Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

249results about How to "Increase powder yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

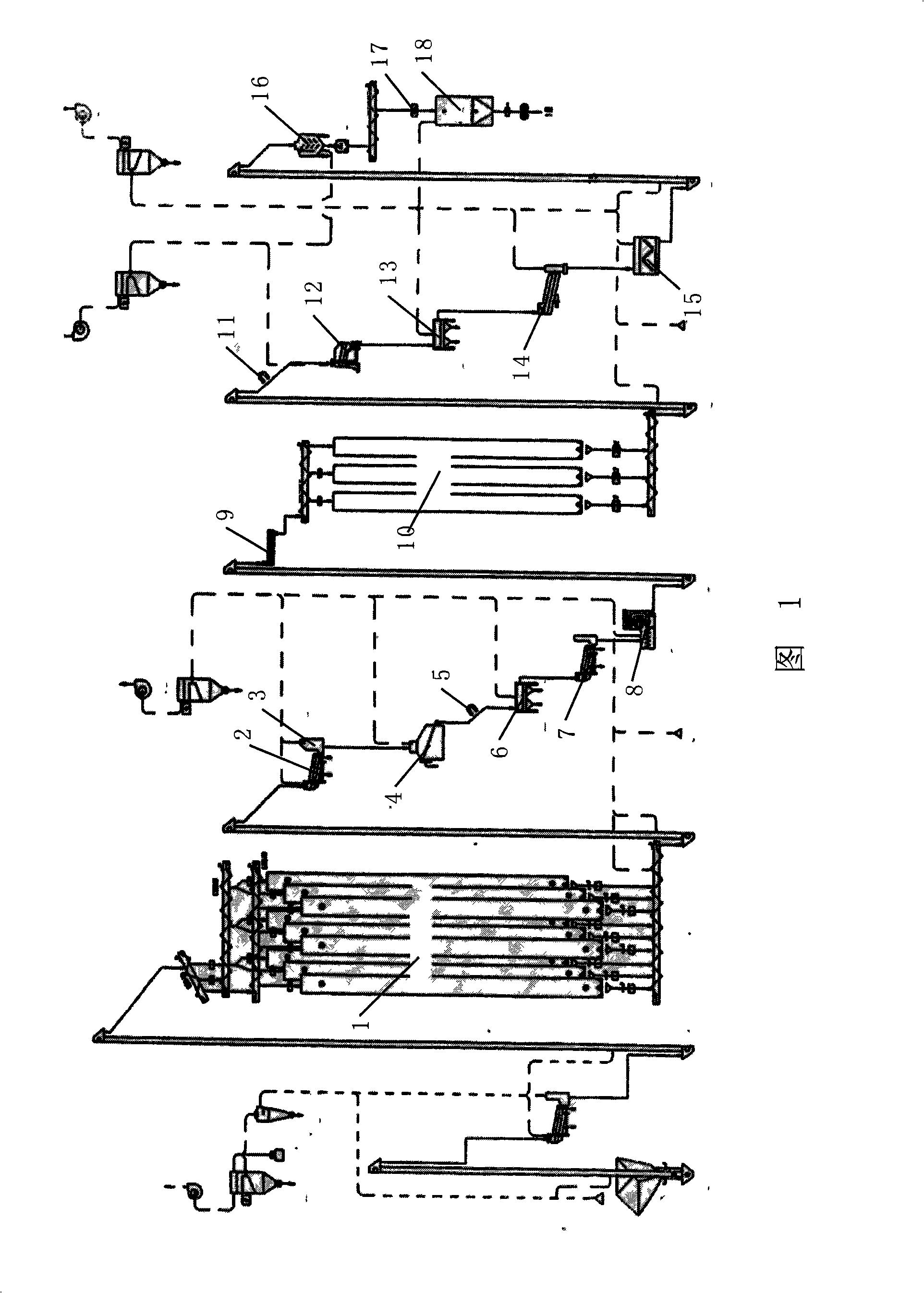

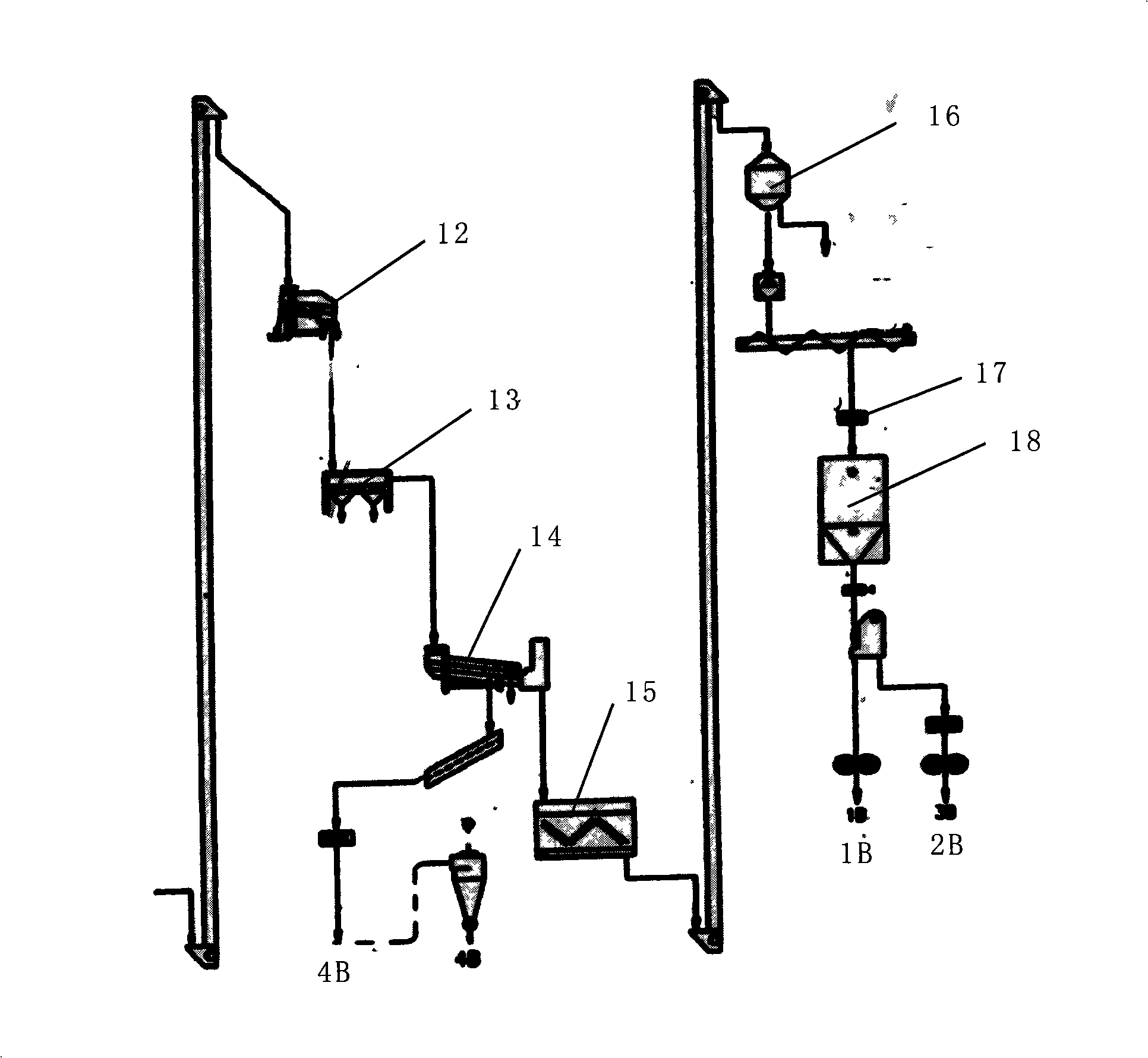

Wheat cleaning and classifying process for flour milling of stone grinder

InactiveCN101342502AReduce bran starLow ashGas current separationGrain millingFood safetyEngineering

The invention relates to a grading technique for cleaning wheat-grains during the process of flour milling by a stone mill. The technical process includes that the wheat grains in compliance with the flour processing quality are processed by a wheat-grain receiving system, a coarse wheat-grain clearing system, a tempering system and a wheat-grain cleaning system. A graded specific-gravity stoner, a suction separator and a screening device are used to clean and process the wheat-grains in a graded manner according to the quality, the lightweight and heavyweight of the wheat grains. Compared with the traditional cleaning techniques, the invention can effectively separate the heavy-weight and light-weight wheat grains; separate the epidermises and the matters attached on the wheat grains to the largest extent; lower the residue of pesticide and microorganism in the flour, and reduce the bran quantity and dust content in the flour; as a result, the purity of the milled material is ensured, the milling effect and flour yield are improved, and the flour processing precision and food safety are enhanced.

Owner:宁夏长湖实业有限公司

Flour processing technology

InactiveCN104646087AIncrease powder yieldImprove completenessGrain treatmentsMaterials preparationWheat Brans

The invention relates to the field of food, in particular to a flour processing technology. The flour processing technology comprises the following steps of (1) material preparation; (2) clean wheat proportion; (3) wheat wetting; (4) grinding; (5) powder purification; (6) flour blending. According to the flour processing technology, the problem that some smaller particles in materials, which are processed by 9 reduction roller mills, 6 shelling mills and a purifier, are difficultly grinded sufficiently in a tail mill in the grinding process is solved. The flour processing technology has the advantages that the smaller particles are grinded more sufficiently by utilization of impact mills, so that the flour yield is improved, the integrity rate of wheat bran is improved at the same time, and the quality of flour and by-products are guaranteed.

Owner:山东津宜润德面业有限公司

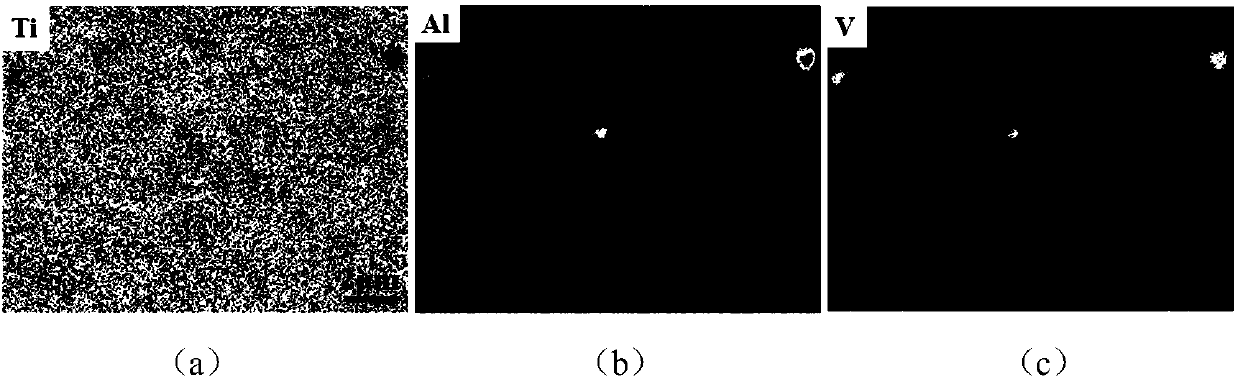

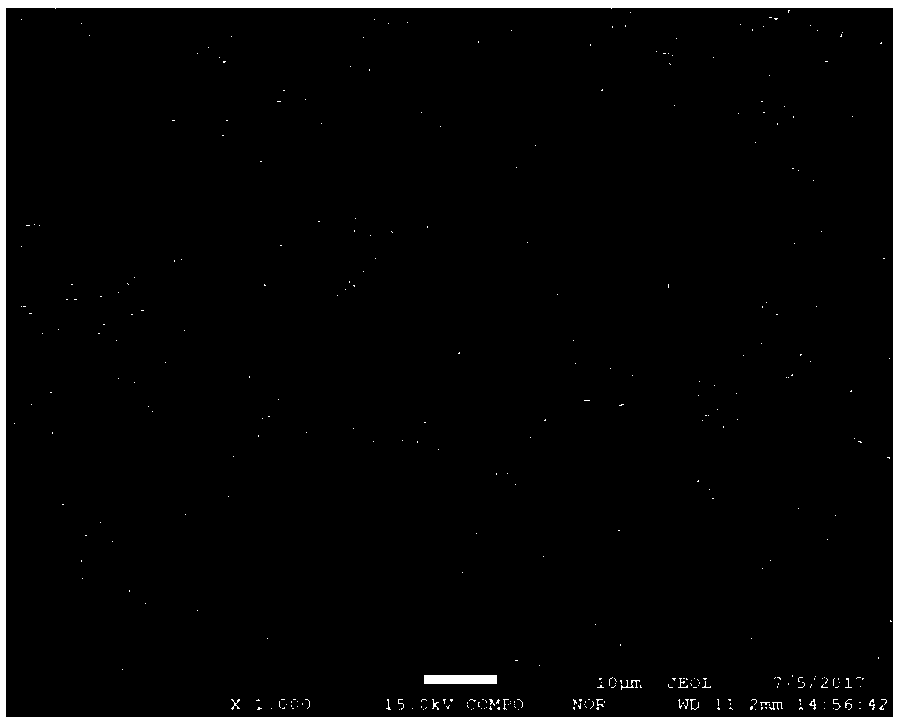

Method for manufacturing titanium and titanium alloy and part thereof by taking hydrogenated sponge titanium as raw material

InactiveCN107760897AGood for controlling oxygen contentImprove compactnessTransportation and packagingMetal-working apparatusTitanium alloyTitanium powder

The invention belongs to the technical field of preparing and processing of titanium and a titanium alloy, and particularly relates to a method for manufacturing titanium and titanium alloy and part thereof by taking hydrogenated sponge titanium as a raw material. The method comprises the following steps: hydrogenating sponge titanium; synchronously ball-milling to prepare hydrogenated titanium powder or mixed powder; pressing the powder; quickly sintering and synchronously dehydrogenizing; thermally mechanically solidifying or forming; performing complete vacuum dehydrogenizing; and obtainingan alloy product. The method realizes synchronously ball-milling to prepare mixed powder from hydrogenated sponge titanium and alloying raw materials, and the powder does not need to screen, so thatthe powder yield is greater than 96%; and under protection of inert atmosphere, pressing, quick heating and alloying, thermal mechanical solidifying and forming are completed. The method is short in process flow, is high in efficiency, can prepare the titanium and the titanium product with high compaction (greater than or equal to 99.8%) and low oxygen content (lower than or equal to 0.26%); mainmechanical properties of the alloy are higher than level of common deformed titanium alloy; and cost is obviously lower than that of conventional powder metallurgical titanium alloy.

Owner:NORTHEASTERN UNIV

Rice vermicelli production technique

The invention provides a preparing process for rice flour, and relates to a preparing process for foodstuff, which is characterized in that the preparing process includes steps of selecting raw materials, washing, soaking the raw materials, draining, grinding into slurry, kneading, boiling, squeezing into filament, and airing. The preparing process for rice flour has advantages of industrial production, long storage life, novel process, high rice flour yield, good toughness and good taste.

Owner:TIANJIN ZHONGYING HEALTH FOOD

Apricot solid drink and preparation method thereof

InactiveCN101536805AIncrease the juice yieldGood instant solubilityFood preparationCarboxymethyl celluloseAdditive ingredient

The invention relates to an apricot solid drink and a preparation method thereof. The ingredients of the apricot solid drink are 10-50% of apricot powder, 20-60% of maltodextrin, 10-30% of saccharose, 0.05-0.10% of citric acid, 0.1-0.2% of xanthan gum, 0.1-0.3% of sodium carboxymethyl cellulose, 0.03-0.1% of sodium alginate and 0.5-1.4% of amorphous silicon dioxide. The preparation method comprises the steps of pre-treating, washing and colour-protecting, blanching and cooling, pulping, zymohydrolysis, glue milling, homogenizing, spray drying, material mixing and granulating, packaging, and sterilizing. The solid drink has high fruit content, natural flavour, excellent stability, and convenient carry and use, thereby meeting requirements of modern consumption and having broad market prospect.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Gradient wheat wetting process

The invention discloses a gradient wheat wetting process, and belongs to the technical field of processing of wheat powder. Ultrasound, microwaves, refrigeration and functional wheat wetting solution are combined to perform gradient wheat wetting for wheat grains by three times, so that the separation of bran from wheat germs is improved, the evacuating degree and the permeation capacity between such structures as wheat grain epidermises, seed coats, germs and endosperm, and macromolecular nutrient substances are improved, the water permeation speed is accelerated, the total wheat wetting process time is shortened to 6-12 h, the flour yield is 78.5-79.5%, the oxidation resistance and the nutrient value of flour are improved, the appearance quality, the physicochemical quality and the food safety of wheat flour are improved, the consumption of such processes as subsequent flour milling is reduced, the production cost is reduced, and a new road is sought for the wheat wetting process.

Owner:宁夏鑫德粮油工贸有限公司

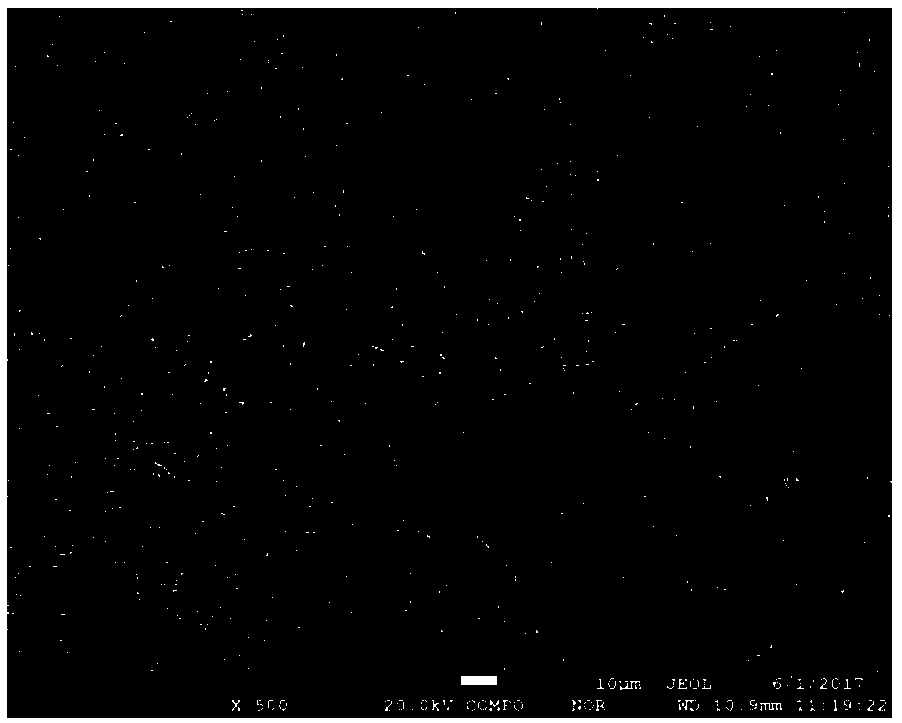

Method for preparing selenium-enriched deodorized supermicro garlic powder

InactiveCN1554279AImprove processing qualityAdd functional ingredientsFood preparationWater contentFreeze dry

The present invention relates to deep agricultural product processing and functional food. The preparation process of selenium-enriched deodorized superfine garlic powder includes the steps of: slicing garlic, constant temperature soaking in selenium solution to reach selenium content of 0.5-0.8 microgram / g, vacuum freeze drying to water content below 2% to reach selenium content of 3.6-5.8 microgram / g, three-stage crushing to average size below 10 micron, and final oxygen eliminating packing. The said process can maintain the active components in garlic, eliminate the bad smell of garlic, and make the garlic powder easy to be absorbed by human body.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

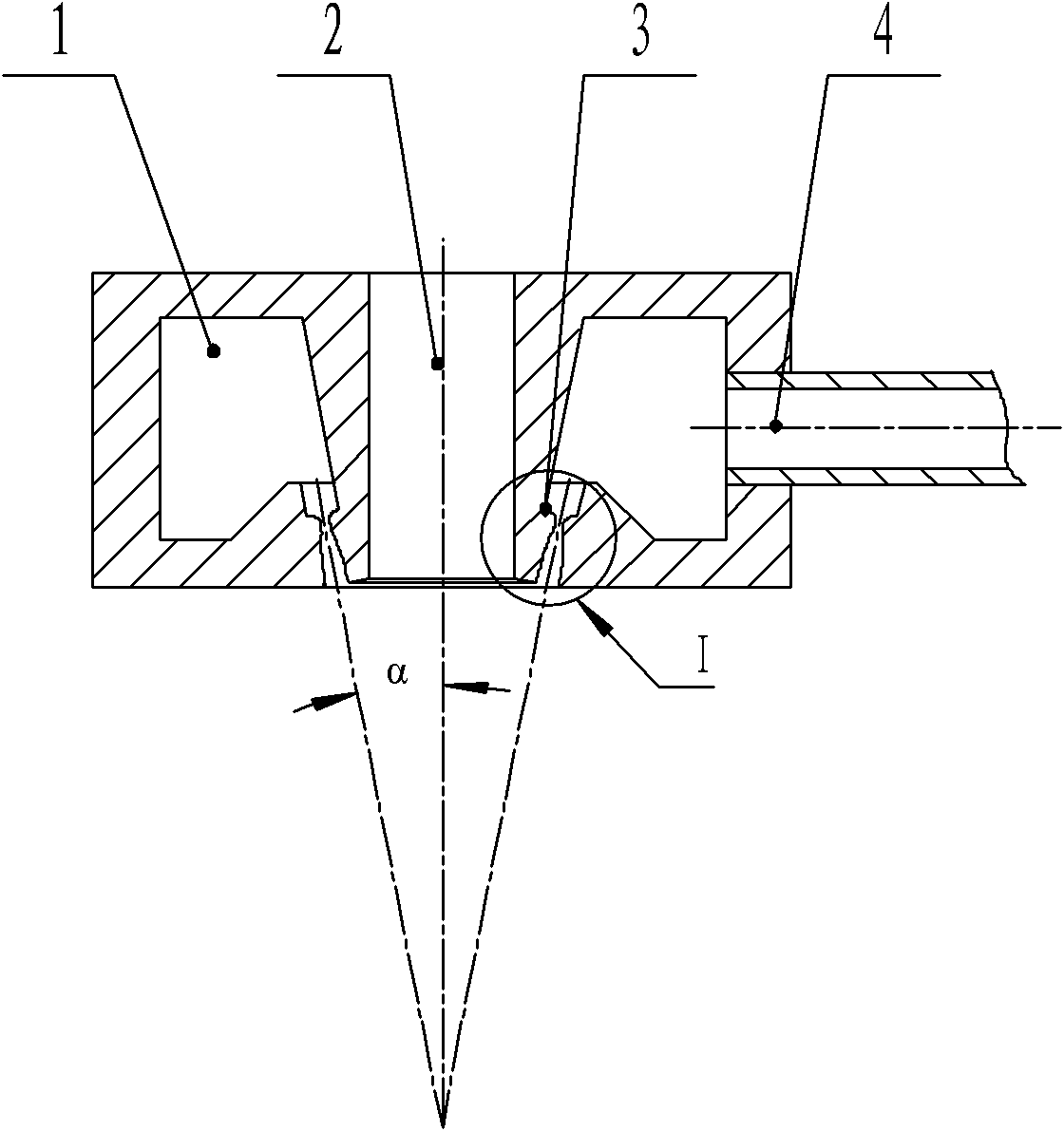

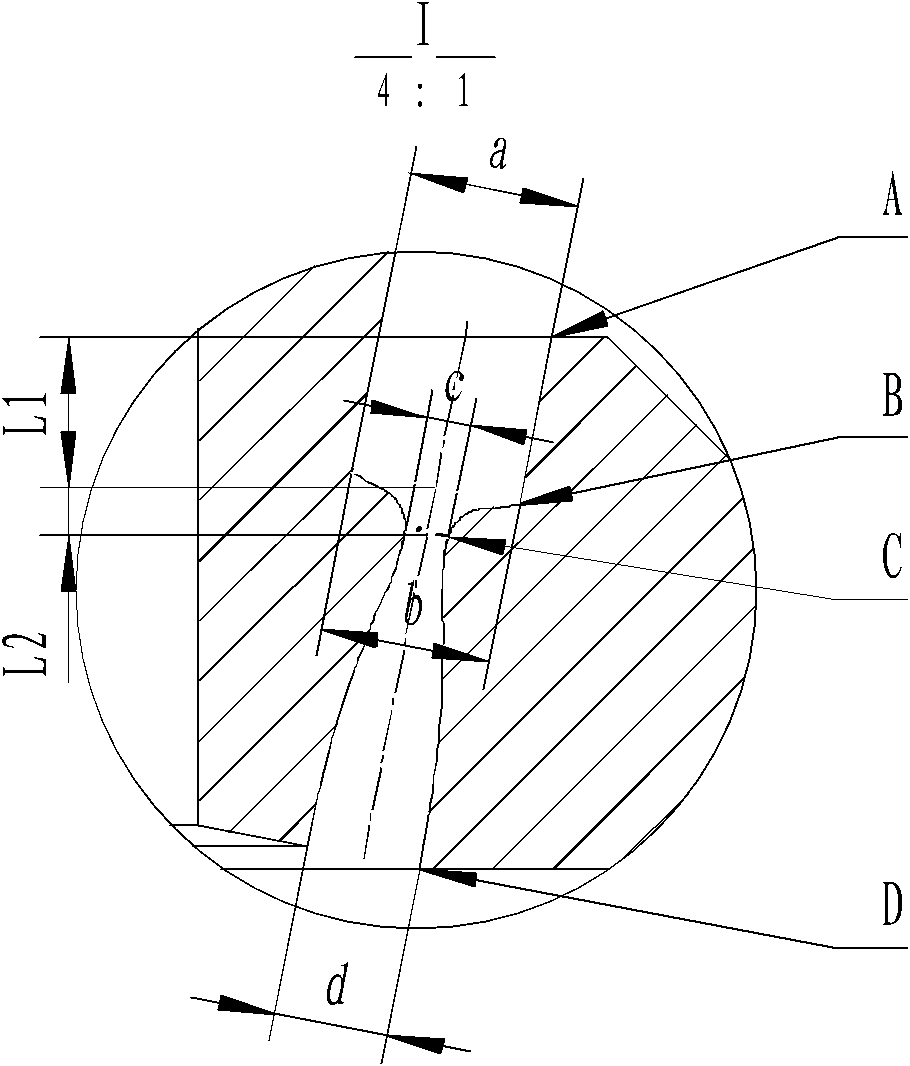

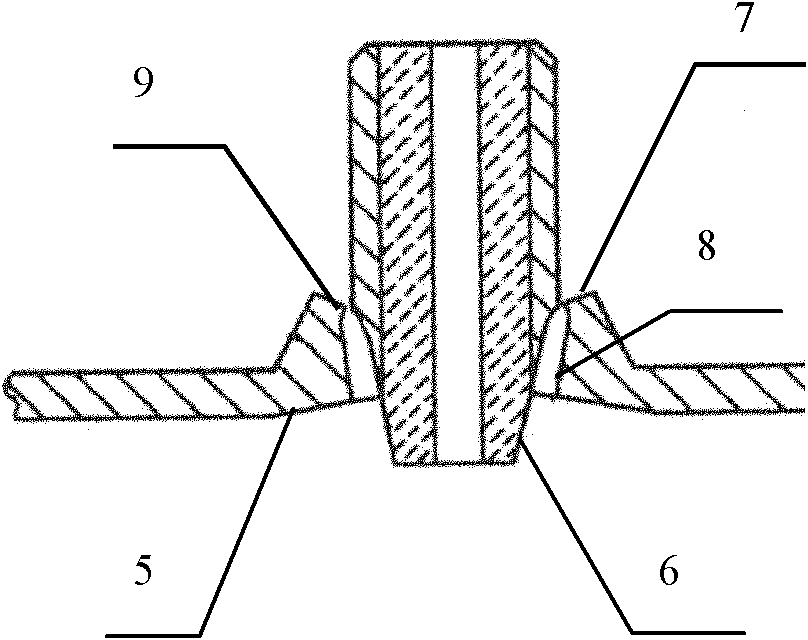

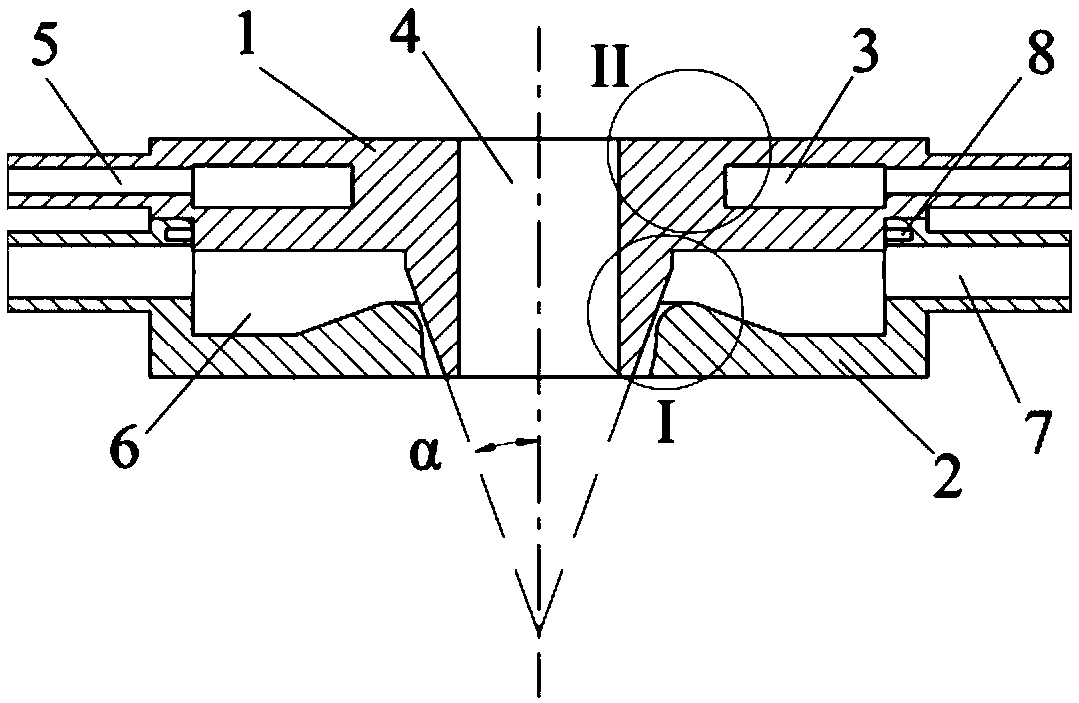

Circumferential seam type supersonic nozzle for metal gas atomization

ActiveCN102581291AUniform velocity distributionReduce turbulenceLiquid spraying apparatusShock waveGas cylinder

A circumferential seam type supersonic nozzle for metal gas atomization comprises a gas inlet pipe (4) connected with an external gas bottle. The gas inlet pipe is connected with an annular gas chamber (1) of the nozzle, the center of the nozzle is provided with a central hole (2), a supersonic gas spray pipe (3) of a circumferential seam structure is formed on the inner chamber wall and the outer chamber wall below the gas chamber and comprises stabilizing sections, contracting sections, throats and diffusion sections, a seam profile consists of symmetric curves, the profile of the whole spray pipe is the seam profile formed by the curves AB, BC and CD to take the axis of central hole (2) as the symmetry axis, the profile rotates by 360 degrees around the axis of the central hole (2) so that a curved surface is obtained, and an included angle alpha ranging from 0 degree to 6 degrees but not equal to 0 degree is formed by an extension line of a central line of each seam passage and the axis of the central hole of the nozzle in the profile of the gas spray pipe (3) passing through the axis of the central hole of the nozzle. The supersonic nozzle for gas atomization has the advantages that gas flow is uniform, turbulence level is low, and shock waves are absent in a flow field.

Owner:有研增材技术有限公司

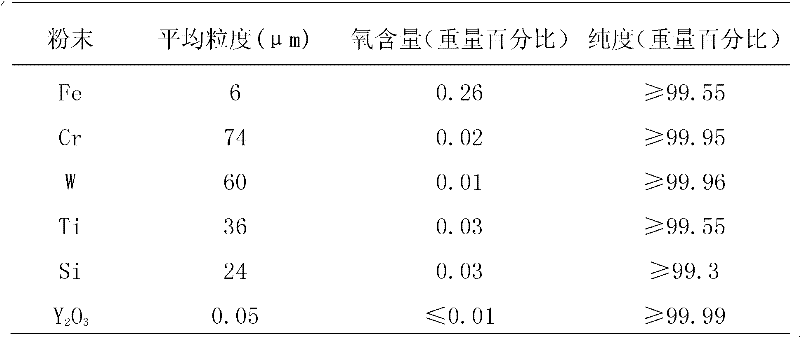

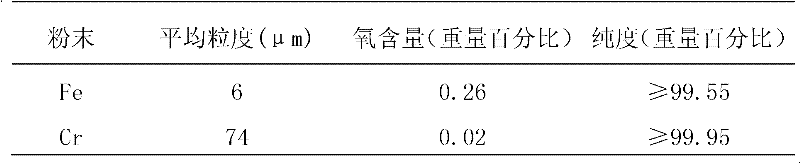

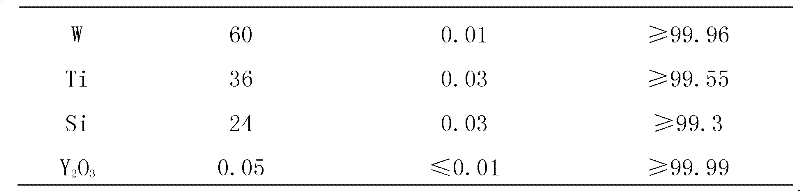

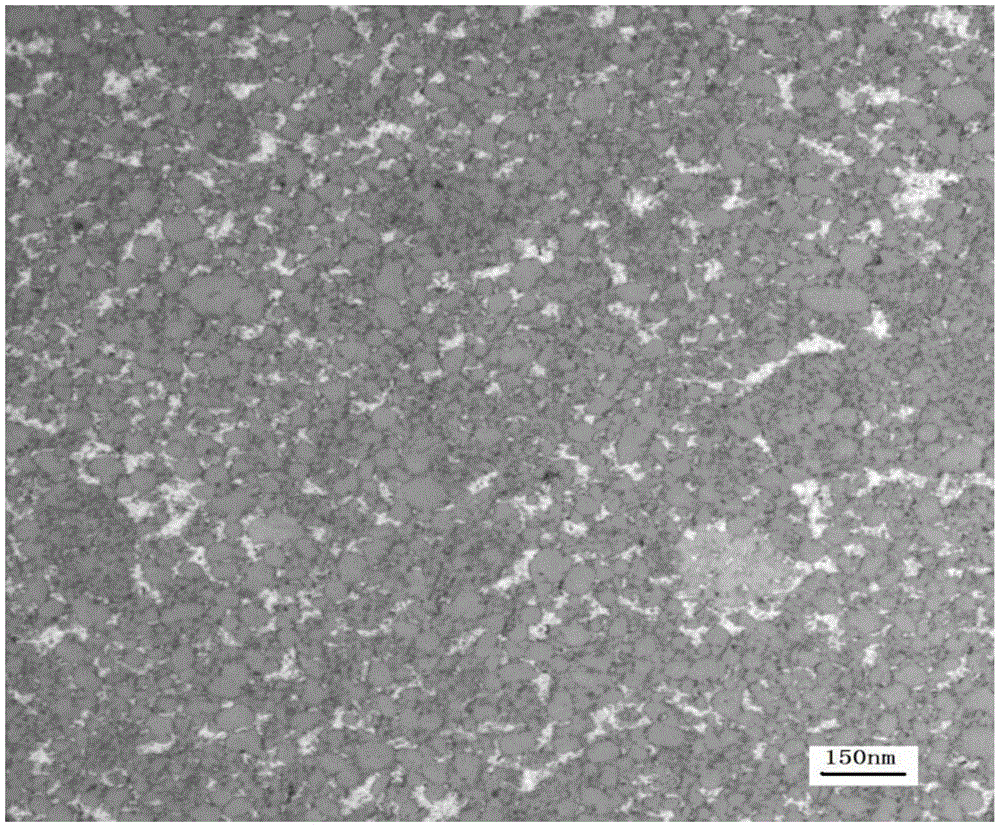

A kind of anti-oxidation iron-based superalloy and preparation method thereof

InactiveCN102286694AIncrease working temperatureIncrease productivityNuclear fusionOxidation resistant

An anti-oxidation iron-based superalloy and a preparation method thereof, which belong to superalloys and a preparation method thereof, solve the problem of unsatisfactory oxidation resistance of existing iron-based superalloys under high-temperature conditions, so as to improve serviceability and broaden high-temperature application fields. The anti-oxidation iron-based superalloy of the present invention has the composition mass percentages of: 12%≤Cr≤14%, 2%≤W≤3%, 0.3%≤Ti≤0.4%, 0.2%≤Si≤2%, 0.25%≤ Y2O3≤0.3%, the balance is Fe; it is made by mechanical alloying, molding and vacuum sintering, and the matrix of the final sintered body is α-(Fe, Cr) single-phase solid solution with uniformly distributed oxides in the matrix. The invention has high production efficiency and low cost, and the prepared anti-oxidation iron-based superalloy has reduced oxidation weight gain and improved anti-oxidation ability under the atmospheric condition of 850°C; the tensile strength at room temperature is ≥600MPa, and the elongation rate is ≥25%, which meets the requirements of automobiles. Requirements for the use of high-temperature structural parts such as engines and gas turbines, nuclear fission fuel cladding tubes, and first wall structural materials of nuclear fusion reactors.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of instant tea powder

The invention discloses a preparation method of instant tea powder. The preparation method comprises the following steps: (1) inoculating Aspergillus niger and aspergillus oryzae strains into a Czapek Dox Agar medium for activation; (2) directly inoculating activated strains into a tea solid medium for fermentation, thereby obtaining a tea semi-finished product, or inoculating activated strains into a fermentation medium for fermentation so as to obtain fermentation liquor rich in cellulose, pectinase, tannase and protease; (3) directly extracting the tea semi-finished product obtained in the step (2), thereby obtaining a tea extracting solution with high brix degree; or adding fermentation liquor obtained in the step (2) in the tea extracting process to obtain a tea extracting solution with high brix degree; and (4) filtering, clarifying, condensing and drying the tea extracting solution obtained in the step (3) so as to obtain the instant tea powder. The preparation method disclosed by the invention is low in cost, wild in extraction condition, and is capable of not only greatly improving the tea extraction rate, but also greatly preserving thermal-sensitivity ingredients in tea leaves, thereby obtaining high-fragrance instant tea.

Owner:南京融点食品科技有限公司

Red-core dragon fruit all-fruit powder and preparation method thereof

InactiveCN103549315AIncrease powder yieldSimple preparation processMulti-step food processesFood shapingBiotechnologyDietary fiber

The invention relates to the technical field of food processing, and mainly relates to red-core dragon fruit all-fruit powder and a preparation method thereof. The red-core dragon fruit all-fruit powder is prepared by adopting the step of carrying out freeze-drying or spray-drying after red-core dragon fruit pulp and beta-cyclodextrin are mixed, wherein the red-core dragon fruit pulp is prepared by peeling and pulping fresh or freezing red-core dragon fruits, the adding amount of the beta-cyclodextrin is 0.2-1.0 percent of the dry weight of the red-core dragon fruit pulp, and the red-core dragon fruit all-fruit powder has the characteristics that the content of betanin is not less than 3.4mg / g, the water content is not more than 4.5 percent, the rehydration ratio is 8.0-10, the content of dietary fibers is not less than 11.0 percent, and the fatty acid content is not less than 7 percent. The red-core dragon fruit all-fruit powder provided by the invention is pure-natural all-nutrition fruit powder, ensures the instant effect and the mouth feel and the special flavor of the red-core dragon fruit, brings convenience for storage, transportation and carrying, and is wider in market prospect.

Owner:ZHEJIANG NORMAL UNIVERSITY

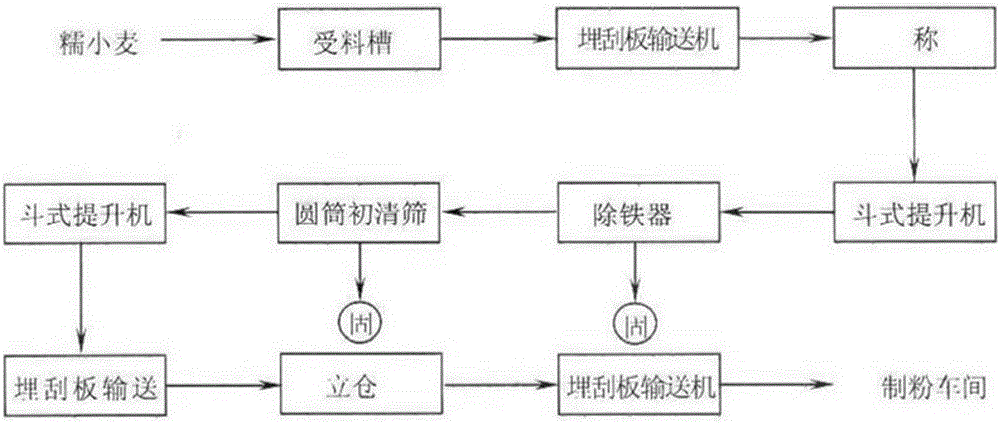

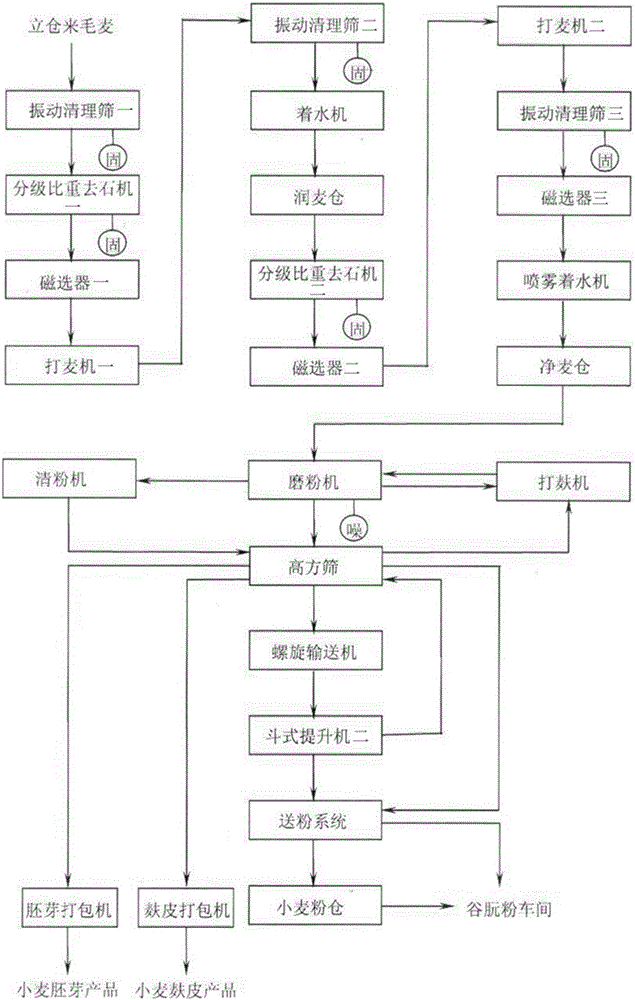

Waxy wheat flour milling technological method

The invention discloses a waxy wheat flour milling technological method. The method comprises the following steps of (1) wheat cleaning; (2) wheat wetting including secondary wheat wetting; and (3) break milling and flour purification. Compared with the prior art, the method has the advantages that damage to starch particles and protein can be reduced in the wheat flour milling process by means of the technological method, the flour yield can be increased, and energy consumption can be reduced.

Owner:丽江心联欣粮油贸易有限公司 +2

Wheat flour containing wheat aleurone layer and preparation method of wheat flour

InactiveCN103876024AFull of nutritionSimple processingFood preparationSuperfine grindingWheat aleurone

The invention discloses a preparation method of wheat flour containing a wheat aleurone layer. The preparation method comprises the following steps: slightly removing a phloem layer accounting for 5.5%-6% by mass of wheat from the wheat to obtain wheat grains with the wheat aleurone layer; screening the wheat grains with the wheat aleurone layer by sieves with different mesh numbers to extract the wheat aleurone layer; performing superfine grinding on the aleurone layer by adopting a superfine grinding technology, uniformly feeding the ground materials into a check sieve for screening, and adding the screened materials into the flour. According to the preparation method, a novel peeling technology, the superfine grinding technology and a wheat aleurone layer extracting and adding technology are organically combined, and the aleurone layer is applied to the flour industry, so that the nutritional element content of the flour is relatively high and the requirements of people are met.

Owner:王定文

Nanometer tungsten carbide silver contact material and manufacturing method

A nano-tungsten carbide silver contact material and a preparation method thereof, wherein the tungsten carbide silver contact material is mainly composed of tungsten carbide powder, nickel powder, silver powder and stearic acid powder and is ball-milled to obtain a nano-WC / Ag composite powder, After reduction, pressing, sintering, re-pressing, and re-firing, nano-tungsten carbide silver electrical contacts are obtained. The weight ratio of tungsten carbide to silver is 40-80:20-60, and the particle size of the tungsten carbide phase is 50-500nm; The addition of the nickel powder is 0-2% of the mass percentage of the tungsten carbide powder; the addition of the stearic acid powder is 0.5-5% of the mass percentage of the tungsten carbide-silver-nickel mixed powder; the preparation method is: Weigh tungsten carbide powder and nickel powder, cemented carbide balls and alcohol according to the proportion and place them in a planetary high-energy ball mill for 12-72 hours. Take out the mixed powder and dry it, mix it with silver powder and stearic acid powder in a specific proportion and place it on a planetary ball mill. Milled in a high-energy ball mill for another 6-24 hours, the nano-WC / Ag composite powder obtained after ball milling is processed by reduction, pressing, sintering, re-pressing, and re-sintering to obtain uniform structure, high density, high hardness, and good electrical conductivity. , Nano-tungsten carbide silver electrical contacts with good anti-welding properties.

Owner:ZHEJIANG YATONG METAL CERAMICS

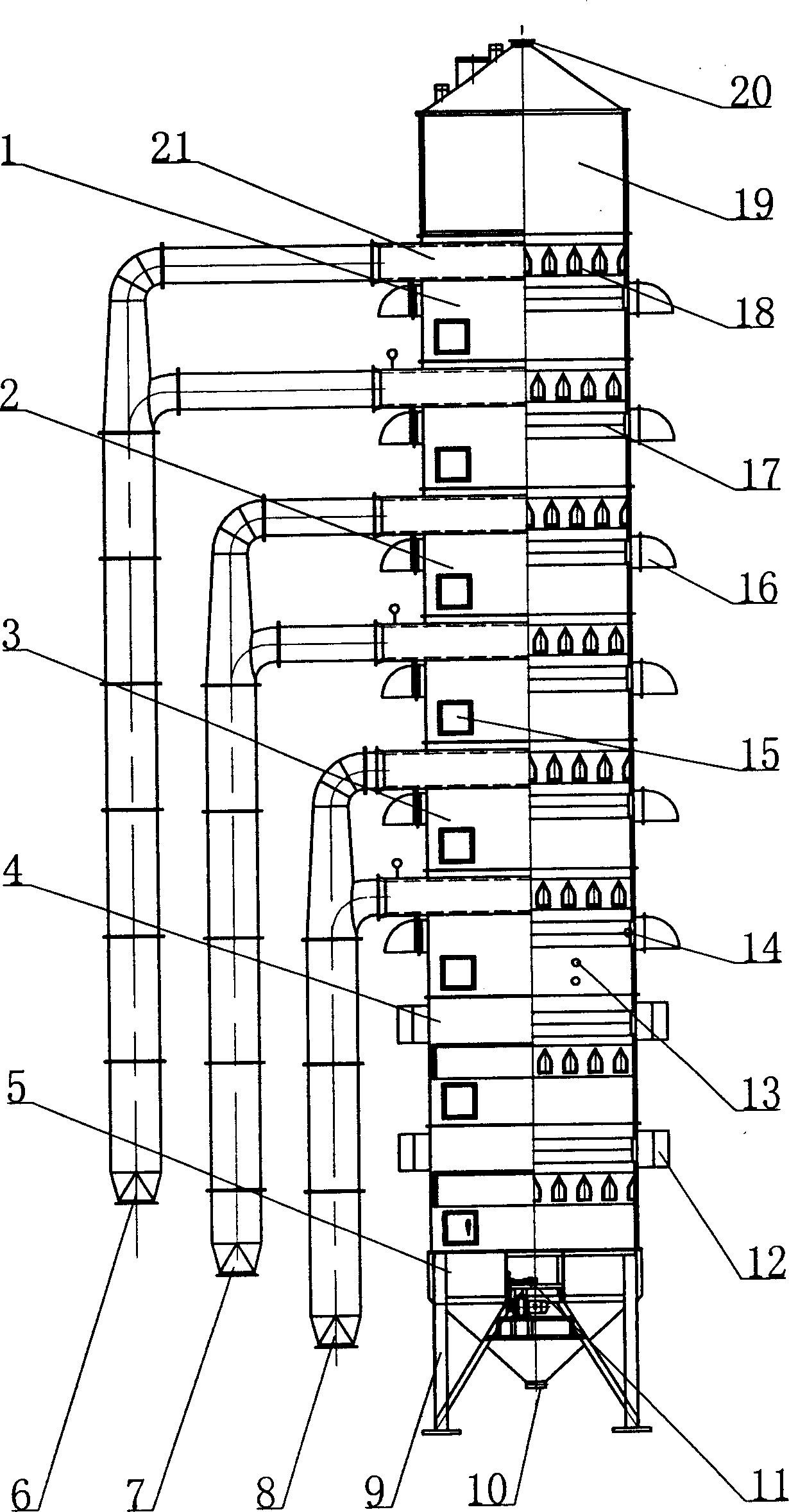

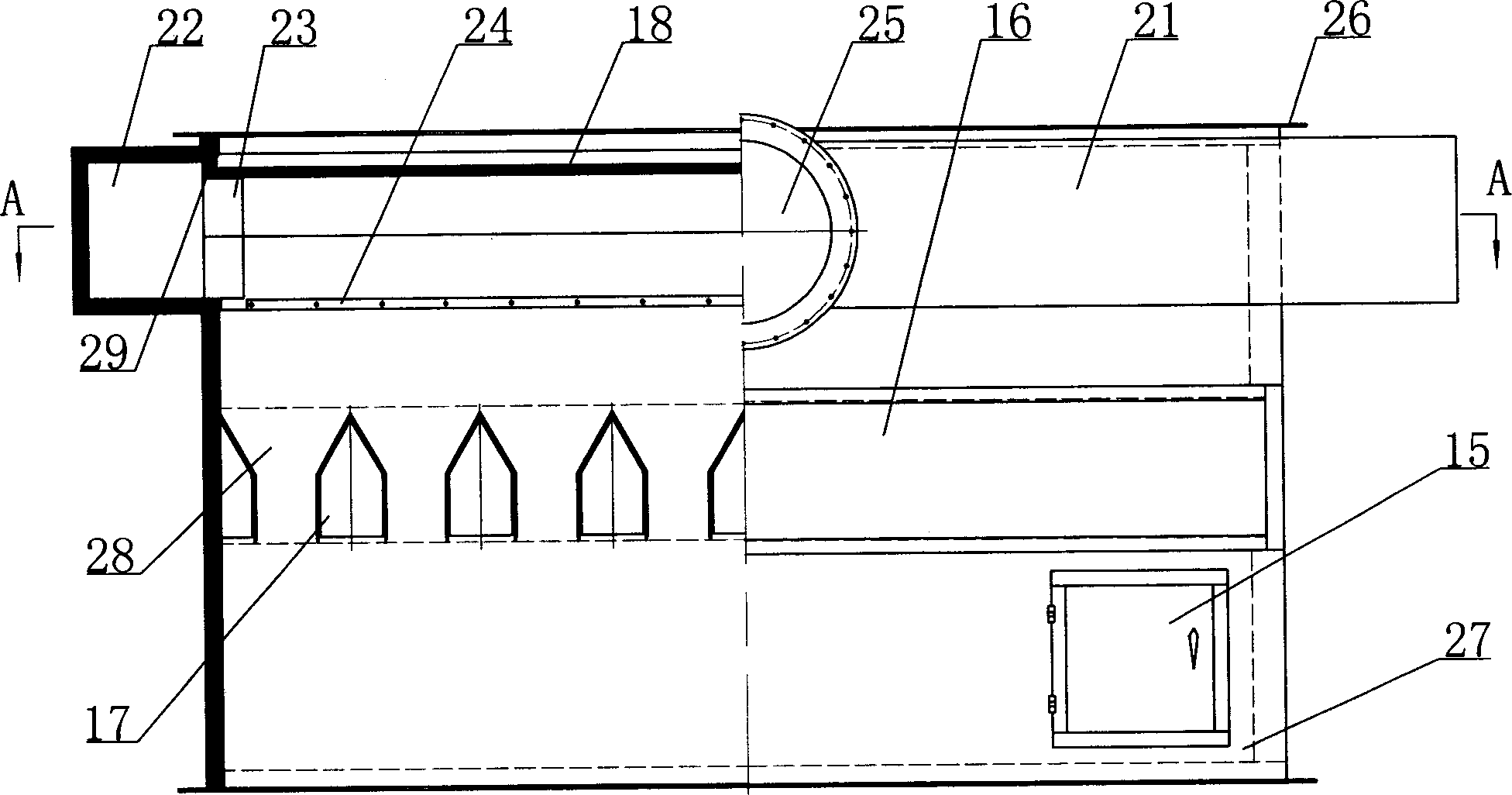

Raw state grain drying apparatus

InactiveCN1811310AReasonable structure matchingLess investmentDrying solid materials with heatHearth type furnacesEngineeringHeat control

The raw state grain drying apparatus includes storing barn, discharging barn and machine and controller in between. The machine includes wind guiding no-bottom boxes in sandwich or single wall structure and slowly dewatering cavities crossly arranged inside the machine body, at least one heat-controlling slow dewatering part and one cooling and slow dewatering part, a hot blast port, a moisture discharging port and a cold blast distributor. The present invention is superior to available technology, and has high grain stoving quality, reasonable dewatering process, easy operation, high control precision, low power consumption, low running cost, great once dewatering rate and other advantages.

Owner:辽宁中田干燥设备制造有限公司

Method for preparing oxide dispersion strengthened copper composite material

The invention relates to a method for preparing an oxide dispersion strengthened copper composite material, and belongs to the field of preparation of copper alloy materials. The method is as follows:firstly reducing Cu powder; alloying element powder, to be more specific, thoroughly mixing the reduced Cu powder with an appropriate amount of Y powder to obtain a Cu powder and Y powder mixture, then packaging the Cu powder and Y powder mixture and grinding balls in a stainless steel ball mill tank, and performing ball milling under an inert gas atmosphere; after the ball milling, annealing alloyed alloy powder by a muffle furnace, and sintering the annealed alloy powder into a block by a discharge plasma sintering furnace, and then rolling the block into a desiring thickness; and finally using a muffle furnace to perform heat treatment on the rolled copper alloy, and cooling in the furnace to obtain the oxide dispersion strengthened copper composite material. The oxide dispersion strengthened copper composite material prepared by the method has uniform distribution of nano-oxide particles with an average size of 5-6 nm, the powder production rate is over 95%, and the process is simple and easy to operate.

Owner:UNIV OF SCI & TECH BEIJING

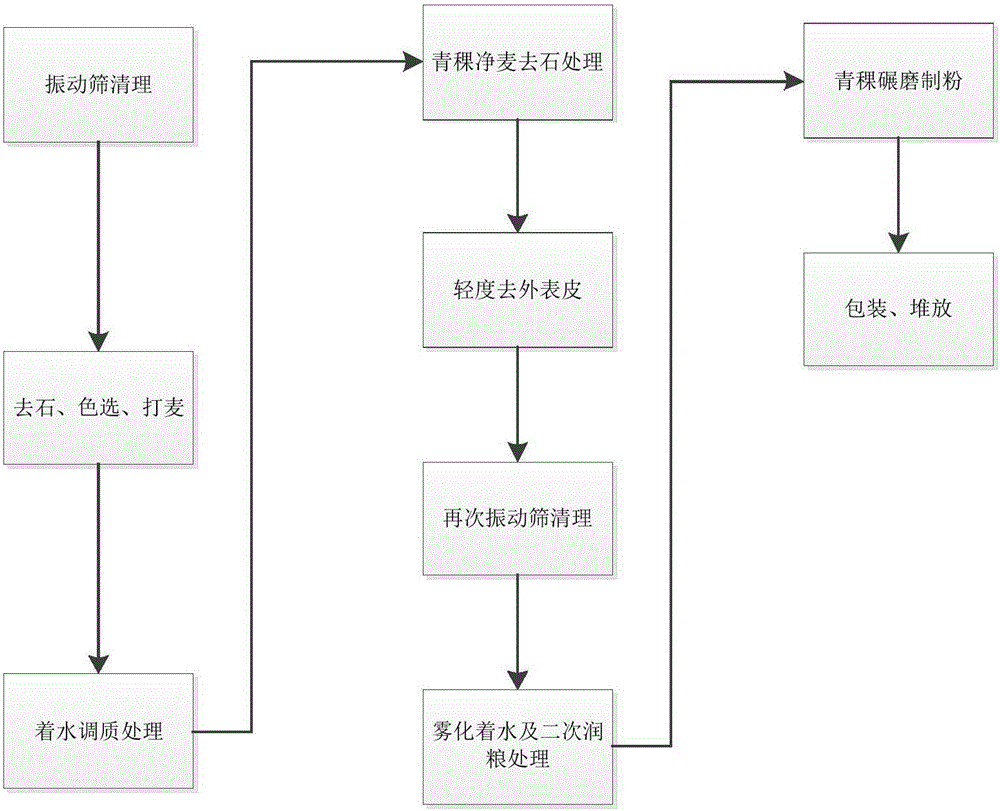

Technique for processing highland barley flour

ActiveCN106269016AControl contentKeep intactGrain huskingGrain polishingHazardous substanceExodermis

The invention provides a technique for processing highland barley flour. The technique includes the step of dehusking, specifically, outer husks are slightly removed. The technique for processing highland barley flour further includes the color sorting step; and multiple times of slight milling and multistage flour production including 4-6 times of break milling, 1-3 times of impacting flour production, 4-7 times of reduction milling, 1-2 times of residue milling, 1-4 times of clear flour purification and 2-4 times of bran finishing are adopted in the flour milling stage. By means of the technique for processing highland barley flour, raw materials such as different-color grains and moldy grains which do not meet requirements can be removed, the highland barley flour production rate is high, efficiency is high, quality is high, finished highland barley flour contains only a few impurities and microorganisms, the quantity of harmful substances such as residual pesticides and heavy metal is small, and food safety is guaranteed; meanwhile, original nutrients of highland barleys are reserved; the highland barley flour can be automatically produced on a large scale, development of highland barley processing is promoted, and the competitiveness of highland barley products is improved; bran completeness is high, and subsequent deep processing of bran is facilitated.

Owner:WUXI DADONG GRAIN ENG TECH CO LTD

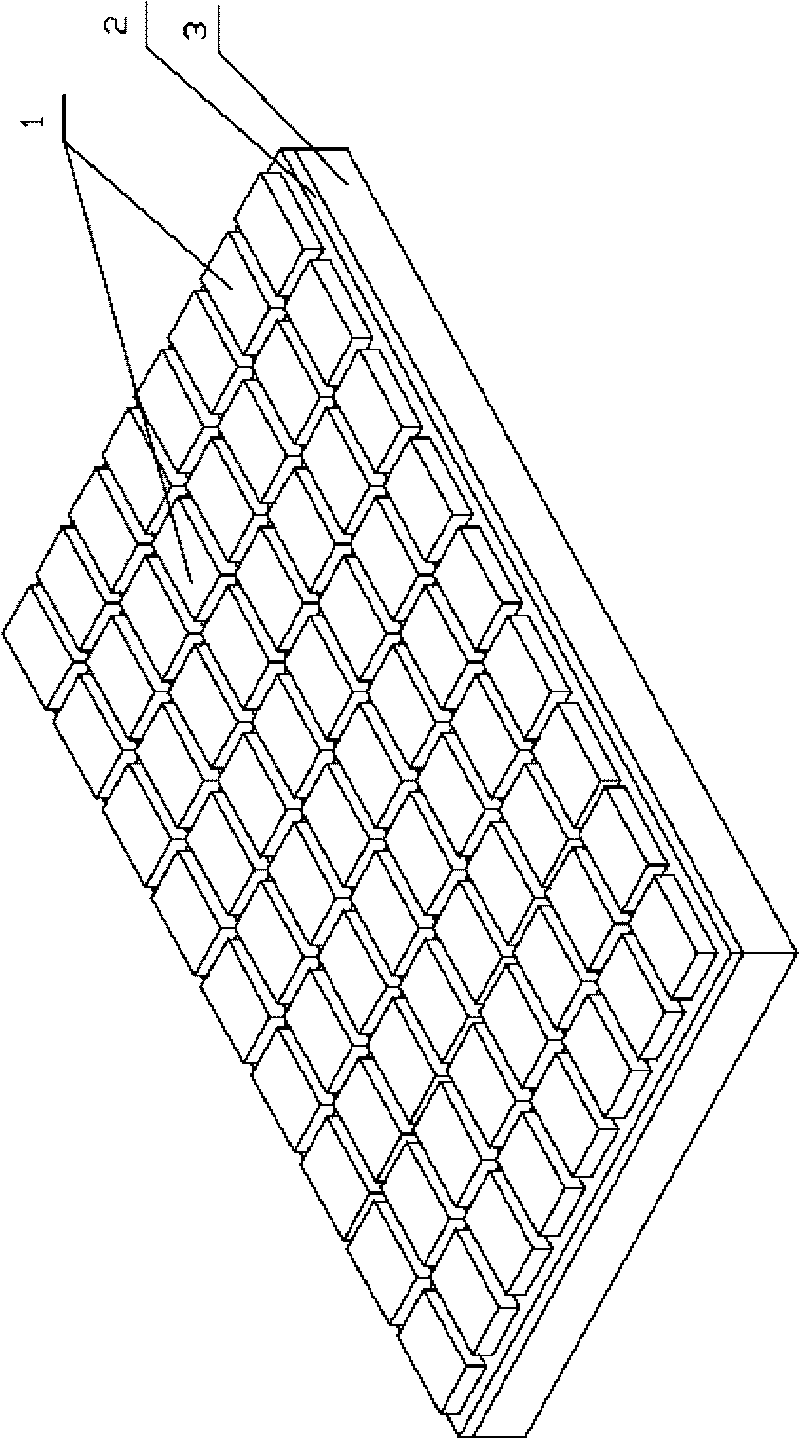

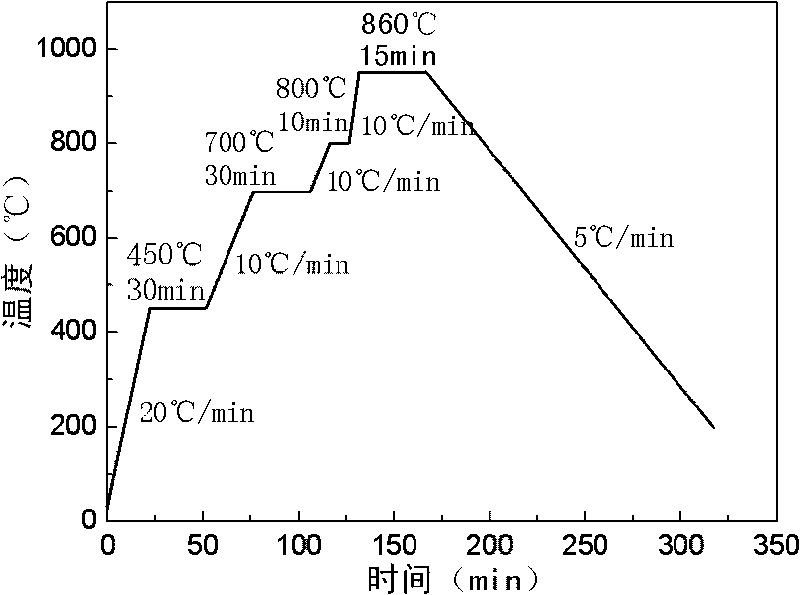

Method for preparing abrasion-resistant ceramic lining plate by using active soldering method

The invention discloses a method for preparing an abrasion-resistant ceramic lining plate by using an active soldering method, which relates to a method for preparing an abrasion-resistant ceramic lining plate. The method solves the problems that the conventional adhesive abrasion-resistant ceramic rubber lining plate has low bonding strength, the ceramic is easy to drop, the rubber material is easy to age, and the conventional bolt connected abrasion-resistant ceramic lining plate is easy to tear and has short abrasion-resistant service life. The method comprises the following steps: firstly, preparing an active metal paste solder; secondly, treating surfaces of a ceramic block and a steel plate; thirdly, preparing a soldering assembly piece; and finally, performing temperature increment and soldering stage by stage to obtain the abrasion-resistant ceramic lining plate. The abrasion-resistant ceramic lining plate of the invention cancels a rubber layer, and improves the bonding strength, abrasion resistance and high-temperature service life; the shearing strength of soldering seams reaches 191MPa; the low temperature reduction rate reduces the residual stress of the lining plate; and the lining plate is not easy to break and has prolonged service life. The obtained lining plate can be used as the abrasion-resistant lining plate for equipment such as bins, hoppers and the like in a coal-conveying and dust-discharging system of a heat power plant and a conveying and preparing system of the metallurgical steel industry.

Owner:HARBIN INST OF TECH

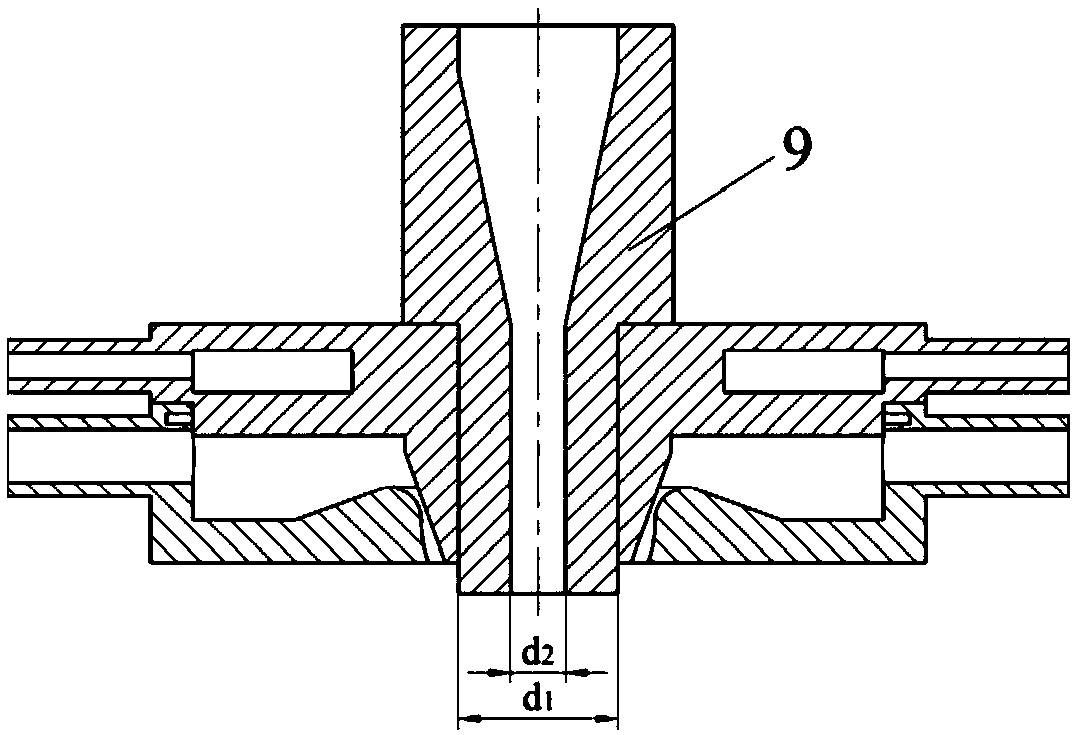

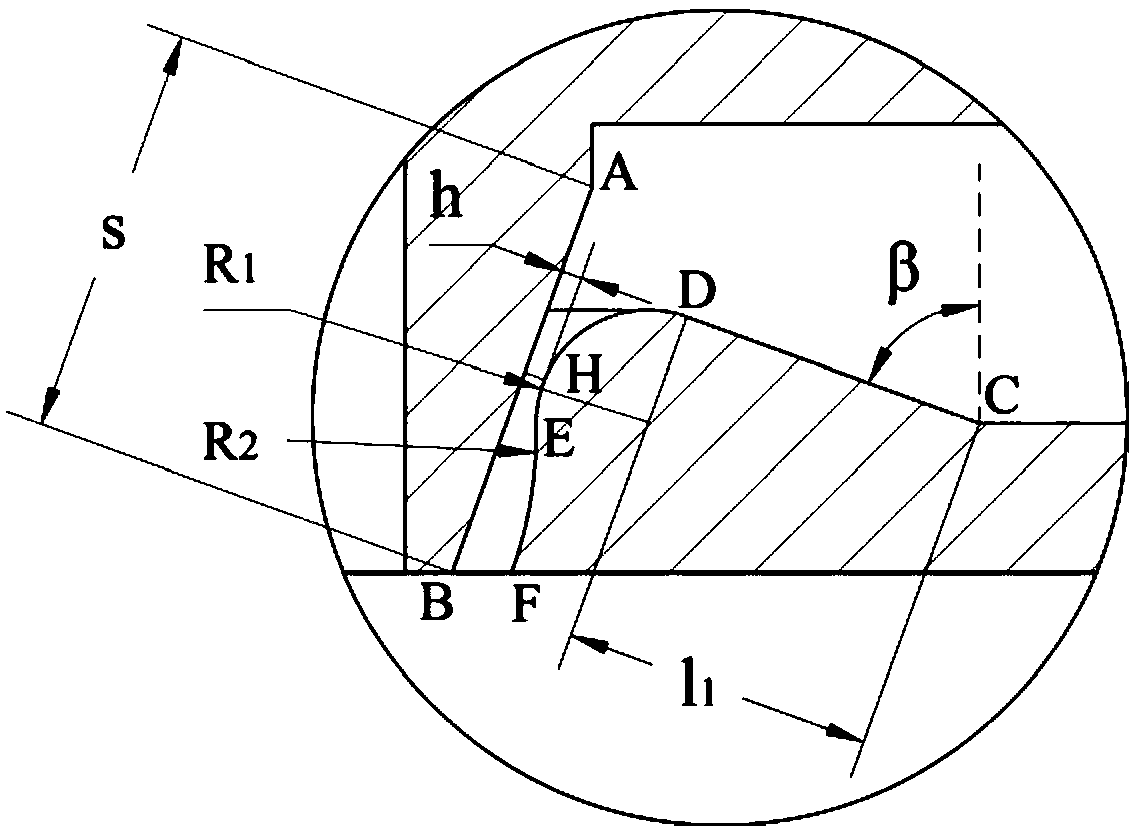

Supersonic gas atomization spraying disc for metal powder preparation

ActiveCN109570518AThroat width adjustableAdjustable Mach numberIncreasing energy efficiencyMetallurgyThermal deformation

The invention relates to a supersonic gas atomization spraying disc for metal powder preparation. The supersonic gas atomization spraying disc for metal powder preparation comprises a spraying disc upper lip and a spraying disc lower lip. An annular cooling water cavity is formed inside the spraying disc upper lip. A center hole which penetrates through the thickness of the spraying disc upper lipis formed in the center of the spraying disc upper lip and used for allowing a flow guide nozzle to be placed. A gas inlet pipeline which is used for being connected with an external gas source is arranged on the spraying disc lower lip. An annular gas cavity can be formed after the spraying disc lower lip and the spraying disc upper lip are assembled, and a nozzle which is of a semi-Laval structure is formed in an outlet of the annular gas cavity after the spraying disc upper lip and the spraying disc lower lip are assembled. According to the supersonic gas atomization spraying disc for metal powder preparation, the thermal deformation of the spraying disc is reduced by circulating cooling water, the sealing performance of the whole spraying disc structure is protected, and the service life of the spraying disc is prolonged. The spraying disc upper lip and the spraying disc lower lip are assembled to form the nozzle which is of the circular seam type semi-Laval structure, and the width of the throat portion of the nozzle is adjustable. According to the supersonic gas atomization spraying disc for metal powder preparation, a technological adjustment window is wide, the gas consumption is low, the gas flow inside the spraying disc is uniform, and the fine powder yield can be substantially improved.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

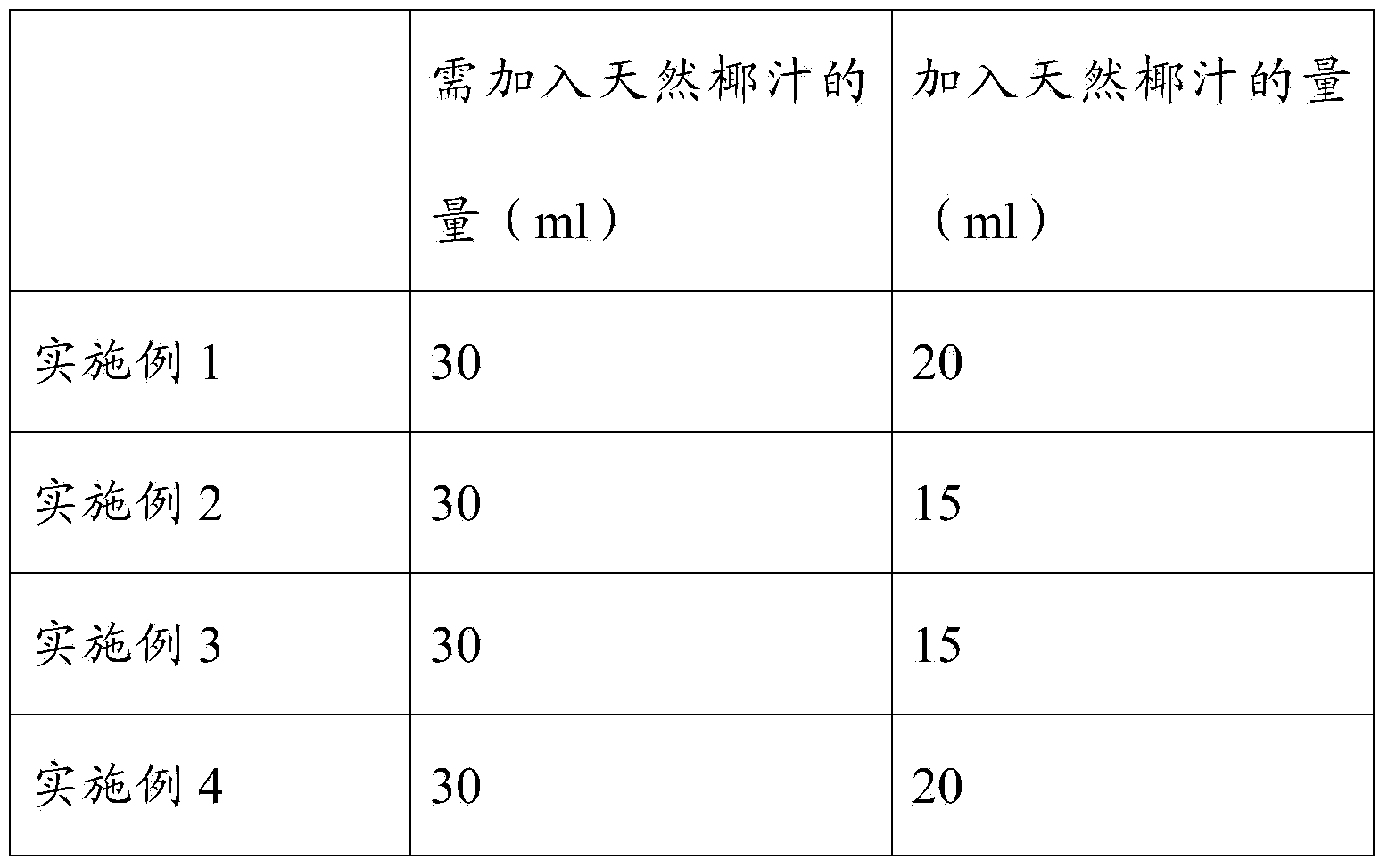

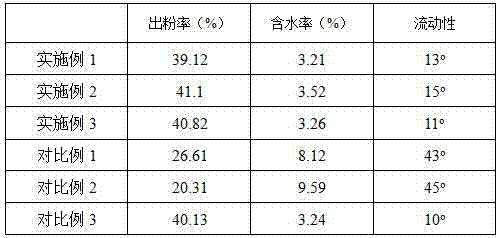

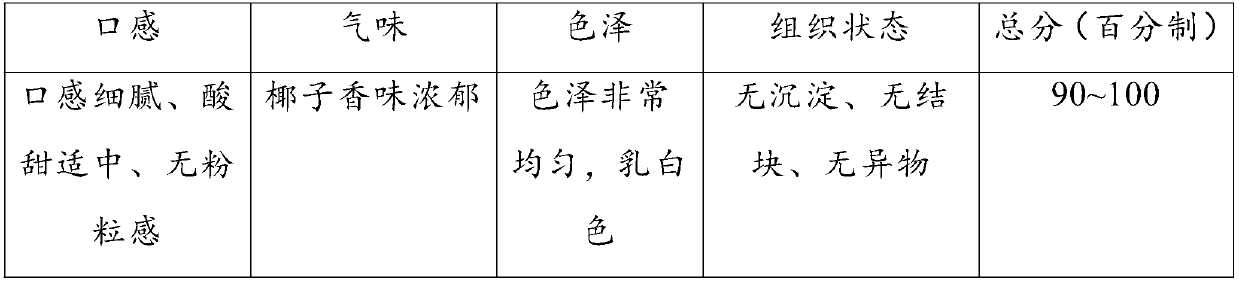

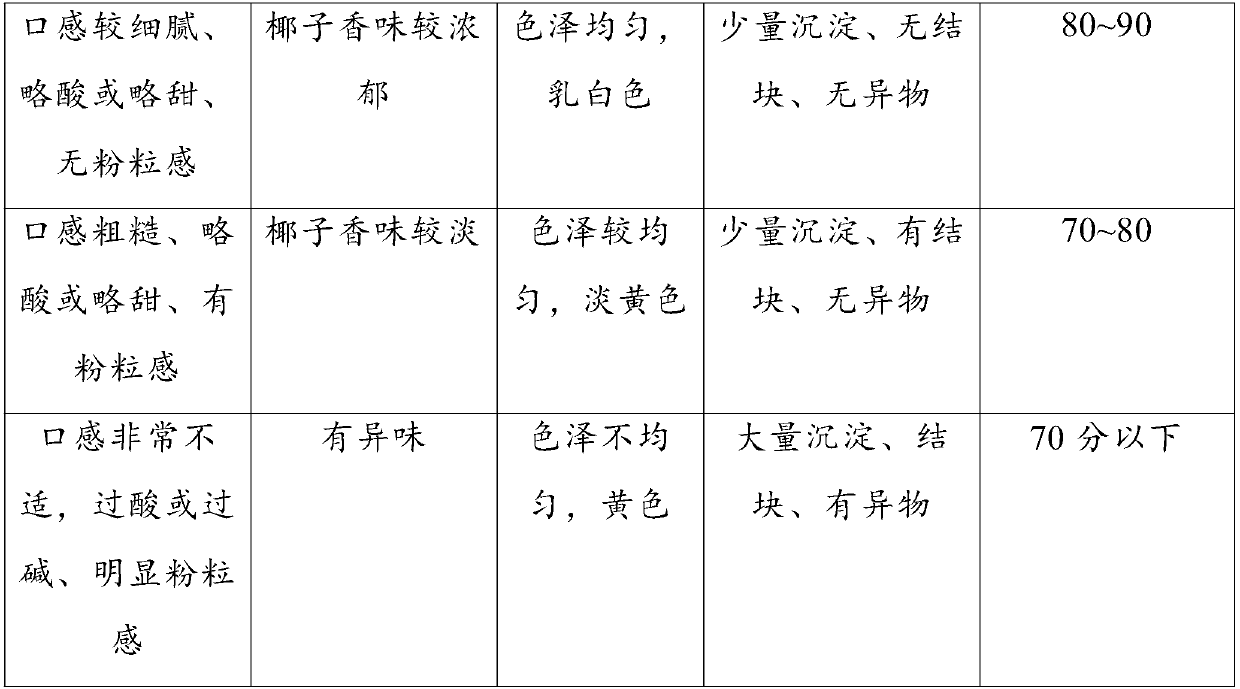

Preparation process of coco powder

ActiveCN103719769ARetain nutrientsIncrease powder yieldFood homogenisationFood precipitationFlavorMixed materials

The invention discloses a preparation process of coco powder. The preparation process is characterized by comprising the following steps in sequence: (1) pulping coco fresh and coco juice to prepare coco jam; (2) grinding the coco jam by using a grinder; (3) homogenizing the coco jam at high pressure; (4) adding an emulsifier and emulsified starch into the coco jam, and mixing the materials; (5) homogenizing a solution of the mixed materials at high pressure again to obtain a solution in a good emulsification state; (6) performing spray-drying on the solution, so as to obtain coco powder. According to the preparation process, an existing process is simplified, simultaneously farthest the nutrient contents, color, flavor and taste of coco are retained, and the coco powder is high in yield good in instant dispersibility and pure in taste.

Owner:BEIJING ALCHEMIST TECH

Preparation method of chromium powder for producing copper-chromium contact

The invention relates to a preparation method of chromium powder for manufacturing a copper-chromium contact. The preparation method mainly comprises the steps as follows: selection of raw chromium block, coarse crushing, vortex fine crushing, vacuum ball milling and vibrating sieving and obtaining the chromium powder; the coarse crushing is carried out by a special hydraulic coarse crusher with a water cooling plant in a room which is provided with an air conditioner and a dehumidifier, after the coarse crushing, the largest particle diameter is less than 3mm, the chromium can be effectively prevented from heating and oxidation in the course of the coarse crushing, the vortex fine crushing is carried out in a closed system which consists of an automatic feeder, a turbo-mill, a powder collector, a vacuum pump, an argon inlet and a cooler, after the vortex fine crushing, the chromium powder is put into a vacuum ball mill for ball milling with the ball-material ratio being 2:1-3:1, the rotary speed of the ball mill is controlled to ensure that the material ball is in a rolling state, and the ball milling time is 91-101 hours. The preparation method has the advantages that the quality of the chromium powder is stable, the production efficiency is high, the energy consumption is low, the powder yield is high, etc.

Owner:ZHEJIANG YATONG METAL CERAMICS +1

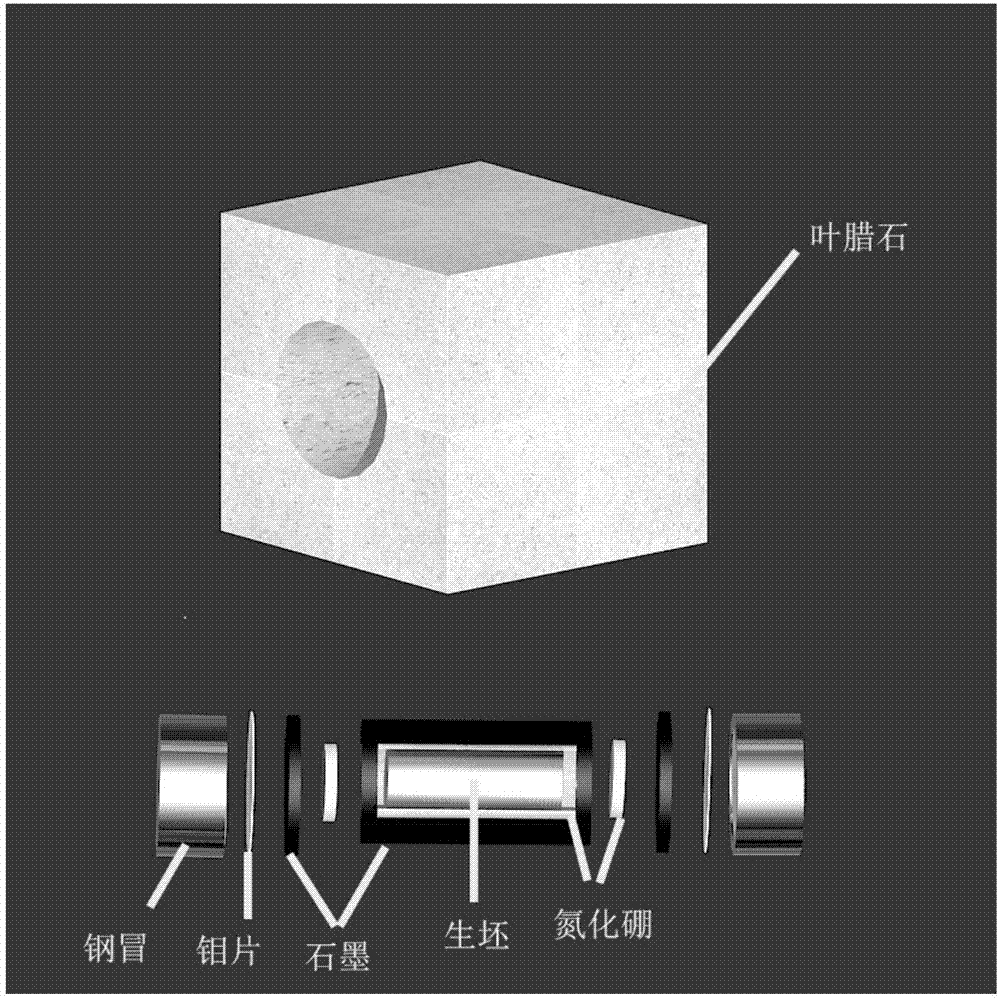

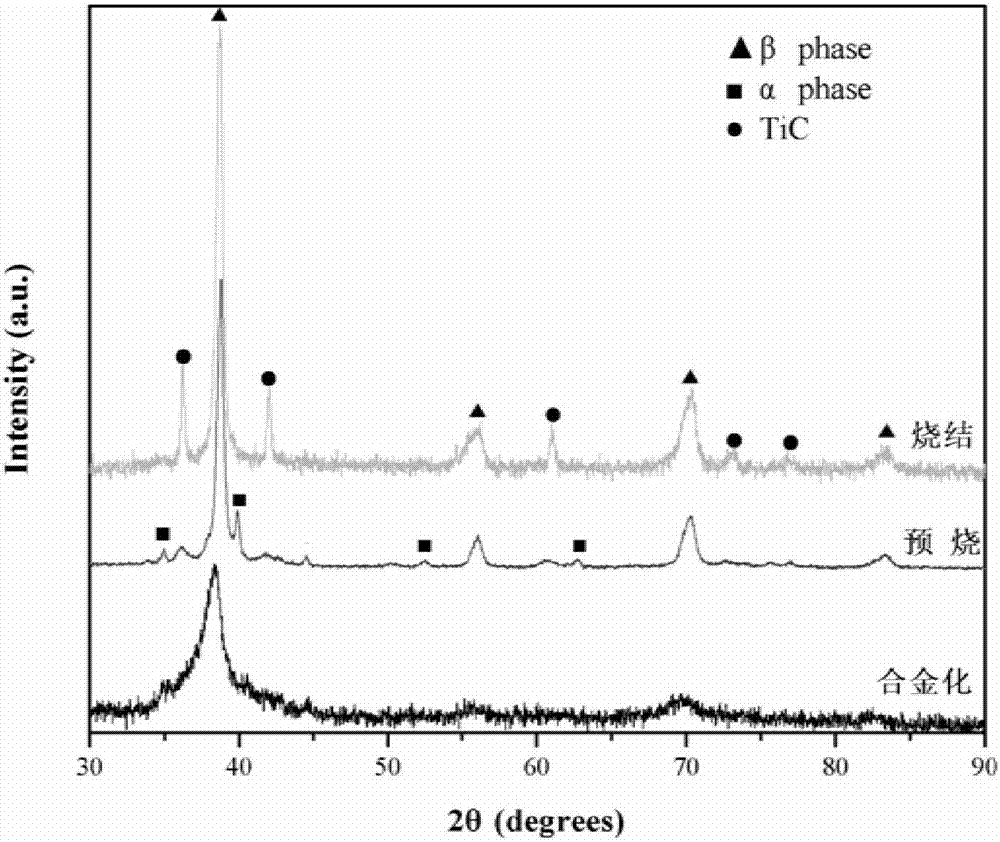

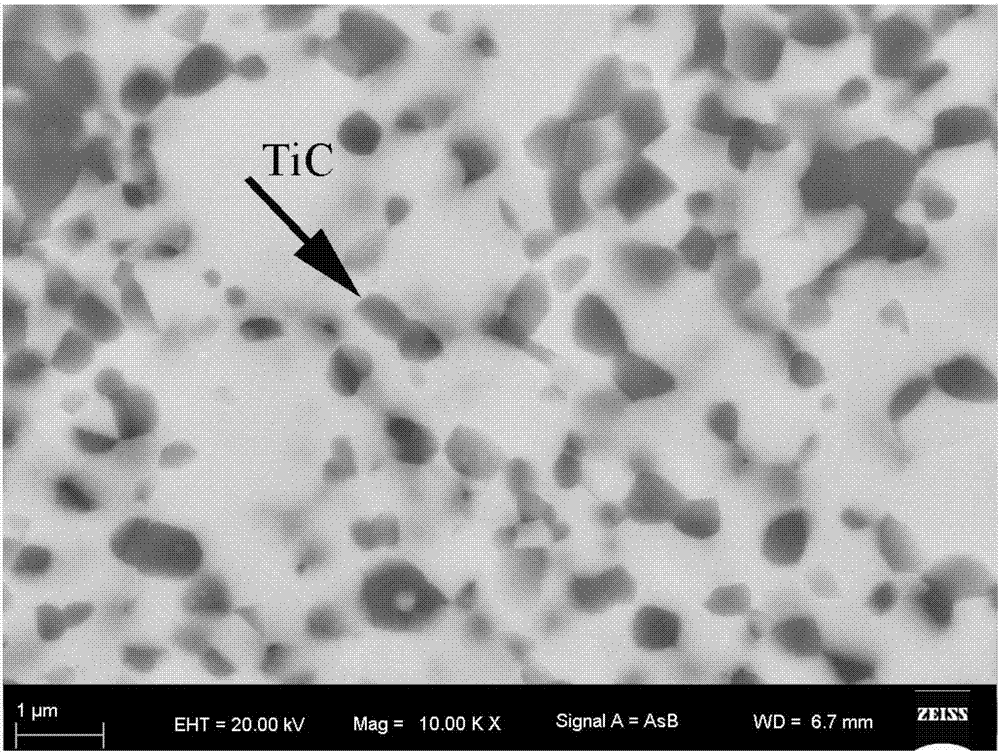

Preparation method for TiC reinforced ultra-fine grain beta titanium and niobium based composite material

The invention discloses a preparation method for a TiC reinforced ultra-fine grain beta titanium and niobium based composite material. According to the preparation method, pure Ti powder and pure Nb powder serve as raw materials, a carbon and hydrogen containing process control agent serves as a carbon source for in-situ synthetic TiC and a process control agent, alloy powder is obtained through ball milling, the alloy powder is subjected to vacuum pre-sintering to remove gas and stress, then, the alloy powder is prepared into green bodies, units are subjected to assembling and sintering, and finally the TiC reinforced ultra-fine grain beta titanium and niobium based composite material is obtained through high-temperature ultrahigh pressure sintering. According to the preparation method, the process control agent serves as the carbon source for in-situ synthetic TiC, powder agglomeration and ball sticking and wall sticking situations in the ball-milling process are effectively relieved, the process control agent plays a role in refining the powder and increasing the powder yield, meanwhile TiC generated through low-temperature pre-burning is combined with high-temperature ultrahigh pressure sintering, the growth of grains is effectively restrained, the prepared TiC reinforced ultra-fine grain beta titanium and niobium based composite material is uniform in reinforcement body, fine in grain and high in density and meanwhile has the beneficial effects of being high in strength and plasticity and resistant to abrasion.

Owner:XIANGTAN UNIV

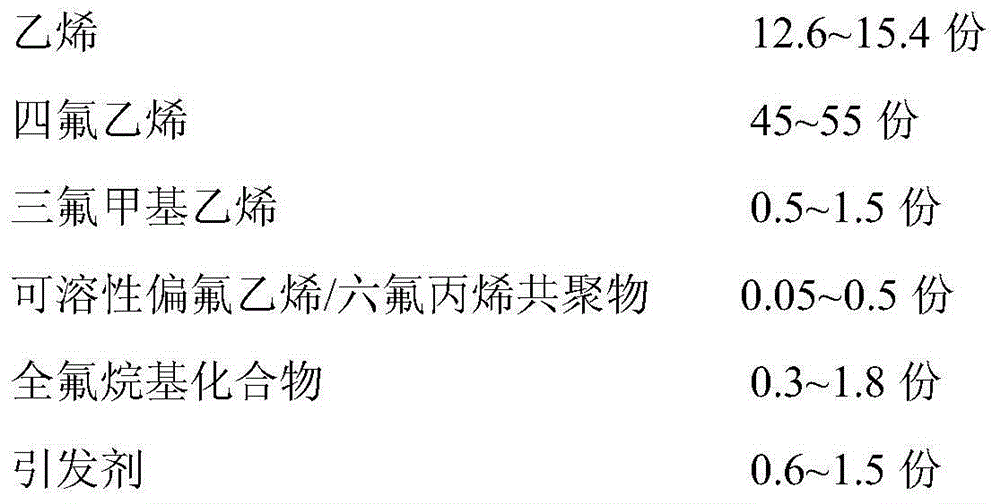

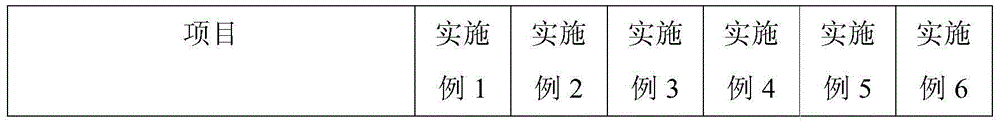

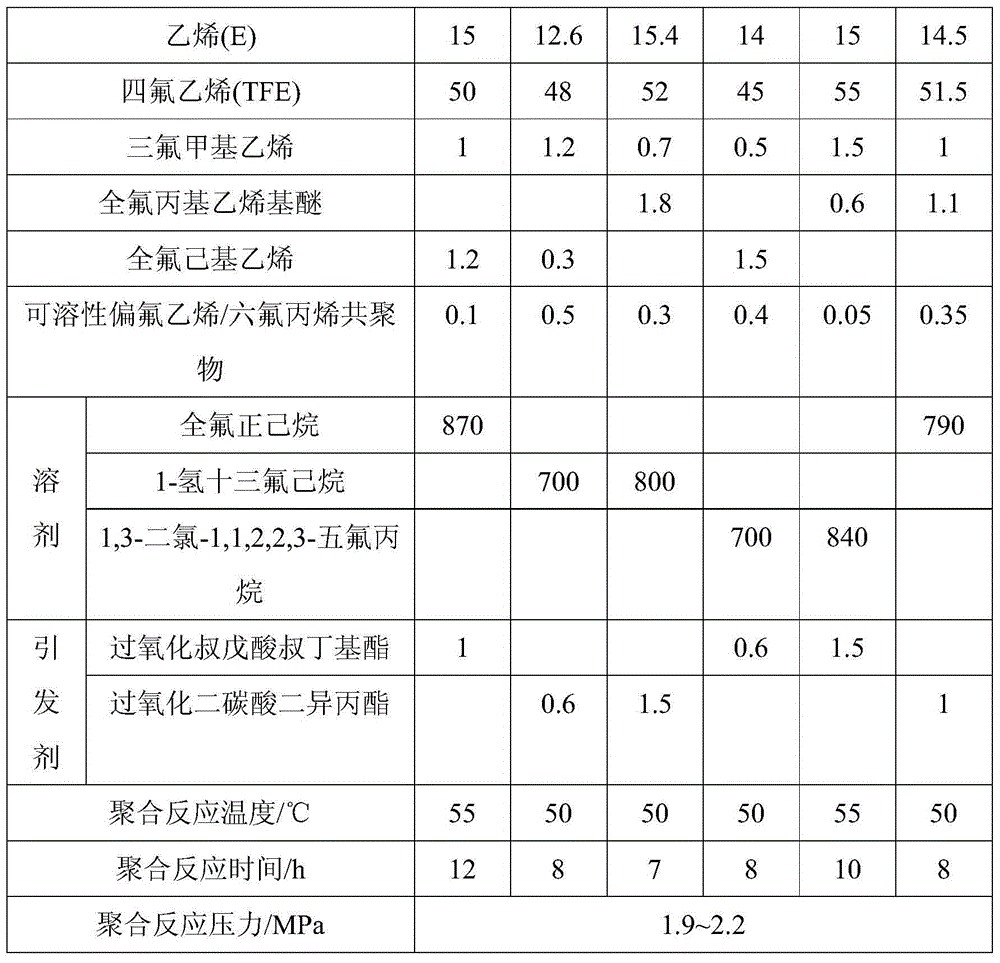

Ethylene/tetrafluoroethylene copolymer powder and method for preparing same

The invention discloses ethylene / tetrafluoroethylene copolymer powder. The ethylene / tetrafluoroethylene copolymer powder comprises, by weight, 12.6-15.4 parts of ethylene, 45-55 parts of tetrafluoroethylene, 0.5-1.5 parts of trifluoromethyl ethylene, 0.05-0.5 part of soluble vinylidene fluoride / hexafluoropropylene copolymers, 0.3-1.8 parts of perfluoroalkyl compounds and 0.6-1.5 parts of initiators. The invention further discloses a method for preparing the ethylene / tetrafluoroethylene copolymer powder. The ethylene / tetrafluoroethylene copolymer powder and the method have the advantages that technologies are simple, and products are excellent in heat resistance, tensile strength and breaking elongation and good in processing performance.

Owner:JUHUA GROUP TECH CENT

Preparation method of anti-adhering spray-drying fruit powder

The invention relates to a preparation method of fruit powder, in particular to a preparation method of anti-adhering spray-drying fruit powder, and belongs to the technical field of food processing. The method comprises the following steps: carrying out freezing-thawing treatment on fruits which are high in sugar content and easy to decay; preheating, adding glycerel monostearte and calsium lactate stearate, and stirring evenly; and adding a drying aid, carrying out homogenization treatment and then carrying out spray drying. According to the method provided by the invention, the usage amount of maltodextrin is greatly reduced; wall adhering is avoided to the greatest extent; and the prepared fruit powder is bright in color and luster and good in taste, is loose powder without progress, and is good in wettability and pure in flavor.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Processing method of konjac refined flour

The invention discloses a processing method of konjac refined flour. A process comprises the following steps: fresh konjac corm cleaning, peeling, slicing, color protecting, crushing, desolventizing purifying, washing, drying, dry-grinding, screening, homogenizing, examining, packing and storing; according to an operation key point, during grinding, konjac flour and an ethanol solution are mixed according to a certain ratio, and are placed in a grinding wheel mill for grinding, the purpose of the operation key point is to grind out impurities on surfaces of refined flour particles, the final concentration of ethanol used for liquid medium selection during separation is better not be lower than 30%, the ethanol solution with the concentration higher than 30% is used for washing the konjac refined flour particles in a filter screen, and then centrifugation separation is conducted. According to the processing method of the konjac refined flour, after ethanol washing and filter pressing are conducted, the content of the impurities in the konjac refined flour is reduced, and the property of the konjac refined flour in aspects of color and lustre, solubility, viscosity, purity and the like is improved.

Owner:周建兵

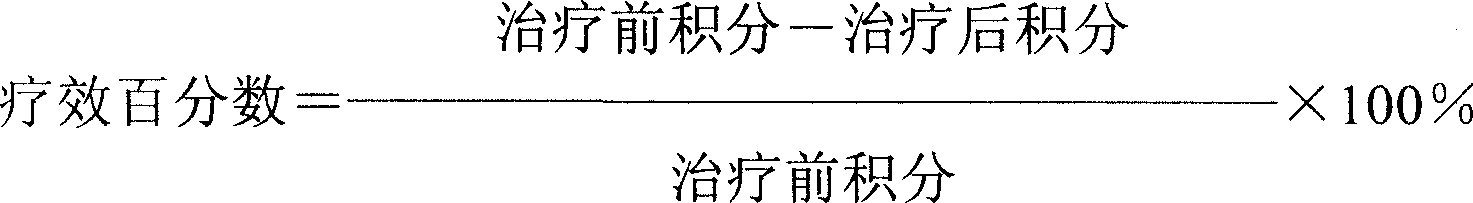

Preparation method of Chinese medicinal capsule for treating apoplexy

ActiveCN1965996ASolve drug production problemsPromote dissolutionNervous disorderAnthropod material medical ingredientsBroom RapeChinese cinnamon

The invention relates to a process for preparing Chinese medicinal capsules for treating apoplexy, which comprises leaching leeches, earthworm, pilose antler and buthus martensi kirsch with ethanol, weathering with warm air, disintegrating leaches into mesh fines, sterilizing with steam, disintegrating Cinnamomum cassia separately, charging water into tortoise shells, water grilling three times, filtering, merging the filter liquors, proportioning fleece-flower root, dried rehmannia root, asparagus root, broomrape, haw, radix paeoniae rubrathe, poria cocos wolf and licorice root, charging water for immersion, water grilling three times, filtering, merging the filter liquors, charging water-grilled liquid of tortoise shell, concentrating into concrete, drying till the water content is between 3-6%, charging pilose antler, buthus martensi karsch, leeches, earthworm, Cinnamomum cassia, mixing homogenously, disintegrating into fines, and loading into capsules.

Owner:HENAN LINGRUI PHARMA

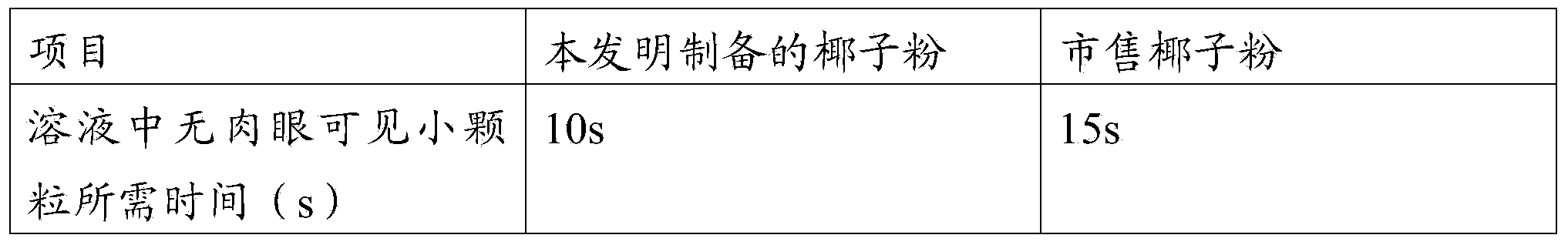

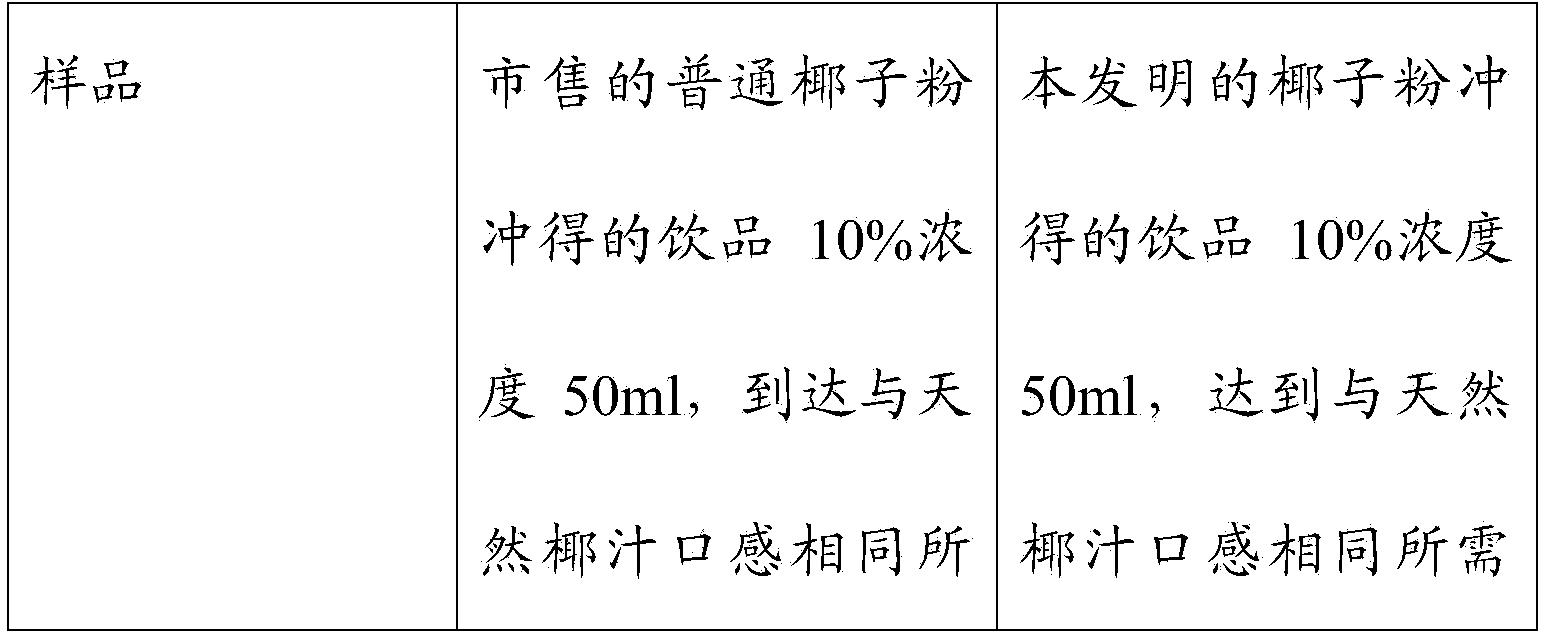

Preparation method of coconut powder

The invention provides a preparation method of coconut powder. The preparation method of the coconut powder mainly involves the following steps of carrying out squeezing, carrying out filtration, carrying out blending, carrying out grinding, carrying out sterilization, carrying out drying, and so on. The preparation method of the coconut powder provided by the invention preserves nutrients, as well as natural color, fragrance and flavor, of the coconut fruits to the maximum extent with the preparation processes simplified; the prepared coconut powder has edible safety and reliability, and is good in fluidity, namely good instant dissolving effects; moreover, the preparation method is high in powder yield so that raw-material costs are saved to the maximum extent. The coconut powder can betaken after direct brewing with water; moreover, the coconut powder can be also utilized as a raw material for making products, including soft drinks, candies, instant foods and so on.

Owner:海南春光食品有限公司

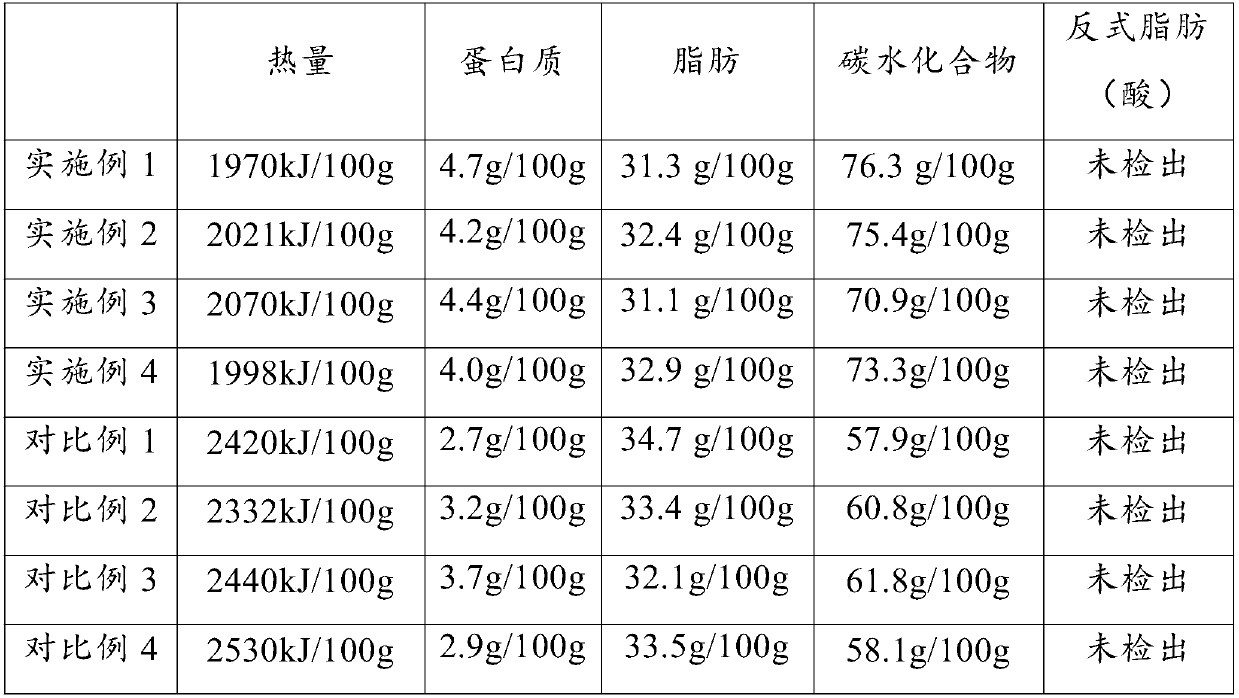

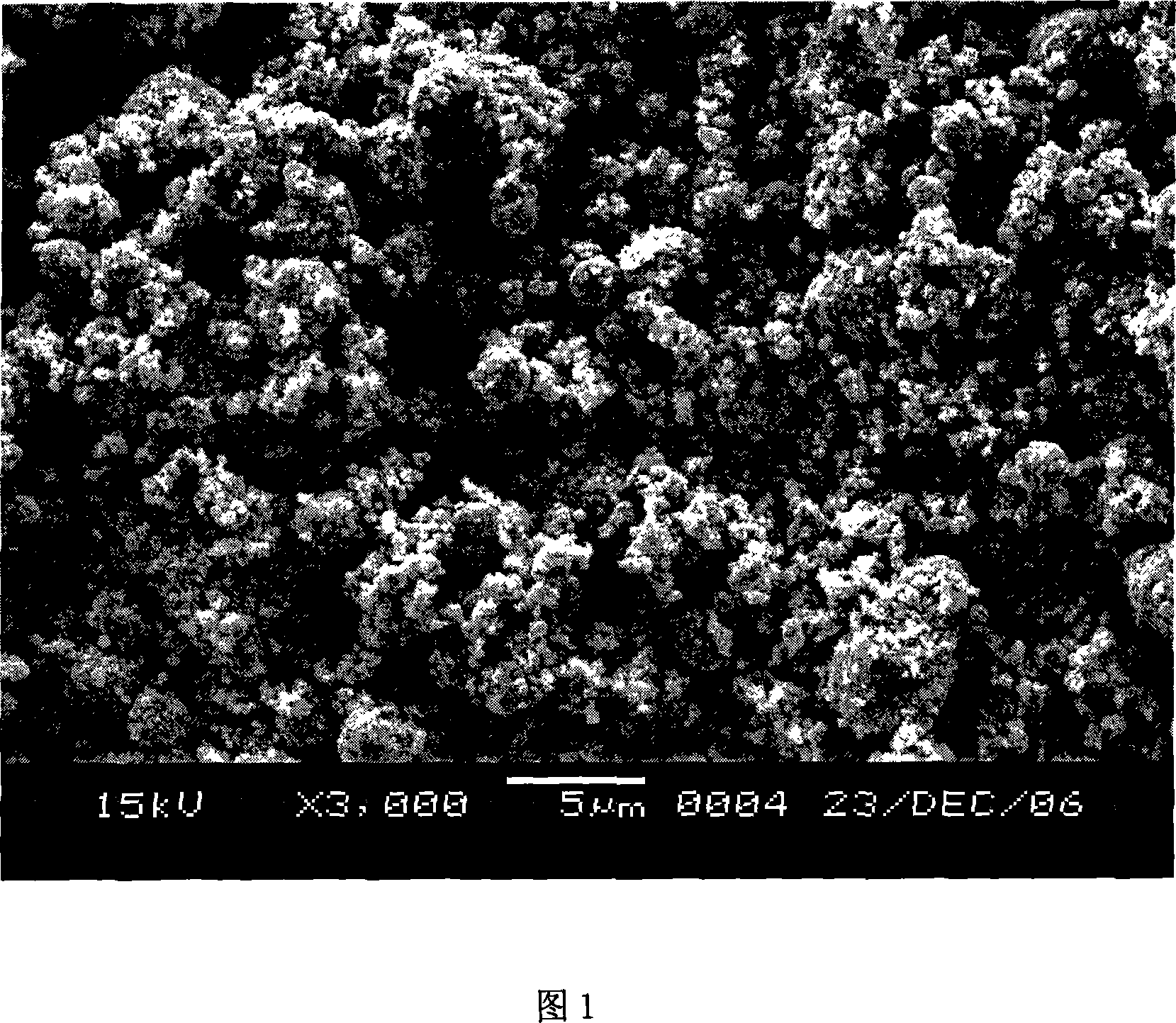

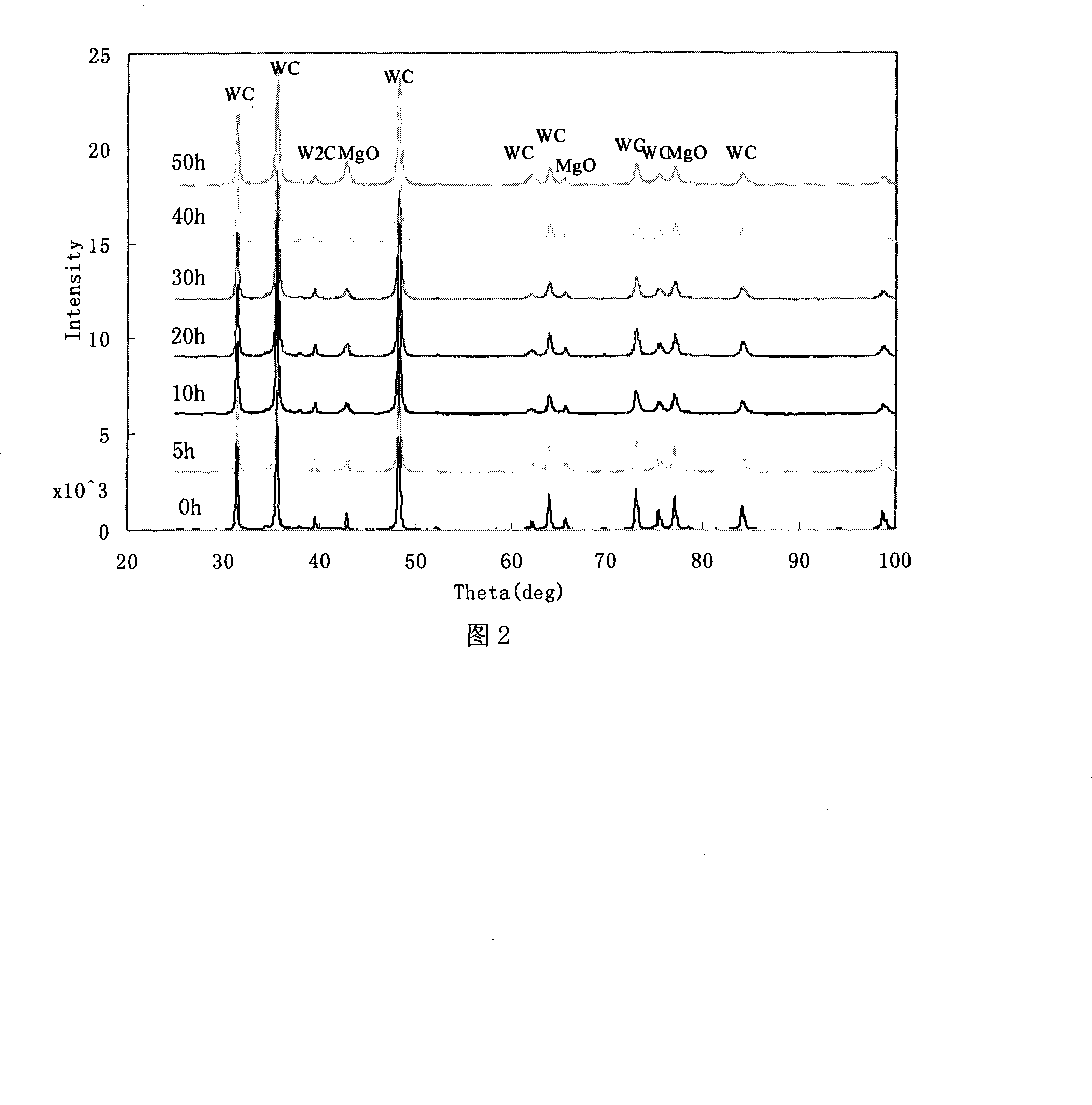

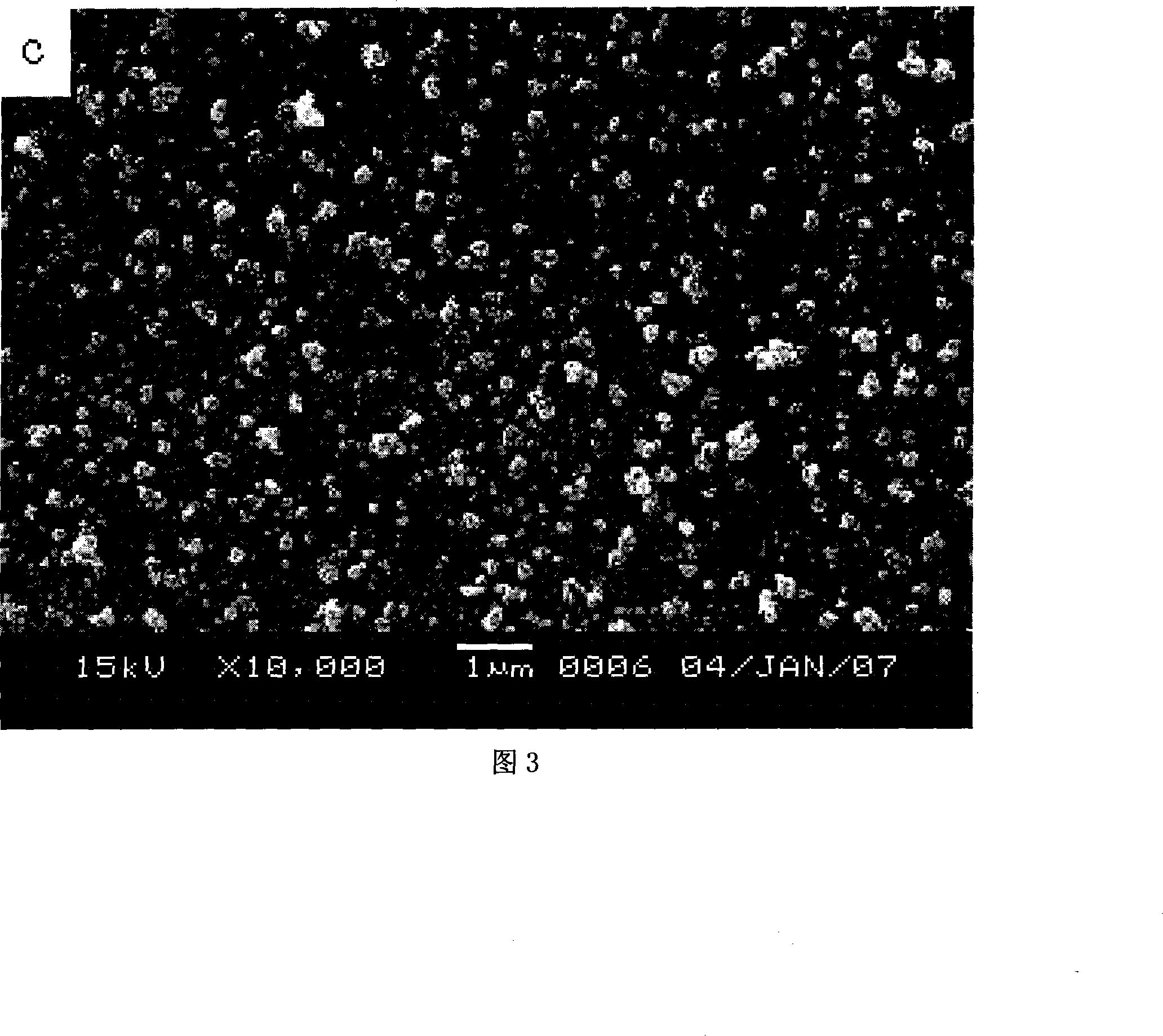

Method for preparing high-performance WC/MgO nano composite material

The invention relates to a method for preparing WC / MgO composites with high performance, which comprises: (1) 1 to 5Mum micron of WC and MgO are mixed according to quality ratio of 4:1 to 20:1; (2) quality percentage of 0.5 to 5 percent of stearic acid is added so as to prevent powder from bonding on a tank wall and a milling ball, thus promoting discharging rate of the powder; (3) a ball material rate is 4:1 to 10:1; (4) a ball milling tank is vacuumized and inert gas is led in; (5) continuous ball milling is carried out at the rotating speed of 100 to 500r / minute for 0 hour to 70 hours to obtain WC / MgO nano-composite powder; (6) the obtained powder is dried, cooled, pressed and formed; (7) pressed blank is put into a sintering device of discharge plasma to carry out sintering and the temperature is maintained for 3 to 5 minutes. The method has a simple process, low cost, less investment and high yield; besides, the manufactured powder has fine grain sizes as well as relatively high hardness and toughness and the performance is as excellent as WC / CO composite ceramic; the MgO successfully replaces the rare and noble metal Co and the invention is applicable to industrial production.

Owner:DONGHUA UNIV

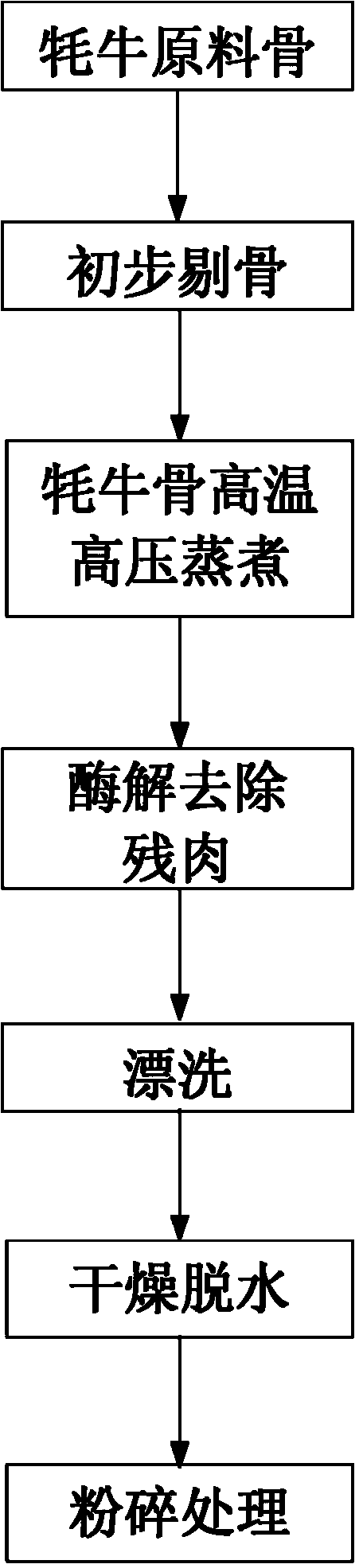

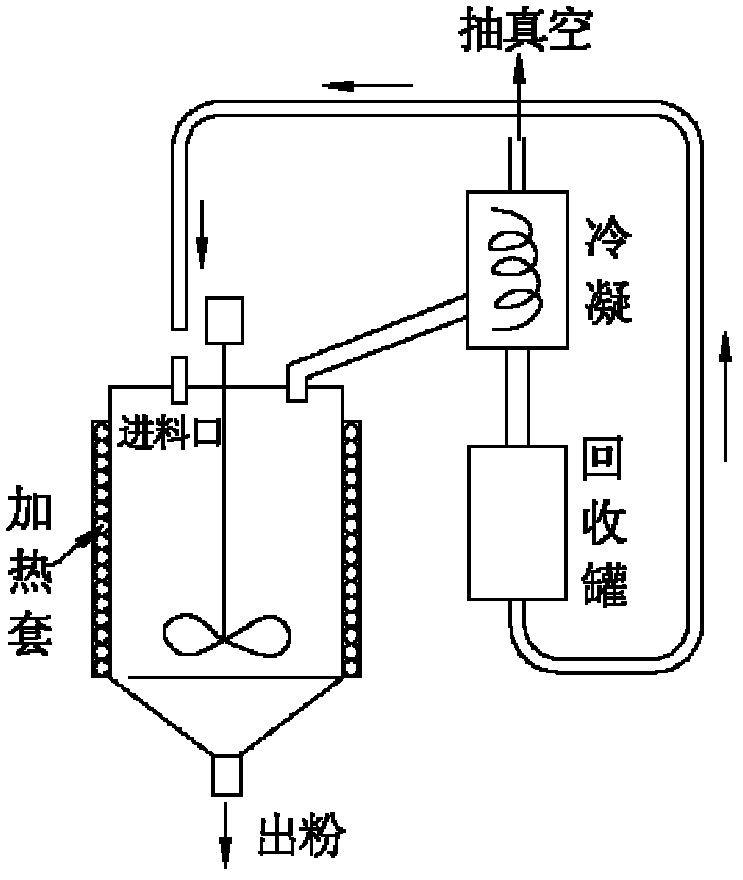

Preparation method of superfine yak bone powder

InactiveCN104187782AIncrease powder yieldLow costMulti-step food processesFood shapingMoistureDrug biological activity

The invention discloses a preparation method of superfine yak bone powder. The superfine yak bone powder of which the particle size is 500-700nm is processed by preliminary boning, enzymolysis and residual meat removal and smashing on the raw material yak bone, wherein trypsase is adopted to process the preliminarily boned yak bone in the enzymolysis and residual meat removal process; the additive amount of the trypsase according to the amount of the yak bone is 1100-1300U / g; the enzymolysis temperature is 45-55 DEG C; the enzymolysis time is 1.5-2.5 hours; and the pH value is 10-11. According to the method disclosed by the invention, through mild degradation by using biological enzyme, impurities such as yak bone meat can be effectively removed, the purpose of high biological activity of calcium ions in the yak bone powder is achieved, the method has the advantages of simplicity in operation and strong practicability, the prepared yak bone powder is free of peculiar smell, the particle size of over 97% of bone powder in the product reaches 500-700nm, the crude protein is greater than or equal to 26%, the moisture is smaller than or equal to 3.2%, the crude fat is smaller than or equal to 0.5%, calcium is greater than or equal to 30%, phosphorus is greater than or equal to 13.8%, the superfine yak bone powder is even in dispersing, good in taste, free of impurity, and the nutrition in the yak bone is completely preserved, and is easy to be directly absorbed and utilized by a human body.

Owner:西藏天虹科技股份有限责任公司

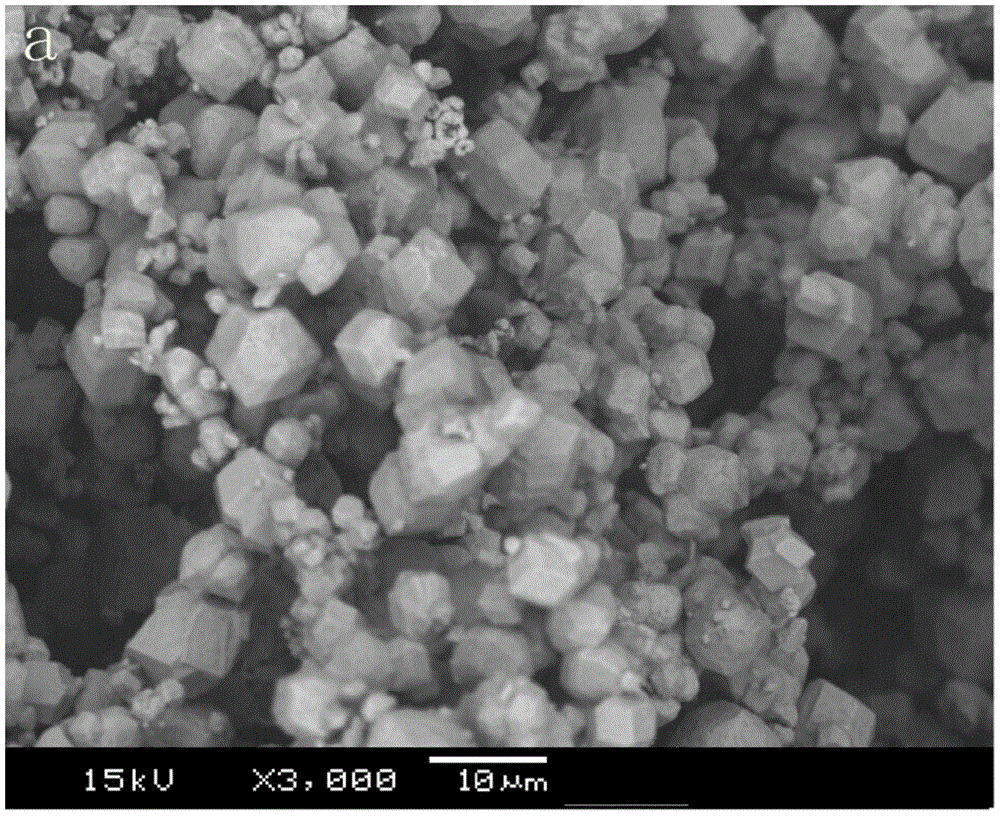

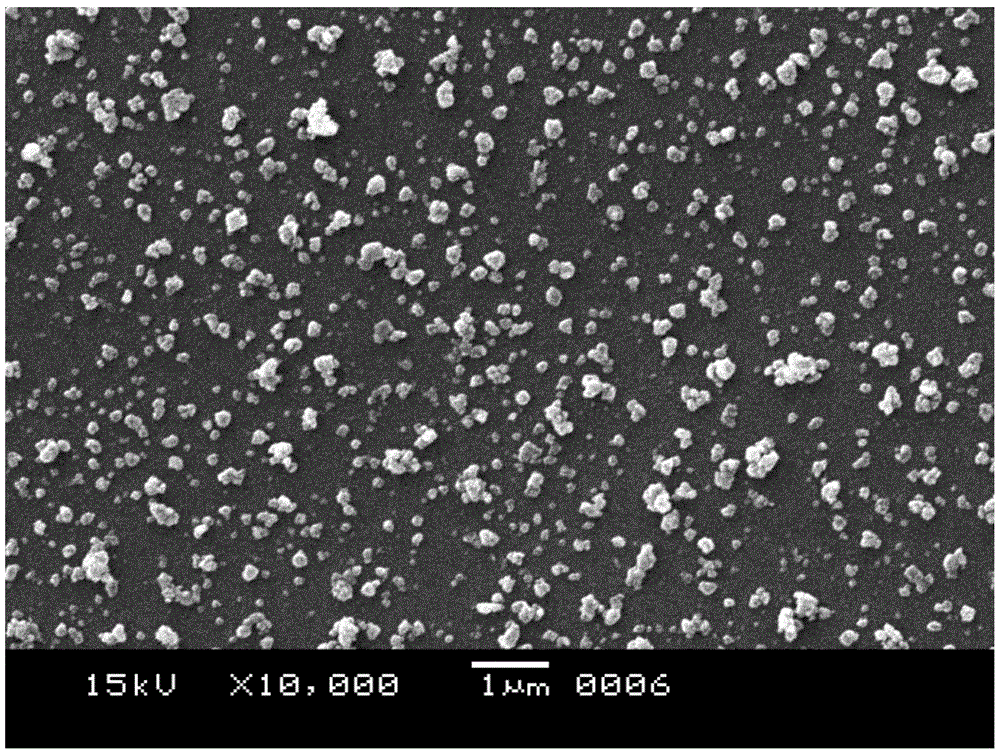

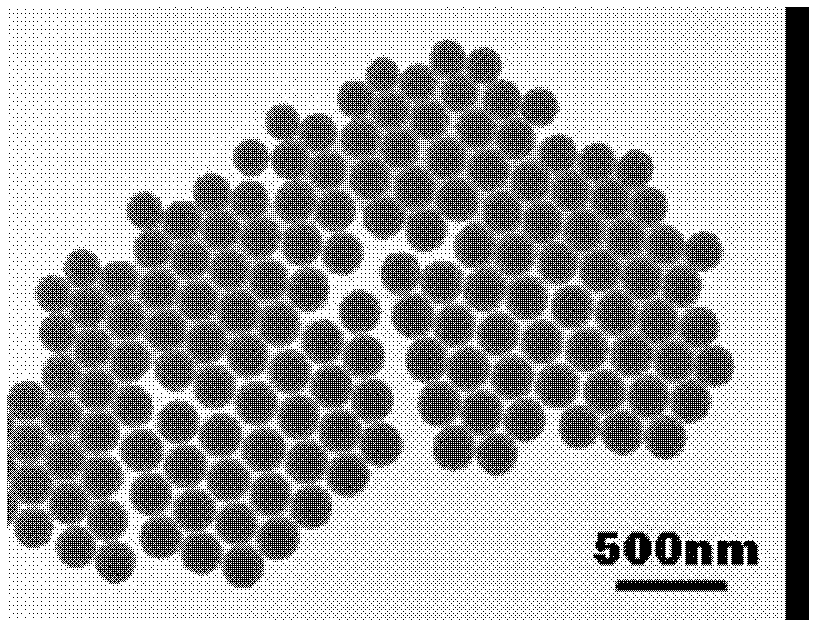

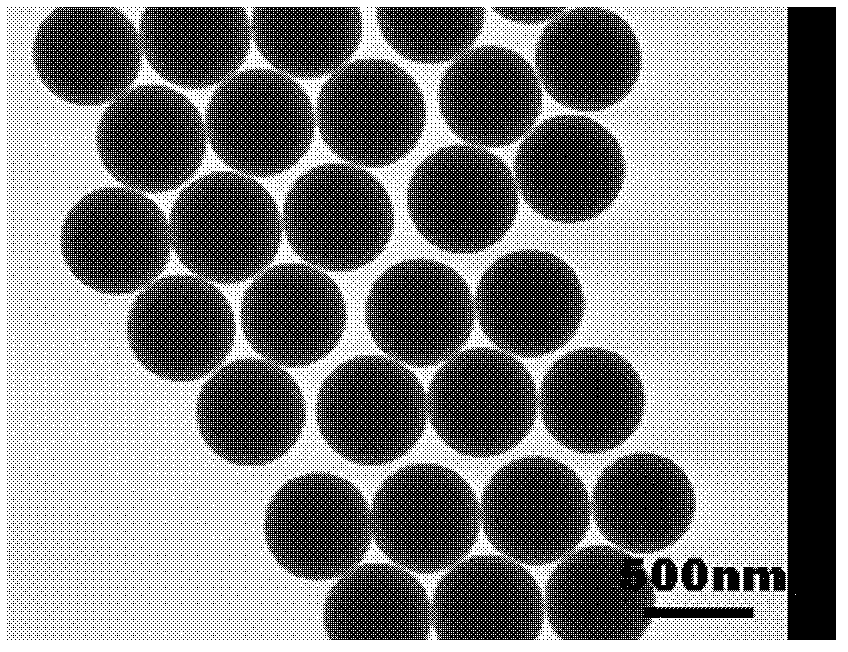

Method for batch preparation of monodisperse submicrometer silica powder

The invention discloses a method for batch preparation of monodisperse submicrometer silica powder. By adopting the method, kilogram-level monodisperse submicrometer silica powder can be further prepared in batches in a one step by formula optimization and self-production of a multifunctional reaction kettle. Compared with the traditional liquid-phase method, the preparation method disclosed by the invention has three main advantages that 1, the procedure is simple; energy is saved and consumption is reduced; and the production cost of the powder is low; 2, the solvent can be used in cycle, and is low-carbon and environment-friendly; and pollution of an organic solvent on air is removed; and 3, the kilogram-level monodisperse submicrometer silica powder or silica concentrated liquor can be prepared in batches, so that storage, transportation and use are facilitated. By adopting the preparation method disclosed by the invention, application development and business development of domestic monodisperse silica are greatly facilitated.

Owner:浩华科技实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com