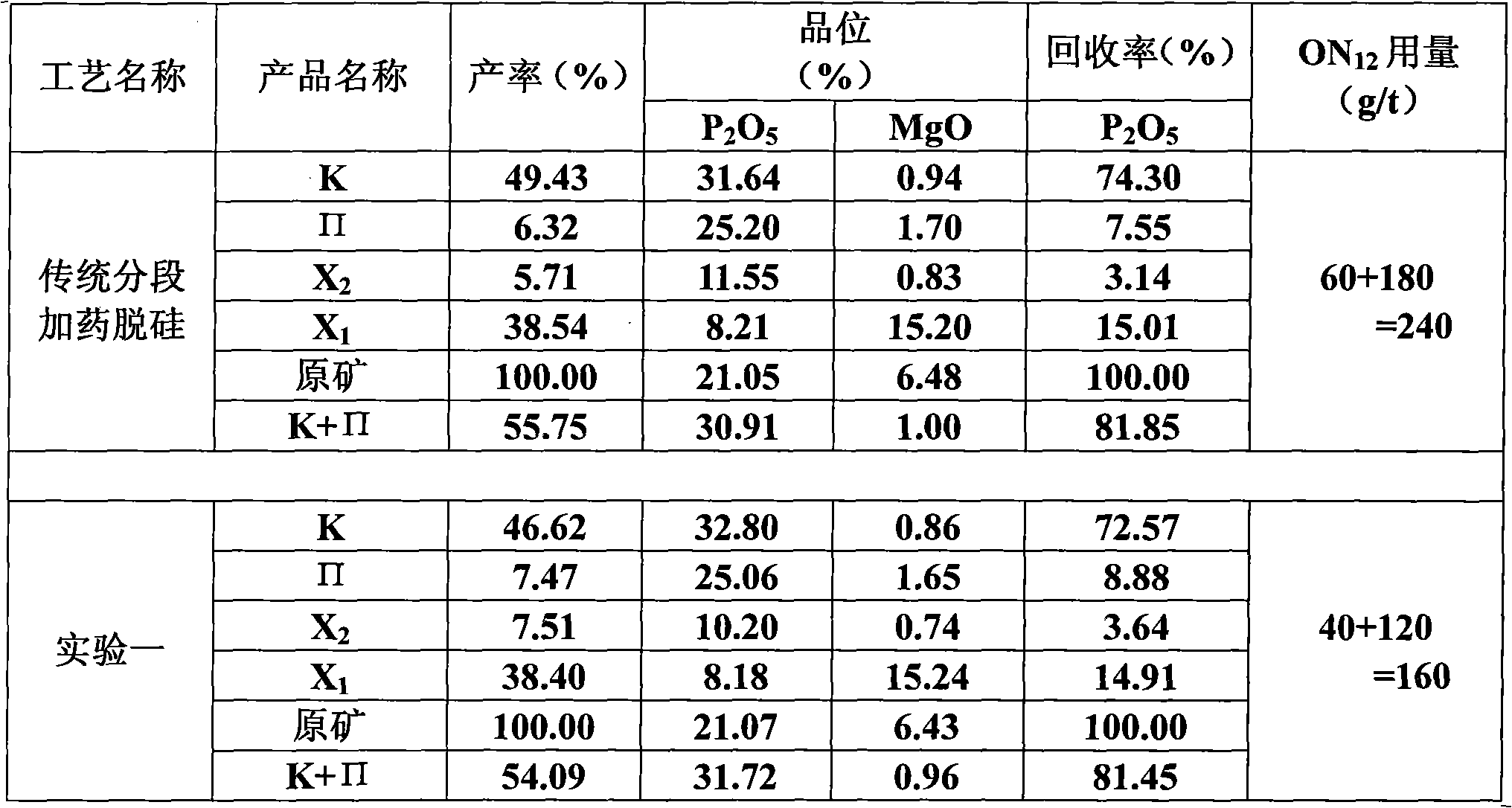

Double reverse flotation process of middle-low grade phosphorite

The invention relates to a double reverse flotation process of middle-low grade phosphorite. The double reverse flotation process is characterized by comprising the following steps of: after milling raw phosphorite ores to the granularity required by flotation, adding a reverse flotation de-magging adjustor and a catching agent for executing rough magnesium flotation operation, wherein de-maggingrough concentrate is in a rough magnesium flotation groove; after adding the regulator in rough magnesium flotation foam, executing magnesium recleaning operation, wherein de-magging middling productis in a magnesium recleaning groove and the magnesium recleaning foam is carbonate gangue; adding a de-silication disperser and a de-silication catching agent in ore slurry in the groove after de-magging, and carrying out de-silication rougher flotation operation I; then adding a de-silication catching agent and non-polar oil for performing the de-silication rougher flotation operation II, wherein ore concentrate is in a rough silicon flotation groove; after combining the foam of the silicon rougher flotation I and the silicon rougher flotation II, adding the de-silication catching agent for performing the silicon recleaning, wherein de-silication middling product is in a silicon recleaning groove, and silicon recleaning foam is silica gangue; and combining the de-silication middling product and the ore concentrate to obtain the comprehensive phosphorus concentrate. The process can increase the catching of the silicon gangue, improve the selecting efficiency and reduce the consumptionof the reverse flotation de-silication catching agent.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Method of production of biofuel from the surface of the open ocean

A method for the production of biofuels from the open ocean comprises the steps: testing the currents to determine that a biomass remains in a zone suitable for harvesting; harvesting a portion of the biomass; and processing a portion of the harvested biomass to produce useful components of biofuels. An improved method of production of a biofuel comprises the additional steps of testing the ocean surface waters to determine any nutrients that are missing, and applying a fertilizer with any missing nutrients. The currents should be such that the biomass created stays in the ocean waters suitable for harvest rather than washed up on shores, or dispersed to other areas of the ocean. Suitable currents include ocean gyres such as the Sargasso Sea. Suitable biomass includes seaweeds that float in the open ocean and aggregate together in floating patches, such as the Sargassum weed in the Sargasso Sea.

Owner:MICHAEL MARKELS JR REVOCABLE TRUST MICHAEL MARKELS JR & ELIZABETH MARKELS CO TRUSTEES

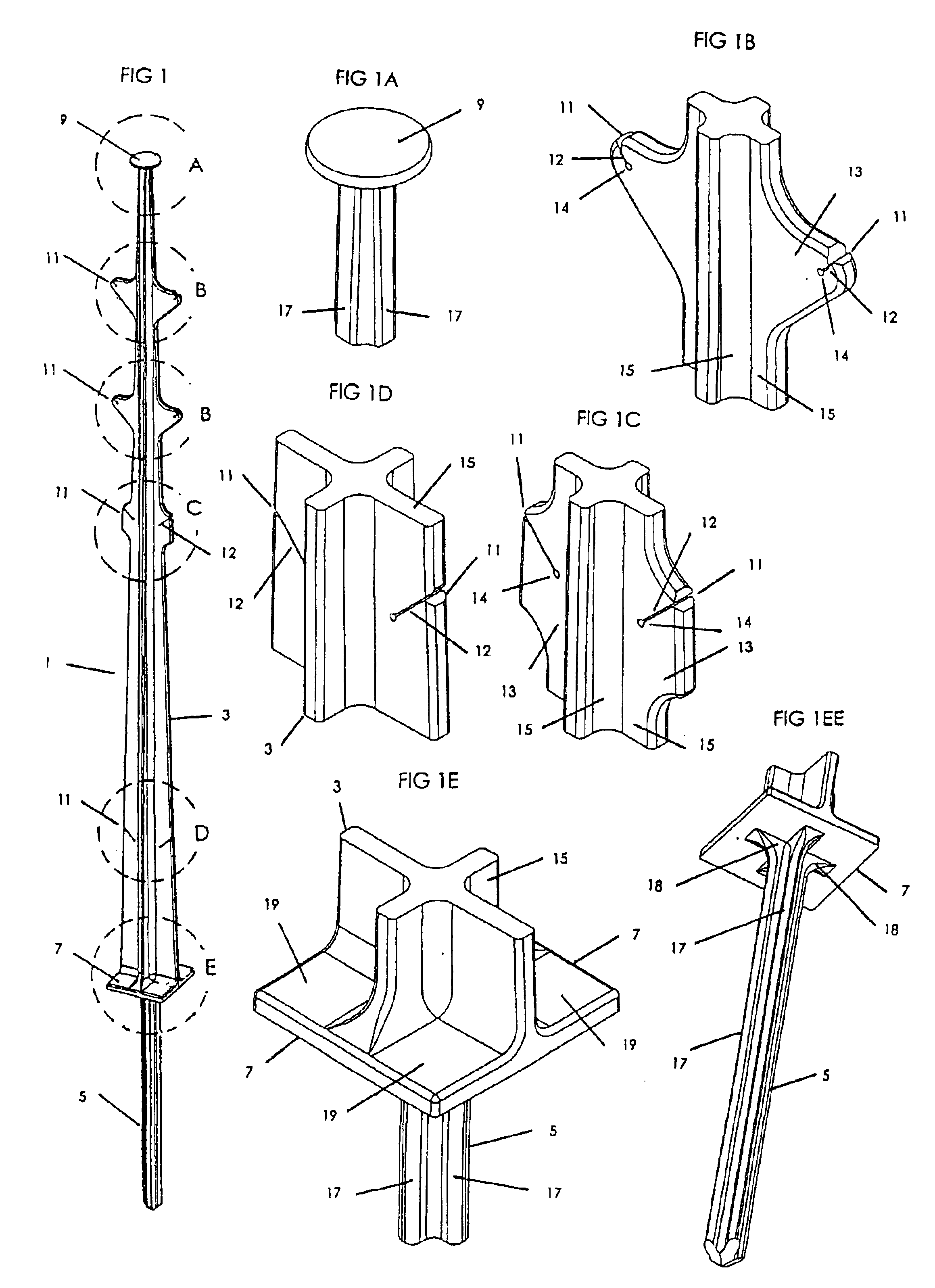

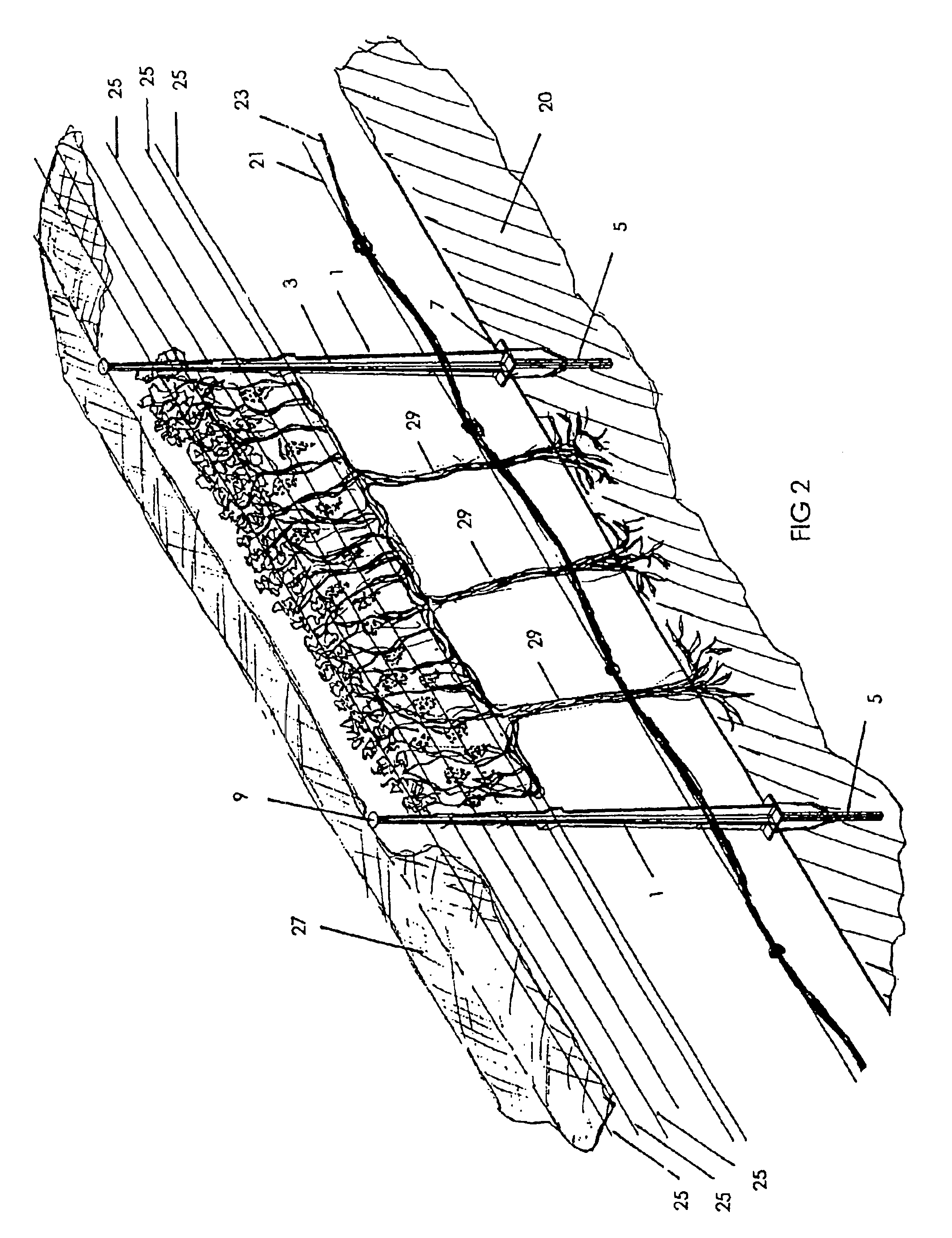

Vine wire support post

InactiveUS6922942B2Increase harvestFlexibilityFencingStands/trestlesEngineeringUltimate tensile strength

A vine wire support post molded as integral unit from plastics has an elongate tapered supporting portion having upper end and lower end, a wire attachment provided on the supporting portion, a peg for holding support post in ground joined to lower end of supporting portion, a foot at the join between peg and supporting portion. The supporting portion is flexible and has variable sectional strength decreasing over a length of supporting portion from a position of higher sectional strength nearer lower end to a position of lower sectional strength nearer upper end.

Owner:VINEYARD INFRASTRUCTURE & NEW ENG TECH

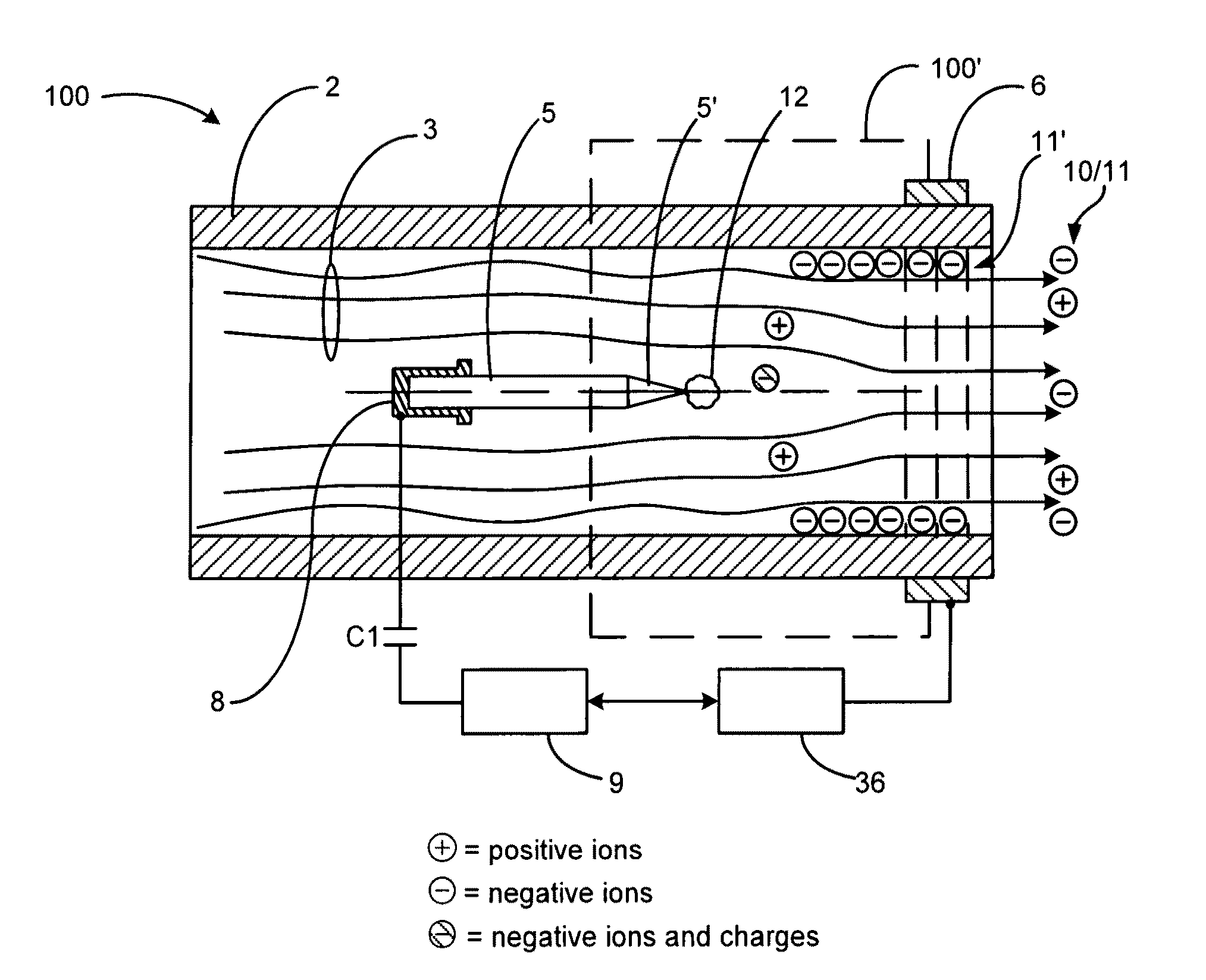

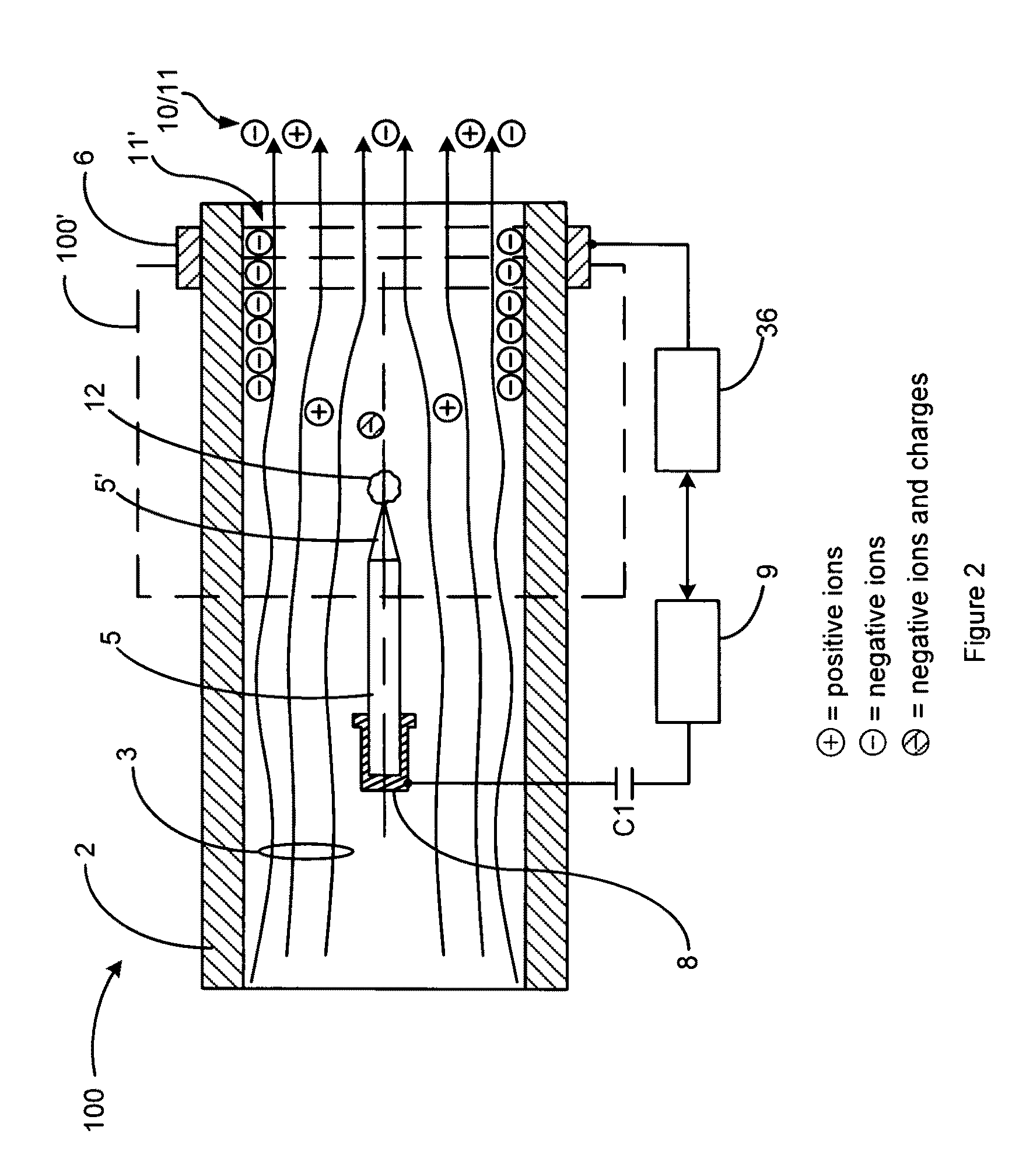

Self-balancing ionized gas streams

ActiveUS8416552B2Increase probabilityIncrease the number ofSpraying power supplyIon beam tubesNoble gasControl system

Self-balancing, corona discharge for the stable production of electrically balanced and ultra-clean ionized gas streams is disclosed. This result is achieved by promoting the electronic conversion of free electrons into negative ions without adding oxygen or another electronegative gas to the gas stream. The invention may be used with electronegative and / or electropositive or noble gas streams and may include the use of a closed loop corona discharge control system.

Owner:ILLINOIS TOOL WORKS INC

Method for Improving Quality of Aquaculture Pond Water

ActiveUS20150336828A1Reduce ammonia levelsIncrease alkalinityWater treatment parameter controlWater contaminantsWater useAquatic species

A method for treating and improving the quality of pond water used in growing aquatic species for aquacultural applications by adding to the pond water active bacteria that are preferably grown on site in combination with a nitrification enhancement agent such as calcium carbonate or calcified seaweed, and an optional reaction surface area modifier such as calcified seaweed or plastic or metal particles or fragments.

Owner:NCH CORP

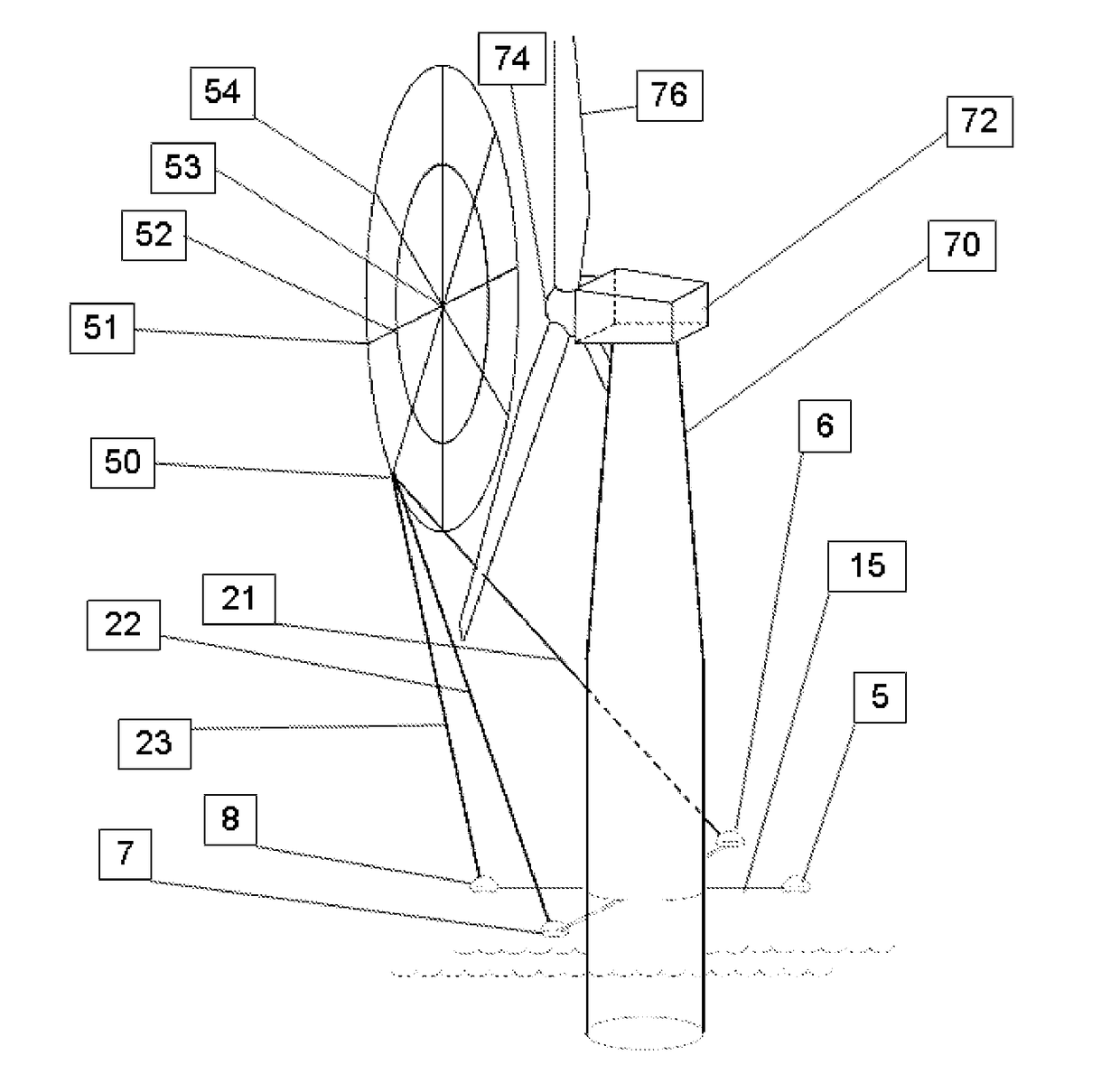

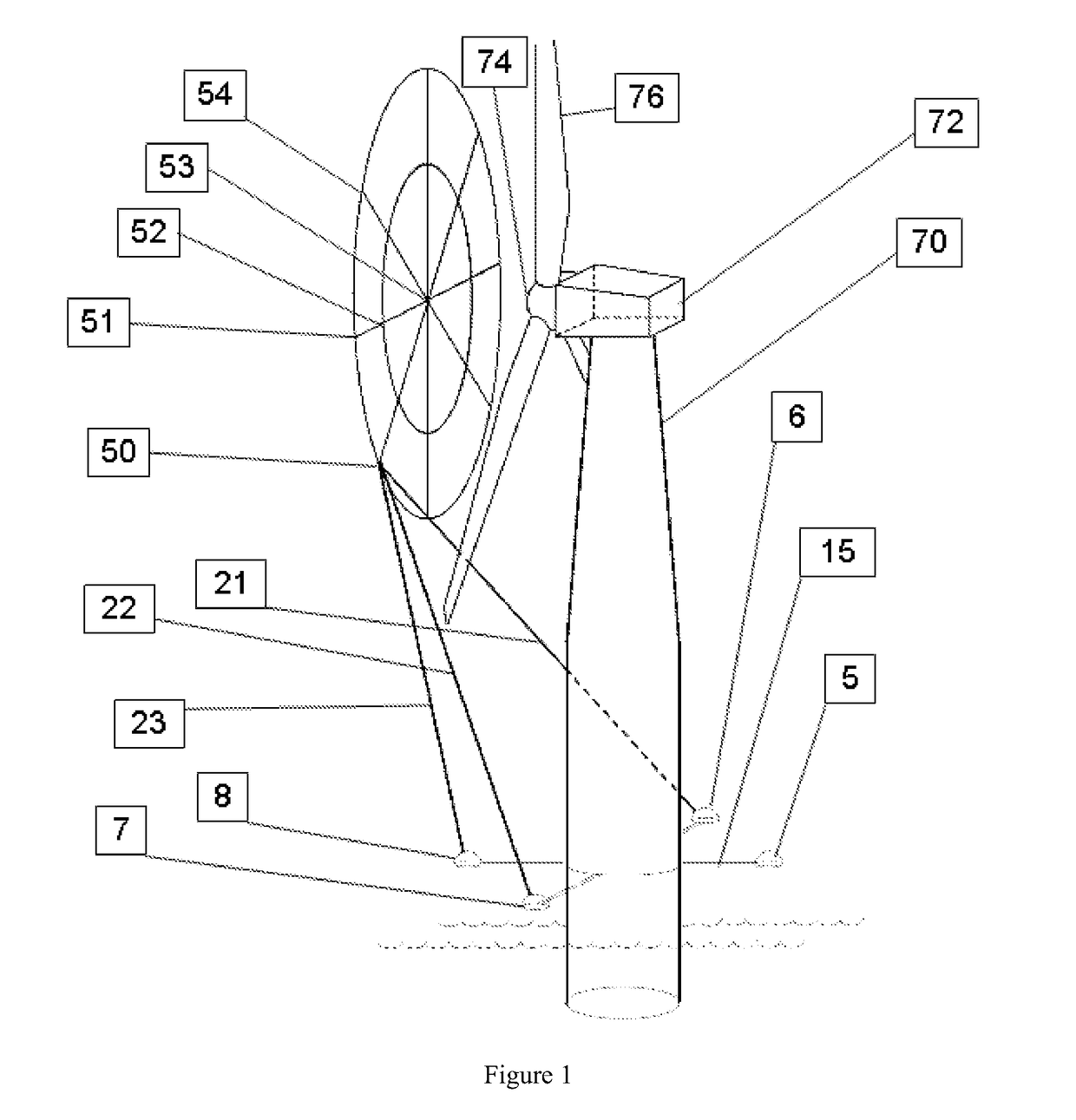

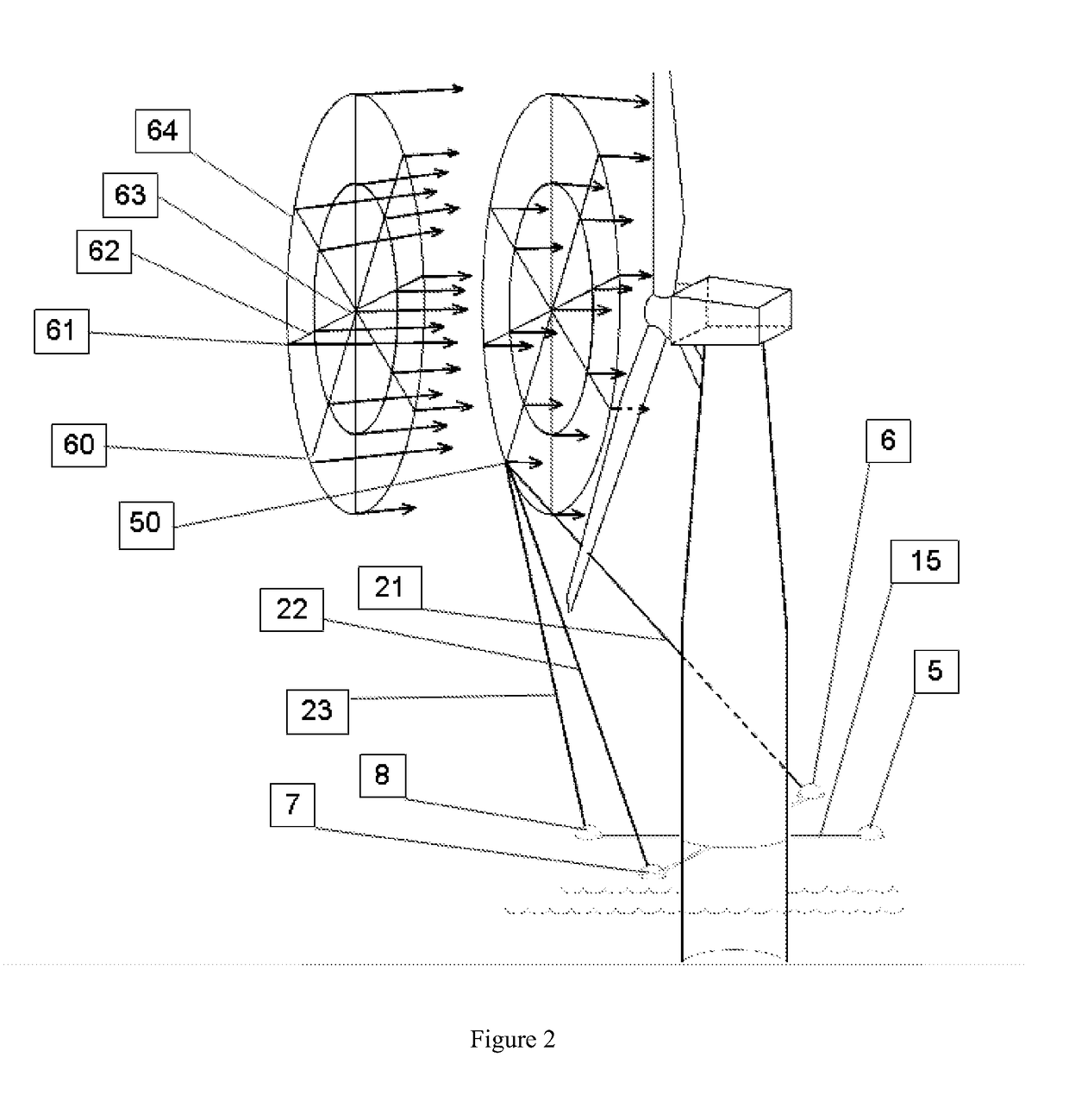

Wind Vector Field Measurement System

ActiveUS20180246138A1Improved Energy HarvestingGood prospectsWind motor controlMachines/enginesBuoyWind field

A three-dimensional wind vector field measurement system employs convergent beams for localised velocity measurement enabling mapping of the wind field across an extended spatial region. This enables characterisation of complex field signatures. This enables advanced control and protective systems for wind turbines. This also enables improved wind harvesting. This also enables improved prospecting. This also enables improved equipment selection. Buoy mounted systems enable measurement in an offshore environment.

Owner:WIND FARM ANALYTICS

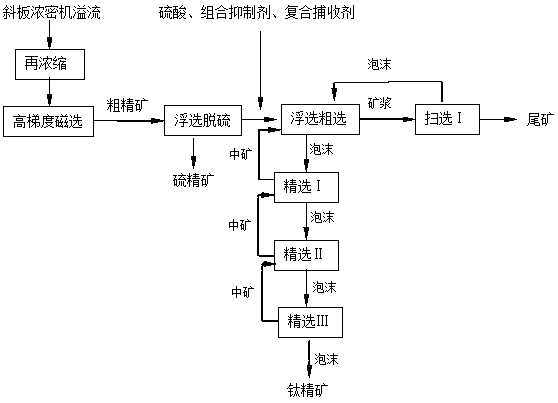

Recovering method for ultra-fine-grain ilmenite in inclined plate thickener overflow

ActiveCN109433406AAchieve high gradient magnetic separation pre-enrichmentEffective dispersionSolid separationMechanical material recoveryRecovery methodUltra fine

The invention discloses a recovering method for ultra-fine-grain ilmenite in an inclined plate thickener overflow. Re-concentration is carried out on the inclined plate thickener overflow; then high-gradient magnetic separation is carried out; magnetic separation rough concentrate is adjusted to a proper flotation concentration for flotation desulfurization; and then after sulfuric acid, a combined inhibitor, and a composite collecting agent are sequentially added, roughing is carried out once, roughing bubbles are subjected to selection for three times, ore pulp in a roughing groove is subjected to scavenging once, the ore is sequentially returned to the previous operations in the selection process, and the bubbles are sequentially returned to the previous operations in the scavenging process. The recovery rate in the flotation operation is greater than 45%, and the grade of the titanium concentrate is 44%-47%.

Owner:KUNMING UNIV OF SCI & TECH

Method for producing organic fertilizer with urban refuse as raw material

InactiveCN101074174AIncrease profitLow investment costBio-organic fraction processingClimate change adaptationLitterOrganic fertilizer

Production of organic fertilizer by urban refuse is carried out by crushing, separating, recovering reused substances from urban refuse, sterilizing by caustic lime, crushing for separated refuse, fermenting, adding into mud, baking accessories and urea and carbon ammonia, inducing while heating for 2-5 days to obtain organics and organic salts, delivering fermented refuse into drying kiln, drying, grinding dried refuse to 200 meshes, screening and packing to obtain powdery fertilizer. It's efficient, cheap, has various raw materials and no environmental pollution and can be reutilized.

Owner:肖国华

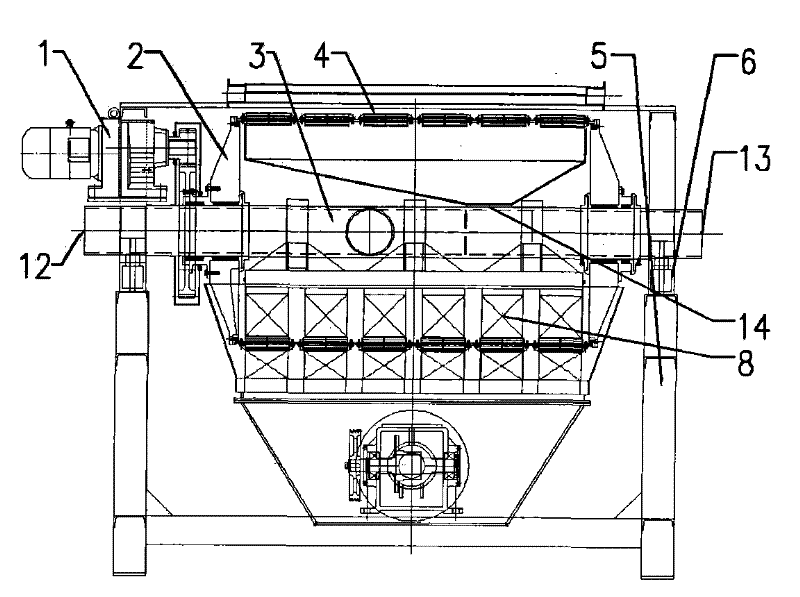

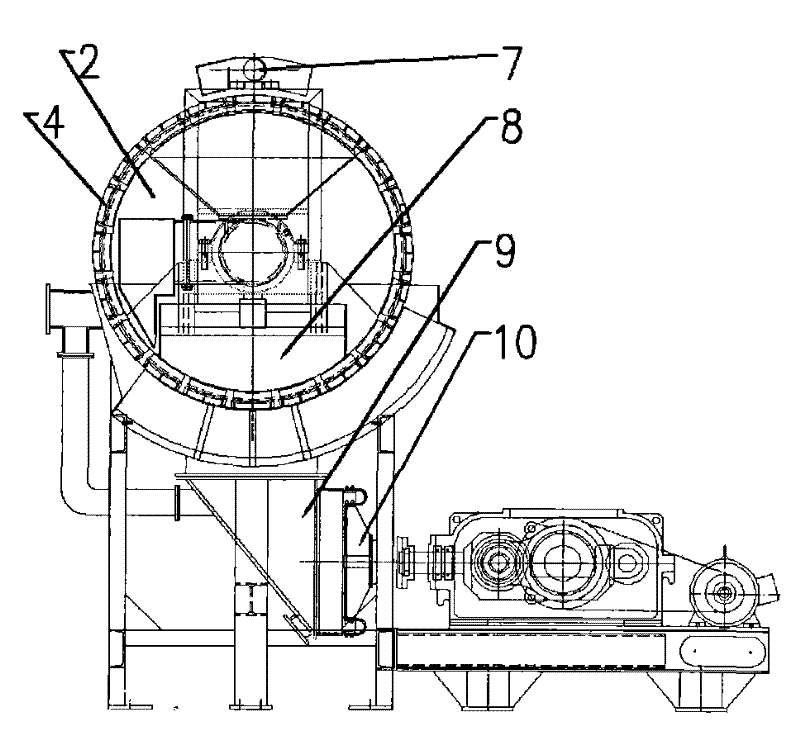

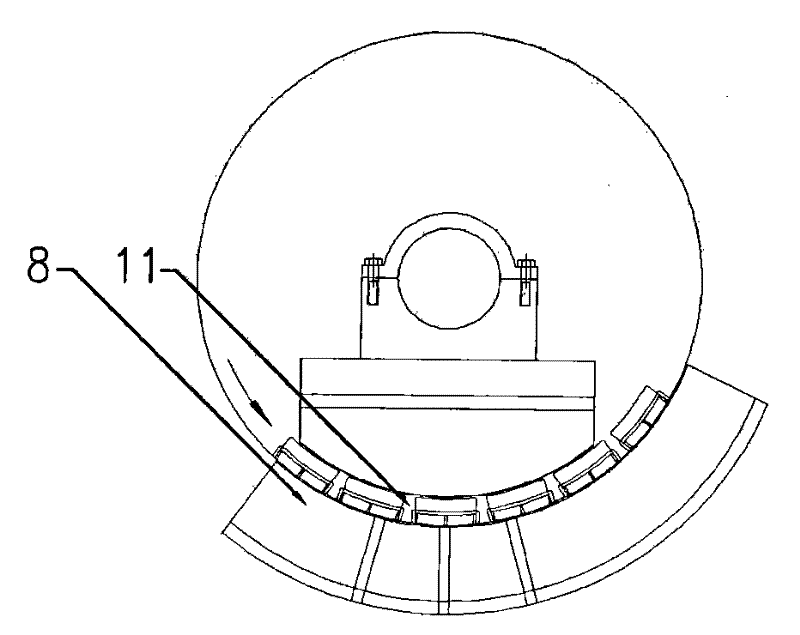

Permanent-magnet cylindrical cage type high-gradient magnetic separator with high processing capacity

ActiveCN102179297AIncrease harvestReasonable load distributionHigh gradient magnetic separatorsMagnetic separatorEngineering

The invention discloses a permanent-magnet cylindrical cage type high-gradient magnetic separator with high processing capacity. A separating cylinder (2) is a cylindrical cage which is a rotary body and is filled with magnetic matrices (4); two ends of the cylindrical cage are supported on a hollow support shaft (3) through bearings; a magnetic system is a permanent-magnet lattice uniform magnetic field system formed by an upper magnetic system and a lower magnetic system, the upper magnetic system is arranged in the cavity of the cylindrical cage and suspended on the hollow support shaft (3), the lower magnetic system is installed outside the cylindrical cage, the hollow support shaft (3) is a non-rotary body, one end of the hollow support shaft (3) is used as an axes feeding port (12),the middle of the hollow support shaft (3) is provided with a baffle plate, and one side of the baffle plate of the hollow support shaft is provided with a separating and feeding port close to the feeding port (12), the other side of the baffle plate of the hollow support shaft is provided with a concentrate feeding port (14), and the other end of the hollow support shaft (3) is used as a concentrate discharging port (13). The permanent-magnet cylindrical cage type high-gradient magnetic separator has the advantages of easiness for maximization, convenience for design and production, low energy consumption, reasonable magnetic distribution, uniform background magnetic field working region as well as high processing capacity and stable separation indexes under limited tonnage and volume.

Owner:马鞍山市天工科技股份有限公司

Method of four-season crop rotation of rice, broad bean and pea

InactiveCN101558716AImprove utilizationIncrease harvestClimate change adaptationRice cultivationFrostLand resources

The invention provides a method of four-season crop rotation of rice, broad bean and pea, in particular to two-season rice, one-season broad bean and one-season pea, totally four-season crop rotation; in the two-season rice, the first-season rice is a nascent rice and the second-season rice is a retooning rice; and the broad bean and the pea adopt an interplanting way to be planted after the retooning rice is harvested. The invention leads the land resources to be furthest utilized, not only is the rice yield increased by one season, but also the selected variety of the broad bean and the pea has high yield and good benefits and the two have good complementarity, thus not only saving fertilizer, pesticide, labor and lands, and simultaneously being capable of playing the role of preventing frozen injury caused by frost season of winter solstice.

Owner:范珍发

Greenhouse environment intelligent monitoring system

ActiveCN104770247AIncrease productionIncrease harvestClimate change adaptationGreenhouse cultivationIntelligent environmentGreenhouse

The invention discloses a greenhouse environment intelligent monitoring system, which is used for automatically monitoring a greenhouse environment. The greenhouse environment intelligent monitoring system consists of an intelligent environment monitor, a data concentrator and a data server, wherein the intelligent environment monitor acquires data of a water content sensor, a temperature sensor and an air humidity sensor inside, analyzes and converts the acquired data, and transmits the converted data to the data concentrator through a wireless module; the data concentrator is used for counting data of a plurality of intelligent environment detectors, and transmitting the counted data to the data server through a mobile phone network antenna; a user lays a basis for agricultural production by downloading data of the data server. By adopting the greenhouse environment intelligent monitoring system, the water content of soil, temperature and air humidity of the greenhouse can be acquired automatically, and data analytical processing can be performed, so that the requirement of scientific and reasonable planting is met, and the yield and harvest of crops are effectively increased. The greenhouse environment intelligent monitoring system is simple in structure, and is high in intelligence degree.

Owner:HUBEI CHUCHE E COMMERCE CO LTD

Method of production of biofuel from the surface of the open ocean

InactiveUS7985267B2Increase harvestEasy to harvestUnicellular algaeAnimal feeding stuffBiofuelSurface water

A method for the production of biofuels from the open ocean comprises the steps: testing the currents to determine that a biomass remains in a zone suitable for harvesting; harvesting a portion of the biomass; and processing a portion of the harvested biomass to produce useful components of biofuels. An improved method of production of a biofuel comprises the additional steps of testing the ocean surface waters to determine any nutrients that are missing, and applying a fertilizer with any missing nutrients. The currents should be such that the biomass created stays in the ocean waters suitable for harvest rather than washed up on shores, or dispersed to other areas of the ocean. Suitable currents include ocean gyres such as the Sargasso Sea. Suitable biomass includes seaweeds that float in the open ocean and aggregate together in floating patches, such as the Sargassum weed in the Sargasso Sea.

Owner:MICHAEL MARKELS JR REVOCABLE TRUST MICHAEL MARKELS JR & ELIZABETH MARKELS CO TRUSTEES

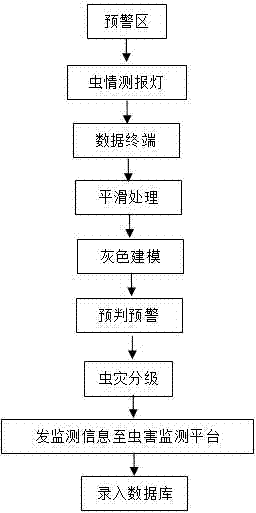

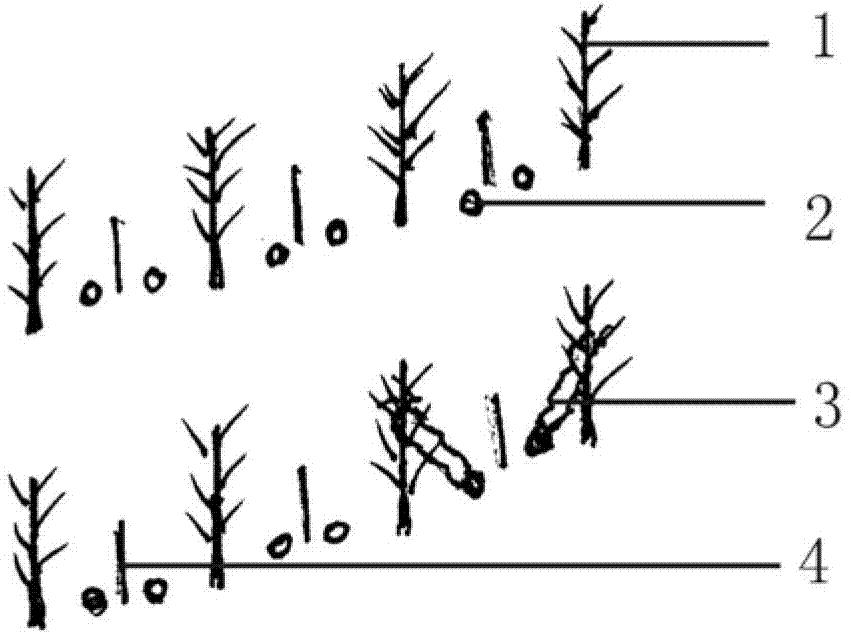

Short-term early warning method for crop pests

ActiveCN107103395ASave preventive treatment costsReduce pesticide residuesForecastingPesticide residueShort terms

The invention discloses a short-term early warning method for crop pests. The short-term early warning method for crop pests comprises the following steps of 1, performing annual monitoring of the number of pests in the early warning area where the pest forecasting lights are located, and sending the monitoring results to the data terminal; 2, smoothly processing data for the monitoring information of the pest forecasting lights; 3, based on the data after the smoothing, using the gray modeling method to establish the normal model of pest situation changes; 4, based on the rising trend of the normal model of pest situation changes, determining the specific time point of crop pest outbreaks; 5, classifying the degree of plague of the early warning area based on the pest data; 6, sending the monitoring information to the plague monitoring network platform; and 7, recording the warning information specific data into the data terminal database. The beneficial effect is that the monitoring is real-time, the implementation is convenient, the manual cost is greatly saved, the early warning is accurate and effective, the prevention cost is saved, the amount of pesticide residues of the crop is reduced, and the crop yield and output are improved.

Owner:宁波鹏博云控科技有限公司

Method for cultivating peas on natural supports

InactiveCN102893798ALow costTake full advantage of the edgeHorticultureAgricultural scienceAgricultural engineering

The invention discloses a method for cultivating peas on a natural supports. The conventional manually built support has the defects of higher cost and large amount of labour, while in the method provided by the invention, cotton plants in cotton fields are not extracted after harvesting, and peas are sown, so that the peas can climb onto the cotton plants after becoming seedlings. According to the invention, the peas are supported by the natural cotton supports after becoming seedlings; and at the same time, by applying the colonial plantation pattern, the tuft plantation of peas and the wide-row dense plantation of cotton are combined, and therefore the method has the advantages of favourableness for exertion of edge advantages of crops, improvement of light energy utilization efficiency, convenience in cultivation and management, economization of labour and support setting costs, and obvious economic benefit.

Owner:叶卸妹

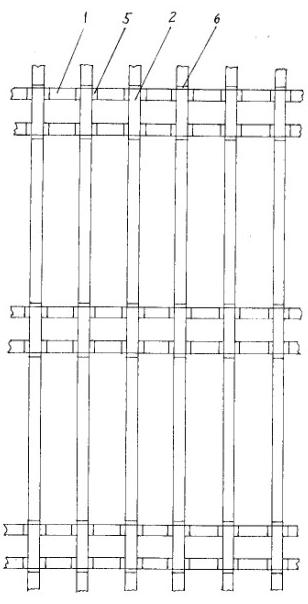

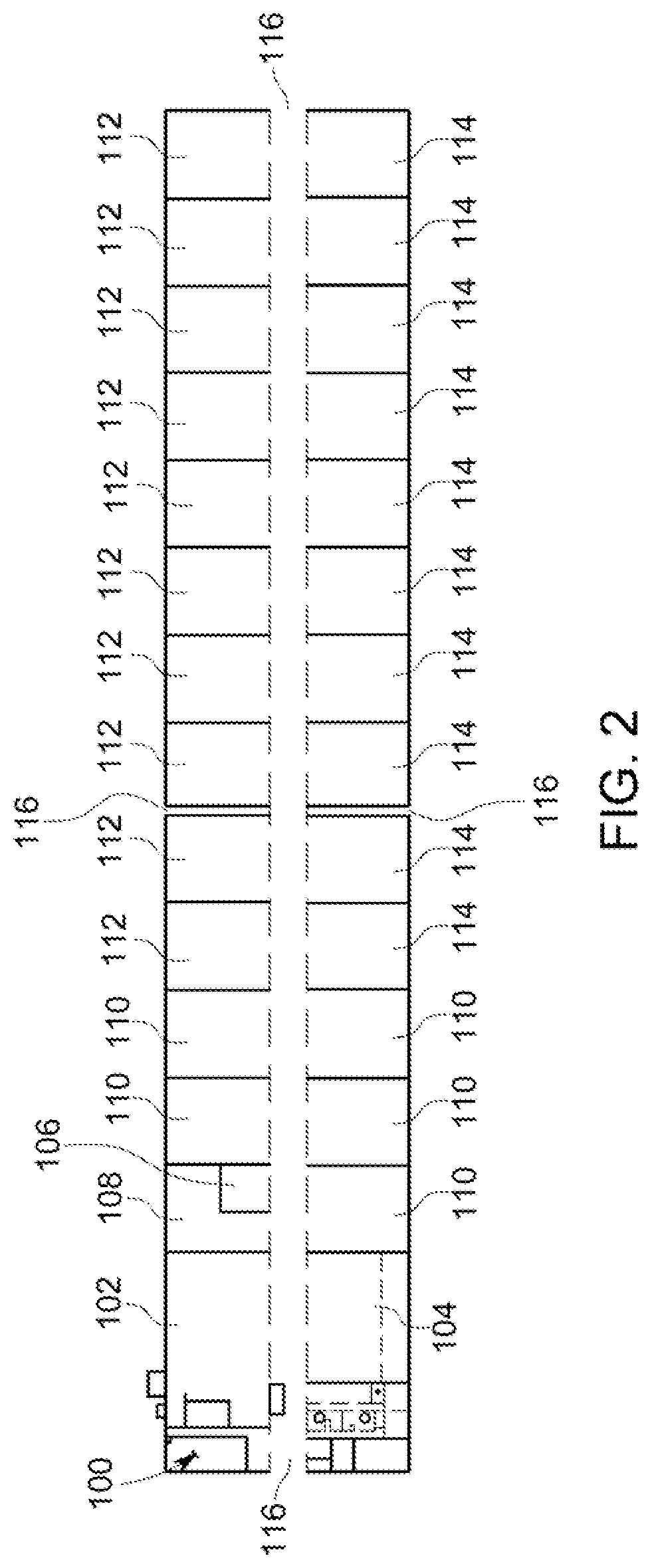

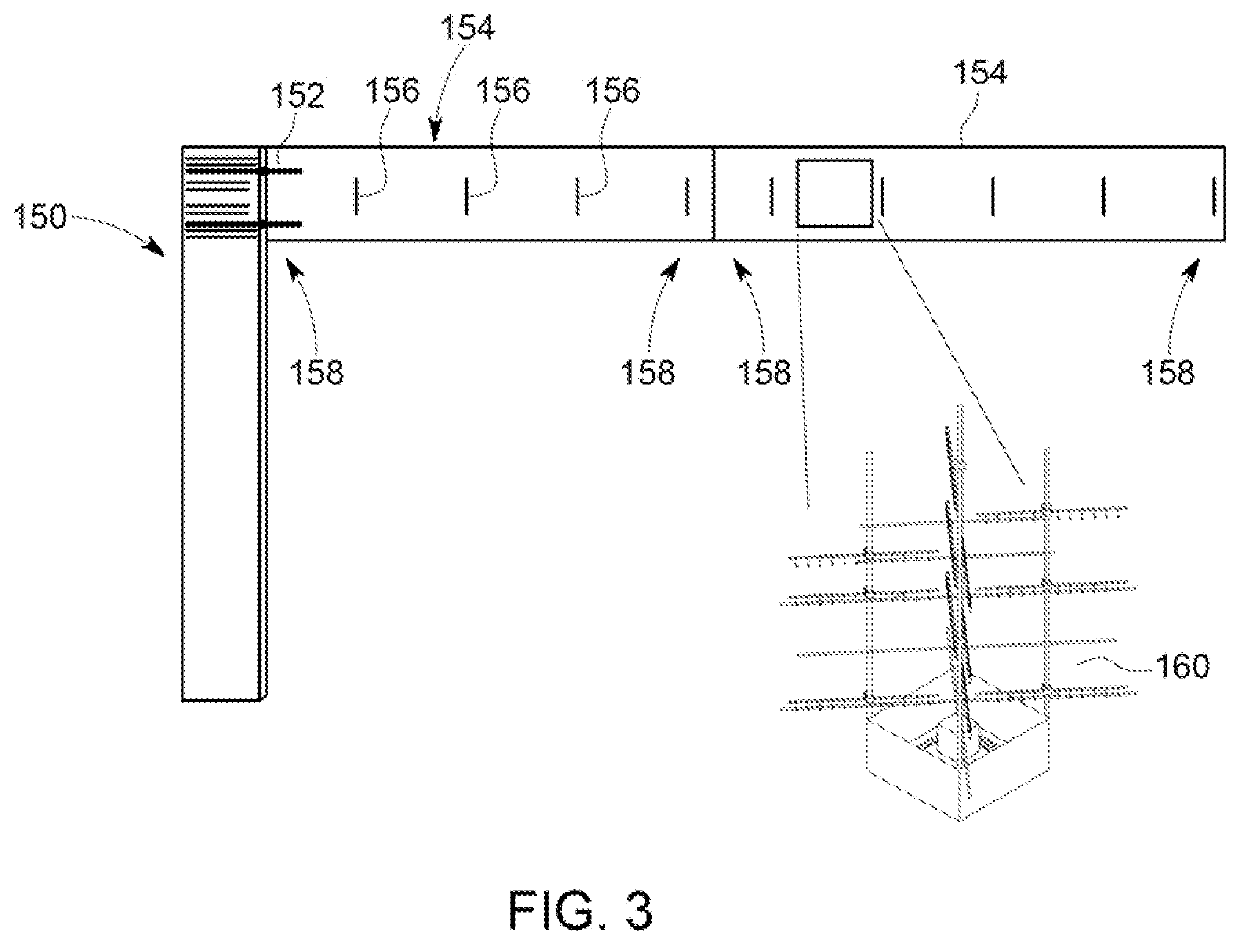

Tray and Trellis System for an Automated Farm with Robots Working on Plants

PendingUS20210243967A1Easy to manufactureLess timeProgramme-controlled manipulatorGraftingTineGrommet

A Tray and Trellis System includes vertical posts or legs, longitudinal members, and cross members. Combs include tines fixed at one end to longitudinal members on one side, and releasably engaged at their other end to other longitudinal members on the other side. Further combs include tines fixed to a cross member at one end, and releasably engaged to another cross member at the other end. There may be intermediate cross members having tines fixed to them and other tines releasably engaged to them. Fixation of the tines may be by clips, rings, welding, bonding, fastening, or by molding as a single piece. The releasably engaged ends of the tines may be engaged with snap-fit slot features in the longitudinal members, the cross members, or the clips or rings, or may be engaged with open grommets inserted into openings in the longitudinal members or cross members.

Owner:BARTROM MICHAEL +2

Ridging film-mulching planting method for potatoes

InactiveCN108901708AIncrease harvestImprove survival rate and increase harvestClimate change adaptationRoot crop cultivationWater savingSolanum tuberosum

The invention discloses a ridging film-mulching planting method for potatoes. The method comprises the following steps: block dicing and germination, soil selection and preparation, ridging and fertilization, seeding and film mulching, topdressing and management, seedling killing, harvesting and the like. Through film mulching, topdressing and management, yield reduction caused by excessive pestsin a late period and influences, caused by bad quality of the potatoes, on sales and eating are avoided, the moisture condition in soil can be maintained fully, and water can be prevented from evaporating; meanwhile, by arranging micro-ditches for collecting rain, the purposes of drought resistance and water saving are achieved, the potato yield is increased, plants and soil are supplemented withpotassium, supplementation of phosphate fertilizer can also be achieved, and the fertility level of the soil and the quality and yield of the potatoes are improved; when the method is compared an existing technique, the yield of the potatoes is improved greatly, better quality of the potatoes is ensured, eating and pollution by the pests are also avoided, and the method has great practicability and is worthy of promotion and application in the future.

Owner:民勤县金诚农业发展有限公司

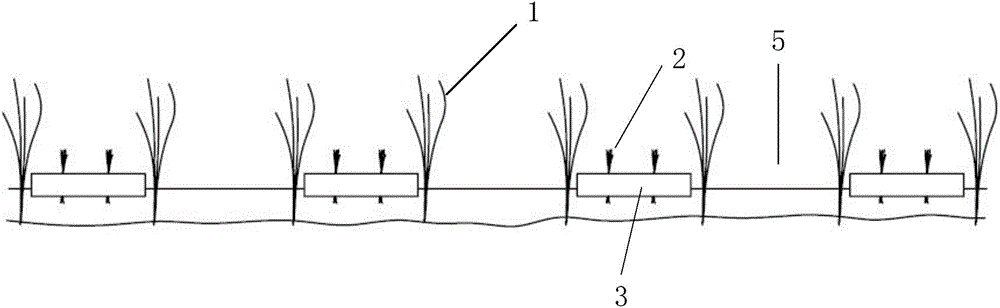

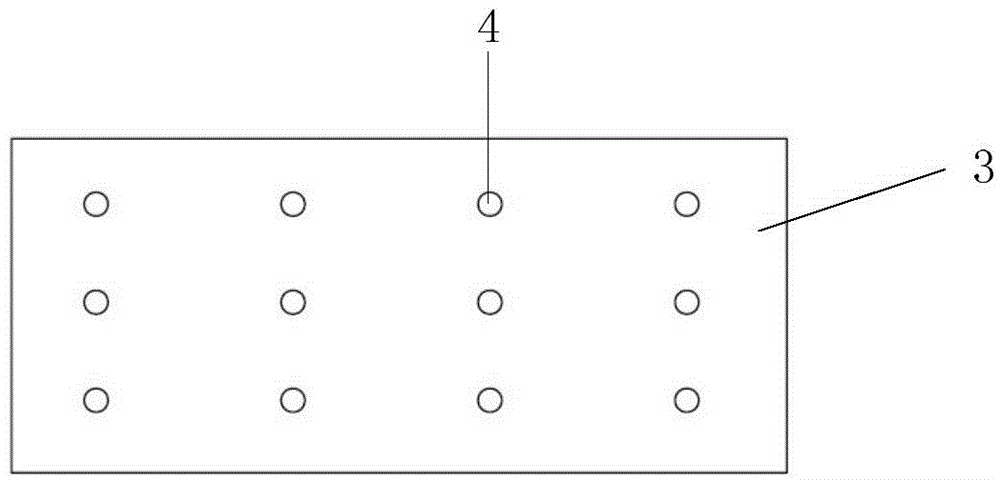

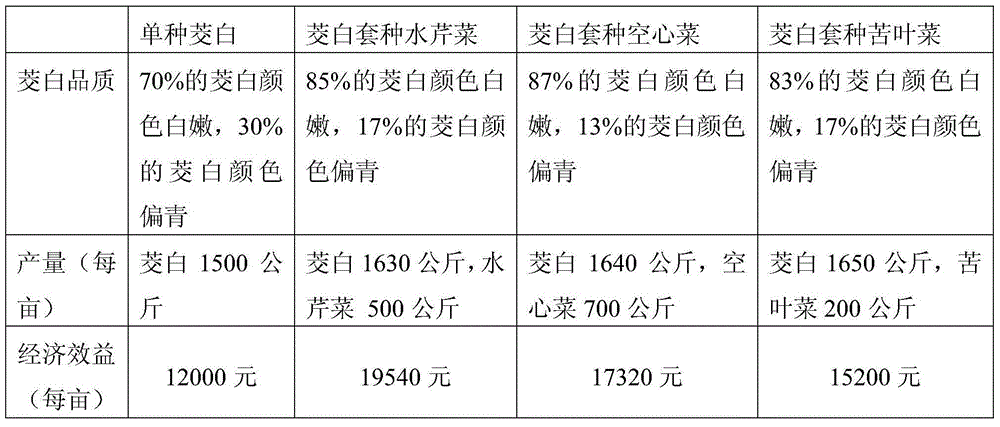

Interplanting method of water bamboo and aquatic vegetables

ActiveCN104350923AImprove qualityGrowth inhibitionPlant cultivationCultivating equipmentsSeedlingWeed

The invention relates to an interplanting method of water bamboo and aquatic vegetables. The interplanting method comprises the following steps: (1) modifying water bamboo field; (2) planting the water bamboo; (3) preparing a plurality of floating plates which are 3cm-8cm thick, wherein the length and the width of each floating plate are set according to the standards of not covering water bamboo seedlings and reserving the growth space of at least 20cm to 30cm for the water bamboo seedlings, a plurality of holes of each having the dimension of 2cm to 3cm are formed in each floating plate, and the space between every two adjacent holes is 10cm to 20cm; (4) laying the floating plates between the lines of the water bamboo seedlings at the seedling stage of the water bamboo without covering the water bamboo seedlings; picking passages for people to walk are further formed in the water bamboo field; the floating plates and the picking passages for people to walk are arranged alternately in order between the lines of the water bamboo seedlings; the aquatic vegetables are interplanted after the water bamboo seedlings are planted, and the aquatic vegetables are harvested in due time. The interplanting method of the water bamboo and the aquatic vegetables is capable of inhibiting the growth of weeds and avoiding weeding because of the interplanting of the aquatic vegetable.

Owner:金华市婺城区张俊华家庭农场

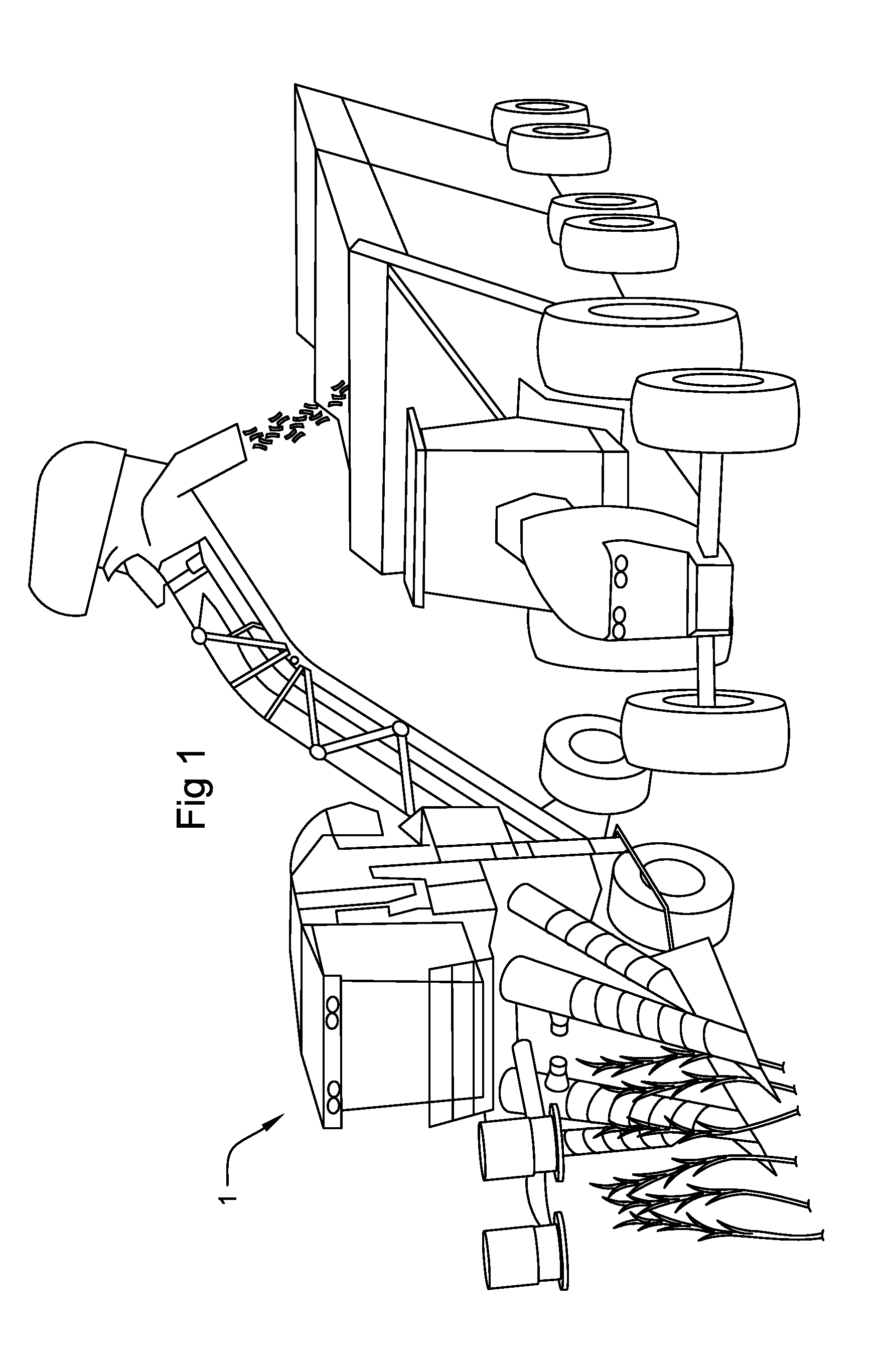

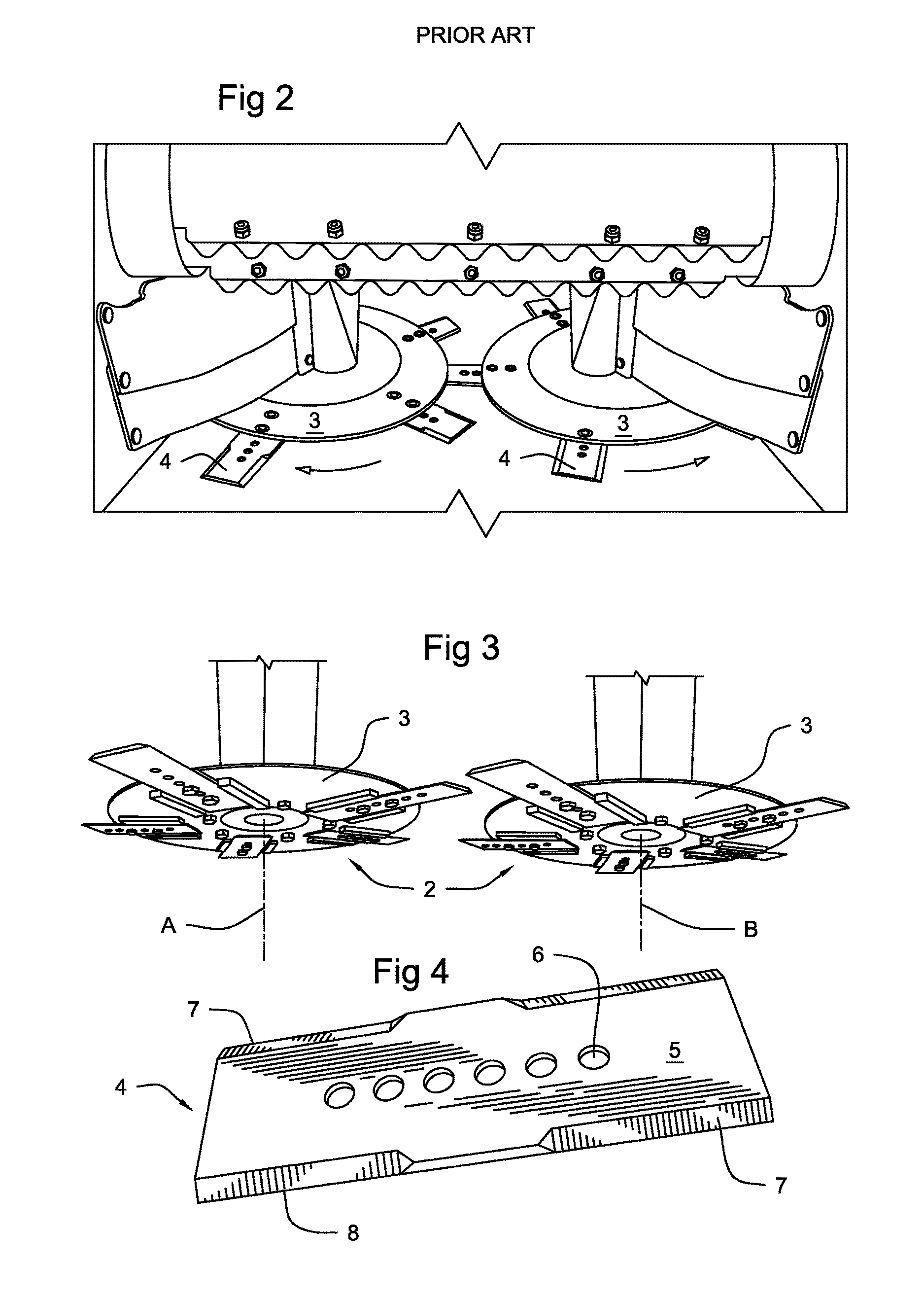

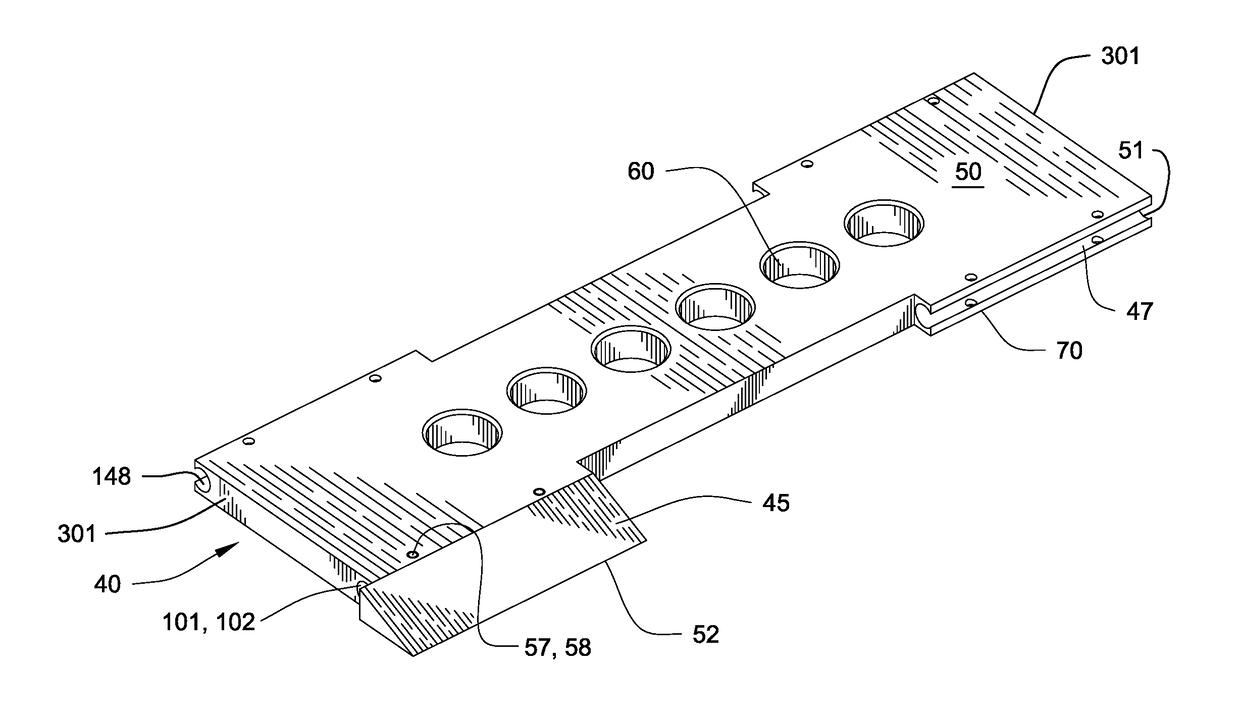

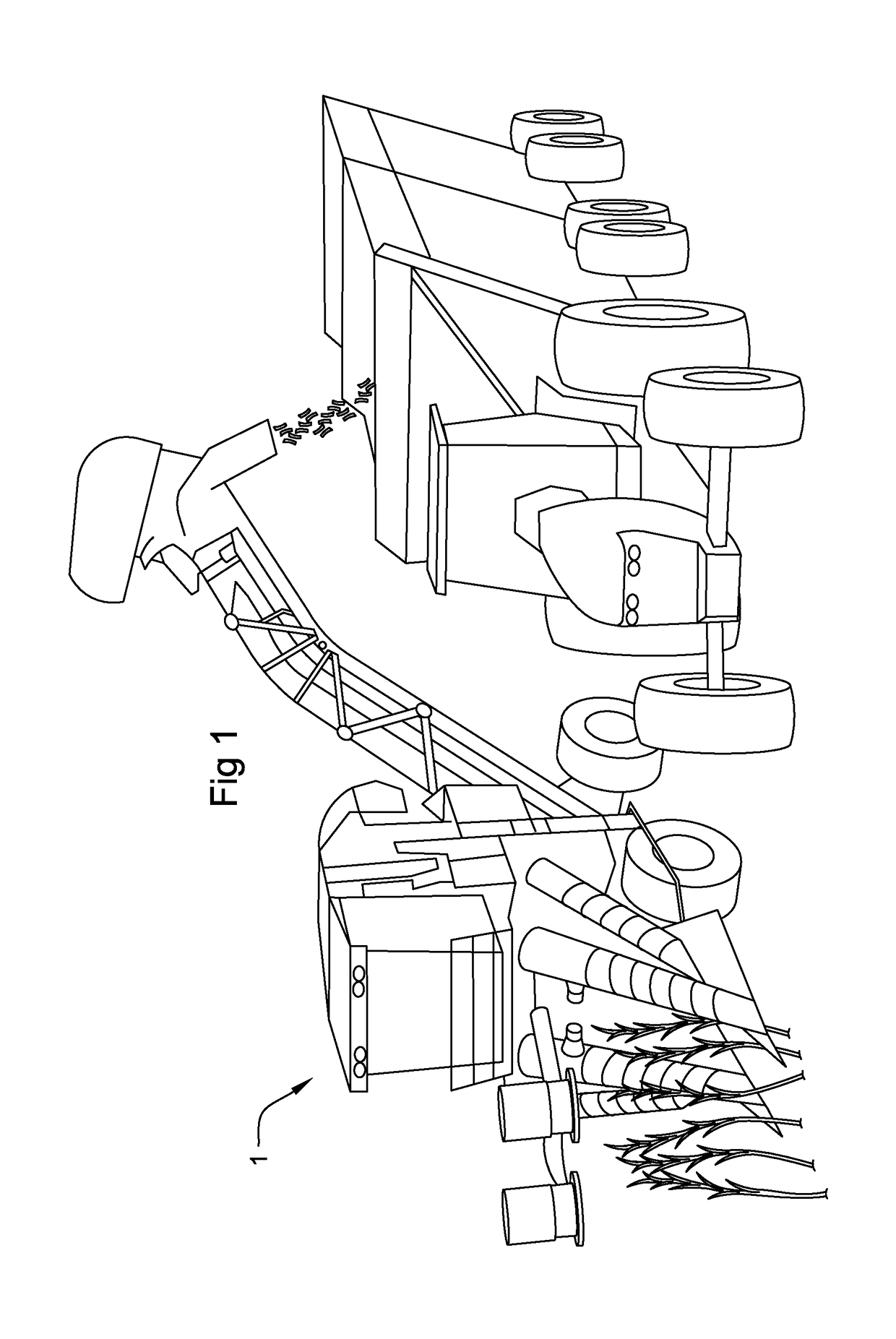

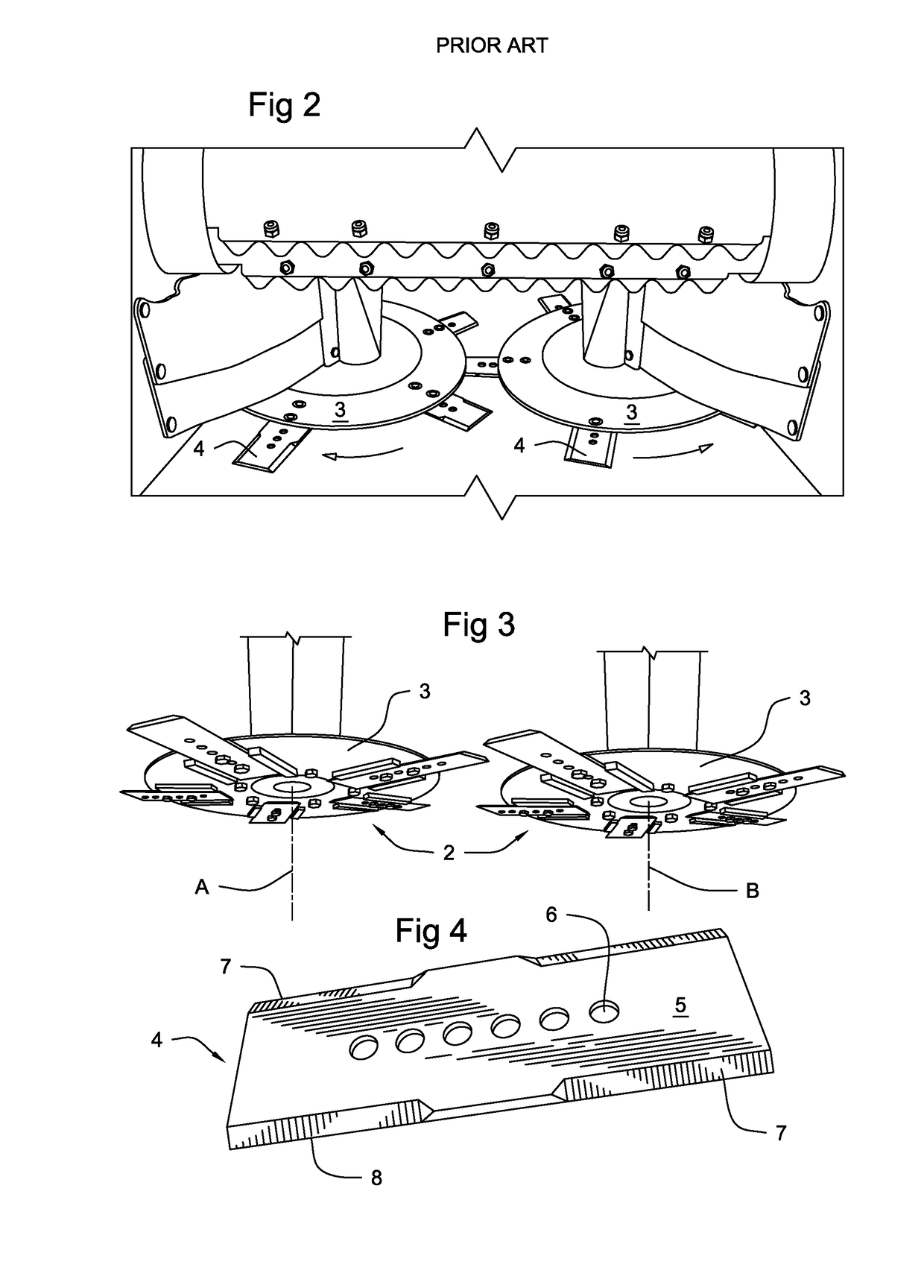

Base Cutter Blade

InactiveUS20160366822A1Quick changeMinimizes can be discarded and recycledMowersLeading edgeKnife blades

An improved base cutter blade suited for use in a sugar cane harvester. The preferred improved blade has a generally elongated flat body with opposing longitudinal edges. A removable, replaceable knife is also provided. The knife is made to releasably engage the leading edge of the body. Grooves are preferably centrally positioned in both edges of the body. In the preferred configuration, the knife dovetails with the portion of the groove corresponding to the leading edge of the body. Thus, the knife will perform most of the cutting work and bear the brunt of the wear suffered by the blade. When the knife becomes dull, only the knife need be replaced, which can be done quickly. This will save a significant amount of time during harvest operations. It will also reduce the amount of material that is consumed in the form of worn out blades.

Owner:CROMPION INT

Method for planting bupleurum chinense

InactiveCN106613075APrevent excessive growthPromote floweringSeed and root treatmentClimate change adaptationBiological regulationGreenhouse

The invention relates to the technical field of Chinese herbal medicine planting and particularly discloses a method for planting bupleurum chinense. The bupleurum chinense is planted in a greenhouse, and a transparent glass culture box is arranged at the top end of the greenhouse. The method includes the following steps of seed treatment, seed cutting and branching, growth management and spaced harvesting. A culture solution is contained in the glass culture box, and algae plants are bred in the culture solution. The method in the base case has the advantages that the algae plants are subjected to color light distribution according to the growth period of the bupleurum chinense, and pertinent light absorption of the bupleurum chinense is promoted; by means of the biological regulation capacity of the algae plants, the temperature difference in the greenhouse is reduced, and the environment is more suitable for growth of the bupleurum chinense; the bred algae plants can serve as new crop output, and crop planting diversification is promoted.

Owner:遵义盛远盈种植有限公司

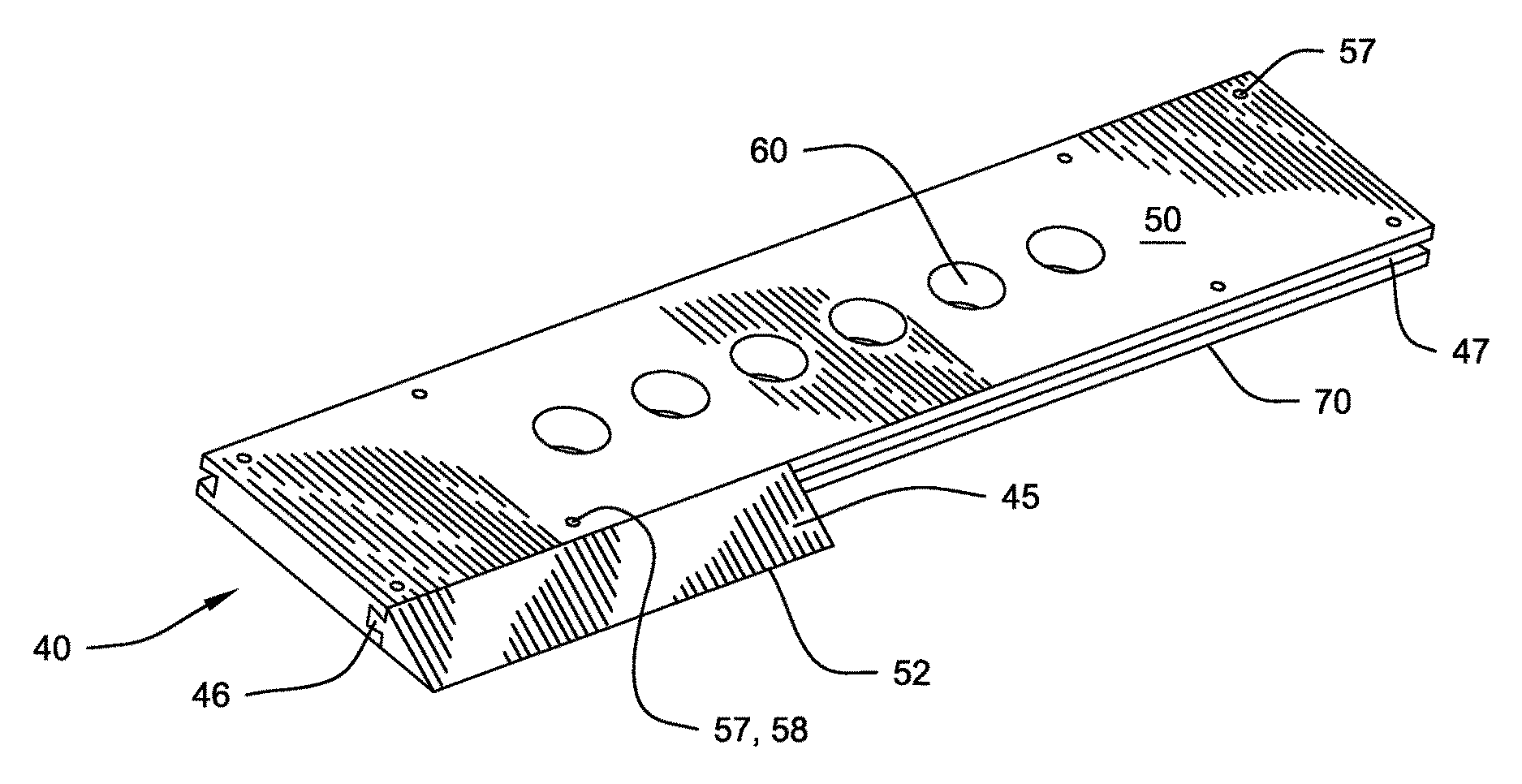

Base cutter blade

InactiveUS20180139901A1Quick changeMinimizes can be discarded and recycledMowersLeading edgeEngineering

An improved base cutter blade suited for use in a sugar cane harvester. The preferred improved blade has a generally elongated flat body with opposing longitudinal edges. A removable, replaceable knife is also provided. The knife is made to releasably engage the leading edge of the body. Thus, the knife will perform most of the cutting work and bear the brunt of the wear suffered by the blade. When the knife becomes dull, only the knife need be replaced, which can be done quickly. This will save a significant amount of time during harvest operations. It will also reduce the amount of material that is consumed in the form of worn out blades.

Owner:TEKO DON RILLO +1

Bamboo fungus culturing method

InactiveCN105393800AIncrease harvestLow priceCalcareous fertilisersCultivating equipmentsSucroseSaccharum

The invention discloses a bamboo fungus culturing method, a whole technology method comprising steps of hybridization, transplantation, maintenance, pluck, cleaning, drying and package as well as storage. Fungus raw material is made from 60% to 80% of broad-leaved tree sawdust, 8% to 12% of corn powder, 9% to 11% of rice bran, 2% to 5% of soybean powder, 0.5% to 3% of sugar and 0.5% to 3% of land plaster, so low price is required; a proper-adumbral forest land containing proper shade is selected for bamboo fungus culture; weeds around the bamboo fungus are removed in real time and the bamboo fungus is warmed at the proper temperature; and the bamboo fungus can be picked 70 to 90 days after transplantation. During the pluck and following-up drying process, fine technologies are employed, so high output of the bamboo fungus can be achieved after plantation; damages to the bamboo fungus due to improper pluck time or improper treatments during the pluck and cleaning processes can be avoided, so high benefits can be guaranteed.

Owner:ANHUI RUNHUA ECOLOGICAL FORESTRY CO LTD

Potted vegetable integral and simplified cultivation method

ActiveCN106376315ASimple methodEasy to operateCultivating equipmentsReceptacle cultivationFiberMicrowave

The invention discloses a potted vegetable integral and simplified cultivation method. The method comprises the following steps of 1) preparing a plantation box, 2) preparing a planting core formed by filling matrix, ecological fertilizer and soil all mixed together and baked via microwave, 3) planting vegetable seeds into a seedling nursing block or planting vegetable seedlings into the planting core, 4) remaining one vegetable seedling in each cave after seeds sprout out, 5) harvesting and eating in time when vegetables ripe. Either rape seed cakes, edible mushroom dregs or pig manure or more are biologically fermented and either turf, coconut fibers, perlite and earthworm mud or more are added to form the filling matrix. Vegetables can be planted by citizens on city floor top, balconies and platforms in an easy way by the use of the method; the method is simple, easy to operate and provide high survival rate; organic vegetables can be provided; a delicate outlet integrating all planting elements is purchased by citizens, and vegetables can be planted personally; and planting experience can be focused and citizens can enjoy the plantation process and harvest fun.

Owner:重庆市潼南区润绿农业开发服务中心

One-empty-in-two-ridge corn planting method

InactiveCN105325136AAchieving high-yield creation goalsGood ventilation and light transmissionFertilising methodsHorticultureControlled releaseRidge

The invention relates to a one-empty-in-two-ridge corn planting method. The method comprises the following steps: (1) preparing land; (2) selecting seeds; (3) performing coating; (4) sowing according to a one-empty-in-two-ridge method; (5) applying fertilizer, using BB fertilizer or slow / controlled-release fertilizer according to a detection result; (6) irrigating; (7) performing field management; (8) harvesting. Compared with the prior art, the beneficial effects of the method are that the method is characterized by simple, scientific, and rational, and the method effectively uses an empty ridge method to realize a marginal effect, so as to increase field ventilation and light penetrating amount and improve growing environment of corns, the method uses a high photosynthetic efficiency principle to realize a planting mode of ridges are border rows and plants are land, thereby improving utilization rate of illumination and accumulated temperature; since fertilizing amount is concentrated, being beneficial for corns to fully absorb intensively, thereby improving utilization rate of fertilizer, preventing problems of excessive or insufficient fertilization, improving corn yield and cultivated land quality, and the method has wide promotional value.

Owner:李振明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com