Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Meet modern requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

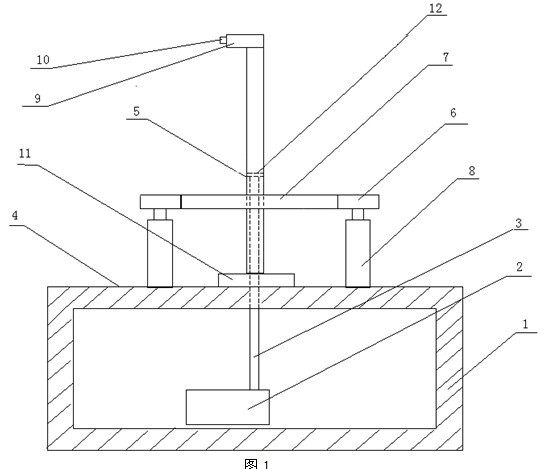

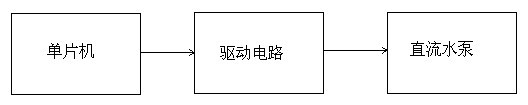

Controllable spraying device

InactiveCN101972721AEven and efficient sprayingFulfil requirementsMovable spraying apparatusMicrocontrollerEnvironmental resistance

The invention discloses a controllable spraying device which comprises a water tank, a direct current water pump, a connecting water pipe, a rotating water pipe, a needle cylinder type piston, a spray head, a rotating drive device, a drive circuit and a controller. The voltage of the direct current water pump is controlled by using a preset spraying distance to ensure that water sprayed out of the spray head only covers the preset range. By depending on the control of a singlechip, the regularization of a water spraying track is intelligently completed, the function of whole water spraying is automatically completed, thus the effects of fully efficiently utilizing water resources and saving water as well as protecting the environment are achieved. The invention can meet the requirement for spraying water drops on various fields of gardens, greenbelts, vegetables and fruits, agriculture and the like. If the spraying liquids are changed into pesticides, paints, anticorrosive paints and the like, the controllable spraying device can carry out the spraying. Irrigation requirements on different use areas can be met through the combination of a plurality of spray heads. Various shapes such as square, triangle, regular hexagon and the like can be obtained through spraying.

Owner:WUHAN UNIV

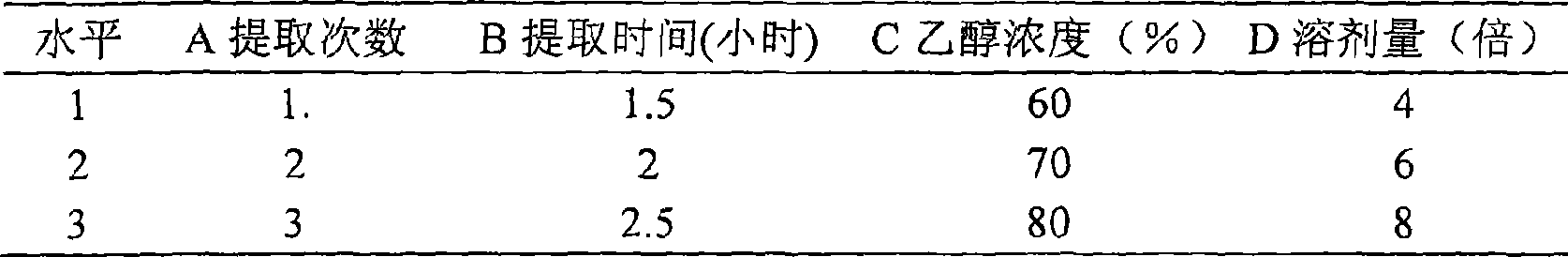

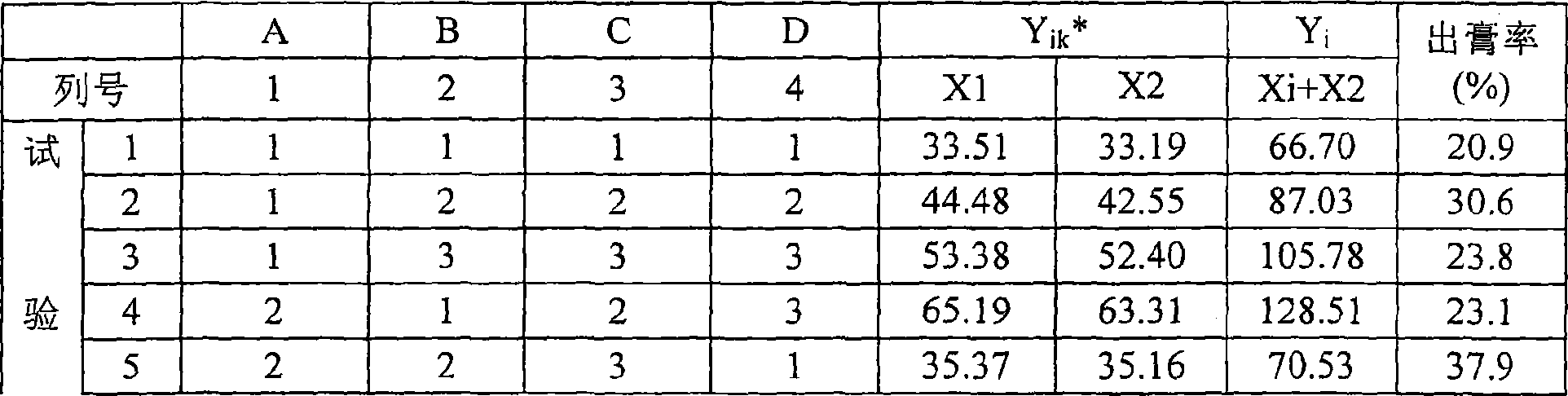

Process for extracting and purifying flavonoids in grosvener siraitia plants

InactiveCN102138958ANo pollution in the processLow priceMetabolism disorderAntinoxious agentsEnvironmental engineeringSiraitia

The invention relates to the technical field of the extraction and purification of flavonoids in medicinal plants, in particular to a process for extracting and purifying flavonoids in grosvener siraitia plants. In the process, ethanol is used as extracting solvent, and extracting solution is purified by macroporous adsorbent resin. The process is characterized by comprising the following steps of: drying, chopping, performing reflux extraction by using the ethanol, filtering, concentrating, adsorbing by using a column, eluting by using water, eluting by using the ethanol, concentrating and drying, dissolving by using the ethanol, filtering, and concentrating and drying. The process has a simple flow, effective substances are high in content, the production cost can be reduced, energy can be saved, and environmental pollution can be controlled.

Owner:湖北汇特生物医药技术有限公司

Method for separating purified seabuckthorn flavonoid from large berry seabuckthorn marc

InactiveCN102579516AHigh purityMeet modern requirementsAntipyreticMetabolism disorderPurification methodsDrug biological activity

A method for separating purified seabuckthorn flavonoid from large berry seabuckthorn marc. The invention relates to a method for separating purified seabuckthorn flvonoid from large berry seabuckthorn marc. The invention solves the problems in the existing separation and purification method of seabuckthorn flavonoid, such as tedious method, complicated techniques, high cost of separation and purification, easy damage to the activity of flavonoid and low purity of flavonoid. The method for separating purified seabuckthorn flavonoid from large berry seabuckthorn marc disclosed by the invention comprises the following steps: first, degreasing the raw materials; second, ultrasonic wave extracting and centrifugating; third, adding metal salt to extracting solution to lead complex reaction between flavonoid and metal, agitating, tempering the pH of solution and collecting sediment; and fourth, adding decomplexing additive to resolve sediment, concentrating in a decompressing way to dryness, using ethanol to dissolve and filter, concentrating filtrate, and obtaining the separated and purified seabuckthorn flavonoid powder after drying. The method for separating purified seabuckthorn flavonoid from large berry seabuckthorn marc disclosed by the invention can ensure the full improvement of the purity of the purified seabuckthorn flavonoid, and maintains the original biological activity of the natural flavonoid, the seabuckthorn flavonoi is safe and nontoxic, and the method disclosed by the invention has the advantages of low production cost and simple process, and is suitable for the large-scale production of the seabuckthorn flavonoid.

Owner:QIQIHAR UNIVERSITY

Chinese medicament for treating gastrosis and preparation method thereof

ActiveCN101940743AMeet modern requirementsImprove immunity against diseaseAnthropod material medical ingredientsDigestive systemCurative effectGastric mucosa

The invention relates to a Chinese medicament for treating gastrosis and a preparation method thereof. The Chinese medicament comprises the following medicaments in part by weight: 45 parts of rhizoma atractylodis macrocephalae, 45 parts of bletilla, 20 parts of astragals, 10 parts of hawthorn fruit, 10 parts of radish seed, 15 parts of chicken's gizzard-membrane, 15 parts of medicated leaven, 10 parts of malt, 20 parts of Indian buead, 30 parts of Mongolian dandelion herb, 20 parts of sea-buckthorn and 30 parts of propolis. The Chinese medicament of the invention has the main effect of protecting the gastric mucosa and restoring all functions of the gastric mucosa as soon as possible, and also has the effects of killing pathogenic bacteria, regulating the spleen and stomach, enhancing the anti-disease immune capability and the like; in addition, the Chinese medicament also has the advantages of high long-term taking safety, no toxic or side effect, high-quality materials, rational combination, scientific preparation, obvious curative effect, safety and reliability, stable quality and quick taking, and meets the modern requirements of Chinese medicinal preparations.

Owner:YANTAI MEISHILIN SHENGWU KEJI

Jaboticaba red wine

The invention belongs to the technical field of wine brewing technology, and particularly relates to jaboticaba red wine. Traditional wine is brewed with grapes; however, grapes has light fruity taste which becomes insufficient due to loss in brewing process; the addition of other fruits for brewing may cover the elegant taste of grapes. The inventor finds jaboticaba which originates in Brazil primitive rainforest, has similar forms, colors, and fruity taste to claret grapes, but has heavier fruity taste, is rich in carbohydrate and anthocyanidin; when jaboticaba is mixed and brewed with grapes, jaboticaba red wine can be prepared by a set of brewing method without sulfur addition; the wine has a violet red color, pure flavor, and pleasant fruity taste; the wine body is complete and full, and exhibits more fruity taste than traditional red wine; the brewing method of the invention is suitable for factory production.

Owner:泰州市大润机械有限公司

Method for comprehensively developing and applying poria cocos and new application of poria cocos

InactiveCN105639617ANo pollution in the processMeet modern requirementsCosmetic preparationsToilet preparationsFiltrationSodium hydroxide

The invention relates to a method for comprehensively developing and applying poria cocos and a new application of the poria cocos. The method mainly comprises the following steps: smashing poria cocos sclerotium, adding water for soaking, performing reflux extraction and filtering, and concentrating and drying an extracting solution to obtain water-soluble pachymaran; performing extraction and suction filtration on a filter residue sodium hydroxide solution, washing filter residues with water to a neutral state to prepare dietary fiber, adjusting the pH value of filtrate to a weakly acidic state, filtering and drying to obtain a mixture of total triterpene of poria and alkali-soluble pachymaran, drying the mixture, adding the mixture into an ethanol aqueous solution, solving and filtering to obtain an alcoholic solution of the total triterpene of poria and an alkali-soluble pachymaran solid; washing the alkali-soluble pachymaran with water and drying; concentrating and drying the alcoholic solution of the total triterpene of poria to obtain total triterpene of poria. By adopting the method, the utilization rate of a poria cocos serving as a medicinal material is increased, and the comprehensive development and application values of the poria cocos on the aspects of medicine, foods, cosmetics and the like are increased.

Owner:HUNAN NUOZ BIOLOGICAL TECH CO LTD

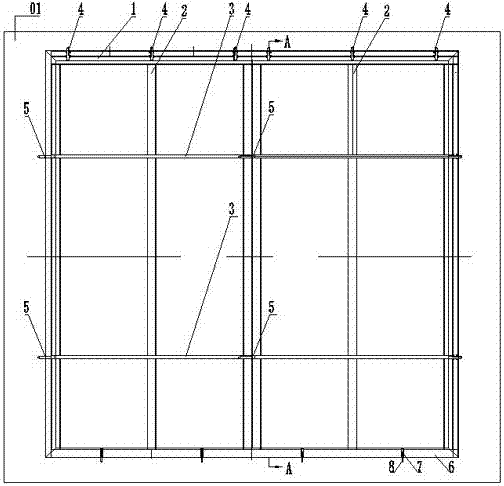

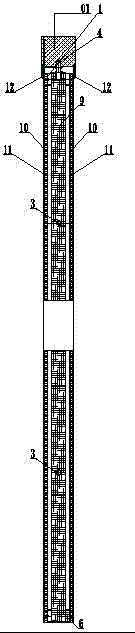

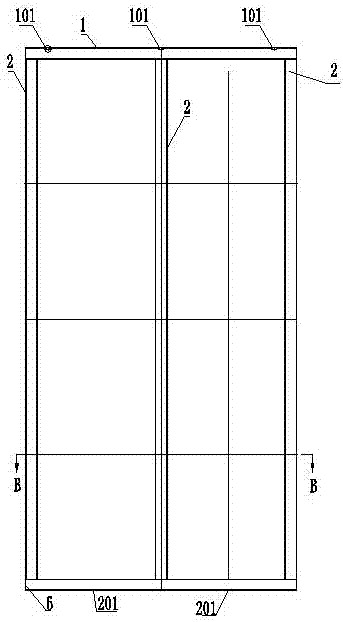

Frame spinning plug-in type integrated inner partition wall plate and installation method thereof

The invention discloses a frame spinning plug-in type integrated inner partition wall plate. The plate is composed of a steel frame, an inner insulation layer, a base layer plate, a surface layer plate, a decorative plate and a frame decoration strip. The steel frame comprises an upper crosspiece, a lower crosspiece, a vertical brace, a horizontal brace tube, a spinning screw pin, a fixing pin, a guide sleeve and a movable pin. The upper crosspiece and the lower crosspiece are vertically connected with the vertical brace. The upper crosspiece is provided with a flanged hole. The vertical brace is provided with a through hole. The horizontal brace tube is fixedly connected with the vertical brace after penetrating through the through hole of the vertical brace. The guide sleeve is vertically connected with the lower crosspiece after penetrating through a through hole of the lower crosspiece. The fixing pin and the through hole of the vertical brace are fixed vertically. The spinning screw pin comprises a screw rod. The screw rod is sleeved with a fixed nut and a movable nut. The fixed nut and the middle of the screw rod are fixedly connected. The frame spinning plug-in type integrated inner partition wall plate has the advantages of being light, thin, high in expressive force, stain-resistant and self-cleaning, A-level fireproofing, anti-knock and anti-cracking, anti-freeze-thaw, acid and alkali resistant, recyclable in using, and low in construction cost.

Owner:NANTONG CHENGYUE DECORATION GRP

Chinese medicine solid preparation for treating climacteric syndrome and preparation method thereof

ActiveCN101461898AReduced consumption of crude drugsProduction mechanizationPowder deliveryPill deliveryAdemetionineRhizome

The invention provides traditional Chinese medicine solid preparation for treating climacteric syndrome, which comprises traditional Chinese medicine components and medicine accessories. The traditional Chinese medicine components consist of the following raw materials by weight portion: 3 portions of glossy privet fruit, 2 portions of raspberry, 2 portions of dodder, 2 portions of medlar, 2 portions of fleece-flower root, 1.5 portions of tortoise shell, 3 portions of cortex lycii radicis, 2 portions of ladybell root, 2 portions of dwarf lilyturf turber, 1 portion of seed of wild jujube, 3 portions of rehmannia, 6 portions of white paeony root, 3 portions of red paeony root, 2 portions of angelica, 6 portions of caulis milletiae, 6 portions of nacre, 3 portions of dendrobe, 3 portions of chrysanthemum, 4 portions of yerbadetajo, 2 portions of mulberry leaves, 3 portions of radix cynanchi atrati, 3 portions of rhizome anemarrhenae, and 3 portions of scutellaria, wherein the fleece-flower root and the white paeony root are raw powder, and the other 21 traditional Chinese medicines are extracts obtained by extracting raw material crude drugs. The solid preparation overcomes the defect that the prior preparation has large oral dosage, and has good bioavailability.

Owner:BEIJING TONGRENTANG CO LTD

Chinese medicinal preparation for clearing heat, relieving sore-throat and stopping pain and preparation method thereof

InactiveCN101879211AIncrease contentMeet different needsHydroxy compound active ingredientsAntipyreticCurative effectMENTHOL CRYSTALS

The invention relates to the field of Chinese medicinal preparations, in particular to a Chinese medicinal preparation for clearing heat, relieving sore-throat and stopping pain and a preparation method thereof. The Chinese medicinal preparation for clearing heat, relieving sore-throat and stopping pain comprises herba sarcandrae, honeysuckle and menthol crystal in a weight ratio of 1,000-1,600:300-1,200:0-2. In the Chinese medicinal preparation, active ingredient content is increased, multiple formulations are enlarged, and different requirements of patients can be met. In the preparation method, parameters such as time, temperature and the like are improved, and the curative effect is definite and safe. The Chinese medicinal preparation combines the advantages of the conventional preparation method and modern preparation method for traditional Chinese medicaments, and meets the requirements of Outline of Development in Modernization of Chinese medicaments (2002-2010) and Outline of Plan in Innovation and Development of traditional Chinese medicine (2006-2020) on the modernization of the traditional Chinese medicaments.

Owner:阙锋

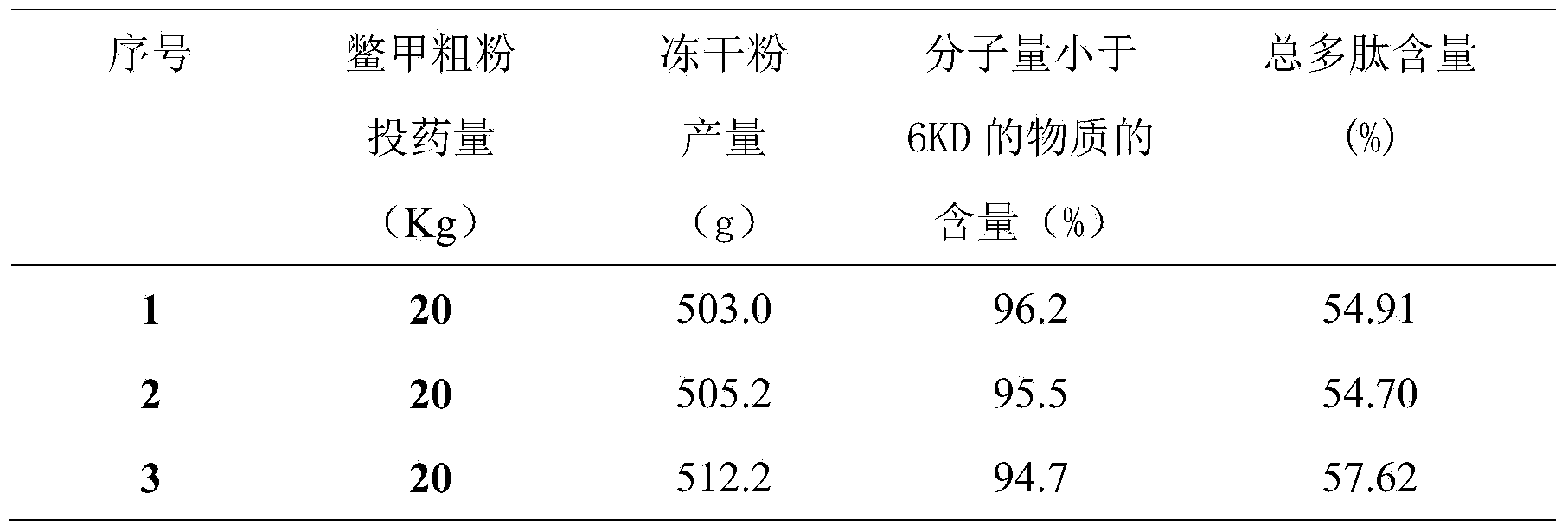

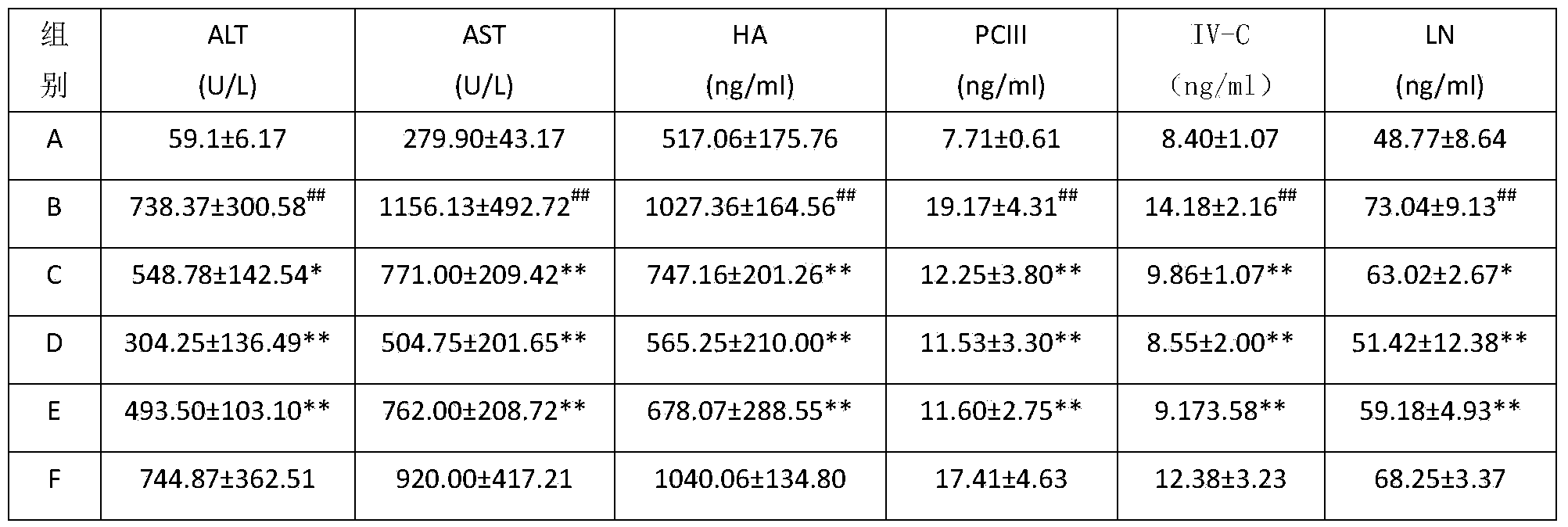

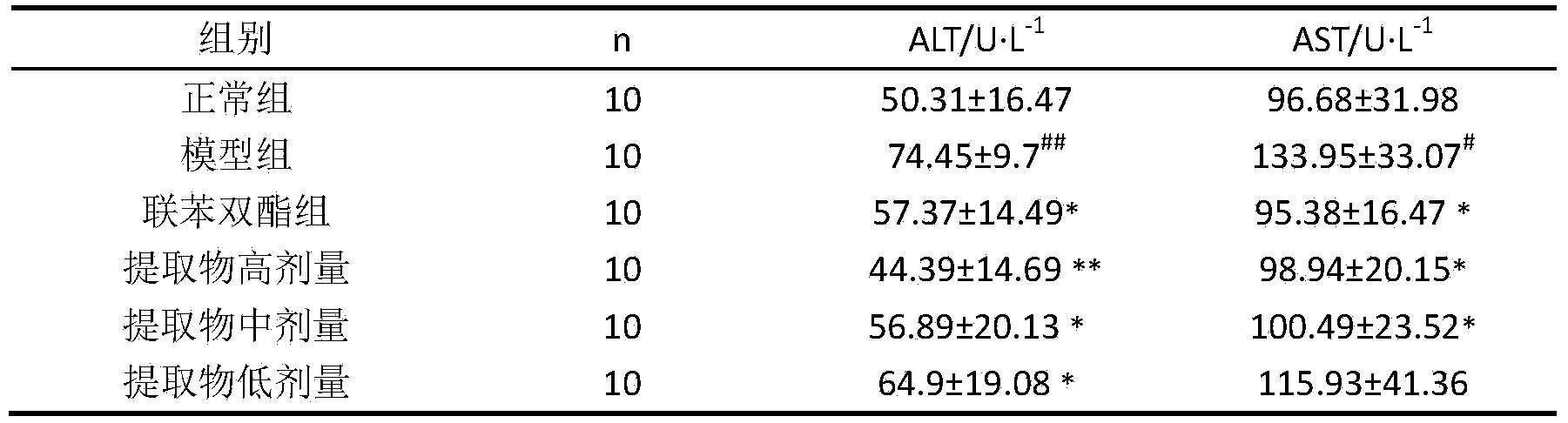

Preparation method and application of turtle shell active polypeptide extractive

ActiveCN103705907ATime consumingExtension of timePeptide/protein ingredientsDigestive systemFreeze-dryingDistilled water

The invention belongs to the technical field of preparation of traditional Chinese medicine extractives, and particularly discloses a preparation method and application of a turtle shell active polypeptide extractive. The preparation method particularly comprises the following steps of decocting a turtle shell by using water for extraction; diluting an extracting solution by using distilled water till the concentration corresponding to contain 4-8 g / 100 mL of turtle shell medicinal materials; respectively carrying out microfiltration and multistage ultrafiltration to obtain ultrafiltrate, carrying out vacuum concentration, and freeze-drying to obtain freeze-dried powder with molecular weight less than 6 KD. The preparation method disclosed by the invention can be used for preparing the active polypeptide substance part of the turtle shell by adopting a multistage membrane separation method, and can transit to industrialization on process parameters through a pilot scale test; the prepared turtle shell active polypeptide extractive has a liver protection effect and can be used for preparing a drug or health-care food used for preventing or treating liver fibrosis and alcoholic liver injury.

Owner:HUBEI UNIV OF CHINESE MEDICINE

Danshan fat reducing granules and preparation method thereof

InactiveCN103316106AMeet modern requirementsGood treatment effectDigestive systemGranular deliveryAdhesiveMedicine

The invention relates to Danshan fat reducing granules and a preparation method thereof. The Danshan fat reducing granules is prepared by three kinds of traditional Chinese medicines of red sage root, fried cassia seed and haw in a mass proportion of 4:3:2. The preparation method comprises the following steps of: (1) weighting Danshan fat reducing granule medicinal material decoction pieces of twice of a prescription amount, adding water with weight ten times of that of the medicinal materials, boiling and extracting three times and 1h per time; (2) after the step (1), filtrating with 100-300-mesh filter cloth, to obtain filtrate; (3) condensing the filtrate by pressure reduction at 50-70 DEG C, and drying by pressure reduction to obtain dried paste powder; (4) mixing the obtained dried paste powder and medicinal dextrin in a mass proportion of 1:1, pelletizing by using ethanol as an adhesive, drying at 50-70 DEG C, straightening granules, and packaging, to obtain the Danshan fat reducing granules. Yield of the Danshan fat reducing granules by the method can reach 96%, and the method can be used for industrialization production. The Danshan fat reducing granules can be used as a medicine for treating a non-alcoholic fatty liver disease.

Owner:湖北省中医院

Granular preparation of daphniphyllum-polygonum, application and preparation method thereof

InactiveCN101549019AImprove yieldUniform particle sizeDigestive systemGranular deliveryPatient complianceDisease

The invention provides a granular preparation of daphniphyllum-polygonum for treating the gastrointestinal tract disease, and application and a preparation method thereof. The granular preparation of daphniphyllum-polygonum is a sugar-type preparation which includes the granular preparation of daphniphyllum-polygonum for treating the gastrointestinal tract disease and including water-extracting ointment of daphniphyllum calycinum and polygonum hydropiper, powdered sugar and dextrin with the mass ratio of 1-5:5-10:0.5-1. The granular preparation of daphniphyllum-polygonum is simple in granulating technology and the extract of the medical material needs not be made into dry powder, the granulating process adopts the ebullated bed one-step granulation technology which reduces dust pollution in industrial production and meets the modernization requirement in the preparation of Chinese traditional medicine. The obtained granular preparation of daphniphyllum-polygonum can be dissolved quickly, has good taste and high bioavailability, and good patient dependence, and is easy to be transported or stored.

Owner:HAIKOU PHARMA FACTORY

Medicine for treating disease caused by heat toxin

A Chinese medicine for treating parotitis, tonsillitis, laryngitis, carbouncle, upper respiratory tract infection, etc is prepared from 5 Chinese-medicinal materials including southern isatis root, borneol, dandelion herb, liquorice root, etc.

Owner:陆中海

Common cold heat clearing chewing tablet and its preparation method

ActiveCN1824190AEasy to takeIt needs to be dissolved in hot water when taking it, and it is easy to carryAntiinfectivesPill deliveryCommon coldMedicine

A Chinese medicine in the form of chewing tablet for treating cold and clearing heat is prepared from 11 Chinese-medicinal materials including schizonepeta ear, mint, ledebouriella root, bupleurum root, etc.

Owner:BEIJING INCREASE INNOVATIVE DRUG RESEARCH CO LTD

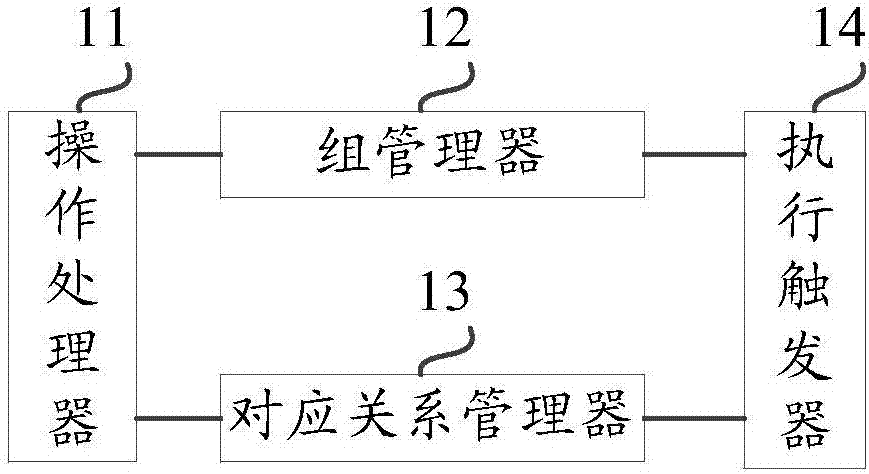

Storage strategy management system

ActiveCN107422991AReduce management complexityReduce management costsInput/output to record carriersActuatorOperating system

An embodiment of the invention discloses a storage strategy management system which comprises an operation processor, a group manager, a corresponding relation manager and an execution trigger. The operation processor can be used for receiving creation information input by a user and generating storage strategy group information to send to the group manager. The group manager is used for storing and maintaining the storage strategy group information. The corresponding relation manager is used for saving and maintaining the binding relation between a volume and the storage strategy group. The execution trigger is used for acquiring the needed storage strategy group information by the way of sending a request to the group manager, acquiring the needed volume information by sending related request to the corresponding relation manager, and then sending the extracted target storage strategy information and the corresponding volume information to the storage strategy actuator. The storage strategy management method based on groups can effectively reduce complexity of storage strategy management so as to reduce cost for storage strategy management and improve storage strategy configuration management efficiency.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

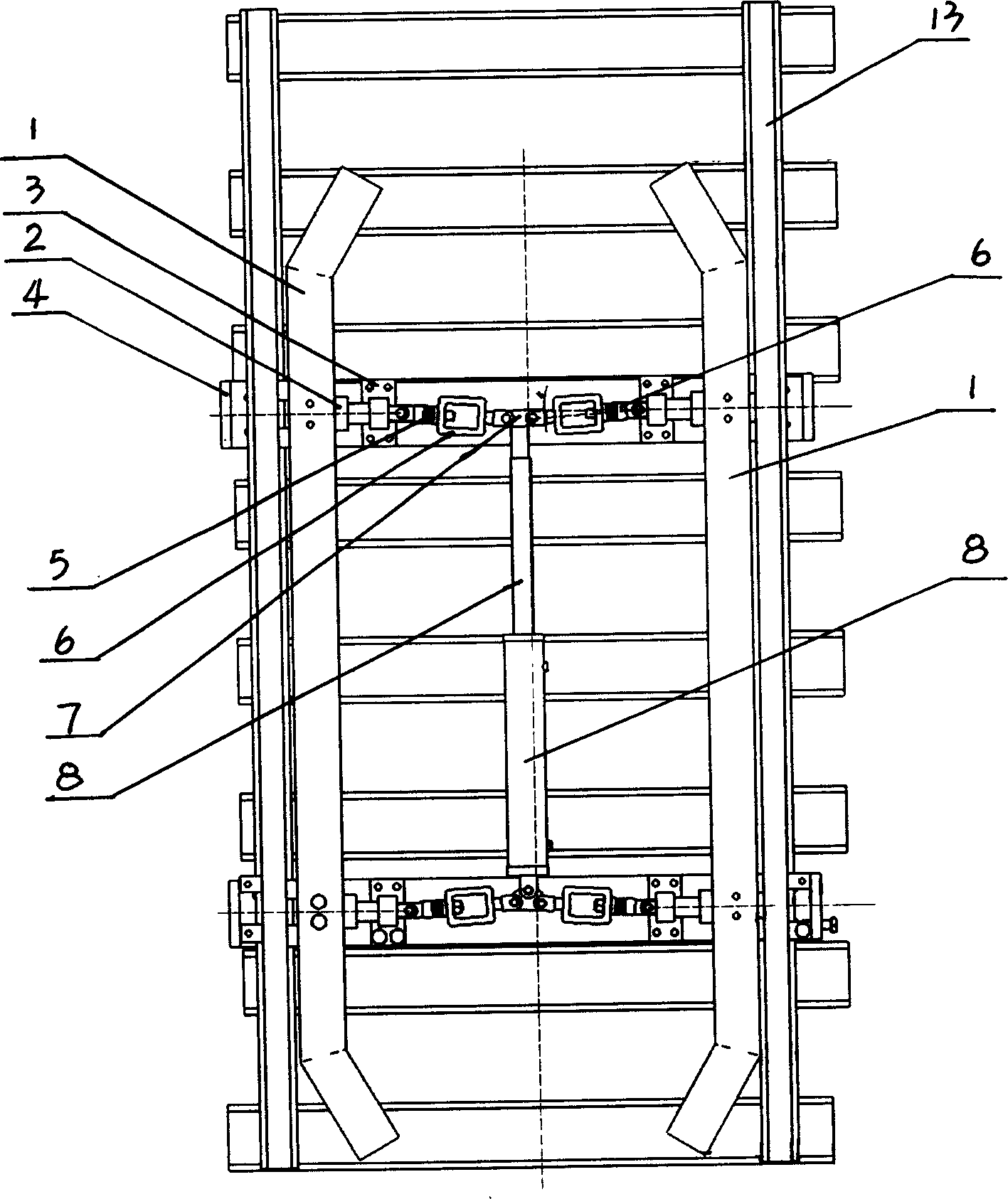

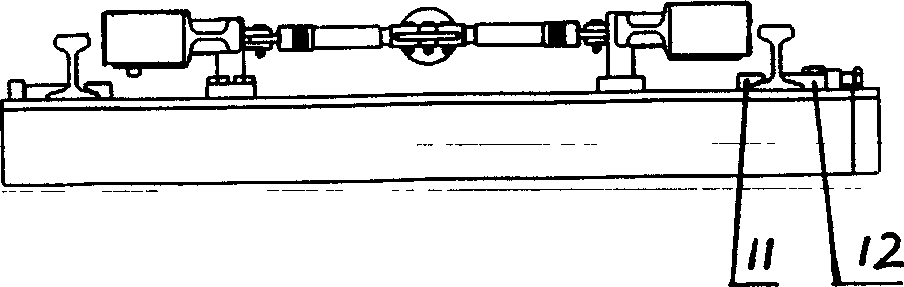

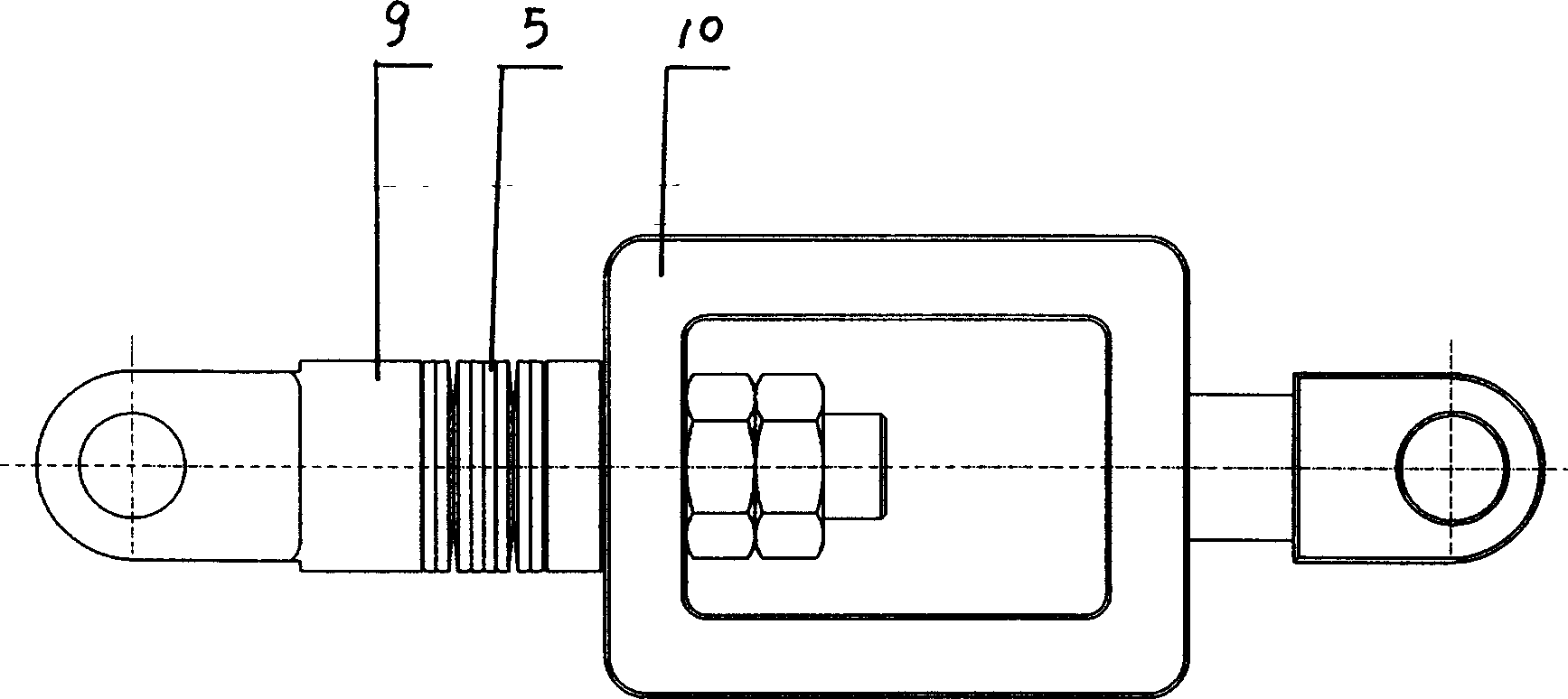

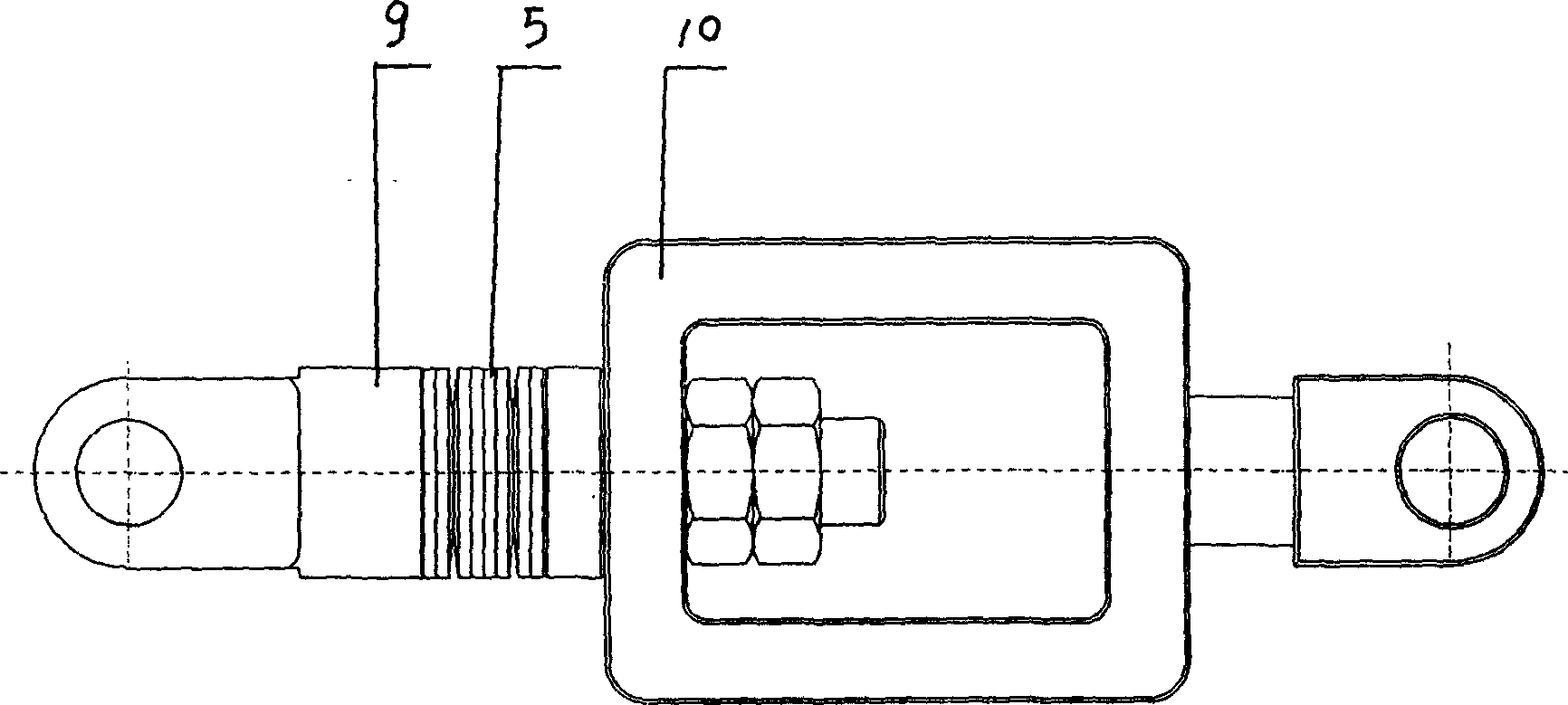

Locomotive anti-slide apparatus

InactiveCN1454805ADoes not cause an automatic conversionReasonable structureTrack brakesHydraulic cylinderControl system

The present invention relates to an antislipping equipment for railcar, specially for locomotive, which comprises brake rail, extension and contraction mechanism, hydraulic device and control system, the middle of brake rail is brake part, its two ends are guide part. Two brake rails are connected in their brake parts by means of extension and contraction mechanism, on the brake part two extension and contraction mechanisms are set, between two extension and contraction mechanisms is movably connected a hydraulic cylinder of hydraulic device by means of their connecting components, and the hydraulic pump of the hydraulic device is connected with control circuit of control system, so that it is an antislipping equipment capable of computer control of information collection, transmission and prompt alarm.

Owner:WUHAN UNIV OF TECH

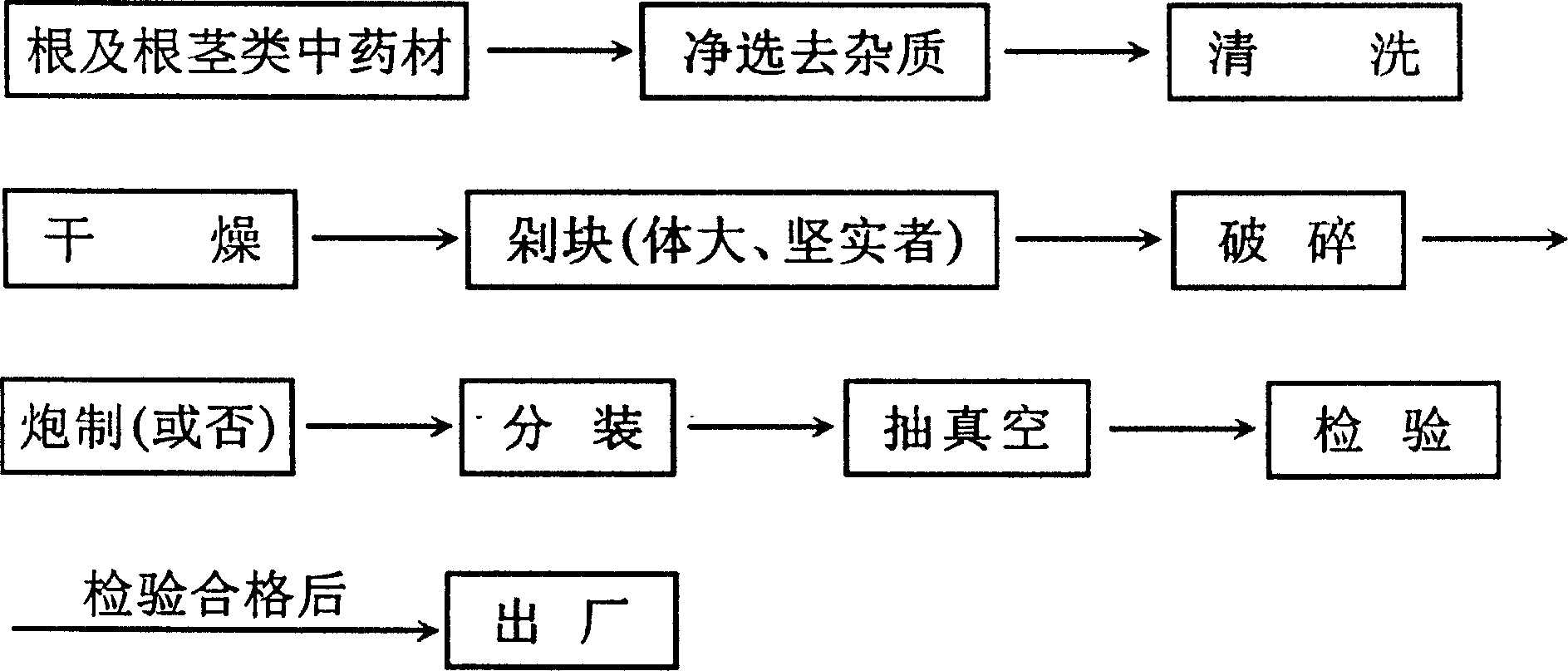

Method for preparing coarse powder of root and rhizome Chinese medicinal materials

InactiveCN1435172AImprove leaching rateReduce the burden of medicinePowder deliveryUnknown materialsMedicinal herbsMedicine

A process for preparing the coarse dust of root and rhizome type Chinese-medicinal materials includes preparing coarse dust and loading it in bags of different dosages for using them as the raw materials of Chinese-medicinal decoction. Its advantages are high extracting rate and low cost.

Owner:段维和

Medicine for treating difficult menstruation and its preparation

InactiveCN1895492AComposition controllableGood curative effectAntipyreticAnalgesicsTraditional medicineMenstruations

A Chinese medicine for treating menalgia is prepared from cyperus tuber and Chinese angelica root through extracting by supercritical CO2 and dispensing. Its preparing process is also disclosed.

Owner:SHANGHAI YOUSEEN NEW MEDICINE EXPLOITION

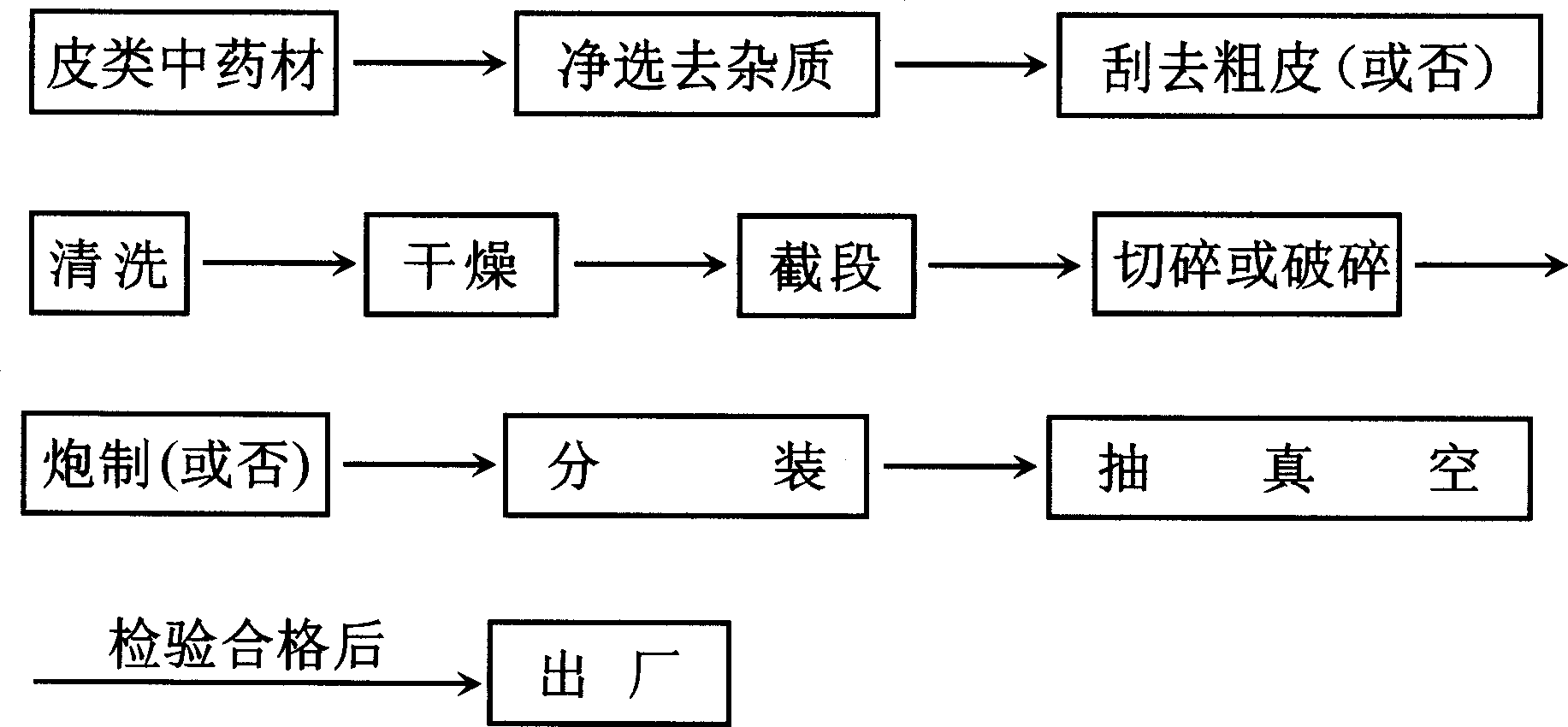

Method for preparing coarse powder of bark Chinese medicinal material

InactiveCN1435170AImprove leaching rateMeet modern requirementsPowder deliveryUnknown materialsMetallurgyRaw material

A process for preparing the coarse dust of bark-type Chinese-medicinal materials including preparing coarse dust and loading in bags of different dosages for using them as the raw material of Chinese-medicinal decoction. Its advantages are high extracting rate and low cost.

Owner:段维和

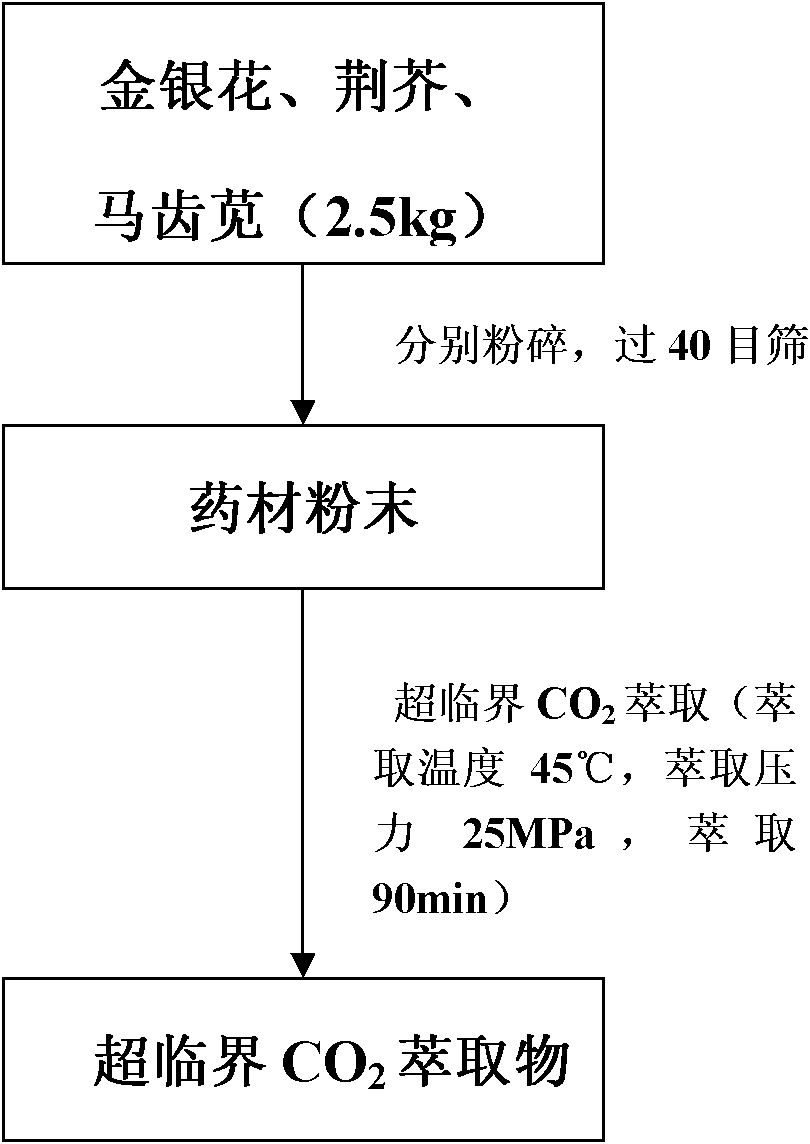

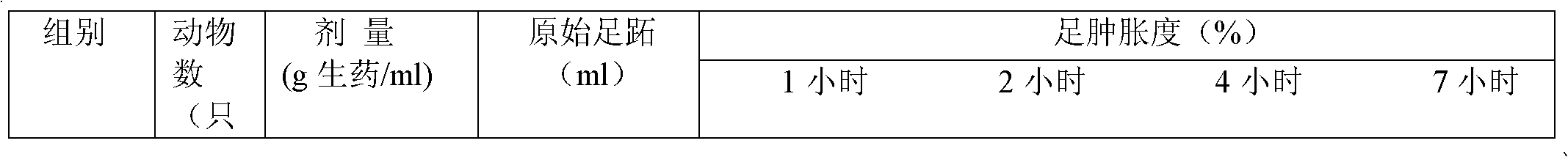

Preparation method of supercritical extractive for Jinxuan hemorrhoid fumigating powder

The invention discloses a preparation method of a supercritical extractive of honeysuckle, fineleaf schizonepeta herb, purslane and other vegetable drugs in a Jinxuan hemorrhoid fumigating powder formula, which comprises the following steps of: taking the honeysuckle, the fineleaf schizonepeta herb and the purslane in proportions according to the formula, and then pulverizing and sieving the three medicinal materials; and extracting in a supercritical CO2 extractor, wherein an extracting temperature is 35-55 DEG C, an extraction pressure is 15-35 MPa, and an extraction time is 30-150 min. The yield of the supercritical extractive for the Jinxuan hemorrhoid fumigating powder reaches 2.36%, wherein the content of pulegone as an active constituent reaches 16.78 mg / g. The extractive has the obvious effects of resisting inflammations and easing pains. The extraction process of the extractive has simple process and higher content of the active constituent, reduces production cost, saves energy sources, controls environmental pollution, reduces potential safety hazards in production and meets the requirement of modernization of a Chinese medicine industry.

Owner:MAYINGLONG PHARMA GROUP

Pharmaceutical formulation of Chinese white olive for relieving cough and preparation method thereof

InactiveCN101411812AProduction mechanizationHigh degree of automationHydroxy compound active ingredientsPill deliveryFritillaria thunbergiiAdditive ingredient

The invention provides a medicine preparation of fructus canarii for relieving cough. The medicine preparation comprises medicine compositions and medicine auxiliary materials; the medicine compositions consist of the following raw materials in weight portion: Fructus chebulae immaturus, herba ephedrae, semen armeniacae amara, gypsum, liquorice, perillae, folia perillae acutae, rhizoma pinelliae, fritillaria thunbergii miq, cortex mori radicis, semen ginkgo meat, scutellaria, flos farfarae and borneol. The medicine preparation comprises all the compositions of a traditional formula, keeps the fixed mixture ratio of the raw material compositions of the original formula, has unchanged curative effect and better dissolution rate and bioavailability than the prior honeyed pill preparation, is convenient to take, carry, store and the like and is easy to widely apply.

Owner:BEIJING TONGRENTANG CO LTD

Traditional Chinese medicine preparation for treating psoriasis and preparation method of traditional Chinese medicine preparation

ActiveCN104547787ARegulate immune functionNo side effectsAnthropod material medical ingredientsInorganic active ingredientsPsoriasisCarthamus

The invention relates to a traditional Chinese medicine preparation for treating psoriasis and a preparation method of the traditional Chinese medicine preparation. The traditional Chinese medicine preparation comprises the following active ingredients in parts by weight: 30-60 parts of rhizoma smilacis glabrae, 20-40 parts of saffron crocus, 30-60 parts of herba cistanches, 10-20 parts of periostracum cicada, 20-40 parts of nodus nelumbinis rhizomatis, 30-60 parts of realgar, 10-20 parts of radix paeoniae rubra and 10-20 parts of palembus dermestoides. The preparation method comprises the steps of mixing and grinding the active ingredients in the above parts into powder of above 100 meshes, mixing the powder and pharmaceutical purified water with equal weight, uniformly stirring to prepare a blank, putting the blank in an environment at 20-25 DEG C, volatilizing water in the blank naturally to prepare a half-dry blank, and finally preparing into a corresponding dosage form. The traditional Chinese medicine preparation adopts high quality materials, is reasonable in compatibility, scientific to prepare, significant in curative effect, convenient and quick to take, safe and reliable, and stable in quality, meets requirements of traditional Chinese medicine preparation modernization and is suitable for industrial mass production.

Owner:山东嘉特医药科技有限公司

Poria cocos total polysaccharide as well as extraction method and application thereof

ActiveCN114292346AImprove pharmacological activityReduce reuseOrganic active ingredientsNervous disorderWolfiporia extensaMicrofiltration

The invention relates to poria cocos total polysaccharide and an extraction method and application thereof, and belongs to the technical field of traditional Chinese medicine extraction. The extraction method comprises the following steps: refluxing poria cocos sclerotium powder in ethanol for 1-3 times to obtain filter residues 1; mixing the filter residue 1 with a KOH solution, reacting for 0.5-3 hours to obtain an alkali extracting solution, and adjusting the pH value of the alkali extracting solution to 6-7 to obtain a gel solid; washing the gel-like solid for 3-6 times by using water, combining filtrates to obtain water washing liquid, and collecting filter residues to obtain the poria cocos alkali-soluble polysaccharide; performing microfiltration on the water washing liquid, collecting permeate and trapped fluid 1, performing ultrafiltration on the permeate, and collecting the trapped fluid to obtain trapped fluid 2; and combining the trapped fluid 1, the trapped fluid 2 and the poria cocos alkali-soluble polysaccharide, and drying to obtain the poria cocos total polysaccharide. The yield of the pachymaran obtained by the extraction process disclosed by the invention reaches 65.72 to 88.94 percent, and the content of the pachymaran reaches 76.20 to 96.14 percent.

Owner:HUBEI UNIV OF CHINESE MEDICINE

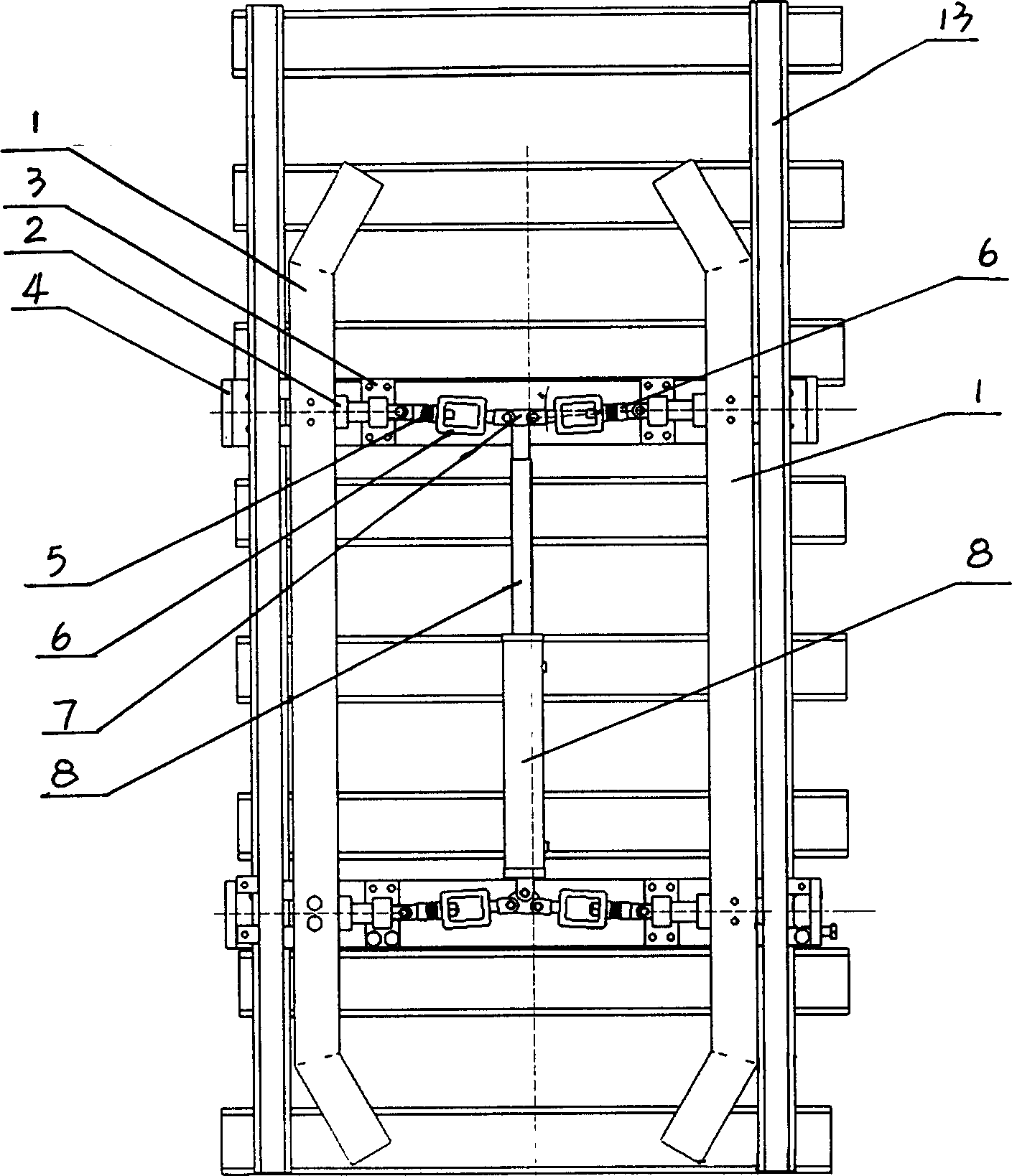

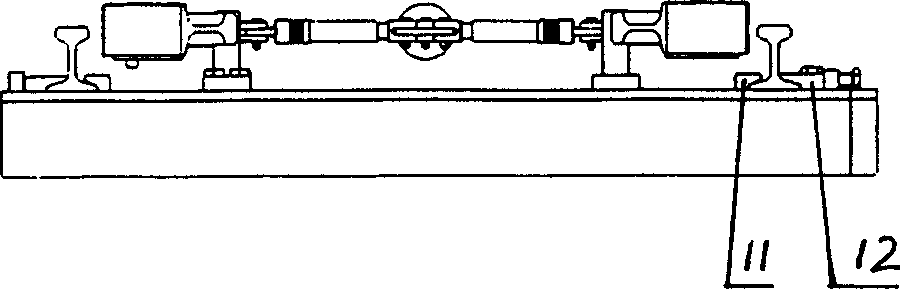

Whole-spinning plug-pin type integrated inner-partition wall board and installation method thereof

PendingCN107190907AGuaranteed energy savingGuaranteed water savingWallsHeat proofingEngineeringBlind hole

The invention relates to a whole-spinning plug-pin type integrated inner-partition wall board and an installation method thereof. The whole-spinning plug-pin type integrated inner-partition wall board comprises a whole core board, a base board, a facing decorative board, spinning screw pins, fixed pins, movable pins, guide sleeves, base plates and decorative frame bars. Blind holes are vertically formed in the centers of the four edges of the whole core board correspondingly, and the blind holes are in clearance fit with or in transition fit with the spinning screw pins, the fixed pins and the movable pins correspondingly; the guide sleeves are installed in the blind holes of the lower edge of the core board, and the guide sleeves are in clearance fit with the movable pins; and the whole core board is sequentially bonded with the base board and the facing decorative board. The whole-spinning plug-pin type integrated inner-partition wall board has the advantages that good light weight, heat preservation, sound insulation, anti-seismic performance and good strength are achieved, and is specifically suitable for the standardized design, the industrialized production, the assembled installation and the informatization management.

Owner:NANTONG CHENGYUE DECORATION GRP

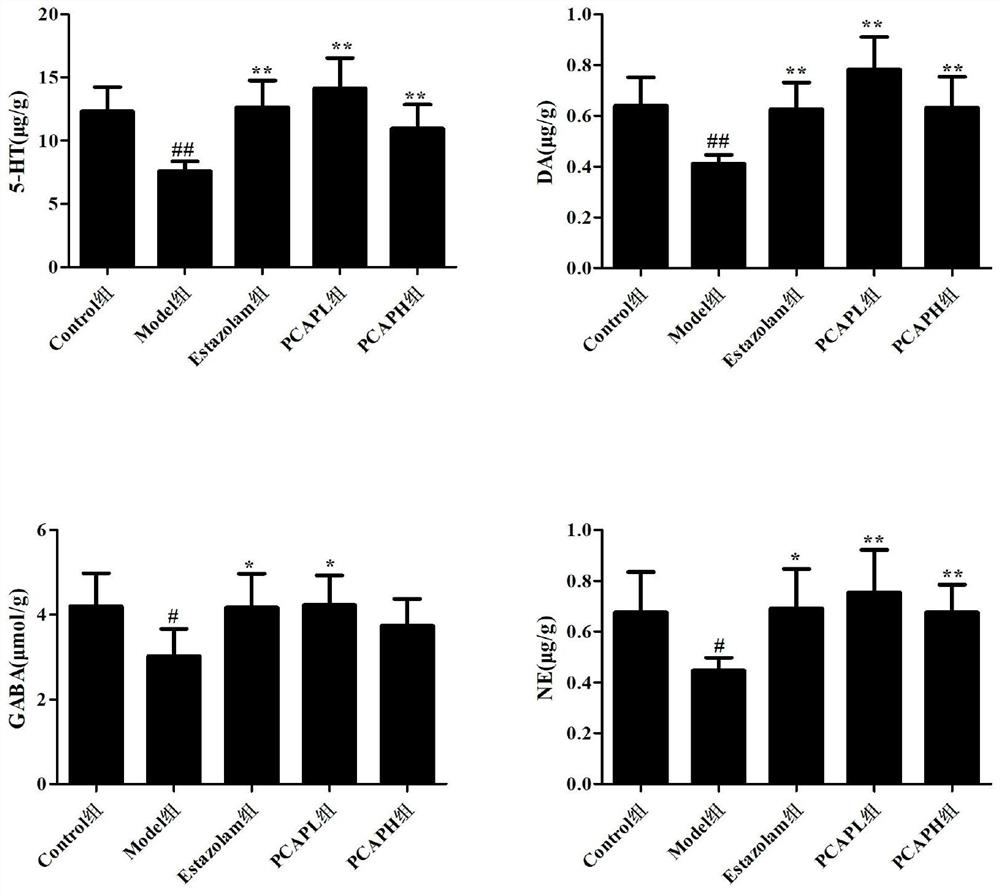

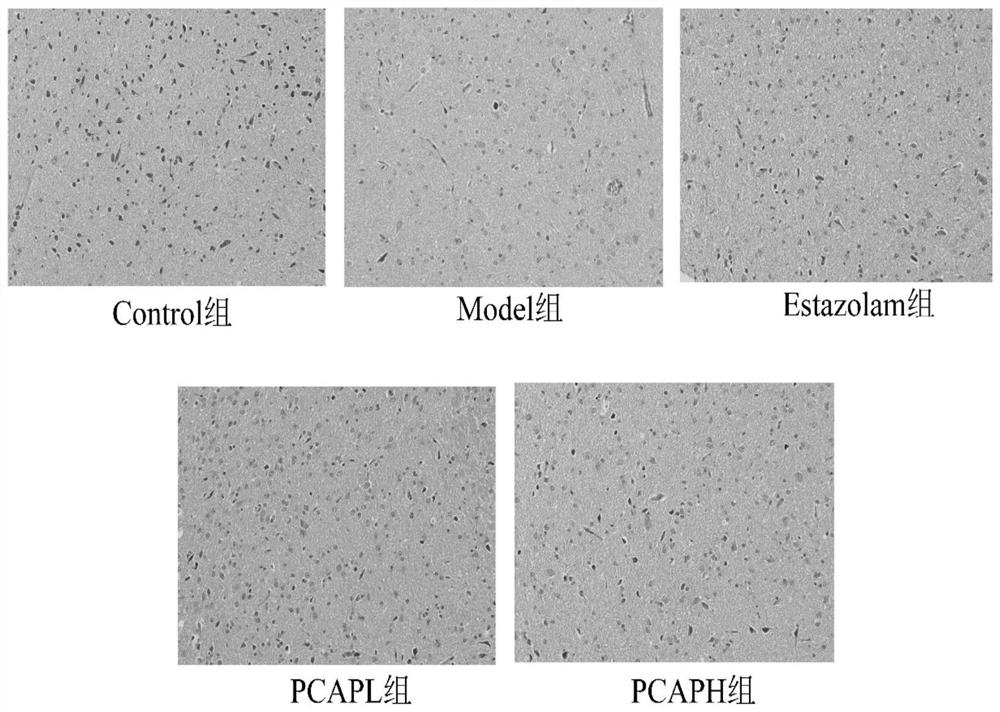

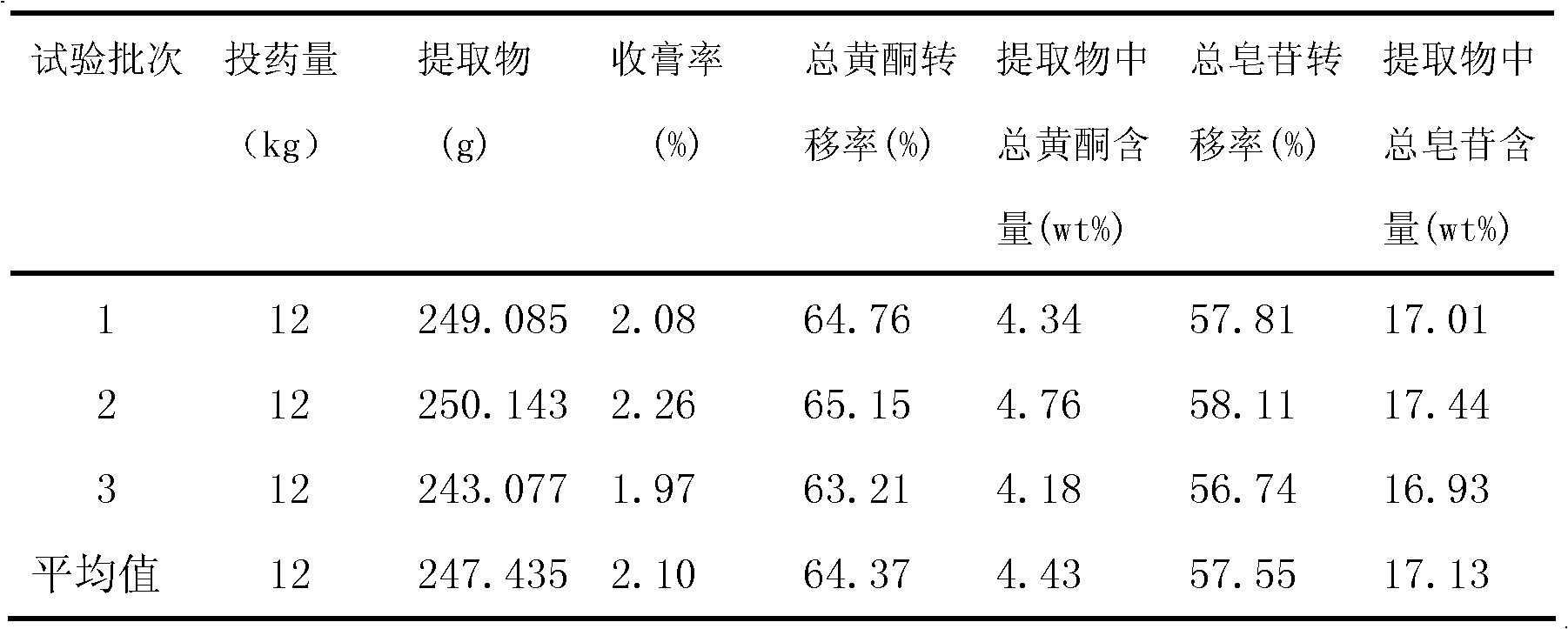

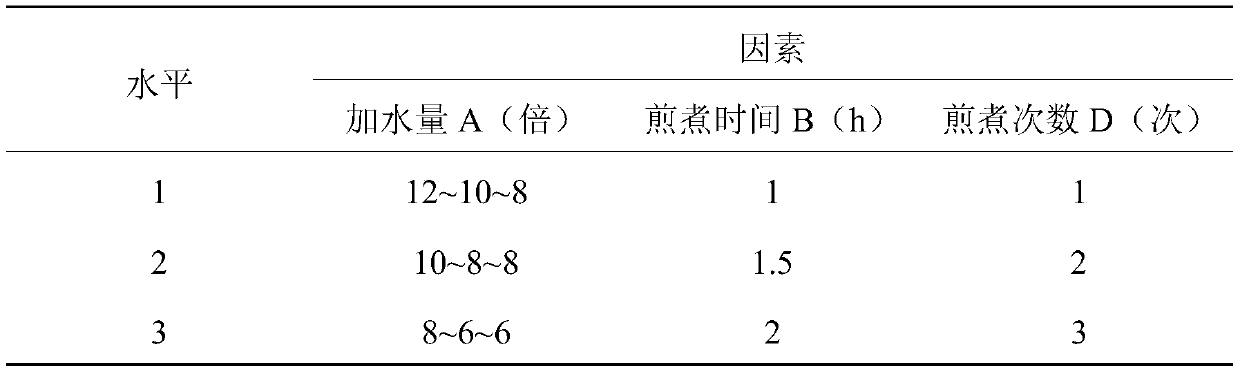

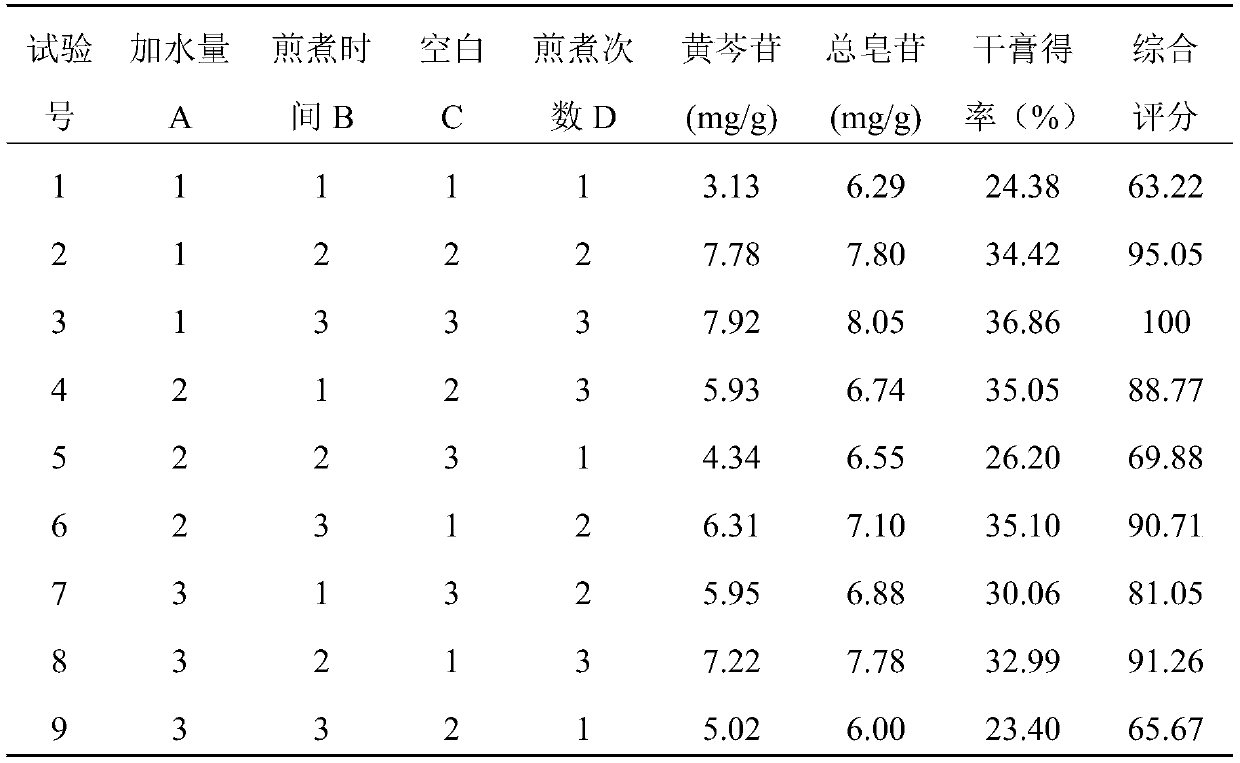

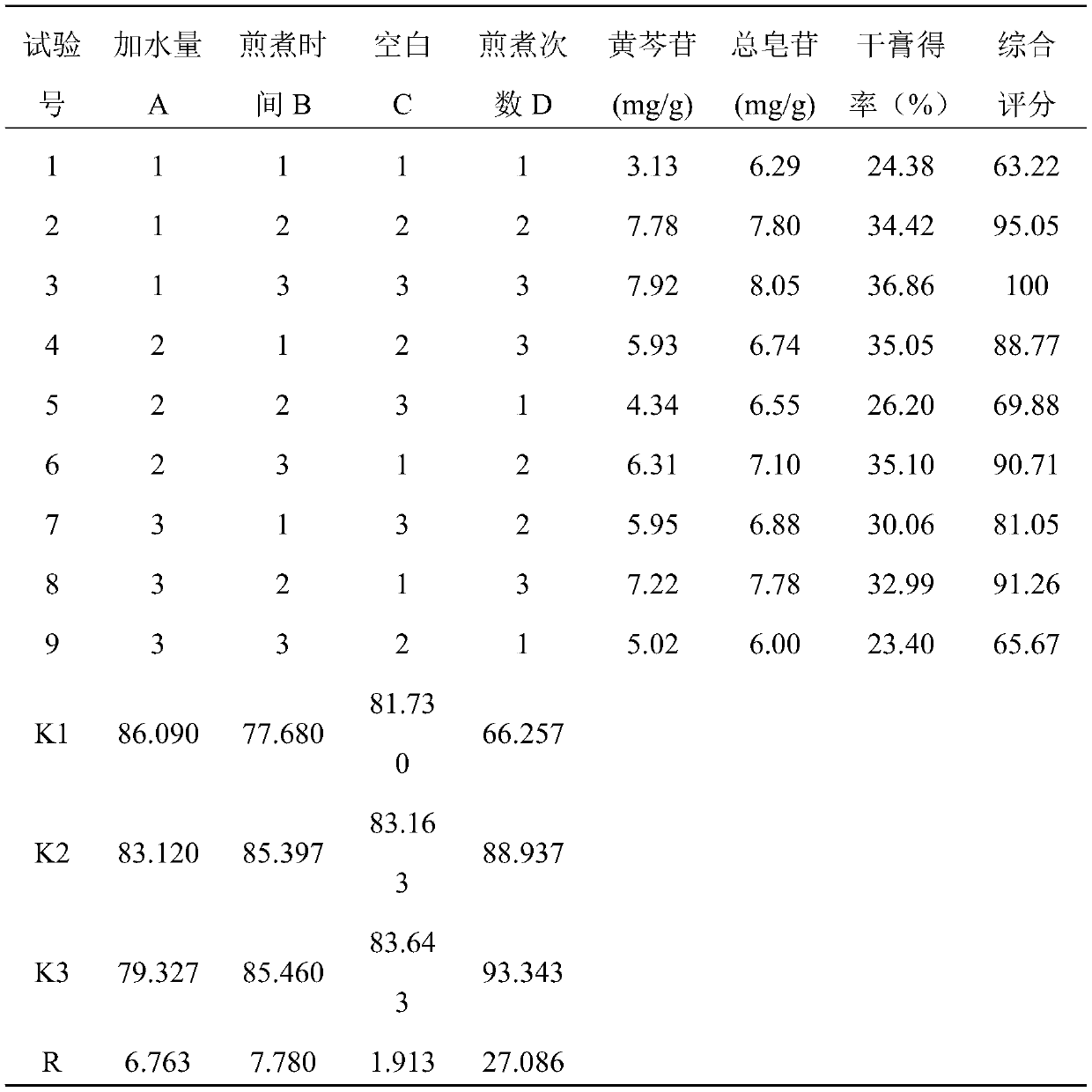

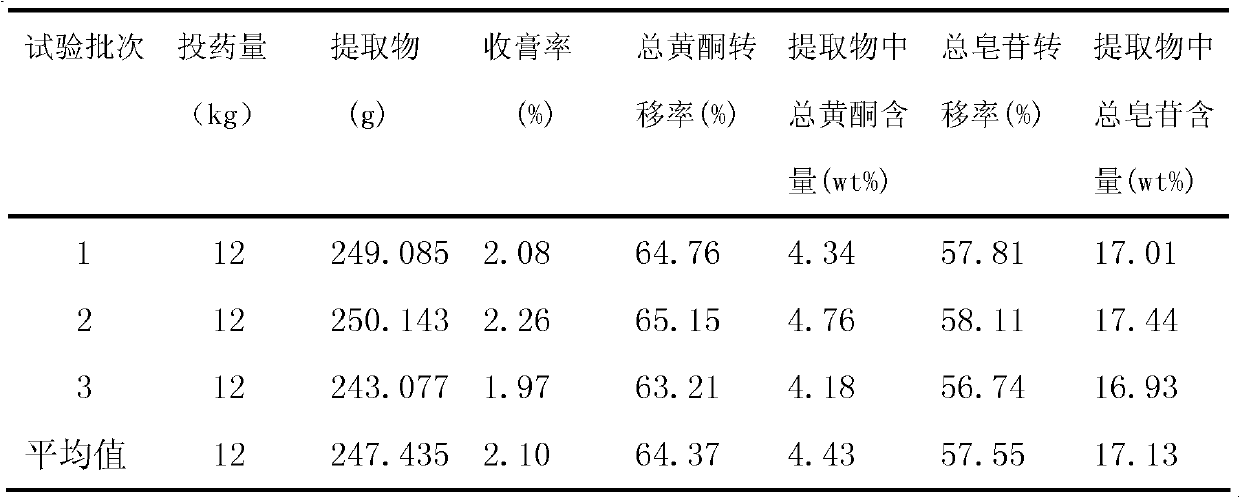

A kind of preparation method of extract of effective fractions of A. japonicus

The invention discloses a preparation method of an alligator alternanthera effective fraction extract, which comprises the following steps: 1. extracting alligator alternanthera with alcohol under reflux; 2. recycling the alcohol extract under reduced pressure, diluting the medicinal liquor, and filtering; 3. adsorbing the filtrate through D101 macroporous adsorbent resin columns, and eluting with distilled water and alcohols with different concentrations; and 4. recycling the eluent under reduced pressure, concentrating to a relative density of 1.01-1.10, and drying to obtain the alligator alternanthera effective fraction extract. The general flavone content of the alligator alternanthera effective fraction extract product is up to 3-5 wt%, the transfer rate is 50-70%; and the general saponin content is up to 15-18 wt%, and the transfer rate is 40-60%. No related data about the preparation technique of the effective fraction extract has been reported at home and abroad. The inventionhas the advantages of simple extraction and purification technique and higher content of effective substances, lowers the production cost, saves the energy, reduces the potential safety hazard in theproduction, and satisfies the modern requirements for traditional Chinese medicine industry.

Owner:武汉回盛生物科技股份有限公司

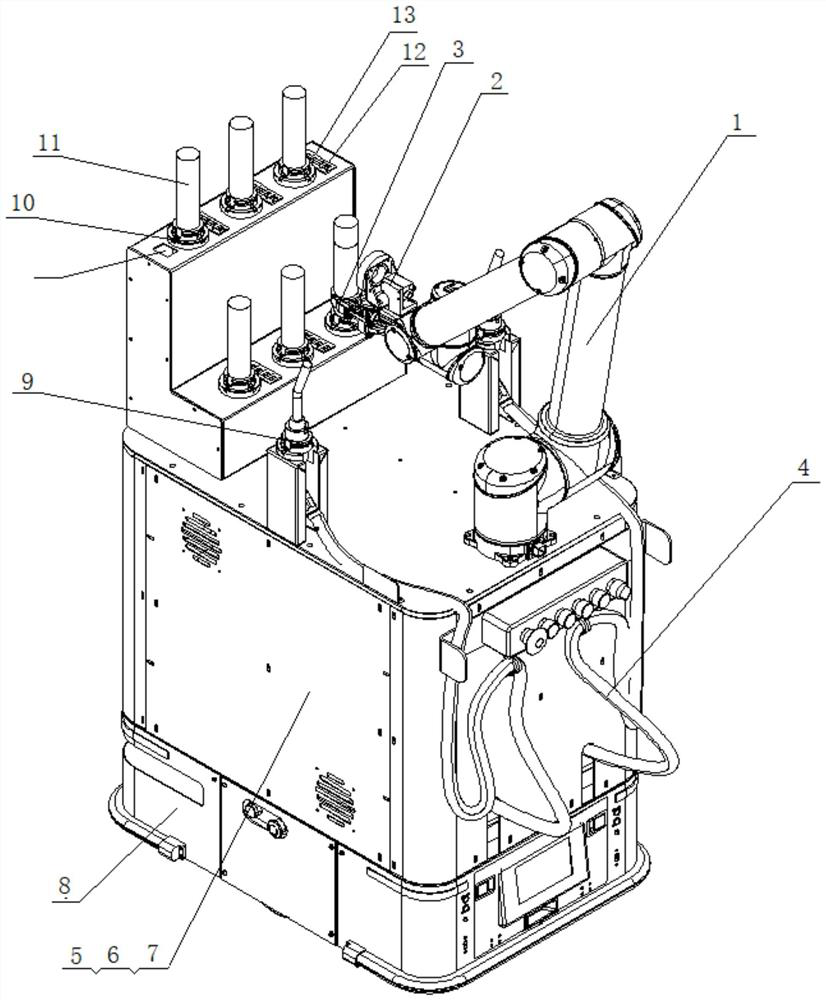

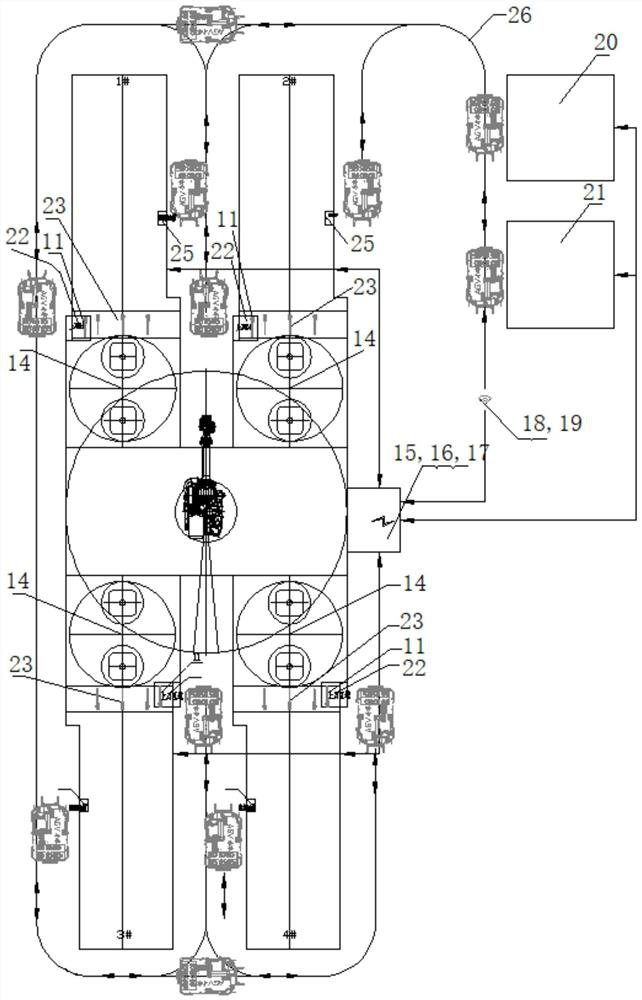

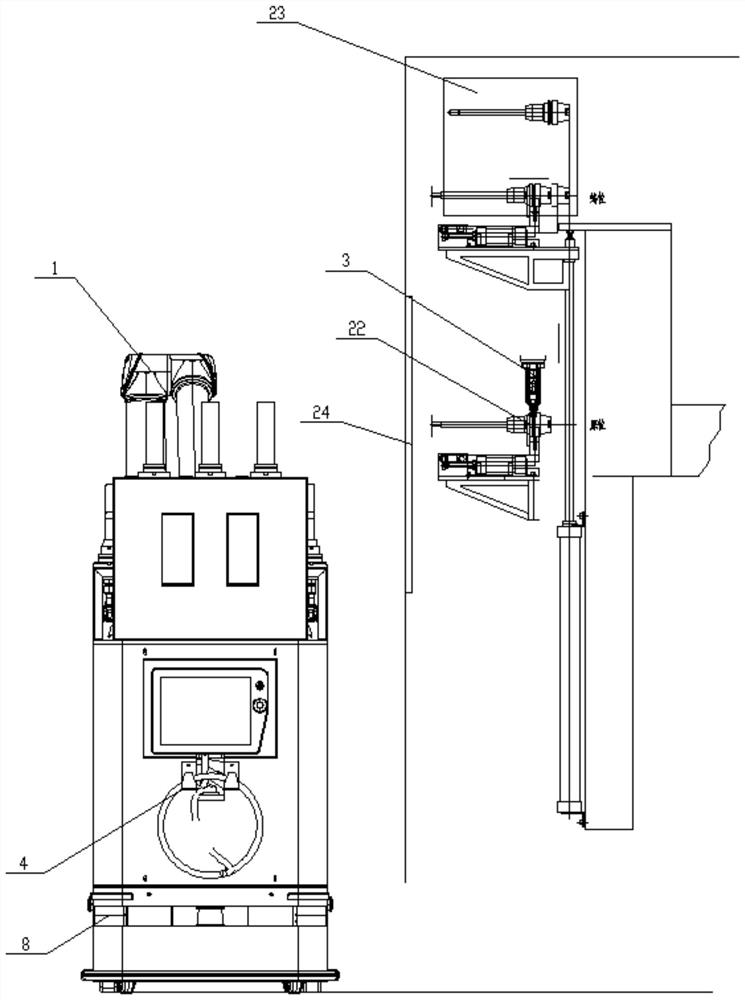

Automatic cutter feeding and oil injection system based on AGV

PendingCN113568384ADoes not affect actuation rateMeet the requirements of modern technologyElectric/hybrid propulsionTotal factory controlProcess engineeringInjection - action

The invention discloses an automatic cutter feeding and oil injection system based on an AGV. The system is characterized by comprising: an AGV, wherein the AGV executes an instruction of a dispatching system, and moves between designated positions according to a preset path; an oil injection device used for storing oil and arranged on the AGV; a tool placing device used for storing a cutter and arranged on the AGV; a collaborative robot for executing cutter replacement and oil injection actions according to the instruction of the dispatching system; and a dispatching system used for receiving cutter replacement and oil injection request information of machining center equipment, deploying the AGV loaded with the cutter or the oil product to a designated position and controlling a collaborative robot to replace the cutter or inject oil. According to the invention, the automatic cutter feeding and oil injection system is simple in structure, low in cost and capable of automatically feeding a cutter and filling oil into equipment, equipment production is not affected, the starting rate of the equipment is not reduced, life-long benefits are achieved through one-time investment, and the automatic cutter feeding and oil injection system has wide popularization value.

Owner:东风设备制造有限公司

Traditional Chinese preparation for treating gout and preparation method thereof

ActiveCN103041238BLower uric acidRestore self-expelling acid functionSkeletal disorderPlant ingredientsPOLYGONUM CUSPIDATUMRadix Ophiopogonis

The invention relates to a traditional Chinese preparation for treating grout and a preparation method thereof. The traditional Chinese preparation comprises the following materials in parts by weight: 50-70 parts of sambucus thunbergiana, 20-40 parts of lily sheets, 30-60 parts of Chinese yams, 10-20 parts of herba ecliptae, 20-40 parts of chinaroot greenbrier, 30-60 parts of radix ophiopogonis, 10-20 parts of polygonum cuspidatum and 20-40 parts of glechoma longituba. The traditional Chinese preparation disclosed by the invention not only has the effects of reducing uric acid and relieving swelling and pain by cooling blood, balancing acid and base and regulating the functions of the liver spleen kidney, but also can be used to recover the automatic acid discharge function and re-establish metabolic mechanism, thereby treating the grout radically.

Owner:山东嘉特医药科技有限公司

Locomotive anti-slide apparatus

InactiveCN1241776CChange working conditionsEasy to operate and controlTrack brakesHydraulic cylinderControl system

Owner:WUHAN UNIV OF TECH

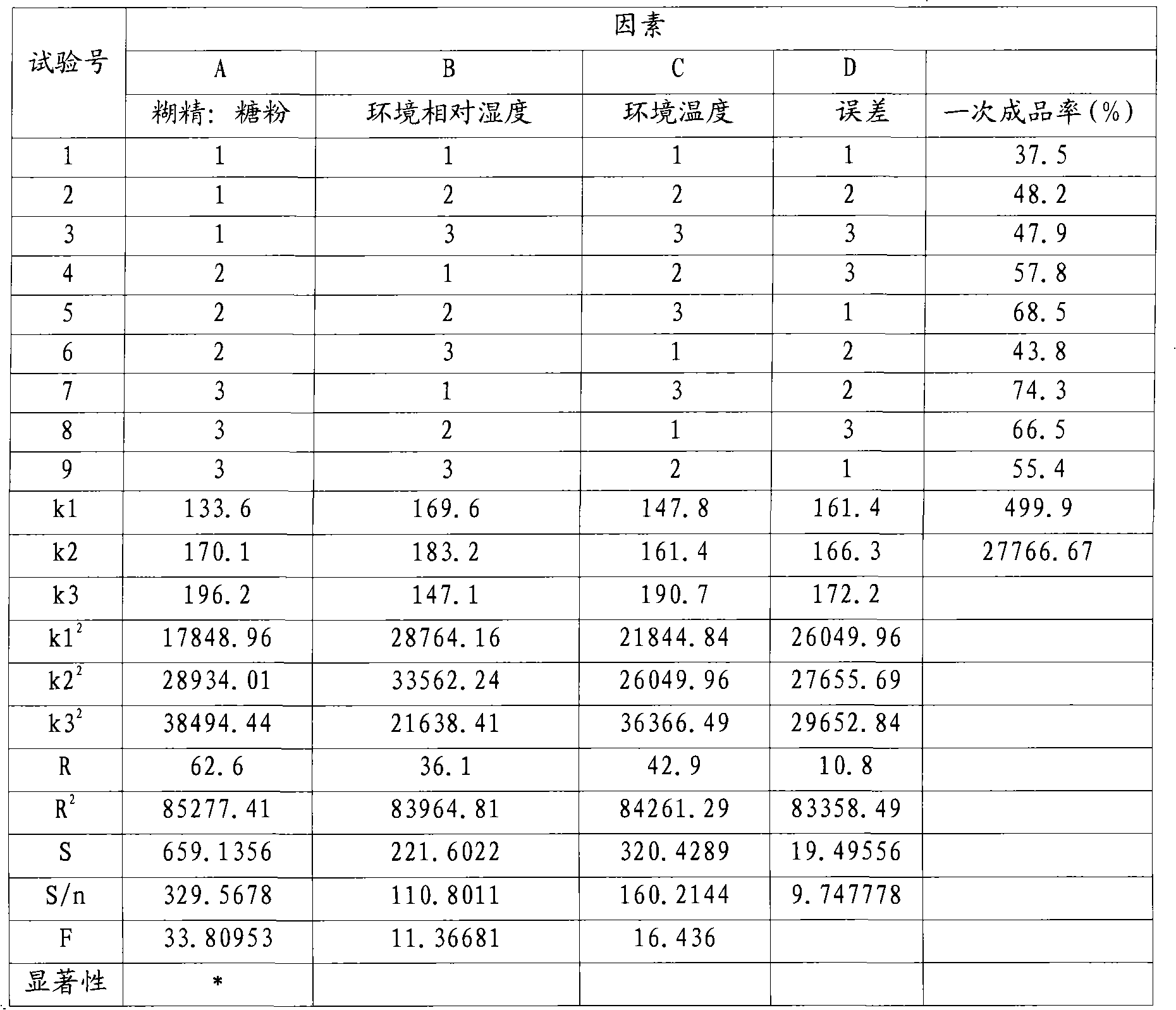

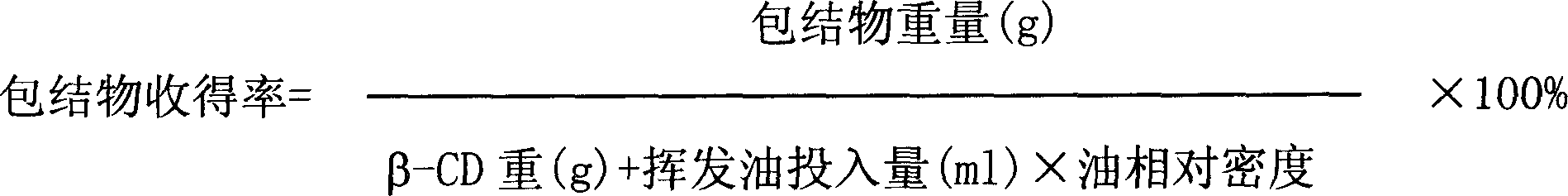

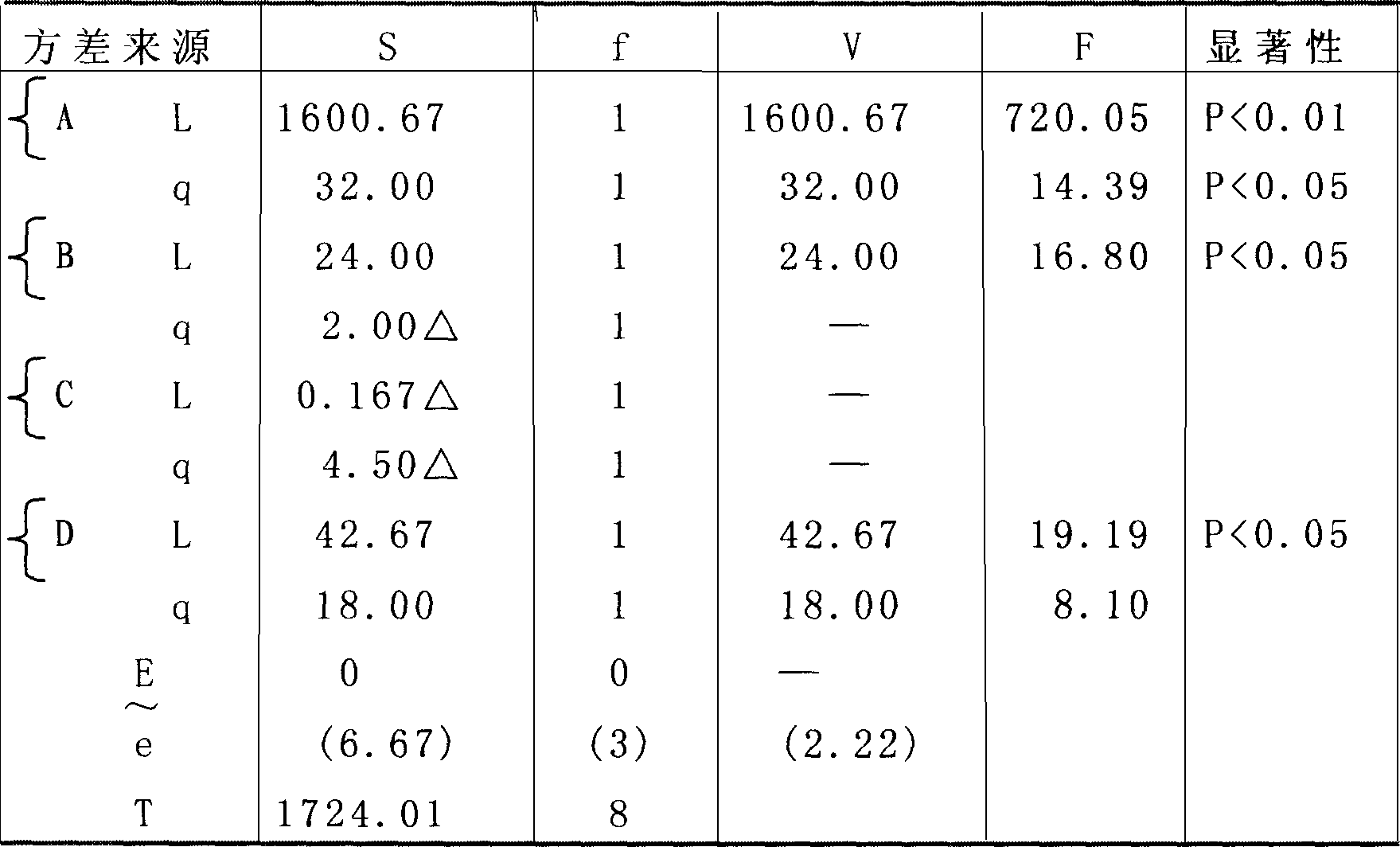

A preparation method of flavored Xiaochaihu granule and application of flavored Xiaochaihu granule

ActiveCN106511925BImprove efficacyGood effectGranular deliveryPlant ingredientsAbdomen diseasesBULK ACTIVE INGREDIENT

The invention relates to the technical field of traditional Chinese medicines, and in particular relates to modified common goldenrop granules as well as a preparation method and applications of the modified common goldenrop granules. The modified common goldenrop granules are prepared from the following components in percentage by weight: 2%-10% of bupleurum chinense volatile oil, 20%-70% of modified common goldenrop granule extract powder, and 20%-70% of dextrin. The modified common goldenrop granules have the advantages that the carrying is convenient, the content of active ingredients is high, and the absorption is convenient. The preparation method of the modified common goldenrop granules comprises the following steps: 1, extracting the bupleurum chinense volatile oil, 2, preparing a clathrate compound; 3, preparing the modified common goldenrop granule extract powder, and 4, carrying out pelleting. With the adoption of the preparation method, the medicinal ingredients of common goldenrop can be well purified, and meanwhile, the prepared granules are convenient to carry; the modified common goldenrop granules can be used for preparing the medicines for treating peptic ulcer and chronic gastritis complications, and thus the application range of the common goldenrop granules in the medicines for treating spleen and stomach diseases is expanded.

Owner:东莞市中医院

Preparation method of alligator alternanthera effective fraction extract

ActiveCN102274254BPollution controlMeet modern requirementsAntiviralsPlant ingredientsAlligatorFlavones

The invention discloses a preparation method of an alligator alternanthera effective fraction extract, which comprises the following steps: 1. extracting alligator alternanthera with alcohol under reflux; 2. recycling the alcohol extract under reduced pressure, diluting the medicinal liquor, and filtering; 3. adsorbing the filtrate through D101 macroporous adsorbent resin columns, and eluting with distilled water and alcohols with different concentrations; and 4. recycling the eluent under reduced pressure, concentrating to a relative density of 1.01-1.10, and drying to obtain the alligator alternanthera effective fraction extract. The general flavone content of the alligator alternanthera effective fraction extract product is up to 3-5 wt%, the transfer rate is 50-70%; and the general saponin content is up to 15-18 wt%, and the transfer rate is 40-60%. No related data about the preparation technique of the effective fraction extract has been reported at home and abroad. The inventionhas the advantages of simple extraction and purification technique and higher content of effective substances, lowers the production cost, saves the energy, reduces the potential safety hazard in theproduction, and satisfies the modern requirements for traditional Chinese medicine industry.

Owner:武汉回盛生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com