Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

254results about How to "Low air resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

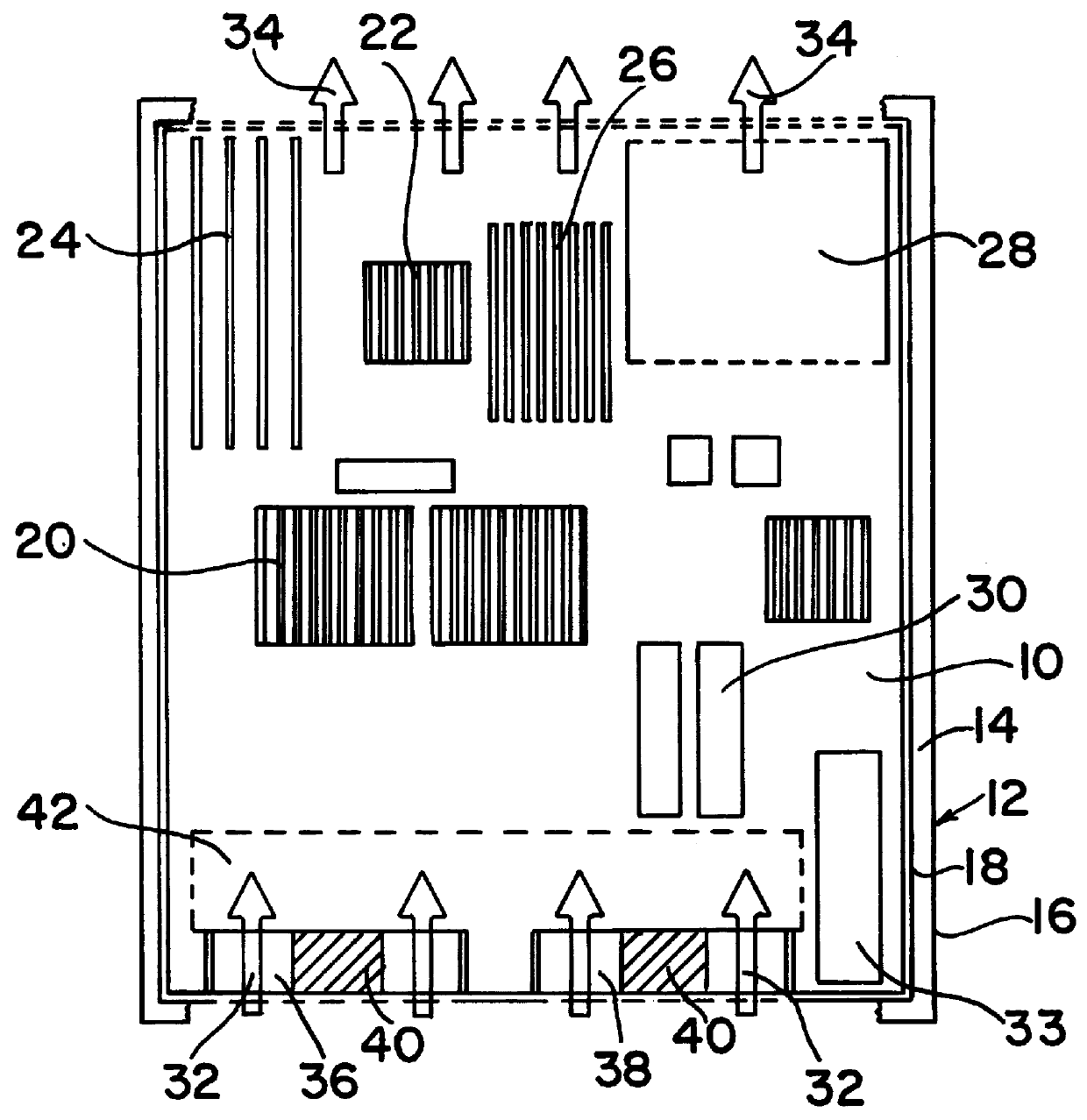

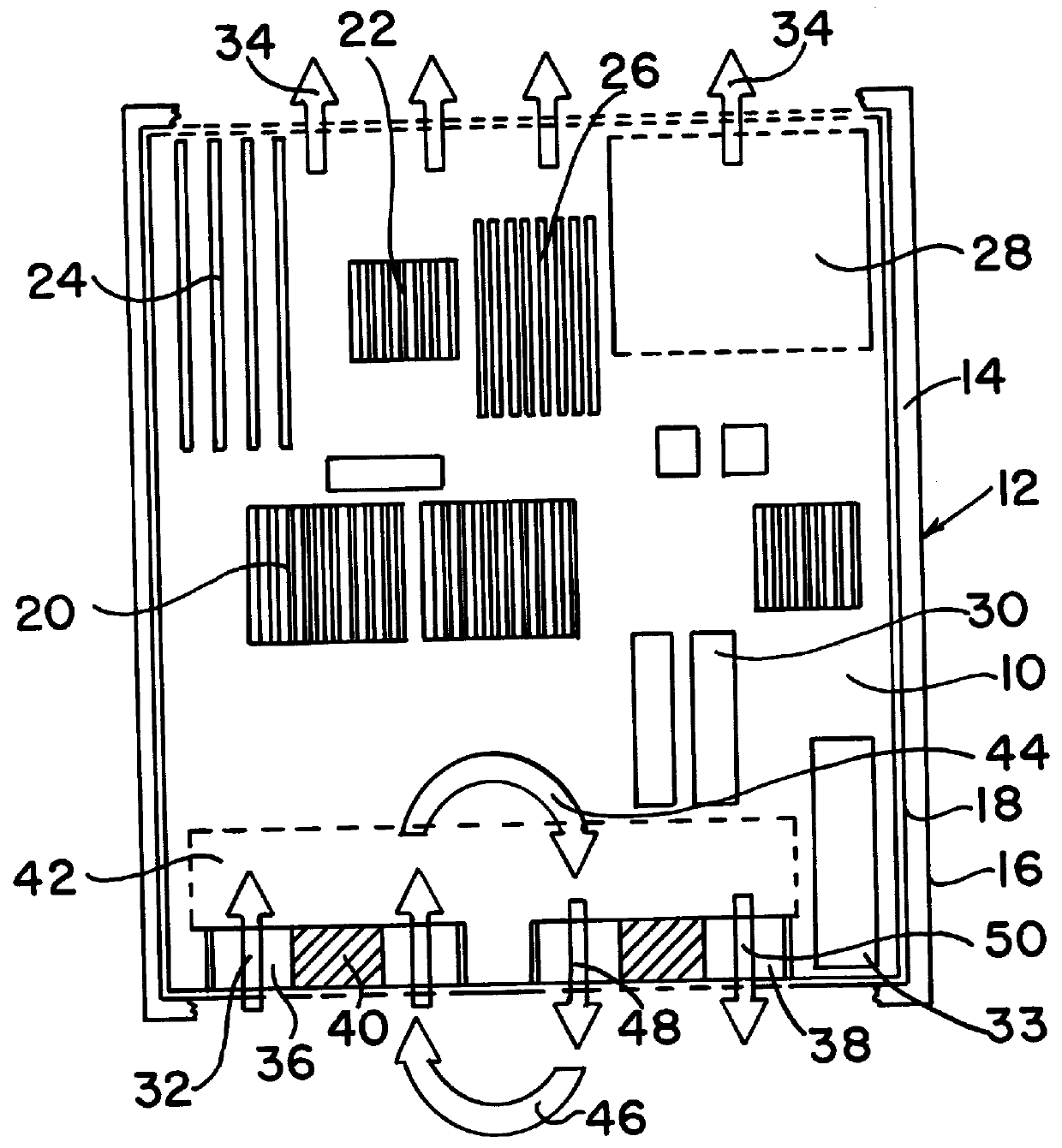

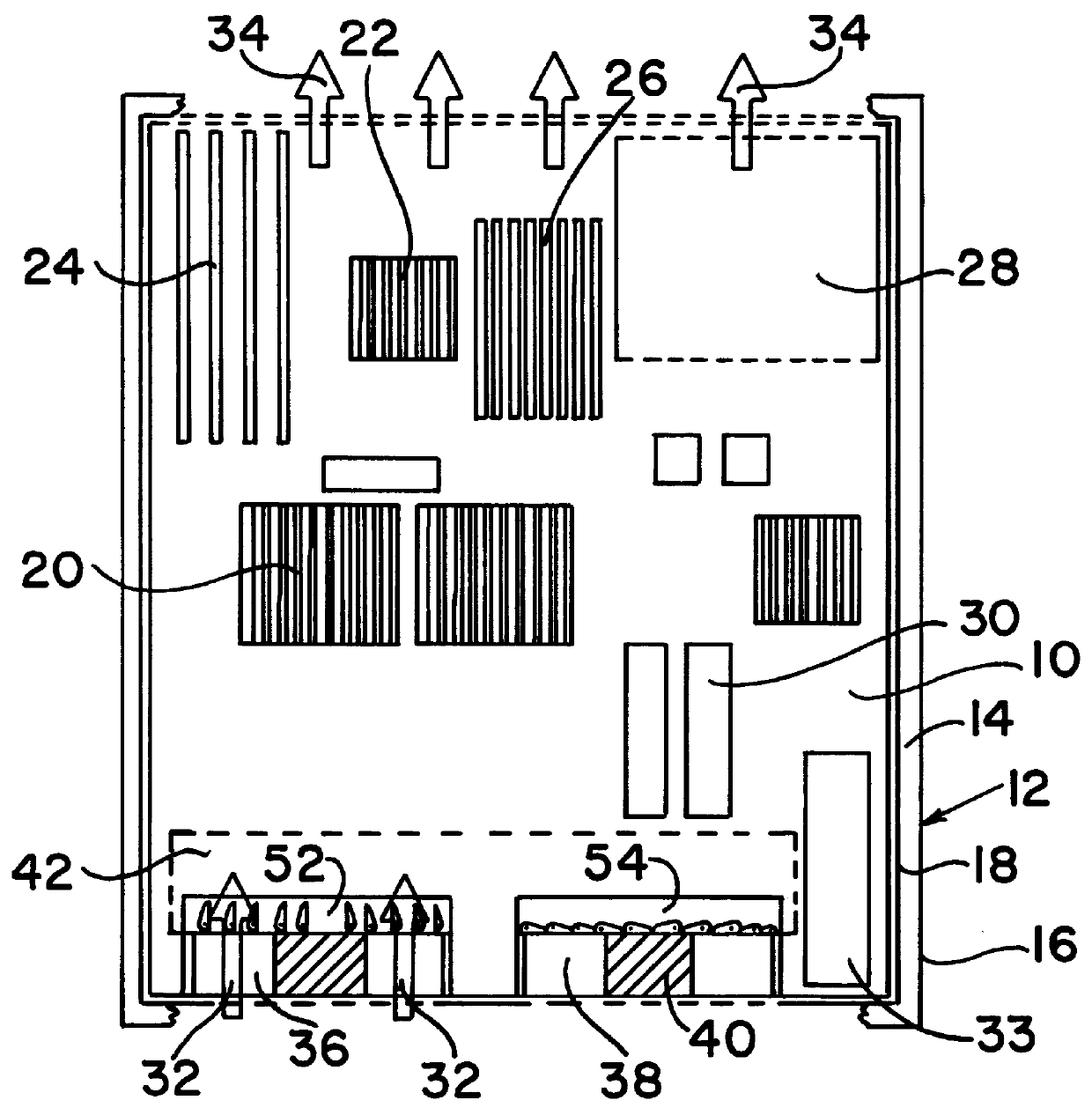

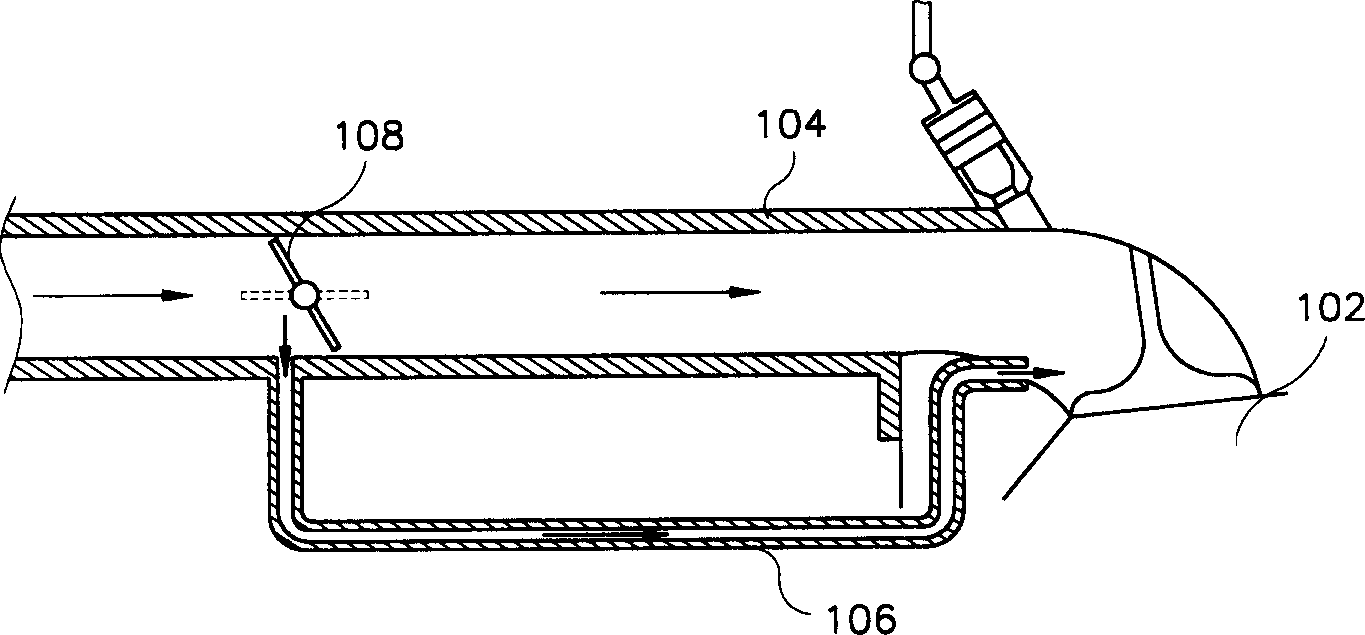

Computer component cooling fan closure device and method thereof

InactiveUS6011689ALow costSpace minimizationLighting and heating apparatusDigital data processing detailsEngineeringAirflow

Disclosed is a system for assisting in preventing over heating of the internal electrical components of a computer in the event of a failure of one of the adjacent fans of an array of fans employed to circulate cooling air over the components. The fans include openings through which air is forced from their inlet sides to their outlet sides. The system includes a vent for each fan arranged adjacent to and aligned with the fan opening at its outlet side. The vents are open and closed by vanes, having hinged slats construction to allow them to fall downwardly by their own weight or additional assistance. The vanes are kept open by the airflow created by the fans. Upon the failure of a fan, the absence of airflow through the opening thereof allows the slats of the vane to drop to close off the fan opening and prevent airflow into the fan opening from its outlet side.

Owner:SUN MICROSYSTEMS INC

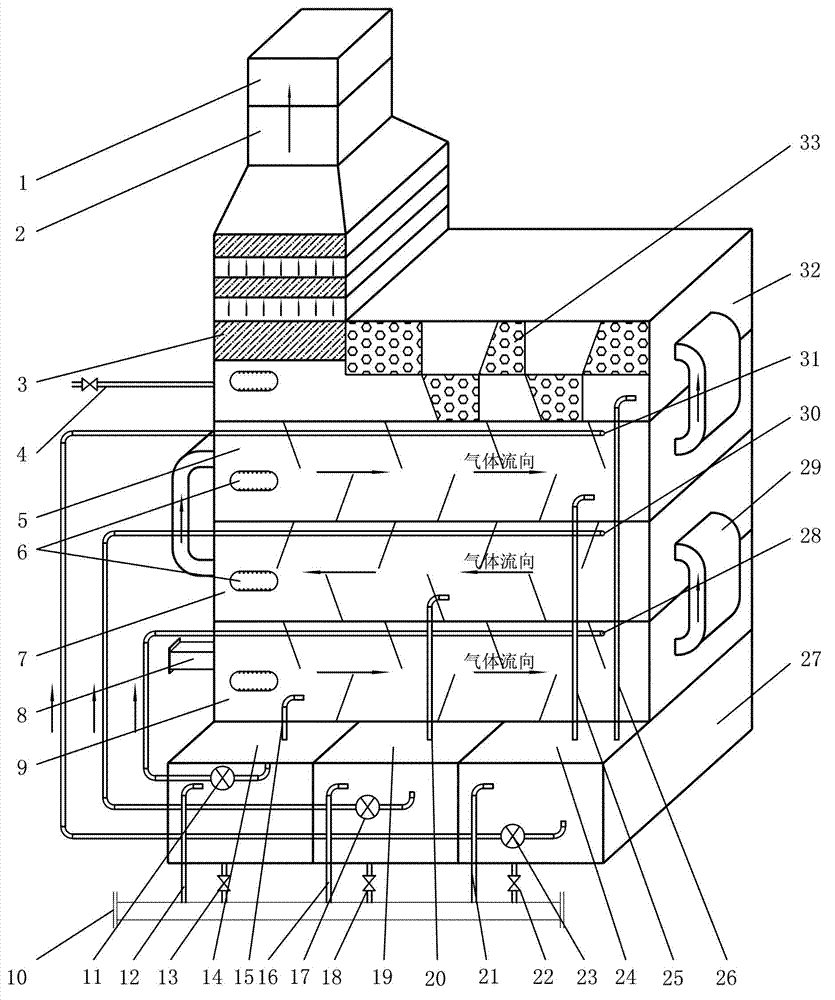

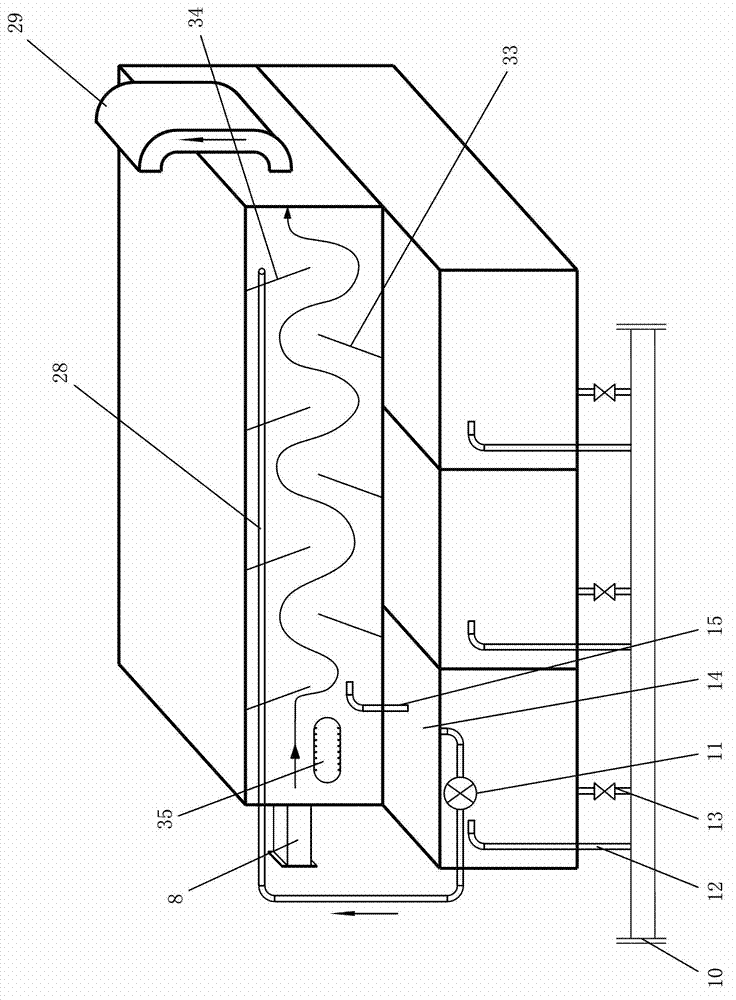

Flue-gas cleaner

InactiveCN103203170AAchieve complete cleanlinessImprove purification effectCombination devicesDraining tubeFlue gas

The invention discloses a flue-gas cleaner, comprising a liquid storage tank, a water spray chamber, an alkali liquor spraying chamber, an oxidized spraying chamber, a gas-liquid separating chamber, an active carbon adsorption chamber and a purified gas outlet, wherein the liquid storage tank is partitioned into at least three sub-tanks; each sub-tank is respectively connected to a sewage master pipe through a sewage branch pipe; the water spray chamber, the alkali liquor spraying chamber, the oxidized spraying chamber and the gas-liquid separating chamber are orderly communicated end to end through a flue-gas pipe, so as to form transverse channels which are connected in series in a reciprocating manner; the inner top part of each chamber is provided with the spraying pipe; and the side is communicated with corresponding sub-tank through a drain tube. The flue-gas cleaner is long in flue-gas flow, large in processing area, high in efficiency, and wide in adaptability, and can comprehensively process various toxic and harmful gases.

Owner:周勇定

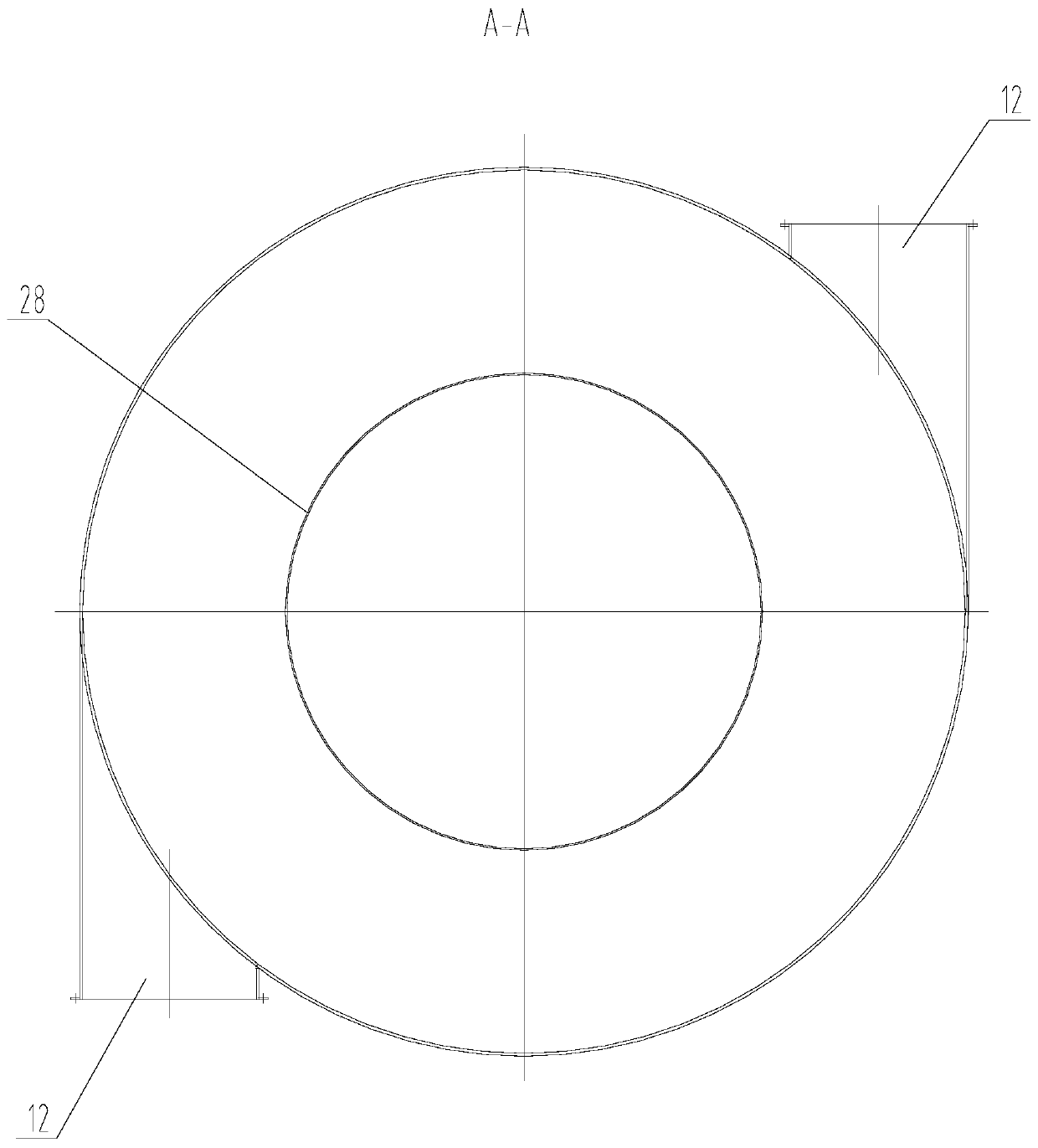

Honeycomb heat accumulator made of silicon carbide-corundum composite materials

ActiveCN101798212ASimple compositionHigh refractorinessChemical industrySmall footprintPetrochemical

The invention relates to a honeycomb heat accumulator made of silicon carbide-corundum composite materials, which comprises the following main raw materials: 20-30wt% of silicon carbide powder, 4-8wt% of zirconia corundum powder, 20-30wt% of corundum powder, 15-20wt% of porzite powder, 15-30wt% of composition of kyanite, andalusite and sillimanite, 4-8wt% of kaolin and 2-5wt% of cellulose powder. The preparation method of the honeycomb heat accumulator comprises the following steps: adding the main raw materials into a ball mill for ball milling; adding stearic acid of which the weight is not greater than 1% of the total weight of the main raw materials for ball milling, and then, sieving to obtain a mixture; respectively adding tung oil of which the weight is not greater than 1% of the weight of the mixture and glycerol of which the weight is not greater than 1% of the weight of the mixture for mixing, aging and vacuum pugmill to form pug segments; carrying out extrusion forming in a mold, and drying; and insulating at the temperature of 1400-1450 DEG C for 4-8 hours, and then, calcining. The honeycomb heat accumulator of the invention has the characteristics of high fire resistance, good thermal shock resistance, strong corrosion resistance, large heat exchange area, small gas flow resistance, high heat accumulating efficiency, small floor space and long service life which can be more than two years, and is widely used for heat accumulating type heating furnaces of black and non-ferrous smelting, thermal power generation, petrochemical industry, ceramics, glass, machining, civil cookers and the like.

Owner:JIANGXI SHINCO ENVIRONMENTAL PROTECTION CO LTD

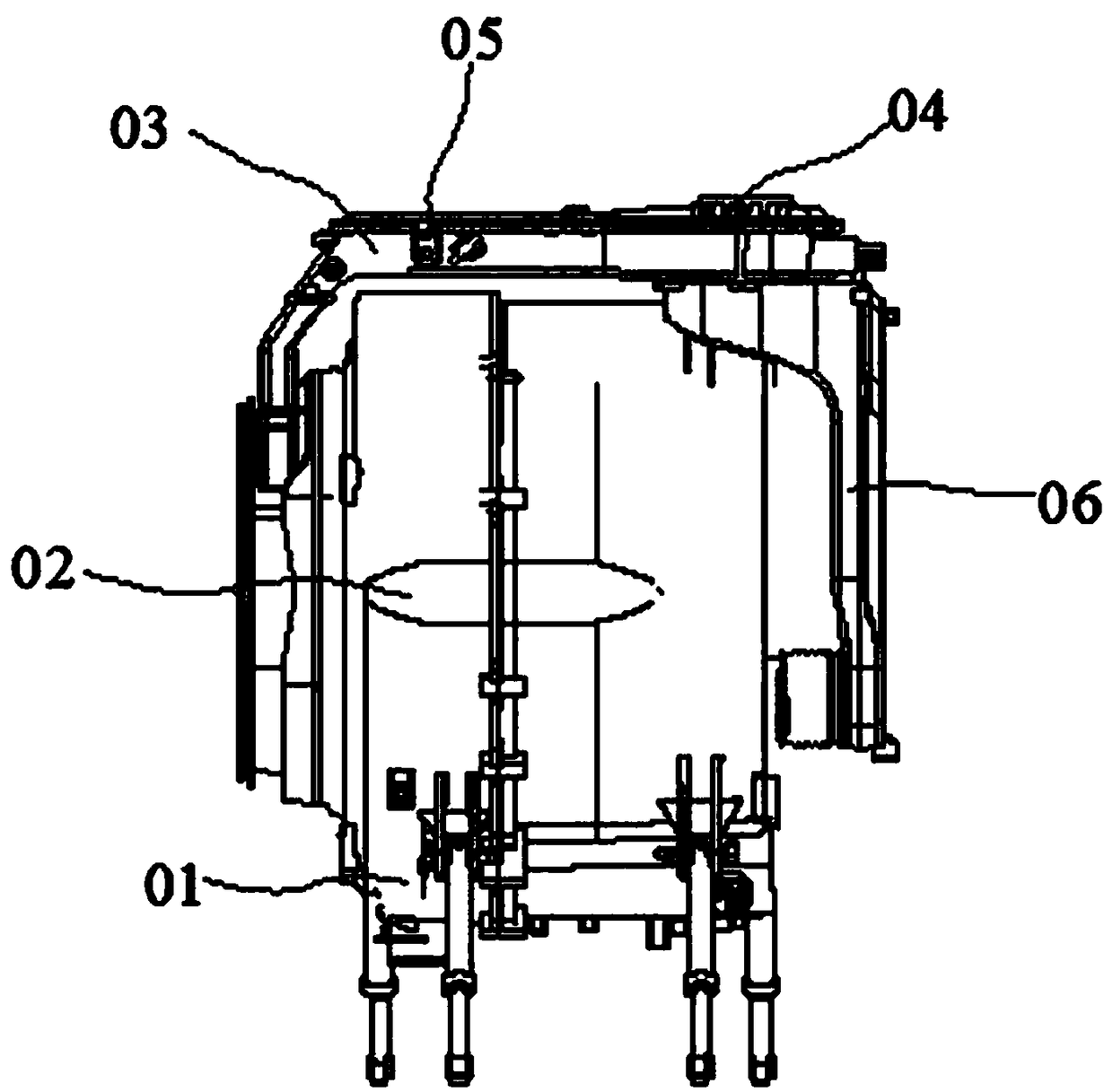

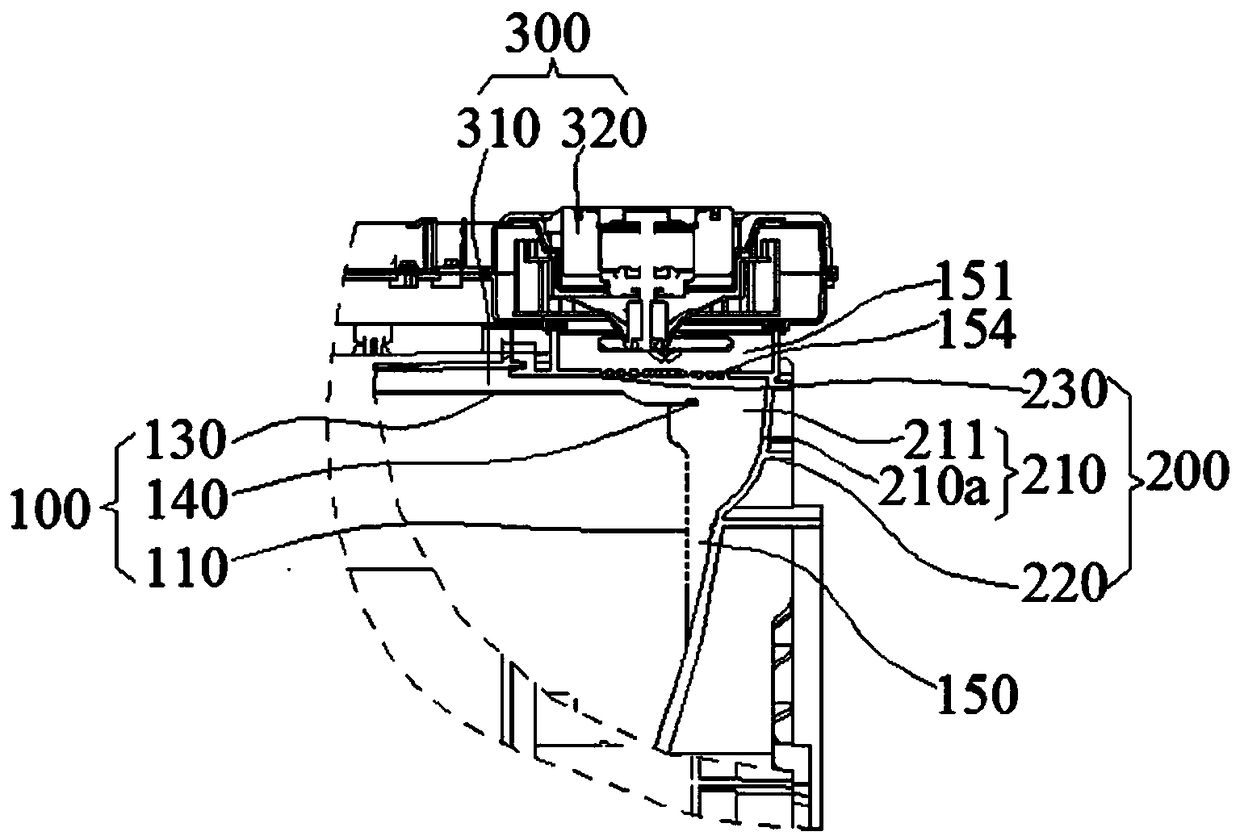

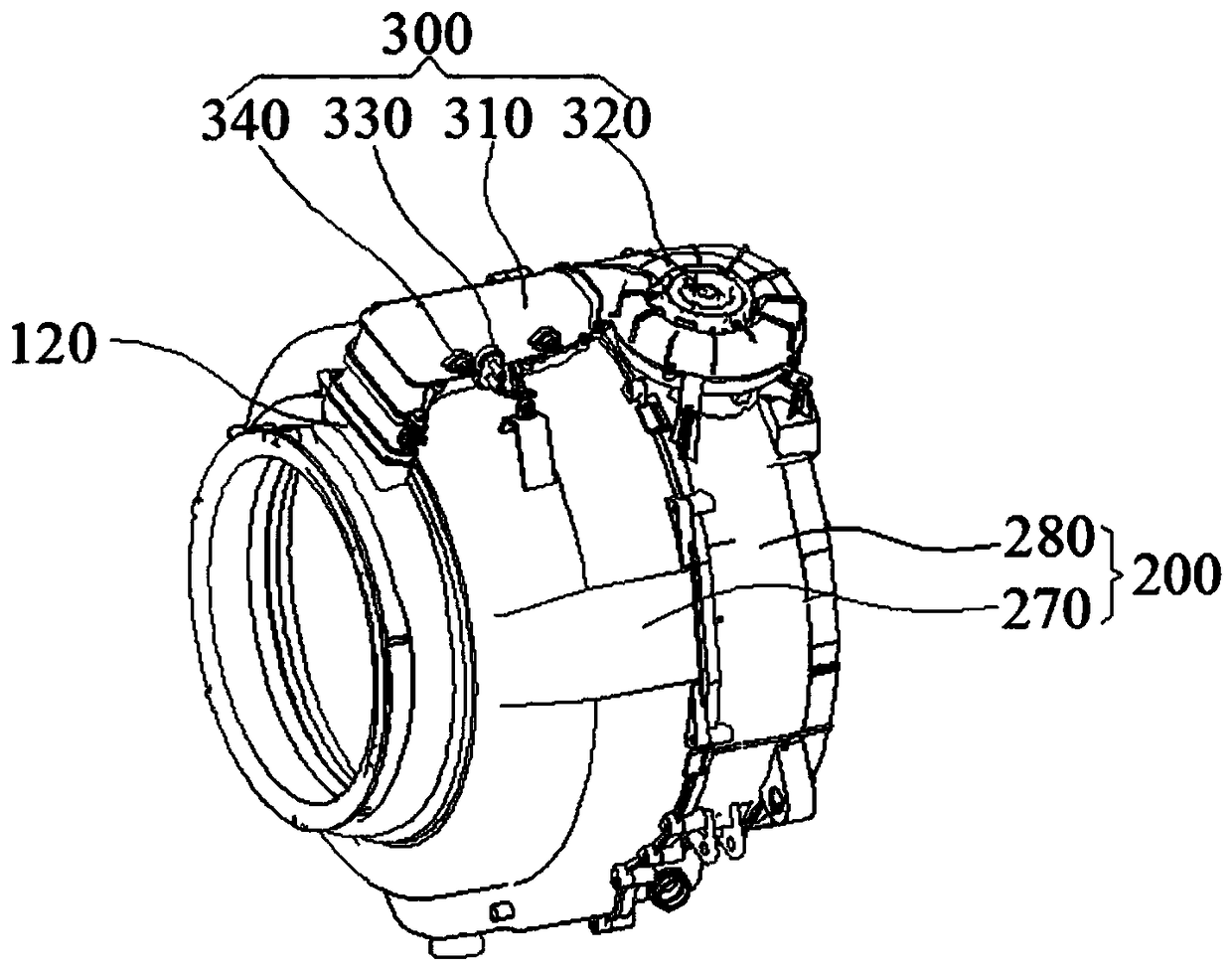

Washing machine with drying function

ActiveCN109267286AReduce escapeLow air resistanceOther washing machinesWashing machine with receptaclesPulp and paper industry

The invention discloses a washing machine with a drying function, and relates to the technical field of washing machines. The washing machine is invented to solve the problem that an existing ultrathin washing machine is poor in drying effect. The washing machine with the drying function comprises an inner barrel, an outer barrel and a drying assembly. A condensation cavity is formed between the rear wall of the inner barrel and the rear wall of the outer barrel, the drying assembly comprises a heating air duct, a fan and a heating device, and the fan and the heating device are arranged in theheating air duct. One end of the heating air duct is communicated with an air outlet of the condensation cavity, the other end of the heating air duct is communicated with the inner barrel, and air in the inner barrel is drawn into the condensation cavity to be condensed through the fan, is guided into the heating air duct an is drawn into the inner barrel o from a circulation after being heatedby the heating device, so that clothes is dried. The position, close to an air outlet of the condensation cavity, in the rear wall of the outer barrel is recessed in the direction away from the innerbarrel to form an expanded cavity. The washing machine with the drying function is used for washing and drying the clothes.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

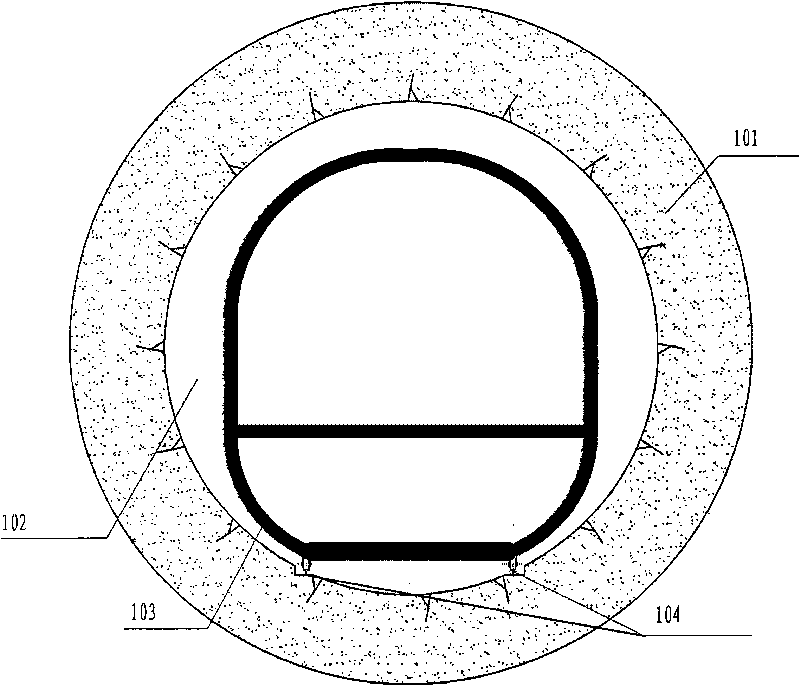

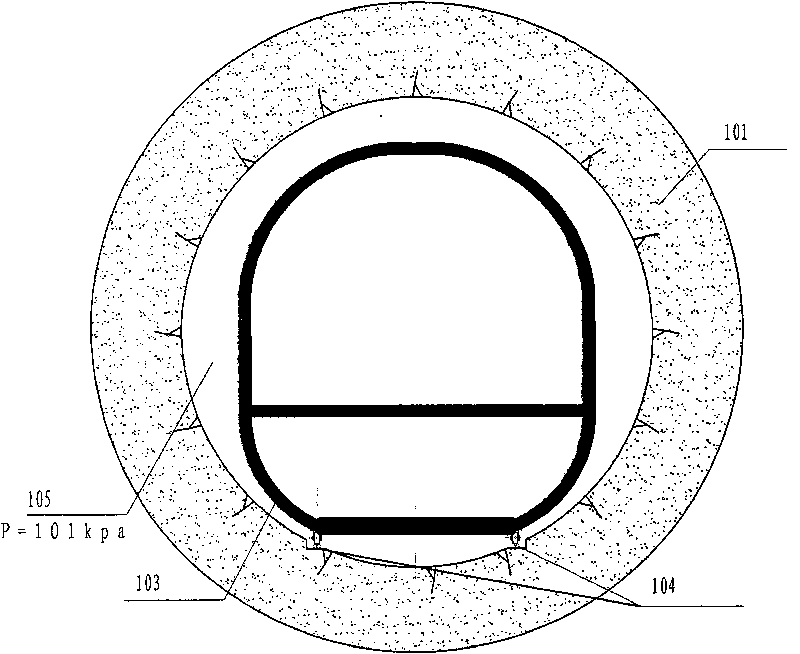

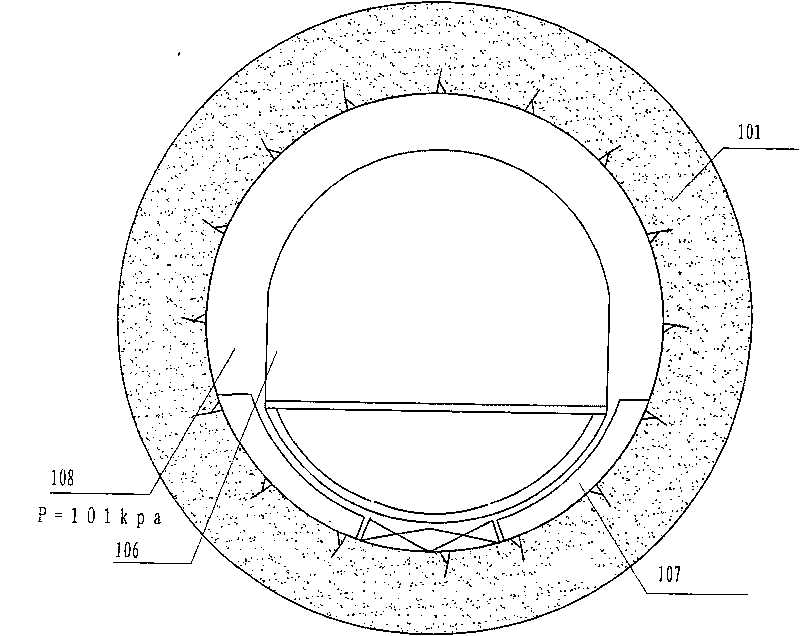

Light gas pipeline

InactiveCN101746378ALow air resistanceRun fastRailway tunnelsElectric propulsionGas pipelineProduct gas

The invention provides a light gas pipeline engineering structure, which can implement pipeline superspeed transportation under normal pressure state, and also can implement higher speed transportation under low vacuum or super low vacuum. The technology not only can remarkably reduce the gas-flow resistance of transporting vehicles in the pipeline so as to improve the running speed, but also can save energy consumption under the same technical condition, reduce project construction and operation management cost, and is easy for constructing because the materials of light gas have rich resources.

Owner:彭智祥

Ultra-low noise cooling tower with integrated structure dropping plate and water tank

InactiveCN1651842AReduce noiseReduce the static head valueSound producing devicesTrickle coolersLow noiseCooling tower

The present invention relates to an ultralow noise cooling tower with water-dripping plate and water-collecting pond integrated structure, belonging to the field of fluid engineering technology. Said cooling tower includes the following main portions: water collector, fan, water inlet pipe, nozzle, filler and integrated structure formed from water-dripping plate, large water-collecting pond and small water-collecting pond. Said invention also provides the concrete structure of the above-mentioned portions and their connection mode. Said invention has the obvious effect of reducing water-dripping noise and saving energy.

Owner:SHANGHAI JIAO TONG UNIV

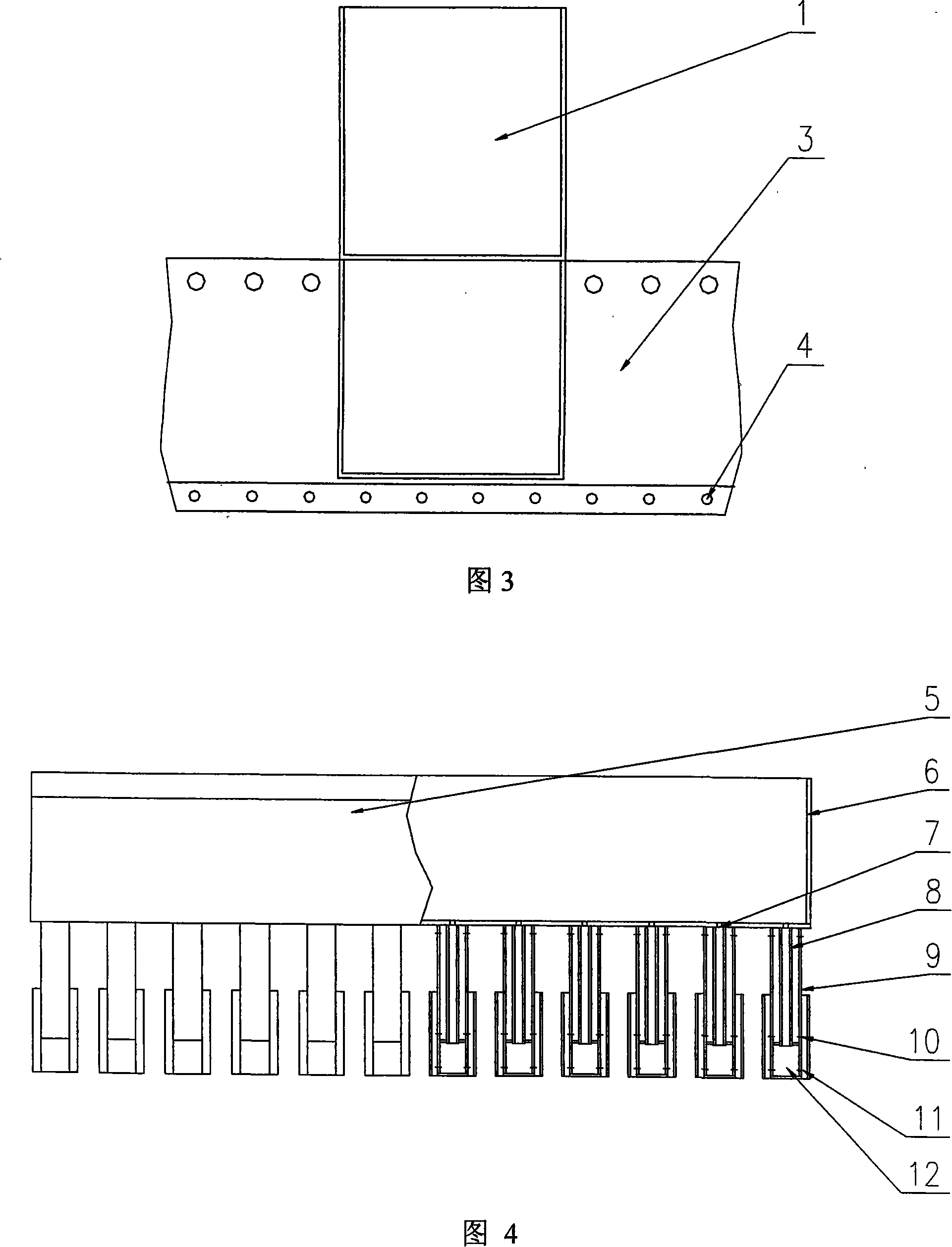

Lamp radiator structure

InactiveCN102242918AWill not affect flowUniform heat load distributionLighting heating/cooling arrangementsLight fasteningsEngineeringCavity wall

The invention discloses a lamp radiator structure and belongs to lamps. The lamp radiator structure comprises a main body frame, a bulb, a reflective bowl, a fan, a heat insulation transparent plate and a radiator, and is characterized in that: the radiator has a cage shape, is enclosed outside a bulb and consists of an upper ring, a chassis, a plurality of fins and one or more closed air guide cavities attached to the main body frame, wherein one end of each fin along an axis is fixed on the circumference of the upper ring and the other end of each fin along the axis is fixed on the circumference of the chassis; an air gap is formed between adjacent fins; partial cavity walls of the air guide cavities consist of the main body frame; the air guide cavities approximately extend from top to bottom along an inner wall of the main body frame; an air outlet of the fan is communicated with a beginning end of the air guide cavities; and a tail end of the air guide cavities passes through a space enclosed by the reflective bowl and the heat insulation transparent plate. Airflow at the air outlet is radially dispersed, the airflow resistance is low, thermal load of the fins is uniform and the radiating effect is good; and the lamp radiator structure is suitable for lamps such as stage lamps, projection lamp and the like.

Owner:PR LIGHTING

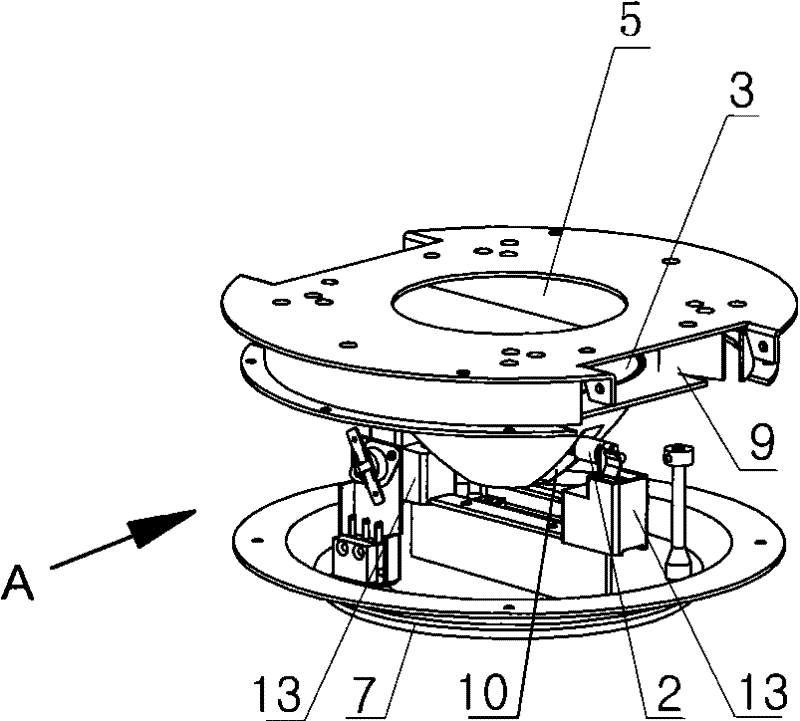

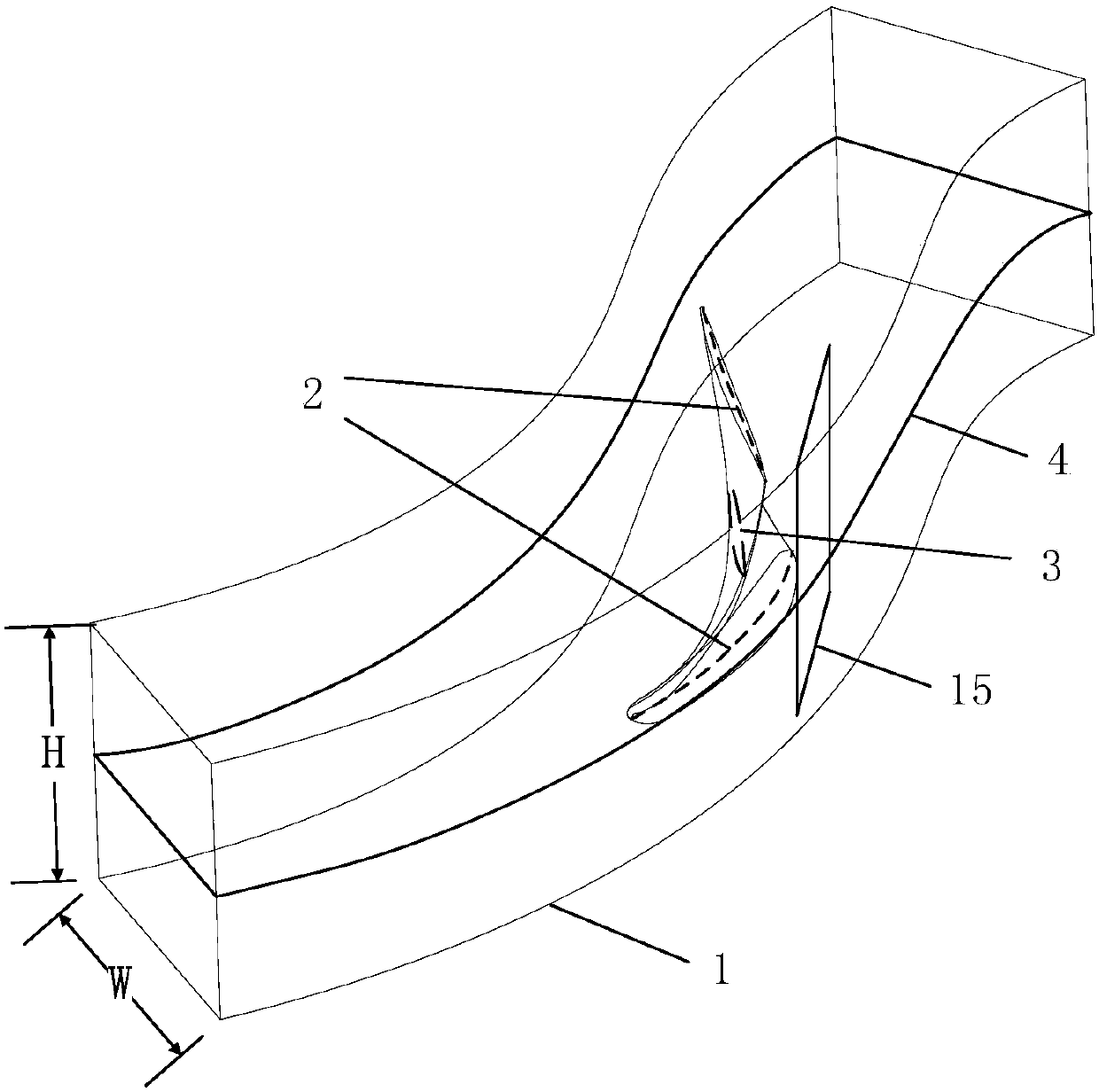

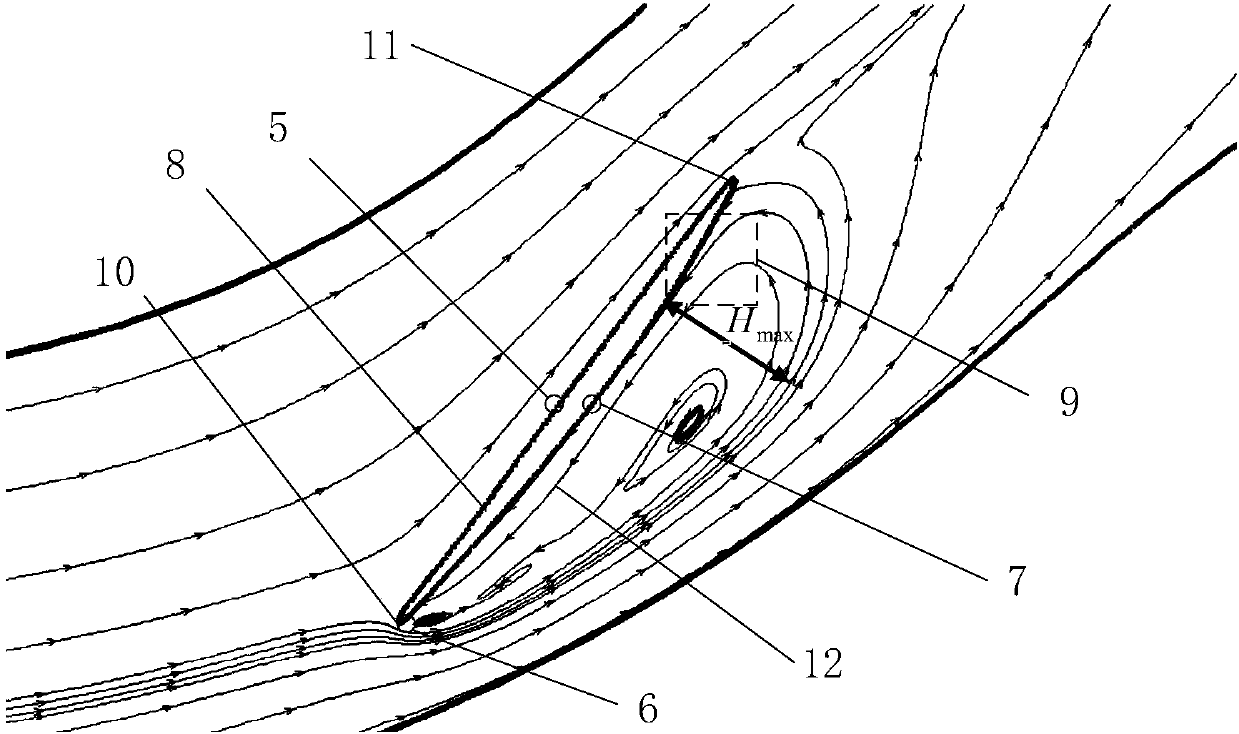

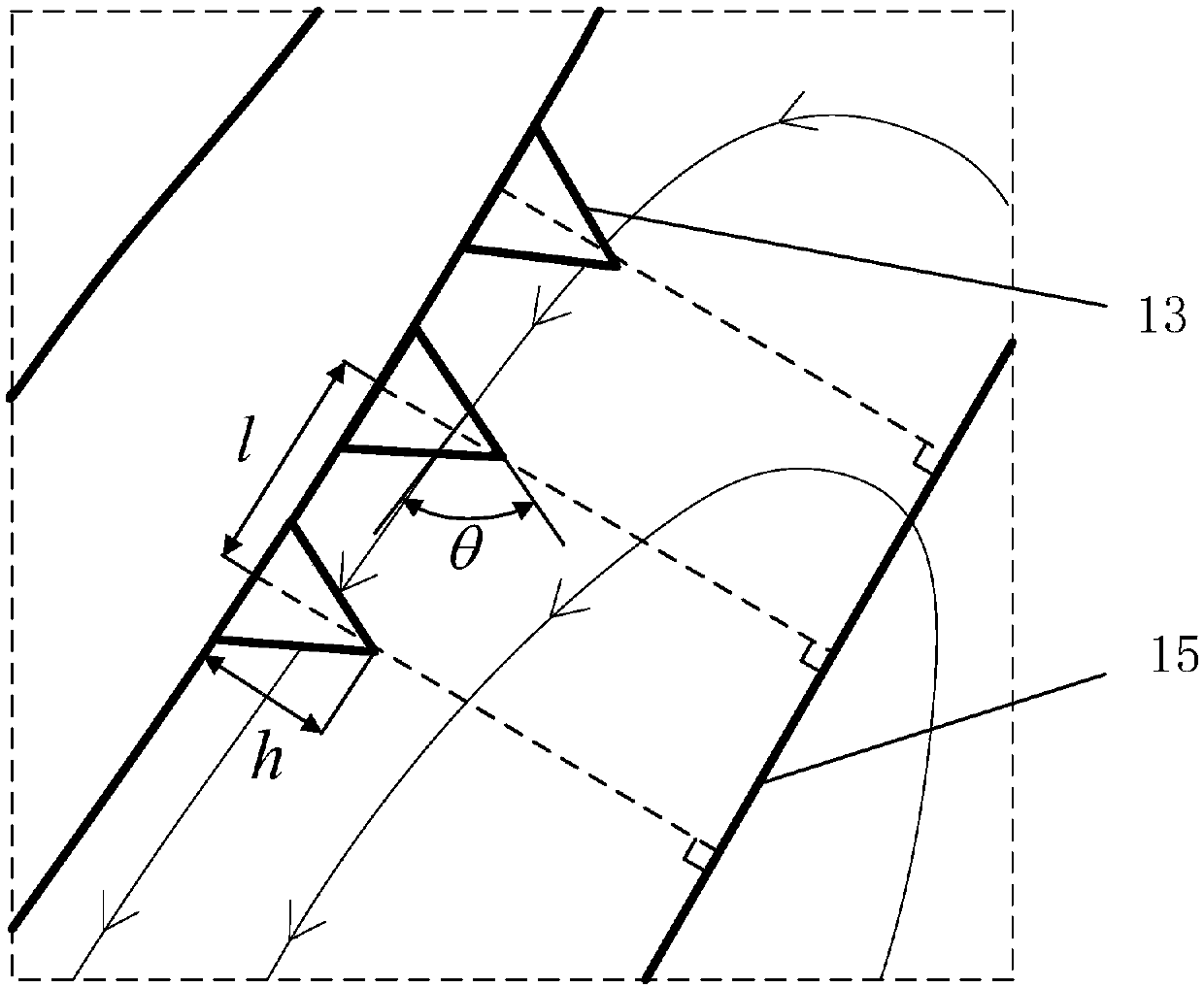

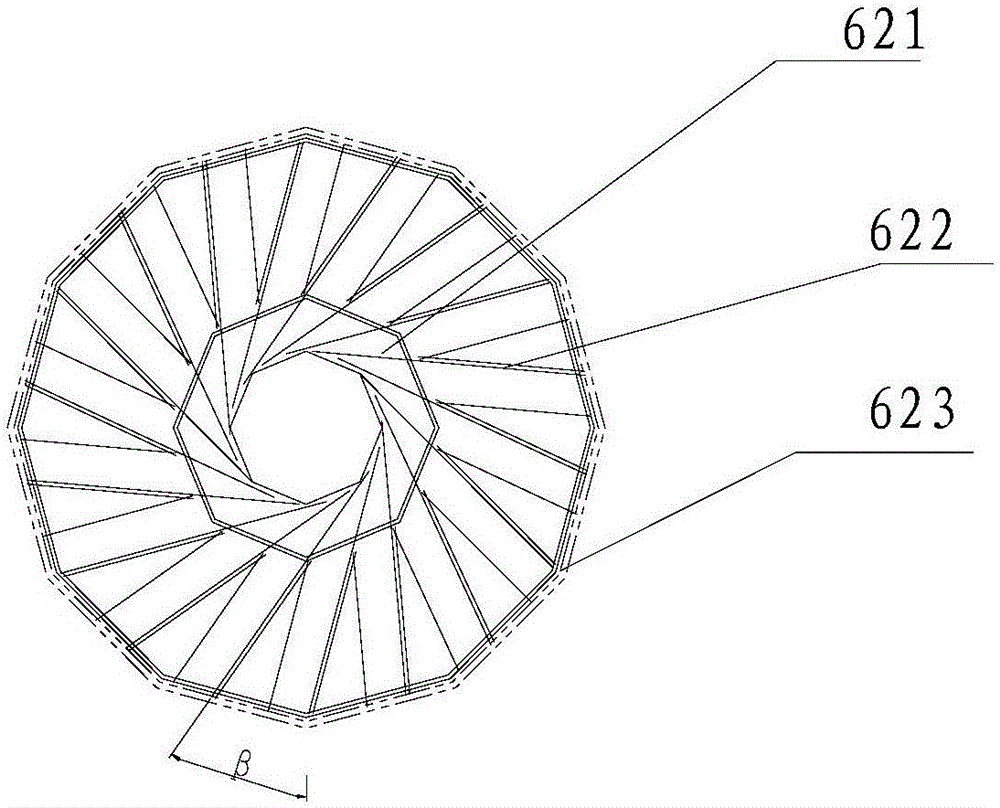

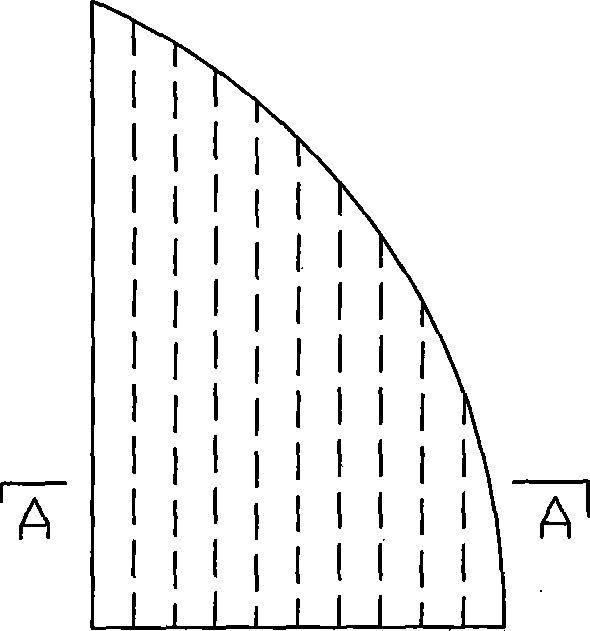

Design method of impeller blade drag reduction micro-texture

ActiveCN107742011ALow air resistanceReduce consumptionGeometric CADSustainable transportationImpellerEngineering

The invention discloses a design method of a blade surface drag reduction micro-texture, and belongs to the field of blade drag reduction. According to an impeller blade model, a flow field domain isestablished; numerical simulation is carried out on the flow field domain, a streamline graph of the middle section of a blade in the height direction is obtained, and accordingly a blade pressure surface, a boundary layer separation area and a suction surface backflow area serve as a micro-texture placement area; the micro-texture placement area is closely attached to a blade wing-shaped arrangement micro-texture section, and the micro-texture placement area sweeps on the surface of the blade in the height direction of the blade to form ribs or grooves; finite element simulation is conductedon the blade model with the rib or groove micro-texture to optimize the placement position and the section shape of the micro-texture, the placement position and the section shape of the micro-texturewith the best drag reduction are obtained, and accordingly the blade surface drag reduction micro-texture is constructed. The drag reduction of the optimized blade surface drag reduction micro-texture reaches 5-10%, the energy consumption is reduced, fuel resources are saved, and the design method of the drag reduction micro-texture can be applied and popularized in other fields.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

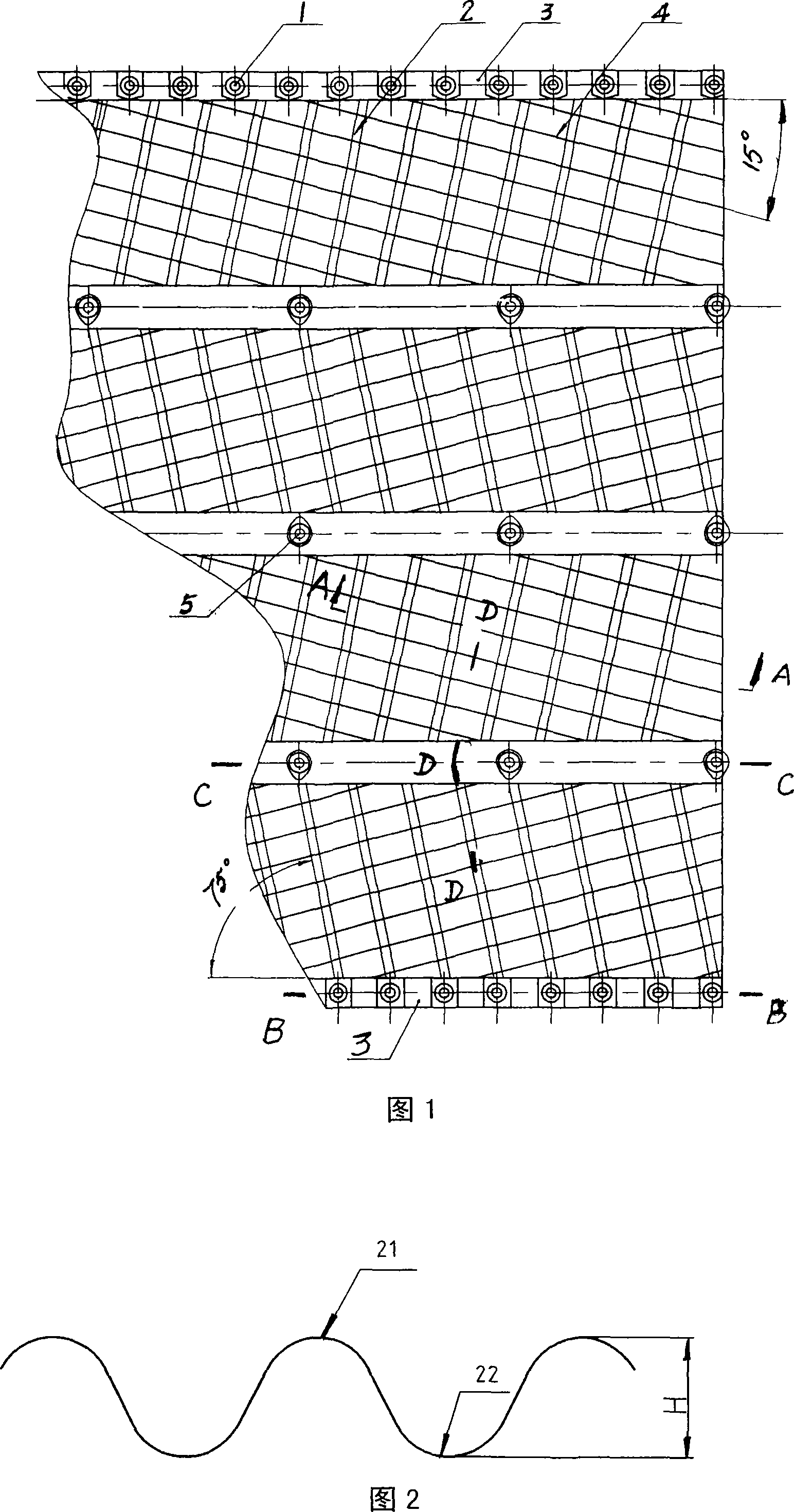

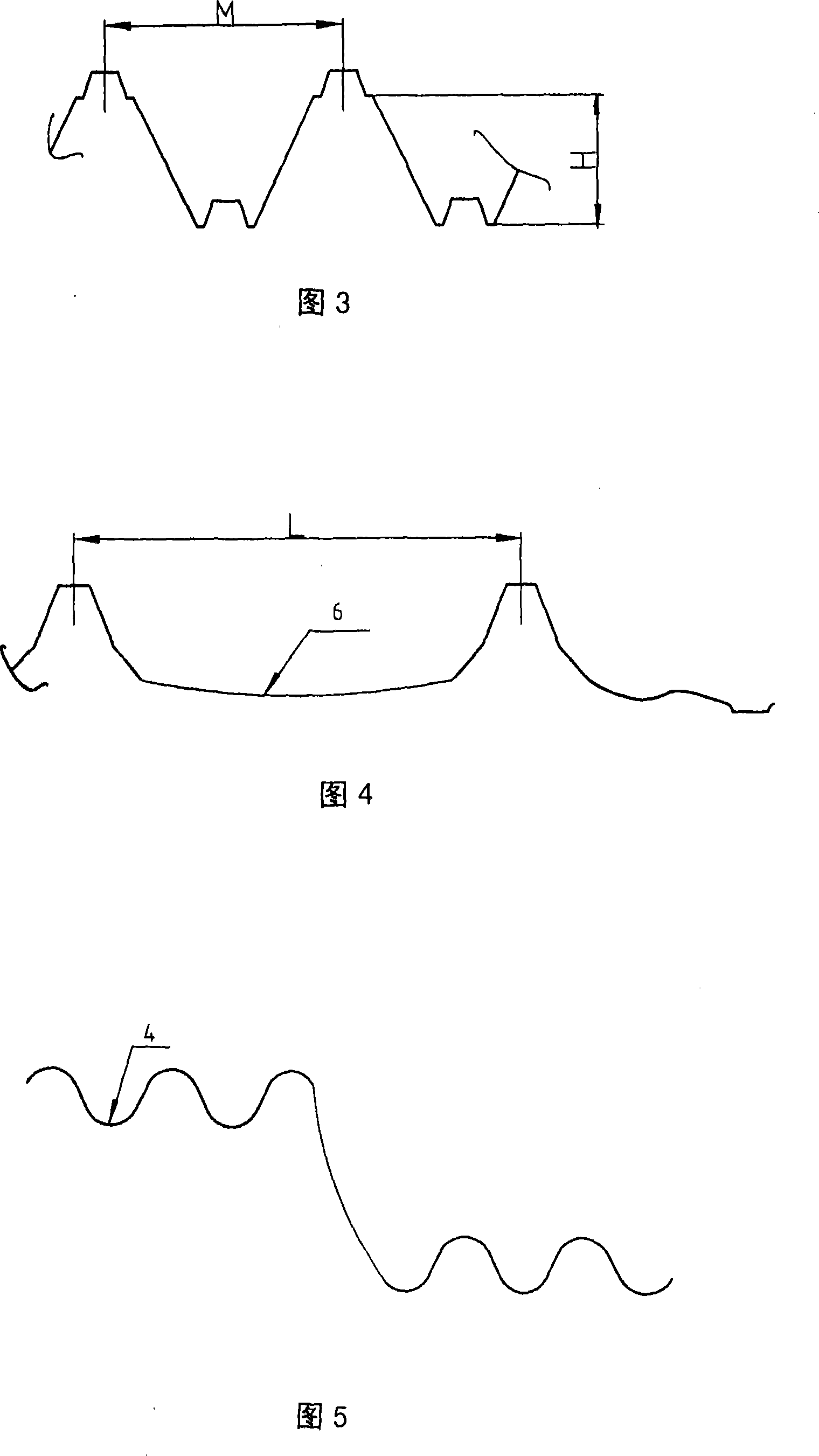

New type dual oblique wave spraywater stuffing for cooling tower

This invention relates to new double-slope wave trickle fillings of a cooling tower, in which two adjacent sets of main cooling wave bands are arranged reversely in stagger with a pitch of waves in between, the distance of the internal binding points is 2-3 times that of the exterior one, a secondary stagnant wave groove is set on the wave band and the cross section is a sine wave, the angle between the stagnant wave groove and the length edge is 15deg, a shunt bank is set between the peak of a main wave band and the valley of the adjacent main wave band to transit smoothly and the highest point of the shunt bank is 4 / 1-2 / 1 of the peak.

Owner:常州金坛塑料厂

Flue gas wet desulphurization, dedusting integrated device and process

ActiveCN106582248AIncrease heightSmall particle sizeCombination devicesGas treatmentFlue gasProcess engineering

The invention discloses a flue gas wet desulphurization, dedusting integrated device and process. Original flue gas sequentially enters into an absorbing tower, then passes a pallet layer, a spraying layer, an ultra-fine atomizing and cooling zone and a swirling flow demisting layer to be discharged from an outlet of the absorbing tower. The pallet layer rectifies the flue gas entering into the absorbing tower, then the flue gas ascends in a uniform flow speed on the section of the absorbing tower. SO2 in the flue gas is absorbed and removed. The desulphurized saturated flue gas carrying tiny slurry droplets and dust undergoes atomizing and spraying to be cooled down. The tiny slurry droplets and dust in the flue gas is cooled down in temperature, then condenses and precipitates to a tower slurry pond. The over-saturated flue gas carrying tiny fog droplets continues to ascend to pass through the swirling, liquid knockout, enrichment and removal. The clean flue gas is emitted. The flue gas wet desulphurization, dedusting integrated device and process not only can enhance the removal efficiency of SO2, but also can obviously enhance the dedusting efficiency of the absorbing tower, and achieve the super low emission of the flue gas.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

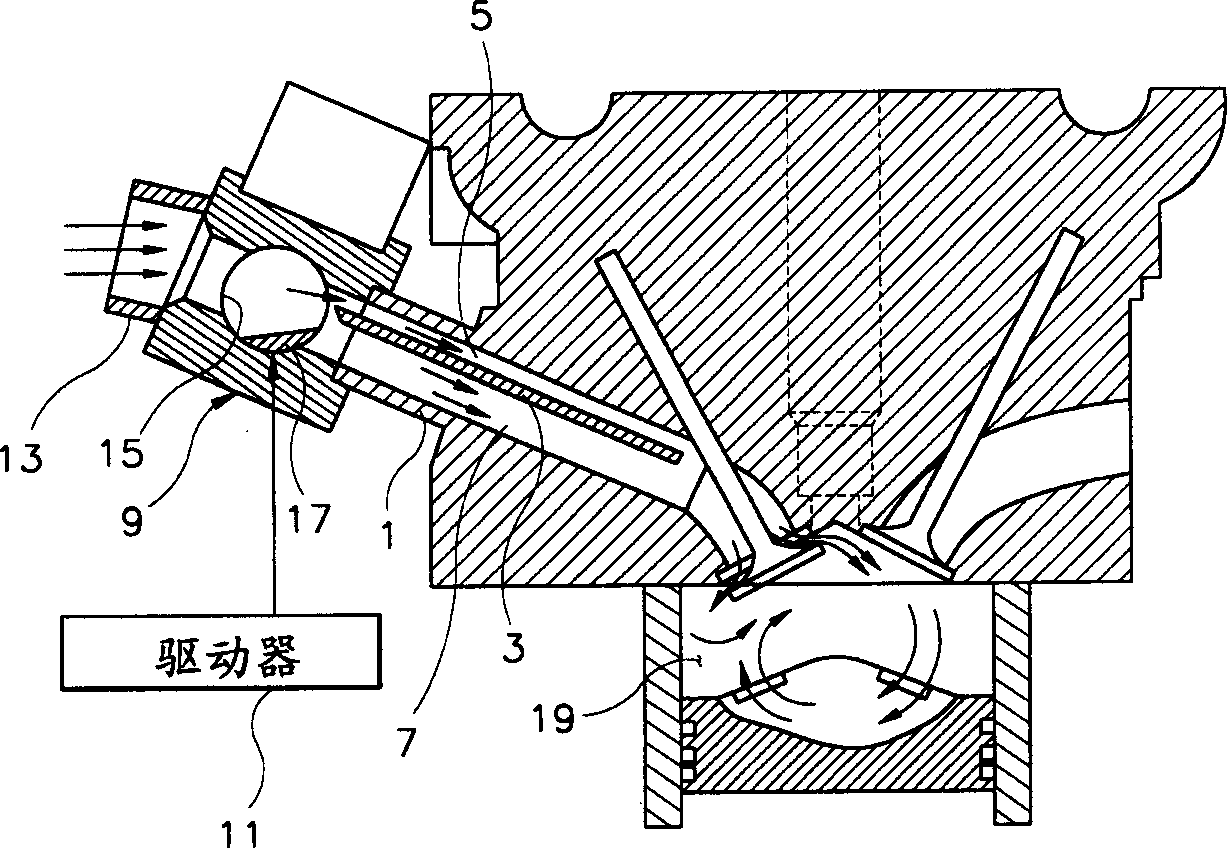

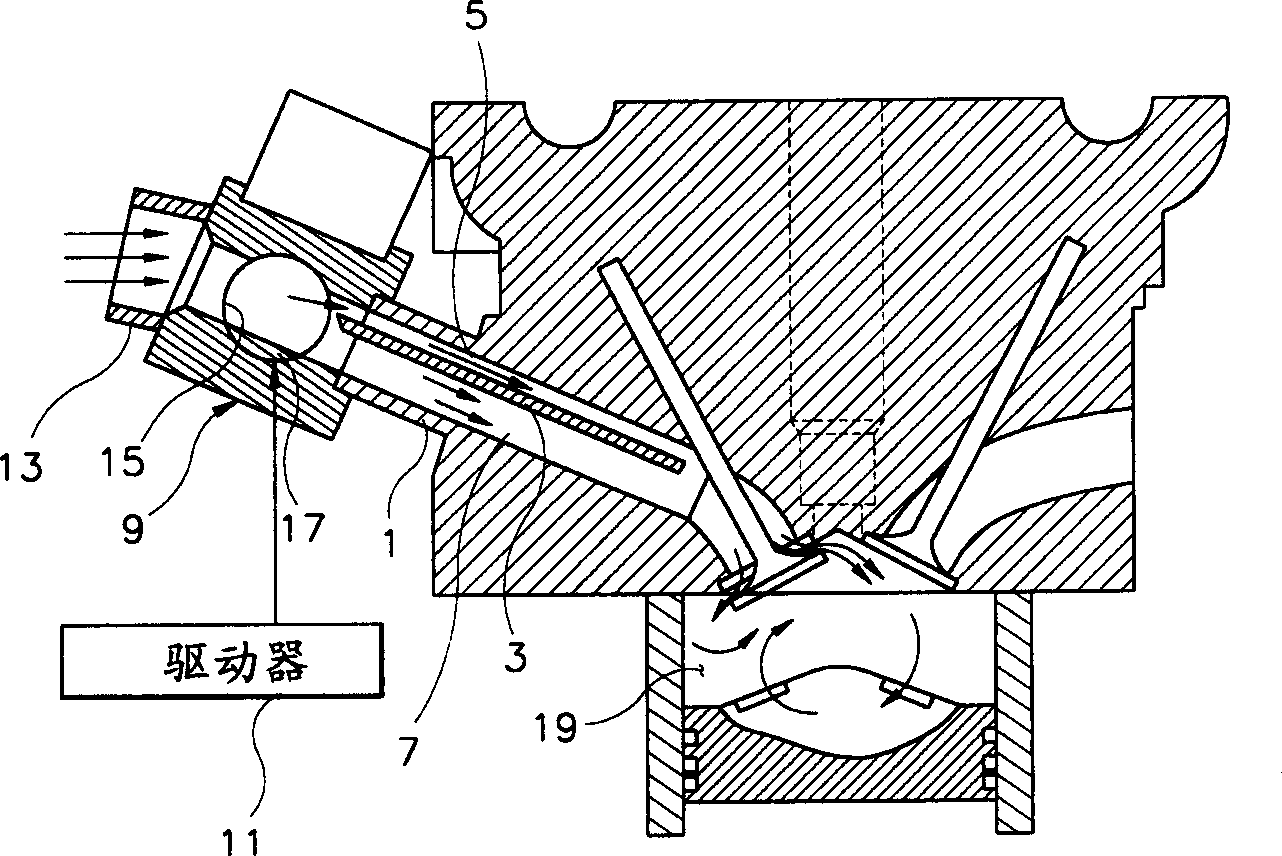

Engine-adjustable whirlwind generator and method for processing air-inlet hole of adjustable whirlwind generator

InactiveCN1362576ALow air resistanceSimple structureInternal combustion piston enginesCylinder headsCombustion chamberControl valves

The present invention relates to a variable tumble flow-generating device, which comprises: a bulkhead for dividing an intake port into a first passage and a second passage; an opening degree control valve for selectively changing an opening degree of the first and second passages; and driving means for operating the opening angle control valve. This variable tumble flow-generating device can generate tumble flow by making air flow through different passages while minizing a flow resistance of air supplied into the combustion chamber, and which has a simple structure so that a limitation in its installation space in relation with other parts can be avoid. Also, the variable tumble flow-generating device is manufactured by adding only a structure where the bulkhead is previously assembled with the intake port core of the prior art. For this reason, this is a simple structure and thus is manufactured at inexpensive costs.

Owner:HYUNDAI MOTOR CO LTD

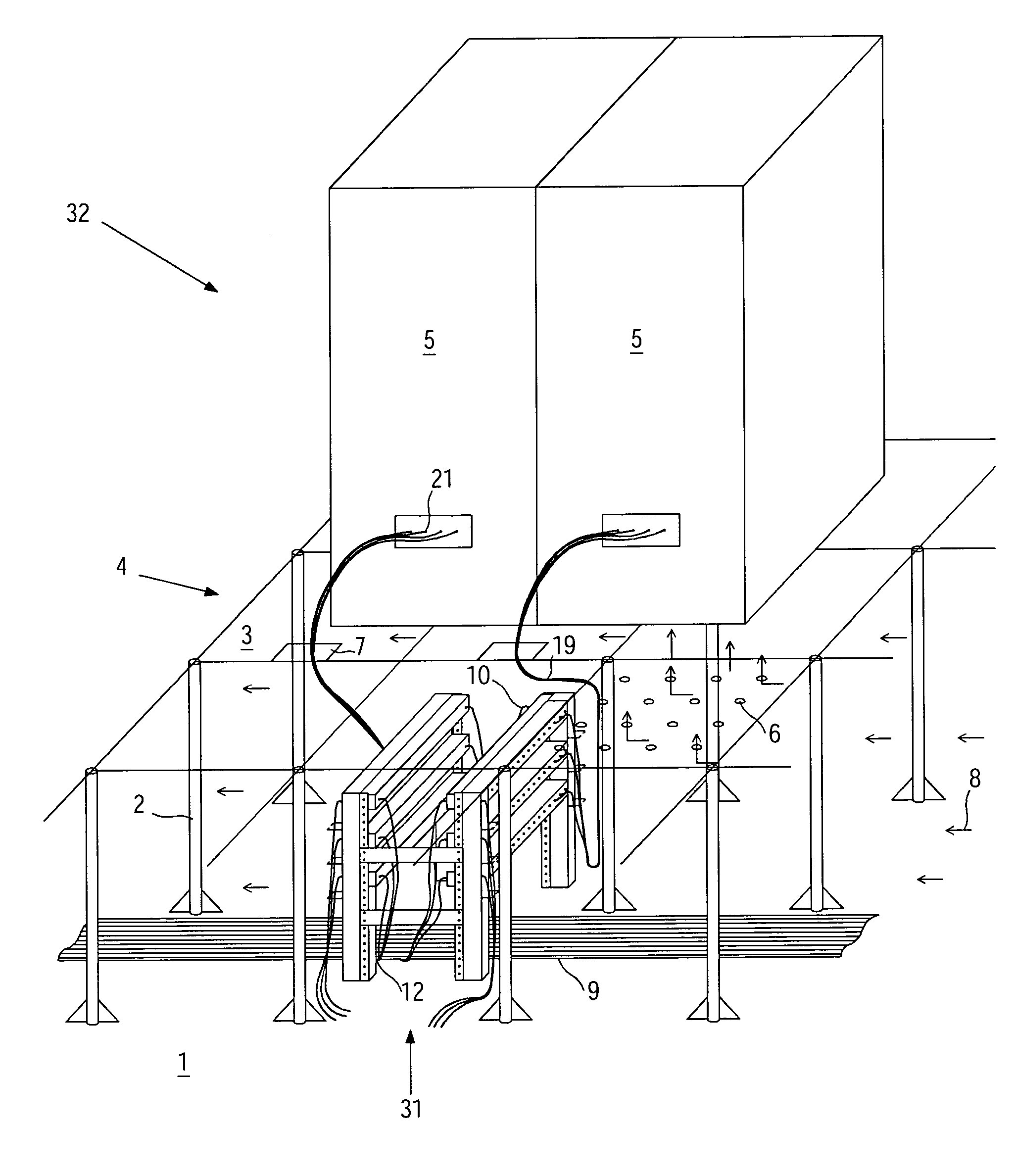

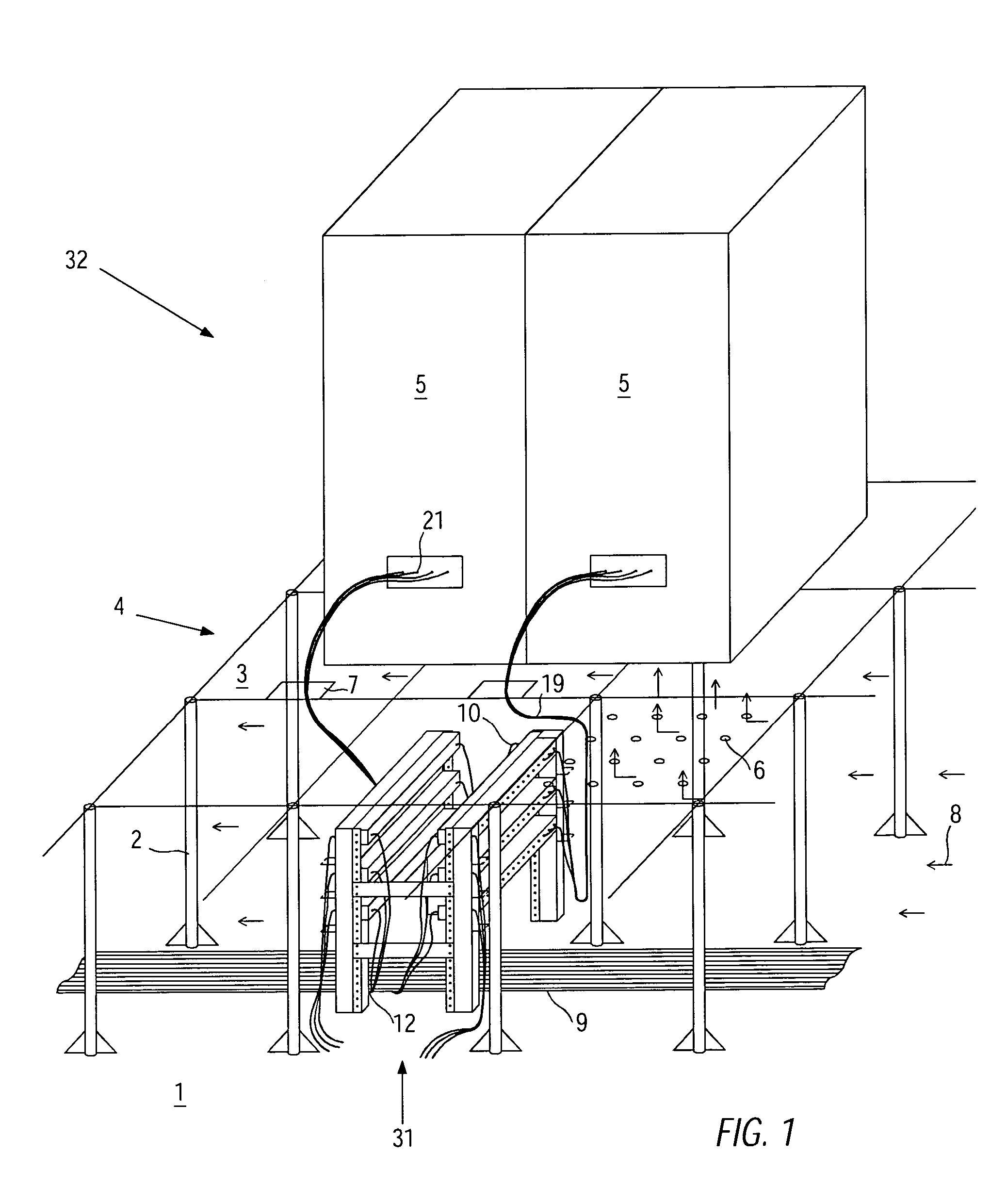

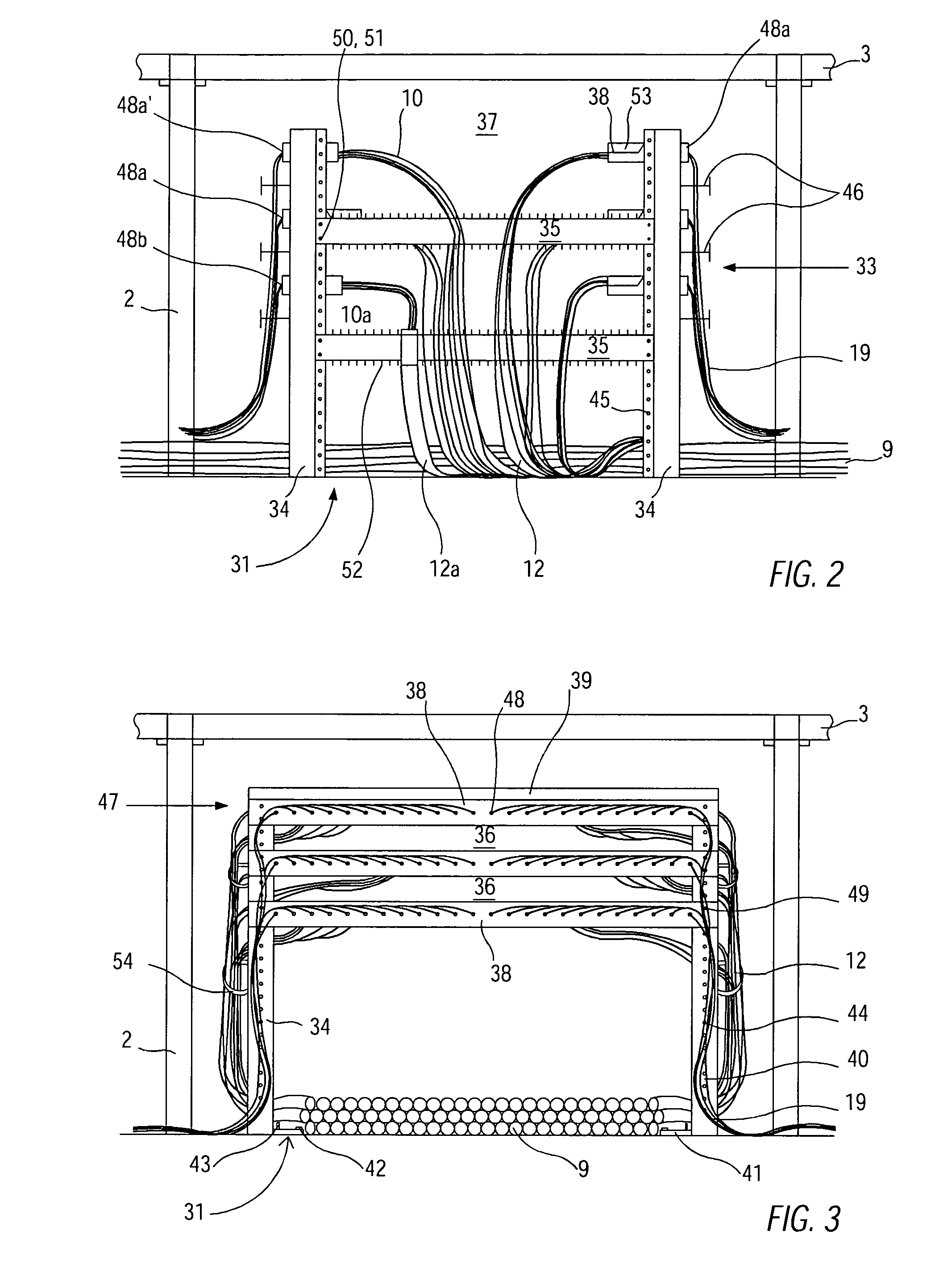

Underfloor cable junction unit and computer center equipped with such junction units

ActiveUS7482536B2Low air resistanceEasy accessBuilding roofsPipe supportsRaised floorWaste management

An underfloor cable junction unit for installation in a raised-floor system used as cooling air supply duct for devices arranged on the raised floor and having floor panels with cooling air outlets has a top side. The top side or at least a major part of it is open to enable the passage of cooling air through the top side toward a floor panel with cooling air outlets.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

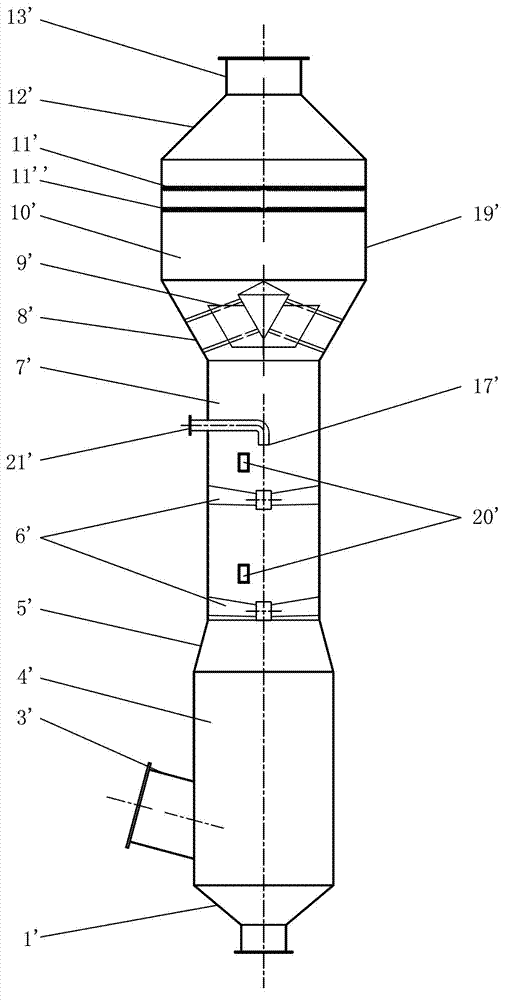

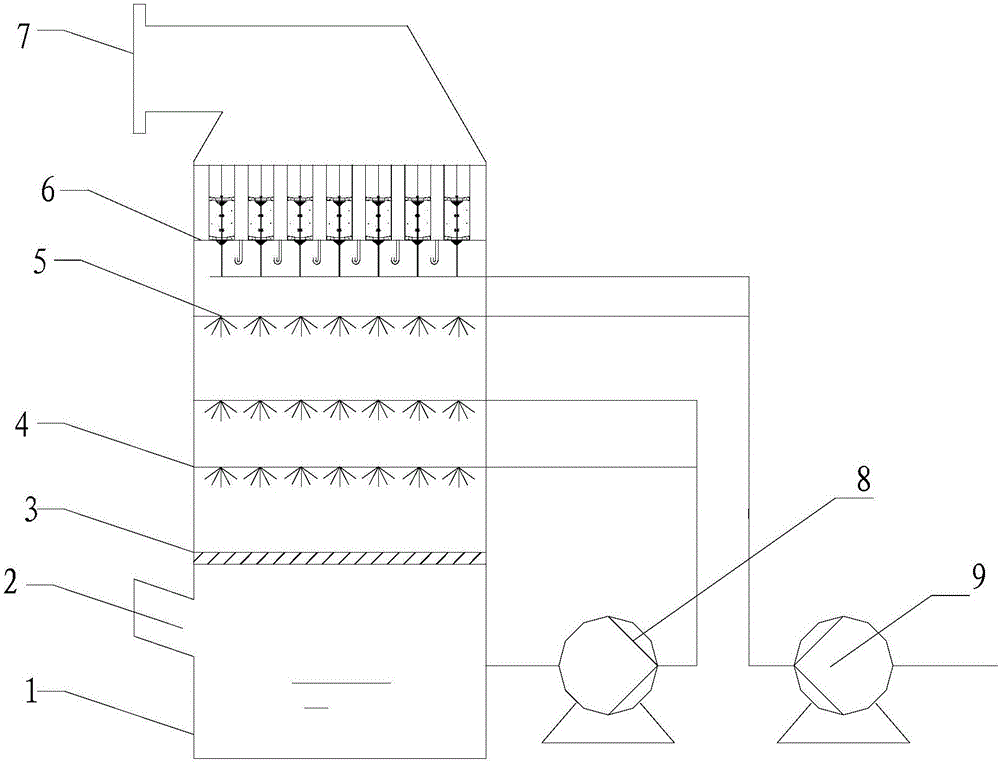

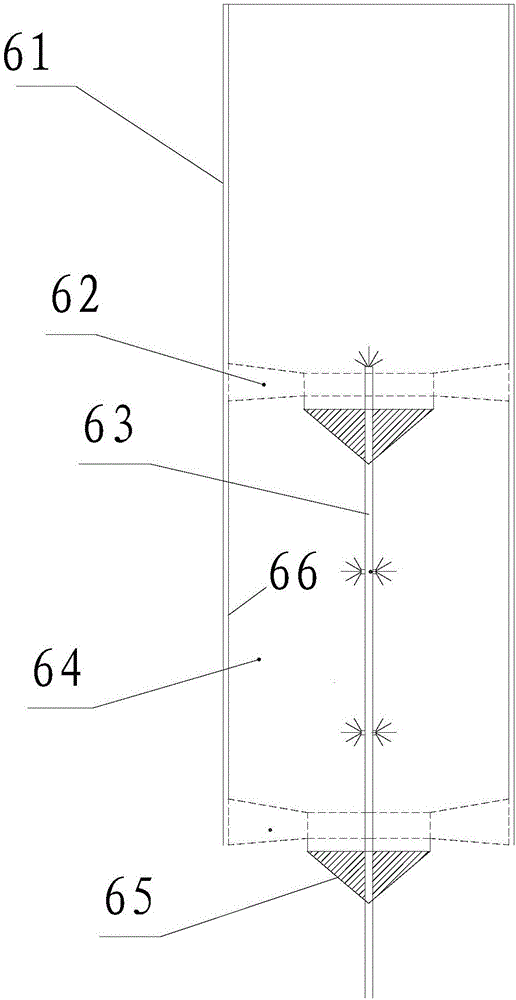

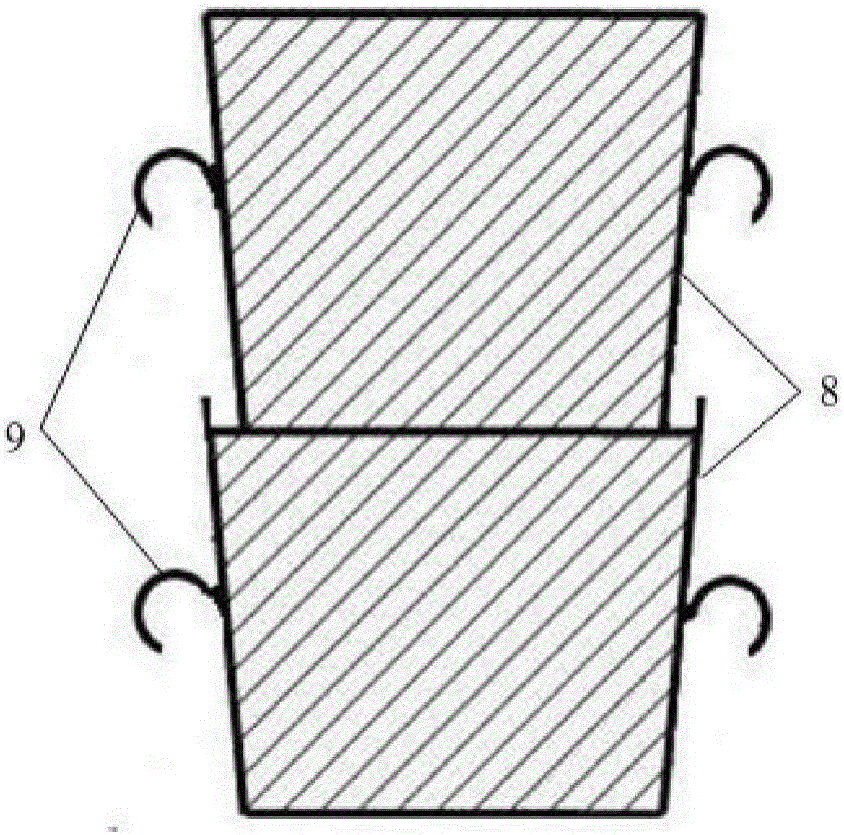

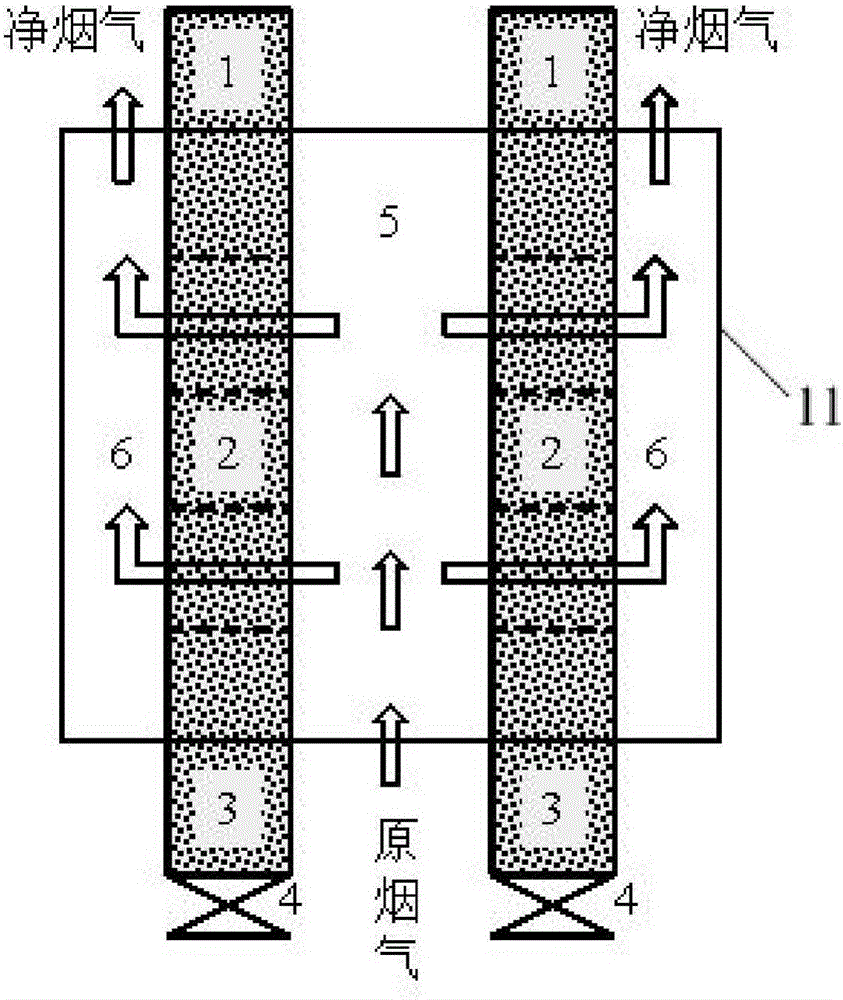

Active coke modular bearing device, absorbing tower and flue gas purifying method

ActiveCN105817118AReduce physical wear and tearImprove operational efficiencyGas treatmentDispersed particle separationFlue gasTower

The invention provides an active coke modular bearing device, an absorbing tower and a flue gas purifying method. The active coke modular bearing device comprises a transmission device and multiple active coke modules, each active coke module is provided with a fixing device, and the multiple active coke modules are vertically overlapped seamlessly and then fixed to the transmission device through the fixing devices; each active coke module is of a net-shaped structure, the bottom of each active coke module is narrower than the upper portion by 3-5 cm, the height and width of each active coke module are independently 50-80 cm, and the length of each active coke module is 80-120 cm. The active coke modular bearing device can effectively reduce abrasion loss of active coke and is high in operation efficiency, airflow in the absorbing tower provided with the device is small in resistance and distributed uniformly, the active coke moves smoothly and is high in use ratio, and the removal efficiency of pollutants in flue gas can be remarkably improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

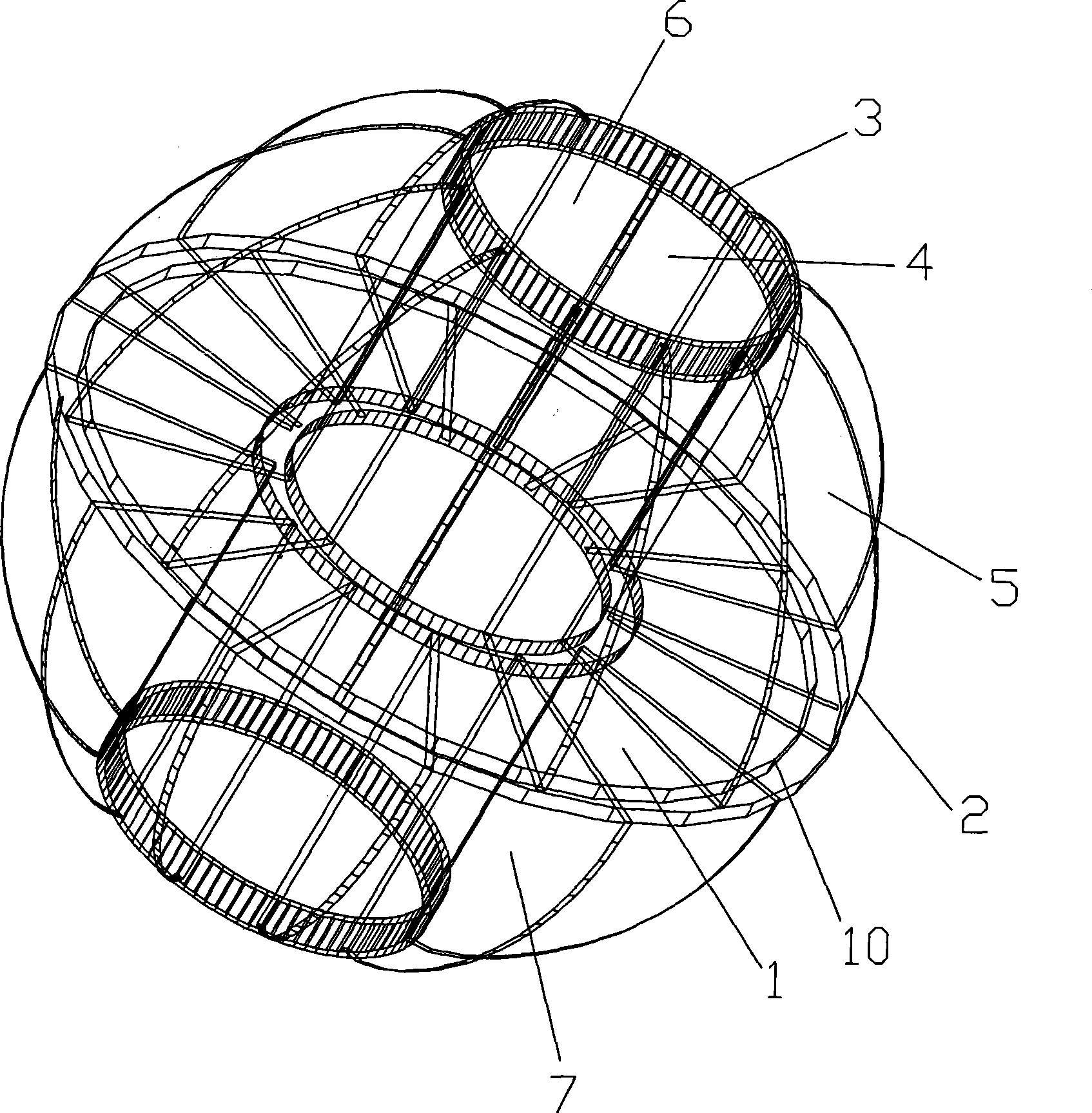

Stuffing with wing veins for biological treatment of exhaust gas

InactiveCN101474549AFavorable for attachment growthPromote sheddingDispersed particle separationSustainable biological treatmentMicroorganismRough surface

The invention relates to a packing with raised grain for biologically treating waste gas. The packing is a grille body of which the external outline surface is a spherical surface enclosed by two hemispheres; the binding surface of the two hemispheres forms an equatorial surface; the outer ring of the equatorial surface is an equatorial ring; each of the hemispheres is provided with at least one latitude ring in parallel with the equatorial ring; a plane which is provided with the latitude ring is a latitude plane; blades divergently distributed around the axes of the hemispheres connect adjacent latitude planes or the equatorial plane and the adjacent latitude plane thereof; the edges of the blades are supported between the adjacent latitude planes or the equatorial plane and the adjacent latitude thereof, and the external circle-arc edges thereof form the external outline of the sphere; grille units are formed by the adjacent blades; the blades are provided with a rough surface facilitating the mounting of microorganism; the packing is provided with a through channel along the axes of the two hemispheres; the inner surface of each grille unit opposing to the external outline surface thereof form the outer edge of the channel.

Owner:ZHEJIANG UNIV OF TECH +1

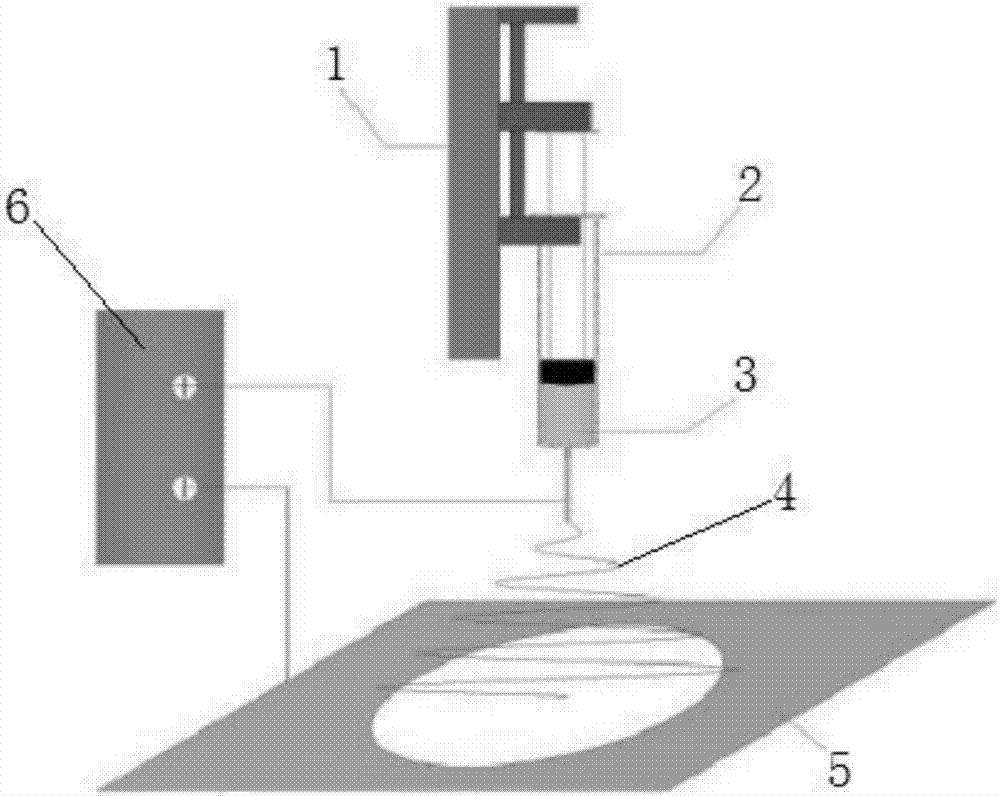

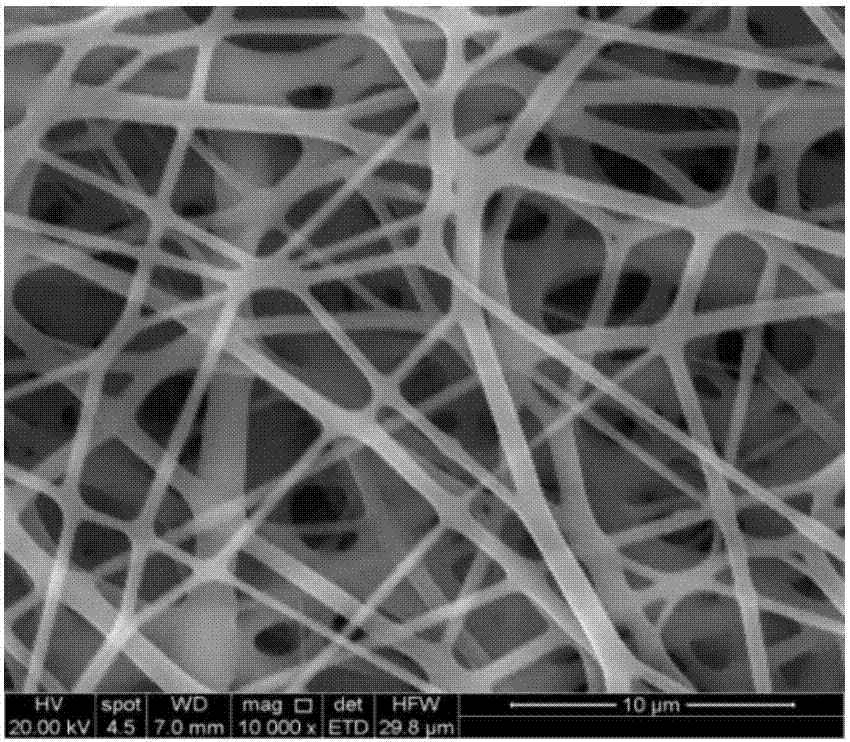

Composite nano-fiber PM2.5 filtering material and preparation method thereof

ActiveCN106925033AEvenly distributedHigh porosityDispersed particle filtrationMembrane filtersCross-linkFiber

The invention discloses a composite nano-fiber PM2.5 filtering material and a preparation method thereof. The material comprises a polyacrylonitrile and gelatin cross-linked composite nano-fiber film. An air filtering material provided by the invention with a polyacrylonitrile and gelatin composite nano-fiber netted cross-linked structure is acquired through the disposable electrostatic spinning and heating after-treatment. The diameter of the polyacrylonitrile and gelatin composite nano-fiber is 150-300nm, the porosity is 80%-90% and the average pore size is 0.5um-6um. The composite nano-fiber with compact structure, uniform netted cross-linking and better mechanical property and hydrophilic air permeability can be acquired; the filtering efficiency thereof for the NaCI aerosol with the median diameter of 200-300nm is 99.82%-99.91%; the pressure drop is 120-150Pa; the breaking strength is 10.92mPa; the elongation at break is 89.85%; the air permeability is 16820mL / (cm<2>.h). The material is especially suitable for the fields of personal protection products, air quality detecting equipment, air purifying equipment, and the like.

Owner:SHAANXI UNIV OF SCI & TECH

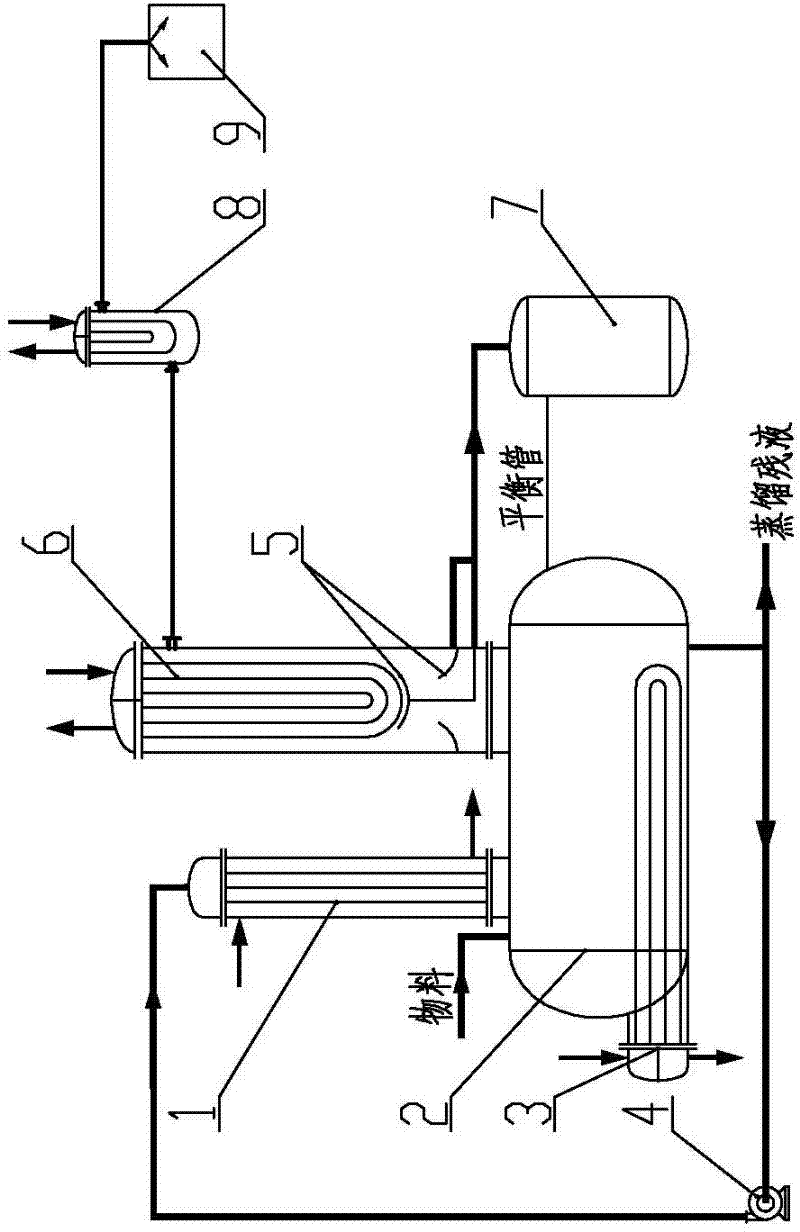

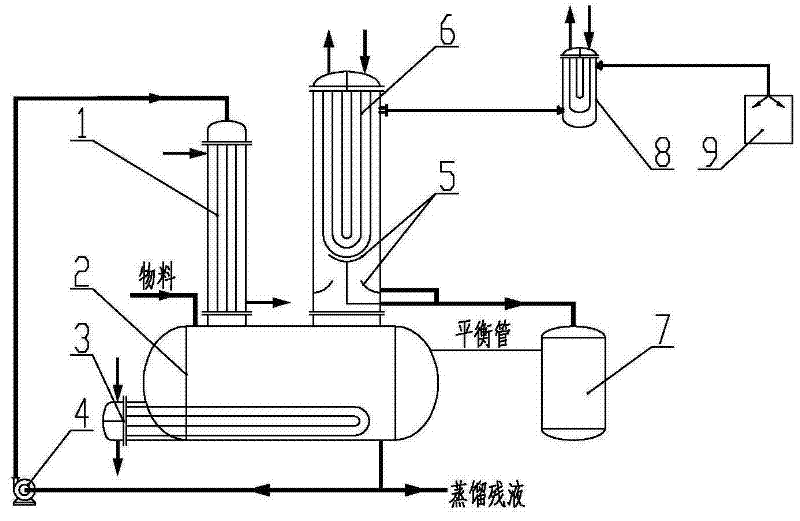

High vacuum distillation purification device

InactiveCN102266677AImprove heat transfer efficiencyEasy to handleEvaporator accessoriesVacuum distillation separationEngineeringVacuum pump

The invention relates to a high vacuum distillation purification device which comprises a falling film evaporator, a gas-liquid separator, a U-shaped tube heater, a U-shaped tube condenser, a material circulating pump, a liquid-accepting tank, a cold trap, and a vacuum pump unit, and is characterized in that the gas-liquid separator is directly connected to the falling film evaporator and the U-shaped tube condenser, and the U-shaped tube heater is disposed at the bottom of the gas-liquid separator. The beneficial effect of the device of the invention is that: the adoption of a directly-connected compact structure, a large-diameter heating tube of the falling film evaporator, and a built-in condenser reduces the airflow resistance inside the device, decreases the air capacity leaked by the device, and guarantees the realization of a high vacuum degree; the material is evaporated by a falling film, which has the advantages of high heat transfer efficiency, great processing capacity, difficult scaling, and the like; situations such as thermal polymerization or thermal decomposition are effectively reduces, and the device has the advantages of high product yield and quality; the device has certain energy saving effect; in addition, the device has a simple structure, low cost, and flexible operation, and is applicable to both continuous operation and intermittent operation.

Owner:武汉市华中化工医药设备工程有限责任公司

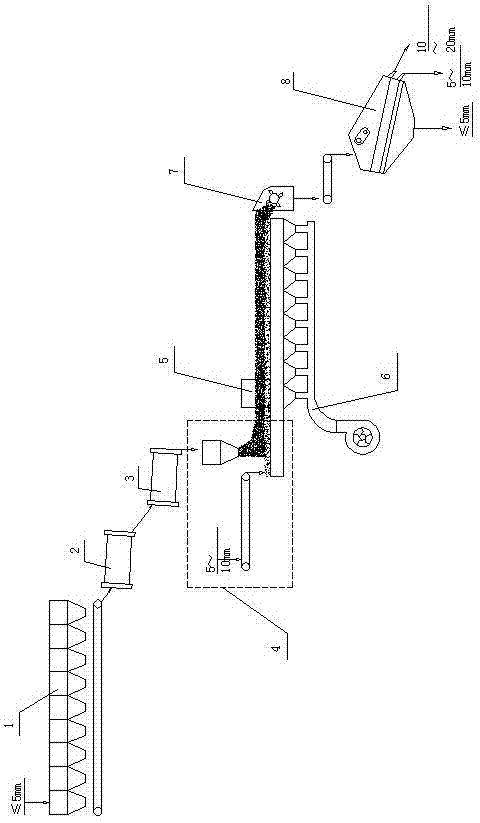

Medium-alkali thick blanking layer sintering and producing method

The invention relates to a medium-alkali thick blanking layer sintering and producing method. The sintering materials comprise, by weight, 50-56% of brown iron ore, 5% of oxidized iron sheet, 2-6% of fly ash, 12-14% of return ore of a sintering machine, 11-15% of return ore of a blast furnace, 4-5% of dolomite powder, 4-5% of white ash and 3-5% of coal powder; mixing and pelleting time is 2.5-3.5 min, bedding layer is 100 mm thick, the sintering materials are 900-1000 mm thick, annealing temperature is 1050+ / -20 degrees Centigrade, sintering time is 1.5-1.8 min, and sintering negative pressure is 13-15 Kpa; cooling negative pressure is 11-16 Kpa, cold air rate is smaller than or equal to 40%, and temperature of sintered ore after cooling is below 250 degrees Centigrade. By the medium-alkali thick blanking layer sintering and producing method, cost of the sintering materials can be reduced, blanking thickness is increased, permeability of the blanking layer is improved, yield and production of the sintered ore are increased and energy consumption is reduced in sintering.

Owner:唐山瑞丰钢铁(集团)有限公司

Industrial waste gas absorbing recovery device

InactiveCN101104126ALow powerLow energy consumption for desorption regenerationDispersed particle separationAir volumeDesorption

The invention relates to a recovery device for industrial exhaust gas adsorption, which includes a gas collection device, a plurality of adsorption tanks, a condenser and a fluid separator; the lower part of each adsorption tank has a gas inlet, the bottom part thereof is provided with a liquid outlet, and the top part is respectively provided with a steam inlet and a tail gas discharge port, the gas inlet, the liquid outlet, the steam inlet and the tail gas discharge port are respectively provided with valves, the gas collection device is communicated with the gas inlet, the liquid outlet is communicated with the condenser, and the condenser is communicated with the liquid separator; exhaust gas adsorption devices are arranged in the adsorption tanks, the exhaust gas adsorption devices are carbon beds laterally disposed in the adsorption tanks, particle activated carbon adsorbents are spread on the carbon beds, the carbon beds are provided with openings, the diameters of the openings are smaller than the diameters of the adsorbents. The invention adopts the activated carbon particles as the adsorbents, which has low consumption of desorption regeneration, little airflow resistance and little power of blower needed, thus low cost and large air quantity treating can be achieved.

Owner:杭州大伟装饰材料有限公司

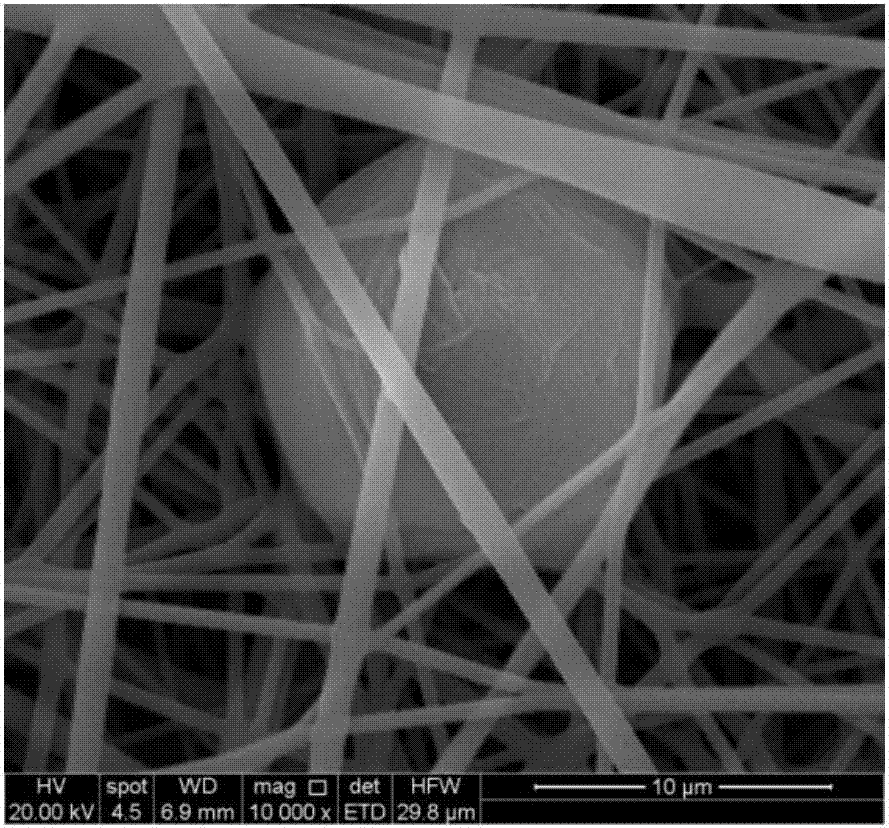

Methods of making single-layer lithium ion battery separators having nanofiber and microfiber constituents

ActiveUS9637861B1Easy to manufactureHigh porosityHybrid capacitor separatorsSemi-permeable membranesPorosityEngineering

An insulating (nonconductive) microporous polymeric battery separator comprised of a single layer of enmeshed microfibers and nanofibers is provided. Such a separator accords the ability to attune the porosity and pore size to any desired level through a single nonwoven fabric. Through a proper selection of materials as well as production processes, the resultant battery separator exhibits isotropic strengths, low shrinkage, high wettability levels, and pore sizes related directly to layer thickness. The overall production method is highly efficient and yields a combination of polymeric nanofibers within a polymeric microfiber matrix and / or onto such a substrate through high shear processing that is cost effective as well. The separator, a battery including such a separator, the method of manufacturing such a separator, and the method of utilizing such a separator within a battery device, are all encompassed within this invention.

Owner:DREAMWEAVER INT

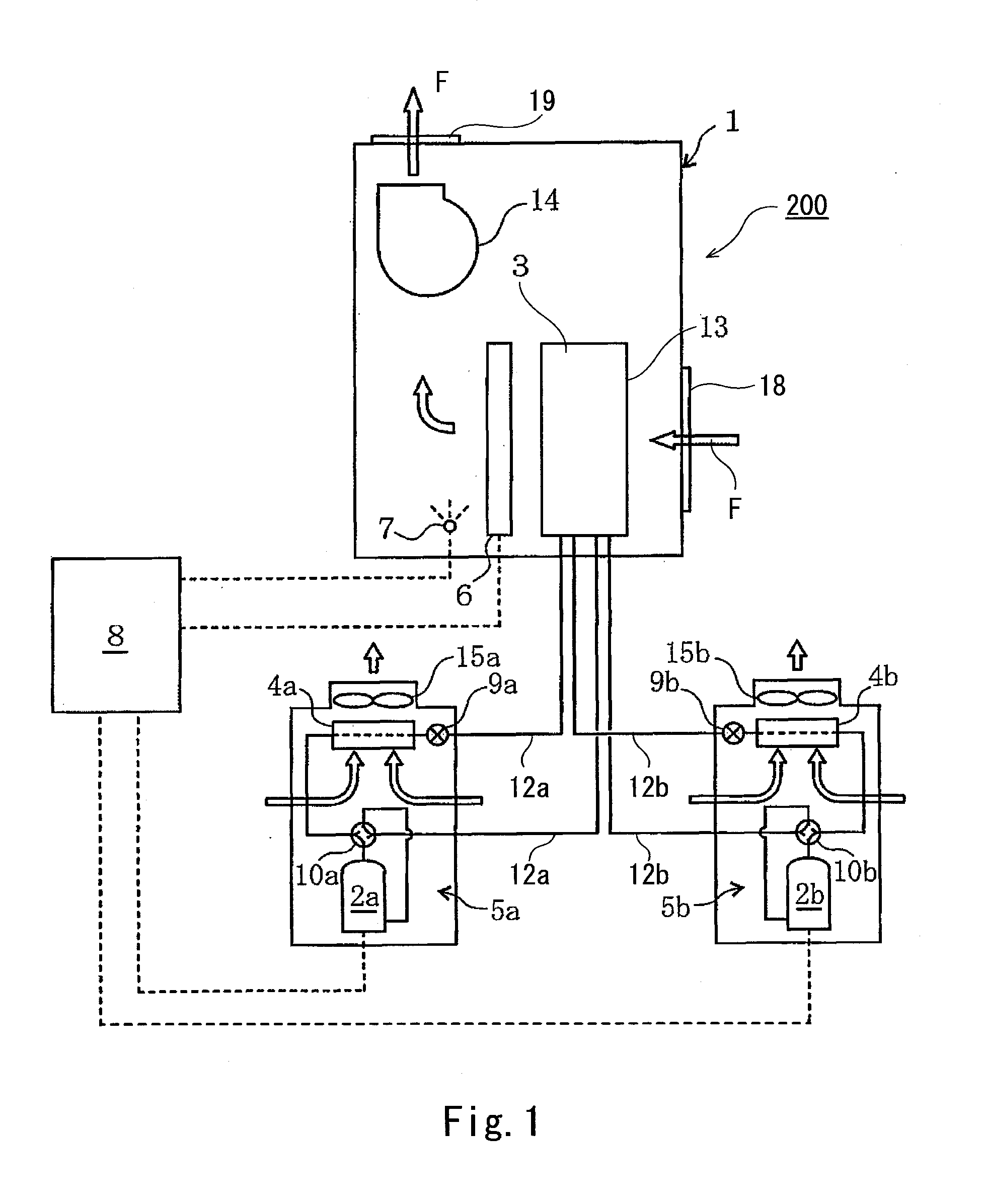

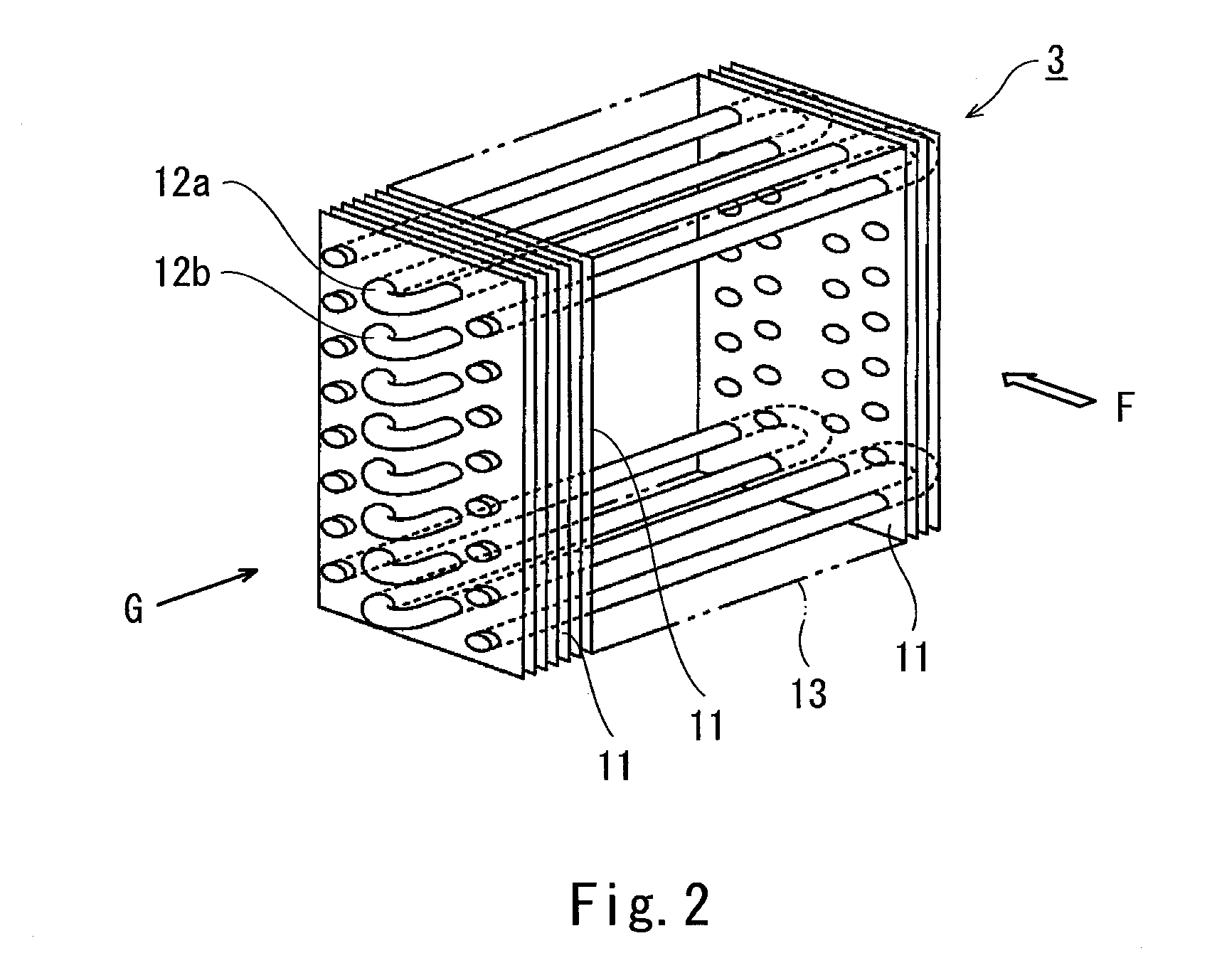

Heat exchange type ventilator

InactiveCN1969152AImprove gas supply capacityEliminate spaceEnergy recovery in ventilation and heatingHeat recovery systemsDouble-walled pipeEngineering

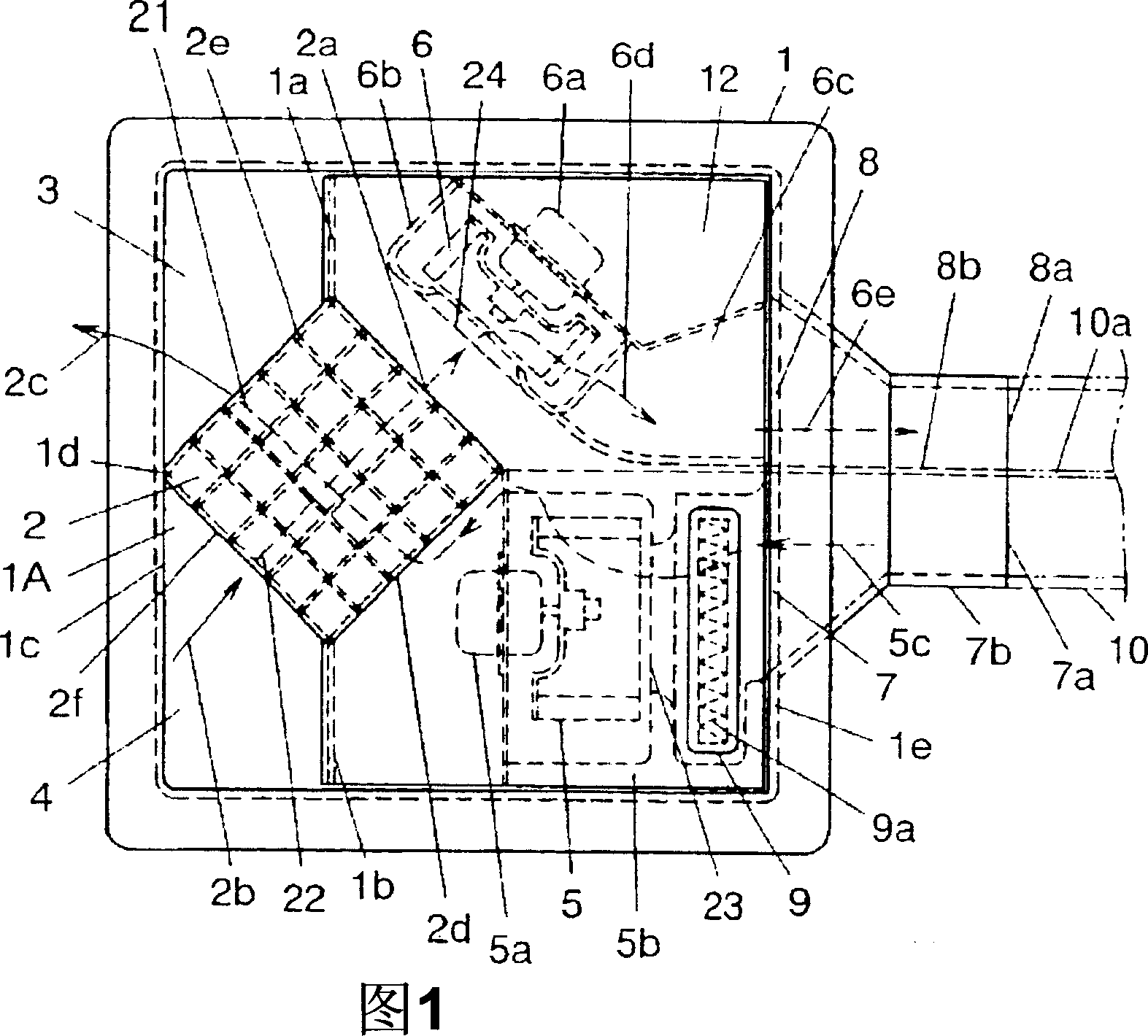

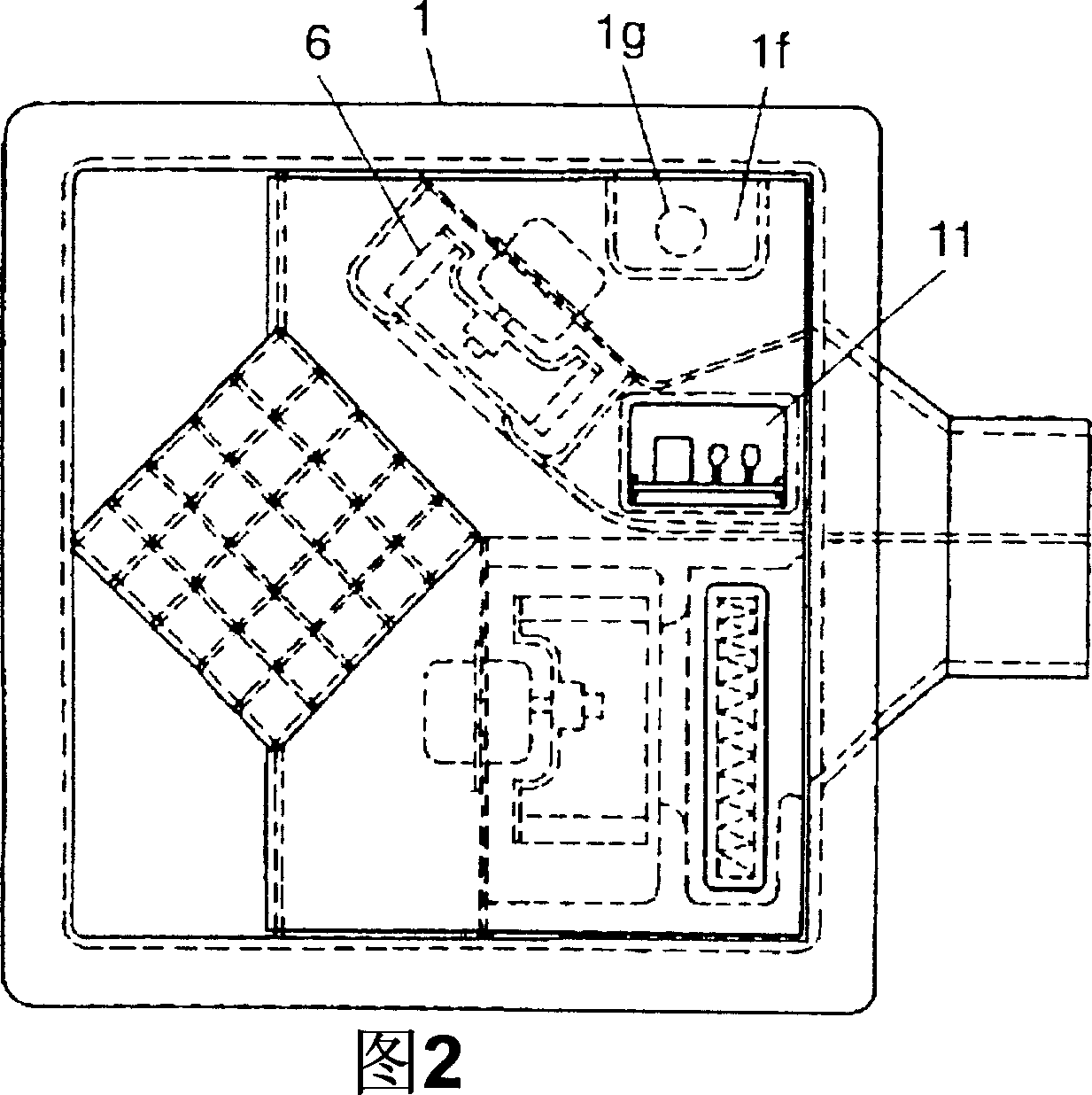

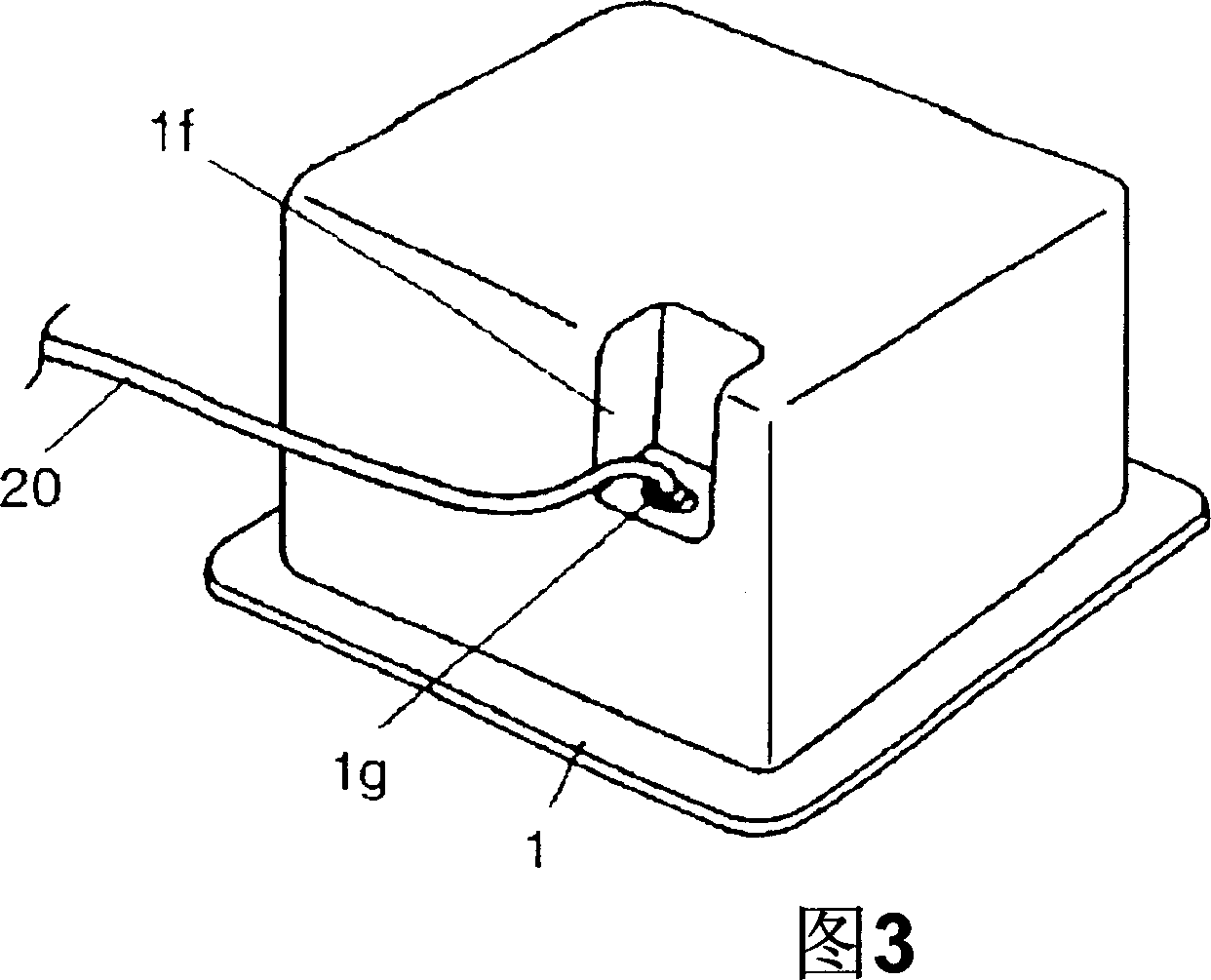

A heat exchange type ventilator enabling a reduction in the size of a device body, comprising a box (1) installed on the surface of a ceiling, having an opening part (1A) in the lower surface thereof, and having a cross section of square shape. A large number of exhaust flow passages (22) and intake flow passages (21) are alternately stacked on each other in the depth direction of the box body (1) so that the exhaust flow passages (22) and the intake flow passages (21) are allowed to cross each other through heat exchange boards. The box also comprises a heat exchange element (2) exchanging heat between an intake flow and an exhaust flow and an intake blower (5) communicating with the intake flow inflow surface (2d) of the heat exchange element (2). The box further comprises an exhaust blower (6) communicating with the exhaust flow outflow surface (2a) of the heat exchange element (2) and an outdoor side intake flow passage inlet (7) formed in the side face of the box on the opposite side of an indoor side intake flow passage outlet (3) on the upstream side of the intake blower (5). In addition, the box comprises, on the downstream side of the exhaust blower (6), an indoor side exhaust flow passage inlet (4) and an outdoor side exhaust flow passage outlet (8) formed in the side face of the box on the opposite side of the indoor side exhaust flow passage inlet, and the outdoor side intake flow passage inlet (7) and the outdoor side exhaust flow passage outlet (8) are positioned adjacent to each other and allowed to communicate with the inside of a bimetallic tube (10) formed by dividing the inside of the tube into two flow passages.

Owner:PANASONIC CORP

Nickel-based structured catalyst for synthesizing m-phenylenediamine through hydrogenation of m-dinitrobenzene and its preparation method

InactiveCN102350361AImprove hydrogenation activityHigh selectivityOrganic compound preparationAmino compound preparationNickel saltPtru catalyst

The invention relates to a nickel-based structured catalyst for synthesizing m-phenylenediamine through hydrogenation of m-dinitrobenzene, which takes cordierite honeycomb ceramic as a matrix, gamma-Al2O3 as a composite carrier of a coating and La modified Ni as an active component. The preparation method comprises the following steps: taking cordierite as a substrate and active alumina as a coating, preparing the gamma-Al2O3 / cordierite composite carrier by using an immersion method; selecting appropriate nickel salt and lanthanum salt, immersing, drying and calcining to obtain a catalyst precursor, reducing through hydrogen to obtain the structured catalyst. The cordierite structured catalyst is capable of keeping the characteristics of an original particles supported Ni catalyst and preparing a structured reactor, so that hydrogenation reaction is carried out under continuous state. Simultaneously, an auxiliary agent La is introduced in the catalyst for inhibiting the interacting effect of the active component and the carrier, and weakening the formation of NiAl2O4 which is not beneficial to the hydrogenation reaction activity. So that the conversion rate and selectivity of m-dinitrobenzene hydrogenation reaction can be enhanced further.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Method and device for electric agglomeration of outdoor fresh air and indoor air fine particles

InactiveCN108339665AHigh efficiency in removing fine particlesEasy to chargeElectrode constructionsFresh airEngineering

The invention discloses a method and device for electric agglomeration of outdoor fresh air and indoor air fine particles, and belong to the technical field of electrostatic precipitation. According to the method and device for the electric agglomeration of the outdoor fresh air and indoor air fine particles, an electric agglomeration zone is arranged between a pre-dedusting zone and an efficientdedusting zone to realize the removal of electric agglomeration of fine particles in airflow. The electric agglomeration zone comprises one or more ionizing charging-agglomeration growth sections. Theionization charging-agglomeration growth section is realized by four ways, specifically, wire-plate electrode configuration, wire-plate electrode configuration matched with a current-guiding column,wire-tube electrode configuration and wire-tube electrode configuration matched with the current-guiding column, and a whole assembly is usually formed. The invention has the advantages of simple structure, convenient maintenance and low air flow resistance, and the removal efficiency for the fine particles is improved.

Owner:BEIHANG UNIV

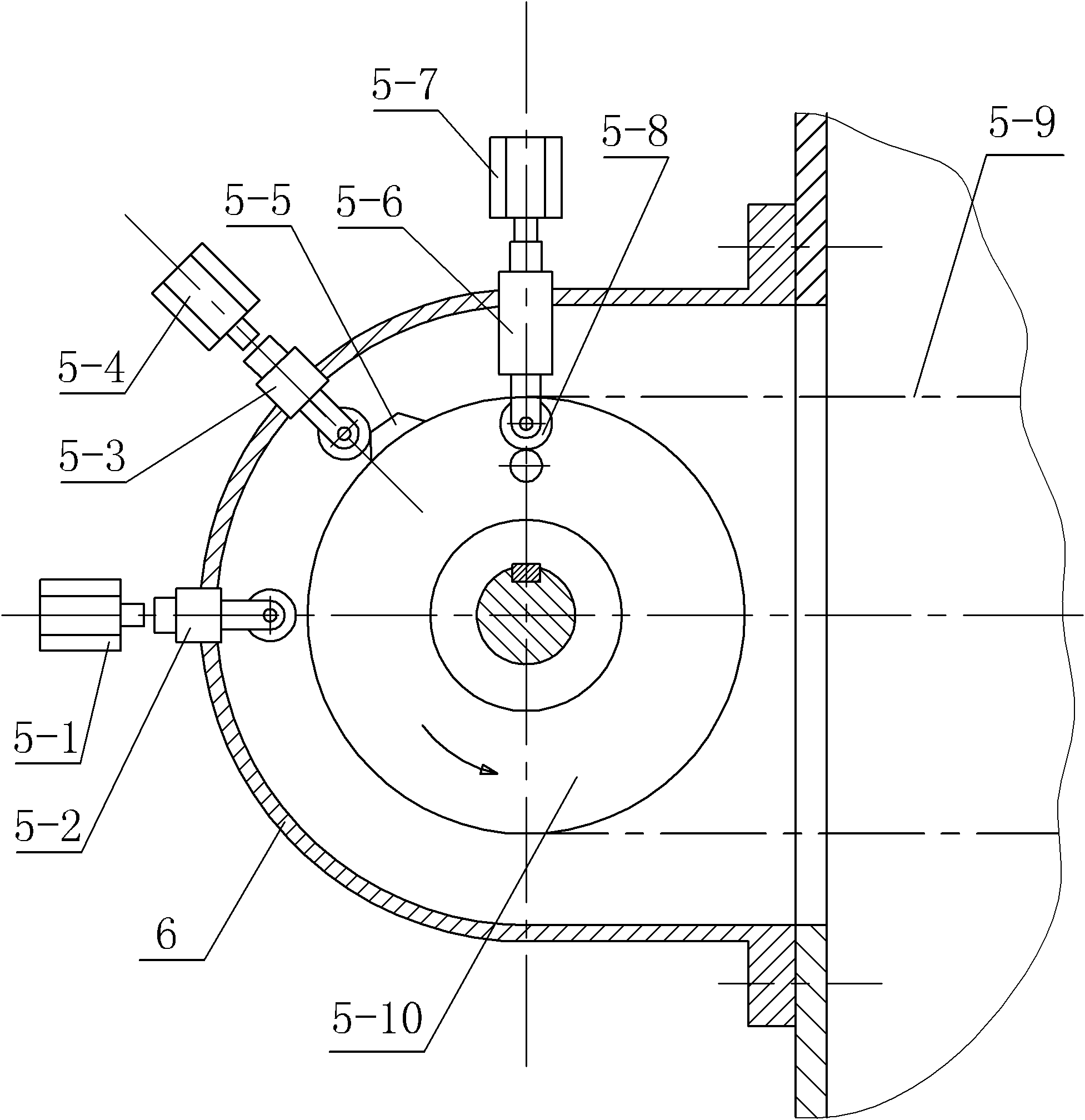

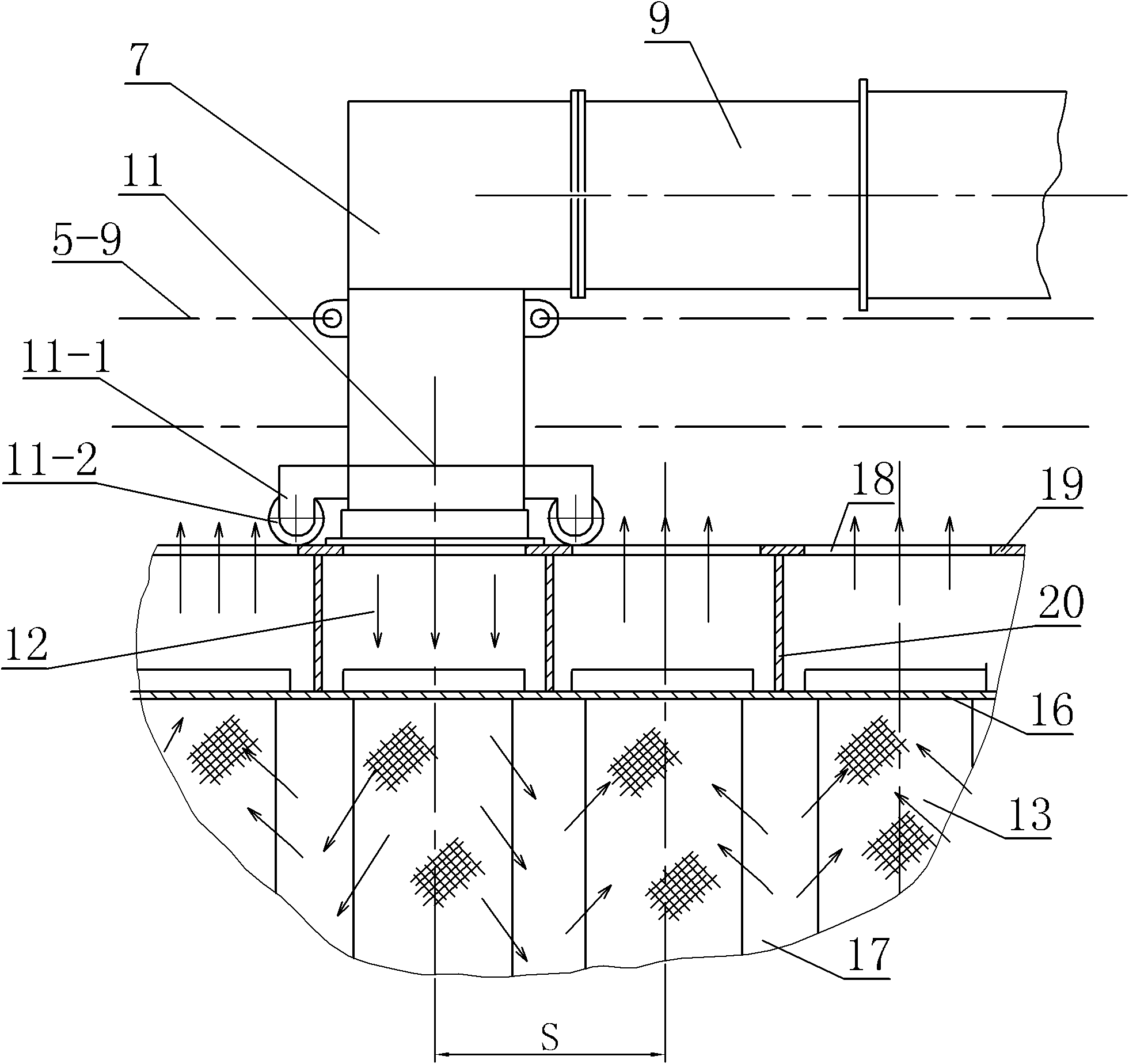

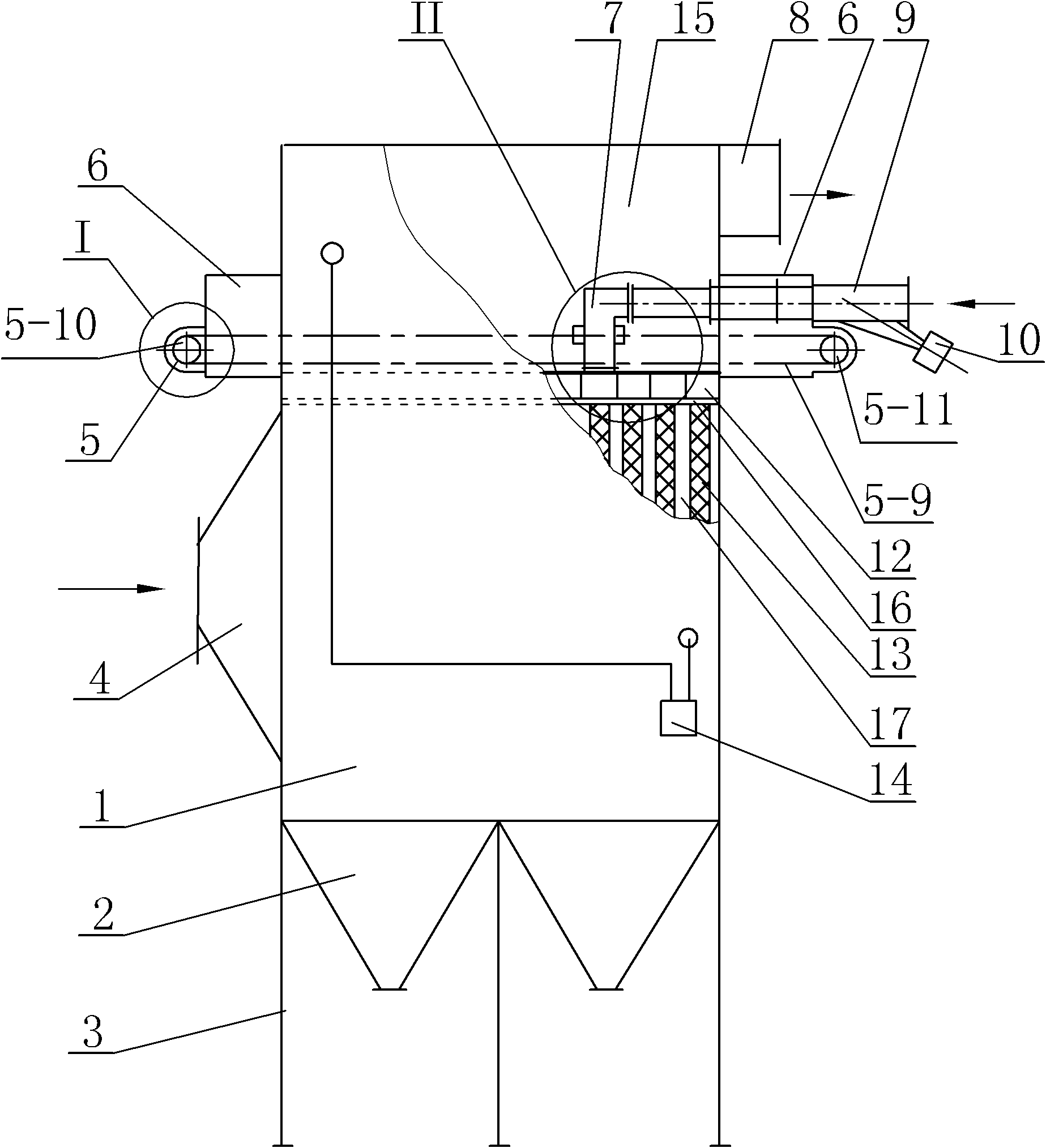

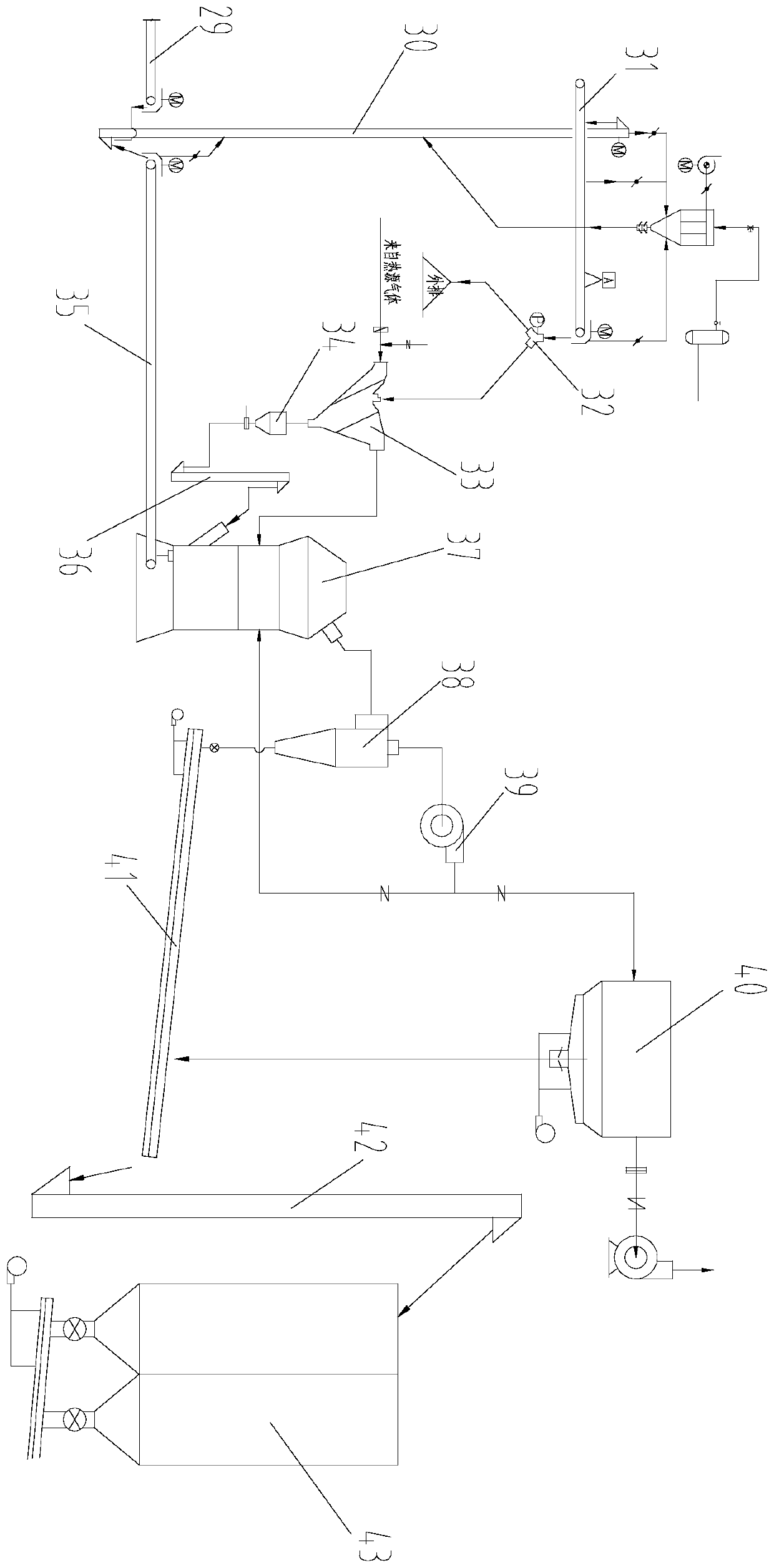

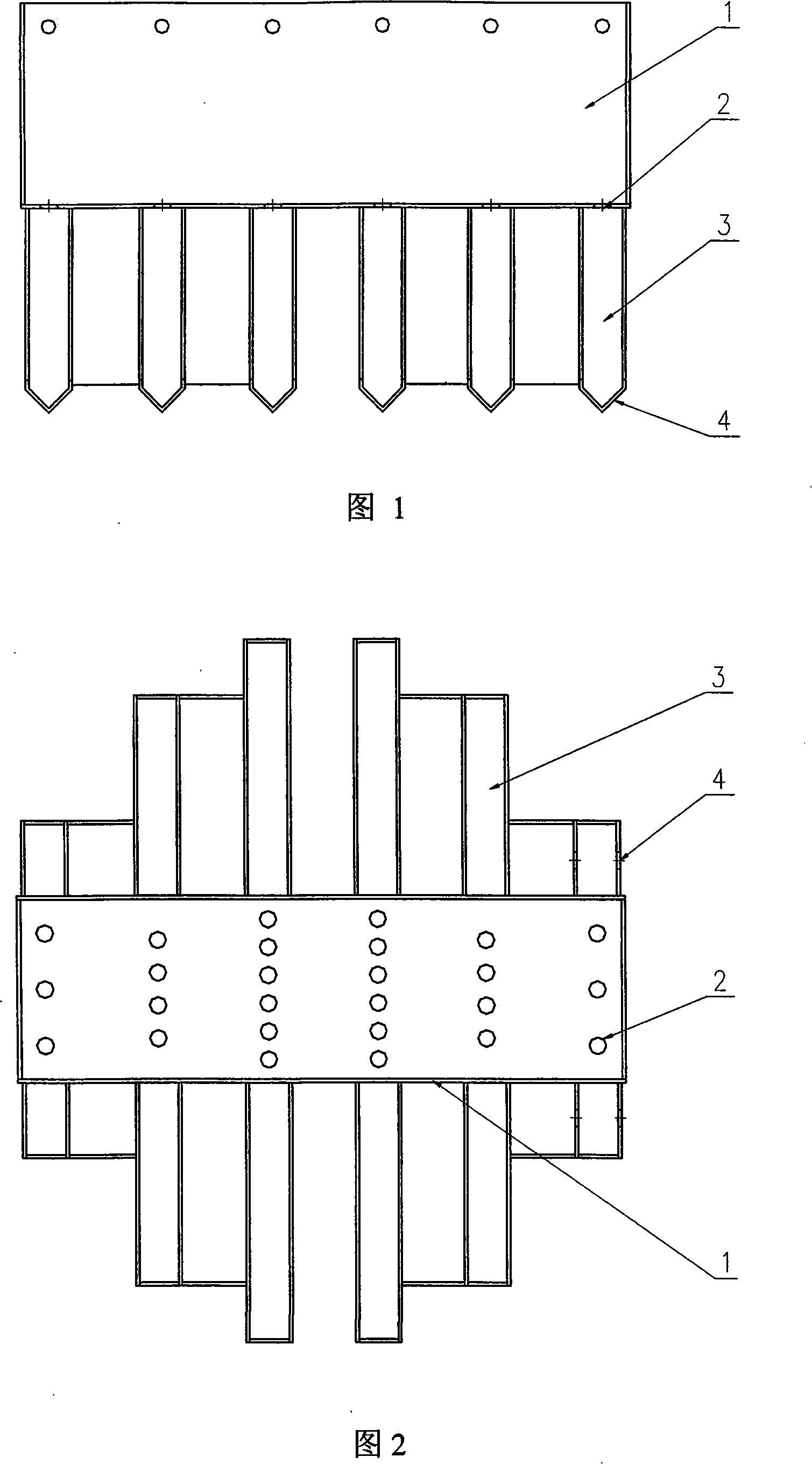

Sub-chamber back blowing bag type dust collector with reciprocating movement back blowing air port

ActiveCN102068864AImprove cleaning abilitySmall running resistanceDispersed particle filtrationChemical industryProcess engineering

The invention discloses a sub-chamber back blowing bag type dust collector with a reciprocating movement back blowing air port, and relates to a bag type dust collector. The bag type dust collector can solve the problems that a deashing mechanism of the conventional bag type dust collector cannot realize port-to-port deashing chamber by chamber, the deashing effect is poor, the structure is complex, faults are easy to occur and the like. The bag type dust collector is technically characterized in that: a sub-chamber back blowing deashing device is arranged in a gas purifying chamber, one end of a telescopic back blowing gas pipe is connected with a deashing gas source for introducing back blowing deashing gas flow, and the other end of the telescopic back blowing gas pipe is connected with the movable back blowing air port; and a transmission mechanism draws the movable back blowing air port and the telescopic back blowing air pipe to reciprocate and move to the outlet of the small gas purifying chamber sequentially for performing port-to-port positioning back blowing deashing chamber by chamber. The sub-chamber back blowing bag type dust collector is mainly applied in dedusting treatment before smoke gas in power stations, metallurgy, chemical industry, mining, cement, grain processing and other industries is discharged.

Owner:彭湃

Processing method of multifunctional air purification filter element

InactiveCN101716443AUniform wind resistanceLow air resistanceDispersed particle filtrationFiltration separationFiltrationAdhesive

The invention belongs to the field of air purification, more particularly to a processing method of a multifunctional air purification filter element. The processing method comprises the following steps of: (1) processing a support frame by adhesive; (2) vibrating the support frame and evenly spattering gas purificant on the support frame; (3) repeating the step (1) and the step (2), and nesting the gas purificant; and (4) encapsulating by a fine filter screen. The processing method has simple process; and the product has a plurality of purification functions of physical adsorption, chemical adsorption, filtration, and the like and can simultaneously purify formaldehyde, benzene series, acidic gases and other pollutants.

Owner:邯郸派瑞电器有限公司

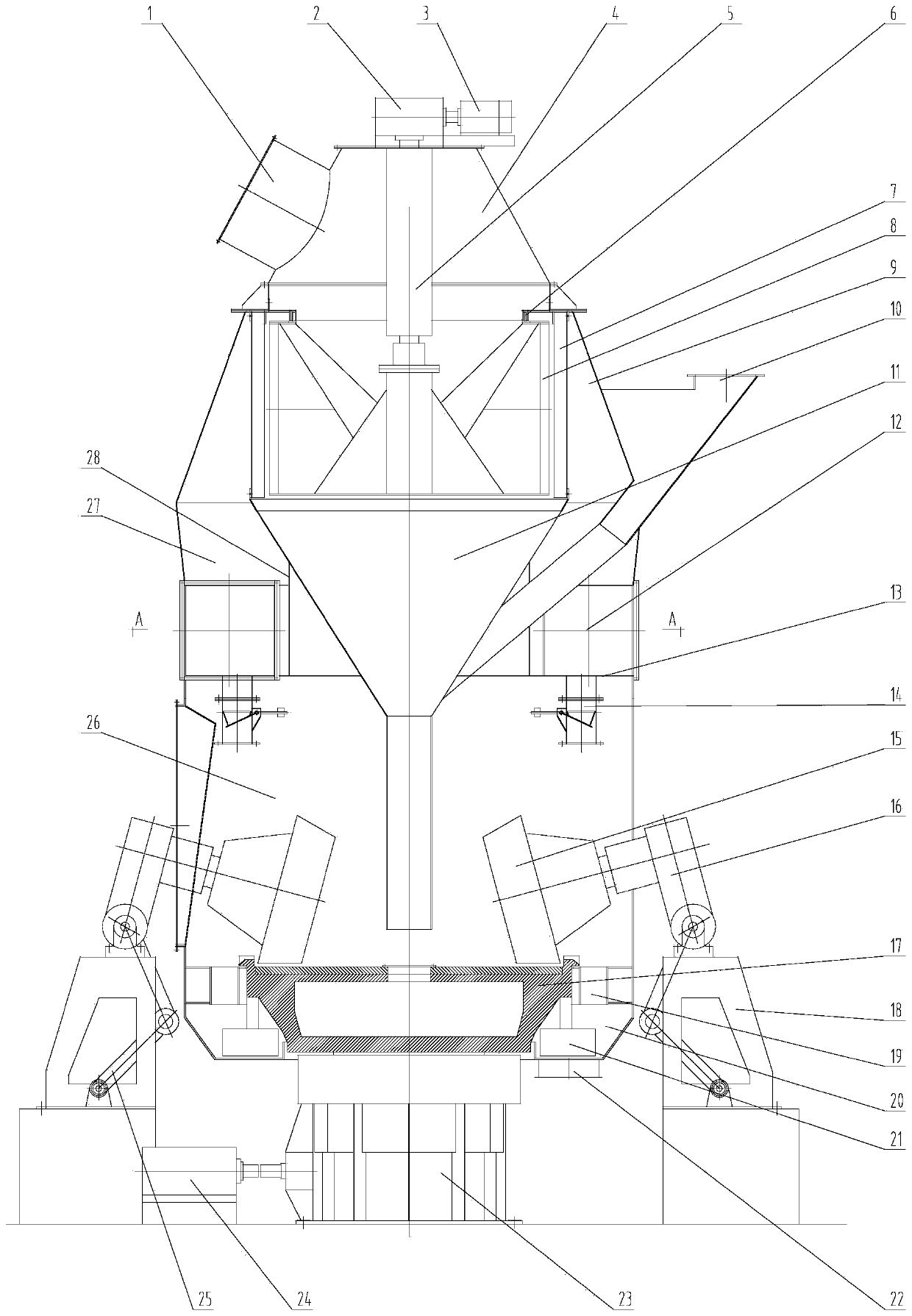

Raw material vertical mill external circulation system and process

PendingCN110860343AImprove sorting efficiencyLow air resistanceVortex flow apparatusGrain treatmentsPowderMaterials science

The invention discloses a raw material vertical mill external circulation system comprising a material proportioning belt conveyor, an elevator, a feeding conveying mechanism, a feeding three-way joint, a V-shaped powder concentrator, an external circulation roller type vertical mill, a cyclone, a circulation draught fan and a dust remover. The external circulation roller type vertical mill comprises a powder milling barrel on the lower portion and a powder concentration barrel on the upper portion. A mill is arranged in the powder milling barrel. The powder concentrator is arranged in the powder concentration barrel. The powder milling barrel and the powder concentration barrel are separated through a partition plate. An outlet of a powder concentration coarse powder ash hopper of the powder concentrator penetrates through the partition plate and extends into the powder milling barrel. Materials are not conveyed to the powder concentrator in a pneumatic manner to be subjected to separation any more, and due to the adoption of concentrated mechanical conveying of the elevator, the gas flow resistance is greatly reduced, and the electricity consumption is substantially reduced. Thepowder concentrator is still above the vertical mill, the civil engineering cost can be greatly reduced, and the device input can also be greatly saved.

Owner:NANJING JULI INTELLIGENT MFG TECH INST CO LTD +1

Double liquid phase groove type distributor

InactiveCN101125262ASimple structureSmall footprintDispersed particle separationDistillation separationDistillationPetrochemical

The present invention relates to a double fluid phase groove type distributing device comprising a primary main groove and a secondary distributing groove. The primary main groove respectively comprises a heavy phase primary main groove and a slight phase primary main groove, and each primary main groove is provided with one to two. The secondary distributing groove is provided with a heavy phase secondary distributing groove and a slight phase secondary distributing groove. The slight phase secondary distributing groove is connected with the bottom of the heavy phase secondary distributing groove. Besides, the liquid lead tube of the slight phase secondary distributing groove is embedded into the heavy phase secondary distributing groove. The lower part of the side wall of the heavy phase secondary distributing groove is provided with an array or a plurality of arrays of little liquid distributing holes, while the upper part of the side wall is provided with an array of overflows. The lower part of the side wall of the slight phase secondary distributing groove is provided with an array or a plurality of arrays of little liquid distributing holes. The present invention has the advantages of simple structure, few area occupied, low current resistance, low pressure, board operation range and easy production and field mounting. The present invention can be widely used in towers such as a distillation tower, particular a distillation tower, an absorption tower, an adsorption tower and a reaction tower in the fields such as chemical, petrochemical, light industry, pharmacy, fertilizer and environmental protection.

Owner:TIANJIN UNIV

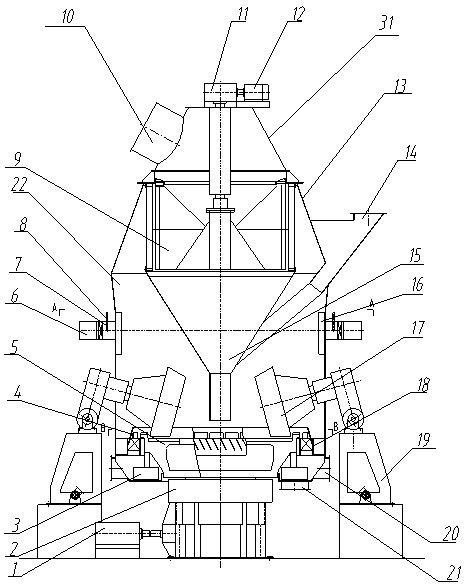

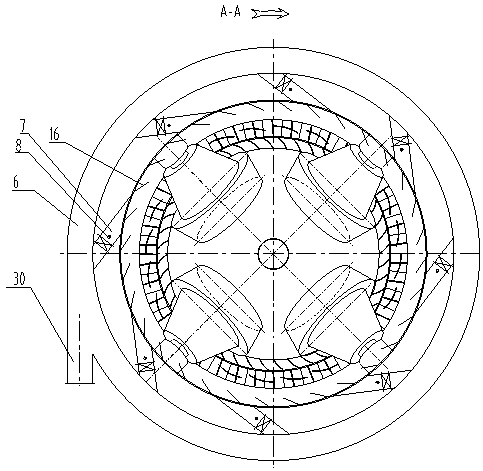

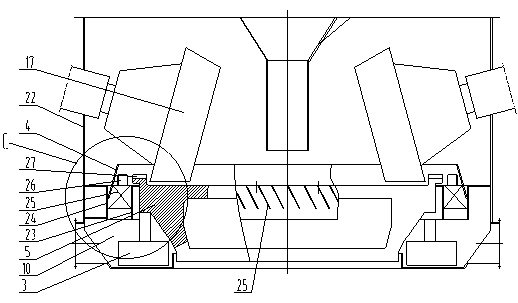

Roll type vertical mill

PendingCN109012888AReduce resistanceBalance and adjust air volumeGrain treatmentsAir volumeEngineering

The invention discloses a roll type vertical mill which comprises mill shell. A grinding disc and grinding rolls are arranged in the mill shell. A nozzle ring is arranged between the outer circumference of the grinding disc and the mill shell. An air inlet is further arranged at the position, on the lower portion of the nozzle ring, of the mill shell. Air enters the air inlet to enter the mill shell to form annular airflow. A material blocking ring is arranged on the edge of the grinding disc and is circumferentially and evenly provided with material stirring plates. Louver air guide blades are annularly and evenly distributed in the nozzle ring. Annularly-distributed impact plates are arranged on the upper portions of the louver air guide blades. A discharging opening used for dischargingis further connected to the bottom of the shell. Annularly-distributed vortex plates are arranged on the inner wall of the middle upper portion of the mill shell, tangential air inlets are arranged at the positions of the mill shell, and air is supplied to the tangential air inlets through an air supplementary annular air flue. According to the roll type vertical mill, the air volume of lifting materials on the nozzle ring can be balanced and adjusted, the material grading efficiency of the nozzle ring can be improved, the air volume of the airflow of the lifting materials can be reduced, thepressure difference can be reduced, energy can be saved, and meanwhile the powder selection efficiency can be improved.

Owner:南京中材粉体工程科技有限公司

Electrostatic air filter paper and preparation method thereof

ActiveCN106283891ALow air resistanceEffective filteringPaper/cardboardFiltration separationGlass fiberEmulsion

The invention discloses electrostatic air filter paper. The electrostatic air filter paper is prepared from polypropylene / polyester composite, chopped glass fiber cotton, modified nano cellulose and waterproof emulsion. The invention also discloses a preparation method of the electrostatic air filter paper. The preparation method comprises the following steps: firstly, beating; secondly, dispersing; thirdly, mixing pulp; fourthly, forming; fifthly, hot pressing; sixthly, impregnating; seventhly, drying. The electrostatic air filter paper obtained by the preparation method disclosed by the invention has the characteristics of higher filtering efficiency, relatively-low filtering resistance and good quality stability.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

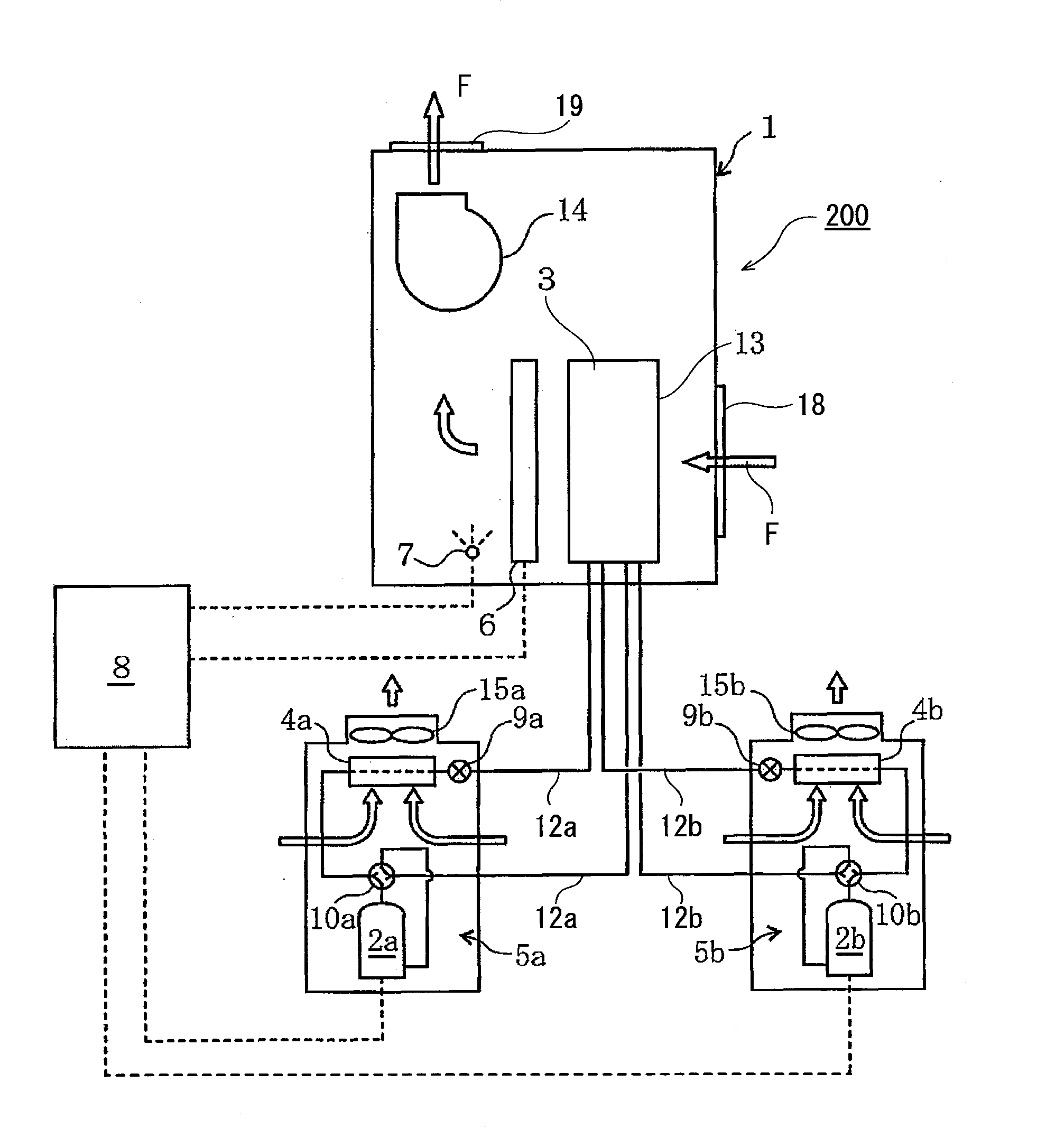

Heat pump air conditioner

InactiveUS20160025384A1Stable air conditioningReduce unevennessAir treatment detailsEvaporators/condensersEngineeringAir conditioning load

A heat pump air conditioner includes an intake side heat exchanger including heat transfer pipes passing a refrigerant and being arranged in a direction along an air inlet face, intake heat exchanger configured to cool or warm air and supply the air to a space. A plurality of heat pumps include a plurality of compressors and configured to compress the refrigerant and supply the compressed refrigerant to the heat transfer pipes and a plurality of heat side exchangers and connected to the respective compressors, the heat pumps sharing the air intake side heat exchanger, and a controller configured to switch a state of the compressors and between an operating state and an operation stopped state. The controller controls the compressors and to switch an operation of each of the compressors and between starting and stopping in accordance with a magnitude of an air-conditioning load.

Owner:KIMURA KOHKI CO LTD

Porous ceramic catalytic oxidizer, preparation method thereof and multipurpose efficient air purification device

ActiveCN110180385AIncrease profitIncrease contact areaGas treatmentDispersed particle separationCatalytic oxidationPorous ceramics

The invention discloses a porous ceramic catalytic oxidizer, a preparation method thereof and a multipurpose efficient air purification device and belongs to the technical field of environments. A columnar ceramic pillar in the porous ceramic catalytic oxidizer takes diatomite as a main material, Fe-Cr-Al alloy wires are taken as support and internal heating wires, cotton and silk are taken as printing templates, a blank is prepared with a compression molding method, the Fe-Cr-Al alloy wires for support are powered on to assist in heating, and calcination in a high-temperature furnace is performed, and the porous ceramic catalytic oxidizer is prepared. The multipurpose efficient air purification device comprises the porous ceramic catalytic oxidizer, a catalytic oxidation electrode, a capturing catalytic oxidation net, a fan and a supply and regeneration device, the porous ceramic pillar of a special structure is supplied with an oxidizer by means of a concentric tube oxidizer supply technology and device, and cooperative treatment of chemical catalytic oxidation and electrocatalytic oxidation of harmful gas is realized in combination with the catalytic oxidation electrode and thecapturing catalytic oxidation net arranged behind the columnar ceramic pillar. The multipurpose efficient air purification device can realize efficient oxidation purification of multiple substances inair and waste gas and has higher economic and environmental benefits.

Owner:湖南中宏新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com