Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

378results about How to "Maximize resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

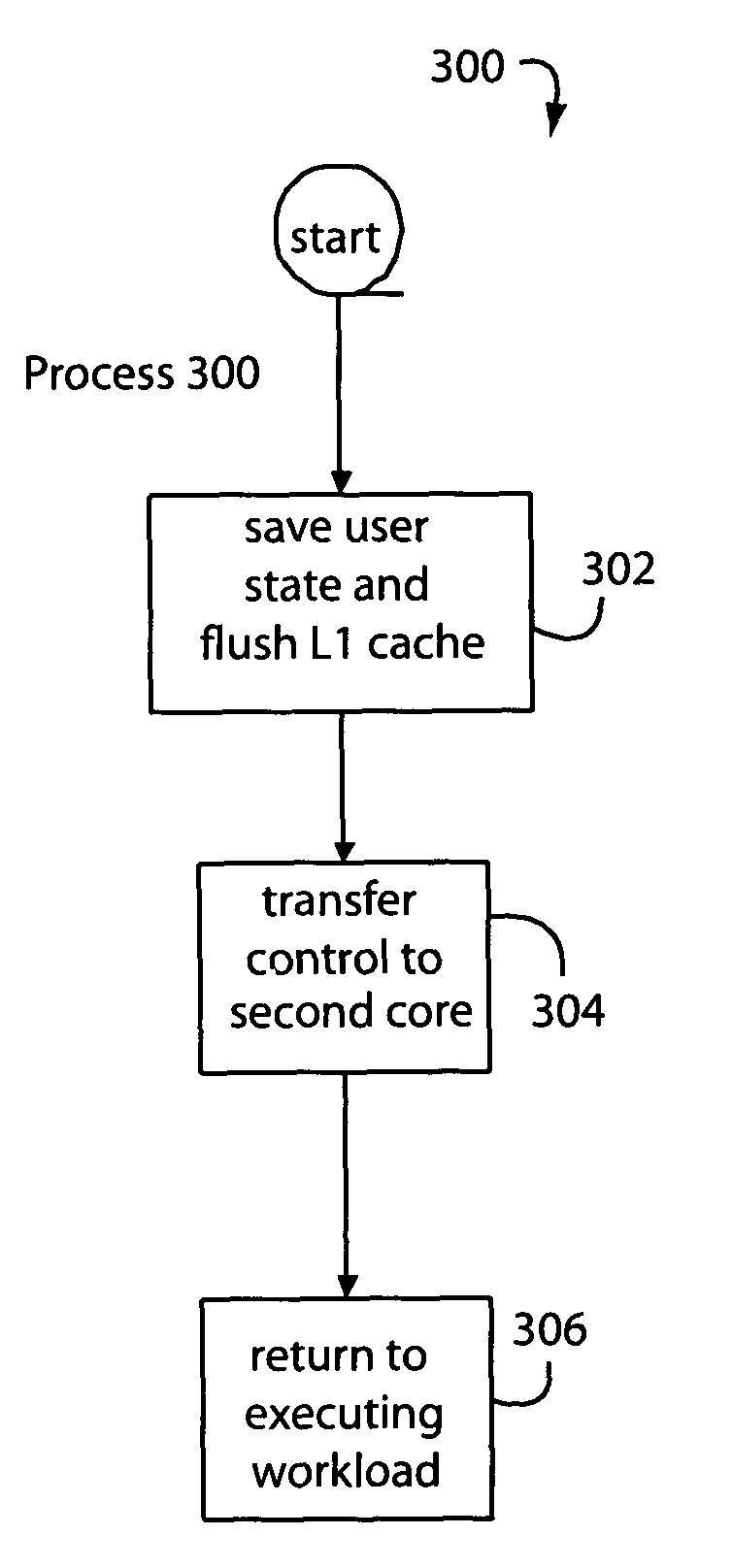

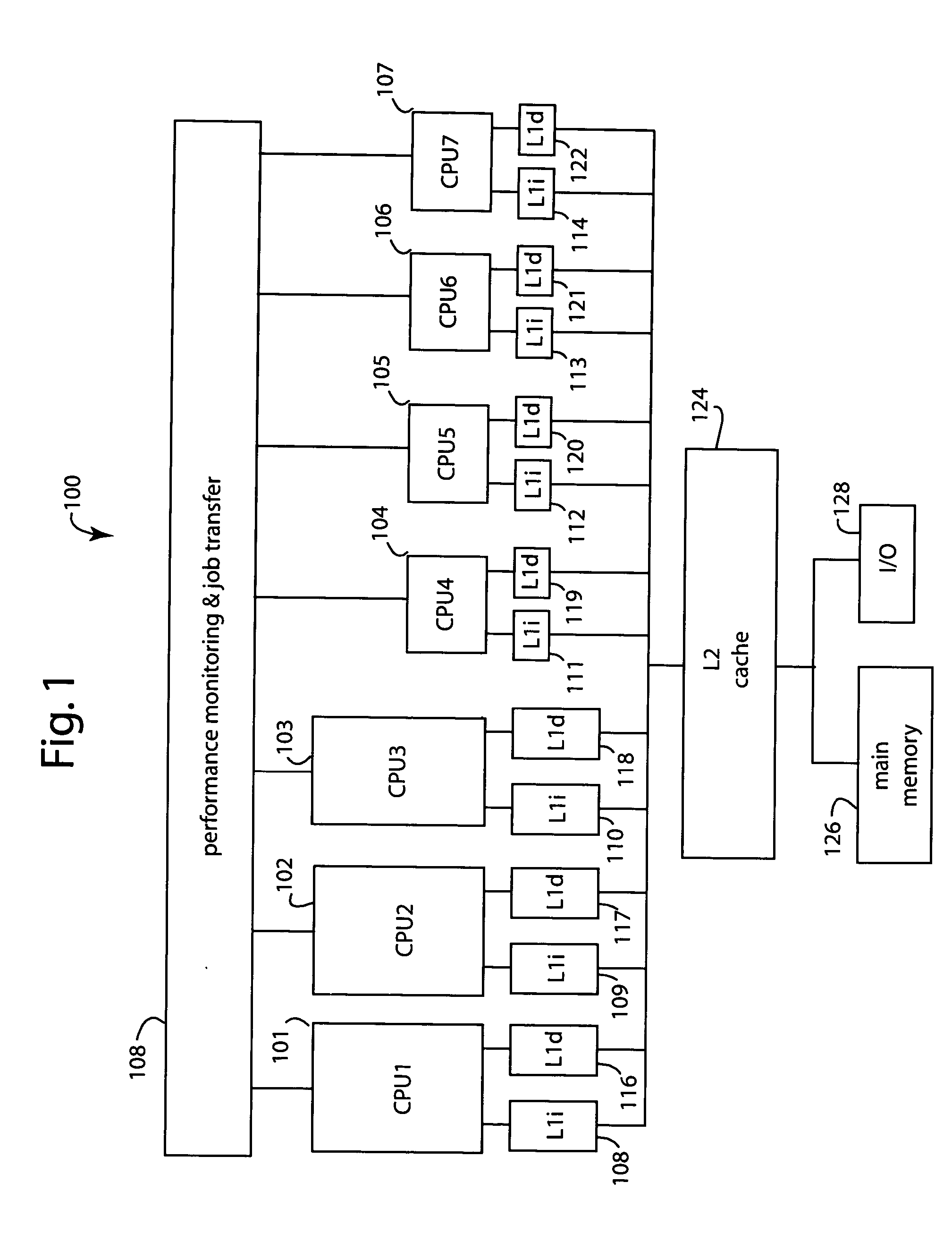

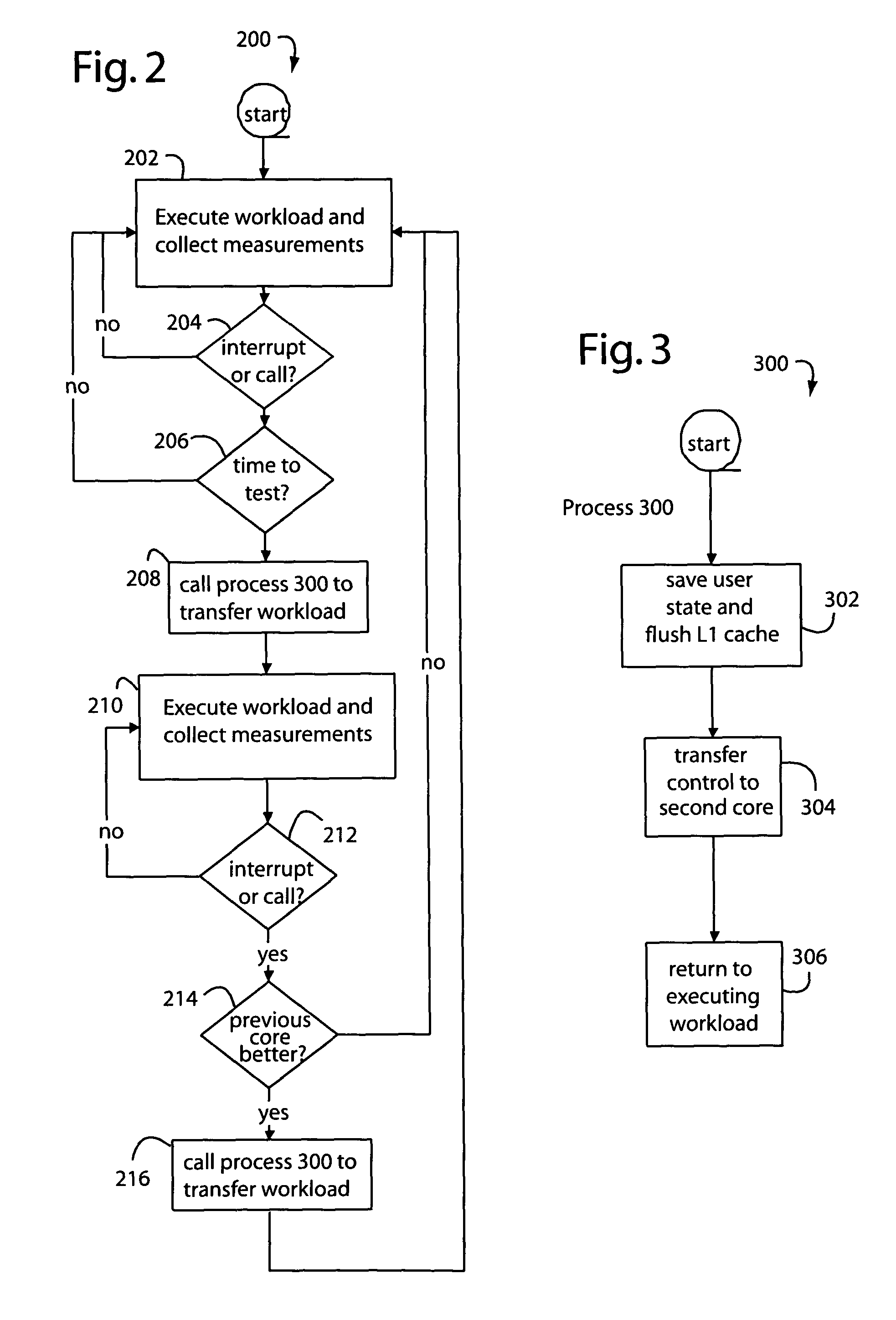

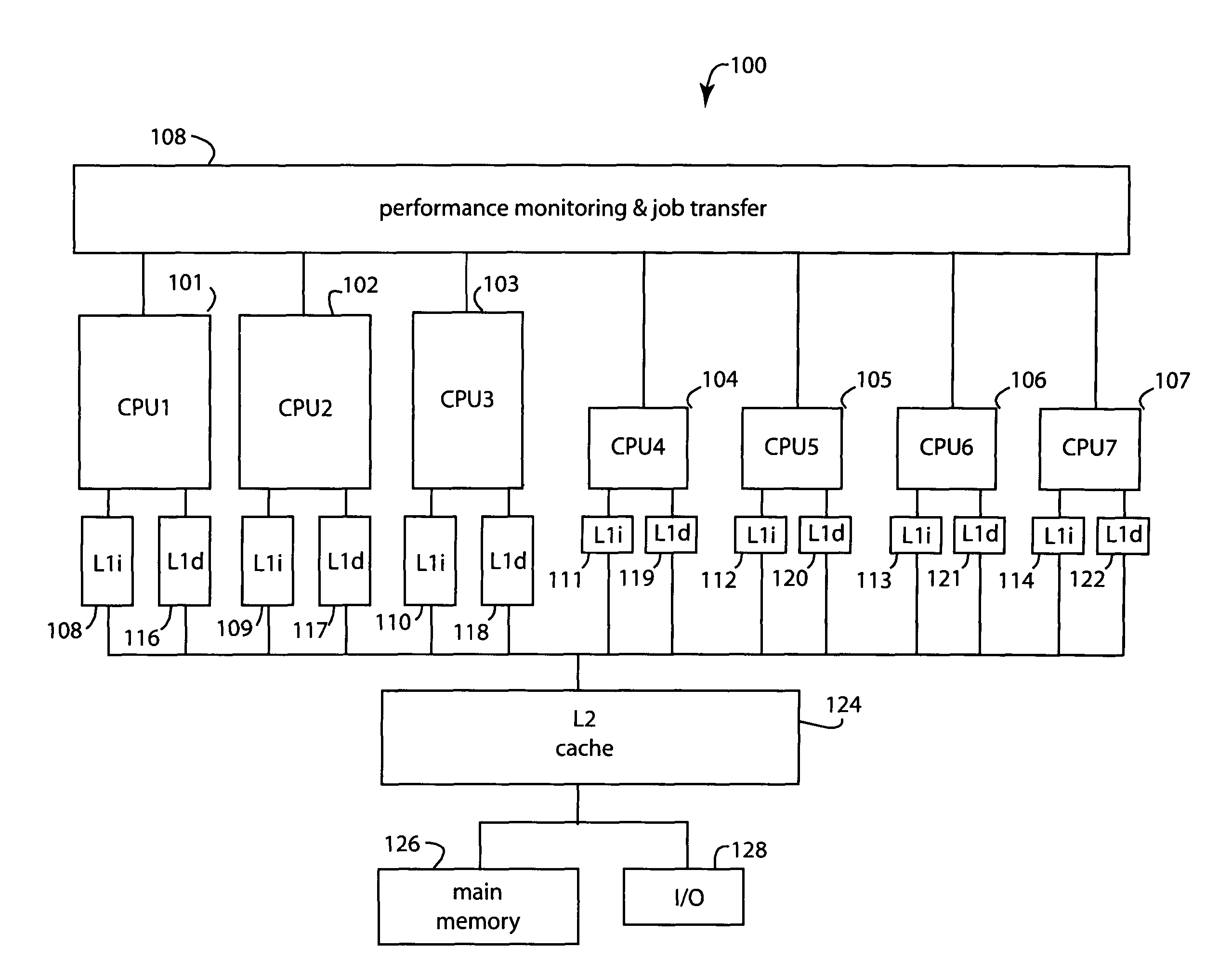

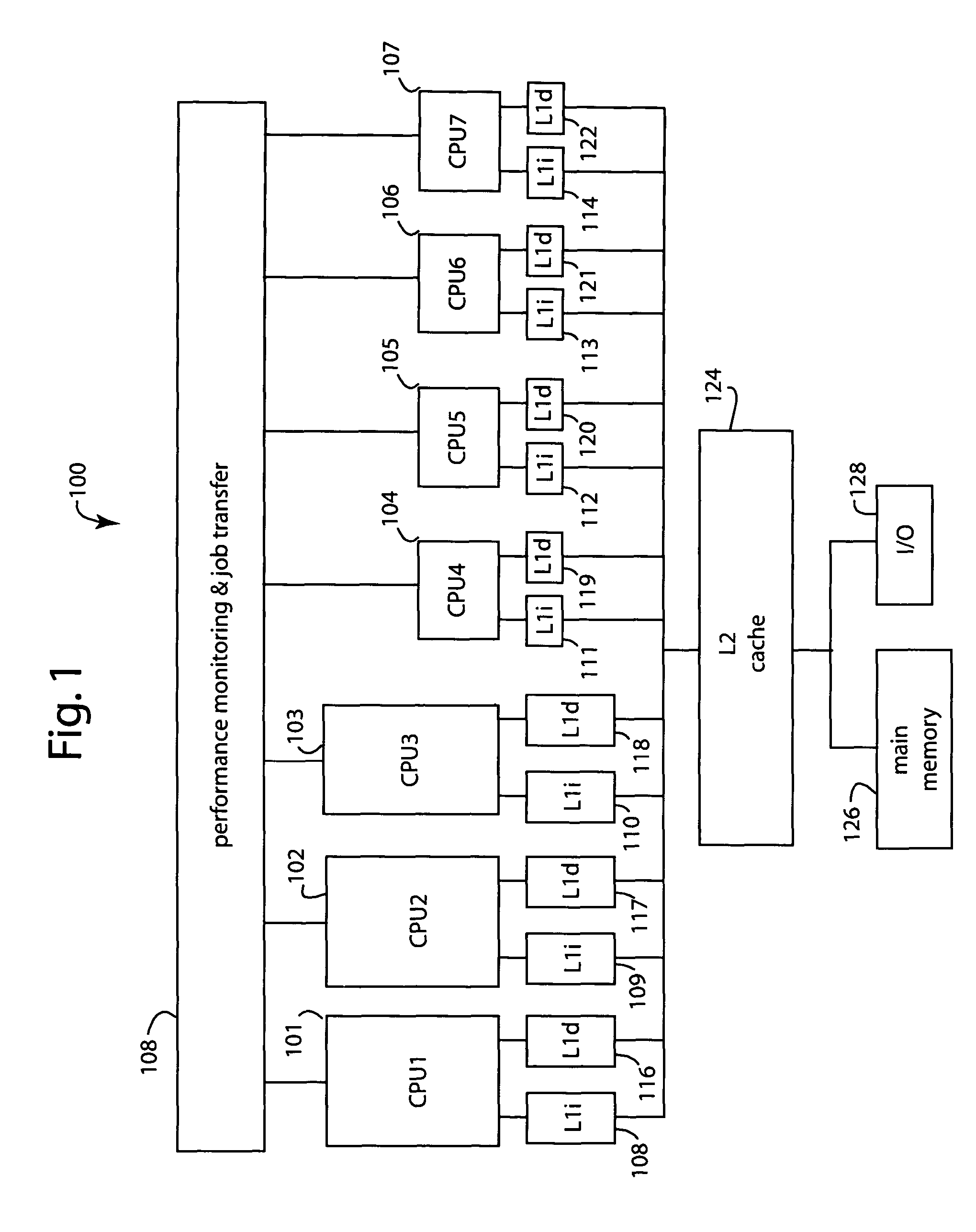

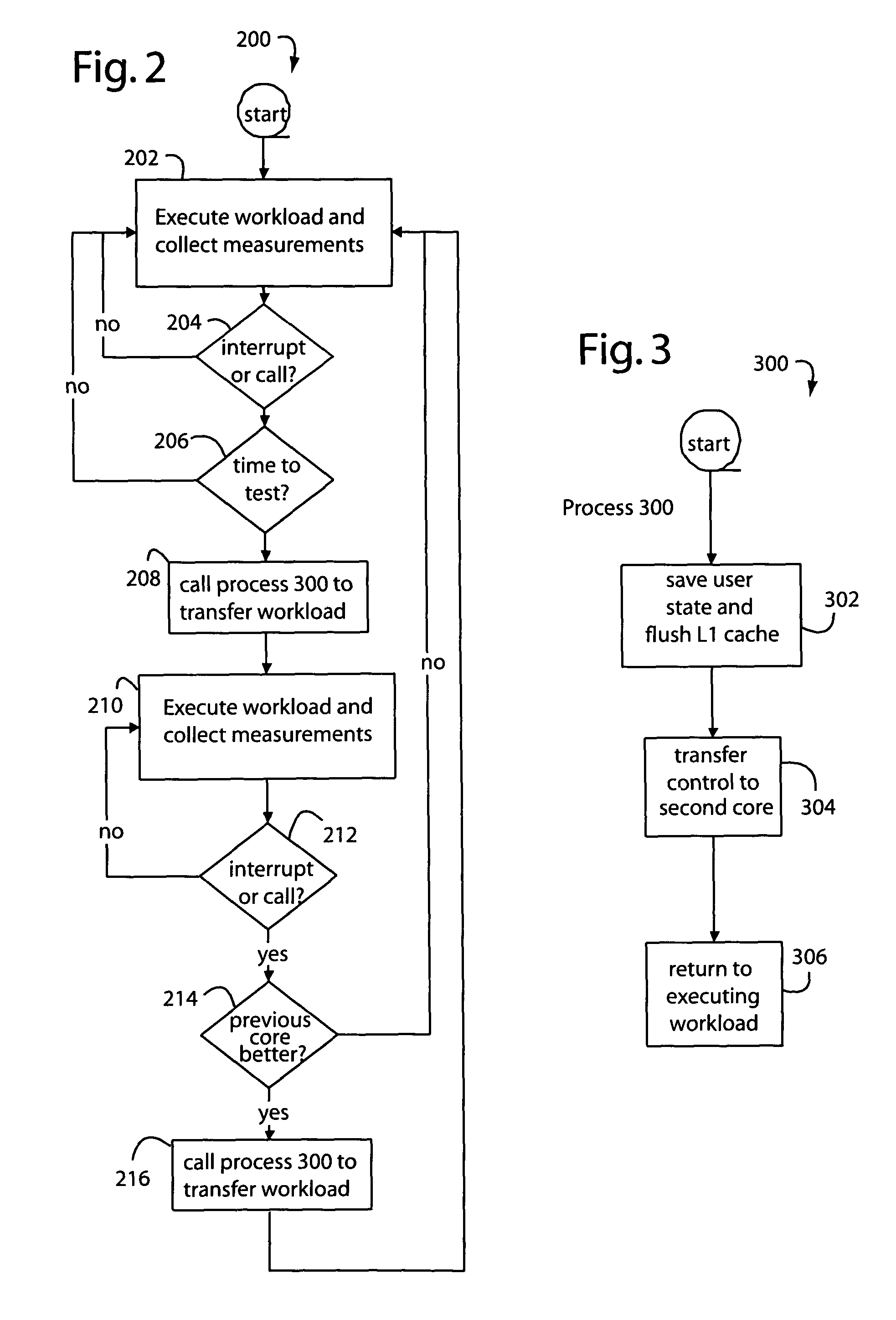

Heterogeneous processor core systems for improved throughput

InactiveUS20050013705A1Improve performanceMaximize resource utilizationResource allocationNuclear monitoringComputerized systemParallel computing

A computer system for maximizing system and individual job throughput includes a number of computer hardware processor cores that differ amongst themselves in at least in their respective resource requirements and processing capabilities. A monitor gathers performance metric information from each of the computer hardware processor cores that are specific to a particular run of application software then executing. Based on these metrics, a workload assignment mechanism assigns jobs to processor cores in order to maximize overall system throughput and the throughput of individual jobs.

Owner:HEWLETT PACKARD DEV CO LP

Heterogeneous processor core systems for improved throughput

InactiveUS7996839B2Improve performanceMaximize resource utilizationResource allocationNuclear monitoringComputerized systemParallel computing

Owner:HEWLETT PACKARD DEV CO LP

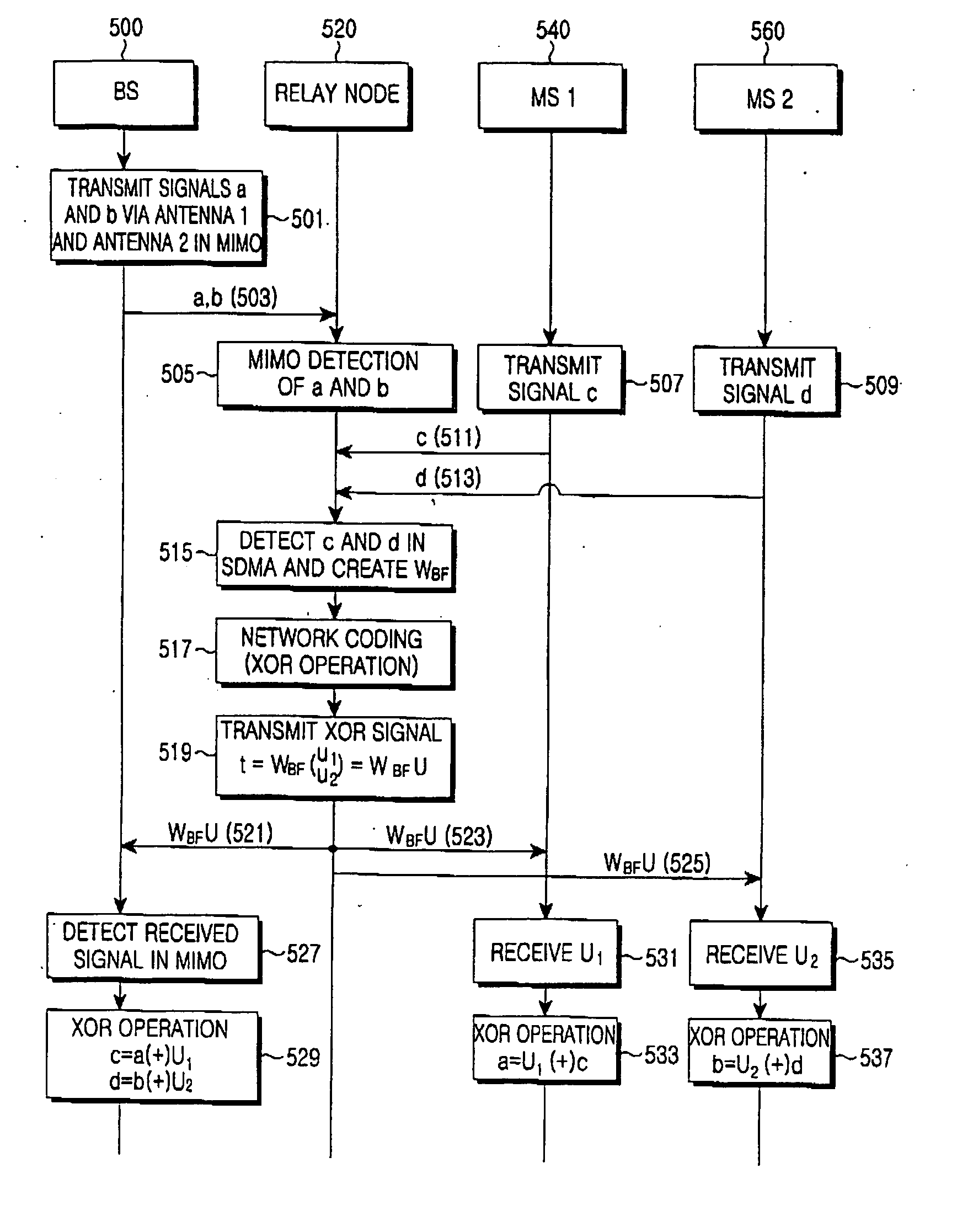

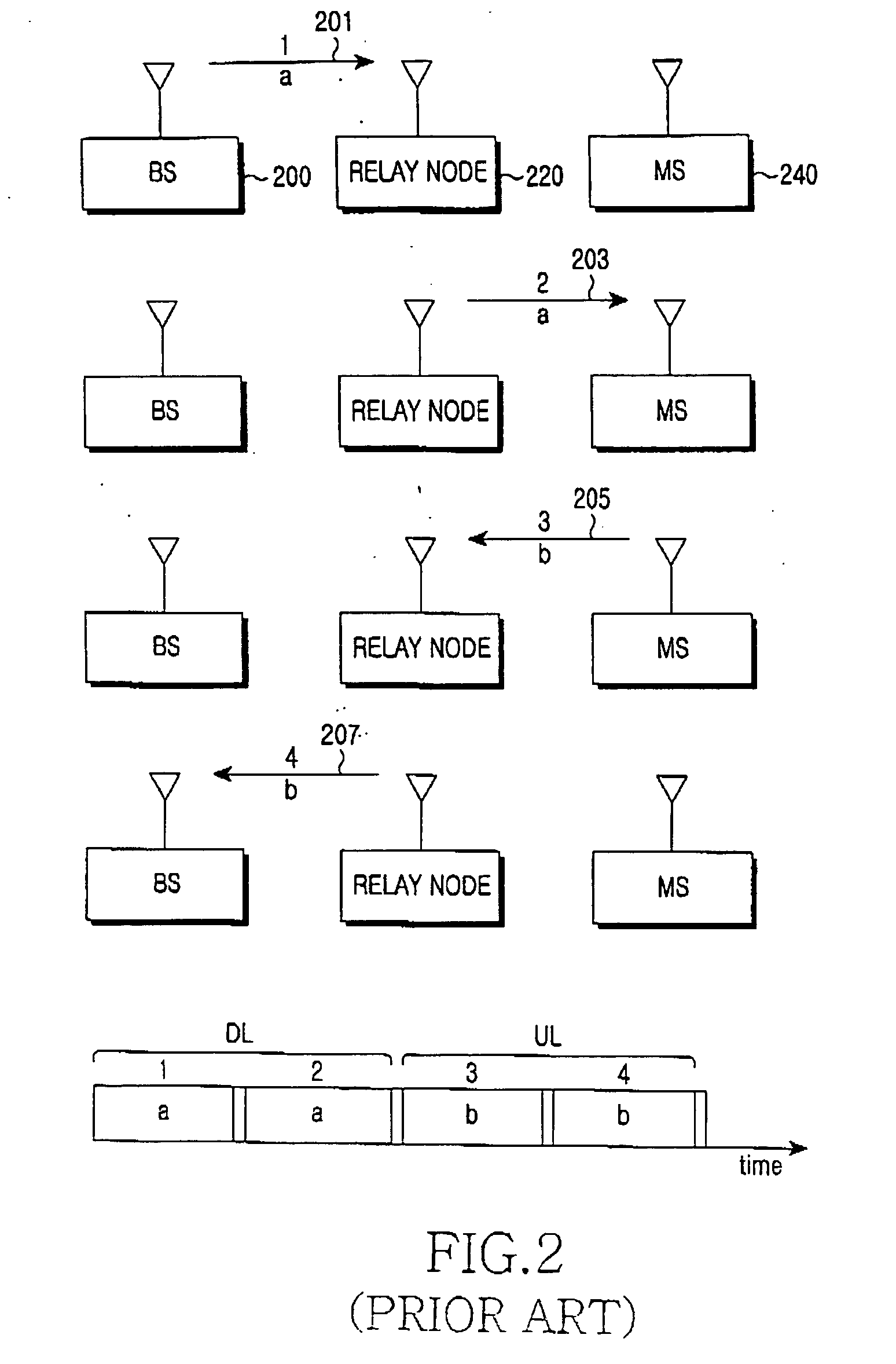

Signal transmitting/receiving method for increasing transmission efficiency in a wireless communication system using multiple antennas and system thereof

InactiveUS20070149117A1Improve data transfer efficiencyMaximize resource utilizationSite diversityActive radio relay systemsCommunications systemMobile station

A method and system for transmitting and receiving signals to increase transmission efficiency in a wireless communication system using multiple antennas are provided. A relay node receives a first signal from a Base Station (BS) according to a first signal scheme and a second signal from a Mobile Station (MS) according to a second signal scheme. The relay node generates a third signal by XOR-operating the first signal and the second signal, multiplies the third signal by a weight matrix, and transmits the multiplied signal to the BS and the MS.

Owner:SAMSUNG ELECTRONICS CO LTD

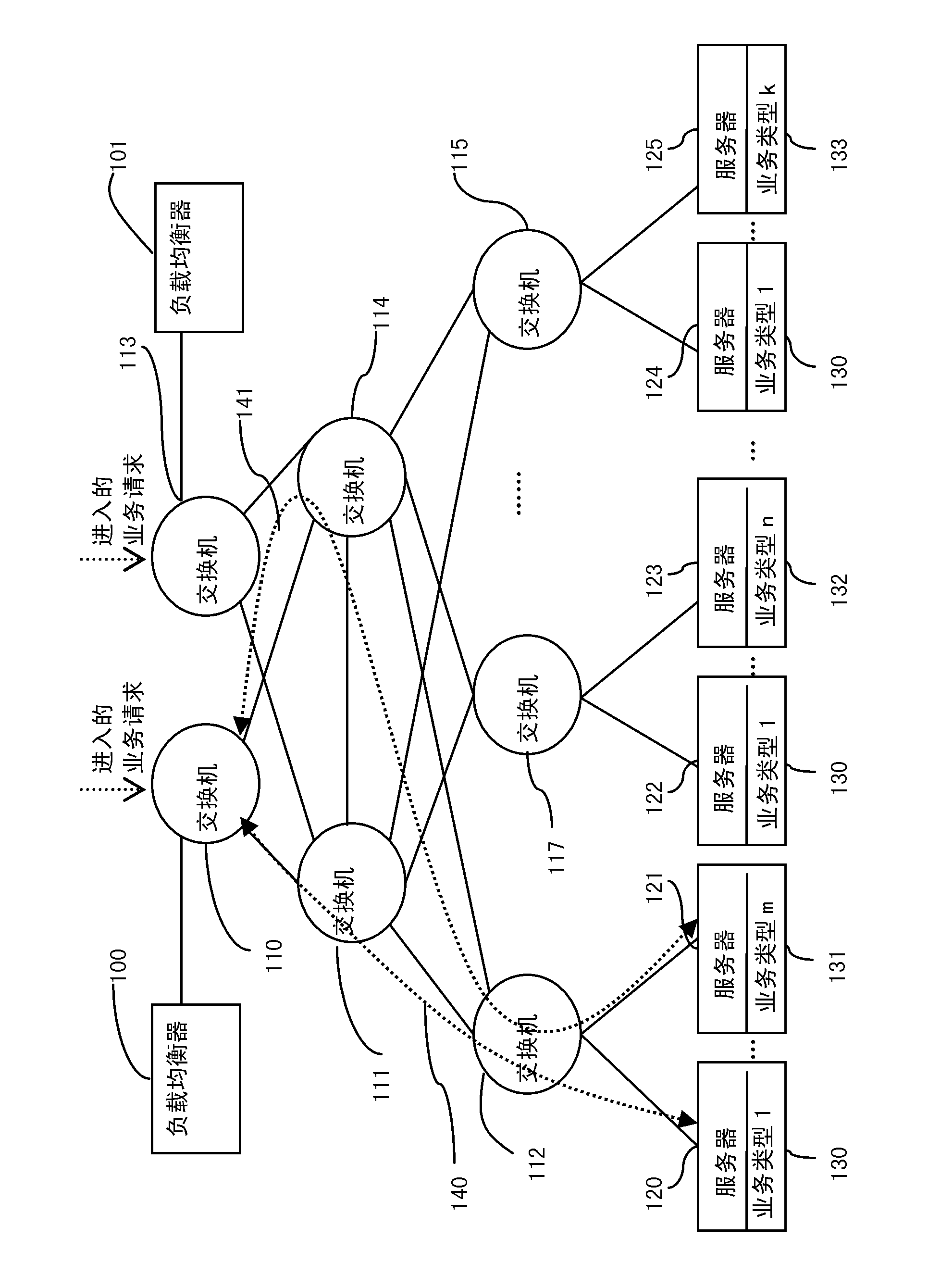

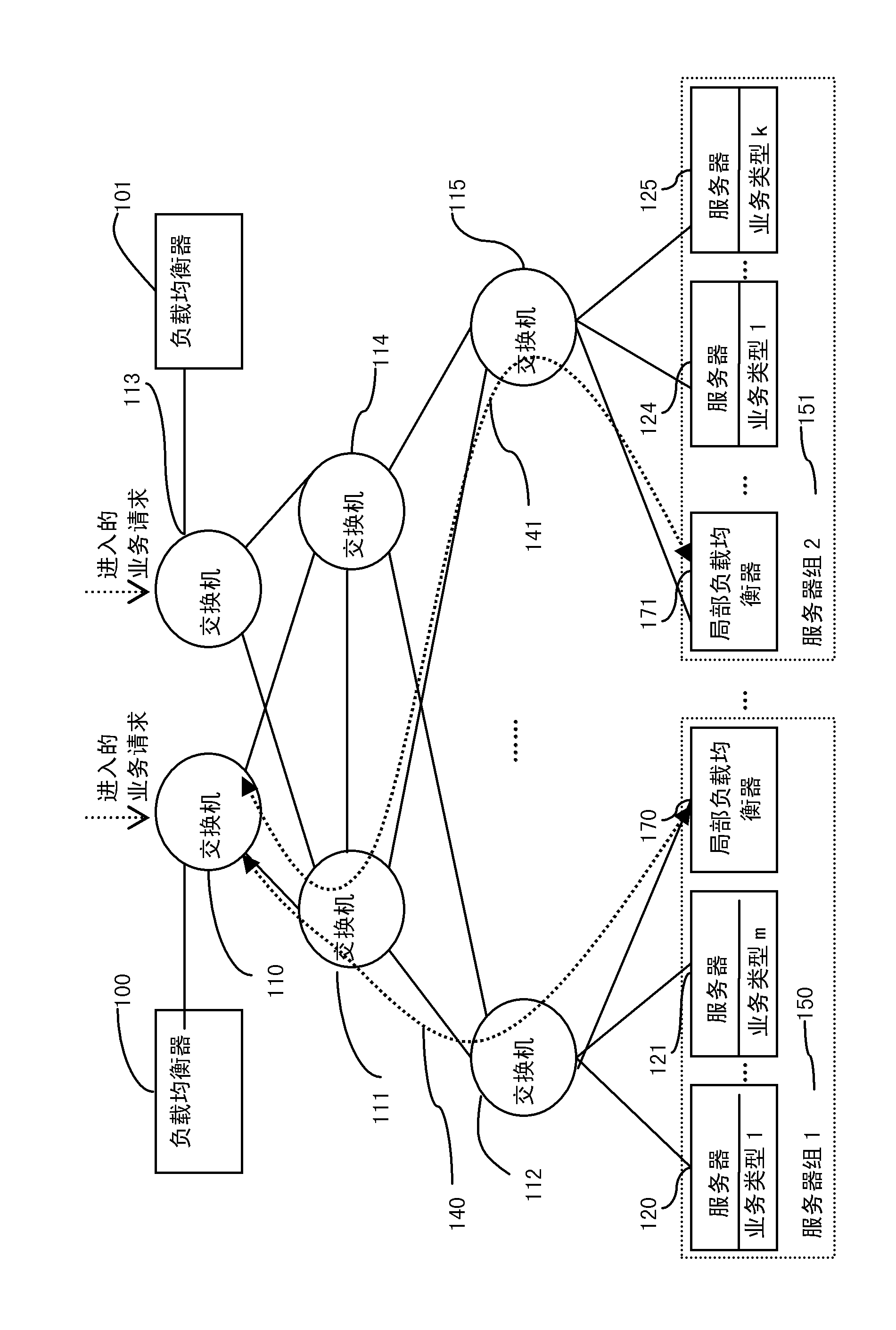

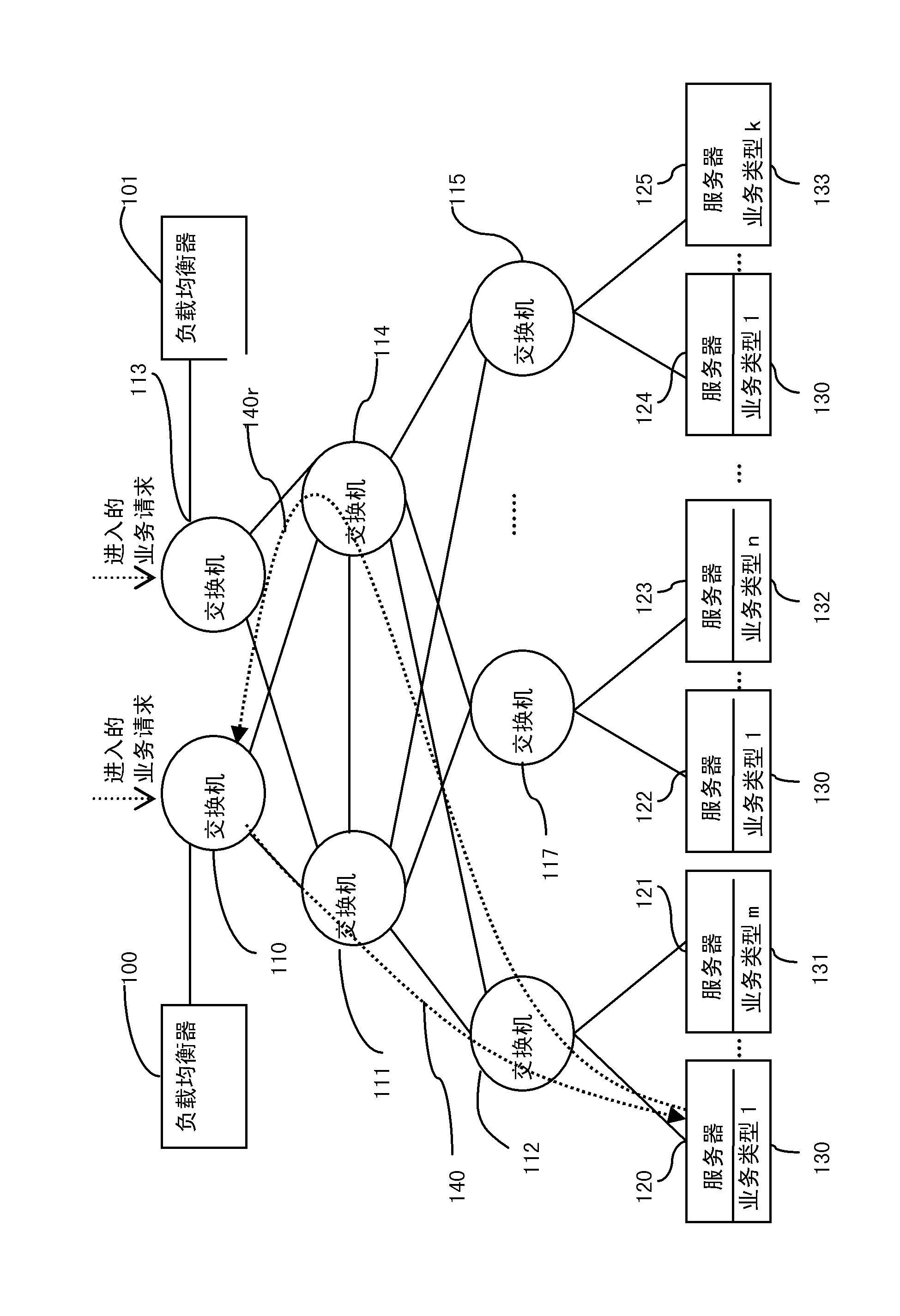

Load balancing device and load balancing method

InactiveCN103259739AReduce construction costsEasy to handleData switching networksResource blockData center

The invention provides a load balancing device and a load balancing method both of which can improve resource distributing efficiency while can balance the service distribution of servers and flow distribution of a route. The services are divided into a plurality of service blocks according to the server resource requirements and network transmission resource requirements of the services, spare server resources and spare network transmission resources of a data center network are divided into a plurality of resource blocks, the spare server resources and the spare network transmission resources of the data center network are monitored, a corresponding relation between the combination, specific to a server, of the spare server resources and the spare network transmission resources and the resource blocks is set, the service block to which the request requirement entering the data center network belongs is identified, and the combination of the spare server resources and the spare network transmission resources is distributed to the service request based on the corresponding relation between the service block and the corresponding resource block.

Owner:HITACHI LTD

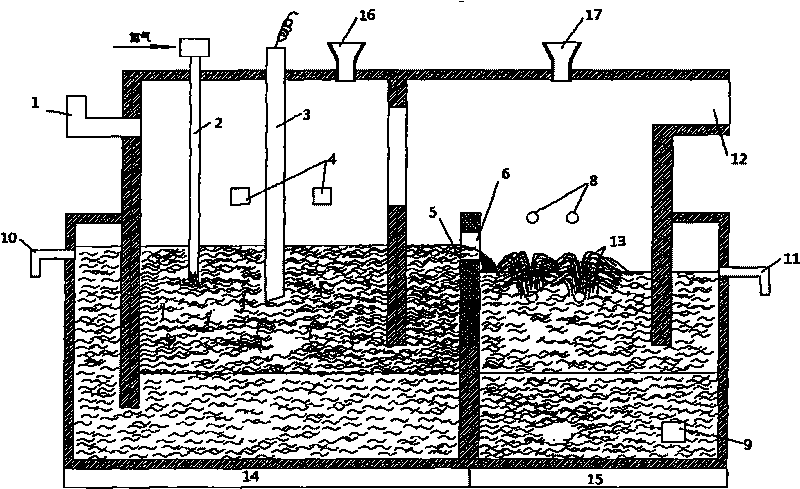

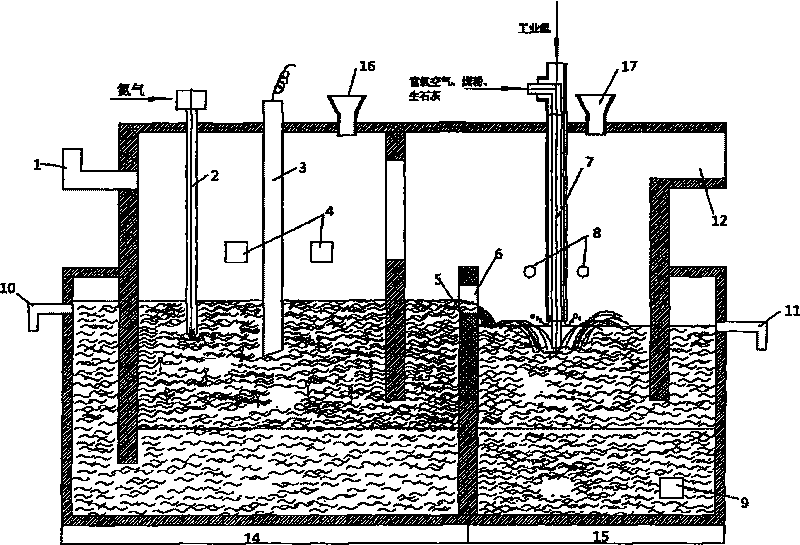

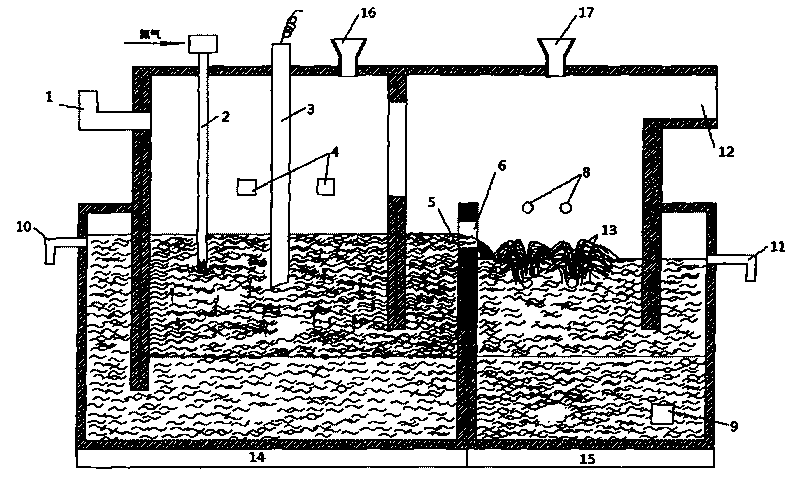

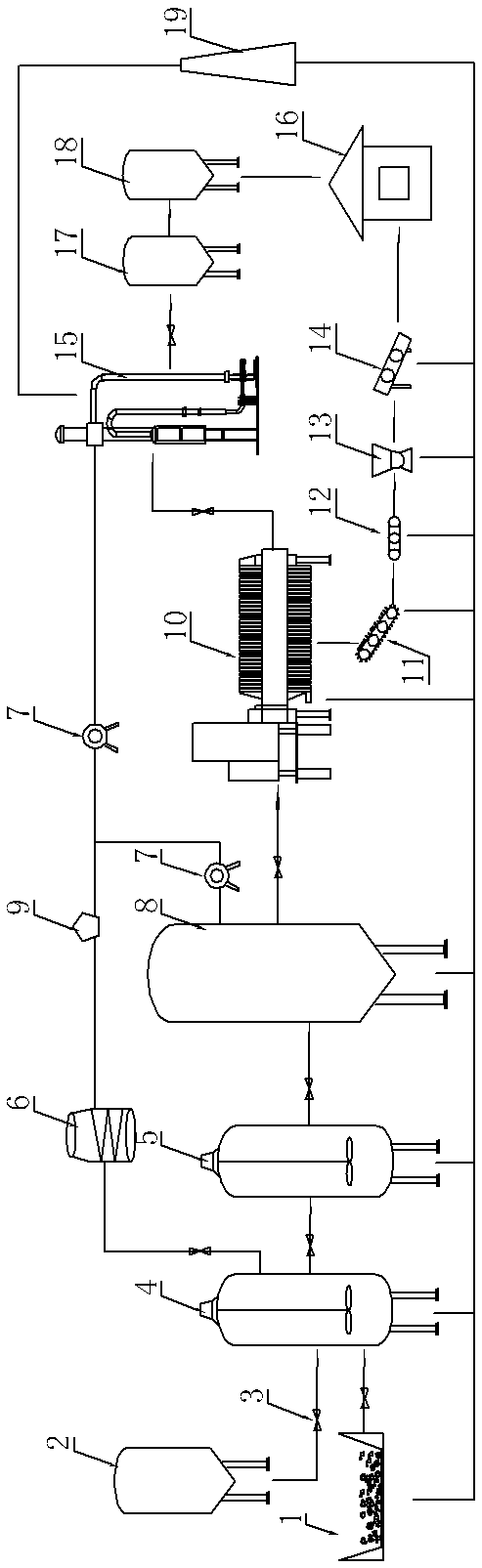

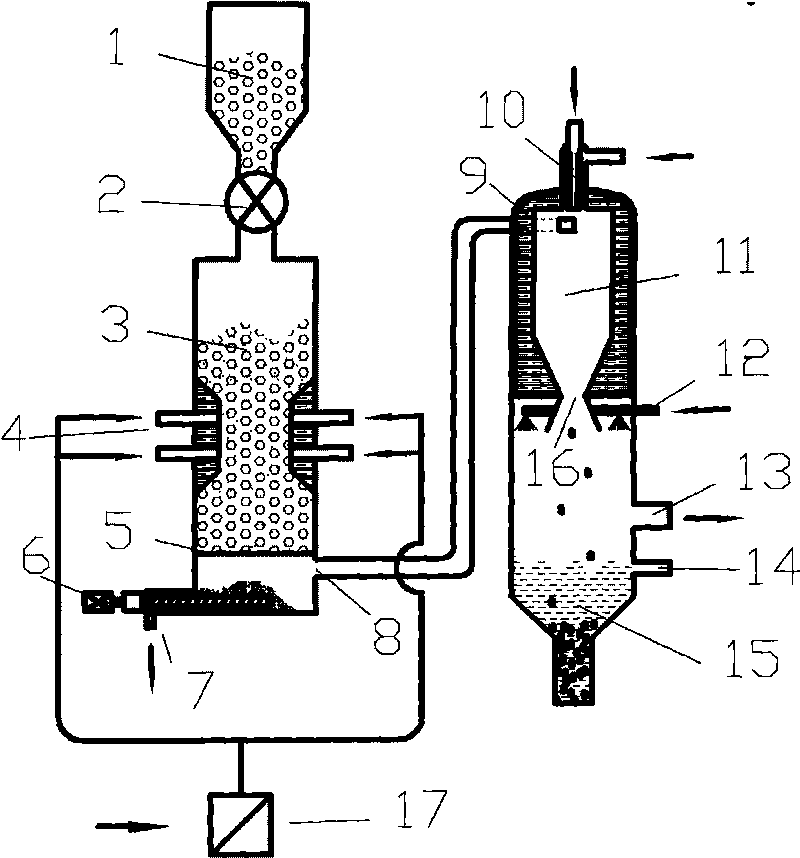

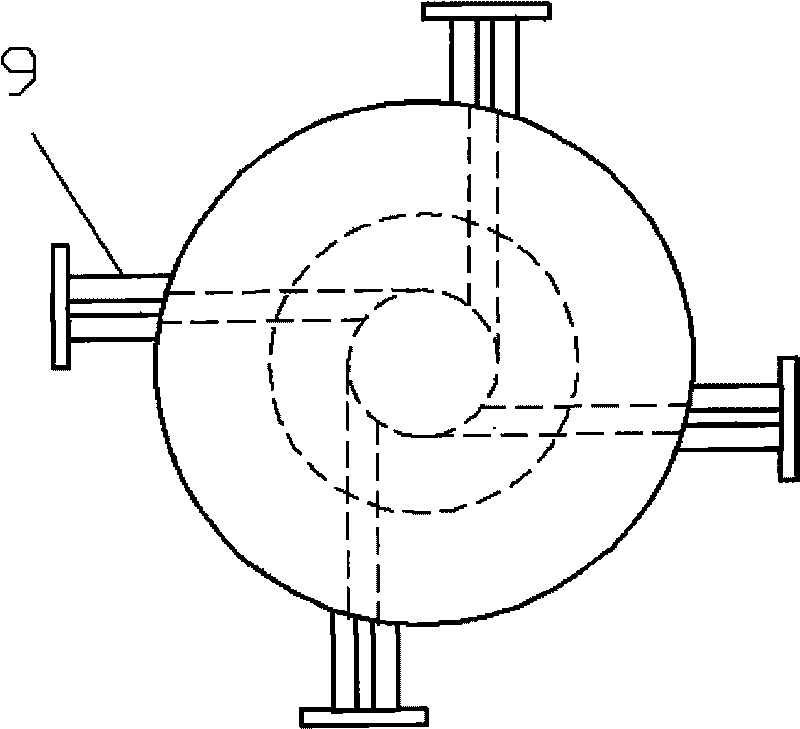

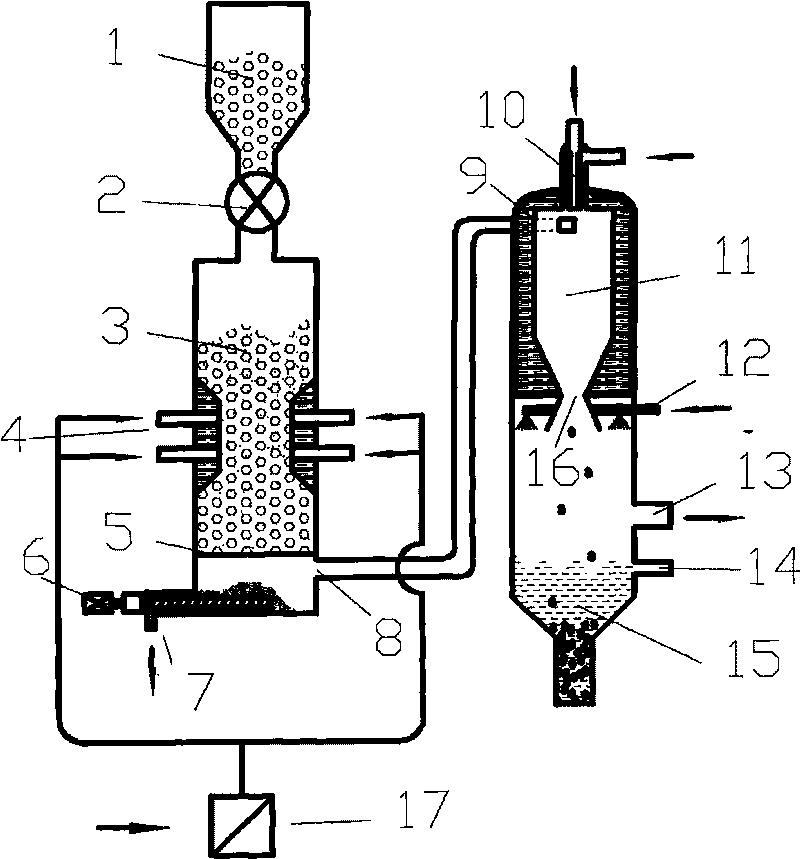

Copper-smelting thermal slag iron-extracting process and device

ActiveCN101705360ASave energy and costReduce equipment investment and floor spaceProcess efficiency improvementThermal energyNitrogen gas

The invention discloses a copper-smelting thermal slag iron-extracting process and a device. The copper-smelting thermal slag is processed in a same furnace to deplete copper and reduce iron. The copper extraction is performed in a first furnace hearth (copper depleting area). Electrode arc or fuel is used for supplying heat. Small matte particle is impacted to grow up by stirring with nitrogen to realize settlement separation. The depleted slag automatically flows into a second furnace hearth (iron reducing area). Coal, quicklime and oxygen-enriched air are blown in from side or top to reduce iron. The invention has the advantages that copper and iron are sufficiently recycled from the copper-smelting slag, the recycling rate of copper is more than 90%, the recycling rate of iron is more than 95%, heat of thermal slag is sufficiently used, the energy source and the cost are saved, the copper extraction and the iron extraction are realized in a same furnace, and the equipment investment and the floor space are both saved.

Owner:YANGGU XIANGGUANG COPPER

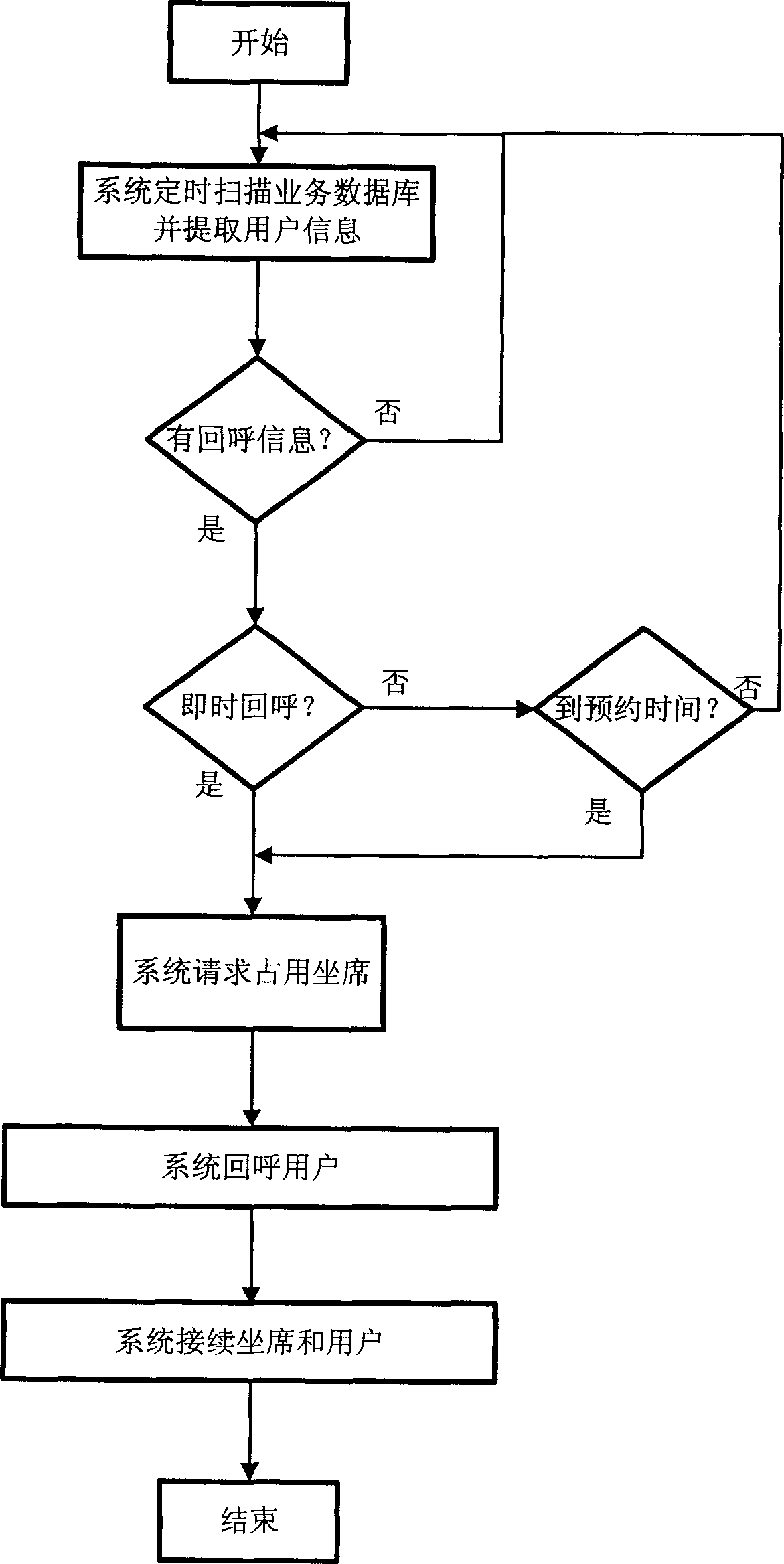

Method for call center realizing active callback and its active callback system

InactiveCN1882019AIncrease usageAchieve interactionSpecial service for subscribersComputer scienceService user

The invention relates to a method for calling center for realizing active call back and relative active call back system, wherein it comprises a call center back service process and an active back call system back process, wherein the second process comprises: (1), the system timely scans the service database to extract out the user information; (2), judging the back type of user, if it is instant back call, going on the process, of it is the advanced back call, judging if reaching the advanced time, if reaching the advanced time, going on the process, or else, backing to the step (1); (3), based on the skill number of user information, requesting occupying the artificial seat of requested service; (4), after success, the system actively calls back the user based on the telephone number of user information; (5), after calling back user successfully, connecting the seat and user, the seat accepts the user service. The invention can realize the interaction between the service user and the calling center, to improve the utilization of artificial seat.

Owner:ZTE CORP

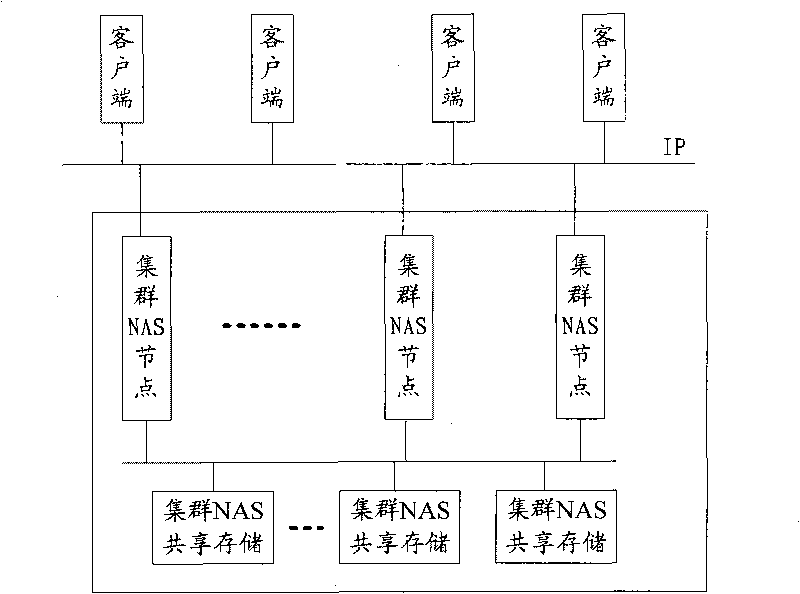

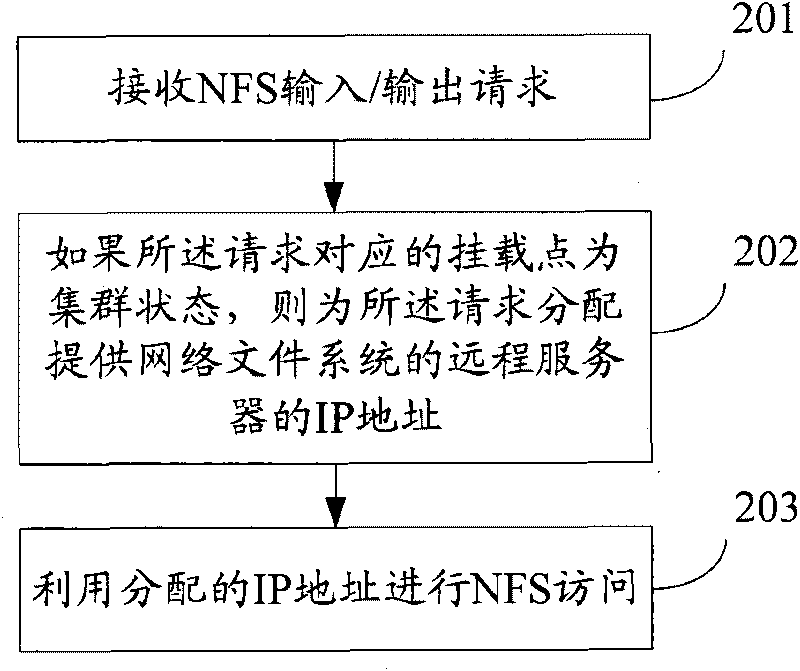

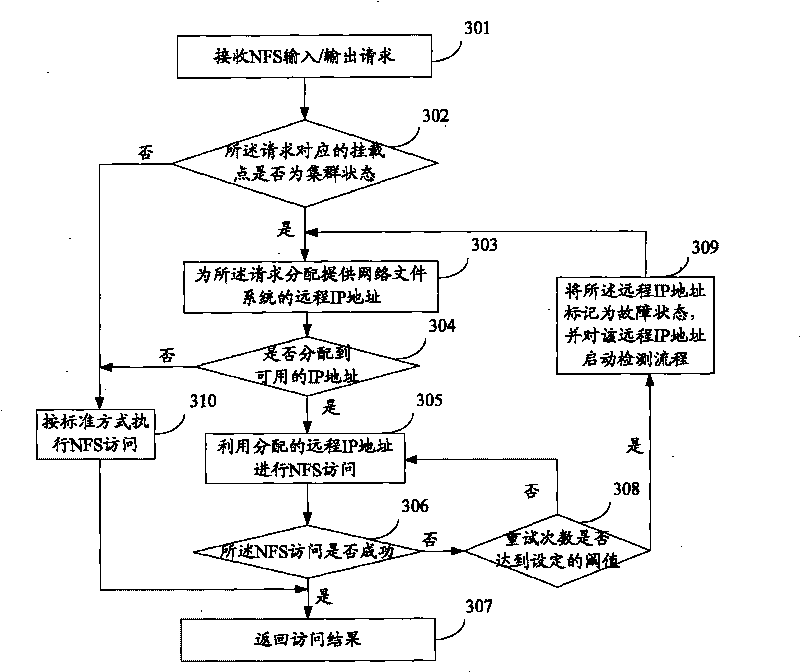

Network file system access method, device and system

The invention relates to the technical field of cluster network attached storage and discloses a network file system access method and device. The method comprises the following steps: receiving network file system input / output request; if the mount point corresponding to the request is in cluster state, distributing the IP addresses of the remote server providing the network file system according to the request; and utilizing the distributed IP addresses to perform network file system access. By using the network file system access method, device and system of the invention, a plurality of different cluster NAS nodes in the cluster can be selected for NFS shared access so as to realize the load balance among the cluster NAS nodes and the maximization of the resource utilization.

Owner:CHENGDU HUAWEI TECH

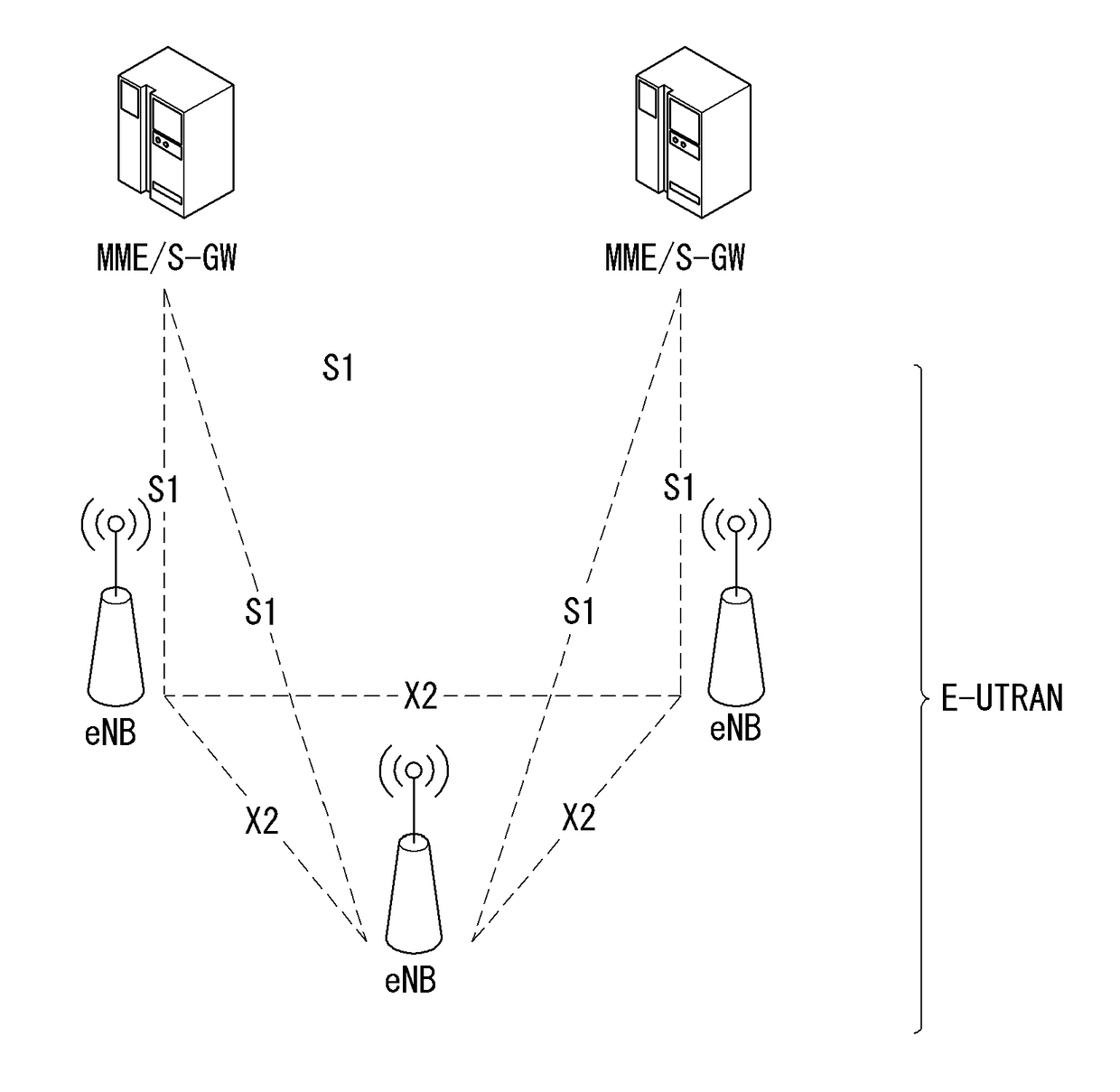

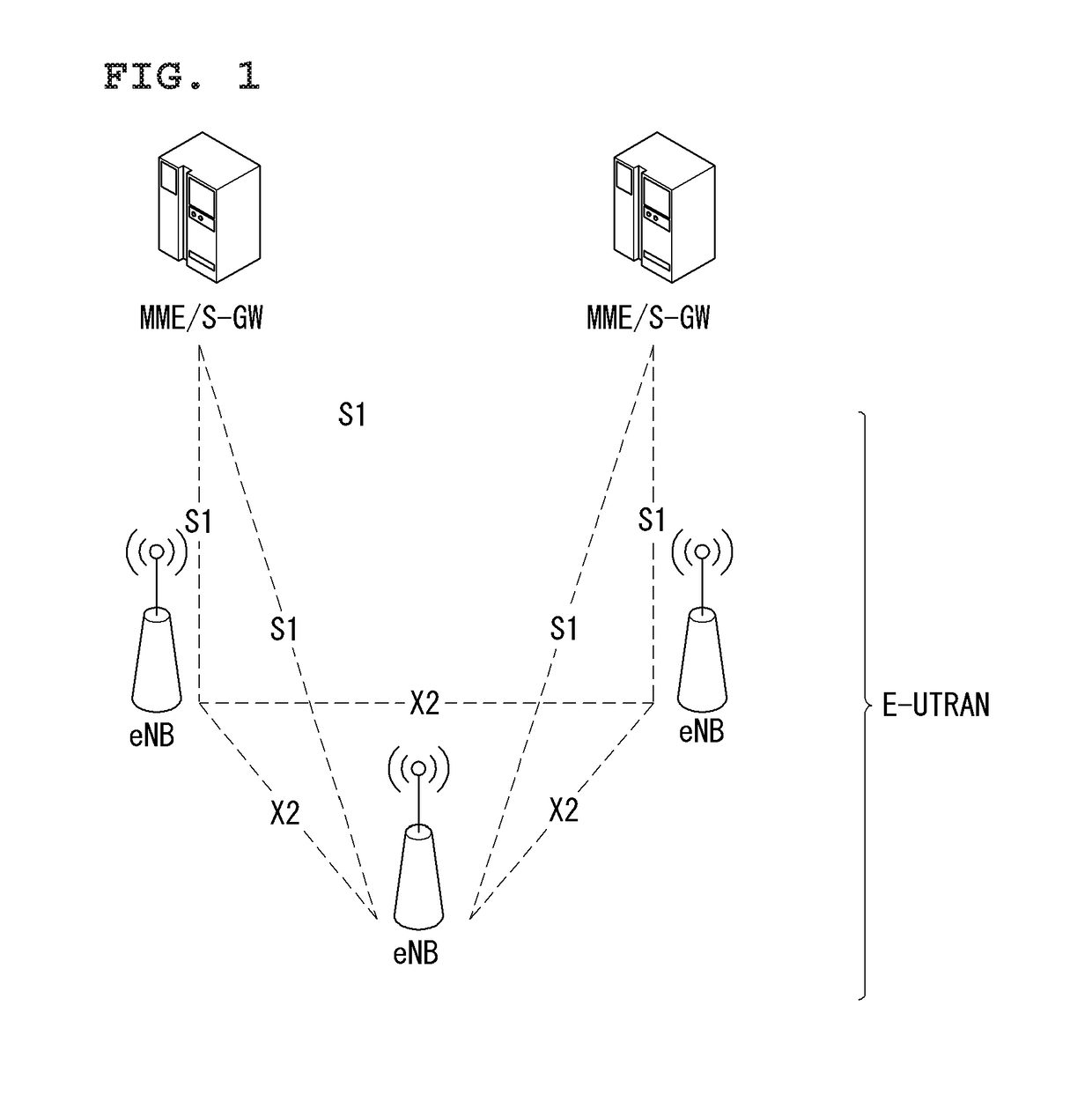

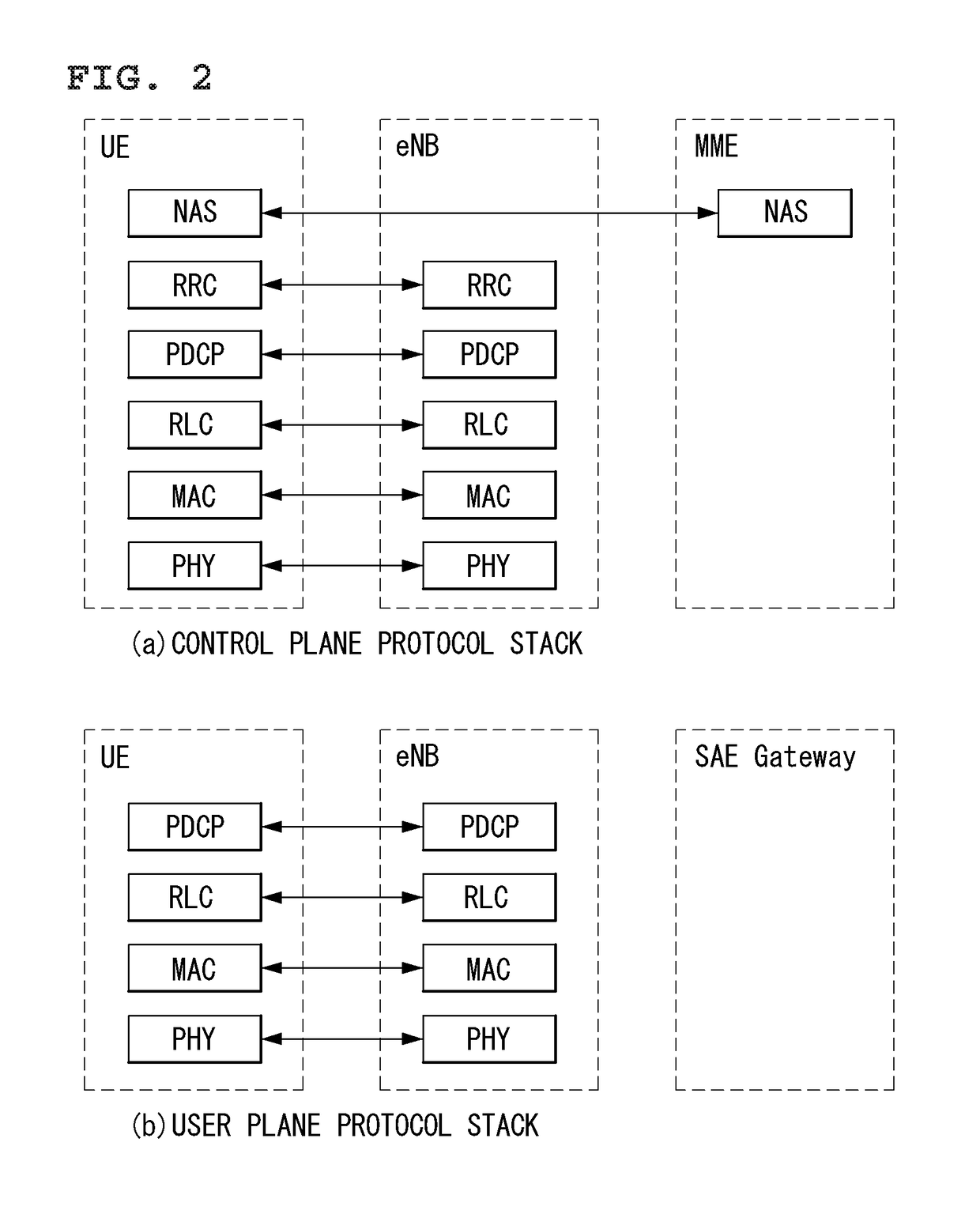

Method and apparatus for scheduling request in a wireless communication system

ActiveUS20180227938A1Increased latencyMaximize resource utilizationSignal allocationConnection managementData transmissionResource information

Provided are a method and apparatus for requesting scheduling for an uplink data transmission in a wireless communication system. The method may include receiving, by a user equipment, an additional scheduling request (SR) resource configuration information including additional SR resource information and buffer size information configured to the additional SR resource in addition to a default SR resource from a base station, transmitting, by the user equipment, an SR through the default SR resource or the additional SR resource to the base station, receiving, by the user equipment, an uplink resource allocation information which is determined according to the resource in which the SR is transmitted from the base station, and transmitting, by the user equipment, the uplink data to the base station through a physical uplink shared channel (PUSCH) resource which is allocated by the uplink resource allocation information.

Owner:LG ELECTRONICS INC

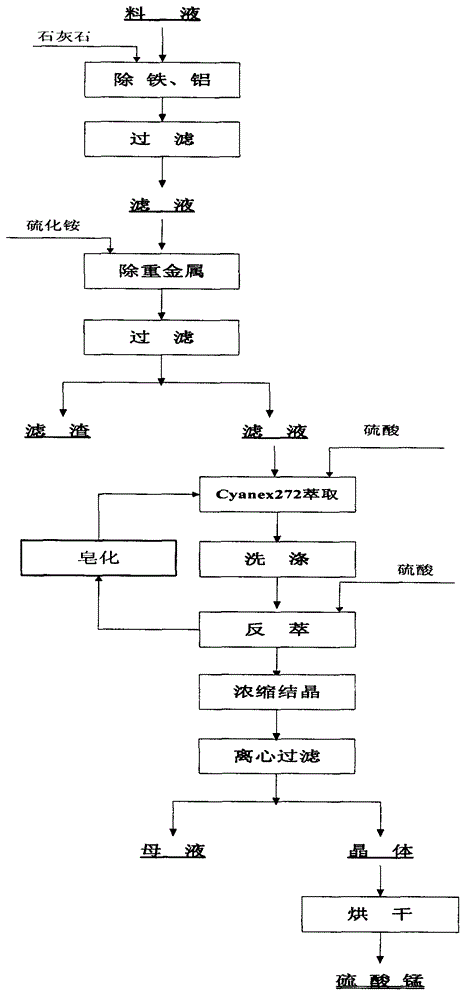

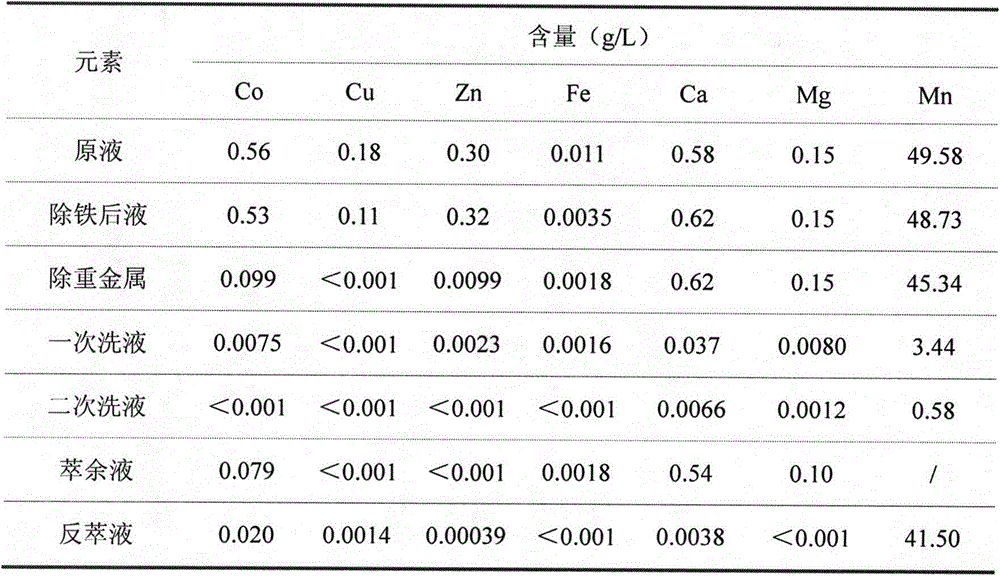

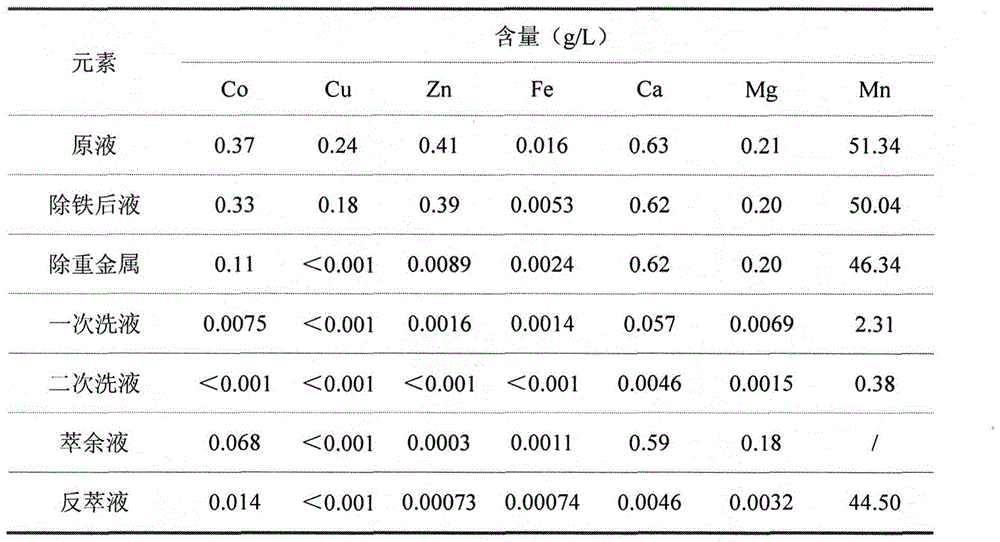

Method for preparing high-purity manganese sulfate from manganese-containing waste liquid

The invention relates to a method for preparing high-purity manganese sulfate from a manganese-containing waste liquid. The existing method for treating the high-manganese-containing waste liquid generated in the wet production of cobalt salts mainly comprises a lime precipitation method and a method for preparing manganese sulfate by removing calcium and magnesium via fluoride and adopting a P204 or P507 extracting agent and has the respective problems that the utilization value of prepared manganese hydroxide is low, the fluoride-containing wastewater is polluted and the like. According to the method, heavy metals are removed by virtue of sulfide, manganese is extracted through a Cyanex272 extracting agent, calcium and magnesium are thrown and the reverse extraction is performed to obtain the high-purity manganese sulfate product which can meet the requirement of a ternary cell material on manganese sulfate; and the method has the advantages of short process flow, no fluoride pollution and the like.

Owner:ZHEJIANG HUAYOU COBALT

Preparation method for preparing derived fuel by utilizing combustible materials in garbage

InactiveCN102041127AImprove sorting rateSuppress generationBiofuelsSolid fuelsRefuse-derived fuelAdhesive

The invention relates to a preparation method for preparing a derived fuel by utilizing combustible materials in garbage, comprising the following steps: (1) disinfecting; (2) carrying out rough selection on the garbage; (3) carrying out fine selection on the garbage; (4) adding CaO the weight of which accounts for 4%-8% of the total weight of the combustible materials into fine combustible materials, mixing and stirring uniformly; (5) adding a combustion improver and an adhesive, mixing and stirring uniformly; (6) draining and drying the fine combustion materials; (7) carrying out extrusion molding; (8) drying and cooling to obtain a finished product; and (9) detecting the heating value of the derived fuel. The preparation method has the beneficial effects that 1, the sorting index of the garbage is high, so that harmful substances in the derived fuel are effectively controlled; 2. the heat value of the derived fuel is high; 3, the CaO is added in the derived fuel of the garbage, effective disinfection is achieved and the generation of the harmful substances such as dioxin and the like in the combustion process is restrained; 4, the adhesive is added, so that the strength of a product is good, the product is not easy to break, and the structure shape is smooth; 5, the space formed by accumulation of the size of the shape of the finished product on a boiler grate is most beneficial to combustion; and 6, the resource utilization is maximized, the cost of production and manufacture is low, the production efficiency is high, the product quality is good, and the transportation and storage are convenient.

Owner:杨健

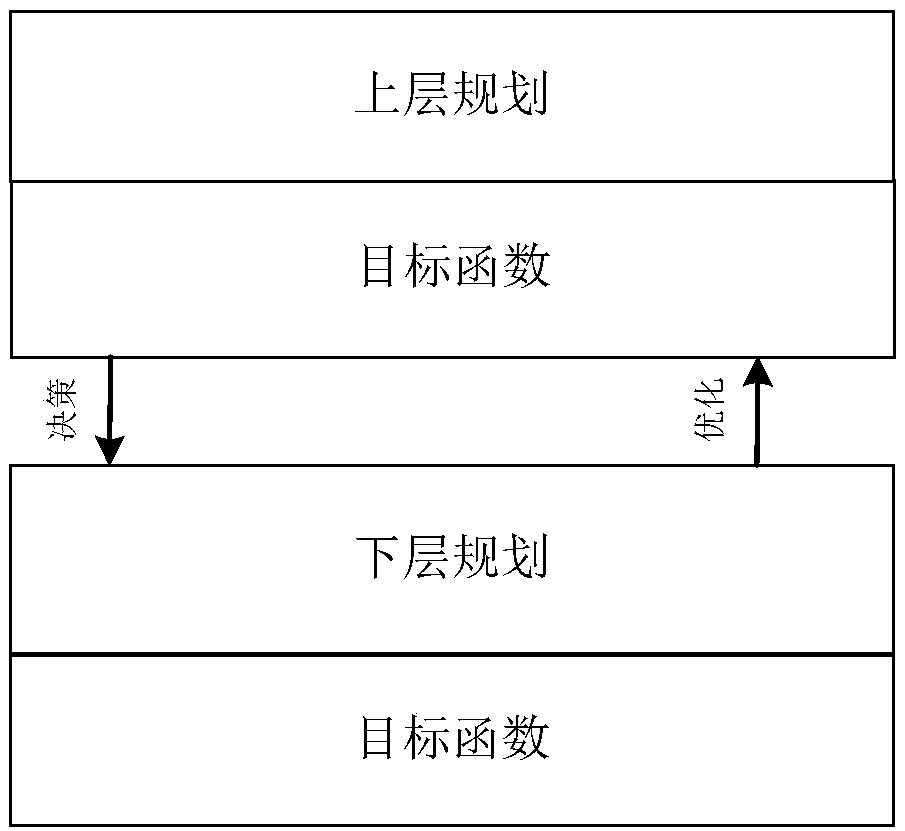

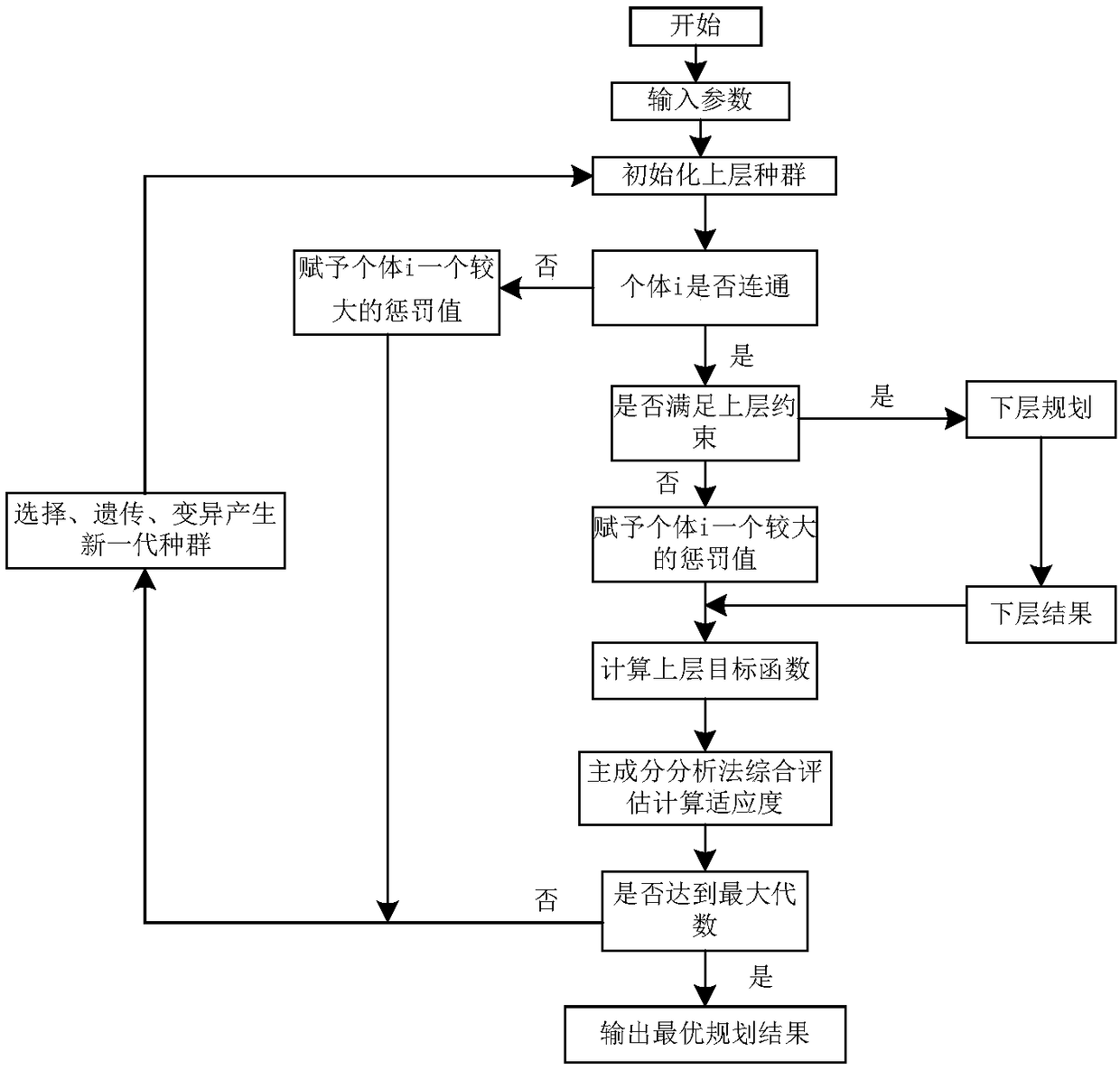

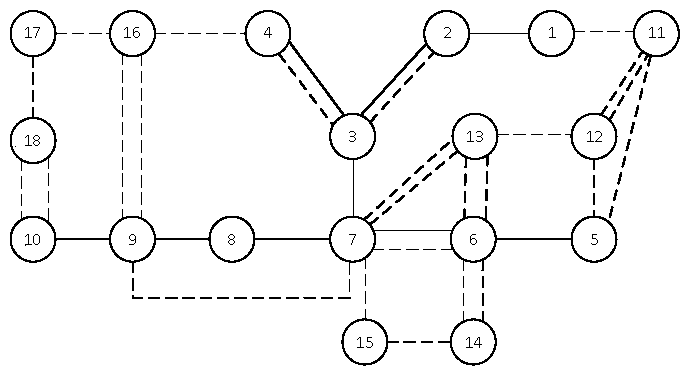

A transmission network planning method considering flexible supply-demand balance

InactiveCN109146706AImprove absorption capacityGuaranteed operating efficiencyGeometric CADData processing applicationsSocial benefitsResource utilization

The invention discloses a transmission network planning method considering flexible supply-demand balance, which comprises the following steps: according to flexible demand and supply under differenttypes and time scales, an evaluation index of power system flexibility considering supply-demand balance being established; based on the evaluation index of power system flexibility, considering economy, reliability and security, a bilevel transmission network expansion planning model being established; based on the bilevel expansion programming model of transmission network, the transmission network being planned. The method effectively solves the problem that the discarding of renewable energy in current system is seriously disjointed with the construction of power source and the planning ofpower network, at the same time, the invention can effectively solve the problem of economical and safe transmission of renewable energy pow generation in a high-proportion renewable energy system, can make scientific and effective guidance for grid planning work, and finally realize the optimization of resource utilization and the maximization of social benefit.

Owner:STATE GRID SICHUAN ECONOMIC RES INST

Active AP scan method for in 802.11 wireless local area network

InactiveCN101635970AImprove operational efficiencyRealize resource utilizationAssess restrictionClient-sideLocal area network

The invention relates to an active AP scan method in an 802.11 wireless local area network, belonging to the technical field of communications. The method comprises the following steps: sending out an exploring request MAC frame; carrying out sniffing scanning before receiving exploring responses of the AP so as to acquire other useful MAC frames, and analyzing all MAC frame header information to acquire related information of the adjacent AP; optimizing the exploring responses, and intercepting data within former 30ms as effective data; updating an AP database by adopting the data acquired in the step 2; repeating all steps to scan continuously if the AP that is suitable for switching is not explored, or finishing the scanning. The invention solves the defects that the scanning time of the AP is overlong during the MAC switching in the prior 802.11 wireless local area network, overcomes the shortages that a network protocol needs to be changed in the prior rapid AP scan method, and the like, just needs to correct client-terminal programs, fully utilizes the non-switching time of an MS and various useful MAC frames in the air, and achieves rapid and effective AP scanning.

Owner:SHANGHAI JIAO TONG UNIV

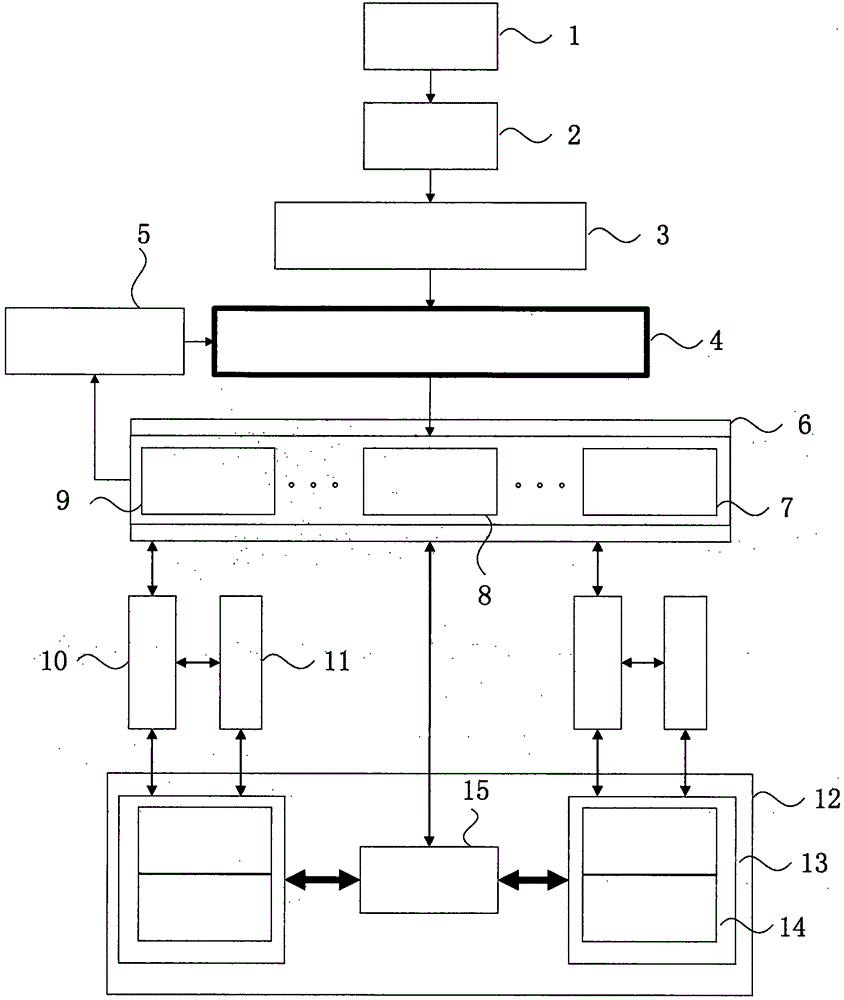

High-end fault-tolerant computer management system and method

InactiveCN104035831AGuaranteed reliabilityMaximize resource utilizationFault responseHardware monitoringCentralized managementComputer science

The invention discloses a high-end fault-tolerant computer management system and method and relates to the field of computers. The high-end fault-tolerant computer management system comprises a system power source, a fan, a switch, a plurality of computational nodes and an SMC, wherein the SMC receives collected information through the switch, and the collected information is reported by the computational nodes; when the reported collected information meets a preset computational node management strategy, the SMC sends a corresponding management operation instruction to the computational nodes through the switch; when the reported collected information meets a preset system power supply and temperature management strategy, corresponding management operations are carried out on the system power source and / or the fan. The invention further discloses the high-end fault-tolerant computer management method. According to the technical scheme, the role of each level in management is fully played, and centralized power supply, centralized heat dissipation and centralized management are achieved under the management structure.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

Method for highly water-soluble nitrophosphate fertilizer production through decomposition of rare earth-containing phosphate rock by nitric acid and for rare earth recovery

ActiveCN102351591AIncrease profitPromote absorptionCalcium/strontium/barium carbonatesRare earth metal compoundsSolubilityDecomposition

The invention discloses a method for highly water-soluble nitrophosphate fertilizer production through decomposition of rare earth-containing phosphate rock by nitric acid and for rare earth recovery. Through the processes of rare earth-containing phosphate rock decomposition by nitric acid, defluorination, freezing separation of calcium nitrate, deep decalcification of ammonium sulfate, neutralization with ammonia water and deposition of rare earth and other impurities, and finally evaporation concentration and crystallization, the nitrophosphate fertilizer can be produced. The method comprises: the first step, acidolysis; the second step, defluorination; the third step, freezing crystallization of calcium nitrate; the forth step, double decomposition of ammonium sulfate for decalcification; the fifth step, neutralization and deposition of rare earth; the sixth step, evaporation concentration and crystallization; the seventh step, phosphogypsum conversion; and the eighth step, re-concentration rare earth in neutralization slag. The method of the invention can produce a highly water-soluble nitrophosphate fertilizer with water solubility of more than or equal to 99.9%, wherein, the nitrate nitrogen is easier for crops to adsorb. With a high utilization rate, the fertilizer in the invention can increase the yield of crops by 8%-25% and can improve product quality simultaneously. With less discharge of waste, the method provided in the invention recovers rare earth in phosphate rock economically and effectively, and maximizes resource utilization, thus breaking a new path for comprehensive utilization of rare earth-containing phosphate rock.

Owner:GUIZHOU RES INST OF CHEM IND

Traffic organization aid decision-making system for expressway network in emergency

InactiveCN101799911AReduce travel timeAchieve inductionData processing applicationsDecision-makingEmergency treatment

The invention provides a traffic organization aid decision-making system for an expressway network in an emergency, which can provide accurate data for a decision maker quickly and scientifically for the decision maker to make decisions, so that scientific processing, quick processing, resource utilization maximum processing and loss minimum processing can be carried out on the emergency. The system comprises a system management module, a map operation management module, an emergency resource searching module, an event influence analysis module, a coping capacity evaluation module, a dynamic traffic organization module and a data application management module, wherein the system management module is a platform of a user login system, through which, users can dispatch the emergency resource searching module when dispatching aid resources, can dispatch the event influence analysis module when determining the requirement of emergency treatment, can dispatch the coping capacity evaluation module when evaluating the emergency event coping capacity, and can dispatch the data application management module when managing, maintaining and updating information; and in the dispatching processes, direct-viewing operations can be carried out through the map operation management module.

Owner:TRAFFIC MANAGEMENT RES INST OF THE MIN OF PUBLIC SECURITY

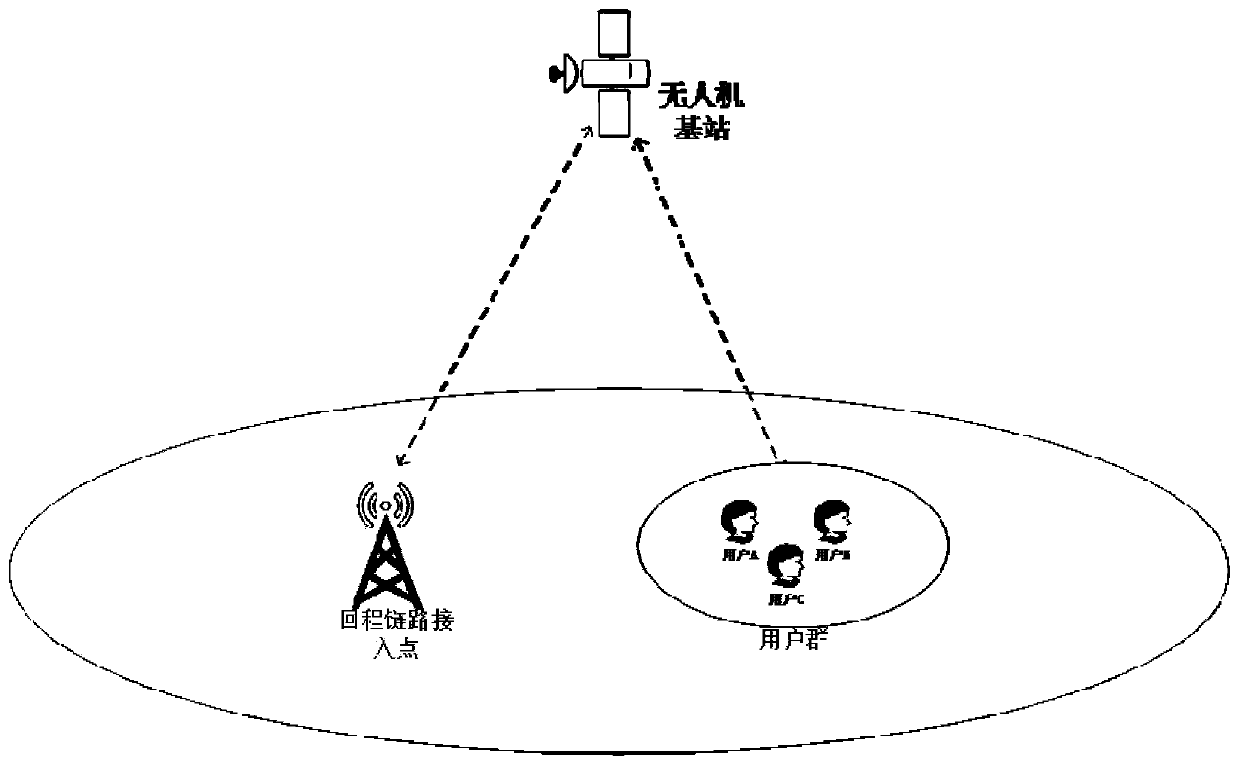

Unmanned aerial vehicle trajectory optimization method based on wireless communication

PendingCN110856191AMaximize minimum throughputMaximize resource utilizationWireless communicationNetwork deploymentSimulation

The invention relates to an unmanned aerial vehicle trajectory optimization method based on wireless communication. The method comprises the following steps: converting a non-convex problem into a convex problem through an optimization algorithm, and achieving the trajectory optimization of an unmanned aerial vehicle through a convex optimization tool box; and the minimum throughput of all groundusers can be maximized, so that the maximization of resource utilization is achieved. The backhaul link access point is introduced into the unmanned aerial vehicle communication network system, an expensive cable structure is not needed to build the system, so that the deployment cost is reduced. Meanwhile, the unmanned aerial vehicle communication technology has the characteristics of convenienceand flexibility, and the convenience and flexibility of wireless communication network deployment can be greatly improved. The method can also solve the problem of communication network congestion ina user dense place, and the optimal trajectory and the optimal user scheduling of the unmanned aerial vehicle are obtained by using an iterative optimization method under the condition of given userscheduling, power and initial trajectory of the unmanned aerial vehicle, so that the throughput of the whole system is improved.

Owner:GUANGDONG UNIV OF TECH

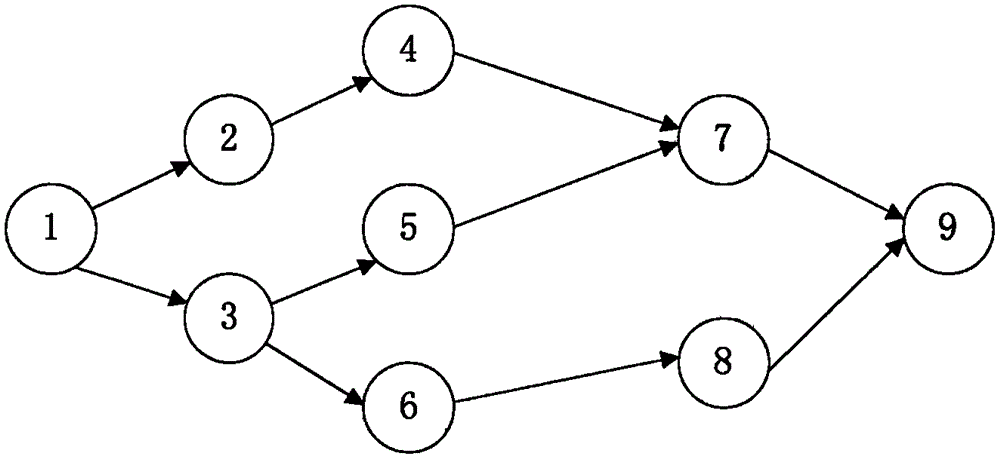

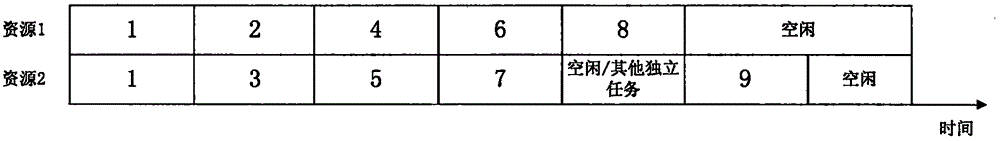

Big data hybrid scheduling model on private cloud condition

InactiveCN105893158AReduce migration costsFast executionResource allocationTransmissionNODALGlobal scheduling

The invention relates to the technical field of cloud computing and big data, in particular to a big data hybrid scheduling model on the private cloud condition. The big data hybrid scheduling model comprises an access control module, a task decomposition module, an overall situation scheduler module based on virtual resources, a resource virtualization mapping module, a virtual resource monitoring module, a physical resource monitoring module, and a local scheduler module based on physical resources. The big data hybrid scheduling model is a hybrid scheduler including physical resource scheduling, virtual resource scheduling, overall situation scheduling and local scheduling. User tasks are decomposed into a plurality of independent subtasks which are distributed on different clusters or computational nodes. Parallel and rapid execution of the tasks is ensured, network and data transfer costs are reduced, physical resource scheduling is utilized for further decomposing subtasks, cluster resources are utilized to be maximum extent, and the task execution time is further shortened.

Owner:BEIJING UNIV OF TECH

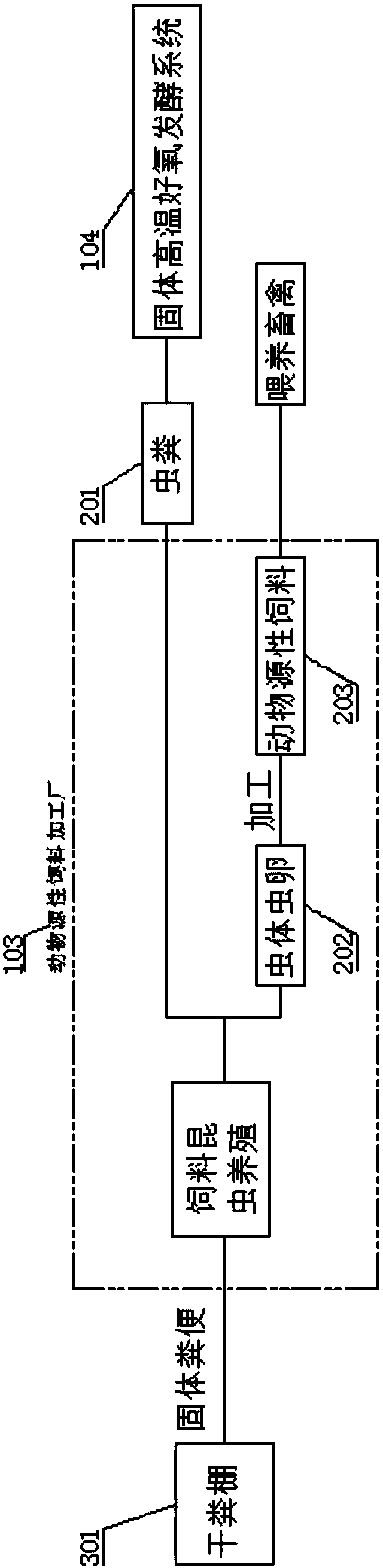

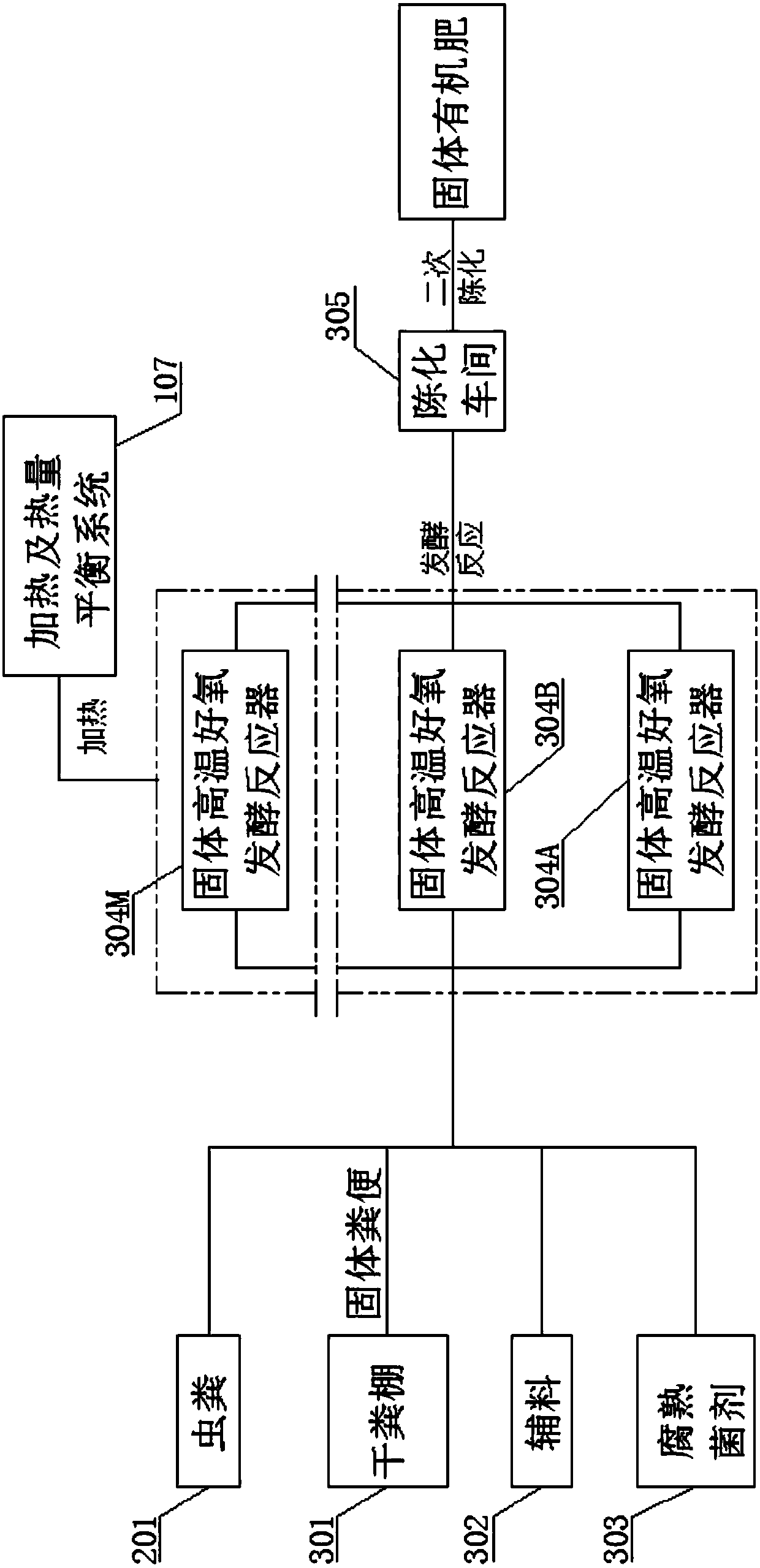

Ecological treatment system and method for pollution of livestock and poultry farm based on combination of planting and breeding

ActiveCN107759254AReduce distractionsHighly consistent qualityBio-organic fraction processingFabaceae cultivationPig farmsFeces

Owner:汪深

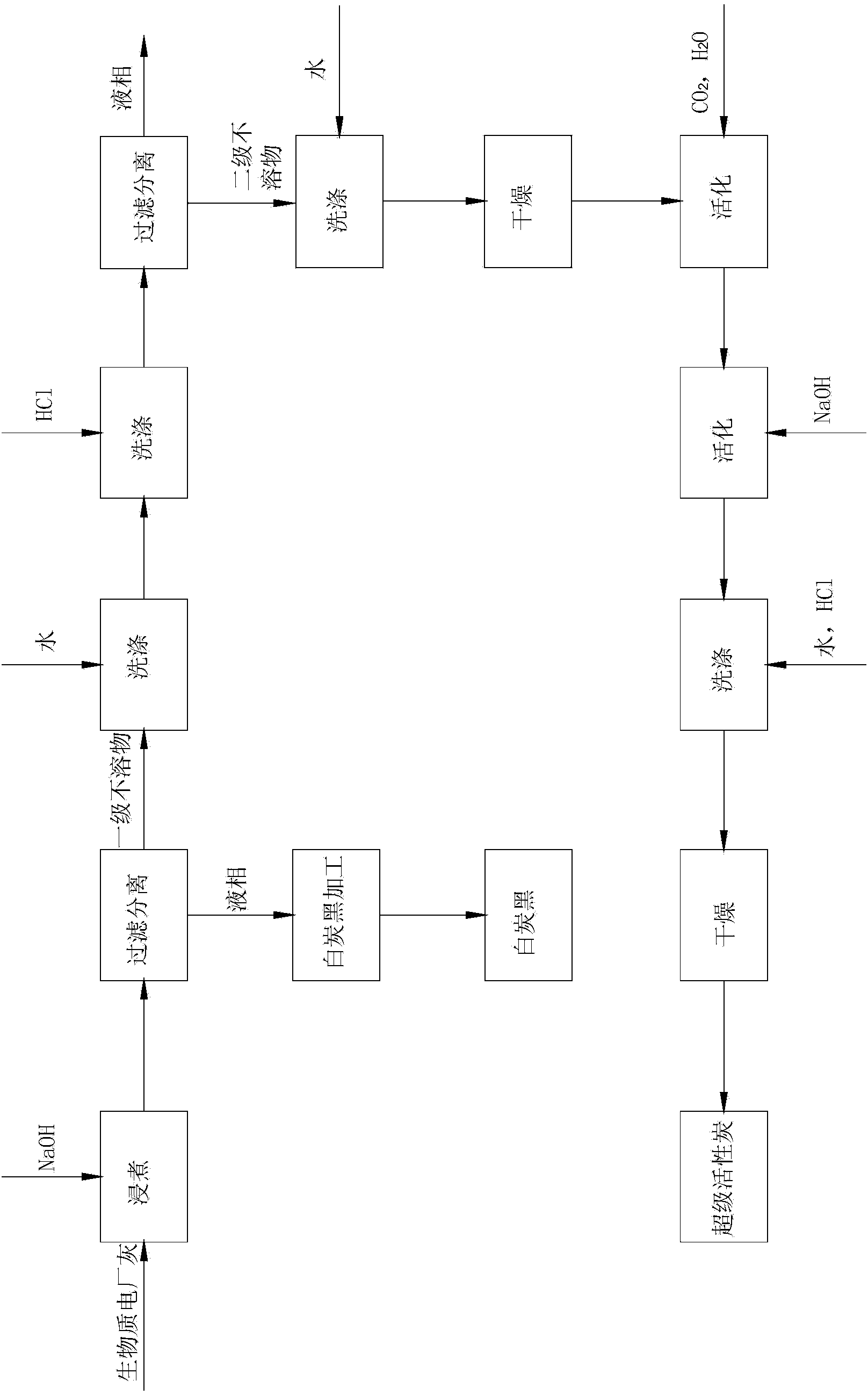

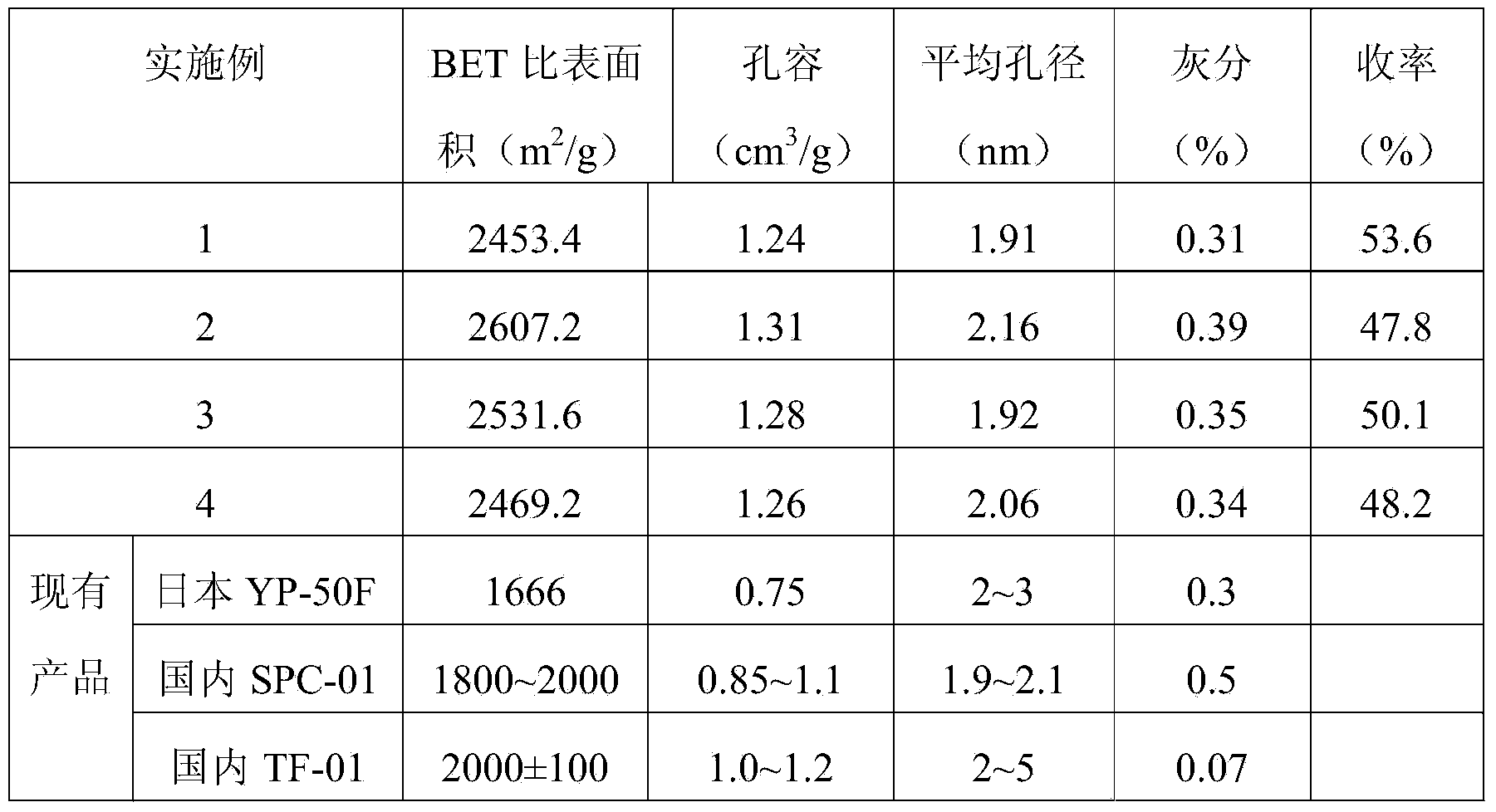

Method for preparing super active carbon by taking biomass power plant ash as raw material

The invention discloses a method for preparing super active carbon by taking biomass power plant ash as a raw material. A particular preparation process is as follows: the biomass power plant ash is boiled by alkali and then is filtered to filter insoluble substances; a hydrochloric acid solution is added into the insoluble substances; impurity removal and water washing are carried out to obtain an active carbon precursor, namely residual carbon; the residual carbon is heated and activated in the atmosphere of water steam and CO2 to obtain a middle product; then the middle product and NaOH are mixed to be heated and activated in the atmosphere of N2; an activated product is washed and dried to obtain the super active carbon. The method takes wastes of a biomass power plant as raw materials and utilizes the NaOH with a low price to replace KOH with the high price, so that the wastes are changed into valuable things to obtain the active carbon with a high additional value for a super capacitor.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

Cascade utilization analyzing method for lithium-ion power batteries

ActiveCN105738830AEnsure consistencyMaximize resource utilizationElectrical testingLithiumPower battery

The invention discloses a cascade utilization analyzing method for lithium-ion power batteries. The influence of temperature and working conditions on sorting of lithium-ion power batteries is taken into consideration. Under a certain temperature condition, the discharge evaluation on lithium-ion power batteries is conducted, and actual available capacity and internal resistance under certain conditions are evaluated, and the lithium-ion power batteries are subjected to reasonable cascade sorting according to the actual available capacity, internal resistance and other parameters, so that the consistency of reused lithium-ion power batteries is ensured. The resource utilization of waste power batteries is maximized.

Owner:SUN YAT SEN UNIV

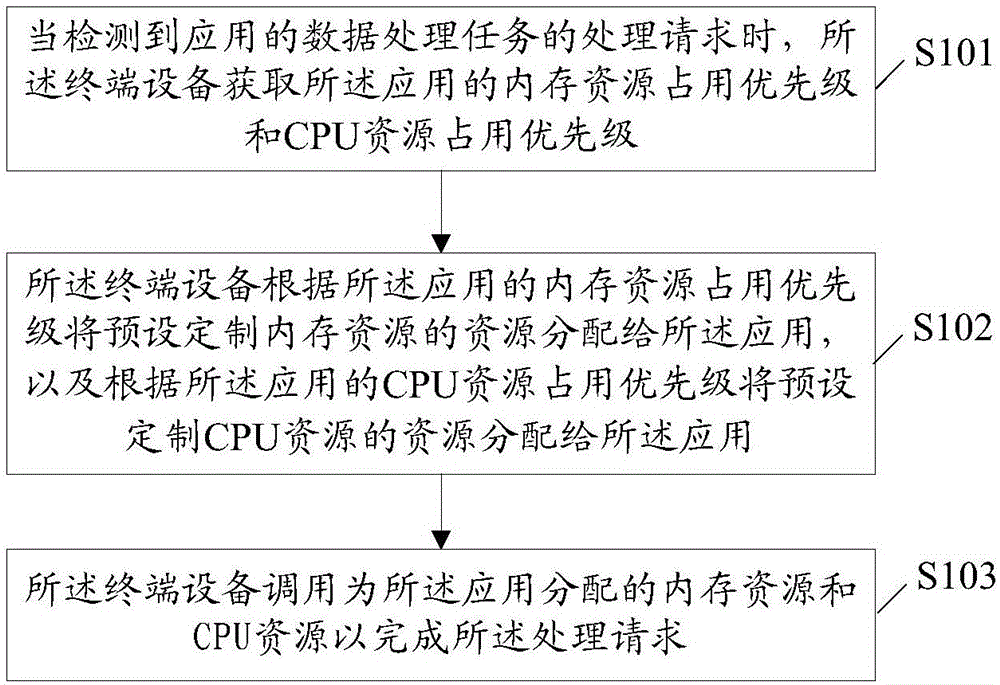

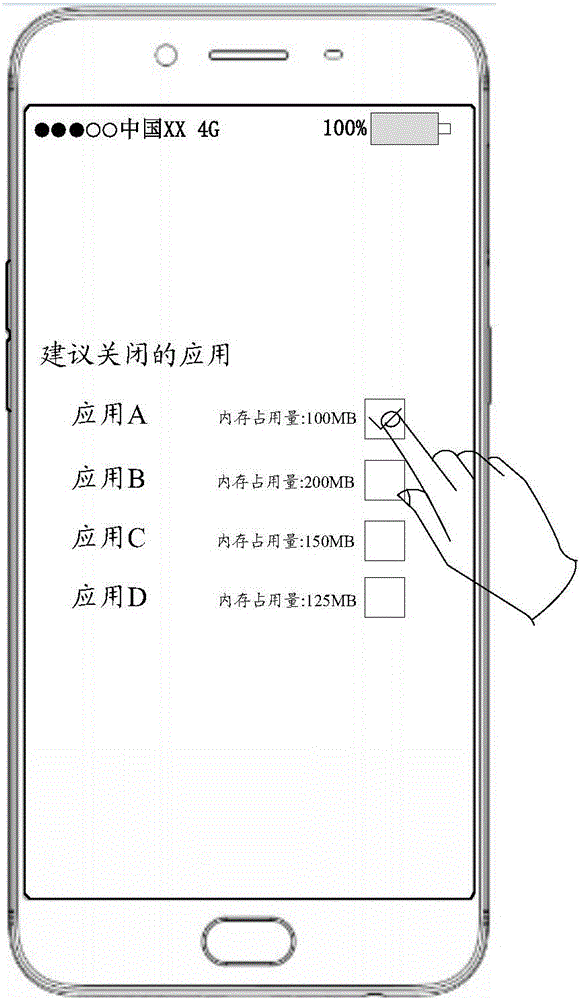

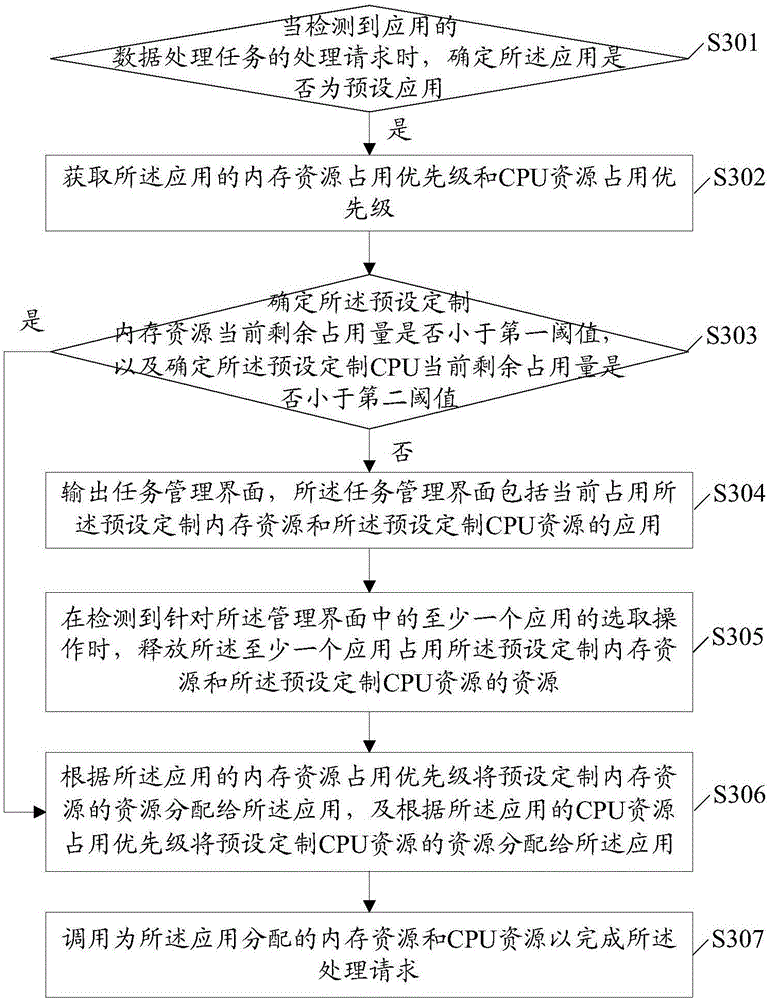

Resource allocation method and device

InactiveCN106776036AReduced response timeMaximize resource utilizationResource allocationTerminal equipmentResource management

The invention discloses a resource management method which is applicable to terminal equipment provided with applications. The method comprises the steps of when a processing request of a data processing mission of an application is received, obtaining memory resource occupation priority and CPU resource occupation priority of the application; distributing resources of preset customized memory resources to the application according to the memory resource occupation priority of the application, and distributing resources of preset customized CPU resources to the application according to the CPU resource occupation priority of the application; calling the memory resources and the CPU resources which are distributed to the application to complete the processing request. The embodiment of the invention further provides a resource management device and the terminal equipment. According to the resource management method, the resource management device and the terminal equipment, the response time of the application can be shortened.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

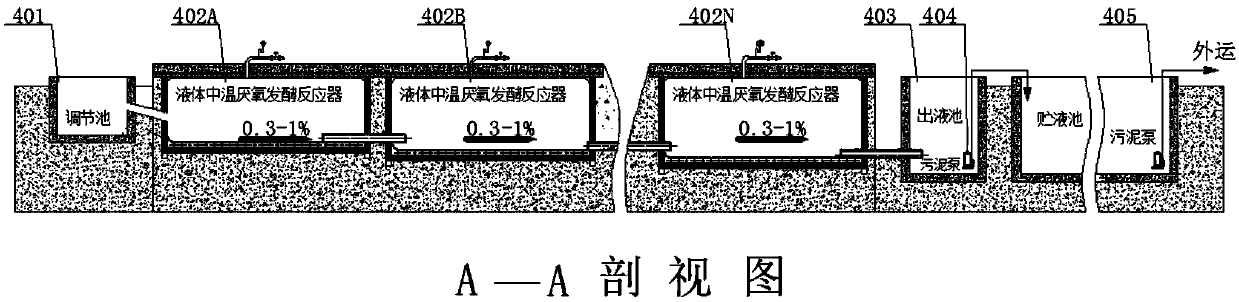

Alkaline thermal hydrolysis treatment method and system for sludge

PendingCN108191192AMaximize resource utilizationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningWater contentChemistry

The invention provides an alkaline thermal hydrolysis treatment method for sludge, which can solve the technical problem that common sludge treatment processes cannot effectively realize the maximum resource utilization. The alkaline thermal hydrolysis treatment method for the sludge is characterized by comprising following steps: (1) sludge blending and preheating: the sludge and a hydrolysis agent are added to a sludge blending and preheating device, the sludge is blended until the water content is 86%-90% and the temperature is 70-90 DEG C, wherein the hydrolysis agent is quick lime, and the adding proportion of the quick lime is 18%-25% of the dry weight of the sludge; (2) a sludge hydrolysis reaction: the blended and preheated sludge is conveyed to a hydrolysis reaction device, heatedto 120 DEG C and kept for 2-3 h, and the hydrolysis reaction process is completed; (3) flash evaporation of the sludge: the sludge completing the hydrolysis reaction is conveyed into a flash evaporation tank for flash evaporation for 0.5 h; (4) solid-liquid separation of the sludge: solid-liquid separation is performed through a solid-liquid separation device after the sludge hydrolysis reaction,obtained filtrate is a protein stock solution which is stored in a stock solution tank, and obtained residues are directly sent into a recycling product production device.

Owner:山西晋联环境科技有限公司

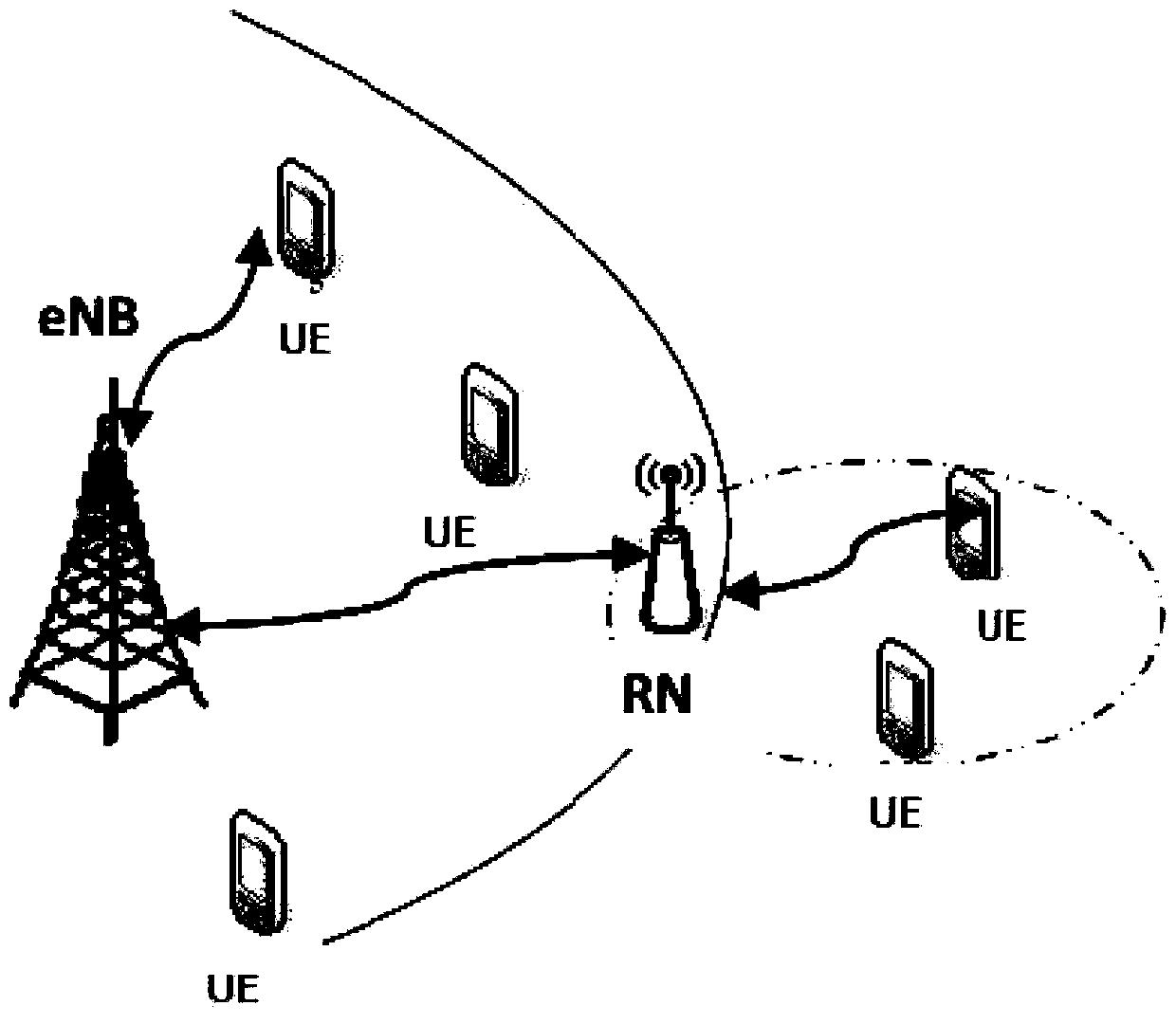

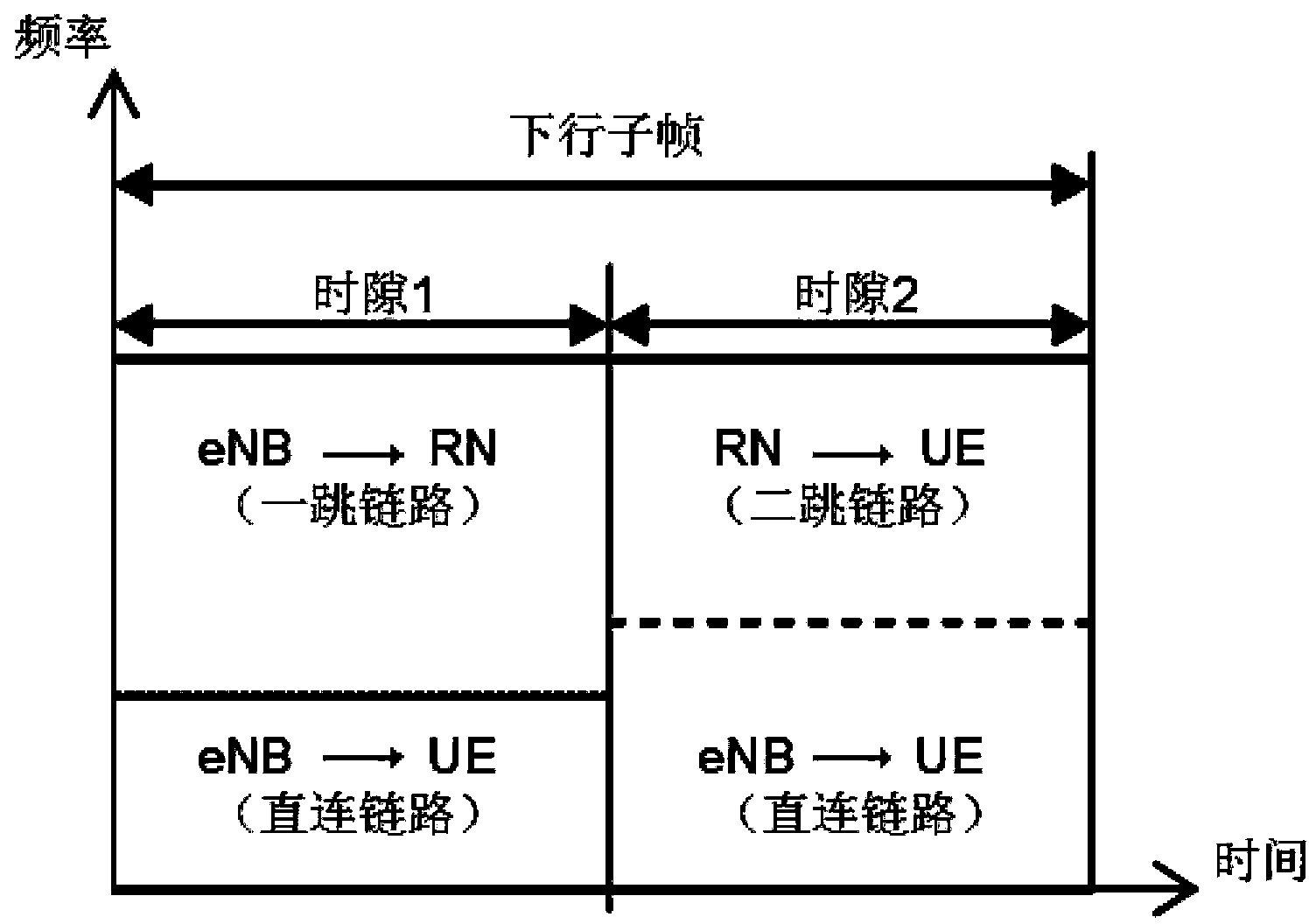

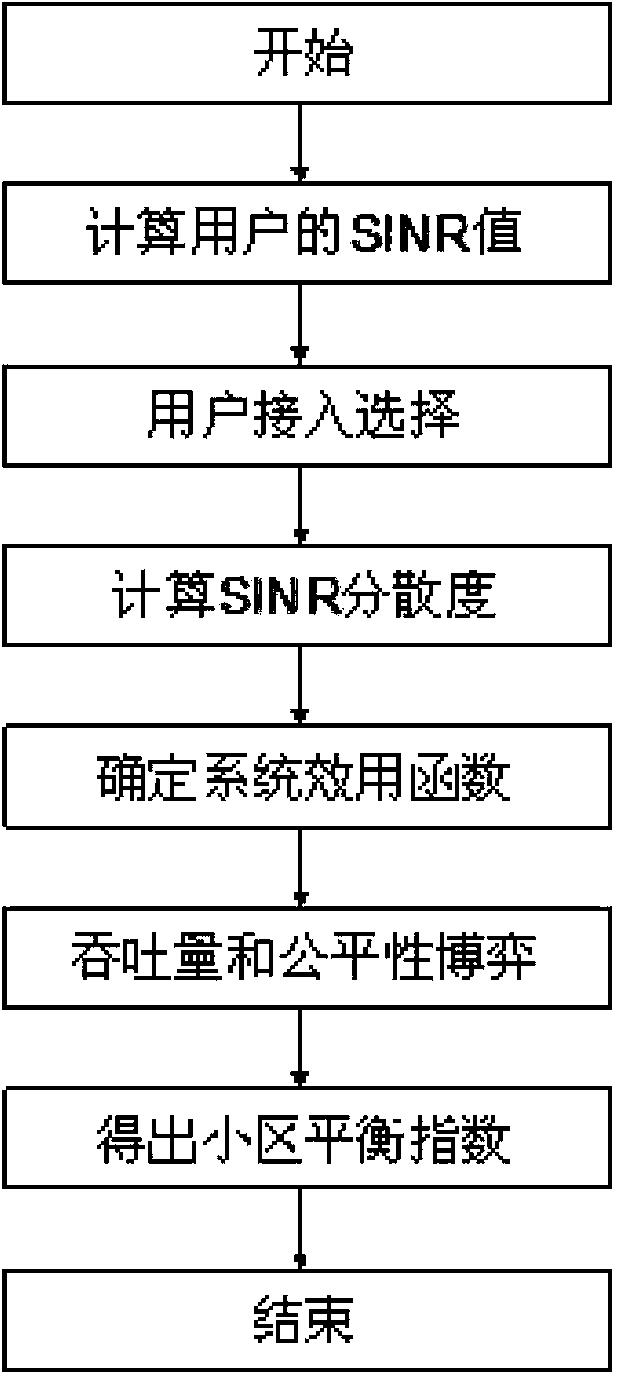

Game theory-based radio resource optimization method in LTE-A relay system

ActiveCN103369568AReduced equity gapEffective throughputNetwork traffic/resource managementDispersityMicro cell

The invention discloses a game theory-based radio resource optimization method in an LTE-A relay system. The method mainly resolves the problem of compromise between system throughput and user fairness when relays are introduced to a cell. The method comprises the steps that SINR values of all users in the cell are calculated, whether the users are connected to a base station or the relays is determined according to the SINR values of the users, the reachable data rate and the minimum required rate of each user are calculated, the SINR dispersity of each micro cell is calculated, and the cell balance index meeting cell throughput maximization and user fairness optimization is obtained through the game theory. According to the game theory-based radio resource optimization method, the SINR dispersity of the users is used as the main parameter of fairness, and fairness of the users in the center of the cell and the users on the edge of the cell are improved obviously; the throughput, the fairness and the game theory are combined, so that system resources are used more effectively, the throughput is maximized under the condition that the fairness is guaranteed, and whole performance of the system is enhanced.

Owner:XI AN JIAOTONG UNIV

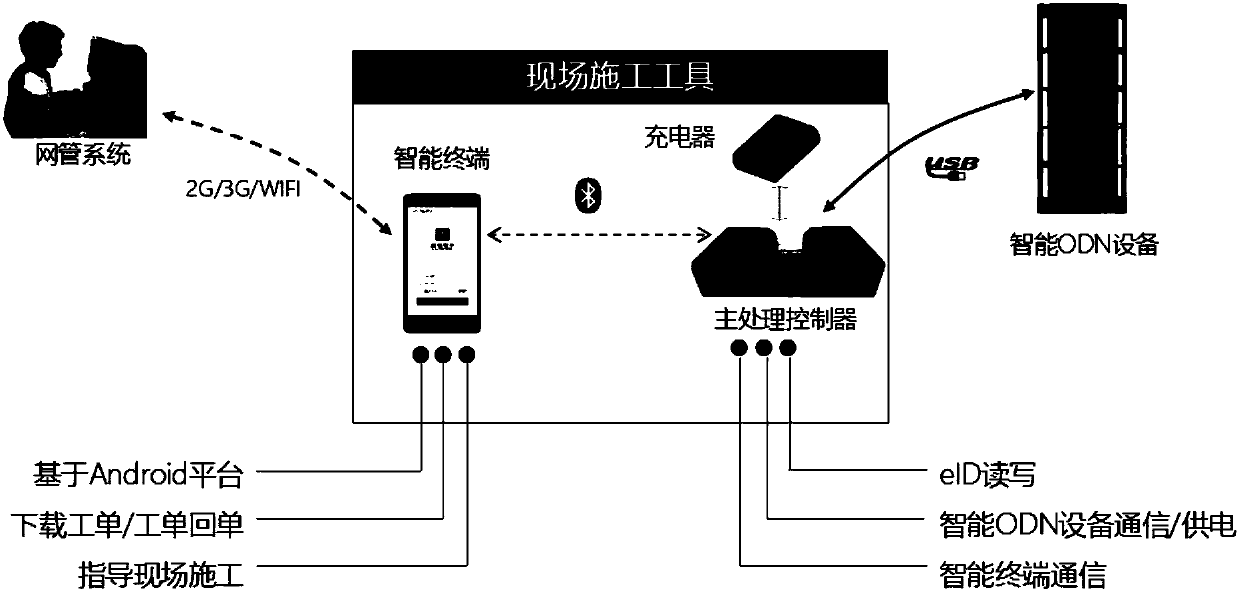

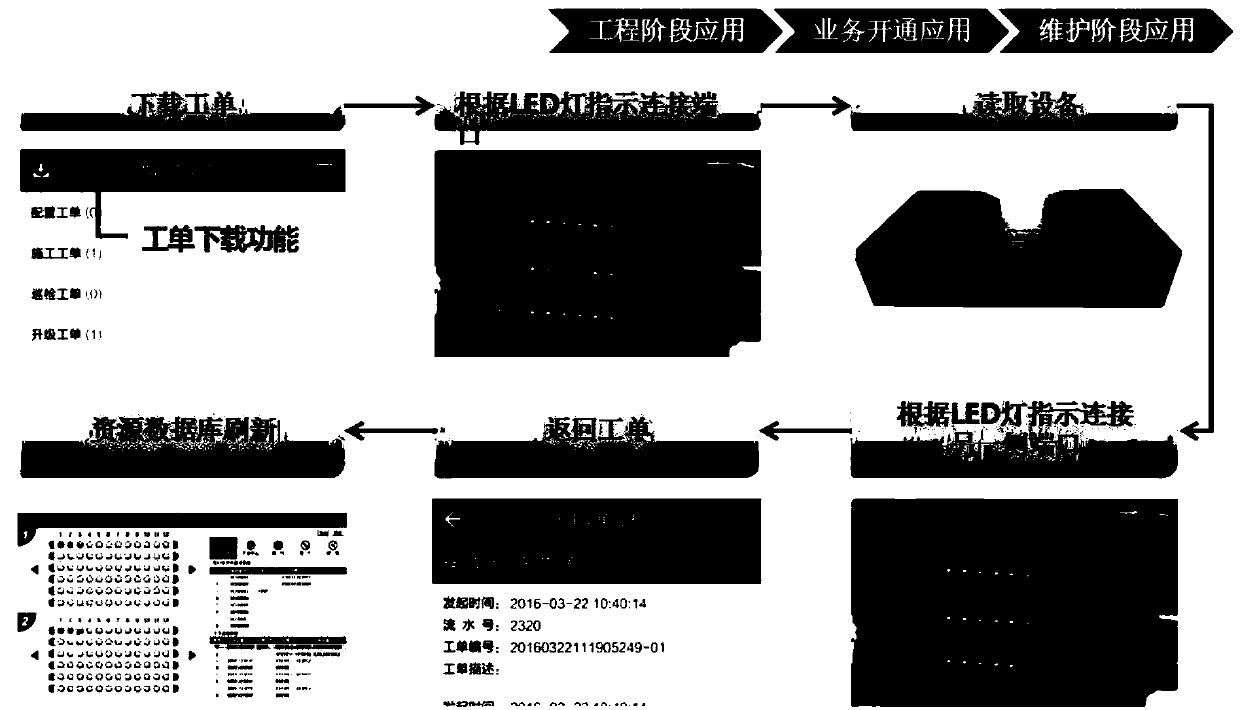

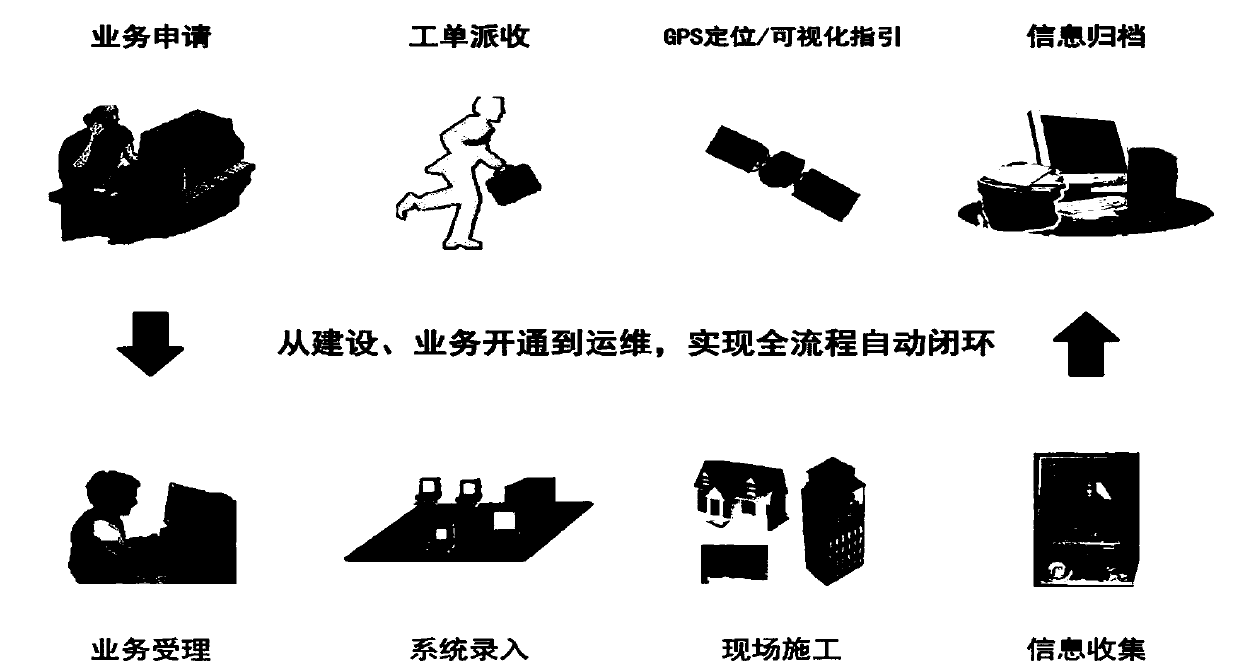

Intelligent ODN device and automatic management and control method of fiber cores

PendingCN107909131AImprove efficiencyImprove accuracyProgramme controlComputer controlFiberResource utilization

The present invention discloses an intelligent ODN device and an automatic management and control method of the fiber cores. The intelligent ODN device comprises an eID electronic label (1) and an intelligent ODN monitoring device, and the intelligent ODN monitoring device comprises a main processing controller (2), a sub-frame controller (3) and a business module collector (4), wherein an external 48V adapter or a 5V mobile power supply supplies power to the main processing controller. The sub-frame controller (3) is connected with the main processing controller (2) and the business module collector (4) separately, and the eID electronic label (1) is connected with the business module collector (4). According to the present invention, the business information of the terminals of the ODN monitoring device, the fiber core states and the link information are managed automatically and are gathered dynamically, a whole process does not need the artificial maintenance, the mass optical fiber resource management problem is solved, the resource obtaining accuracy is higher, and the maintenance efficiency and the resource utilization rate are improved.

Owner:FUJIAN YUXUN TECH CO LTD

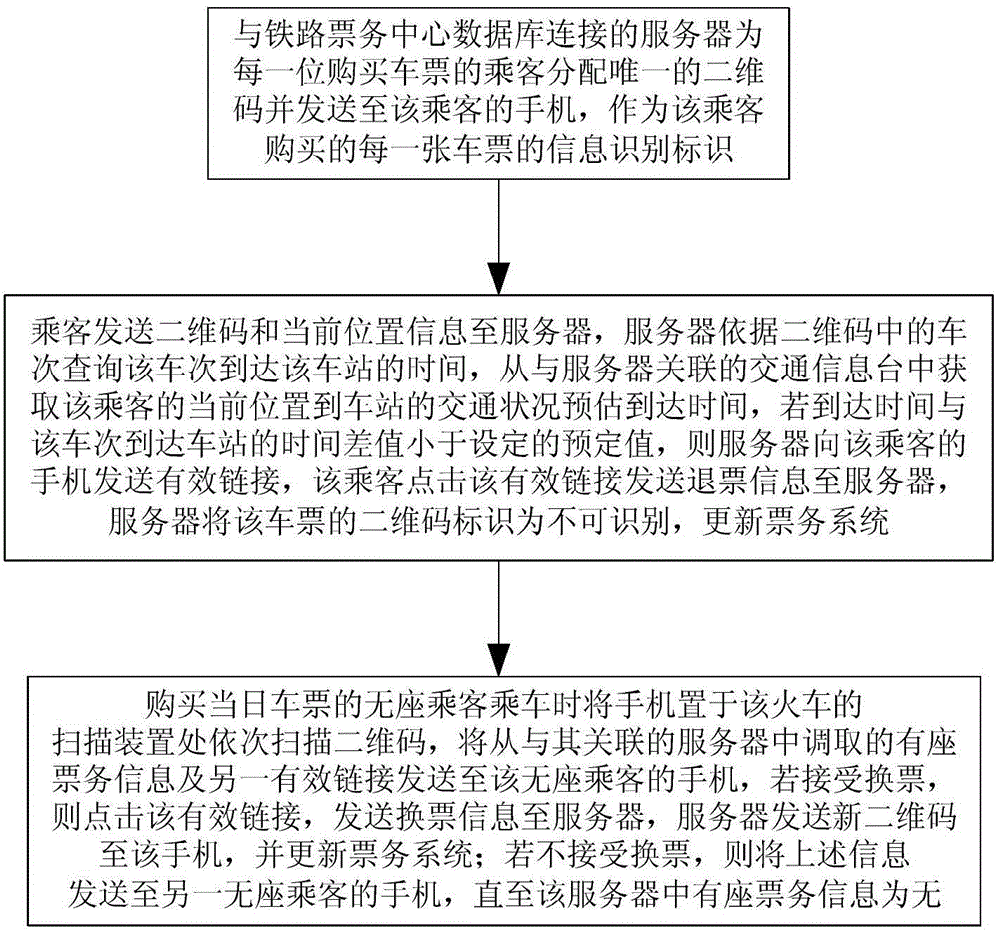

Timely information updating method for railway station ticketing system

ActiveCN104463656AMaximize resource utilizationCo-operative working arrangementsBuying/selling/leasing transactionsArrival timeTraffic conditions

The invention relates to the field of information updating, in particular to a timely information updating method for a railway station ticketing system. The method comprises the steps that a server allocates a unique two-dimensional code to each passenger and sends the two-dimensional code to a mobile phone of the passenger; the passengers send the two-dimensional codes and current position information to the server, the server queries the time when trains arrive at stations according to train numbers in the two-dimensional codes and acquires traffic conditions between the current positions of the passengers and the stations from a traffic information platform associated with the server to estimate arrival time, the server sends valid links to the mobile phones of the passengers if the difference value between the arrival time and the time when the trains arrive at the stations is smaller than a preset value, the passengers click the valid links and send ticket refunding information to the sever, and the server marks the two-dimensional codes of tickets as unrecognizable codes and updates the ticketing system. By means of the method, the passengers can check the arrival information of the trains in time and endorse the tickets in time according to actual conditions, the ticketing information can be updated in time, and the utilization of resources can be maximized.

Owner:江苏东智数据技术股份有限公司

Cleaning treatment technology for isopropyl chloride cyanuric acid production waste water

ActiveCN102897948AAchieving zero emissionsMaximize resource utilizationMultistage water/sewage treatmentNature of treatment waterChemical industryElectrolysis

The invention belongs to the technical field of chemical industry production waste water treatment and discloses cleaning treatment technology for isopropyl chloride cyanuric acid production waste water; a treatment method of this technology comprises the following steps: chloridizing sodium dichloro isocyanurate mother liquor to recycle trichloroisocyanuric acid; acidizing mother liquid, blowing chlorine and by-producing sodium chlorate; alkalifying and reducing the mother liquid so as to recycle cyanuric acid monosodium salt, reducing mother liquid total ammonium; after acidizing the mother liquid, reacting tripolycyanamide with residual cyanuric acid of the mother liquid so as to generate sparingly-soluble melamine cyanurate sediment; separating sediment so as to reduce mother liquid total ammonium; then, absorbing the mother liquid total ammonium by special active carbon so as to further reduce the mother liquid total ammonium; desorbing saturated active carbon by dilute liquid alkali, recycling cyanuric acid trisodium salt; and oxidizing absorbed mother liquid by sodium hypochlorite solution so as to dispel residual cyanuric acid, wherein the total ammonium content of the mother liquid is less than or equal to 2mg / L; treated qualified saline is transferred to a chlor-alkali plant so as to test salt; after tested saline is refined, the tested saline is used for electrolytically producing caustic soda and chorine; isopropyl chloride cyanuric acid is produced again by the caustic soda and the chorine so as to form a circular economic industry chain; and waste water zero emission is realized.

Owner:河北冀衡化学股份有限公司

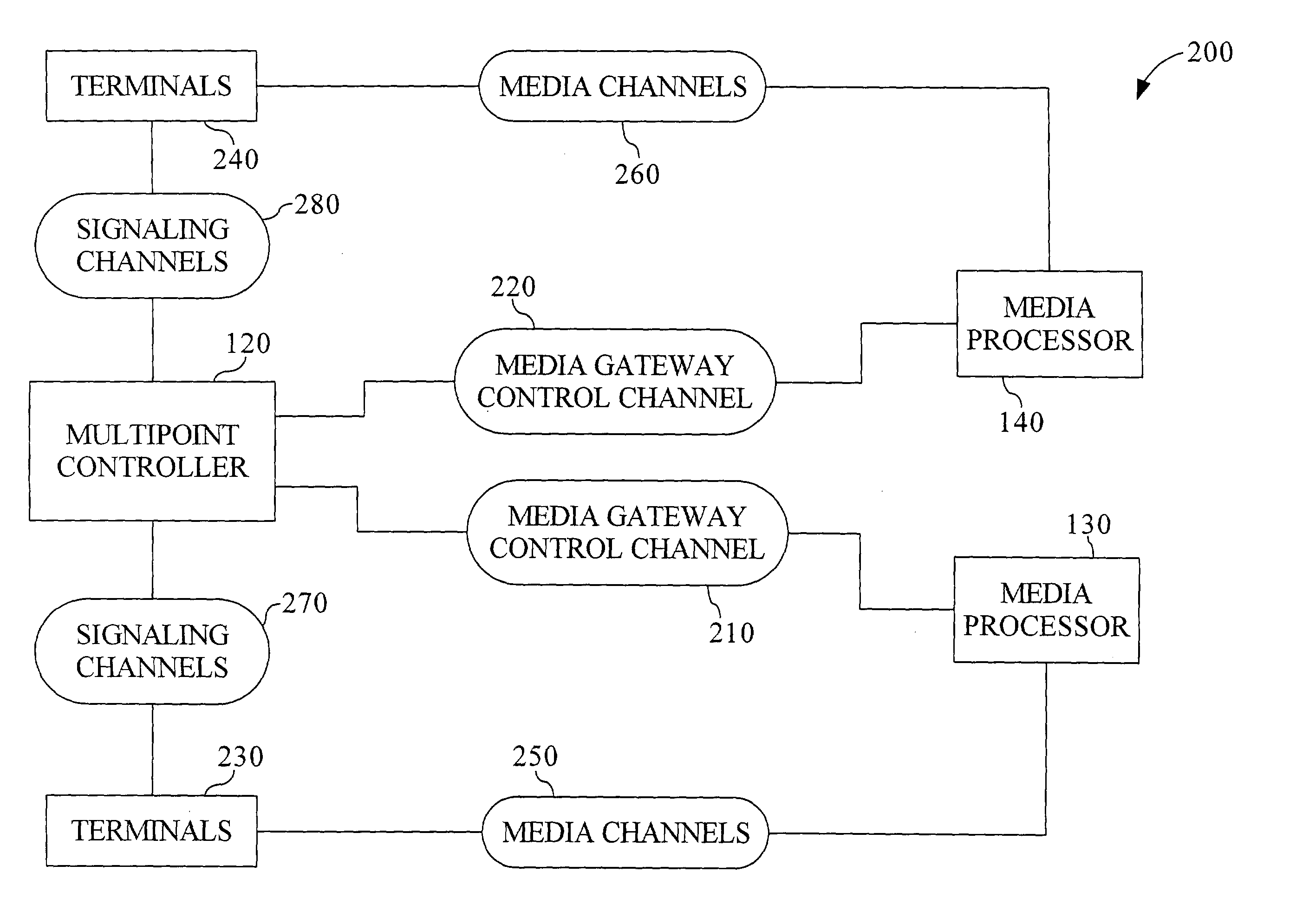

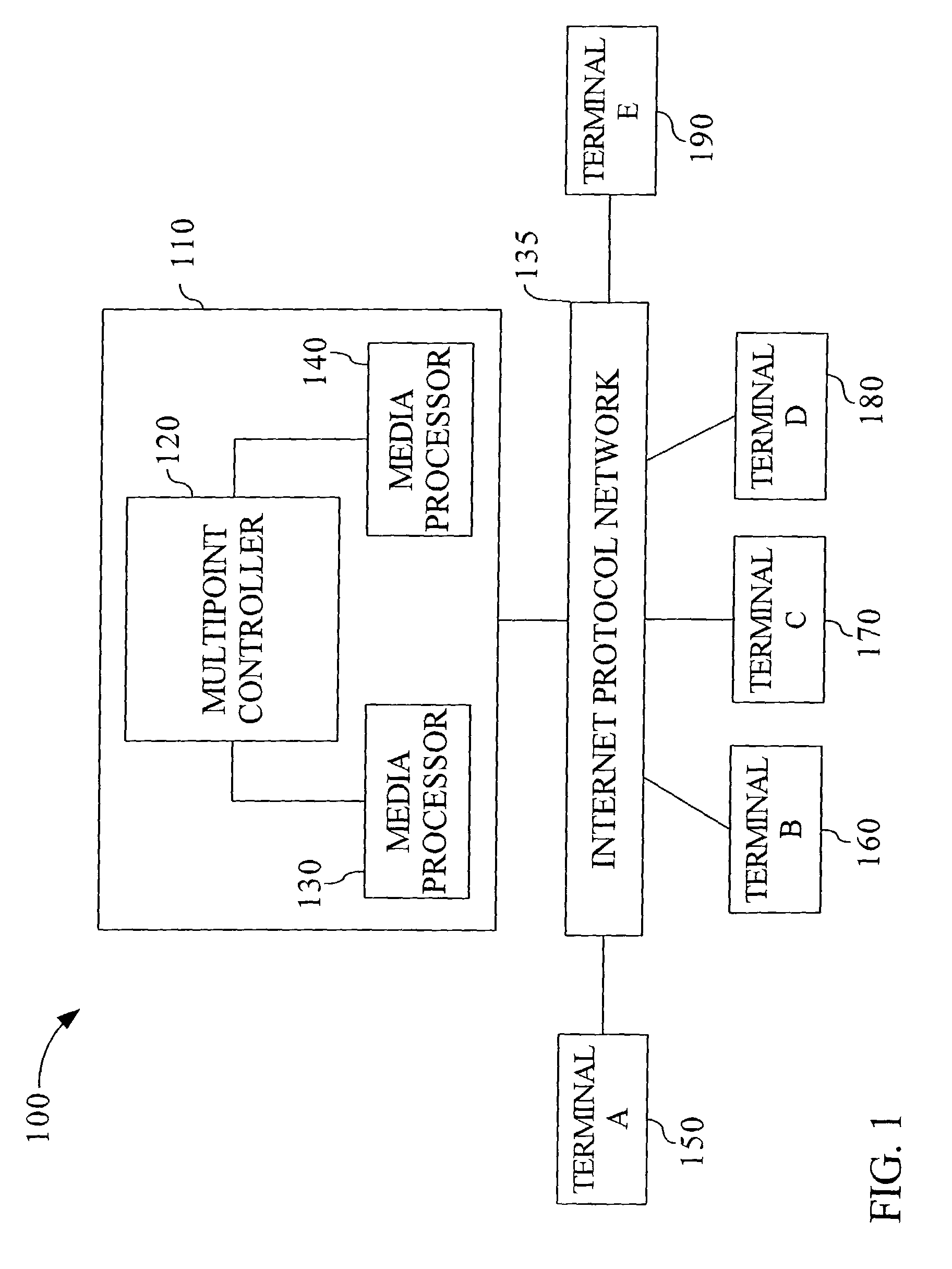

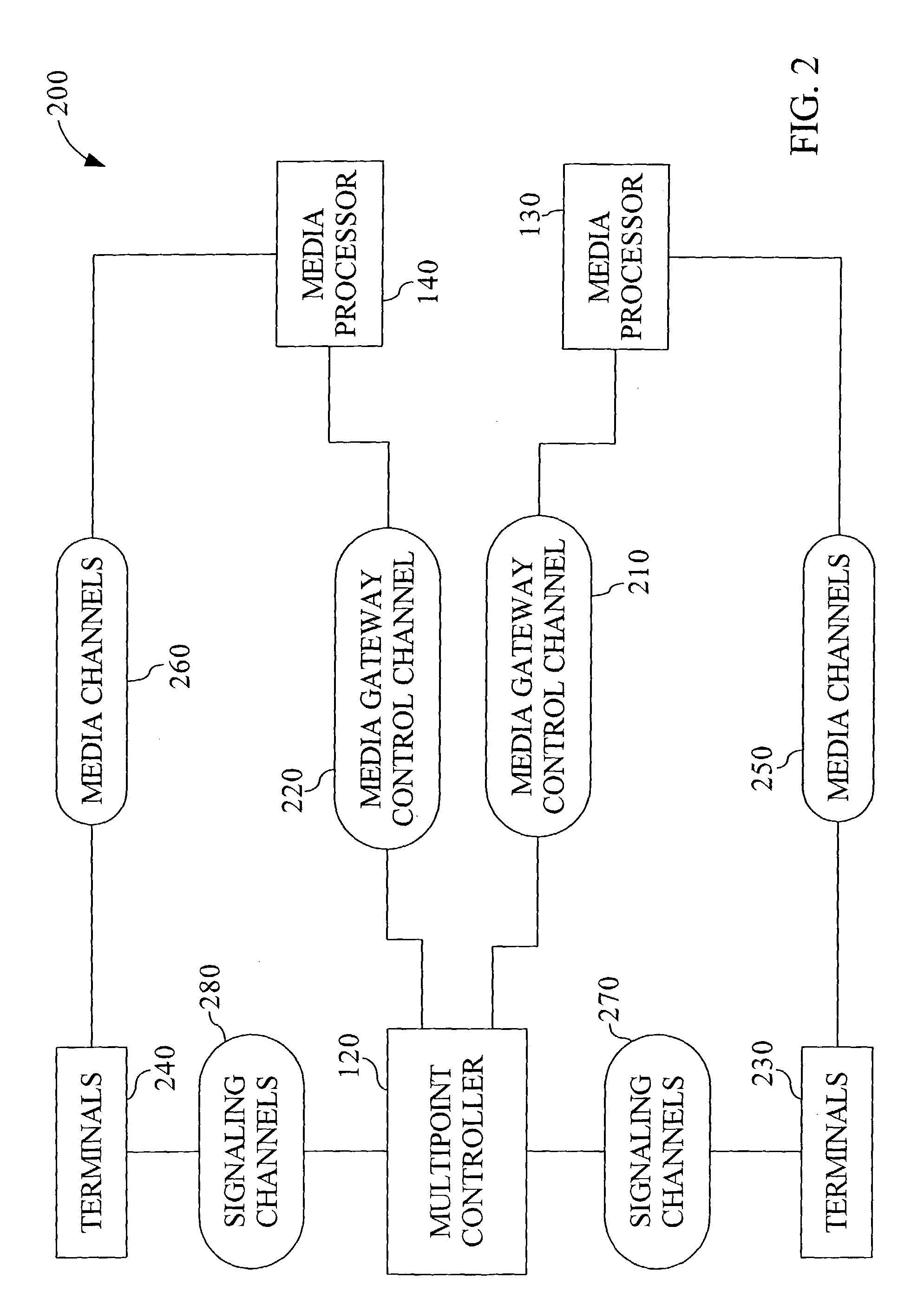

Method and system for balancing the load on media processors based upon CPU utilization information

InactiveUS7761876B2Efficient analysisAvoid OverloadingMultiplex system selection arrangementsSpecial service provision for substationApplication softwareCpu load

The present invention is a method and system for balancing the load on processors based upon the CPU utilization information of the processors. Real time CPU utilization information of processors may be effectively analyzed to prevent overloading of processing resources as assigned by a multipoint controller of a VoIP network. CPU utilization information may include the number of current conferencing channels being supported by each processor, CPU speed and the quantity of other applications being supported by the media processor. CPU utilization information from each processor may be retrieved by establishing a communication protocol with each processor and periodically polling the processors in regard to their CPU load capability. Assignment of processing tasks to processors may be based on which specific processors have the capability to handle the processing task.

Owner:UNIFY INC

Comprehensive treatment method for restoring heavy metal-polluted soil by plants and device

ActiveCN101704013AMaximize resource utilizationAvoid secondary pollutionSolid waste disposalContaminated soil reclamationChemical synthesisSlag

The invention discloses a comprehensive treatment method for restoring heavy metal-polluted soils by plants and a device thereof. The method comprises the steps: gasifying the plants for restoring heavy metal-polluted soils to form gasified cinders and gasified gaseous products, and introducing the gasified gaseous products into an entrained flow bed together with auxiliary fuels, water vapour and oxygenized air for obtaining chemical synthesis gas and slag; sending the chemical synthesis gas to a subsequent procedure for use after cooling, and cooling the slag for obtaining water cooling slag; and recycling heavy metals when cooling water enriched with heavy metal is precipitated and chemically extracted. In the invention, salvaged materials are fully utilized into resources by adopting new production technology, and simultaneously secondary pollution is avoided; the H2 and CO in chemical synthesis gas is finally obtained and can be adjusted between 1 to 3 so as to meet the requirements on different synthesis technology; and the adaptability is stronger, the structure is simple, compact and easy to be enlarged.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Edible fungus medium comprising tea slag as main material and method for producing edible fungi by the edible fungus medium

ActiveCN103274810ASolve processing problemsMaximize resource utilizationHorticultureFertilizer mixturesSlagGypsum

The invention discloses an edible fungus medium comprising tea slag as a main material. The edible fungus medium comprises, by weight, 60 to 70% of tea slag, 30 to 40% of mulberry twig, 0.5 to 1% of table salt, 1% of gypsum powder and 1% of lime powder. The invention also discloses a method for producing edible fungi by the edible fungus medium. The method comprises the following steps of fungus stick making, inoculation, spawn running and fruiting management. The edible fungus medium solves the problem of high tea slag treatment difficulty in industrial production, fully utilizes tea slag in edible fungus cultivation, provides a safe edible fungus product having a sweet and delicious taste for a consumer, realizes maximized tea resource utilization, reduces an edible fungus production cost, and greatly improves a yield.

Owner:黄山神草生物科技有限公司

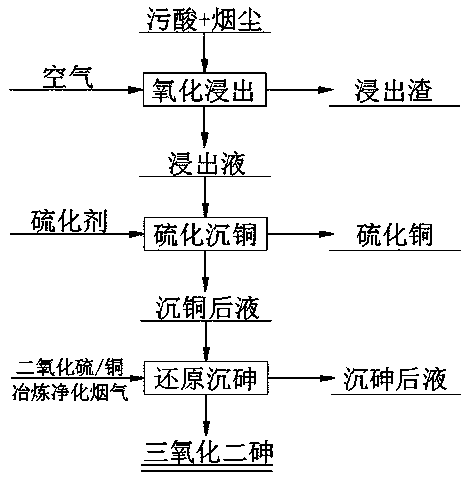

Method for comprehensively extracting arsenic from waste acid and smoke dust in copper smelting industry

PendingCN110331300AHarmless maximizationMaximize resource utilizationArsenic oxides/hydroxides/oxyacidsProcess efficiency improvementSulfur dioxideArsenic

The invention discloses a method for comprehensively extracting arsenic from waste acid and smoke dust in the copper smelting industry, and belongs to the field of nonferrous metallurgy. The method comprises the steps of mixing and leaching the waste acid and the smoke dust, simultaneously introducing air, and enriching the arsenic into a leaching solution; adding a vulcanizing agent into the leaching solution to obtain copper sulfide and a solution after copper precipitation; introducing sulfur dioxide or flue gas after copper smelting purification into the solution after copper precipitation, carrying out arsenic reduction, cooling, crystallizing and separating out arsenic trioxide, and separating to obtain arsenic trioxide and the solution after arsenic precipitation; and enriching other valuable metals in a leaching process of the solution after arsenic precipitation, and further processing and extracting other valuable metal elements after enriching to a certain extent. By means of the method, the combined treatment of copper smelting waste acid and a smoke dust source is achieved, the dispersion of arsenic is reduced, the generation of an arsenic-containing intermediate product is reduced, the direct yield of arsenic is reduced, and the development of arsenic is opened by an arsenic trioxide product; and the method has the advantages of simple process, resource utilization, safety, environmental-friendliness and the like.

Owner:DONGYING FANGYUAN NONFERROUS METALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com