Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Meet cost requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar battery slice technology for efficient and low-cost film crystal silicon

InactiveCN101241952AExcellent electrical performanceAppearance of high qualityFinal product manufactureSemiconductor devicesSilicon solar cellSlurry

The present invention is a technique for manufacturing a crystalline silicon solar cell piece, especially a technique for manufacturing a high-efficiency, low cost and thin-sheet solar cell piece, and the invention belongs to the solar energy application field. The technique aims at the thin-sheet crystal silicon chip with thickness less than 200 mu m, by adopting innovated technique and developing the original technique, combines the domestic cell whole equipment which is independently developed, settles the contradiction between the thin sheet and the fraction ratio, finished product rate and the electrical property, and satisfies the request of the cell piece product line to the high efficiency and low cost. The technique for manufacturing crystal silicon solar cell piece is subdivided to seven steps according to the process flow: eliminating the injury and coarsen the surface, diffusing to make a knot, plasma etching for eliminating the edge, PSG eliminating, PECVD depositing Si3N4 film, printing positive back electrode slurry and back field slurry on the silk screen, and co-baking to form an ohm contact. When the technique is adopted for the size 125*125mm<2>, the efficiency of the single crystalline silicon solar cell piece is up to 16.5, and the efficiency of the polycrystalline silicon solar cell is up to 15.0%.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

Comprehensive avionics system for small-sized general aircraft

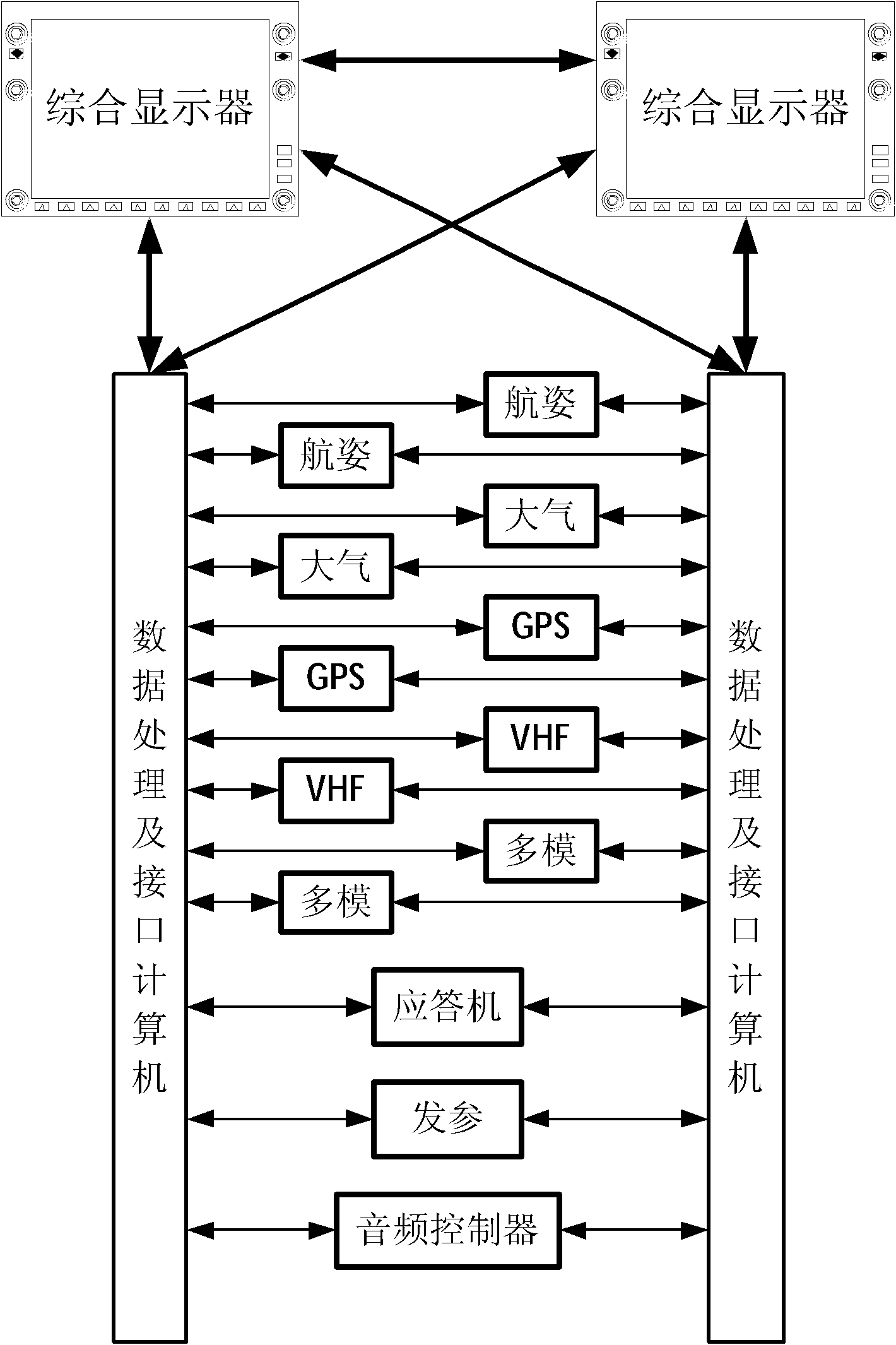

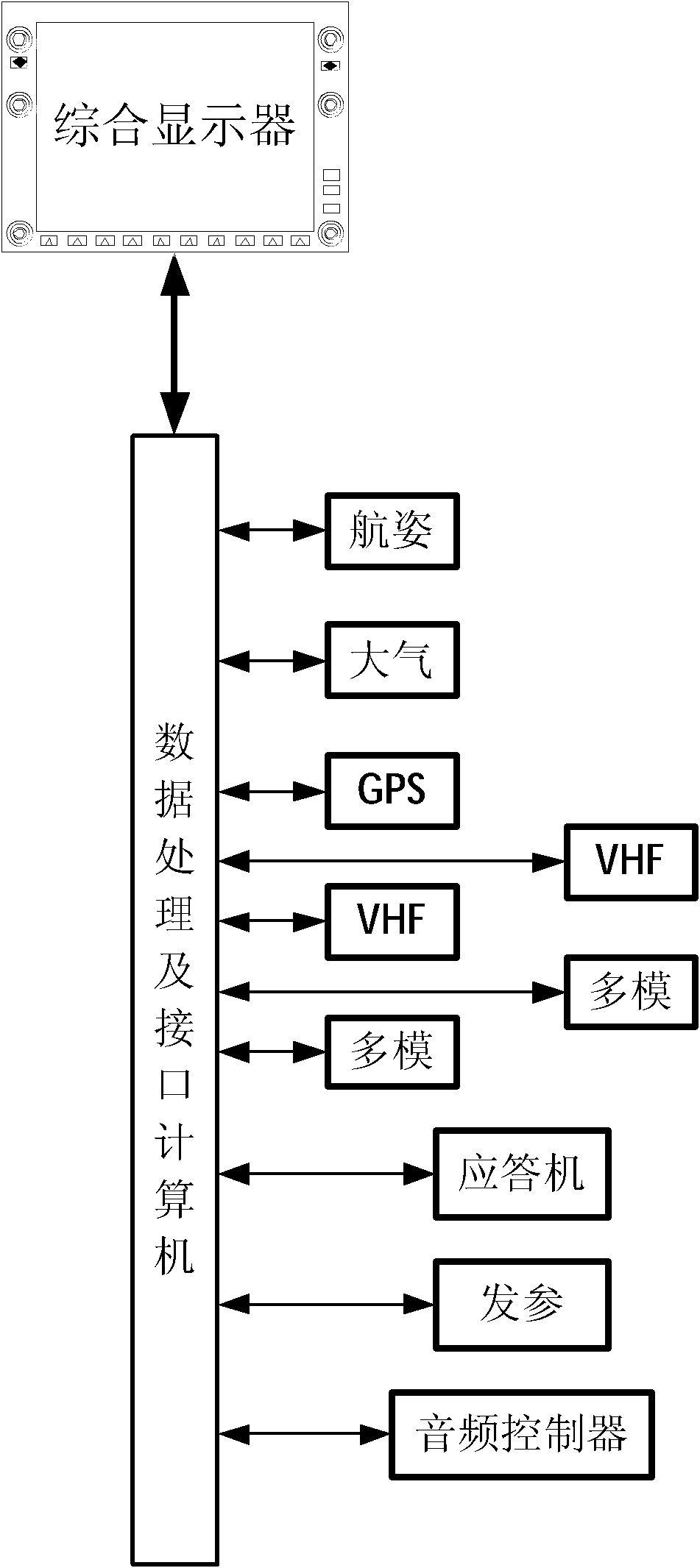

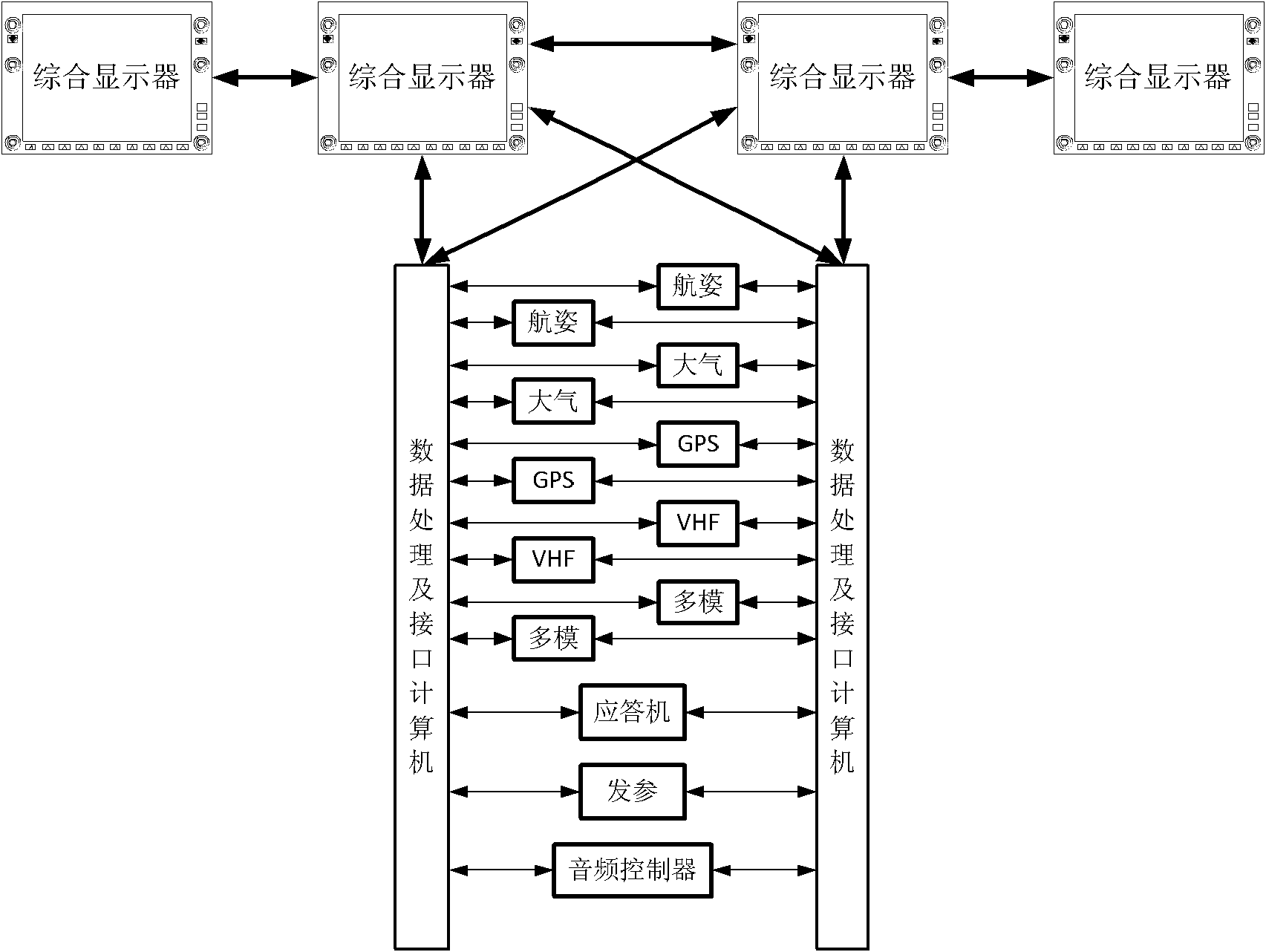

ActiveCN102495635ASame module heightEasy to installAttitude controlPosition/course control in three dimensionsAviationDisplay device

The invention discloses a comprehensive avionics system for a small-sized general aircraft. The comprehensive avionics system comprises a comprehensive display, a data processing and interface computer and a sensor function module, wherein the comprehensive display is connected with the data processing and interface computer; the data processing and interface computer is respectively provided with the sensor function module, the sensor function modulecomprises an attitude heading unit, an air data computer, a GPS (Global Positioning System) navigation satellite receiver, an ultrashort wave radio, a multi-mode receiver, an air traffic-control responder, a motor parameter acquirer and an audio controller; the comprehensive display is connected with the data processing and interface computerthrough a high-speed data bus; and the data processing and interface computer is connected with the sensor function module through a point-to-point data bus. The comprehensive avionics system disclosed by the invention has the characteristics of high integration level, capability of improving flight experience, flexibility for configuration and extension, high reliability, low cost, and capability of meeting requirements of general aircrafts on comprehensive performances.

Owner:XIAN AVIONICS TECH

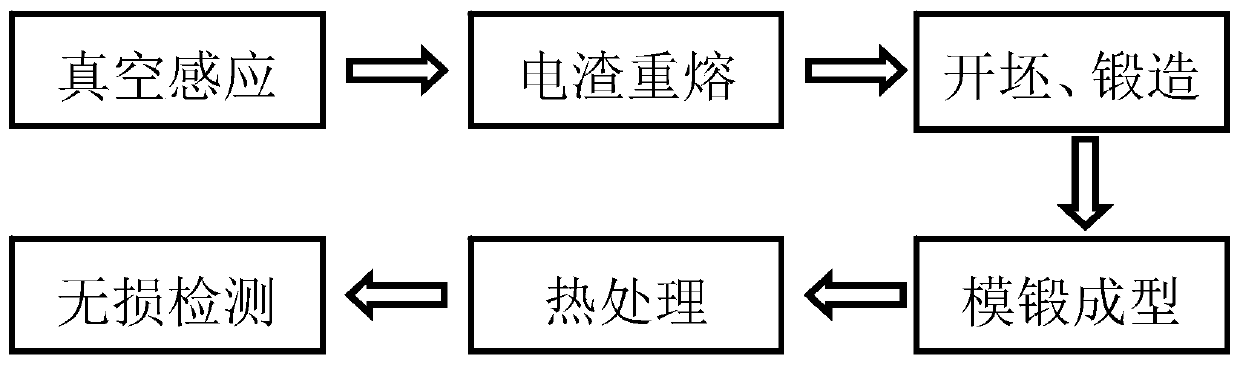

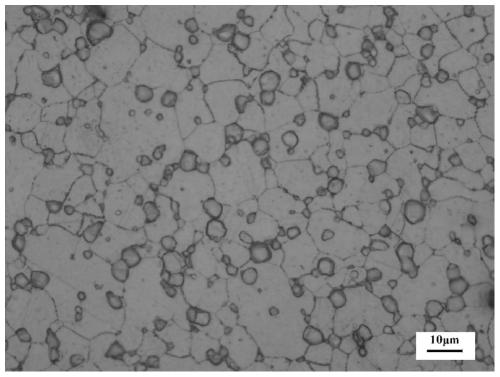

Preparation method for nickel-based superalloy for exhaust valve

InactiveCN102808111AImprove mechanical propertiesReduce chemical composition deviationExhaust valveRoom temperature

Owner:NANTONG WEALTH MASCH TECH CO LTD

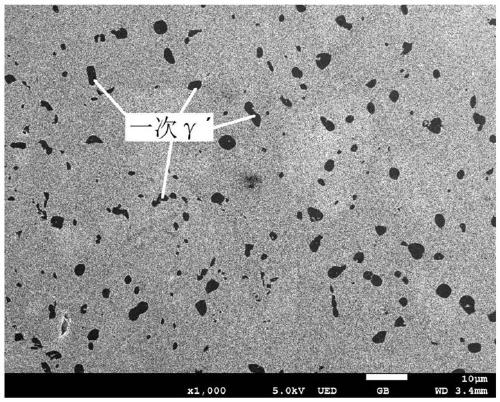

Deformed high-temperature alloy, preparation method of deformed high-temperature alloy, engine hot end rotating part and engine

ActiveCN111378873AHigh ultrasonic detectabilityImprove performanceBlade accessoriesMachines/enginesSuperalloyTurbine

The invention provides a deformed high-temperature alloy, a preparation method of the deformed high-temperature alloy, an engine hot end rotating part and an engine, and relates to the field of nickel-based high-temperature alloy. The deformed high-temperature alloy is prepared from the following components in percentage by mass: 19.0%-22.0% of Co, 10%-16% of Cr, 3.0%-5.0% of Mo, 1.5%-3.5% of W, 2.4%-3.8% of Al, 3.0%-4.5% of Ti, 0.5%-1.5% of Nb, 1.0%-3.0% of Ta, 0.010%-0.040% of B, 0.005%-0.060% of C, 0.030%-0.060% of Zr, 0.0%-0.6% of V, 0.0%-0.3% of Hf, 0.0%-0.01% of Y, 0.0%-1.5% of Fe, 0%-0.5% of inevitable impurities and the balance of Ni. The total mass fraction of Al, Ti, Nb, Ta and V is 9.5%-12.5%. The deformed high-temperature alloy can meet the requirements of high performance, high homogeneity, and low cost for domestic aviation and aerospace equipment, especially hot-end rotating parts such as engine turbine disks.

Owner:BEIJING CISRI GAONA TECH +2

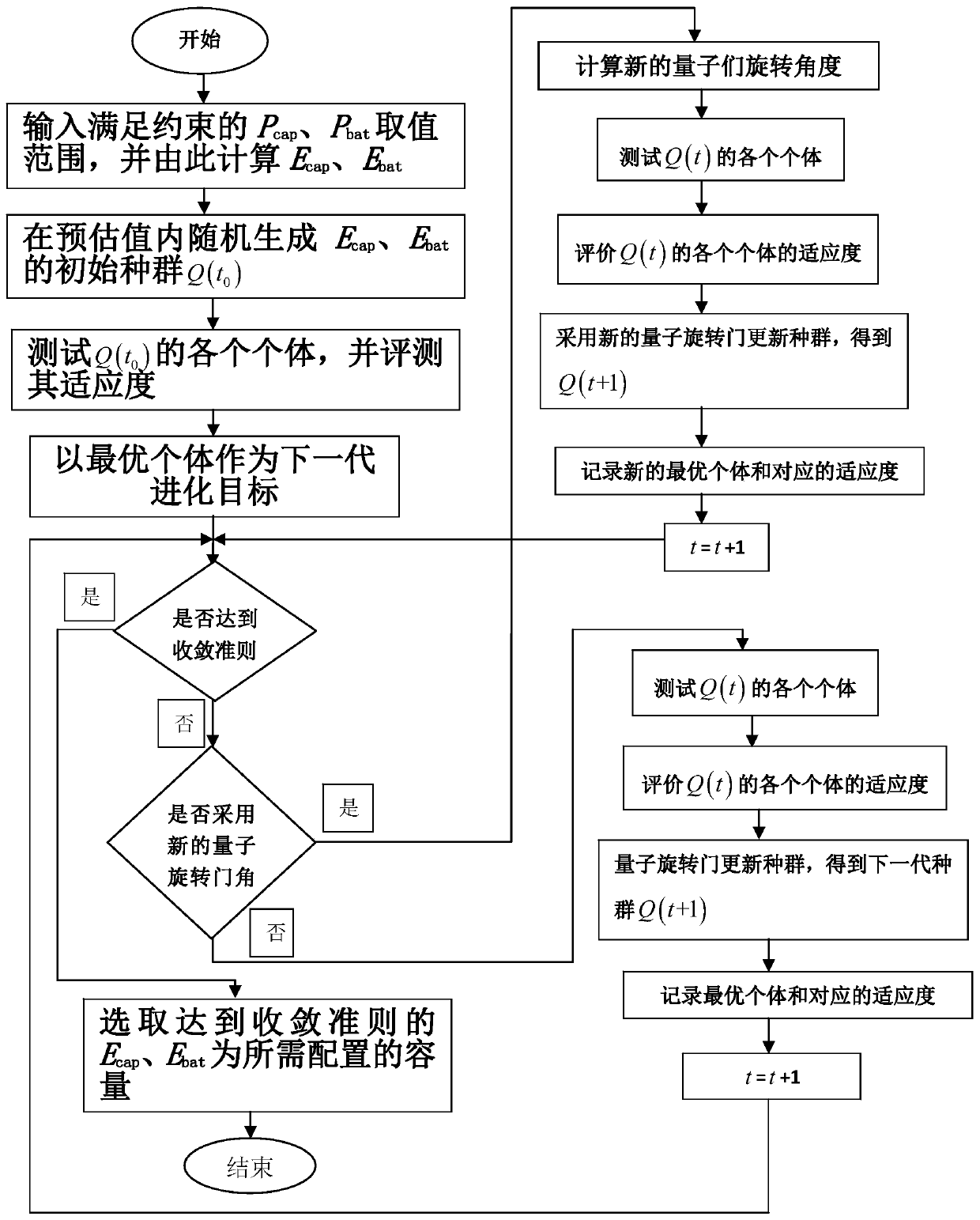

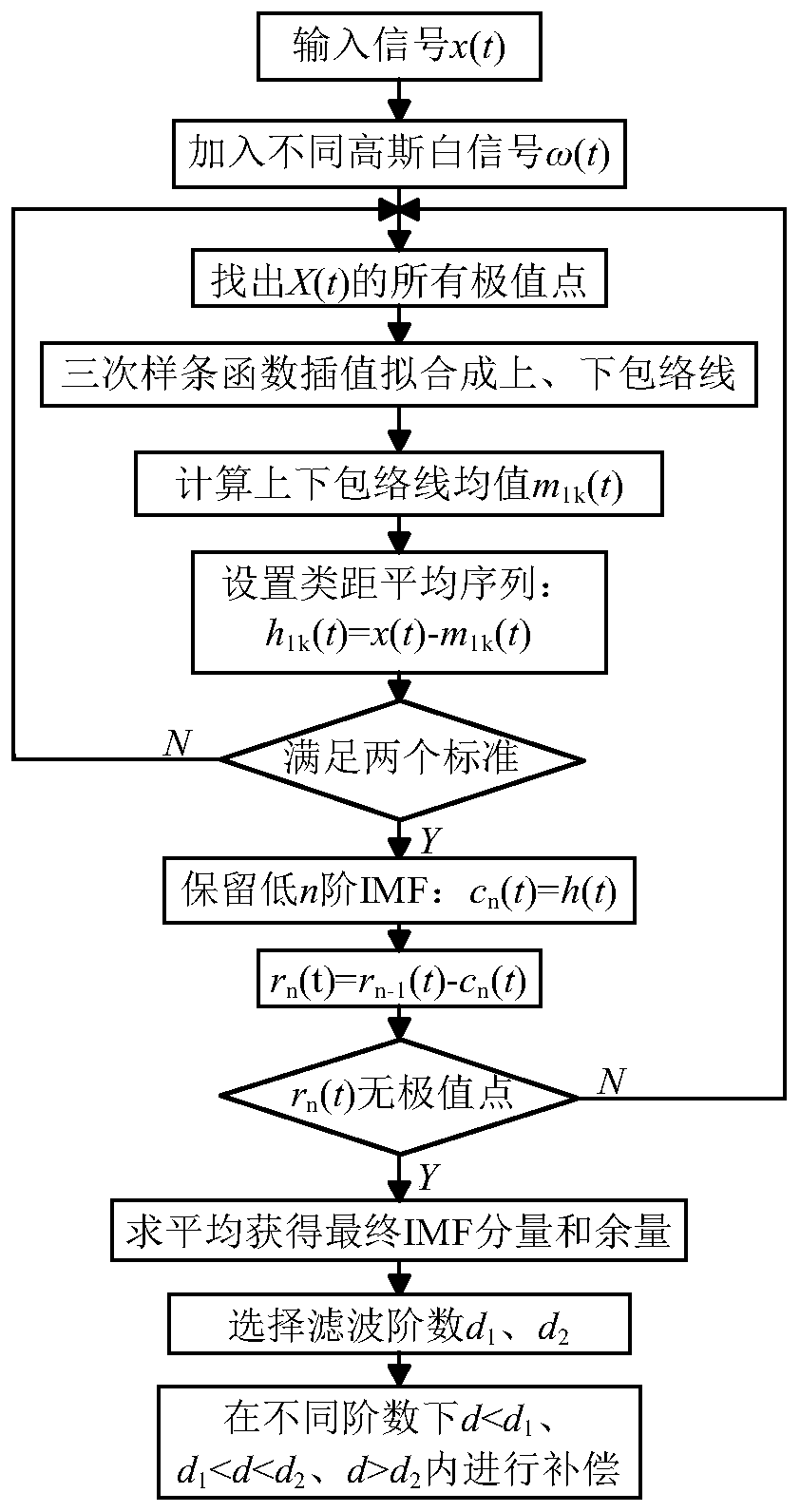

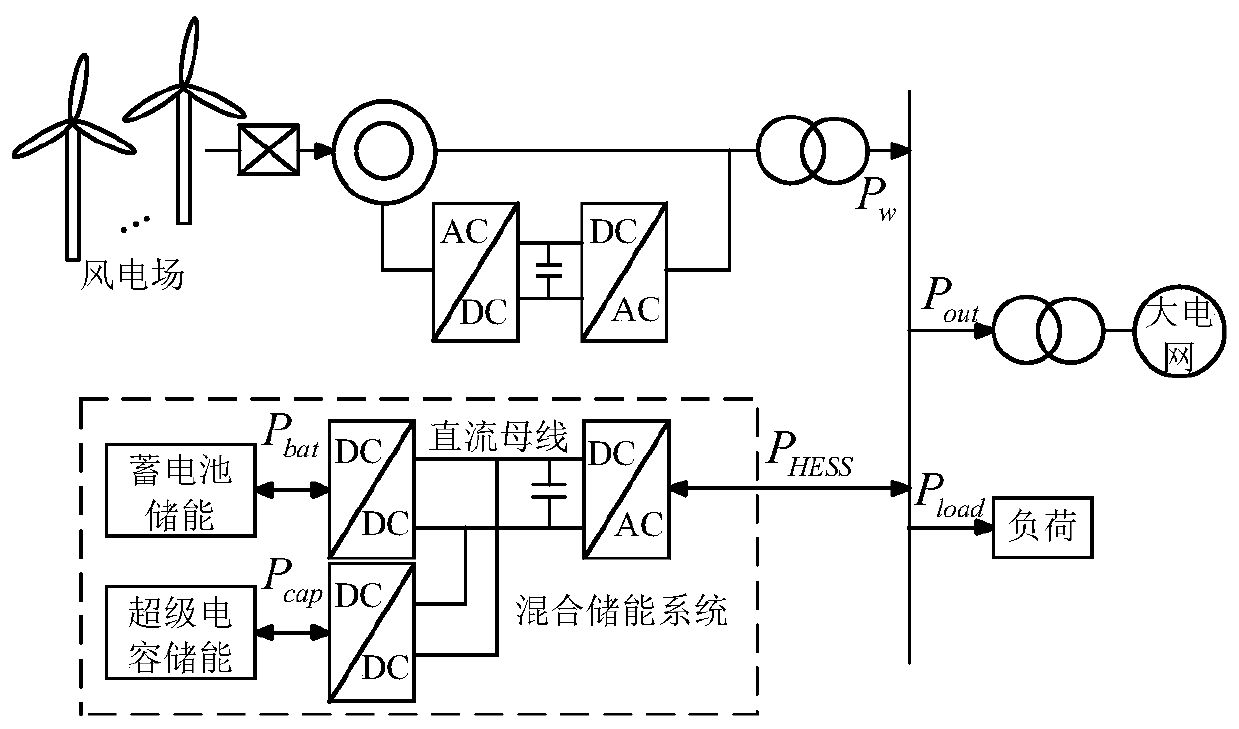

Hybrid energy storage capacity configuration method suitable for wind power grid connection

ActiveCN110676870AReduce system errorImprove search accuracySingle network parallel feeding arrangementsEnergy storageGenetics algorithmsQuantum genetic algorithm

The invention discloses a hybrid energy storage capacity configuration method suitable for wind power grid connection. The method comprises the steps of firstly, decomposing wind power unbalanced power, dividing compensation power of different energy storage equipment, and determining capacity configuration of the different energy storage equipment according to the compensation power; then, introducing a gradient method to optimize the filtering order, comprising the equipment cost of different filtering orders, and selecting the filtering order with the minimum cost as the power and capacitydistribution standard; and finally, establishing an opportunity constraint model according to the fluctuation of the electricity price, and calculating the economic cost of the energy storage equipment by using an improved quantum genetic algorithm on the premise of system stability to obtain the hybrid energy storage capacity configuration which not only meets the requirement of stabilizing windpower instability, but also meets the economic cost. According to the invention, an ensemble empirical mode decomposition method, a gradient method, an improved filtering order optimization control system, an opportunity constraint model and an improved quantum genetic algorithm are combined together, capacity configuration is carried out on the hybrid energy storage system, the instability of wind power can be stabilized, and the effects of peak shaving and valley filling are achieved.

Owner:STATE GRID XINJIANG ELECTRIC POWER CO ECONOMIC TECH RES INST

Steel tank plastic-pasting internal lining antisepsis method

InactiveCN101250701AWon't spread quicklyClosely connectedLiquid surface applicatorsSuperimposed coating processAdhesiveEngineering

The invention relates to a method for preventing corrosion of plastic stuck inside lining of a steel-made tank body, which comprises following steps: removing an oxide layer and an oil stain layer on the inner surface of the steel-made tank body, mixing phosphating solution to phosphatize the surface of the steel-made tank body, using clear water to clean the steel-made tank body after phosphatizing, drying, mixing adhesive, evenly coating the adhesive on the inner surface of the steel-made tank body, clinging a plastic plate whose thickness is 0.5-30mm on the inner surface of the steel-made tank body, leaving joints of 0.1-10cm between different plastic plates, using a stop plate to seal each interface of the steel-made tank body, injecting compressed air into the steel-made tank body, achieving the curing time of the adhesive under the condition of constant pressure 0.03-0.1MPa, curing the adhesive, and then using welding rods to fill the joints between each plastic plate through welding. The method of the invention has the advantages that firstly, an adhesive layer is provided between the steel-made tank body and a plastic anti-corrosion layer, which enables the steel-made tank body and the plastic anti-corrosion layer to be compactly connected, corrosion medium can not be rapidly dispersed by any possibility that leakage happens, secondly, the plastic layer has a comparatively big regulating range, which can satisfy the demands of different users, thirdly, the joints between each plastic plate can be adapted to the changes of the environmental temperature after being filled with the welding rods, and the reliability of products is increased.

Owner:陈晓宇

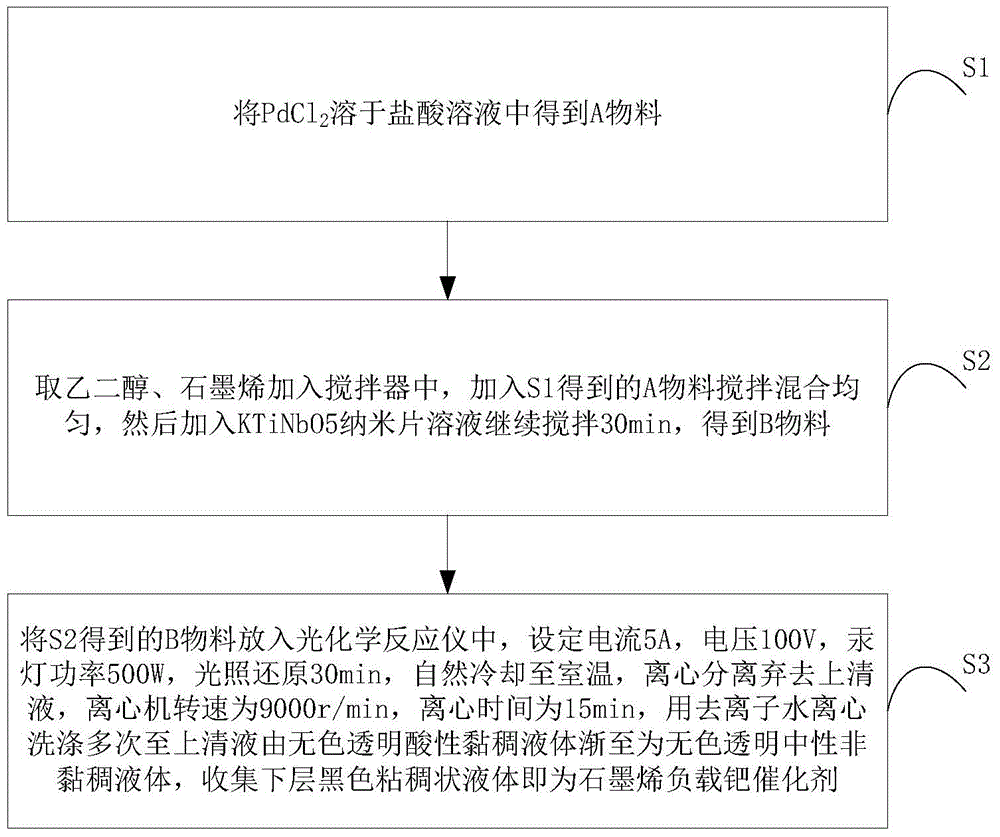

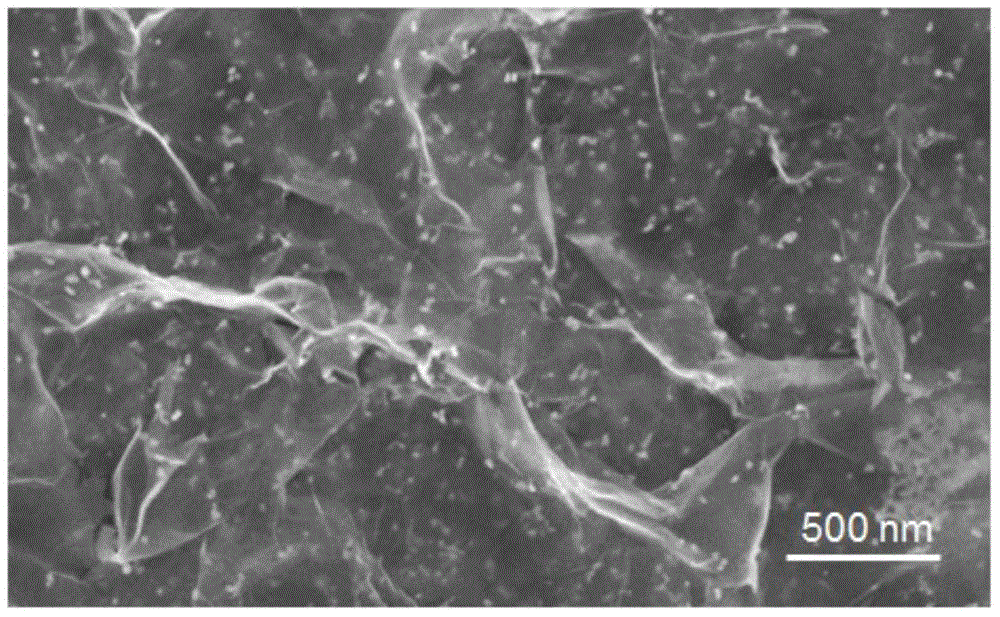

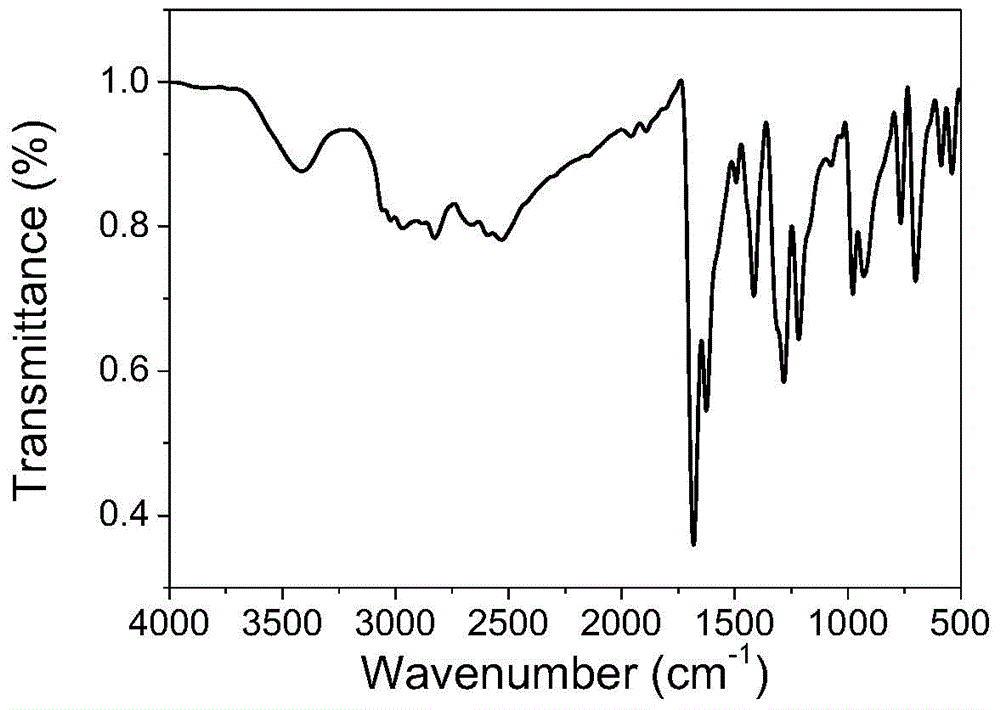

Graphene-supported palladium catalyst, preparation method and application thereof

ActiveCN105126830ASmall dispersionGood dispersionOrganic compound preparationChemical recyclingAfter treatmentPalladium catalyst

The invention discloses a graphene-supported palladium catalyst, which includes following raw materials, by volume, 2-10 parts of a material A, 30-50 parts of ethylene glycol, 100-150 parts of graphene and 5-20 parts of a KTiNbO5 nano sheet solution, wherein the material A includes the raw materials of PdCl2 and hydrochloric acid being 30-37% in concentration, wherein the weight / volume ratio of the PdCl2 to the hydrochloric acid is (0.01-0.1) g : (10-40) ml. The invention also provides the preparation method and an application of the graphene-supported palladium catalyst. In the invention, a conventional method of the graphene-supported palladium catalyst is replaced by the preparation method, which is free of surfactants, is small in particle size, is simple in operation, can be used in synthesis of cinnamic acid, is high in yield of cinnamic acid, is simple in separation and after-treatment, is mild in reaction conditions and is green and economical.

Owner:ANHUI UNIV OF SCI & TECH

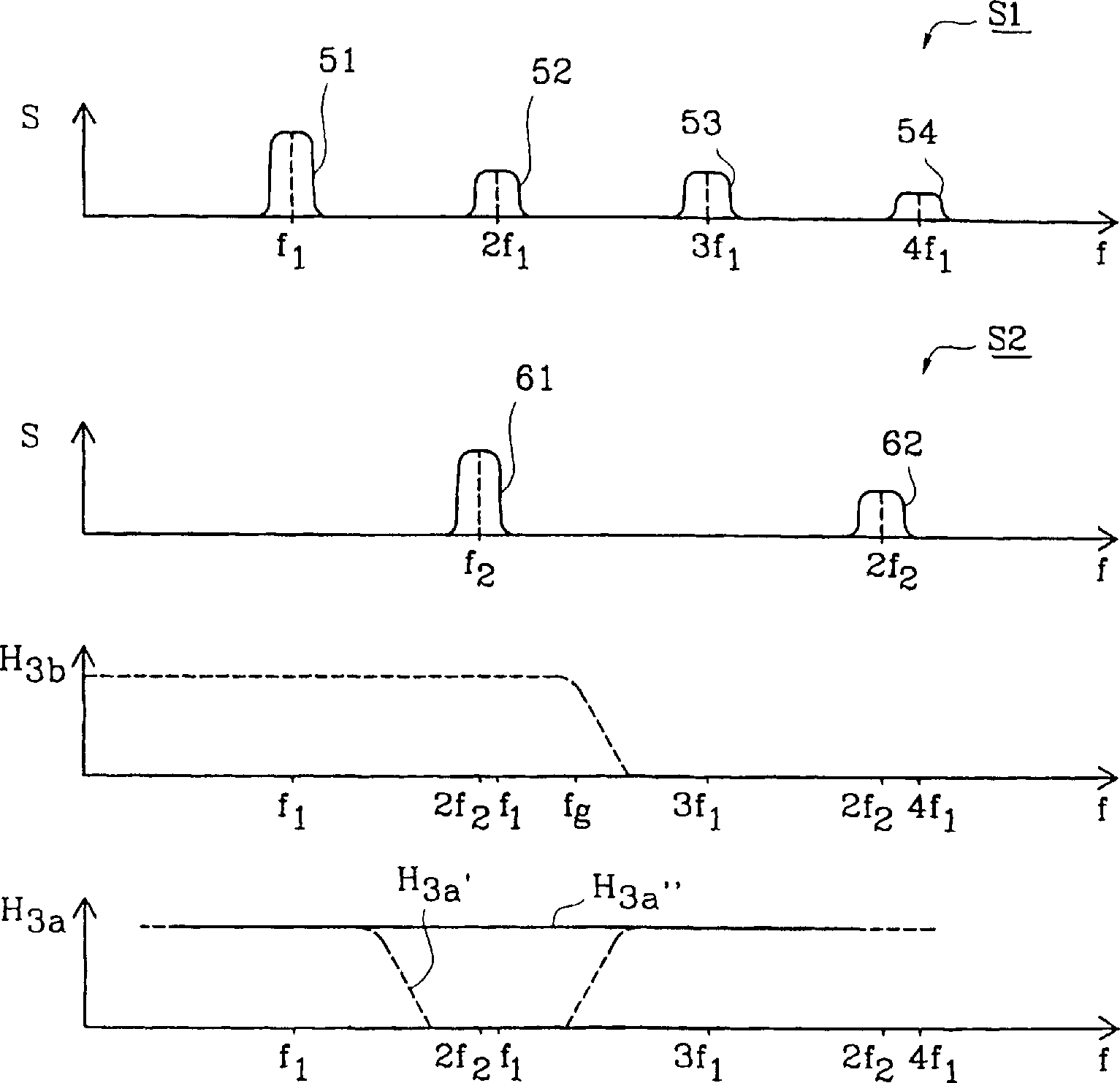

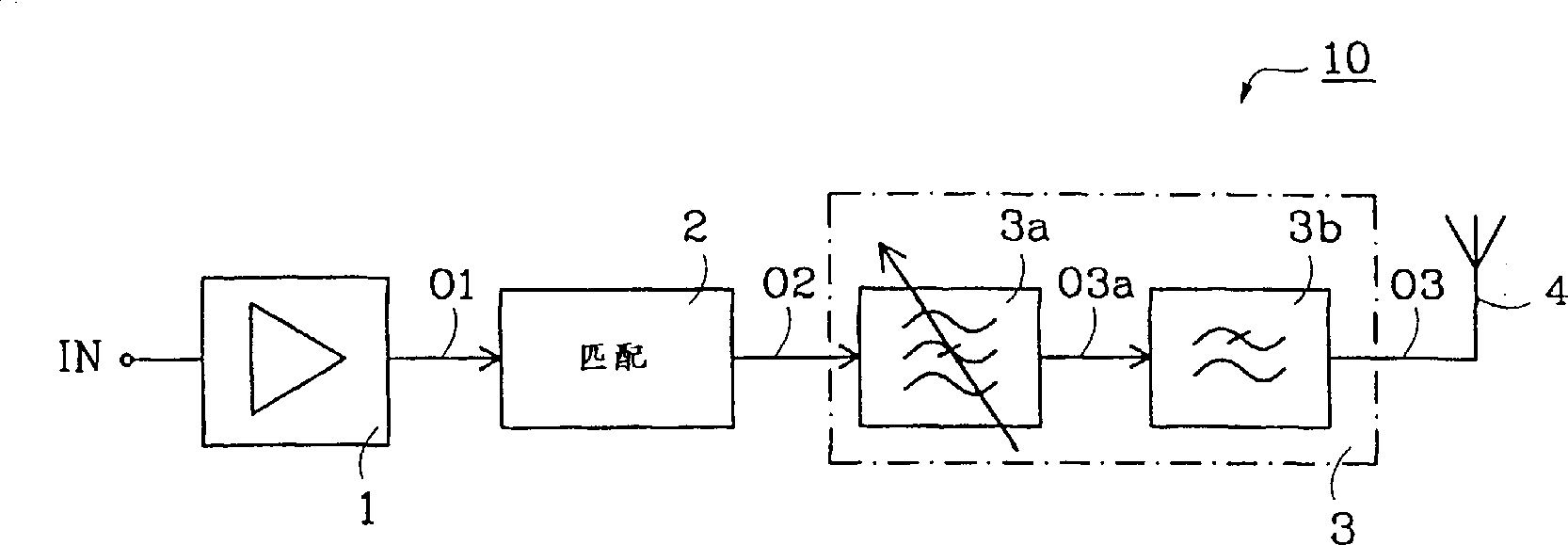

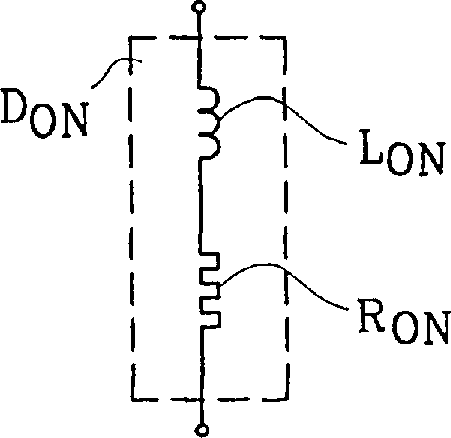

Device and process for telecommunication

InactiveCN1249079ASuppresses RF SignalsHarmonic suppressionMultiple-port networksHigh frequency amplifiersAudio power amplifierHarmonic

The present invention relates to a power amplifier device (10), switchable for at least two separate basic frequency bands, for radio frequency signals with effective suppression of harmonics, where harmonics, corresponding to a first basic frequency band, can be permitted to overlap the frequency range of at least one second basic frequency band. The power amplifier device (10) comprises a power amplifier (1) and an impedance matching circuit (2), switchable by means of a PIN-diode, which provides a load impedance adapted to each individual basic frequency band. Furthermore, the power amplifier device comprises a filter device (3) comprising a fixed low-pass filter (3b) and a switchable filter (3b) acting as an engageable and disengageable notch filter, which comprises at least one reversible PIN-diode. This switchable filter (3a) allows to pass, in a first mode, signals in the first basic frequency band and suppresses at the same time at least one order of harmonics corresponding to this basic frequency band. In a second mode, the second basic frequency band is transmitted without appreciable losses, and harmonics are suppressed by the fixed low-pass filter (3a).

Owner:TELEFON AB LM ERICSSON (PUBL)

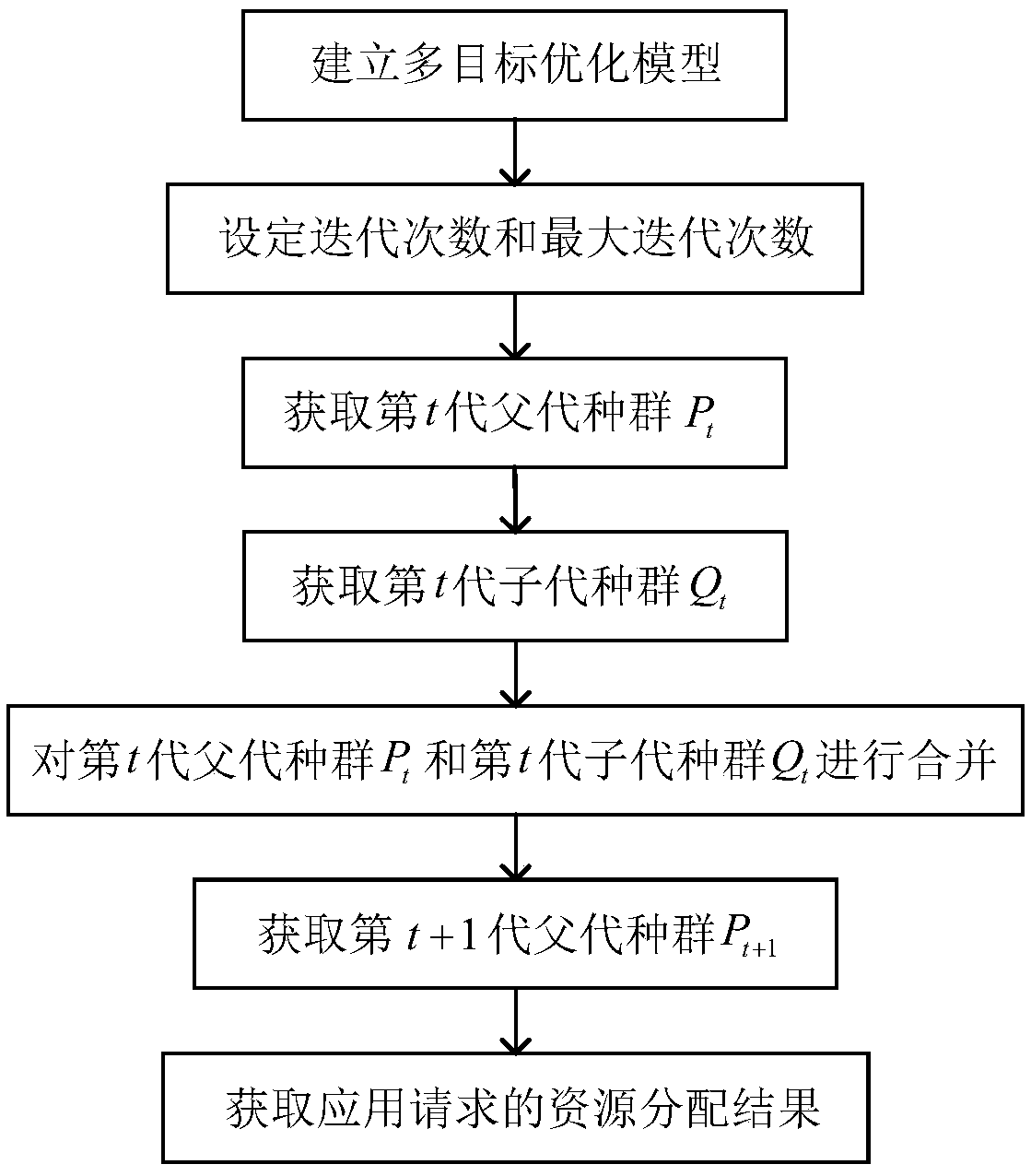

Internet of vehicles cloud system resource distribution method based on multi-target genetic algorithm

ActiveCN109361725AReduce blocking rateMeet cost requirementsInternal combustion piston enginesData switching networksResource utilizationThe Internet

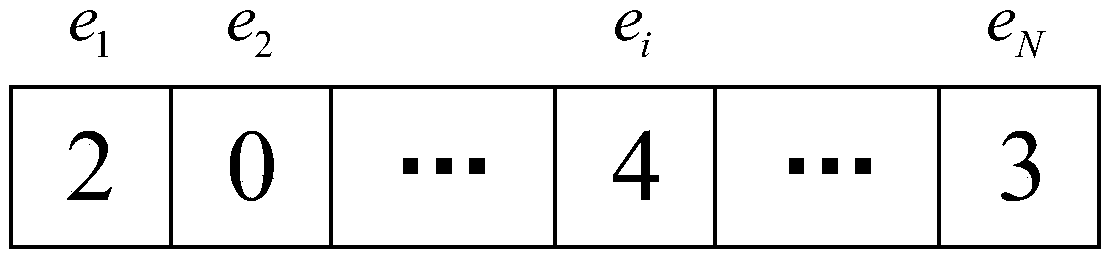

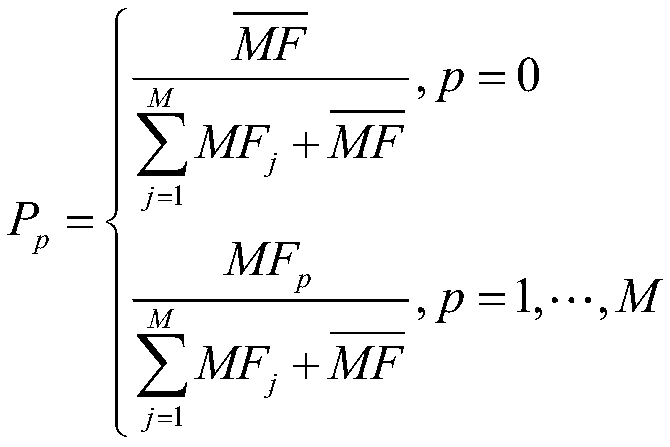

The invention provides an Internet of Vehicles cloud system resource distribution method based on a multi-target genetic algorithm, used for solving the technical problem that the blocking rate of anapplication request is relatively large in current Internet of Vehicles cloud system resource distribution. The method comprises the implementation steps of 1, building a multi-target optimization model; 2, setting the number of iterations and the maximum of iterations; 3, acquiring a t-th generation parent population Pt; 4, acquiring a t-th generation progeny population Qt; 5, combining the t-thgeneration parent population Pt with the t-th generation progeny population Qt; 6, acquiring (t+1)-th surrogate parent population P(t+1); and 7, acquiring a resource distribution result of the application request. According to the method provided by the invention, the minimum blocking rate and the minimum cost are used as target functions, the genetic algorithm is used for solving an optimal resource distribution result set, and under the requirement of meeting the cost, the block rate of the application request is reduced, and the resource utilization rate of the Internet of Vehicles cloud system is increased.

Owner:XIDIAN UNIV

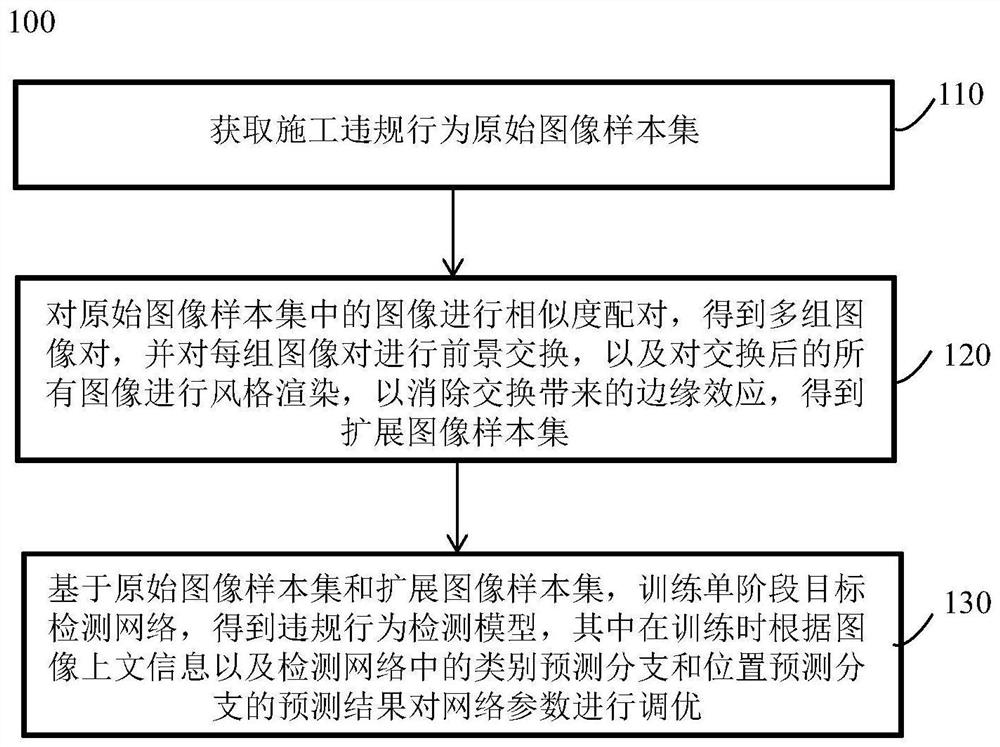

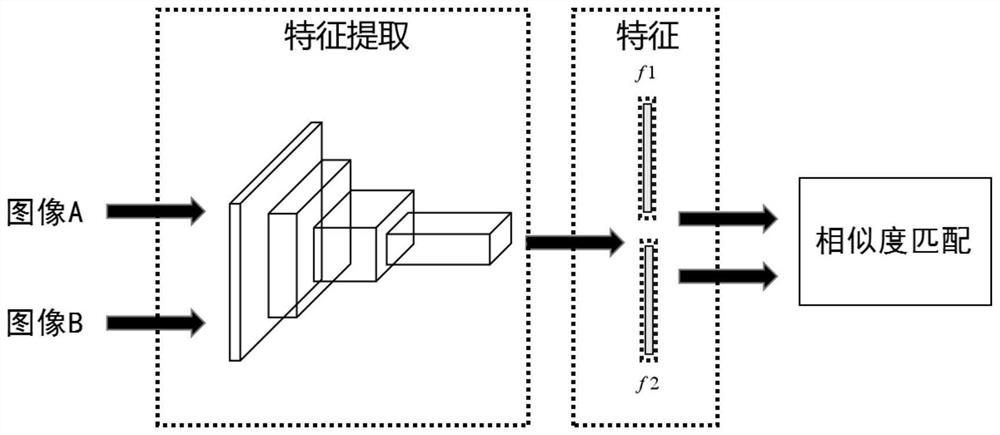

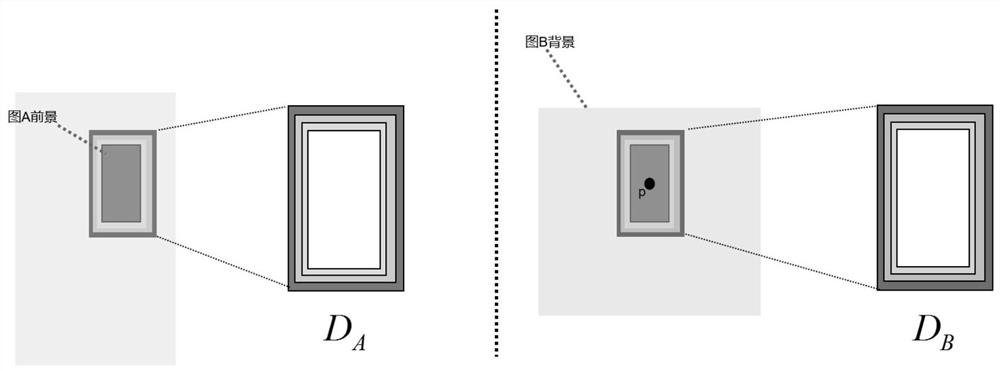

Construction violation behavior detection model construction method and application thereof

ActiveCN111832443ARich diversityMeet cost requirementsCharacter and pattern recognitionNeural learning methodsPattern recognitionAlgorithm

The invention relates to the field of violation behavior detection, and specifically discloses a construction violation behavior detection model construction method and application thereof. The methodcomprises the steps: carrying out the similarity pairing of images in an original image sample set, carrying out the foreground exchange of each group of image pairs, carrying out the style renderingof all exchanged images, and obtaining an extended image sample set; training a single-stage target detection network based on an original image sample set and an extended image sample set, adjustingand optimizing network parameters according to the text information of the images and prediction results of the category prediction branches and the position prediction branches in the detection network during training, and finally detecting violation behaviors based on the constructed violation behavior detection model. According to the method, pairing similarity enhancement is carried out on original samples, and the scale of training samples and the model training precision are greatly improved; in addition, context information is considered during training, regularization is carried out by adding the context information to the network, and the accuracy of target detection is greatly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

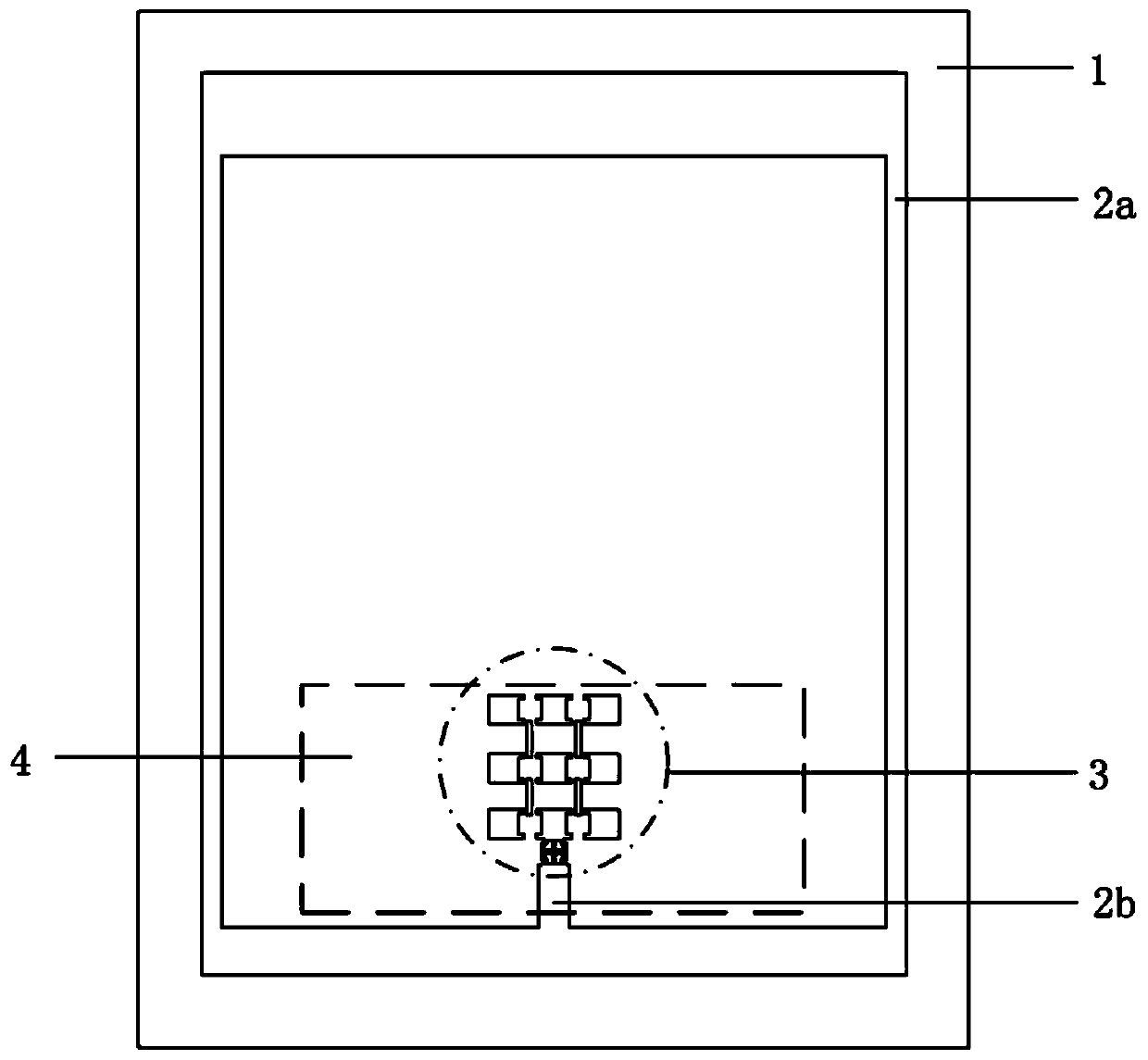

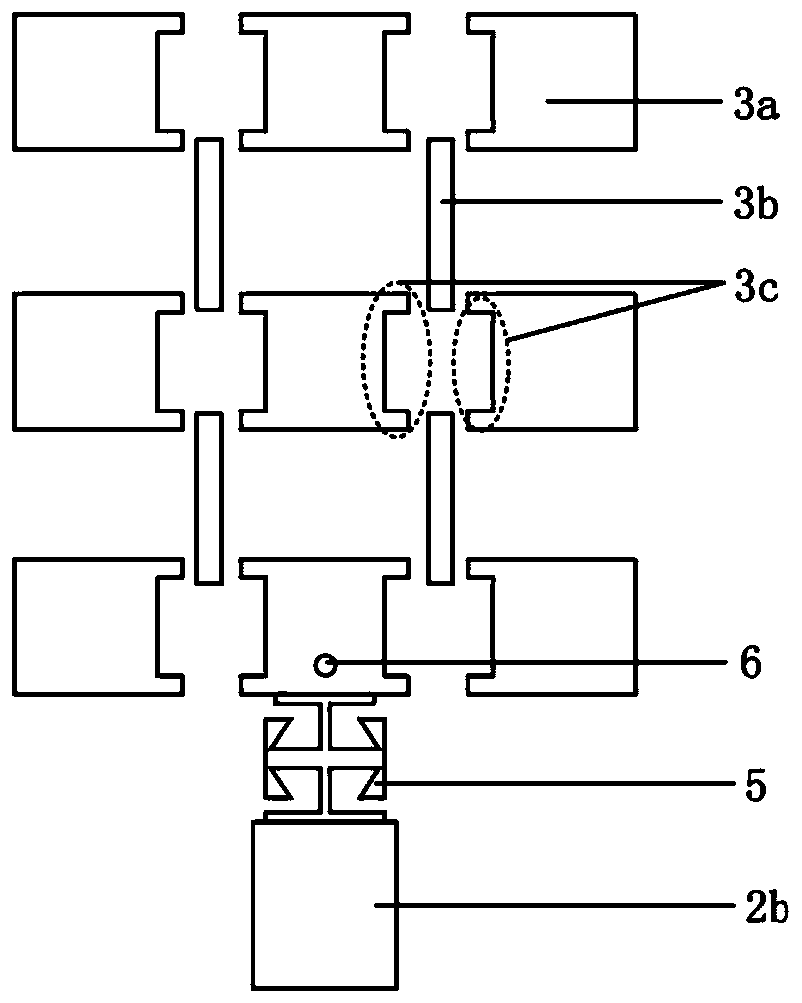

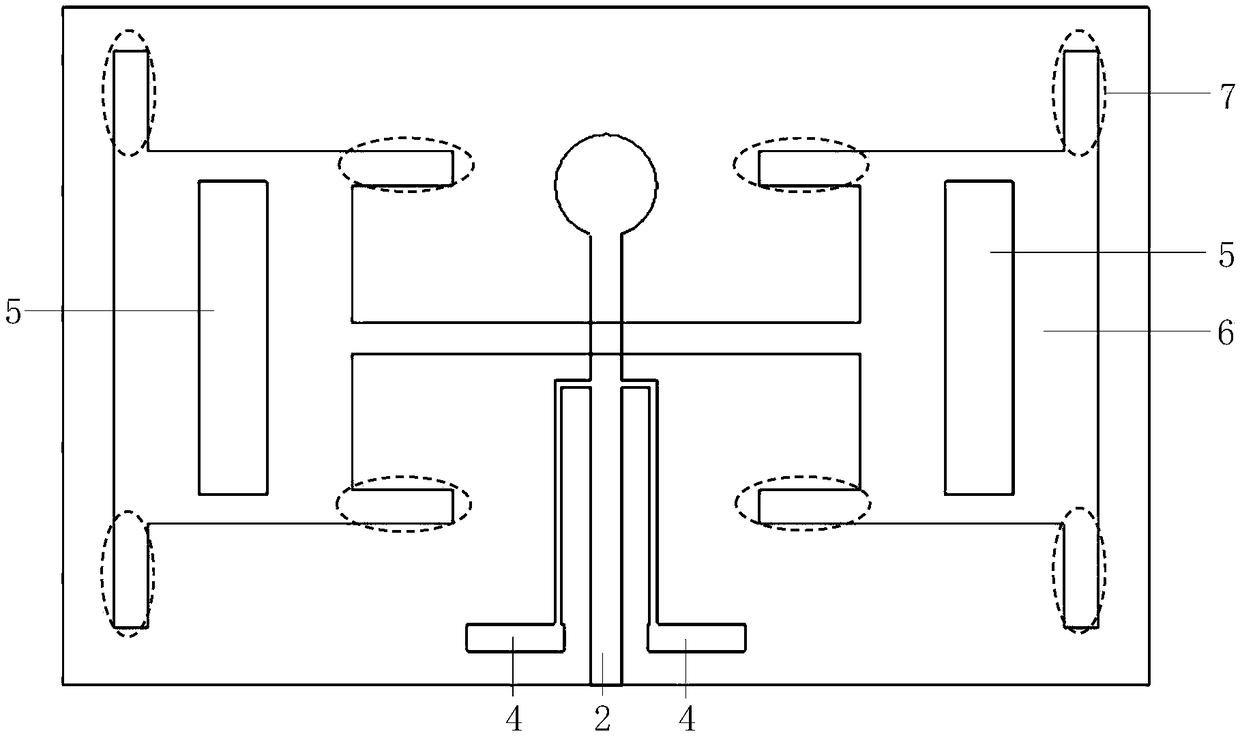

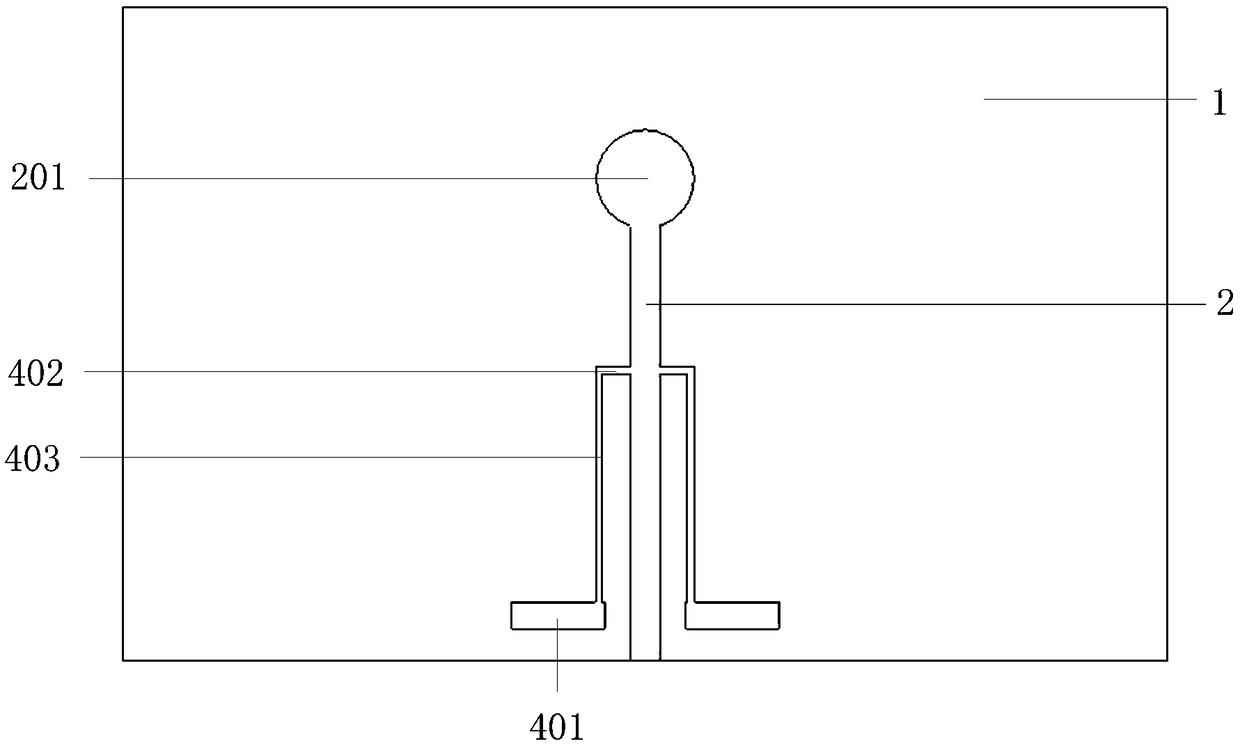

Compact dual-band antenna of large frequency ratio covering sub-6G and 60GHz

PendingCN110247180AIncrease buff effectCompact structureSimultaneous aerial operationsRadiating elements structural formsPatch arrayLow frequency band

The invention discloses a compact dual-band antenna of large frequency ratio covering sub-6G and 60GHz. The compact dual-band antenna comprises a dielectric substrate, a broadband monopole, a compact microstrip resonant unit, a millimeter wave decoupling patch array, a rectangular metal floor and a lumped port. The broadband monopole is printed on the upper surface of the dielectric substrate, consisting of a circular microstrip line and a microstrip feed line. The compact microstrip resonant unit is connected to the millimeter wave decoupling patch array and the microstrip feed line. The millimeter wave decoupling patch array comprises millimeter wave patches, rectangular slottings and decoupled microstrip lines. The rectangular slottings are located on the millimeter wave patches, and the decoupled microstrip lines are located between the millimeter wave patches. The rectangular metal floor is printed on the lower surface of the dielectric substrate. The lumped port is connected to the millimeter wave decoupling patch array and the rectangular metal floor for feeding. The compact dual-band antenna of the invention has wide frequency band and high gain effect, and can meet the application requirements of the 5G low frequency band and the 60GHz millimeter wave band.

Owner:SOUTH CHINA UNIV OF TECH

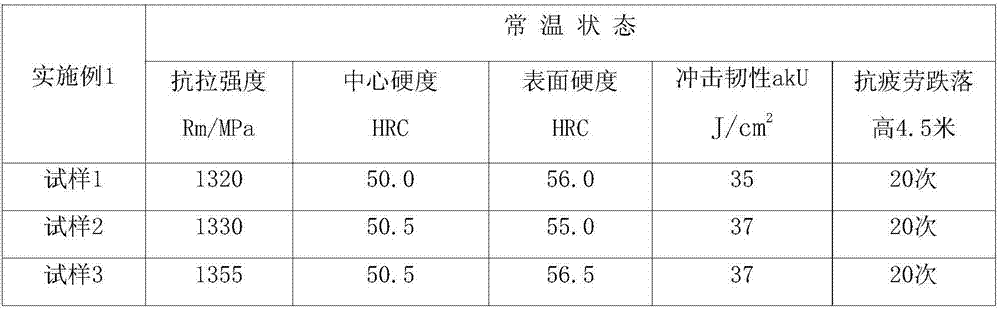

Steel for wear-resistant steel bar, wear-resistant steel bar and preparation method thereof

InactiveCN107475609AImprove toughnessHas alkali corrosion resistanceSteel barUltimate tensile strength

The invention discloses steel for a wear-resistant steel bar. The steel comprises the following components in percentages by weight: 0.55-0.65% of C, 0.2-0.4% of Si, 0.60-1.0% of Mn, 0.9-1.3% of Cr, 0.15-0.25% of Mo, 0.1-0.2% of V, 0.01-0.05% of Ti, less than or equal to 0.020% of S, less than or equal to 0.020% of P and the balance of Fe and inevitable impurities. According to the steel, the wear-resistant steel bar has relatively high strength, hardness, toughness and wear resistance in a rod mill using field, and hardness, hardenability, strength and toughness are substantially balanced and considered. The invention also provides the wear-resistant steel bar made from the steel for the wear-resistant steel bar, and a preparation method of the wear-resistant steel bar.

Owner:侯宇岷

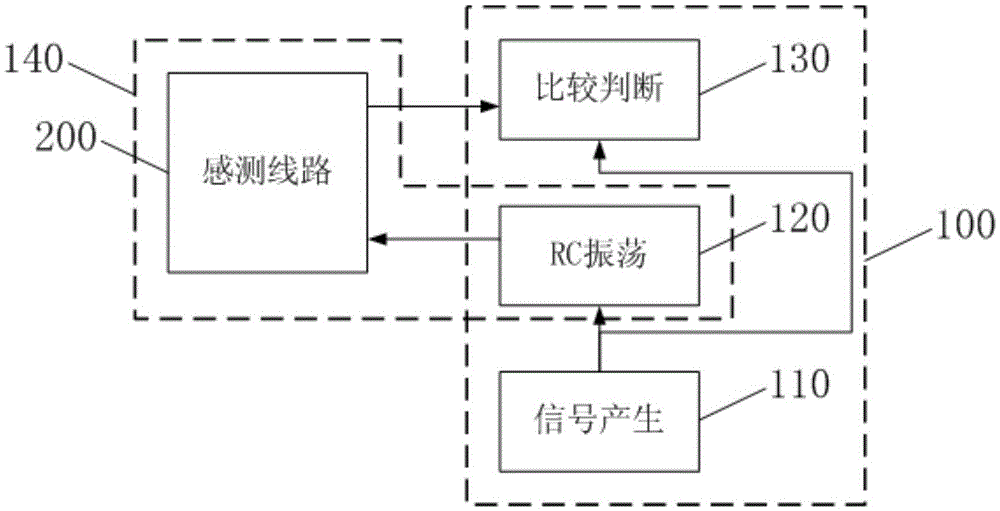

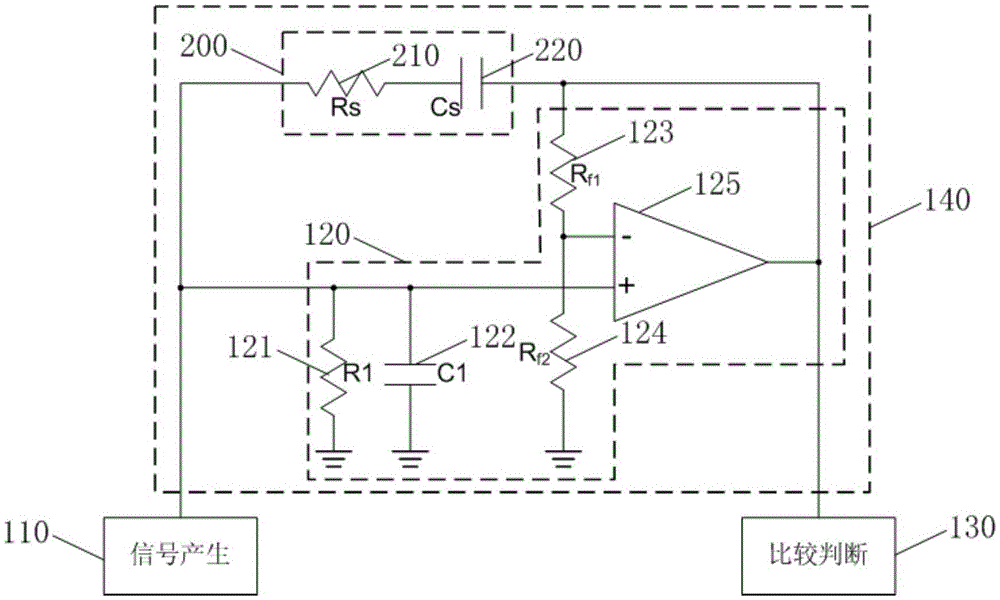

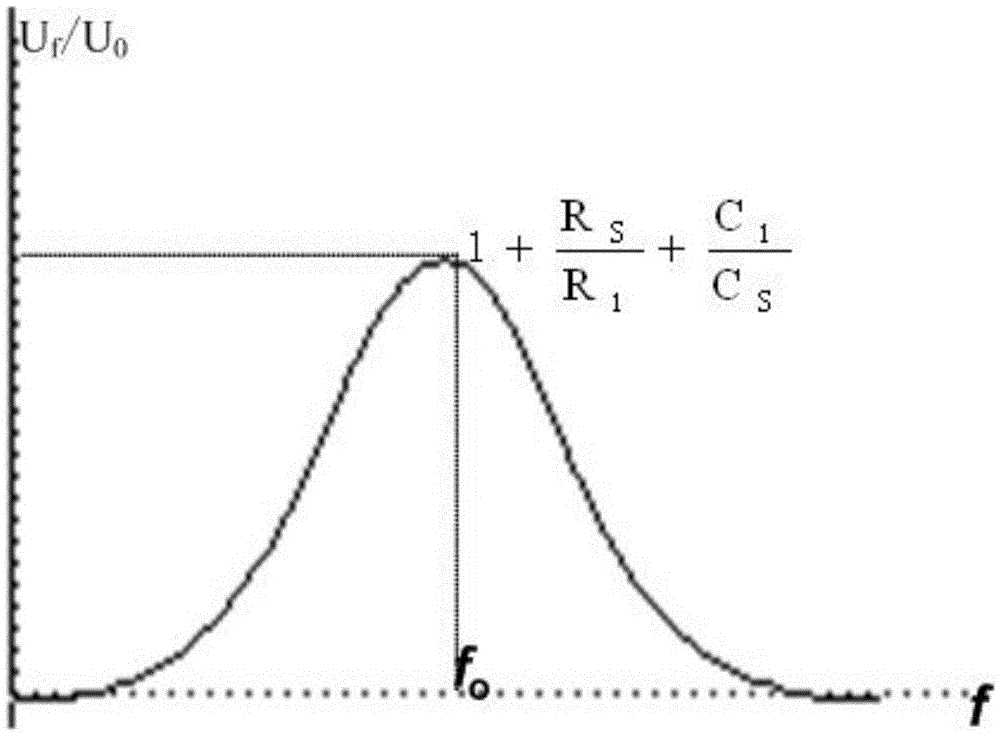

Detection circuit for capacitance sensing line detection, capacitive touch screen and detection method

Embodiments of the invention disclose a detection circuit for capacitance sensing line detection, a capacitive touch screen and a detection method. The detection circuit comprises a signal generation module, an RC oscillation module and a comparison and judgment module. The signal generation module is used for generating and outputting a driving alternating-current signal; the RC oscillation module is electrically connected with the signal generation module, and is electrically connected with a to-be-detected capacitance sensing line to form an RC bridge resonance circuit, the RC bridge resonance circuit generates a corresponding sensing alternating-current signal according to the driving alternating-current signal received by the RC oscillation module, and the sensing alternating-current signal is output through the capacitance sensing line; and the comparison and judgment module is electrically connected with the to-be-detected capacitance sensing line and the signal generation module, and is used for comparing the sensing alternating-current signal and the driving alternating-current signal and judging whether the comparison result is within a preset threshold range so as to get a line detection result according to the judgment result. There is no need to use a capacitor in line detection. The detection method can also be applied to the situation of low-frequency signal transmission, and lines are not scratched. The detection method meets the area and cost demands of ICs.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Aluminum alloy with good toughness and difficulty of cracking for doors and windows

The invention discloses an aluminum alloy with good toughness and difficulty of cracking for doors and windows. The aluminum alloy is characterized by consisting of the following elements in percentage by mass: 0.20-0.25% of chromium, 0.2-0.4% of titanium, 0.1-0.2% of cerium, 0.11-0.14% of yttrium, 0.15-0.17% of strontium, 0.2-0.25% of lead, 0.7-0.9% of copper, 1.1-1.3% of zinc, 1.0-1.3% of silicon, 0.20-0.22% of germanium, 0.15-0.25% of lithium, and the balance of aluminum and impurities. The added components of cerium, yttrium, zinc and the like can improve the corrosion resistance of the alloy, improve the low-temperature toughness and cracking property, the processing performance and the welding performance, enhance the quality of the aluminum alloy, and meanwhile meet the decoration requirement of buildings and the cost requirement of most of people.

Owner:合肥派成铝业有限公司

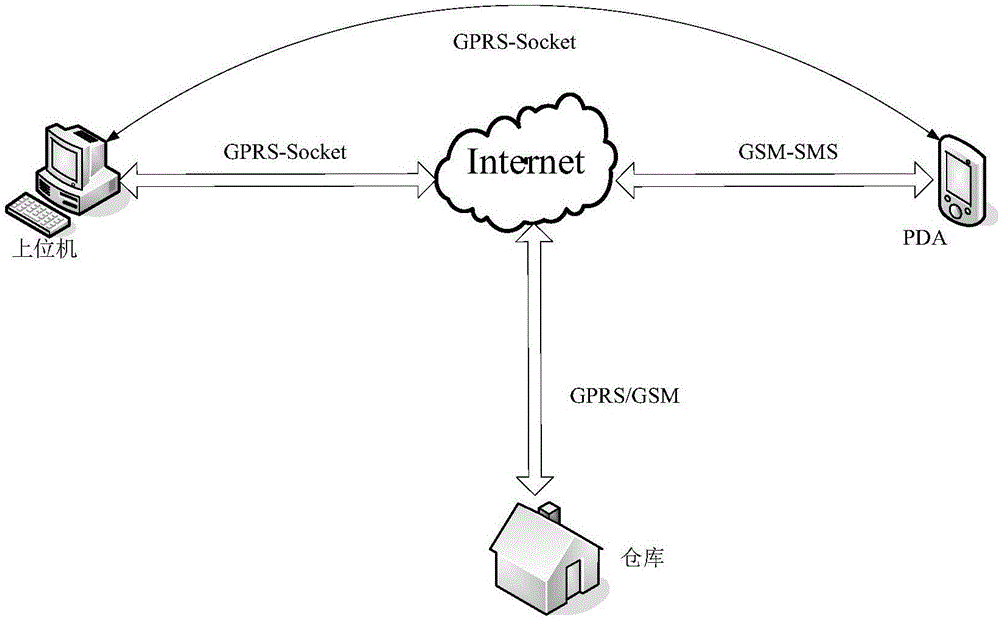

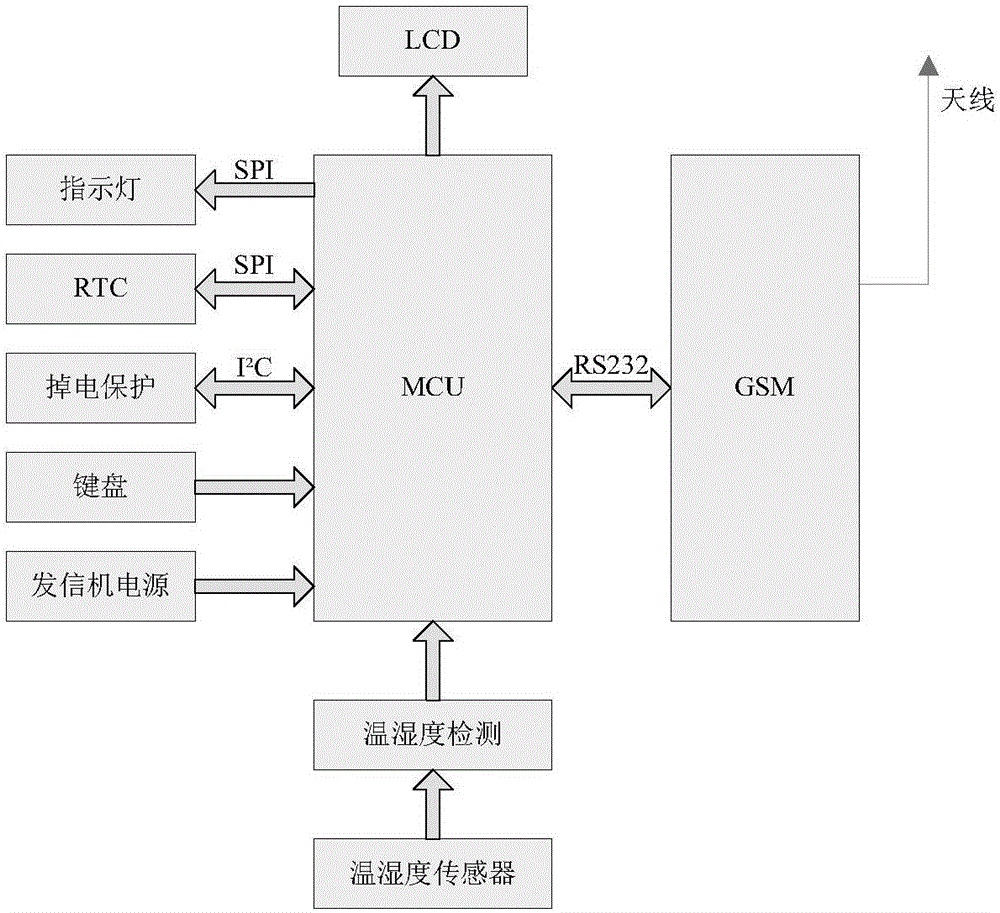

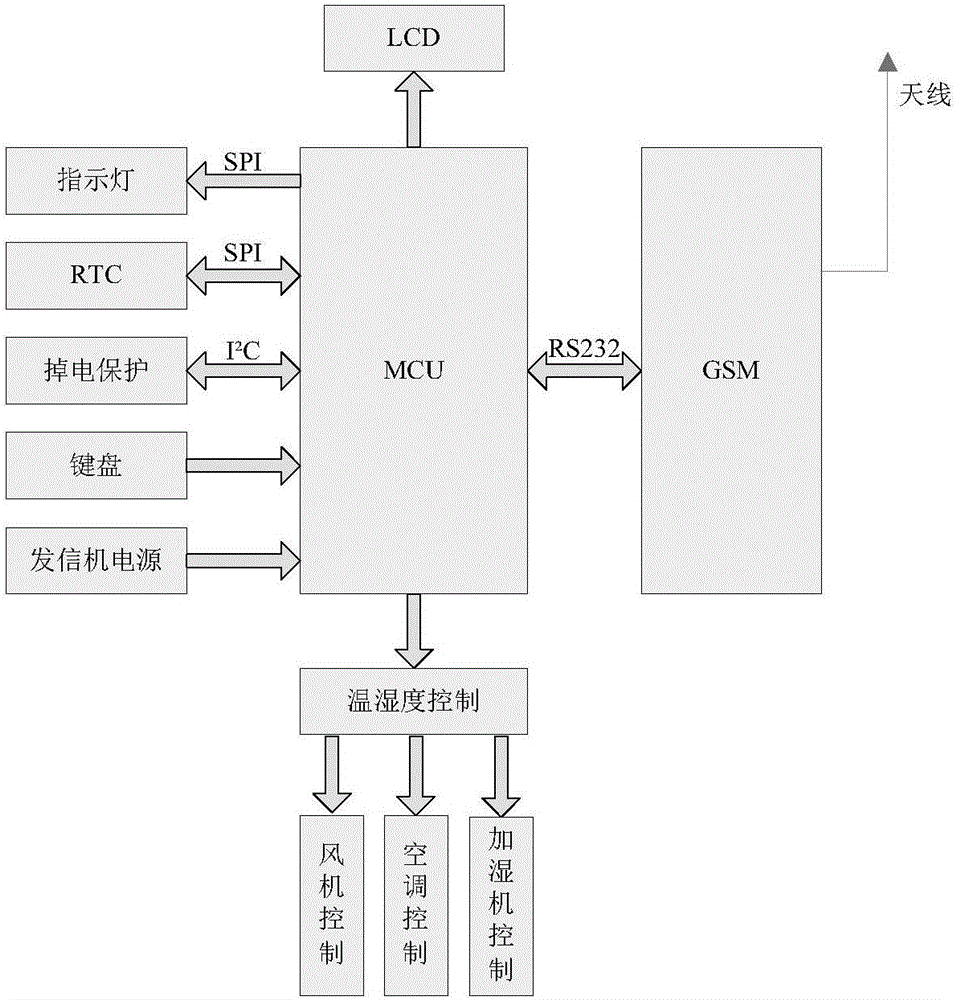

Warehouse temperature and humidity remote intelligent control system based on internet of things

InactiveCN105929874AReduce labor intensityQuality assuranceSimultaneous control of multiple variablesMicrocontrollerComputer monitoring

The invention provides a warehouse temperature and humidity remote intelligent control system based on the internet of things and a control method thereof. The system mainly comprises a transmitter detection and communication system, a receiver control and detection system, an internet of things mobile terminal and a PC upper computer monitoring control system. The internet of things mobile terminal and the upper computer system, the transmitter detection and communication system and the receiver control and detection system establish channel type interconnection based on the internet. The transmitter detection and communication system and the receiver control and detection system perform control communication through a GSM short message service. A single-chip microcomputer controller is used, interconnection of things is realized through the internet of things technology, a mobile equipment intelligent mobile phone of an Android platform acts as a mobile monitoring and control platform, and the PC upper computer realizes remote communication through the Internet so that real-time monitoring and control of warehouse temperature and humidity can be realized, and the system has advantages of being convenient to use, intelligent in control and stable in system without regional restrictions.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

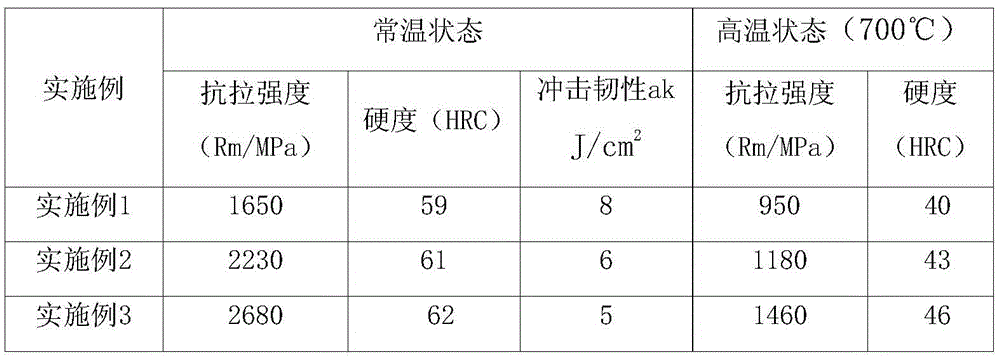

Steel for liner plate forging die, liner plate forging die and preparation method thereof

ActiveCN105463333AImprove room temperature performanceImprove high temperature performanceForging/hammering/pressing machinesUltimate tensile strengthToughness

The invention discloses steel for a liner plate forging die. The steel for the liner plate forging die is prepared from, by weight, C 0.5%-0.6%, Si 0.2%-0.6%, Mn 0.4%-0.8%, W 2%-5%, Cr 3%-5%, Mo 1%-3%, Co 1%-5%, Nb 0.001%-0.005%, V 2%-4%, Ti 0.02%-0.1% and the balance Fe and inevitable impurities. The requirements for normal-temperature performance and high-temperature performance of the forging die are met, the steel has higher strength, hardness, toughness and abrasion resistance in a normal-temperature state and a high-temperature state and is a material used for the forging die and meeting the technical requirements of usage and cost requirements. The invention further provides the liner plate forging die made of the steel for the liner plate forging die and a preparation method of the liner plate forging die.

Owner:SHANDONG HUAMIN STEEL BALL

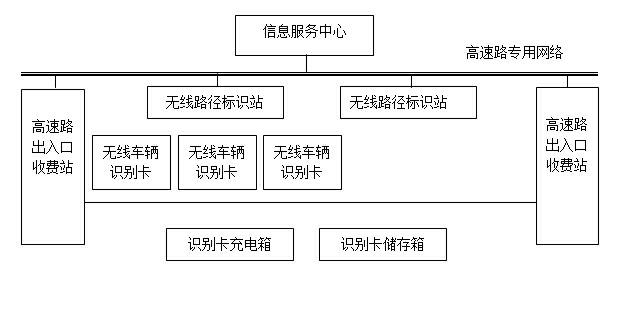

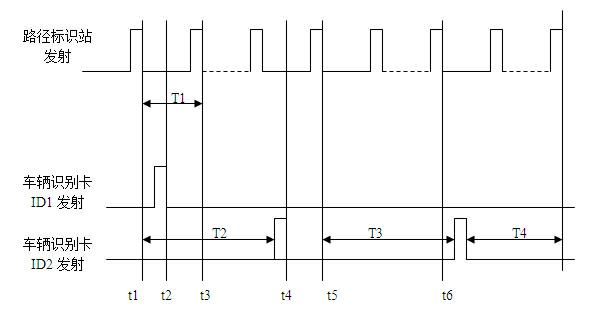

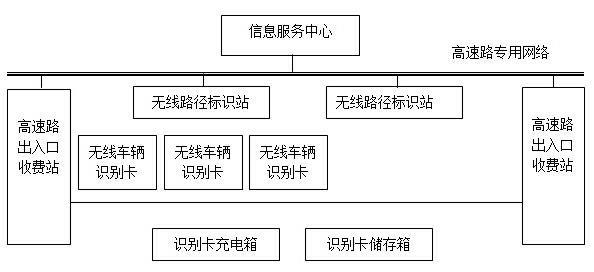

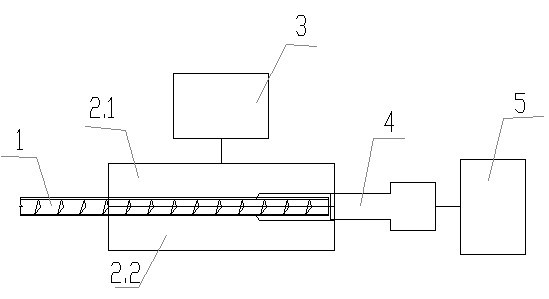

Remote active radio frequency identification device communication control method used for highway

InactiveCN102426641ARealize two-way communication functionGood serviceNear-field transmissionSensing record carriersEmergency rescueTraffic flow

The invention relates to a remote active radio frequency identification device communication control method used for a highway. The invention overcomes the problems of unable bidirectional communication, unable obtaining traffic flow information in real time and unable mastering vehicle paths until the vehicle is turned off the high way in the prior remote active radio frequency identification technology. The remote active radio frequency identification device communication control method used for a highway is provided. A wireless path identification station continually sends a data packet containing an identification number itself in a broadcasting mode at a set time interval T1, and a data packet that represents a vehicle identification number and is sent back by a vehicle identification card is received by the wireless path identification station within the sending interval. Broadcasting of the identification number itself and confirmation of the vehicle identification number are completed in a same data packet, and the vehicle identification card takes corresponded actions according to different situations. A bidirectional communication function between a wireless vehicle identification card and a path identification station is realized. On the premise that a vehicle path identification function is realized and completed, functions of accurate flow monitoring, vehicle localization and emergent rescue and the like can be realized.

Owner:XI AN CHENGFENG TECH CO LTD

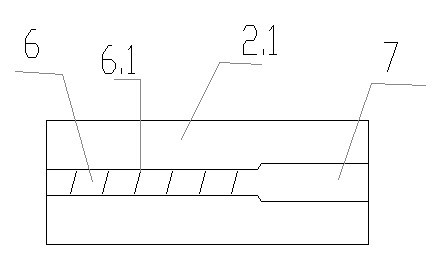

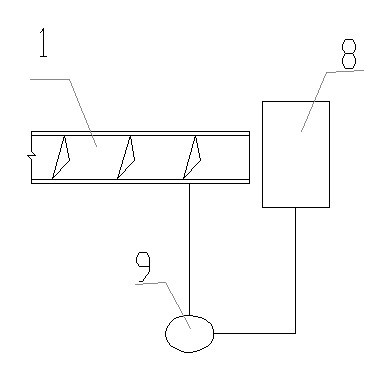

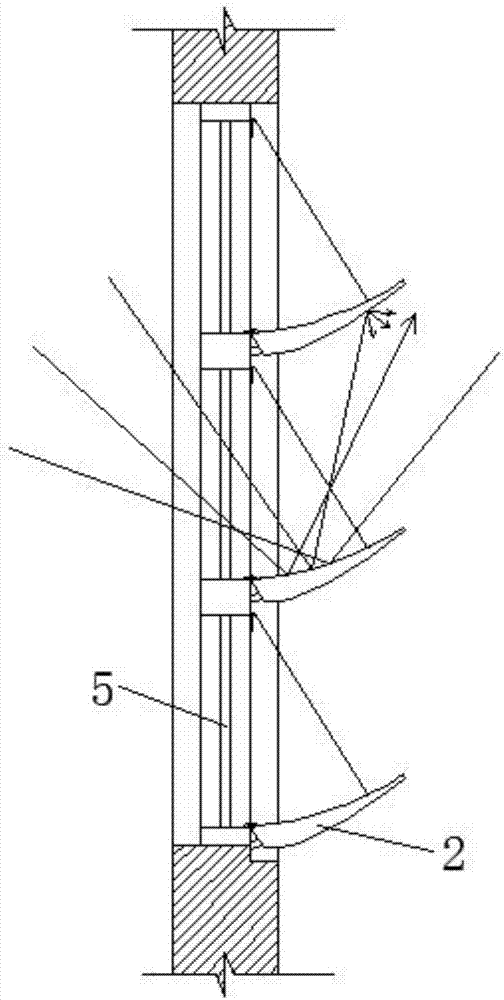

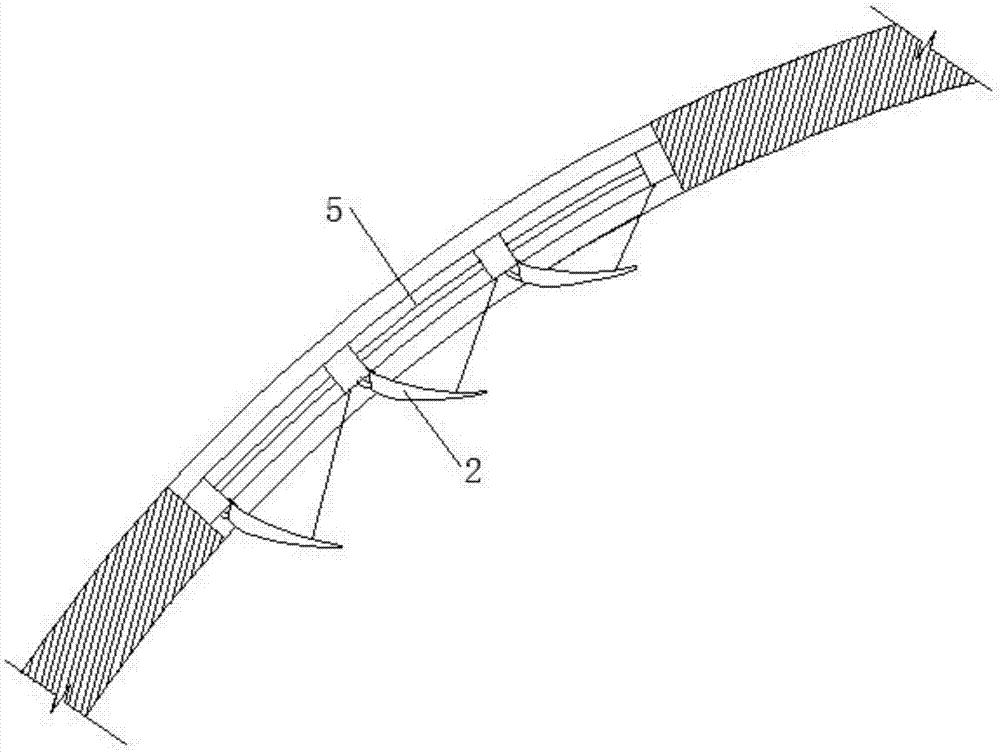

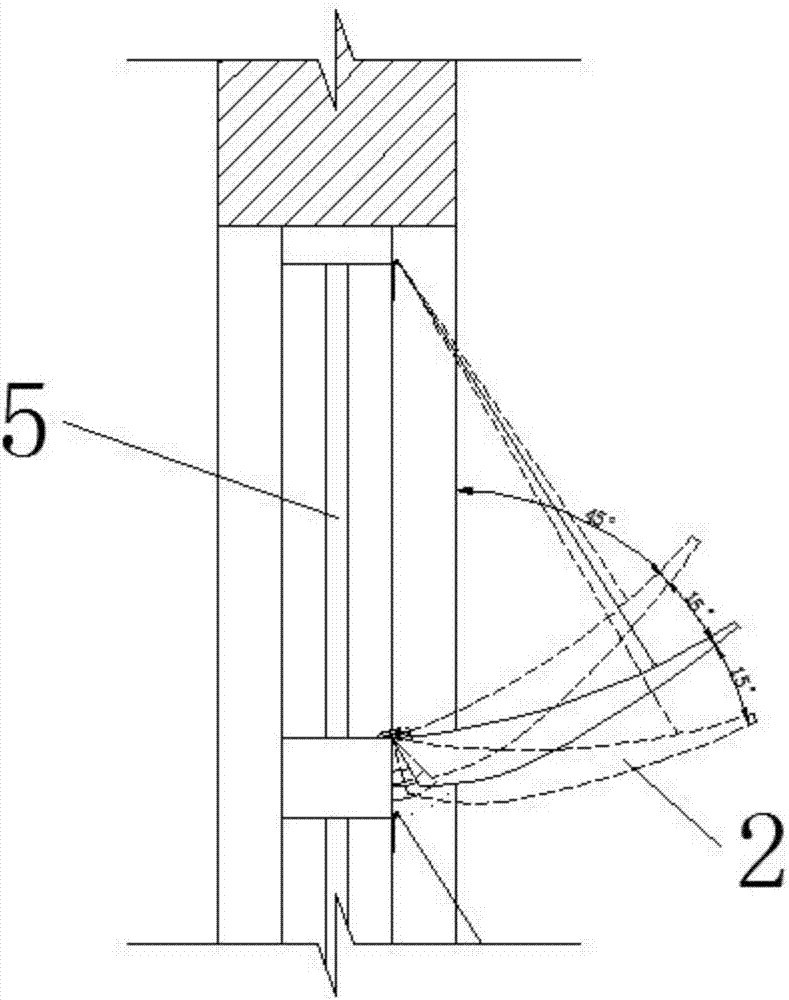

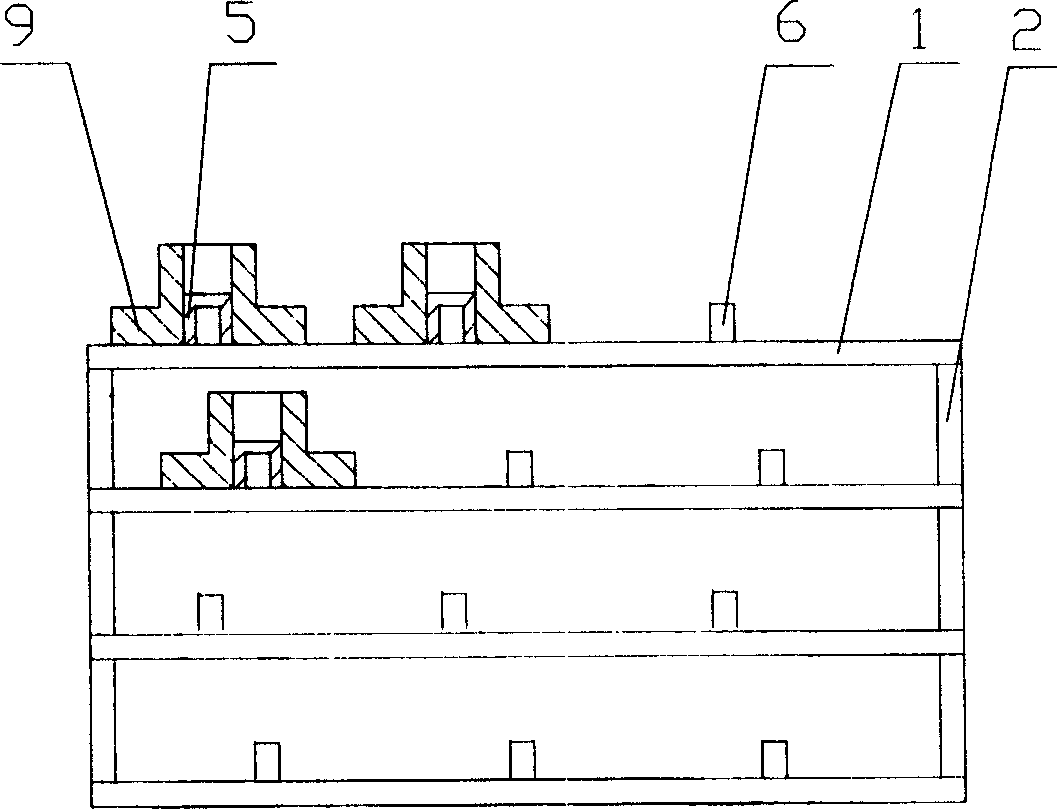

Reinforcing steel bar assembly type structural reinforcing steel bar for building, connecting head part molding method and connecting head part molding mold

InactiveCN102605901AMeet cost requirementsImprove assembly connection construction speedBuilding reinforcementsRebarConcave surface

The invention relates to an improvement on a reinforcing steel bar assembly type structural reinforcing steel bar for a building, also relates to a reinforcing steel bar head part molding method and a reinforcing steel bar head part molding mold. The reinforcing steel bar is characterized in that cylindrical bolt heads and / or cylindrical thread heads are arranged at the two end parts of the reinforcing steel bar, the radial thickening ring edges of the cylindrical bolt heads and / or cylindrical thread heads are more than or equal to 4mm, wherein the axial inner end surfaces of the cylindrical bolt heads are planes, and connecting sleeves are sheathed at the inner sides of the cylindrical bolt heads in advance, the outer ends of the connecting sleeves are inner threads, and the inner ends of the connecting sleeves are inner plane contraction ports. The molding method is implemented as follows: the single end is molded into a cylinder through the steps that the head part is heated until the color of the head part is red at least, then the heated head part is placed in a clamping and thickening limitation mold to be clamped tightly by external force, and the end surface of the heated head part is extruded and thickened to be full of the mold. The mold adopts a folding mold with two symmetrical sections, the folding surfaces are respectively provided with a semi-circular groove, the diameter of which is basically equal to that of the reinforcing steel bar, the concave surface of the semi-circular groove is provided with concave threads basically identical to the threads of the reinforcing steel bar, and a thickened semi-circular groove is arranged at one end of the semi-circular groove, wherein the diameter of the thickened semi-circular groove is more than or equal to 8mm. when a casted concrete member is used for assembling the reinforcing steel bar, the sleeves are adopted for connection, plenty of welding connection amount are omitted, so that the requirement of low cost of the building can be met.

Owner:江苏金砼预制装配建筑发展有限公司

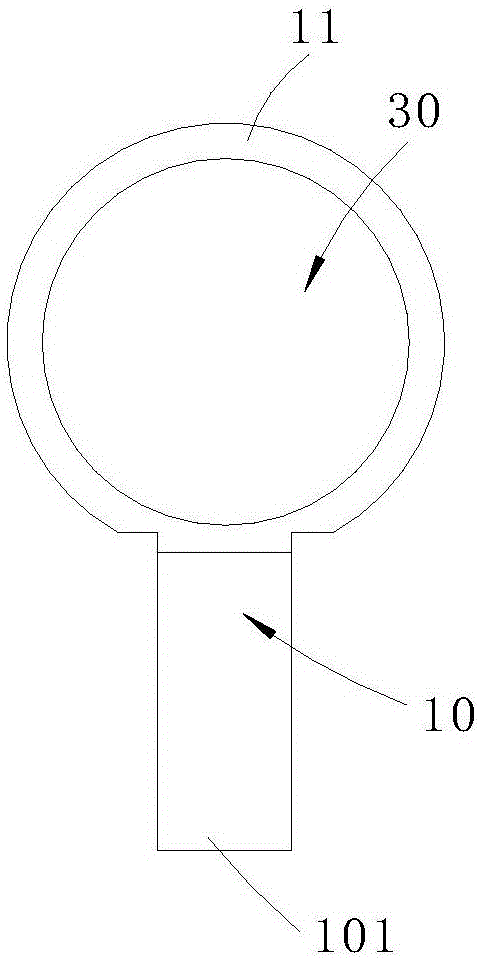

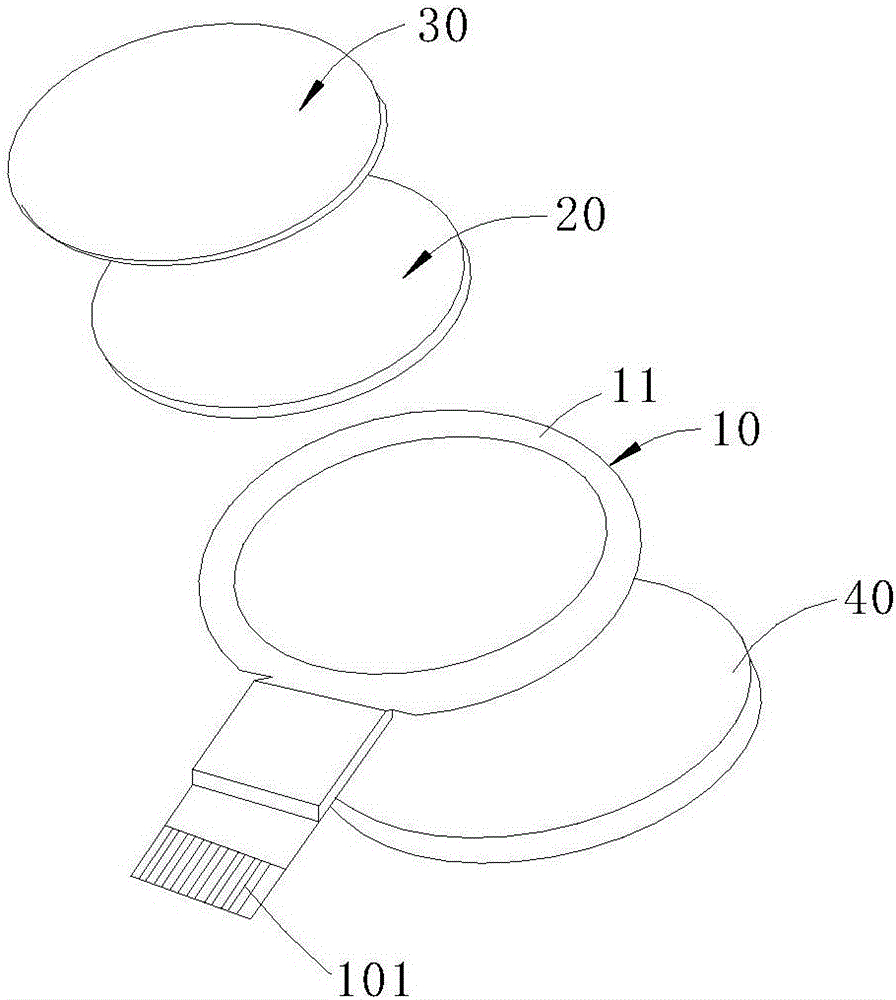

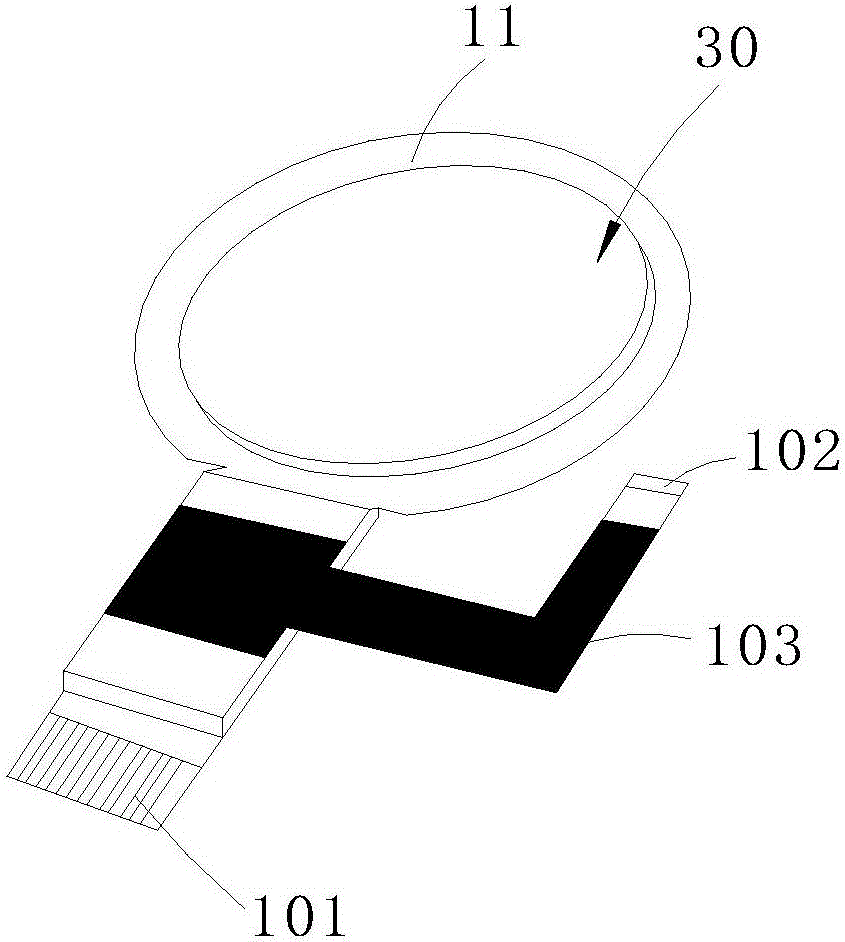

Fingerprint recognition module and electronic equipment

ActiveCN106845433AReduce manufacturing costWith fingerprint recognition functionPrint image acquisitionPattern recognitionFlexible circuits

The invention discloses a fingerprint recognition module. The fingerprint recognition module comprises a flexible circuit board, a fingerprint recognition chip and a touch layer covering the upper surface of the fingerprint recognition chip, the fingerprint recognition chip is arranged on the flexible circuit board, the flexible circuit board comprises a ring of annular copper leakage part arranged at the periphery of the fingerprint recognition chip, and the copper leakage part is connected to the ground. The invention further discloses electronic equipment. By designing the cheap fingerprint recognition module, the manufacturing cost of the electronic equipment can be drastically reduced after applying the fingerprint recognition module to the electronic equipment, thus the electronic equipment has a fingerprint recognition function and meets the cost requirement at the same time, and the product competitiveness is effectively improved.

Owner:JRD COMM (SHENZHEN) LTD

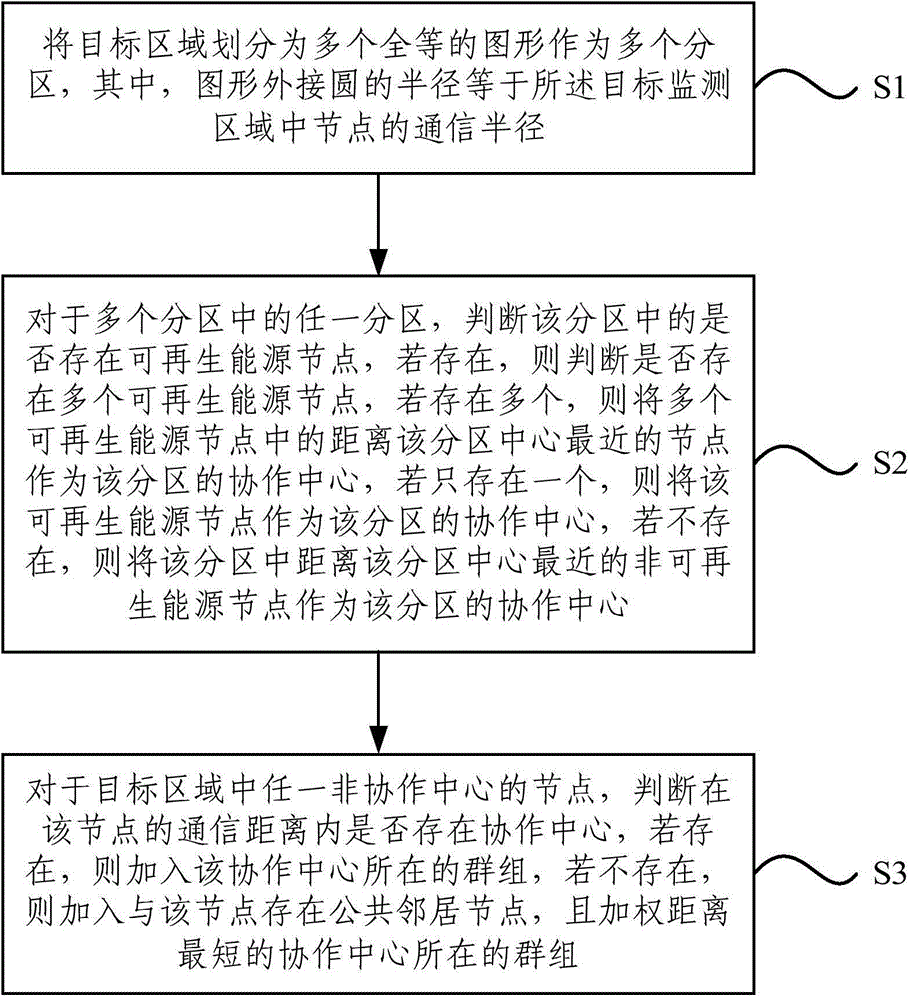

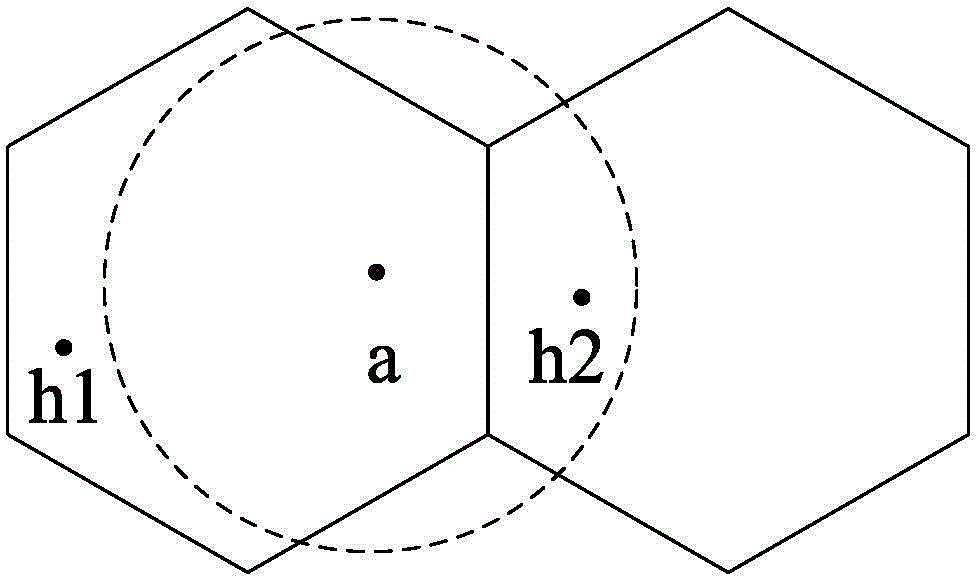

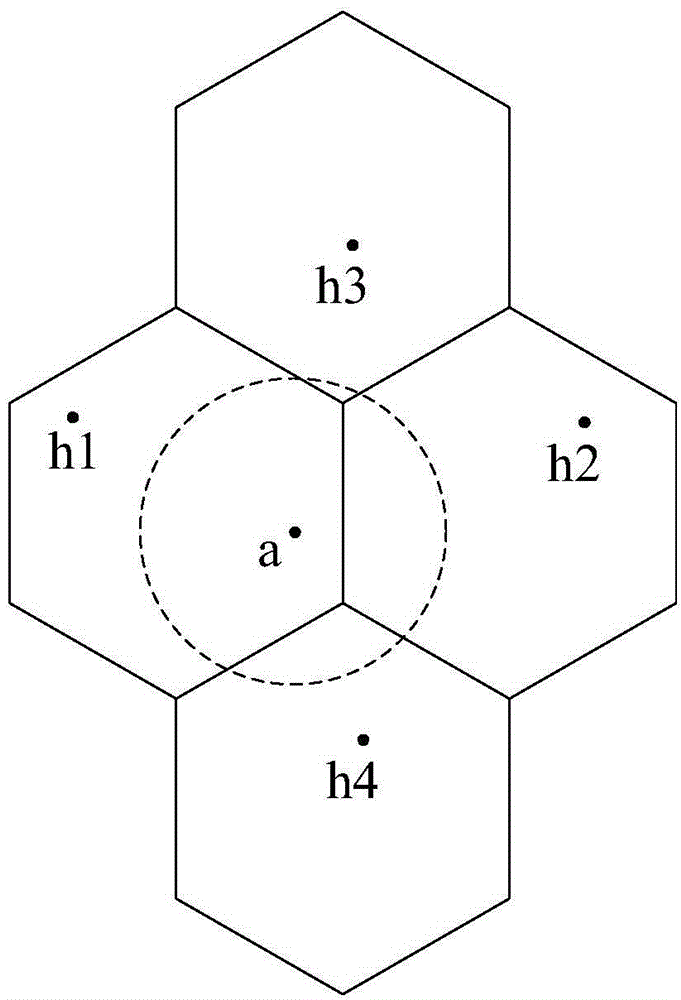

Farmland sensor network multi-antenna-array transmission subarea node energy balance dispatching method

ActiveCN104363647AExtend your lifeReduce energy consumptionPower managementLine sensorEnergy balancing

The invention relates to a farmland sensor network multi-antenna-array transmission subarea node energy balance dispatching method. The farmland sensor network multi-antenna-array transmission subarea node energy balance dispatching method comprises the steps that a target monitored area is divided into multiple congruent figures to be used as multiple subareas; the collaborative center of each subarea is selected according to the types of nodes in the subarea and the distances between the nodes and the center of the subarea; other non-collaborative centers are added to the collaborative centers according to the positions, energy and other factors, so that multiple groups are formed; the data forwarding paths are selected between the groups according to the energy and position conditions of the collaborative centers; in each group, energy consumption balance is achieved by adopting a method for alternation of the collaborative centers in blocks, a method for multiple-node collaborative data transmission and other methods. By the adoption of the farmland sensor network multi-antenna-array transmission subarea node energy balance dispatching method, in a hybrid power supply wireless sensor network considering the energy demand and the cost demand, limited energy of non-renewable energy nodes are saved and equalized, and the effects of efficiently utilizing renewable energy and prolonging the service life of the network are achieved.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

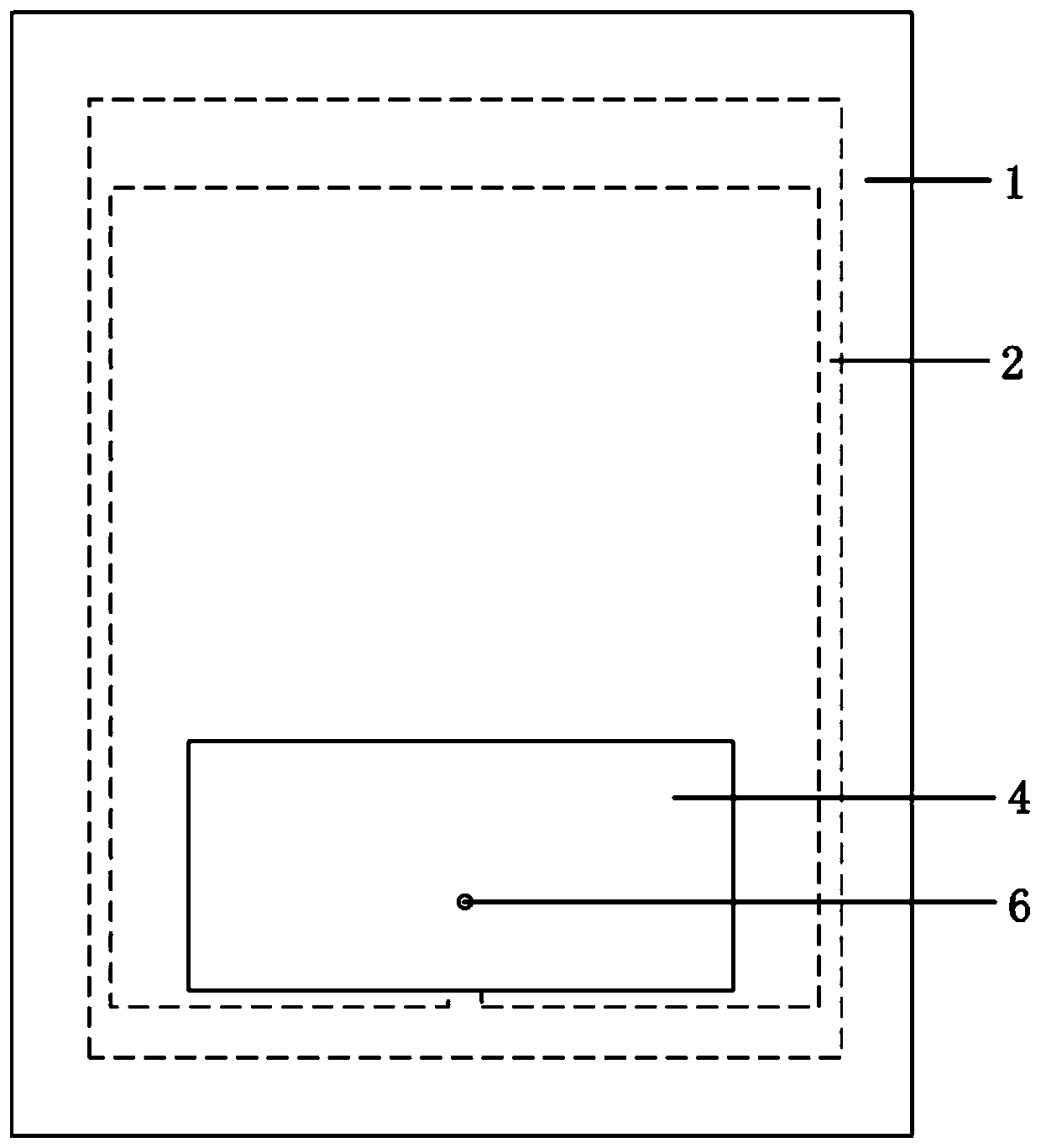

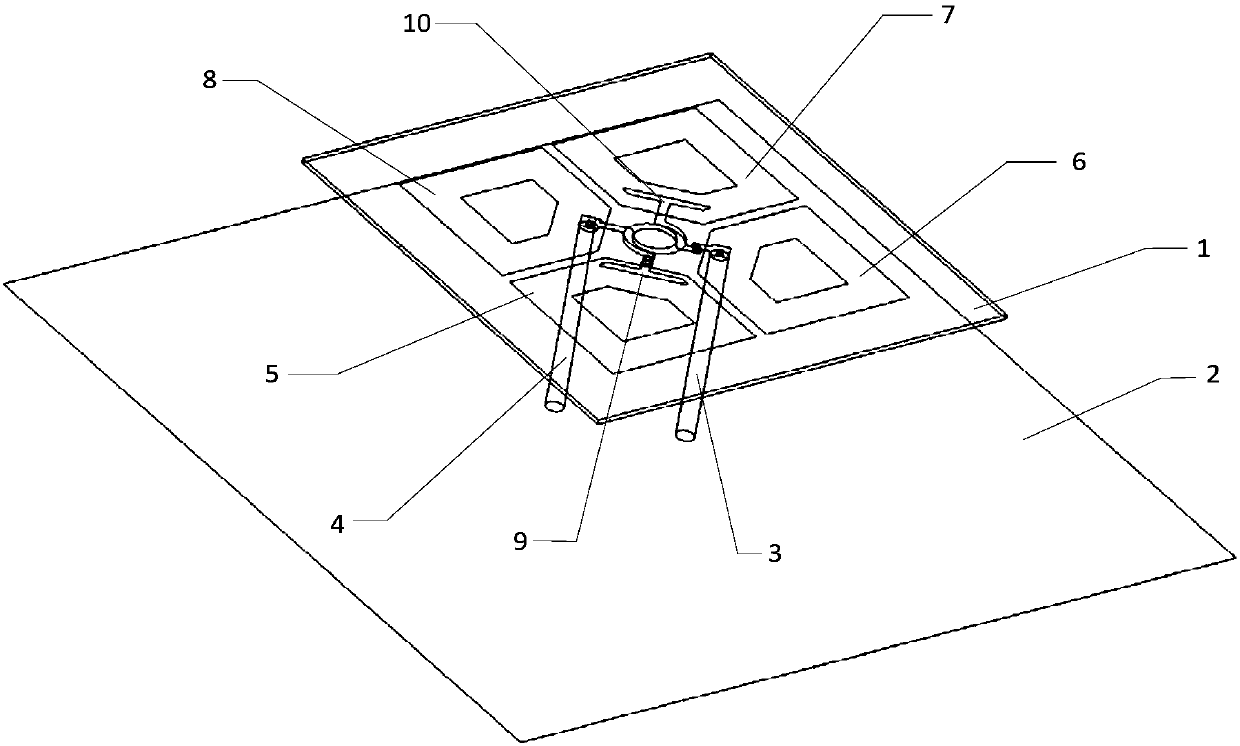

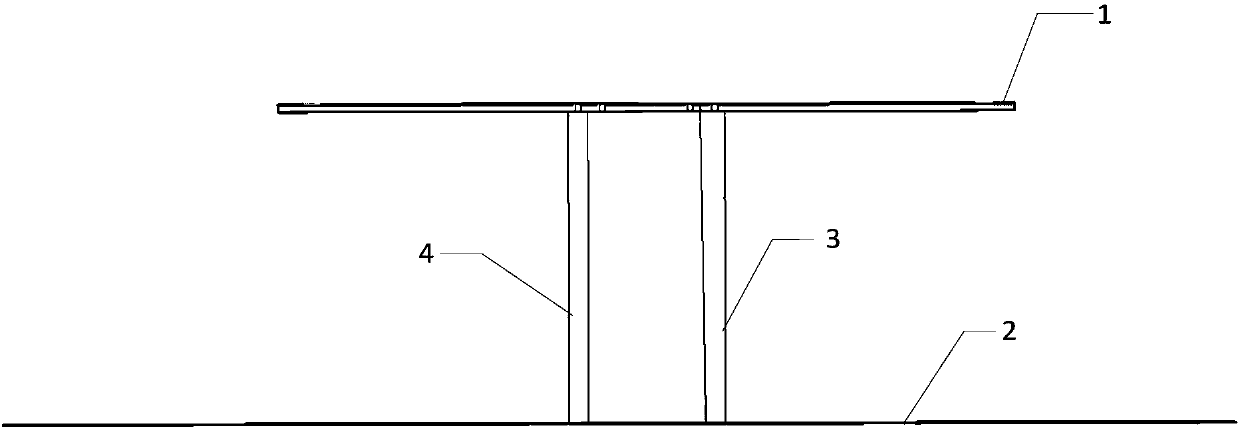

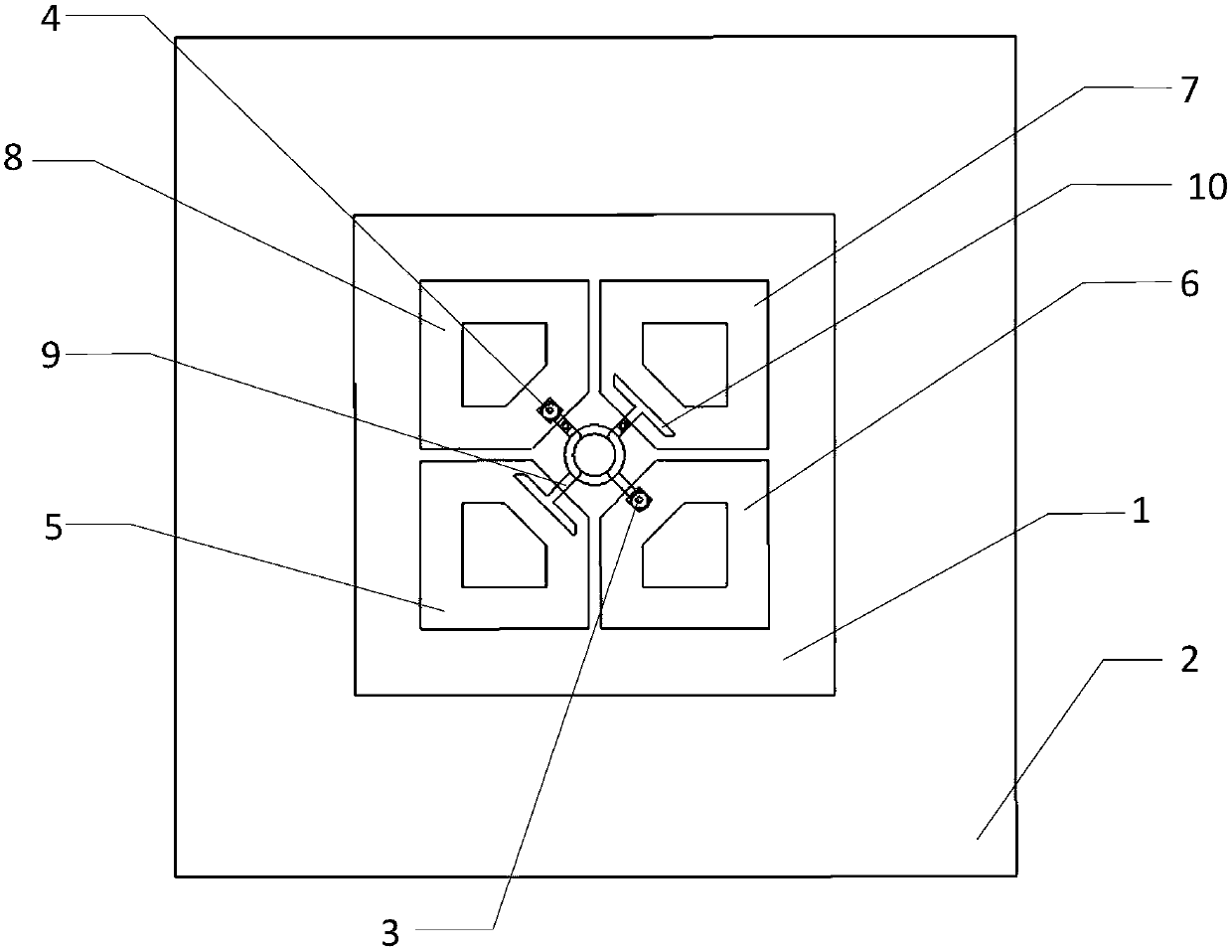

Differential circularly polarized directional antenna

PendingCN107611586AGood Common Mode RejectionImprove performanceRadiating elements structural formsAntennas earthing switches associationPhase shiftedPhysics

The invention discloses a differential circularly polarized directional antenna, which comprises a dielectric substrate, a floor located at the lower part of the dielectric substrate, a first coaxialline and a second coaxial line, wherein the first coaxial line and the second coaxial line are parallel to each other; the dielectric substrate is provided with two 90-degree phase-shift patches and four radiation patches; the four radiation patches are sequentially arranged on the lower surface of the dielectric substrate around the center of the dielectric substrate and are in mirror symmetry; inner conductors at the upper ends of the first coaxial line and the second coaxial line are connected with the two 90-degree phase-shift patches separately and outer conductors are connected with tworadiation patches arranged at opposite angles separately; and the lower ends of the first coaxial line and the second coaxial line pass through the floor. The differential circularly polarized directional antenna is provided with two pairs of dipoles, has a circular polarization characteristic and a difference characteristic, has relatively large impedance bandwidth and axial ratio bandwidth and relatively large gain and can meet the requirements of an LTE mobile phone base station antenna applied to a broadband high-speed wireless communication system of 1.61-2.8GHz.

Owner:SOUTH CHINA UNIV OF TECH

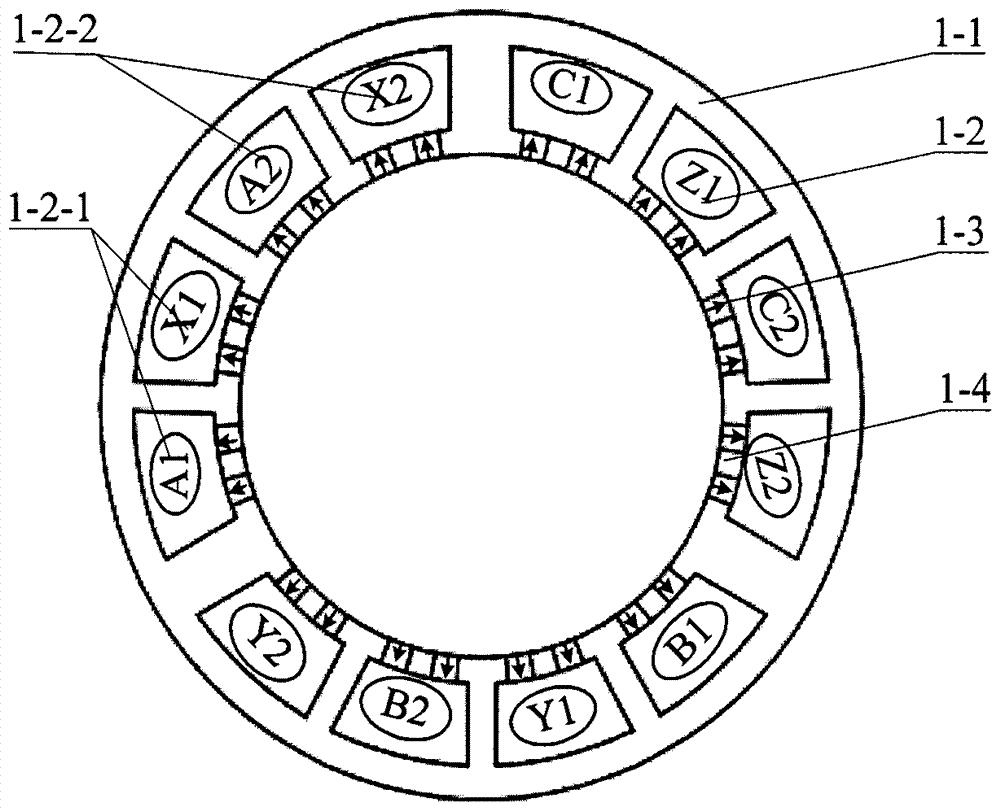

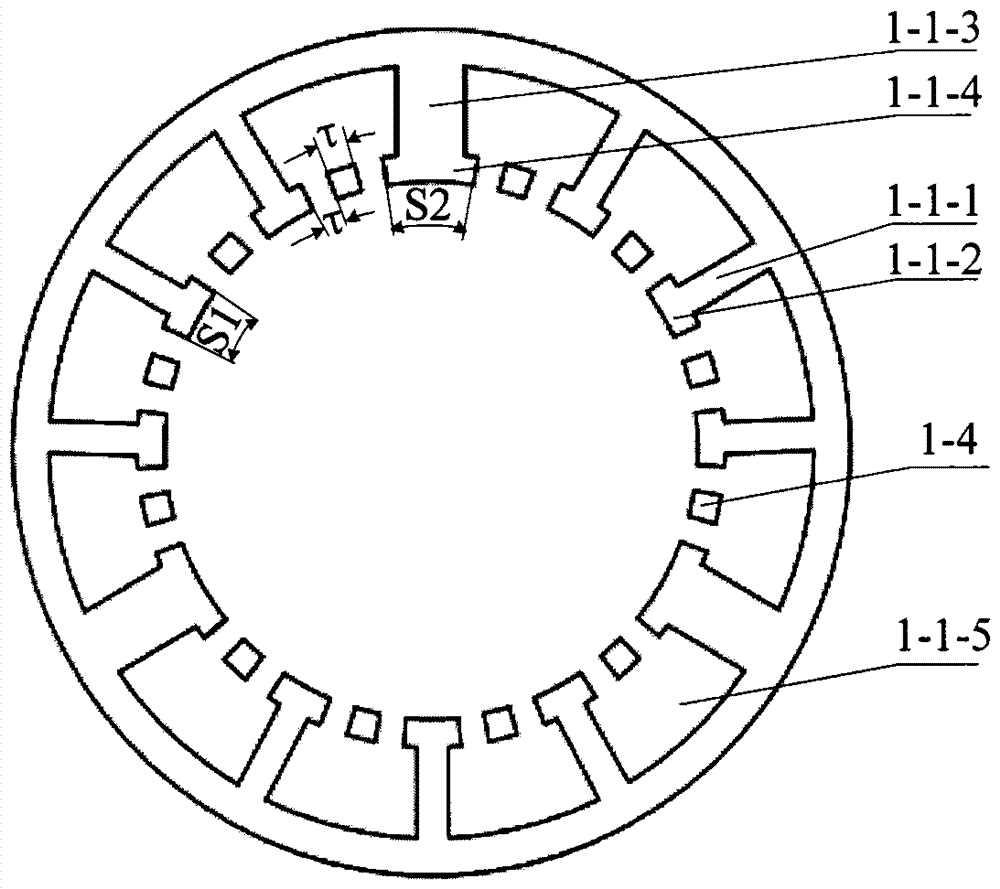

Winding modular permanent-magnet motor

ActiveCN107359712AIncrease profitShorten the lengthMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetizationTorque density

The invention provides a winding modular permanent-magnet motor. The winding modular permanent-magnet motor comprises a stator, a rotor and air gaps, wherein the stator comprises a stator core, armature windings, permanent magnets and magnetic conduction small teeth, large grooves are formed in the stator core, the permanent magnets and the magnetic conduction small teeth are arranged at groove openings facing the air gaps, the arc lengths of the permanent magnets and the magnetic conduction small teeth both are Pi, the magnetization direction of the permanent magnets are same, a positive winding and a negative winding of a single effective coil of each phase are arranged in two adjacent large grooves, N coils in the same phase are sequentially wound around adjacent 2N large grooves according to a single coil winding method, teeth among the grooves where the same phase winding is located are first teeth, teeth among different phase windings are second teeth, the rotor comprises rotor cores and gaps, the arc length distance between adjacent rotor cores is 2Pi, and an air gap is formed between the stator and the rotor. The motor employs a same-phase winding modular structure design, the winding structure is simplified, the length of an end part of the winding is shortened, the winding utilization ratio is improved, and the torque density is improved.

Owner:北京华晖恒泰能源科技有限公司

Wideband filtering slot antenna and wireless communication equipment

ActiveCN108847528AMeet application requirementsBandwidthSimultaneous aerial operationsRadiating elements structural formsDielectric substrateTwo step

The invention discloses a wideband filtering slot antenna and wireless communication equipment. The antenna comprises a dielectric substrate, a microstrip feeder, a floor, two stepped impedance filterbranches and two parasitic patches, wherein the microstrip feeder and the two stepped impedance filter branches are all arranged on an upper surface of the dielectric substrate, the two stepped impedance filter branches are symmetric about the microstrip line and are respectively connected with two sides of the microstrip feeder, the floor is arranged on a lower surface of the dielectric substrate, a dumbbell-shaped gap is etched in the floor, the two parasitic patches are symmetrically arranged at two end groove gaps of the dumbbell-shaped gap, and the wireless communication equipment comprises the antenna. The wideband filtering slot antenna has filtering characteristics, is easy to process, is simple in structure, is low in cost and wide in frequency band and can be applied to wirelesscommunication systems of ISM, Wi-MAX and 5G within a range of 2.14-4.04GHz.

Owner:SOUTH CHINA UNIV OF TECH

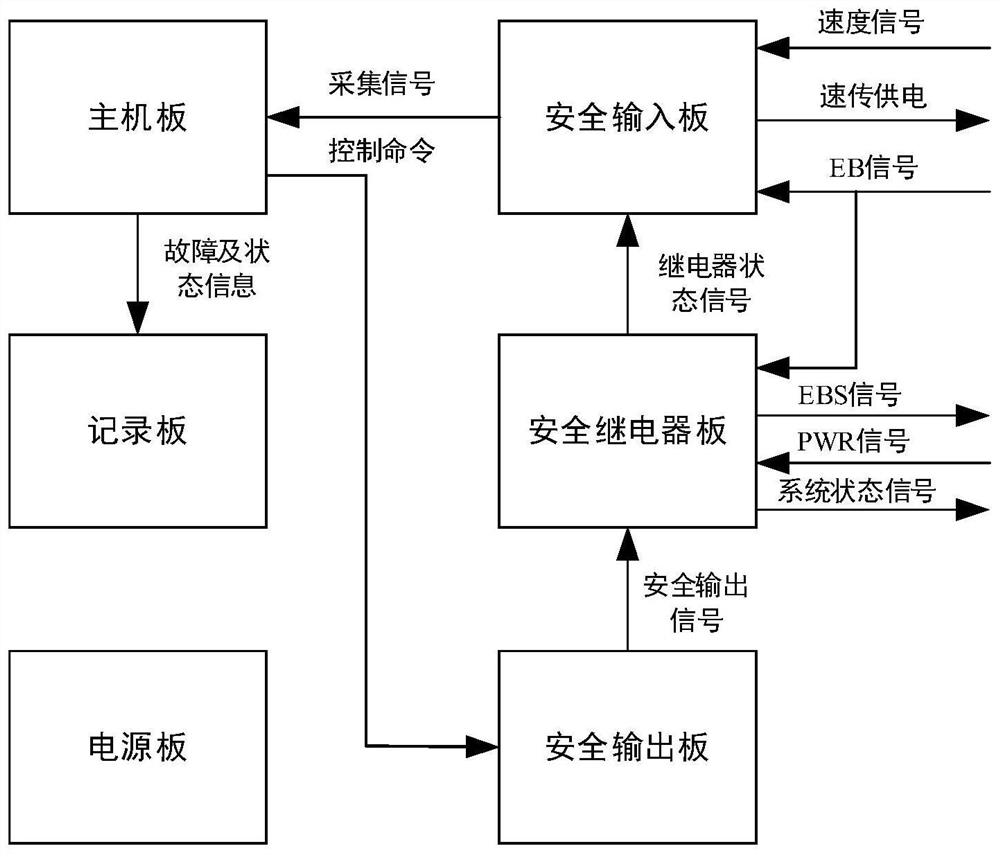

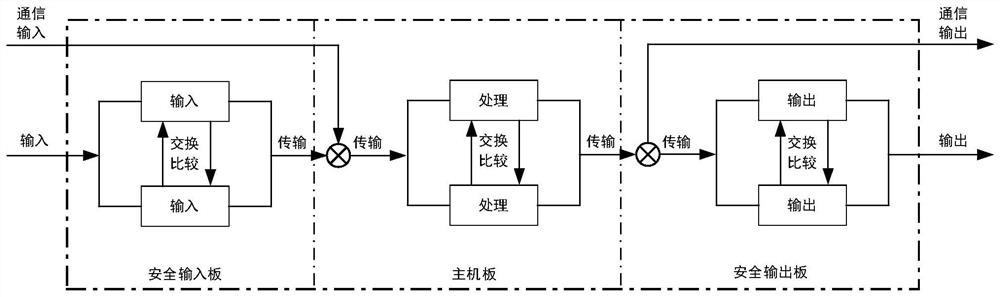

Emergency braking management system and control method thereof

ActiveCN112722012AImprove securityImprove reliabilityRail brake actuationRailway signalling and safetyEmergency brakeInternal logic

The invention provides an emergency braking management system and a control method thereof. The emergency braking management system and the control method thereof can enable the emergency braking system to effectively apply braking force and ensure that a train stops within a safe distance. The system comprises an emergency brake management device used for collecting EB loop signals of a train; wherein the signal acquisition module is connected with a train power supply line to acquire a PWR signal; acquiring a train speed signal from a speed sensor; and according to the high-low level and the speed signal of the EB loop signal, outputting an EBS signal to the I-level emergency braking unit or the II-level emergency braking unit through internal logic operation judgment so as to realize I-level emergency braking or II-level emergency braking.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

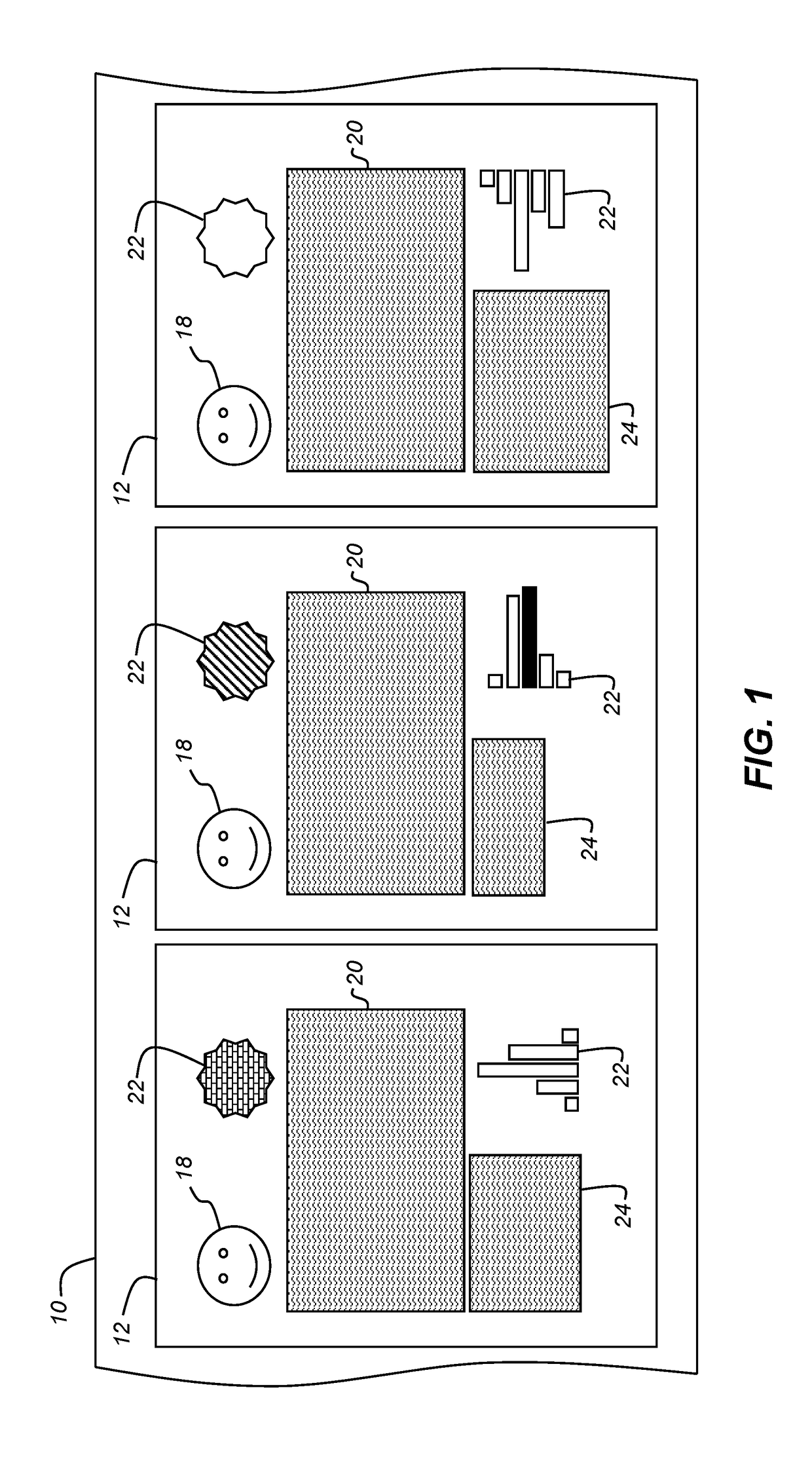

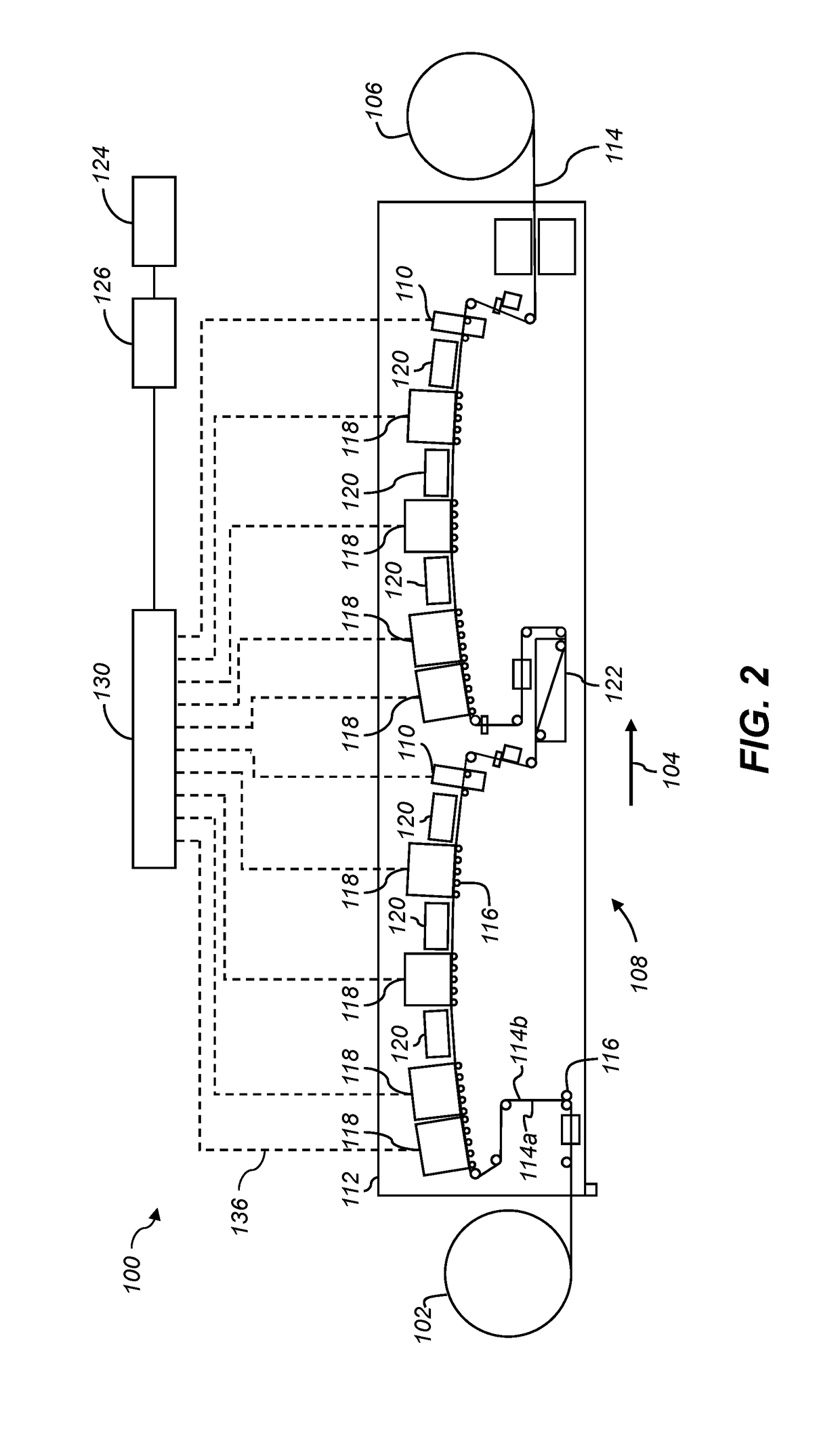

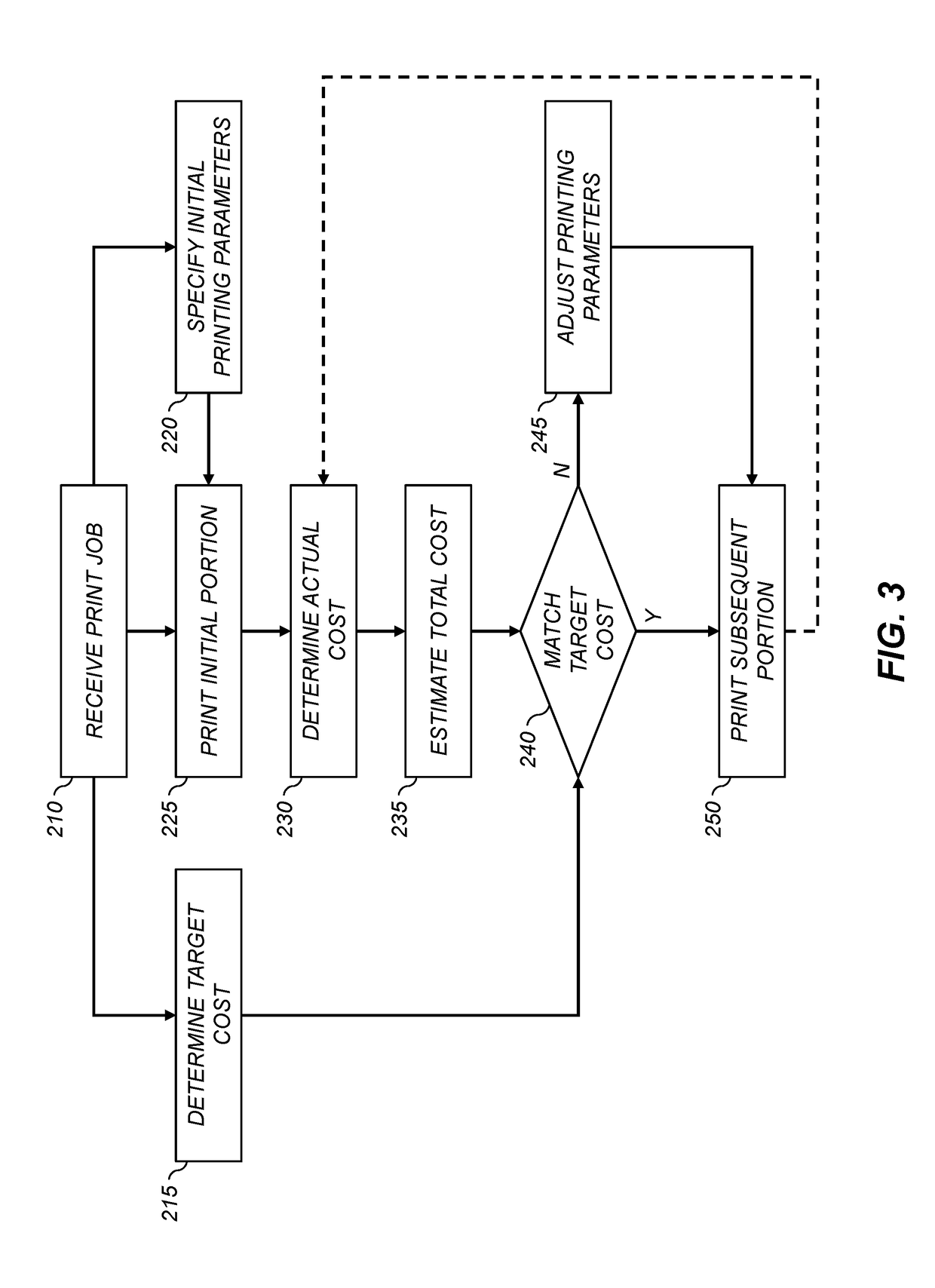

Cost-target-dependent printing using recipient demographics

ActiveUS20190050182A1Meet cost requirementsReduce printing costsMarket predictionsDigital output to print unitsDatabaseComputer science

A method for printing a print job including a plurality of document using a printing system includes receiving demographic information for document recipients associated with each of the documents. Printing parameters for each document are automatically determined such that an estimated total cost for printing the print job is not more than a predefined target cost. The printing parameters used for each document are determined responsive to analyzing the demographic information for the associated document recipient and estimated costs for printing the document using different printing parameters. Each document is printed using the respective determined printing parameters.

Owner:EASTMAN KODAK CO

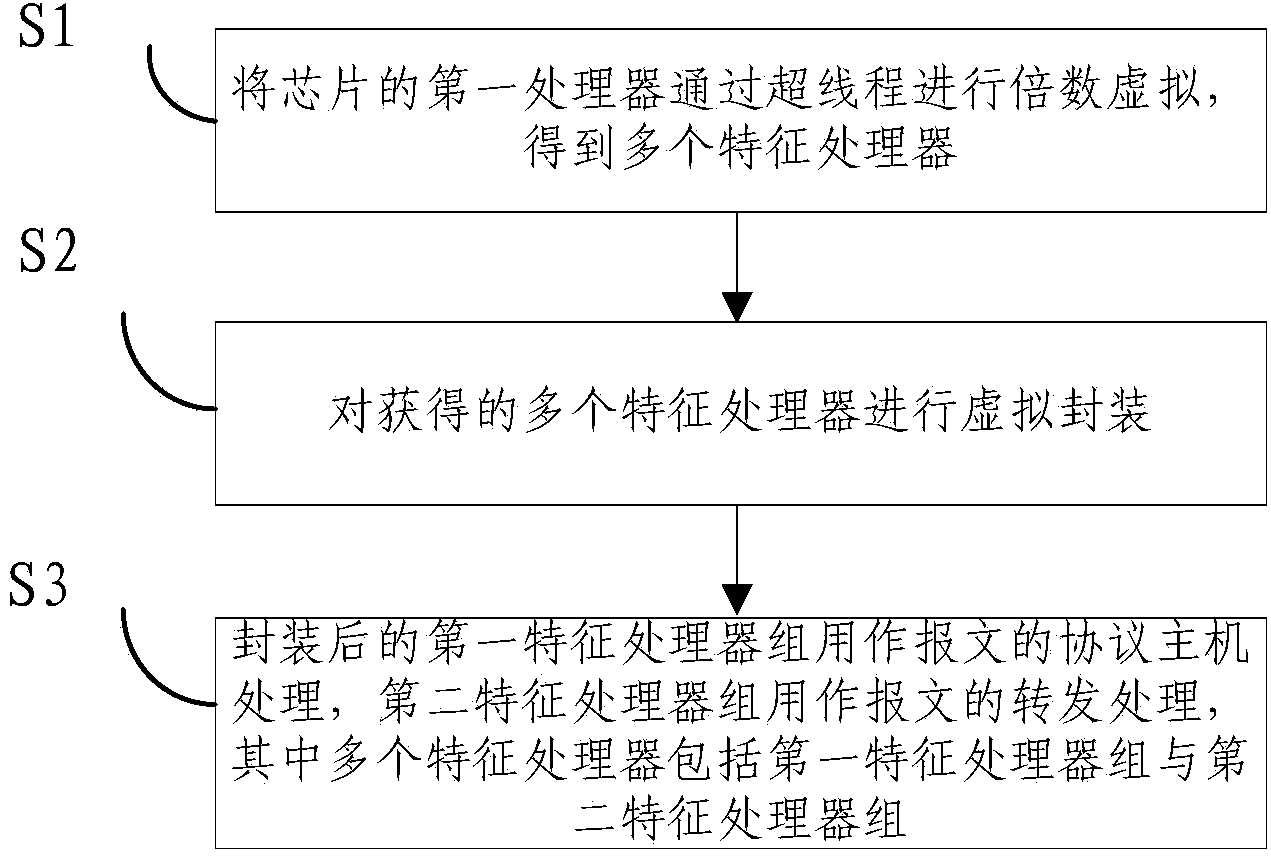

Hyper-threading based rebalancing method for equipment to process business

InactiveCN103823707AMeet cost requirementsLow costSoftware simulation/interpretation/emulationVirtualizationSoftware

The invention relates to a hyper-threading based rebalancing method for equipment to process business. The hyper-threading based rebalancing method includes the steps of S1, performing multiple virtualization on a first CPU (central processing unit) of a chip by means of hyper threading to acquire multiple feature CPUs, S2, performing virtual encapsulation on the multiple feature CPUs, S3, using a fist feature CPU group as a protocol control CPU and using a second feature CPU group as a dataplan CPU after encapsulation. To the equipment with only one CPU on a hard disk, the one CPU is virtualized into two CPUs by means of hyper threading; to software needing multiple CPUs, the CPUs on the control plane and the dataplan plane are virtualized by means of threading and are distinguished by threading; therefore, integral equipment cost is reduced, requirements for cost of low-end equipment are met, and data forwarding and processing performance of signal-core CPUs is improved.

Owner:OPZOON TECH

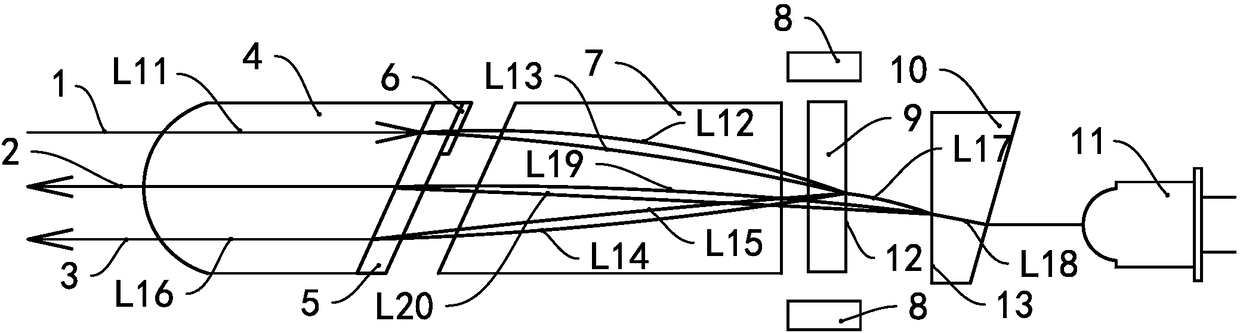

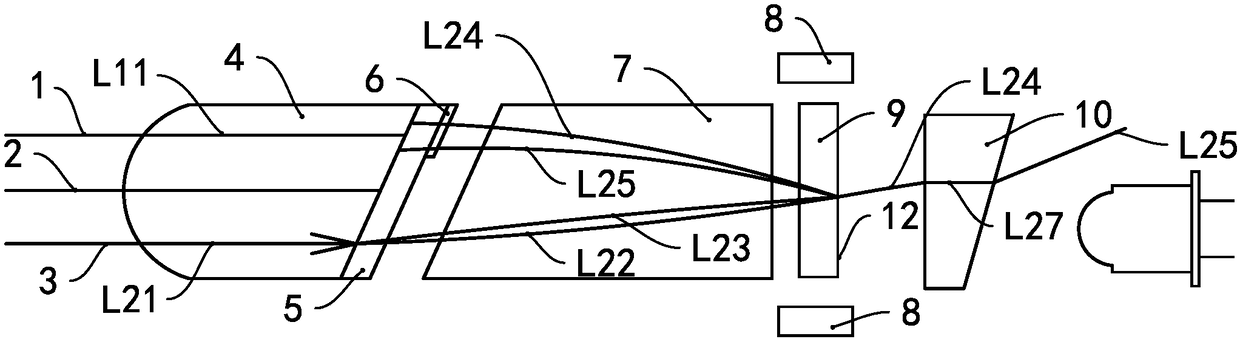

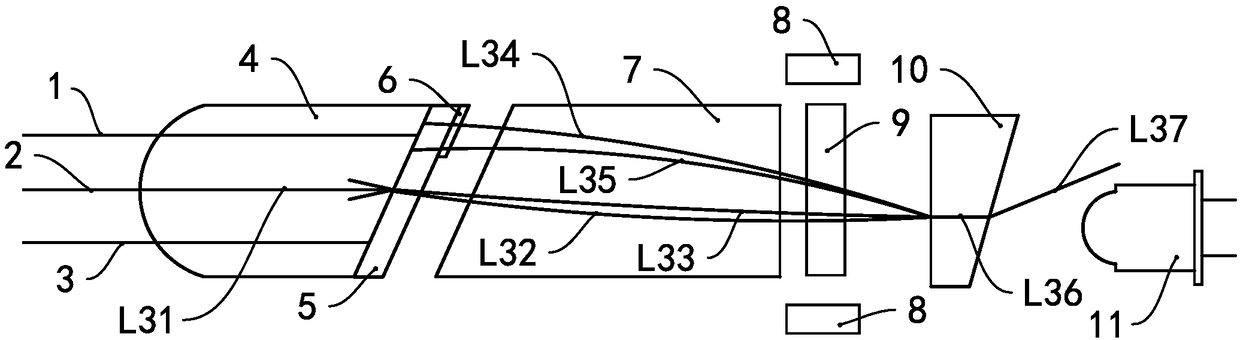

Photoelectronic device

ActiveCN108089352ASolve the problem of taking up too much space in the moduleSolve the problem of too much spaceNon-linear opticsWedge angleTransmittance

The invention provides a photoelectronic device. The photoelectronic device comprises an optical fiber head. Three optical fibers are arranged in the optical fiber head, and extend to the outside of the first end of the optical fiber head. An analyzing crystal is arranged at the second end of the optical fiber head. A half wave plate is arranged on one side, away from the optical fiber head, of the analyzing crystal. A focusing optical rotation component is arranged on one side of the second end of the optical fiber head, and comprises a self-focusing lens and a Faraday optical rotation device. A first reflecting and transmitting film is arranged on one side, away from the optical fiber head, of the focusing optical rotation component. The reflectivity of the first reflecting and transmitting film is much smaller than the transmittivity thereof. A wedge angle sheet is arranged on one side, away from the optical fiber head, of the focusing optical rotation component. A photoelectronic converter is arranged on one side, away from the focusing optical rotation component, of the wedge angle sheet. A second reflecting and transmitting film is arranged on one side, close to the focusingoptical rotation component, of the wedge angle sheet. The reflectivity of the second reflecting and transmitting film is much larger than the transmittivity thereof. The photoelectronic device has theadvantages that miniaturization of an optical mixing device can be realized, and the optical mixing device can have optical isolation and photoelectronic detection functions.

Owner:广东三石园科技有限公司

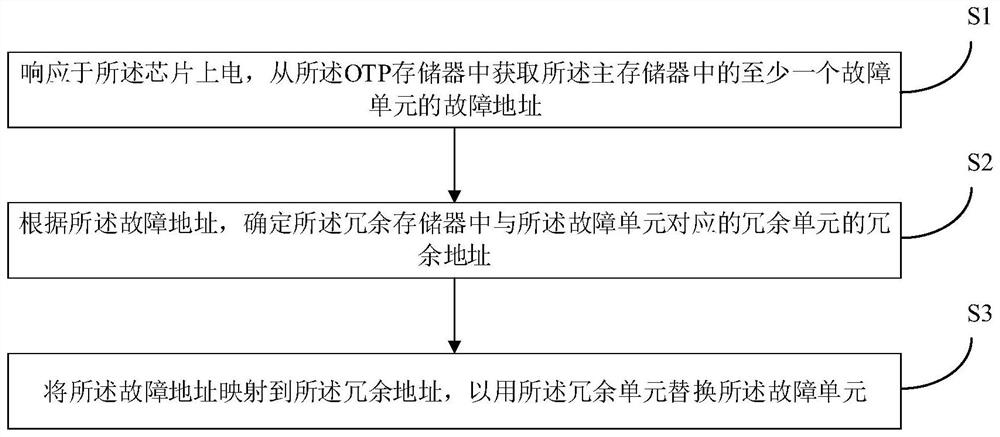

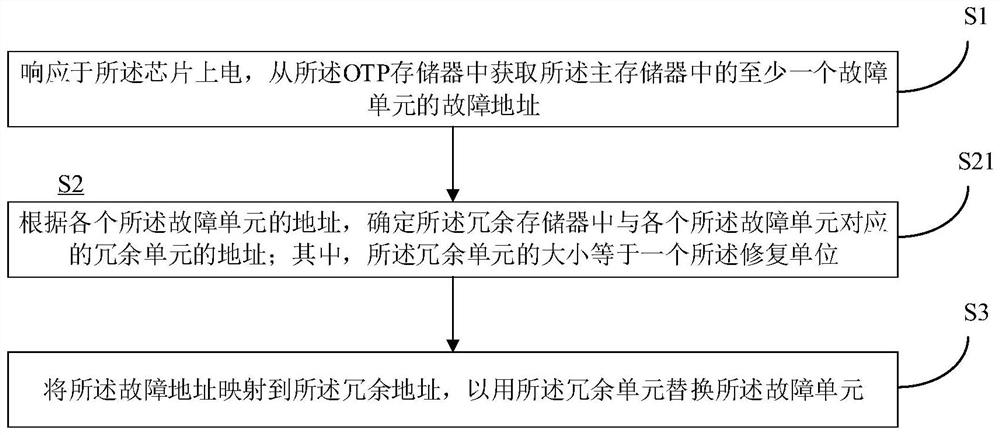

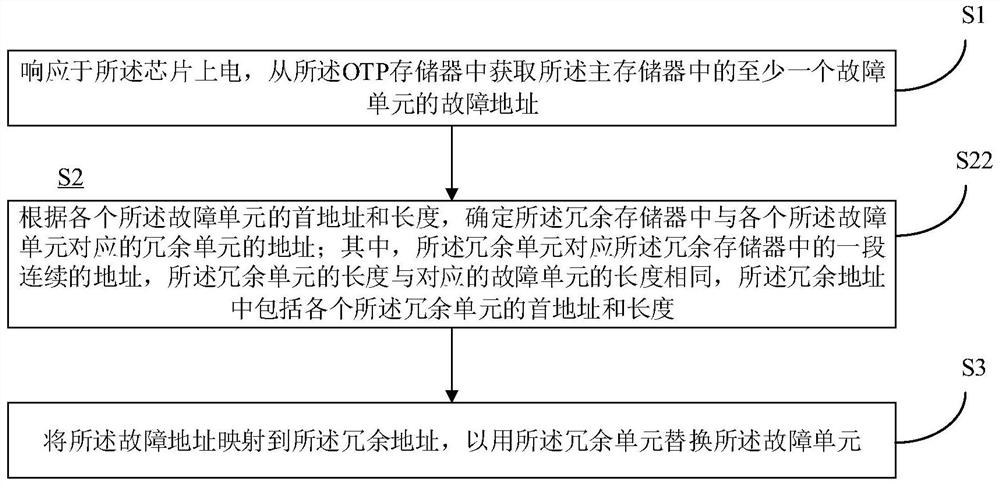

Chip repairing method, repairing device and chip

PendingCN114530189AImplements built-in self-healingImprove repair effectStatic storageComputer hardwareEmbedded system

The invention provides a chip repairing method, the chip comprises a main memory, a redundant memory and a one-time programmable OTP memory, the repairing method comprises the following steps: responding to the power-on of the chip, and obtaining a fault address of at least one fault unit in the main memory from the OTP memory; according to the fault address, determining a redundant address of a redundant unit corresponding to the fault unit in the redundant memory; and mapping the fault address to the redundant address so as to replace the fault unit with the redundant unit. The invention further provides a repairing device and a chip.

Owner:成都宏熠电子科技有限公司

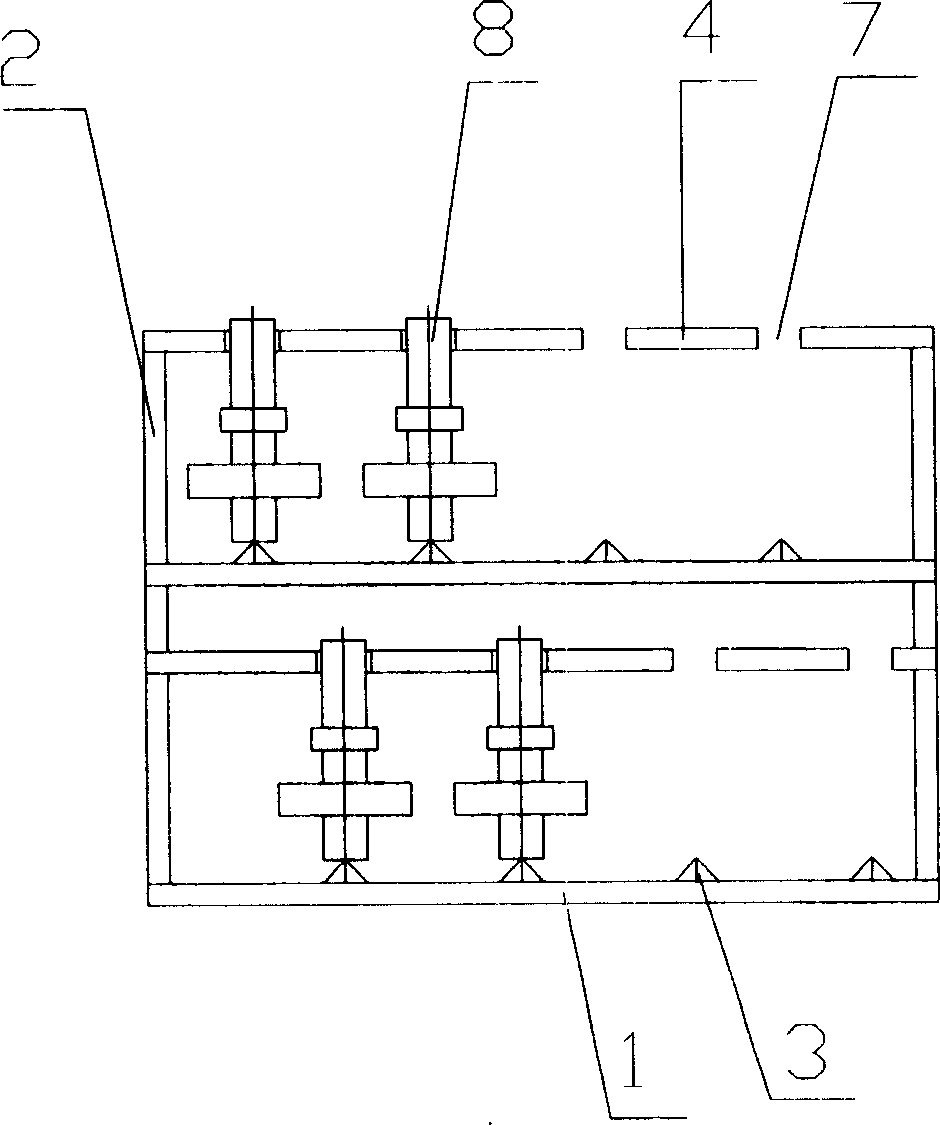

Natural light diffusion type leading-in side window system applied to snow-ice sports building

ActiveCN107503636AControl angle of incidenceAvoid visual impactUnits with parallel planesAngle of incidenceEngineering

The invention discloses a natural light diffusion type leading-in side window system applied to a snow-ice sports building and aims to solve problems of visual interferences on sportsmen and temperature influences of existing normal side windows on ice surfaces and snow surfaces in the snow-ice sports building. The natural light diffusion type leading-in side window system comprises a reflective plate frame, a reflective plate and flexible pull cables. A lower window frame on an indoor side of a side window body is hinged to a lower side frame of the reflective plate frame through hinges, the reflective plate is arranged in the reflective plate frame, an upper surface and a lower surface of the reflective plate are non-concentric arc curved surfaces, the upper surface of the reflective plate is a reflective layer, and the lower surface of the reflective plate consists of a reflective layer portion and a diffuse reflection layer portion. One end of each flexible pull cable is connected with the reflective plate frame, and the other end of each flexible pull cable is connected to the window frame of the side window body. A light incidence angle is effectively controlled while natural light is led in, diffusion type illumination in an upper space of a stadium is formed by reflection, and damages caused by heat of natural light to the ice surfaces are avoided.

Owner:BUILDING DESIGN RES INST HARBIN INST OF TECH

Quenching for material rack by high pressure gas

A workpiece supporting frame for high-pressure gas quenching is composed of supporting plate, supporting rod, supporting needles and shelves, which are connected together by spiral threads to form a multi-layer frame. Some additional elements are used for special workpieces, such as axle, disk, etc. Its advantage is high efficiency of heat treatment.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com